Patents

Literature

1859 results about "Pulse control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

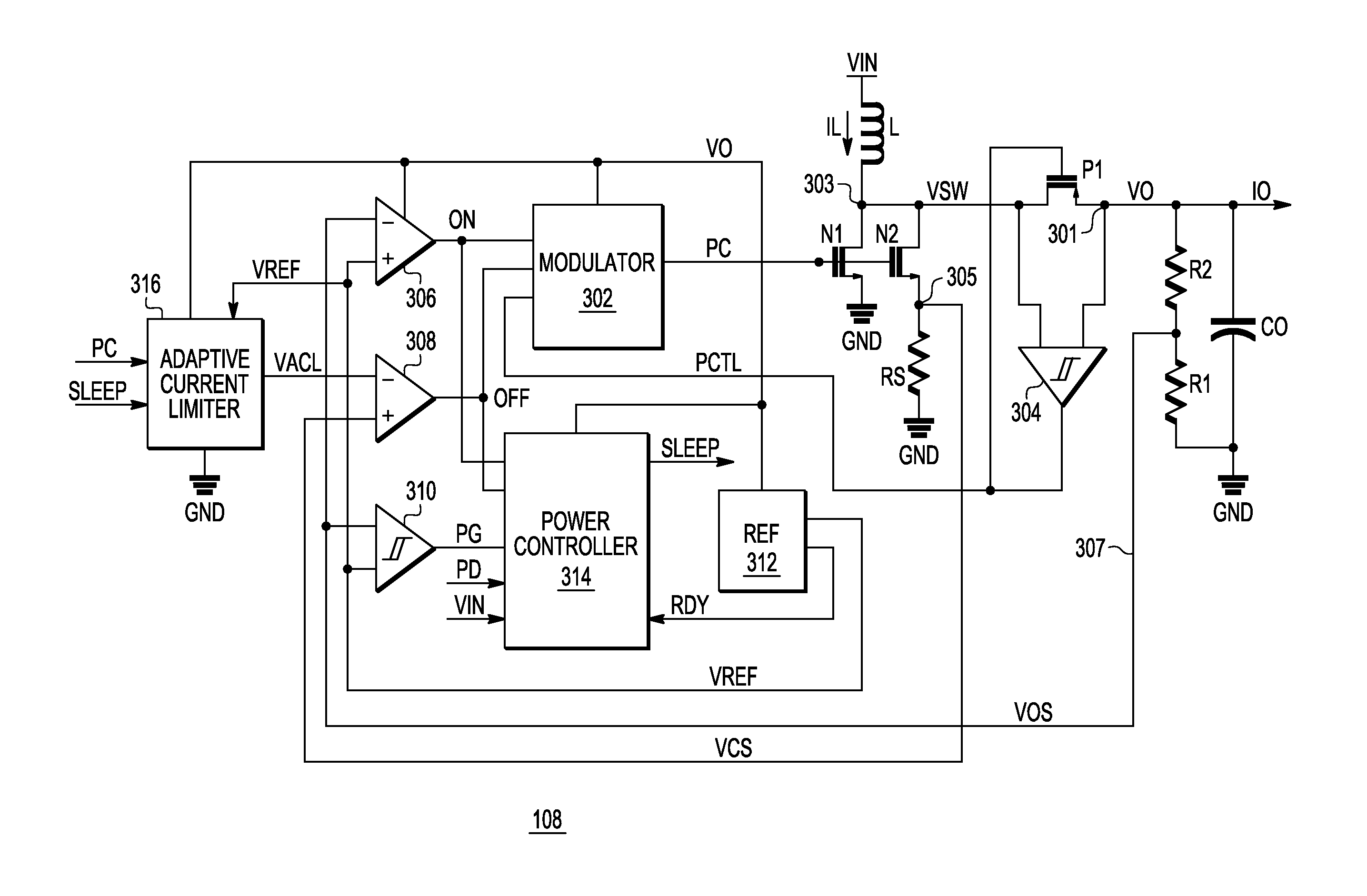

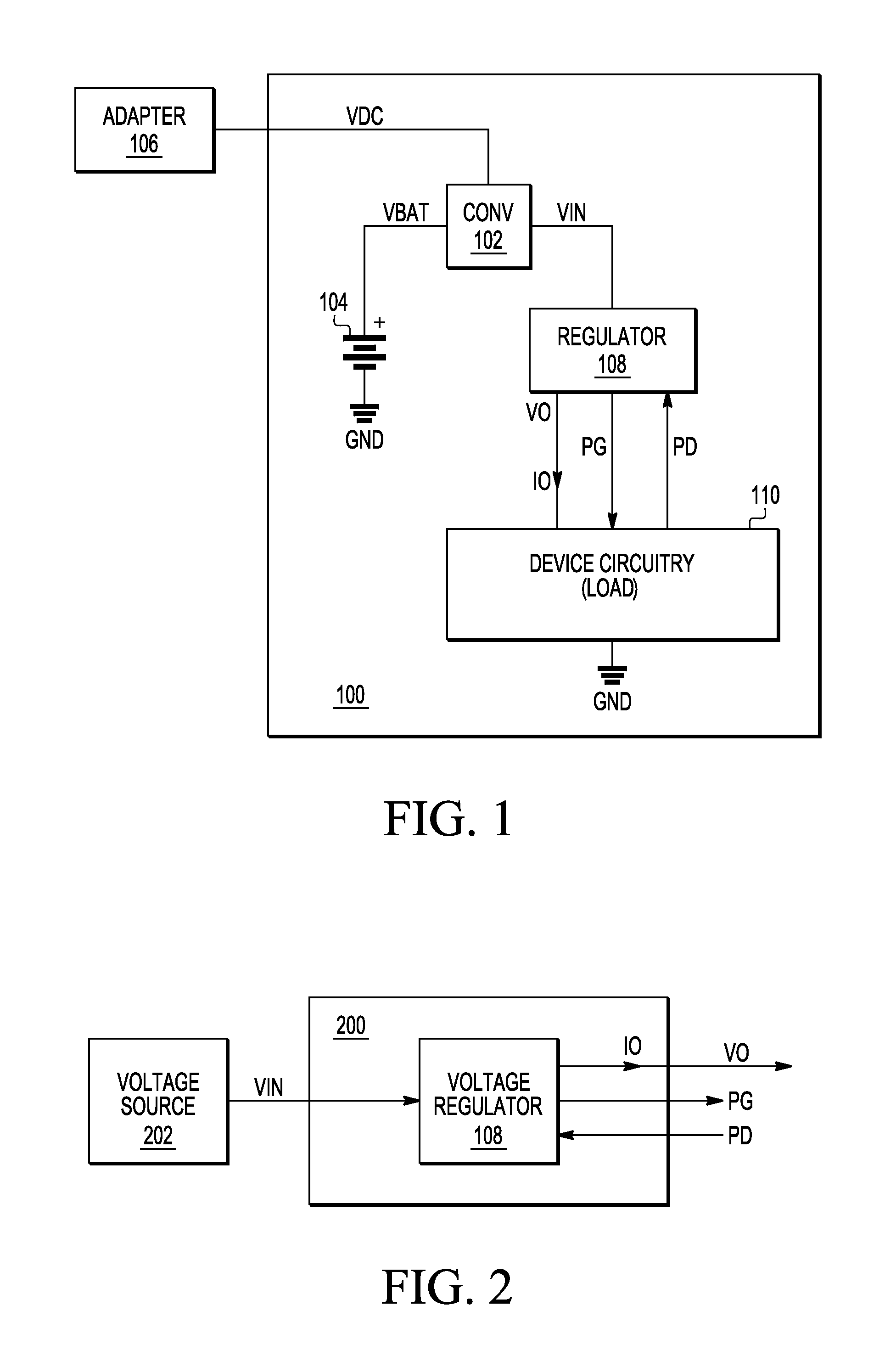

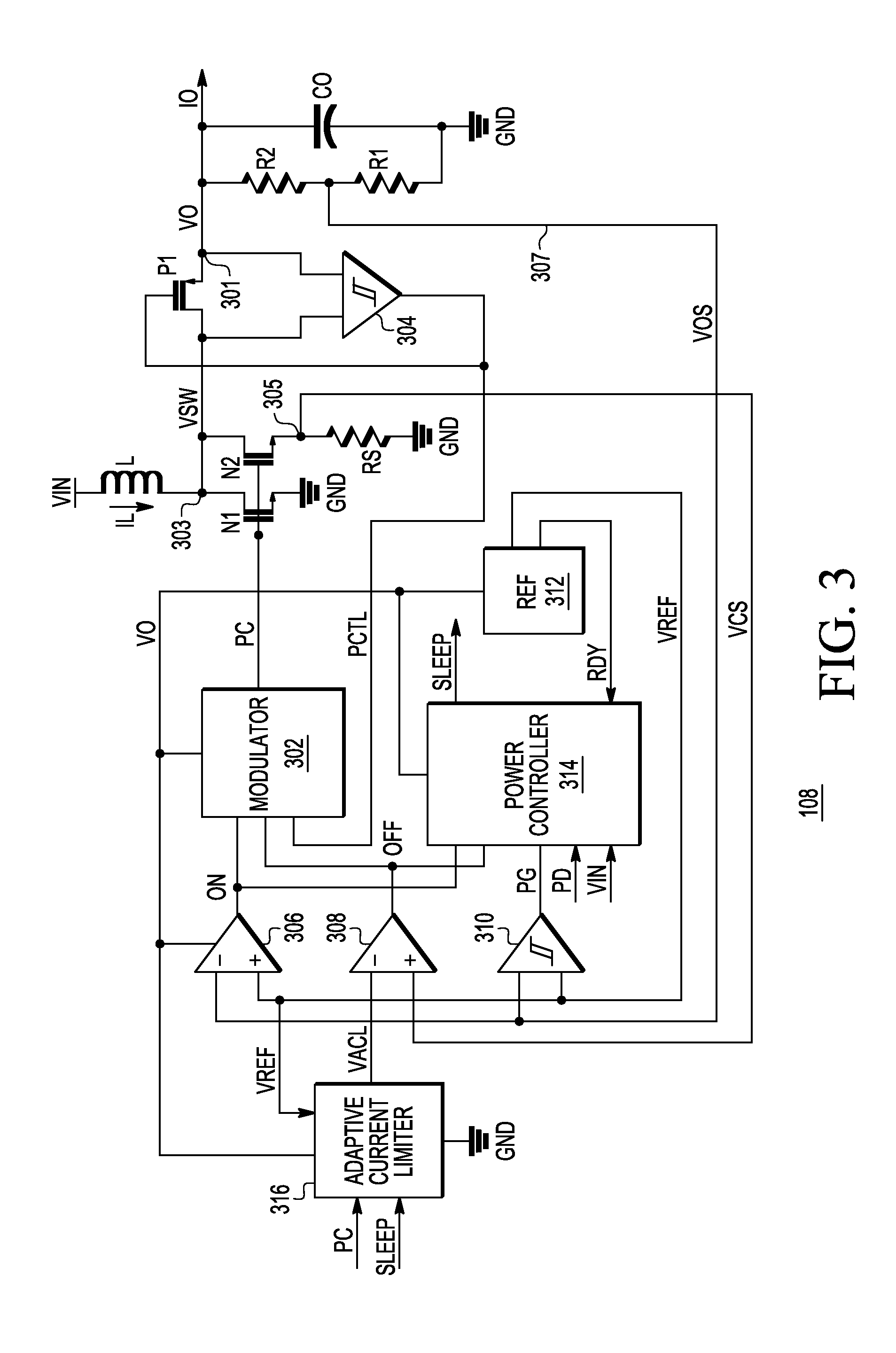

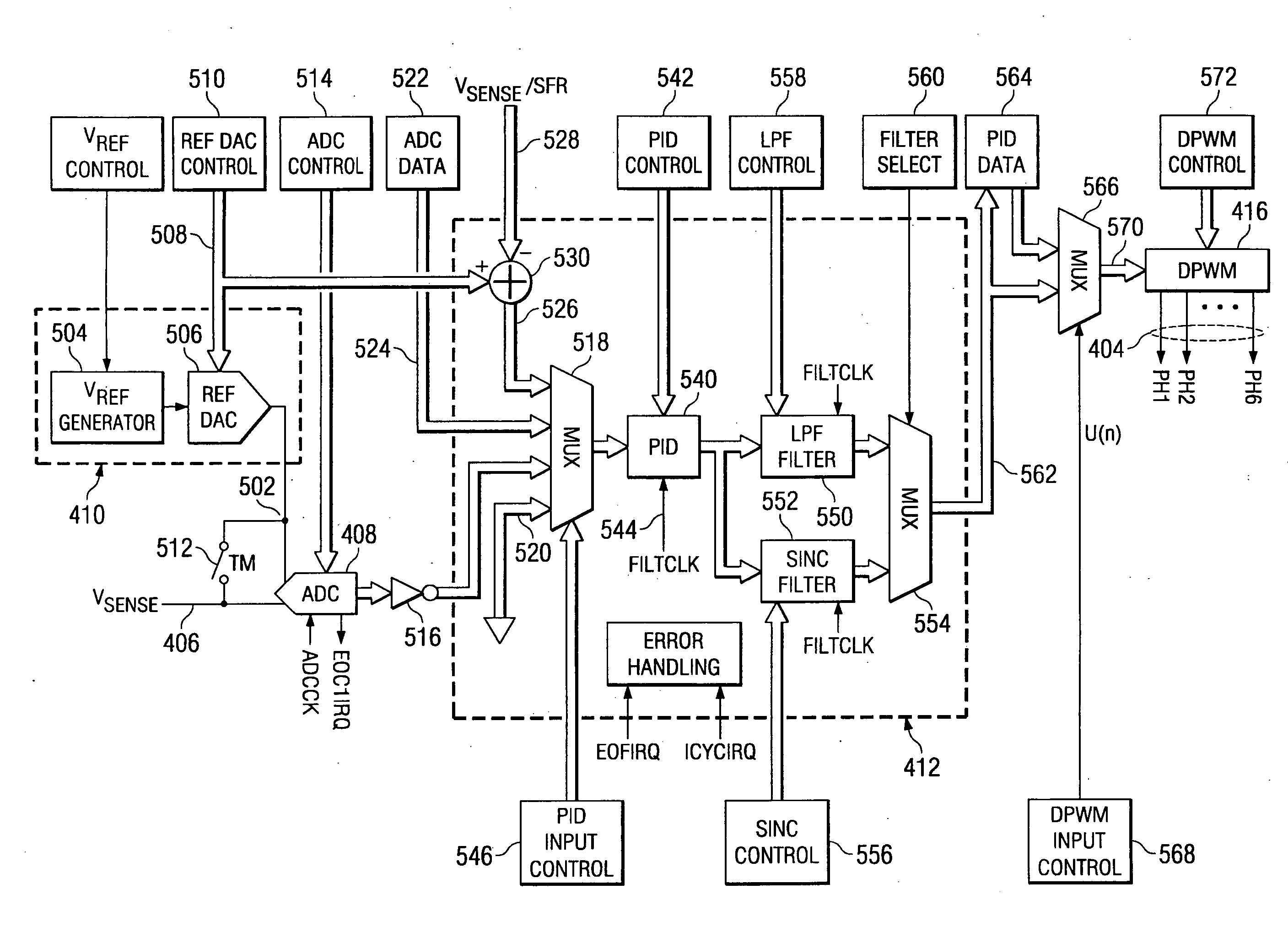

System and method for adaptive current limit of a switching regulator

ActiveUS9099922B2Efficient power electronics conversionDc-dc conversionControl signalReference current

Owner:SILICON LAB INC

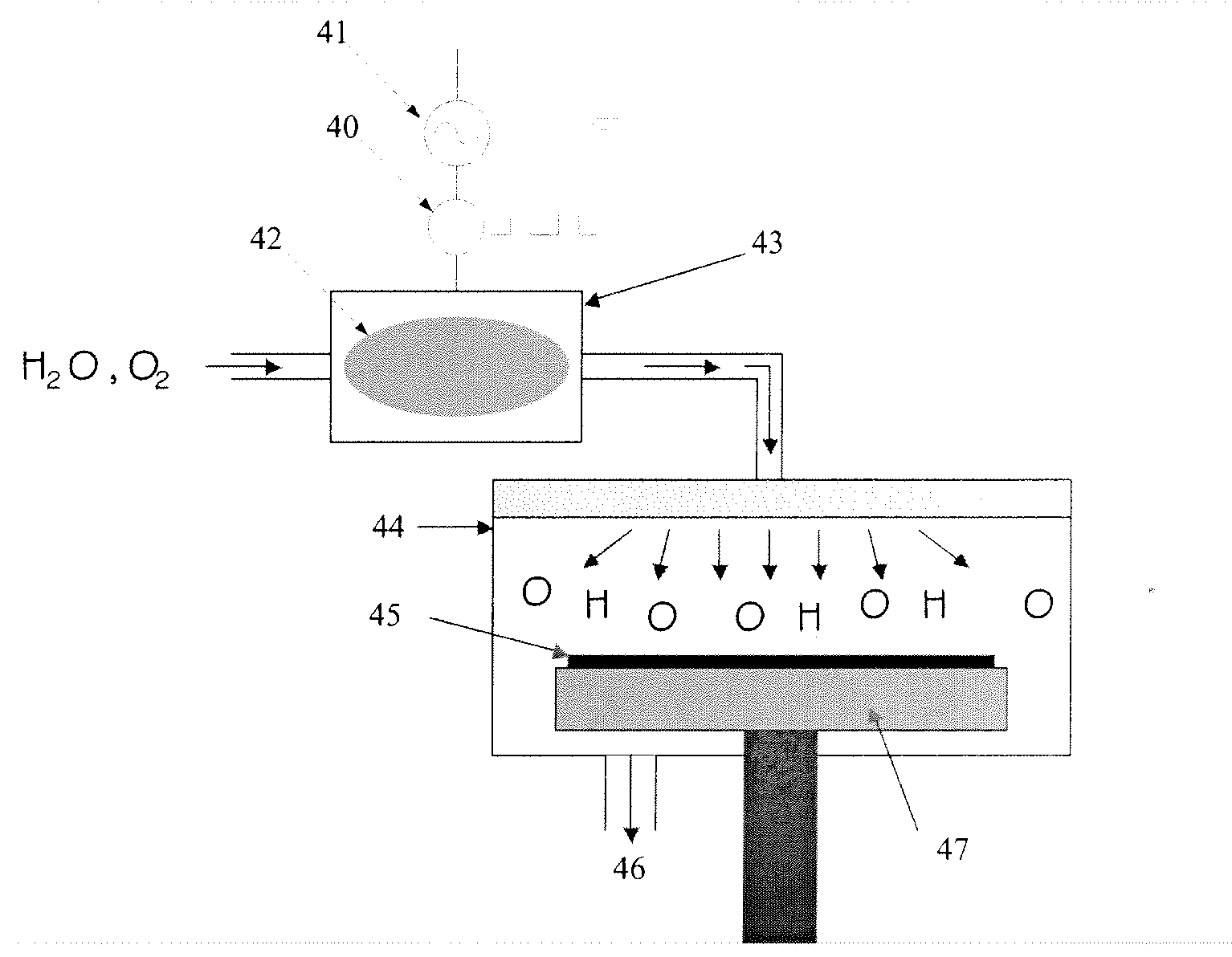

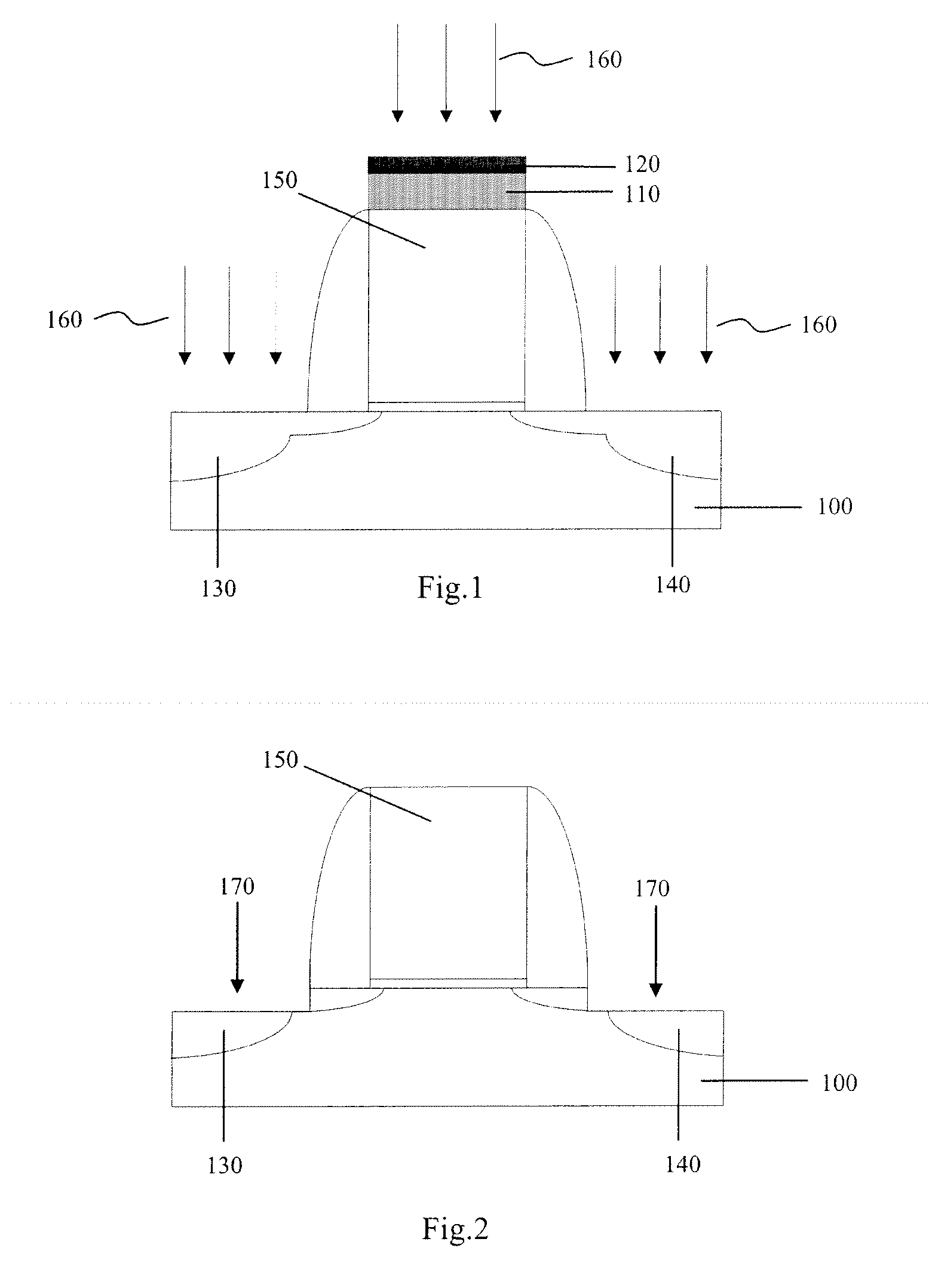

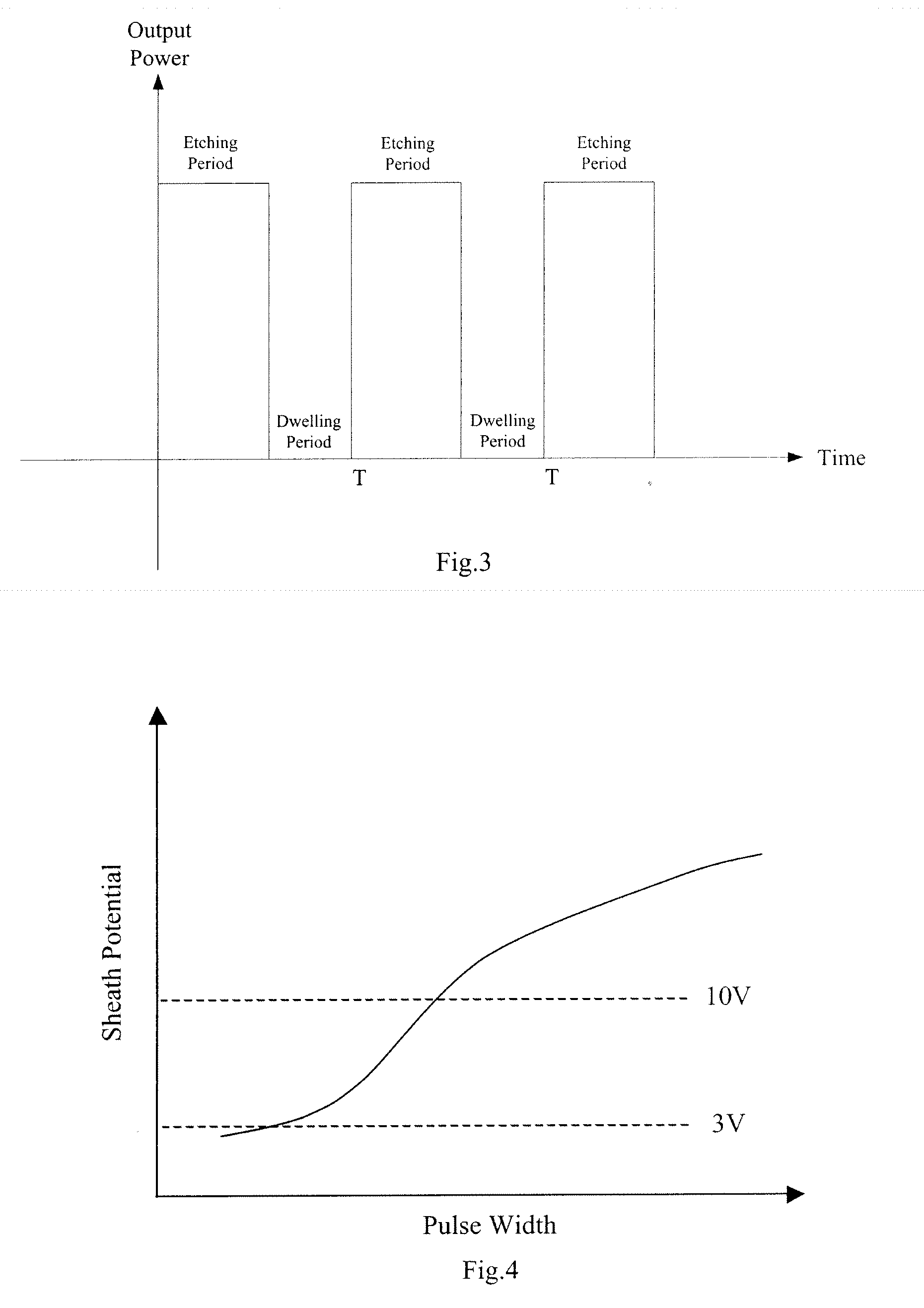

Pulsed plasma etching method and apparatus

InactiveUS20080081483A1High precisionEasy to controlElectric discharge tubesSemiconductor/solid-state device manufacturingPulse controlRadio frequency

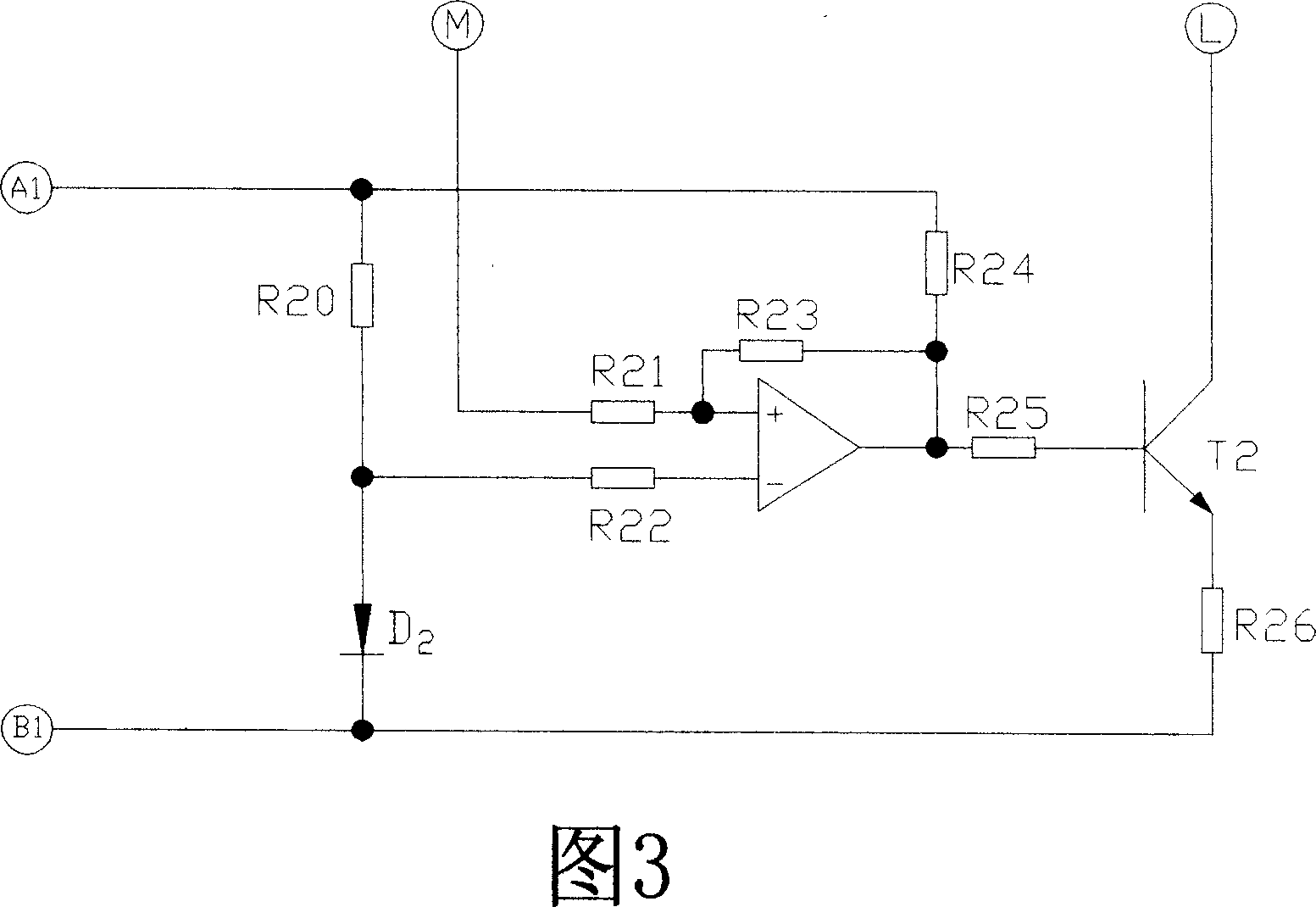

A plasma etching method includes preparing in a reaction chamber a semiconductor substrate on which a material layer to be etched is provided; and injecting an etching gas into the reaction chamber, the etching gas being ionized through an RF (Radio Frequency) power source to generate a plasma, wherein the RF power source outputs RF power in a pulse output mode. The plasma etching apparatus includes a reaction chamber adapted to contain an etching gas; and an RF power source adapted to output RF power for excitation of the etching gas to generate plasma, wherein the apparatus further include a pulse control circuit adapted to control the RF power source to output RF power in a pulse output mode. With the invention, the plasma for etching can be generated in a pulse output mode, thus improving a precision of an endpoint where the etching can be disabled.

Owner:SEMICON MFG INT (SHANGHAI) CORP

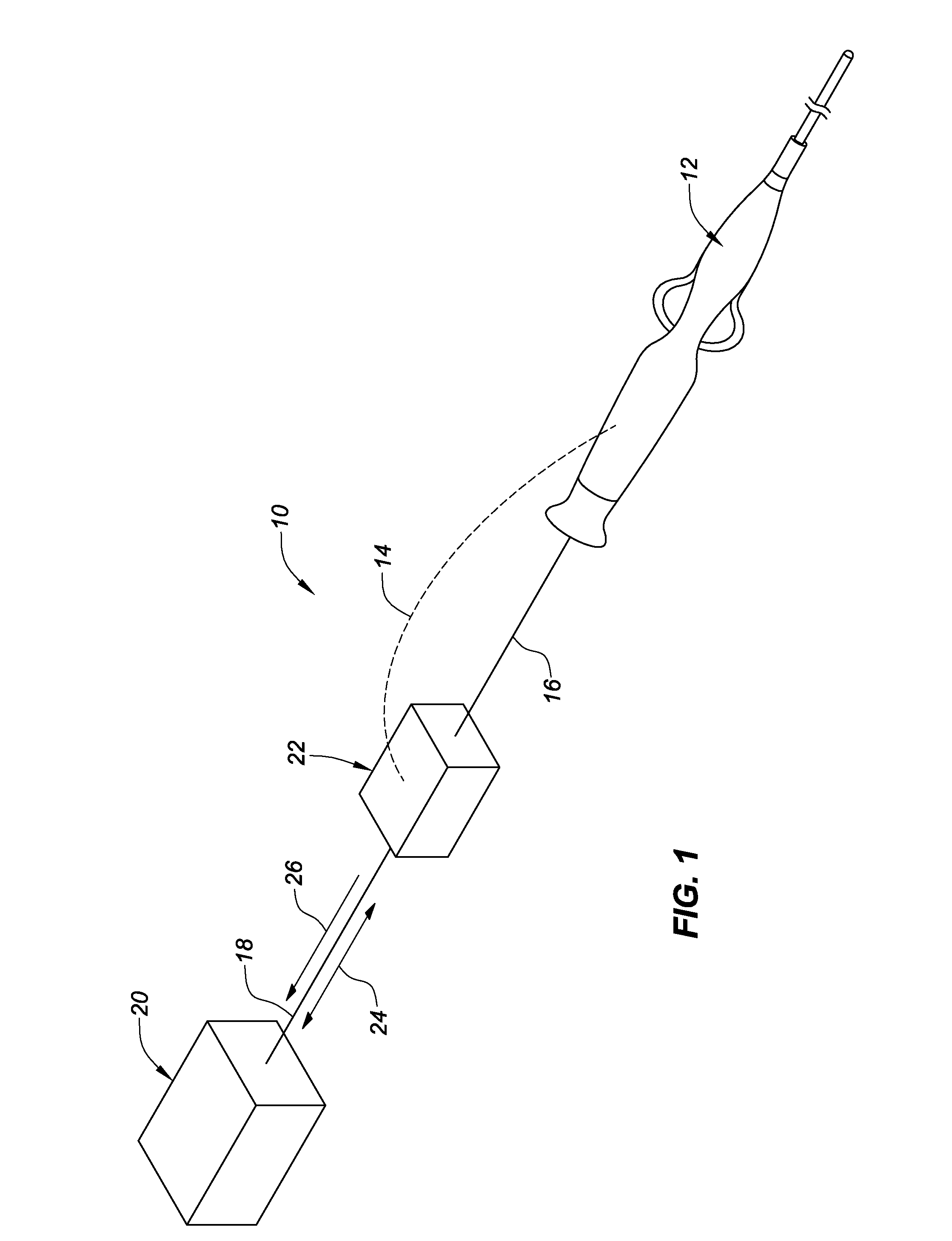

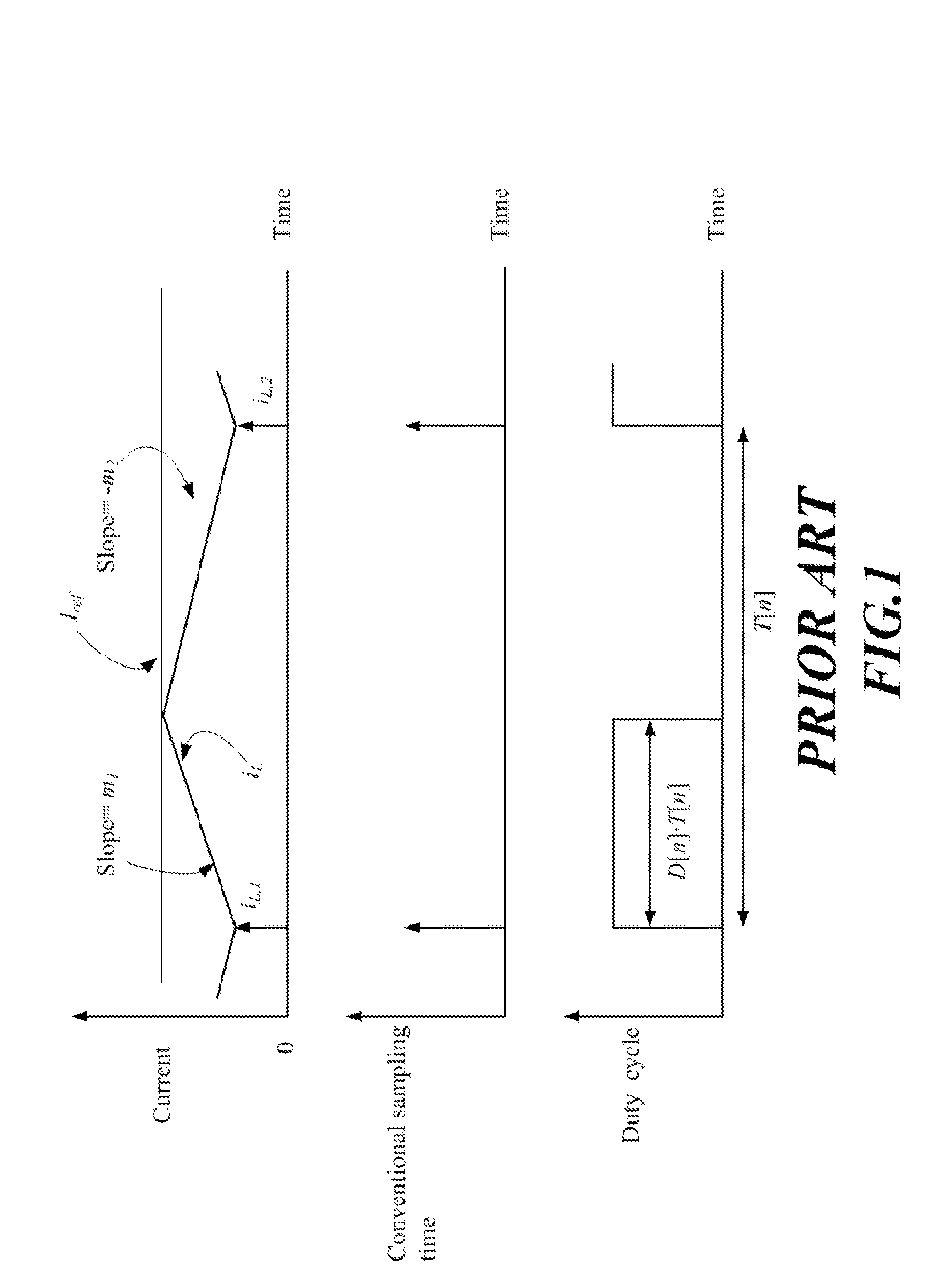

Methods and devices for delivering pulsed RF energy during catheter ablation

ActiveUS20160287312A1Mitigating against overheating of tissueSurgical instruments for heatingSurgical instruments for irrigation of substancesPulse controlRf ablation

Method and devices for delivering pulsed RF ablation energy to enable the creation of lesions in tissue are disclosed. The delivery of RF energy is controlled such that the generator power setting remains sufficiently high to form adequate lesions while mitigating against overheating of tissue. An ablation catheter tip having high-thermal-sensitivity comprises a thermally-insulative ablation tip insert supporting at least one temperature sensor and encapsulated, or essentially encapsulated, by a conductive shell. A system for delivering pulsed RF energy to a catheter during catheter ablation comprises an RF generator and a pulse control box operatively connected to the generator and configured to control delivery of pulsatile RF energy to an ablation catheter comprising at least one temperature sensor mounted in its tip. Also disclose is a method of controlling the temperature of an ablation catheter tip while creating a desired lesion using pulsatile delivery of RF energy.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

