Patents

Literature

718 results about "Alkyl sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyl sulfonates are esters of alkane sulfonic acids with the general formula R-SO₂-O-R'. They act as alkylating agents, some of them are used as alkylating antineoplastic agents in the treatment of cancer, e.g. Busulfan.

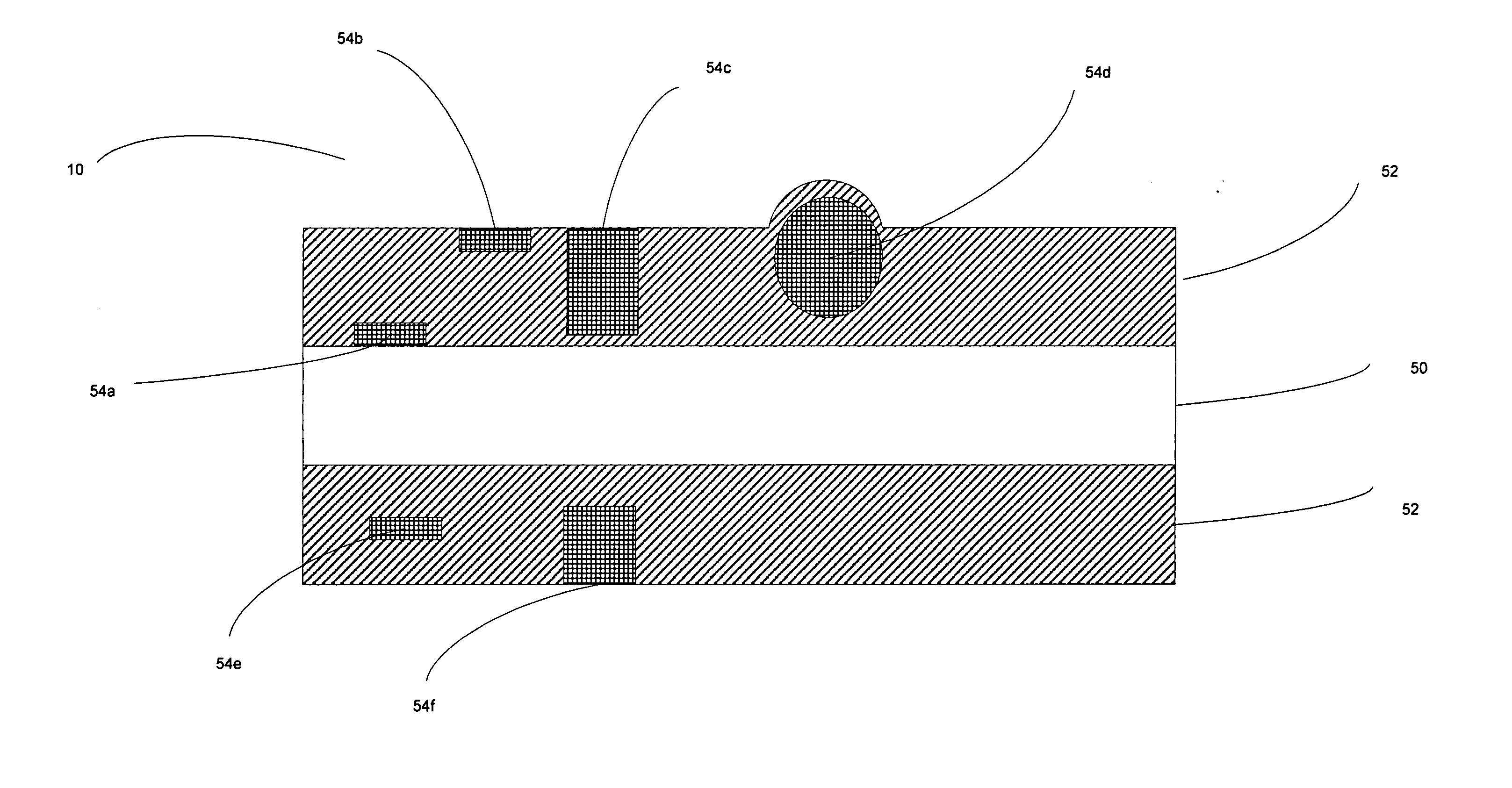

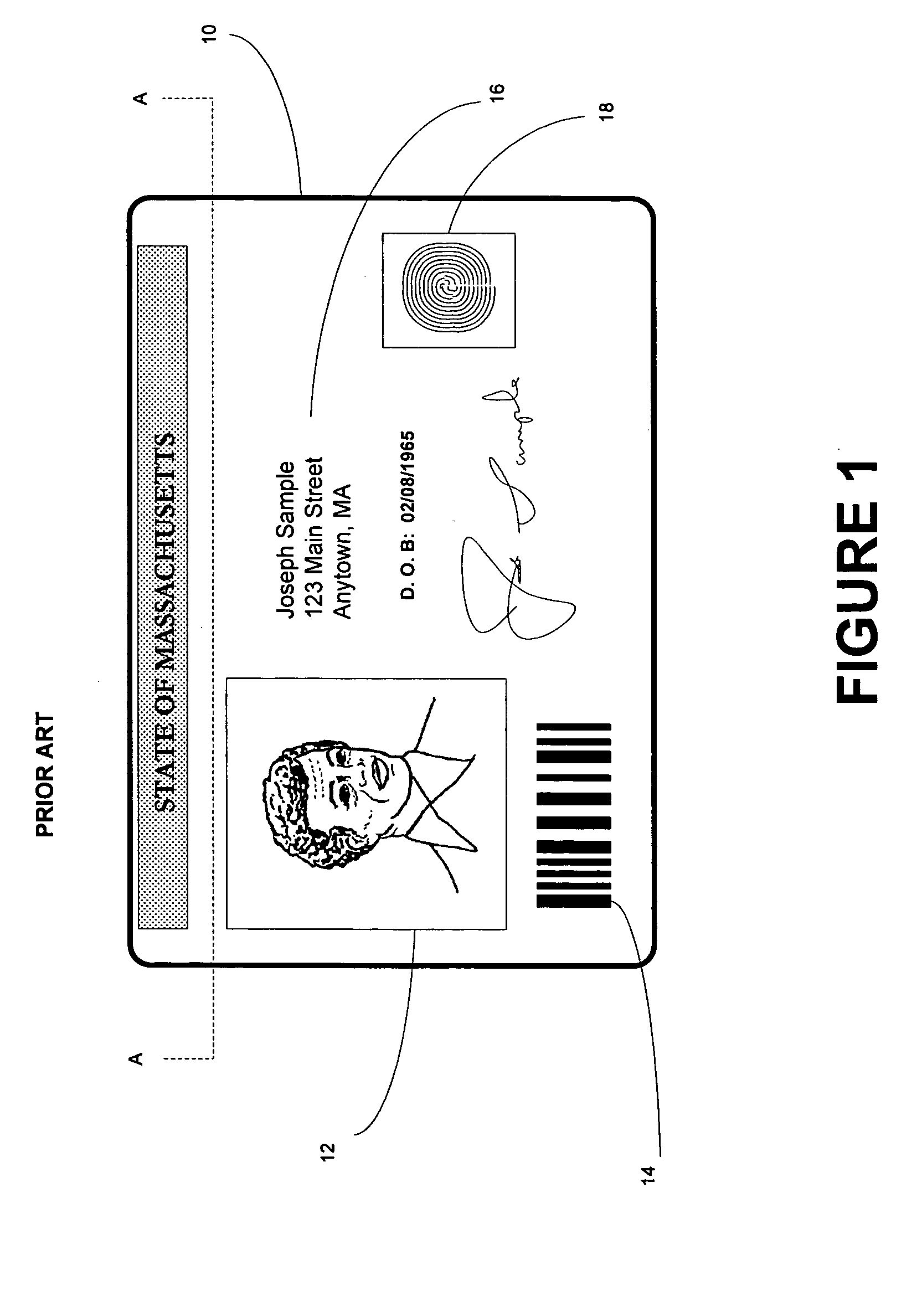

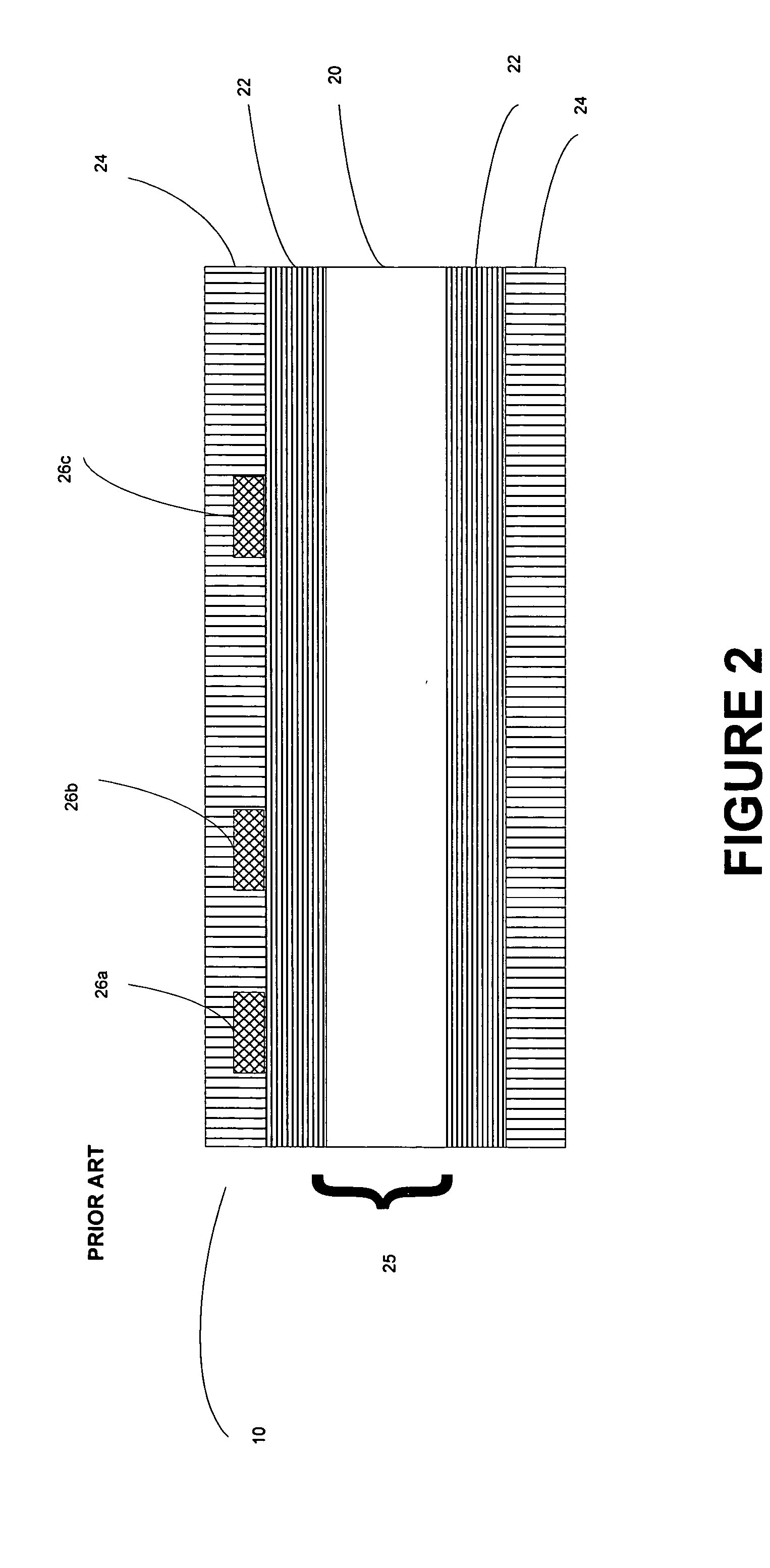

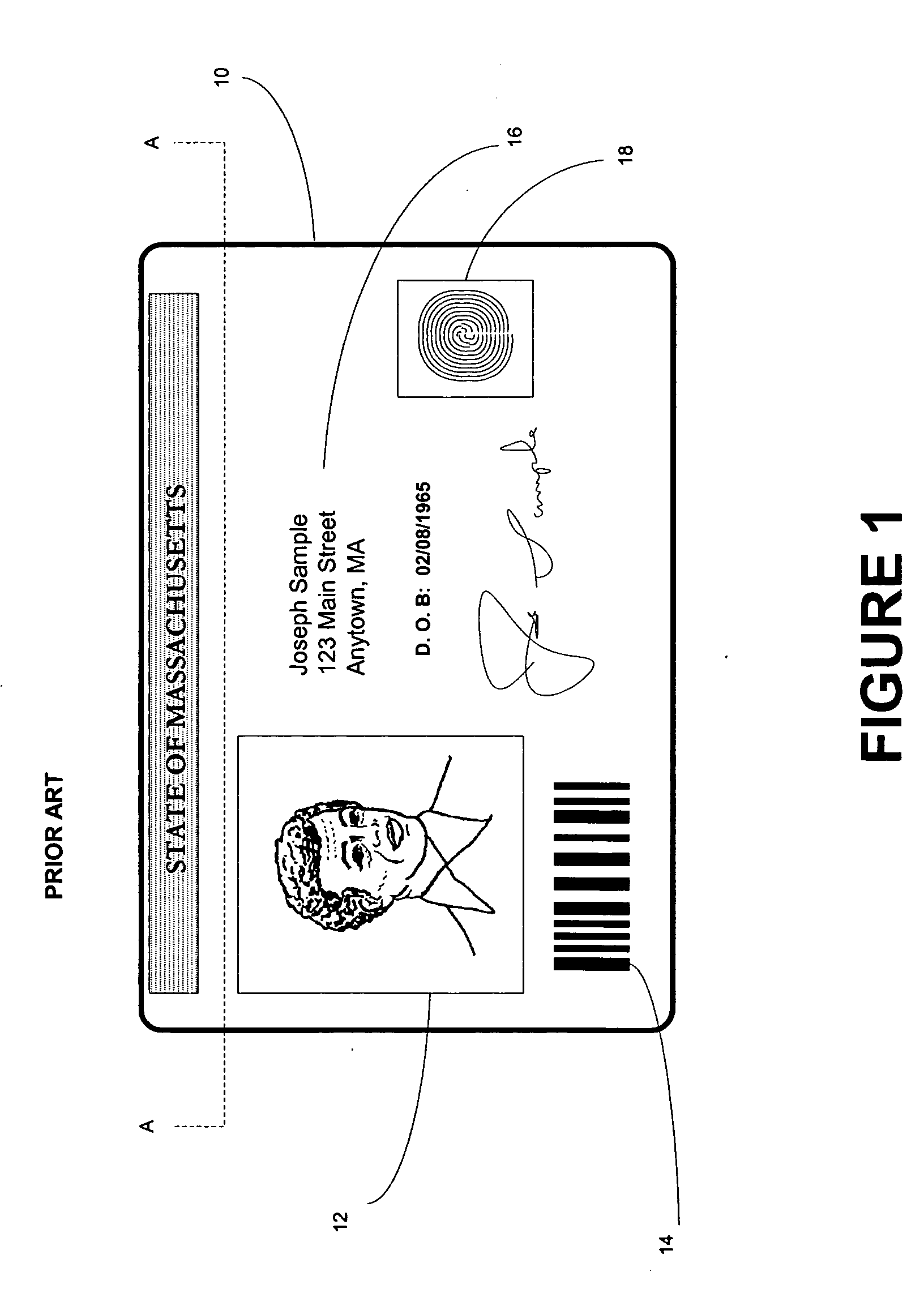

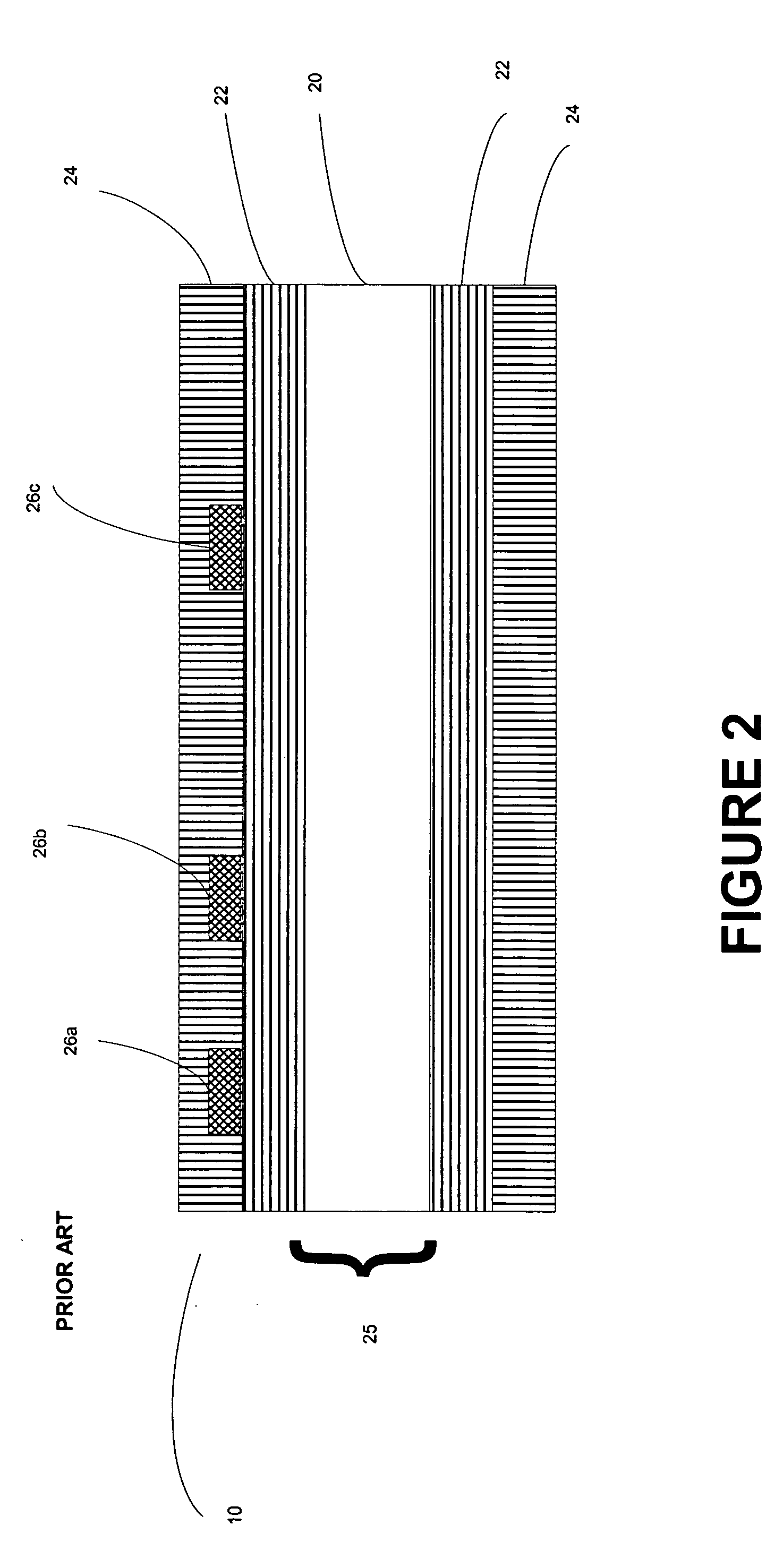

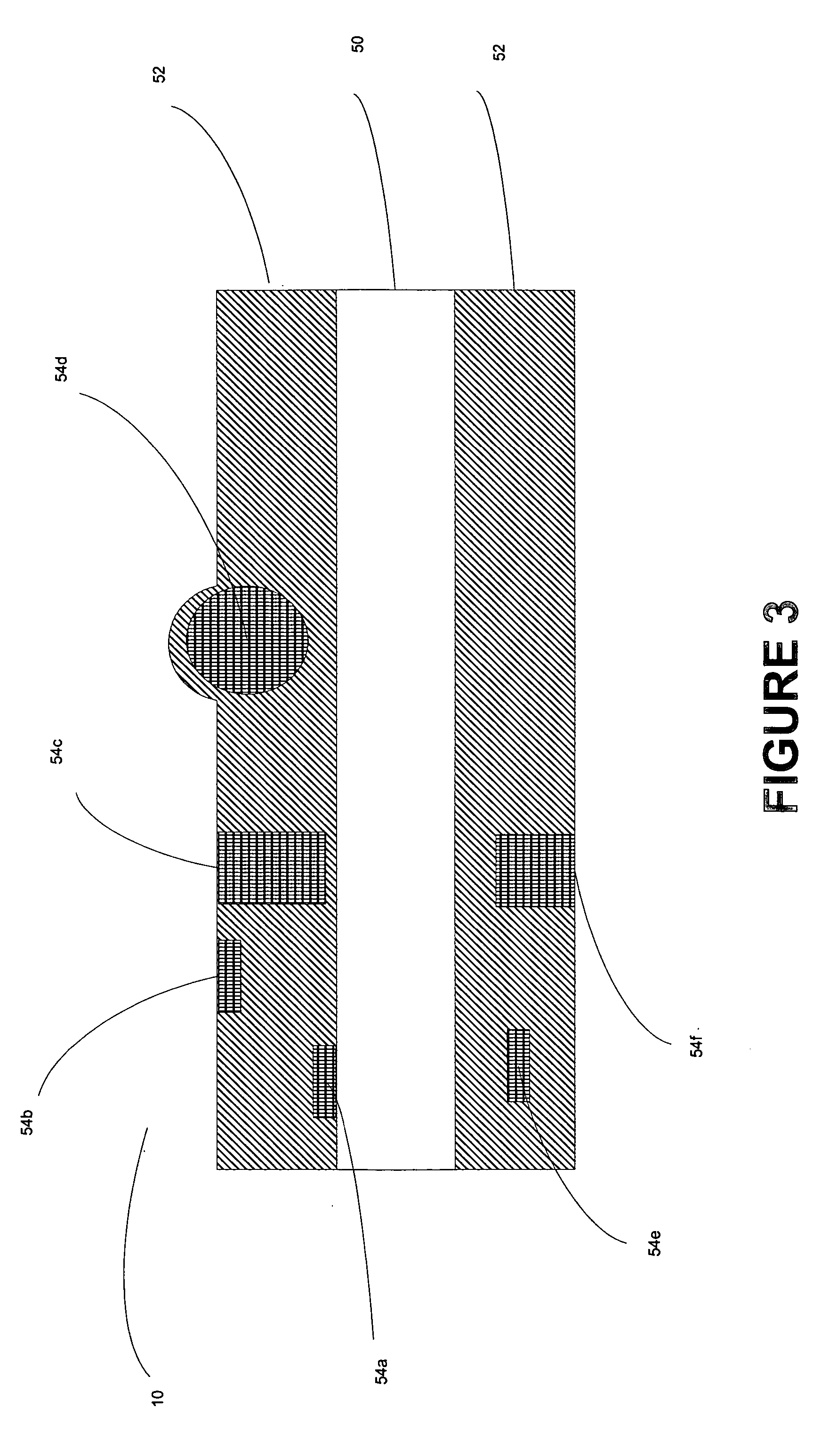

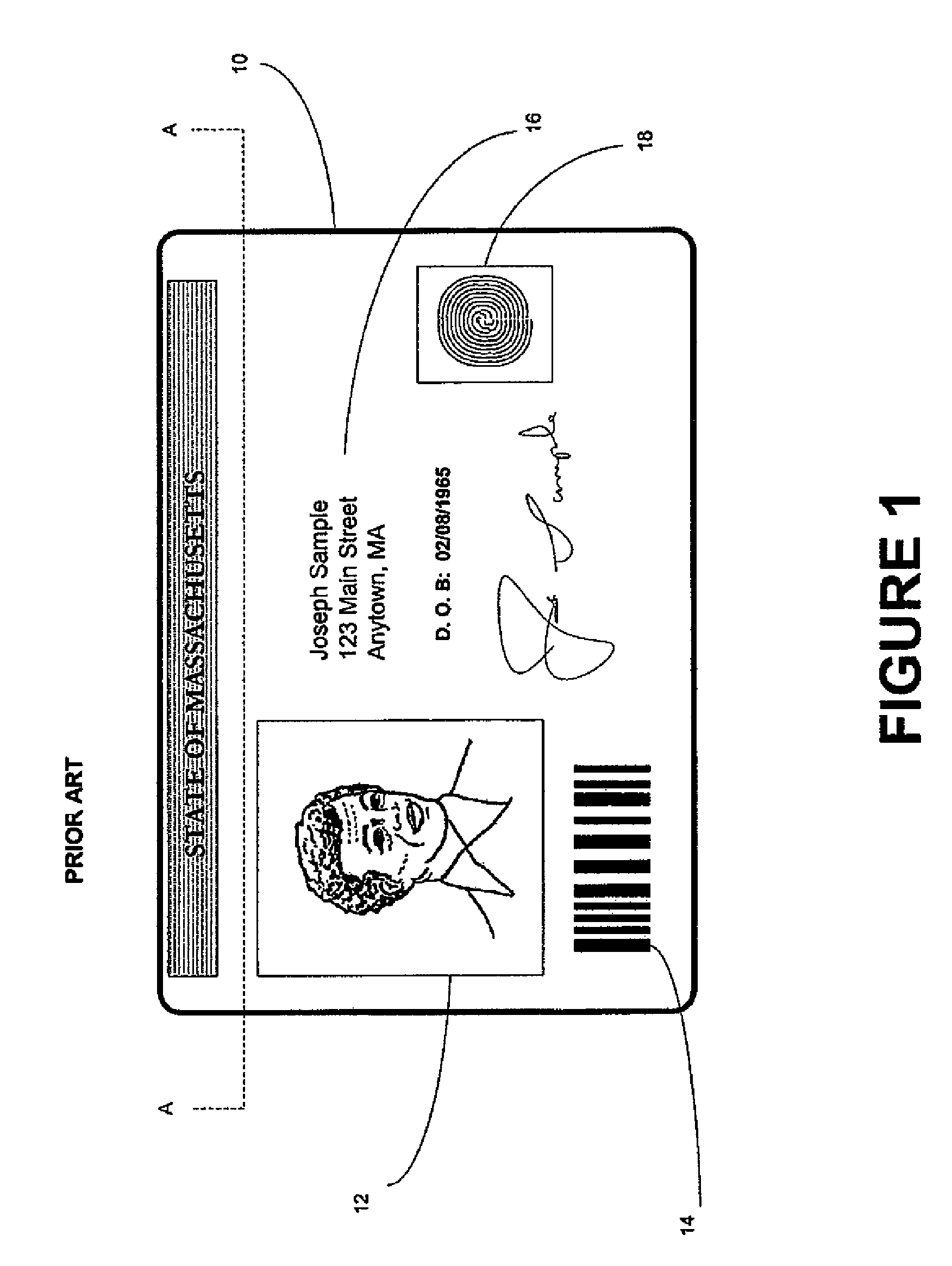

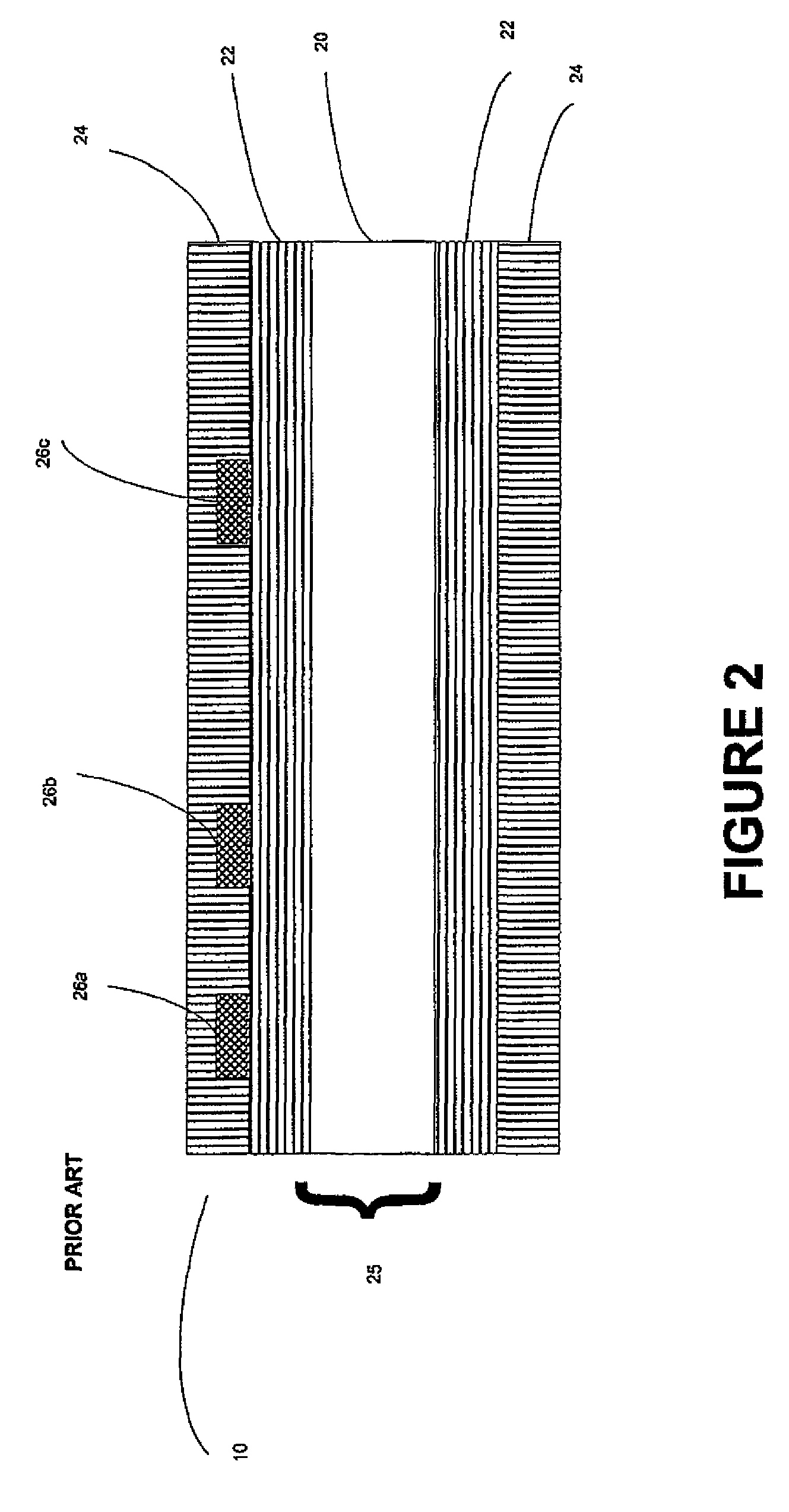

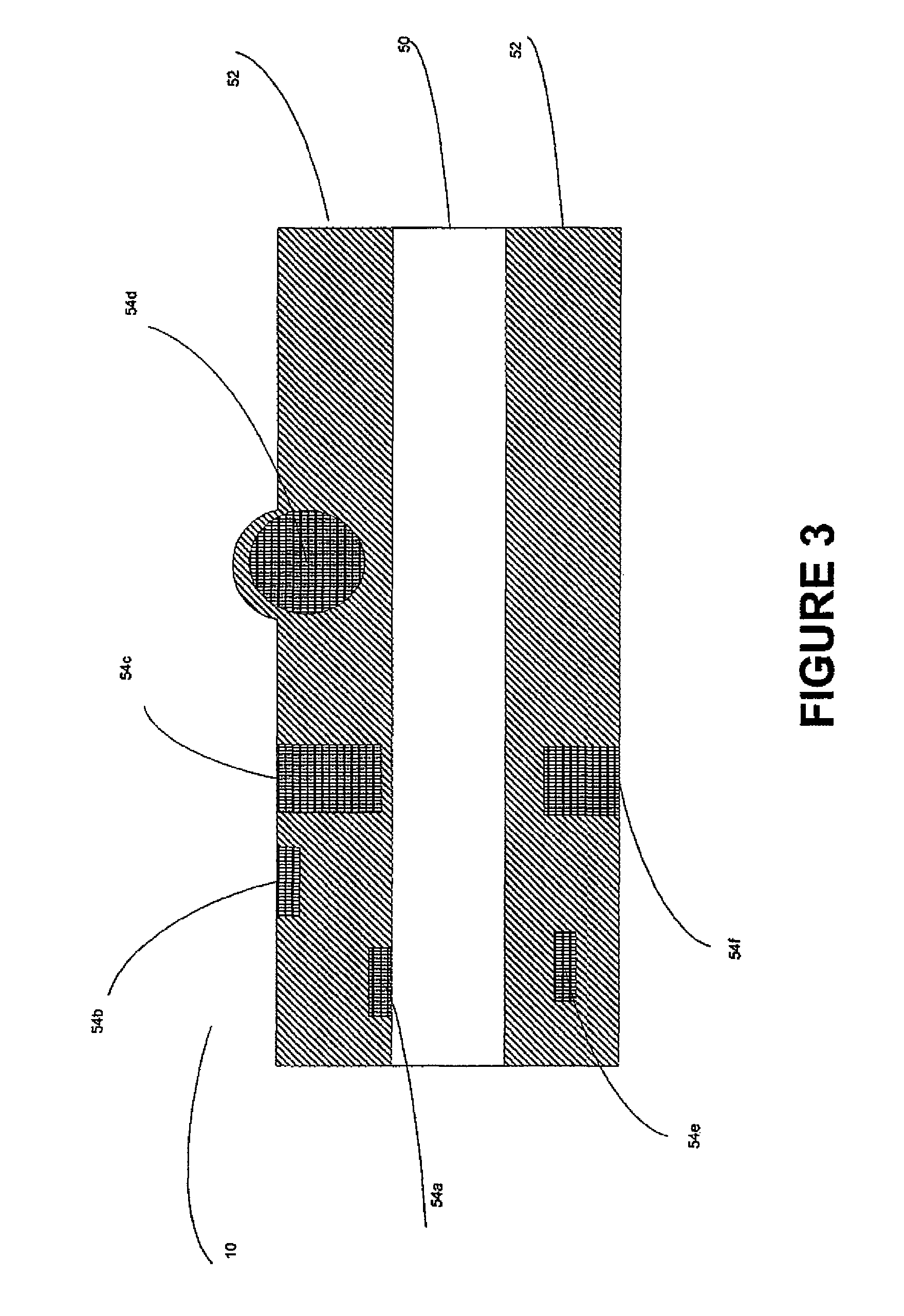

Laser engraving methods and compositions, and articles having laser engraving thereon

ActiveUS20050095408A1Not easy to counterfeitDifficult to alterRadiation applicationsDecorative surface effectsThioester synthesisBarium sulphide

The invention provides a composition having laser engraving properties, comprising a host material and an effective amount of a laser enhancing additive. The laser enhancing additive comprises a first quantity of least one of copper potassium iodide (CuKI3) or Copper Iodide (CuI), and a second quantity at least one substance selected from the group consisting of zinc sulfide (ZnS), barium sulfide (BaS), alkyl sulfonate, and thioester. The composition can be engraved with grayscale images by an Nd:Yag laser and can be added to laminates or coatings. The composition can be used during the manufacture of many articles of manufacture, including identification documents.

