Patents

Literature

55 results about "Environmental function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental functions are defined as possible uses of our natural, biophysical surroundings that are useful for humans. Uses can be either passive or direct and practical. The 'services' of environmental functions are defined as their possibilities or potential to be used by humans for whatever end.

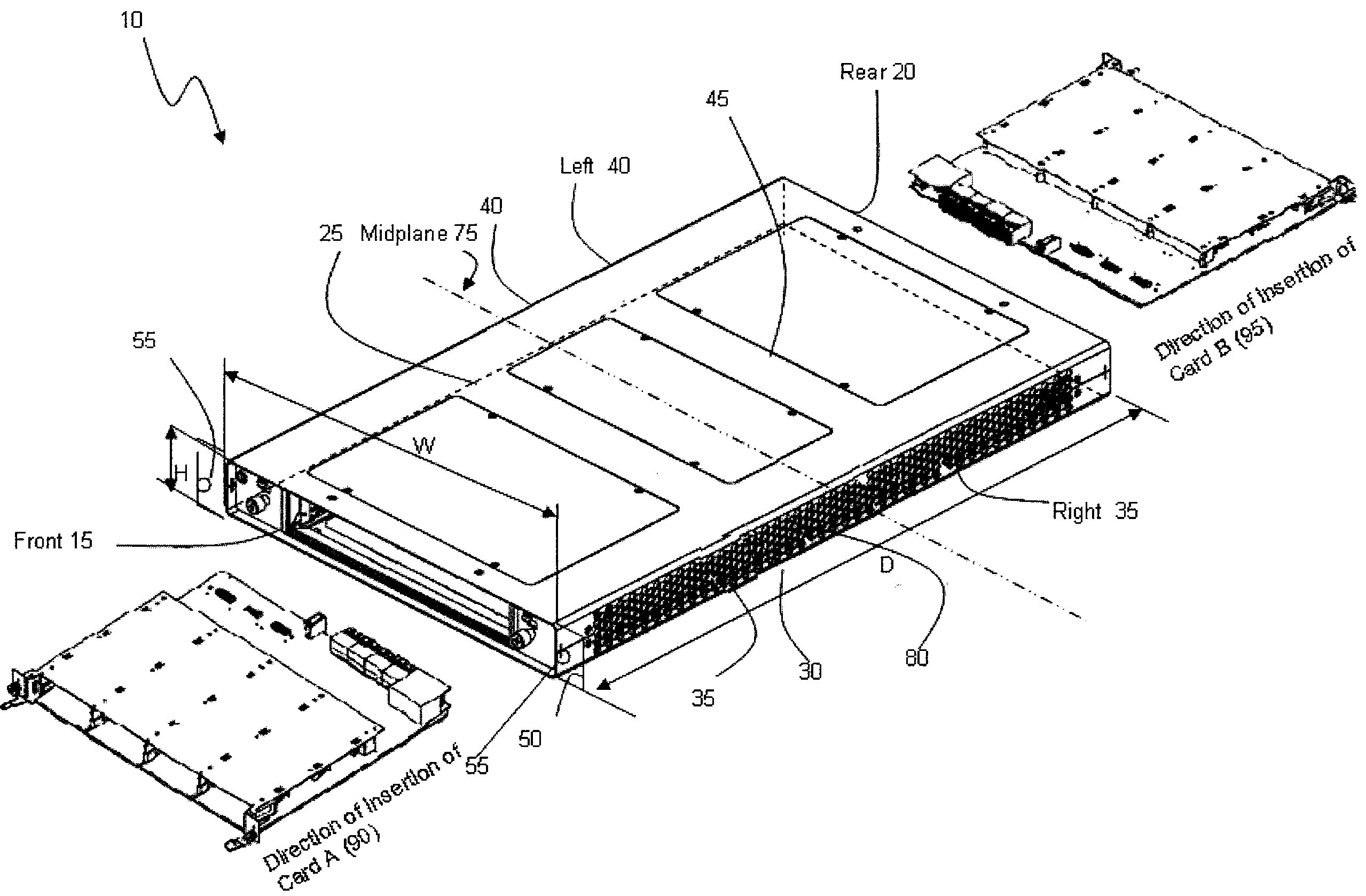

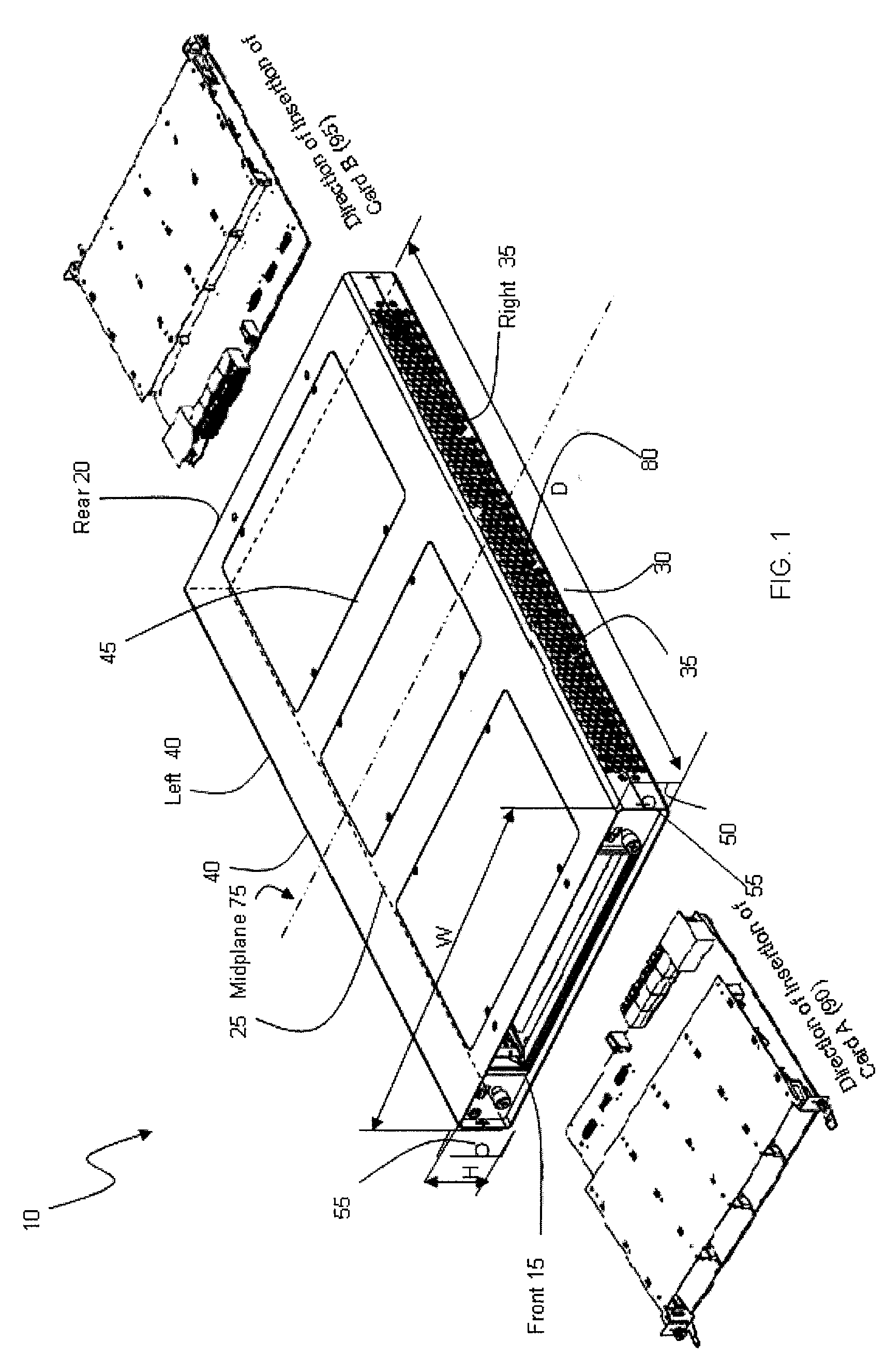

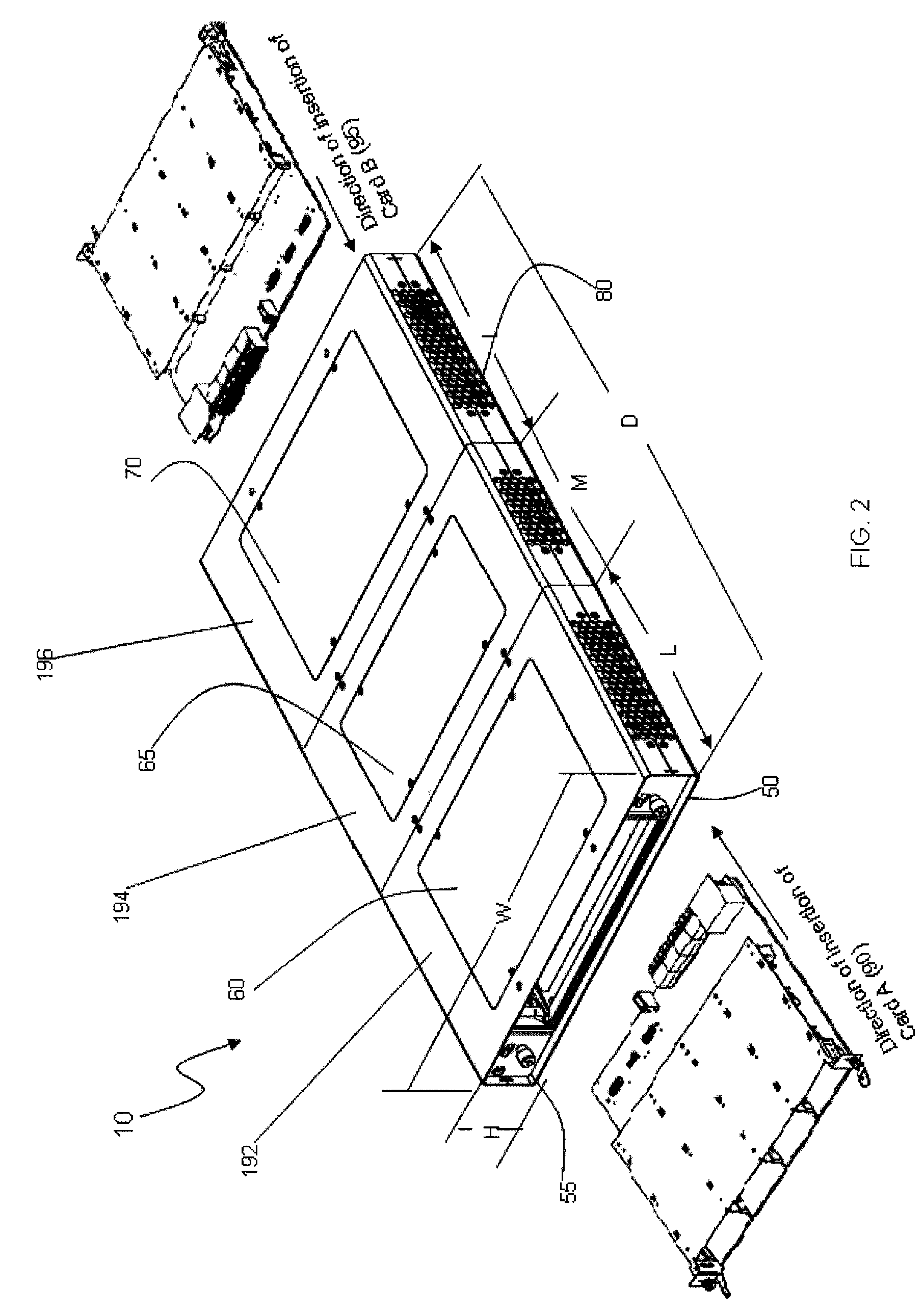

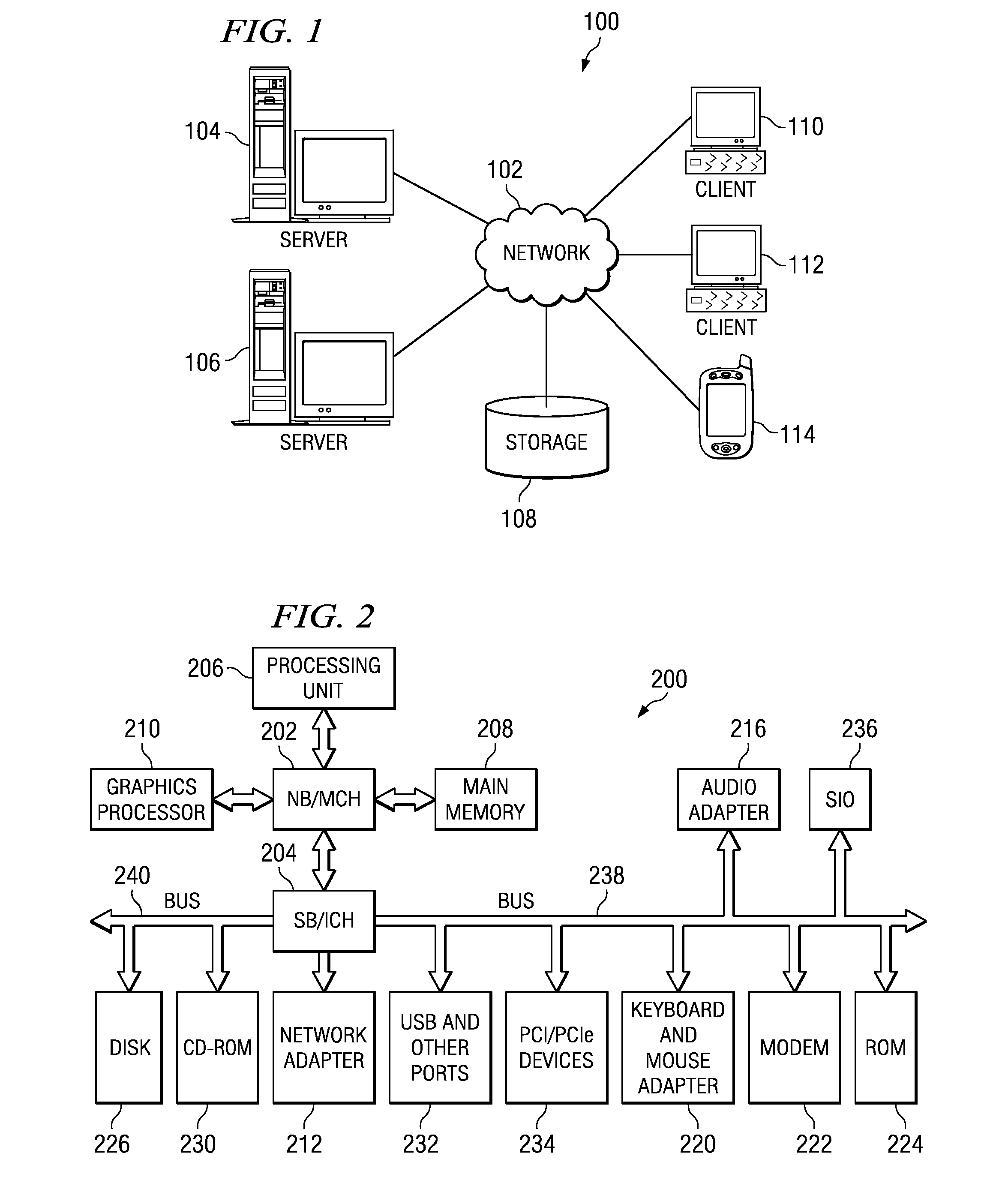

Modular blade for providing scalable mechanical, electrical and environmental functionality in the enterprise using advancedtca boards

A standards-based server blade arrangement is provided wherein individual circuit boards may be compliant with a first industry driven or other standard and housed within an enclosure configured such that one aspect of the enclosure provides each circuit board with a scalable, mechanical, electrical and environmental functionality required for that circuit board to comply with the first industry driven or other standard and a second aspect of the enclosure allows the enclosure to comply with a second industry driven or other standard.

Owner:SLT LOGIC

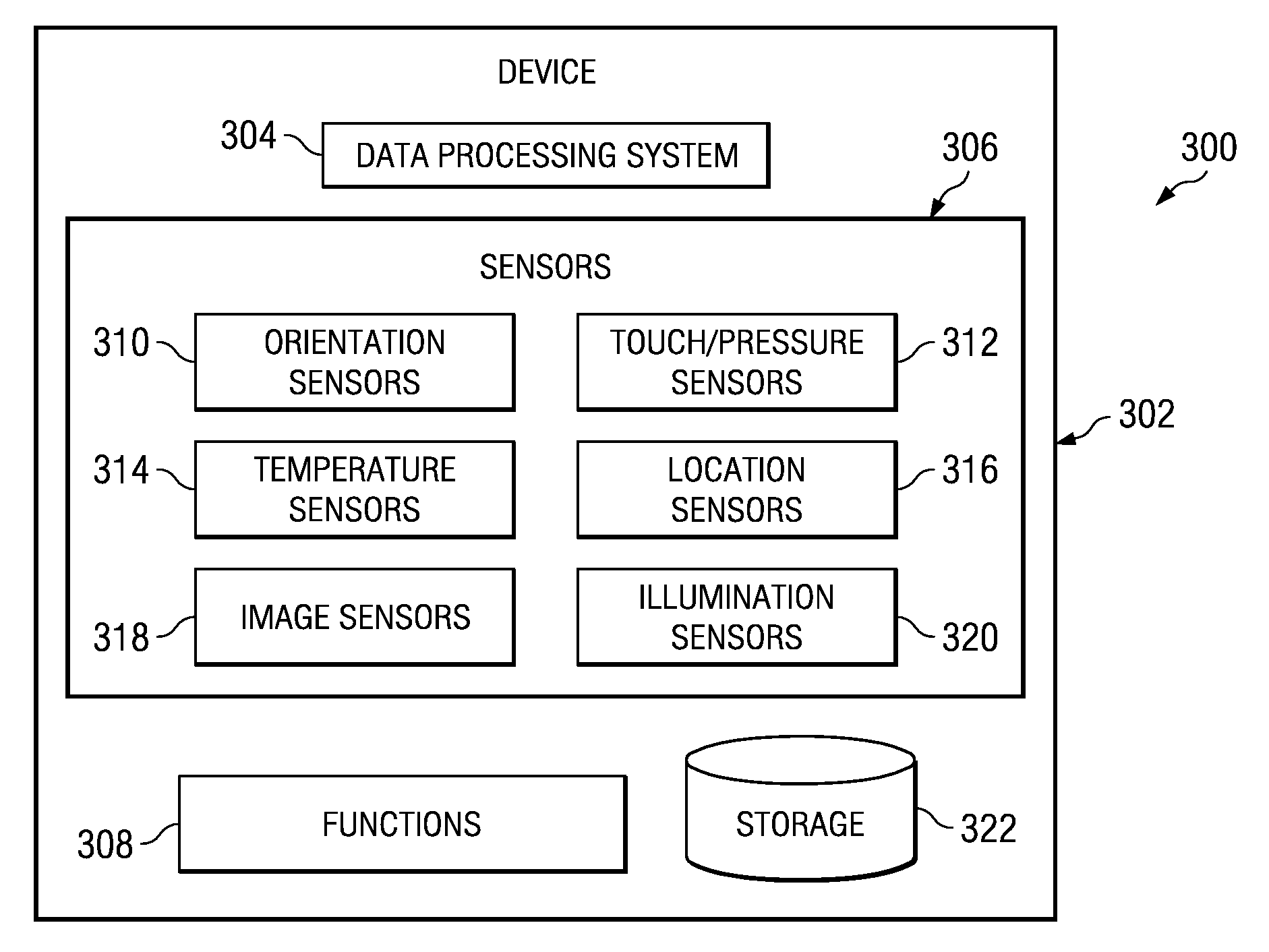

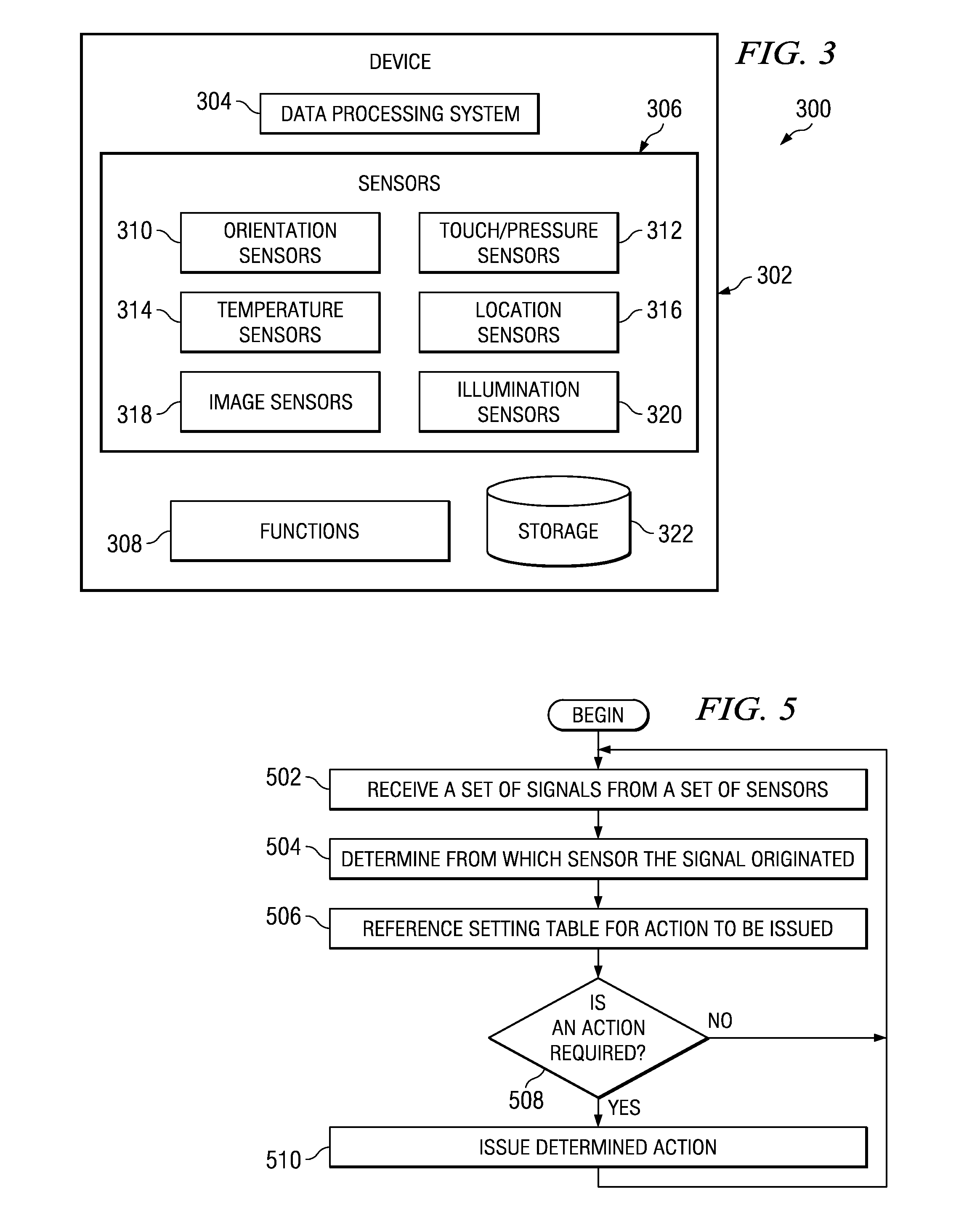

Environmental function changing

ActiveUS20080108340A1Devices with sensorCharacter and pattern recognitionSoftware engineeringProgram code

A computer implemented method, apparatus, and computer usable program code are provided for changing functionality for an electronic device. A set of signals is received from a set of sensors in the electronic device. Each signal in the set of signals includes a type of sensor from which the signal originated in the set of sensors and information detected by the set of sensors. An action is identified to be issued for the electronic device. The action is identified using the type of sensor and the information. The action is automatically initiated in the electronic device. The automatically initiated action changes the functionality for the electronic device.

