Patents

Literature

211results about How to "Chemically active" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

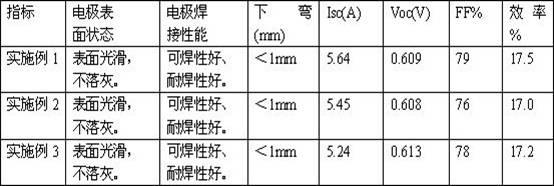

A kind of conductive paste for front electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102280161AImprove conductivityFirmly attachedNon-conductive material with dispersed conductive materialCable/conductor manufactureIndiumCerium

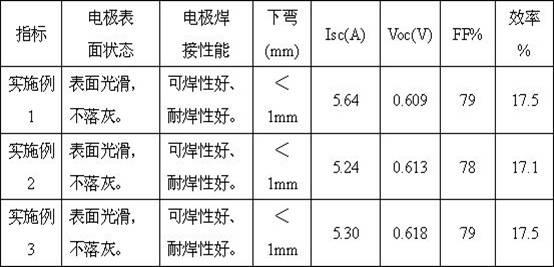

The invention discloses a conductive paste for a positive electrode of a crystal silicon solar cell and a preparation method of the conductive paste. The paste is prepared by mixing and grinding conductive metal powder, alloy powder which is formed by two or more elements selected from silver, zinc, tin, silicon, copper, magnesium, germanium, gold, beryllium, aluminum, indium, cerium, lanthanum, gallium, bismuth, and nickel, an organic carrier, and one or a mixture of transition metal oxide, lead oxide, stannic oxide, zinc oxide, organic compounds of zinc, and organic compounds of titanium according to a certain weight part. In the conductive paste, glass powder is not used as an inorganic binder, the problems of low electrical properties, low weldability and welding resistance, silicon chip bending and the like caused by adding the glass powder into the conductive paste for the positive electrode of thecrystal silicon solar cell in the prior art are solved, the positive electrode of the crystal silicon solar cell prepared from the paste has firm adhesive force, high ohmic contact, high weldability and high welding resistance, and the solar cell has a high electrical property and low deformability.

Owner:陈晓东

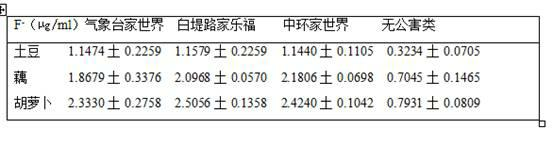

Double-shell epoxy resin microcapsule self-repair material and preparation method thereof

ActiveCN108892407AExcellent Mechanics and AcousticsChemically activeMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

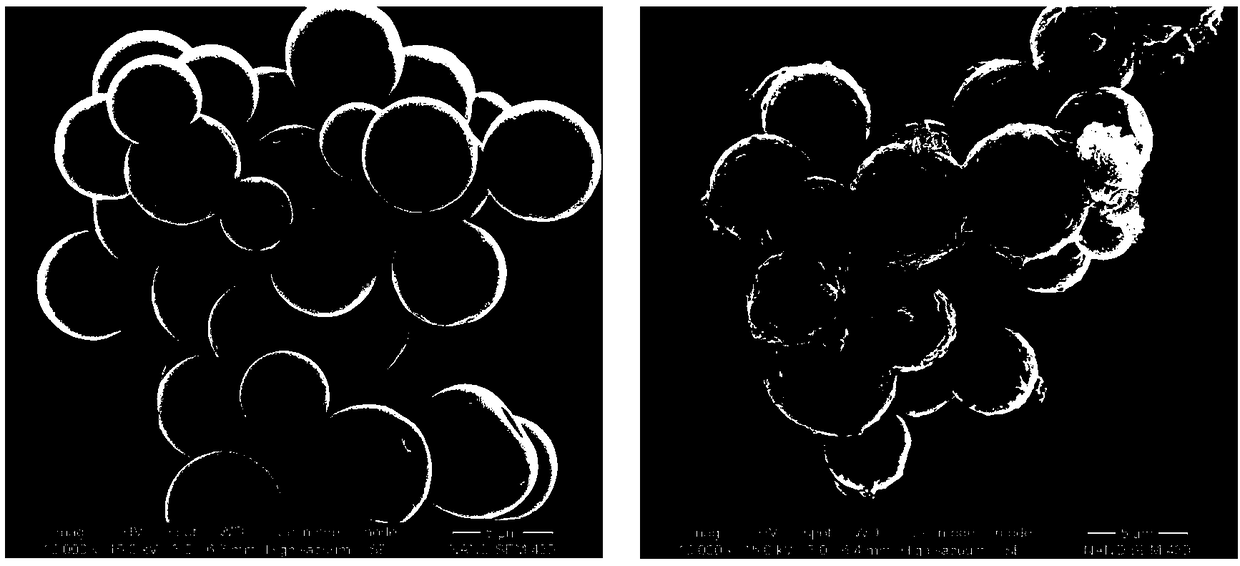

The invention belongs to the technical field of microcapsule self-repair materials and particularly relates to a double-shell epoxy resin microcapsule self-repair material and a preparation method thereof. Epoxy resin serves as a repairing agent core material of the microcapsule self-repair material. Firstly, a single-shell microcapsule self-repair material with melamine-urea-formaldehyde resin asan inner wall material is prepared according to an in-situ polymerization method; then, a sol-gel method is adopted for preparing the double-layer microcapsule self-repair material with an inorganicSiO2 polymer as an outer wall material. Compared with a traditional emulsifying agent, graphene oxide serving as an epoxy resin emulsifying agent has advantages of nontoxicity and environmental friendliness. The inorganic SiO2 polymer with excellent biocompatibility and resistance to acids and alkalis serves as the outer wall material to improve compatibility of the microcapsule self-repair material to cement concrete materials, and the microcapsule self-repair material is enabled to give a full play to the self-repair performance in the cement concrete materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

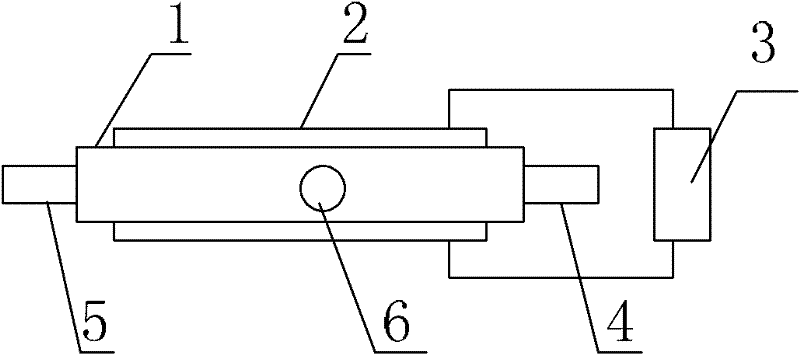

Atomic vapor generation method and device based on dielectric barrier discharge

ActiveCN102519938AReduce distractionsLow detection limitAnalysis by electrical excitationMaterial analysis by electric/magnetic meansHydrogenSignal-to-noise ratio (imaging)

The invention discloses an atomic vapor generation method and device based on dielectric barrier discharge. The method comprises subjecting a mixture of inert gas and hydrogen gas to dielectric barrier discharge under the action of alternating electric field to generate plasma; and allowing a to-be-measured element in a to-be-measured sample to form atomic vapor under the action of the plasma. The inventive device adopts dielectric barrier discharge in which a large number of free radicals and quasi-molecules, such as H, having a very active chemical property are generated, and the free radicals and the quasi-molecules easily react with to-be-measured atoms or other free radicals to generate hydride vapor, so as to effectively separate from the matrix and enter a to-be-measured region; matrix interference brought in by a sample pre-treatment process is reduced to therefore improve the signal to noise ratio of the analyzer and reduce the instrument detection limit, and the device is simple and easy to operate; and dielectric barrier discharge can be realized under the atmospheric pressure, so as to realize small volume, low energy consumption and low gas temperature.

Owner:TSINGHUA UNIV

A kind of conductive paste for back electrode of silicon solar cell and preparation method thereof

InactiveCN102280160AImprove conductivityFirmly attachedNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveSlurry

The invention discloses a conductive paste for the back electrode of a crystalline silicon solar cell and a preparation method thereof. The paste is prepared by mixing and grinding conductive metal powder, a metal adhesive, an organic carrier, and a functional additive in a certain weight ratio. to make. The present invention uses no glass powder as the inorganic binder, which overcomes the poor electrical performance, poor solderability and solderability, and poor solderability and solder resistance of the conductive paste used for the back electrode of silicon solar cells in the prior art due to the addition of glass powder. The back electrode of the crystalline silicon solar cell prepared with this slurry has firm adhesion, good ohmic contact, good solderability and solder resistance, and the solar cell has superior electrical performance and small deformation.

Owner:陈晓东

Preparation method of (TiV)C steel bond hard alloy

The invention provides a preparation method of (TiV)C steel bond hard alloy. Titanium and vanadium whose ratio is 1:1 are prepared, and a mixture and graphite powder are prepared into in-situ synthesized (TiV)C mixed powder, wherein the atomic mole ratio between C and Ti+V is 0.7-1.1; ferrovanadium powder, ferrochromium powder, ferromolybdenum powder, ferroboron powder, ferrous powder, ferrosilicon powder, ferromanganese powder, nickel powder, copper powder, colloidal graphite and a rare earth raw material are prepared according to a required mass ratio of bonded-phase metal chemical components, ball-milling is carried out by a steel ball, absolute ethanol as a medium and PVA (polyvinyl alcohol) are added, after the ball-milling is finished, slurry is dried and pressed for forming, and the steel bond alloy is obtained. In situ reaction synthesis technology and liquid phase sintering technology are combined, and the (TiV)C steel bond hard alloy is prepared. (TiV)C is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean. The comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of modified high-manganese steel base TiC steel bonded carbide

The invention relates to a preparation method of modified high-manganese steel base TiC steel bonded carbide. The preparation method is characterized by preparing in-situ synthesized TiC powder in a required proportion from titanium powder and graphite powder according to the atomic ratio of C to Ti, namely 0.8-1.0; preparing the raw materials including ferromolybdenum powder, ferrovanadium powder, ferrochrome powder, ferromanganese powder, ferrosilicon powder, ferrum powder, nickel powder, colloidal graphite and rare earth according to a required proportion of mass ratios of chemical components of bonding phase metals, filling steel balls, performing ball milling, adding absolute ethyl alcohol used as a medium and PVA (polyvinyl alcohol) to the steel balls, drying the slurry after ball milling, and then forming the slurry by pressing and sintering the product, thus obtaining steel bonded carbide. The preparation method has the advantages that the modified high-manganese steel base TiC steel bonded carbide is prepared by combining an in-situ reactive synthesis technology and a liquid phase sintering technology; as TiC is synthesized in situ inside a matrix through reaction in the sintering process, the reinforced particles have small sizes and do not have sharp corners on the surfaces, and the matrix is better in interface bonding and has a clean interface; the preparation method of steel bonded carbide is conductive to improving the comprehensive mechanical properties of carbide, is low in price and is simple and convenient in process.

Owner:JIANGSU HUICHENG MACHINERY MFG

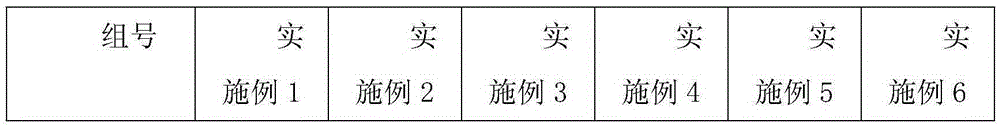

Low-carbon waterborne coating and preparation method thereof

InactiveCN105331268AStrong adhesionStrong aging resistanceFireproof paintsPolyurea/polyurethane coatingsDrying timeFire retardant

The invention discloses a low-carbon waterborne coating. The coating comprises components in parts by weight as follows: 40-80 parts of a basic material, 18-26 parts of a pigment, 10-18 parts of functional filler, 0.2-0.7 parts of a rheological agent, 0.1-0.5 parts of a wetting dispersant, 0.2-0.6 parts of a substrate wetting agent, 0.2-0.5 parts of an anti-settling agent, 0.2-0.6 parts of an antifoaming agent, 0.2-0.6 parts of a thickener, 0.1-0.5 parts of a leveling agent, 2-5 parts of a flame retardant, 15-20 parts of a curing agent and 50-100 parts of deionized water. The low-carbon waterborne coating has the advantages of short drying time, high adhesion, high elasticity, medium resistance, bending resistance, flame retardance, high-and-low-temperature resistance, no adverse effect on the basic material and the like, and is an environment-friendly low-carbon waterborne coating with excellent combination properties.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Production technique of persimmon mead

InactiveCN102086432AReasonable ratio of nutrientsGood color and fragranceMicroorganism based processesAlcoholic beverage preparationPectinaseFood flavor

The invention provides a production technique of persimmon mead, which comprises the following steps: using persimmon and honey as raw materials; adding Aspergillus niger to treat persimmon juice; eliminating precipitate and astringency by utilizing tannase and pectinase generated by the Aspergillus niger; adding the honey, and adding Saccharomyces cerevisiae; fermenting the honey persimmon juice; and finally, treating the liquor with cobalt 60-gamma rays to promote the liquor to become mature. Thus, the invention greatly shortens the maturing time of the persimmon mead, thereby producing the fruit mead with unique flavor and abundant nutrients in a short time.

