Patents

Literature

124 results about "Decamethylcyclopentasiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

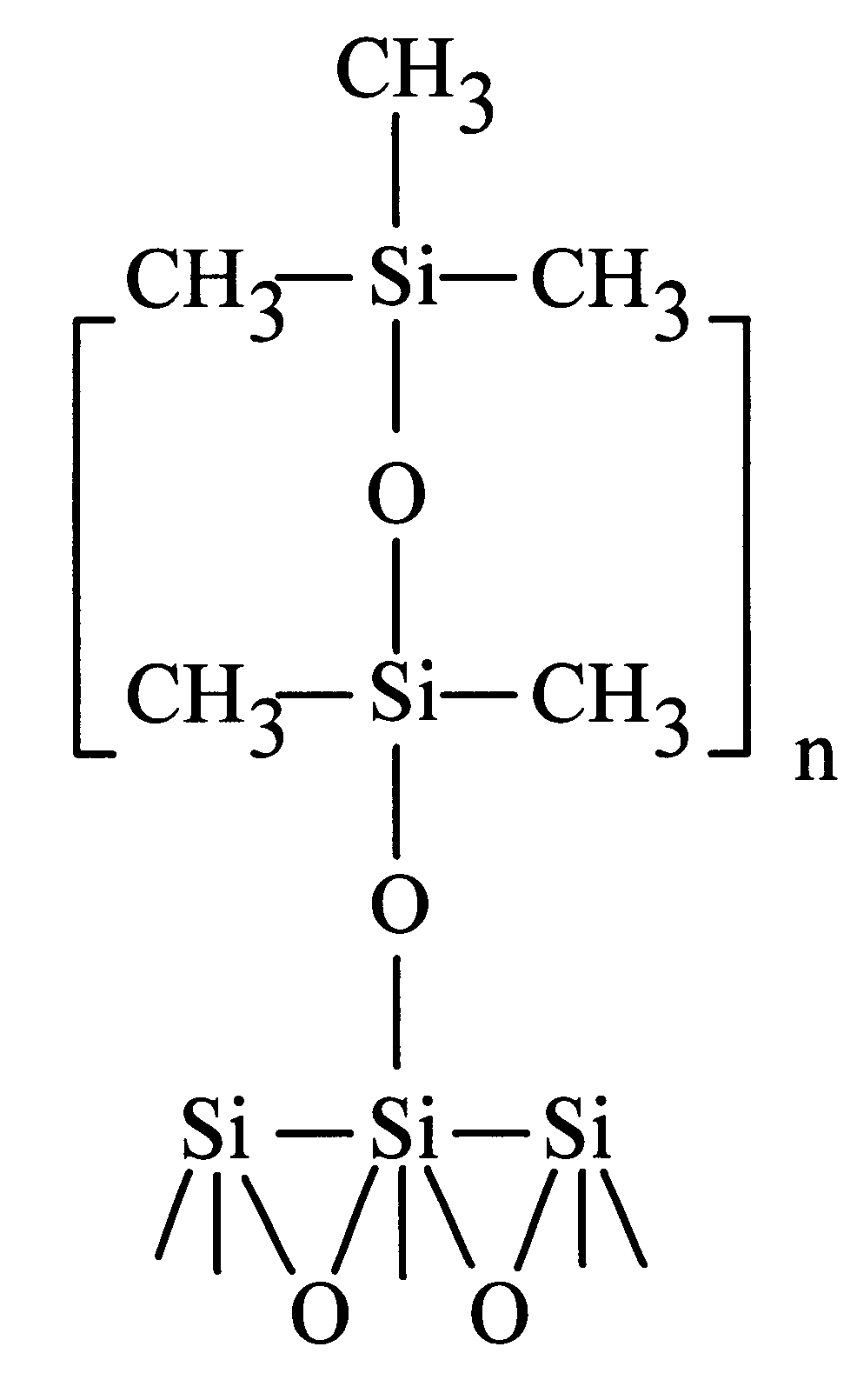

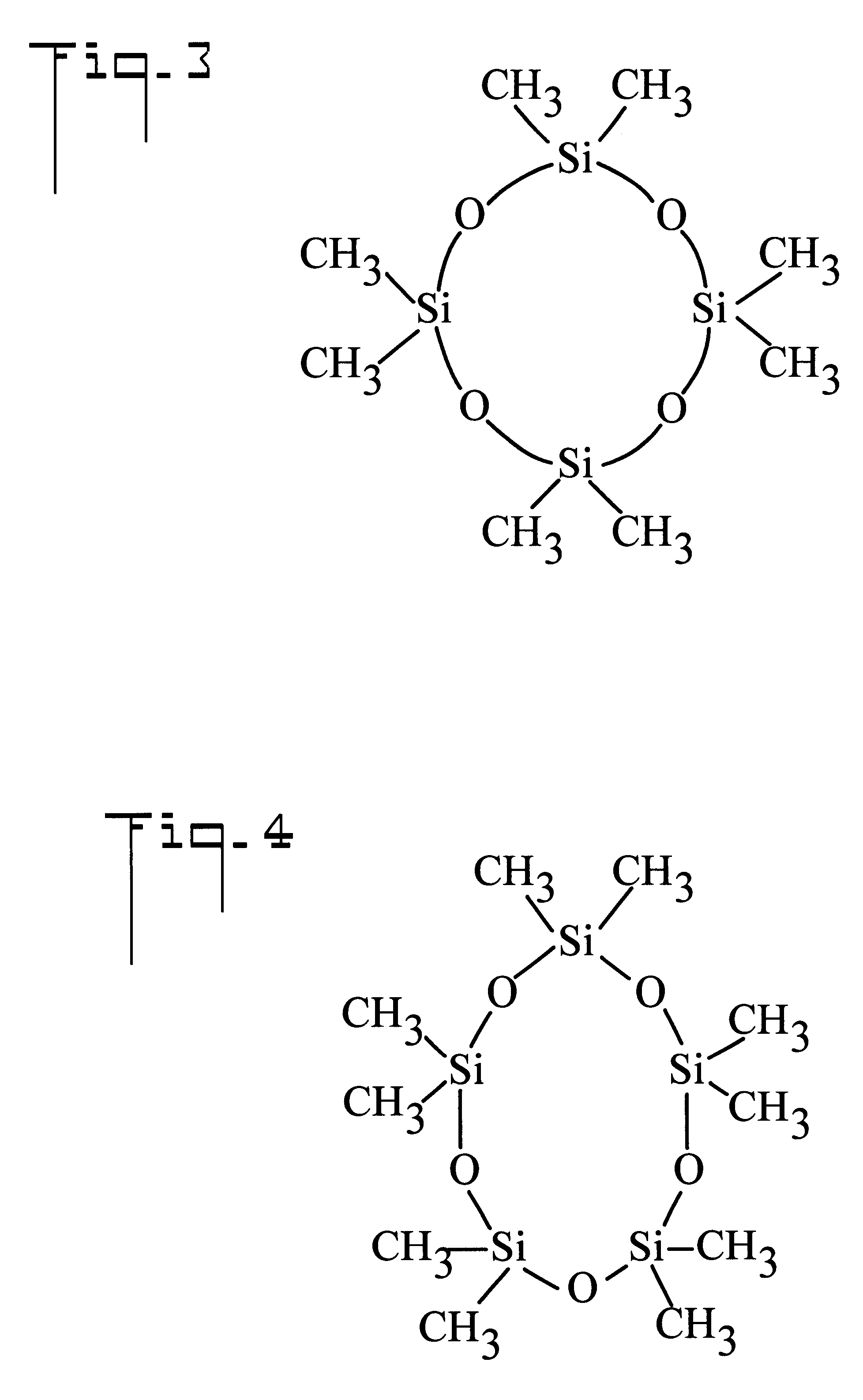

Decamethylcyclopentasiloxane (D₅) is an organosilicon compound with the formula [(CH₃)₂SiO]₅. It is a colorless and odorless liquid that is slightly volatile.

Compositions and Methods for the Treatment of Inflammatory Dermatosis and Other Pathological Conditions of the Skin

InactiveUS20100080768A1Small sizeReduce appearanceOrganic active ingredientsAntipyreticActive agentSjogren's disease

The present invention relates to a composition used as a vehicle for percutaneous absorption of Pharmaceutical and Cosmaceutical active agents that comprises Dimethiconol (hydroxyl-terminated polydimethydimethylsiloxane), dimethicone-350 (polydimethylsiloxane-350), cyclomethicone-5 nf (decamethylcyclopentasiloxane), alkymeth siloxane copolyol-lauryl peg / ppg 18 / 18 methicone (alkymethyl siloxane copolyol), cyclopentasiloxane and dimethicone Crosspolymer (silicone elastomer and decamethylcyclopentasiloxane), stearoxytrimethylsilane and stearyl alcohol (silicone wax), and deionized water. This composition serves several key applications: (1) it is a vehicle for percutaneous absorption of Pharmaceutical and Cosmaceutical active agents; (2) it acts as a method for utilizing other compositions in the treatment of inflammatory conditions of the skin including, but by no means limited to, atopic dermatitis (eczema), allergic contact dermatitis, seborrheic dermatitits, psoriasis, xerosis and atopia; (3) it is a treatment of inflammatory conditions of mucosae; (4) it relates to other compositions and methods for protecting and enhancing the barrier function of the skin.

Owner:MCGRAW THOMAS L +3

Cosmetic

InactiveUS20090232859A1Sufficient levelIncreased durabilityCosmetic preparationsHair cosmeticsArylPolymer science

