Patents

Literature

744 results about "Cold formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold forming is the process of forging metals at near room temperatures. In cold forming metal is formed at high speed and high pressure into tool steel or carbide dies.

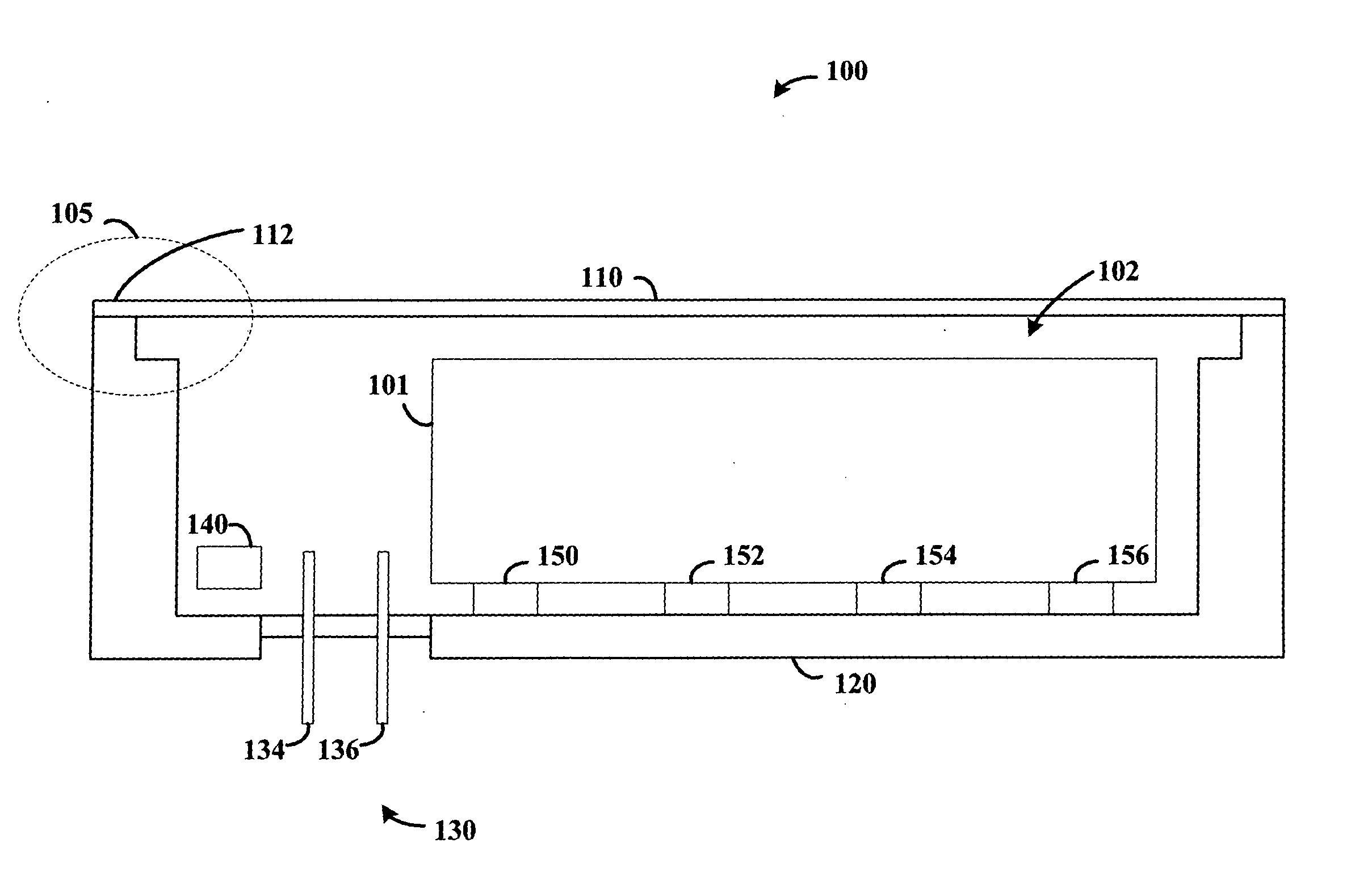

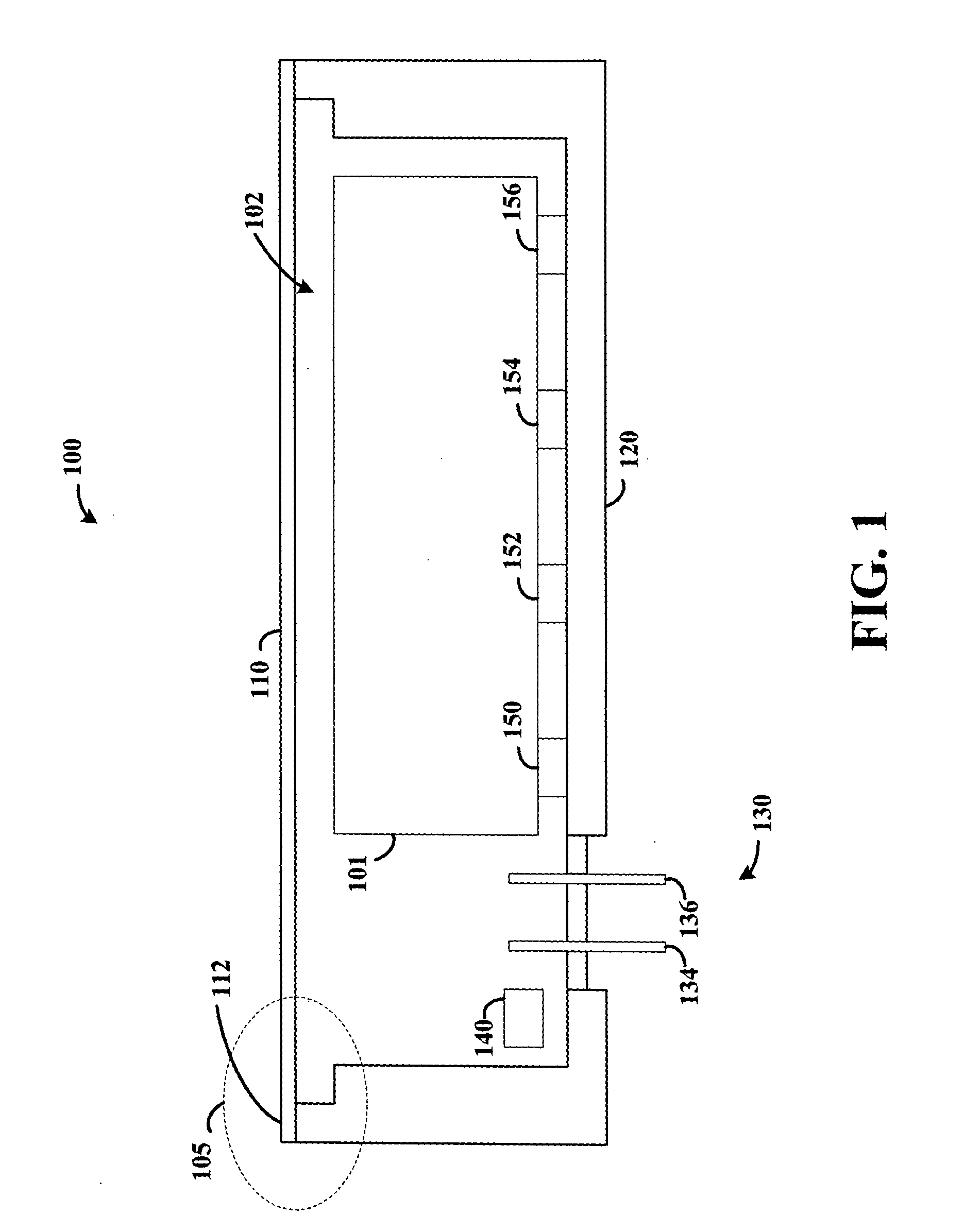

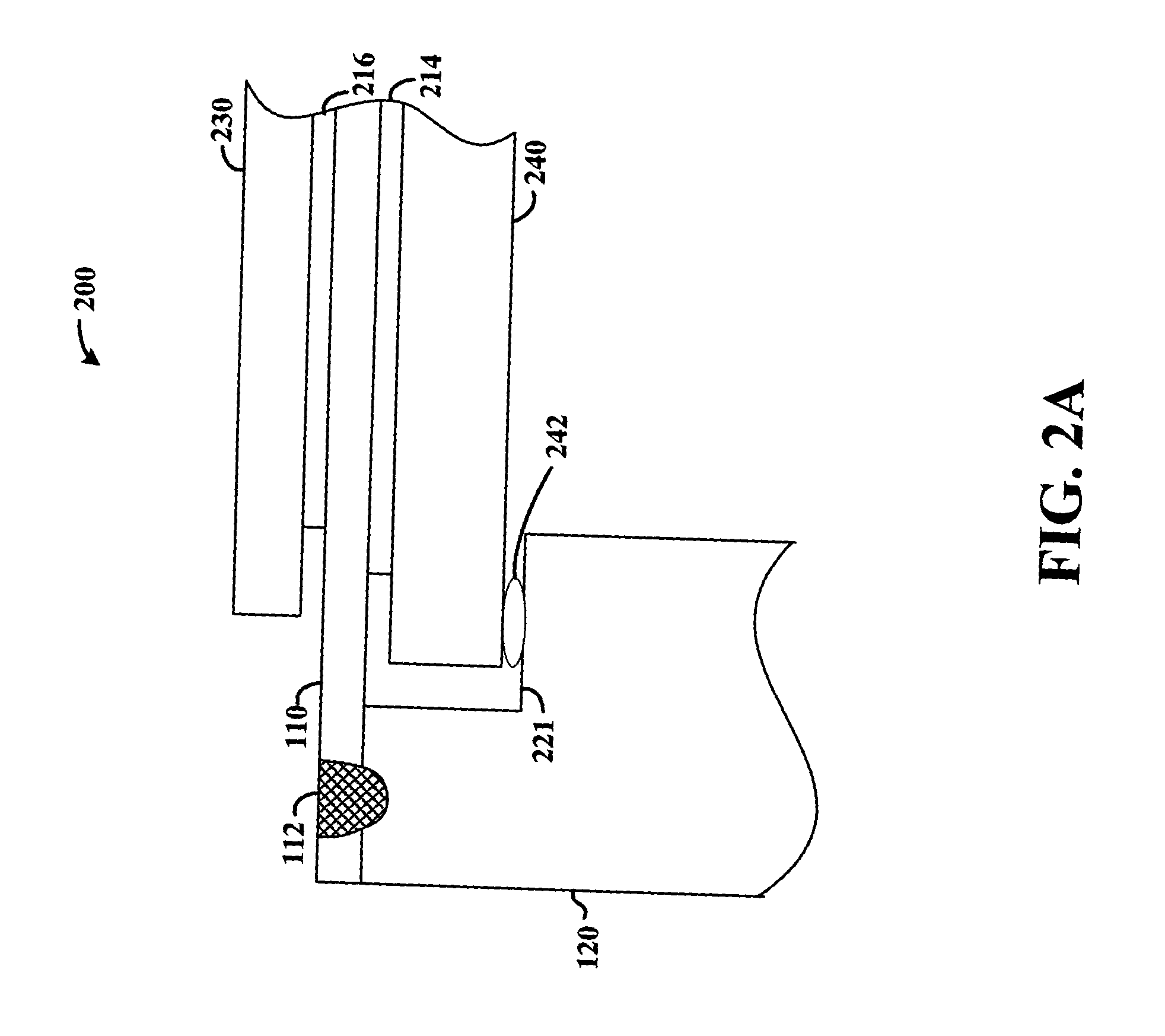

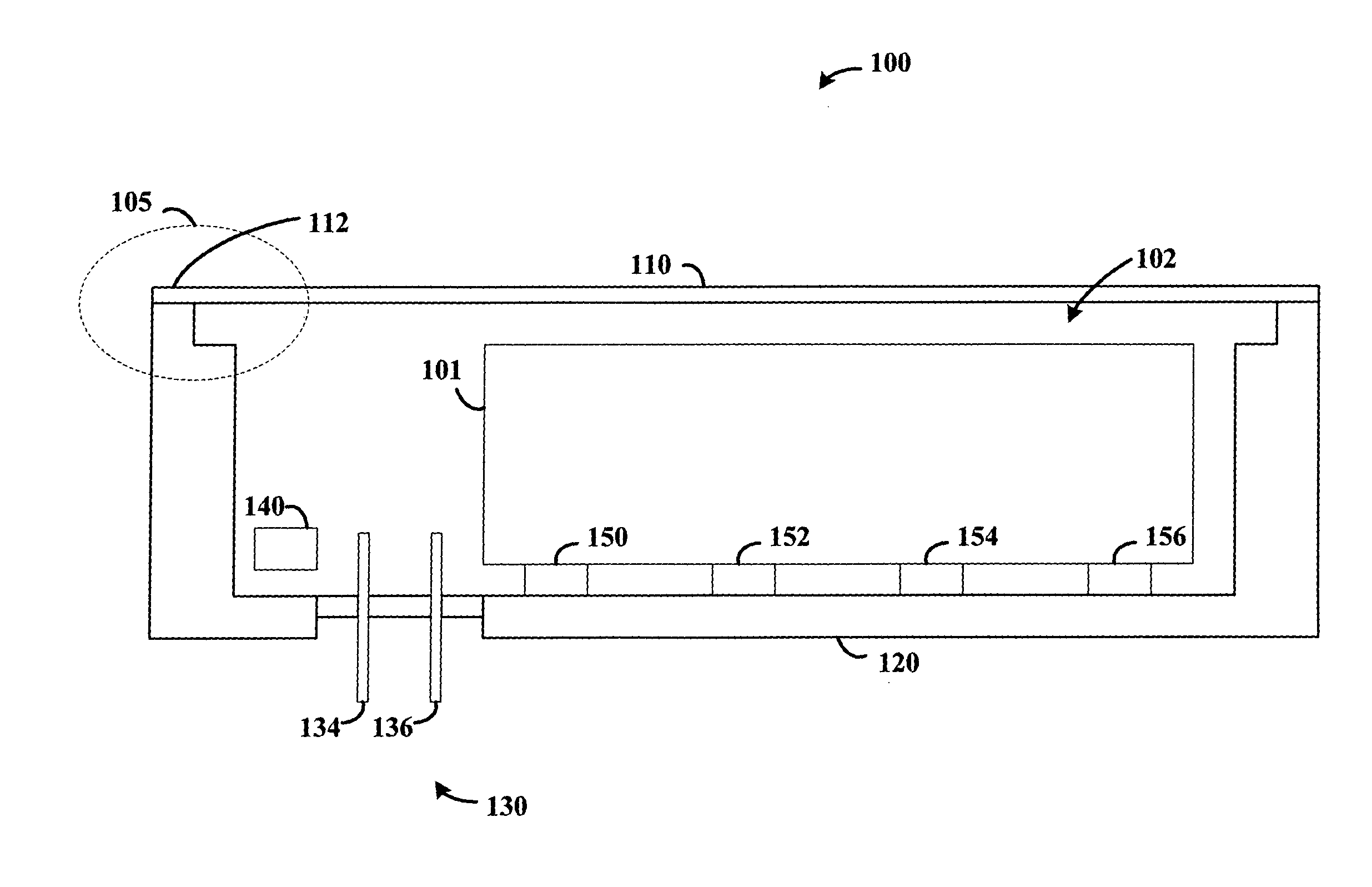

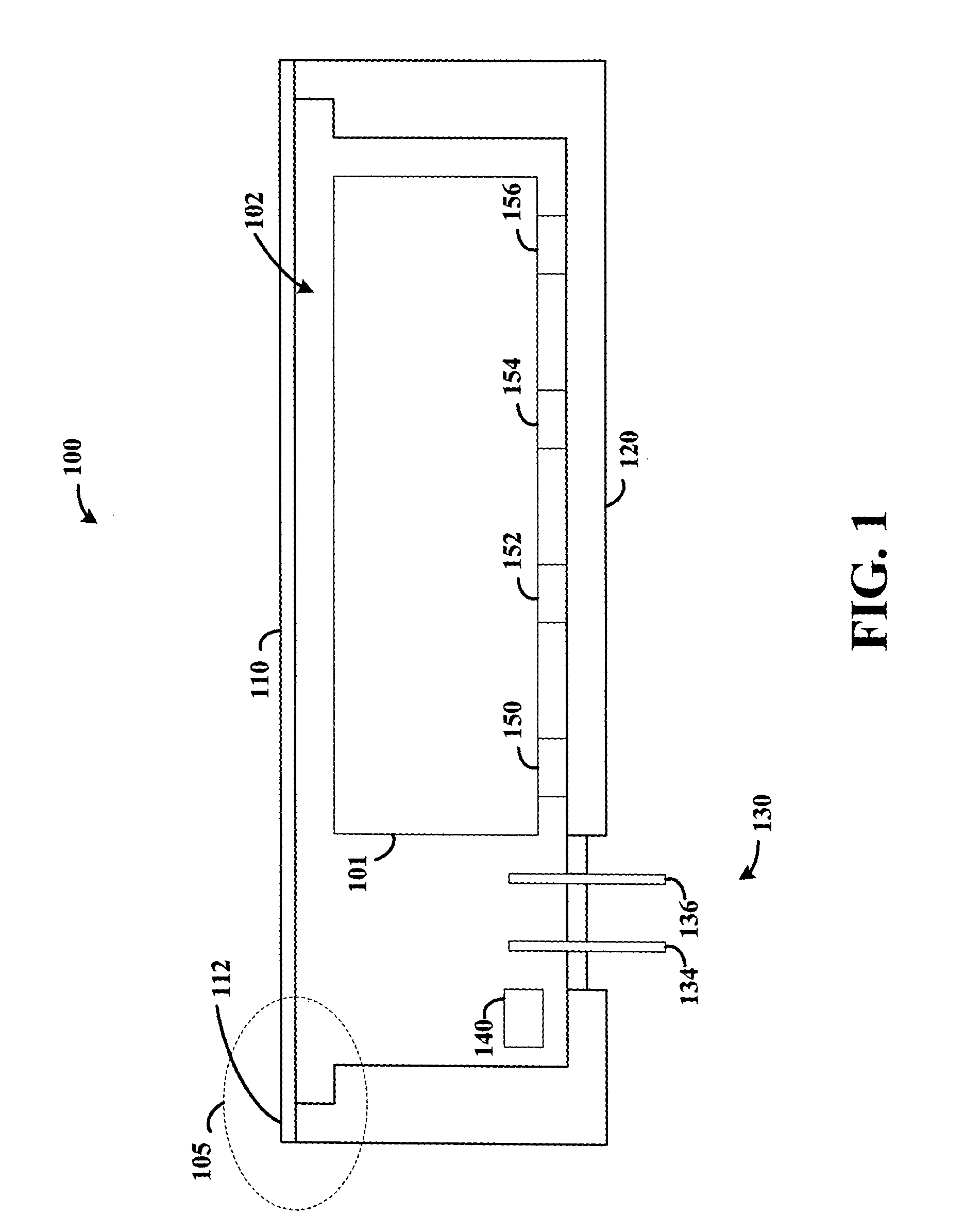

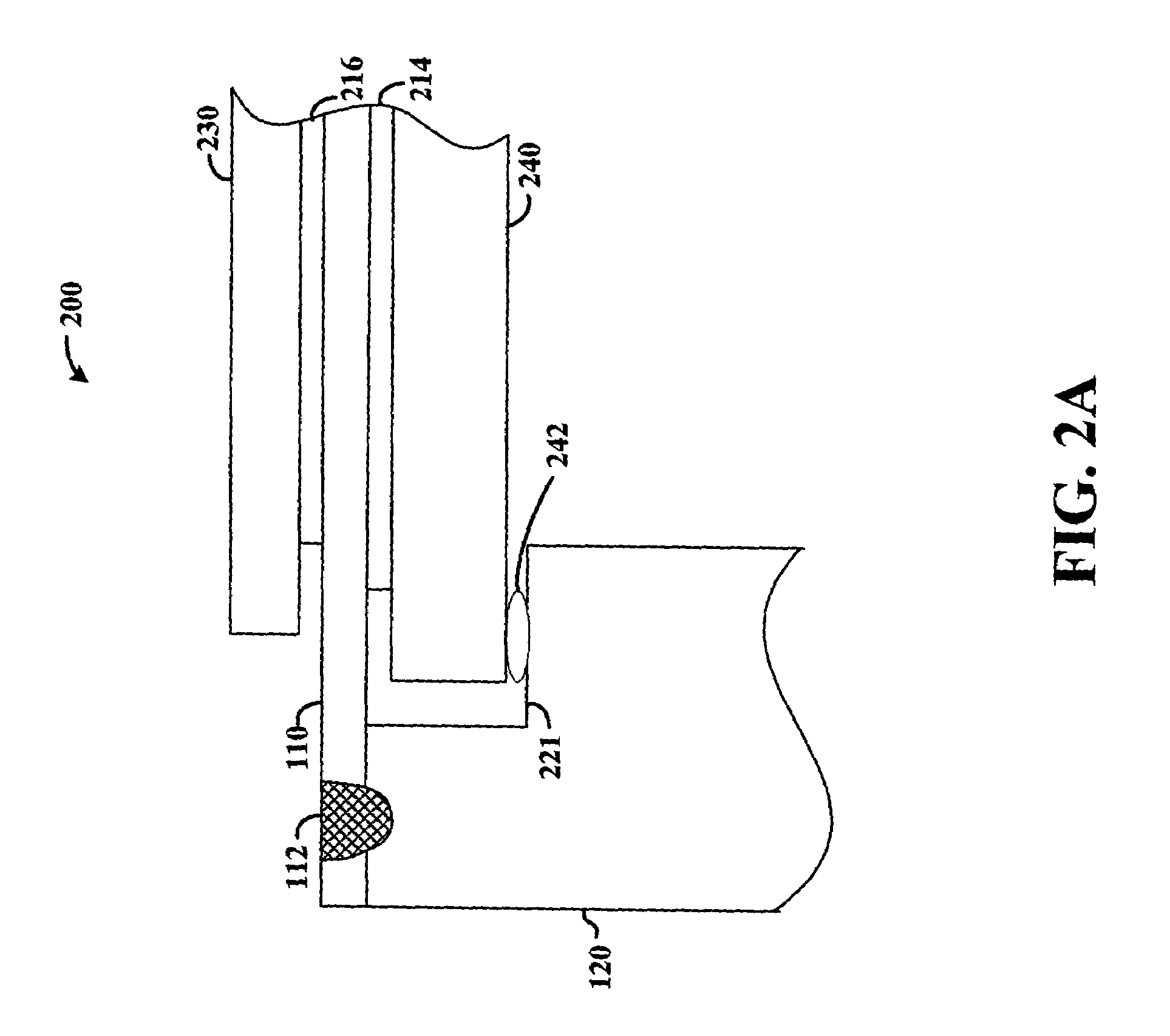

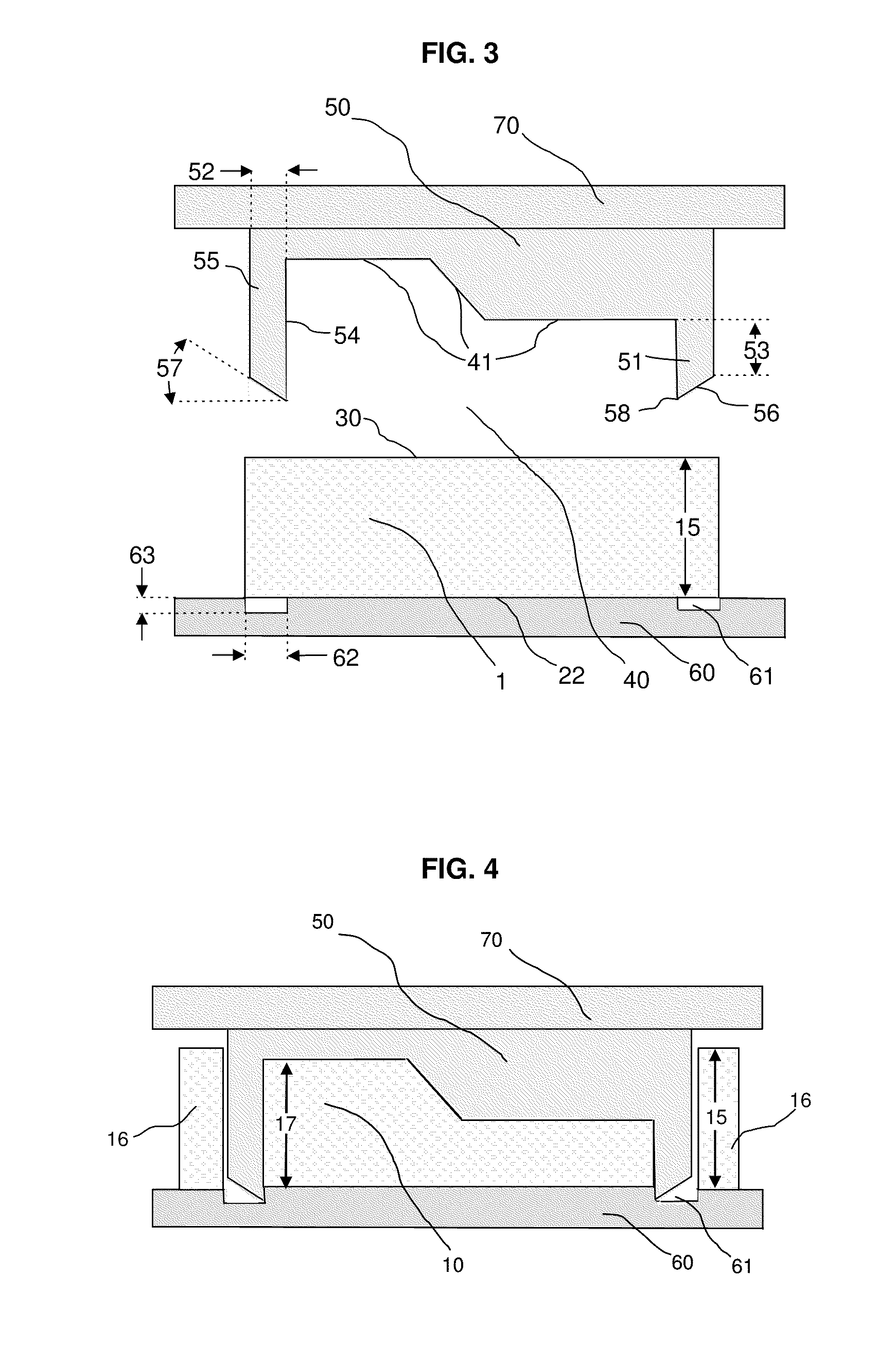

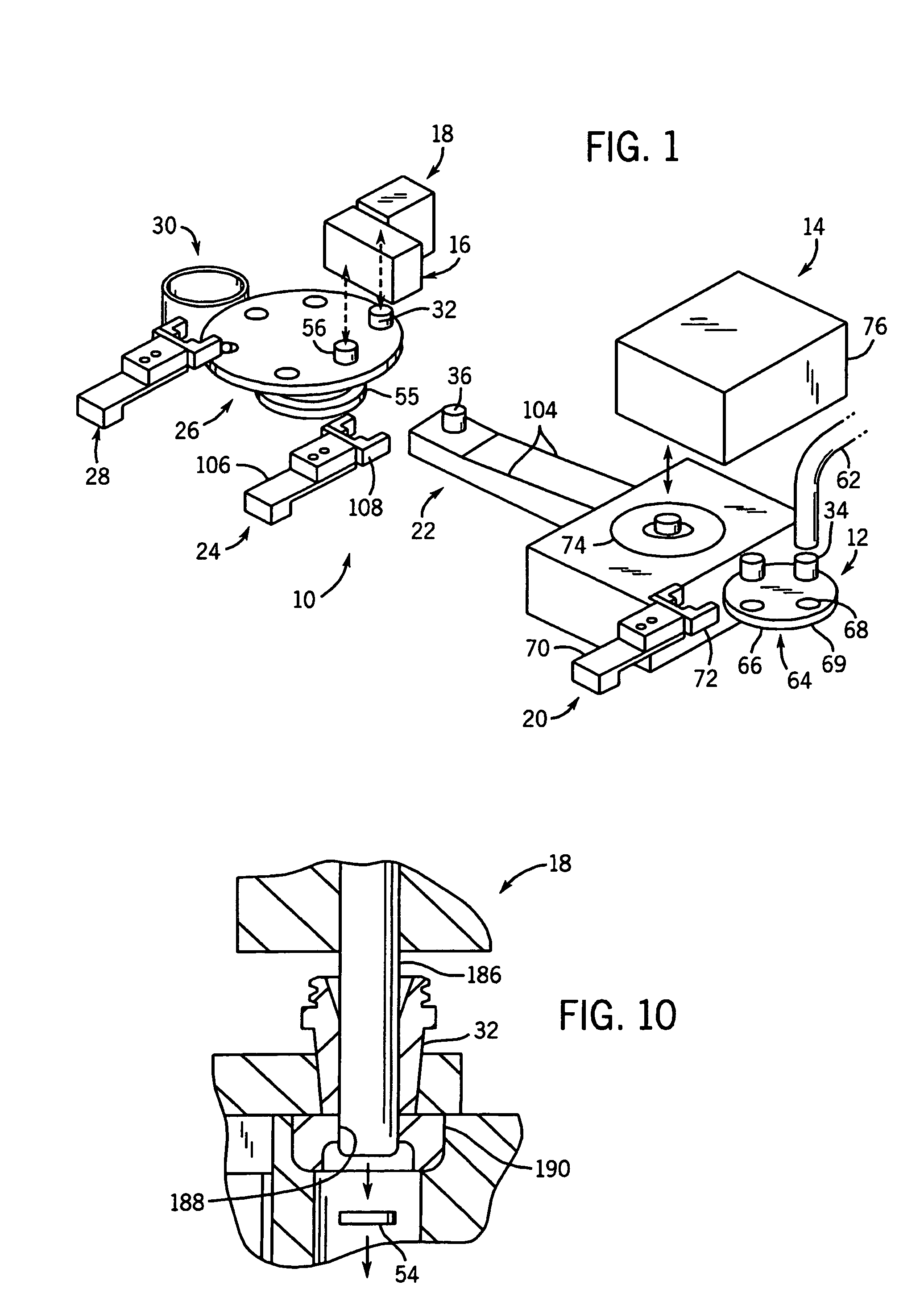

Hermetically sealed electronics arrangement and approach

InactiveUS20050068666A1Reduction of magnetic spacingImprove performanceApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionMetallic enclosureCold formed

A hermetic sealing approach involves welding an Aluminum cover onto a low-cost Aluminum housing. According to an example embodiment of the present invention, a metal housing having a base and sidewalls extending upward therefrom is adapted to receive and couple to an HDD arrangement. The metal housing is formed using material and processing (e.g., cold formed or die cast Aluminum) that are relatively inexpensive. A feedthrough arrangement including a plurality of communication pins extends through an opening in the base and is coupled thereto, with the communication pins adapted to pass signals between the inside and the outside of the metal housing. A metal cover is welded to an upper portion of the sidewalls and, with the feedthrough arrangement, hermetically seals the metal housing.