Patents

Literature

111 results about "Pulse plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulse plating of a low stress film on a solar cell substrate

InactiveUS20080092947A1Photovoltaic energy generationSemiconductor devicesMetal interconnectEngineering

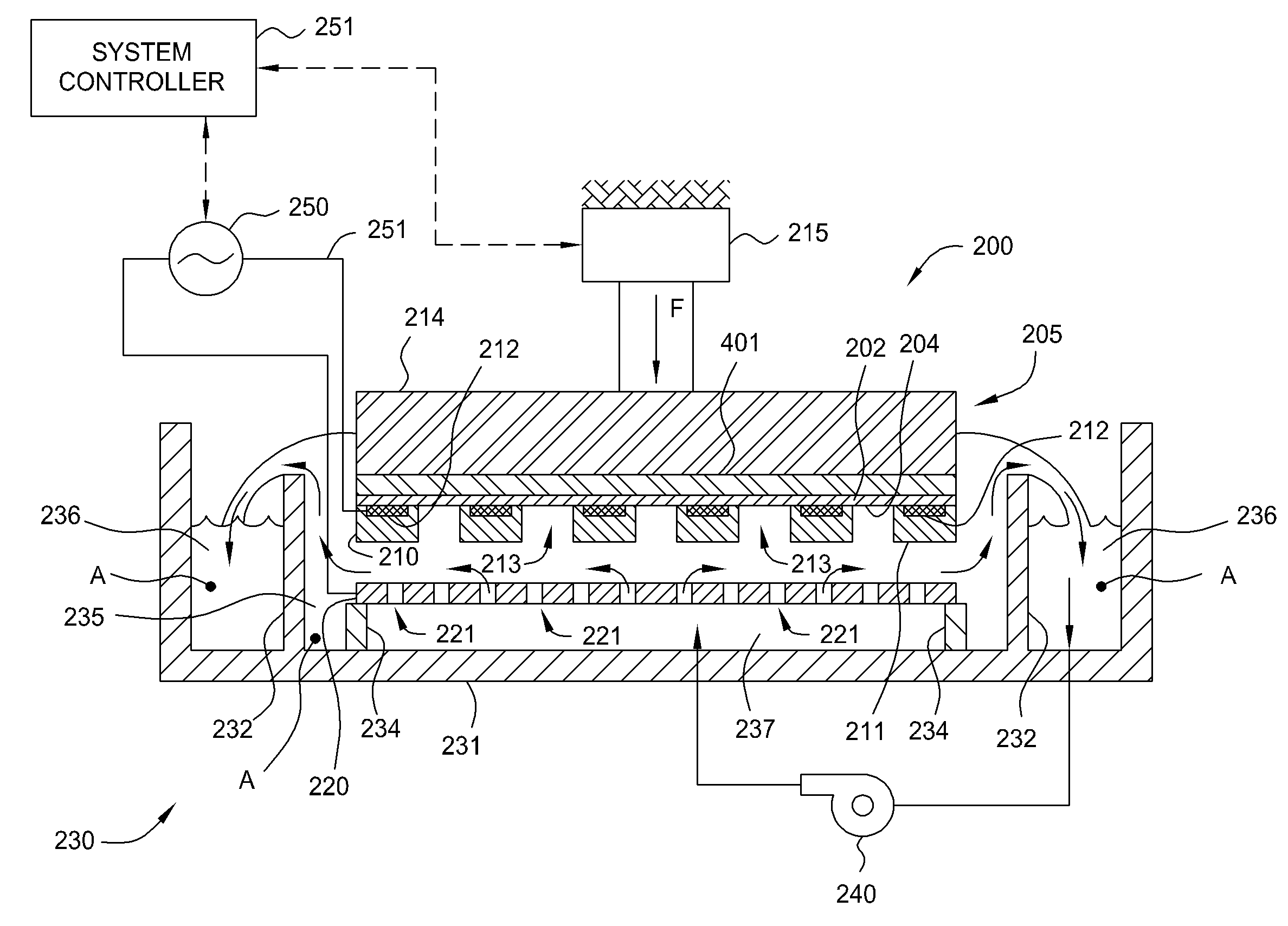

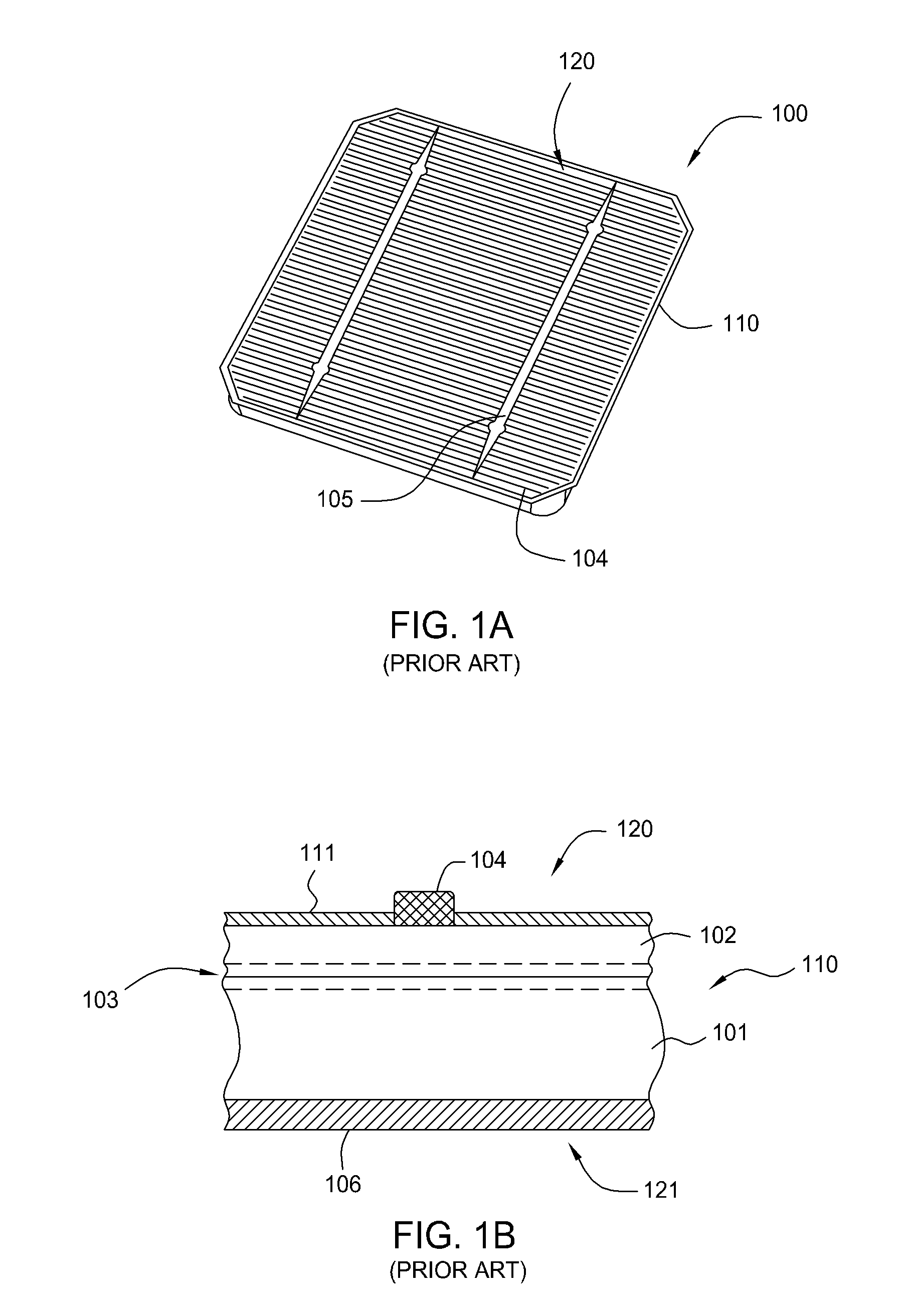

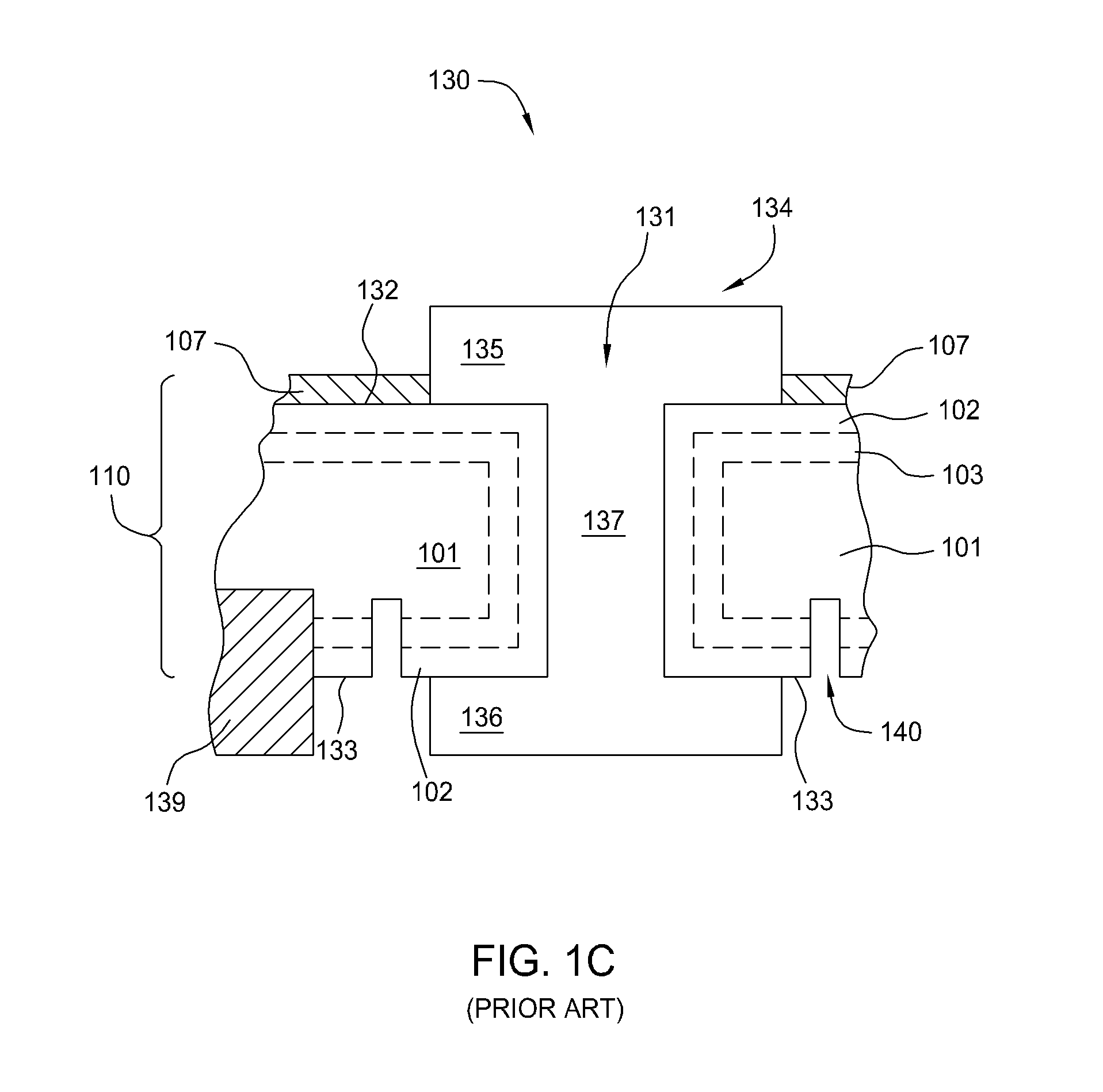

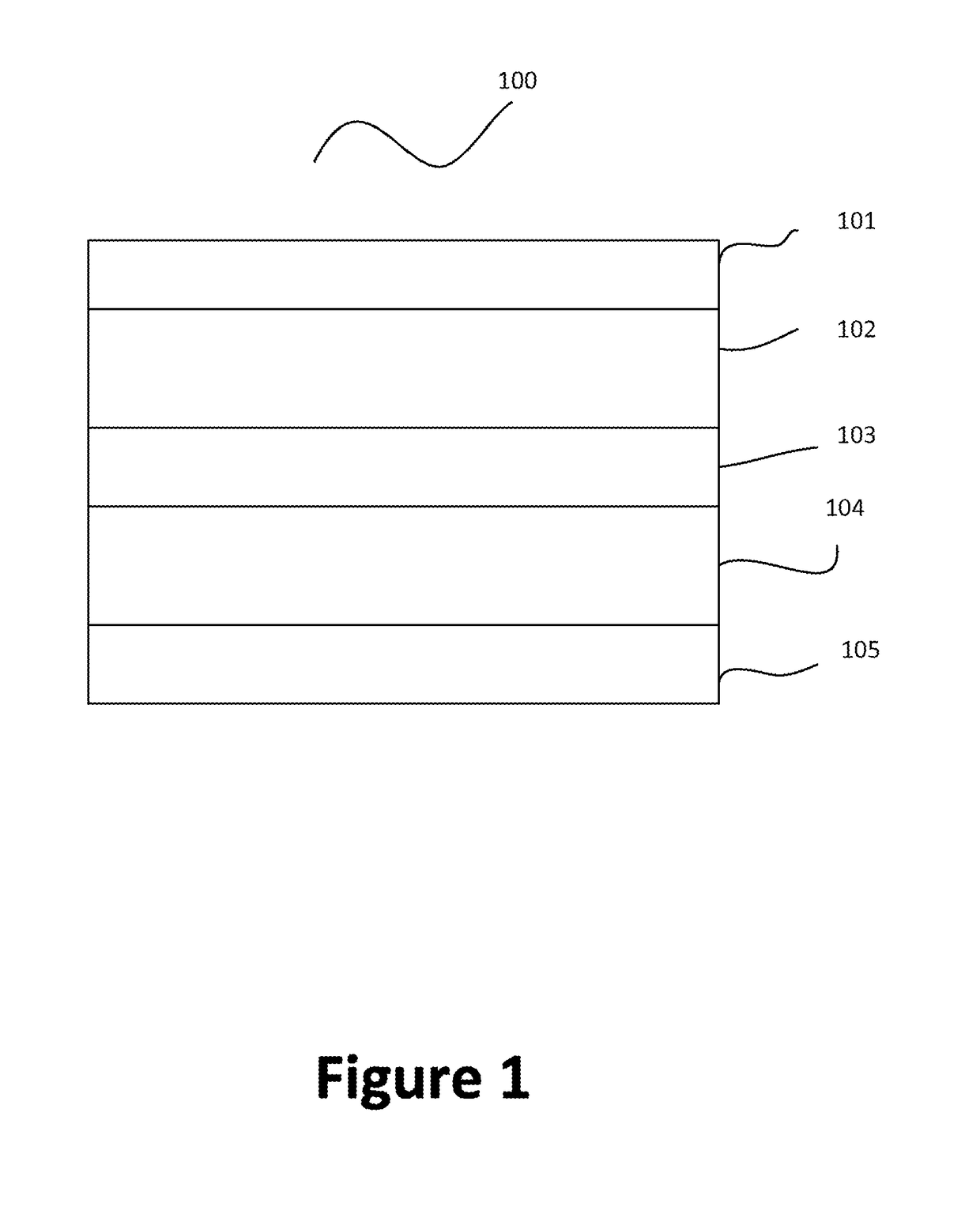

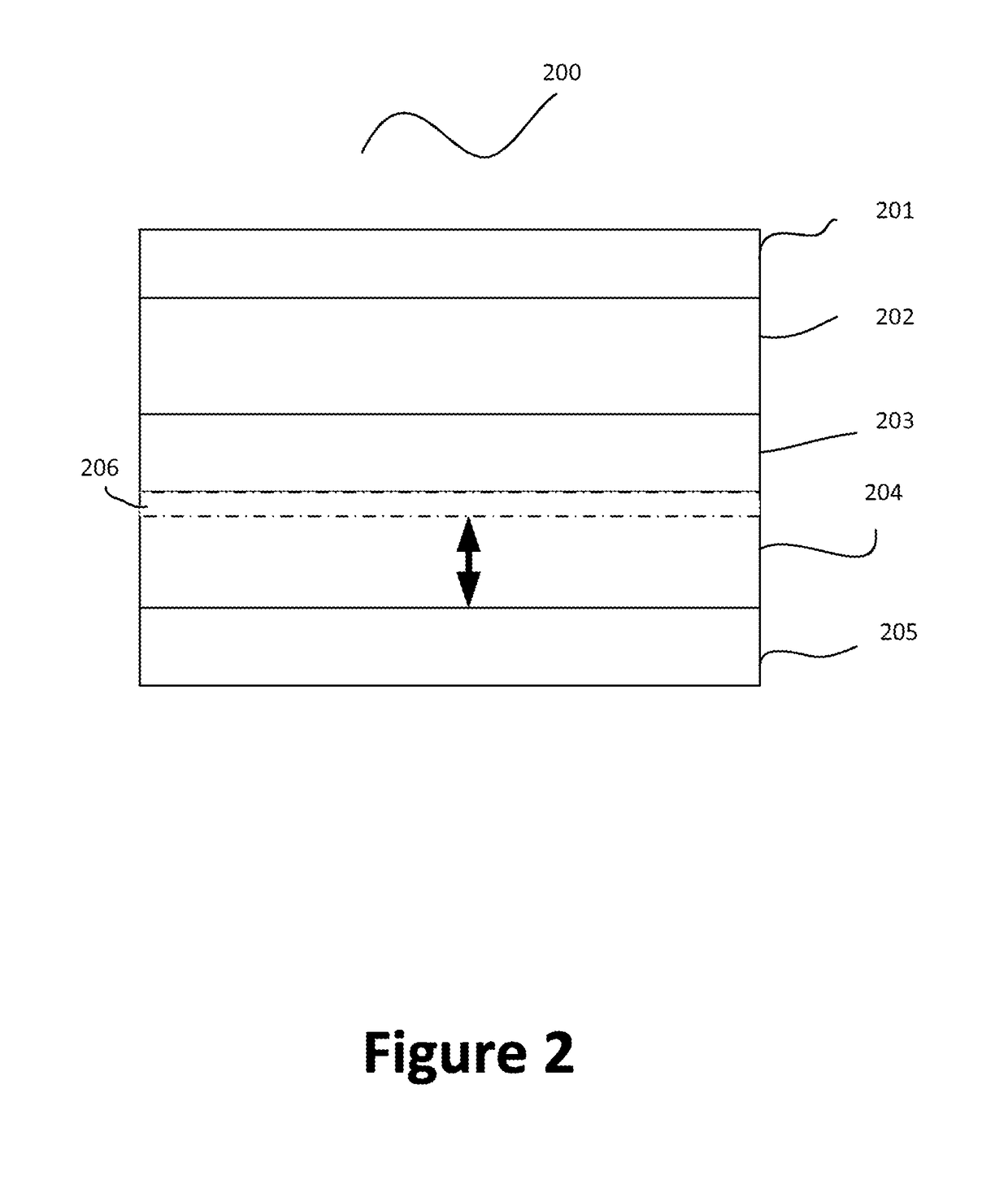

Embodiments of the invention contemplate the formation of a low cost solar cell metal contact structure that has improved electrical and mechanical properties through the use of an electrochemical plating process. The resistance of interconnects formed in a solar cell device greatly affects the efficiency of the solar cell. It is thus desirable to form a solar cell device that has a low resistance connections that is reliable and cost effective. One or more embodiments of the invention described herein are adapted to form a low cost and reliable interconnecting layer using an electrochemical plating process containing common metal, such as copper. However, generally the electroplated portions of the interconnecting layer may contain a substantially pure metal or a metal alloy layer. Methods are discussed herein that are used to form a solar cell containing conductive metal interconnect layer(s) that have a low intrinsic stress.

Owner:APPLIED MATERIALS INC

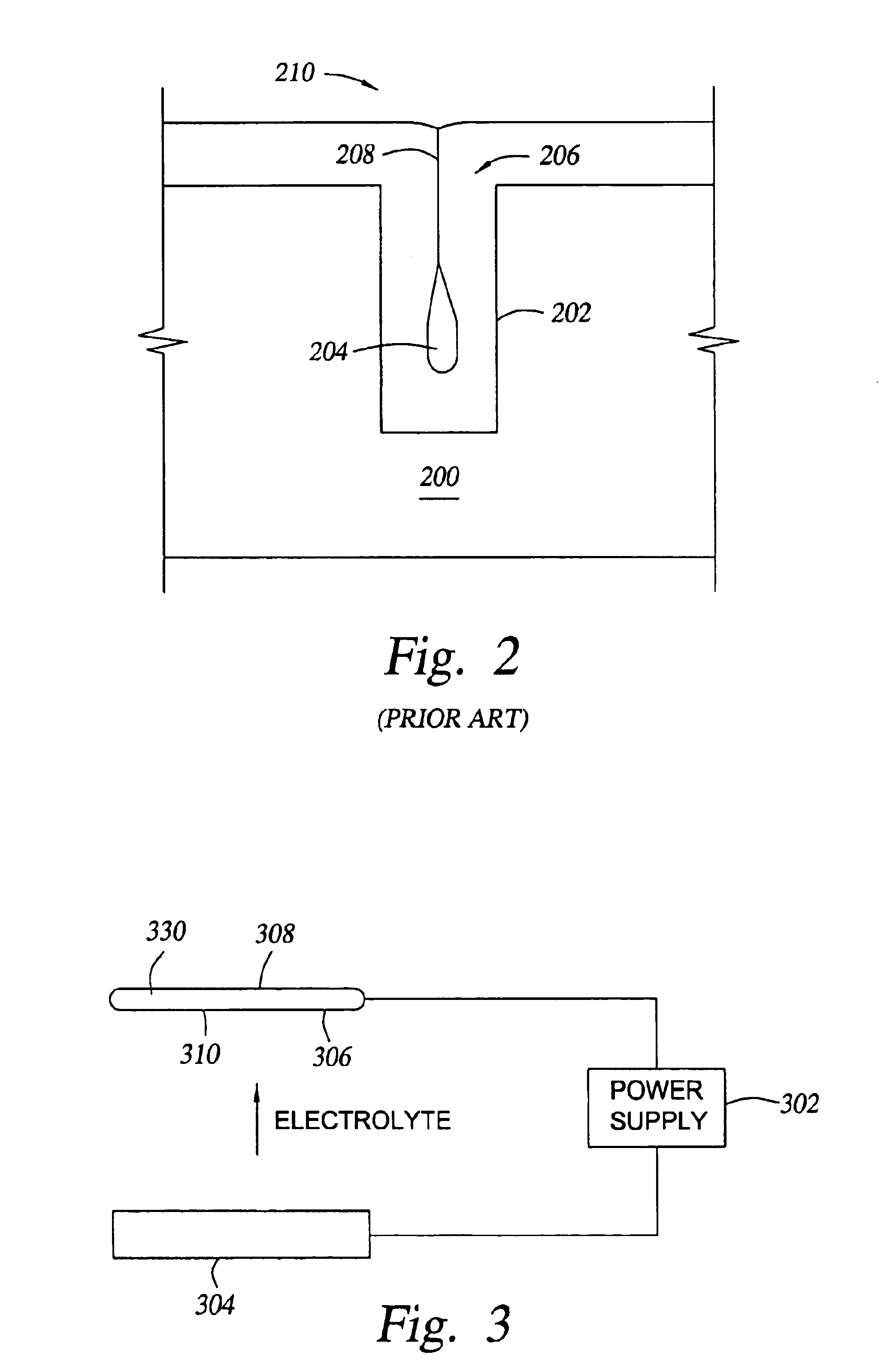

Dynamic pulse plating for high aspect ratio features

A method for depositing a metal on a substrate is provided. The metal is deposited by sequentially applying a electrodeposition pulse followed by an electrodissolution pulse to the substrate. After each electrodissolution pulse an before the next electrodeposition pulse there is provided at least one time interval of zero electrical voltage or current, also known as an “off-time”, between the pulses. The first two electrodeposition pulses should preferably have the same time durations. Thereafter, the time durations of subsequent electrodeposition pulses are gradually decreased to provide a void-free and seam-free deposition of metal in high aspect ratio features.

