Patents

Literature

32results about How to "Avoid contact reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

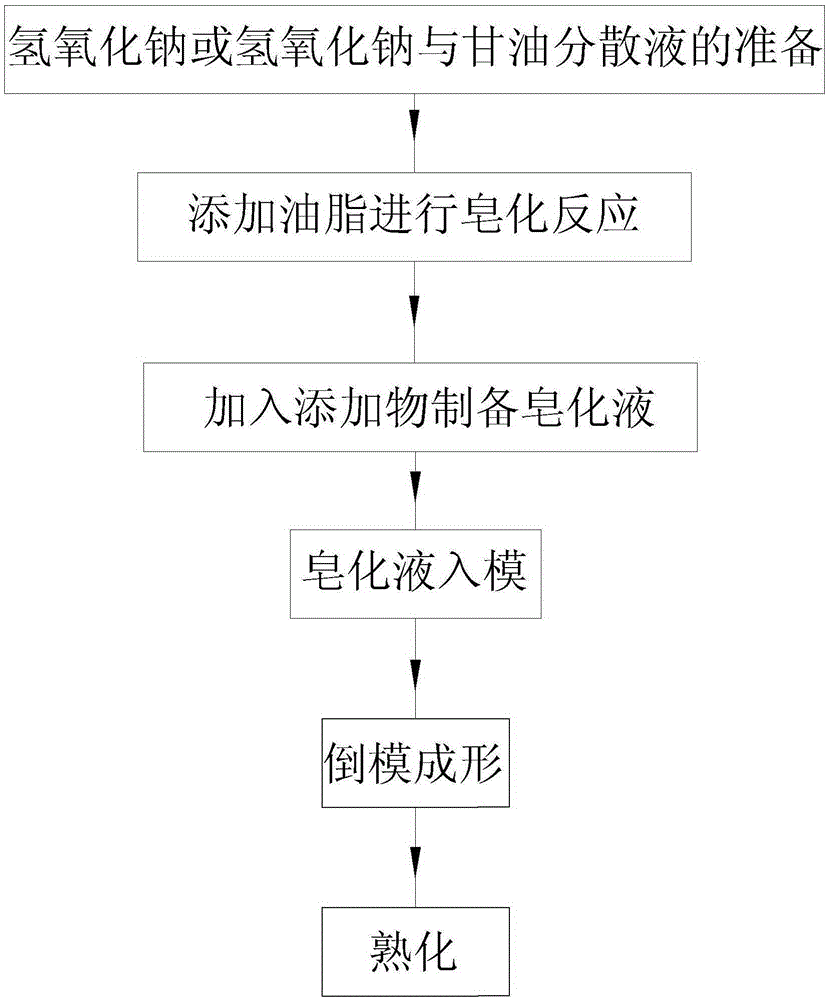

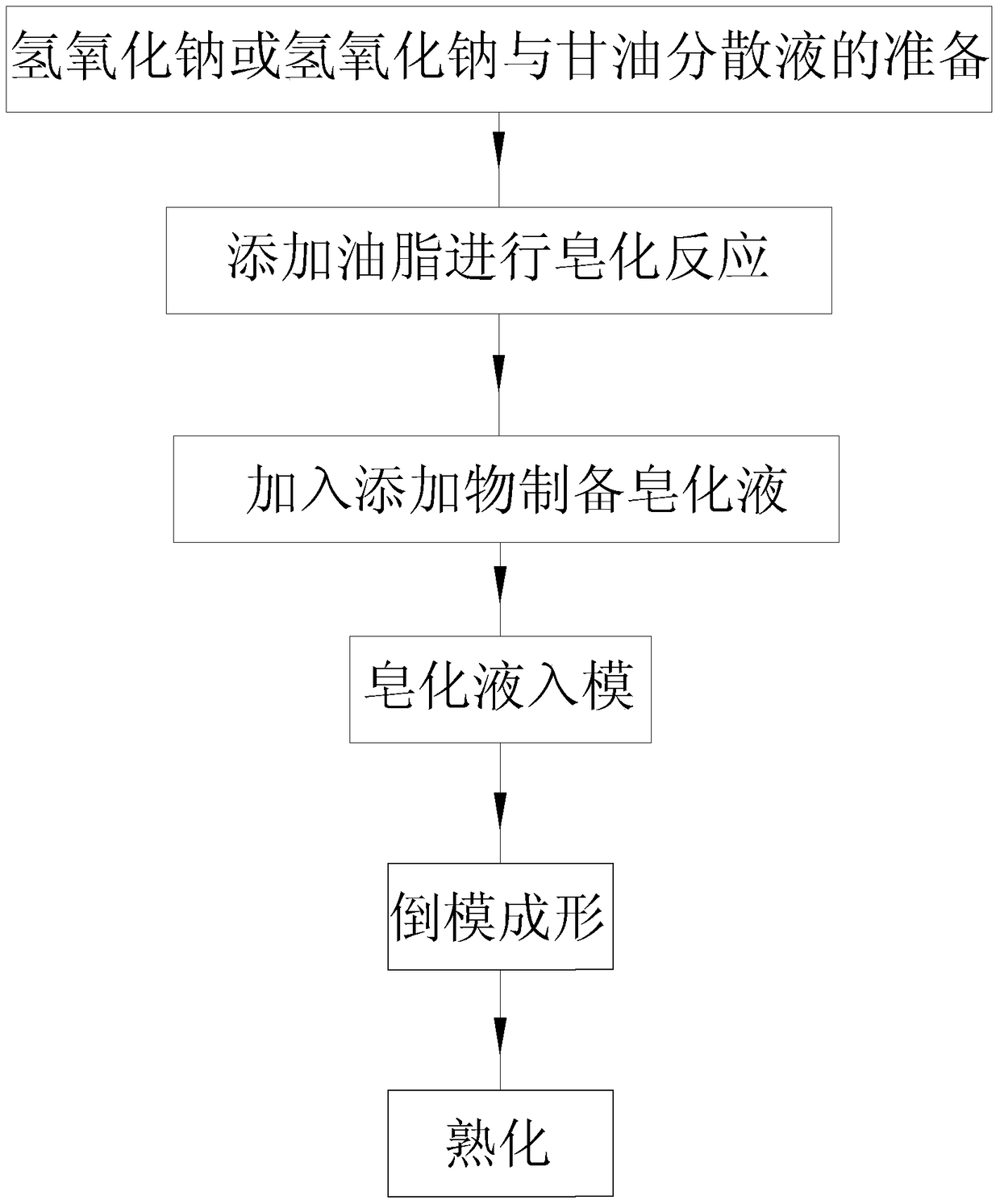

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing corrosion inhibition waterborne aluminum pigment

InactiveCN105482514AImprove stabilityGood sustained release effectPigment flushingPigment treatment with organosilicon compoundsContact reactionsElution

The invention discloses a method for preparing a corrosion inhibition waterborne aluminum pigment. The method comprises the following steps: a step (1) of aluminum powder surface elution treatment; a step (2) of surface hydroxylation treatment; and a step (3) of mixing coating treatment. The method for preparing the corrosion inhibition waterborne aluminum pigment is simple and convenient to operate and easy to implement. According to the method, through aluminum powder surface elution treatment, hydroxylation treatment, slow release treatment and coating treatment, the coating stability of the aluminum pigment surface is improved effectively, the aluminum pigment is prevented from being in contact reaction with water or an air medium, the slow release performance of the aluminum pigment is improved remarkably, and the prepared aluminum pigment is high in stability, good in glossiness and wide in application prospect.