Owner:L 1 SECURE CREDENTIALING

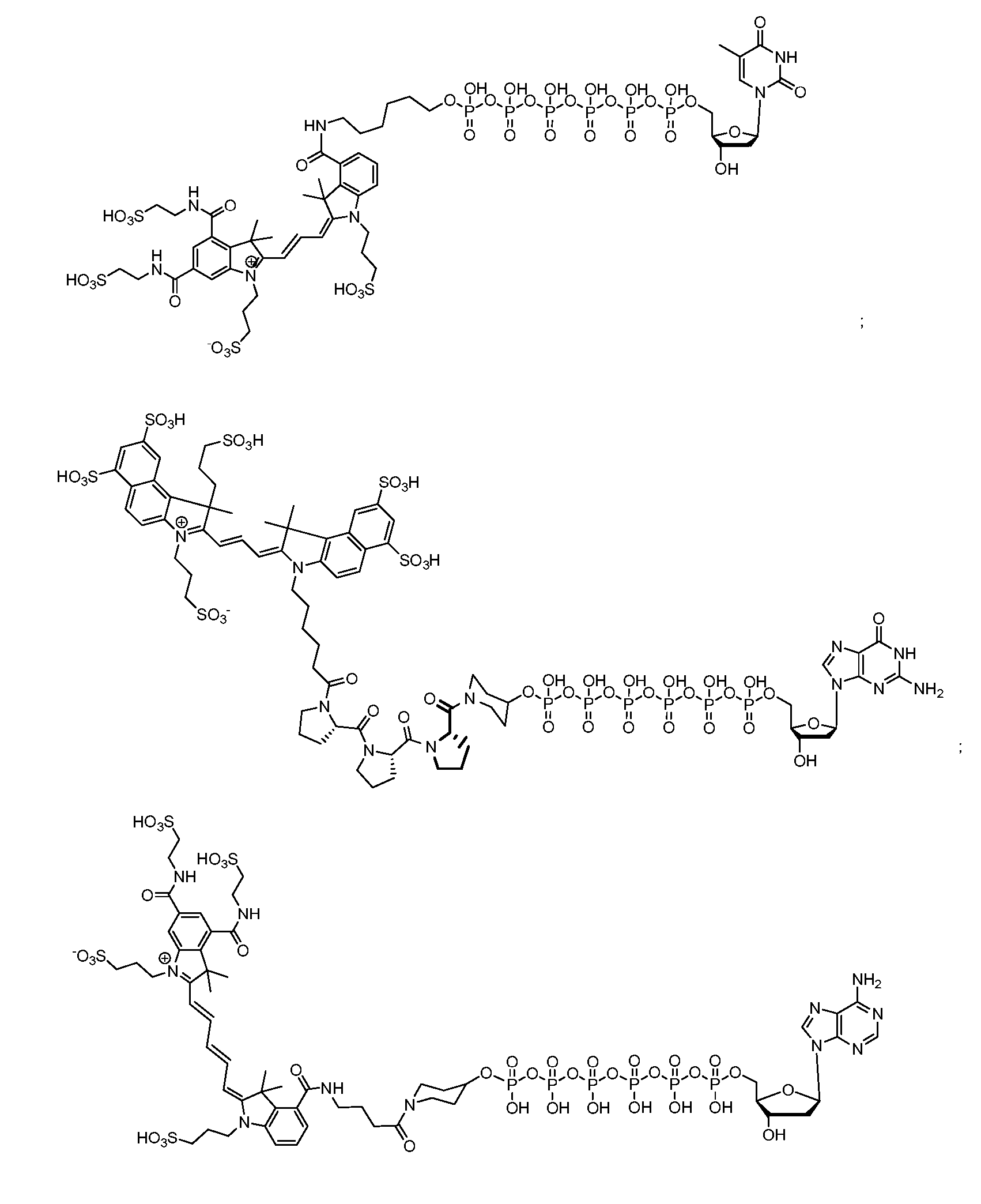

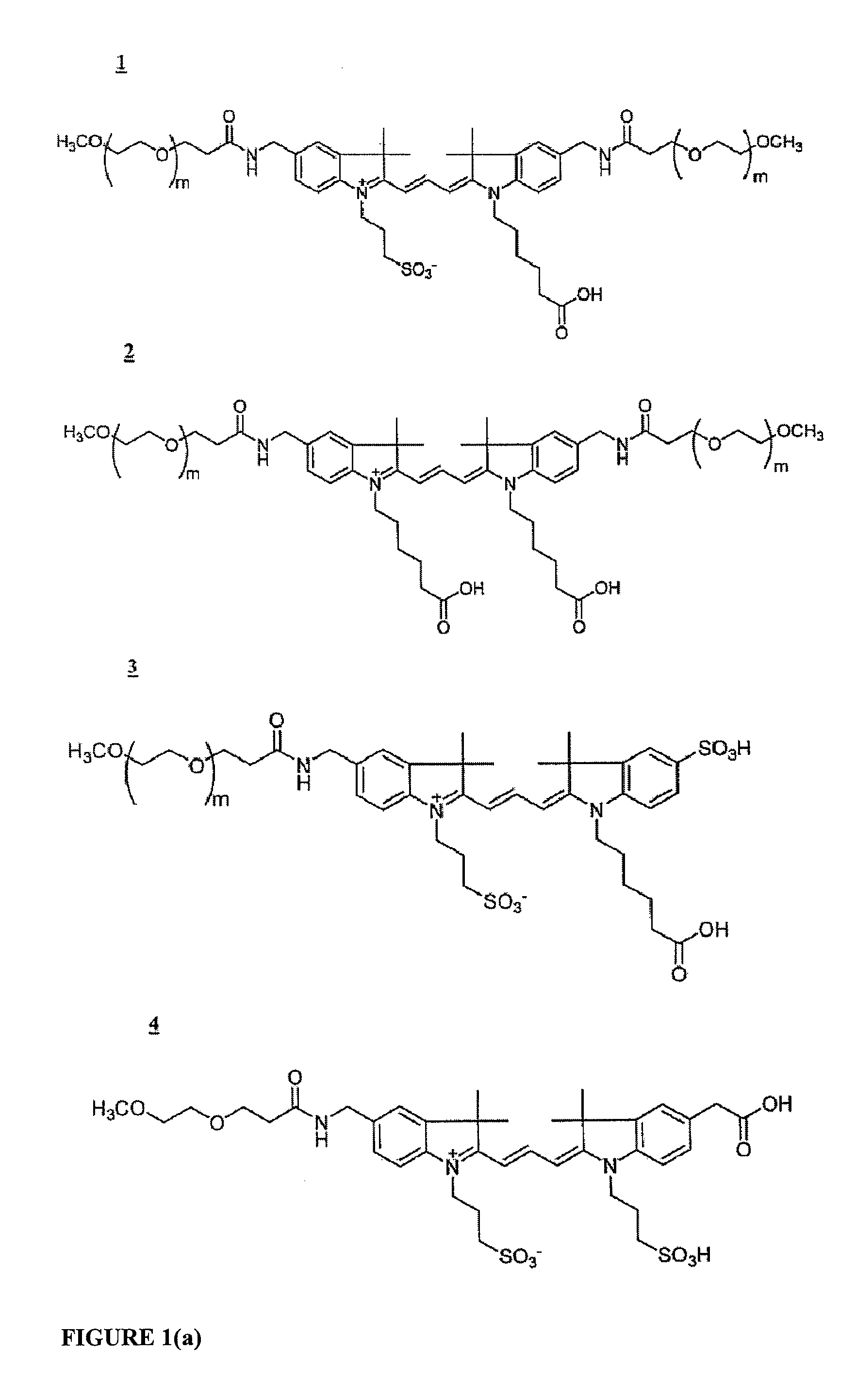

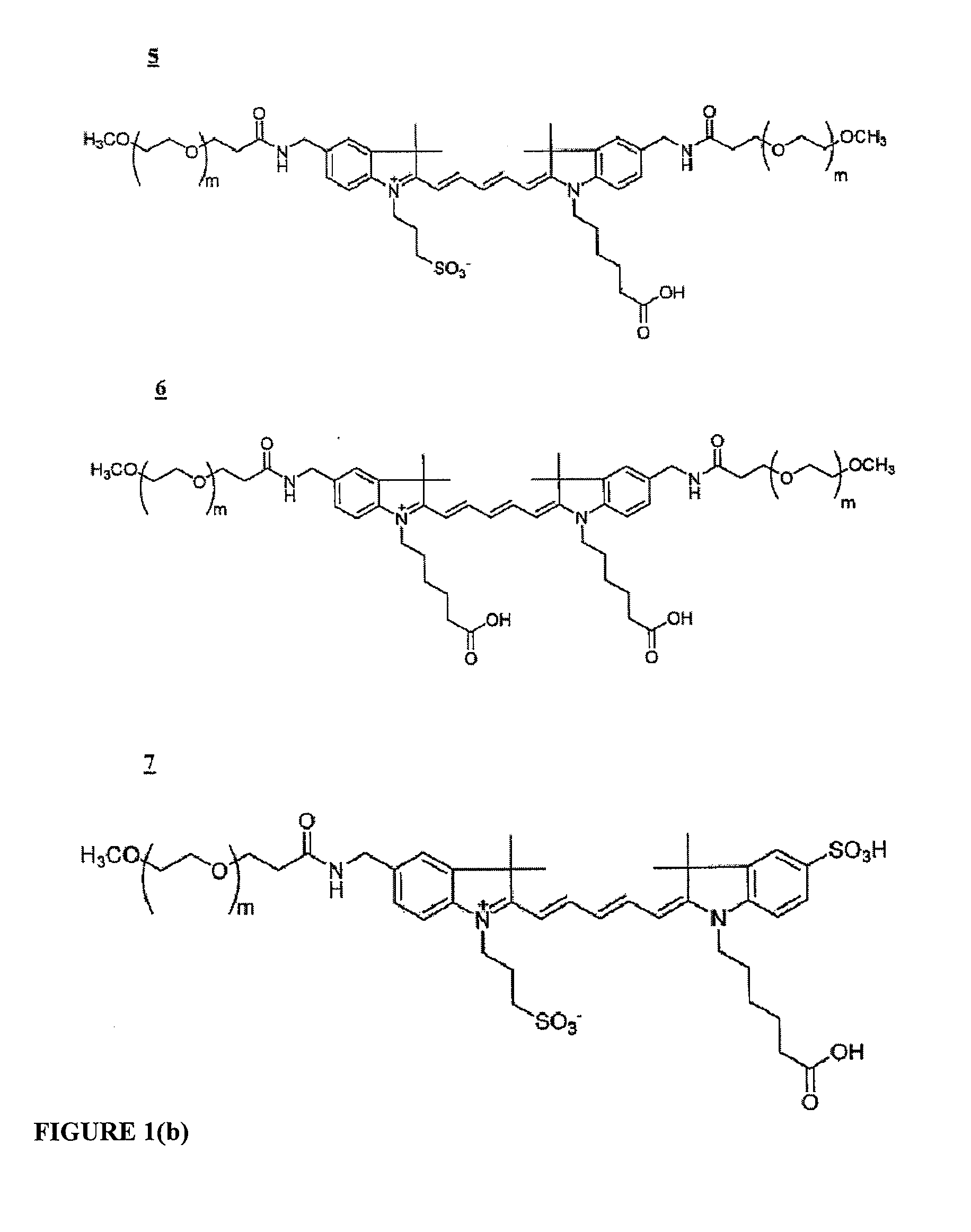

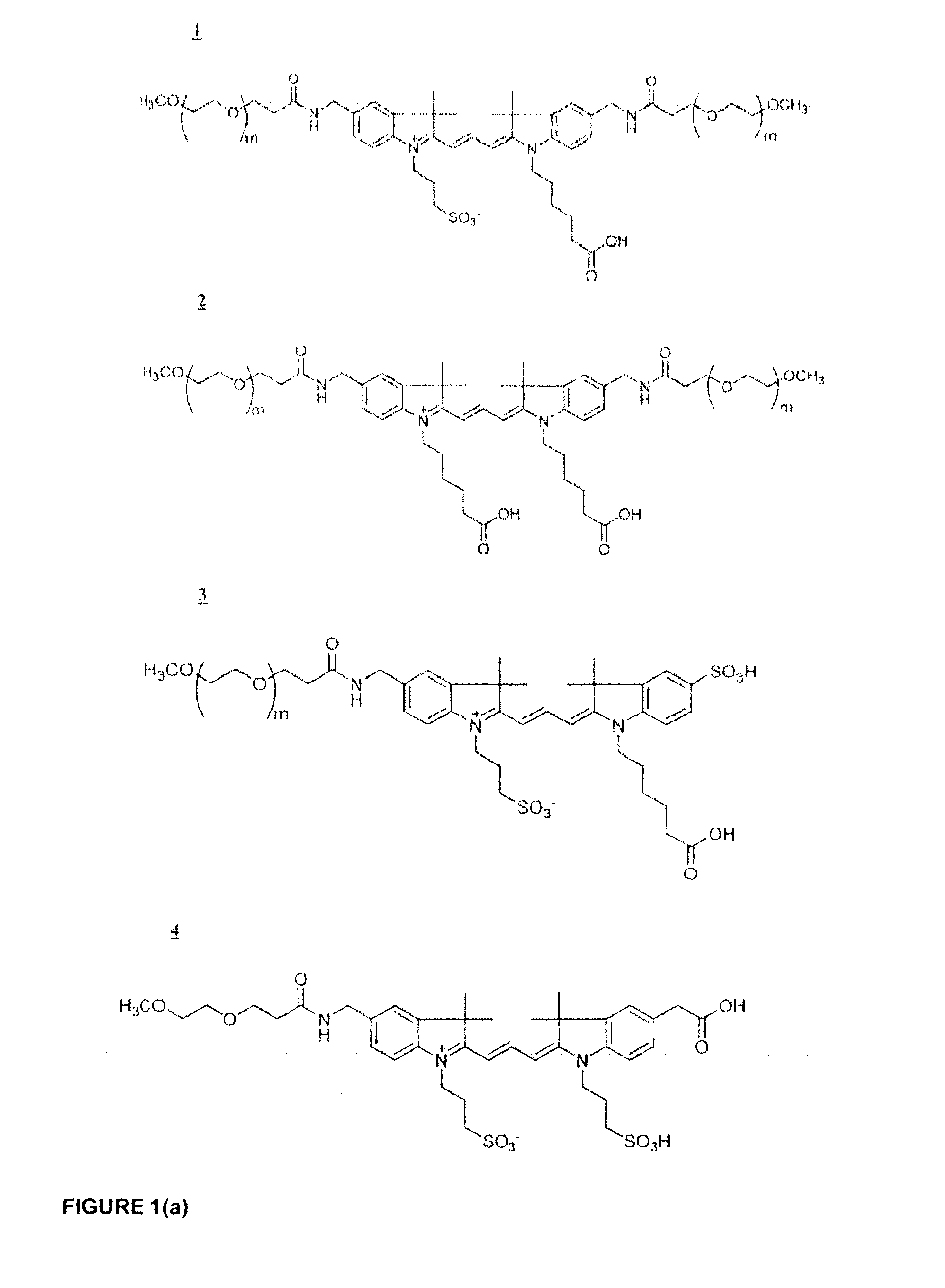

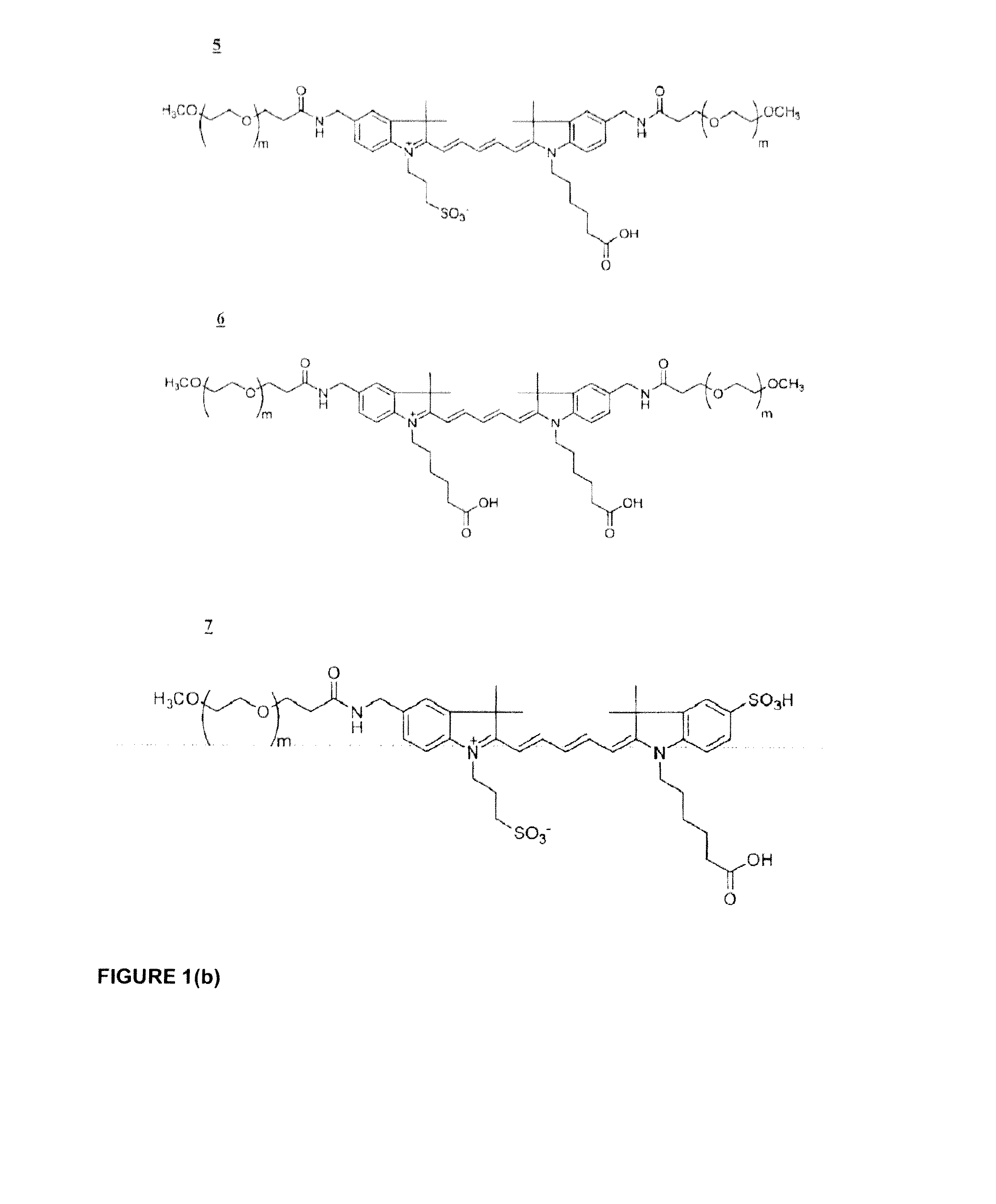

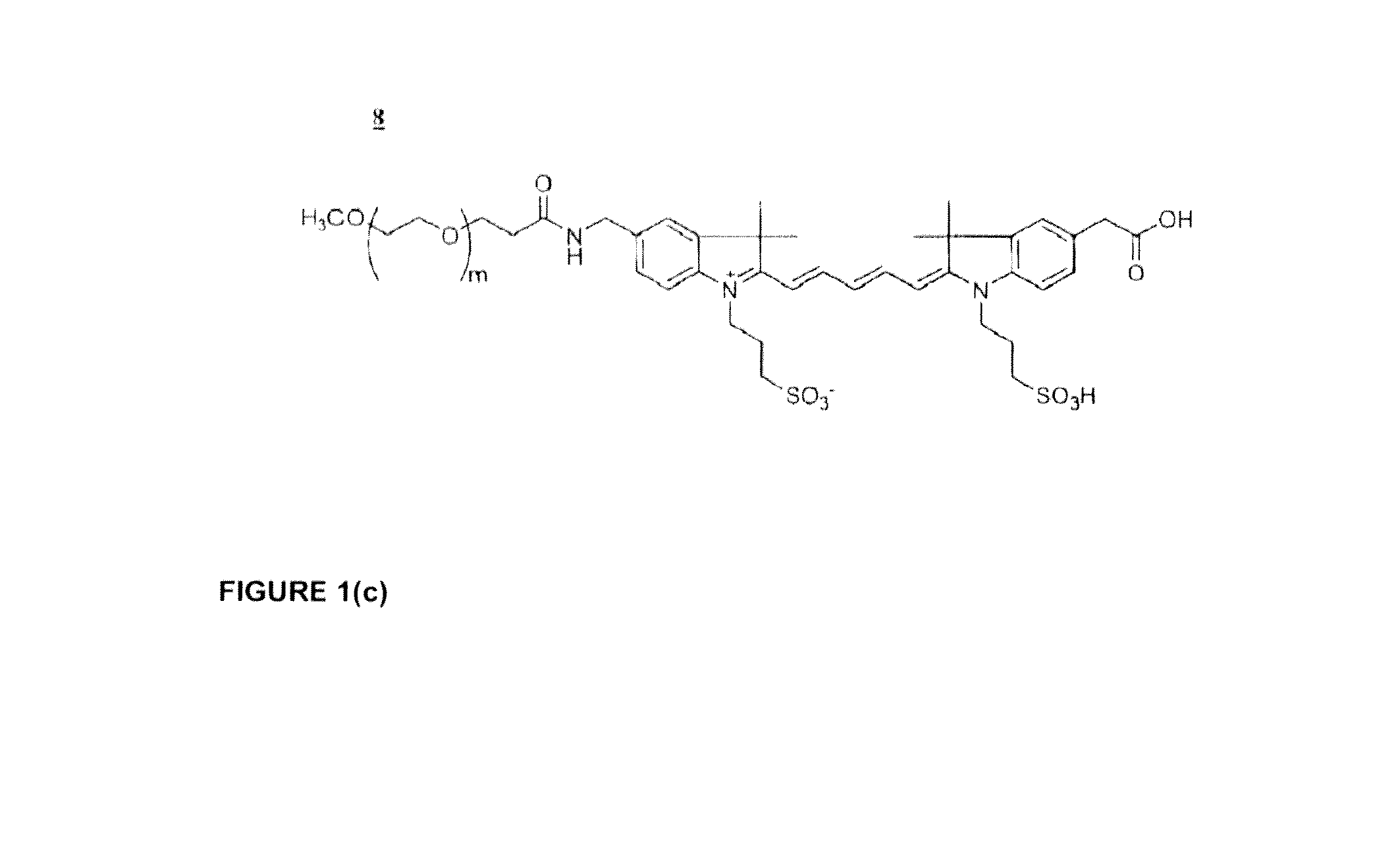

Molecular Adaptors for Dye Conjugates

ActiveUS20120058473A1Improve hydrophilicityReduce aggregationMethine/polymethine dyesSugar derivativesFluorescenceCarboxylate

In various embodiments, the present invention provides fluorescent dyes that are linked to another species through an adaptor moiety. In an exemplary embodiment, the dye is linked to a polyphosphate nucleic acid through an adaptor. An adaptor can be a component of a linker. These conjugates find use in single molecule DNA sequencing and other applications. In various embodiments, the dye moiety is a cyanine dye. Cyanine dyes that are highly charged, such as those including multiple sulfonate, alkylsulfonate, carboxylate and / or alkylcarboxylate moieties are examples of cyanine dyes of use in the compounds of the invention.

