Patents

Literature

246results about How to "Advanced preparation technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

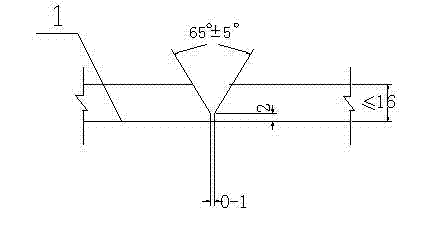

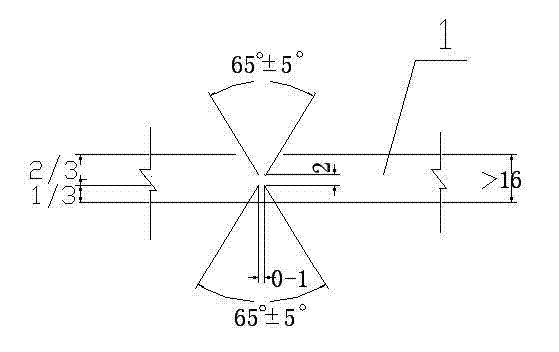

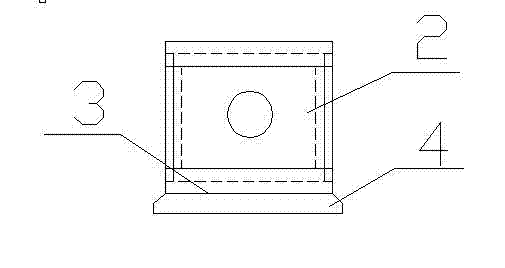

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

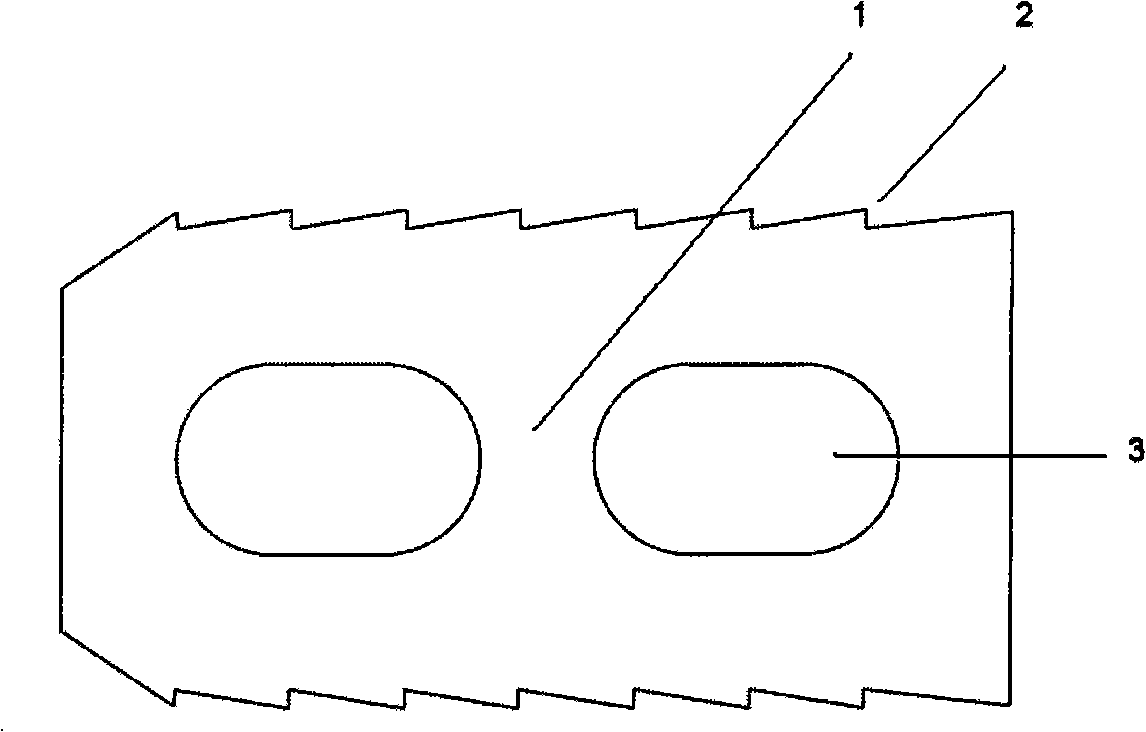

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

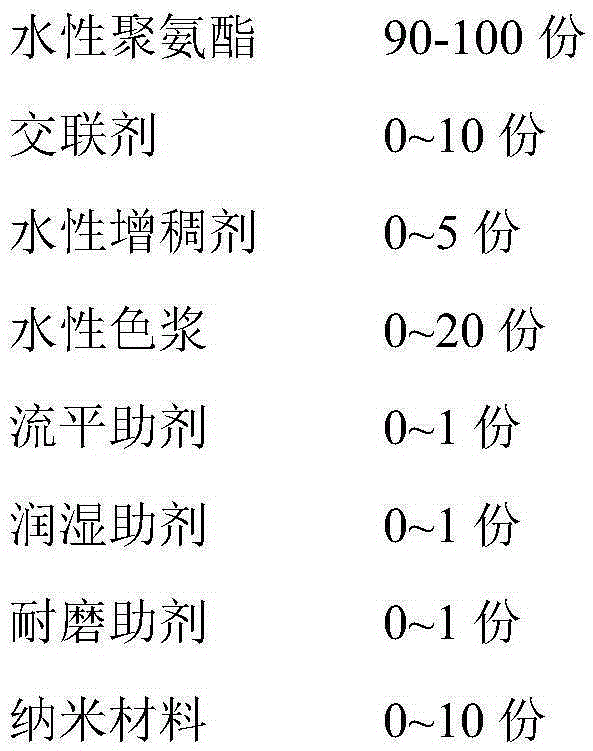

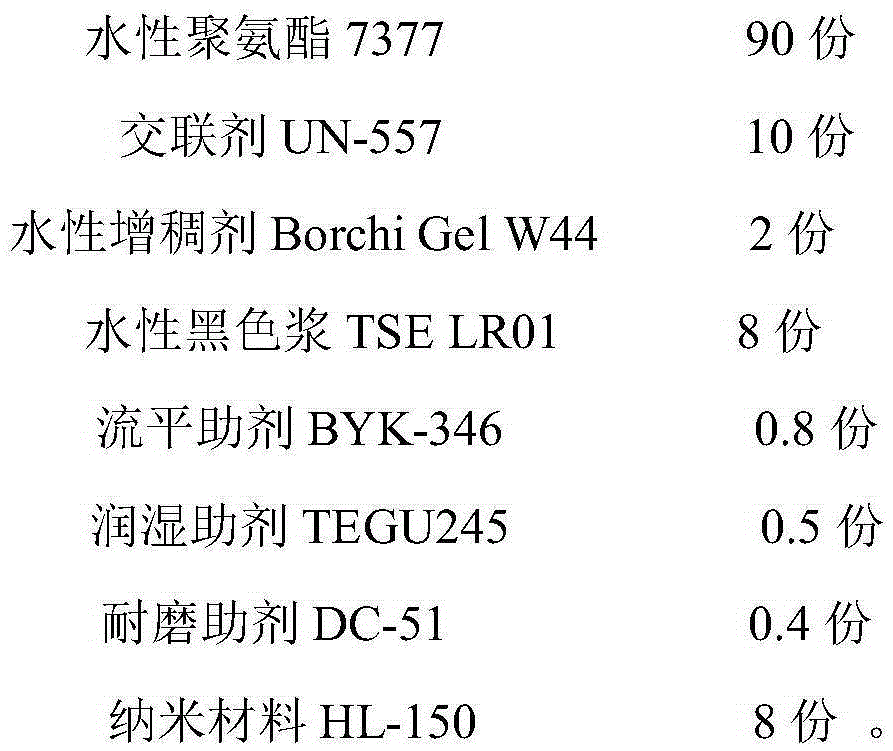

Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

ActiveCN105350342AStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

Cement polymer based high-temperature concrete permeable pavement bricks and manufacturing method thereof

The invention provides cement polymer based high-temperature concrete permeable pavement bricks and a manufacturing method thereof and belongs to the field of road surface pavement materials. Each cement polymer based high-temperature concrete permeable pavement brick is prepared from a permeable base layer and a permeable surface layer, wherein the permeable base layer is prepared from 290 to 345 parts of cement A, 0 to 6 parts of ultra-light aggregate A, 1630 to 1765 parts of coarse aggregate, 255 to 290 parts of sand, 0.50 to 0.85 part of polymer emulsion A, 0.35 to 0.50 part of an interface reinforcing agent A and 0 to 0.65 part of a loose soil constriction resisting agent; the permeable surface layer is prepared from 390 to 425 parts of cement B, 0 to 2 parts of ultra-light aggregate B, 0 to 7.5 parts of micro-pore fine aggregate, 1350 to 1400 parts of wear-resisting fine aggregate, 0.65 to 0.85 part of polymer emulsion B, 0.65 to 0.95 part of an interface reinforcing agent B, 8 to 13 parts of a deicer salt scaling resisting and alkali adsorption agent and 15 to 17 parts of pigment. According to the cement polymer based high-temperature concrete permeable pavement bricks, all technological performances of the permeable bricks are comprehensively improved.

Owner:葛兆明 +3

Antler-deer blood liquor and preparation method thereof

ActiveCN102344879AReduce precipitationHigh active ingredientAlcoholic beverage preparationPenisAlcohol

Owner:信阳东鹿酒业有限公司

Vinorebin powder injection and preparation method

InactiveCN1437942ANot easy to decomposeAdvanced preparation technologyPowder deliveryOrganic active ingredientsDiseaseFreeze-drying

The present invention relates to an injection vinorebin powder injection preparation and its preparation method. It is made up by using vinorebin as main medicine or adding at least one of dextran, mannitol and sorbitol as filling agent, using at least one of solvents of water for injection, acetone and ethyl alcohol to dissolve them to obtain solution, then decolouring with active carbon, filtering by using microporous filtering film, then dehydration drying by using freeze-drying or reduced pressure drying to obtain the invented powder injection for curing the diseases of non-small cell lung cancer, mammary cancer, oophoroma and lymphoma, etc.

Owner:杭州新望族科技有限公司

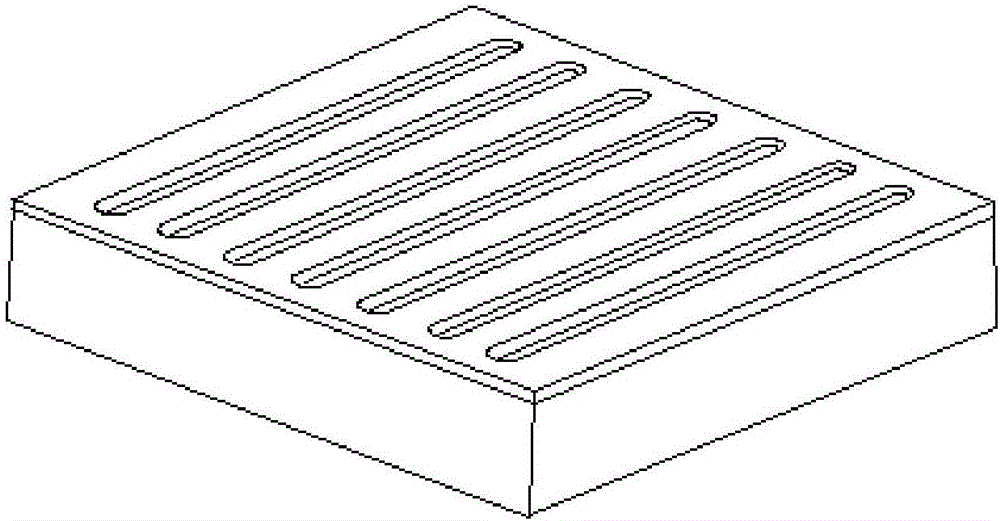

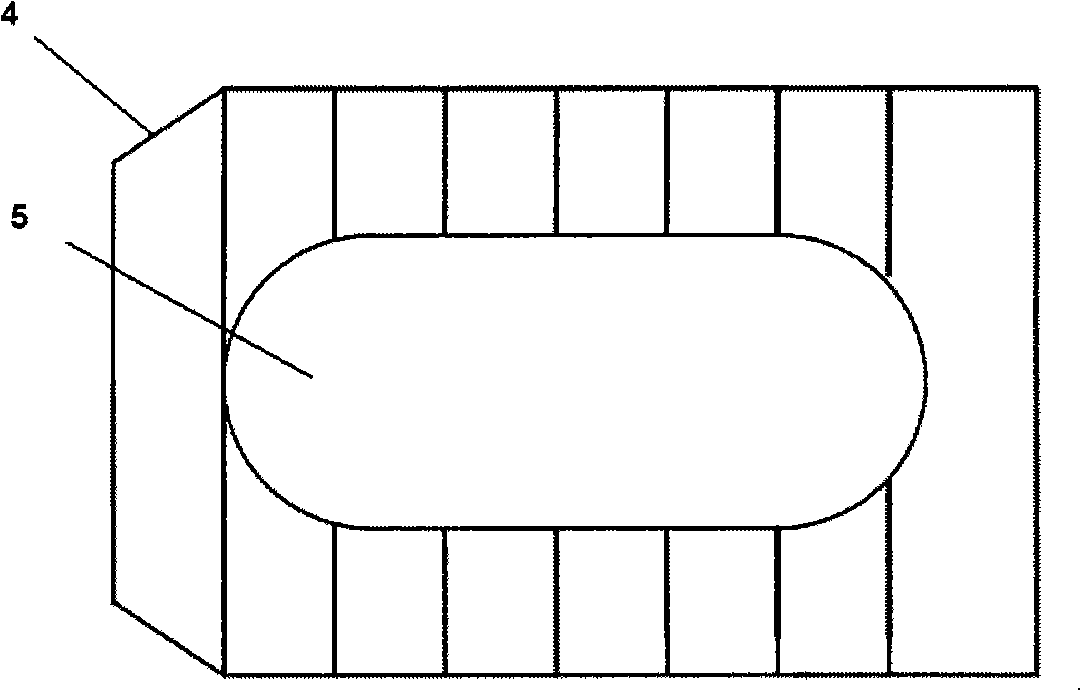

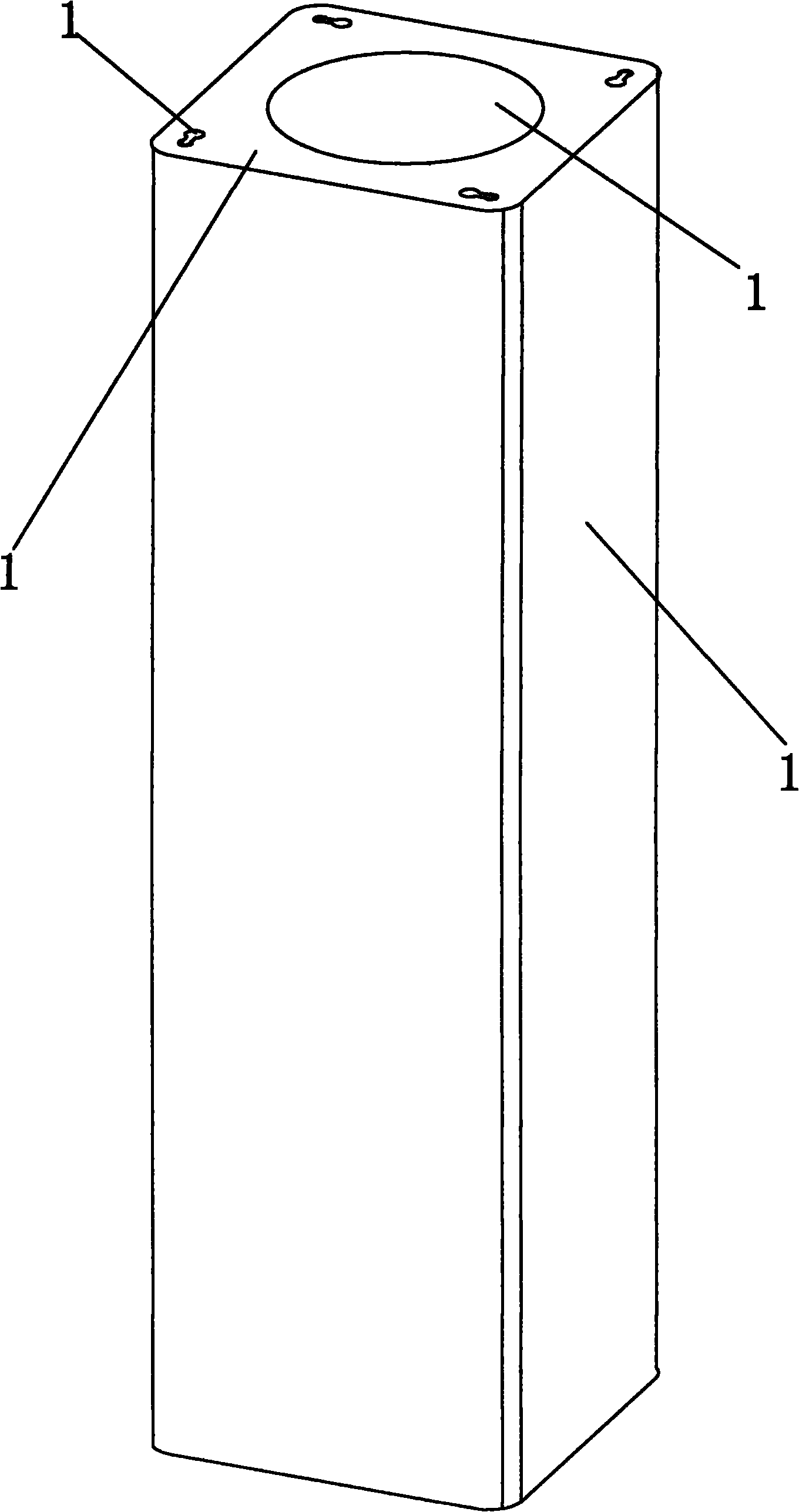

Prestressed concrete hollow square pile and production method thereof

The invention discloses a prestressed concrete hollow square pile comprising a plurality of independent main steel reinforcements. Both ends of each main steel reinforcement are respectively fixedly connected with square end plates; the main steel reinforcements are externally sleeved with steel reinforcement cage racks; each steel reinforcement cage rack comprises a spiral steel reinforcement, and the spiral steel reinforcement is welded with a plurality of auxiliary steel reinforcements; concrete is poured outside the main steel reinforcements and the steel reinforcement cage racks and is combined with the main steel reinforcements and the steel reinforcement cage racks into an integral square pile; and the center of the integral square pile is provided with a central circular hole penetrating through an integral square pile body. The invention aims at providing the prestressed concrete hollow square pile which has the advantages of good molding quality, high single-pile bearing capacity, undamaged steel reinforcement framework before the steel reinforcement framework is used, convenient production, good horizontal anti-bending bearing capacity, high shearing resistant property, convenient stacking and difficult knock damage during pile hoisting, transportation and transferring. The invention also aims at providing a production method of the prestressed concrete hollow square pile.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