Owner:GLOBALFOUNDRIES US INC

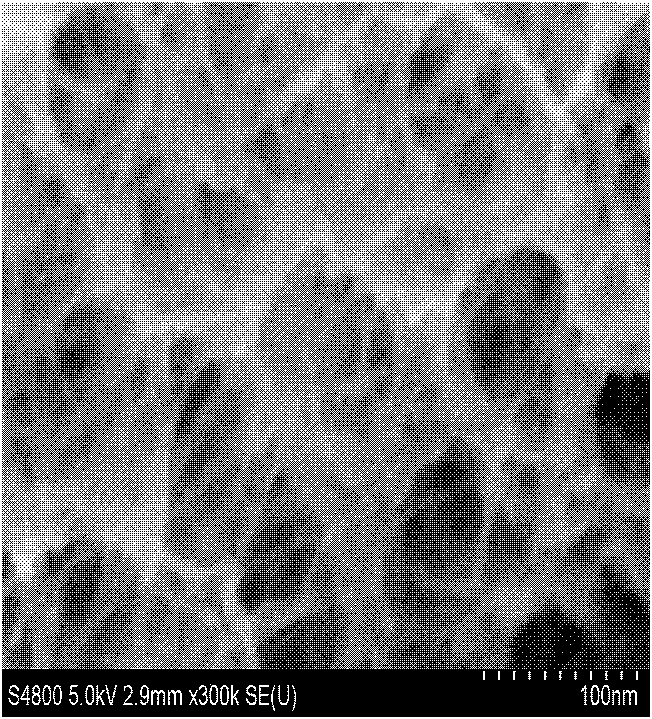

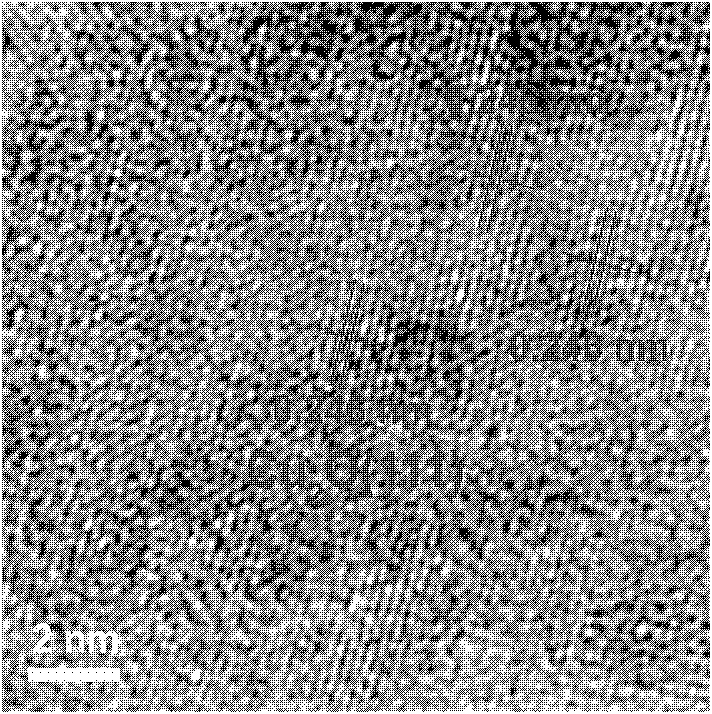

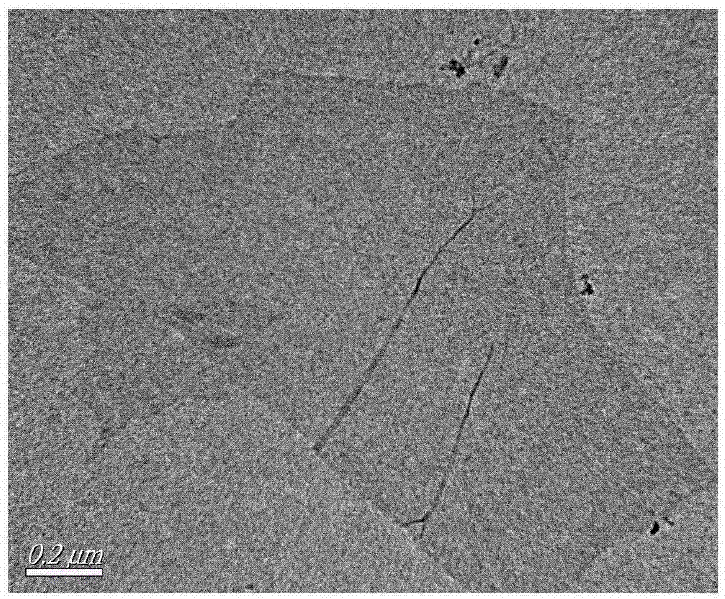

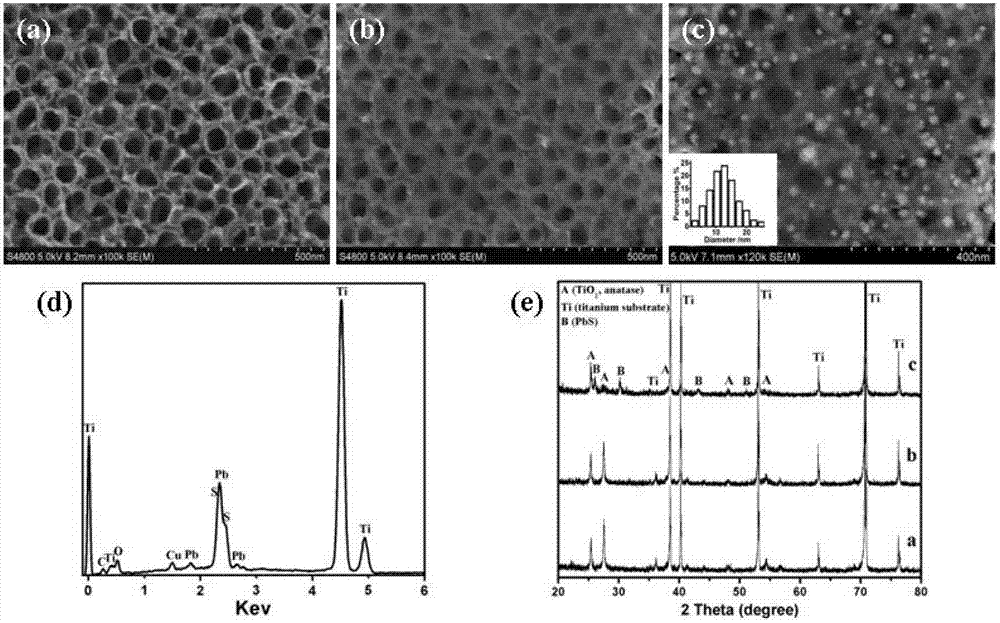

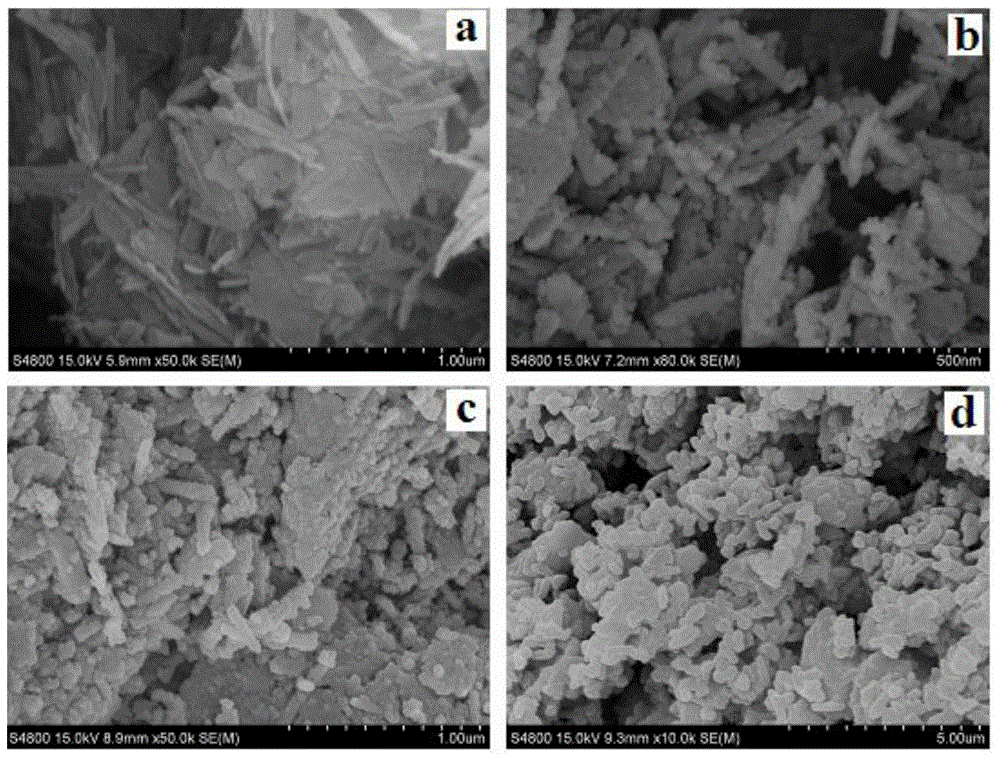

Cu2OTiO2 nanotube array and preparation method thereof

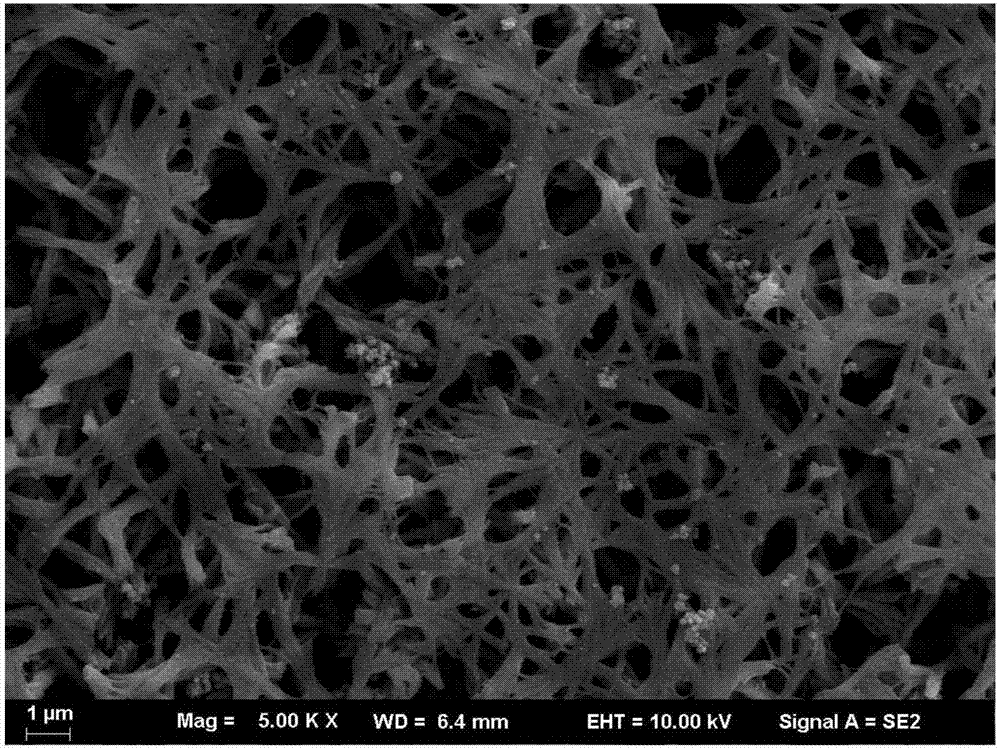

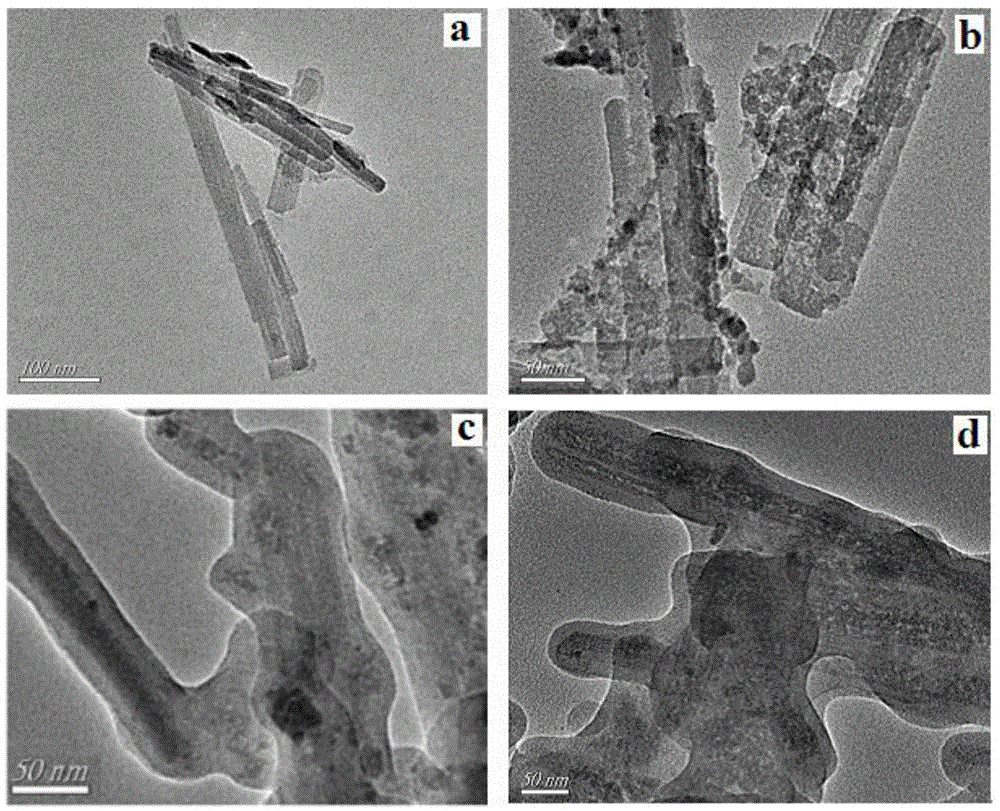

InactiveCN101851772ALarge specific surface areaAperture adjustableAnodisationElectron holeTio2 nanotube

The invention discloses an environmental function nano-material-Cu2O / TiO2 nanotube array and a preparation method thereof. A TiO2 nanotube array is placed in 5mmol-20mmol of CuSO4 solution, and copper is electrodeposited on the TiO2 nanotube array in a standard three-electrode system by using pulse plating so as to obtain the Cu / TiO2 composite nanotube array; and after the deposition, the Cu / TiO2 composite nanotube array is electro-oxidized for certain time in an alkaline solution NaOH to obtain a TiO2 nanotube array modified by ultrafine Cu2O nanowires with the diameter of less than 5 nanometers. The nanaowires are intertwined and connected to from a network structure to be attached to the TiO2 nanotube array but do not fully block TiO2 nanotubes; the Cu2O / TiO2 nanotube array is very favorable for the transmission of photo-carriers, reduces the recombination probability of electron-hole pairs, effectively expands the absorption range of TiO2 in the visible region, reduces optical corrosion, improves photoelectric conversion efficiency, and shows good photocatalytic efficiency.

