Patents

Literature

55results about "Pigment flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

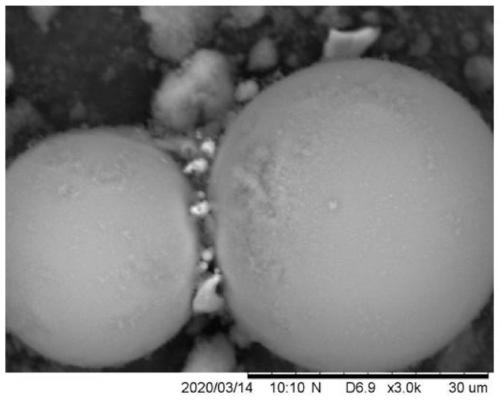

Preparing method of nanometer titanium oxide modified hollow glass beads

ActiveCN105820602AHigh infrared emissivityGood effectPigment flushingEpoxy resin coatingsReaction temperatureTitanium oxide

The invention relates to the field of composite materials, in particular to a preparing method of brand-new nanometer titanium oxide modified hollow glass beads. The obtained hollow glass beads have excellent heat reflecting performance. By controlling technological parameters of concentration of tetrabutyl titanate in a precursor, reaction temperature and time and the dispersant amount, the modified technology of the hollow glass beads is optimized, and the method is easy and convenient to operate. Test results show that the hollow glass beads modified by nanometer titanium oxide particles have low heat conductivity coefficient and high heat reflectivity and can meet the actual needs.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing corrosion inhibition waterborne aluminum pigment

InactiveCN105482514AImprove stabilityGood sustained release effectPigment flushingPigment treatment with organosilicon compoundsContact reactionsElution

The invention discloses a method for preparing a corrosion inhibition waterborne aluminum pigment. The method comprises the following steps: a step (1) of aluminum powder surface elution treatment; a step (2) of surface hydroxylation treatment; and a step (3) of mixing coating treatment. The method for preparing the corrosion inhibition waterborne aluminum pigment is simple and convenient to operate and easy to implement. According to the method, through aluminum powder surface elution treatment, hydroxylation treatment, slow release treatment and coating treatment, the coating stability of the aluminum pigment surface is improved effectively, the aluminum pigment is prevented from being in contact reaction with water or an air medium, the slow release performance of the aluminum pigment is improved remarkably, and the prepared aluminum pigment is high in stability, good in glossiness and wide in application prospect.

Owner:常熟市环虹化工颜料厂

Water-based aluminum silver slurry and preparation method thereof, as well as application of water-based aluminum silver slurry in ink

The invention provides water-based aluminum silver slurry and a preparation method thereof, as well as application of the water-based aluminum silver slurry in ink. The preparation method comprises the following steps: (a) mixing oil-based aluminum silver slurry with an alcohol solvent, and carrying out ultrasonic dispersion and solid-liquid separation in sequence to obtain a solid mixture; (b) mixing the solid mixture, the alcohol solvent, a pH value adjuster, a silane coupling agent and tetraethoxysilane, and carrying out reaction, then aging and solid-liquid separation to obtain aluminum-coated silver slurry; (c) drying the aluminum-coated silver slurry to obtain aluminum silver powder; (d) mixing the aluminum silver powder with a solvent, and carrying out solid-liquid separation to obtain the water-based aluminum silver slurry. According to the water-based aluminum silver slurry and the preparation method thereof, the oil-based aluminum silver slurry is washed with the alcohol solvent to wash off fatty acid in the oil-based aluminum silver slurry, so that the oil-based aluminum silver slurry can be better dispersed in the alcohol solvent, and wrapping of aluminum silver slurry is better realized; due to the combination of a drying and solvent mixing treatment method, the obtained water-based aluminum silver slurry is relatively low in volatile organic compound and can meet higher requirements; the application field of the water-based aluminum silver slurry is expanded, and the stability of the water-based aluminum silver slurry is high.

Owner:长沙族兴新材料股份有限公司

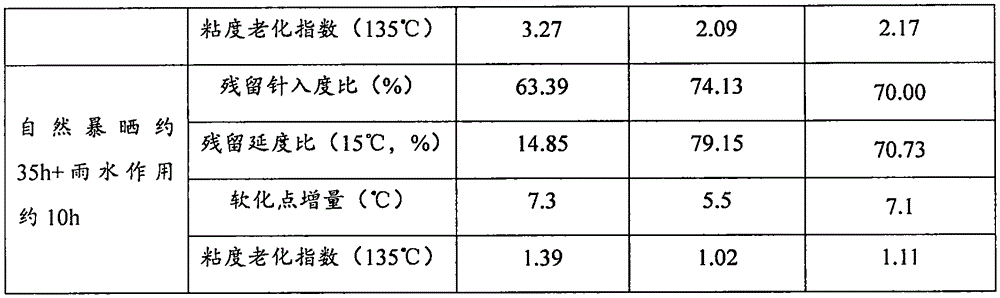

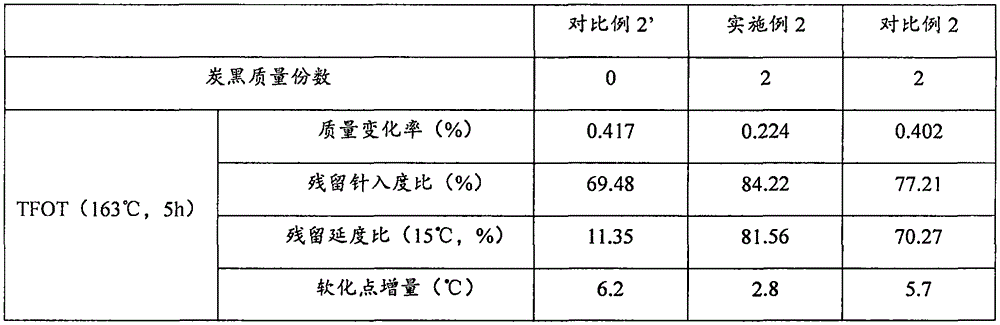

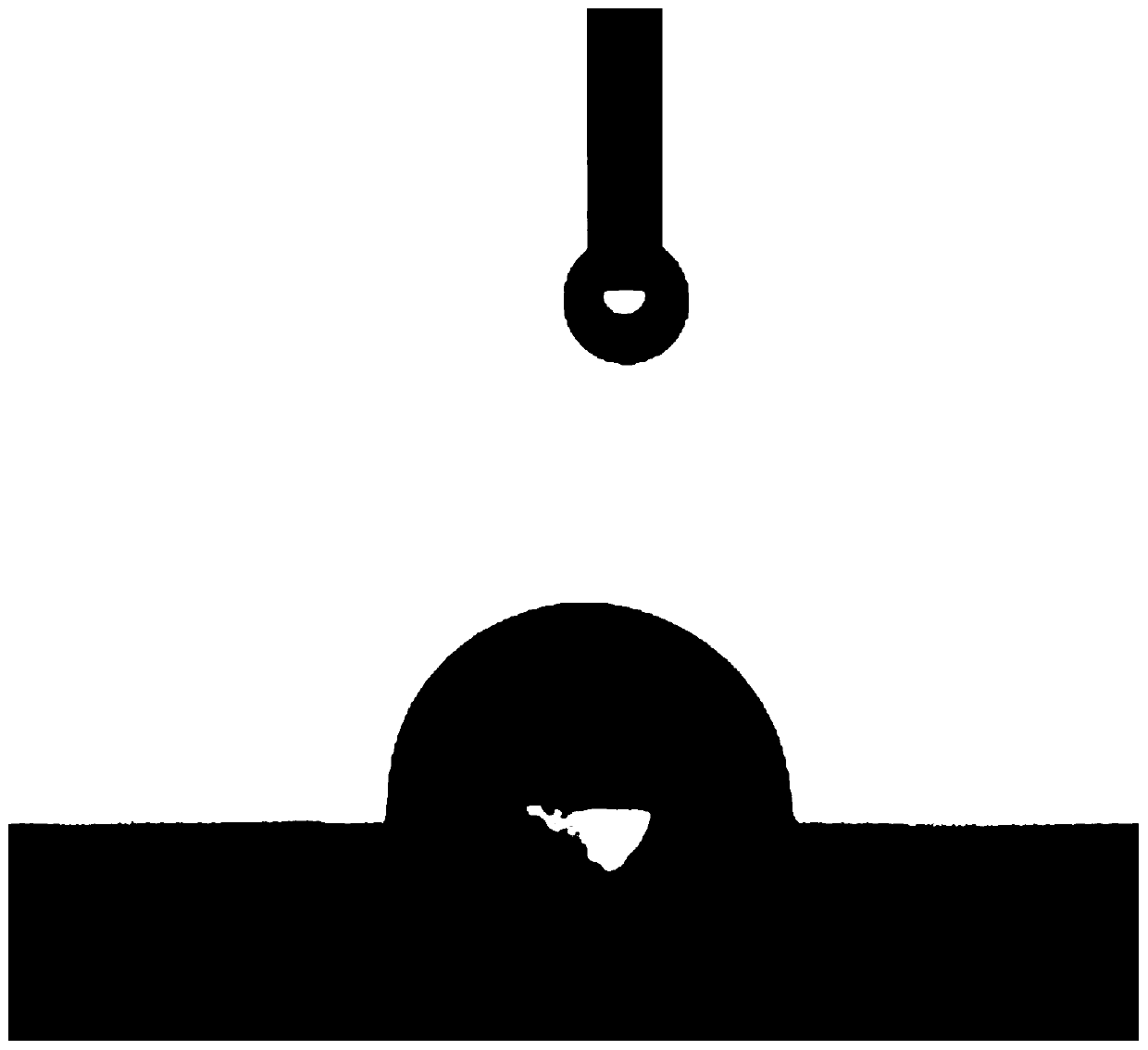

Modified carbon black, modified asphalt and preparation method of modified carbon black and modified asphalt