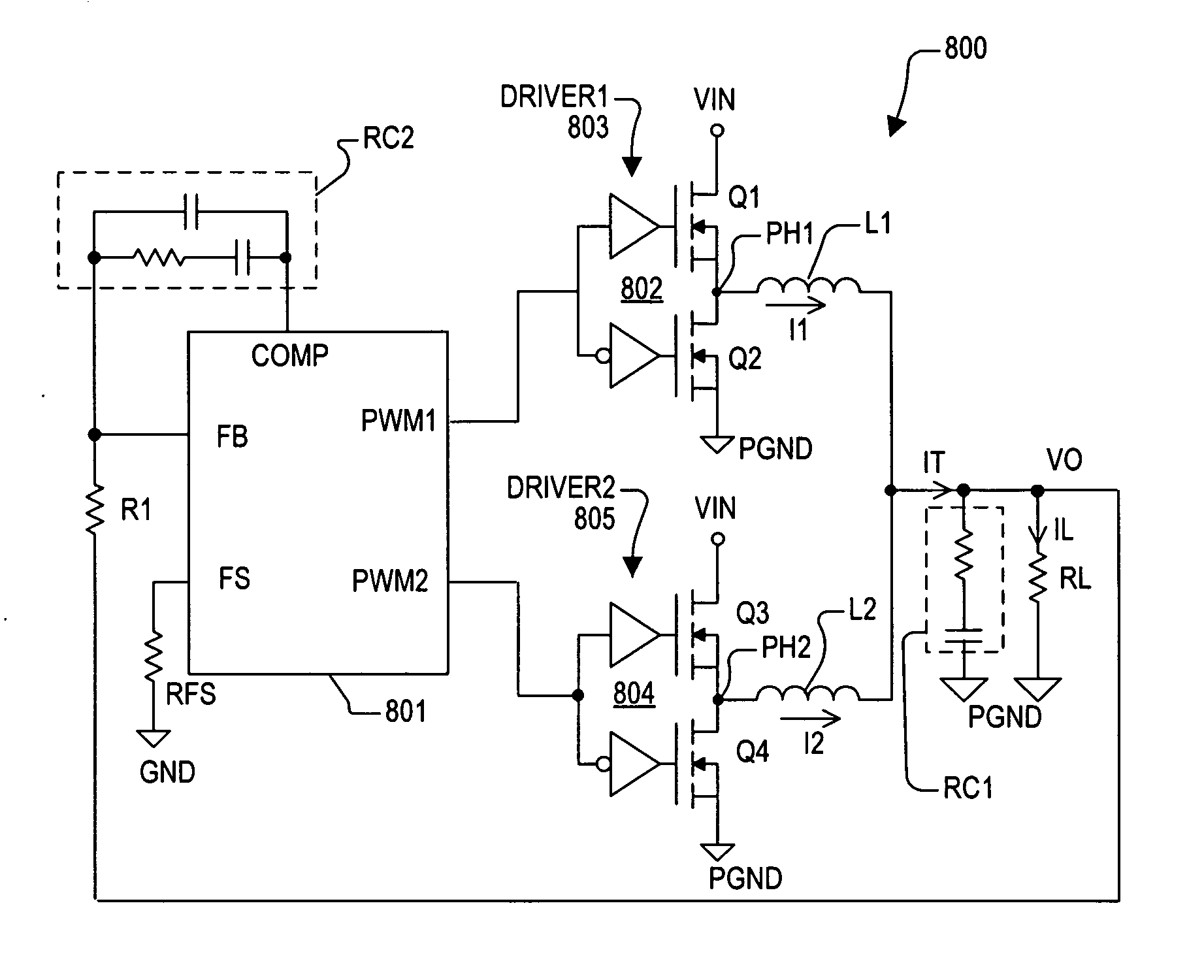

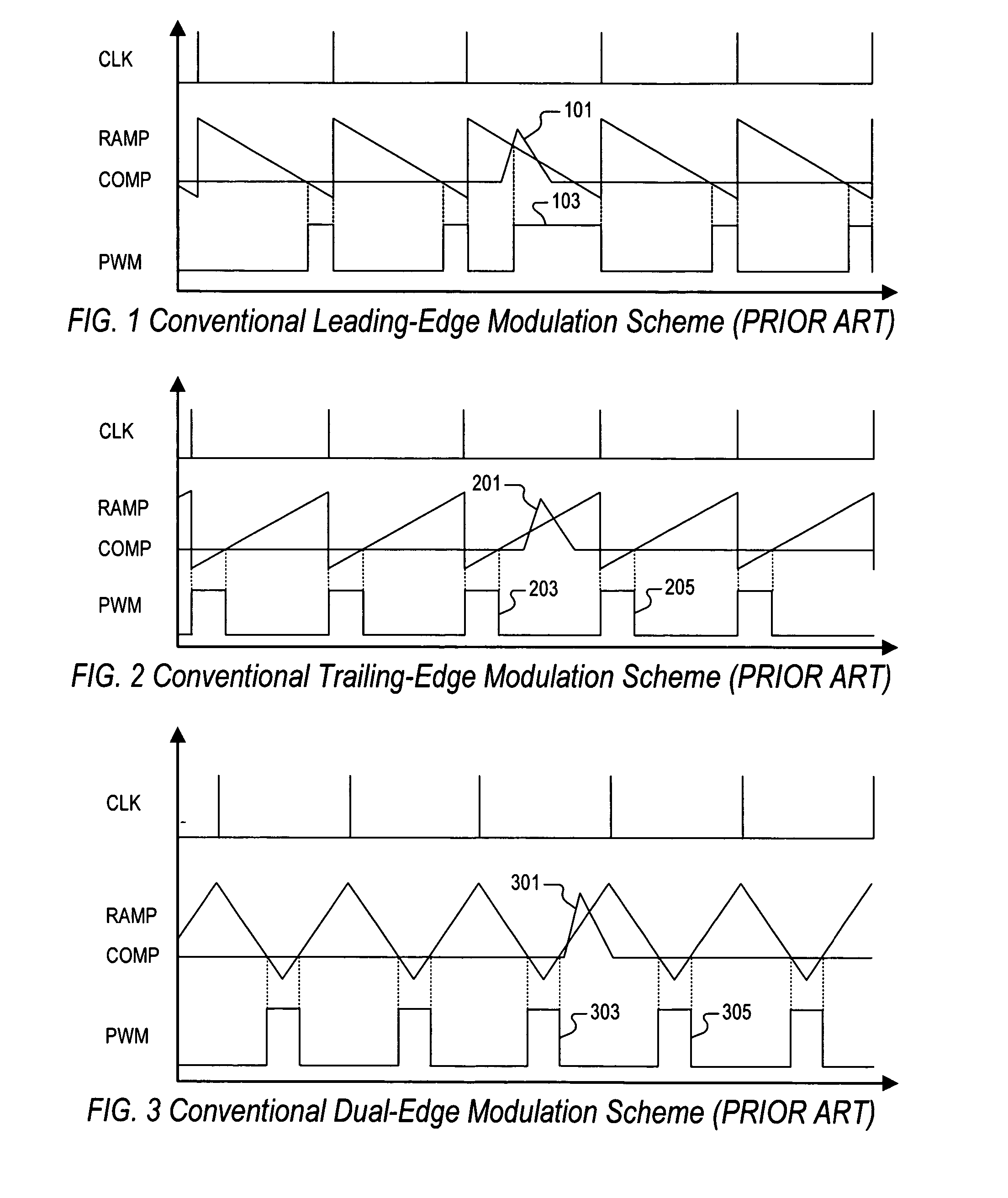

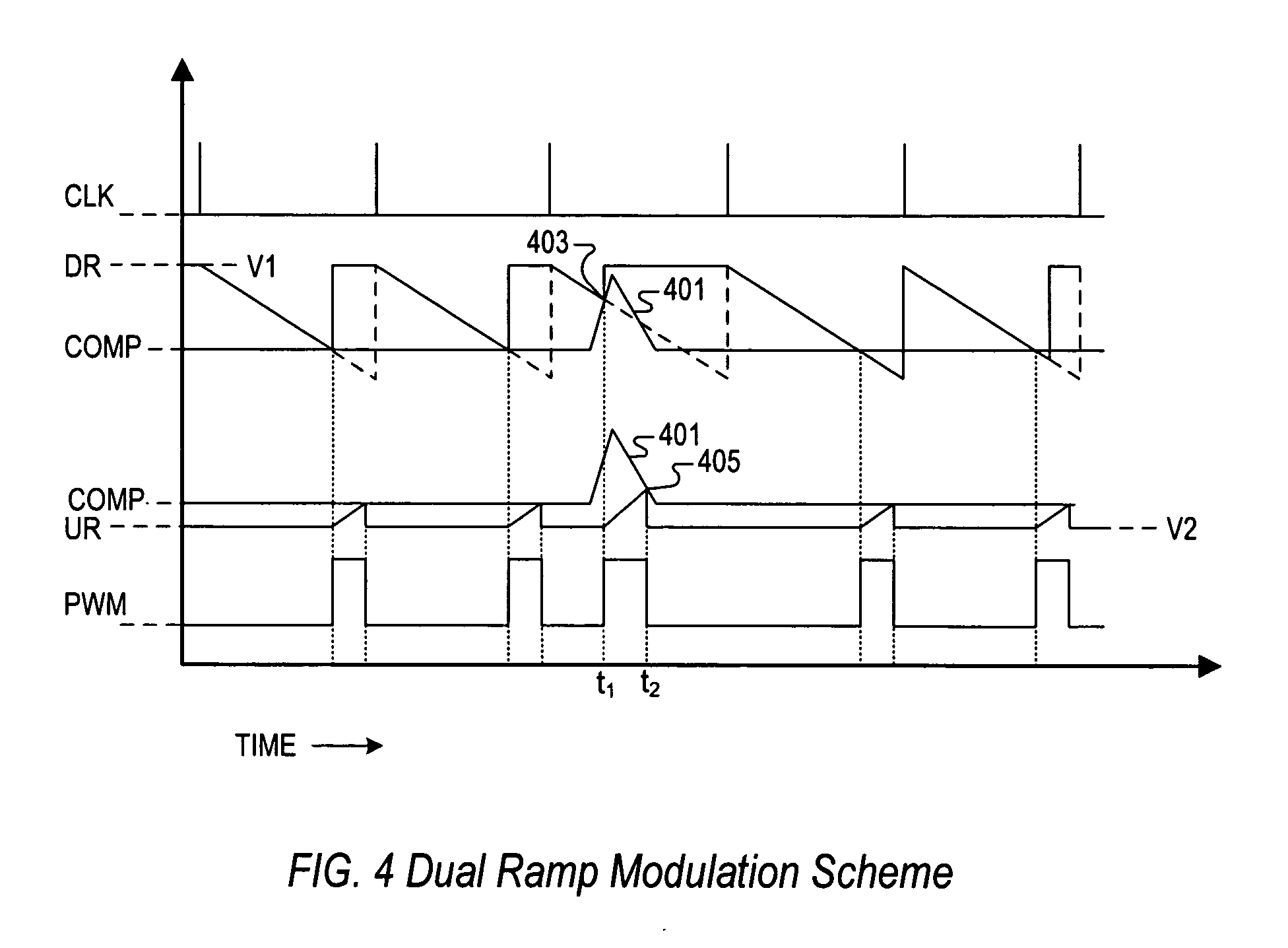

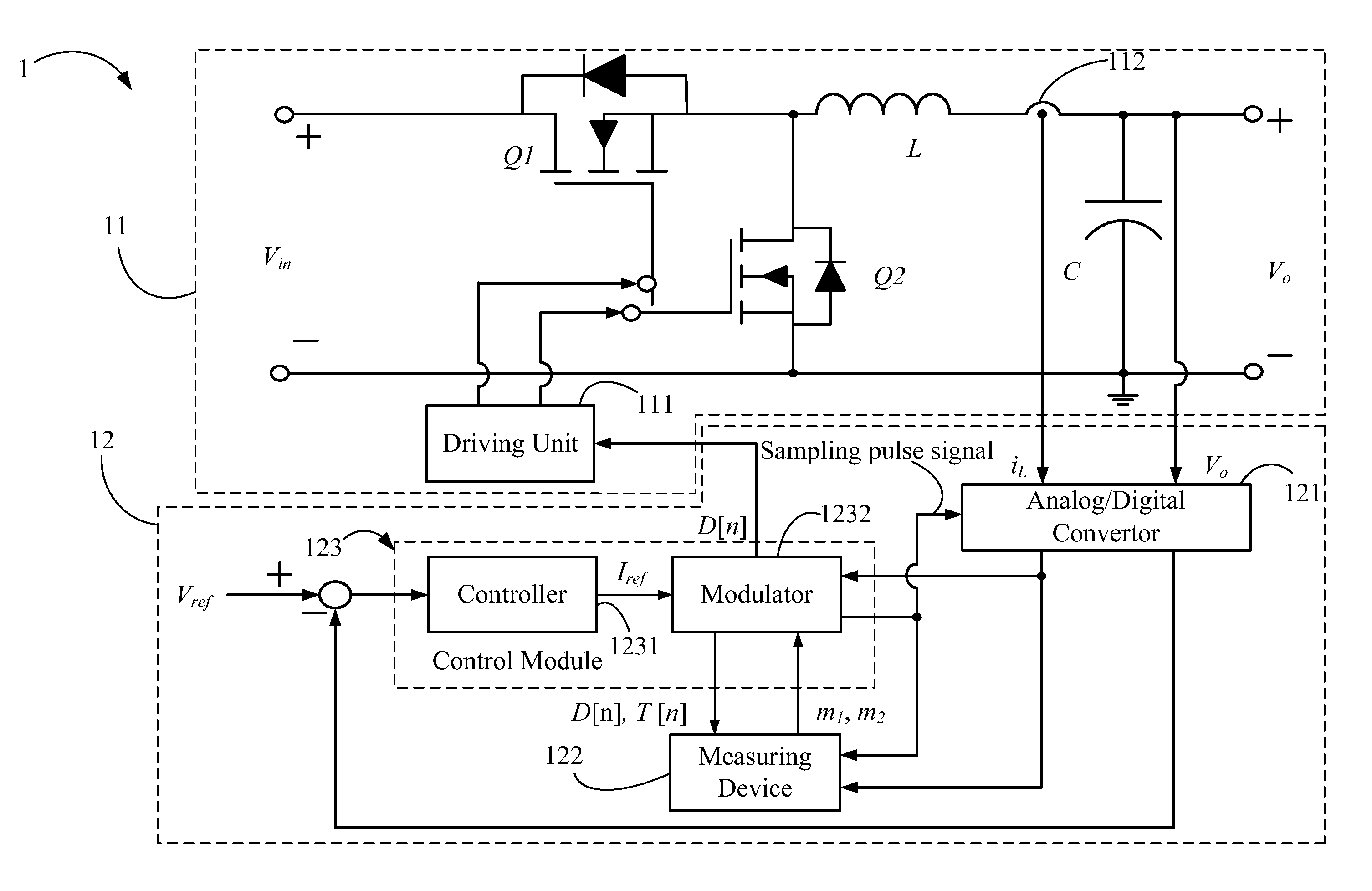

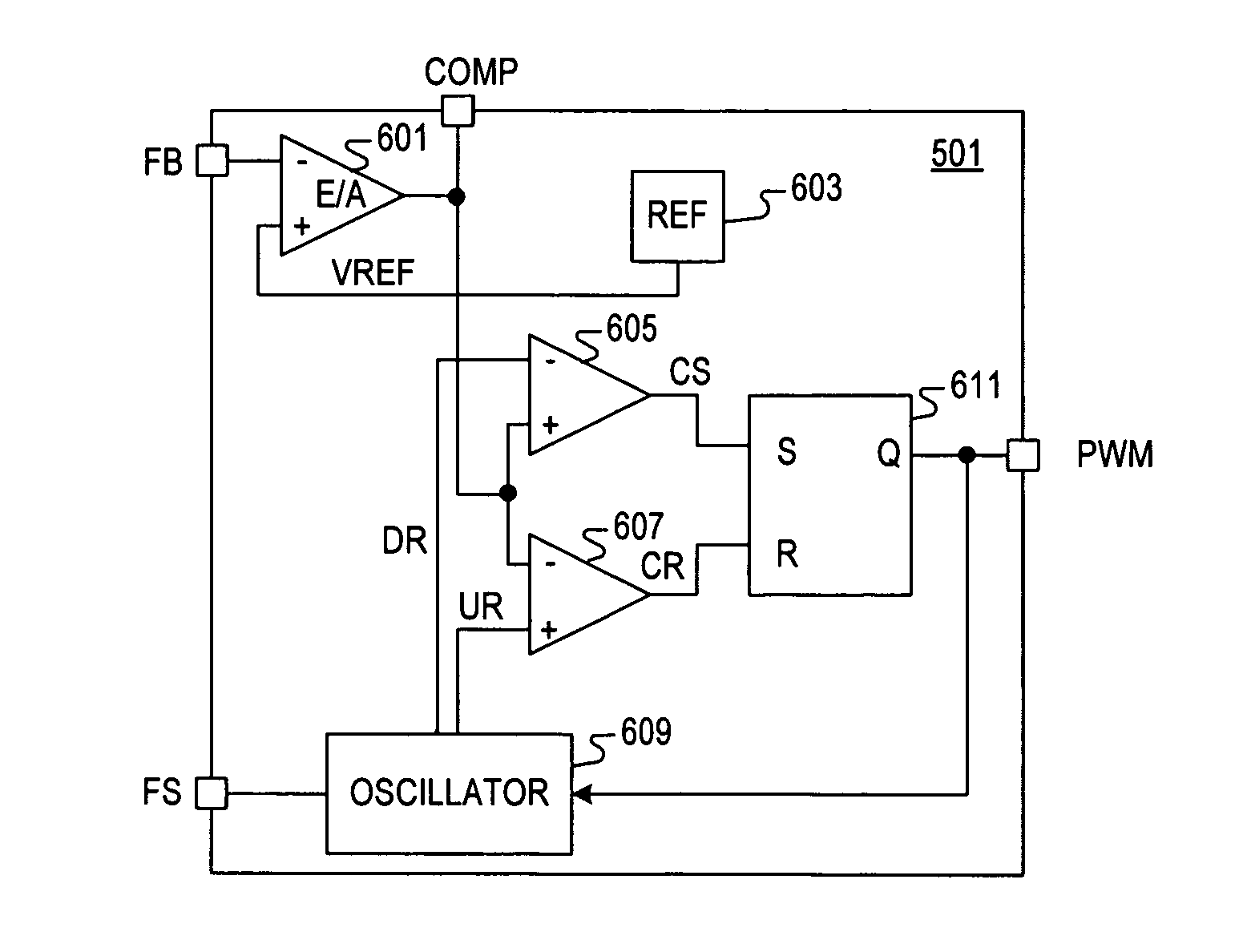

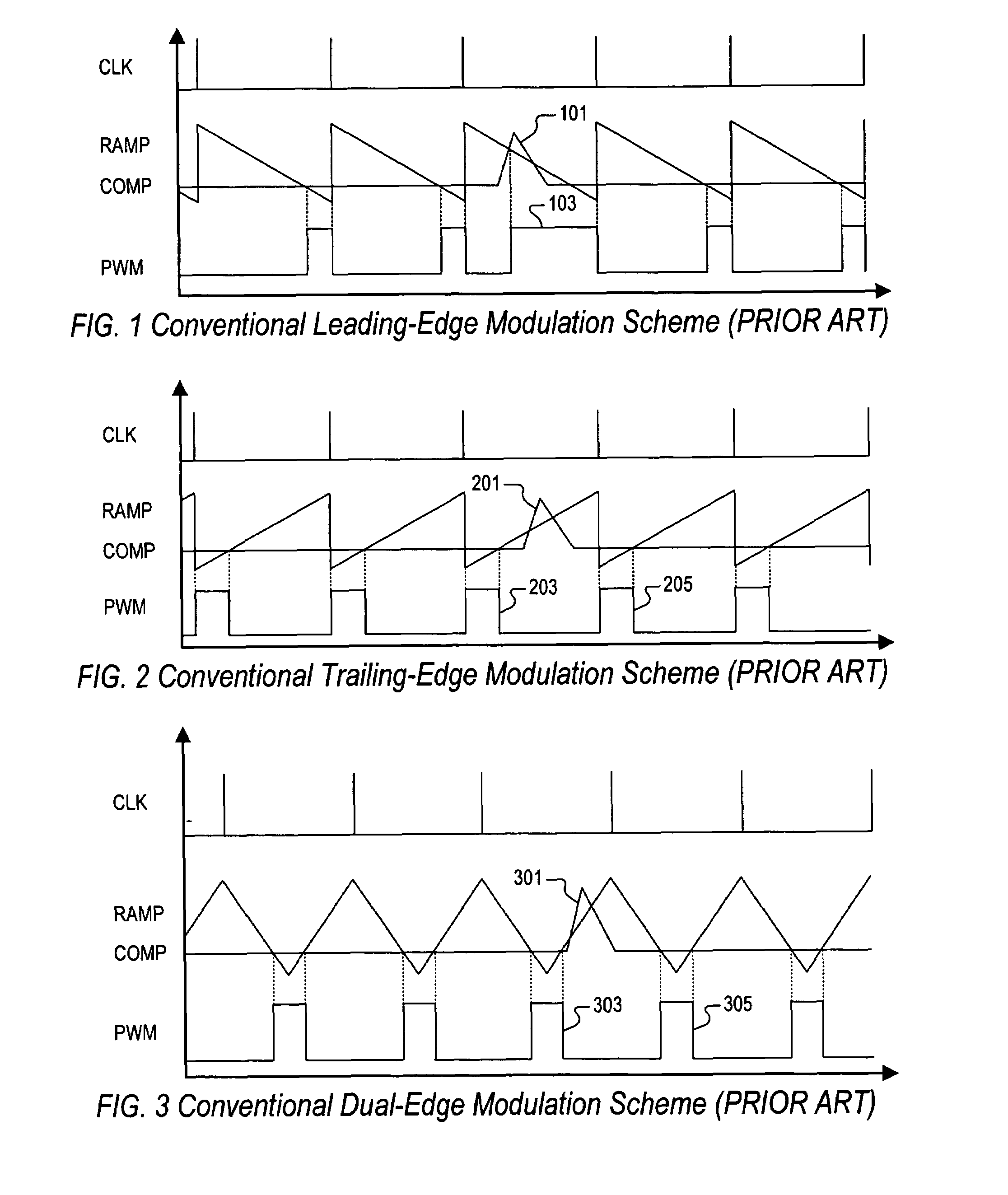

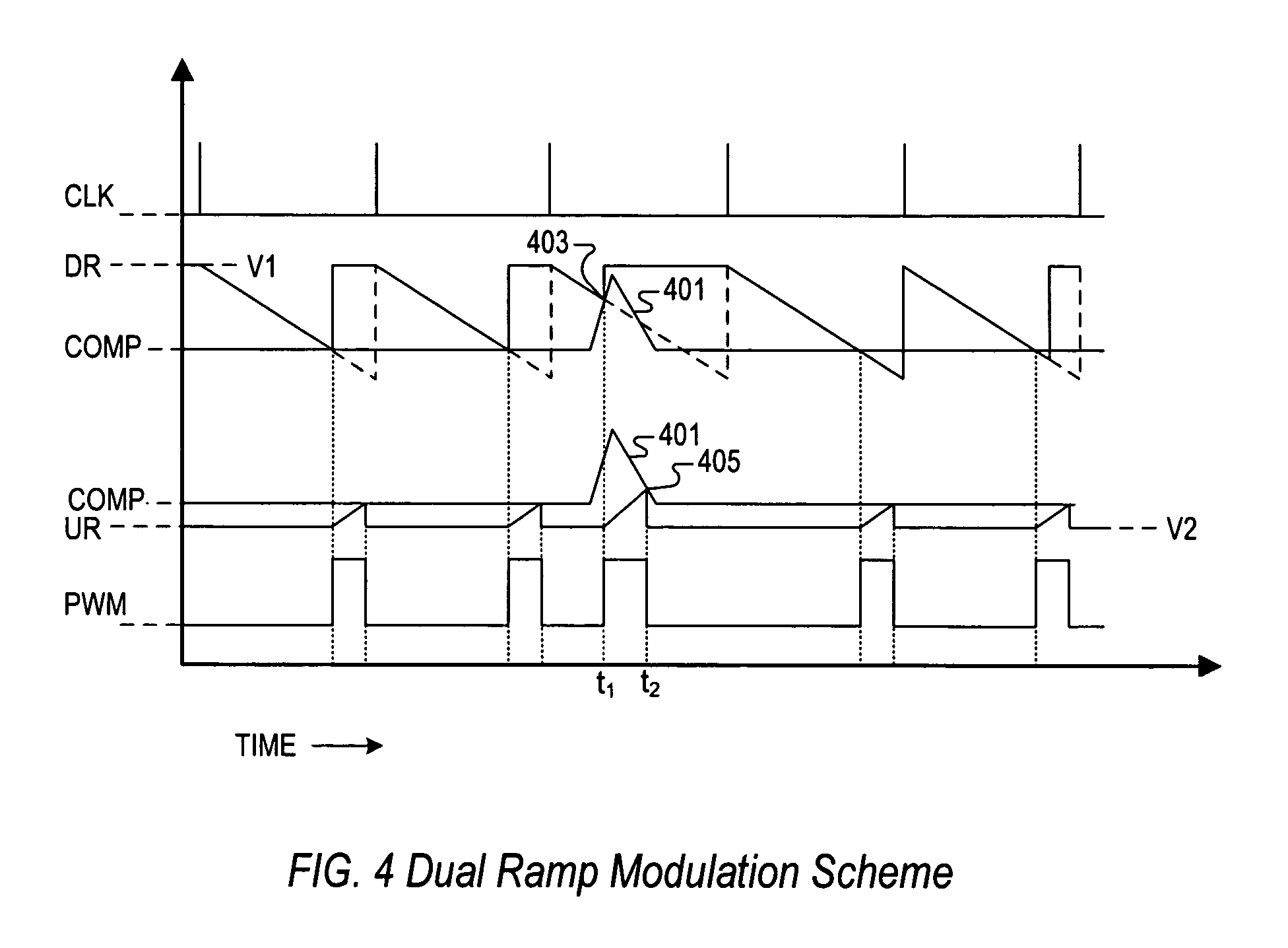

PWM controller with dual-edge modulation using dual ramps

ActiveUS20070013356A1Efficient power electronics conversionDc-dc conversionLeading edgePulse control

A dual-edge modulation controller including first and second ramp circuits, first and second comparators, an error amplifier and pulse control logic. The first ramp circuit provides a leading-edge ramp synchronous with a clock. The error amplifier compares a feedback signal with a reference and provides a compensation signal. The first comparator compares the leading-edge ramp with the compensation signal and asserts a set signal. The second ramp circuit provides a trailing-edge ramp that begins ramping when the set signal is asserted. The second comparator compares the trailing-edge ramp with the compensation signal and asserts a reset signal. The pulse control logic asserts a PWM signal when the set signal is asserted and de-asserts the PWM signal when the reset signal is asserted. The controller may control multiple phases with current balancing. The slew rate of the ramps may be adjusted based on the number of PWM signal asserted.

Owner:INTERSIL INC

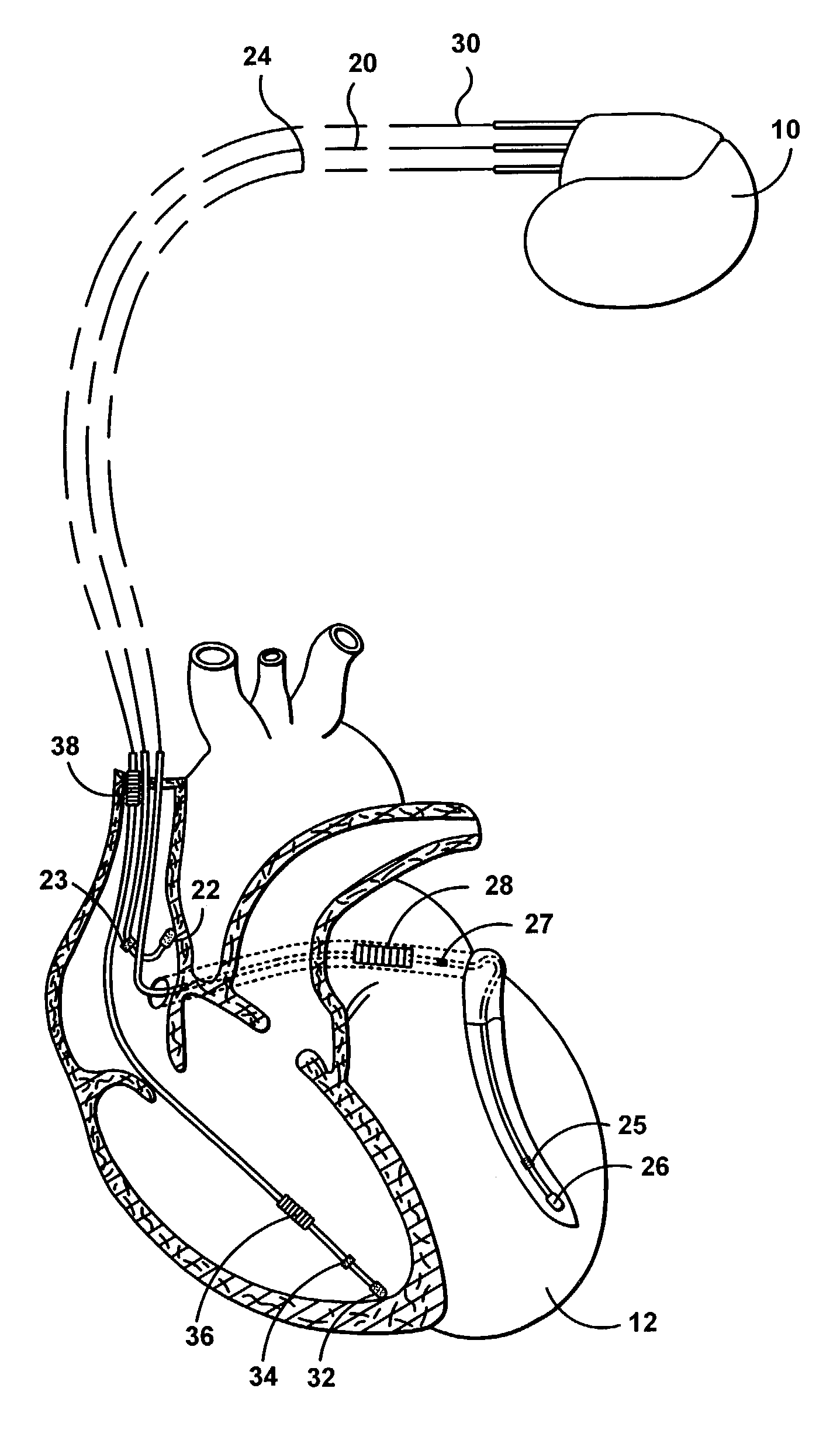

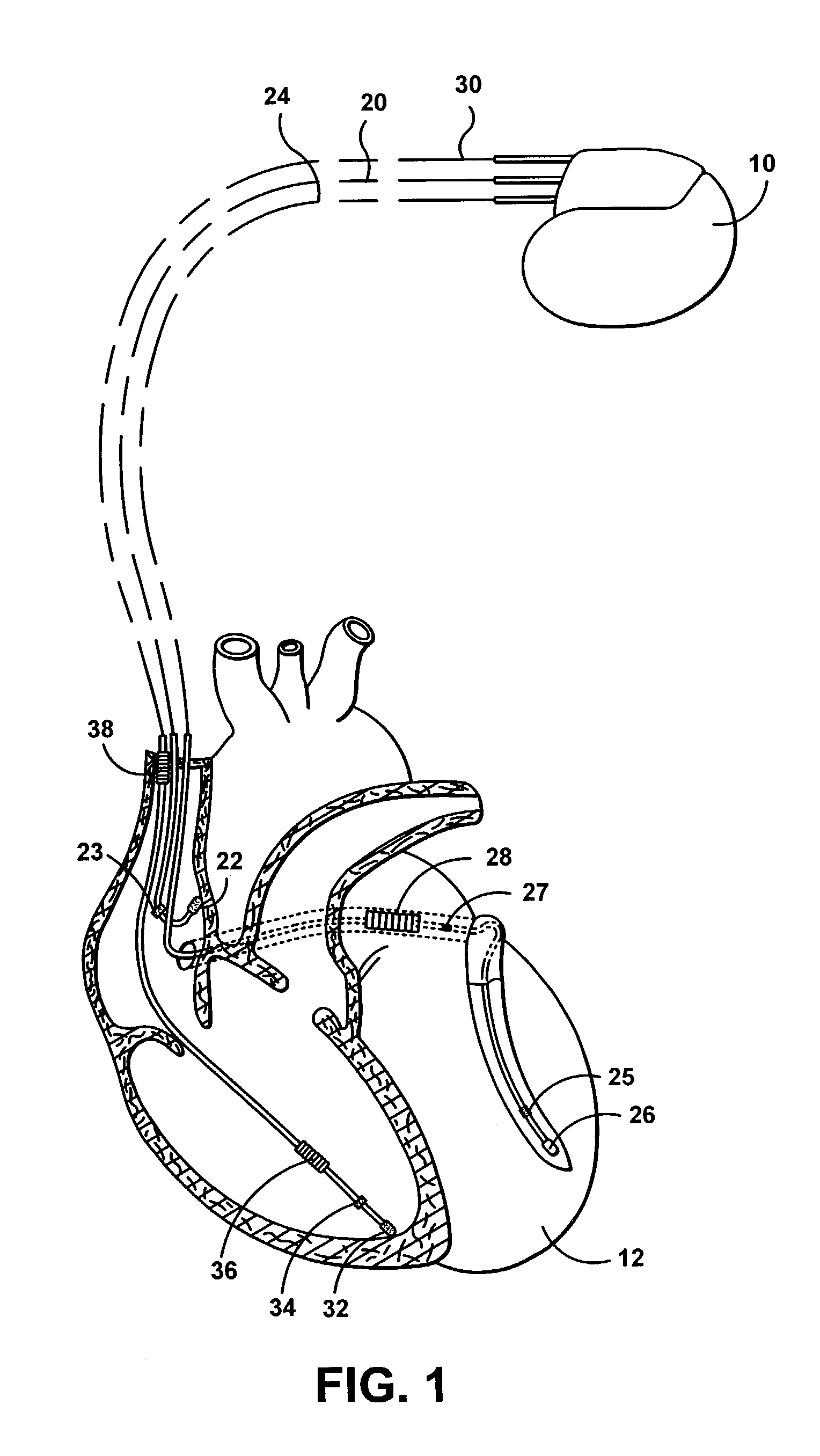

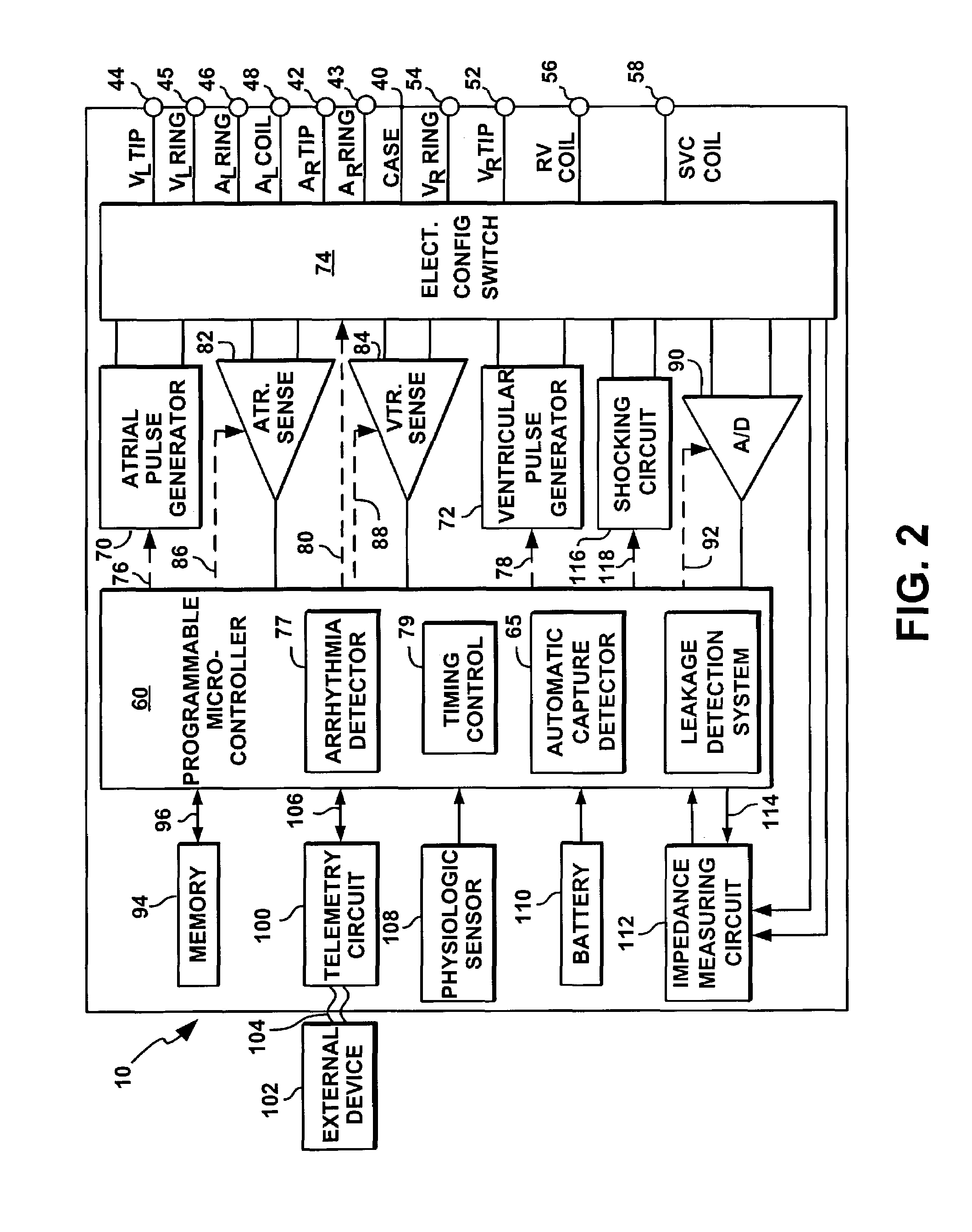

System and method for measuring lead impedance in an implantable stimulation device employing pulse-train waveforms

InactiveUS7065403B1High stimulation thresholdReduced sensationElectrotherapyArtificial respirationLead impedanceElectrical polarity

A leakage detection system for use in an implantable cardiac stimulation device, such as a cardioverter defibrillator. The leakage detection system includes a switch bank and a controller that regulates the switching arrangements of various switches. The leakage detection system causes pulse generators to generate a pulse-train waveform comprised of a sequence of pulses of opposite polarities, and to deliver these pulses in a preselected temporal relation. The controller detects the current leakage from the pulse generator to the tissues by sensing and analyzing the voltage or current of the pulse generator, leads, and electrodes. The pulsatility and alternating polarities of biphasic pulse-train waveforms increase the stimulation threshold of the motor or sensory nerves and excitable tissues.