A kind of fish tofu and preparation method thereof

InactiveCN102283381APromote absorptionIncrease health functionFood preparationSodium bicarbonateMonosodium glutamate

The invention discloses a fish bean curd and a preparation method thereof. Based on the conventional fish meat processing, the fish bean curd comprises the following raw materials in percentage by weight: 0.1 to 0.3 percent of monosodium glutamate, 0.1 to 0.3 percent of microcrystalline cellulose, 0.1 to 0.3 percent of glucolactone, 0.03 to 0.06 percent of carrageenan, 0.1 to 0.3 percent of sodium bicarbonate, 0.1 to 0.3 percent of ginger, 0.1 to 0.3 percent of shallot, 0.1 to 0.3 percent of garlic, 1 to 3 percent of salt, 0.5 to 1 percent of egg white, 5 to 15 percent of fresh vegetable juice, 28 to 35 percent of fish meat, 18 to 25 percent of starch, 18 to 25 percent of water and 8 to 15 percent of lard. By the special process, the comprehensive nutritious amount of the product is improved, and the absorption of human bodies on proteins, carotene, various vitamins and various mineral substances such as calcium, phosphorus, iron and the like which are contained in aloe (or peanut, soybean, celery, carrot and the like) early vegetable juice is increased, so that the aim of health care of human bodies is fulfilled.

Owner:万泽辉

Cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, lattice composite wall and its manufacturing method

InactiveCN102731031AWith insulationWith sound insulationWallsBuilding material handlingReinforced concreteSlag

Disclosed are a cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, a lattice composite wall and its manufacturing method. The invention relates to the lattice composite wall shuttering, its manufacturing method, the lattice composite wall manufactured by the use of the shuttering and the manufacturing method thereof, so as to solve disadvantages of complicated operational processes and inflammable insulation materials in the prior art. The above purpose is realized by the following scheme: the shuttering comprises components of polyphenyl granules, cement, fly ash or slag, a shuttering bonding agent and water; the components are mixed with stirring to prepare a mixture of cement and polyphenyl granules; the shuttering bonding agent is diluted by the use of water, the solution of the shuttering bonding agent is added into the above mixture of cement and polyphenyl granules with stirring, the mixture is poured into a die, followed by compacting into half-plate cement polyphenyl granule concrete lattice composite wall shutterings; the two half plates undergo buckling and butt joint, and the composite wall is composed of the composite wall shuttering and a reinforced concrete core; and the several cement polyphenyl granule concrete lattice composite wall shutterings are respectively spliced in both vertical and transverse directions, steel bar is mounted in a core aperture, and self-compacting concrete is poured.

Owner:葛兆明 +1

Oral Chinese medicinal preparation for treating vascular dementia

ActiveCN1657084AShort course of treatmentQuick effectNervous disorderUnknown materialsActive ingredientRhizome

An orally taken Chinese medicine for treating vascular dementia is prepared from fleece flower root, astragalus root, Chinese angelica root, Chuan-xiong rhizome and lucid ligustrum fruit.

Owner:SHANGHAI PHARMA GRP QINGDAO GROWFUL PHARMA CO LTD

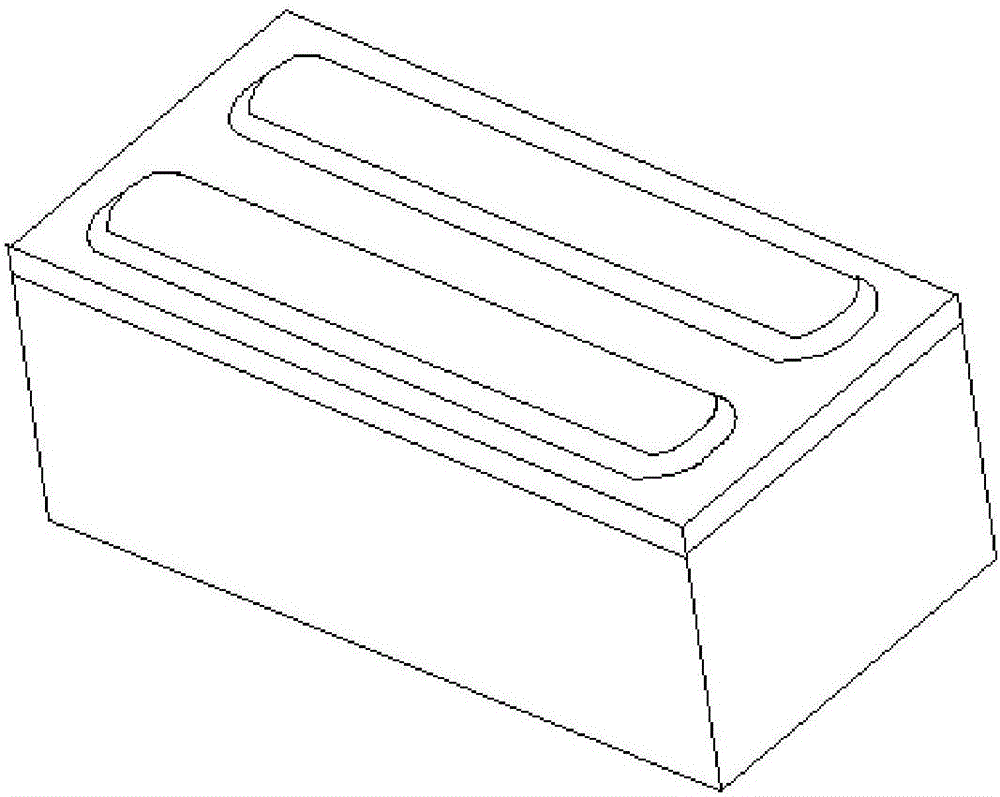

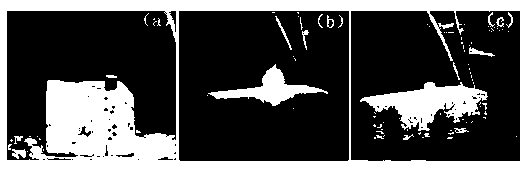

Intervertebral fusion device and method of preparing the same

InactiveCN101254140AReasonable shape and structureReasonable design structureInternal osteosythesisSpinal implantsCarbon compositesSpinal cage

The invention provides an interbody fusion cage for posterior lumbar spinal surgery and a preparation method thereof, and belongs to the application field of biomedical composite materials. The rectangular interbody fusion cage has side surface drainage through-holes, end surface chamfers, and triangle toothed structures on the upper and the bottom surfaces. The preparation method comprises the following steps of profiling the interbody fusion cage with carbon / carbon composite material as target, and preparing hydroxyapatite coating layers on the upper and the bottom surfaces of the interbody fusion cage sequentially by sandblasting pretreatment, plasma spraying, vacuum heat treatment and simulated body fluid immersion. The interbody fusion cage prepared by the inventive method has the advantages of novel material, advanced preparation method, reasonable structural design and good osteoconductivity function.

Owner:SHANDONG UNIV

Compound medicine of ginkgo leaf extract and dipyridamole and preparing method thereof

InactiveCN1454596AReduce lossesAdvanced preparation technologyOrganic active ingredientsBlood disorderFiberDipyridamole

The invention is a manufacturing method for vein medicament of gingkgo leaves extraction materials and di-pyridine compound drug. It is based on that the stability of gingkgo flavone in low thickness aqueous solution is higher than in high thickness aqueous solution, the gingkgo leaves extraction materials and di-pyridine is dissolved at the same time, after the two are frozen and dried into even solid, the stability of gingko flavone is higher than the solid which is only frozen and dried from itself, and produces the infusion agent and powder pin agent. The manufacturing process doesn't use active carbon, but uses middle hole fiber film filtering new technology to wipe off impurities, enhances thep quality of the product. The method is simple, convenient, and good curative effect.

Owner:张哲峰

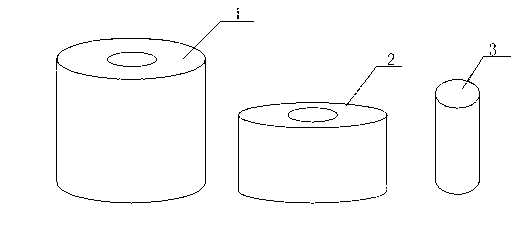

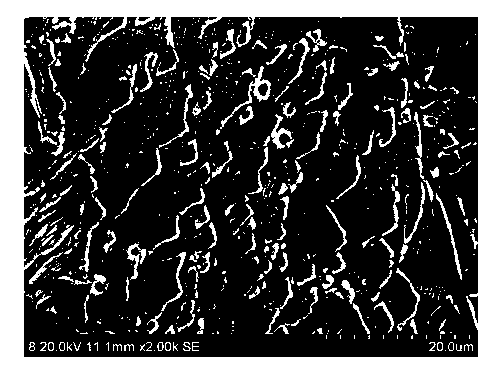

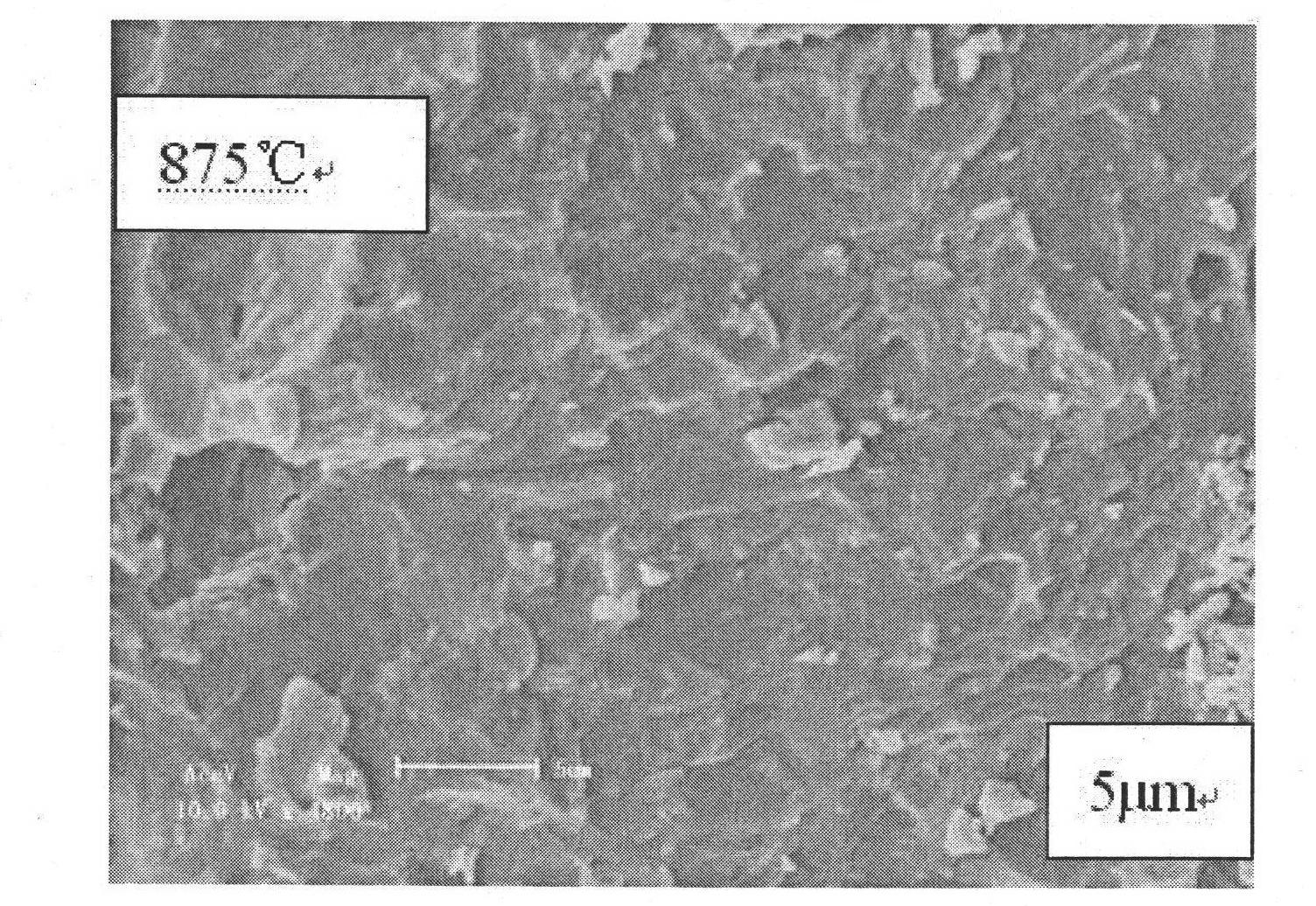

Laser sintering synthesis method of ceramic-particle-reinforced nickel-aluminum-based composite

InactiveCN102876926AEasy to control speedPlay a role in strengthening the matrixNumerical controlPhase formation

The invention belongs to the technical field of material processing and particularly relates to a laser sintering synthesis method of a ceramic-particle-reinforced nickel-aluminum-based composite. The technical scheme includes that the laser sintering synthesis method includes the steps: mixing nickel powder with aluminum powder according to the atomic ratio of Ni to Al of 3:1, adding tungsten concentrate powder accounting for 0.5-2wt% of the total weight of nickel-aluminum mixed powder, performing ball milling to obtain uniformly-mixed mixed powder, compacting the mixed powder to a cylindrical compact, placing the compact on a numerically-controlled machine tool, starting a CO2 laser machine with the laser powder of 900-1200W for laser radiation for 10-20s, and lighting the surface of the compact to enable the compact to generate self-propagating reaction, so that the ceramic-particle-reinforced nickel-aluminum-based composite by laser sintering synthesis is obtained. According to the laser sintering synthesis method, matrix reaction, reinforced phase formation and metal-based composite preparation are combined together, and the reinforced ceramic phase subjected to in-situ synthesis enables high-temperature mechanical properties of a nickel-aluminum intermetallic compound to be obviously improved and enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

Kiwi fruit micro-powder and preparation process thereof

ActiveCN104473071ASave raw materialsHigh nutritional valueFood preparationAdditive ingredientKiwi fruit

The invention provides kiwi fruit micro-powder and a preparation process thereof, and relates to fruit powder and a preparation method of the fruit powder. According to the technical scheme provided by the invention, the preparation process of the kiwi fruit micro-powder comprises the following steps: cleaning kiwi fruit, draining off, and cutting into slices for later use; enclosing the cut kiwi fruit into a charging tray; putting into a vacuum drying room, dewatering and drying; crushing the dried kiwi fruit in a fully-closed state under the protection of nitrogen, and then sieving, so as to obtain micro-powder; and bagging the micro-powder in a low-temperature environment, and sealing in vacuum. The preparation process disclosed by the invention is advanced; 100% of skin, pulp and seeds of the kiwi fruit are utilized; raw materials are fully saved; the utilization efficiency is improved; and the kiwi fruit micro-powder is good in keeping of nutritional ingredients, good in color and luster, and convenient to store and transport for a long period of time.

