Patents

Literature

342results about How to "Good size consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

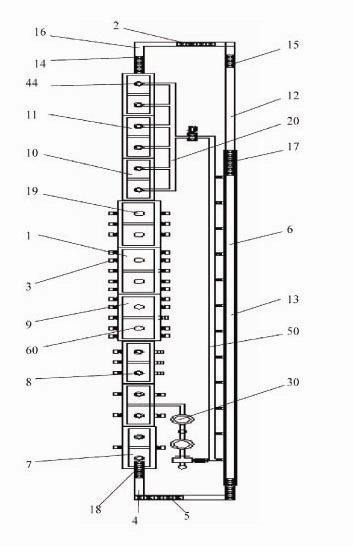

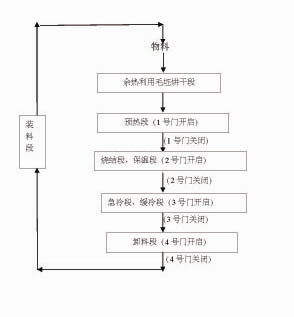

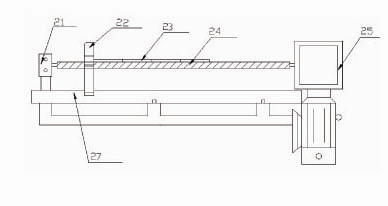

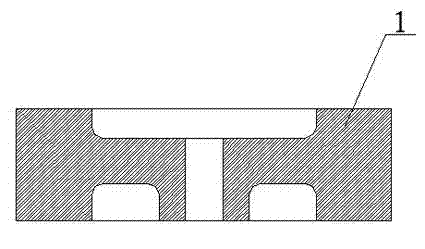

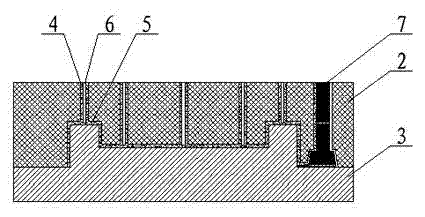

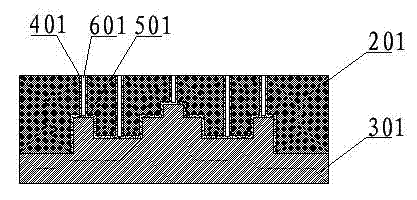

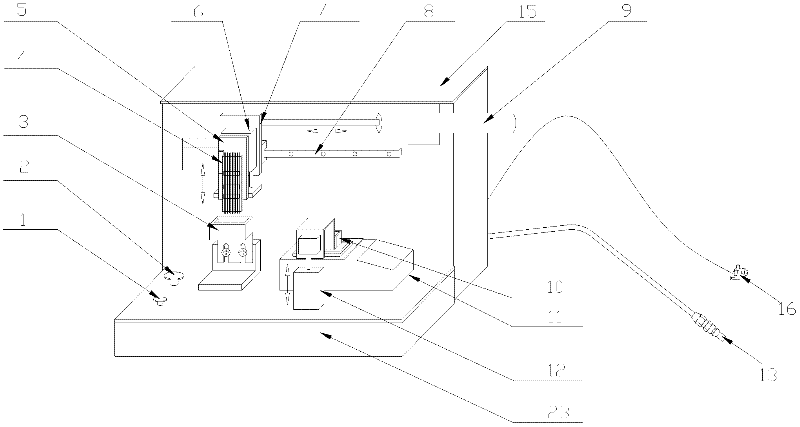

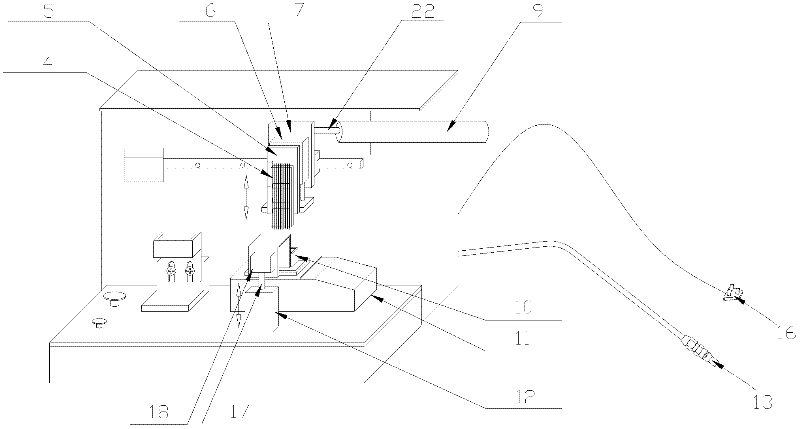

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

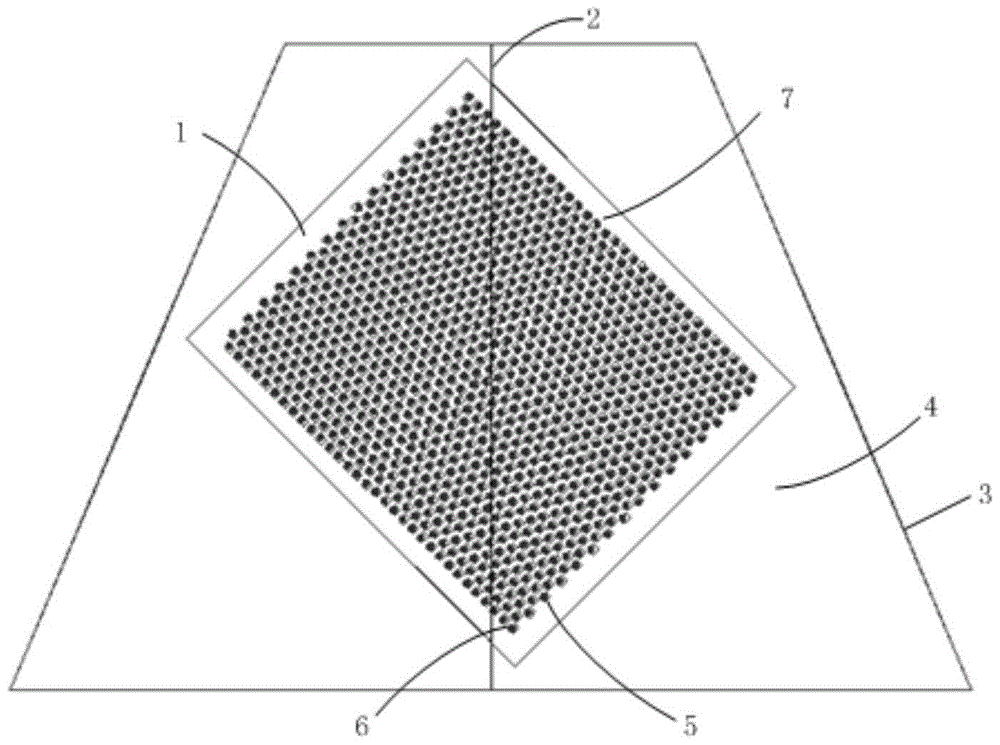

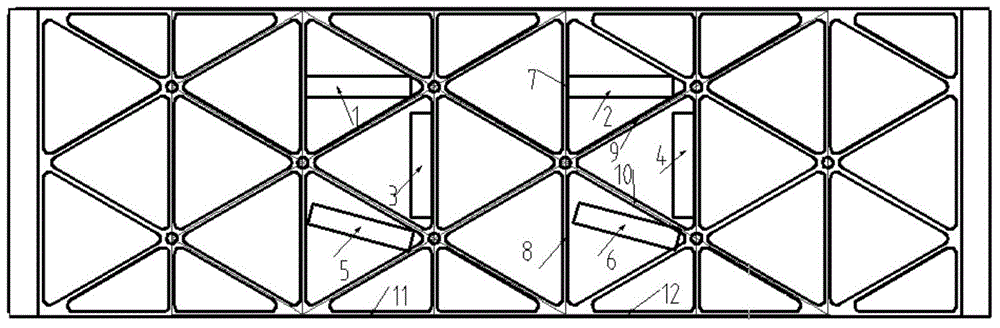

