Patents

Literature

511results about "Electrochemical processing of electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

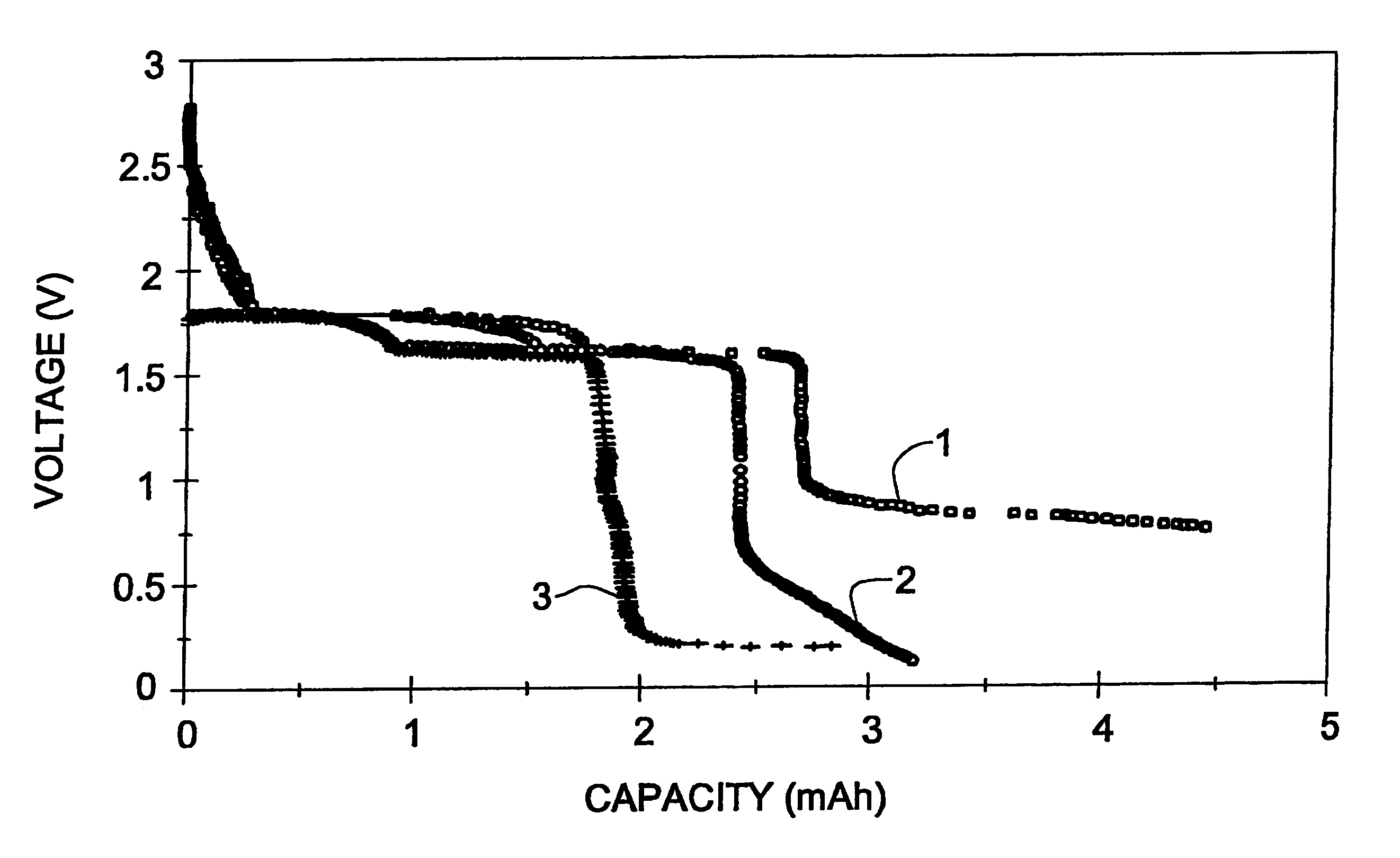

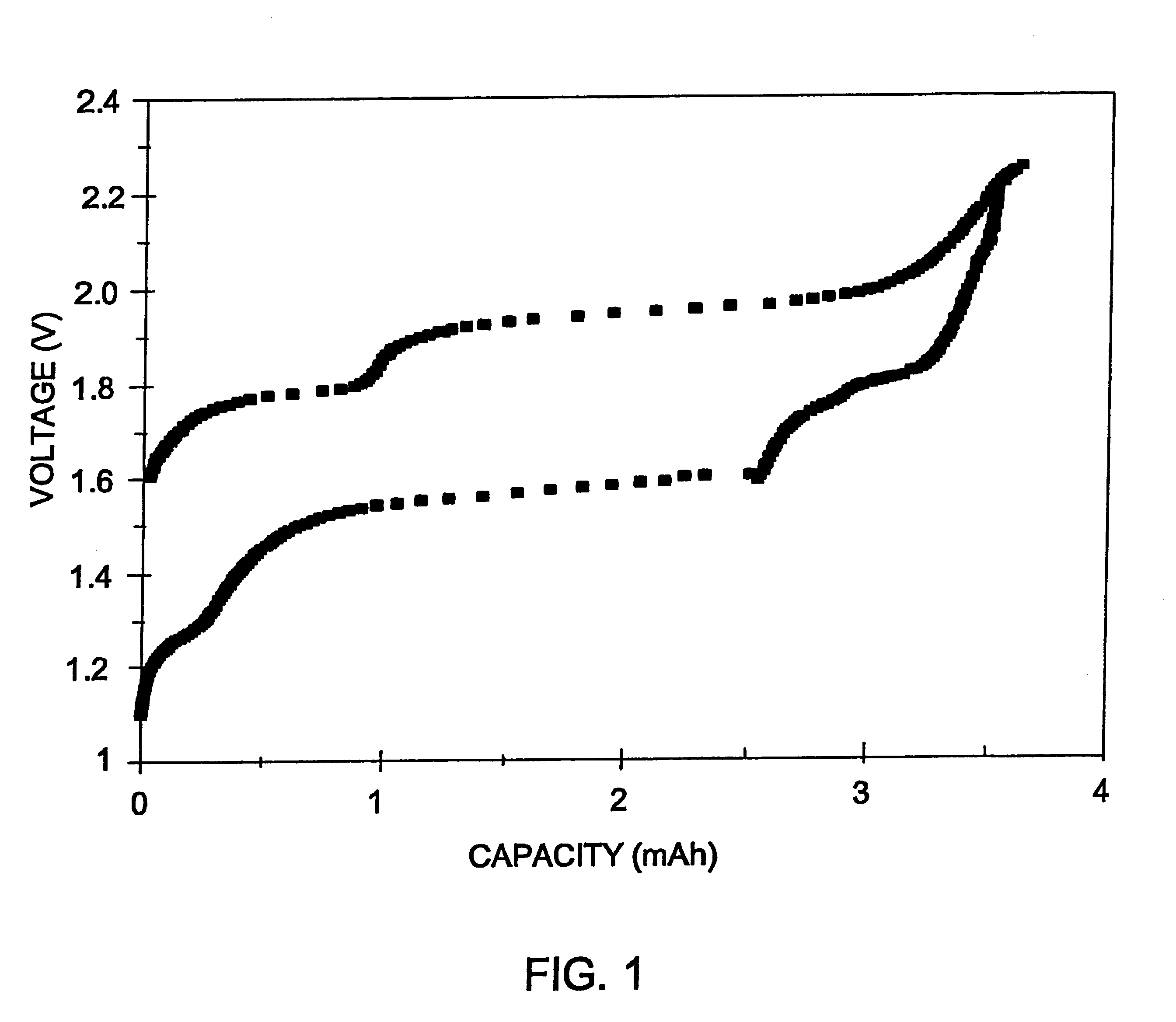

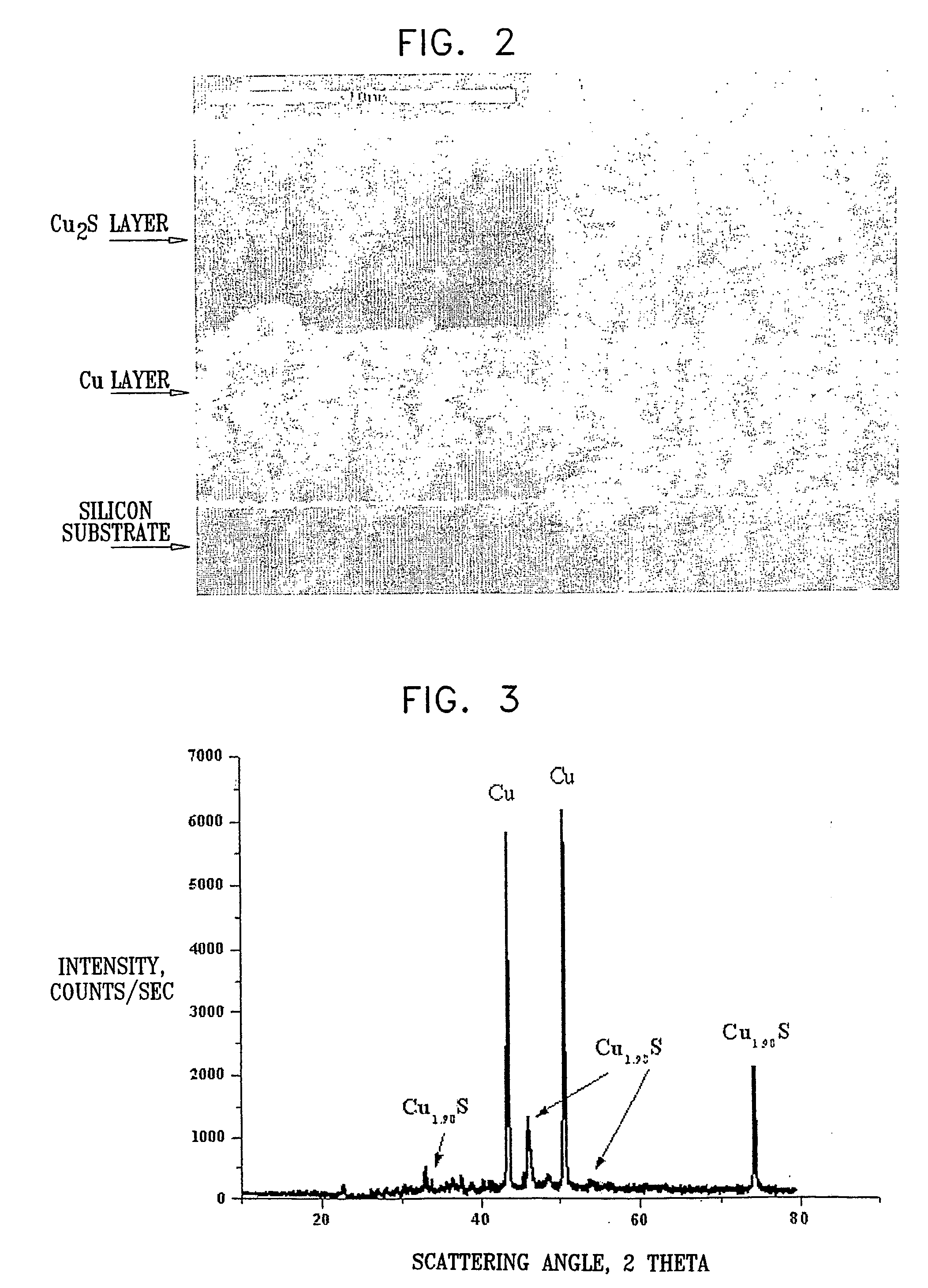

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

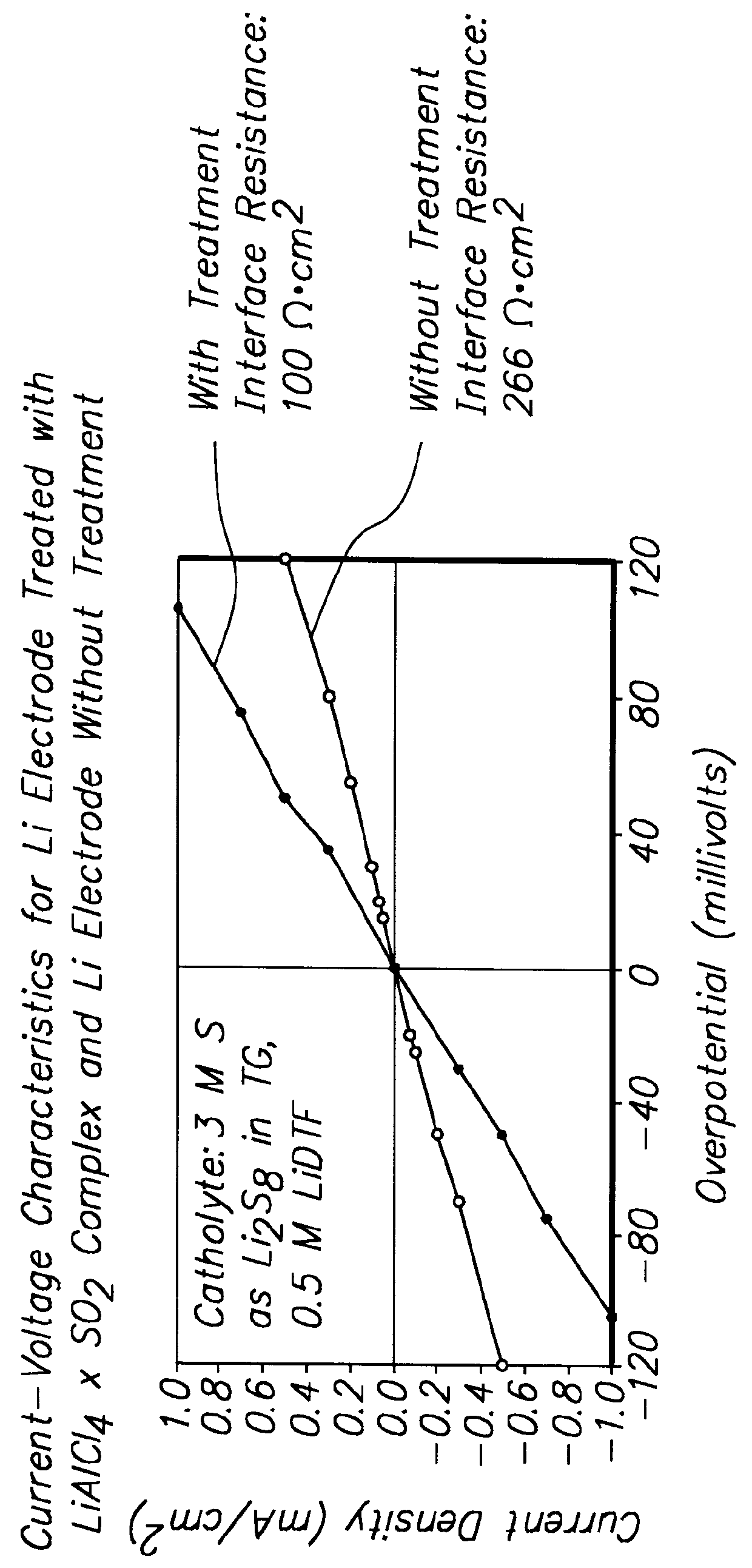

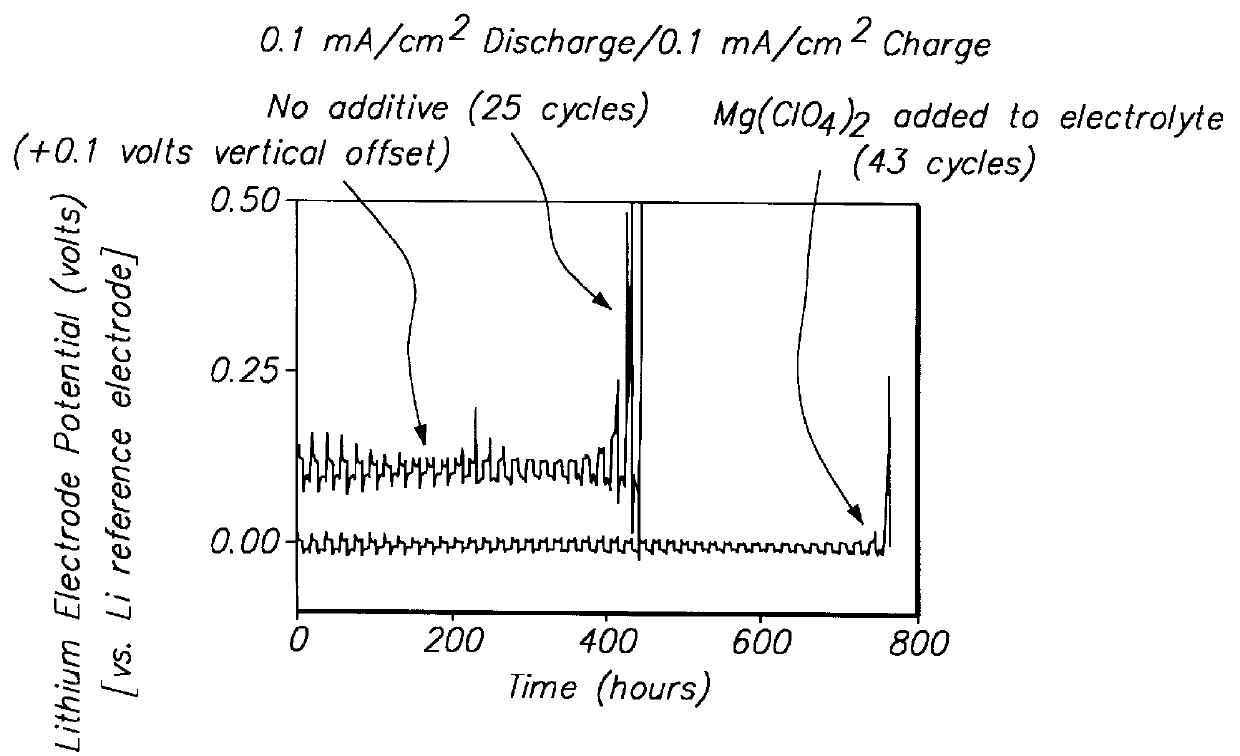

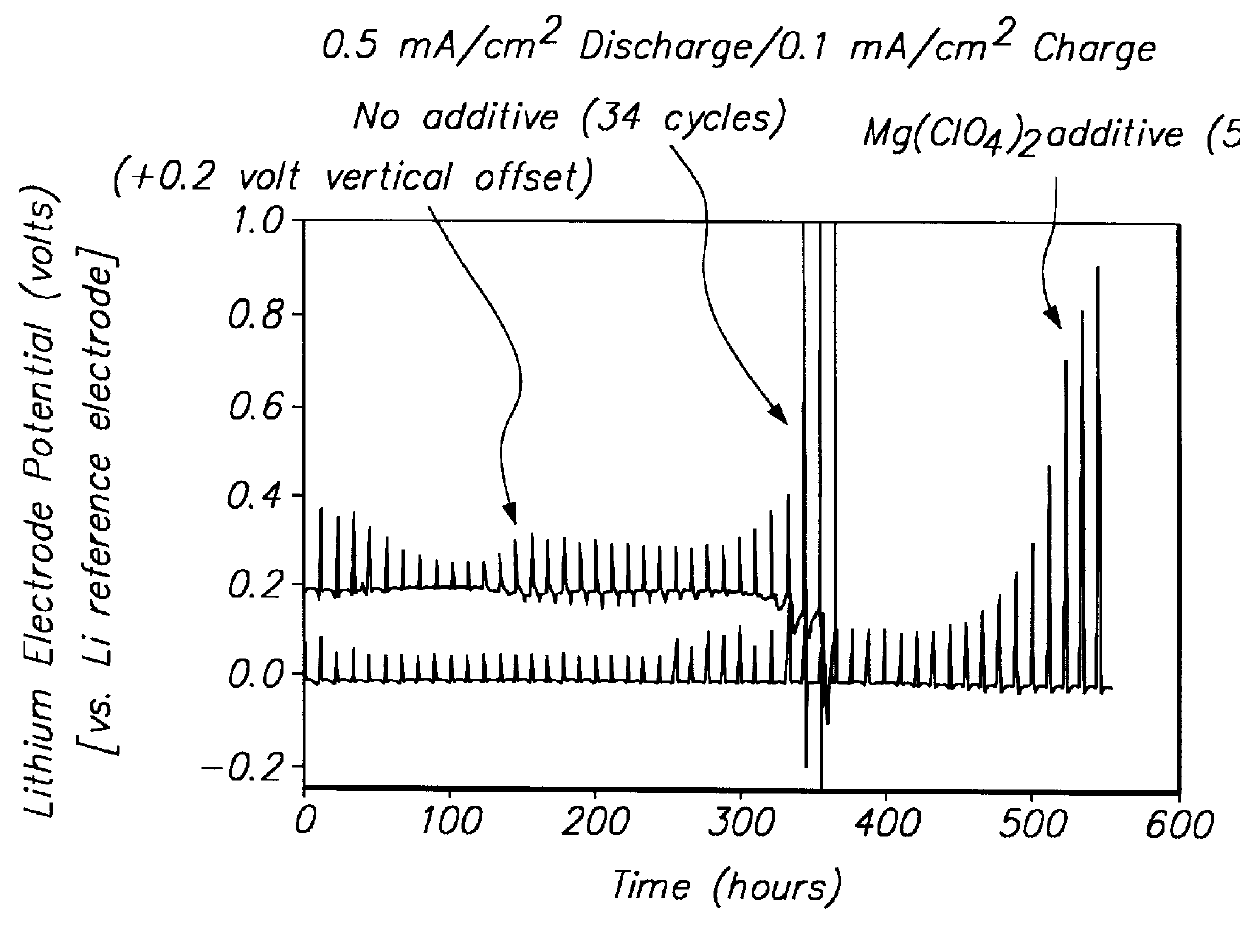

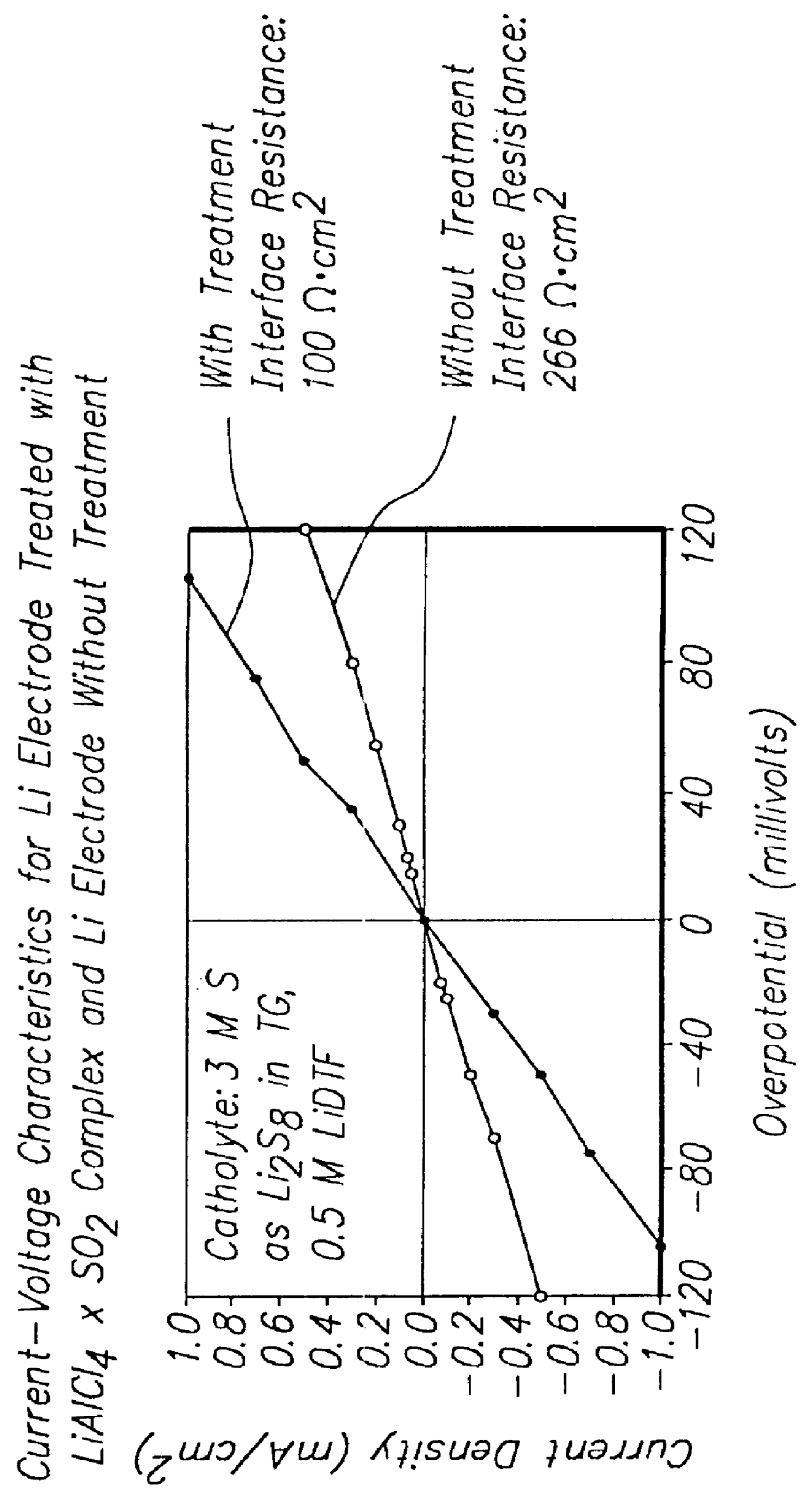

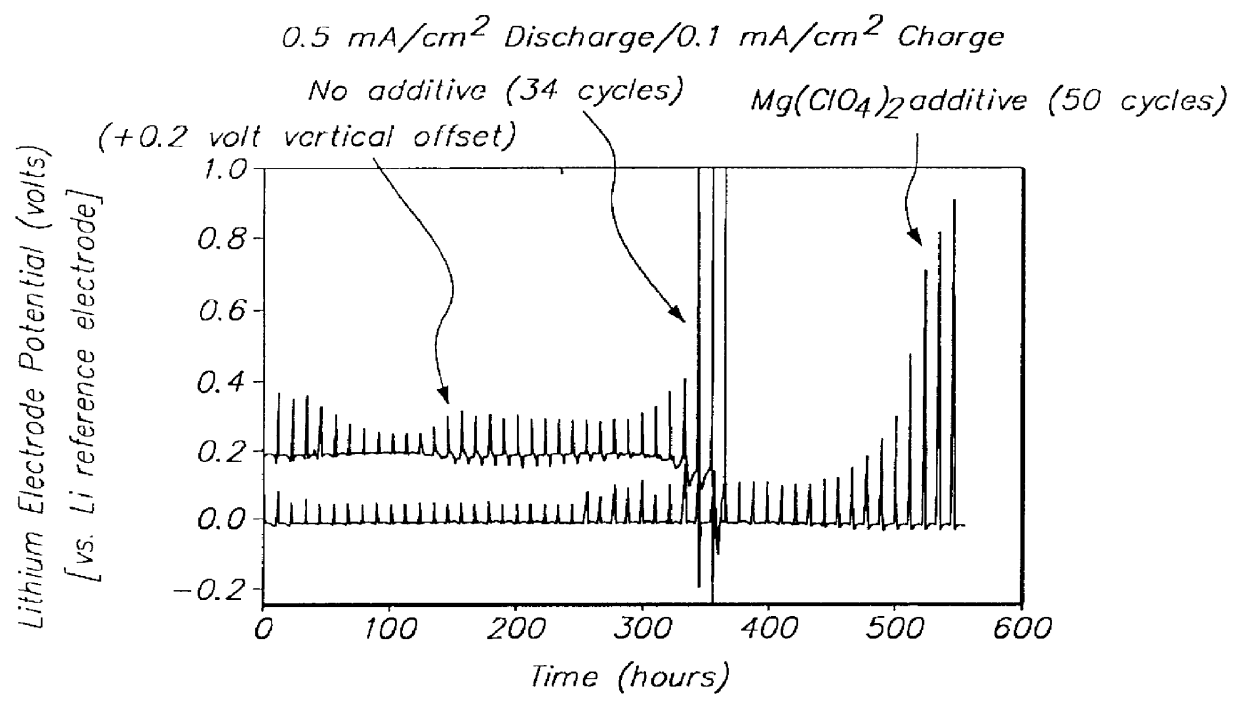

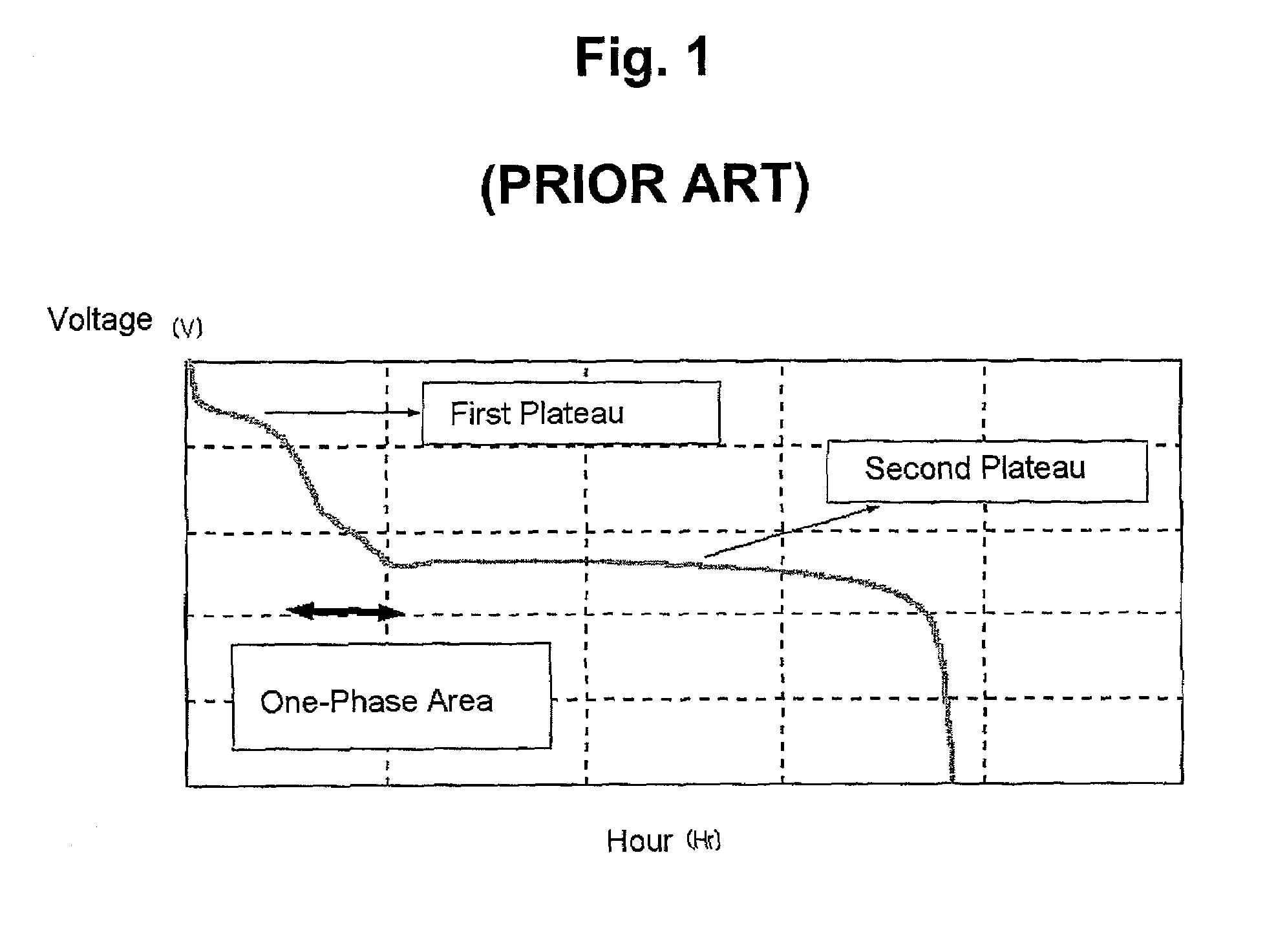

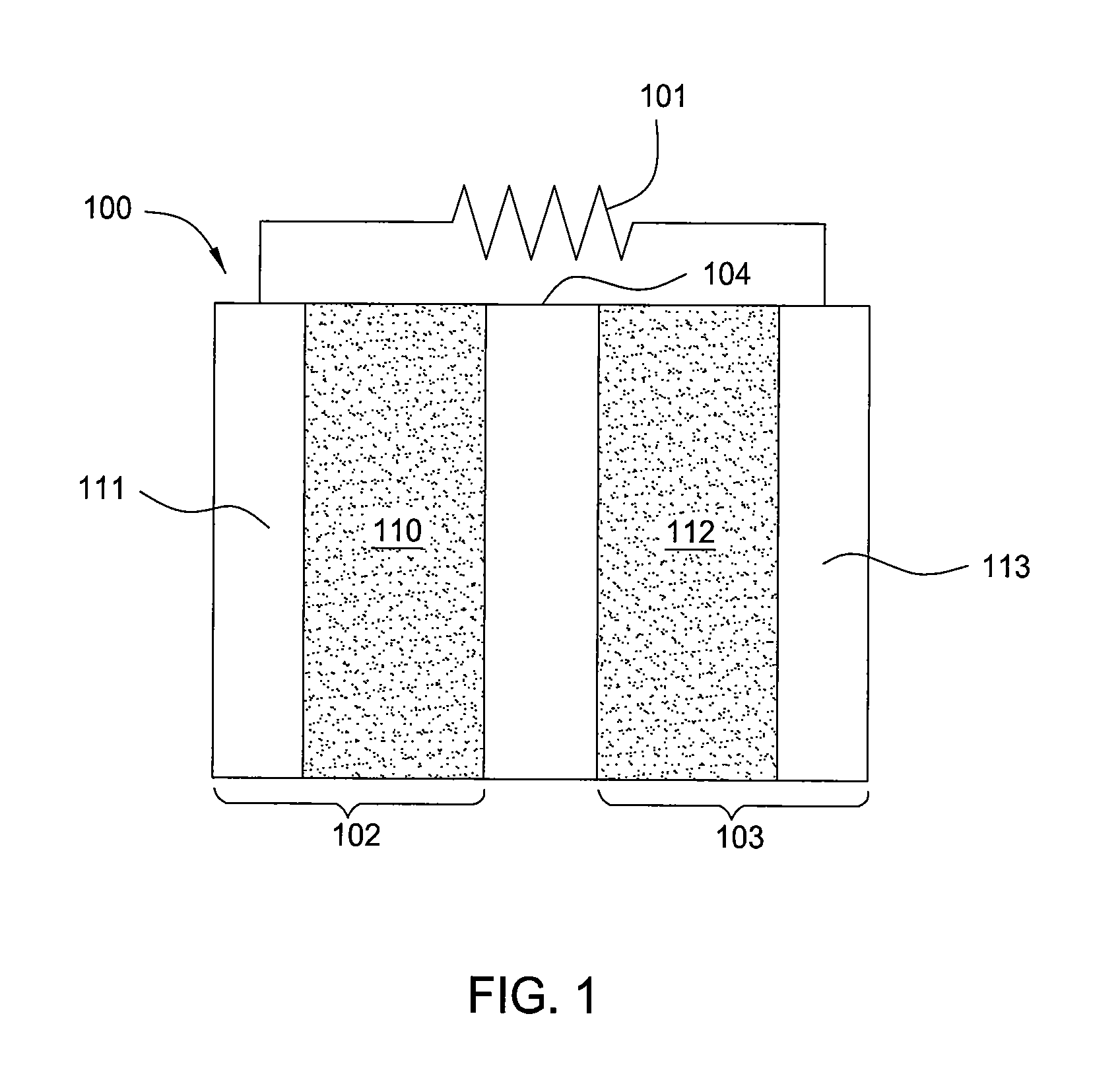

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

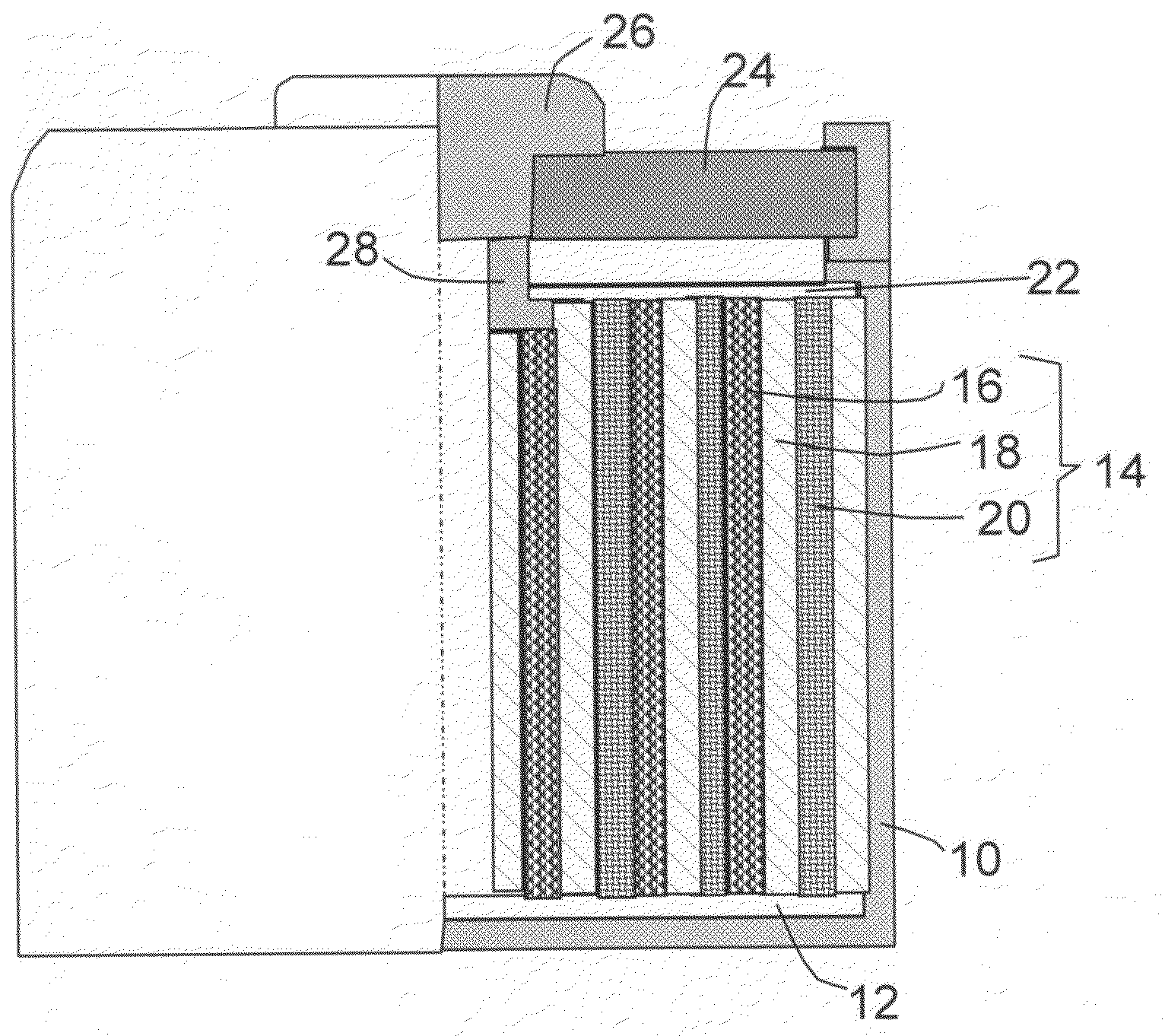

Lithium-ion rechargeable battery based on nanostructures

A nanowire-based Li-ion rechargeable battery having superior performance with little capacity fade for use in applications including consumer electronics and medical devices is made by incorporating nanowire construction of the cathode. The nanowire-based battery system includes a nanostructured high surface area cathode structure fabricated by electrodeposition using alumina nanopore templates.