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

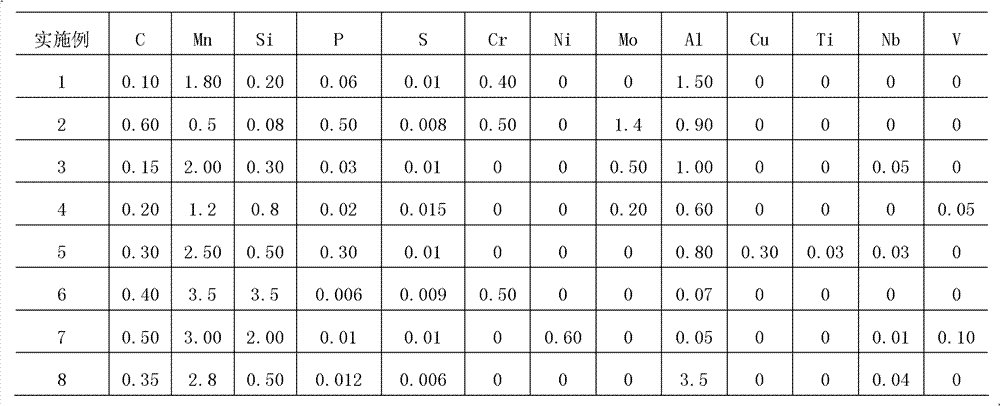

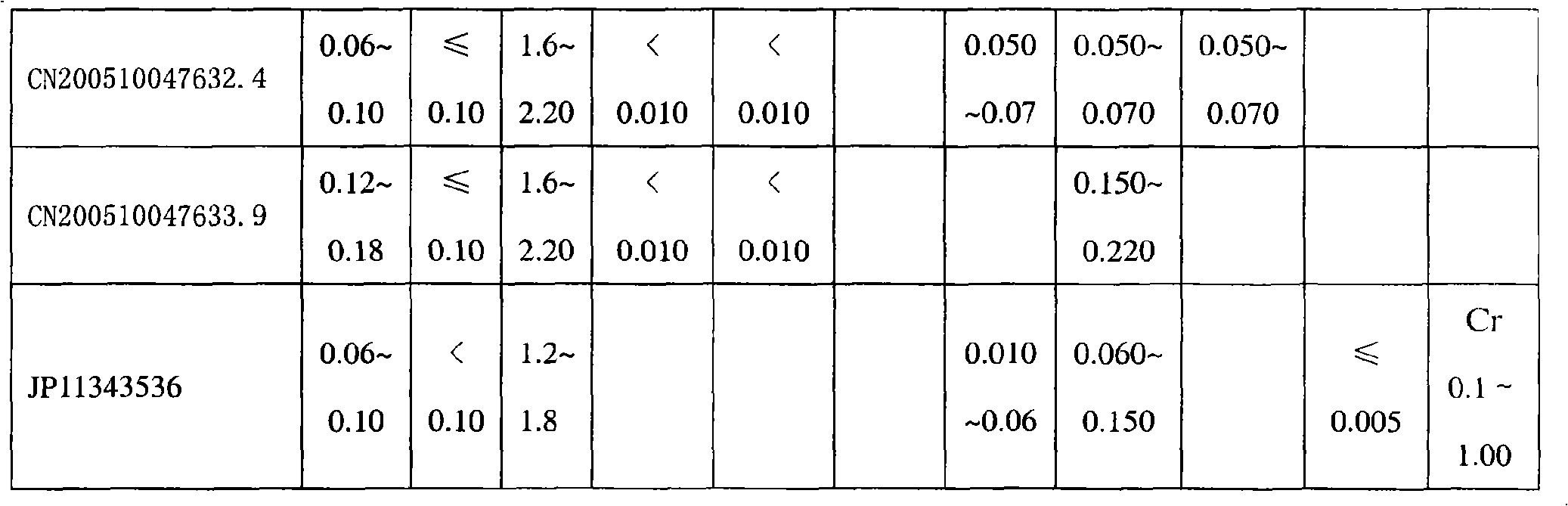

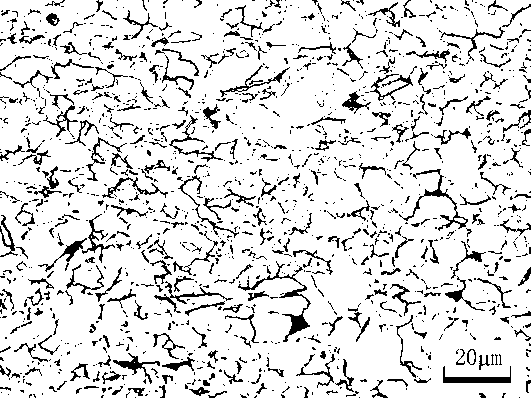

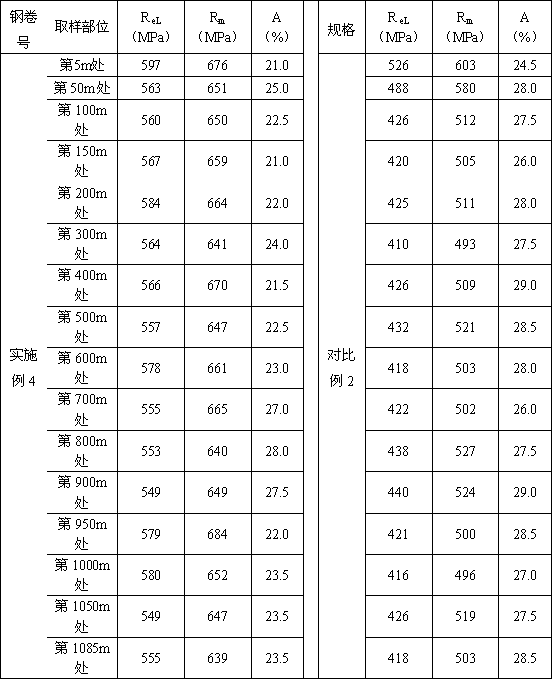

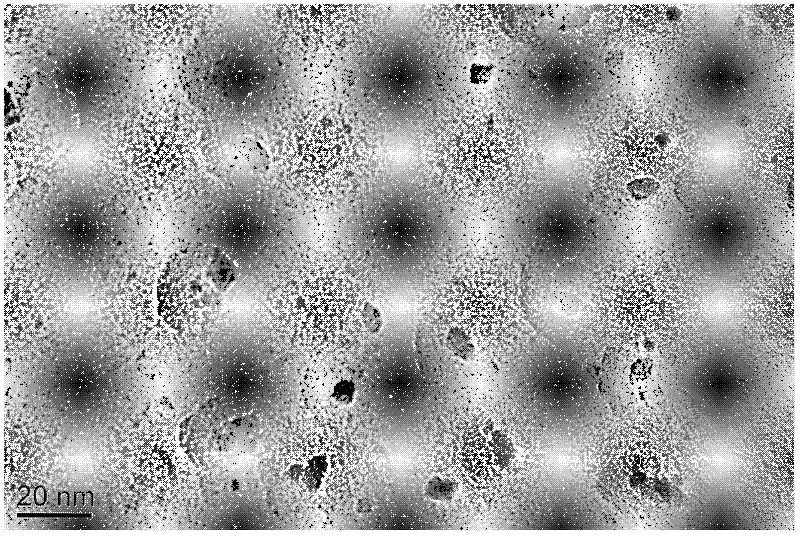

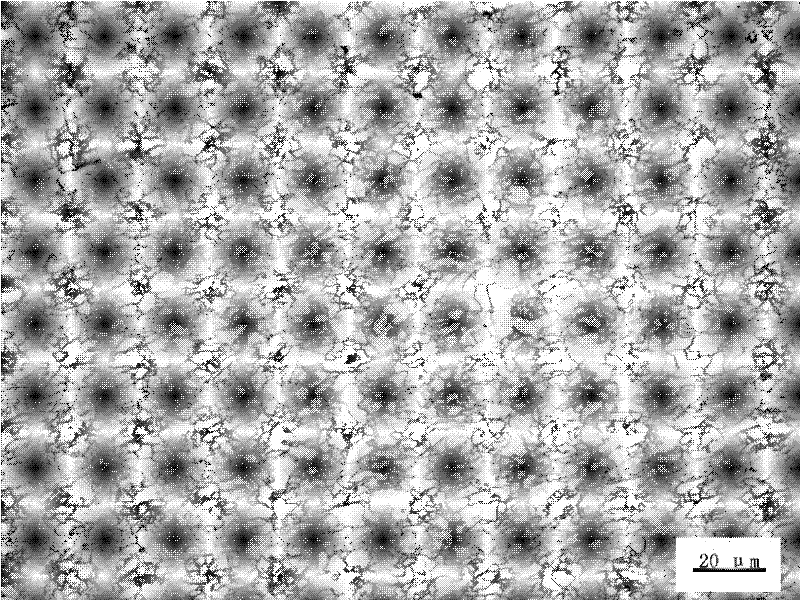

Production method of ultrahigh strength steel plate for cold forming and steel plate

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

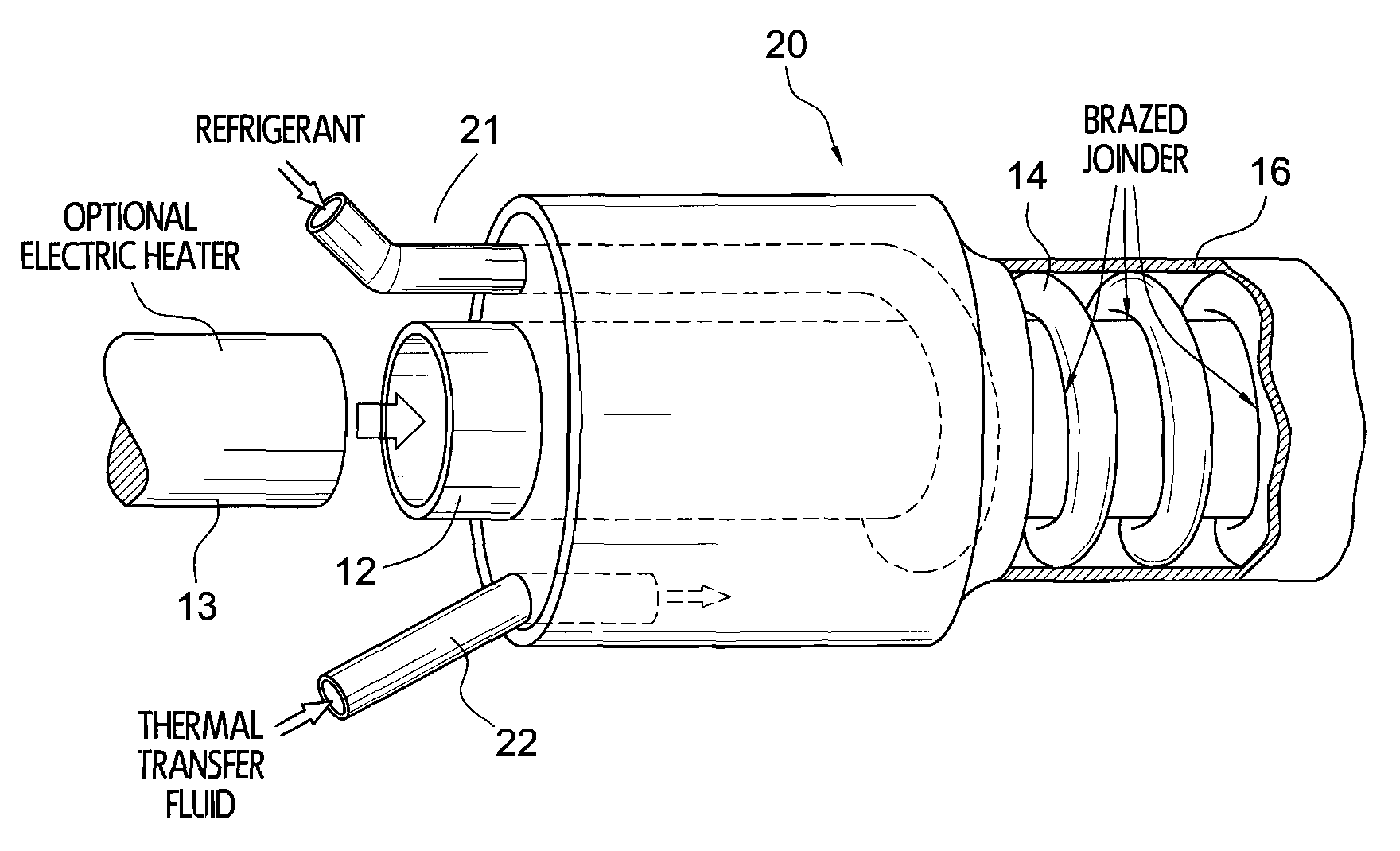

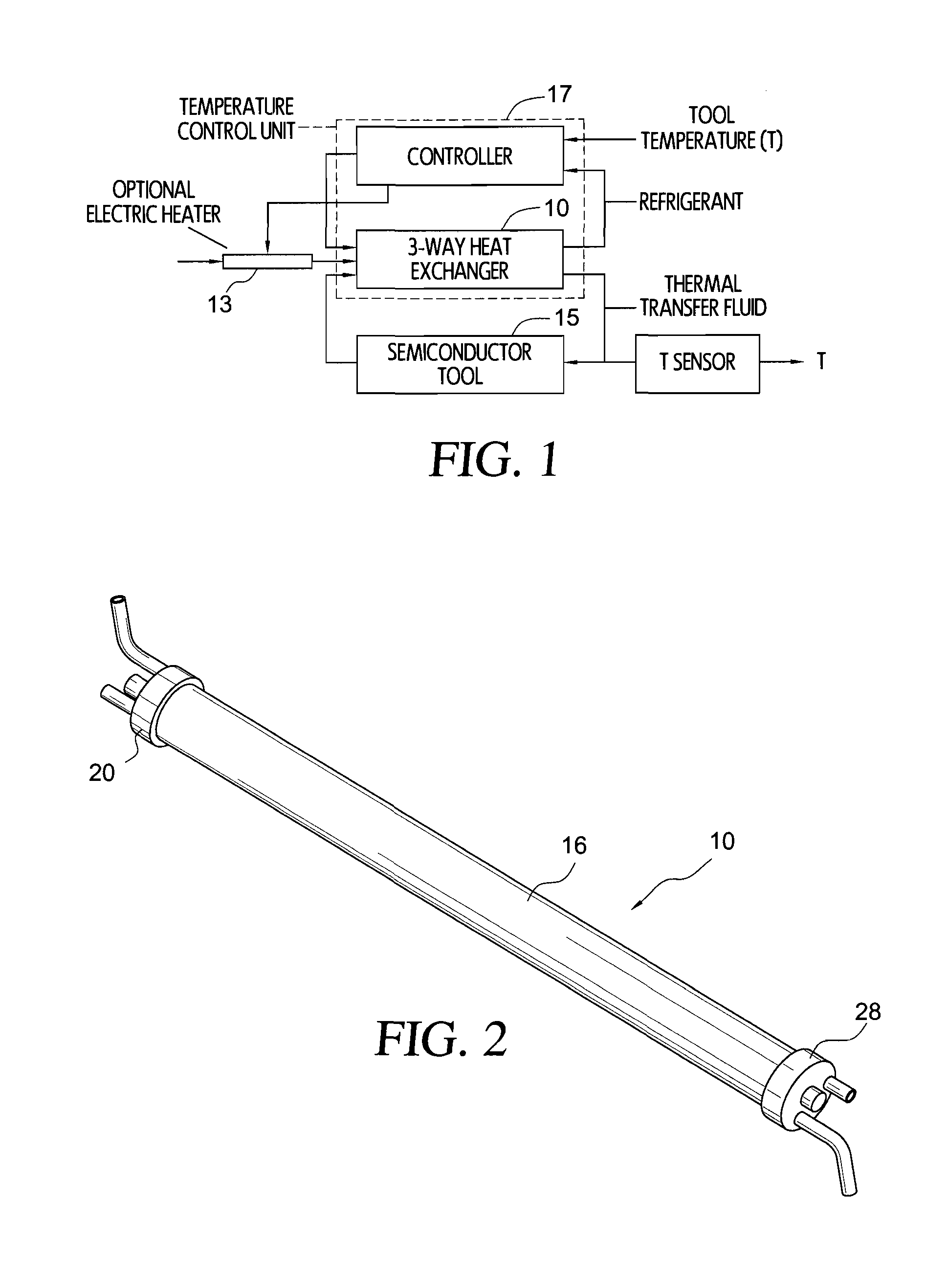

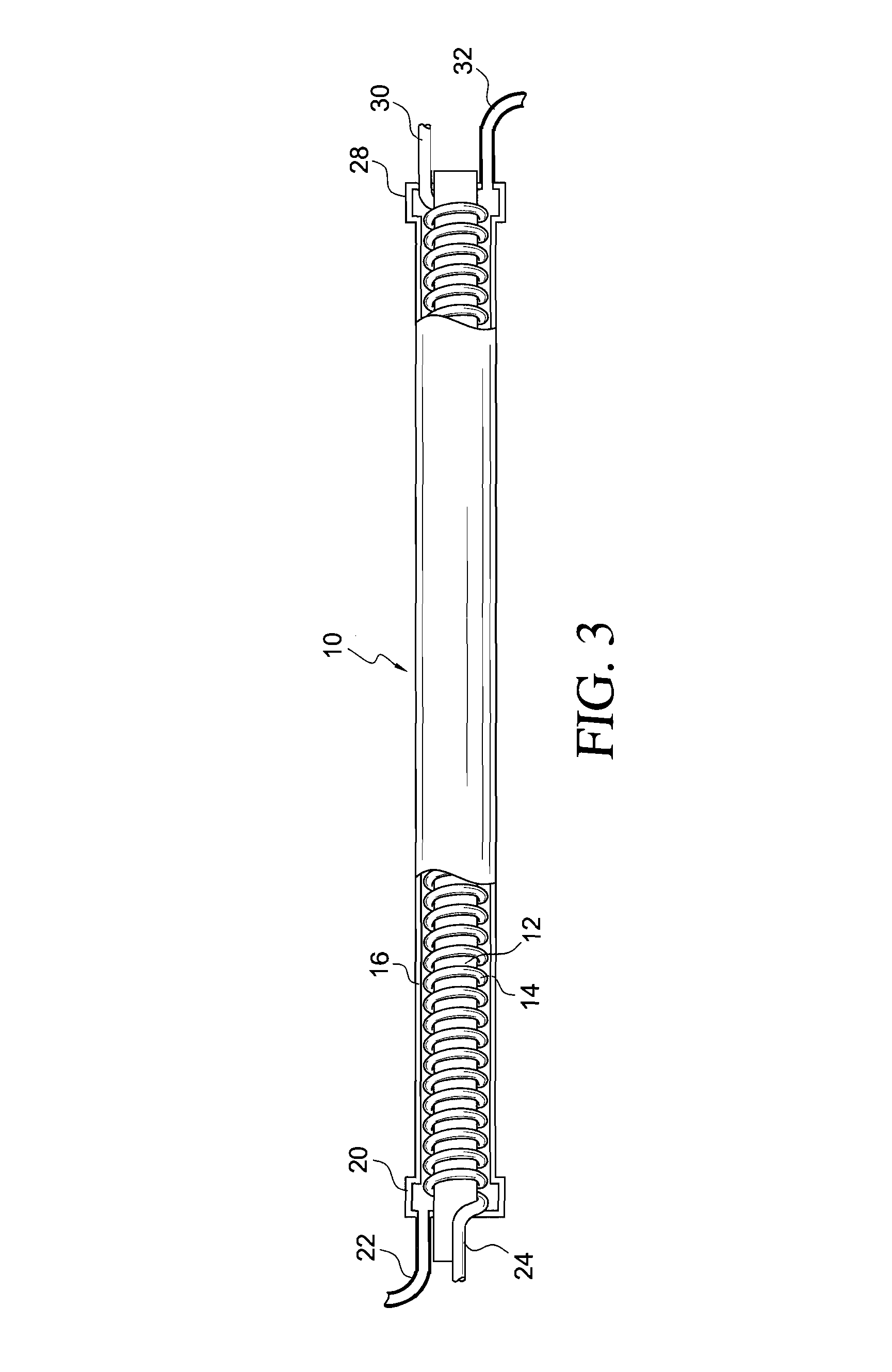

Heat exchangers for fluid media

ActiveUS7661460B1Increase temperatureReduce system costSemiconductor/solid-state device manufacturingCompression machines with several evaporatorsThermal energyCold formed

A compact heat exchanger for interchanging thermal energy between at least two fluids, one of which fluids may be a refrigerant in hot or cold form or in a liquid / vapor phase, and another of which fluids is a thermal transfer fluid. The heat exchanger may incorporate an internal heating element. The thermal transfer fluid is transported between two concentric metal tubes, while the refrigerant moves along a tubing helically wrapped about or between the tubes and is in thermal contact therewith.