Owner:南阳市三辰生物科技有限公司

Wastewater purification active coke adsorbent and preparation method thereof

InactiveCN101766990AGood adsorption and purification performanceAdvanced preparation technologyOther chemical processesWater/sewage treatment by sorptionTarChemistry

The invention provides a wastewater purification active coke adsorbent and a preparation method thereof, and the wastewater purification active coke adsorbent is obtained by carrying out the steps of deashing, kneading, molding, drying, carbonization, activation and the like on lignite and coking coal which are crushed into a certain fineness, as well as tar, asphalt, solid metal salts and water. The wastewater purification active coke adsorbent prepared by adopting the raw materials and the method not only realizes good purification effect, but also has the advantages of low cost, simple preparation and strong practicality.

Owner:赵英杰

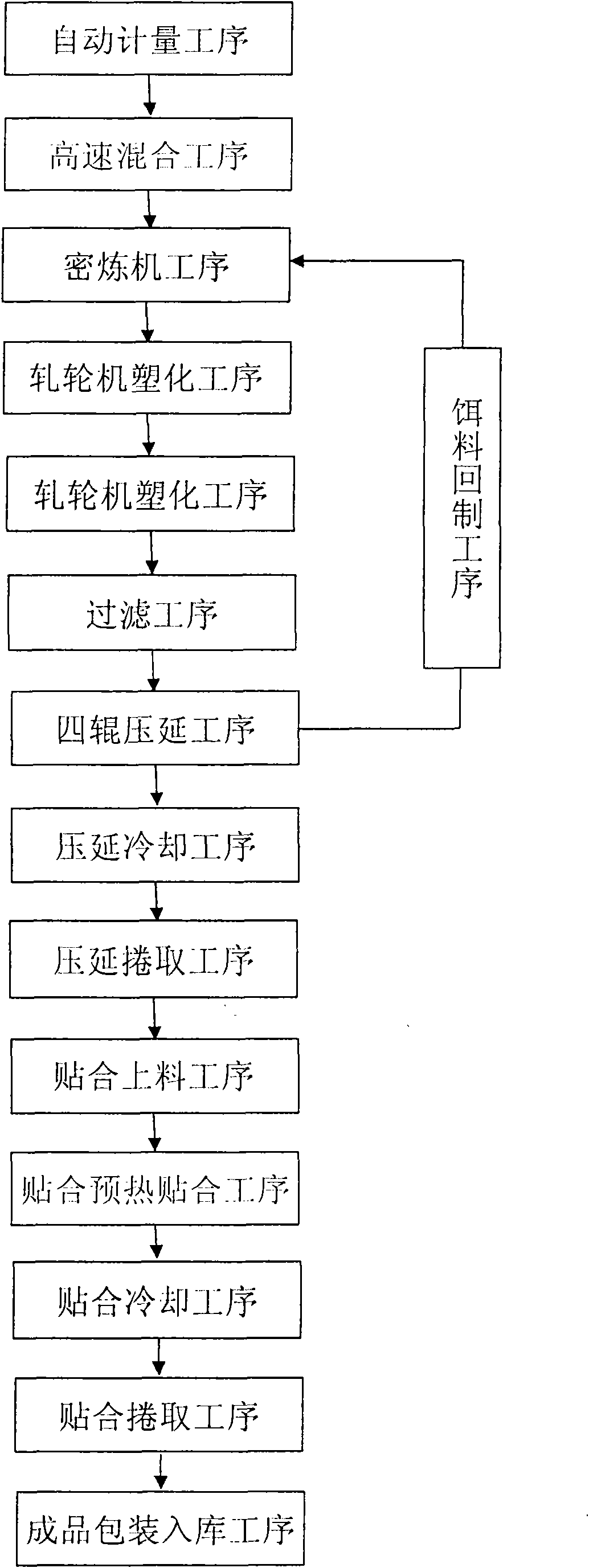

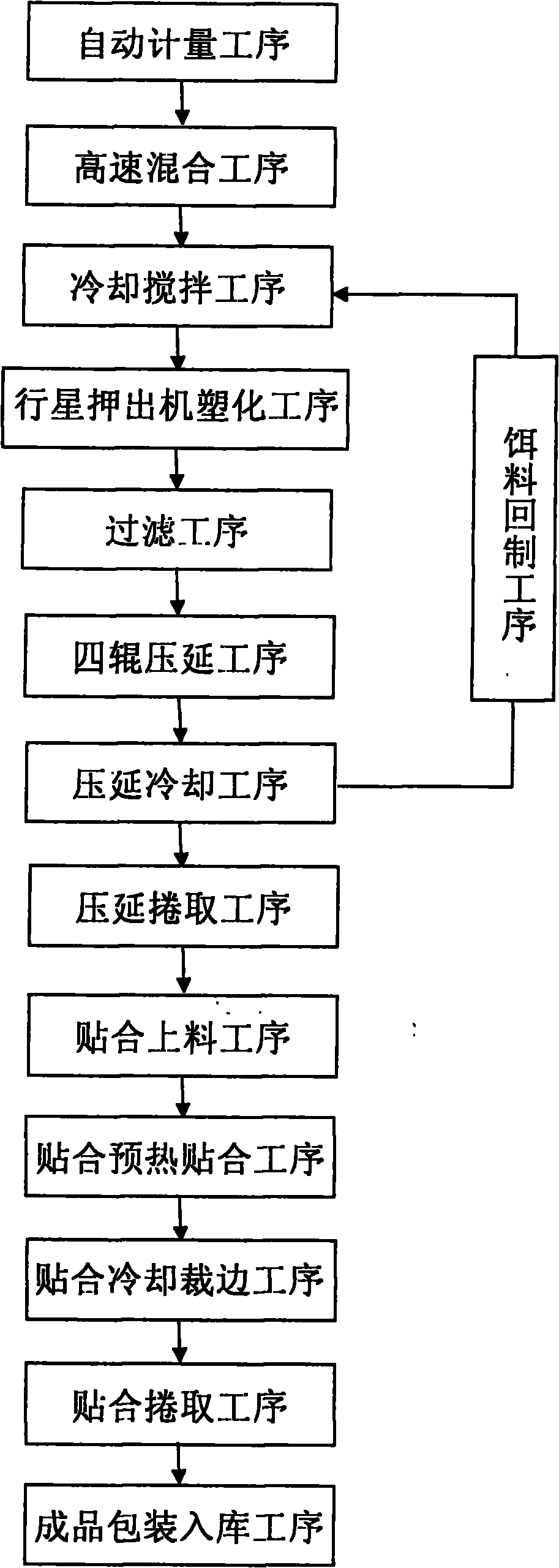

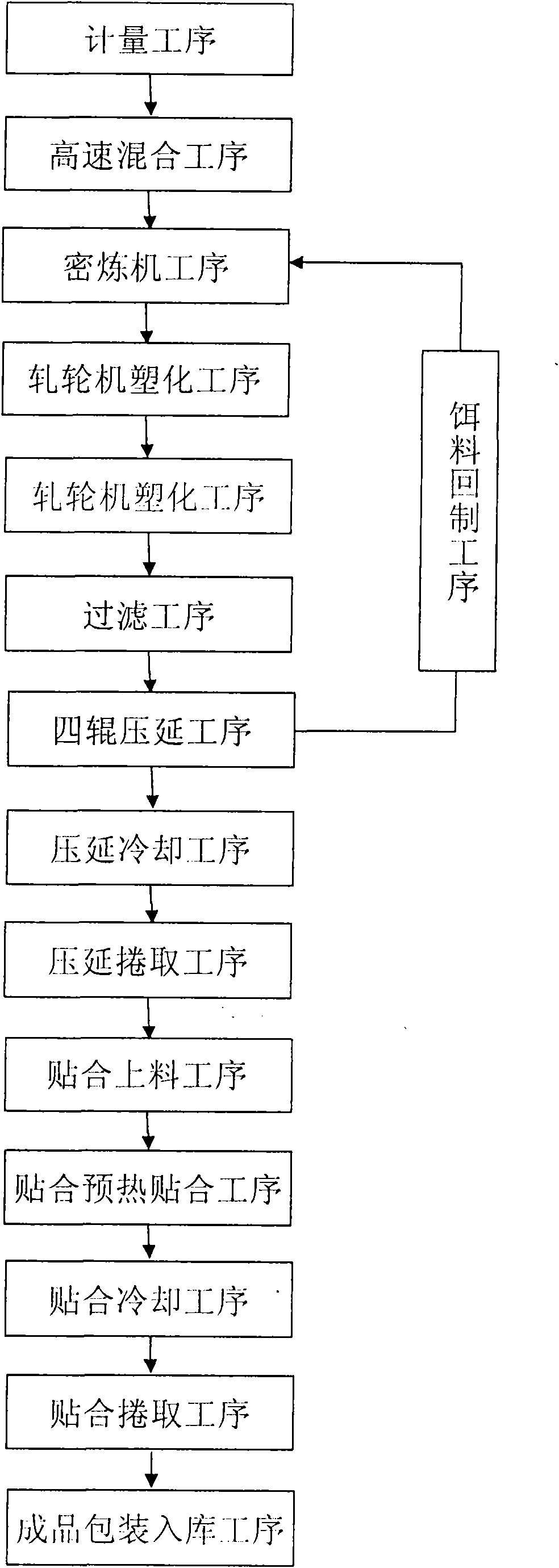

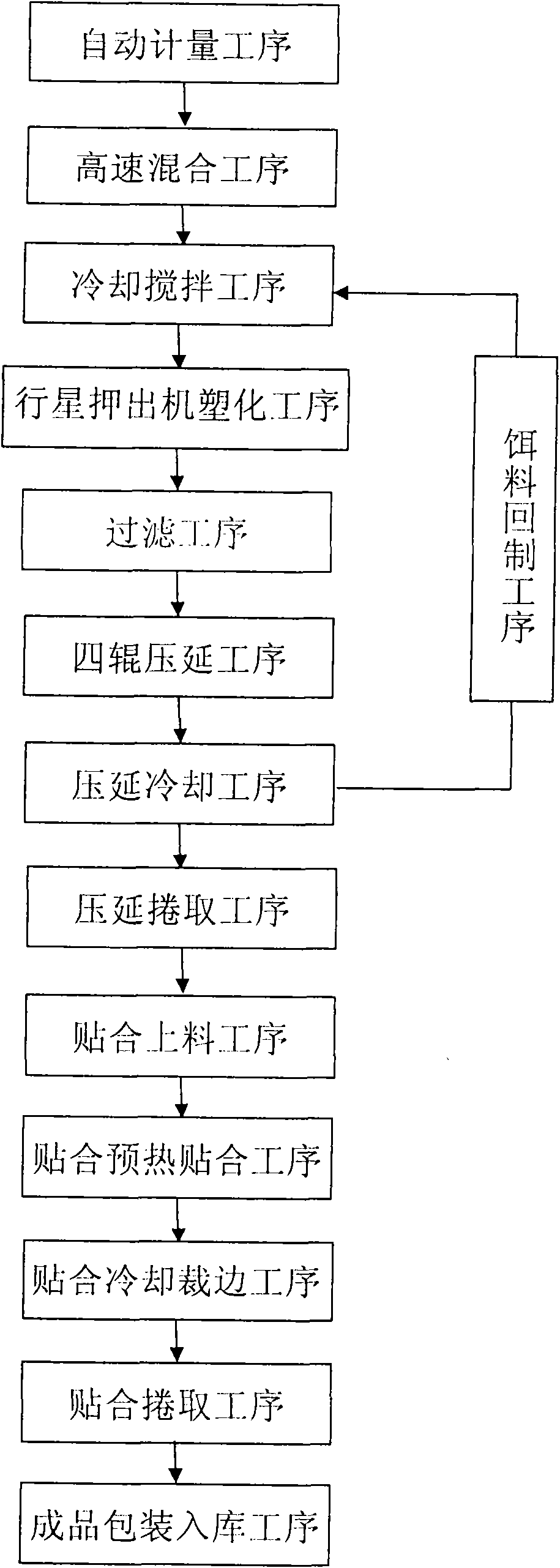

White-light laminated crystal board and making method thereof

ActiveCN101775181AHigh transparencyReduce plasticizing heating timeSynthetic resin layered productsLaminationProcedure AgentsPhosphate

The invention relates to a white-light laminated crystal board and a making method thereof. The white-light laminated crystal board comprises the following ingredients: 100 polyvinyl chloride, 40-60 dioctyl phthalate, 1.6-2.5 liquid barium-cadmium-zinc stabilizers, 0.1-0.6 acrylic acid processing assistant, 0.03-0.08 pigment and 0.2-0.6 PHR of non-toxic phosphate. The making method comprises the following procedures of automatic metering, high-speed mixing, cooling and stirring, plastification by using a planetary extrusion machine, filtering, four-roller calendaring, calendaring and cooling, bait remaking, calendaring and reeling, laminating and feeding, preheating and laminating, lamination cooling and trimming, lamination reeling, and packaging and warehousing of finishing products. The product has better elasticity than that of glass and has high surface transparency and illumination, the surfaces of films have good flatness and small water wave, a single laminated film approaches to be colorless, and the films have high transparency.

Owner:TIANJIN HONGMAO PLASTICS

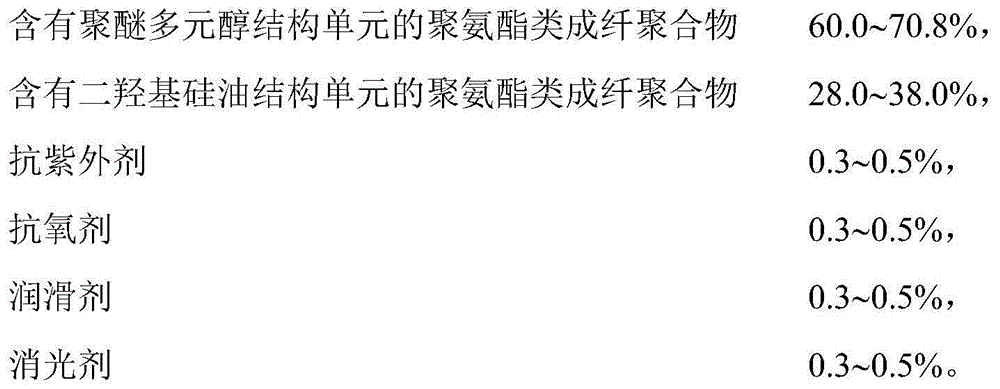

Comfort spandex fiber and preparation method thereof

InactiveCN104928798AHigh reboundHigh modulusConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberPolymer science

The invention relates to a comfort spandex fiber and a preparation method thereof. A formula of the comfort spandex fiber comprises the following raw materials in percentage by mass: 60.0% to 70.8% of polyurethane fiber-forming polymer including a polyether glycol structural unit, 28.0% to 38.0% of polyurethane fiber-forming polymer including a dihydroxyl silicone oil structural unit, and 1.2% to 2.0% of additive. The preparation method comprises the following steps of 1, preparing a prepolymer including the polyether glycol structural unit and a prepolymer including the dihydroxyl silicone oil structural unit respectively, carrying out chain extension, so as to prepare a fiber-forming high polymer, and mixing the fiber-forming high polymer with additive slurry; 2, afterwards, storing and curing an obtained mixture under ultrasound and agitation, so as to prepare a spinning stock solution; 3, finally, preparing the comfort spandex fiber through a dry spinning device and technique. The comfort spandex fiber provided by the invention has the characteristics of high resilience and low modulus, and meets the requirements of the field of the application of comfort spandexes; the constraint feeling to skin is lightened; a consumer is enabled to feel comfortable and free doubly; an oil agent is not needed to be used for a silk coil in a coiling process; a product is more clean; the subsequent use is more convenient.

