Patents

Literature

54results about How to "Non-oxidizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

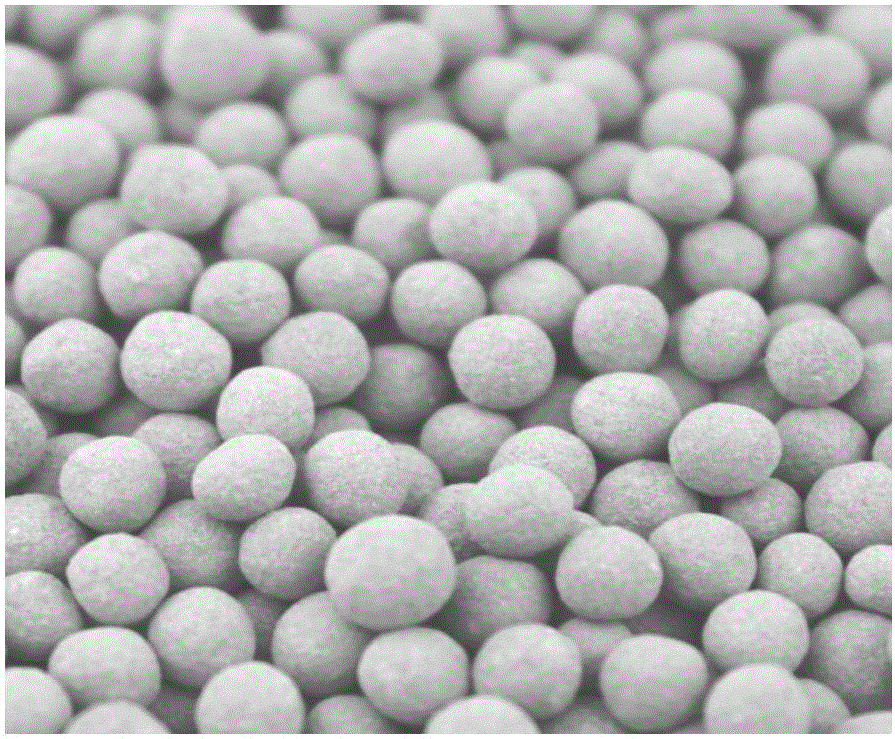

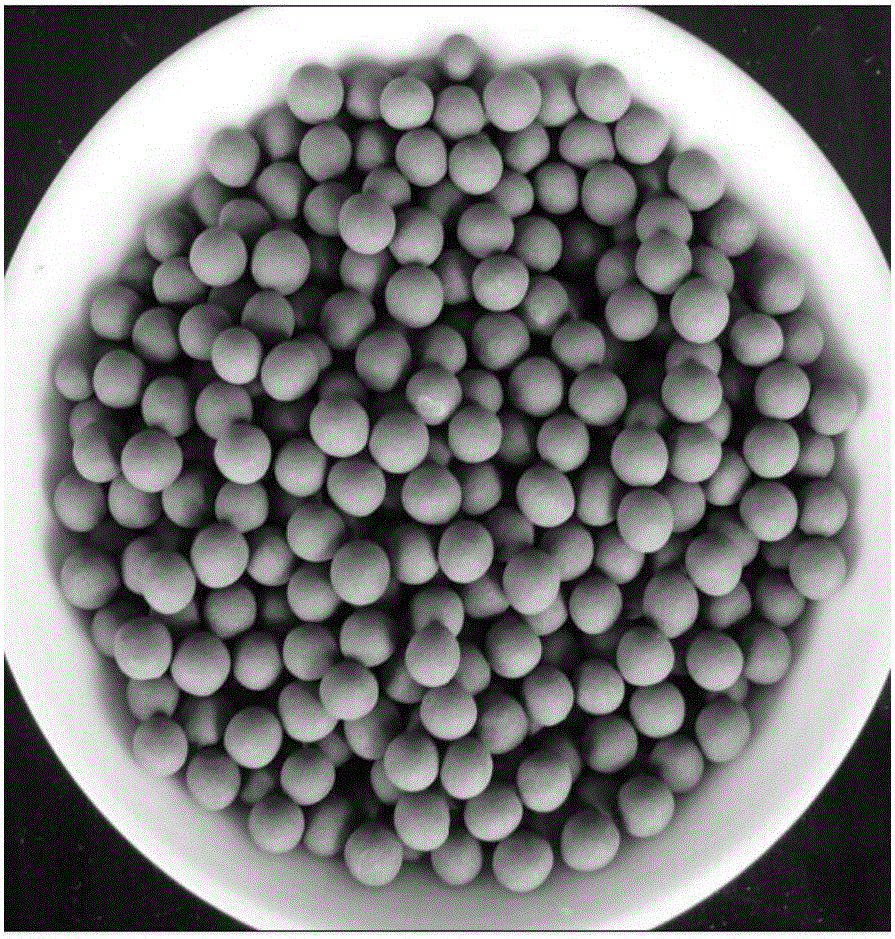

Ceramal material for manufacturing hydrogen-enriched water and preparing method and application thereof

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

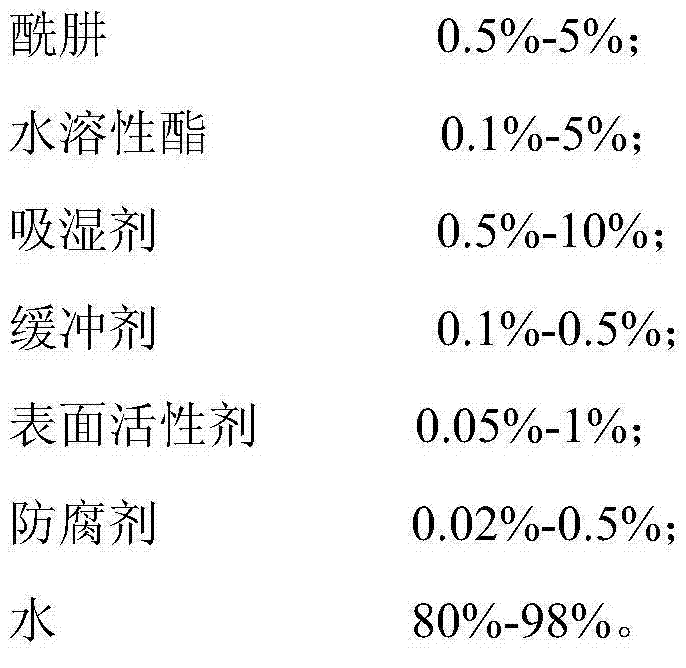

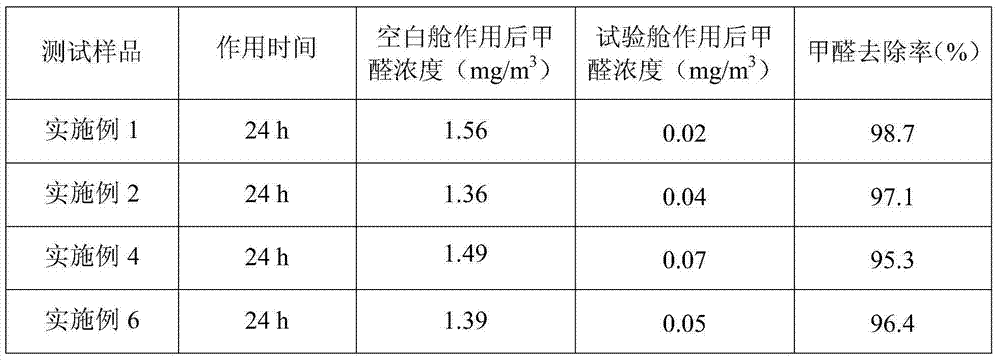

Efficient low-toxicity formaldehyde scavenger

ActiveCN104324583ANon-toxic or low toxicityNon-oxidizingDispersed particle separationScavengerPreservative

The invention discloses an efficient low-toxicity formaldehyde scavenger containing the following raw material components by weight: 0.5%-5% of hydrazide, 0.1%-5% of a water-soluble ester, 0.5%-10% of a moisture absorbent, 0.1%-0.5% and of a buffer, 0.05%-1% of a surface active agent, 0.02%-0.5% of a preservative and 80%-98% of water. The free hydrazine content in the efficient low-toxicity formaldehyde scavenger product is controlled in the range as low as possible by the manner of fine selection of the hydrazide raw material, control of free hydrazine content, adding of the water-soluble ester, adding of the buffer, and the like, and the efficient low-toxicity formaldehyde scavenger product has better security. The efficient low-toxicity formaldehyde scavenger product is good in formaldehyde removal effect, safe to people and objects, and simple in production process, and can be used for governance of the problem of formaldehyde exceeding the standard in new decorated residence or furniture.

Owner:广州超威生物科技有限公司

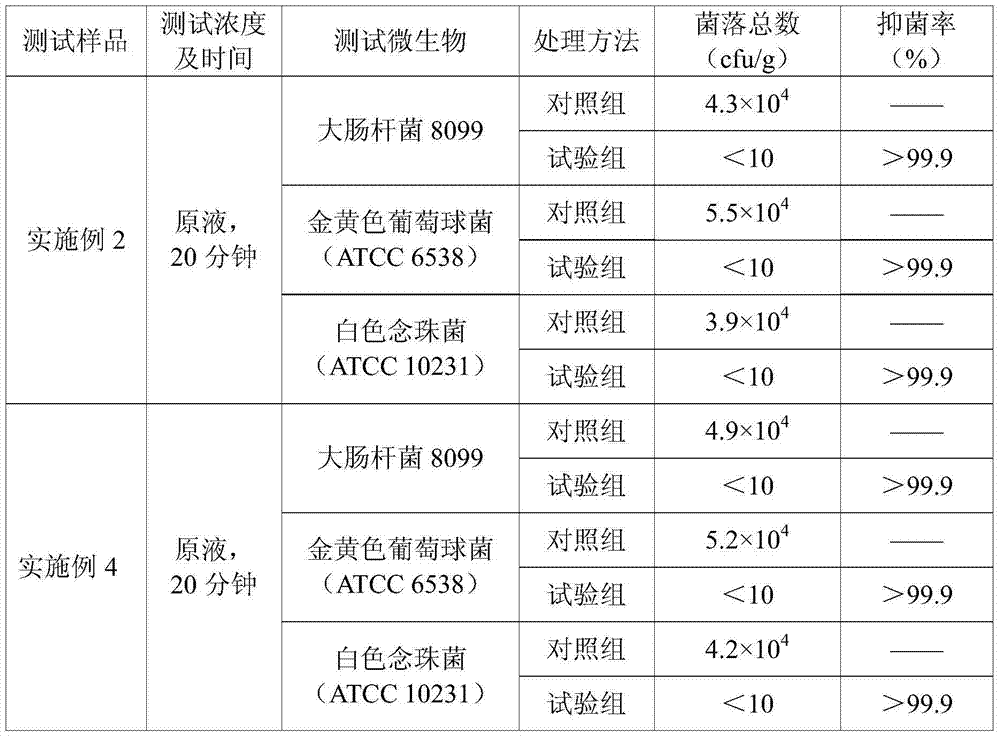

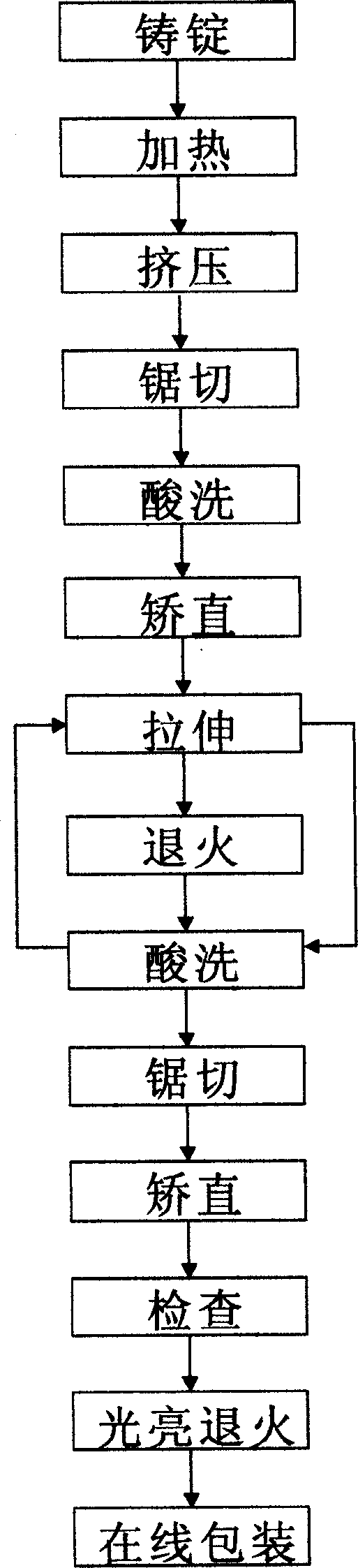

Preparation method for polycarboxylic acid series comb-shaped surface active agent

InactiveCN102199298AEnergy savingShort preparation timeTransportation and packagingMixingSolventSurface-active agents

The invention discloses a preparation method for a polycarboxylic acid series comb-shaped surface active agent, which comprises the following steps of: mixing two comonomers, an initiator, a chain transfer agent and a solvent under the protection of nitrogen, heating to a reacting temperature for polymerization to obtain an intermediate polymer; adding a graft compound, a catalytic agent and a dissolvant into the intermediate polymer, carrying out graft reaction at graft temperature, decompressing and removing part of solvent in a reaction system after reaction, and then precipitating the product with a precipitator; dissolving filter cakes with the solvent; precipitating the dissolved solution with the precipitator again, dissolving repeatedly, precipitating again and then refining, and finally decompressing and drying the product to the constant weight. The preparation method has the advantages of reasonable technology, simple operation, low preparation cost, mild reacting conditions and good product quality.