Owner:BE AEROSPACE INCORPORATED

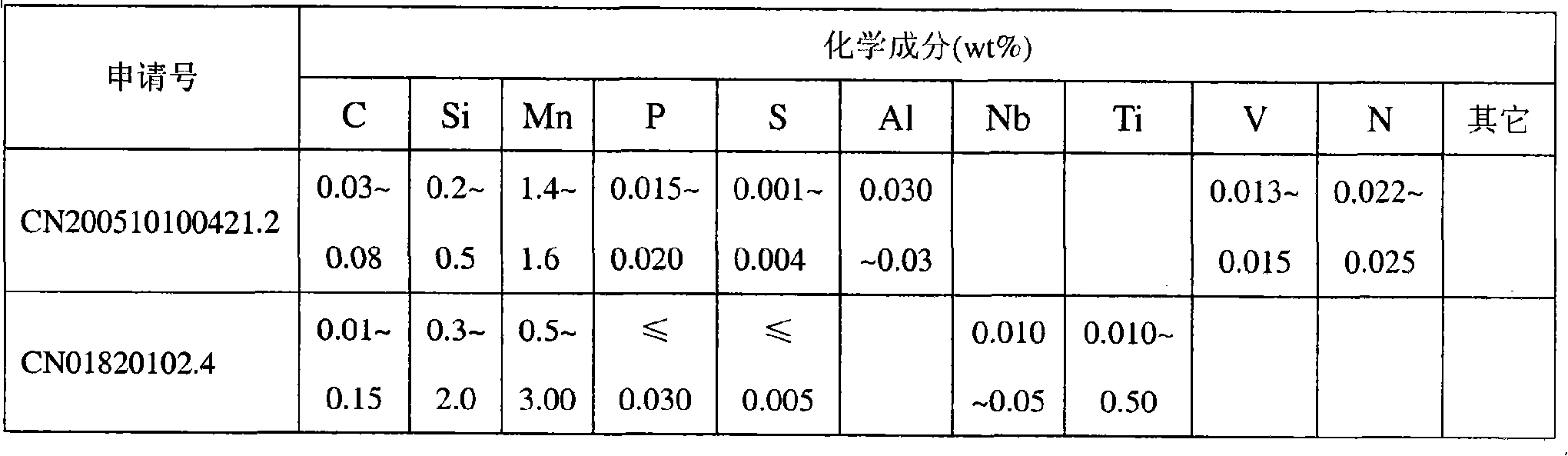

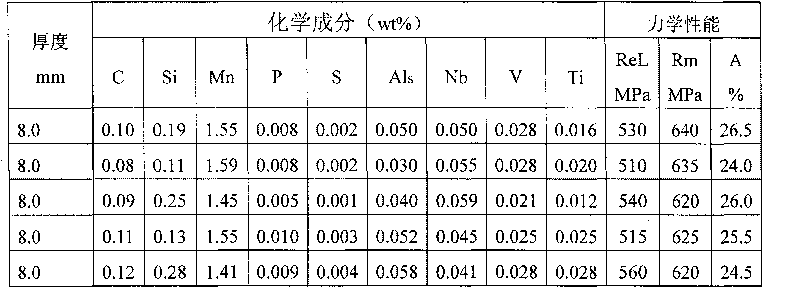

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

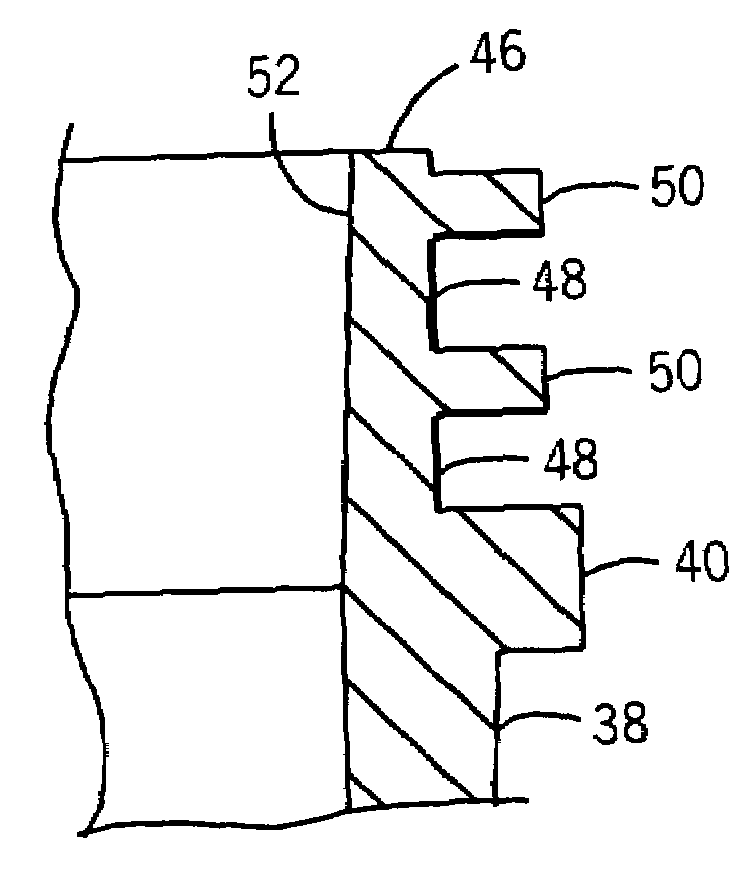

Hermetically sealed electronics arrangement and approach

InactiveUS7123440B2Preventing moisture from reaching portionsCorrosion of heads and disks can be reduced and/or eliminatedApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionCold formedHermetic seal

A hermetic sealing approach involves welding an Aluminum cover onto a low-cost Aluminum housing. According to an example embodiment of the present invention, a metal housing having a base and sidewalls extending upward therefrom is adapted to receive and couple to an HDD arrangement. The metal housing is formed using material and processing (e.g., cold formed or die cast Aluminum) that are relatively inexpensive. A feedthrough arrangement including a plurality of communication pins extends through an opening in the base and is coupled thereto, with the communication pins adapted to pass signals between the inside and the outside of the metal housing. A metal cover is welded to an upper portion of the sidewalls and, with the feedthrough arrangement, hermetically seals the metal housing.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Methods of producing high-strength metal tubular bars possessing improved cold formability

ActiveUS20070216126A1Maintain mechanical propertiesOvercome problemsTorsion springsInduction heatingAlloyHigh intensity

A method for producing a tubular bar, more particularly a stabilizer bar, is provided. The method comprises providing a tubular bar of desired size having an outer and inner surface, heating the bar to an elevated temperature, quenching the bar by application of a cooling fluid to the surfaces of the bar, and forming the tube to a desired shape without annealing. The method further provides for the composition of a high-strength, high formability carbon steel alloy to be used in conjunction with the method. Advantageously, the bar is formable without thermal processing subsequent to quenching. In this fashion, metal tubular bars, such as stabilizer bars, may be formed at reduced cost.

Owner:TENARIS CONNECTIONS

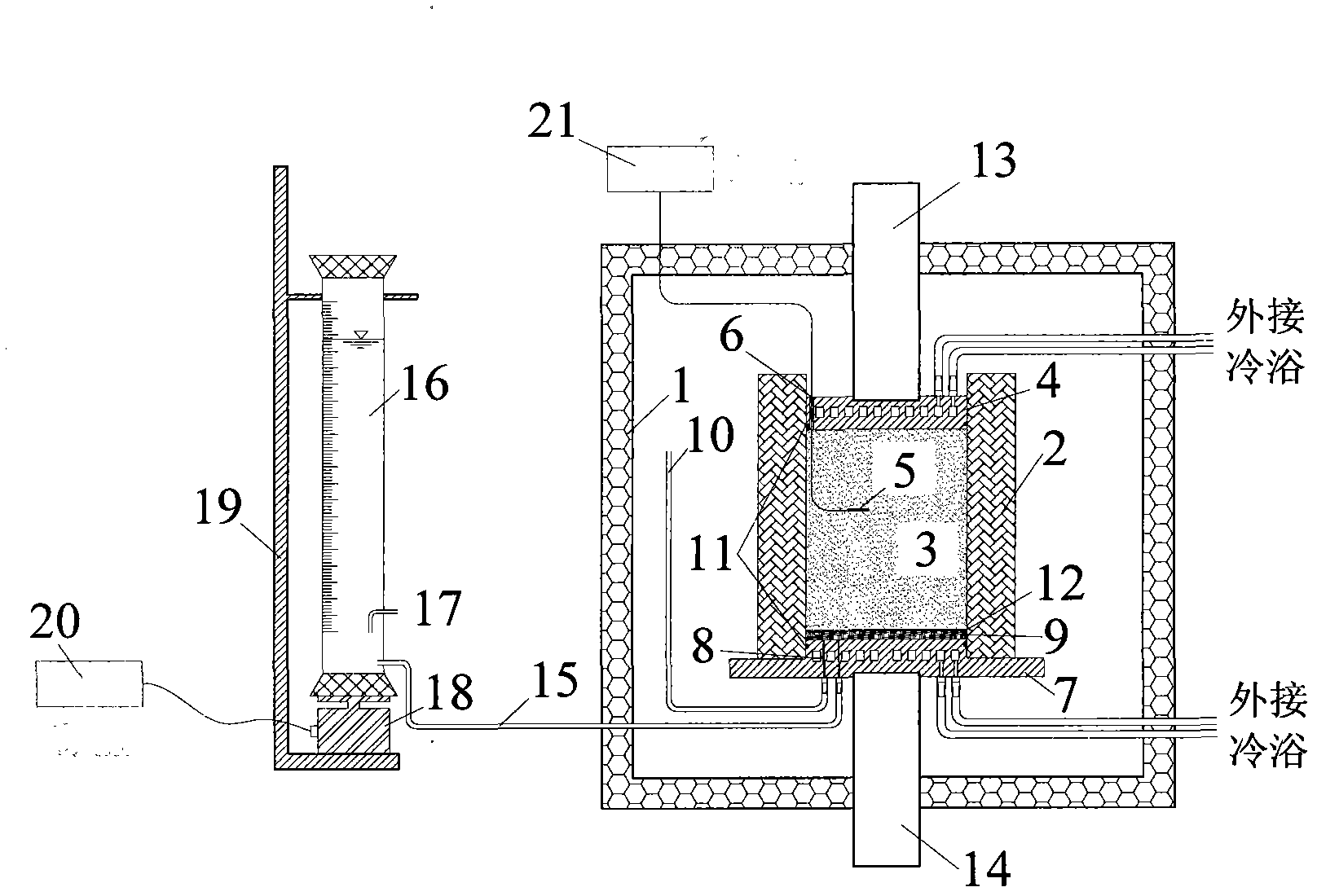

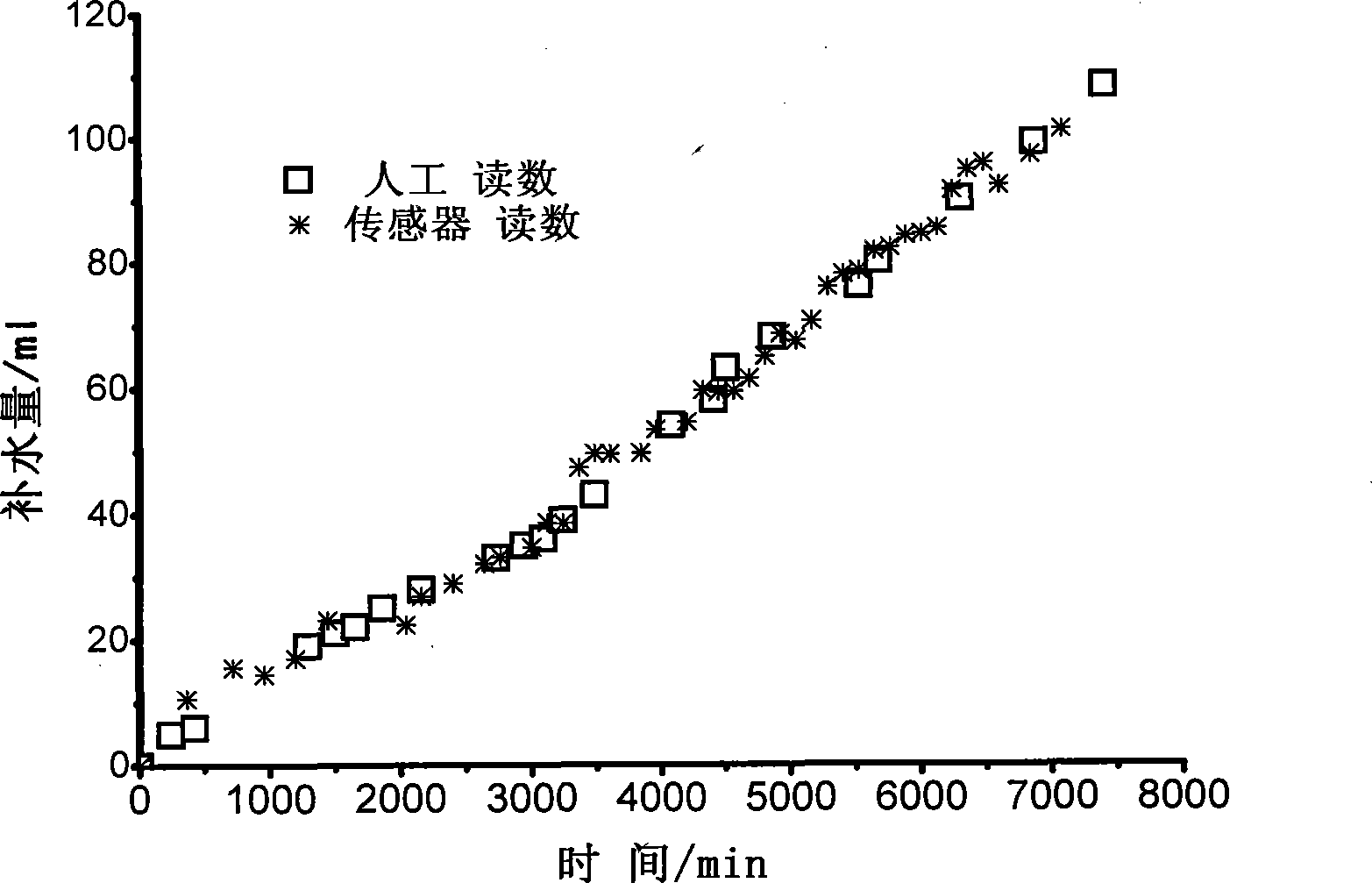

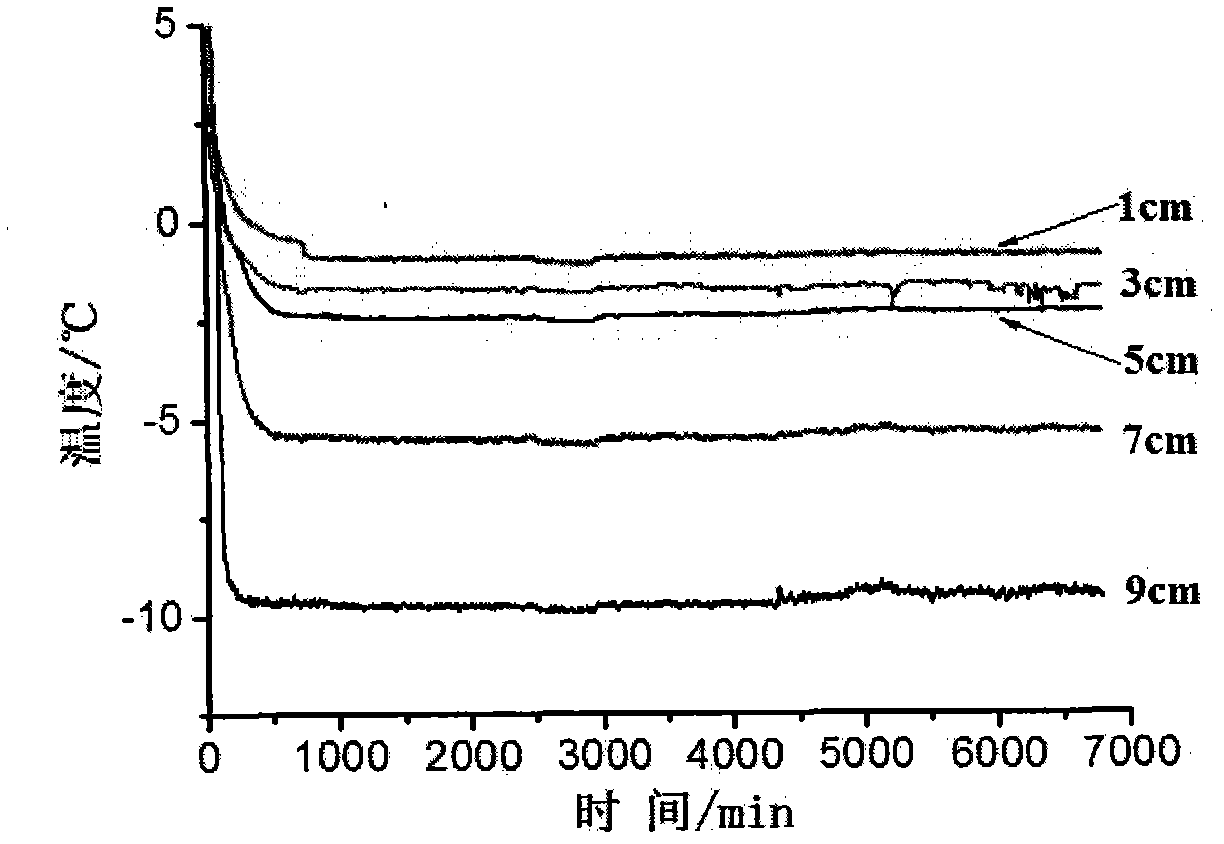

Testing system for deep soil freezing/thawing process

ActiveCN102590468AReduce distractionsMove up and down flexiblyEarth material testingGraduated cylinderCold formed

The invention relates to a testing system for deep soil freezing / thawing process, which is structurally characterized in that a temperature-controlled box is connected with an external cold bath; a high pressure-resistant organic glass cylinder is arranged on a temperature-controllable steel base; two small holes are formed in the base, one is connected with a water guide pipe, and the other is connected with a pressure adjusting pipe; a permeable stone, a piece of filter paper and a sample are sequentially arranged at the upper part of the lower base, and a temperature sensor is mounted in the sample; a temperature-controllable upper press head is arranged at the upper part of the sample; a line leading-out hole is formed in the upper press head, and is sealed through sealant after the line is lead out; the upper press head is connected with the transmission rod of a testing machine; a measuring cylinder is connected with the sample through the water guide pipe; and the measuring cylinder is arranged on a weighing sensor and fixed through a bracket. By adopting the testing system, the freezing / thawing process of the deep soil can be rather systematically researched, so as to obtain the frost heaving rate and the water absorbing / draining rate of the deep soil which is in different depths frozen under the different temperature gradients. The testing system provides the technical guarantee for the research in clarifying the action of the external load on the forming processes of the freezing soil and the frozen soil cold-formed structures, and the mutual action of the temperature, the moisture content and the pressure of the soil body in the process of freezing under the high-pressure action.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

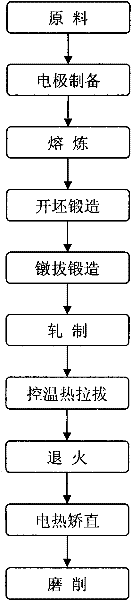

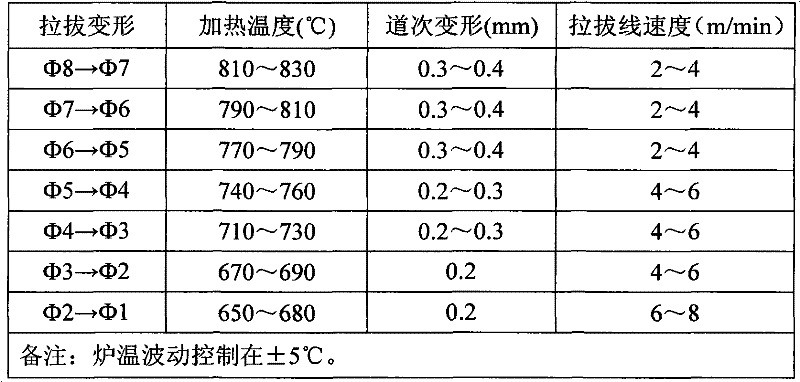

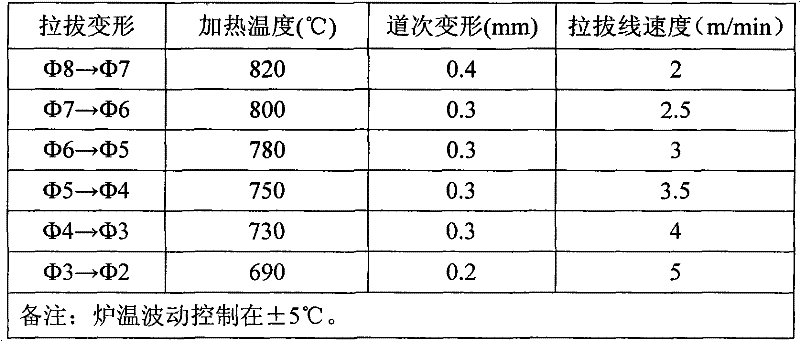

Medical high-strength titanium alloy wire and preparation method thereof

The invention provides a medical high-strength titanium alloy wire and a preparation method thereof and relates to component control of a Ti-6Al-4V titanium alloy wire having high strength and good cold molding characteristic and a preparation method thereof. The component control of the Ti-6Al-4V titanium alloy wire is as follows: based on weight percent, 6.0%-6.3% of main element Al, 4.2%-4.5% of V, 0.13-0.15% of interstitial element O and 0.08%-0.12% of Fe. The alloy obtained according to the component control is subjected to smelting, cogging and forging, multiple heating numbers of upsetting and forging, large-deformation rolling, temperature-control hot drawing, stress relief annealing, electric heating straightening and grinding processes so as to prepare the high-strength titanium alloy wire. The Ti-6Al-4V titanium alloy can obtain high strength (tensile strength of more than or equal to 1200Mpa and elongation A of more than or equal to 8%) and excellent plasticity, and can be applied to a medical Kirschner wire fixing system.