Owner:HUNAN UNIV

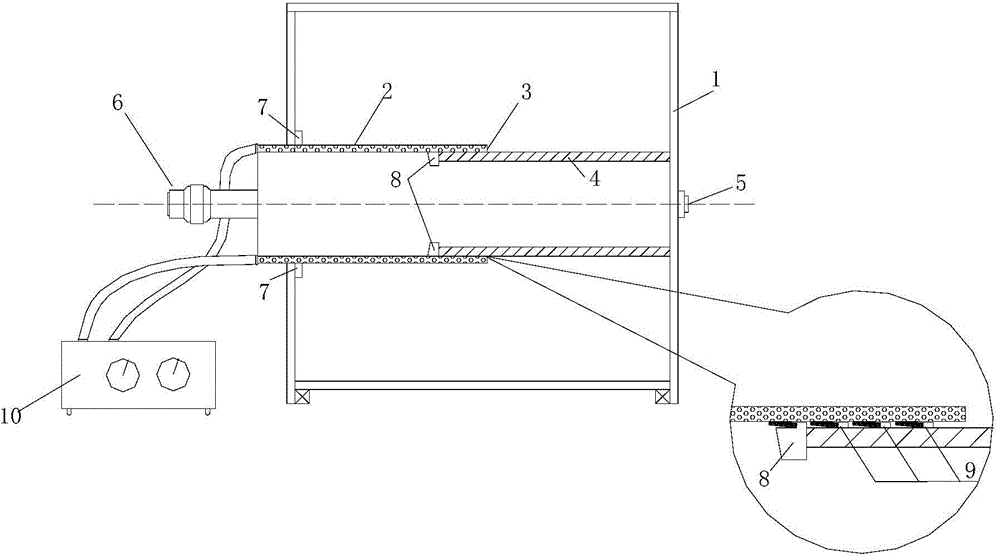

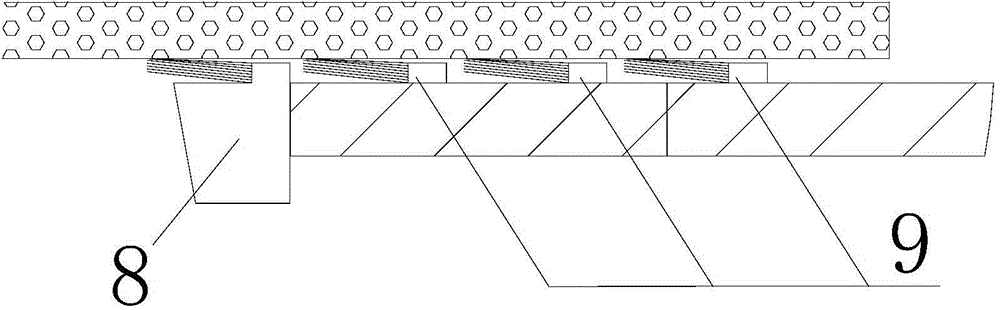

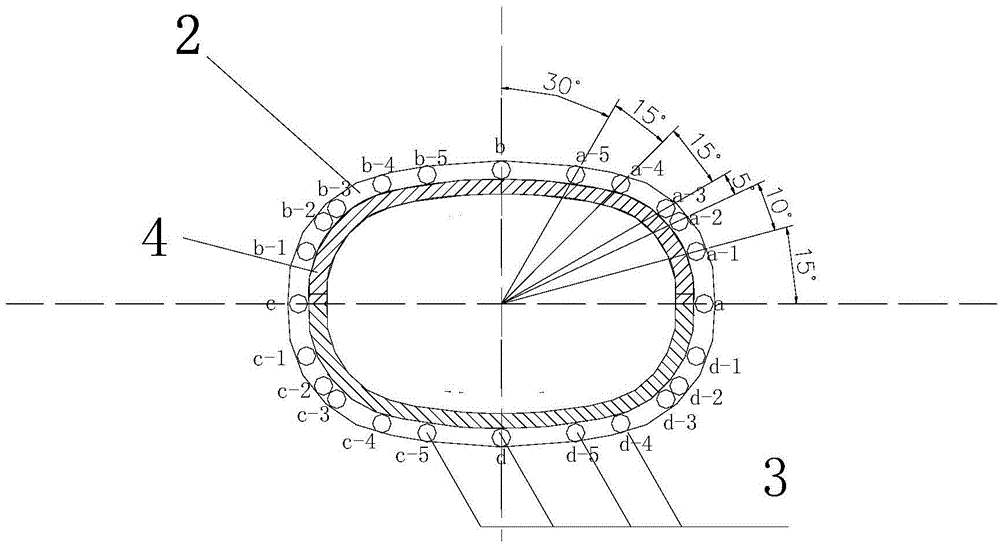

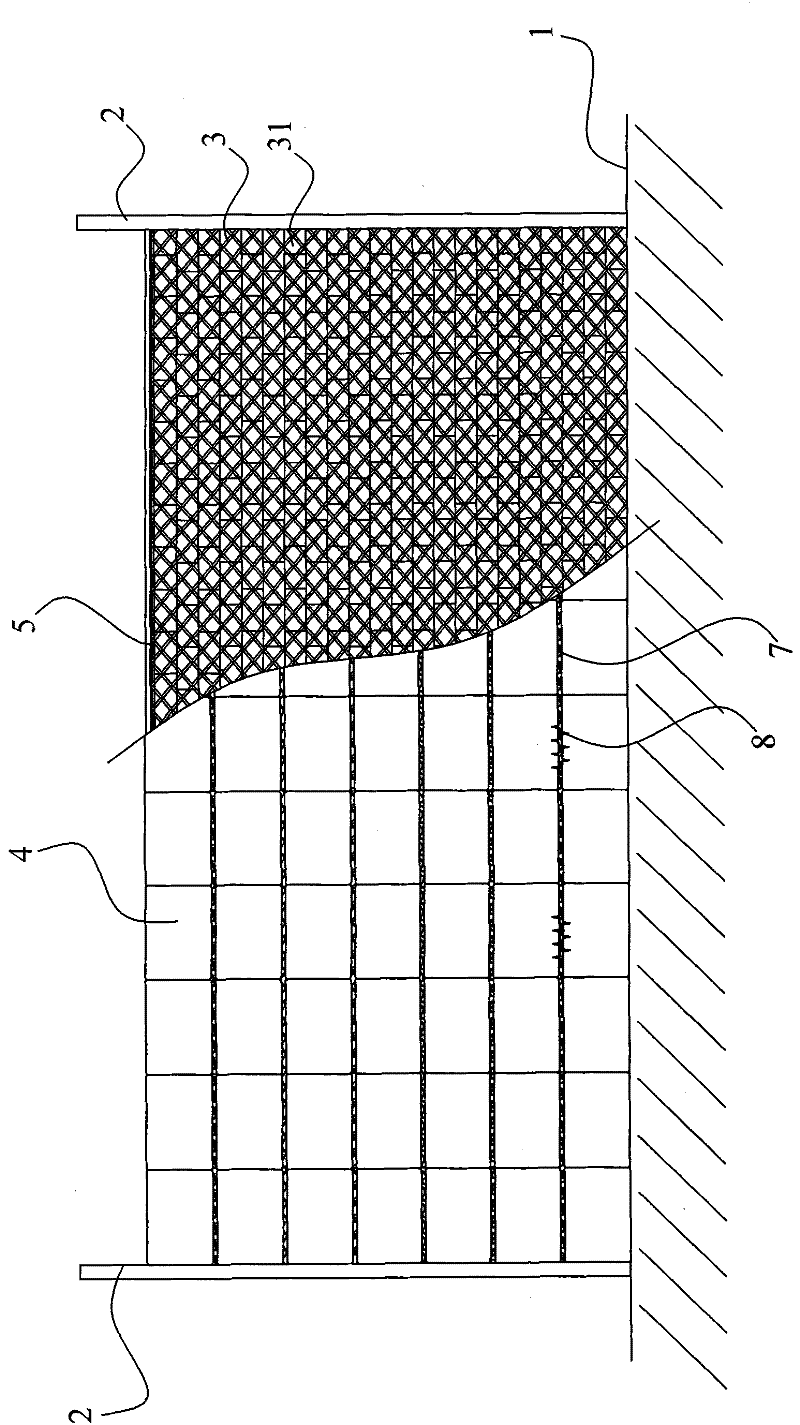

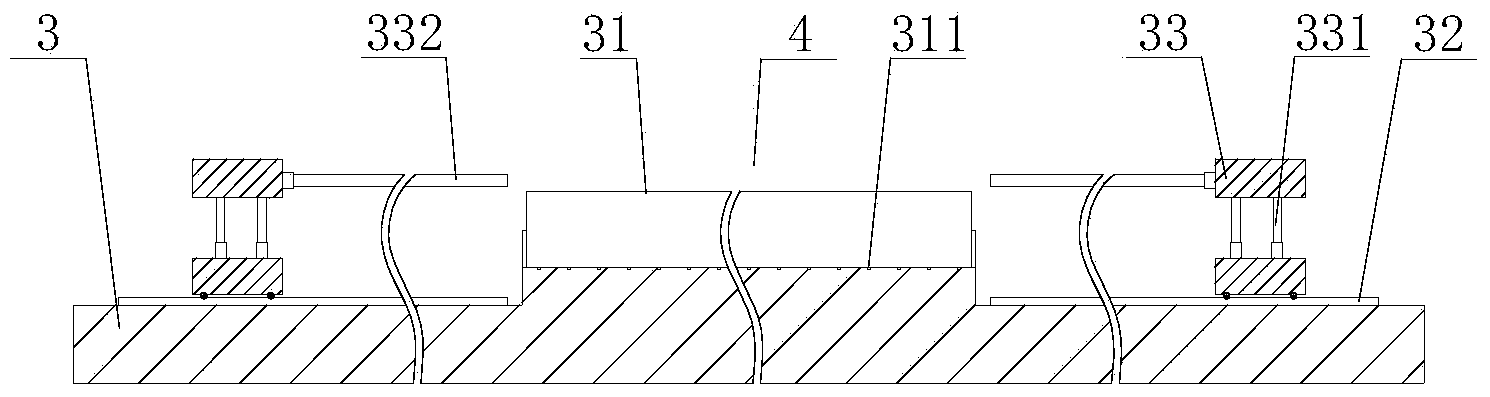

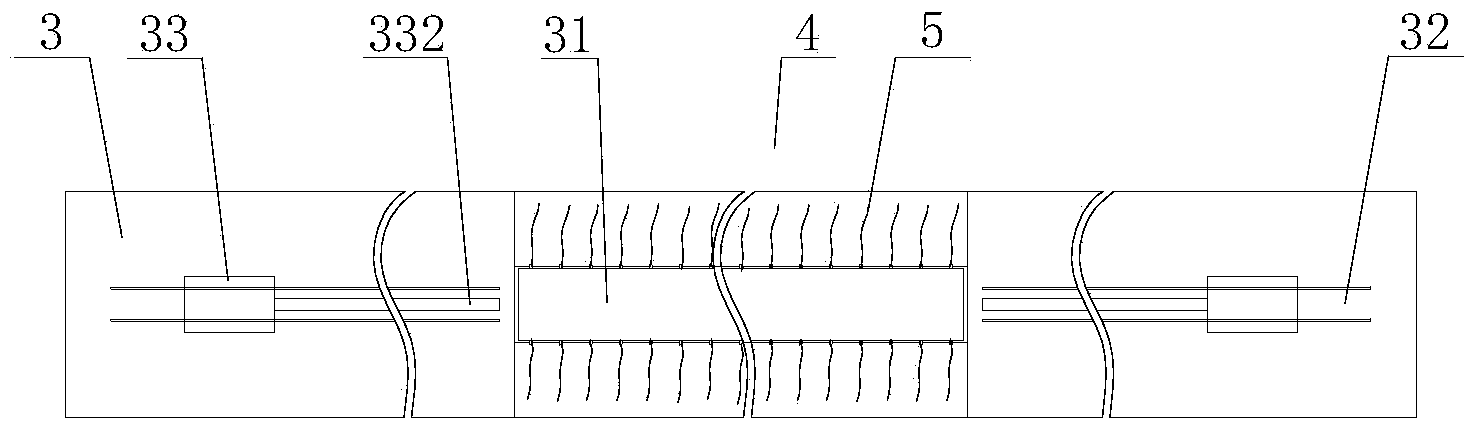

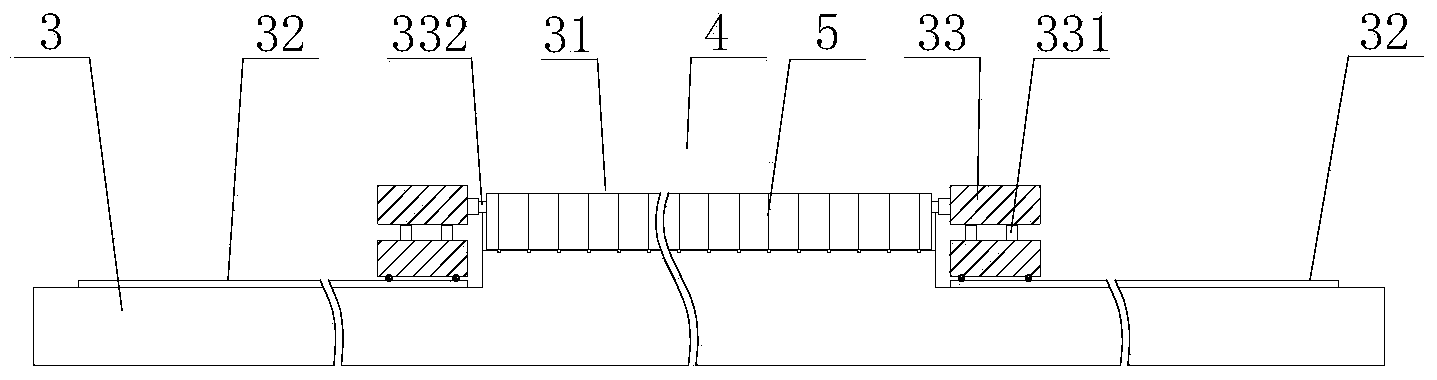

Visual quasi-rectangular shield synchronous grouting slurry diffusion mode research platform and application

A visual quasi-rectangular shield synchronous grouting slurry diffusion mode research platform includes model soil and model slurry both equipped for realizing the indoor visual environmental function, a reduced scale quasi-rectangular shield type synchronous grouting physical process simulation test device and a commercial particle image velocimetry system, wherein the model soil and model slurry are equipped by transparent soil, the model soil is used for realizing the visual shield environment, and the model slurry is diffused by the reduced scale quasi-rectangular shield type synchronous grouting physical process simulation test device. The invention further discloses application of the platform, the visual environment is utilized to dynamically simulate and accurately observe the whole process of synchronous grouting of a quasi-rectangular shield machine, a convenient research platform is provided for the layout scheme research of grouting pipes of the quasi-rectangular shield machine, and a condition is provided for the research of the slurry diffusion mode of quasi-rectangular shield type synchronous grouting.

Owner:TONGJI UNIV +2

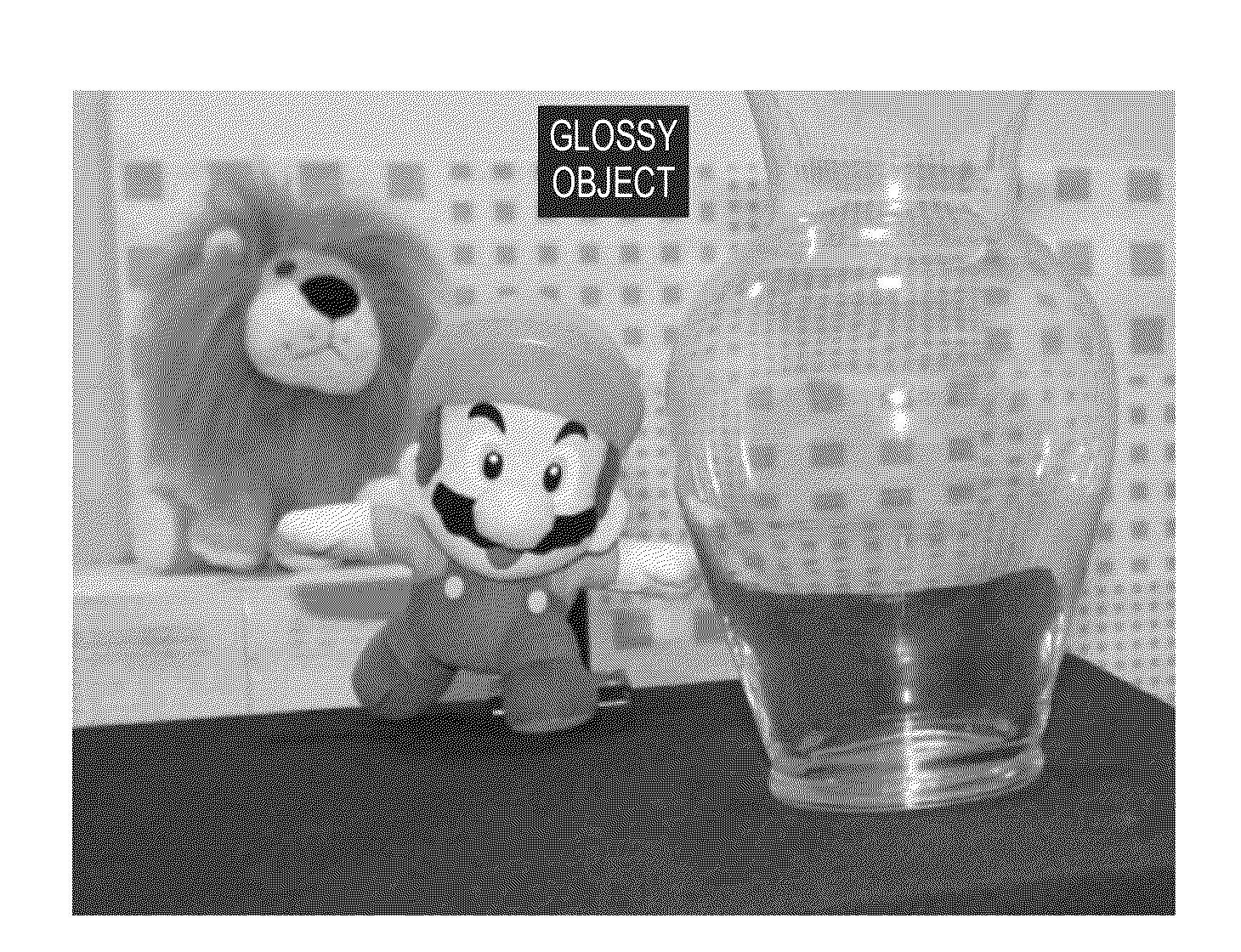

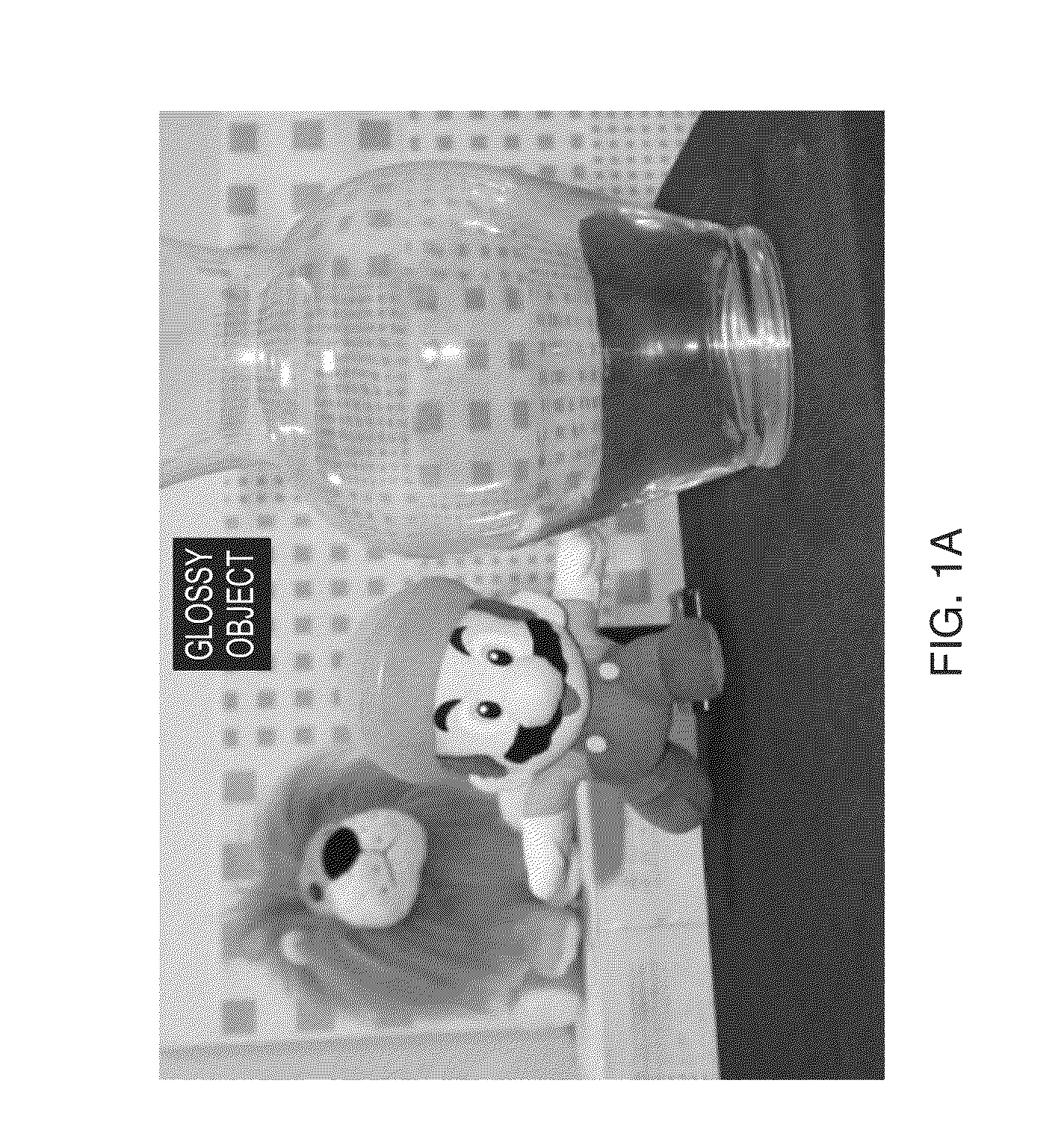

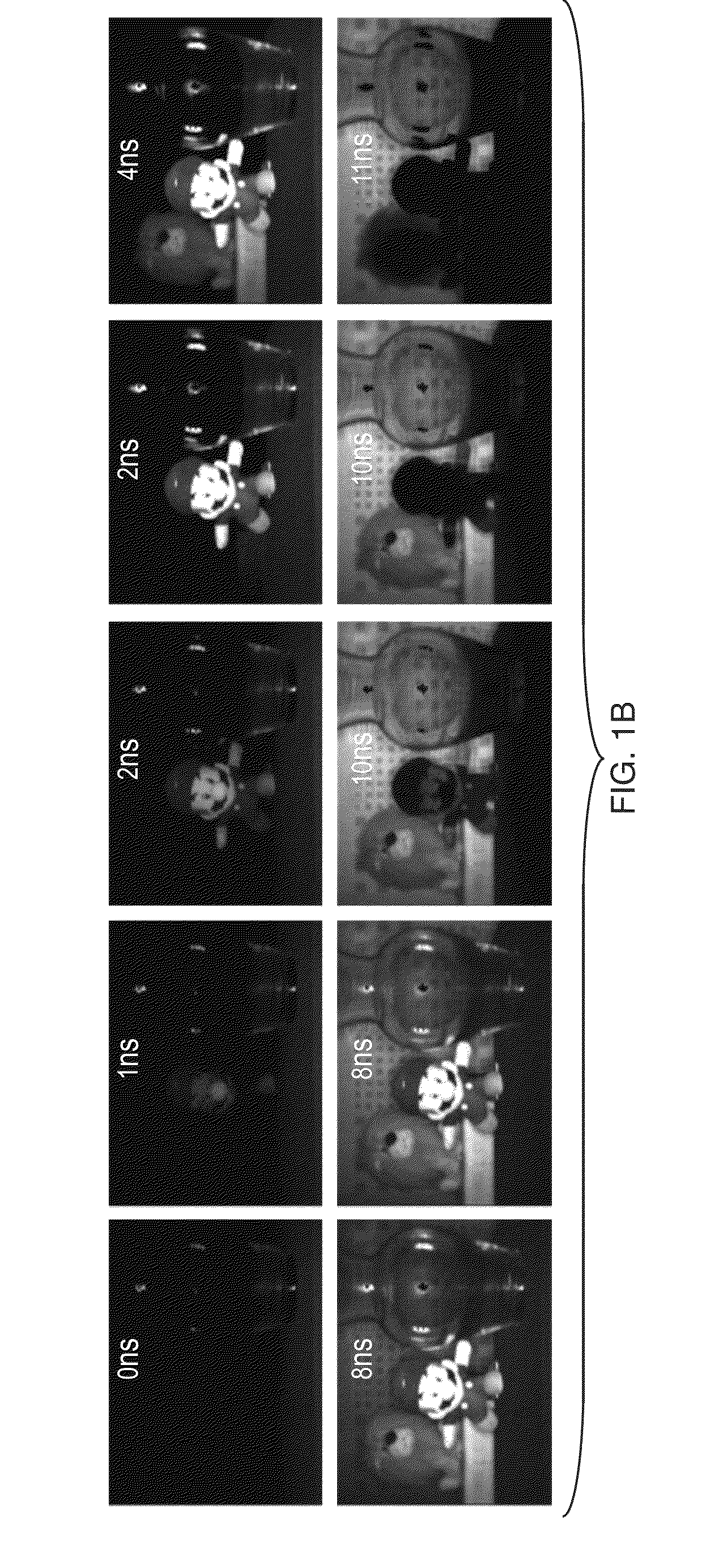

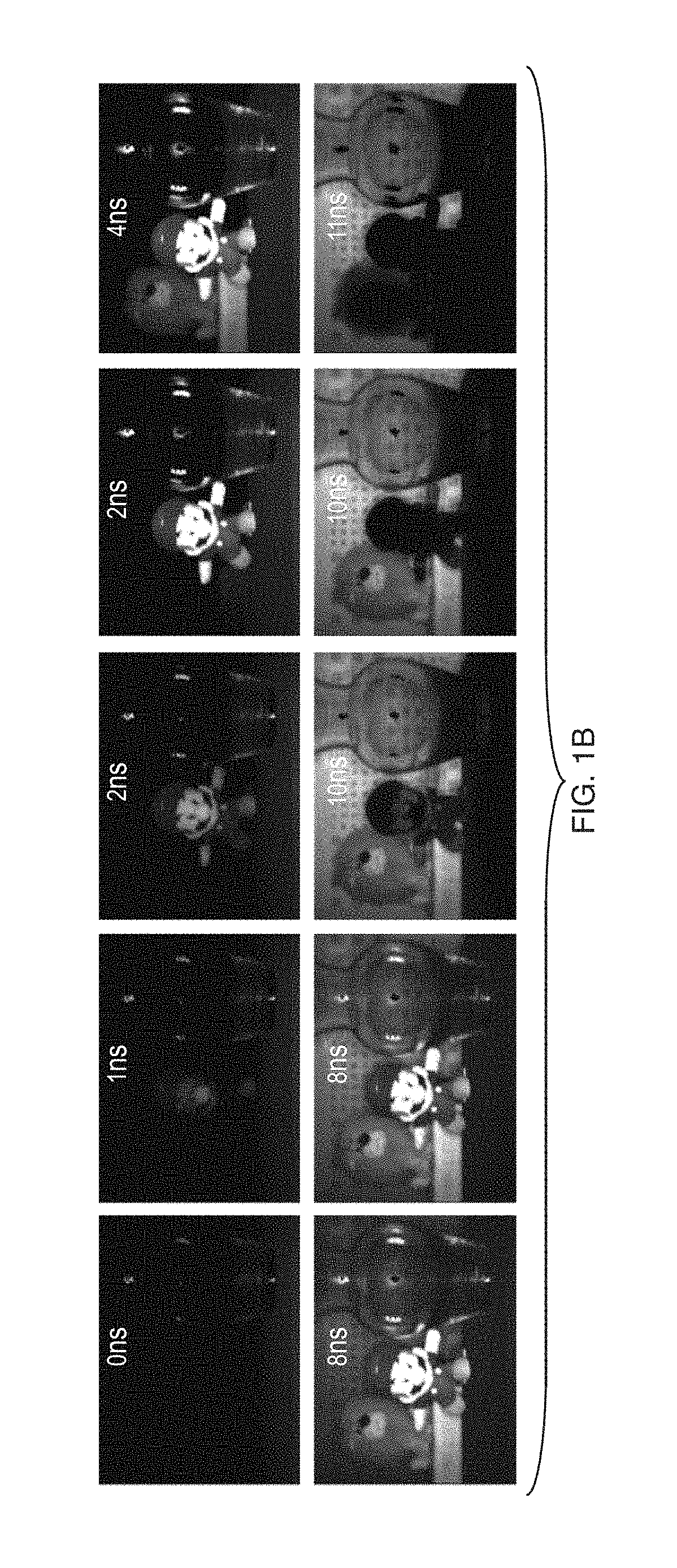

Methods and Apparatus for Coded Time-of-Flight Camera

ActiveUS20150120241A1Accurate measurementDepth accurateOptical rangefindersMechanical depth measurementsWiener deconvolutionMultipath interference

In illustrative implementations, a time-of-flight camera robustly measures scene depths, despite multipath interference. The camera emits amplitude modulated light. An FPGA sends at least two electrical signals, the first being to control modulation of radiant power of a light source and the second being a reference signal to control modulation of pixel gain in a light sensor. These signals are identical, except for time delays. These signals comprise binary codes that are m-sequences or other broadband codes. The correlation waveform is not sinusoidal. During measurements, only one fundamental modulation frequency is used. One or more computer processors solve a linear system by deconvolution, in order to recover an environmental function. Sparse deconvolution is used if the scene has only a few objects at a finite depth. Another algorithm, such as Wiener deconvolution, is used is the scene has global illumination or a scattering media.

