Apparatus and method for forming 3D nanostructure electrode for electrochemical battery and capacitor

a technology of electrochemical batteries and capacitors, applied in the field of apparatus and methods for forming electrochemical batteries or capacitors having electrodes with 3d nanostructure, can solve the problem of small amount of electrical energy, achieve the effects of improving process performance, reducing production costs, and improving li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

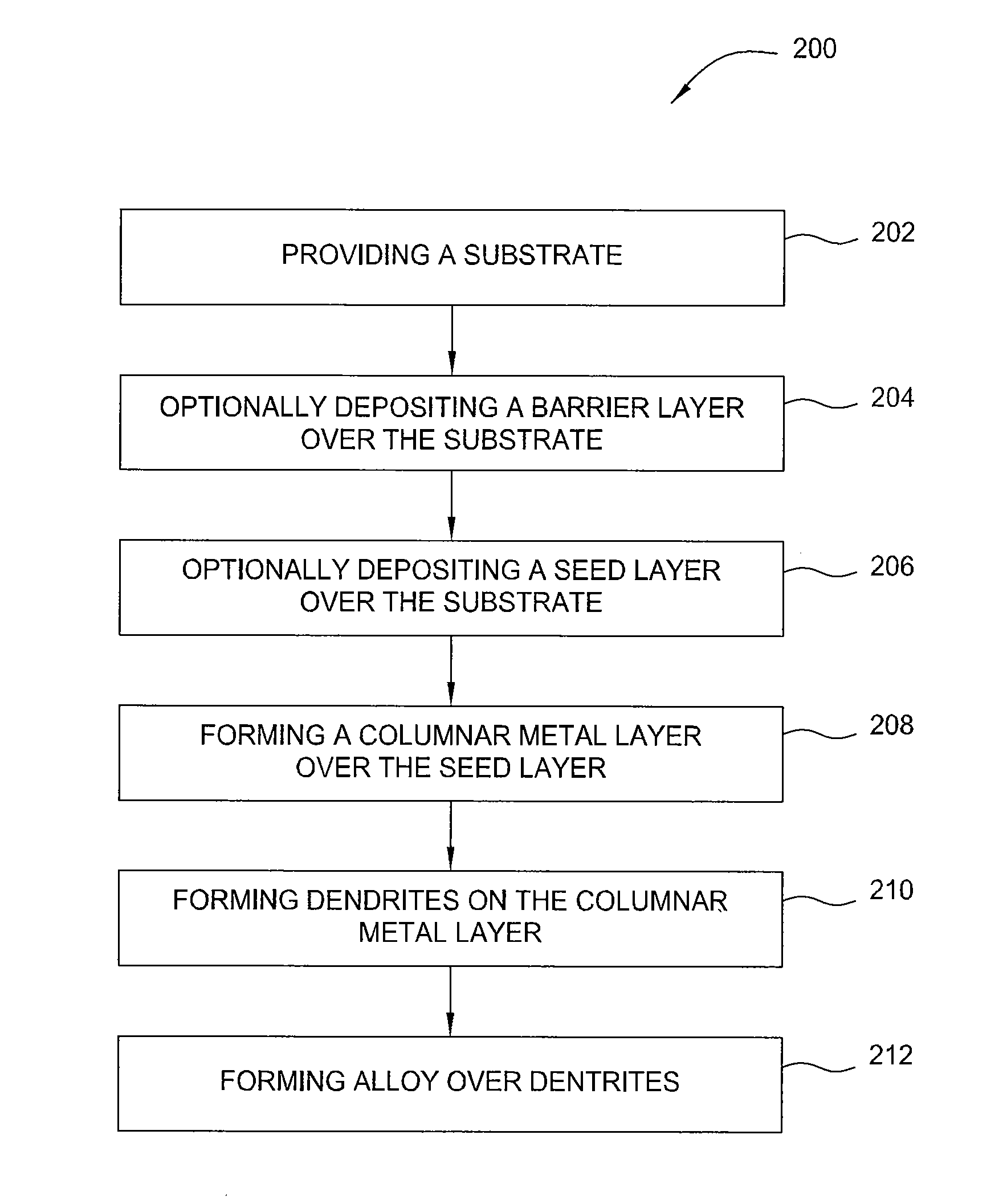