Owner:PACIFIC BIOSCIENCES

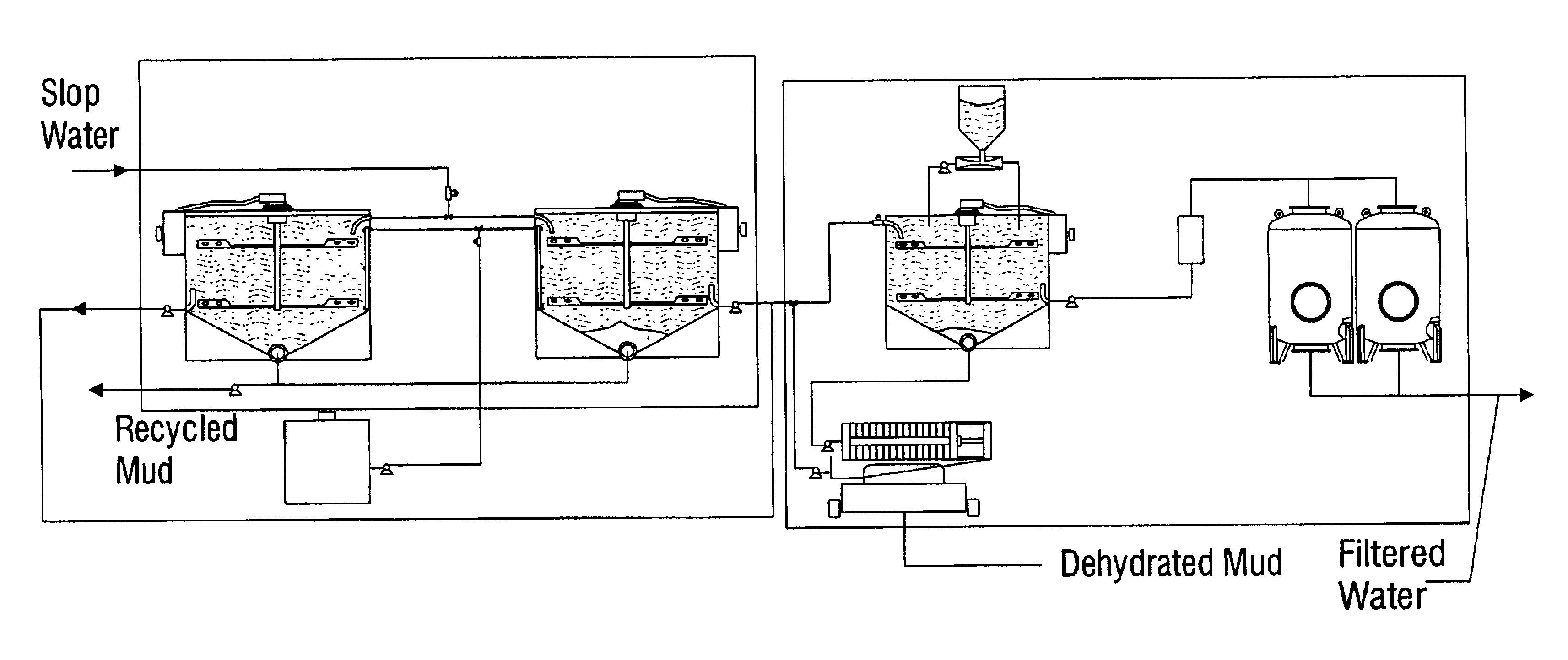

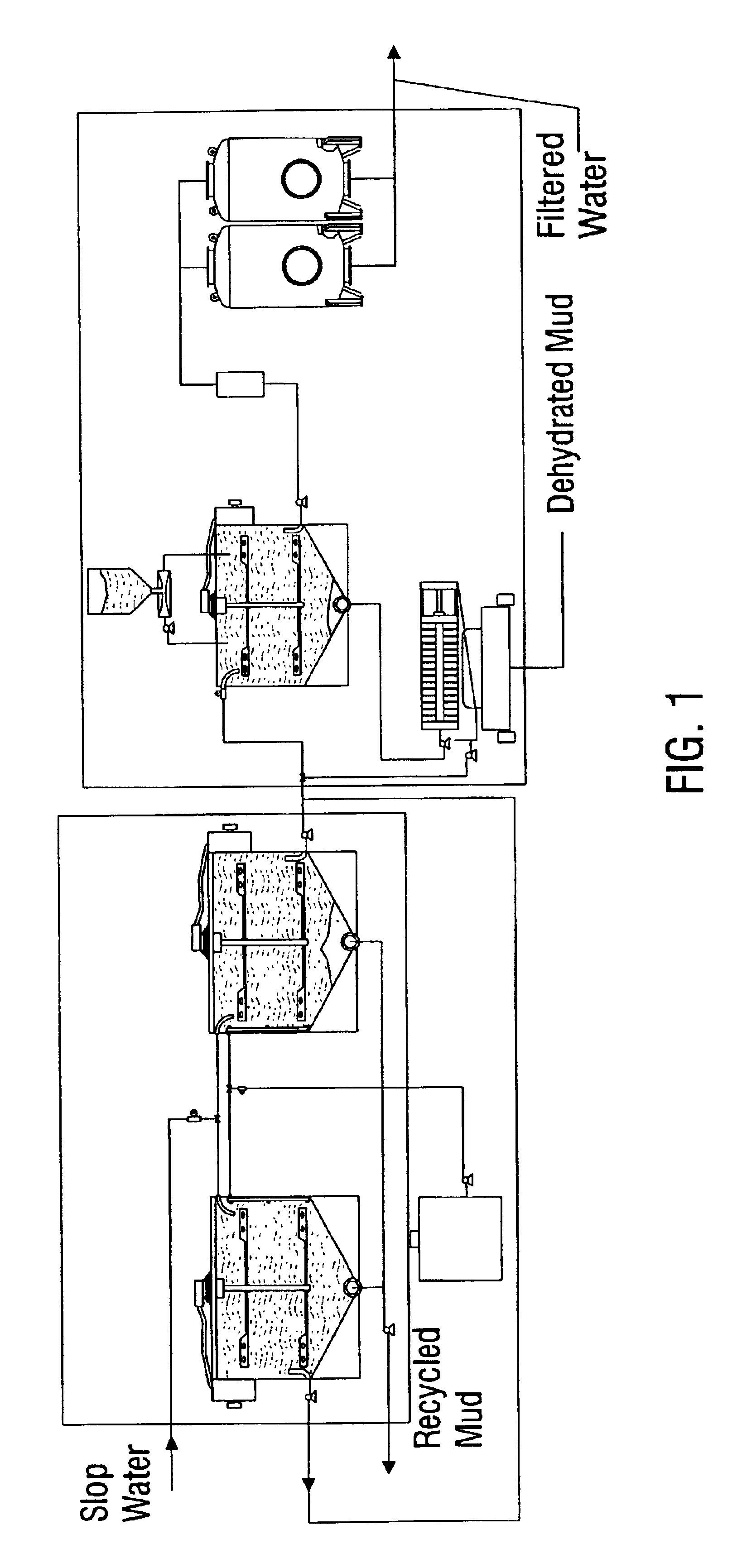

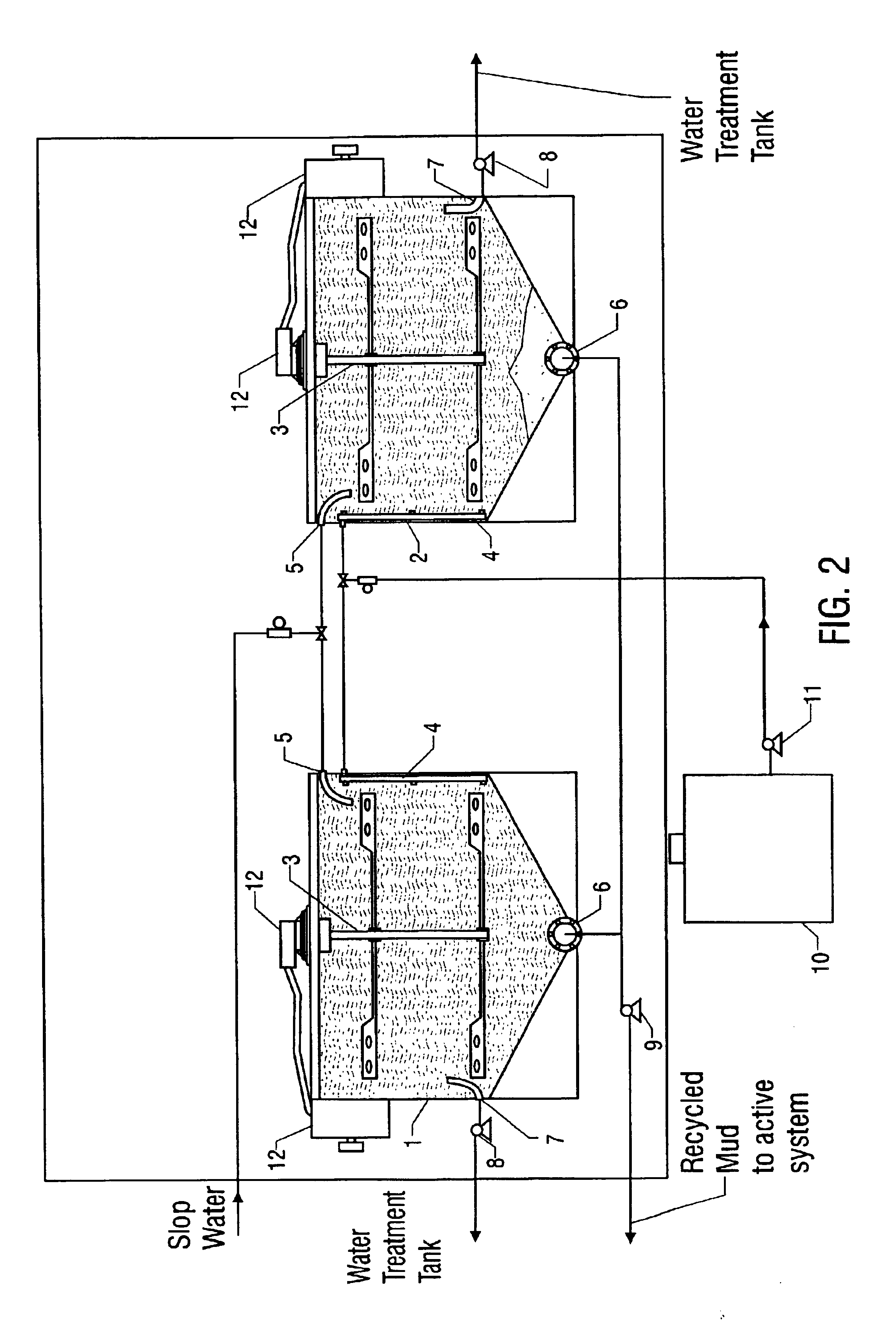

Method for recycling of oil based drilling fluid contaminated with water and water contaminated with oil based drilling fluid

InactiveUS6881349B2Waste water treatment from quariesDewatering/demulsification with chemical meansDemulsifierAlkyl polyglycoside

A mobile apparatus and method for recycling an invert emulsion based drilling fluid, in which the invert emulsion based drilling fluid includes an oleaginous component and an aqueous component. The apparatus includes an emulsion breaking tank, a water treatment tank, a filter press, and hydrocarbon filters. The method includes: mixing said invert emulsion drilling fluid with a emulsion breaker, wherein the emulsion breaker is a mixture of an alkyl glucoside and an alkane sulfonate; and separating the oleaginous component of the invert emulsion drilling fluid from the aqueous component of the invert emulsion drilling fluid. The method preferably utilizes an emulsion breaker that is a combination of an anionic surfactant, a nonionic surfactant and an alkyl polyglycoside surfactant.

Owner:MI

Biodegradable Polyester Compositions

InactiveUS20090162683A1High impact strengthHigh transparencySynthetic resin layered productsThin material handlingMasterbatchBiodegradable polyester

The present invention relates to a biodegradable polyester composition having excellent transparency and impact strength, in particular to a biodegradable polyester composition comprising polylactic acid and a metal alkyl sulfonate as impact modifier as well as to a masterbatch composition useful in the preparation of the biodegradable polyester composition, and to films, sheets, profiles or moulded articles made thereof.

Owner:SUKANO FINANCE AG

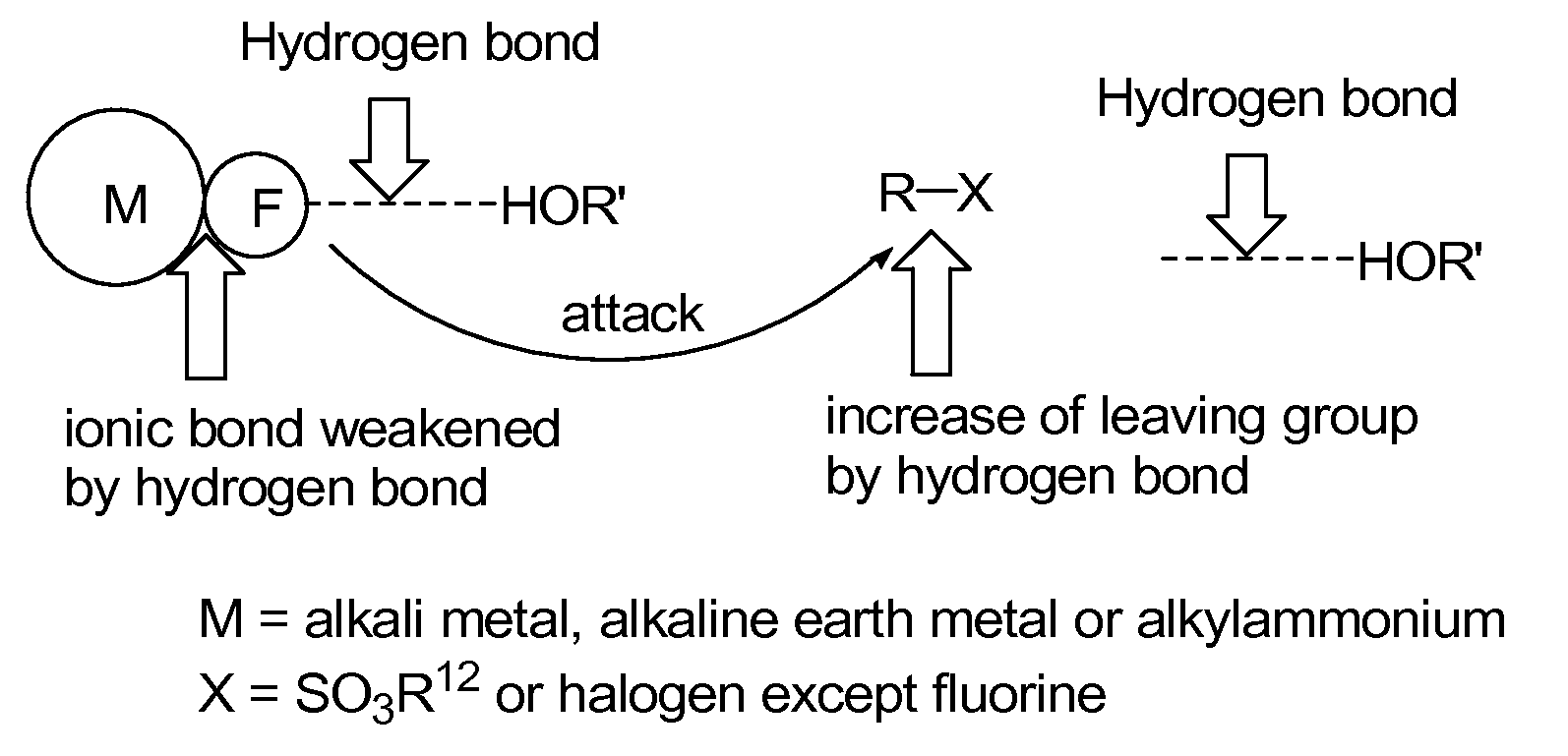

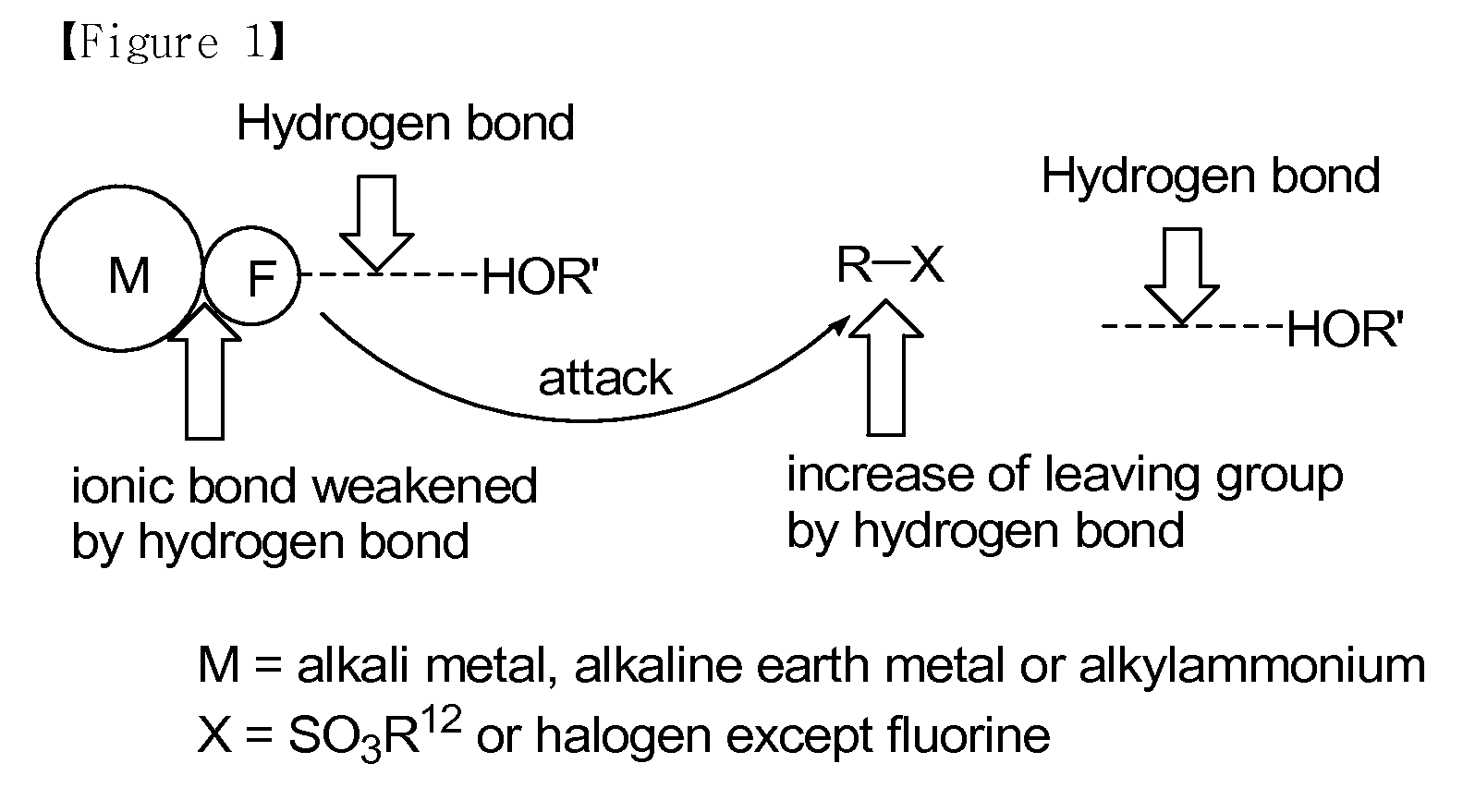

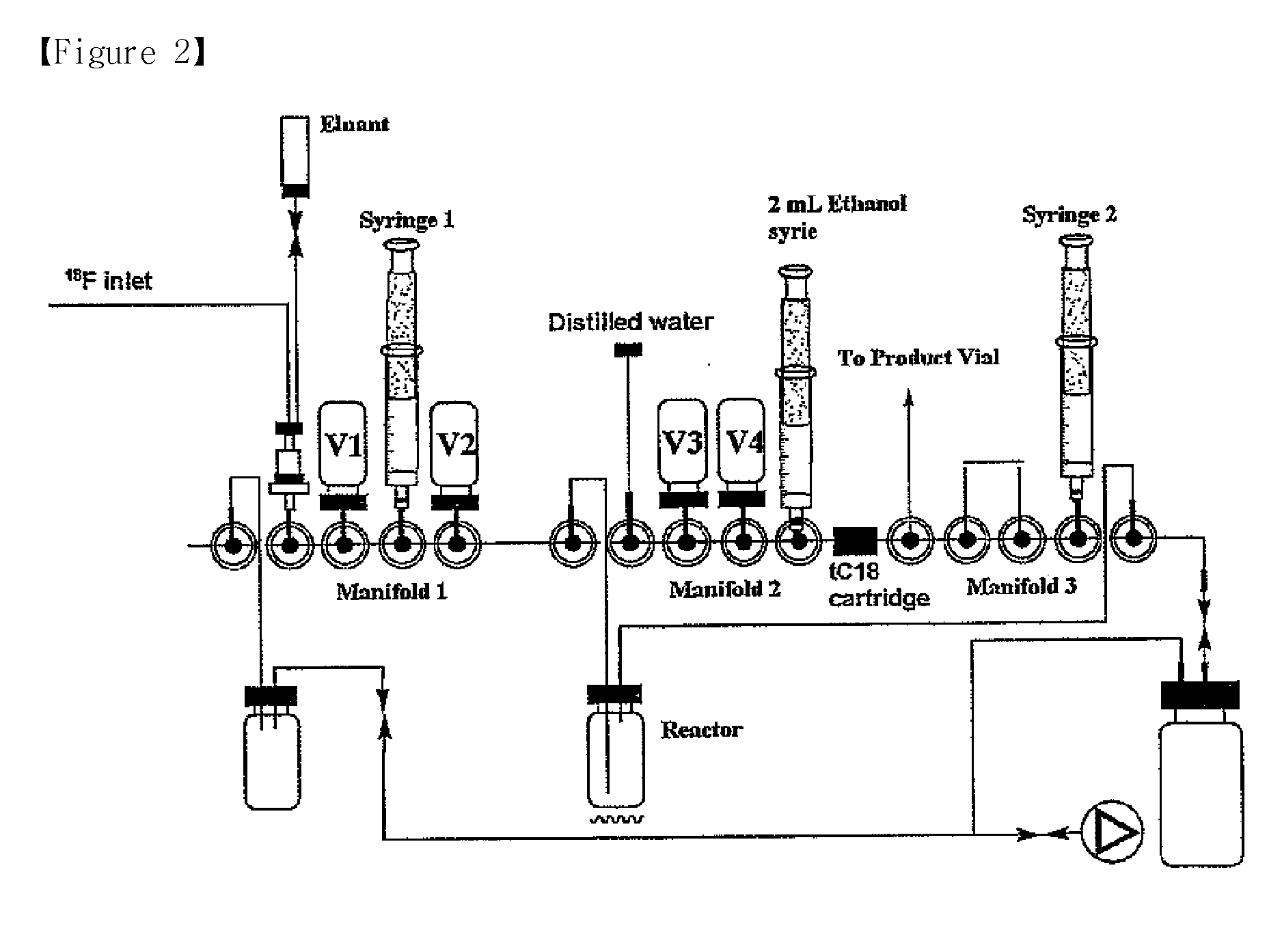

Method for preparation of organofluoro compounds in alcohol solvents

InactiveUS20100113763A1Inhibition formationReduced responseIsotope introduction to heterocyclic compoundsIn-vivo radioactive preparationsAlcoholIsotope

The present invention relates to a method for preparation of organofluoro compounds containing radioactive isotope fluorine-18. More particularly, the present invention relates to a method for preparation of organofluoro compound [18F]florbetaben or [18F]AV-45 having <Chemistry Formula 11> and <Chemistry Formula 12>, respectively, by reacting fluorine salt containing radioactive isotope fluorine-18 with alkyl halide or alkyl sulfonate in the presence of alcohol of Chemistry Formula 1 as a solvent to obtain high yield of organofluoro compound. Synthesis reaction according to the present invention may be carried out under mild condition to give high yield of the organofluoro compounds and the reaction time is decreased, and thereby is suitable for the mass production of the organofluoro compounds.

Owner:FUTURECHEM +1

Laser engraving methods and compositions, and articles having laser engraving thereon

InactiveUS20050003297A1Not easy to counterfeitDifficult to alterRadiation applicationsLayered productsThioester synthesisBarium sulphide

The invention provides a composition having laser engraving properties, comprising a host material and an effective amount of a laser enhancing additive. The laser enhancing additive comprises a first quantity of least one of copper potassium iodide (CuKI3) or Copper Iodide (CuI), and a second quantity at least one substance selected from the group consisting of zinc sulfide (ZnS), barium sulfide (BaS), alkyl sulfonate, and thioester. The composition can be engraved with grayscale images by an Nd:Yag laser and can be added to laminates or coatings. The composition can be used during the manufacture of many articles of manufacture, including identification documents.

Owner:L 1 SECURE CREDENTIALING

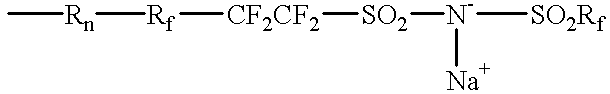

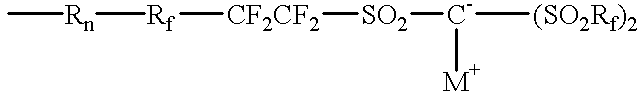

Ionomers and ionically conductive compositions

Disclosed are ionomers comprising functionalized polyolefins having fluoroalkyl sulfonate pendant groups and ionically conductive compositions formed therefrom by the addition of solvents.

Owner:EI DU PONT DE NEMOURS & CO

Method of producing thermoplastic fluoropolymers using alkyl sulfonate surfactants

Nonfluorinated surfactants selected from C7–C20 linear 1-alkanesulfonates, 2-alkanesulfones, and 1,2-alkanedisulfones are particularly effective for stabilizing emulsions in preparing non-elastomeric fluoropolymers containing at least 71 wt % vinylidene fluoride and having at least a 2% crystalline polyvinylidene fluoride content. Processes for making such fluoropolymers using these surfactants, particularly in combination with one or both of a nonionic polymerization initiator and the use of mechanical coagulation to isolate the product, are also provided, as are fluoropolymers made thereby.

Owner:ARKEMA INC

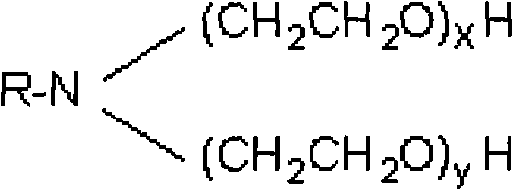

Fabric one-bath deoiling agent

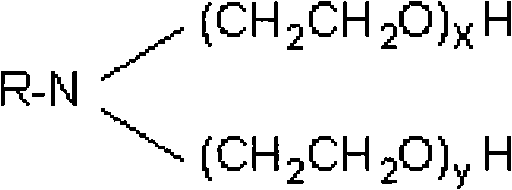

ActiveCN101629130AHigh affinityGood emulsificationNon-ionic surface-active compoundsDry-cleaning apparatus for textilesFiberPolymer science

The invention relates to a fabric deoiling agent, in particular to a fabric one-bath deoiling agent not only suitable for the single deoiling treatment of fabrics, such as terylene, chinlon, cotton, and the like, but also particularly suitable for treating chemical fiber fabrics, such as the terylene, the chinlon, and the like by a deoiling dyeing one-bath method. The invention provides the fabric one-bath deoiling agent with favorable deoiling effect under acidic conditions and an application thereof. The fabric one-bath deoiling agent comprises the following ingredients in percentage by weight: 10-60 polyoxyethylene alkyl amine, 5-40 alkyl sulfonate, 10-50 sulfate surface active agent or / and phosphate salt surface active agent and the balance of water. The fabric one-bath deoiling agent can be used for treating the fabrics of the terylene, the chinlon, the cotton, and the like by the deoiling dyeing one-bath method.