Owner:PACESETTER INC

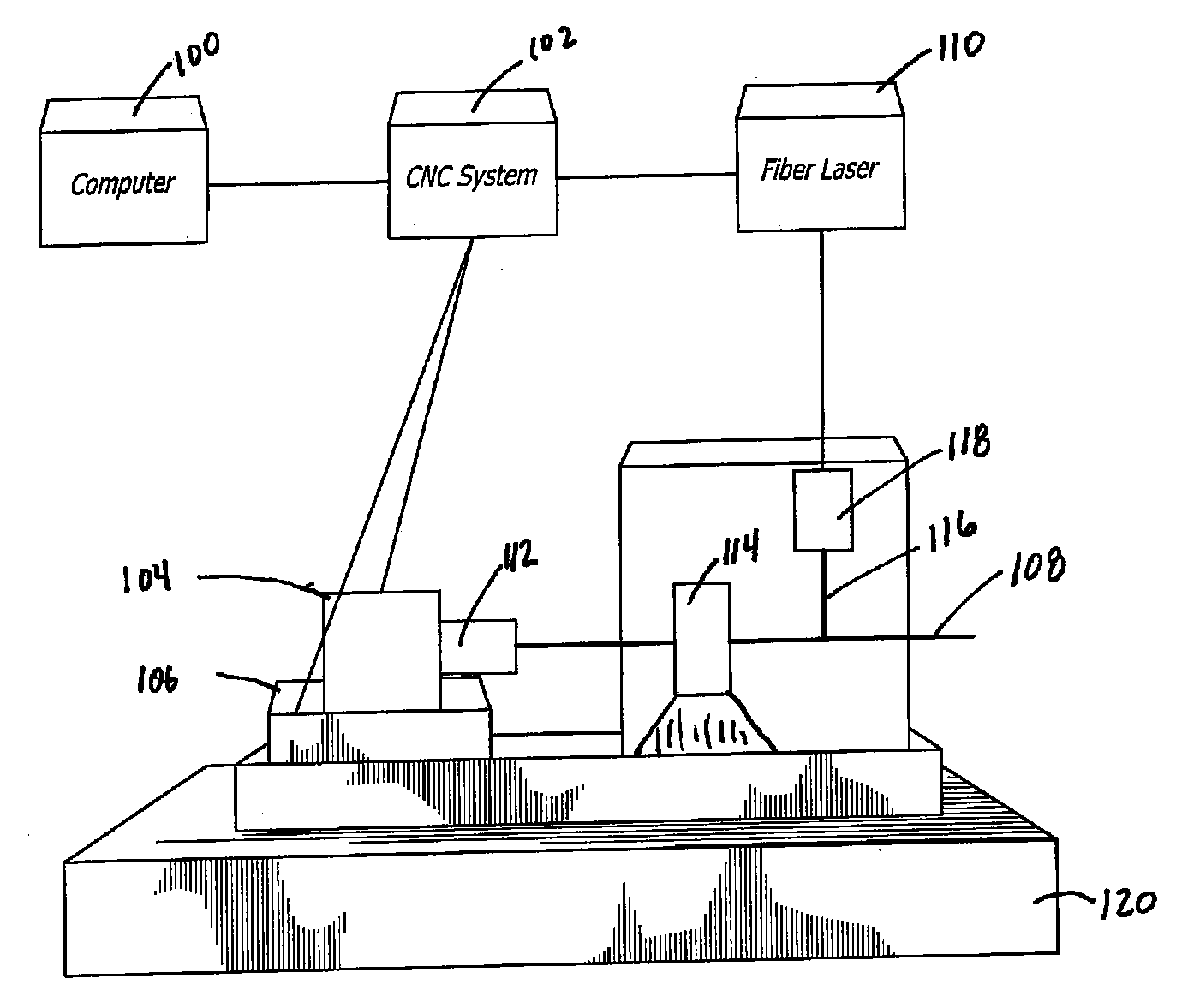

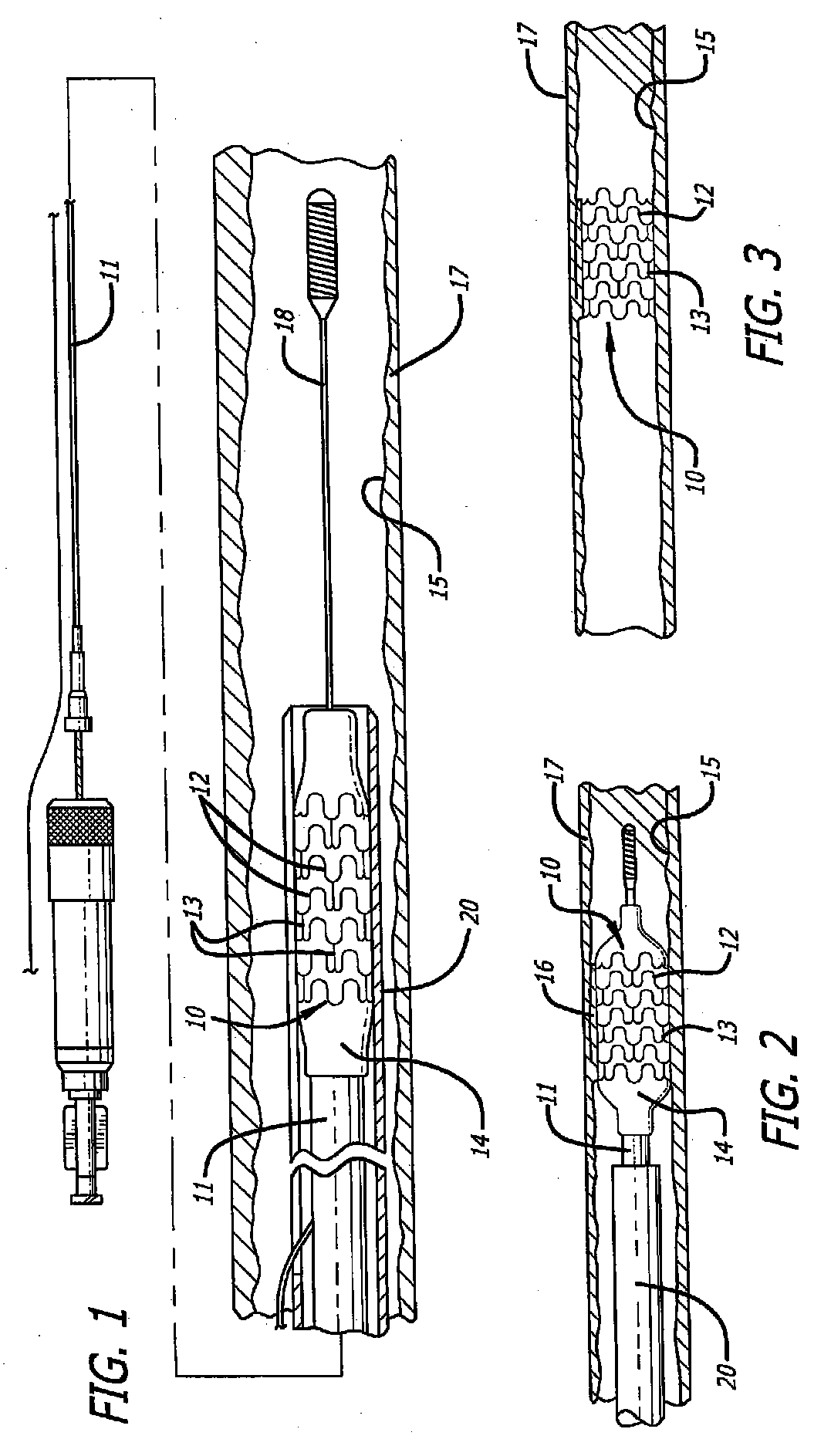

Pulsed Synchronized Laser Cutting of Stents

InactiveUS20070228023A1High resolutionMinimal heat build-upStentsSpecial data processing applicationsPulse controlInsertion stent

A system for pulsed synchronized laser cutting of stents and / or other medical products includes a numerical controller and a machine for moving a tube of material during cutting. A pulsed fiber laser is configured to cut the tube into, for example, a stent, the numerical controller being in communication with the machine and configured to send movement control information to the machine. The numerical controller may also receive movement speed information from the machine. The numerical controller is also in communication with the pulsed fiber laser and is configured to send pulse control information to the pulsed fiber laser. The numerical controller is configured to cause average laser power to decrease by decreasing frequency of laser pulses as stent cutting speed decreases, and to cause average laser power to increase by increasing frequency of laser pulses as stent cutting speed increases.

Owner:ABBOTT CARDIOVASCULAR

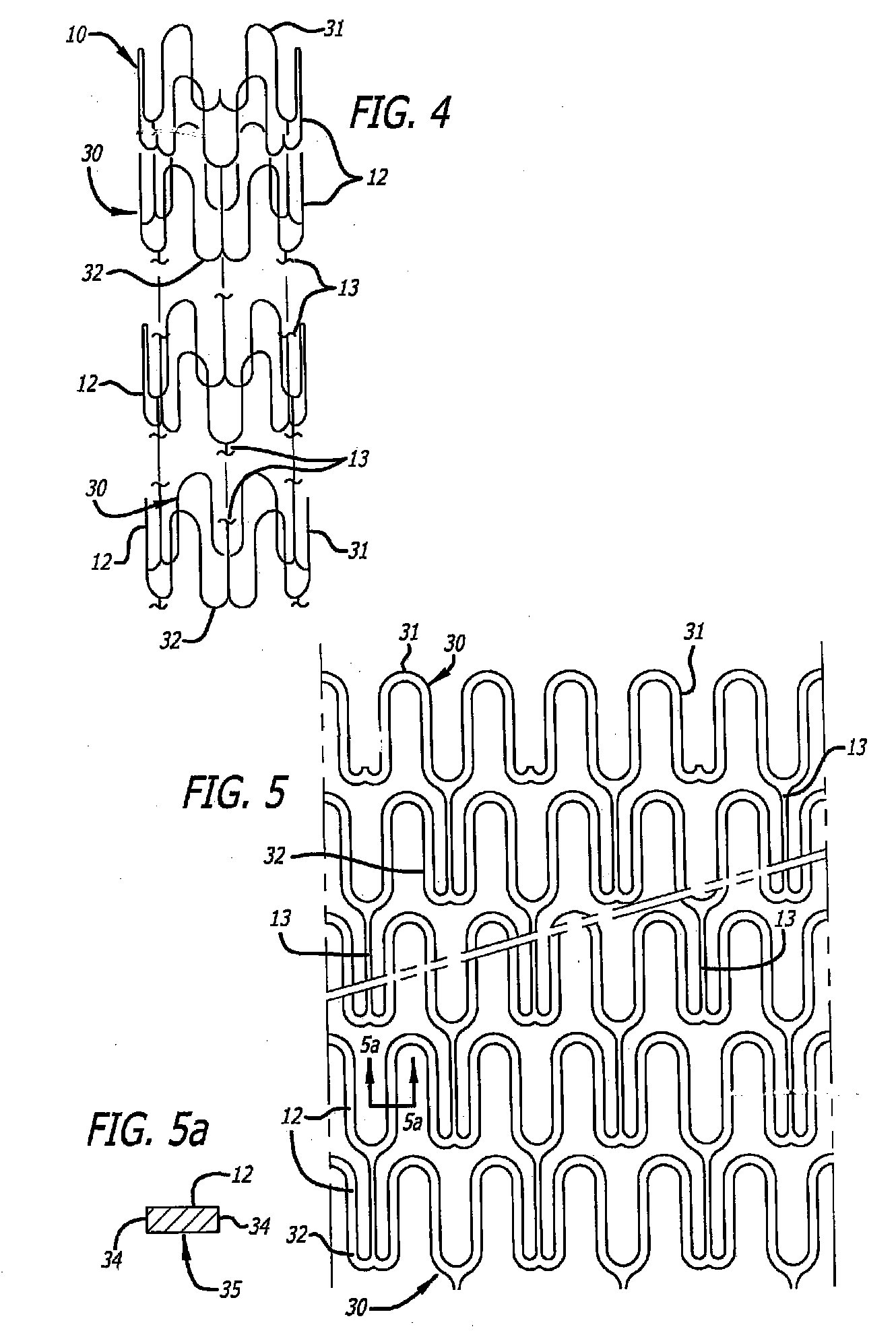

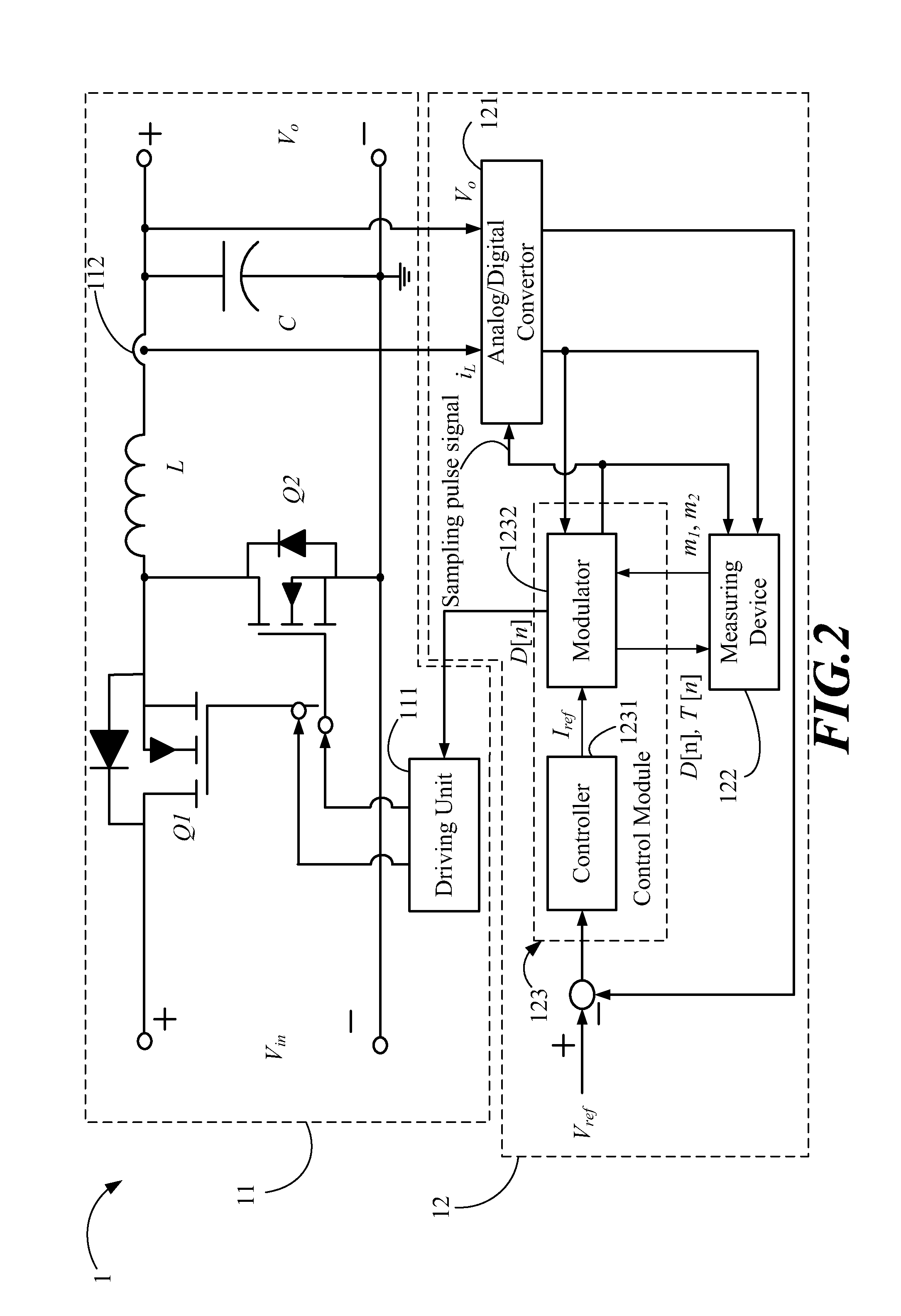

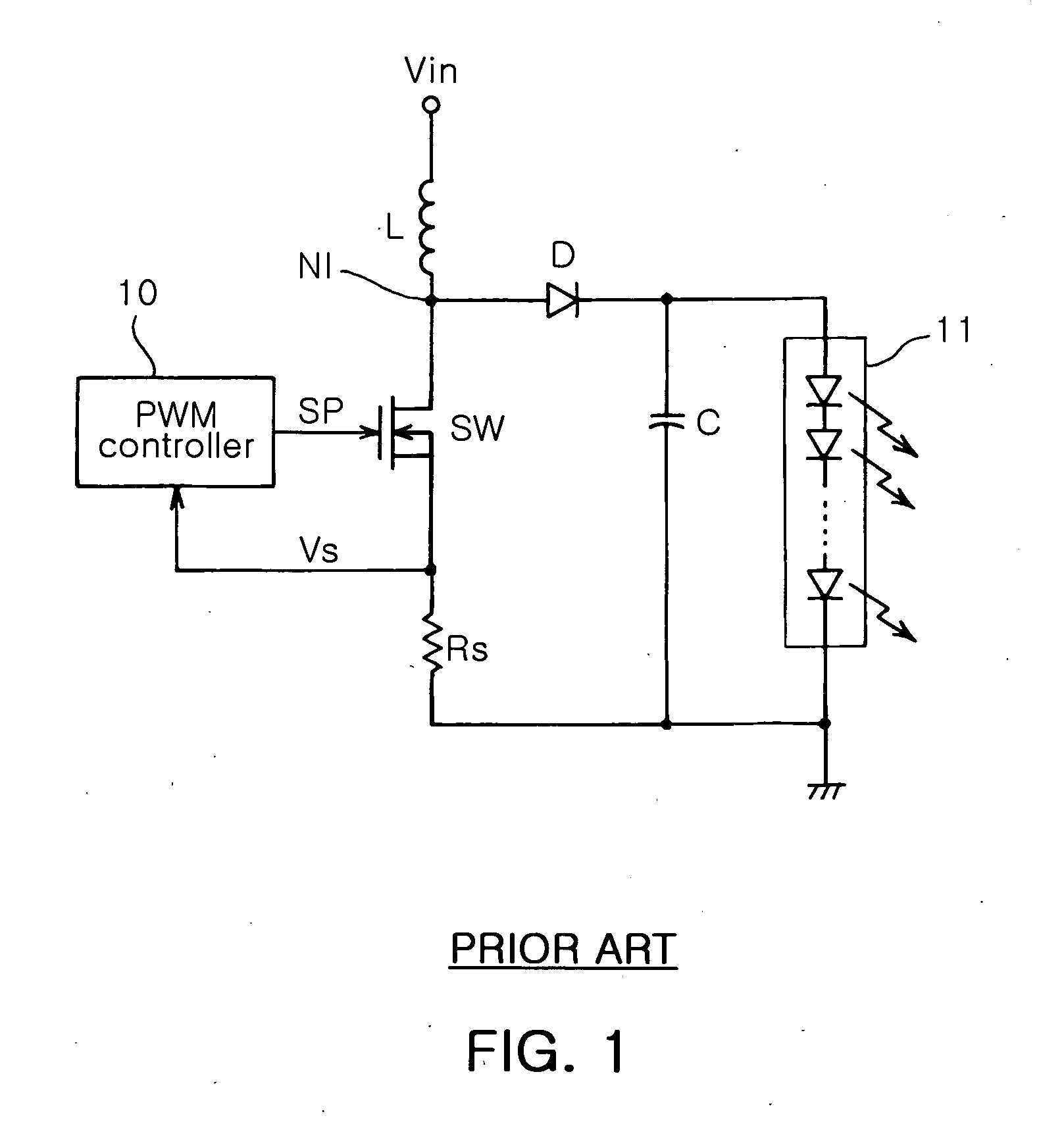

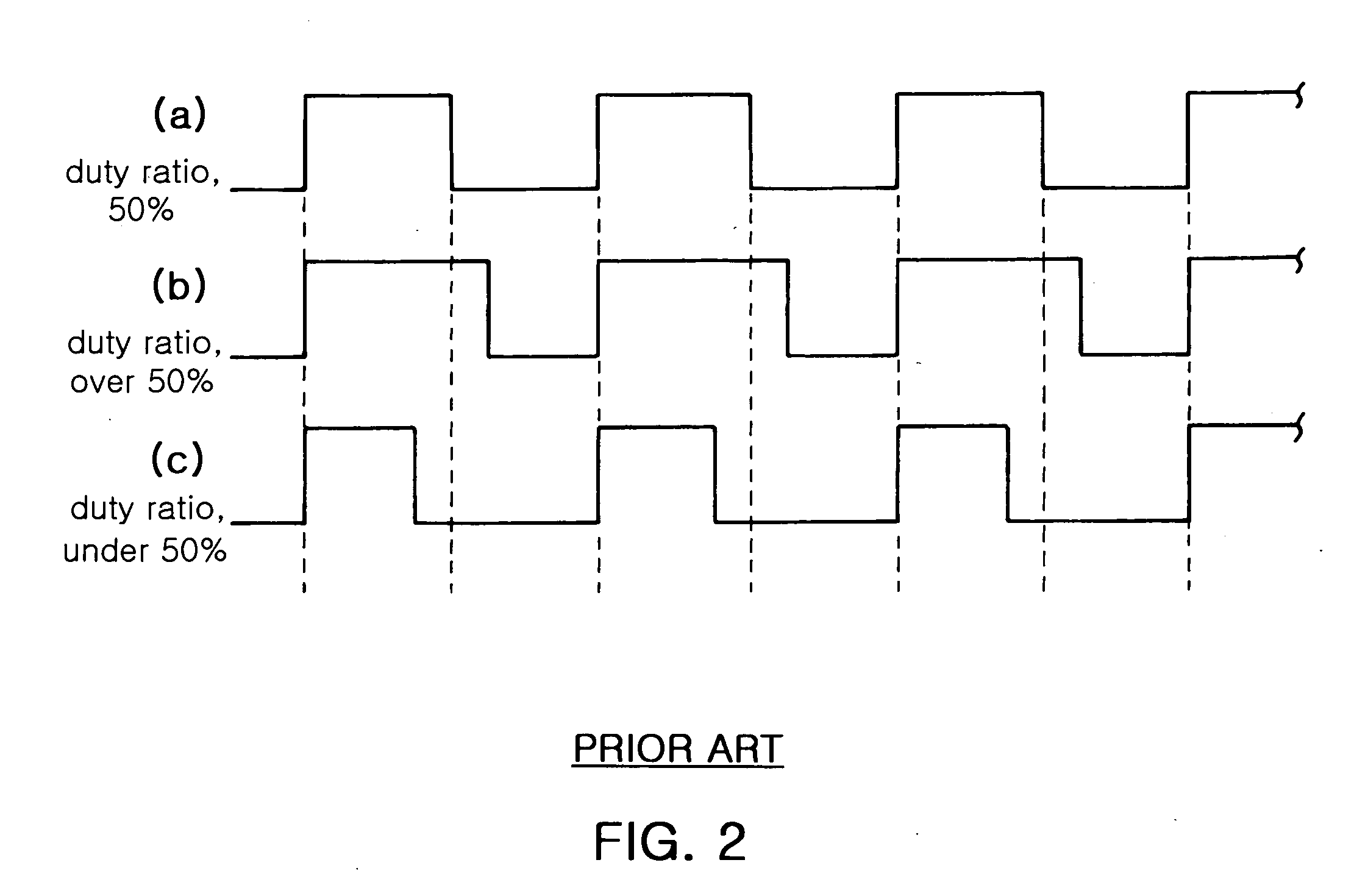

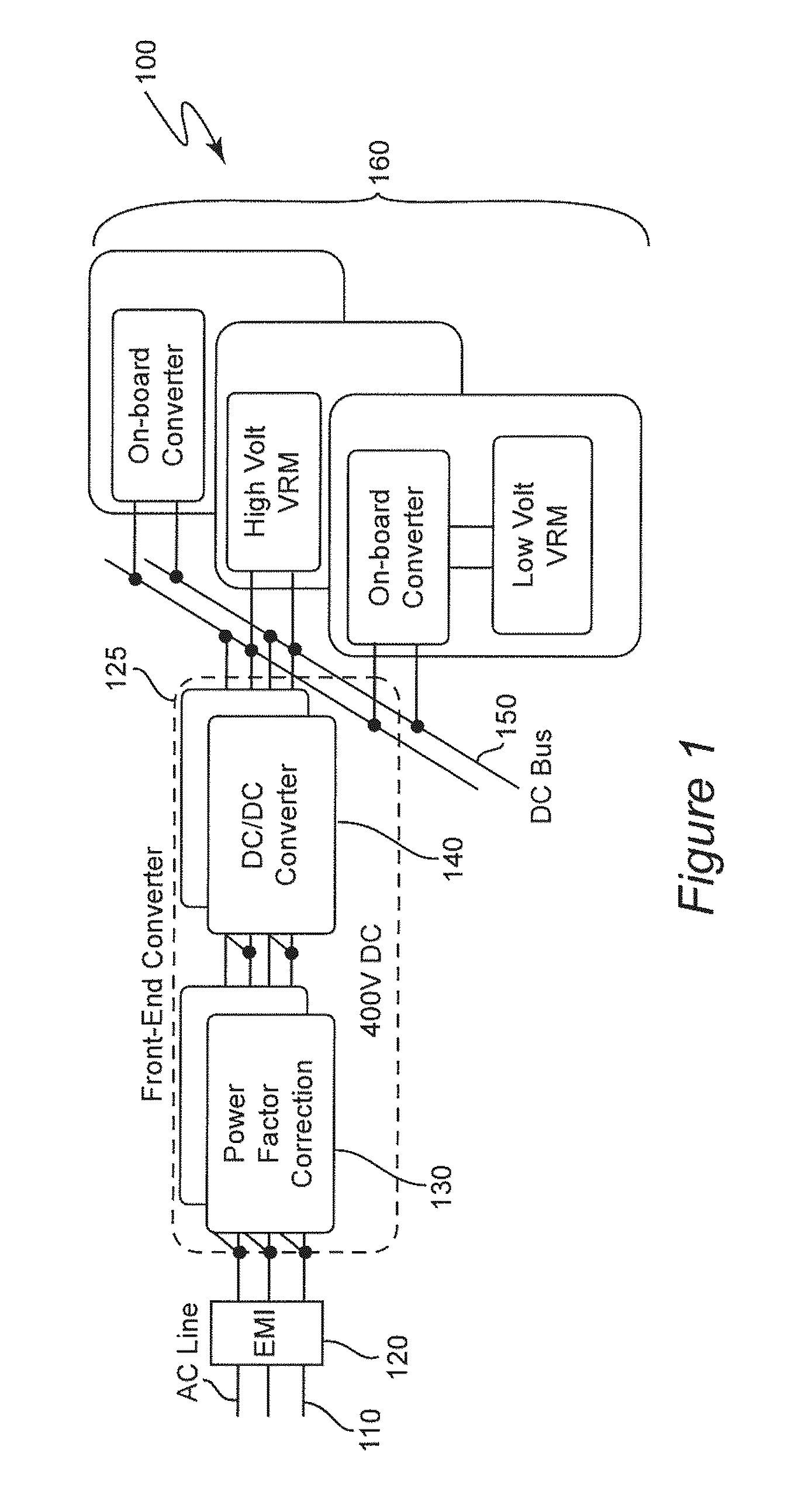

Driving control device and method for power converting system

ActiveUS8080986B2Reduce the sampling frequencyEfficient power electronics conversionDc-dc conversionPulse controlInductor

Owner:NAT TAIPEI UNIV OF TECH

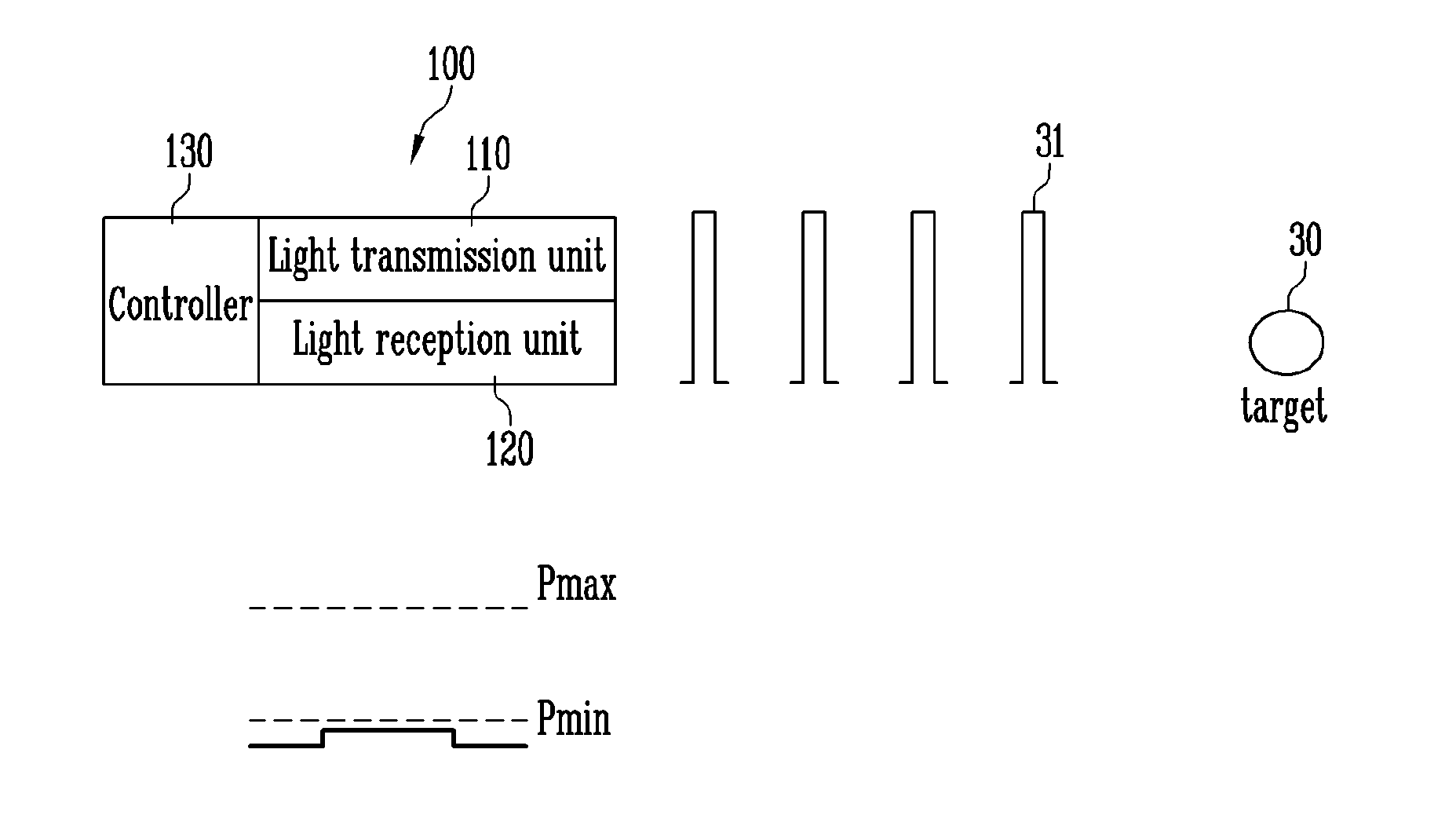

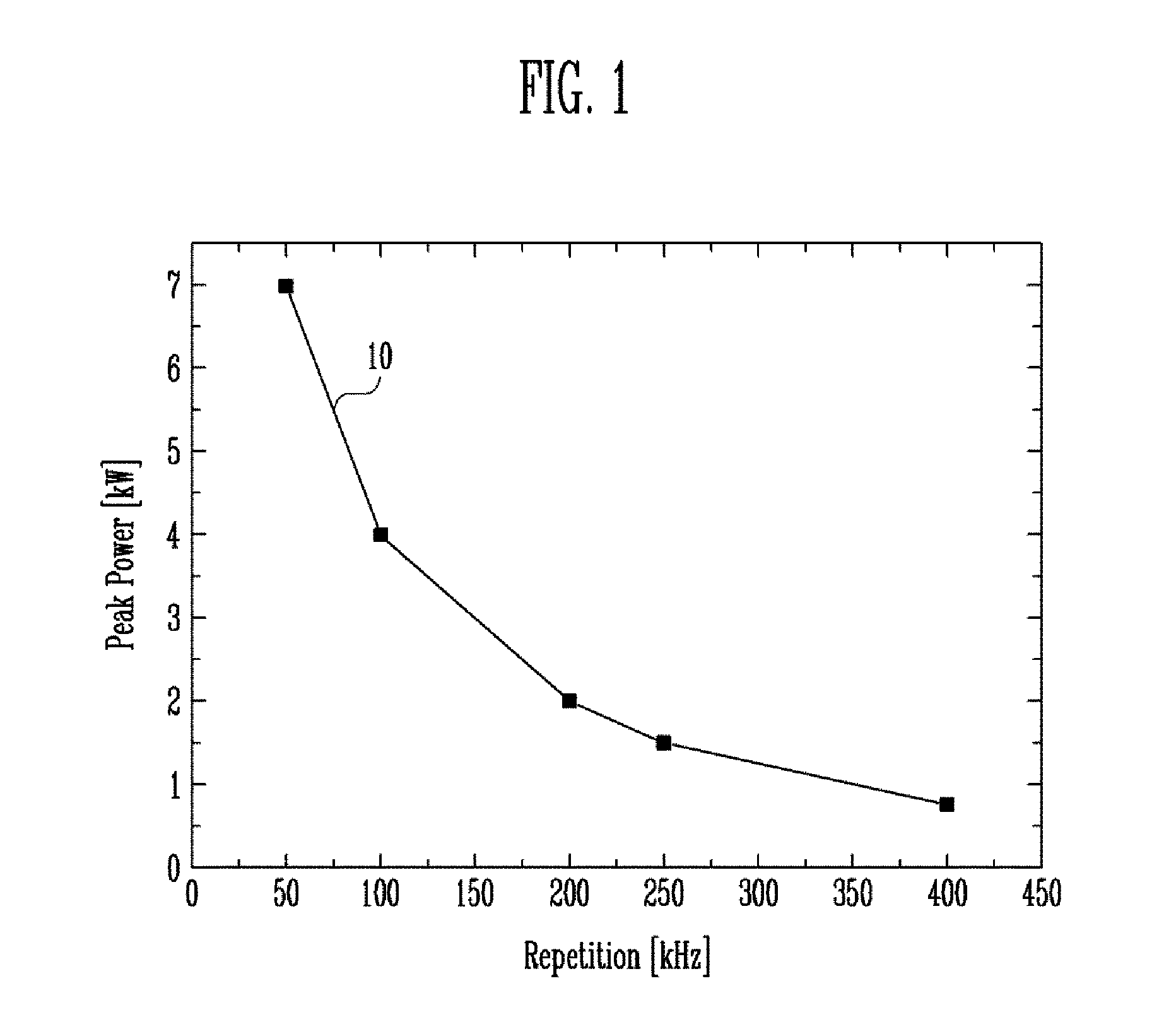

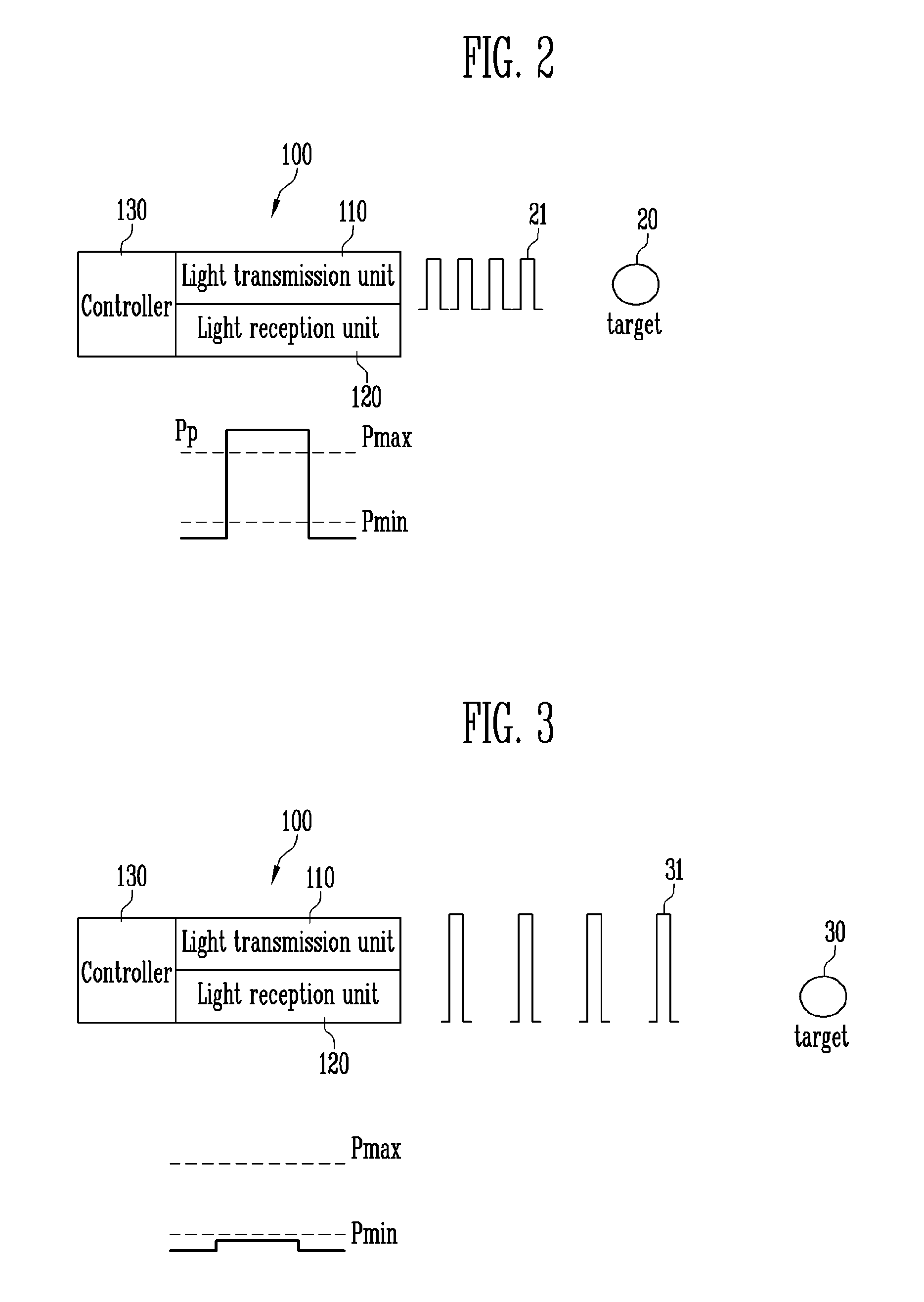

Laser radar apparatus and method of acquiring image thereof

ActiveUS20150226853A1Easy to useOptical rangefindersElectromagnetic wave reradiationPulse controlRadiation angle

Disclosed is a laser radar apparatus. The laser radar apparatus includes: a light transmission unit configured to output a laser pulse by using a light source; a light reception unit configured to receive a reflected laser pulse in connection with the laser pulse; and a controller configured to adjust a repetition rate of the laser pulse of the light source, in which the controller adjusts the repetition rate of the laser pulse based on at least one of reception power, a target distance, a movement speed, a vertical angle, and a radiation angle.

