Patents

Literature

2531results about "Capacitor manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

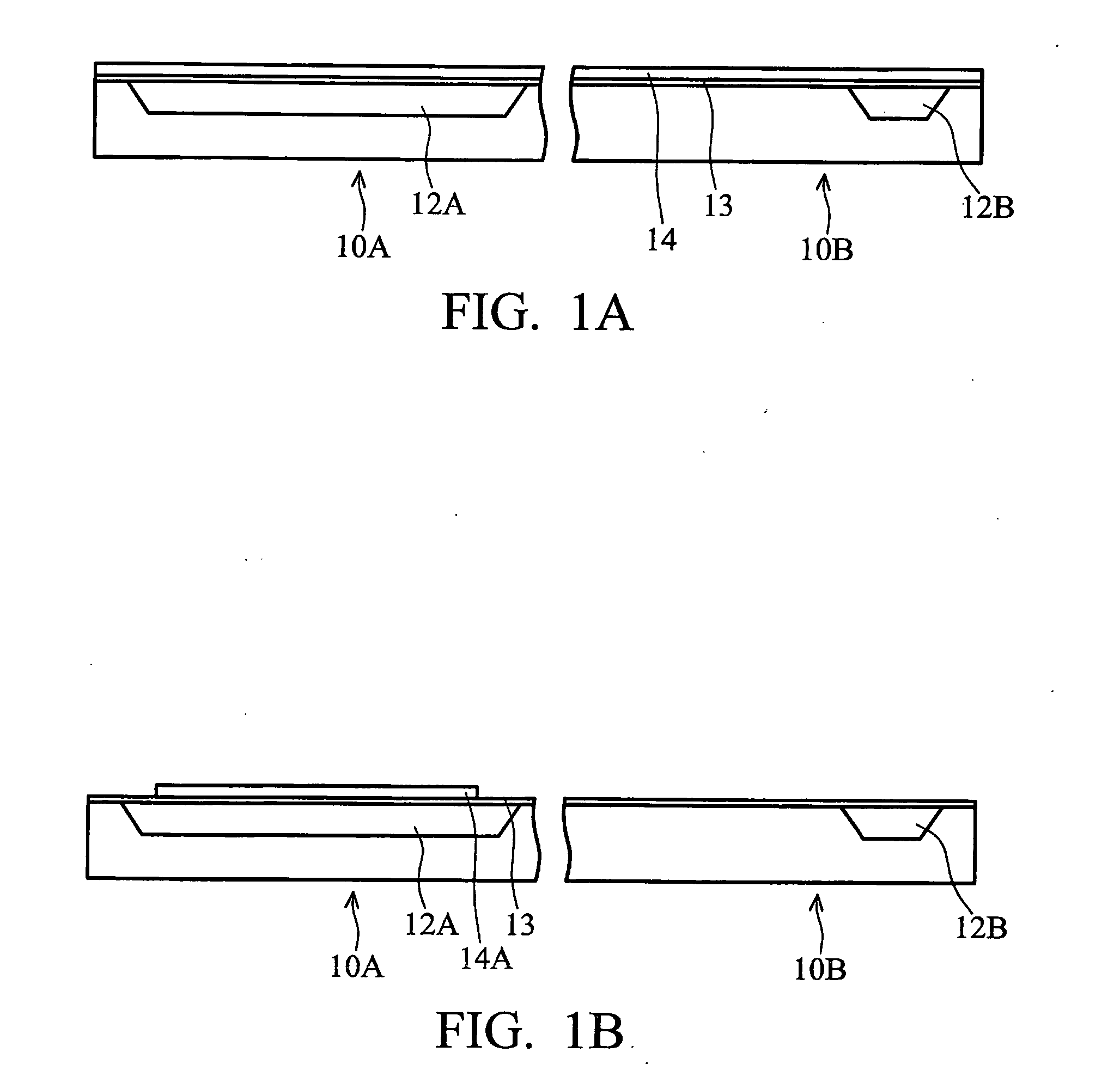

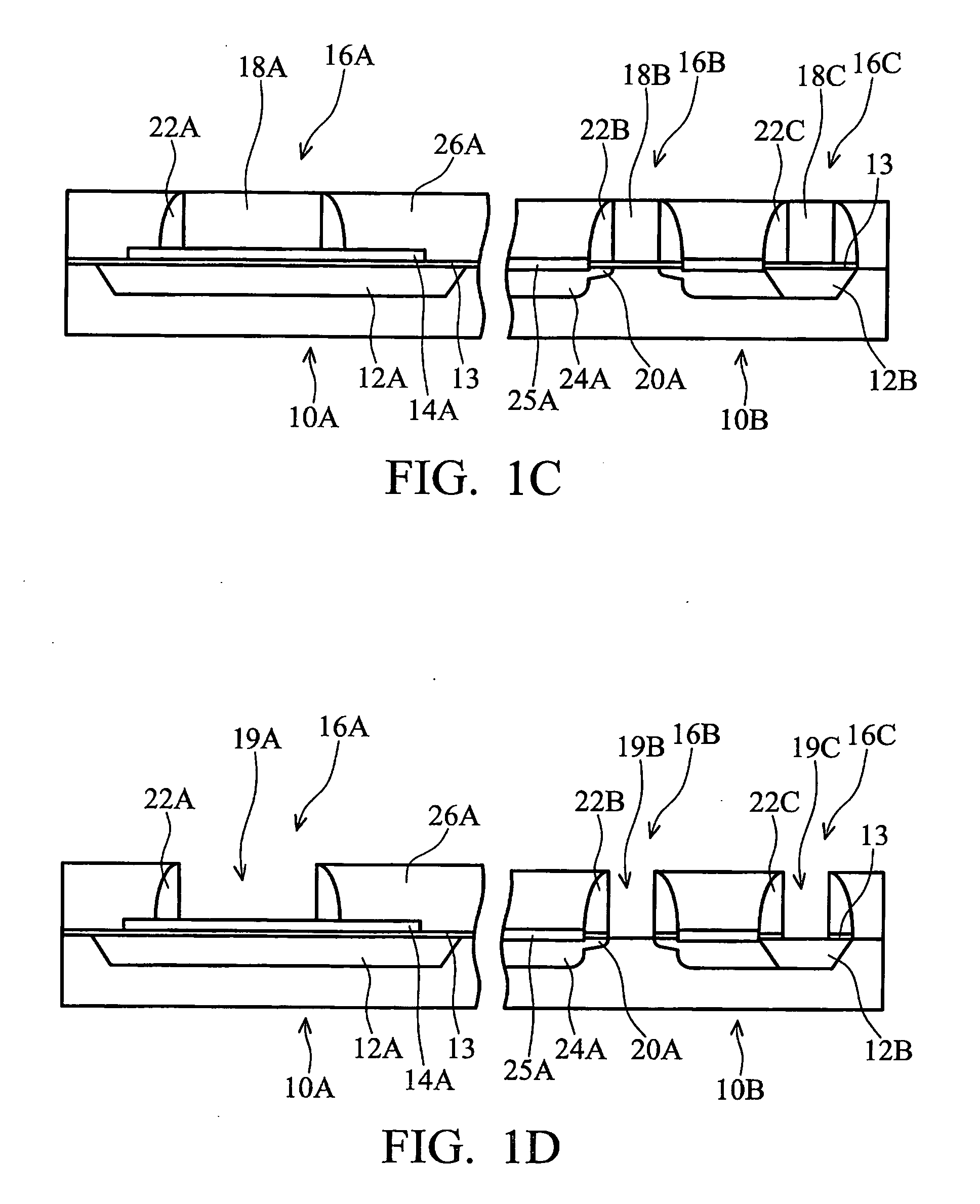

Plated terminations

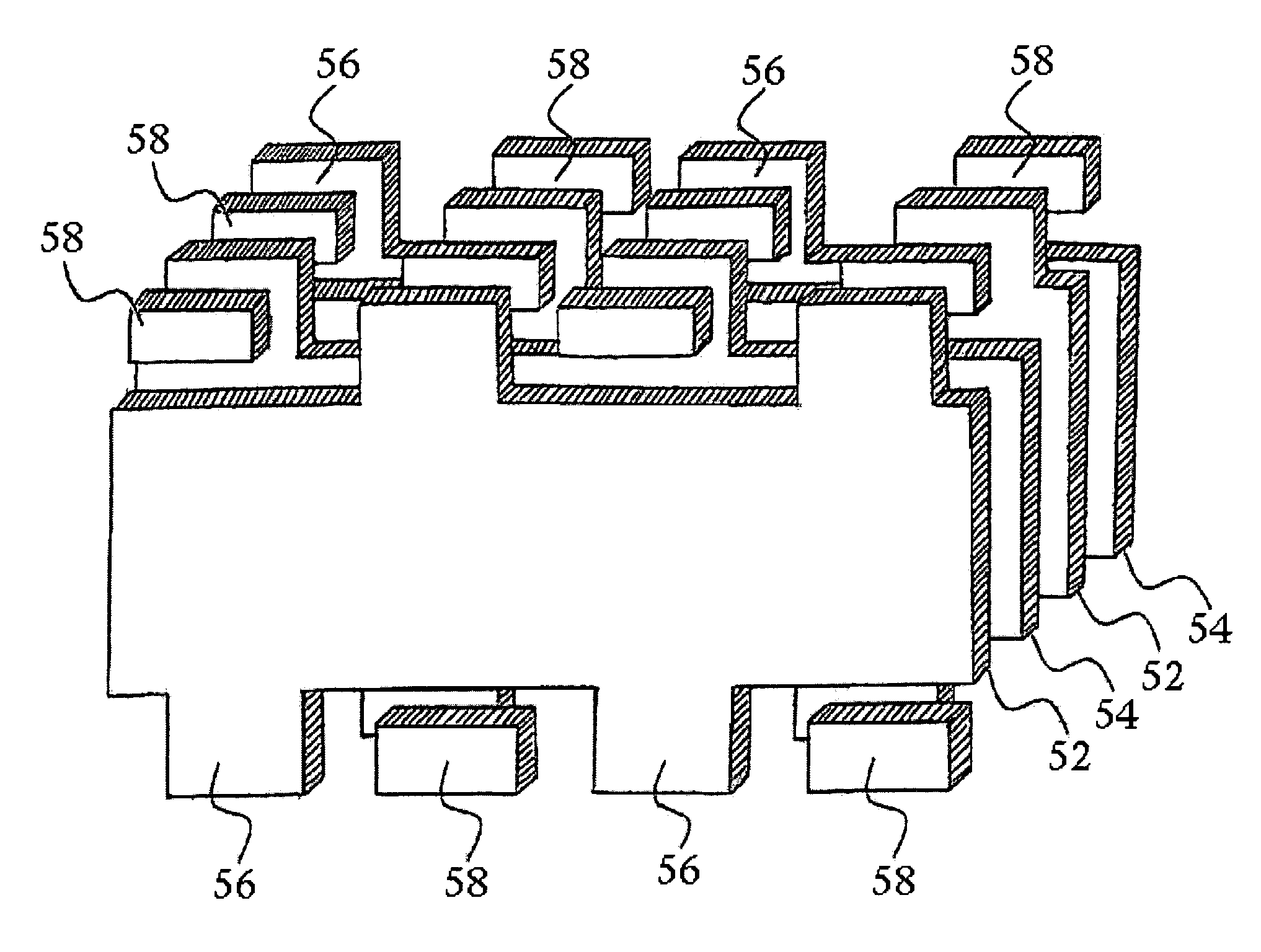

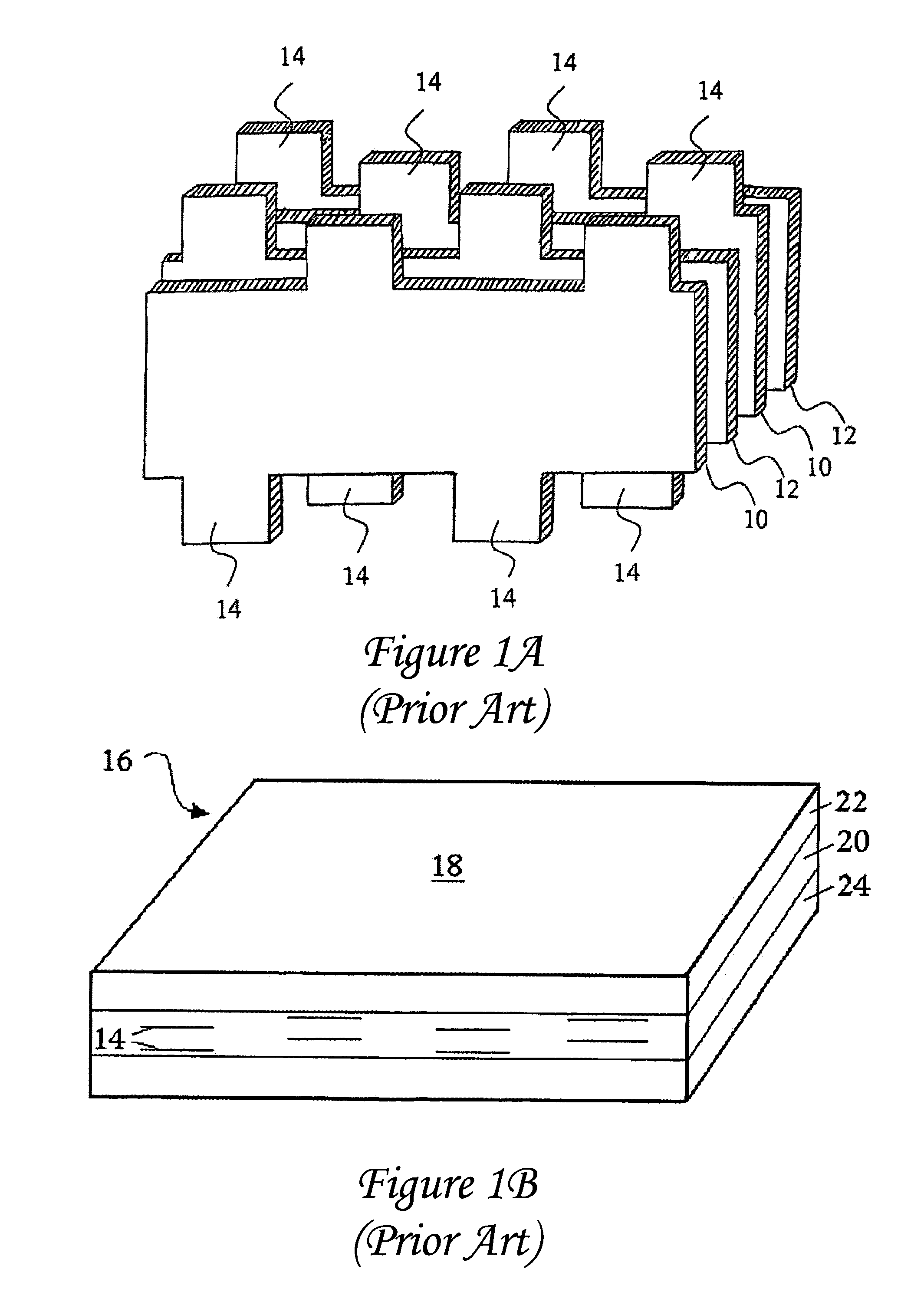

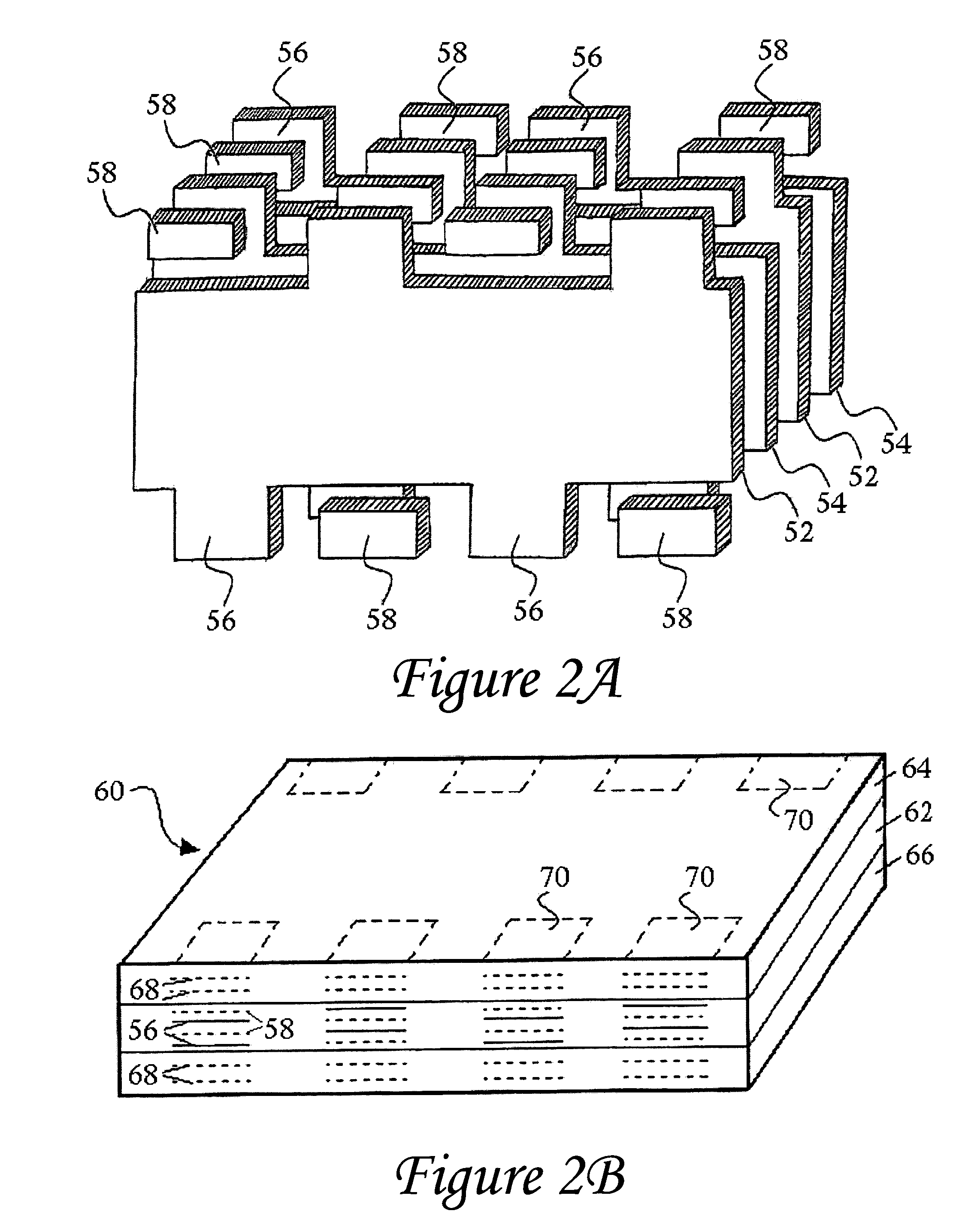

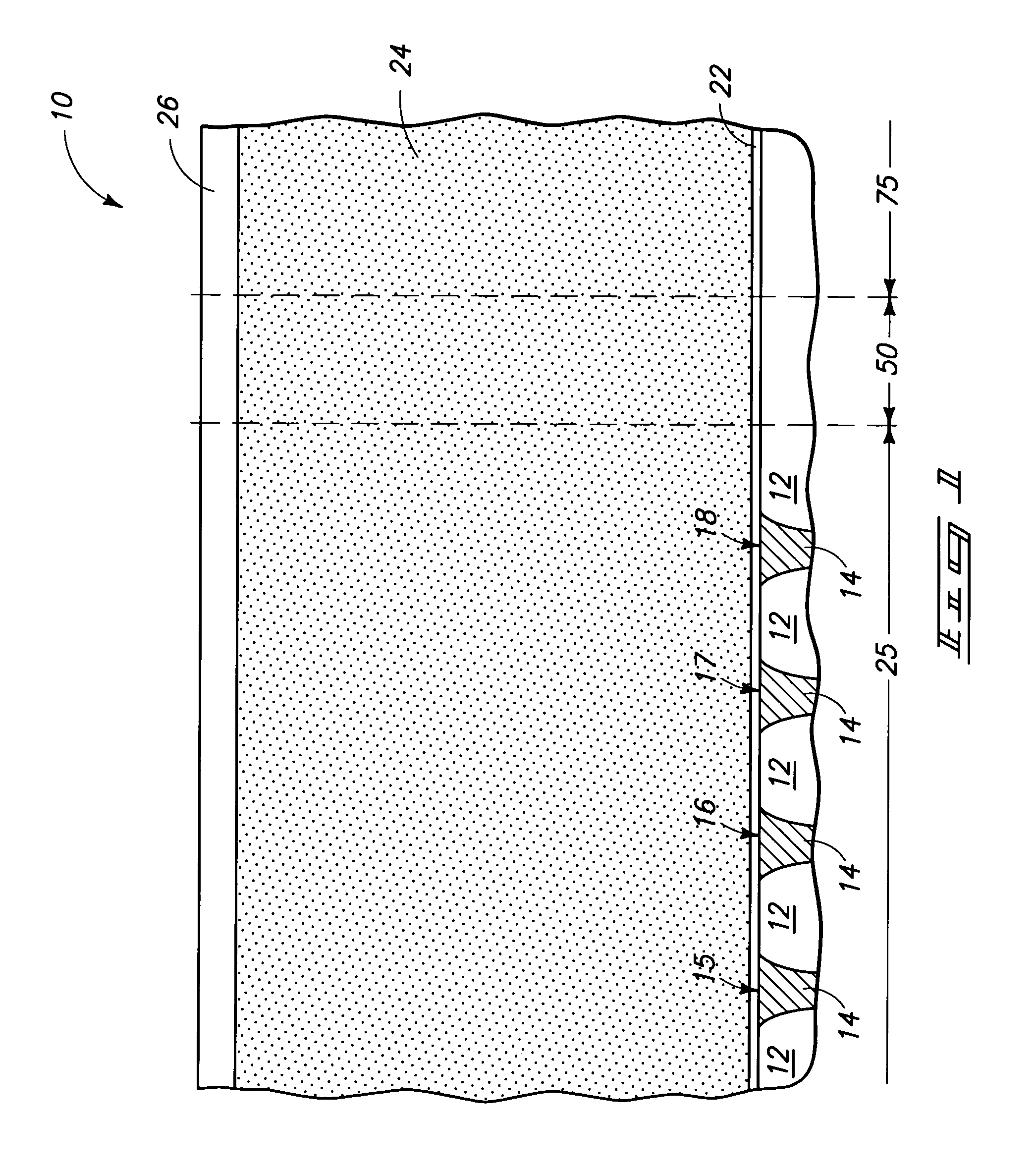

InactiveUS7177137B2Improved termination featureEliminate or greatly simplify thick-film stripesFixed capacitor electrodesFixed capacitor dielectricHigh densityEngineering

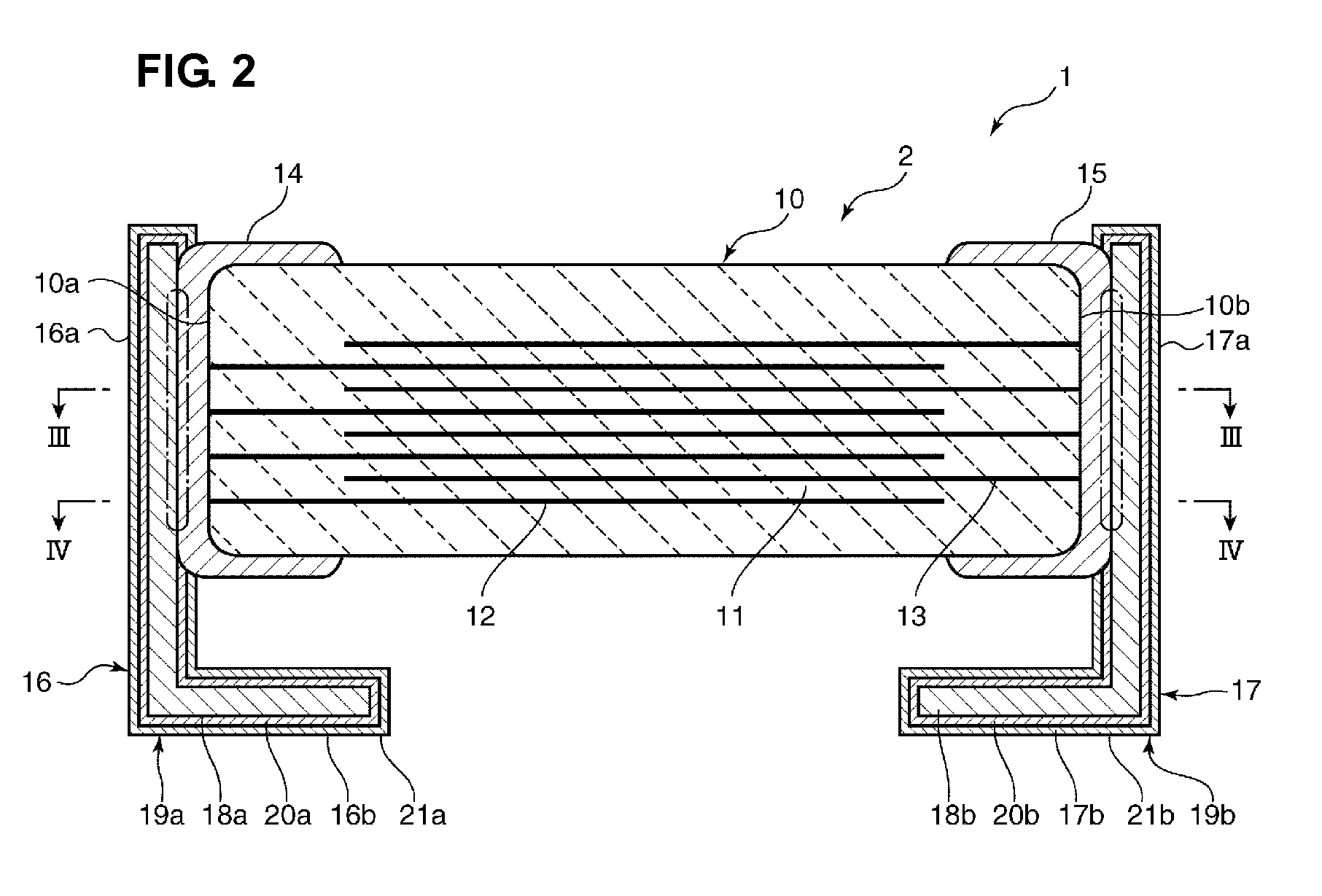

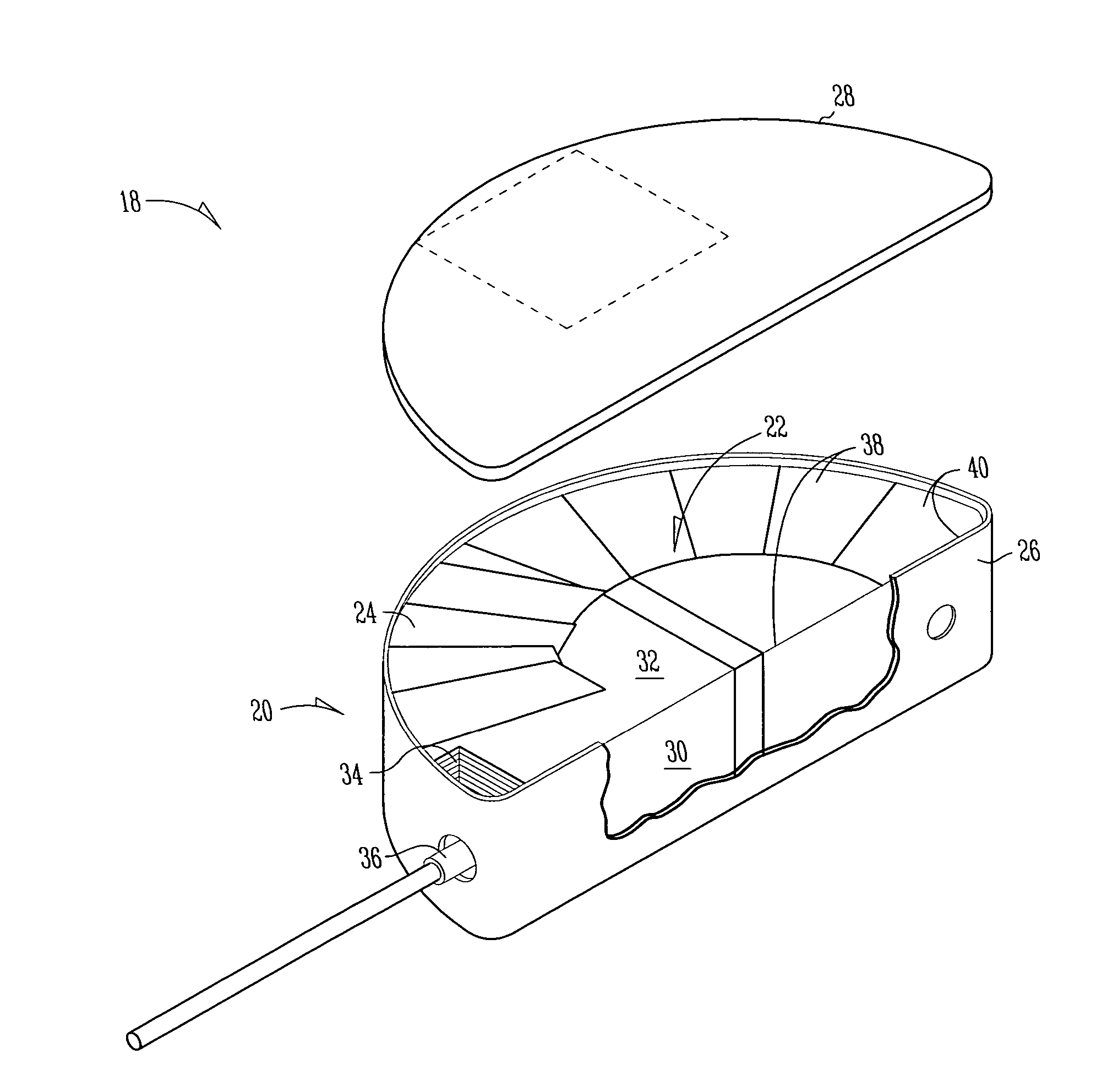

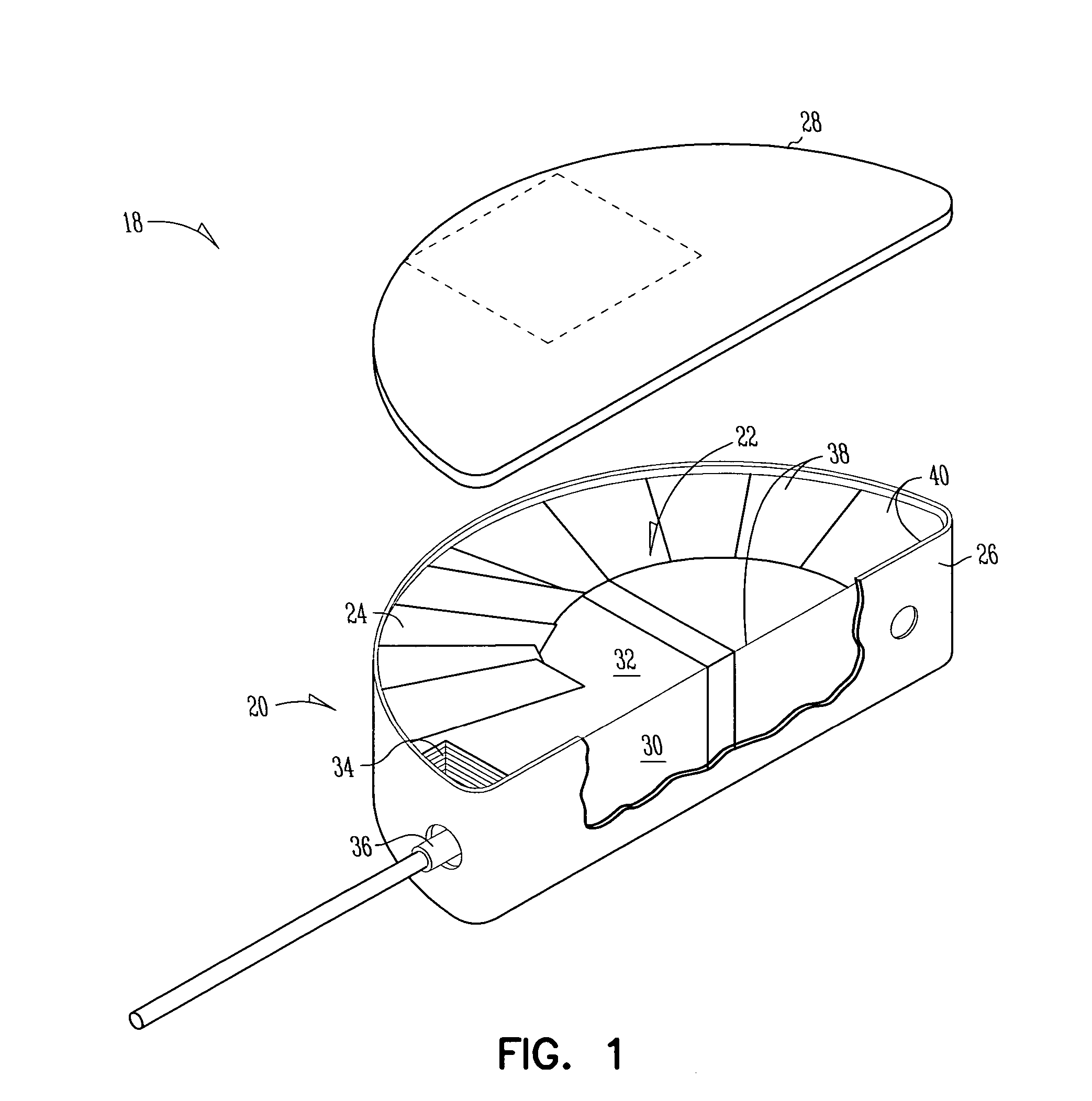

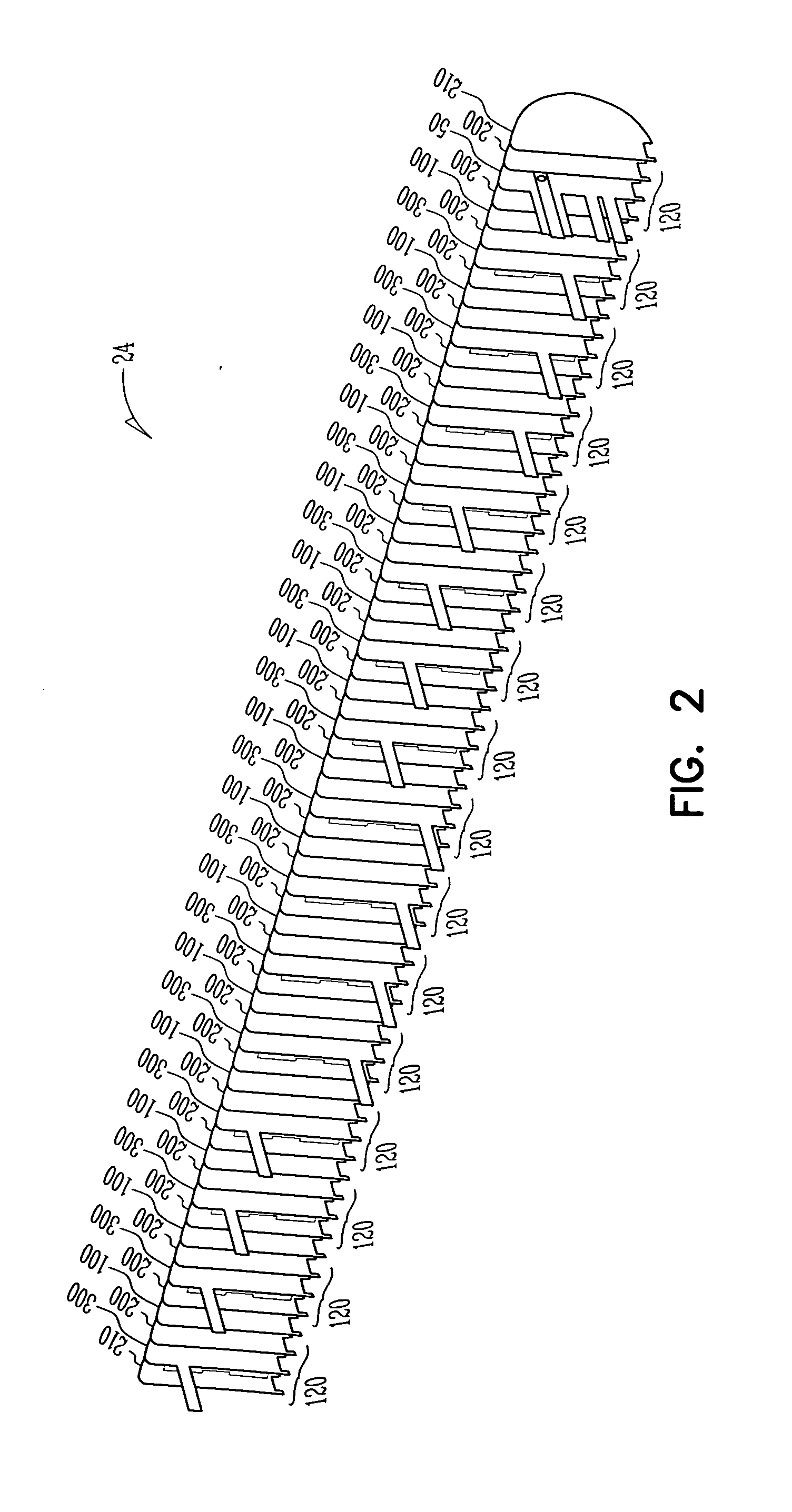

A multilayer electronic component includes a plurality of dielectric layers interleaved with a plurality of internal electrode elements and a plurality of internal anchor tabs. Portions of the internal electrode elements and anchor tabs are exposed along the periphery of the electronic component in one or more aligned columns. Each exposed portion is within a predetermined distance from other exposed portions in a given column such that bridged terminations may be formed by depositing one or more plated termination materials over selected of the respectively aligned columns. Internal anchor tabs may be provided and exposed in prearranged relationships with other exposed conductive portions to help nucleate metallized plating material along the periphery of a device. External anchor tabs or lands may be provided to form terminations that extend to top and / or bottom surfaces of the device. Selected of the conductive elements may be formed by a finite volume percentage of ceramic material for enhanced durability, and external lands may be thicker than internal conductive elements and / or may also be embedded in top and / or bottom component surfaces. A variety of potential internal electrode configurations are possible including ones configured for orientation-insensitive component mounting and for high density peripheral termination interdigitated capacitors.