Owner:MASSACHUSETTS INST OF TECH

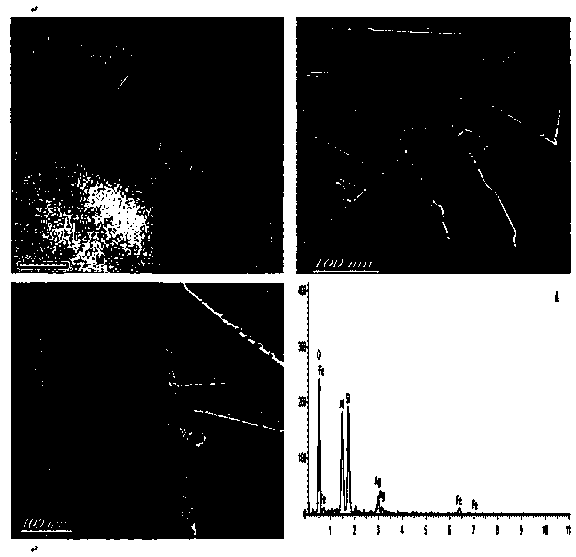

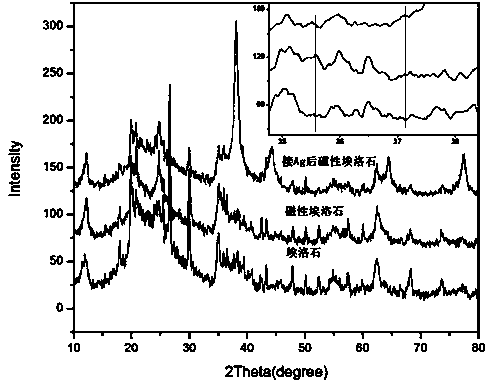

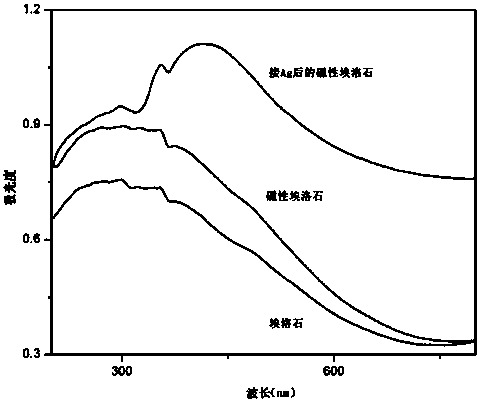

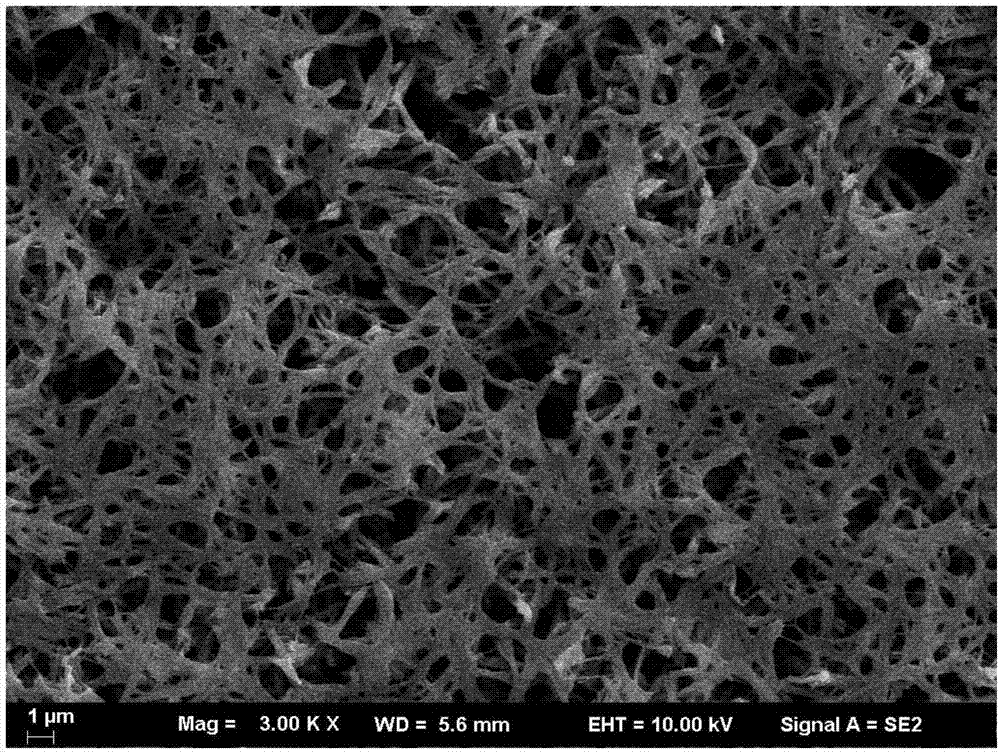

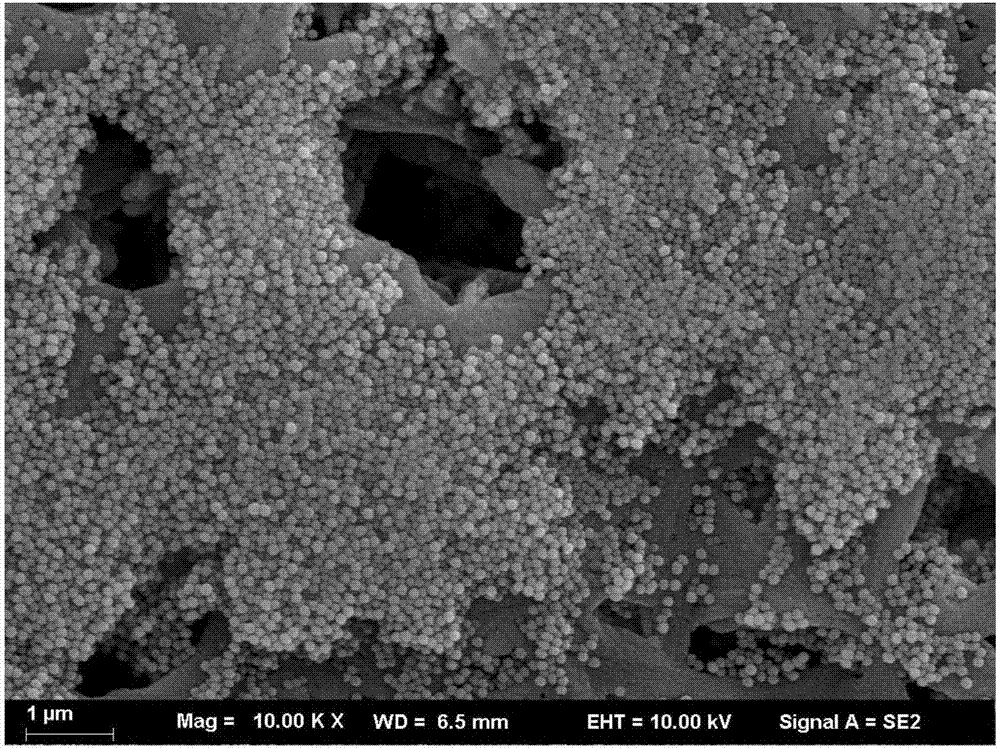

Preparation method of magnetic composite catalyst Ag/HNTs/Fe3O4

InactiveCN103638944AHigh catalytic activityGood magnetic response propertiesMetal/metal-oxides/metal-hydroxide catalystsNanotubeReducing agent

The invention relates to a preparation method of magnetic composite catalyst Ag / HNTs / Fe3O4, and belongs to the technical field of environmental function material preparation; a simple and effective chemical reduction method is used to prepare a Fe3O4 / Halloysite Nanotubes (HNTs / Fe3O4) magnetic composite material, then a silver nitrate solution and ammonia are mixed into a fresh silver ammonia solution as an oxidizing agent, glucose is used as a reducing agent, Ag nanoparticles are deposited on the magnetic composite material by a silver mirror reaction to prepare the magnetic composite catalyst Ag / HNTs / Fe3O4, and the magnetic composite catalyst Ag / HNTs / Fe3O4 is used for catalytic degradation of p-nitrophenol in a water solution.

Owner:JIANGSU UNIV

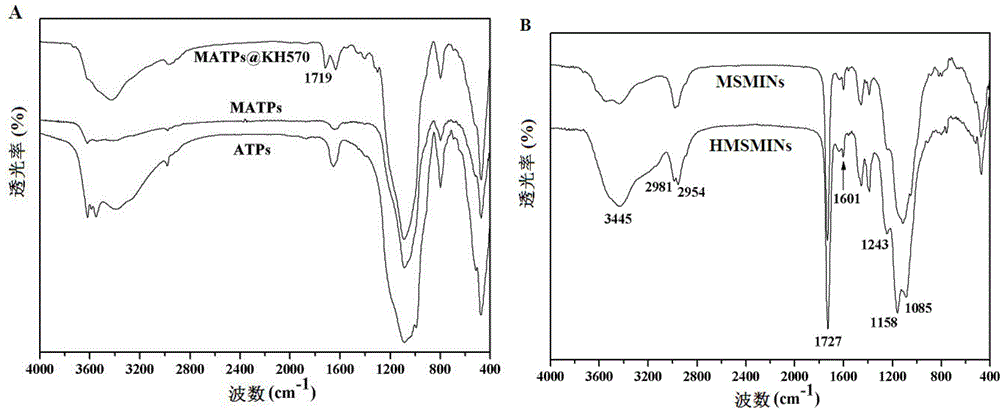

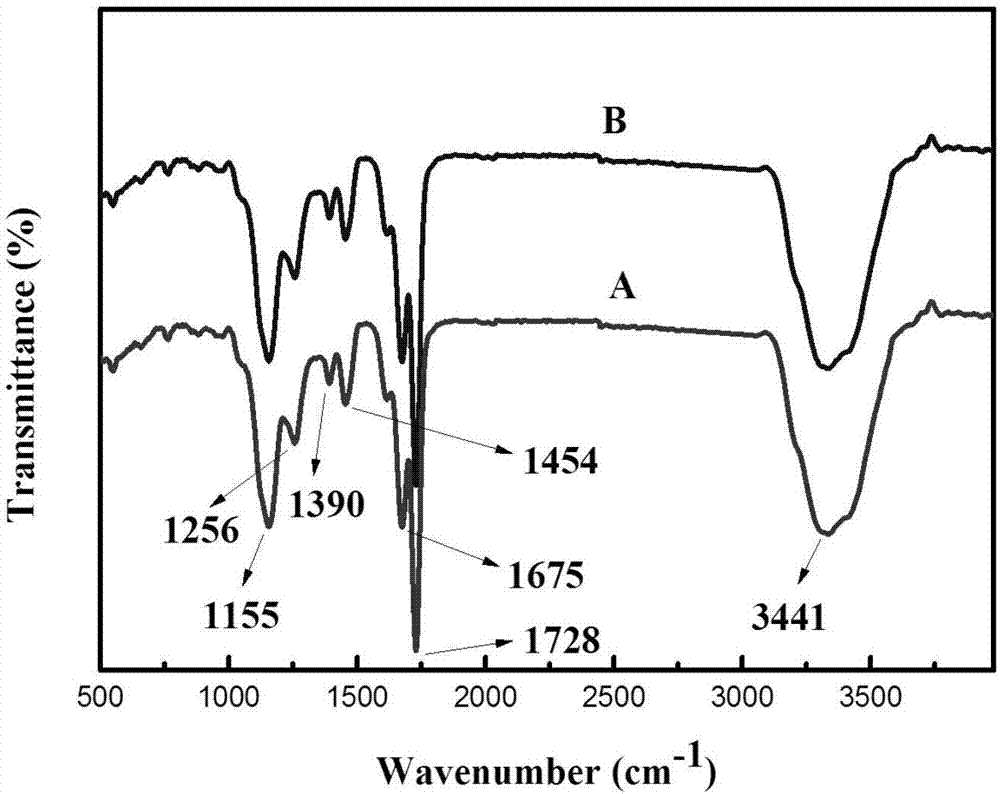

Lithium-ion imprinted polyvinylidene fluoride (PVDF) membrane as well as preparation method and application of lithium-ion imprinted PVDF membrane

InactiveCN107344095AImprove mechanical propertiesStable structureSemi-permeable membranesOther chemical processesLithiumPolyvinylidene difluoride

The invention relates to a preparation method of a bionic dopamine-modified lithium-ion imprinted polyvinylidene fluoride (PVDF) membrane and application of the bionic dopamine-modified lithium-ion imprinted PVDF membrane, belonging to the technical field of environmental function materials. Polyvinylidene fluoride (PVDF) is taken as a base membrane material, surface hydrophilic modification is carried out through dopamine, and a dopamine membrane is formed on the surface to improve the adhesivity and the hydrophilcity of the membrane material; the surface modification is carried out by using a silane coupling agent to further improve the performance of the membrane; and finally the bionic dopamine-modified lithium-ion imprinted PVDF membrane with high selectivity and good adsorption property is prepared through an imprinting polymerization process. The preparation method has a relatively good application prospect.