Owner:CHINA RES INST OF DAILY CHEM IND

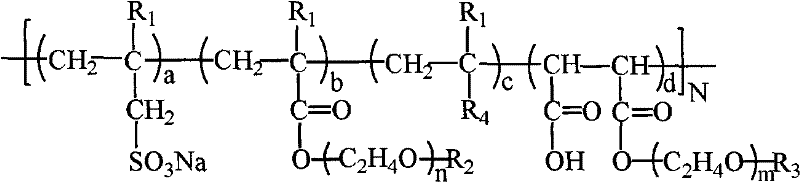

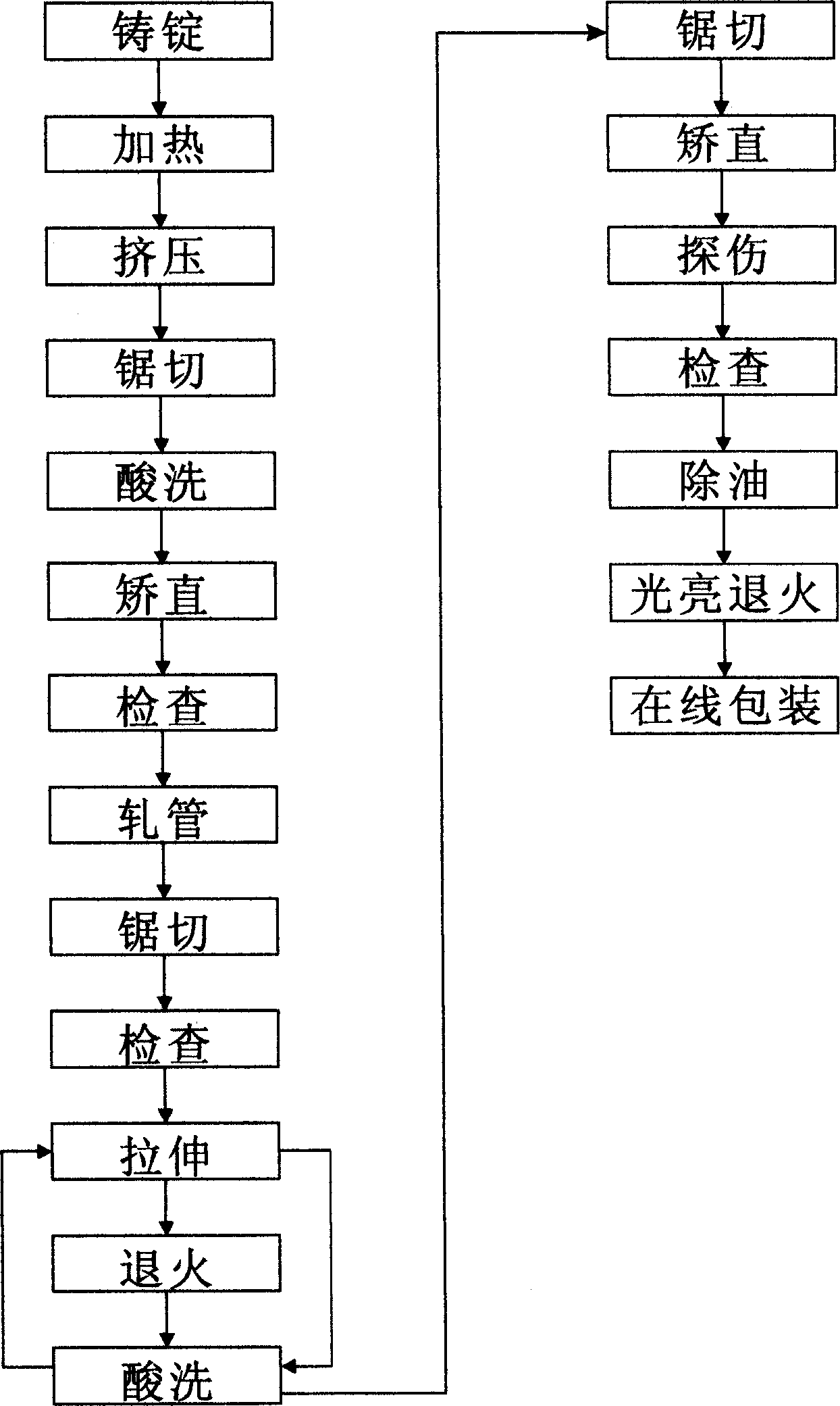

Method for producing red brass pipe

The production process of red brass pipe includes the steps of: fusion casting, heating, extruding, finishing, acid pickling, inspection, rolling, cutting to required size, inspection, annealing, acid pickling, forming head, drawing, finishing, inspection, deoiling, and product annealing. The present invention features that in common pressure processing apparatus, with common brass as material and through extrusion to generate red, acid pickling to increase color, drawing to decrease color, further acid pickling to increase color and annealing to maintain color, red brass pipe with high anticorrosion and homogeneous performance may be produced in low cost.

Owner:中铝洛阳铜业有限责任公司

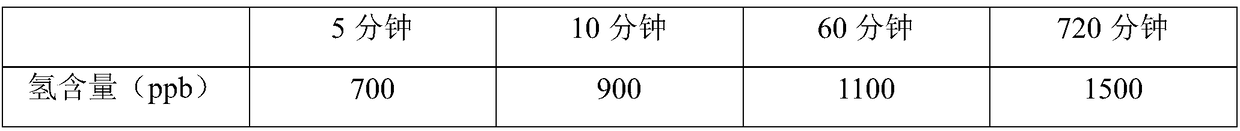

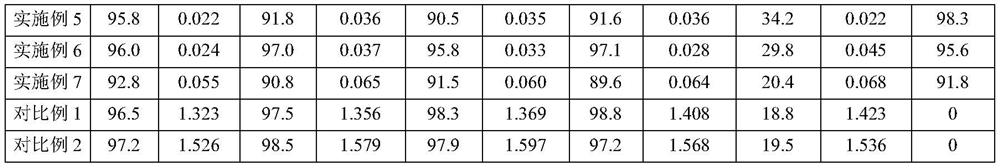

Multiple-efficiency water purification ceramic material as well as preparation method and application thereof

InactiveCN108727007AImprove antibacterial functionPurifyingWater/sewage treatment by irradiationWater/sewage treatment by substance additionCelluloseSodium Bentonite

The invention belongs to the field of new material technology for hydrogen production, and particularly relates to a multiple-efficiency water purification ceramic material as well as a preparation method and application thereof. The multiple-efficiency water purification ceramic material is prepared from the following raw materials: 30-50 parts of substrate component, 20-40 parts of hydrogen-richcomponent, 2-5 parts of antibacterial component and 3-10 parts of binder; wherein the substrate component is made from tourmaline, Shuiyuan stone, medical stone, calcium oxide and zeolite; the hydrogen-rich component is prepared from metallic magnesium powder, magnesium oxide powder, KDF alloy powder and three-dimensional graphene; the antibacterial component is prepared from far-infrared ceramicpowder, nanometer zinc oxide, titanium oxide and nanometer zirconium dioxide; the binder is prepared from highly pure distilled water, carboxypropyl cellulose and bentonite. The multiple-efficiency water purification ceramic material of the invention can not only produce hydrogen but also store hydrogen when being added to water, and can significantly increase the hydrogen content in the water. The invention also provides the preparation method and application of the multiple-efficiency water purification ceramic material, and the process is simple and easy to implement, and the multiple-efficiency water purification ceramic material is applied to products such as a water purifier, a water filter pitcher and a water cup.

Owner:天津嘉宝艾依琳科技发展有限公司

A silver containing chitosan fiber having antimicrobial function and preparation method

InactiveCN1308509CNon-oxidizingWill not oxidize and turn blackArtifical filament manufactureFiberBacteria

This invention relates to a silver-bearing crustamine fabric with anti-biotic action and its preparing method, which is composed of 90.0-99.9 percent of crustamine powder in weight and 0.1-10 percent of insoluble silver compounds particles. The invention has great anti-biotic action, and can be used as medical dressing to restrict the bacteria on wound.

