Comprehensive performance testing machine for ultra-high speed oil bearing

A comprehensive performance, ultra-high-speed technology, used in mechanical bearing testing and other directions, to achieve stable performance, simple structure, high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

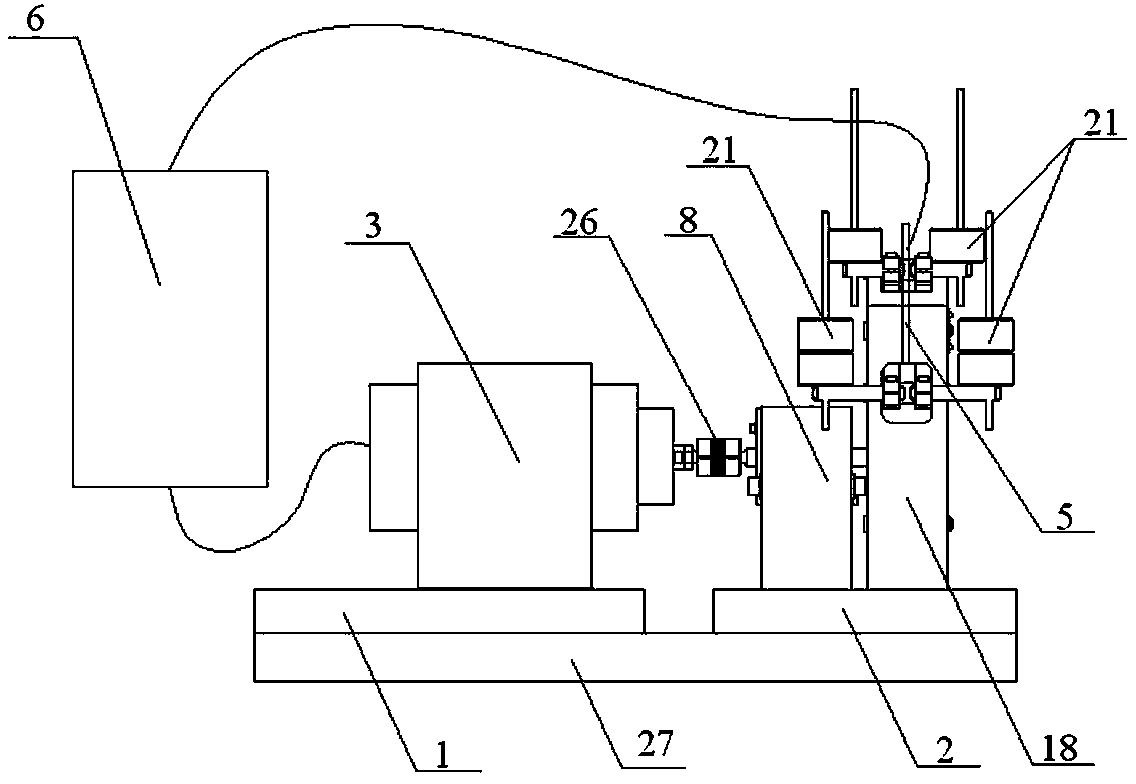

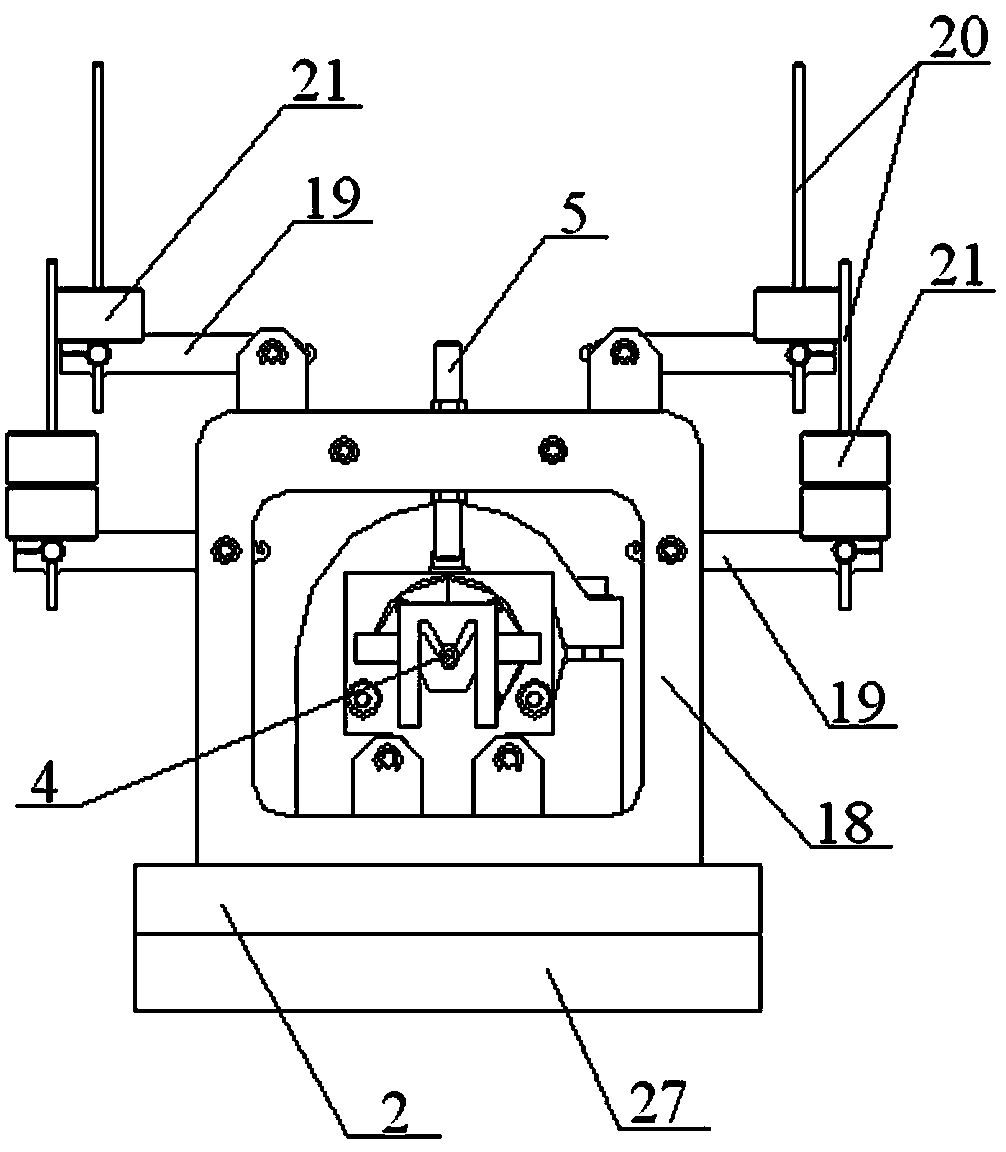

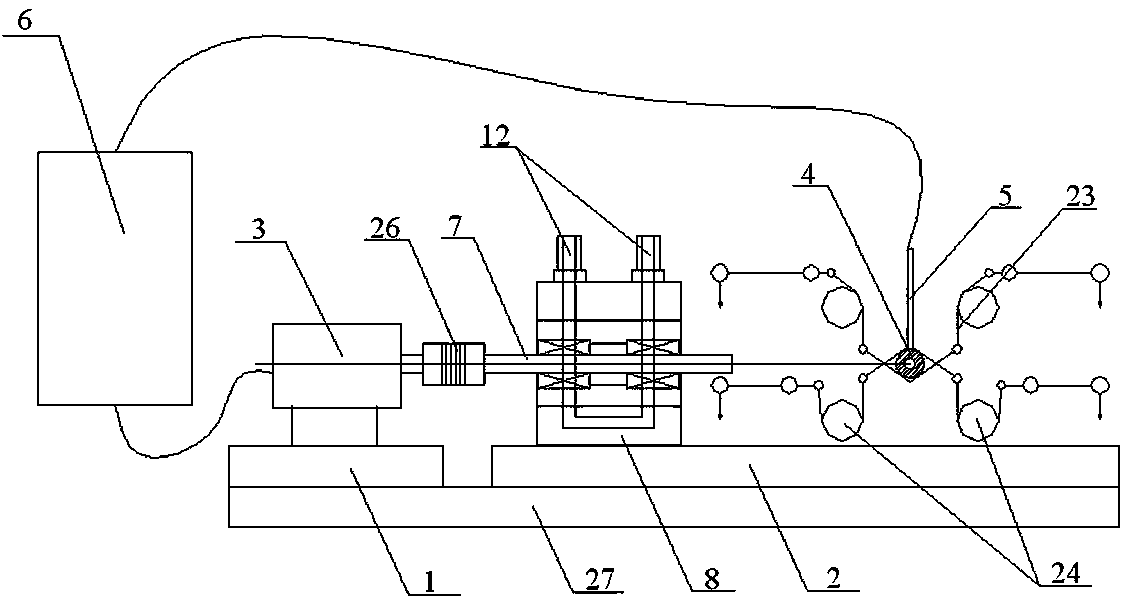

[0033]The ultra-high-speed oil-impregnated bearing comprehensive performance testing machine includes two separate test benches I1 and II2, the driving device 3 on the test bench I1 and the load device on the test bench II2. The interior of the load device is A clamping device for clamping the oil bearing 4 to be tested is provided, and the top of the clamping device is provided with a temperature measuring hole for inserting a temperature sensor 5, and the temperature sensor 5 is inserted into the hole to contact the outer surface of the oil bearing 4 to be tested, And the temperature sensor 5 and the driving device 3 are all connected with a peripheral electric control cabinet 6, and the output shaft of the driving device 3 is connected with a dynamic pressure tester for rotating and inserting in the center hole of the oil bearing 4 to be tested. Shaft 7, the outer side of the dynamic pressure test shaft 7 is provided with a slewing support device. The output shaft of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com