Owner:常熟市环虹化工颜料厂

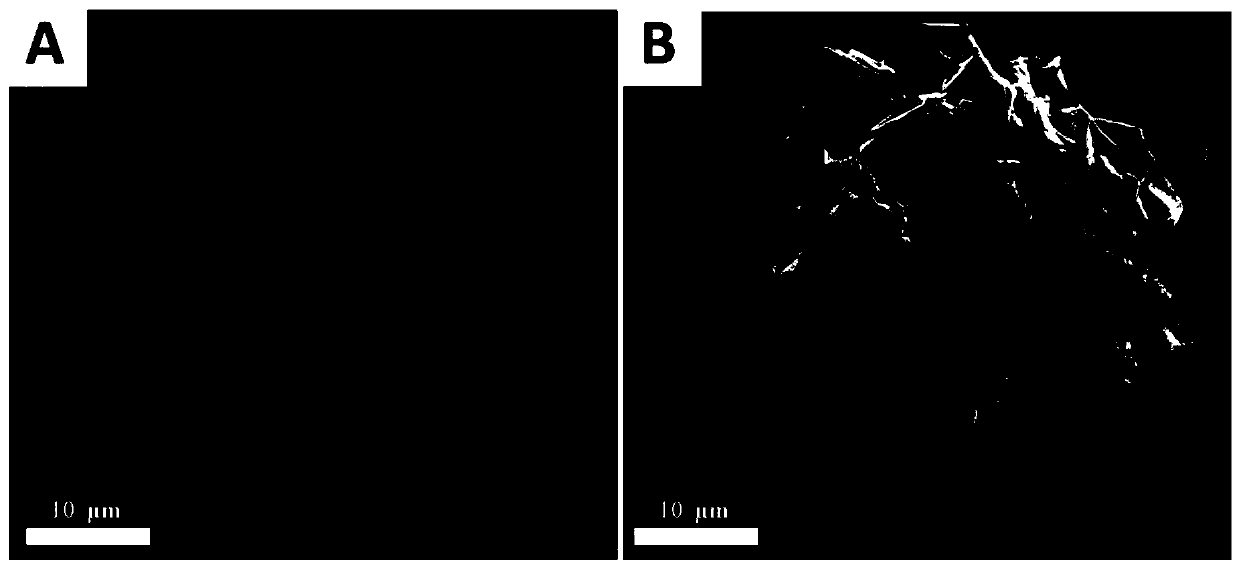

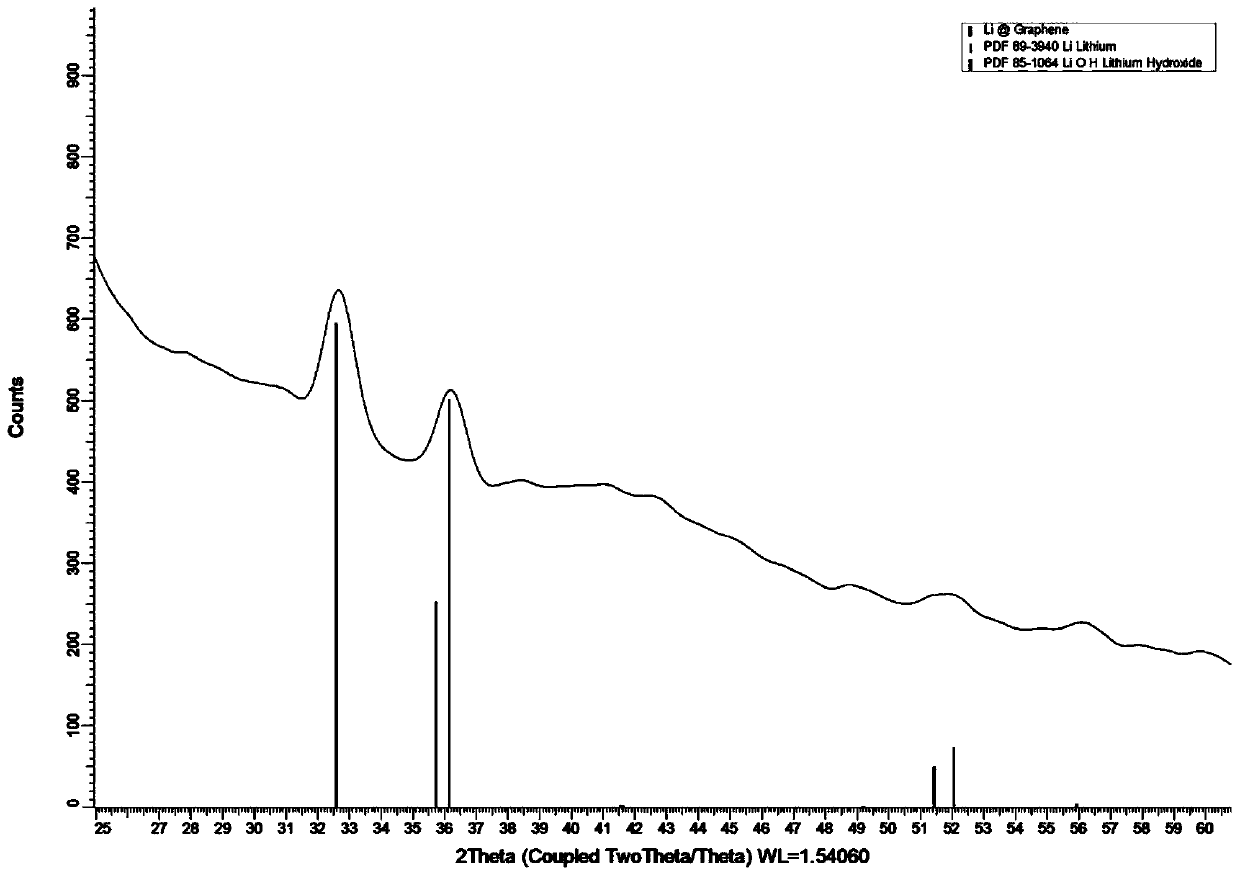

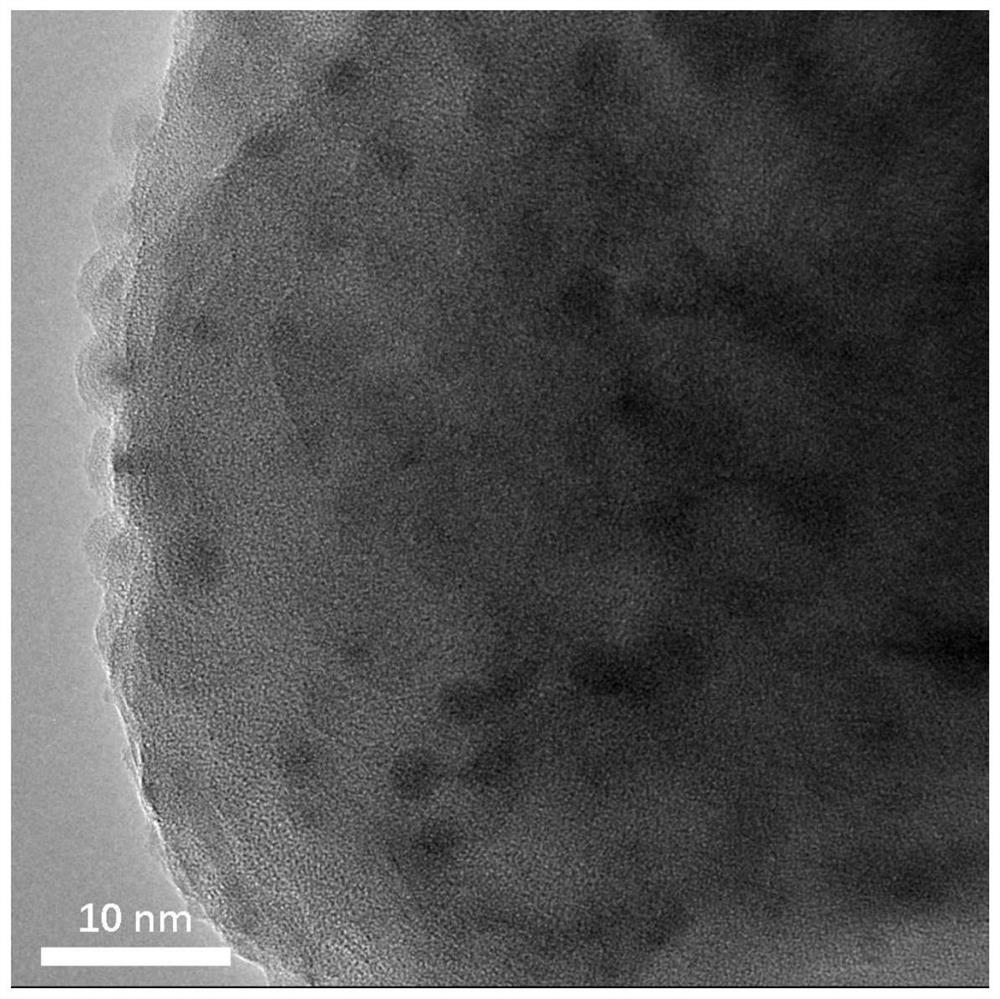

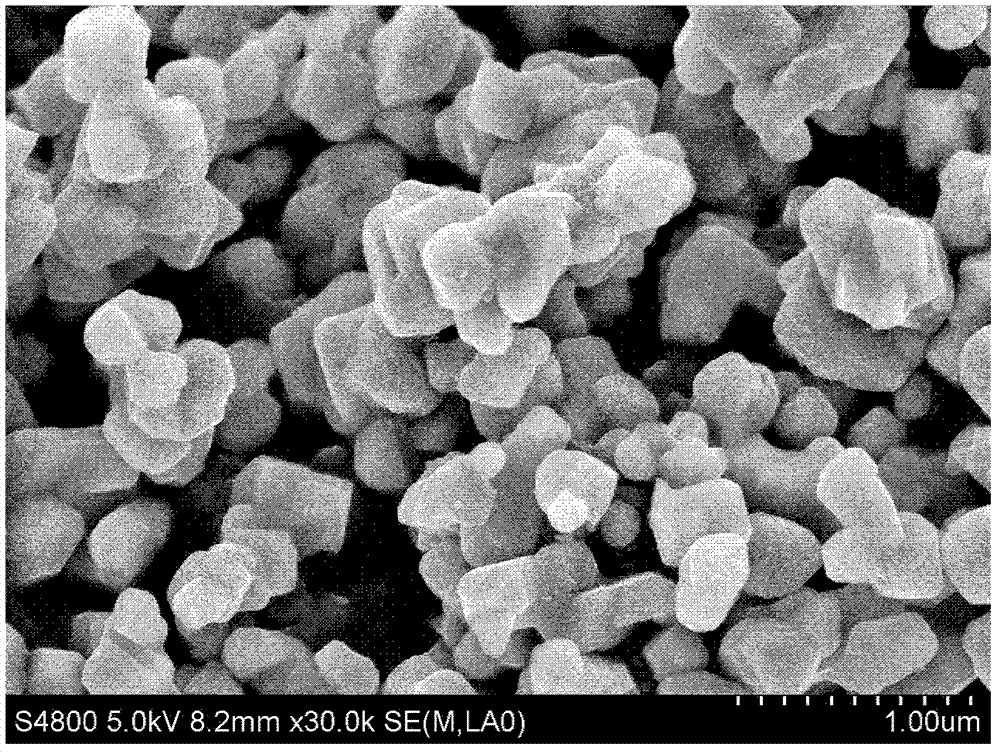

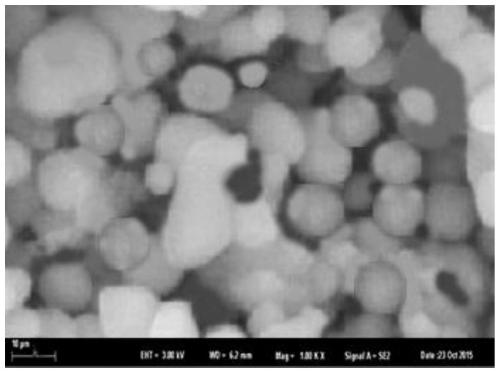

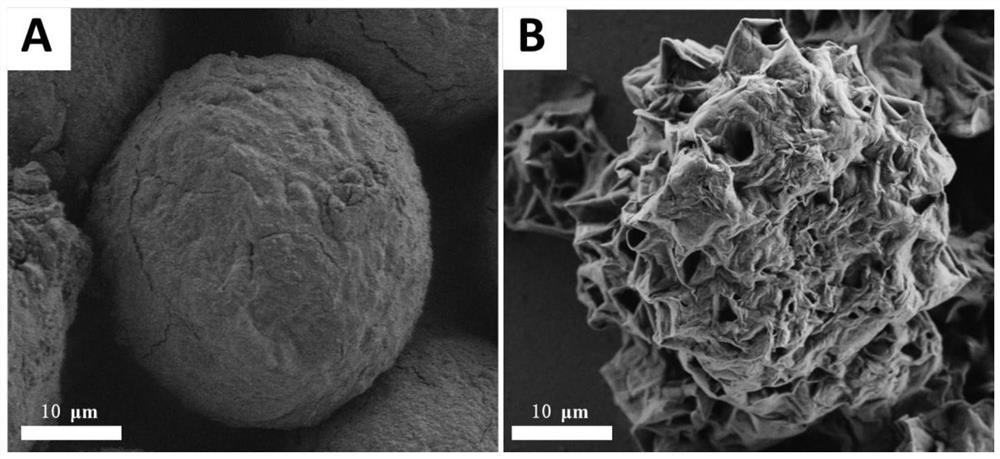

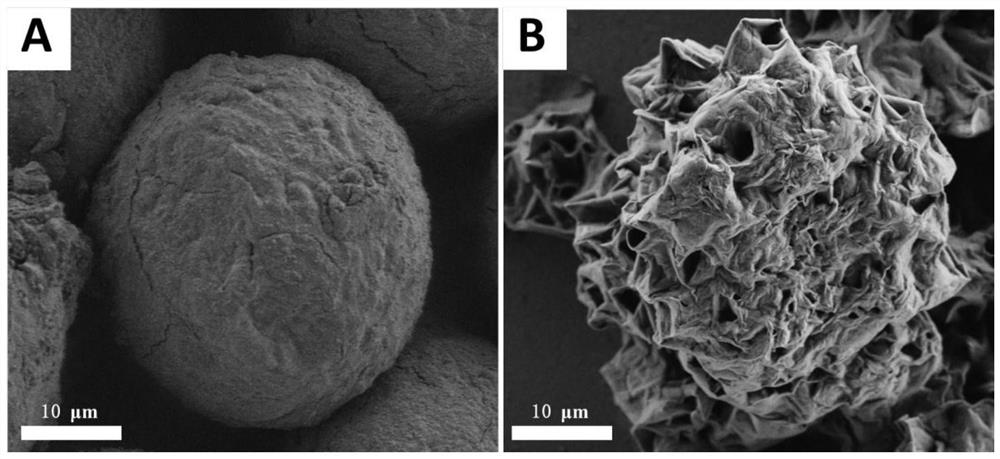

Method for preparing graphene coated protective metal lithium microspheres

ActiveCN110190257AAvoid contact reactionsImprove conductivityCell electrodesSecondary cellsMetallic lithiumHydrogen

The invention discloses a method for preparing graphene coated protective metal lithium microspheres. The method comprises steps that S1, metallic lithium is dispersed in inert solvent without activehydrogen to form metal lithium microsphere dispersion liquid; S2, the graphene having a surface functional group is dispersed in the inert solvent without the active hydrogen to form graphene dispersion liquid; S3, the metal lithium microsphere dispersion liquid of the step S1 and the graphene dispersion liquid of the step S2 are mixed and thoroughly stirred, the inert solvent is separated by filtration or evaporated for drying, and the graphene coating is utilized to protect the metal lithium microspheres. The method is advantaged in that the graphene is used as a protective layer of metalliclithium powder, the graphene protective layer has characteristics of high stability and excellent electrical conductivity, the preparation method further has properties of simple preparation processand easy enlargement, and products have controllable particle size and high stability.

Owner:上海泓昌新材料科技有限公司

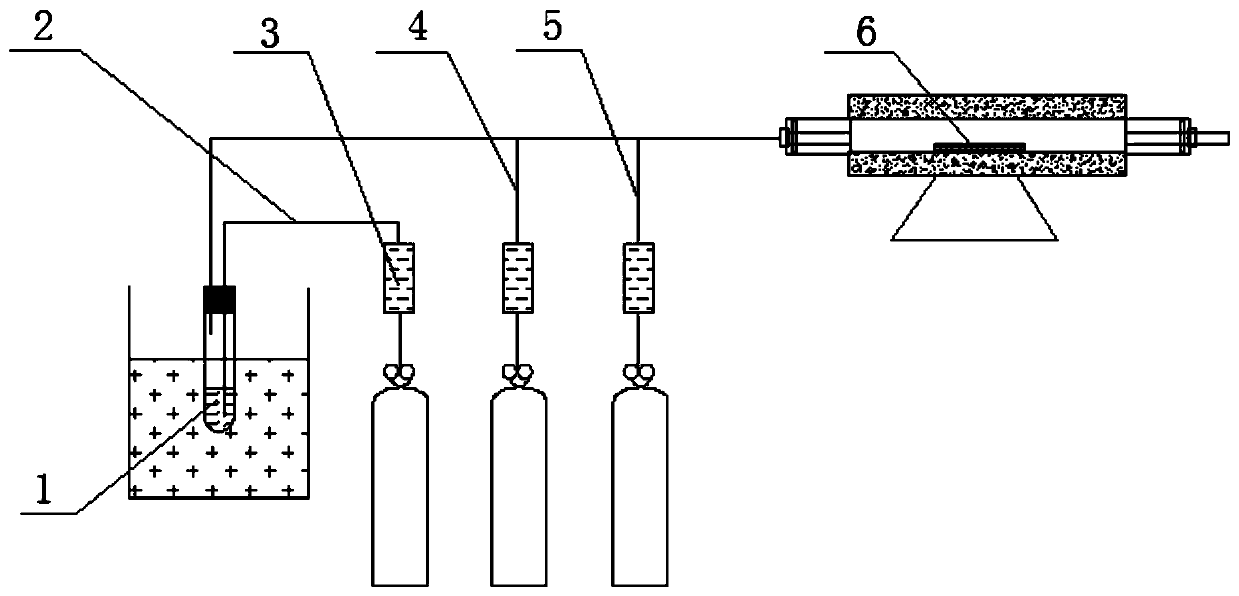

Method for preparing pyrolytic boron nitride material

InactiveCN107265416AIncrease productivityFast deposition growthNitrogen compoundsBoron nitrideChemical vapor deposition

The invention discloses a method for preparing a pyrolytic boron nitride material. The method comprises the following steps: putting a substrate mold in an air-carrying atmosphere carrying borazine vapor under a vacuum condition, and pyrolyzing borazine which constantly deposits on the depositing surface of the substrate mold by adopting a chemical vapor deposition method to form the pyrolytic boron nitride material. The preparation method of the pyrolytic boron nitride material has the advantages of simple and easily controlled process, low cost, low energy consumption, high yield, environmental friendliness and the like.

Owner:NAT UNIV OF DEFENSE TECH

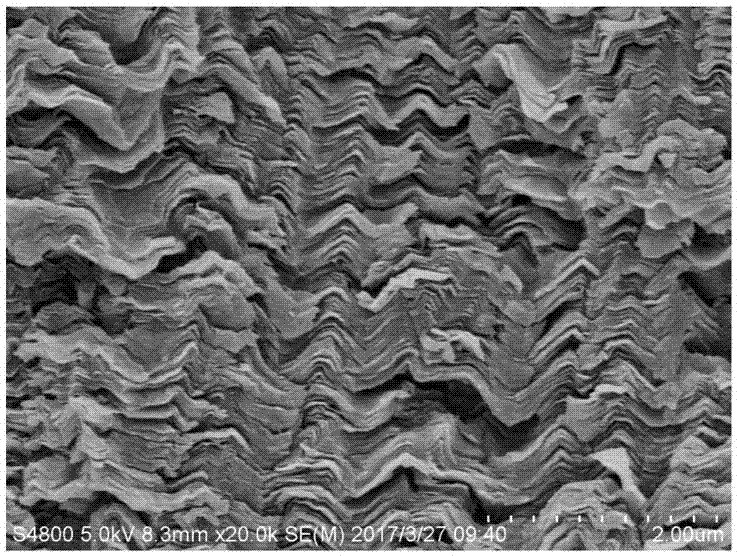

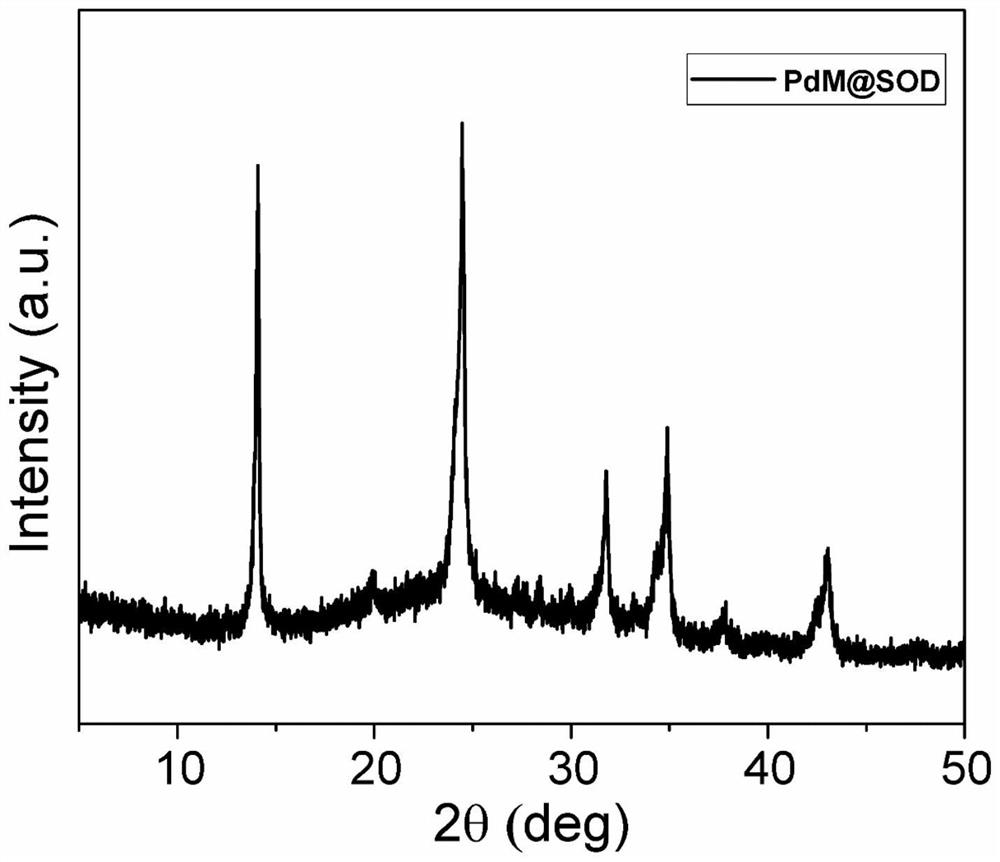

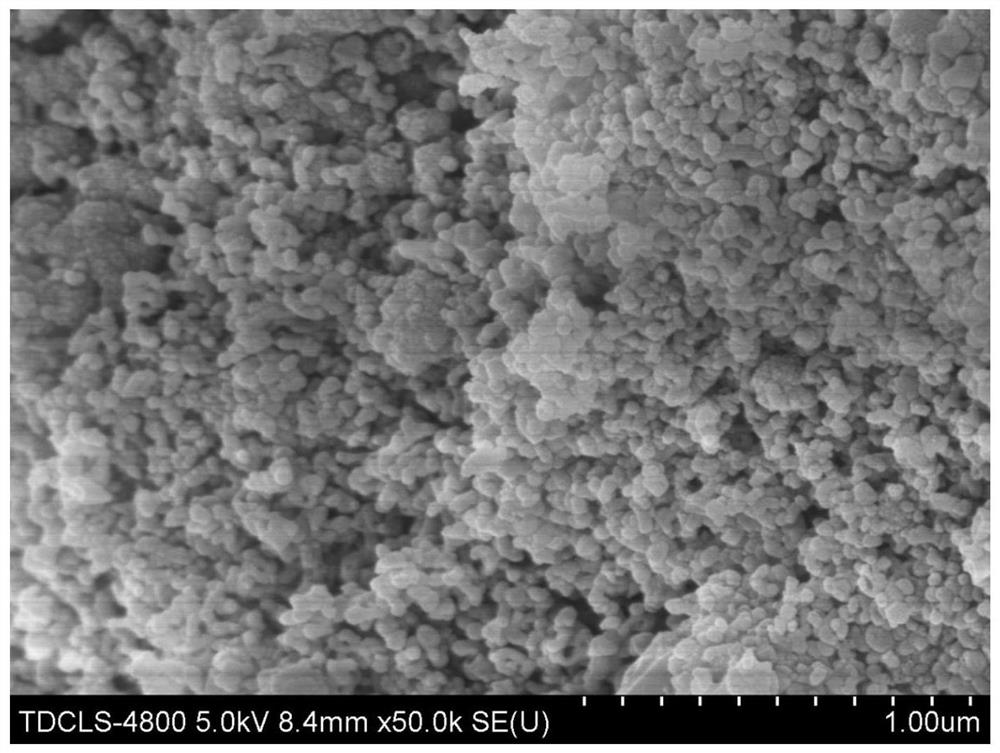

Pd-based alloy packaged molecular sieve catalyst, as well as preparation method and application thereof

ActiveCN112570015AAvoid flying temperatureHydrogenation reaction process safetyMolecular sieve catalystsHydrocarbon by hydrogenationChemistryMolecular sieve

The invention belongs to the technical field of molecular sieve catalysts, and discloses a Pd-based alloy packaged molecular sieve catalyst, a preparation method and applications thereof. The molecular sieve catalyst comprises a sodalite molecular sieve, and PdM nano-alloy particles are packaged in the sodalite molecular sieve; the preparation method comprises the following steps: firstly preparing a sodalite molecular sieve, then impregnating and loading Pd metal and an M metal precursor, roasting and reducing to form a molecular sieve catalyst impregnated and loaded with nano alloy particles; then uniformly mixing with a silica-alumina sol solution, uniformly stirring and mixing the solution, evaporating the solution to dryness, then adding ethylene glycol, grinding the mixture into uniform paste, carrying out hydrothermal reaction, and cooling, washing, drying, roasting and reducing the reaction product to obtain the catalyst. The molecular sieve catalyst is applied to acetylene selective hydrogenation reaction, can avoid an excessive hydrogenation process, and has relatively high acetylene conversion rate and ethylene selectivity.

Owner:TIANJIN UNIV

Antibacterial-enhanced aqueous aluminum pigment with zinc oxide/silver compound powder

InactiveCN106221309AImprove corrosion resistanceGood dispersionAntifouling/underwater paintsInksTalc / Zinc OxideDibenzoyl Peroxide

The invention discloses an antibacterial-enhanced aqueous aluminum pigment with zinc oxide / silver compound powder. The antibacterial-enhanced aqueous aluminum pigment is characterized by being prepared from the following raw materials in parts by weight: 40 to 45 parts flaky aluminum powder, 100 to 110 parts of isopropyl alcohol, 0.3 to 0.35 part of copper sulfate crystal, a proper amount of deionized water, 4 to 4.5 parts of phenolic ether type phosphate, a proper amount of absolute ethyl alcohol, 9 to 10 parts of tetraethoxysilane, 6 to 7 parts of vinyltriethoxysilane, 9 to 10 parts of ammonia water with the weight concentration of 20 percent, 200 to 220 parts of butyl acetate, 5 to 6 parts of crylic acid, 5 to 6 parts of methacrylic acid, 0.6 to 0.65 part of dibenzoyl peroxide, 13 to 15 parts of propylene glycol monomethyl ether, 2 to 3 parts of zirconium phosphate, 4 to 5 parts of nano-zinc oxide, 2 to 3 parts of carboxymethylcellulose, 0.8 to 1 part of sodium polyacrylate, 2 to 3 parts of glycerinum and 4 to 5 parts of a silver nitrate solution with the weight concentration of 10 percent. The product disclosed by the invention can be well dispersed in finished products such as an aqueous coating and ink, and is high in antibacterial property.