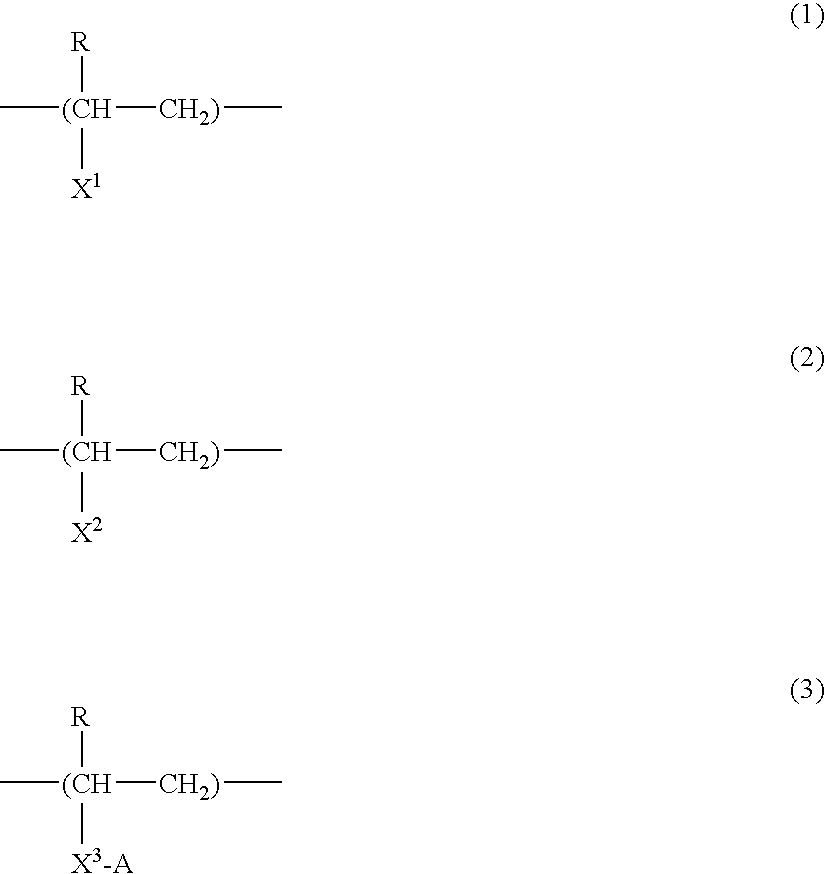

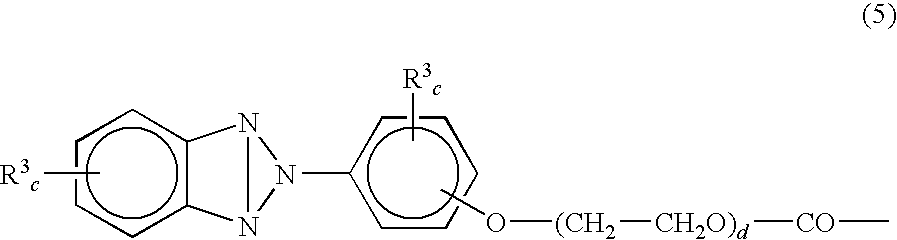

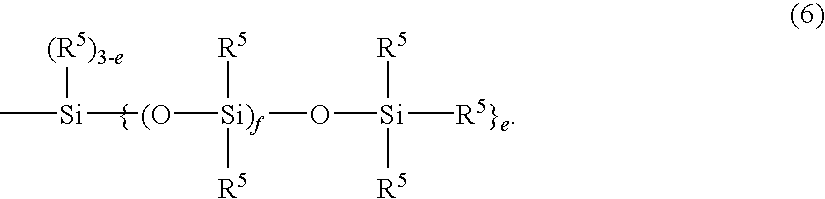

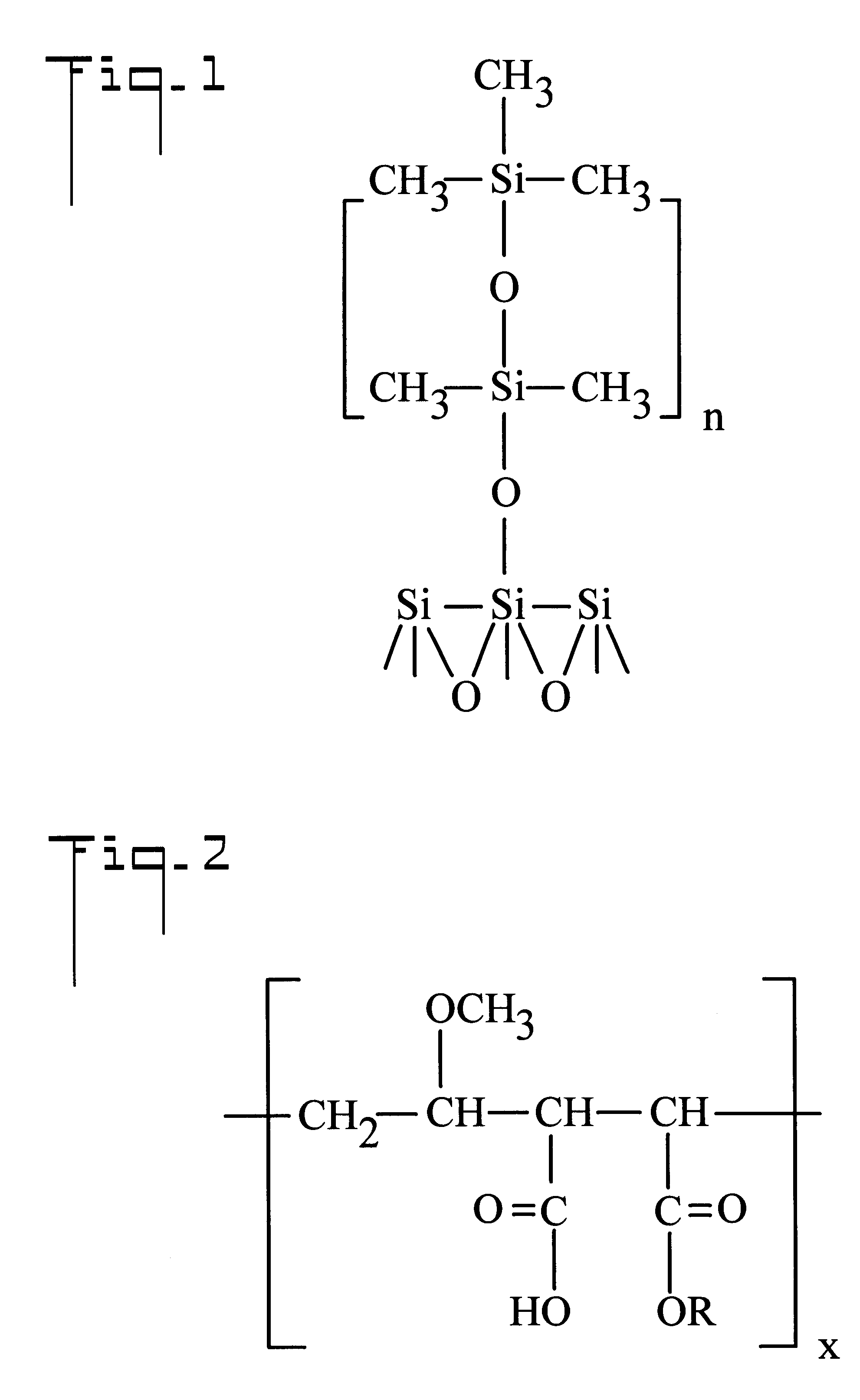

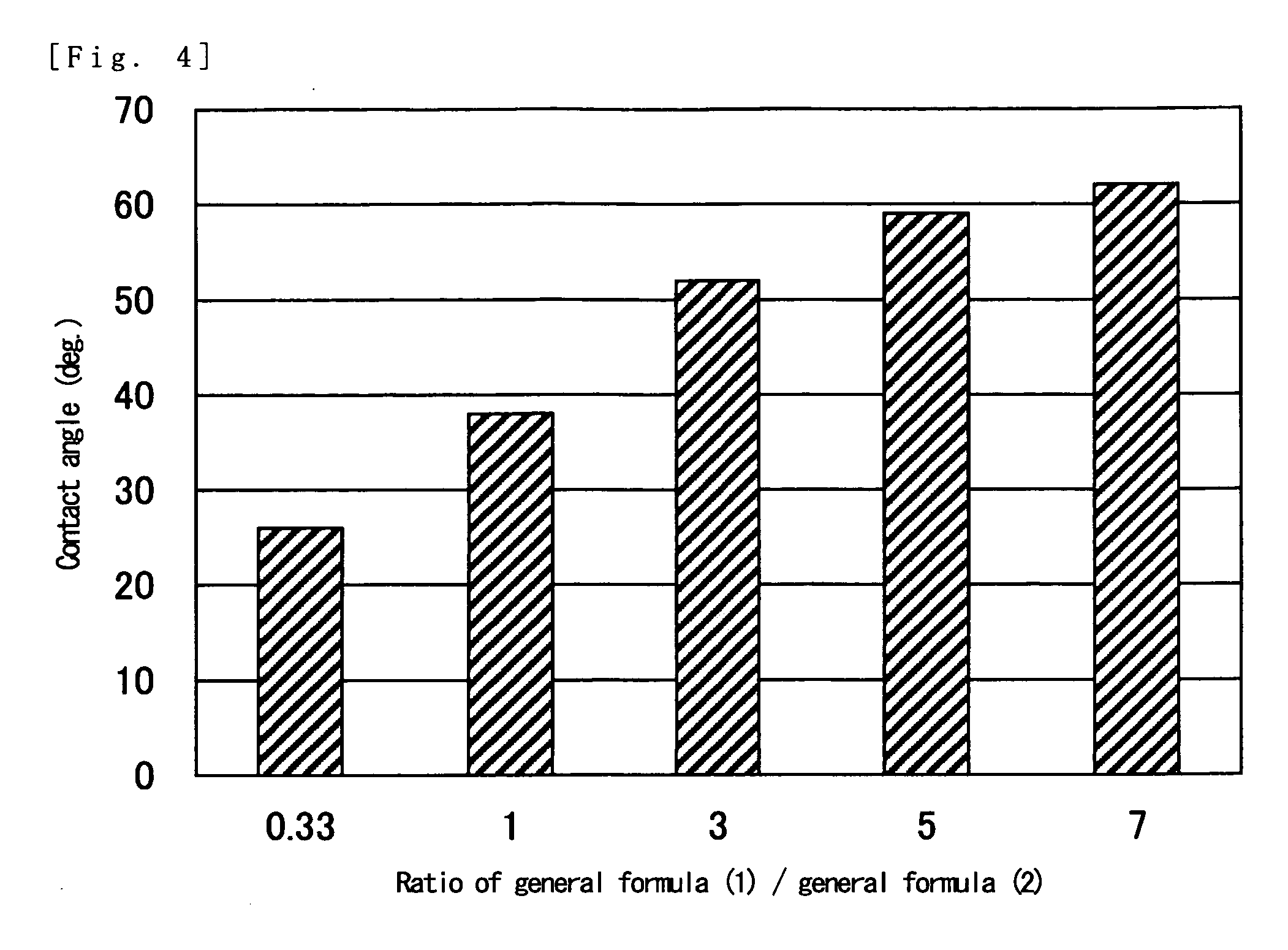

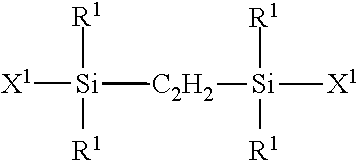

A cosmetic, comprising a polymer (A) which comprises a repeating unit represented by the following formula (1), a repeating unit represented by the following formula (2) and a repeating unit represented by the following formula (3), said polymer (A) containing the repeating unit represented by the formula (3) in an amount of from 30 to 90 mass %, based on a total mass of the polymer (A), and being soluble in decamethylcyclopentasiloxane,wherein R is a hydrogen atom or a methyl group, X1 is —COOR1, a phenyl group or an organic group represented by the following formula (4):—COO(CaH2aO)b−R2 (4)X2 is an organic group represented by the following formula (5):X3 is a C6-10 divalent aryl group or —C(═O)OR4—, and A is an organopolysiloxane residue represented by the following formula (6):