Owner:KYOCERA AVX COMPONENTS CORP

Methods of etching polysilicon and methods of forming pluralities of capacitors

A method of etching polysilicon includes exposing a substrate comprising polysilicon to a solution comprising water, HF, and at least one of a conductive metal nitride, Pt, and Au under conditions effective to etch polysilicon from the substrate. In one embodiment, a substrate first region comprising polysilicon and a substrate second region comprising at least one of a conductive metal nitride, Pt, and Au is exposed to a solution comprising water and HF. The solution is devoid of any detectable conductive metal nitride, Pt, and Au prior to the exposing. At least some of the at least one are etched into the solution upon the exposing. Then, polysilicon is etched from the first region at a faster rate than any etch rate of the first region polysilicon prior to the etching of the at least some of the conductive metal nitride, Pt, and Au.

Owner:MICRON TECH INC

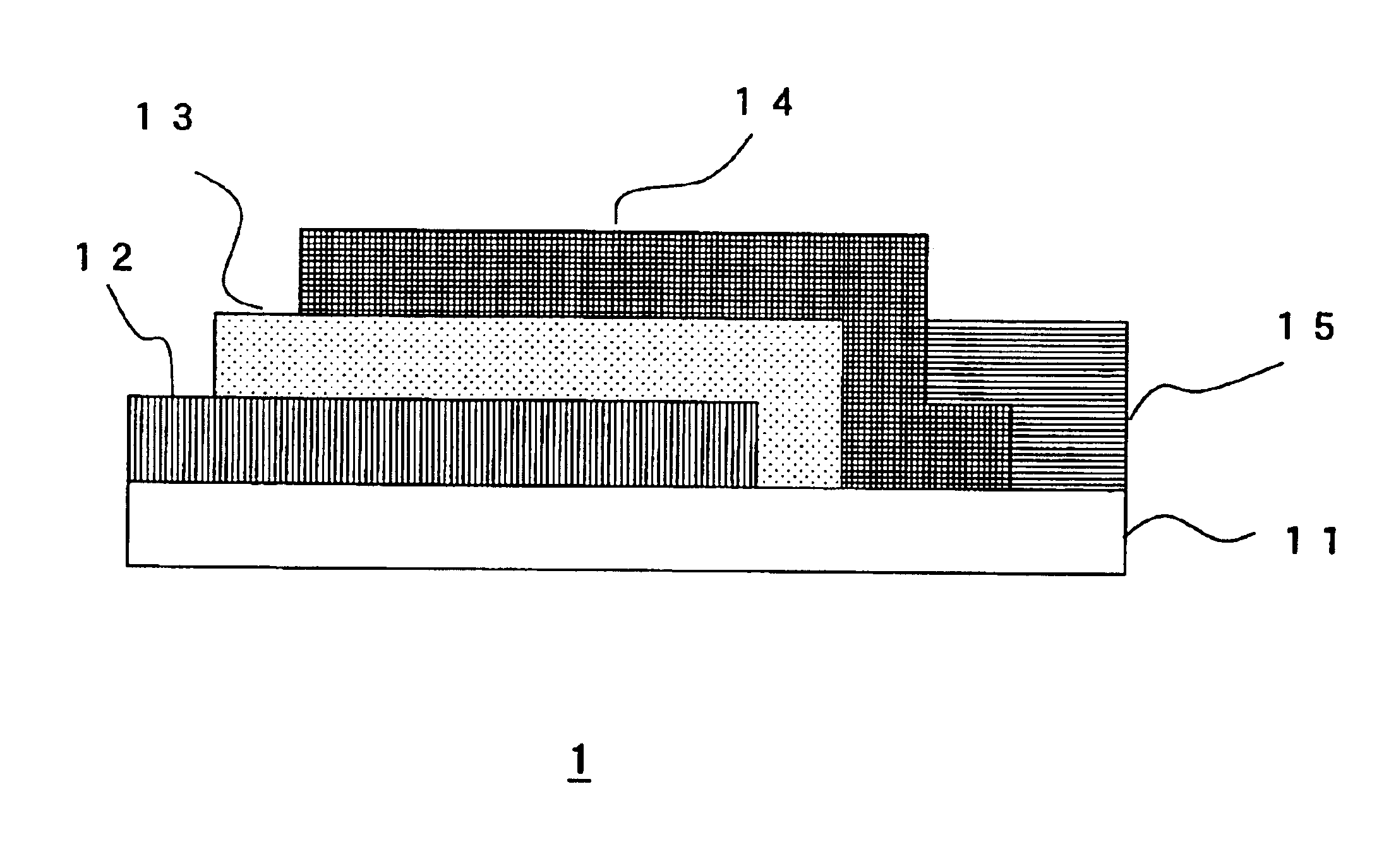

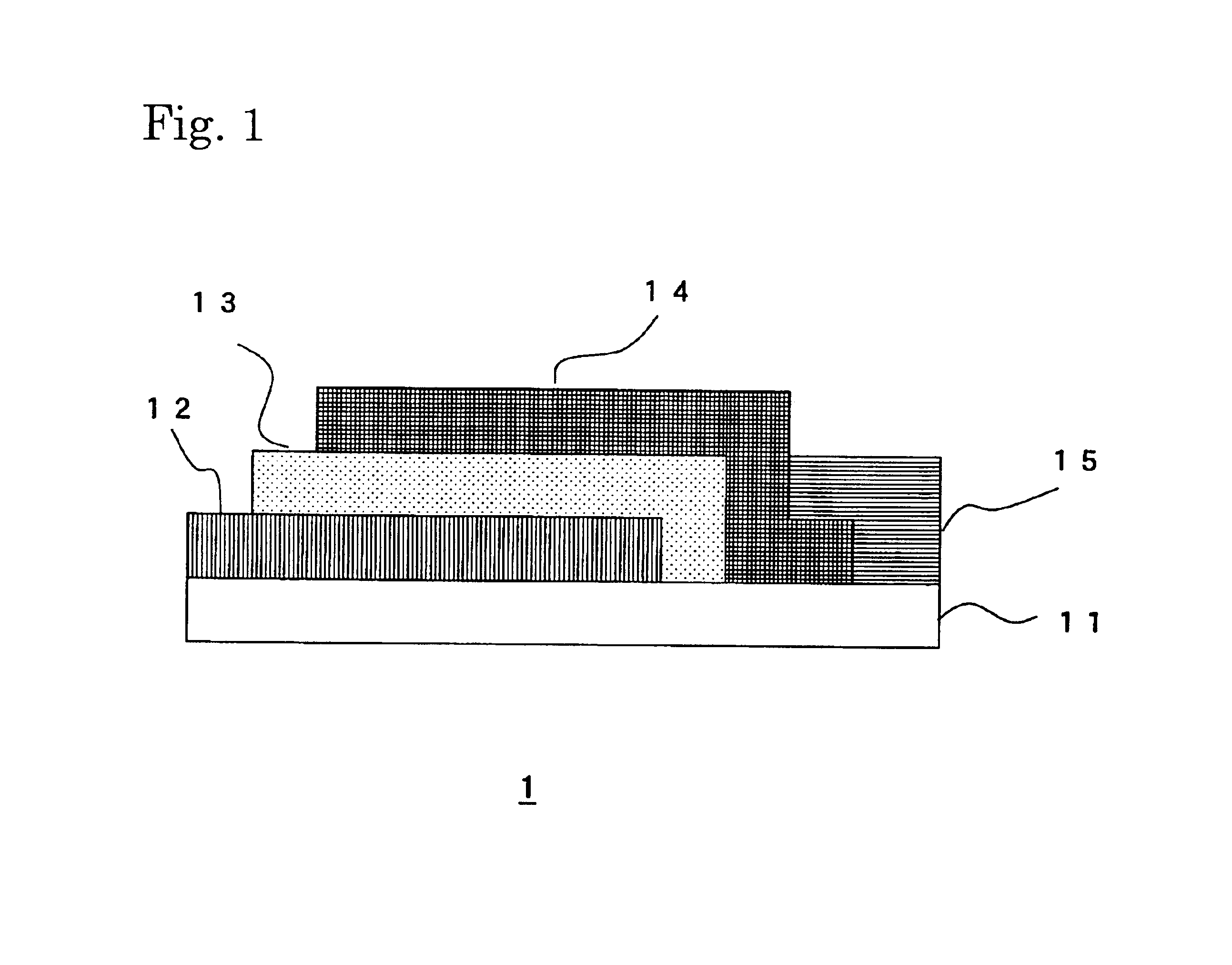

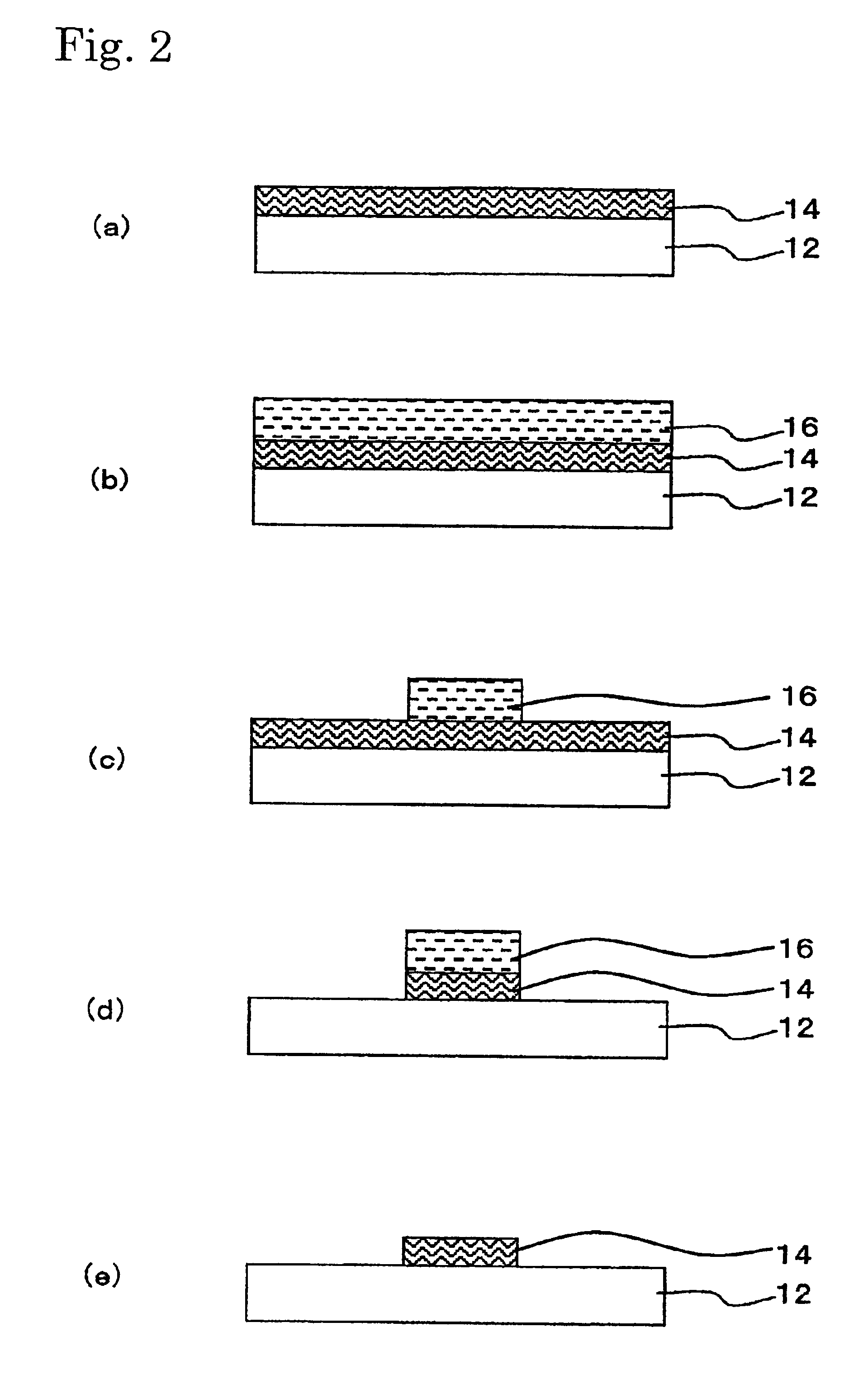

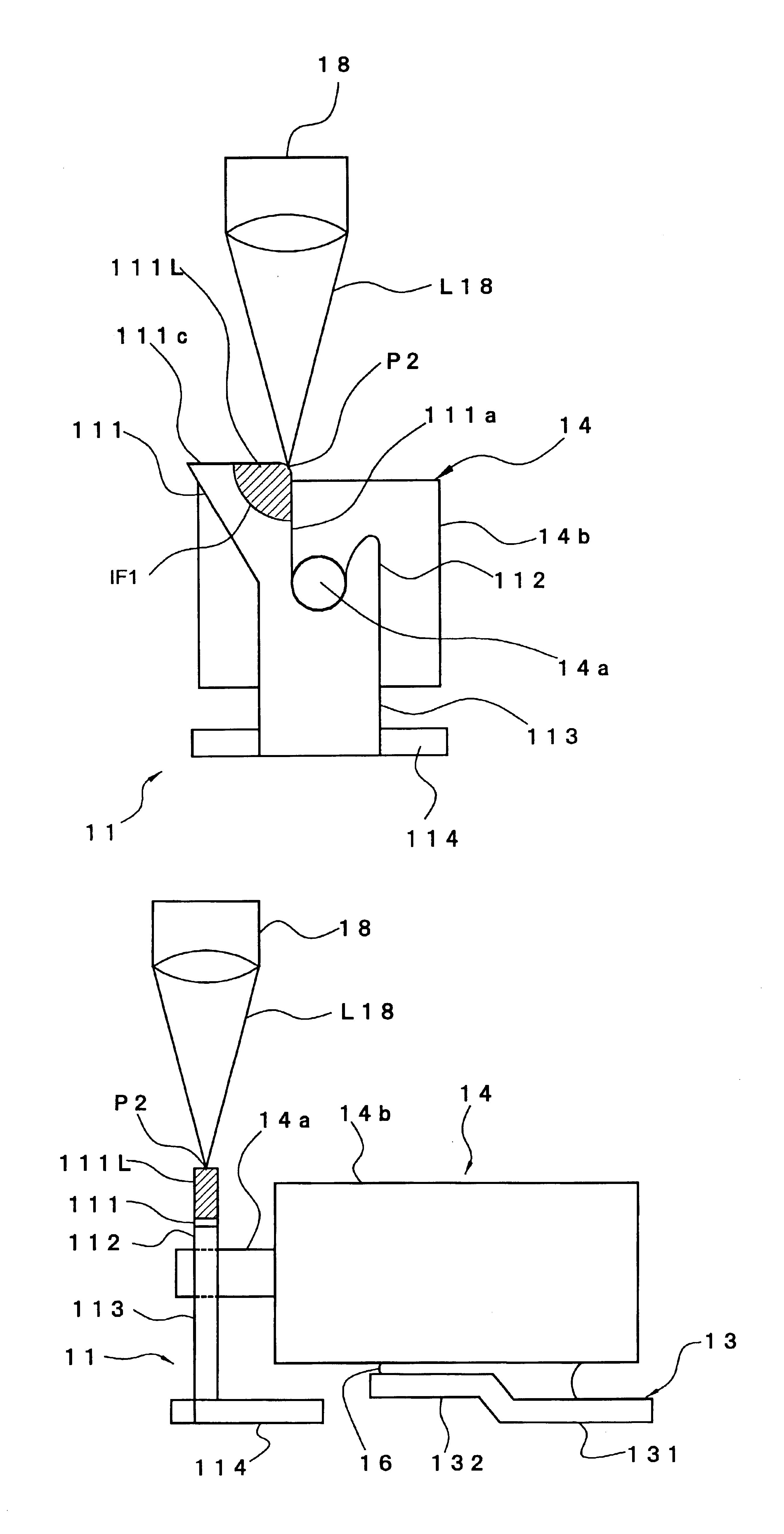

Ceramic electronic component and method for manufacturing the same

ActiveUS20090296311A1Improve reliabilityIncrease resistanceMultiple fixed capacitorsFixed capacitor dielectricMetal particleElectronic component

A ceramic electronic component has a ceramic element assembly, external electrodes, and metal terminals. The external electrodes are arranged on the surface of the ceramic element assembly. The external electrodes contain a sintered metal. The metal terminals are electrically connected to the external electrodes, respectively. The external electrode and the metal terminal are directly diffusion-bonded by diffusion of metal in the metal terminals into the external electrodes. The above arrangement provides a ceramic electronic component having highly reliable metal particle bonding and a method for manufacturing the same.

Owner:MURATA MFG CO LTD

Wet electrolytic capacitor containing a gelled working electrolyte

ActiveUS9105401B2Hybrid capacitor electrolytesCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A wet electrolytic capacitor is provided. The capacitor contains an anode comprising an anodically oxidized pellet formed from a pressed and sintered powder, a cathode that contains a metal substrate coated with a conductive polymer, and a working electrolyte in communication with the anode and the cathode. The working electrolyte is in the form of a gel and comprises an ammonium salt of an organic acid, inorganic oxide particles, an acid, and a solvent system that comprises water. The working electrolyte has a pH value of from about 5.0 to about 8.0.

Owner:KYOCERA AVX COMPONENTS CORP

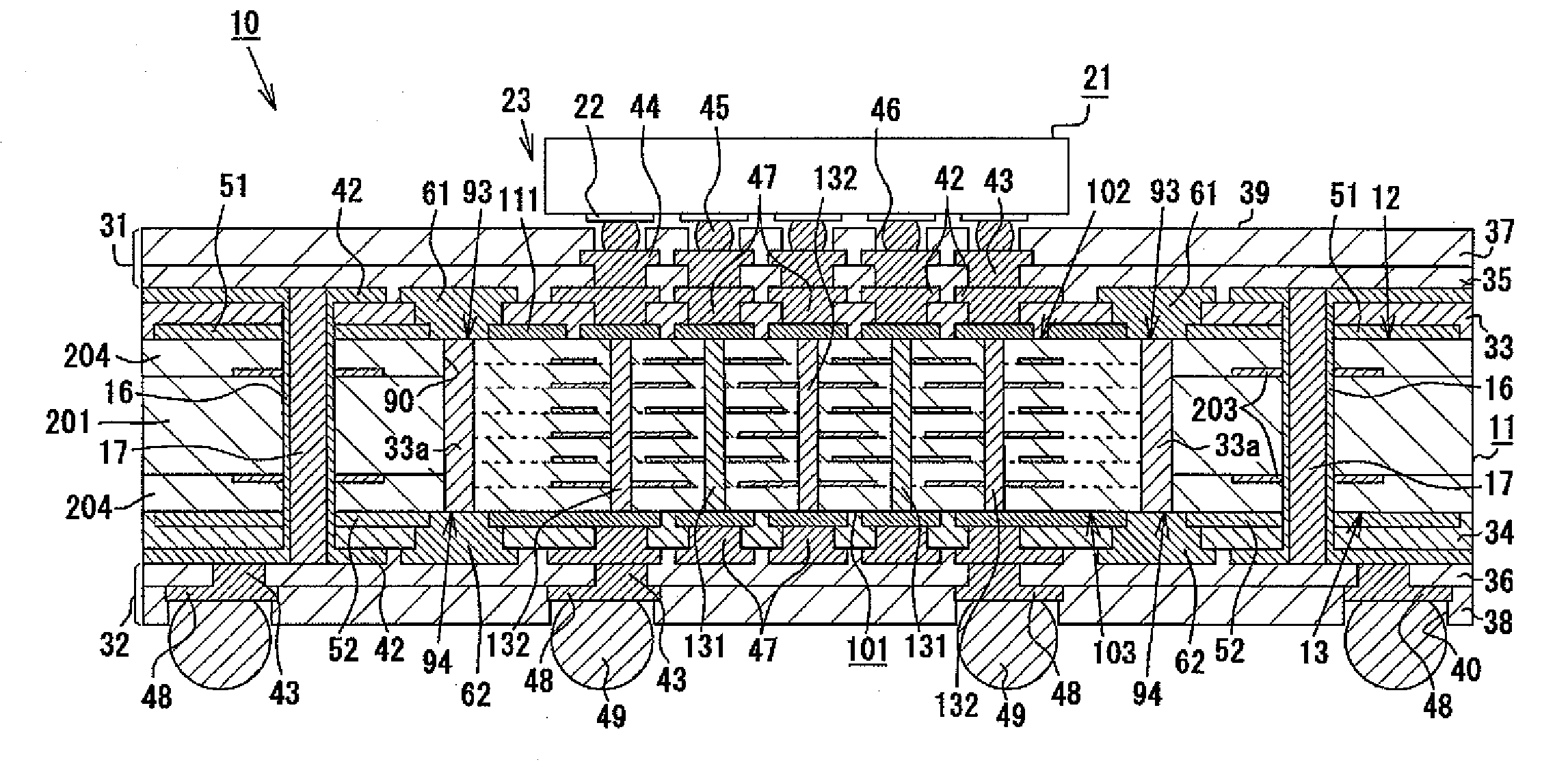

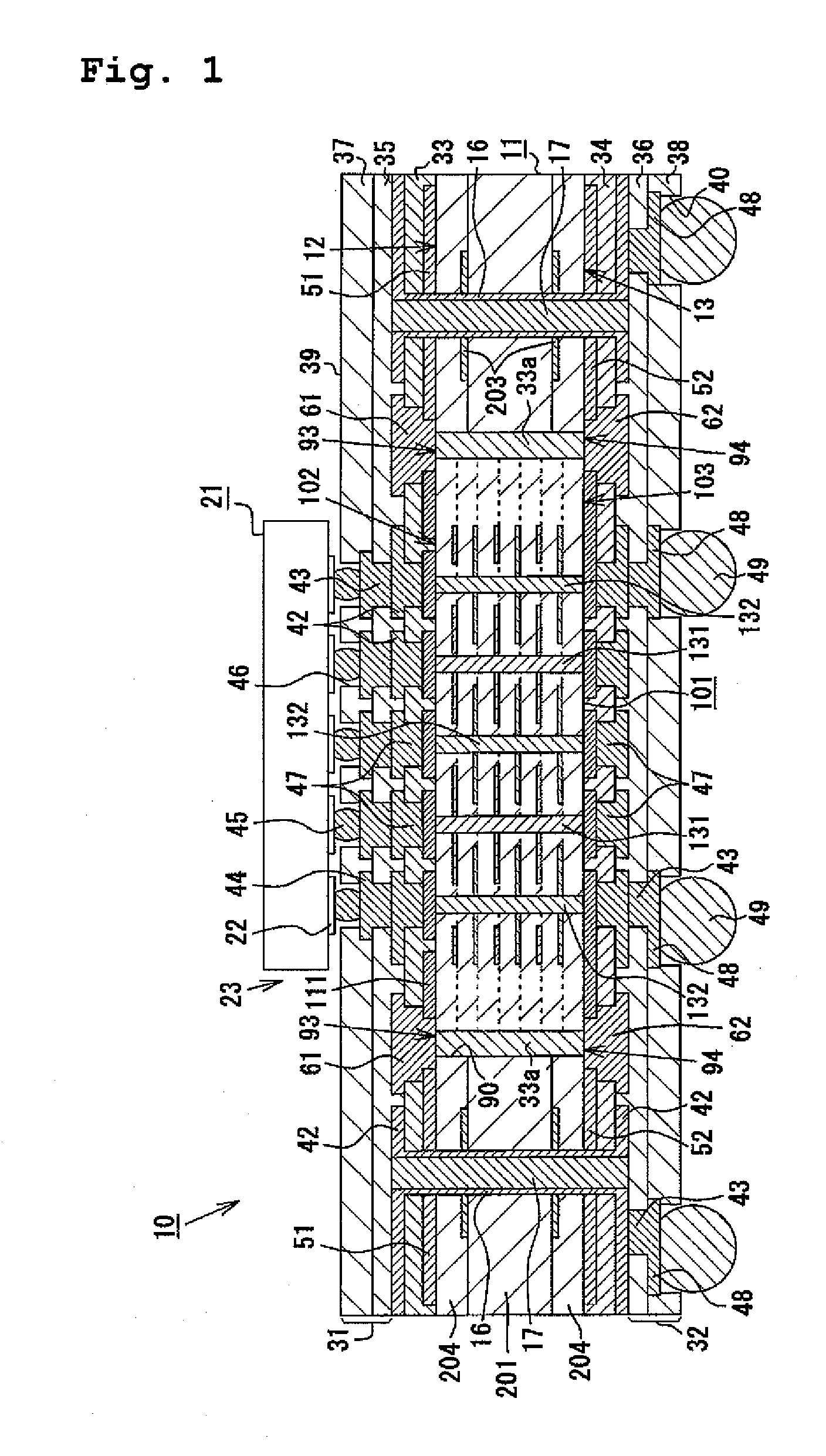

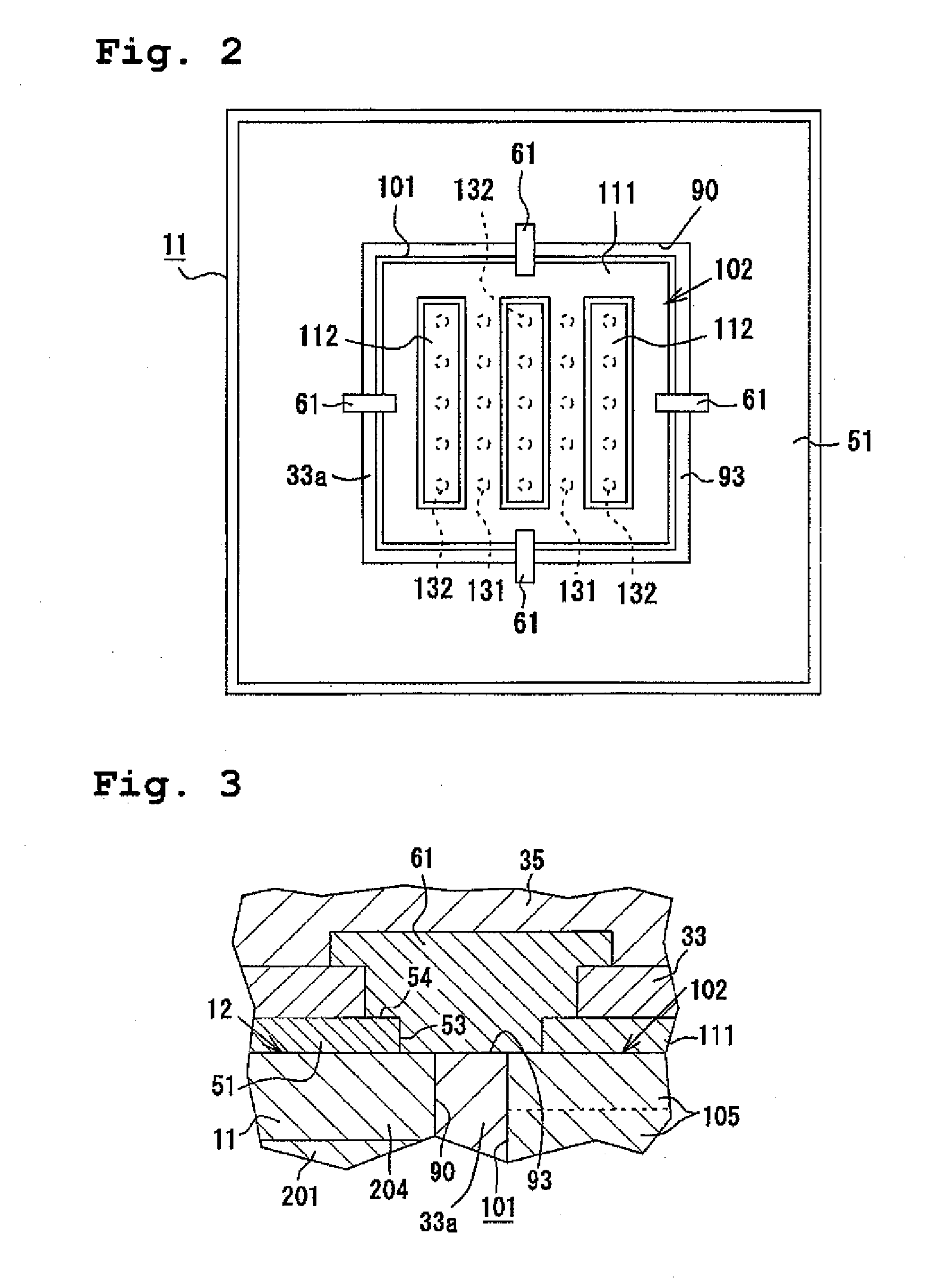

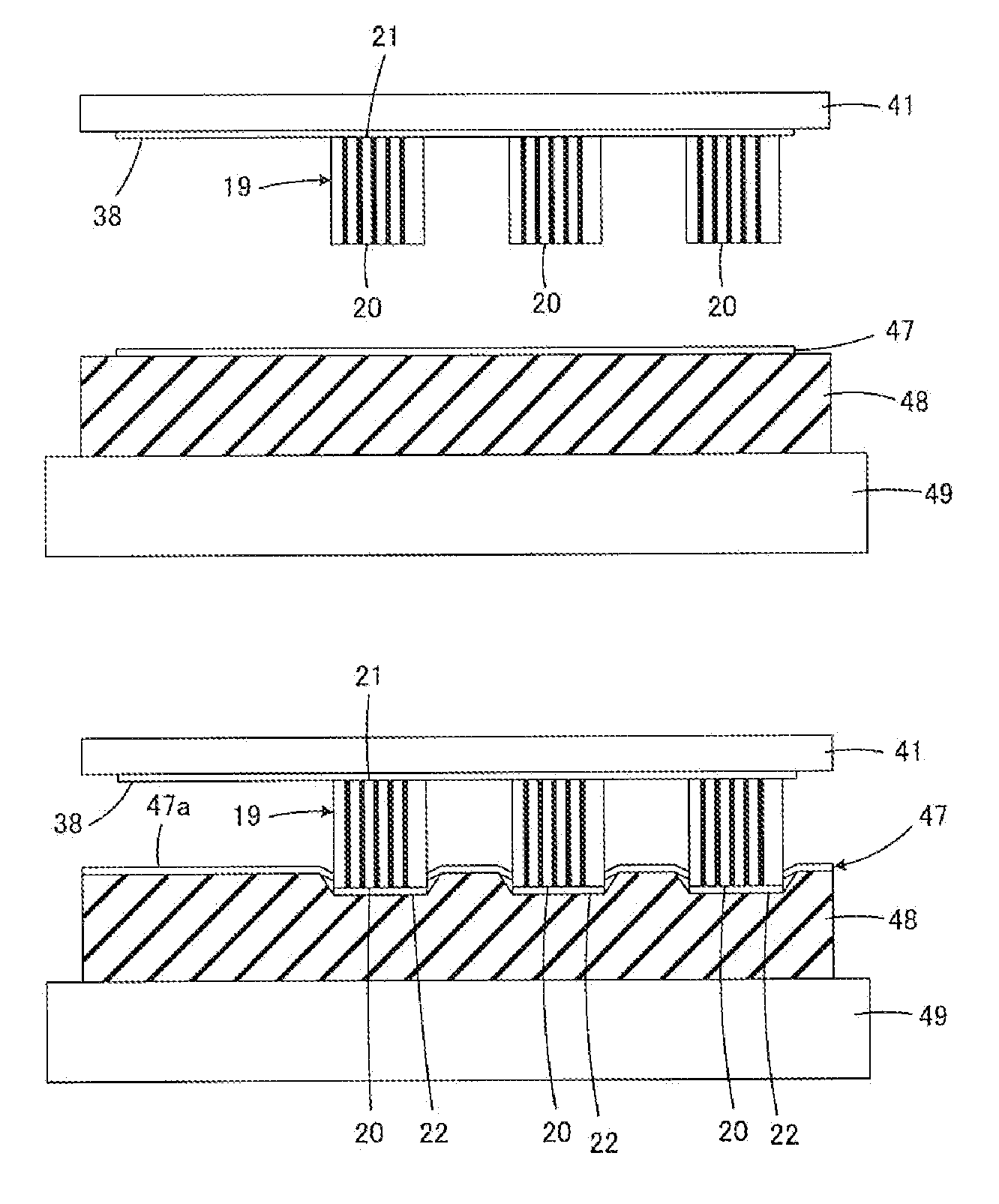

Method for manufacturing wiring board

ActiveUS20070281394A1Electrolytic capacitorsSemiconductor/solid-state device detailsElectrical conductorElectronic component

A method for manufacturing a wiring board which can simplify a manufacturing step. In a preparation step, a core board and an electronic component are prepared. In an insulating layer formation and fixing step, after accommodating the electronic component in an accommodation hole, a lowermost resin insulating layer is formed, and a gap between the electronic component and the core board is filled with a part of the lowermost resin insulating layer so as to fix the electronic component to the core board. In an opening portion formation step, a portion of the lowermost resin insulating layer located directly above the gap between the electronic component and the core board is removed so as to form an opening portion exposing a part of a core board main surface side conductor and a component main surface side electrode. In a main surface side connecting conductor formation step, a main surface side connecting conductor is formed in the opening portion so as to connect the core board main surface side conductor to the component main surface side electrode.

Owner:NGK SPARK PLUG CO LTD

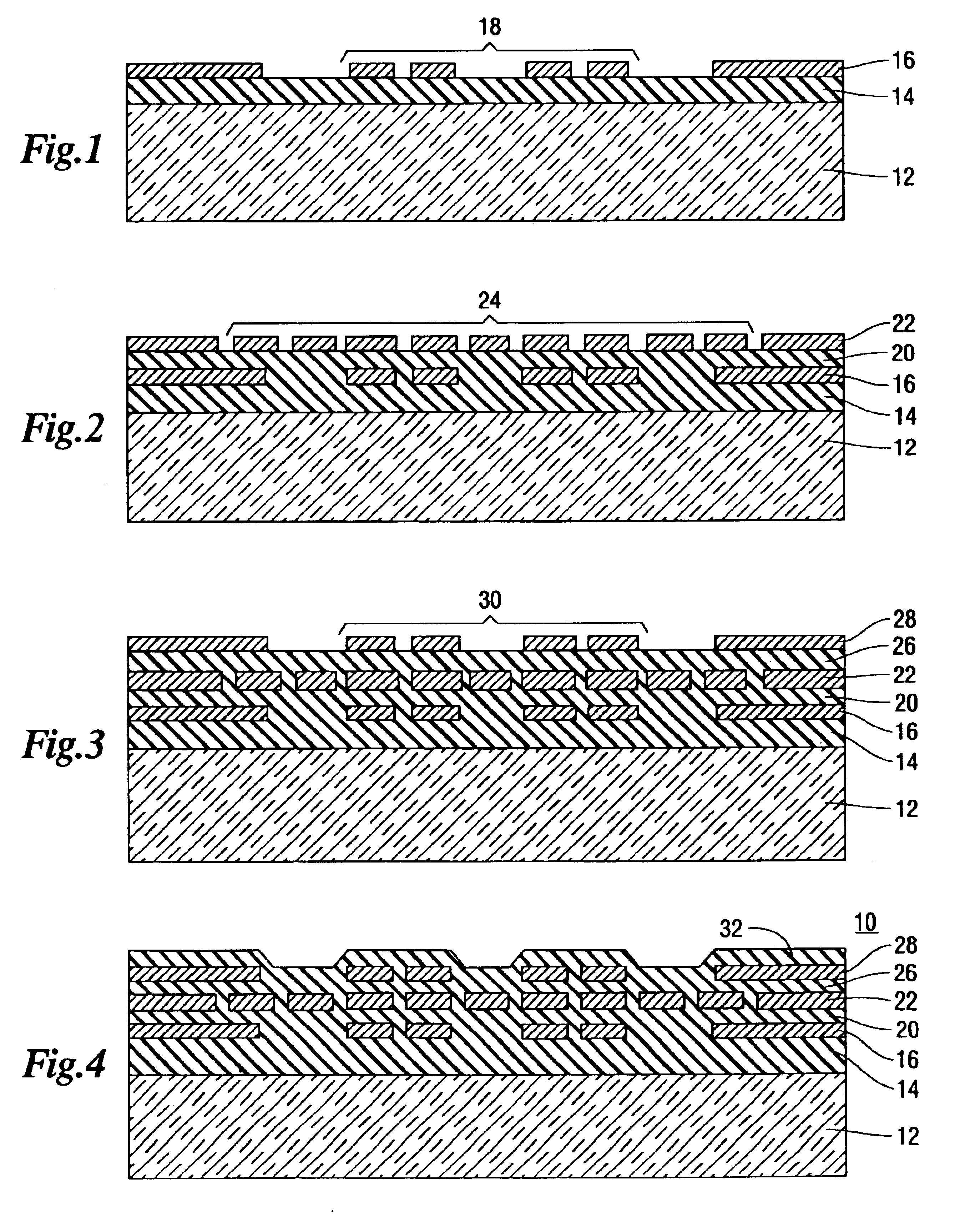

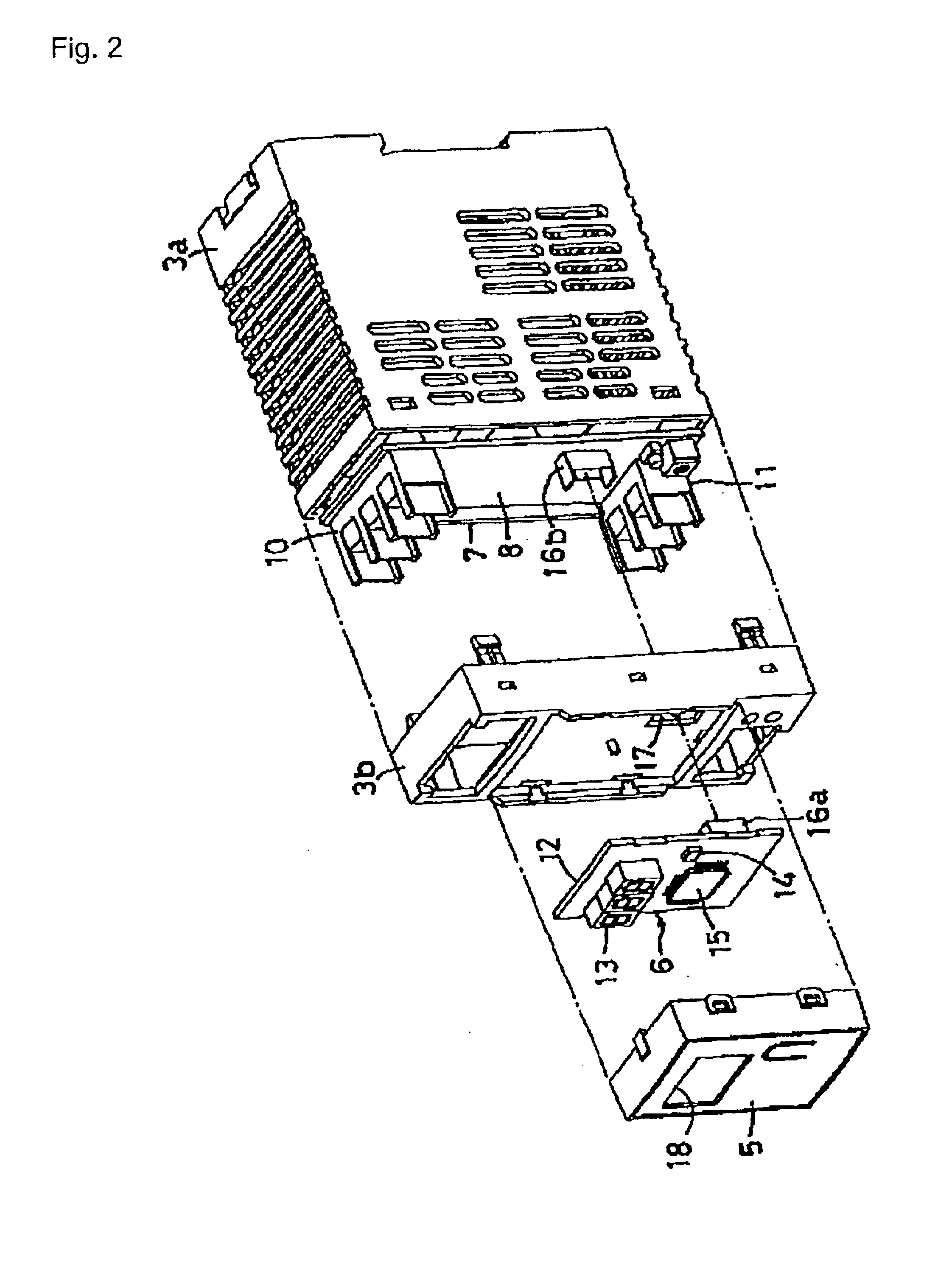

Multi-metal layer MEMS structure and process for making the same

The present invention is directed to a structure comprised of alternating layers of metal and sacrificial material built up using standard CMOS processing techniques, a process for building such a structure, a process for fabricating devices from such a structure, and the devices fabricated from such a structure. In one embodiment, a first metal layer is carried by a substrate. A first sacrificial layer is carried by the first metal layer. A second metal layer is carried by the sacrificial layer. The second metal layer has a portion forming a micro-machined metal mesh. When the portion of the first sacrificial layer in the area of the micro-machined metal mesh is removed, the micro-machined metal mesh is released and suspended above the first metal layer a height determined by the thickness of the first sacrificial layer. The structure may be varied by providing a base layer of sacrificial material between the surface of the substrate and the first metal layer. In that manner, a portion of the first metal layer may form a micro-machined mesh which is released when a portion of the base sacrificial layer in the area of the micro-machined mesh is removed. Additionally, a second layer of sacrificial material and a third metal layer may be provided. A micro-machined mesh may be formed in a portion of the third metal layer. The structure of the present invention may be used to construct variable capacitors, switches and, when certain of the meshes are sealed, microspeakers and microphones.