Owner:ENABLE IPC

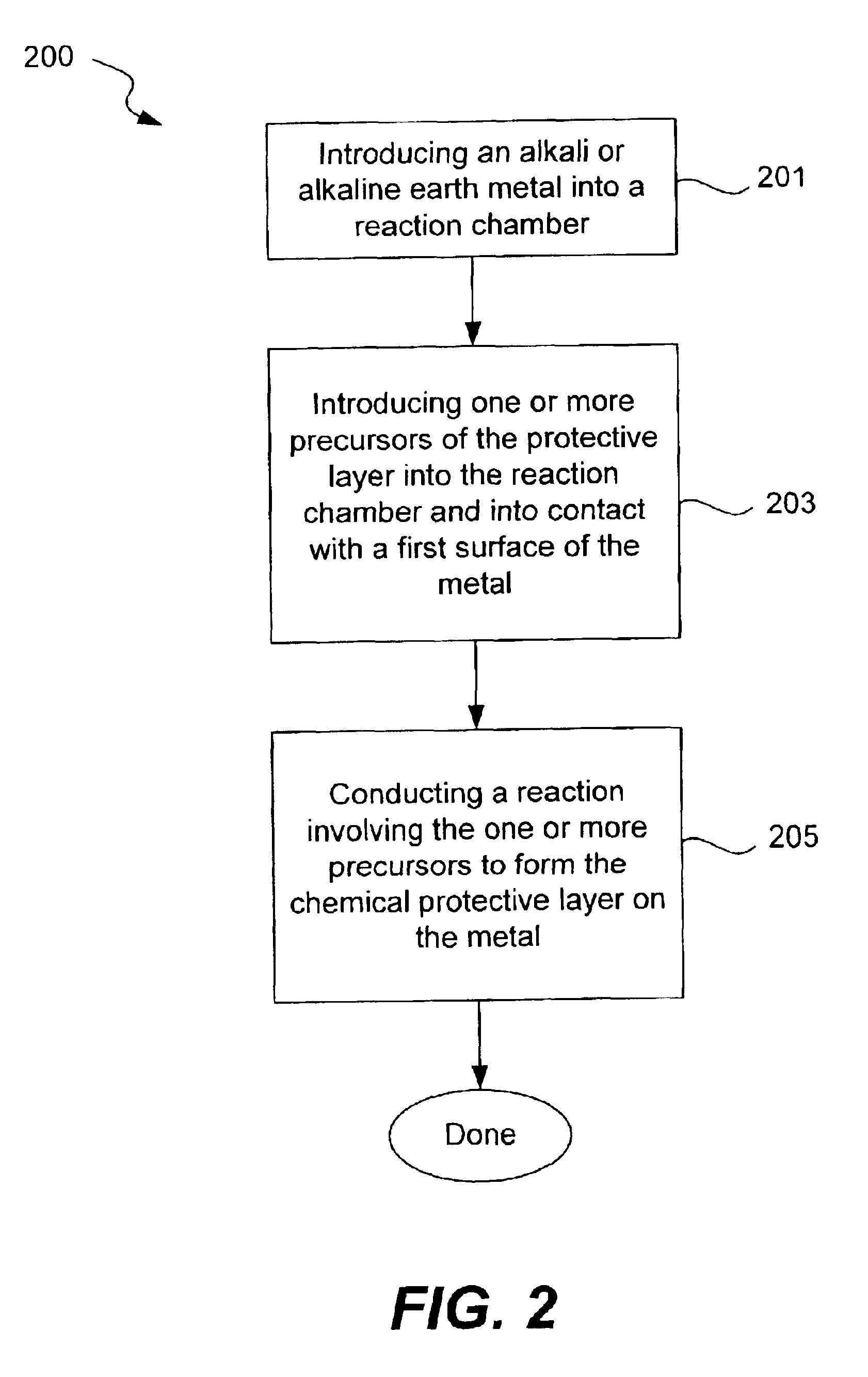

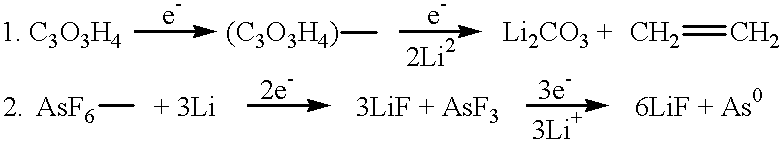

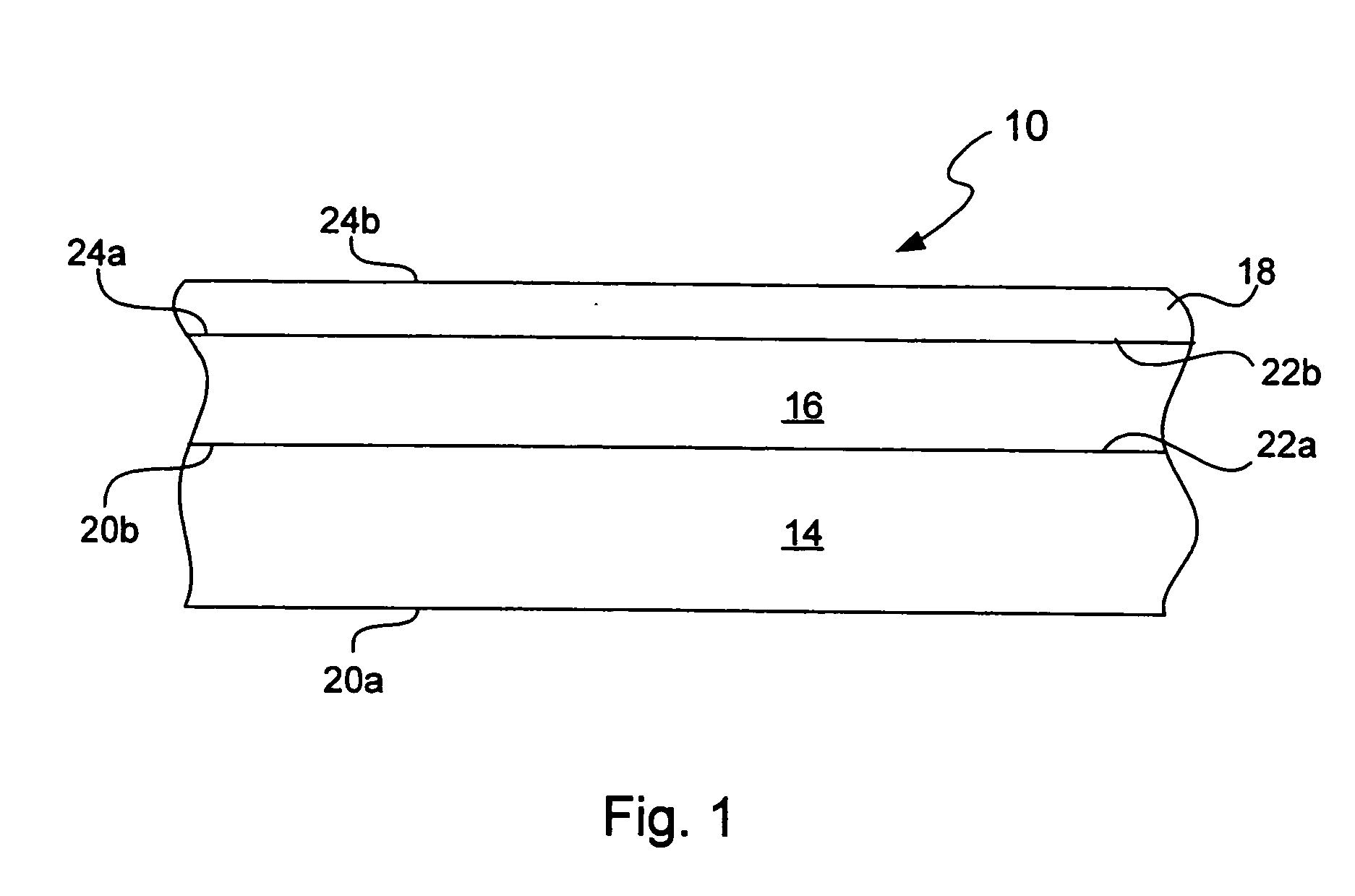

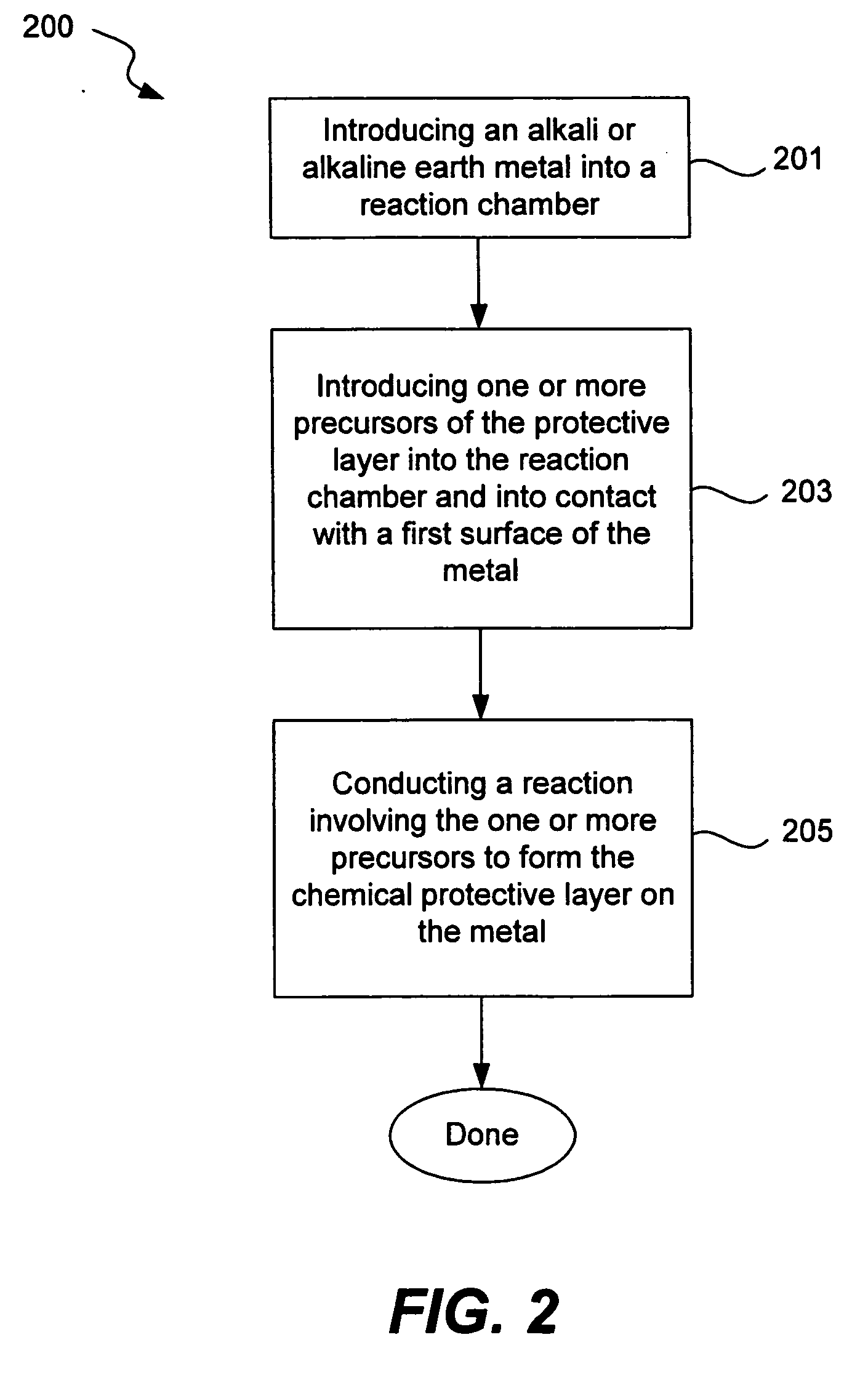

Chemical protection of a lithium surface

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

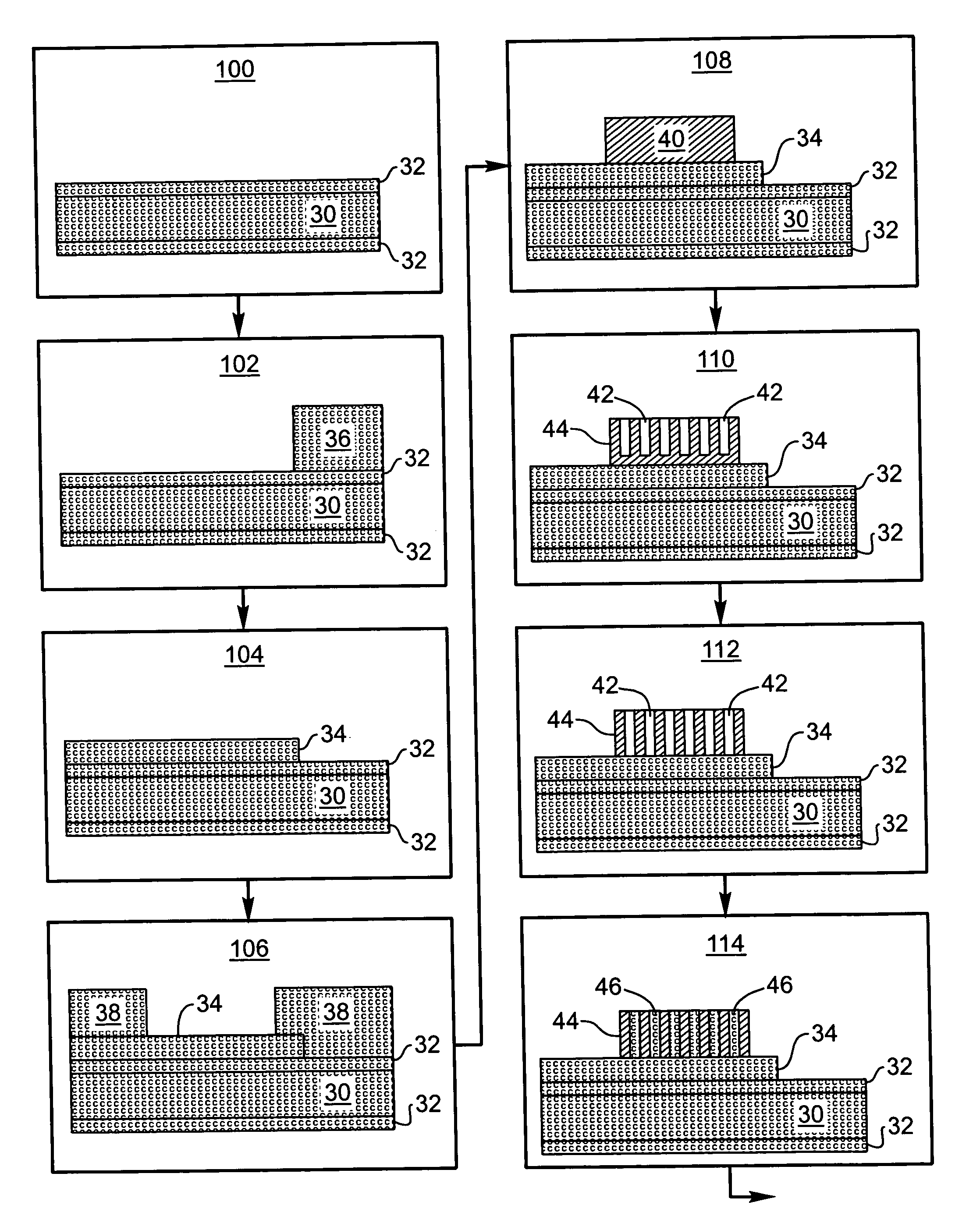

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Long cycle-life alkali metal battery

InactiveUS6203947B1Improve cycle lifeFast charging rateElectrochemical processing of electrodesElectrode carriers/collectorsHigh pressureElectrochemical cell

The present invention provides a cathode for use in a secondary electrochemical cell, such cathode being coated with a very thin, protective film, permeable to ions. The protective film of the cathode usually has a thickness of up to about 0.1 mum and it provides protection against high voltage charging and overdiscbarging. The present invention further provides a secondary electrochemical cell comprising such a cathode.

Owner:RAMOT UNIV AUTHORITY FOR APPLIED RES & INDAL DEVMENT

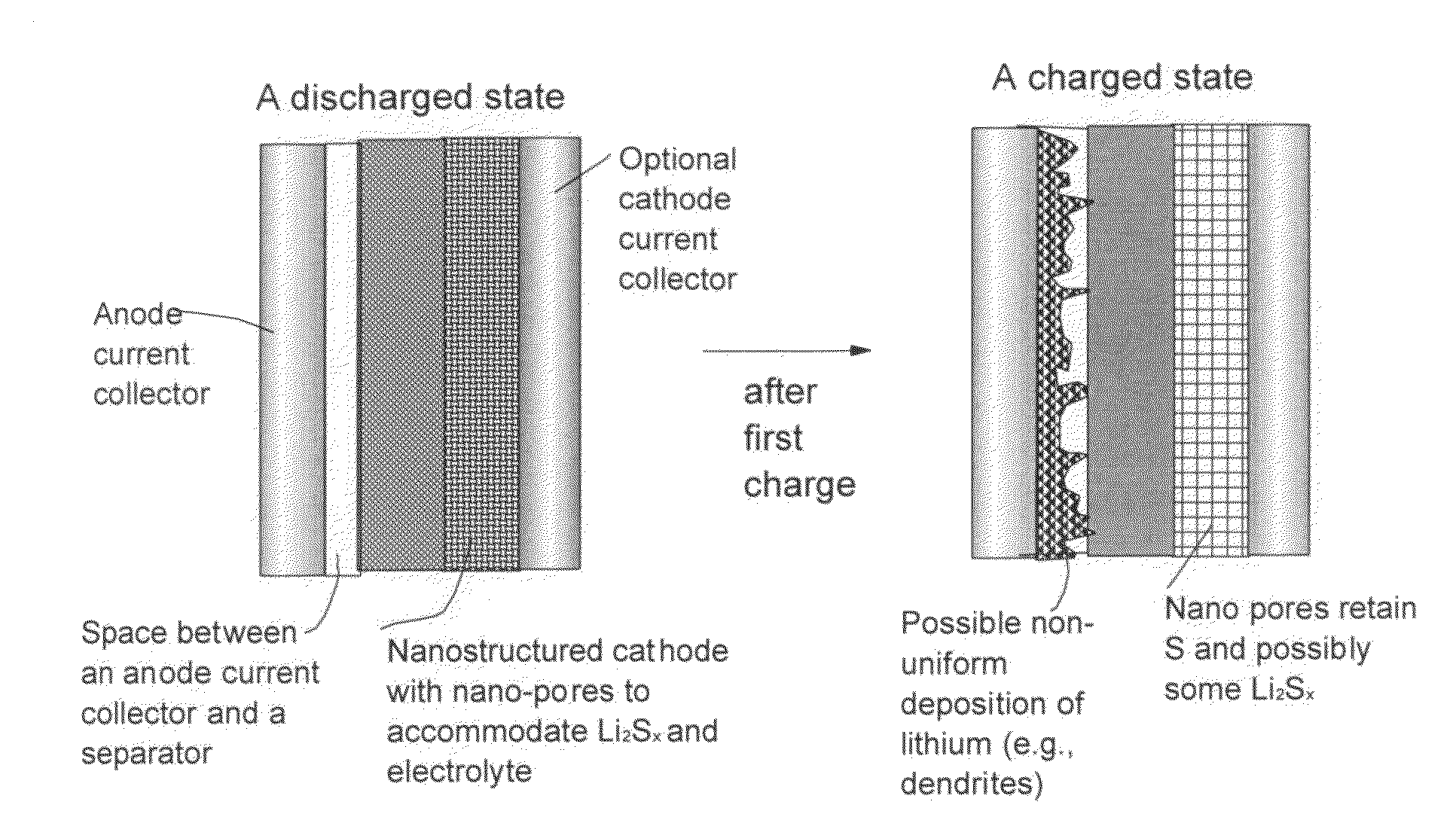

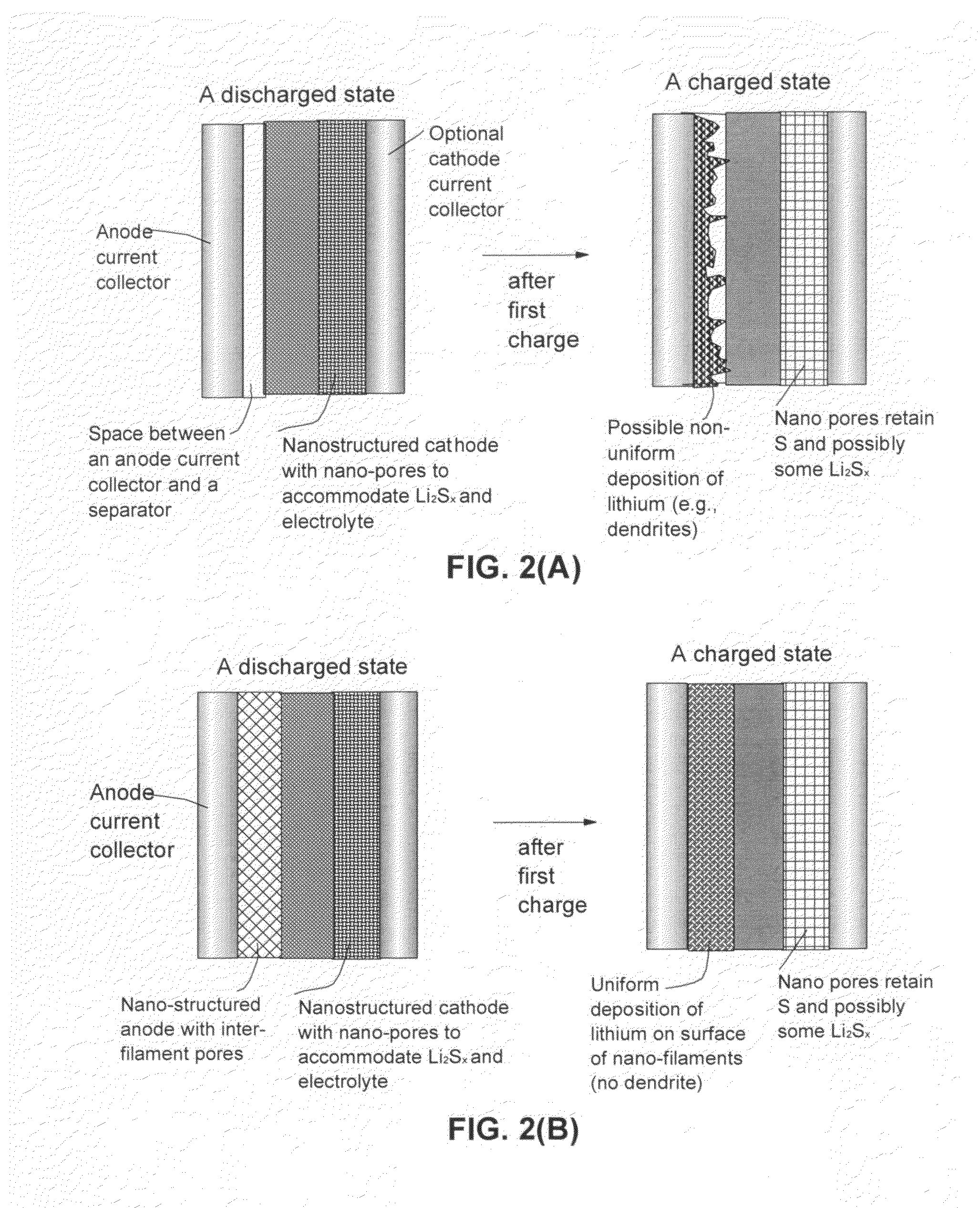

Lithium metal-sulfur and lithium ion-sulfur secondary batteries containing a nano-structured cathode and processes for producing same

ActiveUS20110165466A1High specific capacityImprove the immunityMaterial nanotechnologyElectrochemical processing of electrodesSpecific energyLithium metal

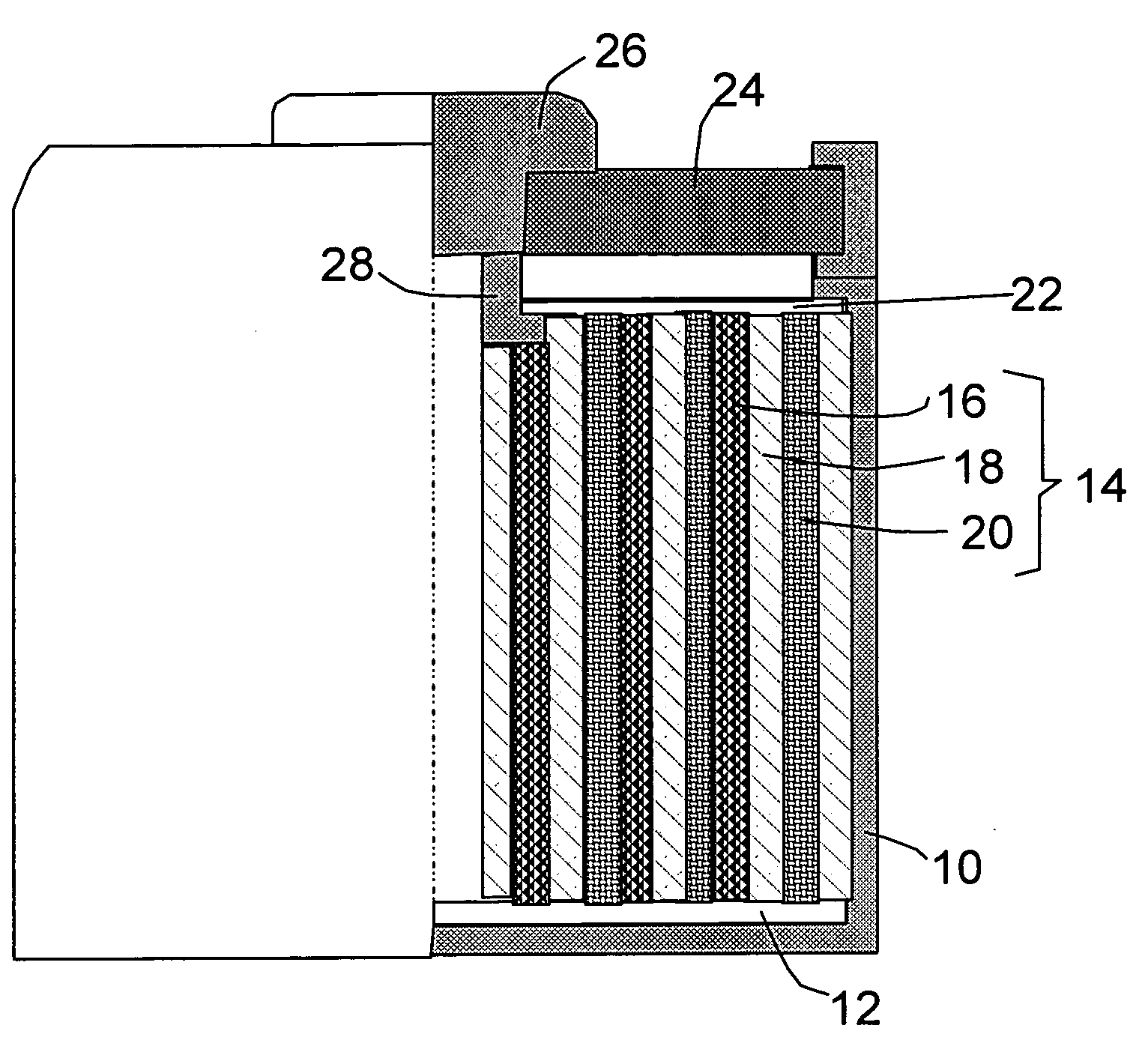

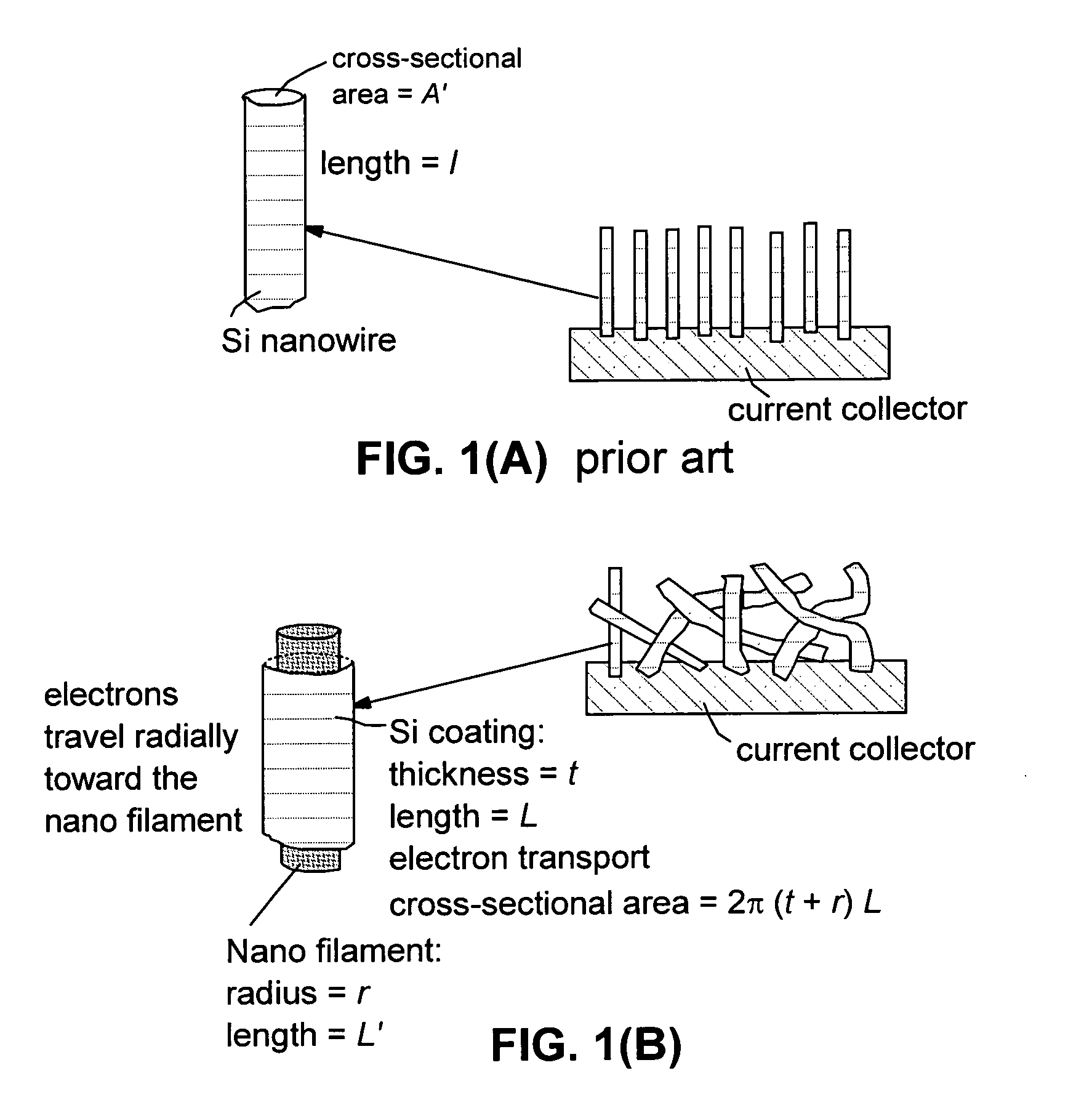

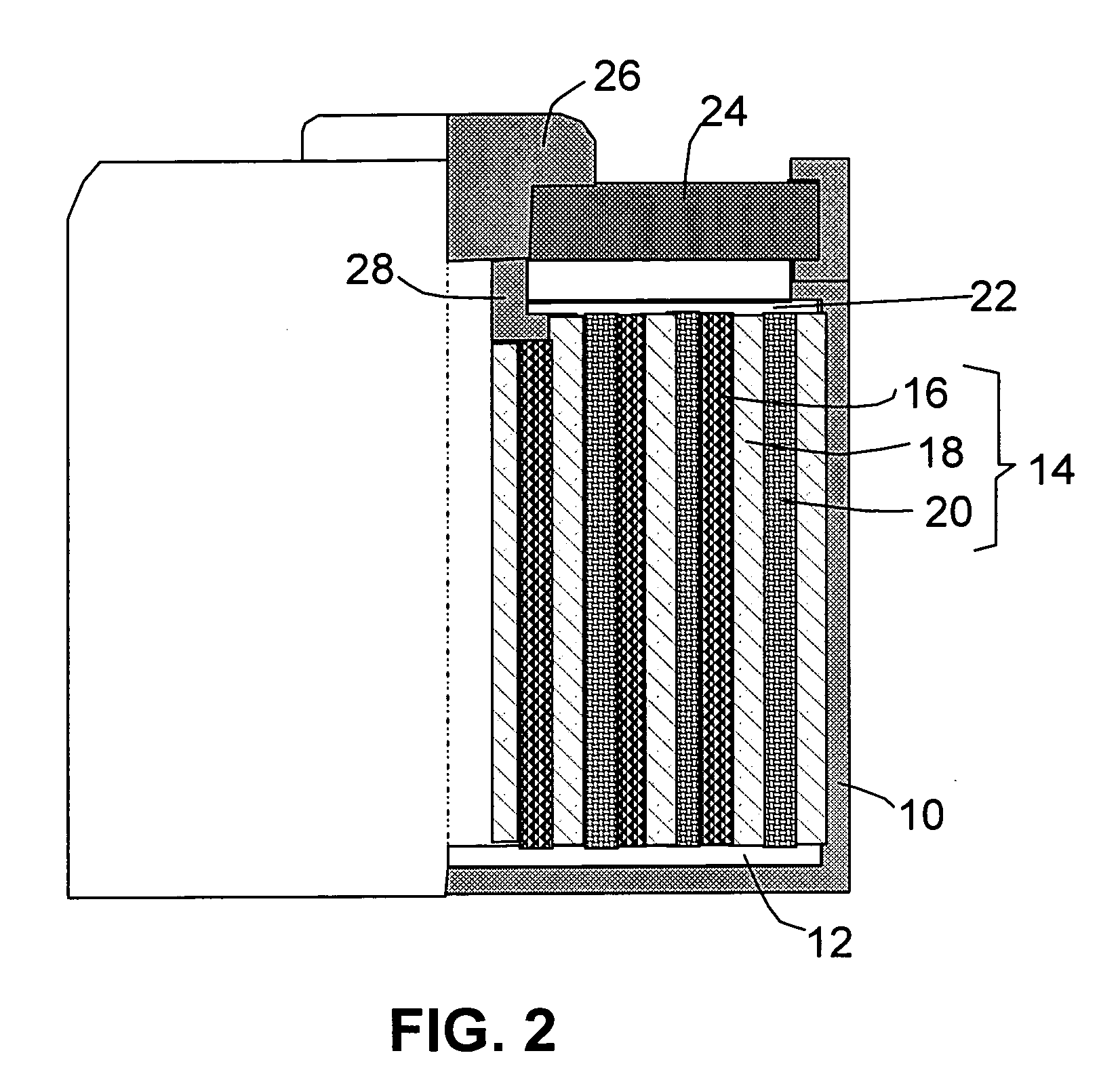

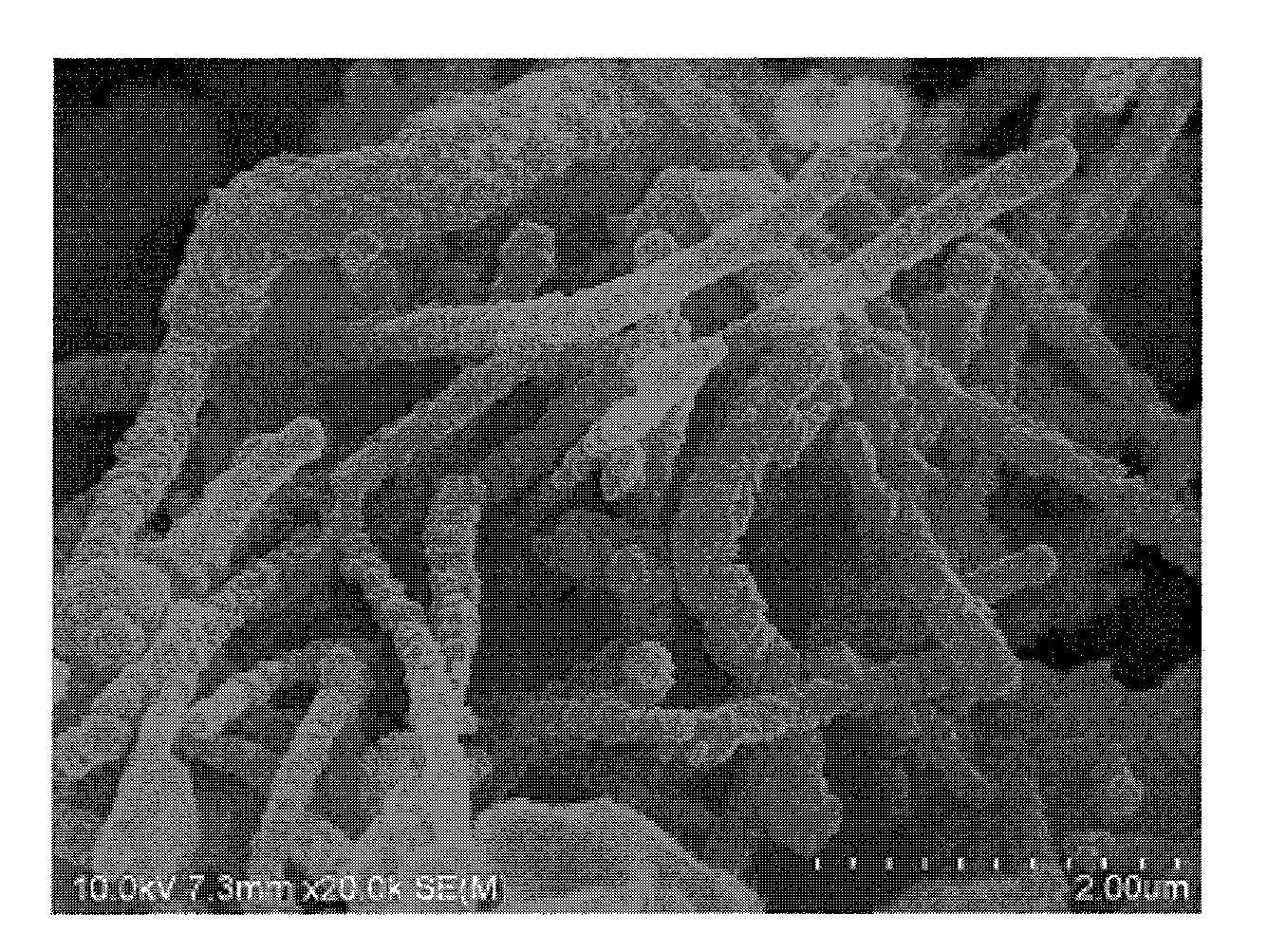

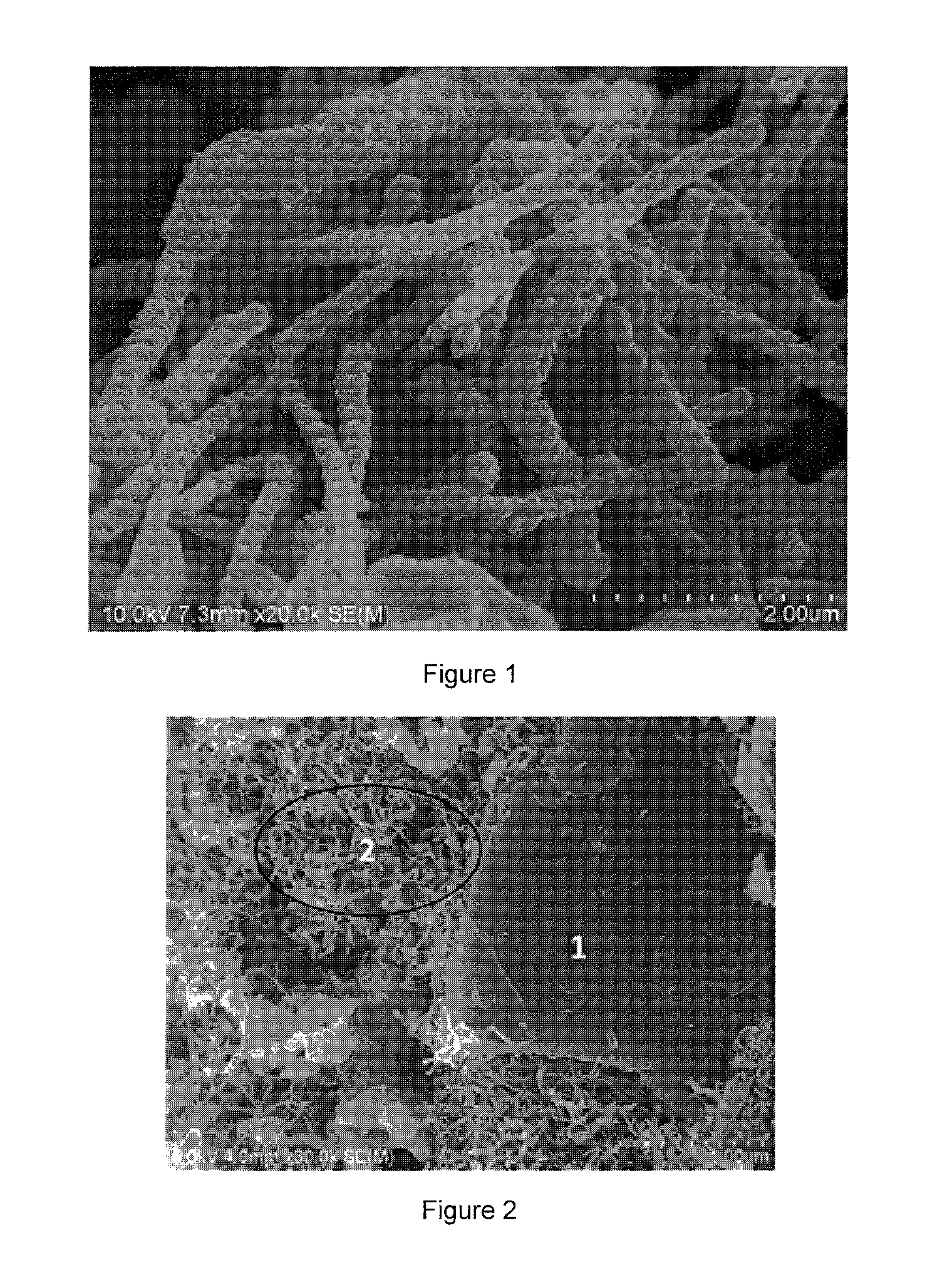

An electrochemical cell comprising an anode, electrolyte or an electrolyte / separator combination, and a nano-structured cathode, wherein the cathode comprises: (a) an integrated nano-structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising pores with a size smaller than 100 nm (preferably smaller than 10 nm), wherein the filaments have a transverse dimension less than 500 nm (preferably less than 100 nm); and (b) powder or salt of lithium-containing sulfide (lithium polysulfide) disposed in the pores, or a thin coating of lithium-containing sulfide deposited on a nano-scaled filament surface wherein the lithium-containing sulfide is in contact with, dispersed in, or dissolved in electrolyte liquid and the lithium-containing sulfide-to-filament weight ratio is between 1 / 10 and 10 / 1 which is measured when the cell is in a fully discharged state. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Chemical protection of a lithium surface