Owner:西安赛特金属材料开发有限公司

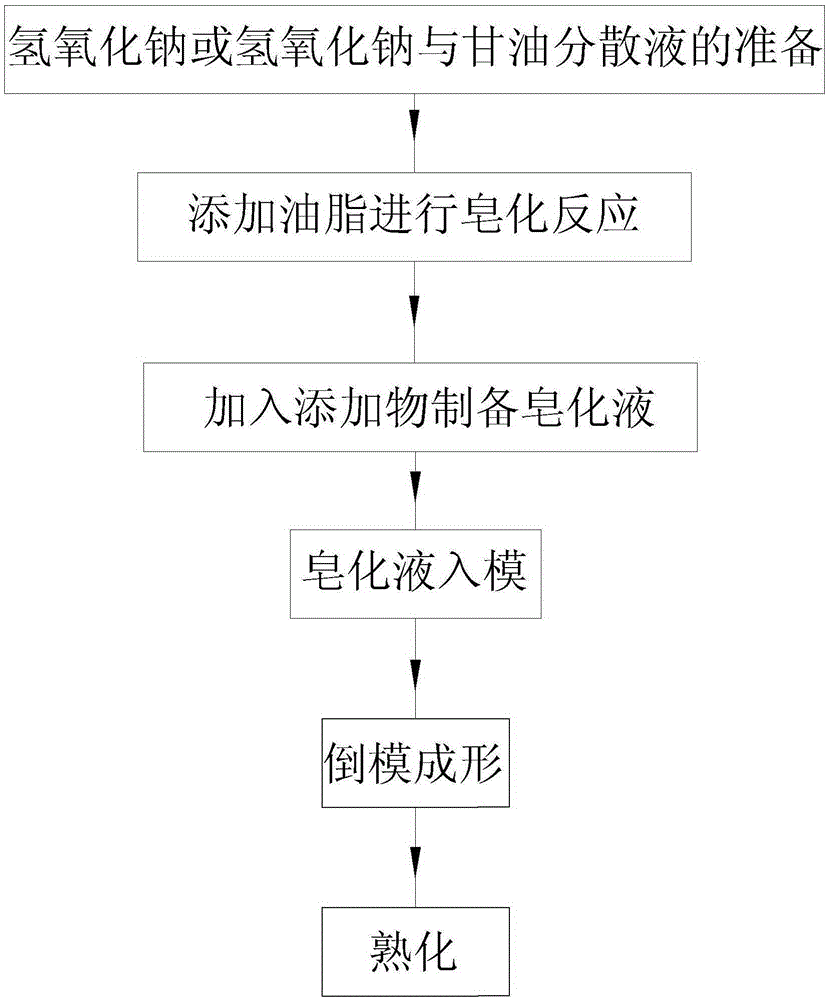

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

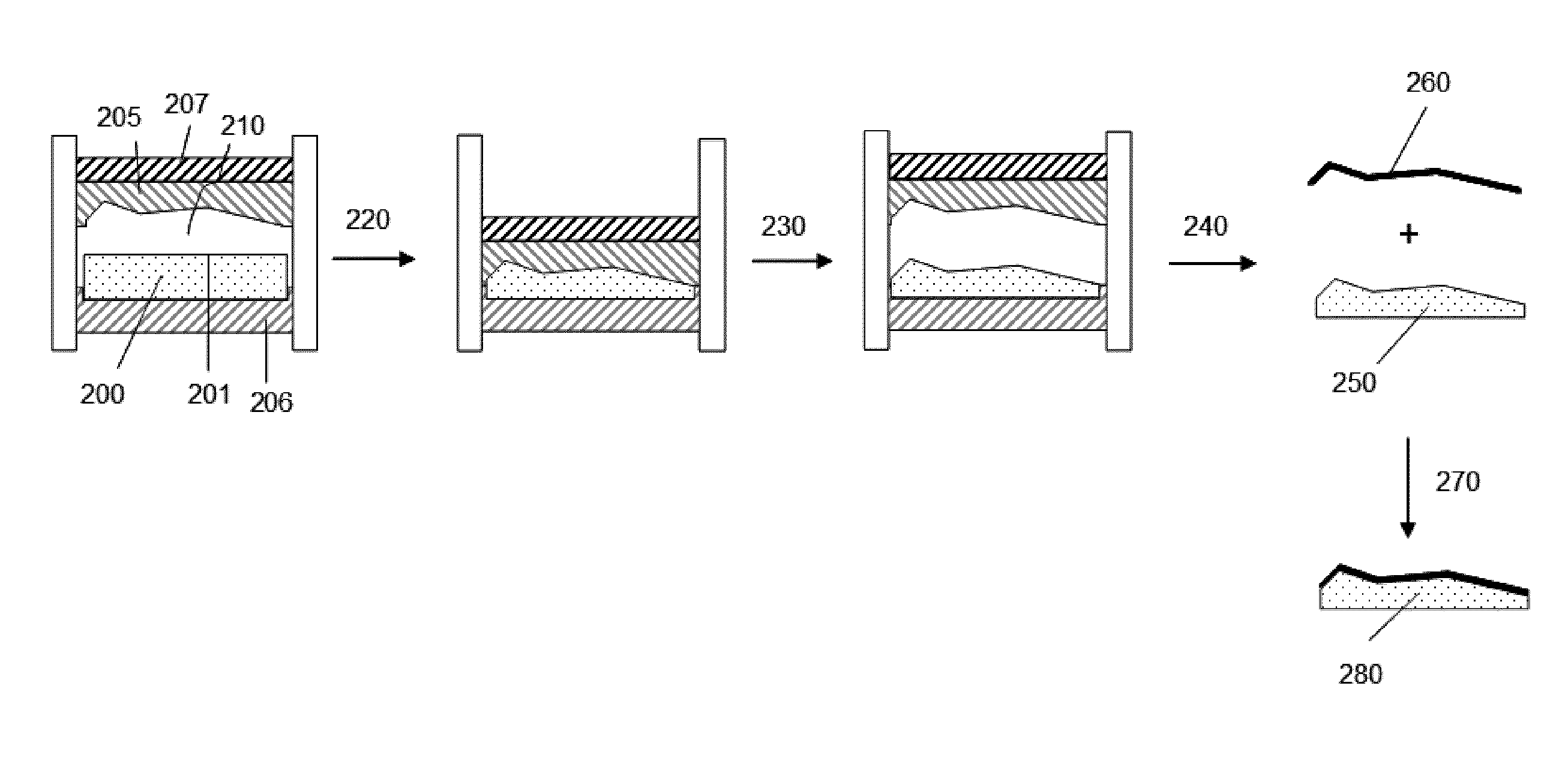

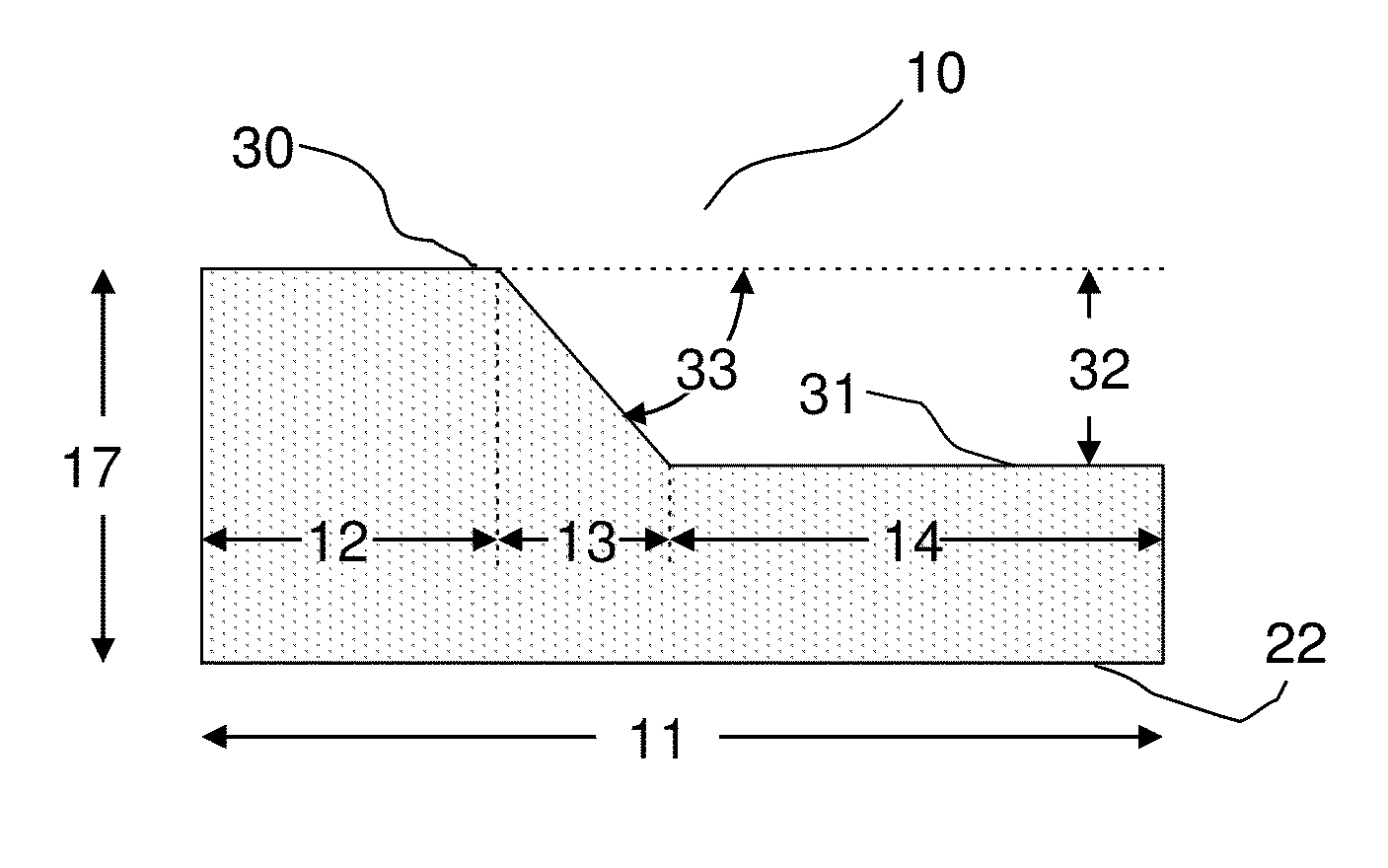

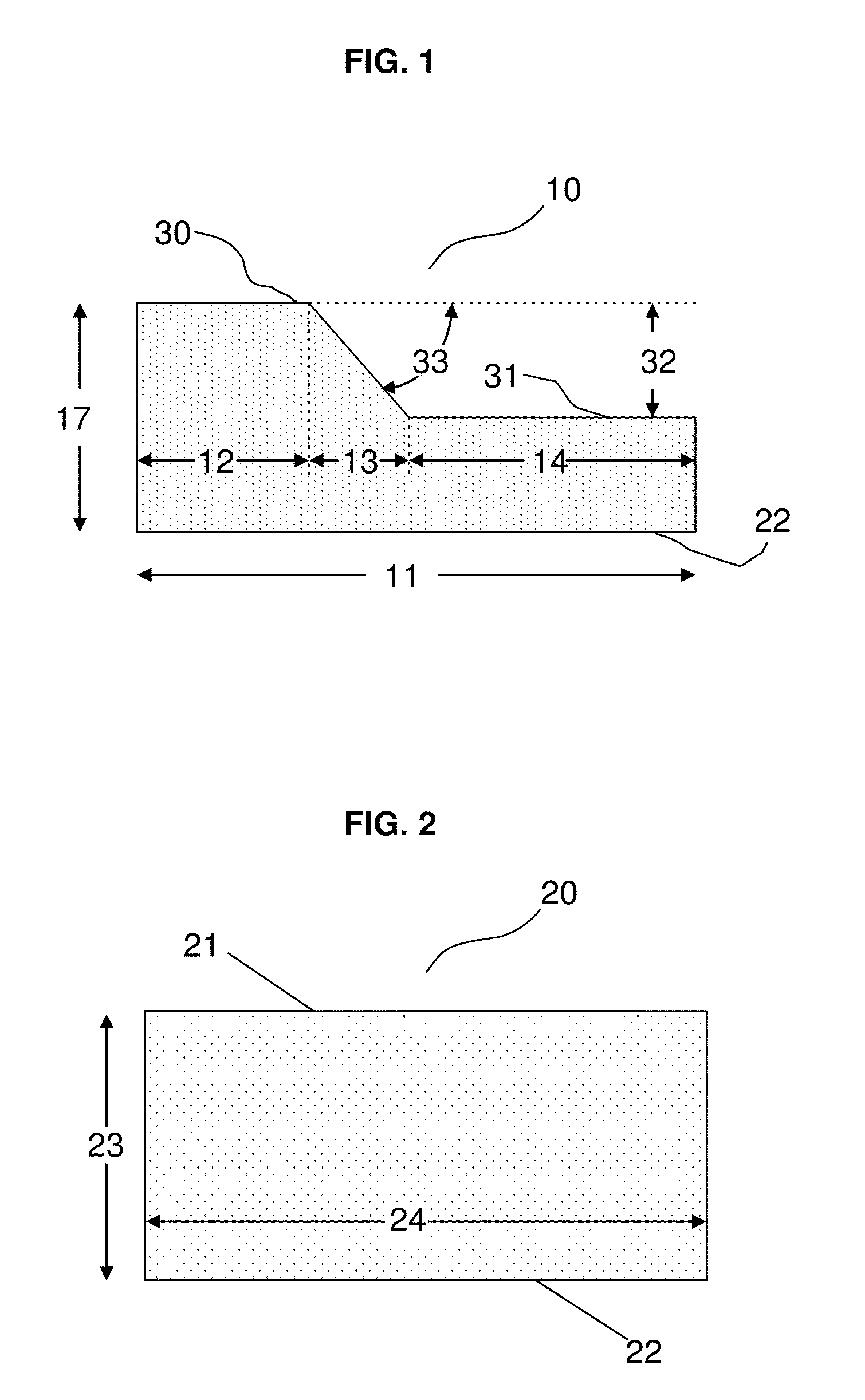

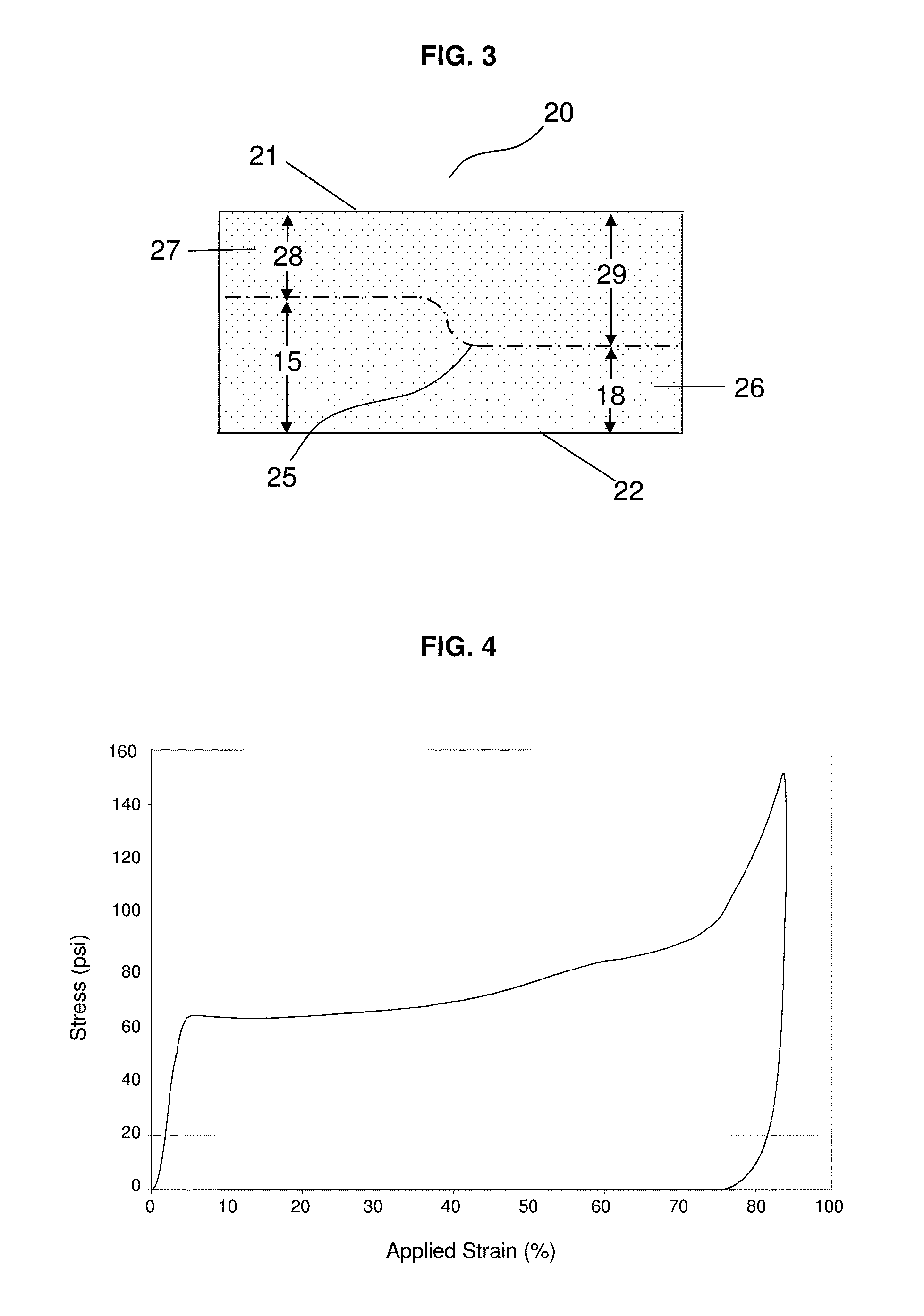

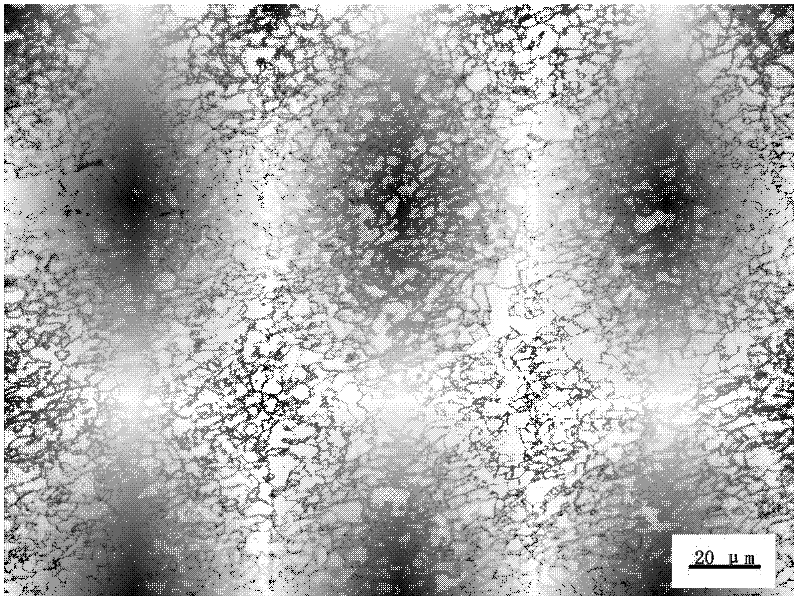

Shaped foam composite article

InactiveUS20110293914A1Simple and cost-effectiveLong cycle timeLaminationLamination apparatusCold formedPolymer science

The present invention is a method to manufacture shaped foam composite articles comprising a foam core and one or more skin and shaped foam composite articles made therefrom. Specifically, cold formed shaped foam articles having an upper and lower surface having a skin applied to one or both of the surfaces. Preferably the foam comprises a styrenic polymer foam and the skins may independently be mono-layered or multi-layered. The shaped foam article and the skin may be made from the same or different materials. In the case where there are more than one skin, the skins may comprise the same or different materials.

Owner:MAURER MYRON J +7

Corrosion resistant material

A material which is suitable for equipment in oilfield technology and a process for making the material. The material consist essentially of C, Si, Mn, Cr, Mo, Ni, Cu, N in certain weight percentages, with the balance iron and contaminants due to manufacture. The material is hot formed in a condition free of nitride precipitates and without precipitated associated phases. After a cooling, it is cold formed in a condition free of ferrites. The material has certain values of relative magnetic permeability, yield strength (Rp0.2), notched impact strength, fatigue strength under reversed stresses, and fracture appearance transition temperature.

Owner:SCHOELLER BLECKMANN OILFIELD TECH +1

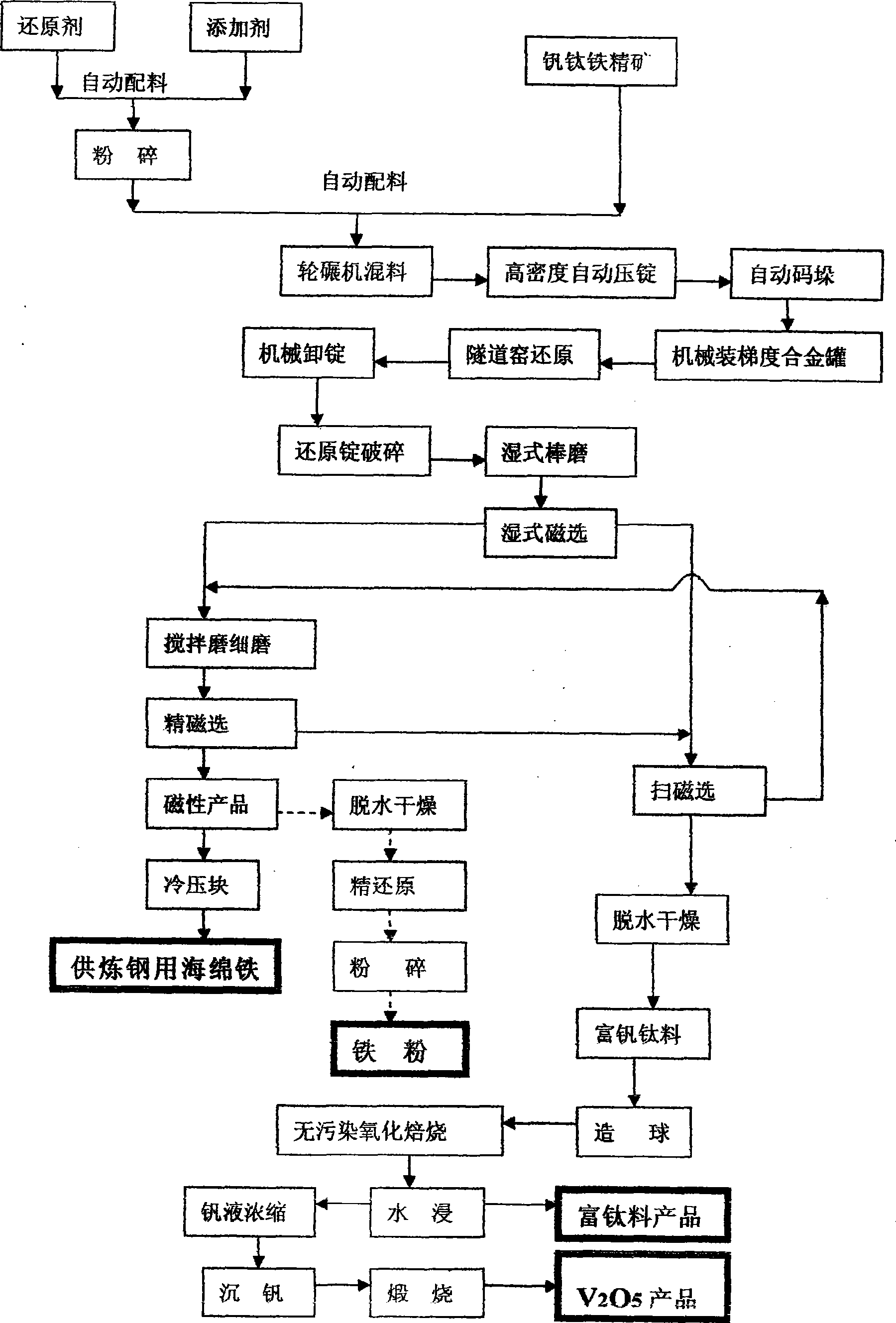

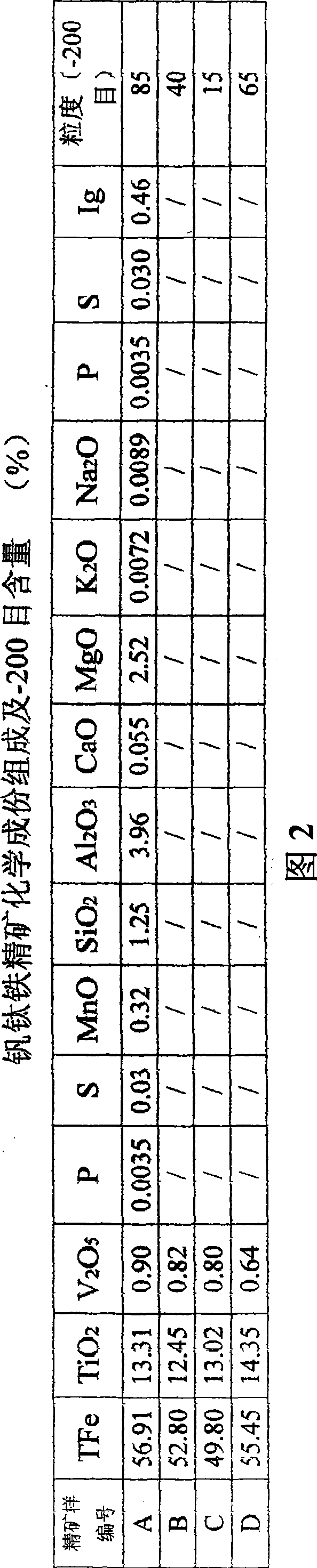

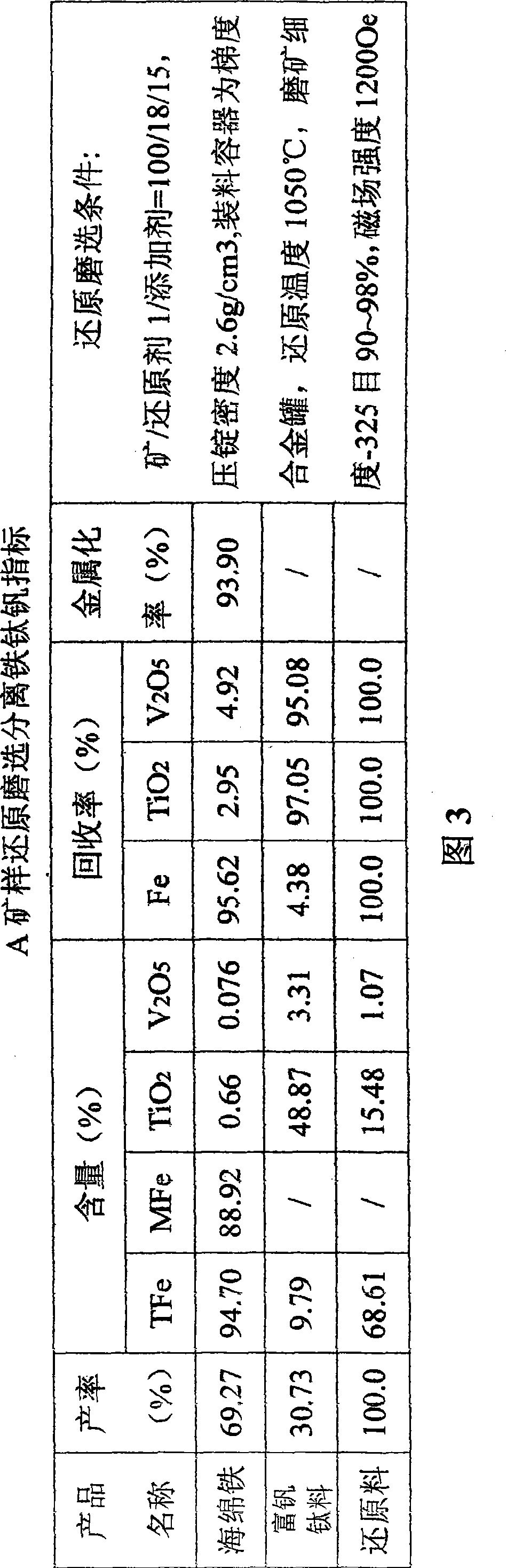

Novel industrialization method for comprehensive utilization of vanadium ferrotitanium ore concentrate

InactiveCN101418370AHigh Sponge Iron YieldHigh yieldVanadium oxidesMagnetic separationSteelmakingTunnel kiln

The invention relates to a novel industrialized method for comprehensively utilizing vanadium titanium iron ore concentrate. Raw material, an additive and a solid reducing agent are made into a higher-density round ingot through a full automatic press after being mixed evenly by an edge mill; the mixed material is charged into a gradient alloy can and is directly reduced in a tunnel kiln; and after being crushed, the reduced ingot is ground and is magnetically separated to obtain high-quality sponge iron with 92 to 96 percent of TFe and material containing abundant vanadium and titanium with 2.8 to 3.4 percent of V2O5 and 48 to 49 percent of TiO2. After being cold formed, the sponge iron is used for electric steelmaking or is sold as iron powder through deep processing. The material containing abundant vanadium and titanium can be used for producing V2O5 with the purity more than or equal to 98.5 percent through a simplified wet method vanadium extraction process; and vanadium slag with the TiO2 content more than or equal to 48 percent can be used as sulfuric acid method titanium white or other industrial raw materials. The method can greatly improve the capacity of the tunnel kiln and the service life of a charging vessel, has high comprehensive utilization degree, reliable technology, investment conservation and low production cost, energy conservation and emission reduction, and little pollution, and creates conditions for industrialization.