Owner:ZHEJIANG UNIV

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

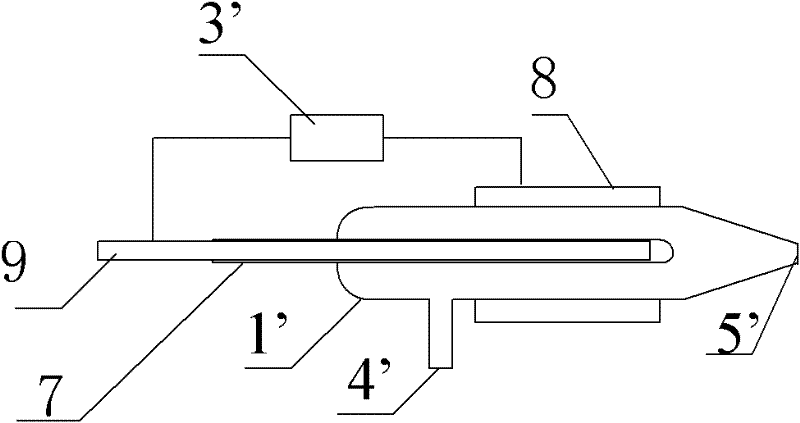

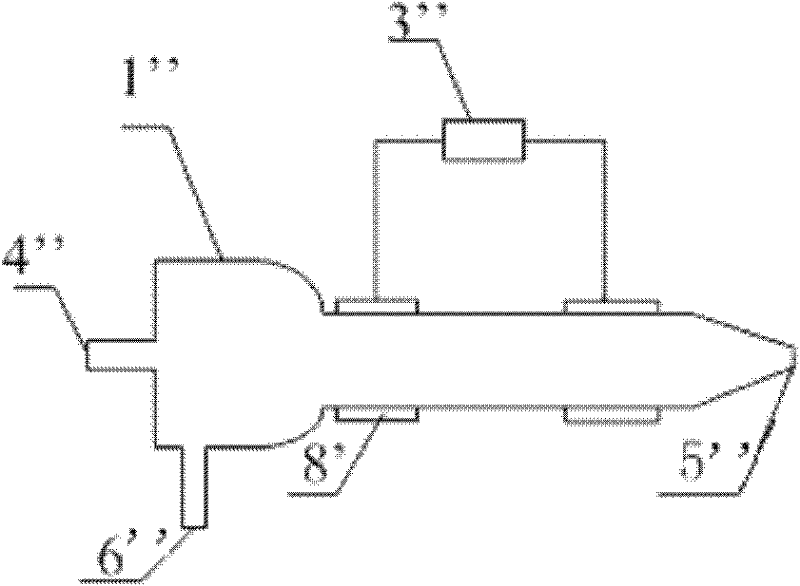

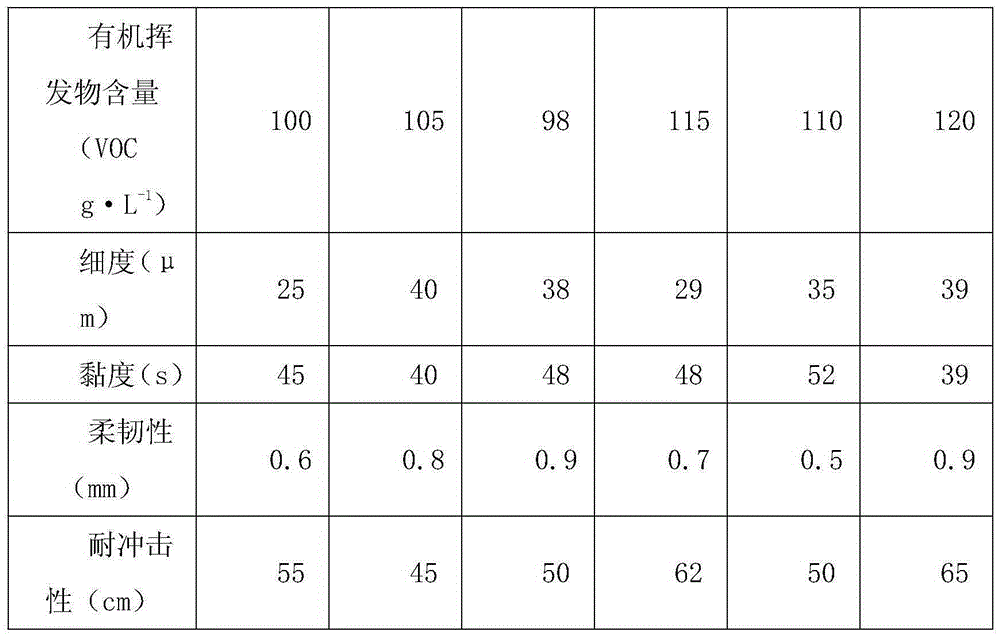

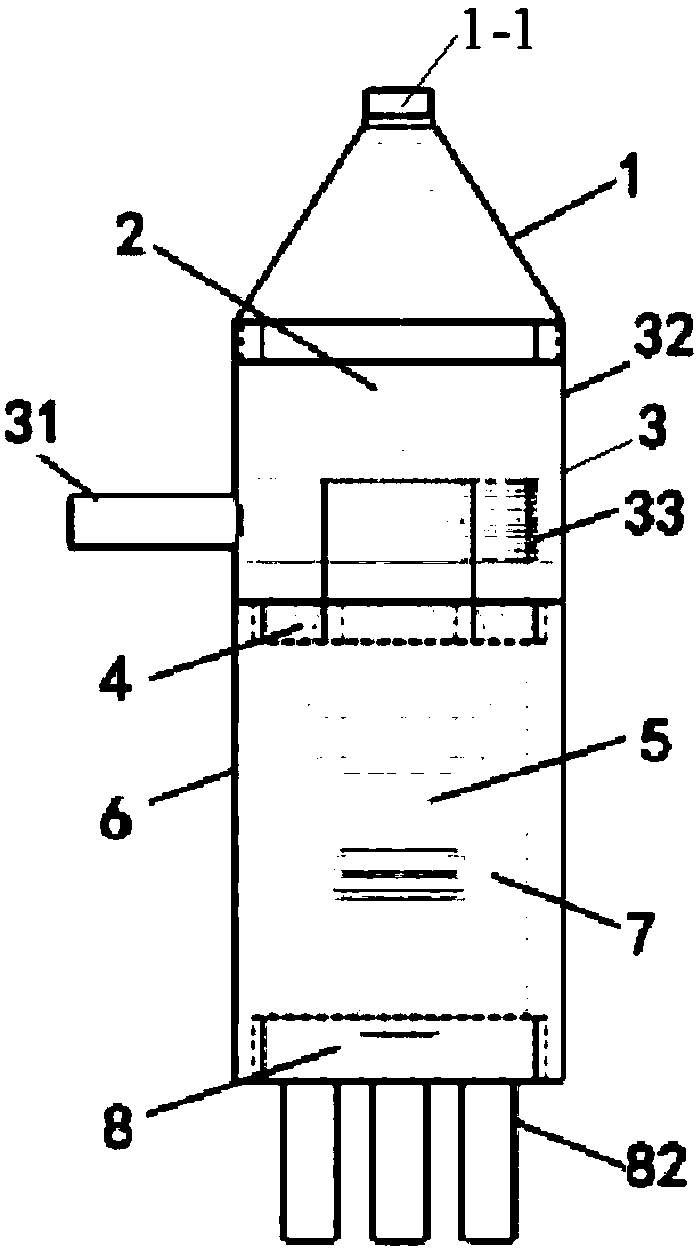

Pre-combustion type plasma igniter and ignition method

ActiveCN107842427AEasy to assembleIncrease production capacityTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

Preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy

The invention relates to a preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy. The preparation method is characterized by comprising the following steps: preparing titanium powder and graphite powder into in-situ synthesized TiC powder with the required proportion according to the C / Ti atomic ratio of 0.8-1.0; preparing ferromolybdenum powder, ferrovanadium powder, ferrochromium powder, ferromanganese powder, ferrosilicon powder, iron powder, nickel powder, colloidal graphite and rare earth raw materials according to the required mass ratio of bonded-phase metal chemical components, performing ball-milling by a steel ball, adding absolute ethanol as a medium and PVA (polyvinyl alcohol), after the ball-milling process is finished, drying slurry, pressing for forming, and sintering to obtain the steel bond alloy. According to the preparation method, the ultrahigh-manganese steel based TiC steel bond hard alloy is prepared by combining an in-situ reaction synthesis technology with a liquid-phase sintering technology; as TiC is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean; the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Seaweed tea and its preparation method

InactiveCN1823604AInhibition of abnormal fermentationPromote excretionMetabolism disorderTea substituesMedicineNutritional composition