Owner:ELECTRONICS & TELECOMM RES INST

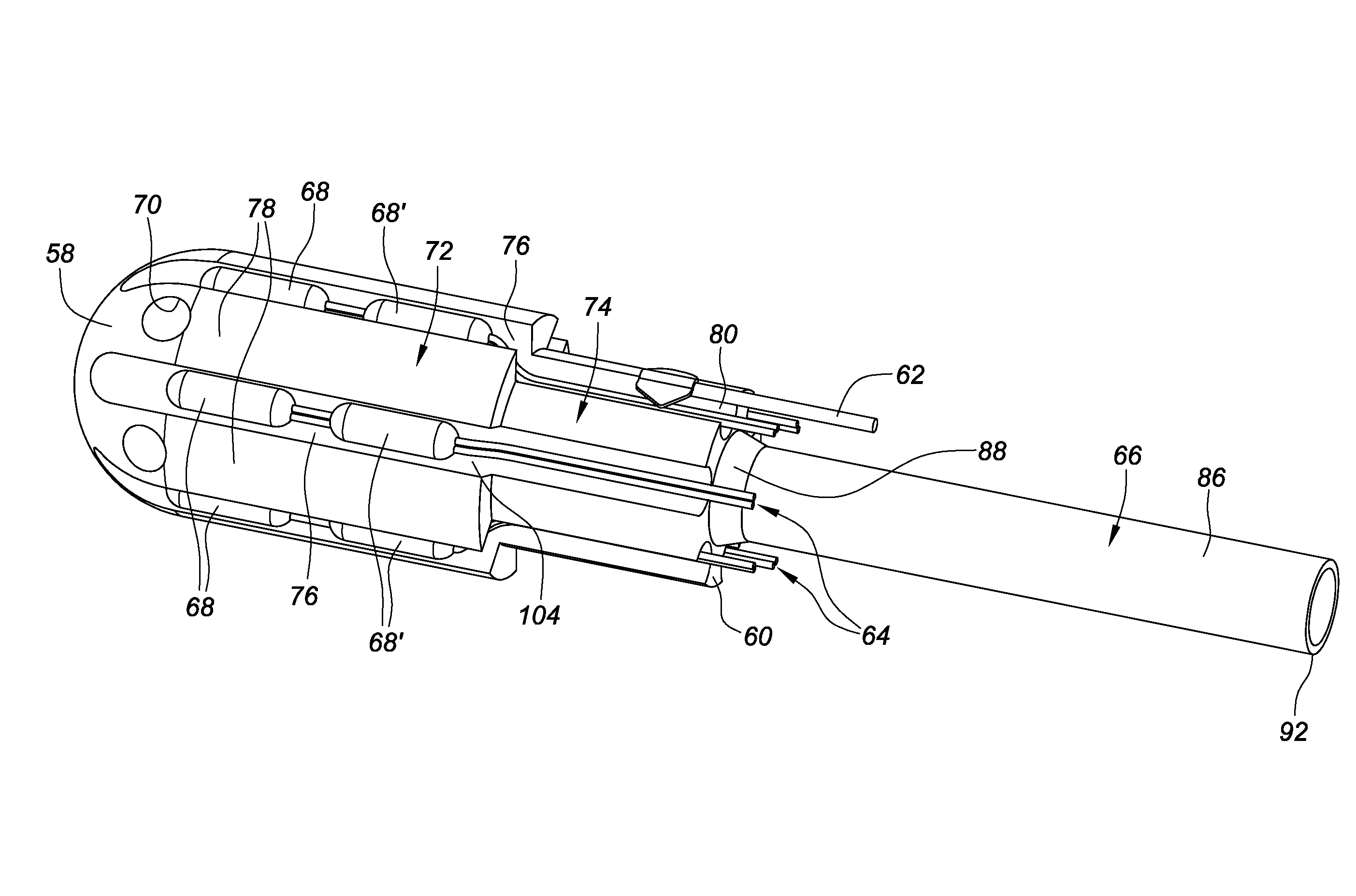

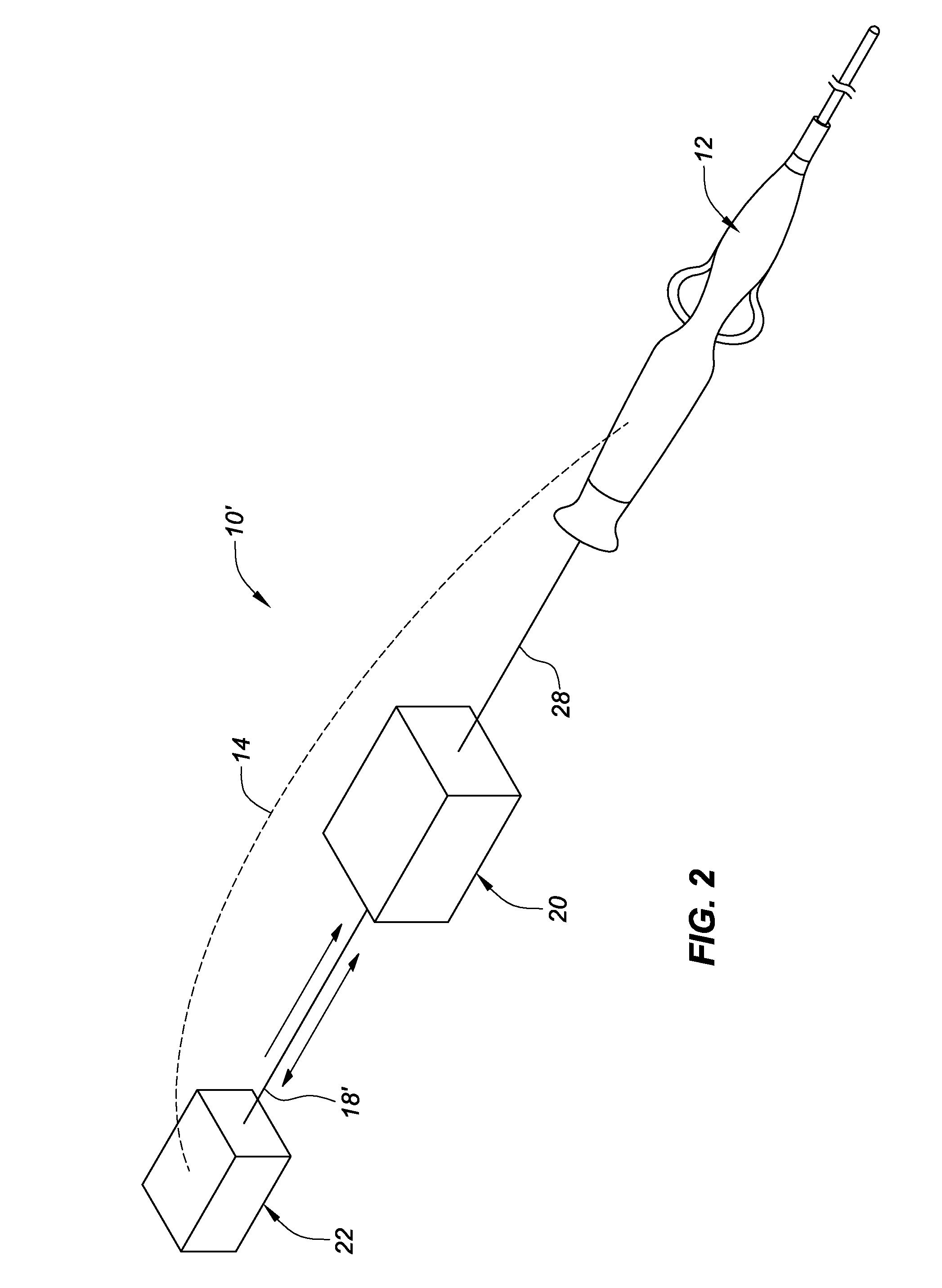

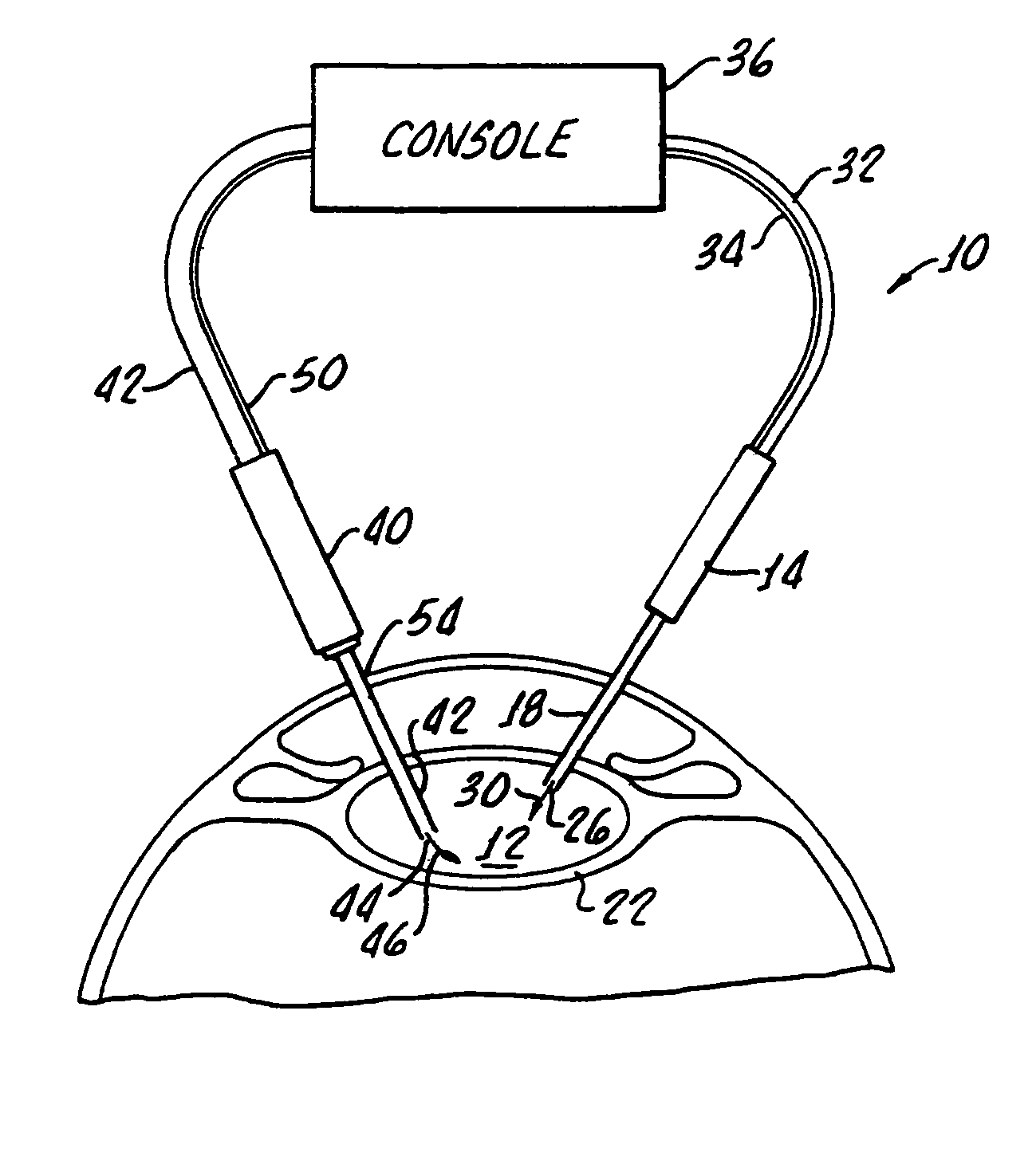

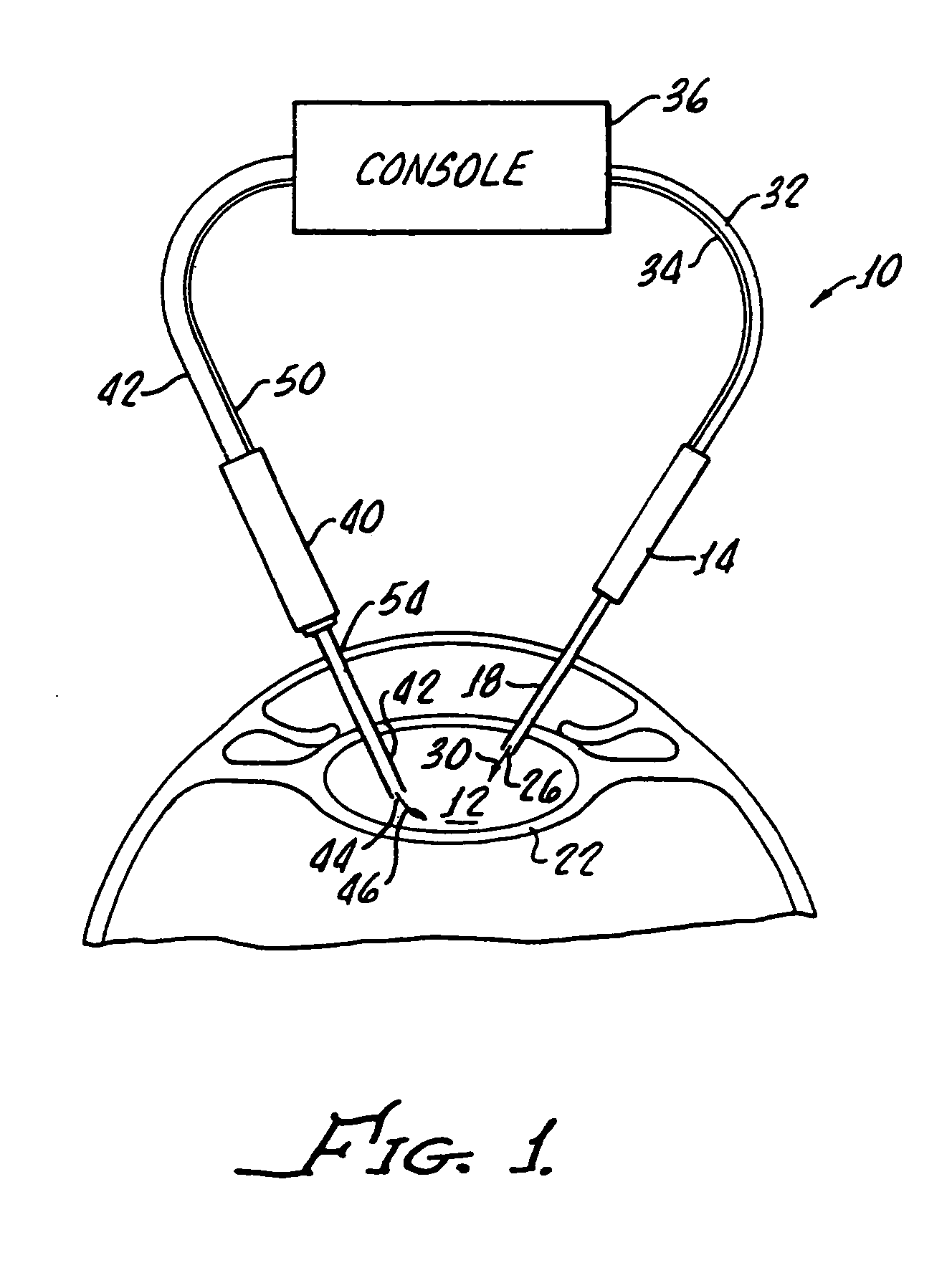

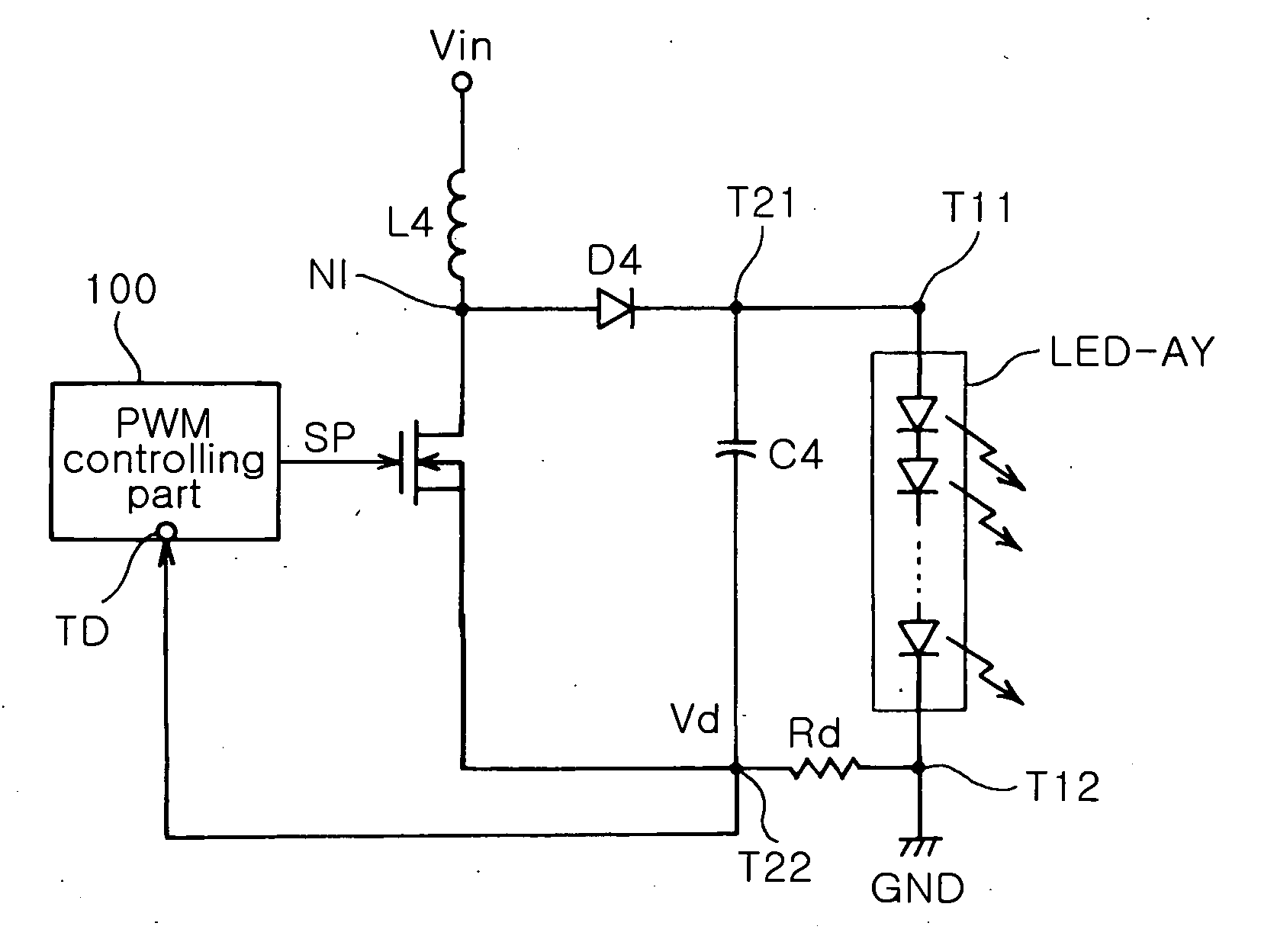

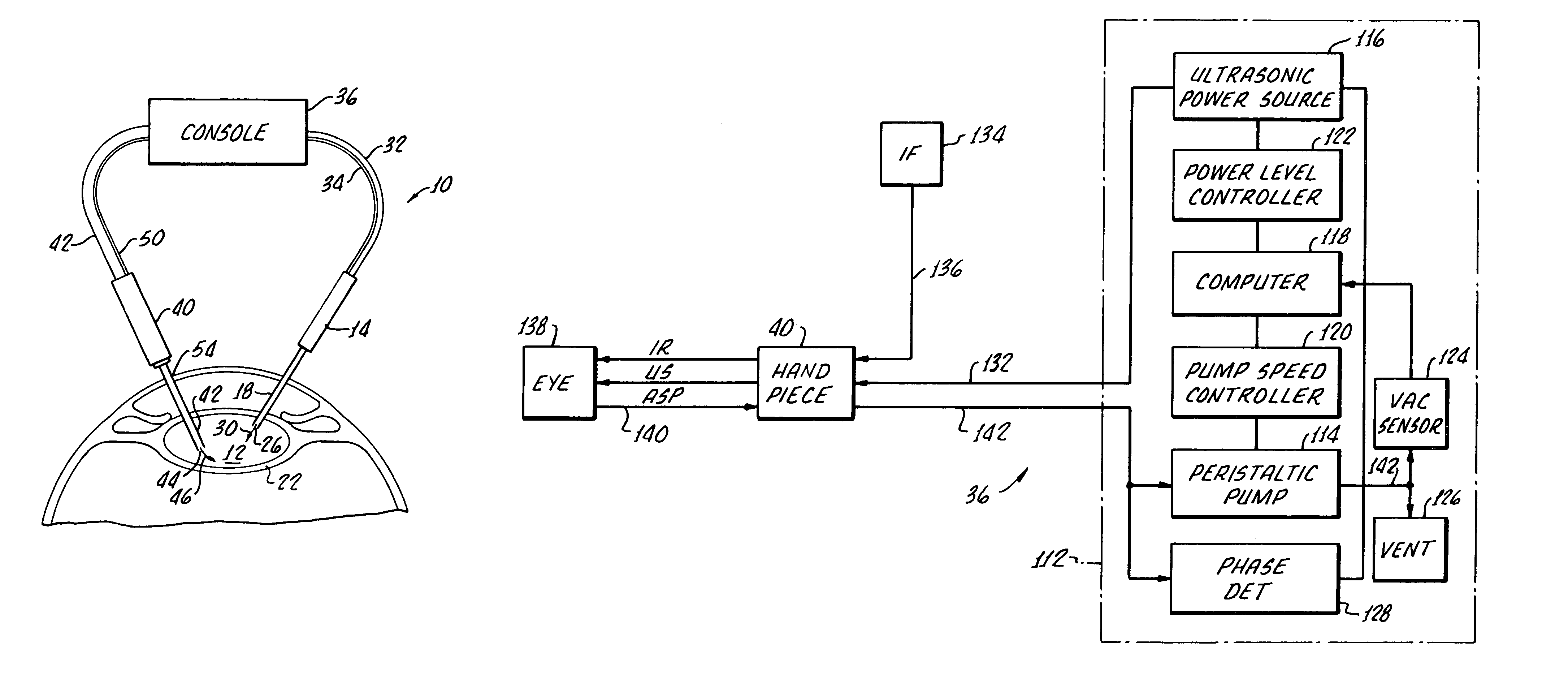

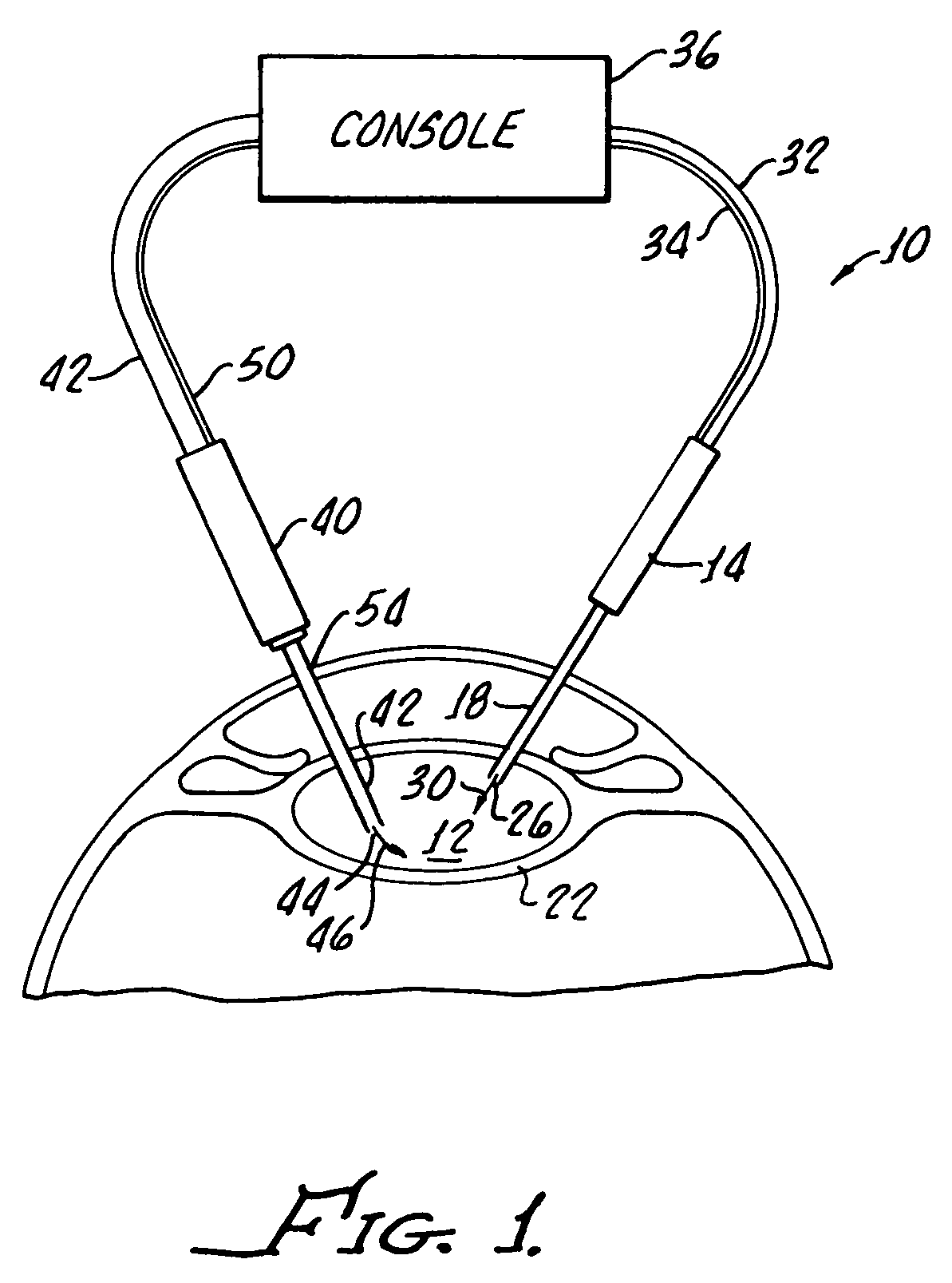

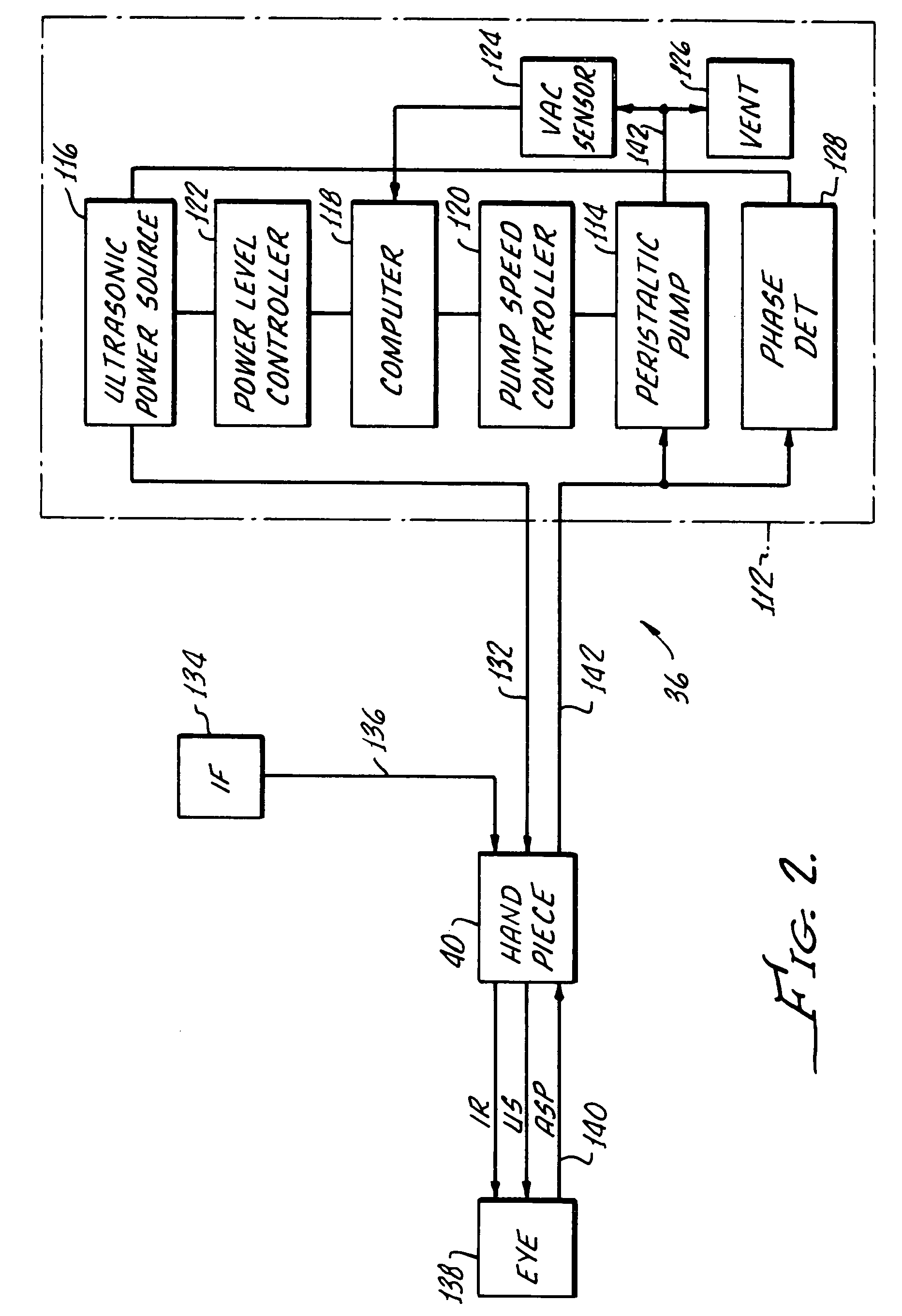

Cataract extraction apparatus and method with rapid pulse phaco power

InactiveUS7182759B2Prevent crashAvoid heat damageLaser surgerySurgical instrument detailsPulse controlLens crystalline

Apparatus for the removal of lens tissue includes a first handpiece having a laser emitting probe sized for insertion into a lens capsule and radiating a lens therein. The laser emitting probe includes a lumen for introducing irrigation fluid into the lens capsule. A second handpiece includes a pulsed controlled vibrated needle for insertion into the lens capsule and emulsifying laser eradiated lens tissue. The vibrated needle includes a lumen therethrough for aspiration of emulsified lens tissue and irrigation fluid.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

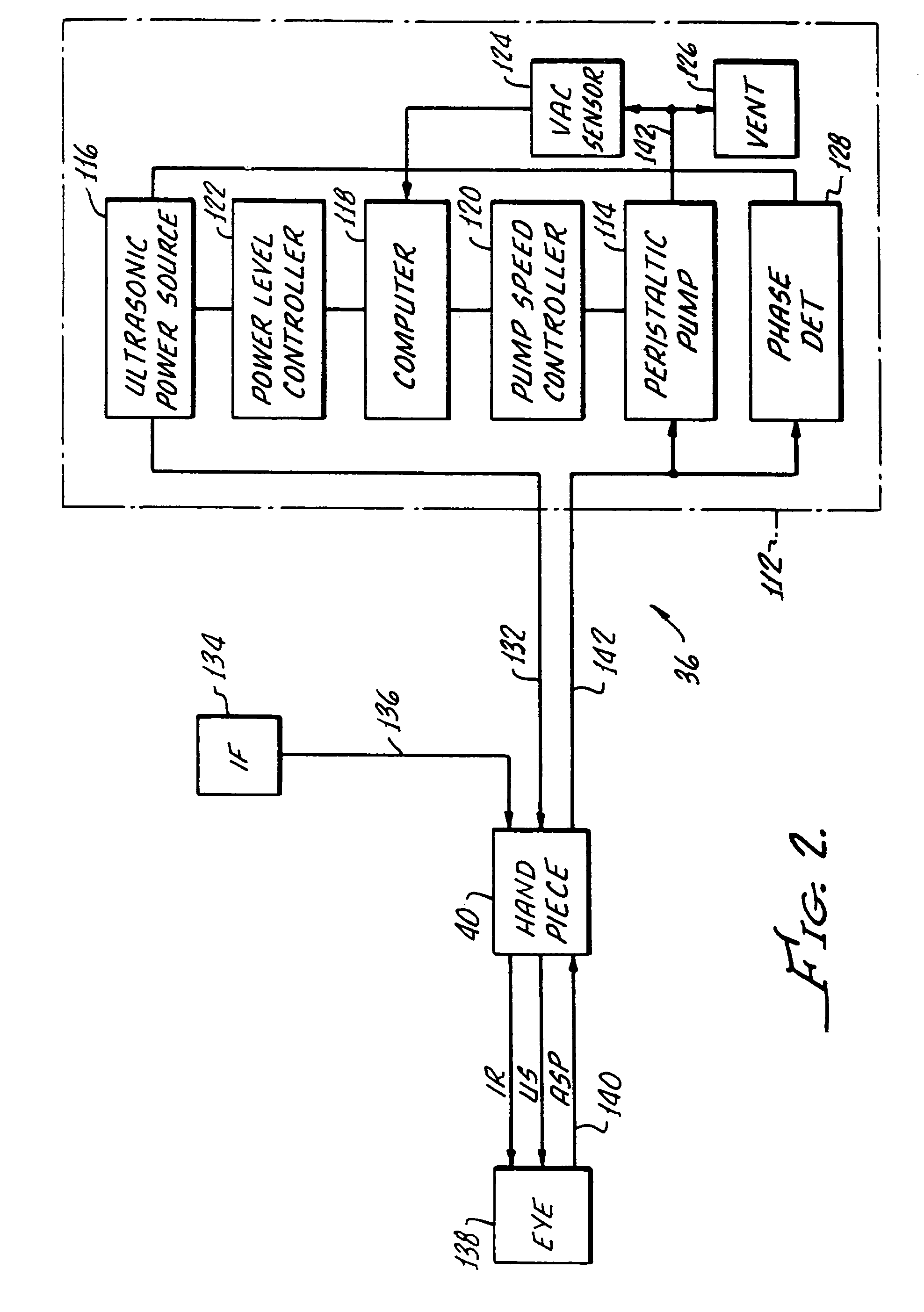

Light emitting diode driving circuit for backlight having constant current control function

ActiveUS20070001625A1Improvement in driving current detectionIncrease currentStatic indicating devicesElectroluminescent light sourcesVoltage referenceVoltage control

An LED driving circuit of a backlight unit includes a switch connected between an input of direct voltage and a ground to switch the direct voltage according to a switching pulse; a rectifying diode connected between a connecting node and one terminal of the LED array to rectify driving voltage supplied according to switching operation of the switch; a smoothing capacitor having one terminal connected to a cathode of the rectifying diode and the other terminal connected to a ground; a voltage detecting resistor connected between the other terminal of the LED array connected to the ground and the other end of the smoothing capacitor to detect voltage from the current flowing to the ground; and a PWM controlling part for controlling on / off status of the switching according to the switching pulse, wherein the switching pulse has a duty ratio determined according to a preset internal reference voltage and the voltage detected by the voltage detecting resistor. The driving current of can be controlled at a constant current and thus be stabilized.

Owner:SAMSUNG ELECTRONICS CO LTD

Cataract extraction apparatus and method with rapid pulse phaco power

InactiveUS6962583B2Prevent crashAvoid heat damageLaser surgerySurgical instrument detailsPulse controlLens crystalline

Apparatus and method for the removal of lens tissue includes a first handpiece having a laser emitting probe sized for insertion into a lens capsule and radiating a lens therein. The laser emitting probe includes a lumen for introducing irrigation fluid into the lens capsule. A second handpiece includes a pulsed controlled vibrated needle for insertion into the lens capsule and emulsifying laser eradiated lens tissue. The vibrated needle includes a lumen therethrough for aspiration of emulsified lens tissue and irrigation fluid.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

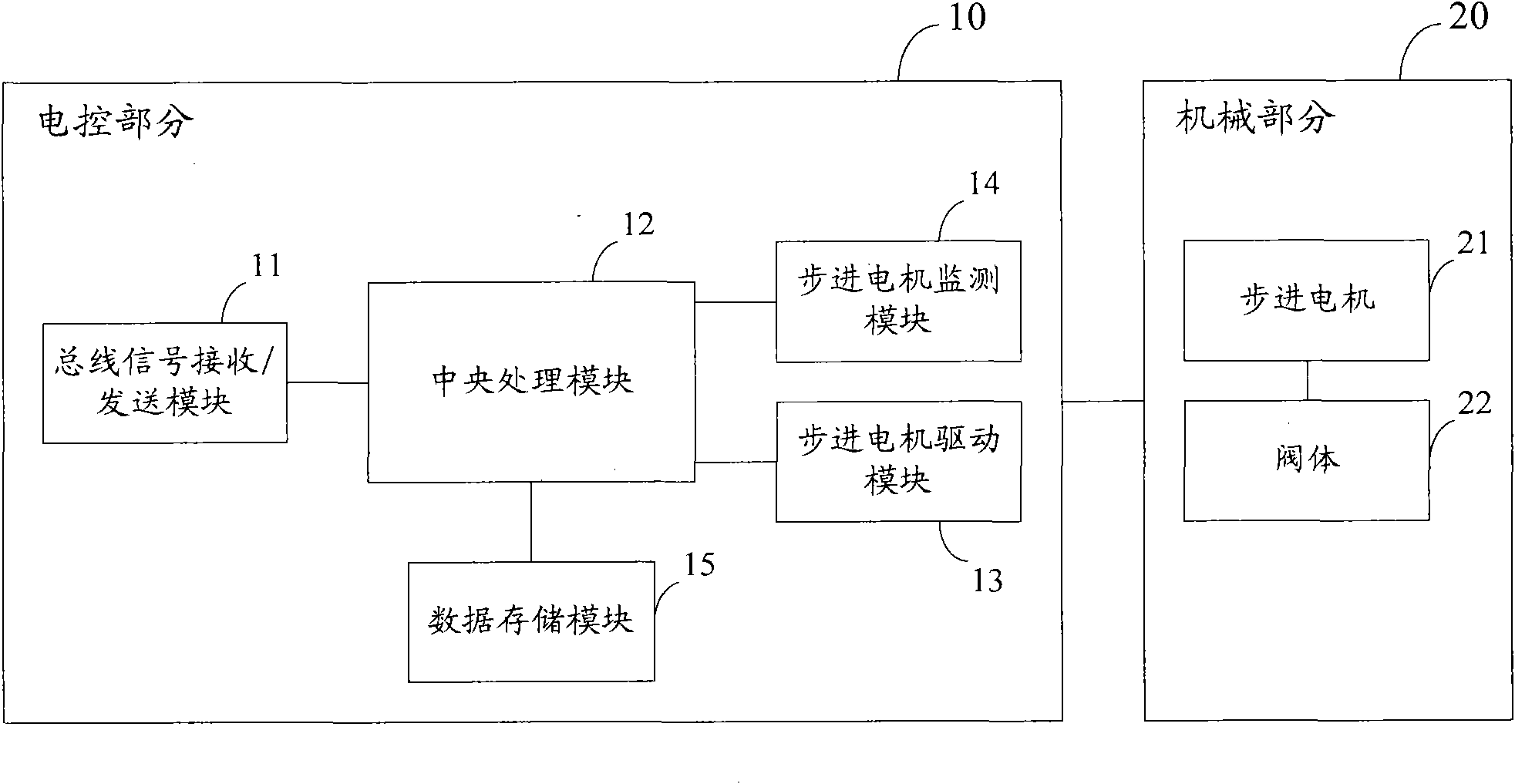

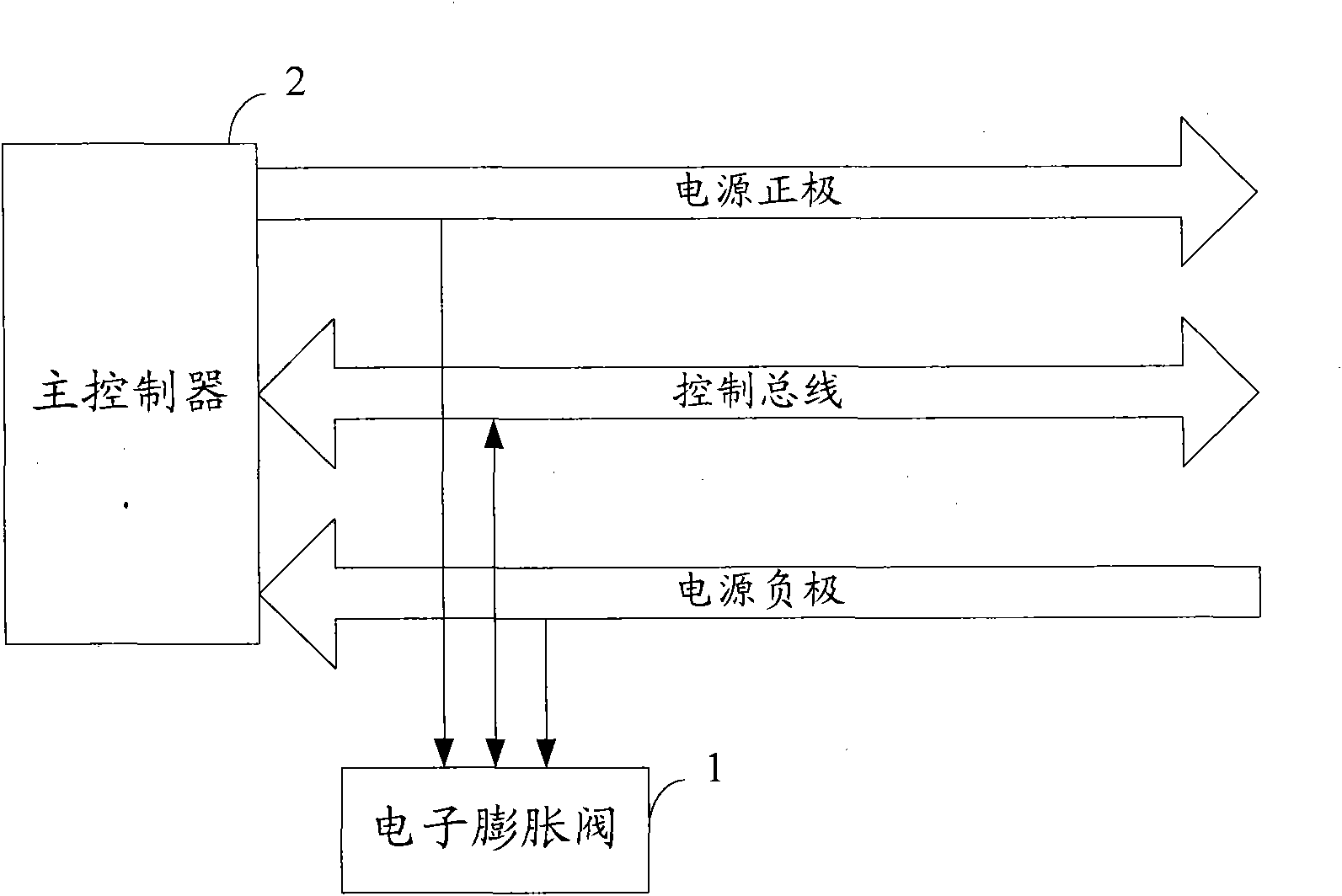

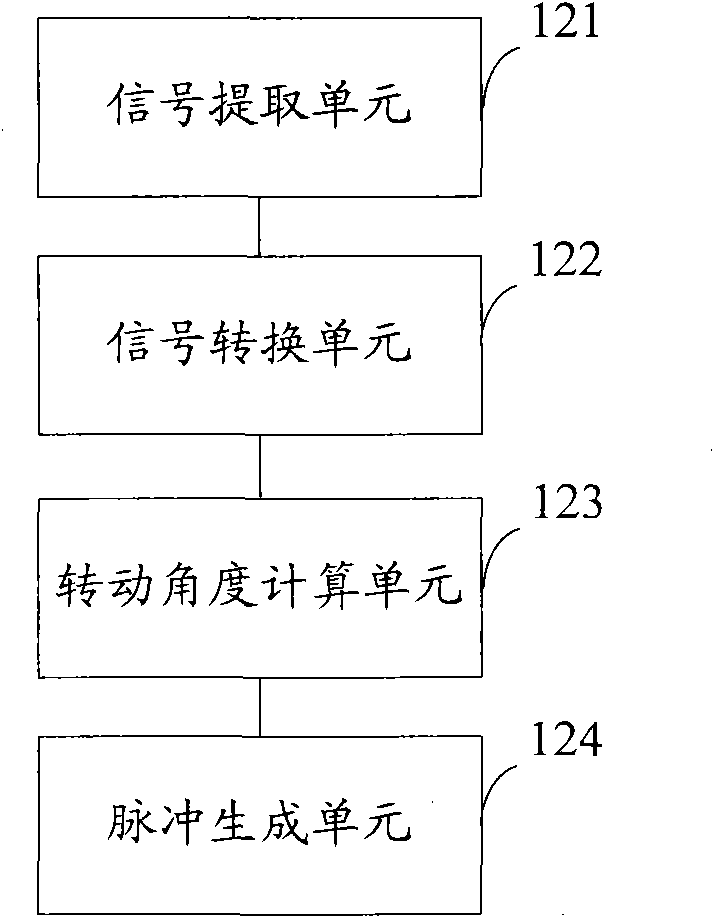

Electronic expansion valve, stepper motor and reversing valve

ActiveCN102374328AReduce in quantitySimple structureOperating means/releasing devices for valvesDynamo-electric converter controlPulse controlControl signal

The invention discloses an electronic expansion valve, which comprises an electrical control part and a mechanical part. The electrical control part comprises a bus signal reception / transmission module, a central processing module and a stepper motor driving module; wherein the bus signal reception / transmission module is used for receiving a bus control signal and transmitting the bus control signal to the central processing module; the central processing module is used for extracting valve opening information included in the bus control signal, generating a corresponding pulse control signalin combination with current position information of a stepper motor read from a data storage module, and outputting the pulse control signal to the stepper motor driving module; and the stepper motordriving module is used for driving the stepper motor to adjust the valve opening according to the pulse control signal. The invention also discloses a stepper motor and a reversing valve. The number of drive wires directly connected with a main control board can be reduced, the structure of the main control board can be simplified, and the manufacturing cost can be saved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

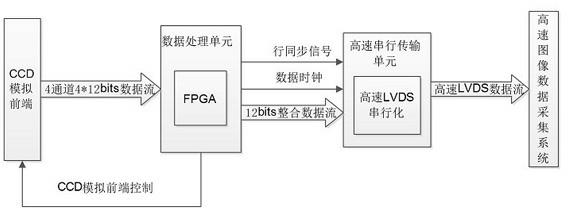

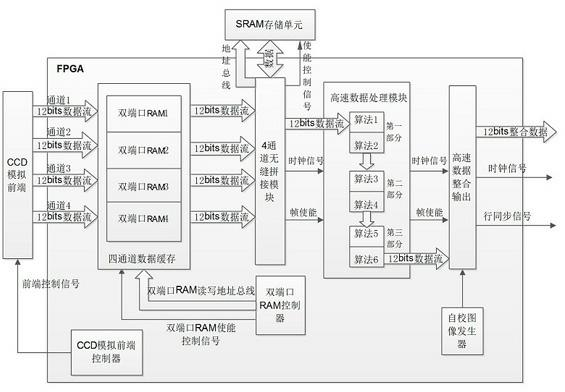

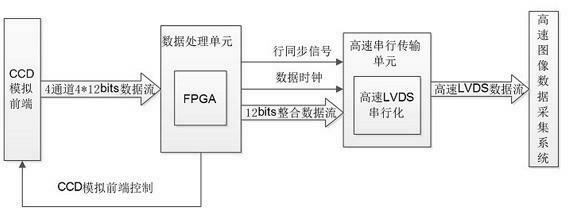

Data processing and transmitting system of high-speed multichannel CCD (charge-coupled device)

InactiveCN102638661AReal-time processingReduce in quantityTelevision system detailsPulse modulation television signal transmissionSerial transferData stream

The invention discloses a data processing and transmitting system of high-speed multichannel CCD (charge-coupled device), which comprises a CCD analog front end, a data processing unit, a high-speed serial transmission unit and a high-speed image data collection system which are sequentially connected. The CCD analog front end is used for converting an analog signal output by a CCD detector and subjected to sampling and pulse control into n channels of digital image data via n A / D (analog / digital) converters, transmitting the digital image data to the data processing unit, and acquiring data of each channel at the same time. The data processing unit is used for transmitting single-channel high-speed data streams, a data transmitter clock and a horizontal synchronizing signal acquired from integration of the digital image data to the high-speed serial transmission unit. The high-speed serial transmission unit is used for converting single-channel high-speed data streams via LVDS (low-voltage differential signaling) serial chips into high-speed LVDS data streams for transmitting. The high-speed image data collection system is used for collecting the high-speed serial LVDS data streams and realizing real-time storing and displaying of the image data.