Owner:HEFEI SUNRISE PIGMENTS

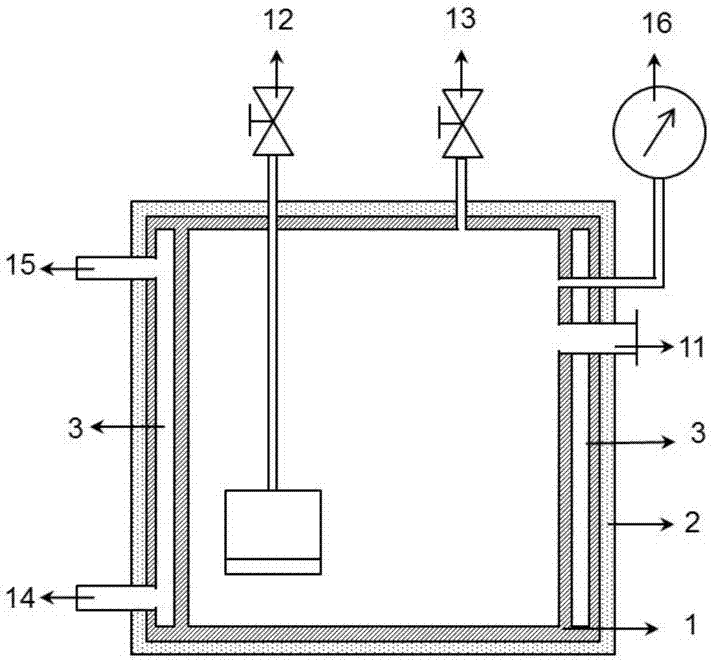

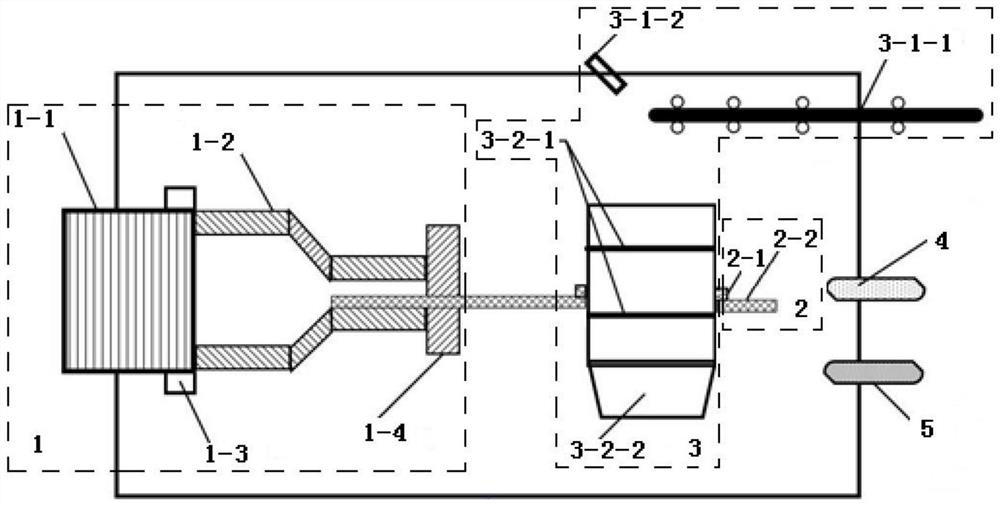

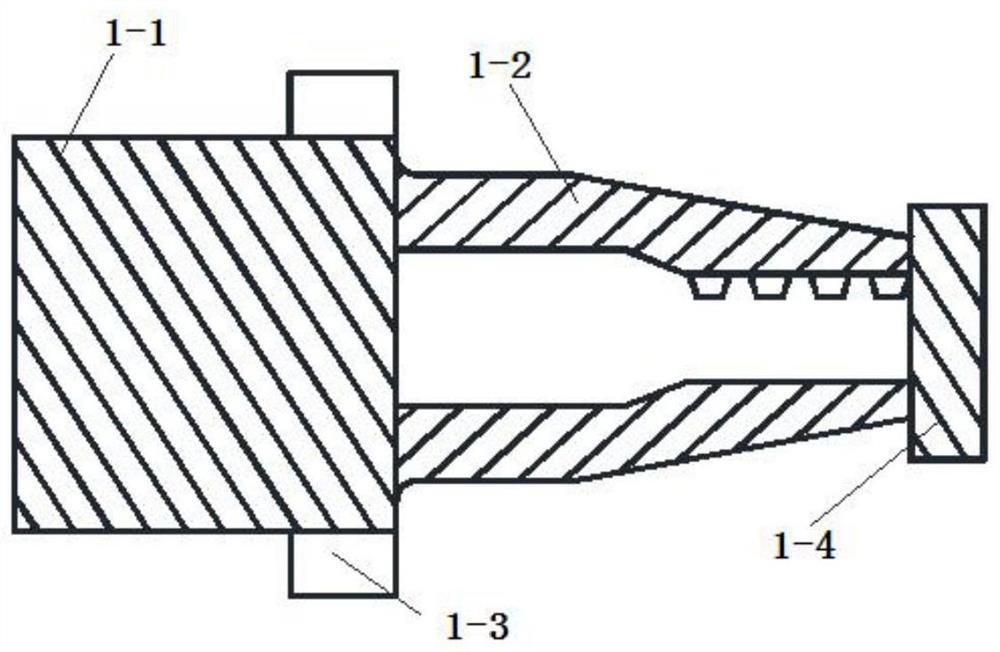

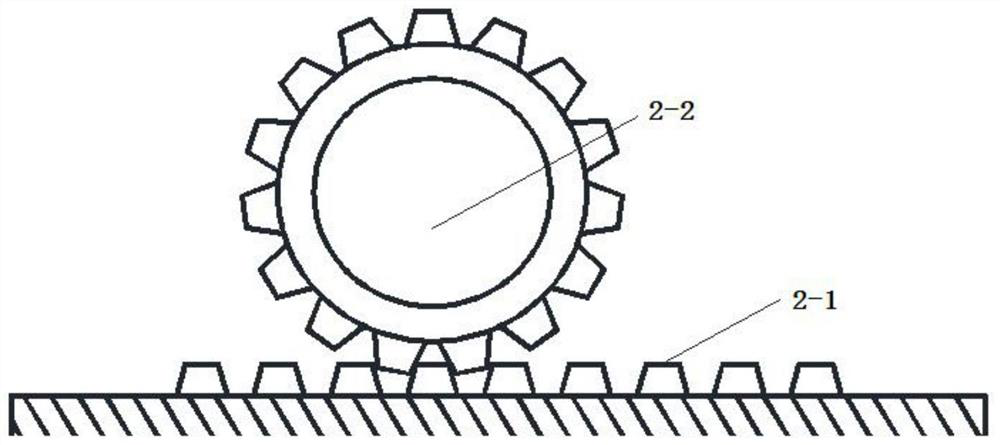

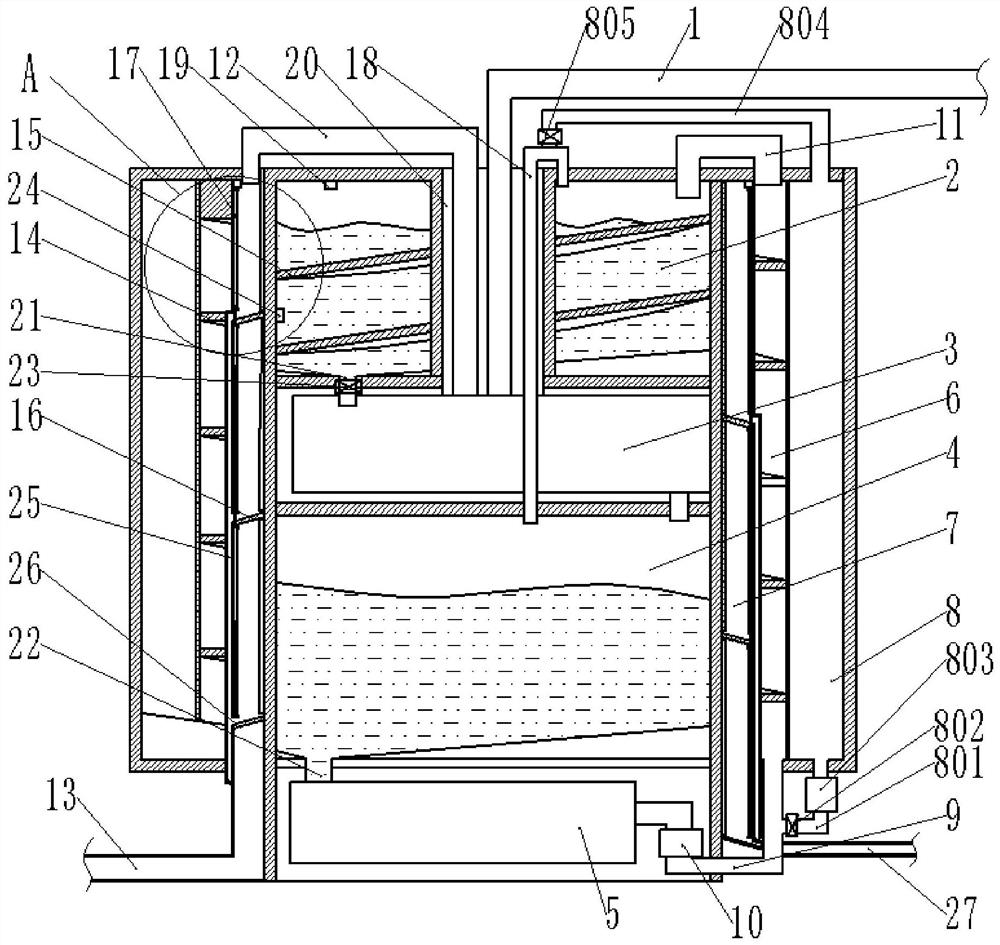

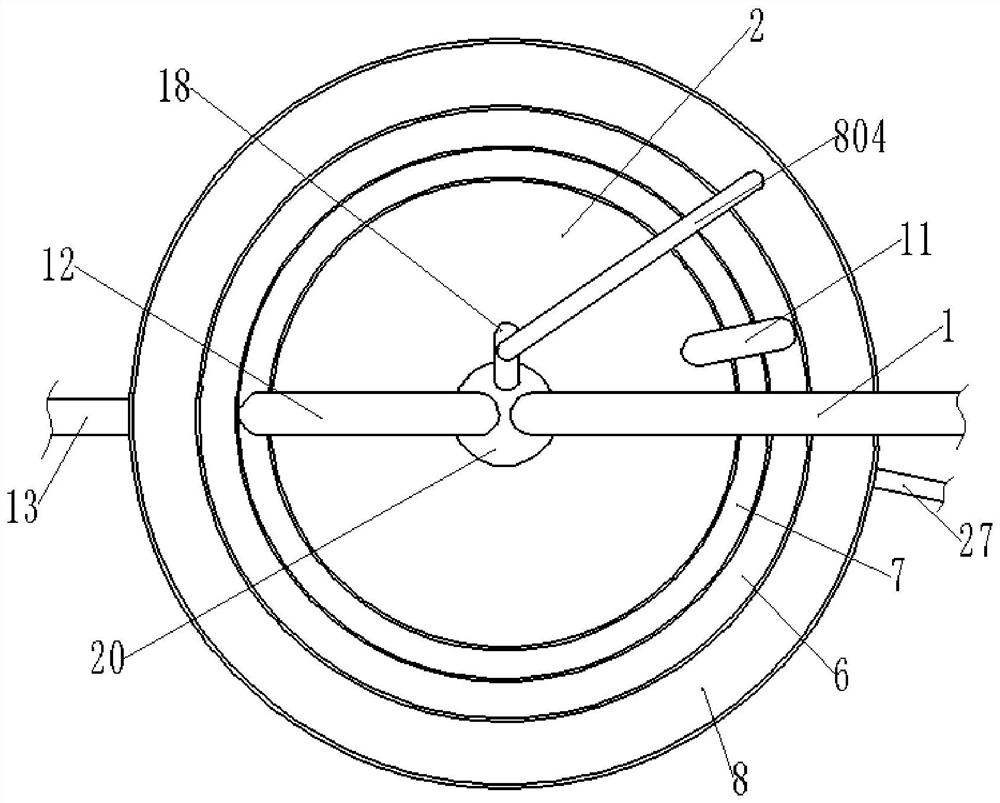

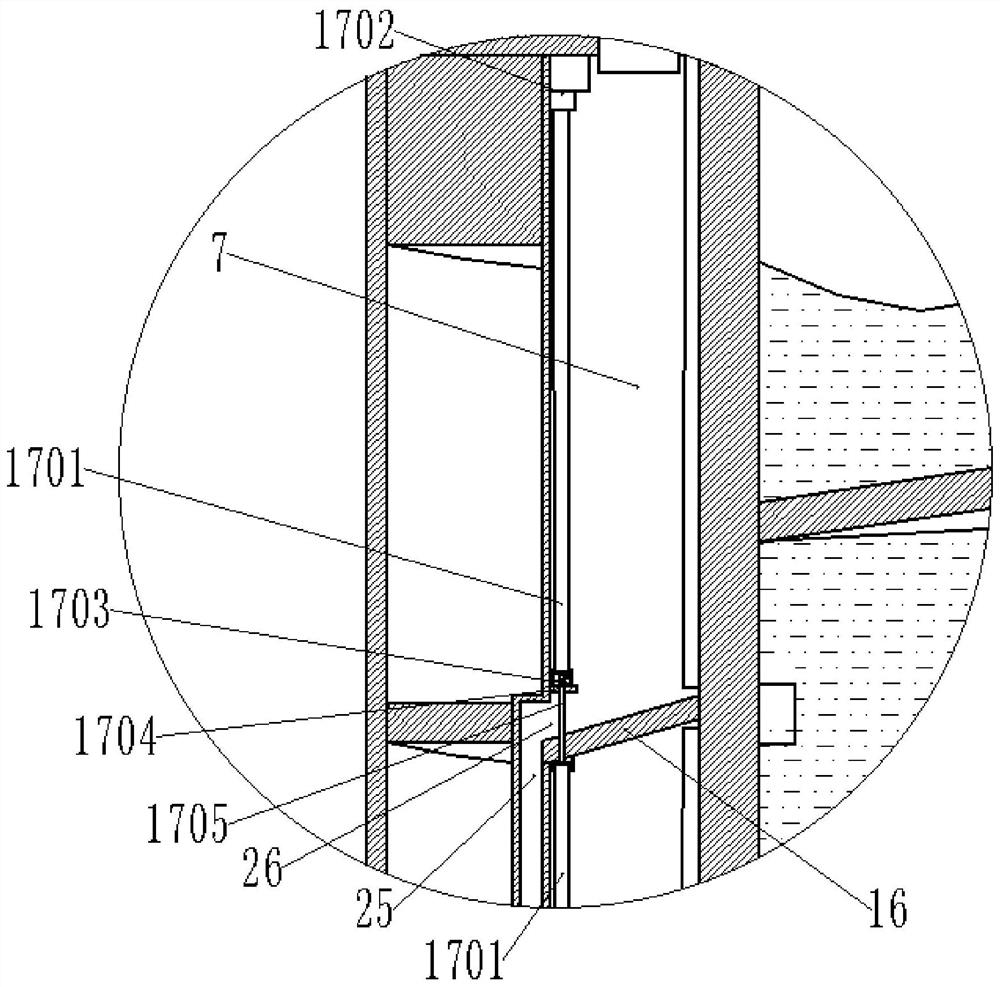

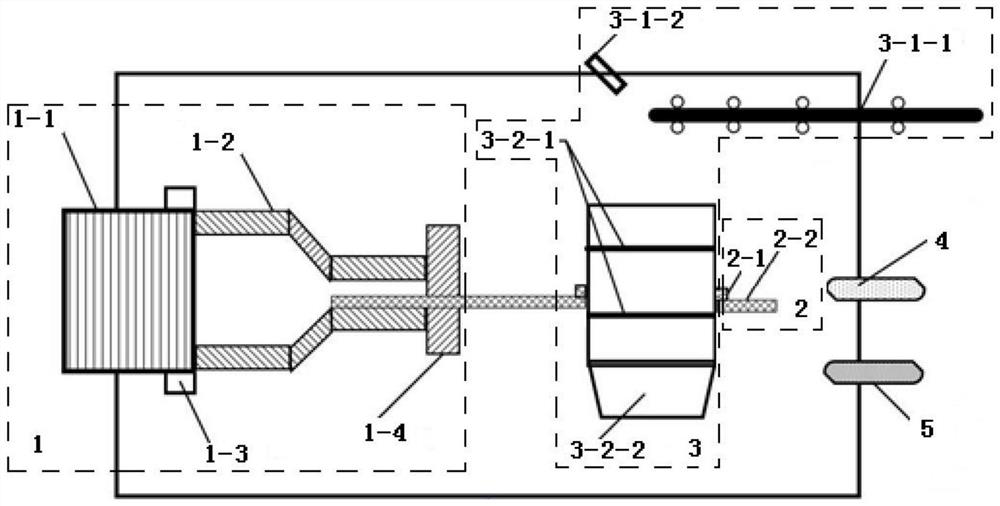

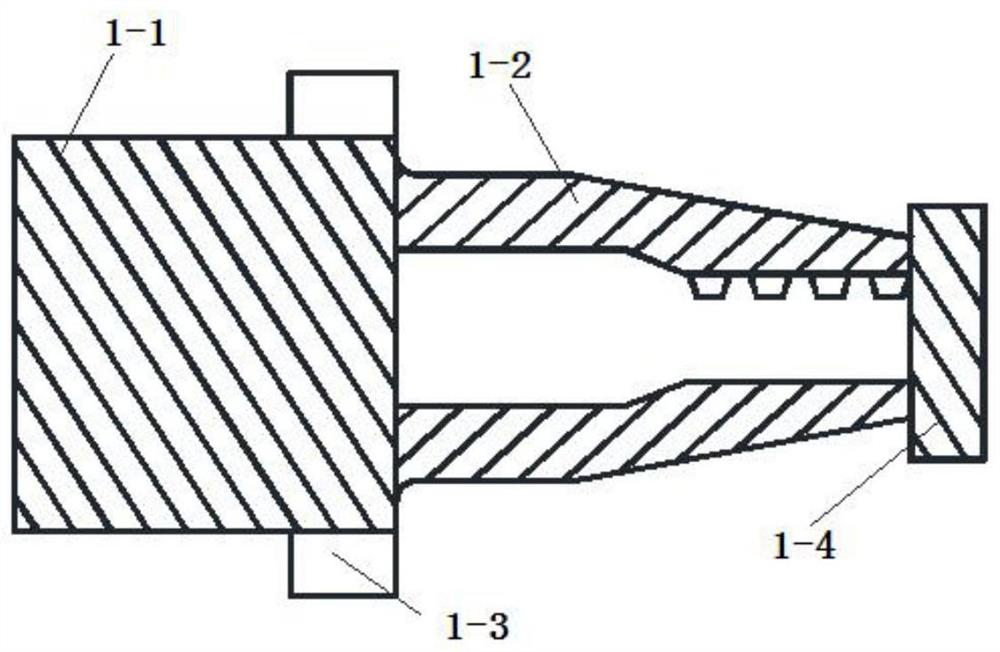

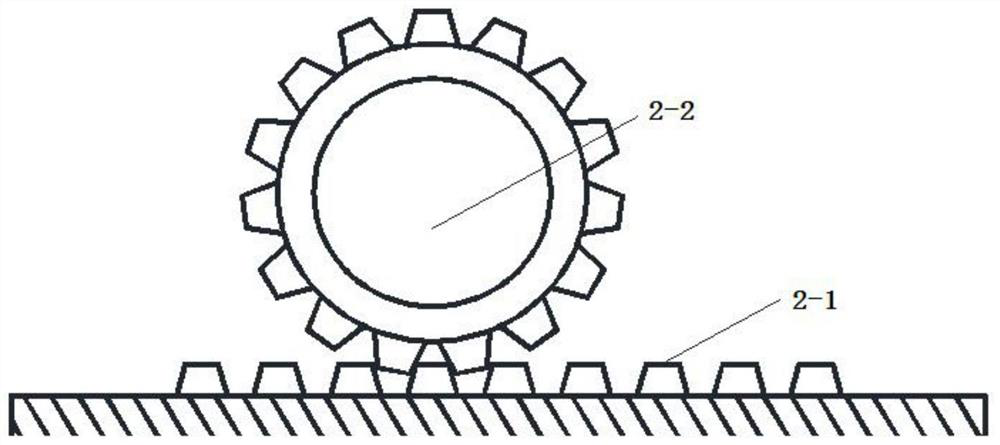

Ultrasonic atomization device and method for preparing spherical metal powder

The invention belongs to the technical field of spherical metal powder preparation, and particularly relates to an ultrasonic atomization device and a method for preparing spherical metal powder. The ultrasonic atomization device comprises an ultrasonic vibration system (1), a gear rack system (2) and an atomization system (3), wherein the ultrasonic vibration system (1) comprises a transducer (1-1) and an amplitude-change pole (1-2) which are fixedly connected; the atomization system (3) comprises a fuse wire system (3-1) and an atomization chamber (3-2) positioned below the fuse wire system (3-1); a mesh sieve (3-2-1) is arranged in the atomization chamber (3-2); the amplitude-change pole (1-2) is meshed with the gear rack system (2); and the gear rack system (2) is meshed with the atomization chamber (3-2). According to the device, the amplitude-change pole does not make contact with molten metal, and cavitation corrosion does not exist.

