Microwave-assisted inverse emulsion preparing method and application of heavy metal ion imprinting material

A technology of heavy metal ions and imprinted materials, applied in water/sludge/sewage treatment, water pollutants, adsorbed water/sewage treatment, etc., to achieve the effect of strong specific adsorption capacity, high yield and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

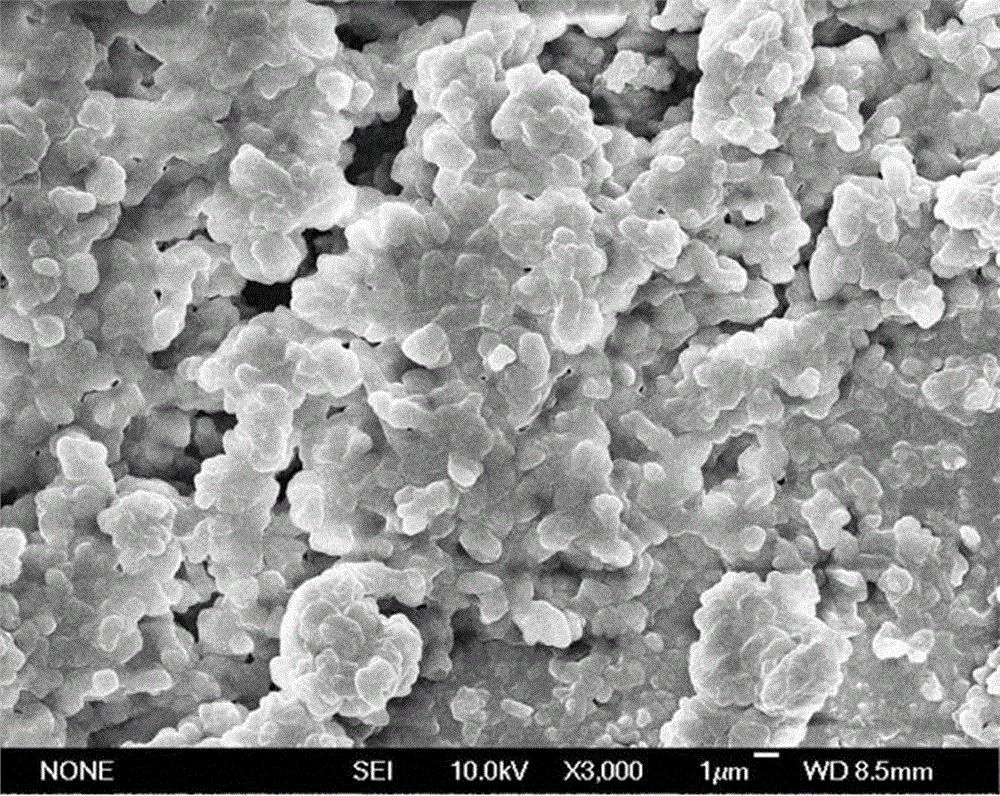

Image

Examples

Embodiment 1

[0026] Dissolve 5mmol α-cyclodextrin and 50mmol acrylamide in double distilled water, add 12mmol cadmium chloride aqueous solution, stir in water bath at 80°C for 10min;

[0027] Add 1g of Span80 and 1g of Tween80, then add 30g of liquid paraffin, and stir at high speed for 60min to form an inverse pre-emulsion;

[0028] Add 3wt% epichlorohydrin in the total mass of the oil phase and the water phase and 0.02wt% potassium persulfate in the total mass of the oil phase and the water phase, and put them in a microwave reactor at 240W for 20 minutes;

[0029] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0030] Add a mixed solution of methanol: acetic acid (1:1), shake at 20°C for 8 hours, and vacuum filter to obtain the precipitate;

[0031] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 7;

[0032] The washed polymer was placed in a vacuum drying oven, and dried at 30° C. for 4...

Embodiment 2

[0034] Dissolve 3mmol β-cyclodextrin in double distilled water, add 6mmol cadmium nitrate aqueous solution, add 40mmol methacrylamide aqueous solution, stir in water bath at 30°C for 40min;

[0035] Add 4.8g of Span60 and 1.2g of Tween20, then add 33.5g of kerosene, and stir at high speed for 30min to form an inverse pre-emulsion;

[0036] Add ethylene glycol dimethacrylic acid of 5 wt% of the total mass of the oil phase and the water phase and azobisisobutyronitrile of 0.1 wt% of the total mass of the oil phase and the water phase, put it into a microwave reactor and react at 400W for 1 min;

[0037] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0038] Add a mixed solution of methanol: acetic acid (3:1), shake at 30°C for 7 hours, and vacuum filter to obtain the precipitate;

[0039] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 6;

[0040] The washed polymer was placed in...

Embodiment 3

[0042] Dissolve 4mmol γ-cyclodextrin in double distilled water, then add 30mmol N,N-dipropyl-2-methacrylamide and 10mmol cadmium sulfate aqueous solution, and stir at 60°C for 20min;

[0043] Add 5g of Span40 and 1g of Tween40, then add 36.4g of white oil, and stir at high speed for 40min to form an inverse pre-emulsion;

[0044]Add 7wt% N,N-methylenebisacrylamide of the total mass of the oil phase and the water phase and 0.3wt% dimethyl azobisisobutyrate of the total mass of the oil phase and the water phase, put them in a microwave reactor Reaction under 20W for 80min;

[0045] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0046] Add a mixed solution of methanol: acetic acid (5:1), shake at 50°C for 5 hours, and vacuum filter to obtain the precipitate;

[0047] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 7;

[0048] The washed polymer was placed in a vacuum drying oven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com