InactiveUS20050186469A1Easy to produceEasy to processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process is the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

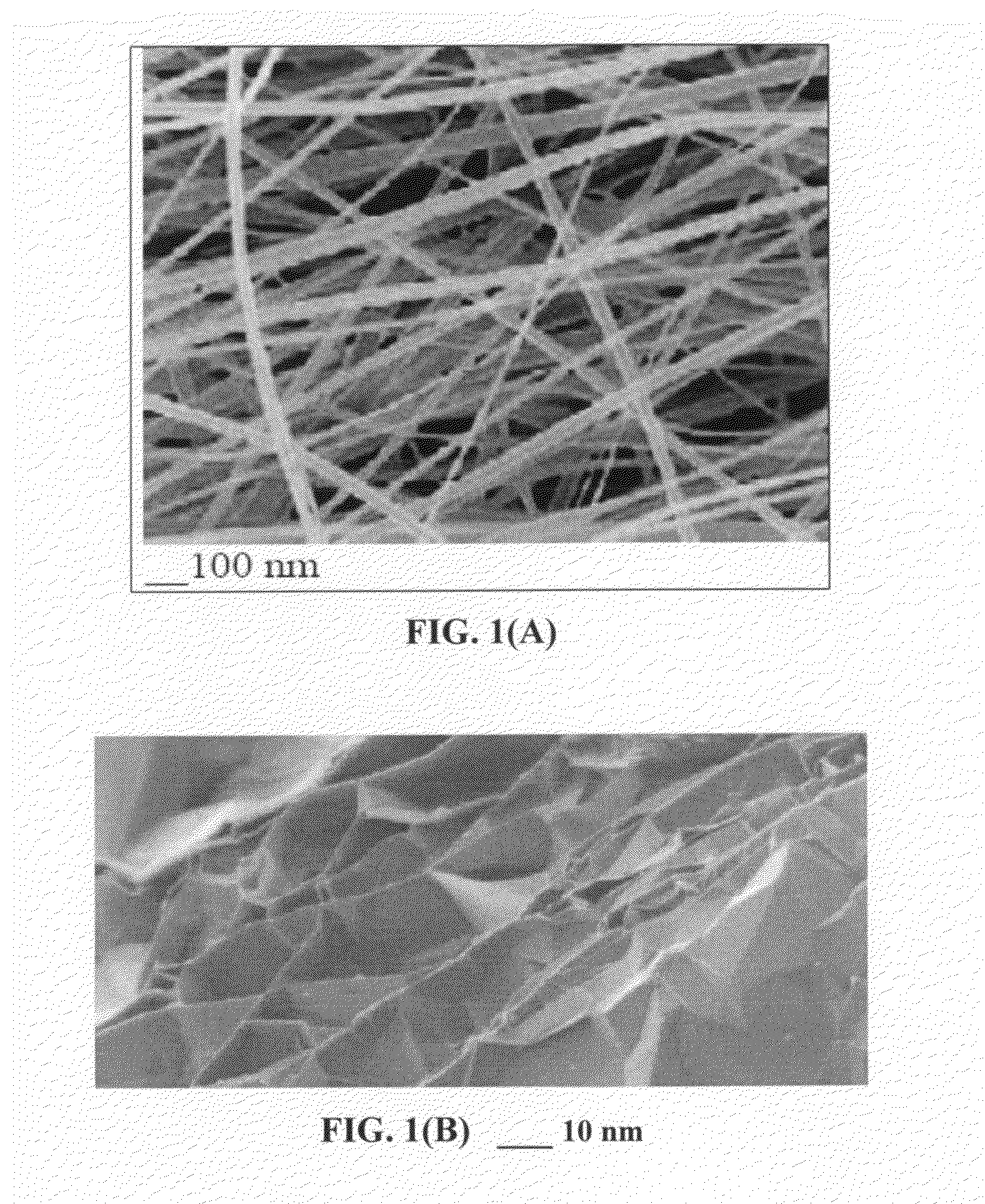

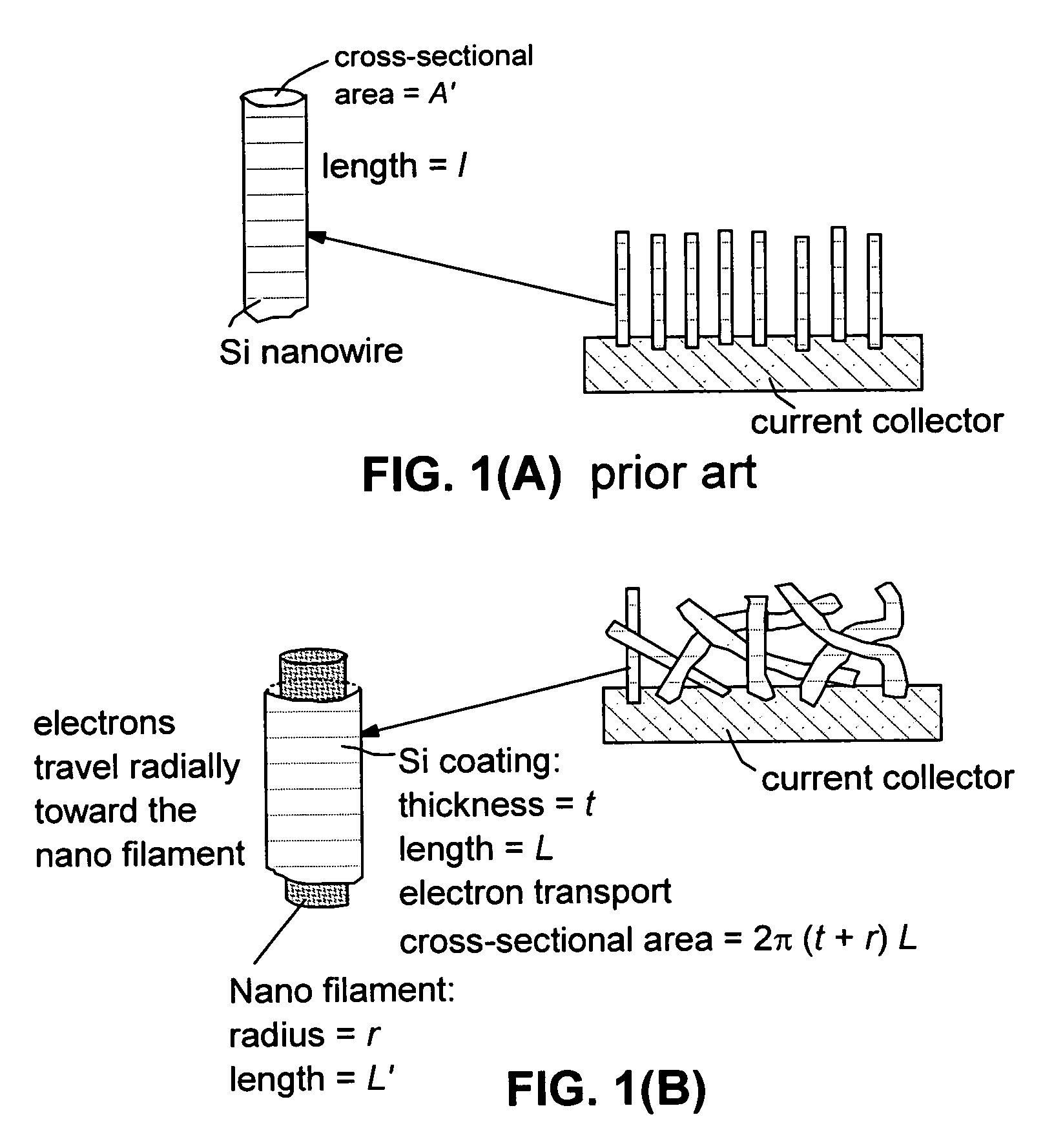

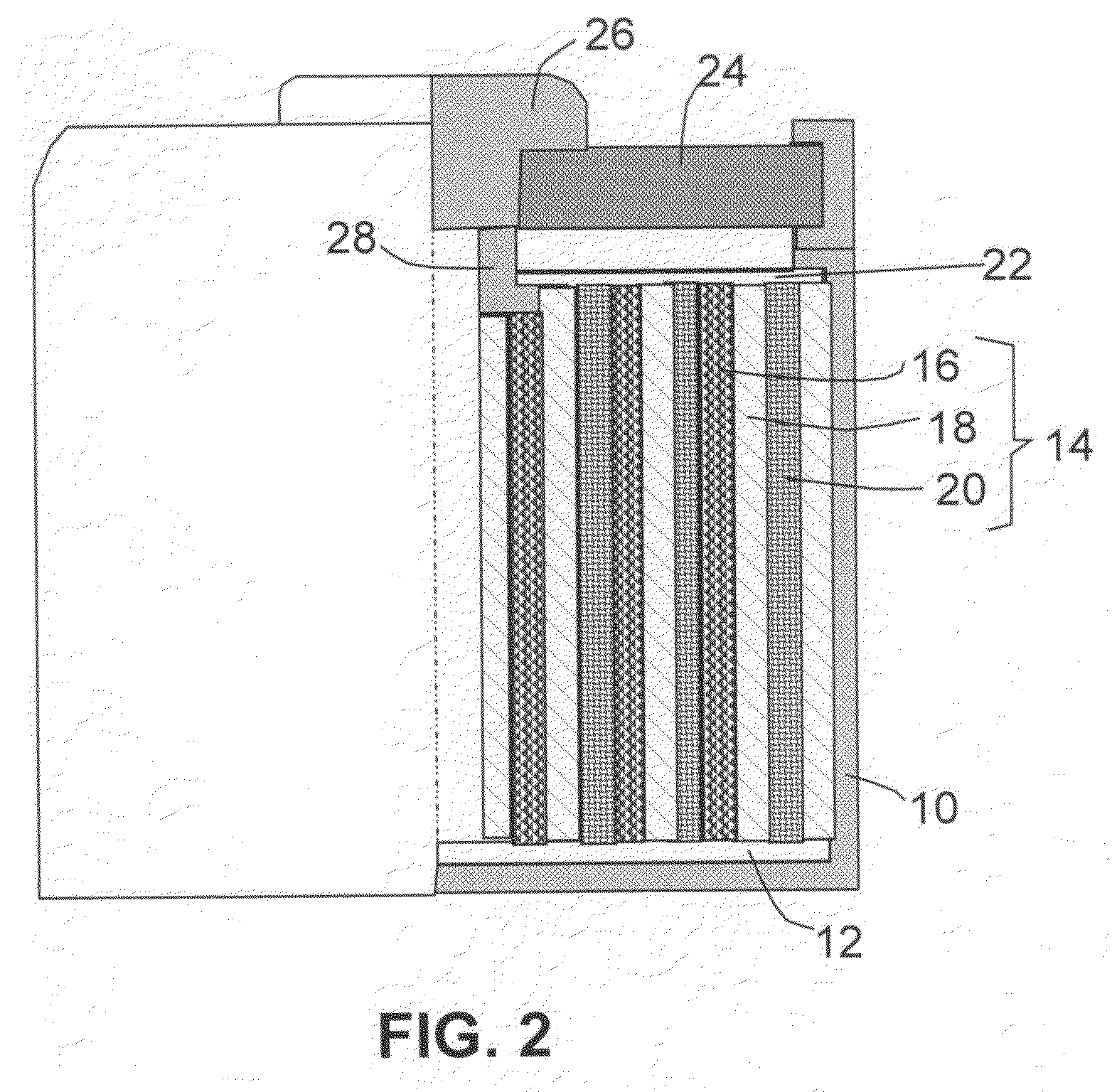

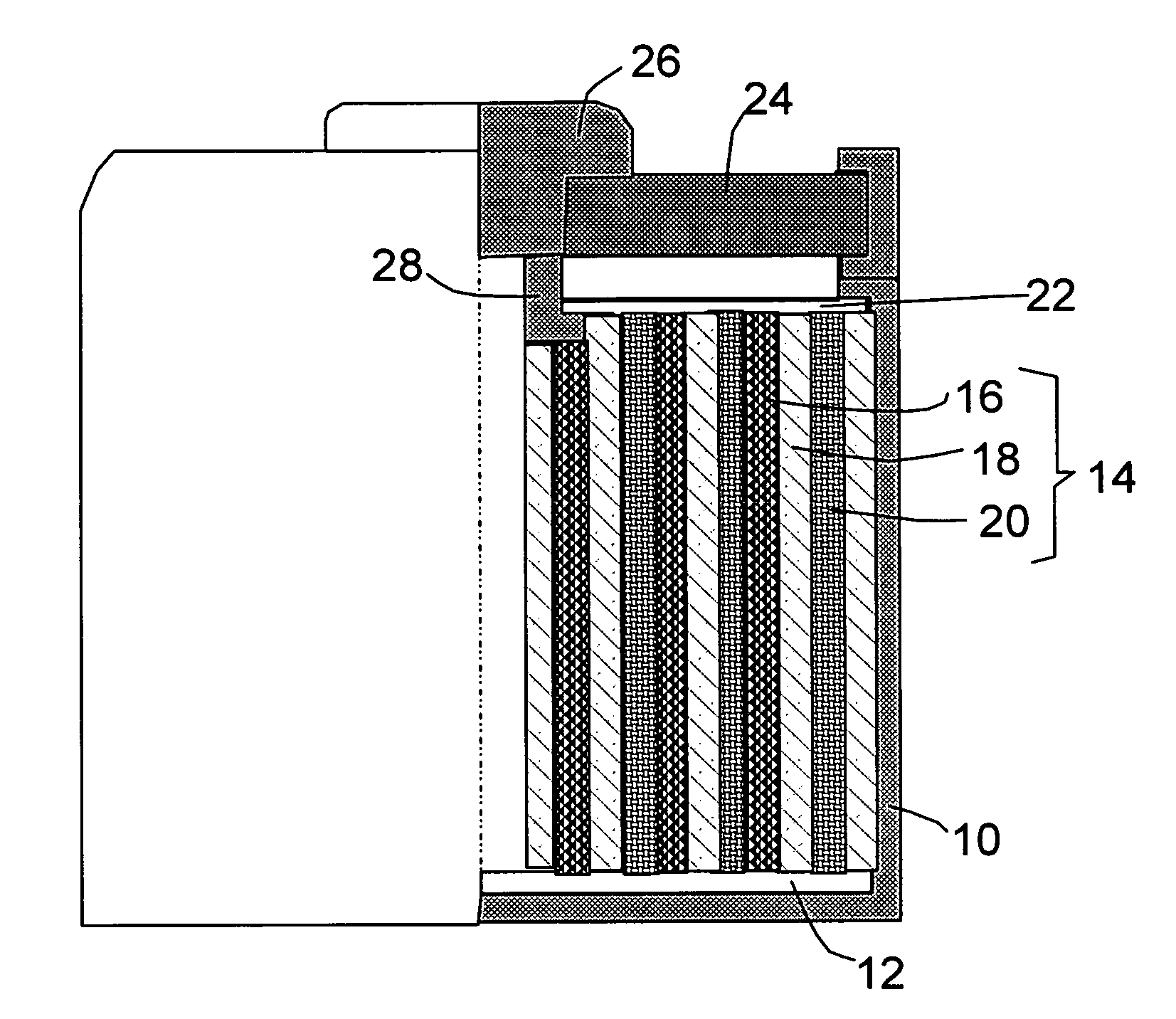

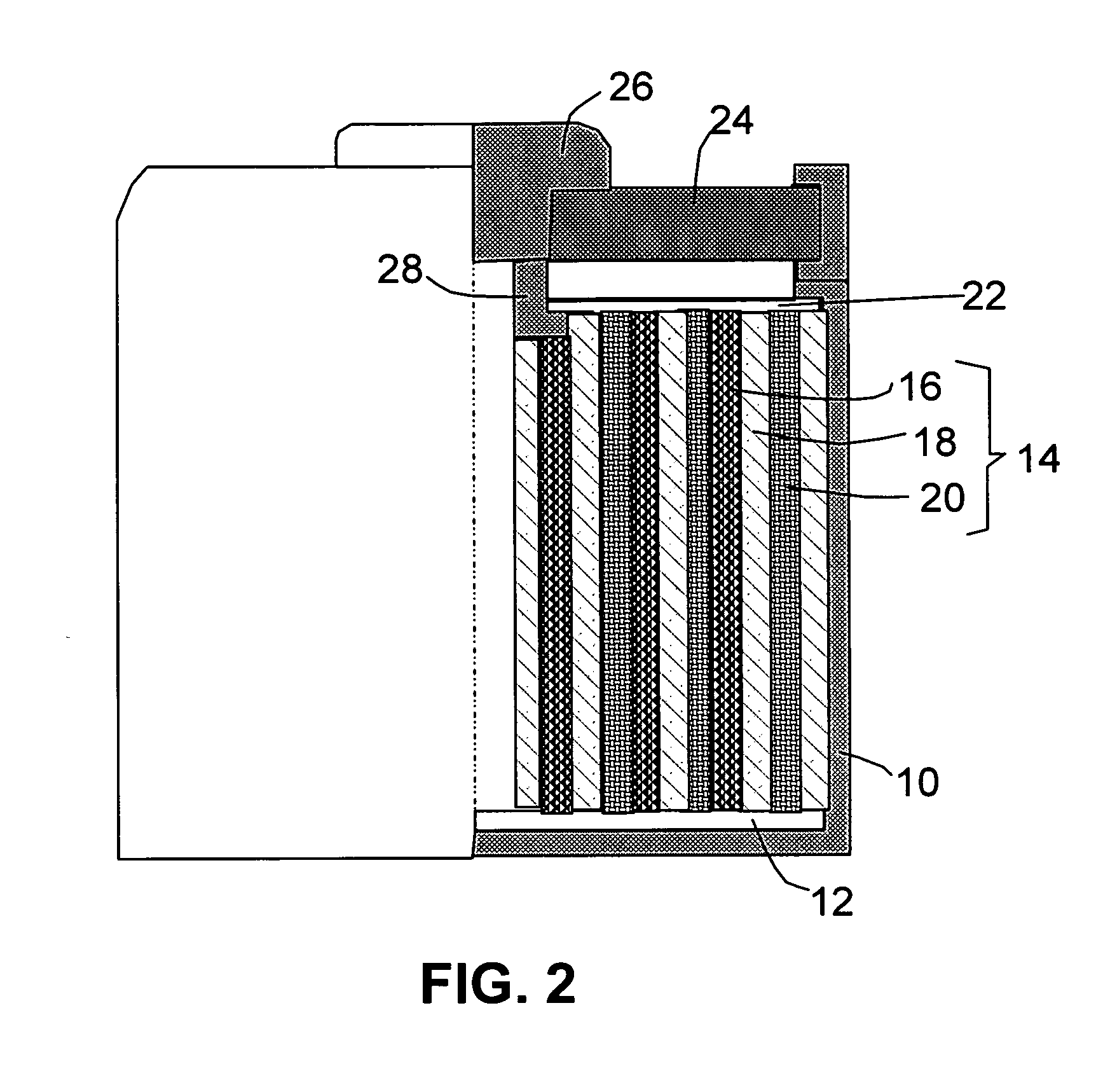

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

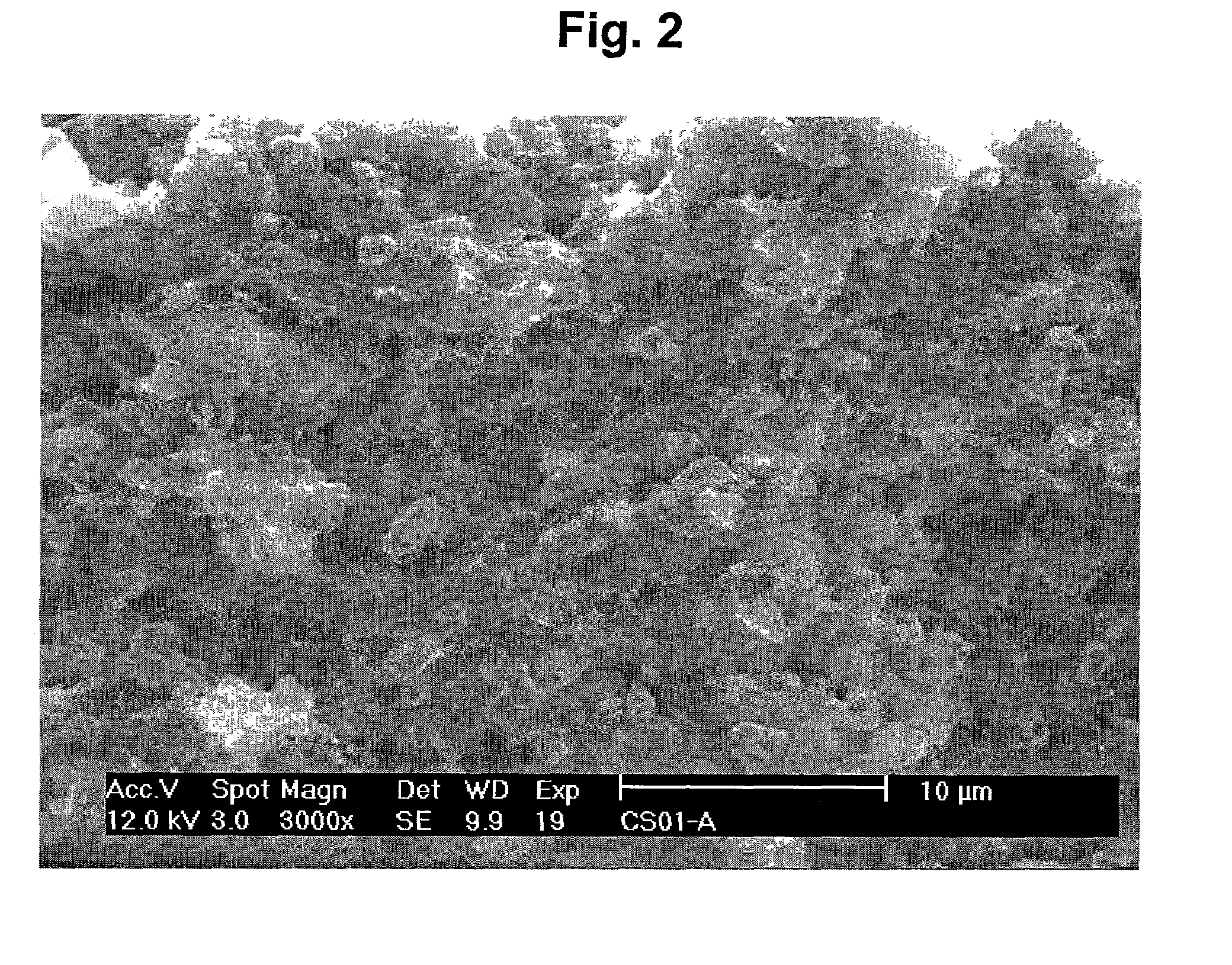

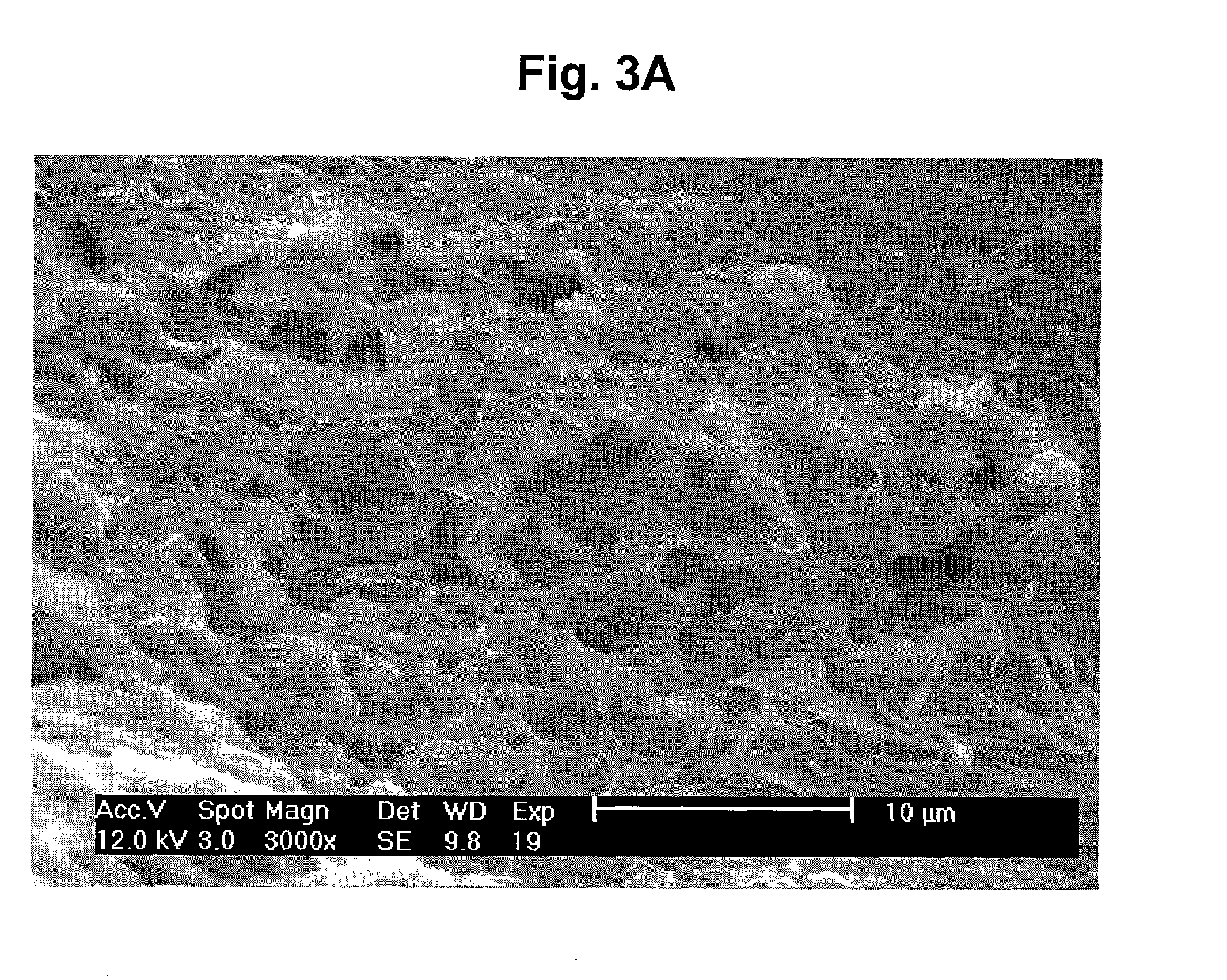

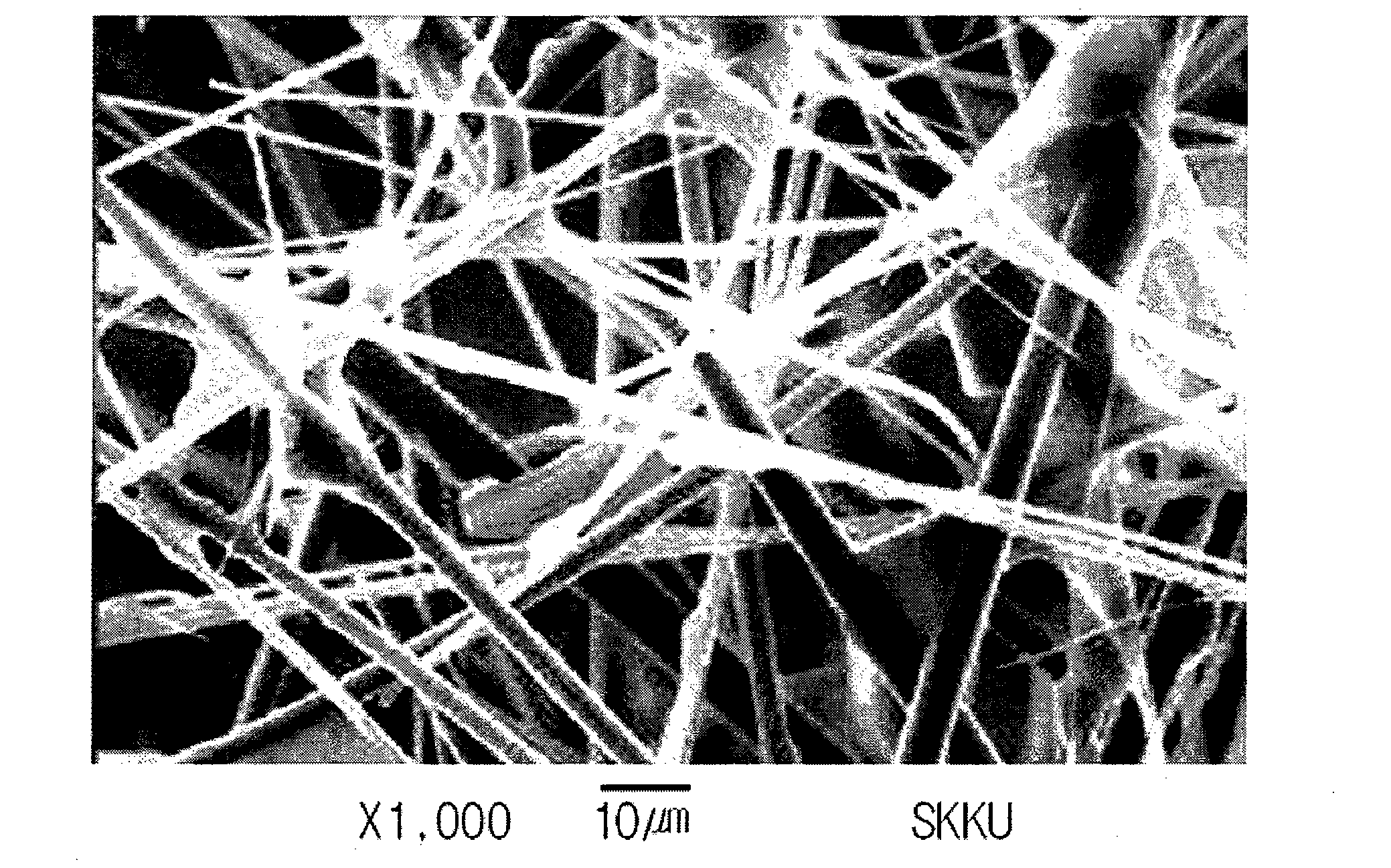

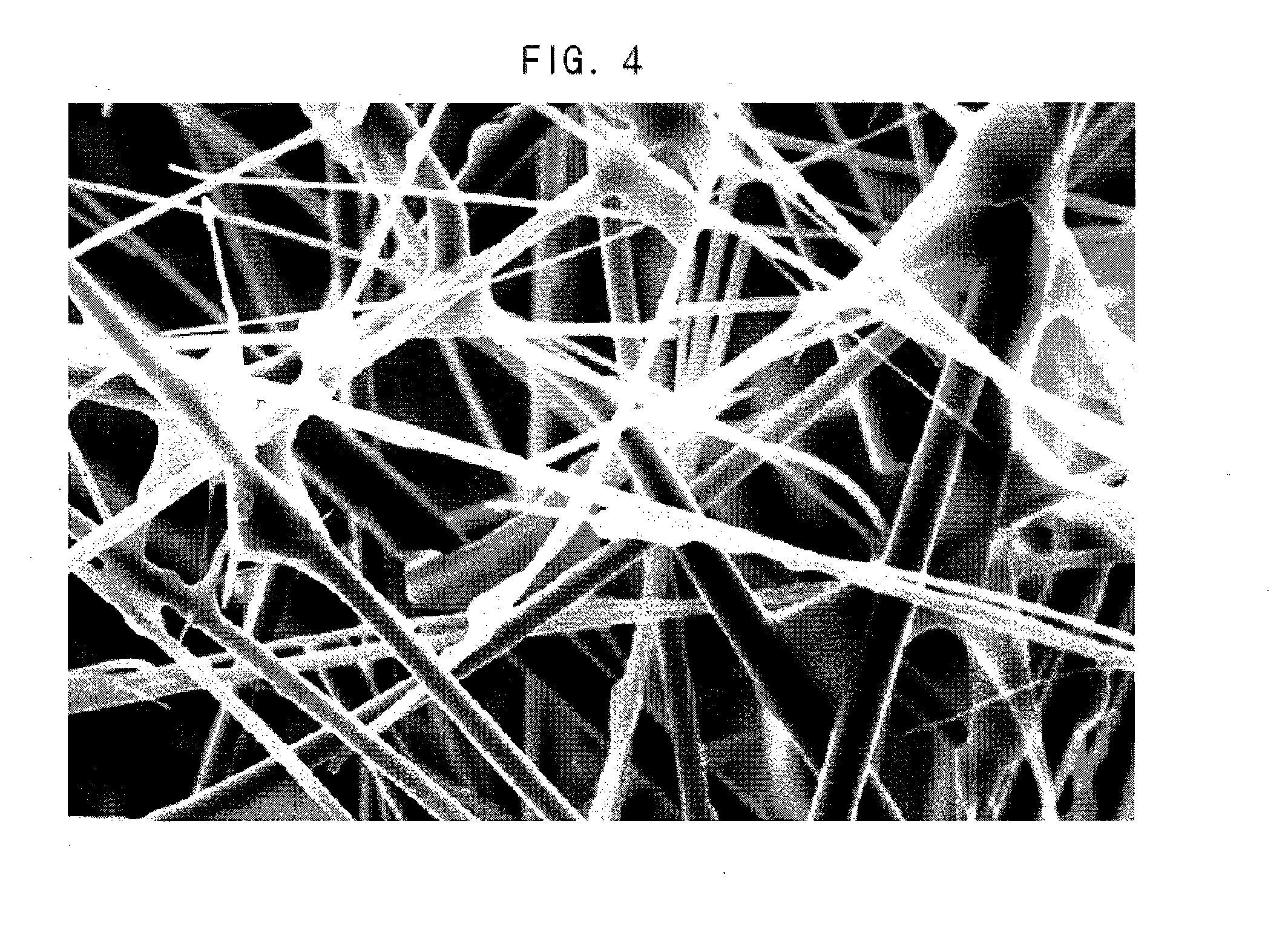

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Hybrid nano-filament cathode compositions for lithium metal or lithium ion batteries

InactiveUS20090186276A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesSecondary cellsNanometreElectrically conductive

This invention provides a hybrid nano-filament composition for use as a cathode active material. The composition comprises (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter or thickness being less than 500 nm; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises a cathode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm, preferably less than 1 μm and more preferably less than 500 nm. Also provided is a lithium metal battery or lithium ion battery that comprises such a cathode. Preferably, the battery includes an anode that is manufactured according to a similar hybrid nano filament approach. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