Owner:SHANGHAI UNIV

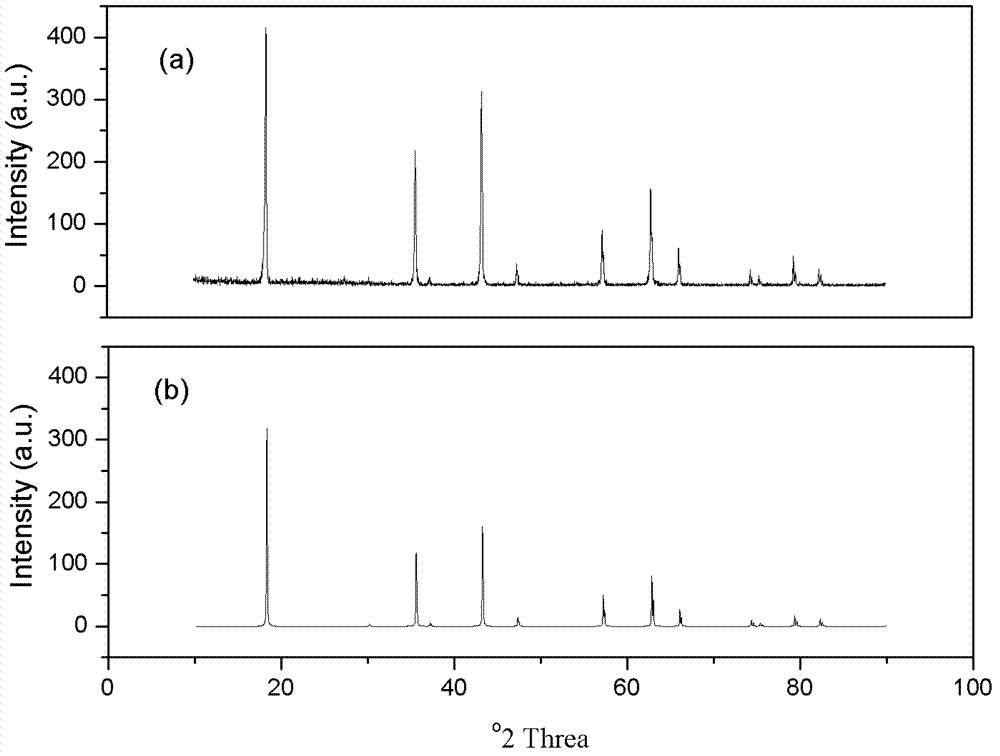

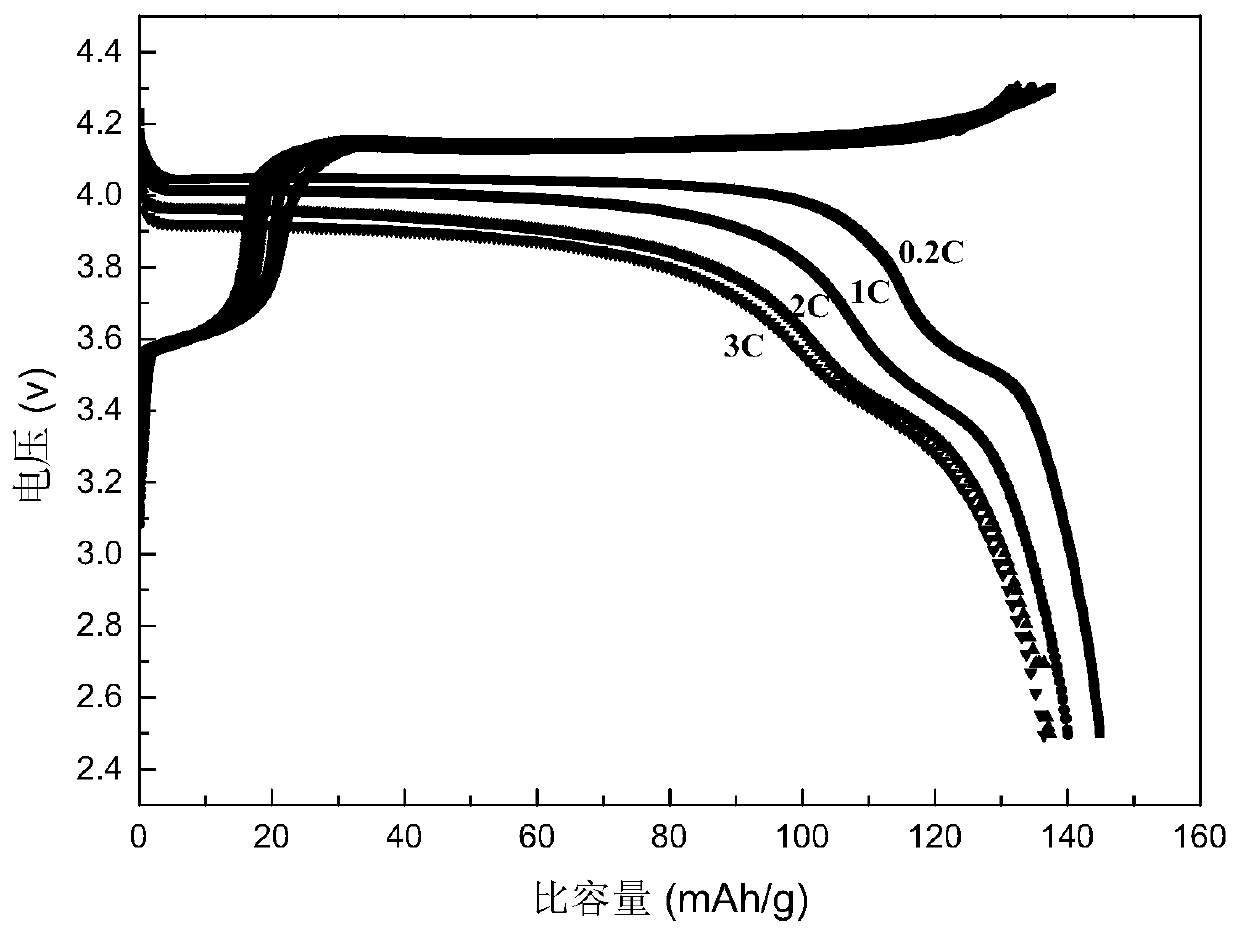

Preparation method of aluminum-oxide-coated nano lithium titanate composite material

ActiveCN102376947BImproved magnification performanceImprove cycle performanceCell electrodesFree coolingRoom temperature

The invention discloses a preparation method of aluminum-oxide-coated nano lithium titanate composite material, which comprises the steps of: adding aluminum salt solution into prepared Li4Ti5O12 suspending liquid under the stirring condition, wherein the adding quantity of the aluminum salt solution is in accordance with the molar ratio as follows: Ti: Al=5: x, and x=0.01-0.55; simultaneously, adding a right amount of ammonia water, and adjusting the pH value to be 8-10; stirring for reaction for 30-50 minutes, and standing still for about 6 hours; after filtering, washing and drying, obtaining precursor of the aluminum-oxide-coated nano lithium titanate composite material; and finally, sintering the obtained precursor of the aluminum-oxide-coated nano lithium titanate composite materialat 400-600 DEG C for 4-10 hours, naturally cooling to be room temperature, and obtaining the aluminum-oxide-coated nano lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

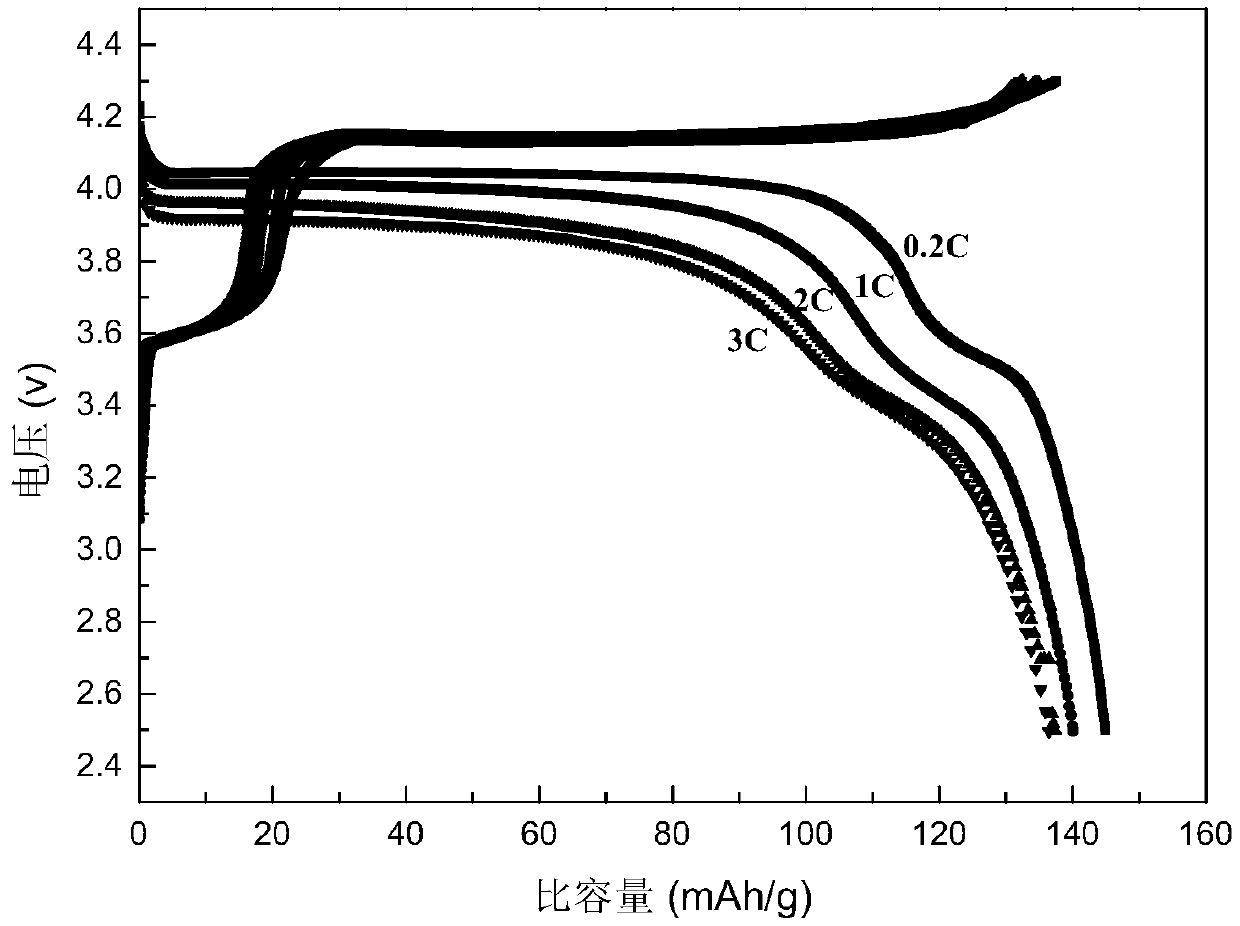

A preparation method of titanium nitride and carbon double-coated lithium manganese iron phosphate composite material

ActiveCN106058220BEasy to useImprove uniformityCell electrodesSecondary cellsGas phaseTitanium nitride

The invention discloses a preparation method for a lithium manganese iron phosphate composite coated by both titanium nitride and carbon. The preparation method comprises the following steps: adding a certain amount of a carbon source during synthesis of a precursor; and then during sintering, introducing NH3 in a protective atmosphere, introducing TiCl4 with N2 as carrying gas and uniformly depositing a layer of a titanium nitride coating on the surface of lithium manganese iron phosphate by using a chemical vapor deposition method so as to prepare the lithium manganese iron phosphate composite uniformly coated by both titanium nitride and carbon. According to the invention, through adjustment of a carbon source addition amount during synthesis and the flow and deposition time of the three gases during vapor deposition, the granularity, thickness and bulk density of the coating can be adjusted, and the lithium manganese iron phosphate composite uniformly coated by both titanium nitride and carbon can be obtained. The coating has good uniformity and consistency; the composite has high tap density and good conductivity; a lithium ion positive electrode material using the composite has good charge and discharge rate and cycle stability; and the preparation method is simple, controllable and easy for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

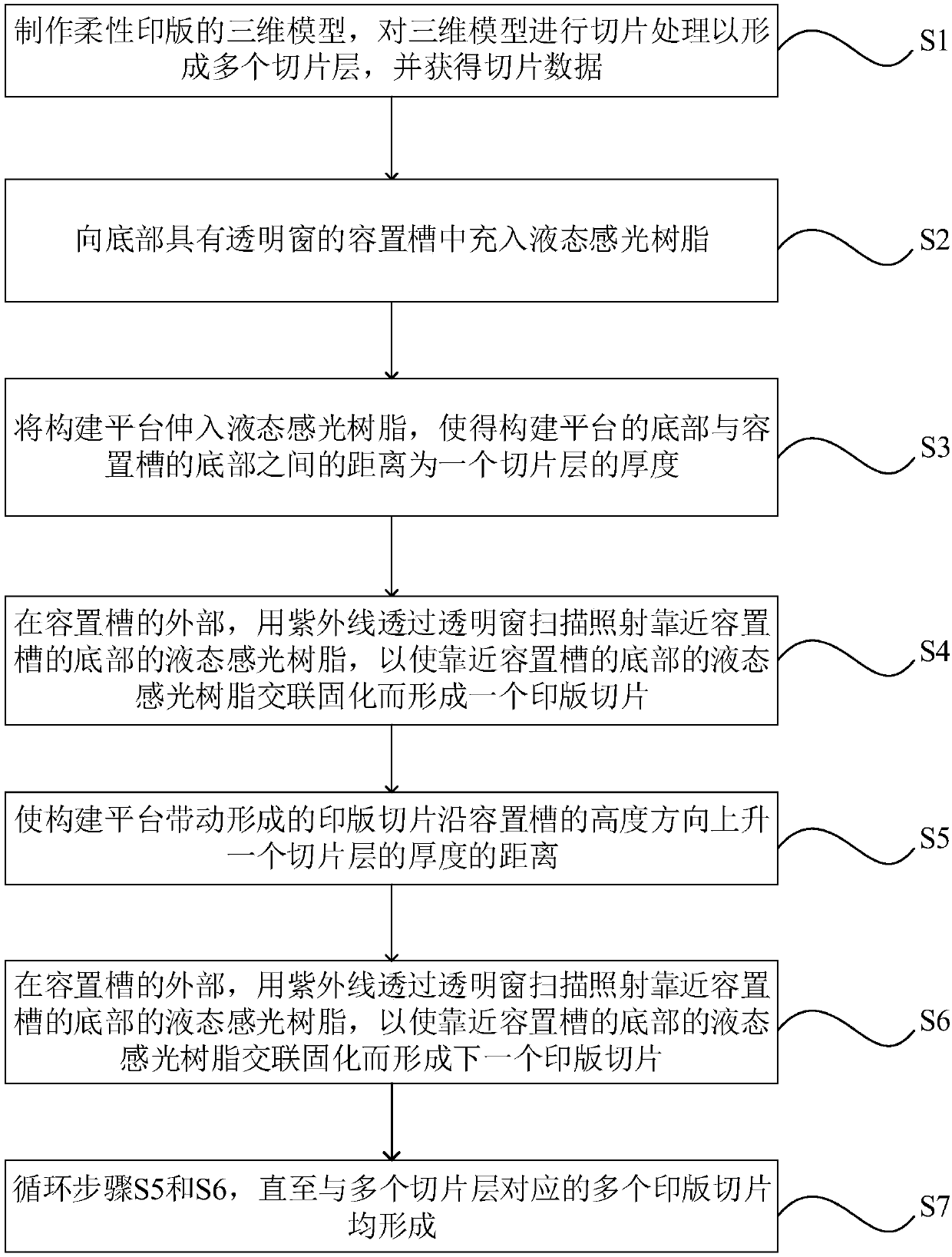

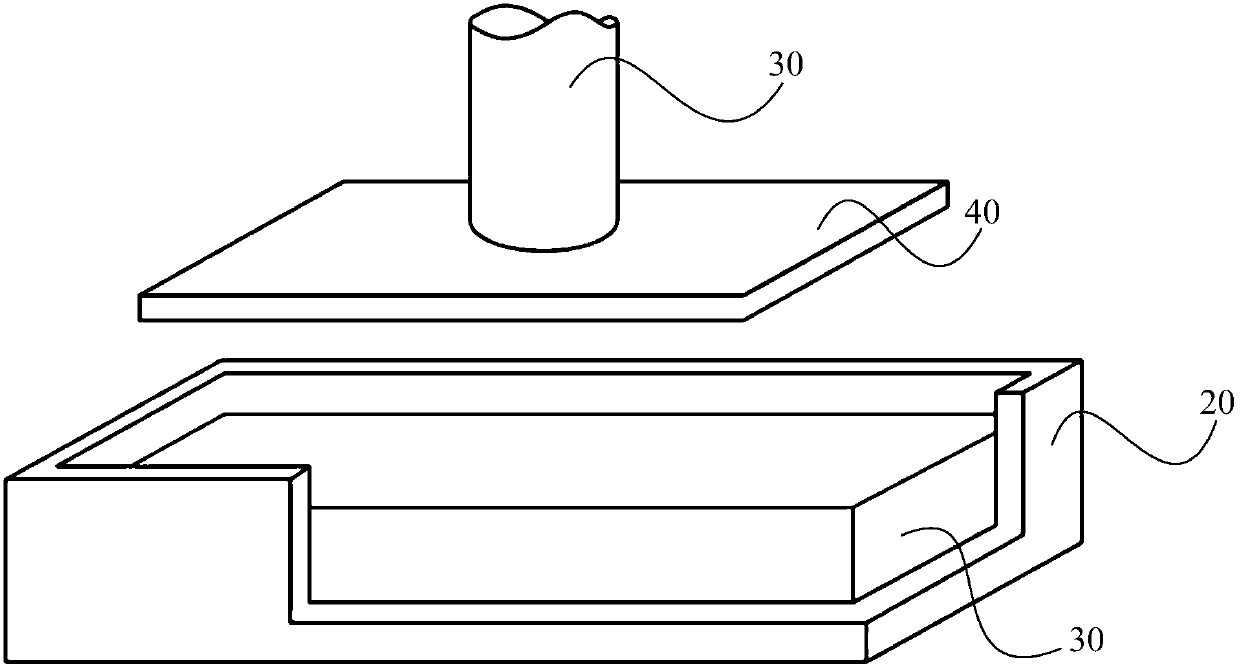

Plate making method of flexible printing plate based on three-dimensional photo-curing molding method

InactiveCN110142960ARandom combinationEasy to manufacture3D object support structuresDomestic articlesUltravioletEngineering

The invention discloses a plate making method of a flexible printing plate based on a three-dimensional photo-curing molding method. The method comprises the following steps that S1, a three-dimensional model of the flexible printing plate is made, the three-dimensional model is subjected to slicing treatment to form a plurality of slicing layers, and slicing data is obtained; S2, a container groove is filled with liquid photosensitive resin; S3, a construction platform is extended into the liquid photosensitive resin, so that the distance between the bottom of the construction platform and the bottom of the container groove is the thickness of one slicing layer; S4, the liquid photosensitive resin at the bottom of the container groove is scanned and irradiated by using ultraviolet rays toform a printing plate slice; S5, the construction platform drives the formed printing plate slice to rise to the distance of the thickness of one slicing layer; S6, the liquid photosensitive resin atthe bottom of the container groove is scanned and irradiated by using the ultraviolet rays to form the next printing plate slice; and S7, the step 5 and the step 6 are repeated until the plurality ofprinting plate slices are formed. The method has the advantages of being few in working procedures, saving in materials, and beneficial to environmental protection.

