Patents

Literature

516results about How to "Low oil absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

InactiveCN102491397AProcessability can be optimizedEasy to processCalcium/strontium/barium carbonatesNanotechnologyDispersitySlurry

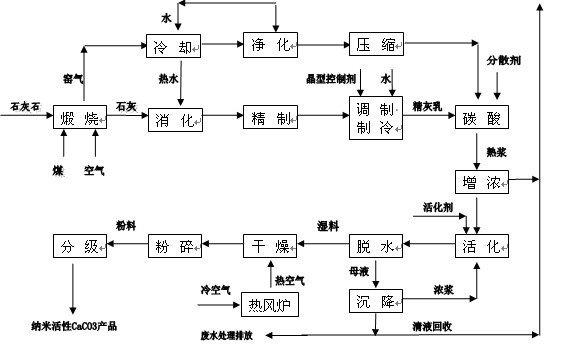

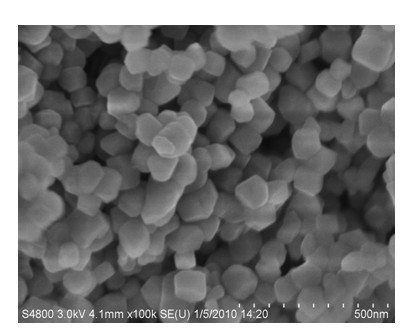

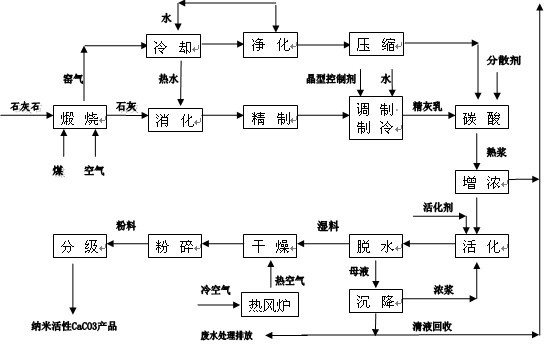

The invention discloses a preparation method of nano-calcium carbonate SCC-2 special for a silicone sealant, belonging to the technical field of inorganic chemical industry. According to an adopted technical scheme, the method comprises the following steps of: calcining limestone, crushing to obtain CaO; digesting, refining and aging the CaO in a hot state in the ratio of 1:4.8 of CaO to H2O; adding 1 percent of white granulated sugar crystal form control agent for undergoing a carbonation reaction to obtain CaCO3 slurry; performing activation surface treatment; and dehydrating, drying, crushing and degrading to obtain a nano-active CaCO3 product of 60-100 nanometers. The crystal form, size, regularity, oil absorption value and pH value of CaCO3 are controlled, so that 'hard aggregation' among particles is avoided from a surface modification production process, and the product has low oil absorption value and high bulk specific weight and has high dispersity in polymers.

Owner:广东嘉维化工实业有限公司

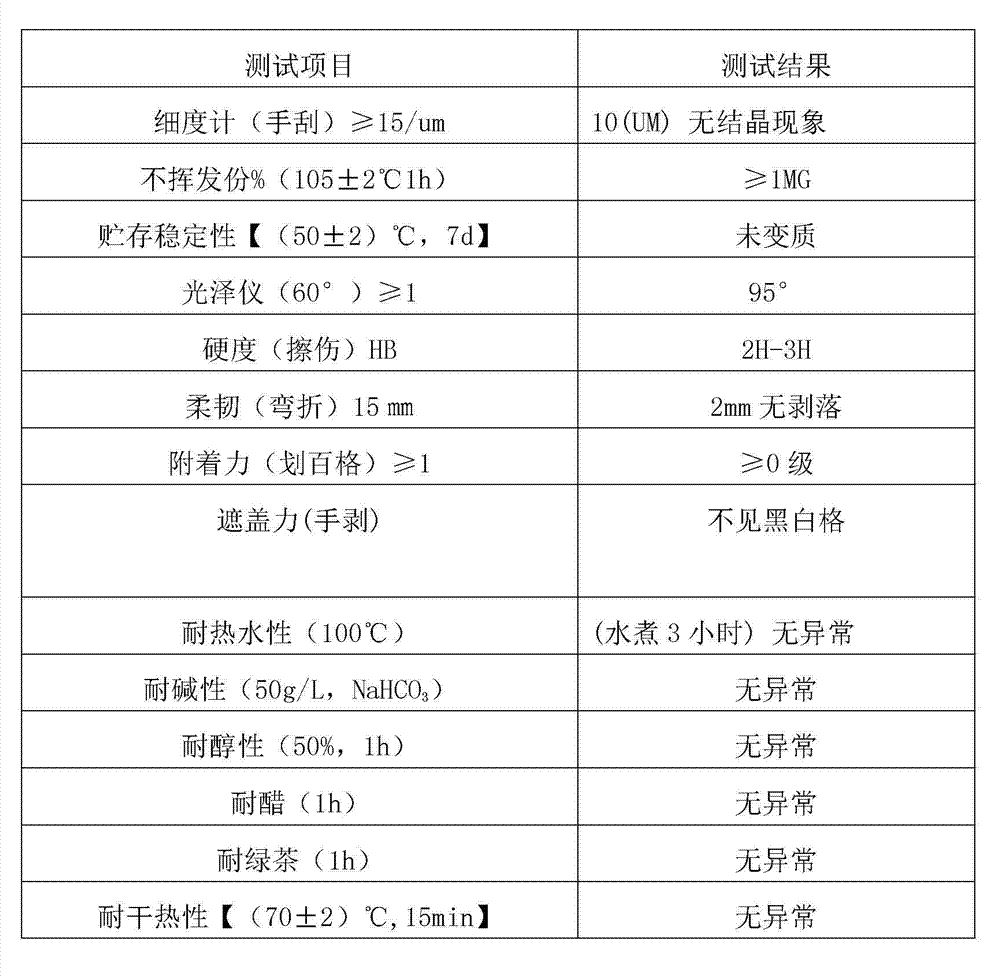

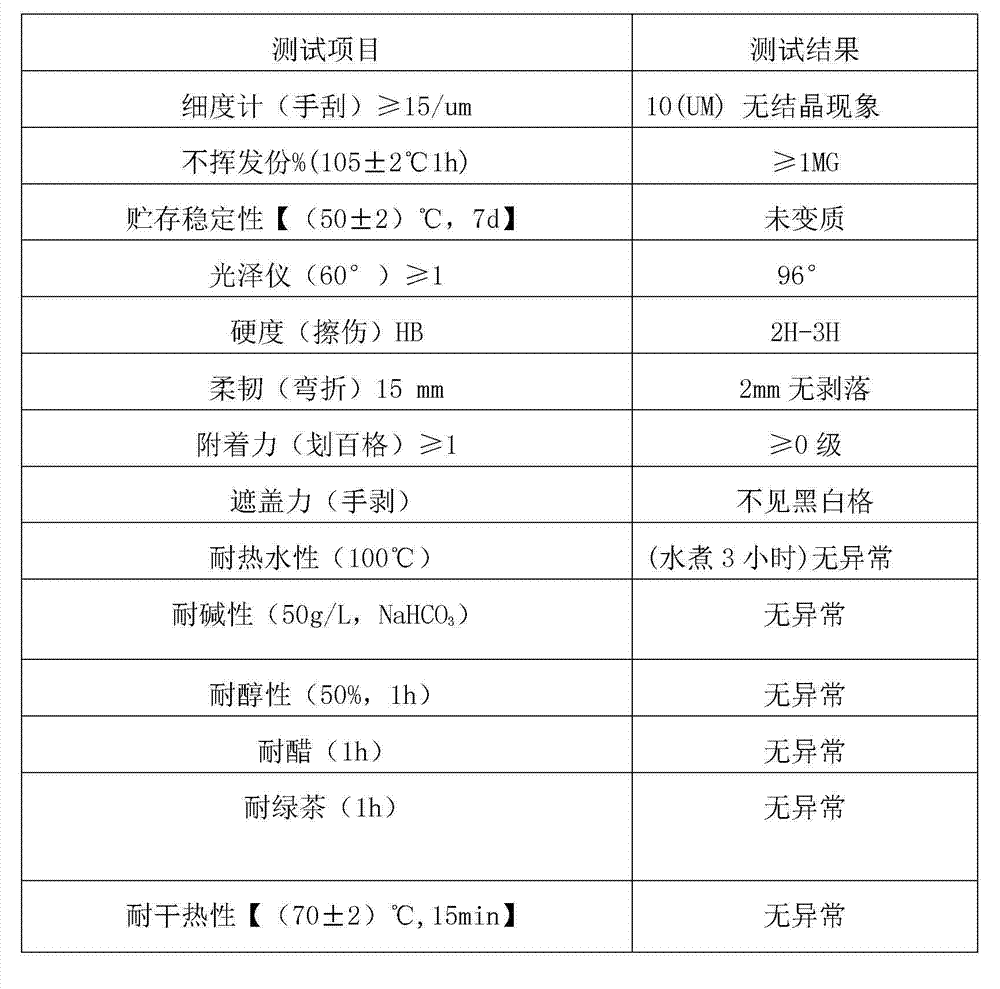

White finish coat photocurable UV (ultraviolet) paint and preparation method thereof

ActiveCN103031034AHigh glossNot easy to yellowPolyurea/polyurethane coatingsEpoxy resin coatingsChemical industryReactive diluent

The invention belongs to the field of chemical industry, and particularly discloses white finish coat photocurable UV (ultraviolet) paint and a preparation method thereof. The photocurable UV paint comprises the following components in percentage by weight: 20-60% of epoxy acrylate, 20-60% of polyurethane acrylate, 2-5% of phenyl acetone photoinitiator, 0.2-1% of diphenyl phosphine oxide photoinitiator, 0.2-1% of dispersant, 0.2-1% of leveling agent, 1-40% of titanium white TiO2, 5-15% of two-functional-group reactive diluent and 5-30% of three-functional-group reactive diluent. The paint has the characteristics of favorable gloss, adhesive force and leveling property, thus ensuring that the white UV paint can be better applied.

Owner:AODA KOALA PAINT HUIZHOU

Method for preparing special nano calcium carbonate for plastic master batch

ActiveCN103897434AThe melt index will not changeImprove performanceCalcium/strontium/barium carbonatesPigment treatment with macromolecular organic compoundsDispersityPolyolefin

The invention provides a method for preparing special nano calcium carbonate for a plastic master batch. According to the method, on the basis of calcium carbonate and characteristics thereof in application in plastics, internal indicators, such as crystal form, particle size, whiteness, pH value and the like, of nano-CaCO3 are controlled, meanwhile, the agglomeration and second-time surface coating of nano-CaCO3 particles caused by dry-activation modification are avoided by adopting wet activation, the dispersity of nano-CaCO3 is improved by one-time conventional coating, the oil absorption value of nano-CaCO3 is lowered by the one-time conventional coating, the compatibility of nano-CaCO3 with polyolefin plastics is improved by second-time coupling coating, and the processability and compatibility of nano-CaCO3 in the master batch are effectively improved, so that the prepared nano master batch has reinforced, toughened, high-dispersion and high-extrusion characteristics.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