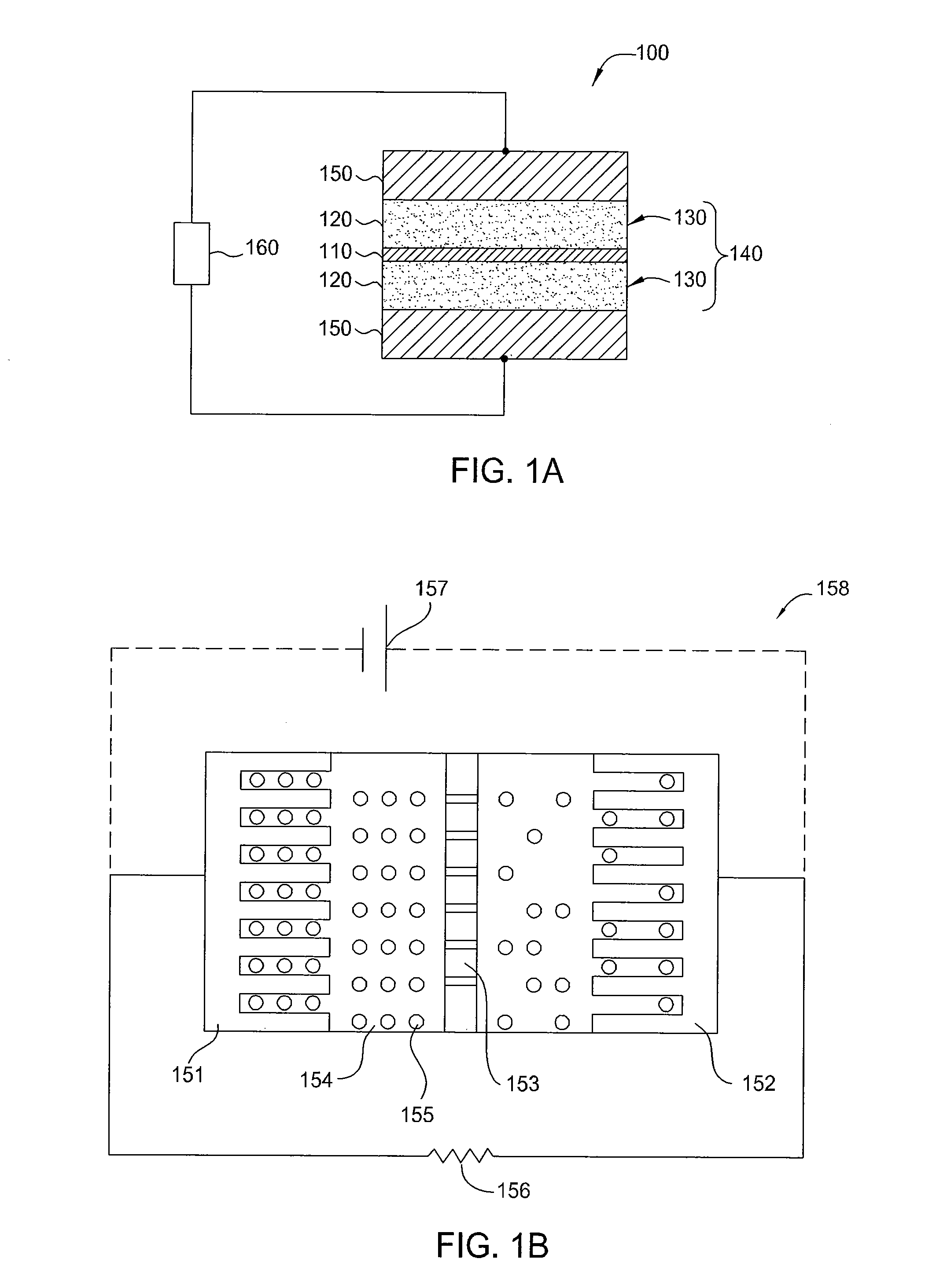

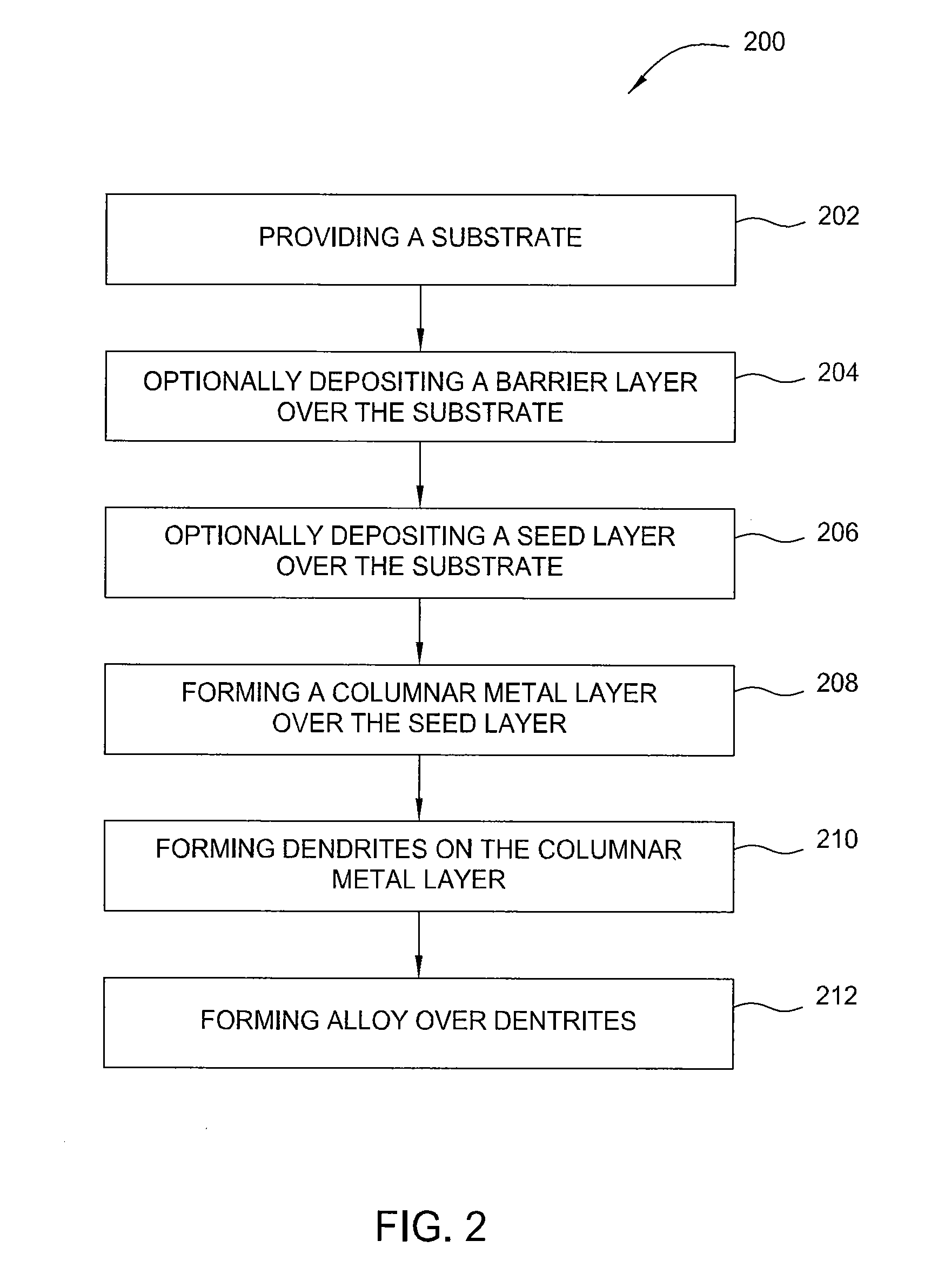

[0040]Embodiments described herein generally relate to an electrode structure, particularly for an electrochemical battery or capacitor, apparatus and methods of creating a reliable and cost efficient electrochemical battery or capacitor electrode structure that has an improved lifetime, lower production costs, and improved process performance. One embodiment provides a substrate plating system comprising a first plating chamber configure to form a columnar structure on a seed layer of a substrate, and a second plating chamber configured to form a porous layer on the columnar structure. One embodiment provides a plating chamber configured to plate one or more large area substrate. In one embodiment, the plating chamber comprises a feed roll, a bottom roll and a take up roll configured to position large area substrates formed in a continuous flexible base in a processing volume, and to transfer the large area substrates in and out the processing volume. In another embodiment, the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com