Dissolving-resisting-type foam extinguishing agent

A technology of foam fire extinguishing agent and antifreeze agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of high development cost, achieve good environmental protection, ideal extinguishing effect, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

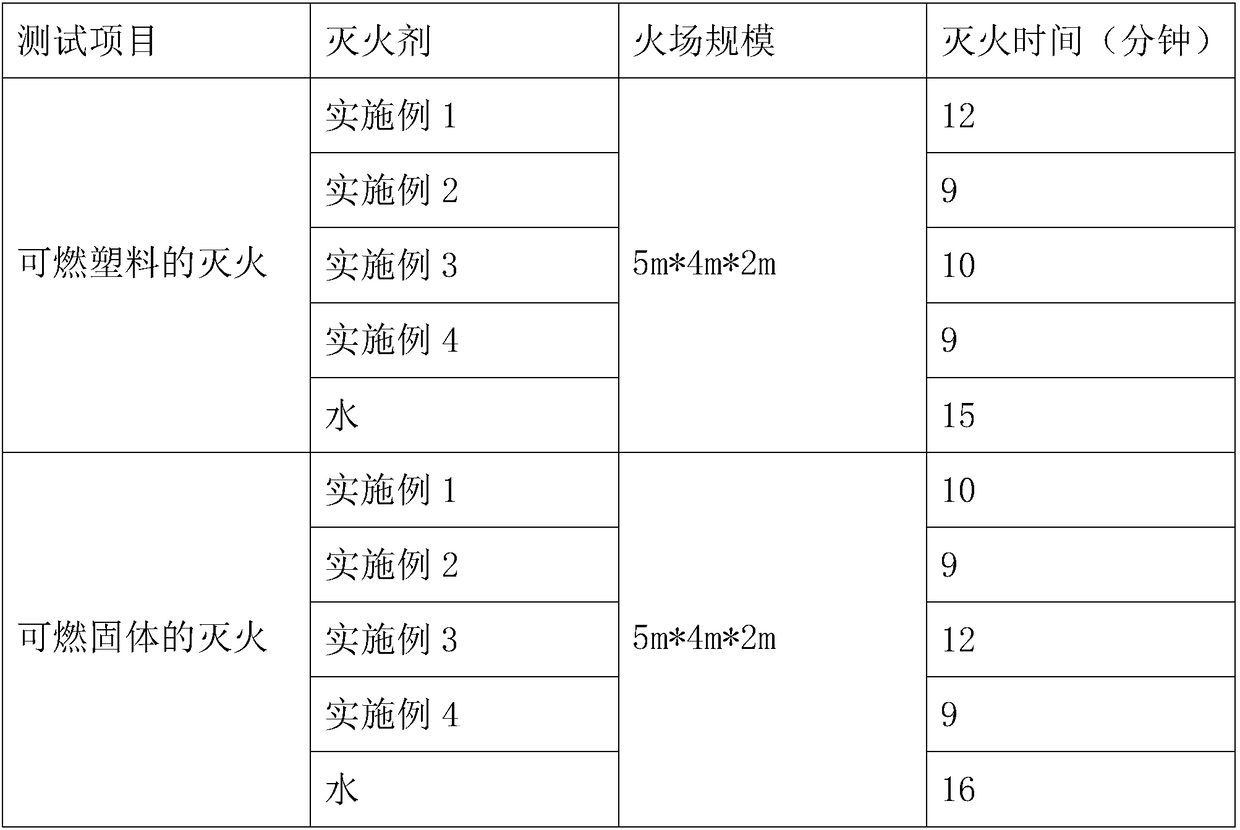

Examples

Embodiment 1

[0021] A kind of preparation method of anti-solvent type foam fire extinguishing agent is:

[0022] (1) The number of parts by mass is 15 parts of straight-chain alkyl sulfate, 7 parts of straight-chain fatty alcohol polyoxyethylene ether sulfate, 6 parts of straight-chain alkyl sulfonate, 4 parts of straight-chain α- Add olefin sulfonate, 3 parts of linear alkylbenzene sulfonate, and 15 parts of water into the reaction kettle, and react at 55°C to prepare a hydrocarbon surfactant.

[0023] (2) 25 parts by mass of bacterial polysaccharides, 12 parts of seaweed polysaccharides and 25 parts of water were added into the reactor and mixed uniformly to obtain biological polysaccharides.

[0024] (3) 15 parts of ethanol, 3 parts of ethylene glycol, 5 parts of propanol, 6 parts of propylene glycol, and 8 parts of glycerol are uniformly mixed to obtain an antifreeze agent.

[0025] (4) Add 25 parts by mass of urea, 8 parts of EDTA, and 25 parts of water into the reactor, and stir at ...

Embodiment 2

[0029] A kind of preparation method of anti-solvent type foam fire extinguishing agent is:

[0030] (1) The number of parts by mass is 12 parts of straight-chain alkyl sulfate, 8 parts of straight-chain fatty alcohol polyoxyethylene ether sulfate, 5 parts of straight-chain alkyl sulfonate, 3 parts of straight-chain α- Add olefin sulfonate, 3 parts of linear alkylbenzene sulfonate, and 15 parts of water into the reaction kettle, and react at 50°C to prepare a hydrocarbon surfactant.

[0031] (2) 20 parts by mass of bacterial polysaccharide, 15 parts of seaweed polysaccharide, and 30 parts of water were added into the reaction kettle and mixed uniformly to obtain biological polysaccharide.

[0032] (3) 12 parts of ethanol, 2 parts of ethylene glycol, 6 parts of propanol, 5 parts of propylene glycol, and 6 parts of glycerol are uniformly mixed to obtain an antifreeze agent.

[0033] (4) Add 30 parts by mass of urea, 10 parts of EDTA, and 30 parts of water into the reactor, and s...

Embodiment 3

[0037] A kind of preparation method of anti-solvent type foam fire extinguishing agent is:

[0038] (1) The number of parts by mass is 18 parts of straight-chain alkyl sulfate, 8 parts of straight-chain fatty alcohol polyoxyethylene ether sulfate, 8 parts of straight-chain alkyl sulfonate, 3 parts of straight-chain α- Add olefin sulfonate, 3 parts of linear alkylbenzene sulfonate and 20 parts of water into the reaction kettle, and react at 50-70°C to prepare hydrocarbon surfactant.

[0039] (2) 26 parts by mass of bacterial polysaccharide, 13 parts of seaweed polysaccharide, and 30 parts of water were added into the reaction kettle and mixed uniformly to obtain biological polysaccharide.

[0040] (3) 10 parts of ethanol, 4 parts of ethylene glycol, 3 parts of propanol, 8 parts of propylene glycol, and 10 parts of glycerol are uniformly mixed to obtain an antifreeze agent.

[0041](4) Add 25 parts by mass of urea, 10 parts of EDTA, and 30 parts of water into the reactor, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com