Owner:AKUSTICA

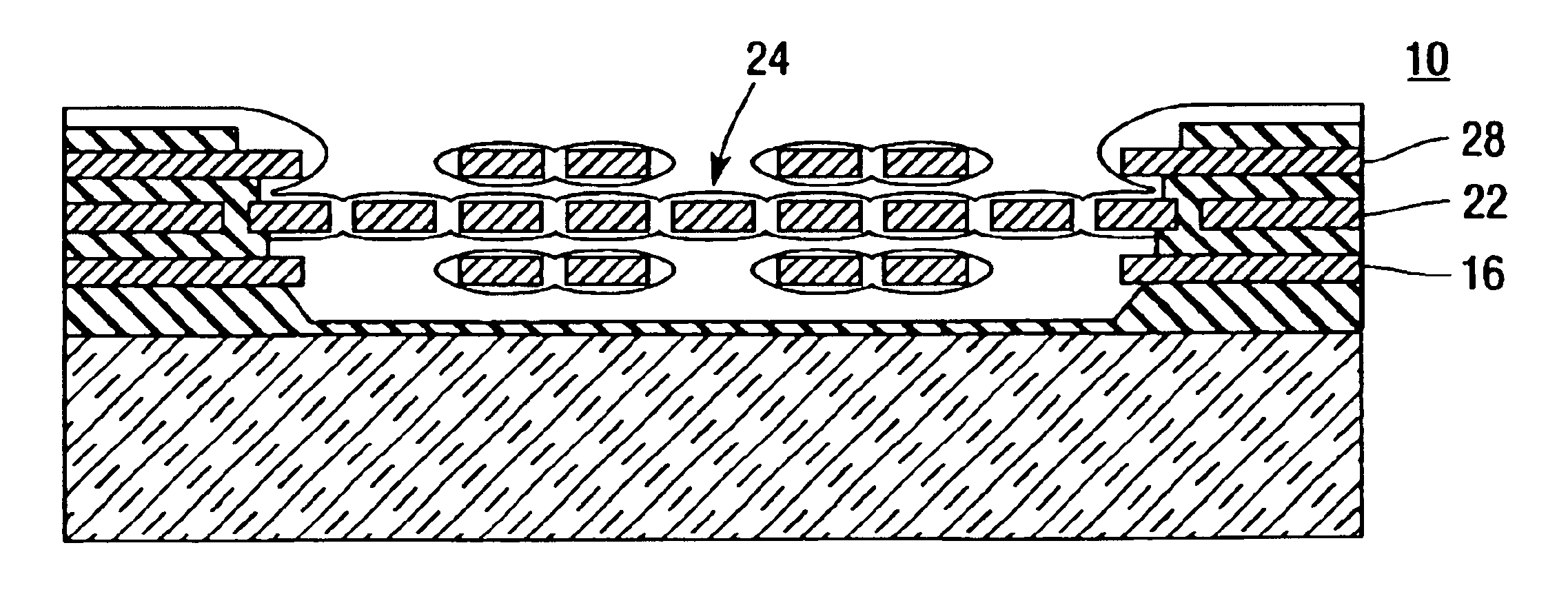

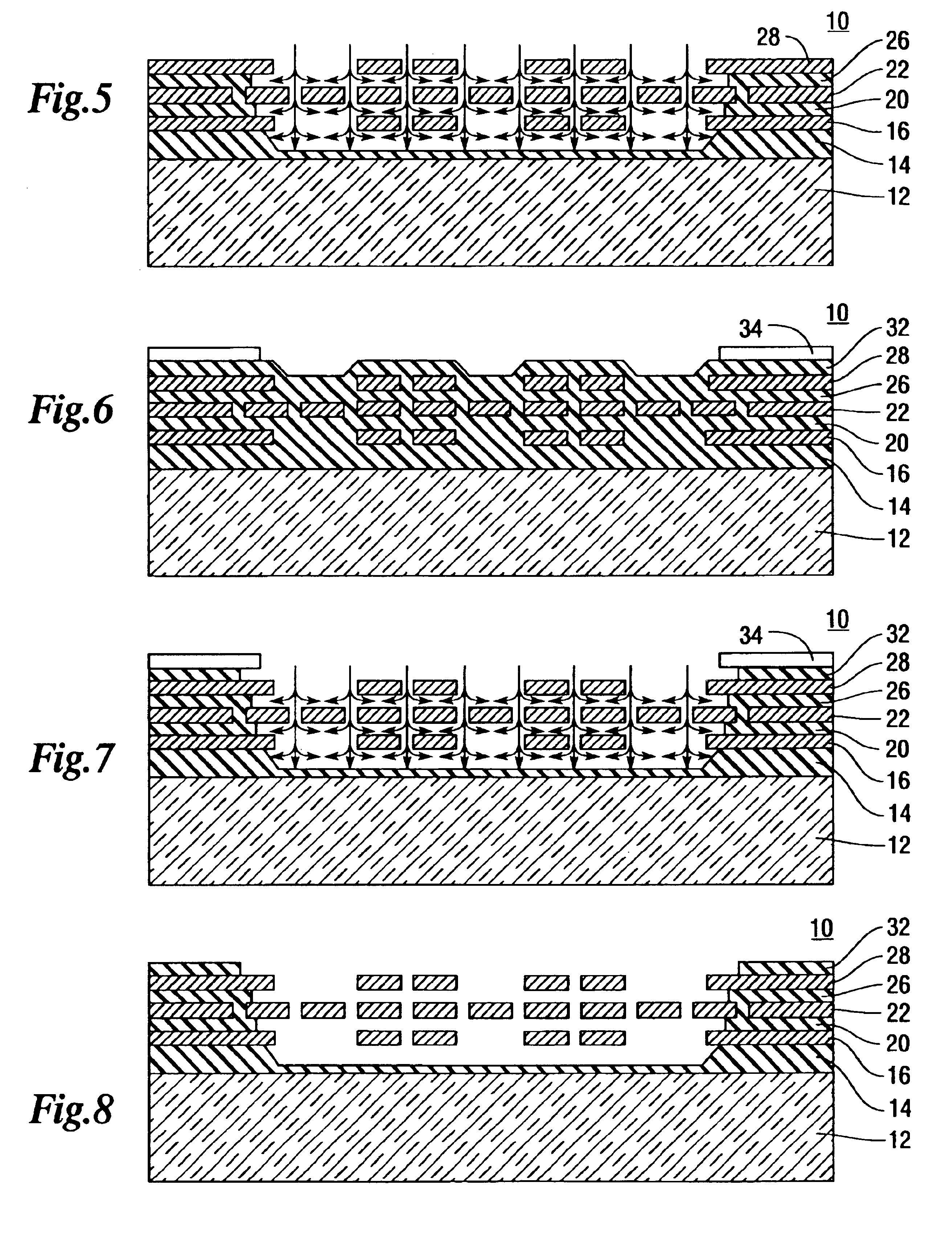

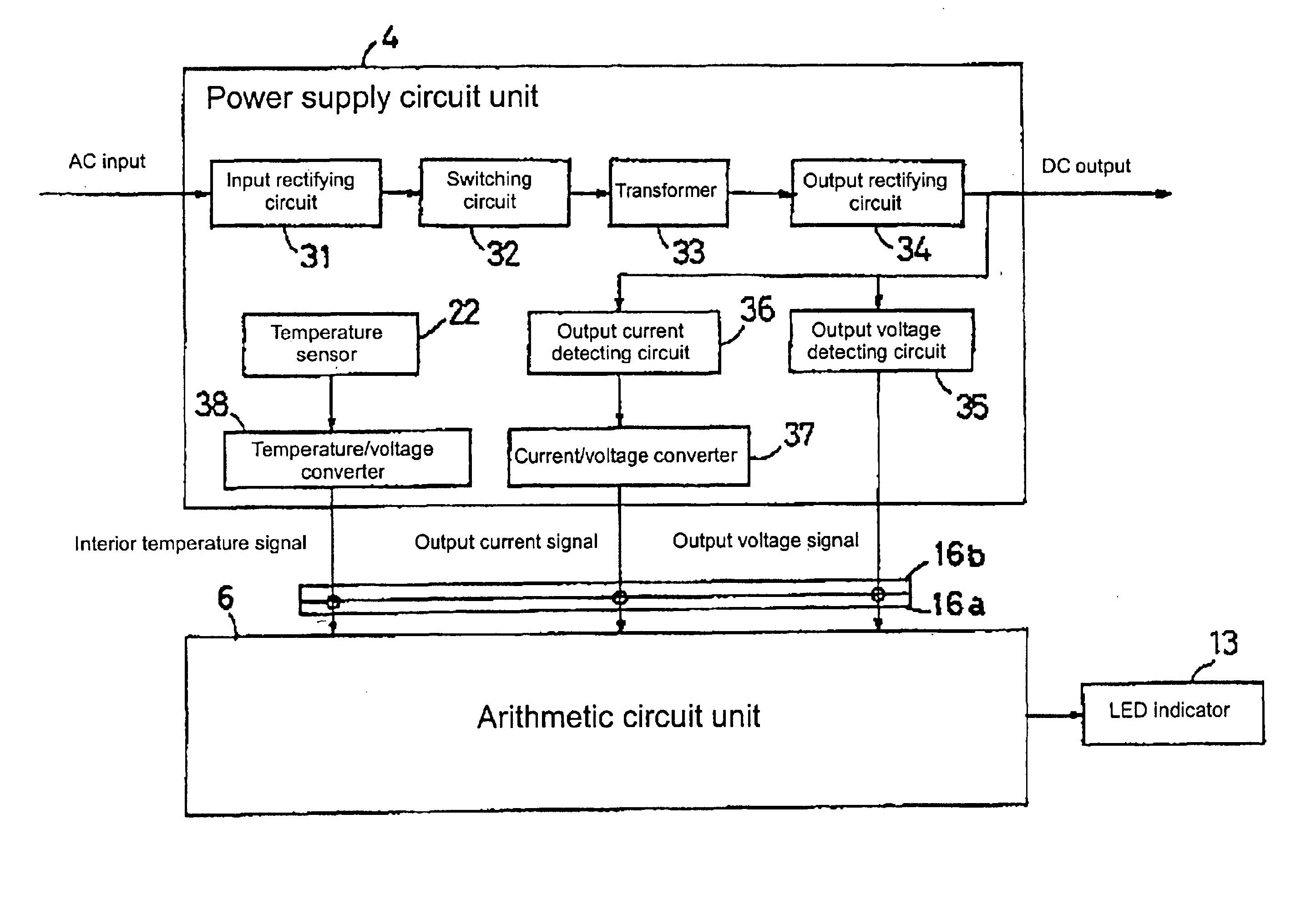

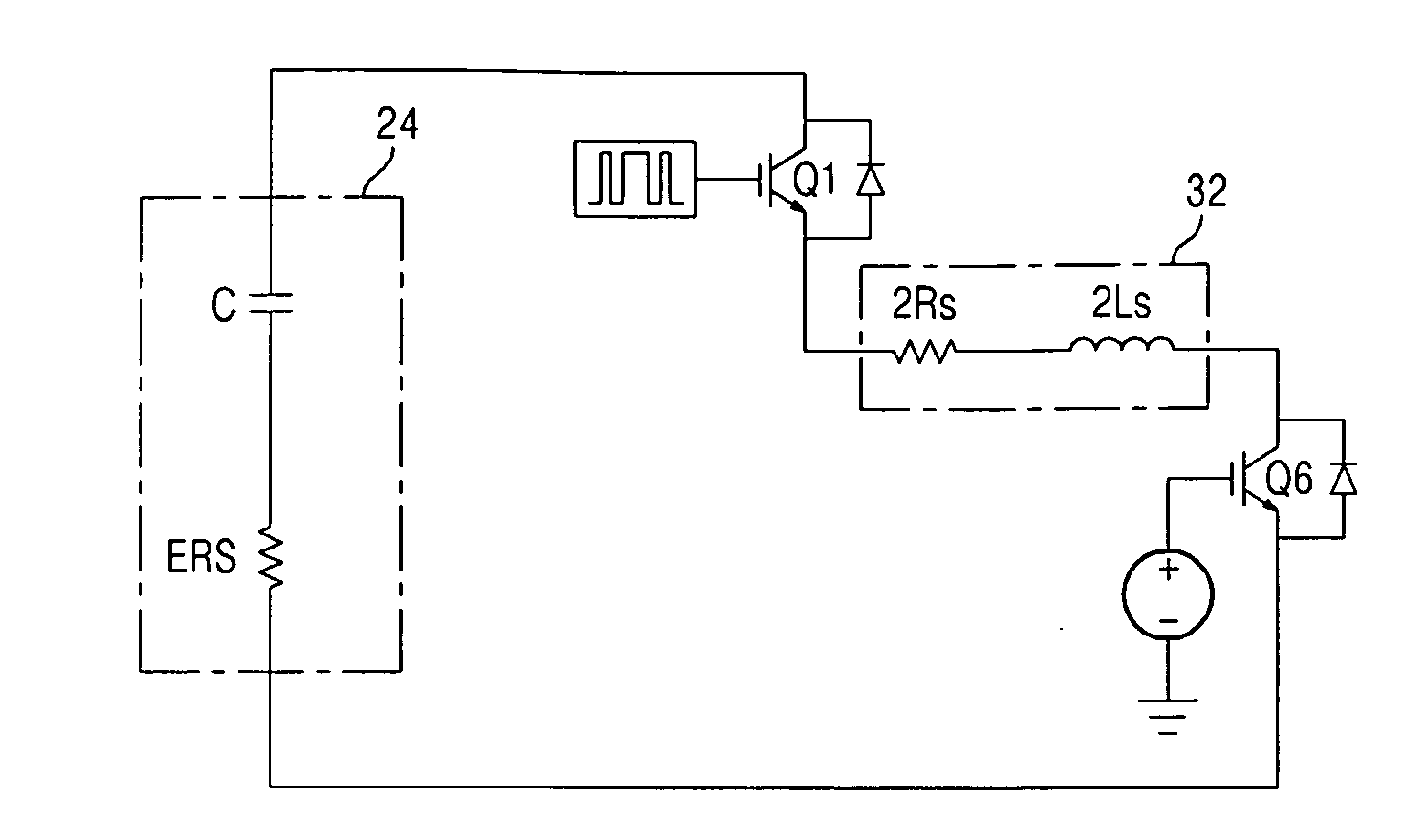

Remaining lifetime estimating method, temperature detecting structure and electronic equipment

InactiveUS6880967B2Accurate estimateAccurate conversionTesting dielectric strengthThermometers using mean/integrated valuesEngineeringElectrolytic capacitor

A temperature of an electrolytic capacitor 24 incorporated in equipment is detected, a remaining lifetime in actual use is calculated based on a temperature-lifetime law, and the remaining lifetime is indicated. A thin film tape 23 is wound around a temperature sensor 22 for insulation, and the electrolytic capacitor 24 and the temperature sensor 22 are accommodated in a heat-shrinkable tube 25, the secondary temperature sensor 22 is brought into tight contact with the primary electrolytic capacitor 24.

Owner:ORMON CORP

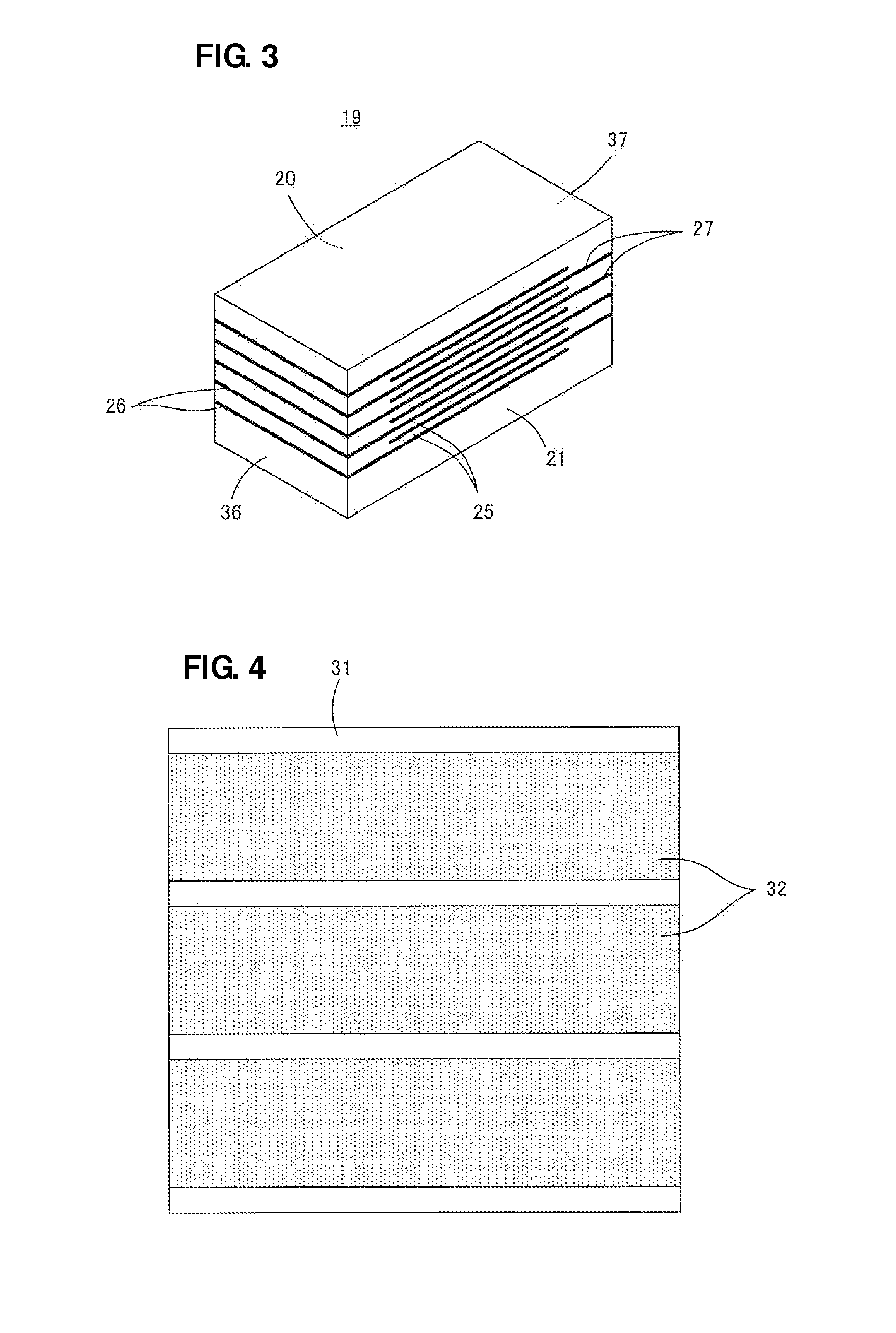

Manufacturing method for monolithic ceramic electronic component

ActiveUS20120234462A1Reduce the possibilityReduce chanceLamination ancillary operationsFixed capacitor dielectricAdhesiveElectronic component

In a manufacturing method for a monolithic ceramic electronic component, a plurality of green chips arrayed in row and column directions which are obtained after cutting a mother block are spaced apart from each other and then tumbled, thereby uniformly making the side surface of each of the green chips an open surface. Thereafter, an adhesive is applied to the side surface. Then, by placing a side surface ceramic green sheet on an affixation elastic body, and pressing the side surface of the green chips against the side surface ceramic green sheet, the side surface ceramic green sheet is punched and stuck to the side surface.

Owner:MURATA MFG CO LTD

Solid electrolytic capacitor

InactiveUS6920037B2Small sizeLarge capacitanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEngineering

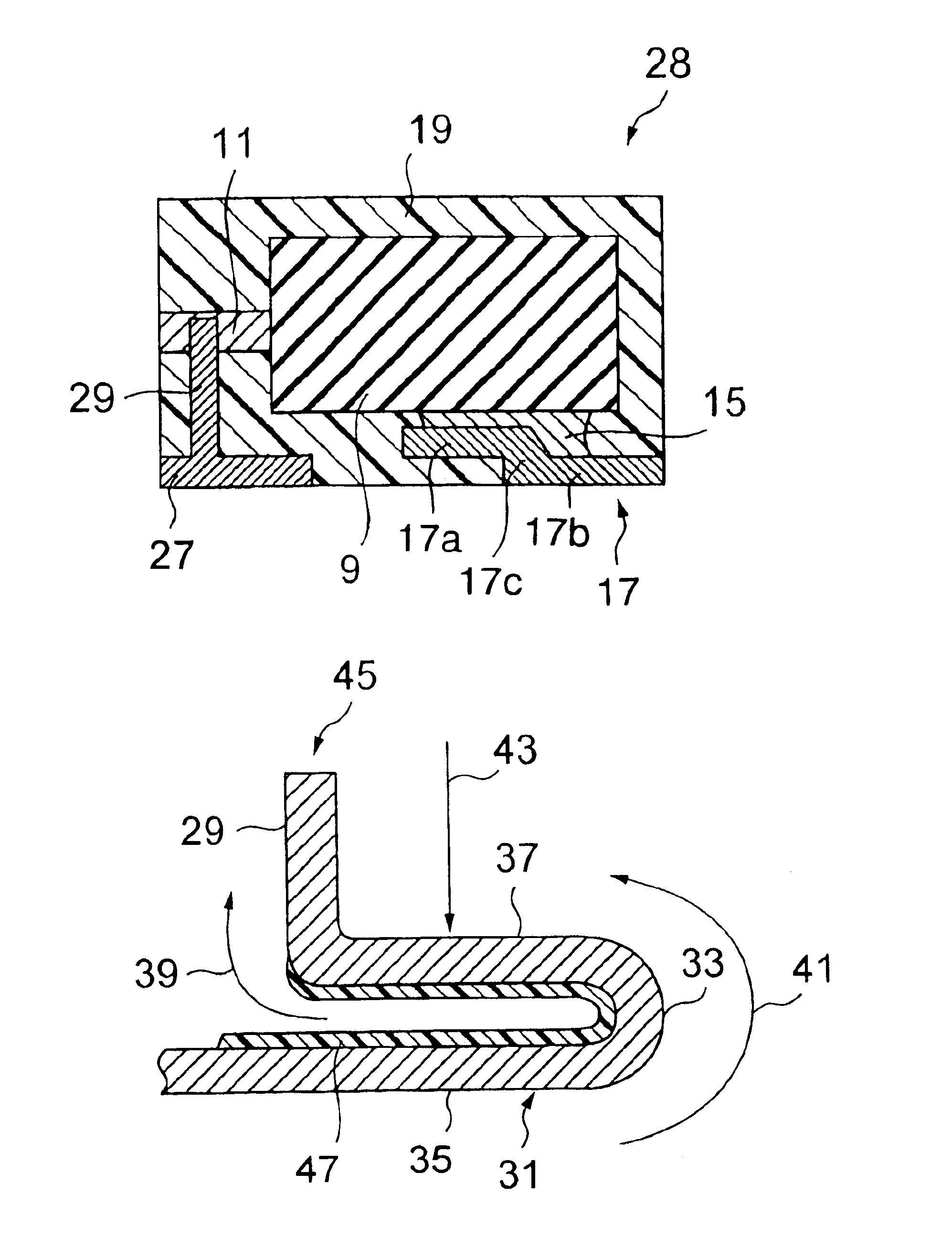

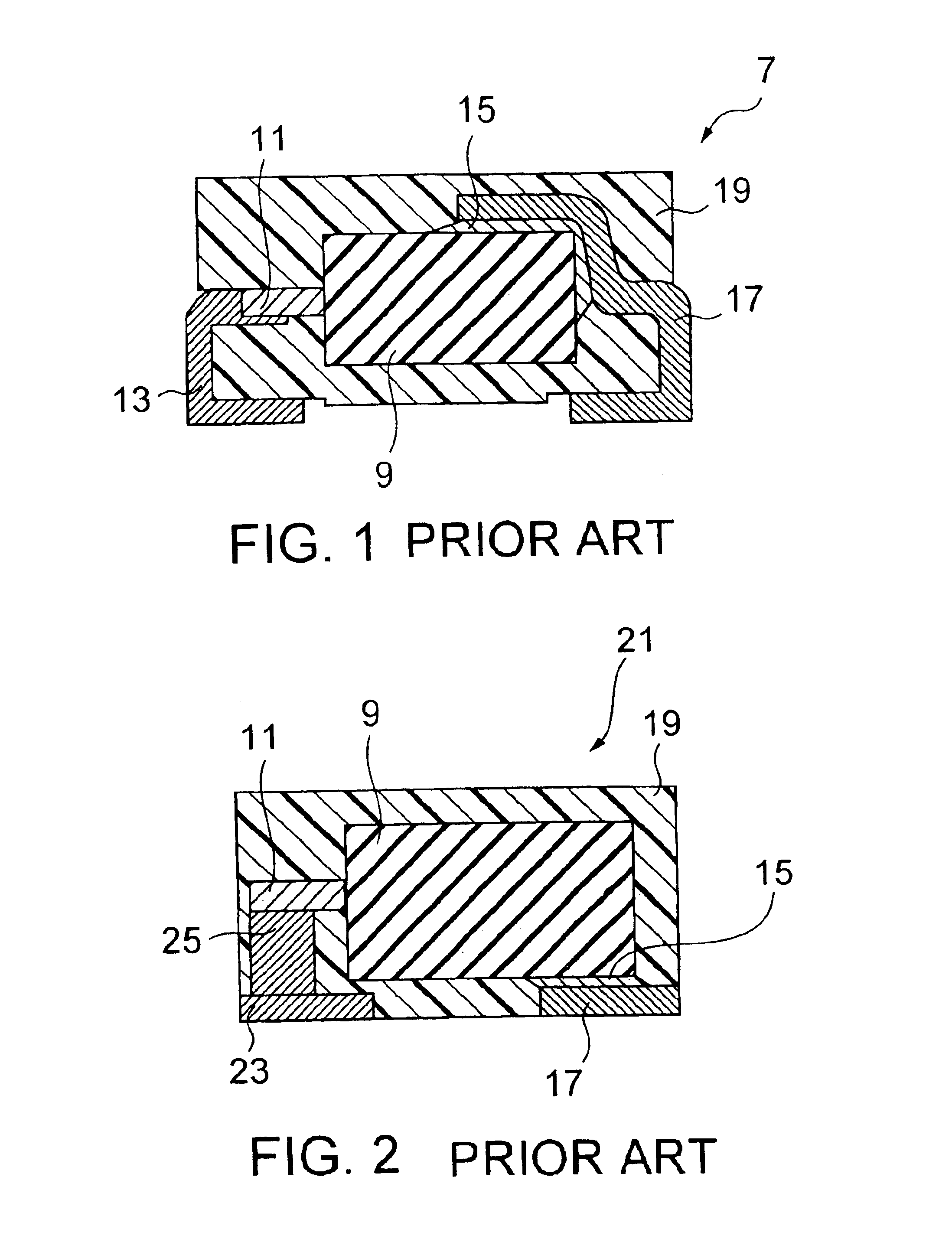

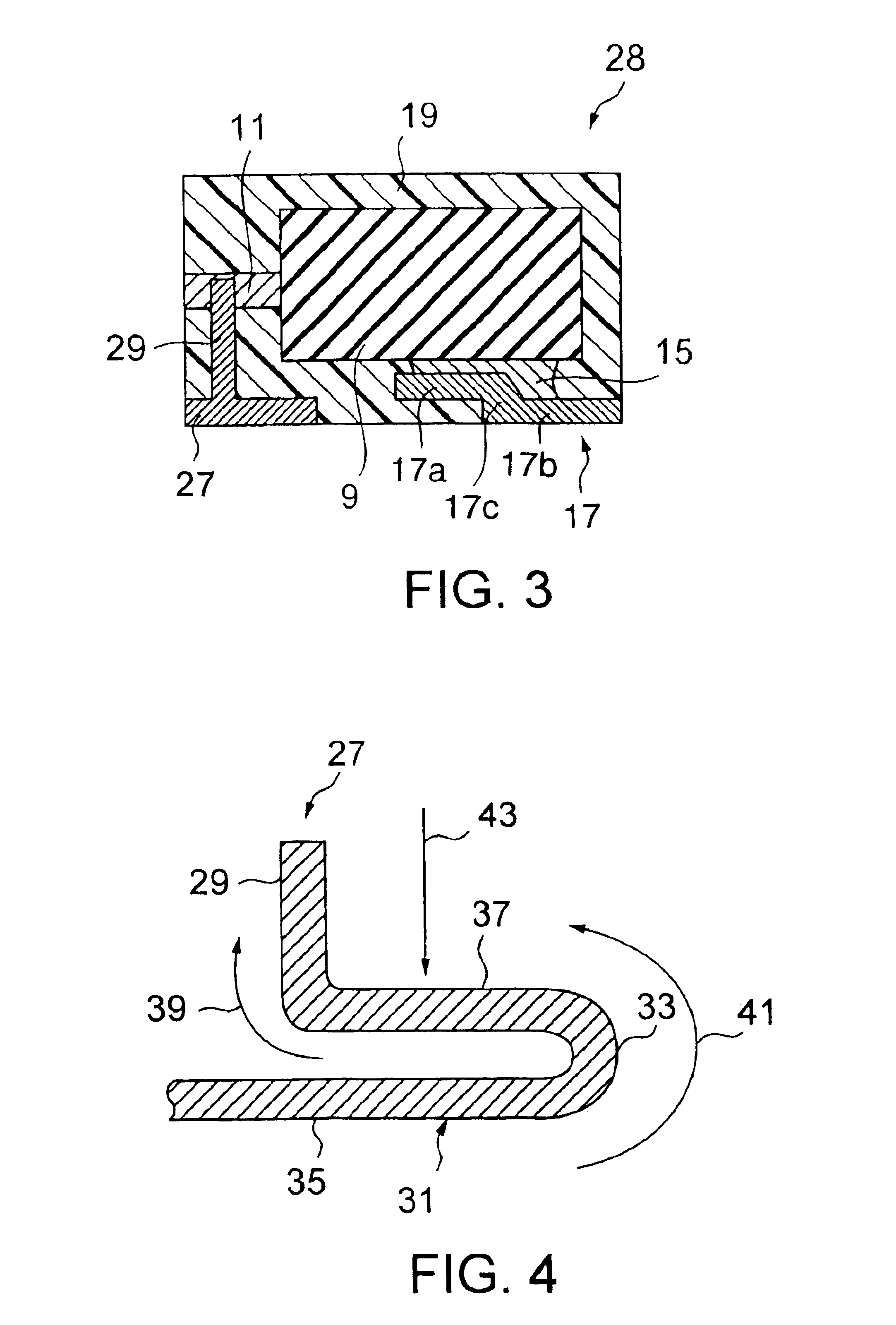

In a solid electrolytic capacitor, an anode terminal (27 in FIG. 3) has a T-shaped section in which two plate pieces intersect at right angles. One of the two plate pieces is exposed to the mounting surface of the solid electrolytic capacitor, while the other is perpendicularly erected to an anode lead (11). The two plate pieces are made of a series of continuous members.

Owner:TOKIN CORP

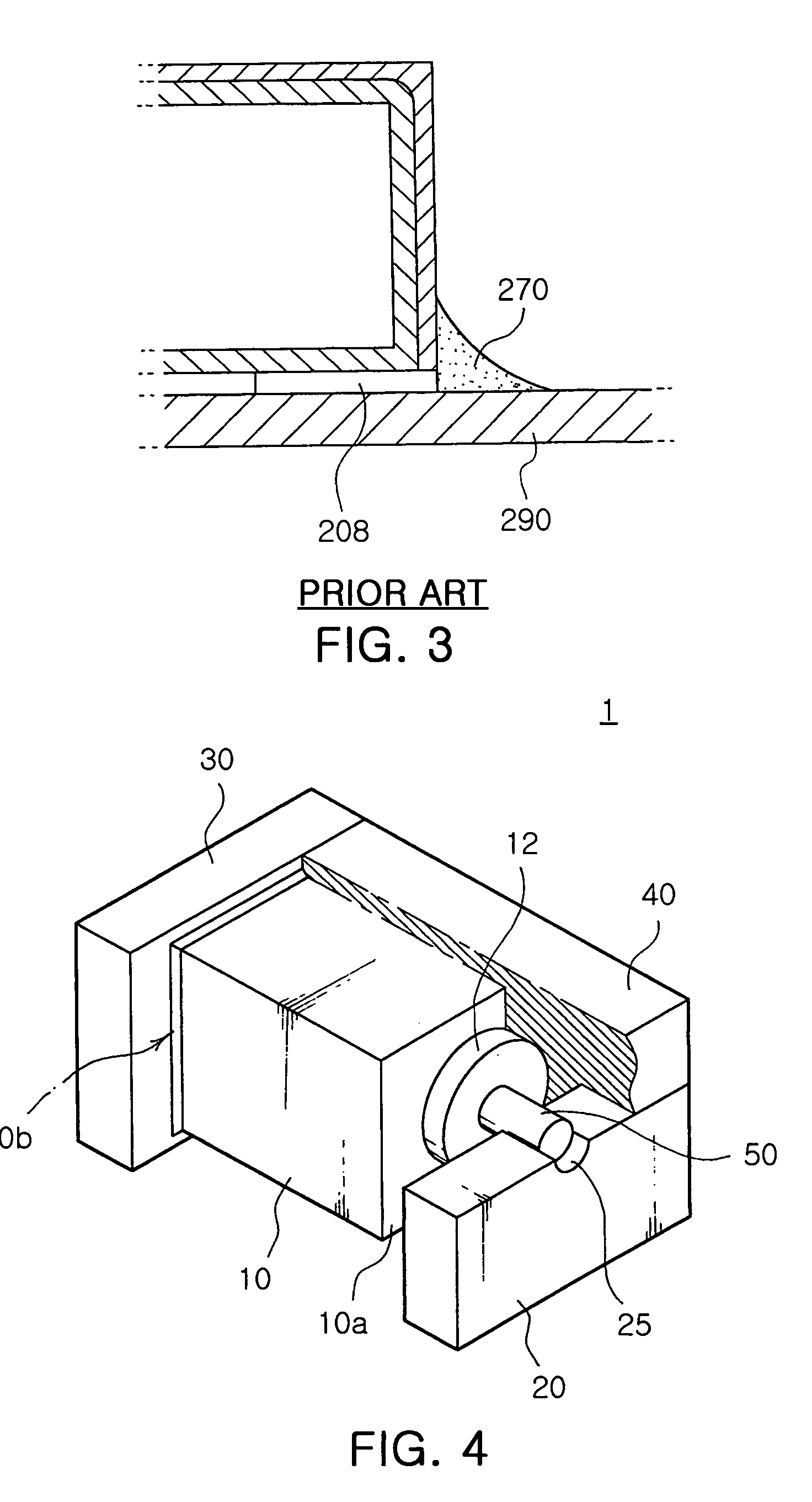

High aspect ratio openings

A capacitor forming method includes forming an electrically conductive support material over a substrate, with the support material containing at least 25 at % carbon. The method includes forming an opening through at least the support material where the opening has an aspect ratio of at least 20:1 within a thickness of the support material. After forming the opening, the method includes processing the support material to effect a reduction in conductivity, and forming a capacitor structure in the opening.