Owner:福建省晋江新德美化工有限公司

Ionomers and ionically conductive compositions

Disclosed are ionomers comprising functionalized polyolefins having fluoroalkyl sulfonate pendant groups and ionically conductive compositions formed therefrom by the addition of solvents.

Owner:EI DU PONT DE NEMOURS & CO

Phospholinked dye analogs with an amino acid linker

ActiveUS20120052507A1Enhanced interactionLowering KoffMethine/polymethine dyesSugar derivativesPhosphorylationFluorescence

In various embodiments, the present invention provides fluorescent dyes that are linked to another species through an amino acid or peptide linker. In an exemplary embodiment, the dye is linked to a polyphosphate nucleic acid through an amino acid or peptide linker. These conjugates find use in single molecule DNA sequencing and other applications. In various embodiments, the dye moiety is a cyanine dye. Cyanine dyes that are highly charged, such as those including muliple sulfonate, alkylsulfonate, carboxylate and / or alkylcarboxylate moieties are examples of cyanine dyes of use in the compounds of the invention.

Owner:PACIFIC BIOSCIENCES

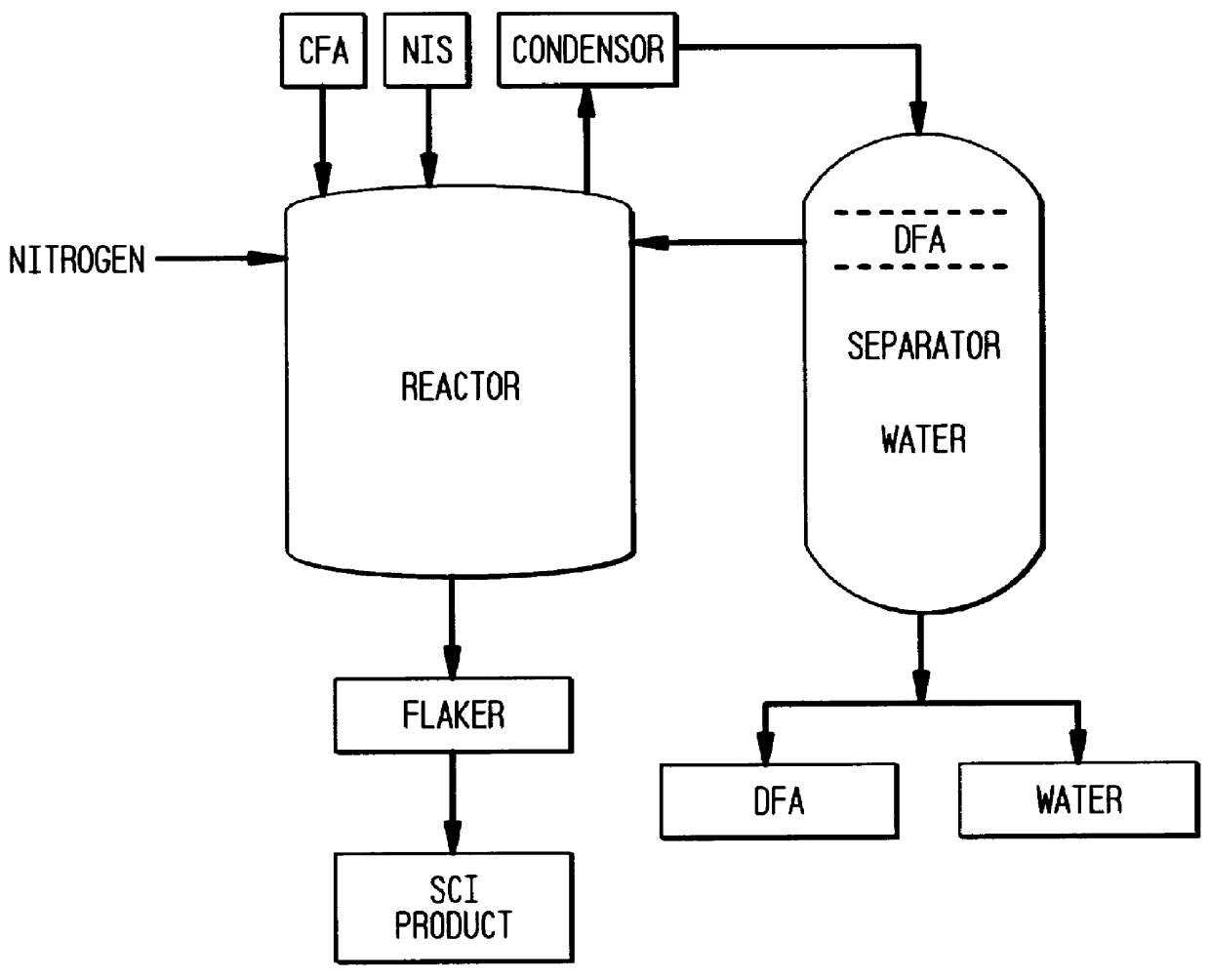

Fatty acid esters of hydroxyalkyl sulfonate salts and process for producing same

InactiveUS6069262ANegligible changeMaintain good propertiesOrganic compound preparationSurface-active detergent compositionsPersonal careHair care

Compositions of matter comprising fatty acid esters of hydroxyalkyl sulfonate salts, in particular sodium cocoyl isethionate (SCI) and process for preparing same. The esters are useful for personal care cleansing products, such as bar and liquid soaps, skin and hair care products.

Owner:INNOSPEC ACTIVE CHEM

Binder systems for microcapsule treatments to fibers, fabrics and garments

InactiveUS20060043328A1Liquid surface applicatorsOrganic detergent compounding agentsWrinkle skinFiber

A binder system for applying microcapsules to textile materials includes microcapsules in a binder composition. The binder composition includes: (i) a component selected from the group consisting of: an alkoxylated fatty acid amide, alkyl sulfonate salt, an amino-silicone softener, and mixtures thereof; an (ii) a component selected from the group consisted of: a global type wrinkle resistant resin, an imidazole type wrinkle resistant resin, a cationic polyamide, a curable silicone resin, a polyurethane resin, and mixtures thereof. Methods for making the binder system as well as methods for applying the binder system to textile materials are also provided.

Owner:INVISTA NORTH AMERICA R L

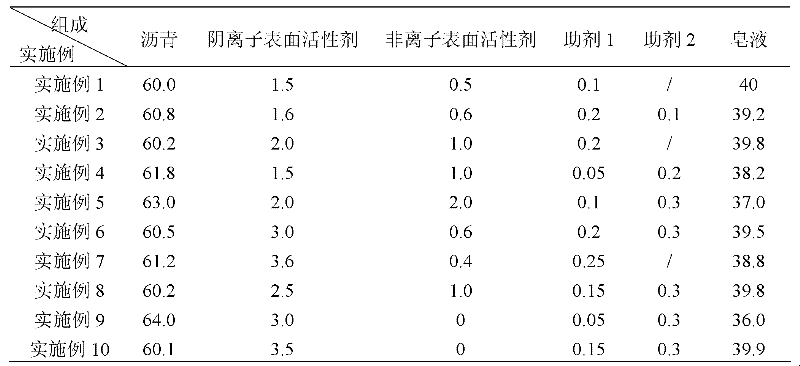

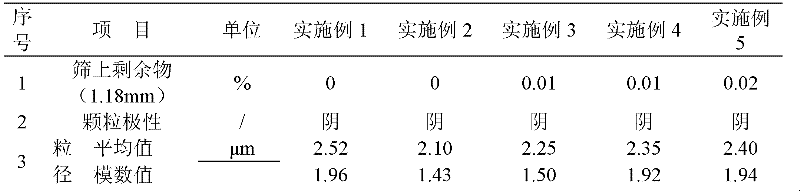

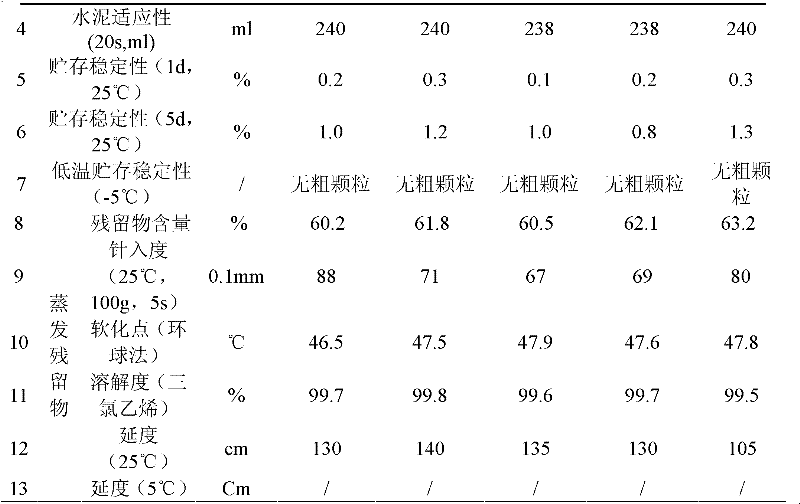

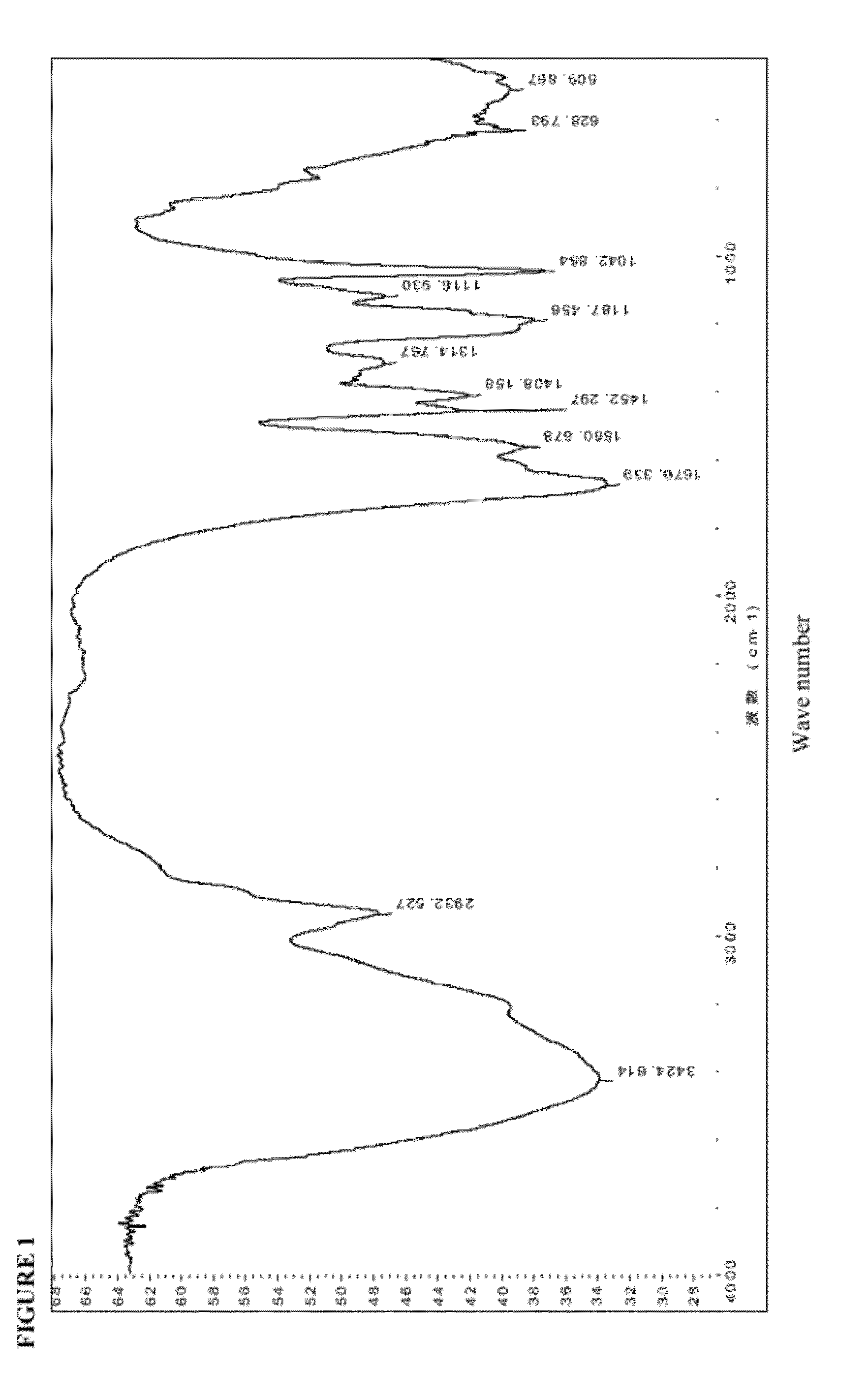

Anionic emulsified asphalt and preparation method thereof

ActiveCN102286205AAdvanced preparation technologyImprove homogeneityBuilding insulationsSulfateLignosulfonates

The invention provides anionic emulsified asphalt and a preparation method thereof. The cement emulsified asphalt comprises the following components in percentage by weight: 55 to 65 percent of asphalt, 0.5 to 5 percent of anionic surfactant, 0.02 to 4 percent of aid, and the balance of water. The anionic surfactant can be one of tall oil sulfonate, alkyl sulfonate, alkylbenzene sulfonate, alkyl sulfate and lignosulfonate. The emulsified asphalt provided by the invention has the advantages of good storage stability, wide temperature adapting range, good adaptability with cement, good compatibility and the like; and the cement emulsified asphalt mortar prepared by using the emulsified asphalt has good flow property, long service life and wide temperature adapting range, does not produce dissociation or lamination, has excellent physical and mechanical properties, and fully meets the requirement of construction, so that the emulsified asphalt can be effectively used for the cement emulsified asphalt mortar in plate type ballastless tracks of high speed railways.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Copolymer and preparation method and application thereof

ActiveUS20120077718A1Good effect of loss controlDrilling compositionSaline waterDodecylsulfonic acid

A copolymer and preparation method and application thereof are disclosed. The copolymer is random copolymer obtained from monomers consisting of acrylamide, acrylic acid, alkenyl sulfonate, 2-acrylamido-dodecyl sulfonate, p-styrene sulfonate or isoprene sulfonate and so on. The copolymer of present invention can be used as fluid loss additive and has good fluid loss properties, which would not make the drilling fluid thicken at high temperature of 200° C. and high salt conditions of saturated brine. It has a medium-pressure fluid loss after aging and rolling for 16 h at high temperature of 200° C., as measured in accordance with the American Petroleum Institute Standard Test at room temperature, and has good properties of high temperature-resisting and salt-resisting.

