Triggering and conducting method used for switching of capacitor of thyristor AC non-contact switch

A non-contact switch, switching capacitor technology, used in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of insufficient control accuracy, affecting safety and reliability, and complex current waveform detection and control. Simple control method, great economic and social benefits, no gap in current waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

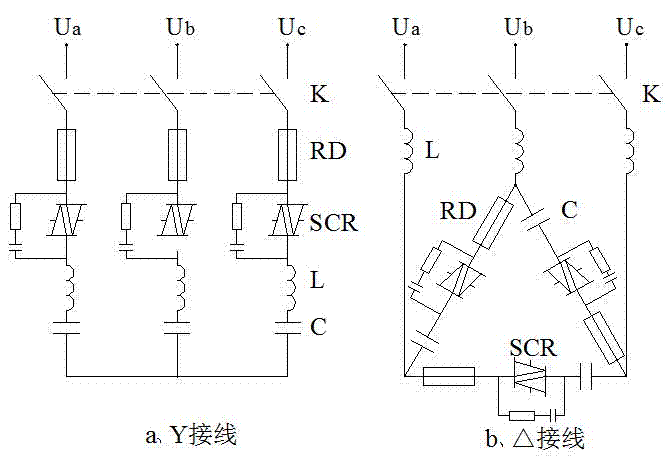

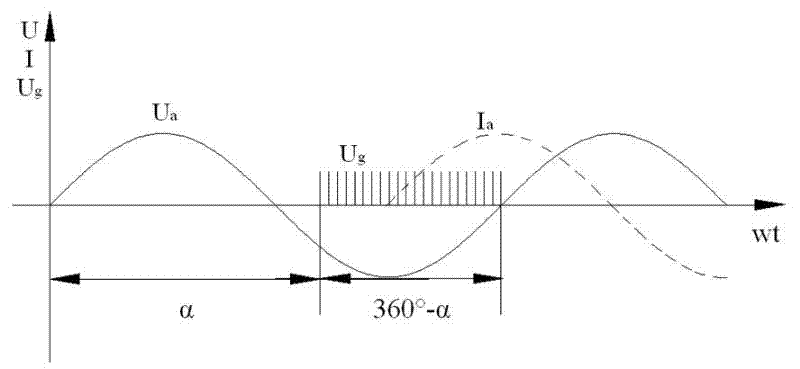

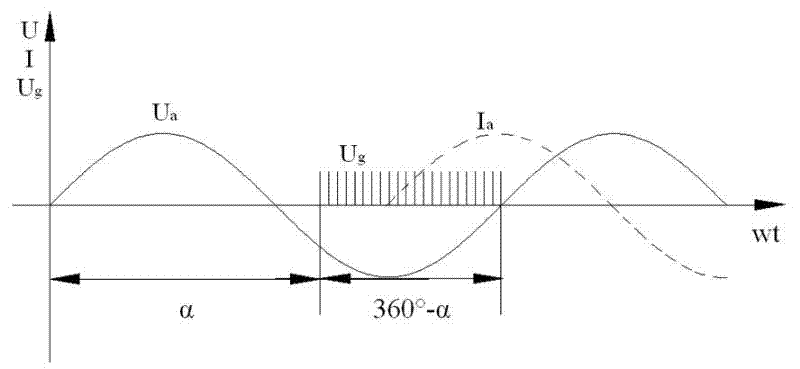

Embodiment 1

[0035] Reactive power compensation controller and trigger pulse board, there are many types of products on the market can be selected, this embodiment uses a three-phase bridge full-control rectification trigger board Type 6.0 standard trigger board, a thyristor AC non-contact trigger board in this embodiment The method of triggering conduction when the switch is switched on and off is to use the multi-turn potentiometer on the trigger board to detect with an oscilloscope and adjust the control angle α to 210°. Specifically, first adjust the control angle α to 30° (210° -180°=30°), and then invert the synchronous power signal to get the control angle α to be 210°, which is fixed, then change the small capacitor of the circuit on the trigger board to a larger size, and increase the pulse width to 150° (360° °-210°=150°), also fixed. Therefore, the control system becomes very simple and reliable, and there is no current impact when the capacitor is switched on.

[0036] In this...

Embodiment 2

[0038] The basic steps are the same as in Example 1, the difference is that the control angle α is adjusted to 200° through the oscilloscope detection and remains unchanged, specifically, the control angle α is first adjusted to 20° (200°-180°=20°) , and then invert the synchronous power supply signal to obtain a control angle α of 200°; the pulse width is adjusted to 160°, which is also fixed. Thyristor AC non-contact switch triggers conduction when switching capacitors, high control precision, no current impact when capacitors are switched in, complete waveform, smooth zero crossing, no gaps and no harmonics.

Embodiment 3

[0040] The basic steps are the same as in Example 1, the difference is that the control angle α is adjusted to 220° through the oscilloscope detection and remains unchanged, specifically, the control angle α is first adjusted to 40° (220°-180°=40°) , and then invert the synchronous power supply signal to obtain a control angle α of 220°; the pulse width is adjusted to 140°, which is also fixed. Thyristor AC non-contact switch triggers conduction when switching capacitors, high control precision, no current impact when capacitors are switched in, complete waveform, smooth zero crossing, no gaps and no harmonics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com