Owner:陈惠玉 +1

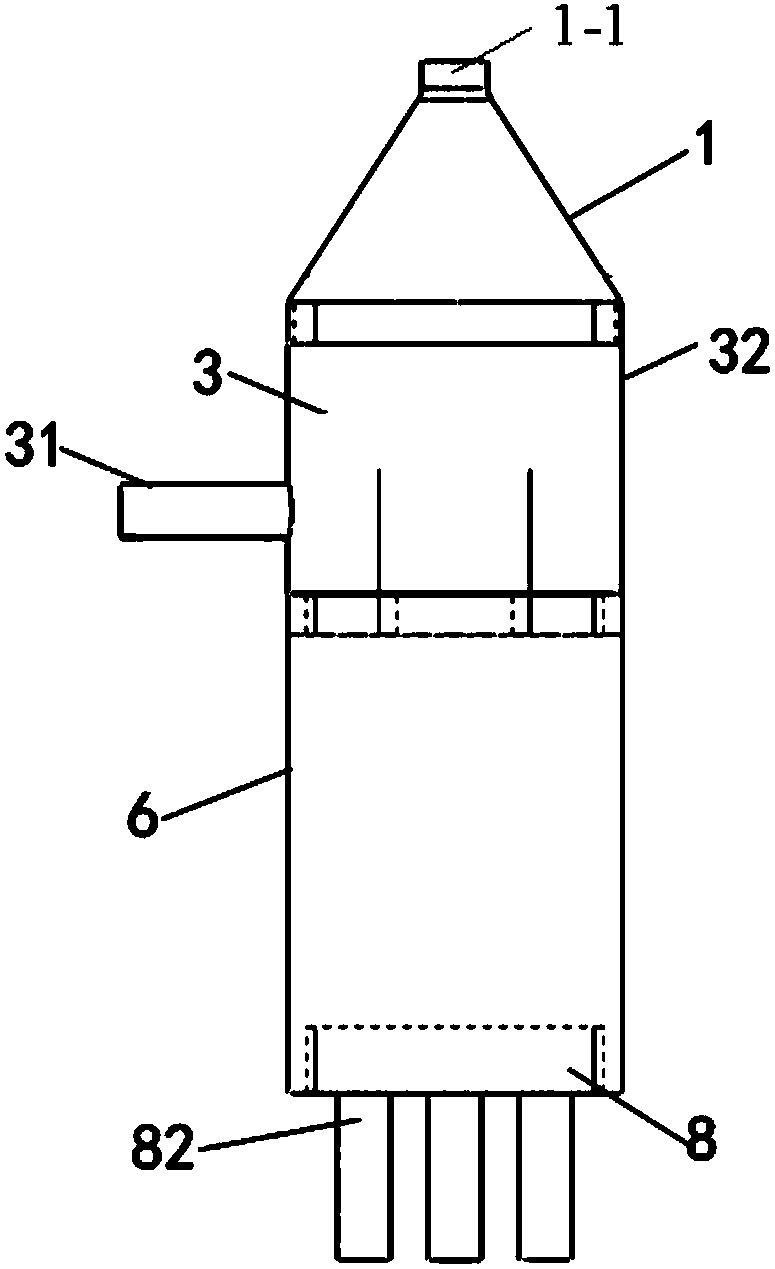

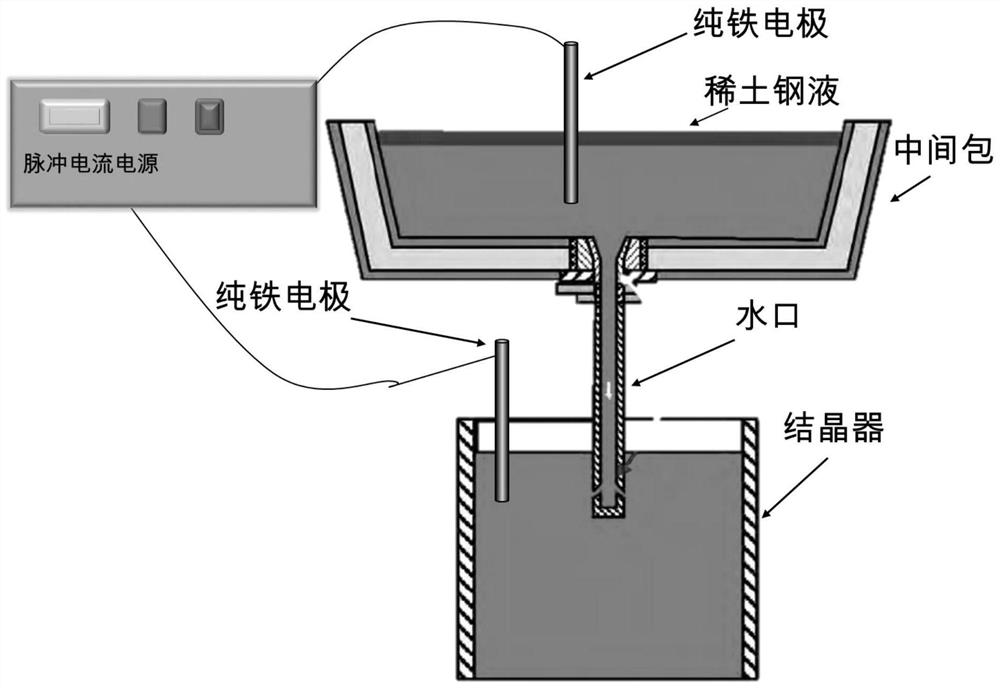

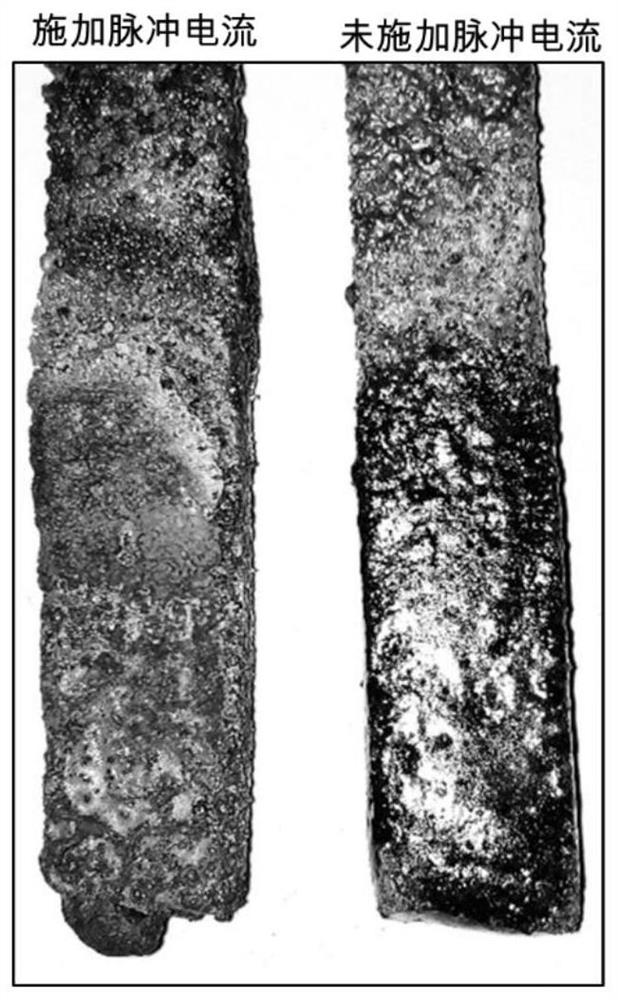

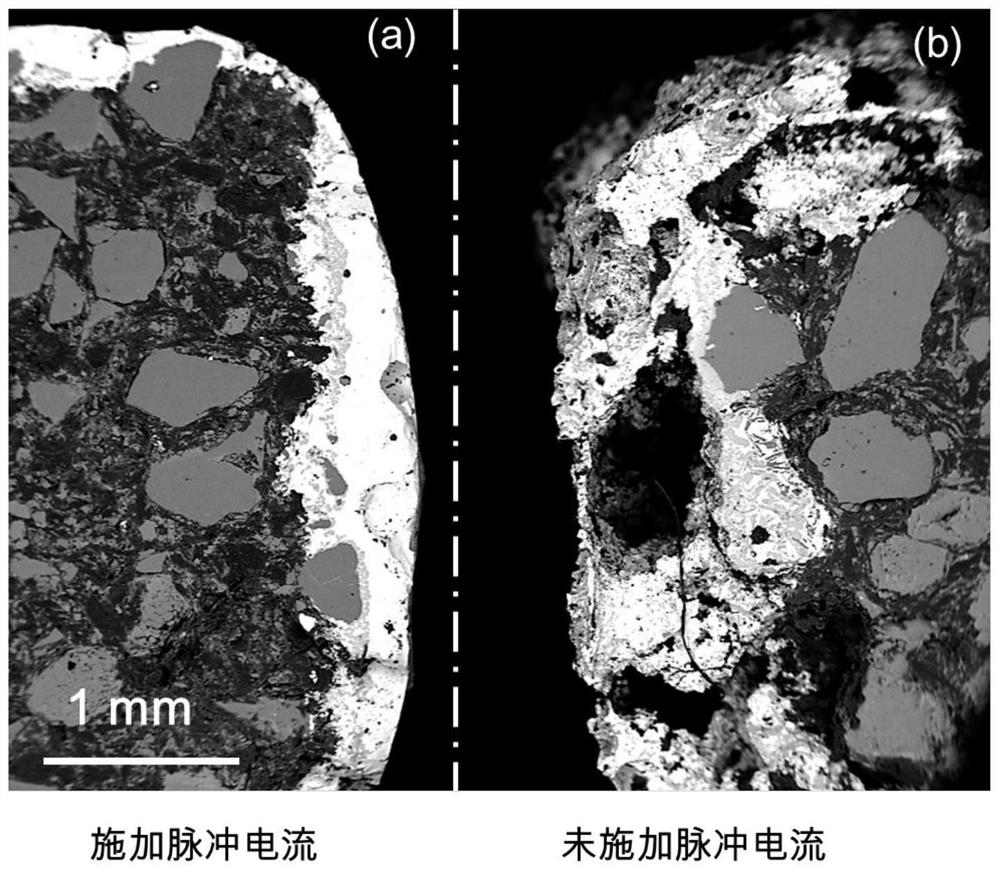

Method for inhibiting blockage of rare earth molten steel pouring nozzle through pulse currents

ActiveCN111906266AChemically activeAccelerated decarbonizationMelt-holding vesselsMischmetalEngineering

The method includes the steps that an electrode is inserted into rare earth molten steel, the pulse currents are applied to the electrode through a power supply device, the erosion reaction between the inner wall of the nozzle and an interface of the rare earth molten steel is intervened through the pulse currents, the rare earth molten steel corrosion resistance of the inner wall of the nozzle isimproved, and inclusions in the molten steel are further prevented from adhering to the inner wall of the nozzle. The method for inhibiting blockage of the rare earth molten steel pouring nozzle through the pulse currents is provided in order to solve the problems that rare earth metal elements in the molten steel erode the nozzle and rare earth inclusions adhere to the nozzle to cause nodulationand blockage of the nozzle in rare earth steel smelting and pouring, so that a rare earth steel smelting and continuous casting process is stabilized, and the quality of continuous casting billets isimproved. The invention discloses a method for inhibiting blockage of a rare earth molten steel pouring nozzle through pulse currents, and relates to the field of rare earth steel smelting and casting.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of TiC high-wear-resistant steel-bonded hard alloy

The invention relates to a preparation method of a TiC high-wear-resistant steel-bonded hard alloy. The preparation method is characterized by comprising the following steps: using titanium powder and graphite powder to prepare in-situ synthesized TiC powder according to the atomic ratio 0.7-1.1 of C to Ti; mixing ferrochromium powder, ferromolybdenum powder, ferrovanadium powder, ferrotungsten powder, ferroniobium powder, nickel powder, ferroboron powder, iron powder, colloidal graphite and a rare earth material according to the chemical component mass ratio of the bonding phase metals; filling the mixed powder in a steel ball mill; adding absolute ethyl alcohol as a medium and PVA (Polyvinyl Acetate) to the ball mill; after ball milling, drying the obtained slurry, pressing, molding and sintering the dried substance to obtain the steel-bonded hard alloy. The preparation method disclosed by the invention combines the in-situ reaction synthesis technology with the liquid-phase sintering technology to prepare the TiC high-wear-resistant steel bonded hard alloy. As TiC is prepared by in-situ synthesis inside the substrate through the reaction during the sintering process, the reinforced particle size is fine, the surface is free of sharp corners, the substrate interface bonding effect is good, and the interface is clean. The preparation method for the steel-bonded alloy can improve the comprehensive mechanical property of the alloy, and is low in price and simple and convenient in the technology.

Owner:JIANGSU HUICHENG MACHINERY MFG

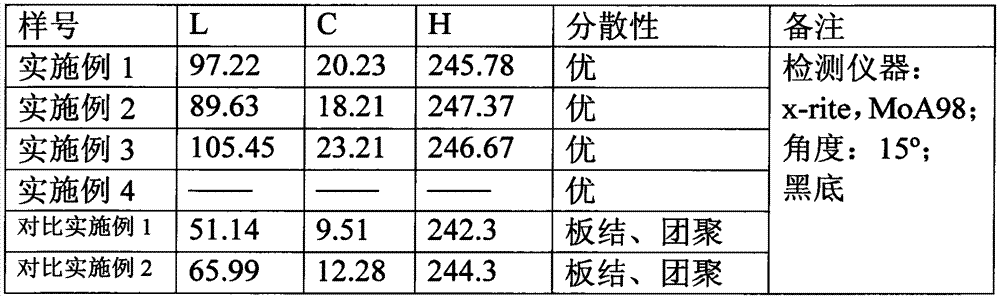

High temperature resistant pearlescent pigment and preparation method thereof

ActiveCN104327552AChemically activeSmall thermal expansionInorganic pigment treatmentColor ScaleHot Temperature

The invention relates to a high temperature resistant pearlescent pigment including a synthetic mica substrate, one layer or multi layers of metal oxide layer coating the synthetic mica substrate, and a zirconia high temperature resistant layer coating the metal oxide layer. The high temperature resistant pearlescent pigment using high temperature is up to 1150 DEG C, the high temperature resistant pearlescent pigment can be stably and well dispersed at high temperature, and can be widely used in underglaze color, in-glaze color, overglaze color, enamel, enamel paper transfers, architectural enamel plates, permanent color scales, high temperature resistant paints and other industries, and the usage amount is 0.5 ~ 50% of that of a glaze or a coating.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