Owner:CHINA PETROCHEMICAL CORP +1

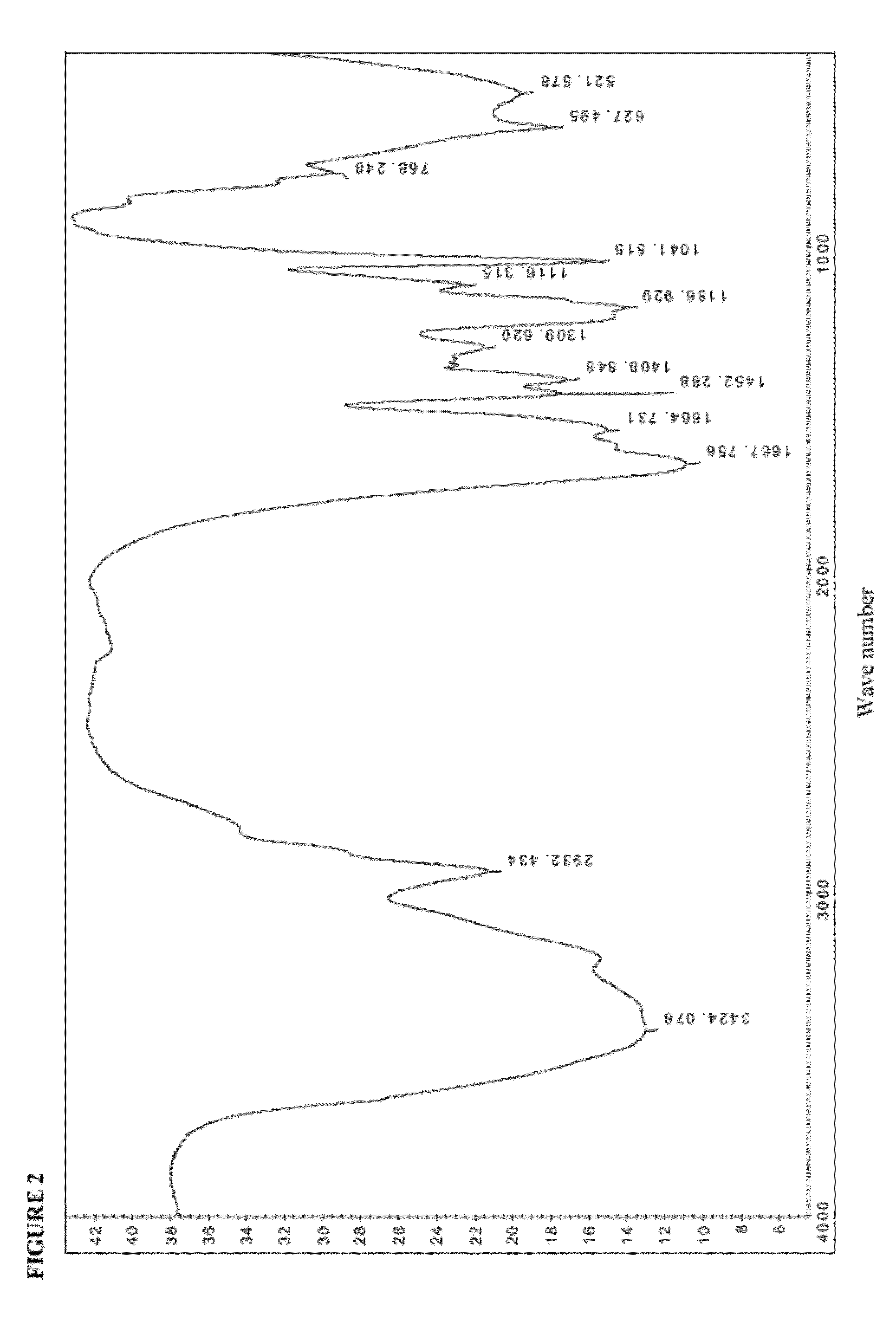

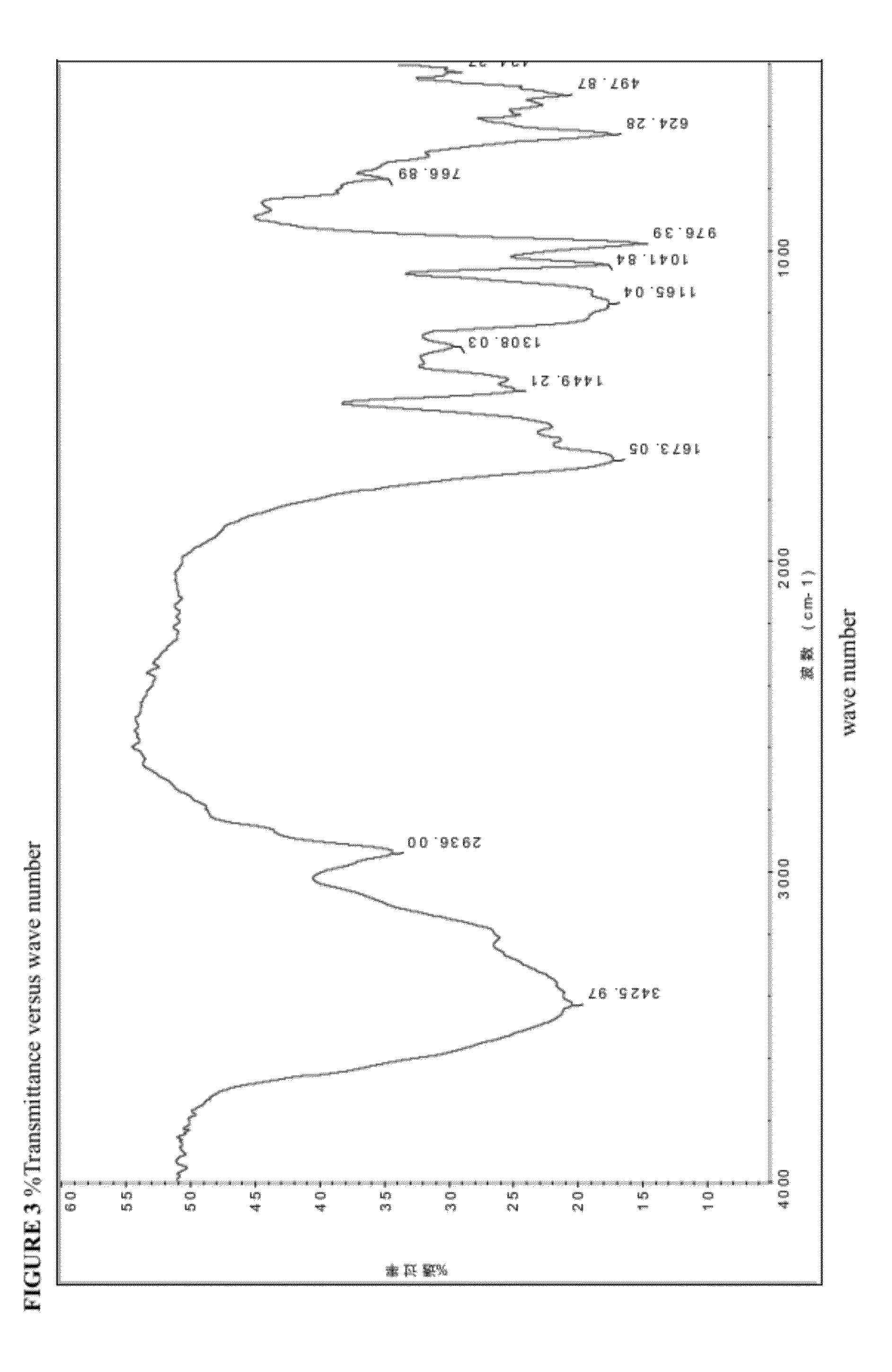

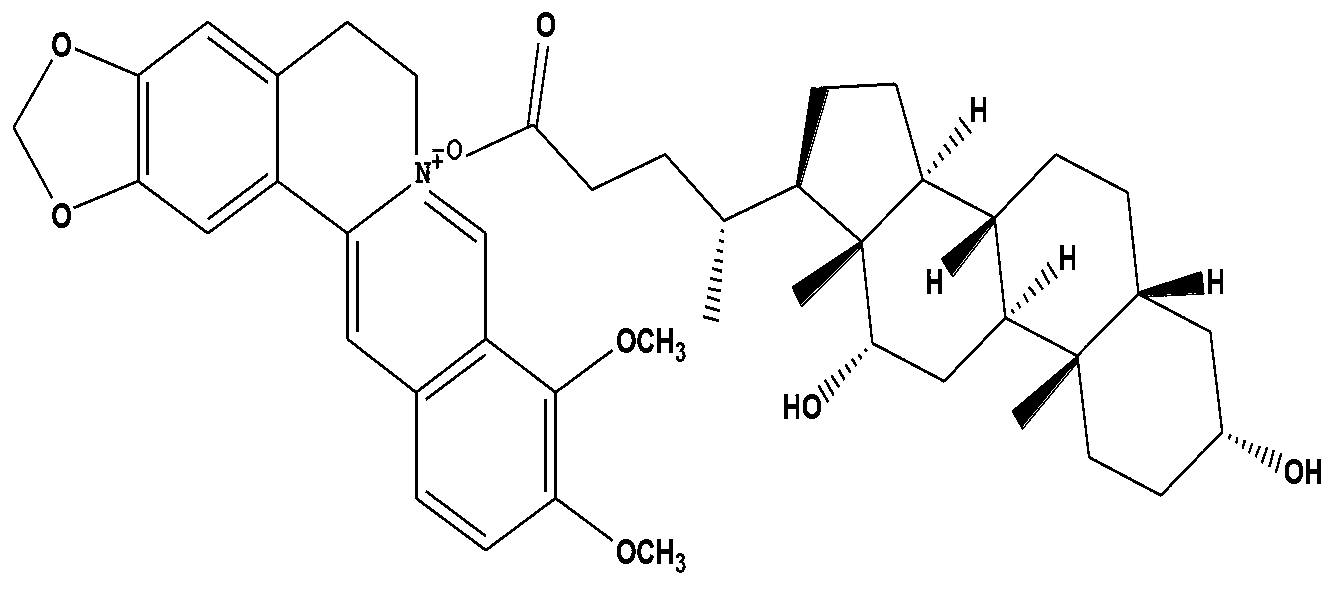

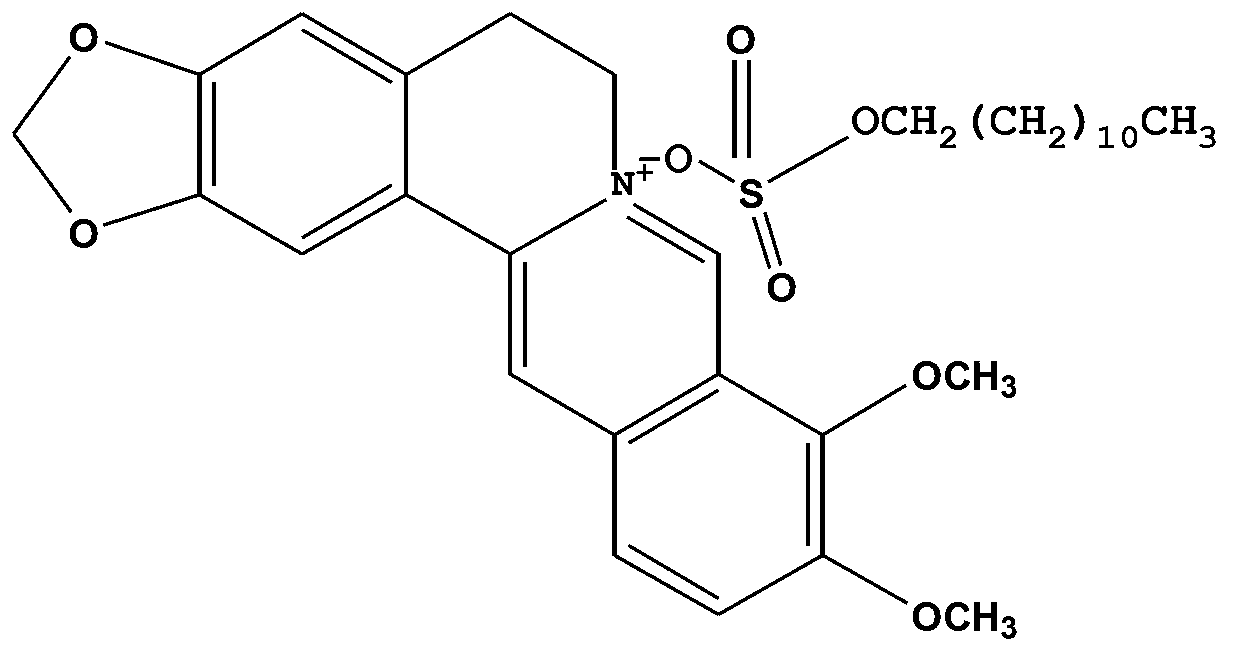

Berberine electrostatic composite and preparation method of berberine electrostatic composite

ActiveCN102702190AIncrease biofilm permeabilityImprove oral bioavailabilitySteroidsCarboxylic acid salt preparationChemical synthesisFatty acid

The invention discloses a berberine electrostatic composite and a preparation method of the berberine electrostatic composite, which are applied to medical and health industries. The berberine electrostatic composite is prepared from anionic surfactant and berberine or berberine salt by compositing; the molar ratio of the anionic surfactant to the berberine or berberine salt is 1 to 0.5-10; the molar ratio of anion to the berberine salt is 1 to 1; the anionic surfactant is one or more of alkyl sulfate or alkyl sulfonate or fatty acid salt; the alkyl sulfate is one or more of sodium cholesteryl sulfate, lauryl sodium sulfate and deoxysodium cholate; the alkyl sulfonate is one or more of sodium heptanesulfonate and sodium dodecyl sulfate; the fatty acid salt is one or more of sodium caprate and sodium enanthate, and the berberine and berberine salt are obtained by chemical synthesis or by extracting traditional Chinese medicine. The berberine is prepared into the berberine electrostatic composite to increase the biological membrane penetrating ability of the berberine and improve the oral bioavailability of the berberine, and the berberine electrostatic composite plays a significant treatment role on important chronic metabolic disorder diseases such as diabetes mellitus, complication of the diabetes mellitus, hyperlipidemia and the like.

Owner:NORTHEAST PHARMA GRP

Production of polycrystalline silicon solar battery suede

InactiveCN1983645AConcentration disorderQuality improvementFinal product manufactureSemiconductor/solid-state device manufacturingCrystal orientationSolar battery

The invention is concerned with a kind of production method for the textured polysilicon solar cell. Input polysilicon into alkaline eroded solution and the solution is mixed liquor made up by NaOH, sodium alkyl sulfonate and EDAT. And the concentration of NaOH is 5-10%, the concentration of sodium alkyl sulfonate is 0.5-4%, and the concentration of EDAT is 2-10%, and the eroded temperature is 85 centigrade and the time is 2 to 10 minutes. The reflectivity of textured surface made by this method is less than the reflectivity of textured surface made by acid solution, and the grain boundary of each crystal is not clear so there is no photometric and colorimetric contrast formed by different crystal orientations when observed with naked eye. The method can remove the scathing layer with 10um-30um on the silicon and the concentration of the alkaline solution is sustaining to keep the steady quality of textured surface of polysilicon solar cell.

Owner:SHANGHAI SOLAR ENERGY S&T

Polyhydroxyl hydrolyzed micelle acidolysis blockage removal agent and blockage removal technology

ActiveCN104371684ASolve the blockageSolve the problem of low success rate of unblockingCleaning apparatusDrilling compositionHigh concentrationPolyethylene glycol

The invention relates to a polyhydroxyl hydrolyzed micelle acidolysis blockage removal agent and a blockage removal technology. The polyhydroxyl hydrolyzed micelle acidolysis blockage removal agent is prepared by mixing the following compositions in percentage by mass: 0-30% of alcohol substances, 0-10% of polyethylene glycol, 1-40% of organic solvents, 0-20% of alkyl sulfonate, 0-20% of alkyl sulfobetain, 0-20% of polyoxyethylene ether, 0-20% of sorbitan monstearate, 0-20% of ammonium fluoride, 0-20% of organic acid, 0-20% of organic phosphonic acid, 0.5-2% of acidizing corrosion inhibitor, and the balance of industrial hydrochloric acid, then performing high-temperature high-speed stirring, adding other treating agents and evenly stirring; the blockage removal technology comprises the following steps: performing sand removal, injecting prepad fluid, then sequentially firstly injecting high-concentration polyhydroxyl hydrolyzed micelle acidolysis blockage removal agent solution and low-concentration polyhydroxyl hydrolyzed micelle acidolysis blockage removal agent solution, then injecting displacement fluid, finally injecting water to be filled in an oil pipe, reacting, and restoring the water injection. The blockage removal success rate is high.

Owner:西安胜特油田技术服务有限责任公司

Copper wire high-speed fine wire drawing and superfine wire drawing lubricating liquid and preparation method and application method thereof

ActiveCN102311857AGood dispersionStable and fine dispersionLubricant compositionPolymer scienceCopper wire

The invention discloses a copper wire high-speed fine wire drawing and superfine wire drawing lubricating liquid, as well as a preparation method thereof and an application method thereof. Raw materials of the lubricating liquid comprise triethanolamine, boric acid, aqueous extreme-pressure lubricant, dicarboxylate-based complex, benzotriazole, sodium alkyl sulfonate, anti-hard-water agent, non-ionic emulsifier, aliphatic ester, low-viscosity base oil, distilled water and defoaming agent. Lubricating performance, corrosion resistance and cleaning performance of the lubricating liquid disclosed by the invention can be matched for a long time; the lubricating liquid disclosed by the invention has excellent lubricating performance, antirust performance and settlement performance, each index reaches up to or exceeds related indexes in GB6144-2010, copper strip corrosion is 1 A, cast iron antirust uniwafer is more than 72 hours, and particle size of dispersed particles in the lubricating liquid is less than 0.05 mu m; outgoing speed of the lubricating liquid is more than 2400 m / min when being used for drawing copper wires with the diameter of being in the range from 0.5 to 0.03 mm; interprocess antirust time of the produced copper wire is more than 3 days; and oil change period of a concentrated oil pool is 2-3 years, and the oil change period of a standalone oil pool is 4-6 months.

Owner:苏州安美润滑科技有限公司

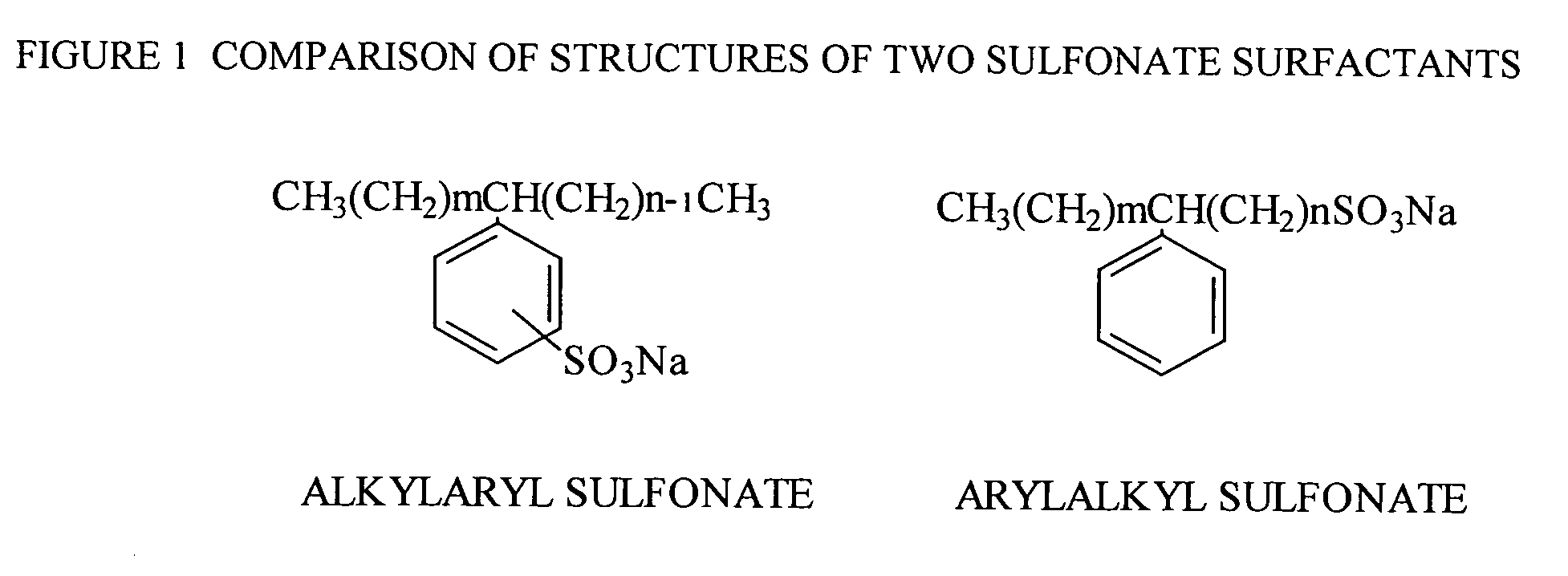

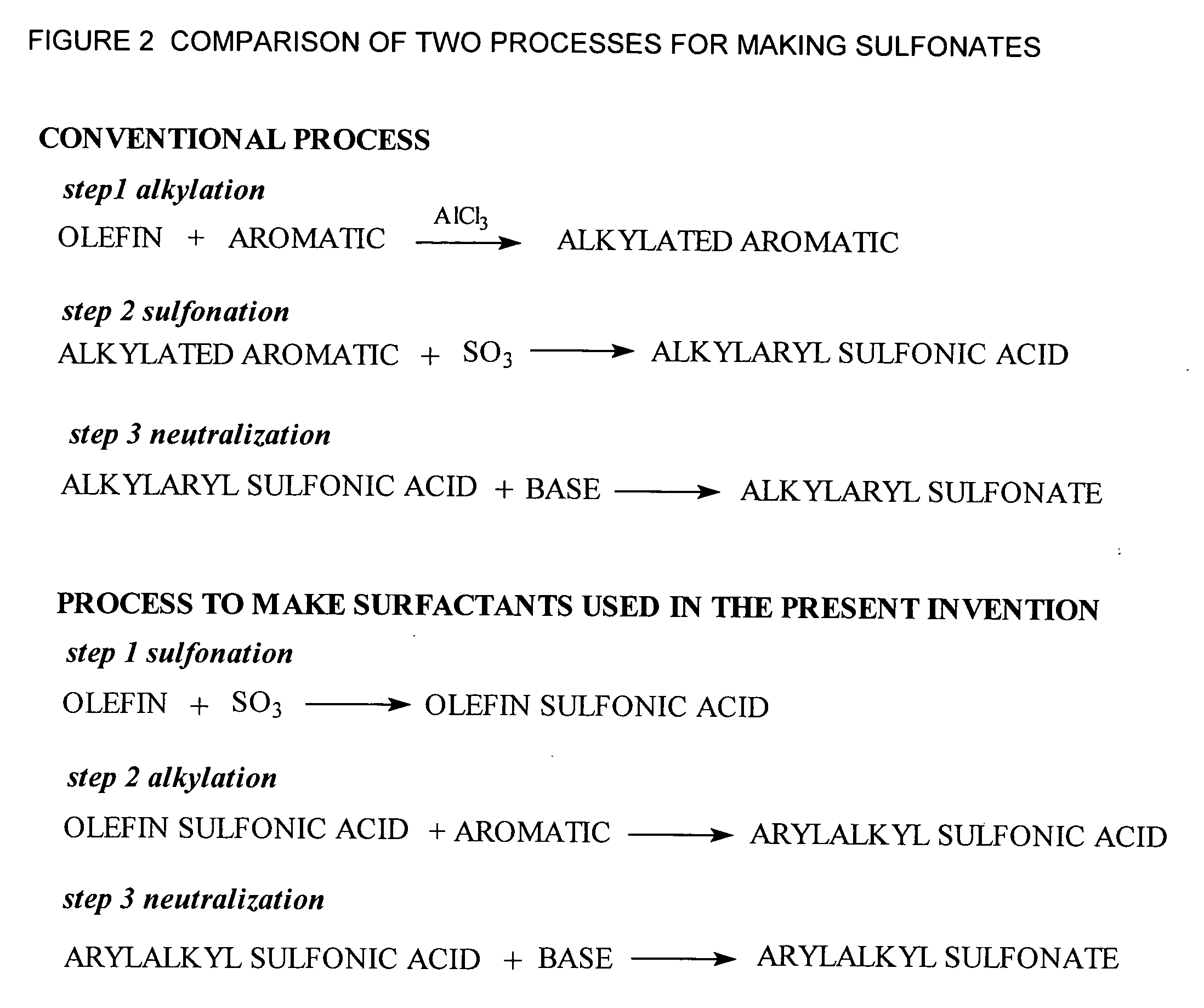

Oil recovery composition and method using arylalkyl sulfonate surfactants derived from broad distribution aplha-olefins

An oil recovery method is disclosed which uses injection fluids containing a particular class of arylalkyl sulfonate surfactants that are derived from an alpha-olefin stream having a broad distribution of carbon numbers ranging from more than 10 to greater than 30. The alpha-olefin stream is reacted with sulfur trioxide to form the olefin sulfonic acids, and then these are reacted with aromatic feedstock, such as benzene, toluene, xylene, ethylbenzene, phenol, substituted phenol, naphthalene or substituted naphthalene, or a mixture thereof, and neutralized to form arylalkyl sulfonate surfactants. The resulting surfactants have high solubility in a wide range of brines and provide ultra low interfacial tension with crude oils. The resulting surfactants also have economical advantages over the conventional alkylaryl sulfonate surfactants derived from a broad distribution of alpha-olefin stream due to the elimination of the costly alkylation process and the toxic catalyst used in the process.