Owner:SHIN ETSU CHEM IND CO LTD

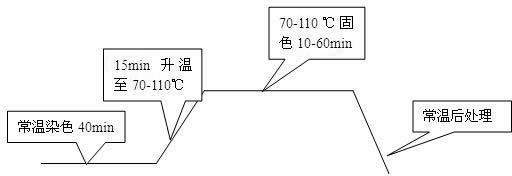

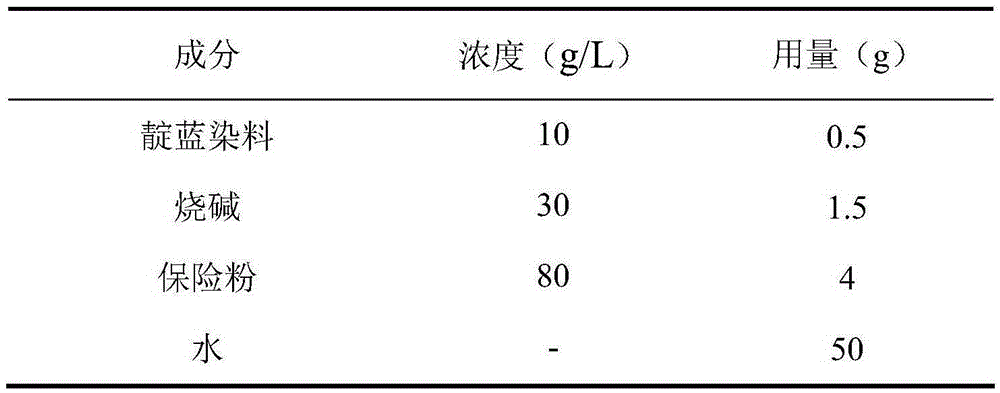

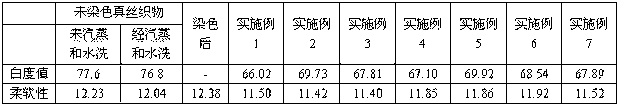

Dyeing process of pure cotton fabric

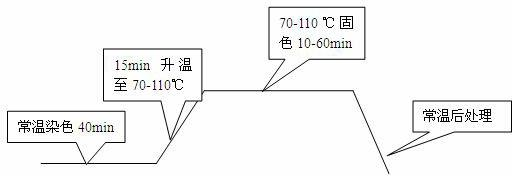

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

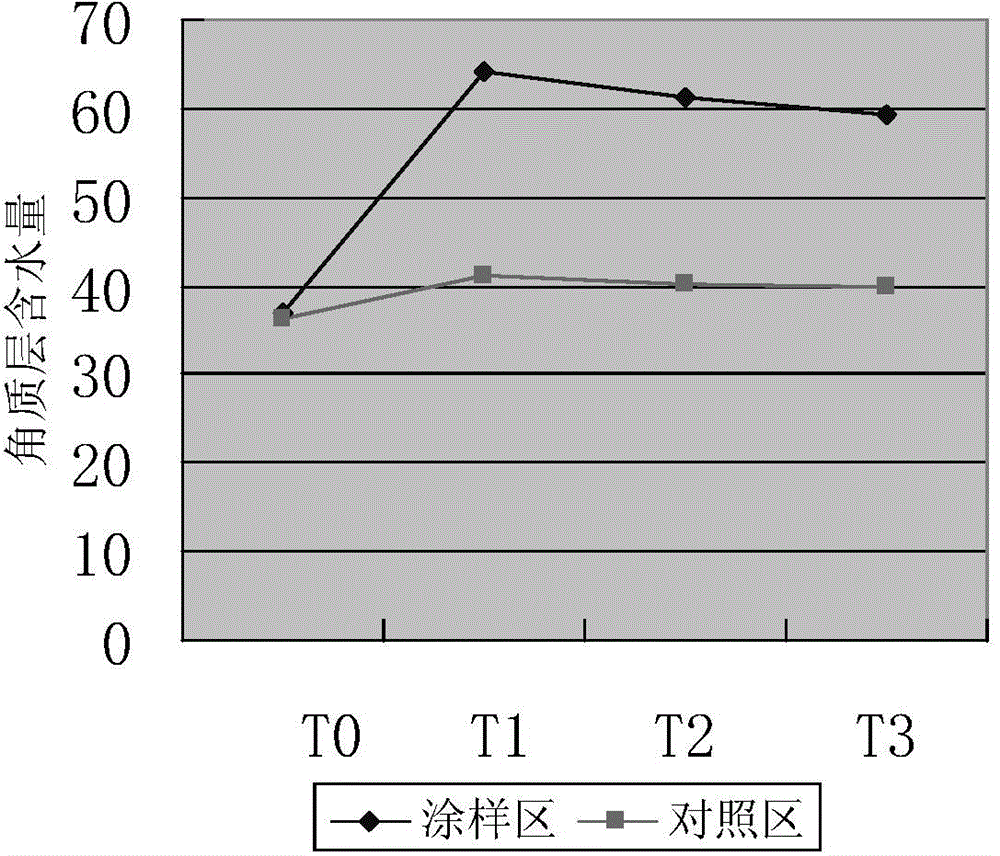

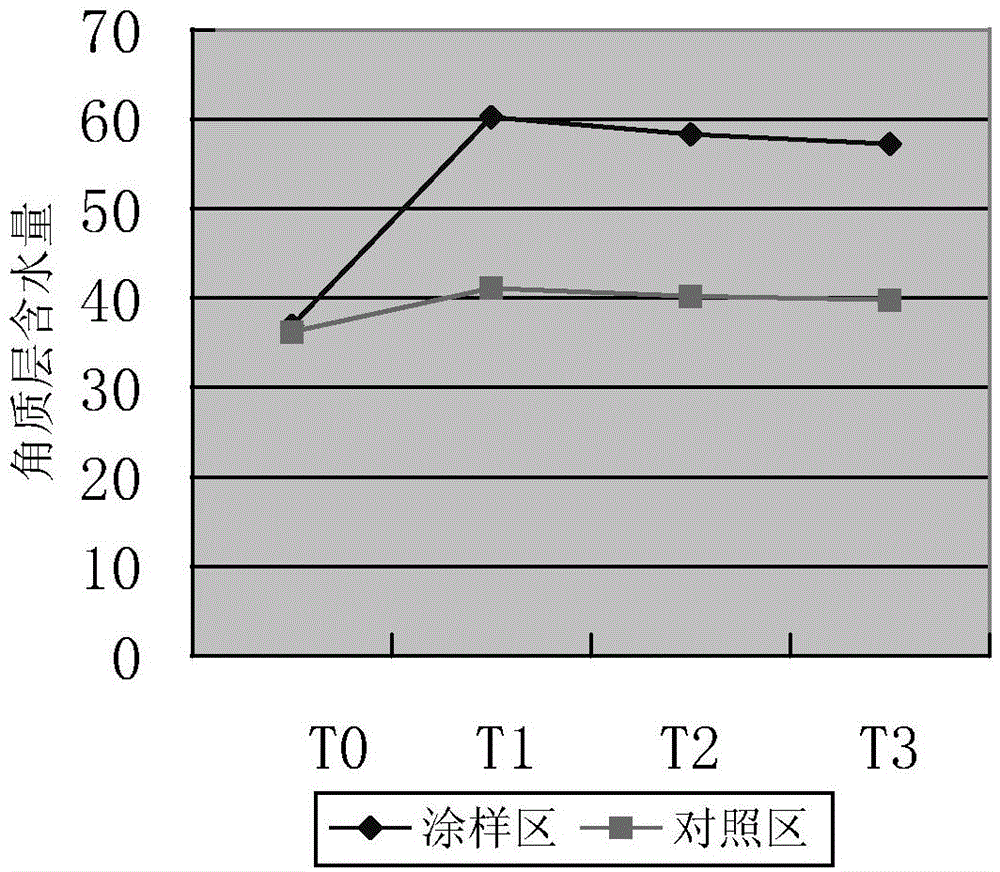

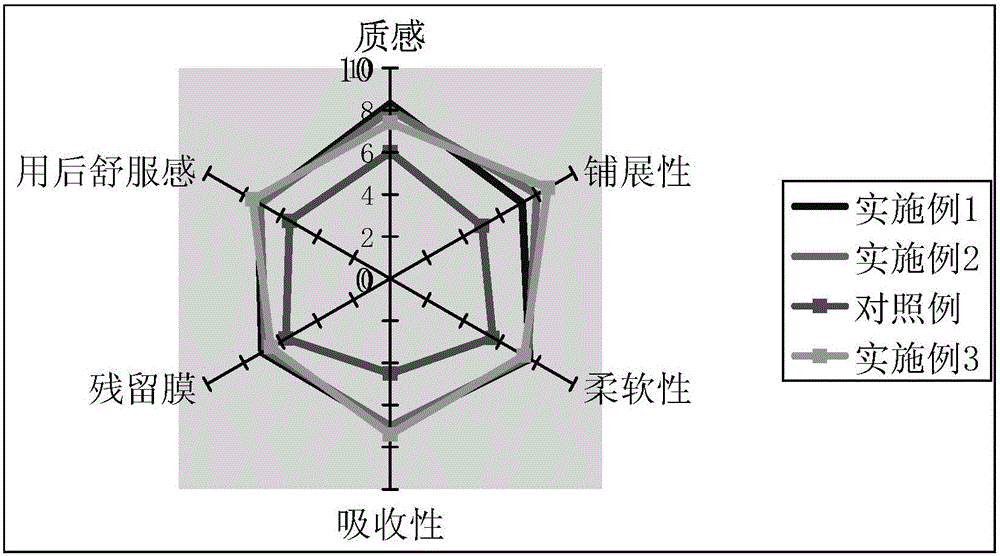

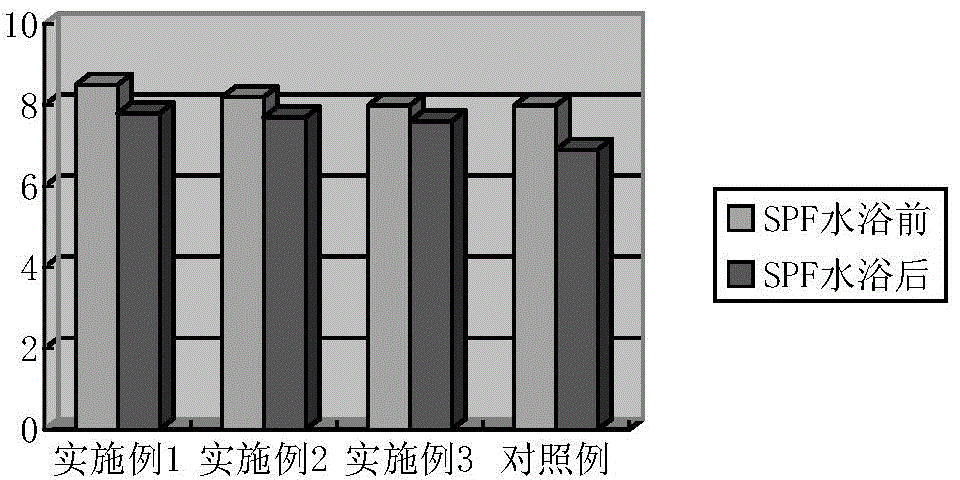

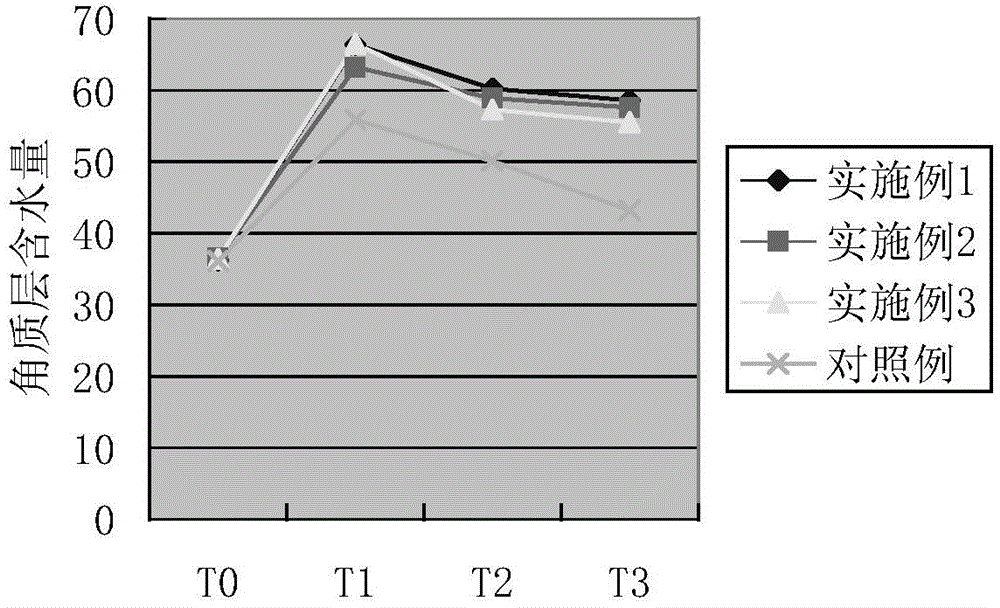

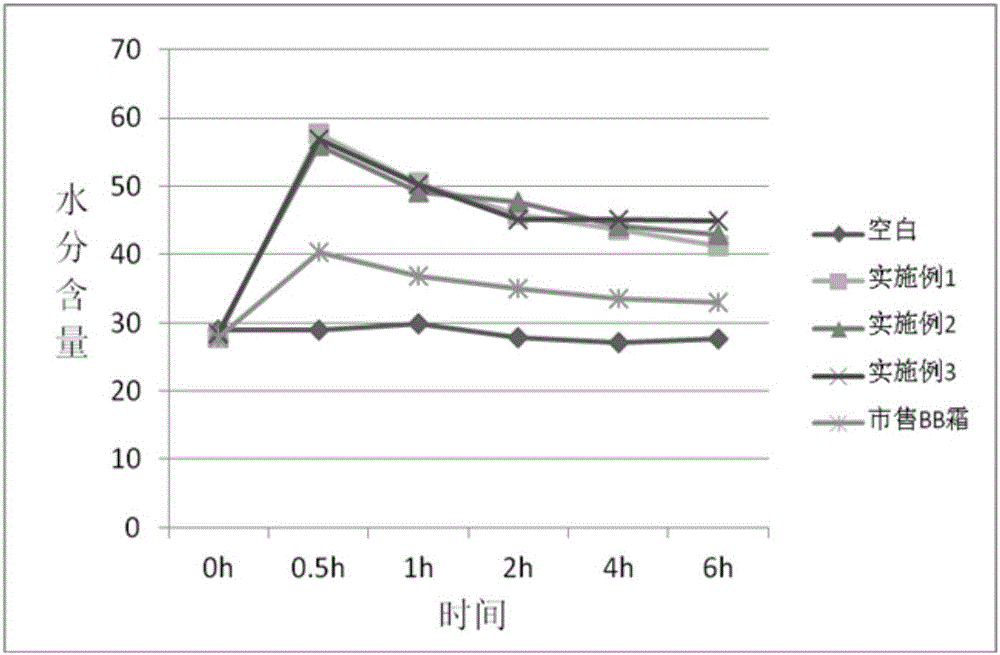

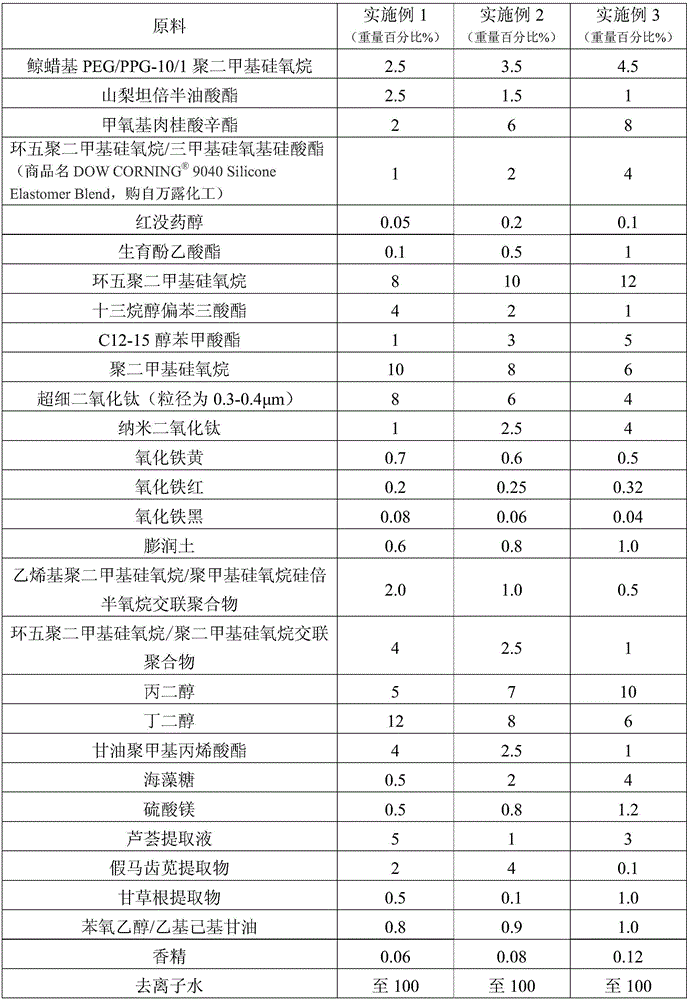

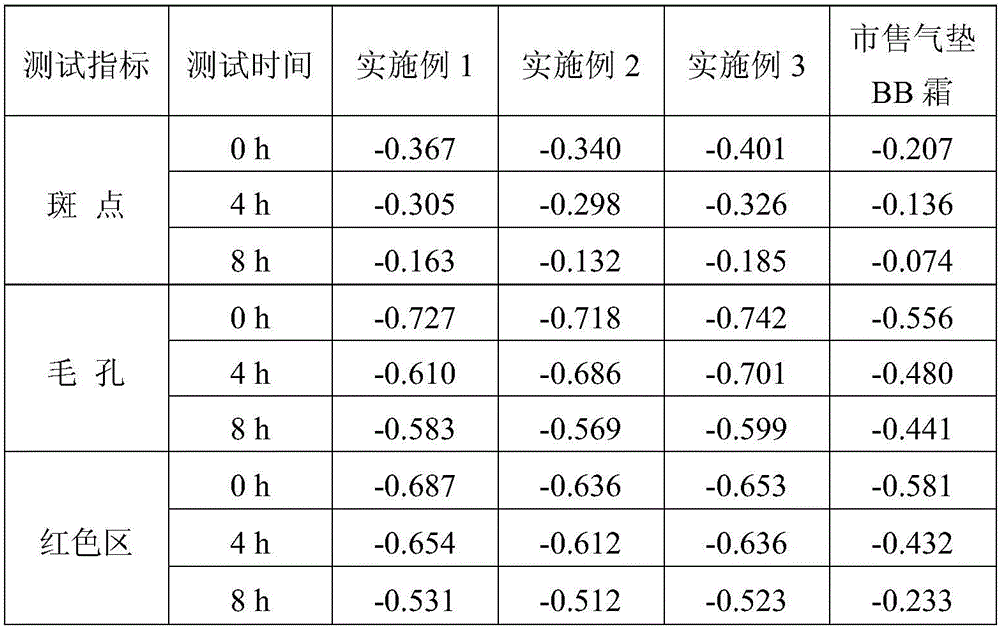

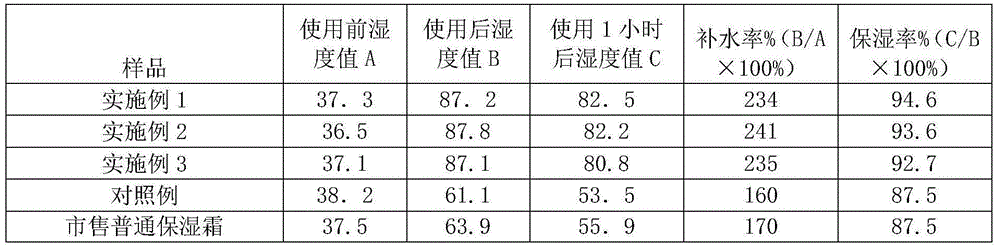

BB cream having long-acting moisturizing function and preparation method thereof

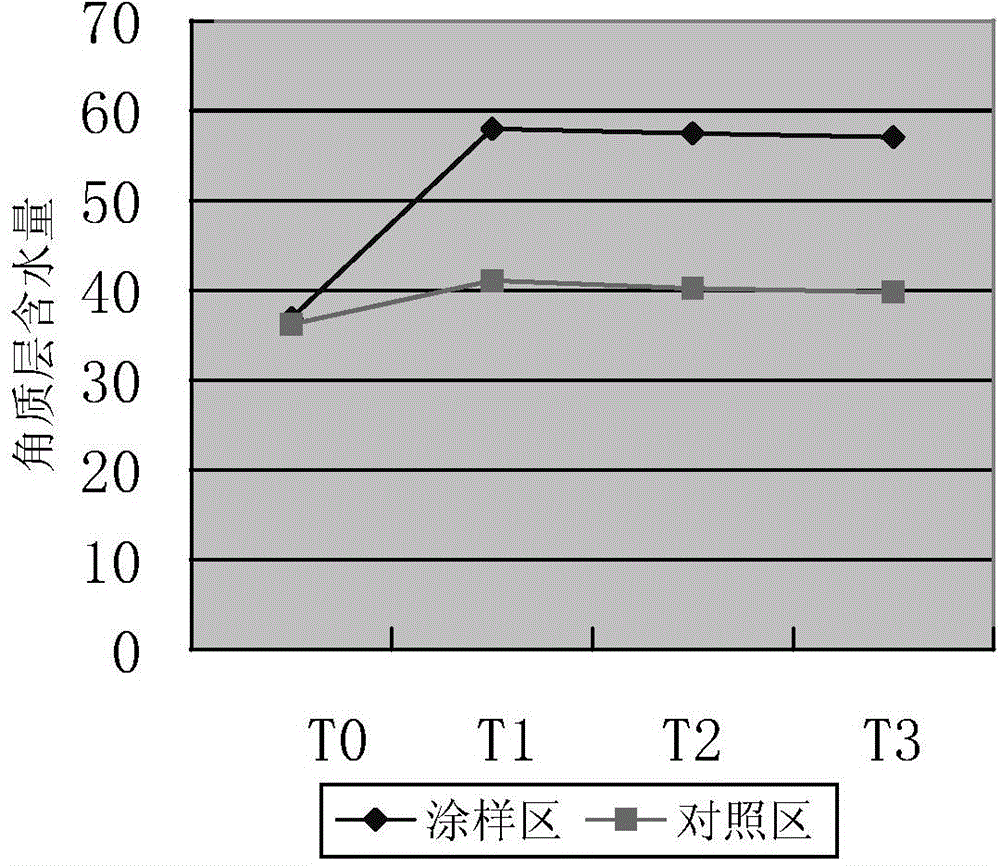

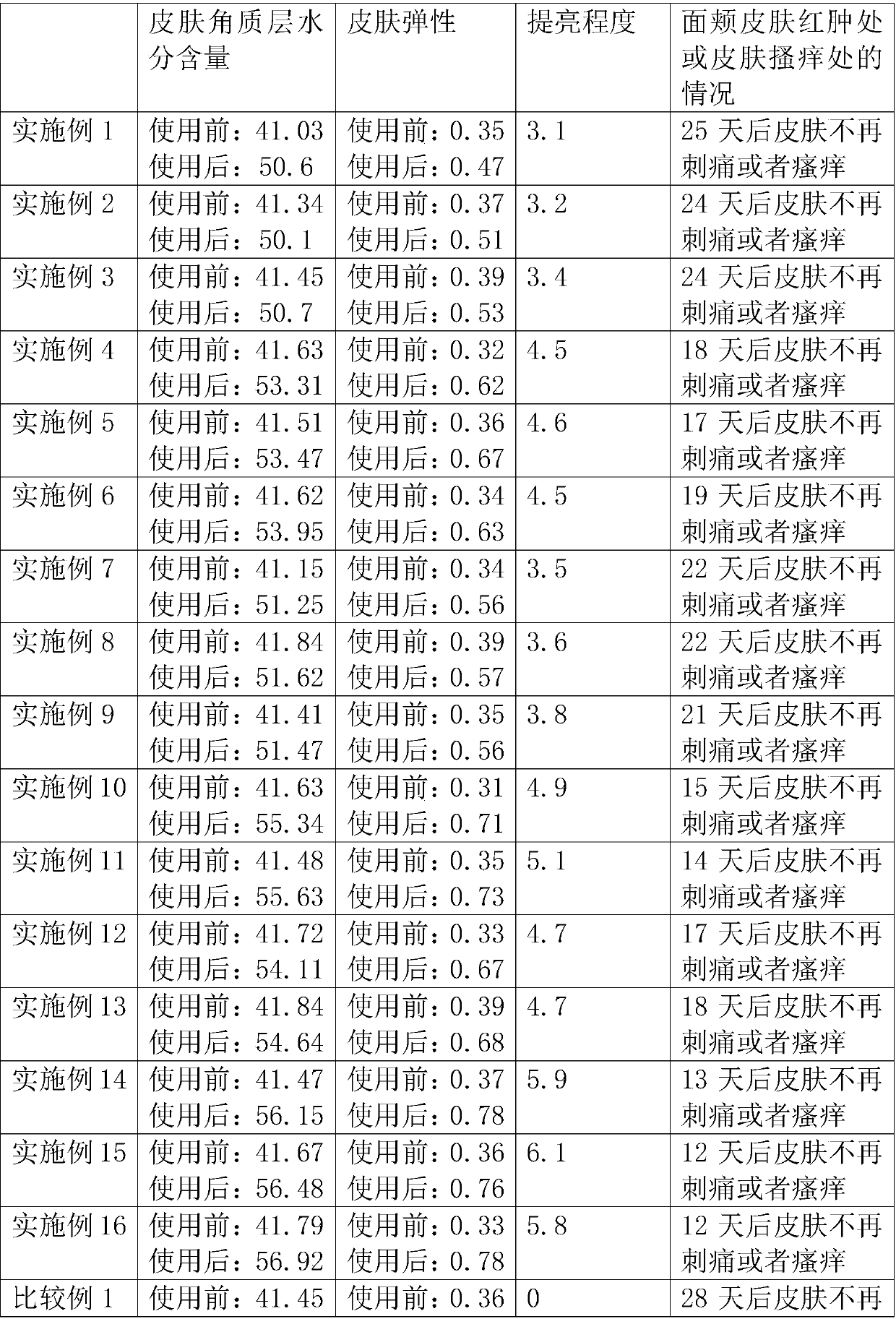

InactiveCN104146887ADelicate skinIncrease moisture contentCosmetic preparationsToilet preparationsNano siliconCuticle

The invention provides a BB cream having a long-acting moisturizing function. The BB cream consists following components: decamethylcyclopentasiloxane, isotridecyl isononanoate, ultrafine silicon processed titanium dioxide, nano silicon processed titanium dioxide, PEG-9 polydimenthylsiloxyethyl dimethicone, phenyl trimethicone, polydimethylsiloxane, PEG-10 polydimethylsiloxane, decamethylcyclopentasiloxane (and) polydimethylsiloxane / vinyl polydimethylsiloxane crosslinking polymer (and) polydimethylsiloxane, decamethylcyclopentasiloxane / disteardimonium hectorite / Propylene carbonate and the like. The invention also provides a preparation method of the BB cream. The BB cream is fine and smooth in skin feel, is light and weight and is air-penetrating, has a moisturizing function which can last for 8 hours, can significantly increasing moisture content in skin cuticle and can achieve long-acting moisturization without makeup floating.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

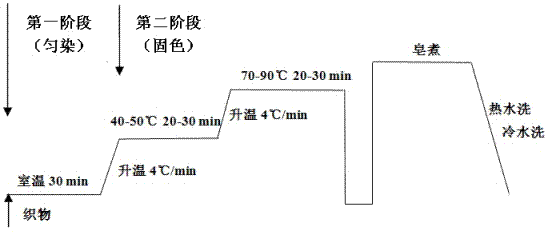

Reactive dye ecological dyeing method of silk fabrics

InactiveCN102767099ASave water for dyeingEasy to operateDyeing processSodium bicarbonateSodium Bicarbonate Solution

The invention provides a reactive dye ecological dyeing method of silk fabrics, which comprises the following steps of: (1) even dyeing: using reactive dye and decamethyl cyclopenta siloxane (D5) according to the mass ratio of 1:10 to 50 to prepare a reactive dye / D5 suspending dispersed liquid; padding the silk fabrics in 30 to 90 g / l of sodium bicarbonate solution; and dyeing the silk fabrics in the reactive dye / D5 suspending dispersed liquid with the rolling liquid rate of 160 to 200% at room temperature for 25 to 35 minutes, wherein the rolling liquid rate is used for ensuring even dyeing of the silk fabrics; and (2) color fixing: heating a mixture system obtained from the step (1) to 40 to 50 DEG C, and keeping the temperature for 20 to 30 minutes; then heating to 70 to 90 DEG C, and keeping the temperature for 20 to 30 minutes; and taking the silk fabrics out, and performing soap boiling. In the process of dyeing provided by the invention, an electrolyte is not added for dyeing acceleration, the dyeing rate of the dye is close to 100%, the fixing rate is higher than that of traditional bath dyeing, and the fastness of the fabrics is good after dyeing. Because the electrolyte is not needed for dyeing acceleration, the burden of treating dyeing waste water is effectively reduced, and the ecological environment is protected.

Owner:ZHEJIANG SCI-TECH UNIV

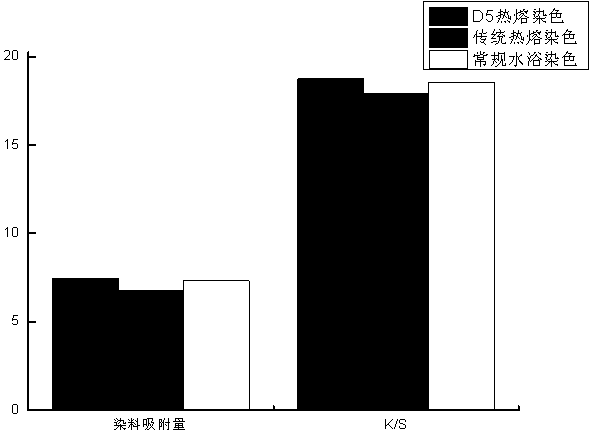

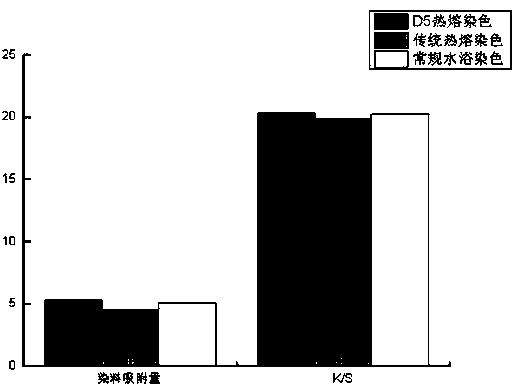

Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

InactiveCN104278576ASave water for dyeingReduce sublimationDyeing processDisperse dyeEcological environment

The invention discloses a disperse dye thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as a medium. The method comprises the following steps: (1) pretreating polyester fabric; (2) adding a certain amount of pure disperse dyes into a dyeing medium D5, controlling the amount of the dyeing medium D5, so that a ratio of the weight of a to-be-dyed fabric to the weight of the medium D5 is 1:10 to 1:30, dyeing in a dyeing machine, heating the system to 90-100 DEG C, preserving the temperature for 5-10 minutes, heating to the temperature of 180-200 DEG C, and performing thermosol fixation, wherein the fixation time is 10-30 minutes; and (3) performing reduction clearing on the dyed fabric according to a GB2394-80 method after dyeing. According to the method, non-aqueous medium dyeing is adopted, lots of water resources are saved, the thermosol temperature can be obtained under normal pressure, the conventional dyeing equipment can be adopted, the operation is simple, pure disperse dyes are adopted for dyeing, lots of dispersing aids are saved, the utilization rate of the dyes is improved, wastewater emission is reduced, and ecological environment protection is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

Sun-blocking and moisturizing composition and preparation method thereof

InactiveCN104146922AGood moisturizing effectGood sun protectionCosmetic preparationsToilet preparationsPurslane extractGlycerol

The invention provides a sun-blocking and moisturizing composition and a preparation method thereof. The composition is composed of following components including, by weight, 4-6% of propylene glycol laurate / ethyecellulose / propylene glycol isostearate, 1-2% of shea butter, 0.2-0.3% of tocopheryl acetate, 2% of ethylhexyl methoxycinnamate, 2.5% of butyl methoxydibenzoylmethane, 3-4% of isononyl isononanoate, 2% of decamethylcyclopentasiloxane, 1% of polydimethylsiloxane, 0.3-0.4% of an acrylic acid (ester) / C10-30 alkanolacrylate crosslinking polymer, 0.1% of xanthan gum, 0.02% of disodium EDTA, 0.02% of sodium hyaluronate, 3-4% of butanediol, 3-4% of glycerin, 3% of glyceryl polyether-26, 0.15-0.2% of an aminomethyl propanol / water premixed substance, 3% of water / butanediol / purslane extract, 0.5% of a bacteriostatic agent, 2% of a water / glycerin / phenoxyethanol / [beta]-glucan premixed substance and the balance deionized water. The sun-blocking and moisturizing composition is suitable for sensitive skin, has a touching-melt texture, can form a compact and soft residual film on a skin surface and enable active components to be absorbed better by the skin.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

Anti-sweat lotion

InactiveUS6319491B1Fast dryingSmooth skinCosmetic preparationsToilet preparationsAdditive ingredientHydrophobic silica

The present invention includes an anti-sweat lotion specifically designed for use by people suffering from hyperhidroses. In a preferred embodiment, the lotion of the present invention is a composition of the follow ingredients:a. denatured ethyl alcohol;b. hydrophobic silica;c. a monoethyl ester of the copolymer of methyl vinyl ether and maleic anhydride;d. iso-octahexacontane;e. octamethylcyclotetrasiloxane; and,f. hydroxypropylcelluose.In another preferred embodiment, the octamethylcyclotetrasiloxane is replaced by decamethylcyclopentasiloxane.