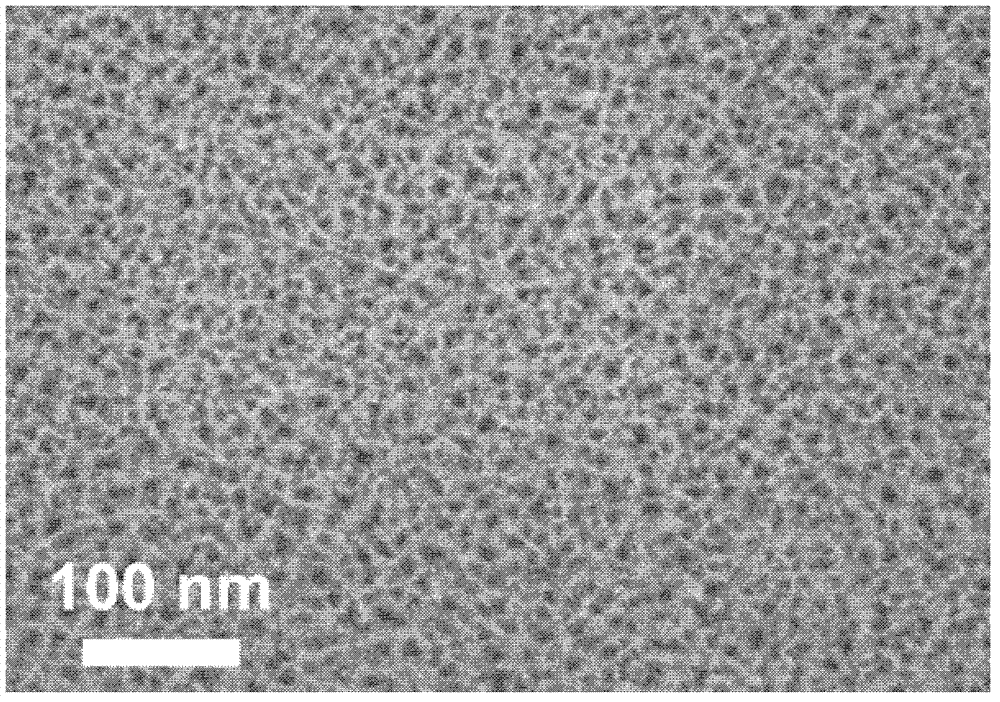

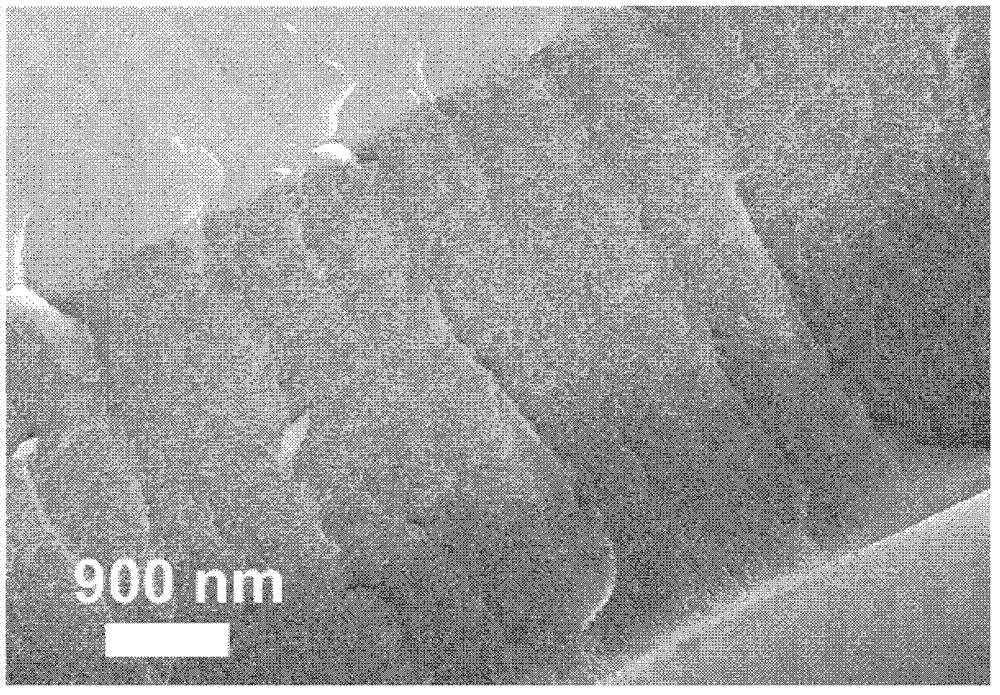

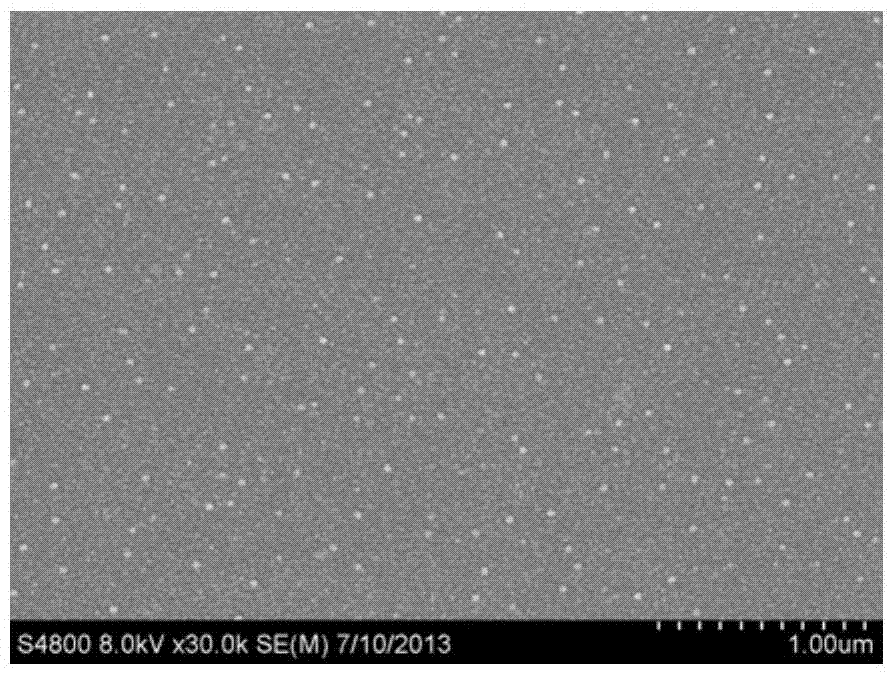

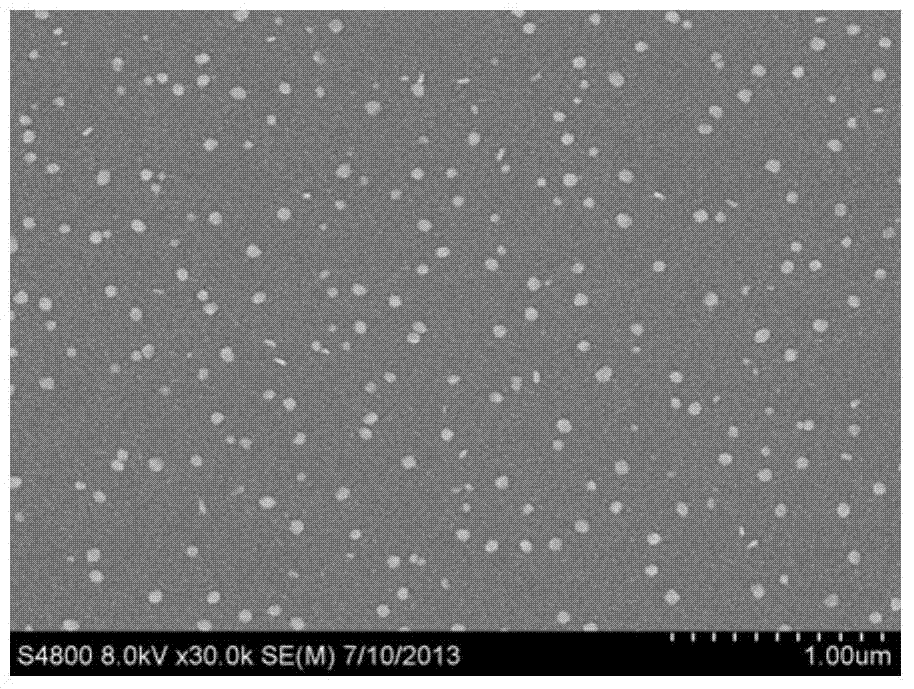

Surface-enhanced Raman substrate, preparation method and application thereof

The invention provides a preparation method of a surface-enhanced Raman substrate. The method comprises the following steps of: electrolyzing a silicon wafer in an electrolyte with hydrofluoric acid to prepare a porous silicon substrate; immersing the porous silicon substrate into a silver nitrate aqueous solution to react, then taking the porous silicon substrate out, and subsequently, drying the porous silicon substrate to prepare the surface-enhanced Raman substrate. The invention also provides an application of the surface-enhanced Raman substrate prepared by the method in trace detection of a surface-enhanced Raman spectrum, in particular an application in TNT (trinitrotoluene) detection.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

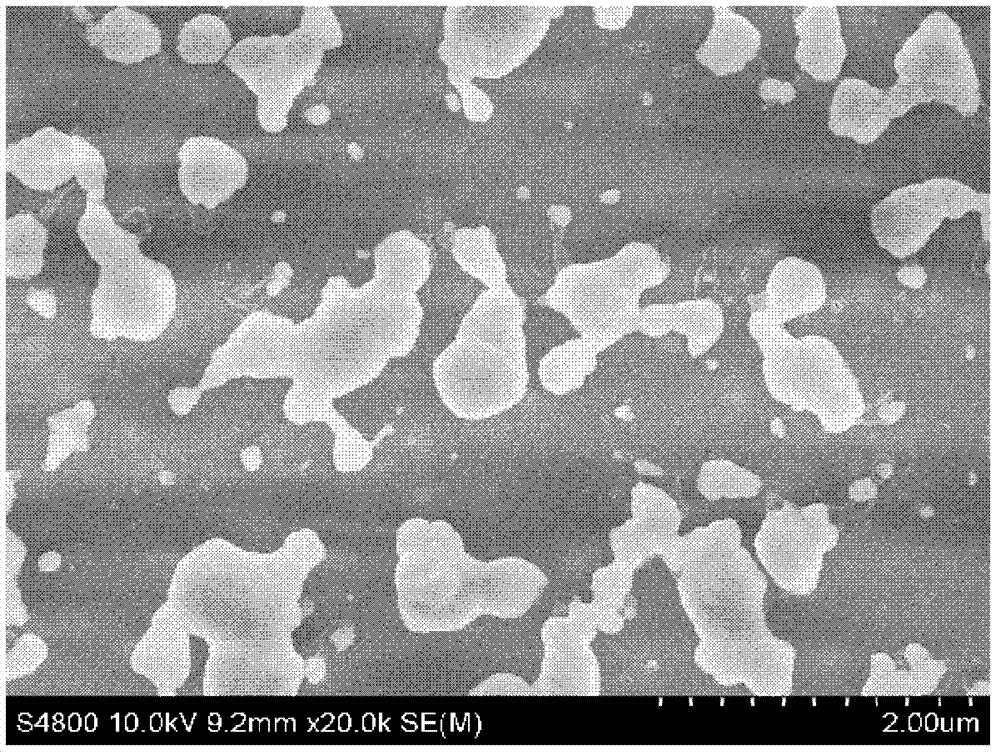

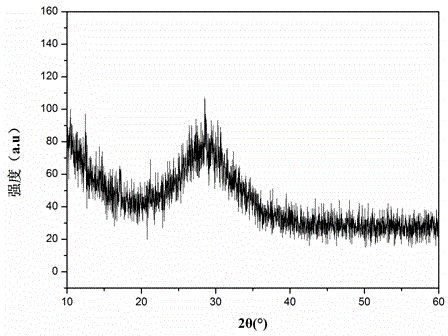

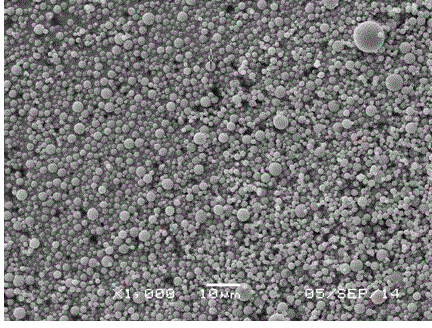

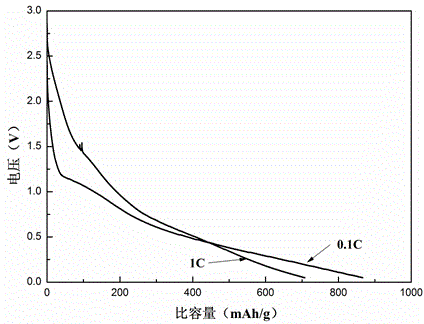

Preparation method of lithium ion battery anode material FeV2O4

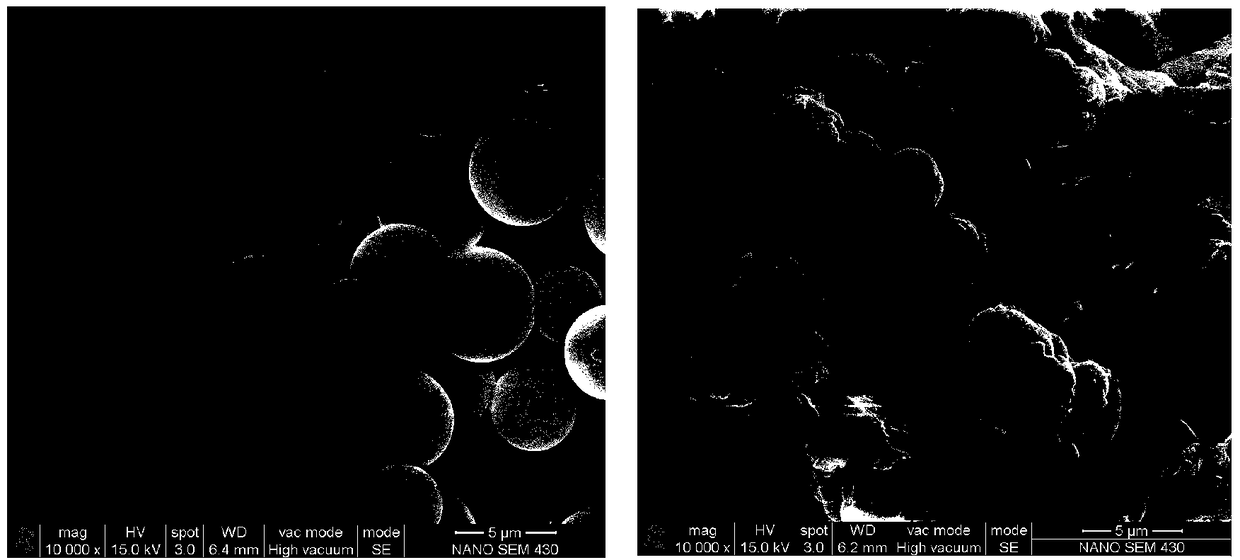

ActiveCN104485450AIncrease volumetric energy densityImprove physical processing performanceCell electrodesSecondary cellsPhysical chemistryAmmonium metavanadate

The invention discloses a preparation method of lithium ion battery anode material FeV2O4. The preparation method comprises the following steps: (1) adding ferrous oxalate solution and ammonium metavanadate solution in a stirring reaction kettle simultaneously under a protective atmosphere according to the ratio of 1: 2 of a ferrous ion concentration to a vanadium ion concentration, stirring, reacting, adjusting the pH value to 2-6, and further reacting for 1-4h to obtain a dark blue turbid liquid; (2) adding the turbid liquid obtained in the step (1) in ethyl alcohol with volume equivalent to 1-3% of the volume of the turbid liquid, and then carrying out spray-drying to obtain a precursor material; and (3) carrying out heat treatment on the precursor material obtained in the step (2) for 8-15h at 200-400 DEG C under the protective atmosphere, and then adding liquid nitrogen and quenching to obtain the lithium ion battery anode material FeV2O4. The method disclosed by the invention is low in heat treatment temperature; the prepared FeV2O4 anode material particles are of a microspherical structure, high in tap density, high in charge-discharge characteristics and long in cycle life.

