Agitation of electrolytic solution in electrodeposition

a technology of electrolysis solution and electrodeposition, which is applied in the direction of process and machine control, material dimension control, instruments, etc., can solve the problems of unwanted closed voids in vias and less uniform deplating rate, so as to reduce agitation power and improve compensation , the net plating rate is made more uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The embodiments described in this section illustrate but do not limit the invention. The invention is defined by the appended claims.

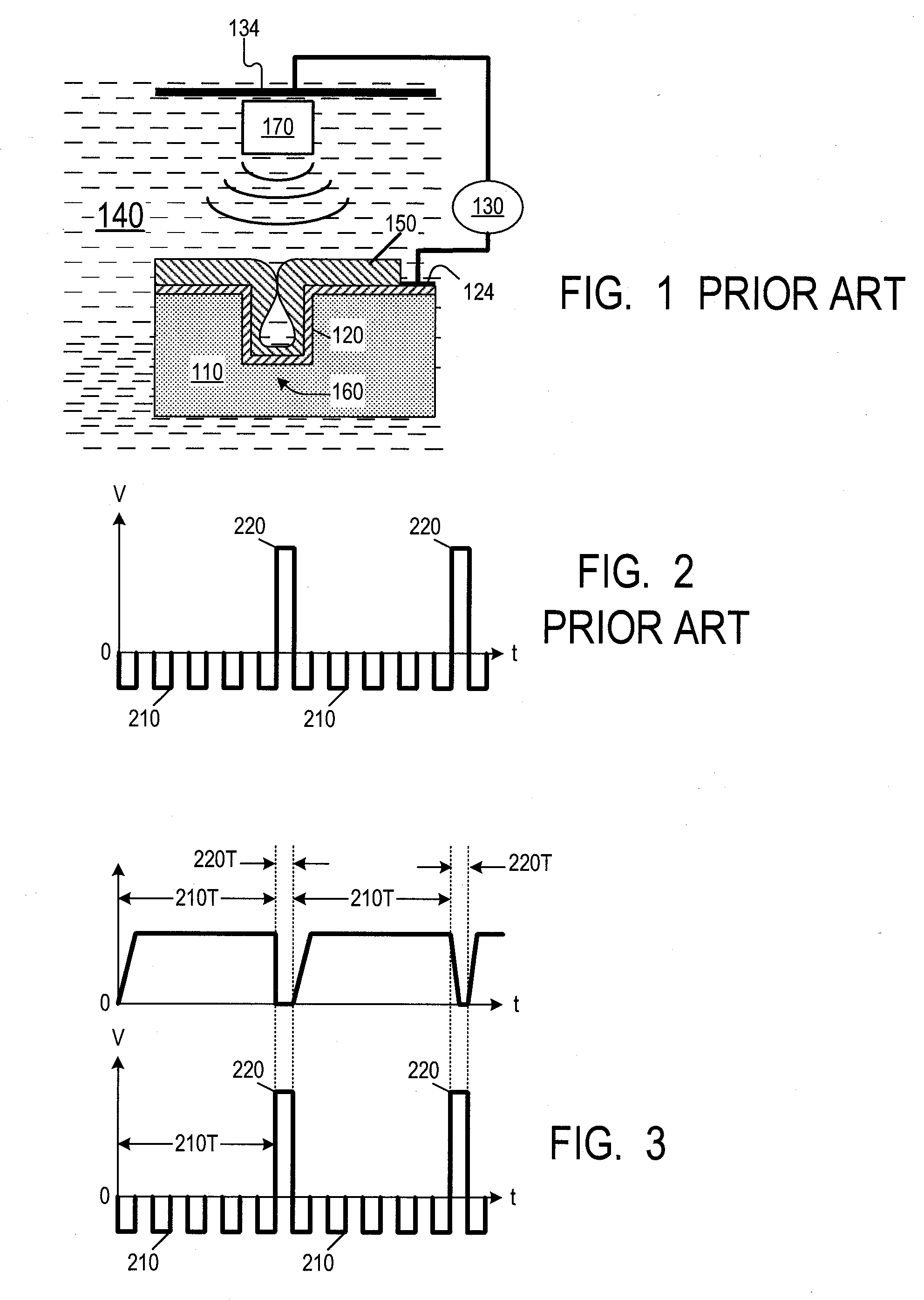

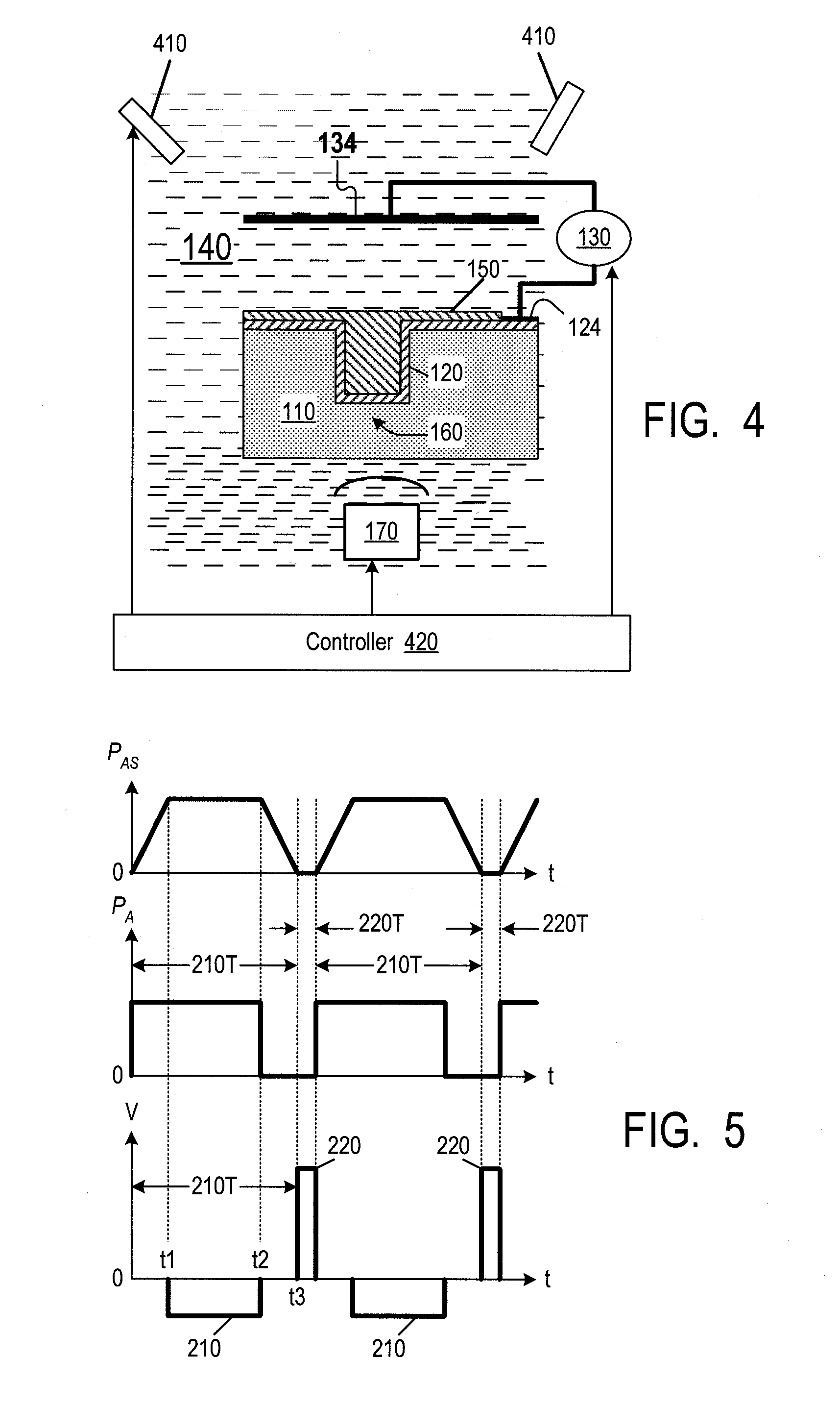

[0016]FIG. 3 illustrates timing diagrams for the electroplating voltage (the voltage at terminal 124 relative to terminal 134) and the agitation power in some embodiments of the present invention. The electroplating voltage is as in FIG. 2, with one or more negative pulses 210 delivered in each time period 210T, then one or more positive pulses 220 delivered in a time period 220T. The agitation power PA is positive during at least a portion of each time period 210T, but the agitation is turned off during each positive-pulse period 220T, or at least the maximum value of the agitation power in each period 220T is below the maximum value in each period 210T. Consequently, the deplating rate inside the via is lowered relative to the top of substrate 110.