Owner:MICRON TECH INC

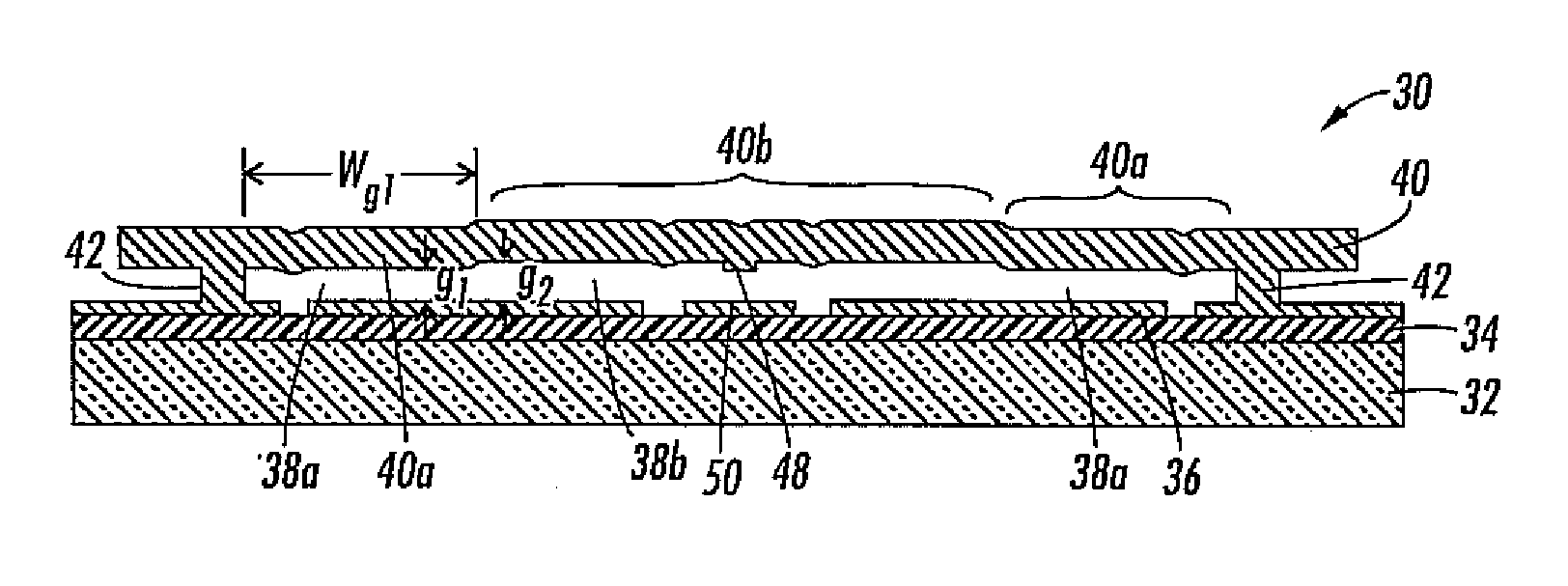

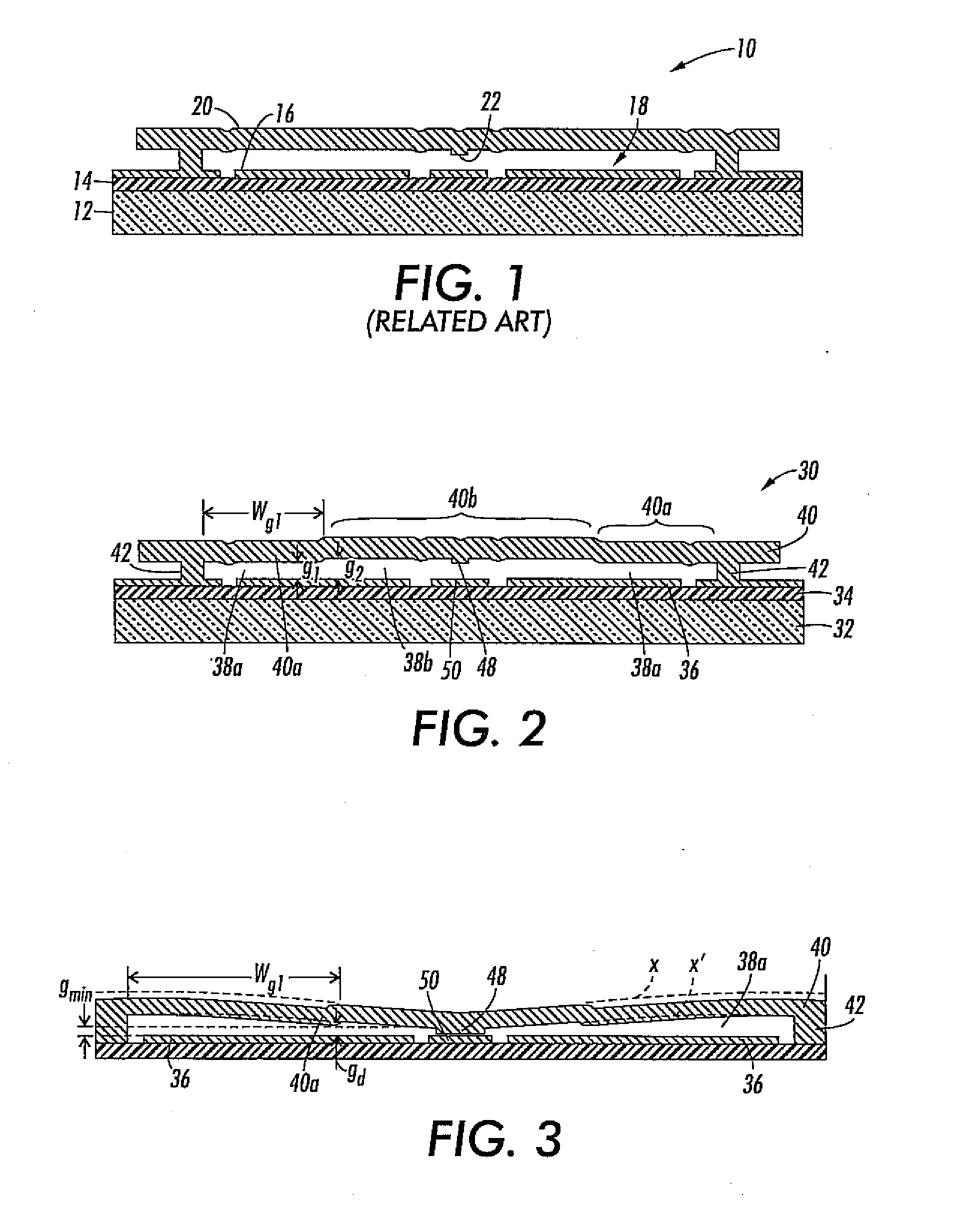

Electrostatic actuator device and method of making the device

InactiveUS20080048520A1Reduce decreaseReduce the amount requiredElectrostatic/electro-adhesion relaysElectrolytic capacitorsEngineeringElectrostatic actuator

The present application is directed to novel electrostatic actuators and methods of making the electrostatic actuators. In one embodiment, the electrostatic actuator comprises a substrate, an electrode formed on the substrate and a deflectable member positioned in proximity to the electrode so as to provide a gap between the electrode and the deflectable member. The deflectable member is anchored on the substrate via one or more anchors. The gap comprises at least one first region having a first gap height positioned near the one or more anchors and at least one second region having a second gap height positioned farther from the anchors than the first region. The first gap height is smaller than the second gap height.

Owner:XEROX CORP

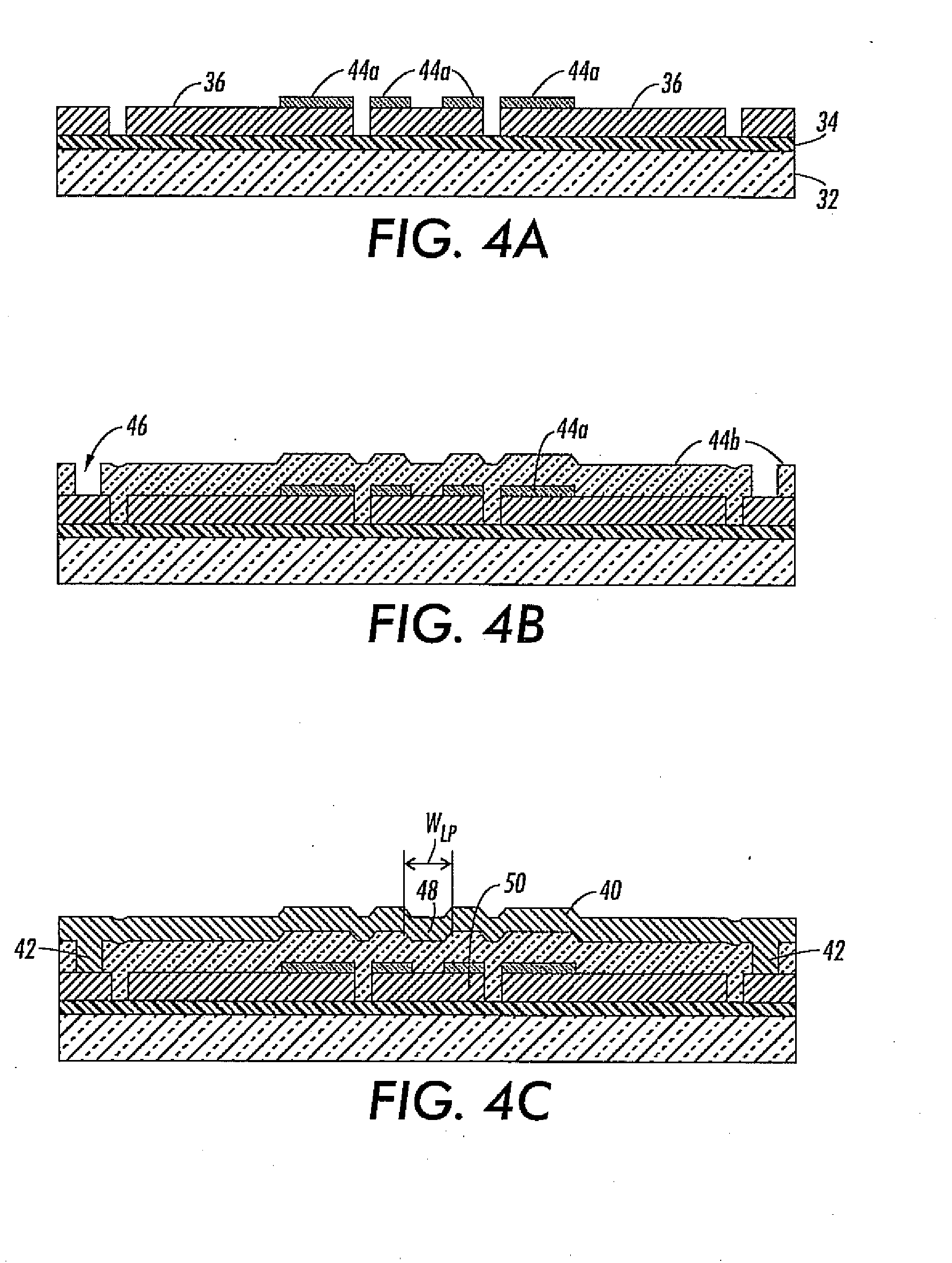

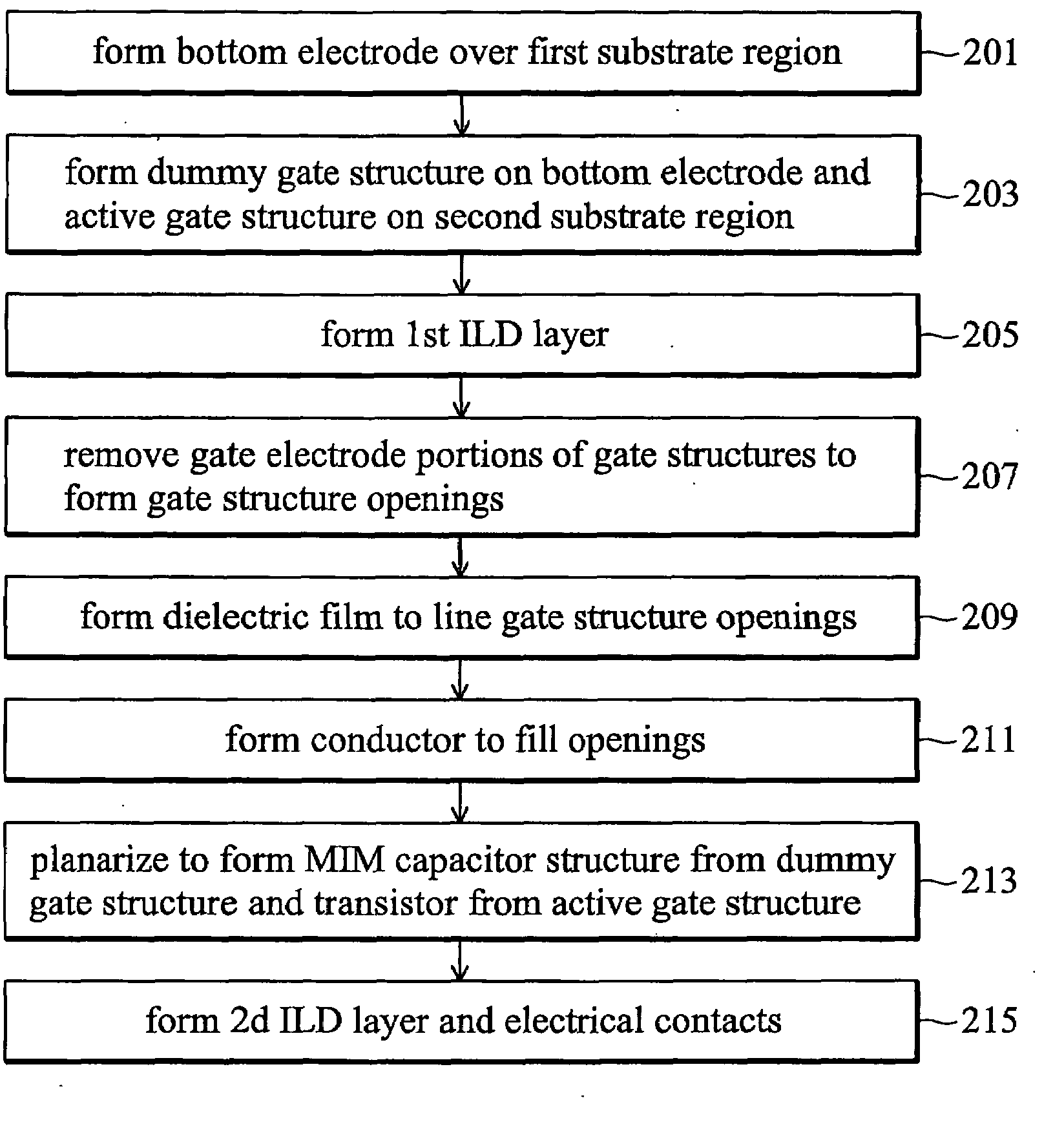

MIM capacitor and metal gate transistor

ActiveUS20080173978A1Simple structureLow costTransistorSolid-state devicesElectrical conductorEngineering

An embedded MIM capacitor in a logic circuit and method for forming the same are disclosed. The device includes a substrate, a bottom electrode, a dielectric film, and a top electrode. The substrate comprises an insulator region. The bottom electrode comprises a first conductor and overlies the insulator region. The dielectric film overlies the bottom electrode, remaining parts of the bottom plate exposed. The top electrode comprises a second conductor and overlies the dielectric film. The dielectric film lines sidewalls and bottom of the top electrode.

Owner:TAIWAN SEMICON MFG CO LTD

MXene-base composite fiber super capacitor

InactiveCN107680824AImprove conductivityHigh specific capacityHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceFiber

The invention discloses an MXene-base composite fiber super capacitor. First, an MXene-base composite fiber is obtained by wet spinning and reduction. Then, a negative fiber, which is the MXene-basedcomposite fiber, and a positive fiber are immersed in a liquid electrolyte to obtain the super capacitor or the negative fiber and the positive fiber are coated with gel electrolyte and then dried toobtain a flexible MXene-base composite fiber super capacitor. The MXene-base composite fiber super capacitor is easy to manufacture, low in cost, suitable for large-scale industrial production, good in conductivity, high in specific capacitance, good in cycling property and good in toughness, and can be used in fields such as energy storage, flexible materials and the like.