Owner:CENT SOUTH UNIV

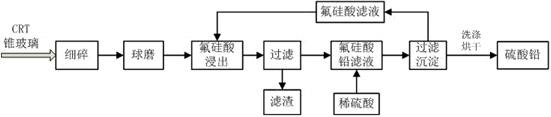

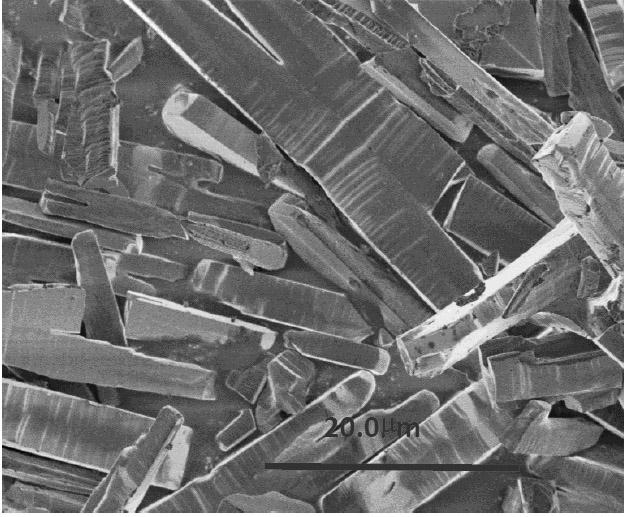

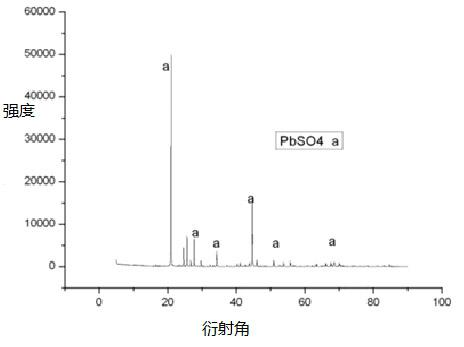

Method for extracting lead from waste CRT (Cathode Ray Tube) cone glass

InactiveCN102676826AEfficient extractionReduce pollutionProcess efficiency improvementLead smeltingEngineering

The invention relates to a method for extracting lead from waste CRT (Cathode Ray Tube) cone glass, comprising the specific steps of: (A) mechanically and roughly crushing the waste CRT cone glass and then finely crushing the waste CRT cone glass into 100-200 meshes; then mechanically milling for 4-12 hours to obtain a reaction raw material; (B) taking fluosilicic acid as an extracting agent at the temperature of 90-100 DEG C and continuously strengthening and leaching for 4-12 hours; and cooling and filtering to obtain a lead fluorosilicate solution; (C) slowly adding a pre-prepared dilute sulfuric acid solution into the lead fluorosilicate solution to form lead sulfate sediment; adjusting pH (Potential of Hydrogen) to complete precipitate; and (D) cooling and filtering; repeatedly washing a filter cake with de-ionized water for 3-5 times; and drying a white lead sulfate filter cake at 80 DEG C for 2-8 hours in vacuum to obtain a lead sulfate product with a higher purity, wherein the collected filtering solution is a regenerated fluosilicic acid solution and can be recycled and reused. The process does not generate secondary pollution; a waste liquid closed loop is realized in the whole process; and compared with a pyrogenic process lead smelting technology, the method has the advantages of low cost, simple technology and high production addition value.

Owner:TONGJI UNIV

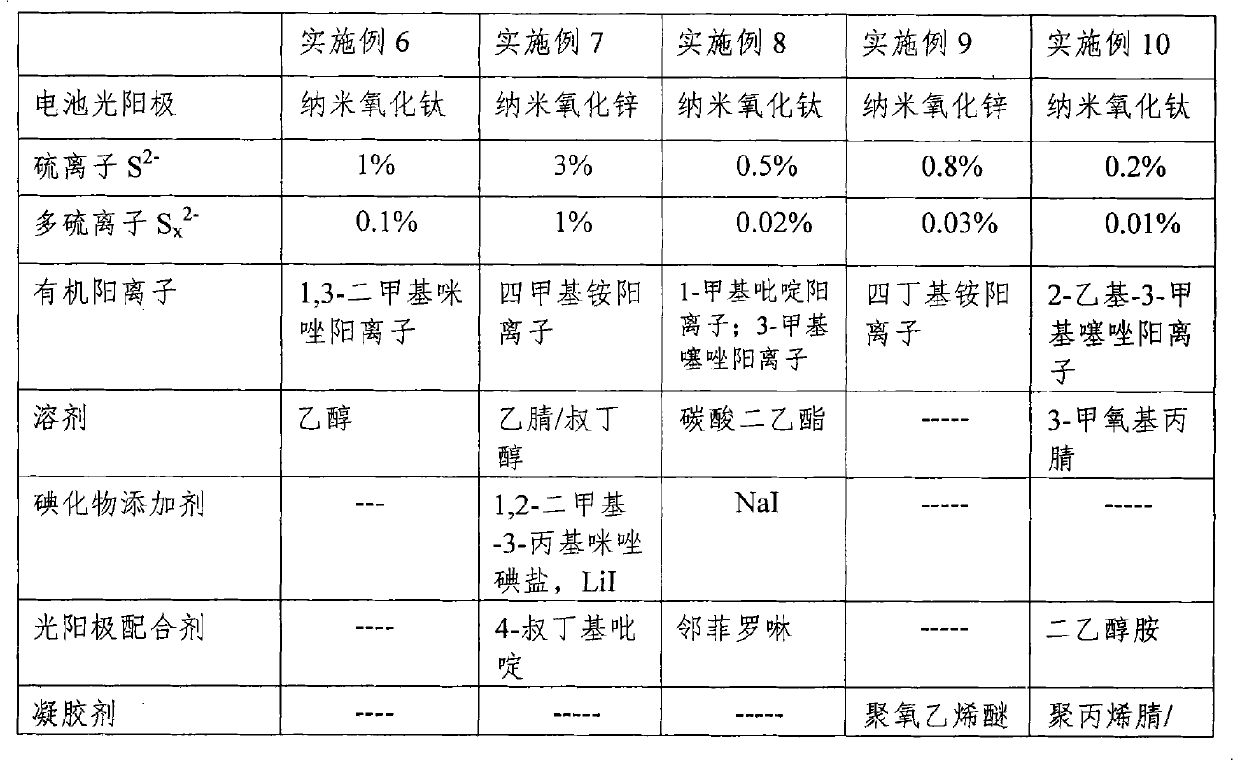

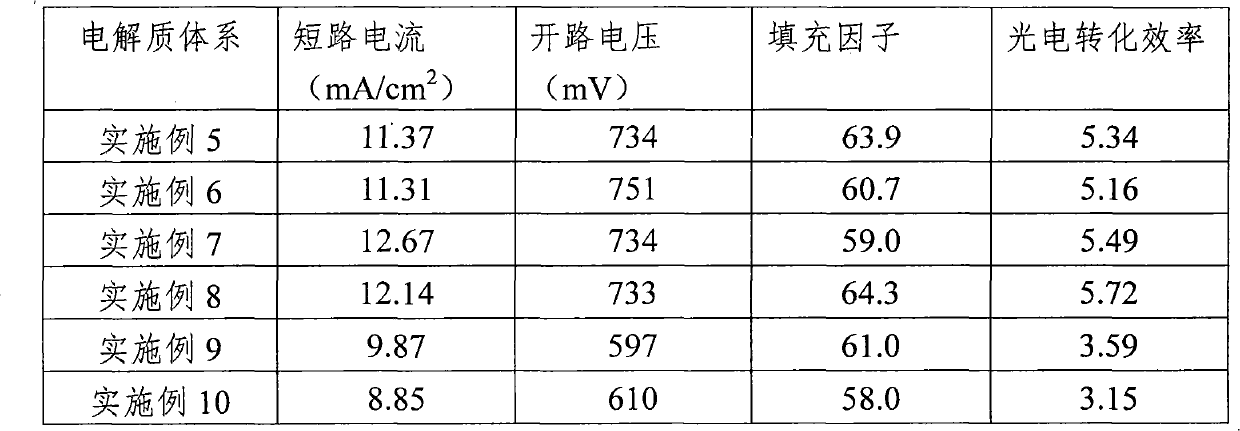

Solar battery electrolyte and application thereof

InactiveCN102024569ASimple manufacturing processReduce manufacturing costLight-sensitive devicesFinal product manufactureElectricityQuantum dot

The invention provides a solar battery electrolyte and an application thereof, belonging to the technical field of solar batteries. The electrolyte can be liquid, jellylike or quasi-flow colloid. The invention is characterized in that the electrolyte at least comprises S<2-> / Sx<2-> redox couples, and organic cation solvent matched with S<2-> / Sx<2-> or a mixture of solvent and gelatinizer, wherein x is an integer between 2 and 6. The invention also relates to an application of the electrolyte in dye-sensitized solar batteries and quantum point batteries. By utilizing the S<2-> / Sx<2-> redox couple electrolyte into the dye-sensitized solar batteries and quantum point solar batteries, most of flow concentration materials can be directly used and can not be corroded by the electrolyte, thus the preparation process of batteries can be greatly simplified, the production cost can be lowered, and the performance of the prepared battery is approximate to that of the battery in the prior art.

Owner:DALIAN HEPTACHROMA SOLAR TECH CO LTD

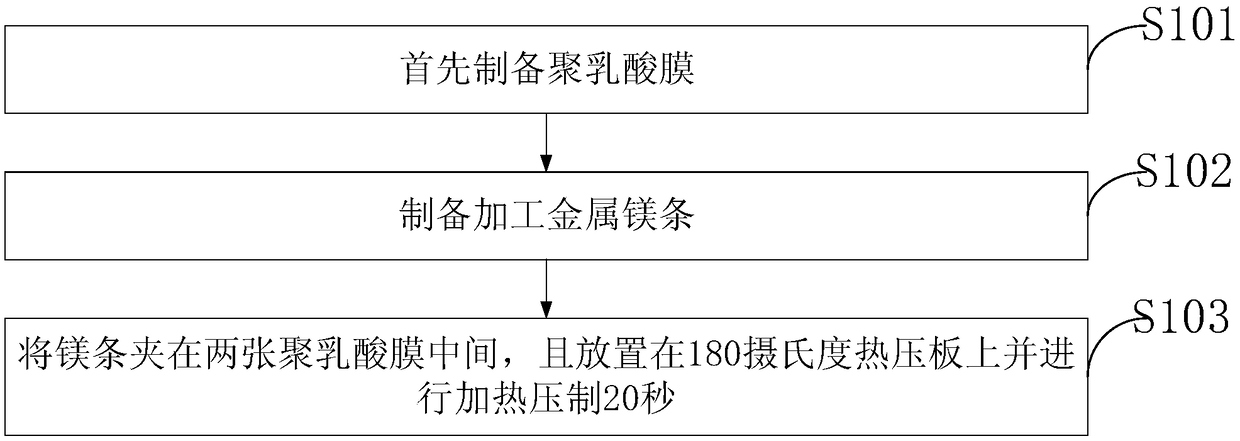

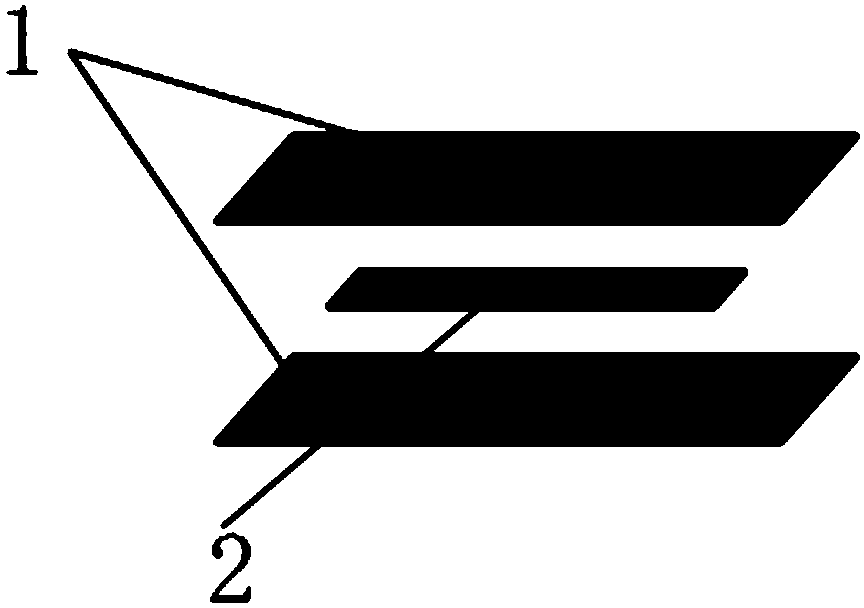

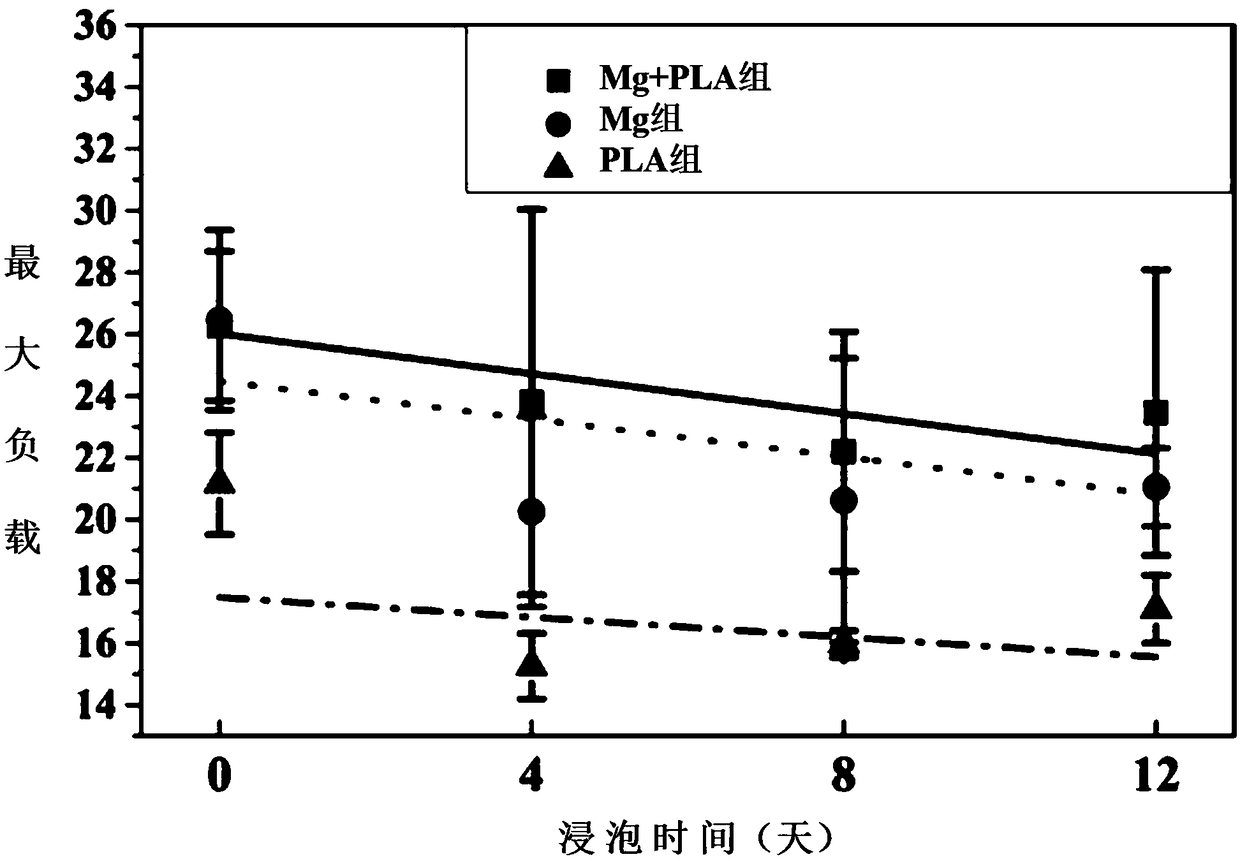

Biodegradable compound type guided bone regeneration barrier membrane and preparation method thereof