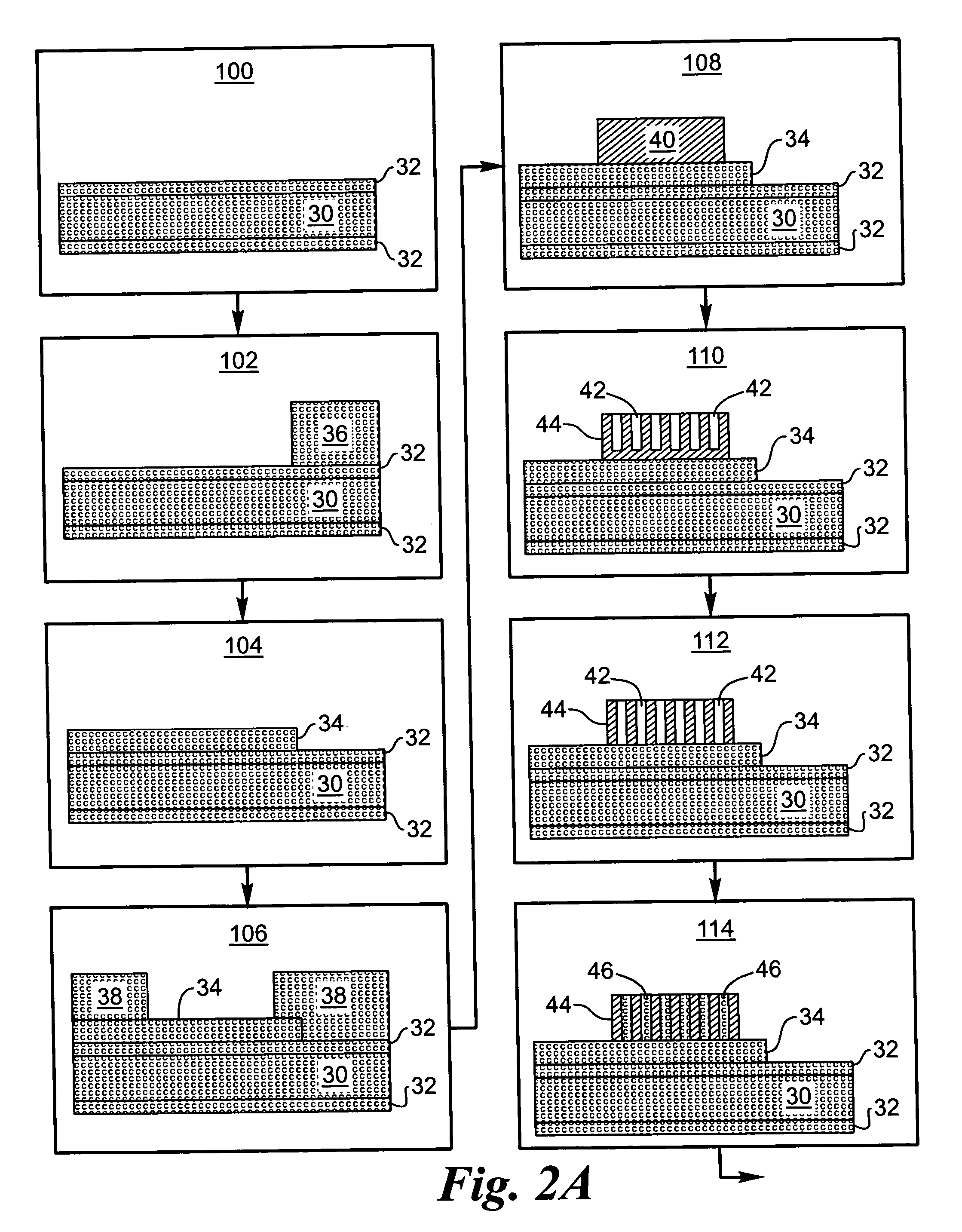

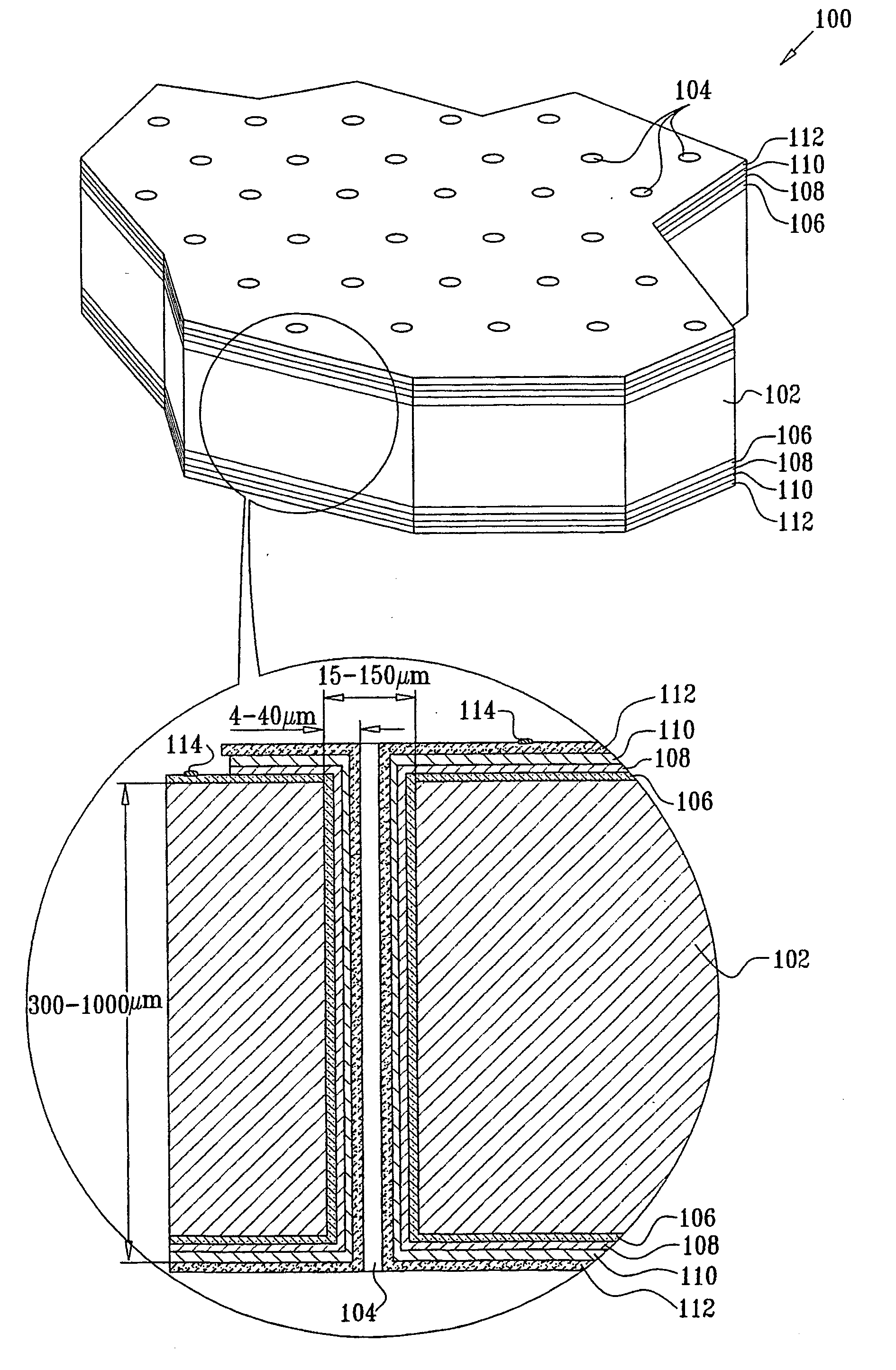

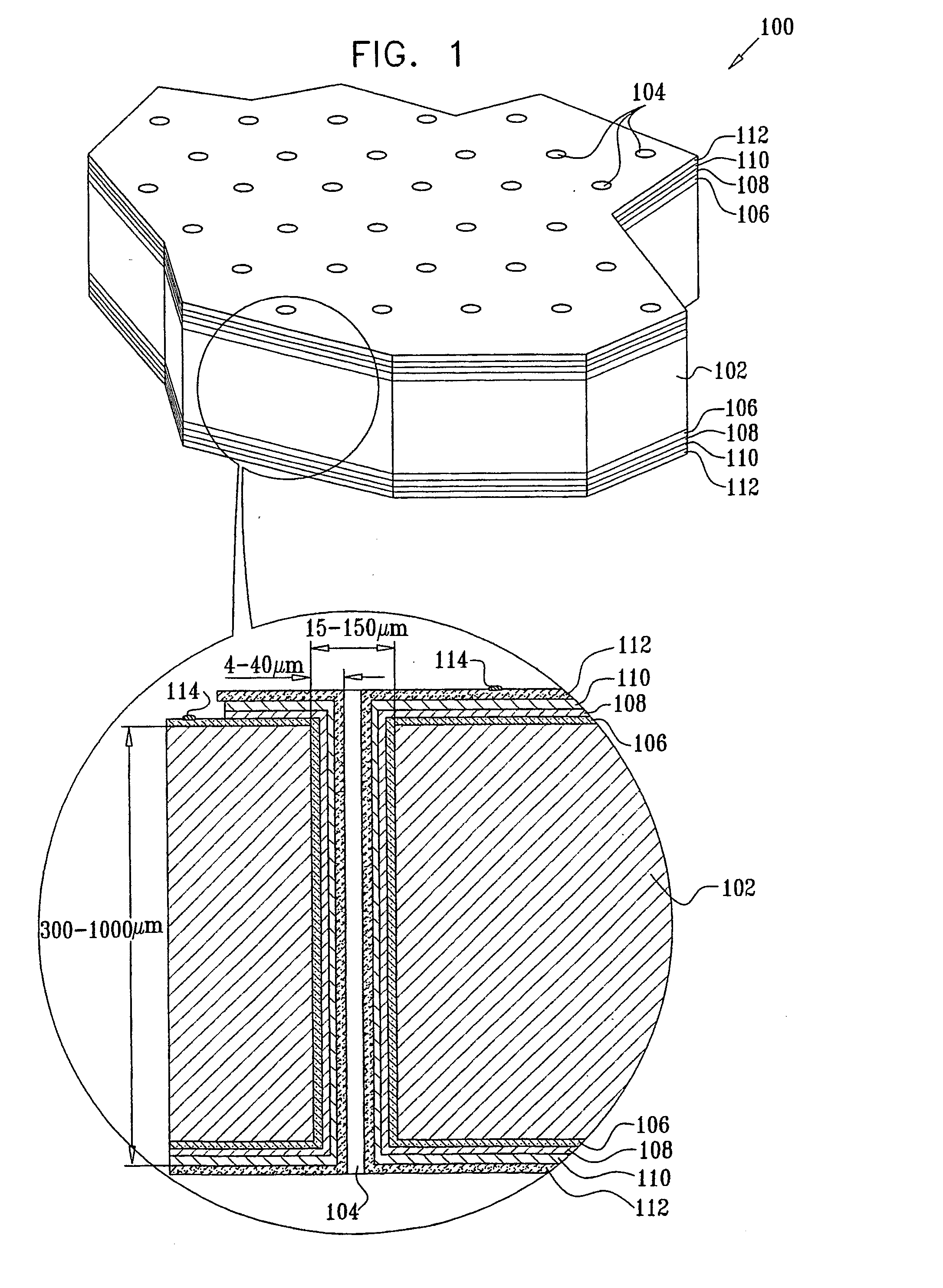

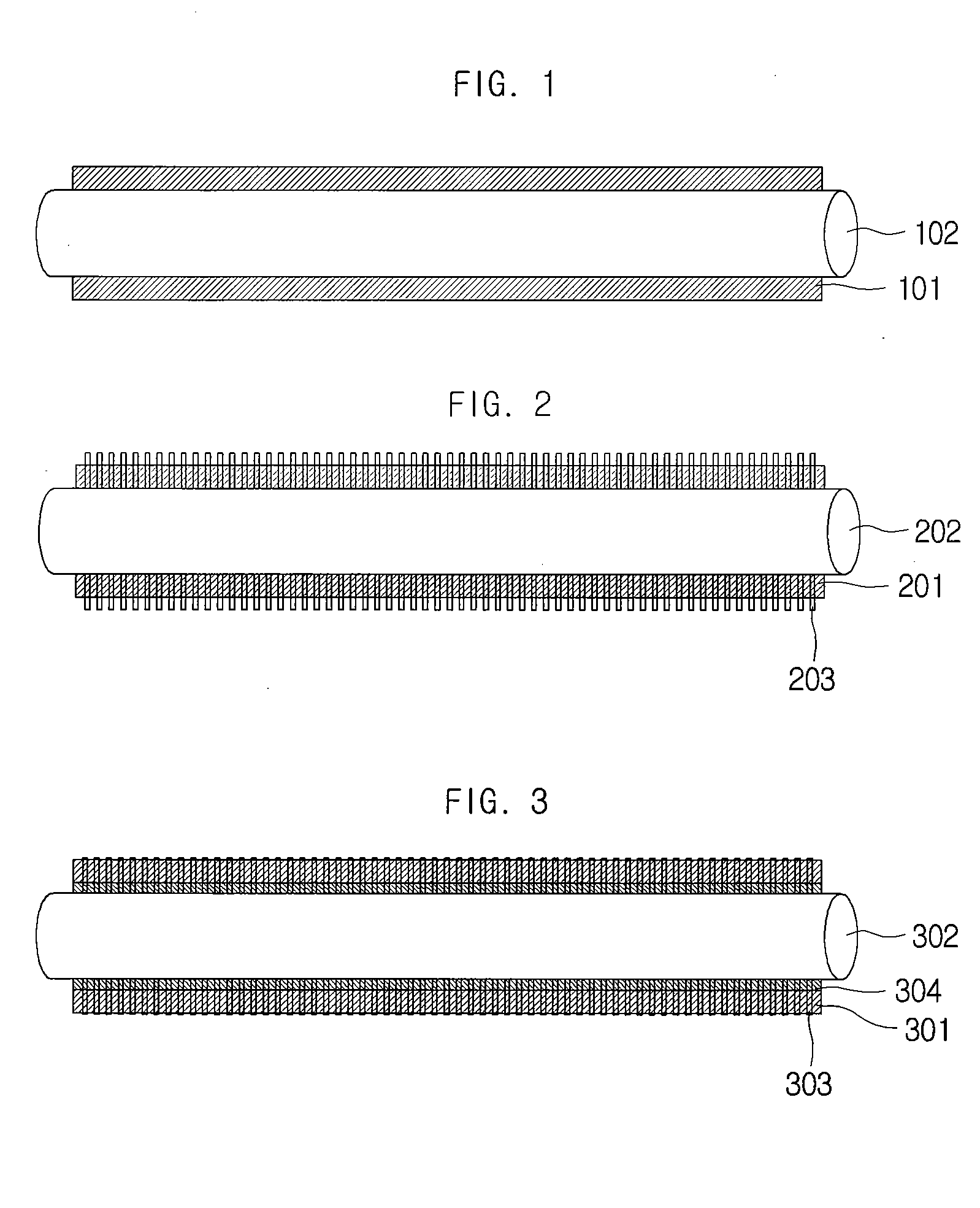

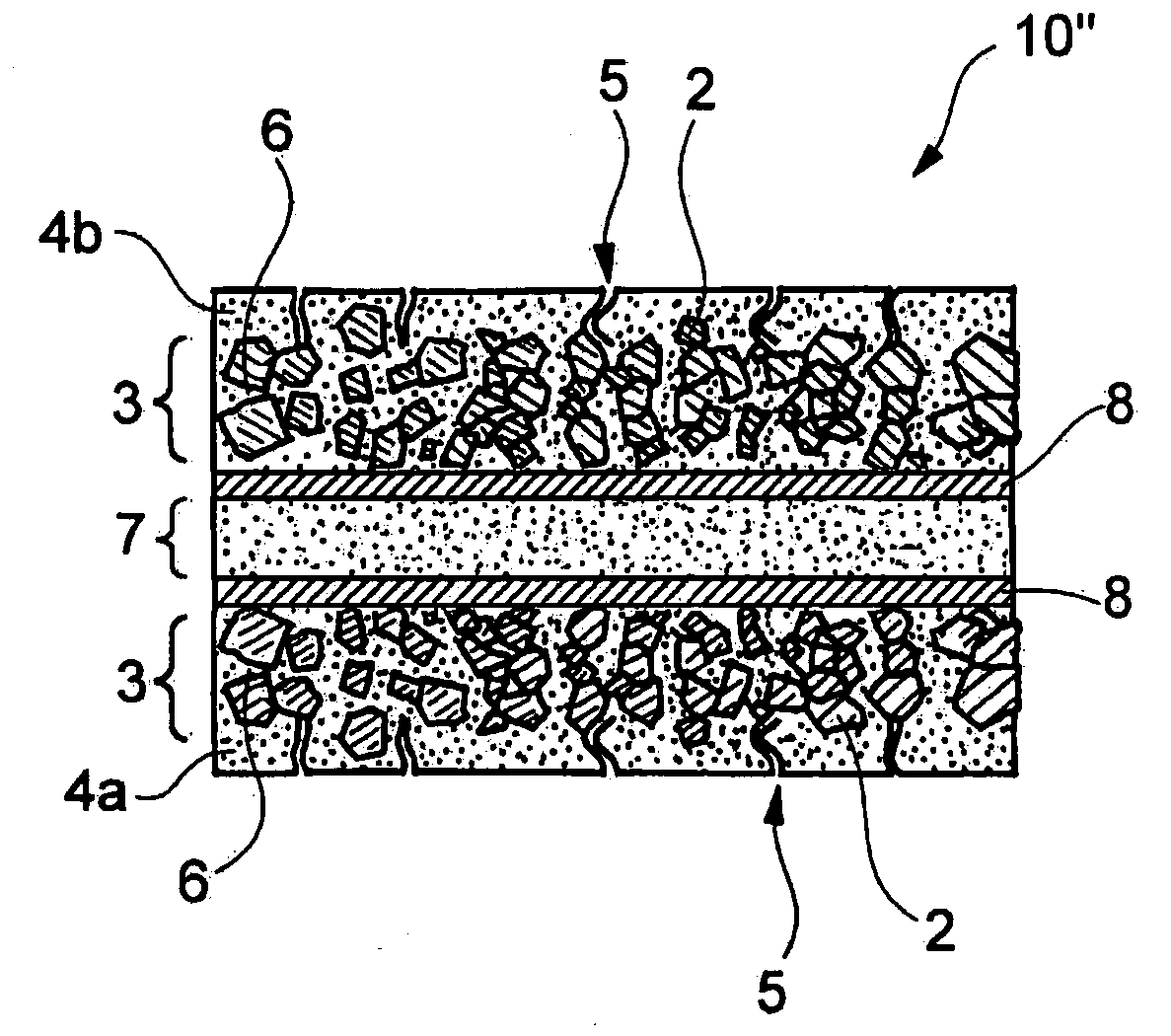

Anode for nonaqueous secondary battery, process of producing the anode, and nonaqueous secondary battery

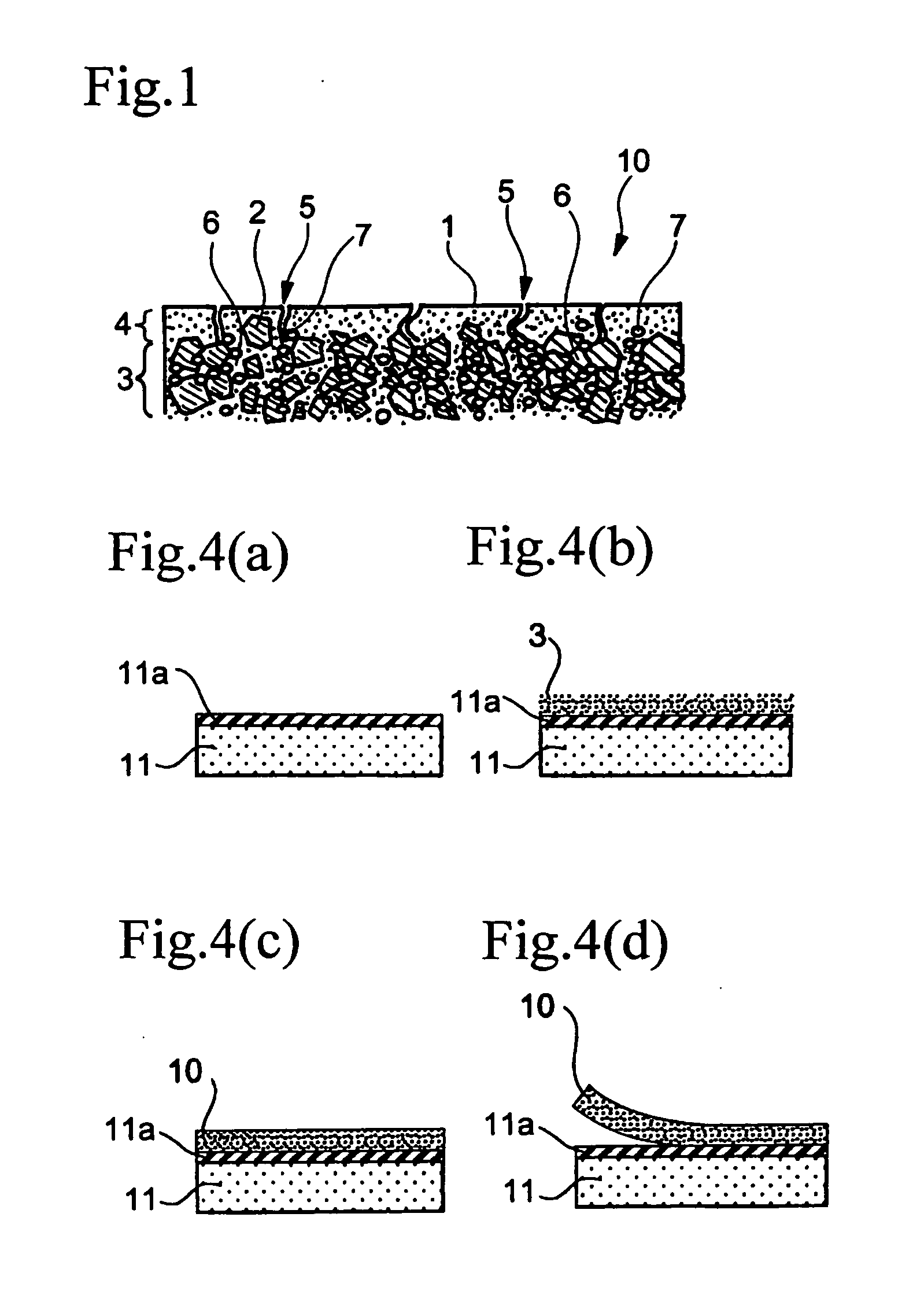

InactiveUS20060147802A1Simple materialRaise the ratioCellsElectrochemical processing of electrodesSurface layerLithium compound

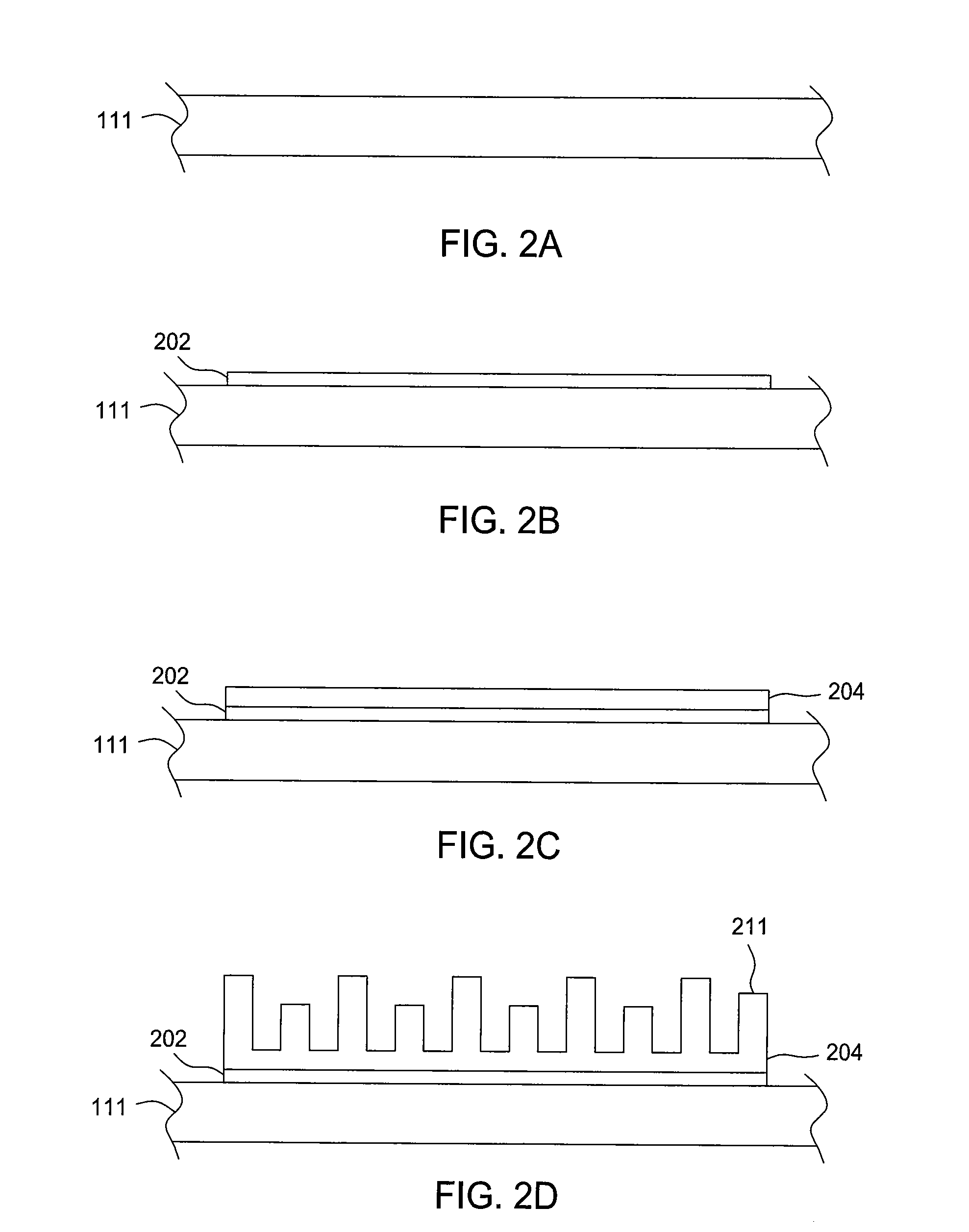

A negative electrode for nonaqueous secondary batteries is disclosed. The negative electrode has a pair of current collecting surface layers of which the surfaces are adapted to be brought into contact with an electrolyte and at least one active material layer interposed between the surface layers. The active material layer contains particles of an active material having high capability of forming a lithium compound. The material constituting the surfaces is preferably present over the whole thickness of the active material layer to electrically connect the surfaces so that the electrode exhibits a current collecting function as a whole. The surface layers each preferably have a thickness of 0.3 to 10 μm.

Owner:MITSUI MINING & SMELTING CO LTD

Lithium secondary battery

InactiveUS20050008939A1Improve featuresElectrochemical processing of electrodesFinal product manufactureLithiumPhosphate

A lithium secondary battery comprising a positive electrode, a negative electrode, and a nonaqueous electrolyte, wherein the positive electrode or the negative electrode is an electrode obtained by depositing a thin film of active material capable of lithium storage and release on a current collector, the thin film is divided into columns by gaps formed therein in a manner to extend in its thickness direction and the columnar portions are adhered at their bottoms to the current collector, and the nonaqueous electrolyte contains at least one selected from phosphate ester, phosphite ester, borate ester and carboxylic ester having a fluoroalkyl group.

Owner:SANYO ELECTRIC CO LTD

Lithium-sulfur batteries

InactiveUS7250233B2Improved cycle life characteristicsElectrochemical processing of electrodesFinal product manufactureElectrochemical responseLithium–sulfur battery

A lithium-sulfur battery having a positive electrode including a positive active material including an active sulfur, where the positive electrode comprises an electron-conductive path and an ion-conductive path, and includes active pores of the average size of up to 20 μm having both electron-conductive and ion-conductive properties, and are filled with the active sulfur during an electrochemical reaction of the battery.

Owner:SAMSUNG SDI CO LTD

Negative electrode for lithium secondary battery, lithium secondary battery, and manufacturing methods thereof

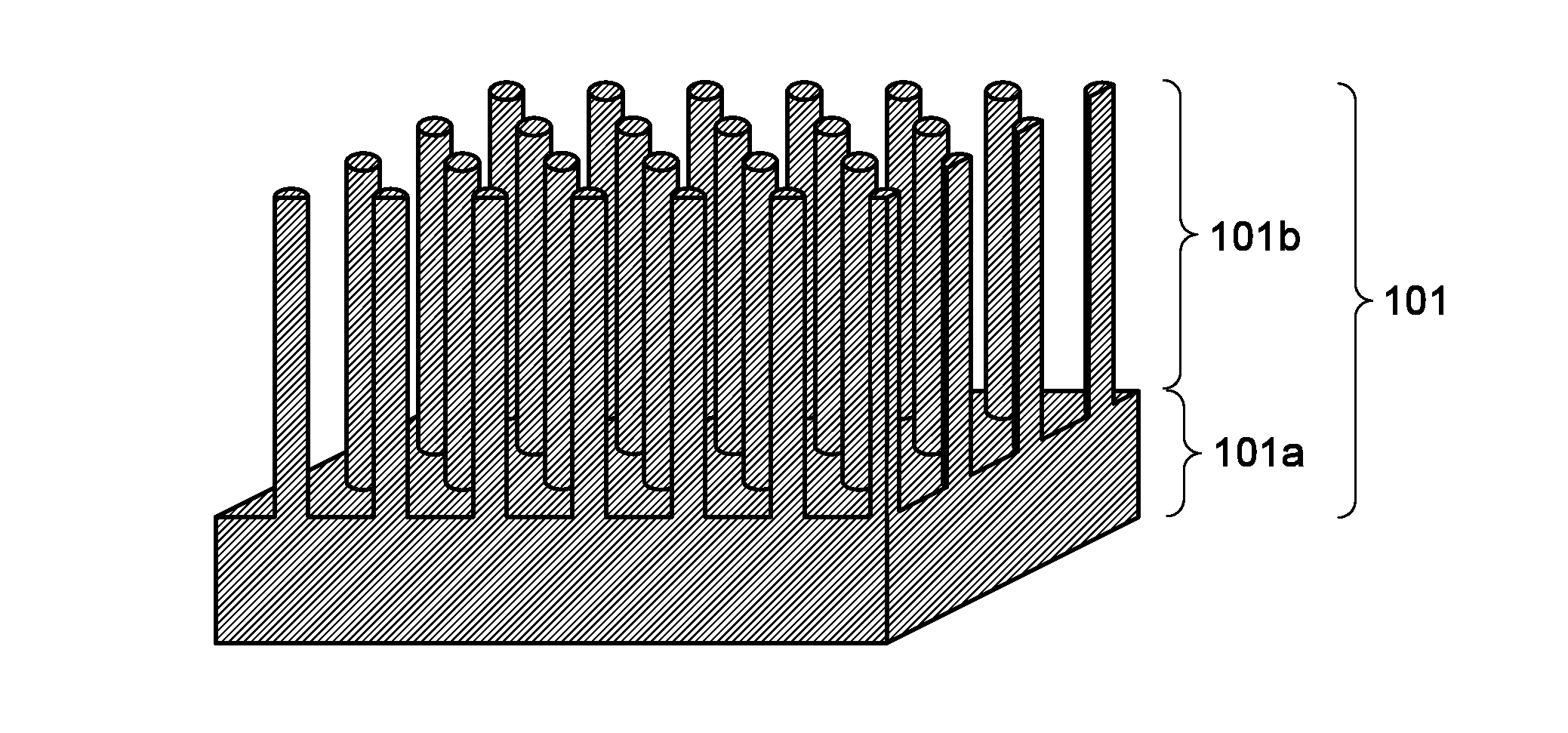

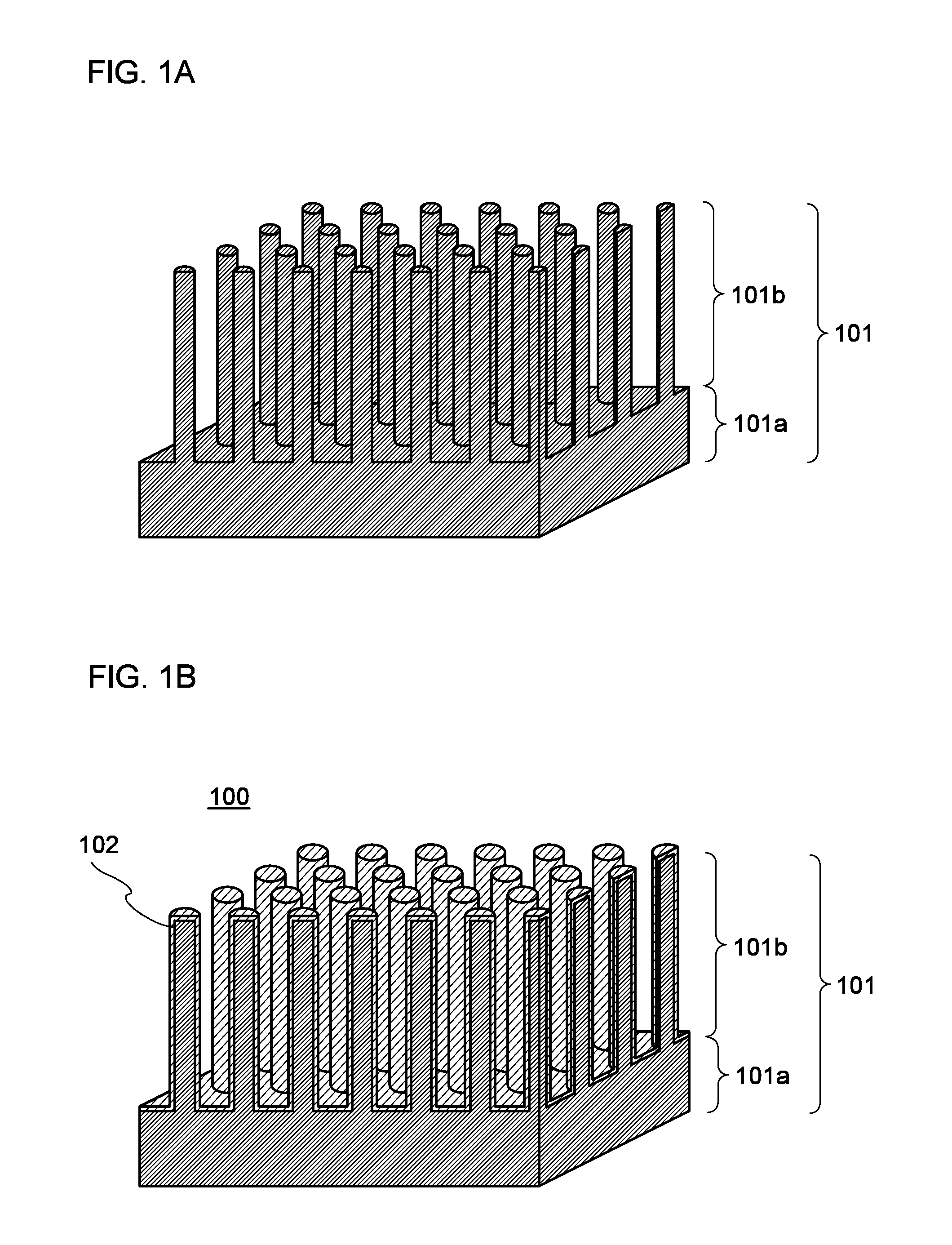

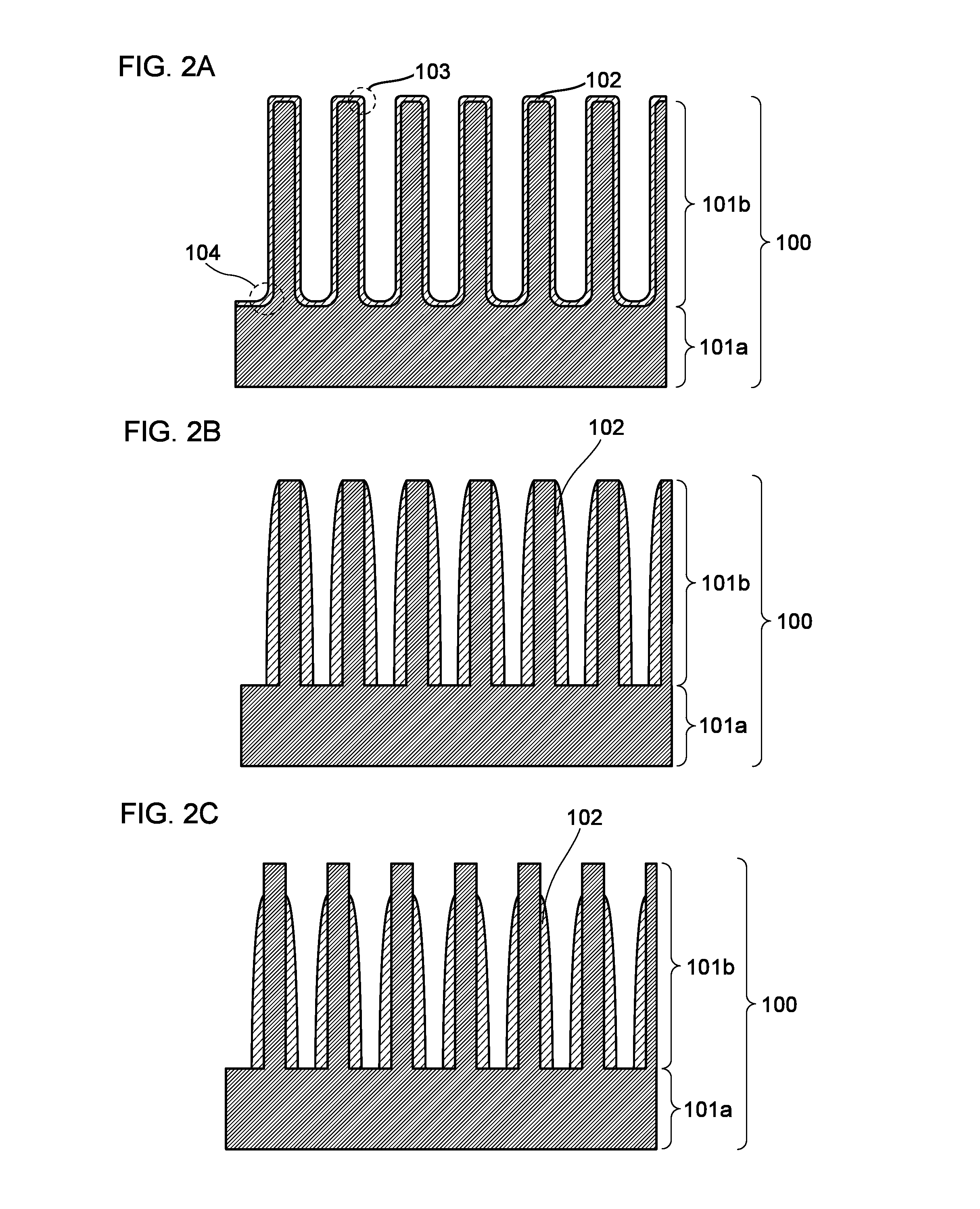

InactiveUS20130149605A1Avoid separationImprove reliabilityMaterial nanotechnologyElectrochemical processing of electrodesElectrical batteryCurrent collector

A lithium secondary battery which has high charge-discharge capacity, can be charged and discharged at high speed, and has little deterioration in battery characteristics due to charge and discharge is provided. A negative electrode includes a current collector and a negative electrode active material layer. The current collector includes a plurality of protrusion portions extending in a substantially perpendicular direction and a base portion connected to the plurality of protrusion portions. The protrusion portions and the base portion are formed using the same material containing titanium. A top surface of the base portion and at least a side surface of the protrusion portion are covered with the negative electrode active material layer. The negative electrode active material layer may be covered with graphene.