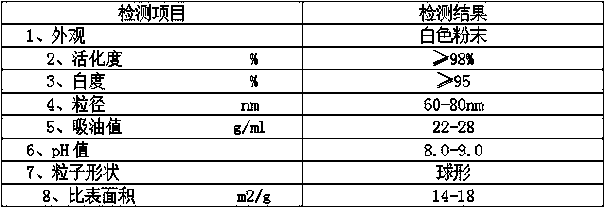

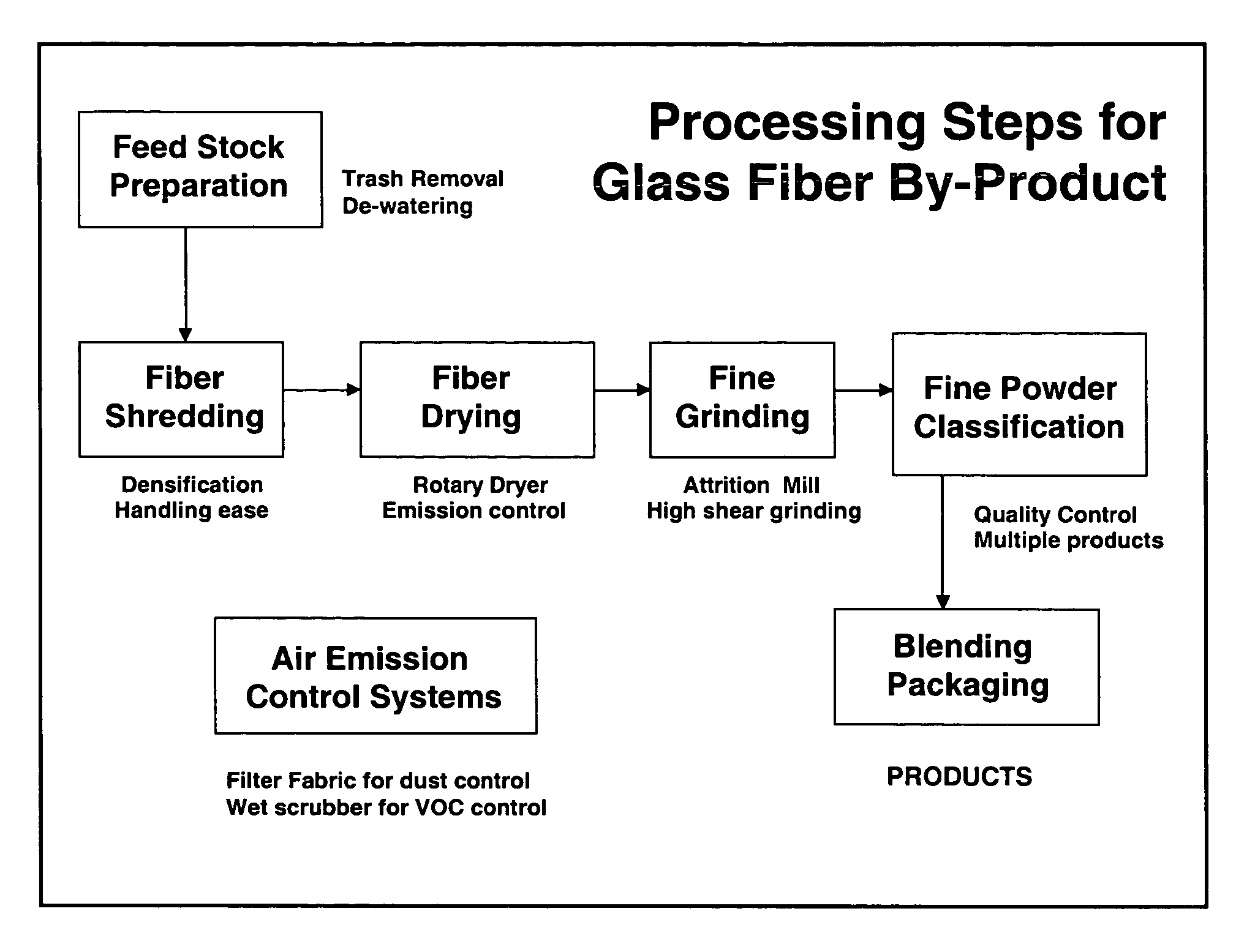

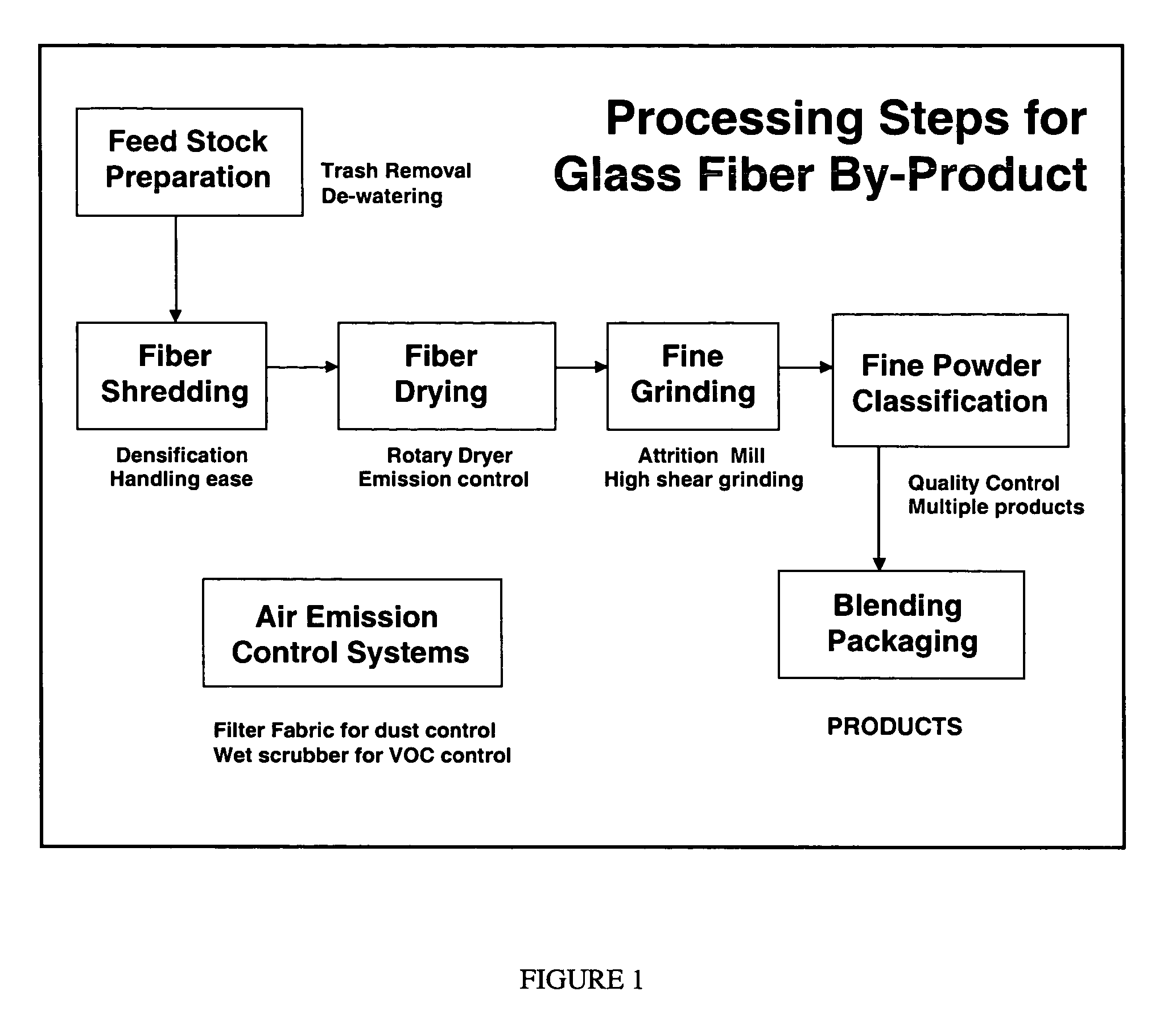

Low alkali, non-crystaline, vitreous silica fillers

A substantially white powder for use as a filler and / or extender derived from by-products of manufacturing vitreous low alkali, low iron glass fibers, and a method for producing the powder. The filler has very low alkalinity and by virtue of its being essentially free of crystalline silica is non-hazardous to health and therefore safe for consumer-based and industrial-based uses.

Owner:ALBACEM

Odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and preparation method thereof

The invention belongs to the field of coatings and particularly relates to an odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and a preparation method thereof. The odorless and wear-resisting smooth UV matt finish paint coating comprises components in percentage by weight as follows: 25%-50% of hexa-functional polyurethane acrylate prepolymers, 15%-50% of trifunctional modified polyurethane acrylate prepolymers, 15%-50% of acrylate monomers, 1%-10% of a photoinitiator, 0.2%-2% of a wetting dispersant, 0.2%-1% of a leveling agent, 0.2%-0.5% of a defoaming agent and 1%-15% of a matting agent. According to the odorless and wear-resisting smooth UV matt finish paint coating, the technical problems that a pungent smell is left, wetting of the matting agent is difficult, matting is difficult, a paint film is prone to floating and the like after curing of a conventional UV matt finish paint coating are solved, and meanwhile, the defect of crispness of the paint film caused by improvement of the wear resistance of the conventional UV matt finish paint coating is overcome.