Owner:CHANGSHA DONGXIN MINING & METALLURGICAL TECH DEV

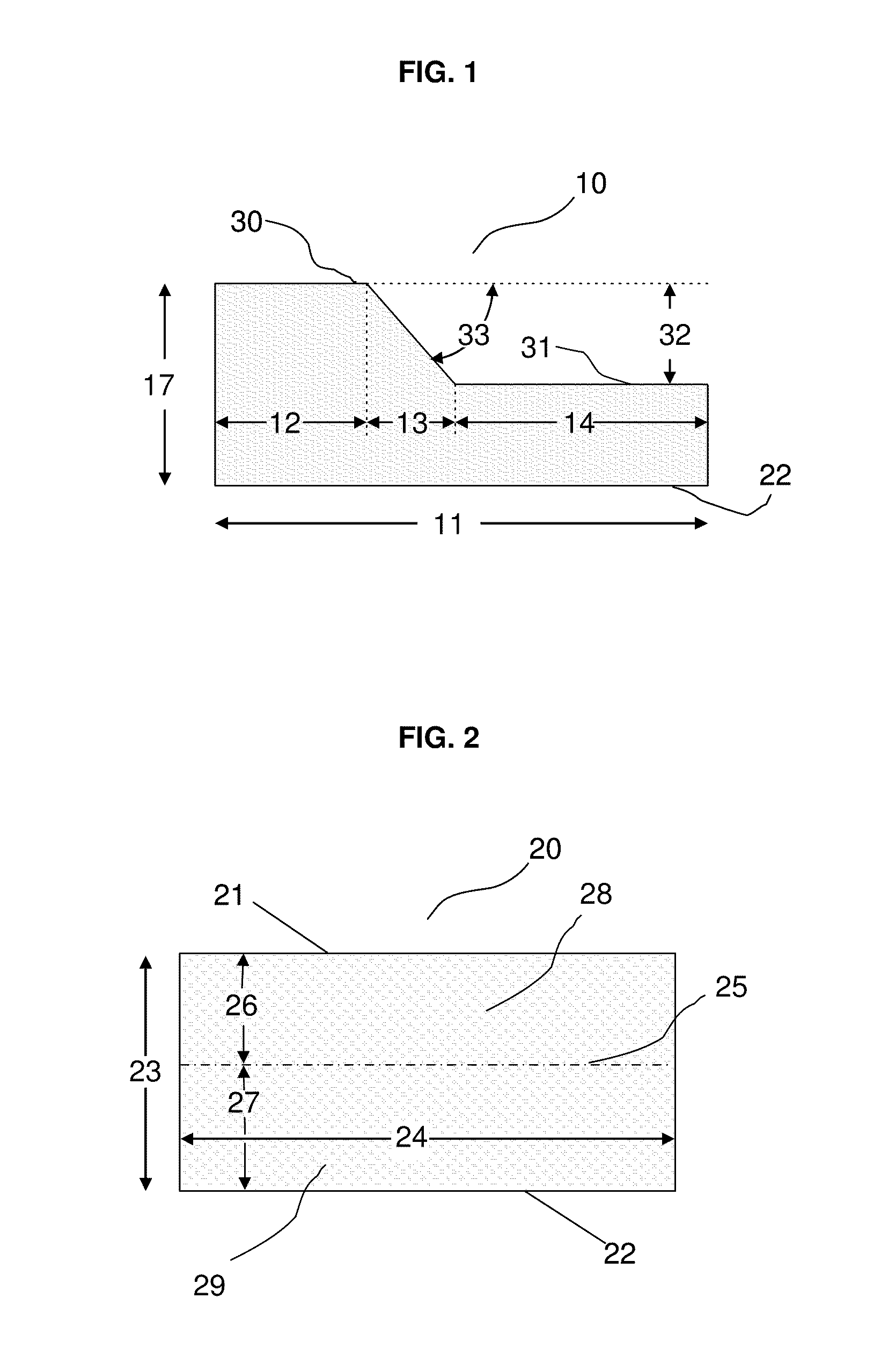

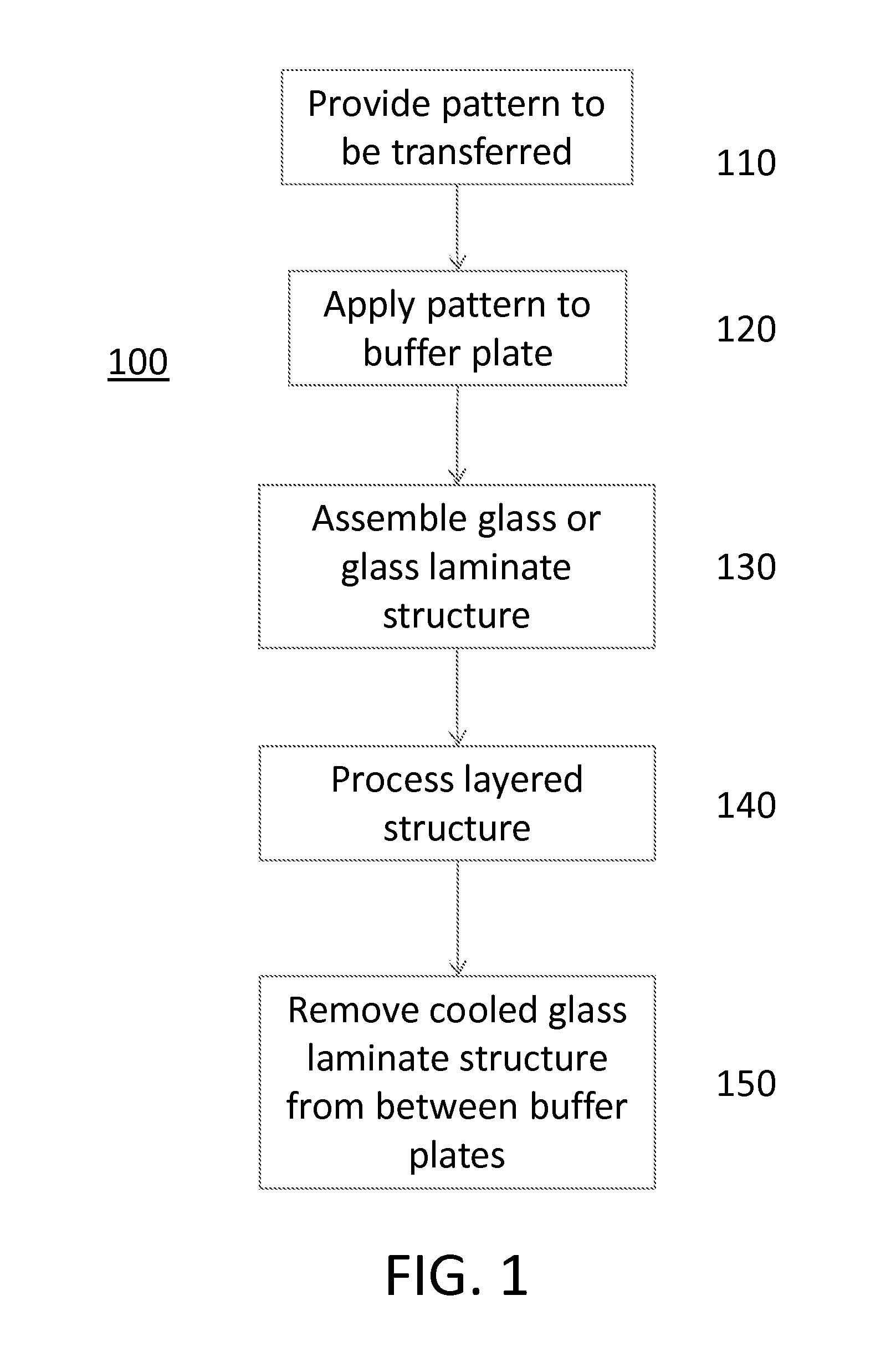

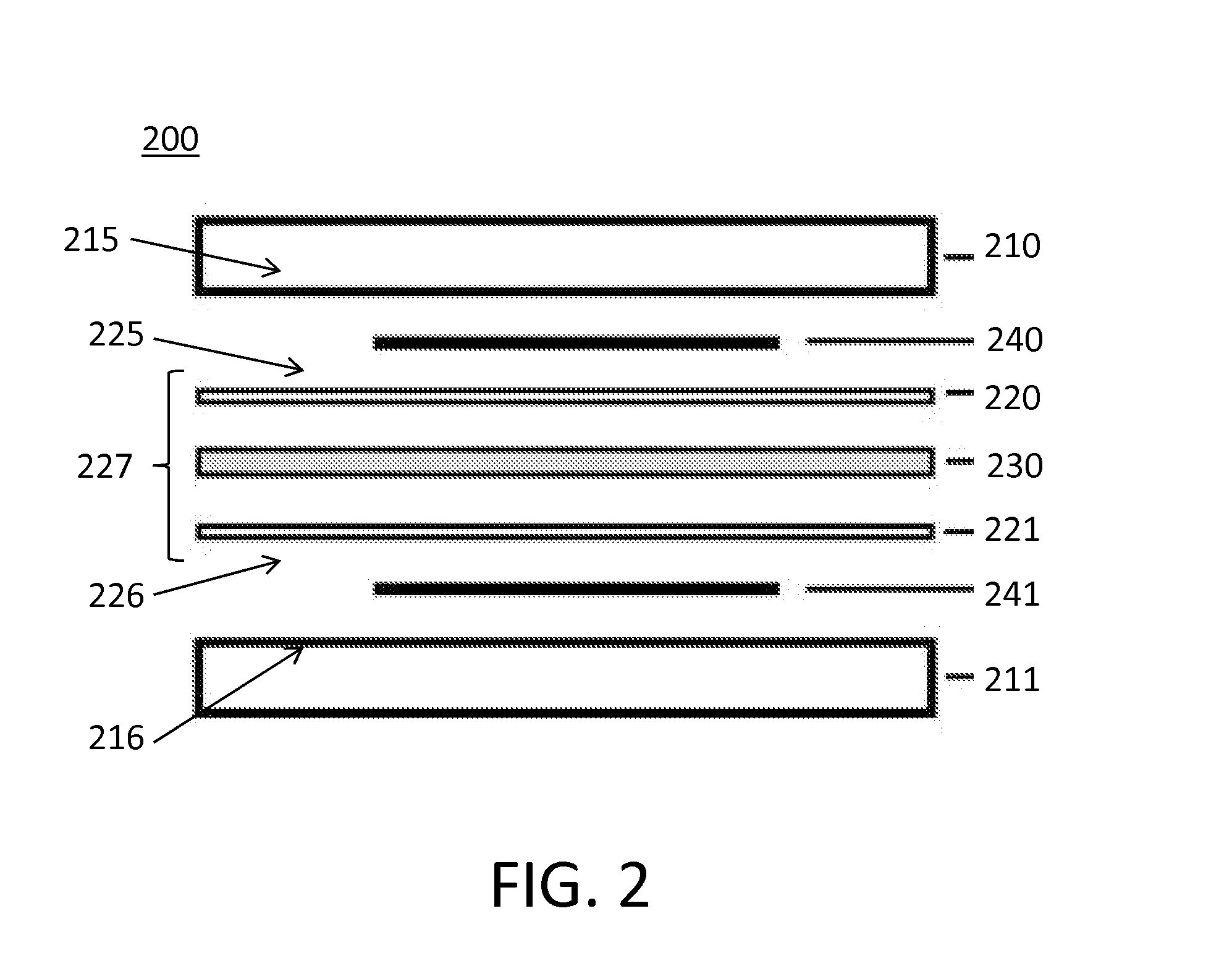

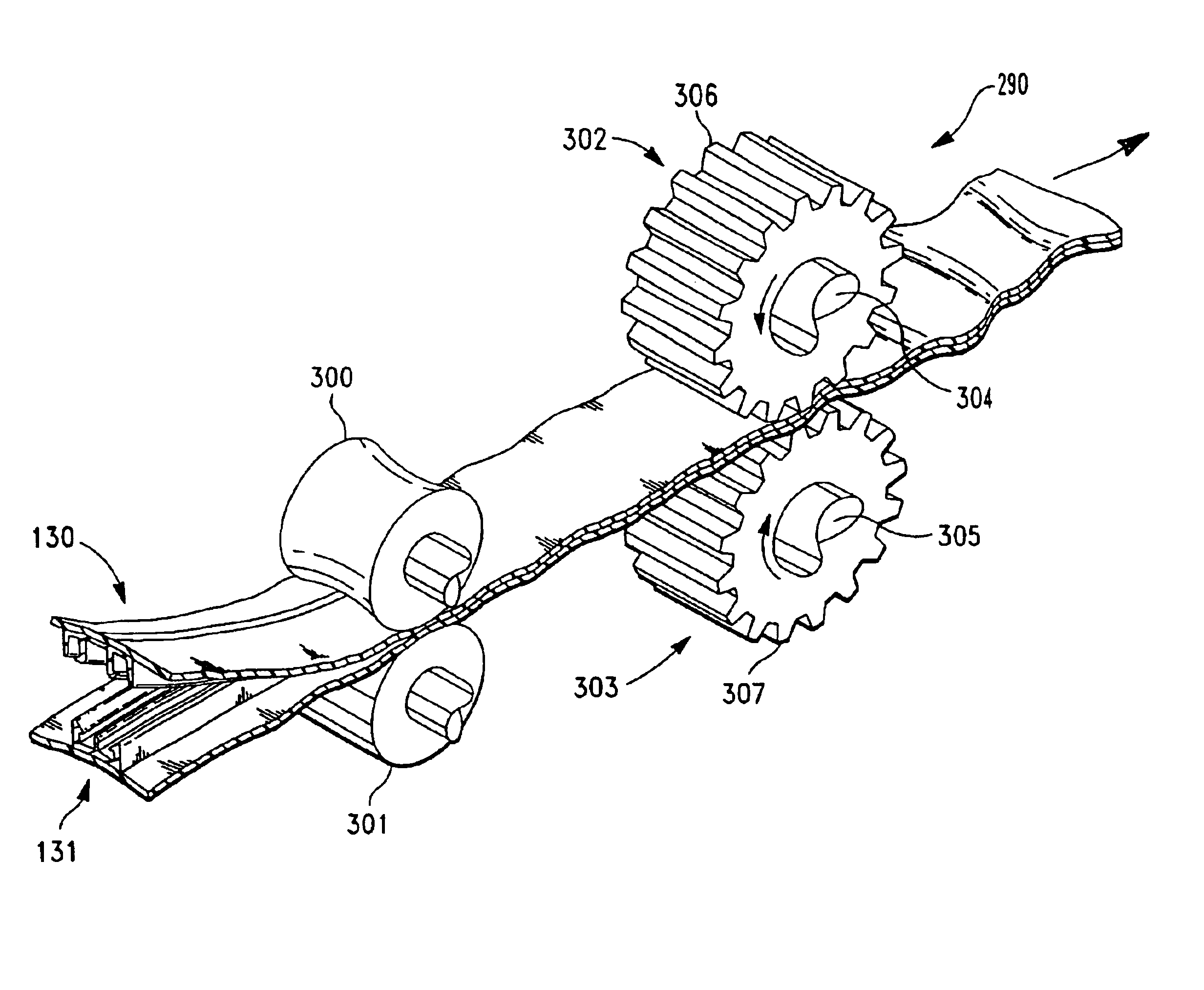

Methods for forming patterns in thin glass laminate structures

InactiveUS20160297176A1Tendency to deformSpecial ornamental structuresLaminationCold formedEngineering

A method of cold forming a glass laminate structure. The method includes assembling a multi-layer structure having two buffer plates and a glass laminate structure intermediate the two buffer plates, wherein one or both of the two buffer plates includes a pattern formed thereon or therein or the multi-layer structure includes non-deformable materials forming a pattern. The method further includes cold forming the glass laminate structure in the autoclave by heating the assembled structure to a temperature about 5 to 10 degrees above the softening point of the polymer interlayer for a predetermined period of time at a predetermined pressure. After processing the glass laminate structure can be removed from between the buffer plates wherein the pattern formed in or on the one or both buffer plates or non-deformable materials has been transferred to the glass laminate structure as a function of variances of thicknesses in the glass laminate structure.

Owner:CORNING INC

Cold-forming die steel collars anticentripetal composite casting technique for rail beam and section

The invention discloses a centrifugal composite casting technology for a cold working die steel roll collar used for a rail beam and section mill. The chemical compositions by weight percentage are as follows: outer layer compositions: 1.2 to 2.0 percent of C, less than 0.05 percent of P, less than 1.0 percent of Si, less than 0.05 percent of S, less than 1.0 percent of Mn, less than 1.0 percent of Ni, 10 to 15 percent of Cr, 0.1 to 1.0 percent of Mo, 0.1 to 1.5 percent of V, and the balance being Fe; core compositions: 1.2 to 3.0 percent of C, less than 0.05 percent of P, 1.0 to 3.0 percent of Si, less than 0.05 percent of S, 0.5 to 2.0 percent of Mn, less than 1.0 percent of Cr, less than 1.0 percent of Ni, less than 1.0 percent of Mo, and the balance being Fe. The centrifugal casting technology is adopted to manufacture the cold working die steel roll collar used for various rail beam and section mills; a core adopts high-toughness graphitic steel when the outer layer obtains high wearing resistance; and reasonable casting parameter matching is designed to guarantee the good combination of cold working die steel and the core. Compared with products produced by the prior forging method, the technology has equivalent application effect and low manufacturing cost, and the performance-price ratio is far higher than that of the forging production method. The technology realizes the casting which substitutes the forging, and satisfies the development direction of the industry.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

ActiveCN102839321AIncrease the effective Ti contentImprove precipitation strengthening effectCold formedLaminar cooling

An ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level comprises the chemical components by weight: 0.02-007%of C, less than or equal to 0.50% of Si, 0.50-1.40% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.11% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O, or 0.17-0.20% of C, less than or equal to 0.50% of Si, 0.50-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.08% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O. The process comprises melted iron desulfuration, converter blowing, argon blowing, LF furnace refining, continuous casting, rotary descaling, soaking pit soaking, descaling, seven-frame finish rolling, stream cooling and coiling. The ultrathin hot-rolled sheet strip has the advantages that the addition of the alloying element is low, the mechanical property is as follows: the yield strength is more than or equal to 500MPa, the product thickness is less than or equal to 1.4mm, the sheet shape is good, the production flow is short, and excellent cold forming and welding performances are achieved.

Owner:武汉钢铁有限公司

Method of producing an animal food product with a core and shell

ActiveUS20070020355A1Simple wayNot produce unpleasantMilk preservationAnimal feeding stuffFiberCold formed

The present invention relates to a method of producing an animal food product with a core and a shell at least partially covering the core, in which the core starting material includes meat and / or meat-like components, water, oil and / or fat, vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives, vegetable fibres, and other ingredients. The shell starting material includes vegetable and / or animal protein, cereal, starch and / or dextrin, blood plasma, water, cereal derivative and / or sugar or sugar derivative, and vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives. The method includes the steps of: either producing core particles by mixing the core materials, baking the mixture thus obtained, conditioning, cutting into small pieces and conditioning again, or producing core particles by mixing the core materials, cold forming the mixture thus obtained and cutting it into small pieces, and then mixing the core particles with the components of the shell in a coating pan, baking or deep-frying and finally conditioning.

