White finish coat photocurable UV (ultraviolet) paint and preparation method thereof

A light-curing and topcoating technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor adhesion, low paint gloss, poor leveling, etc., to achieve good transparency, anti- Good sinking performance and excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

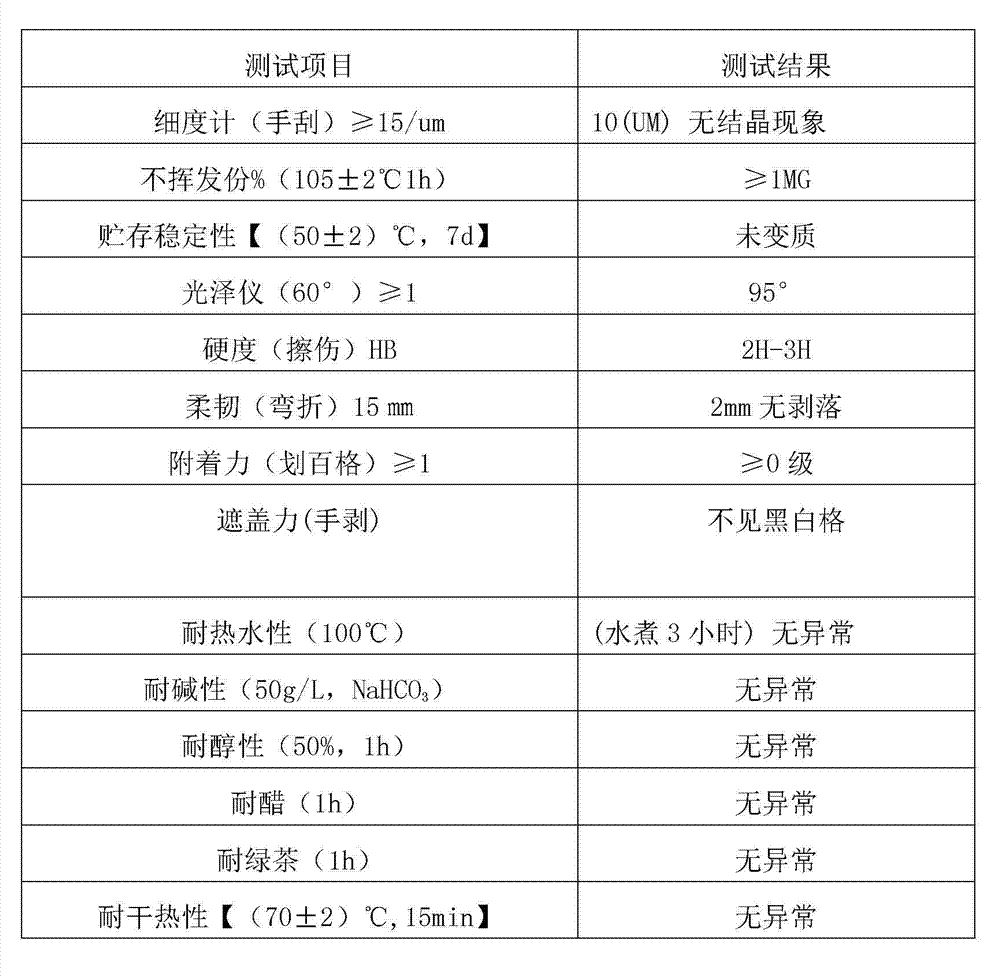

Embodiment 1

[0015] A kind of white top coat photocuring UV coating, calculated in weight percent:

[0016] Amine modified epoxy resin (light curing): 40%

[0017] Aliphatic polyurethane resin (light curing): 20%

[0018] 2-Hydroxy-2-methyl-phenylacetone (photoinitiator): 2.5%

[0019] Diphenylphosphine oxide (photoinitiator): 0.5%

[0020] Modified polyurethane polymer (dispersant): 0.6%

[0021] Polysiloxane polyether copolymer (leveling agent): 0.4%

[0022] Titanium dioxide (TiO 2 ) (titanium dioxide): 10%

[0023] 1,6-Hexanediol diacrylate (reactive diluent): 12%

[0024] Trimethylolpropane Triacrylate (reactive diluent): 14%

[0025] The preparation method is as follows:

[0026] A. Add 40% amine-modified epoxy resin and aliphatic polyurethane into the paint-making tank, put in the modified polyurethane high polymer dispersant under the condition of stirring, and stir evenly.

[0027] B. Add titanium dioxide under the condition of stirring, and after stirring evenly, pass th...