Owner:JIAXING UNIV

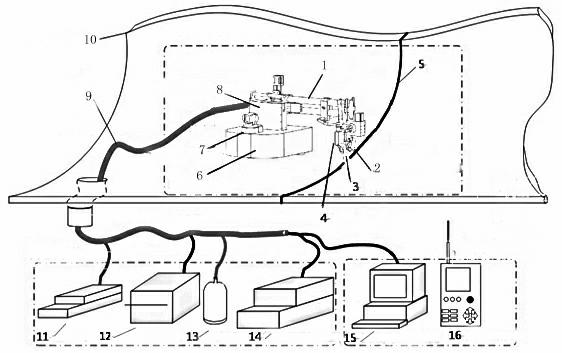

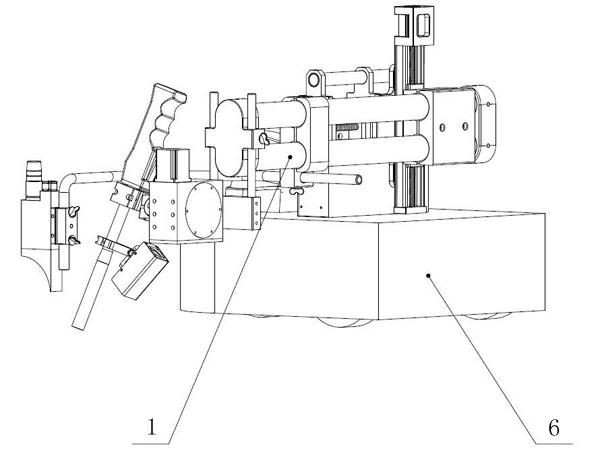

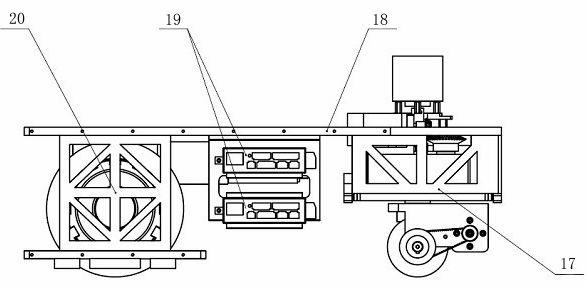

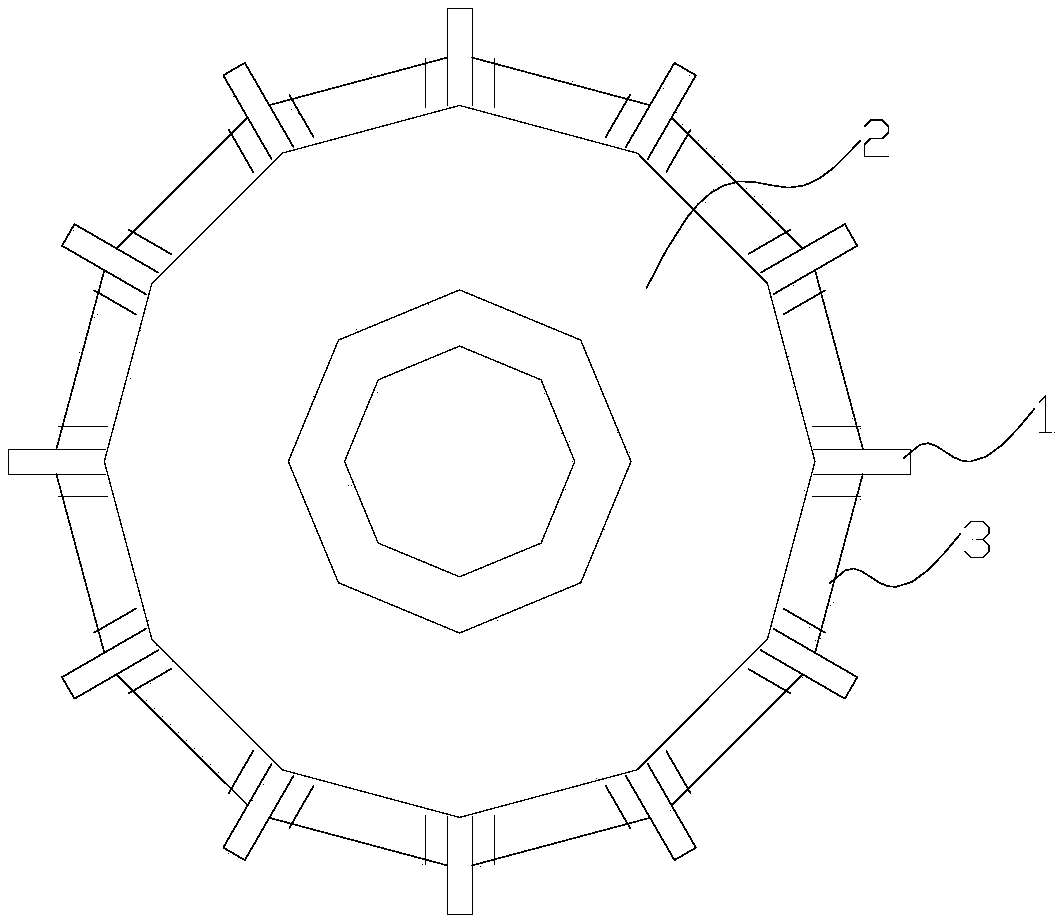

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

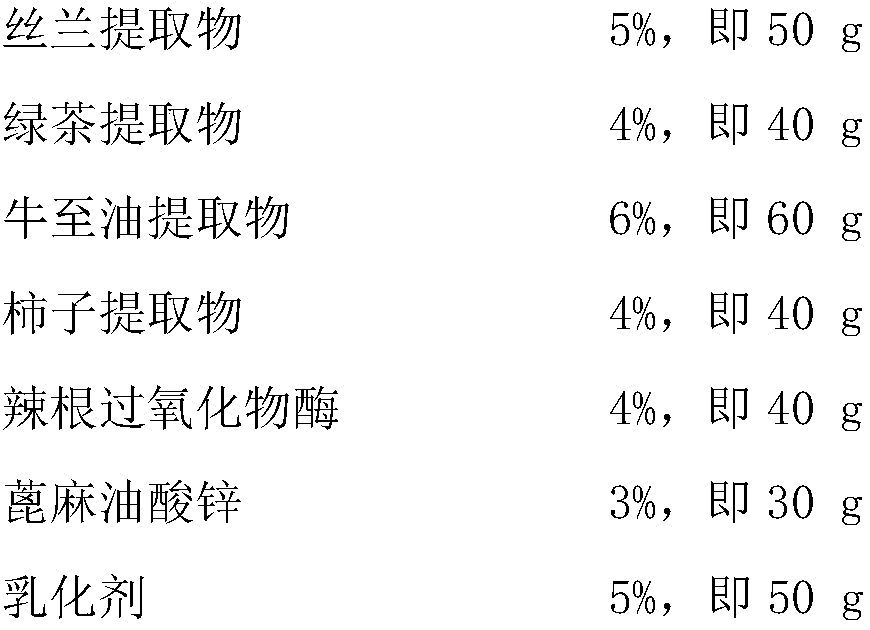

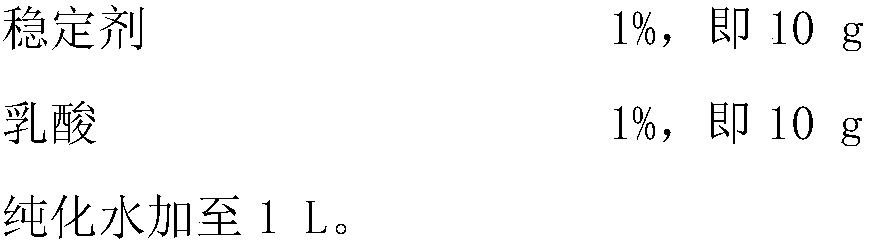

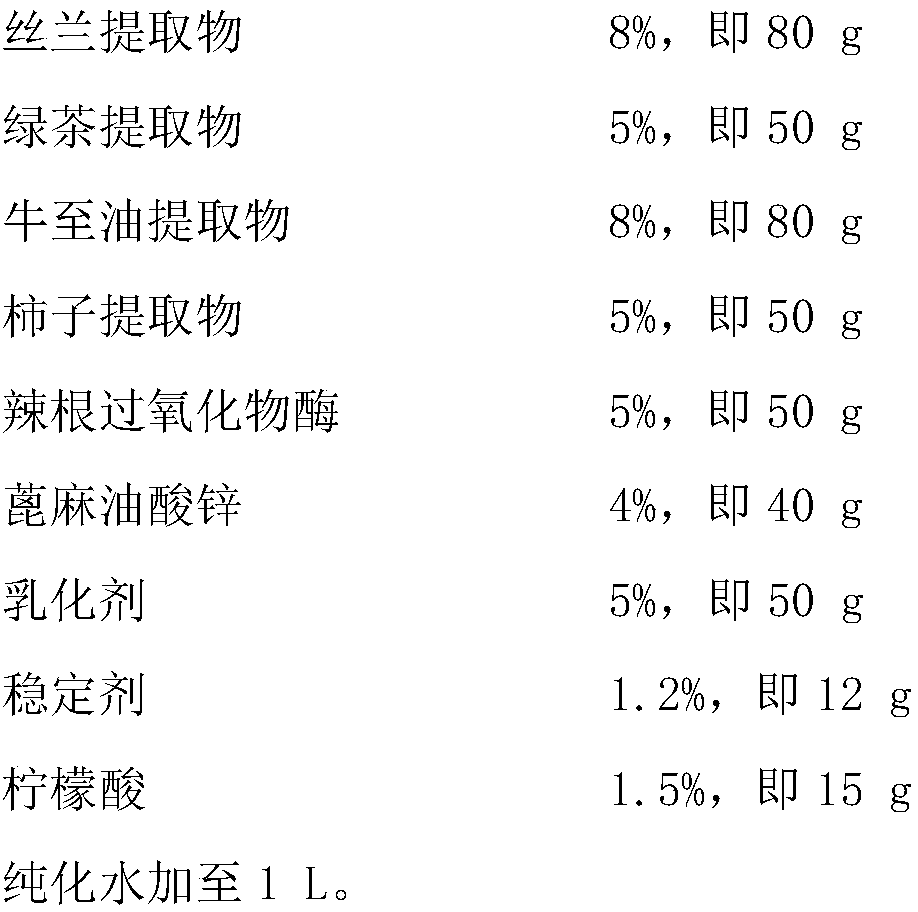

Composite biological deodorization spray for pets and preparation method thereof

ActiveCN109646361AGood deodorizing propertiesEfficient removalCosmetic preparationsToilet preparationsORIGANUM OILFeces odor

The invention relates to composite biological deodorization spray for pets and a preparation method thereof. The spray is suitable for solving the problems of halitosis, body odor, feces odor and thelike of dogs and cats. The deodorization spray comprises, by mass, 5-8% of a Spanish bayonet extract, 4-5% of a green tea extract, 6-8% of an origanum oil extract, 4-5% of a persimmon extract, 4-5% ofa horseradish extract, 3-4% of zinc diricinoleate, 5-6% of an emulsifier, 1-2% of a stabilizing agent, 1-2% of a pH value regulator and the balance purified water. It is proved through deodorizationeffect identification that the deodorization performance of the spray is good, and the spray can quickly eliminate ammonia gas, hydrogen sulfide, methyl mercaptan, dimethyl sulfide, dimethyl disulfideand various common odor molecules of the pets within 5 minutes. Meanwhile, pathogenic microorganisms can be effectively inhibited and killed, and generation of odor can be inhibited from the source.

Owner:SHANDONG SINDER TECH +2

Detergent

InactiveCN102108322ARestore surface finishRestore cleanlinessOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsActive componentSURFACTANT BLEND

The invention relates to the field of clearing, cleaning water scales and other stubborn scales. The invention discloses a detergent which comprises the following main active components in parts by weight: 1-5 parts of nonionic surfactant, 0.5-10 parts of anionic surfactant, 0.5-5 parts of ampholytic surfactant, 2-50 parts of methylsulfonic acid, 1-5 parts of hydroxy ethylidene di-phosphonic acid and 0.3-1.0 part of corrosion inhibitor. The detergent can effectively remove the water scales, rusty scales, tea scales, oil scales, dust scales and urine scales on daily life appliances of people, has the effects of removing the scales, cleaning, sterilizing, removing odor and the like, and can be used for hard surfaces of plastic, metal, stainless steel, porcelain and other products.

Owner:BEIJING REWARD HOME CARE CHEM

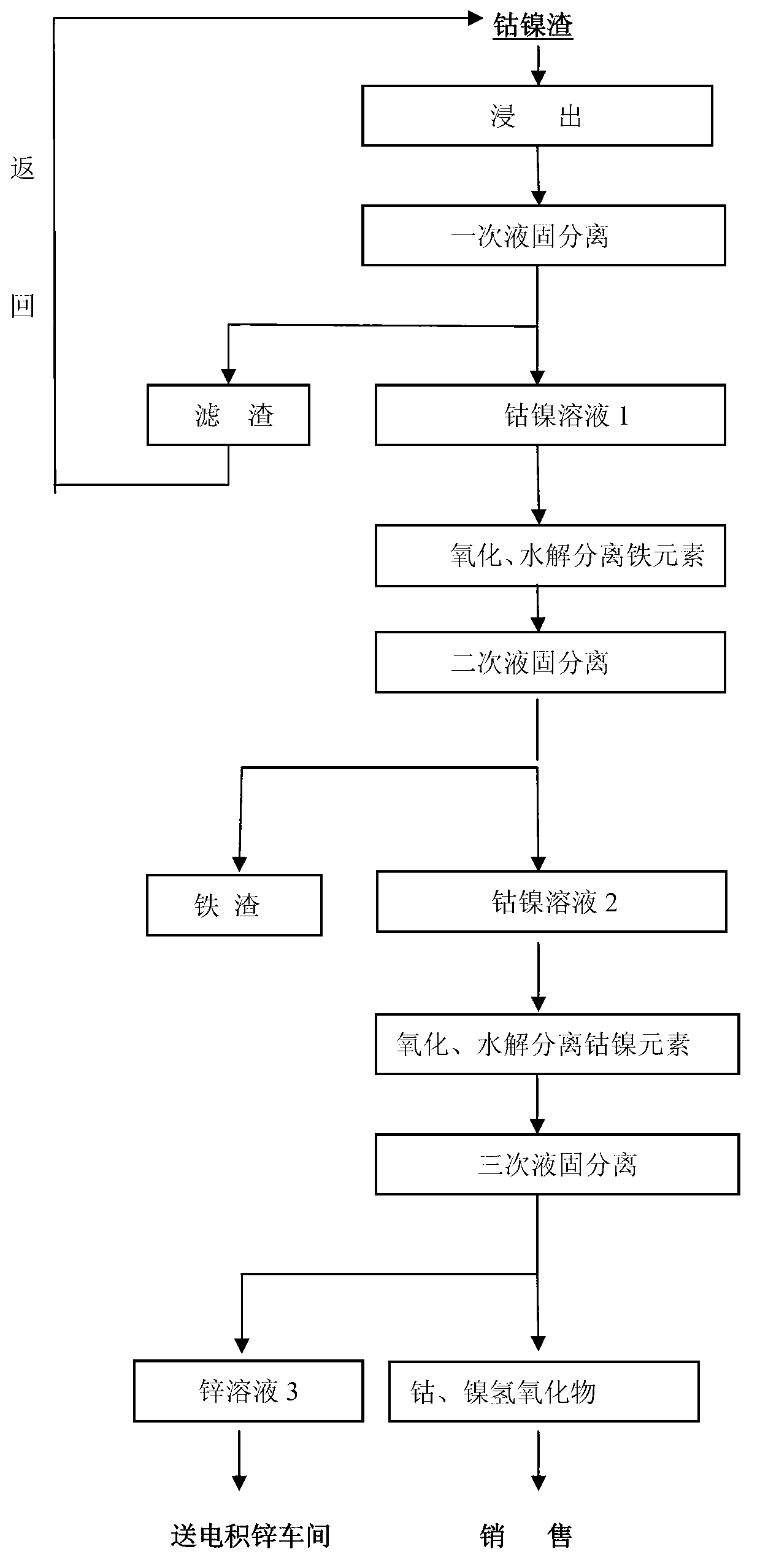

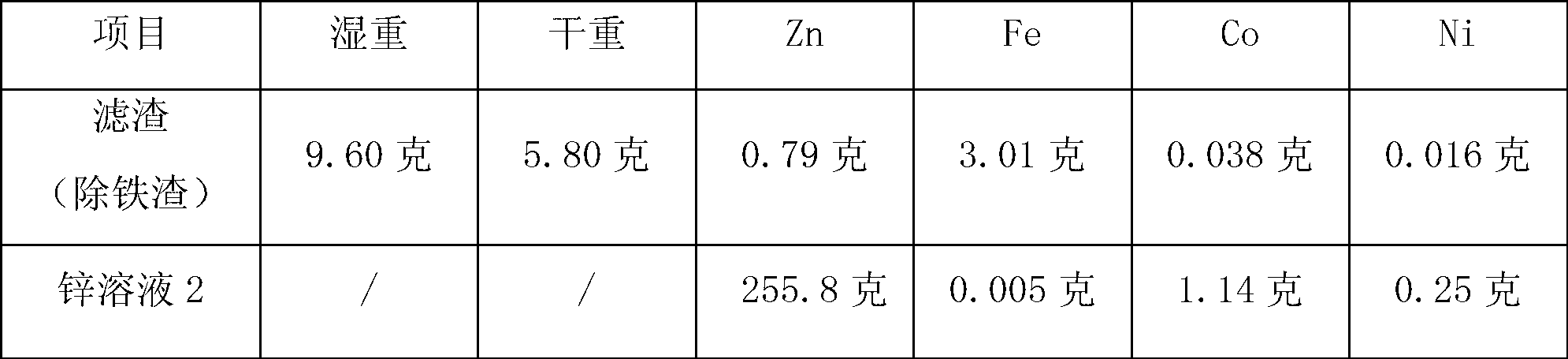

Process method for separating zinc, iron and cobalt and nickel ore concentrates from cobalt and nickel slag

InactiveCN103014346ASimple processing methodOvercoming complexityIron compoundsProcess efficiency improvementZinc metalSlag

The invention discloses a process method for separating zinc, iron and cobalt and nickel ore concentrates from cobalt and nickel slag. The method comprises the steps of: leaching, primary solid-liquid separation, oxidation and hydrolysis to separate iron element, secondary solid-liquid separation, oxidation and hydrolysis to separate cobalt and nickel elements, third solid-liquid separation and the like. The method solves the problem that raw materials are higher in price, complex in refining process, high in energy consumption and large in pollution of byproducts in conventional cobalt and nickel refining industry, and is suitable for the industry of smelting zinc by the wet method. Zinc metal and iron, and noble metals such as cobalt and nickel can be directly separated from cobalt and nickel slag with a simple process, low cost, short period, higher efficiency and low pollution.