Owner:JIANGSU UNIV

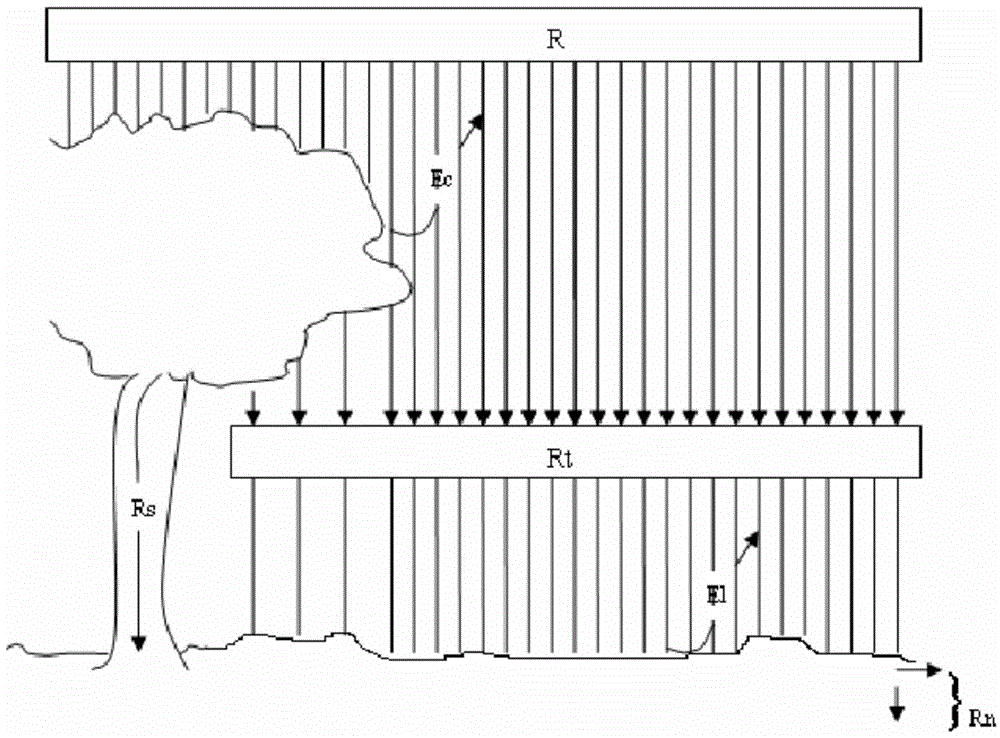

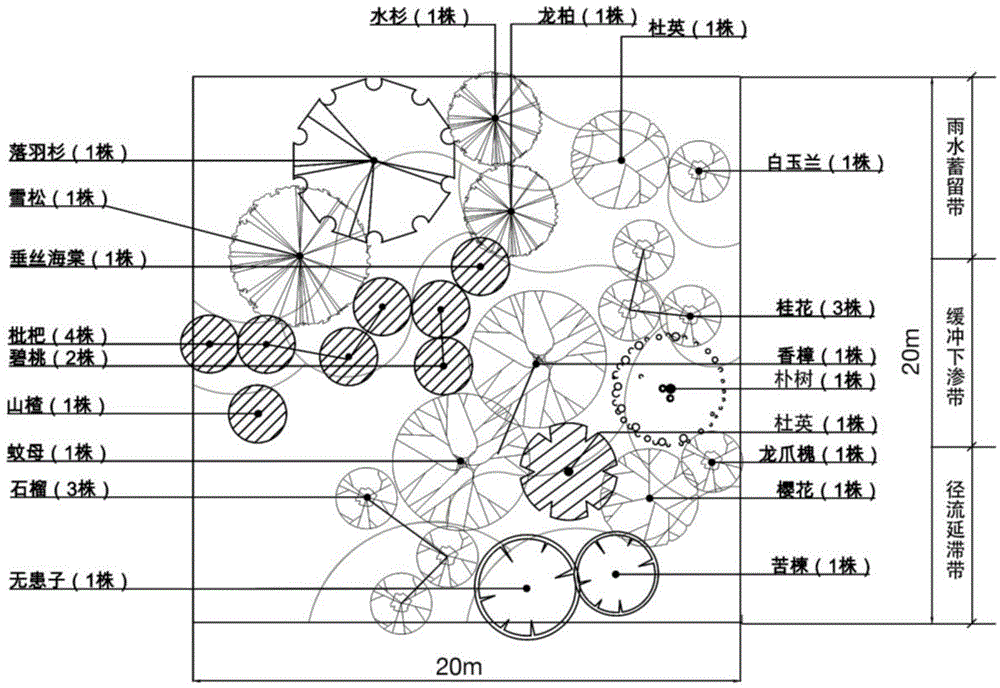

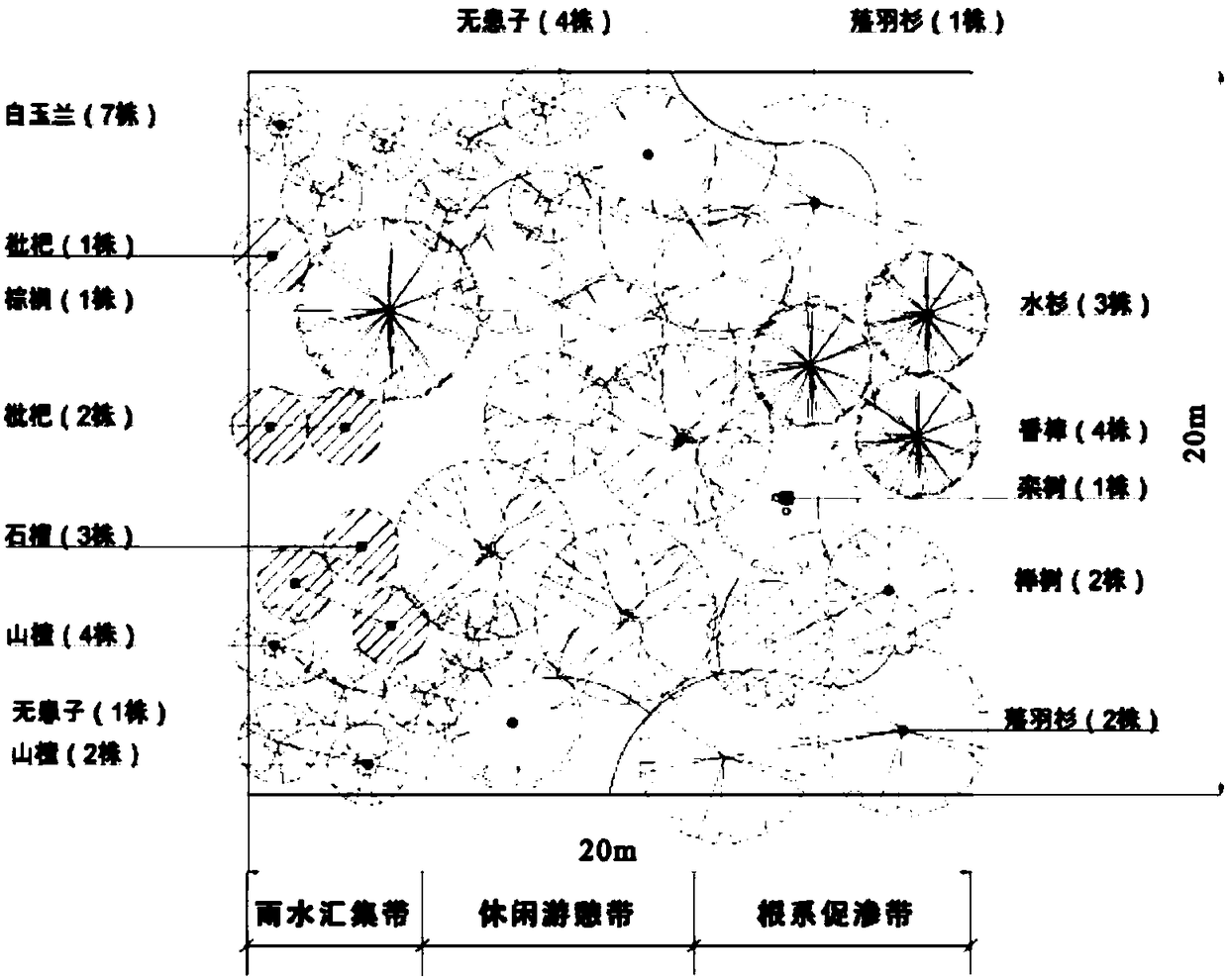

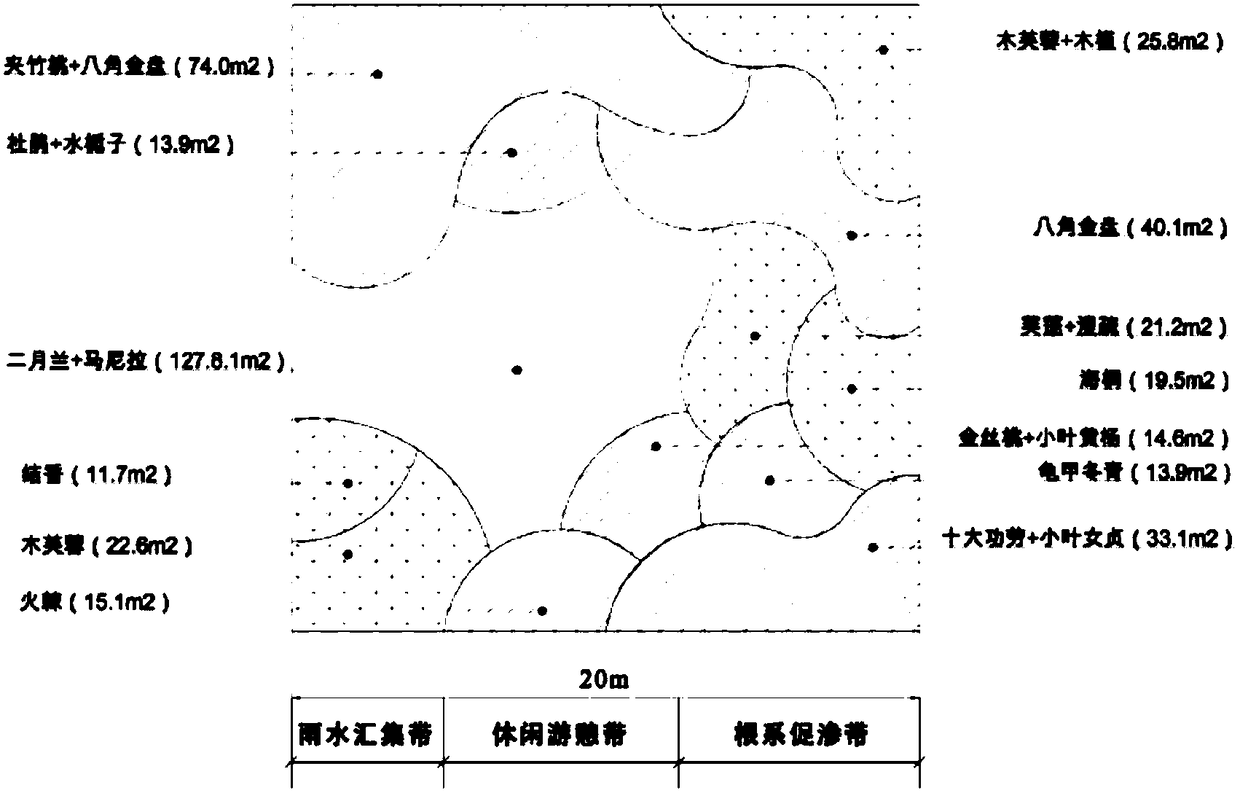

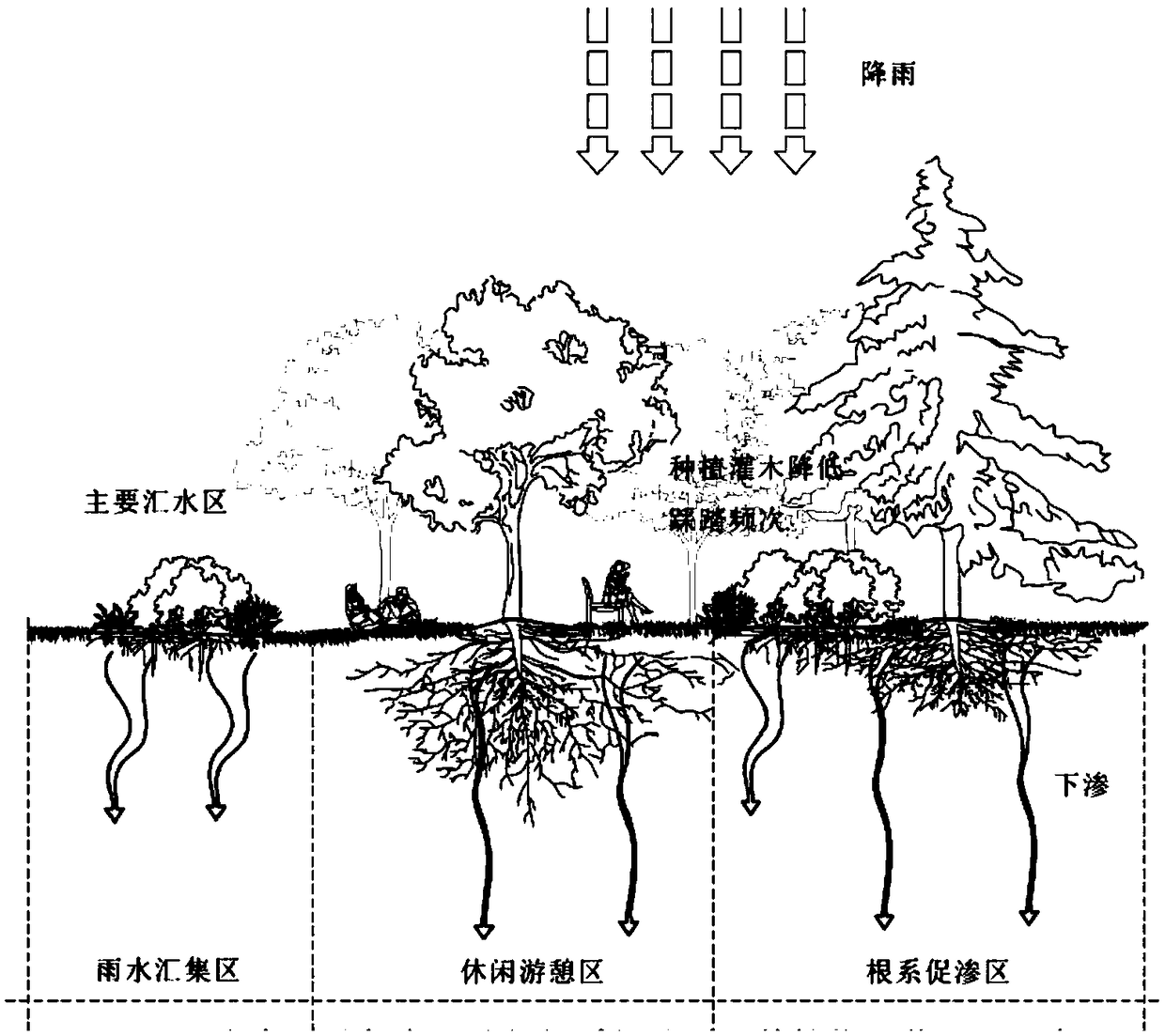

Method for building water storage type landscape plant community

The invention discloses a method for building a water storage type landscape plant community. The method includes the concrete steps that landscape plants are divided into a high functionality level, a medium functionality level and a low functionality level according to the water storage capacity per unit area; the landscape plants at all the levels are planted in a planting area in a combined mode to form the multiple-layer mixed plant community, the multiple-layer mixed plant community comprises a horizontal structure and a vertical structure, according to the area ratio of 3:2:3, the planting area is divided into a rain water storing and retaining zone away from a boundary, a buffering and infiltrating zone located in the middle part and a runoff retardation zone close to the boundary by the horizontal structure in the direction parallel to roads and the water edge boundary, and the planting area is divided into an upper layer, a middle layer and a lower layer by the vertical structure. The water storage type landscape plant community built by the method can play a role in storing and retaining rain water and reducing overland runoff, and bring ecological benefits and the environmental function into play, and has the excellent landscape aesthetics function.

Owner:SHANGHAI JIAO TONG UNIV

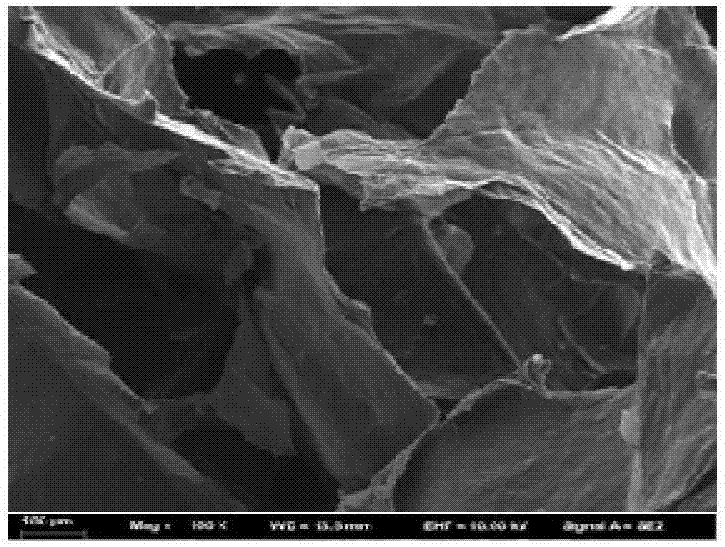

Preparation method of bamboo nanocellulose/reduced graphene oxide composite carbon aerogel and application of preparation method

InactiveCN107265434AImprove mechanical propertiesReduce manufacturing costCarbon preparation/purificationEthylenediaminePretreatment method

The invention belongs to the field of environmental function material preparation and pollutant treatment and relates to a preparation method of bamboo nanocellulose / reduced graphene oxide composite carbon aerogel. The preparation method comprises the steps of firstly adopting bamboo as a raw material, preparing the nanocellulose through a peroxide pretreatment method and an ultrasonic stripping method; inducing nanocellulose and graphene oxide solution gelatinization through ethylenediamine to prepare the bamboo nanocellulose / graphene oxide aerogel; and washing to remove residual ethylenediamine and obtaining low-density, hydrophobic, porous and flame-retardant bamboo nanocellulose / reduced graphene oxide composite carbon aerogel by combining a freeze drying method and a high-temperature pyrolysis method. The material has high adsorption capacity on oil and organic solvent pollutants. By adopting cheap and renewable bamboo as the raw material, the prepared composite carbon aerogel material is excellent in performance and suitable for large-scale production.

Owner:JIANGSU UNIV

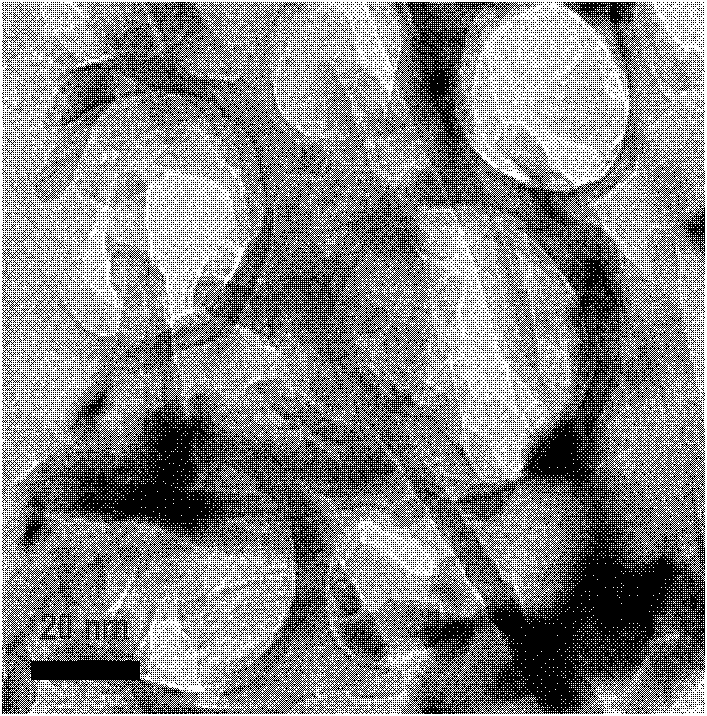

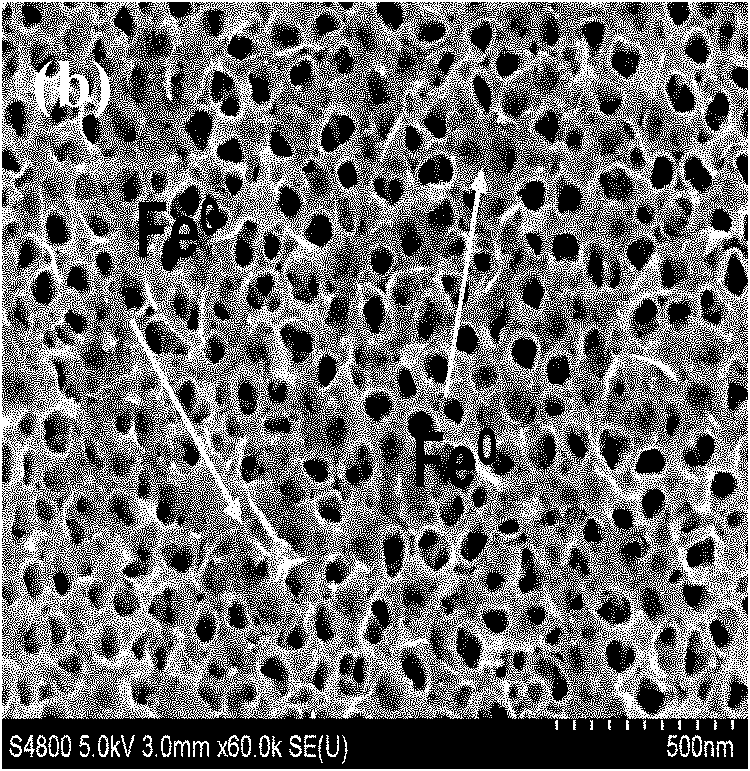

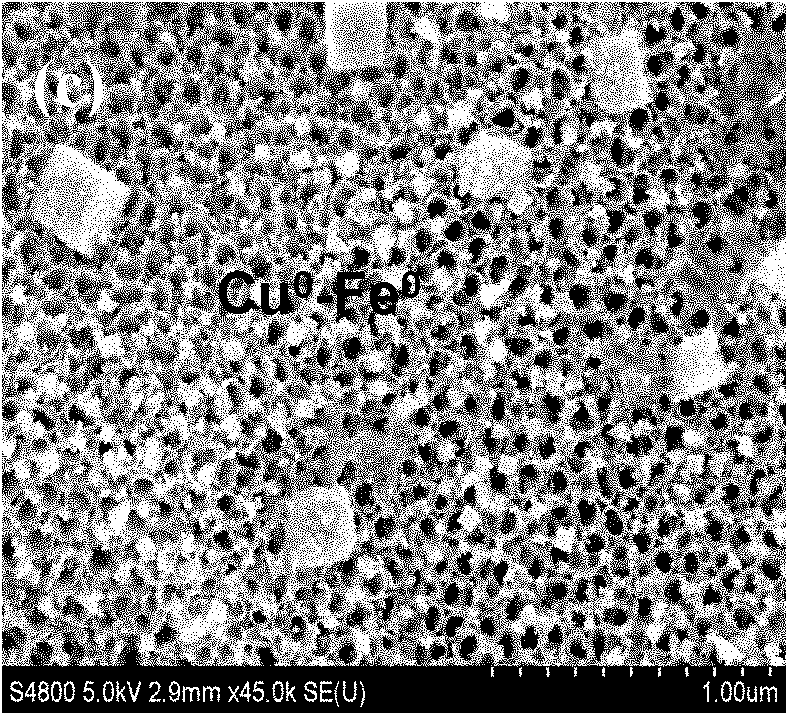

Environmental-function nano material Cu-Fe/TiO2 nanotube array, and preparation and application thereof

InactiveCN102071449AIncrease the areaAperture adjustableWater/sewage treatment by irradiationSurface reaction electrolytic coatingTio2 nanotubePhotocatalytic reaction

The invention discloses an environmental-function nano material Cu-Fe / TiO2 nanotube array, and preparation and application thereof. The preparation method of the Cu-Fe / TiO2 nanotube array comprises the following steps: preparing a TiO2 nanotube array by using an anodic oxidation process; depositing copper on the inside and surface of the TiO2 nanotube by using a pulse electrodeposition process, so that the Cu-TiO2 composite nanotube array has stronger adsorption capability and electronic conduction capability; and depositing iron nanoparticles on the inside of the Cu-TiO2 composite nanotube by using a pulse electrodeposition process, thereby increasing the concentration of hydroxyl free radicals in the photocatalytic reaction process. The electrodeposition of multiple metals by multiple steps is favorable for obtaining the uniformly-distributed granular photocatalytic nano material. The TiO2 nanotube array modified by iron and copper effectively widens the absorption range of TiO2 in visible light regions, reduces the photo-corrosion, enhances the photoelectric conversion efficiency, and shows excellent photocatalytic efficiency in the research on photocatalytic degradation of toxic organic pollutants and photo-reduction of heavy metal ions.

Owner:HUNAN UNIV

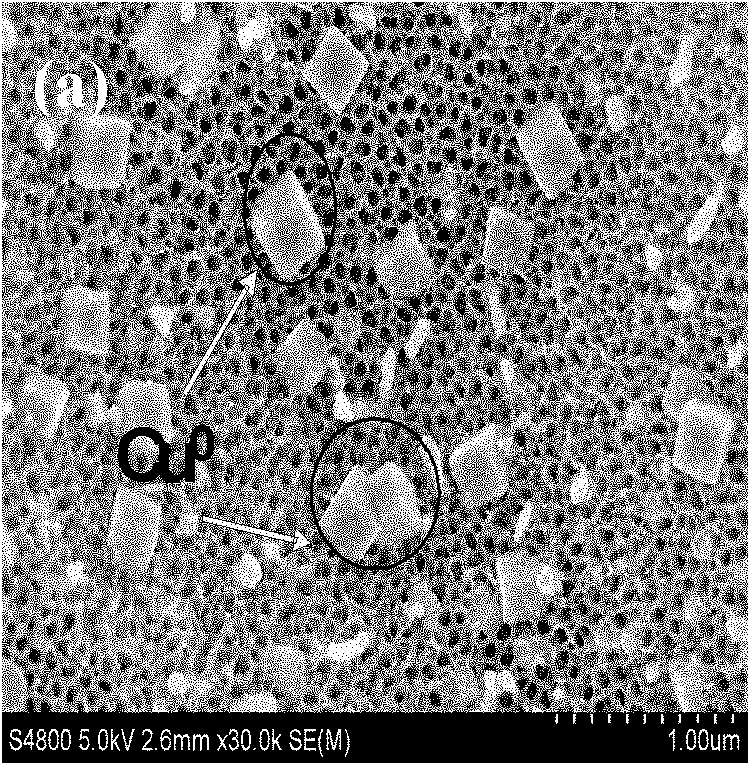

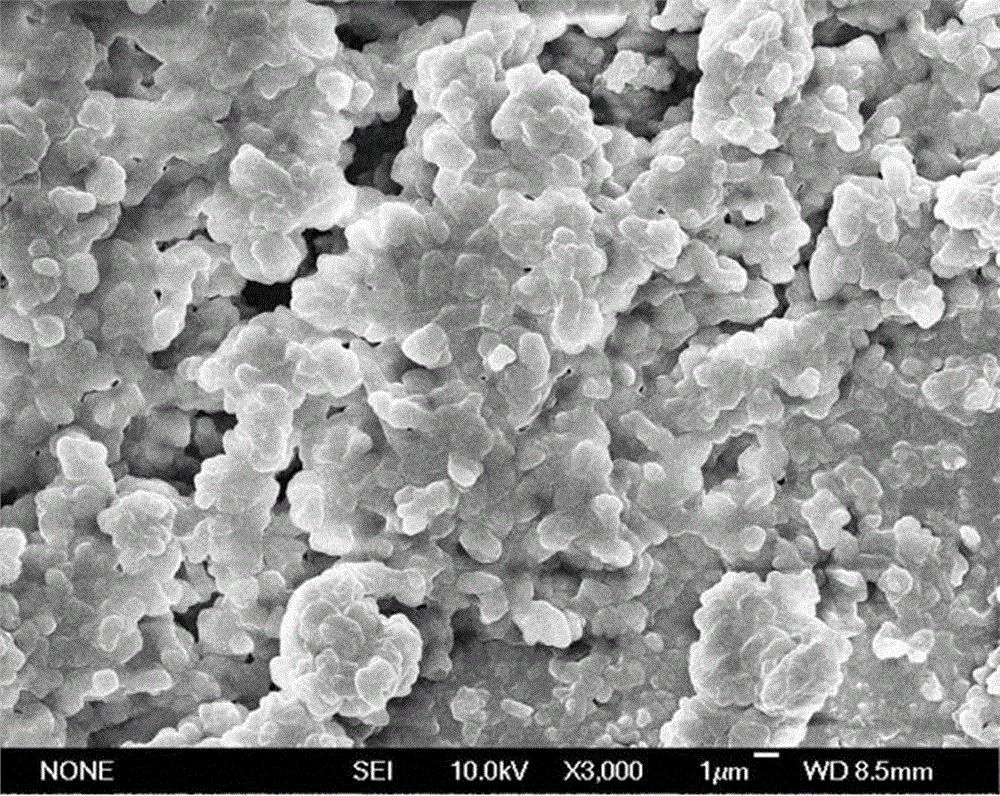

Environment functional material based on nanoparticles hydrated manganese oxide and preparing method thereof

InactiveCN101224408AHigh adsorption selectivityImprove adsorption capacityCation exchanger materialsOther chemical processesNanoparticleSafety control

The invention discloses an environmental function material based on nanometer particles hydrous manganese oxide and the corresponding preparation method. The frame of the material is cation exchange resin; the appearance of the material is black spherical particle with the particle size being 0.4 to 1.5 mm, the surface area being 3 to 30 m <2> / g, and the mean pore size being 0.5 to 10 nm; the solid supported quantity of the hydrous manganese oxide is 10 to 100 mg / g resin counted by manganese. The steps of the preparation method are that: a water soluble Mn (II) salt is dissolved in water to obtain a solution A; the cation exchange resin is put into an adsorption column and the solution A is led to flow through the column to contact and exchange with the resin; the obtained cation exchange resin is added into the mixed solution of sodium hypochlorite and NaOH for reacting 12 to 48 hours, and the solution is stirred continually during the reacting process; the resin is taken out and washed by distilled water until the Ph value reaches 6 to 8; the required materials are obtained after the resin is dried. The composite material obtained by the preparation has extremely high adsorptive selectivity and adsorption capacity to heavy metals, and can reduce the concentration of common heavy metals such as Pb <2+>, Cd <2+> and Zn<2+> to the Safety Control Standard.

Owner:NANJING UNIV

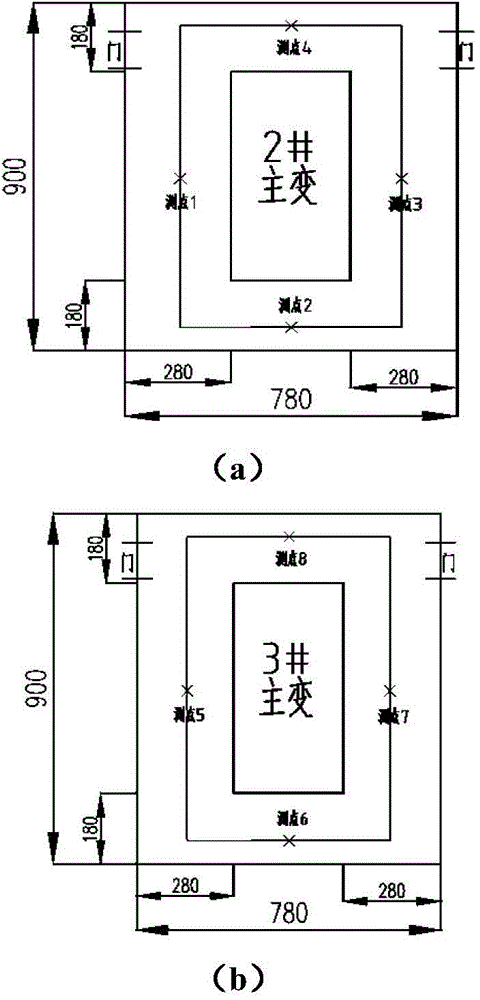

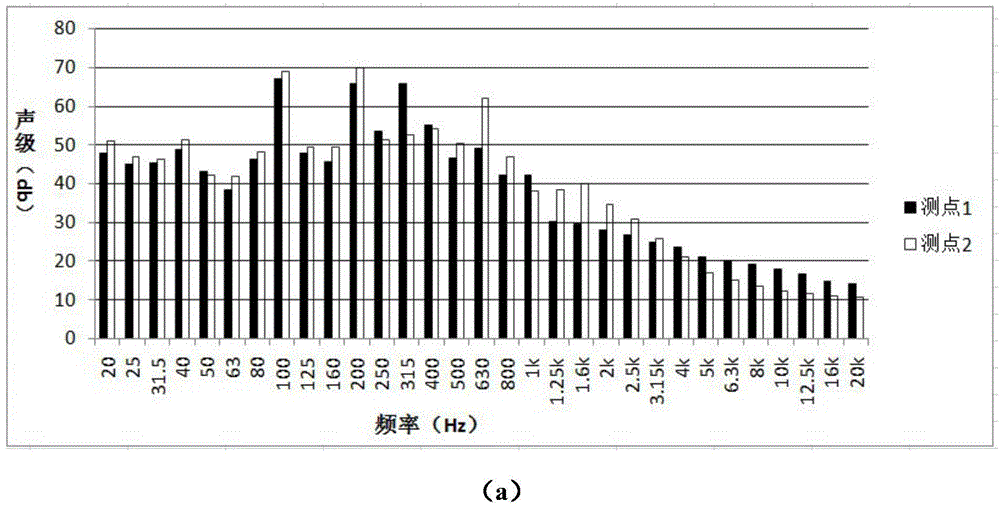

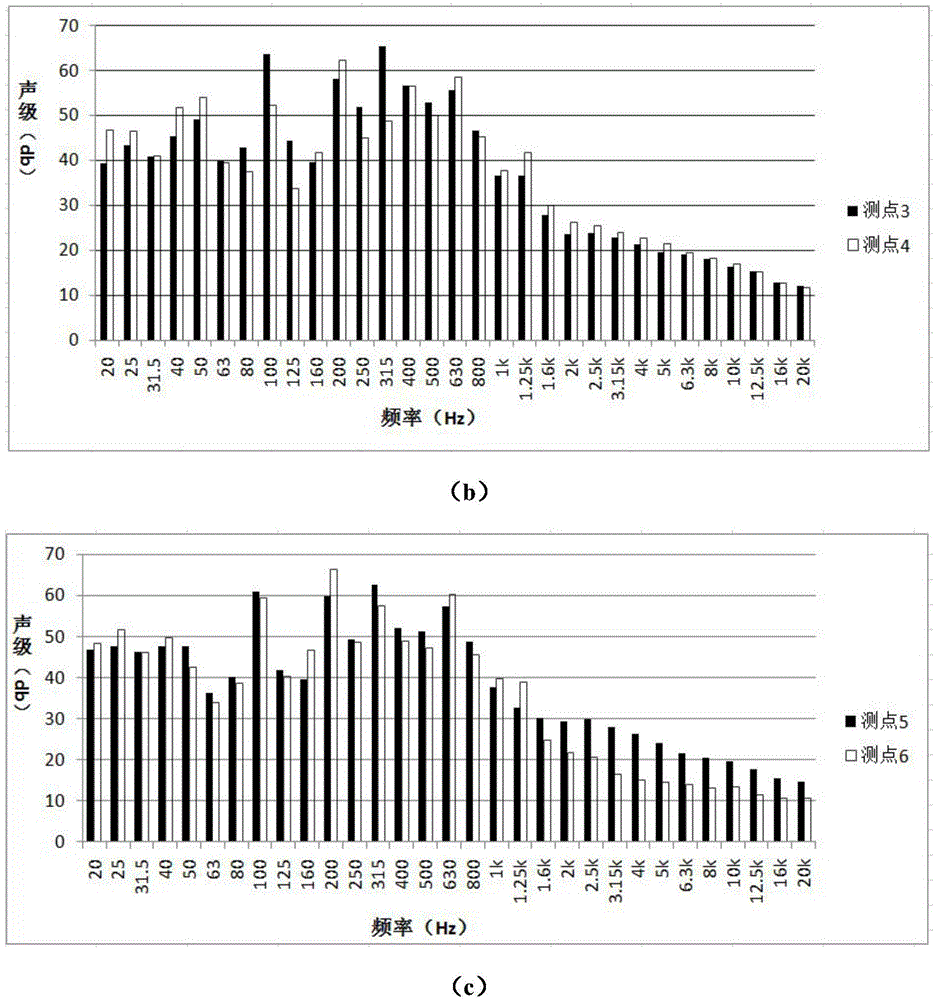

Transformer station noise reduction method

ActiveCN106285083AGood effectNo pollutionTransformer housesNoise suppressionFrequency spectrumSound sources