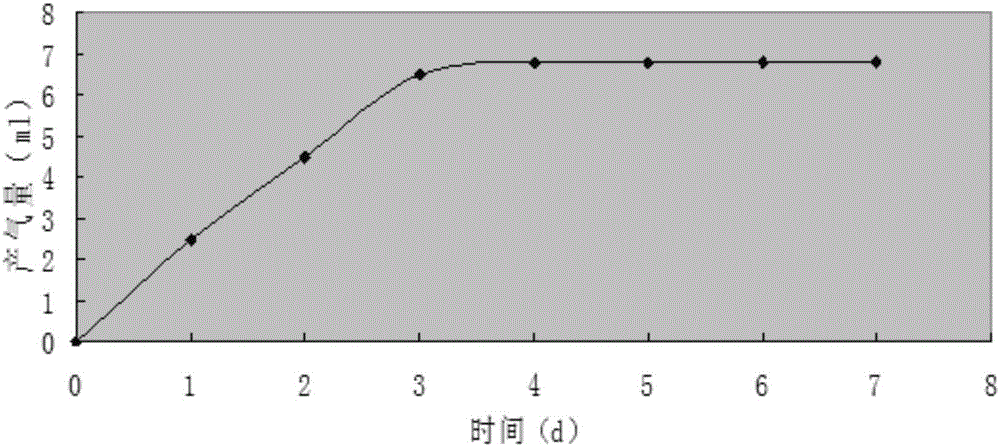

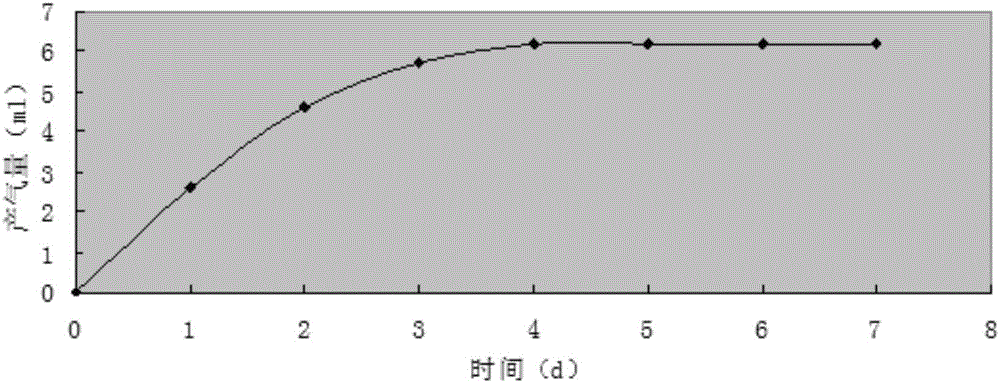

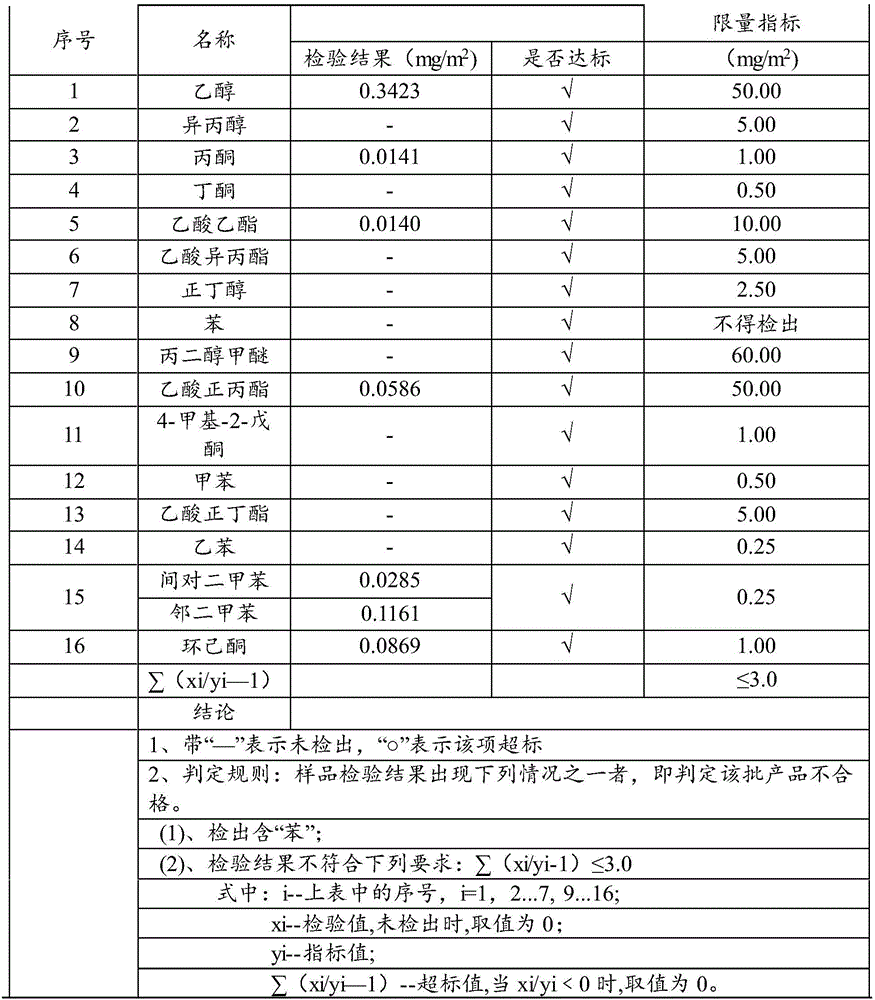

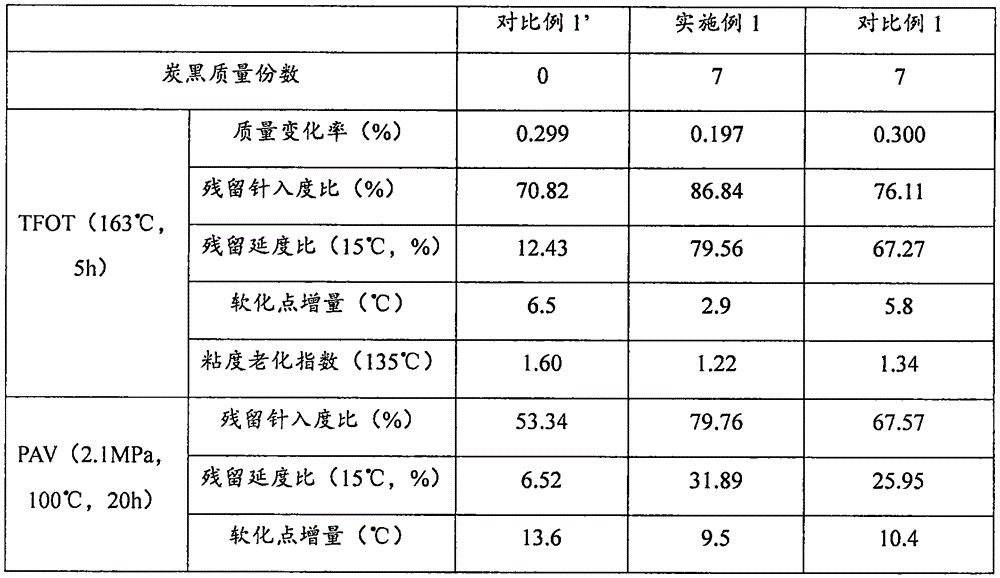

InactiveCN105542495AImprove aging resistanceGood dispersionPigment flushingBuilding insulationsDispersityModified carbon

The invention provides modified carbon black capable of being taken as an asphalt additive. The modified carbon black is prepared by performing anaerobic high-temperature pyrolysis on waste rubber, washing with a washing agent, oxidizing with an oxidizing agent and activating with a surface active agent in sequence. The invention further provides a preparation method and application of the modified carbon black. The modified carbon black provided by the invention is much higher in aging resistance than that of ordinary carbon black, good in dispersity and difficult to aggregate; therefore, compared with the ordinary carbon black, the modified carbon black can more efficiently improve the thermal-oxidative aging and ultraviolet aging resistance of the asphalt.

Owner:CHANGAN UNIV

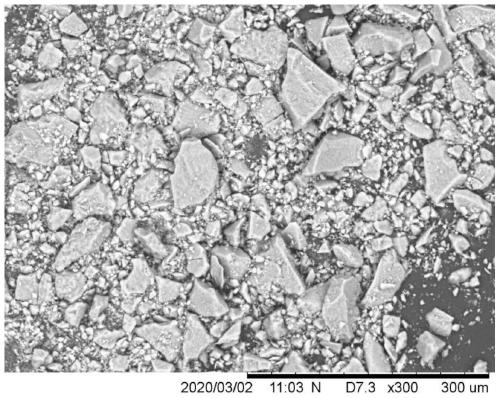

Method for preparing air blocking agent for tire inner liners by taking black talc as raw material

PendingCN111004527AComplete sheet structureFine particle size and narrow distributionChemical industryPigment flushingMagnetiteCalcite

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a method for preparing an air blocking agent for tire inner liners by taking black talc as a rawmaterial. The method comprises the following steps: 1, raw ore pretreatment including two steps of water washing and screening, wherein in the step of water washing, clay impurities attached to the surface of ore are removed through a water washing method, and in the screening step, associated minerals such as quartz, calcite, dolomite and magnetite are manually removed; 2, coarse crushing, wherein coarse crushing equipment is used for crushing the raw ore to 80-200 meshes; and 3, magnetic separation, wherein a magnetic separation machine is adopted to remove particles in crushed raw ore withhigh iron content. The method is capable of improving the precision of crushing of black talc, improving the dispersity of the black talc powder and the affinity of the black talc powder with a rubbermatrix, and meanwhile the comprehensive effect that associated minerals and heavy metal impurities which are difficult to grind can be effectively removed is achieved.

Owner:湖南鑫天源新材料有限公司

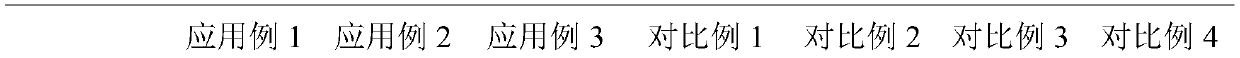

Environment-friendly flame retardant and intumescent fireproof coating prepared therefrom

ActiveCN111234564AHigh degree of graphitizationHigh strengthFireproof paintsPigment flushingCarbon layerFurfurylamine

The invention discloses an environment-friendly flame retardant. The flame retardant is prepared by firstly utilizing tetrabutyl ammonium hydroxide and phosphoric acid to peel zirconium phosphate andthen utilizing furfuryl amine to coat zirconium phosphate. The flame retardant can effectively solve the problems that zirconium phosphate is easy to agglomerate and the like, and can play a synergistic flame-retardant role with an intumescent flame-retardant system in a fireproof coating. When the flame retardant is used to prepare an intumescent fire retardant coating, the film-forming property,the fire resistance, the durability and the like of the obtained fire retardant coating can be remarkably improved. The obtained flame retardant integrates flame retardance, smoke suppression and enhancement functions and is low in halogen-free cost, good in char forming property, high in carbon layer strength, environmentally friendly and wide in applicability, and the related preparation methodis simple in process, mild in reaction conditions and suitable for application and popularization.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

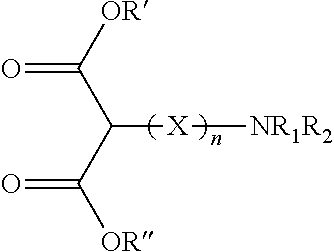

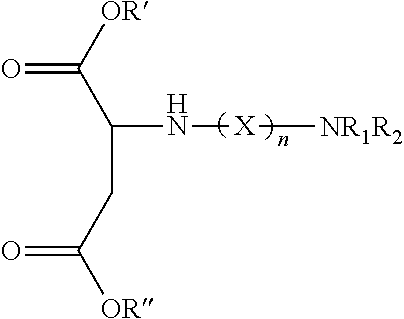

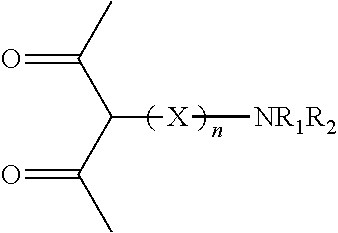

Laminates prepared from decor paper comprising self-dispersing pigments

The disclosure provides a laminate comprising decor paper, wherein the décor paper comprises a self-dispersing pigment having an isoelectric point of at least about 8, more typically about 8 to about 10, comprising an inorganic particle, more typically a pigment, having a silica treatment and an outermost treatment prepared by sequentially by (a) hydrolyzing an aluminum compound or basic aluminate to deposit a hydrous alumina surface; and (b) adding a dual-functional compound comprising: an anchoring group that attaches the dual-functional compound to the pigment surface, and a basic amine group comprising a primary, secondary or tertiary amine. Typically, the inorganic particle is titanium dioxide, TiO2. The décor papers comprising the self-dispersing pigments are useful in making paper laminates.