Owner:河池市津泰资源再生有限公司

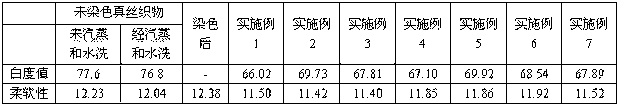

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

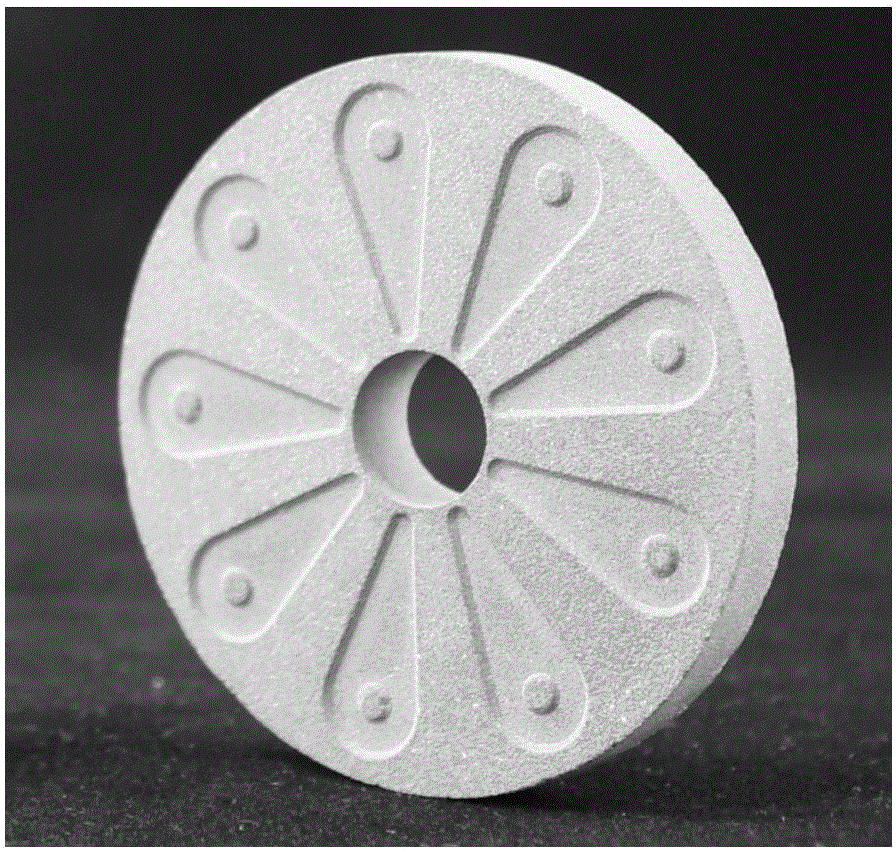

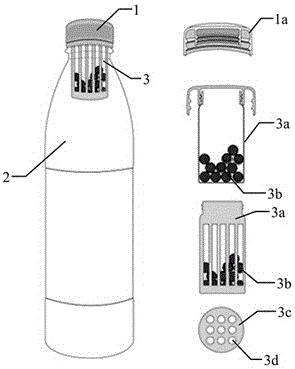

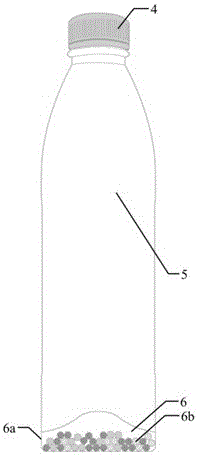

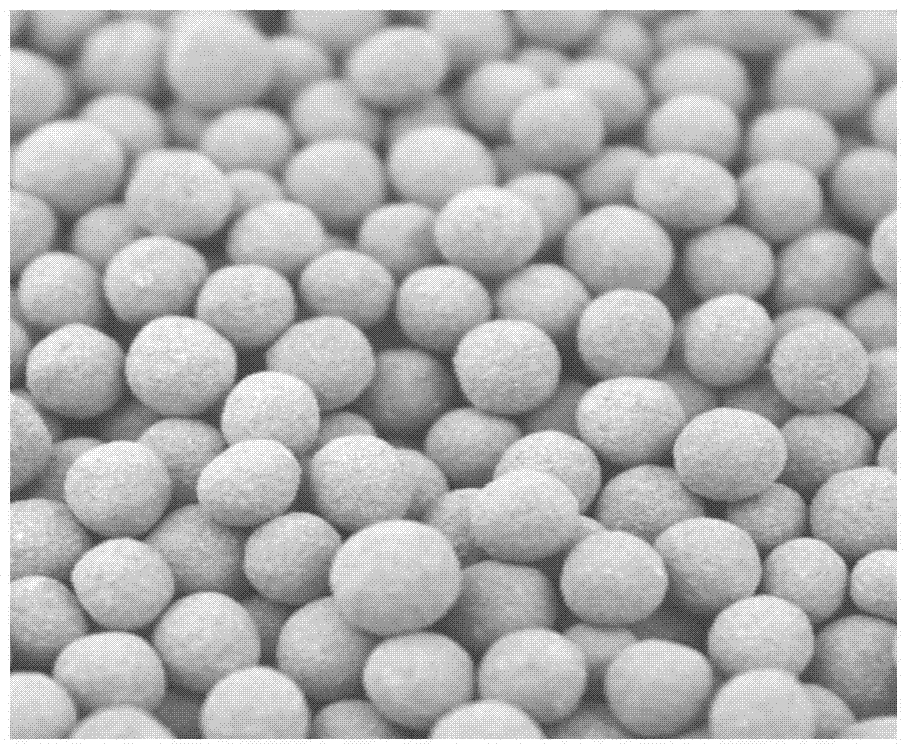

Beverage bottle capable of generating healthy water

InactiveCN105905426AWith far infrared disinfection functionExtended shelf lifeWater/sewage treatment by irradiationSpecific water treatment objectivesAlkalinityHydrogen

A beverage bottle capable of generating healthy water comprises a bottle body and a bottle cap; and a healthy water generator is fixed below the cap bottom of the bottle cap and / or above the bottle bottom of the bottle body and comprises a shell and hydrogen composite ceramic water purifying particles in the shell. A hydrogen composite ceramic water purifying material is a pure natural hydrogen-rich material, tourmaline, medical stone, lapilli and other thirteen kinds of ore are smashed into an ultramicro powder material, then various kinds of rare earth metal materials, photocatalytic enzymes and other elements are blended in the ultramicro powder material, mixing and forming are performed, and finally, the particles in different sizes and different shapes are prepared through baking and low-temperature firing. Firstly, the particles are placed in the beverage bottle, then the beverage bottle is filled with potable water in the market, the potable water can react with the above hydrogen composite ceramic water purifying material to generate hydrogen-rich small molecular group water, and meanwhile, negative electric potential water and weak alkalinity water are made, namely so-called healthy water.

Owner:蒋亚熙

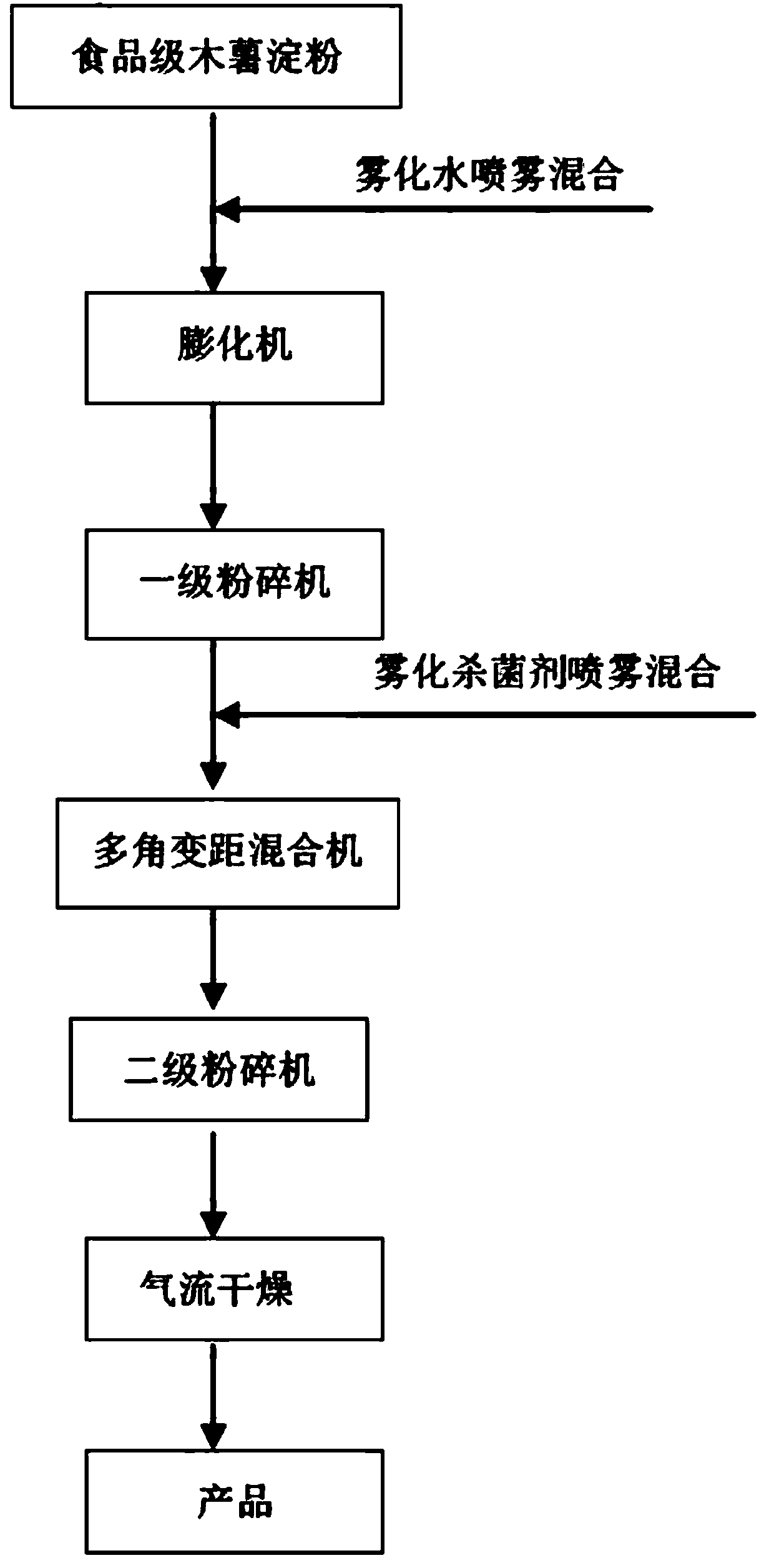

Pre-gelatinized starch and preparation method thereof

InactiveCN103739721AFeed water content is lowReduce energy consumptionTemperature resistanceSaline water

The invention provides pre-gelatinized starch and a preparation method thereof. The pre-gelatinized starch comprises the following components in percentage by weight: 87.00-99% of pre-gelatinized tapioca starch, 0.1-1% of 2-methyl-4-isothiazolin-3-one (MI), 0.1-1% of 5-chloro-2-methyl-4-isothiazolin-3-one (CMI) and the balance of water. The product provided by the invention has the characteristic of perfect liquidity like fine sand, and the characteristic is very convenient to use on the site; although as a powdery product, the product does not generate dust and avoids harm to the physical health of workers on the site; after being added into water or slurry, the product can be automatically and uniformly dispersed and quickly dissolved, and the phenomenon of caking or fish eyes is avoided even without stirring; the requirement on the water loss of 4% salt water and saturated salt water slurry at normal temperature is met; the temperature resistance is good, and the acceptable temperature can reach 120 DEG C in 4% NaCl and saturated salt water slurry; and the product is not a toxic substance and does not have oxidability, corrosivity and radioactivity.

Owner:KAIPING LIANJI CHEM

Black sand device and preparation method thereof

The invention discloses a black sand device and a preparation method thereof. The black sand device is prepared from the following raw materials in parts by weight: 50-80 parts of kaolin and 20-50 parts of carbon slag, wherein the mass percent of iron in the kaolin is 3-5%. }The preparation method comprises the following steps: pulping; forming; airing a billet; firing; glazing; and discharging. The obtained black sand device has specific black gloss, can not be oxidized, can not discolor and has firm texture. Experiments show that the black sand device has higher thermal stability and high temperature resistance, also has corrosion resistance, is harmless to human bodies, and is very suitable for cooking food in daily life.