The invention relates to a transformer station noise reduction method; the method comprises the following steps: handling transformer station main sound source equipment and structure layout according to transformer station construction civil engineering drawings and equipment lists; selecting a reference station; using field measure and noise mapping technology to predict noise frequency spectrum characteristics and propagation influence rules of a newly built transformer station; carrying out type selecting and application designs for low frequency noise reduction sound absorbing materials, structure and devices; combining finite element simulation analysis, considering sound field, flow field and heat effect multi-field coupling, and carrying out scheme simulation optimization design while satisfying noise reduction, heat radiation and air channel optimization factors, thus reducing station border noise emission from the sound absorption, sound insulation and noise abatement aspects. When the construction is finished, the measured station border noise is 43.61dB, thus satisfying I type sound environment function zone standards; the novel method can effectively control station border noise emission, thus providing references for designs of same type transformer stations under increasingly strict environmental protection requirement situations.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

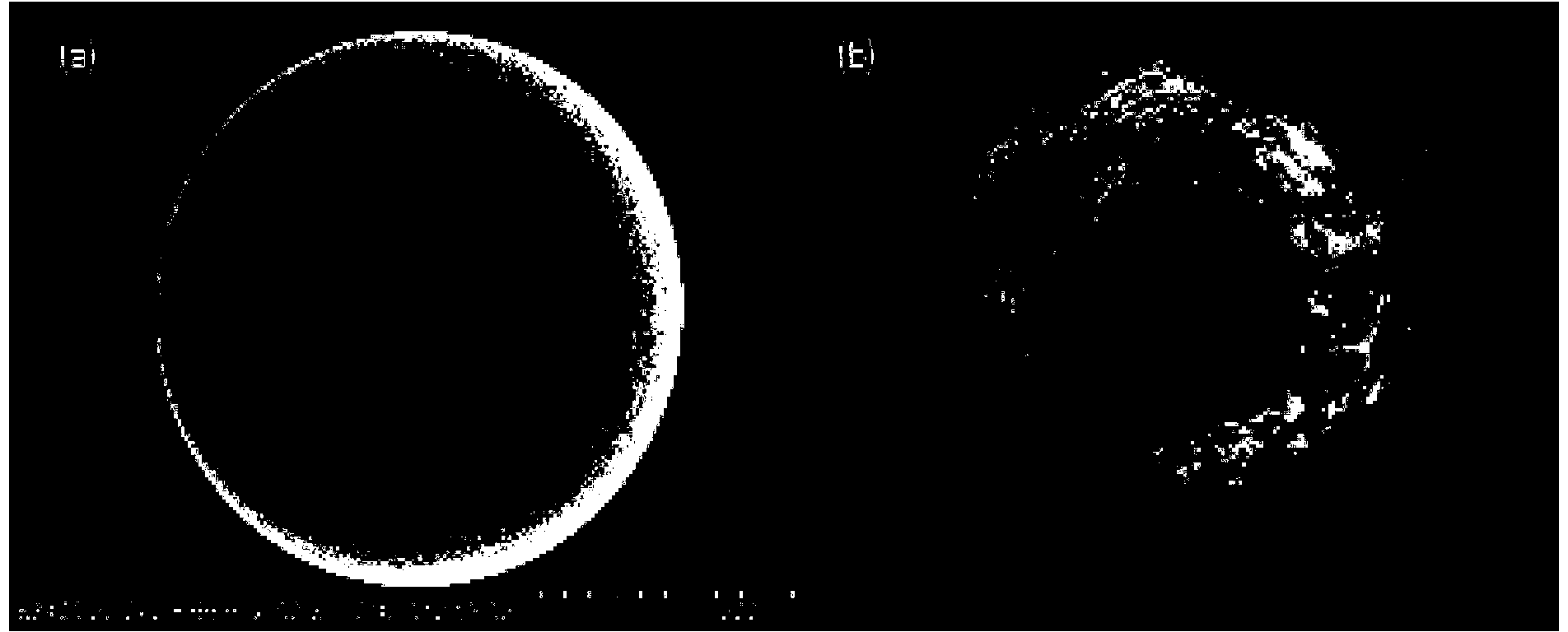

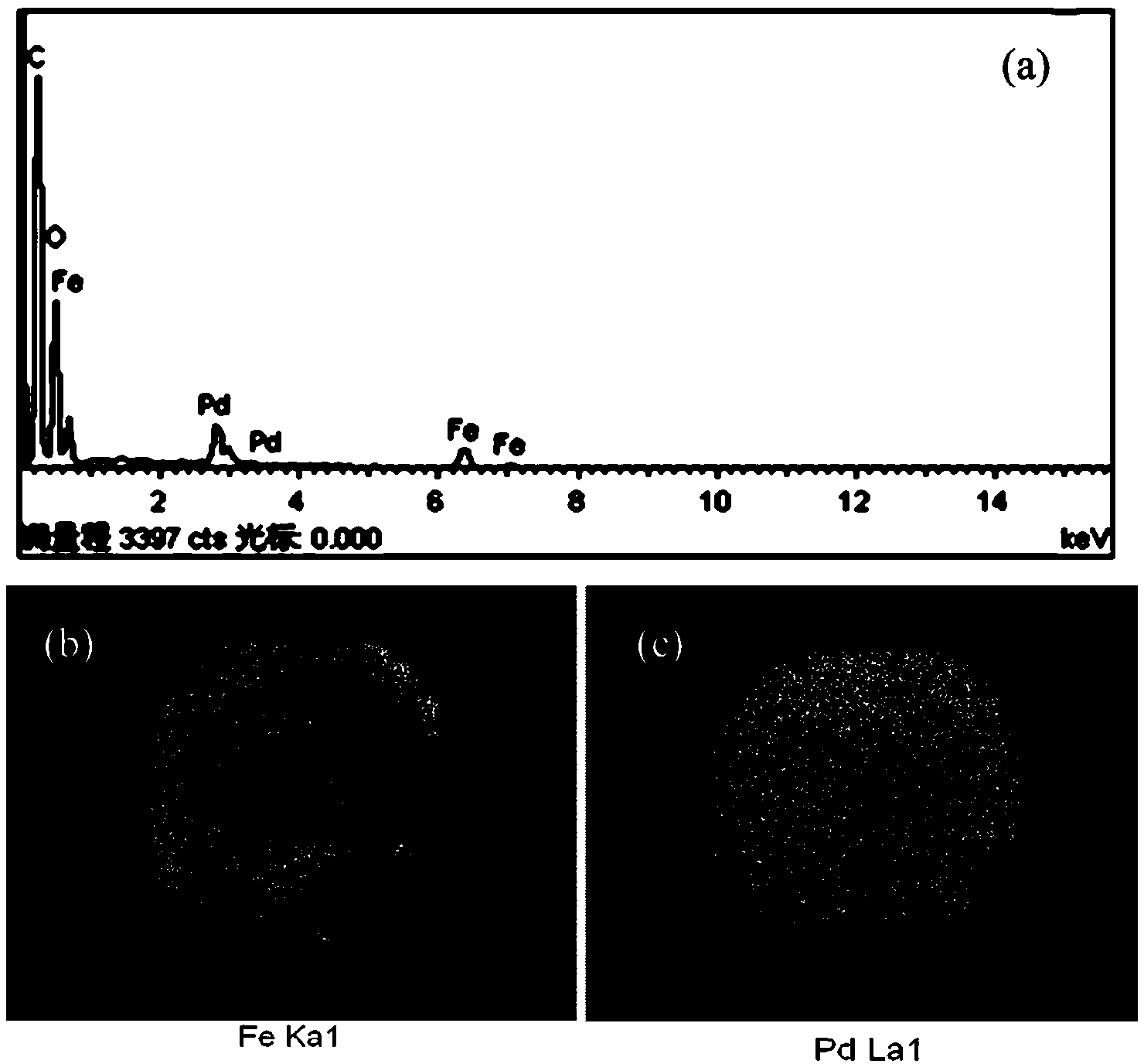

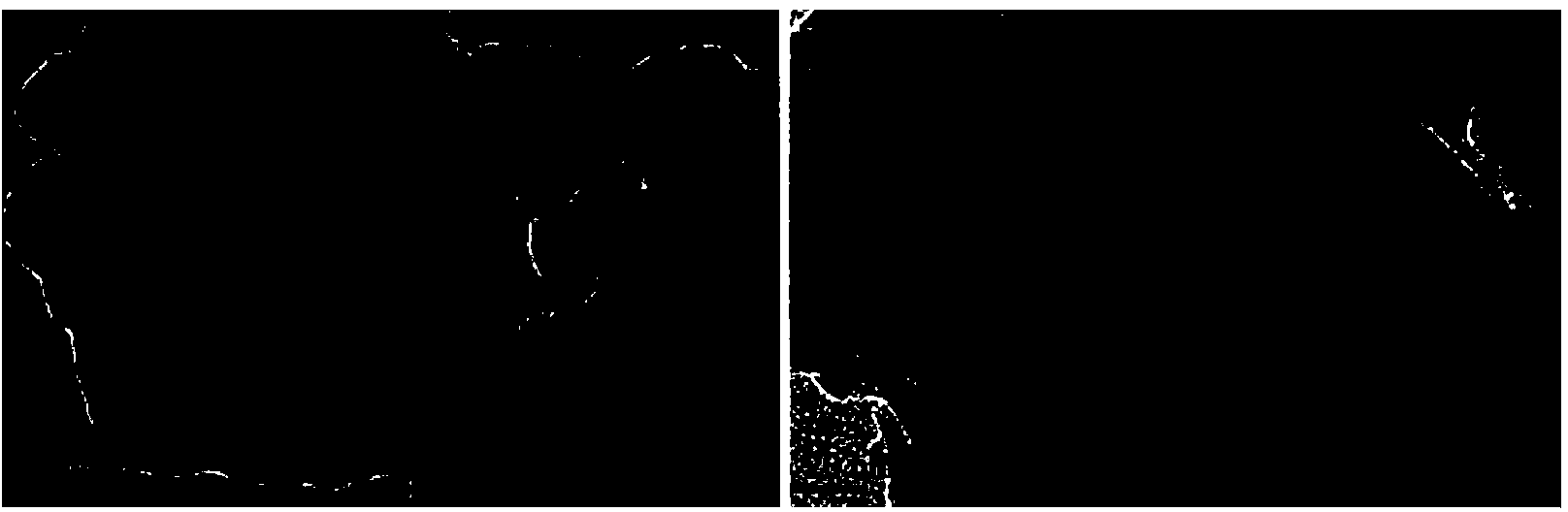

Applications of nanometer iron-palladium double-metal composite material, method for removing nitrates and phosphates in water, and subsequent treatment method

ActiveCN104386794AAvoid Excessive DissolutionAvoids the need to use hydrogen as a reducing agentOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPhosphateAcid washing

The present invention discloses applications of a nanometer iron-palladium double-metal composite material, a method for removing nitrates and phosphates in water, and a subsequent treatment method, and belongs to the field of environmental function composite materials. The preparation method of the loaded nanometer iron-palladium double-metal composite material comprises: respectively and sequentially loading Fe<3+> or Fe<2+> and Pd<2+> on a chelating resin containing the nitrogen pyridyl functional group in a chelating manner, adopting a NaBH4 solution to reduce the iron-palladium double-metal ion loaded on the resin, and carrying out vacuum drying to obtain the loaded iron-palladium double-metal composite material, wherein nitrates and phosphates in water can be synchronously removed, and the nitrate is reduced into the nitrogen gas. In addition, the hydrochloric acid solution is adopted to treat the failure loaded iron-palladium double-metal composite material, such that the composite material being subjected to the acid washing treatment can be recycled. According to the present invention, the nitrate removing efficiency and the phosphate removing efficiency are high, metal ion dissolution and other secondary pollution problems do not exist, the composite material can be reused, the operation condition is simple, and advantages of economy, environmental protection and the like are provided.

Owner:NANJING UNIV

Microwave-assisted inverse emulsion preparing method and application of heavy metal ion imprinting material

ActiveCN105688845AHigh yieldChemically activeOther chemical processesWater contaminantsSpecific adsorptionEmulsion

The invention relates to the field of environmental function adsorbents, in particular to a method for preparing a heavy metal ion imprinting material with a microwave-assisted inverse emulsion polymerization method and an application of the heavy metal ion imprinting material. The method includes the steps that heavy metal ions serve as imprinting ions, cyclodextrin matter and acrylamide matter are used as functional monometers, the functional monometers are polymerized in a microwave-assisted mode with the inverse emulsion method, and the imprinting material with the small and even particle size is prepared. The method for preparing the heavy metal ion imprinting material is easy to operate, and the imprinting material has the advantages of being small in particle size, large in specific surface area, high in specific adsorption capacity and the like.

Owner:TAIYUAN UNIV OF TECH

Recovery method of sulfonated polyether ether ketone (SPEEK) / polyaniline (PANI) / propylene glycol monomethyl acetate (PMA) composite proton exchange membrane

InactiveCN102838777AReduce recycling costsWide variety of sourcesPlastic recyclingRecovery methodHeteropoly acid

The invention discloses a recovery method of a sulfonated polyether ether ketone (SPEEK) / polyaniline (PANI) / propylene glycol monomethyl acetate (PMA) composite proton exchange membrane. The composite proton exchange membrane is formed by composition of SPEEK with sulphonation degree of 50%-70%, PANI and PMA. The membrane is firstly pretreated. Then the membrane is dissolved into 1-methyl-2-pyrrolidone solutions to produce membrane solutions. Eventually, casting film forming is carried out to produce a recasting membrane, and the proton exchange membrane is formed. The recovery method has the advantages that a waste membrane or leftover materials of the SPEEK / PANI / PMA composite proton exchange membrane are used as the raw materials, sources of the raw materials are wide, raw material cost is low, the recovery preparation process and needed instruments are simple, manufacturing cost of the membrane is reduced, meanwhile, the problem of treatment of the waste membrane is solved, environmental pollution is avoided, and significant environmental functions are achieved.

Owner:NANTONG UNIVERSITY +1

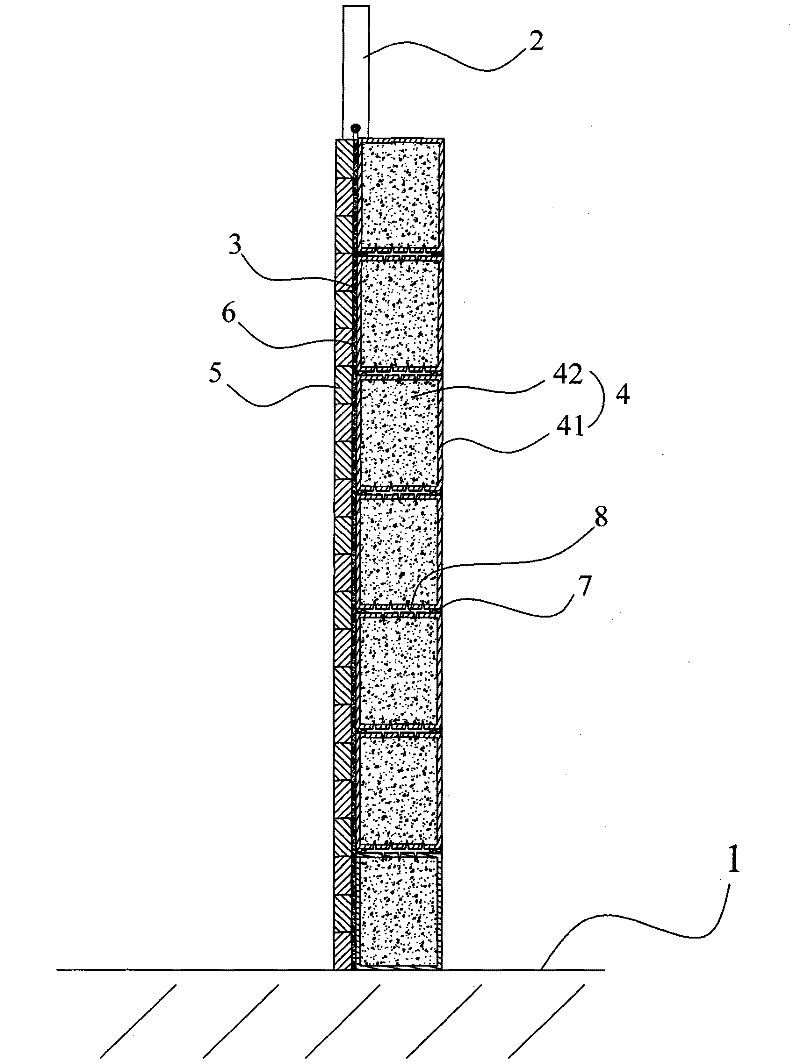

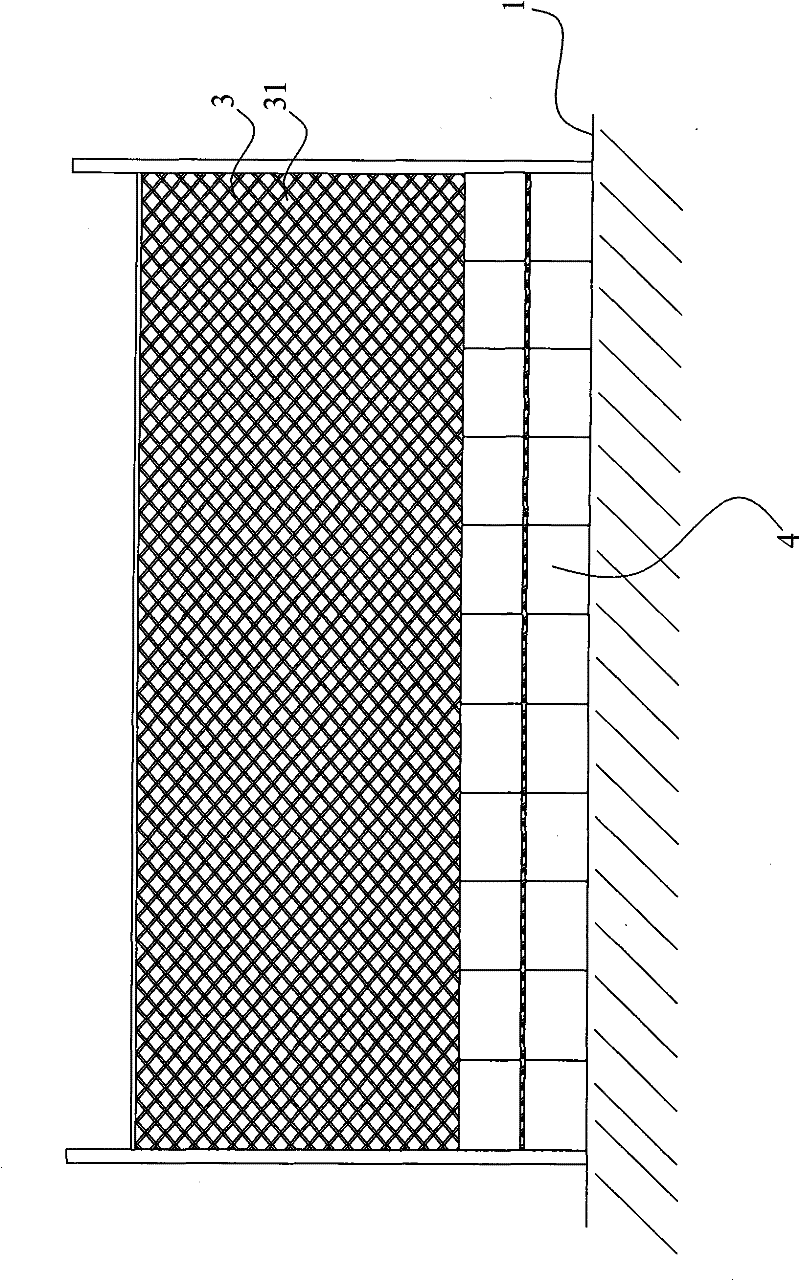

Ecological greening wall and constructing method thereof

The present invention relates to an. The ecological greening wall comprises a plurality of fixing posts stood on the ground and arranged at interval, wherein reinforcements with holes are fixedly fixed among the fixing posts, and are vertically arranged along the fixing posts; planting bags for planting and greening are piled on at least one side in two sides of each reinforcement; the planting bags comprises air and pervious bag bodies and plant growth material filled in the air and pervious bag bodies; and the air and pervious bag bodies and the reinforcements are fixedly connected by reinforcement wall bodies to enable concrete wall bodies, the reinforcements and the planting bags to form a whole body. Thus, the planting bags are used for greening to form the ecological greening wall having the advantages of simple structure, stable entirety, heat and sound insulation and easy construction. The ecological greening wall has a greening and environmental function, and can be widely applied to the aspects of sound insulating walls on house base walls, highway insulation belts, guiderails on two sides and viaducts, and the like.

