A grinding mechanism for automatic grinding and cleaning machine of crankshaft

A cleaning machine and grinding technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding drive devices, etc., can solve the problems of low automation and work efficiency, poor quality of polished products, and workpiece Easy to jam and other problems, achieve good practical effect, improve the quality of grinding products, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

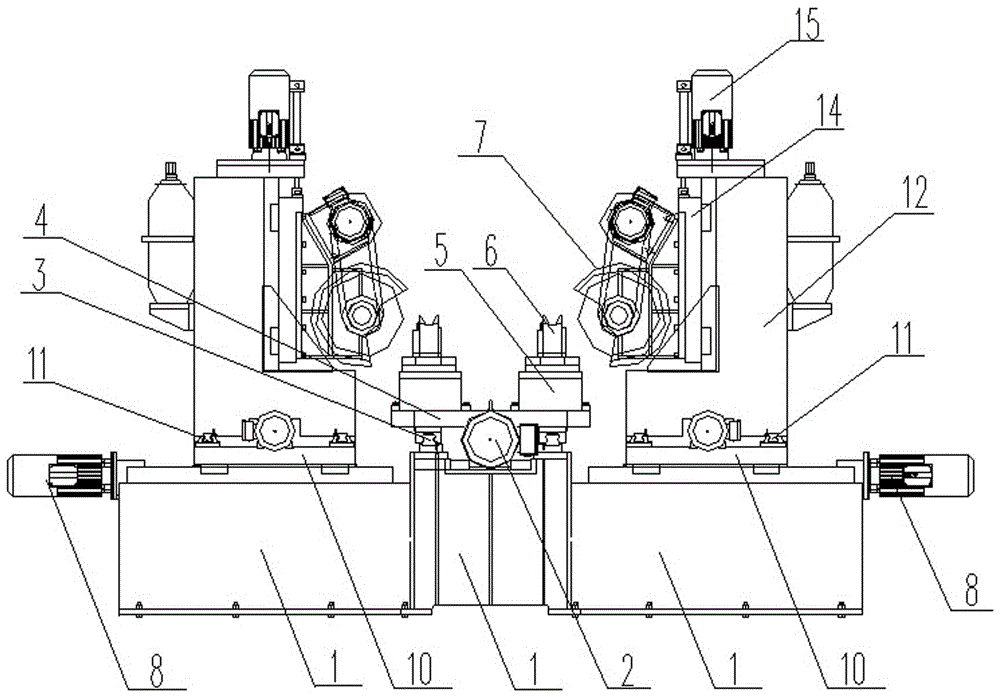

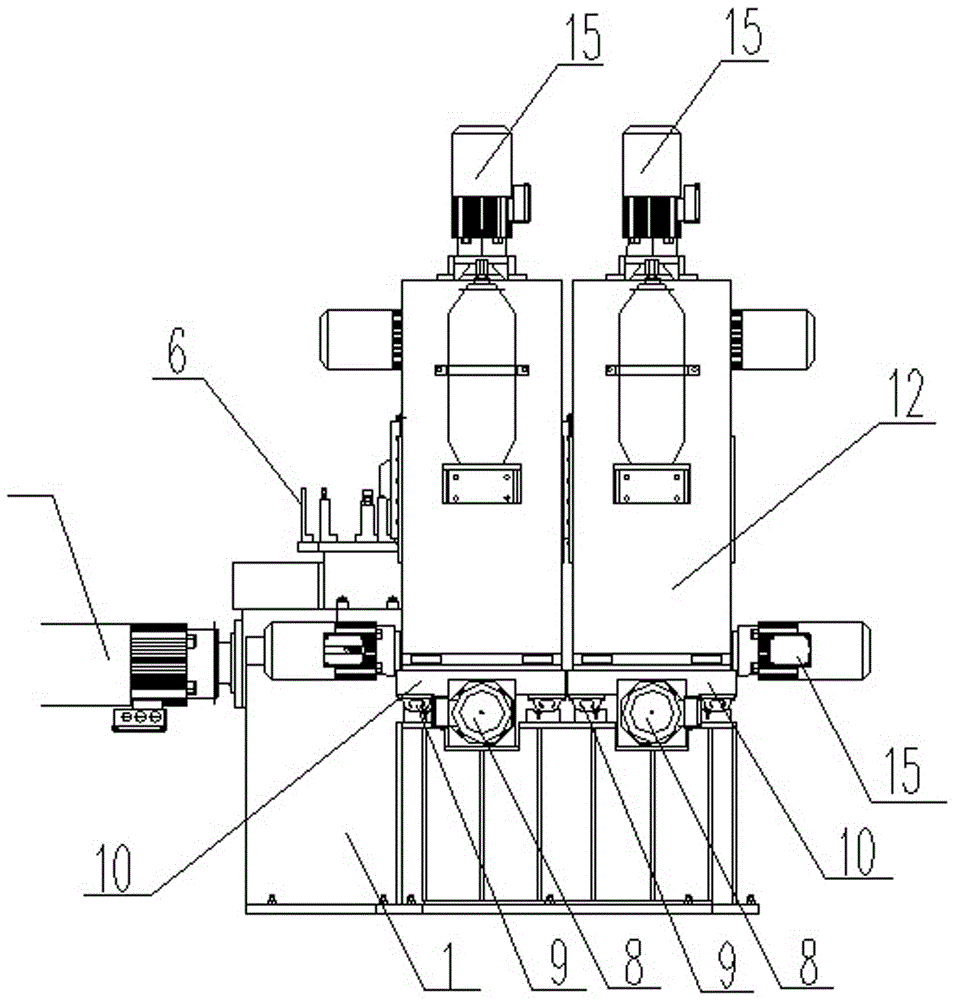

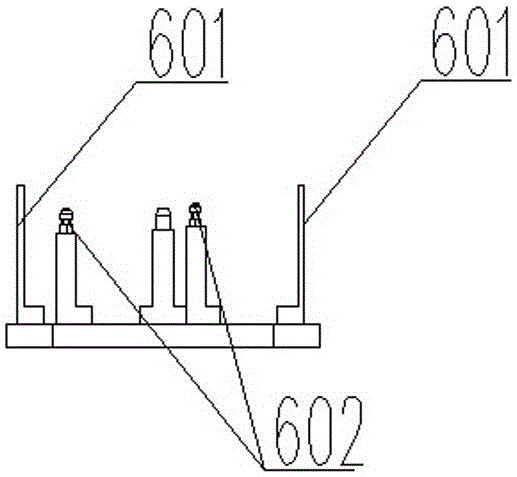

[0030] A grinding mechanism for an automatic crankshaft grinding and cleaning machine, the grinding mechanism includes a horizontally arranged bed 1, a workbench arranged on the bed 1, a workpiece feeding device 2, and multiple sets of grinding wheel assemblies. The workbench consists of a linear guide rail I3 installed on the bed 1, a slide table 4 that can move back and forth along the linear guide rail I3 driven by the workpiece feeding device 2, and a plurality of workpiece CNC rotary tables 5 set on the slide table 4 , the top of each workpiece CNC rotary table 5 is provided with a set of workpiece fixtures 6 for supporting a crankshaft to be ground, and corresponding to the top of each workpiece CNC rotary table 5 is also provided with a set for pressing the crankshaft to be ground The workpiece clamping device, the axial direction of the crankshaft supported on the workpiece fixture 6 is consistent with the direction in which the slide table 4 moves back and forth along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com