Owner:雅安农耕时代生态农业有限公司

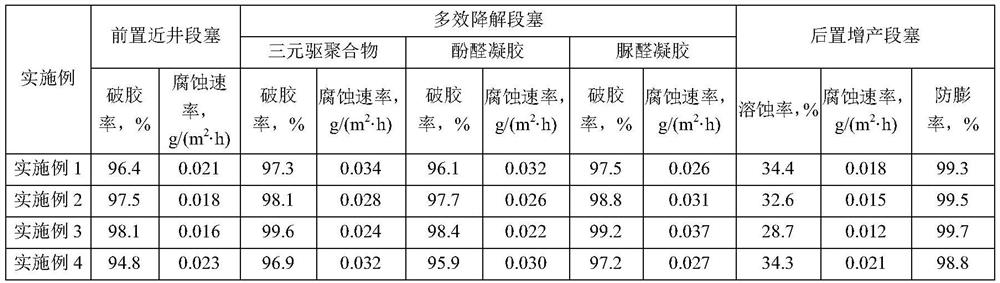

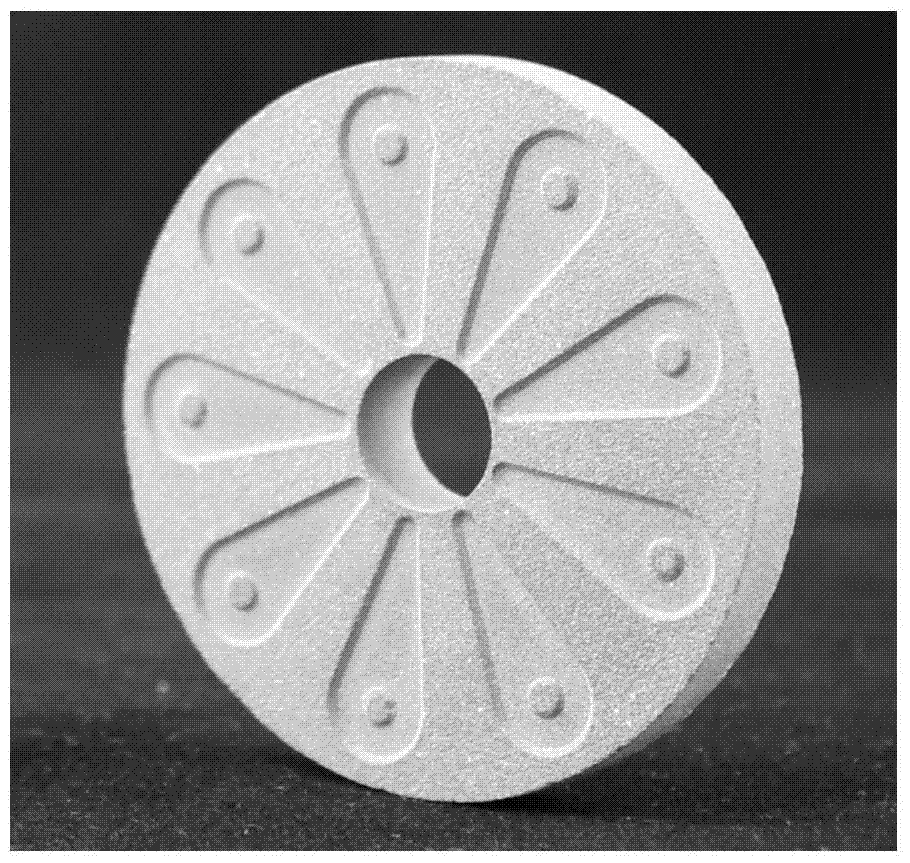

Multi-functional blocking remover and preparation method thereof

The invention discloses a multi-functional blocking remover and a preparation method thereof. The multi-functional blocking remover is composed of functional components with different percentage contents and oilfield produced water, and a front near-well slug blocking remover, a multi-effect degradation slug blocking remover and a rear yield increase slug blocking remover are prepared according to a certain proportion. The multi-functional blocking remover provided by the invention has the advantages of immediate preparation, non-oxidizing property, simple construction process, high gel breaking rate (96.1% or more), wide applicable temperature range (20-120 DEG C), low corrosion rate (lower than 0.04 g / (m<2>. h), good safety and the like, can effectively remove various blockages such as scale, polymers, polymer gel and oil sludge generated in the ASP flooding profile control process, realizes recycling of oilfield produced water, is beneficial to improving the communication capacity between oil-water wells and delaying scale deposition, and can achieve multiple effects of dissolving, plug removal, deposition prevention, low-permeability reservoir pollution reduction, injection increase and pressure reduction and the like during application.

Owner:PETROCHINA CO LTD

Manufacture of hydrogen-rich water alloy ceramic material and its preparation method and application

ActiveCN105084468BHas antibacterial propertiesRich in trace elementsWater/sewage treatment by irradiationWater basedCellulose

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

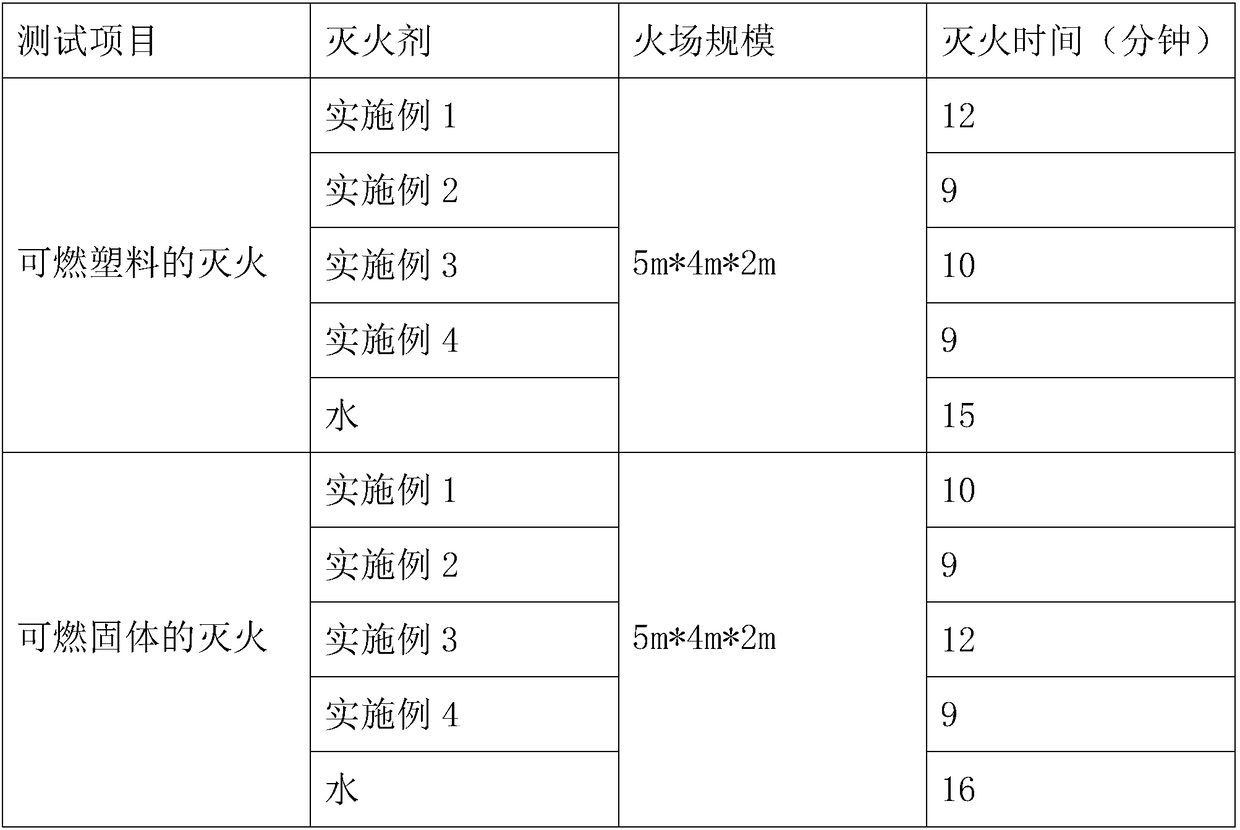

Dissolving-resisting-type foam extinguishing agent

The invention relates to the field of extinguishing materials, in particular to a dissolving-resisting-type foam extinguishing agent. The dissolving-resisting-type foam extinguishing agent is high inenvironment-friendly degree. The components of the dissolving-resisting-type foam extinguishing agent comprise, by mass, 40-60 parts of alkyl glycoside foaming agents, 10-20 parts of carbon hydrogen surfactants, 15-20 parts of biological polysaccharide, 6-15 parts of antifreeze agents, 4-6 parts of foam stabilizers, 4-6 parts of wetting agents and 20-40 parts of pure water. The dissolving-resisting-type foam extinguishing agent has the good foaming characteristic which is mainly shown in dense and lasting foams, the stacking speed is high, and contact of comburent and air can be quickly isolated. In addition, the dissolving-resisting-type foam extinguishing agent adopts the nonhazardous chemical raw materials and accordingly is small in pollution to the environment.

Owner:EASTEX XIAMEN FIRETEC

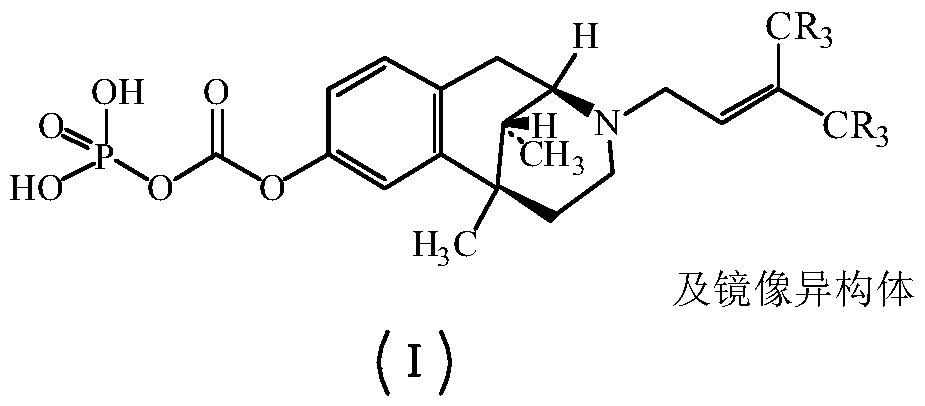

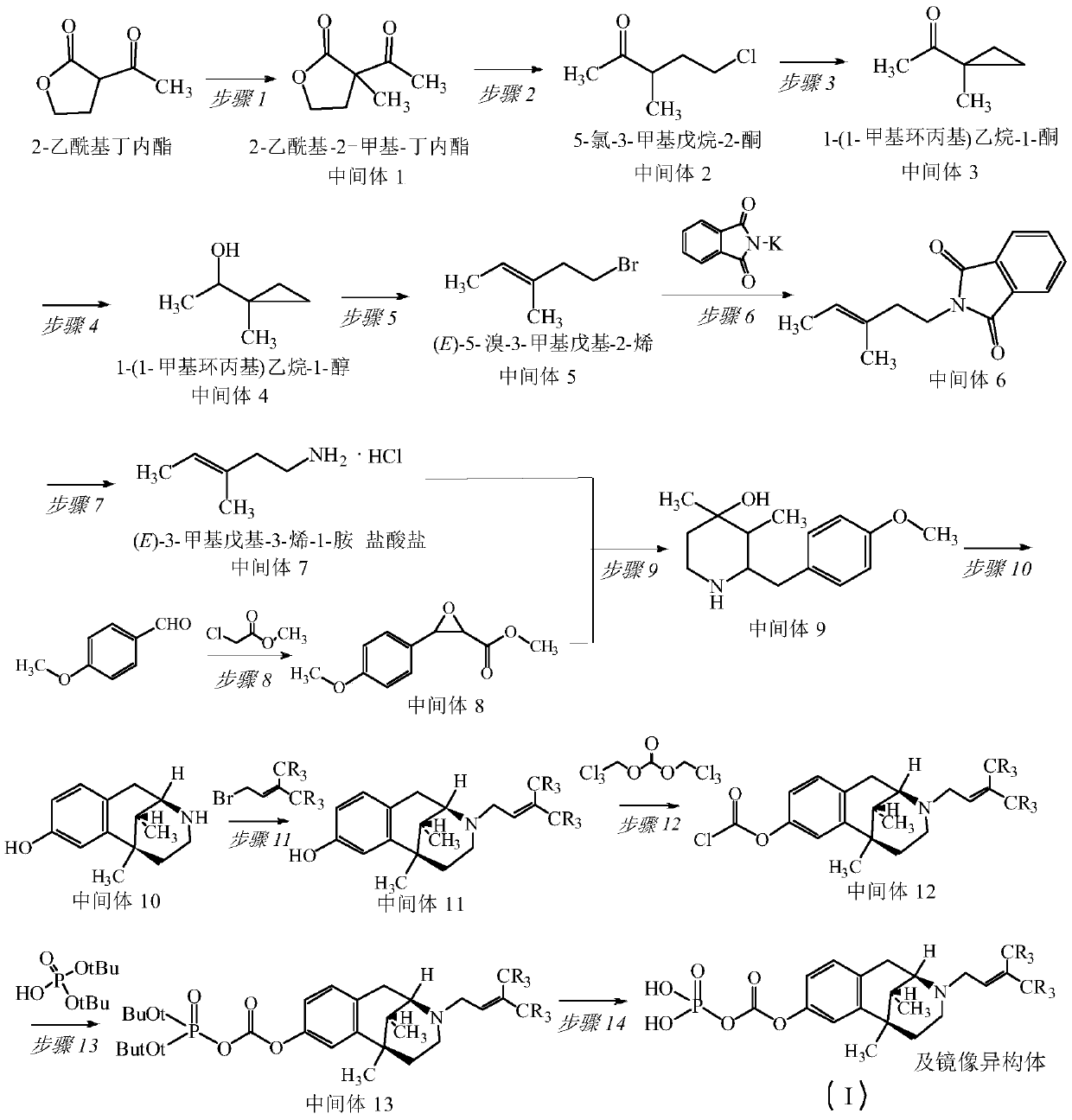

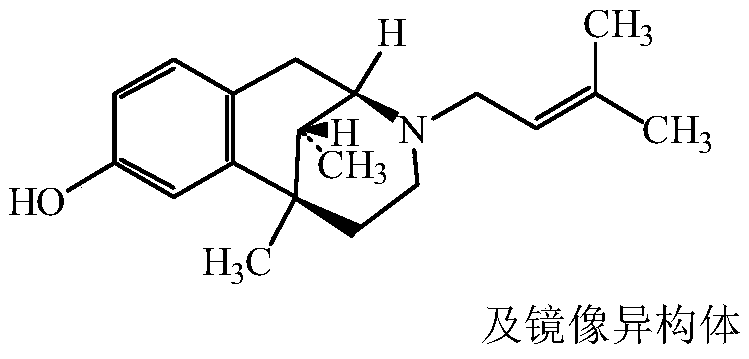

Pentazocine prodrug as well as preparation method and application thereof

PendingCN111349111AConducive to dosingGood water solubilityOrganic active ingredientsAntipyreticBlood concentrationPentazocine

The invention discloses a pentazocine prodrug shown as a formula (I), a preparation method thereof and medical application of a pharmaceutical preparation containing the pentazocine prodrug, wherein Ris hydrogen or deuterium. The water solubility of the prodrug compound is improved by 20 times or above at room temperature, the prodrug compound is chemically stable, the onset time is delayed, thedrug effect is prolonged, meanwhile, the same parent drug blood concentration is generated at a low dosage, and the prodrug compound has a wide clinical application prospect.