Owner:杭州德烯科技集团有限公司

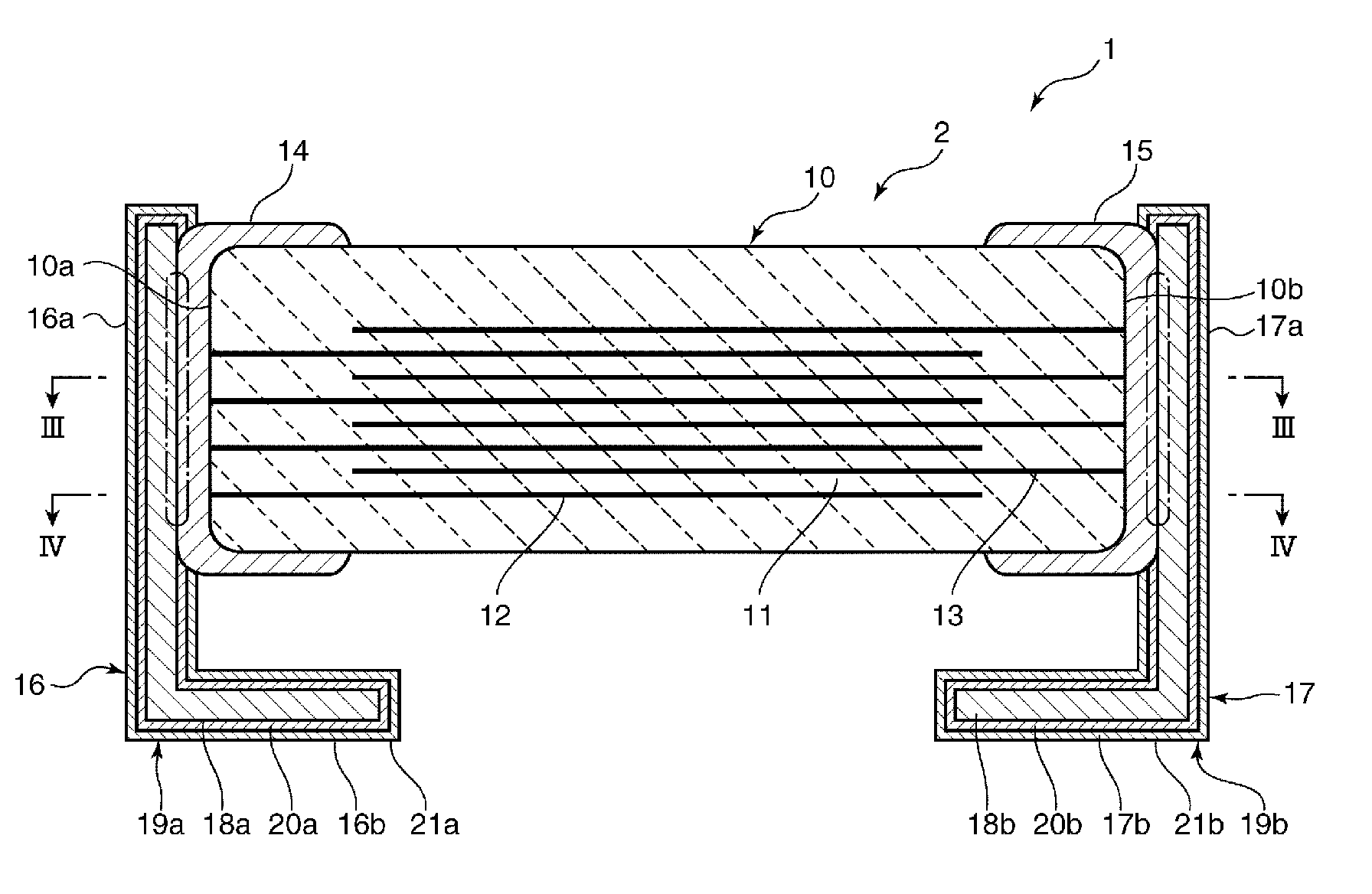

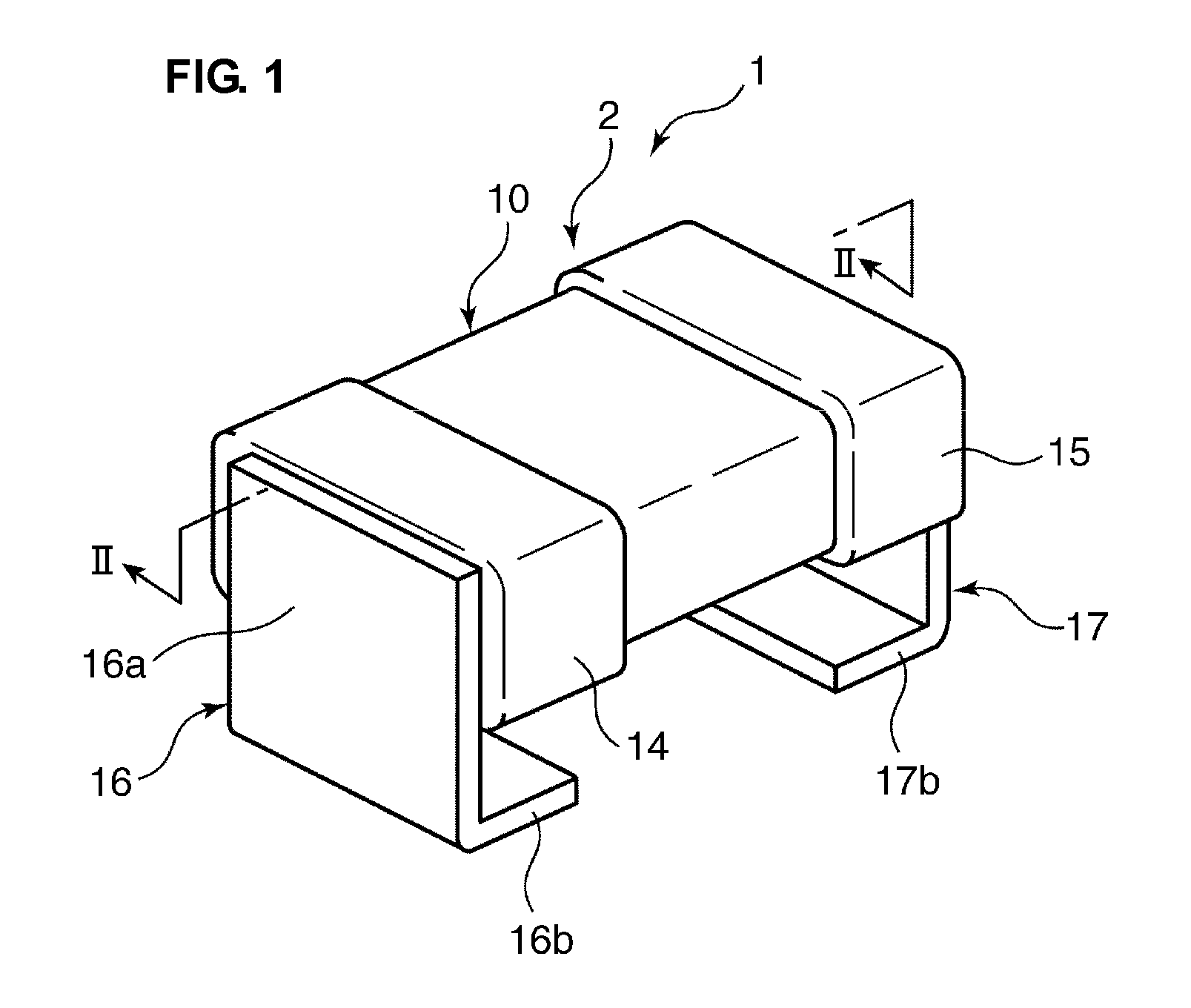

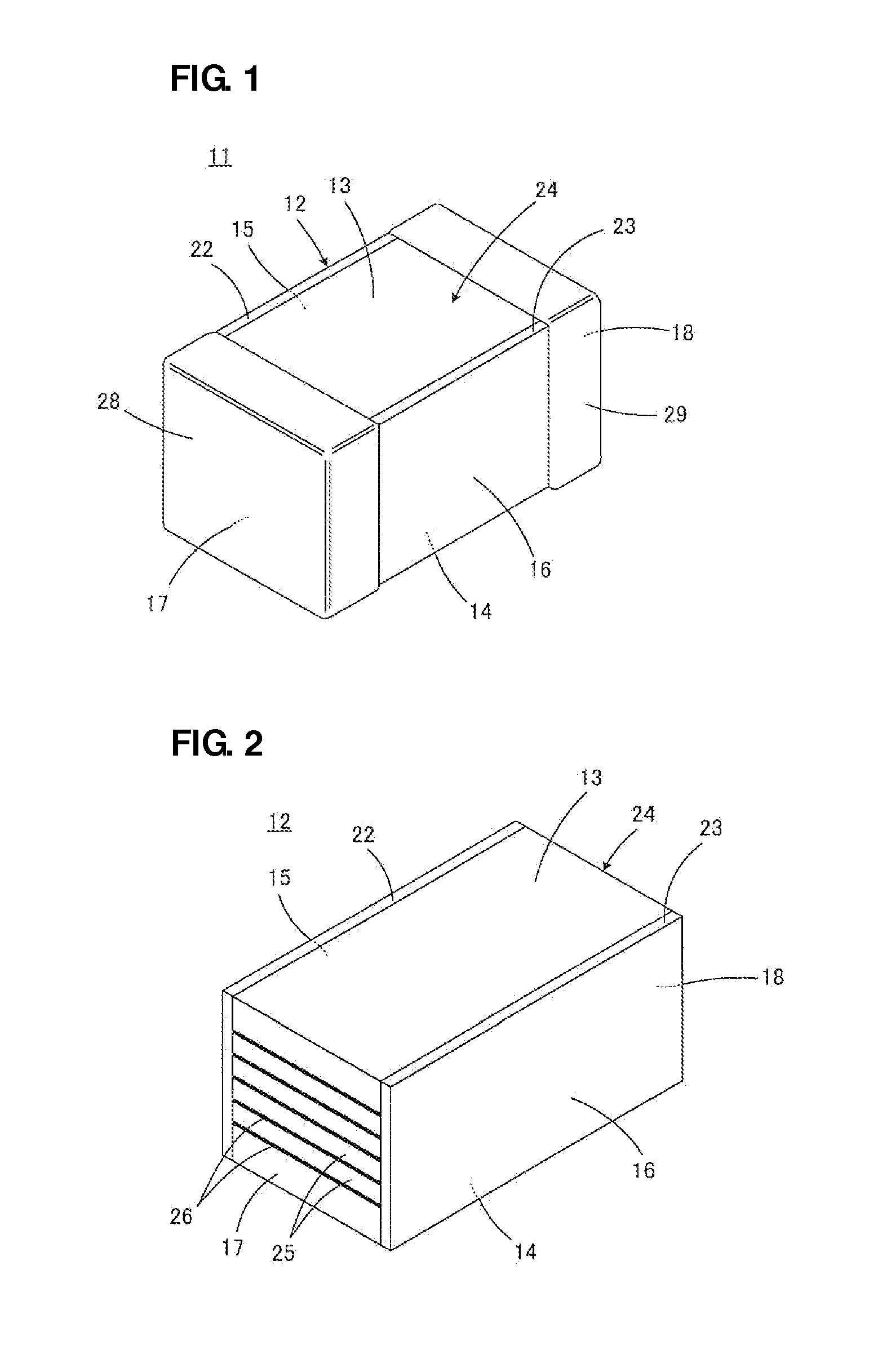

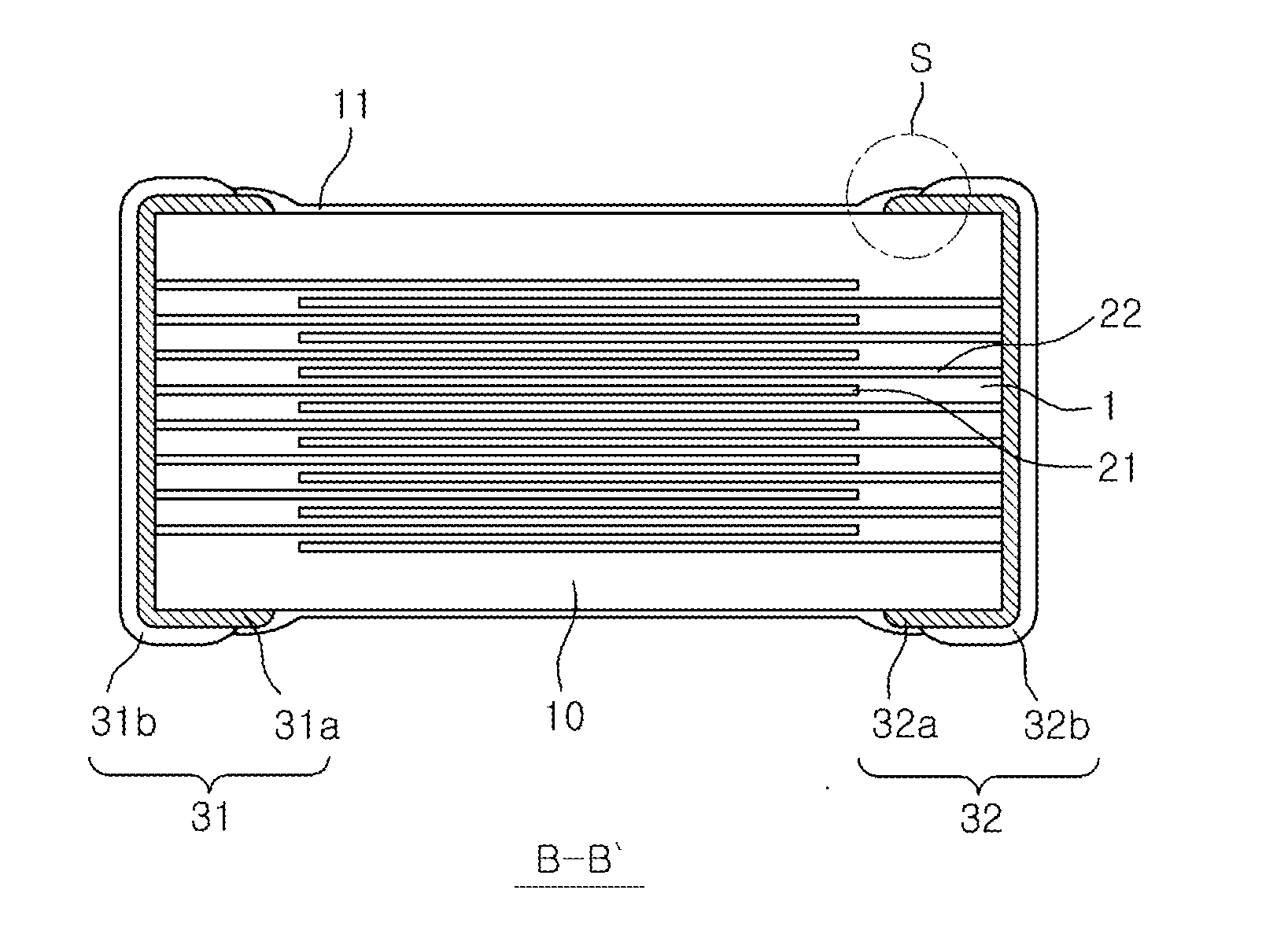

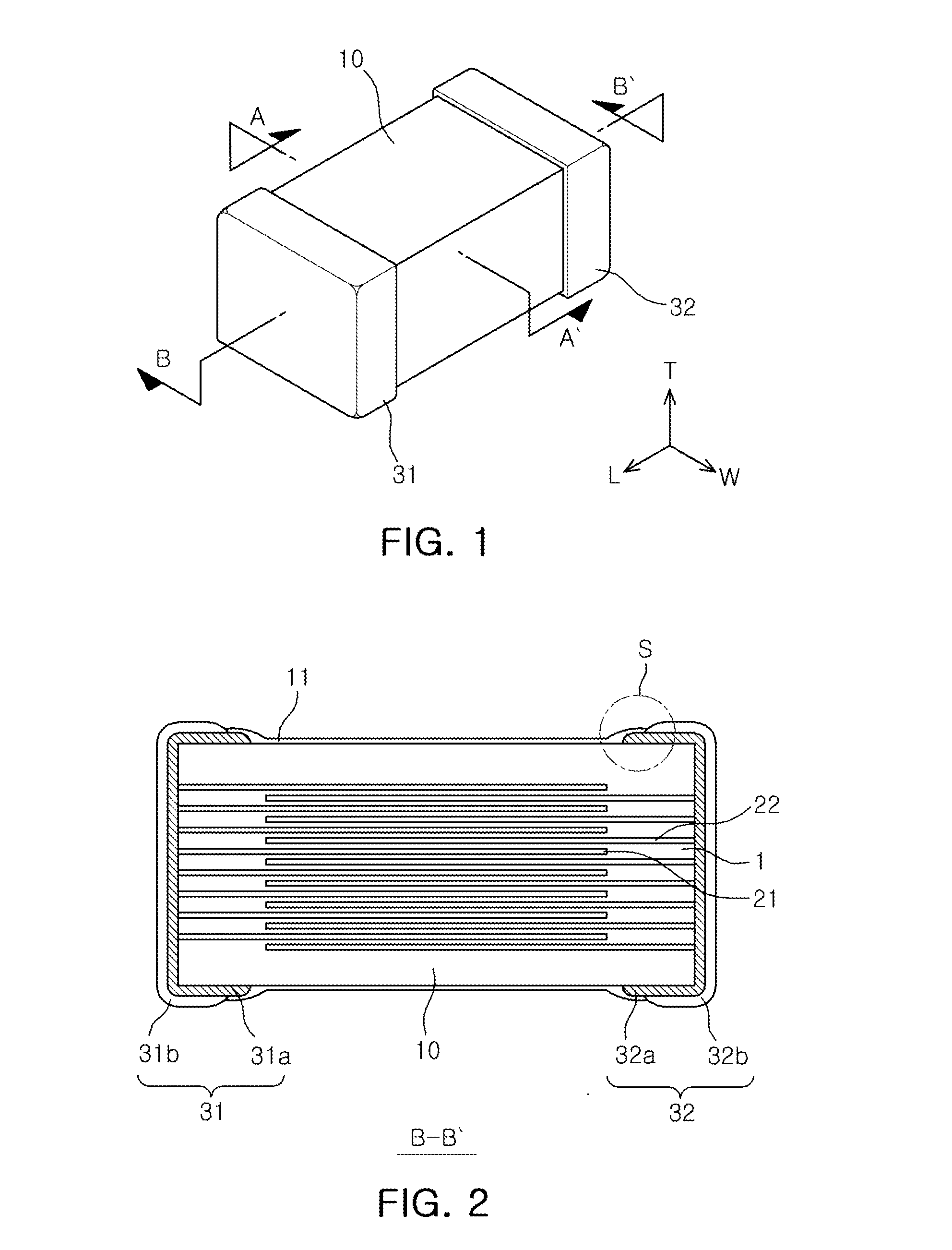

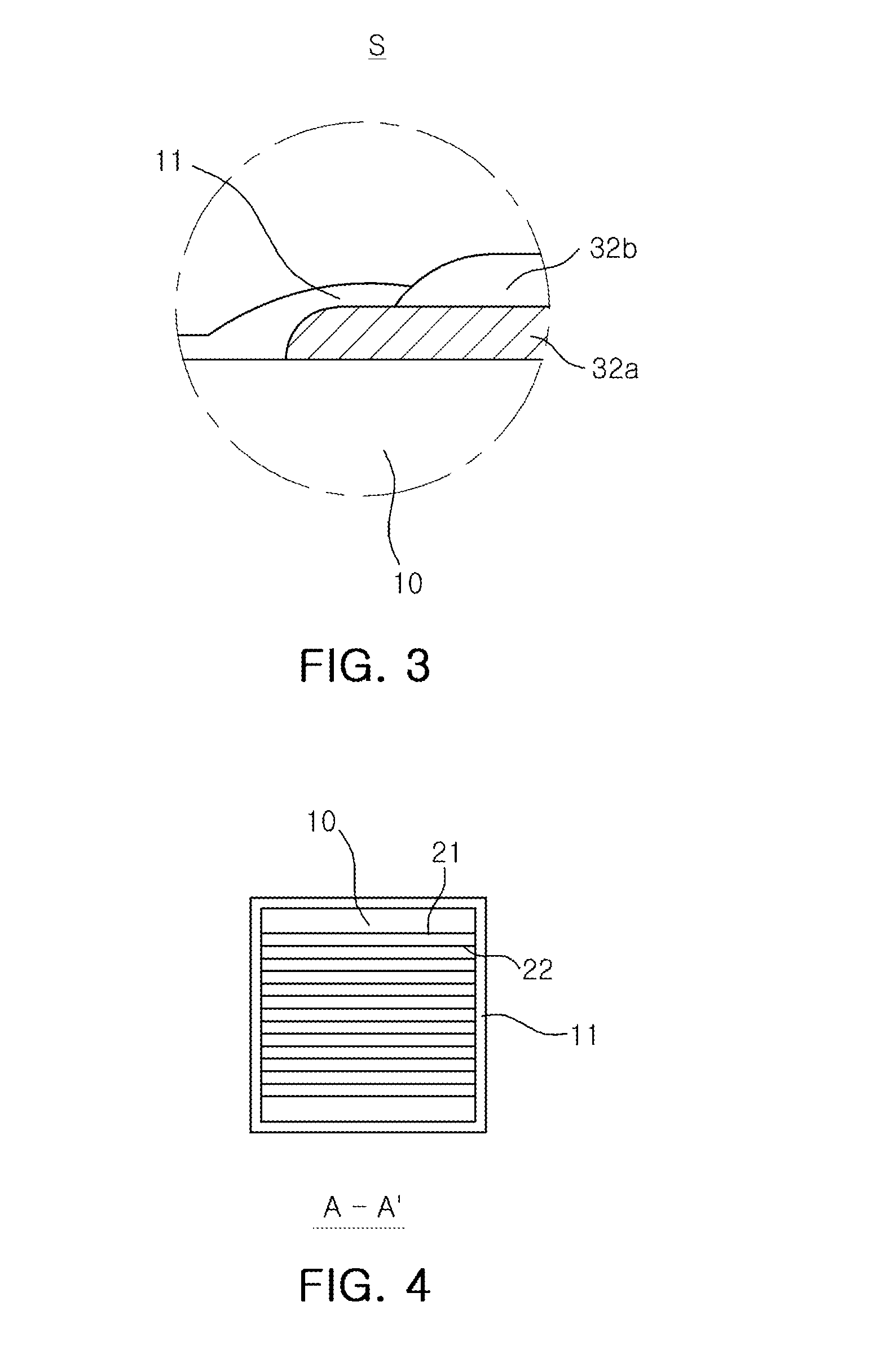

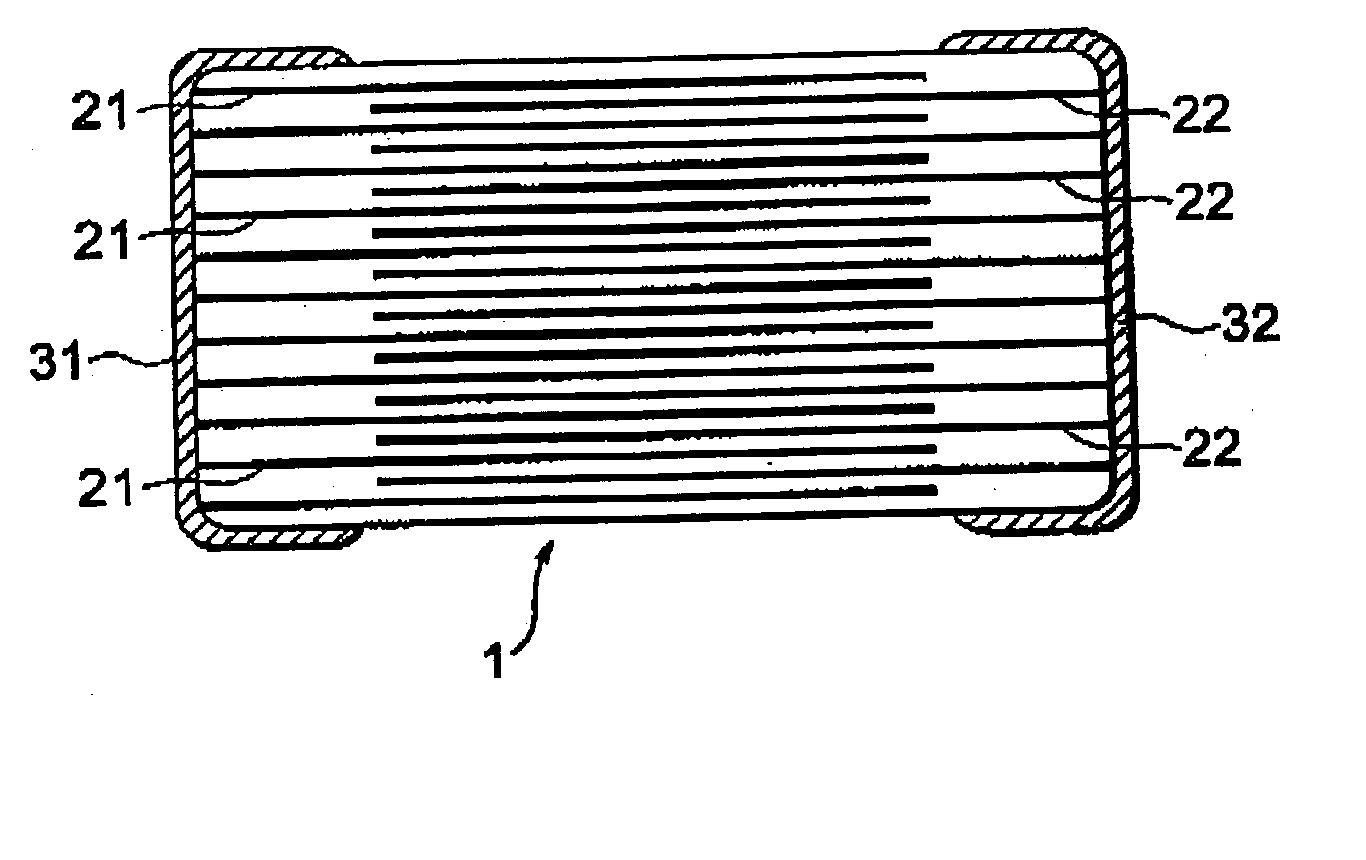

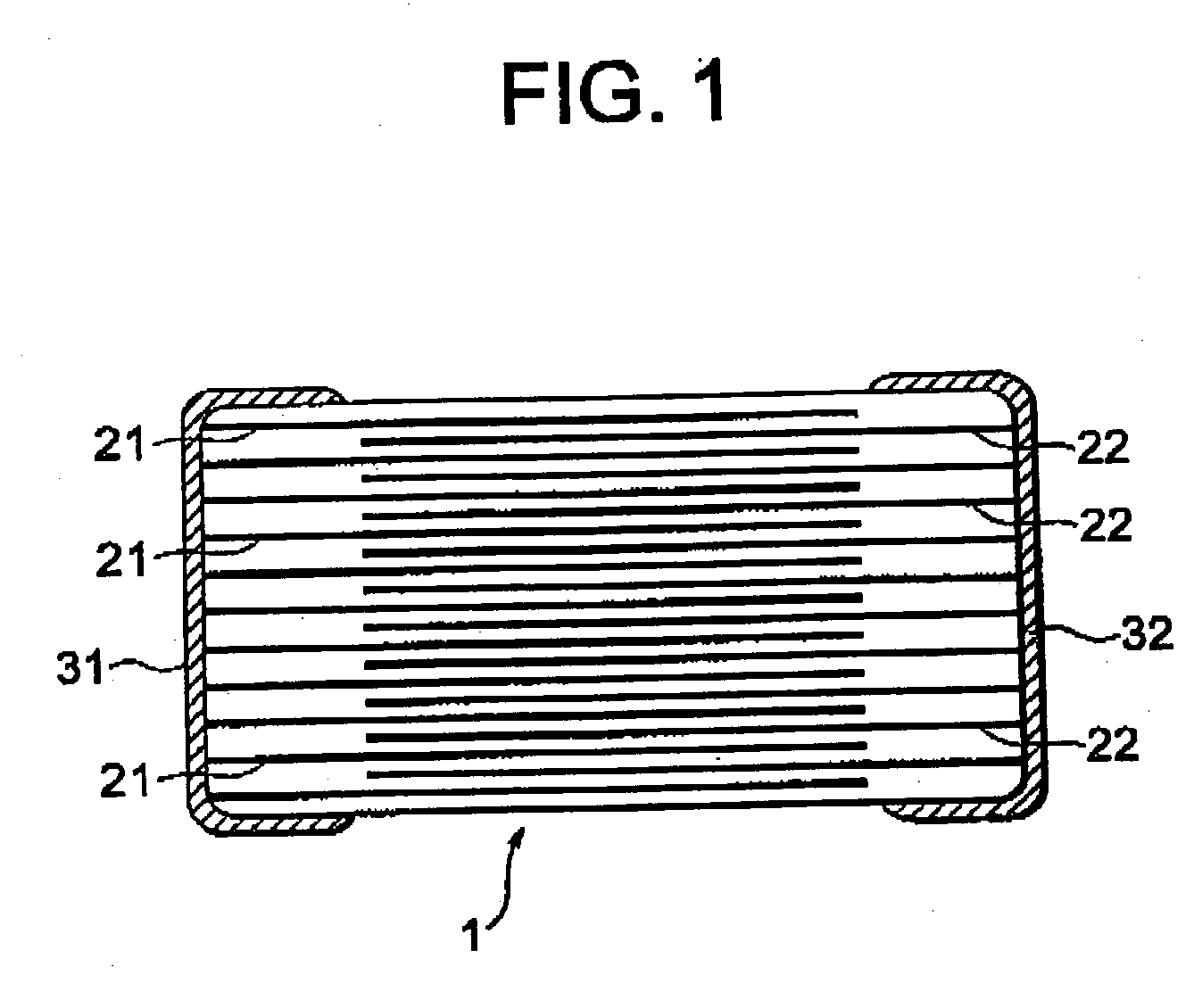

Multilayer ceramic capacitor and method of manufacturing the same

ActiveUS20140085767A1Improve reliabilityLamination ancillary operationsFixed capacitor dielectricCeramic capacitorMaterials science

There is provided a multilayer ceramic capacitor including a ceramic body having first and second side surfaces opposing each other and third and fourth end surfaces connecting the first and second side surfaces, first and second internal electrodes formed in the ceramic body and having one ends exposed to the first and second side surfaces and the third end surface or exposed to the first and second side surfaces and the fourth end surface, first and second external electrodes formed on an outer side of the ceramic body and electrically connected to the first and second internal electrodes, and a plating layer partially formed on certain regions of the first and second external electrodes, wherein a polymer layer is additionally formed on the ceramic body on regions of upper portions of the first and second external electrodes on which the plating layer is not formed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

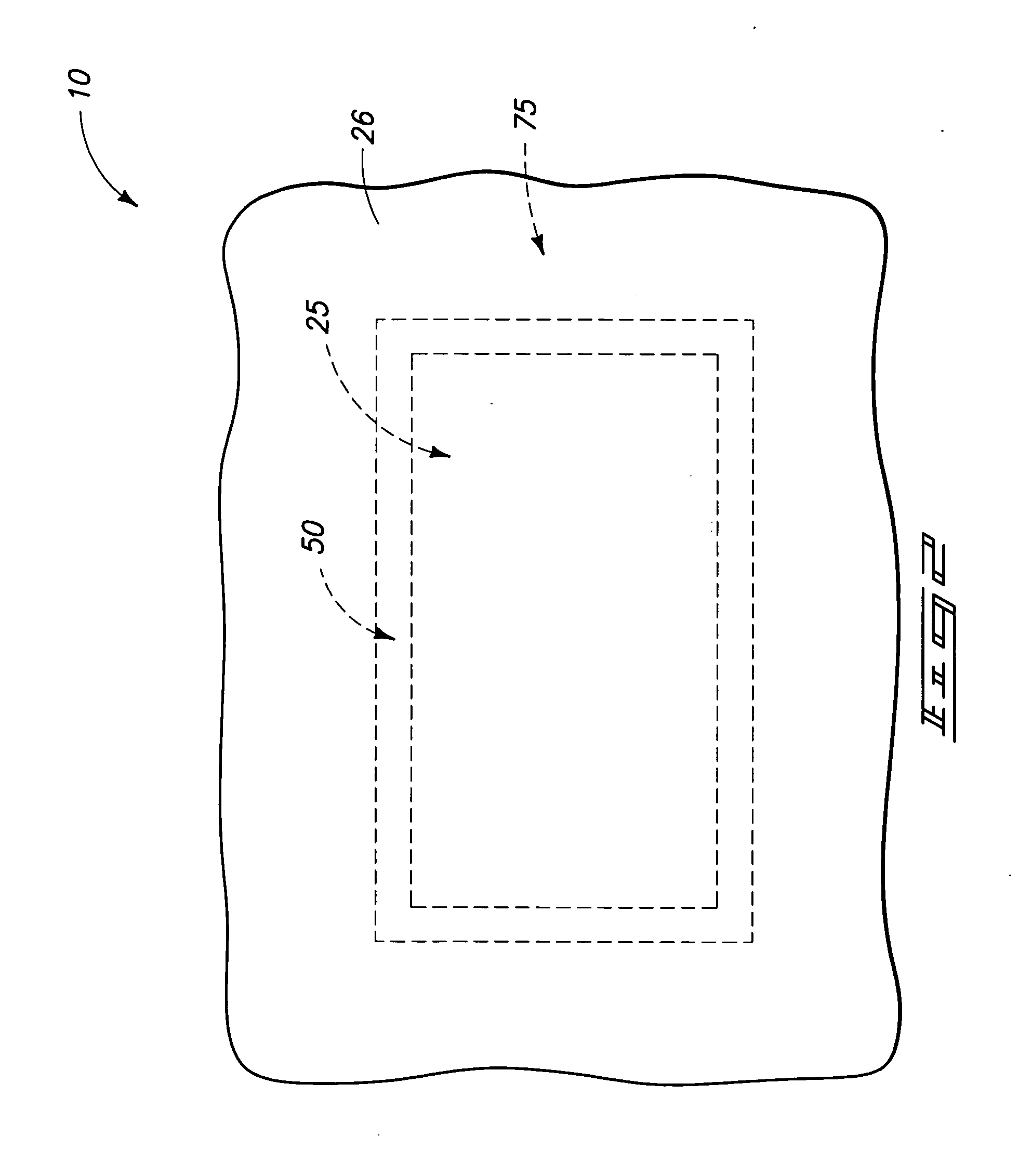

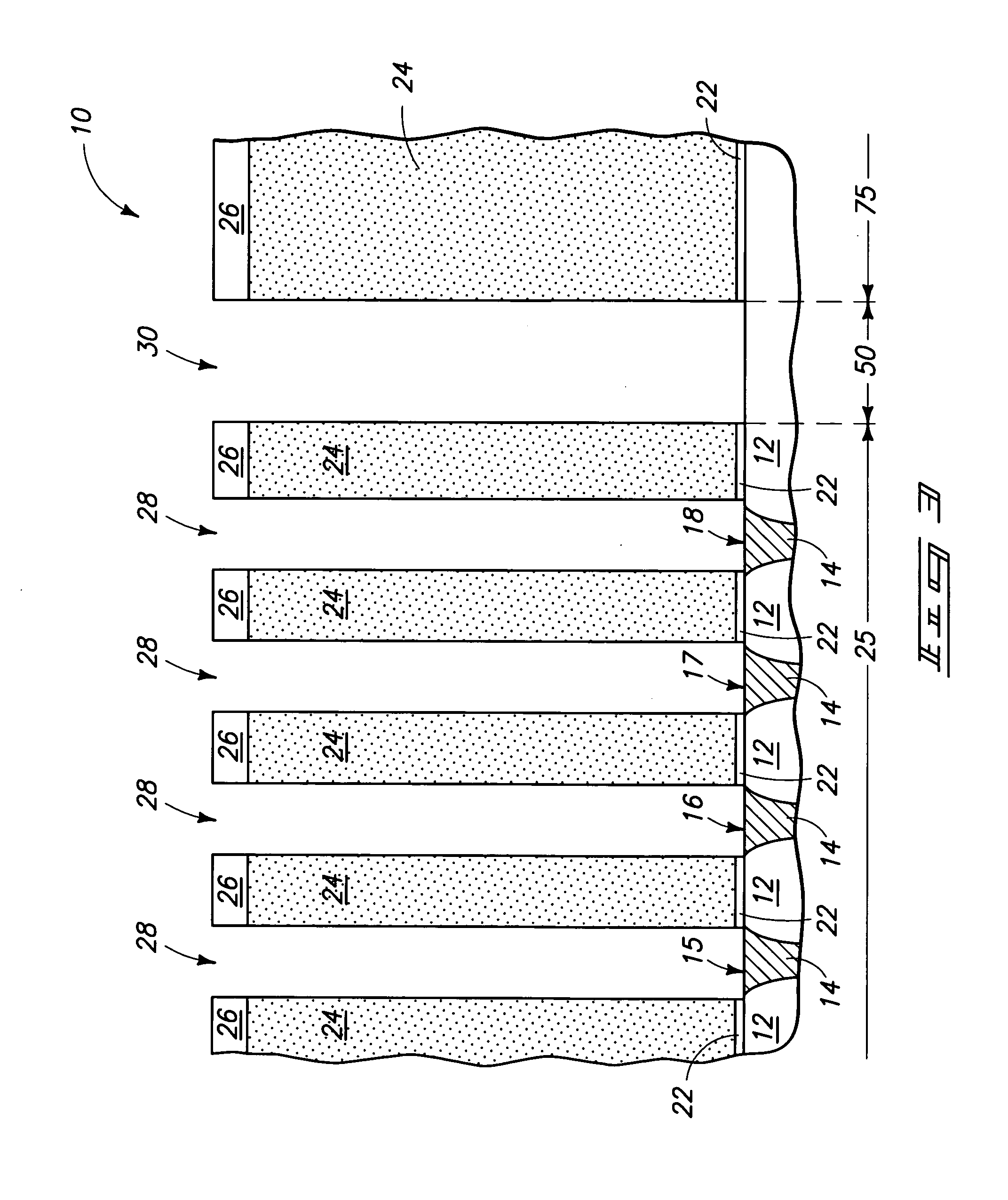

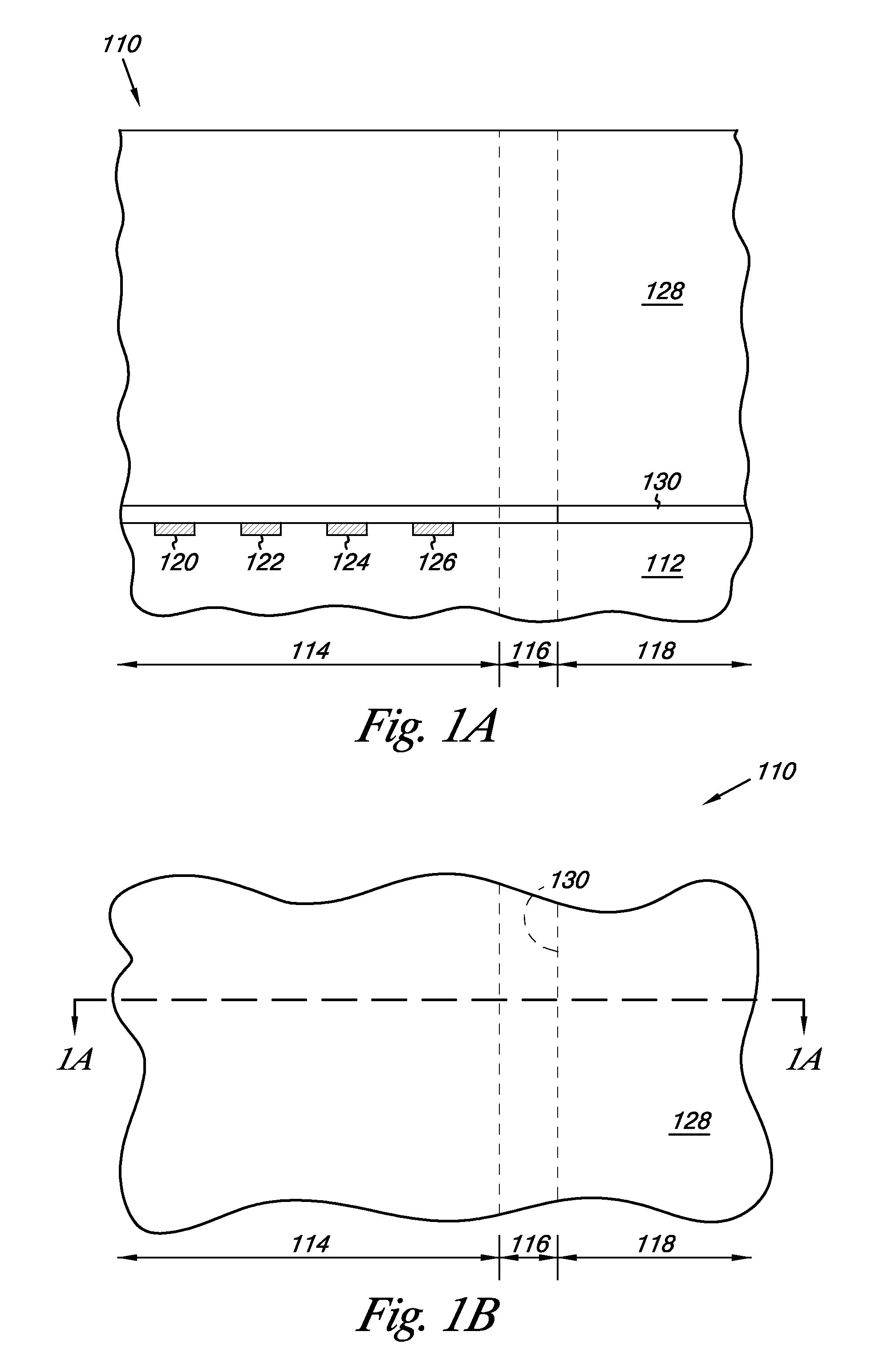

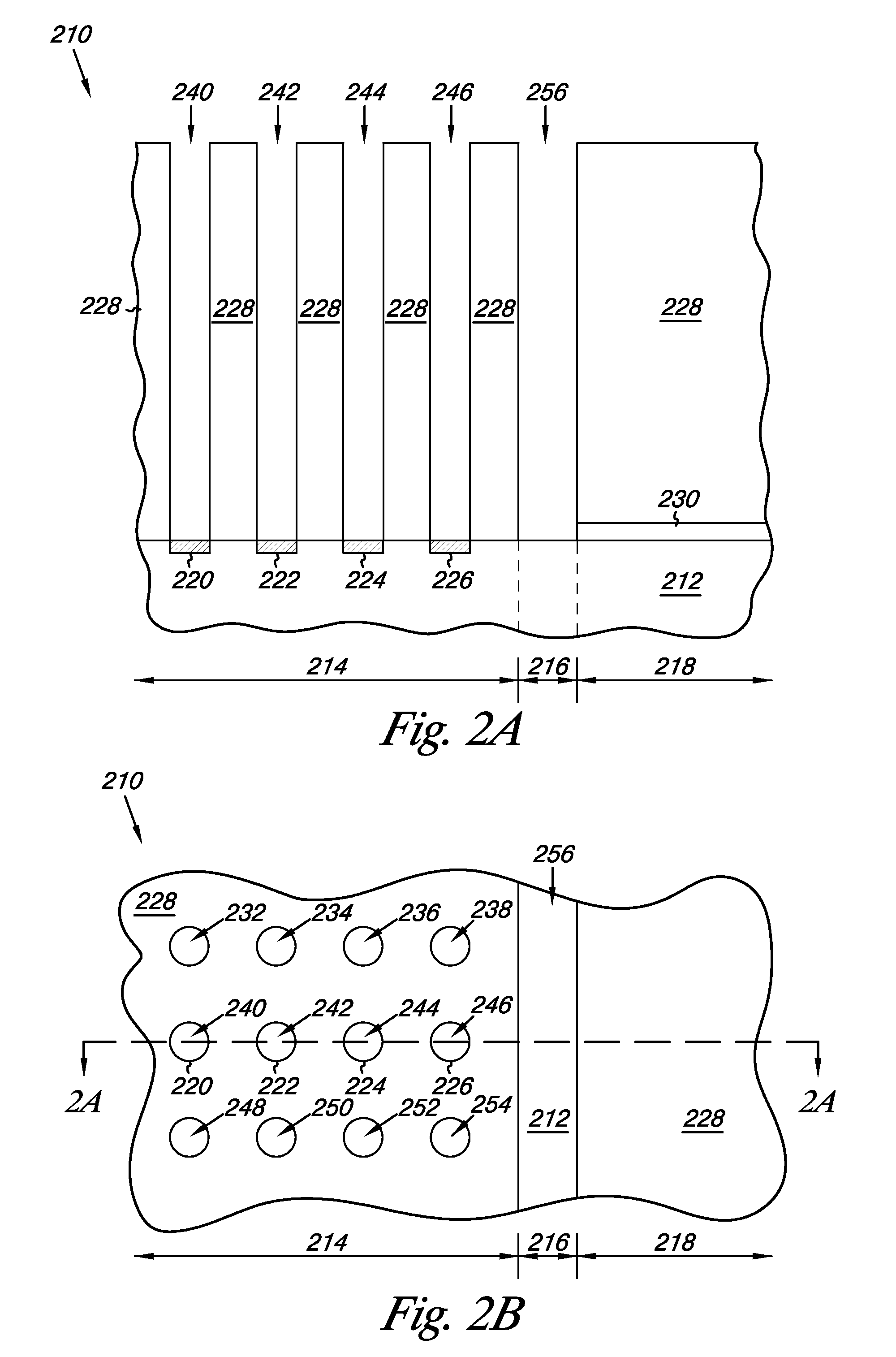

Method for aligning capacitor plates in a security tag and a capacitor formed thereby

InactiveUS20050183264A1Radiating elements structural formsPrinted capacitor incorporationCapacitanceEngineering

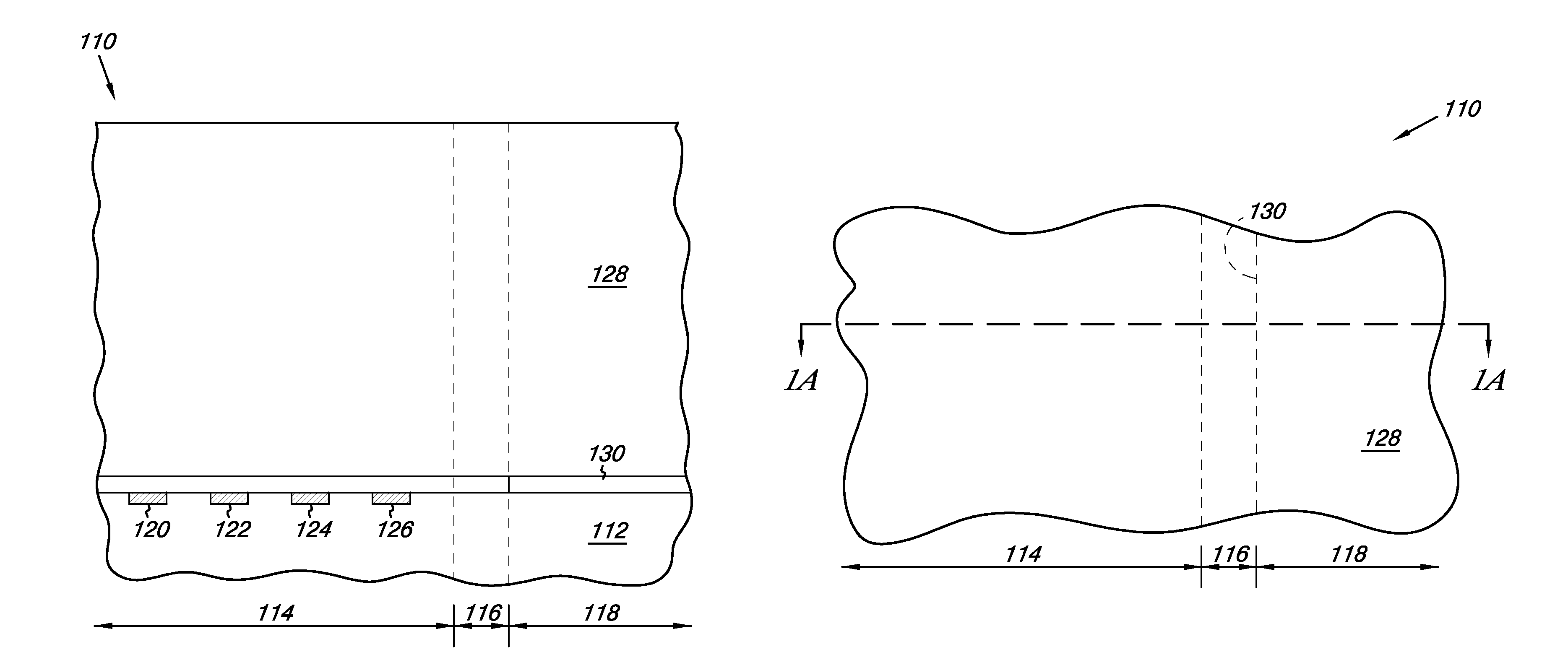

A circuit element the presence of the circuit element includes first and second capacitor plates disposed over the surface of the substrate in an aligned relationship with each other. The aligned relationship has manufacturing variations in the relative positioning of the first and second capacitor plates and a dielectric layer disposed between the first and second capacitor plates. At least one of the first and second capacitor plates is formed substantially smaller relative to the other of the first and second capacitor plates. The at least one of the capacitor plates is disposed at a predetermined offset in at least one planar direction from an edge of the other of the first and second capacitor plates. The predetermined offset is selected according to the manufacturing variations to prevent variations in the value of capacitance of the capacitor due to the manufacturing variations.