Owner:AODA KOALA PAINT HUIZHOU

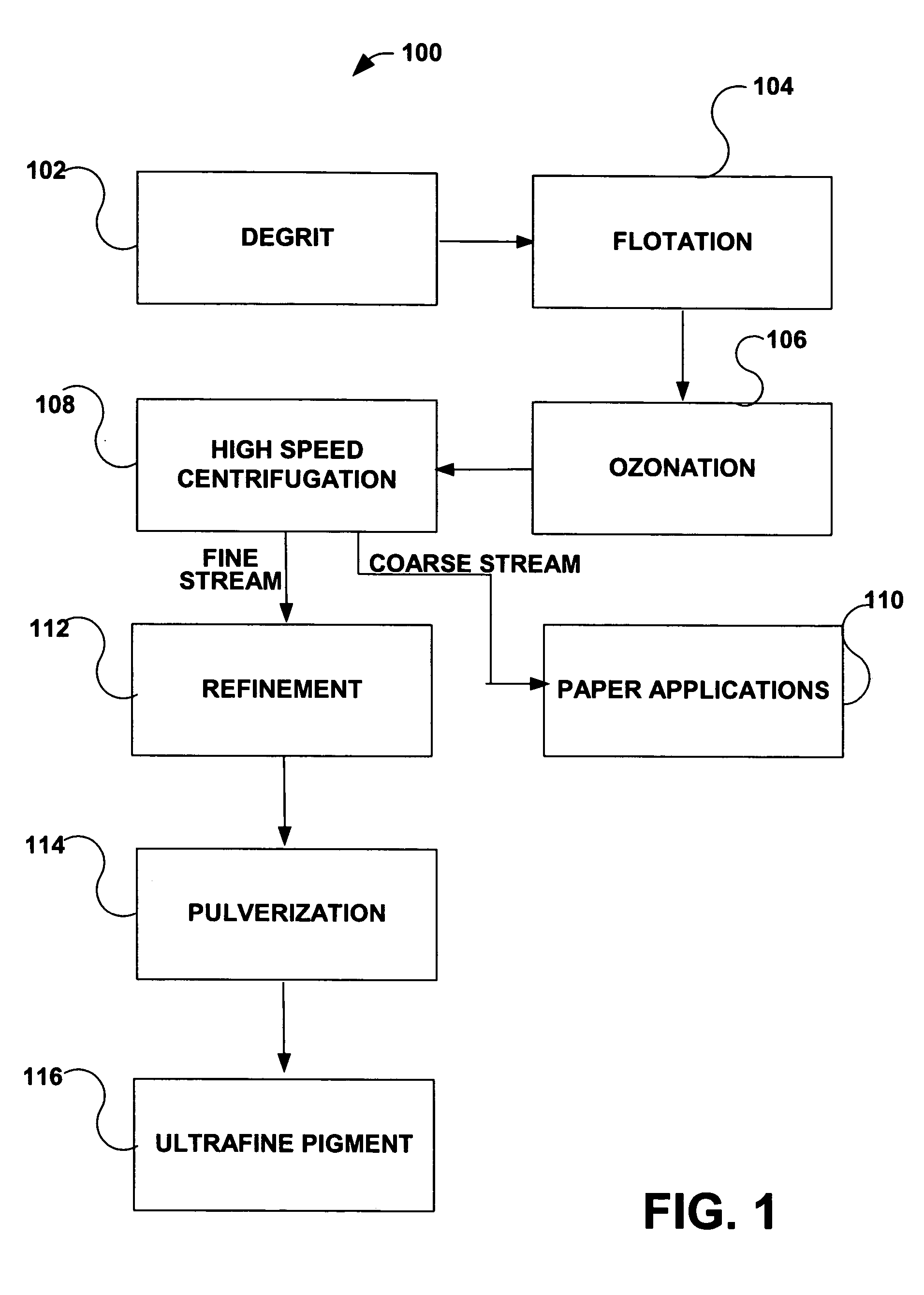

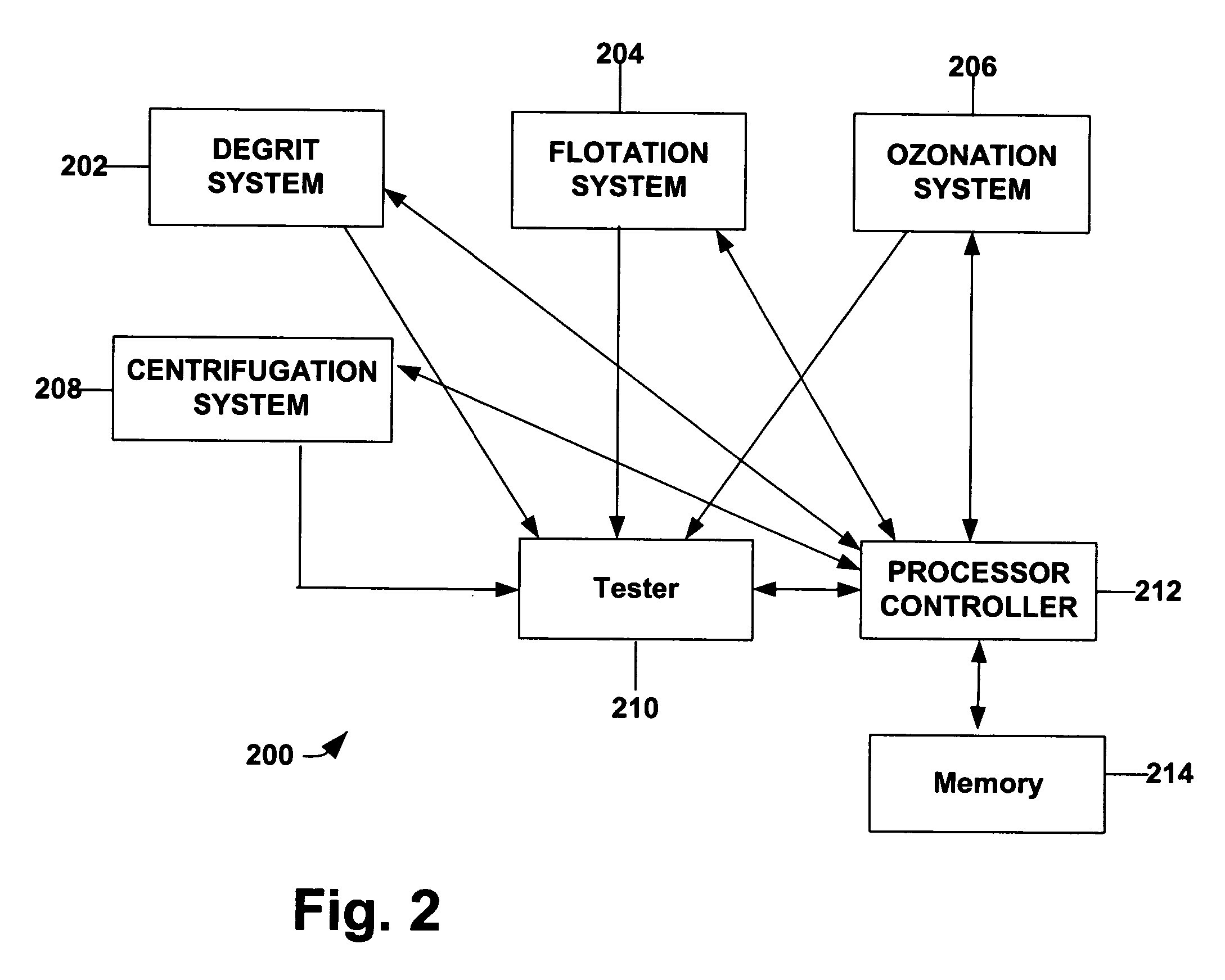

Ultrafine hydrous kaolin pigments, methods of making the pigments, and methods of using the pigments in gloss paint formulations

InactiveUS20060047047A1Large specific surface areaLow oil absorptionMaterial nanotechnologyInorganic pigment treatmentPigmentChemistry

Disclosed are methods of processing kaolin to produce ultrafine hydrous kaolin. The methods involve processing gray crude kaolin by subjecting the kaolin crude to flotation and then centrifuging the kaolin to provide a fine stream that is subject to refinement. Also disclosed are systems for the automated processing of gray crude kaolin to produce the ultrafine hydrous kaolin and paint compositions that contain the ultrafine hydrous kaolin.

Owner:BASF CORP

Low-viscosity active calcium carbonate, preparation method and application thereof

InactiveCN101585976ALow oil absorptionImprove dispersibility and compatibilityPigment treatment with non-polymer organic compoundsCalcium carbonateFatty alcohol

The invention discloses low-viscosity active calcium carbonate, a preparation method and application thereof. The preparation method comprises the following steps: (1) calcium carbonate is heated up to 100-120 DEG C in a high-speed stirrer or a mixer, and then a surface conditioning agent containing 0.1-0.5 percent of calcium carbonate according to the weight is added and mixed at a high speed for 3-5 minutes; (2) fatty alcohol polyoxyethylene ether containing 0.3-1.0 percent of calcium carbonate according to the weight is added at 130-140 DEG C, mixed at a high speed for 3-5 minutes and cooled; and (3) the mixture is sieved so as to obtain the low-viscosity active calcium carbonate. The active calcium carbonate prepared by the method can be applied to PVC resin leather. When the calcium carbonate is applied to PVC paste resin for reducing the viscosity of the PVC paste resin system, 20-25 percent of the dosage of dioctylphthalate (DOP) which is a plasticizing agent can be reduced or 15-20 percent of the filler content of the calcium carbonate can be improved, thereby reducing the production cost of the PVC resin leather.

Owner:FUJIAN SANNONG CALCIUM CARBONATE CO LTD

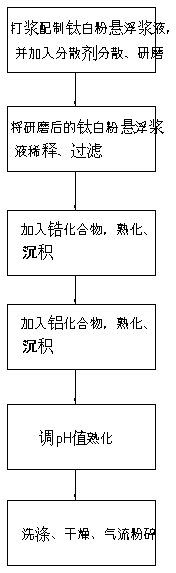

Preparation method of special titanium dioxide for oily system

InactiveCN103131212AImprove weather resistanceLow oil absorptionPigment treatment with organosilicon compoundsPigment physical treatmentHigh contrastWeather resistance

The invention discloses a preparation method of a special titanium dioxide for an oily system. The method comprises the following steps: 1, pulping to prepare a titanium dioxide suspension slurry, adding a dispersant, dispersing, and grinding; 2, diluting the ground titanium dioxide suspension slurry, and filtering; 3, adding a zirconium compound, curing, and depositing; 4, adding an aluminum compound, curing, and depositing; 5, adjusting the pH value, and curing; and 6, washing, drying, and carrying out airflow crushing. The method allows the surface of a titanium dioxide particle to be respectively coated with a zirconium oxide film and an alumina film inside out and a silane coupling agent hydrolysate to be adopted to carry out organic treatment, so the special titanium dioxide has the advantages of substantially-increased weather resistance, lipophilicity and luster, low oil absorption, good dispersity, realization of the hiding capability same to import titanium dioxide, high contrast rate, good temperature resistance, and no ink layer yellowing.

Owner:江苏镇钛化工有限公司

Surface treatment method for nanometer calcium carbonate applied to fill silicone sealant

ActiveCN105400237AGood dispersionImprove hydrophobicityNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsActive agentAlkylphenol

A disclosed surface treatment method for nanometer calcium carbonate applied to fill a silicone sealant comprises the following steps: adding a nanometer calcium carbonate slurry into a reaction kettle, stirring and heating to 60-80 DEG C, so as to obtain a nanometer calcium carbonate suspending slurry; slowly adding a compound surfactant composed of saturated aliphatic acid and coconut oil into the nanometer calcium carbonate suspending slurry for first surface treatment; then slowly adding an alkylphenol polyoxyethylene ether dimeric surfactant for secondary surface treatment, so as to obtain a nanometer calcium carbonate modification solution; and performing dewatering, drying, crushing and sieving on the nanometer calcium carbonate modification solution, so as to obtain the nanometer calcium carbonate for filling the silicone sealant. The nanometer calcium carbonate obtained according to the surface treatment method possesses good dispersibility, hydrophobicity and relatively low oil absorption value, and is capable of improving the storage stability, mechanical properties, ageing resistance, photothermy resistance, oxidation resistance and other performances of the silicone sealant when being applied to fill the silicone sealant.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

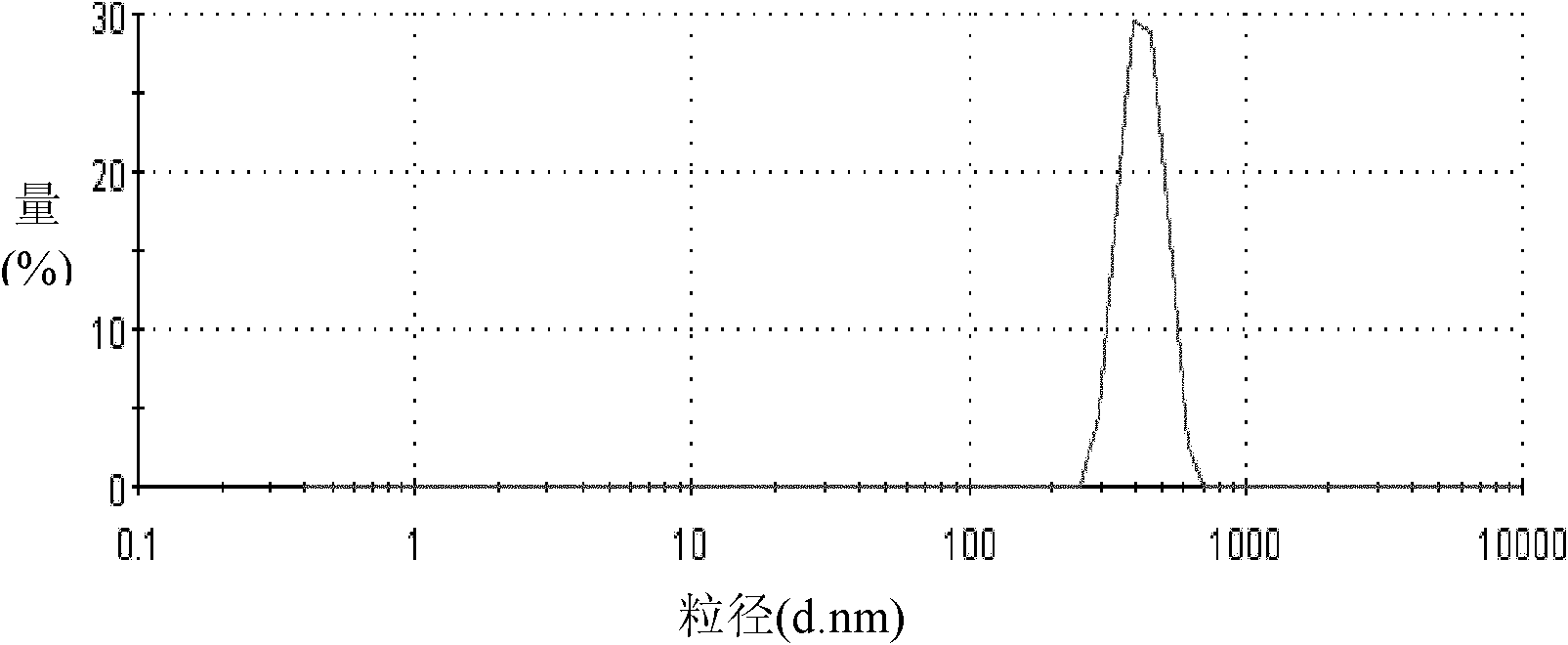

Preparation method for submicron active calcium carbonate special for PVC and with low oil absorption value

ActiveCN103754914ASmall particle sizeLow oil absorptionCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideSucrose

The invention discloses a preparation method for submicron active calcium carbonate special for PVC and with low oil absorption value. The preparation method comprises the main steps: preparing a solution of a refined calcium hydroxide slurry with a weight percentage of 5-7%, adding a crystal-form controlling agent cane sugar accounting for 0.4-0.8% by weight of calcium hydroxide, introducing kiln gas containing carbon dioxide with a concentration of 25% or more, controlling the temperature of the reaction slurry at 27-30 DEG C for carbonization, when the carbonization rate is 15-25%, stopping cooling water, continuing to introduce kiln gas for normal-temperature carbonization, wherein the carbonization terminal point is that the pH value of the slurry is less than 7; then heating the slurry to 80 DEG C, adding a saponification emulsion of stearic acid accounting for 2.5-4.5% by weight of calcium carbonate, and under the effect of high shearing force of an emulsification pump, synchronously finishing dispersing and surface cladding of the calcium carbonate slurry; and finally performing filtering, drying and depolymerizing on the slurry to obtain the PVC special-purpose low-oil-absorption-value submicron active calcium carbonate product with the particle size of 200-400 nm and the oil absorption value of 16-18.