Owner:APPLIED MATERIALS INC

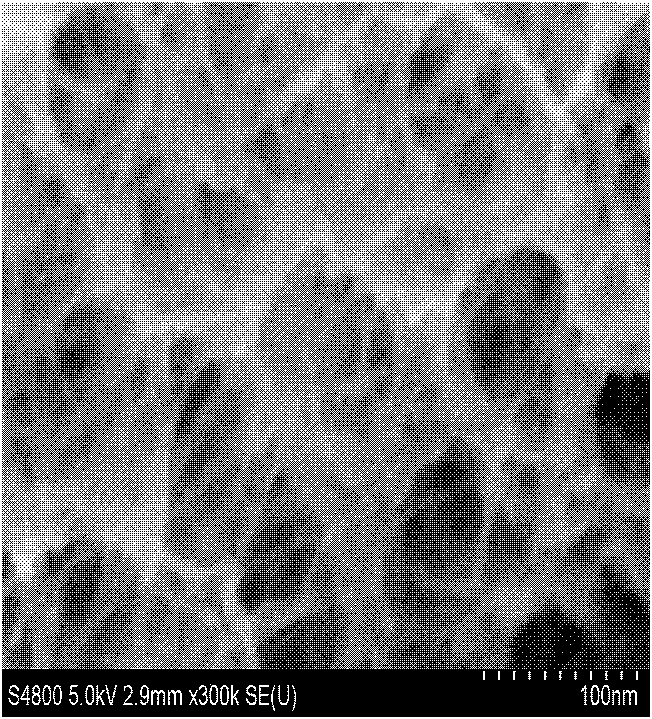

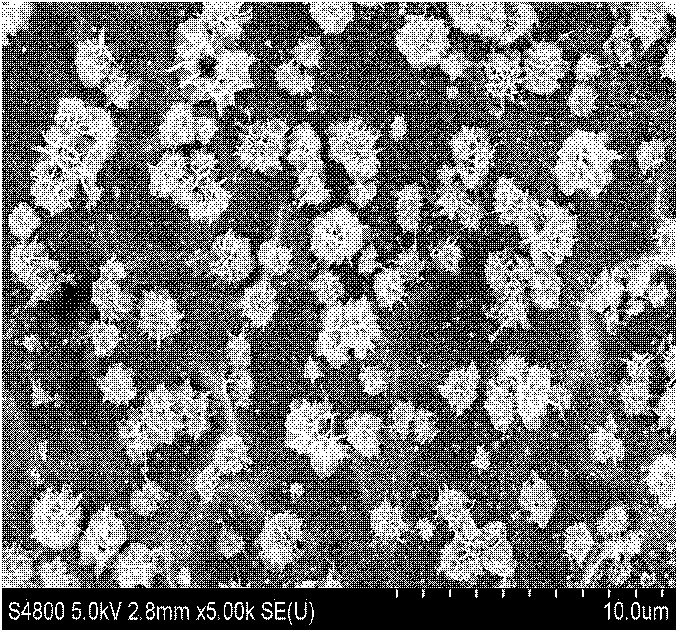

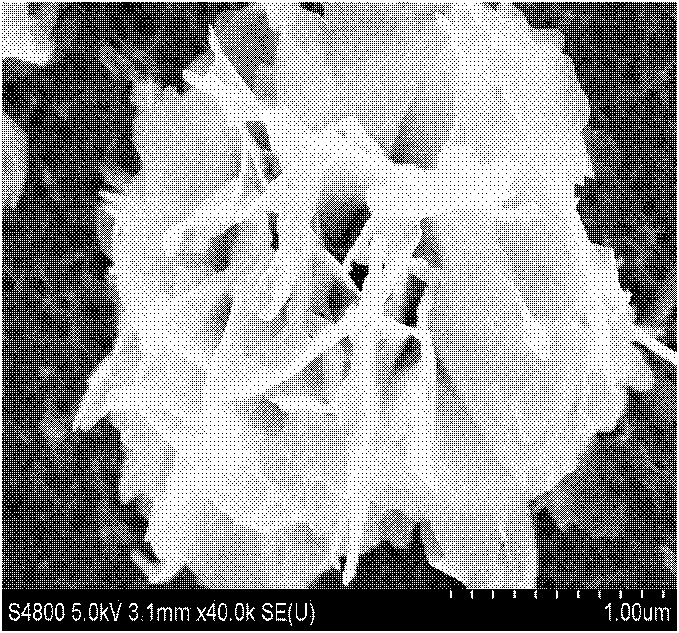

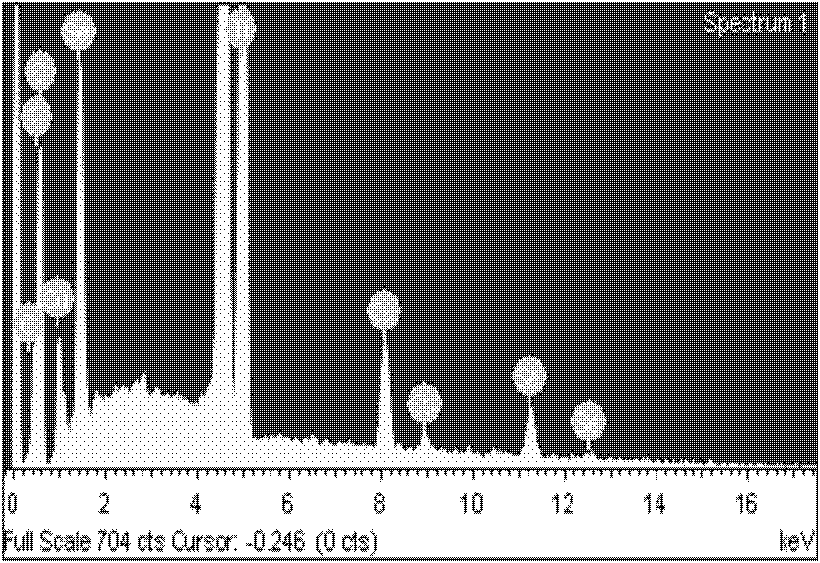

Cu2OTiO2 nanotube array and preparation method thereof

InactiveCN101851772ALarge specific surface areaAperture adjustableAnodisationElectron holeTio2 nanotube

The invention discloses an environmental function nano-material-Cu2O / TiO2 nanotube array and a preparation method thereof. A TiO2 nanotube array is placed in 5mmol-20mmol of CuSO4 solution, and copper is electrodeposited on the TiO2 nanotube array in a standard three-electrode system by using pulse plating so as to obtain the Cu / TiO2 composite nanotube array; and after the deposition, the Cu / TiO2 composite nanotube array is electro-oxidized for certain time in an alkaline solution NaOH to obtain a TiO2 nanotube array modified by ultrafine Cu2O nanowires with the diameter of less than 5 nanometers. The nanaowires are intertwined and connected to from a network structure to be attached to the TiO2 nanotube array but do not fully block TiO2 nanotubes; the Cu2O / TiO2 nanotube array is very favorable for the transmission of photo-carriers, reduces the recombination probability of electron-hole pairs, effectively expands the absorption range of TiO2 in the visible region, reduces optical corrosion, improves photoelectric conversion efficiency, and shows good photocatalytic efficiency.

Owner:HUNAN UNIV

Agitation of electrolytic solution in electrodeposition

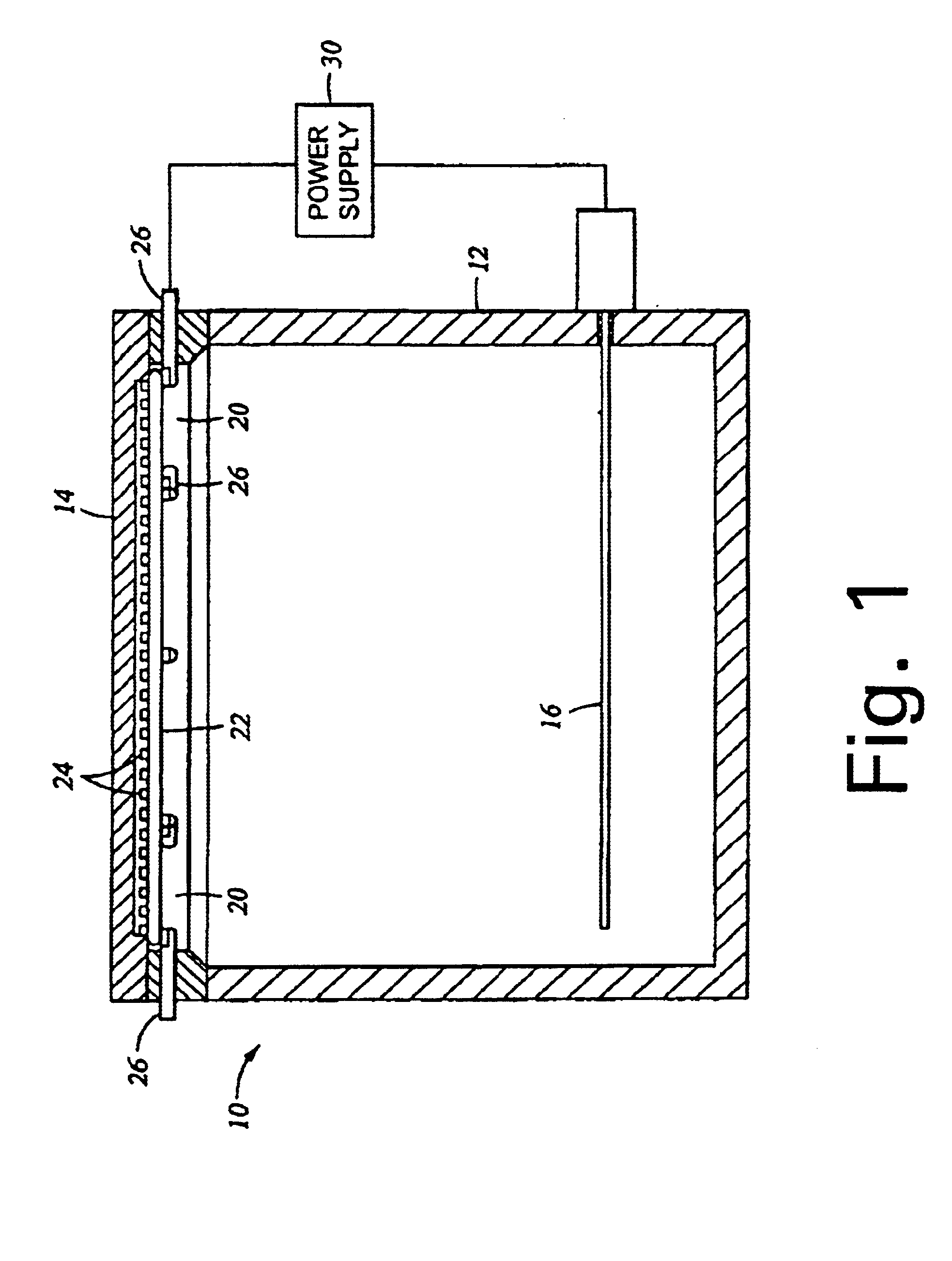

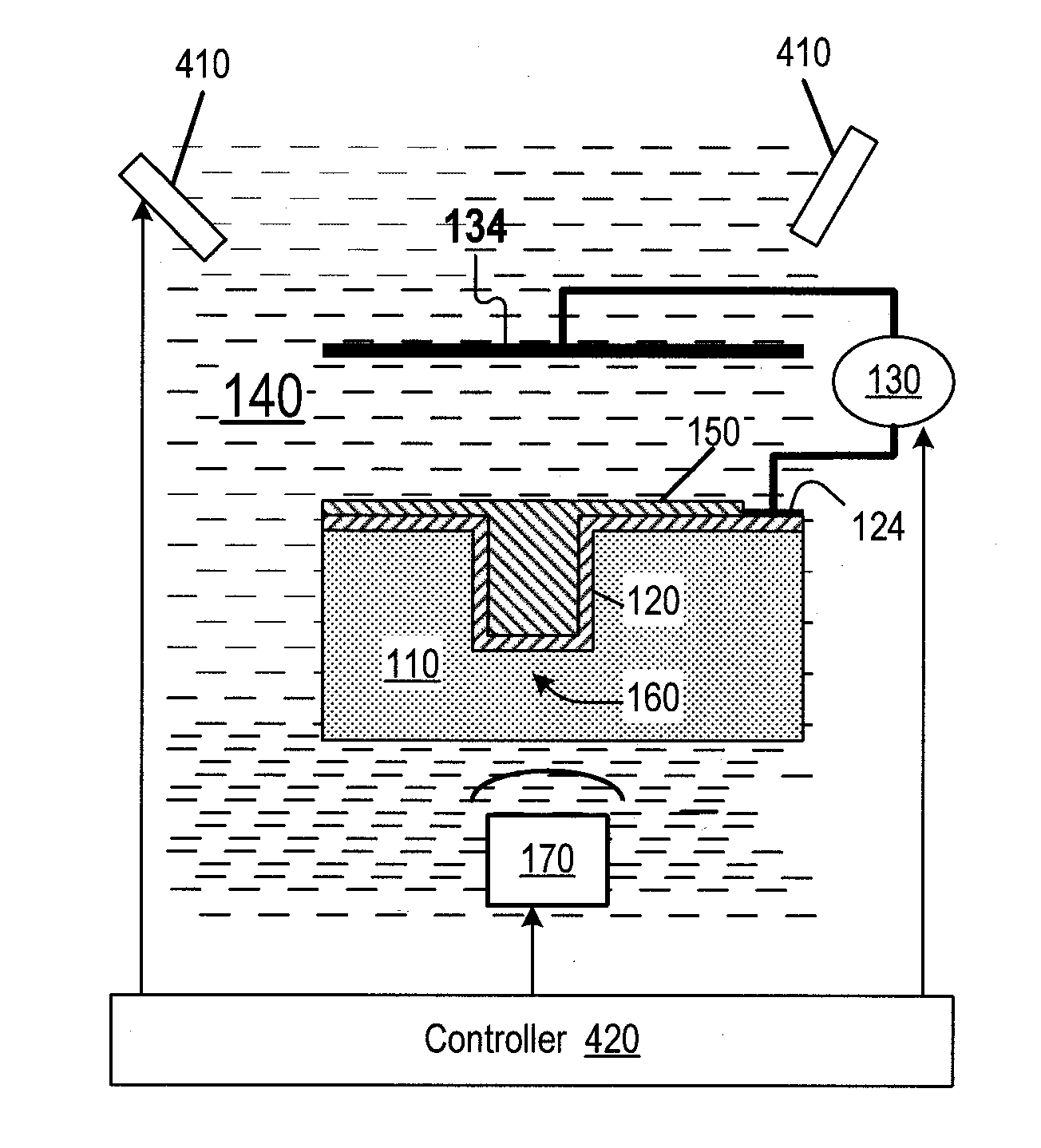

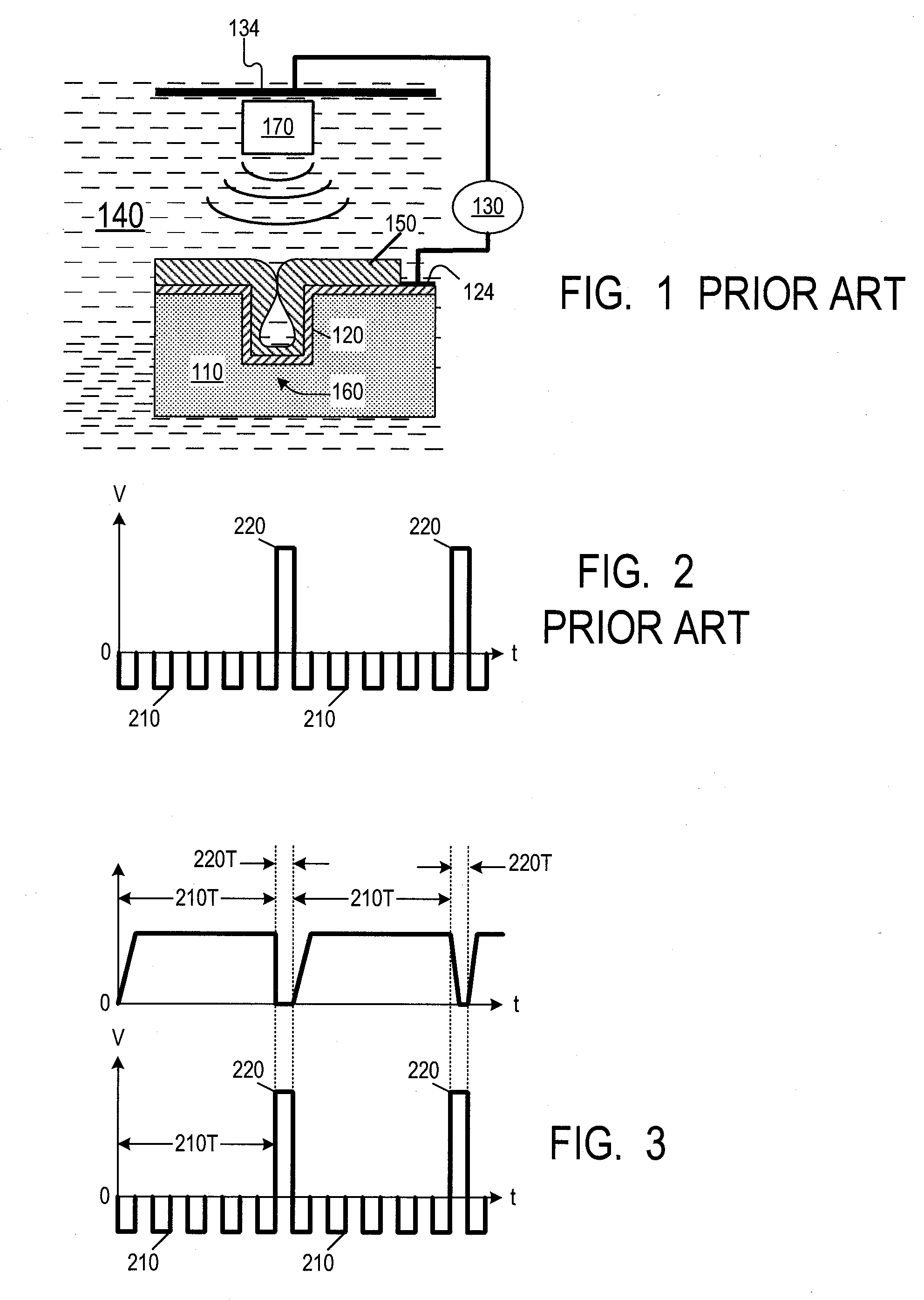

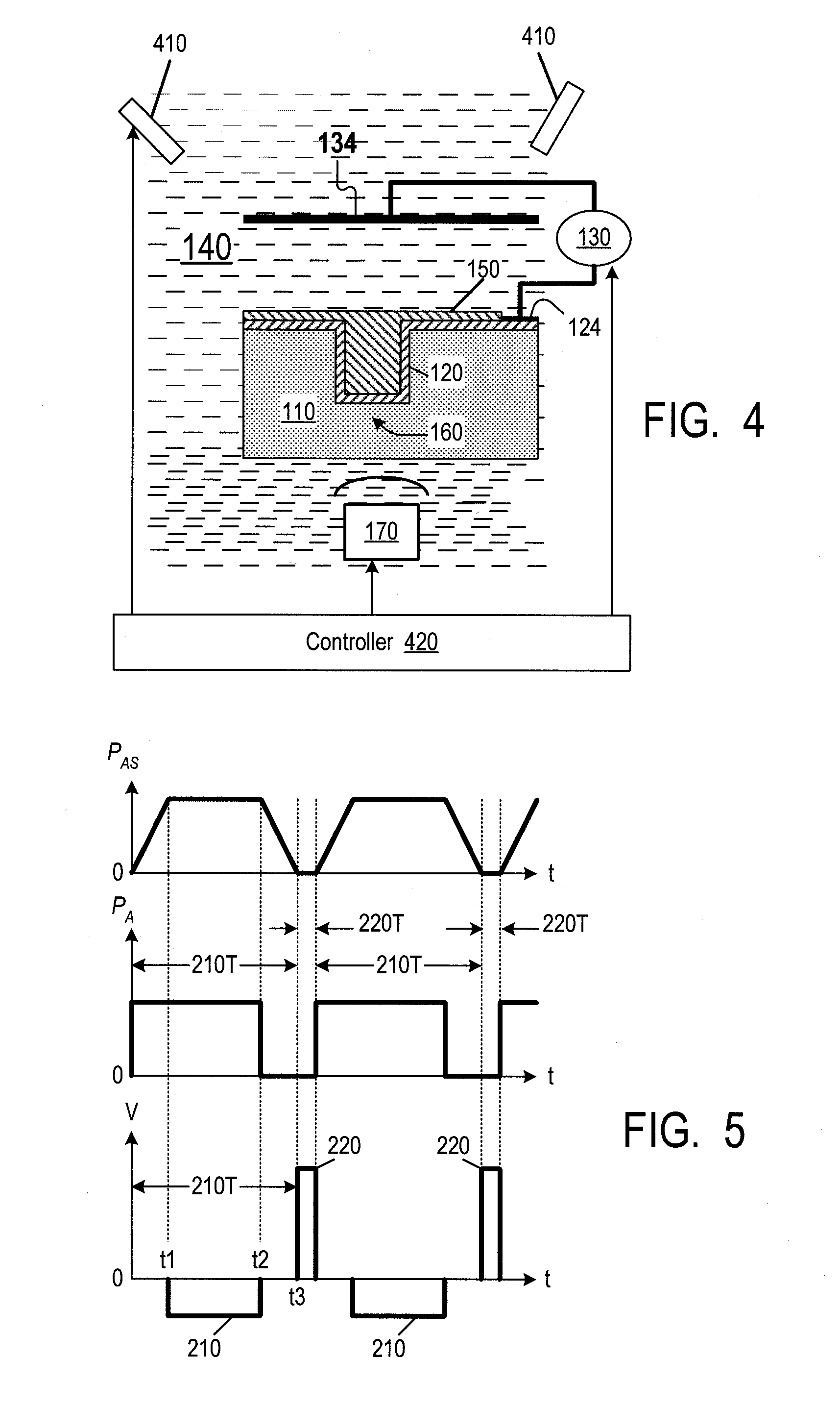

InactiveUS20080271995A1Good compensationReduce the required powerCellsMechanical power/torque controlPulse platingPhysics

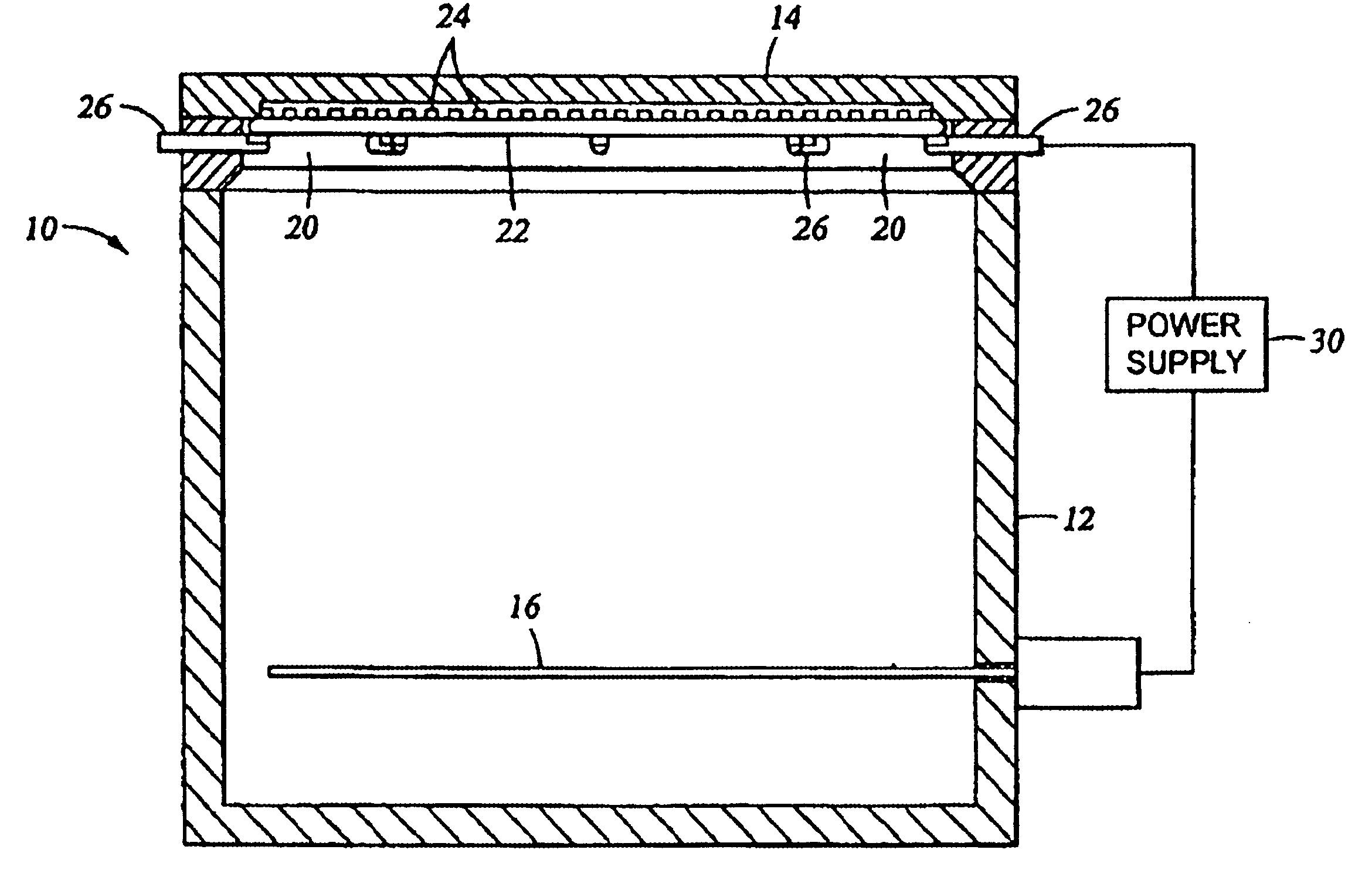

In a reverse pulse plating of a substrate (110), the electrolytic solution is agitated with a greater power on forward pulses (210) than on reverse pulses (220). An ultrasound agitation source (170) can be positioned at the bottom of the substrate (110) if the anode (134) is at the top. The ultrasound source may contact the substrate's bottom. Other features are also provided.