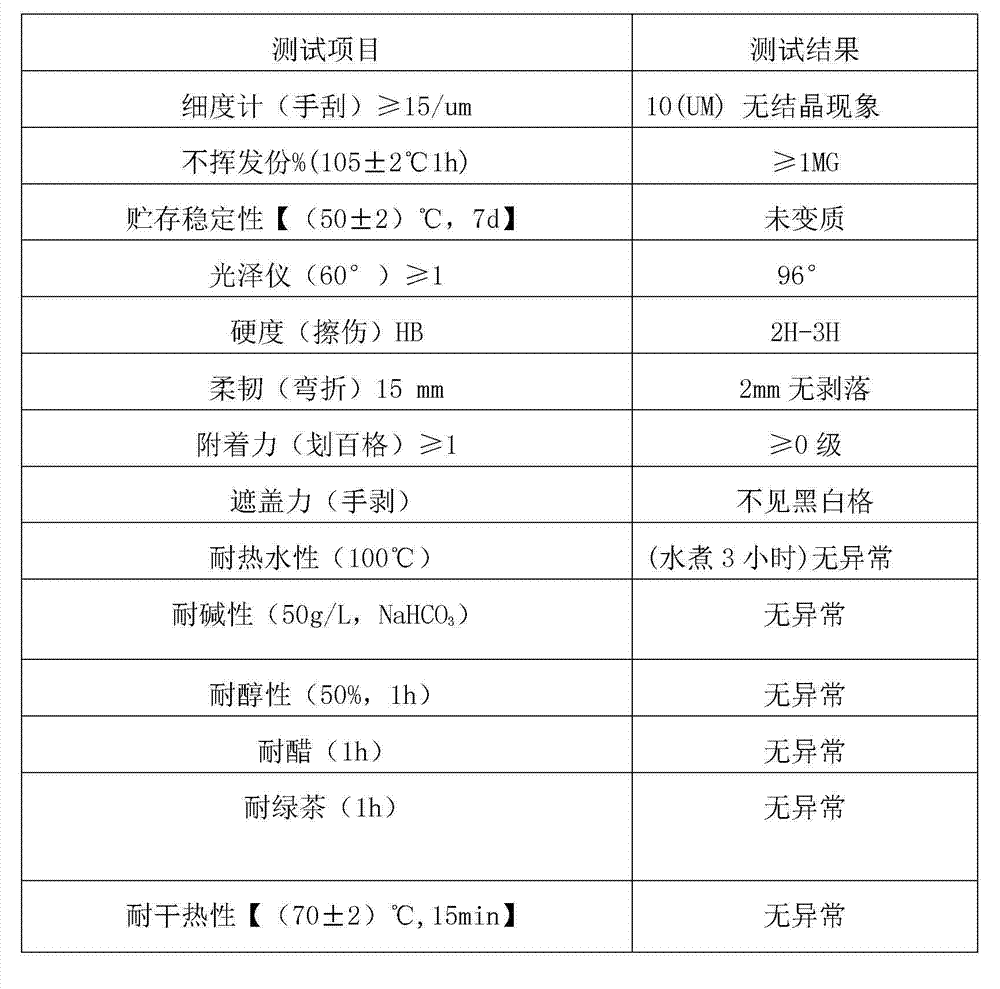

Embodiment 2

[0039] A kind of white top coat photocuring UV coating, calculated in weight percent:

[0040] Amine modified epoxy resin (light curing): 35%

[0041] Aliphatic polyurethane resin (light curing): 25%

[0042] 2-Hydroxy-2-methyl-phenylacetone (photoinitiator): 2.5%

[0043] Diphenylphosphine oxide (photoinitiator): 0.5%

[0044] Modified polyurethane polymer (dispersant): 0.6%

[0045] Polysiloxane polyether copolymer (leveling agent): 0.4%

[0046]Titanium dioxide (TiO 2 ) (titanium dioxide): 10%

[0047] 1,6-Hexanediol diacrylate (reactive diluent): 12%

[0048] Trimethylolpropane Triacrylate (reactive diluent): 14%

[0049] The preparation method is as follows:

[0050] A. Add 40% amine-modified epoxy resin and aliphatic polyurethane into the paint-making tank, put in the modified polyurethane high polymer dispersant under the condition of stirring, and stir evenly.

[0051] B. Add titanium dioxide under the condition of stirring, and after stirring evenly, pass thr...

Embodiment

[0061] A kind of white top coat photocuring UV coating, calculated in weight percent:

[0062] Amine-modified epoxy resin (light curing): 28%

[0063] Aliphatic polyurethane resin (light curing): 32%

[0064] 2-Hydroxy-2-methyl-phenylacetone (photoinitiator): 2.5%

[0065] Diphenylphosphine oxide (photoinitiator): 0.5%

[0066] Modified polyurethane polymer (dispersant): 0.6%

[0067] Polysiloxane polyether copolymer (leveling agent): 0.4%

[0068] Titanium dioxide (TiO 2 ) (titanium dioxide): 10%

[0069] 1,6-Hexanediol diacrylate (reactive diluent): 12%

[0070] Trimethylolpropane Triacrylate (reactive diluent): 14%

[0071] The preparation method is as follows:

[0072] A. Add 40% amine-modified epoxy resin and aliphatic polyurethane into the paint-making tank, put in the modified polyurethane high polymer dispersant under the condition of stirring, and stir evenly.

[0073] B. Add titanium dioxide under the condition of stirring, and after stirring evenly, pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com