Owner:THE CHEMOURS CO TT LLC

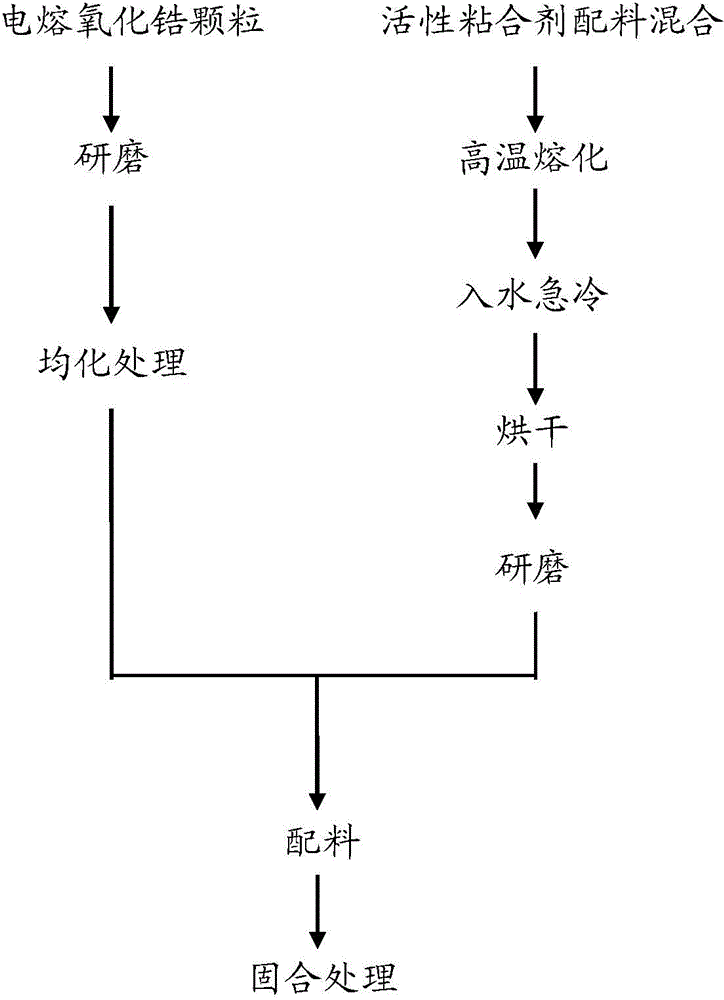

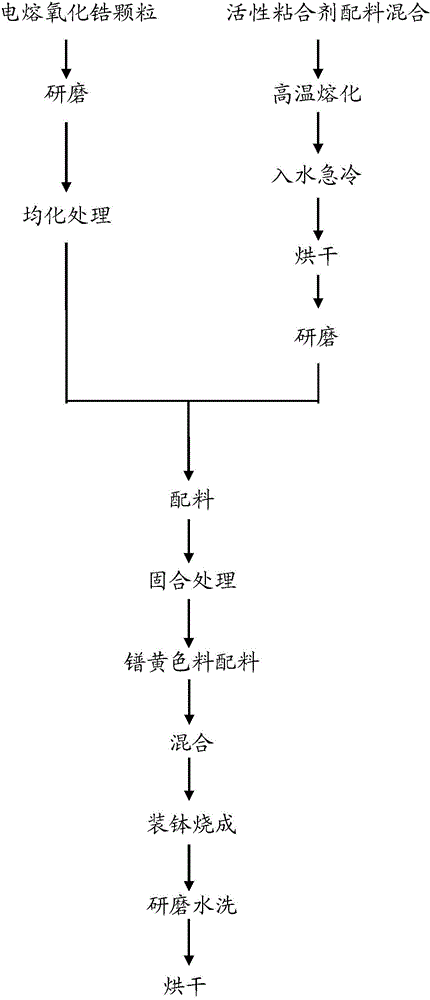

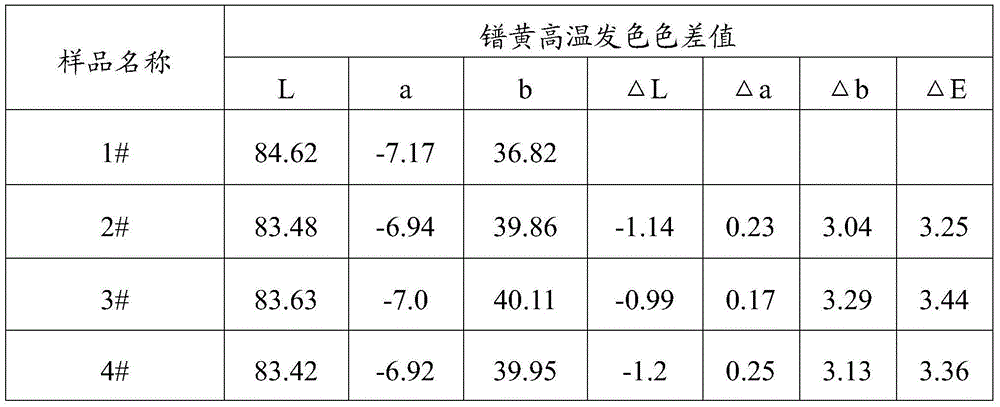

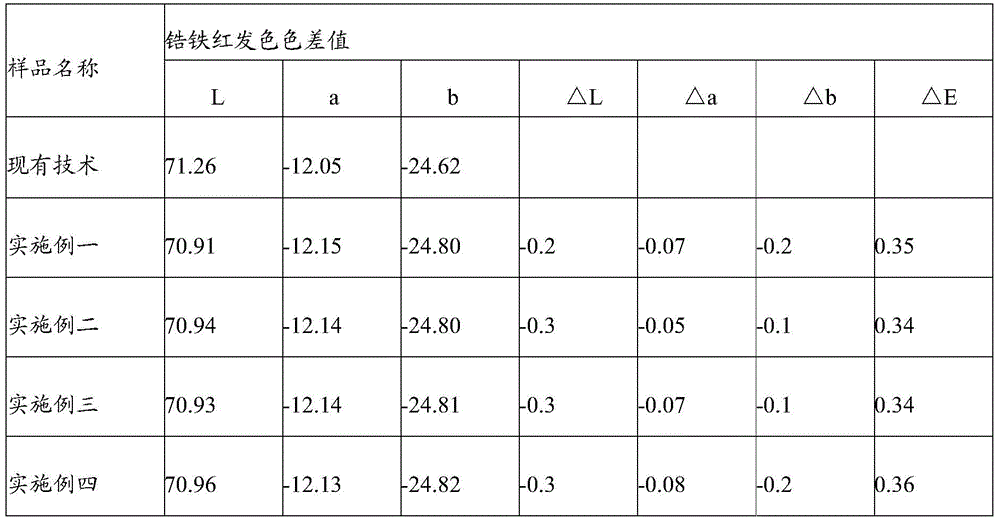

Preparation method for modified fused zirconia and praseodymium yellow pigment

ActiveCN104529541AReduce manufacturing costMeet the use requirementsPigment flushingAdhesiveTemperature resistance

The invention relates to a preparation method for modified fused zirconia and praseodymium yellow pigment. The method includes: firstly conducting grinding and homogenization treatment to control the grain composition of fused zirconia in a reasonable scope, improving the specific surface area of fused zirconia, and then adding an appropriate active adhesive to conduct mixing so as to improve the reaction activity of fused zirconia, thus obtaining modified fused zirconia with specific surface area and reaction activity both close to chemical zirconium. The ceramic pigment produced from the modified fused zirconia has temperature resistance close to that of high temperature resistant ceramic pigment prepared from chemical zirconium. The modified fused zirconia can completely replace chemical zirconium to produce high temperature resistant ceramic pigment, the application bottleneck of fused zirconia in the high-end ceramic pigment field can be overcome, and the production cost of high temperature resistant ceramic pigments is reduced.

Owner:SANXIANG ADVANCED MATERIALS

Pretreatment method of zircon powder and preparation method of vanadium-zirconium blue material

ActiveCN105733310AHigh reactivityFully debondedZirconium compoundsPigment flushingPretreatment methodPre treatment

The invention relates to a pretreatment method of zircon powder. The pretreatment method comprises: performing heating and pressurizing treatments on zircon powder, wherein the temperature of the heating treatment is 350-400 DEG C, and the pressure of the pressurizing treatment is 0.4-0.6MPa; then performing acid cleaning on the zircon powder after the heating and pressurizing treatments until the zircon powder is neutral; and performing drying at first and then performing grinding on the zircon powder after acid cleaning to obtain zircon powder after pretreatment. The invention also relates to a preparation method of a vanadium-zirconium blue material. The pretreatment method of the zircon powder, provided by the invention, can significantly reduce reaction impurities and significantly improve the reactivity of the zircon powder; and the preparation method of the vanadium-zirconium blue material, provided by the invention, has the advantages of improving the productive rate and being simple and easy to control.

Owner:SANXIANG ADVANCED MATERIALS

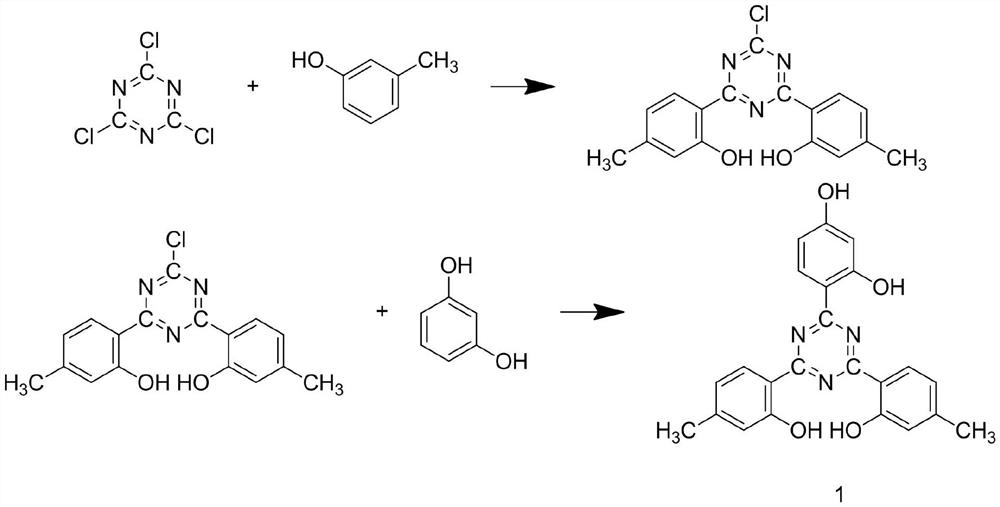

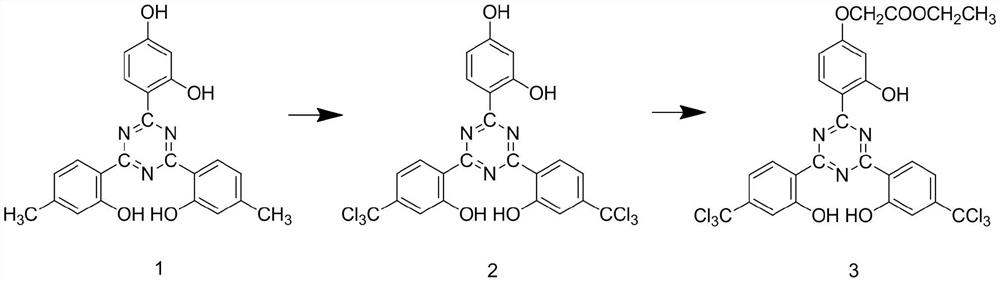

Anti-aging EB floor and preparation method thereof

InactiveCN112029385APrevent photoaging reactionImprove photostabilityLiquid surface applicatorsOrganic chemistrySolid woodPolymer science

The invention disclsoes anti-aging EB floor and a preparation method thereof. The surface of a solid wood floor is coated with an EB coating through an electron beam immobilization technology, an anti-aging agent is prepared in the preparation process of the anti-aging EB floor, and when the anti-aging EB floor is illuminated, hydrogen bonds in the anti-aging agent are broken, so that a compound reaches an unstable high-energy state; when the anti-aging agent in the high-energy state needs to return to the low-energy state, heat release is needed, then light energy is converted into heat energy, and after the anti-aging agent returns to the low-energy state, hydrogen bonds in molecules of the anti-aging agent are formed again, so that the anti-aging agent can continuously consume the lightenergy, and the molecules of the anti-aging agent can decompose peroxides and generate nitroxide free radicals; the nitroxide free radicals can capture free radicals and quench singlet oxygen, so that the light stability of the polymer is enhanced, and the prepared EB floor is better in aging resistance.