Owner:SEMICON ENERGY LAB CO LTD

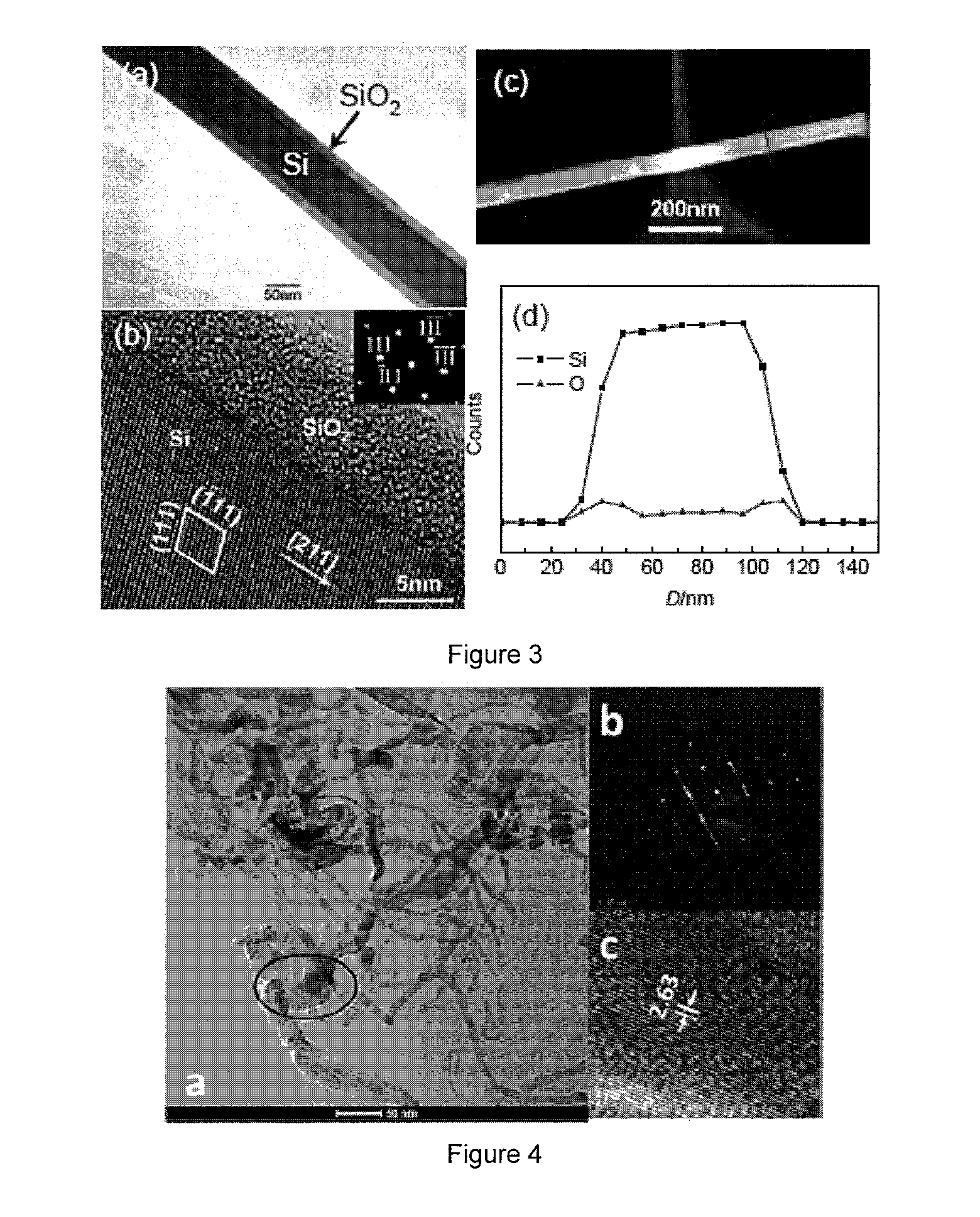

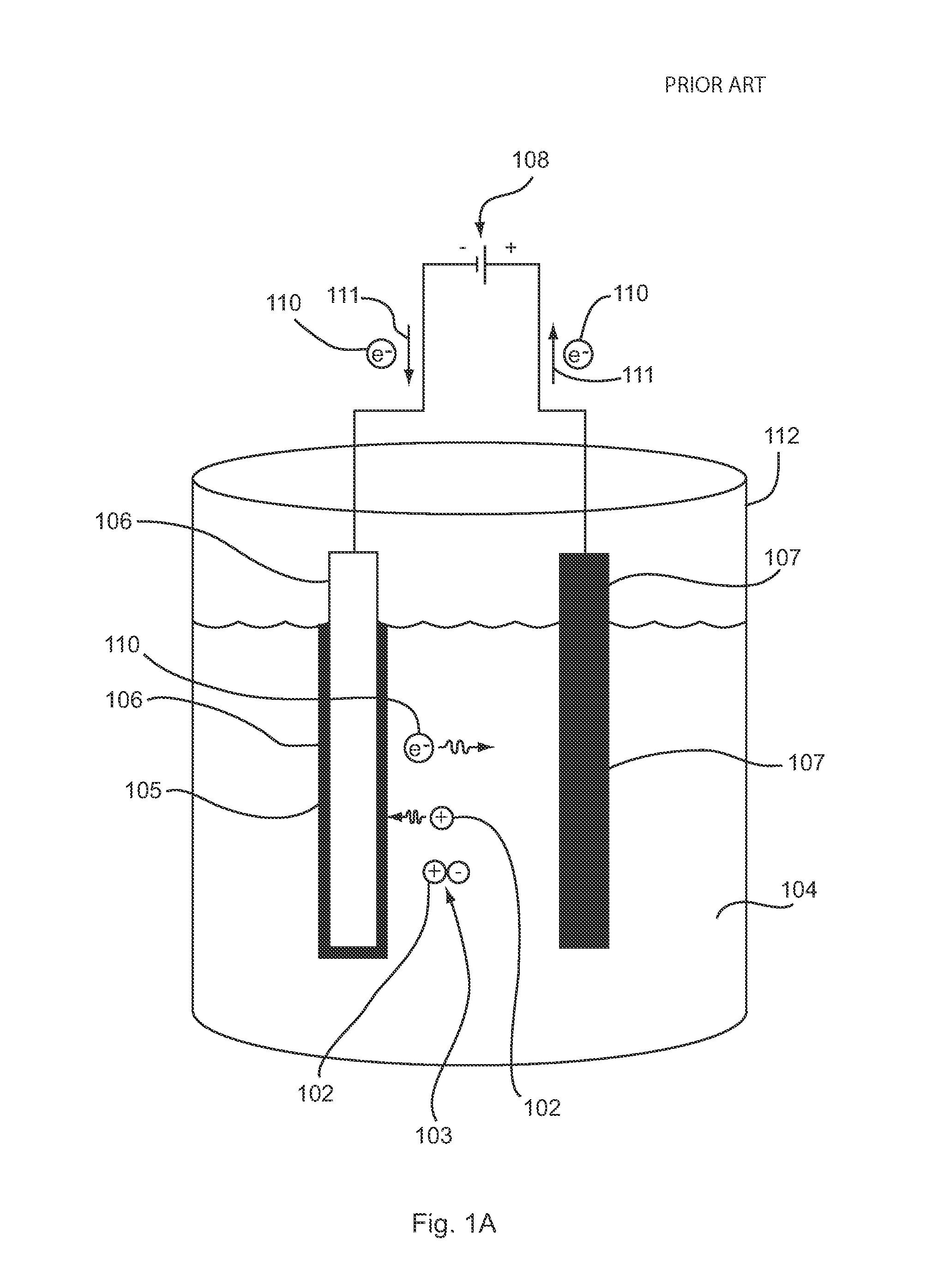

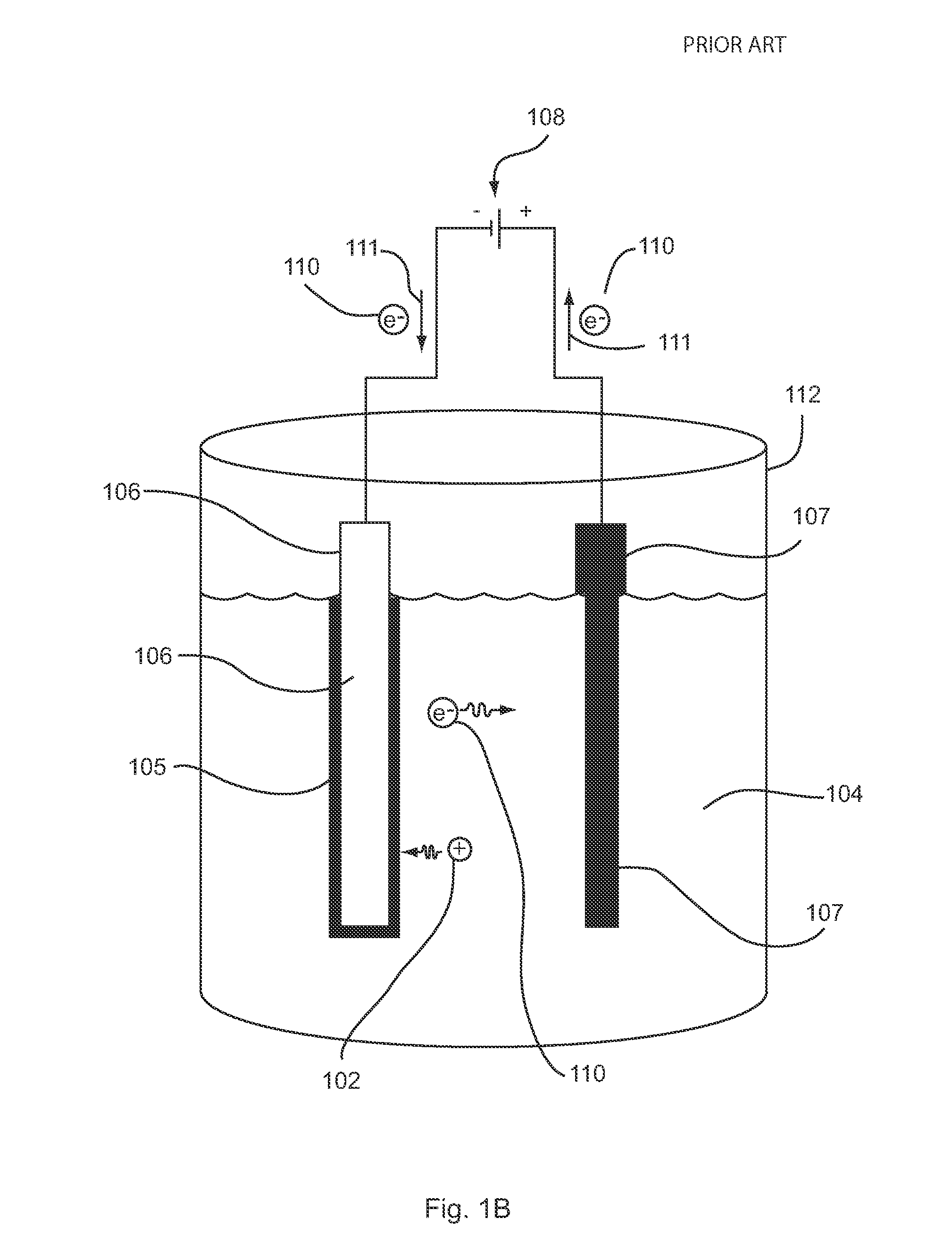

NANO silicon-carbon composite material and preparation method thereof

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

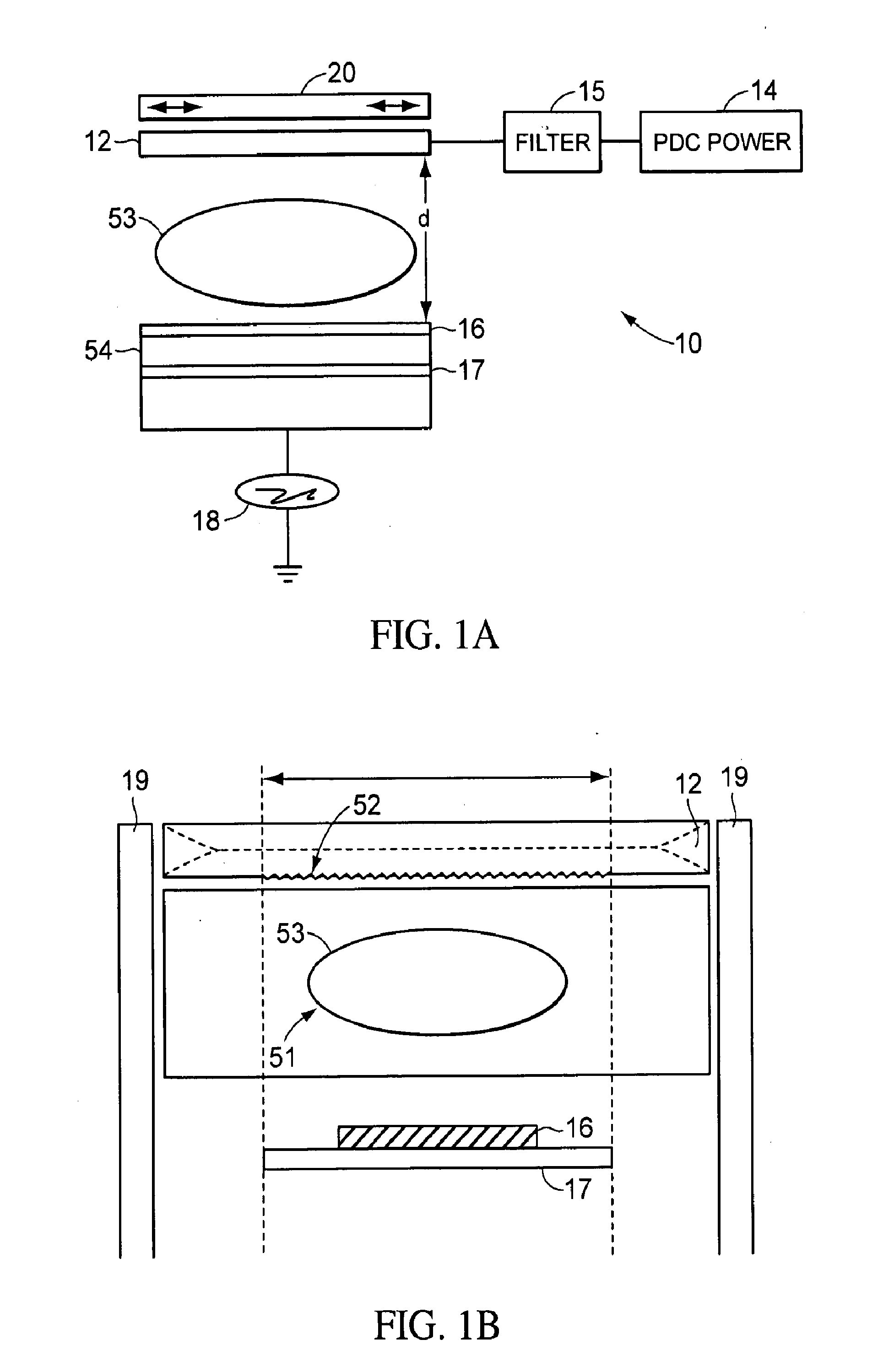

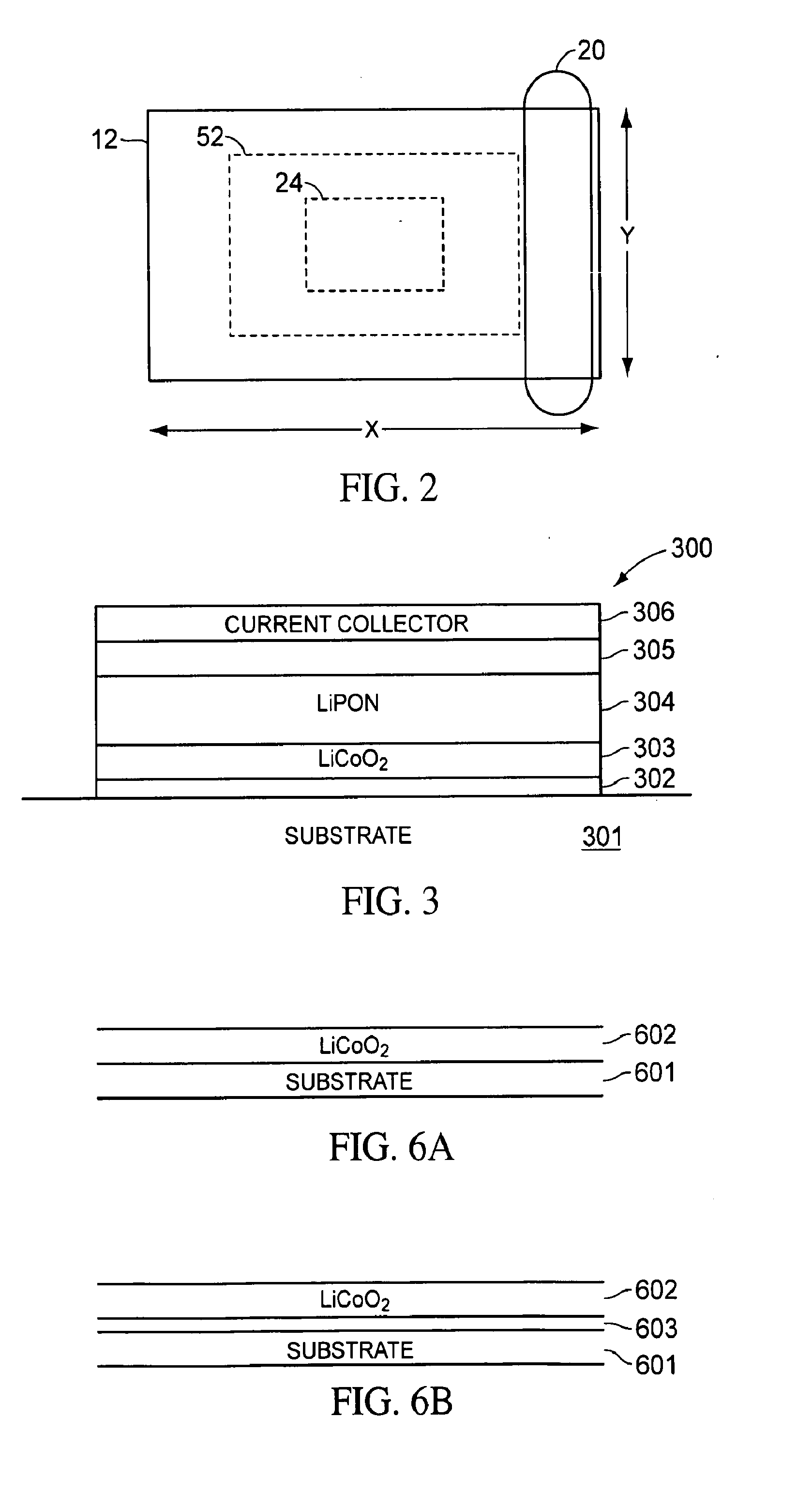

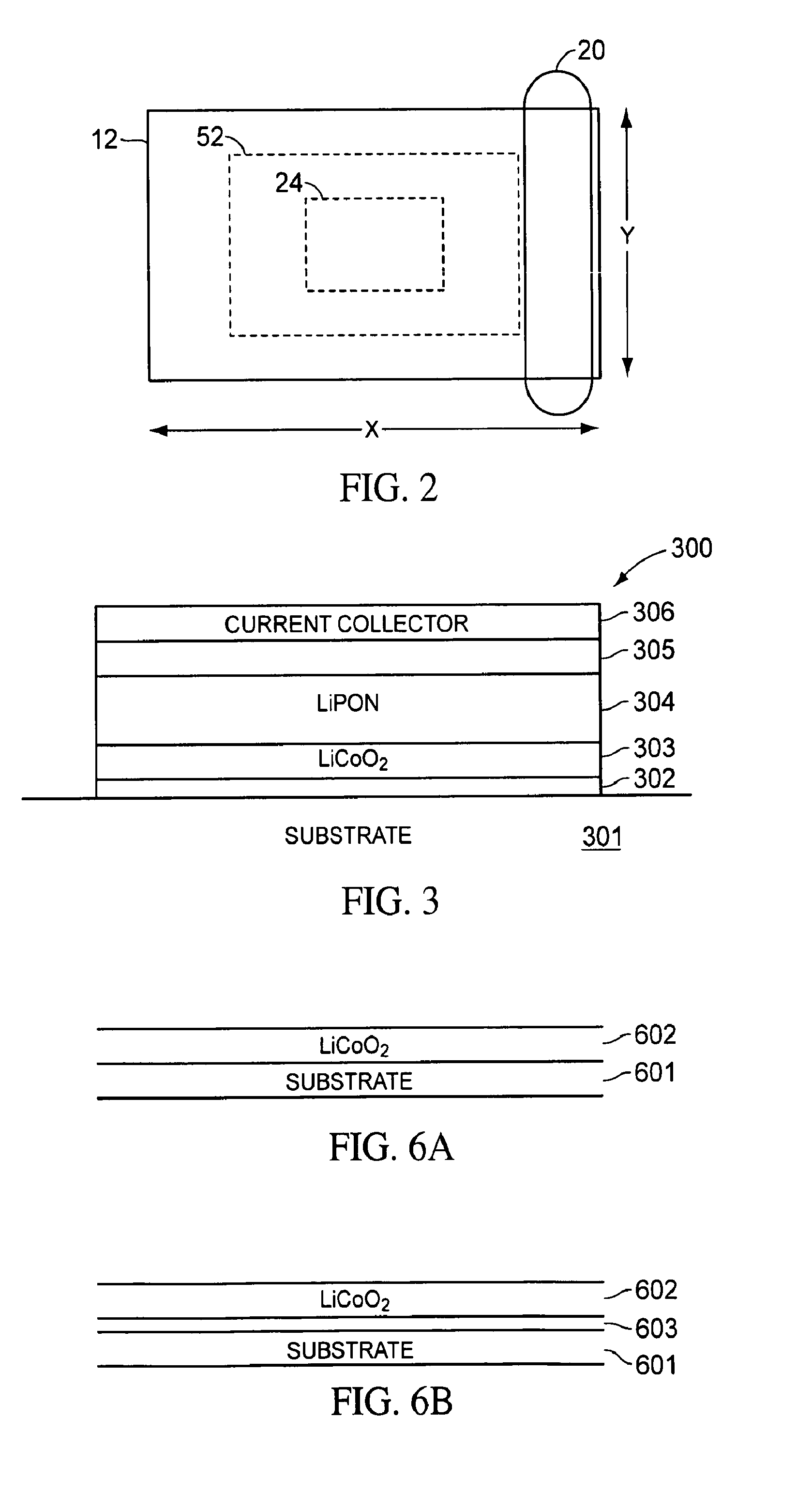

DEPOSITION OF LiCoO2

ActiveUS20070125638A1Increase deposition rateIncrease chanceElectrochemical processing of electrodesElectrode thermal treatmentHigh rateSolid-state

In accordance with the present invention, deposition of LiCoO2 layers in a pulsed-dc physical vapor deposition process is presented. Such a deposition can provide a low-temperature, high deposition rate deposition of a crystalline layer of LiCoO2 with a desired (101) or (003) orientation. Some embodiments of the deposition addresses the need for high rate deposition of LiCoO2 films, which can be utilized as the cathode layer in a solid state rechargeable Li battery. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the LiCoO2 layer. Some embodiments of the process can improve a battery utilizing the LiCoO2 layer by utilizing a rapid thermal anneal process with short ramp rates.

Owner:SAPURAST RES

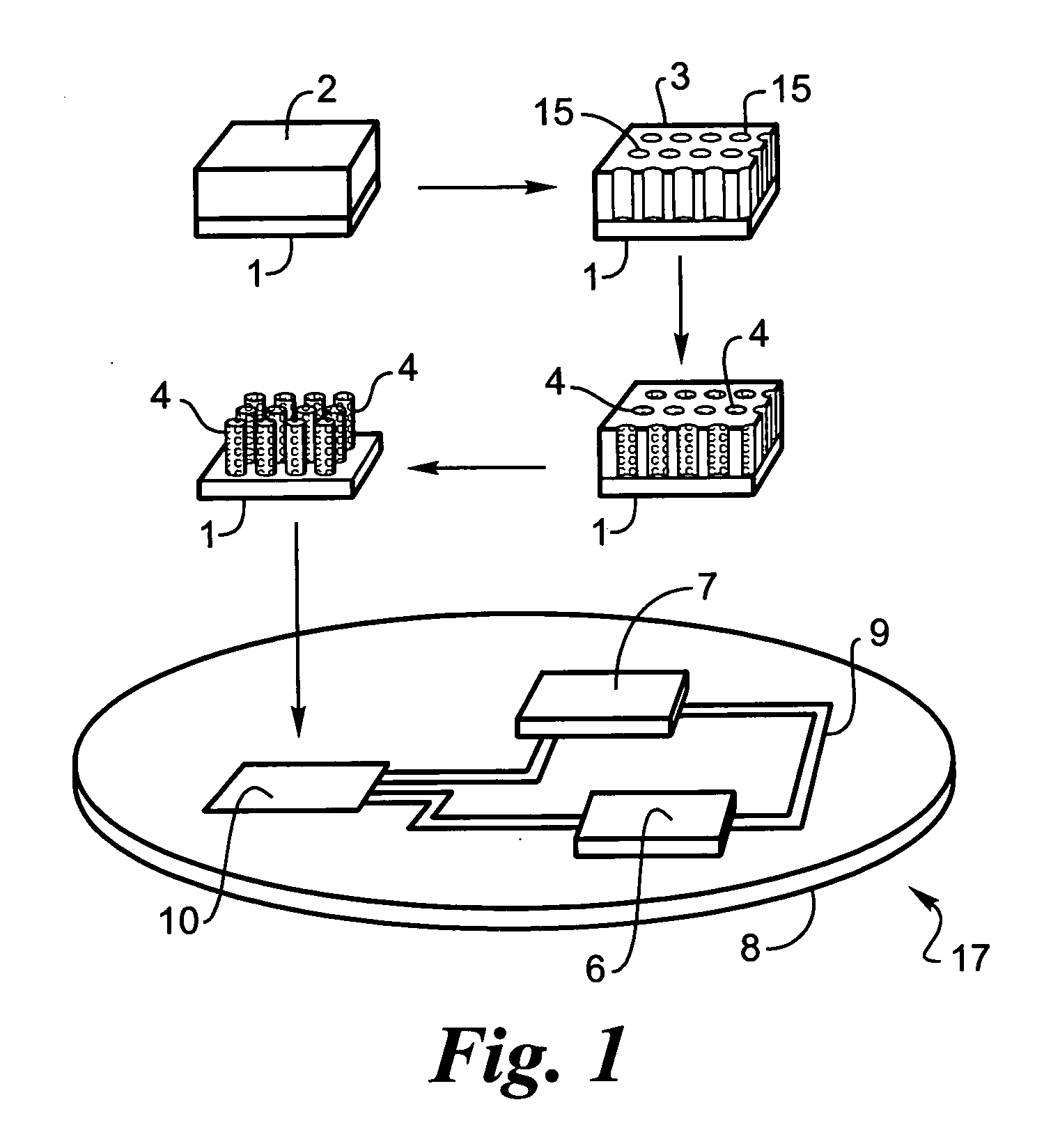

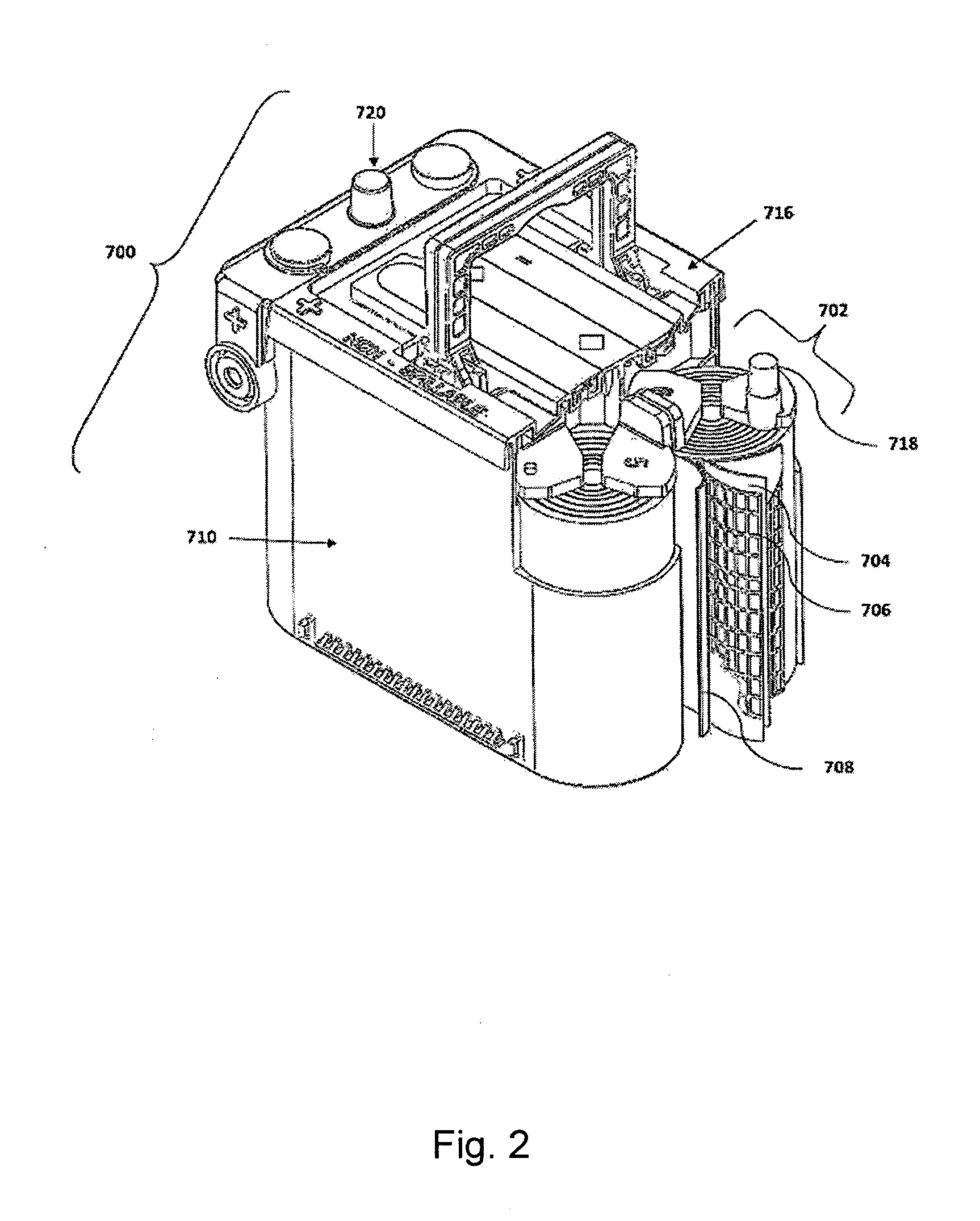

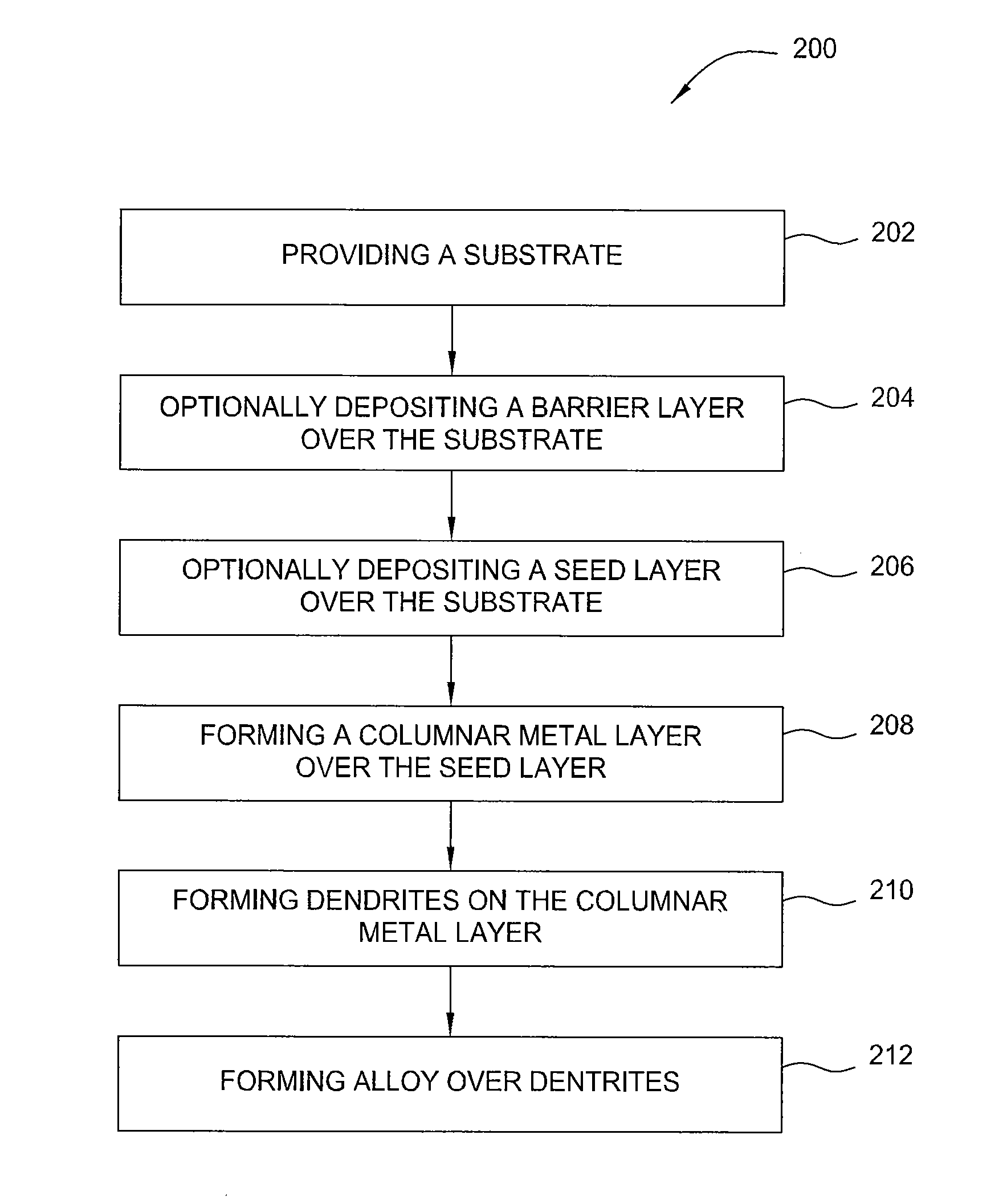

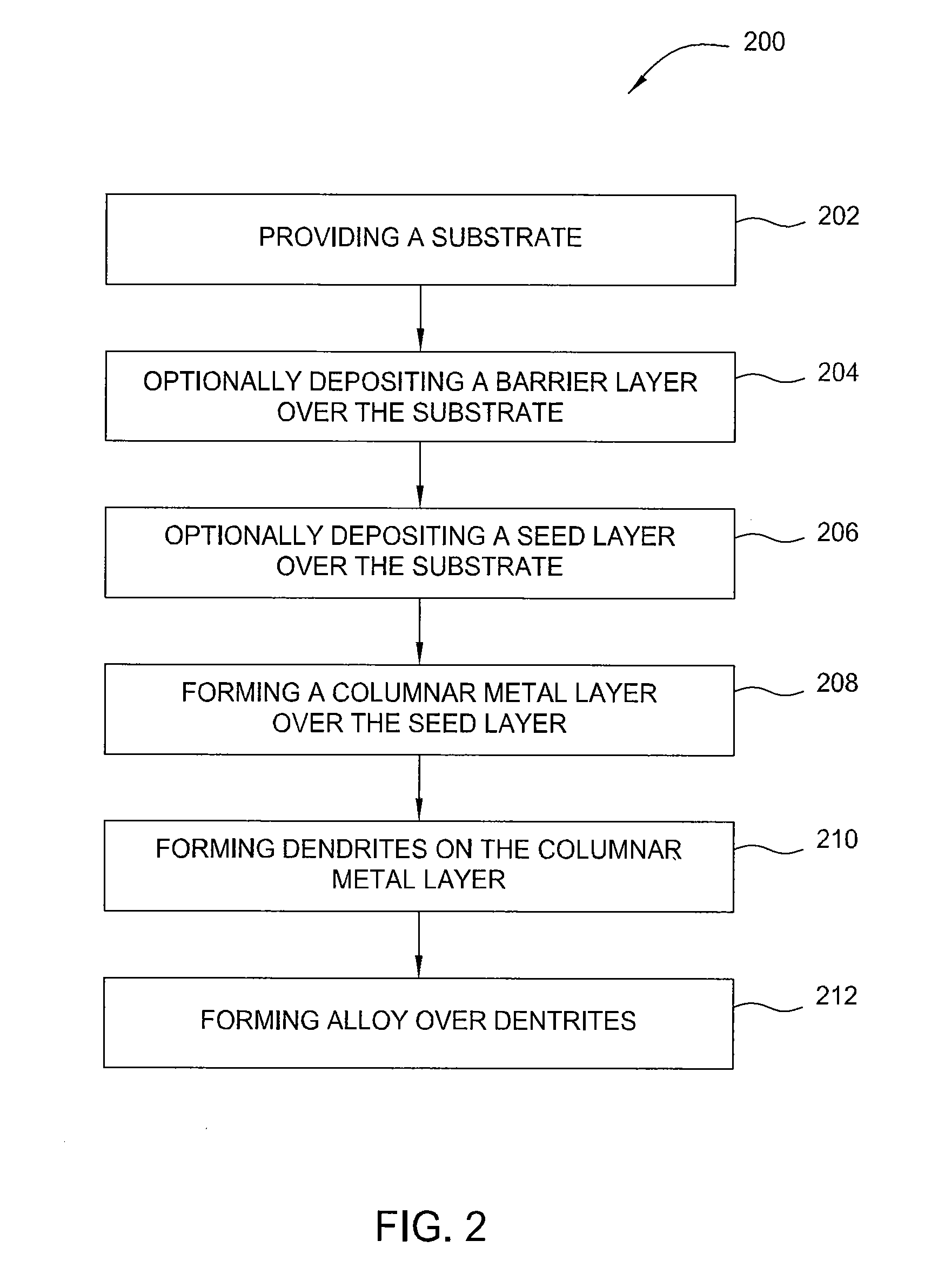

Porous three dimensional copper, tin, copper-tin, copper-tin-cobalt, and copper-tin-cobalt-titanium electrodes for batteries and ultra capacitors