Owner:INVENSAS CORP

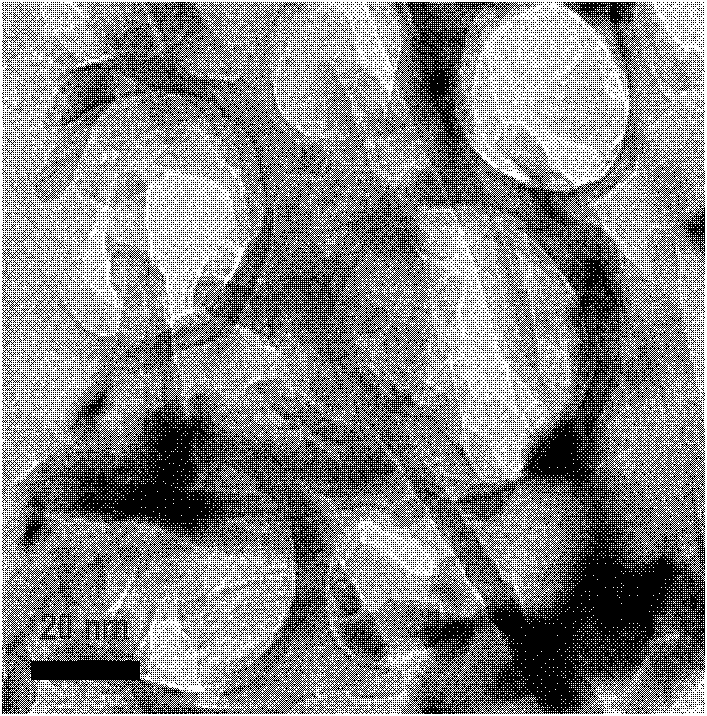

CuxSe/TiO2 nanotube array of p-type semiconductor nano material and preparation method thereof

InactiveCN101871117ALarge specific surface areaAperture adjustableFinal product manufactureSurface reaction electrolytic coatingNanowireTio2 nanotube

The invention discloses a CuxSe / TiO2 nanotube array of a p-type semiconductor nano material and a preparation method thereof. The method comprises the following steps: putting a TiO2 nanotube array in 5mmol-20mmol of CuSO4 solution; electrodepositing elementary substance Cu on the TiO2 nanotube array by adopting pulse plating in a standard three-electrode system to obtain a Cu / TiO2 compound nanotube array; carrying out electrooxidation in an NaOH alkaline solution for a certain time after deposition is ended to obtain a superfine Cu2O nanowire-modifying TiO2 nanotube array; and then putting the Cu2O / TiO2 nanotube array in a selenium ion solution, and stirring for 30-60 min under light to obtain a copper selenide nanotube array. Based on the superfine Cu2O nanowire-modifying TiO2 nanotube array, the absorption range of TiO2 in a visible light area can be effectively expanded and the compounding probability of an electron hole pair can be reduced, and more photoelectrons and photoholes can be generated under visible light, thereby being more beneficial to Cu2O to react with the selenium ion solution to generate copper selenide. The CuxSe / TiO2 nano material with a novel structure has potential application in the aspects of solar batteries, solar radiation absorbers, nano switches, thermoelectric photoelectric converters, superconductors, air-sensitive sensors and the like.

Owner:HUNAN UNIV

Electrolytic plating method

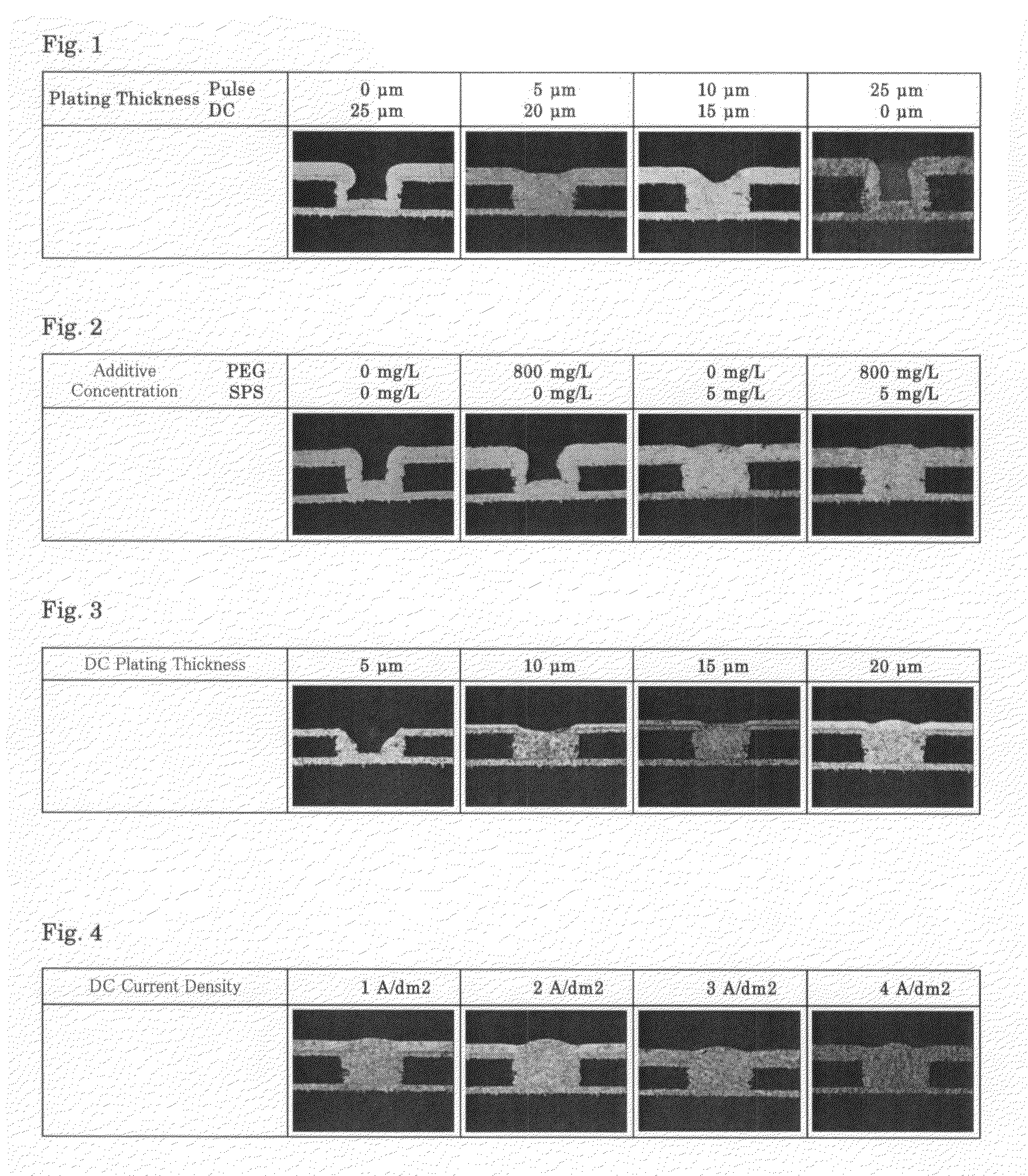

InactiveUS20080023218A1Easy to fillEfficiently and consistentlySemiconductor/solid-state device detailsPrinted circuit aspectsElectrolysisDesorption

A novel electrolytic plating method suitable for filling non-through holes with metal is disclosed. The electrolytic plating method uses a plating solution containing additives such as a surfactant, a brightening agent and a smoothing agent and includes pulse plating for controlling adsorption and desorption of tie additives on the surface and in the non-through holes of substrate and subsequent DC plating for filling up the non-through holes with metal.

Owner:NIPPON MACDERMID

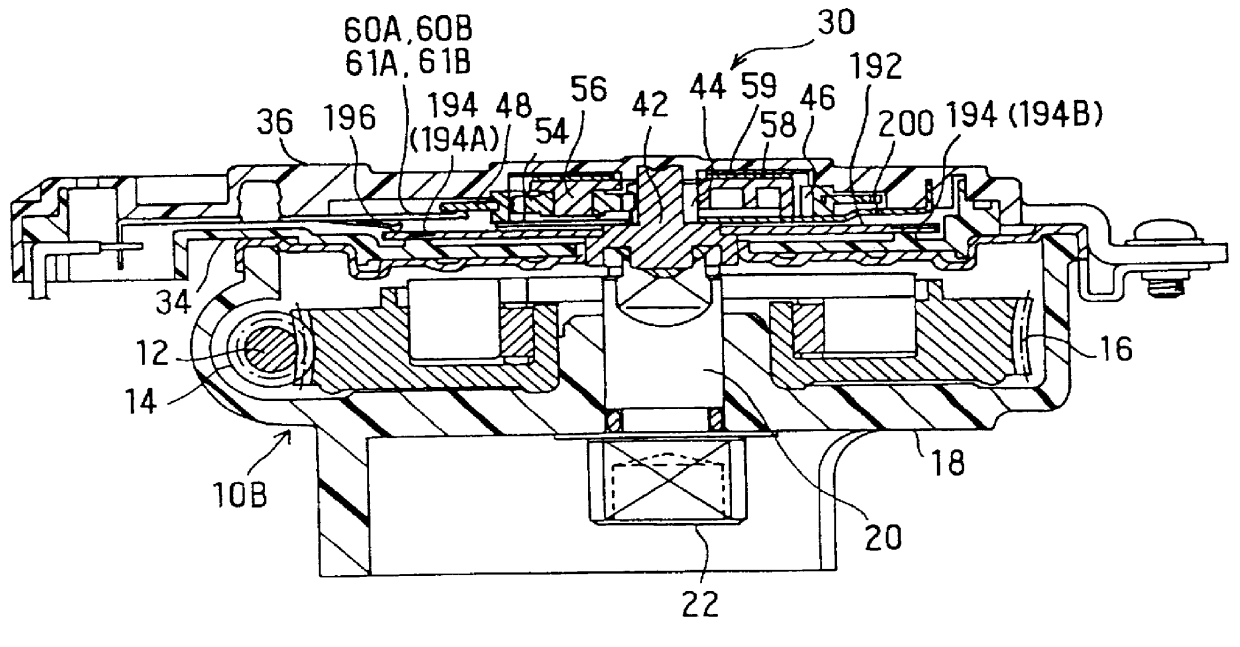

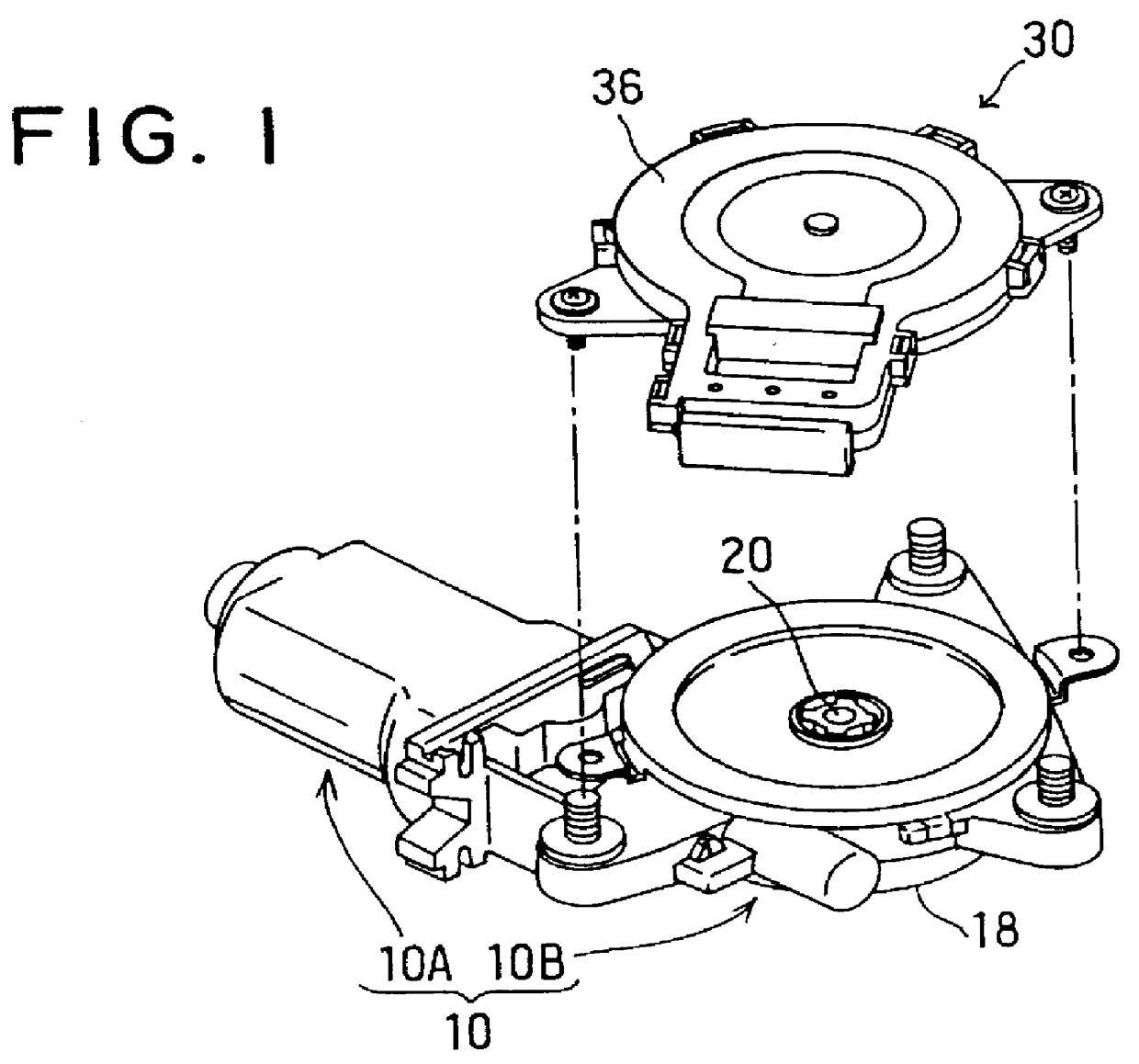

Position detector for motor

A position detector for a motor includes a pulse plate, having a fitting hole, for generating pulse signal, a connection shaft having protrusion portions and a washer having a connection hole. Each protrusion portion of the connection shaft is inserted into the fitting hole of the pulse plate and further inserted into the connection hole of the washer, and top ends of each protrusion portions are fastened to the washer. Thus, even if a rotational torque transmitted from the connection shaft to the pulse plate becomes large, the rotational force of the connection shaft can be accurately transmitted to prevent only the connection shaft from idling without releasing the connection between the connection shaft and the pulse plate.

Owner:ASMO CO LTD

Pulse plating of lithium material in electrochemical devices

ActiveUS20170338465A1Electrochemical processing of electrodesFinal product manufactureLithiumElectrical polarity

Owner:QUANTUMSCAPE CORP

Plating diamond tool with glass hard high-strength tyre case material and production method thereof

InactiveCN101195923AShorten the manufacturing cycleElectrolytic coatingsDiamond cuttingPulse plating

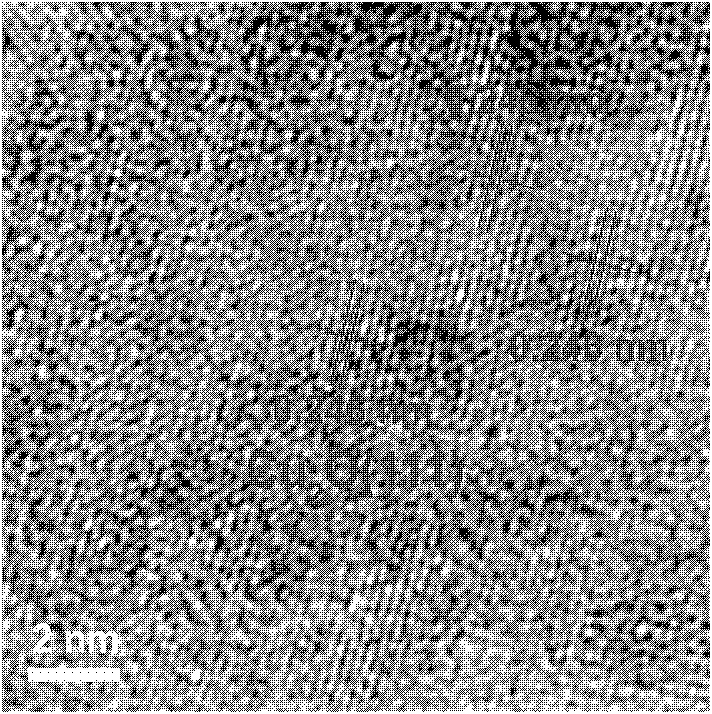

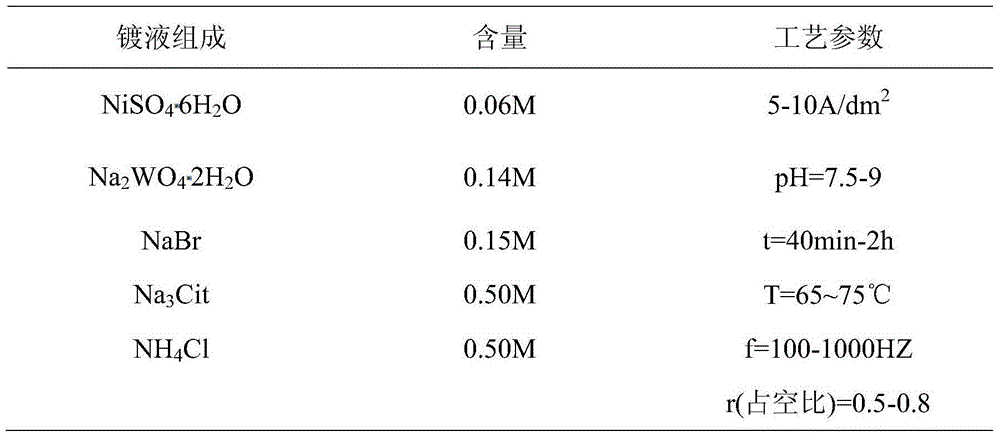

The utility model relates to an electroplate diamond tool equipped with high hardness and high strength matrix material, the coating on the electroplate diamond tool is nanometer nickel material. The method for preparing the electroplate diamond tool comprises the preparation of the electroplating solution, the treatment before electric plating, and the process of the electric plating; during the electric plating, the pulse plating method is adopted, and the electroplating solution is made of NiSO4 is multiplied by 7H2O,NiCl2 is multiplied by 6H2O, H2BO3, refined addition agent, and sodium dodecyl sulfate; the refined crystal grain is easy to obtain by matching the electroplating solution adopted by the invention with the impulse current measures, thereby, the Nano-crystal material can be obtained, and the non-cohesive diamond grain can be inlayed and consolidated in the coating, and the diamond cutting tool for different machining material can be prepared; the preparing method also has the advantages that the manufacturing cycle of the tool is shortened, and the cost is reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

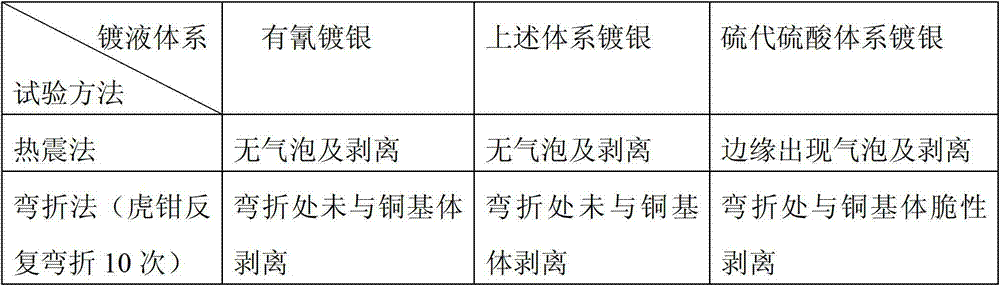

Plating solution and plating method of cyanide-free plating silver

The invention discloses a plating solution and a plating method of cyanide-free plating silver. 20-60g silver nitrate, 70-90g ammonium acetate, 70-110g nicotinic acid, 60-90g potassium carbonate, 40-70g potassium hydroxide, 0.2-1.2g o-benzoyl sulfimide sodium and 0.16-0.64g polyethylene glycol are contained in 1L of the plating solution with a pH value of 9-10. According to the plating solution and the plating method of the cyanide-free plating silver, the plating solution does not contain cyanide ions; the pollution of wastewater treatment is reduced; the injury to a human body due to precious metal plating is reduced; a formula of the plating solution is simple, and easy to control; compared with other cyanide-free plating, the current density is higher; and the deposition efficiency of a silver coating can be improved. With the adoption of pulse plating, a coating that is small in coating stress and good in compactness and brightness, and combines with a matrix well can be obtained.

Owner:XI AN JIAOTONG UNIV +1

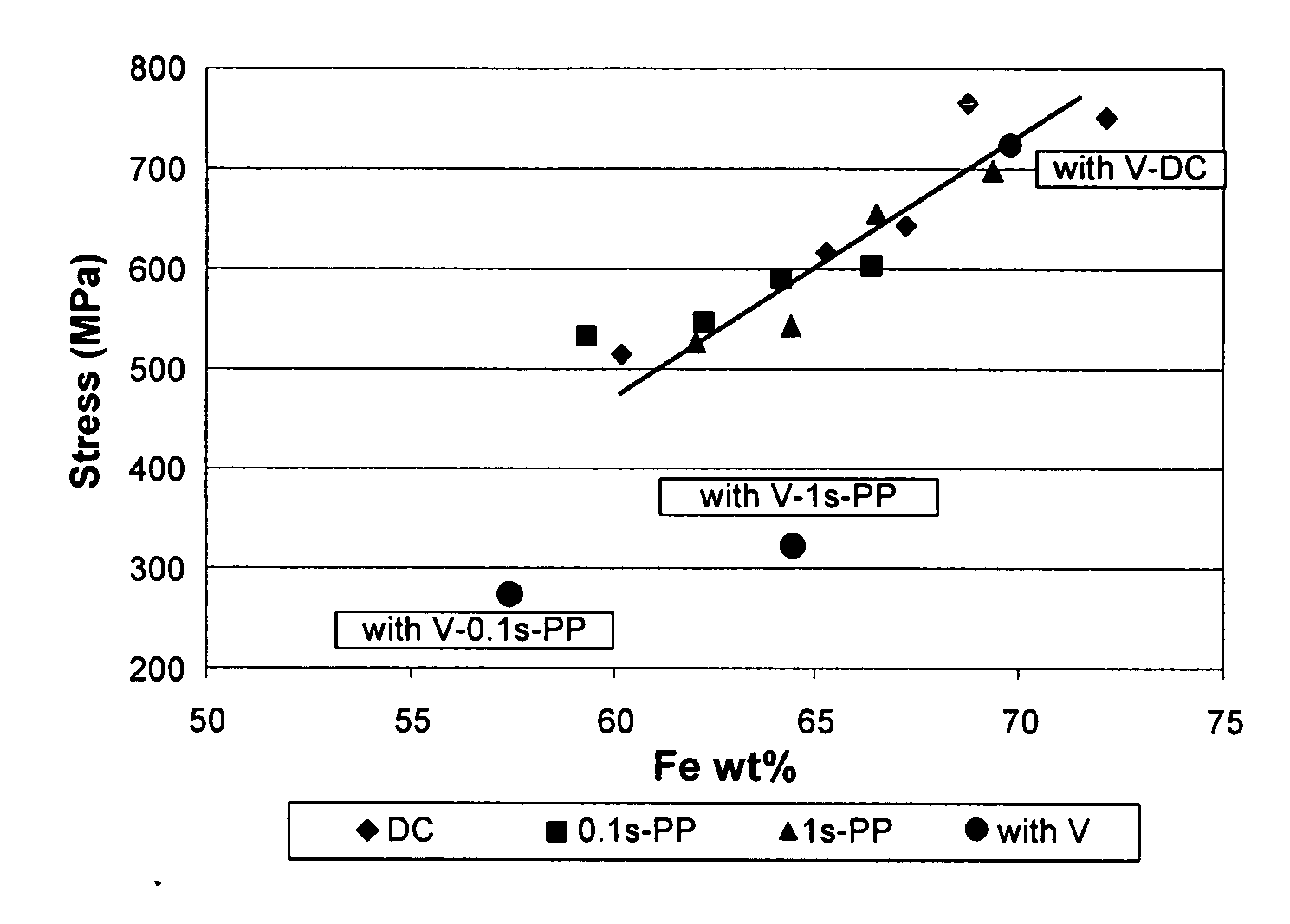

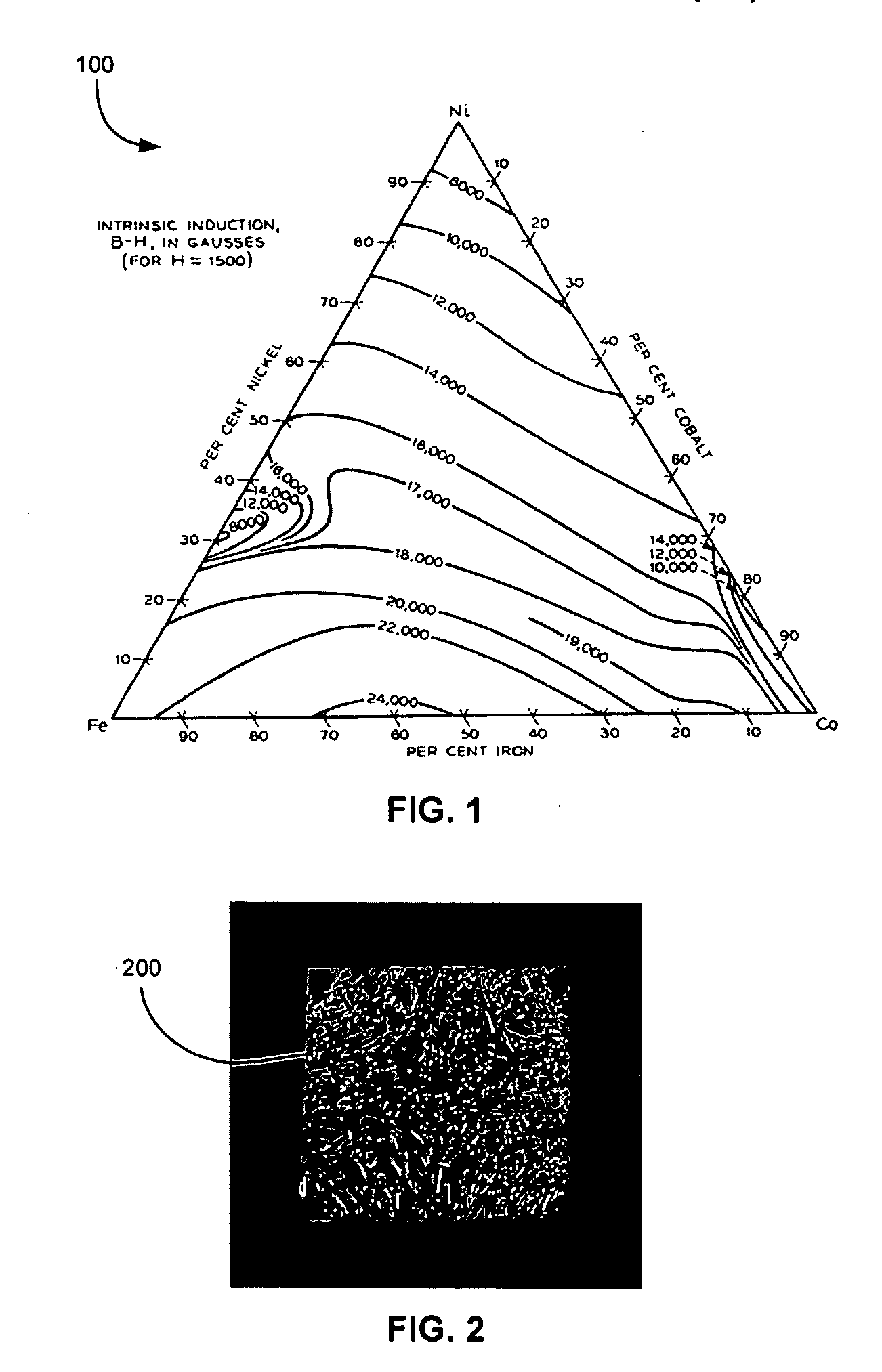

Method for lowering deposition stress, improving ductility, and enhancing lateral growth in electrodeposited iron-containing alloys