Owner:SHANGHAI PUBLISHING & PRINTING COLLEGE

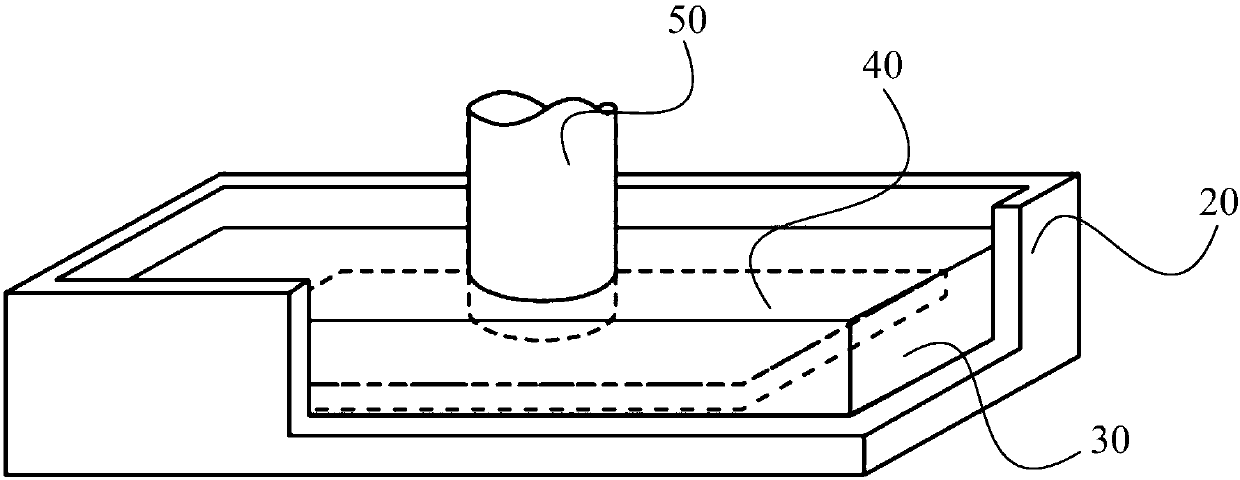

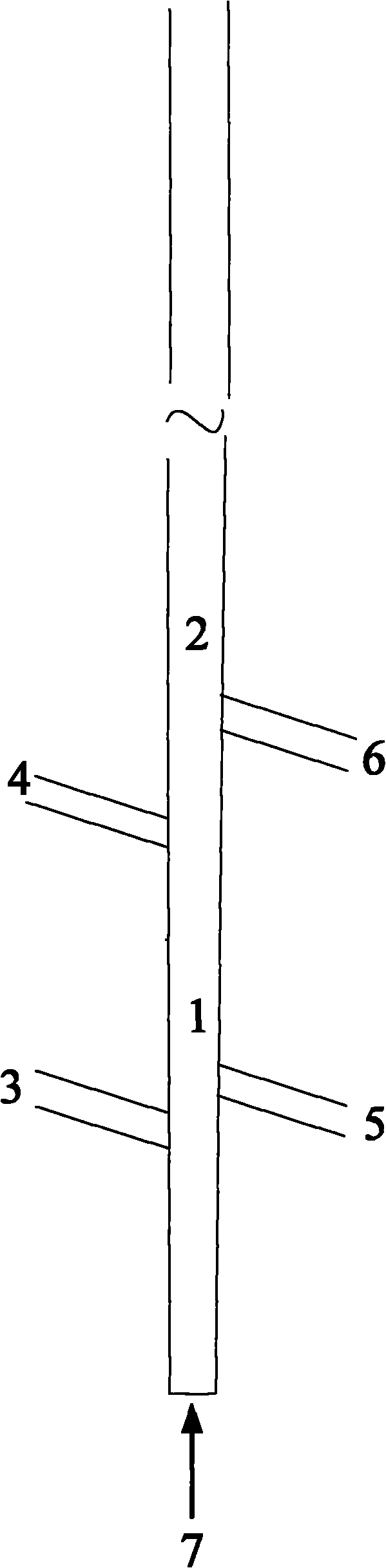

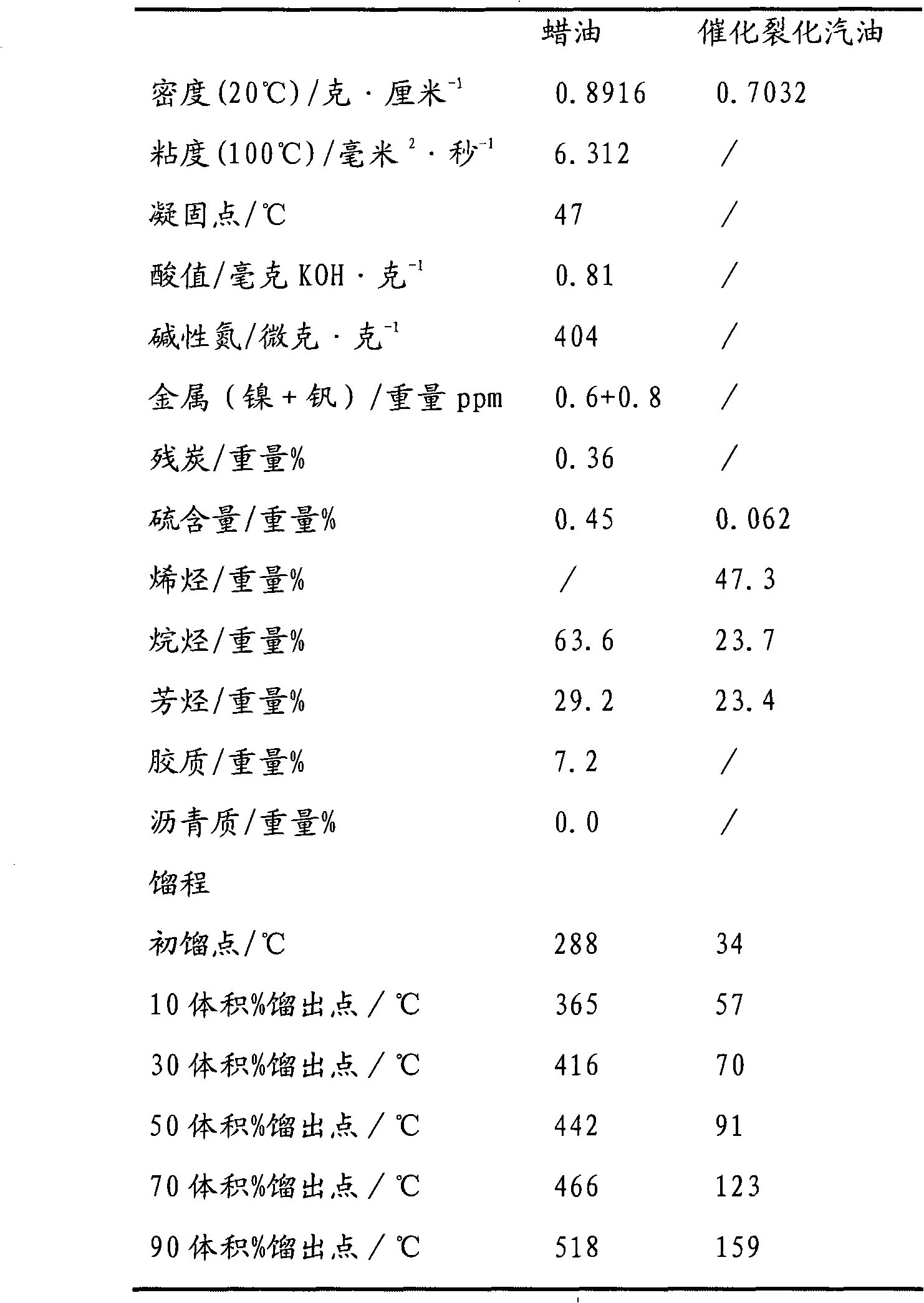

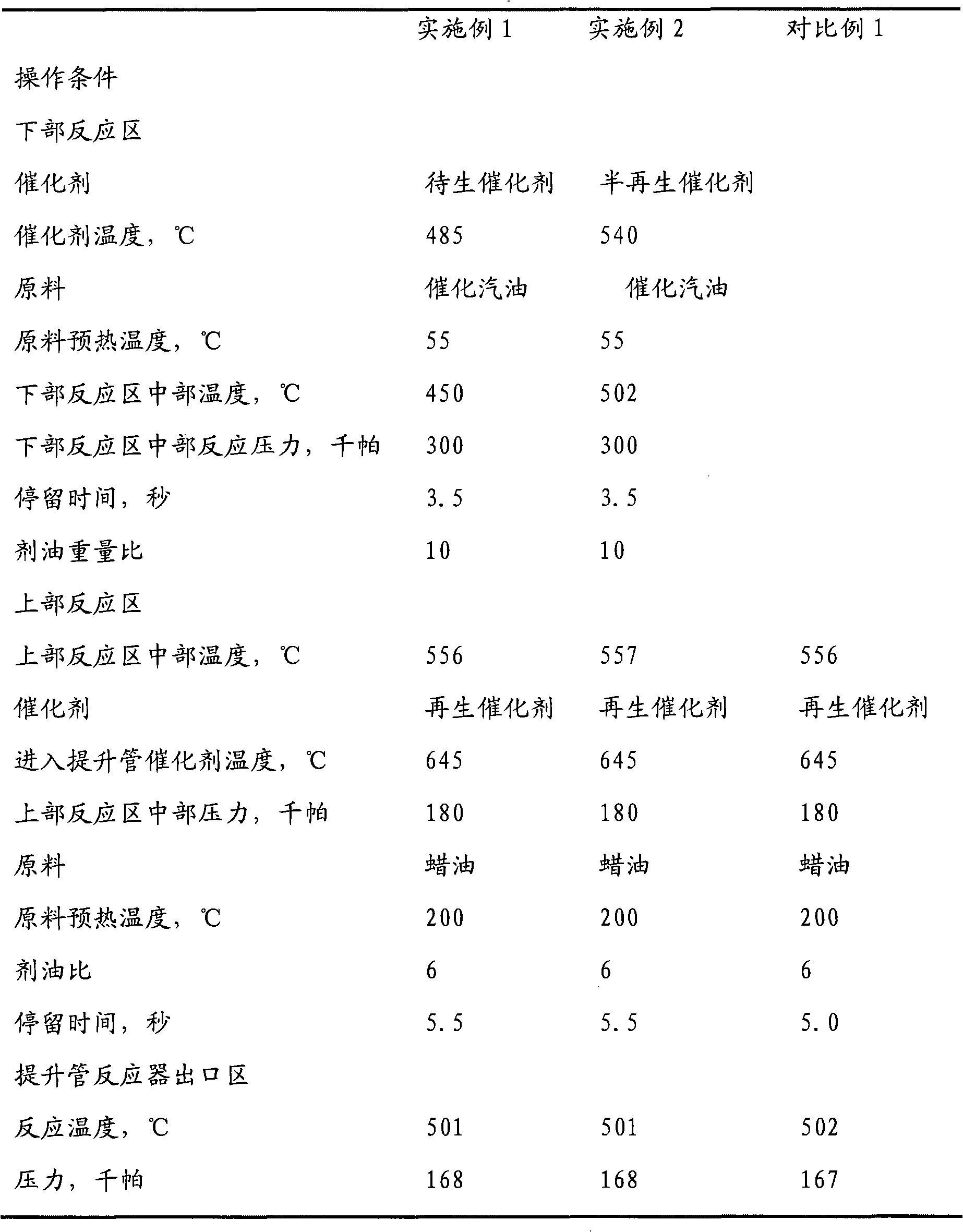

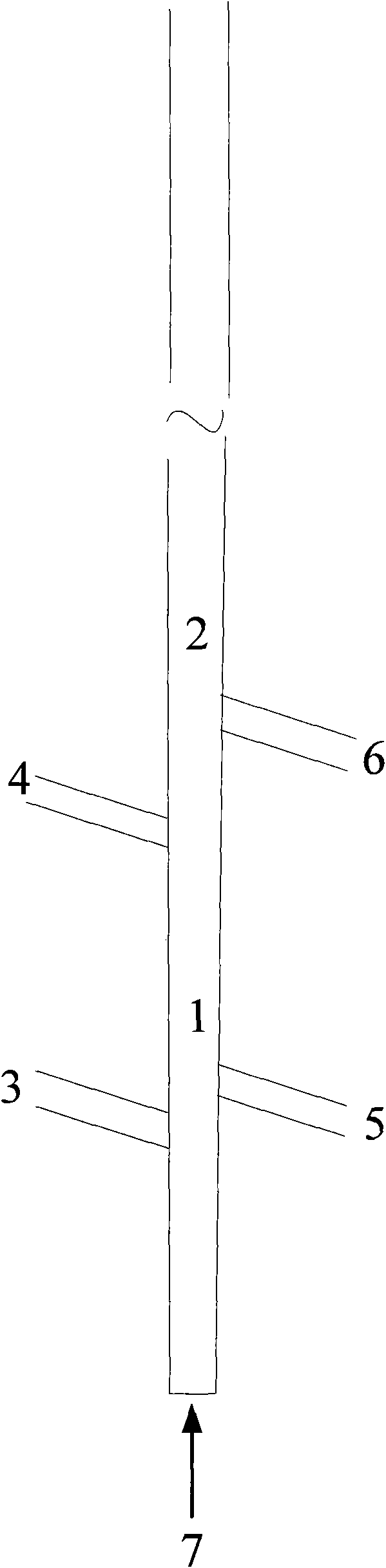

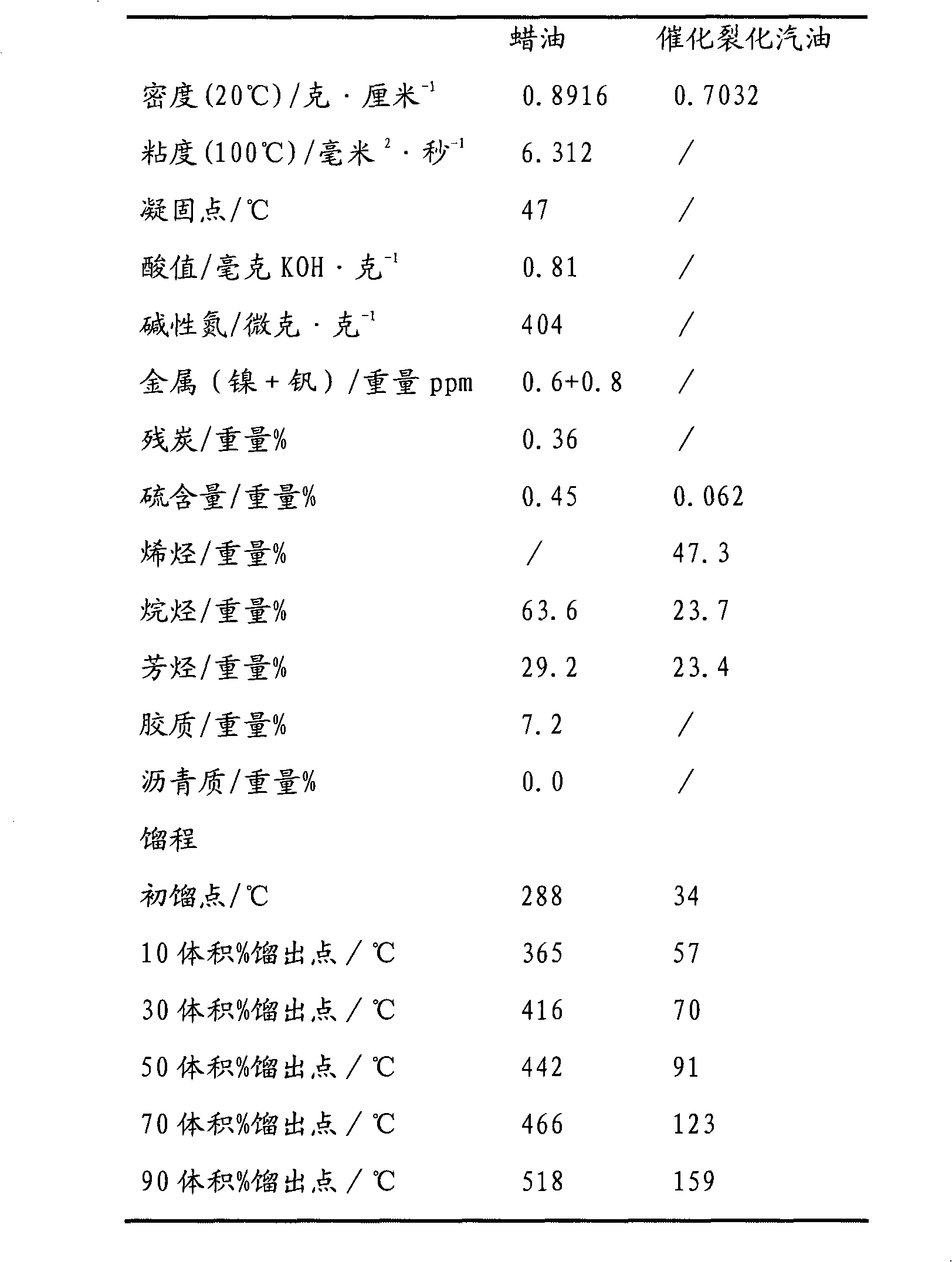

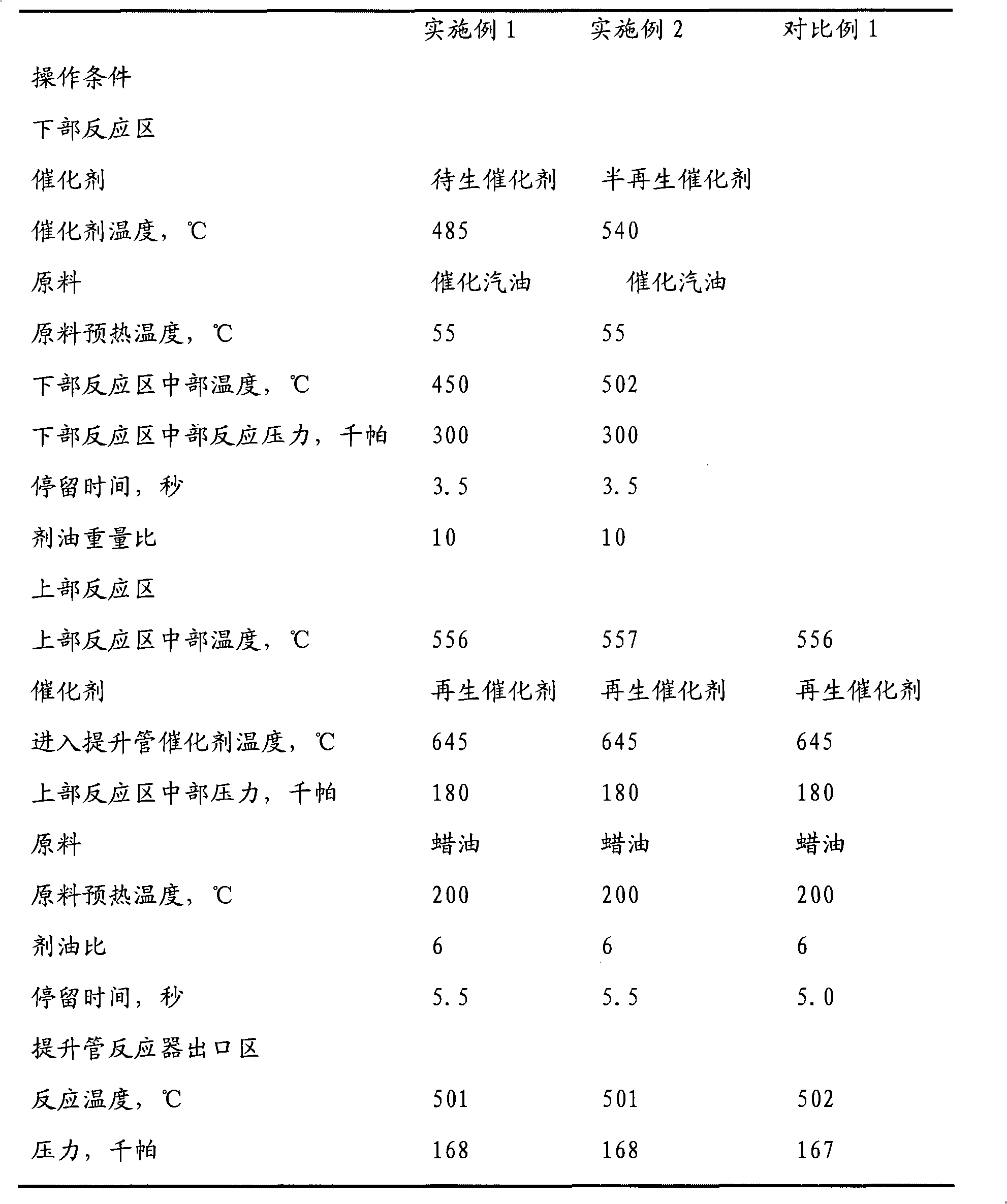

Catalytic cracking method of hydrocarbon oil

ActiveCN101928589AReduce sulfur contentReduce olefin contentCatalytic crackingPtru catalystFluidized bed

The invention relates to a catalytic cracking method of hydrocarbon oil. The processes are carried out in a riser tube or a fluidized bed reactor at least comprising upper and lower reaction zones. The method comprises the following steps: leading raw gasoline and a spent catalyst and / or a semi-regenerated catalyst in the lower reaction zone to carry out contact reaction; and leading heavy raw materials and a regenerated catalyst in the upper reaction zone to carry out contact reaction with the oil and gas and the catalyst from the lower reaction zone. The method can increase the yield of theliquid and simultaneously improve the quality of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anticorrosion waterborne aluminum pigment for reinforcing UV reflection ability

InactiveCN106221304AImprove corrosion resistanceGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPhosphateCordierite

The invention discloses an anticorrosion waterborne aluminum pigment for reinforcing UV reflection ability. The pigment is prepared from the following raw materials by weigh: 40-45 parts of flake aluminum powder, 100-110 parts of isopropanol, 0.3-0.35 part of copper sulfate crystal, a proper amount of deionized water, 4-4.5 parts of phenol ether-type phosphate ester, a proepr amount of absolute ethyl alcohol, 9-10 parts of ethyl orthosilicate, 6-7 parts of ethylsiloxane, 9-10 parts of ammonia with concentration of 20wt%, 200-220 parts of butyl acetate, 5-6 parts of acrylic acid, 5-6 parts of methacrylic acid, 0.6-0.65 part of dibenzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 0.5-0.6 part of lignocellulose, 0.7-0.8 part of polyethylene pyrrolidone, 4-5 parts of cordierite powder, 3-4 parts of far infrared ceramic powder, 3-4 parts of urea aqueous solution with concentration of 20wt%, and 1.5-2 parts of poly olefin wax. The product has high ultraviolet reflectivity.

Owner:HEFEI SUNRISE PIGMENTS

Corrosion-resistant aqueous aluminum pigment with shielding effects

InactiveCN106167632AImprove corrosion resistanceGood dispersionAnti-corrosive paintsPigment treatment with macromolecular organic compoundsCarbon fibersPhosphate

The invention discloses corrosion-resistant aqueous aluminum pigment with shielding effects. The corrosion-resistant aqueous aluminum pigment is characterized by being prepared from the following raw materials in parts by weight: 40-45 parts of sliced aluminum powder, 100-110 parts of isopropanol, 0.3-0.35 part of copper sulfate crystals, an appropriate amount of deionized water, 4-4.5 parts of phenol ether phosphate, an appropriate amount of anhydrous ethanol, 9-10 parts of tetraethyl orthosilicate, 6-7 parts of vinyl triethoxysilane, 9-10 parts of an ammonia solution of which the concentration is 20wt%, 200-220 parts of n-butyl acetate, 5-6 parts of acyclic acid, 5-6 parts of methacrylic acid, 0.6-0.65 part of benzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 2-3 parts of animal oleic acid, 3-4 parts of carbon fibers, 4-5 parts of 200-mesh spherical permalloy powder, 1.5-2 parts of stearic acid and 1-1.2 parts of polyvinyl alcohol. According to the corrosion-resistant aqueous aluminum pigment disclosed by the invention, the carbon fibers and the permalloy powder are added during preparation of products, so that the magnetic conduction rate of materials is reduced, the corrosion-resistant aqueous aluminum pigment can be added during preparation of shielding materials, and coating films are even.

