Cu2OTiO2 nanotube array and preparation method thereof

A nanotube array and nanotube array technology, applied in the field of environmental science, can solve the problems of inability to make full use of natural sunlight, inability to form nanotube-like structures, and insufficient specific surface area to achieve excellent photocatalytic efficiency and improve photoelectric conversion efficiency. , the effect of mass production improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Grinding the surface of the base material, cleaning it for later use;

[0024] (2) Electrolyte preparation: the electrolyte is composed of 0.5-3% hydrofluoric acid dimethyl sulfoxide or 0.25-0.5% NH4F alcohol solution by mass percent;

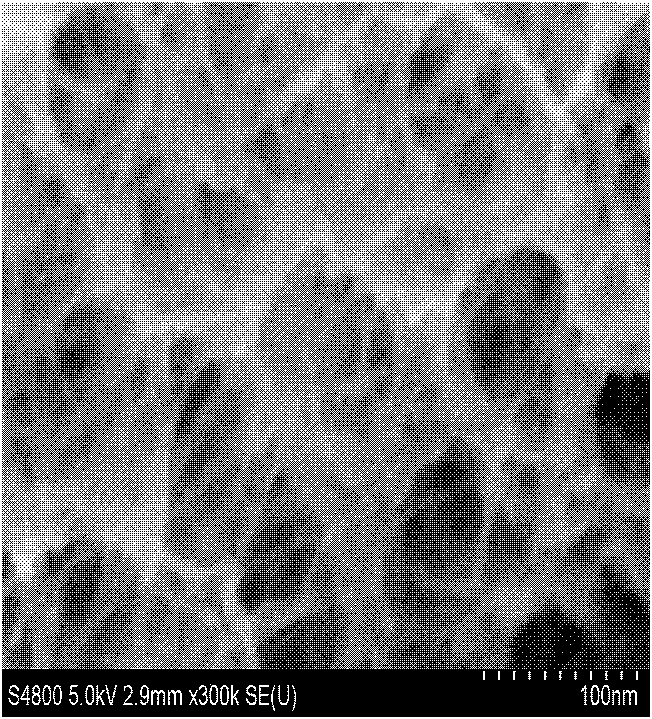

[0025] (3) Under 25-100V DC voltage, using pure titanium or titanium alloy as the anode and platinum sheet as the cathode, electrolytically prepare titanium oxide nanotubes in the electrolyte;

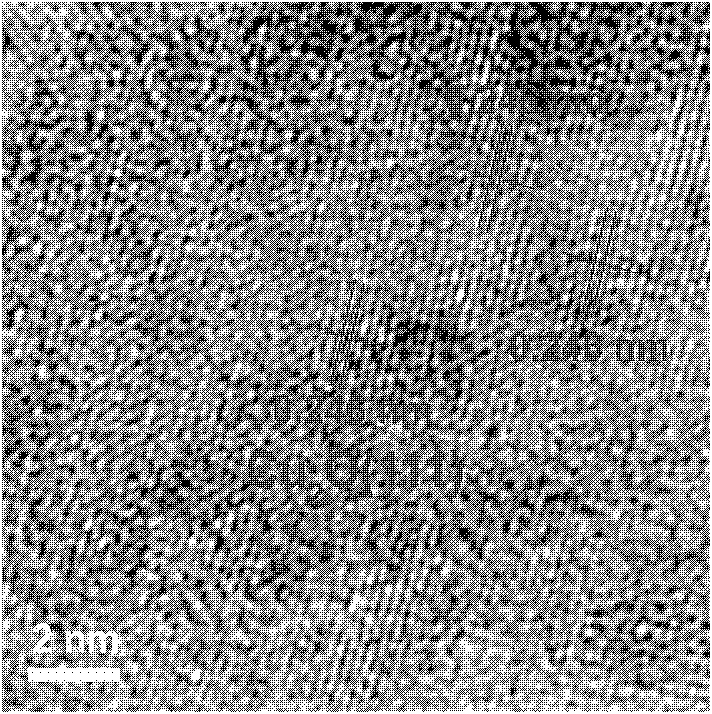

[0026] (4) Calcining the titanium oxide nanotube array prepared above under aerobic conditions at 400°C-500°C for 4-6h to crystallize it into TiO 2 array of nanotubes.

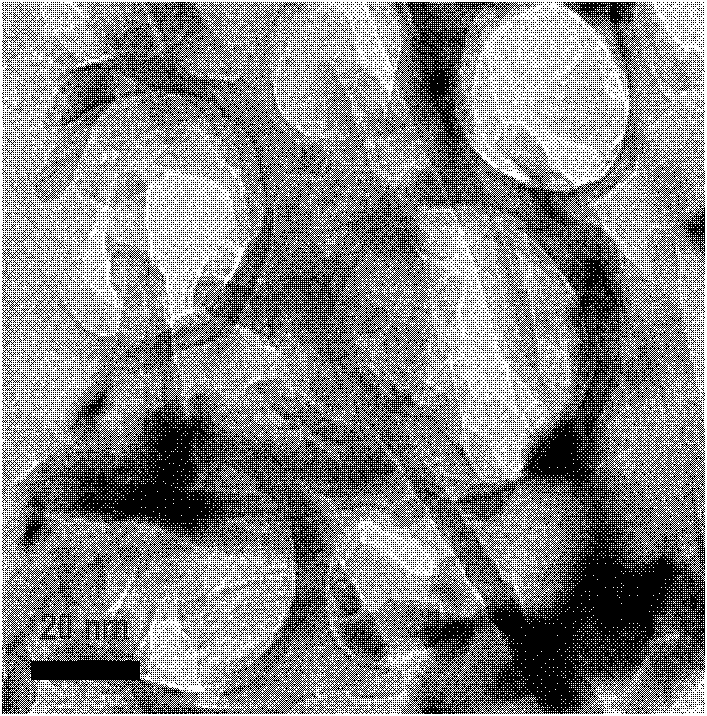

[0027] (5) Put 2cm×5cm TiO 2 Nanotube array set 5mmol-20mmolCuSO 4 In the solution, the method of pulse electroplating is used to use the platinum sheet as the counter electrode, Ag / AgCl as the reference electrode, TiO 2 Electrodeposition of simple copper in a standard three-electrode system in which the nanotube array is the working electrode; the on-off voltage ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com