InactiveUS20060222871A1Reduce a tensile stress of a material formedThin material handlingMetal layered productsMicro structureAlloy

The present invention provides an electrodeposition / plating method for metal films and alloys in a bath which contain ferric ions and which usually deposit with high stress, but which when electrodeposited under pulse plating conditions in the presence of low valence vanadium or other ions capable of existing in multiple valence states produce low stress films and alloys and furthermore when plated through a mask creep laterally through walls and creep laterally along the surface of the mask to permit formation of overhangers, bridges, heat exchangers, and other complex three dimensional micro structures of low stress.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

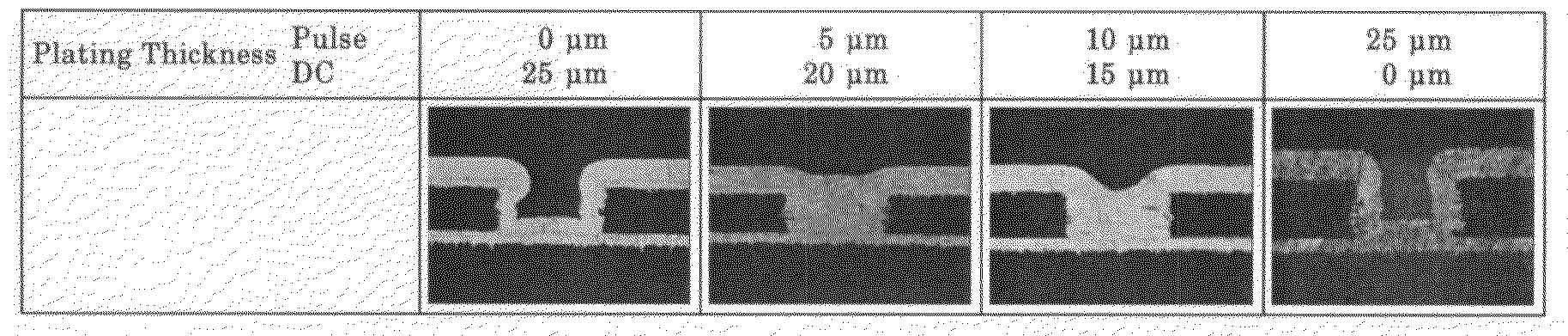

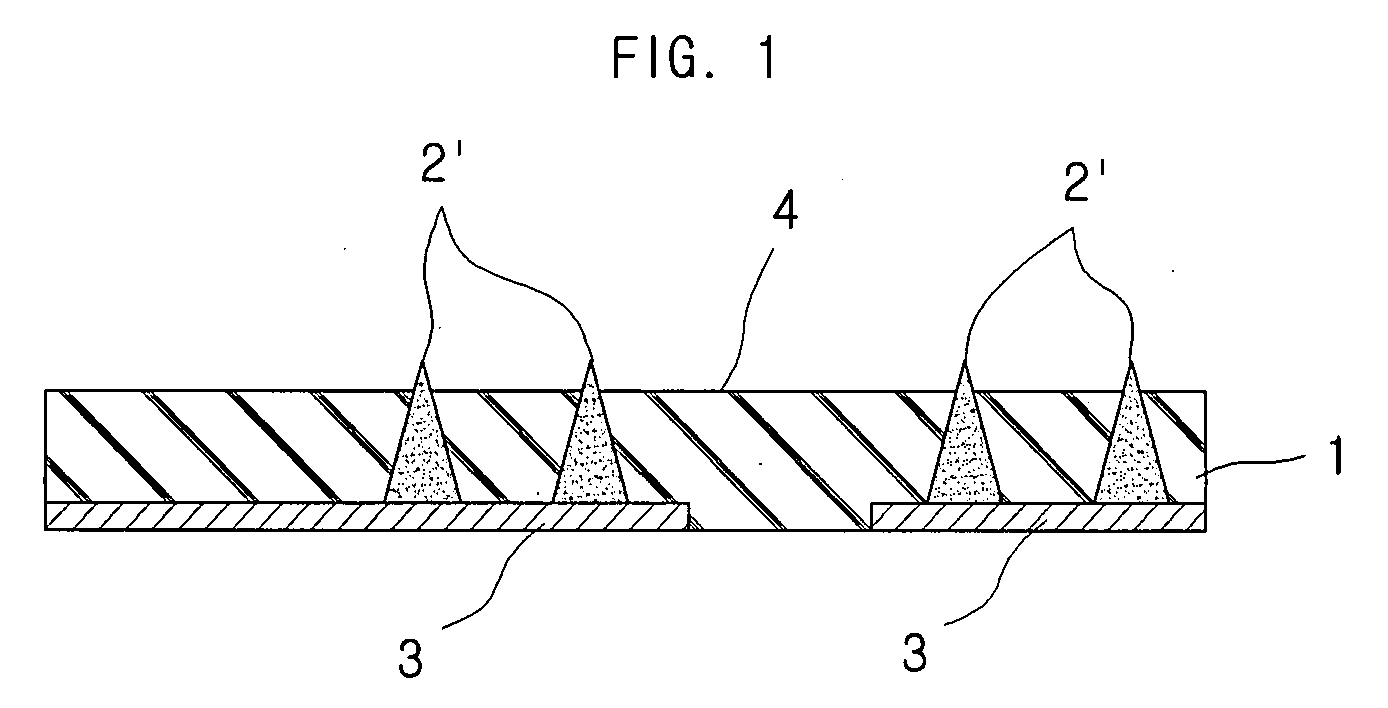

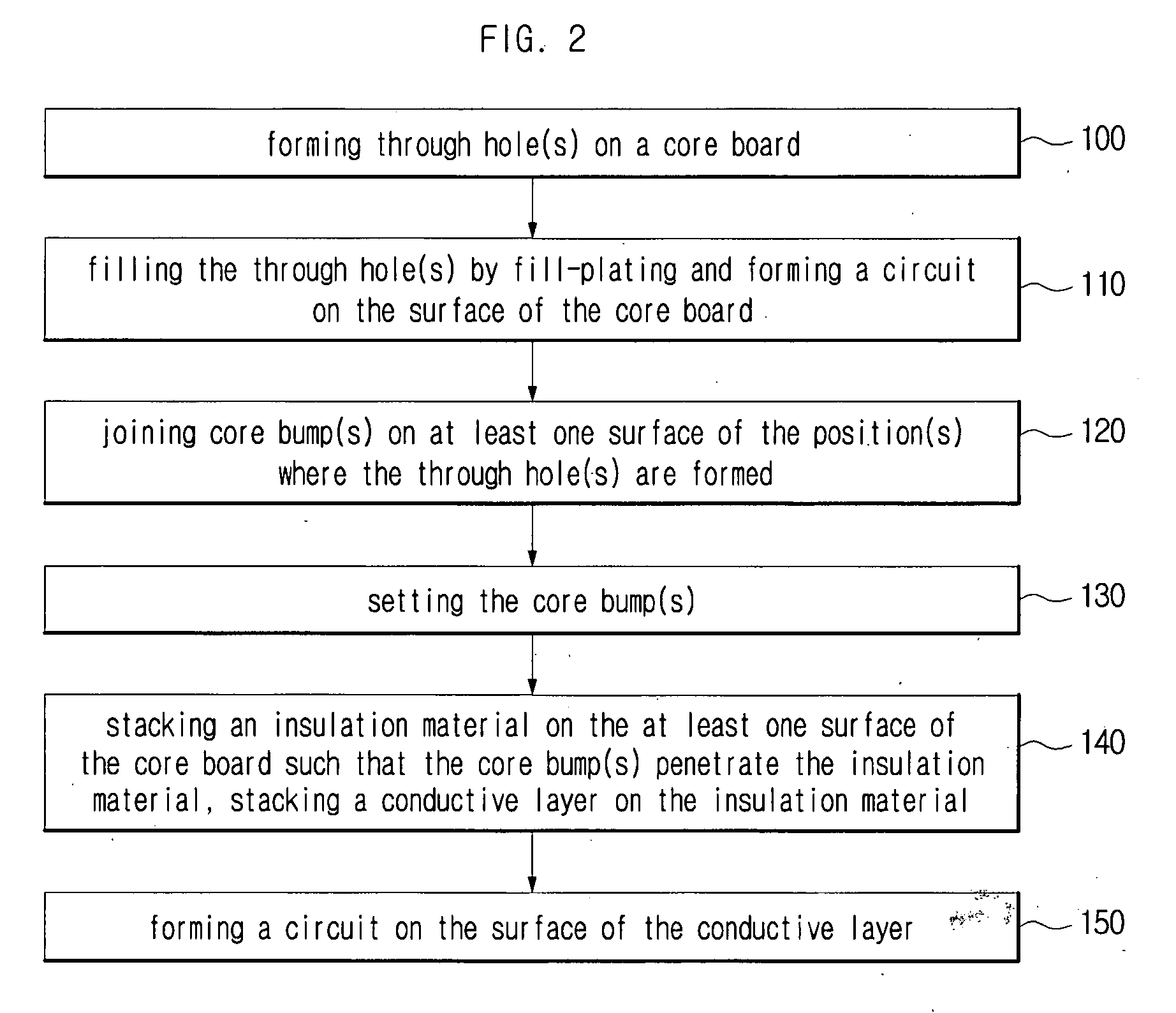

Printed circuit board using bump and method for manufacturing thereof

InactiveUS20070235220A1Easy to joinImprove cooling effectPrinted circuit aspectsPrinted circuit manufactureInsulation layerSolder paste

The present invention provides a method for manufacturing a printed circuit board and a print circuit board manufactured thereby, in which through holes of a core board are filled by reverse pulse plating so that it allows to manufacture a core board having greater than 100 μm of a thickness which has been a processing limitation with conventional technologies and form bumps on a thick insulation layer, which has been difficult till now, and thus providing resistance against pressure of paste bumps produced during stacking due to the increased strength of a core board, convenience to join between layers, excellent heat-releasing effect, and collectively stacking of core boards, which was not possible with conventional methods.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Thermal interconnect systems methods of production and uses thereof

Layered interface materials described herein include at least one pulse-plated thermally conductive material, such as an interconnect material, and at least one heat spreader component coupled to the at least one pulse-plated thermally conductive material. A plated layered interface material having a migration component is also described herein and includes at least one pulse-plated thermally conductive material; and at least one heat spreader component, wherein the migration component of the plated layered interface material is reduced by at least 51% as compared to the migration component of a reference layered interface material. Another layered interface material described herein includes: a) a thermal conductor; b) a protective layer; c) a layer of material accept solder and prevent the formation of oxides; and d) a layer of solder material. Methods of forming layered interface materials are described herein that include: a) providing a pulse-plated thermally conductive interface material; b) providing a heat spreader component; and c) physically coupling the thermally conductive interface material and the heat spreader component. At least one additional layer, including a substrate layer, a surface, adhesive, a compliant fibrous component or any other suitable layer or a thermal interface material, can be coupled to the layered interface material.

Owner:HONEYWELL INT INC

Method for pulse plating of copper using pyrophosphate with neodymium-iron-boron permanent magnet

The invention discloses a method for pulse plating of copper using pyrophosphate with neodymium-iron-boron permanent magnet, wherein the formula for the electroplate copper process and galvanizing solution includes, copper sulphate, normal potassium pyrophosphate, ammonial solution, polishing agent, wetting agent, and copper ions.

Owner:TIANJIN CIQIANG TECH DEV

Production method of replacement embedded copper block of circuit board

ActiveCN106961806AAddress reliabilitySolve the problem of layer explosionPrinted circuit aspectsPrinted element electric connection formationCopperRejection rate

The invention discloses a production method of a replacement embedded copper block of a circuit board. The production method comprises steps that a target hole is drilled in a production board after early stage stitching, and a through hole is drilled in the position of the target hole; glue refuses on the production board are removed by adopting plasma glue removing operation, and the through hole is metalized by adopting an electroless plating copper and full board electroplating operation; the copper (electro)plating bridging of the middle position of the metalized through hole is carried out by adopting an pulse plating bridging operation, and then a double-sided blind hole is formed; the copper (electro)plating is carried out in the double-sided blind hole to fill and level up the double-sided blind hole by adopting a full board filling electroplating operation; the circuit board is produced by sequentially carrying out the drilling operation, the electroless plating copper operation, the full board electroplating operation, and other latter operations on the production board. A metal copper block is formed on the production board in an electroplated way to replace a conventional high heat conduction metal copper block or a metal block embedded in the circuit board, and the problems of the circuit board such as poor reliability and delamination and blistering caused by the filling of the metal block product are solved, and therefore the production efficiency of the circuit board, a rejection rate is reduced, and the excellent heat dissipation performance of the product is guaranteed.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

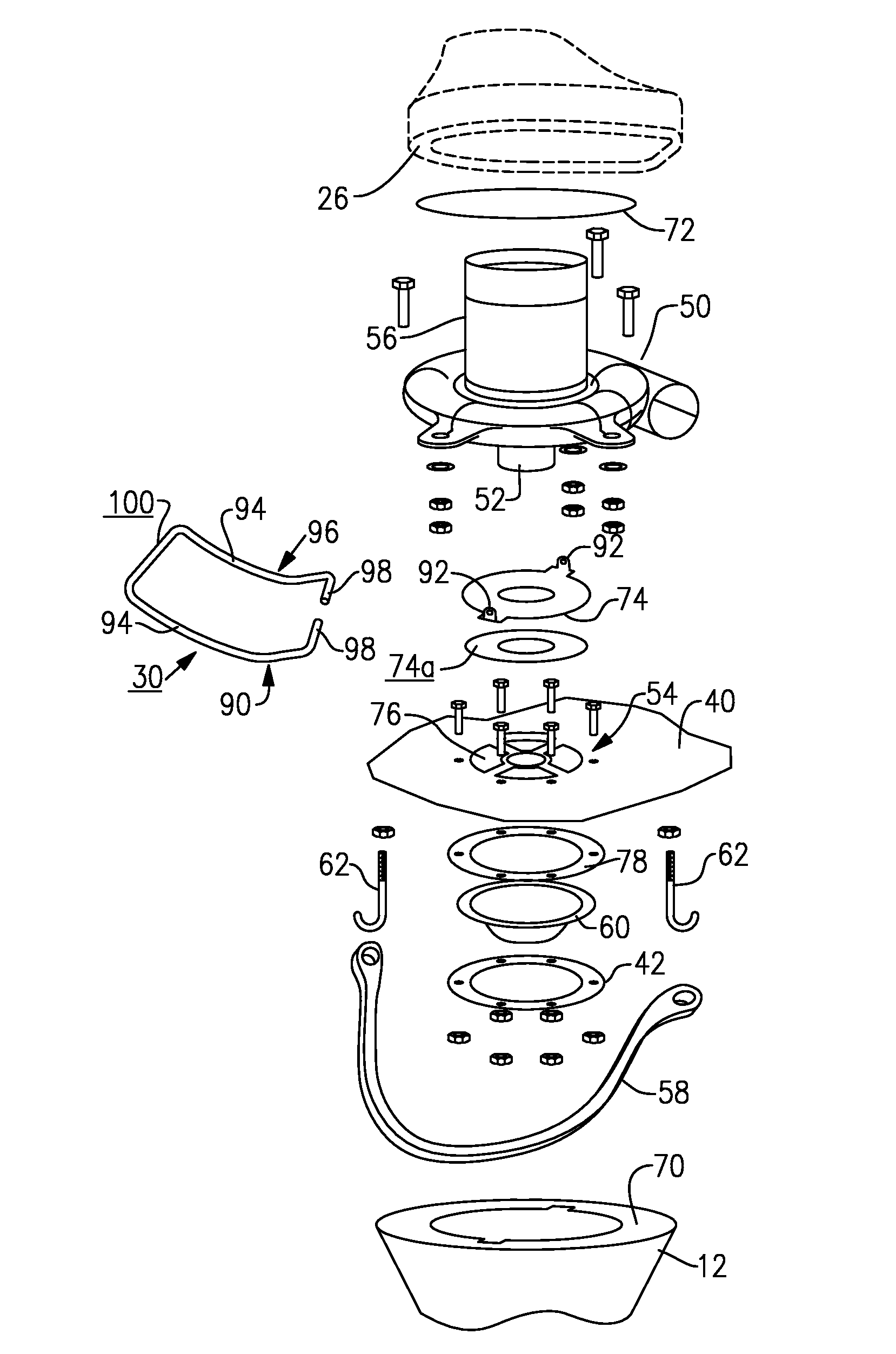

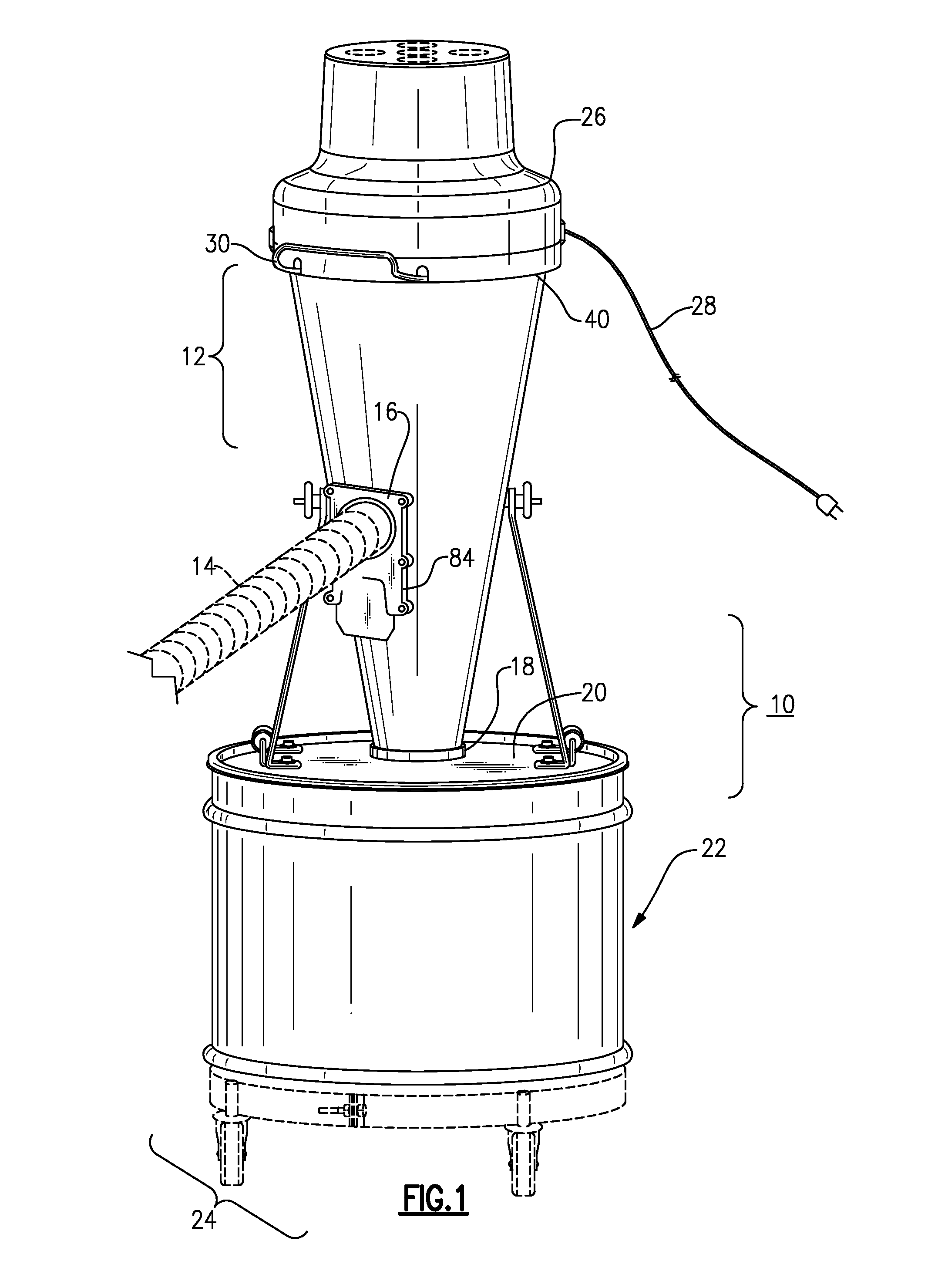

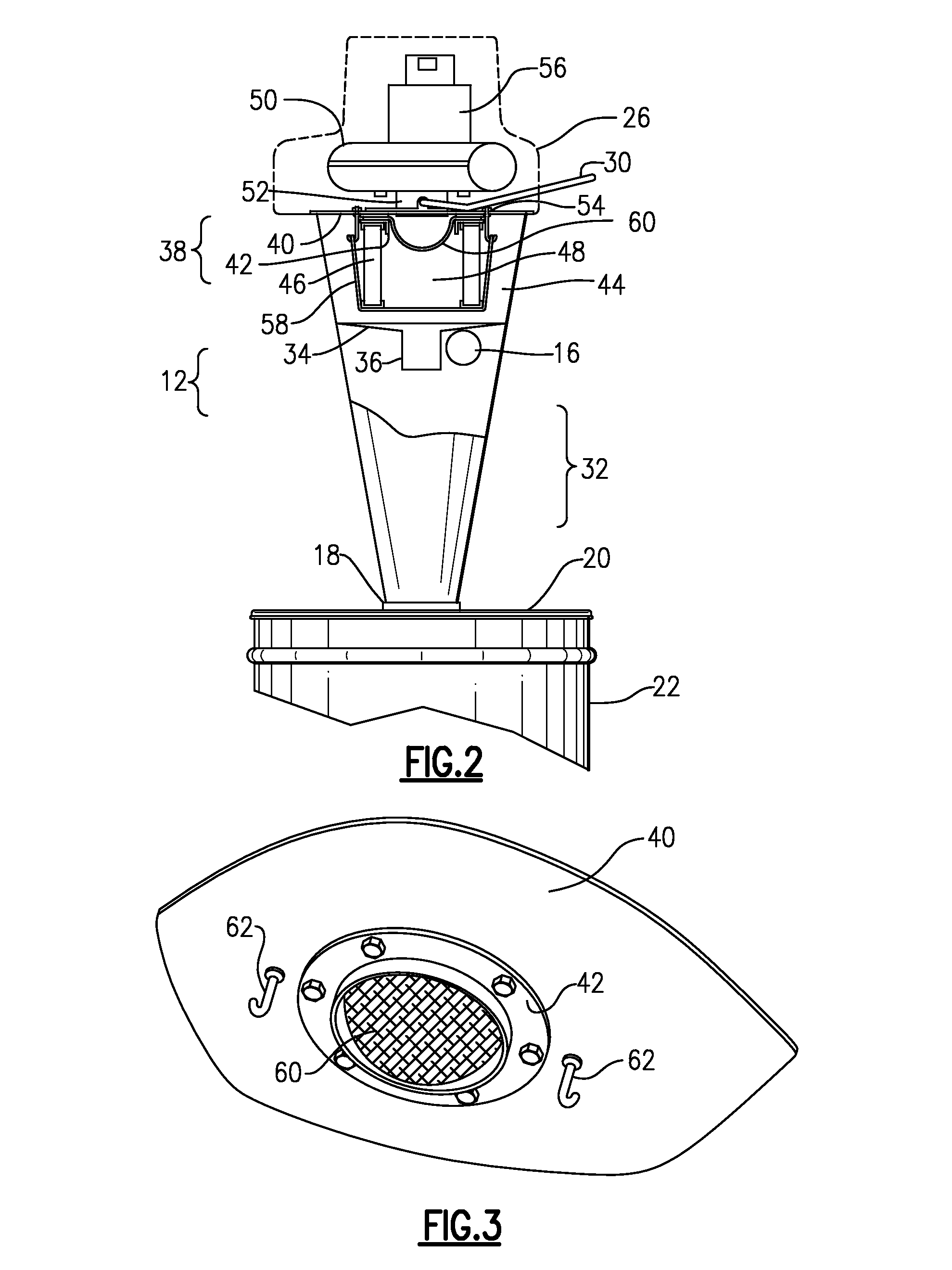

Pulse filter cleaner for portable cyclonic dust collector/vacuum cleaner

ActiveUS9125535B2Efficient but simplified designNot impare and complicate normal operation of deviceCleaning filter meansSuction filtersEngineeringDeflagration

A cyclonic portable vacuum cleaner / dust collector has a cyclonic chamber and a filter chamber. The filter chamber contains a filter cartridge with a hollow core positioned over the discharge opening of a motor plate that closes the filter chamber. A vacuum blower is mounted on the motor plate, with an intake tube at the discharge opening of the motor plate. An annular pulse-cleaning plate is positioned over an associated annular opening that surrounds the motor plate discharge opening and has an open center that slides up and down on the intake tube of the vacuum blower. A bail handle or lever extends from the pulse-cleaning plate to a handle portion outside the cover or shroud. The handle is pushed down to lift the pulsing plate to provide a reverse pressure air pulse to the filter to blast off accumulated dust. An anti-deflagration screen may be present at the center of the motor plate.