Owner:HEFEI SUNRISE PIGMENTS

Aluminium pigment with high dispersion, corrosion inhibition, dual coating and water resistance

InactiveCN106221306AImprove corrosion resistanceGood dispersion performanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsIonGuar gum

The invention discloses an aluminium pigment with high dispersion, corrosion inhibition, dual coating and water resistance. The pigment is characterized in that the pigment is prepared by the following raw materials in parts by weight: 40-45 parts of sheet shaped aluminium powder, 100-110 parts of isopropanol, 0.3-0.35 parts of copper sulphate crystal, a proper amount of deionized water, 4-4.5 parts of phenolic ether phosphate ester, a proper amount of absolute ethanol, 9-10 parts of ethyl orthosilicate, 6-7 parts of triethoxyvinylsilane, 9-10 parts of ammonia water whose concentration is 20wt%, 200-220 parts of butyl acetate, 5-6 parts of acrylic acid, 5-6 parts of methacrylic acid, 0.6-0.65 parts of dibenzoyl peroxide, 13-15 parts of 1-methoxy-2-propanol, 1.5-2 parts of polyether polyester modified organosiloxane, 0.9-1.2 parts of guar gum, 0.4-0.6 parts of soya bean lecithin, 0.8-1 part of propyl gallate, 4-5 parts of mica powder, and 2-3 parts of titanium dioxide. The product is completely coated, and has good water resistance; the product can be uniformly dispersed in an aqueous system.

Owner:HEFEI SUNRISE PIGMENTS

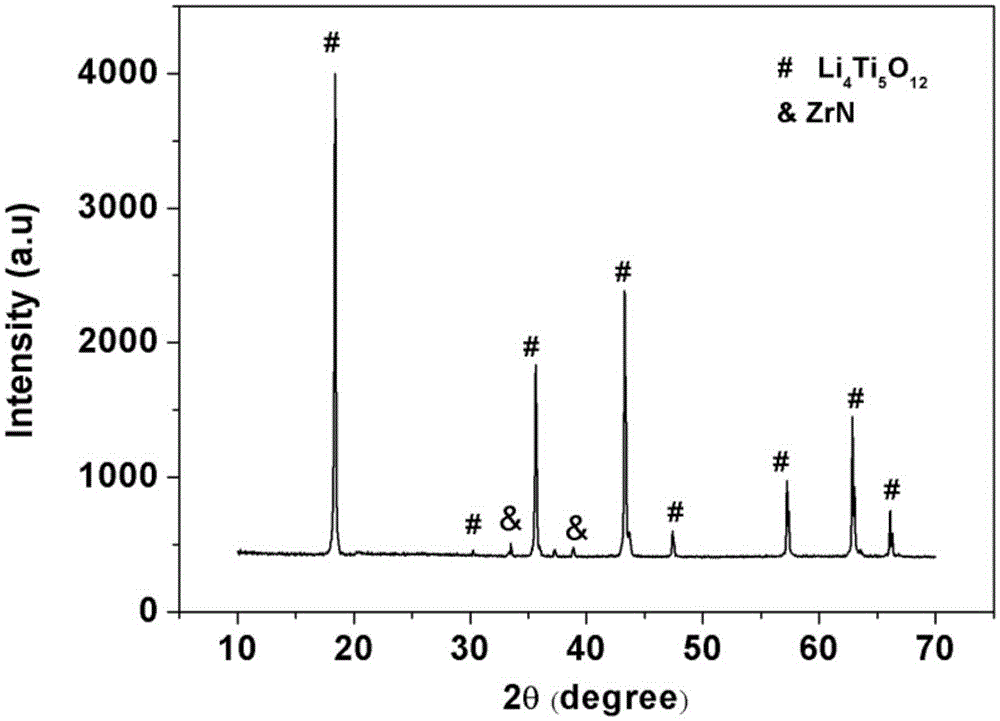

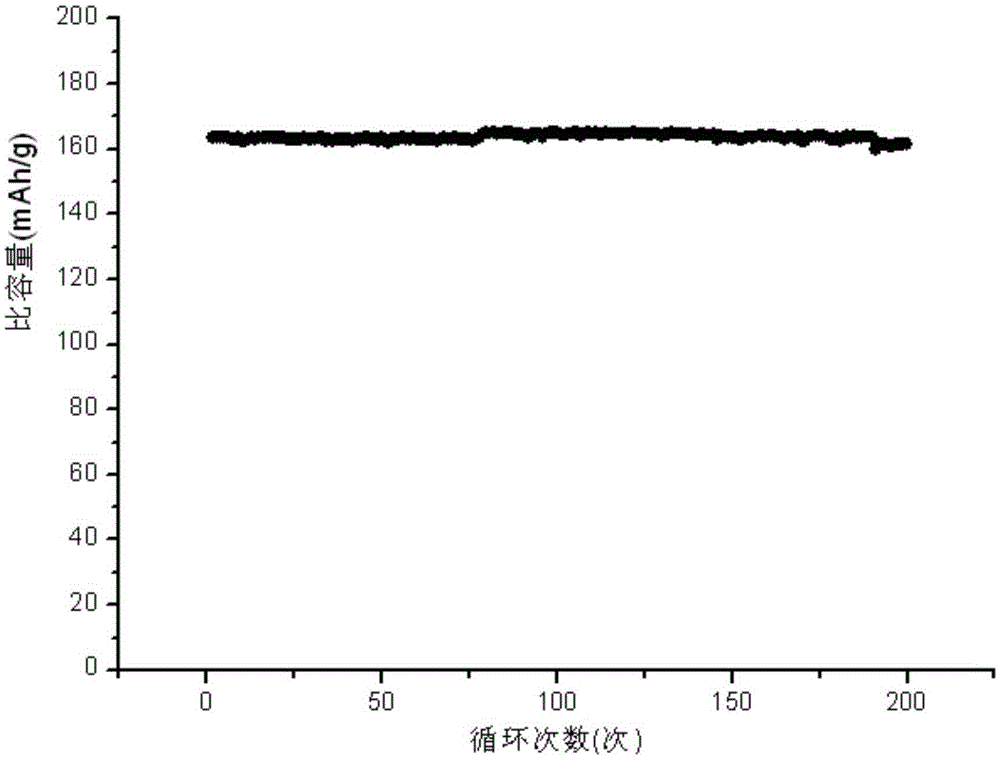

Preparation method of zirconium nitride coated lithium titanate composite material

ActiveCN103985852BControl the degree of coatingImprove uniformityCell electrodesSecondary cellsHigh energyNitrogen

The invention discloses a preparation method for a zirconium nitride-coated lithium titanate composite material, relating to the field of a negative electrode material of a lithium ion battery. The preparation method comprises the steps of preparing lithium titanate precursor powder, performing high-energy ball grinding on zirconium powder, a lithium titanate precursor and an additive under inert atmosphere, and finally performing high-temperature sintering under nitrogen mixing atmosphere to realize synthesis of lithium titanate and nitridation reaction of surface zirconium. According to the zirconium nitride-coated lithium titanate composite material prepared by the preparation method disclosed by the invention, the zirconium nitride coating layer is high in uniformity, good in coating effect and high in conductivity; the problem of low conductivity of lithium titanate is solved; meanwhile, the problem of swelling of a battery of the lithium titanate system is effectively solved; the circulation stability of a lithium titanate negative electrode material is improved, and the cycle life of the battery is greatly prolonged; furthermore, the preparation process of the preparation method is simple and controllable; the coating degree of the zirconium nitride can be controlled by controlling technical parameters for preparing the zirconium nitride-coated lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

