Novel lithium pre-embedding method of lithium ion capacitor

A technology for capacitors and pre-intercalation of lithium, which is used in capacitors, capacitor manufacturing, hybrid capacitors, etc., can solve the problems of high production cost of pre-intercalated lithium, great safety hazards, and complicated processes, and achieves improved effects, improved safety, and simplified processes. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

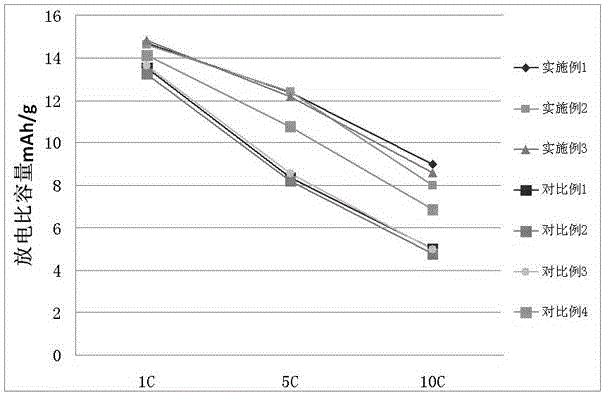

Examples

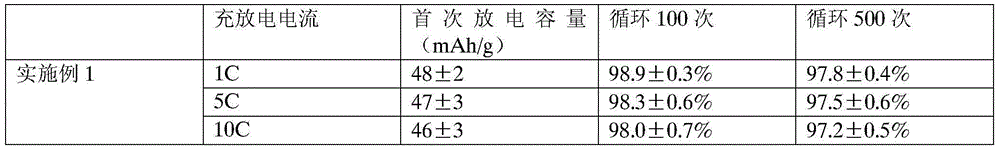

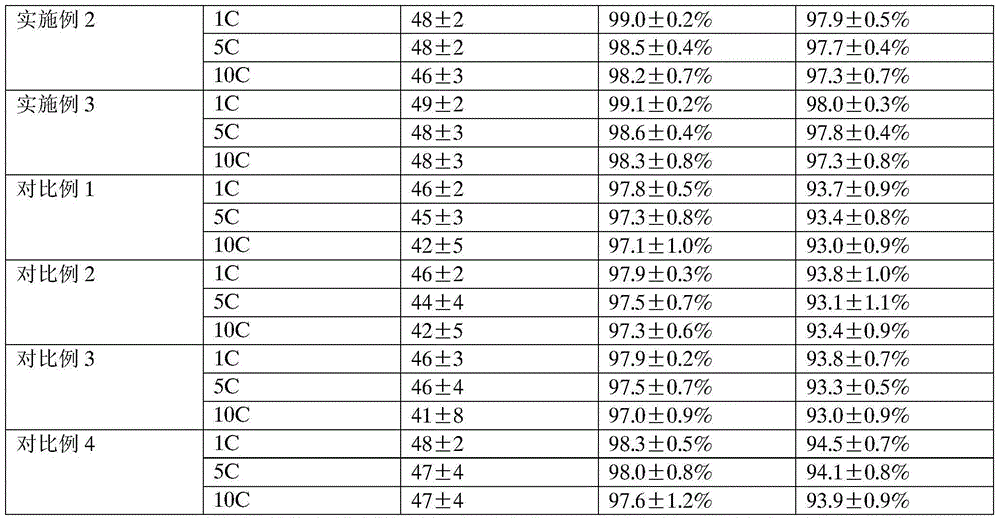

Embodiment 1

[0030] A manufacturing method of a lithium ion capacitor, the steps are as follows:

[0031] (1) The slurry with activated carbon as the active material is attached to non-porous aluminum foil as the positive electrode, and the slurry with mesocarbon microspheres as the active material is attached to the non-porous copper foil as the negative electrode. PP / PE / PP three-layer polymer For the diaphragm, stack the sheets according to the diaphragm, negative electrode, diaphragm, and positive electrode to form a battery cell, and fix it with tape, and weld the positive electrode current collector and negative electrode current collector to the positive and negative electrode lugs or lead-out terminals respectively;

[0032] (2) After drying, immerse the cell in a beaker filled with LiPF6-EC / PC / DEC solution;

[0033] (3) Connect the positive and negative poles of the charge-discharge tester to the positive and negative poles respectively, charge to 3.8V with a constant current equiv...

Embodiment 2

[0036] A manufacturing method of a lithium ion capacitor, the steps are as follows:

[0037] (1) The slurry with activated carbon as the active material is attached to the non-porous aluminum foil as the positive electrode, the slurry with artificial graphite as the active material is attached to the non-porous copper foil as the negative electrode, and the PP / PE / PP three-layer polymer is used as the diaphragm, According to the way of diaphragm, negative electrode, diaphragm and positive electrode, stack the sheets into a cell, and fix it with tape, and weld the positive electrode current collector and negative electrode current collector to the positive and negative electrode lugs or lead-out terminals respectively;

[0038] (2) After drying, immerse the cell into a beaker filled with LiBF4-PC / DMF solution;

[0039] (3) Use the positive and negative poles of the charge-discharge tester to connect the positive pole and the negative pole respectively, charge it with a constant ...

Embodiment 3

[0042]A manufacturing method of a lithium ion capacitor, the steps are as follows:

[0043] (1) The slurry with activated carbon as the active material is attached to the porous aluminum foil as the positive electrode, the slurry with the hard carbon as the active material is attached to the porous copper foil as the negative electrode, and the single-layer PP polymer film is used as the separator. According to the separator, negative electrode, The diaphragm and the positive electrode are wound into a cell and fixed with adhesive tape, and the positive and negative current collectors are welded to the positive and negative tabs or lead-out terminals respectively;

[0044] (2) After drying, immerse the cell in Li 2 CO 3 in a beaker of organic solution;

[0045] (3) Use the positive and negative poles of the charge-discharge tester to connect the positive pole and the negative pole respectively, charge it with a constant current equivalent to 0.2C to 3.8V, then disconnect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com