Owner:ANHUI HEALSTAR PHARM CO LTD

Manufacture technology of inlaying injection circuit in mold

ActiveCN103158228AOvercome the disadvantages of bondingSimple processCoatingsSolvent moleculeMolten state

The invention relates to the technical field of circuit printing technology, in particular to manufacture technology of a printing circuit. The manufacture technology of inlaying an injection circuit in a mold comprises the manufacture technology of a printing circuit film and further comprises film molding integration technology. The printing circuit film is embedded into a mold cavity of an injection mold and formed together with plastics in a molten state in an injection mode, and an integration injection part is manufactured. By the adoption of the technical scheme, the film and plastic gluing technology is once completed in an injection mold. The printed circuit film and a main molding part body are firmly integrated, and the manufacture technology of inlaying the injection circuit in the mold has the advantages that the printed circuit film does not desquamate and not to be oxidated without escaping of small solvent molecules and the like.

Owner:上海志承新材料有限公司 +1

Environment-friendly and efficient kitchen oil dirt detergent

InactiveCN105670826AHigh oil removal efficiencyNon-oxidizingOrganic detergent compounding agentsNon-ionic surface-active compoundsSURFACTANT BLENDCooking process

Kitchen oil dirt comes from the cooking process and needs to be frequently cleared away, otherwise, attractiveness is affected, and bacteria can be spread. Existing detergent products mostly comprise strong-basicity ingredients, volatile solvent ingredients, oxidizing ingredients, enzyme preparation ingredients or ingredients having obvious harm to the environment, and adverse influences may be caused to devices, human bodies and the environment. Thus, the invention provides an environment-friendly and efficient kitchen oil dirt detergent. The environment-friendly efficient kitchen oil dirt detergent is prepared from, by weight, 0.1-10% of compound surfactant, 1-20% of a contact regulating agent, 1.5-40% of a reaction regulating agent, 0.02-2% of an ion regulating agent and the balance water and has the advantages that the oil removing efficiency is high, and the detergent is safe, free of irritation, obvious odor and oxidability , stable and reliable.

Owner:宋德安

Acidic bathroom detergent

ActiveCN101372649BEfficient removalImprove acid resistanceOrganic detergent compounding agentsSurface-active detergent compositionsThioureaActive component

The invention relates to the cleaning and washing field of sanitary facilities. A thickening acidic bathroom cleaner disclosed by the invention comprises the following main active components by mass portions: 10-20 portions of a nonionic surfactant, 0.5-5.5 portions of an anionic surfactant, 2-5 portions of methanesulfonic acid, 0.3-1.0 portion of thiourea and 2-15 portions of oxydol. The cleanercan effectively remove human excrement and urine scale without corrosiveness, and has the functions of decontamination, cleaning, sterilization and deodorization.

Owner:BEIJING REWARD HOME CARE CHEM

Metal heat compound addition fluxing agent and preparing method thereof

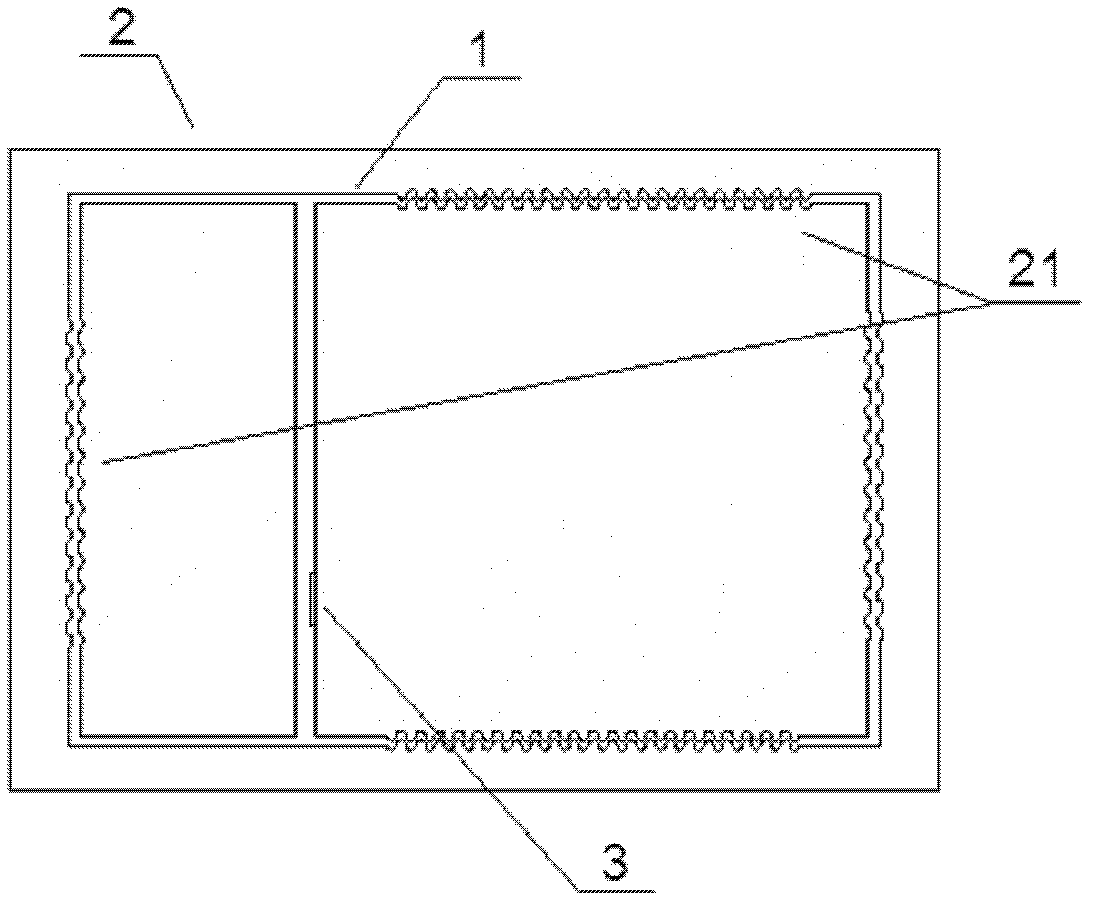

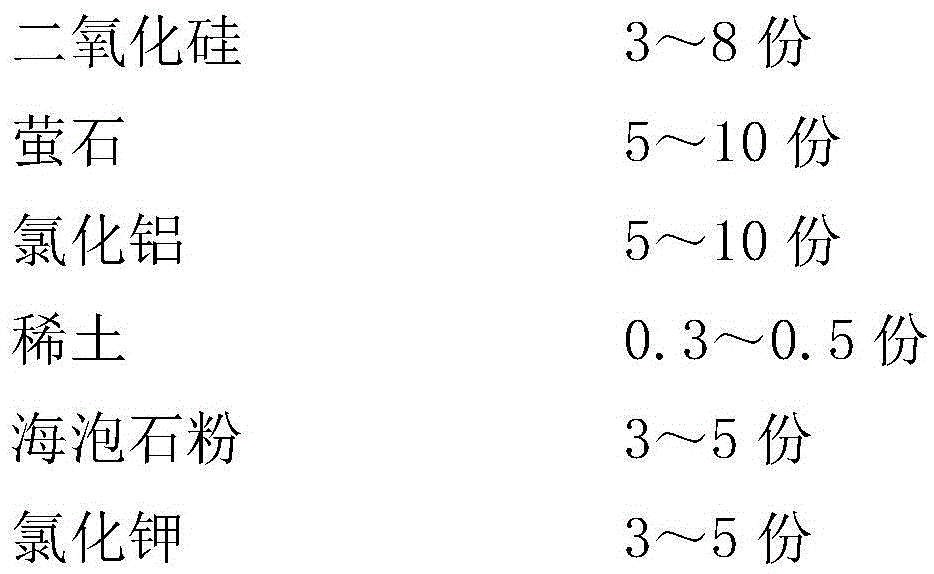

The invention relates to the technical field of alloy fluxing agents, in particular to a metal heat compound addition fluxing agent and a preparing method thereof. The metal heat compound addition fluxing agent is characterized by comprising, by weight, 3-8 parts of silicon dioxide, 5-10 parts of fluorite, 5-10 parts of aluminum chloride, 0.3-0.5 part of rare earth, 3-5 parts of sepiolite powder, 3-5 parts of potassium chloride, 2-4 parts of magnesium oxide and 2-3 parts of calcium fluoride. The method comprises the following steps that the silicon dioxide, the fluorite, the aluminum chloride, the rare earth, the sepiolite powder, the potassium chloride, the magnesium oxide and the calcium fluoride are subjected to grinding treatment, then powder obtained through grinding is screened, the size of a mesh sieve ranges from 100 meshes to 200 meshes, and the powder obtained after screening is sufficiently mixed under the condition of the temperature ranging from 70 DEG C to 100 DEG C. The material of the fluxing agent has good mobility and can float to a dead head along with the molten steel liquid level, the defect of slag is not generated, and a compound face is tight. The fluxing agent has the beneficial effects of being free of oxidization, free of deposition and free of cavity bonding.