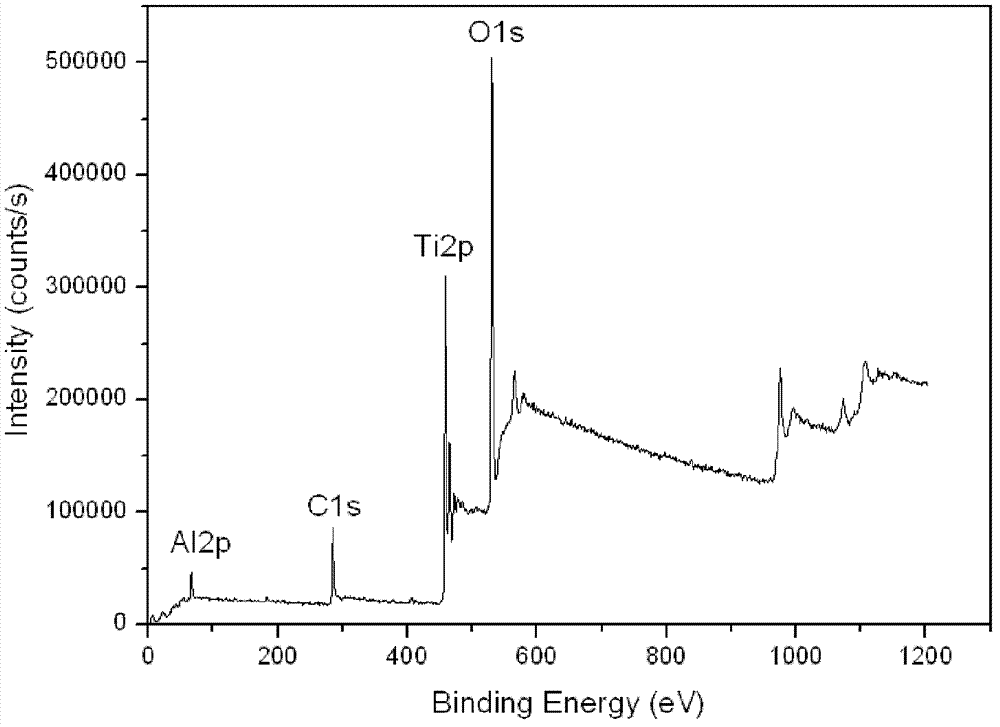

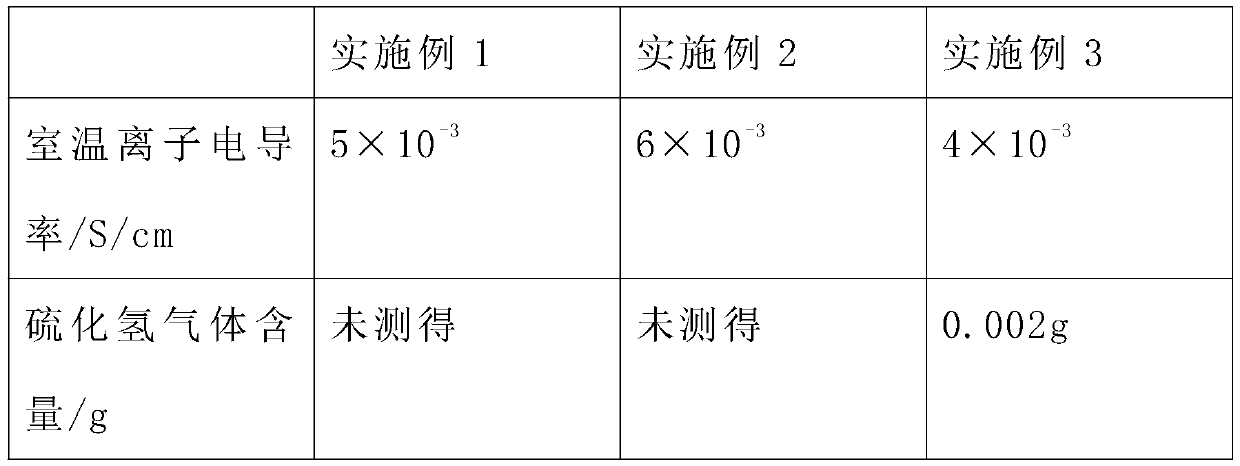

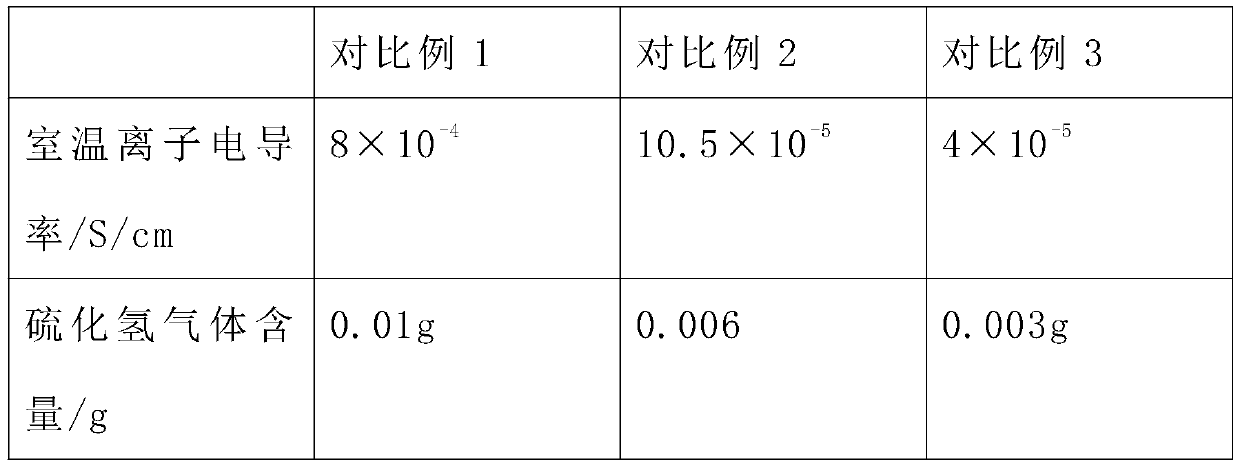

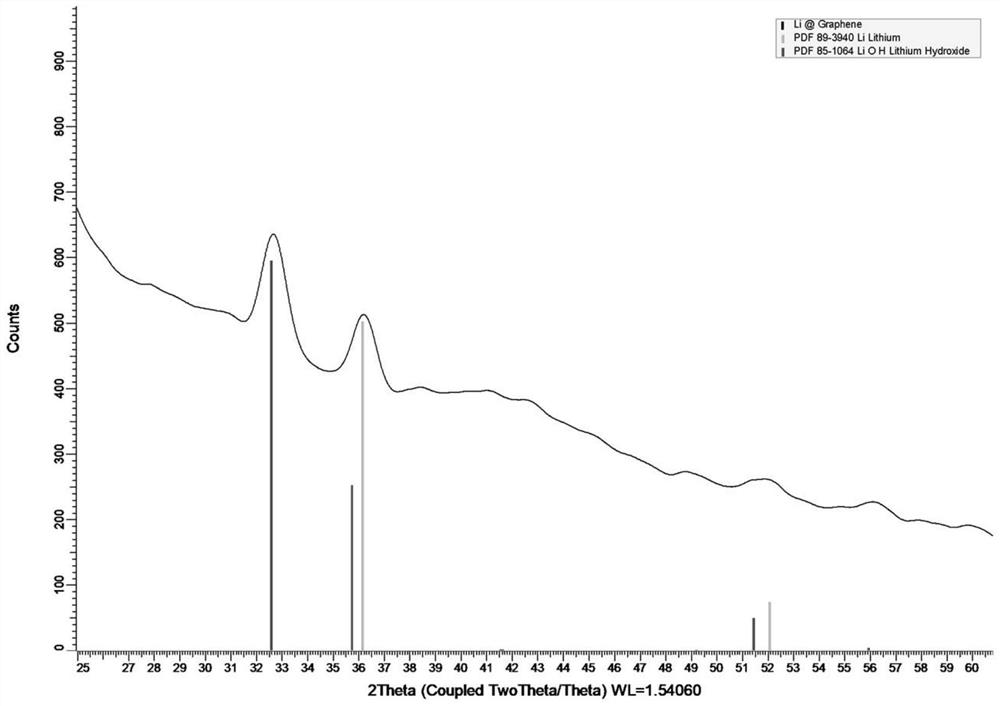

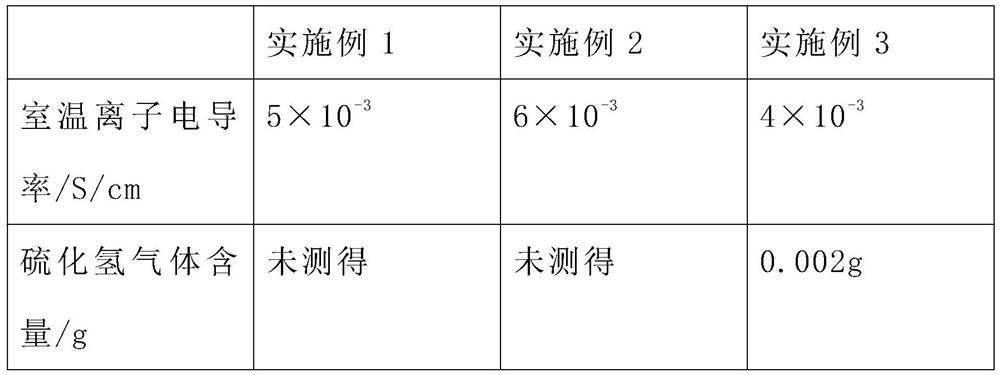

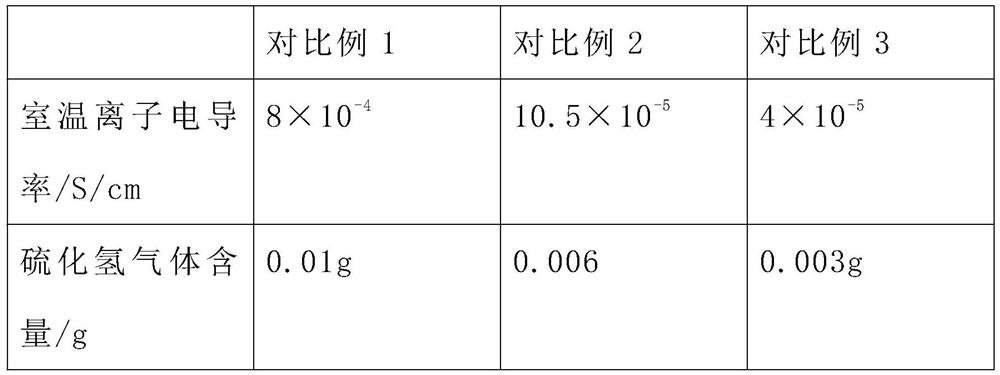

Sulfide electrolyte and preparation method thereof

ActiveCN111129572AReduced activityAvoid contact reactionsSolid electrolytesLi-accumulatorsPhysical chemistrySulfide compound

The invention discloses a sulfide electrolyte and a preparation method thereof, and belongs to the technical field of battery materials. The sulfide electrolyte in the product developed by the invention is Li<4-x>Ge<1-x>M<x>S<4>, wherein the sulfide electrolyte contains Li<4-x>Ge<1-x>M<x>S<4> which is partially crystallized; and the sulfide electrolyte comprises 1-3% of silicon microcrystals, wherein the mass ratio of the crystallized Li<4-x>Ge<1-x>M<x>S<4> to the non-crystallized Li<4-x>Ge<1-x>M<x>S<4> is 1: 5 to 1: 20. The average particle size of the partially crystallized Li<4-x>Ge<1-x>M<x>S<4> is 0.01-50 [mu]m, and the average specific surface area is 1-20 m<2> / g. The product obtained by the preparation method disclosed by the invention not only has good ionic conductivity, but also has good air stability.

Owner:来骑哦互联网技术(深圳)有限公司

Dual coated aqueous aluminum pigment for antifouling paint

InactiveCN106009866AImprove corrosion resistanceGood dispersionAntifouling/underwater paintsPaints with biocidesPhosphateFatty acid

The invention discloses dual coated aqueous aluminum pigment for antifouling paint. The dual coated aqueous aluminum pigment is characterized by being prepared from the following raw materials in parts by weight:40 to 45 parts of flaky aluminum powder, 100 to 110 parts of isopropanol, 0.3 to 0.35 part of copper sulfate crystals, a proper amount of deionized water, 4 to 4.5 parts of phenol ether phosphate, a proper amount of absolute ethyl alcohol, 9 to 10 parts of ethyl orthosilicate, 6 to 7 parts of vinyltriethoxysilane, 9 to 10 parts of ammonium hydroxide with the concentration being 20 weight percent, 200 to 220 parts of butyl acetate, 5 to 6 parts of acrylic acid, 5 to 6 parts of methacrylic acid, 0.6 to 0.65 part of dibenzoyl peroxide, 13 to 15 parts of propylene glycol monomethyl ether, 2 to 3 parts of polyvinyl alcohol, 1.5 to 2 parts of fatty acid, 4 to 5 parts of anatase nanometer titanium dioxide, 1.5 to 2 parts of ferric oxide, 2 to 3 parts of carbon nanometer tube and 0.5 to 0.6 part of polyamide wax. The dual coated aqueous aluminum pigment can be used in the antifouling paint; the dust pollution is reduced; the self-cleaning antifouling efficiency is achieved.