Owner:MARS INC

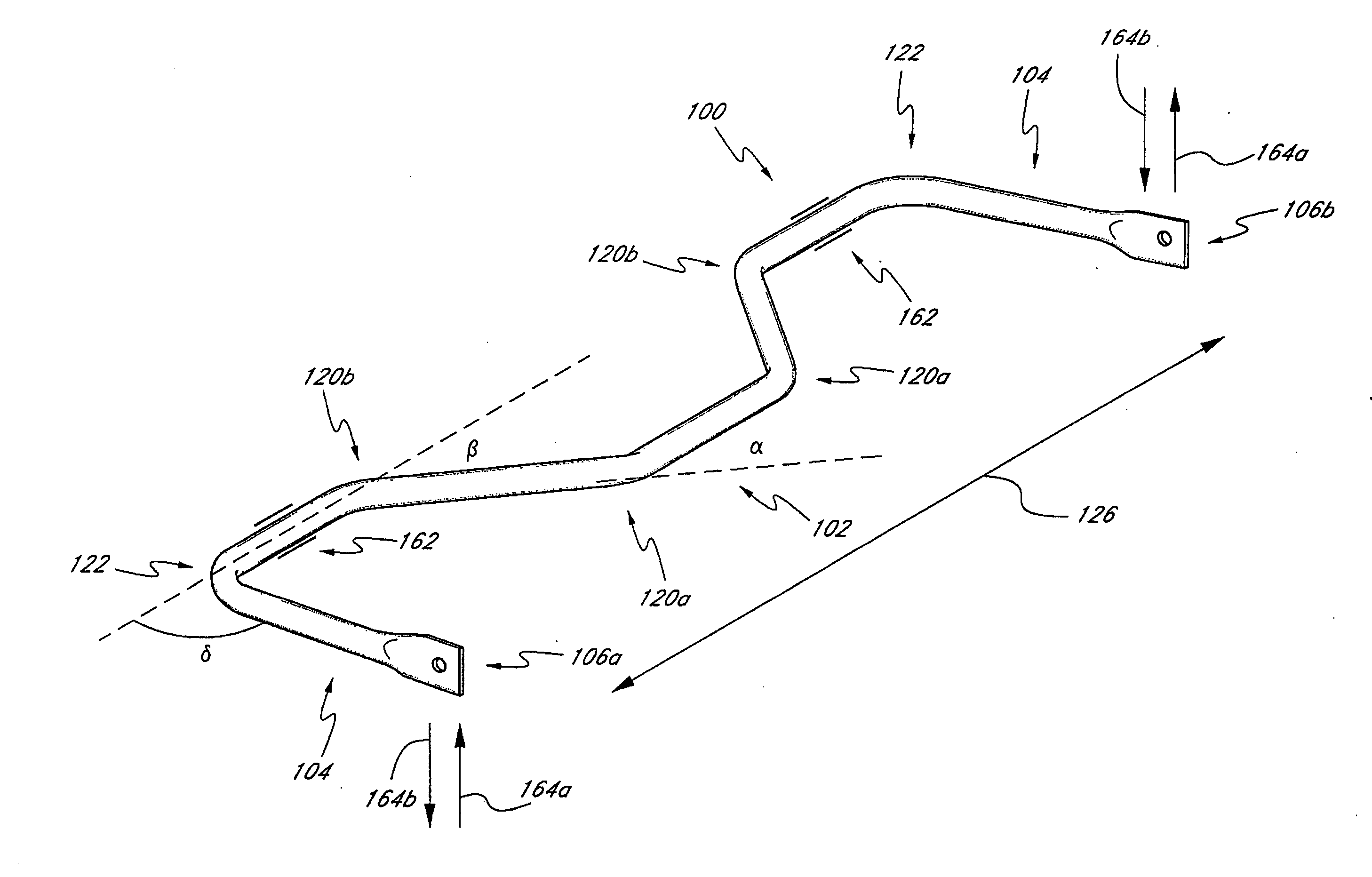

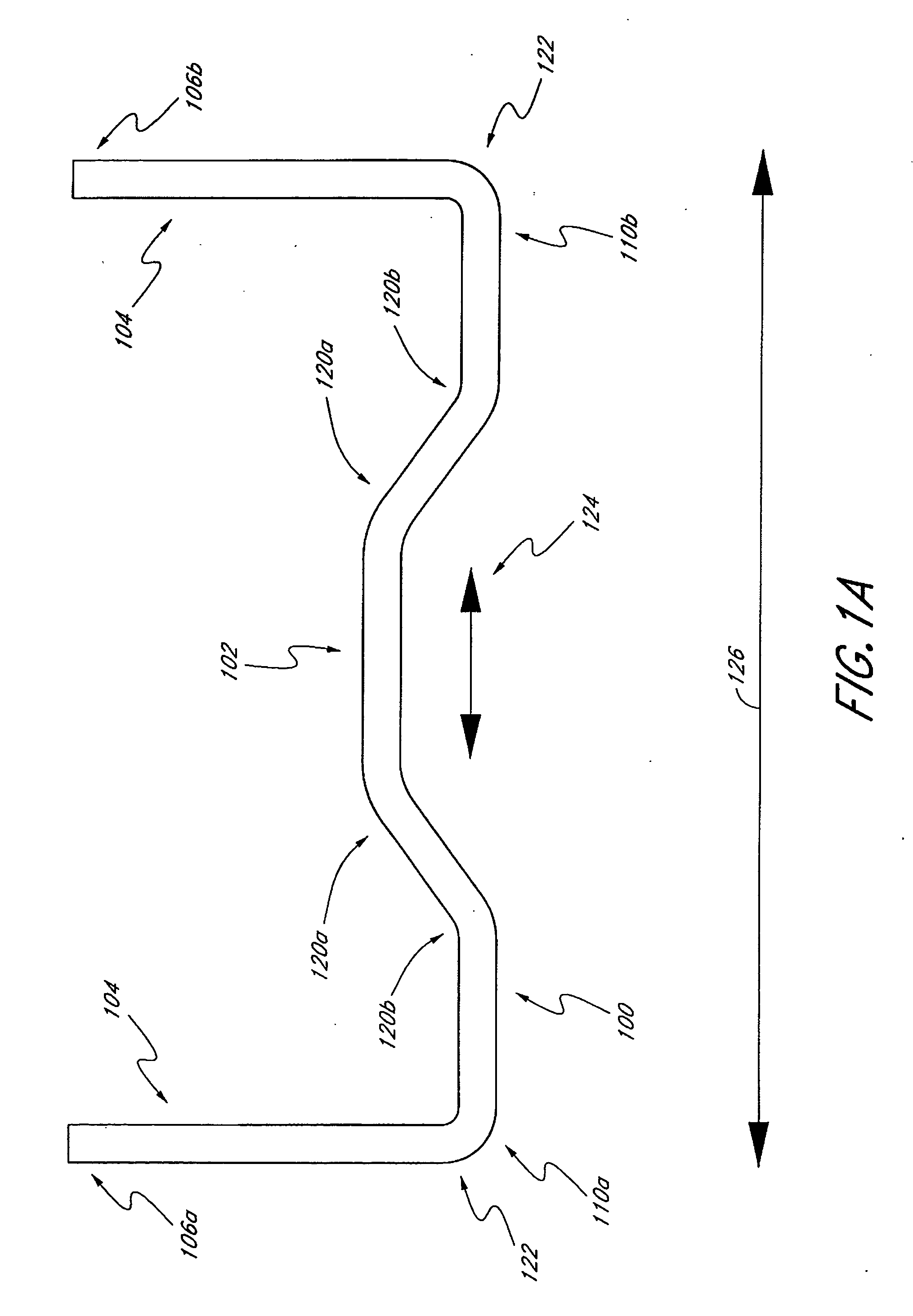

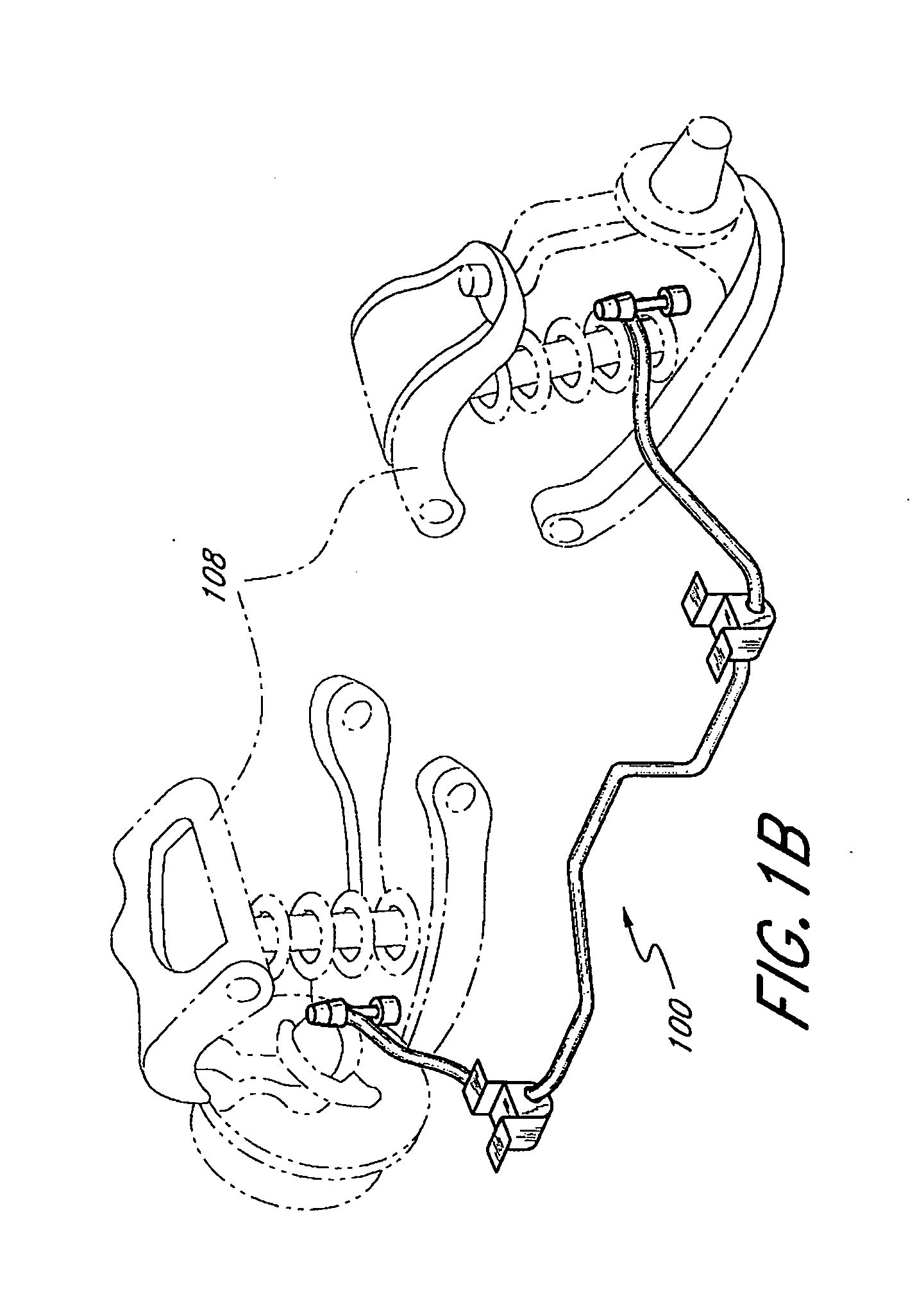

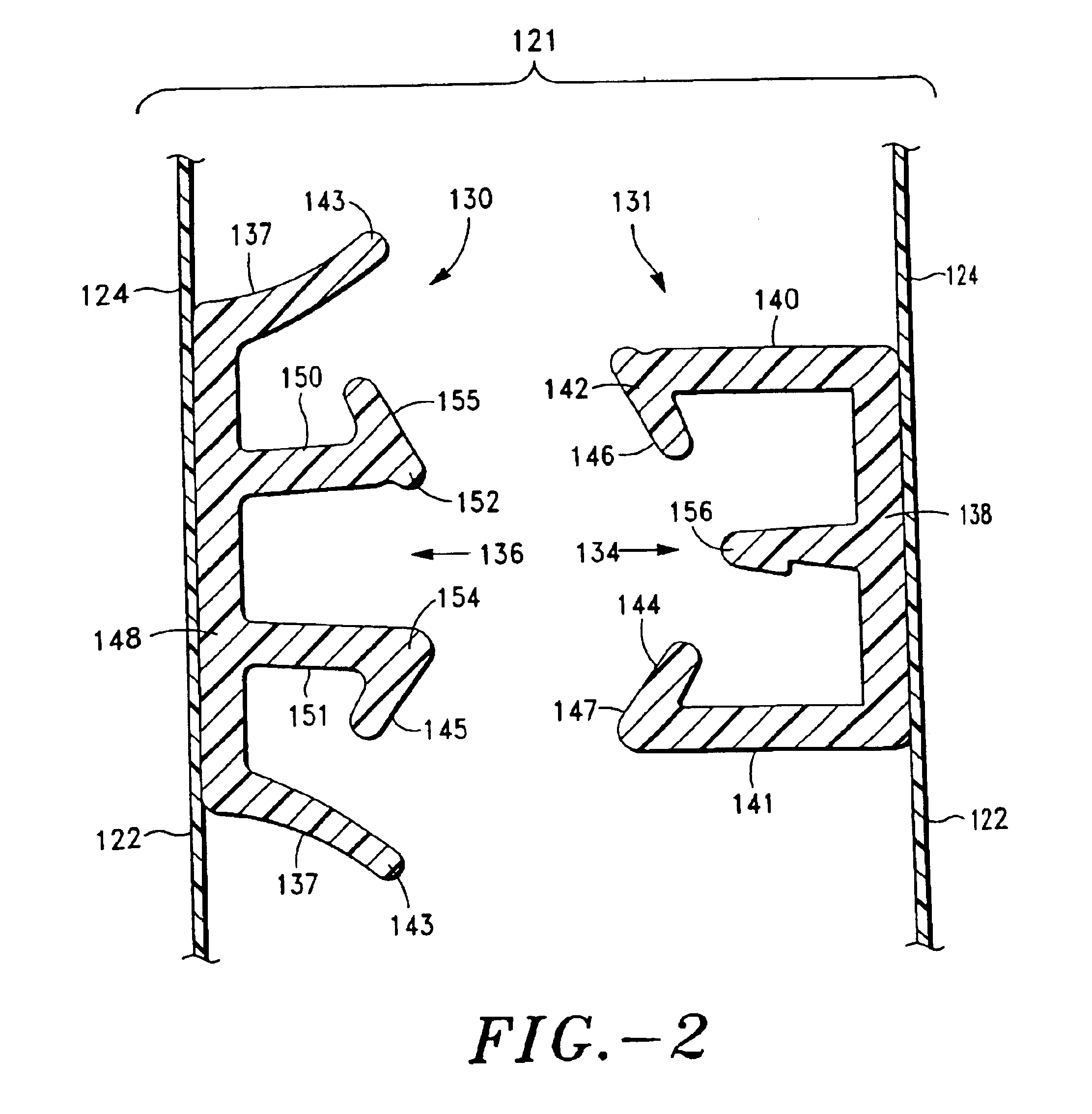

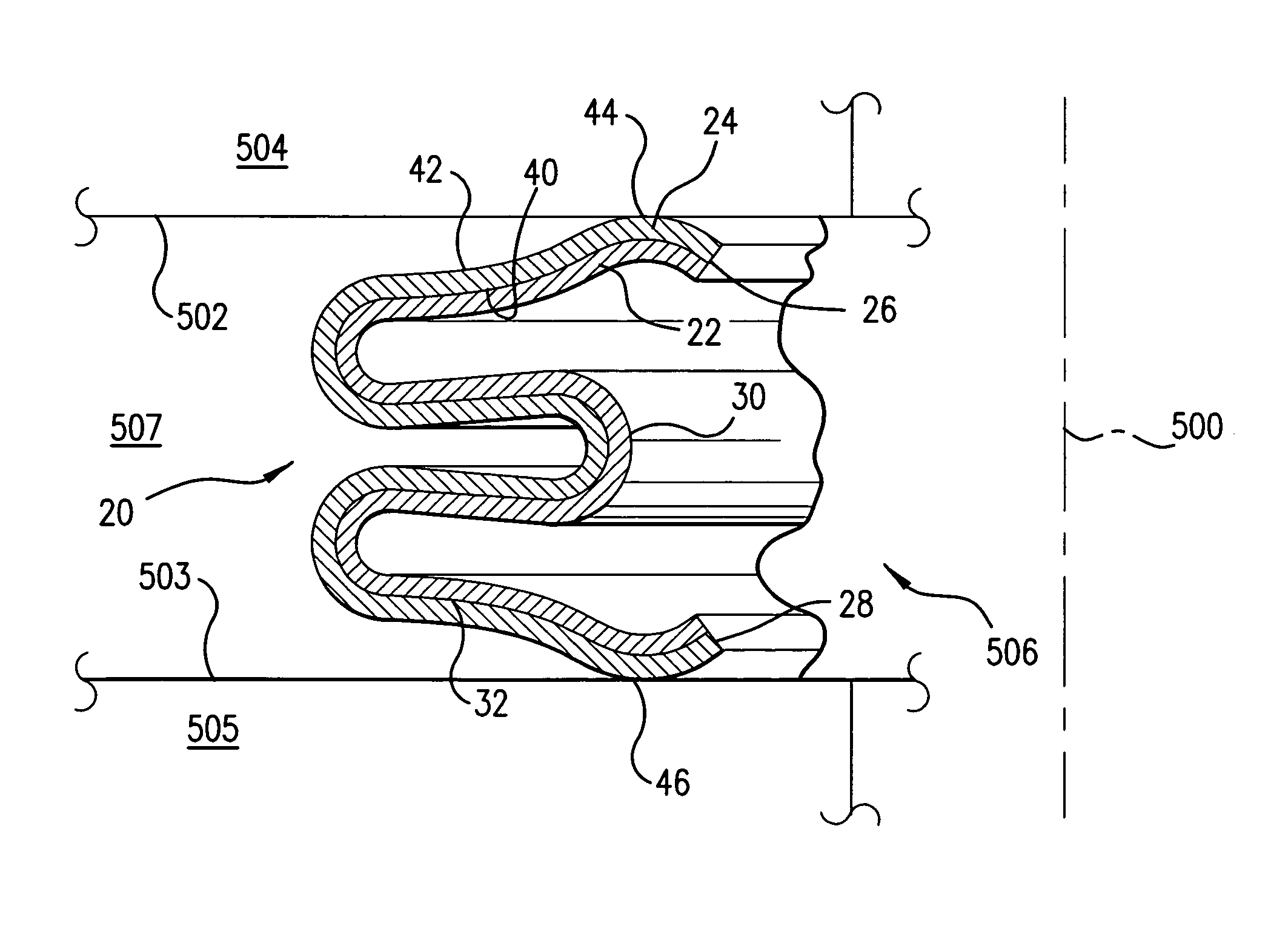

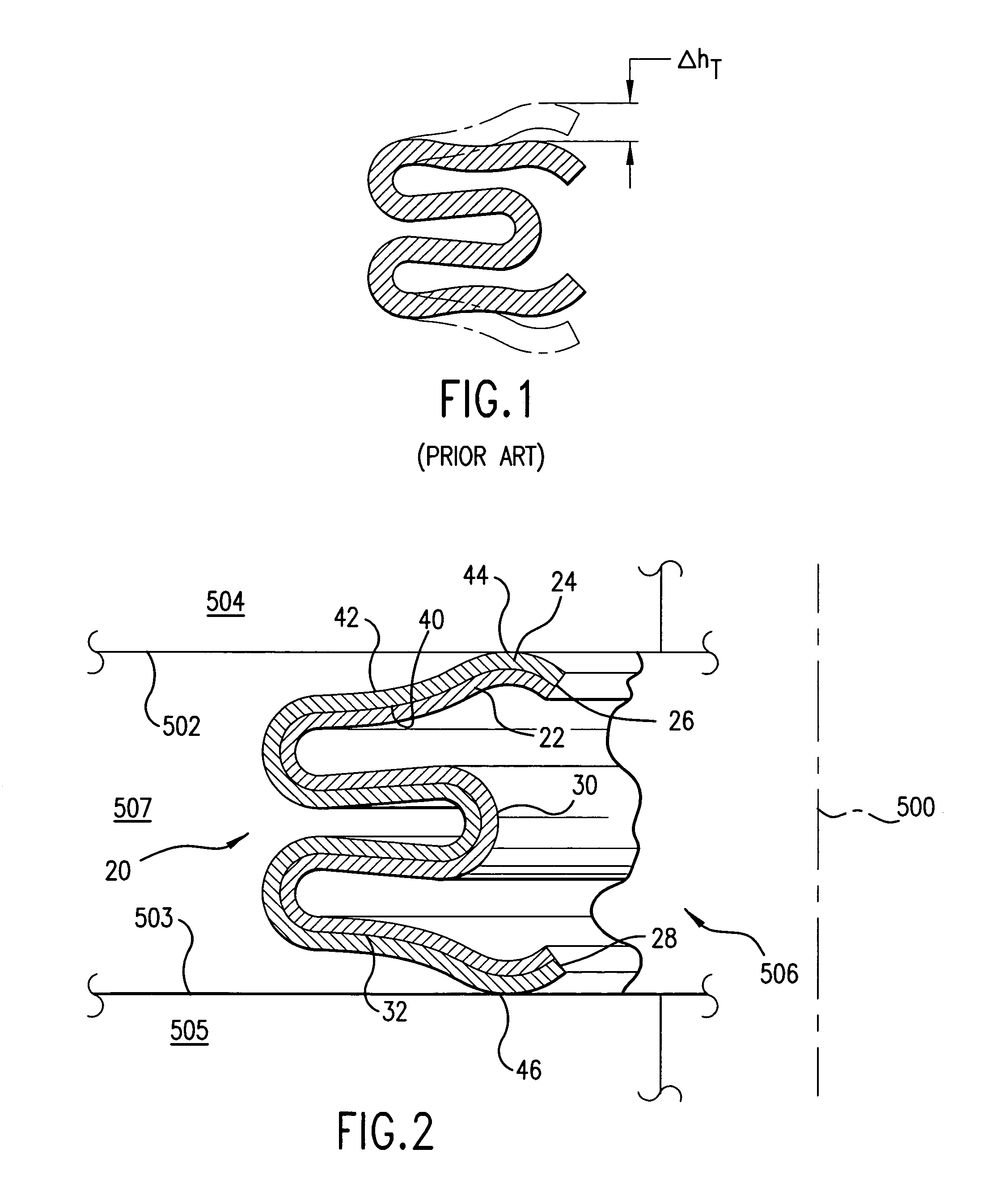

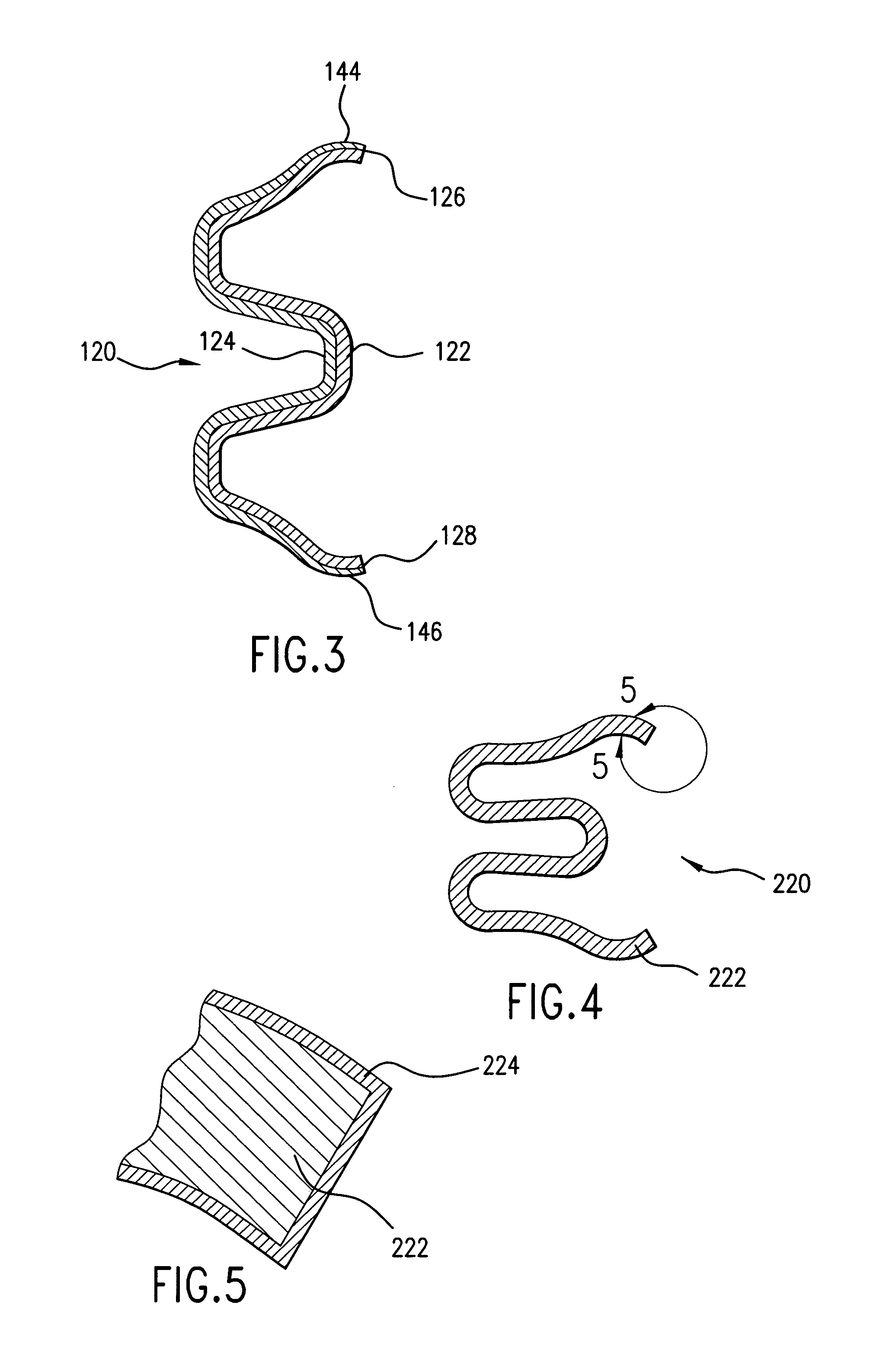

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

Steel for extended automobile crossbeam and mfg, method thereof

This invention relates to a king-sized automobile crossbeam using steal and its manufacturing method, tiny alloy elements of Nb, Ti, V are added in the steal. Their weight percentage is that C 0.07-0.12, ,Si 0.15-0.40, Mn 1.00-1.50,P less than 0.025,S less than 0.015,Nb 0.020-0.050,V 0.025-0.050, Ti 0.010-0.030,and tiny Ca, the rest are iron and other tiny impurities. Board butt is continuous cast, rolling and cooling control technique are used in hot rolling, the butt is heated to 1180-1250 degree centigrade, the temperature is 1020 to 1060 degree centigrade after rough rolling. Then it is finish rolled through blimp, the rolling temperature is maintained at 840 to 880 degree centigrade, the coiled sheet is cooled to 560 to 620 degree centigrade through laminar flow cooling. Because of the multiple unit tiny alloy elements design of the material chemical element, strong strength is got after above process and with good plastic laminar flow, cool formability, so it is specially propitious to king-sized automobile crossbeam making of cladding forming technique.

Owner:宝钢集团上海梅山有限公司

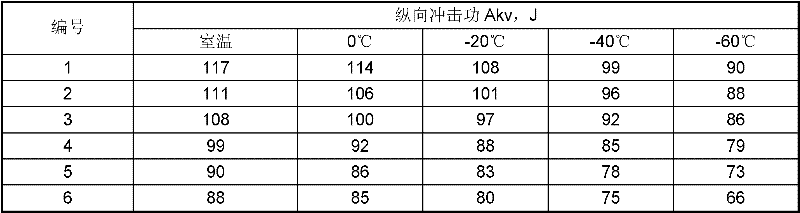

610MPa automobile girder steel and production method thereof

ActiveCN101748329AGood low temperature impact propertiesTemperature control deviceChemical compositionRoll forming

The invention discloses a 610MPa automobile girder steel, and the weight percentage (wt%) of the chemical composition of the steel is as follows: C: 0.08 to 0.12; Si: 0.10 to 0.30; Mn: 1.40 to 1.60; P: less than or equal to 0.010; S: less than or equal to 0.005; Nb: 0.040 to 0.060; V: 0.020 to 0.030; Ti: 0.010 to 0.030; Al: 0.030 to 0.060; Ca: tiny amount; and the rest is iron and residual trace impurities. The invention also discloses a production method for the 610MPa automobile girder steel, which adopts a 2250mm hot rolling line, and a continuously cast slab is heated to 1200 DEG C to 1250 DEG C; after rough rolling, the temperature is 1000 DEG C to 1050 DEG C, the continuously cast slab enters a finishing mill via a heat cover and is rolled, the finish rolling temperature is 820 DEG C to 880 DEG C, and the rolled steel coil is rapidly cooled to 530 DEG C to 580 DEG C by way of laminar cooling, and is then coiled. Since the chemical composition and the production technique are adopted, the tensile strength of an automobile girder is larger than 610MPa, the yield strength is larger than 500MPa, the specific elongation is larger than 20 percent, minus 60 DEG C longitudinal impact energy AKV is larger than 70J, and the automobile girder has excellent cold formability and high fatigue strength. The product is applicable to heavy-duty automobile members such as side members and cross members, which are produced by cold-roll forming and stamping forming techniques.

Owner:MAANSHAN IRON & STEEL CO LTD

Process for producing a shaped foam article

InactiveUS20110091688A1Reduce warpageReduce crackingLayered productsThin material handlingPolymer scienceCold formed

The invention relates to an improved method of cold forming a shaped foam article wherein the improvement is using a near net-shaped foam blank cut from a foam plank having a vertical compressive balance equal to or greater than 0.4 to produce the shaped foam article.

Owner:DOW GLOBAL TECH LLC

High-strength steel for 750 to 880 MPa-level vehicles and production method thereof

The invention relates to high-strength steel for 750 to 880 MPa-level vehicles and a production method thereof. The high-strength steel comprises the following chemical ingredients in percentage by weight: 0.07 to 0.09 percent of C, 0.15 to 0.25 percent of Si, 1.4 to 1.9 percent of Mn, 0.04 to 0.06 percent of Nb, 0 to 0.15 percent of Mo, 0 to 0.04 percent of V, 0.07 to 0.14 percent of Ti, 0.01 to 0.06 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.008 percent of N and the balance of Fe and inevitable impurities. The production method comprises the following steps of: smelting; casting to form a casting blank; heating to the temperature of between 1,180 and 1,250 DEG C; performing final rolling at the temperature of between 820 and 850 DEG C; performing final cooling at the temperature of between 560 and 600 DEG C; and after a steel coil rolls off a production line, cooling slowly. By the production method, the strength of the material is between 750 and 880 MPa, and the steel has high low-temperature impact toughness and cold forming performance.

Owner:SHOUGANG CORPORATION

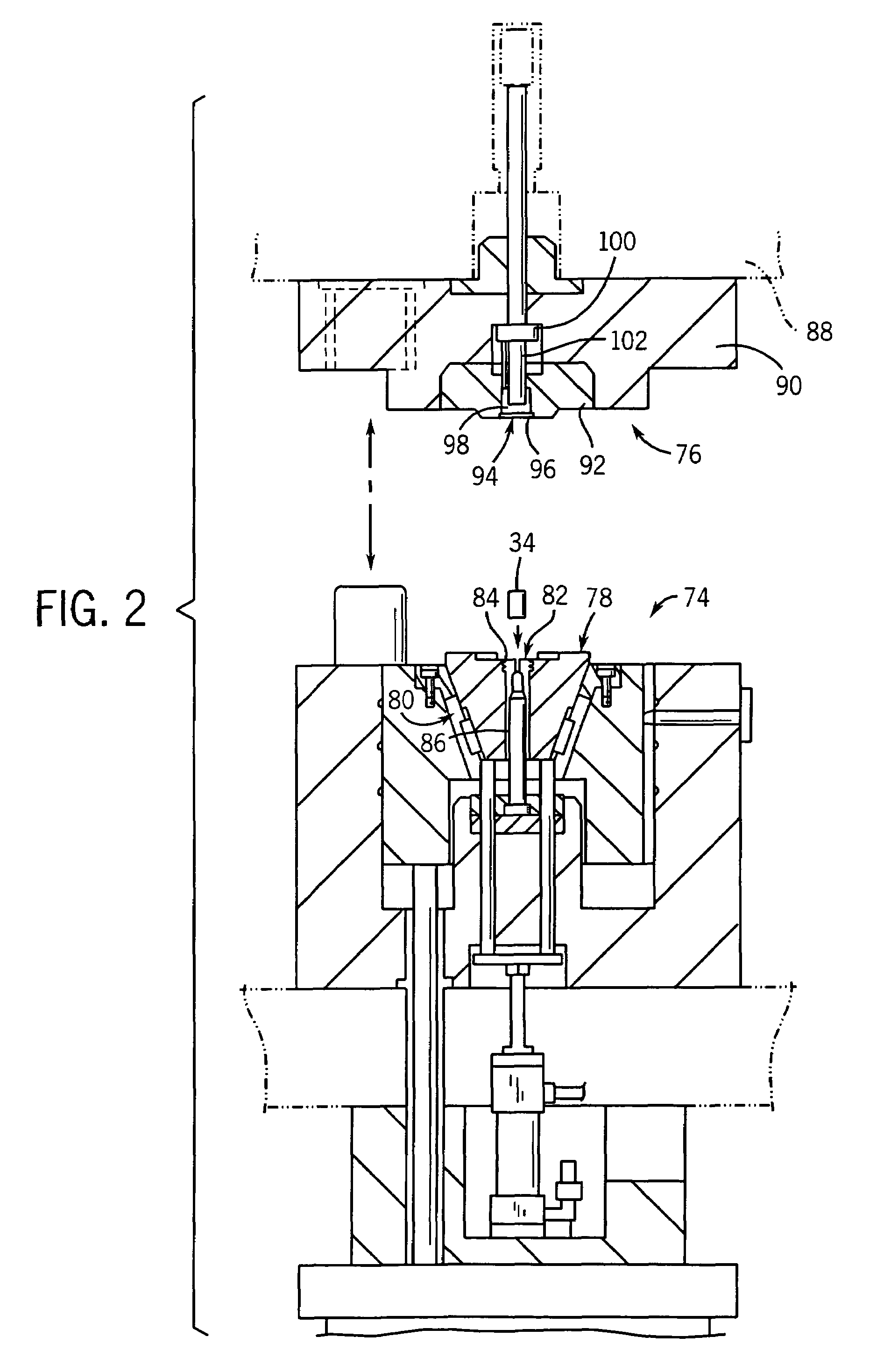

Method and apparatus for manufacturing a battery terminal with undercut rings

InactiveUS7021101B2Prevent electrolyte leakageEasy to manufactureLead-acid accumulatorsSmall-sized cells cases/jacketsCold formedMetal forming

A method and apparatus utilizing a radial rolling process to cold form rings on a lead battery terminal with undercuts or overhangs to improve the sealing properties of the rings. The apparatus includes a fixture configured to securely position the battery terminal beneath a rolling station. The rolling station includes a radial rolling spindle having a plurality of cam shaped rollers configured to transform at least one ring on the battery terminal from having an initial rectangular cross-sectional shape into a desired arrowhead cross-sectional shape when the terminal and cold metal forming member are rotated relative to each other. A drive assembly is configured to rotate the battery terminal and radial rolling head relative to each other.