Owner:ZHEJIANG HUAFENG SPANDEX

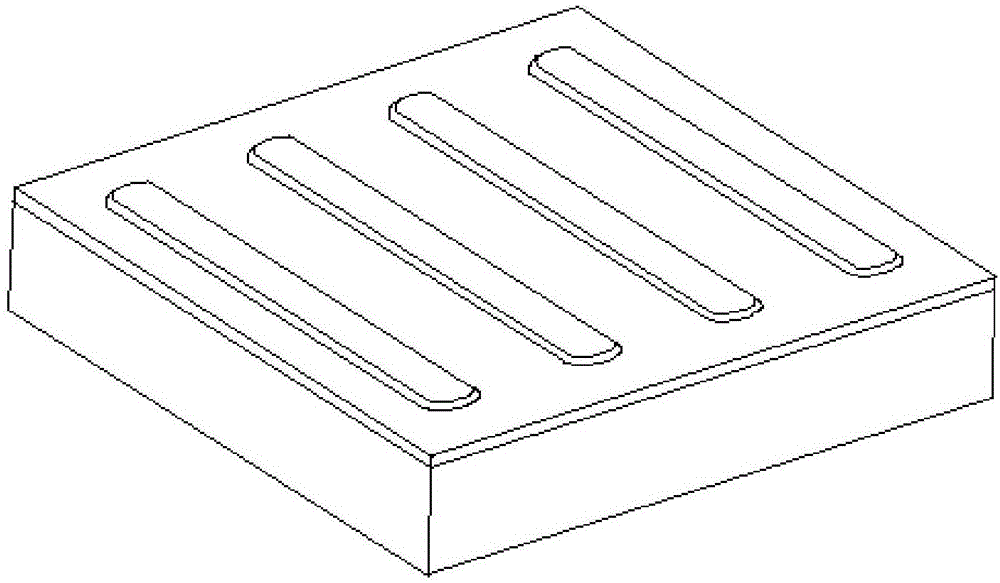

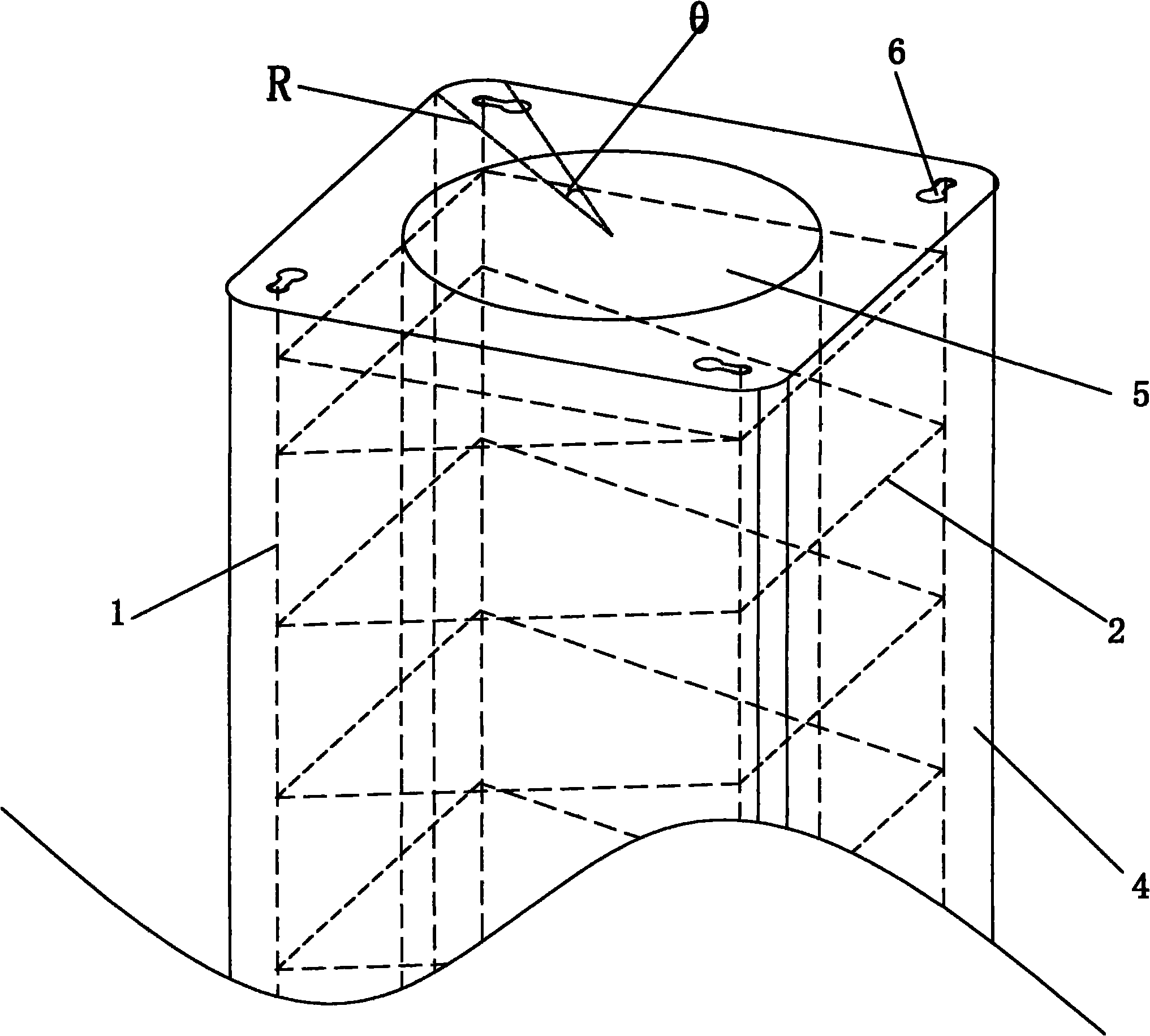

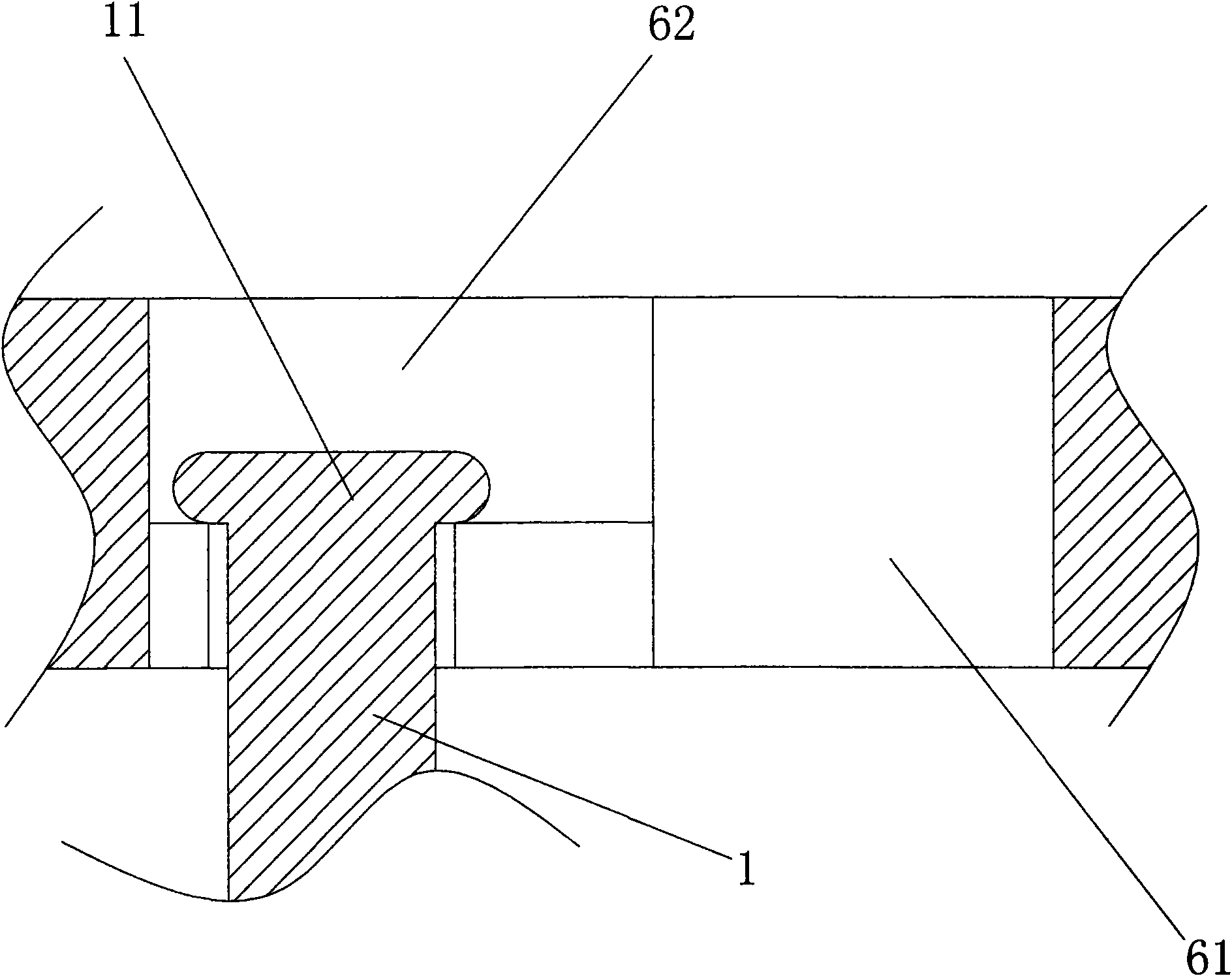

Pretensioned prestressed concrete quadrilateral pile and production method thereof

InactiveCN101914913AImprove compactnessRaise the intensity levelCeramic shaping apparatusBuilding reinforcementsPre stressRebar

The invention discloses a pretensioned prestressed concrete quadrilateral pile, which is characterized by comprising a plurality of main reinforcements, wherein the main reinforcements are welded with spiral reinforcements; the heads of the main reinforcements are greater than the diameters of the main reinforcements; both ends of the main reinforcements are connected with quadrilateral end plates respectively; concrete is poured outside a reinforcement cage frame consisting of the main reinforcements and the spiral reinforcements; the concrete is combined with the reinforcement cage frame into an integral quadrilateral pile body; and the center of the quadrilateral pile body is provided with a central round hole passing through the whole quadrilateral pile body. Aiming to overcome the deficiencies in the prior art, the invention provides the pretensioned prestressed concrete quadrilateral pile which has the advantages of high molding quality, high bearing capacity of a single pile, damage resistance during use of the reinforcement frameworks, high bending resistance bearing capacity, high shearing resistance, convenient stacking, and difficult damage during hoisting, transporting and transferring the pile. The invention also aims to provide a production method of the pretensioned prestressed concrete quadrilateral pile.

Owner:句容长江建材有限公司

Emulsion pressure-sensitive adhesive for protecting adhesive tape and preparation method thereof

InactiveCN103320065AAdvanced preparation technologyEasy to makeFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateHigh humidity

The invention provides an emulsion pressure-sensitive adhesive for protecting an adhesive tape and a preparation method thereof. The emulsion pressure-sensitive adhesive is prepared from butyl acrylate, 2-ethylhexyl acrylate, methyl methacrylate, styrene, crylic acid, hydroxy-propyl acrylate, an initiator, a buffer agent and an emulsifier in a polymerization manner. The preparation method of the emulsion pressure-sensitive adhesive comprises the following steps: a) selecting a synthetic material; b) preparing pre-emulsion; c) performing polymerizing emulsion; d) detecting a product. The invention discloses the emulsion pressure-sensitive adhesive for protecting the adhesive tape and the preparation method thereof. The emulsion pressure-sensitive adhesive is advanced in preparation technology, and simple in preparation process; the prepared emulsion pressure-sensitive adhesive not only has strong initial tension and high peel strength, but also has good high-temperature, high-humidity and aging resistance, and high application value.

Owner:KUNSHAN HANBAO TAPE TECH

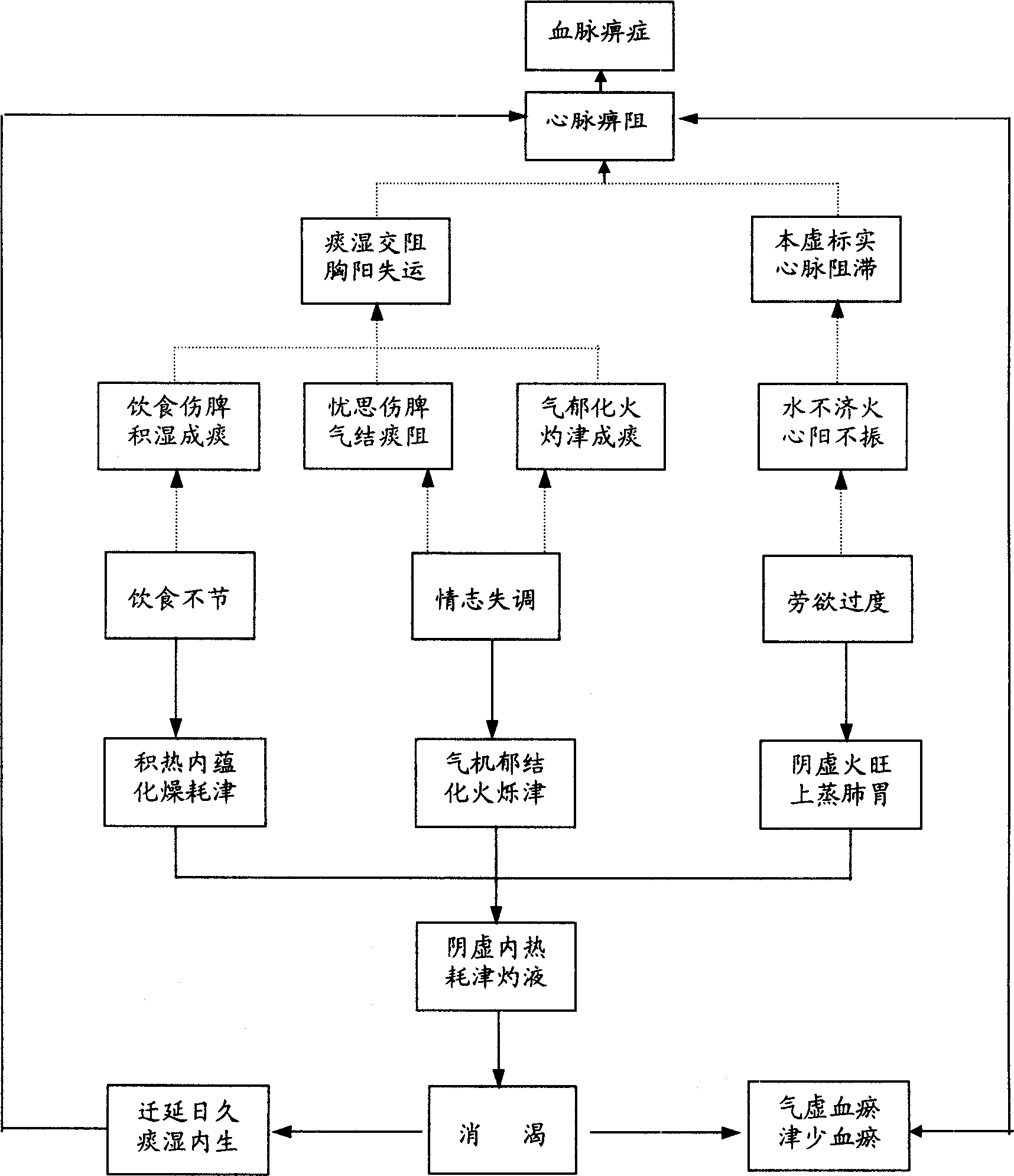

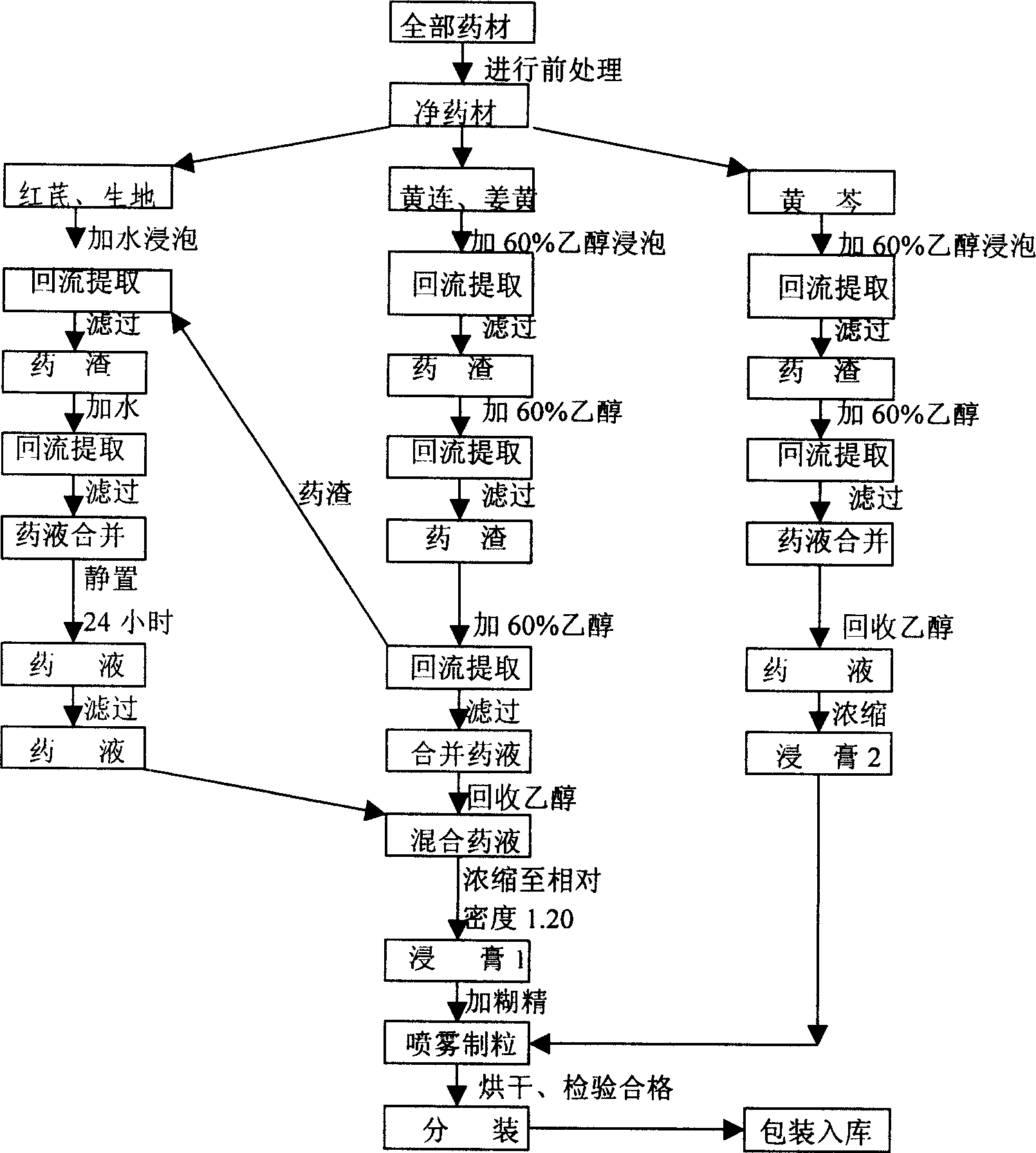

Medicine for treating diabetes, and its prepn. method

ActiveCN1724065AAdvanced technologyReliable qualityMetabolism disorderGranular deliveryDiabetes mellitusCoptis

A Chinese medicine in the form of particles for treating diabetes and its vascular complication and decreasing blood fat is prepared from 5 Chinese-medicinal materials including coptis root, rehmannia root, scutellaria root, turmeric, etc through proportionally immersing them in alcohol, thermal reflux extracting, filter, concentrating, spray granulating and baking.