Owner:WHIPPLE MICHAEL B

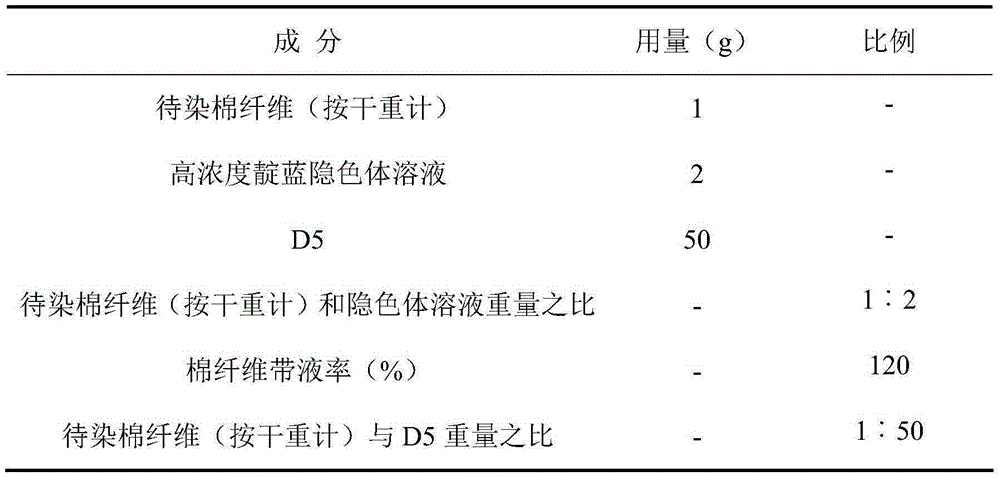

One-time deep dyeing method for cotton fiber employing indigo dye

ActiveCN105401463AImprove dye uptakeAchieve a deep color effectDyeing processHigh concentrationFiber

The invention discloses a one-time deep dyeing method for a cotton fiber employing an indigo dye. The method is a process of finishing dyeing of the cotton fiber with the indigo dye in a non-aqueous medium of decamethyl cyclopentasiloxane (D5). The method comprises the following steps: (1) refining, washing and dewatering the cotton fiber, and controlling the final take-up rate for dyeing; (2) preparing a high-concentration indigo leuco body; (3) firstly, adding a proper amount of high-concentration indigo leuco body to the D5 to prepare a dye liquor, and then putting the cotton fiber with certain take-up rate into a non-aqueous dye liquor for dyeing; and 4) after dyeing, carrying out oxidation treatment, and then carrying out soap boiling to remove the surface floating color. The cotton fiber is dyed in the D5 by the indigo dye; oxidation of the indigo leuco body in the dyeing process and invalid decomposition of sodium hydrosulfite can be effectively suppressed; the one-time deep dyeing effect is reached; the dyeing procedure is greatly simplified; the dyeing time is shortened; the work efficiency is improved; the cost is saved; and dyeing wastewater emission is significantly reduced.

Owner:ZHEJIANG SCI-TECH UNIV

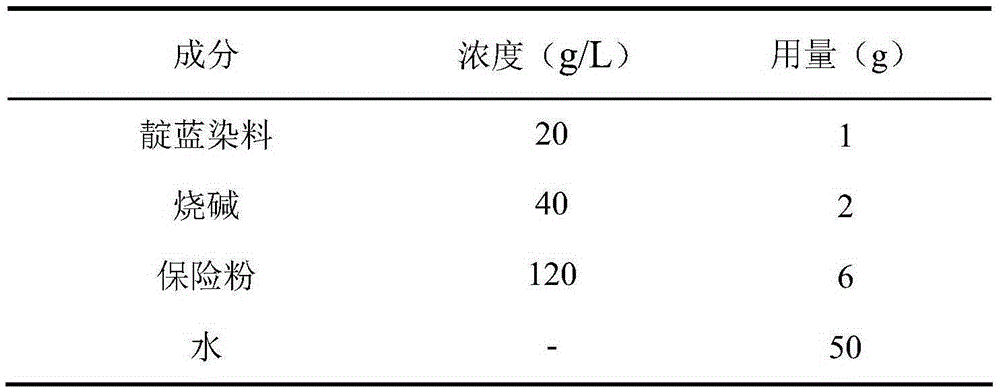

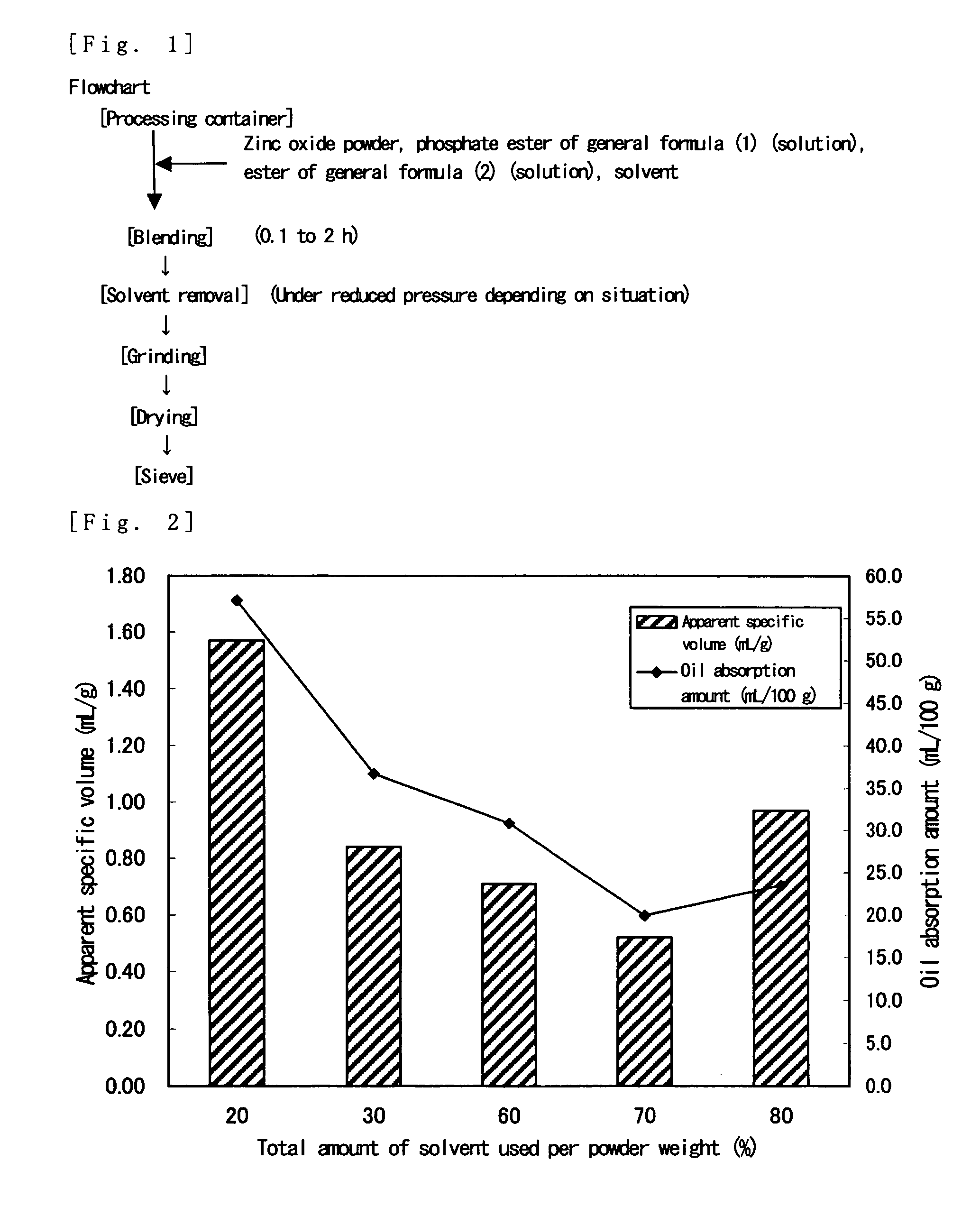

Sun-Block Cosmetic

InactiveUS20070264292A1Reduce absorptionSuperb ease of washabilityCosmetic preparationsToilet preparationsSpecific volumeZinc

The invention is a sunscreen cosmetic containing (a) a specific hydrophobic zinc oxide powder, (b) decamethylcyclopentasiloxane, and (c) an alkyl trimethicone having 6 to 12 carbons. Hydrophobic powder that has the noticeable effects of low oil absorption and a low apparent specific volume is stably blended into a sunscreen cosmetic as a UV radiation dispersing agent to produce a sunscreen cosmetic that has remarkably improved ease of washability after use.

Owner:SHISEIDO CO LTD

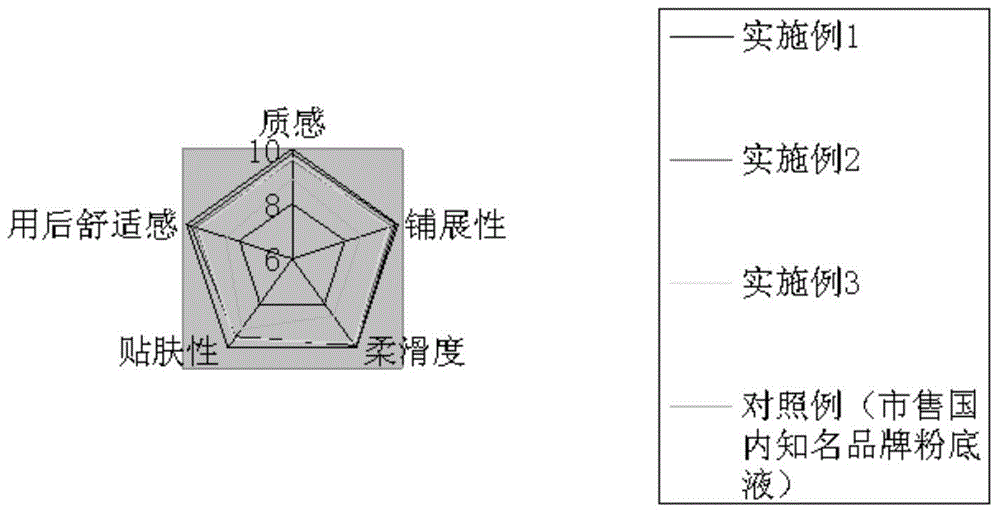

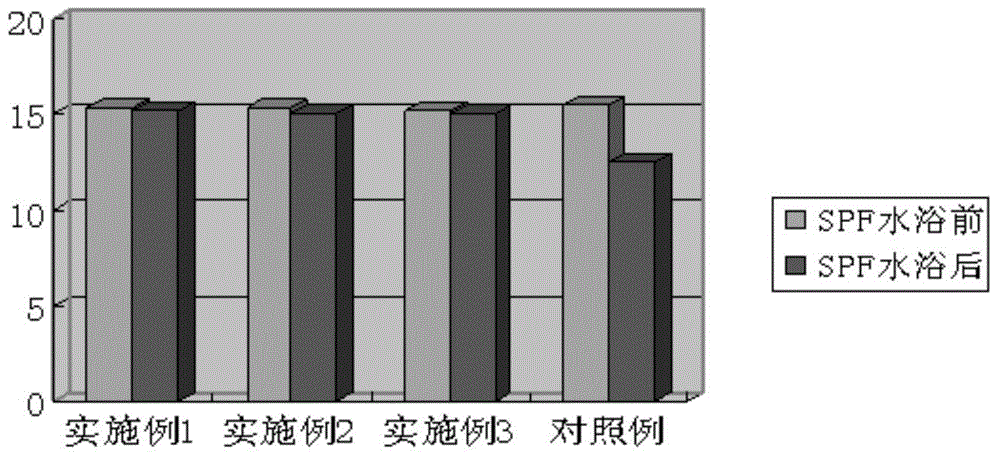

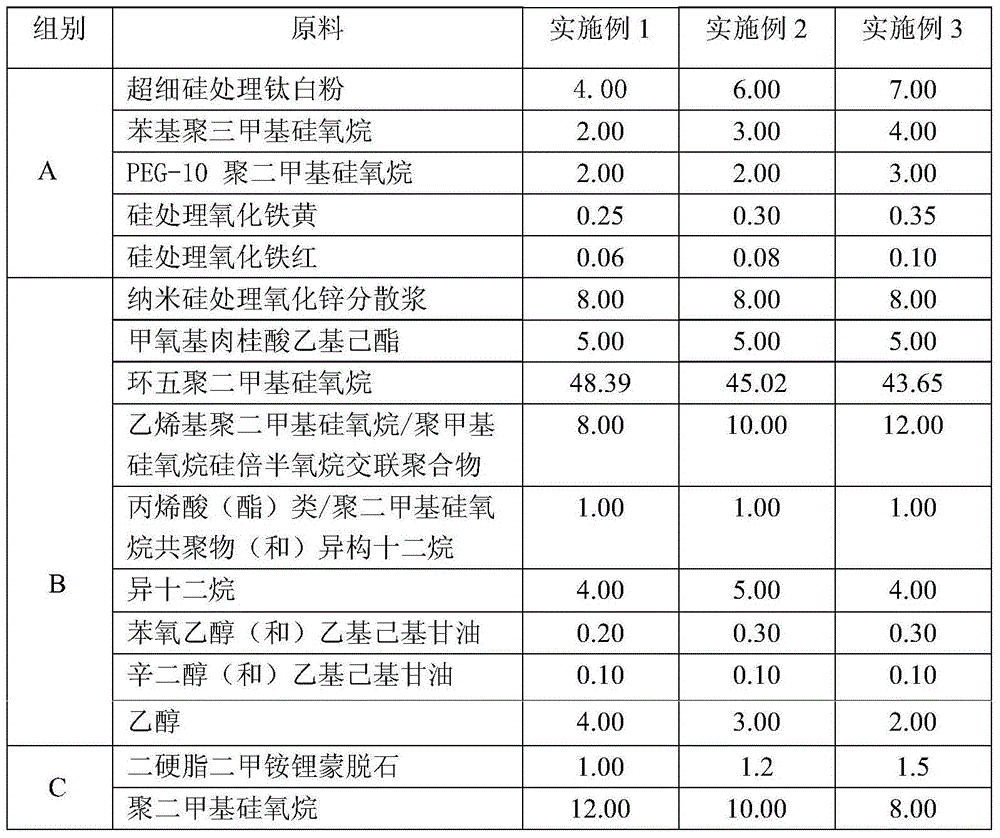

Silky soft skin feeling type essence liquid foundation and preparation method thereof

InactiveCN104434570APrevent moisture from evaporatingGood moisturizing effectCosmetic preparationsBody powdersCross-linkSlurry

The invention provides a silky soft skin feeling type essence liquid foundation. The silky soft skin feeling type essence liquid foundation comprises the following components: decamethylcyclopentasiloxane, polydimethylsiloxane, a vinyl polydimethylsiloxane / polymethylsiloxane silsesquioxane cross-linked polymer, ultrafine silicon treated titanium dioxide, nano silicon treated zinc oxide dispersed slurry, octyl 4-methoxycinnamate, 2,2,4,4,6-pentamethylheptane, ethanol, trimethylphenylsilane, disteardimonium hectorite, acrylic acid (ester) / polydimethylsiloxane copolymer / 2,2,4,4,6-pentamethylheptane, PEG-10 polymethylsiloxane, phenoxyethanol / ethylhexyl glycerin, octylene glycol / ethylhexyl glycerin, silicon treated iron oxide yellow and silicon treated iron oxide red. The silky soft skin feeling type essence liquid foundation is good in water resistance, good in ductility, and fine and smooth in skin feeling.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

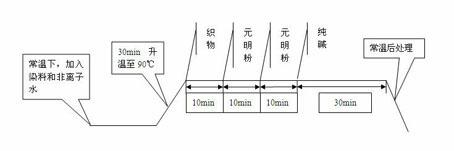

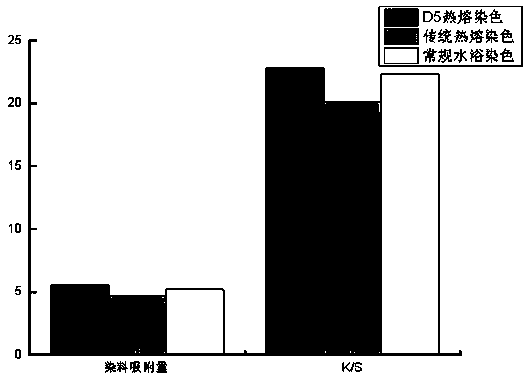

Active dye-decamethylcyclopentasiloxane suspension system dyeing process of cotton fabric

InactiveCN103485198ASolve the low dye uptake rateSolve water consumptionDyeing processVegetal fibresWater savingWater baths

The invention relates to an active dye-decamethylcyclopentasiloxane suspension system dyeing process of a cotton fabric. The process comprises the following steps: S1, preparation of an active dye-D5 (Decamethylcyclopentasiloxane) suspension system; S2, pre-treatment of the cotton fabric; S3, dyeing. The process provided by the invention has the beneficial effects of being capable of realizing salt-free and water-saving dyeing, and effectively solving the problem that the dye-uptake of the dye is low, the water consumption and the pollution emission are high, and the saltness of wastewater is high in conventional water bath dyeing by the active dye. Compared with conventional water bath dyeing, according to the active dye-D5 suspension system dyeing process provided by the invention, the dye-uptake is close to 100% and the total fixation rate is about 90% under a condition that no salt is used for accelerating the dyeing, the dye-uptake and the total fixation rate are far higher than those in the conventional water bath dyeing; meanwhile, the process has the relatively good color fastness.