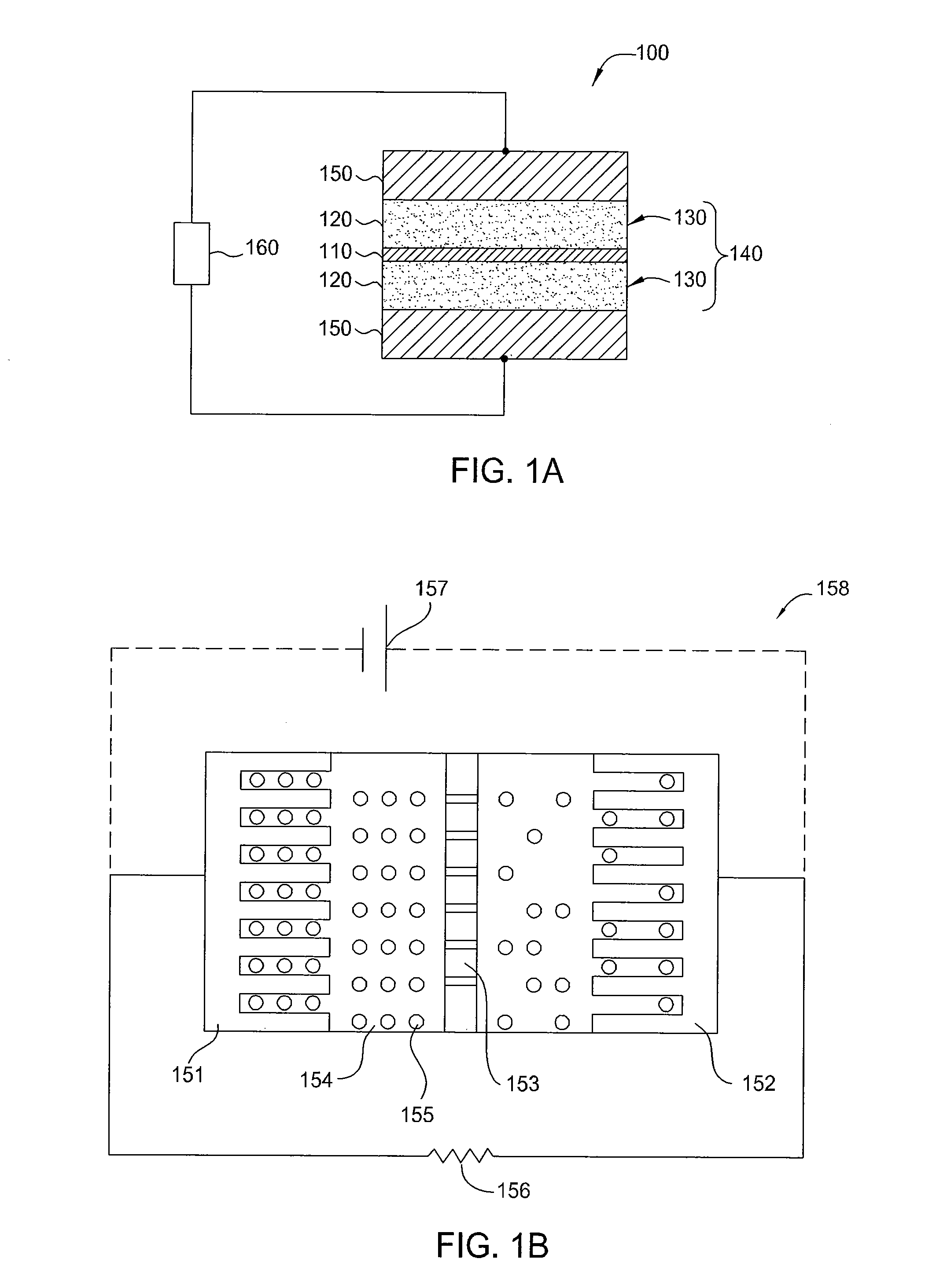

InactiveUS20100193365A1Electrochemical processing of electrodesElectrolysis componentsTitanium electrodePorous electrode

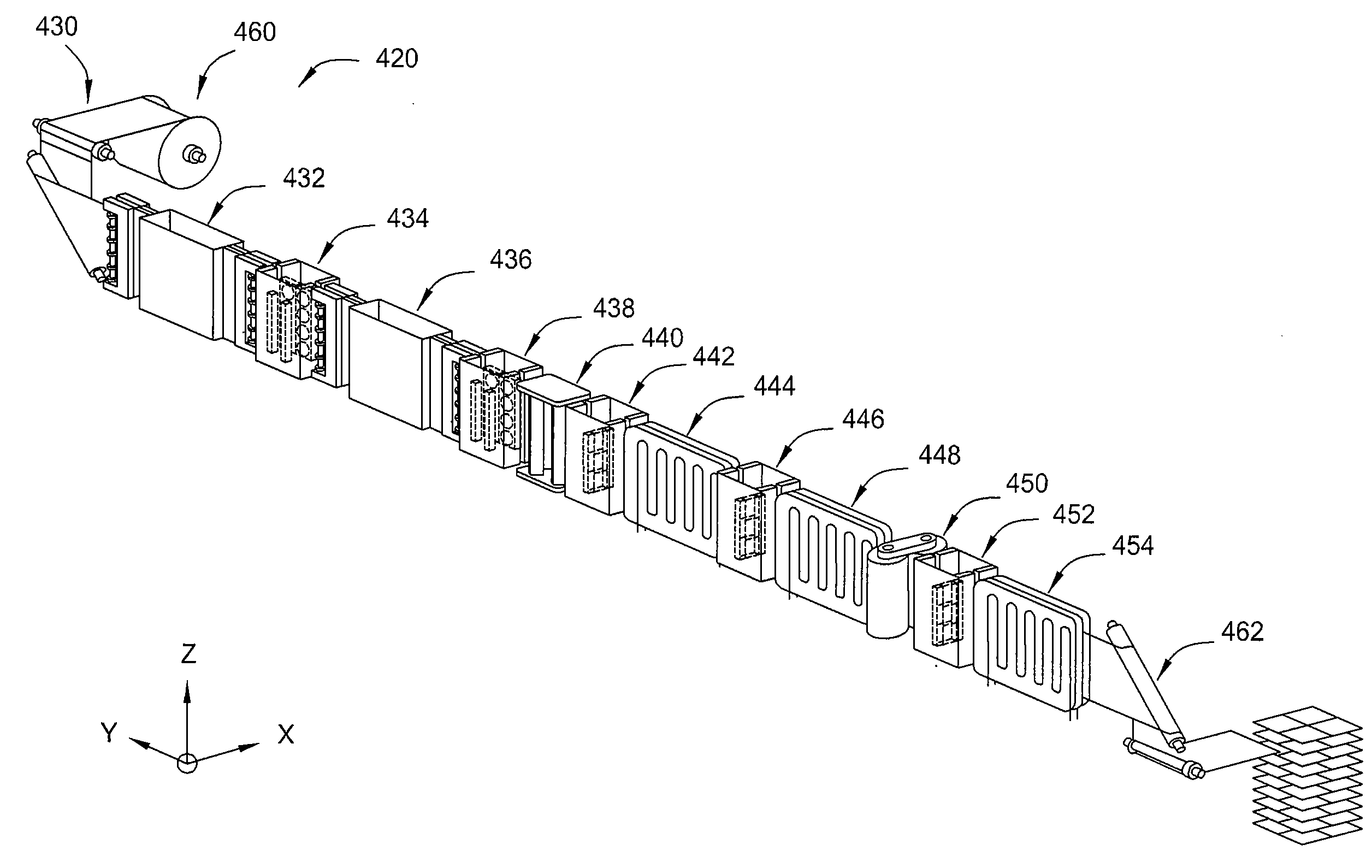

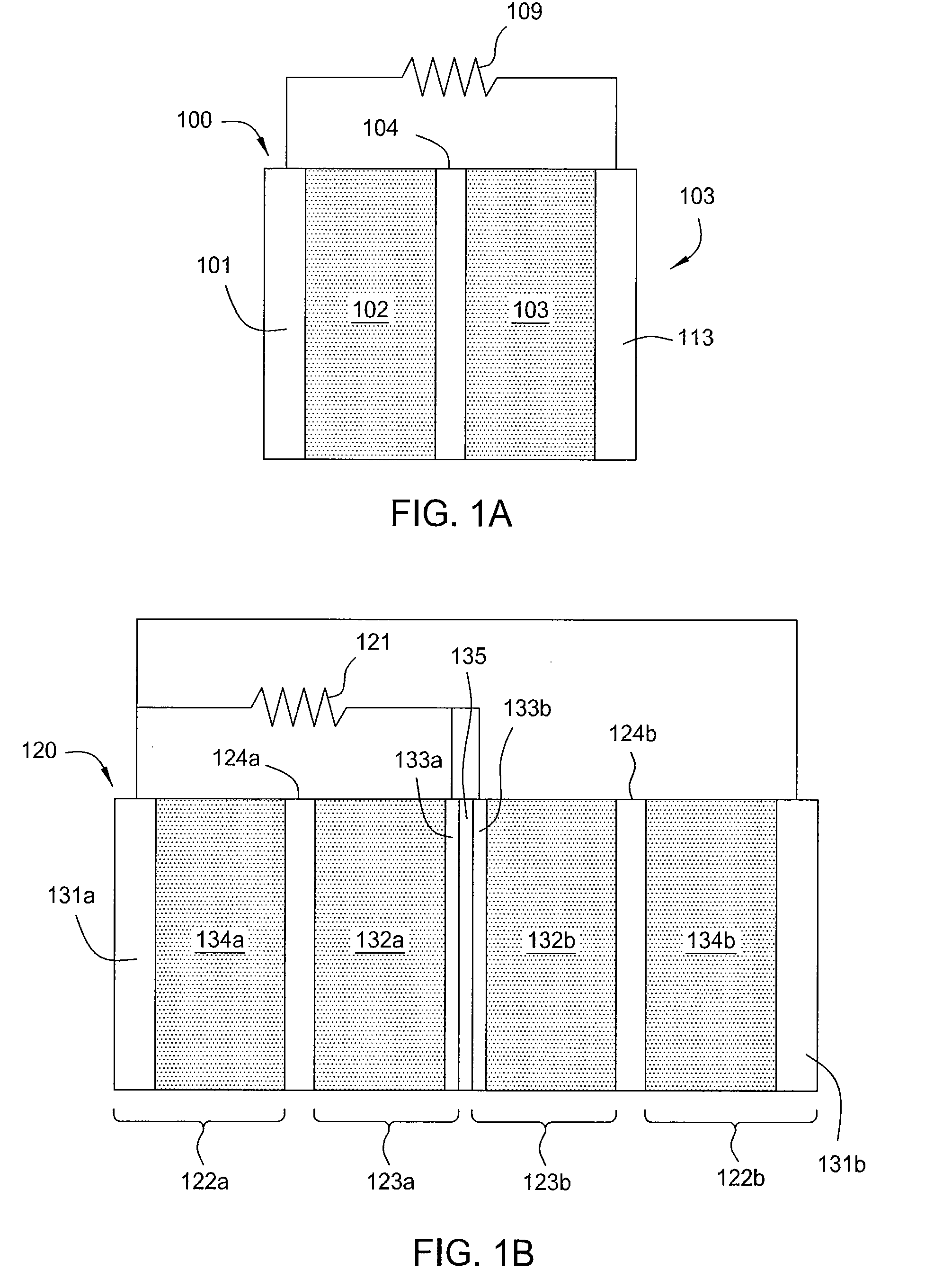

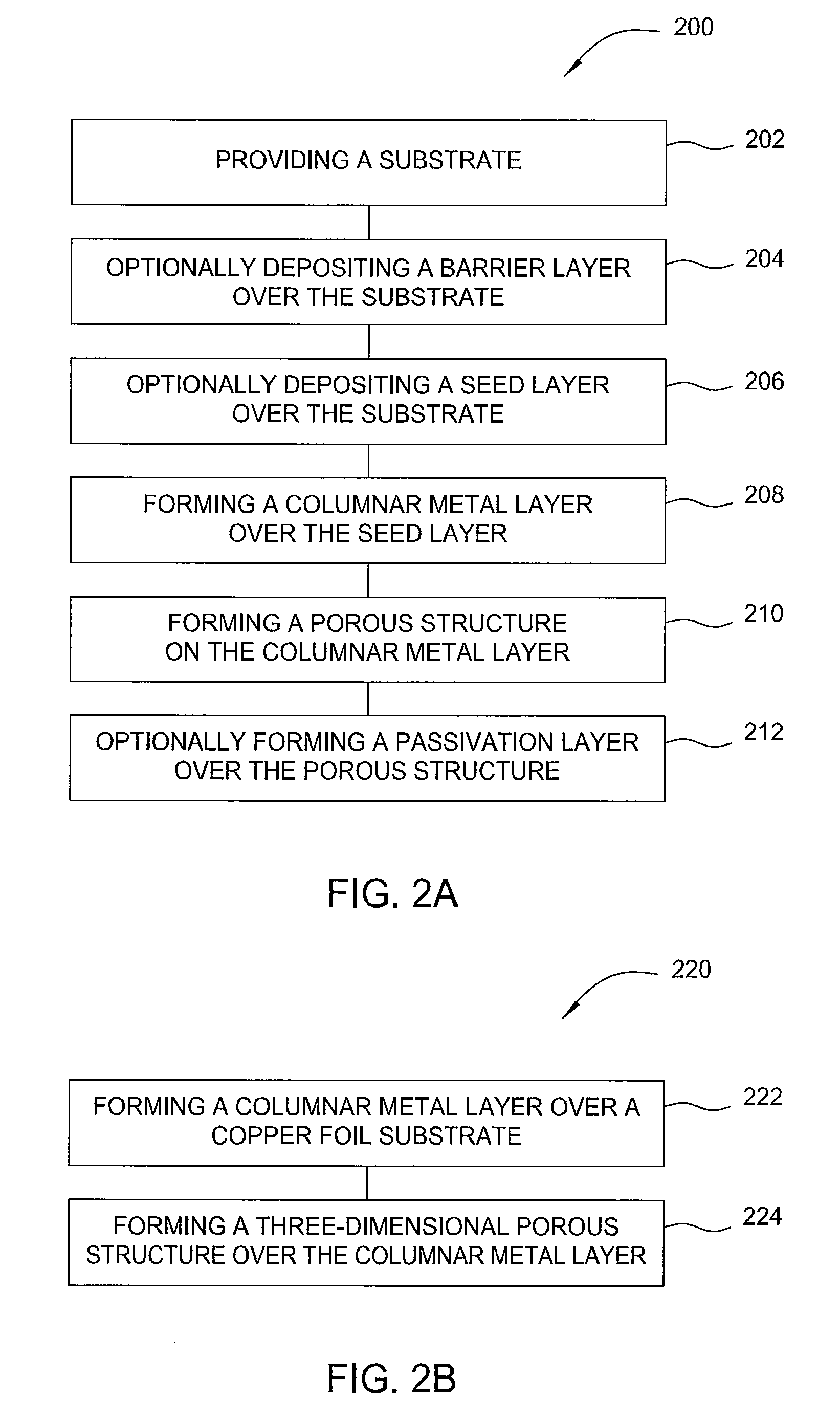

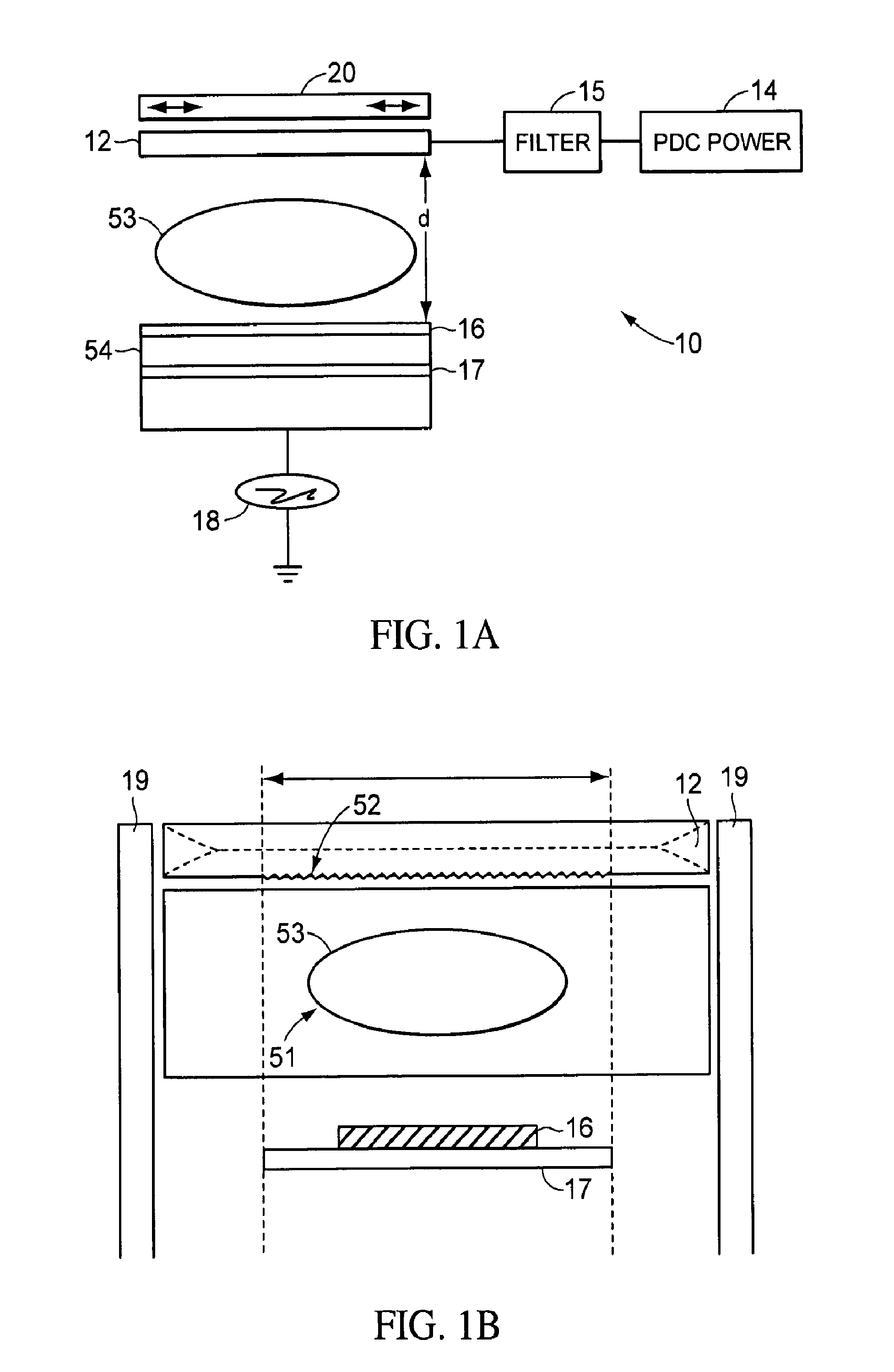

A method and apparatus for forming a reliable and cost efficient battery or electrochemical capacitor electrode structure that has an improved lifetime, lower production costs, and improved process performance are provided. In one embodiment a method for forming a three dimensional porous electrode for a battery or an electrochemical cell is provided. The method comprises depositing a columnar metal layer over a substrate at a first current density by a diffusion limited deposition process and depositing three dimensional metal porous dendritic structures over the columnar metal layer at a second current density greater than the first current density.

Owner:APPLIED MATERIALS INC

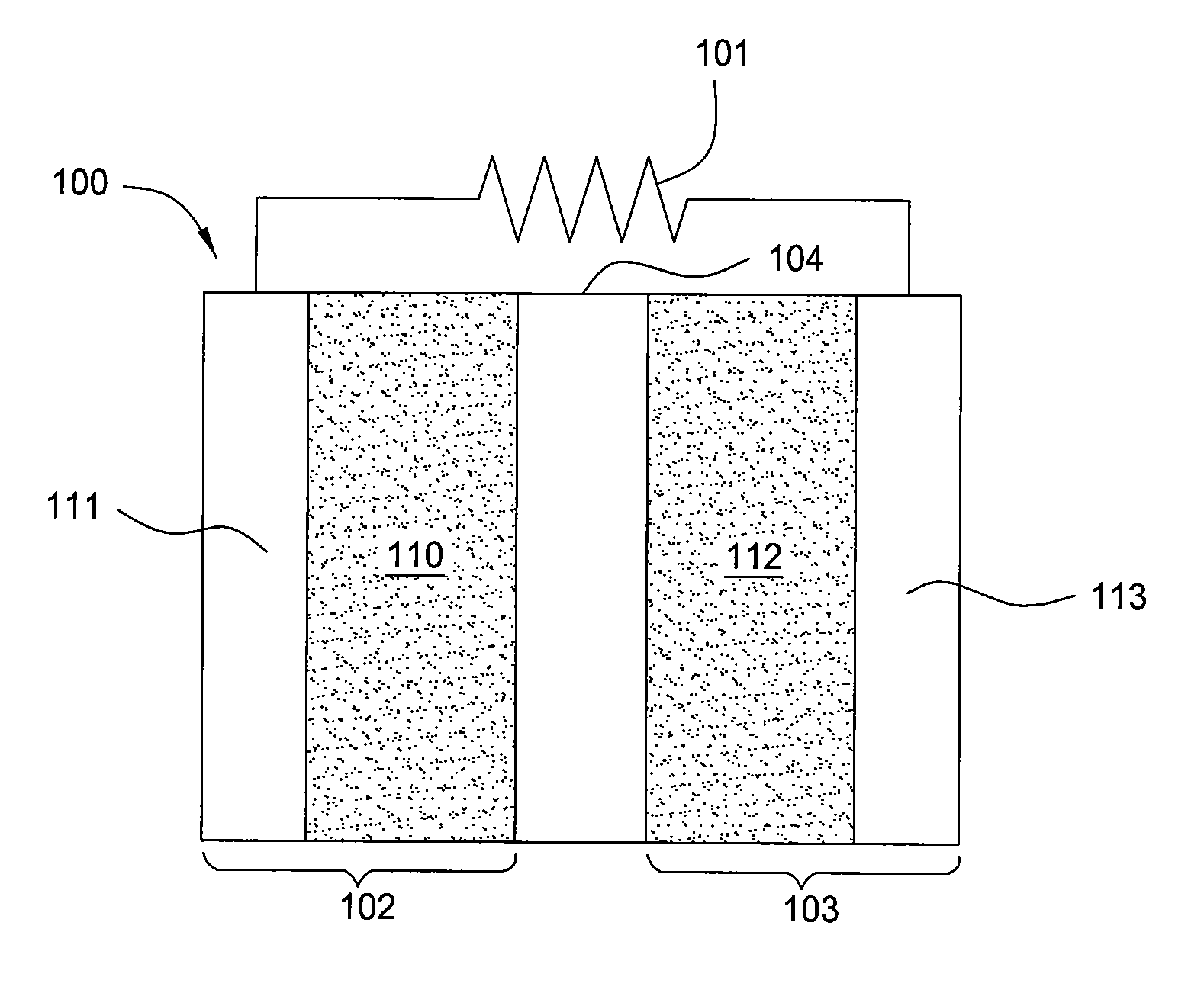

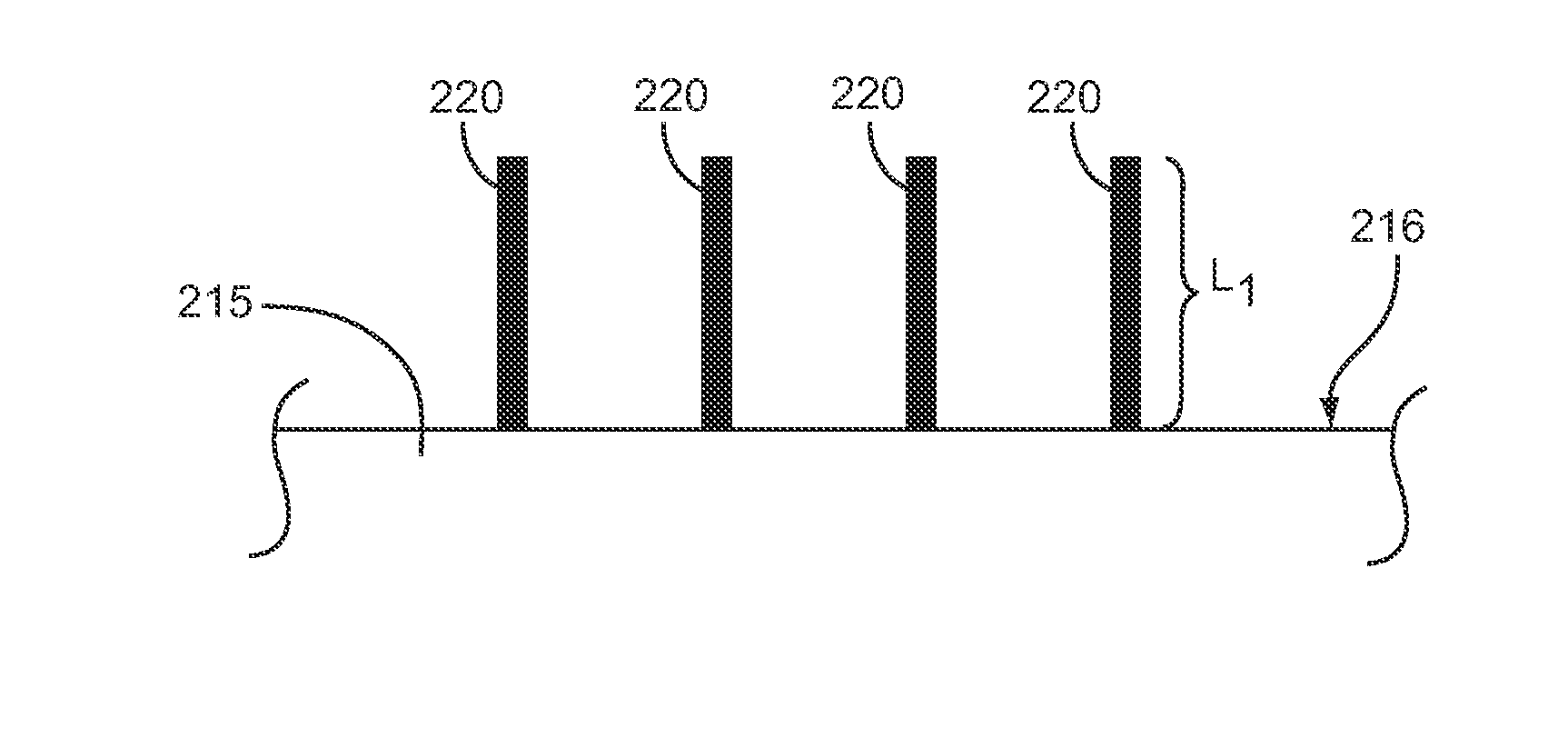

Passivation film for solid electrolyte interface of three dimensional copper containing electrode in energy storage device

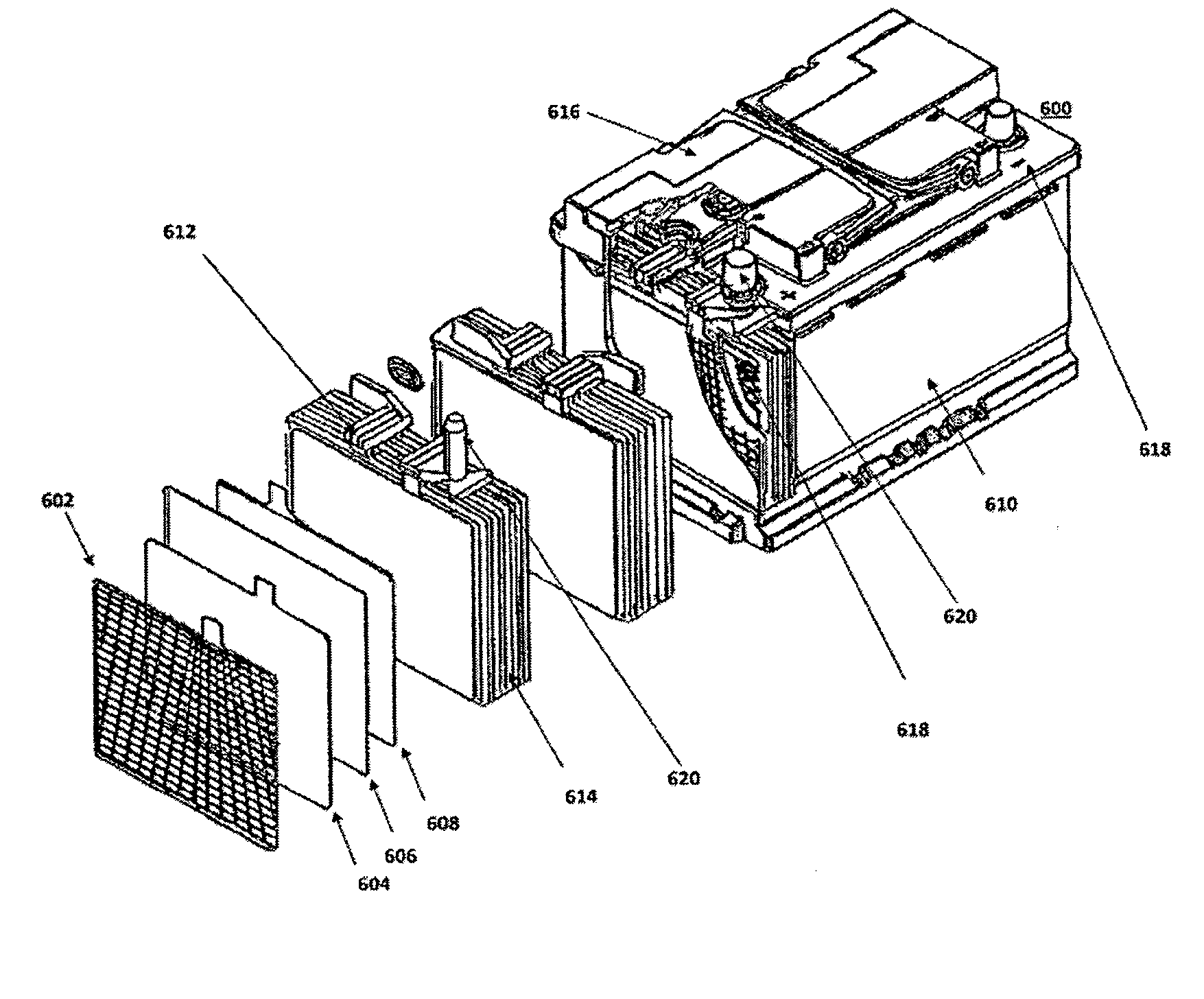

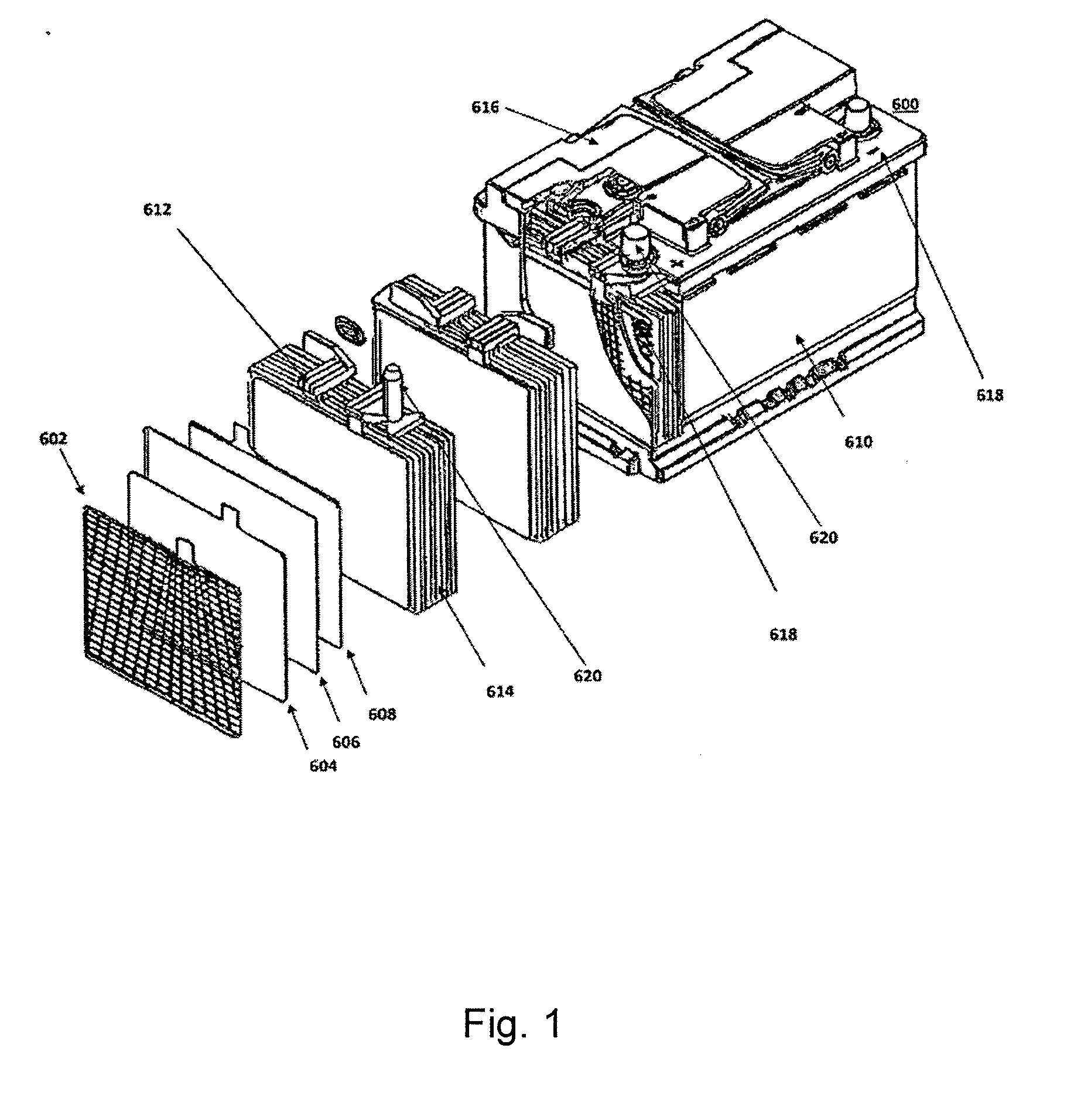

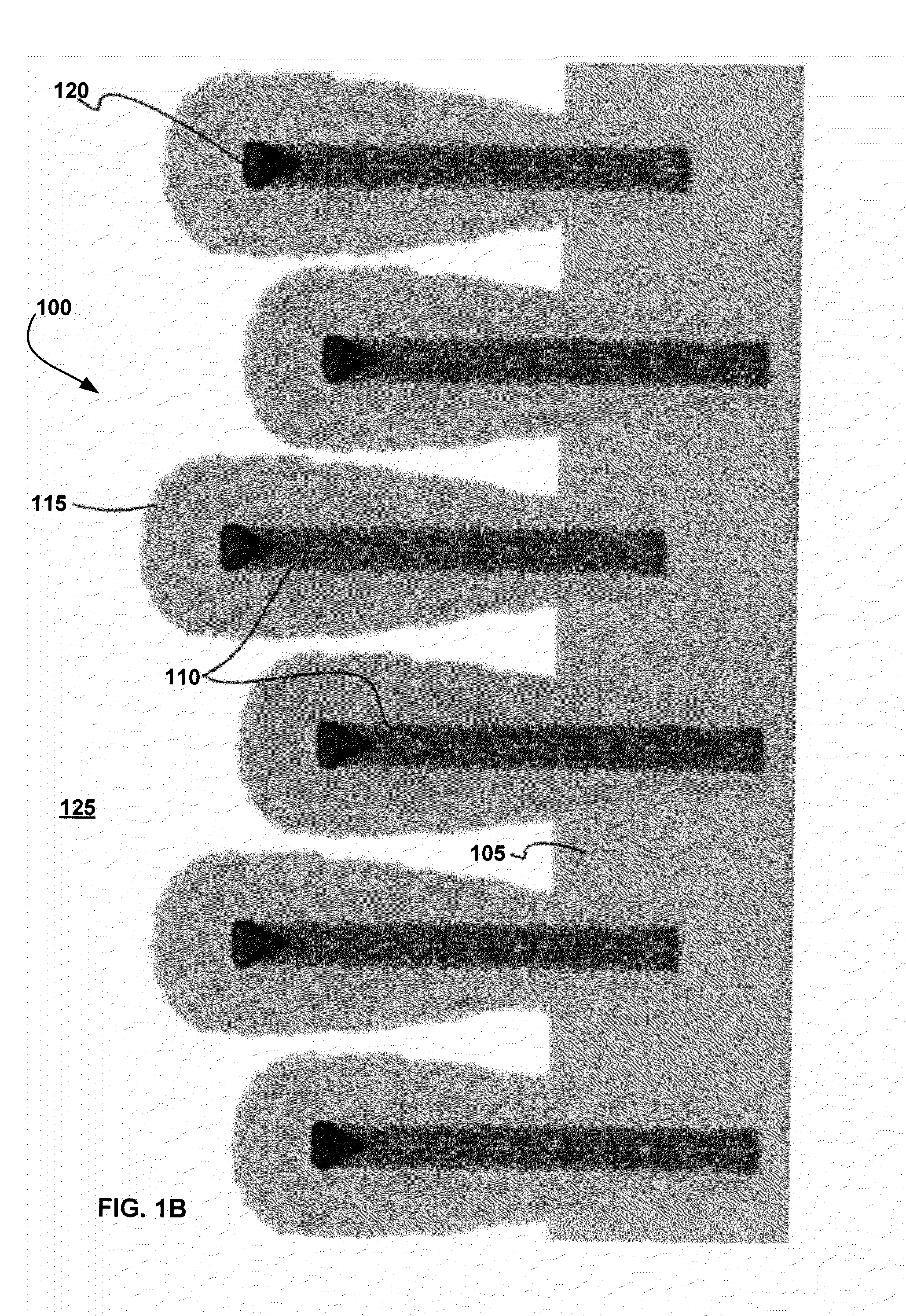

InactiveUS20100330425A1Electrochemical processing of electrodesElectrode carriers/collectorsOptoelectronicsCopper

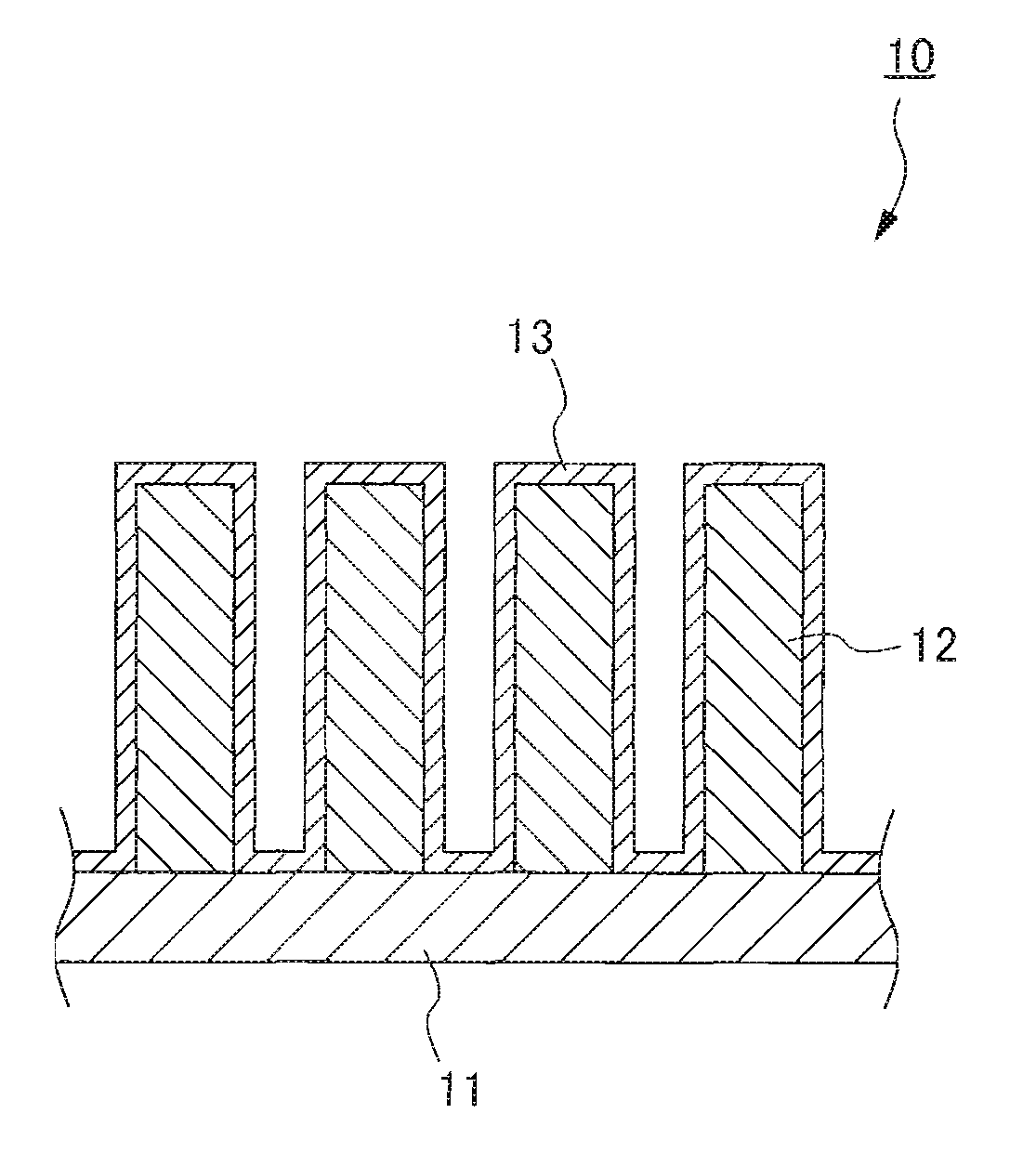

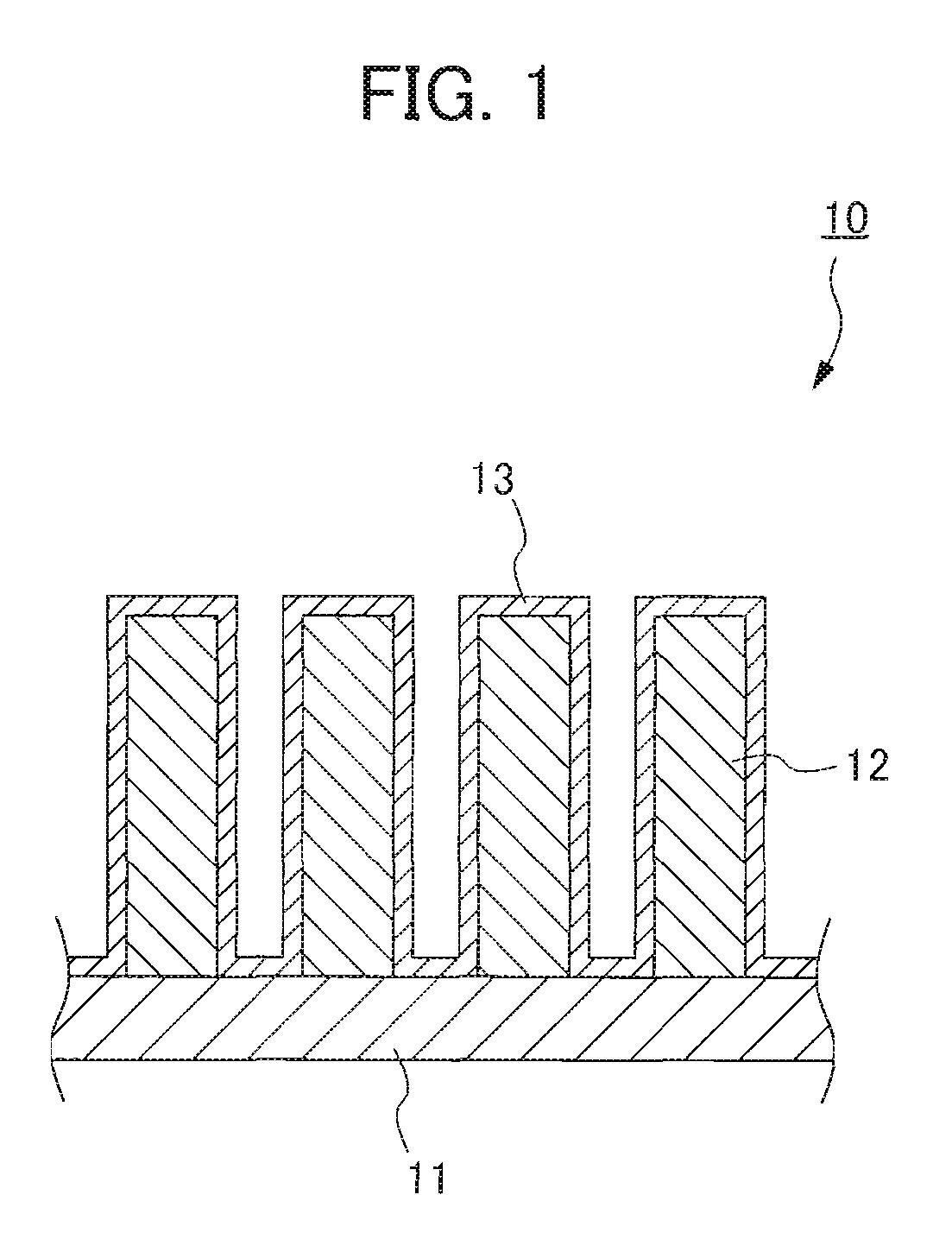

A system and method for fabricating lithium-ion batteries using thin-film deposition processes that form three-dimensional structures is provided. In one embodiment, an anodic structure used to form an energy storage device is provided. The anodic structure comprises a conductive substrate, a plurality of conductive microstructures formed on the substrate, a passivation film formed over the conductive microstructures, and an insulative separator layer formed over the conductive microstructures, wherein the conductive microstructures comprise columnar projections.