Owner:WUHU ZHUOYUE NANO NEW MATERIALS

Special flour for twisted dough-strips and making method thereof

ActiveCN101711559ALow oil absorptionReduce manufacturing costFood preparationFlavorCarboxymethyl cellulose

The invention discloses special flour for twisted dough-strips and a making method thereof. The invention aims to realize the goal of making high-bulkiness twisted dough-strips without adding alum which is harmful to human health mainly by adding a purpose-made bulking agent into the raw material flour; the carboxymethyl cellulose, which can cooperate with the emulsifying agent in the bulking agent, is added to reduce the oil-taking rate of the twisted dough-strips; and thus, the invention not only reduces the cost for making twisted dough-strips, but also satisfies low-oil low-fat requirements for food from people, and has both nutrients and delicate flavor. When the special flour for twisted dough-strips is used for making twisted dough-strips, the twisted dough-strip flour is firstly mixed with clear water evenly, and the dough is leavened for 20-40 minutes and then can be fried in the pot. Thus, the invention saves the material proportioning procedure of adding alum to the flour, and has the advantages of simple operation, time saving and labor saving.

Owner:青岛品品好食品发展有限公司

Sun-Block Cosmetic

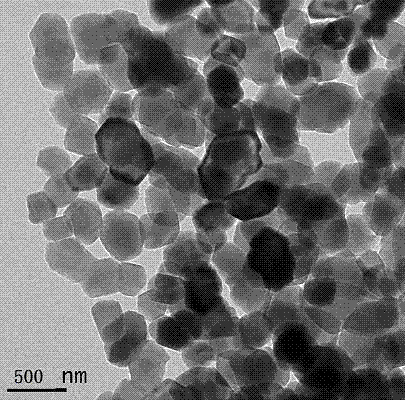

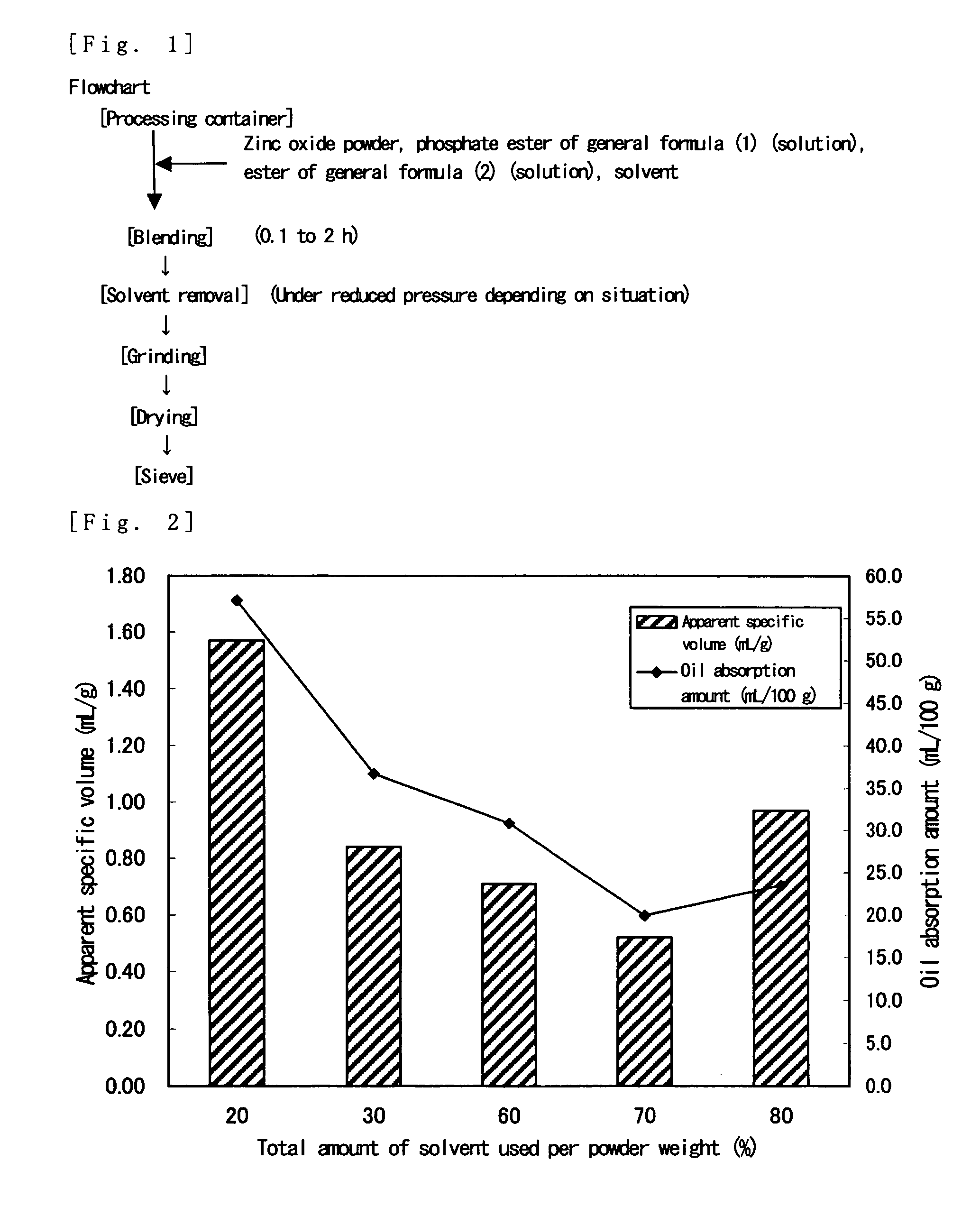

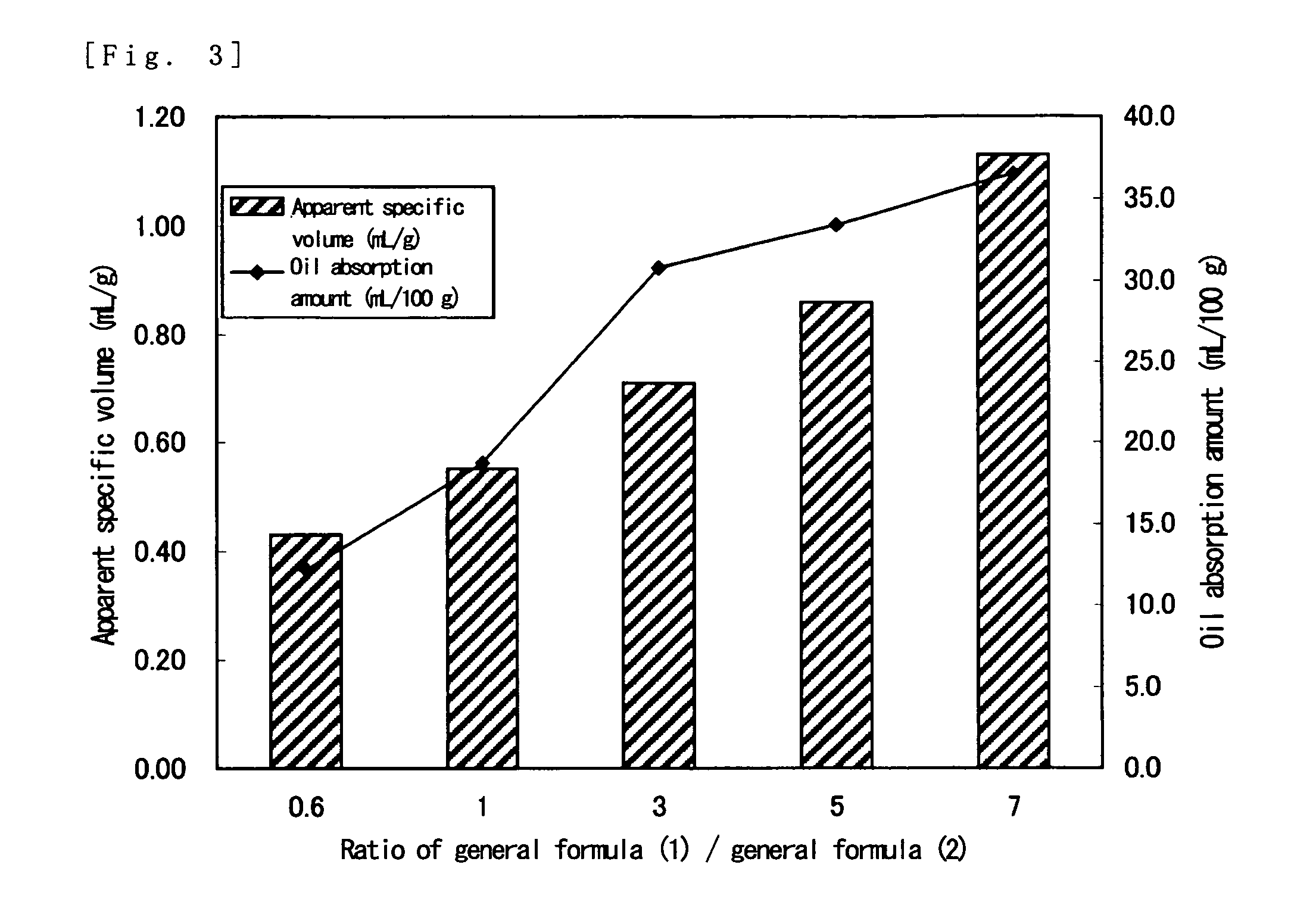

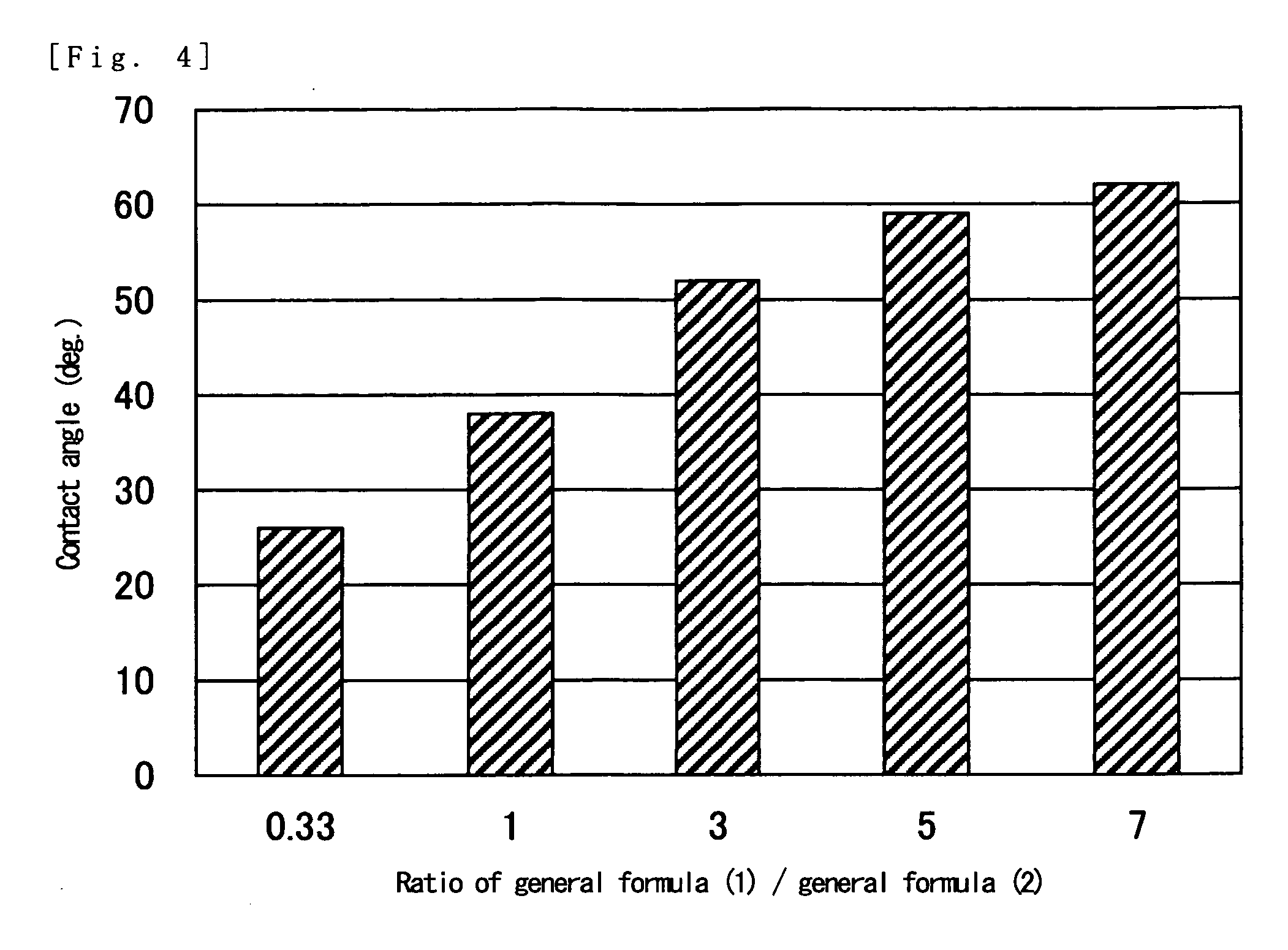

InactiveUS20070264292A1Reduce absorptionSuperb ease of washabilityCosmetic preparationsToilet preparationsSpecific volumeZinc

The invention is a sunscreen cosmetic containing (a) a specific hydrophobic zinc oxide powder, (b) decamethylcyclopentasiloxane, and (c) an alkyl trimethicone having 6 to 12 carbons. Hydrophobic powder that has the noticeable effects of low oil absorption and a low apparent specific volume is stably blended into a sunscreen cosmetic as a UV radiation dispersing agent to produce a sunscreen cosmetic that has remarkably improved ease of washability after use.