Owner:ANHUI YANGZI FLOORING

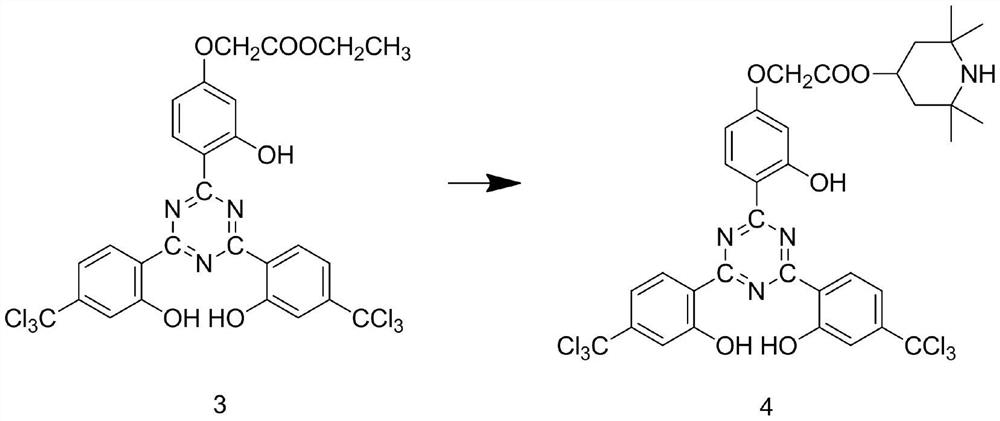

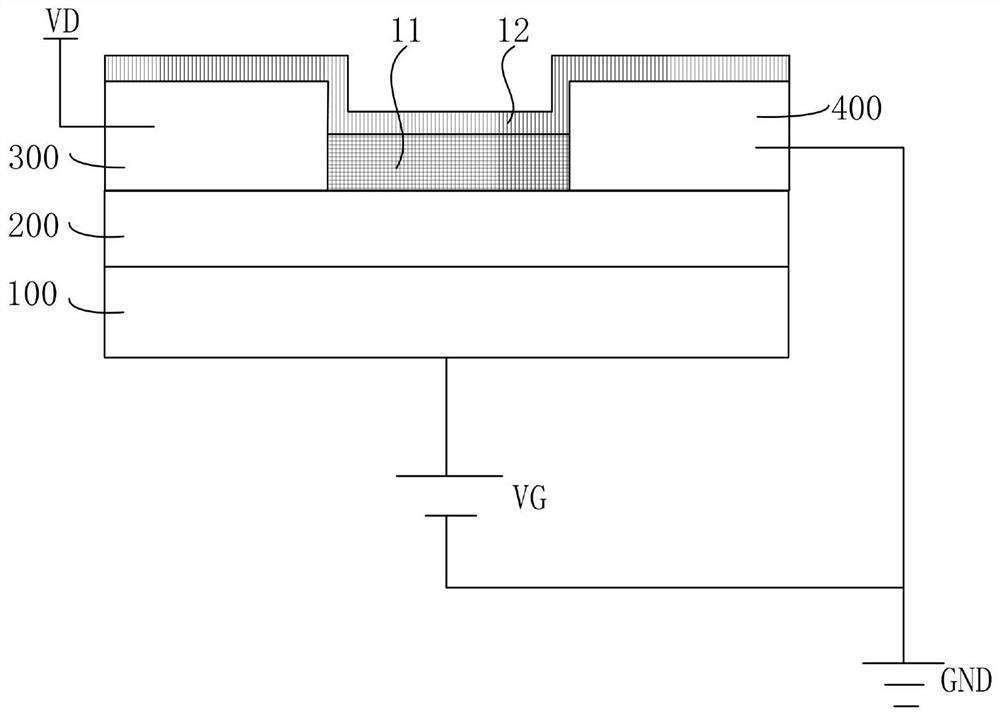

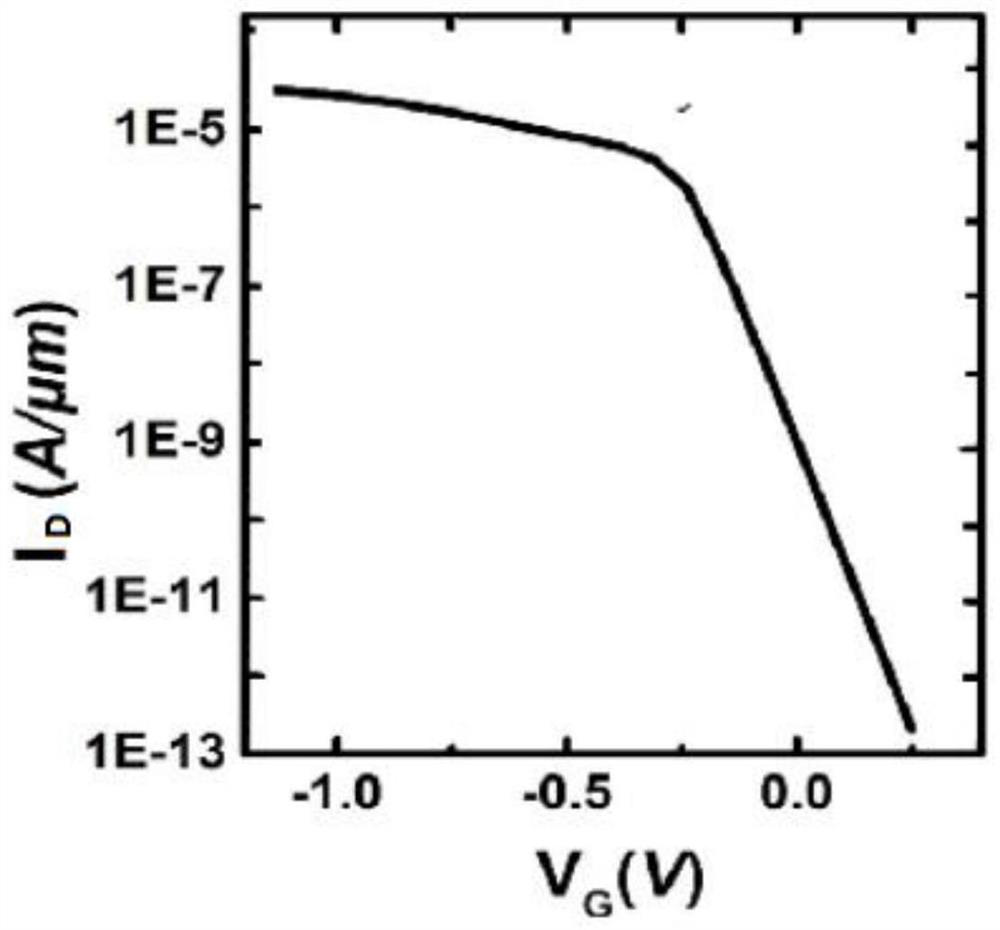

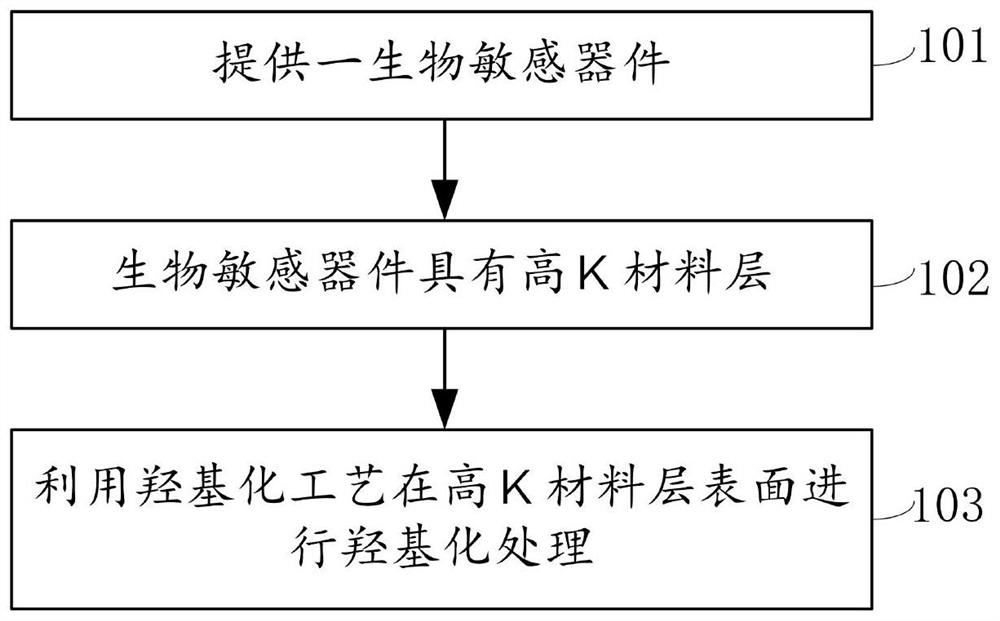

Manufacturing method of biosensor, biosensor and application of biosensor

InactiveCN111693589AHigh sensitivityHighly specific detectionMaterial analysis by electric/magnetic meansPigment flushingEngineeringOrganic chemistry

The invention discloses a manufacturing method of a biosensor, the biosensor and application of the biosensor, and relates to the technical field of biosensors. Hydroxylation process treatment is carried out on the surface of the high-K material layer, the number of hydroxyl groups on the surface of the high-K material layer is increased, then functional groups for fixing probe molecules are increased, and high-sensitivity and high-specificity detection of an object to be detected is achieved. The manufacturing method of the biosensor comprises the following steps: providing a biosensitive device with a high-K material layer, and carrying out hydroxylation treatment on the surface of the high-K material layer by utilizing a hydroxylation process. The manufacturing method of the biosensor is applied to manufacturing of the biosensor, and the biosensor is applied to detection of bioactive substances.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Antioxidant metal-like plastic master batch and preparation method thereof

InactiveCN111777811AImprove antioxidant capacityAccelerated corrosionPigment flushingPigment treatment with organosilicon compoundsMasterbatchTriethoxysilane

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method of porous light silicon dioxide filler

ActiveCN111471321AHigh strengthIntegrity guaranteedPigment flushingPigment physical treatmentPorosityHeat resistance

The invention discloses a preparation method of a porous light silicon dioxide filler, and relates to the technical field of inorganic materials, and the preparation method comprises the following steps: (1) pulping and cleaning; (2) freezing and concentrating; (3) drying and calcining; (4) crushing and grading; (5) high-temperature spray burning; (6) flotation classification. The silicon dioxideprepared by the method has the characteristics of light weight, porosity, high strength, low specific surface area and low oil absorption value, and particularly, the strength of the material is far higher than that of hollow materials such as hollow glass beads; the preparation method is easy to realize industrialization, and solves the problems that the glass beads are easy to break in the processing process, lose weight reduction after breaking and reduce the dielectric constant; and meanwhile, the prepared silicon dioxide has a spherical shape and is beneficial to large-proportion fillingin a resin matrix, so that the rigidity, the strength, the heat resistance, the wear resistance, the corrosion resistance, the machinability and the like of the resin matrix are improved.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

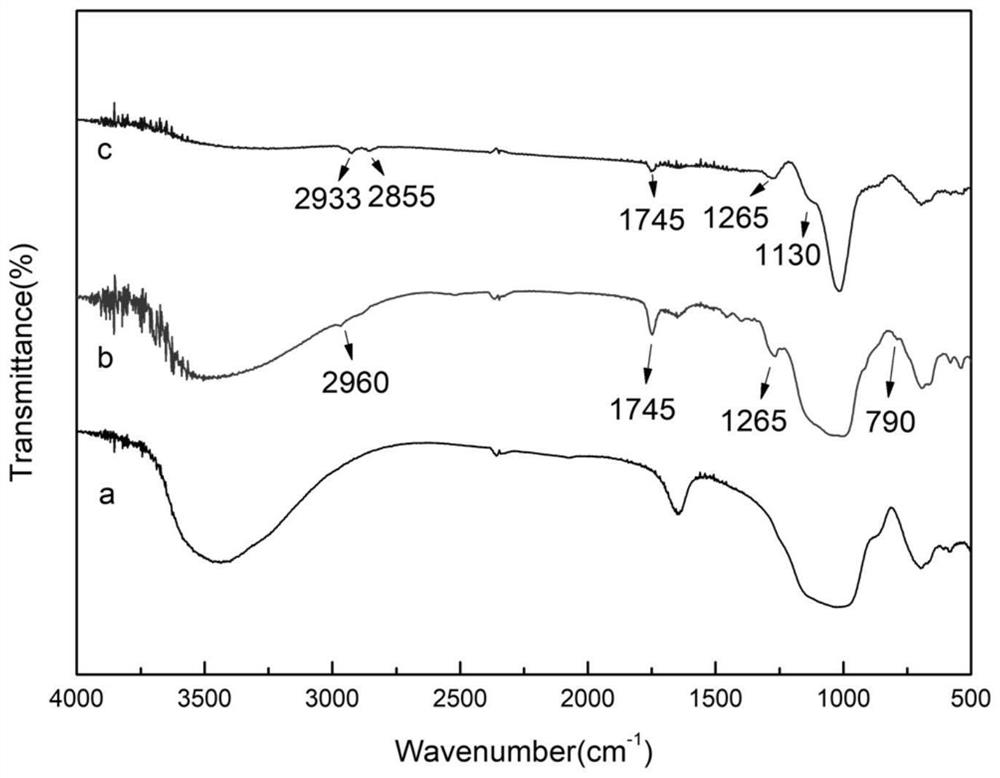

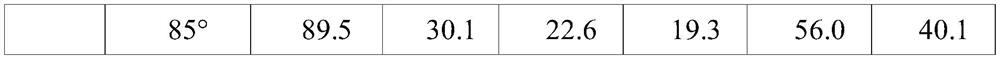

Preparation method of sericite nano micro-sheets

The invention discloses a preparation method of sericite nano micro-sheets.The preparation method includes the following steps that S1, material selection is performed: required sericite ore raw materials are selected, high-quality ore raw materials are manually picked out and are coarsely broken, and then sericite reprocessing is performed through wet-process stripping and grading processes so as to obtain sericite graded at the first time; S2, dispersion is performed: sericite slurry is fed into a high-temperature drying oven for sericite drying, then the dried sericite is put into an ultrasonic dispersion machine, the mesh number of the sericite is increased through ultrasonic dispersion, and the dispersed sericite is put into a stirring machine.The thin-sheet-layer, complete-crystal-structure and high-quality sericite nano micro-sheets are finally obtained by combining lithium chloride and the sericite, dispersing the lithium chloride and the sericite through the ultrasonic dispersion machine and the fusing the sericite ultra-refined through a wet process and the lithium chloride.

Owner:ANHUI HENGHAO SCI & TECH

Preparation method of high-dispersity ultramarine pigment, pigment obtained through preparation method and application of pigment

ActiveCN113214682AGood dispersionImprove stabilityPigment flushingPigment physical treatmentPtru catalystFormate

The invention discloses a preparation method and application of a high-dispersity ultramarine pigment, and the preparation method comprises the following steps: dissolving an ultramarine raw material in a solvent to form pigment color paste, and then adding the pigment color paste into a ball milling tank containing mixed zirconia beads; adding diethylene glycol dichloro-formate, an acid-binding agent and a catalyst into a ball-milling tank, sealing the tank, and putting the ball-milling tank into a ball mill for ball-milling reaction to obtain an acylating chlorination ultramarine dispersion liquid; after the reaction is finished, opening the ball-milling tank, adding excessive diethylamine into the ball-milling tank, sealing the tank, and continuing the ball-milling reaction; and finally, removing the solvent from the mixed solution, washing with ethanol and deionized water, and finally drying and grinding to obtain the modified ultramarine pigment. The modified ultramarine prepared by taking diethylene glycol dichloro-formate as a bridging agent and diethylamine as a modifier has better dispersity and dispersion stability in CR39 resin, and colorless and transparent lenses can be obtained after curing.