InactiveCN108379656AEasy mechanical strengthEasy to operateTissue regenerationProsthesisPressboardBiocompatibility Testing

The invention belongs to the technical field of medical materials, and discloses a biodegradable compound type guided bone regeneration barrier membrane and a preparation method thereof. The biodegradable compound type guided bone regeneration barrier membrane comprises a biomedical magnesium rod and polylactic acid membranes pressed on the upper and lower faces of the magnesium rod. The method comprises the steps that the magnesium rod is clamped between two polylactic acid membranes, placed on a 180-DEG C hot pressboard, and conducted with hot pressing for 20 seconds. The biodegradable compound type guided bone regeneration barrier membrane and the preparation method thereof have the advantages that the novel bio-barrier membrane with good biocompatibility, capacity of selectively guiding the regeneration of tissues, certain mechanical strength, biodegradability, degradation rate coordinating with a process of bone tissue regeneration and other characteristics, the preparation technology is simple, and the cost is low.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

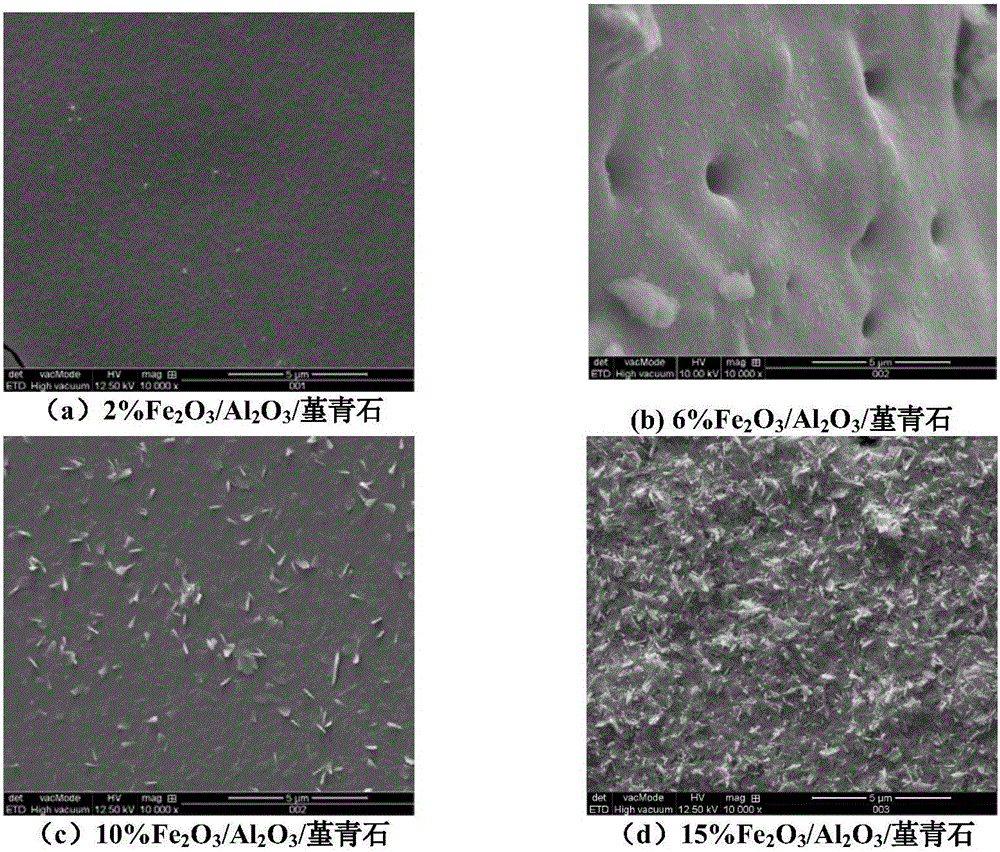

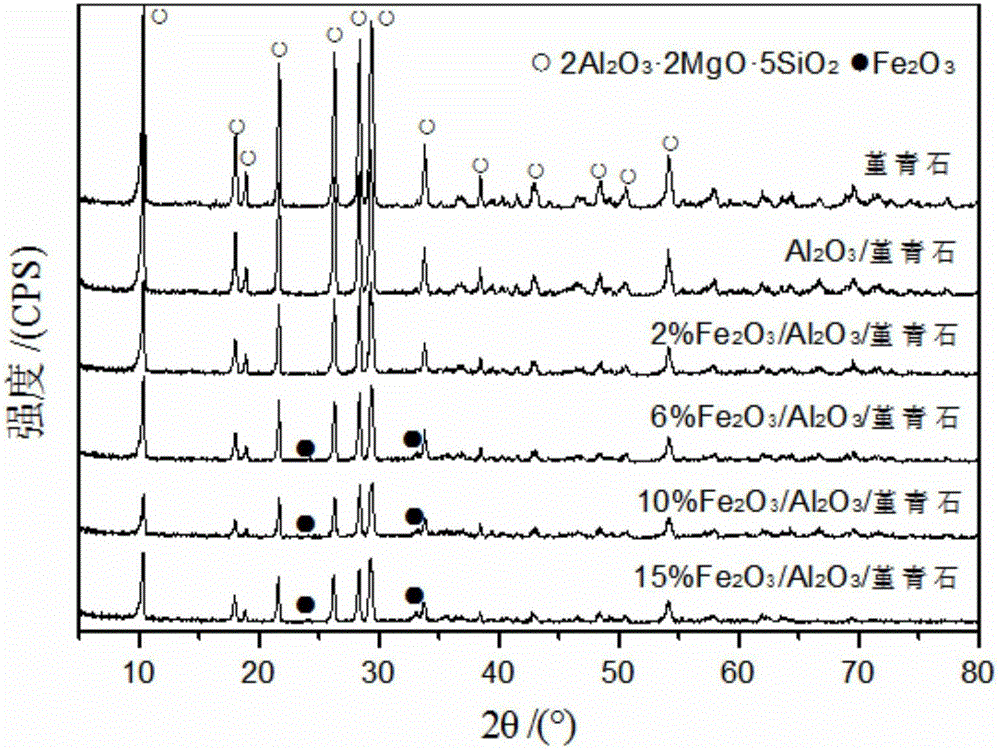

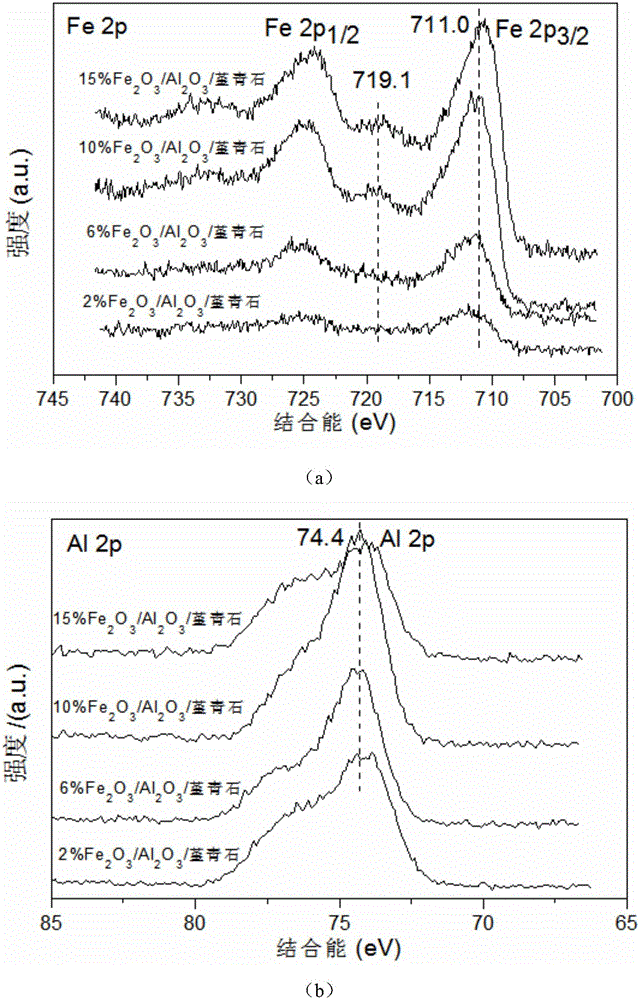

Fe2O3/Al2O3/cordierite catalyst and preparation method thereof

InactiveCN105148914AEfficient denitrification efficiencyChemically activeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasThin layer

The invention relates to a Fe2O3 / Al2O3 / cordierite catalyst and a preparation method thereof. According to the invention, the catalyst comprises cordierite used as a carrier, an Al2O3 sol layer coated on the surface of the cordierite, and an iron oxide layer dispersed on the surface of the Al2O3 sol layer; the preparation method comprises the following steps: pretreatment of the carrier, preparation of aluminum sol, coating of the aluminum sol and impregnation of Fe(NO3)3; and NOX in industrial flue gas is removed with the Fe2O3 / Al2O3 / cordierite monolithic catalyst as the catalyst and with hydrocarbon as a reducing agent. The invention has the following beneficial effects: the aluminum sol is well coated on the surface of the cordierite, so a thin layer of amorphous aluminium oxide is formed; nanometer-grade iron oxide is uniformly dispersed on the aluminium oxide coating, so an SCR active center is formed; and the hydrocarbon is used as the reducing agent, so highly-efficient denitration efficiency is obtained.

Owner:DONGHUA UNIV

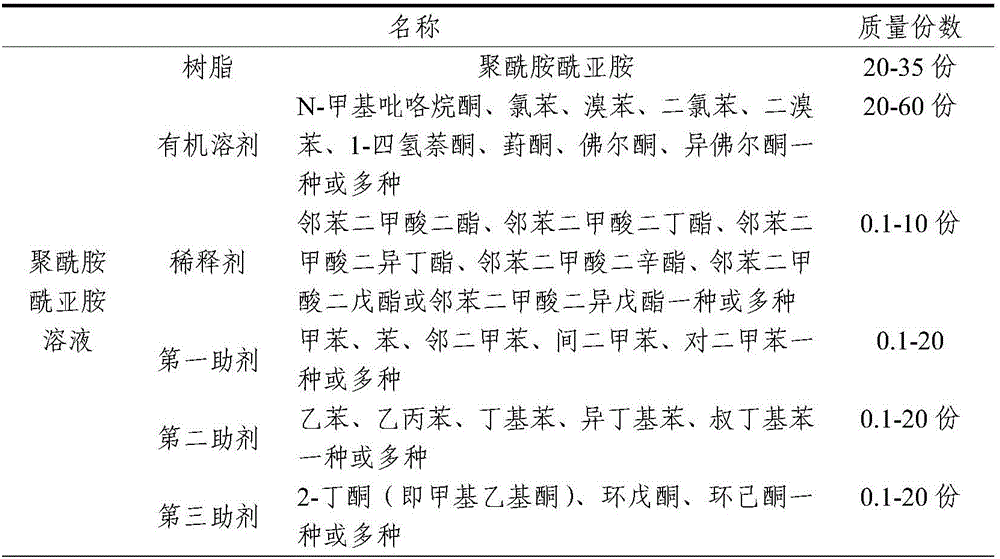

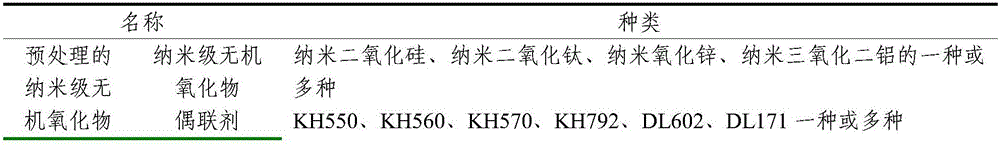

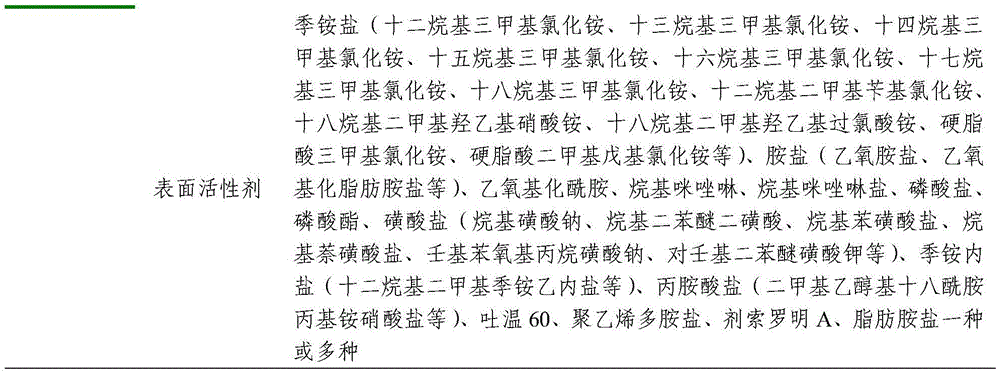

Nanometer polyamide imide film containing inorganic oxide and preparation method of nanometer polyamide imide film

The invention discloses a nanometer polyamide imide film containing inorganic oxide. The nanometer polyamide imide film containing the inorganic oxide is prepared from the following components in parts by weight: 100 to 120 parts of polyamide imide solution and 0.5 to 10 parts of pretreated nanometer inorganic oxide material. The thickness of the nanometer polyamide imide film containing the inorganic oxide is 10 to 100nm; the polyamide imide solution is prepared from the following components in parts by weight: 20 to 35 parts of polyamide imide resin and 20 to 60 parts of organic solvent. The pretreated nanometer inorganic oxide material is obtained by pretreating nano inorganic oxide, a coupling agent and a surfactant according to the weight ratio of 10:(2 to 6):(0.2 to 0.5). The nanometer polyamide imide film disclosed by the invention has the advantages of excellent mechanical property, stable chemical properties, high temperature resistance, high self-lubricating property and long service life, and can be widely applied in the enamelled wire industry.