Owner:ONEIDA AIR SYST

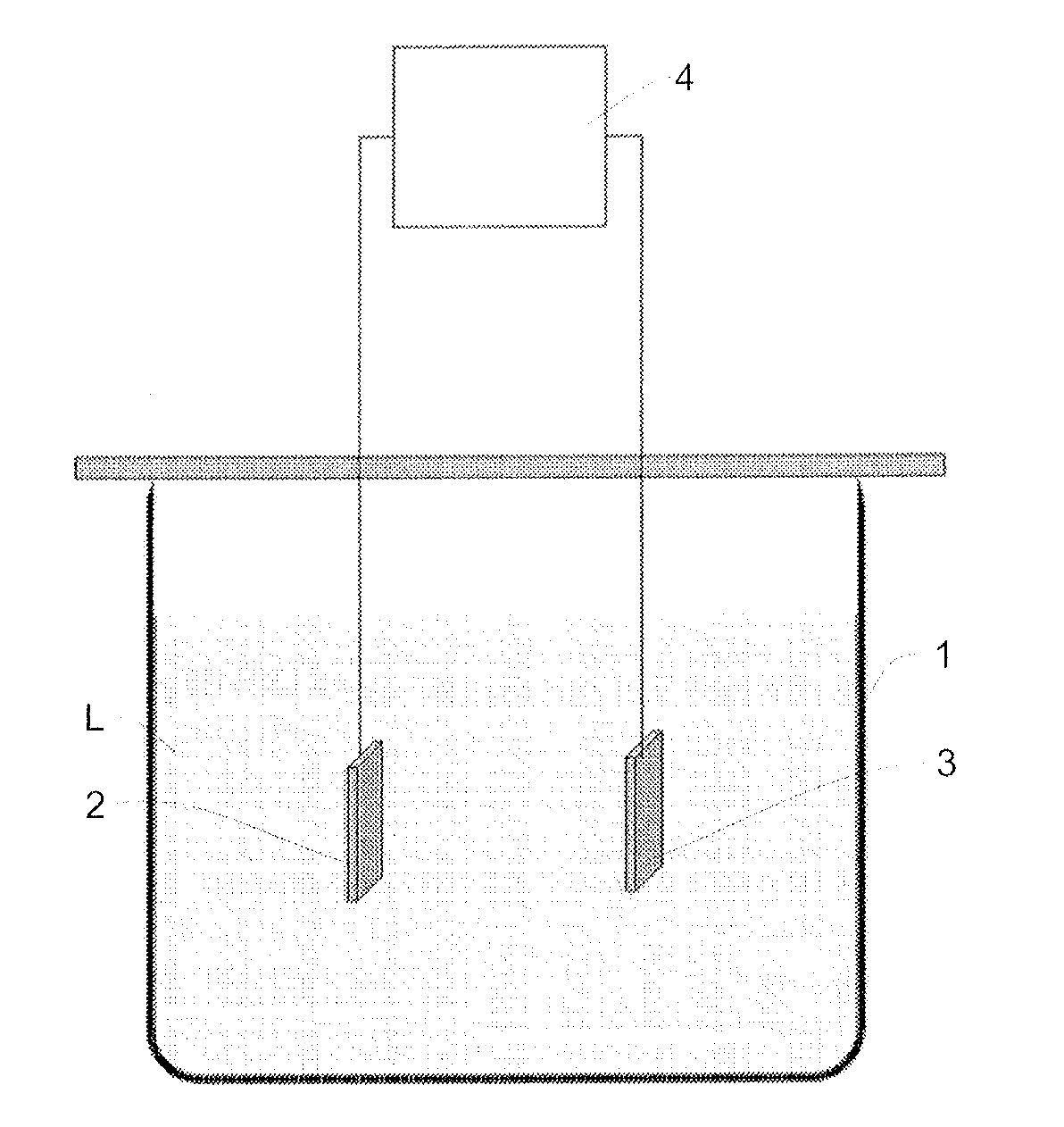

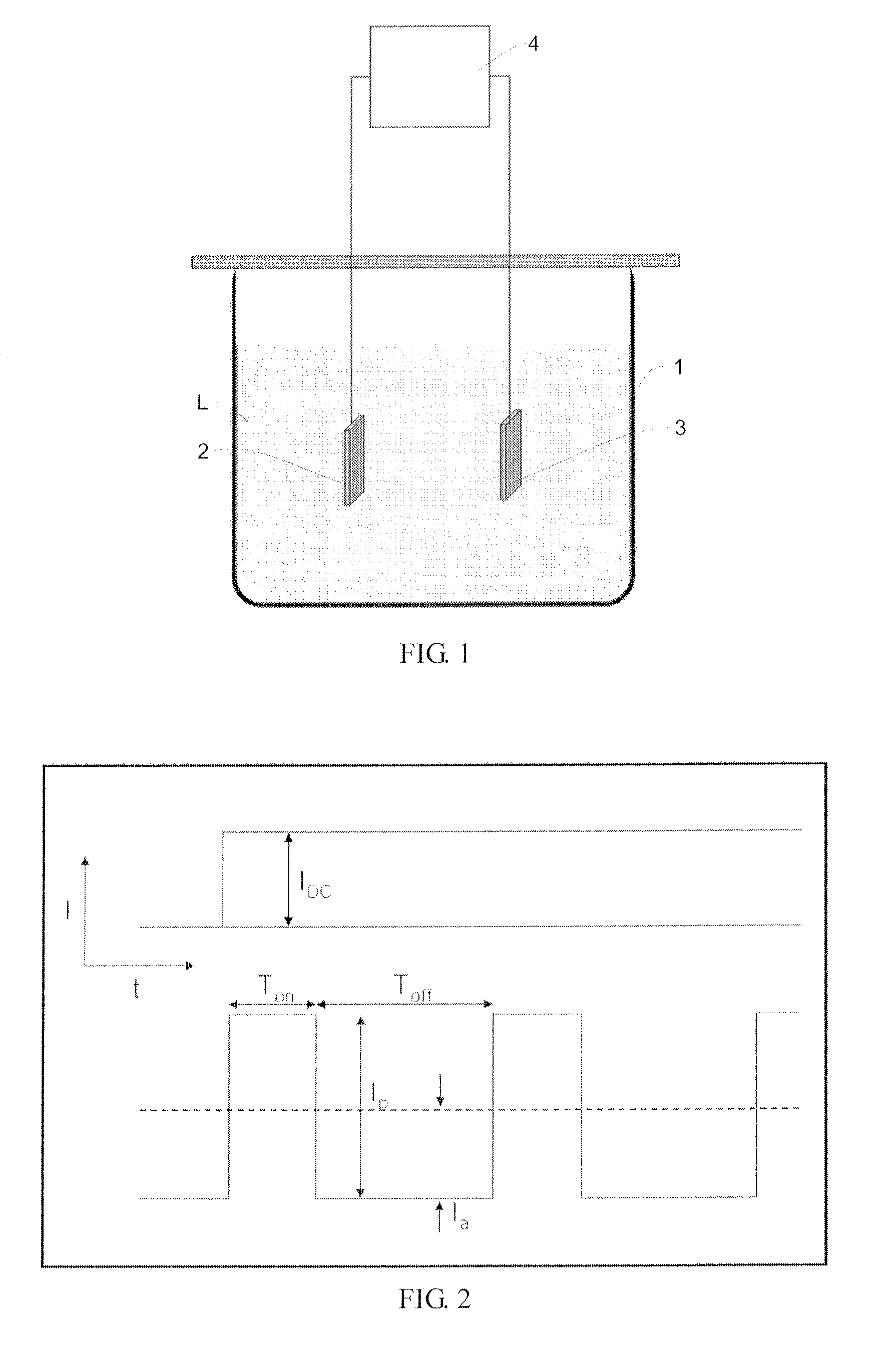

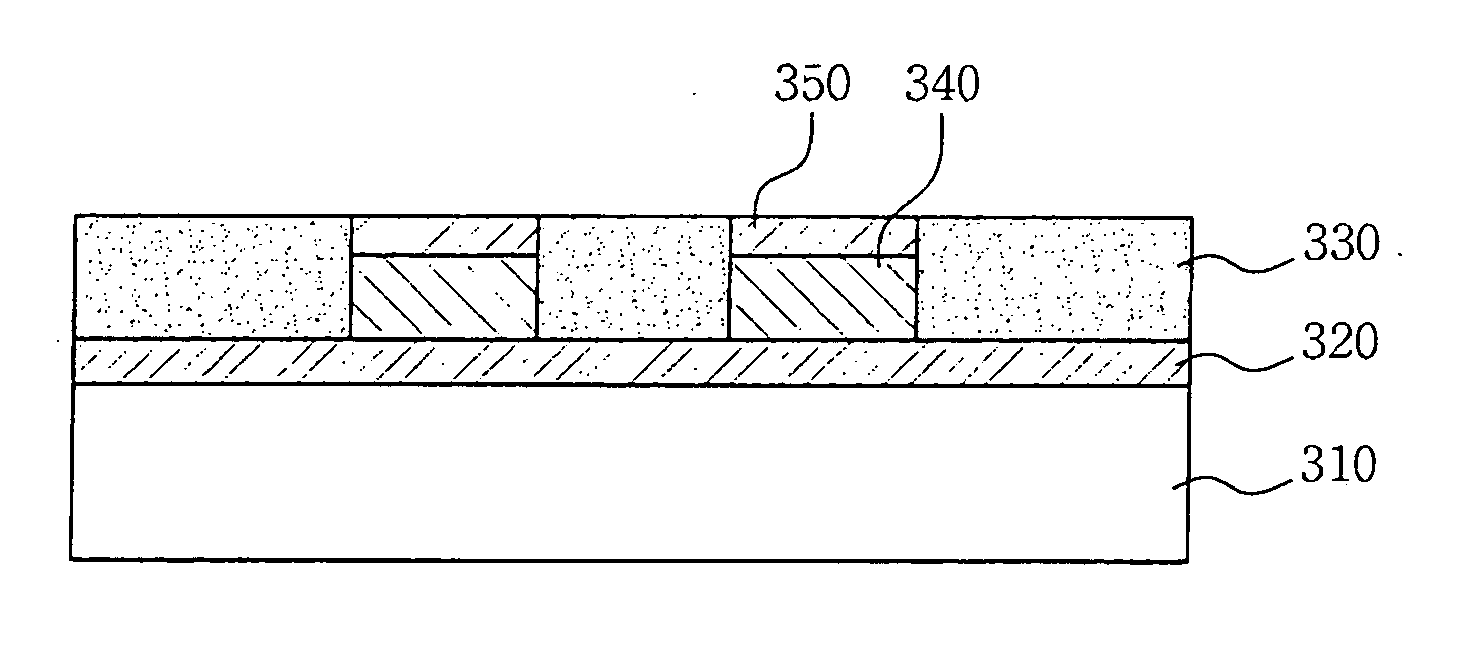

Method for coating metallic interconnect of solid oxide fuel cell

InactiveUS20100122911A1Improve bindingImprove conductivityCollectors/separatorsAverage currentVolumetric Mass Density

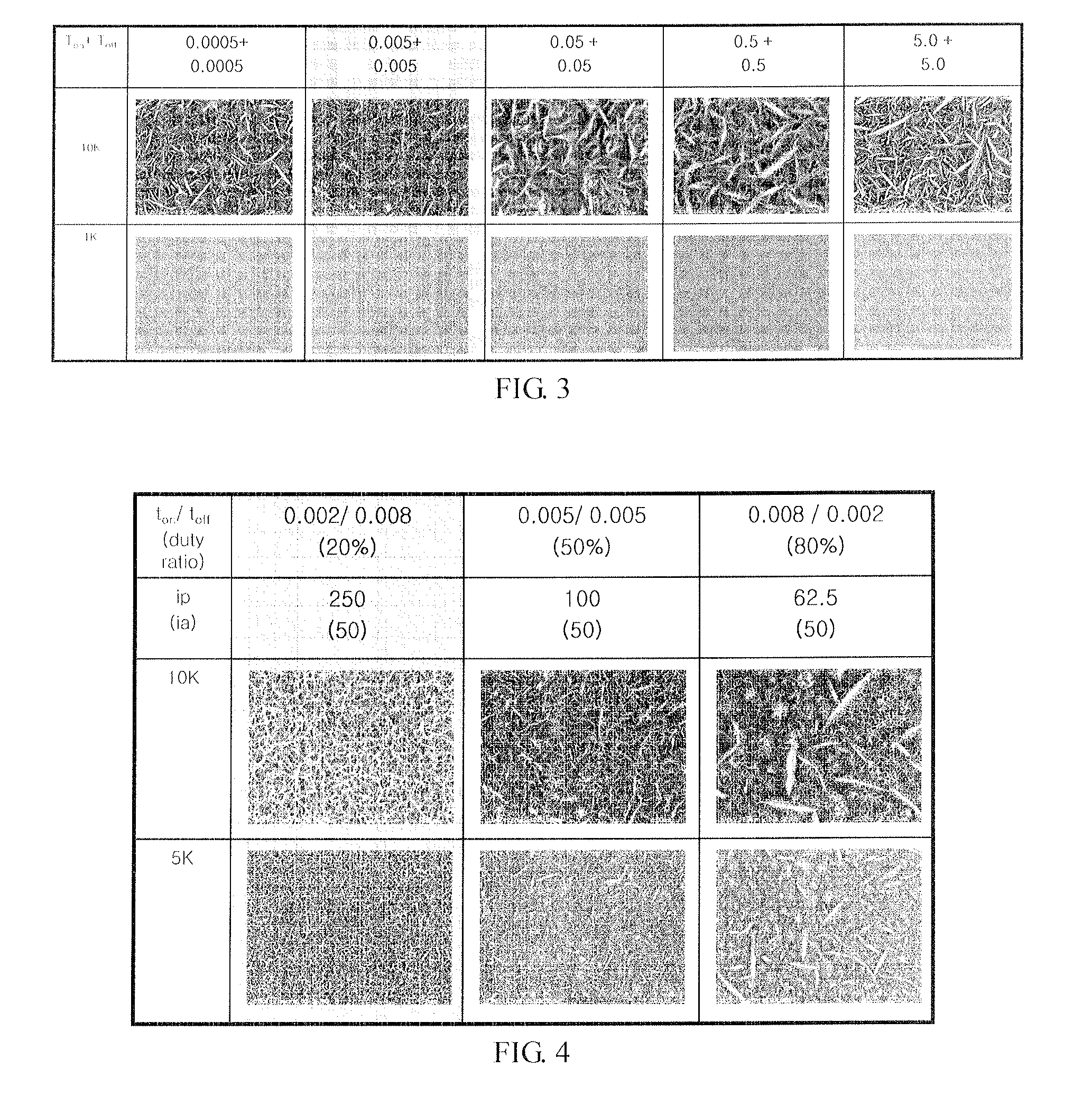

Disclosed is a method for coating a metallic interconnect for a solid oxide fuel cell (SOFC), the method including the steps of: carrying out pre-treatment for removing impurities adhered on a surface of the metallic interconnect; and carrying out pulse plating with cobalt as an anode, and the metallic interconnect as a cathode, in which an average current density (Ia) is set in a room-temperature cobalt plating solution, and a maximum current density (Ip), a current-on time (Ton) and a current-off time (Toff) are adjusted based on Ia=Ip×Ton / (Ton+Toff). Through the disclosed method, it is possible to obtain a metallic interconnect having a coating surface which has a high electrical conductivity and a high chrome volatilization inhibiting property and can minimize the occurrence of micro-cracks and micro-pores, thereby improving the performance of the SOFC.

Owner:KOREA INST OF ENERGY RES

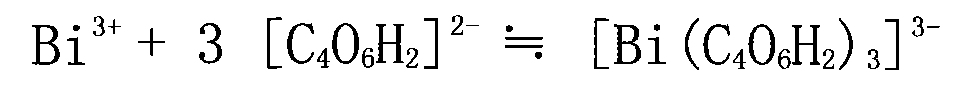

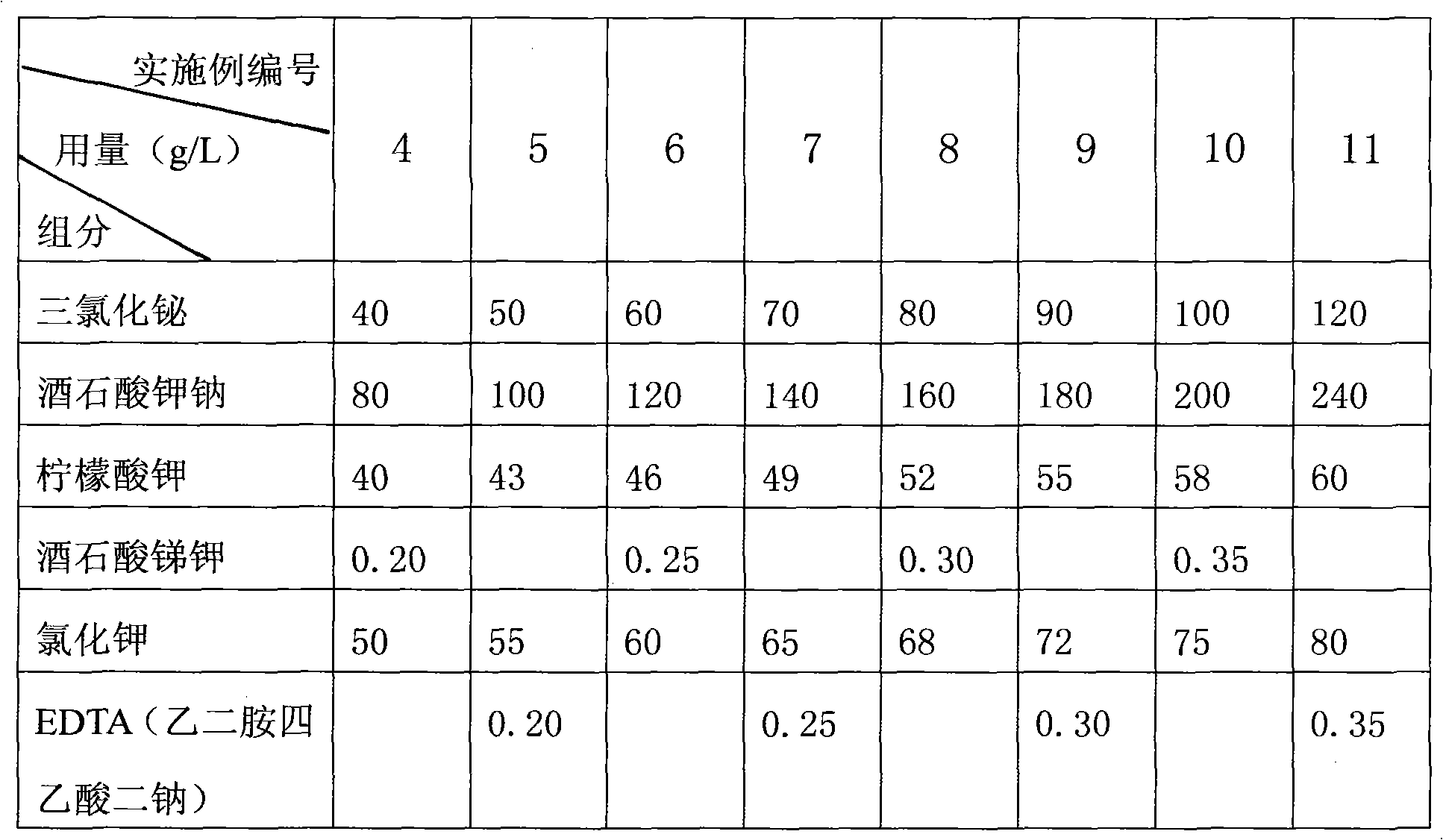

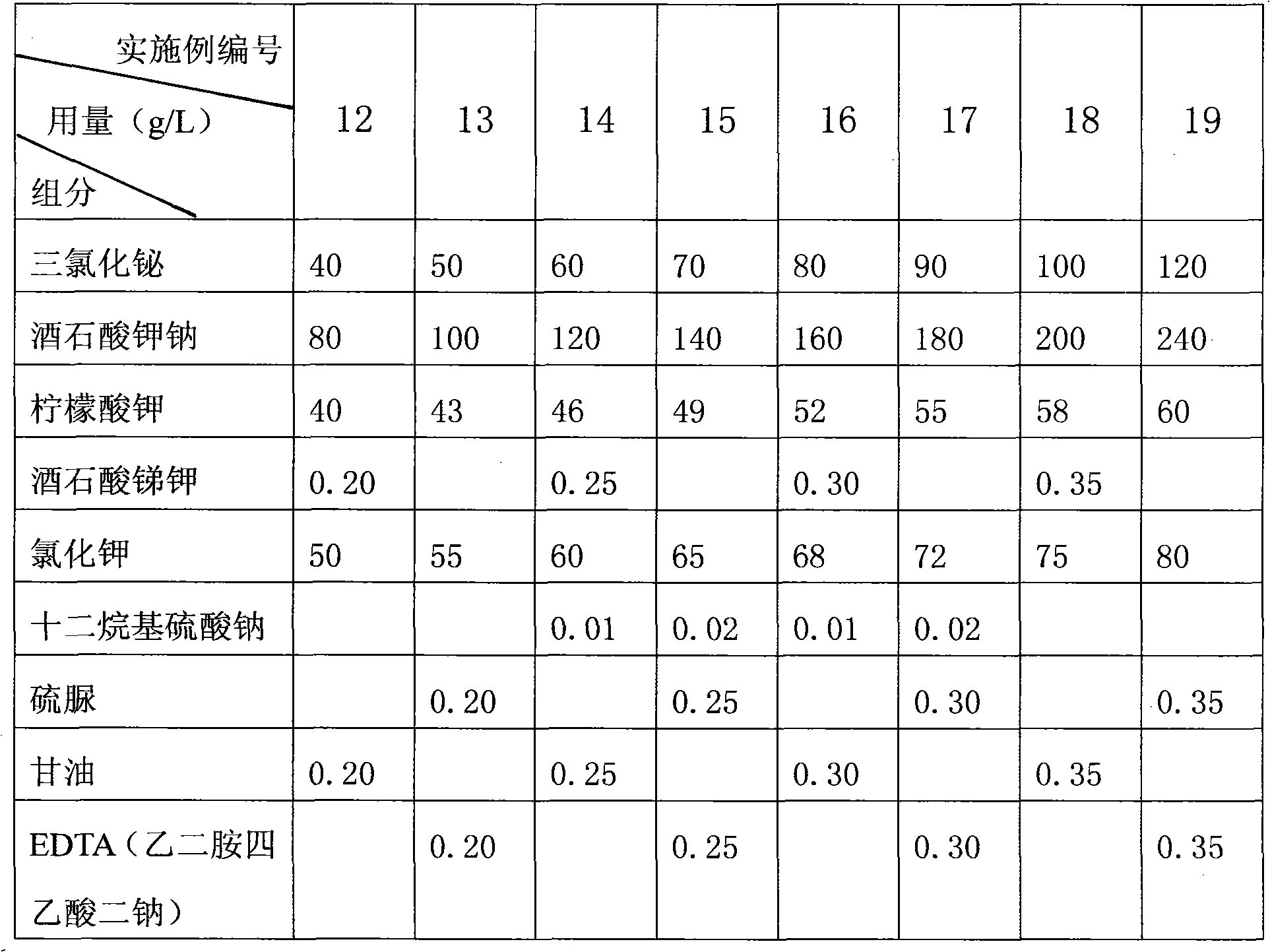

Method for preparing bismuth film by pulse plating process

The invention discloses a method for preparing a bismuth film by a pulse plating process. The method is characterized by comprising the following steps of: preparing one liter of plating solution by using 40 to 120g of bismuth trichloride, 80 to 240g of sodium potassium tartrate, 40 to 60g of potassium citrate, 0.20 to 0.35g of antimony potassium tartrate and 50 to 80g of potassium chloride; and plating by using a copper sheet as a cathode and using a pure gold plate as an anode under the pulse plating process conditions that the current density is 0.55 to 0.85A / dm<2>, the frequency is 500 to 700Hz, the duty ratio is 1:7-1:11, the temperature of the plating solution is 25 to 50 DEG C and the pH value is 7.5 to 11.5, wherein the film deposited on the copper sheet is the prepared bismuth film. The cyanogen-free plating solution is environmentally-friendly and has stable performance; and the prepared bismuth film has smooth and bright surface, low porosity, good bonding force and easily controlled thickness, and has broad application prospect in the fields of electronic materials, component industry and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