Owner:ANHUI NINGGUO HUADA WEAR RESISTANT MATERIALS

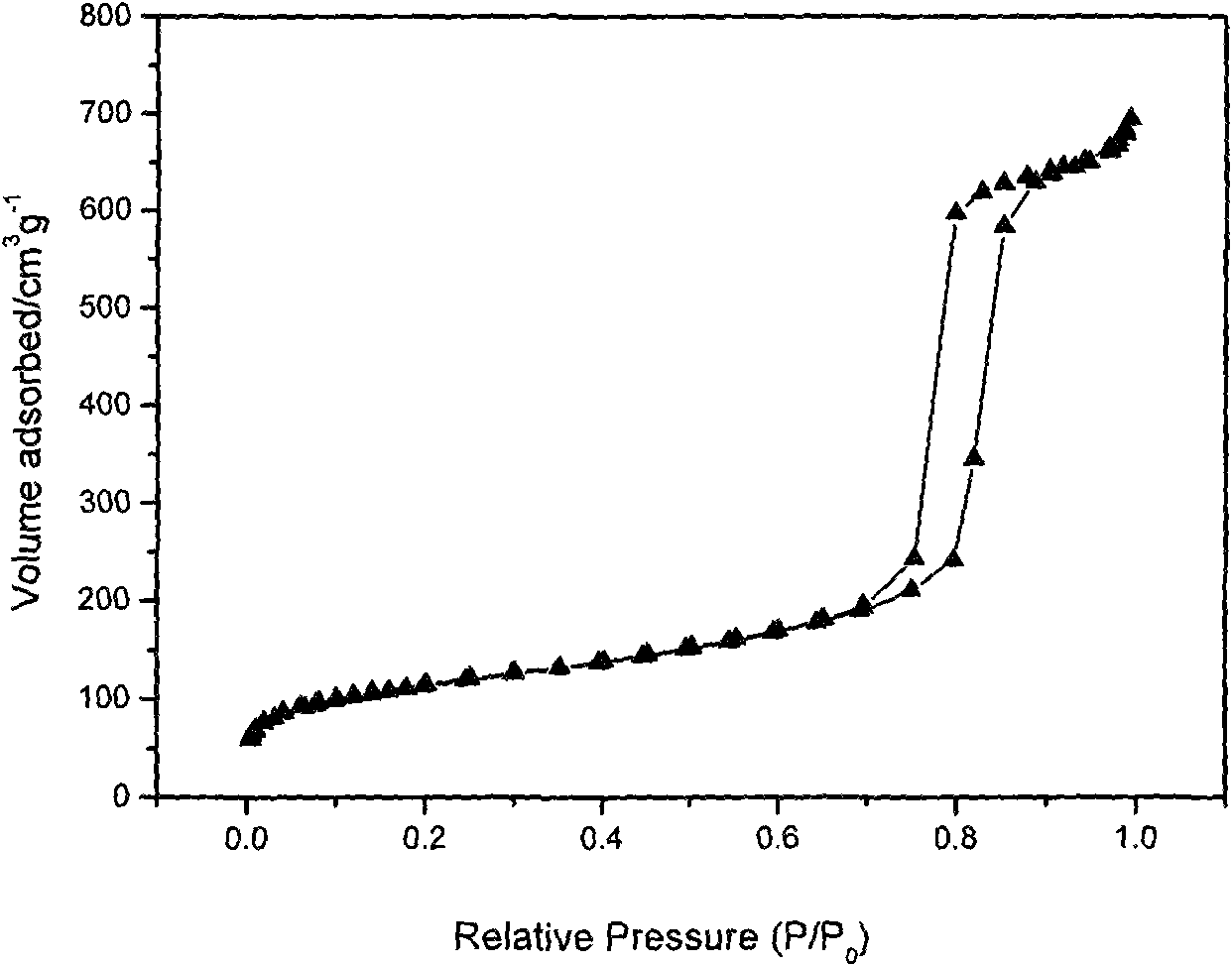

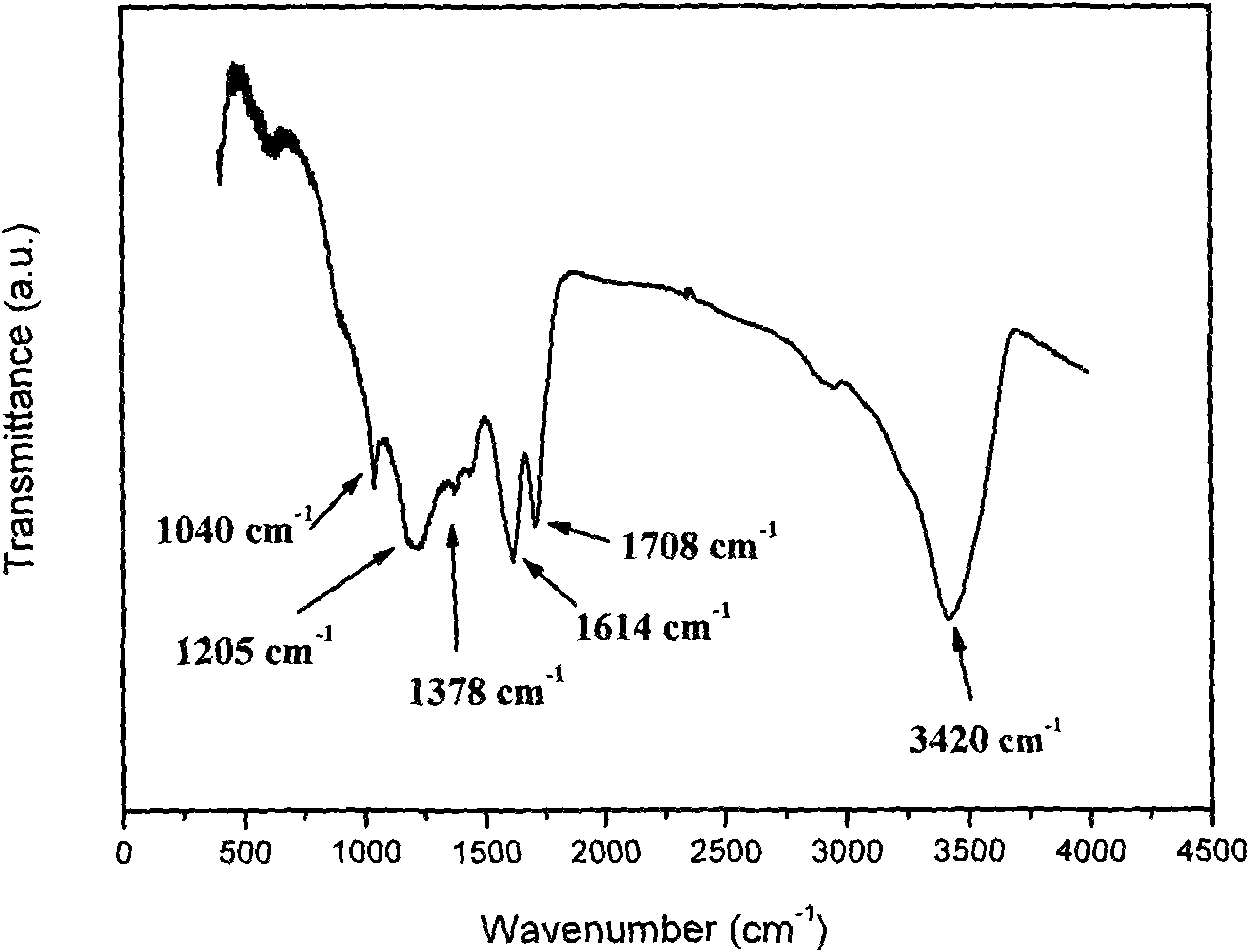

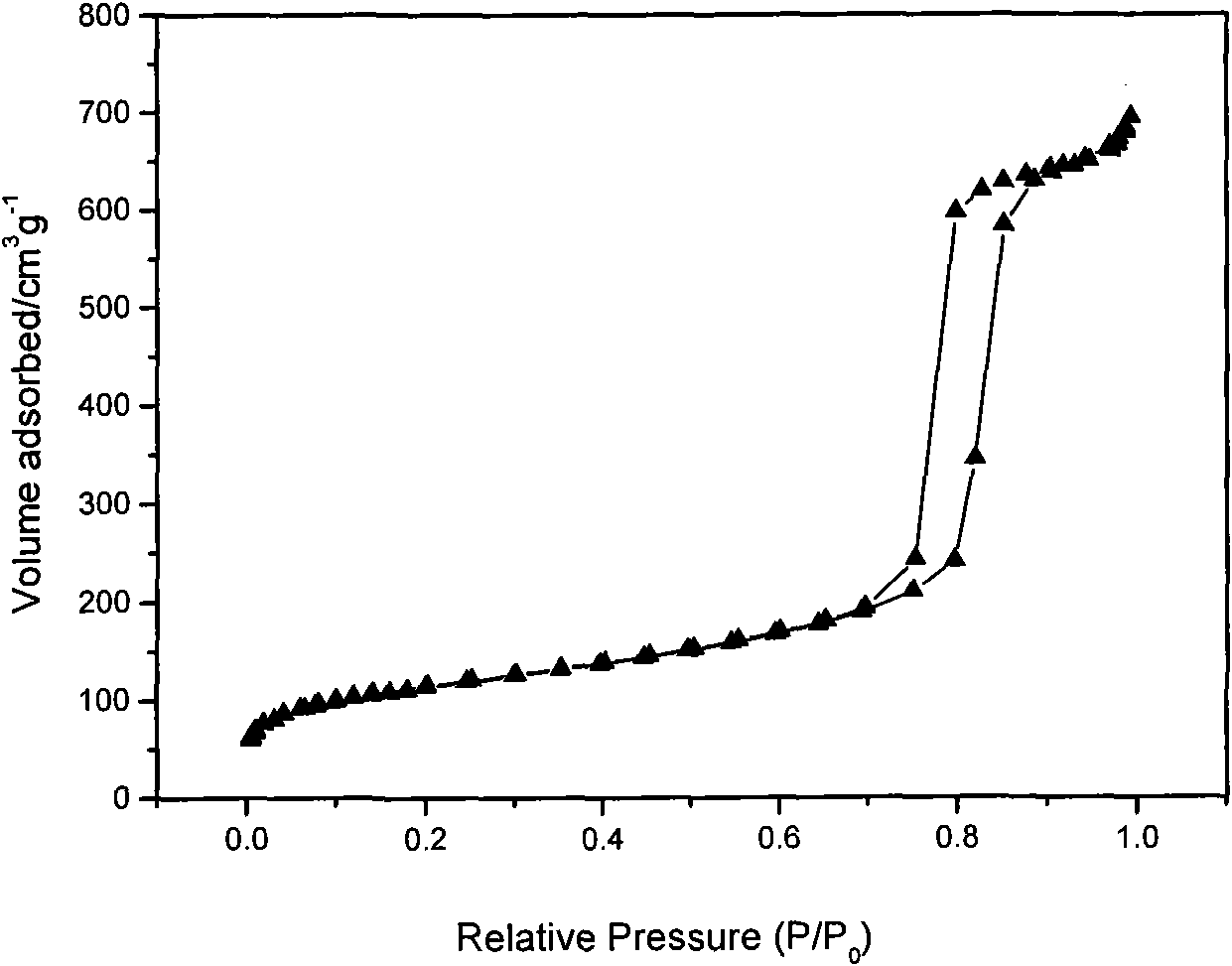

Method for fast synthesizing mesoporous solid acid catalyst immobilized with sulfonic acid

InactiveCN102019203AHighly orderly arrangement of poresUniform pore sizeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFiltration

The invention relates to a method for fast synthesizing a mesoporous solid acid catalyst immobilized with sulfonic acid, which comprises the following steps of: heating mesoporous molecular sieves with template agents, which are used as raw materials, in sulfuric acid solution with certain concentration so that the template agents in molecular sieve pore paths are carbonized and sulfonated; then,carrying out suction filtration, extraction and baking to obtain the mesoporous solid acid catalyst immobilized with the sulfonic acid. Compared with the tradiational mesoporous solid acid catalysts,the catalyst has simple preparation method and little time consumption. Sulfonic acid base groups are prepared through carbonizing and sulfonating the template agents, the use of expensive organic reagents is avoided, the production cost is greatly reduced, and the goal of waste utilization is also reached. In addition, the catalyst has orderly height distribution of the pore pathes, uniform porediameter and large specific surface area, is simple to separate and easy to store and shows good reaction activity when applied to the catalysis of aldolization.

Owner:NANKAI UNIV

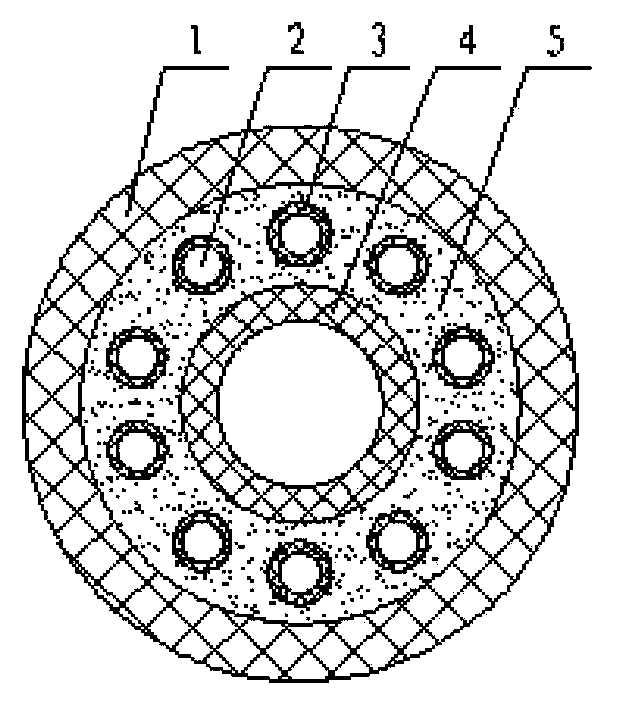

Carbon commutator and manufacturing method thereof

PendingCN108123344AHigh strengthFirmly connectedRotary current collectorCommutators manufactureCopperUltimate tensile strength

The invention discloses a carbon commutator. The carbon commutator comprises copper brackets, an insulating pedestal and carbon sheet plates, wherein one surfaces of the copper brackets and the carbonsheet plates are in brazing connection under vacuum by using a solder paste; the insulating pedestal is arranged on the other surfaces of the copper brackets; longitudinal bulges arranged at junctions of the copper brackets and the insulating pedestal are implanted into the insulating pedestal; transverse bulges arranged at junctions of the copper brackets and the carbon sheet plates are embeddedinto the carbon sheet plates. The carbon commutator disclosed by the invention is high in strength of an overall connecting structure, good in firmness of connection between a carbon basic body and acommutator piece and long in service life. The invention further discloses a manufacturing method of the carbon commutator. The solder paste for bonding the copper brackets and the carbon sheet plates comprises multiple metal elements such as nickel, chromium, iron, silicon, boron and scandium, and a junction of the commutator piece and the carbon sheet plate of the carbon commutator prepared from the solder paste is a metal layer, so that bonding is tight and firm and the reliability is high.

Owner:扬州华昌汽车电器有限公司

Special cable of automatic welding robot

InactiveCN103903684AGuaranteed functionalityCompact structureWelding/cutting auxillary devicesArc welding apparatusElectrical conductorShielding gas

The invention relates to a special cable of an automatic welding robot. The special cable comprises an outer sheath, a welding conductor and control line cores. An inner gas pipe through which protection gas and a welding wire pass is coaxially arranged in the outer sheath. The space between the inner gas pipe and the outer sheath is filled with the welding conductor and a number of control line cores. According to the invention, the special cable of the automatic welding robot has the advantages of ingenious design and reasonable structure, is suitable for popularization and application, and is clean and environment-friendly; and three functional elements are integrated in the cable, which reduces the occupied space, improves the use convenience, and ensures the orderliness of the whole line.

Owner:TIANJIN KEBO ELECTRIC POWER TECH DEV

Environmentally-friendly anticorrosion emulsion paint

InactiveCN102993858AStrong anti-exposure abilityNo burningAnti-corrosive paintsEmulsion paintsIonChemistry

The invention relates to an environmentally-friendly anticorrosion emulsion paint. The paint comprises the following constituent parts: 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium hexametaphosphate, 9-12 parts of titanium oxide, 10-20 parts of deionized water and 20-30 parts of kaolin. The environmentally-friendly anticorrosion emulsion paint further comprises 1-5 pars of ethylene glycol. The environmentally-friendly anticorrosion emulsion paint also comprises 8-12 parts of talcum powder. The environmentally-friendly anticorrosion emulsion paint is not toxic, is tasteless, belongs to non-dangerous goods, is non-ignitable and non-explodable, does not have oxidability and has strong acid resistance and exposure resistance.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Boiler descaling agent

InactiveCN106635519AAct as scale inhibitorImprove utilization efficiencyWater contaminantsWater softeningChemistrySodium triphosphate

The invention provides a boiler descaling agent. The boiler descaling agent is prepared from the following ingredients in percentage by weight: 5% to 10% of citric acid, 6% to 10% of methylsulfonic acid, 10% to 16% of trisodium phosphate, 10% to 16% of sodium tripolyphosphate, 3% to 6% of penetrant, 4% to 10% of polyaluminum silicate sulfate and the balance of water. The descaling agent can be used for rapidly removing scales from a boiler, and the scales in the boiler can be cleared cleanly in 50 to 100 minutes.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