Owner:张宇顺

Method for preparing diatomite-based functional material for interior walls

The invention discloses a preparation method of a diatomite-based interior wall functional material, which comprises the following steps in sequence: a) weighing diatomite, sintering aid, dispersant, water, and binder according to a certain ratio and then mixing , add zirconia balls and grind in a high-efficiency fast grinder, filter and dry in an electric blast constant temperature drying oven, and then calcined after crushing and electro-hydraulic sample preparation to obtain a diatomite-based functional ceramic body; b) silicon A certain amount of tourmaline, sintering aid, water, dispersant, and binder are added to diatomite, and after ultra-fine grinding, the slurry is sprayed onto the surface of diatomite-based functional ceramics, dried and calcined at low temperature, that is A diatomite-based interior wall functional material with environmental functional properties was obtained. The product obtained by the invention has large specific surface area, good adsorption performance, environmental friendliness and low cost, and has good market prospect.

Owner:营口渤海科技有限公司

Hot air vulcanization process of multi-layer winding rubber straight tube with polyester film as coating

A hot-air vulcanization process for multi-layer winding rubber straight tubes with polyester film as the coating layer. Polyester film is used as the coating layer of rubber tube vulcanization. During vulcanization, the product quality can be guaranteed without applying vulcanization pressure, reducing It reduces vulcanization energy consumption, saves cost, and can make the vulcanized hose surface smooth and beautiful without impurities. Moreover, this kind of polyester film can be recycled and reused. In the environment where existing resources are becoming more and more scarce, it plays the role of environmental protection and resource saving; It is very good to ensure the safety of production. The rubber hose produced by the invention can be used for the flexible connection of diesel engine pipelines or the flexible connection of water and gas pipelines of equipment such as automobiles and engineering machinery.

Owner:XIAMEN CHUANGXINYUAN RUBBER PROD

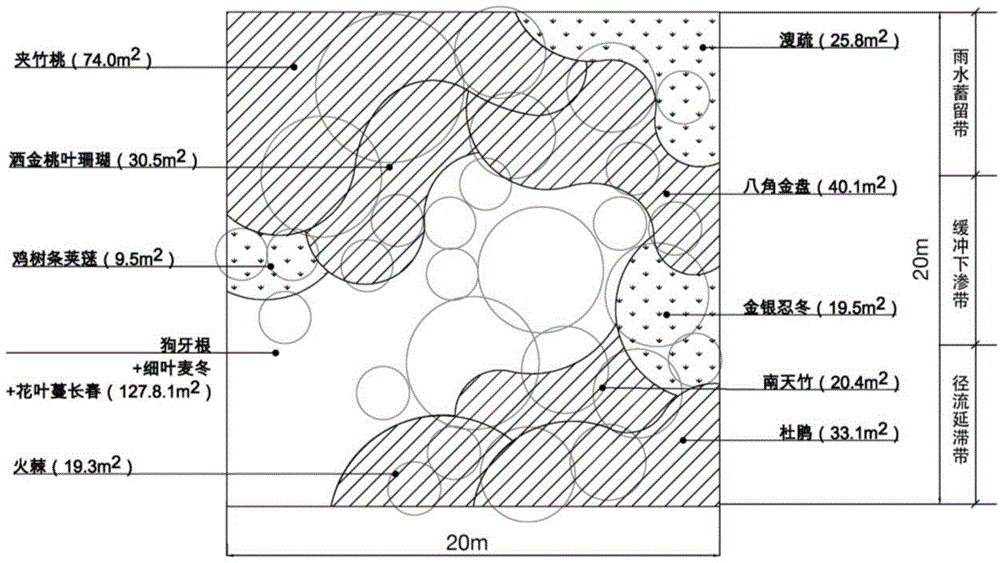

Method for constructing root system permeation enhancing landscape plant community

ActiveCN108157111AReduce management costsImprove environmental functionFlowers cultivationCultivating equipmentsPlant communityGarden plants

The invention discloses a method for constructing a root system permeation enhancing landscape plant community. The method includes measuring root system data of common landscape plants and corresponding physical-chemical properties of soil, acquiring relation data between the landscape plants and soil permeation, ranking the comprehensive permeation enhancing ability of the landscape plants for the soil, and selecting landscape plant species having high permeation enhancing ability; dividing the landscape plants into a strong functional type, a intermediate functional type, and a weak functional type according to the comprehensive permeation enhancing ability of the landscape plants for the soil; and planting the landscape plants in a planting region in a complex manner, and forming a complex hybrid plant community. The complex hybrid plant community includes a landscape community suitable for high tread frequency green lands and a landscape community suitable for low tread frequencygreen lands. The constructed landscape plant community having high rainwater root system permeation enhancing ability can store permeated rainwater and reduce surface runoff, can generate ecological benefits and play an environmental function, and has an excellent landscape aesthetic function.

Owner:SHANGHAI JIAO TONG UNIV +1

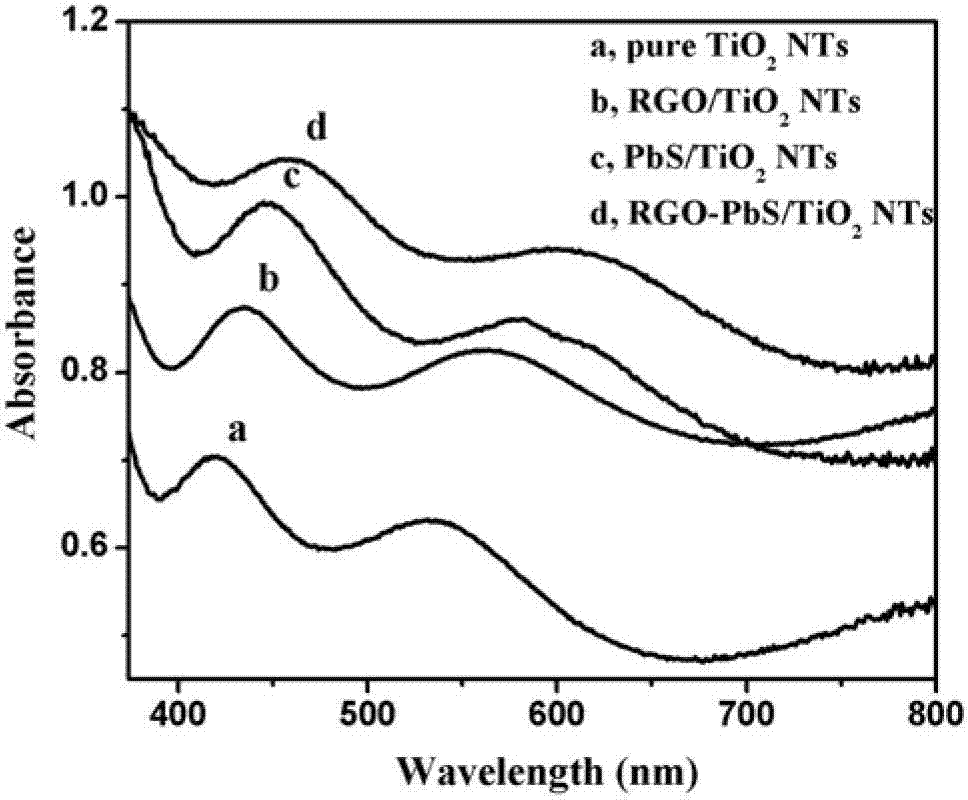

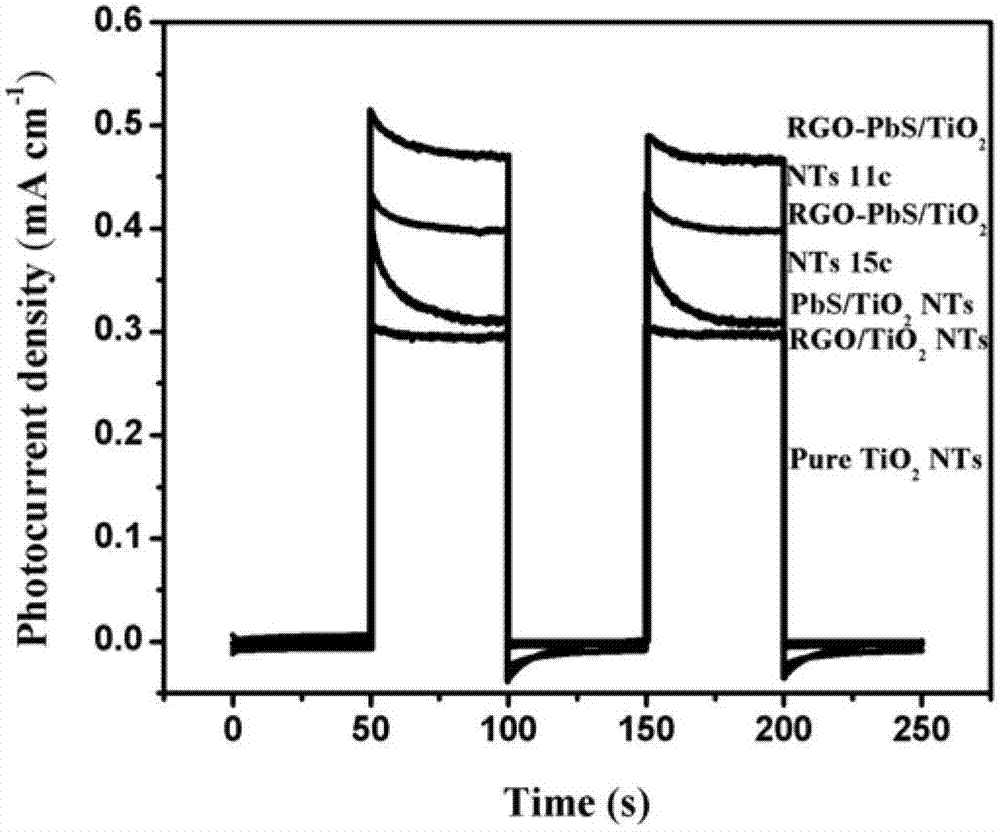

Composite photocatalyst, its preparation and application

InactiveCN102962080ALarge specific surface areaAbsorption Strength and Absorption Range and Strength EnhancementWater/sewage treatment by irradiationWater contaminantsWastewaterSemiconductor Nanoparticles

The invention relates to a composite photocatalyst, its preparation and application. In the invention, a graphene-PbS / TiO2 nano-composite material is adopted. Graphene and PbS semiconductor nanoparticles are compounded on an outer surface of a titanium dioxide nanotube array, an opening of the nanotube array and an inner surface through electrodeposition, thus obtaining the composite material. The novel nano-material graphene-PbS / TiO2 with efficient environmental functions can be used as a photocatalyst, and has excellent performance in treatment of organic pollutant wastewater.

Owner:HUNAN UNIV

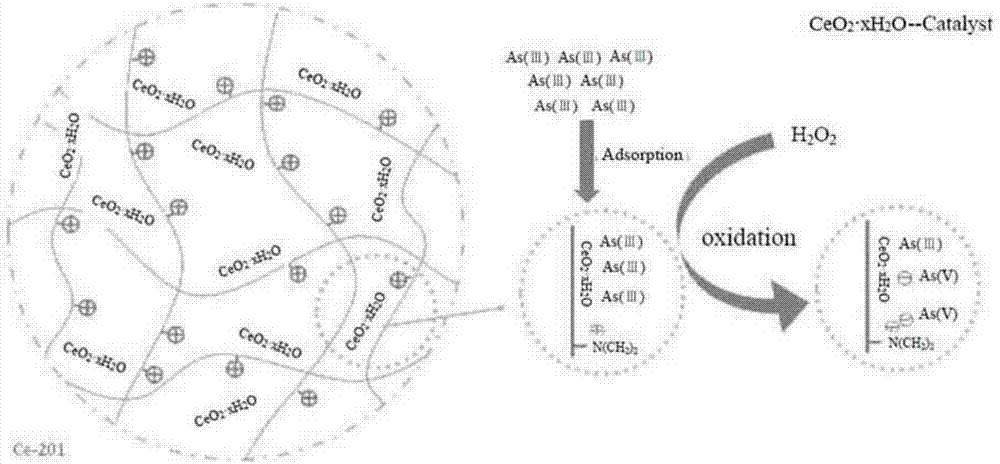

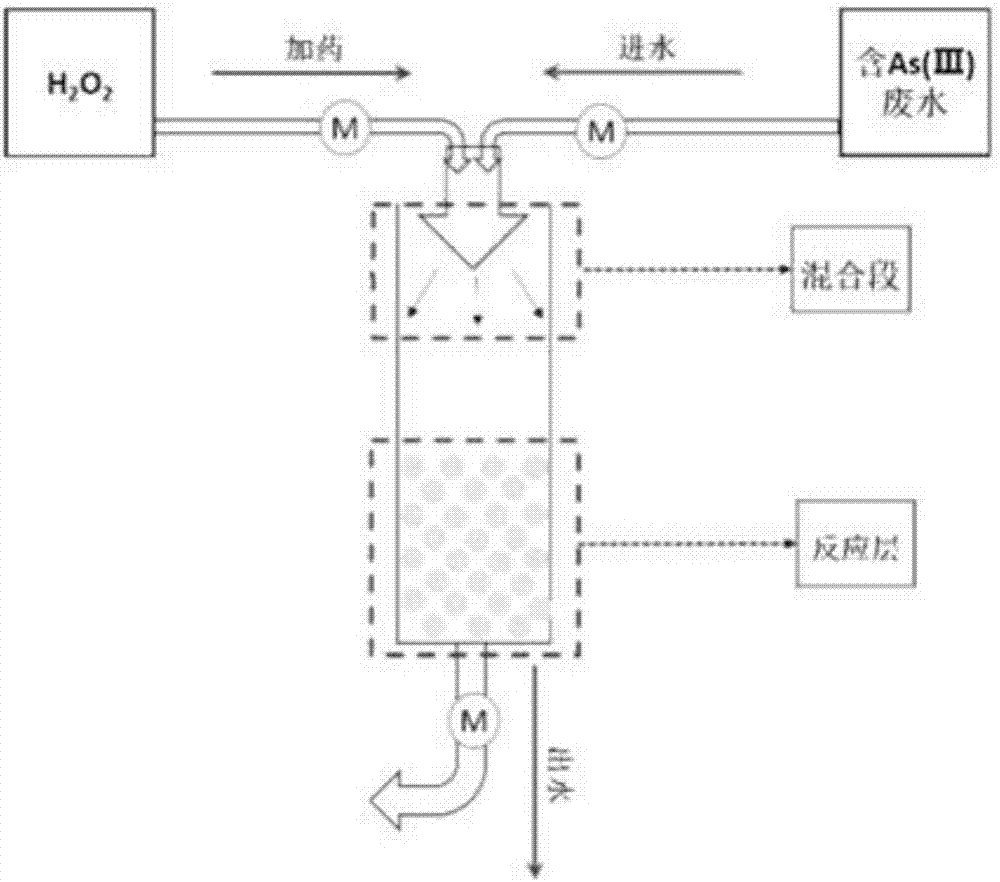

Preparation method of novel difunctional resin matrix nanocomposite material, composite material and method for removing trivalent arsenic in depth of water body

ActiveCN107457000AReduce dosageStrong oxidizingOrganic-compounds/hydrides/coordination-complexes catalystsTreatment involving filtrationIndustrial waste waterCatalytic oxidation

The invention discloses a preparation method of a novel difunctional resin matrix nanocomposite material, a composite material and a method for removing trivalent arsenic in the depth of a water body, belonging to the field of drinking water, industrial waste water and environmental function nanometer materials. The preparation method comprises the steps of taking strongly basic anion exchange resin as a raw material, and enabling (NH4)2Ce(NO3)6, HNO3 and NaNO3 water solutions with different proportions to serve as reagents to prepare the nanocomposite material through reaction. In the nanocomposite material, the carrier content of Ce is 50-200mg / g. The novel difunctional resin matrix nanocomposite material has dual functions of catalytic oxidation and adsorption, of which the concrete manifestation is that H2O2 synergistic effect is used for realizing oxidation and synchronous absorption of As (III) in the water body, the removal capacity of micro-As (III) in the water body is improved by a large margin, compared with the same traditional type of As (III)-removing technology, the proportion is generally improved by more than 20 times, the arsenic in the water body can be effectively removed, and the water body environment quality is improved.

Owner:NANJING UNIV

Methods and apparatus for coded time-of-flight camera

ActiveUS9778363B2Accurate measurementDepth accurateElectromagnetic wave reradiationWiener deconvolutionMultipath interference

In illustrative implementations, a time-of-flight camera robustly measures scene depths, despite multipath interference. The camera emits amplitude modulated light. An FPGA sends at least two electrical signals, the first being to control modulation of radiant power of a light source and the second being a reference signal to control modulation of pixel gain in a light sensor. These signals are identical, except for time delays. These signals comprise binary codes that are m-sequences or other broadband codes. The correlation waveform is not sinusoidal. During measurements, only one fundamental modulation frequency is used. One or more computer processors solve a linear system by deconvolution, in order to recover an environmental function. Sparse deconvolution is used if the scene has only a few objects at a finite depth. Another algorithm, such as Wiener deconvolution, is used is the scene has global illumination or a scattering media.

Owner:MASSACHUSETTS INST OF TECH

Nitric oxide adsorbent prepared by supercritically modifying natural zeolite

InactiveCN102091592AReduce manufacturing costOther chemical processesAluminium silicatesSorbentNitric oxide

The invention relates to the technology of natural zeolite material modification and aims to provide a nitric oxide adsorbent prepared by supercritically modifying natural zeolite. The adsorbent is prepared by a method comprising the following steps: dissolving a volatile metallo-organic compound into a supercritical medium and placing the natural zeolite undergoing dealuminzation and ammonium exchange in the atmosphere to carry out supercritical replacement in the supercritical atmosphere; drying at the temperature of 120 DEG C after alcohol washing and water washing and then roasting at the temperature of 300-600 DEG C, thus obtaining the metal element containing nitric oxide adsorbent prepared by modifying natural zeolite, wherein the volatile metallo-organic compound is any one of ester, alcoholate or corresponding metal chloride which can be dissolved in the supercritical medium of Ti, Zr, Al, V or Sn. The adsorbent can be used as the environmental function material and is used for adsorbing and purifying the industrial tail gases, flue gases and automobile tail gases containing nitric oxides. The nitric oxide adsorbent has low production cost and has wide market prospect as the environmental function material.

Owner:ZHEJIANG UNIV

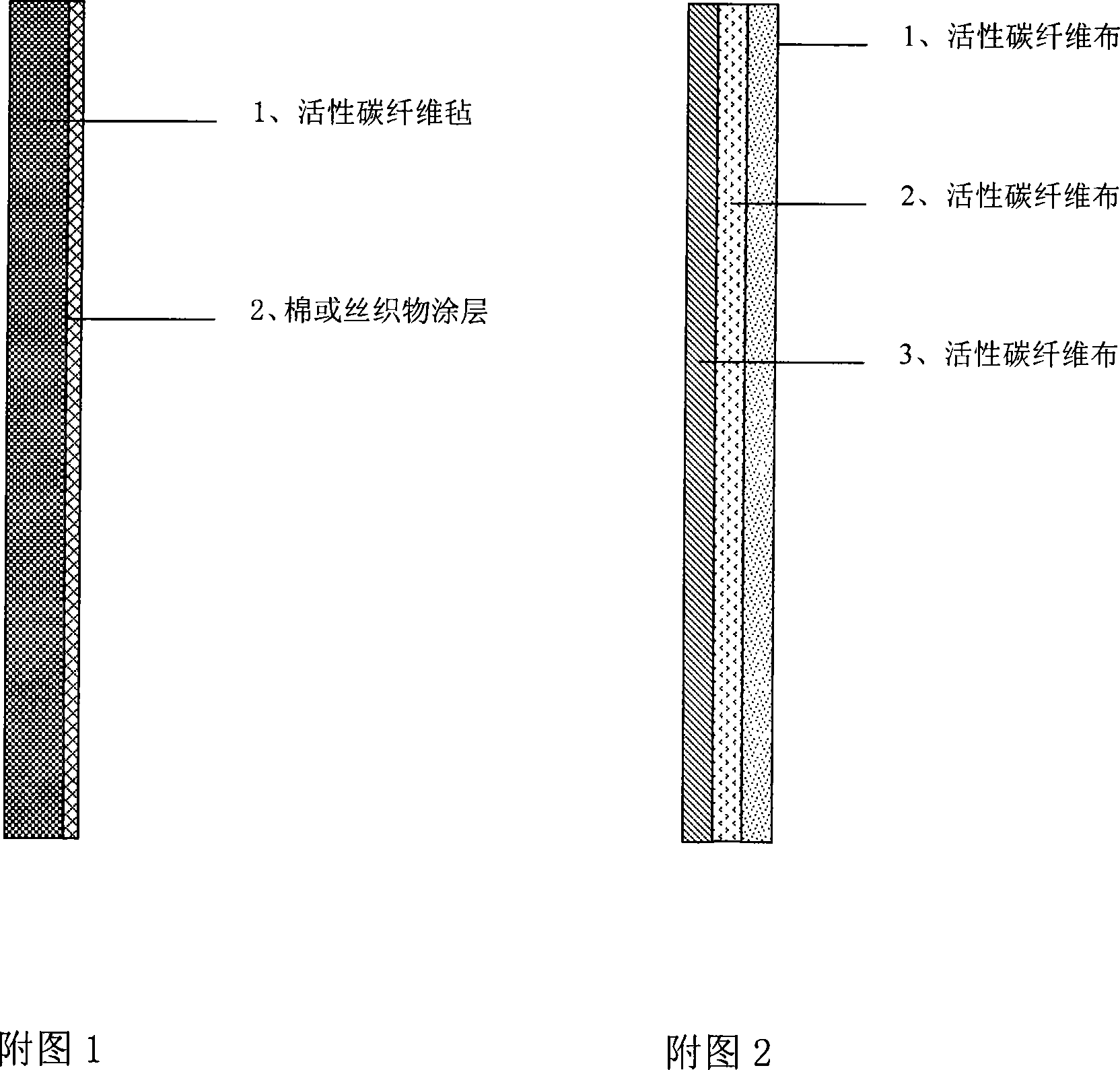

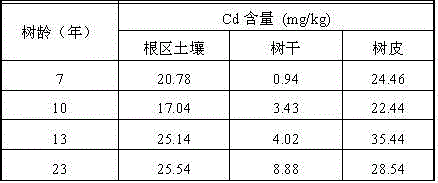

Multifunctional anti toxic tapestry

InactiveCN101225579ANo change in adsorptionImprove adsorption capacityLayered productsOrnamental structuresFiberYarn

The invention relates to a multifunctional antigas tapestry, which is mainly used to overcome the defect of the prior common tapestry with only appreciation of art and without absorption function for noxious gas and radiation ray. The multifunctional antigas tapestry is characterized in that the tapestry can be made by taking the activated carbon fiber yarn as raw material and using the weaving method of common carpet; or taking the activated carbon fiber felt as raw material and coating a layer of cotton or silk fabric with flare or other artistic effect on the felt surface (the felt surface must be polished before processing) based on the coating technique; or taking the activated carbon fiber fabric as raw material and printing the various decorative textures and patterns on the fabric surface after sewing with stacked layers; or taking the yarn mixed with activated carbon short fiber and terylene short fiber as raw material and using the weaving method of common carpet. The multifunctional antigas tapestry has the advantages that the tapestry can adsorb the toxic gas and the harmful radiation ray emitted by the decorative materials in living room, so the tapestry has not only the appreciation of art but also the specific environmental function.