Owner:TULIP MOLDED PLASTICS CORP

High temperature metallic seal

InactiveUS6968615B1Cost-effective fabricationExcellent substituteEngine sealsMetal rolling stand detailsTemperature stressCold formed

A metallic seal includes a cold formed substrate layer and one or more additional layers. At least one of the layers offers improved resistance to high temperature stress relaxation.

Owner:PARKER INTANGIBLES LLC

High-strength cold-formed hot continuous rolled steel plate and method of preparing the same

ActiveCN101153371AImprove mechanical propertiesReduce weightTemperature control deviceHeat treatment process controlCold formedQuenching

The invention relates to a high-strength cold-forming hot-continuous-rolling steel plate and the manufacture method thereof, wherein, the chemical composition of the steel plate is as follows: 0.05wt percent to 0.10wt percent of C, 0.10wt percent to 0.50wt percent of Si, 1.0wt percent to 2.0wt percent of Mn, less than or equal to 0.025wt percent of P, less than or equal to 0.010wt percent of S, 0.03wt percent to 0.08wt percent of Nb, 0.05wt percent to 0.15wt percent of Ti, 0.10wt percent to 0.50wt percent of Mo, 0.0010wt percent to 0.0050wt percent of Ca, 0.01wt percent to 0.05wt percent of Al and the rest, Fe and other inevitable impurities; the technical process of the steel plate includes hot metal deep desulfurization to converter top and bottom blowing to secondary refining to continuous casting (machine cleaning) to hot charging hot feeding soaking pit to plate blank reheating to controlled rolling to controlled cooling to coiling to finishing. With the yield strength reaching 700 MPa, the steel plate has excellent mechanical property and processing properties such as welding and roll forming; meanwhile, because less alloying element is added during the manufacture process of the steel plate, the invention has low production cost and convenient operation during big production without adopting heat treatment processes such as tempering and quenching and tempering. The invention can be used in fields such as engineering machinery and structural parts and container for special vehicle and strongbox, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

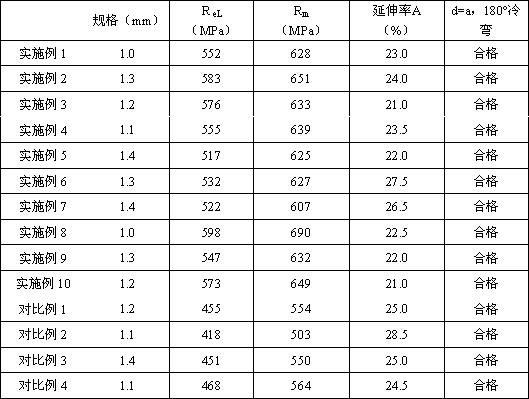

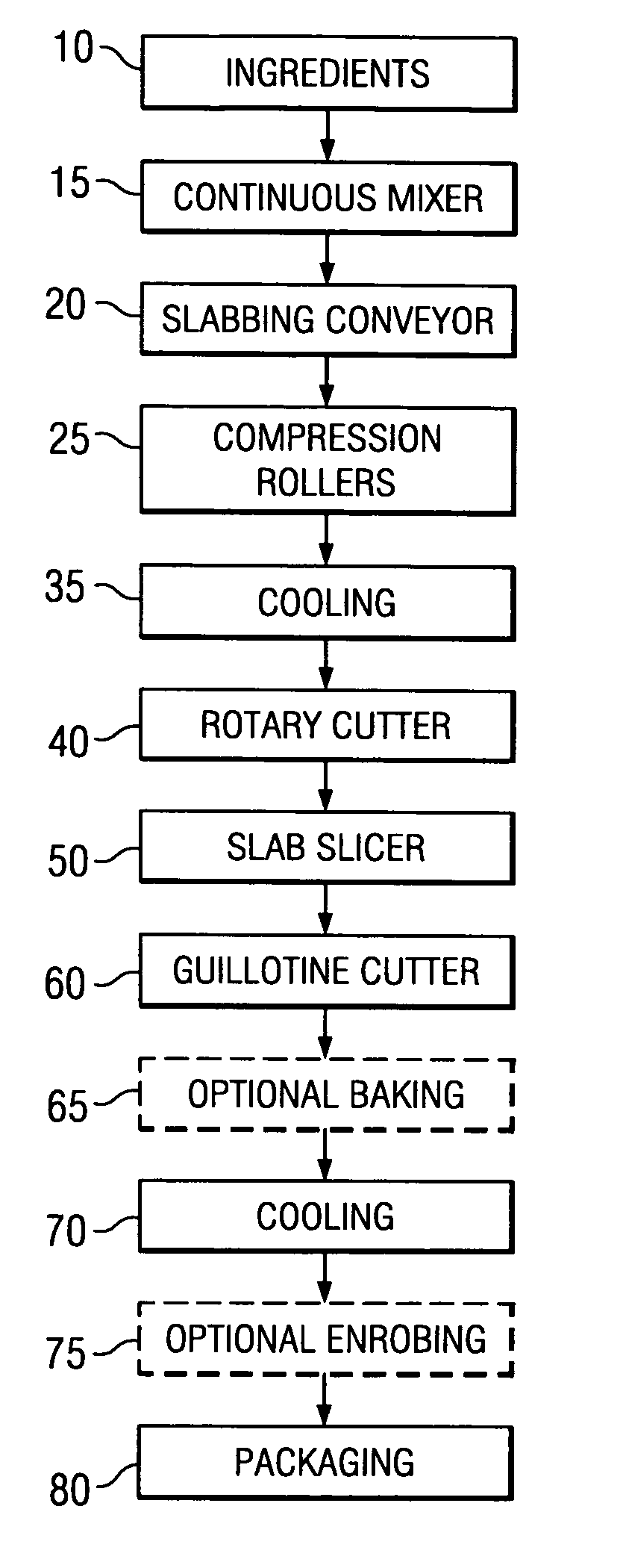

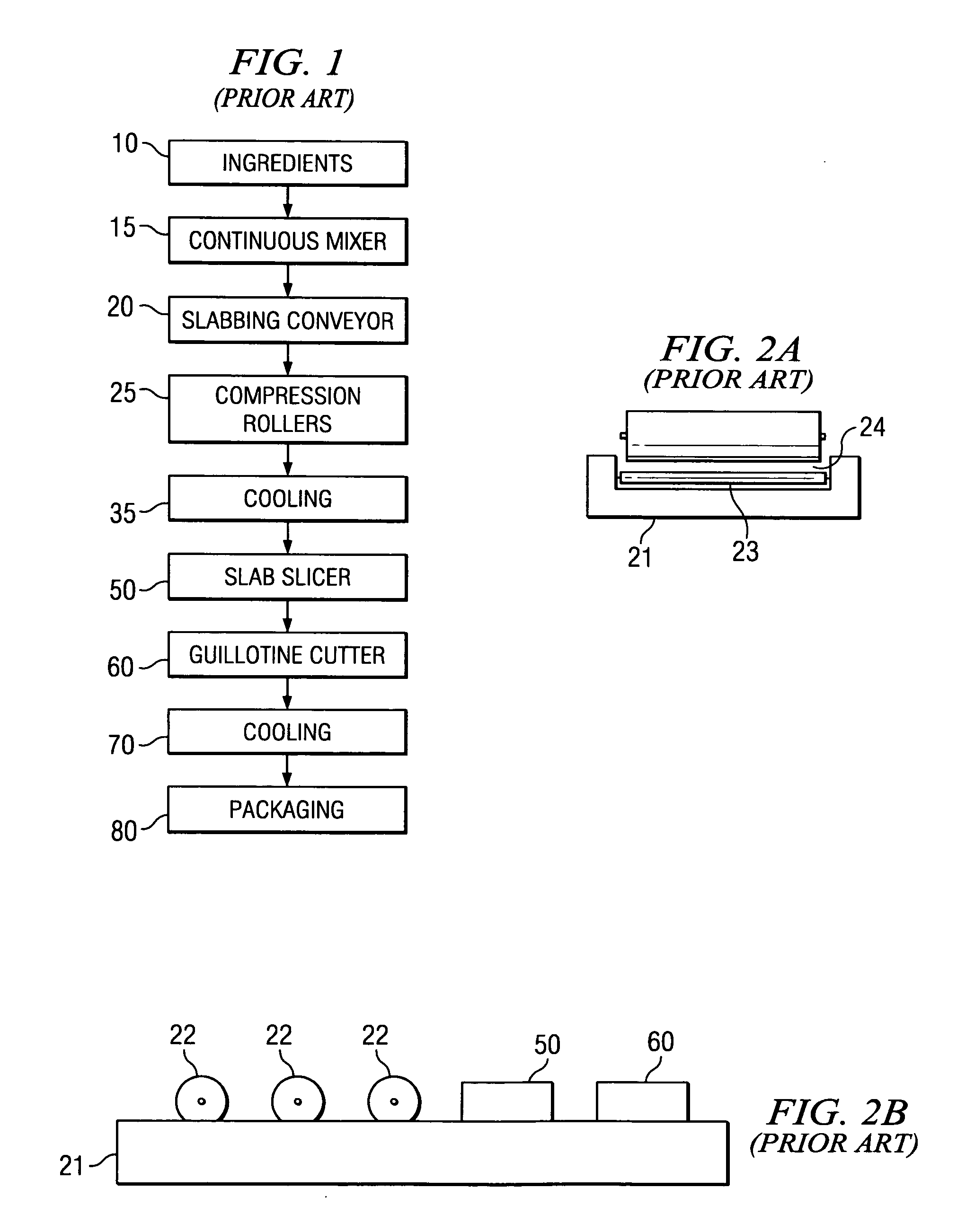

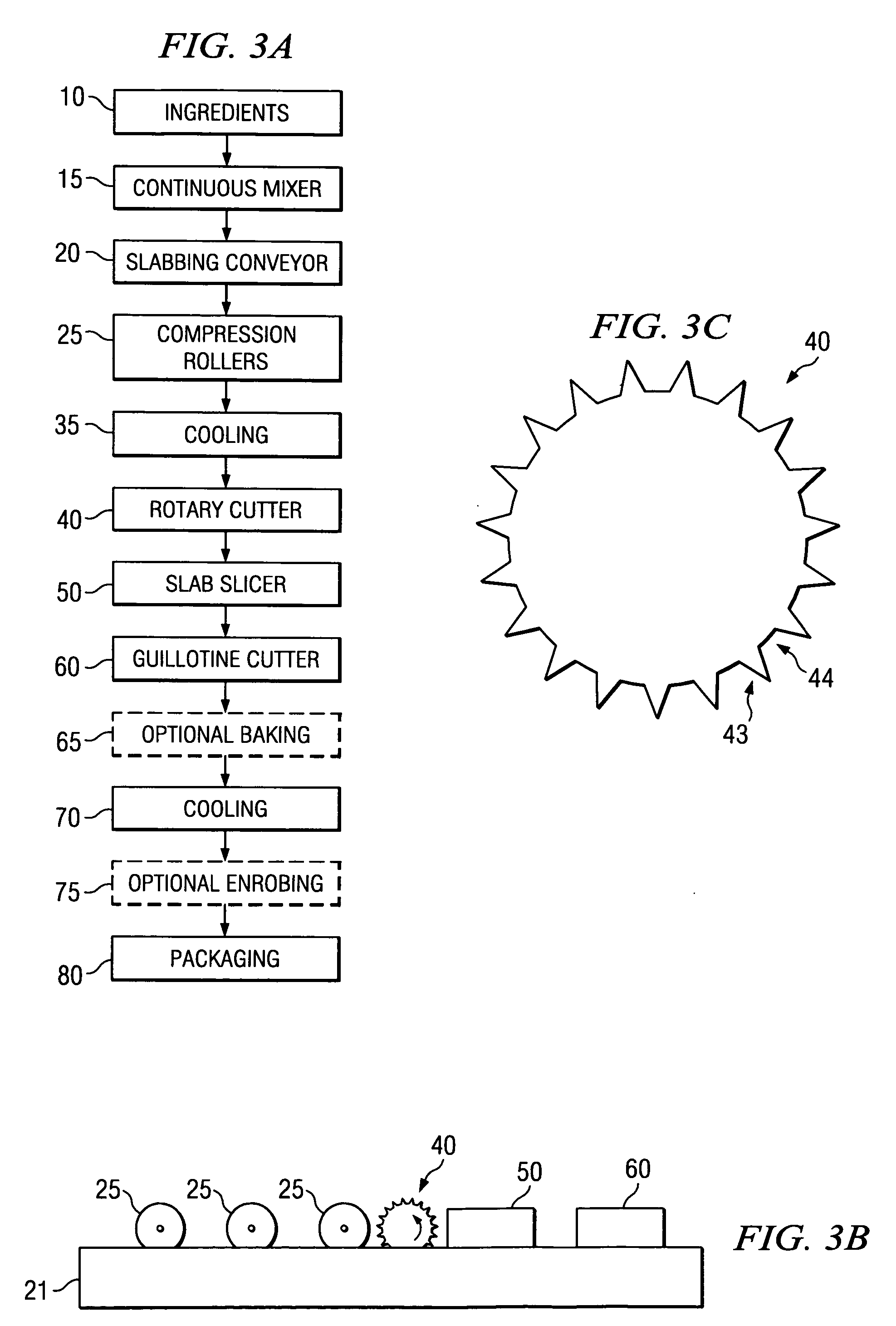

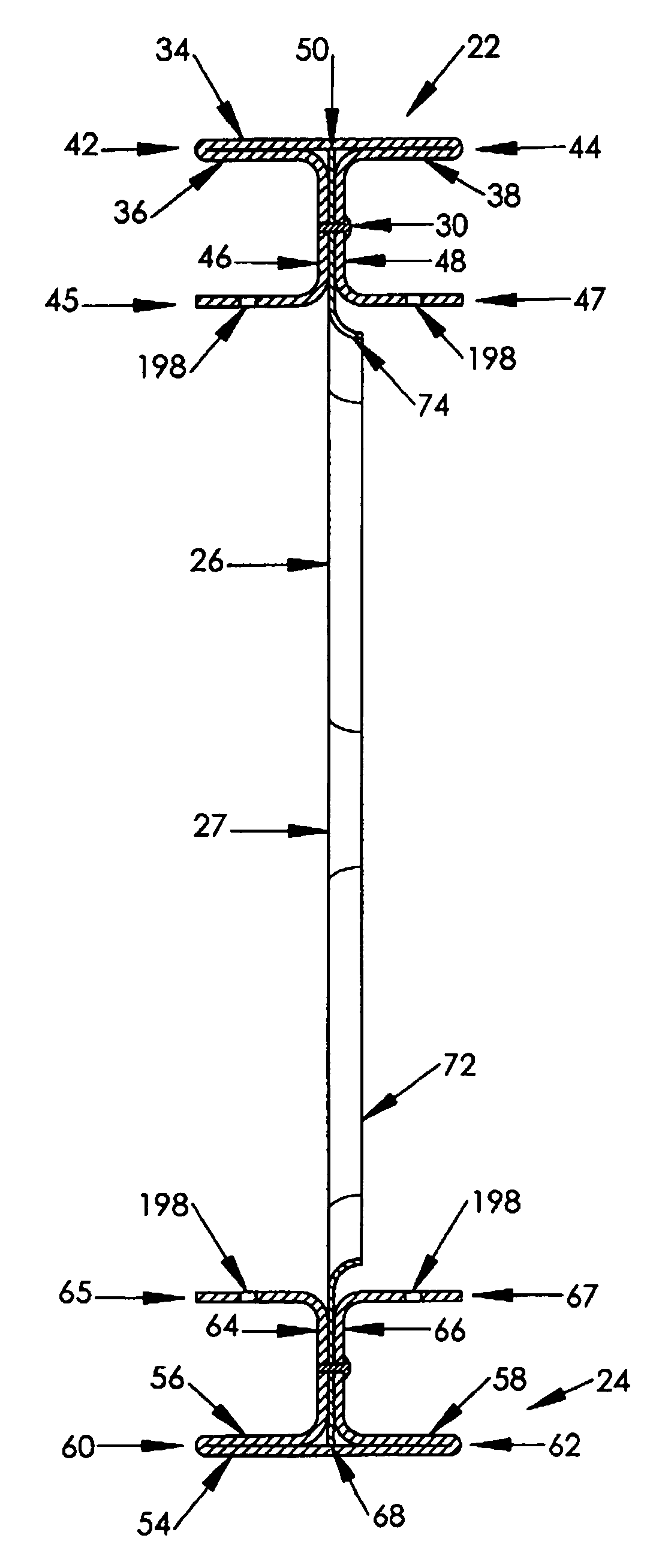

Method for making a cold formed segmented food product

A method for creating bite-sized or segmented pieces of a cold formed bar such as a granola bar. The invention is an improved process for manipulating and shaping granola without having the granola lose its characteristic texture. In one aspect, the invention adds a rotary cutter to a conventional slabbing operation. In one aspect, the invention uses a rotary molder to force granola into female molds where it can be shaped as desired.