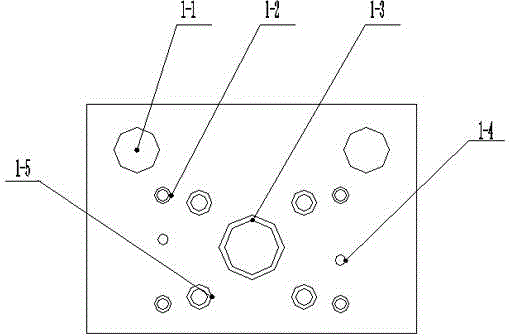

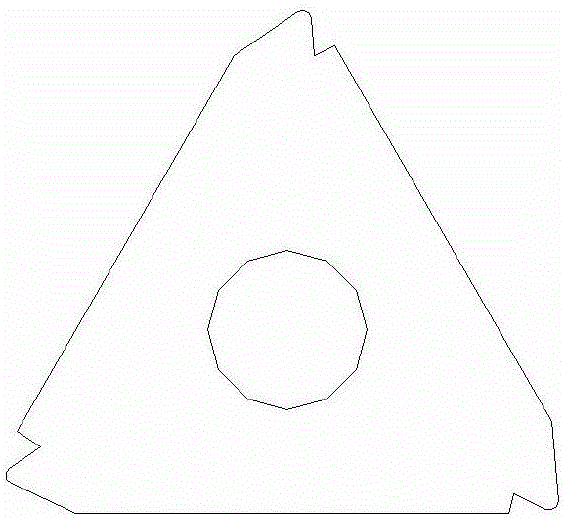

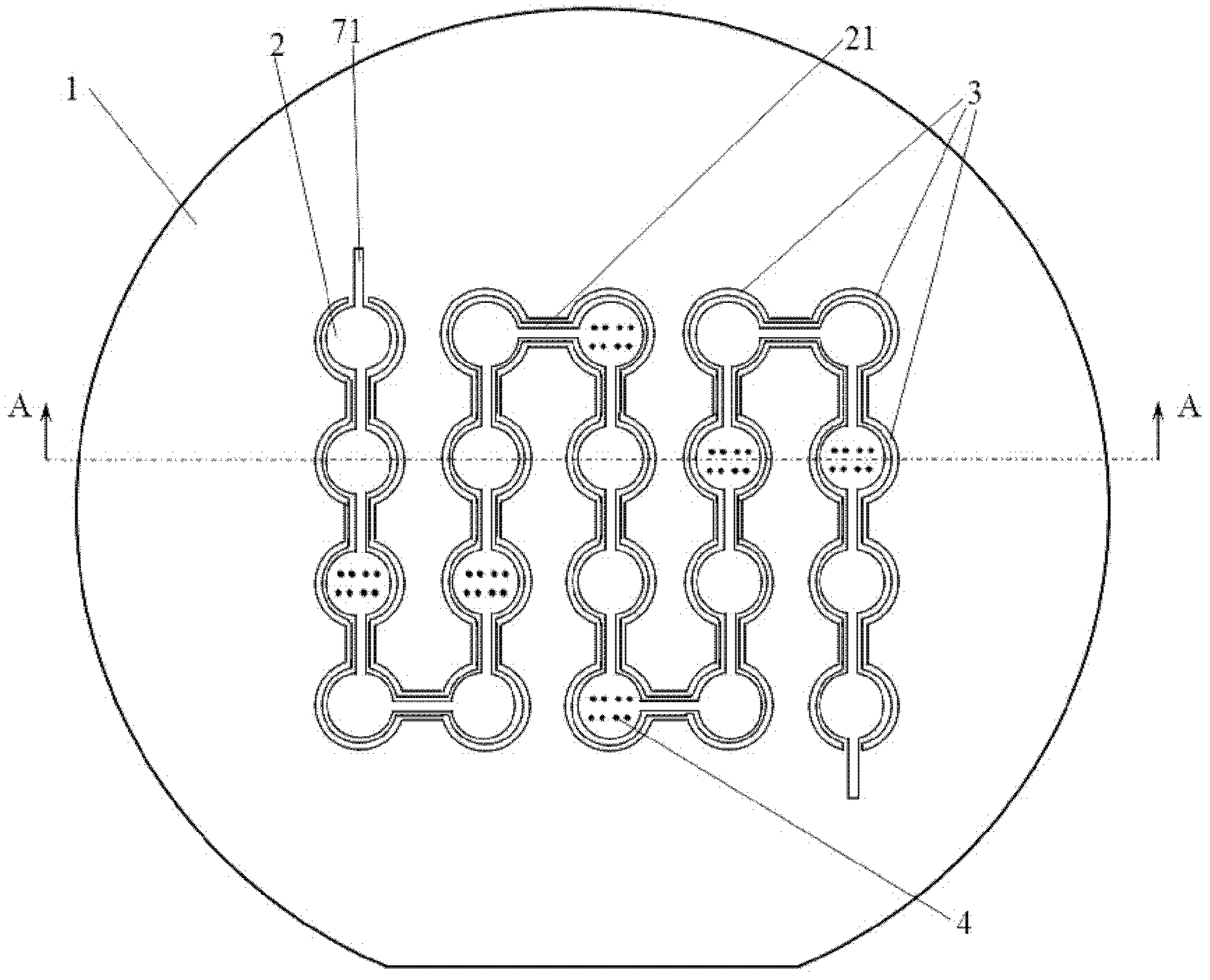

Large K-waveband conformal antenna array plane and preparation method thereof

ActiveCN106099337AGood axial ratioWide bandwidth and good angular axis ratioParticular array feeding systemsRadiating elements structural formsMicrostrip patch antennaElectrical conductor

The invention discloses a large K-waveband conformal antenna array plane and aims to provide a conformal phased array antenna array plane which does not generate a frequency deviation or a relatively high derotation component, and has a good broadband wide-angle scanning gain characteristics and good broadband wide-angle scanning circular polarization characteristics. The large K-waveband conformal antenna array plane is realized through the following technical scheme: conductor patches are divided into four groups and are arranged on an upper surface of a lower dielectric substrate in a form of a quadrant sequence rotation array, and projections of feeding points of a micro-strip patch antenna on a plane plate are arranged triangularly; the conductor patches are sandwiched between an upper dielectric substrate and the lower dielectric substrate; a radio frequency coaxial connector sequentially passes through the plane plate, a metal cone and the lower dielectric substrate to jointly form the micro-strip patch antenna; the radio frequency coaxial connector carries out coaxial probe feeding on the micro-strip patch antenna; and a pair of orthogonal polarization degenerate modes which have equal amplitudes and a phase difference of 90 degrees are excited on the conductor patches to form the conformal phased array antenna array plane for radiating right-handed circular polarization electromagnetic waves.