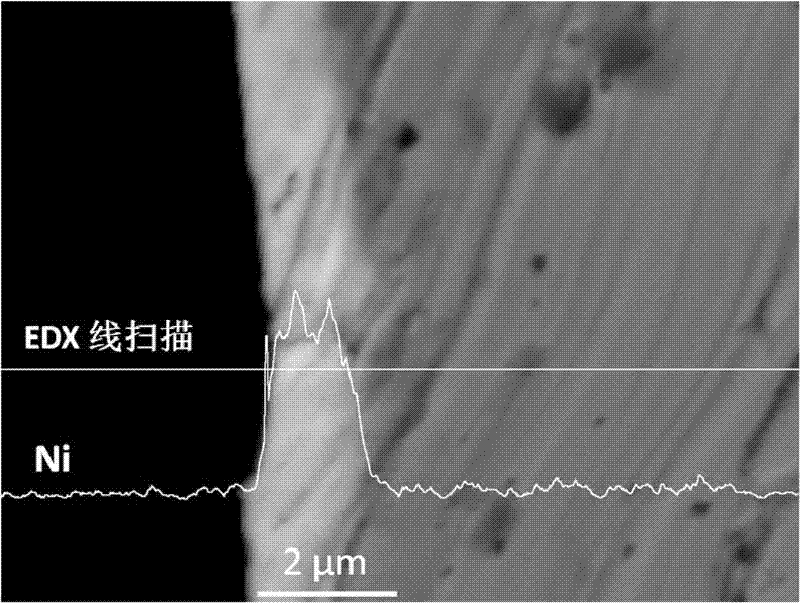

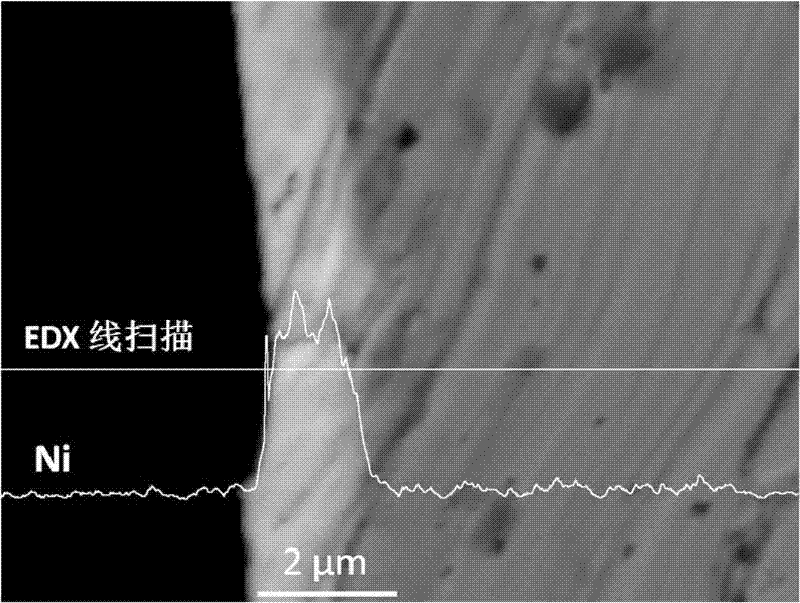

Pulse electrochemical deposition and tissue adjustment processes for nickel plating copper belt

The invention discloses pulse electrochemical deposition and tissue adjustment processes for a nickel plating copper belt. The process comprises the following steps of: performing pulse plating on a nickel coating; performing subsequent cold machining deformation and vacuum heat treatment processes, and the like. By the pulse electrochemical deposition process, the thickness of the nickel coating deposited on the copper belt and the uniformity of a microscopic structure can be effectively ensured; and by the subsequent cold machining deformation and vacuum heat treatment processes, the comprehensive mechanical property, particularly the bending resistance and the physical property of the nickel plating copper belt can be improved, so that high-quality nickel plating copper belts required in industries such as electronics, batteries, electrovacuum, electric light sources and the like can be possibly processed. The pulse nickel plating and tissue adjustment process is low in required equipment investment, has a simple method, is convenient to operate and is suitable for industrial production.

Owner:CHANGSHA STORM ENERGY TTECH

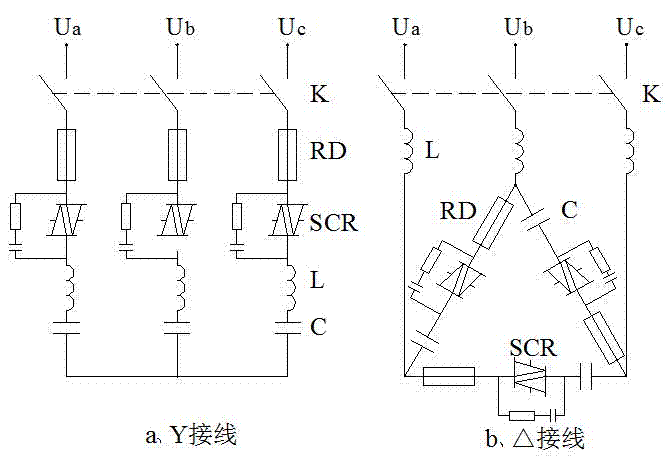

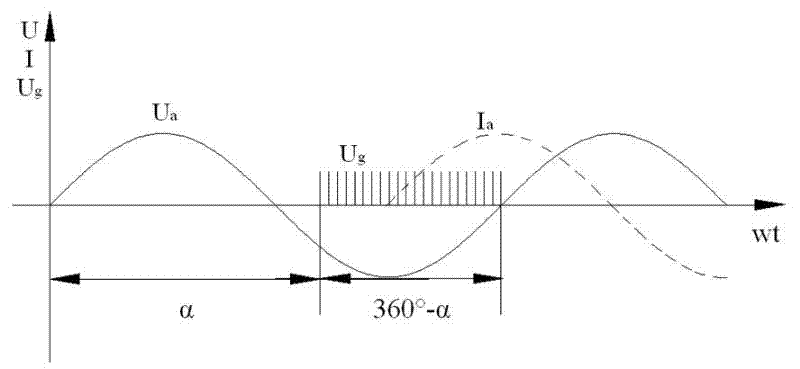

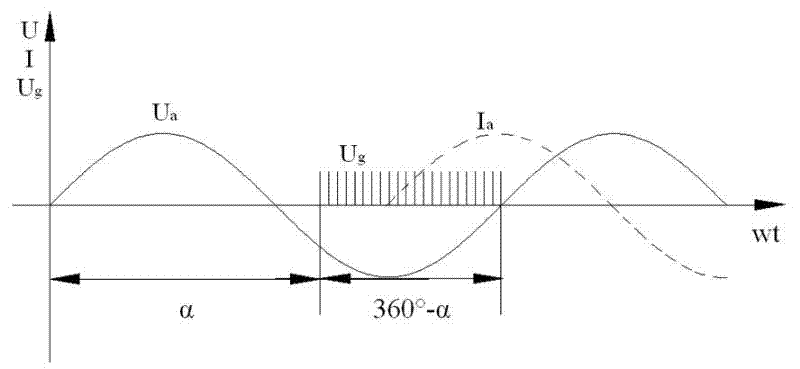

Triggering and conducting method used for switching of capacitor of thyristor AC non-contact switch

ActiveCN102570474AGood safety and reliabilityTrigger conductionReactive power adjustment/elimination/compensationReactive power compensationCapacitanceOvervoltage

The invention discloses a triggering and conducting method used for the switching of a capacitor of a thyristor AC non-contact switch, belonging to the field of triggering and conducting method of thyristors. The method comprises the following steps of: (1) regulating a multi-turn potentiometer on a triggering pulse plate, adjusting the control angle alpha to 180-270 degrees, and keeping the value of the control angle alpha unchanged; (2) regulating the capacitance of a return circuit on the triggering pulse plate, so that the triggering pulse width is 360-alpha degrees, and keeping the triggering pulse width unchanged until the anode potential is higher than the cathode potential and the capacitor current arises smoothly from zero. By using the triggering and conducting method, inrush current and operation overvoltage are avoided during switching of the capacitor, a compensating device itself does not generate harmonic wave, the control system is simple and reliable, the control precision is high, the current waveform does not have notches, and greater economic and social benefits are achieved in reducing the grid loss and voltage fluctuation, improving the grid quality, enhancing the grid safety, etc.

Owner:郑学超

Pulse plating process for deposition of gold-tin alloy

The invention relates to a solution for use in connection with the deposition of a gold-tin alloy on an electroplatable substrate. This solution generally includes water, stannous tin ions, a complexing agent to render the stannous tin ions soluble, complexed gold ions, and an alloy stabilization agent that includes an imine functional group. The alloy stabilization agent is present in an amount sufficient to stabilize the composition of the gold-tin deposit over a usable current density range. The solution has a pH of between about 2 and about 10 and the deposit having a gold content less than about 90% by weight and a tin content greater than about 10% by weight. An advantageous way for providing the desired deposit is by a pulse plating technique.

Owner:TECHNIC INC

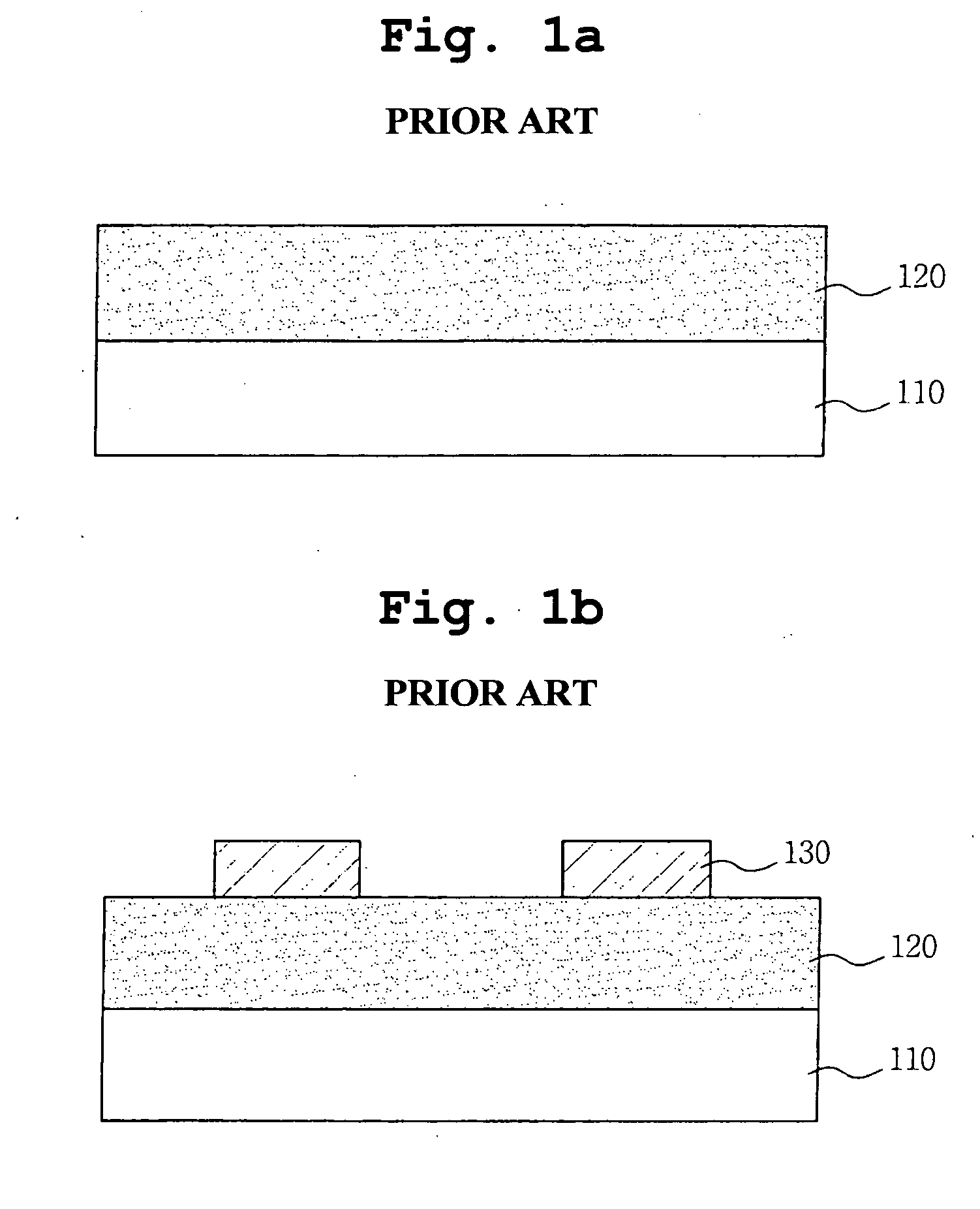

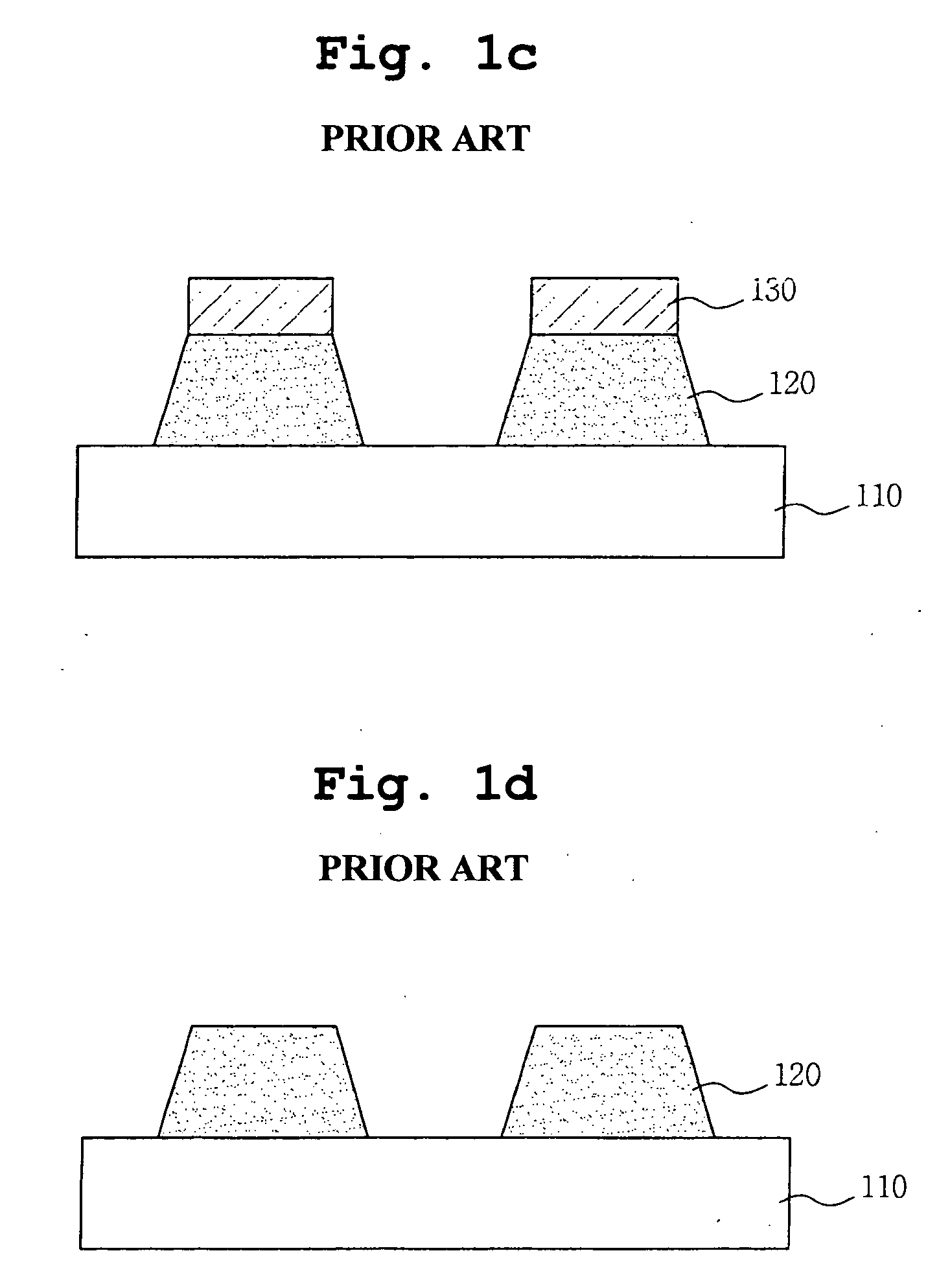

Method of forming bump pad of flip chip and structure thereof

InactiveUS20050142836A1Improve featuresImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCopper platingHigh density

Disclosed is a method of forming a bump pad of a flip chip and a structure thereof, characterized in that a resist pattern is formed through coating of a photosensitive material on an electroless copper plating layer, exposure to light and development, and then a bump pad is prepared by pulse plating and direct current plating of the resist pattern, thereby fabricating a substrate with a high density and high reliability.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for providing an efficient thermal transfer through a printed circuit board

InactiveUS8112884B2Printed circuit aspectsConductive pattern formationSurface mountingConductive materials

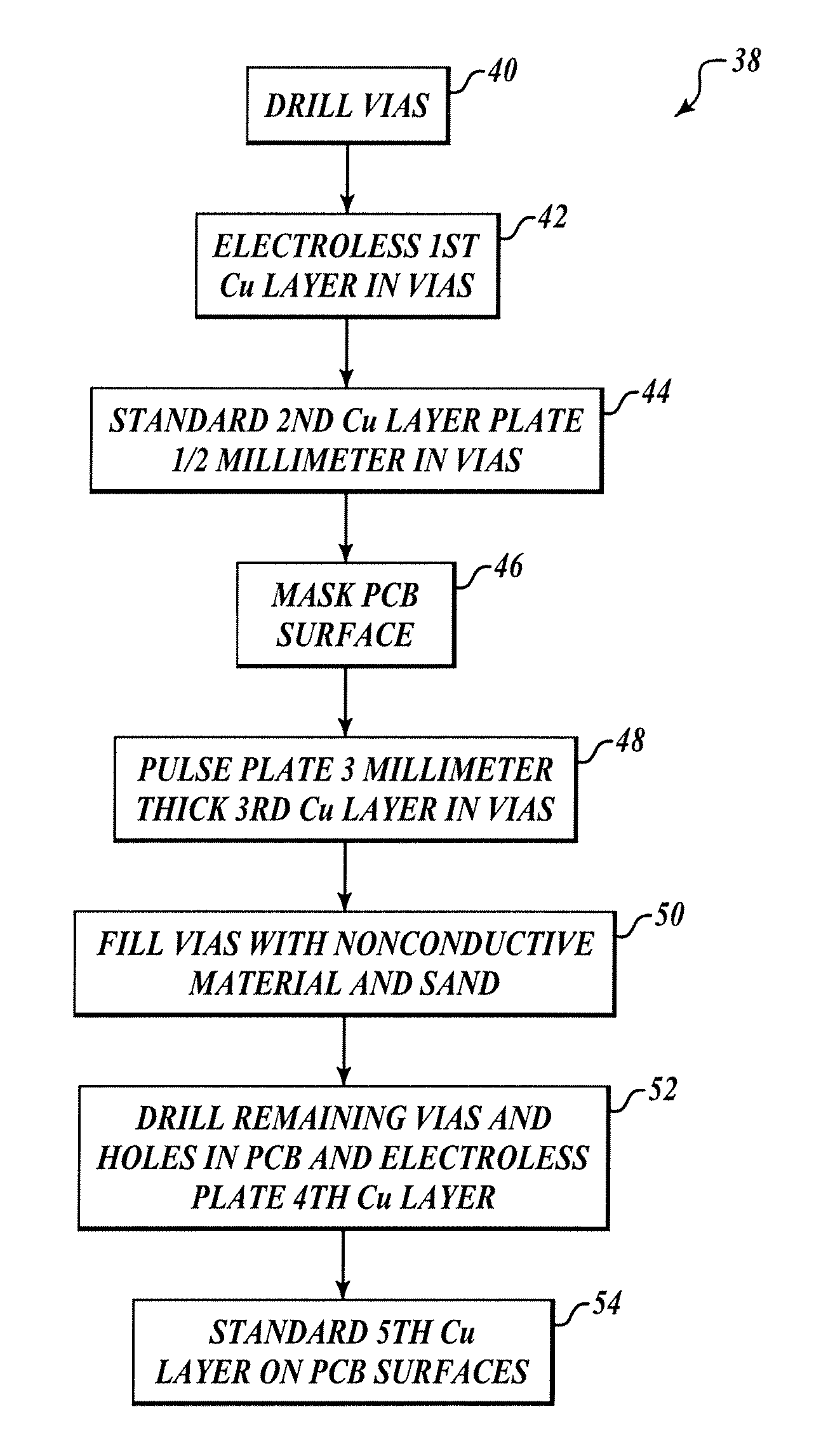

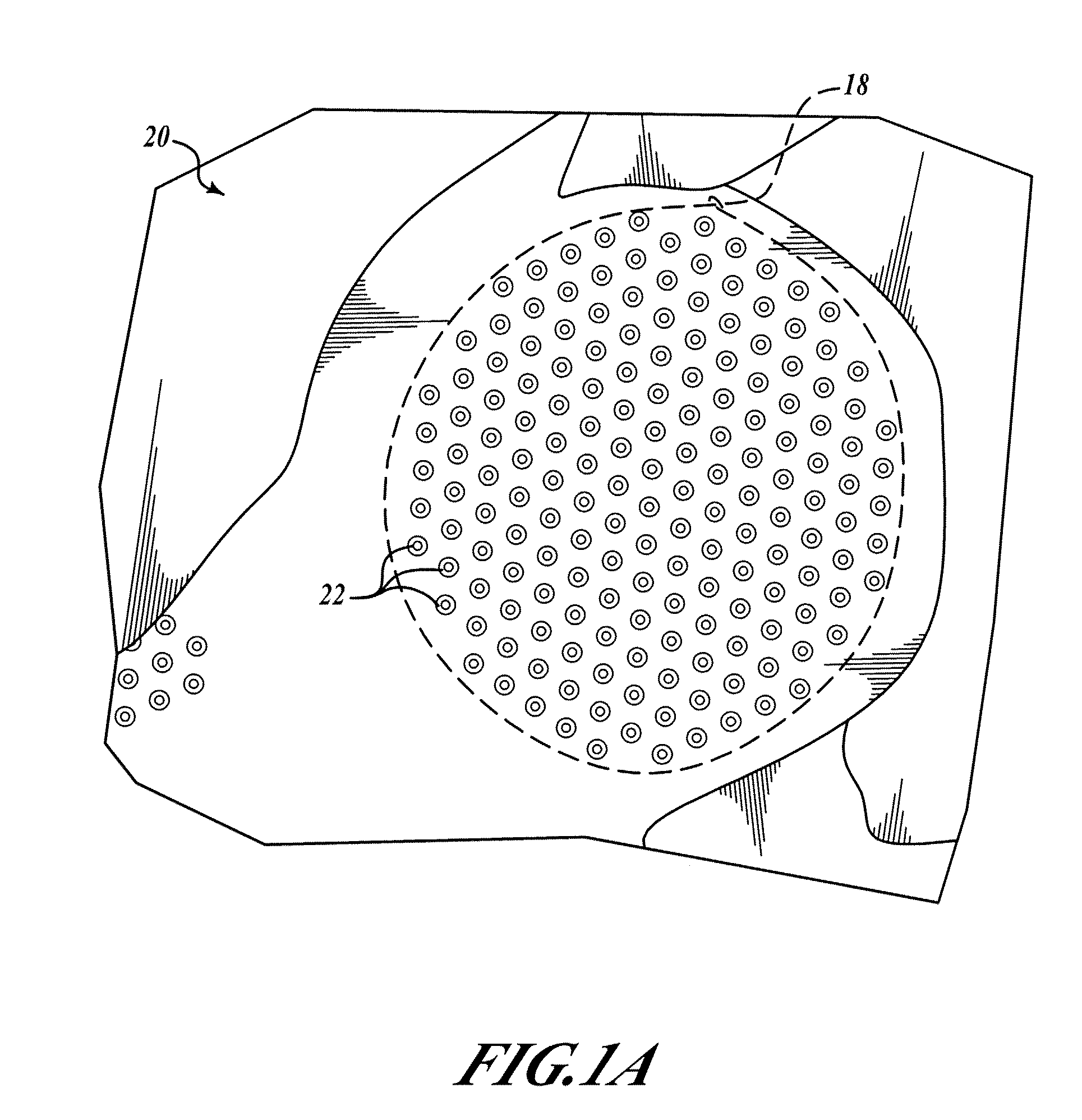

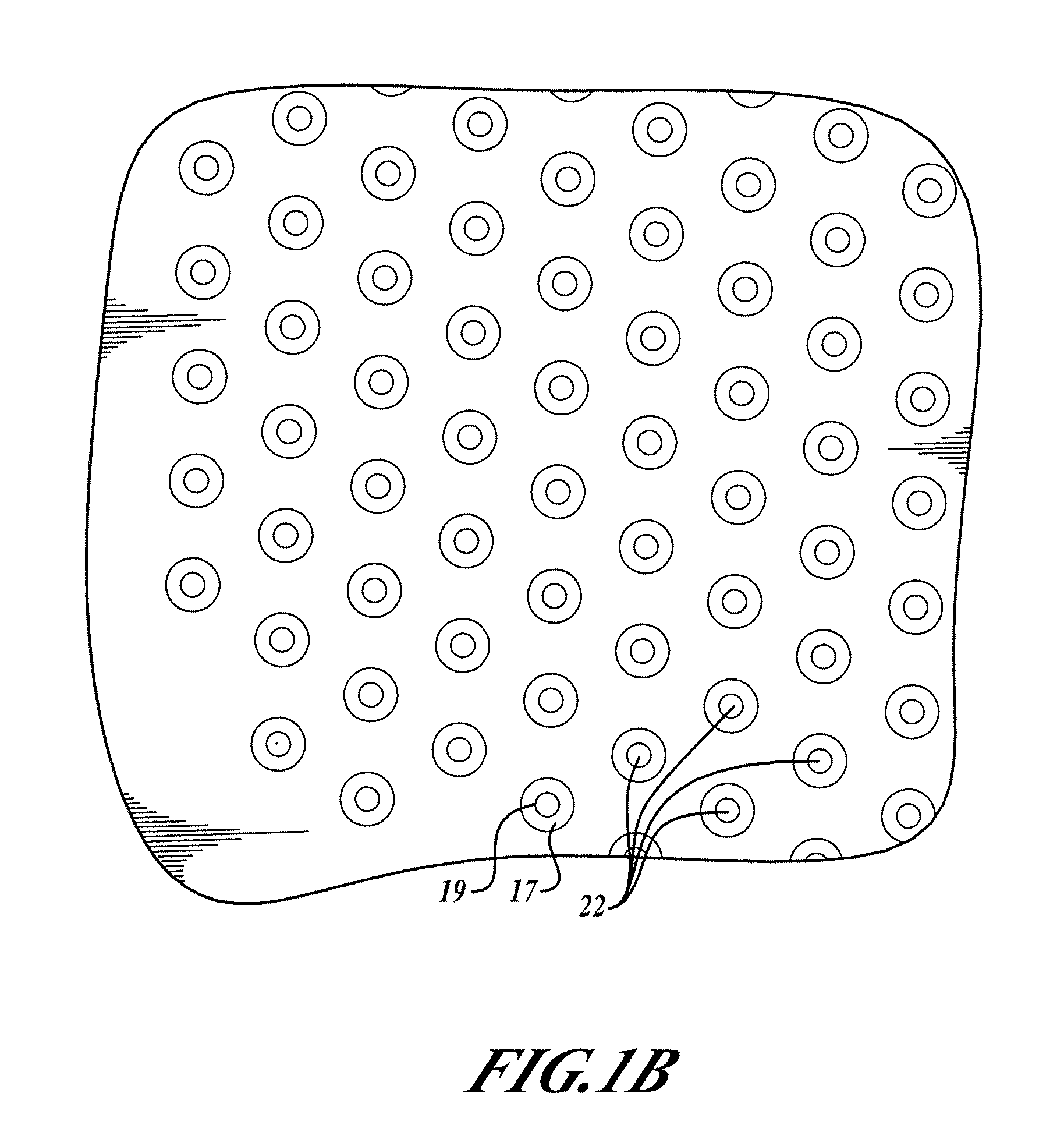

A method of heat sinking a surface mount device (SMD) component. In an example method through holes are formed in a printed circuit board (PCB), a first copper layer is electroless plated in the holes, a second copper layer is standard plated in the holes and surrounding surfaces of the PCB, a third copper layer is masked and pulse plated in the holes, the holes are filled with non-conductive material and then is sanded flush with the second copper layer. A fourth copper layer electroless plated on the PCB over the area of the holes, a fifth copper layer (or pad) plated on the PCB over the area of the holes, and a surface mount device is attached to the fifth copper layer.