Owner:NANJING UNIV OF SCI & TECH

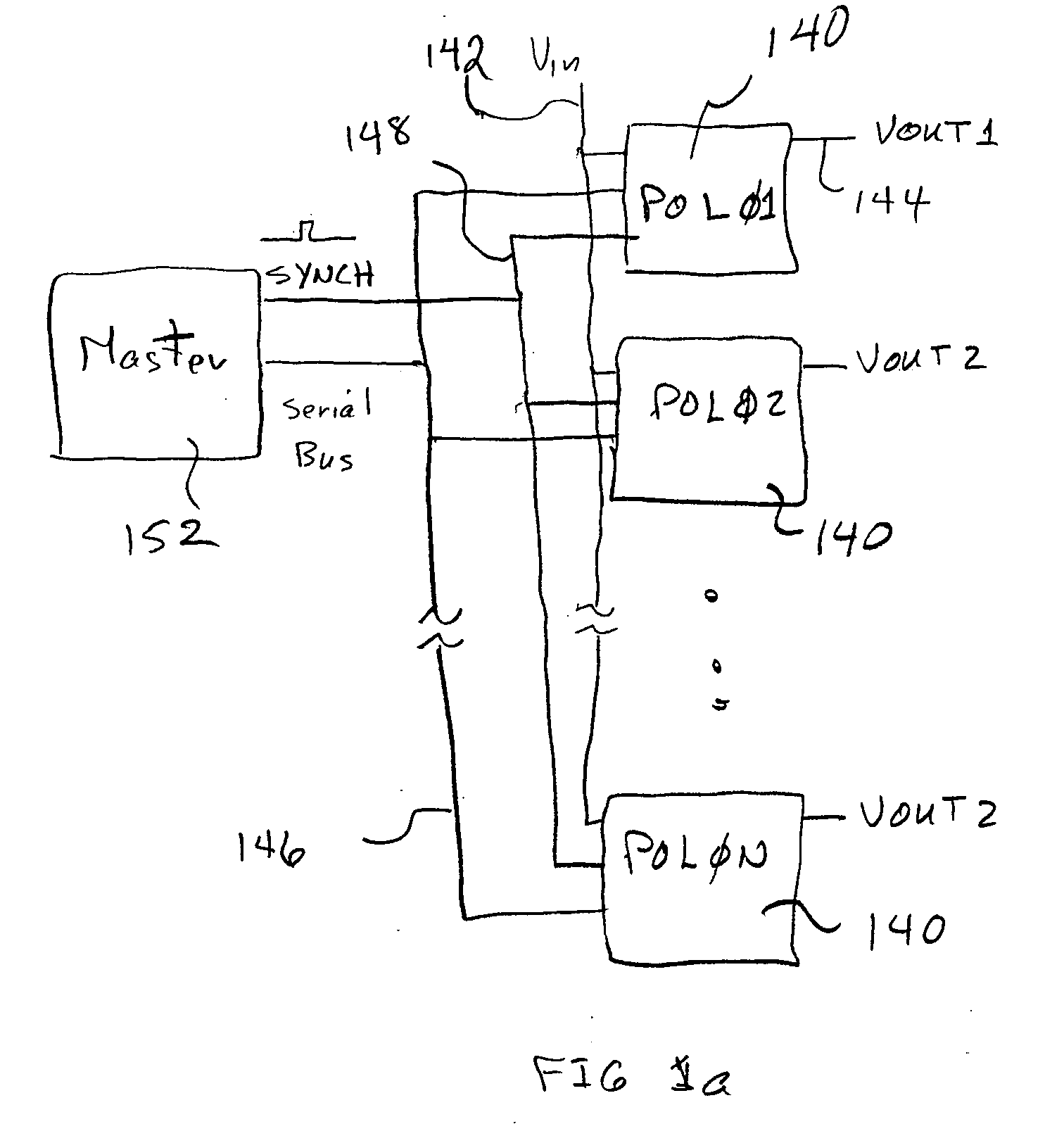

Digital DC/DC converter with SYNC control

InactiveUS20060172783A1Analogue/digital conversionDc-dc conversionCommunication interfaceTime information

A power converter is disclosed for receiving an input voltage and converting it to a DC output voltage at a different voltage level than the input voltage. It includes a switching power converter for receiving the input voltage on an input and converting the input voltage to an output as the DC output voltage in response to pulse control signals. A switching controller is provided for generating the pulse control signals during a switching cycle and a processor controls the switching controller to define the length and initiation of the switching cycle. A communication interface interfaces with a first data communication bus for receiving data therefrom and with a second communication bus for receiving timing information therefrom. The processor and the switching controller operate in either a first operating mode to control the switching controller and the generation of the pulse control signals independent of timing information, or in a second operating mode to control the timing of the generation of the pulse control signals generated by the switching controller in response to timing information received from the communication bus.

Owner:SILICON LAB INC

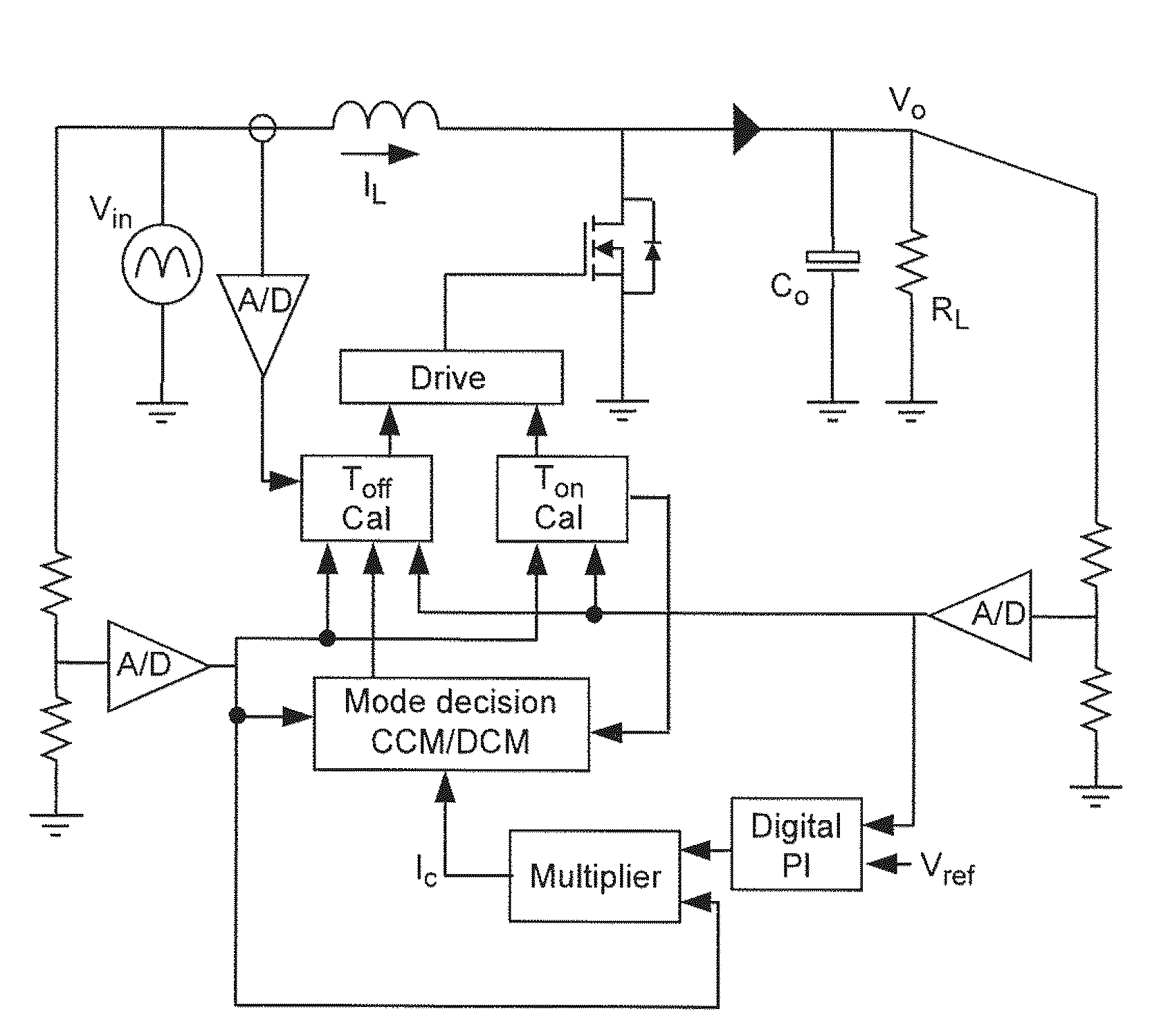

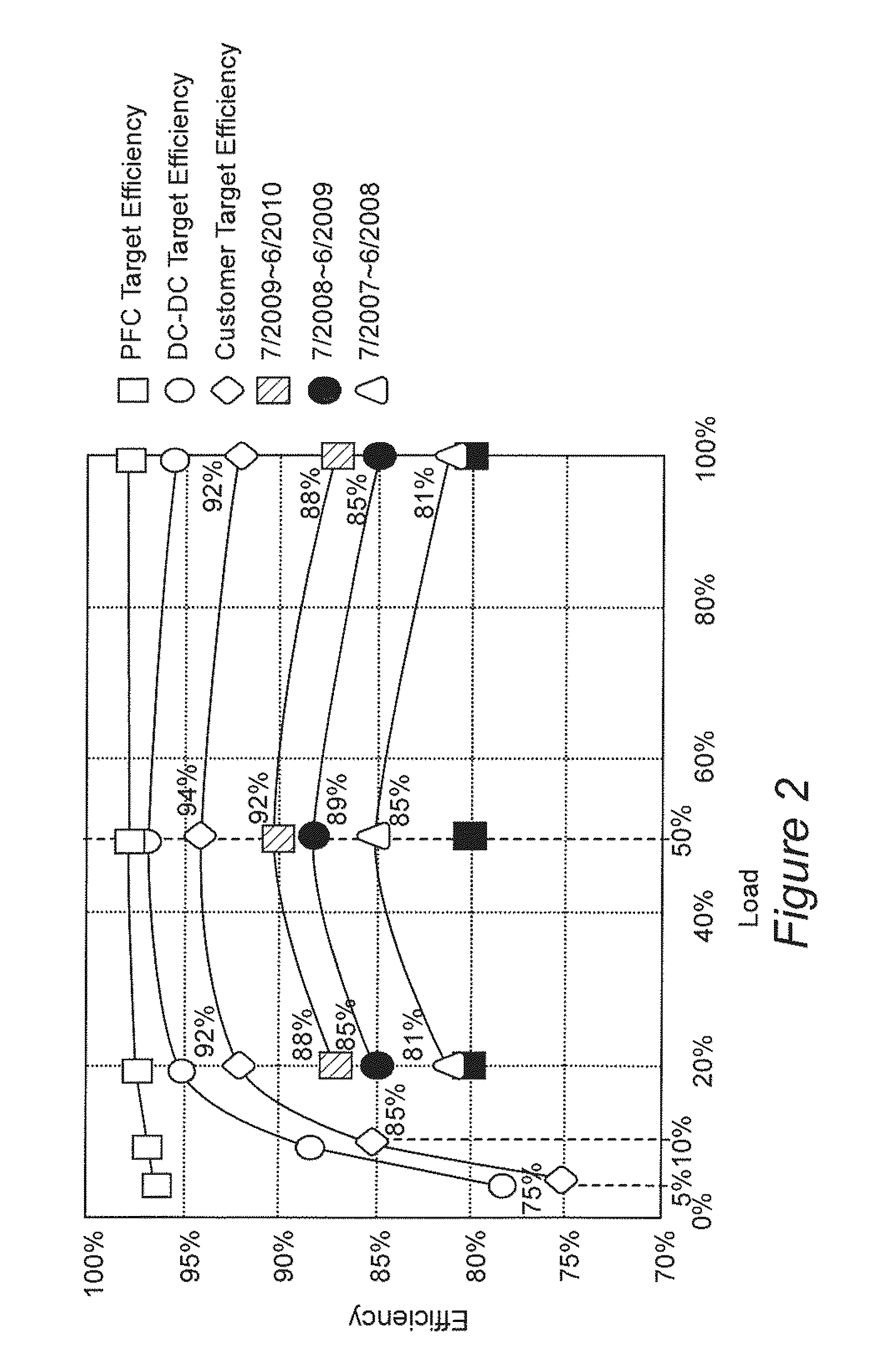

Adaptive on-time control for power factor correction stage light load efficiency

ActiveUS20120014148A1Total current dropImprove efficiencyEfficient power electronics conversionDc-dc conversionHigher order harmonicsSwitching frequency

Light load efficiency of a power factor correction circuit is improved by adaptive on-time control and providing for selection between a continuous conduction mode and a discontinuous conduction mode wherein the discontinuous conduction mode increases time between switching pulses controlling connection of a cyclically varying voltage to a filter / inductor that delivers a desired DC voltage and thus can greatly reduce the switching frequency at light loads where switching frequency related losses dominate efficiency. The mode for controlling switching is preferably selected for each switching pulse within a half cycle of the cyclically varying input voltage. A multi-phase embodiment allows cancellation of EMI noise at harmonics of the switching frequency and adaptive change of phase angle allows for cancellation of dominant higher order harmonics as switching frequency is reduced.

Owner:VIRGINIA TECH INTPROP INC

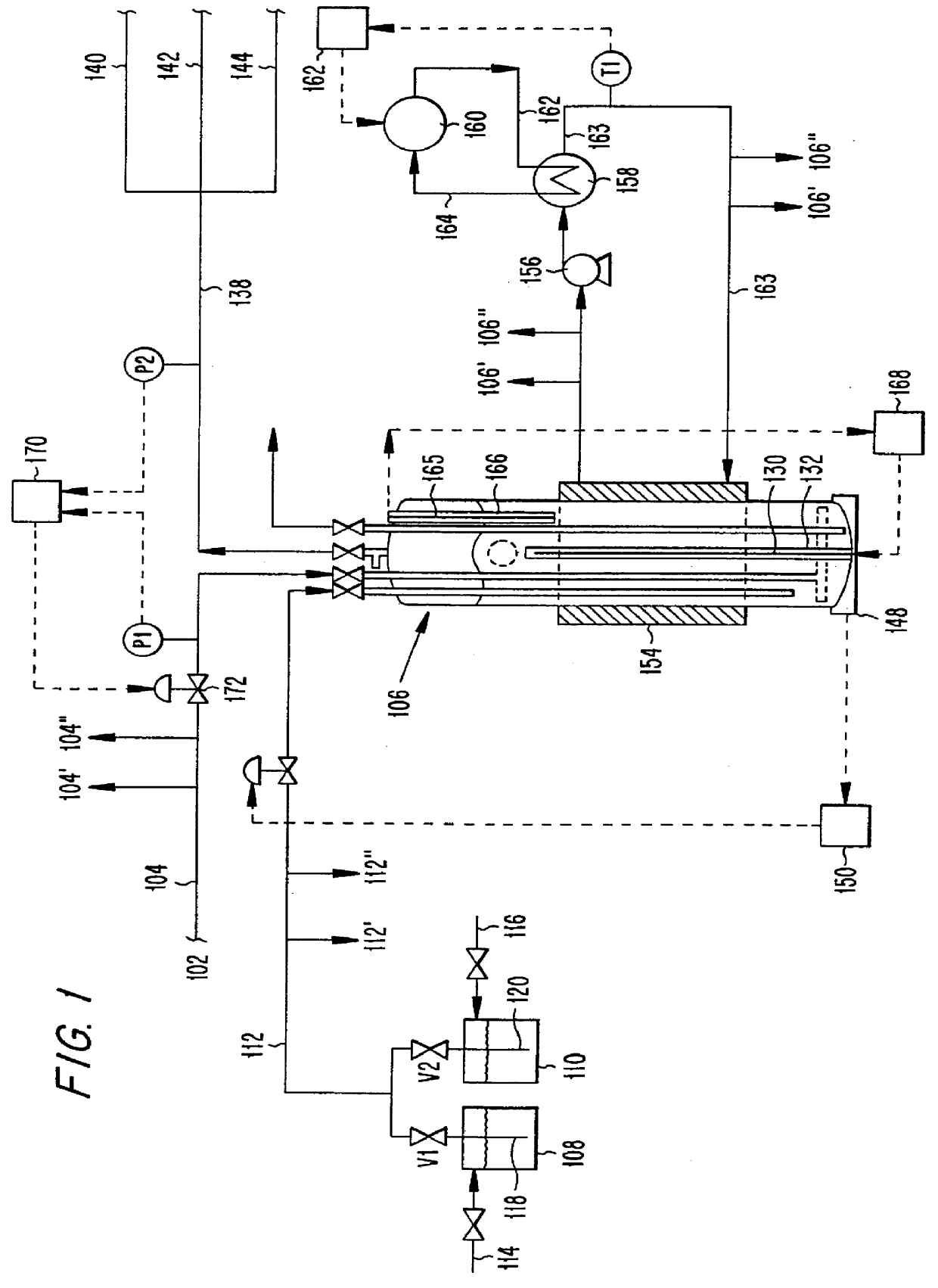

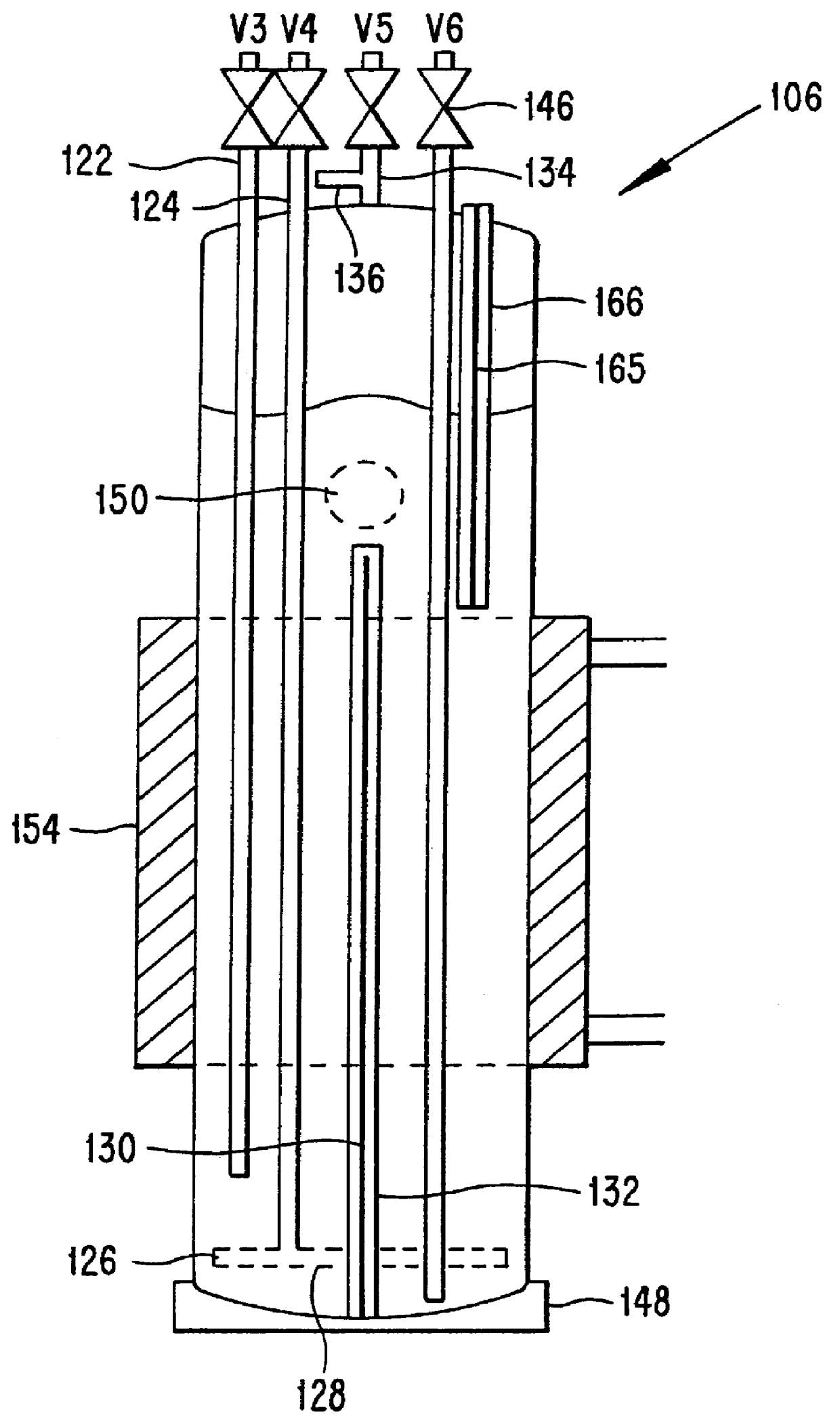

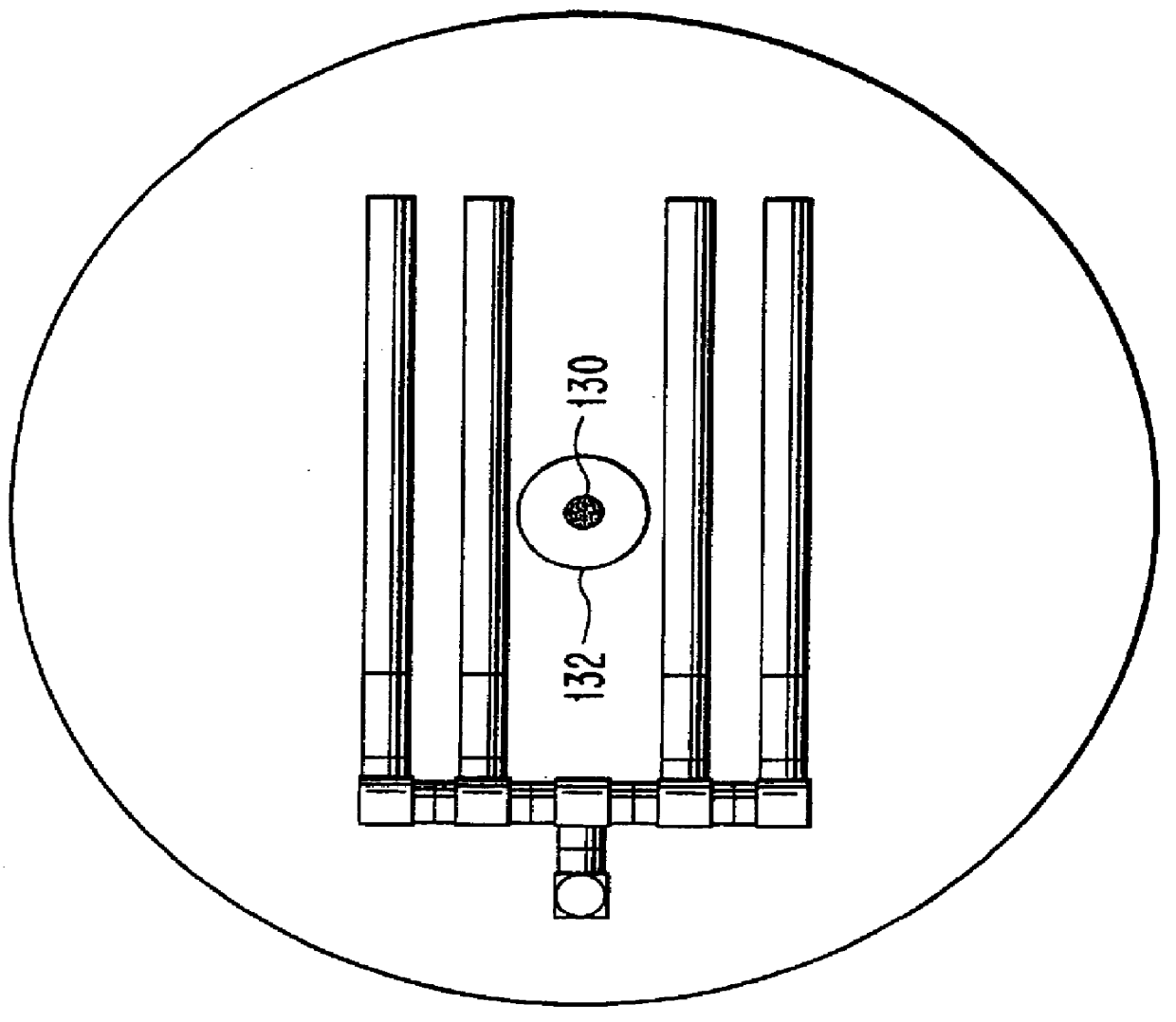

Continuous gas saturation system and method

Provided are a system and method for saturating a gas with a vapor from a liquid chemical. The system includes: (a) a saturation vessel connected to receive a liquid chemical and a carrier gas; (b) a gas sparger in the saturation vessel for sparging the carrier gas into the liquid chemical; (c) means for maintaining the liquid chemical in the saturation vessel at a substantially constant level; (d) means for controlling the temperature of the liquid chemical in the saturation vessel to a desired value, comprising (I) a system for cooling the liquid chemical, and (ii) a heater inside the saturation vessel extending vertically in the liquid a distance at least half of the height of the liquid chemical level for heating the liquid chemical; and (e) means for controlling the pressure of the saturated gas to a desired value. The invention also relates to novel methods and systems for controlled delivery of a vaporized liquid chemical. The invention has particular applicability to the semiconductor manufacturing industry.

Owner:AIR LIQUIDE AMERICA CORP

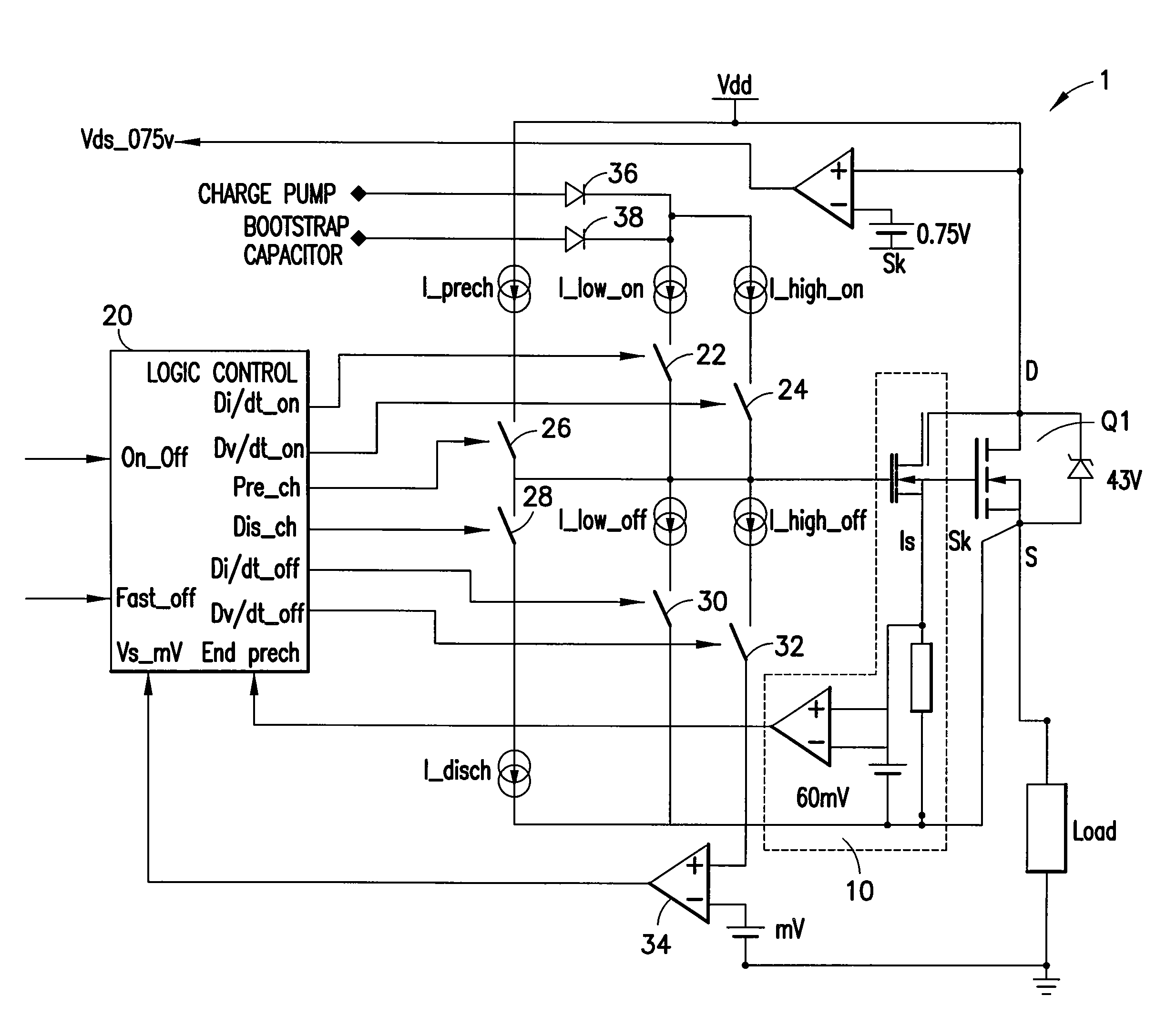

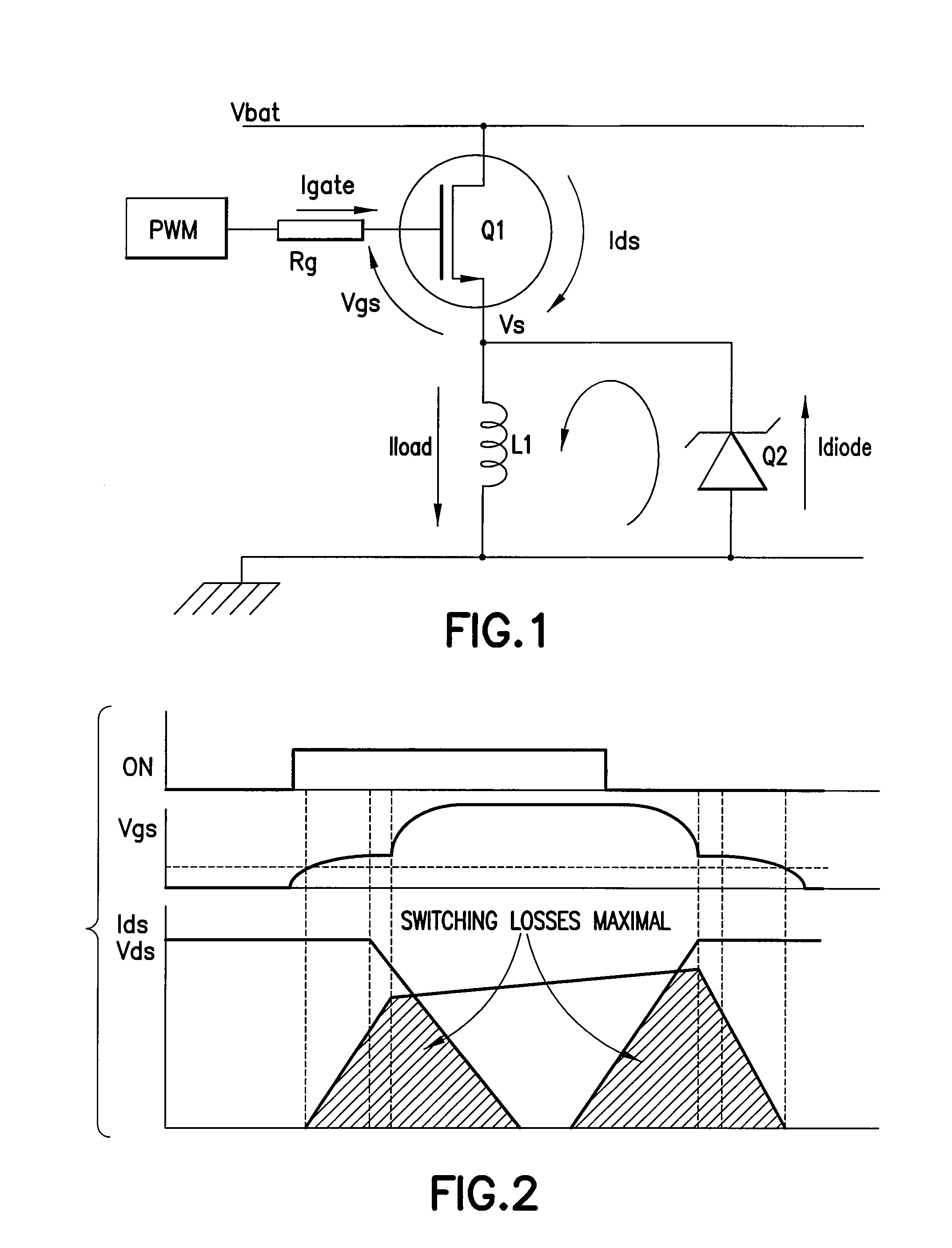

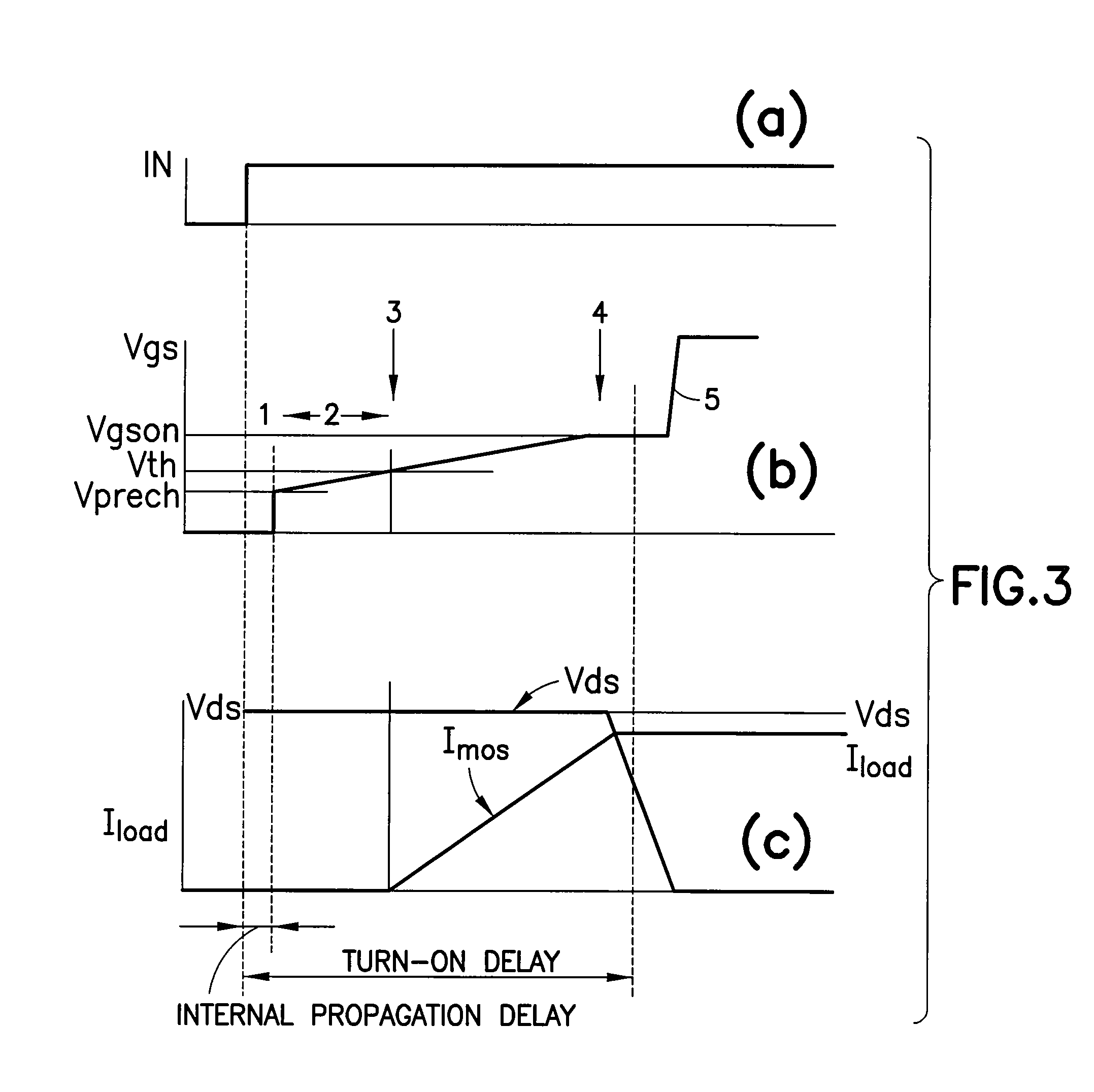

DC brushed motor drive with circuit to reduce di/dt and emi, for mosfet vth detection, voltage source detection, and overpower protection

ActiveUS20090027096A1Reduce electromagnetic interferenceMinimize switching lossesTransistorElectronic switchingMOSFETPulse control

A gate driver for performing gate shaping on a first transistor of having gate, source, and drain terminals, the first transistor being selected from a switching stage of a power switching circuit having high- and low-side transistors series connected at a switching node for driving a load. The gate driver includes the following steps: upon receipt of an ON pulse pre-charging the gate terminal until gate to source terminal voltage equals Vth, controlling the di / dt(ON) flowing in the first transistor while free wheeling current is flowing in a second transistor of the switching stage, and controlling the dv / dt(ON) of the first transistor while a charge on the gate terminal is present; and upon receipt of an OFF pulse controlling the dv / dt(OFF) of the first transistor until free wheeling current is flowing in the second transistor, and controlling the di / dt(OFF) flowing in the first transistor while the gate to source terminal voltage equals Vth.