Owner:SHISEIDO CO LTD

Single-component addition type high-temperature-resistant high-thermal-conductivity silica gel and preparation method thereof

The invention provides single-component addition type high-temperature-resistant high-thermal-conductivity silica gel and a preparation method thereof. The single-component addition type high-temperature-resistant high-thermal-conductivity silica gel is prepared from the following raw materials in parts by weight: 80 to 100 parts of vinyl silicone oil, 0.1 to 5 parts of cross-linking agent hydrogen-containing silicone oil, 500 to 2000 parts of a thermal-conductive filler, 1 to 20 parts of a treating agent, 1 to 4 parts of a catalyst and 1 to 8 parts of a pigment, and the hydrogen-containing silicone oil comprises at least one of terminated hydrogen-containing polysiloxane and side hydrogen-containing polysiloxane; and the hydrogen content of the end hydrogen-containing polysiloxane is 0.16 to 3.00 mmol / g, and the hydrogen content of the side hydrogen-containing polysiloxane is 0.9 to 9 mmol / g. Compared with silicone grease and silicon gaskets which are frequently used in the market at present, the single-component addition type high-temperature-resistant high-thermal-conductivity silica gel provided by the invention has the advantages of higher heat conductivity coefficient, higher bearing temperature, almost unchanged thermal resistance after long-time aging and the like, and further ensures that a heat-conducting interface material always keeps high heat-conducting efficiency in a long-term use process.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Antiseptic and antistatic terrace paint and its prepn process

InactiveCN1974701ASmall volume shrinkageGood chemical resistanceAntifouling/underwater paintsPaints with biocidesDefoaming AgentsChemistry

The present invention provides one kind of antiseptic and antistatic terrace paint and its preparation process. The paint includes two components, component A and component B. The component A includes water-thinned epoxy curing agent, water, defoaming agent, wetting agent, leveling agent, anticracking agent, stuffing, pigment and color paste; and the component B includes water-thinned epoxy resin emulsion, antiseptic and antistatic agent and water. The preparation process includes preparing the component A through high speed dispersing, grinding, filtering and other steps; and preparing the component B through low speed dispersing, filtering and other steps. The antiseptic and antistatic terrace paint has excellent and lasting antiseptic and antistatic performance, ideal environment friendly performance, fireproof performance, waterproof performance, high chemical corrosion resistance and other advantages.

Owner:YANCHENG INST OF IND TECH +1

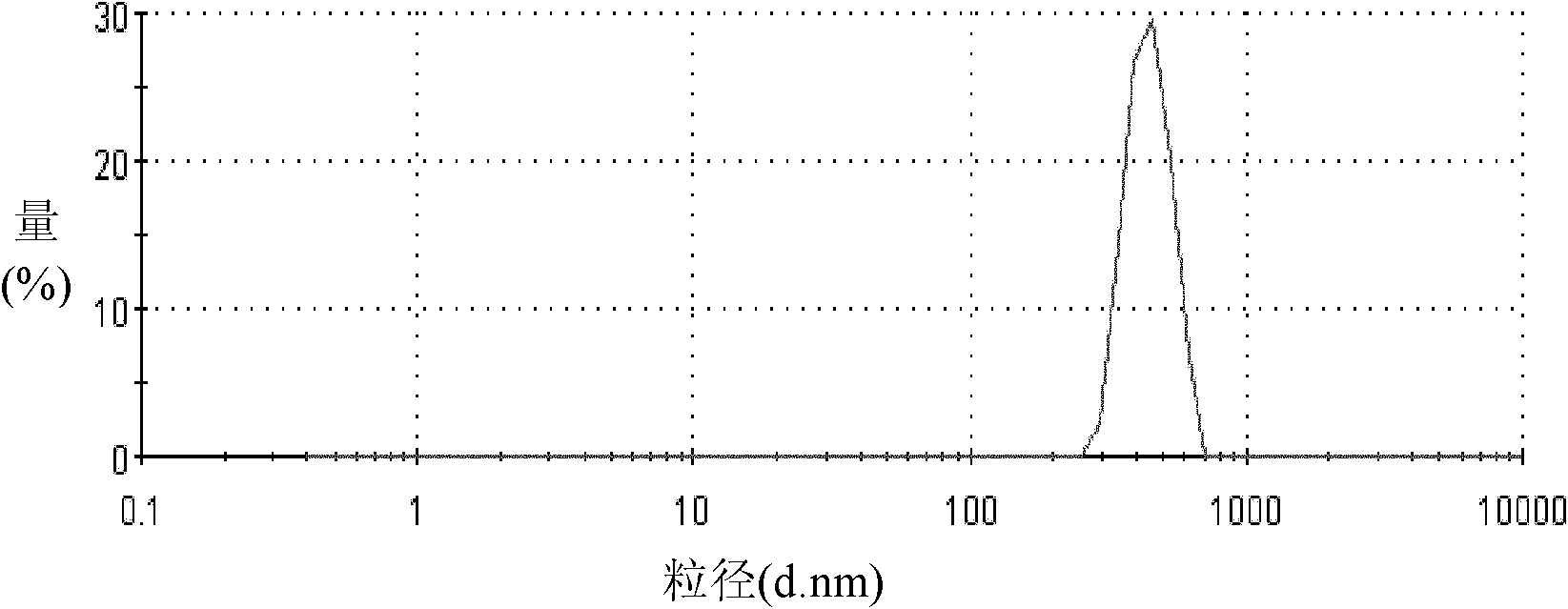

Method for preparing silver powder for touch screen silver paste

The invention relates to a method for preparing silver powder for a touch screen silver paste and belongs to the technical field of preparation of conductive metal powder. The method comprises the following steps: using silver nitrate as a raw material and controlling the speed of liquid phase reduction reaction by regulating the process conditions of reaction temperature, charging manner and charging speed so as to prepare approximately spherical or spherical particle reduced silver powder with a particle size of 300 nm to 800 nm; sufficiently stirring and modifying the silver powder in absolute ethyl alcohol solution containing two modifiers of oleic acid, stearic acid, hexadecanol, a polyacrylate dispersing agent and a graft copolymer dispersing agent, carrying out batching on the obtained modified silver powder and phi3 stainless steel beads according to a mass ratio of 1:10 after drying at a temperature of 60 DEG C, and grinding for 10 to 24 hours; and after finishing grinding, carrying out bead and material separation, sieving the obtained silver powder by 300 meshes to obtain the high dispersion approximately spherical or spherical silver powder with D50 of 1.5 to 2.5mum and tap density of 4.0 to 6.0 g / cm<3>. The silver powder prepared by the method disclosed by the invention has high crystallinity, is suitable for an addition volume of silver of 70 to 85 percent and can be used for printing capacitive screen silver paste of a thin wire with a specification below 80 mum.

Owner:云南铜业科技发展股份有限公司

Meta titanate treatment method

The invention relates to a meta titanate treatment method, comprising the following steps of: pulping metatitanic acid; adding an alkaline compound into the metatitanic acid pulp until the pH value is above 3; filtering and washing; adding dissoluble aluminum salt, dissoluble phosphate, dissoluble potassium-containing compounds and zinc-containing compounds into a filter cake and mixing uniformly; and calcining and crushing to obtain titanium dioxide. Compared with the prior art, the meta titanate treatment method provided by the invention has the advantages that the energy consumption is reduced; the production efficiency is improved; and the mellowness of the titanium dioxide is improved.

Owner:LOMON BILLIONS GRP CO LTD

Method for modifying surface of nano calcium carbonate

ActiveCN108047766AGood dispersionEasy to processPigment treatment with non-polymer organic compoundsDispersityBiological activation

The invention discloses a method for modifying the surface of nano calcium carbonate. The method comprises the steps that 1, lime milk is added to a bubbling carbonatation reaction kettle, mixed gas containing carbon dioxide is introduced to the reaction kettle for a carbonatation reaction, carbonatation is conducted till the pH is equal to 7.0, carbonatation is completed, and a nano calcium carbonate suspension solution is obtained; 2, a stabilizer is added to the nano calcium carbonate suspension solution, the temperature is controlled within 50-60 DEG C, and heat preservation is conducted for 20-30 min; 3, a fatty acid modifier is heated and melted in water, an emulsifier is added to the fatty acid modifier, stirring is conducted for 10-30 min, and a modifier emulsion is obtained; 4, the nano calcium carbonate suspension solution obtained in the second step is added to the modifier emulsion, stirring is conducted for 30-60 min, and then through filter-pressing dehydration, drying and smashing, a nano calcium carbonate product is obtained. The prepared nano calcium carbonate has the advantages of good dispersity and processability, low oil absorption value, high thixotropy and activation rate, good stability, pH value close to neutral and the like. The method is low in production cost and simple in technology, facilitates industrial production and has good economic, social and ecological benefits.