Owner:HEFEI SUNRISE PIGMENTS

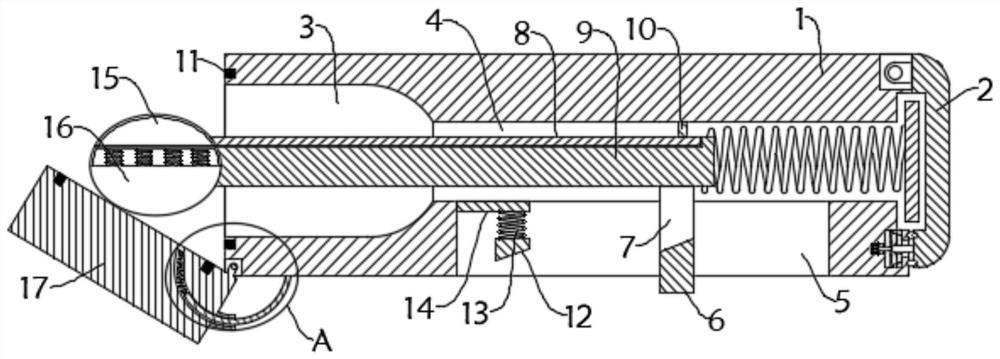

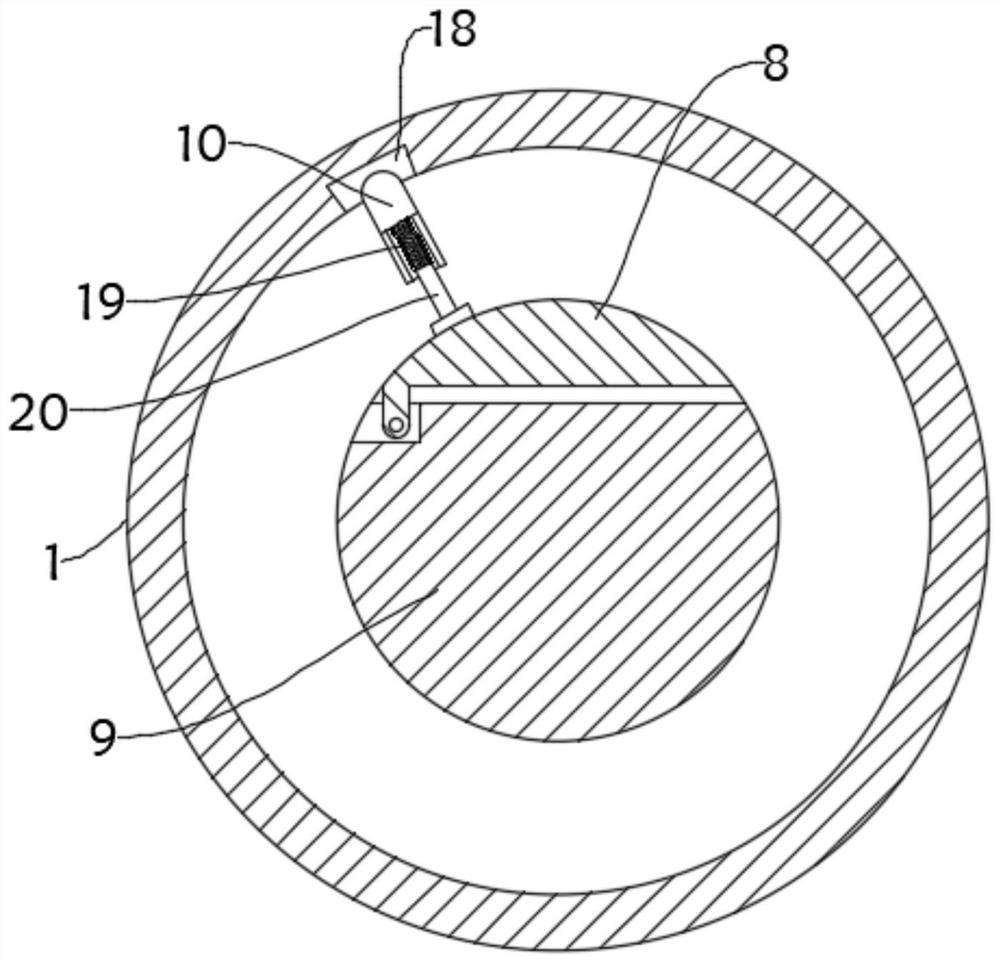

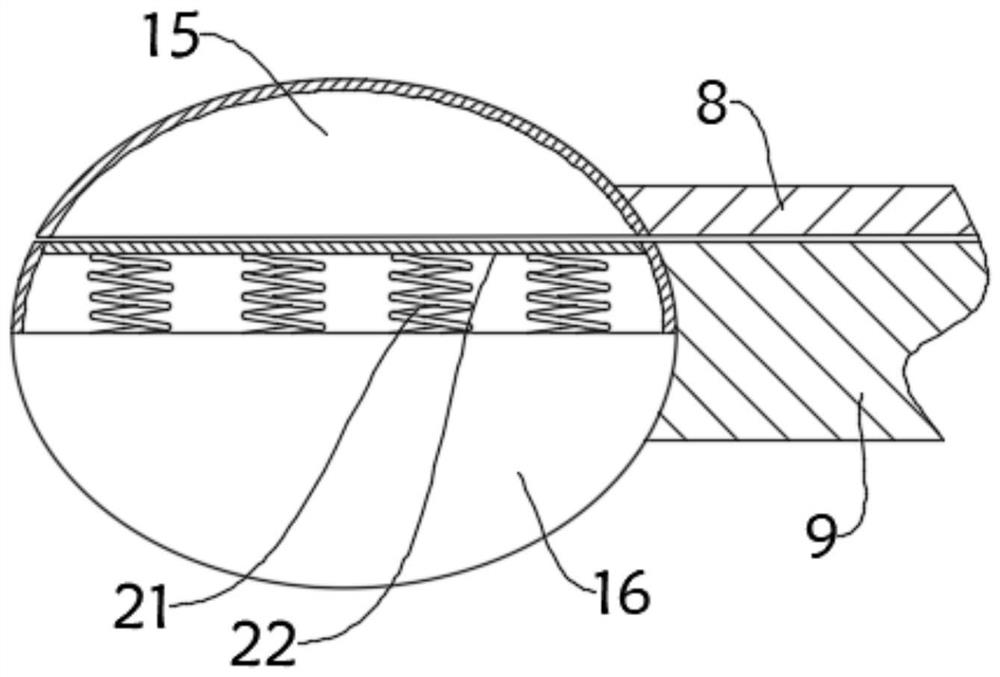

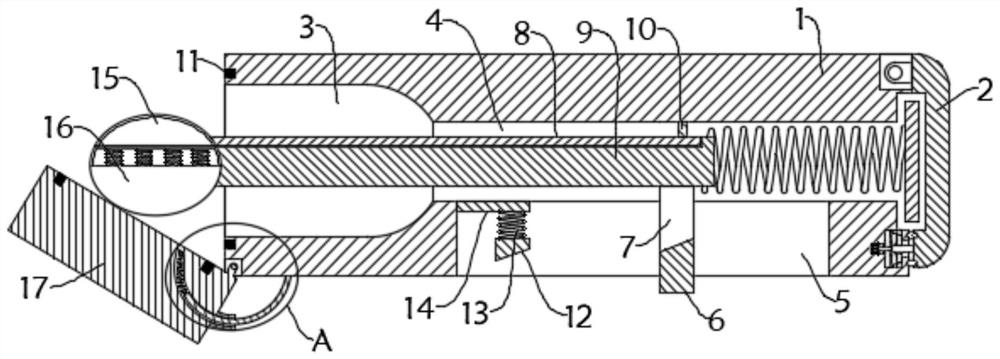

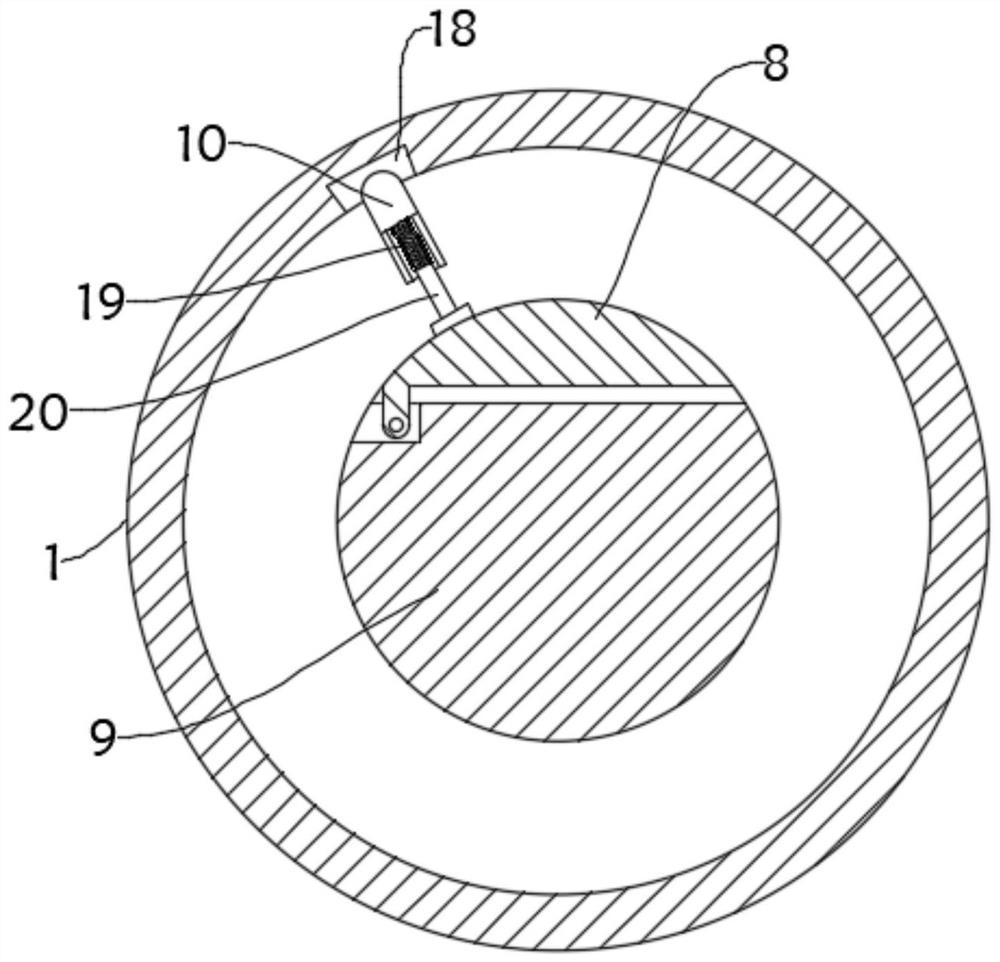

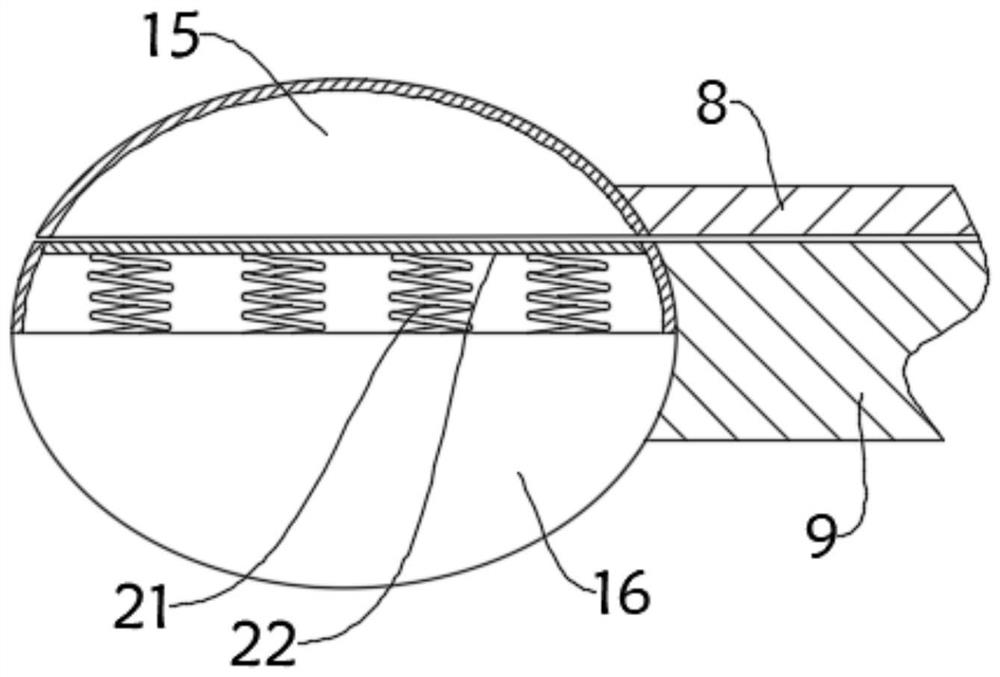

Sampling device for chemical agent analysis

ActiveCN113000086APrevent openingAvoid contact reactionsAnalysis material containersChemistryProcess engineering

The invention is applicable to the related field of chemical agent production, and provides a sampling device for chemical agent analysis, which comprises a sampling assembly for digging and containing a chemical agent; a sealing assembly used for storing the chemical agent in the sampling assembly in a sealing manner; a storage assembly is used for storing the sealing assembly and the sampling assembly; and an operation assembly used for moving the sampling assembly out of the storage assembly. After the sampling assembly completes sampling of chemical agents, the sealing assembly seals the sampling assembly, so that the chemical agents in the sampling assembly are isolated from a large amount of air, in addition, the containing assembly limits and buckles the sealing assembly and the sampling assembly, and the sealing assembly and the sampling assembly are prevented from being opened in the transferring process; and the problem that the chemical agent may volatilize or the chemical agent contacts and reacts with substances in the air for a long time in the long-distance transfer process is effectively avoided.

Owner:江苏省徐州医药高等职业学校

High-brightness and high-stability of corrosion-resistant water-based aluminum pigment

InactiveCN106084959AImprove corrosion resistanceGood dispersionInksAnti-corrosive paintsWater basedPhosphate

The invention discloses a high-brightness and high-stability of corrosion-resistant water-based aluminum pigment, which is prepared from the following raw materials in parts by weight: 40 to 45 parts of flaky aluminum powder, 100 to 110 parts of isopropyl alcohol, 0.3 to 0.35 parts of copper sulfate crystal, an appropriate amount of deionized water, 4 to 4.5 parts of phenolic ether phosphate, an appropriate amount of absolute ethanol, 9 to 10 parts of ethyl orthosilicate, 6 to 7 parts of vinyl triethoxysilane, 9 to 10 parts of ammonia with concentration of 20wt%, 200 to 220 parts of butyl acetate, 5 to 6 parts of acrylic acid, 5 to 6 parts of methacrylic acid, 0.6 to 0.65 part of dibenzoyl peroxide, 13 to 15 parts of propylene glycol monomethyl ether, 1.2 to 1.5 parts of polyvinyl alcohol, 0.3 to 0.4 part of sodium polyacrylate, 6 to 7 parts of nano antimony tin oxide, 1.2 to1.4 parts of dimethyl silicone oil, and 0.8 to 1 part of polydimethylsiloxane. The product prepared by the invention is not corroded in an aqueous system and has strong stability.

Owner:HEFEI SUNRISE PIGMENTS

Water-resistant aluminum pigment with high magnetism

InactiveCN106189452AImprove corrosion resistanceGood dispersionMagnetic paintsInksPhosphateWater resistant

The invention discloses a water-resistant aluminum pigment with high magnetism. The water-resistant aluminum pigment is prepared from the following raw materials in parts by weight: 40-45 parts of flaky aluminum powder, 100-110 parts of isopropanol, 0.3-0.35 part of copper sulfate crystal, a proper amount of deionized water, 4-4.5 parts of phenolic ether phosphate ester, a proper amount of absolute ethyl alcohol, 9-10 parts of ethyl orthosilicate, 6-7 parts of vinyltriethoxysilane, 9-10 parts of ammonia water of which the concentration is 20 percent by weight, 200-220 parts of butyl acetate, 5-6 parts of acrylic acid, 5-6 parts of methacrylic acid, 0.6-0.65 part of dibenzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 1-1.5 parts of ethylene-vinyl acetate wax, 2-3 parts of dimethyl silicone oil, 0.8-1 part of carboxymethylcellulose, 6-7 parts of ferrous sulfate, 3-4 parts of anhydrous sodium acetate, 4-5 parts of sodium hydroxide solution of which the concentration is 10 percent by weight, 3-4 parts of citric acid and 0.3-0.5 part of sodium dodecyl sulfate. The water-resistant aluminum pigment can be applied to magnetic printing ink.

Owner:HEFEI SUNRISE PIGMENTS

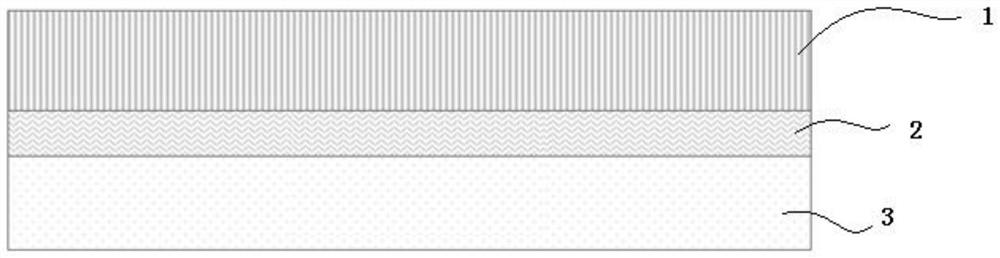

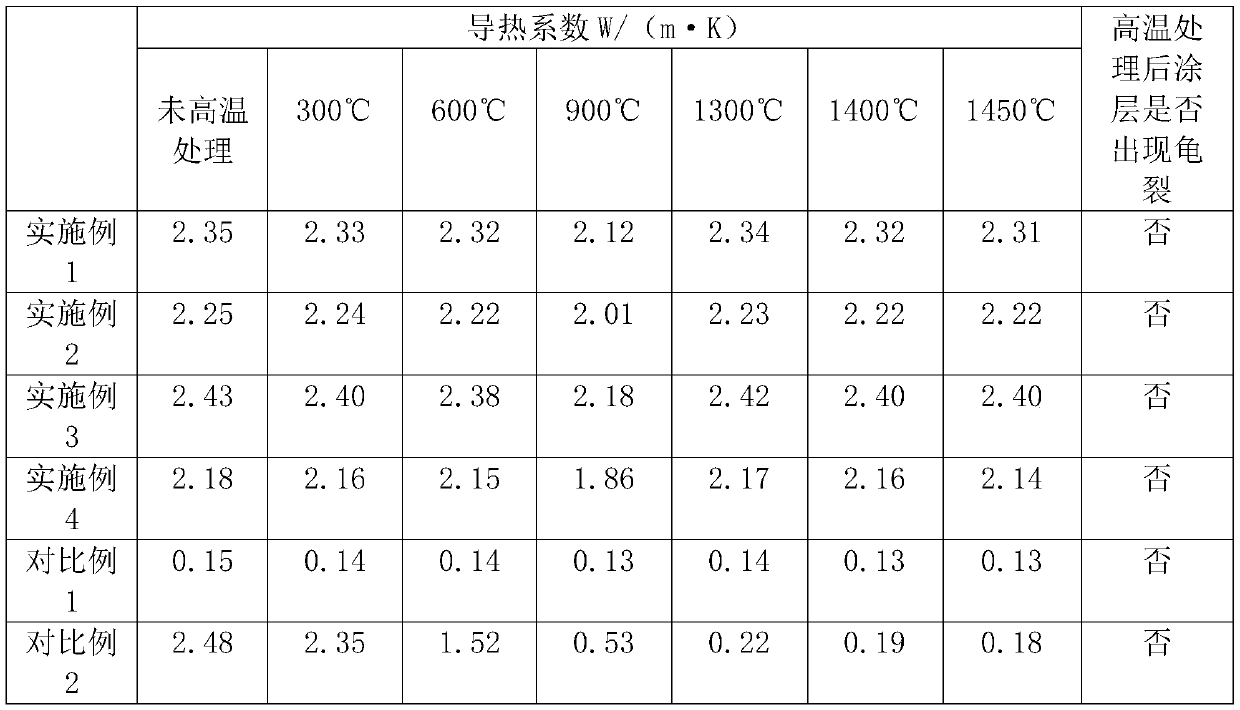

Non-wettability coating suitable for resisting high-temperature aluminum permeation and preparation method of non-wettability coating

PendingCN114672755AHas aluminophobic propertiesExcellent anti-aluminum penetration effectMolten spray coatingVacuum evaporation coatingAluminum electrolysisAluminium

The invention discloses a non-wettability coating suitable for resisting high-temperature aluminum permeation and a preparation method of the non-wettability coating. The non-wettability coating suitable for resisting high-temperature aluminum permeation is composed of an alloy matrix, a bonding layer and a surface ceramic layer in sequence. Wherein the thickness range of the bonding layer is 50-100 microns; the thickness of the surface ceramic layer ranges from 100 micrometers to 500 micrometers. According to the coating and the preparation method of the coating, a non-infiltrating coating material resistant to high-temperature aluminum permeation is obtained, so that parts such as a tank wall and a steel shell aluminum core anode claw are prevented from being in contact reaction with an aluminum solution in the aluminum electrolysis process, the service life of related equipment is prolonged, the production cost is saved, and the production efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

A thermal power plant high-temperature flue gas waste heat recovery device using single-tank molten salt heat exchange

ActiveCN113503760BPrevention of dry burningAvoid contact reactionsHeat storage plantsCombustion technology mitigationMolten saltDust control

Owner:BICHENG SHANGHAI AMPEREX TECH CO LTD

Graphite-based water-based heat-conducting silicate coating and preparation method thereof

InactiveCN111378306AImprove heat resistanceImprove high temperature resistanceAlkali metal silicate coatingsPhysical chemistryGraphite

The invention relates to the technical field of coatings, and discloses a graphite-based water-based heat-conducting silicate coating and a preparation method thereof. The coating is prepared from thefollowing components in parts by weight: 60 to 80 parts of a film forming matter, 15 to 20 parts of quartz sand, 10 to 15 parts of dolomite, 5 to 10 parts of modified graphite, 1 to 3 parts of pigment, 0.5 to 1 part of a defoaming agent, 0.5 to 1 part of a dispersing agent and 30 to 50 parts of water. The brake pad is good in wear resistance and heat resistance and stable in friction coefficient;the preparation method of the coating comprises the following steps: firstly, adding a film-forming substance, quartz sand, dolomite, a defoaming agent and water into a stirring kettle and stirring for 30 to 50min at a stirring speed of 400 to 500r / min; and then adding the modified graphite, the pigment and the dispersing agent into the premix, and continuing to stir for 20-30 minutes at the stirring speed of 600-800r / min so as to obtain the high-temperature-resistant and high-pressure-resistant coating. The silicate heat-conducting coating disclosed by the invention has excellent high-temperature resistance and heat-conducting and heat-dissipating properties.

Owner:段尚军

An ultrasonic atomization device and method for preparing spherical metal powder

The invention belongs to the technical field of spherical metal powder preparation, and in particular relates to an ultrasonic atomization device and a method for preparing spherical metal powder. The ultrasonic atomization device provided by the invention comprises an ultrasonic vibration system (1), a rack and pinion system (2) and an atomization system (3); the ultrasonic vibration system (1) comprises a fixedly connected transducer (1- 1) and a horn (1‑2); the atomization system (3) includes a fuse system (3‑1) and an atomization chamber (3‑2) below the fuse system (3‑1) ); the mesh sieve (3-2-1) is set in the atomization chamber (3-2); the horn (1-2) and the rack and pinion system (2) mesh; the gear teeth The bar system (2) and the spray chamber (3‑2) mesh. In the device provided by the invention, the horn has no contact with the molten metal, and there is no cavitation corrosion.

Owner:SHANGHAI UNIV

A kind of preparation method of cold handmade soap

ActiveCN105400617BAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A sampling device for chemical analysis

ActiveCN113000086BPrevent openingAvoid contact reactionsAnalysis material containersPhysical chemistryProcess engineering

Owner:江苏省徐州医药高等职业学校

Catalytic cracking method of hydrocarbon oil

The invention relates to a catalytic cracking method of hydrocarbon oil. The processes are carried out in a riser tube or a fluidized bed reactor at least comprising upper and lower reaction zones. The method comprises the following steps: leading raw gasoline and a spent catalyst and / or a semi-regenerated catalyst in the lower reaction zone to carry out contact reaction; and leading heavy raw materials and a regenerated catalyst in the upper reaction zone to carry out contact reaction with the oil and gas and the catalyst from the lower reaction zone. The method can increase the yield of theliquid and simultaneously improve the quality of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of graphene coating protection metal lithium microsphere

ActiveCN110190257BAvoid contact reactionsImprove conductivityCell electrodesSecondary cellsMetallic lithiumGraphene coating

The invention discloses a preparation method of graphene-coated and protected metal lithium microspheres, which comprises the following steps: S1, dispersing metal lithium in an inert solvent without active hydrogen to form a dispersion of metal lithium microspheres; S2, dispersing metal lithium microspheres with Graphene with surface functional groups is dispersed in an inert solvent without active hydrogen to form a graphene dispersion; S3, mixing the metal lithium microsphere dispersion of step S1 with the graphene dispersion of step S2, and after fully stirring, the The inert solvent is separated by filtration or volatilized and dried to prepare graphene-coated and protected metal lithium microspheres. The present invention uses graphene as the protective layer of metal lithium powder, and the graphene protective layer has the characteristics of high stability and excellent electrical conductivity. The preparation process of the method of the present invention is simple and easy to scale up, and the product has the advantages of controllable particle size and high stability. .

Owner:上海泓昌新材料科技有限公司

A kind of sulfide electrolyte and preparation method thereof

ActiveCN111129572BReduced activityAvoid contact reactionsSolid electrolytesLi-accumulatorsPhysical chemistrySulfide compound

Owner:来骑哦互联网技术(深圳)有限公司

Corrosion-inhibiting aqueous aluminum pigment being used for antistatic coating

InactiveCN106065214AImprove corrosion resistanceGood dispersionAnti-corrosive paintsElectrically-conductive paintsPhosphateDibenzoyl Peroxide

The invention discloses a corrosion-inhibiting aqueous aluminum pigment being used for an antistatic coating. The pigment is prepared from, by weight, 40-45 parts of sheet aluminum powder, 100-110 parts of isopropyl alcohol, 0.3-0.35 parts of copper sulfate crystal, a proper amount of deionized water, 4-4.5 phenolic-ether-type phosphate, a proper amount of anhydrous ethanol, 9-10 parts of tetraethoxysilane, 6-7 parts of vinyltriethoxysilane, 9-10 parts of ammonia water being 20 wt% in concentration, 200-220 parts of butyl acetate, 5-6 parts of acrylic acid, 5-6 parts of methylacrylic acid, 0.6-0.65 parts of dibenzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 1.5-2 parts of polyethylene wax, 2-3 parts of gelatin, 2-3 parts of zinc oxide, 4-5 parts of tin oxide, 0.8-1 part of sodium tripolyphosphate, 0.3-0.4 parts PVP, and 0.2-0.3 parts of sodium dodecyl benzene sulfonate, The pigment has strong corrosion-inhibiting performance in water.

Owner:HEFEI SUNRISE PIGMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com