Owner:BERGER PAUL DANIEL +1

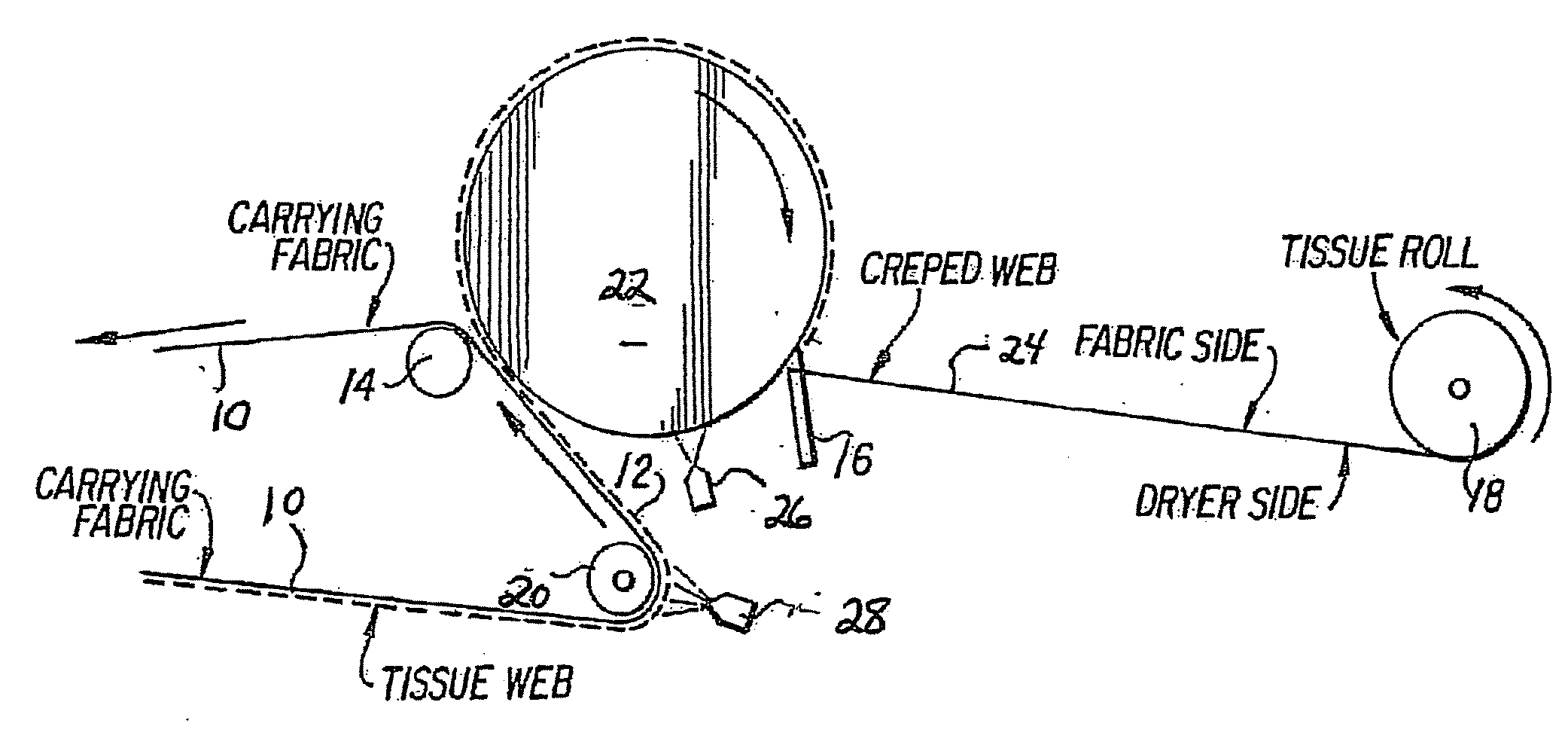

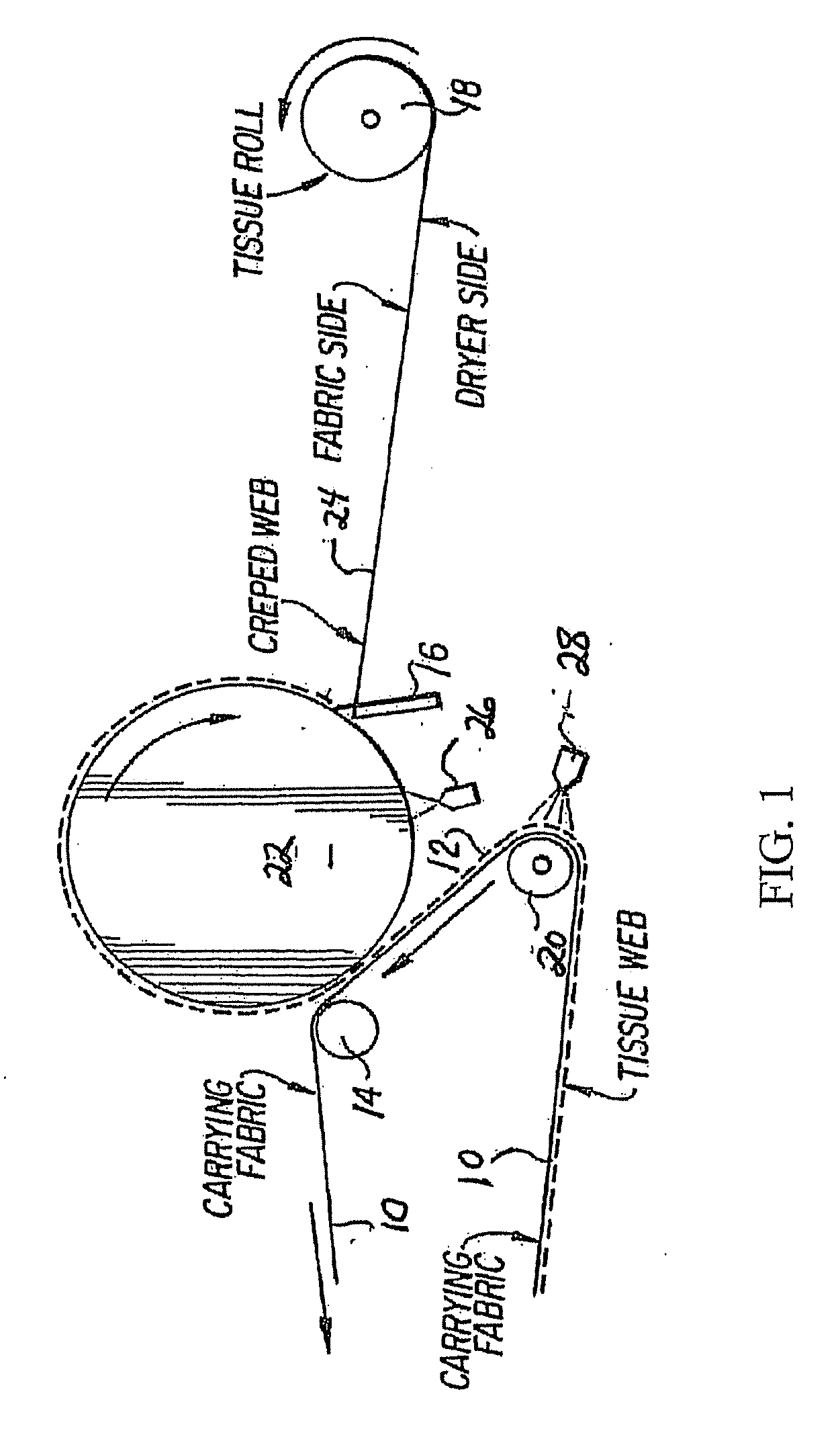

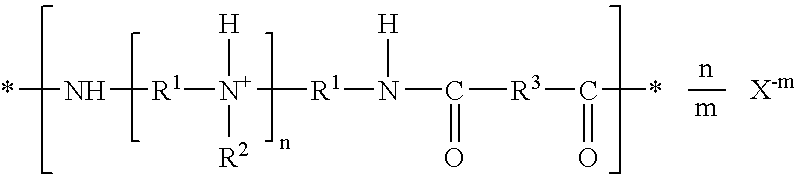

Acidified polyamidoamine adhesives, method of manufacture, and use for creping and ply bond applications

InactiveUS20080257507A1Excellent crepingExcellent plyNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveIodide

A paper adhesive composition includes a cationic non-crosslinked acidified solution of a polyamidoamine with the repeating unitswherein n≧1; m=1 or 2; X−m is chloride, bromide, iodide, sulfate, bisulfate, nitrate, oxalate, alkyl carboxylate, aryl carboxylate, hydrogen phosphate, dihydrogen phosphate, alkyl sulfonate, aryl sulfonate, or a combination comprising at least one of the foregoing anions; R1 is a divalent aliphatic, cycloaliphatic, or araliphatic group having from 1 to 24 carbon atoms; R2 is hydrogen or a monovalent aliphatic, cycloaliphatic, or araliphatic group having from 1 to 24 carbon atoms; and R3 is a divalent hydrocarbon radical derived from a dibasic carboxylic acid.

Owner:KEMIRA CHEM

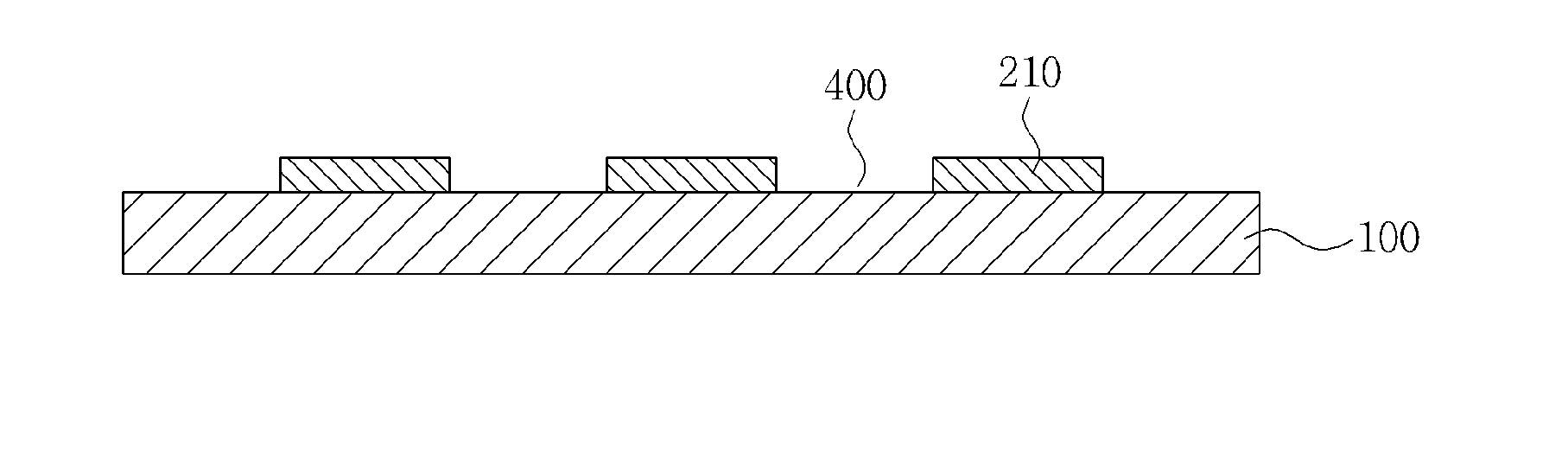

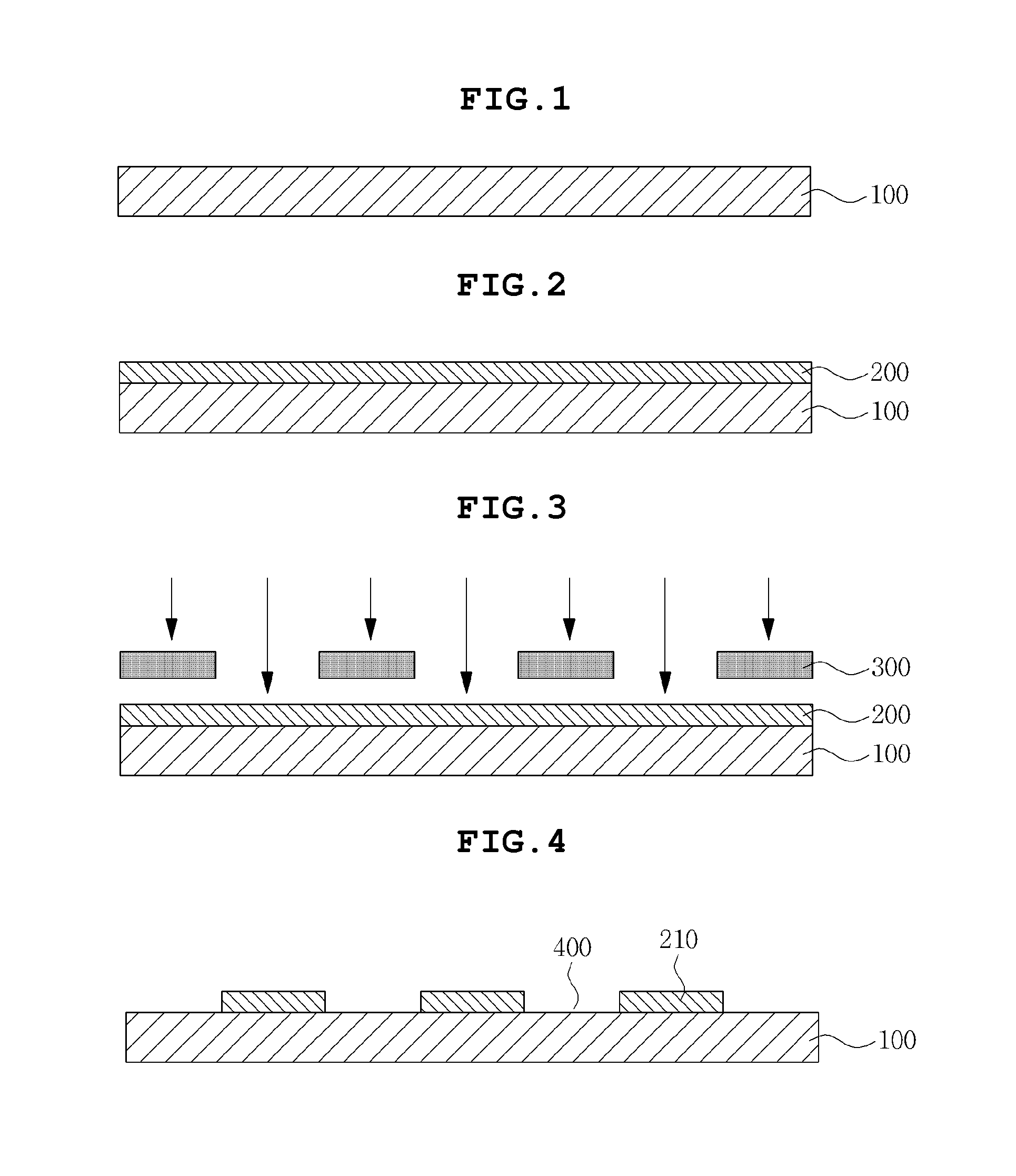

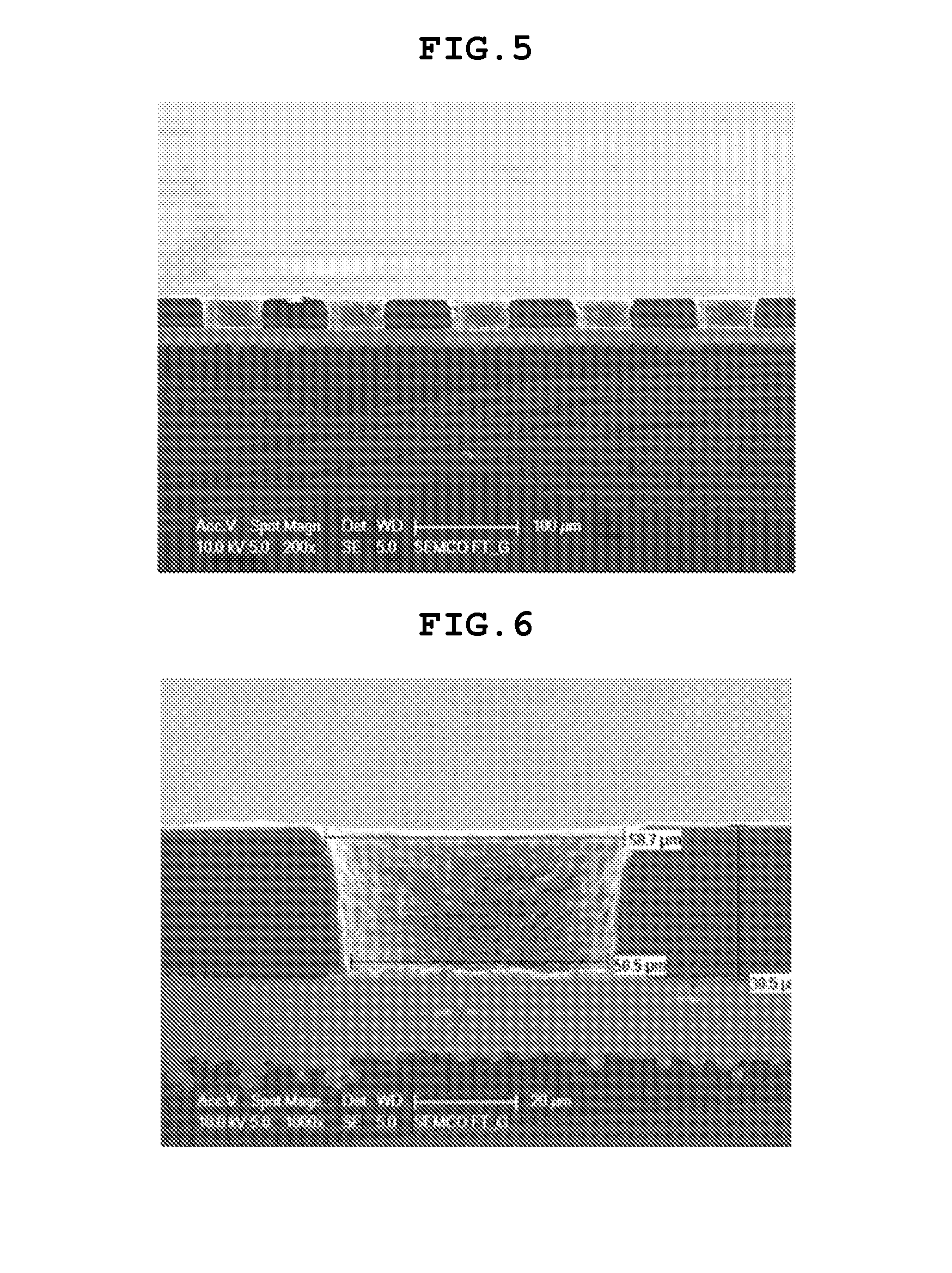

Resin composition, printed circuit board using the composition, and method of manufacturing the same

ActiveUS20150050473A1Improve adhesionPhotosensitive materialsDecorative surface effectsTetrazolePhotoinitiator

A resin composition, a printed circuit board using the composition, and a method of manufacturing the printed circuit board. The resin composition includes: a photopolymerizable compound, such as one having an ethylenically unsaturated bond which is polymerizable in a molecule, a photoinitiator, and a surface-modified silica by an alkyl sulfonated tetrazole compound.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

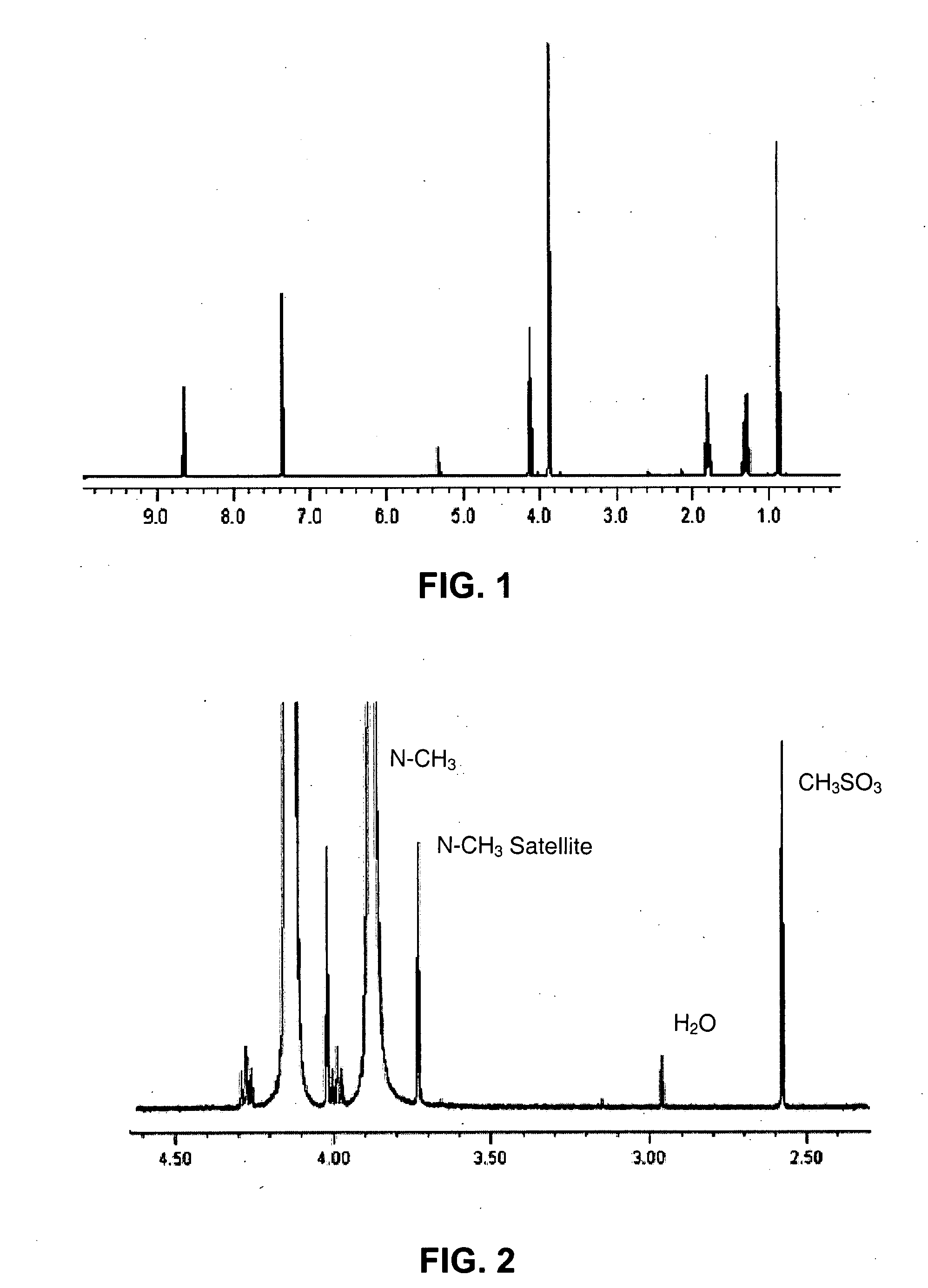

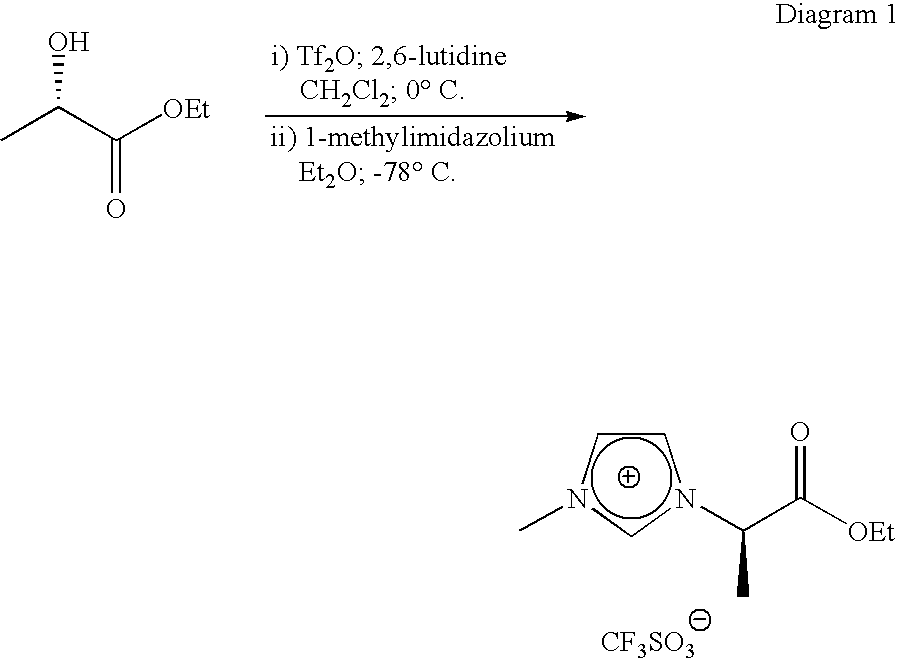

Method of preparation of halogen-free ionic liquids and ionic liquids prepared in this manner