Owner:ANHUI PROVINCE XUNCHENG CITY HUANA NEW MATERIAL TECH CO LTD

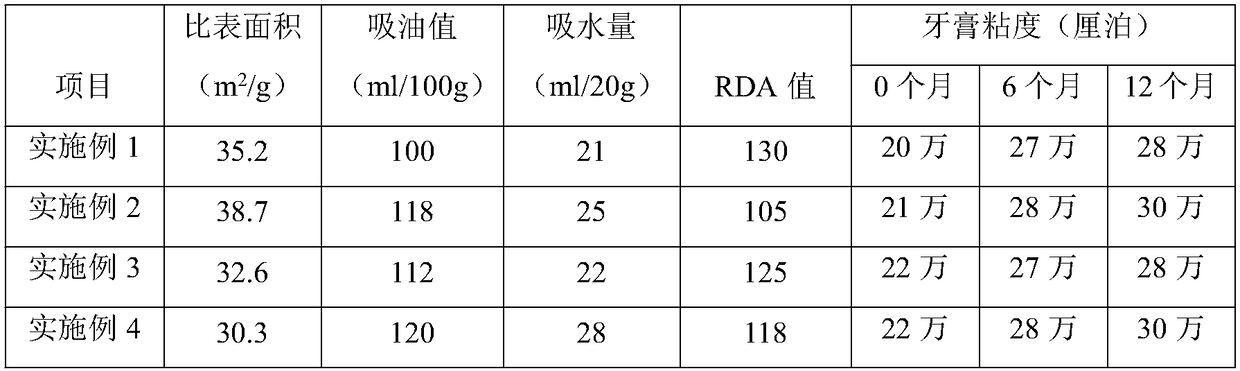

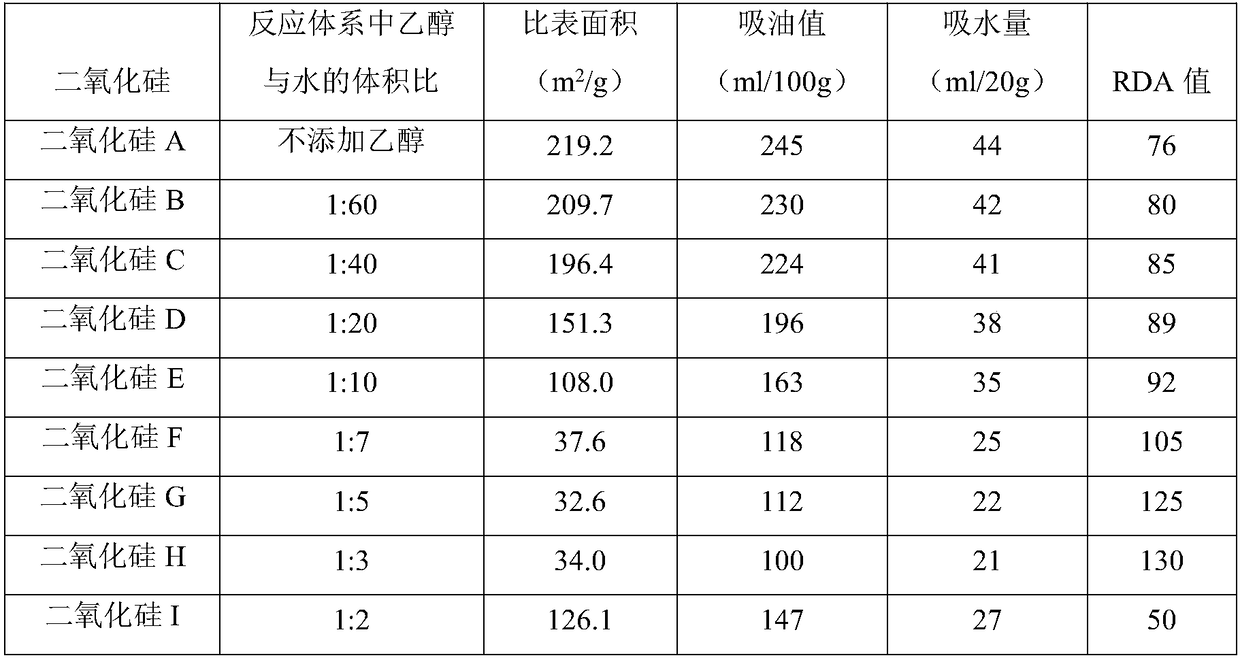

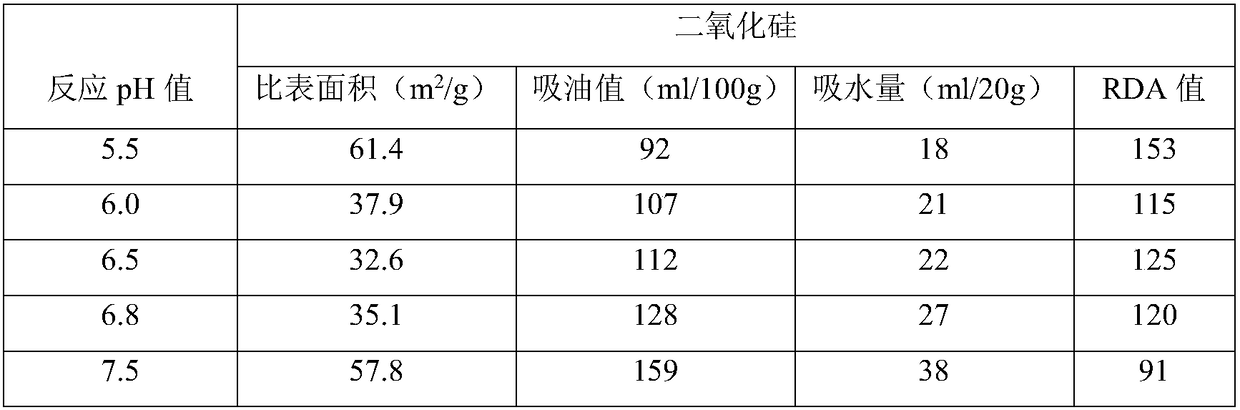

Preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide

InactiveCN108190900ASmall specific surface areaSimple methodSilicon compoundsChemistryAqueous solution

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide.The preparation method comprises the steps that S1, 8-12 m<3> of ethanol aqueous solution is injected and heated to 60-70 DEG C, and stirring starts; S2, water glass and sulfuric acid are added dropwise to carry out a parallel flow reaction, the pH value in the reaction process is controlled to be 6.0-6.8, meanwhile, absolute ethyl alcohol is added every 5-10 minutes in the reaction process to keep the volume ratio of ethyl alcohol to water in a reaction system to be 1:(3-7), after the water glass is dropwise added, dropwise addition of sulfuric acid is stopped, and stirring continues; S3, stirring and heating are stopped, aging is conducted for one hour, and pressure filtration, washing, drying and crushing are conducted on the on formed silicon dioxide to prepare silicon dioxide. The silicon dioxide has the advantages of a low in specific surface area, a high oil absorption value, a high water absorption amount, the friction property and the like; toothpaste has good friction and cleaning performance after the silicon dioxide is used, and meanwhile, the problem of expansion of the viscosity of the toothpaste is well solved.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Low-viscosity ferric oxide yellow pigment

InactiveCN104559331ASimple production processSimple processPigment pastesPigment physical treatmentFerric oxide yellowPhysical chemistry

The invention discloses a preparation method of a low-viscosity ferric oxide yellow pigment. The preparation method of the low-viscosity ferric oxide yellow pigment comprises the following steps: (1) preparing the raw material which is common synthetic ferric oxide yellow powder; (2) ball milling, namely preparing a ball milling device and fully milling the ferric oxide yellow powder by moving a steel ball in a manner of circulating from top to two sides and bottom according the moving trajectory of the inner powder under continuous powerful vibration; (3) ultrafine grinding, namely ultrafine grinding the ball-milled ferric oxide yellow powder by using a grinding machine so as to completely break the unbroken cracks in the presence of high-speed shear force; and (4) preparing a finished product, namely detecting the color and the viscosity of the processed ferric oxide yellow powder to prepare the finished product.

Owner:ZHEJIANG UNITED PIGMENT

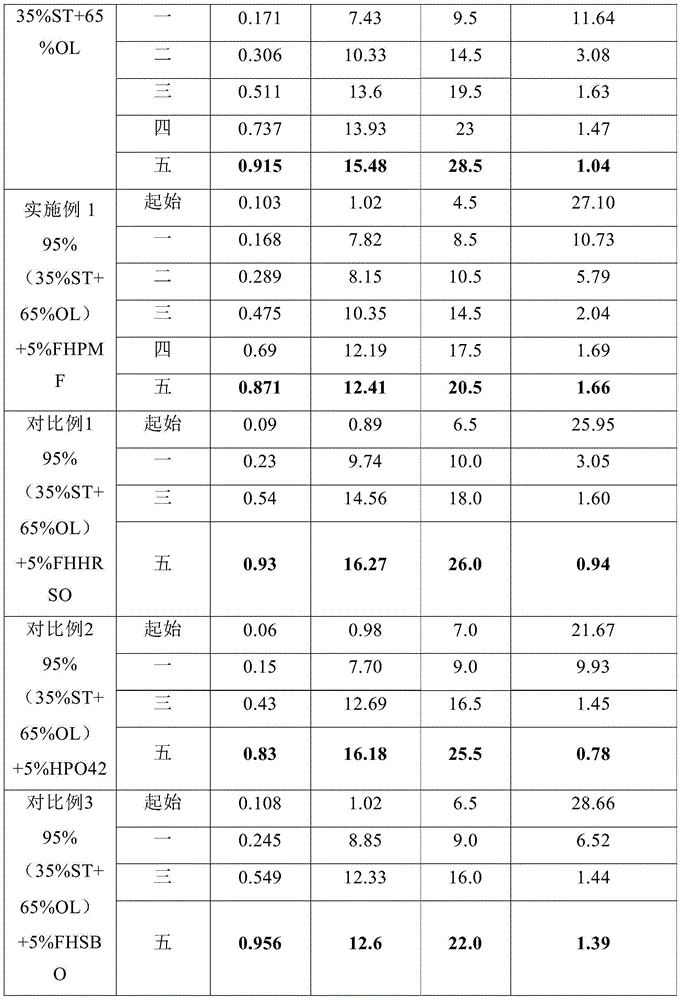

Grease composition for frying

The invention provides a grease composition for frying; the grease composition contains a fully hydrogenated palm oil intermediate fraction. The invention also relates to a preparation method of the grease composition for frying and a method of improving the frying performance of frying oil; the methods include the step of mixing the fully hydrogenated palm oil intermediate fraction and the frying oil. The invention also includes a use of the fully hydrogenated palm oil intermediate fraction in preparation of the grease composition for frying or improvement of the frying performance of the frying oil. The grease composition for frying does not have a health problem of trans-fatty acids, the frying stability is markedly improved, the oil absorption rate of fried products is significantly reduced, and color, luster, brittleness, flavor and greasy feeling are all improved.

Owner:嘉里特种油脂(上海)有限公司

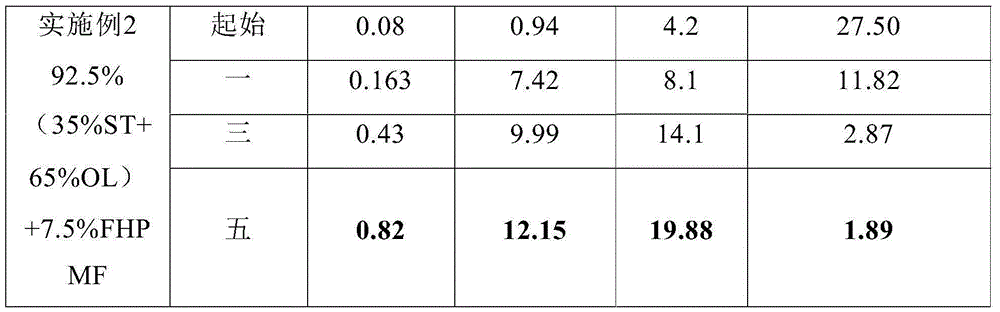

Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

The invention discloses an oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve and a preparation method thereof. The label sleeve consists of the following components in parts by weight: 60 to 80 parts of matrix resin, 15 to 25 parts of linear low-density polyethylene, 5 to 15 parts of polymer compatilizer, 32 to 70 parts of phosphorous nitrogen series expansible halogen-free flame retardant, 0 to 30 parts of inorganic flame retardant, 3 to 5 parts of titanium white powder, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant and 1 to 2 parts of sensitizer. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding with a double-screw extruder, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould, radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance and good oil resistance, produces little smoke, permanently preserves the label, and keeps good mechanical property, electric insulating performance and heat resistance.