Owner:INFINEON TECH AMERICAS CORP

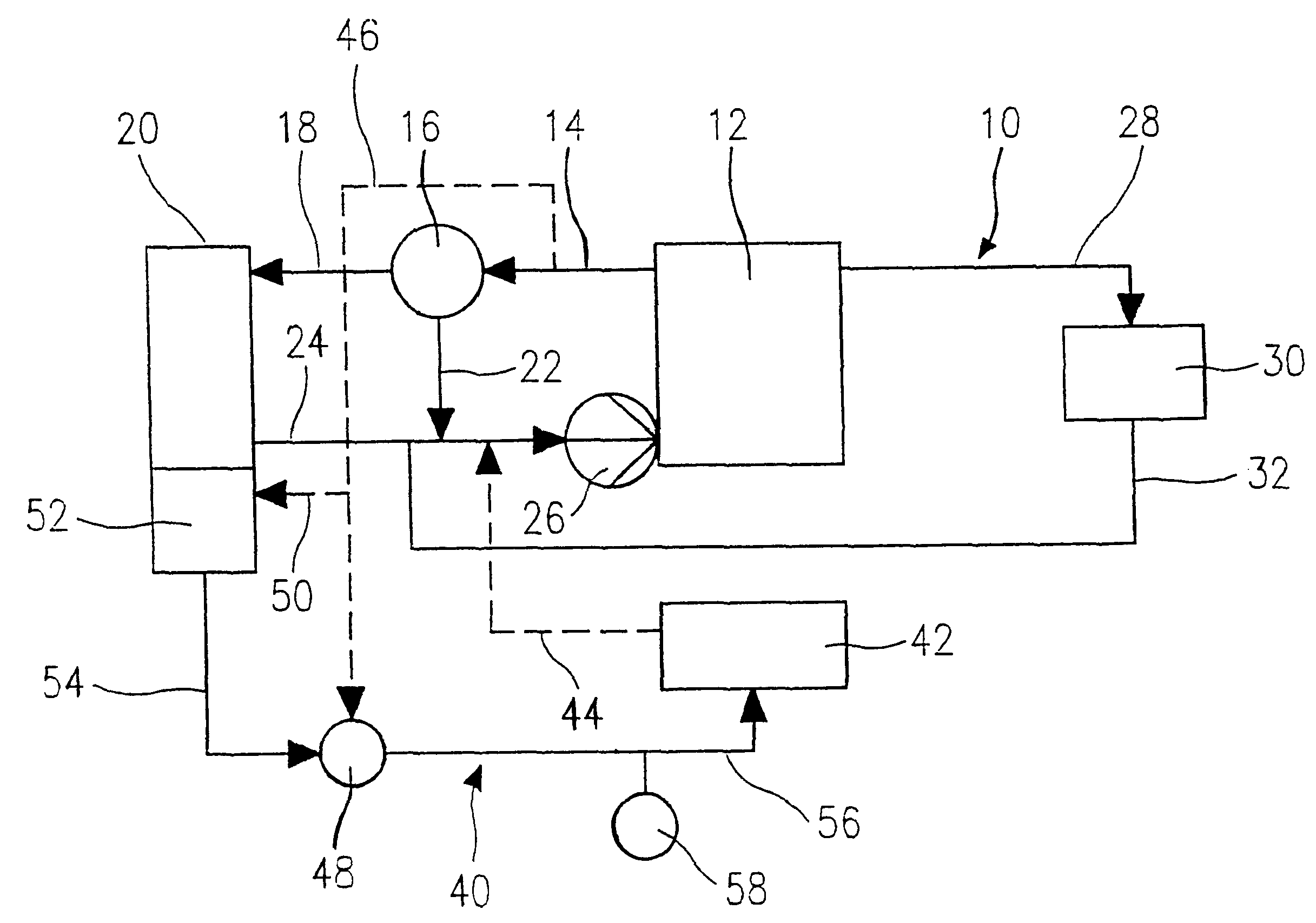

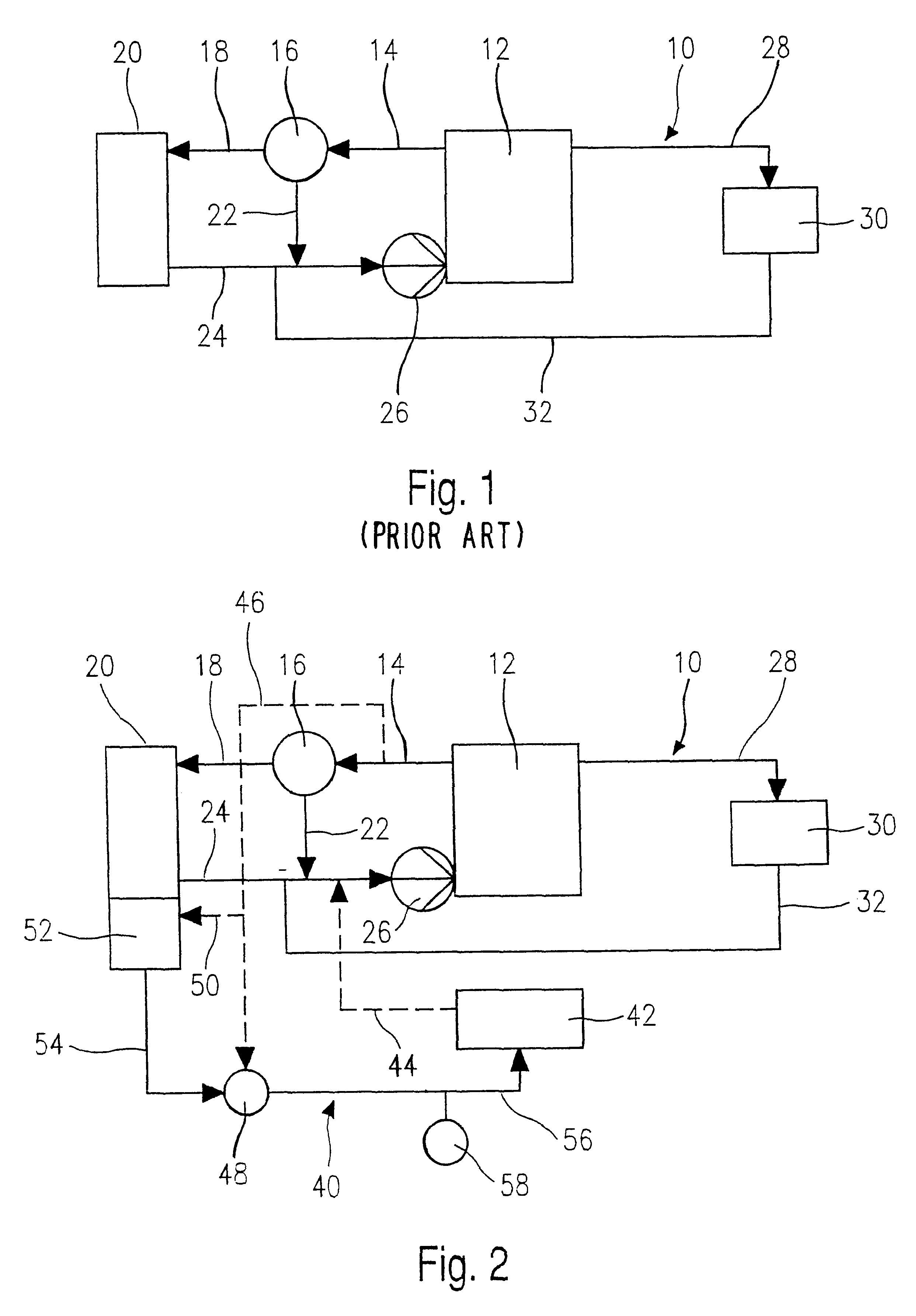

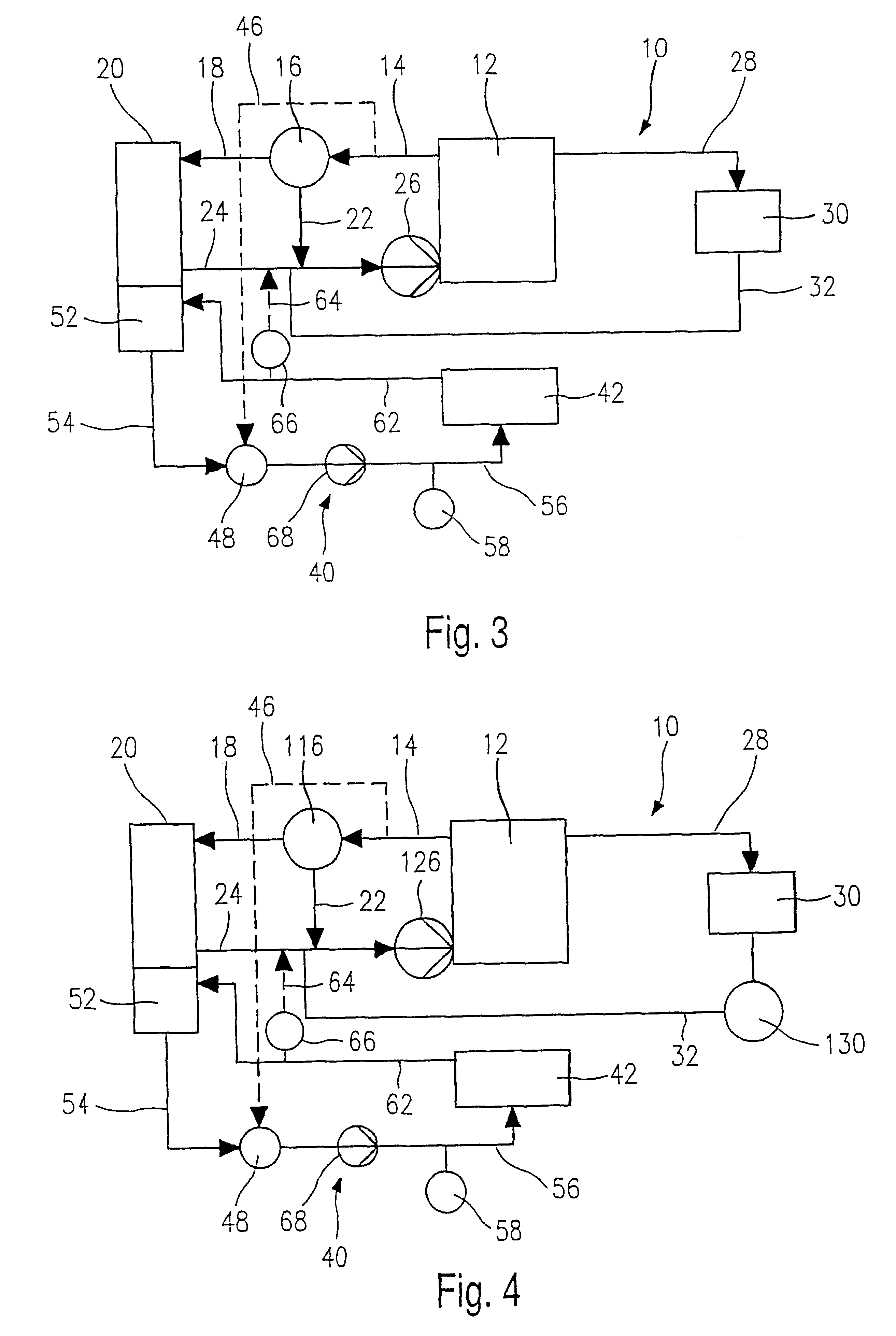

Method and device for transporting heat energy that is produced in a motor vehicle

A method and an apparatus for transporting thermal energy produced in a motor vehicle provides that the waste heat of an electronic component (42), such as a pulse-controlled inverter, be utilized to heat other vehicle parts, such as the internal combustion engine (12) or the passenger compartment. To that end, preferably two coolant circuits (10, 40) are provided, which can be coupled to one another or decoupled from another in order to control the flow of heat.

Owner:ROBERT BOSCH GMBH

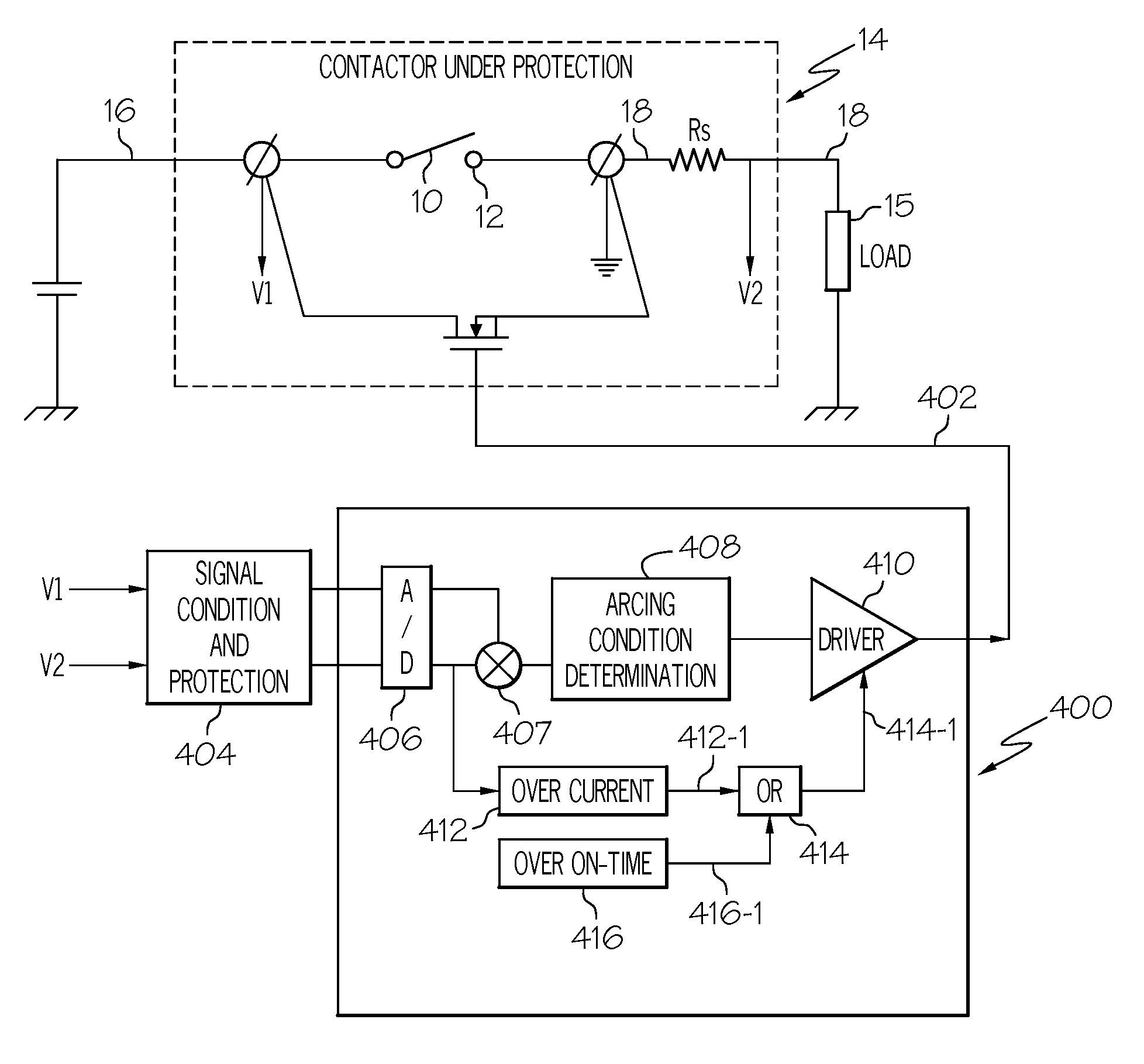

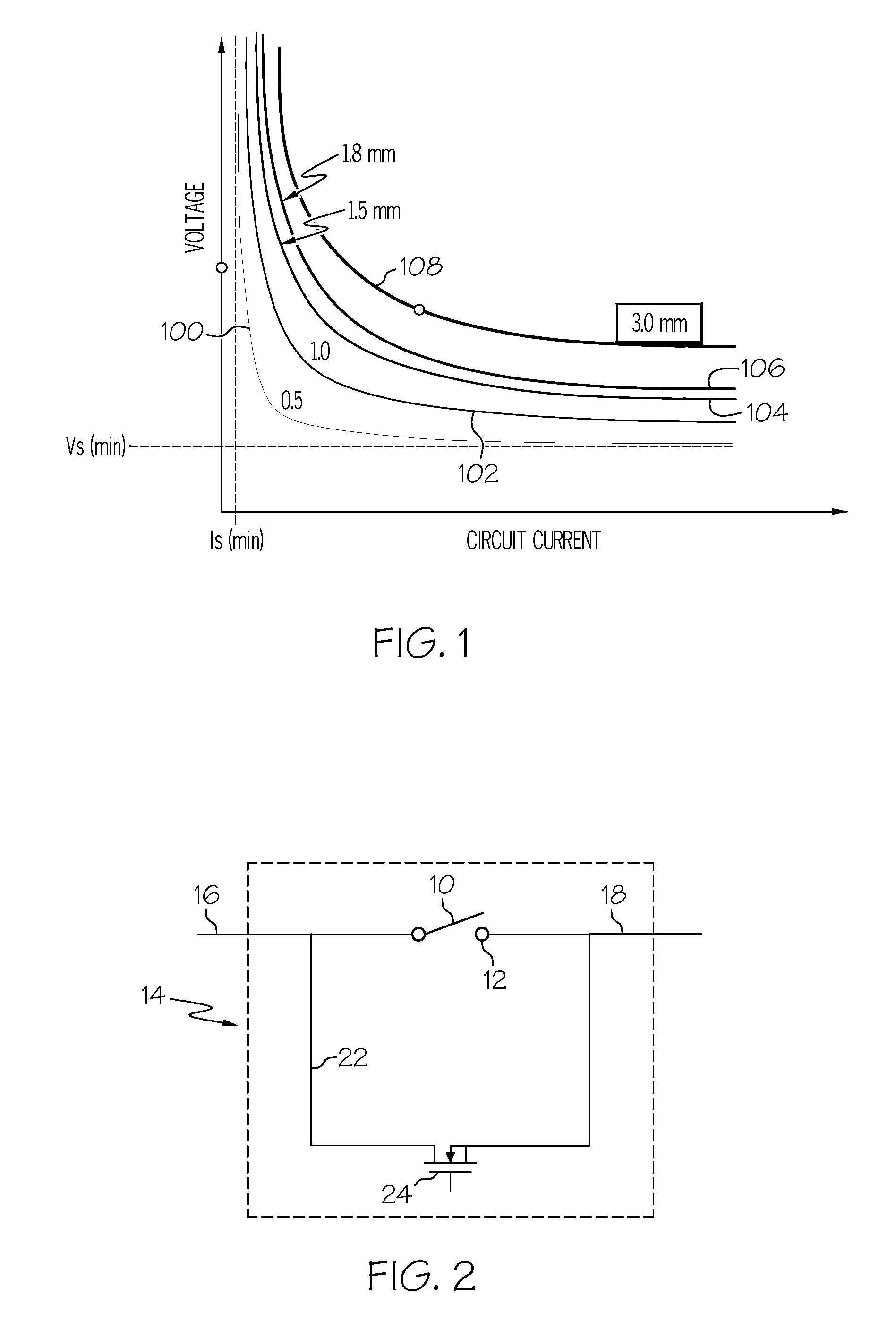

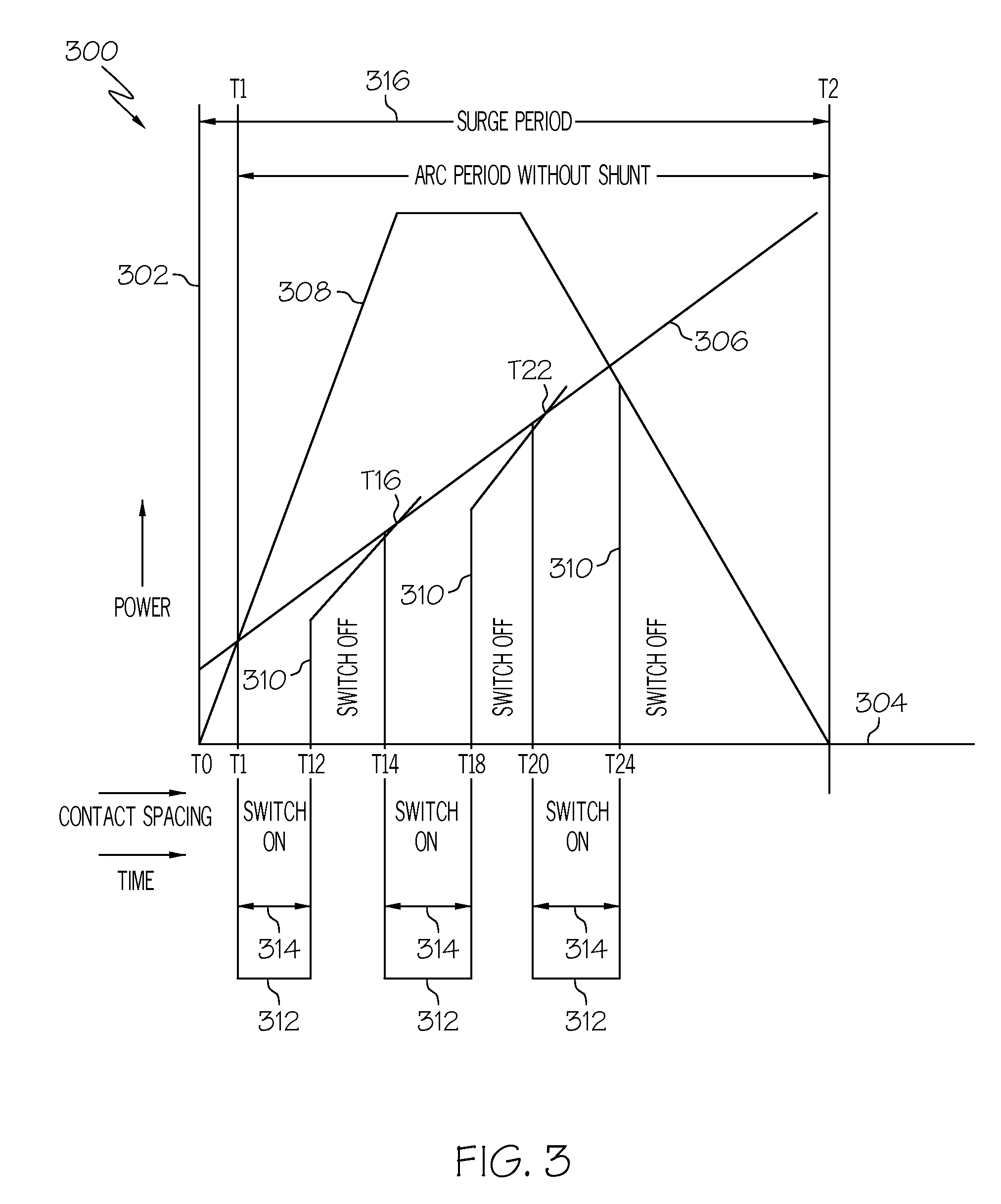

Hybrid high voltage DC contactor with arc energy diversion

InactiveUS20090168273A1Electric switchesEmergency protective arrangements for automatic disconnectionShunt DevicePulse control

Owner:HONEYWELL INT INC

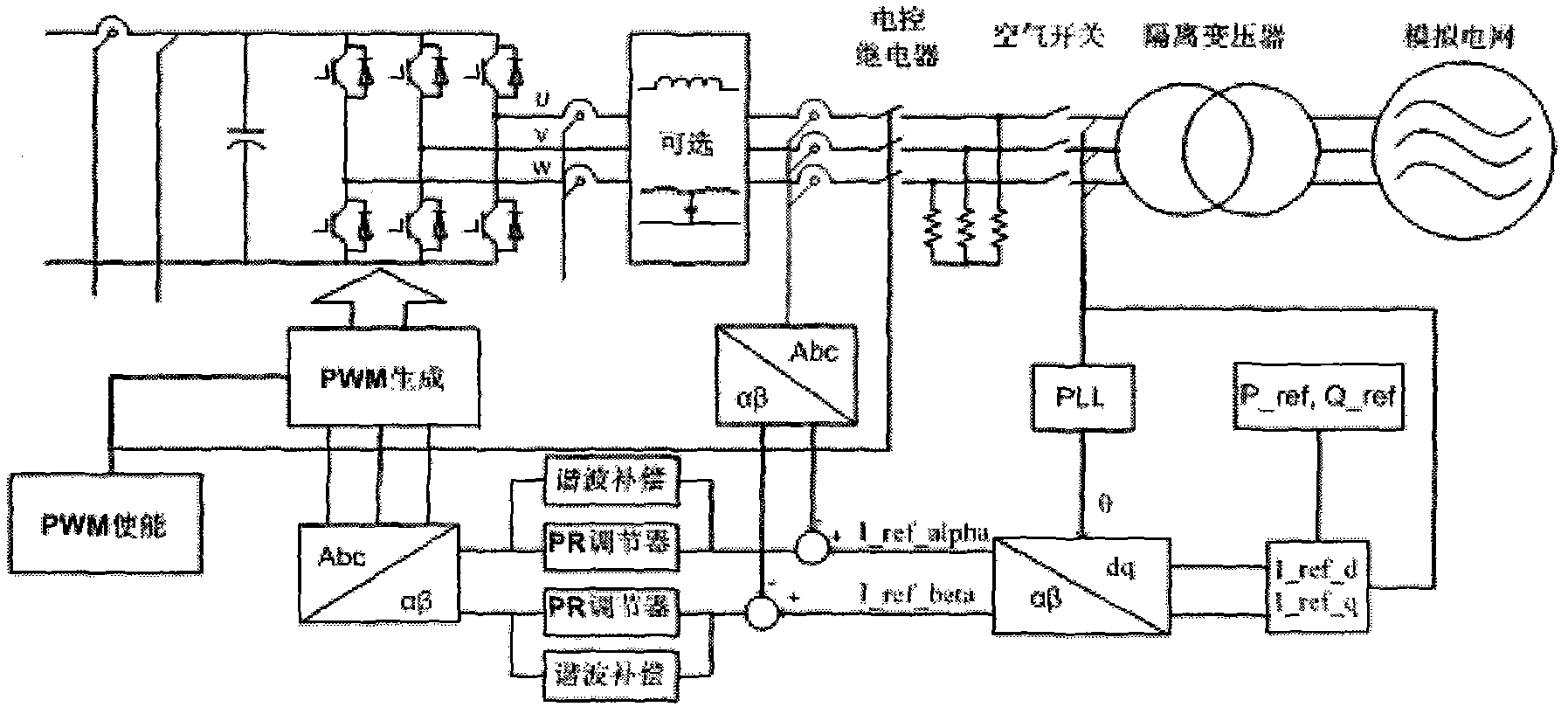

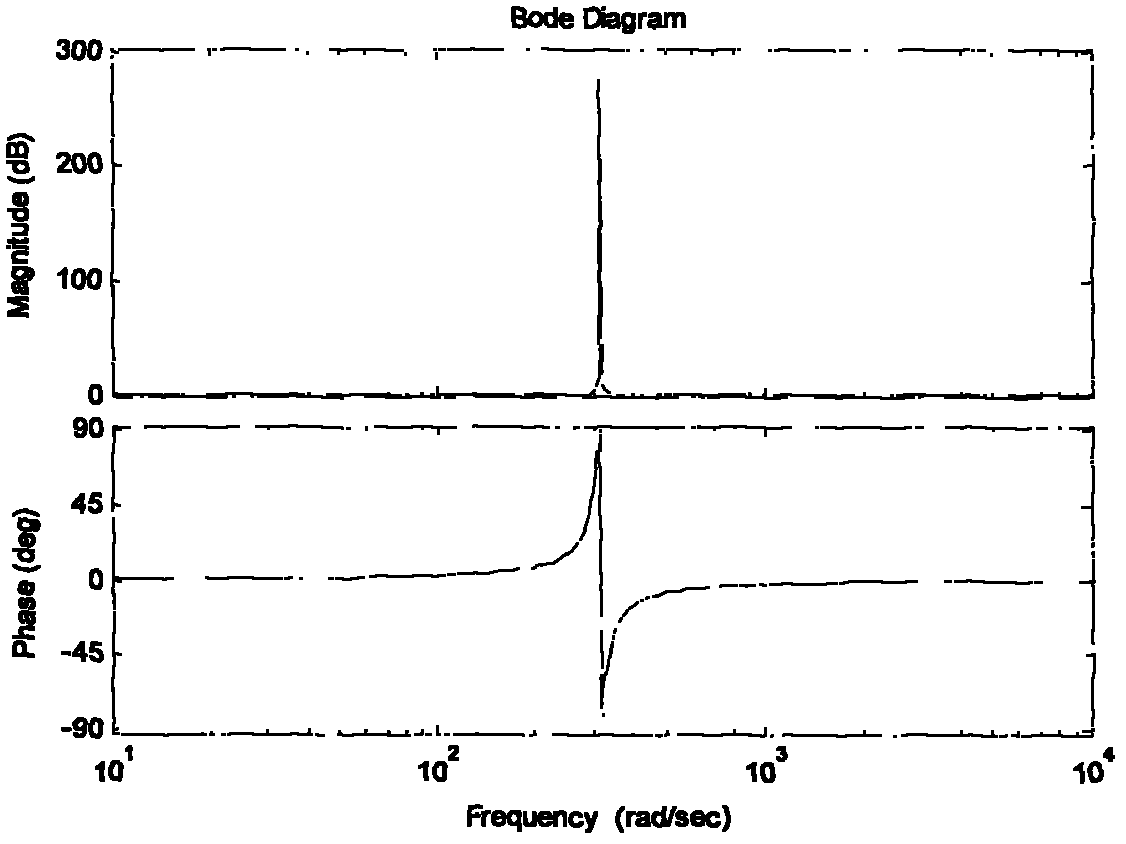

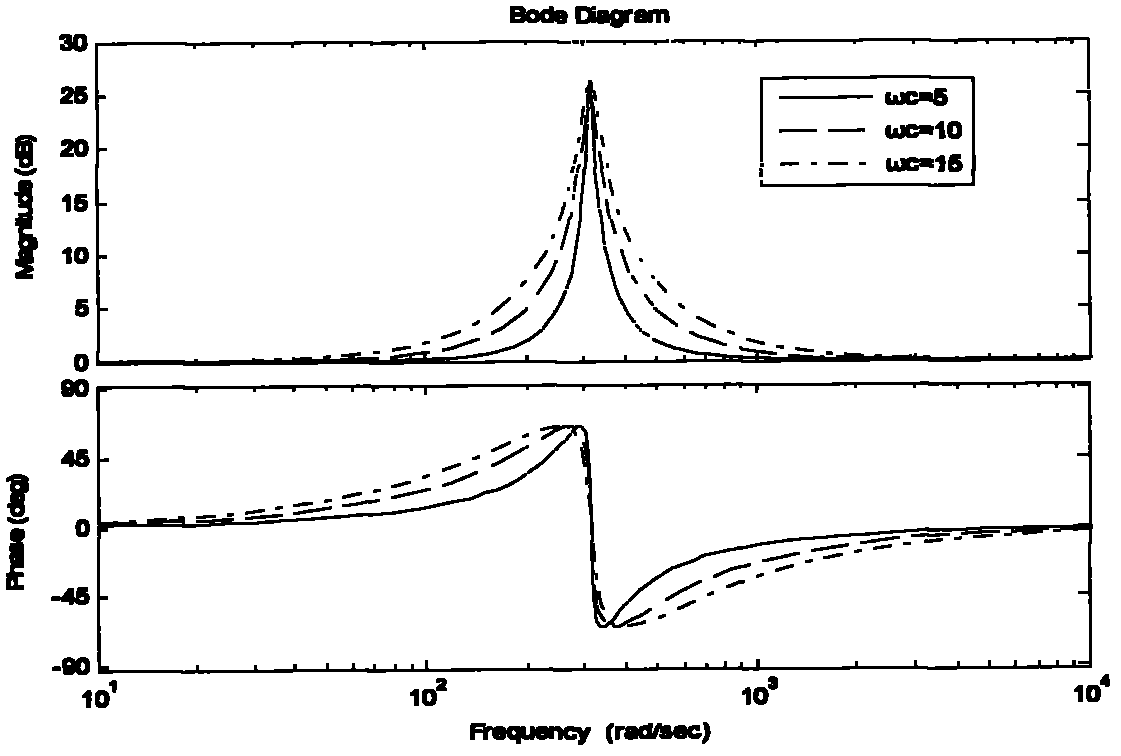

Control method of three-phase grid-connected inverter based on modified proportional resonant regulator

InactiveCN102223100AExcellent tracking abilityFast, accurate and error-free tracking capabilityEfficient power electronics conversionAc-dc conversionPulse controlPower inverter

The invention discloses a control method of a three-phase grid-connected inverter based on a modified proportional resonant regulator. The method comprises the following steps of: firstly, computing according to given active and reactive powers of the inverter and a voltage of a power grid to obtain required d-axis and q-axis currents under a synchronous coordinate system, and performing coordinate transformation by combining with phase information which is measured by a phase locking loop and a measured three-phase voltage signal of the power grid to obtain a current reference signal under a stationary alpha-beta coordinate system; secondly, performing coordinate transformation on an output current signal of the inverter to the alpha-beta coordinate system, controlling and tracking the current reference signal by the modified proportional resonant regulator with a harmonic compensator; and finally, returning to an abc coordinate system by coordinate transformation to generate a pulse-width modulation (PWM) pulse-control three-phase full-bridge inverter output, so as to make a distributed generation system grid-connected for power generation. By the method, a large number of complicated computation processes are eliminated, and a control structure is simplified. The control method of the three-phase grid-connected inverter based on the modified proportional resonant regulator is an accurate and high-efficiency novel inverter control method and has a bright development future.