Owner:CHONGQING DONGTIAN PHARMA

Compound macrostem onion preparation for curing chronic obstructive lung disease and its preparing method

InactiveCN1425441ASignificantly relieve cough and reduce phlegmSignificant antiasthmatic effectUnknown materialsRespiratory disorderTwigMedical prescription

The compound Chinese onion preparation for treating chronic obstructive lung disease is prepared with Chinese onion, trichosanthes peel, Chinese goldthread, immature bitter orange, cassia twig and other chinese medicine materials. The preparation process includes crushing material, ethanol extraction, depression recovery of ethanol, concentration, adding supplementary material, vacuum drying to obtain dry extract, crushing, and further steps to prepare tablet, capsule, drip pills and micro pills. The compound Chinese onion preparation has obvious functions of relieving cough, eliminating phlegm and relieving asthma, and may be used to treat chronic obstructive lung disease effectively. It is ideal medicine for COPD in acute stage and COPD in prolonged stage and chronic stage.

Owner:南京中医药大学附属医院

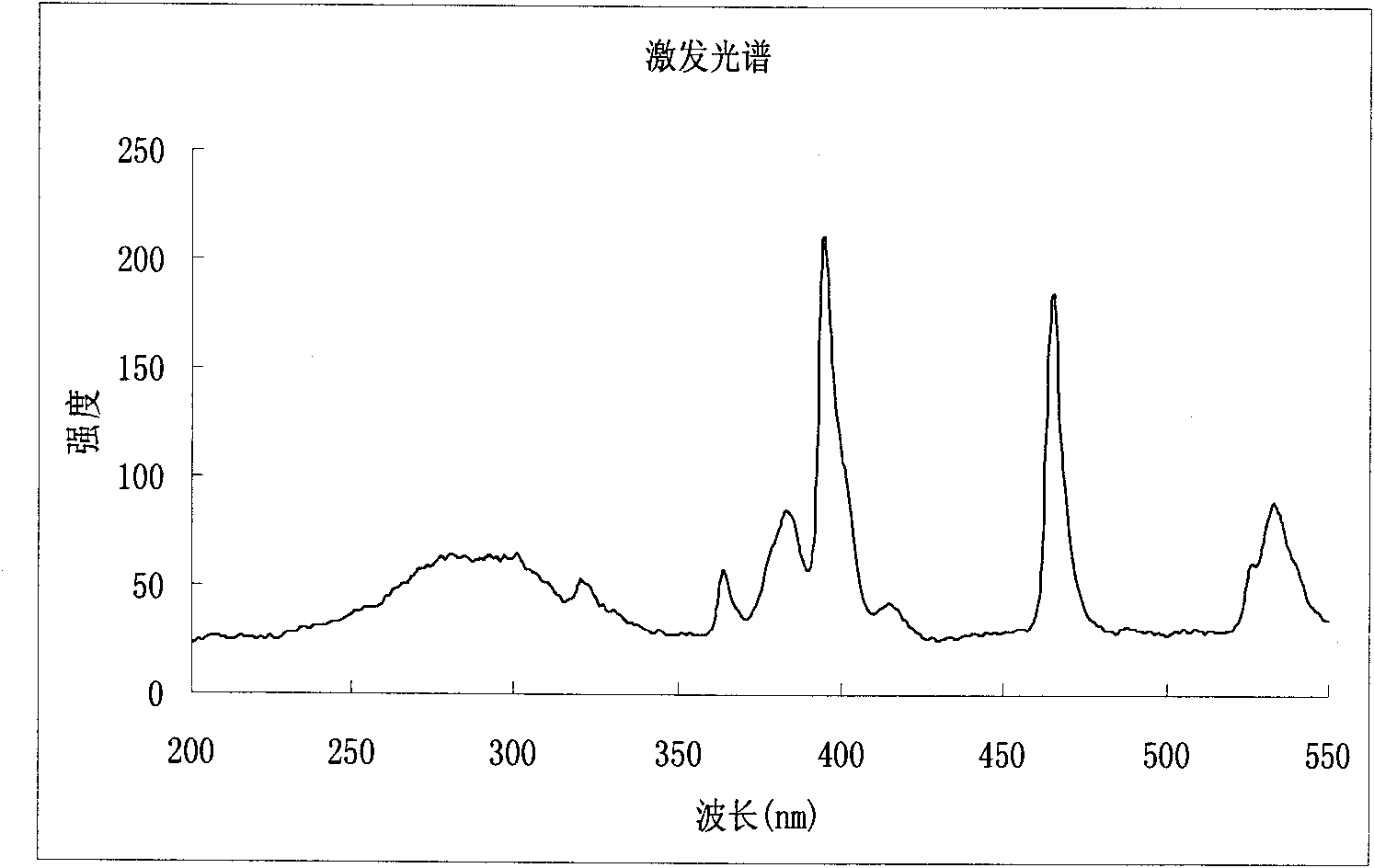

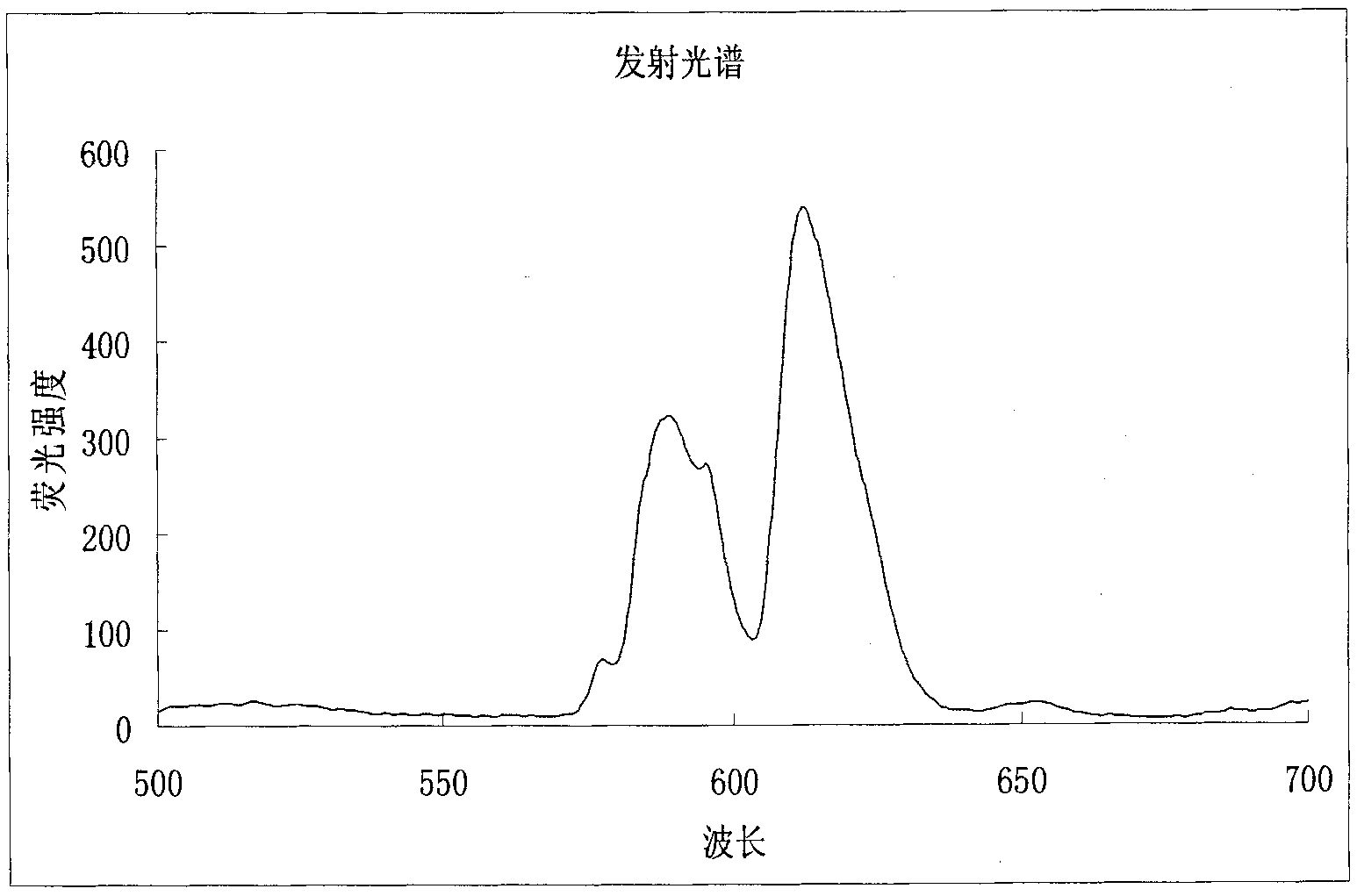

Light-emitting low-temperature co-fired ceramic powder, preparation method thereof and light-emitting low-temperature co-fired ceramic

The invention provides a light-emitting low-temperature co-fired ceramic powder, a preparation method thereof and a light-emitting low-temperature co-fired ceramic prepared from the light-emitting low-temperature co-fired ceramic powder. The light-emitting low-temperature co-fired ceramic powder is prepared from 15-20mol% of CaCO3, 60-70mol% of Si(OC2H5)4, 10-25mol% of B2O3, 3-11mol% of photoactivating agent, 0.9-3.2mol% of sensitizing agent and charge compensation agent gel equivalent to the total content of the photoactivating agent and the sensitizing agent by calcination. The low-temperature co-fired ceramic powder has the advantages of low sintering temperature, small dielectric loss, high mechanical strength and high light intensity, and can be used in the fields of ceramic base plates, electronic devices such as resonators and the like, other micro electronic potting materials and white light LED potting materials.

Owner:TSINGHUA UNIV

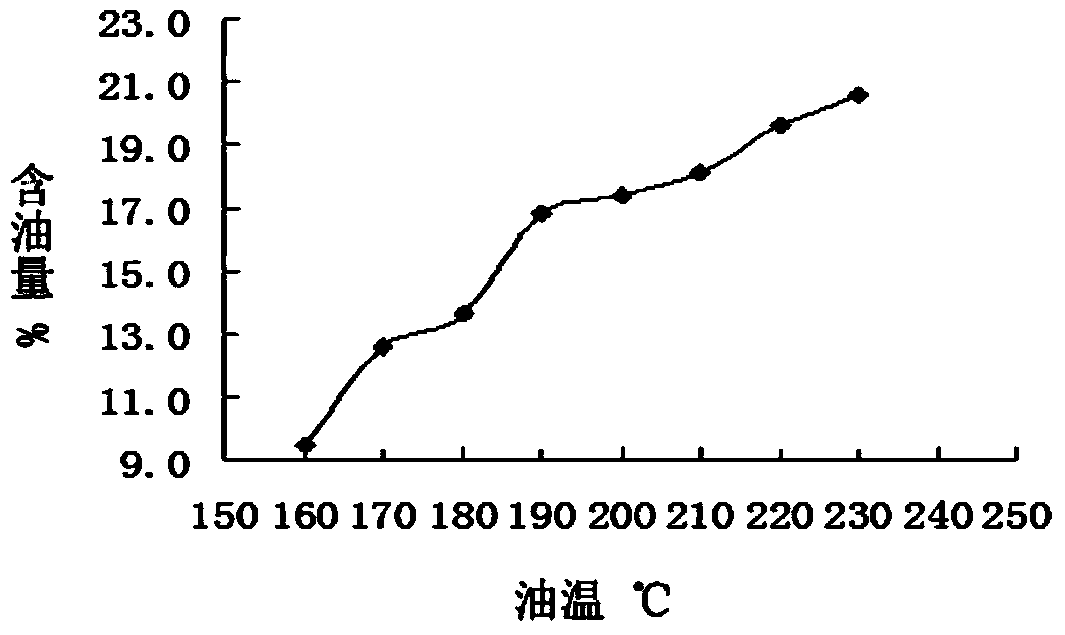

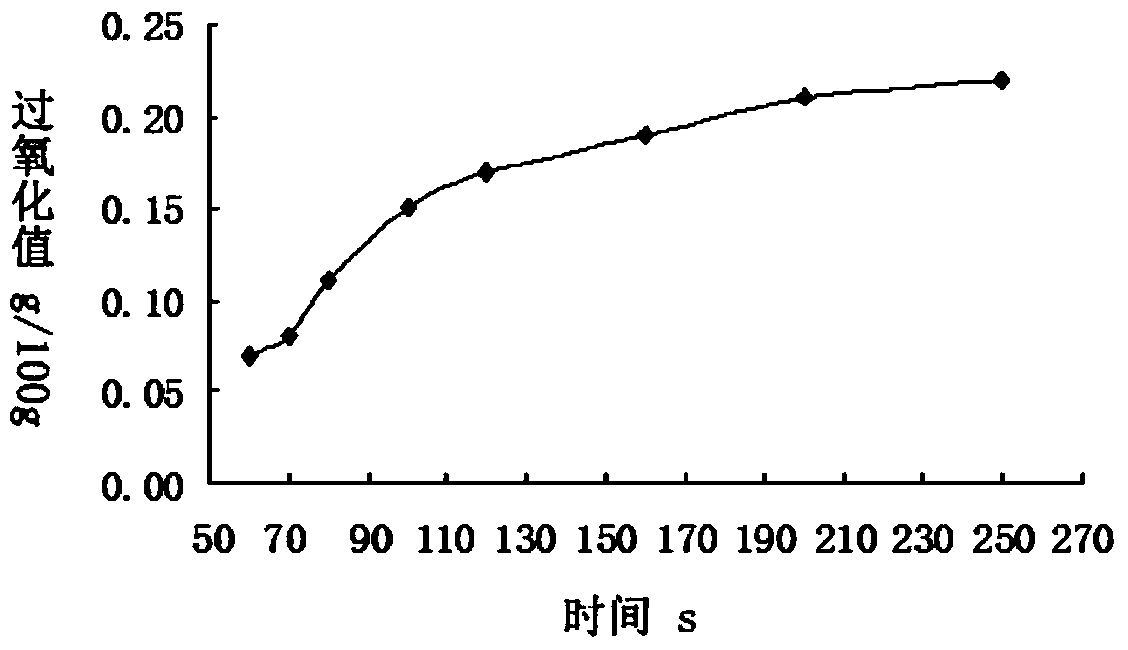

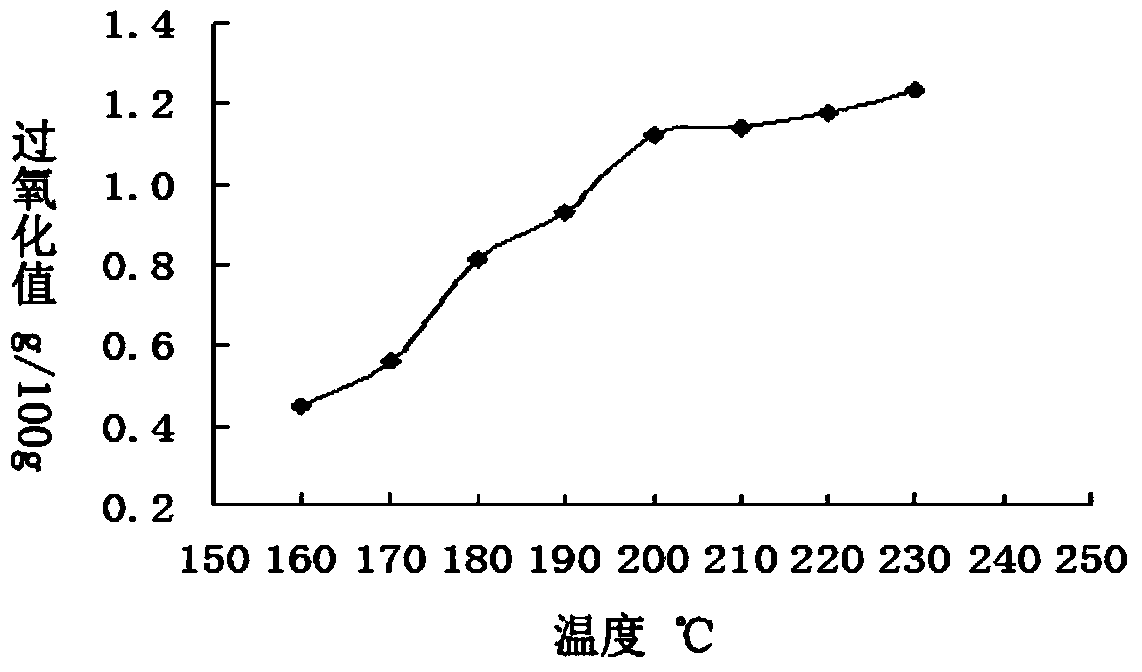

Quick-frozen fresh-keeping deep-fried dough stick and making method thereof

ActiveCN103875755AFull of nutritionPromote expansionDough treatmentPre-baking dough treatmentFrost crackQuick Freeze