Owner:广州凯恒科塑有限公司

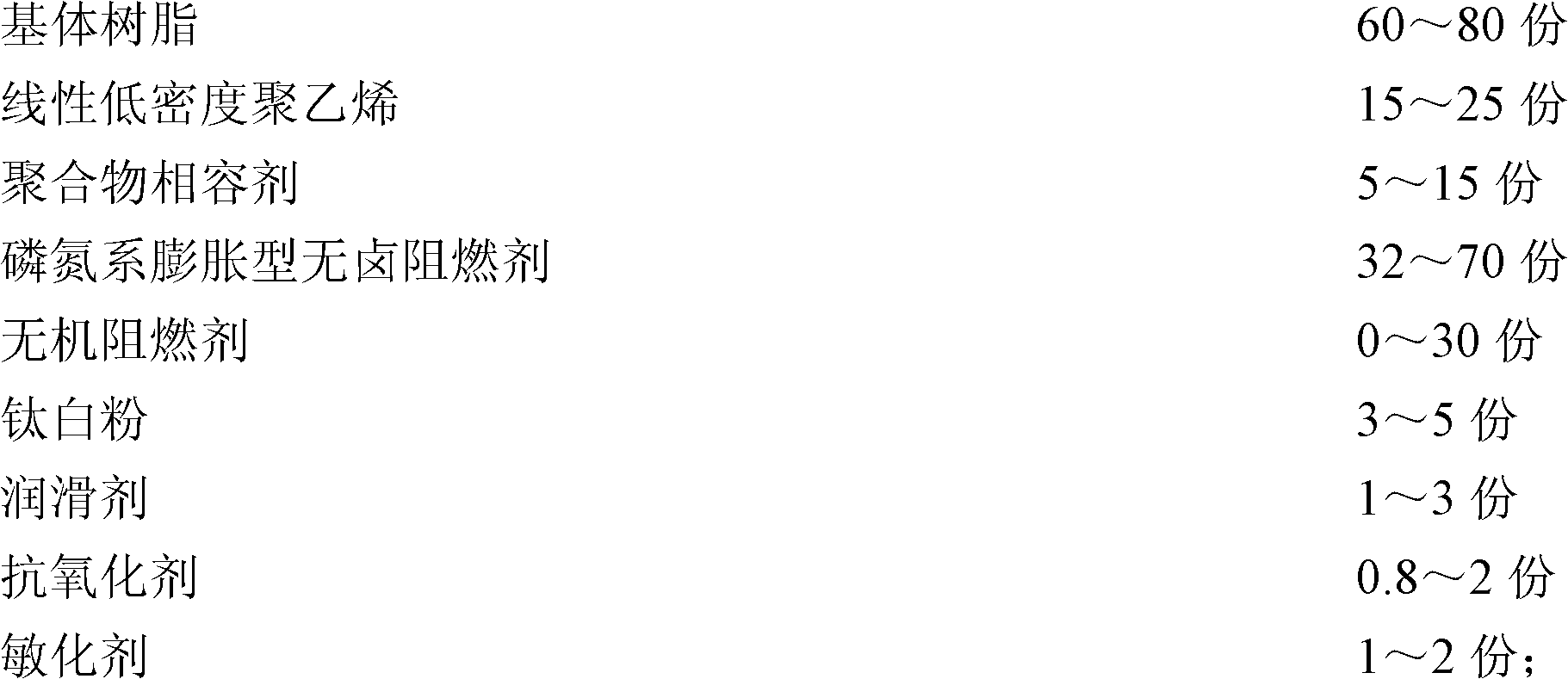

Processing method of soybean oil

InactiveCN105038977AReduce phosphorus contentRelieve pressureFatty-oils/fats refiningActivated carbonPhosphatidase

The invention discloses a processing method of soybean oil. The method comprises the following steps: 1, preparing crude soybean oil; 2, adding phosphatidase C, and carrying out primary degumming treatment to obtain primary degummed soybean oil; 3, adding phosphatidase A1, and carrying out secondary degumming treatment to obtain secondary degummed soybean oil; 4, carrying out alkali refining depickling treatment to obtain depickled soybean oil; 5, adding waste white clay to the depickled soybean oil, carrying out pre-decoloring treatment to obtain pre-decolored soybean oil, adding attapulgite and active carbon to the pre-decolored soybean oil, and carrying out re-decoloring treatment to obtain re-decolored soybean oil; and 6, carrying out deodorizing treatment on the re-decolored soybean oil to obtain finished soybean oil. The processing method of the soybean oil has the advantages of safety, environmental protection, simple process, convenient operation, low cost and high refining rate, and is suitable for soybean oil processing industrial production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

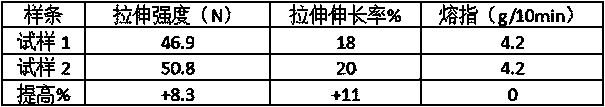

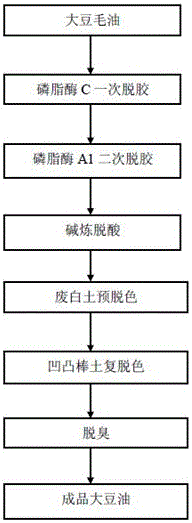

Modified wollastonite, and preparation method and application thereof

PendingCN111303487AImprove modification efficiencyHigh tensile strengthPhysical chemistryWollastonite

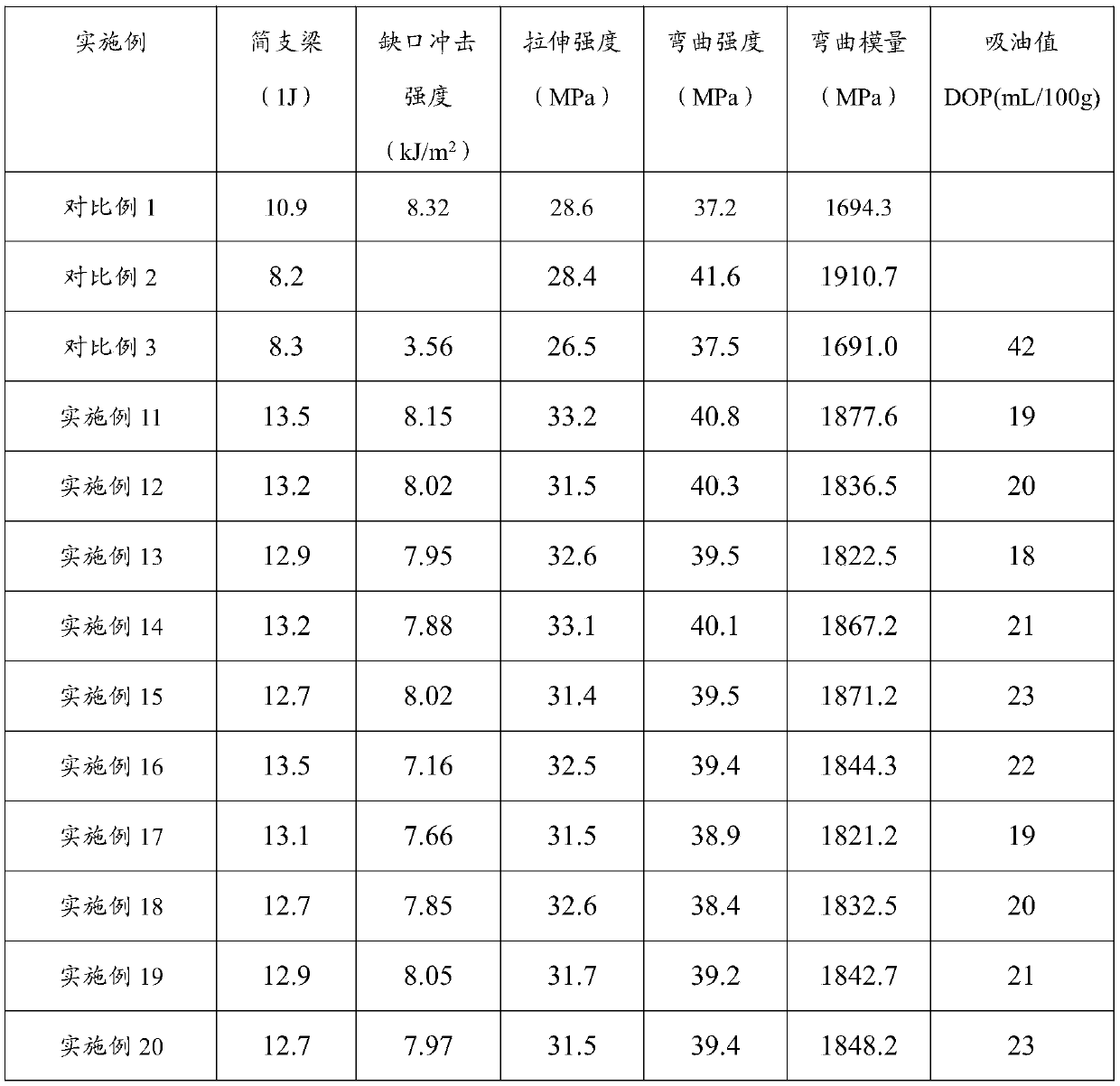

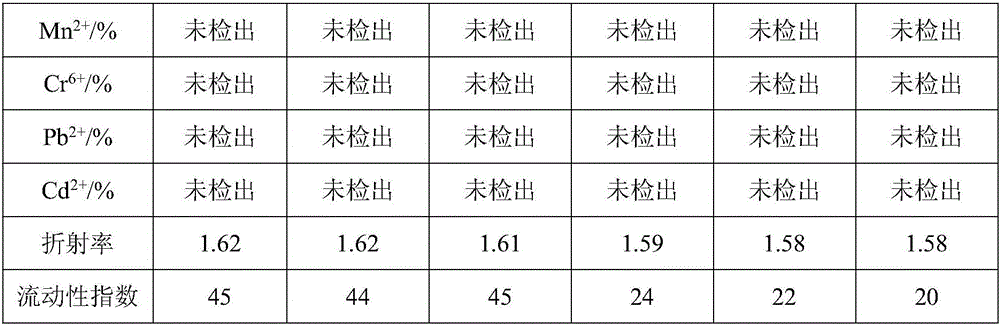

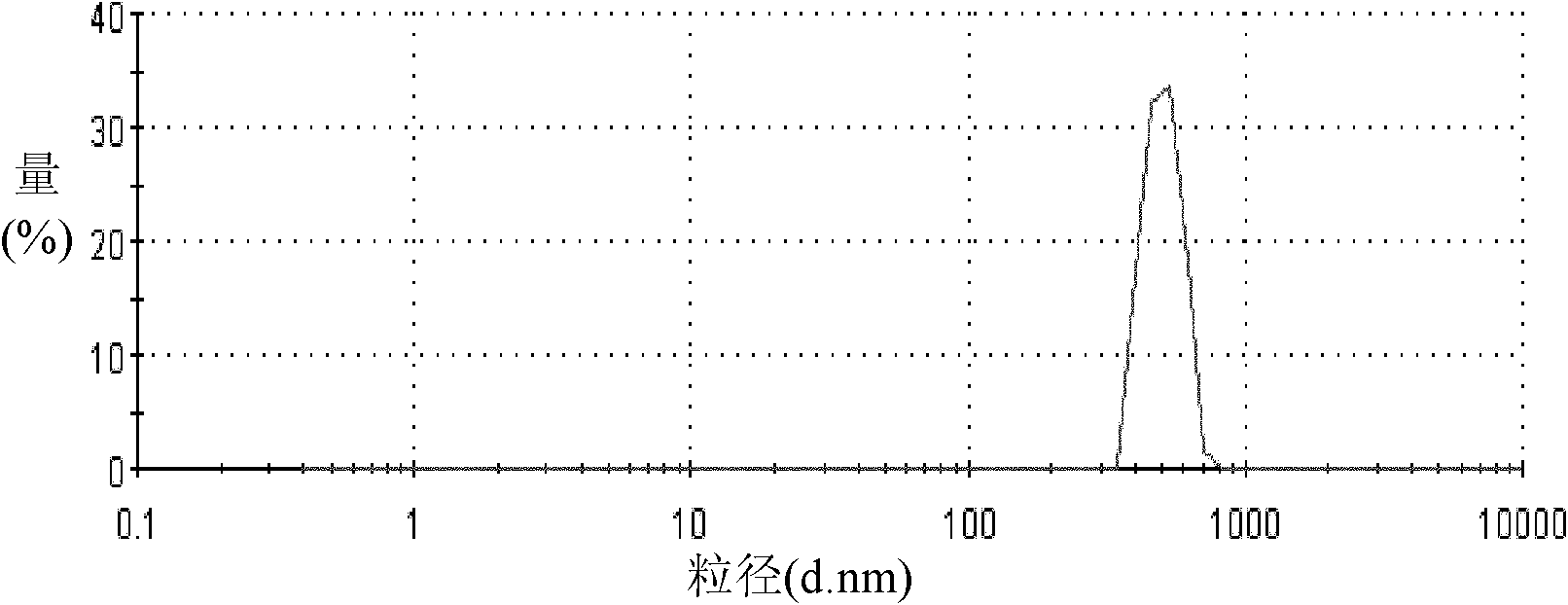

The invention provides modified wollastonite, and a preparation method and application thereof, belonging to the field of mineral material processing and application. The preparation method of the modified wollastonite provided by the invention comprises the following steps: mixing wollastonite with a titanate coupling agent, stearic acid and fatty acid polyoxyethylene ester, and carrying out a modification reaction to obtain inorganic modified wollastonite powder. According to the invention, a composite modifier composed of the titanate coupling agent, the stearic acid and the fatty acid polyoxyethylene ester is adopted for modification of the wollastonite, so the interface interaction between the wollastonite and a filling material can be improved, and the obtained modified product has improved binding capacity with PP and other materials and is improved in mechanical properties. Results of embodiments show that a PP composite material obtained by filling the PP with the modified wollastonite has a simply supported beam strength of more than 12.5 J, notch impact strength of no less than 7kJ / m<2>, tensile strength of more than 31 MPa, bending strength of more than 38 MPa, bendingmodulus of more than 1820 MPa and an oil absorption value of less than or equal to 23 mL / 100 g.

