Production of polycrystalline silicon solar battery suede

A technology of solar cells and polysilicon, which is used in circuits, electrical components, and final product manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

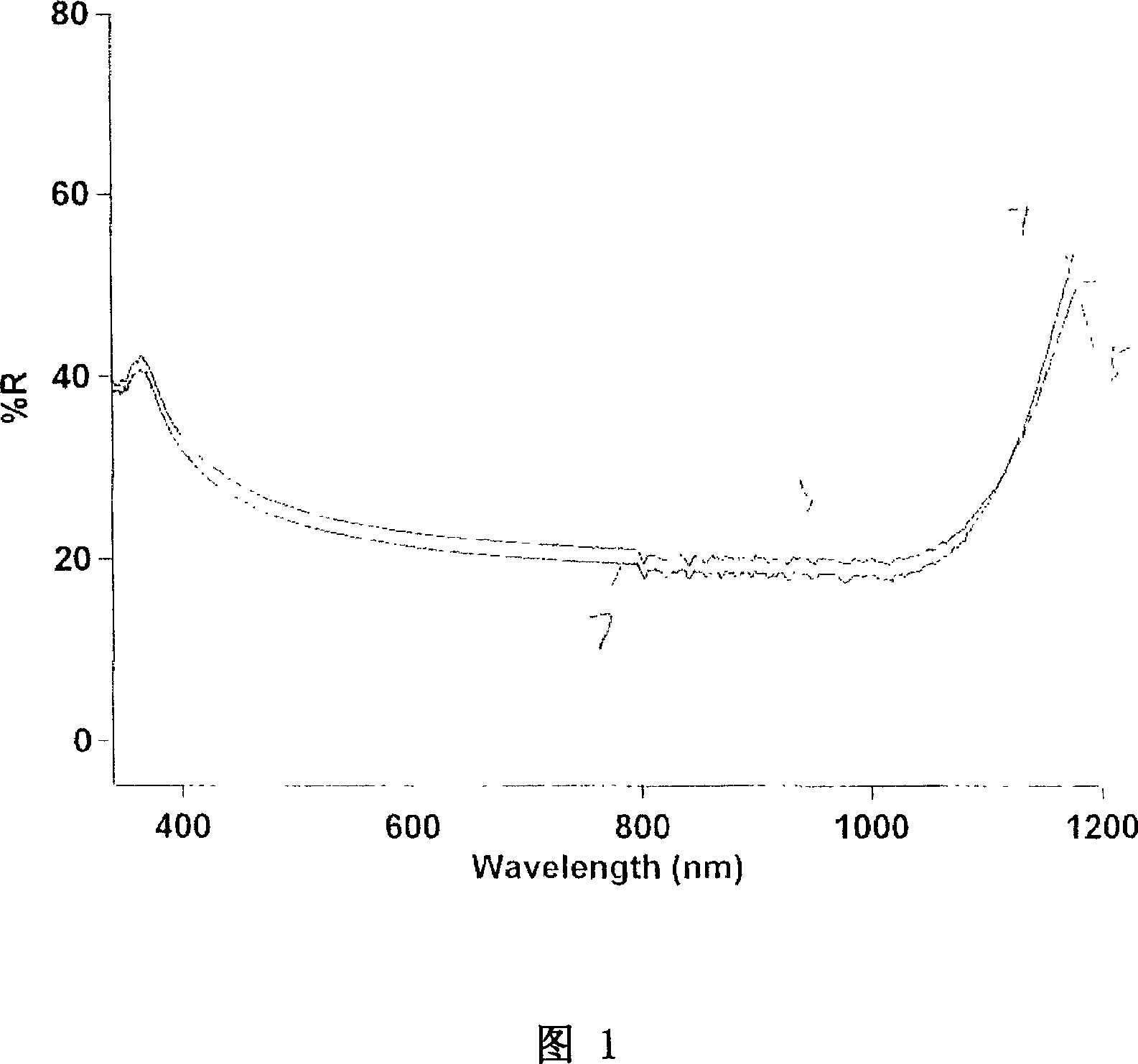

[0017] A mixed aqueous solution of NaOH, sodium alkylsulfonate and EDAT is prepared, and the concentrations of NaOH, sodium alkylsulfonate and EDAT are 10%, 0.5% and 2% respectively. Immerse the polysilicon in the above solution at 85°C and etch for three minutes. The obtained suede surface has uniform facets, fuzzy grain boundaries between crystal grains, no obvious color difference between crystal grains, a thickness reduction of 25um, and a measured reflectance of 20.8%.

Embodiment 2

[0019] Prepare a mixed aqueous solution of 5% NaOH, 1% sodium alkylsulfonate and 2% EDAT. The polysilicon is immersed in this solution at 85°C and etched for five minutes. The obtained suede surface has uniform facets, fuzzy grain boundaries between crystal grains, no obvious color difference between crystal grains, a thinning of 20um, and a measured reflectance of 21.4%.

Embodiment 3

[0021] Prepare a mixed aqueous solution of 5% NaOH, 0.5% sodium alkylsulfonate and 2% EDAT. The polysilicon is immersed in this solution at 85°C and etched for three minutes. The obtained suede surface has uniform facets, fuzzy grain boundaries between crystal grains, no obvious color difference between crystal grains, a thinning of 15um, and a measured reflectance of 20.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflection | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com