Owner:KUNSHAN WANFENG GARMENT

Air cushion BB cream and preparation method thereof

InactiveCN105687045AImprove efficacyHigh oil absorptionCosmetic preparationsMake-upSodium BentoniteC12-15 Alkyl benzoate

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

Tone-up cream

ActiveCN110179740AImprove smoothnessHigh transparencyCosmetic preparationsToilet preparationsSkin colorComposition B

The invention relates to the technical field of cosmetics, and provides a tone-up cream aiming at the problem that skin color is difficult to improve by a tone-up cream. The tone-up cream dprovided bythe invention comprise a composition A, a composition B and a composition C. The composition A is prepared from the following ingredients in parts by mass: 0.5 parts of pammonium acryloyldimethyltaurate-VP copolymer and 1-2 parts of propylene glycol dicaprylate / dicaprate. The composition B is prepared from the following ingredient in parts by mass: 1-4 parts of titanium dioxide, 1-4 parts of cetyl alcohol, and 1-4 parts of sodium polyacrylate / / polydimethylsiloxane / / decamethylcyclopentasiloxane / / tridecyl polyether-6 / / PEG / PPG-18 / 18 polydimethylsiloxane. The composition C is prepared from the following ingredients in parts by mass: 0.5-0.75 parts of 4-butyl resorcinol, 0.01-0.1 parts of Chinese galla extract, and 5-10 parts of nicotinamide. 4-Butyl resorcinol, Chinese gall extract and nicotinamide are adopted to cooperate so as to achieve a synergistic effect, which is beneficial to improve the smoothness and transparency of the skin, and is beneficial to improve the skin color effect ofthe one-up cream.