Owner:APPLIED MATERIALS INC

Energy storage devices comprising carbon-based additives and methods of making thereof

InactiveUS20120251876A1Improve charge acceptanceReduce conductivityElectrochemical processing of electrodesPretreated surfacesEngineeringEnergy storage

The present invention is directed to energy storage devices, such as lead-acid batteries, and methods of improving the performance thereof, through the incorporation of one or more carbon-based additives.

Owner:EXIDE TECHNOLOGIES LLC

Thin-film cathode for 3-dimensional microbattery and method for preparing such cathode

InactiveUS20060032046A1Electrochemical processing of electrodesElectrolytic inorganic material coatingThin film cathodesThin membrane

A method for producing a microbattery including providing a conductive substrate, forming a thin film cathodic layer on at least one surface of the conductive substrate, subsequently forming a thin film electrolyte layer over the cathodic layer and subsequently forming a thin film anodic layer over the electrolyte layer

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

Negative electrode base member

ActiveUS20100119939A1Increase energy densitySuperior in discharge cycle characteristicElectrochemical processing of electrodesFinal product manufactureOrganic filmComposite film

The present invention aims to realize a battery having high output voltage, high energy density and excellent charge and discharge cycle characteristics through a constitution different from those of conventional batteries. Specifically, one of the following negative electrode base members is used as a negative electrode base member for lithium ion secondary batteries: a negative electrode base member wherein a metal film is formed on a support having an organic film; such a negative electrode base member wherein the surface layer of the organic film is covered with a metal oxide film; a negative electrode base member wherein a metal film is formed on a support having a composite film formed from a composite film-forming material containing an organic component and an inorganic component; and a negative electrode base member wherein a silica coating is formed, on a support having a photoresist pattern, from a silica film-forming coating liquid and a metal film is formed on the support after removing the photoresist pattern.

Owner:TOKYO OHKA KOGYO CO LTD +1

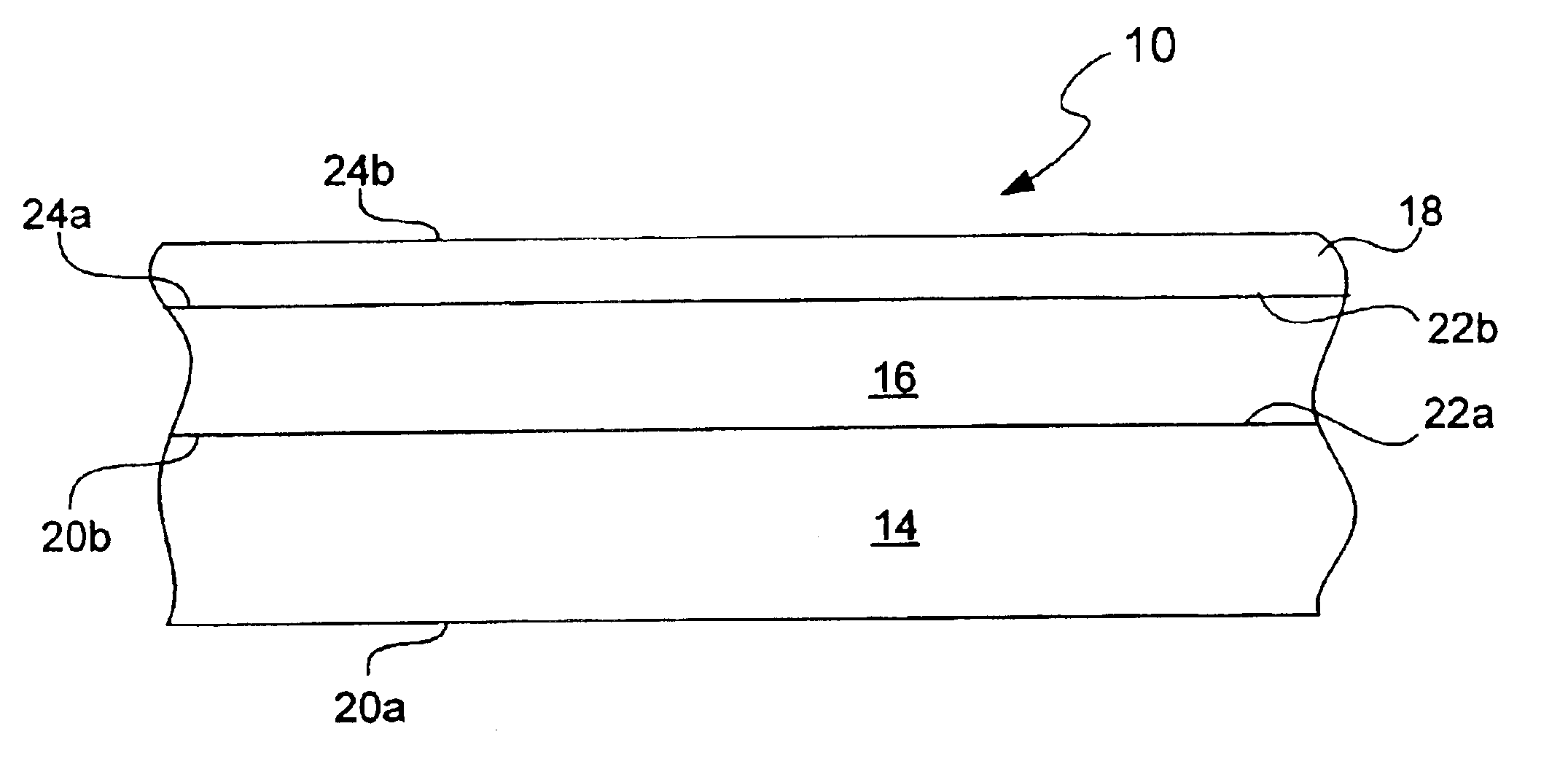

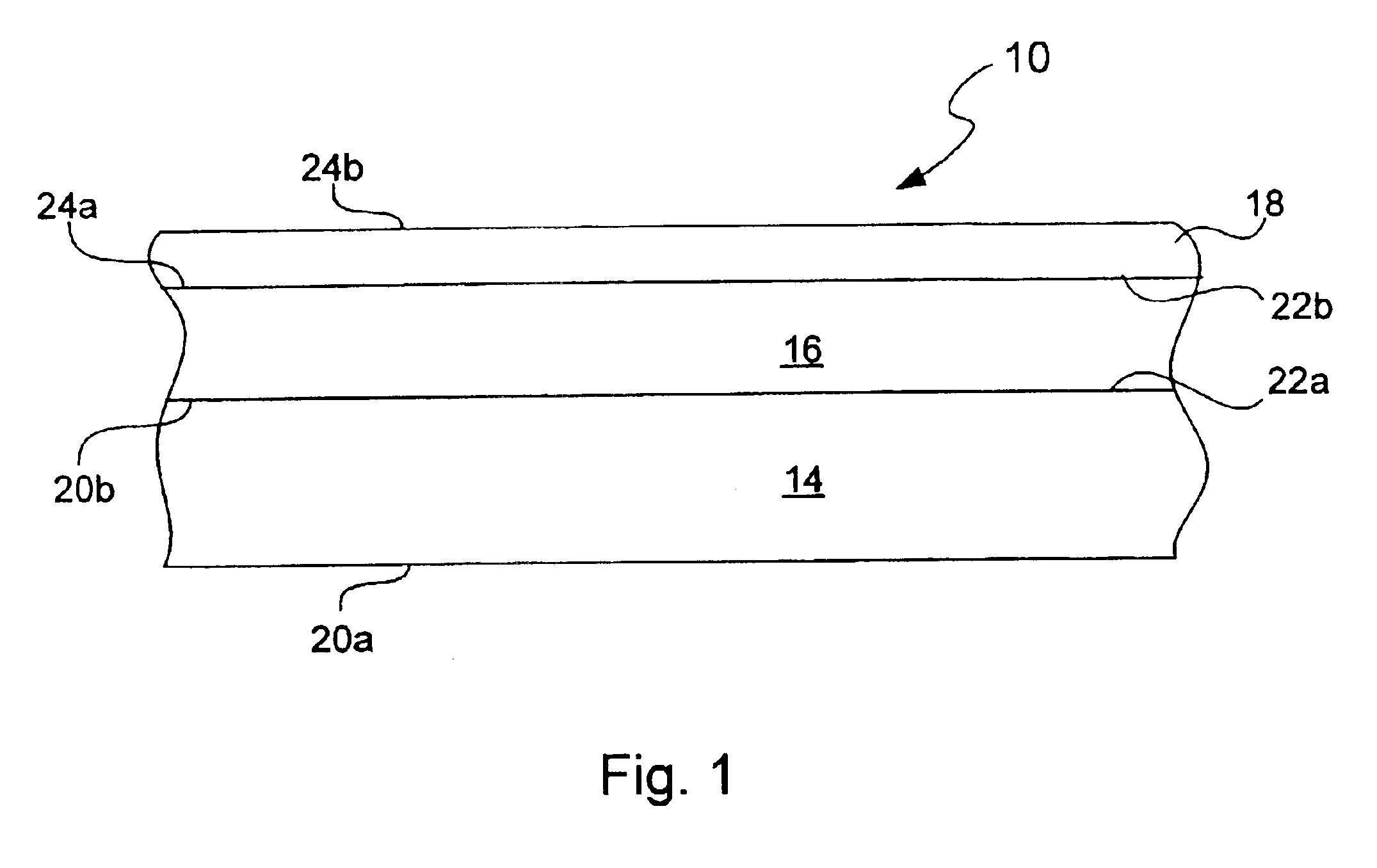

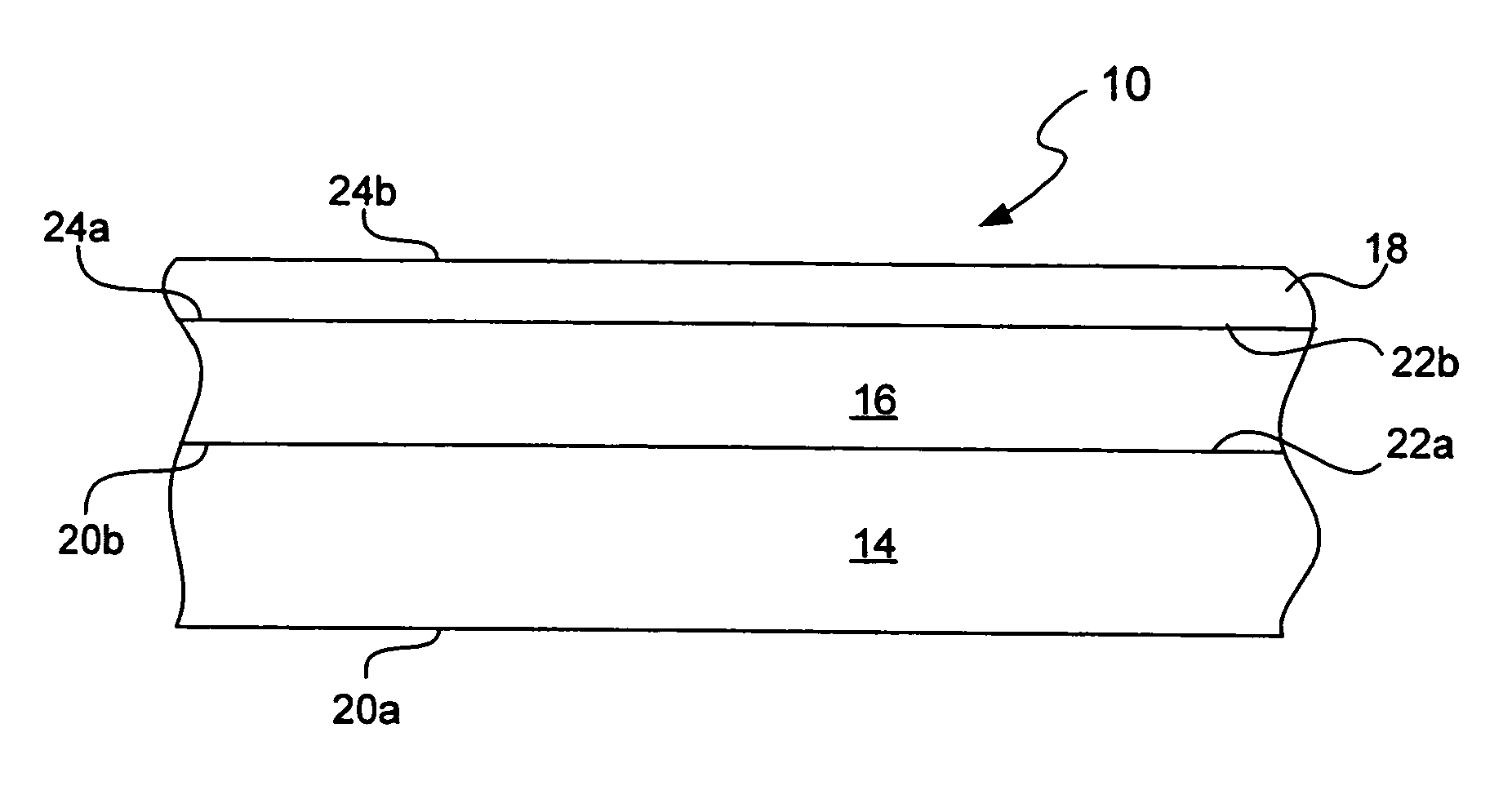

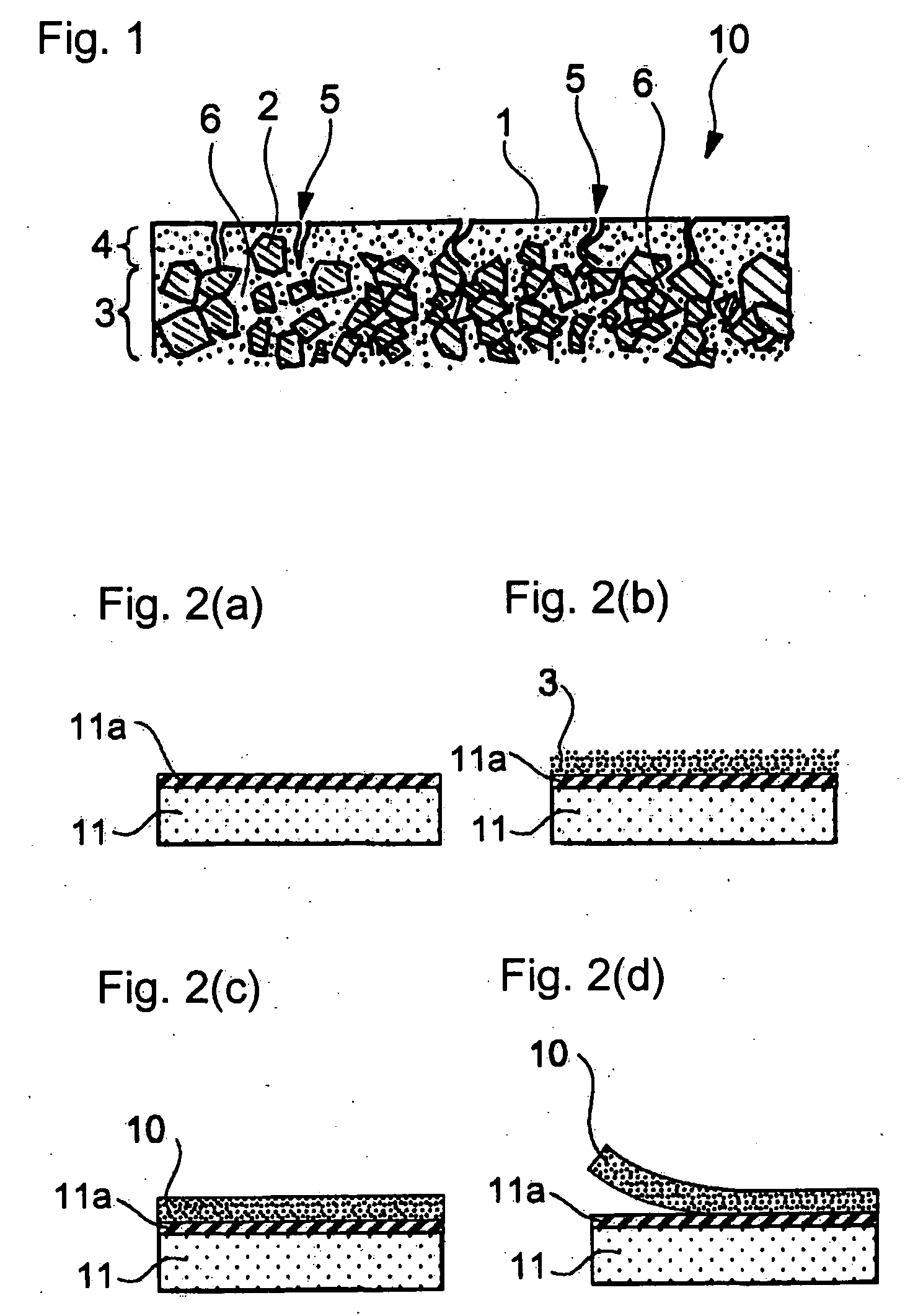

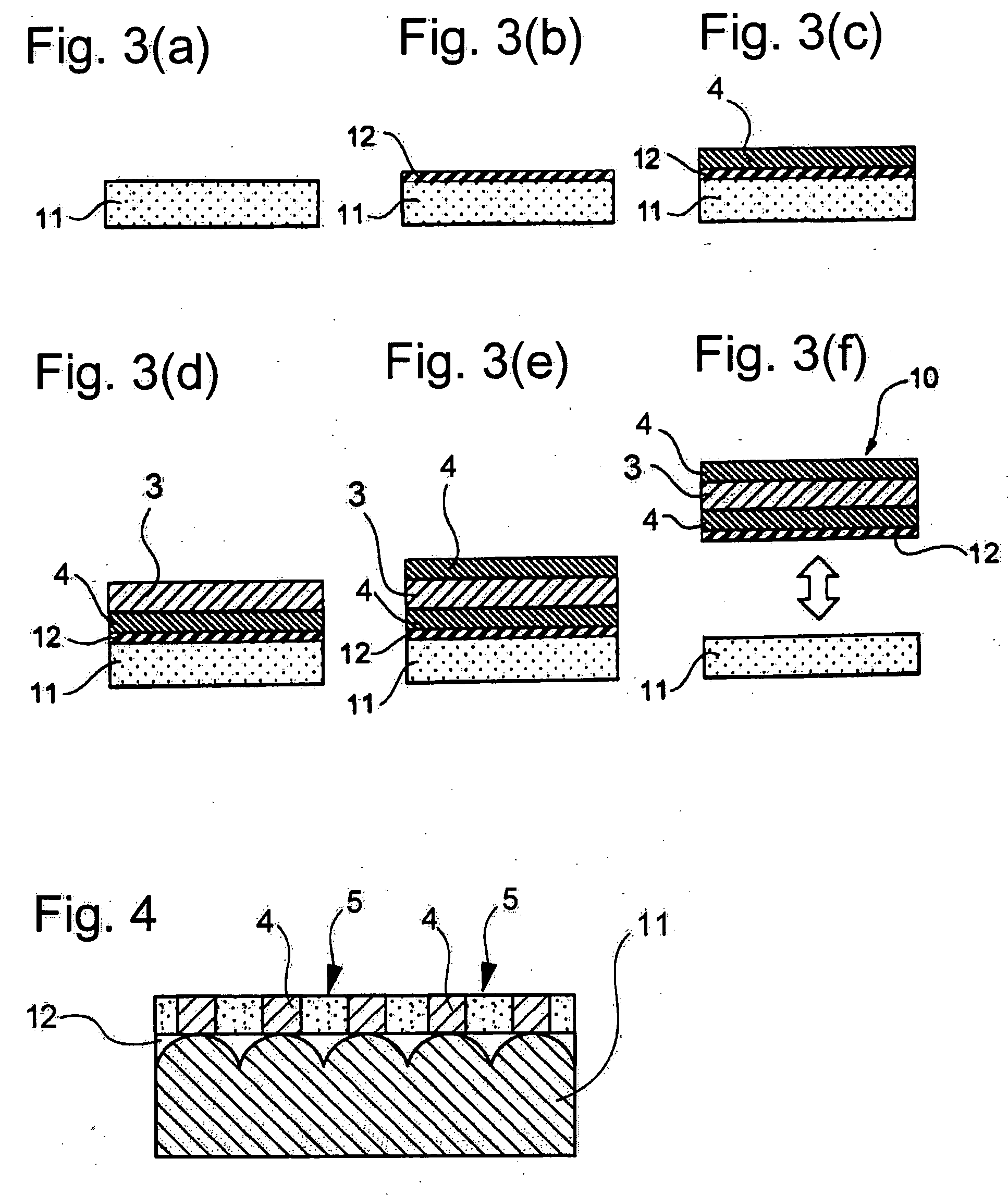

Negative electrode for nonaqueous secondary battery

InactiveUS20060051677A1Electrochemical processing of electrodesElectrode carriers/collectorsMetallic materialsMaterials science