Owner:CHECKPOINT SYST INC

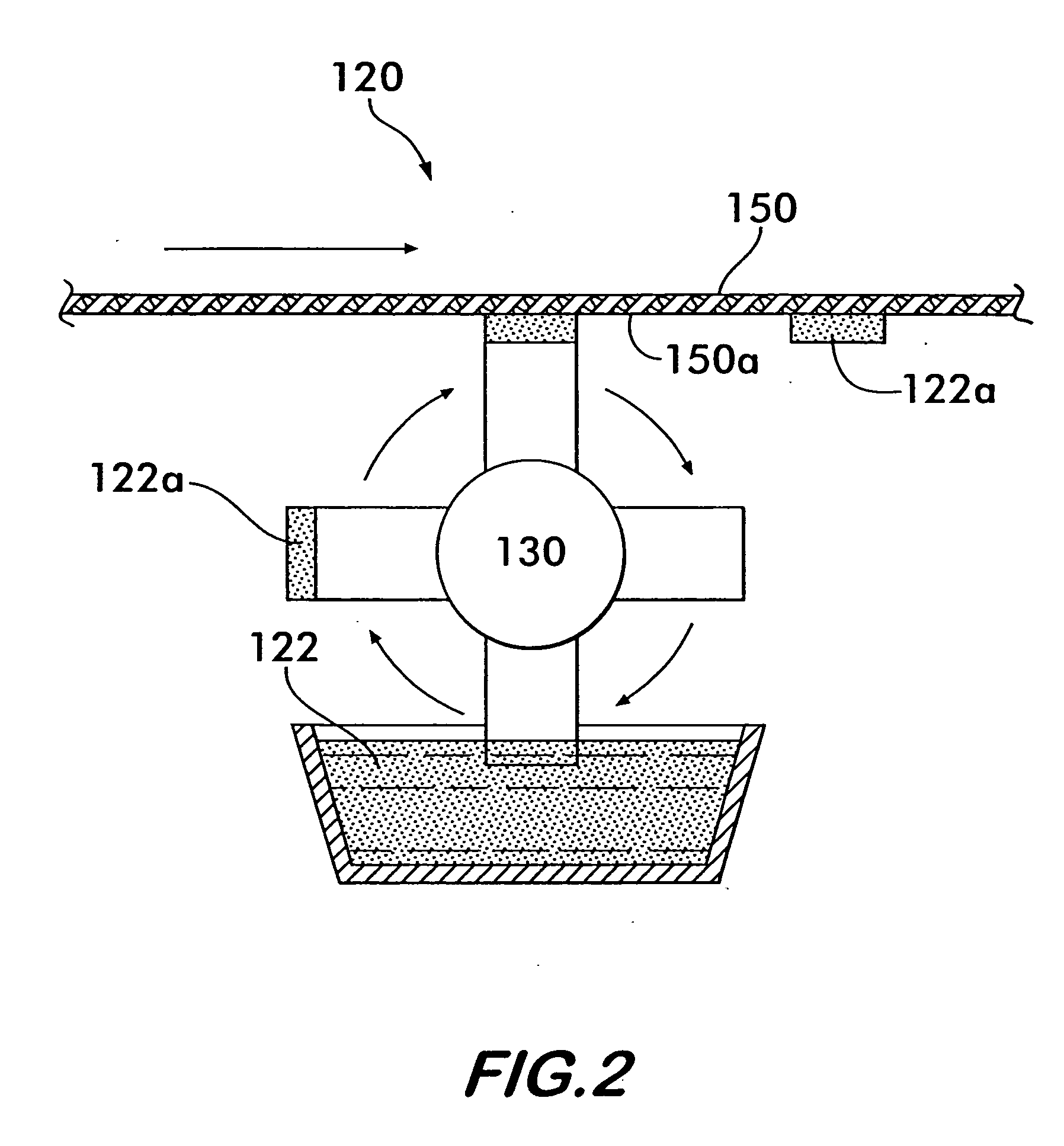

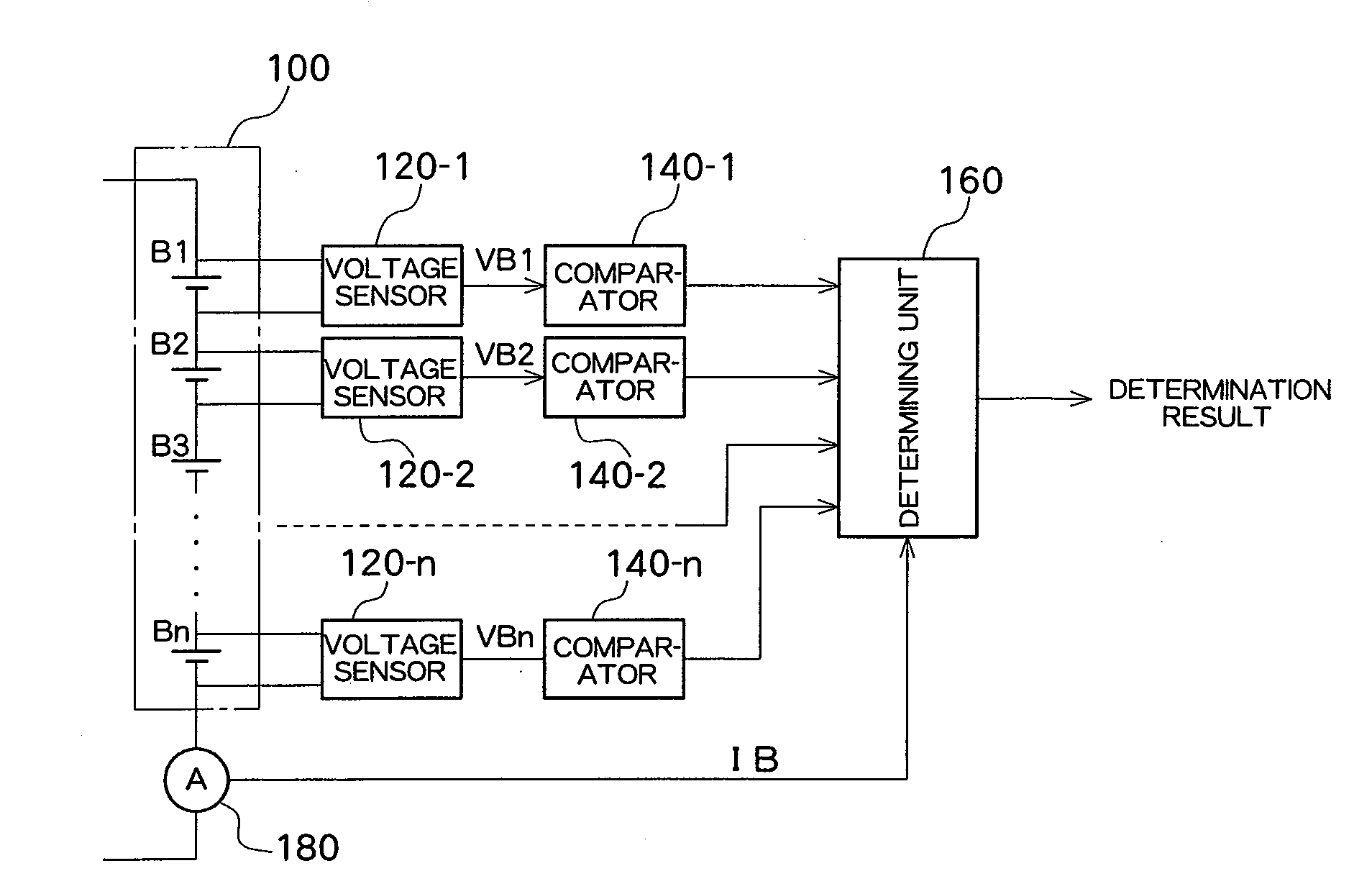

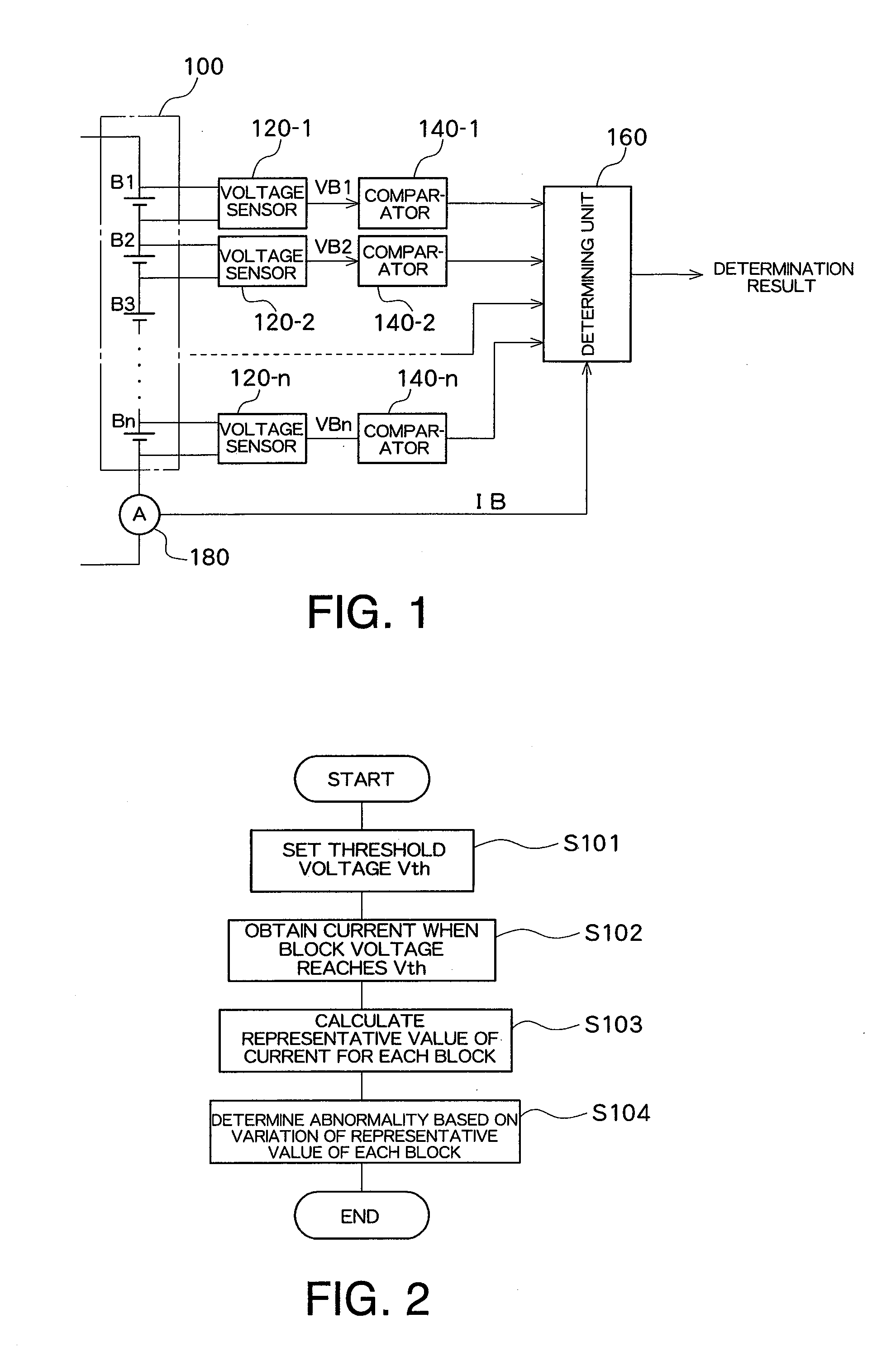

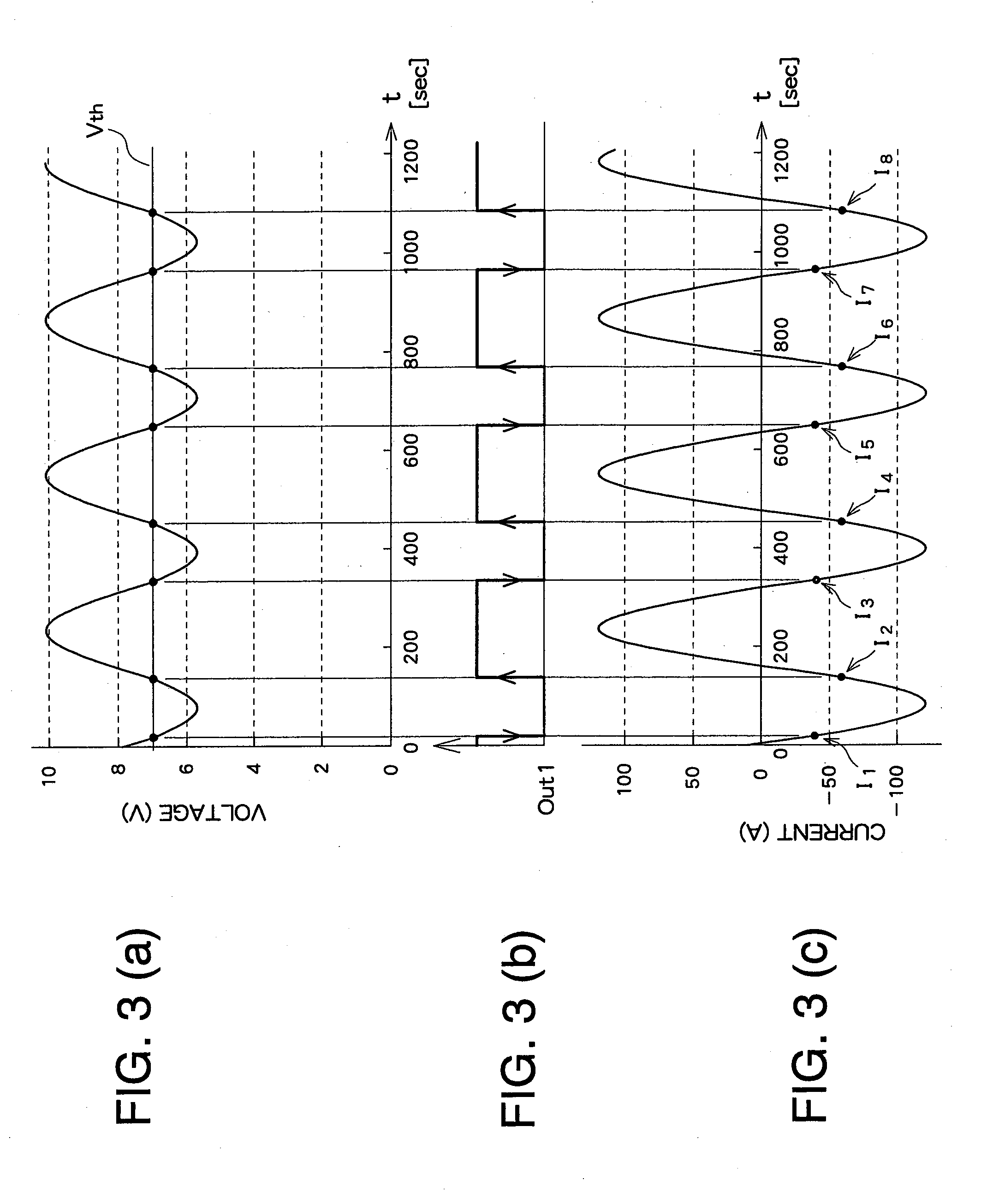

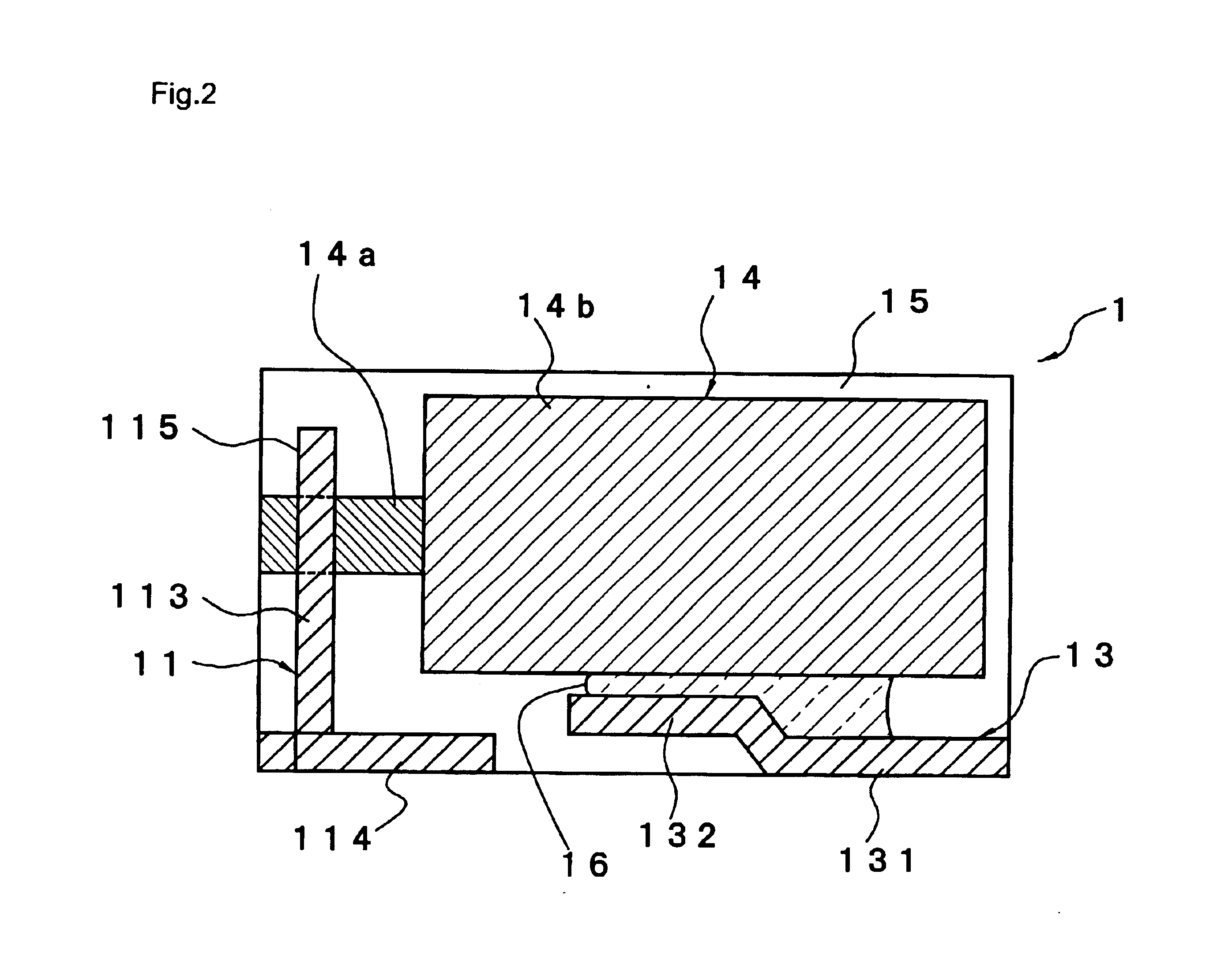

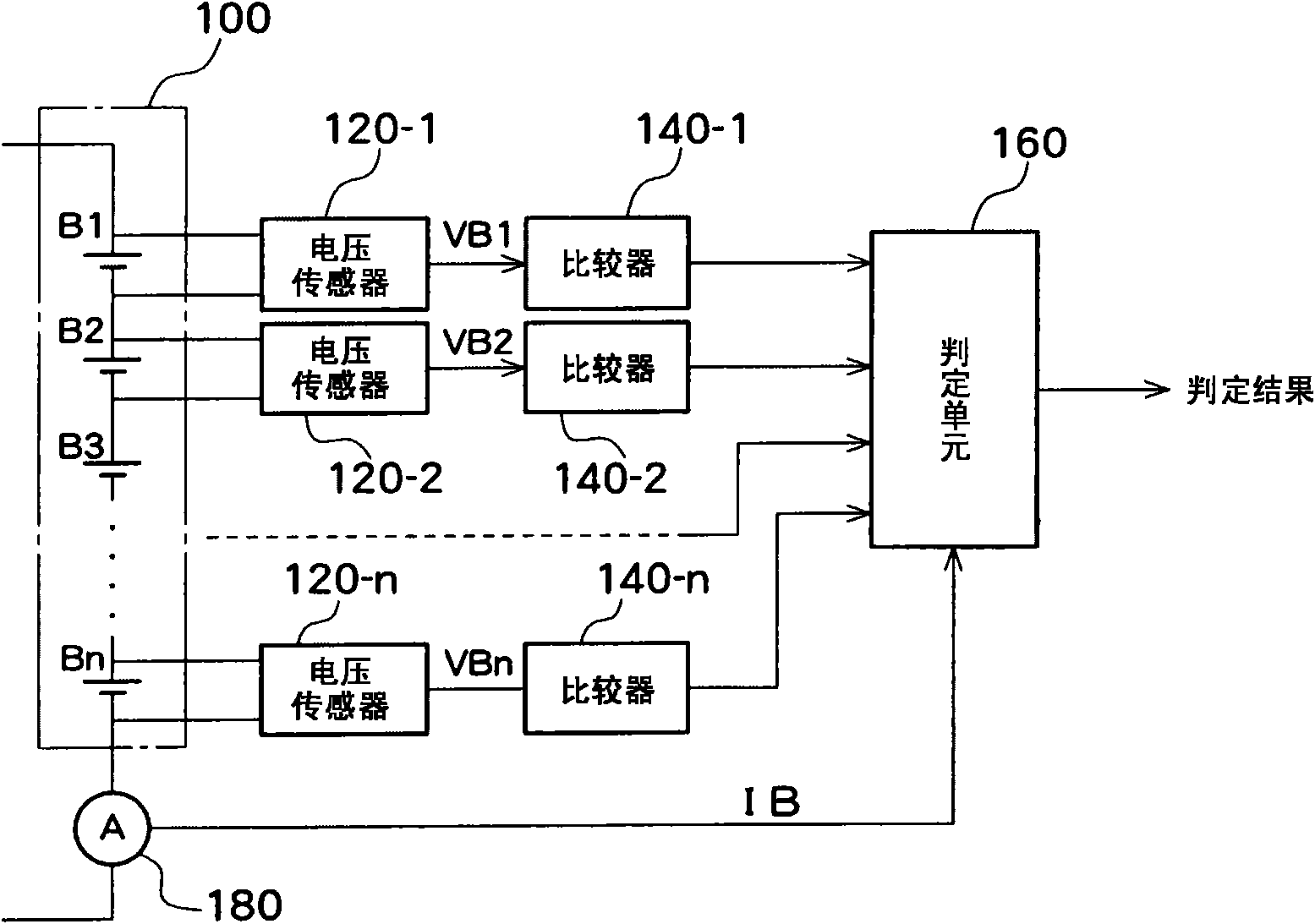

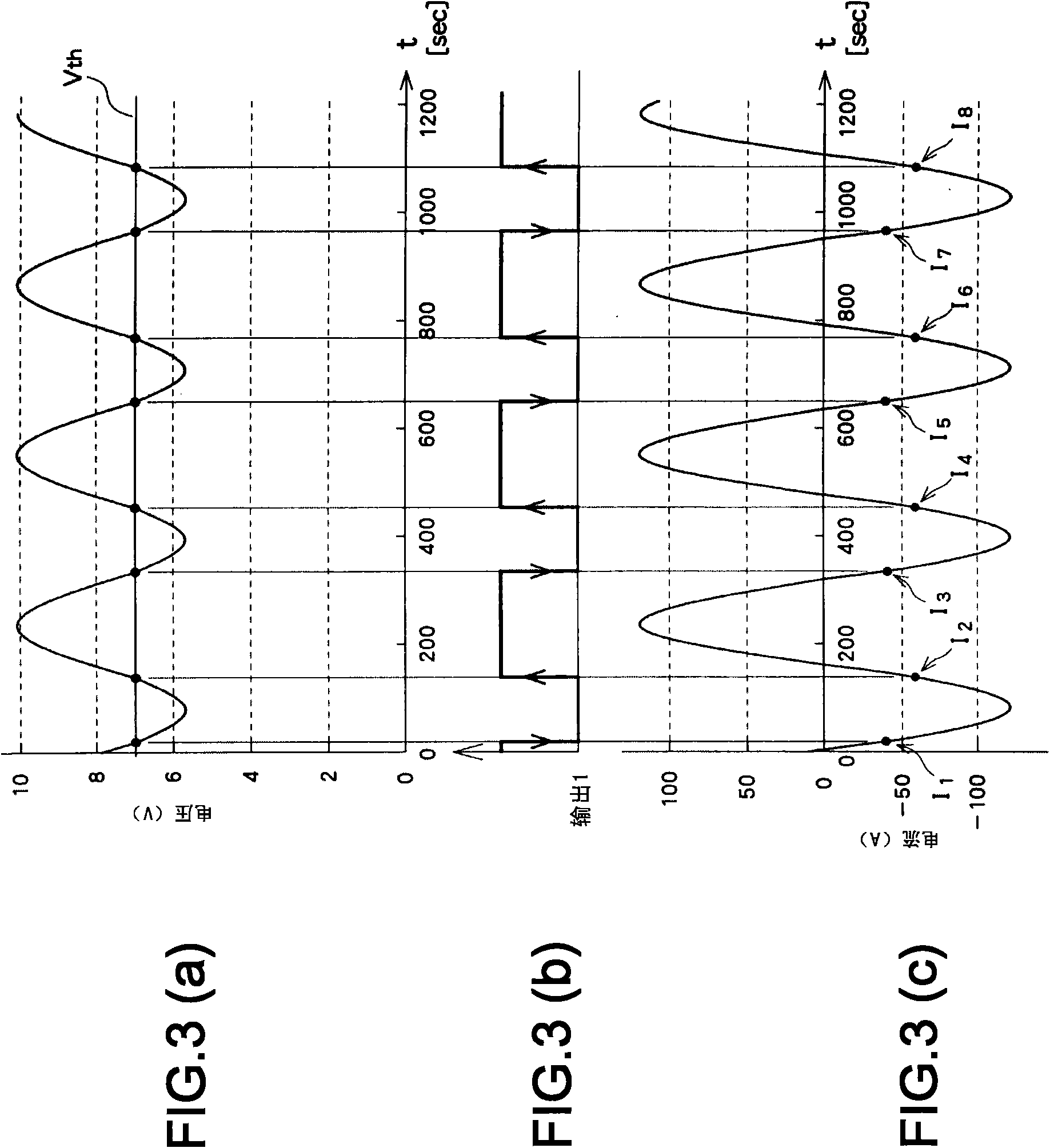

Device and method for detecting abnormality of electric storage device

ActiveUS20100004885A1Small and simple structureQuickly and accurately detectBatteries circuit arrangementsDouble layer capacitorsCapacitanceInternal resistance

Provided is an abnormality detecting device for detecting an abnormality of electric storage devices such as a battery pack. Comparators (140-1) to (140-n) detect a time when a voltage reaches a prescribed voltage, for each block of a battery pack (100). A judging section (160) detects a current at a time when the voltage reaches the prescribed voltage, and a representative current value is calculated for each block. The deviation of the representative current value of each block is compared with the threshold value, and when the deviation is large, it is judged that there are abnormalities such as short-circuiting, minute short-circuiting, IR (internal resistance) increase, capacitance reduction, and the like.

Owner:PANASONIC EV ENERGY CO LTD

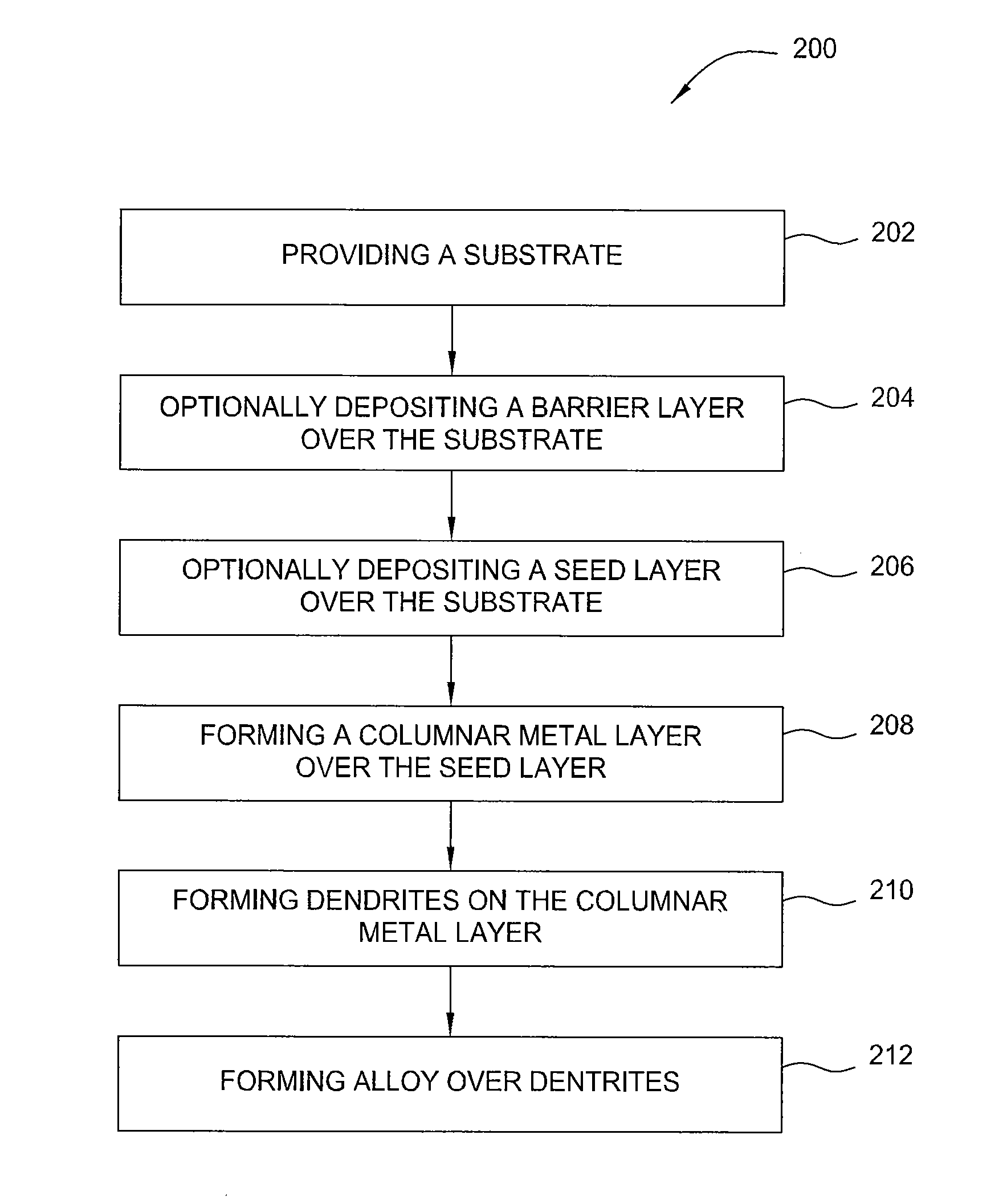

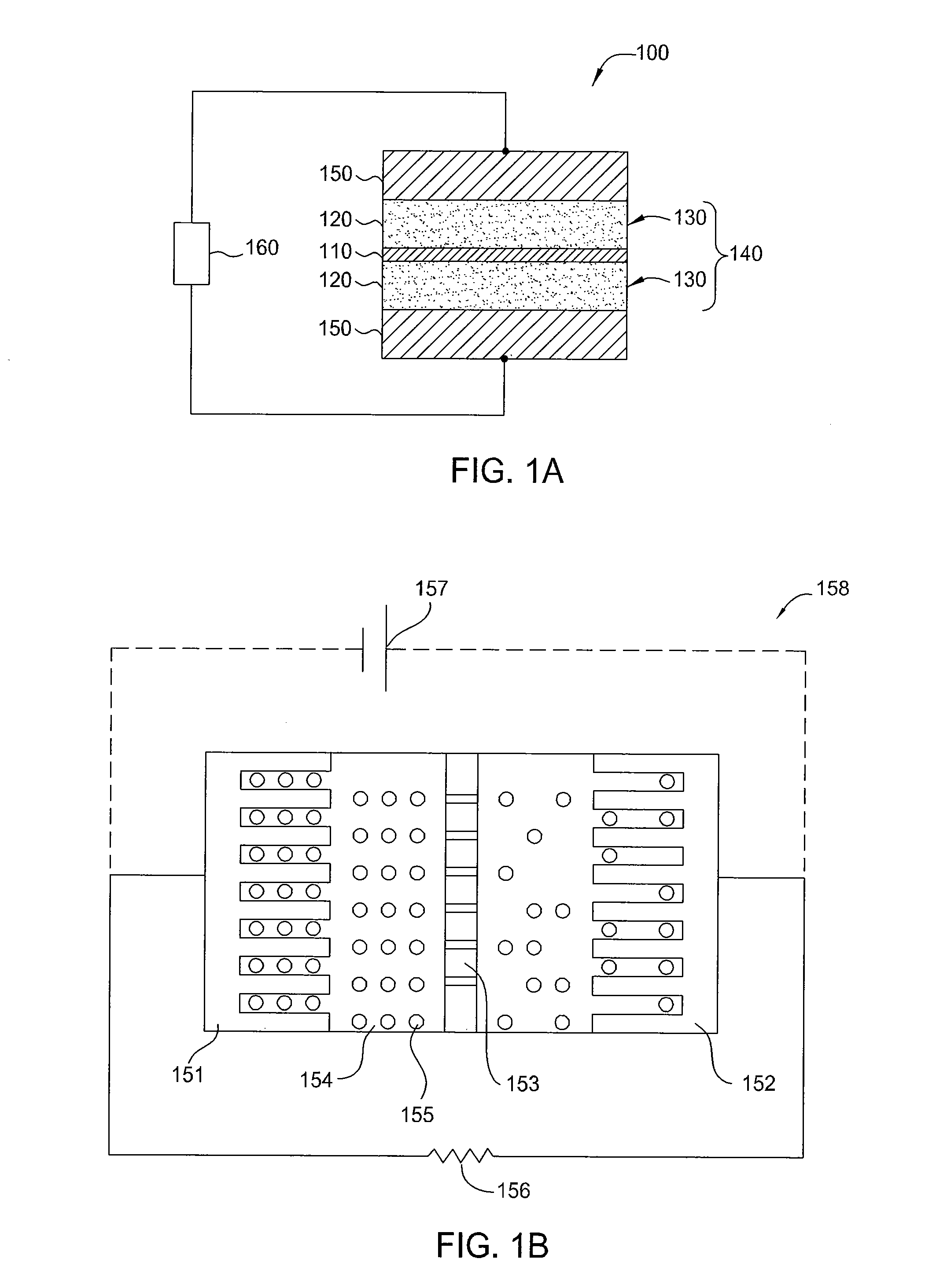

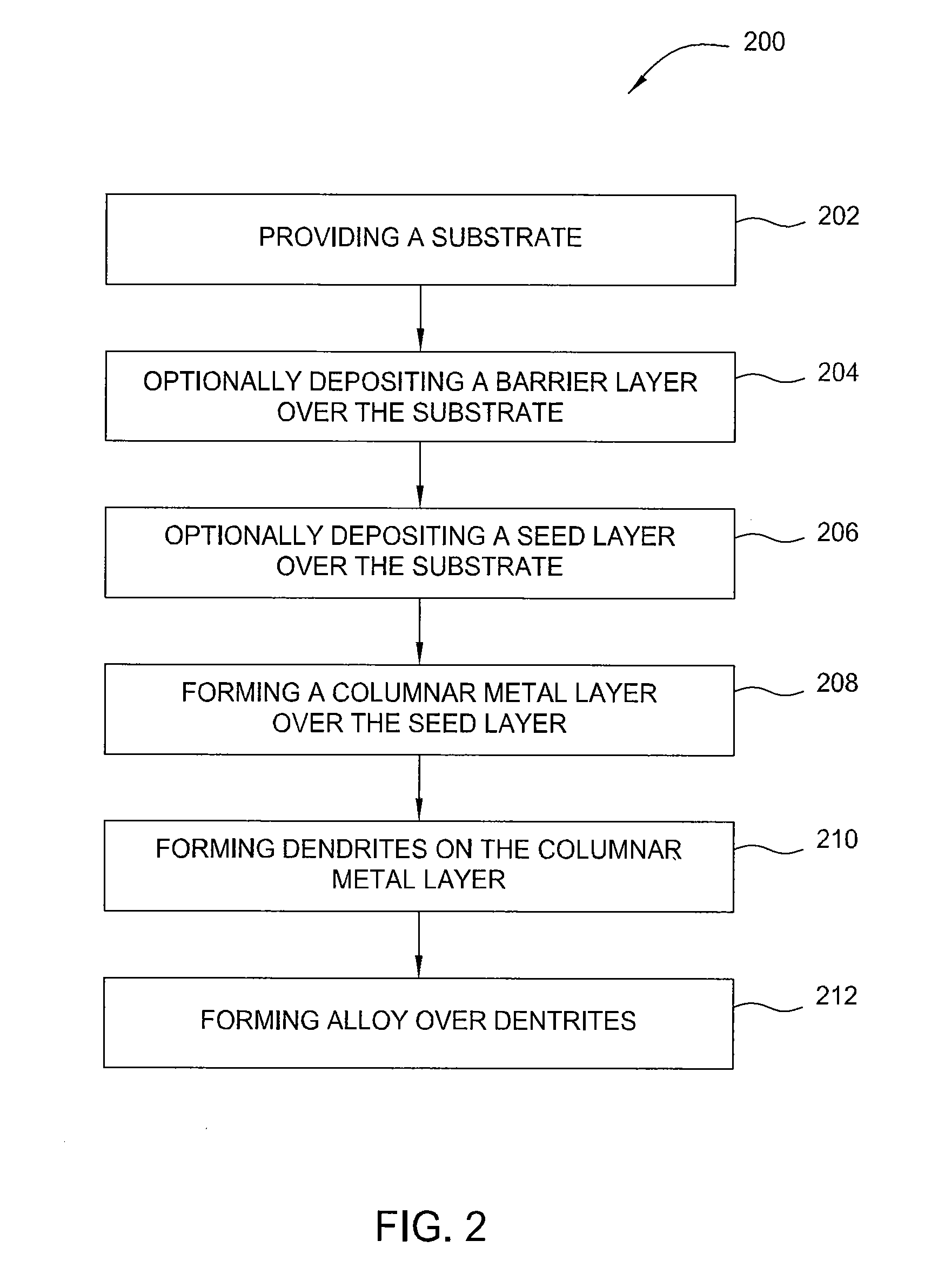

Apparatus and method for forming 3D nanostructure electrode for electrochemical battery and capacitor

InactiveUS20100126849A1Extended service lifeLow production costCellsElectrochemical processing of electrodesNano structuringElectrical battery

Embodiments described herein generally relate to an electrode structure for an electrochemical battery or capacitor, particularly, apparatus and methods of creating a reliable and cost efficient 3D electrode nano structure for an electrochemical battery or capacitor that has an improved lifetime, lower production costs, and improved process performance.

Owner:APPLIED MATERIALS INC

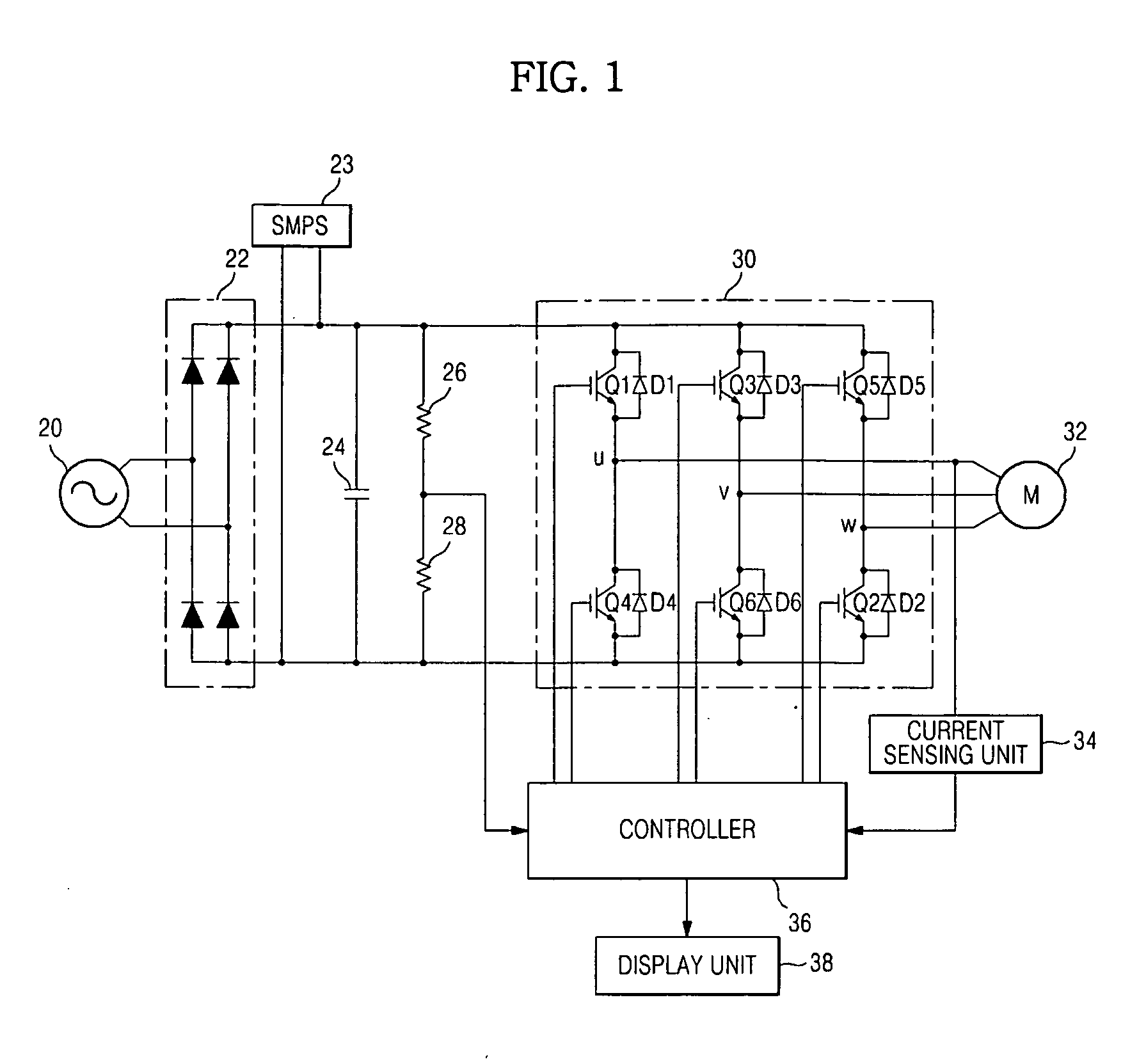

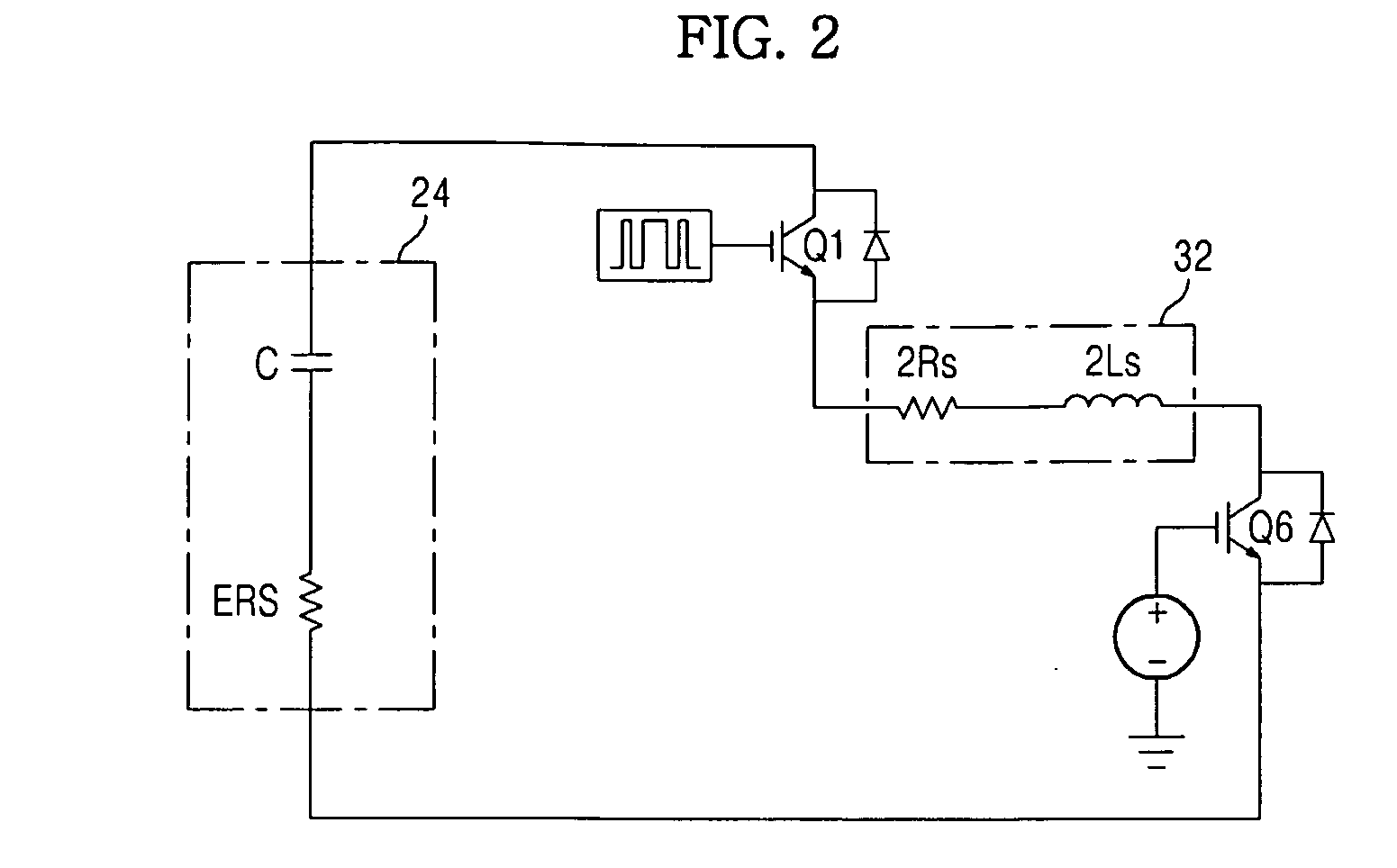

Apparatus and method to detect failure of smoothing electrolytic capacitor

InactiveUS20090072839A1Accurate fault detectionTesting dielectric strengthCapacitor testingPhase currentsMotor drive

An apparatus and method to detect failure of an electrolytic capacitor that smoothes a DC voltage in an inverter circuit. The apparatus detects failure of a smoothing electrolytic capacitor in a motor drive inverter circuit that rectifies and smoothes an AC voltage through a rectifier and the smoothing electrolytic capacitor and converts a rectified and smoothed DC voltage into a 3-phase voltage to drive a motor. The apparatus includes a voltage meter, a current sensing unit, and a controller. The voltage meter measures a DC voltage of an inverter when the motor is not in operation. The current sensing unit measures a phase current of the motor when the motor is not in operation. The controller estimates an ESR value of the smoothing electrolytic capacitor from the DC voltage of the inverter and the motor phase current to detect failure of the smoothing electrolytic capacitor.