Owner:NANCHANG UNIV +1

Preparation method of modified calcium carbonate

ActiveCN106317963AGood printabilityEvenly dispersedPigment treatment with organosilicon compoundsPigment physical treatmentDispersityCalcite

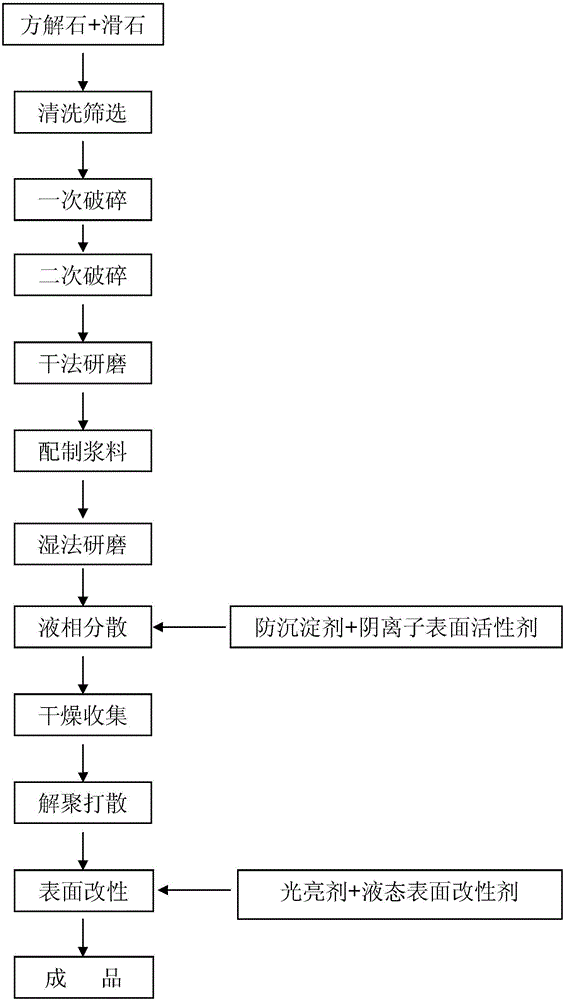

The invention provides a preparation method modified calcium carbonate. The preparation method includes: mixing and crushing calcite and talcum, performing dry grinding to obtain raw slurry with solid content being 70-75%, performing constant-temperature stirring and grinding to obtain processed slurry with average particle size being 0.9-1.1 micrometers, adding naphthalene sulfonate type anti-precipitation agent and anionic surfactant into the processed slurry to perform liquid-phase dispersing, drying, collecting, depolymerizing and dispersing, adding brightener and liquid surface modifier to perform wrapping treatment, and stirring to obtain the modified calcium carbonate. By the preparation method, the modified calcium carbonate which is good in printing performance, good in dispersity, good in surface brightness and applicable to films adhered to car bodies can be prepared.

Owner:JIANGXI GUANGYUAN CHEM

Hydrolysis method for producing electronic-grade special titanium white by sulfuric acid process

ActiveCN101913647ANarrow particle size distributionLow impurity contentTitanium dioxideNarrow rangeGranularity

The invention belongs to the field of chemical industry and relates to a hydrolysis method for producing electronic-grade special titanium white by a sulfuric acid process. The technical problem to be solved is that the electronic-grade special titanium white with narrow particle size distribution and low impurity content is prepared by the sulfuric acid process. The method improves the hydrolysis method in the sulfuric acid process, and the improved hydrolysis method comprises the following steps of: A, adding titanium liquid with the concentration of 140 to 190g / L which is preheated to the temperature of between 75 and 95 DEG C into water which is preheated to the temperature of between 80 and 95 DEG C; B, heating the system to boil, and keeping the system boiling; C, when the hydrolysis system becomes steel grey, continuously keeping boiling for 5 to 25 minutes, stopping heating and stirring, and curing; and D, heating the system to boil with stirring, and keeping the system slightly boiling until the hydrolysis is finished. The obtained titanium white has the mean grain size of 800 to 1,200nm, the half-peak width of 70 to 98nm, narrow range of particle size distribution and low impurity content, and can be used as electronic-grade special titanium white.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Method for preparing smooth dense silver-coated copper powder through chemical plating method

ActiveCN110551995AHigh solid contentImprove adhesionTransportation and packagingMetal-working apparatusChemical platingRoom temperature

The invention relates to a method for preparing smooth dense silver-coated copper powder through a chemical plating method. The preparing method comprises the following steps that deionized water anda dispersing agent are added into activated copper powder to obtain a copper nano-particle suspension liquid; a complexing agent is added into a silver nitrate water solution to prepare a silver complexing solution; and the above solutions are mixed, a reducing agent solution and a nano-silver suspension liquid are sequentially added, stirring is carried out at room temperature to obtain a silver-coated copper nanoparticle suspension liquid, and standing, washing and drying are carried out to obtain the smooth dense silver-coated copper powder. Compared with the prior art, nano-silver particles are added into a plating solution, so that the obtained silver-coated copper powder is dense in coating, smooth and non-porous in surface, excellent in conductivity and oxidation resistance, and extremely high in application value in the electronic slurry industry.

Owner:SHANGHAI JIAO TONG UNIV

Special scratch-resistant talcum powder for polypropylene and preparation method thereof

ActiveCN102127261ALow oil absorptionHigh oil absorption valuePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsCouplingBiological activation

The invention relates totalcum powder and preparation method thereof, in particular to special scratch-resistant talcum powder for polypropylene and a preparation method thereof. The talcum powder comprises the following components in parts by weight: 0.1-0.5 part of titanate coupling agent, 0.1-0.5 part of silane coupling agent, 97-99 parts of superfine talcum powder and 0.1-0.5 part of high molecular weight siloxane copolymer. The invention has the following advantages and effects: the activation rate of the talcum powder provided by the invention is more than 99.0%, the oil adsorption value is less than 1.5mL / 100g, the product purity is high and the particle size is 1-50mu m. Through the inspections of the professional inspection institution, the scratch resistance of the polypropylene car bumper special material prepared from the talcum powder which is provided the invention satisfies the grade A of the multi-finger scratch test and the Delta L in the Erichsen cross test is less than 1.5.

Owner:LIAONING JINGHUA NEW MATERIAL CO LTD

Oil absorption material and preparation method and use thereof

The invention relates to an oil absorption material and belongs to the field of preparation of organic materials. The invention further relates to a preparation method and use of the oil absorption material. The oil absorption material is powder made from foamed plastic. The powder made from foamed material provided by the invention has high oil absorption and low water absorption. The foamed material is cut and smashed to obtain powder with the grain size being about 2-1000 microns. The oil absorption of the obtained polyurethane foam block to gasoline is reduced by no greater than 10% but the water absorption is greatly reduced to below 20% of the original water absorption.

Owner:金碳环境科技(天津)有限公司

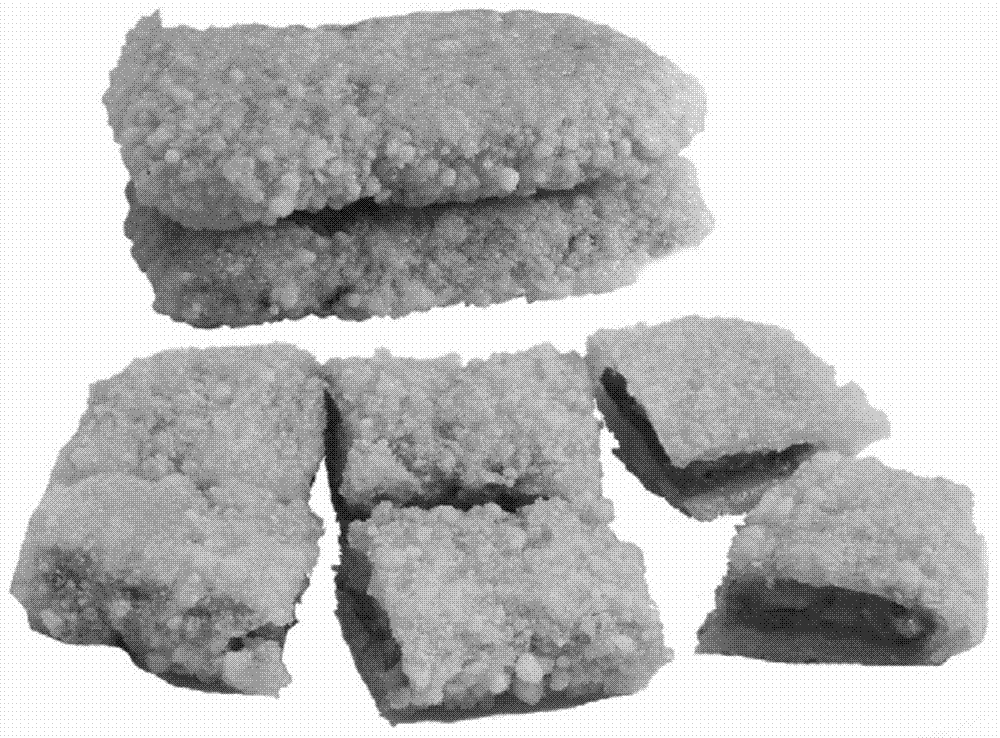

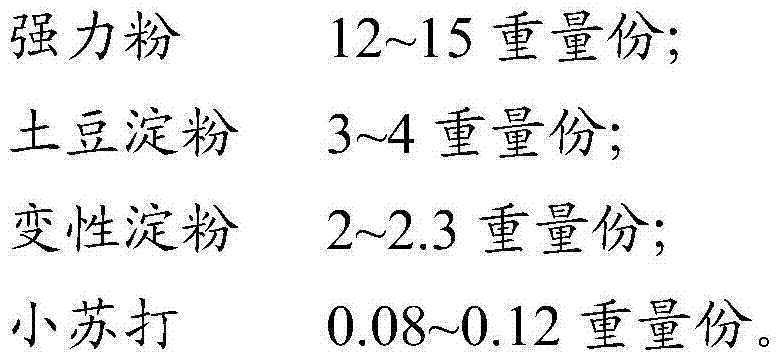

Wrapping powder

The invention provides wrapping powder. The wrapping powder comprises the following components in parts by weight: 10-15 parts of strong powder, 2-5 parts of potato starch, 1.8-2.5 parts of modified starch and 0.05-0.15 part of sodium bicarbonate. Compared with the conventional wrapping powder, the wrapping powder contains the strong powder, the potato starch, the modified starch and the sodium bicarbonate, and the modified starch has high binding power and modeling property, high-temperature expansion and stability, so that the wrapping powder has high binding power and cohesion, and golden yellow appearance and high crispness are provided; the sodium bicarbonate is heated to be decomposed into sodium carbonate, carbon dioxide and water after being fried at high temperature, and the high-temperature expansion of the wrapping powder is further improved; the modified starch, the strong powder, the potato starch and the sodium bicarbonate are mixed according to a specific ratio, and the modified starch with high expansion, the sodium bicarbonate, the potato starch with low expansion and the strong powder without expansion are mixed, so that the fried product has the scaly appearance after being fried.

Owner:SHANDONG FENGXIANG

Titanium dioxide with low oil absorption and preparation method of titanium dioxide

ActiveCN104877393AGood dispersionLow oil absorptionPigment treatment with macromolecular organic compoundsPigment physical treatmentDispersitySodium aluminate

The invention discloses a preparation method of titanium dioxide with low oil absorption. The preparation method comprises the following steps: (1) mixing rutile titanium dioxide, water and a first dispersing agent to obtain slurry; (2) sanding the slurry obtained in the step (1) and optionally diluting and heating the sanded material; (3) mixing the slurry obtained in the step (2) and a second dispersing agent and then performing primary curing; (4) adding a sodium aluminate solution and an acid solution at the same time into the material obtained after primary curing and performing secondary curing; and (5) adjusting the pH value of the material obtained after secondary curing to 7-7.8 and performing third curing. The titanium dioxide with low oil absorption, obtained through the method disclosed by the invention, has the advantages of excellent dispersity and low oil absorption; particularly, the dispersity of the prepared titanium dioxide can reach 5.76-6.5HB and the oil absorption can be reduced to 16.5-18g / 100g so that the prepared titanium dioxide has relatively good fluidity and color contrast property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com