Preparation method of porous light silicon dioxide filler

A lightweight silica, pulping technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of high cost, low strength, difficult recycling of waste, etc. The effect of low surface area and low oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

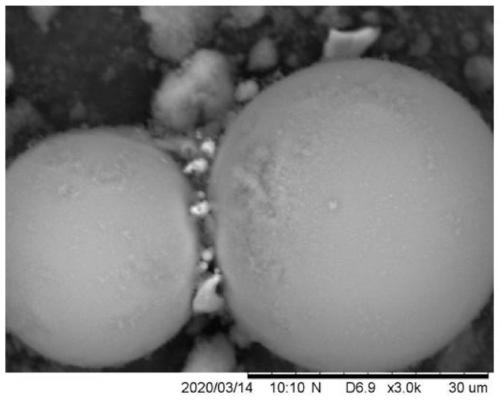

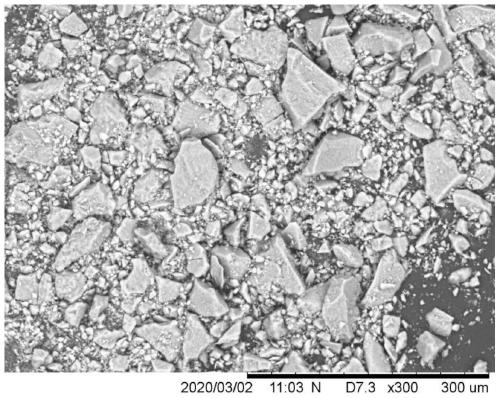

Embodiment 1

[0032] The precipitated silica was made into a slurry with a mass concentration of 10%, and silica sol accounting for 6% of the mass of the silica was added under stirring, and the ion was cleaned until the conductivity was 45 μS / cm. After ion cleaning, put it into the freezer, control the temperature at -14°C, freeze for 12 hours, freeze it completely, raise the temperature until the slurry is completely melted, remove the supernatant, put it into the freezer again, adjust the freezing according to the above, and then thaw, remove The supernatant was repeated three times, concentrated and filtered with suction. After suction filtration, the cake was dried at 150°C for 24 hours, and the dried material was placed in a muffle furnace for calcination at 1000°C for 10 hours with a heating rate of 5°C / min. The calcined product is crushed, ground, jet milled, classified, and processed into a powder with a median particle size of 15um. The powder is passed into the flash furnace wit...

Embodiment 2

[0034] The precipitated silica was made into a slurry with a mass concentration of 10%, and the silica sol accounting for 10% of the mass fraction of the silica was added under stirring, and the ion was cleaned until the conductivity was 40 μS / cm. After ion cleaning, put it into the freezer. The temperature is controlled at -14°C, and the freezing time is 15 hours. It is completely frozen. The supernatant was repeated three times, concentrated and filtered with suction. After suction filtration, the cake was dried at 150°C for 30 hours. Place the dried material in a muffle furnace for calcination at 1000°C for 10h with a heating rate of 5°C / min. The calcined product is crushed, ground, jet milled, classified, and processed into a powder with a median particle size of 15um. The powder is passed into the flash furnace with oxygen carrier gas, the temperature of the flash furnace is 1700°C, and it is flashed for 25 minutes by air circulation in the high temperature area, flotat...

Embodiment 3

[0036] Fumed silica was made into a slurry with a mass concentration of 5%, and silica sol accounting for 8% mass fraction of silica was added under stirring, and ion cleaning was performed until the conductivity was 43 μS / cm. After ion cleaning, put it into the freezer, control the temperature at -14°C, freeze for 12 hours, freeze it completely, raise the temperature until the slurry is completely melted, remove the supernatant, put it into the freezer again, adjust the freezing according to the above, and then thaw, remove The supernatant was repeated 8 times, concentrated and filtered with suction. After suction filtration, dry the cake at 150°C for 20 hours. The dried material was calcined at 900°C for 15 hours in a muffle furnace, with a heating rate of 2°C / min. The calcined product is crushed, ground, jet-milled, classified, and processed into a powder with a median particle size of 20um. The powder is passed into the flash furnace with oxygen carrier gas, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com