The invention discloses a quick-frozen fresh-keeping deep-fried dough stick and a making method thereof and belongs to the technical field of food processing. The quick-frozen fresh-keeping deep-fried dough stick is mainly composed of, by weight, 110-120 parts of flour special for making deep-fried dough sticks, 8-10 parts of acetylated wheat modified starch, 10-15 parts of white glutinous rice flour, 60-70 parts of water, 2-3 parts of leavening agents, 0.1-0.2 part of yeast, 3-5 parts of soybean oil, 5-10 parts of edible salt, 5-10 parts of eggs and 7-12 parts of white sugar. The flour special for making the deep-fried dough sticks, the acetylated wheat modified starch and the white glutinous rice flour are adopted, so that forming of a gluten network can be promoted, strength and gluten tenacity of the deep-fried dough stick are improved, and frost crack rate of skin of the deep-fried dough stick after quick freezing can be lowered; a low-temperature quick deep-fry method and a quick freezing method are adopted to make the deep-fried dough stick, so that water content, oil content, acid value and peroxide value of the deep-fried dough stick can be lowered, and original freshness and nutrition facts of the deep-fried dough stick can be maintained furthest.

Owner:云鹤食品有限公司

Preparation method of milk/egg nutrition beverage

InactiveCN102132736AAdvanced preparation technologyImprove nutritional functionMilk preparationNutrition functionFalling film evaporator

The invention relates to a preparation method of a milk / egg nutrition beverage, which specifically comprises the steps of: selecting fresh eggs, and evenly stirring the egg liquid; removing the bad smell of the egg liquid by bad smell removing equipment; concentrating under vacuum, and putting the sterilized and bad-smell-removed egg liquid into a double-effect falling film evaporator for concentrating; homogenizing under a high pressure, smashing the egg liquid into material points by a plurality of tinny valve openings under a high pressure, and evenly distributing the material points into a material liquid; atomizing and drying, and evenly spraying the plainwhite into a drying tower by a nozzle to prepare egg powder; and adding the egg powder into sterilized fresh milk, adding water, adding a food additive and white granulated sugar, stirring, and canning into a milk / egg mixed beverage. The preparation method is advanced in preparation technology, and the milk and the egg are scientifically mixed with each other, so that the nutrition functions of the milk and the egg are intensified. The beverage can be drunk at any time and any place, is very convenient, is good in mouthfeel, is suitable for drinking in four seasons, and is good for the children and the adults.

Owner:赵庆国

Grain, citrus and orange juice

InactiveCN103099267AEfficient productionAdvanced preparation technologyFood scienceBiotechnologyMenthol

The invention discloses a grain, citrus and orange juice which is prepared through the following steps of: firstly, cleaning main materials and ingredients; weighting grains, i.e., rice, millet and corn according to the proportion of (8-6): (3-5): (3-1) based on the basic proportion of 10, soaking the grains in clear water for 24-26hours, grinding the grains by using a grinder, and then, filtering out grain pulp by using a filter; respectively weighting citruses and oranges according to the proportion of (7-6): (5-6), placing the citruses and the oranges into a grinder for grinding, filtering out citrus and orange juice by using a filter; weighting the ingredients, i.e., menthol juice and condiments according to the proportion of (2-3): (1-2), uniformly stirring the ingredients by using the stirrer to form ingredient pulp; and then, weighting the grain pulp, the citrus and orange juice, mineral water and the ingredient pulp according to the proportion of (7-8): (5-6): (3-2): (0.4-0.3) based on the basic proportion of 100, uniformly stirring the grain pulp, the citrus and orange juice, the mineral water and the ingredient pulp by using the stirrer, and filtering out initial grain, citrus and orange juice by using the filter, then, filling the initial grain, citrus and orange juice into a special container by using a special filling machine, heating and sterilizing by using a cooking machine for 45-55minutes, and then, sealing, storing and upgrading for 8-10days, wherein the obtained grain, citrus and orange juice is strong in grain fragrance and taste.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