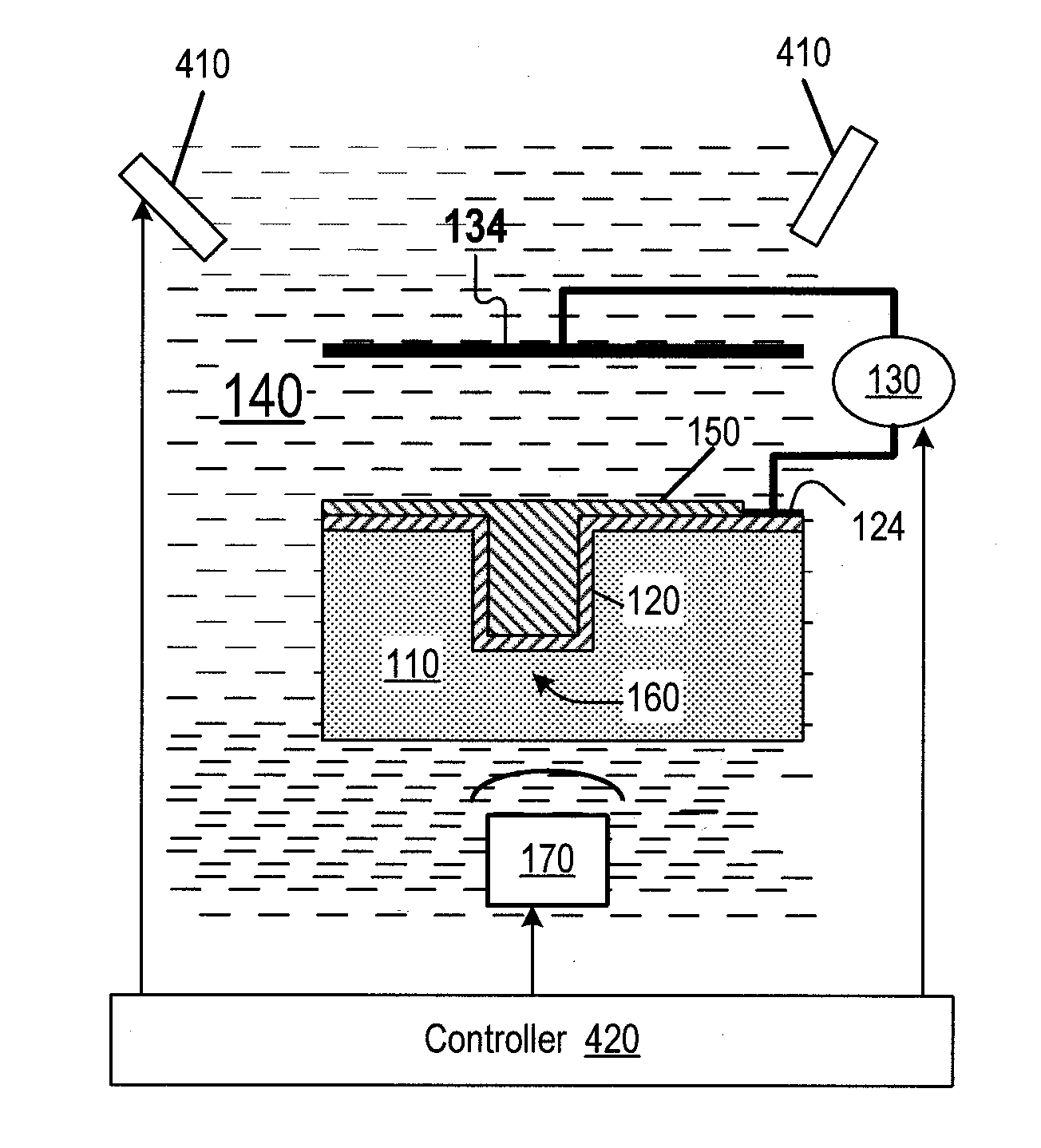

[0017]The agitation can also be provided by mechanical stirring or perhaps in other ways. FIG. 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com