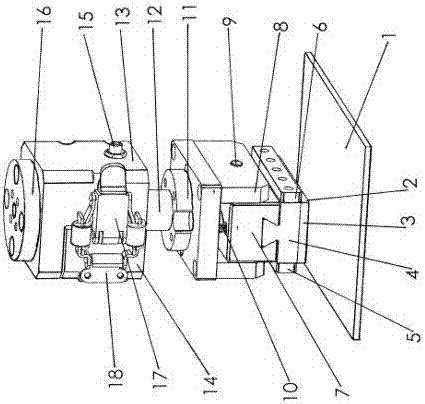

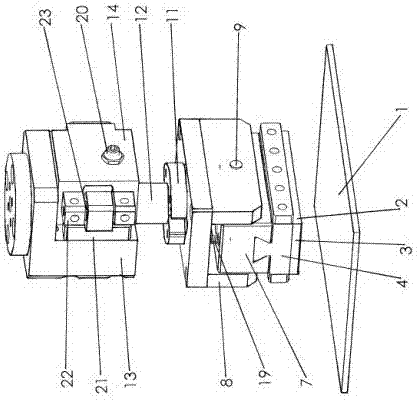

Grinding head mechanism of full-automatic grinding machine

A fully automatic grinding machine and grinding head technology, which is applied in the field of grinding head, can solve the problem of unclean and thorough cleaning of glass substrate grinding and cleaning dirt, and achieve the effect of avoiding grinding dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the drawings:

[0012] A grinding head mechanism of a fully automatic grinding machine, including a rotating shaft connecting flange 16, an inverted L-shaped right upper clamping block 13, an I-shaped left upper clamping block 14, a connecting shaft 12, and an inverted groove seat 8. The shaft connecting flange 16 is fixedly arranged on the top surface of the upper clamping block 13 of the inverted L-shaped right petal, and the lower end of the connecting shaft 12 is fixedly connected with the top plate of the inverted groove seat 8 through the groove seat flange 11, The L-shaped right flap upper clamping block 13 and the I-shaped left flap upper clamping block 14 are movably buckled together, and a connecting shaft is provided between the inverted L-shaped right flap upper clamping block 13 and the I-shaped left flap upper clamping block 14 12, the upper end of the connecting shaft 12 is set in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com