Owner:BEIJING ZHONGNENG QINGYUAN TECH

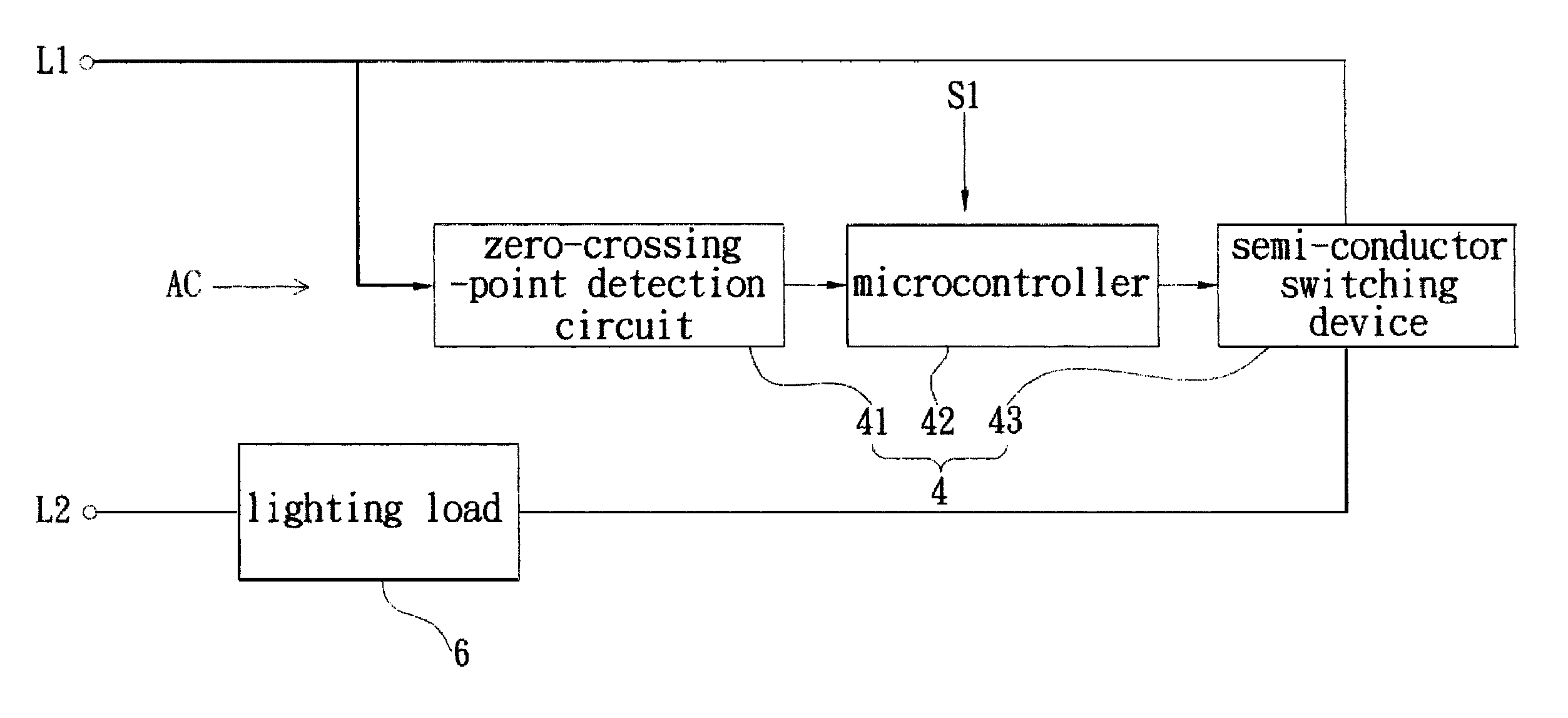

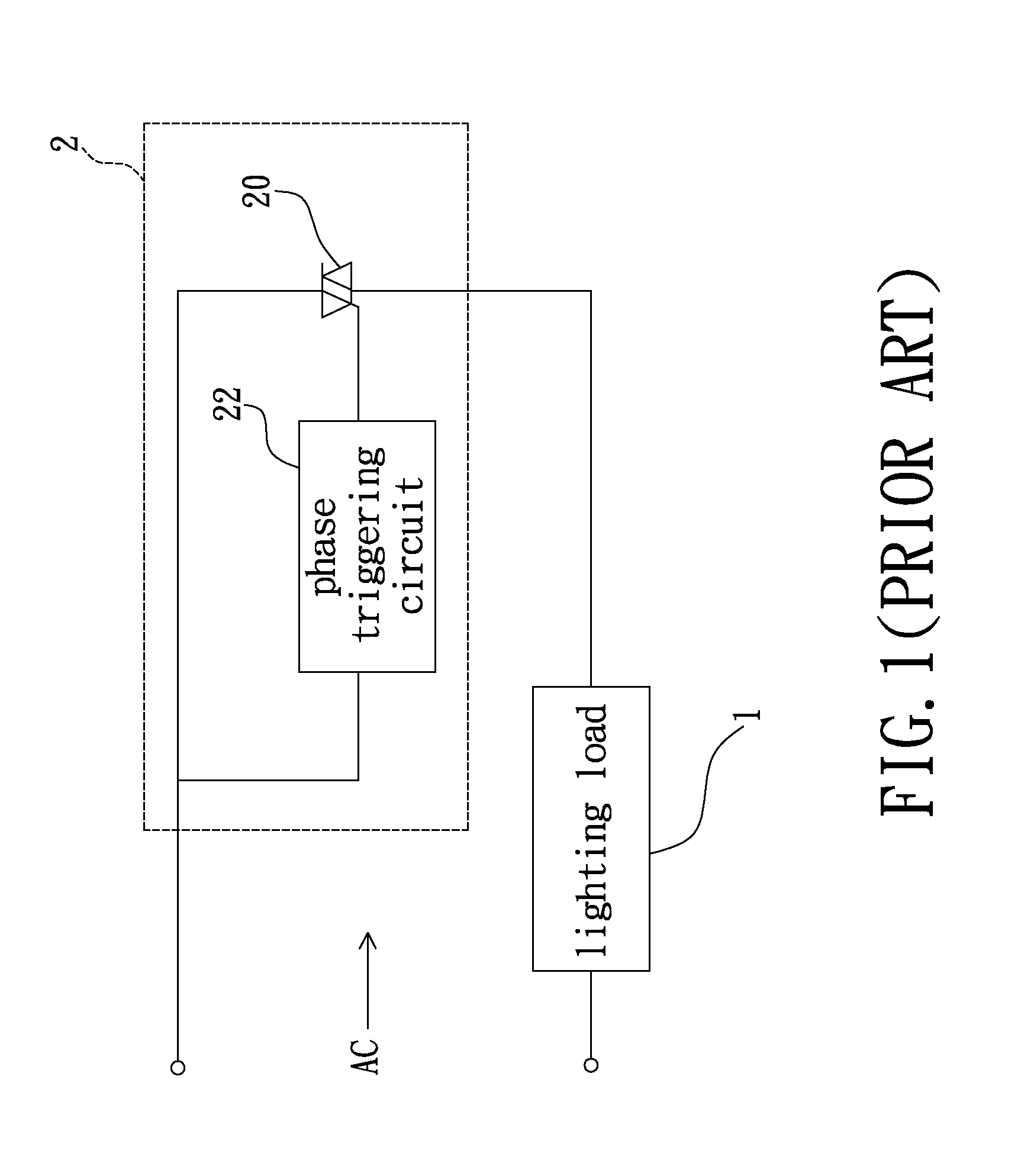

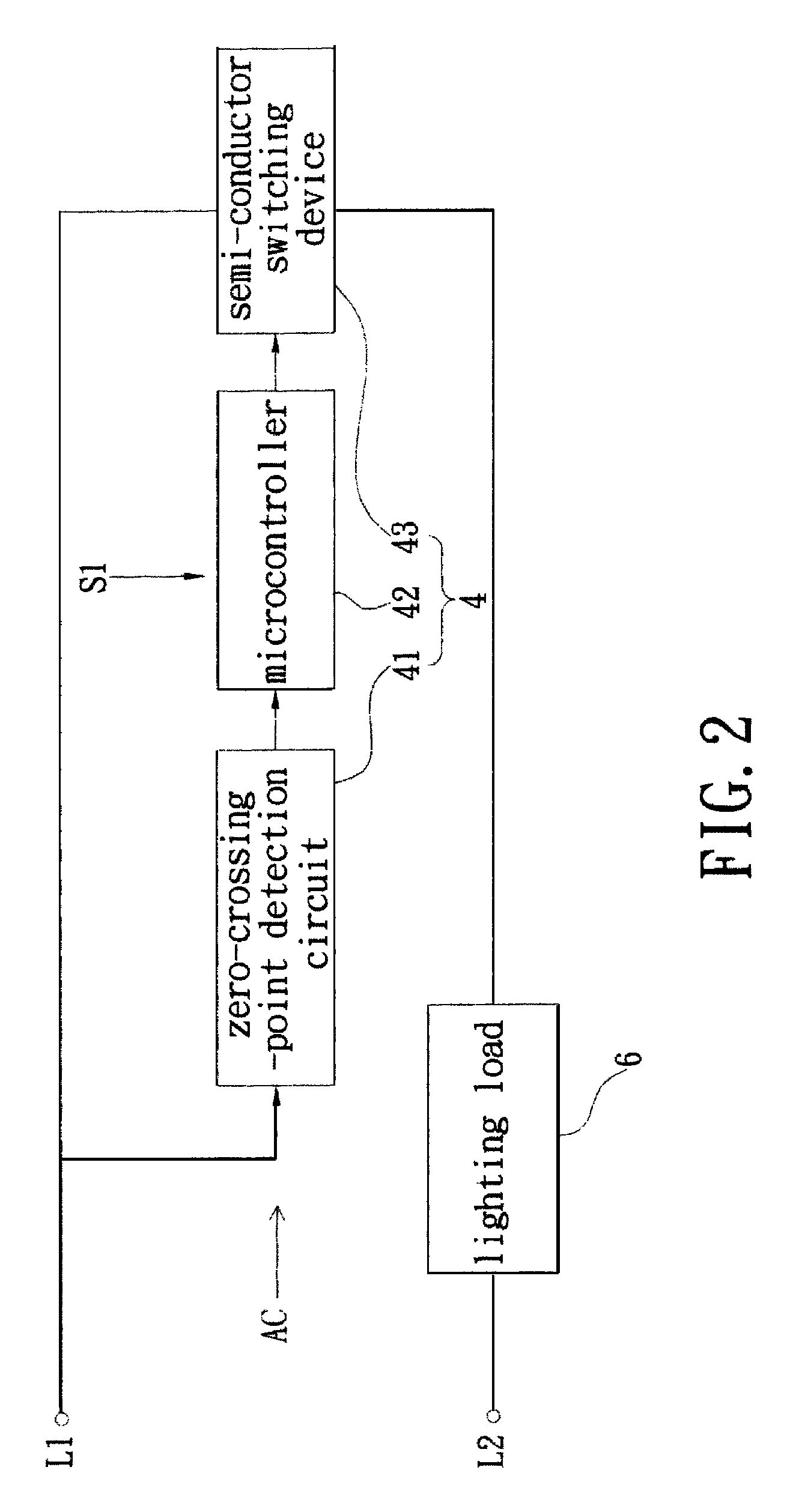

Microcontroller-based lighting control system and method for lighting control

ActiveUS8310163B2Efficient power savingLow costElectrical apparatusElectroluminescent light sourcesMicrocontrollerTime delays

A lighting control system employs a microcontroller to generate time-delay pulses that are synchronized with the AC power. The time-delay pulses control conduction period of a semi-conductor switching device for transmitting AC power to a lighting load. This lighting control system enables the lighting load performing two-level or multi-level illumination in a simple and power saving manner. While the conventional circuits use cumbersome passive resistor-capacitor scheme to generate required timing control, this lighting control system uses simple scheme based on a built-in oscillator in the microcontroller. This scheme provides high flexibility and accuracy to implement delay-time triggering. The system and method in the present invention may simultaneously be applicable to lighting loads of different impedance types, especially to incandescent lamp, fluorescent lamp, and AC light emitting diode.

Owner:VAXCEL INT

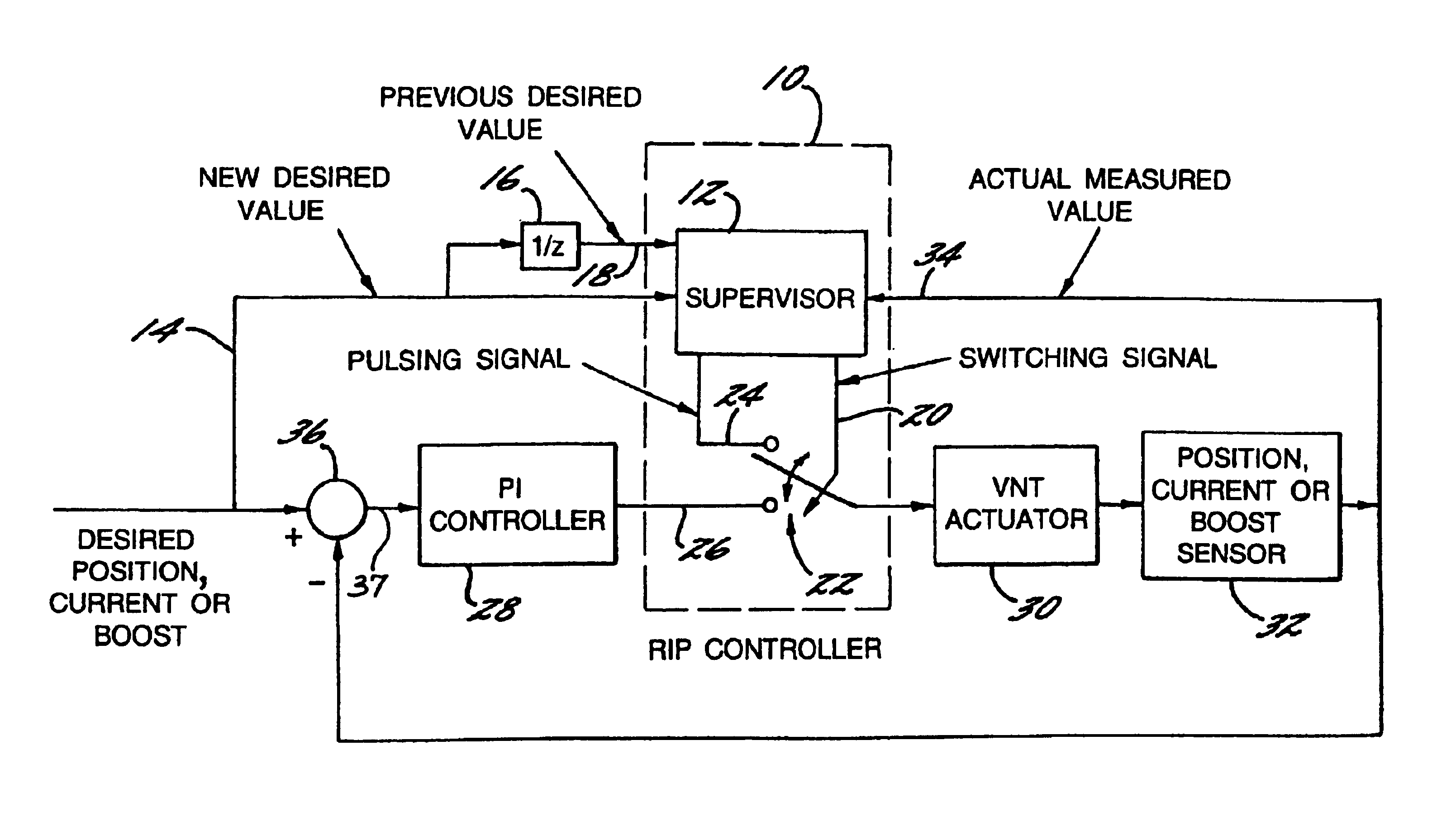

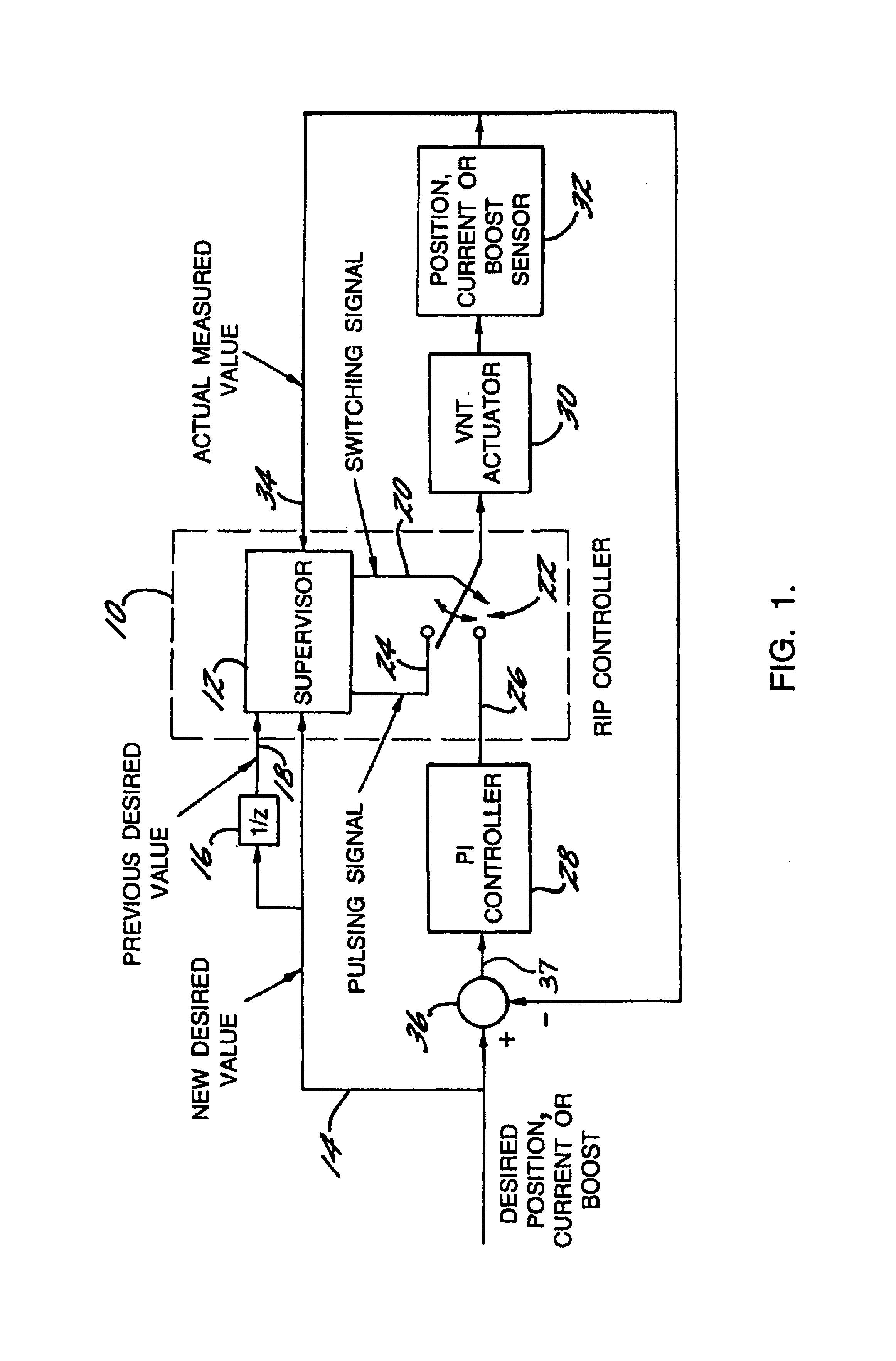

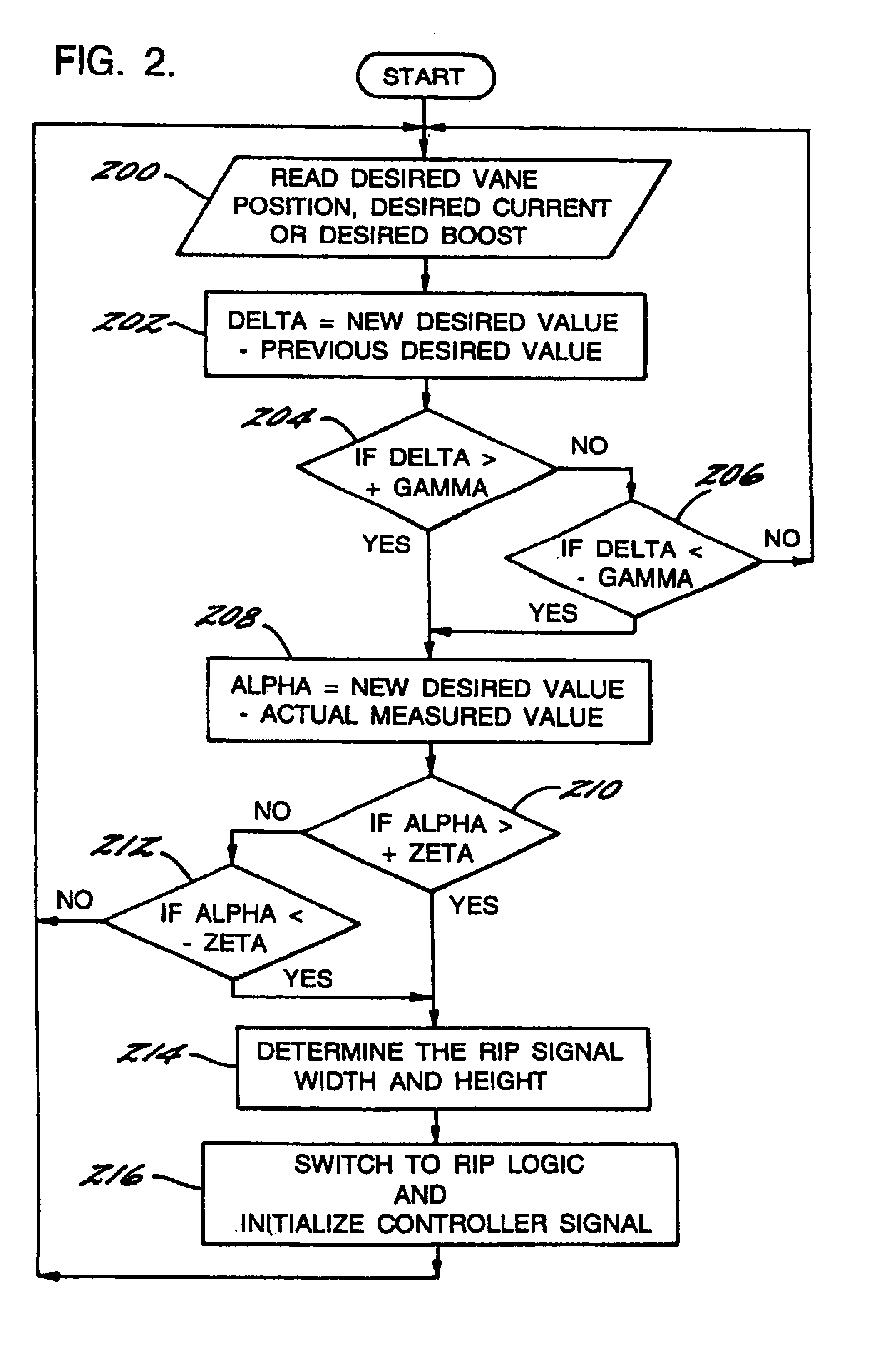

Control system for improved transient response in a variable-geometry turbocharger

A control system for a variable-geometry turbocharger includes a supervisor logic (12) selecting a pulse control output (24) for large variation of desired and previous control signal inputs exceeding a threshold differential and a normal control signal (26) for small control signal input changes. The control system calculates an amplitude and duration for the pulse control output based on input control signal variation or the actual versus desired position of the variable-geometry system in the turbocharger.

Owner:GARRETT TRANSPORATION I INC

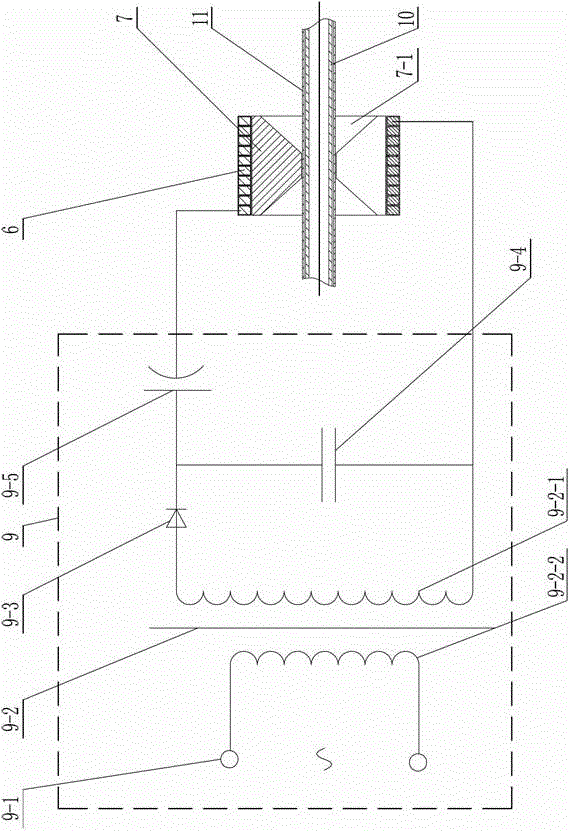

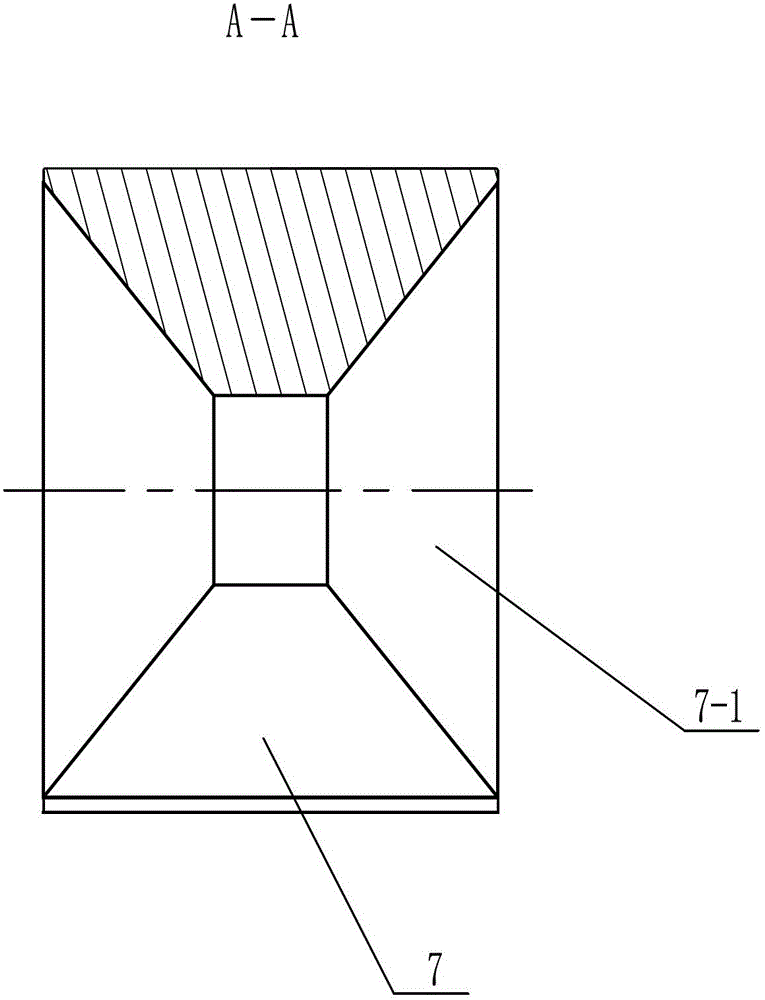

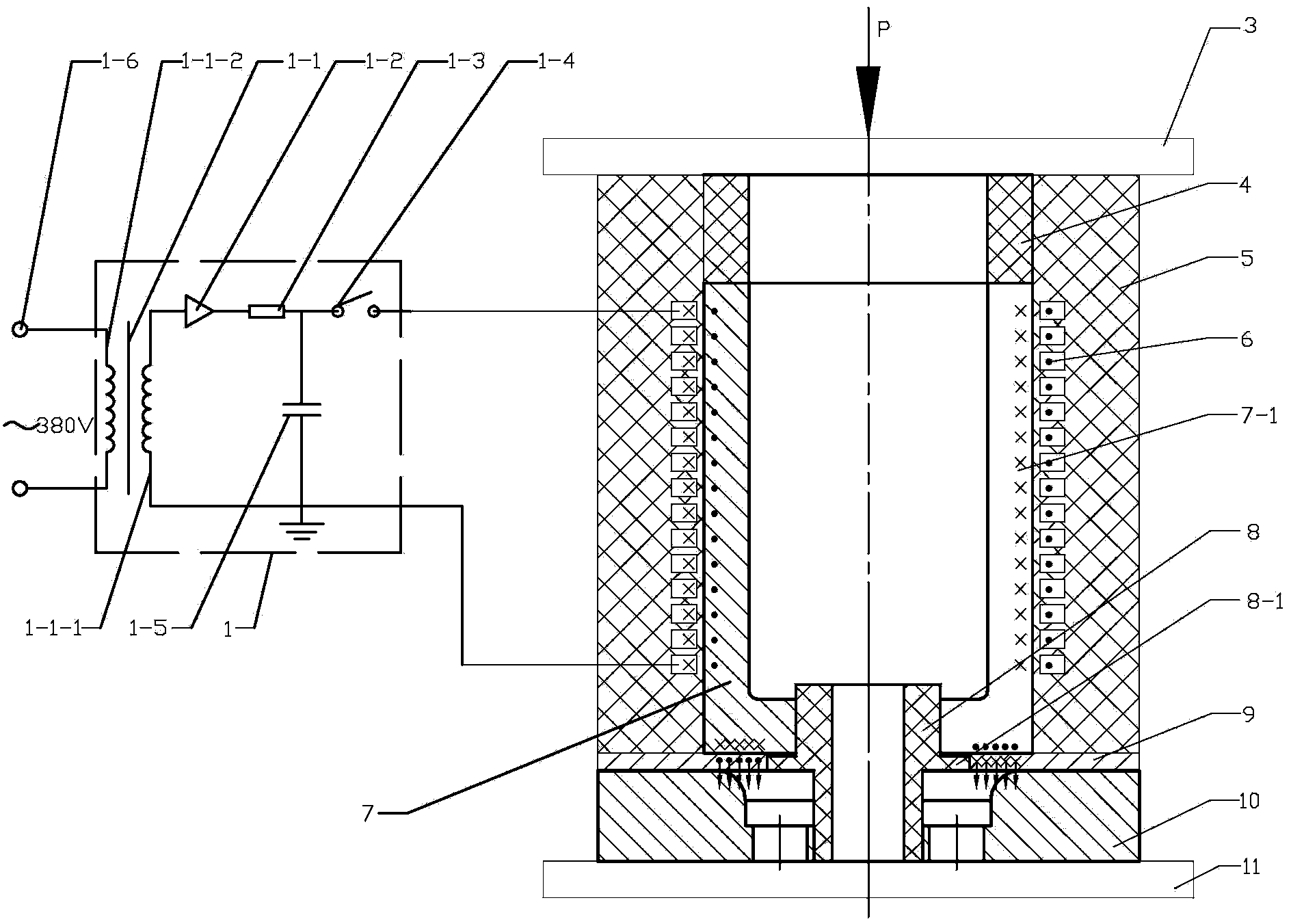

Magnetic pulse forming device and method of bimetal composite pipe

ActiveCN102744310AImprove bindingEconomic Forming Manufacturing TechnologyPulse controlMagnetic tension force

The invention relates to a magnetic pulse forming device and method of a bimetal composite pipe, relates to magnetic pulse forming devices and methods of composite pipes, and is is used for solving the problems of the composite bimetal pipe having the disadvantages of being low in combination intensity and limited in application occasions by adopting a cold forming method, as well as is high in investment and complex in production process by adopting a thermal processing method, and is high in dangerousness by adopting an explosion composite method. A pair of movable flat tongs is glidingly matched with a base fixing plate; a pair of fixed flat tongs is fixedly arranged on the base fixing plate; a pipe billet clamping block is fixedly arranged on the flat tongs; a screw rod is connected with the base fixing plate; the screw rod is installed on the movable flat tongs; a support frame is fixedly connected with the base fixing plate; a magnetic trap is supported through the support frame; a magnetic coil is wound on the outer annular surface of the magnetic trap; two output ends of a magnetic pulse control circuit are connected with two ends of the magnetic coil; and the method comprises the following steps of: cleaning the surface of a pipe billet to be composited; locating and clamping internal and external pipe billets; compositing and forming for first time; and subsequently and progressively compositing and forming till the bimetal composite pipe with required length is obtained. The magnetic pulse forming device and method of the bimetal composite pipe, disclosed by the invention, are used for magnetic pulse forming of the bimetal composite pipe.

Owner:HARBIN INST OF TECH

PWM controller with dual-edge modulation using dual ramps

A dual-edge modulation controller including first and second ramp circuits, first and second comparators, an error amplifier and pulse control logic. The first ramp circuit provides a leading-edge ramp synchronous with a clock. The error amplifier compares a feedback signal with a reference and provides a compensation signal. The first comparator compares the leading-edge ramp with the compensation signal and asserts a set signal. The second ramp circuit provides a trailing-edge ramp that begins ramping when the set signal is asserted. The second comparator compares the trailing-edge ramp with the compensation signal and asserts a reset signal. The pulse control logic asserts a PWM signal when the set signal is asserted and de-asserts the PWM signal when the reset signal is asserted. The controller may control multiple phases with current balancing. The slew rate of the ramps may be adjusted based on the number of PWM signal asserted.

Owner:INTERSIL INC

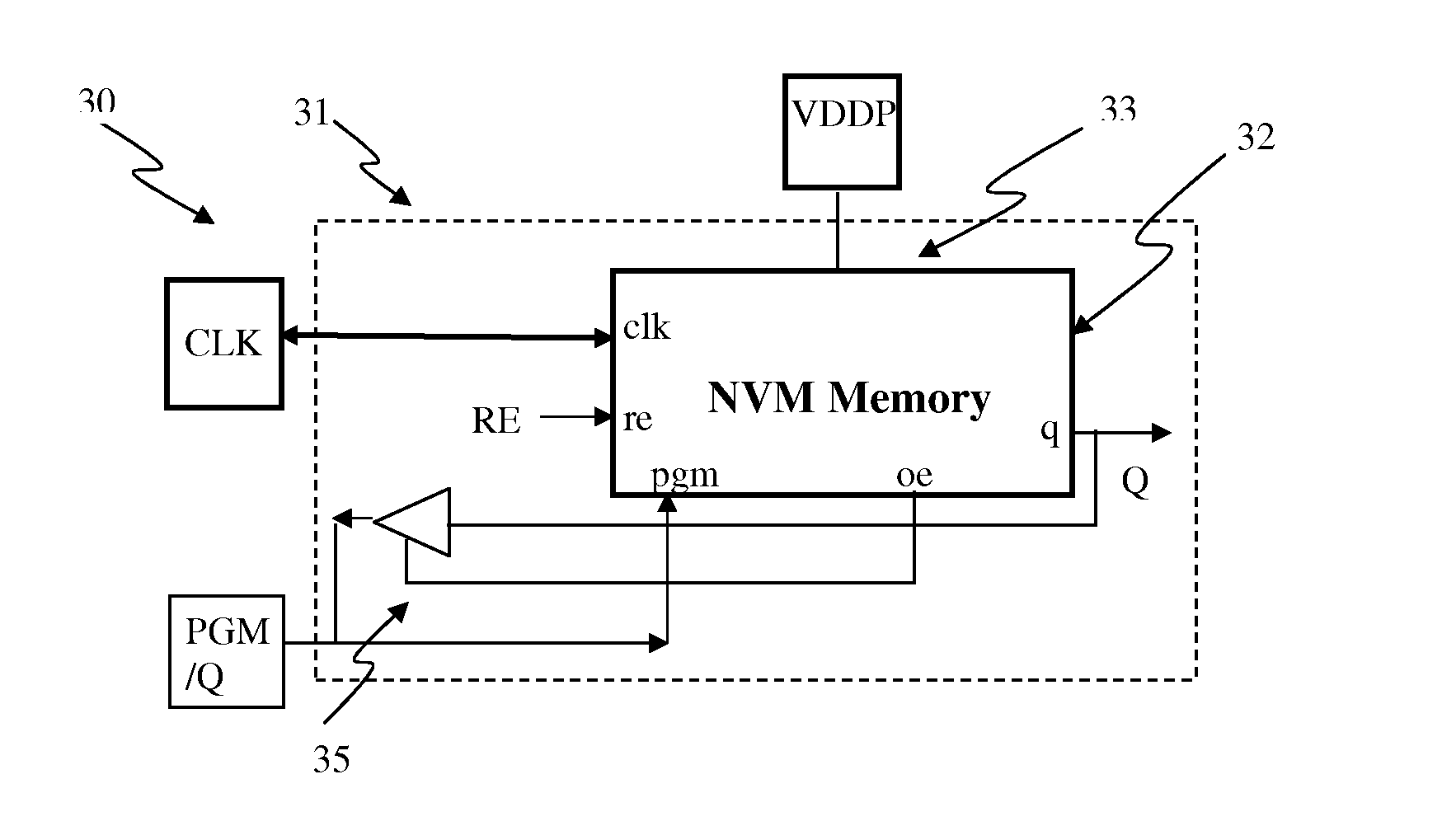

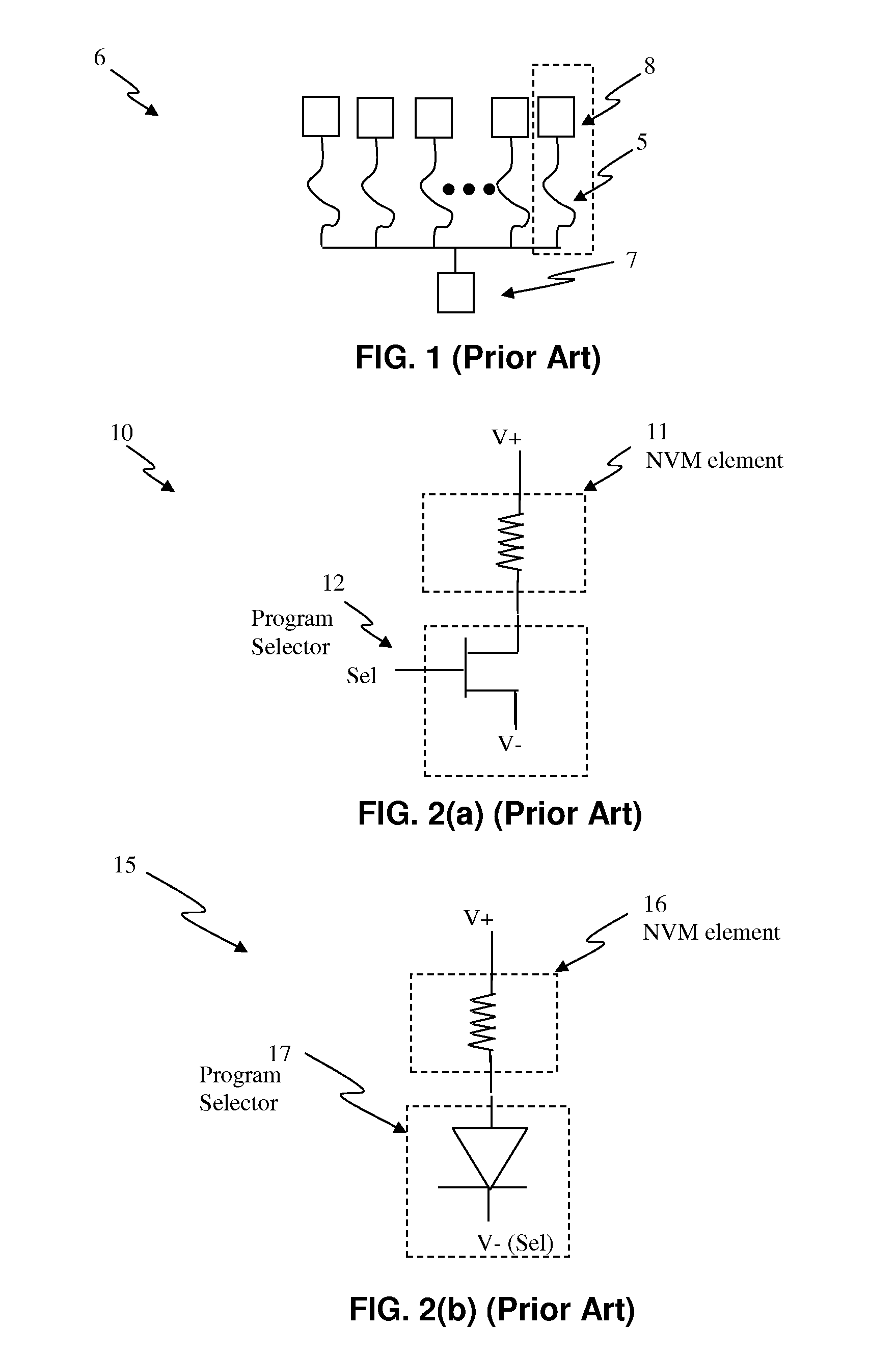

Low-Pin-Count Non-Volatile Memory Interface with Soft Programming Capability

ActiveUS20140340954A1Easily integrated into integrated circuitReduce areaRead-only memoriesDigital storagePulse controlControl signal

A low-pin-count non-volatile (NVM) memory with no more than two control signals that can at least program NVM cells, load data to be programmed into output registers, or read the NVM cells. At least one of the NVM cells has at least one NVM element coupled to at least one selector and to a first supply voltage line. The selector is coupled to a second supply voltage line and having a select signal. At least one of the selected NVM cells can be coupled to at least one output register. No more than two control signals can be used to select the at least one NVM cells in the NVM sequentially for programming the data into the at least one NVM cells or loading data into the at least one output registers controlled by the pulse of the first signal and voltage level and / or timing of the second signal. Programming into the NVM cells, or loading data into output registers, can be determined by the voltage levels of the first to the second supply voltage lines. Reading at least one of the NVM cells can be activated by a third signal or by detecting ramping of the first or the second supply voltage line.