InactiveUS20080045723A1The method is simple and fastGroup 8/9/10/18 element organic compoundsPetroleum industryAlkaneFiltration

The reaction of N-alkylimidazol with alkyl sulfonates, at room temperature, favors the production of 1,3-dialkylimidazolium alkane-sulfonates as crystalline solids at high yields. The alkane-sulfonate anions may be easily substituted by a series of other anions [BF4, PF6, PF3(CF2CF3)3, CF3SO3 and (CF3SO2)2N] through simple anion, salt, or acid reactions in water at room temperature. The extraction with dichloromethane, filtration, and evaporation of the solvent, allows the production of the desired ionic liquids at a yield of 80-95%. The purity of these ionic liquids (in some cases >99.4%) is performed using the intensity of 13C satellite signals from the magnetic resonance spectrums of the N-methyl imidazolium group as an internal standard.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Enhanced deposit control for lubricating oils used under sustained high load conditions employing glycerine derivative with a grafted hindered phenolic and/or a hindered phenolic containing a thioether group

The present invention is directed to a lubricating oil for use in engines subjected to sustained severe load conditions, said lubricating oil comprising a base oil, and an additive package comprising one or more neutral / low TBN or a mixture of neutral / low TBN, and overbased / high TBN alkali or alkaline earth metal alkyl sulfonates, alkyl phenates, alkyl salicylates, an antioxidant selected from the group consisting of glycerine derivatives comprising glycerine grafted with a hindered phenol, hindered phenolic containing a thioether group, and mixtures thereof, optionally an additional conventional antioxidant and / or an organomolybdenum compound, and other additives, and to a method for enhancing the deposit formation resistance of a lubricating oil used in engines operated under sustained severe load comprising the addition to the lubricant of the aforesaid additive package.

Owner:EXXON RES & ENG CO

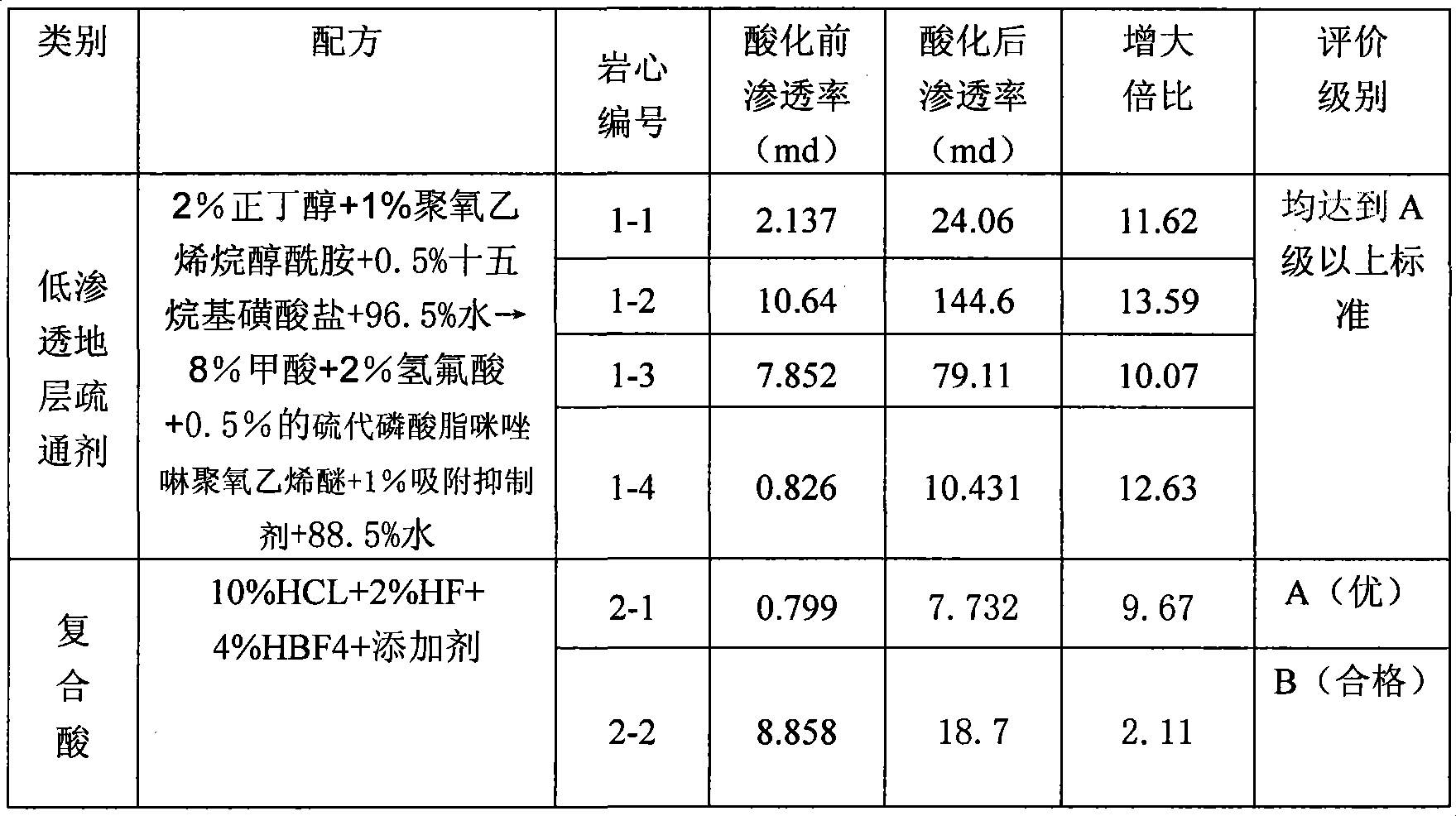

Formation opener agent for low permeable reservoir of oilfield

The invention relates to a stratum opener agent which is applied to oilfield low permeability reservoir. The stratum opener agent comprises two parts: pre-disposal liquid and acid inhibitor system; according to the weight percentage, the pre-disposal liquid consists of solvent and surfactant as follows: 1-3% of organic solvent such as higher alcohol, 0.2-1% of non-ionized surfactant polyoxyethylene alkylolamide, 0.3-0.5% of tenthfive alkyl sulfonate, and the residual quantity of stratum water; according to the weight percentage, the acid inhibitor system comprises 5-10% of low-carbon organic acid, 1-3% of hydrofluoric acid, 0.5% of inhibitor thio-phosphate imidazoline polyoxyethylene ether, 1% of adsorption inhibitor and the residual quantity of water; the adsorption inhibitor comprises 0.5-2% of ethyl dimethylene-bi-cetyltrimethylammonium ammonium bromide, 0.2-1% of quaternary ammonium salt small kation, 2-5% of inorganic salt, 0.2% of 1,3-amine group propyl alcohol N-methyl sodium phosphate or potassium dihydrogen phosphate or sodium hexametaphosphate. The opener agent can effectively improve the seepage capability of reservoir and achieve the objects of decompression and augmented injection and improving the yielding.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Increasing thermal conductivity of host polymer used with laser engraving methods and compositions

InactiveUS7980596B2Improve security levelReduce chancePhotosensitive materialsPretreated surfacesIodideSodium iodide

the invention provides a composition having laser engraving properties, comprising a host material and a laser enhancing additive. The host material comprises a material, such as a polymer, modified by a first process, whereby the host material as modified by the first process has increased thermal conductivity as compared to the host material before the first process. The laser enhancing additive comprises a first quantity of at least one of copper potassium iodide (CuKI3), Copper Iodide (CuI), potassium iodide (KI), sodium iodide (NaI), and aluminum iodide (AlI), and a second quantity of at least one substance selected from the group consisting of zinc sulfide (ZnS), barium sulfide (BaS), alkyl sulfonate, and thioester.

Owner:L 1 SECURE CREDENTIALING

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

InactiveCN101289256AAvoid corrosionSimple processTreatment using complexing/solubilising chemicalsPeroxydisulfateNuclear chemistry

The invention discloses a quaternary polymeric form corrosion and scale inhibitor which consists of maleic anhydride, hydroxy-propyl acrylate, acrylic acid, sodium alkyl sulfonate, sodium peroxydisulfate, sodium hypophosphite, isopropyl alcohol and water. The invention also discloses a preparation method of the quaternary polymeric form corrosion and scale inhibitor. The corrosion and scale inhibitor has good performance in inhibiting calcium carbonate scale, calcium sulphate scale, calcium phosphate scale and zinc scale and good dispersing performance for dispersing ferric oxide and is also characterized by corrosion resistance, high temperature resistance, stable molecule structure and low phosphorus content; the whole production process has no emission of 'the three wastes'. The technique of the product of the invention for treating circular cooling water is simple and the product of the invention has the advantages of little dosage, low cost, good effect and good economic benefit and wide social benefit.

Owner:NANJING FORESTRY UNIV

Biodegradable polyester resin composition and films, sheets and other molded articles thereof

InactiveUS20040024141A1Transparency is impairedImprove antistatic performanceAntistatic agentShell molding

The present invention provides a biodegradable polyester resin composition having excellent antistatic ability, wherein the antistatic ability is provided to biodegradable resins such as polyester polymer or resin, in particular, polylactic acid and films, sheets and molded articles. In the biodegradable polyester resin composition of the invention, the combined ratio of (A) glycerin mono fatty acid ester and (B) alkyl sulfonate as antistatic agents is 0.2~5 weight parts in relation to 100 weight parts of biodegradable polyester resin.

Owner:RIKEN VITAMIN COMPANY

Biocidal cleaner composition containing acid-anionic surfactant-alcohol combinations and method of using the composition

InactiveUS20030083219A1Organic detergent compounding agentsSurface-active detergent compositionsArylMicroorganism

A method of substantially reducing biofilm-associated microorganisms on a surface and a composition designed to substantially reduce biofilm-associated microorganisms on surfaces are disclosed. In one embodiment, the composition is an anionic surfactant selected from the group consisting of alkyl sulfates, alkyl sulfonates, and aryl sulfonates with alkyl or aryl substituents, an acid, and an alcohol solvent, wherein the pH of the composition is between pH 1 and pH 5.

Owner:SC JOHNSON & SON INC

Alkali lignose concrete air-leading water-reducing agent, preparation and use thereof

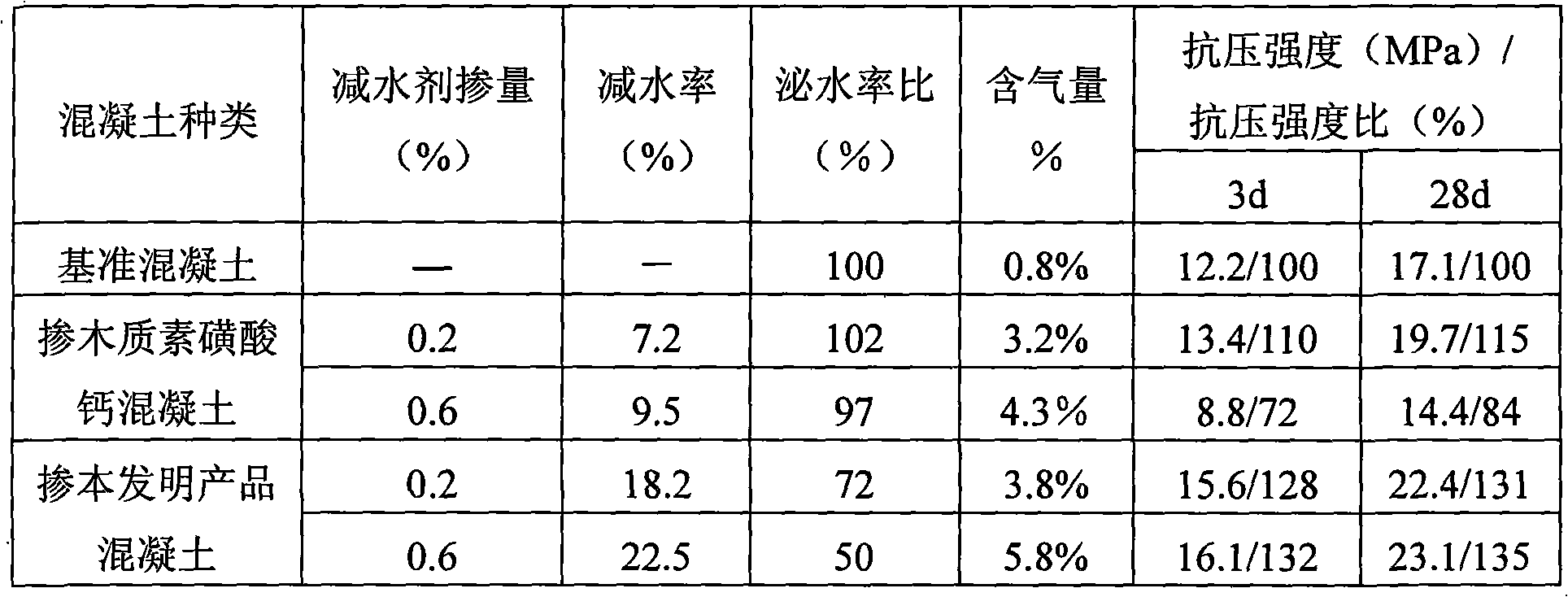

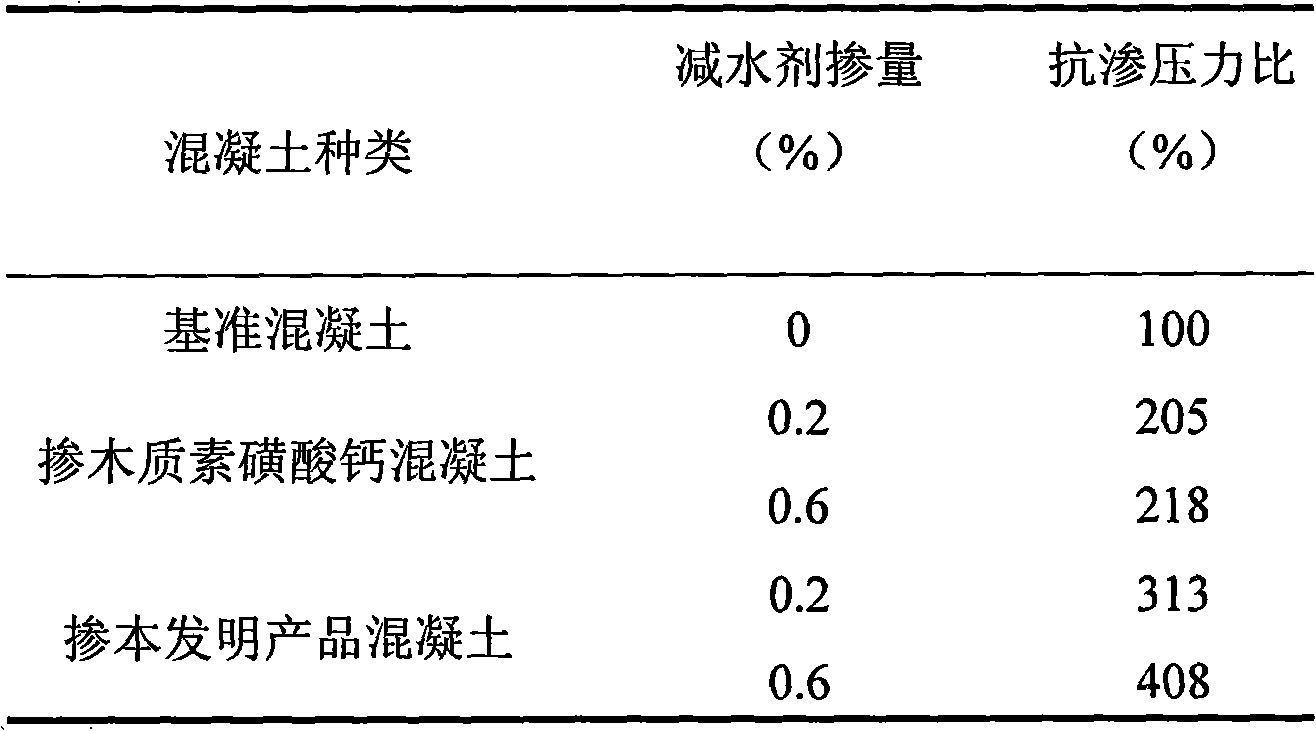

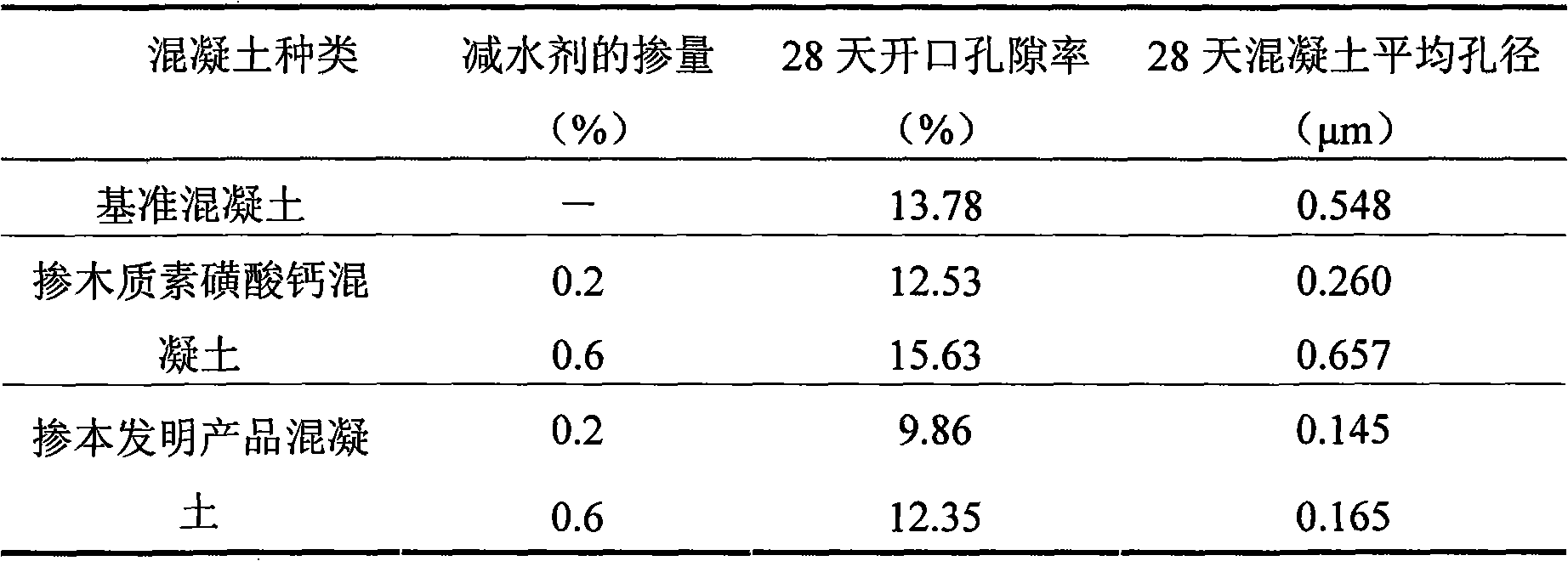

The invention discloses an alkali lignin concrete water reducing agent, a preparation method and application thereof. The preparation method comprises the following steps: dissolving the alkali lignin in water, adding amines and dropping aldehydes into the mixed solution, reacting the mixed solution to get aminating alkali lignin; adding sulfonating agent into the aldehydes and reacting to get alkane sulfonate compounds; then mixing the aminating alkali lignin and the alkane suflonate compounds to conduct polycondensation, getting alkali lignin concrete water reducing agent, wherein the alkali lignin is 100 parts, amines are 5-20 parts, aldehydes are 20-50 parts, sulfonating agent is 50-100 parts and the surfactant is 2-6 parts(by weight part). The water reducing agent is used for preparing concrete, and the dosage of the water reducing agent according to the weight percentage is 0.2-0.6% of the cement in the concrete. The concrete water reducing agent of the invention has advantages of abundant material source, no toxic, simple production technology and low cost with a water-reducing rate of 22.5%, which significantly increases the fluidity of the concrete and improves the intension of the concrete.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com