Method for coating metallic interconnect of solid oxide fuel cell

a technology of solid oxide fuel cell and metallic interconnection, which is applied in the direction of fuel cell details, fuel cells, electrochemical generators, etc., can solve the problems of difficult to achieve the durability of up to 40000 hours required for commercialization, concentration polarization, and serious environmental problems, etc., to achieve high electrical conductivity, enhance binding force, and inhibit chrome volatilization. inhibiting property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Hereinafter, an exemplary embodiment of the present invention will be described with reference to the accompanying drawings. It is to be understood, however, that the following embodiment is illustrative only, and the scope of the present invention is not limited thereto. Also, those skilled in the art will appreciate that various modifications, additions and substitutions are possible.

[0036]In the operation of a solid oxide fuel cell (SOFC), a chrome oxide scale formed on the surface of a metallic interconnect at a high temperature causes some problems, such as reduction of a sealing property by peeling of the scale, pollution of a cathode by volatilization of chrome from the scale, or the like. These problems reduce output performance and long-term durability of the SOFC.

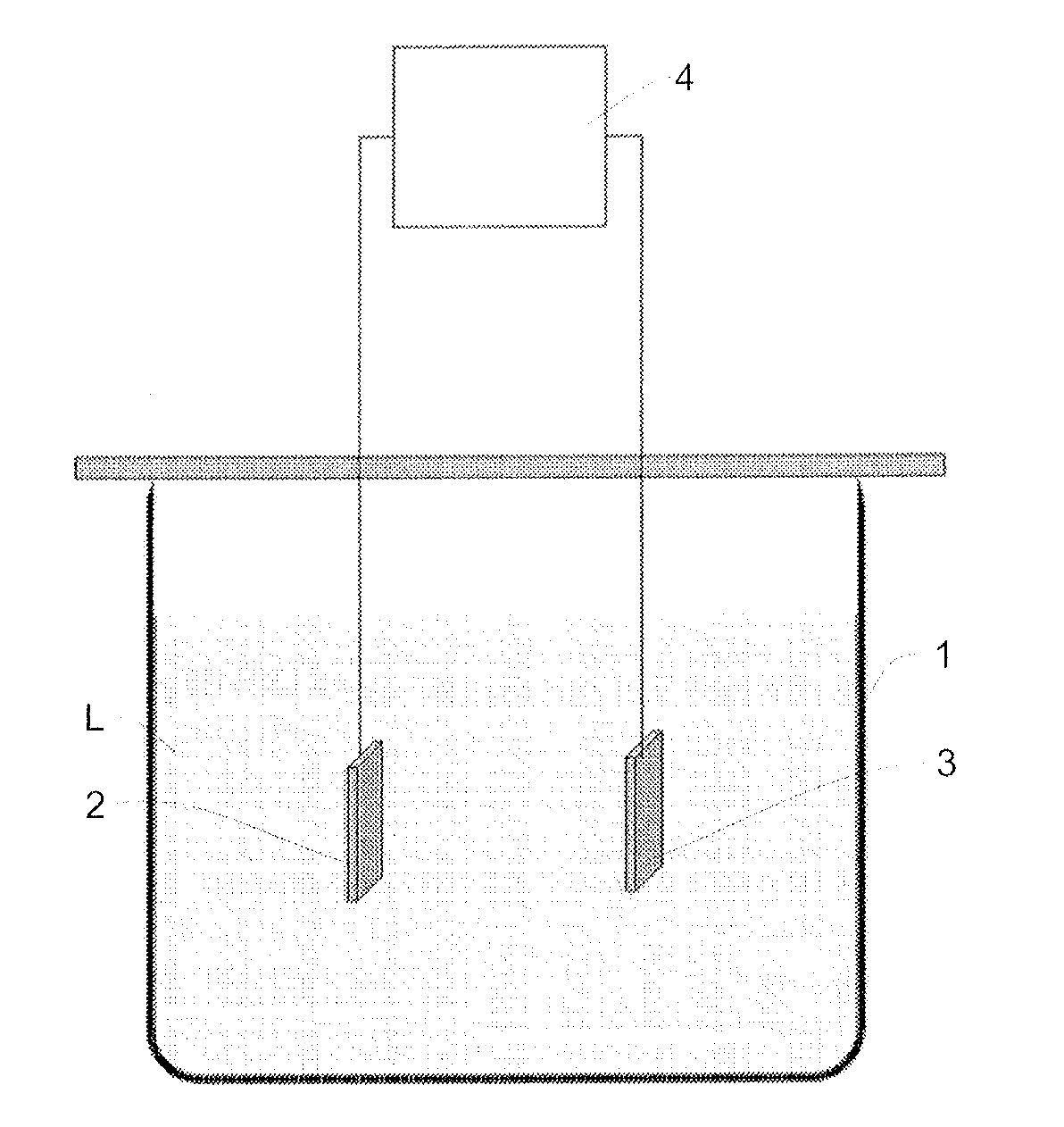

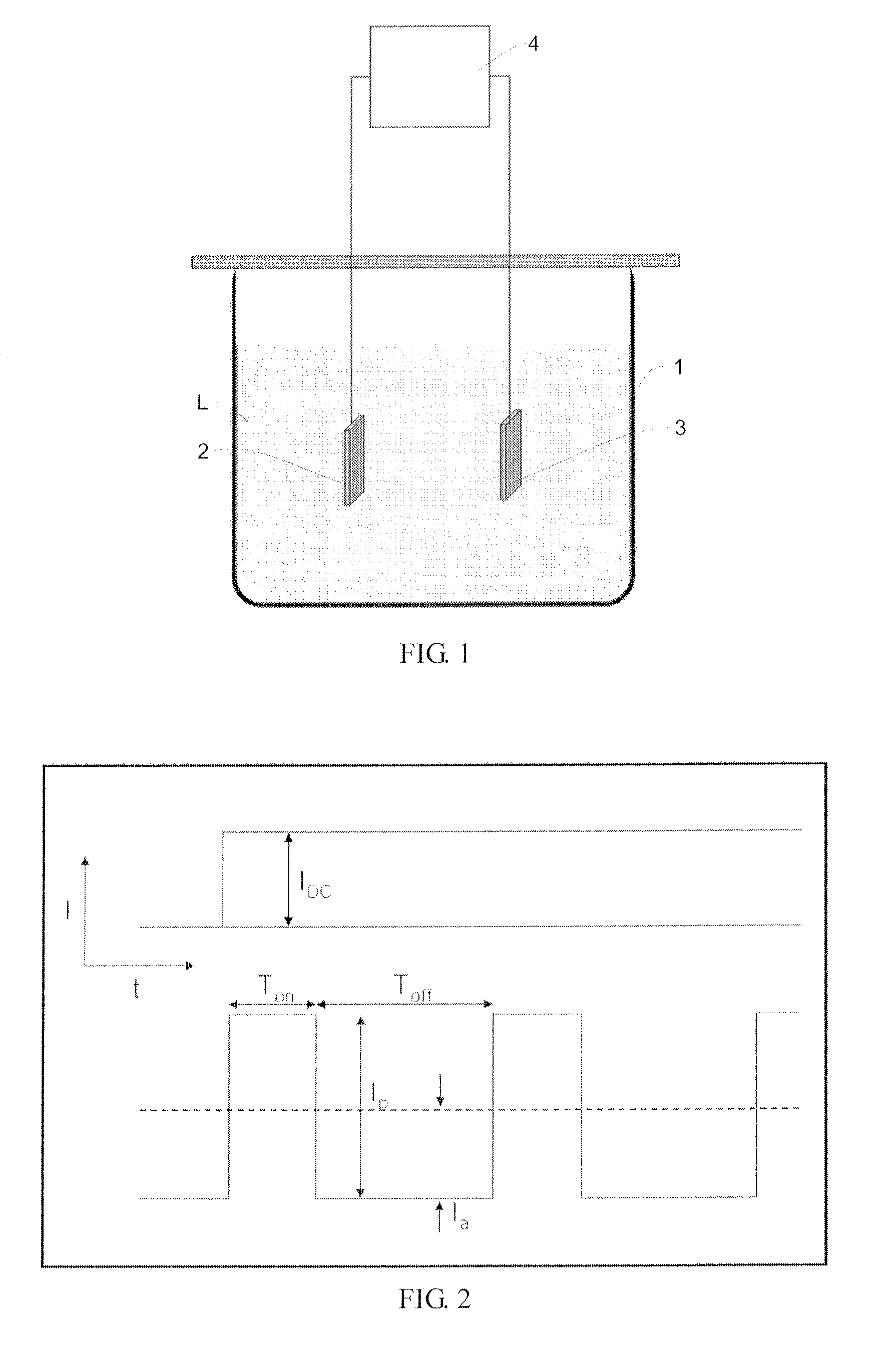

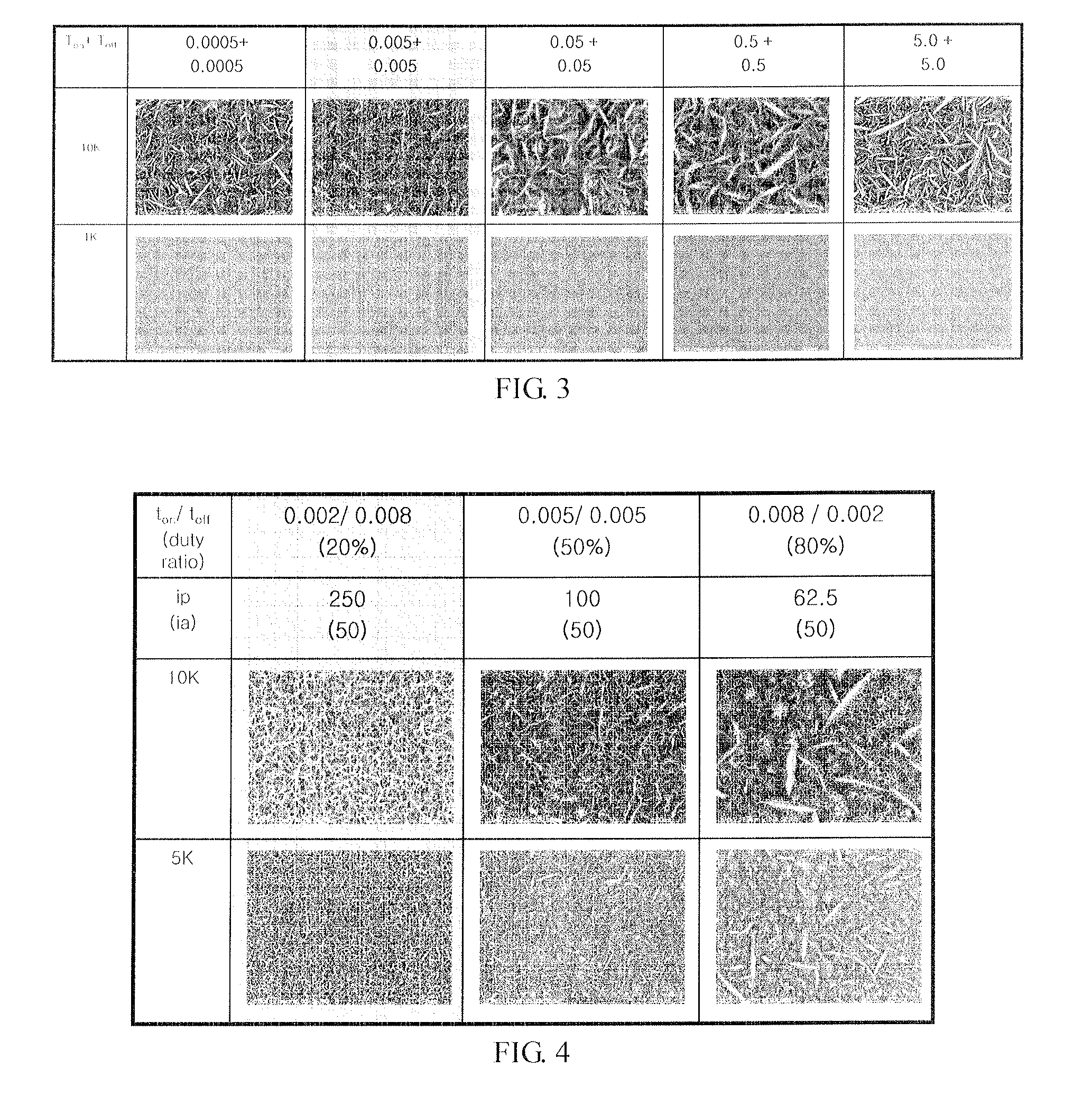

[0037]Accordingly, in the method according to the present invention, on the surface of a metallic interconnect, cobalt, one of transition metals for forming a spinel layer with a high electrical conductivity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com