Owner:SAMSUNG ELECTRONICS CO LTD

Solid electrolytic capacitor and manufacturing method

ActiveUS6970345B2Improve efficiencySufficient electrostatic capacitanceSolid electrolytic capacitorsLiquid electrolytic capacitorsLead frameElectrolytic capacitor

Disclosed is a solid electrolytic capacitor, wherein a capacitor element has a front surface from which an anode lead wire is protruded. A cathode layer is formed on an outer surface of the capacitor element. A flat-shaped cathode lead frame is surface-contacted with an entire rear surface of the capacitor element. A flat-shaped anode lead frame has a concave portion formed at a central end portion thereof, in which the anode lead wire of the capacitor element is seated and electrically connected to the concave portion. A mold is formed to surround the capacitor element, to partially surround the anode lead frame, and to contact a face of the cathode lead frame which is surface-contacted with the capacitor element.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

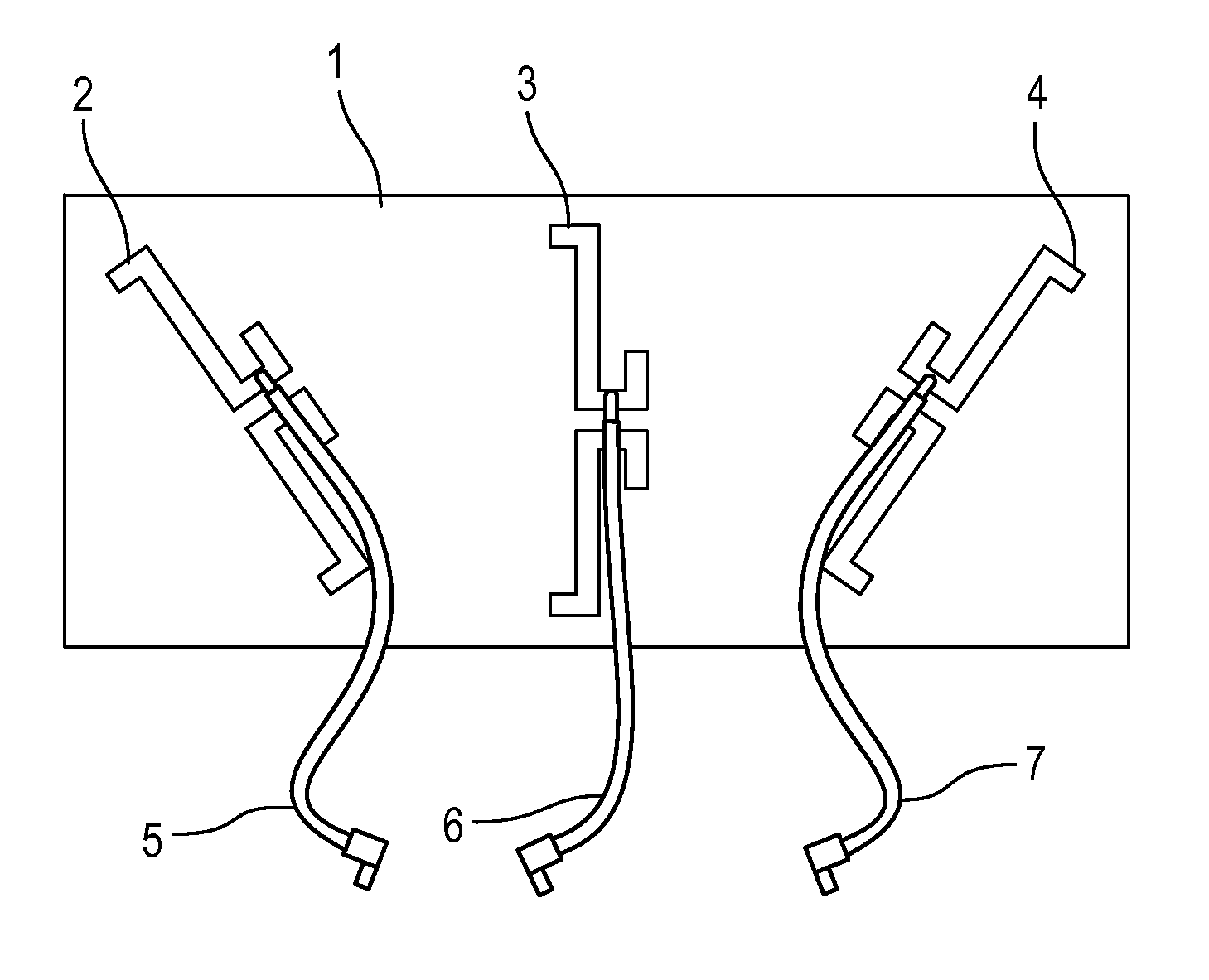

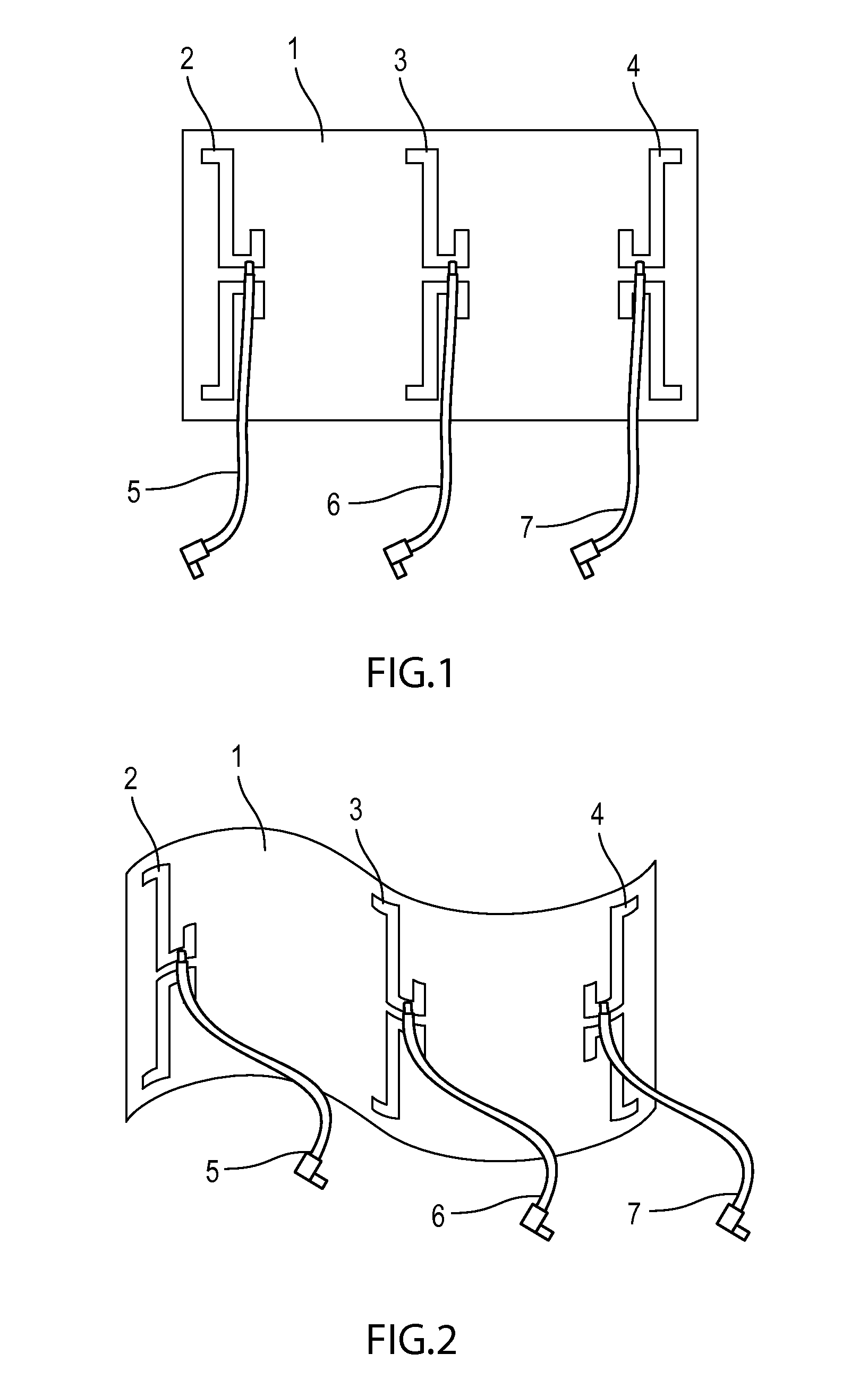

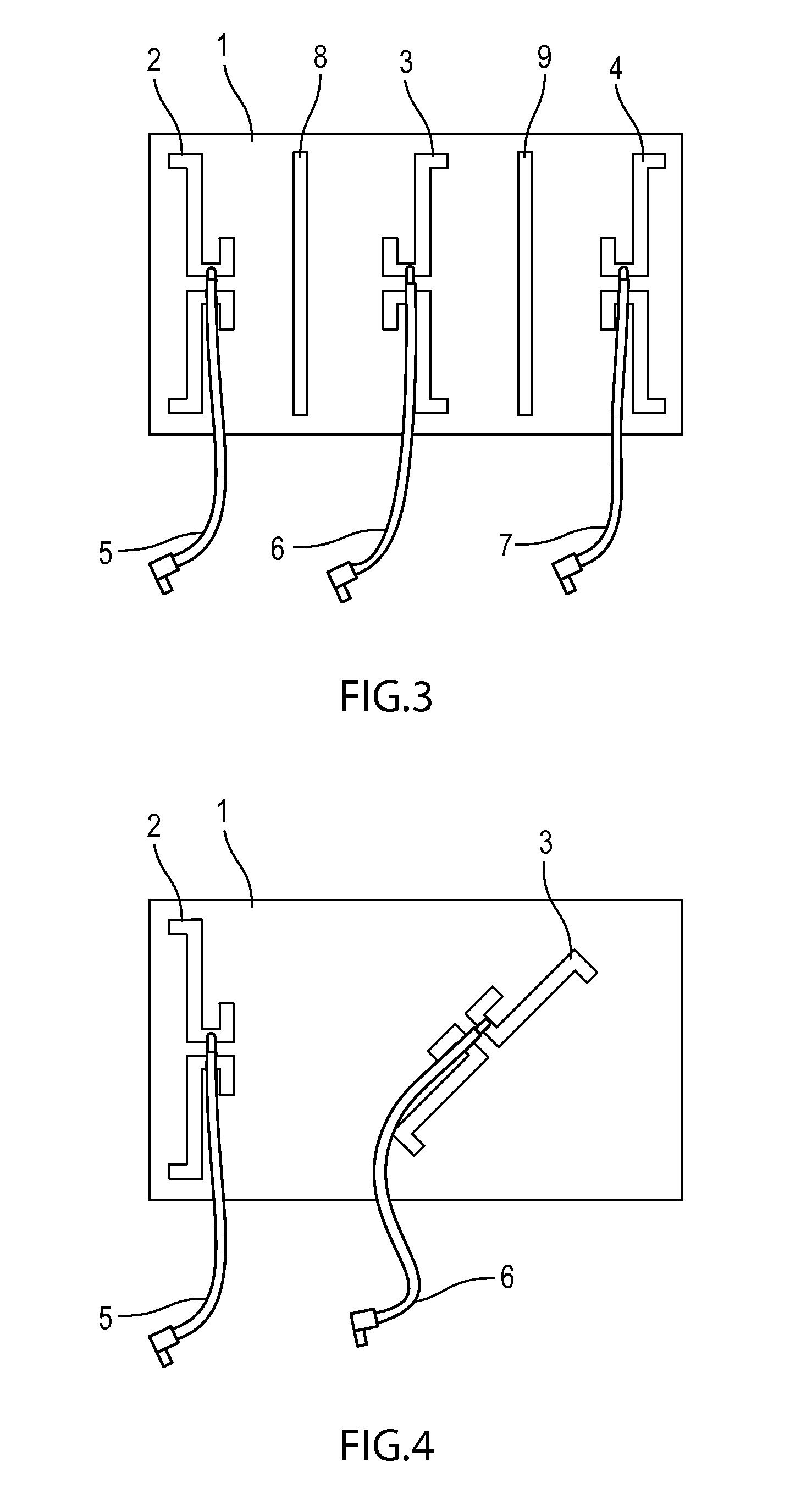

Integrated MIMO antenna system

ActiveUS20130321240A1High precisionEasy to controlThin/thick film capacitorElectrolytic capacitorsMimo antennaAntenna fabrication

An integrated MIMO antenna system is described wherein multiple antennas are fabricated on a single substrate. Antenna spacing and alignment is enhanced and controlled to a finer degree than with conventional discrete antenna fabrication techniques. Rotation of one or multiple antennas in relation to the other antennas in the system can be performed to within the accuracy of current photo-etching techniques. Metalized traces can be designed and etched on the single substrate and positioned between antenna elements to enhance inter-element isolation. The integrated MIMO antenna system can be fabricated on flexible printed circuit (FPC) material, or can be fabricated on rigid metallized substrate such as common FR4 materials. Portions of one or multiple antenna elements can be photo-etched on opposite sides of the substrate to provide an additional degree of freedom in terms of antenna placement, spacing, and rotation angle.

Owner:TAOGLAS GROUP HLDG LTD

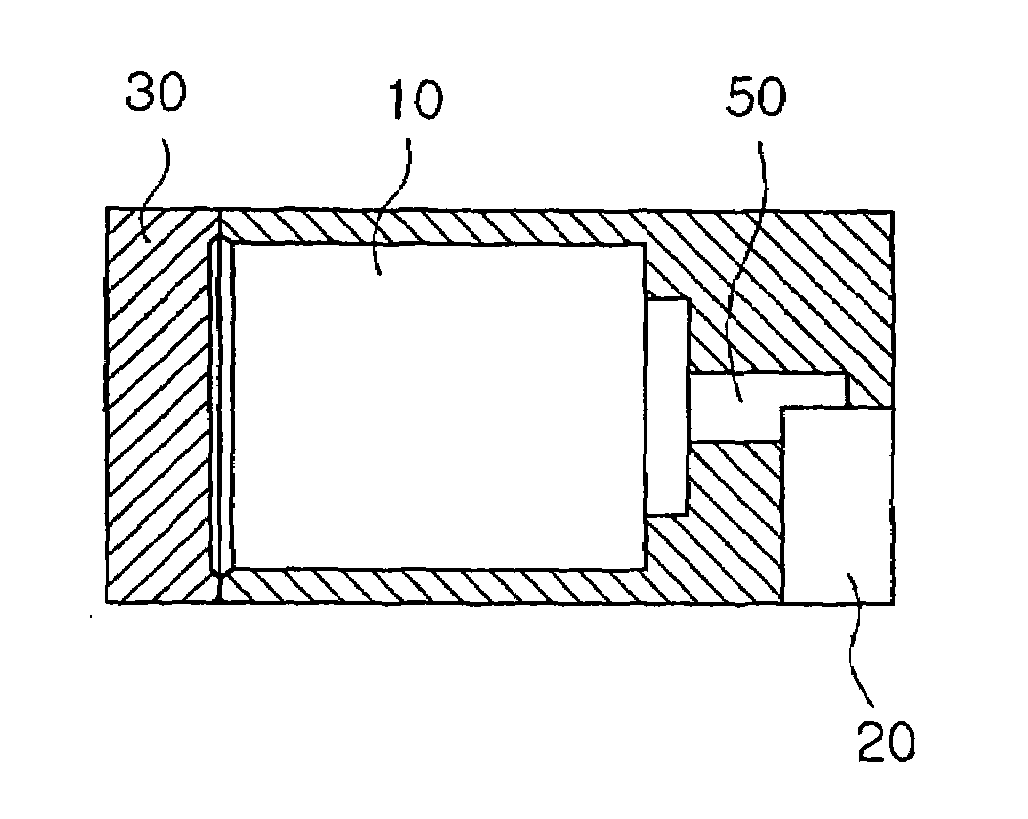

Capacitor and method of manufacturing the same

InactiveUS6934144B2Improve featuresEasy to introduceMaterial nanotechnologyFixed capacitor electrodesCross-linkCarbon nanotube

To provide a capacitor capable of utilizing carbon nanotube characteristics effectively to obtain excellent electric or mechanical characteristics, and a method of manufacturing the same. The capacitor is characterized by including two opposing electrodes, at least one of the two electrodes being formed from a coating film of a carbon nanotube structure in which plural carbon nanotubes with functional groups bonded constitute a mesh structure by cross-linking the functional groups through chemical bonding. The method of manufacturing a capacitor includes: a coating step for coating a surface of a base body with a solution that contains plural carbon nanotubes with functional groups bonded; and a cross-linking step for forming a carbon nanotube structure layer in which the functional groups are chemically bonded to one another, thereby causing the carbon nanotubes to cross-link to one another and build a mesh structure.

Owner:FUJIFILM BUSINESS INNOVATION CORP

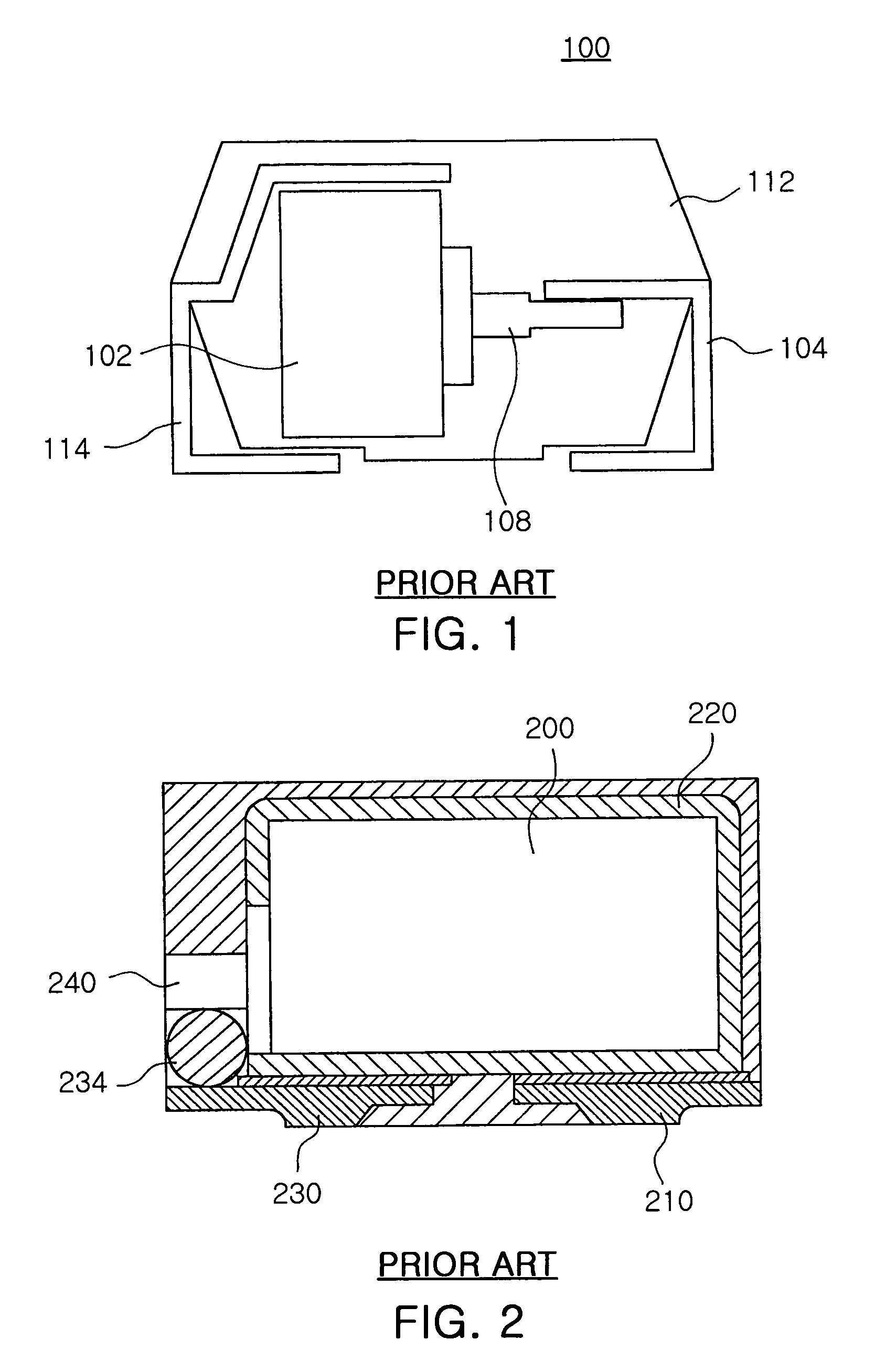

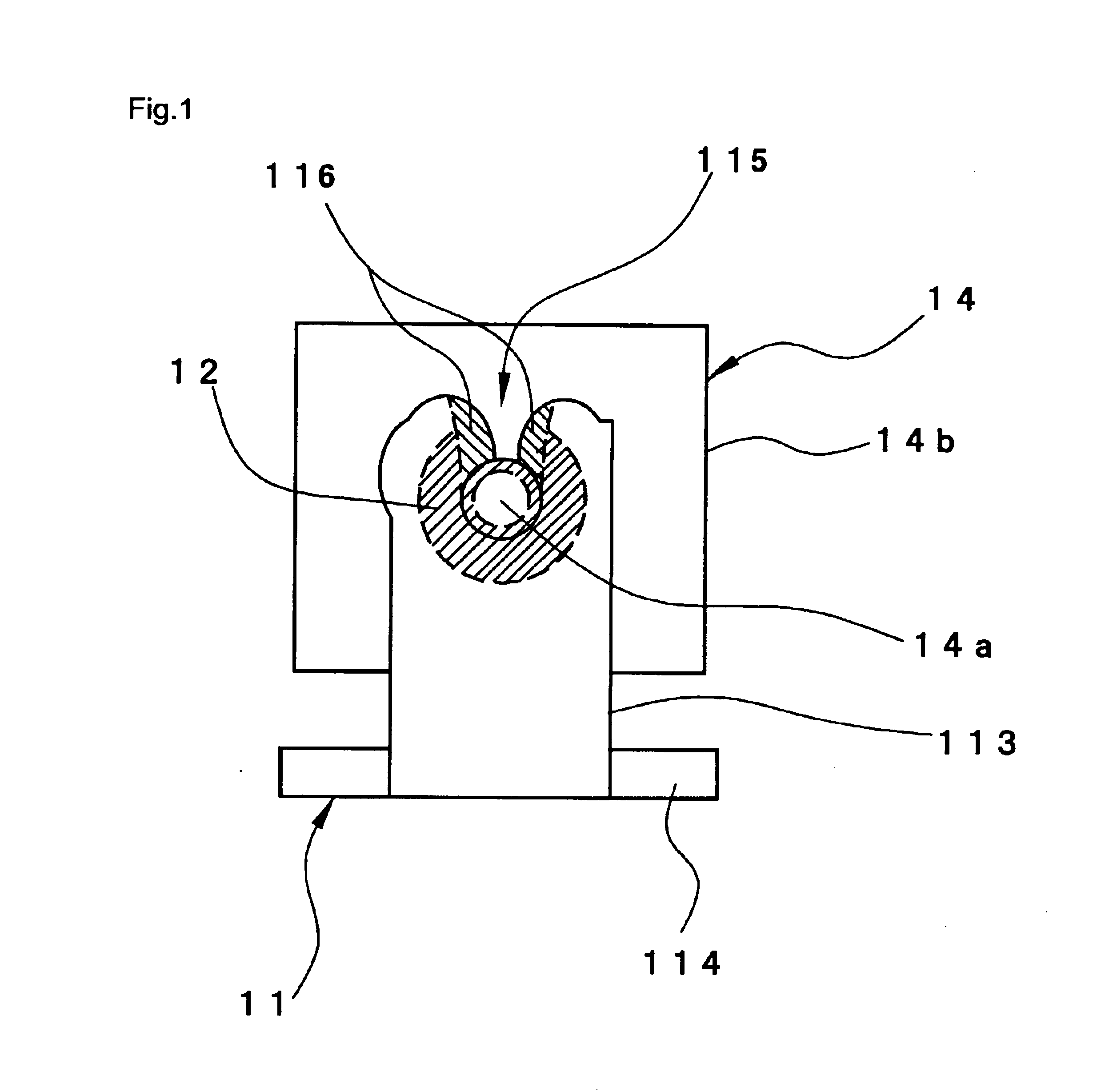

Chip type capacitor, method for preparing the same and anode terminal used for preparing the same

InactiveUS6903922B2Improve reliabilityEasy to wetLiquid electrolytic capacitorsFixed capacitor terminalsElectrolytic capacitorBond strength

A chip type capacitor which has improved bond strength between an anode lead wire and an anode terminal and enhanced reliability, and a method for preparing the chip type capacitor and an anode terminal. The chip type capacitor has a solid electrolytic capacitor element including an element body having an anode body, a dielectric and a cathode body, and an anode lead wire partially extending from the anode body of the element body. An anode terminal is electrically connected to the portion of the anode lead wire extending from the anode body. This extending portion of the anode lead wire has about 75% or more of its periphery, in the direction substantially perpendicular to the extending direction of the anode lead wire, covered with solidified matter resulting from solidification of a melt, thereby bonding the anode terminal and the anode lead wire to each other.

Owner:TOKIN CORP

Device and method for detecting abnormality of electric storage device

InactiveCN101622547ABatteries circuit arrangementsDouble layer capacitorsCapacitanceInternal resistance

Provided is an abnormality detecting device for detecting an abnormality of electric storage devices such as a battery pack. Comparators (140-1) to (140-n) detect timing in which a voltage reaches a prescribed voltage, for each block of a battery pack (100). A judging section (160) detects a current at a time when the voltage reaches the prescribed voltage, and a representative current value is calculated for each block. The deviation of the representative current value of each block is compared with the threshold value, and when the deviation is large, it is judged that there are abnormalities such as short-circuiting, minute short-circuiting, IR (internal resistance) increase, capacitance reduction, and the like.

Owner:PANASONIC EV ENERGY CO LTD

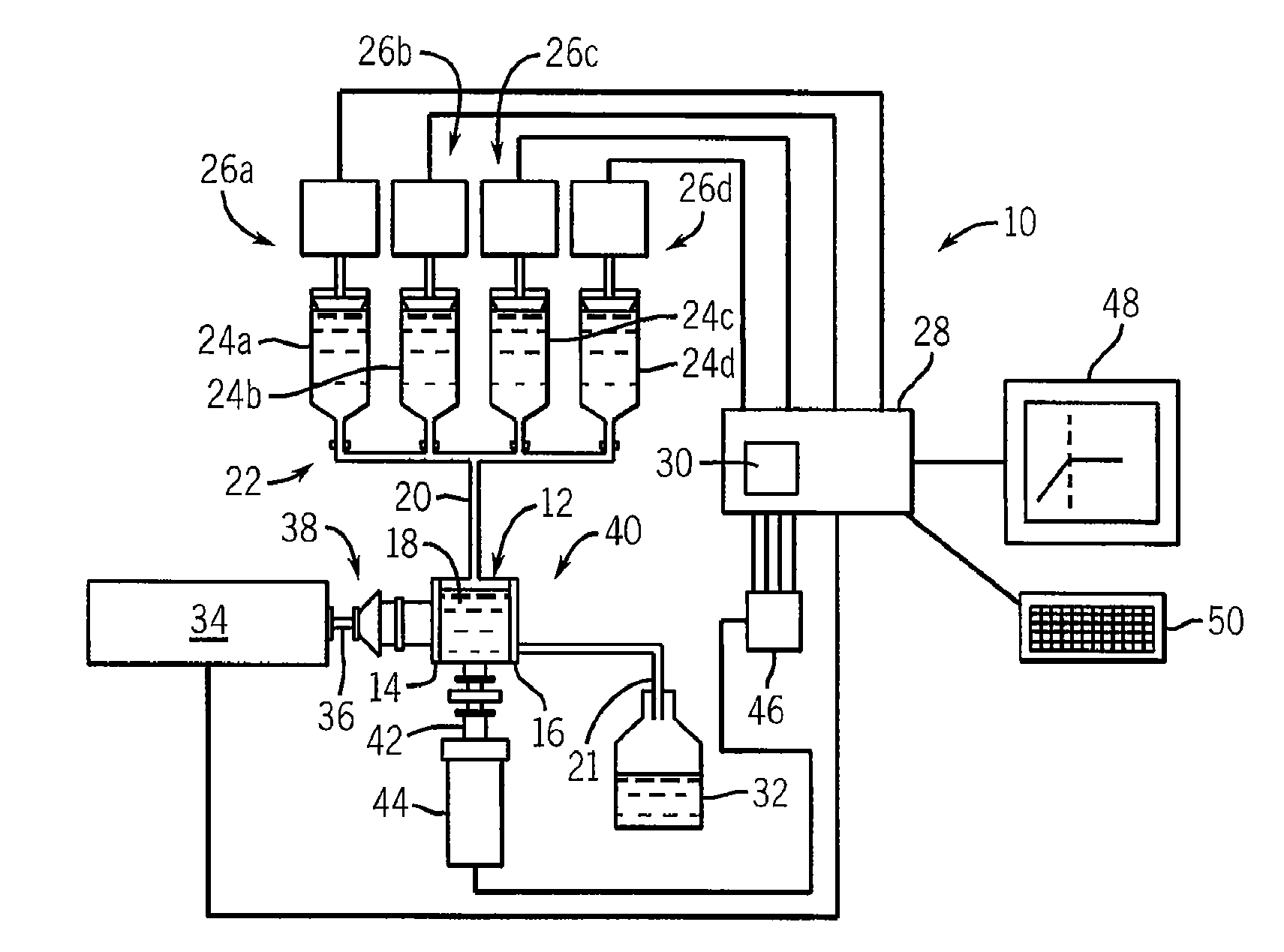

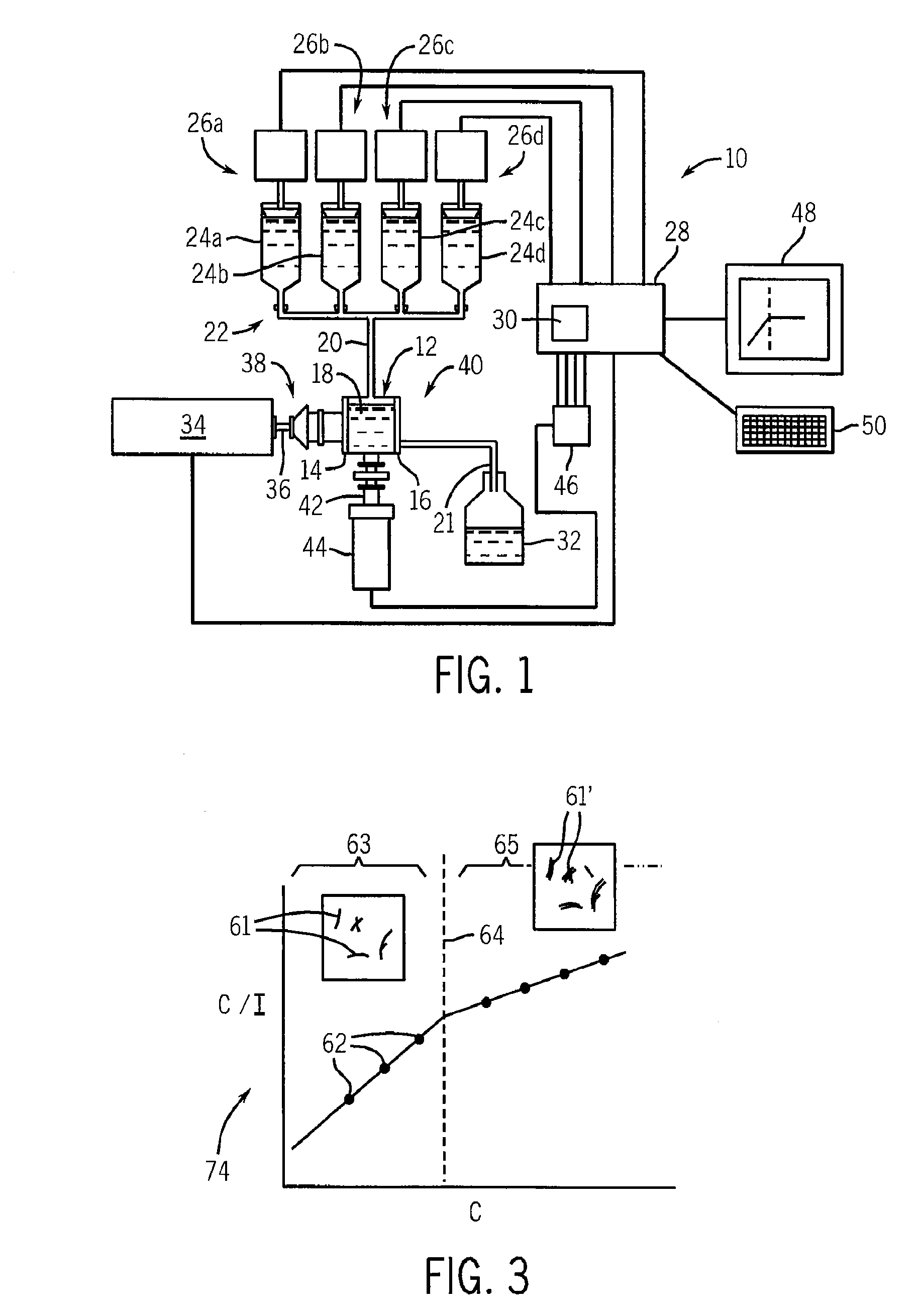

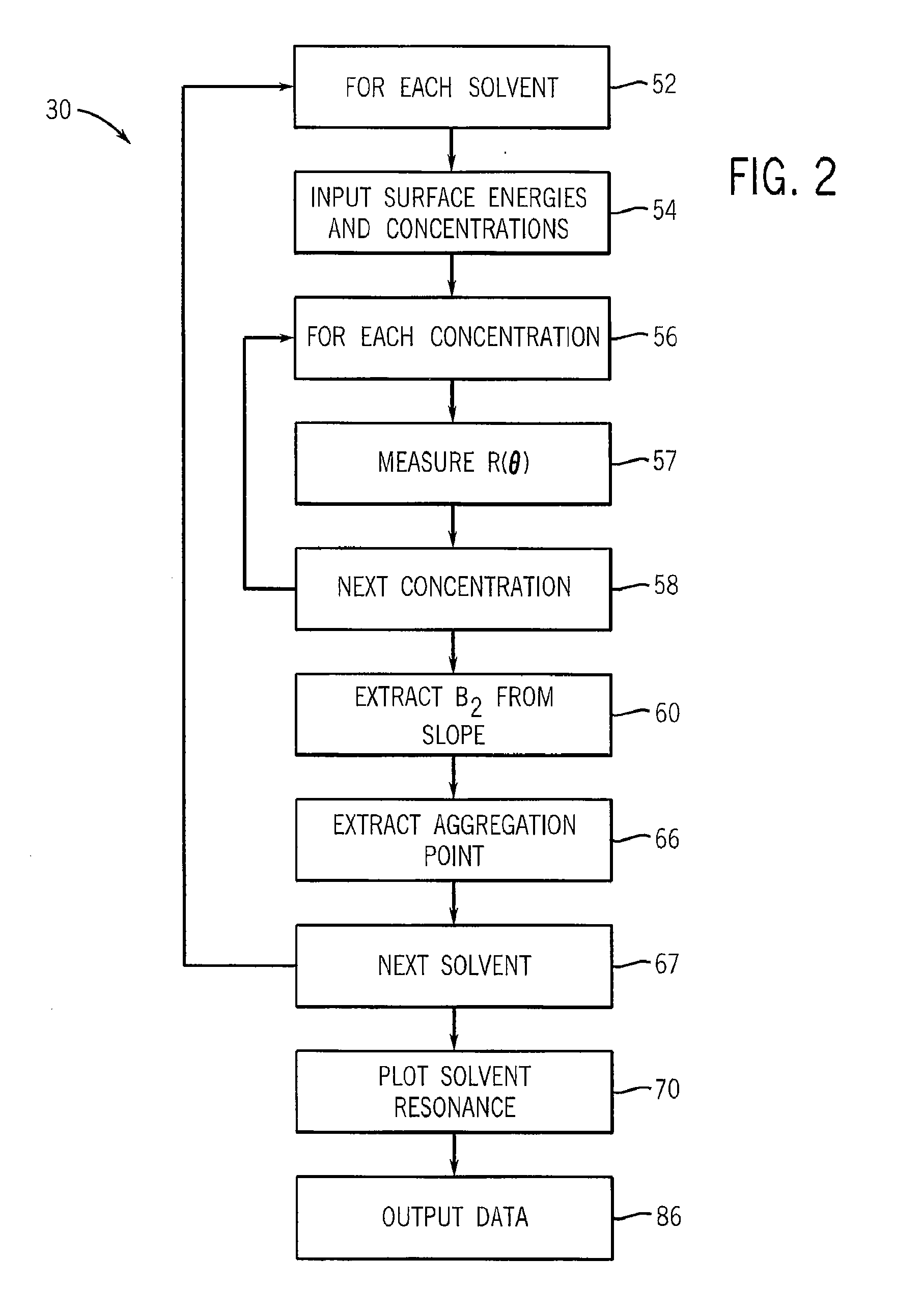

Method And Apparatus For Identifying And Characterizing Material Solvents And Composited Matrices And Methods Of Using Same

ActiveUS20110117361A1High composite strengthMaterial nanotechnologyElectrode manufacturing processesRayleigh scatteringRayleigh Light Scattering

Solvents for macromolecules generally believed to be insoluble in their pristine form are identified by generation of a ‘solvent resonance’ in the relationship between solvent quality (deduced by Rayleigh scattering) and an intrinsic property of solvents. A local extreme of the solvent resonance identifies the ideal intrinsic property of an ideal solvent which may then be used to select a particular solvent or solvent combination. A solvent for graphene is used in the production of transparent conductive electrodes.