Owner:广州市瑞芬化妆品有限公司

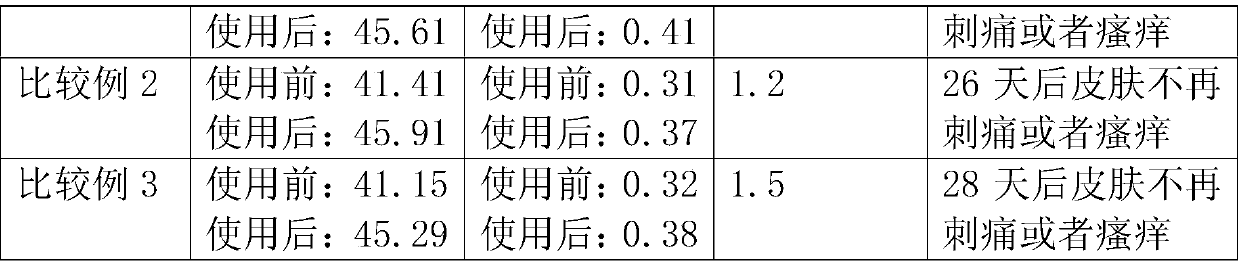

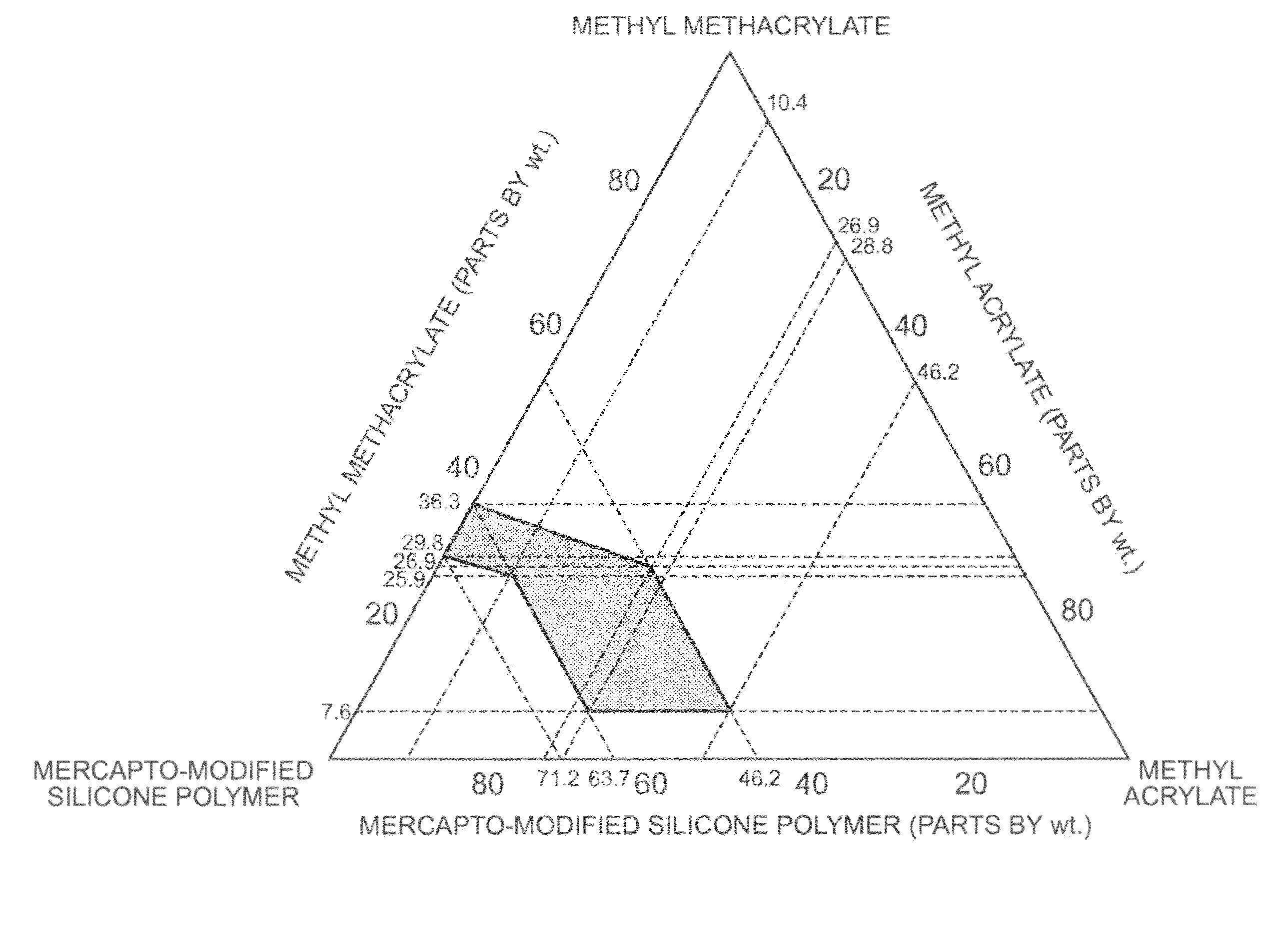

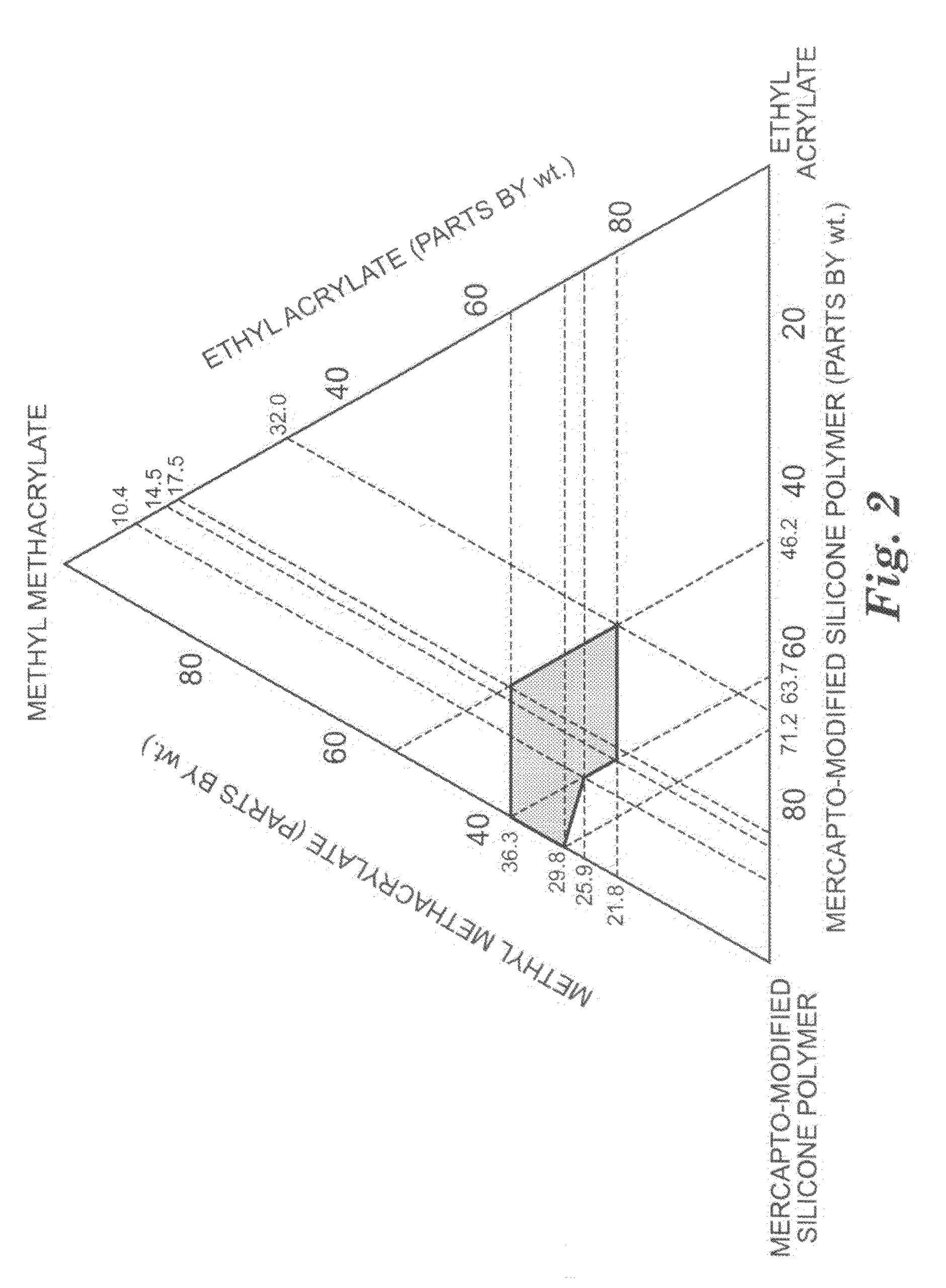

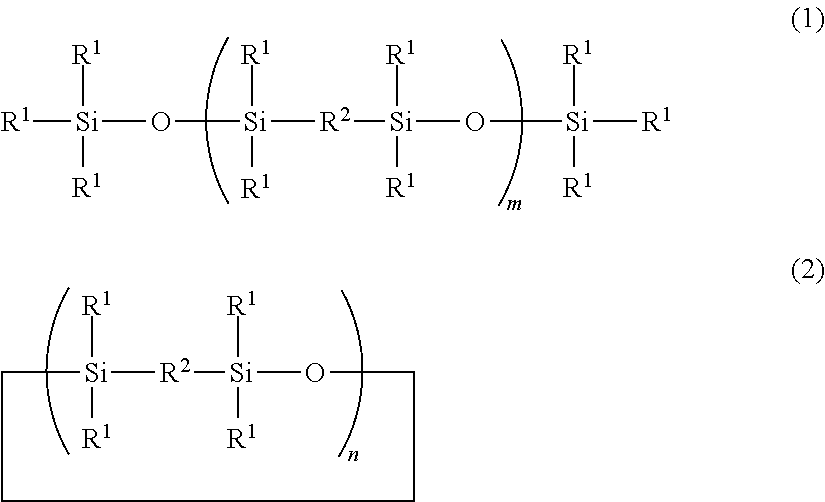

Grafted silicone polymer and products made therewith

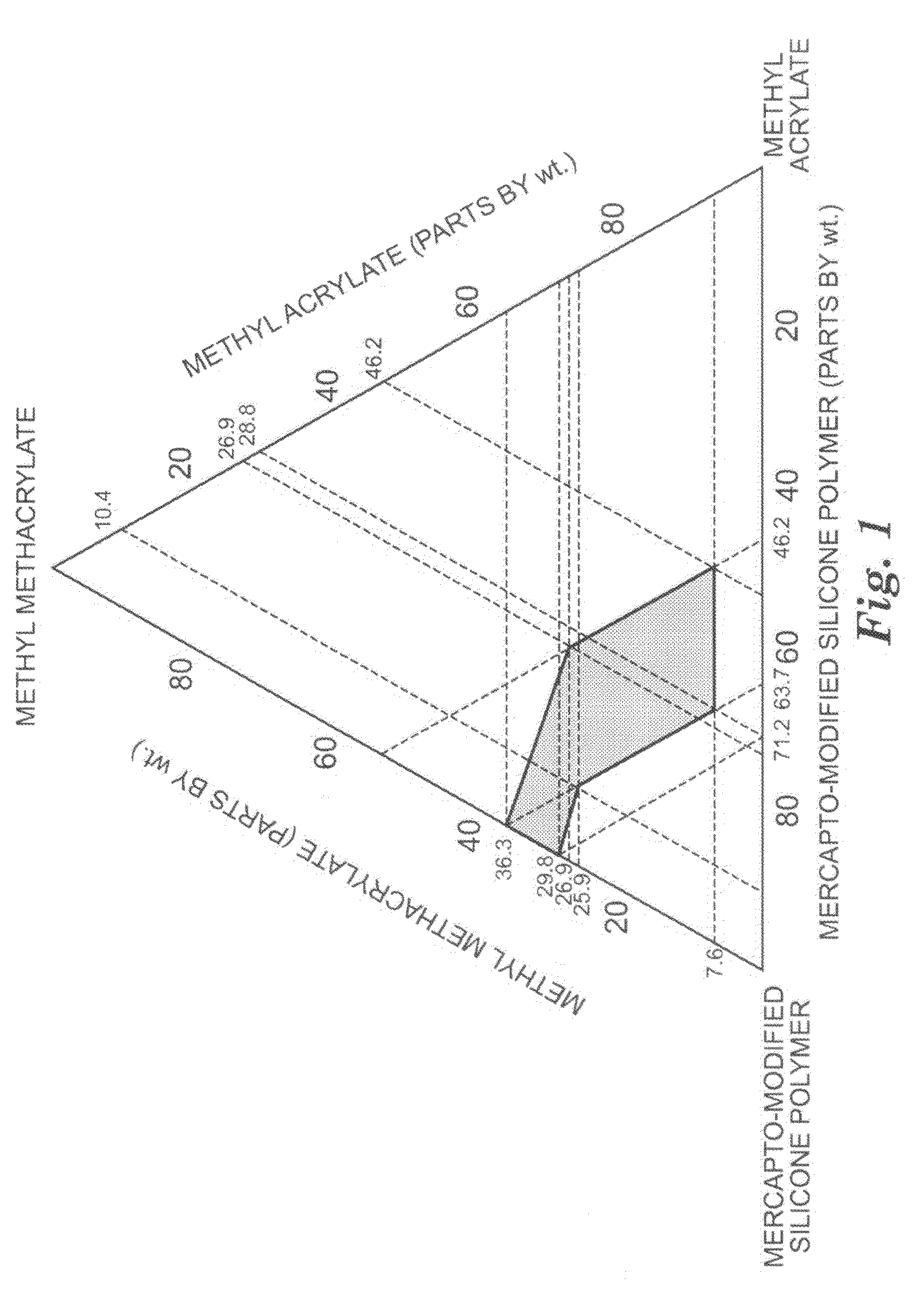

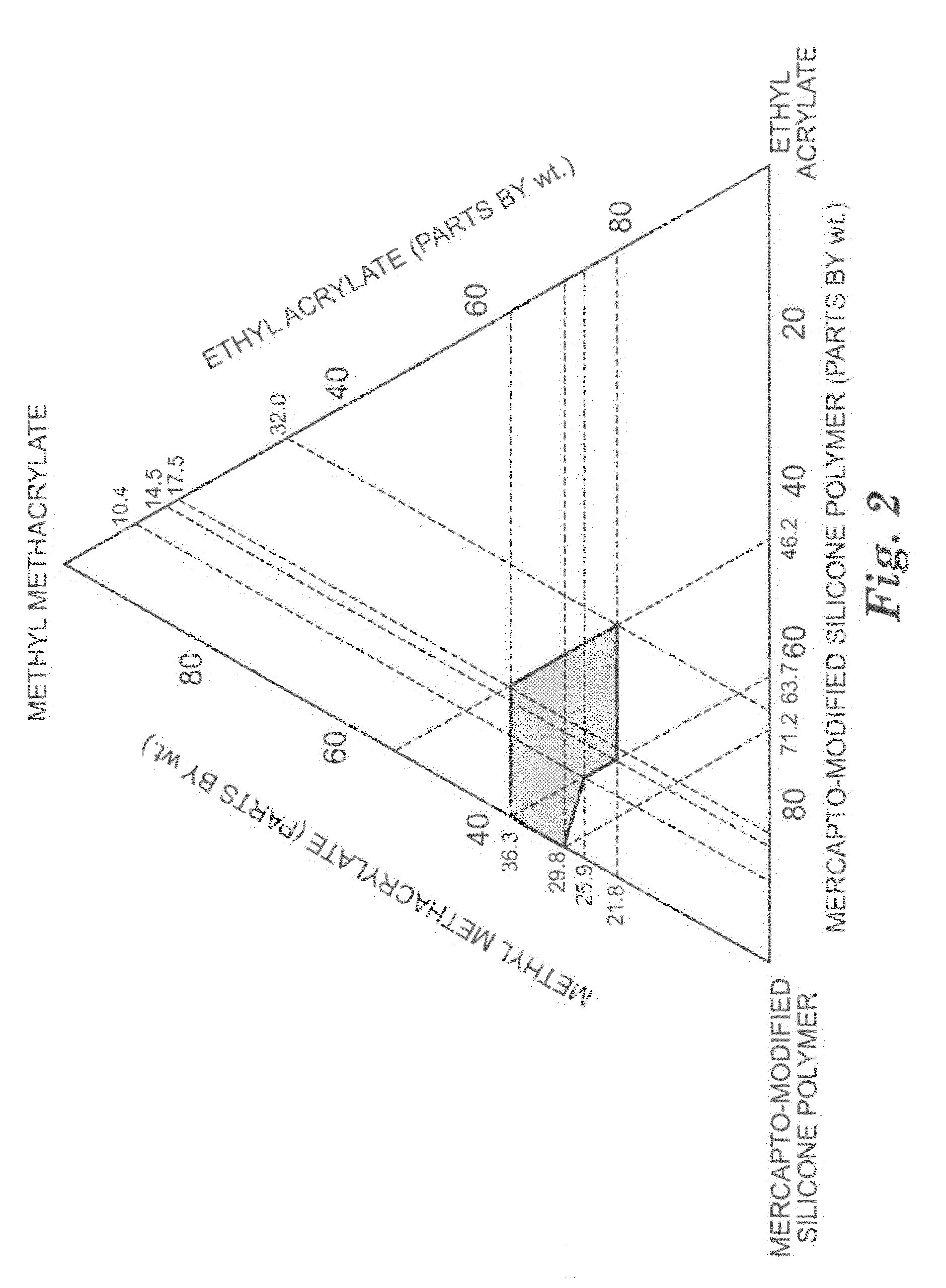

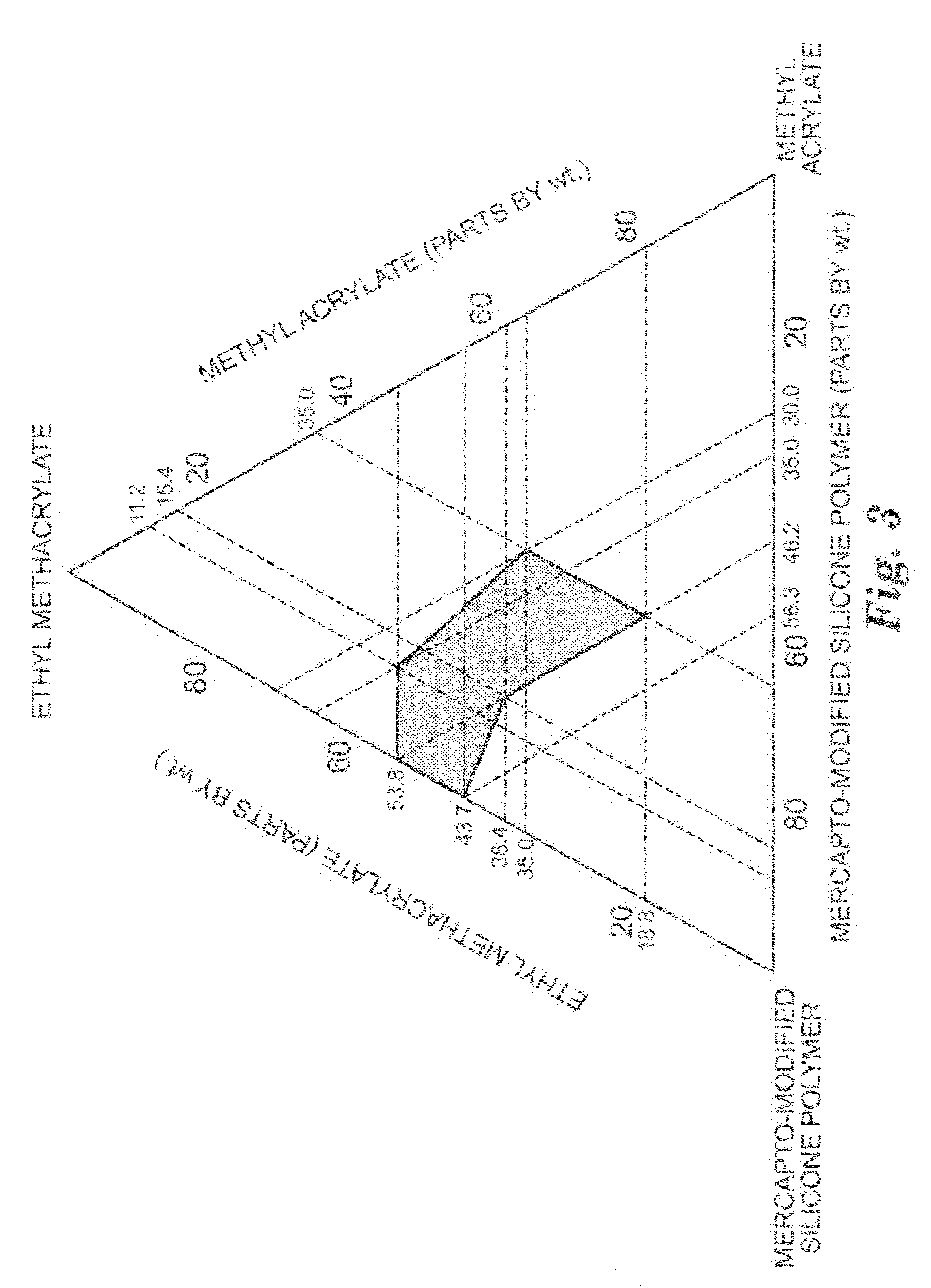

InactiveUS8258243B2Improve solubilityHigh water resistanceCosmetic preparationsMake-upPolymer scienceMeth-

The grafted silicone polymer comprises a polymerization product of (a) a mercapto-modified silicone polymer and (b) a radically polymerizable monomer component comprising (meth)acrylic acid and / or a (meth)acrylic acid alkyl ester selected so that the solubility parameter of a polymer obtained only from the radically polymerizable monomer component is at least 9.14 (cal / cm3)1 / 2, wherein the grafted silicone polymer has a elastic storage modulus of 1 105 Pa or greater at 37° C., 1 Hz and dissolves in decamethylcyclopentasiloxane by 1 weight percent or greater at 23° C.

Owner:3M INNOVATIVE PROPERTIES CO

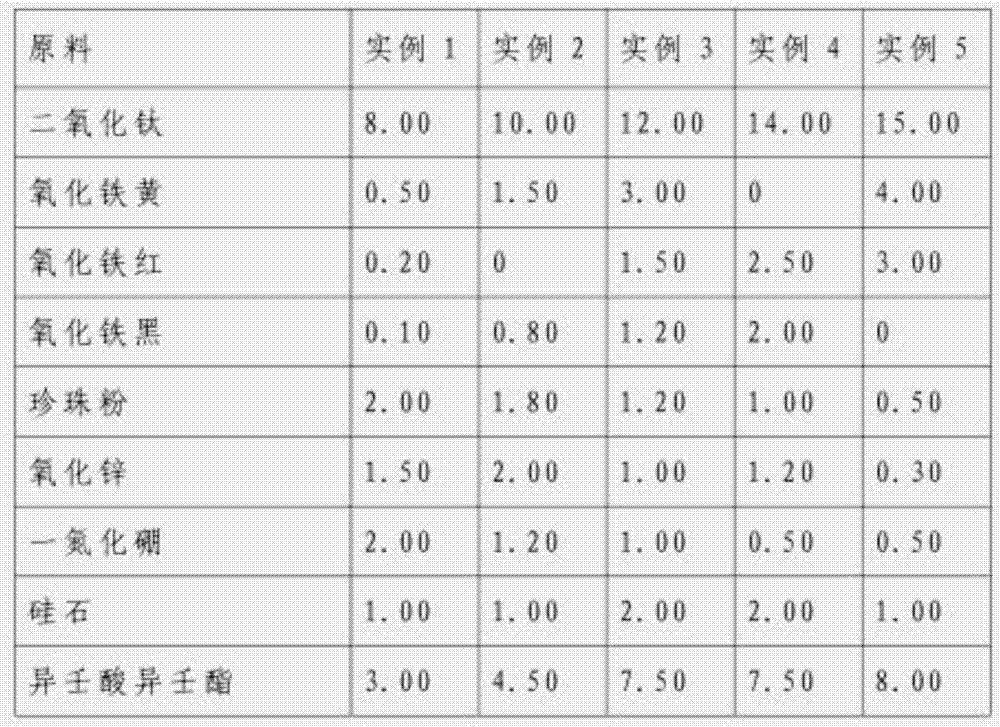

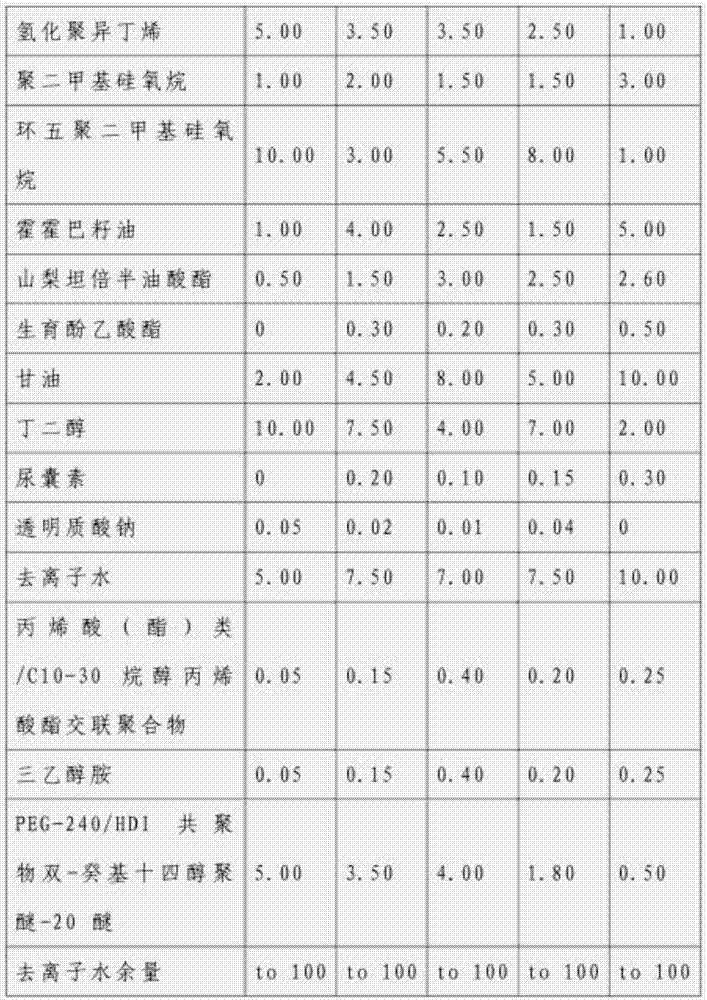

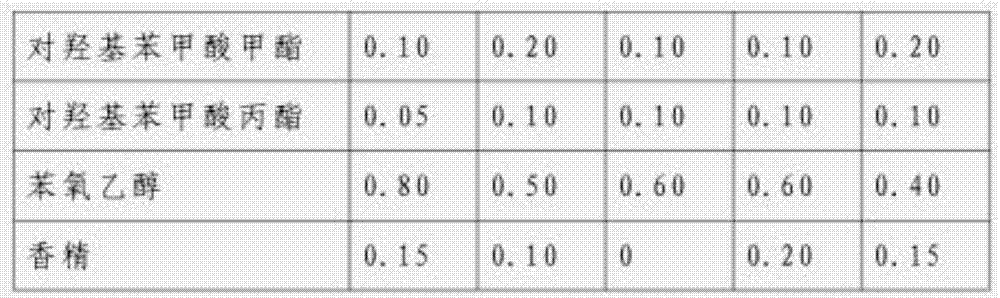

Jelly-like foundation makeup and preparation method of same

InactiveCN107412115ALong-lasting makeupNo greasy feelingCosmetic preparationsMake-upButanediolDimethyl siloxane

The invention discloses a jelly-like foundation makeup and a preparation method of same. The foundation makeup includes the following components: titanium dioxide, iron oxide yellow, iron oxide red, iron oxide black, pearl powder, zinc oxide, boron nitride, silica, isononyl isononanoate, hydrogenated polyisobutene, polydimethylsiloxane, decamethylcyclopentasiloxane, Jojoba seed oil, sorbitan sesquioleate, tocopheryl acetate, glycerol, butanediol, allantoin, sodium hyaluronate, acrylate / C10-30 alkanol acrylate crosslinked polymer, triethanolamine, PEG-240 / HDI compolymer bis-decyl tetradecanol polyether-20 ether, methyl 4-hydroxybenzoate, propyl 4-hydroxybenzoate, phenoxyethanol, essences, and the balanced being deionized water. The jelly-like foundation makeup, through dual-emulsification technology, has long-lasting makeup effects, is water-proofing and oil-proofing, has no greasy sense and integrates moisturizing, concealing, isolating and sun-screening and the like functions. The preparation method can achieve large-scale mass production.

Owner:SUZHOU ANTE COSMETICS CO LTD

Grafted silicone polymer and products made therewith

InactiveUS20100130693A1Improve solubilityIncrease freedomCosmetic preparationsMake-upSolubilityPolymer chemistry

The grafted silicone polymer comprises a polymerization product of (a) a mercapto-modified silicone polymer and (b) a radically polymerizable monomer component comprising (meth)acrylic acid and / or a (meth)acrylic acid alkyl ester selected so that the solubility parameter of a polymer obtained only from the radically polymerizable monomer component is at least 9.14 (cal / cm3)1 / 2, wherein the grafted silicone polymer has a elastic storage modulus of 1 105 Pa or greater at 37° C., 1 Hz and dissolves in decamethylcyclopentasiloxane by 1 weight percent or greater at 23° C.

Owner:3M INNOVATIVE PROPERTIES CO

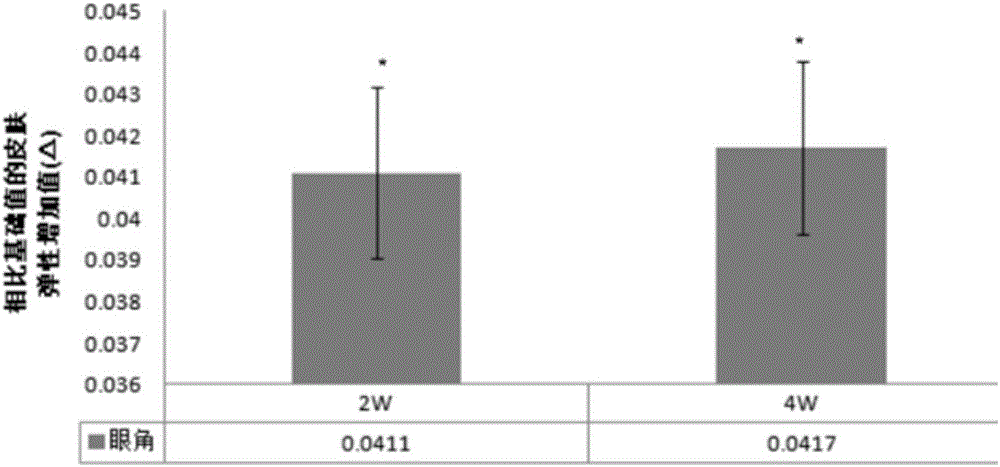

Oil-in-water sun-proof product with water-resisting and skin-elasticity-improving functions and preparation method of oil-in-water sun-proof product

ActiveCN110075007AWaterproofIncrease elasticityCosmetic preparationsToilet preparationsBis-ethylhexyloxyphenol methoxyphenyl triazineSkin elasticity

The invention belongs to the technical field of cosmetics, and provides an oil-in-water sun-proof product with water-resisting and skin-elasticity-improving functions and a preparation method of the oil-in-water sun-proof product. The oil-in-water sun-proof product is prepared from the following components in parts by weight: 1-3 parts of cetostearyl alcohol, 1-5 parts of polydimethylsiloxane, 1-5parts of decamethylcyclopentasiloxane / cyclohexasiloxane, 3-8 parts of dibutyl adipate, 3-8 parts of propylene glycol dicaprylate / dicaprate, 3-10 parts of titanium dioxide, 5-10 parts of ethylhexyl methoxycinnamate, 1-4 parts of diethylaminohydroxybenzoyl hexyl benzoate, 1-4 parts of ethylhexyl triazone, 1-3 parts of bis-ethylhexyloxyphenol methoxyphenyl triazine, 1-5 parts of octocrilene, 2-10 parts of glycerinum, 2-10 parts of butanediol, 0.1-1 part of triethanolamine, 0.01-0.1 part of an ethylenediaminetetraacetic acid (EDTA) disodium salt, 0.01-2 parts of a thickener, 0.1-2 parts of a preservative, 0.5-2 parts of an emulsifier and 46.5-63.7 parts of water. By adopting the scheme, the problems of poor refreshing property and water resistance of a sun-proof product in the prior art are solved.