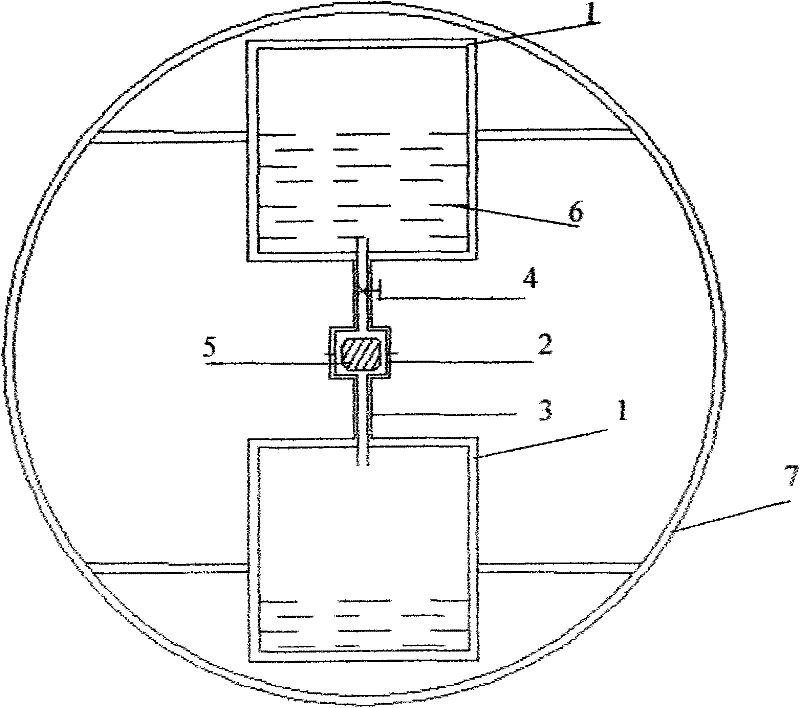

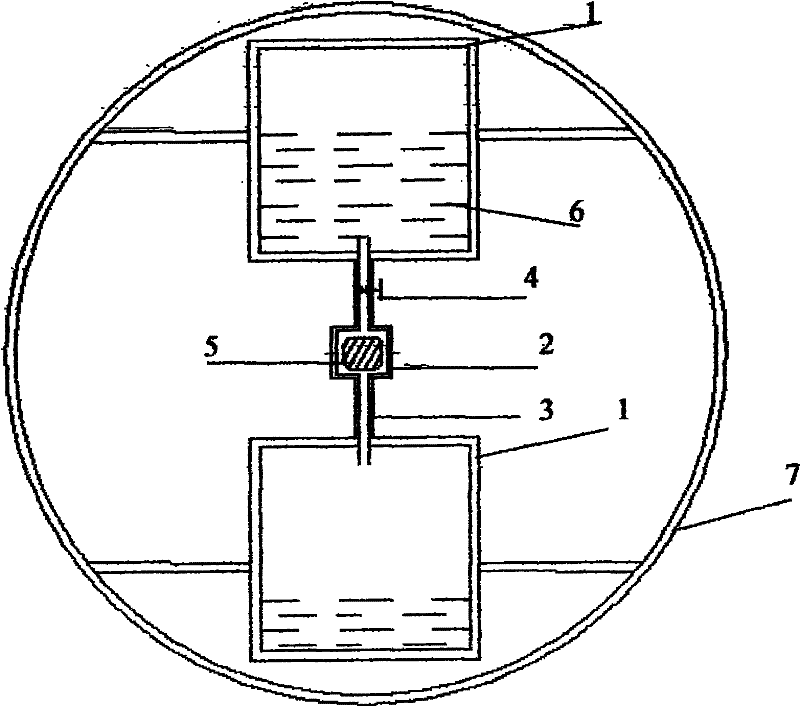

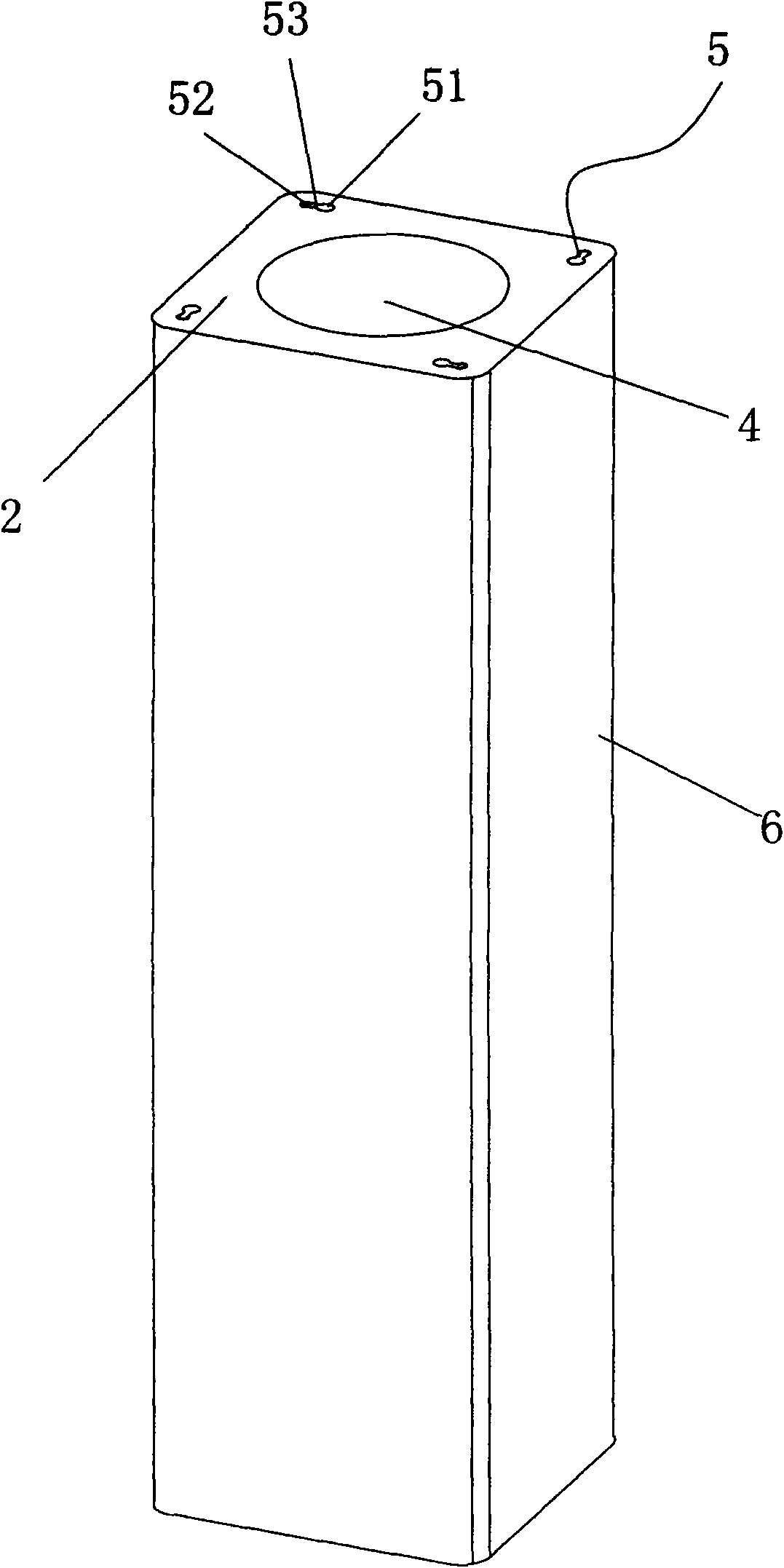

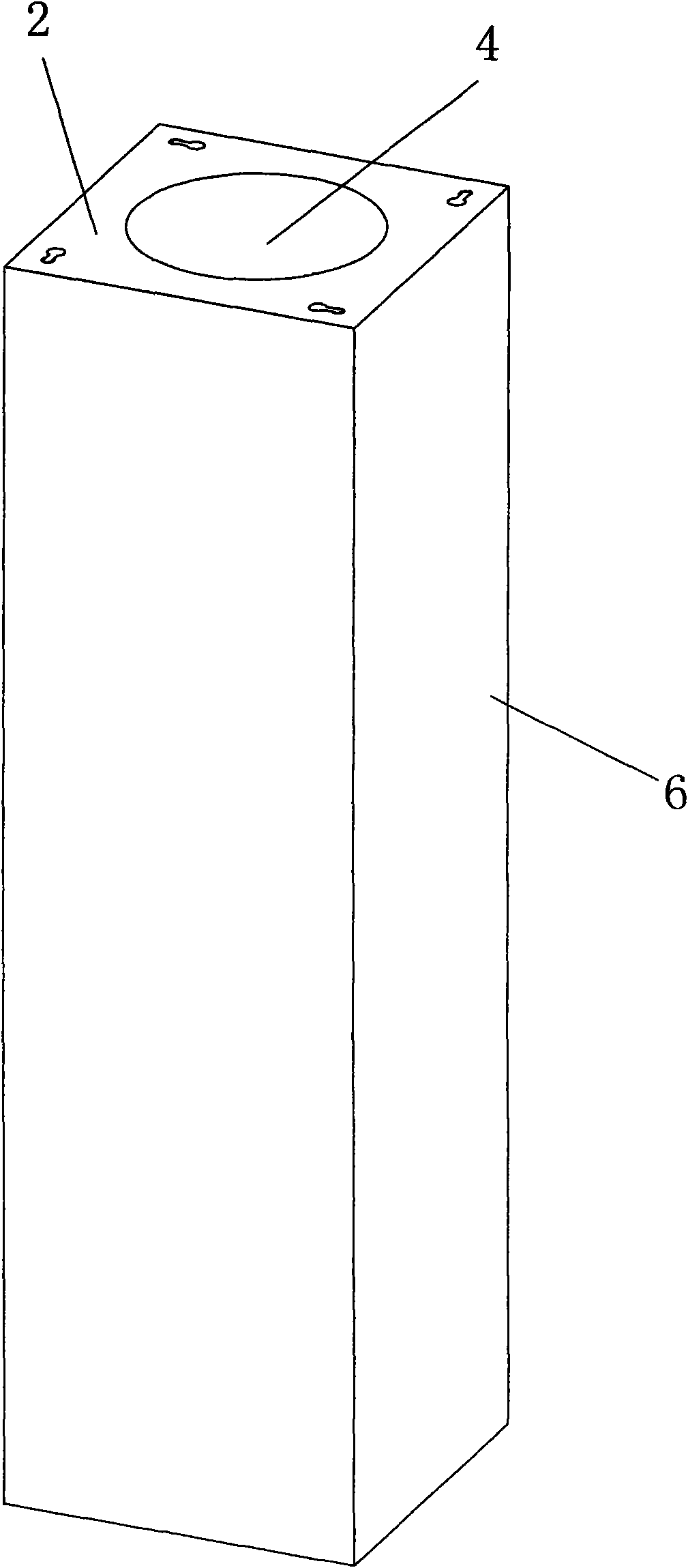

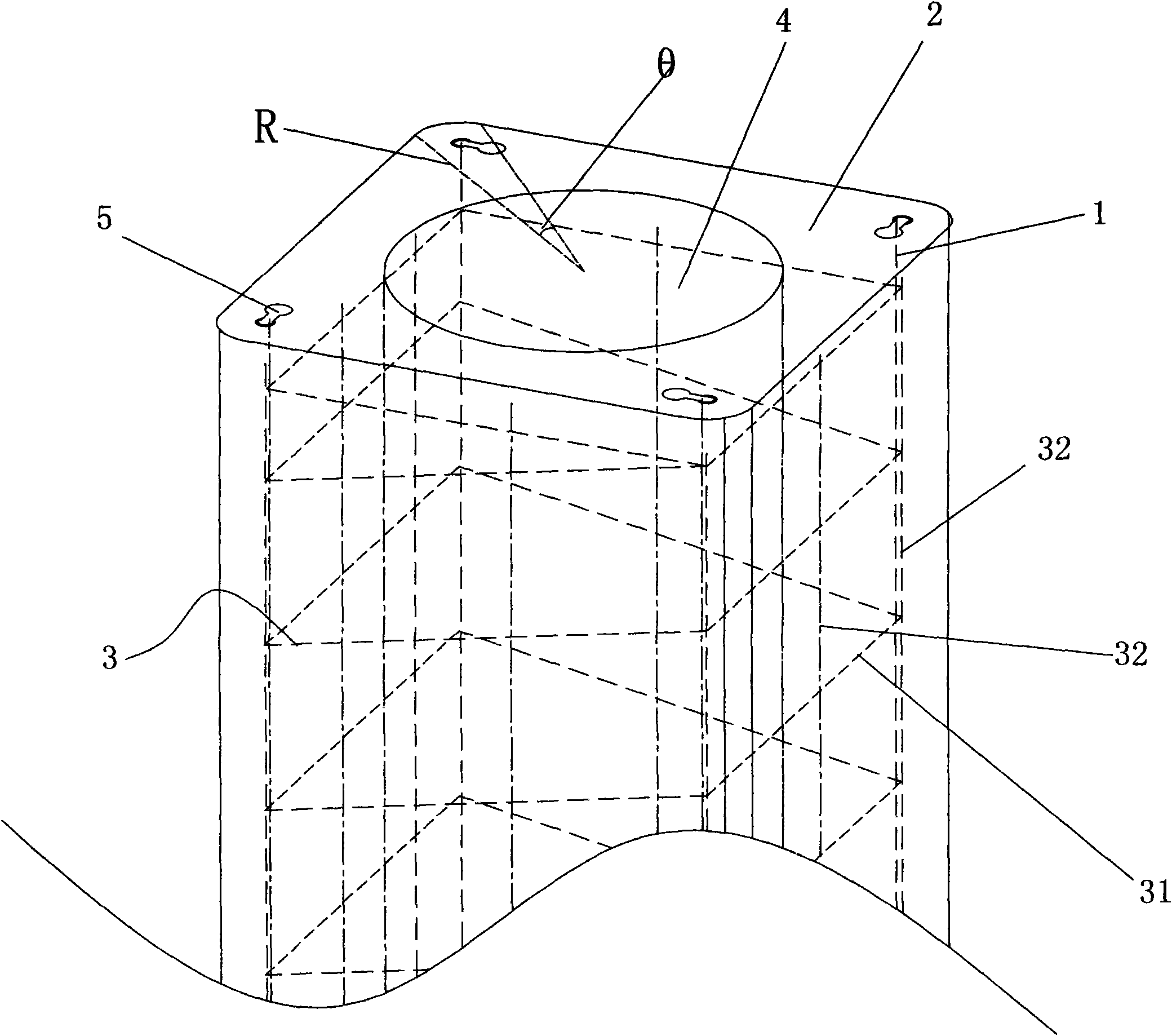

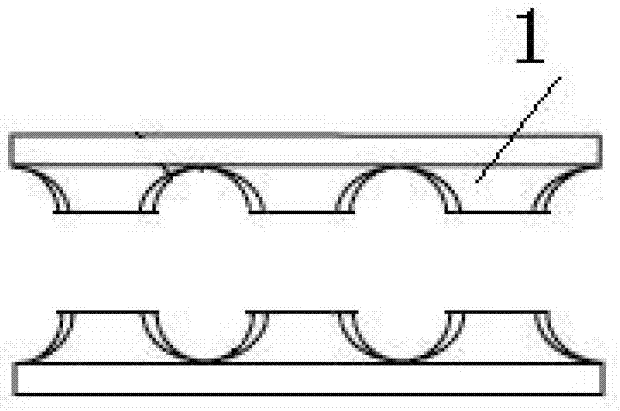

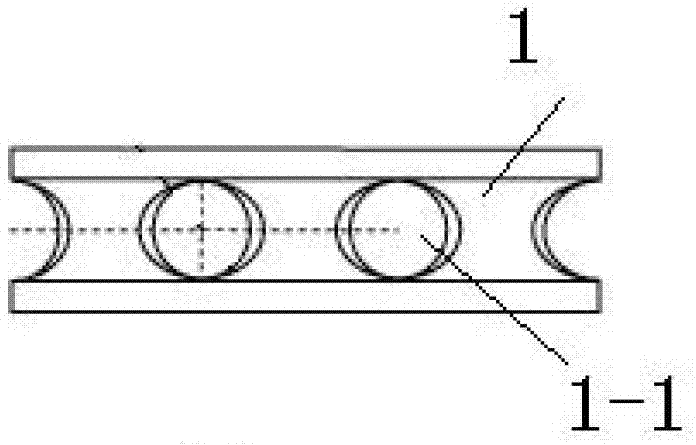

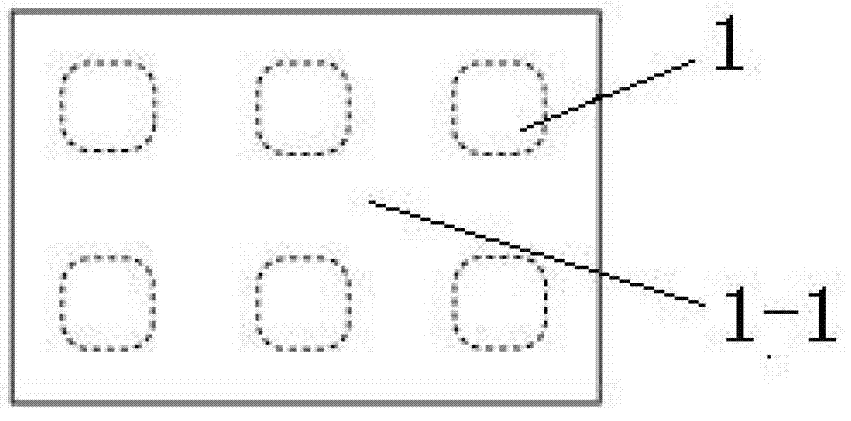

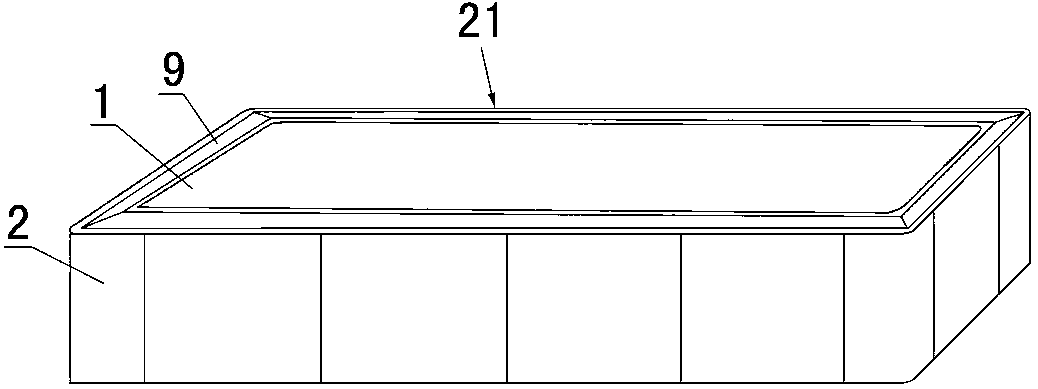

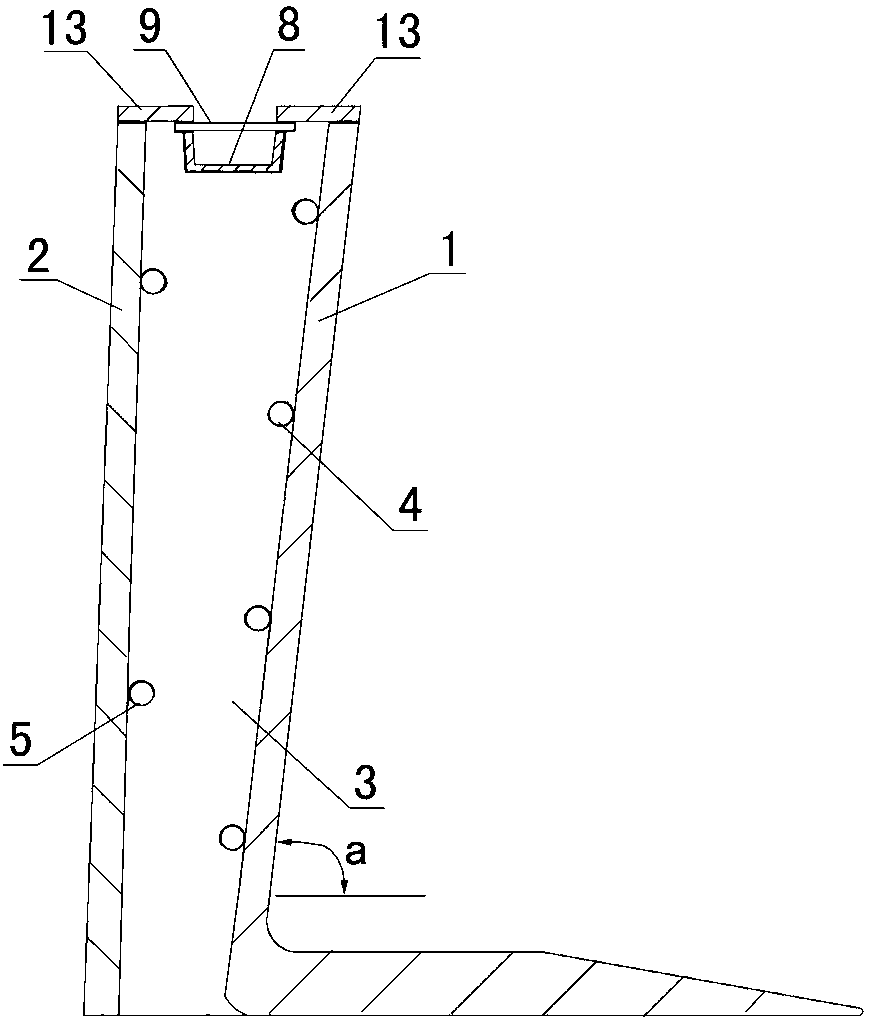

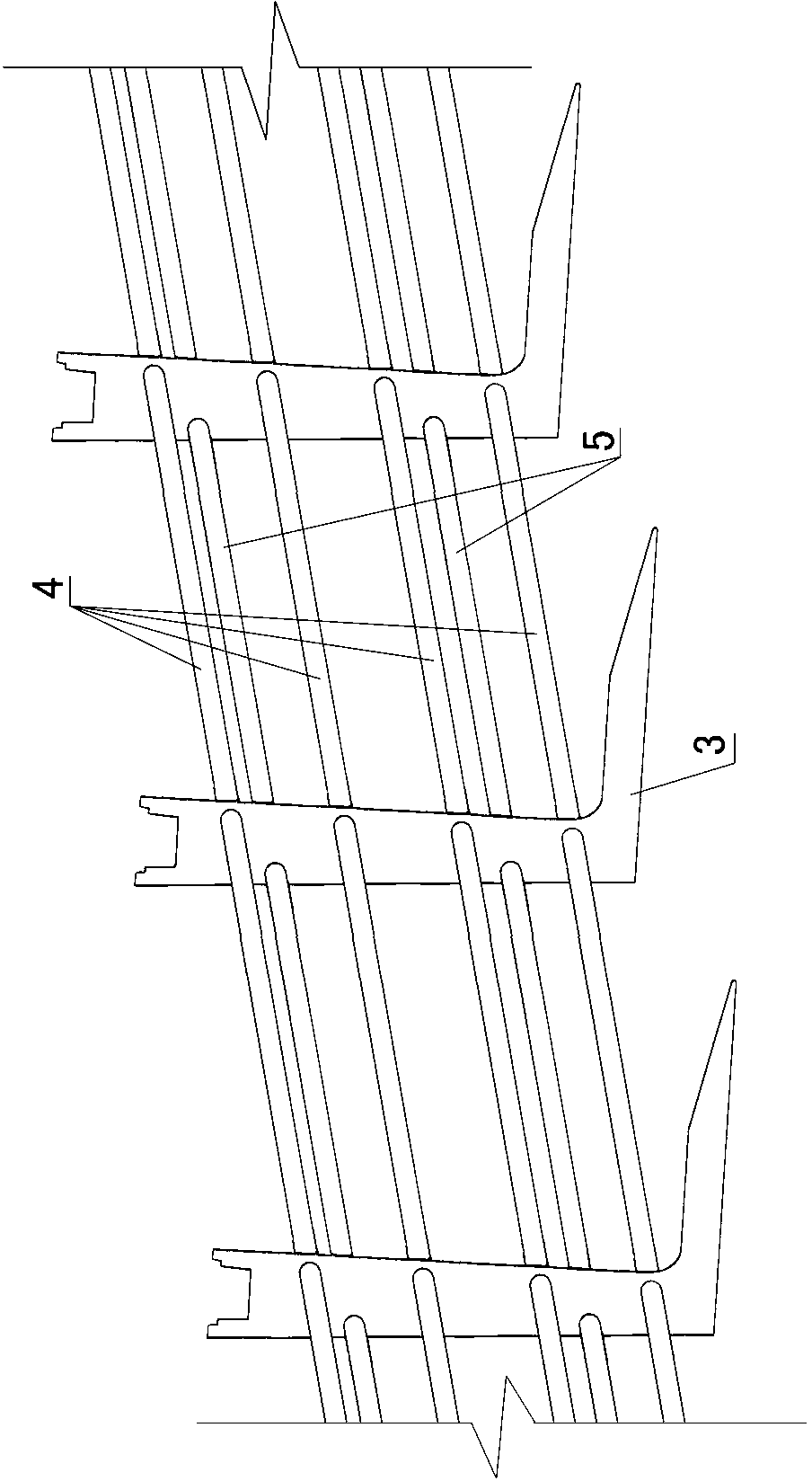

Internal pressure type swimming pond adopting assembled structure and multifunctional swimming pond tent

InactiveCN103306511AMeet various needs in stylingRich and colorful appearanceGymnasiumSwimming poolsInternal pressureEngineering

The invention provides an internal pressure type swimming pond adopting an assembled structure and a multifunctional swimming pond tent. The swimming pond wall of the swimming pond comprises a swimming pond wall frame body, a pond wall inner wall plate connected to the inner side of the swimming pond wall frame body and a pond wall outer decorating plate connected to the outer side of the swimming pond wall frame body, wherein the swimming pond wall frame body comprises supports arranged at intervals and connecting pipes connected among the supports; the connecting pipes comprise a row of inner connecting pipes and a row of outer connecting pipes; the inner connecting pipes are arranged on the inner sides of the supports from the top down; the outer connecting pipes are arranged on the outer sides of the supports from the top down; the side surface on the side, adjacent to the swimming pond wall frame body, of the pond wall inner wall plate leans against the inner connecting pipes; the side surface on the side, adjacent to the swimming pond wall frame body, of the pond wall outer decorating plate leans against the outer connecting pipes; the pond wall inner wall plate and the pond wall outer decorating plate are connected with the supports through upper pressure plates. According to the swimming pond, the pond wall outer decorating plate can be hung while no steel-structure sway brace is arranged, so that the swimming pond has rich and colorful appearance styles, is very beautiful and is especially appropriate in a square shape.

Owner:侯宝权

Apple juice and its preparation method

The present invention relates to a pure apple juice, in which the soluble solids are 11.5 deg.BX-12 deg.BX, total acid content is 0.40-0.45%, fruit flesh content is (-3%, and in each 100g of apple juice the ascorbic acid content is 50-100 mg. Said invention also discloses its preparation method, it is a pure natural fruit juice containing no chemical adjuvant and preservative, and said preparation process does not adopt enzymolysis and pectin tannin precipilation process, and can retain all the nutrient components of the original apple.