Owner:NANJING UNIV OF TECH +1

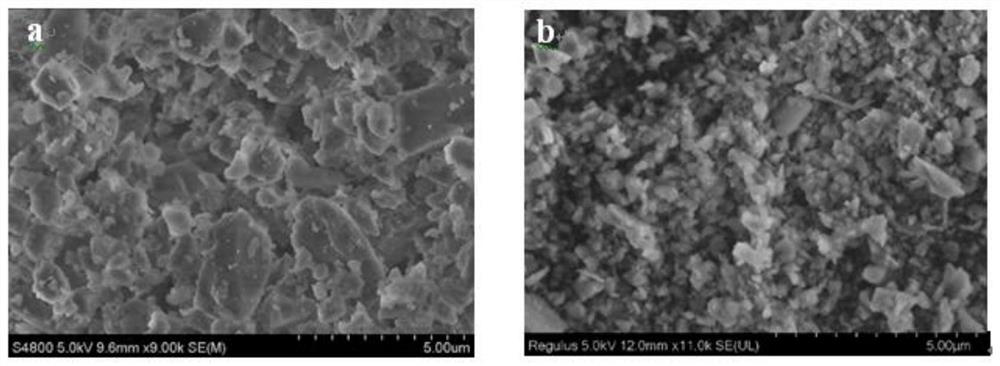

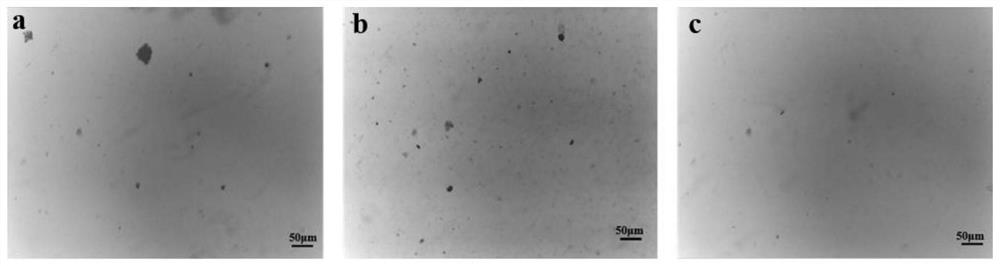

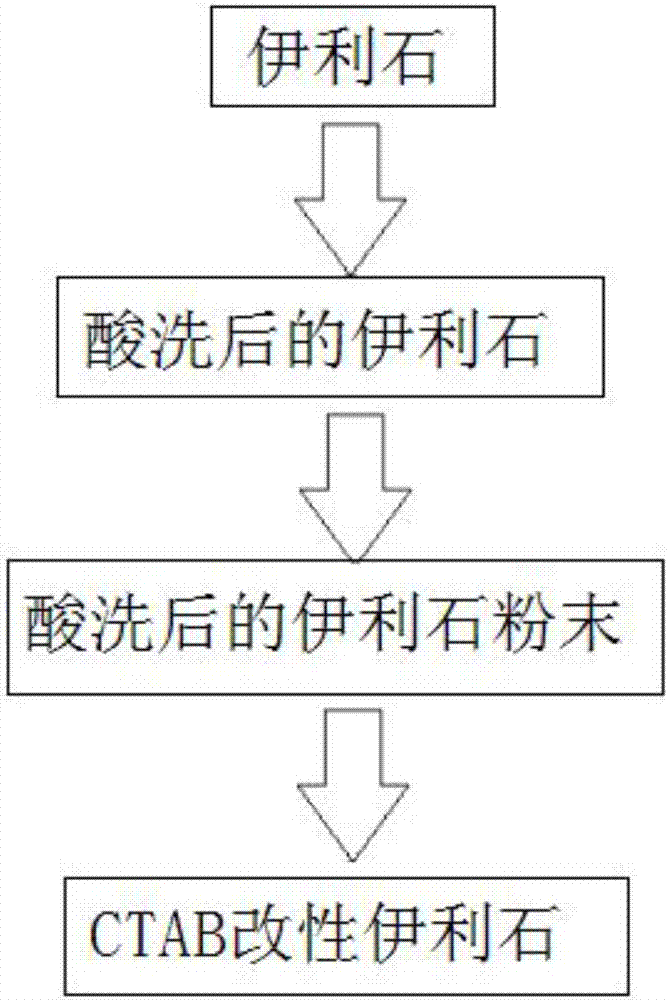

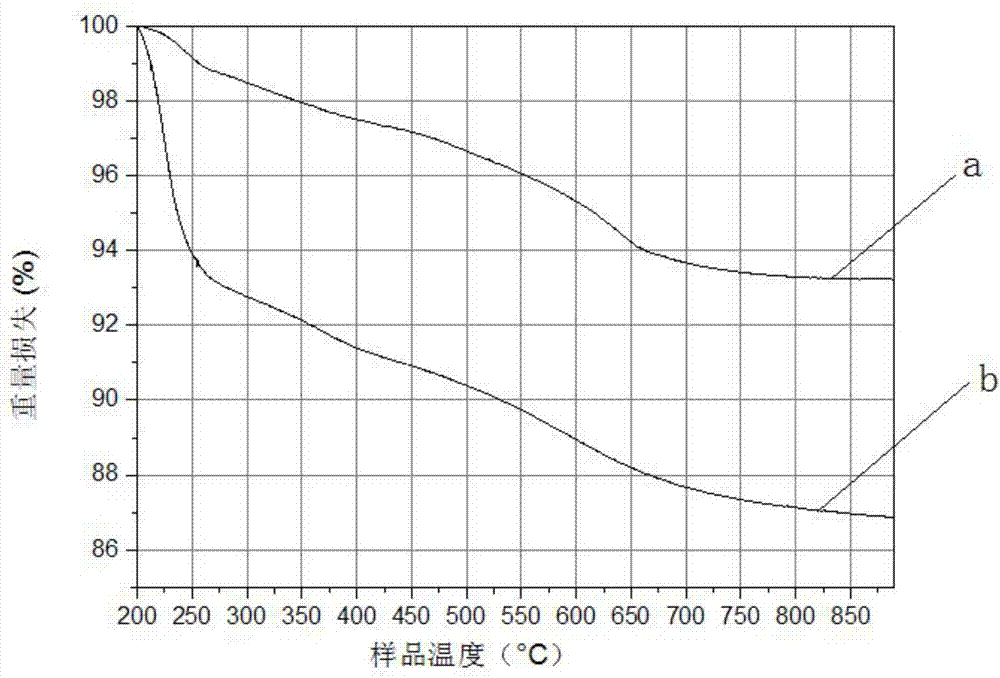

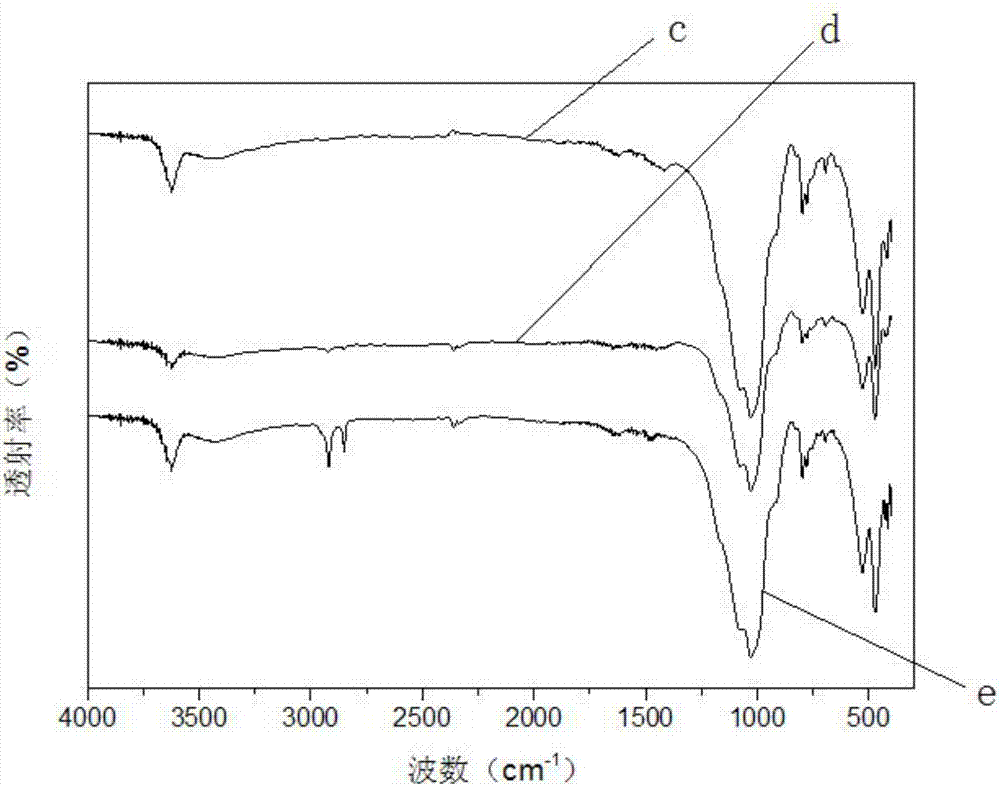

Preparation method of modified illite for improving performance of natural rubber

InactiveCN107189496AGood dispersionIncrease contentPigment flushingPigment physical treatmentPolymer scienceCoupling

The invention relates to a preparation method of modified illite for improving performance of natural rubber, and belongs to the field of chemical engineering and technology. The method comprises: mixing illite powder and a certain concentration of hydrochloric acid, performing stirring, flushing the obtained product with distilled water and performing filtering to obtain acid-washed illite; and mixing acid-washed illite with cetyl trimethyl ammonium bromide in 50% of an isopropanol aqueous solution, carrying out a reaction, and performing centrifugation and drying to obtain modified illite. The prepared modified illite is mixed with natural rubber, and sulfuration is carried out to obtain an illite and natural rubber composite material. The prepared modified illite is high in modifier load, and compared with a modified illite made from a silicane coupling agent, the prepared modified illite is short in reaction time and low in reaction temperature. The cetyl trimethyl ammonium bromide (CTAB) used as a cationic modifier is cheaper than a silicane coupling agent, and the prepared modified illite can be well dispersed in rubber and is excellent in mechanical properties.

Owner:CHANGCHUN UNIV OF TECH

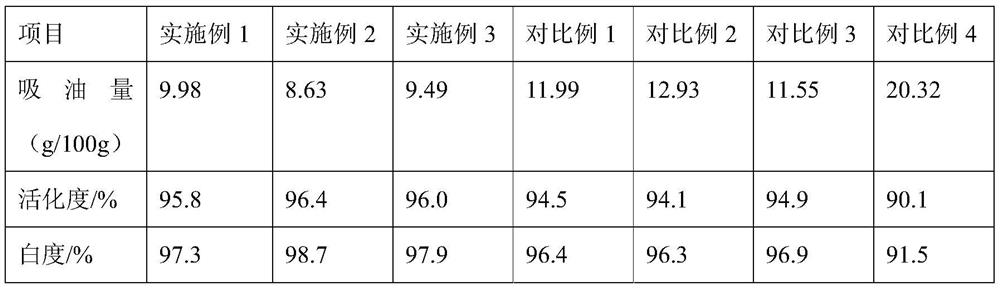

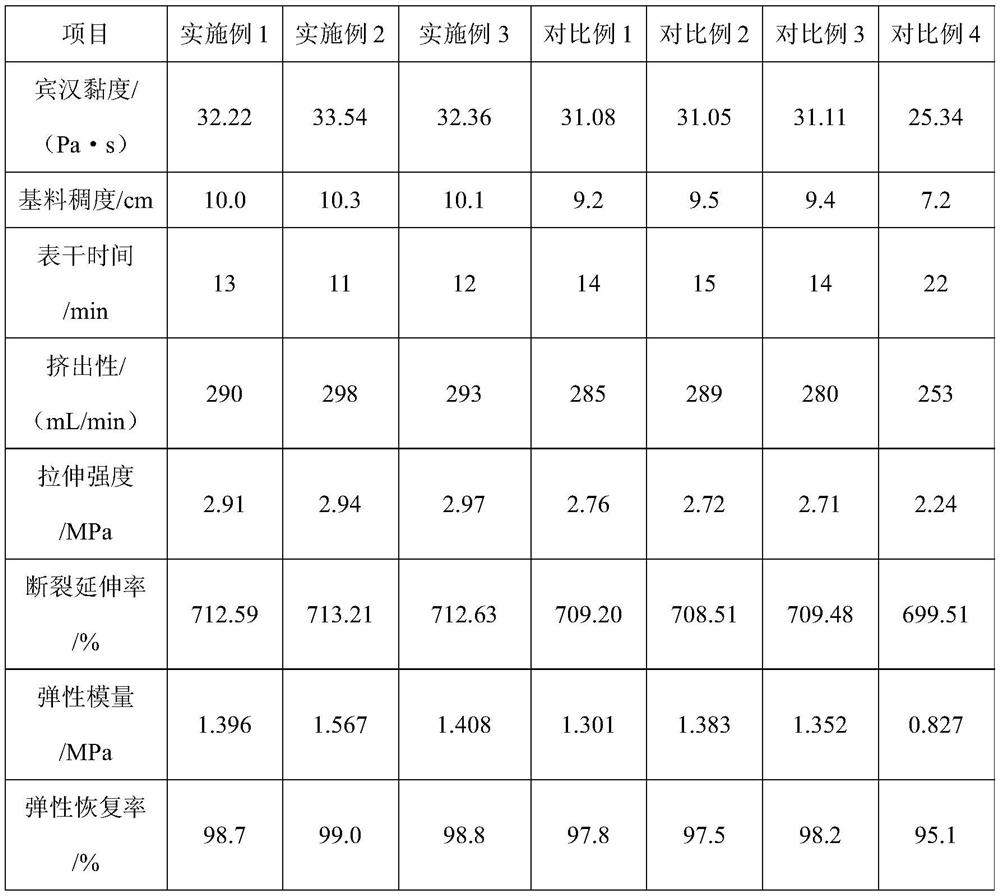

Preparation method of heavy calcium carbonate for high-activation-degree silicone adhesive

ActiveCN113088102AGood dispersionIncrease activationNon-macromolecular adhesive additivesPigment flushingHigh activationPhysical chemistry

The invention discloses a preparation method of heavy calcium carbonate for a high-activation-degree silicone adhesive. The preparation method sequentially comprises the steps of ore storage, cleaning, mineral separation, crushing and homogenizing, grinding, grading, powder collection, quality inspection I, activation, cooling and quality inspection II. The preparation method disclosed by the invention is simple and easy to implement, the prepared calcium carbonate powder has good dispersity, extremely high activation degree, relatively high whiteness and extremely low oil absorption value, and the thixotropy and tensile strength of a silicone adhesive can be effectively improved.