Owner:HONEYWELL INT INC

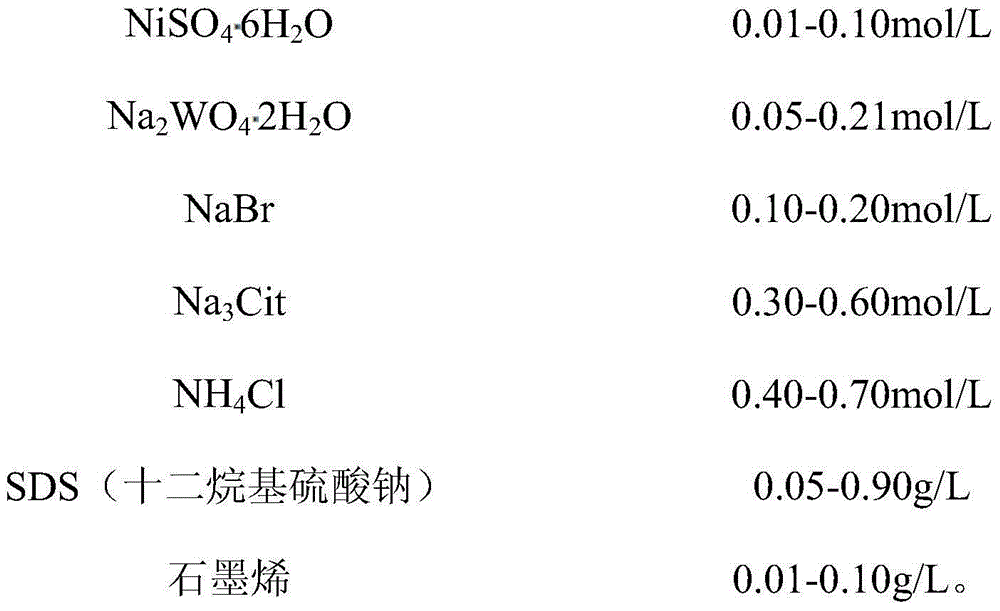

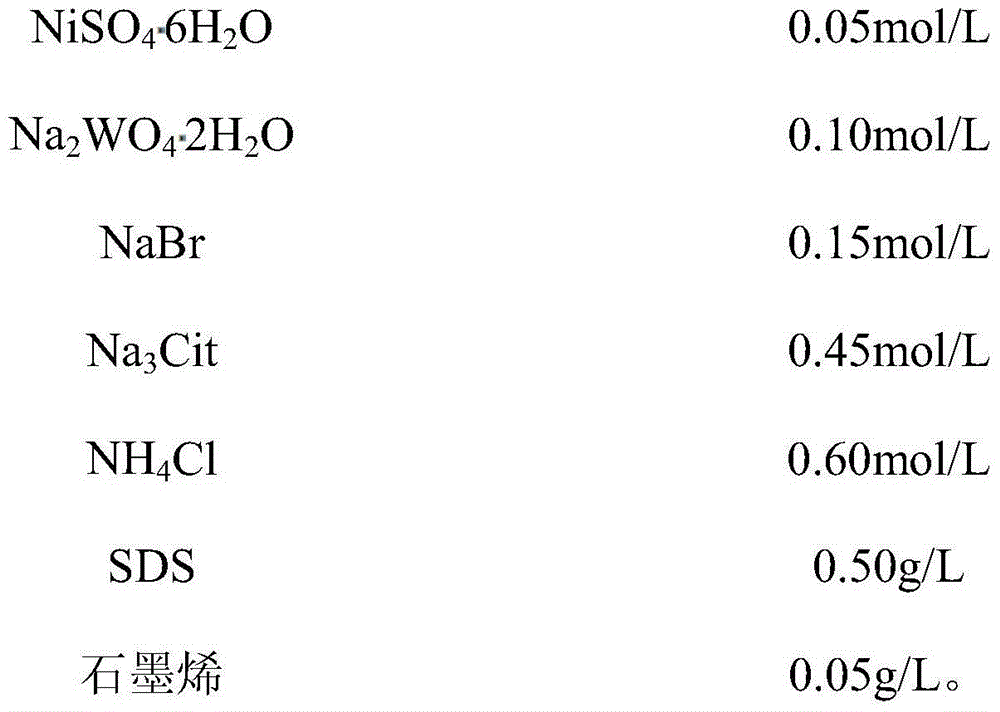

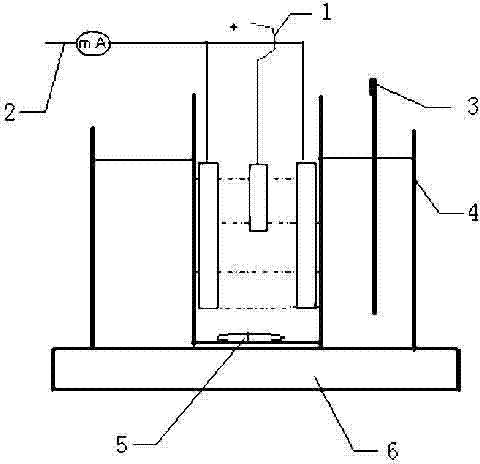

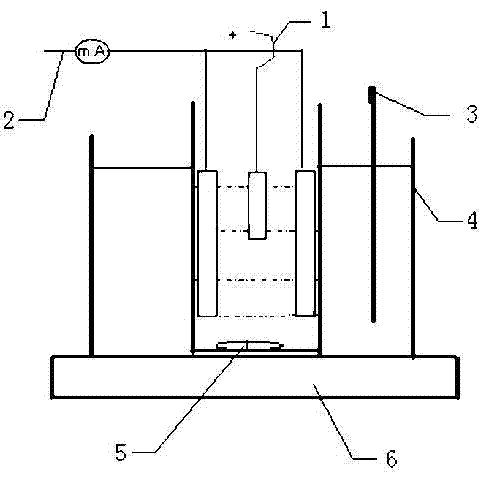

Nickel, tungsten and graphene composite plating solution, plated film and making method of plated film

InactiveCN104911652AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateNucleation

The invention discloses a nickel, tungsten and graphene composite plating solution, a plated film and a making method of the plated film. GE with good mechanical performances and effective dispersion property is introduced into the plating solution, and the GE is effectively deposited and dispersed in a Ni-W matrix in the electroplating process. The Ni-W-GE composite plated film is successfully made on a carbon steel matrix through a pulse plating codeposition technology. Graphene is dispersed in the Ni-W matrix, and the structure of the plated film is improved by effectively changing the competition relation between crystal nucleation and growth in the codeposition process in order to make a deposited film layer uniform and compact, so the intercrystalline corrosion is weakened, the diffusion path of a corrosion medium is prolonged, the self-corrosion potential is improved, local corrosion is effectively inhibited, and the stability of a passive film is improved, thereby the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

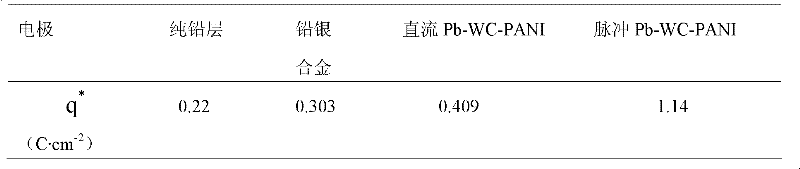

Preparation method of titanium-based lead-tungsten carbide-cerium oxide-polyaniline composite anode plate

ActiveCN102296330ALow costLow priceElectrolytic coatingsElectrodesPotassium hydroxidePotassium sodium tartrate

The invention discloses a method for preparing a titanium-based lead-tungsten carbide-cerium oxide-polyaniline composite anode plate, and belongs to the technical field of nonferrous metal electro-deposition treatment. The method sequentially comprises the following steps of: (1) performing surface treatment; (2) preparing electrolyte; (3) performing pulse plating; and (4) drying, wherein the electrolyte during pulse plating contains yellow lead oxide, potassium sodium tartrate, potassium hydroxide, tungsten carbide, cerium oxide and polyaniline. The method has the advantages of low cost of plating solution and low equipment investment; a compact film layer is formed on the surface of an anode of the composite anode plate prepared by the method, so that the anode is in an insoluble state; and when nonferrous metal electro-deposition is performed, the voltage of an electro-deposition tank can be obviously reduced, and power consumption can be reduced, so that the quality of a cathode product is improved.

Owner:晋宁理工恒达科技有限公司

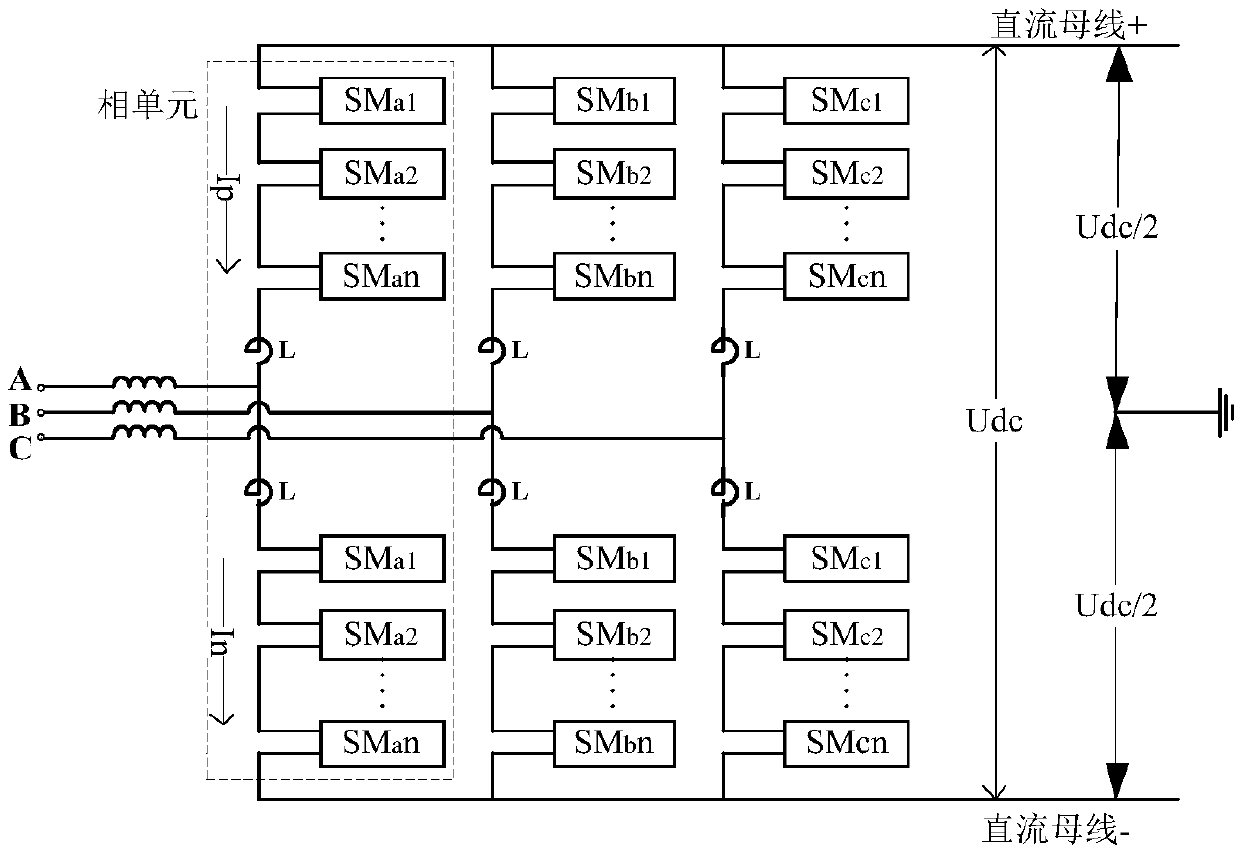

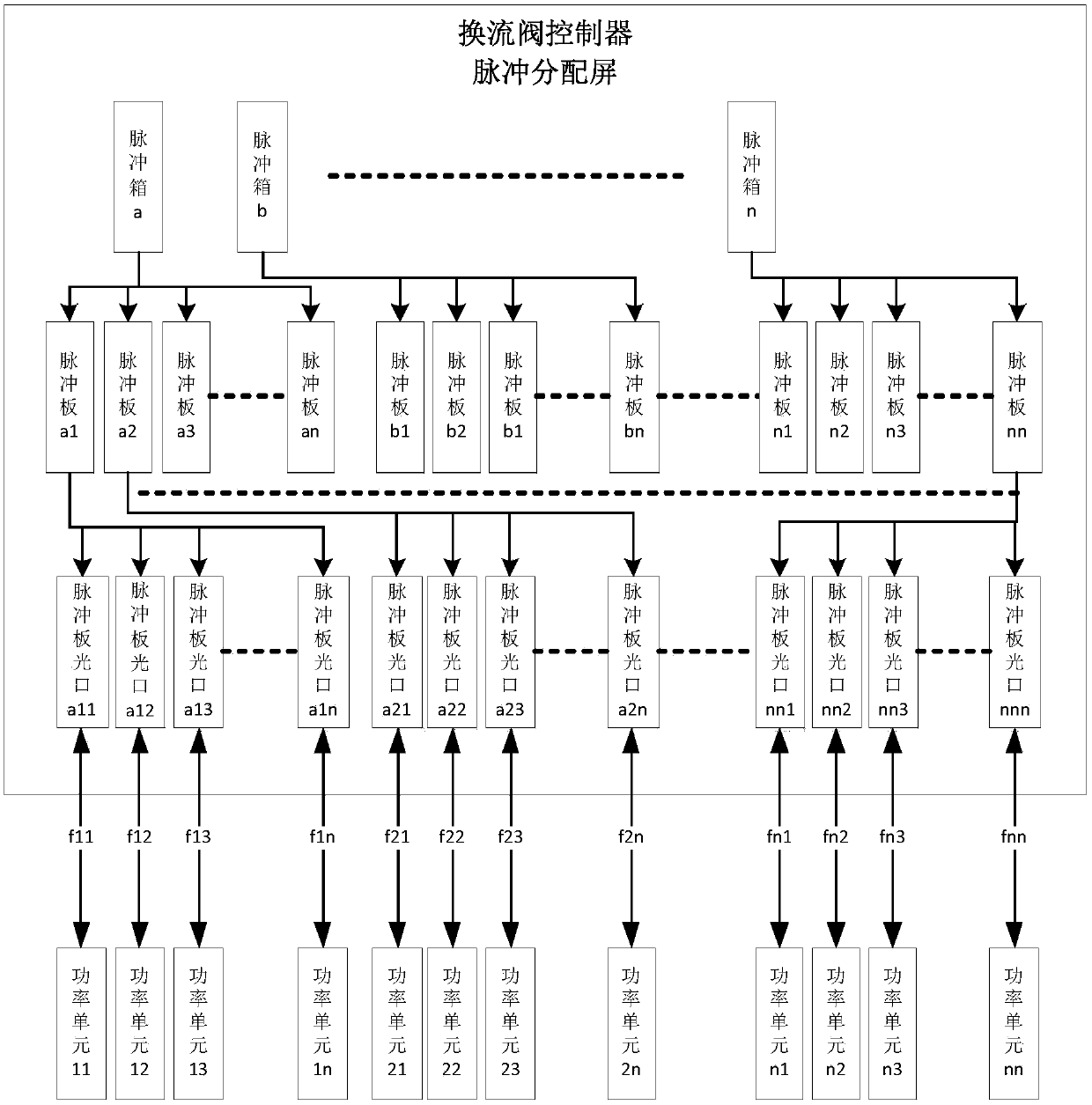

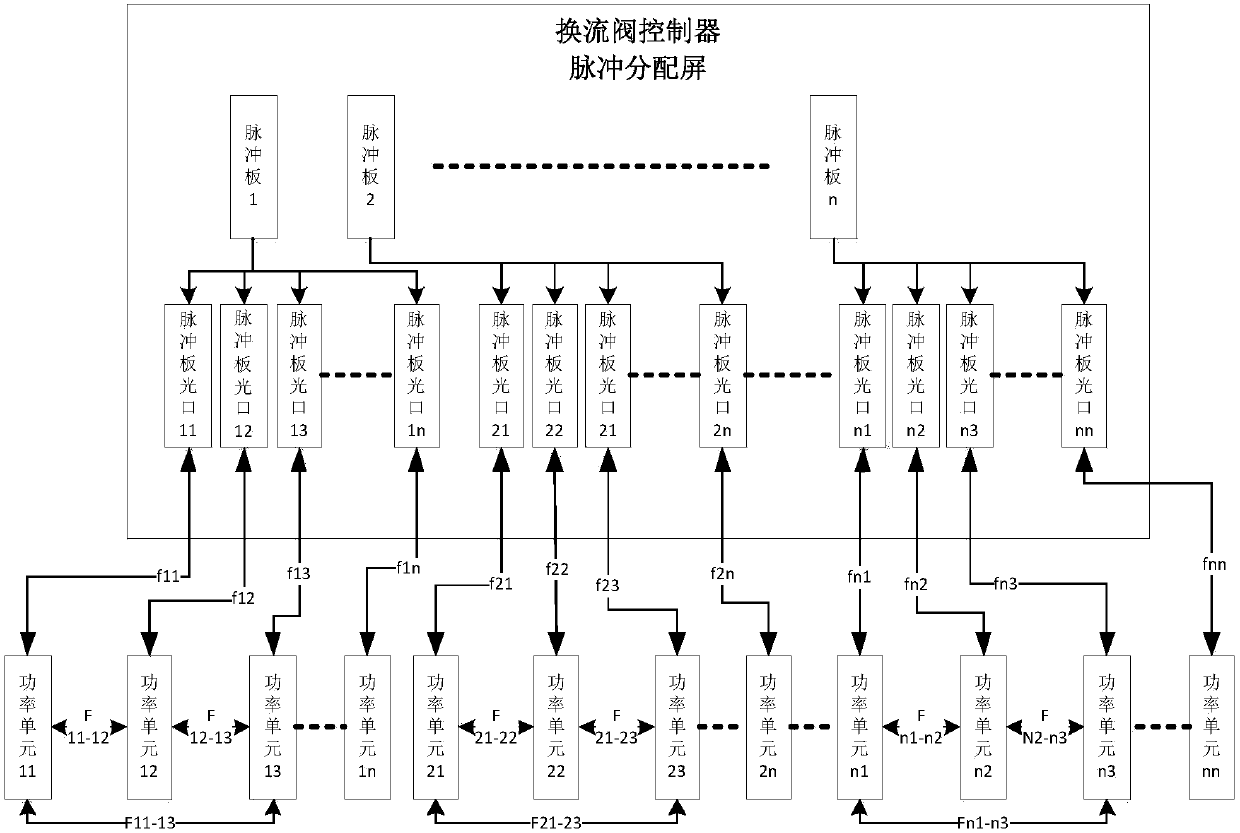

Communication network topology and method suitable for flexible modular multilevel converter valve

PendingCN107707105AIncrease communication connectionLow failure rateElectric power transfer ac networkPower conversion systemsFiberNetwork connection

The invention provides a communication network topology and method suitable for a flexible modular multilevel converter valve. The communication network topology comprises a plurality of pulse plates,a plurality of transceiving fibers and a plurality of power units, wherein each pulse plate comprises a plurality of pulse plate optical openings, the plurality of power units are divided into a plurality of power unit groups, each power unit group at least comprises two power units, at least one power unit is connected with the pulse plate via the pulse plate optical opening by the transceivingfiber, and the power units in the power unit group are in fiber connection. By the communication network topology, communication connection among the power units is improved, and information interaction among the units can be achieved through fibers; and on the basis, a communication network connection among the power units can be classified to a plurality of types, the high-reliability requirement of a high-voltage large-capacity flexible modular multilevel convertor valve system and the occasion requirement of the converter valve comprising relatively many power units can be met, communication equipment is saved, and the fault rate is reduced.

Owner:TIANSHENGQIAO BUREAU CSG EHV POWER TRANSMISSION CO +1

Pulse plating method of Ag-Ni alloy for electric contact material

The invention relates to a pulse plating method of an Ag-Ni alloy for an electric contact material, and the pulse plating method comprises the following steps: sanding, washing a surfactant to remove oil, washing, activating, washing, performing pulse plating, washing and blow-drying, wherein a plating solution consists of 0.3-0.6mol / L NiSO4.6H2O, 0.03mol / L AgCH3SO3, 1.5mol / L KI, 20g / L H3BO3 and 10g / L H2NCONH2. The parameters of the pulse plating are as follows: the frequency is 700Hz, the duty cycle is 20%, the dual-pulse ratio is (12-14):1, the current density is (0.25-0.6)A / dm<2>, and the temperature is 30-40 DEG C. By adopting the method provided by the invention, the nickel content of the prepared Ag-Ni alloy is 20-30%, the plating hardness is high, the wear resistance is good, and the Ag-Ni alloy is an excellent electric contact material.