Owner:GUANGDONG JINGDA REA SPECIAL ENAMELED WIRE CO LTD +1

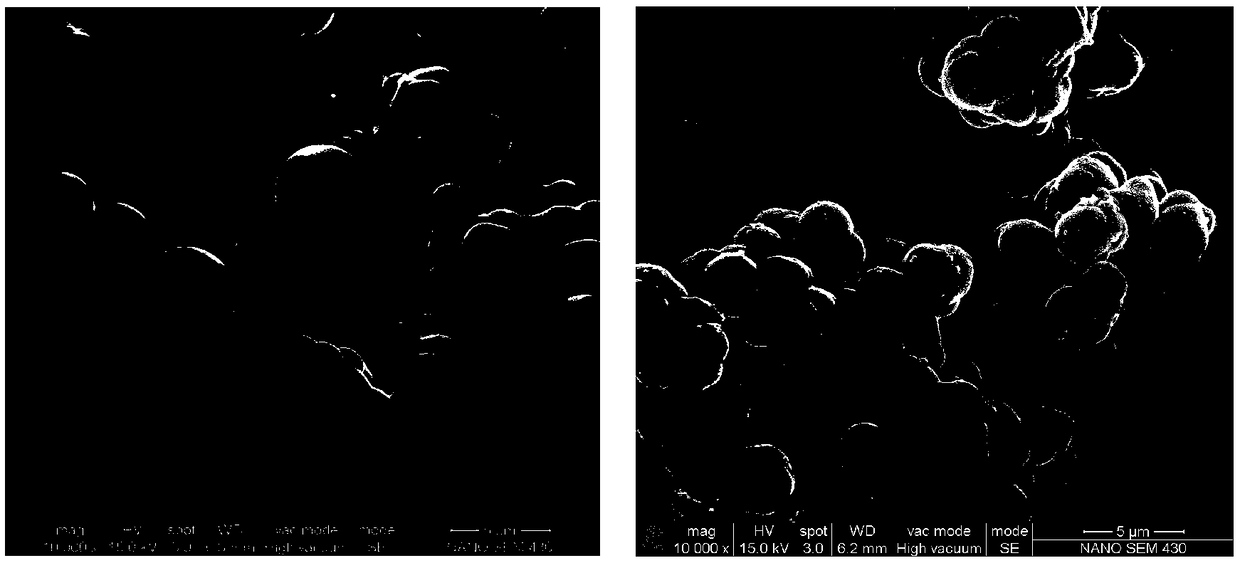

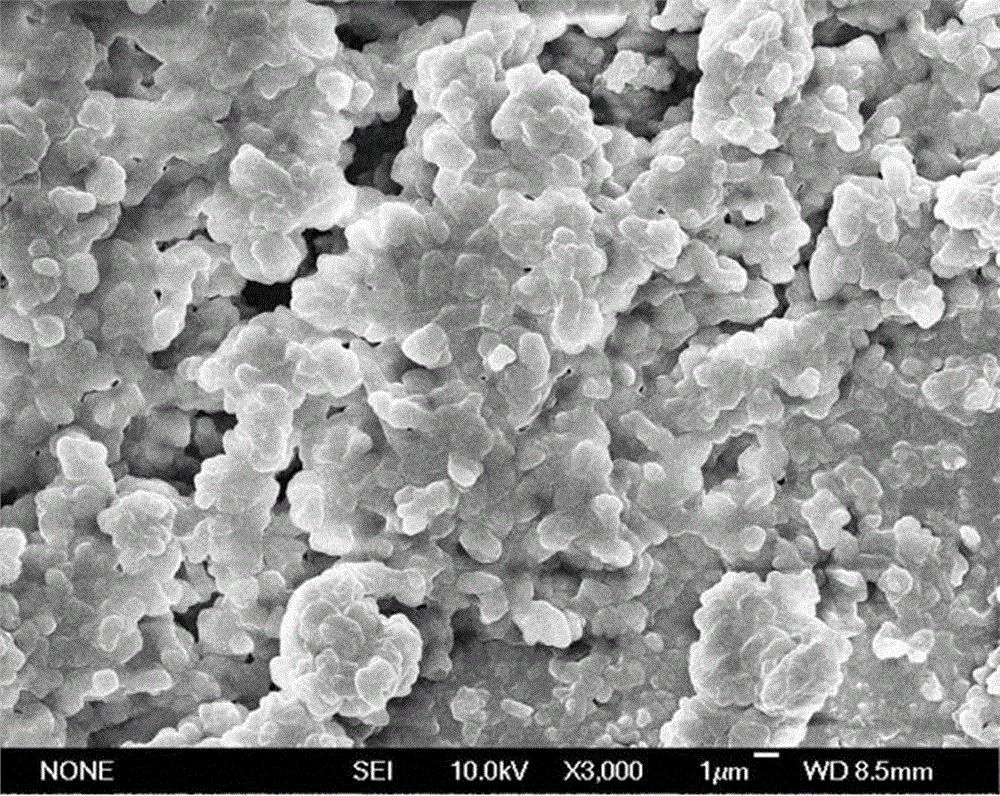

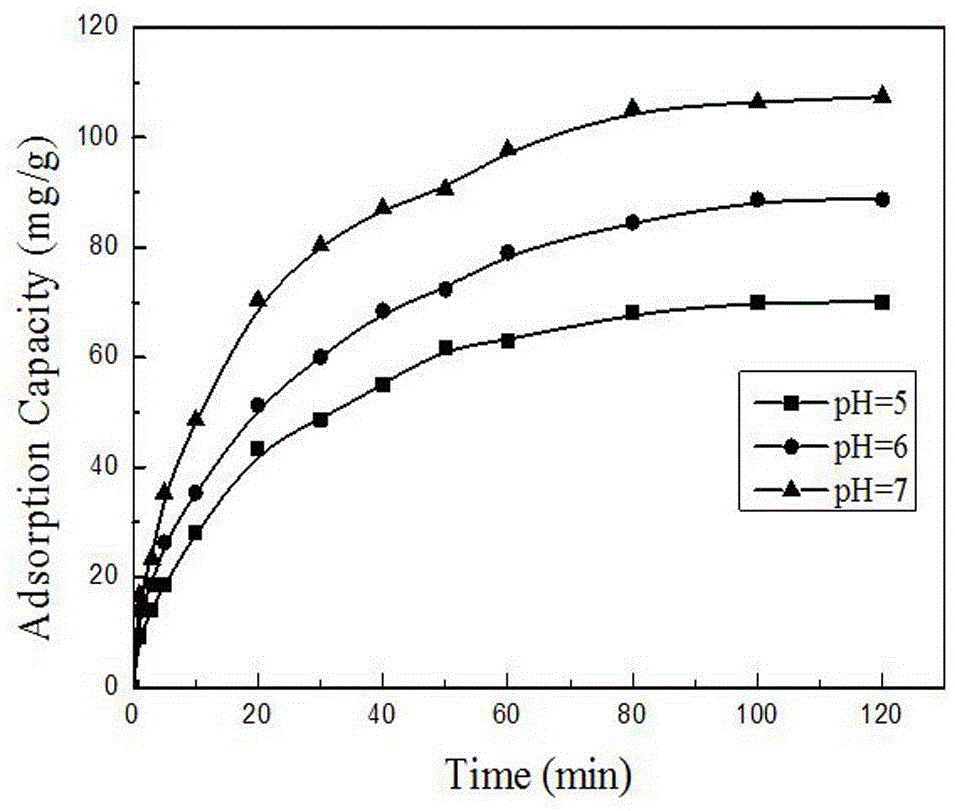

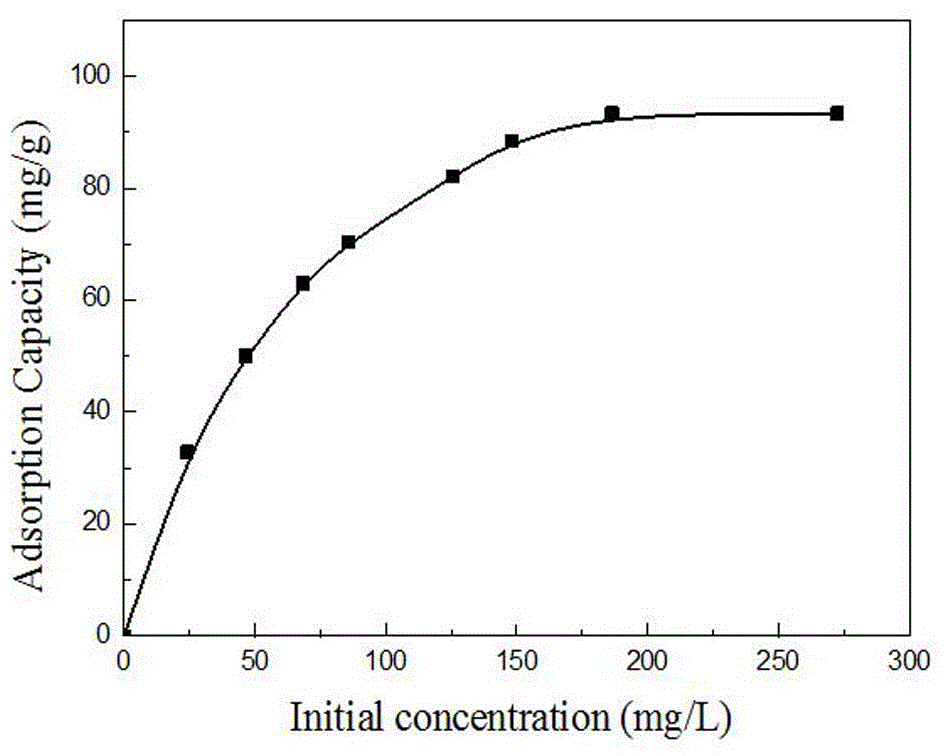

Microwave-assisted inverse emulsion preparing method and application of heavy metal ion imprinting material

ActiveCN105688845AHigh yieldChemically activeOther chemical processesWater contaminantsSpecific adsorptionEmulsion

The invention relates to the field of environmental function adsorbents, in particular to a method for preparing a heavy metal ion imprinting material with a microwave-assisted inverse emulsion polymerization method and an application of the heavy metal ion imprinting material. The method includes the steps that heavy metal ions serve as imprinting ions, cyclodextrin matter and acrylamide matter are used as functional monometers, the functional monometers are polymerized in a microwave-assisted mode with the inverse emulsion method, and the imprinting material with the small and even particle size is prepared. The method for preparing the heavy metal ion imprinting material is easy to operate, and the imprinting material has the advantages of being small in particle size, large in specific surface area, high in specific adsorption capacity and the like.

Owner:TAIYUAN UNIV OF TECH

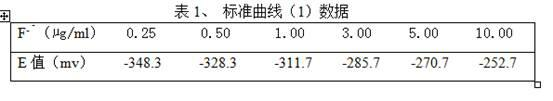

Method for quickly detecting fluorine content in specific vegetables

InactiveCN102175745AHigh residual fluorineChemically activeMaterial analysis by electric/magnetic meansLeafy vegetablesFluoride

The invention discloses a method for quickly detecting fluorine content in specific vegetables. In the invention, an ion selective electrode method is used to detect the concentration content of fluoride in vegetables; Fluorine contents in leafy, root and tuber, and fruit vegetables from the majority of supermarket in Tianjin, and reasons of fluorine content difference in the vegetables are analyzed, wherein the fluorine content in common leafy vegetable is obviously higher than that in the other two vegetables, the main reason is probably that the leafy vegetable absorbs fluorine from the air and solid dust through pores on leaf surfaces during the growing process and the fluorine are enriched continually; meanwhile, fluorine content in green vegetables is far lower than that in the same common vegetables. The results show that the method for quickly detecting fluorine content in the specific vegetables is effective.

Owner:TIANJIN NORMAL UNIVERSITY

Diamond/silicon carbide composite material and preparing method thereof

The invention discloses a diamond / silicon carbide composite material. The diamond / silicon carbide composite material comprises, by weight, 10-15 parts of binder, 5-20 parts of carbon black, 30-60 parts of silicon carbide and 30-60 parts of diamond. According to the diamond / silicon carbide composite material, silicon carbide is added into the raw materials, carbon black is used for replacing graphite, so that gaseous silicon completely penetrates in the siliconing reaction and reacts with carbon black, no remaining carbon exists in the generated composite material, and the composite material is not prone to deformation.