Owner:广西贺州市科隆粉体有限公司 +1

Preparation method of titanium dioxide special for papermaking

ActiveCN111471323AImprove responseUniform dense depositionPigment flushingInorganic compound additionMetallurgySlurry

The invention discloses a preparation method of titanium dioxide special for papermaking. A finished product is obtained through slurry preparation, coating, three times of washing, flash evaporationand powder steaming. Particularly, hydroxyl-containing polybasic acid is selected as a coating agent. According to the invention, the hydroxyl-containing polybasic acid is used as a special coating agent, so that a film layer is more compact, and higher light resistance and covering power are achieved; the hydroxyl-containing polybasic acid is attached to the surface of the titanium dioxide in a bonding manner, cannot be remained in a filtrate, cannot influence VOCs, and further cannot influence the environment.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

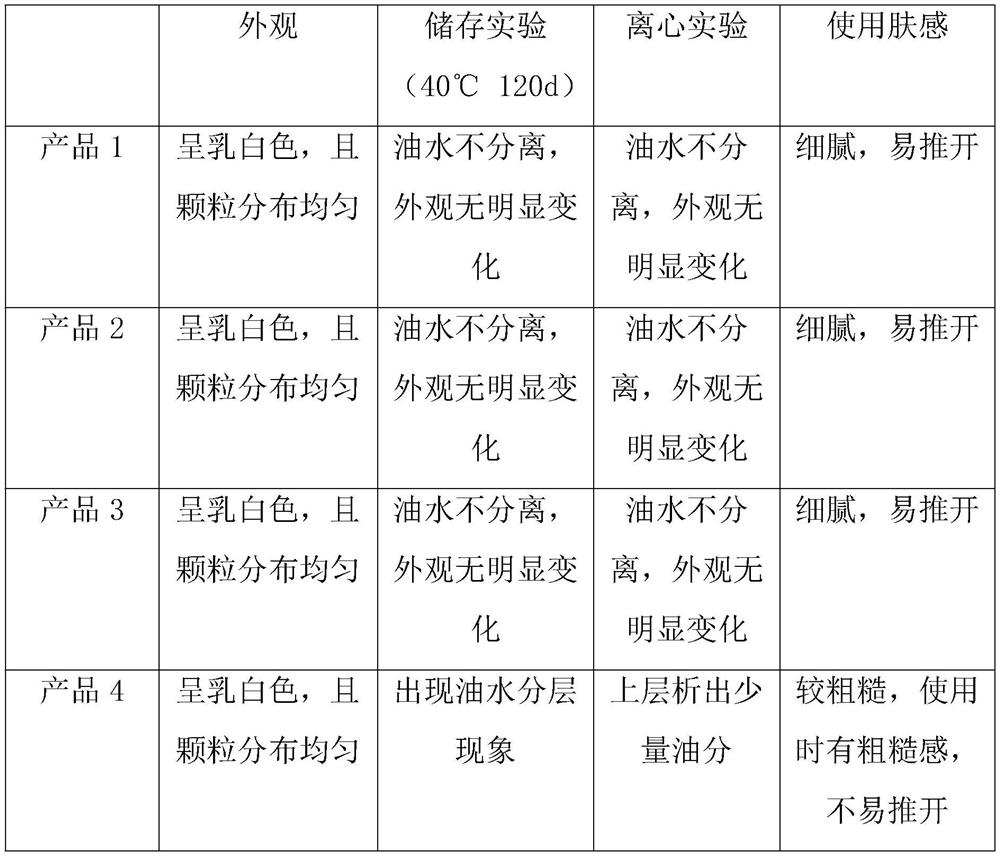

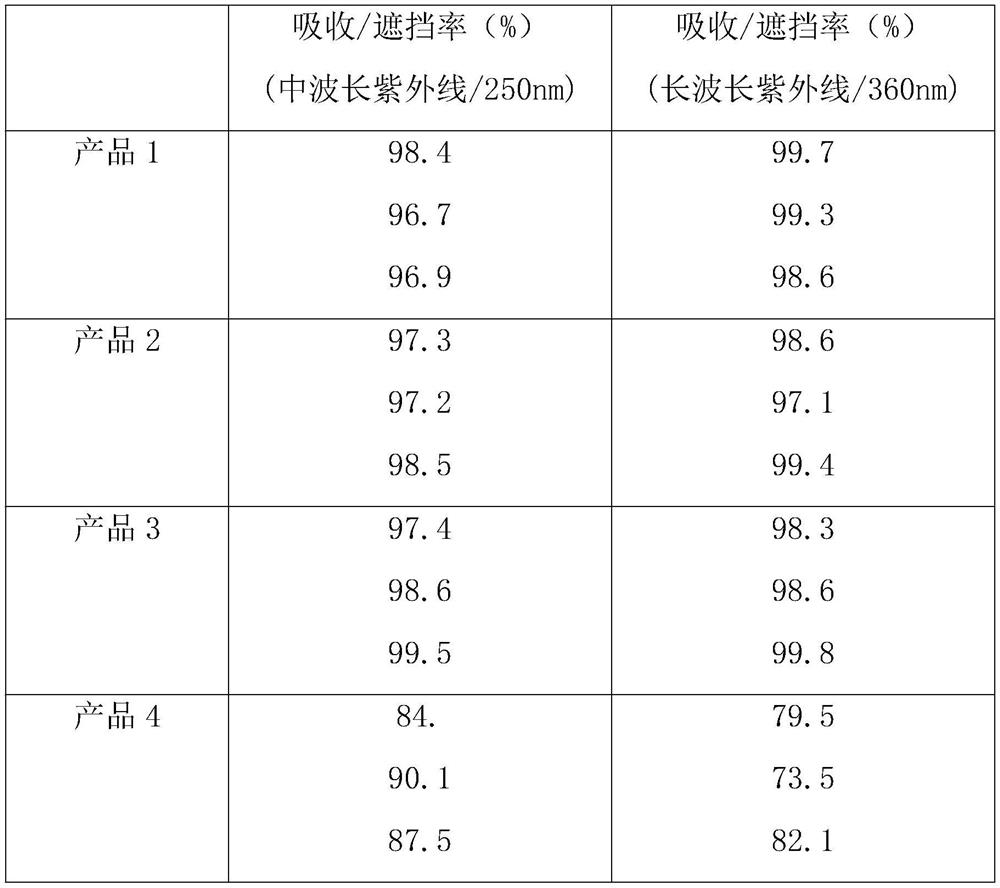

Preparation method of modified titanium dioxide

PendingCN114539817ASuitable to addEasy to useCosmetic preparationsToilet preparationsStearic acidSkin Care Product

The invention relates to the technical field of titanium dioxide modification, in particular to a preparation method of modified titanium dioxide, which comprises primary modification and secondary modification, and modifiers adopted in the primary modification and the secondary modification are stearic acid and a silane coupling agent respectively. Therefore, the quality and the use experience of the skin care product are improved.

Owner:集美精化科技(广西)有限公司

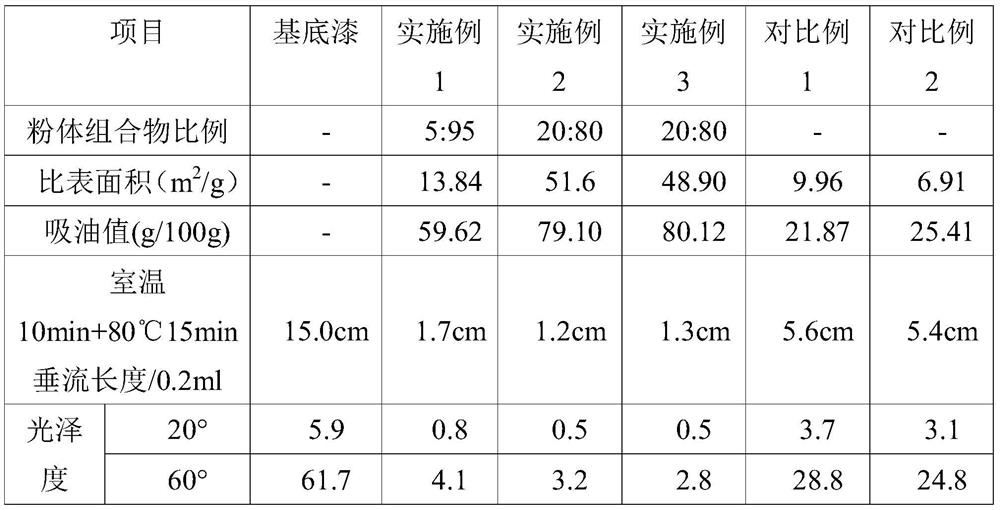

Gloss-adjustable inorganic powder composition for extinction and application of gloss-adjustable inorganic powder composition

PendingCN111763442AEasy to prepareEasy production controlInksPigment flushingPhysical chemistryPrinting ink

The invention discloses a gloss-adjustable inorganic powder composition for extinction and application of the gloss-adjustable inorganic powder composition and belongs to the technical field of delustering agents. The inorganic powder composition is composed of porous silicon dioxide powder and fused quartz powder; the porous silicon dioxide powder is formed by aggregation of nano silicon dioxide,and the nano silicon dioxide is connected through chemical bonds to form a pore passage interpenetrating structure. When the composition of the porous silicon dioxide powder and the fused quartz powder is applied to paint, coating and printing ink, the glossiness, viscosity and vertical flow resistance can be adjusted within a large range, and different requirements of customers are met; meanwhile, the two kinds of powder have clear and obviously different effects, and when quality fluctuation occurs, the source can be easily and rapidly found, and the problem can be solved in a targeted mode.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

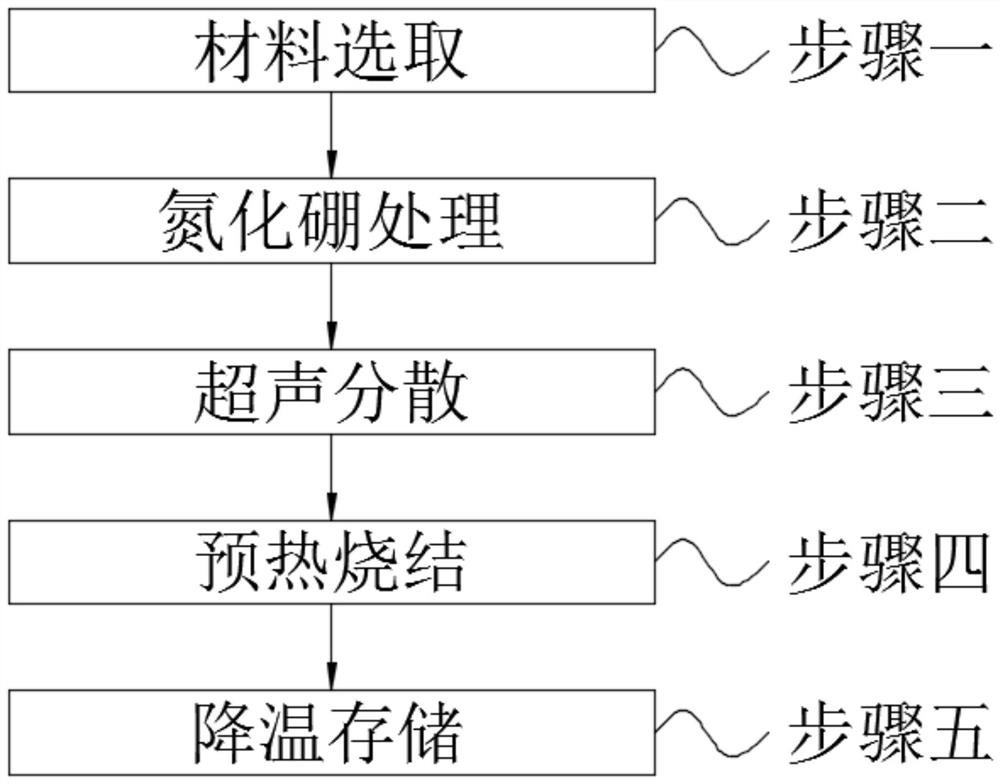

High-thermal-conductivity boron nitride powder filler and preparation method thereof

InactiveCN112980215ALarge particle sizeImprove thermal conductivityHeat-exchange elementsPigment flushingEpoxyAlcohol

The invention discloses a high-thermal-conductivity boron nitride powder filler and a preparation method thereof. The high-thermal-conductivity boron nitride powder filler is prepared from sodium hydroxide, boron nitride, an epoxy silane coupling agent, absolute ethyl alcohol and deionized water. The mass percentage of each component is as follows: 15 to 25 parts of sodium hydroxide, 40 to 60 parts of boron nitride, 20 to 30 parts of epoxy silane coupling agent, 10 to 20 parts of absolute ethyl alcohol and 5 to 10 parts of deionized water. The preparation method is safe and reliable, the microsphere boron nitride easily forms a heat conduction network, the particle size of the boron nitride is optimized, the heat conduction effect of the filler is improved, the wet modification process conditions of the epoxy silane coupling agent on the boron nitride powder are optimized, so that the boron nitride powder has good compatibility with organic matters, and the viscosity, the oiliness, the water content and the like meet the technical index requirements; and the process is simple and rigorous, can replace other expensive high-thermal-conductivity boron nitride powder filler production processes, has the advantages of significant effect, cheap raw materials and low cost, greatly saves the production cost, and is beneficial to processing and production.