Owner:WUXI SANZHOU COLD ROLLED SILICON STEEL

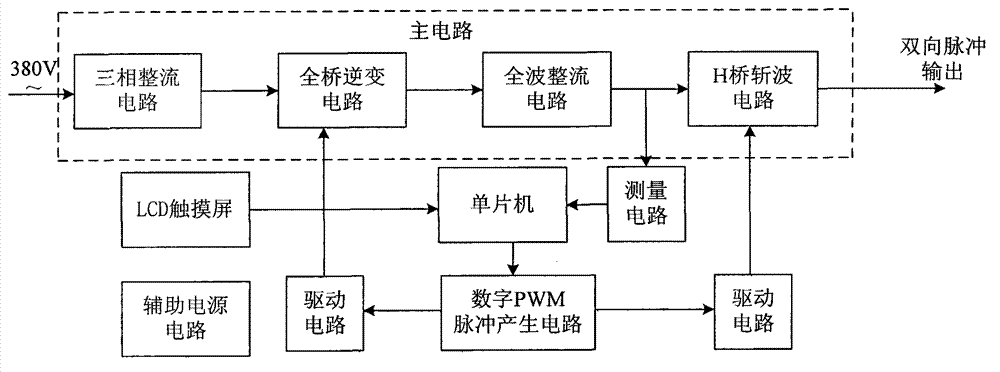

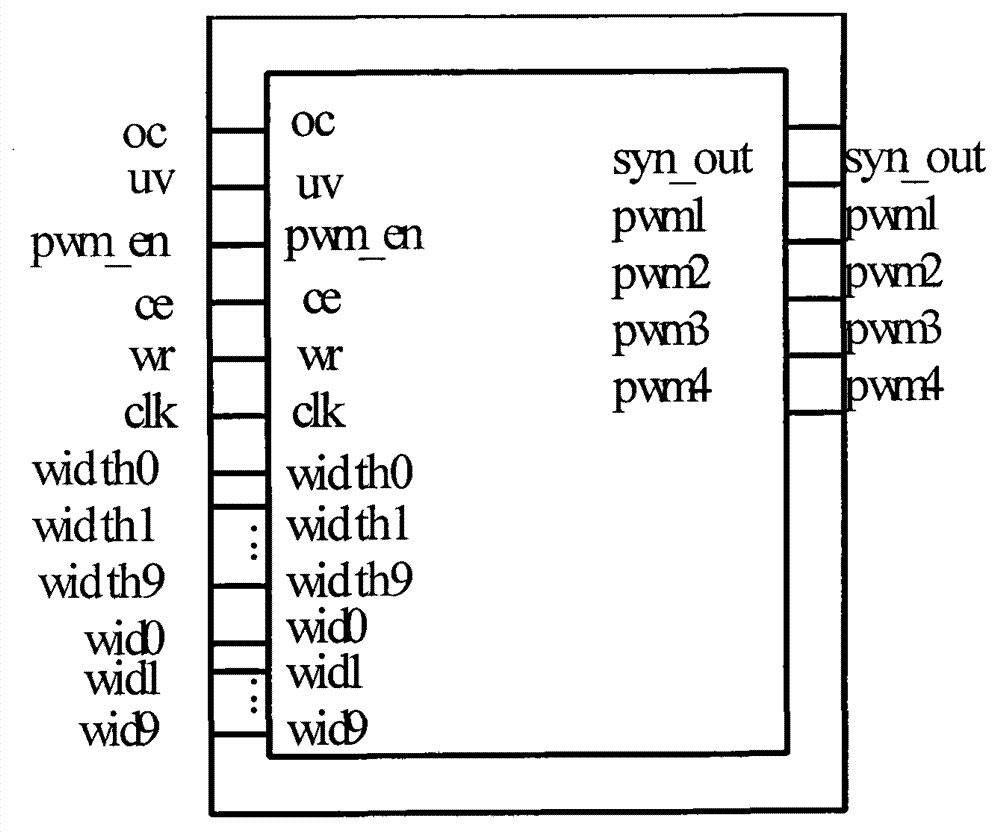

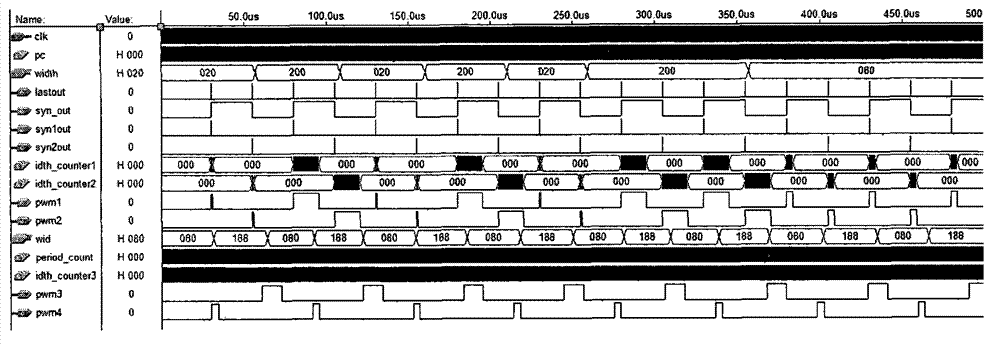

Bidirectional pulse plating switch power source based on complex programmable logic device (CPLD) control

The invention discloses a full-bridge conversion and chopper circuit which achieves pulse-width modulation (PWM) trigger pulse control through complex programmable logic device (CPLD) and relates to a bidirectional pulse plating switch power source based on CPLD control. A feedback control system with a singlechip as a core is adopted, amplitude and width of the pulse voltage can be automatically controlled accurately by means of matching between the singlechip and the CPLD through a fuzzy proportional-integral-derivative (PID) algorithm, and the amplitudes of a positive pulse and a negative pulse are not equivalent and maintained on the corresponding values. Simultaneously, the system is provided with a protection circuit for detecting the current and the voltage, and abnormal states of overcurrent, overvoltage and the like in the system are protected timely, so that a driving circuit is ensured to drive an insulated gate bipolar translator (IGBT) pipe of a conversion bridge and a metal-oxide-semiconductor field effect transistor (MOSFET) pipe of a chopper circuit effectively and accurately. Corresponding conversion frequency and dead time are arranged in a digital PWM chip to ensure a full-bridge conversion circuit and an H-bridge chopper circuit to work safely. The bidirectional pulse plating switch power source is applicable to development and research of the electroplate technology of industrial development and scientific research institutions.

Owner:YANCHENG INST OF TECH

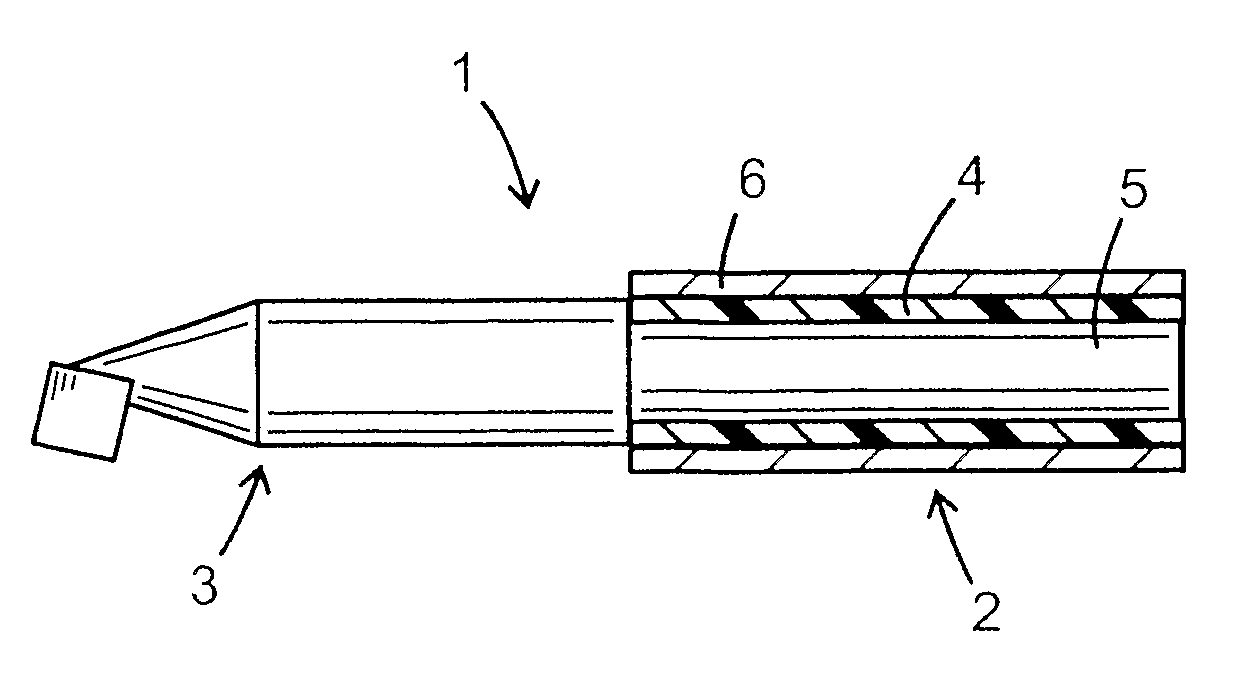

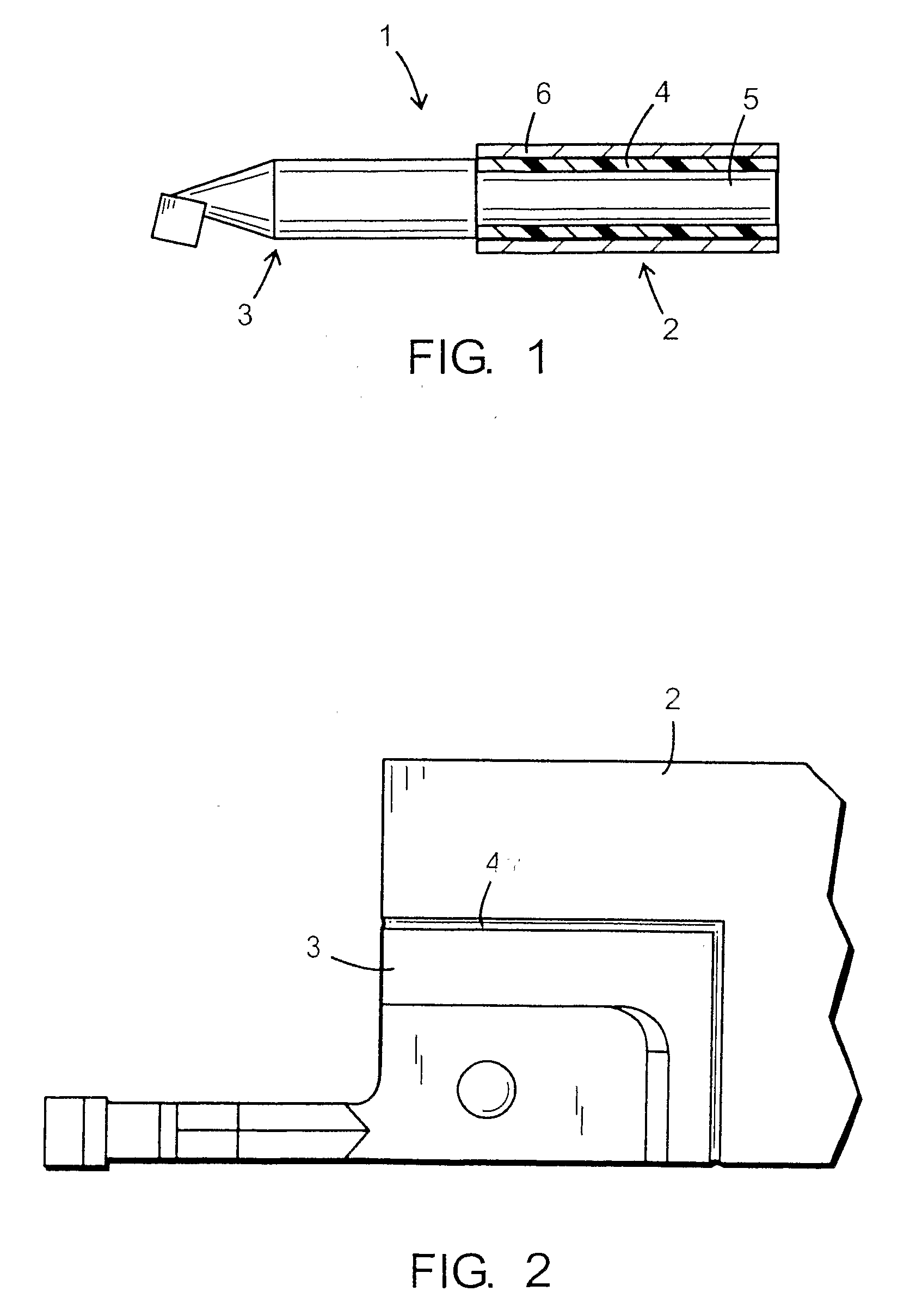

Tool Holder with Vibration Damping Means and a Method for Manufacturing the Same

A tool holder 1 has a shaft 2 intended to be arranged in a tool holder in a manufacturing machine, a head 3 on which a cutter is intended to be arranged and a vibration-damping material 4 arranged between, and attached to, the shaft 2 and the head 3 such that the cutter is in contact with the manufacturing machine solely through the vibration-damping material 4, where the vibration-damping material is a metal or an alloy of metals selected from the group consisting of Cu, Ti, Zn, Al and Ni. A method for manufacturing a tool holder in which the surface covering of vibration-damping material is created by electrochemical pulse plating through the tool holder, when functioning as an electrode, being lowered into an electrolyte containing ions of at least one metal selected from the group consisting of Cu, Ti, Zn, Al and Ni.

Owner:MIRCONA

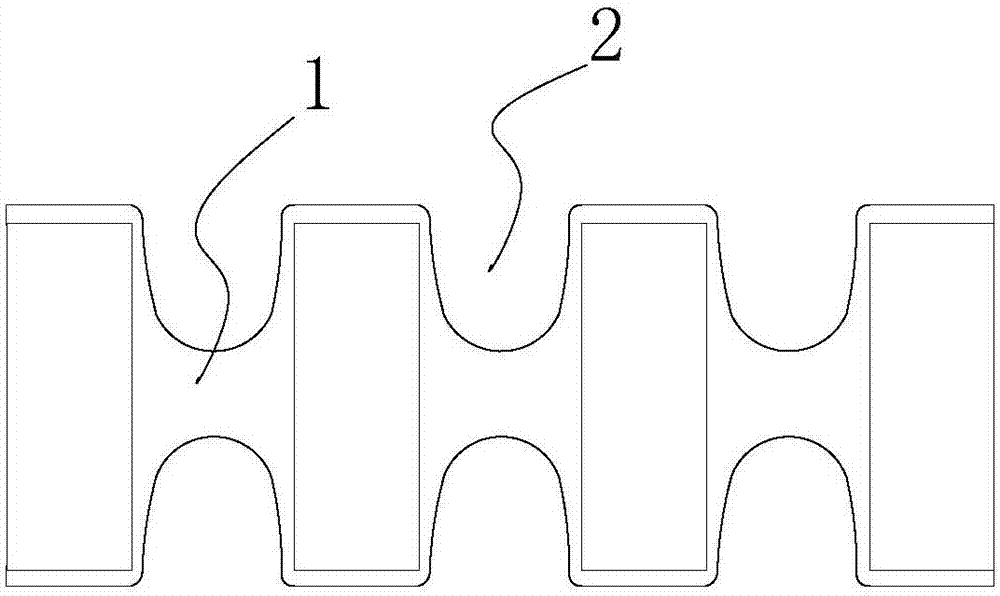

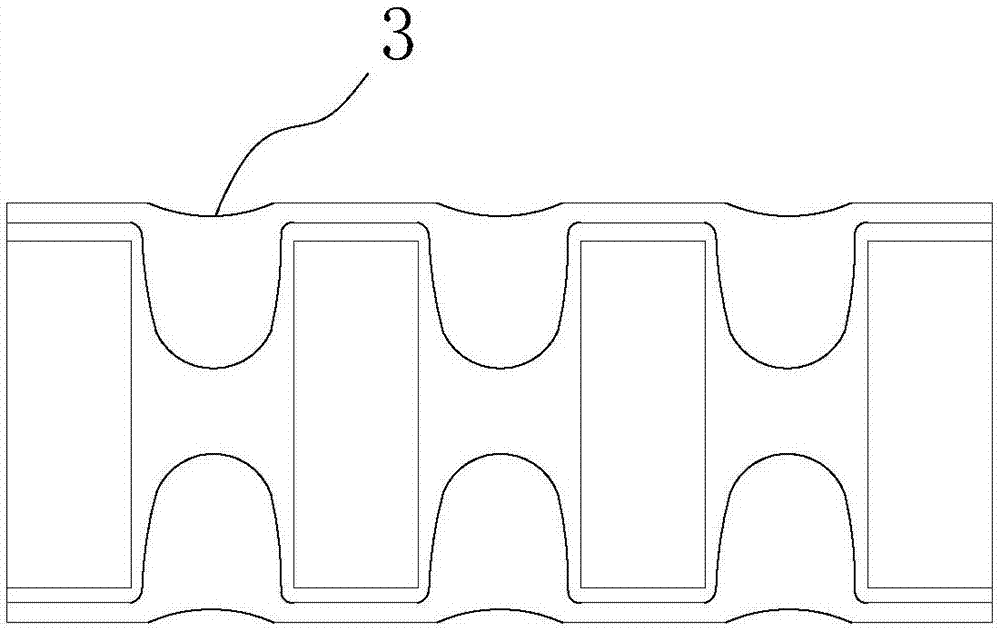

Filling through-holes

InactiveCN105517371AInhibition of nodule formationWell-filled viasPrinted circuit aspectsLiquid/solution decomposition chemical coatingOptoelectronicsCopper

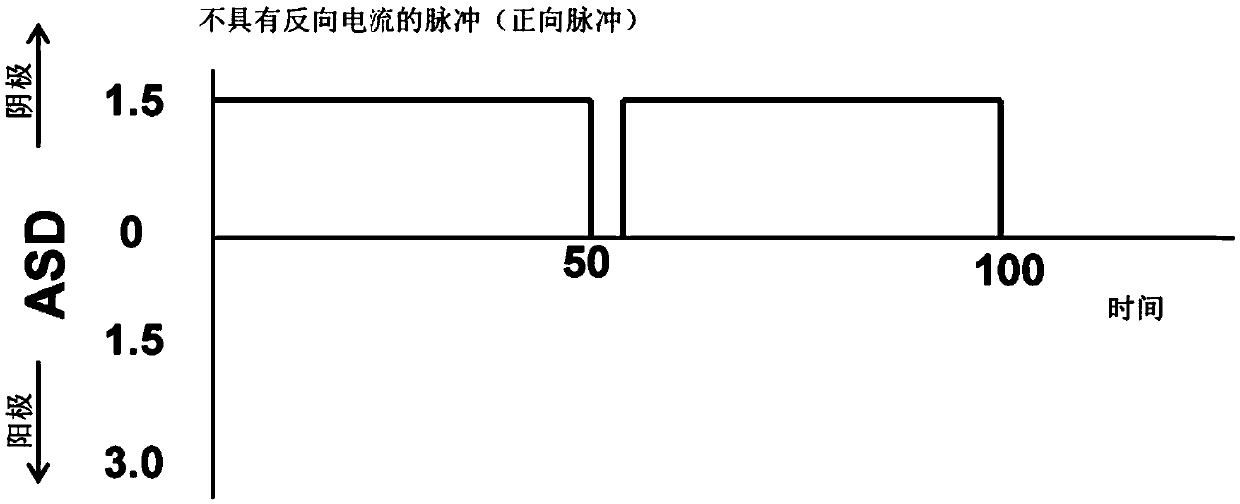

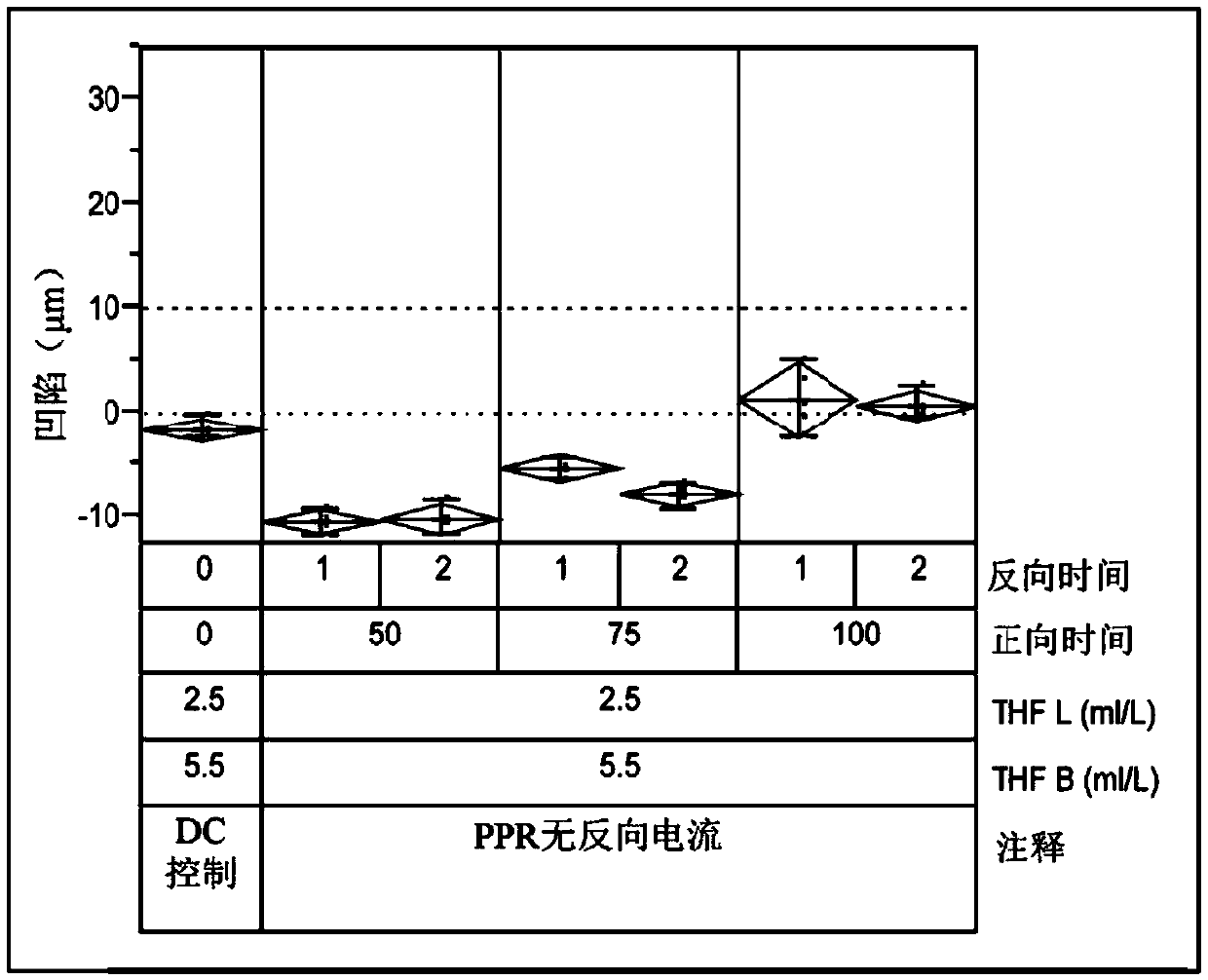

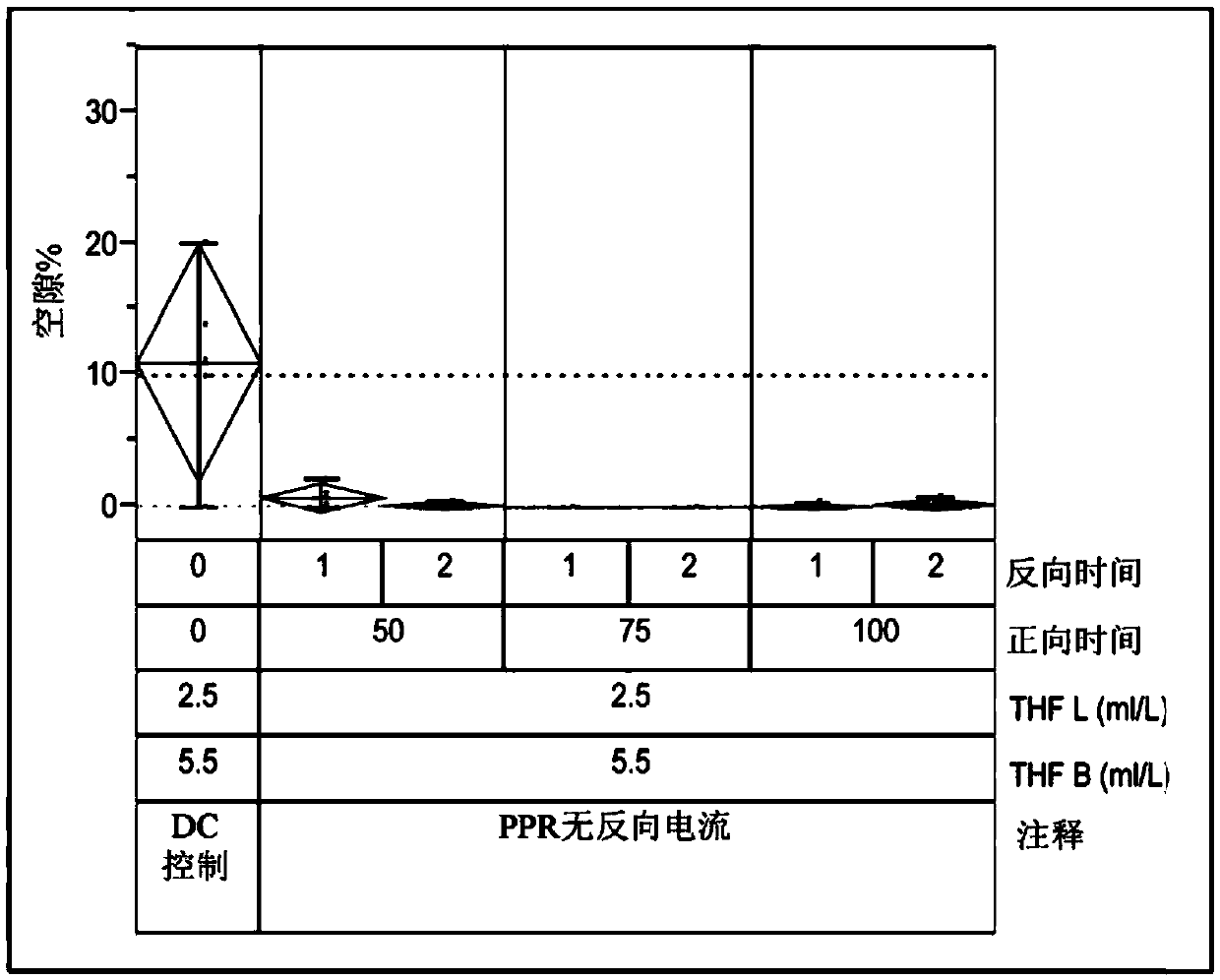

Pulse plating methods which include a forward pulse but no reverse pulse inhibit or reduce dimpling and voids during copper electroplating of through-holes in substrates such as printed circuit boards. The pulse plating methods may be used to fill through-holes with copper, wherein the through-holes are coated with electroless copper or flash copper.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com