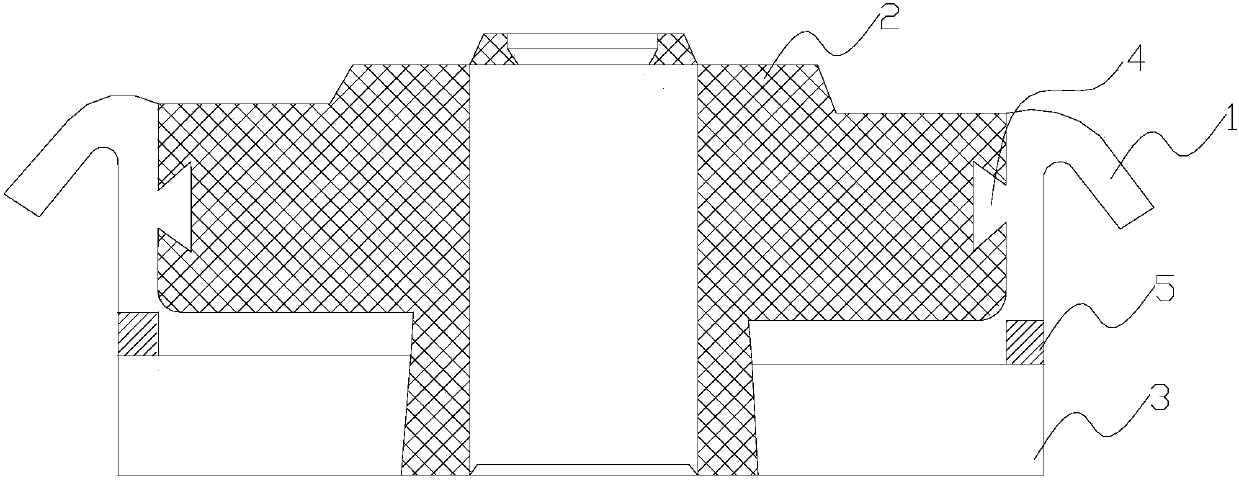

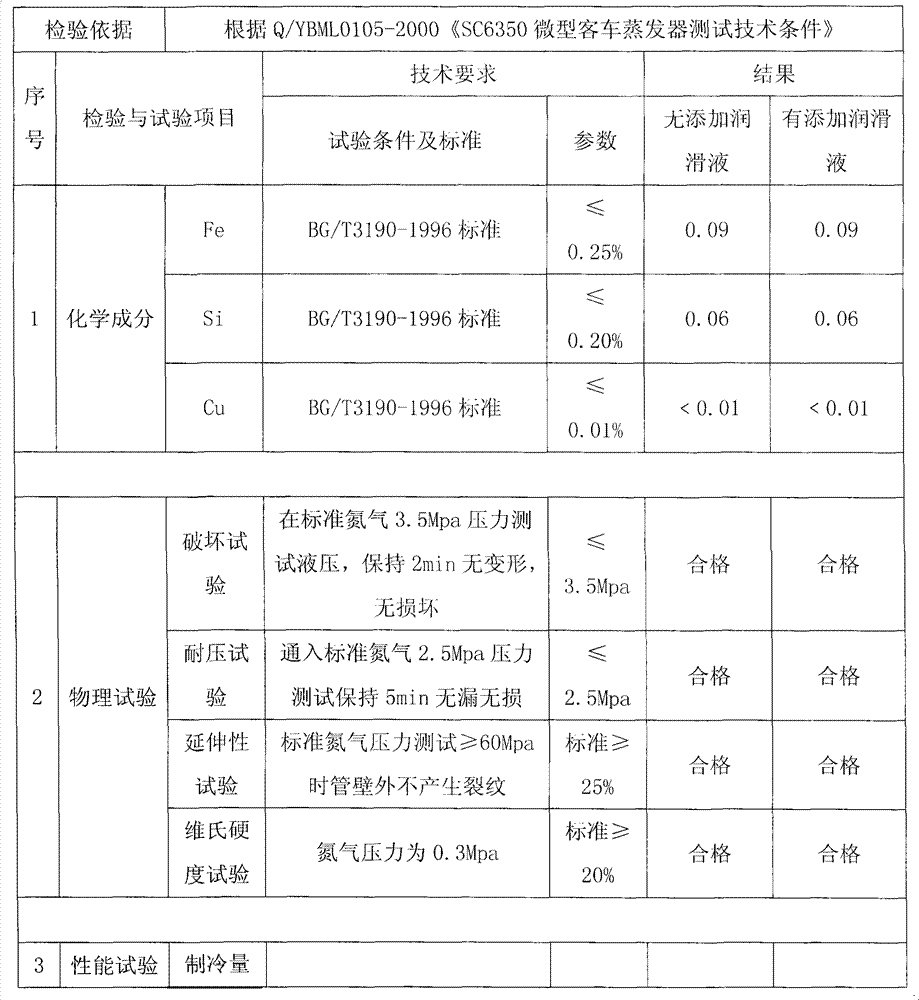

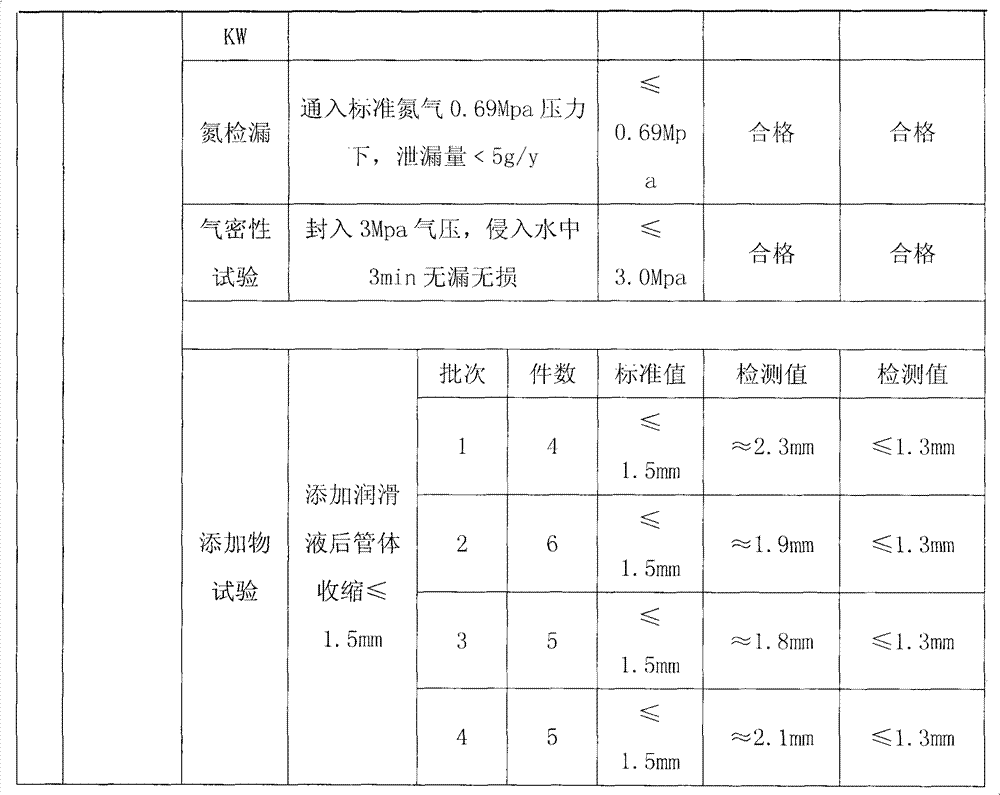

Lubricating liquid for use in aluminum pipe expansion and aluminum pipe expansion method

The invention provides a lubricating liquid for use in aluminum pipe expansion and an aluminum pipe expansion method using same. The lubricating liquid is prepared from the following materials in percentage by weight: 0.9 to 1 percent of trichloroethylene, 1.8 to 2 percent of chromic anhydride, 6 to 7 percent of liquid cleanser essence solution in which the water to liquid cleanser essence is 1:5,000, and 90 to 91.3 percent of washing-up liquid. The aluminum pipe expansion method comprises the following steps: 1) spreading the lubricating liquid on the inner wall of the aluminum pipe before the expansion of the aluminum pipe; and 2) washing the lubricating liquid with high-pressure constant-temperature water after the expansion of the aluminum pipe. The lubricating liquid has the following advantages of: 1) avoiding damaging the aluminum pipe due to no corrosive and oxidizing properties; 2) washing easily enough to keep the smooth of the pipe, increasing the flexibility of the aluminum pipe to prevent the aluminum pipe from cracking and improving rate of finished products; 3) forming a protective film which can protect an evaporator and prolong the service life of the product; and 4) realizing the replacement of copper by aluminum, reducing product cost and making the aluminum achieve the same heat conducting effect as copper.

Owner:广州市铭城汽车配件有限公司

Solid phase catalyst for preparing methyl formate, preparation method therefor and application thereof

ActiveCN105013539AStable formLow reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMuffle furnaceCopper sulfate

The invention discloses a preparation method of methyl formate and belongs to the technical field of ester synthesis. According to the preparation method of the methyl formate, formic acid and methanol can react under the action of solid-phase catalyst to produce the methyl formate. The step of preparing the solid-phase catalyst comprises (a) adding kaolin into deionized water; (b) dissolving aluminum sulfate and copper sulfate into water to obtain solution, immersing the kaolin processed in the step (a) into the solution; (c) mixing cation exchange resin with a substance A and grinding the mixture to obtain a substance B; (d) preparing 30% carborane acid solution, immersing the substance B into the solution and taking the substance B out of the solution, drying the substance B in vacuum, roasting the substance B inside a muffle furnace, and grinding the substance B to obtain the solid-phase catalyst. The preparation method of the methyl formate is non-toxic and harmless, significantly improves the reaction velocity and is low in requirements on reaction conditions and energy consumption, and meanwhile, the catalyst is recyclable, so that the production cost can be effectively reduced, and the preparation method of the methyl formate is applicable to industrial production.

Owner:CHUANHUA GRP

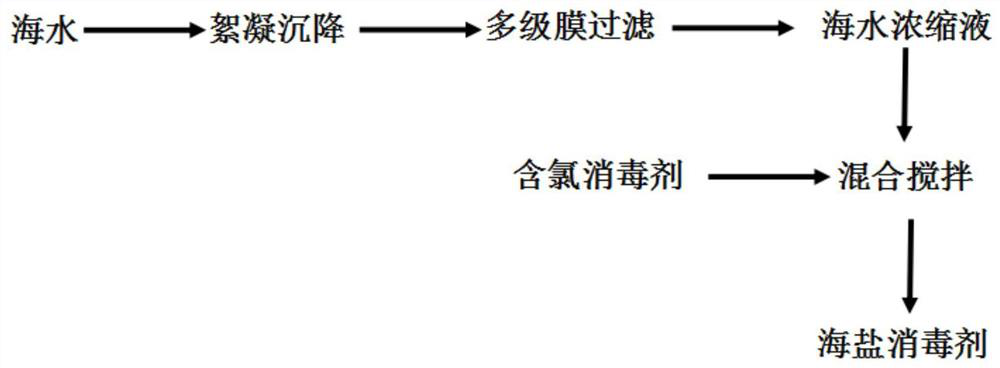

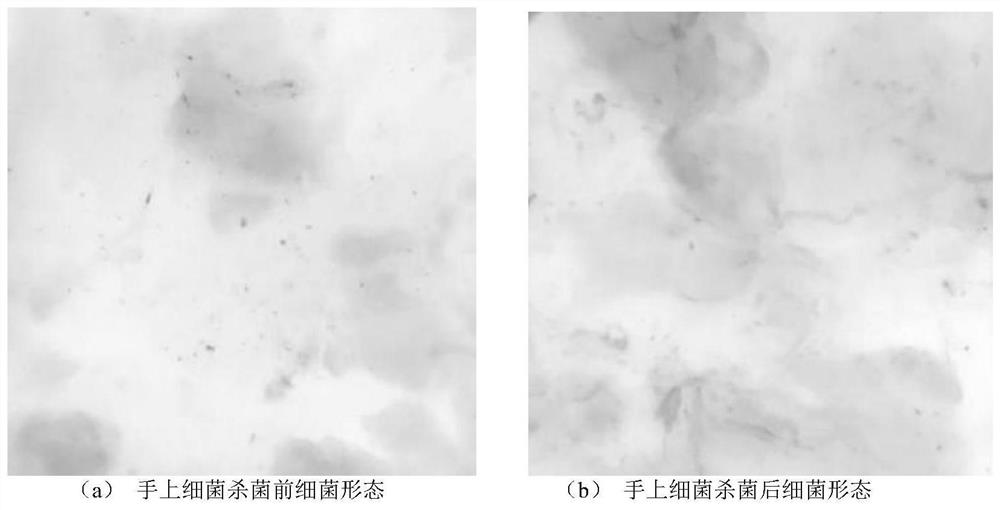

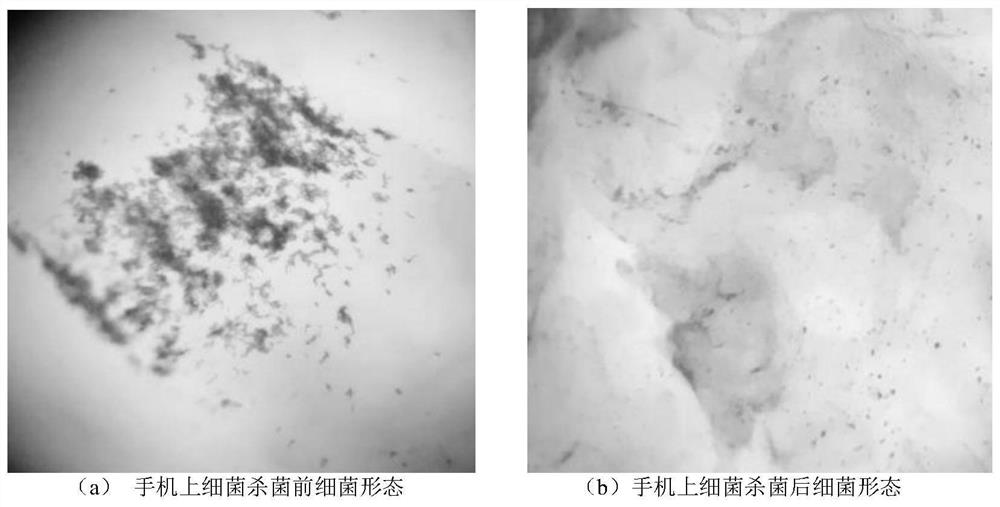

Preparation method of sea salt disinfectant

ActiveCN112956488AGood for skin care and nutritionThe production process is green and environmentally friendlyBiocideMultistage water/sewage treatmentSea saltDisinfectant

The invention provides a preparation method of a sea salt disinfectant, which comprises the following steps: by taking seawater, brine or old brine as a raw material, purifying the seawater, brine or old brine, separating sodium chloride in the solution by adopting a nanofiltration membrane, then discharging, retaining the trapped fluid of the nanofiltration membrane, adding a small amount of chlorine-containing disinfectant solution, uniformly mixing, performing filling to obtain a disinfectant, and discharging the permeated fluid of the nanofiltration membrane. According to the preparation method of a sea salt disinfectant, a sea salt disinfectant used for sterilization of daily life, public places, breeding place environments, body surfaces of raised livestock, poultry and pets, plant leaf surfaces and the like is provided.

Owner:天津海桓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com