Owner:广州微肽生物科技有限公司

High-settling-resistant and high-color depth pigment nanocapsule coating as well as preparation method and application

ActiveCN108716141AChange densityImprove anti-settling performanceDyeing processCoatingsEmulsion polymerizationHigh color

The invention discloses a high-settling-resistant and high-color depth pigment nanocapsule coating which has good settling resistance. The invention further discloses a preparation method of the high-settling-resistant and high-color depth pigment nanocapsule coating. The preparation method comprises the following steps: putting a great deal of low-density inert volatile decamethylcyclopentasiloxane or octamethylcyclotetrasiloxane into an acrylic monomer, and carrying out nano capsulation treatment on an organic pigment through fine emulsion polymerization, thereby obtaining a uniform and stable nano capsule coating. The coating is green and environmental-friendly in preparation process, easy in raw material obtaining, simple in process and high in color coating efficiency. The invention further provides application of the pigment nanocapsule coating to fabric coating printing, a dark fabric of which a K / S value is greater than or equal to 25 can be made, the air permeability retentionrate of the printed fabric is greater than 70%, the stiffness amplification of the printed fabric is less than 30%, the dry / wet friction resistance solidness of the printed fabric is greater than orequal to grade 4, and the objective hand feeling grade of the printed fabric is greater than or equal to 4.

Owner:ZHEJIANG NAMEI MATERIAL TECH

Multifunctional composite gas phase anti rust agent and preparation method thereof

The invention discloses a multifunctional composite gas phase anti rust agent, which is characterized by comprising the following raw materials by weight: 1-2 parts of nitrite dicyclohexylamine, 1-2 parts of hydroxyethyl ethylenediamine, 0.5-1 part of ethyl maltol, 1-2 parts of propylene glycol alginate, 4-6 parts of decamethylcyclopentasiloxane, 2-4 parts of palm oil, 1-2 parts of glyceryl triisocaprylate, 1-2 parts of trimethylolpropane trioleate, 0.5-1 part of barium petroleum sulfonate, 6-8 parts of chitosan, 1-2 parts of mannitol, 6-8 parts of sodium tripolyphosphate, 2-4 parts of sodium alginate, 4-6 parts of a performance additive and 40-50 parts of water. The multifunctional composite gas phase anti rust agent has both contact antirust and gas phase antirust effects. The multifunctional composite gas phase anti rust agent has good antirust effect on iron and steel, copper, aluminum, zinc and other various metal materials, the time of duration is long, and the multifunctional composite gas phase anti rust agent has sustained release and controlled release effect, and is suitable for occasions requiring both waterborne antirusting and sealed space gas phase antirusting effects.

Owner:SUZHOU QINAN IND & TRADE

Sunscreen and preparation method thereof

InactiveCN109589277AAchieve the double combination of chemical sunscreen and physical sunscreenEvenly dispersedCosmetic preparationsToilet preparationsAdditive ingredientDimethyl siloxane

The invention discloses a sunscreen. The sunscreen is prepared from a component A, a component B and a component C, wherein the component A comprises the following ingredients: propylene glycol, xylitol, xanthan gum, sodium chloride and sodium hyaluronate; the component B comprises the following ingredients: decamethylcyclopentasiloxane, cetyl PEG / PPG-10 / 1 dimethicone, sorbitan isostearate, zinc oxide, octocrylene, 2-ethylhexyl 4-methoxycinnamate, polydimethylsiloxane, isopropyl myristate, tocopheryl acetate, disteardimonium hectorite, a methyl methacrylate crosslinked polymer and titanium dioxide; the component C comprises the following ingredients: phenoxyethanol, ethylhexylglycerin and the balance of deionized water. The sunscreen can realize chemical sunscreen and physical sunscreen, realizes the dual-sunscreen effect and has good skin fitting performance and sunscreen effect. The invention further discloses a preparation method of the sunscreen. The preparation method is simple, the sunscreen has a good dispersion effect, so that the sunscreen product has good skin fitting performance and a good absorption effect.

Owner:广州欧盛化妆品有限公司

Method for splitting dimethyl dichlorosilane hydrolysate

ActiveCN104059099AHigh activityIncrease alkalinitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTrimethylsilanolHydrolysate

The invention discloses a method for splitting dimethyl dichlorosilane hydrolysate. The method comprises the following steps: carrying out load reaction onto strong-basicity macroporous anion exchange resin, potassium hydroxide, potassium trimethylsilanolate and [bmim]BF4 ionic liquid to obtain a composite catalyst after the reaction is ended; adding dimethyl dichlorosilane hydrolysate into a splitting kettle to obtain a ring-body mixture by splitting and re-arranging solvent oil, the composite catalyst and the hydrolysate; and washing with water to remove high-boiling point residues and low-boiling point residues to obtain products such as octamethylcyclotetrasiloxane D4, hexamethylcyclotrisiloxane and decamethylcyclopentasiloxane.

Owner:九江星成高分子材料有限公司

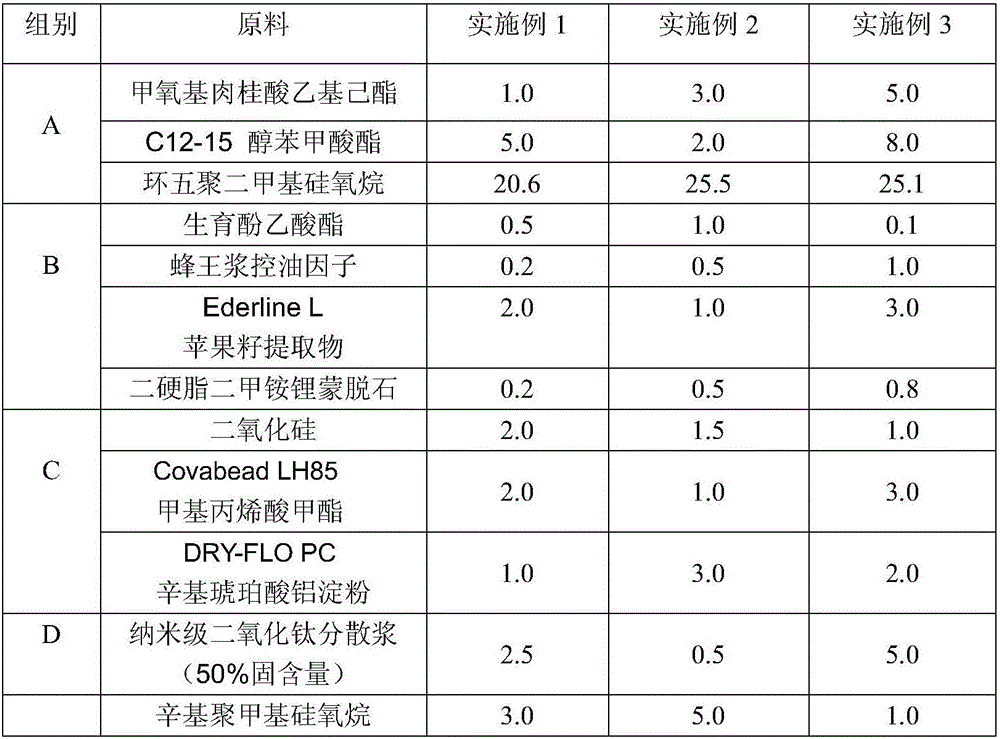

Skin care product with oil-control function and preparation method thereof

ActiveCN106265431AInstant and long-lasting dry skin feelAvoid harmCosmetic preparationsToilet preparationsC12-15 Alkyl benzoateSilicon dioxide

The invention provides a skin care product with an oil-control function and a preparation method thereof. The skin care product comprises, by mass, 0.2-12 parts of oil-control composition, 2.0-8.0 parts of C12-15 alkyl benzoate, 20.6-52.6 parts of decamethylcyclopentasiloxane, 0.1-0.5 part of tocopheryl acetate, 0.2-0.8 part of disteardimonium hectorite, 1.0-5.0 parts of carprylyl methicone and 5.0-20.0 parts of diphenyl dimethicone, wherein the oil-control composition comprises, by mass, 0.2-1.0 part of royal jelly oil-control factor, 1.0-5.0 parts of silicon dioxide, 1.0-3.0 parts of methyl methacrylate and 1.0-3.0 parts of aluminum starch octenylsuccinate in the skin care product. The skin care product has the advantages that the oil-control effect is good, people feel good when using the skin care product, and flakes will not occur in the using process.

Owner:广州集妍化妆品科技有限公司

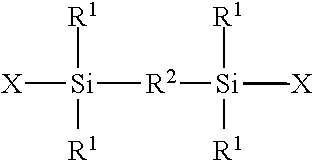

Linear And Cyclic Siloxanes And Cosmetic Compositions Made Thereof

ActiveUS20120237583A1Reduce the degree of polymerizationImprove stabilityCosmetic preparationsSilicon organic compoundsUltravioletDegrees of freedom

The present invention relates to a novel organopolysiloxane having a specified structure and a cosmetic containing the aforementioned organopolysiloxane. The novel organopolysiloxane according to the present invention is volatile, possesses stability at low temperature, provides superior glossiness, and has a superior property with respect to miscibility with a UV-ray absorber, and which is useful as a replacement of octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane, or methyltrime-thicone. The cosmetic according to the present invention can provide superior feeling to the touch during use and a superior outer appearance. Furthermore, a degree of freedom in blending various components such as UV-ray absorbers into the cosmetic according to the present invention is increased.

Owner:DOW TORAY CO LTD

Methods and compositions for cleaning articles

InactiveUS20060191075A1Easy to disassembleLower energy requirementsNon-ionic surface-active compoundsOrganic detergent compounding agentsEmulsionSolvent