Owner:SHENGHONG GRP CO LTD

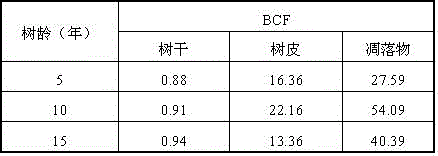

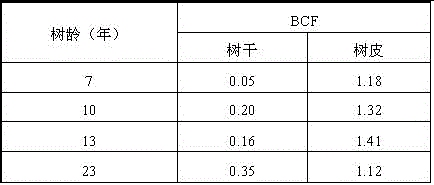

Method for repairing heavy metal cadmium contaminated soil in drought regions by aid of populus hopeiensis

Owner:LANZHOU UNIVERSITY

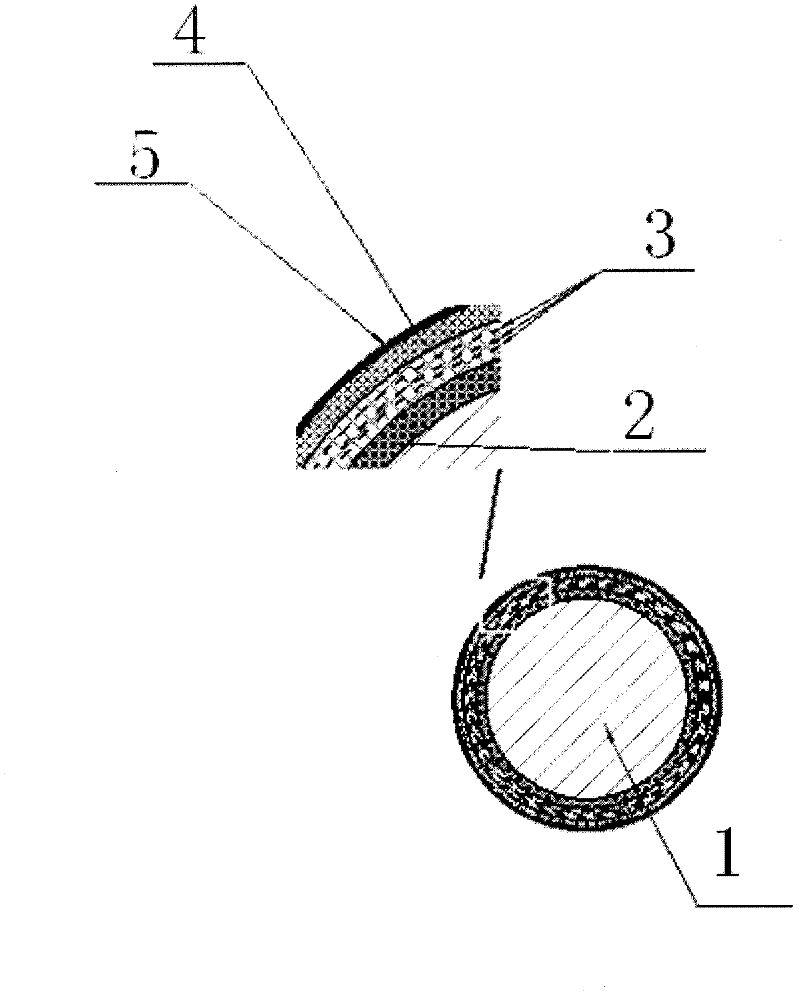

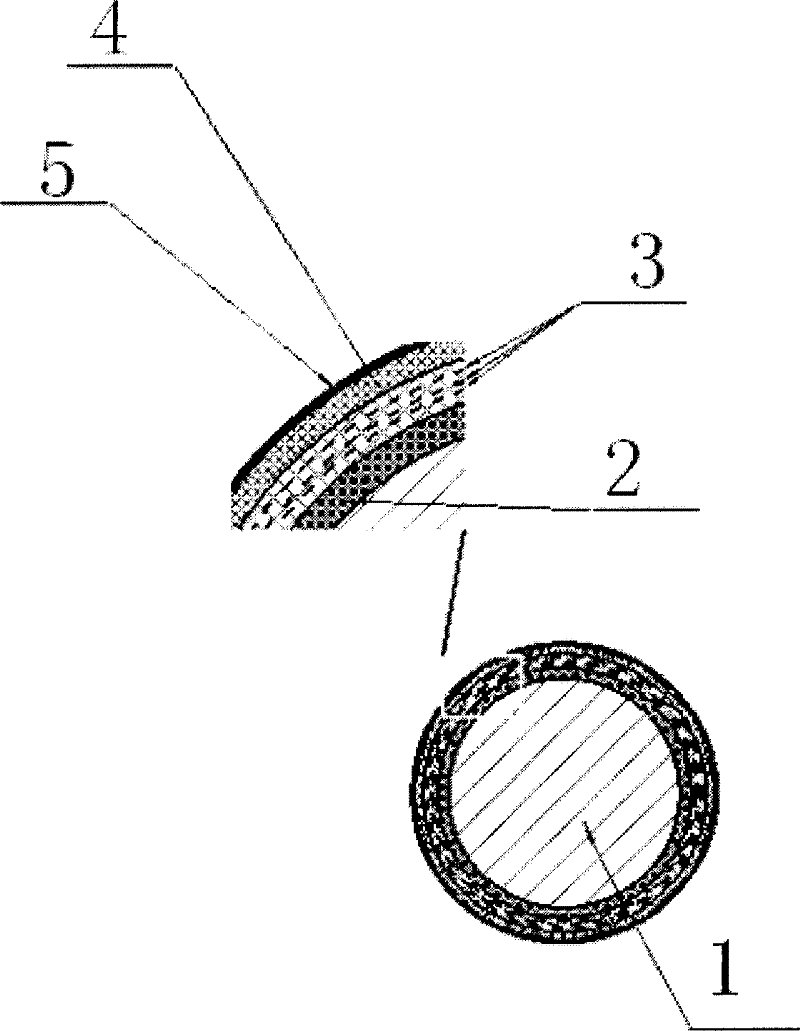

Multi-layer special-material integrated pipe and manufacturing technique thereof

ActiveCN103912735ATraffic resistanceEasy to scaleRigid pipesTubular articlesEngineeringThermal expansion

Disclosed are a multi-layer special-material integrated pipe and a manufacturing technique thereof. The integrated pipe comprises an outer primary pipe and an inner secondary pipe which are produced and integrated through on-line production equipment, the primary pipe is produced in advance or online, a blank of the secondary pipe is produced online and is composed of a plastic base layer and a solid gum layer, the external diameter of the blank is slightly larger than the internal diameter of the primary pipe, the blank forms a frozen body via U-shaped deformation, and finally the frozen body is inserted into an inner cavity of the primary pipe subjected to thermal expansion to be integrated. When an integrated body is used in high temperature or extremely cold environment, the primary pipe and the secondary pipe are still firmly connected without cracking and layering. By the technical scheme, the defects of lack of smoothness and high passing resistance, or proneness to scaling and falling off, or proneness to layering and deforming, or high manufacturing difficulty and high input cost, or poor applicable temperature-difference environmental function and the like of a protective coating on the inner wall of an existing hard pipe used for water supply, gas supply and oil supply and delivery are overcome; the integrated pipe is suitable for water, gas and oil delivery of various municipal works and industrial and mining establishments, and particularly suitable for pipe products for water supply of the municipal works.

Owner:HUNAN ZHENHUI PIPE IND

Preparation method of magnetic attapulgite surface imprinted hydrophilic nanocomposite

InactiveCN103599756BUniform sizeEvenly distributedOther chemical processesWater/sewage treatment by magnetic/electric fieldsHalloysiteMagnetite Nanoparticles

The present invention relates to a magnetic attapulgite surface imprinting hydrophilic nanometer composite material preparation method, and belongs to the technical field of environmental function material preparation. According to the preparation method, an impregnation method and a high temperature reduction method are adopted to synthesize a magnetic attapulgite nanometer composite material, wherein the magnetic nanoparticles have characteristics of uniform size and uniform distribution; with a surface silanization reaction, vinyl is grafted on the surface of magnetic halloysite, and with reverse atom transfer radical precipitation polymerization, the molecular imprinting polymerization layer covered on the magnetic attapulgite surface can be well controlled to tens of nanometers; and due to the presence of the ATRP active group on the outer surface, the hydrophilic polymer brush is successfully grafted, and is successfully applied for selective removal and rapid magnetic separation of sulfamethazine in the water environment, and an excellent reproduction performance is provided.

Owner:JIANGSU UNIV

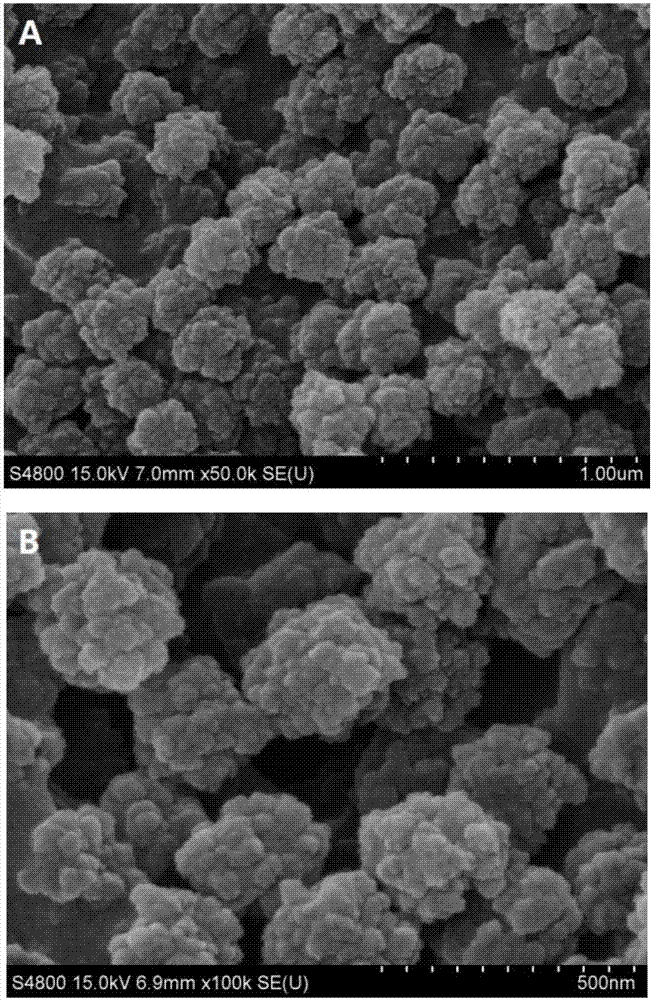

Preparation method of nickel-based catalyst for treating alkaline organic waste water

InactiveCN109225231ALow costSimple methodWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsDispersityNickel salt

The invention belongs to the field of water treatment technology and environmental function materials, and particularly relates to a preparation method of a nickel-based catalyst for treating alkalineorganic waste water. Reagents used in the preparation method are nickel salt, ammonia water and sodium hydroxide, a nickel-based catalyst precursor can be synthesized in one step by adjusting the synthetic temperature as well as the concentration of a nickel salt, ammonia water and sodium hydroxide solution, the operation is simple and safe, nontoxic, harmless and easy to control; and the nickel-based catalyst can be prepared by virtue of simple calcination. The invention provides a method for preparing a high-dispersity flaky nickel-based catalyst, and the nickel-based catalyst prepared in acalcining manner at 450 DEG C under the protection of nitrogen has optimum activity; and the activation efficiency of an oxidant S2O8<2-> can be improved by utilizing the prepared high-performance and stable nickel-based catalyst, so that the reaction rate of an advanced oxidation technology in the alkaline organic waste water treatment can be increased, and the energy consumption can be reduced.

Owner:SOUTHWEST UNIVERSITY

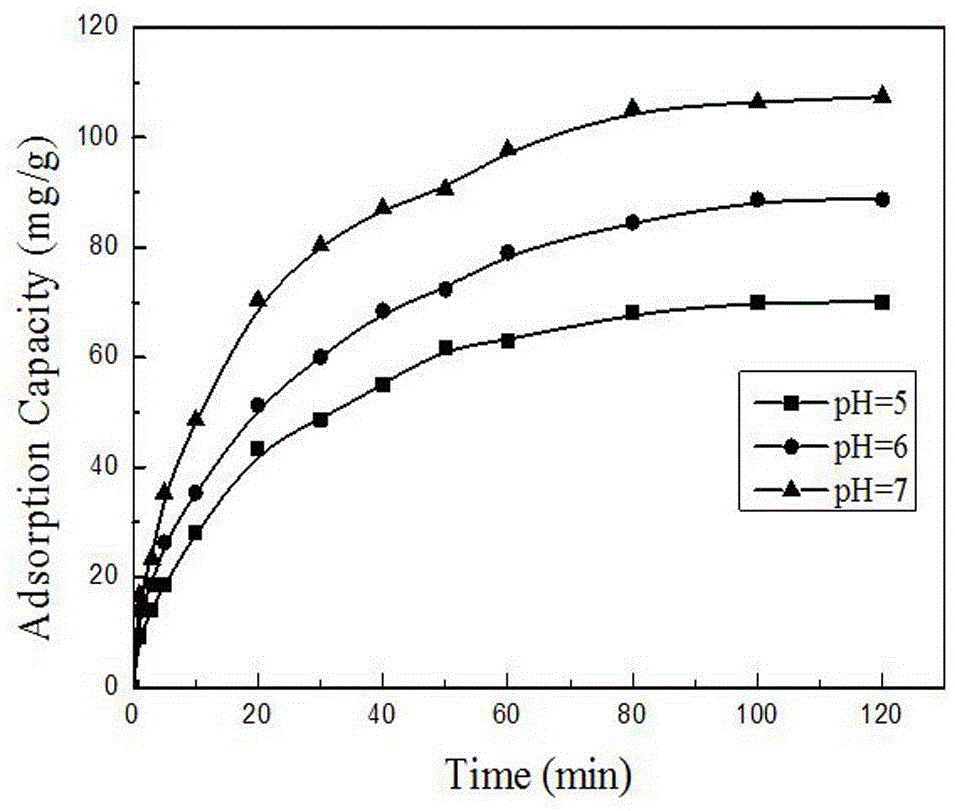

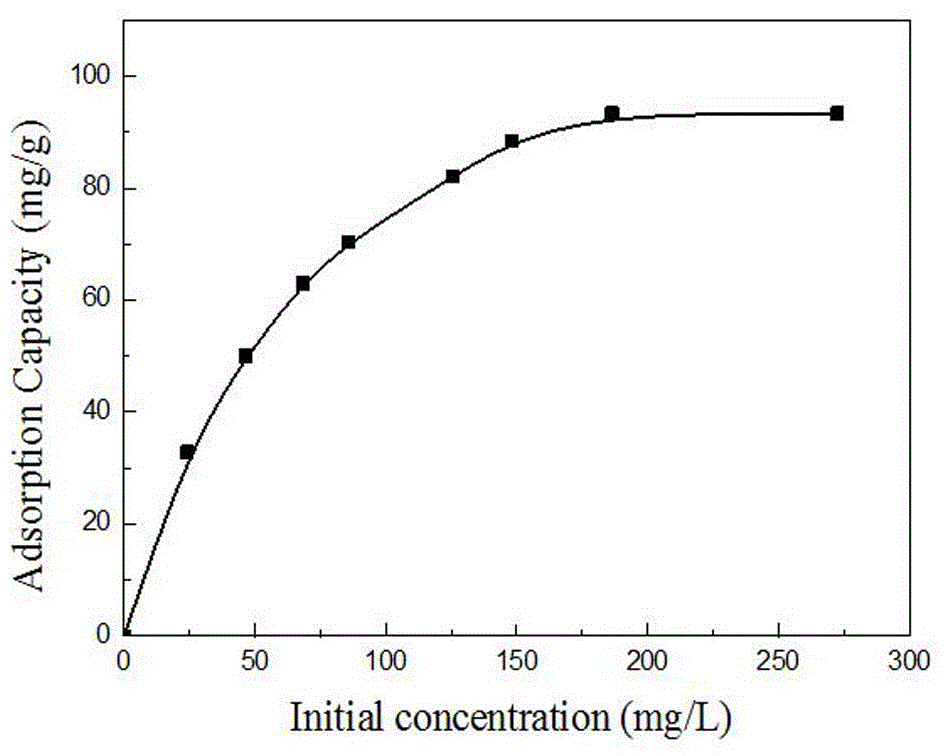

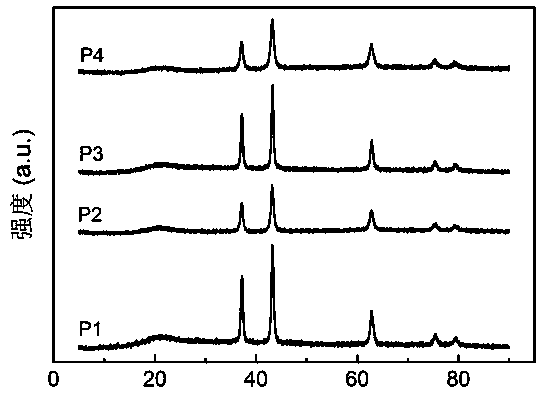

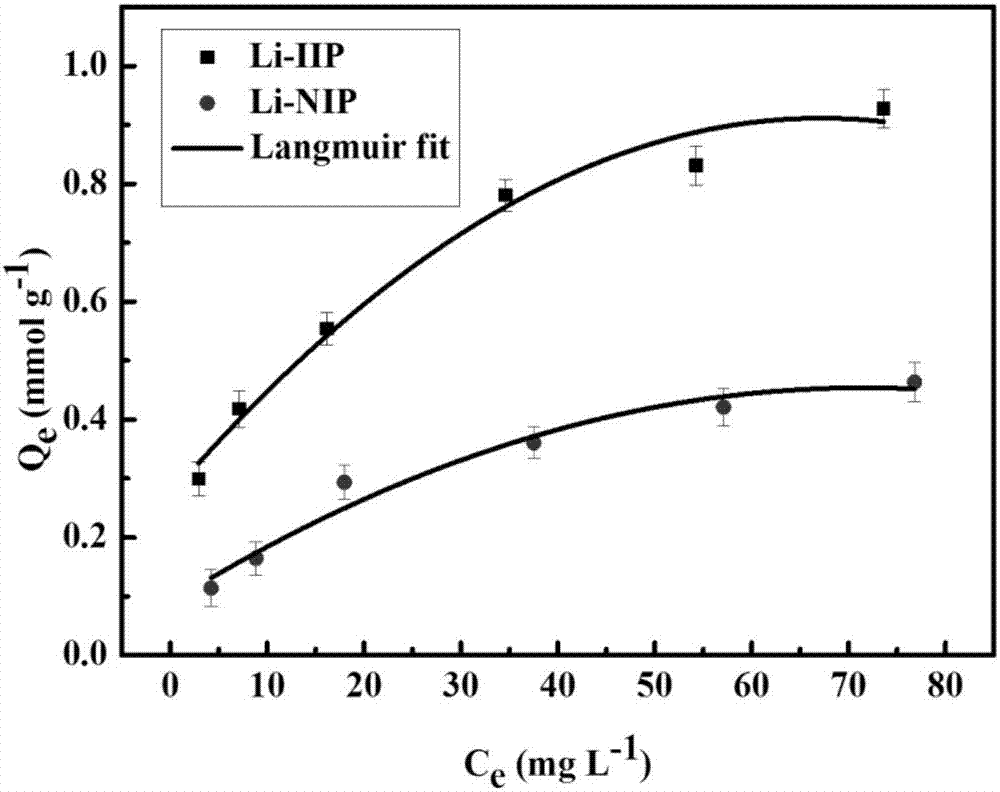

High-selectivity cauliflower-shaped lithium ion absorbent, and preparation method and application

InactiveCN107442087AStable structureImprove adsorption capacityIon-exchange process apparatusOther chemical processesSorbentAcid washing

The invention relates to a high-selectivity cauliflower-shaped lithium ion absorbent, and a preparation method and an application, and belongs to the technical field of preparation of environmental-function materials. The preparation method comprises the following steps of: firstly dissolving 12 crown-4-ether and lithium perchlorate in acetonitrile solution, and fully and uniformly mixing; then adding acrylamide, and slowly stirring for a period of time at a normal temperature; then adding N' N-methylene bisacrylamide and azodiisobutyronitrile, introducing N2 for minutes, then sealing, putting in a water-bathing oscillator, and oscillating at a constant temperature and standing for a night; and finally, washing by using methyl alcohol and drying products obtained by centrifugation, carrying out acid washing in diluted HCl solution, washing off lithium ions, and drying to obtain the cauliflower-shaped lithium ion absorbent (Li-IIP). The Li-IIP prepared can recognize and separate the lithium ions selectively.

Owner:JIANGSU UNIV

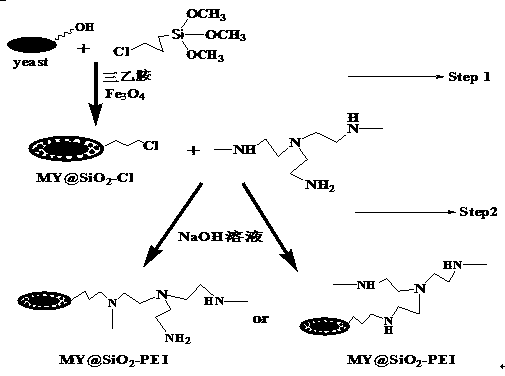

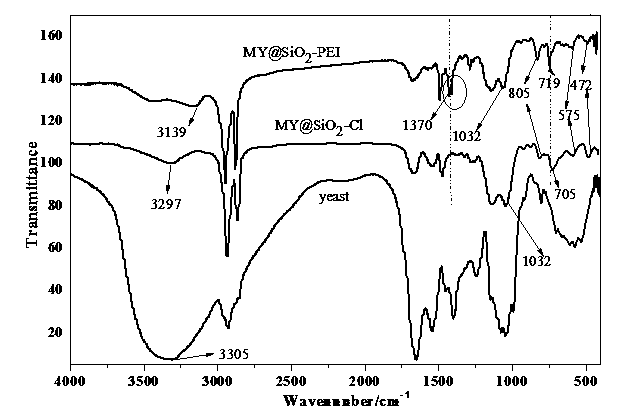

Preparation method and application of magnetic silicon-coated yeast grafted polyethyleneimine biological composite material

InactiveCN103657608AWide variety of sourcesLow costOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerSorbent

The invention belongs to the technical field of environmental function material preparation and relates to a preparation method of a magnetic silicon-coated yeast grafted polyethyleneimine biological composite material for adsorptive separation of cerium ions and strontium ions. According to the technical scheme, the preparation method comprises the following steps: at first, ultrasonically mixing activating yeasts with magnetic nanoparticles, and reacting the mixture with triethylamine and 3-chloropropyl trimethoxysilane in a methylbenzene system to prepare magnetic silicon-coated yeasts; then, adding polyethyleneimine as a functional monomer, producing a substitution reaction of chlorine groups on the surfaces of the magnetic silicon-coated yeasts with a polyethyleneimine solution, and grafting polyethyleneimine onto the surfaces of the magnetic silicon-coated yeasts to prepare the biological composite material. According to the method, the yield of a matrix material is increased; a prepared adsorbent overcomes the deficiency of low mechanical strength of a conventional biological material, is good in magnetic responsibility, can achieve quick separation, is higher in adsorption capacity and adsorption kinetics performance, and can achieve the purpose of quick and efficient adsorptive separation of the cerium ions and the strontium ions.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com