Owner:东莞东超新材料科技有限公司

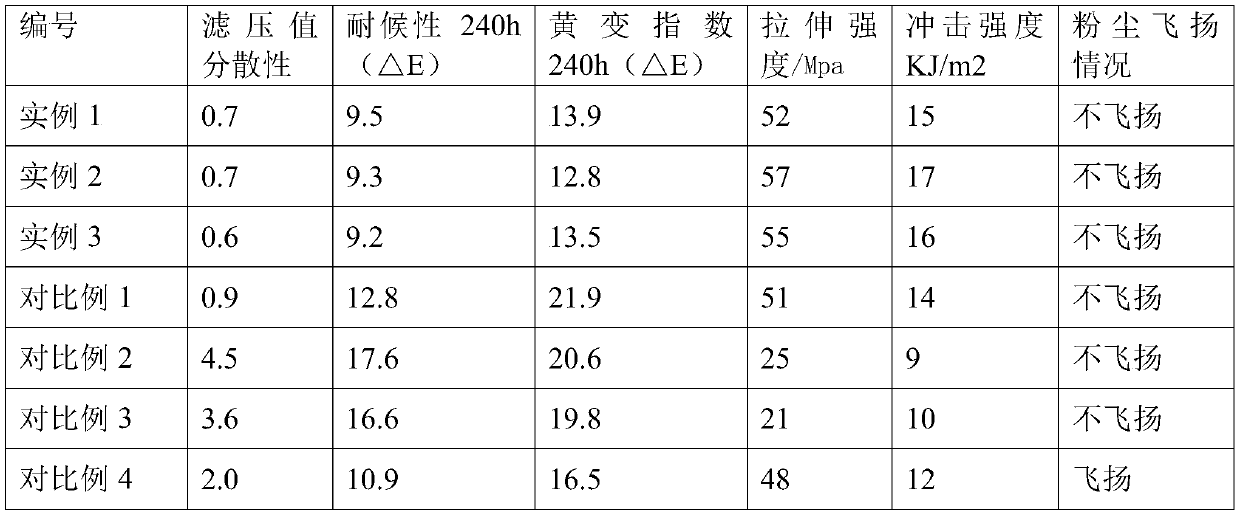

Preparation method of high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment

PendingCN111073351AClose to spherical high proportionSmall particle sizePigment flushingPigment treatment with macromolecular organic compoundsAluminatePolyolefin

The invention relates to a preparation method of a high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment, and the method comprises the following steps: producing a titanium dioxide primary product by a chlorination process, pulping in desalted water to prepare a slurry, regulating the pH value with an inorganic acid or alkali, dispersing, and grinding; heating the slurry, adding an alkaline aluminate compound, and simultaneously maintaining the pH value constant by using inorganic acid or an acidic aluminum compound to form an inorganic aluminum film coating layer on the surface of titanium dioxide particles; adjusting the pH value by adopting an inorganic alkali solution, and adding a polysiloxane liquid containing an active group to form an organic silicon film coating layer; filtering with deionized water, washing, and drying; adding a citrate ester organic treating agent in the steam-pulverizing process, and performing steam-pulverizing treatment to obtain a titanium dioxide finished product. The advantages are that: the titanium dioxide pigment prepared by the method has high weather resistance, high whiteness, high covering power andexcellent dispersion processability, has low dust flying in the production and use processes, is environment-friendly, and is suitable for the application fields of high-end color master batches suchas polyolefin, engineering plastics and the like

Owner:中信钛业股份有限公司

Preparation method of highly-dispersed titanium pigment

InactiveCN108384285AAvoid formingGood dispersionPigment flushingPigment physical treatmentDispersityTitanium

The invention relates to a preparation method of a highly-dispersed titanium pigment. The preparation method comprises the following steps of 1), inorganically enveloping the sand-ground slurry of a titanium pigment, washing enveloped slurry, and then pulping anew, so as to obtain thinned slurry; 2), adding TMP into the thinned slurry for the first time, and ultrasonically dispersing for a periodof time, so as to obtain dispersed slurry; 3), drying the dispersed slurry, and steam-grinding to obtain the highly-dispersed titanium pigment, wherein the TMP is added for the second time during steam grinding. The method provided by the invention can be used for completely avoiding the formation of an aggregate before the slurry of the titanium pigment is dried; thus, the dispersity of the titanium pigment is improved; the grinding can be carried out by adopting a lower-intensity gas stream, and the steam grinding cost is decreased.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

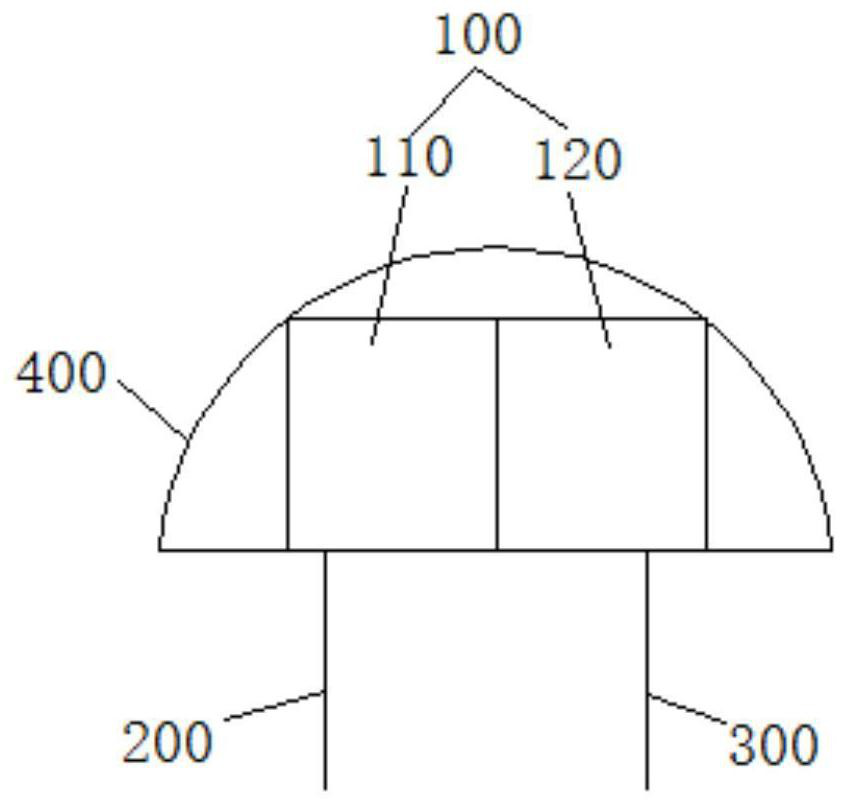

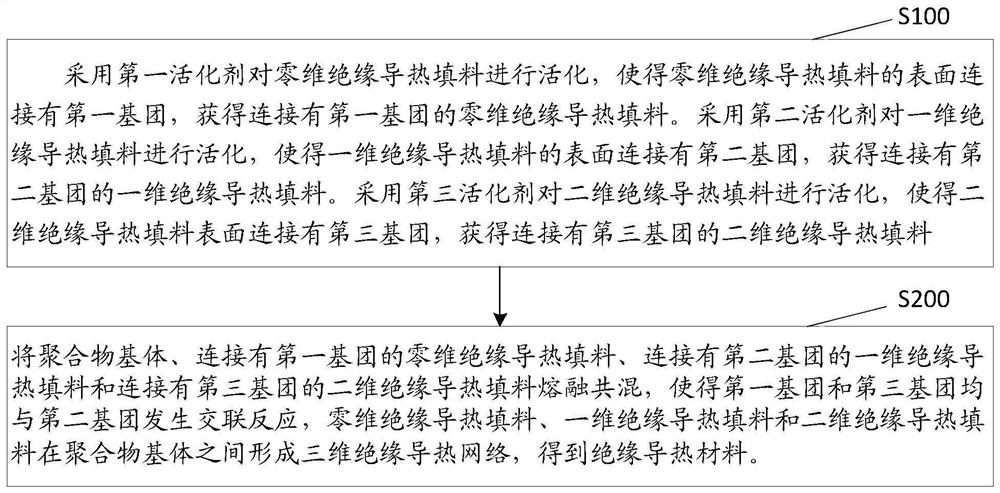

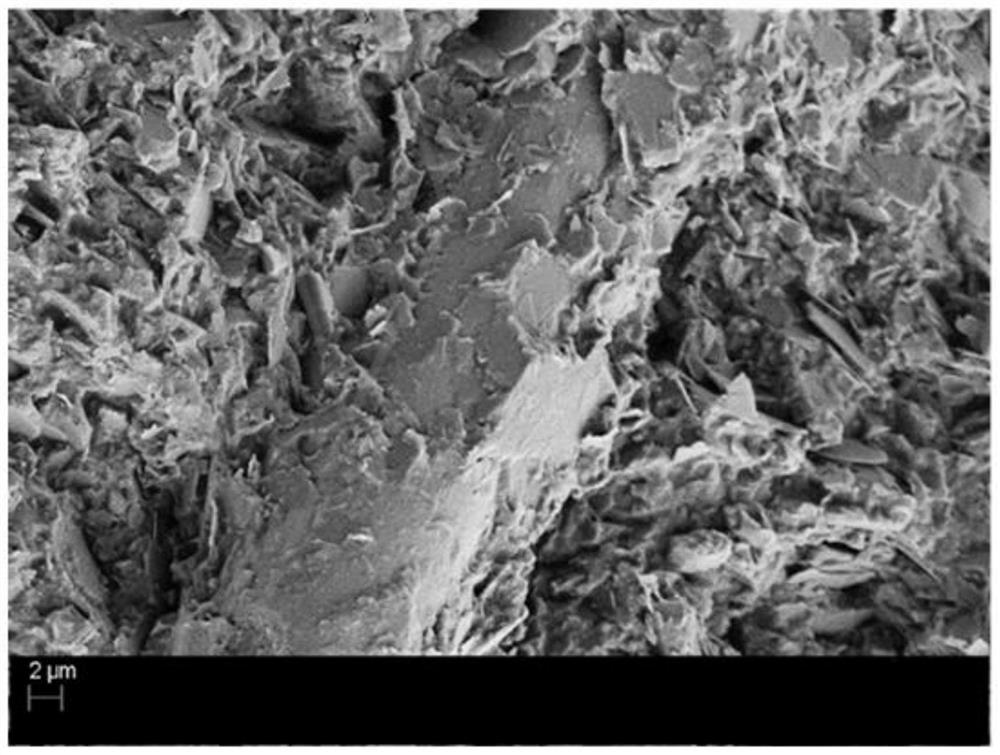

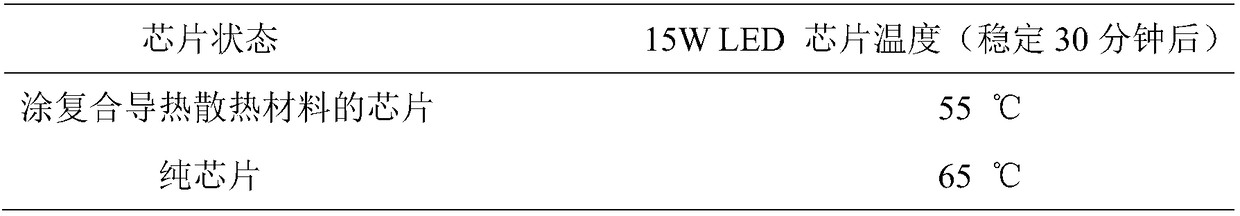

Insulating heat-conducting additive, insulating heat-conducting material, preparation method of insulating heat-conducting material and light emitting diode

PendingCN112759798APigment flushingPigment treatment with organosilicon compoundsLight-emitting diodeComposite material

The invention discloses an insulating heat-conducting additive, an insulating heat-conducting material, a preparation method of the insulating heat-conducting material and a light-emitting diode, relates to the technical field of light-emitting diodes, and aims to enable the insulating heat-conducting material to have good heat-conducting property. The insulating and heat-conducting additive comprises a zero-dimensional insulating and heat-conducting filler, a one-dimensional insulating and heat-conducting filler and a two-dimensional insulating and heat-conducting filler; the zero-dimensional insulating and heat-conducting filler is connected with a first group, the one-dimensional insulating and heat-conducting filler is connected with a second group, and the two-dimensional insulating and heat-conducting filler is connected with a third group. The first group and the third group can be subjected to cross-linking reaction with the second group, so that a three-dimensional insulating heat-conducting network is formed among the zero-dimensional insulating heat-conducting filler, the one-dimensional insulating heat-conducting filler and the two-dimensional insulating heat-conducting filler. The insulating heat-conducting additive provided by the invention is used for improving the heat-conducting property of the insulating heat-conducting filler.

Owner:BULL GRP CO LTD

A kind of graphene-containing composite electronic heat conduction and heat dissipation material and its preparation method and application

ActiveCN106634047BImprove thermal conductivityGood thermal emissivityHeat-exchange elementsPigment flushingFiberFiltration

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Special powder materials for weapons and equipment

ActiveCN106810929BImprove oxidation resistanceDelay the oxidation processPolyurea/polyurethane coatingsPigment flushingEmissivityAging resistance

The invention provides a powdery material special for weaponry. After aluminum powder is treated by a surface modifier of the powdery material special for the weaponry, a layer of protective film is formed on the surface of the treated aluminum powder, so that oxidation resistance of the aluminum powder is improved, and an oxidation process of the aluminum powder in use can be delayed. The powdery material for the weaponry has the advantages that an infrared stealthy coating prepared from the powdery material is low in infrared emissivity and excellent in aging resistance, an aging process of the infrared stealthy coating slows down, service life of the coating is prolonged, and infrared emissivity increase is slow during thermal aging testing.