Owner:ATTOPSEMI TECH CO LTD

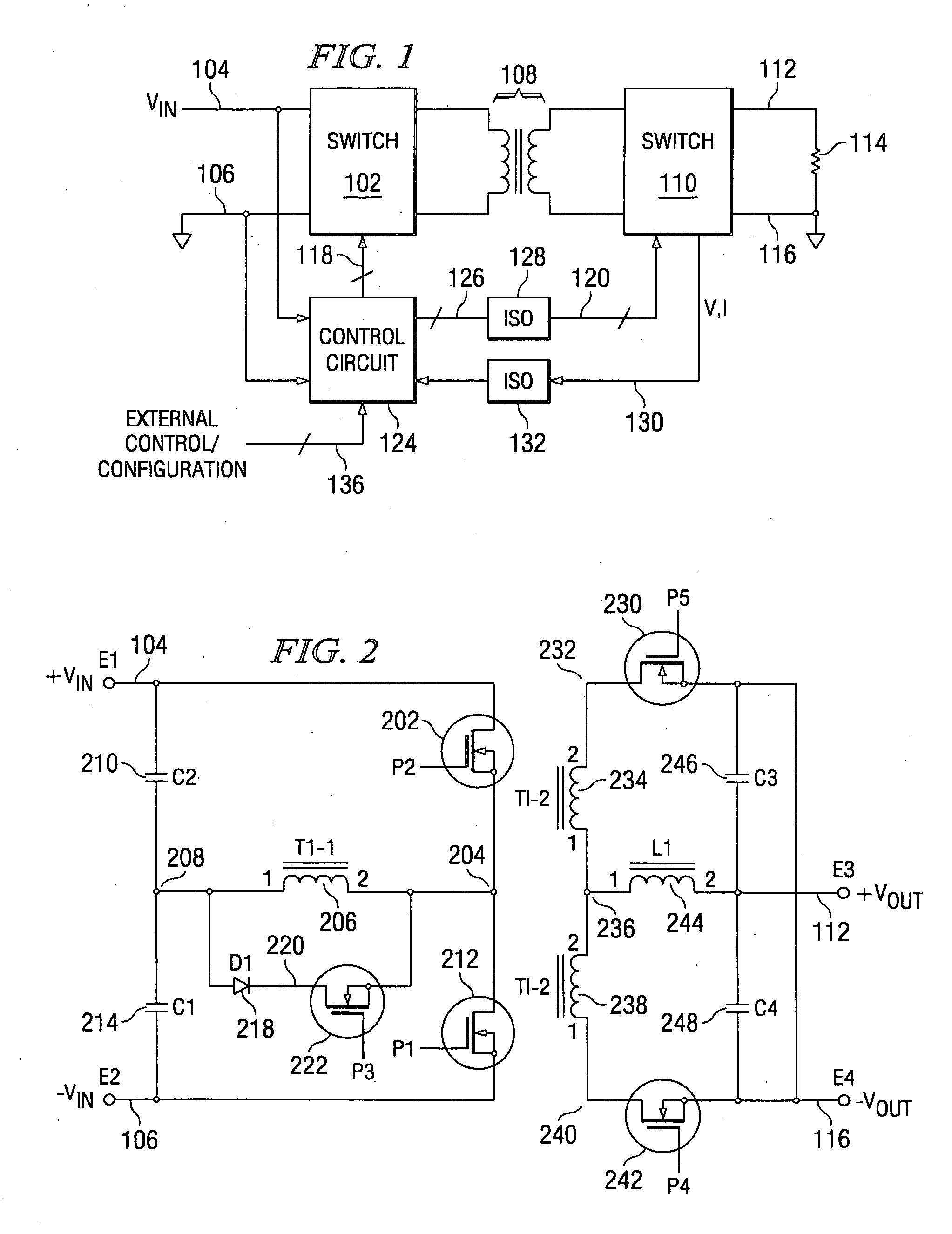

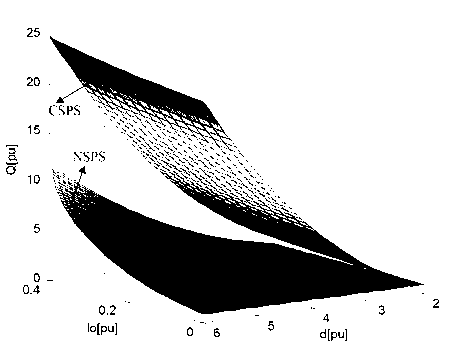

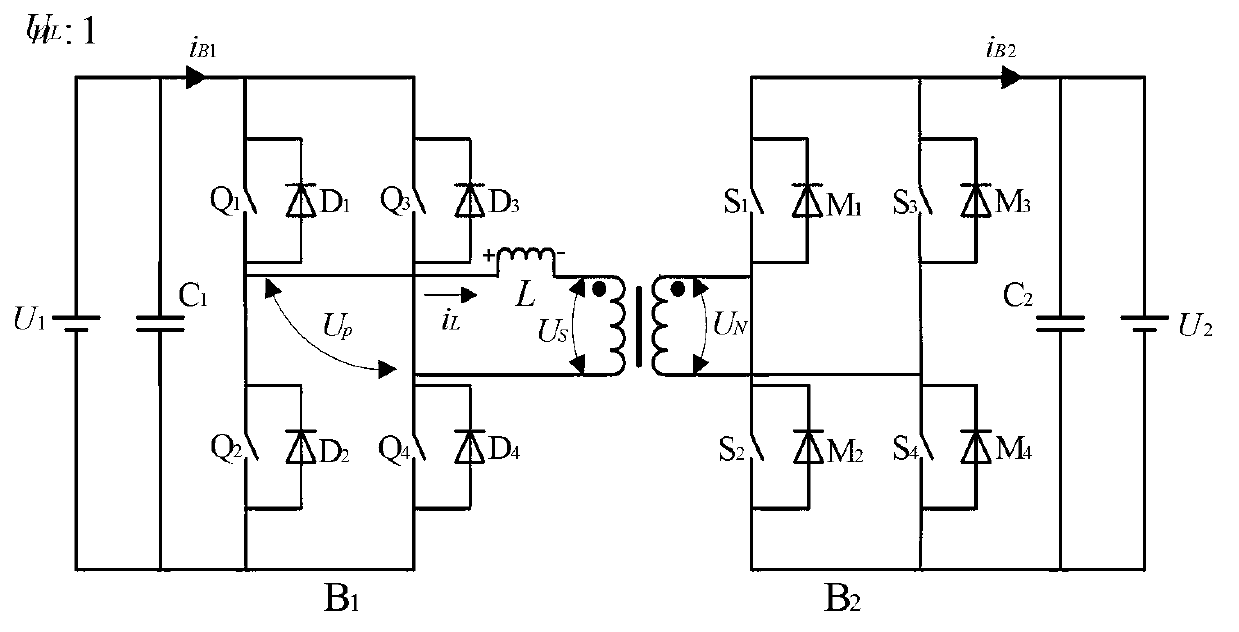

Method for controlling drive pulses of DAB type bidirectional isolation DC-DC converter

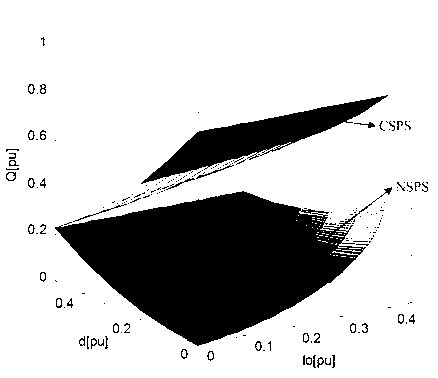

InactiveCN103199707AReduce peak currentReduced effectivenessApparatus with intermediate ac conversionPulse controlDc dc converter

The invention relates to a method for controlling drive pulses of a DAB type bidirectional isolation DC-DC converter. The method for controlling the drive pulses of the DAB type bidirectional isolation DC-DC converter comprises the steps of firstly, carrying out drive pulse control on the DAB type bidirectional isolation DC-DC converter based on a drive pulse working principle; and then inferring relevant formulas in the mode of control, and carrying out characteristic analysis and verification. The method for controlling the drive pulses of the DAB type bidirectional isolation DC-DC converter only needs to control a single variable, is simple and practical, applicable to the state of light load of a system, simple in algorithm, convenient to achieve, and prone to feedback regulation, reduces stress of devices, and effectively improves system efficiency when the system is in light load.

Owner:BEIJING JIAOTONG UNIV

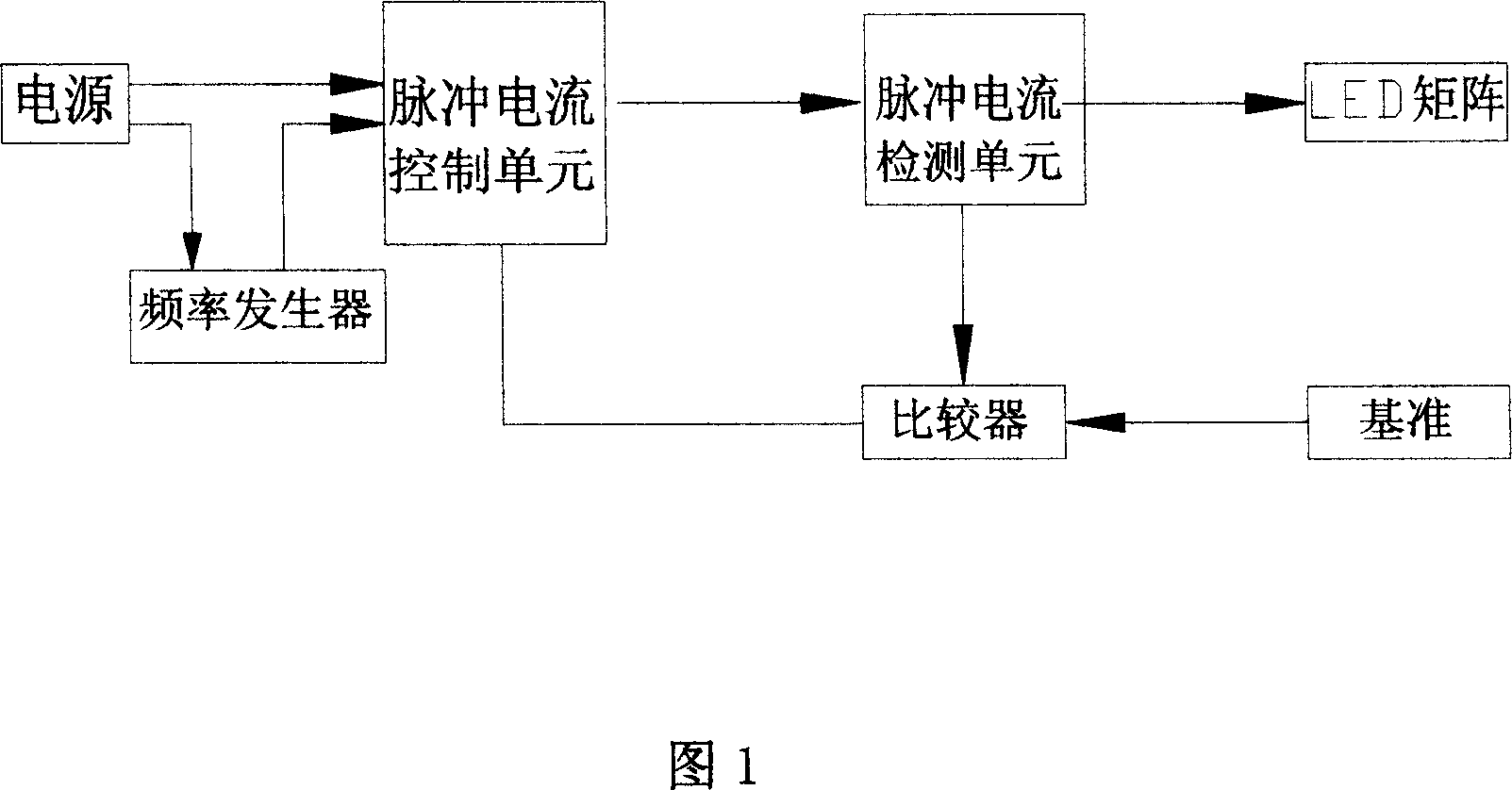

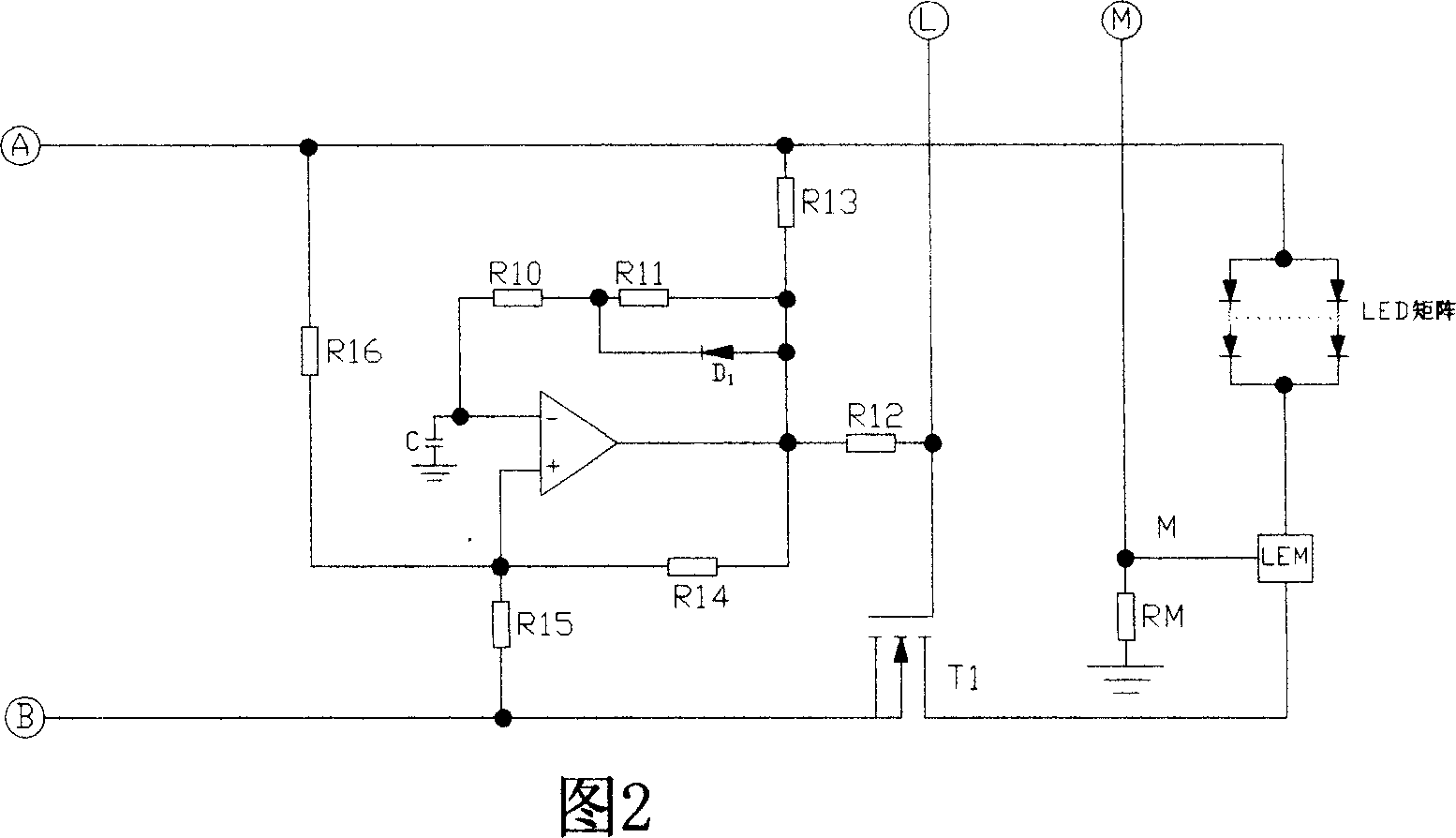

Method for driving LED emitting

InactiveCN101052254AMeet the needs of brightnessPush to expandElectrical apparatusElectroluminescent light sourcesContinuous lightPulse control

The method comprises: after powering on, the pulse generation device generates a pulse current being over the rating and having a certain duty ratio; the over rating pulse current has frequencies from 1KHz to 1GHz; the over rating pulse current is used to drive the LED to generate a ultra brightness light in certain time interval; the frequency of the time interval reaches a required high frequency such that the human eye considers it as a continuous light. The driving circuit comprises: a frequency generator, a pulse control unit, a pulse detection unit, a reference current unit and a comparator.

Owner:深圳市华之梦实业有限公司

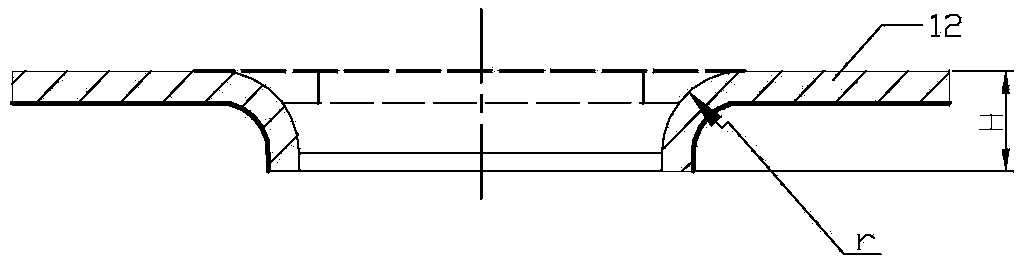

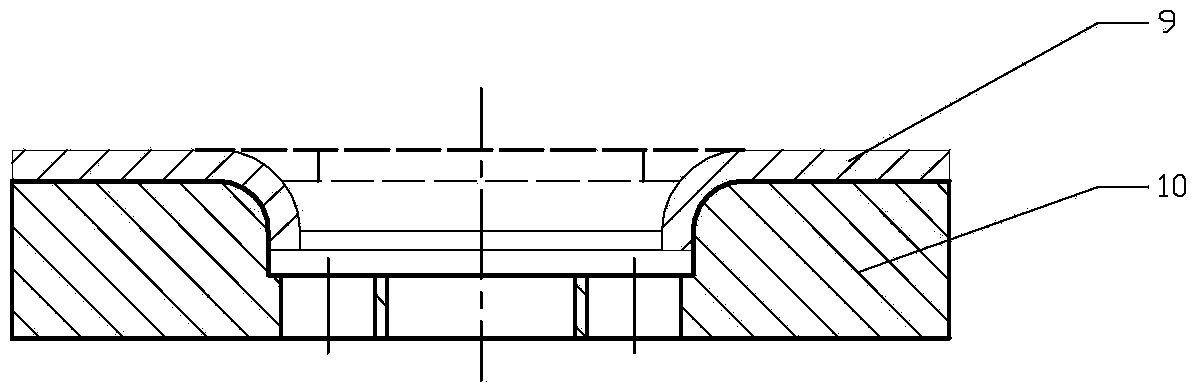

Device and method for forming small-diameter flanging holes in aluminum alloy plate through magnetic pulses

ActiveCN103861930AImprove the strength of its own structureImprove structural strengthPulse controlAlloy

The invention discloses a device and method for forming small-diameter flanging holes in an aluminum alloy plate through magnetic pulses, and belongs to the field of metal plate part plastic forming and manufacture. The device and method solve the problems that when the flanging holes are formed in the aluminum alloy plate through an existing magnetic pulse forming technology, the service life of a coil is short, damage easily happens to the machined workpiece, a plurality of flanging and forming procedures exist when a steel die is adopted, and the forming quality is not stable. A coil wire turn is packaged in a coil framework, a flanging female die is fixed to a bottom plate, the upper section of a positioning ring and the lower section of the positioning ring are arranged in a columnar magnetic trap and the flanging female die, a magnetic trap limiting ring is arranged on the upper end face of the columnar magnetic trap, the solenoid coil is arranged on the outer side wall of the columnar magnetic trap and the outer side wall of the magnetic trap limiting ring in a sleeved mode, and a longitudinal seam is formed in the side wall of the columnar magnetic trap. An upper pressing plate is arranged on the upper end face of the magnetic trap limiting ring and the upper end face of the coil framework. The aluminum alloy plate is arranged between the flanging female die and the coil framework, and two output ends of a magnetic pulse control circuit are connected with two wiring terminals of the coil wire turn. The device and method are used for forming the small-diameter flanging holes in the aluminum alloy plate through magnetic pulses.

Owner:HARBIN INST OF TECH

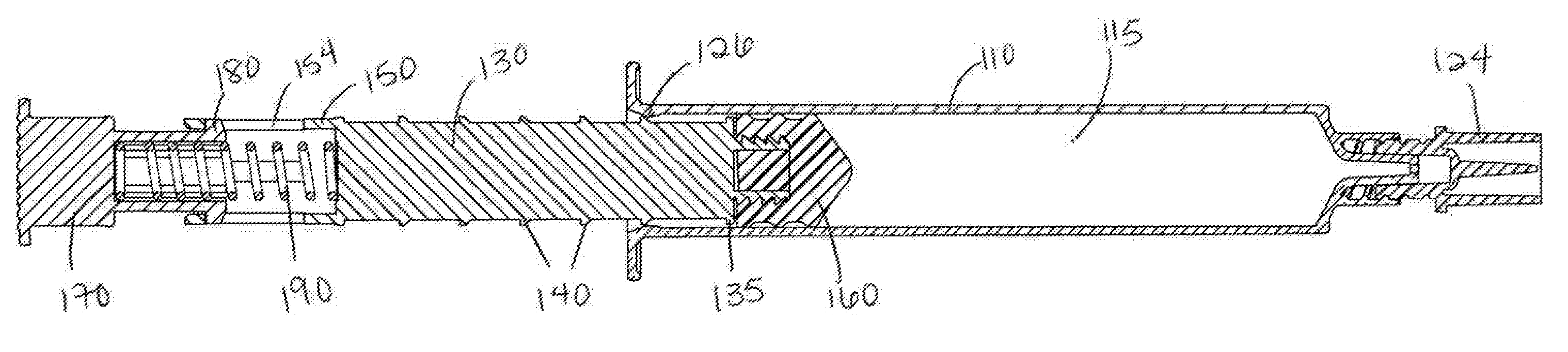

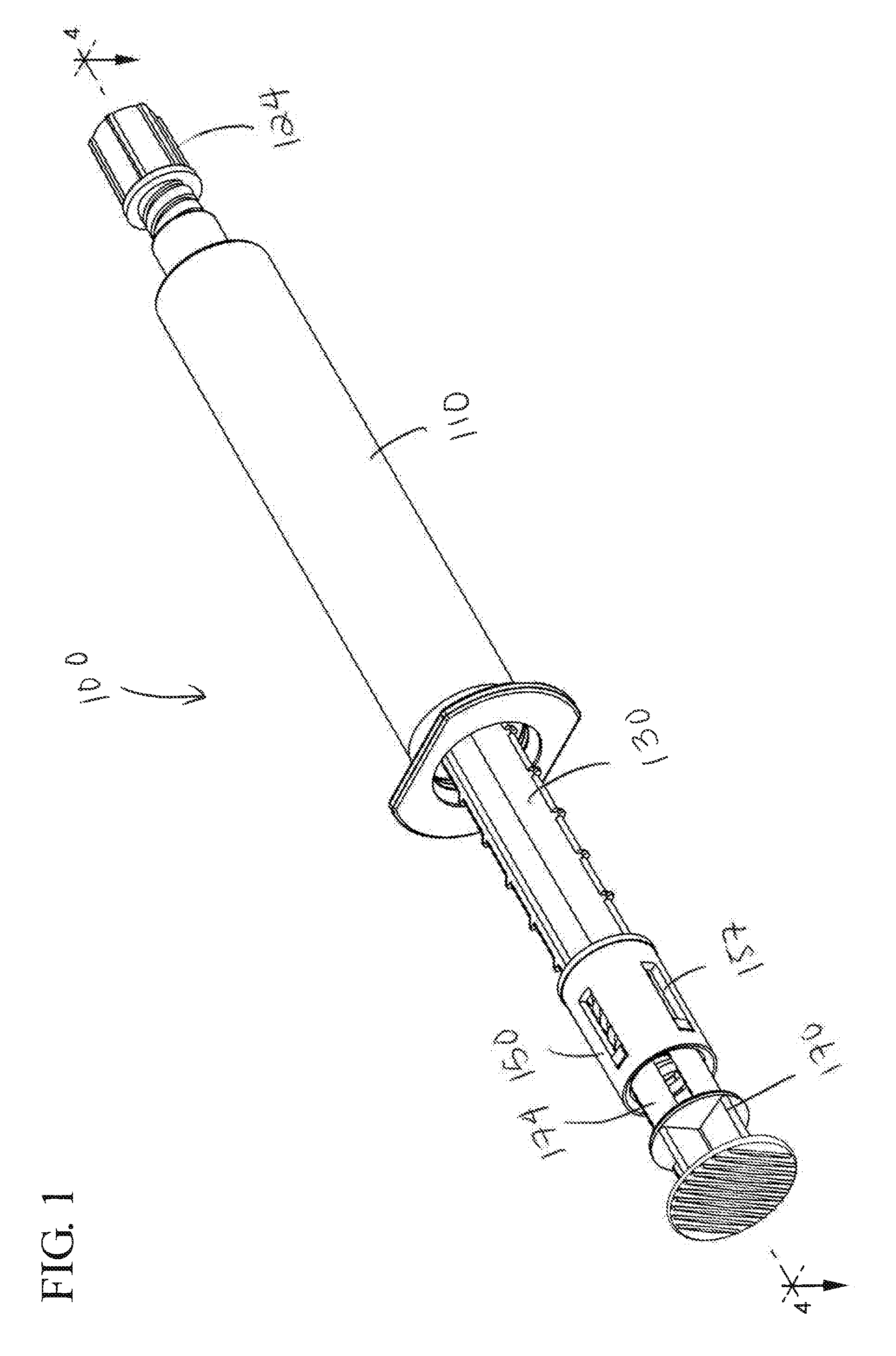

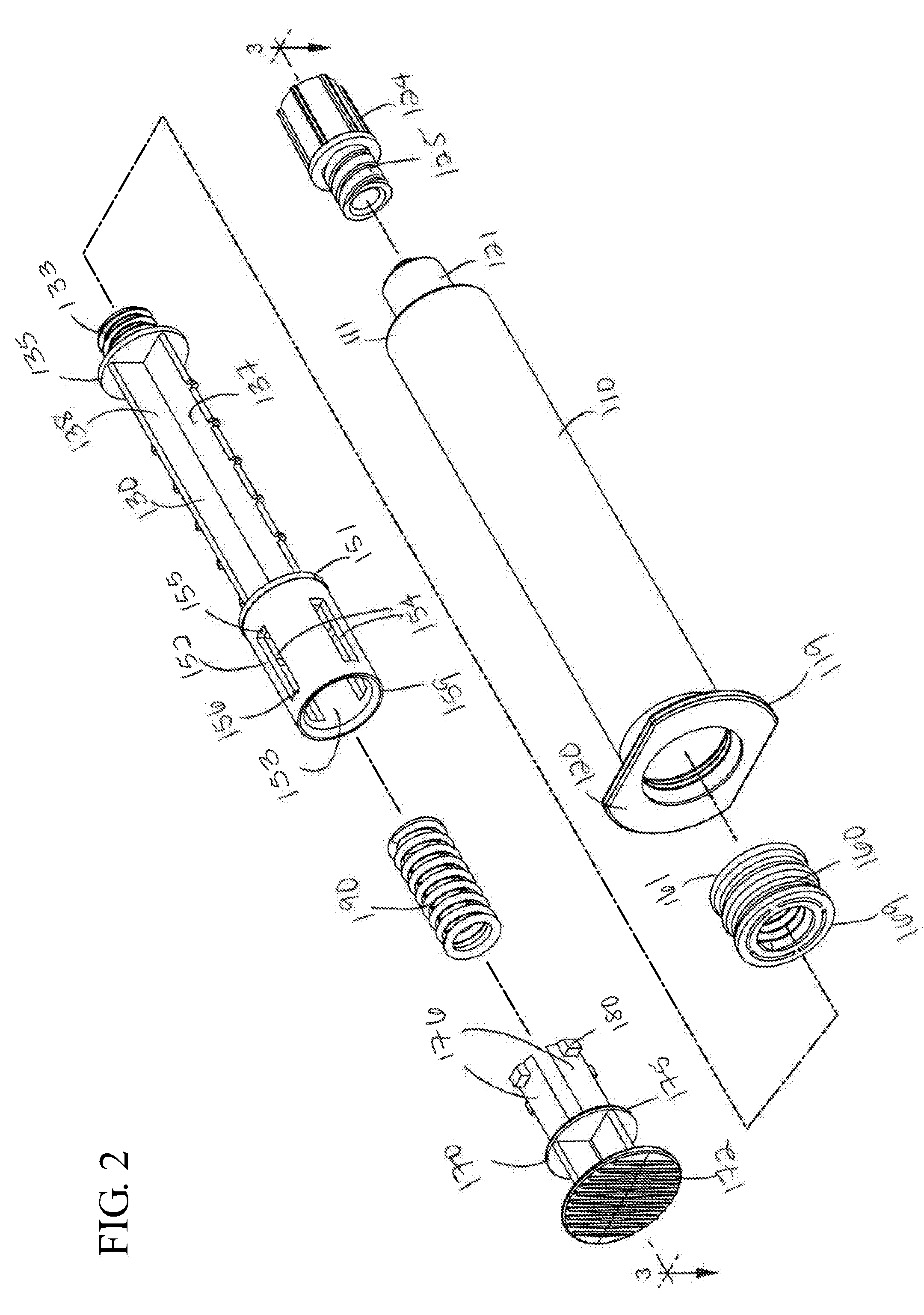

Flush Syringe Assembly with Controlled Pulsatile Flushing

ActiveUS20110009830A1Reduce and increase lengthIncrease the lengthInfusion syringesMedical devicesPulse controlBiomedical engineering

Flush syringe assemblies capable of creating pulsatile movement of the plunger rod as it moves in the distal direction within a syringe barrel, while preventing overpressurization of the cathether are provided. An exemplary flush syringe assembly includes a syringe barrel with a first pulsing element and a chamber with flush solution, a plunger rod with a stopper and a second pulsing element that interacts with the first pulsing element to provide an engagement force that causes pulsatile movement of the plunger rod and a thumb press slidably attached to the plunger rod with a pulse control element. The pulse control element is compressible to create a compression force that is greater than the engagement force of the first pulsing element and the second pulsing element.

Owner:BECTON DICKINSON & CO

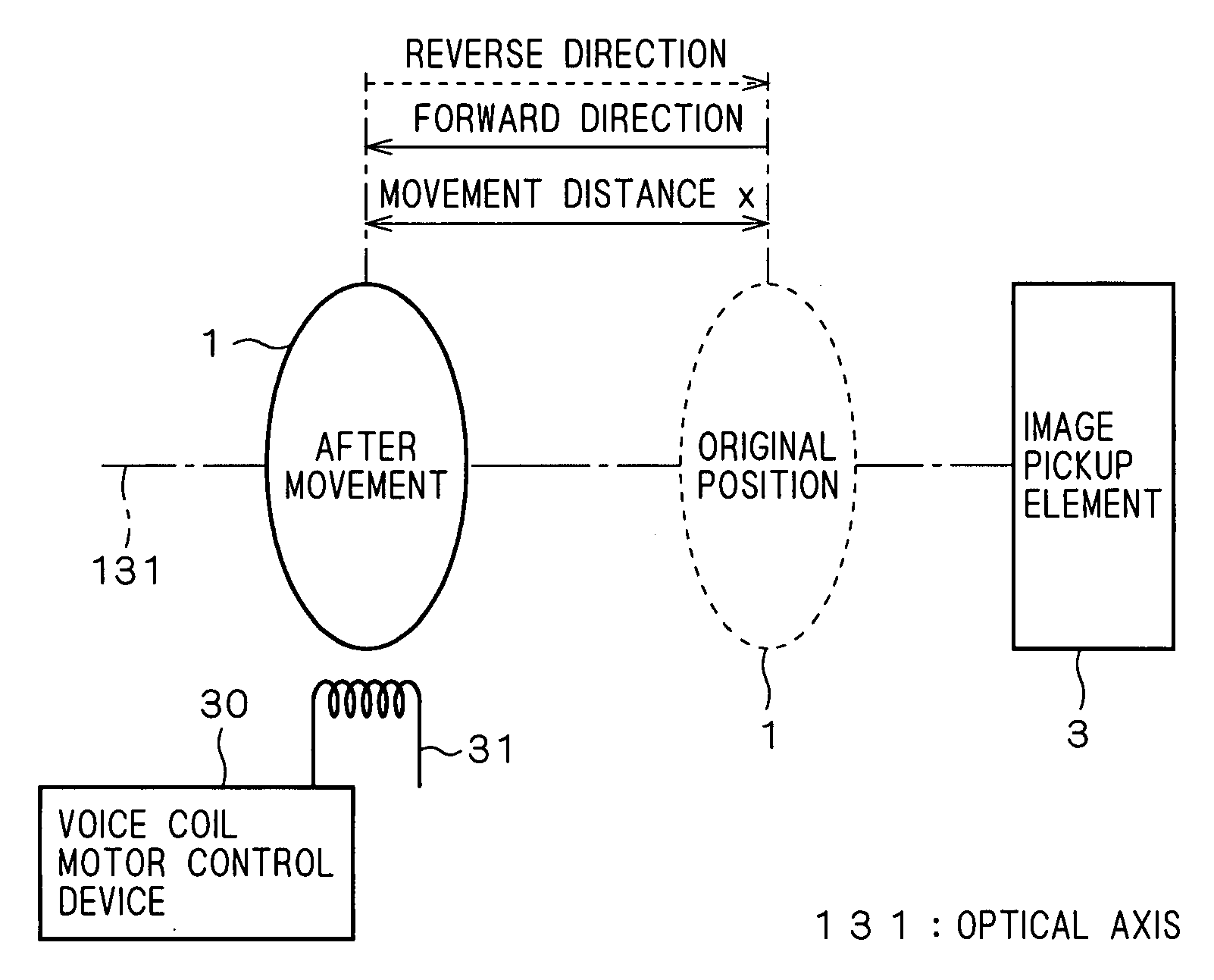

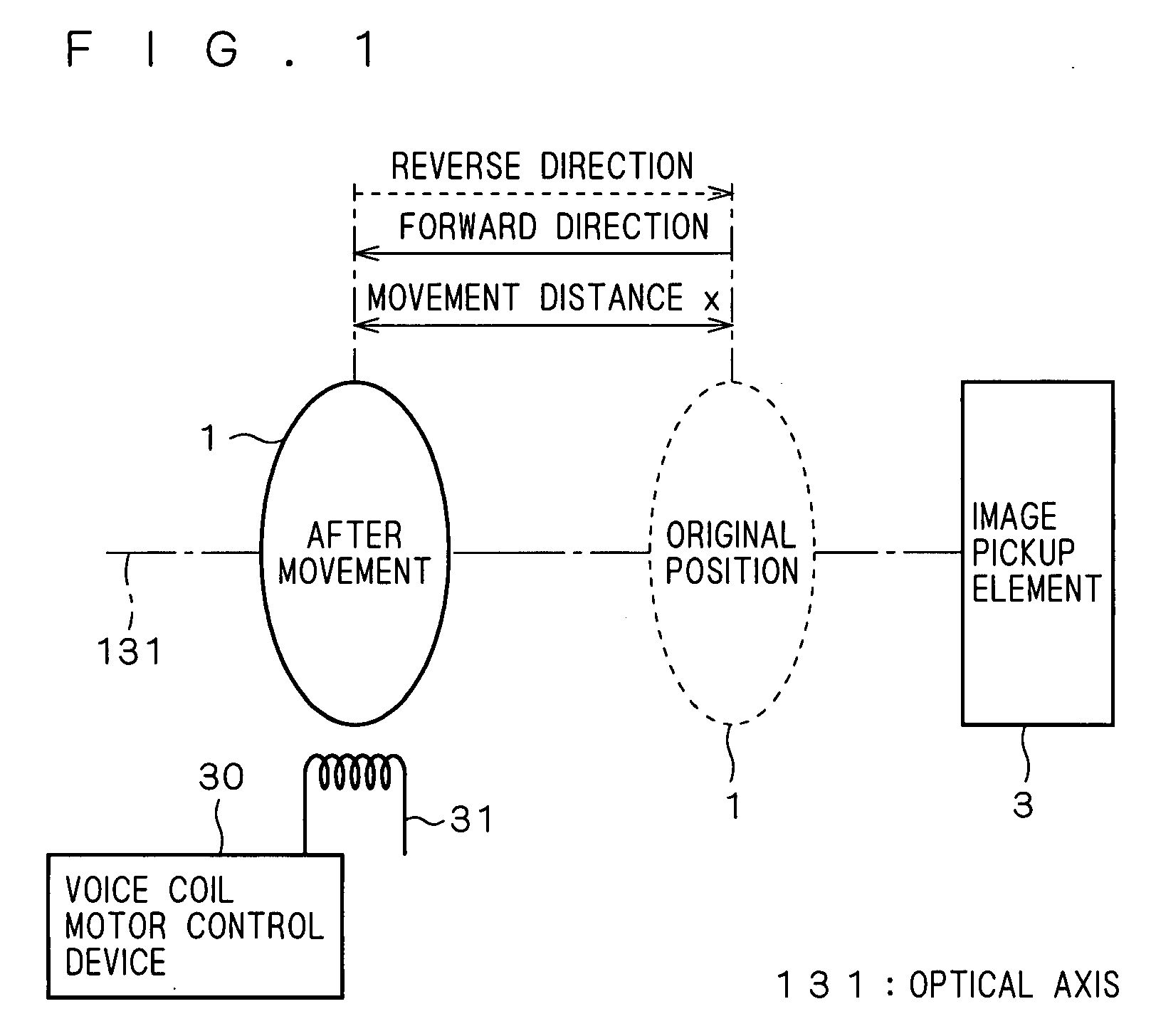

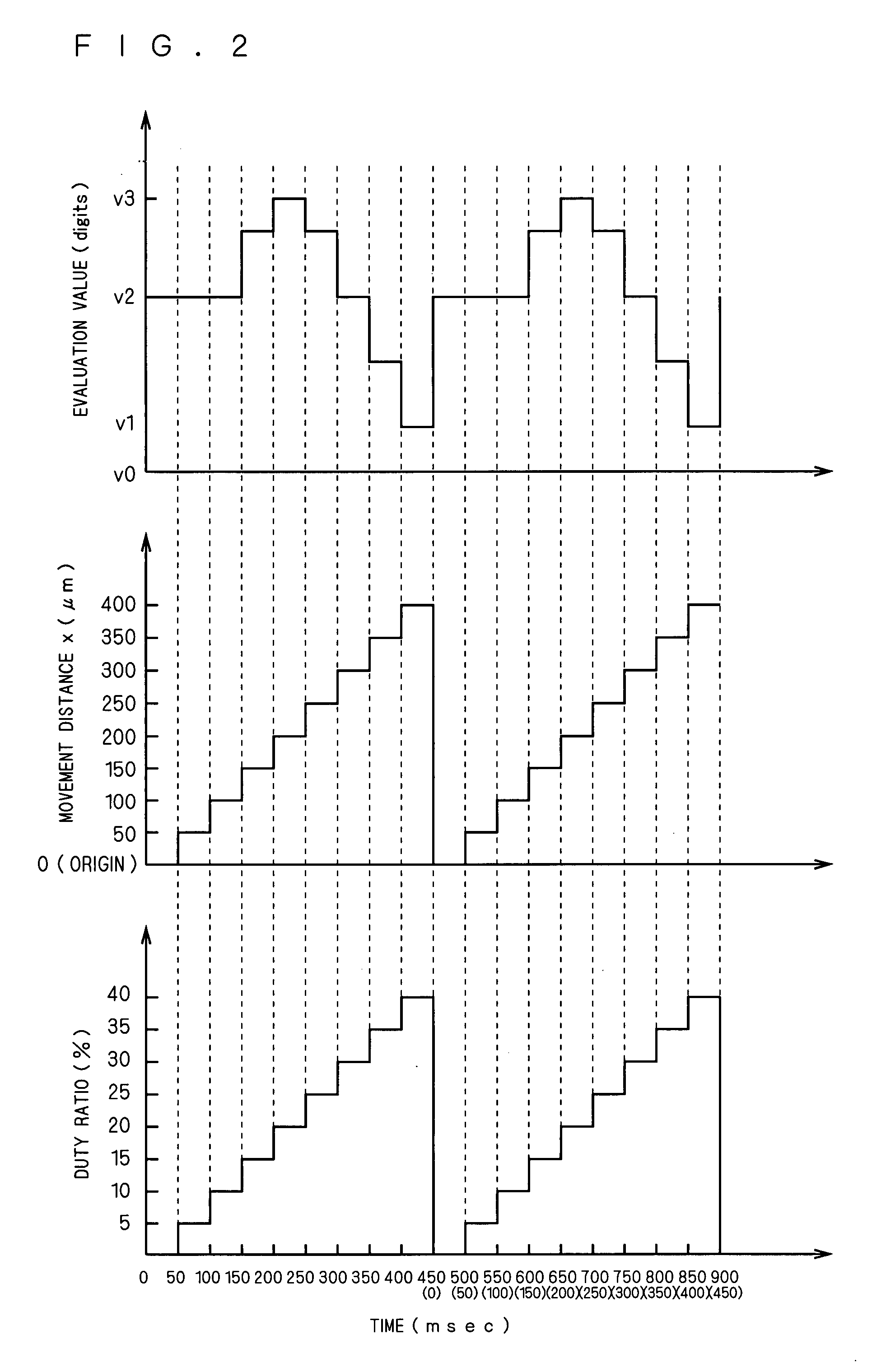

Voice Coil Motor Control Device and Method of Driving the Same, Image Pickup Device

InactiveUS20080130134A1Hysteresis characteristicSuitable lensTelevision system detailsAC motor controlDriving currentHysteresis

The present invention provides a control device capable of improving hysteresis characteristics of a voice coil motor (31) and attaining a suitable lens position without complicating the structure of the control device. As solving means of the invention, a voice coil motor control device (30) includes a driving current control part (34) that controls a driving current supplied to the voice coil motor (31) in accordance with a driving pulse subjected to pulse width modulation, and a driving pulse control part (32) that divides a drive period of the voice coil motor (31) into a movement period and a holding period, and controls the driving pulse by changing the duty ratio of the driving pulse during the movement period in accordance with a duty setting value and fixing the duty ratio of the driving pulse during the holding period to the duty setting value.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com