Preparation method of titanium-based lead-tungsten carbide-cerium oxide-polyaniline composite anode plate

A composite anode and tungsten carbide technology, which is applied in the direction of electrodes, electrolytic coatings, coatings, etc., can solve the problems of high cost and cumbersome preparation process, and achieve the effects of low cost, simple process and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

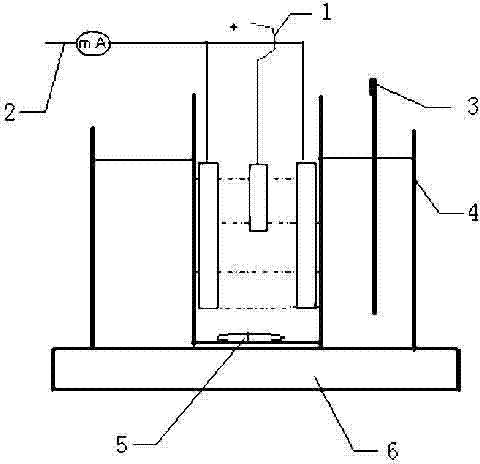

Method used

Image

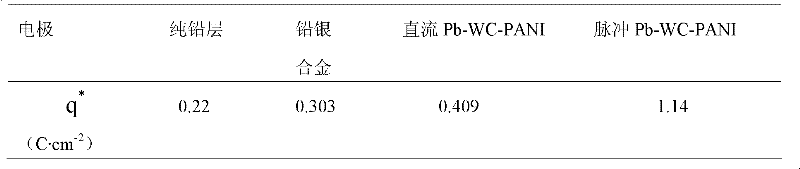

Examples

Embodiment 1

[0034] Composite co-deposition of lead-tungsten carbide-cerium oxide-polyaniline on a titanium substrate, and the titanium plate is processed into a small sample of 50mm×20mm×2mm. The process flow is: pure titanium sheet→sand blasting→water washing→oil removal→water washing→chemical etching→water washing→composite co-deposition→water washing→drying→testing and characterization. The formula and process conditions of the composite co-deposition described therein: yellow lead oxide 100g / L, potassium sodium tartrate 150g / L, potassium hydroxide 55g / L, cerium oxide 5g / L, tungsten carbide 10g / L, polyaniline 5g / L L, the temperature is 20°C, the average current density is 2A / dm 2, pulse width 0.1ms, period 0.5ms, duty cycle range 0.1, electroplating under magnetic stirring for 1.5 hours;

[0035] The tungsten carbide has a particle size of 1.5 μm, the cerium oxide has a particle size of 0.3 μm, and the polyaniline has a particle size of 3 μm.

Embodiment 2

[0037] Composite co-deposition of lead-tungsten carbide-cerium oxide-polyaniline on a titanium substrate, and the titanium plate is processed into a small sample of 50mm×20mm×2mm. The process flow is: pure titanium sheet→sand blasting→water washing→oil removal→water washing→chemical etching→water washing→composite co-deposition→water washing→drying→testing and characterization. The formula and process conditions of the composite co-deposition described therein: yellow lead oxide 100g / L, potassium sodium tartrate 150g / L, potassium hydroxide 55g / L, cerium oxide 10g / L, tungsten carbide 20g / L, polyaniline 10g / L L, the temperature is 30°C, the average current density is 2.5A / dm 2 , pulse width 0.3ms, period 1ms, duty cycle range 0.5, electroplating under magnetic stirring for 1.5 hours;

[0038] The tungsten carbide has a particle size of 1.5 μm, the cerium oxide has a particle size of 0.3 μm, and the polyaniline has a particle size of 3 μm.

Embodiment 3

[0040] Composite co-deposition of lead-tungsten carbide-cerium oxide-polyaniline on a titanium substrate, and the titanium plate is processed into a small sample of 50mm×20mm×2mm. The process flow is: pure titanium sheet→sand blasting→water washing→oil removal→water washing→chemical etching→water washing→composite co-deposition→water washing→drying→testing and characterization. The formula and process conditions of the composite co-deposition described therein: yellow lead oxide 100g / L, potassium sodium tartrate 150g / L, potassium hydroxide 55g / L, cerium oxide 20g / L, tungsten carbide 40g / L, polyaniline 20g / L L, the temperature is 35°C, the average current density is 5A / dm 2 , pulse width 0.7ms, period 2ms, duty cycle range 0.7, electroplating under magnetic stirring for 1.5 hours;

[0041] The tungsten carbide has a particle size of 1.5 μm, the cerium oxide has a particle size of 0.3 μm, and the polyaniline has a particle size of 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com