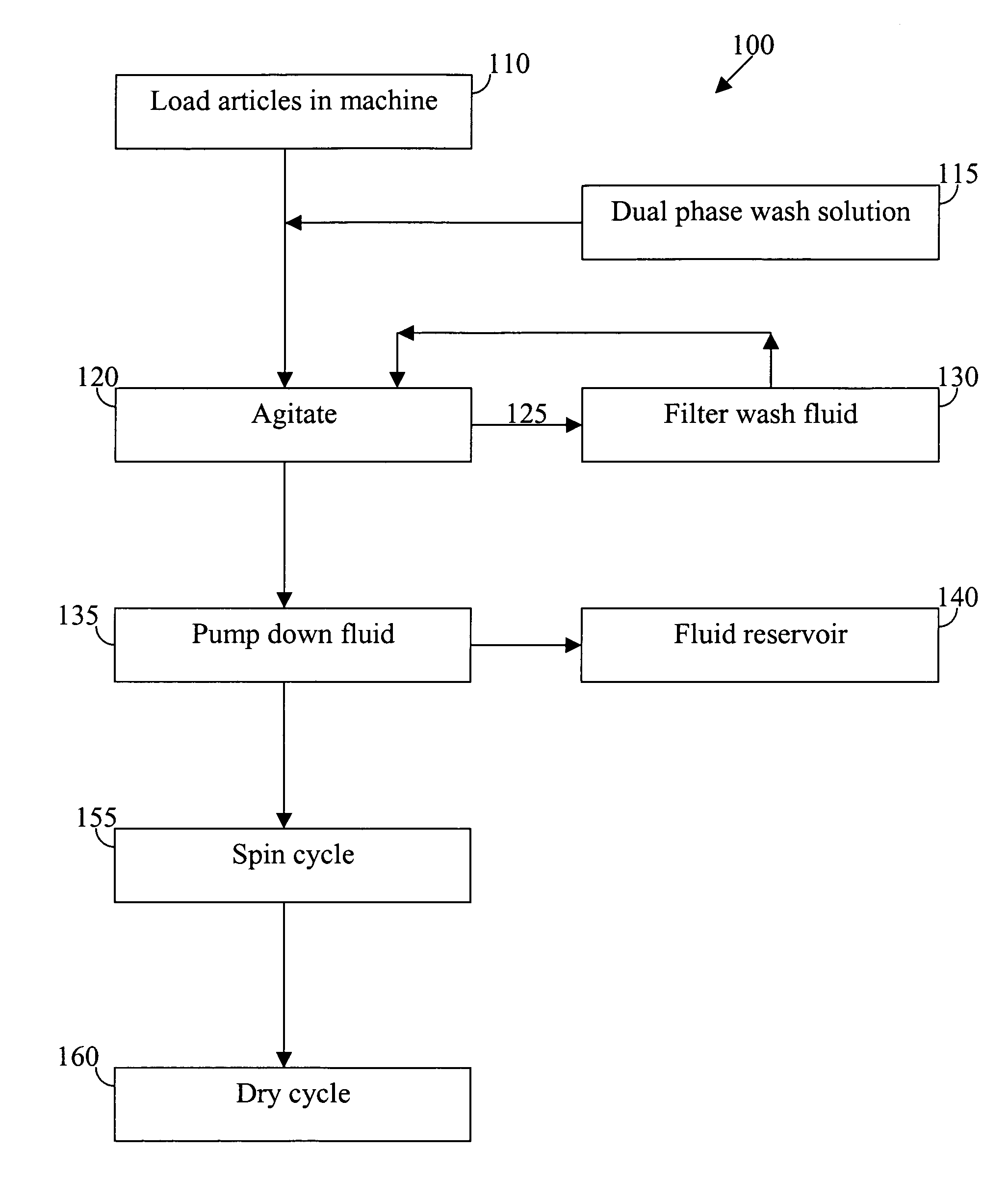

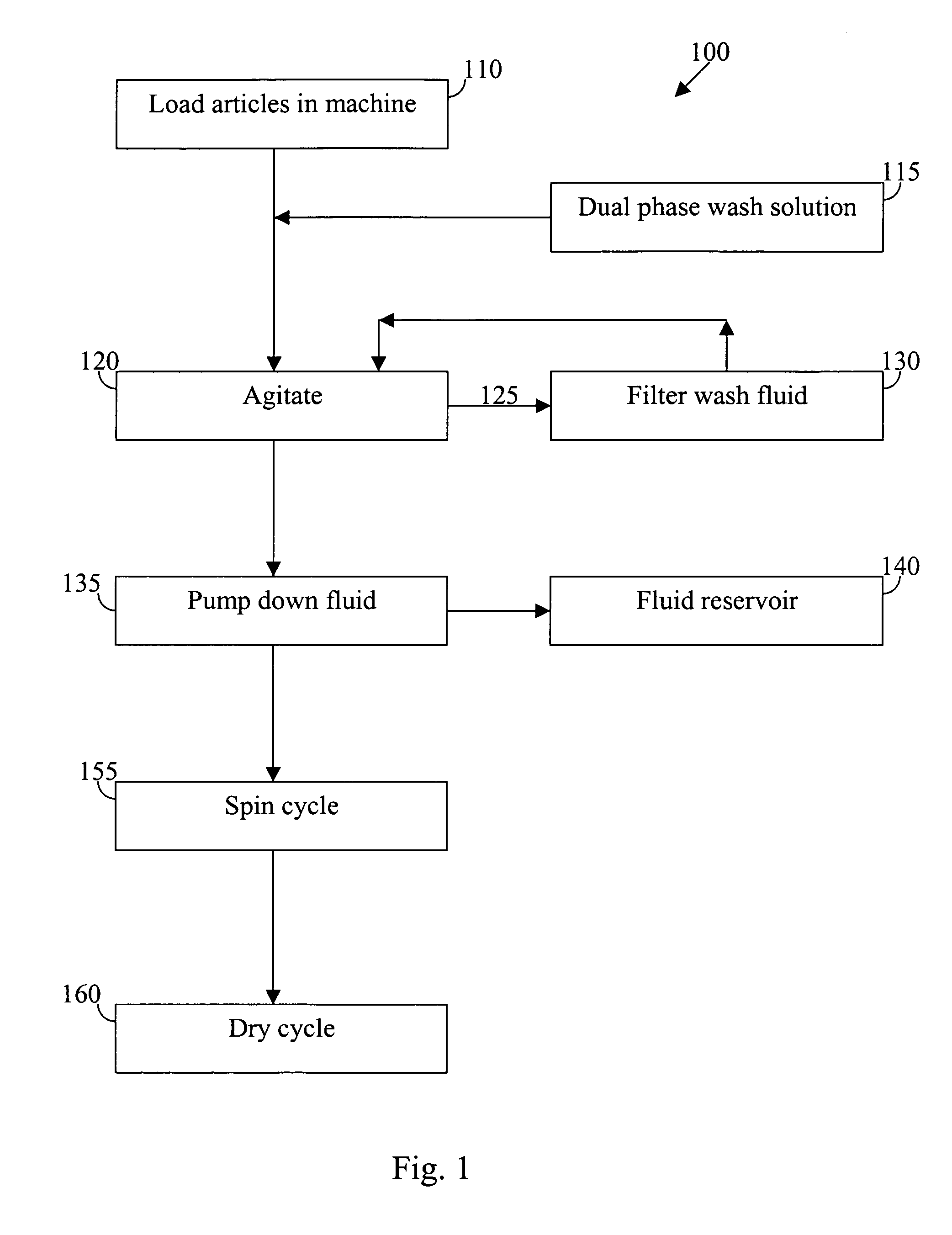

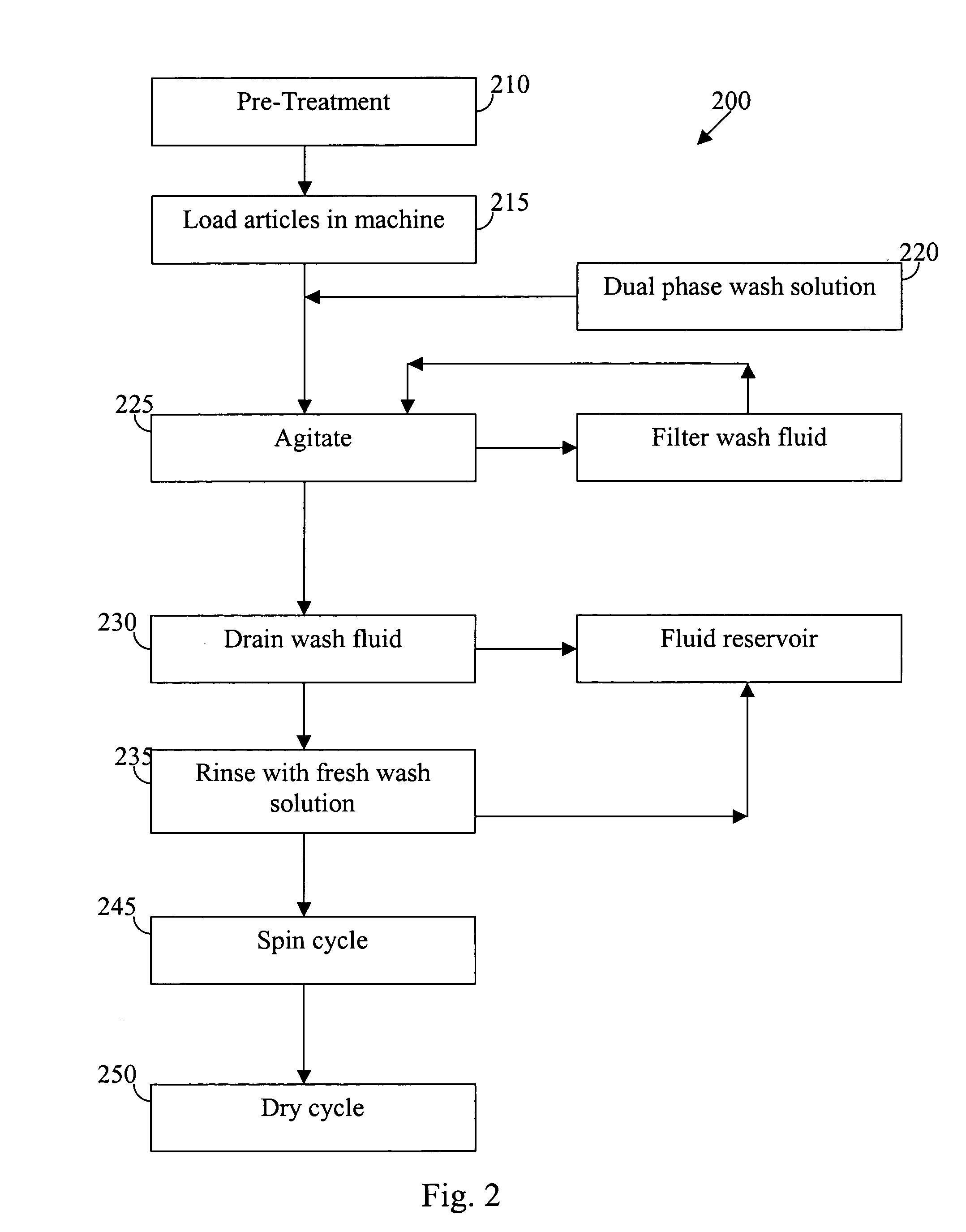

The present invention provides methods and compositions for cleaning using dual phase wash solutions. The dual phase wash solutions comprise emulsions of polar and non-polar solvents with emulsifiers, surfactants and detergents. The methods of the present invention comprise the steps of charging an article to a washing machine comprising a washing drum, exposing the article in the wash drum to a wash solution comprising 0.125 to 20 percent water; a detergent comprising an ionic surfactant, a non-ionic surfactant and an emulsifier; and decamethylcyclopentasiloxane, agitating the article and wash solution in the washing drum, draining the wash solution from the drum, optionally, adding a rinse solution comprising substantially the same components as the wash solution; agitating the article in the rinse solution; and separating the rinse solution from the article by allowing the rinse solution to drain out of the drum and spinning the drum to drive off residual rinse solution through centrifugal force.

Owner:GENERAL ELECTRIC CO

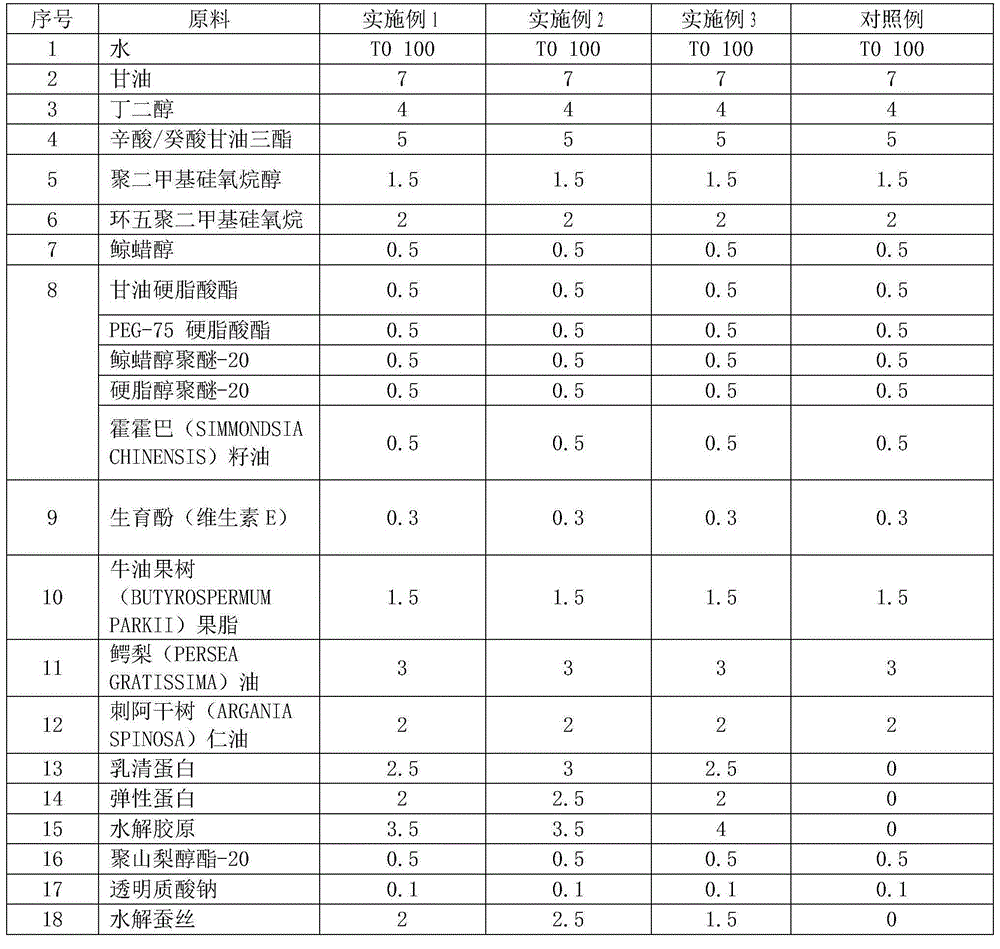

Addition face fake composite silicon rubber and preparation method thereof

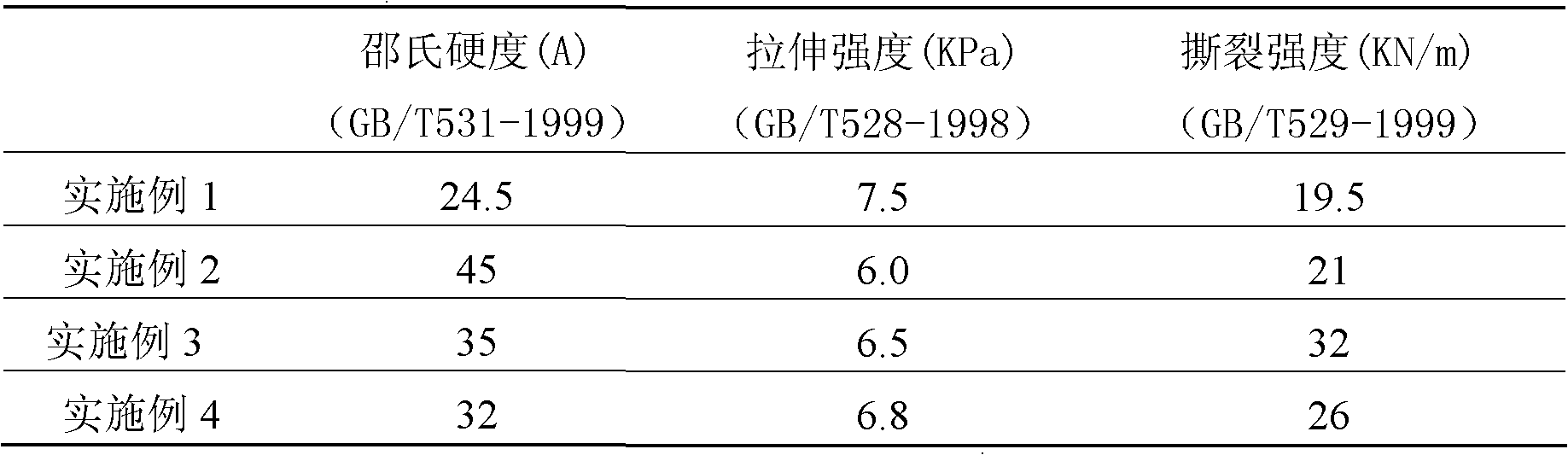

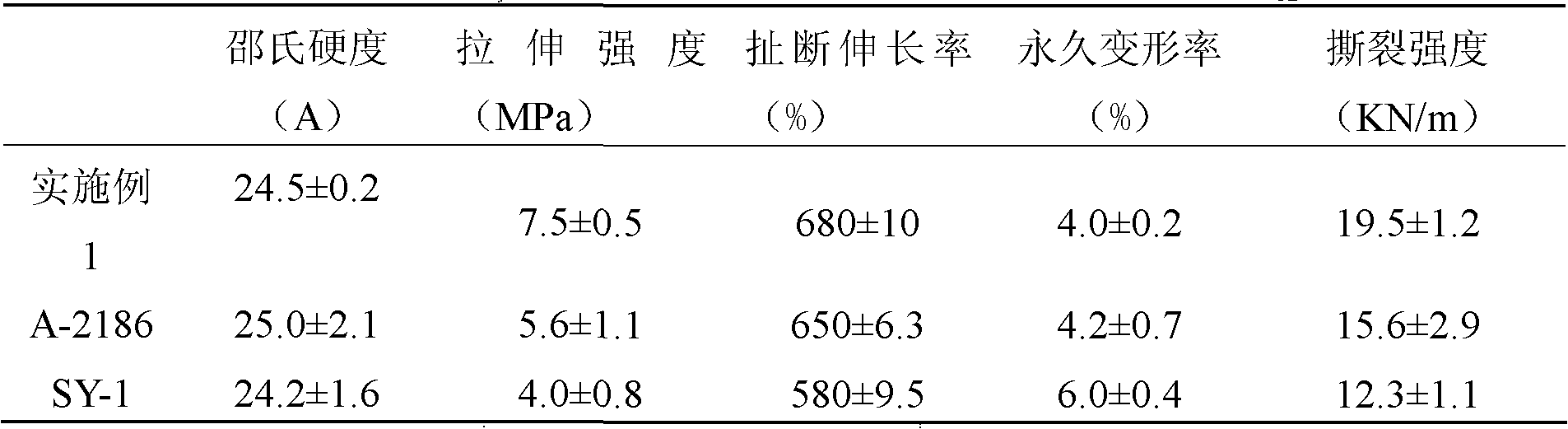

The invention relates to medical addition face fake composite silicon rubber and preparation method thereof. The invention is characterized in that: octamethylcyclotetrasiloxane or mixture composed of hexamethylcyclotrisiloxane, octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane or organic silicon base polymer synthesized by taking divinyl tetramethyldisiloxane and tetramethyl ammoniumhydroxide as catalyst is selected according to the performance requirement of fake composite silicon rubber material; catalyst adopts platinum complex, polymerization inhibitor adopts composite of butynol and tetramethyl tetravinylcyclotetrasiloxane, and poly methyl hydrogen silicone oil polymer is taken as cross linking agent; modified gas phase method white carbon is taken as filler; and the addition face fake composite silicon rubber is prepared by the following raw materials by weight percent: 20-80% of base polymer, 15-75% of filler and 5-15% of cross linking agent, catalyst and polymerization inhibitor. The invention can prepare medical fake composite silicon rubber with the hardness of 20-45HA, tensile strength more than 6.0MPa and tearing strength more than 18KN / m.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

Addition type facial prosthesis silicone rubber and preparation method thereof

The invention relates to medical addition type facial prosthesis silicone rubber and a preparation method thereof. The medical addition type facial prosthesis silicone rubber is characterized in that according to the performance requirements of the prosthesis silicone rubber material, an organic silicon basic polymer synthesized from octamethyl cyclotetrasiloxane or a mixture comprising hexamethylcyclotrisiloxane, the octamethyl cyclotetrasiloxane, decamethylcyclopentasiloxane and the like, and divinyltetramethyldisiloxane by taking tetramethyl ammonium hydroxide as a catalyst is selected; the catalyst, namely a platinum metal complex, a polymerization inhibitor (a compound of butynol and tetramethyl tetravinyl cyclotetrasiloxane) and a cross-linking agent, namely a poly-methyl hydrogen silicone oil polymer are further selected; and modified fumed silica is taken as a filler. The addition type facial prosthesis silicone rubber is prepared from the following raw materials in percentage by weight: 20%-80% of basic polymer, 15%-75% of filler and 5%-15% of cross-linking agent, catalyst and polymerization inhibitor. According to the method, the medical prosthesis silicon rubber with the hardness of 20-45HA, tensile strength of above 6.0MPa and tearing strength of above 18KN / m can be prepared.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

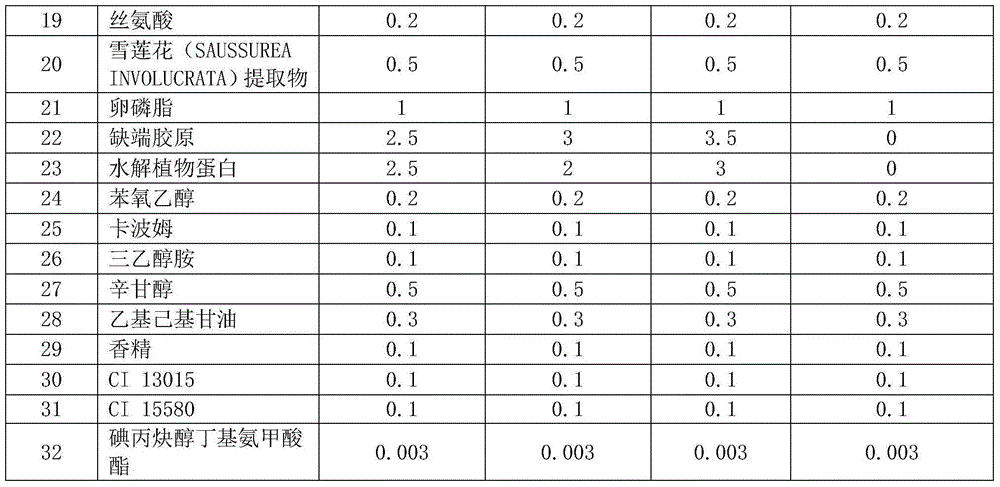

Whey protein cream capable of restoring skin elasticity and preparation method thereof

InactiveCN106214597APrevent agingQuickly restore moisturizing functionCosmetic preparationsToilet preparationsGlycerolDimethyl siloxane

The invention discloses a whey protein cream capable of restoring skin elasticity. The whey protein cream comprises glycerol, butanediol, decanoyl / octanoyl-glycerides,poly[oxy(dimethylsilylene)], decamethylcyclopentasiloxane, cetanol, sterin, PEG-75 stearate, POE (20) isohexadecyl ether, steareth-20, jojoba seed oil, tocopherol, avocado tree grease, avocado oil, Argania spinosa kernel oil, whey protein, elastin, hydrolytic collagen, polysorbate 20, sodium hyaluronate, hydrolyzed cocoon fiber, serine, Saussurea involucrata extract, lecithin, Atelocollagen, hydrolyzed plant protein, phenoxyethanol, carbomer, triethanolamine, 1,2-octanediol, ethylhexylglycerin, essence, CI 13015, CI 15580, iodopropynyl butylcarbamate and the balance of deionized water. The combination of the micro-grease-capsule-coated elastin, hydrolyzed cocoon fiber, hydrolyzed collagen, whey protein and Atelocollagen is added into the moisturizing formula, so that the whey protein cream can moisturize the skin and restore the skin elasticity.

Owner:广州安欣化妆品股份有限公司

Preparation method of linear or body fluorine modified organosilicon material

ActiveCN103554501AGood solvent resistanceGood weather resistanceTetramethylammonium hydroxideSolvent

The invention discloses linear or body fluorine modified polysiloxane and a preparation method thereof. The preparation method disclosed by the invention mainly comprises the following steps of: by taking quaternary ammonium base (such as tetramethylammonium hydroxide (TMAH)) siloxanolate or quaternary phosphorus alkali (such as tetrabutyl phosphorus hydroxide (TBPH)) siloxanolate as the catalyst, taking fluorine-containing cyclosiloxane (such as trifluoropropylmethyl cyclotrisiloxane (D3F)), alkyl cyclosiloxane (such as hexamethyl cyclotrisiloxane (D3), octamethyl cyclotetrasiloxane (D4) or decamethyl cyclopentasiloxane (D5)) or alkyl polycyclosiloxane (bi(heptamethyl cyclotetramethoxy)-ethane(bis-D4)) as the raw material, carrying out ring opening polymerization, and obtaining the linear or body fluorine modified organosilicon material. The preparation method of the linear or body fluorine modified organosilicon material disclosed by the invention is simple in preparation process and low in cost; furthermore, the molecular weight of the prepared product can be adjusted according to requirements; the linear or body fluorine modified organosilicon material has excellent antifouling property, solvent resistance, weather fastness and heat stability and has strong industrialization ability and application prospect.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com