Owner:JIANGXI LEFU IND

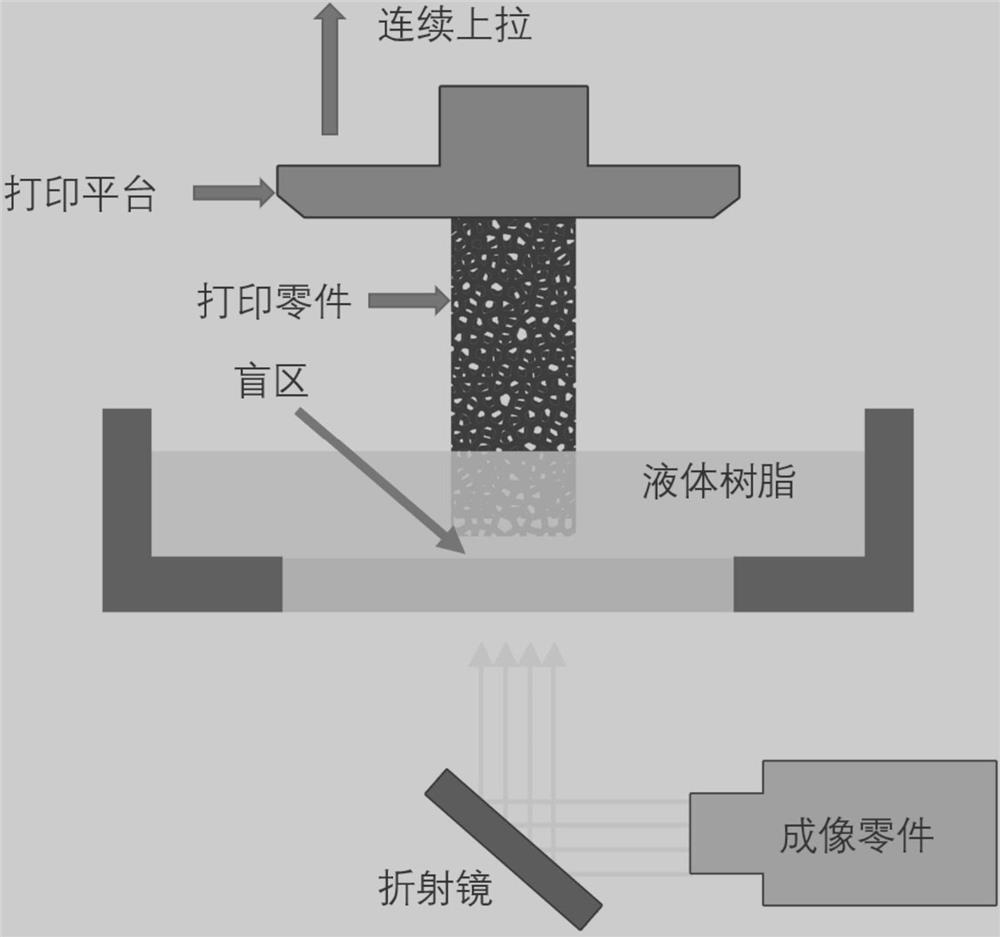

Amino polymerization inhibition modified heat-conducting particle and preparation method thereof

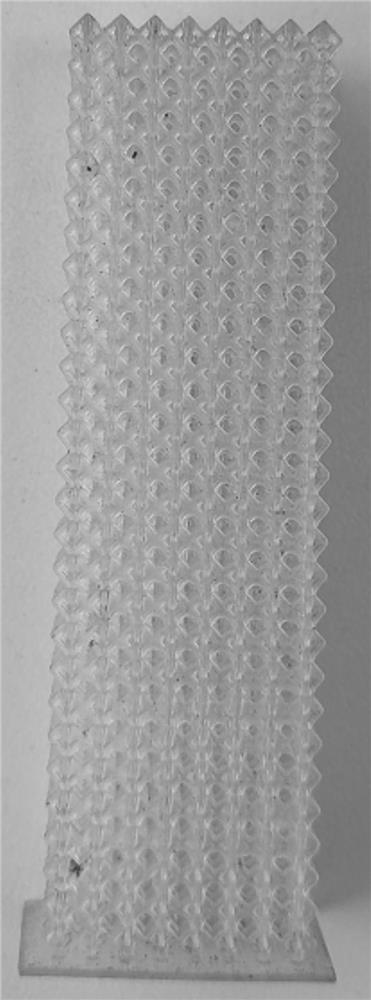

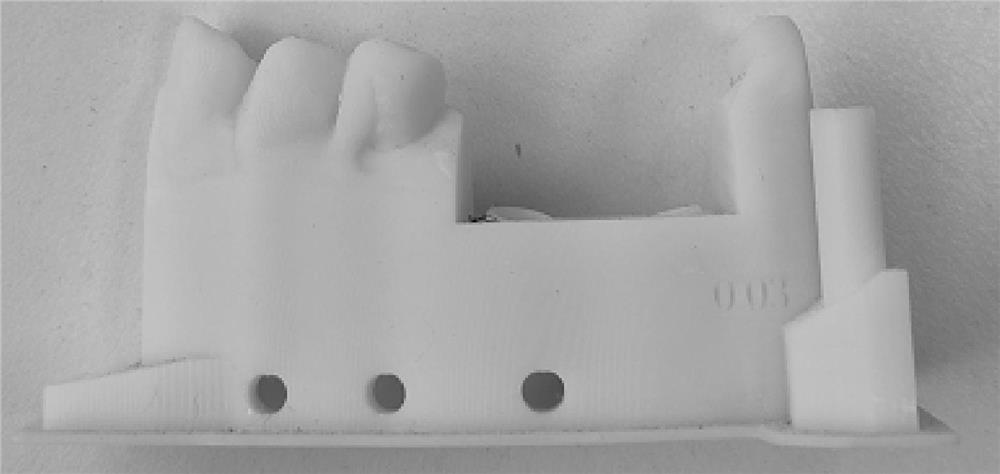

ActiveCN113462200ARealize printingReduce crackingAdditive manufacturing apparatusPigment flushingEpoxyPolymer science

The invention relates to the technical field of additive manufacturing, in particular to amino polymerization inhibition modified heat conduction particles and a preparation method thereof. At present, according to a CLIP technology, oxygen must be continuously introduced into the bottom of a resin tank, an uncured liquid layer can be constructed at the bottom of liquid photosensitive resin to achieve continuous photocuring 3D printing only by adopting an expensive breathable Teflon film, and application and popularization of the CLIP technology are seriously limited through the method. Based on the problems, the amino polymerization inhibition modified heat conduction particles are provided, after being added into the epoxy resin-based liquid photosensitive resin for CLIP printing, the amino polymerization inhibition modified heat conduction particles can settle in the epoxy resin-based liquid photosensitive resin, and finally a layer of blind area is formed at the bottom of the epoxy resin-based liquid photosensitive resin. the amino polymerization inhibition modified heat conduction particles in the blind area can neutralize protonic acid generated in the photopolymerization reaction of the epoxy resin-based liquid photosensitive resin, so that CLIP printing can be realized.

Owner:本时智能技术发展上海有限公司

Pretreatment method of zircon powder and preparation method of vanadium zirconium blue material

ActiveCN105733310BHigh reactivityFully debondedZirconium compoundsPigment flushingPretreatment methodPre treatment

The invention relates to a pretreatment method for zircon powder. The method comprises the following steps that the zircon powder is subjected to heat treatment and pressurization treatment, the heattreatment temperature is 350-400 DEG C, the pressurization treatment pressure is 0.4-0.6 MPa, then the zirconium powder subjected to heat treatment and pressurization treatment is subjected to acid pickling to be neutral, and the zircon powder subjected to acid pickling is dried and then ground so as to obtain the pretreated zircon powder. The invention further relates to a preparation method fora vanadium-zirconium pigment. According to the pretreatment method for the zircon powder, reaction impurities can be remarkably reduced, and in addition, the reaction activity of the zircon powder canbe remarkably improved. The preparation method for the vanadium-zirconium pigment has the advantages of being capable of improving the yield and simple and easy to control.

Owner:SANXIANG ADVANCED MATERIALS

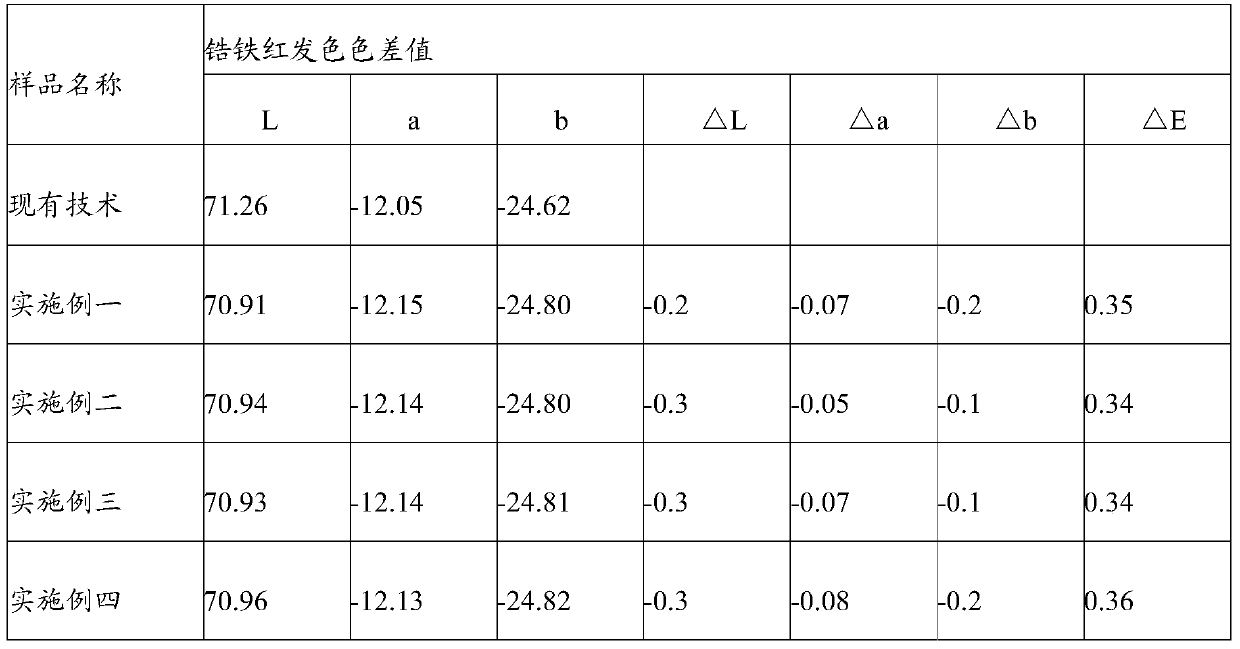

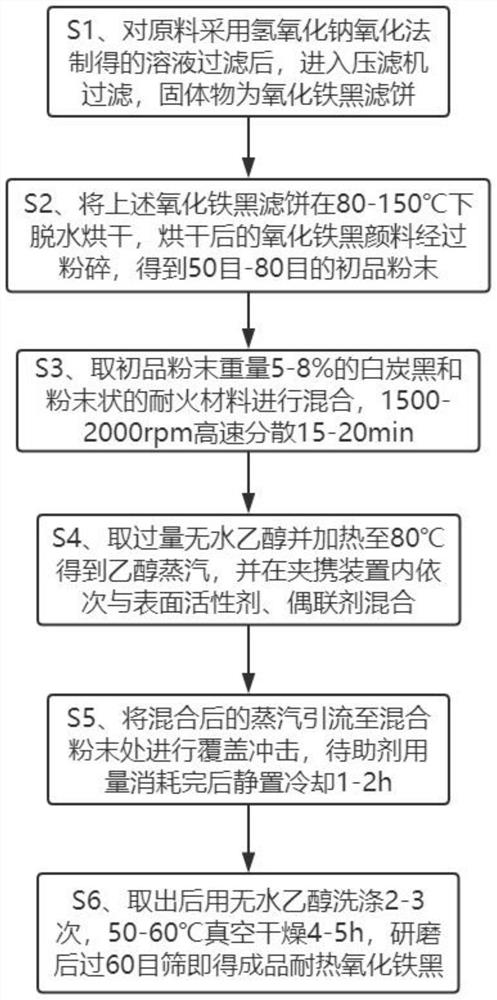

A kind of production technology of heat-resistant iron oxide black

ActiveCN112111179BImprove temperature resistanceGood alkali resistanceFerroso-ferric oxidesPigment flushingIron oxide blackActive agent

The invention discloses a production process of heat-resistant iron oxide black, which belongs to the field of chemical pigments. It is a production process of heat-resistant iron oxide black. The invention can realize dehydration and drying after the iron oxide black filter cake is obtained by adopting the sodium hydroxide oxidation method dry, and preliminarily powdered and mixed with white carbon black and powdered refractory materials, and then after high-speed uniform dispersion, innovatively introduce an entrainment device, using anhydrous ethanol vapor to entrain surfactants and coupling agents , based on the fluidity and contact properties of the gas, the powdery refractory material is uniformly and comprehensively covered on the surface of the iron oxide black, and the coating dead angle is not easy to appear, forming a dense high temperature resistant film, which significantly improves the resistance of the iron oxide black High temperature performance, acid resistance, alkali resistance, light absorption, tinting strength, compatibility and dispersibility have all been greatly improved.

Owner:YIXING YUXING IND & TRADE

Washing technology of titanium dioxide after inorganic surface treatment

InactiveCN111057400AImprove washing efficiencyGood washing repeatabilityTitanium dioxidePigment flushingBüchner funnelPhysical chemistry

The invention discloses a washing technology of titanium dioxide after an inorganic surface treatment, and belongs to the technical field of titanium dioxide treatment. The invention provides a washing technology of titanium dioxide after inorganic surface treatment. The washing technology comprises the following steps: curing titanium dioxide slurry after an inorganic surface treatment, transferring the cured titanium dioxide slurry into a Buchner funnel, adding washing water into the funnel at a constant speed, keeping the liquid level of the washing water in the funnel at 1 / 3-2 / 3 of the height of the funnel, stirring while adding; stopping stirring and adding water when the use amount of the washing water reaches half of the total use amount, continuously adding the washing water to 1 / 3-2 / 3 of the height of the funnel after the filter cake is formed; and when the washing water is completely added and a certain number of cracks appears on the surface of the filter cake, stopping washing. By controlling the temperature and dosage of the washing water and the stirring condition of adding the washing water, the washing technology after an inorganic surface treatment of titanium dioxide in a laboratory is more effective, a better washing effect is achieved, and the washing efficiency is improved.

Owner:CHONGQING TITANIUM IND OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com