Automatic crank shaft grinding and cleaning machine

A technology for cleaning machines and crankshafts, which is applied in the direction of grinding racks, grinding machine parts, grinding machines, etc. It can solve the problems of low automation and work efficiency, poor quality of workpiece grinding products, and high failure rate of crankshaft grinding machines. Good practical effect, improve the quality of grinding products, and good transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

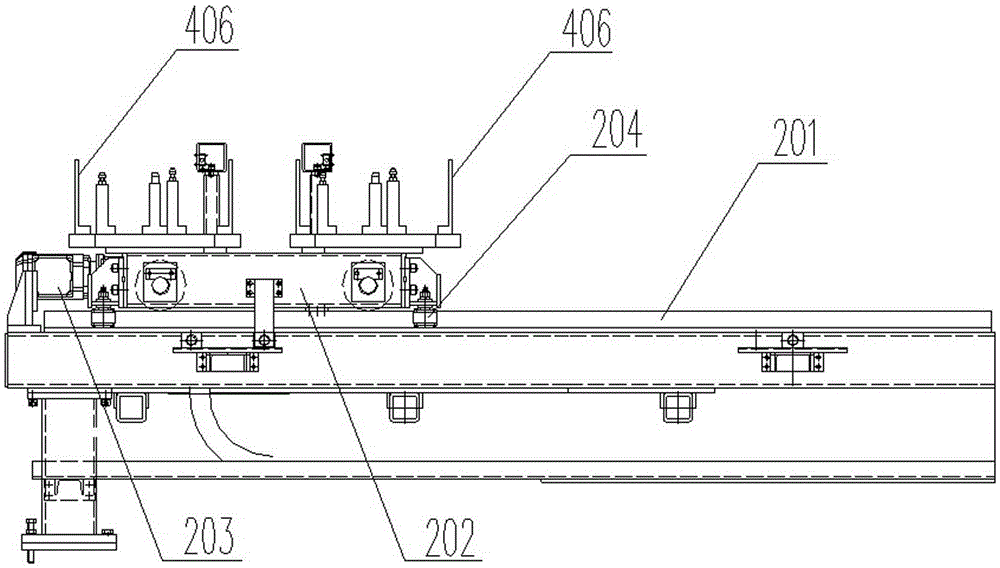

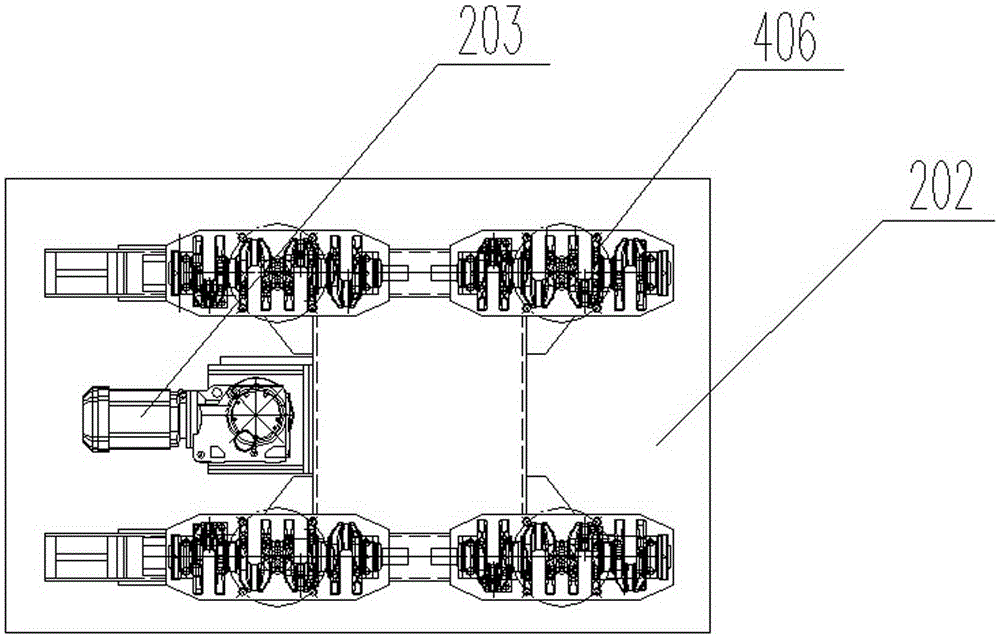

[0043] The crankshaft automatic grinding and cleaning machine includes a frame 1 and a feeding device 2, a workpiece transfer device 3, a grinding mechanism 4 and a discharge device 5 arranged on the frame 1. The workpiece transfer device 3 is erected through a support column 6 Above the frame 1 , the crankshaft to be ground conveyed by the feeding device 2 is conveyed to the grinding mechanism 4 for grinding, and then the crankshaft is conveyed to the discharging device 5 for output.

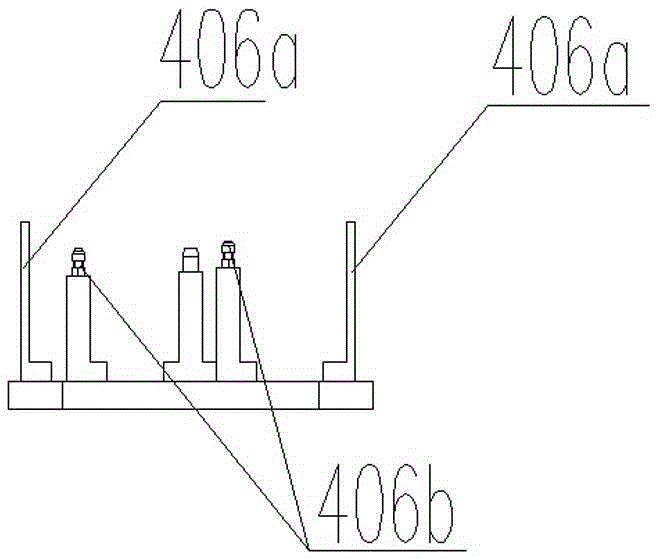

[0044] The feeding device 2 or the discharging device 5 includes a working platform 201, a material transporting trolley 202 and a first drive motor 203, and the first driving motor 203 drives the material transporting trolley 202 on the working platform 201 through a rack and pinion. To carry out the material transporting operation, the top of the material transporting trolley 202 is provided with four sets of workpiece fixtures 406 for supporting the four crankshafts to be transported respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com