Owner:FRITO LAY NORTH AMERICA INC

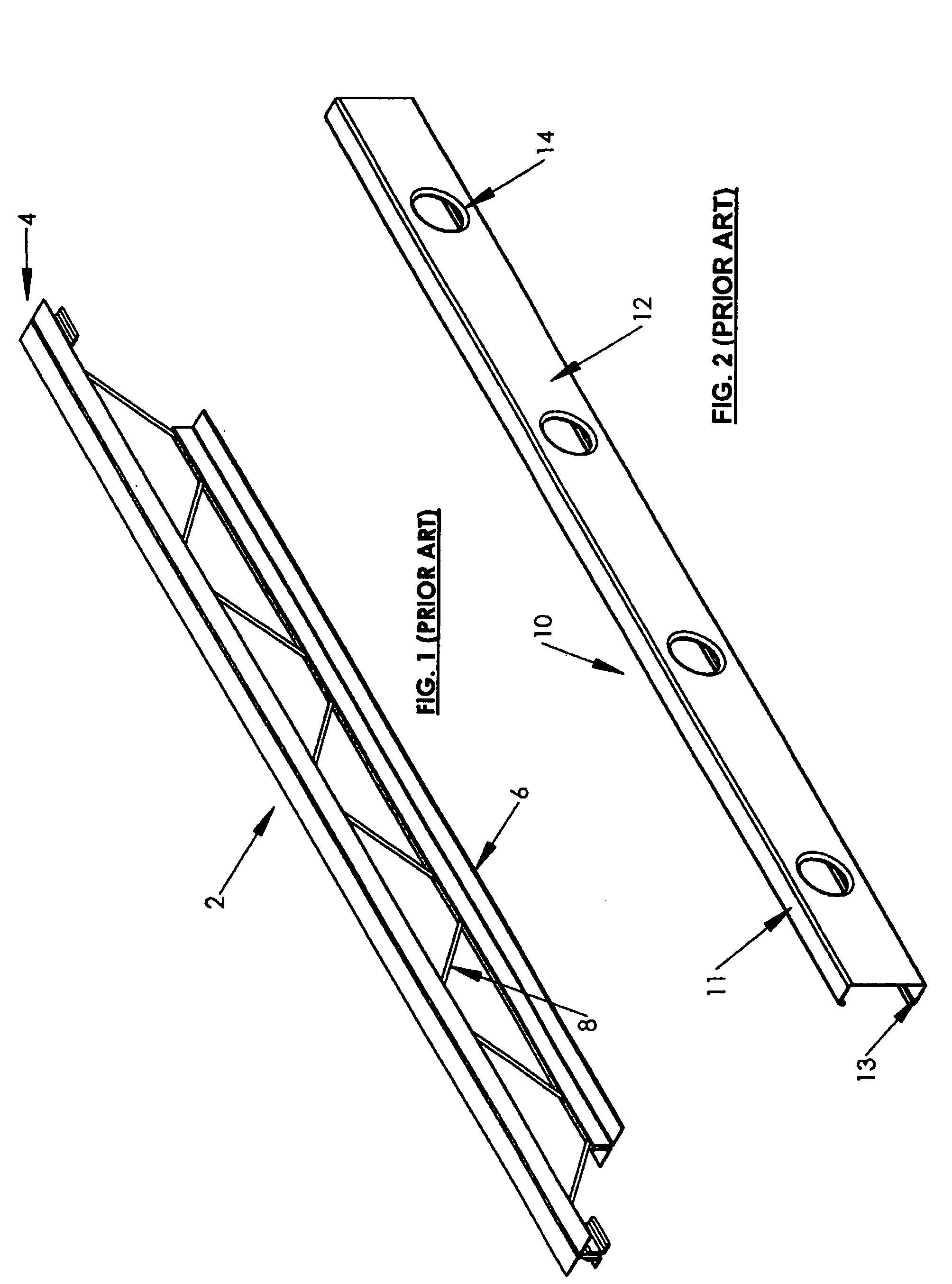

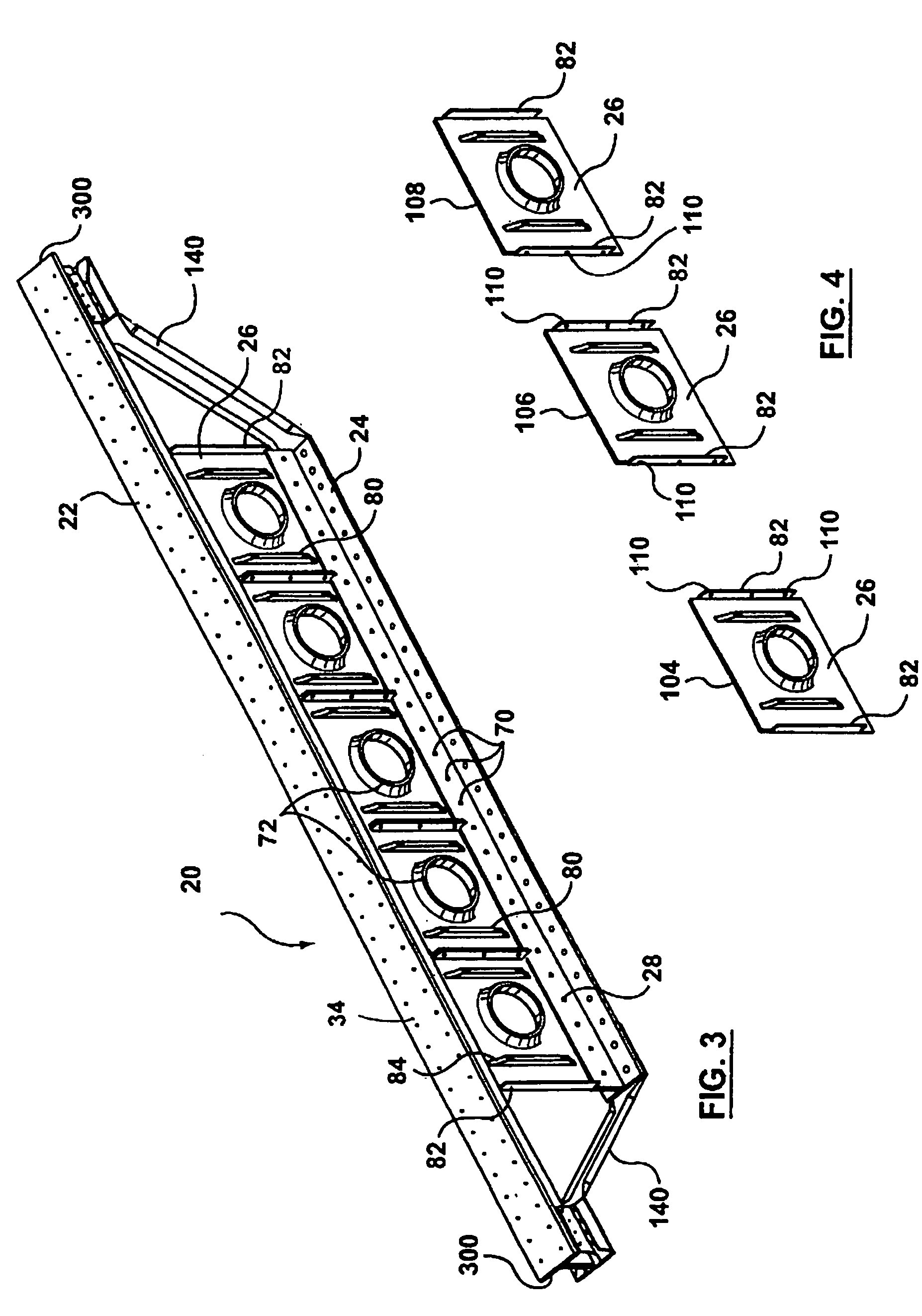

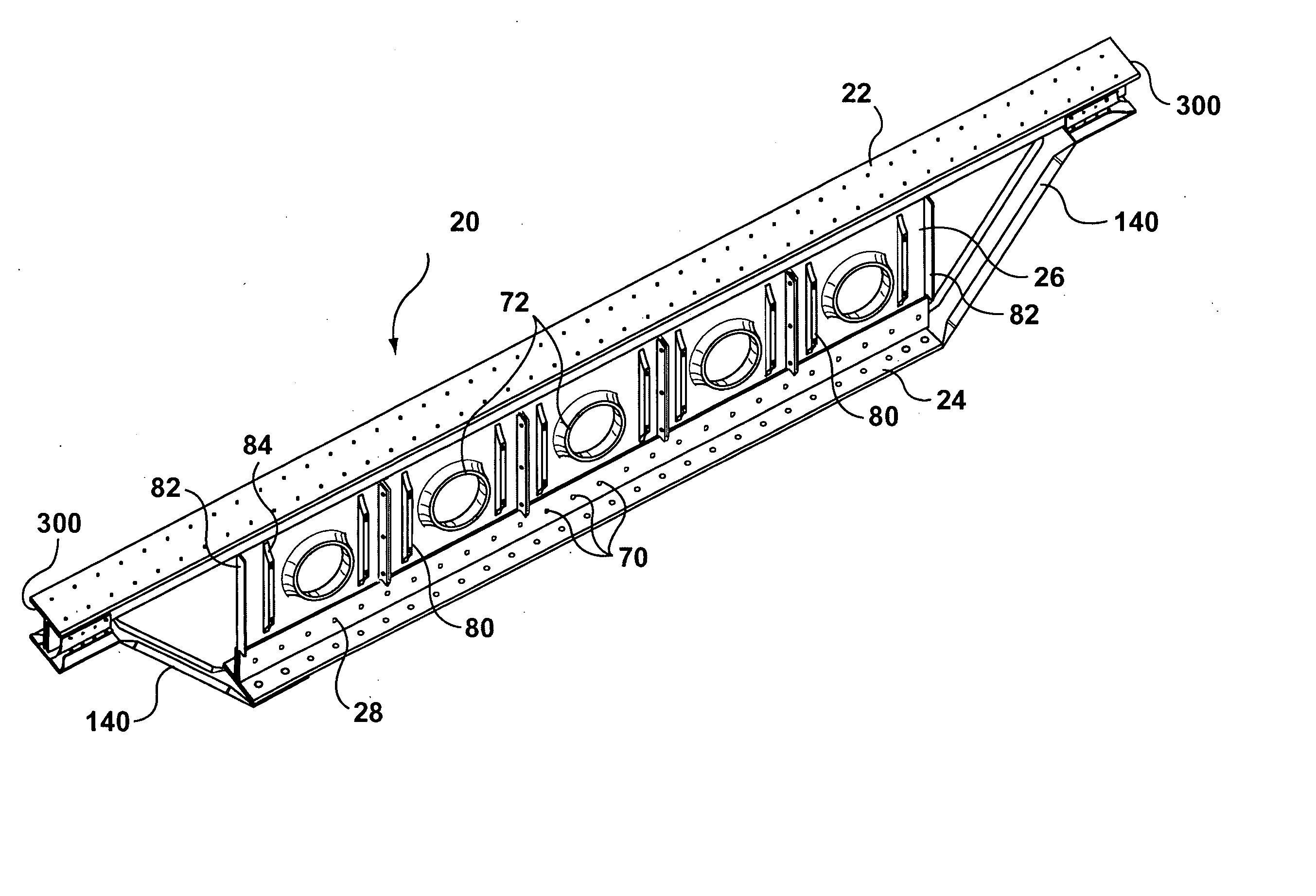

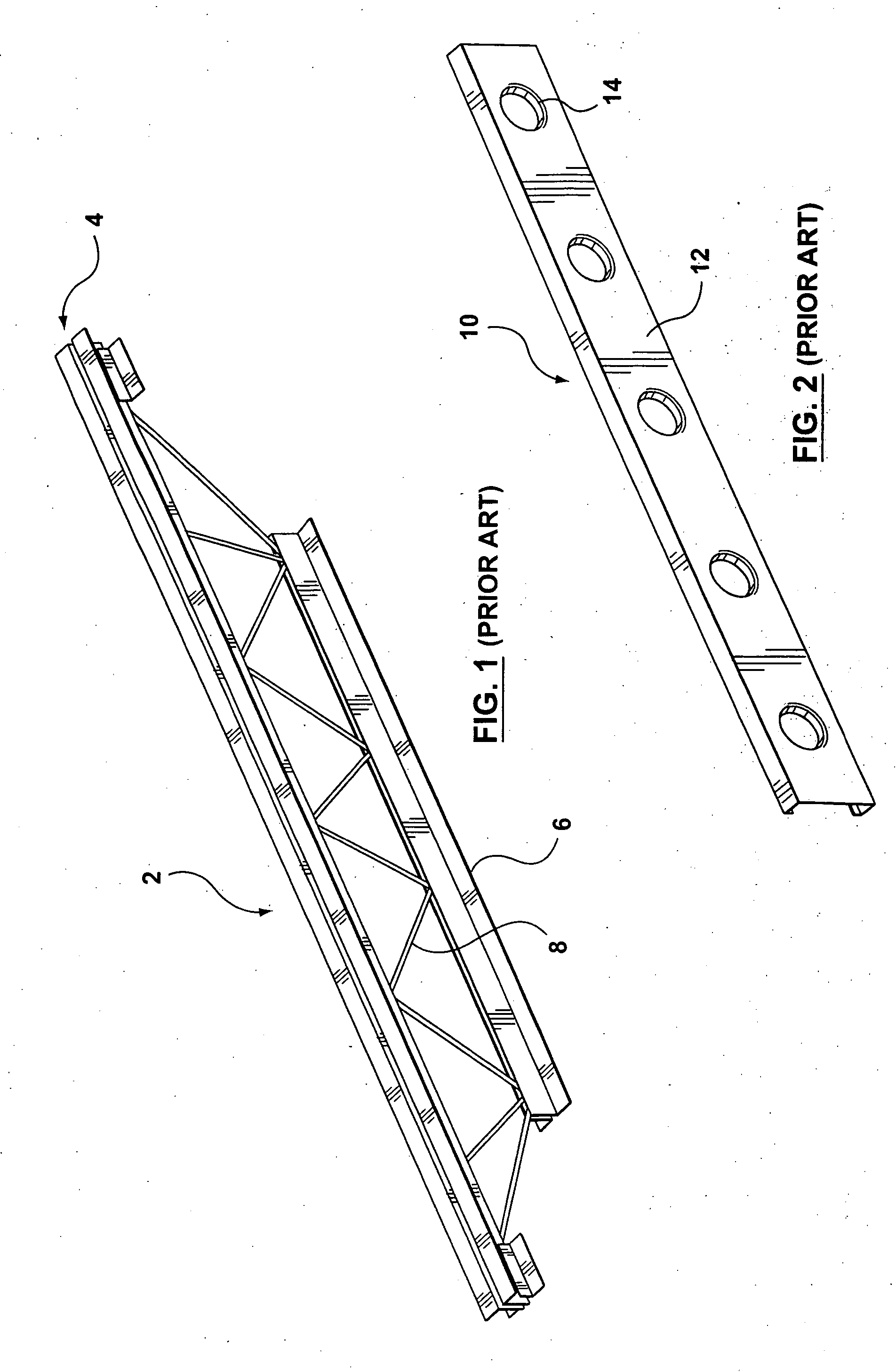

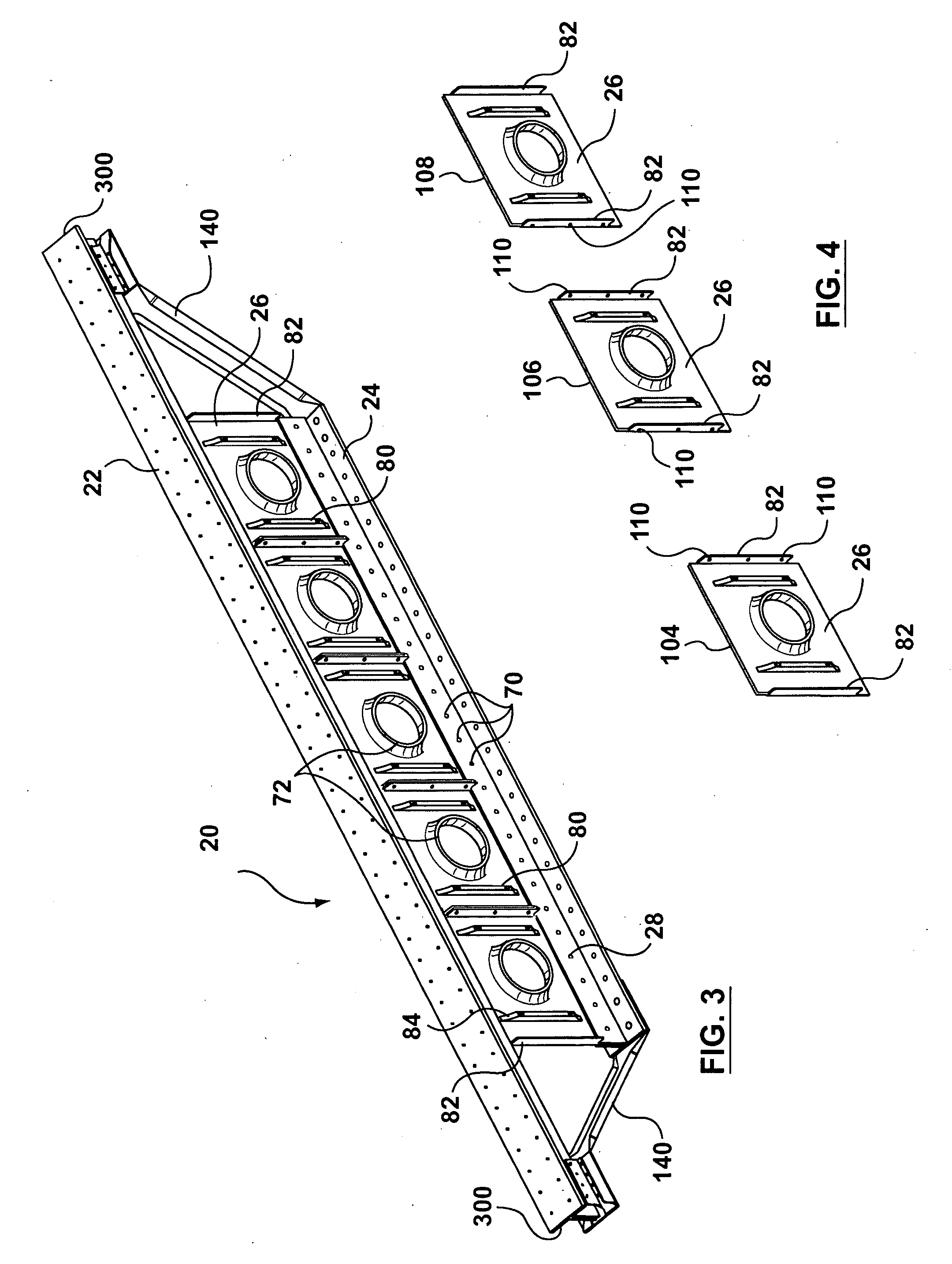

Cold-formed steel joists

A joist comprised of at least one cold-formed steel elongated chord member; a cold-formed steel web having a plurality of web members and means for securing said web to said chord member. A plurality of joists are generally for use in a support system for a platform or a deck in the construction of floors and roofs. The support system is of particular use in a composite floor and roof systems.

Owner:ISPAN SYST LP

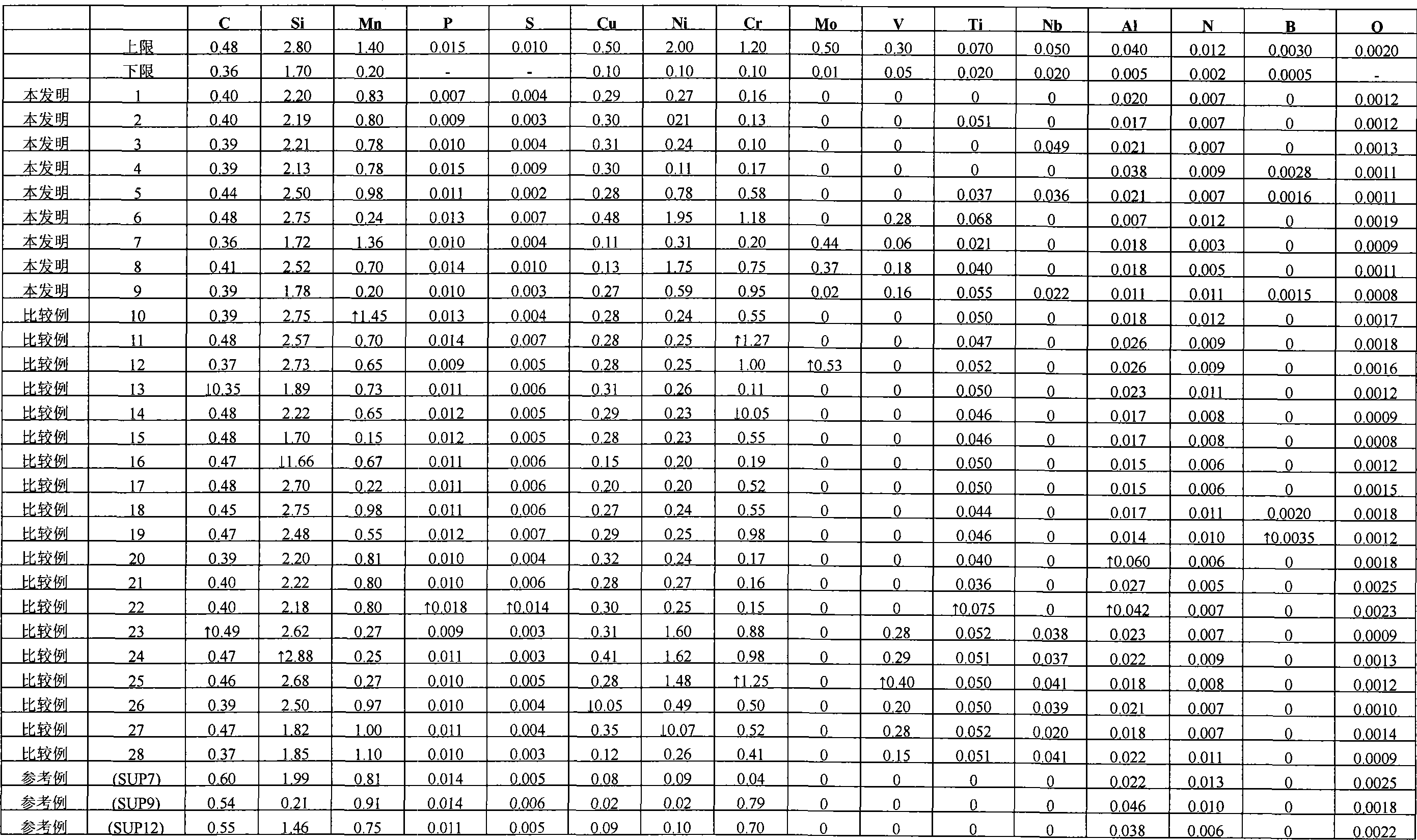

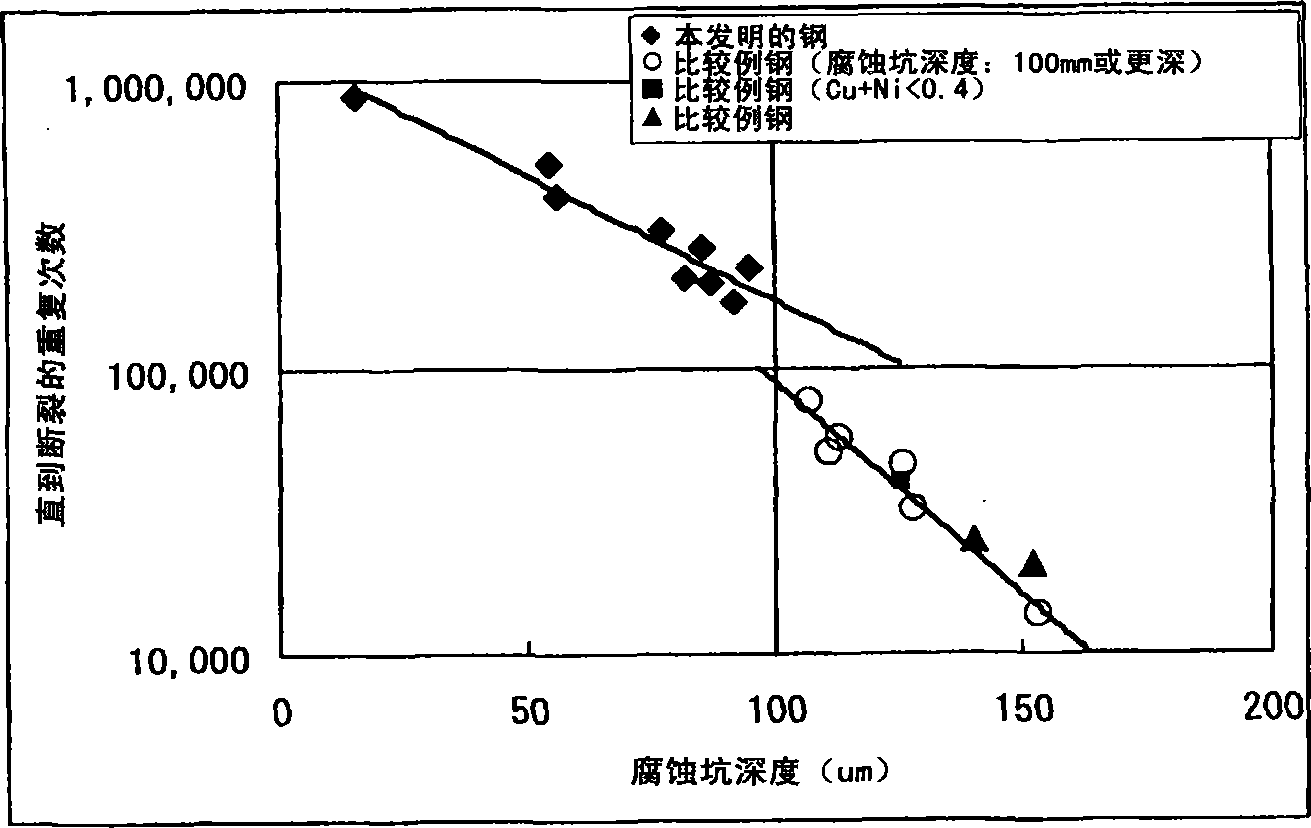

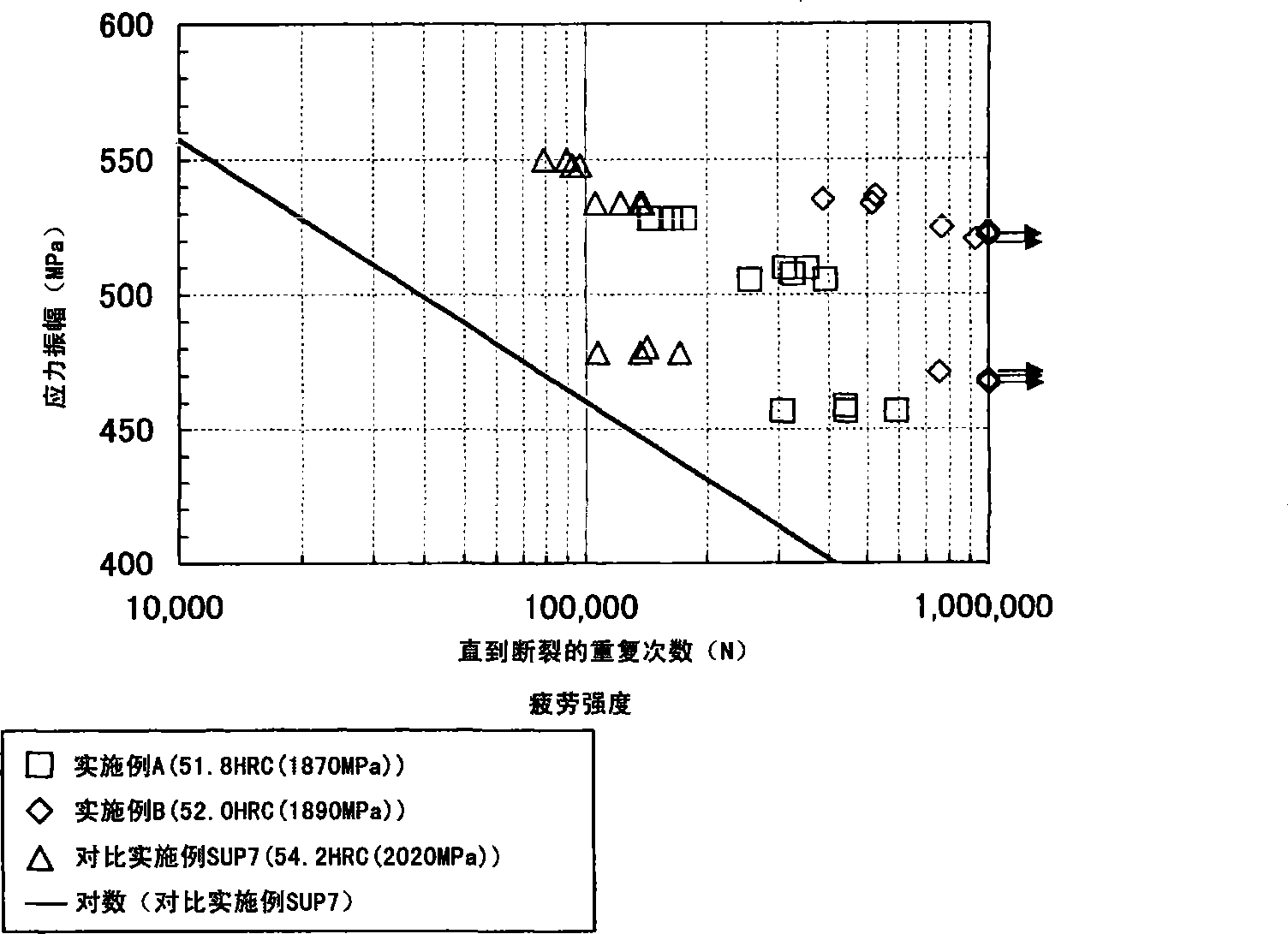

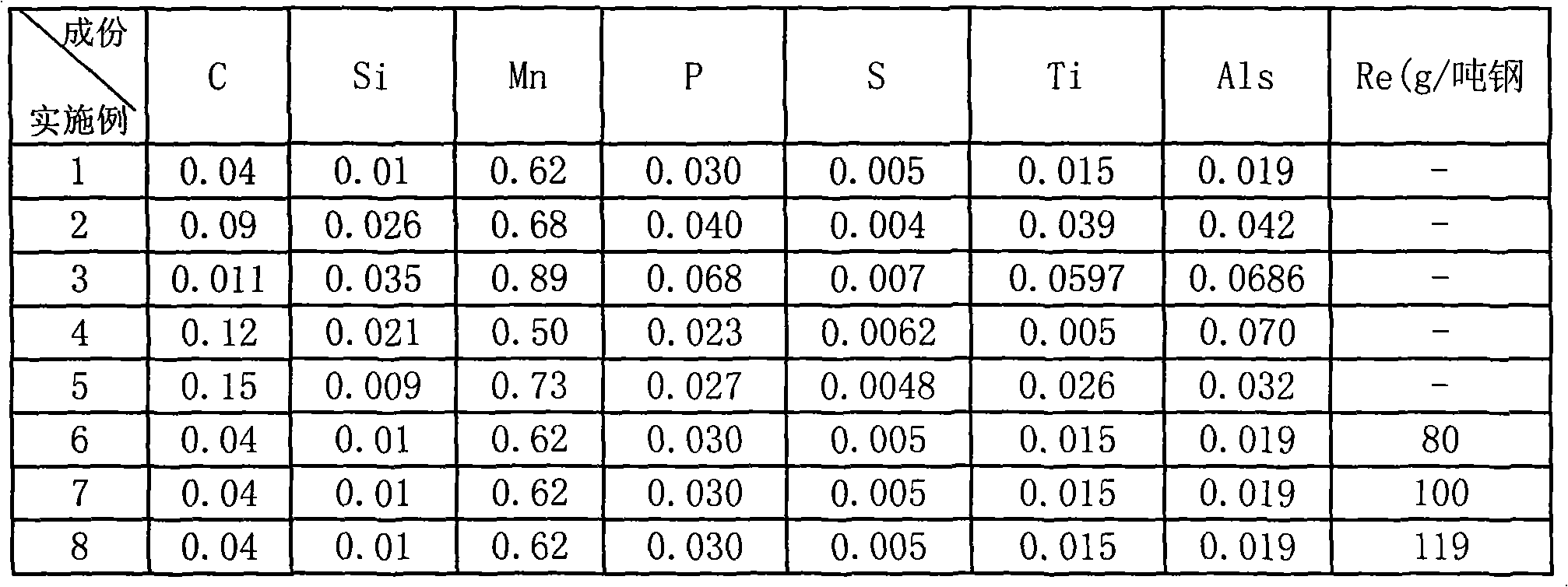

Steel for high strength spring, and high strength spring and method for manufacture thereof

Owner:NHK SPRING CO LTD

High-strength steel for water heater inner container and production method thereof

InactiveCN101255530AReduce manufacturing costEasy to weldRoll force/gap control deviceTemperature control deviceImpurityFormability

The invention relates to a high-strength steel for water heater containers, which solves the current drawbacks of complex welding process, non-once-forming steel plate, many alloy elements, low strength, poor pressure resistance and easy deformation to make enamel drop off. The steel is mainly composed of 0.01% to 0.15% by weight of C, no more than 0.04% by weight of Si, 0.50% to 0.90% by weight of Mn, no more than 0.070% by weight of P, 0.015% by weight of S, 0.005% to 0.060% by weight of Ti, 0.005% to 0.070% by weigh of Als, and the balance Fe and unavoidable impurity. The production method comprises the following steps: desulphurization of hot metal, and converter bottom-top composite blowing; argon blowing; all-protected casting to form a plate blank; and hot rolling by controlling rolling and controlling cooling. According to the invention, the microalloy elements are less, the production cost is low, the welding is convenient, the cold formability is good, the pressure resistance is superior, the yield stress reaches up to 360MPa, the plate is capable of bearing 320MPa or more strength, being once-formed, and directly being enameled to various heater containers.

Owner:武汉钢铁有限公司

Segmented cold formed joist

A joist comprised of at least one cold-formed elongated chord member; a cold-formed web having a plurality of web members and means for securing said web to said chord member.

Owner:BEST JOIST

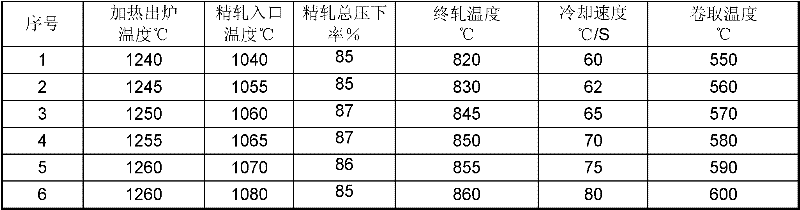

High-strength hot rolled steel plate with excellent cold forming property and preparation method thereof

InactiveCN102226249AHigh accuracy of shape and sizeHigh dimensional accuracyRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a high-strength hot rolled steel plate with excellent cold forming property. The steel plate comprises the following chemical components by weight: 0.04-0.08% of C, 0.15-0.3% of Si, 1.20-1.90% of Mn, 0.020-0.060% of Al, not more than 0.015% of P, not more than 0.0009% of S, 0.06-0.08% of Nb, 0.09-0.12% of Ti, 0.05-0.1% of Mo, not more than 0.002% of O and not more than 0.004% of N. A preparation method is characterized in that the heating temperature is 1240-1260 DEG C; the rough rolling temperature is 1230-1100 DEG C; the finish rolling inlet temperature is 1080-1040 DEG C; the final rolling temperature is 820-860 DEG C; the total finish rolling reduction ratio is not less than 85%; the laminar flow is cooled at a speed being not less than 60 DEG C / s after finish rolling; and the coiling temperature is controlled between 550 DEG C and 600 DEG C.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com