Owner:HUATONG XINAN BEIJING SCI & TECH DEV +1

Method for treating water solution heavy metallic ion by using trititanic acid sodium whisker

InactiveCN101117729AExtended service lifeSimple processPolycrystalline material growthIon-exchange column/bed processesIon exchangeWater quality

The present invention discloses a method for removing heavy metal ions from water solutions with sodium tri-titanate whiskers (cation exchange method). Sodium tri-titanate whiskers are directly used as the ion exchange resin in an ion exchange column, and when water passes through the ion exchange column, the contained heavy metal ions can be removed. The Sodium tri-titanate whiskers are prepared by the following steps: mixing materials, sintering, quenching and crushing to a demanded granularity. The method of the present invention has simple process, large exchange capacity, high exchange rate and low cost, and is suitable for treatment of low heavy-metal water of various qualities and nuclear waste containing radioactive heavy metal ions.

Owner:江西隆亨新材料有限公司

Method for producing magnesium arsenate by using arsenic-containing waste liquid

ActiveCN106495215AHigh purityEasy to purifyArsenites/arsenatesWater contaminantsLiquid wasteArsenate

The invention relates to a method for producing magnesium arsenate by using arsenic-containing waste liquid. The arsenic-containing waste liquid produced in the acid-making process of non-ferrous metal smelting enterprises by adopting a 'pyrogenic-process smelting-smoke acid-making system' process is used as a raw material to produce the magnesium arsenate. Firstly, iron, zinc and copper are removed in sequence, then As<3+> in the liquid is oxidized into As<5+> and Mg<2+>, full compounding is performed to produce a Mg3(AsO4)2 crude product, and finally the Mg3(AsO4)2 crude product is purified to produce a magnesium arsenate product. The arsenic-containing waste liquid is treated while high-purity magnesium arsenate is produced, and the effects of saving energy, reducing emissions and recycling resources are achieved.

Owner:林子柯

Preparing method for high-toughness and heat resisting TiC/TiN steel bond hard alloy

The invention relates to a preparing method for a high-toughness and heat resisting TiC / TiN steel bond hard alloy. The preparing method is characterized that one of TiO2 powder, TiH2 powder and Ti powder and colloidal graphite powder are prepared according to the C / Ti atomic ratio of 0.7-1.1, one of the TiO2 powder, the TiH2 powder and the Ti powder and urea ((NH2)2CO) are prepared according to the N / Ti atomic ratio of 0.4-1.1, and accordingly in-situ synthesized TiN mixed powder is prepared; ferro-molybdenum powder, ferro-vanadium powder, ferro-chromium powder, ferro-manganese powder, ferro-silicon powder, iron powder, ferro-boron powder, nickel powder, colloidal graphite and rare earth raw materials are prepared according to the needed proportion for the bonding phase metal chemical component mass ratio to be arranged into a steel ball mill, absolute ethyl alcohol serving as a medium and PVA are added, after ball milling and slurry drying, pressing forming is conducted, and the steel bond alloy is obtained through sintering. The in-situ reaction synthesizing technology and the liquid phase sintering technology are combined, reinforced particles are fine in size, the surfaces are free of sharp corners, base body interface bonding is good, and the interface is clean. Through the method for preparing the steel bond alloy, the comprehensive mechanical performance of the alloy can be improved, cost is low, and the technology is easy and convenient to conduct.

Owner:JIANGSU HUICHENG MACHINERY MFG

Active coupling agent for contact reaction of graphite and stainless steel and brazing method thereof

ActiveCN110682029AChemically activeHigh affinityWelding/cutting media/materialsSoldering mediaSS - Stainless steelGraphite

An active coupling agent for contact reaction of graphite and stainless steel is prepared by taking 10-20% of Ti powder, 10-60% of CuLi10 powder, 10% of binder and the balance Cu powder, by mass, anduniformly stirring the powder to obtain the pasty active coupling agent. The brazing method comprises the steps: processing the surface to be welded of a stainless steel block into the corrugated surface, cleaning the surfaces to be welded of a graphite block and the stainless steel block, coating the surfaces with the active coupling agent, combining the graphite block and the stainless steel block into a butt joint sample, pre-coating the contact surface of a fixture and the sample with a brazing resist, fixing and compressing the sample on the fixture, placing the sample in a vacuum chamberof a brazing furnace, applying welding pressure to the sample, carrying out vacuumizing, then heating and insulating the butt joint sample, and cooling the butt joint sample to room temperature alongwith the furnace to complete brazing. By means of a contact reaction principle, the high-reliability, high-density, brazing filler metal-free and brazing flux-free coupling between the graphite and the stainless steel is realized, the brazing temperature of the graphite and the stainless steel can be reduced, and the mechanical property of a matrix material can be guaranteed.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

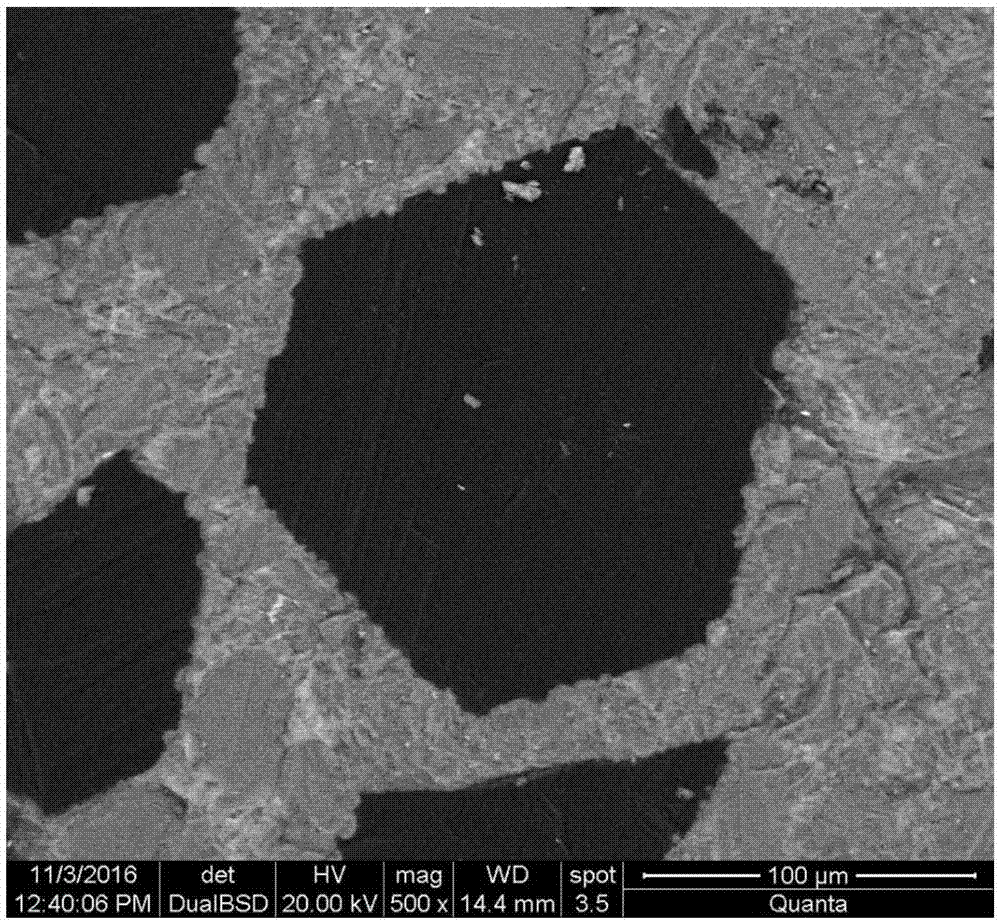

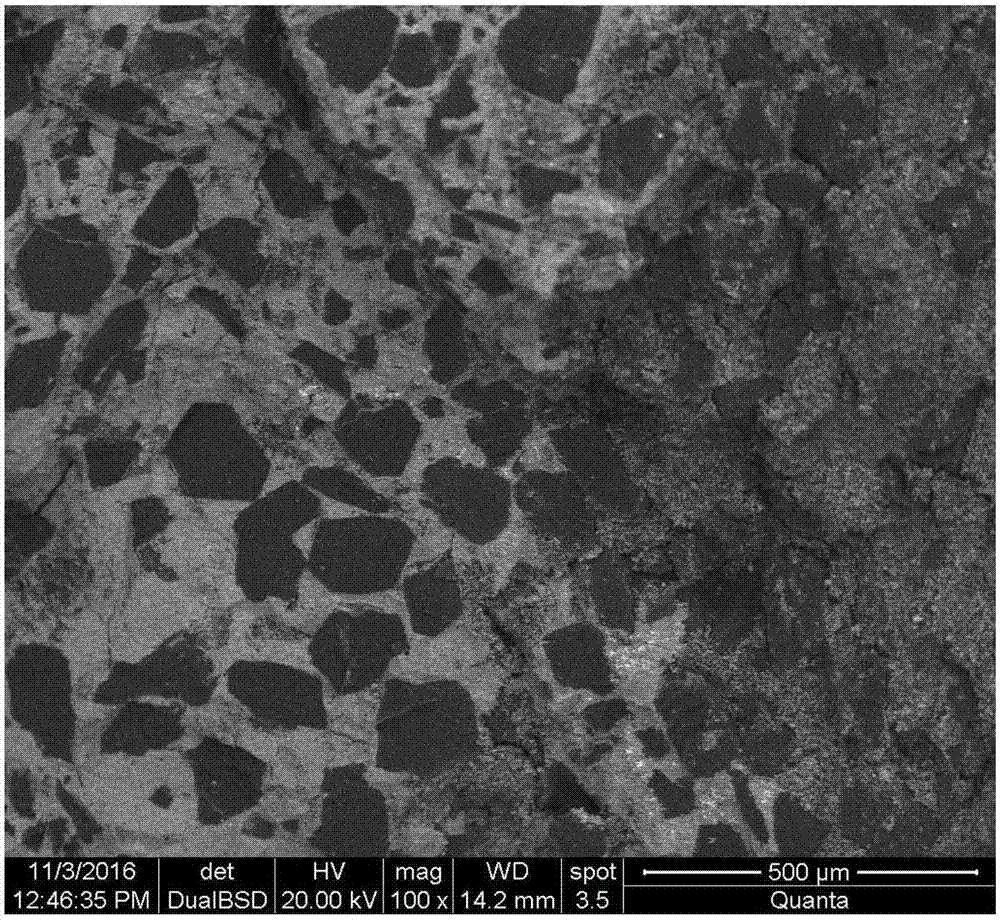

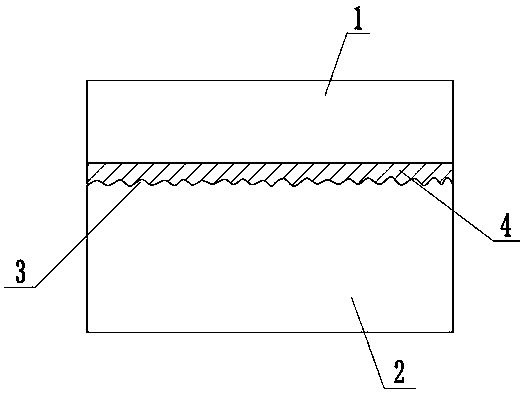

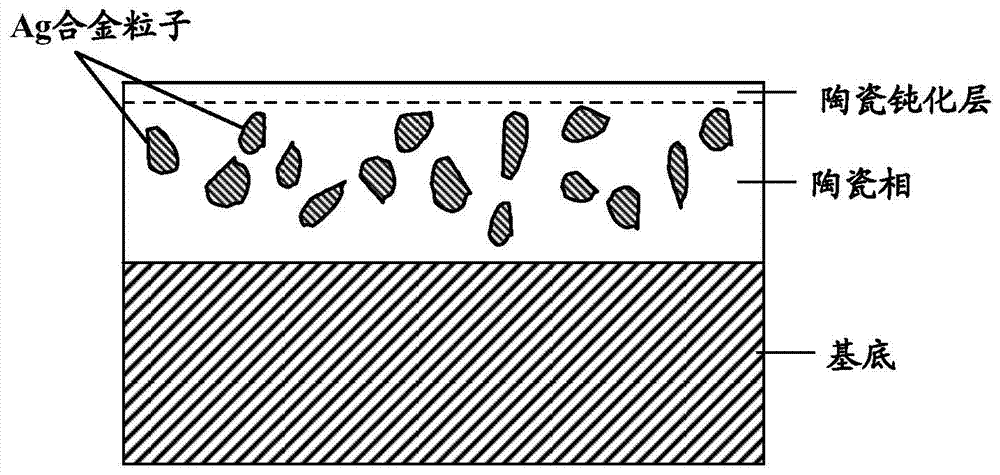

Noble metal ceramic film and preparation method thereof

ActiveCN103572233ALow priceGood antioxidant propertiesVacuum evaporation coatingSputtering coatingPlasma resonanceMulti targeting

The invention discloses a noble metal ceramic film, wherein the noble metal ceramic film comprises a noble metal alloy / ceramic composite layer, and a ceramic passivation layer, wherein the noble metal alloy particles in the composite layer are embedded into a ceramic phase; the ceramic passivation layer is covered at the surface of the composite layer; matrix metal of the noble metal alloy is Ag; the doped metal is Al or Ti; the ceramic phase is Al2O3 or SiO2; the ceramic passivation layer is Al2O3 or SiO2 passivation layer. The invention also discloses a preparation method of the noble metal ceramic film. The method is carried out by adopting a multi-target magnetron co-sputtering technology; the preparation technology is simple; components and a micro-structure of the film are easily regulated and controlled; the obtained noble metal ceramic film has strong surface plasma resonance absorption characteristics in ultraviolet and visible light areas, and has excellent high temperature resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com