Owner:连云港市东海果汁有限公司

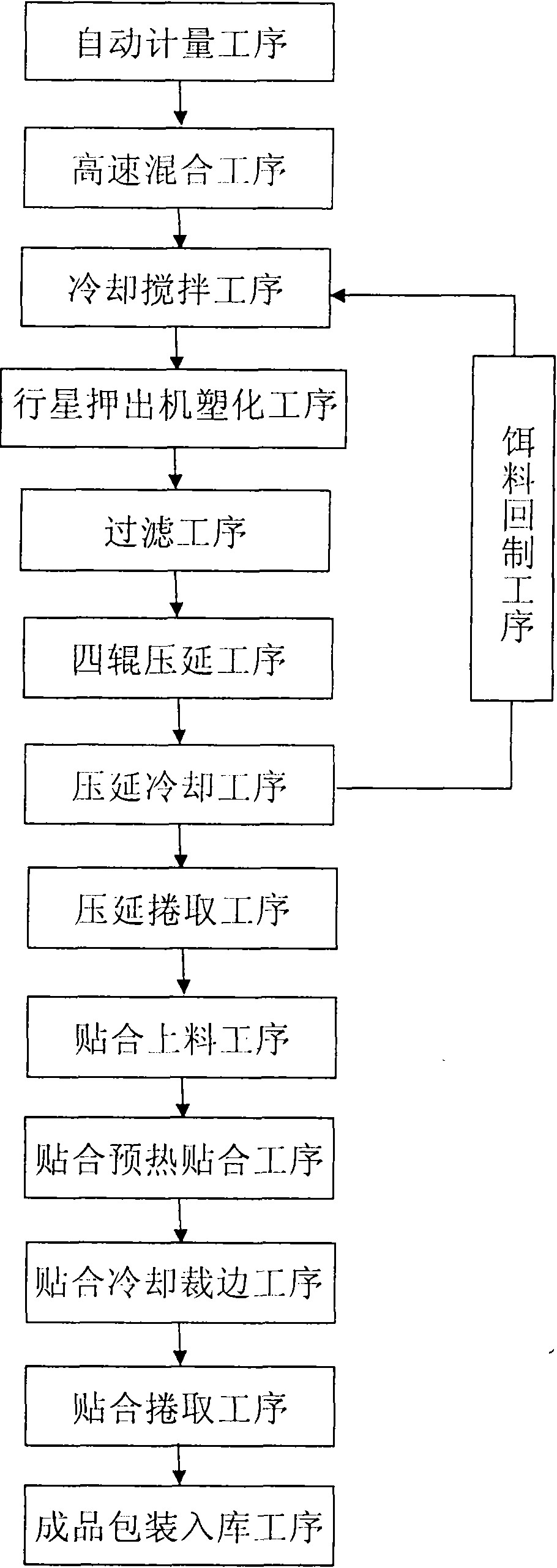

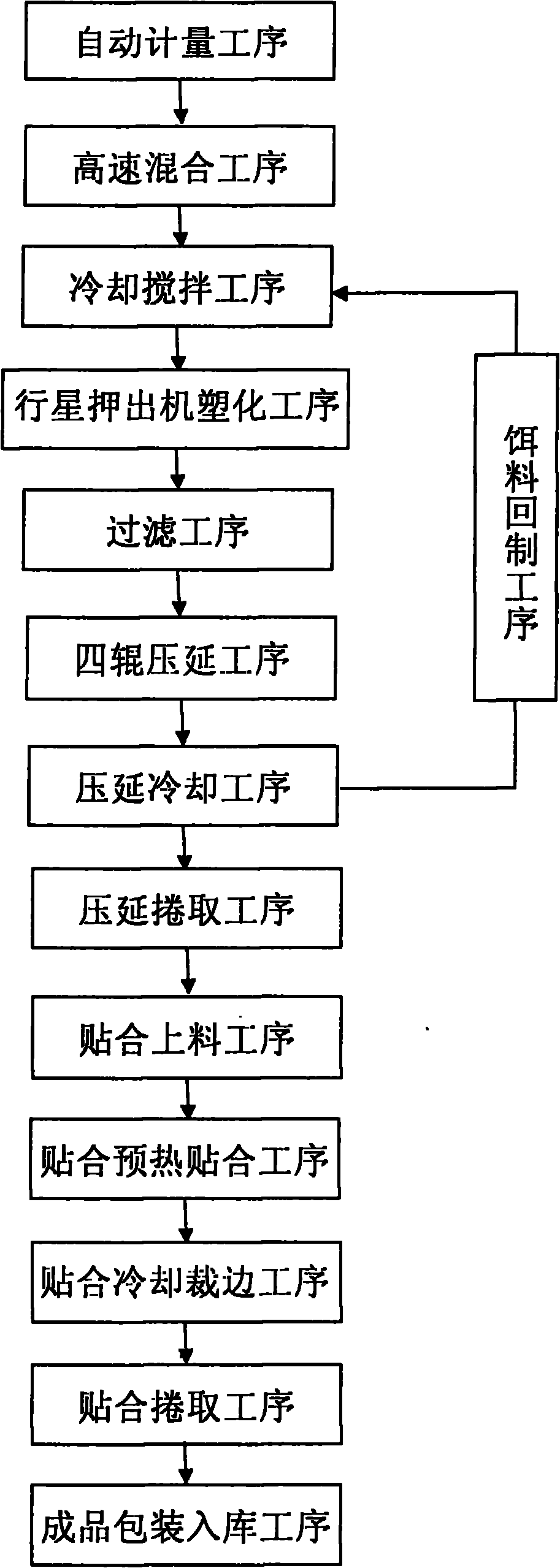

Environment-friendly low-toxicity white-light gluing crystal board and manufacture method thereof

The invention discloses an environment-friendly low-toxicity white-light gluing crystal board and a manufacture method thereof. The formula of the crystal board comprises the following components: 100 polrvinyl chloride, 40-60 diisononyl ortho-phthalate, 1.8-2.5 liquid Ba-Zn stabilizer, 0.3-0.6 acrylicacid processing aid, 0.05-0.08 pigment and 0.3-0.6 PHR nontoxic phosphate. The process comprises the following working procedures of automatically metering; mixing at a high speed; stirring by cooling; plasticizing by using a planet extruder; filtering; four-roll calendaring; calendaring and cooling; bait reusing; calendaring and winding; gluing and feeding; gluing, preheating and gluing; gluing, cooling and cutting edge; gluing and winding; and packing and put finished products in storage. The invention accords with the REACH regulatory requirements and has short process flow, less material plasticizing and processing time and high production efficiency. The environment-friendly low-toxicity white-light gluing crystal board has superior elasticity to glass, high surface transparency and brightness, good surface planeness and small water wave; in addition, a single gluing film is approximate to be colorless, has high transparency and has the characteristics of glass.

Owner:TIANJIN HONGMAO PLASTICS

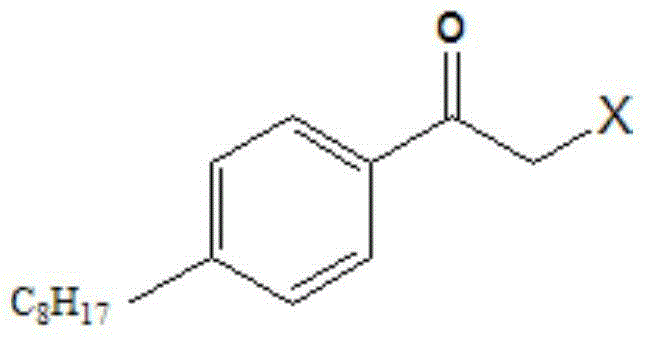

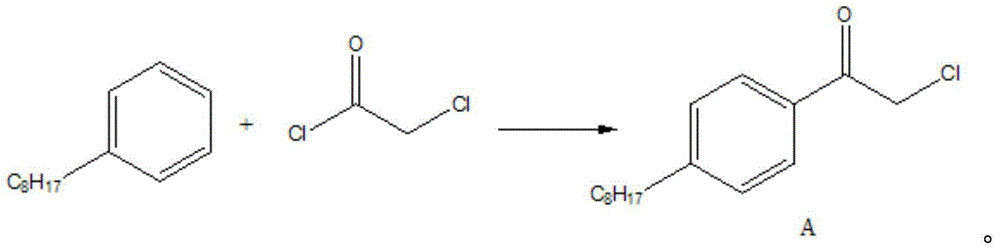

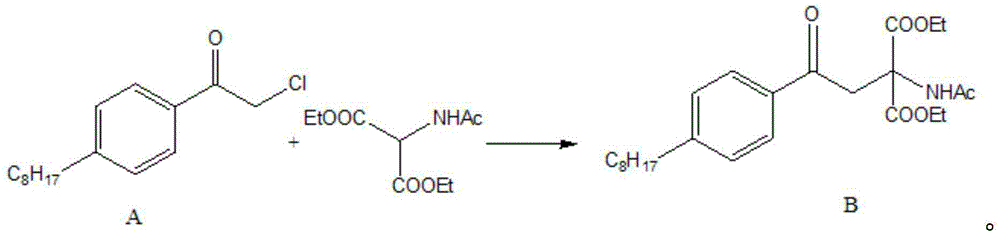

Preparation method and preparation intermediate of fingolimod hydrochloride

InactiveCN104529734AAdvanced preparation technologyHigh yieldOrganic compound preparationAmino-hyroxy compound preparationKetoneBenzene

The invention relates to the field of drug synthesis, and specifically relates to a preparation method and a preparation intermediate of fingolimod hydrochloride. The method provides a completely novel synthesis route. According to the method, n-octyl benzene and chloroacetyl chloride are adopted as initial raw materials; and fingolimod hydrochloride is prepared through the steps of Friedel-Crafts acylation, coupling, ketone carbonyl reduction, ester group reduction, amide hydrolysis, hydrochloride formation, and the like. The preparation method is completely novel; preparation process is advanced; yield is high; the method is stable; and cost can be effectively reduced.

Owner:湖北金赛药业有限公司

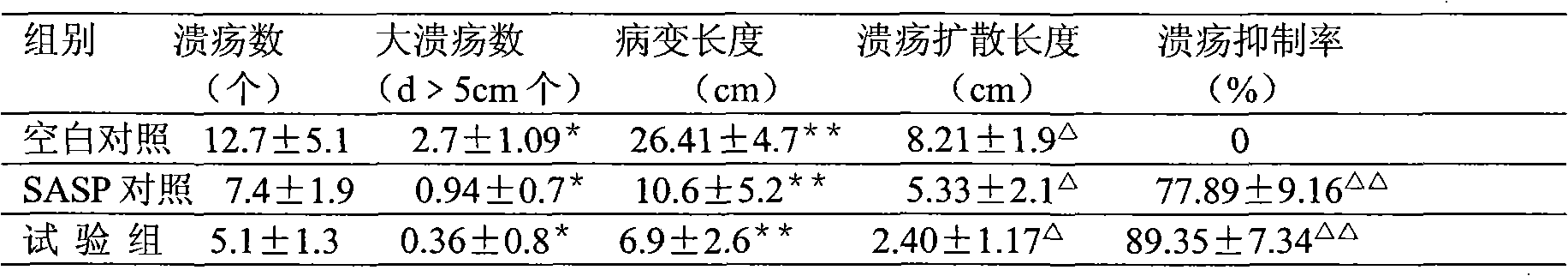

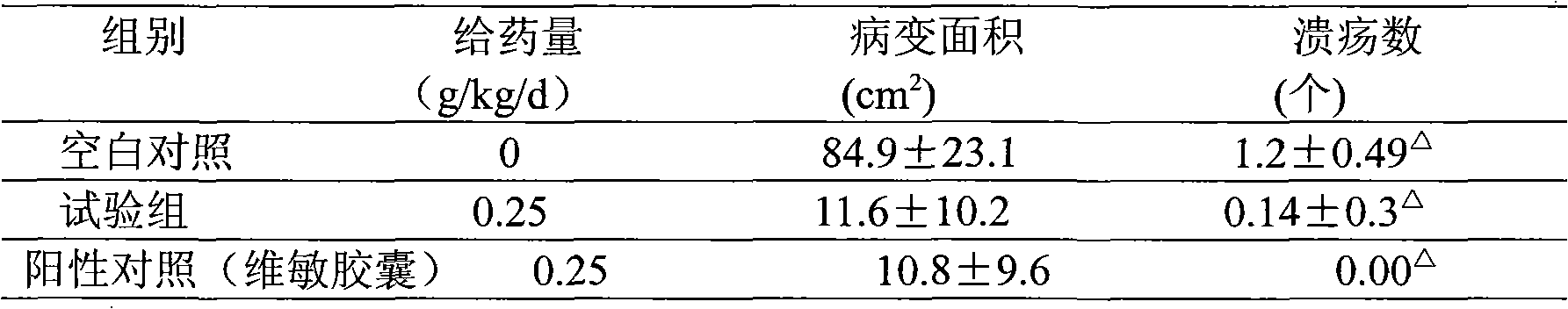

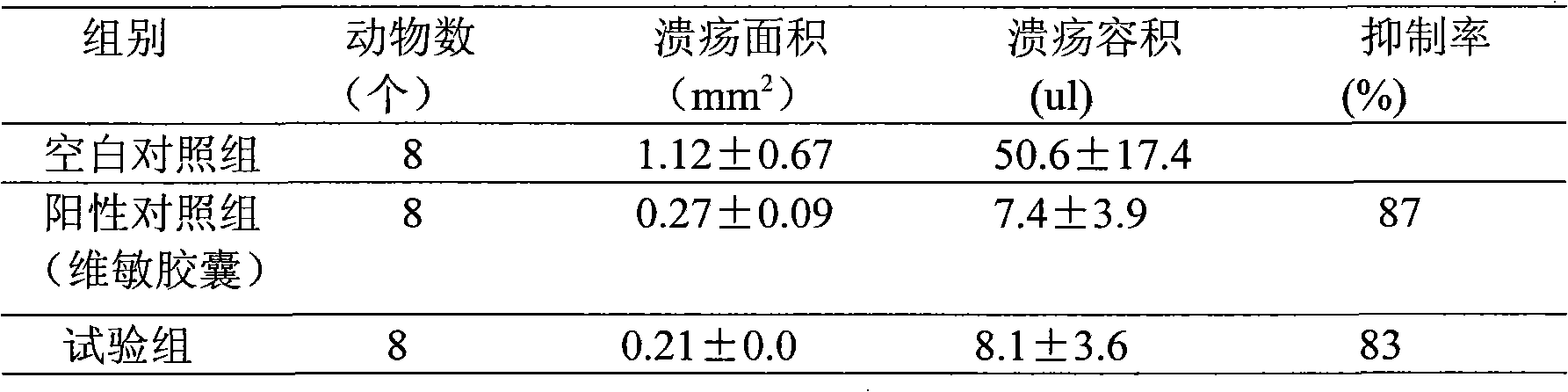

Colloidal bismuth tartrate medicine and preparation method and use thereof

ActiveCN101491507AChemically stableSmall particle sizeHeavy metal active ingredientsDigestive systemTherapeutic effectGastroenterology department

The invention relates to a colloid tartro-bismuthate and a drug preparation, a preparation method and application of the colloid tartro-bismuthate. The colloid tartro-bismuthate consists of tartaric acid, trivalent metal bismuth ion oxide or salt and low methoxyl-D-polygalacturonase; and the colloid tartro-bismuthate is subjected to centrifugal spraying and drying by dissolution, mixing, precipitation and other methods to form microcrystalline fine powdery colloid tartro-bismuthate. The drug has obvious treatment effect on chronic nonspecific ulcerative colitis, irritable bowel syndrome and chronic colonic inflammation, has good treatment effect on chronic atrophic gastritis and other stomach diseases, has small toxicity and side effect and belongs to a safe, nontoxic and effective drug of a gastroenterology department.

Owner:山西双雁生物科技有限公司

Non-shrinkage high-sound-isolation self-heat-insulation heat-isolation sand light wall module and manufacturing method thereof

ActiveCN105272018AScalableWon't crackSolid waste managementCeramic shaping apparatusIsolation effectFire resistance

The invention provides a non-shrinkage high-sound-isolation self-heat-insulation heat-isolation sand light wall module and a manufacturing method thereof and belongs to the field of wall materials. The module and the manufacturing method solve the technical problems that sand with the sand content larger than 3% can not be used as an existing wall material, cracking occurs, the sound-isolation effect is poor, and a light wall material can not serve as a self-bearing wall. A non-bearing wall module is manufactured through super-light aggregate, cement, sand, bulk cement shrinkage-preventing agents, interface activity enhancers, solution viscosity hollow particle polymer and water. A self-bearing wall module further comprises coarse aggregate. The non-bearing wall module is manufactured in the steps that materials are stirred, poured into a half-piece type mould, pressurized and formed through variable-frequency vibration and buffering, and maintained; adhesive faces are cut flattened and bonded together, and the periphery of the module is cut and flattened. The self-bearing wall module is manufactured in the steps that materials are stirred, poured in a whole-piece mould, pressurized and formed through variable-frequency vibration and buffering, and maintained. The wall module integrates non-shrinkage, self-heat-insulation, heat-isolation, high-sound-isolation and fire resistance, sand with the sand content being 3-25% is used, the manufacturing method is simple, and construction is convenient.

Owner:福建华东坚信科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com