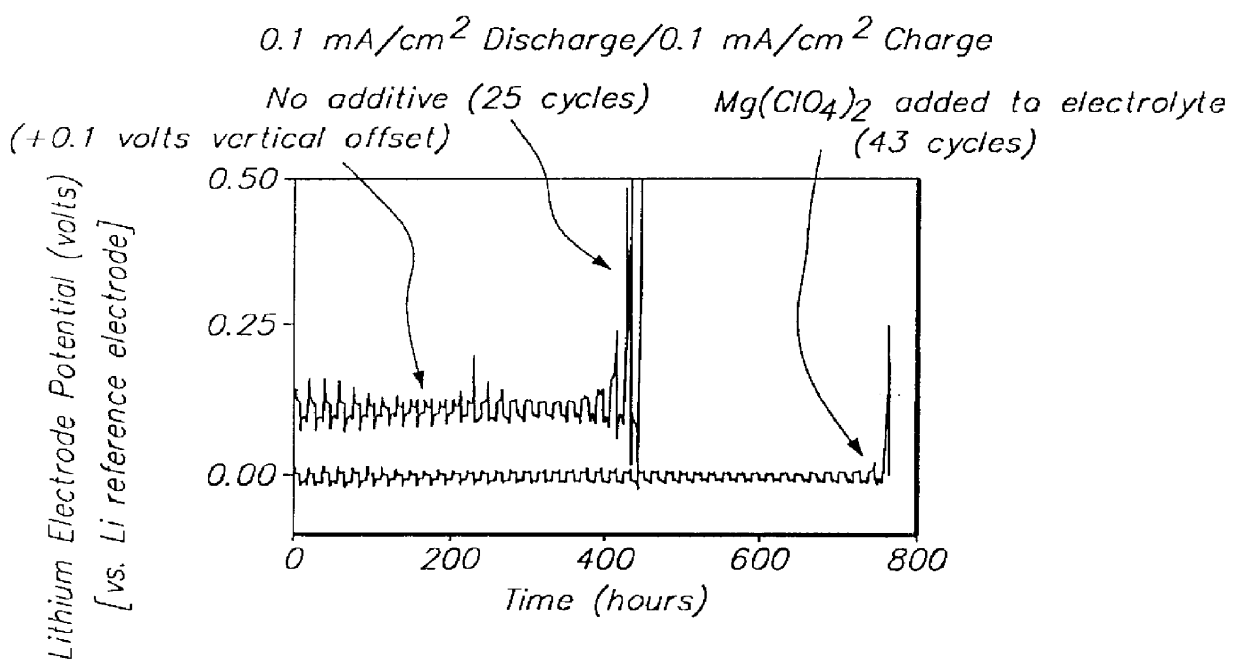

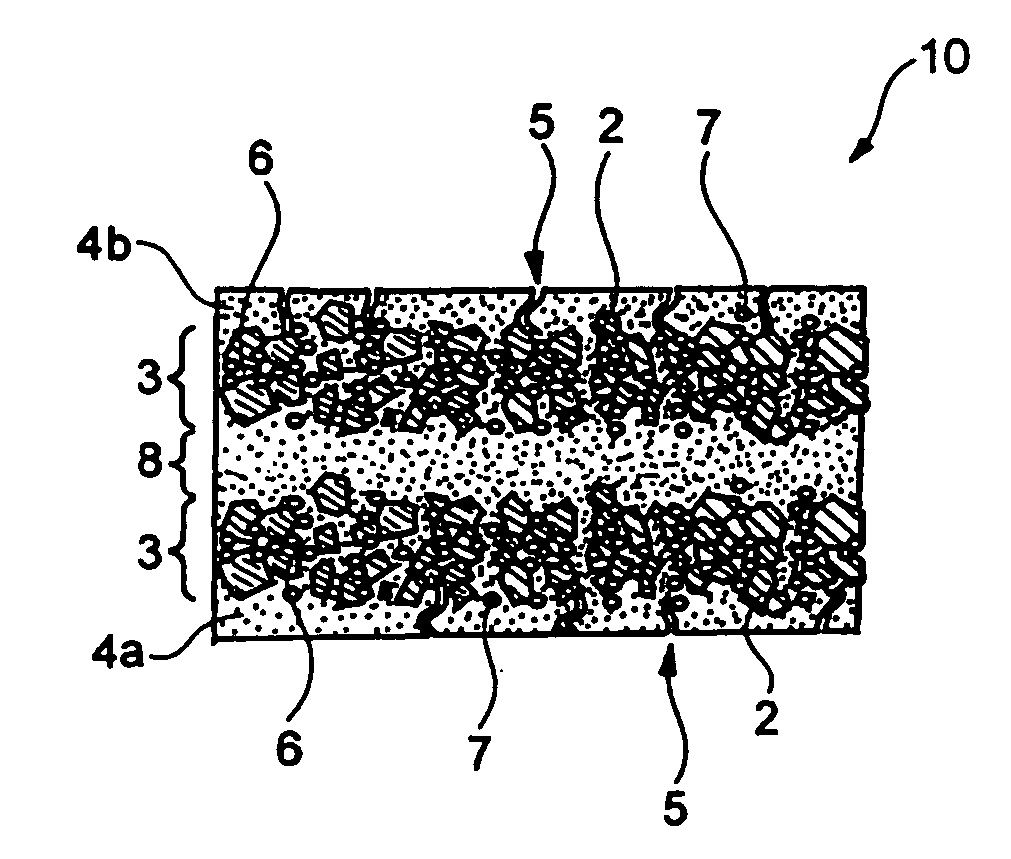

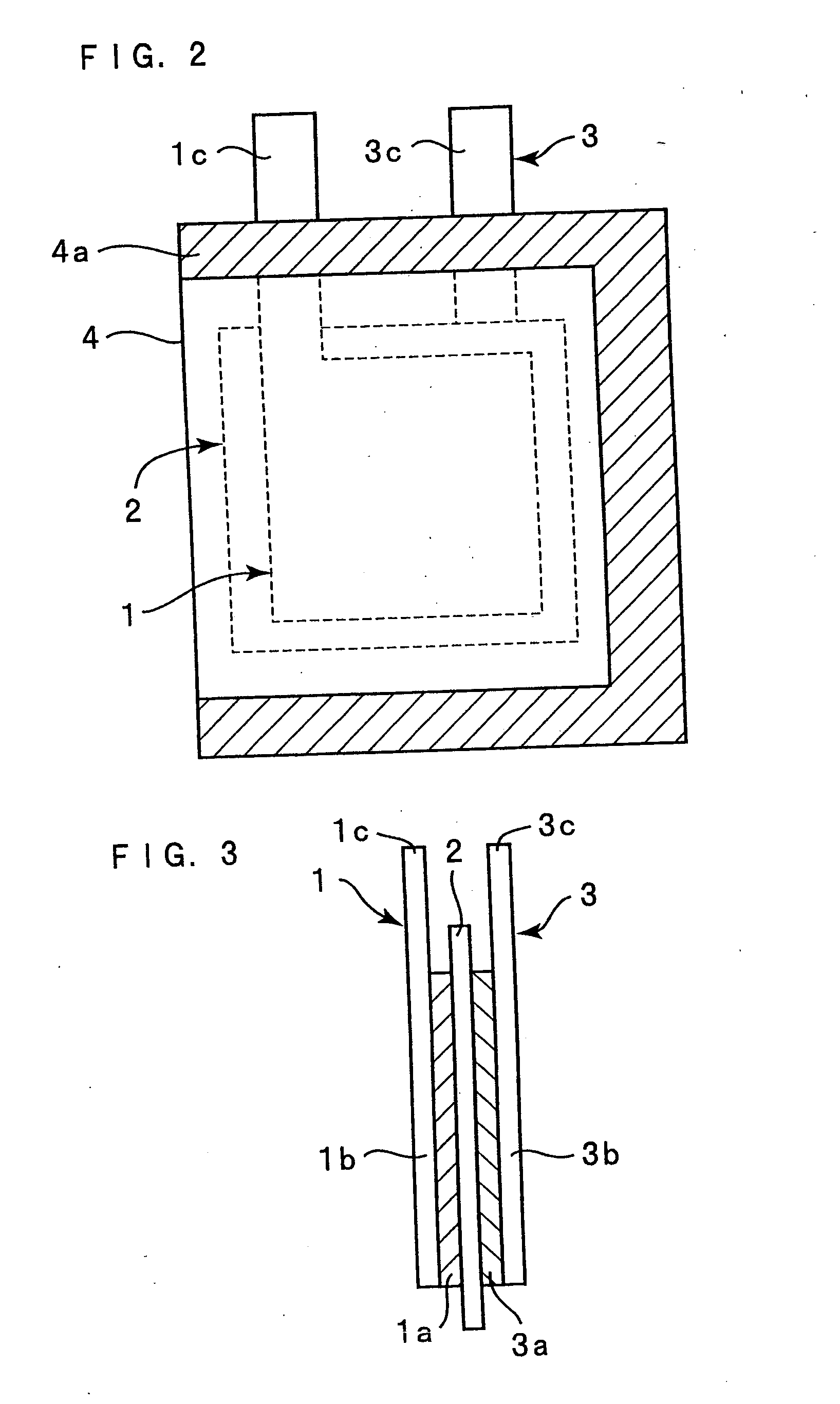

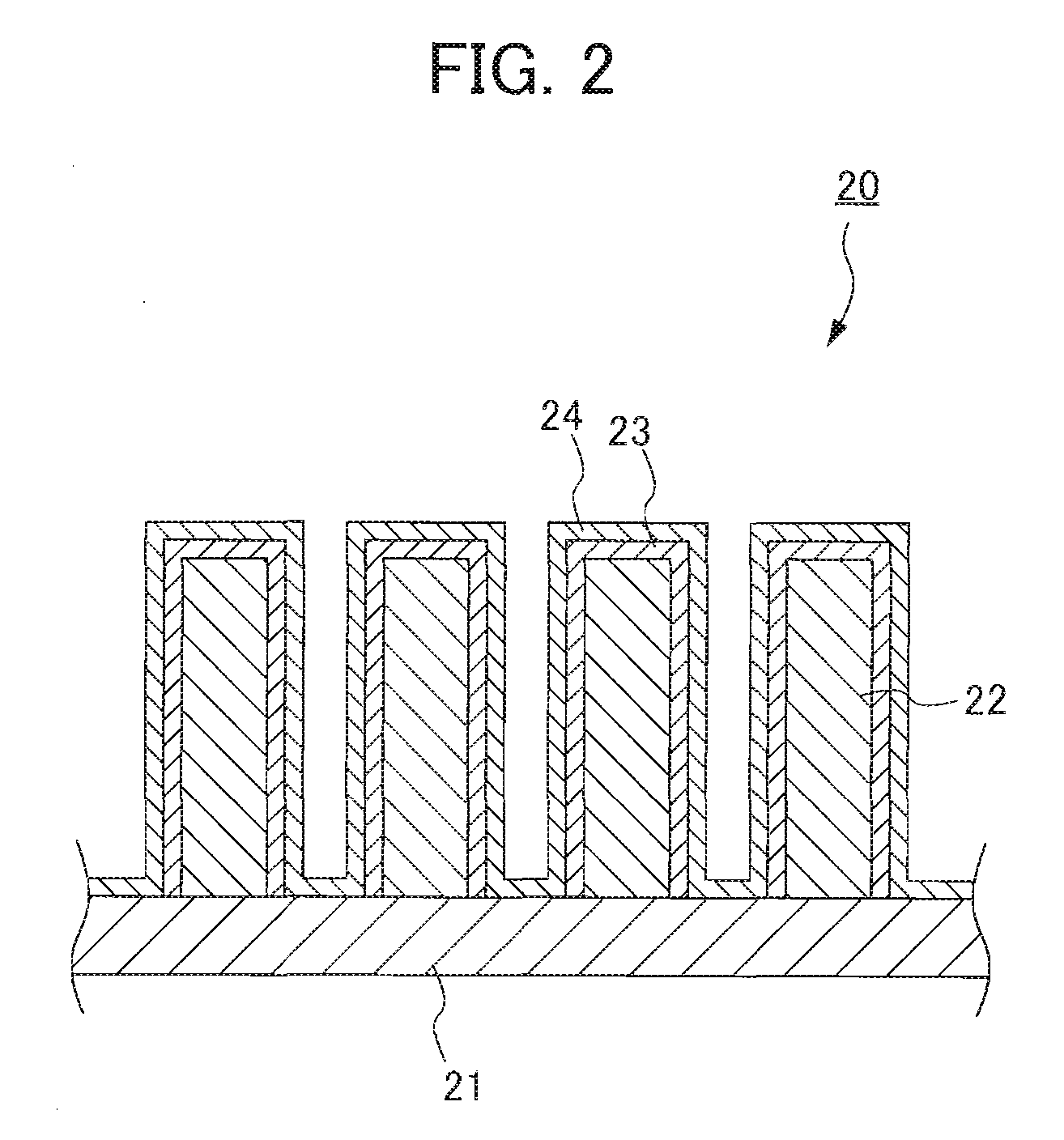

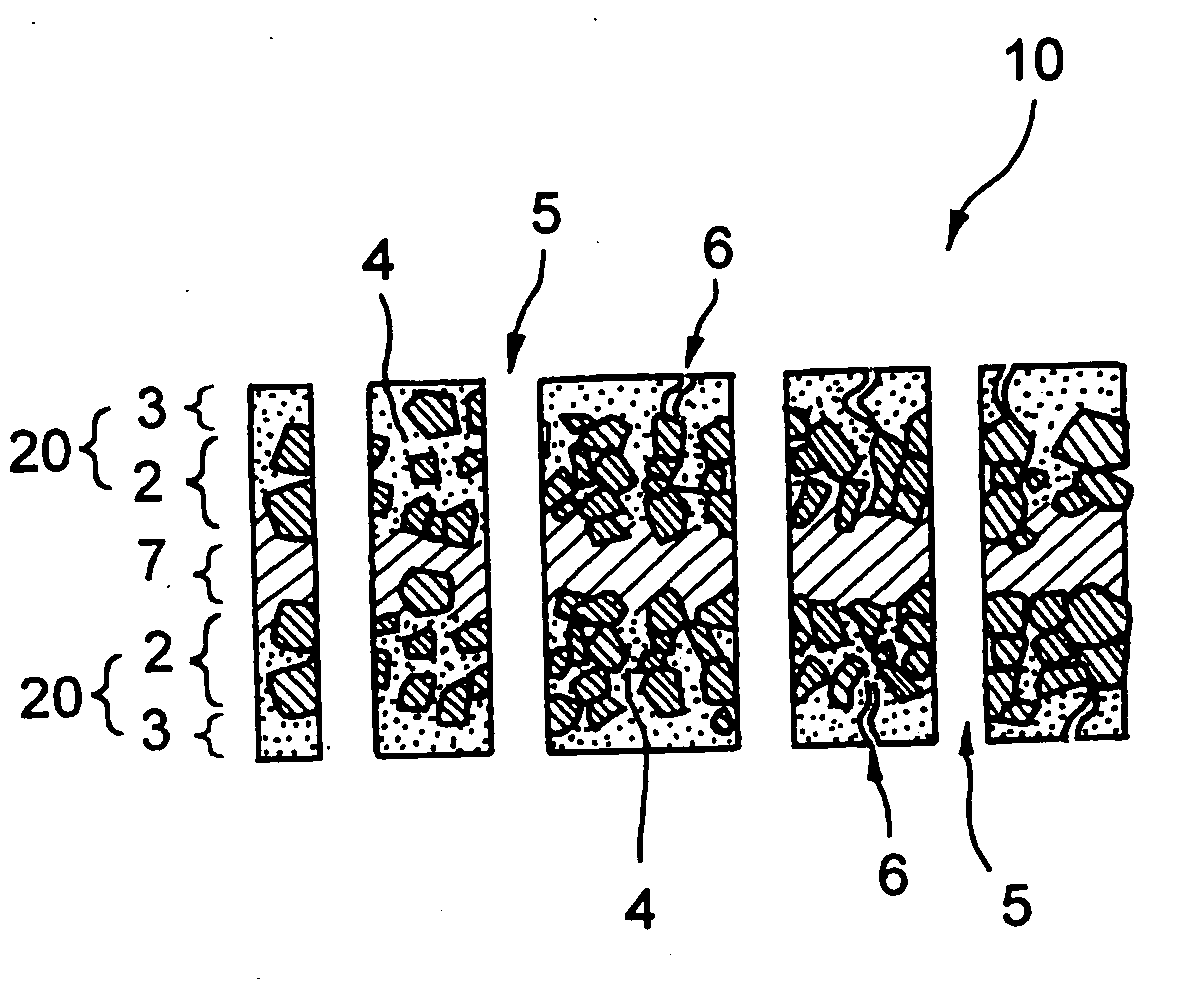

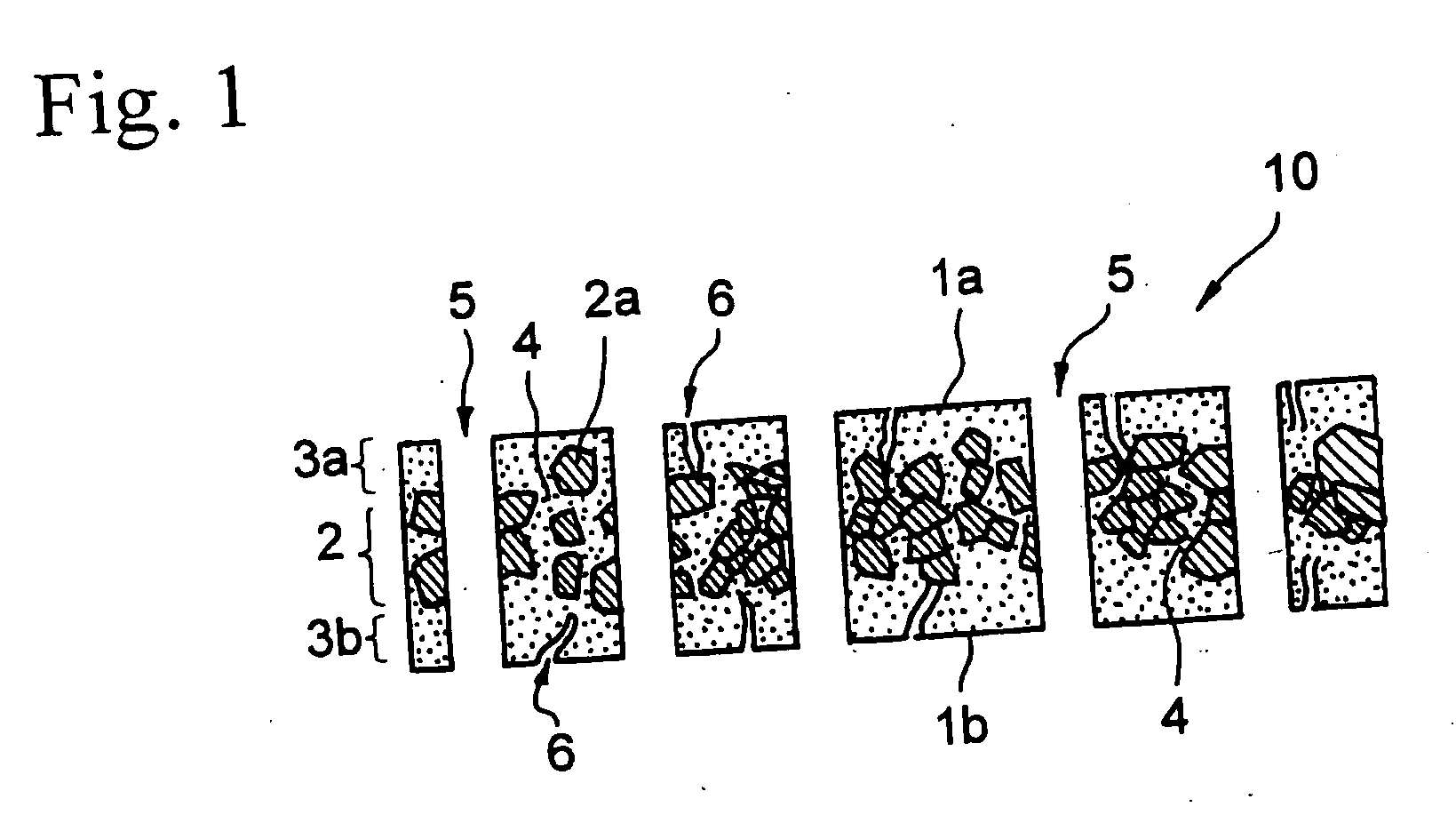

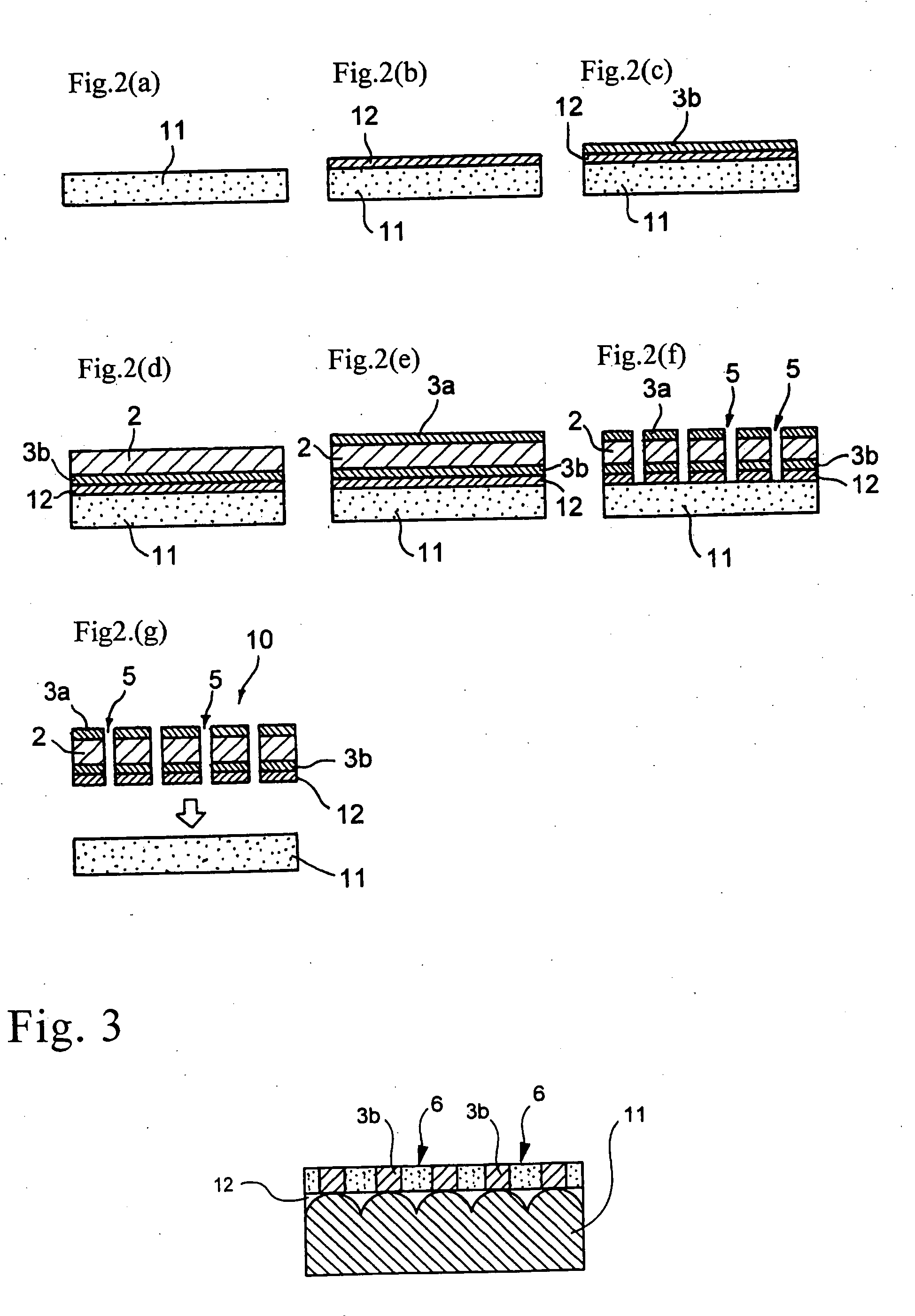

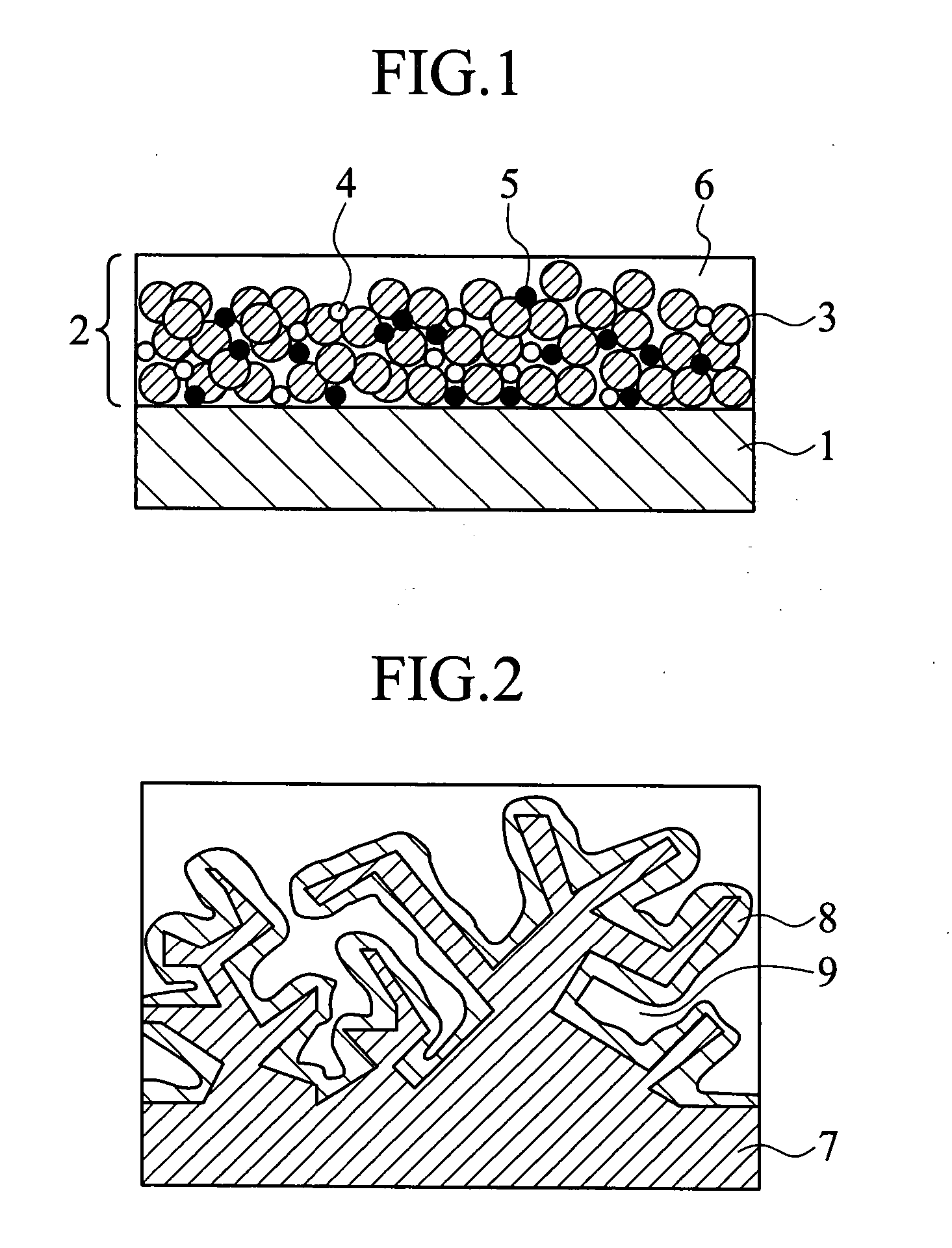

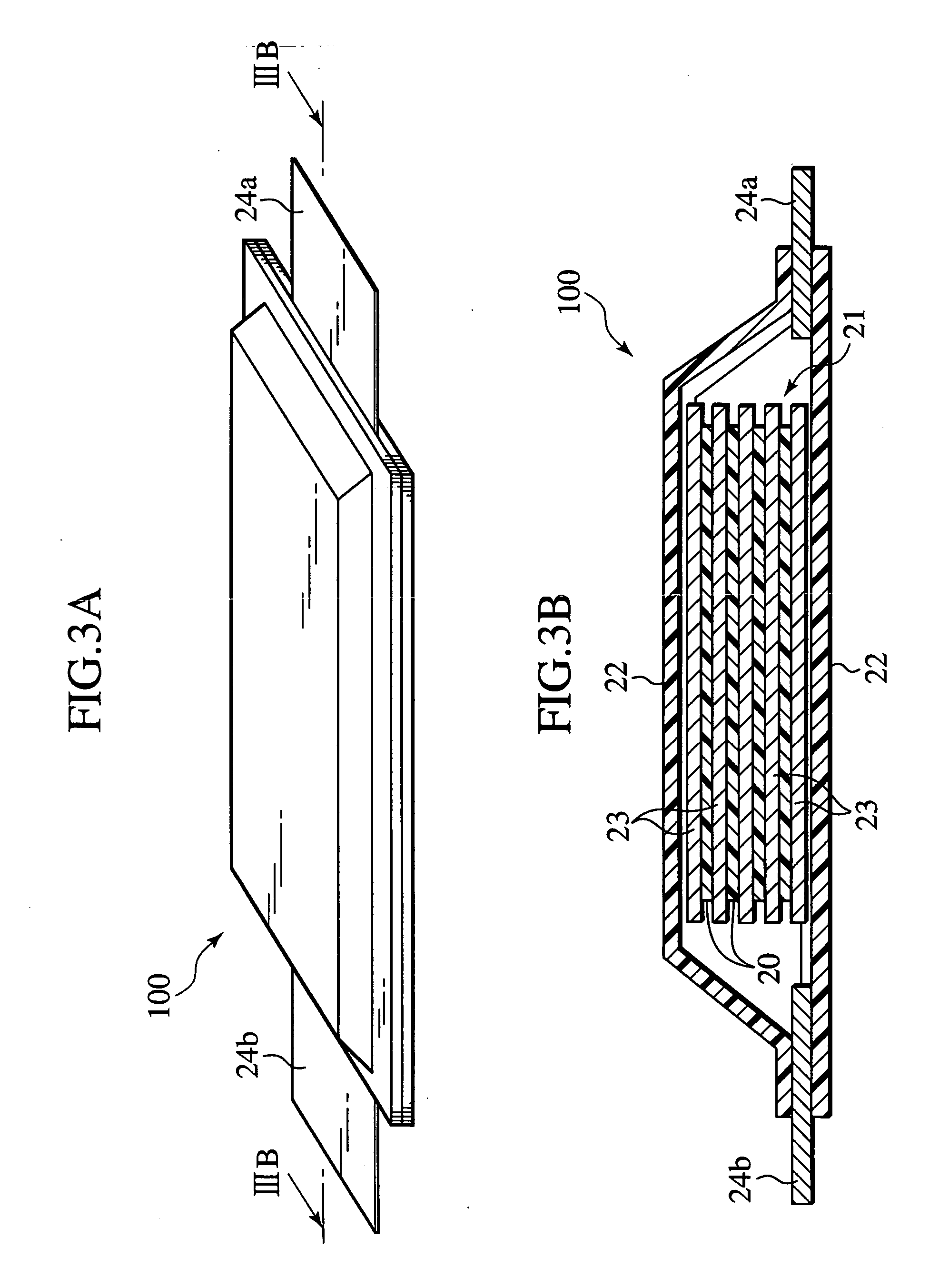

A negative electrode 10 for a nonaqueous secondary battery, has an active material layer 2 containing active material particles 2a. The active material layer 2 has a metallic material 4 deposited among the particles by electroplating. The negative electrode 10 has a large number of holes 5 open on at least one side thereof and extending through the thickness of the active material layer. The negative electrode 10 further has a pair of current collecting layers 3a and 3b adapted to be brought into contact with an electrolyte. The active material layer 2 is between the current collecting layers 3a and 3b. The holes 5 open on the negative electrode 10 preferably have an opening area ratio of 0.3% to 30%. At least one of the pair of the current collecting layers 3a and 3b preferably has a thickness of 0.3 to 10 μm.

Owner:MITSUI MINING & SMELTING CO LTD

Hybrid Energy Storage Device Charging

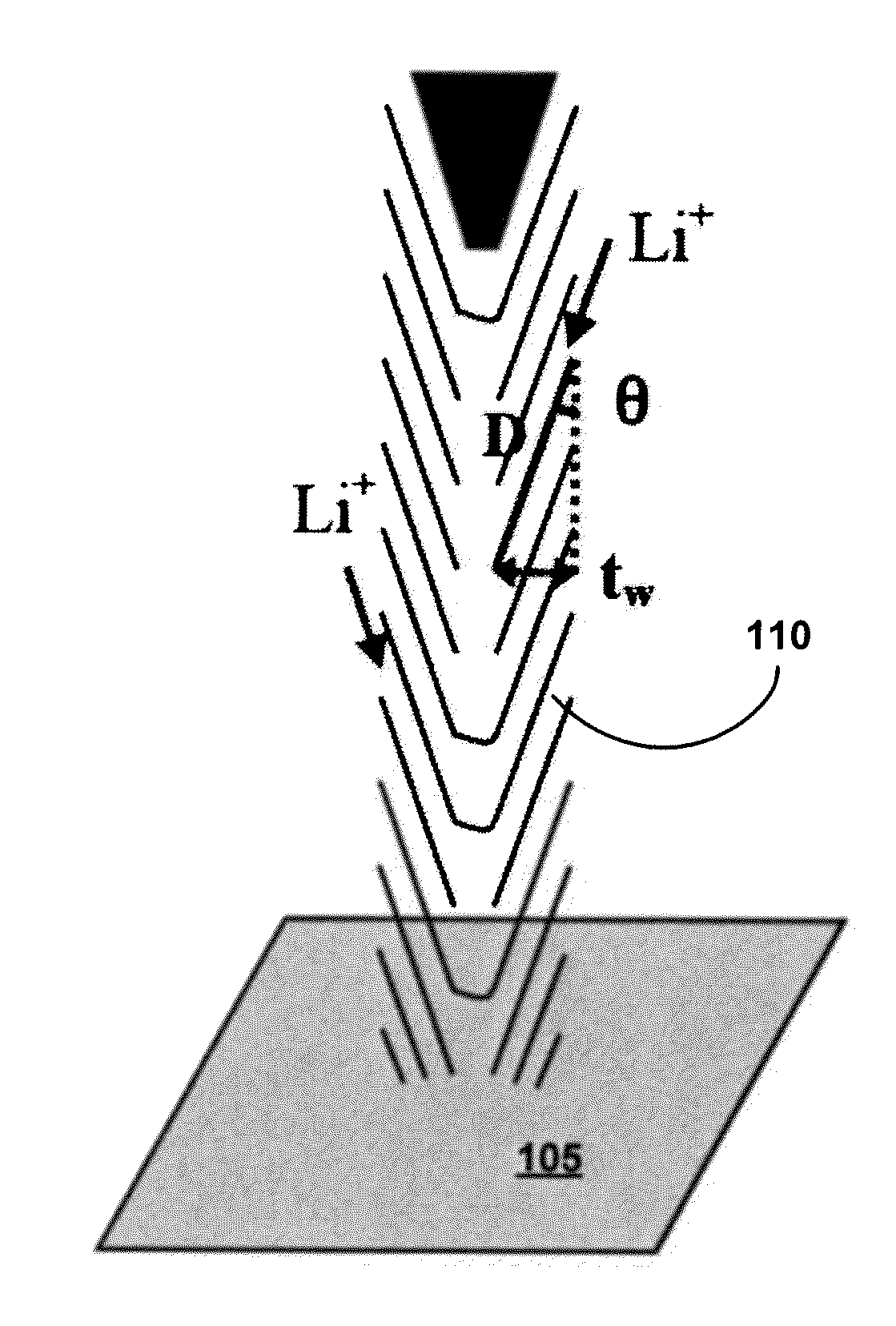

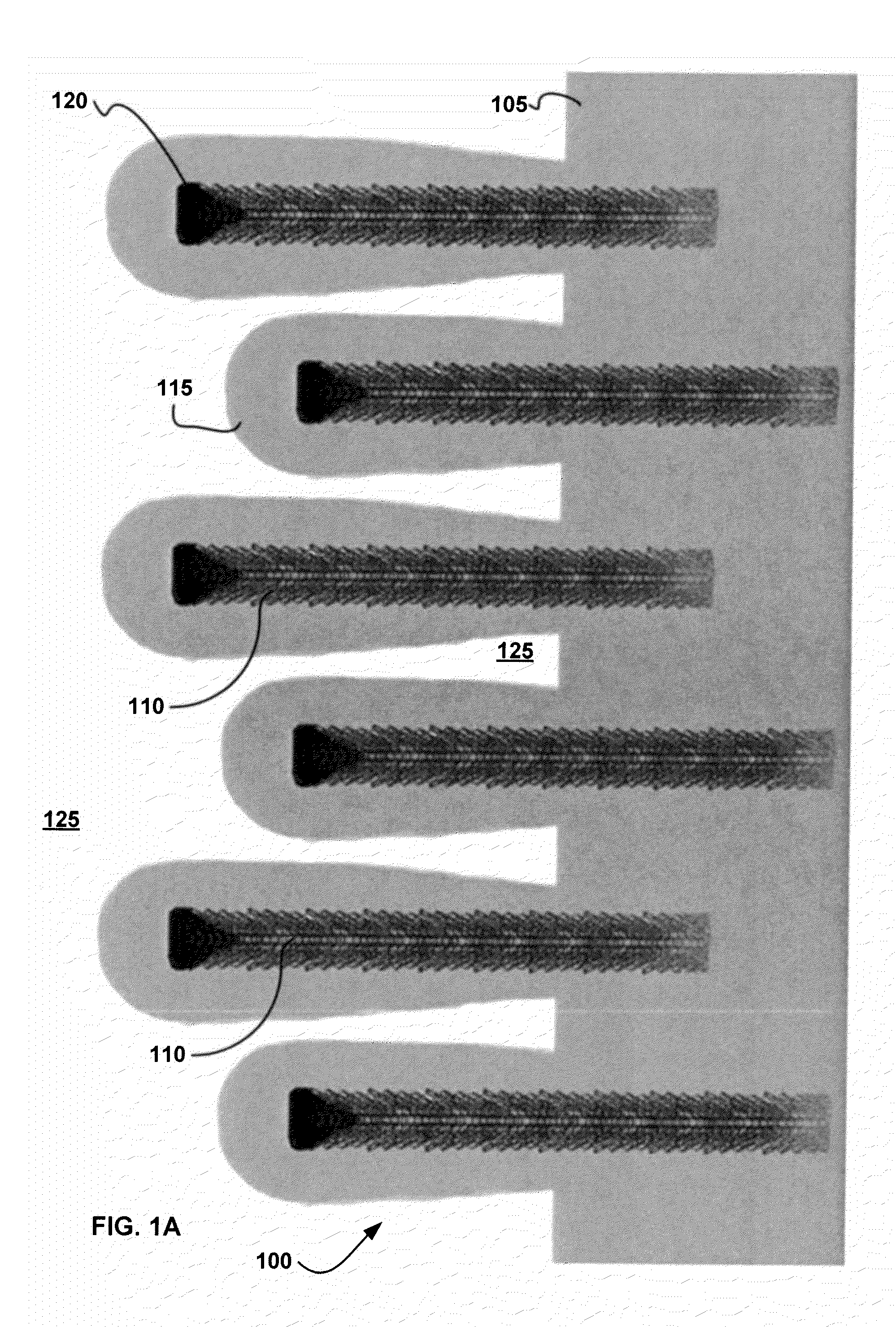

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

Composite electrode and method for manufacturing the same

InactiveUS20100273051A1Large specific surface areaImprove high temperature stabilityElectrochemical processing of electrodesElectrolytic capacitorsComposite electrodeConductive polymer

A composite electrode and a method for manufacturing the same are disclosed. By using a composite electrode that includes a porous support made of ceramic or metal and a conductive polymer or a metal oxide formed on a surface of the porous support, a capacitor or secondary cell that provides increased charge / discharge capacity and increased energy / output density, as well as high-temperature stability and high reliability, can be manufactured.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

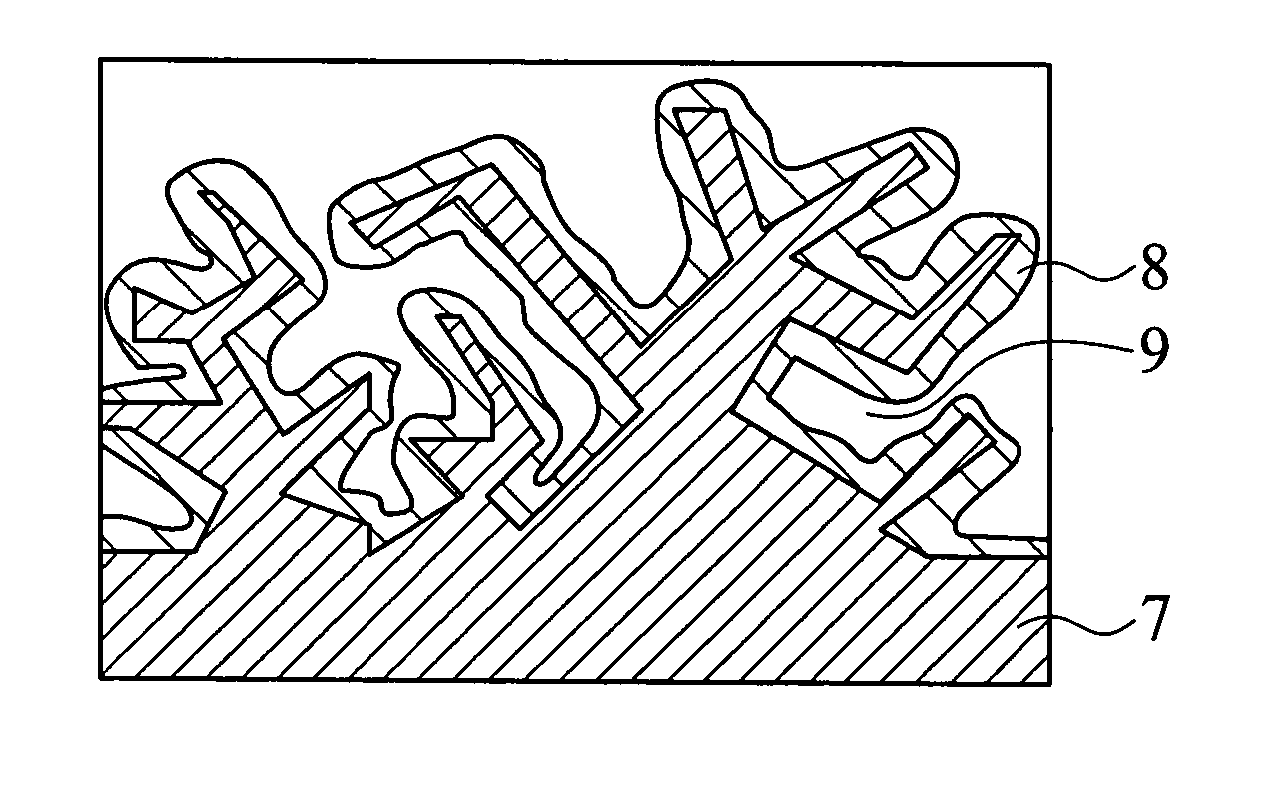

Anode coated with lithium fluoride compounds, method for preparing the same, and lithium secondary battery having the same

ActiveUS20110177388A1Prevent degradationElectrochemical processing of electrodesActive material electrodesBattery chargePhysical chemistry

An anode for a lithium ion secondary battery includes an anode, and a LiF-based coating layer formed with LiF-based particles on a surface of the anode. The LiF-based coating layer has a thickness of 0.05 to 1 μm. The anode allows the LiF-based coating layer created by side reaction of LiPF6 during a battery charging / discharging process to be relatively uniformly formed on the anode surface, thereby elongating the life cycle of a lithium ion secondary battery.

Owner:LG ENERGY SOLUTION LTD

Non-aqueous electrolyte secondary battery

InactiveUS20050048371A1Easy to chargeIncrease the reaction areaElectrochemical processing of electrodesElectrode thermal treatmentConductive materialsCharge and discharge

A non-aqueous electrolyte secondary battery of the present invention has an electrode and an electrolyte layer. The electrode includes a collector having a lot of fine pores on its surface, and a membrane layer made of an electrode active material provided along the surface shape of the fine pores of the collector. By this structure, the battery can manifest an excellent performance even in charging and discharging at high speed without using a binder and conductive material.

Owner:NISSAN MOTOR CO LTD

Deposition of LiCoO2

ActiveUS7959769B2Increase deposition rateElectrochemical processing of electrodesElectrode thermal treatmentHigh rateEngineering

In accordance with the present invention, deposition of LiCoO2 layers in a pulsed-dc physical vapor deposition process is presented. Such a deposition can provide a low-temperature, high deposition rate deposition of a crystalline layer of LiCoO2 with a desired (101) or (003) orientation. Some embodiments of the deposition addresses the need for high rate deposition of LiCoO2 films, which can be utilized as the cathode layer in a solid state rechargeable Li battery. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the LiCoO2 layer. Some embodiments of the process can improve a battery utilizing the LiCoO2 layer by utilizing a rapid thermal anneal process with short ramp rates.

Owner:SAPURAST RES

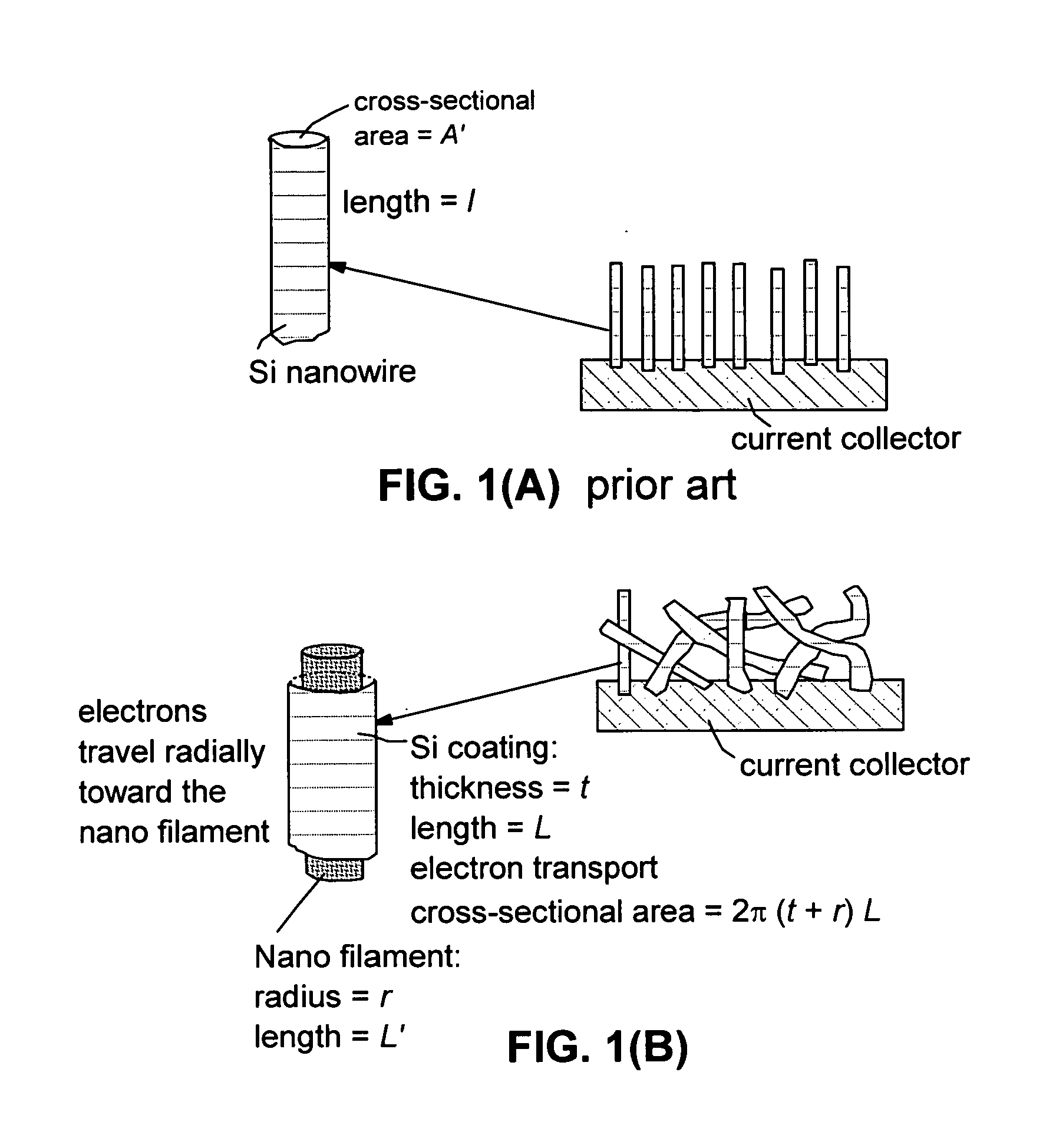

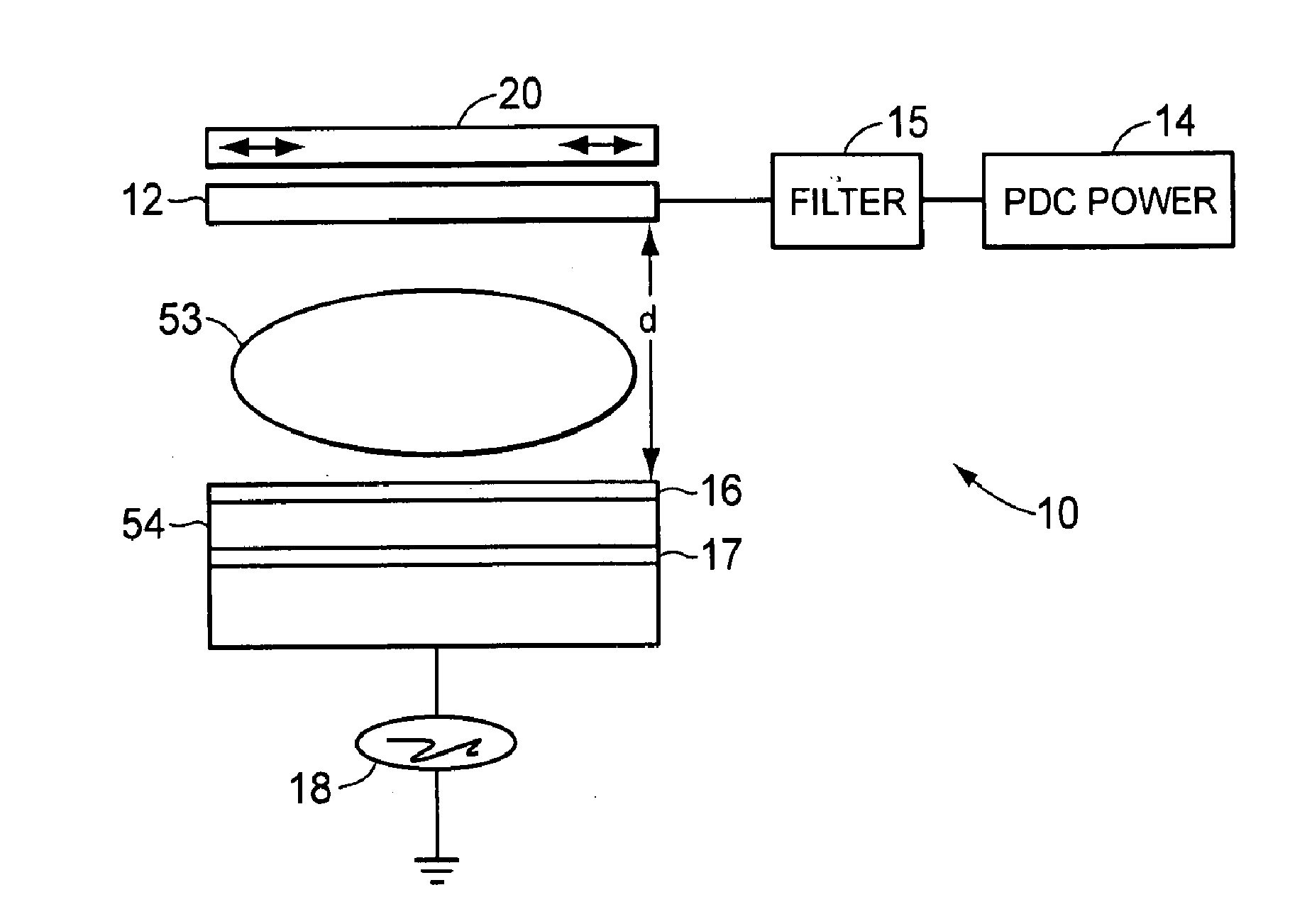

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

Electrode for secondary battery, process of producing the electrode, and secondary battery

InactiveUS20060121345A1Electrochemical processing of electrodesElectrolytic coatingsElectrolysisEngineering

The invention provides an electrode as a cathode or an anode of a secondary battery. The electrode has a first and a second surface that are electrically conductive and adapted to be brought into contact with an electrolytic solution. The electrode has an active material layer containing active material particles between the first and second surfaces. The electrode has a large number of microvoids open on the first and second surfaces and leading to the active material layer.

Owner:MITSUI MINING & SMELTING CO LTD

Apparatus and method for forming 3D nanostructure electrode for electrochemical battery and capacitor

InactiveUS20100126849A1Extended service lifeLow production costCellsElectrochemical processing of electrodesNano structuringElectrical battery

Embodiments described herein generally relate to an electrode structure for an electrochemical battery or capacitor, particularly, apparatus and methods of creating a reliable and cost efficient 3D electrode nano structure for an electrochemical battery or capacitor that has an improved lifetime, lower production costs, and improved process performance.

Owner:APPLIED MATERIALS INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com