Owner:WISYS TECH FOUND

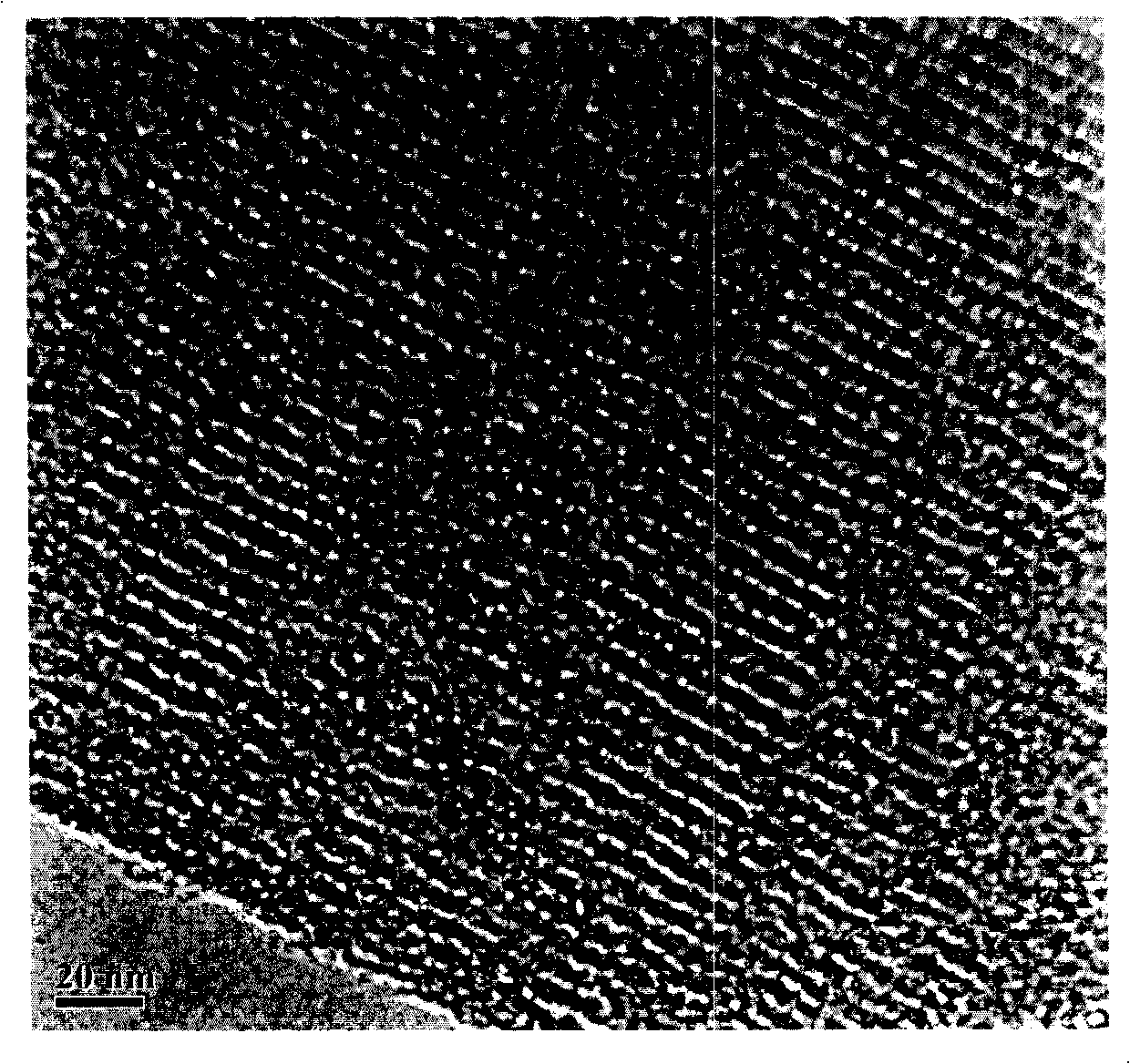

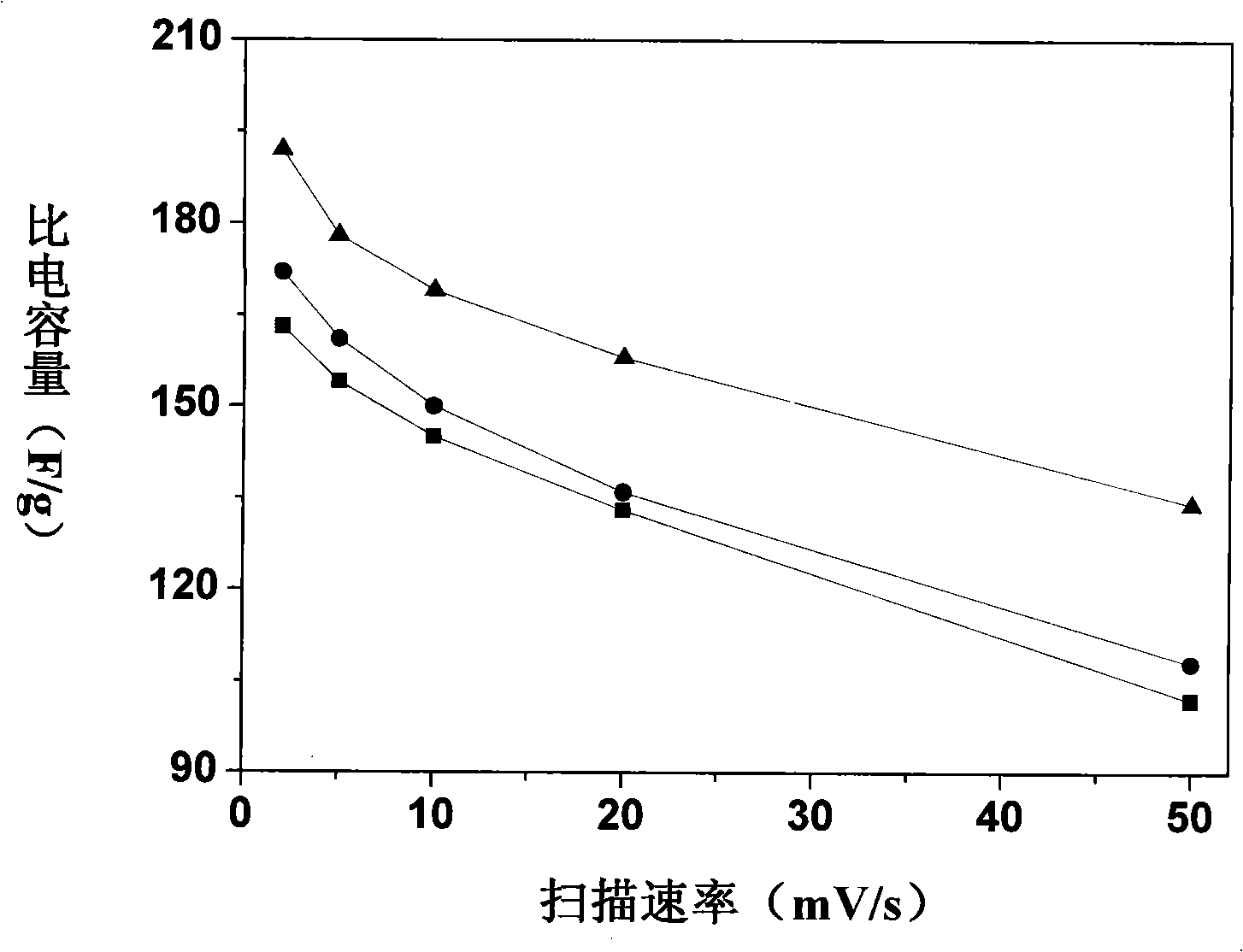

Stephanoporate carbon electrode material and preparation method thereof

InactiveCN101299397AFast deliveryExcellent electrochemical capacitance performanceHybrid capacitor electrodesElectrolytic capacitorsPorous carbonCarbonization

The invention relates to a porous carbon electrode materials and the preparation method, belonging to the electrochemistry and the novel energy source materials, wherein the porous carbon electrode materials adopt the template carbonization and the method combined with the CO2 post-processing using the meso-porous oxide silicon as the remplate, and the cane sugar, furfuryl alcohol, polyacrylonitrile and the like as the precursors, through the technology steps of the liquid phase impregnation, the high temperature carbonization and the template removal and the like, then combines high temperature process, obtaining the super capacitor porous carbon electrode materials. The porous carbon electrode materials prepared by the method has high surface area, large pore volume, adjustable pore structure and multilevel-microporous pore structure, wherein the pore channel is composed of a meso-porous of 2-5 nm and the microporous with the meso-porous wall of 0.1-2 nm, so the electrochemistry capacity of the prepared porous carbon electrode is marked increased, and the integral property of good.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

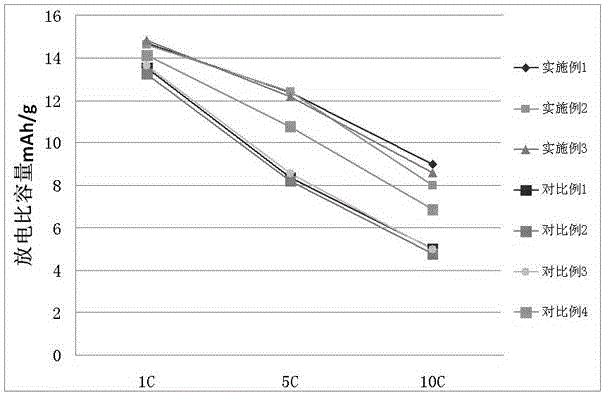

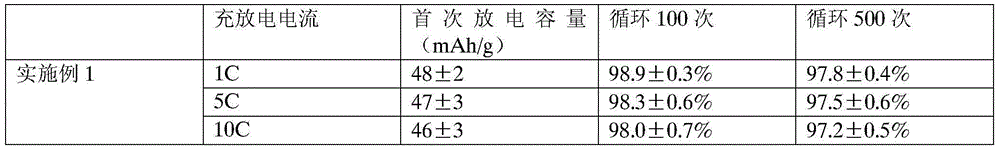

Novel lithium pre-embedding method of lithium ion capacitor

ActiveCN104681311ALow costImprove securityHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorLithium metalPre embedding

The invention provides a novel lithium pre-embedding method of a lithium ion capacitor. The method comprises the following steps that (1) a battery cell is assembled, and is soaked into an organic solution containing lithium salts; (2) a positive electrode and a negative electrode are respectively connected with a charging and discharging test instrument, and once discharging after once charging is used as a cycle, 1 to 1000 times of cycles are totally carried out, and the lithium pre-embedding on the negative electrode is completed; (3) the battery cell after the lithium pre-embedding completion is taken out and is put into a packaging case, the packaging case is filled with electrolyte and is assembled into a lithium ion capacitor single body. When the method is adopted, the problem of too high cost due to lithium metal, porous current collectors and the like can be effectively solved, the safety can be improved, the technical flow process can be simplified, and the method is applicable to industrial production.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

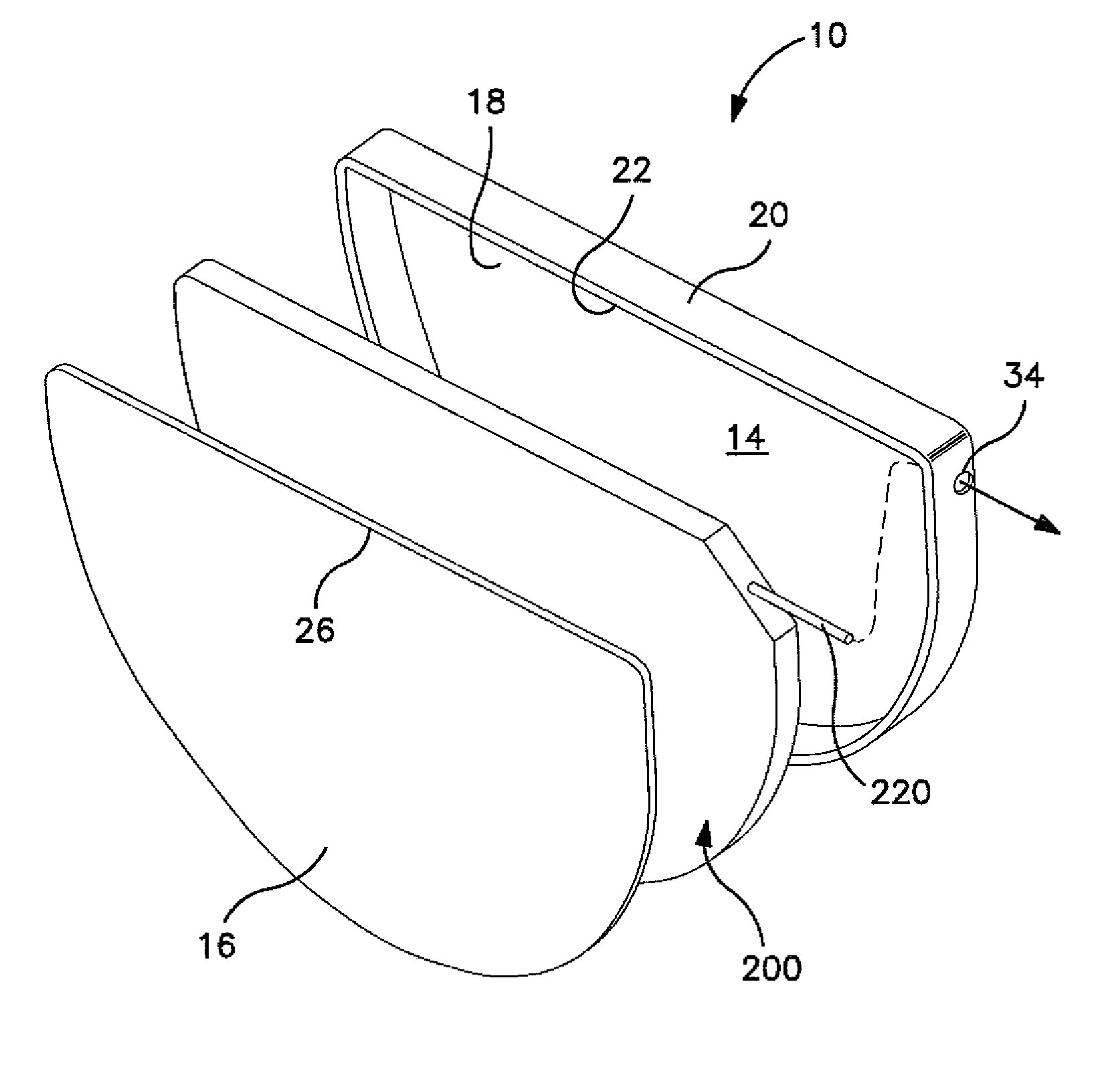

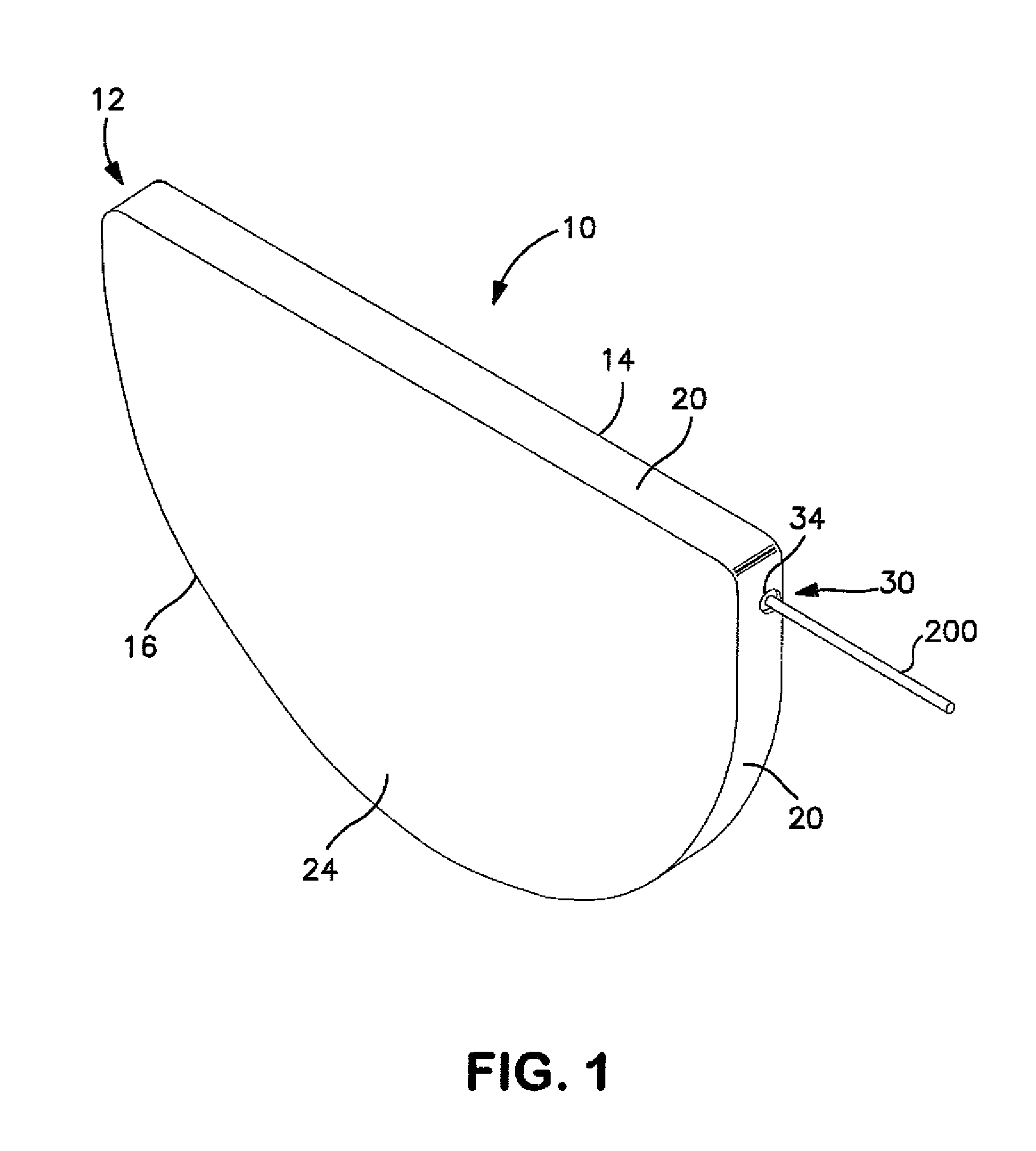

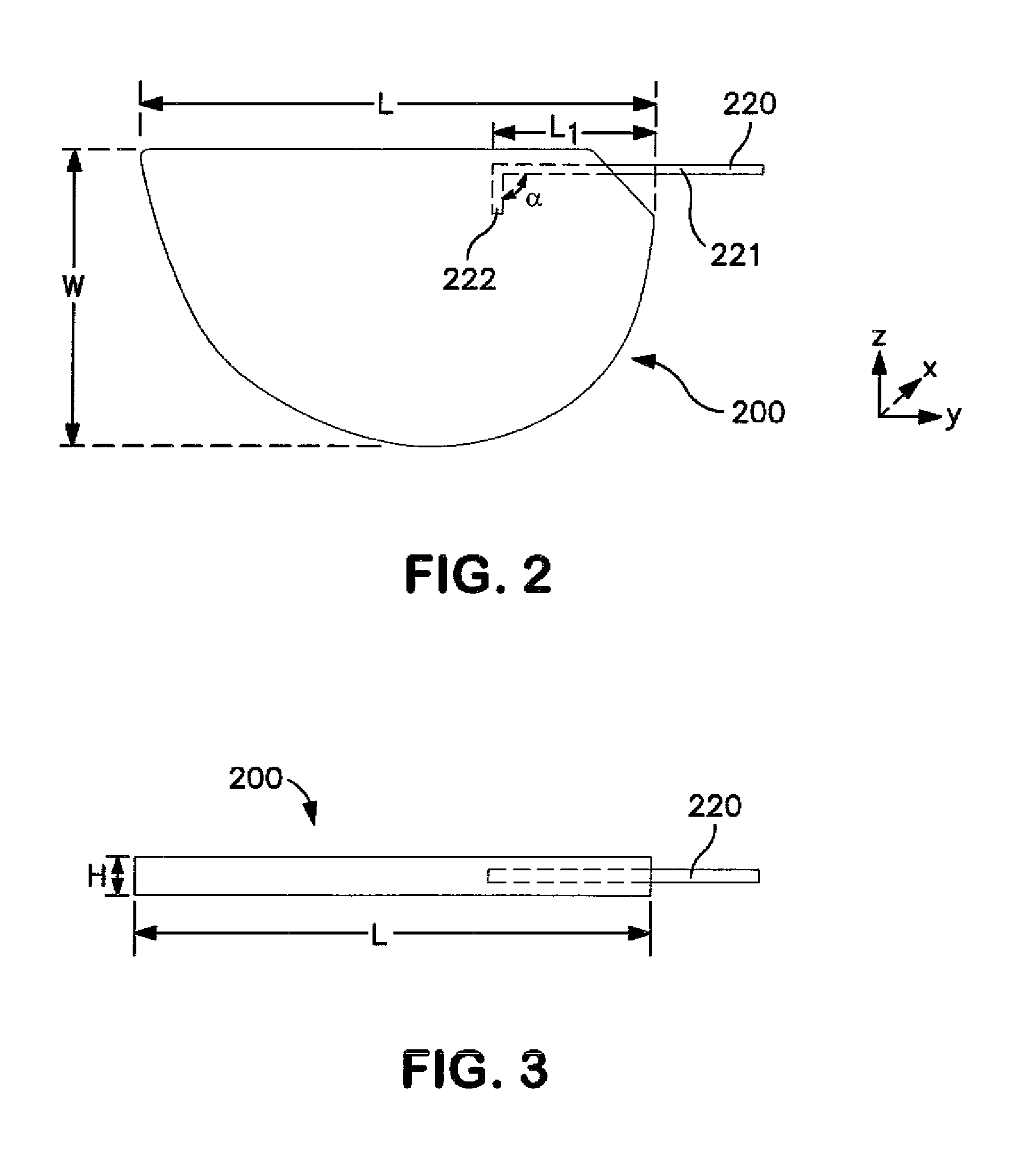

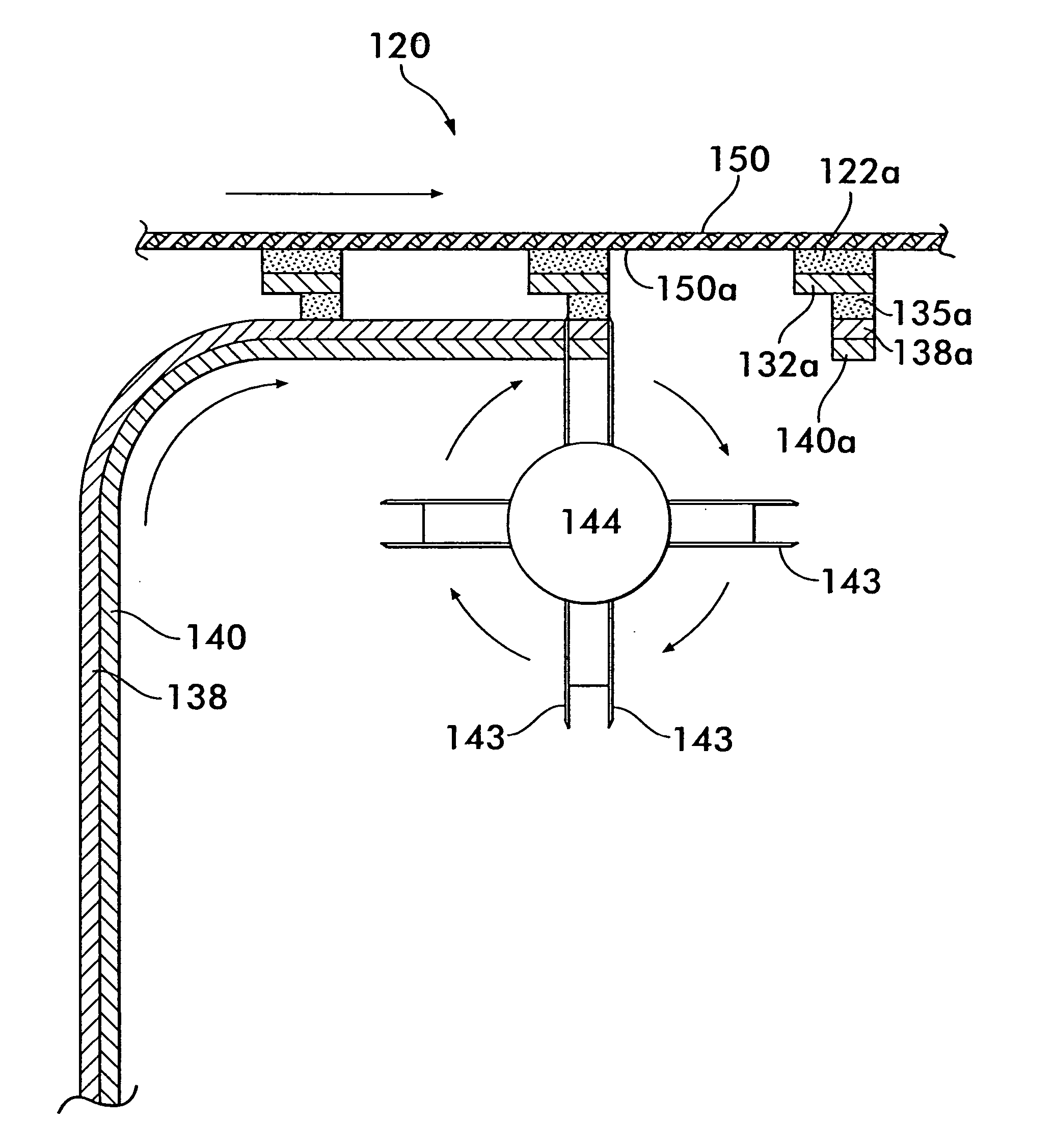

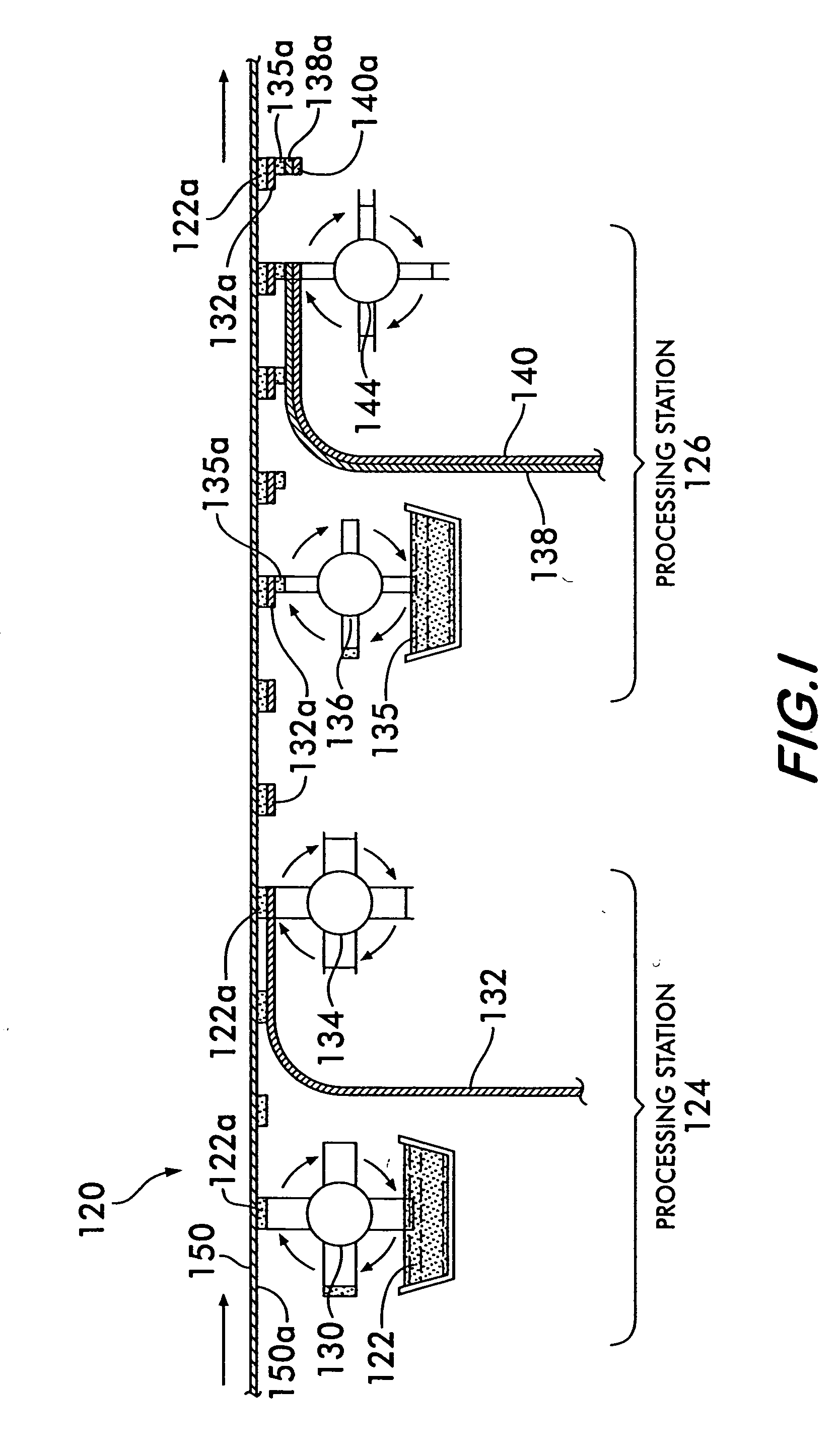

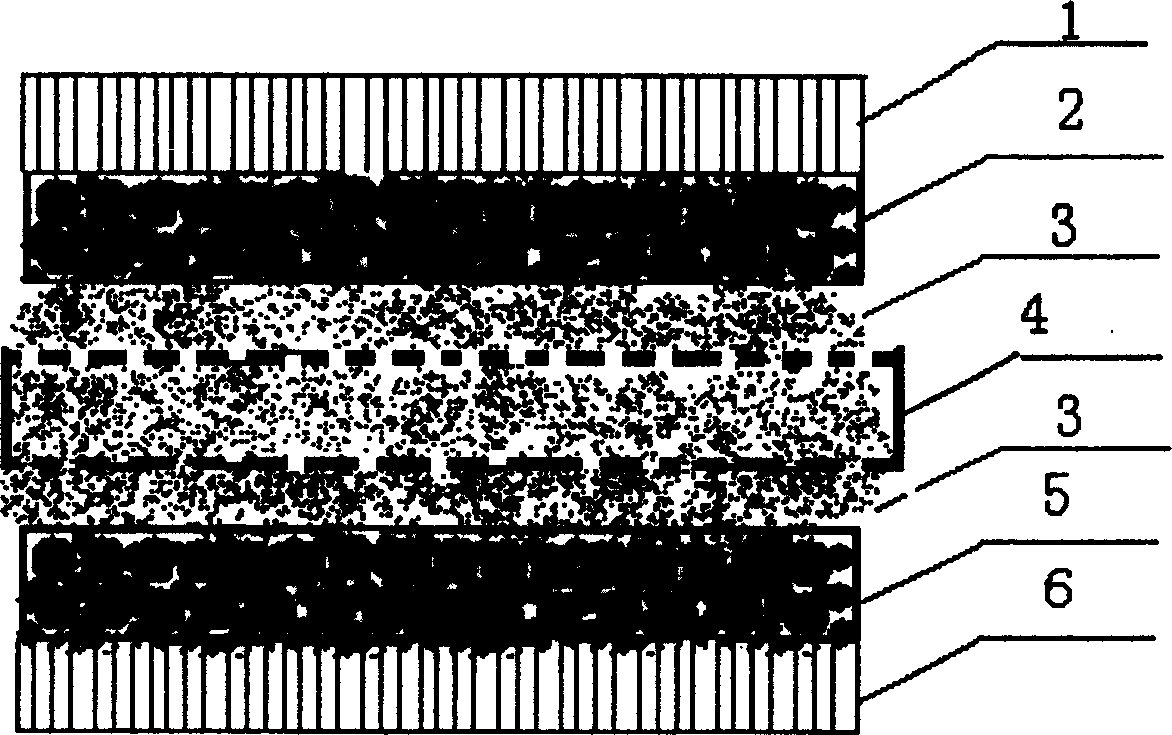

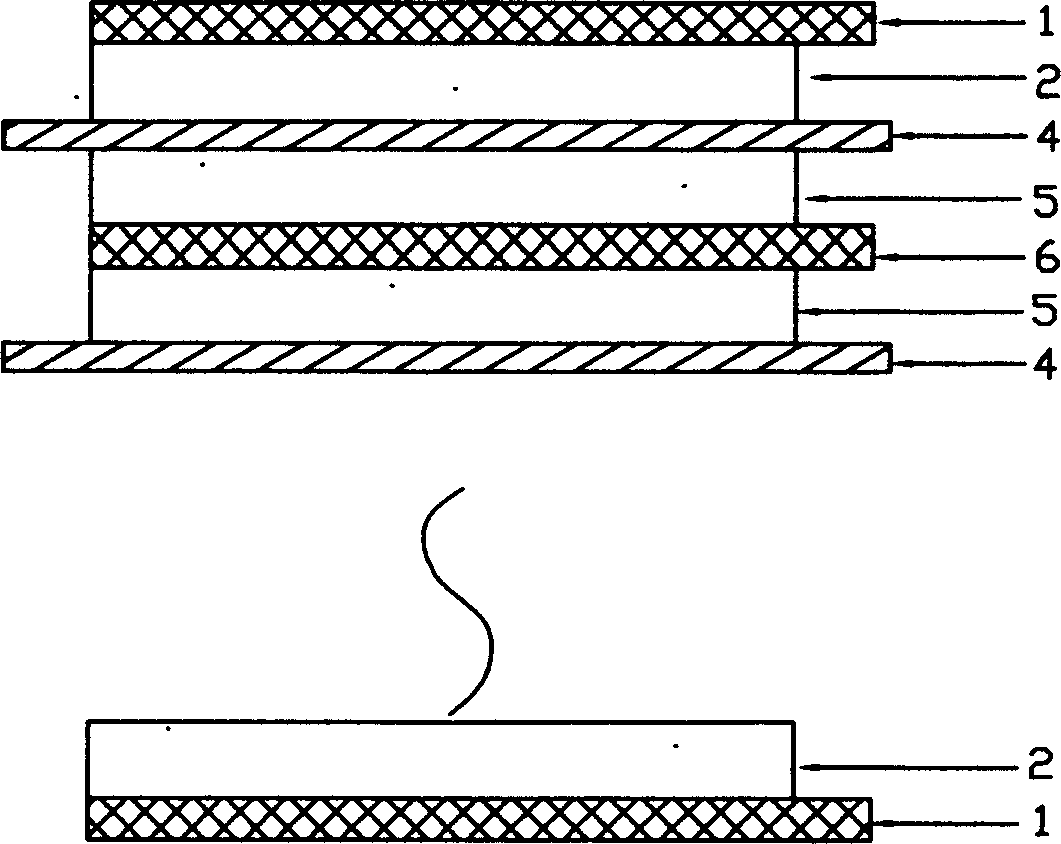

Method of constructing a capacitor stack for a flat capacitor

InactiveUS20050010253A1Increase surface areaGood size consistencyElectrolytic capacitorsDecorative surface effectsEngineeringCapacitor

In one aspect, a method of manufacturing a capacitor includes disposing one or more conductive layers of a first electrode stack in a recess of an alignment mechanism, where the recess is positioned relative to two or more alignment elements. The method further includes placing a separator over the one or more conductive layers where an outer edge of the separator contacts the two or more alignment elements. In one embodiment, a capacitor includes anode and cathode foils having offsetting edge portions. In one embodiment, a multiple tab cathode for a flat capacitor. A plurality of cathode tabs are portioned into a plurality of cathode tab groups positioned in different locations along the edge of the capacitor stack to reduce the amount of space required for connecting and routing the cathode tabs.

Owner:CARDIAC PACEMAKERS INC

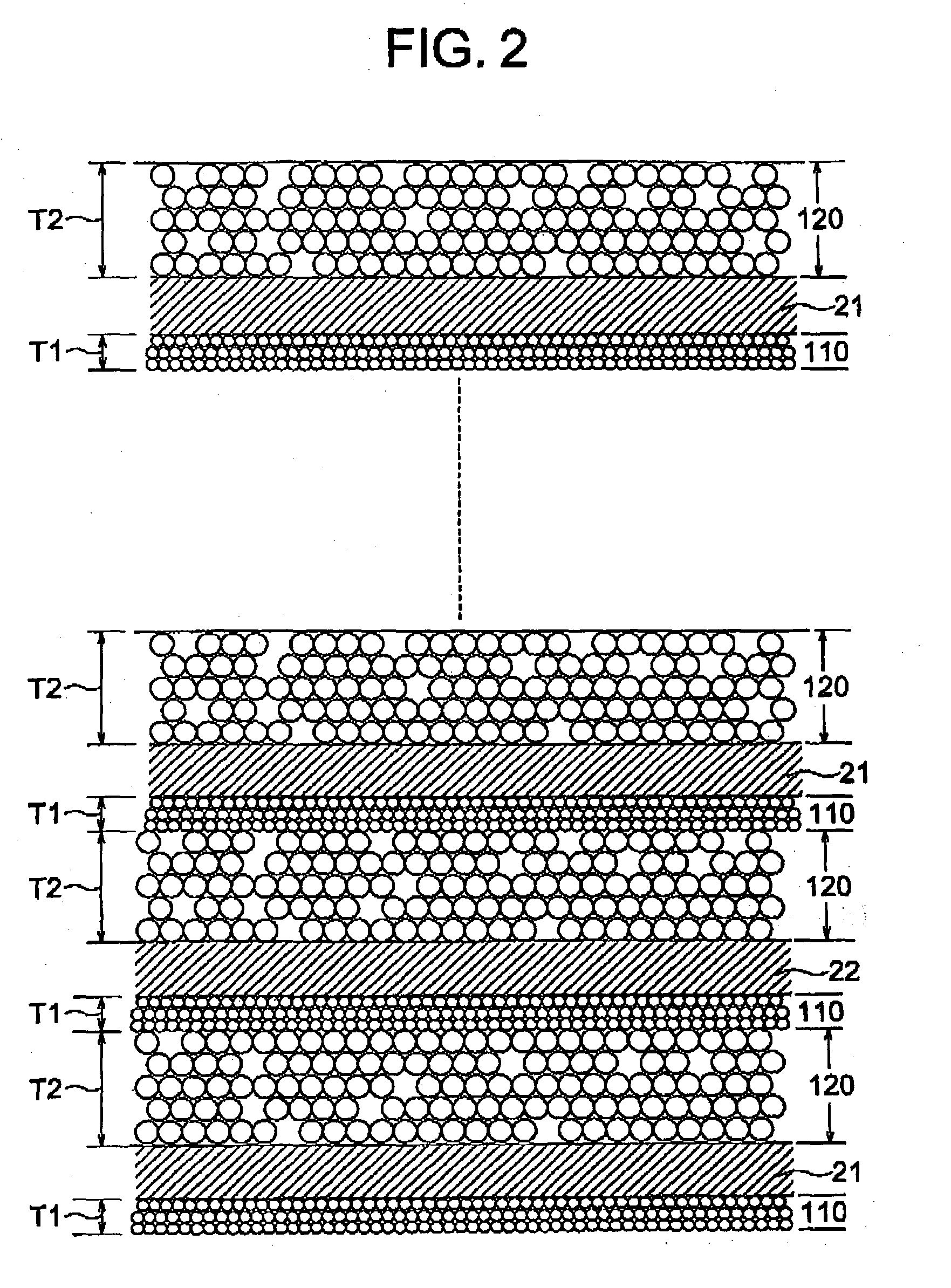

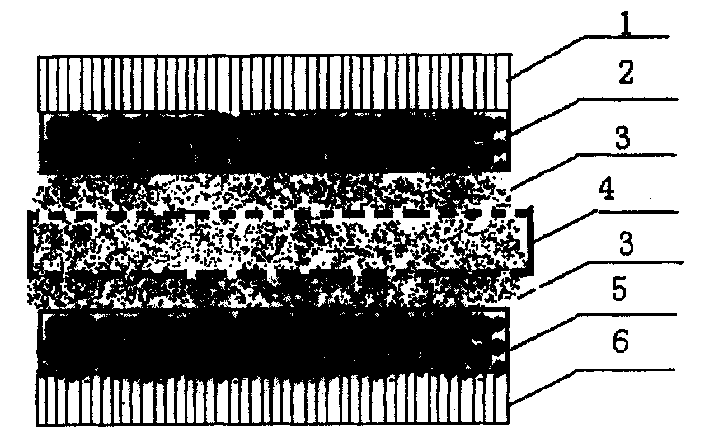

Ceramic electronic device and method of production of same

InactiveUS20030170432A1Reduce difficulty in peeling and probability of occurrence of defectImprove accuracyDead plant preservationArtificial flowers and garlandsCeramic coatingMetallurgy

A method of production of a ceramic electronic device such as a multilayer ceramic capacitor, comprising forming a first ceramic coating layer on the surface of a substrate, forming an internal electrode on the surface of the first ceramic coating layer, then forming a second ceramic coating layer on the surface of the first ceramic coating layer so as to cover the internal electrode. In this case, when a mean particle size of ceramic particles of the first ceramic coating layer is alpha1, a thickness of the first ceramic coating layer is T1, a mean particle size of ceramic particles of the second ceramic coating layer is alpha2, and a thickness of the second ceramic coating layer is T2, the conditions of alpha1<=alpha2, 0.05<alpha1<=0.35 mum, T1<T2, and 0<T1<1.5 mum are satisfied. As a result, it is possible to provide a ceramic electronic device, in particular a multilayer ceramic capacitor, resistant to short-circuit defects, withstand voltage defects, and other structural defects.

Owner:TDK CORPARATION

A composite carbon-based electrode material for super capacitor and method for making same

InactiveCN1567493AImprove conductivityLower internal resistanceHybrid capacitor electrodesElectrolytic capacitorsFiberCarbon fibers

The invention discloses a composite carbon-based electrode material used for super capacitors and its preparing method, and it is composed of nano metals, nano metal composite oxide, activated carbon and nano carbon fiber, effectively using the activated carbon with high specific surface area and the nano carbon fiber to provide a double electric layer capacitor for a super capacitor, combining a Faraday quasi-capacitor provided by the nano metal oxide, and at the same time using the high electric conductivity of the nano carbon fiber and nano metals and the nano cooperation effect, thus increasing its capacitor and power densities and able to obtain the super capacitors with high energy and power densities, and the invention is low-cost and easy for commercial application.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Stacked super condensor and its manufacturing method

ActiveCN1538470AEasy molding controlEasy to adjust sizeElectrolytic capacitorsSecondary cellsTemperature controlSupercapacitor

The method of manufacturing laminated super capacitor includes such steps: coating mixed pulp prepared from carbon active material, conducting agent, cementing material, and solvent onto surface of metal body of collecting current by using flow casting machine or coating mould; carrying out rolling, drying and cutting operations on automatic temperature-controlled reduction roller mill so as to obtain electrode in carbon active material; single super capacitor is made after stacking bodies of collecting current of positive and negative electrode as well as porous isolation membranes, then adding electrolyte and sealed; cascaded and paralleled more single capacitor produces super capacitor with higher voltage and high capacity. The invented capacitor provides features of high power density, stable cycle performance and low expansivity of electrode.

Owner:深圳石墨烯创新中心有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com