Owner:10TH RES INST OF CETC

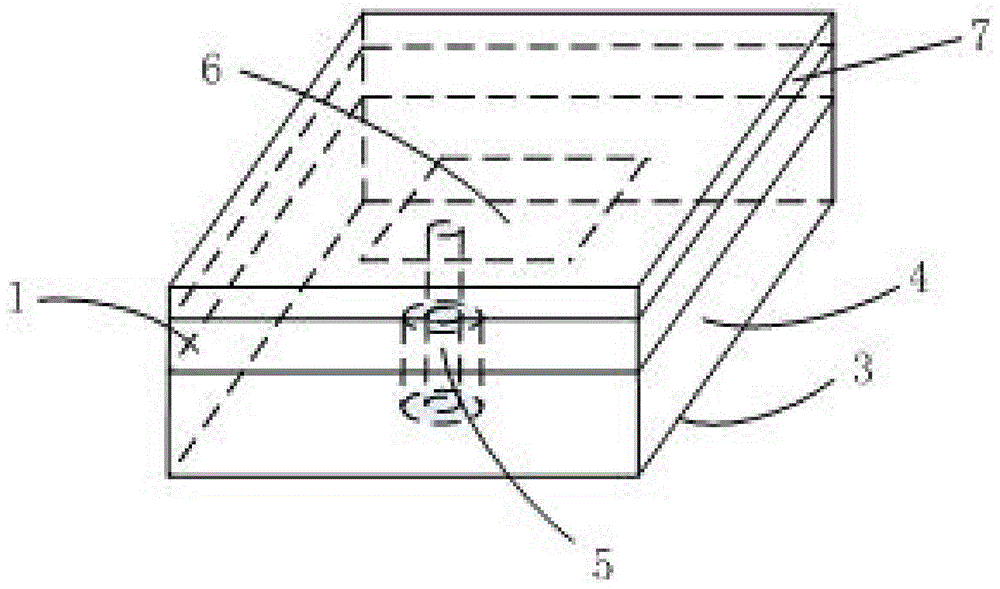

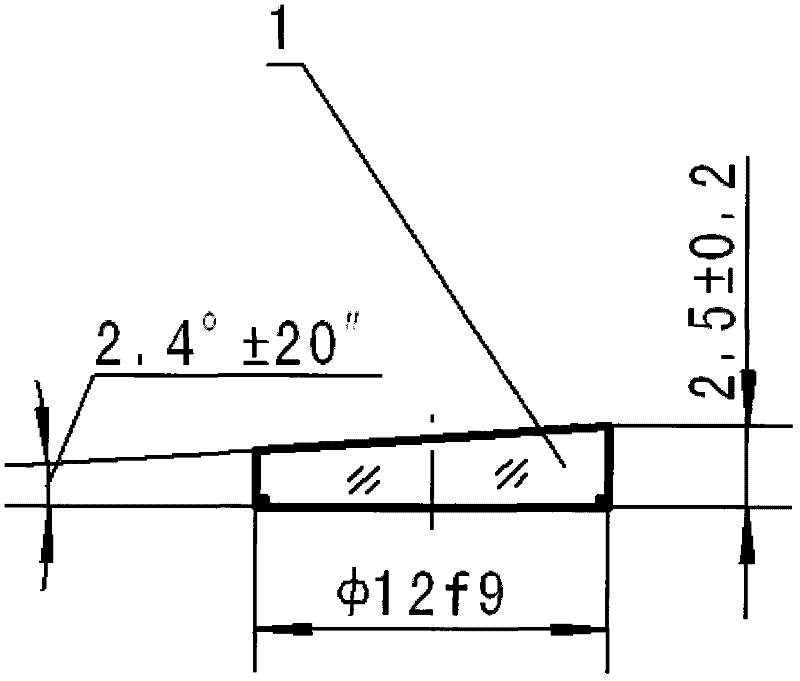

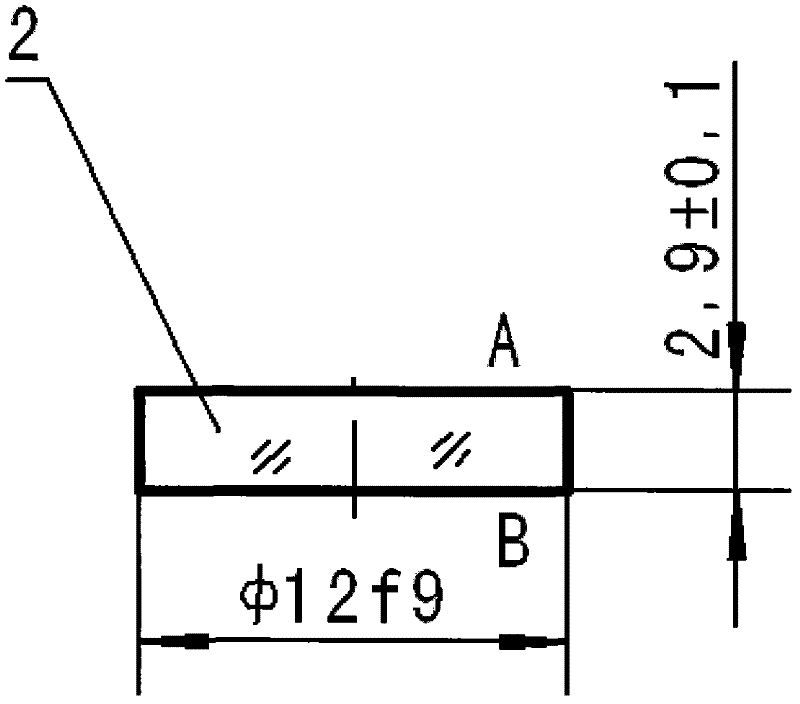

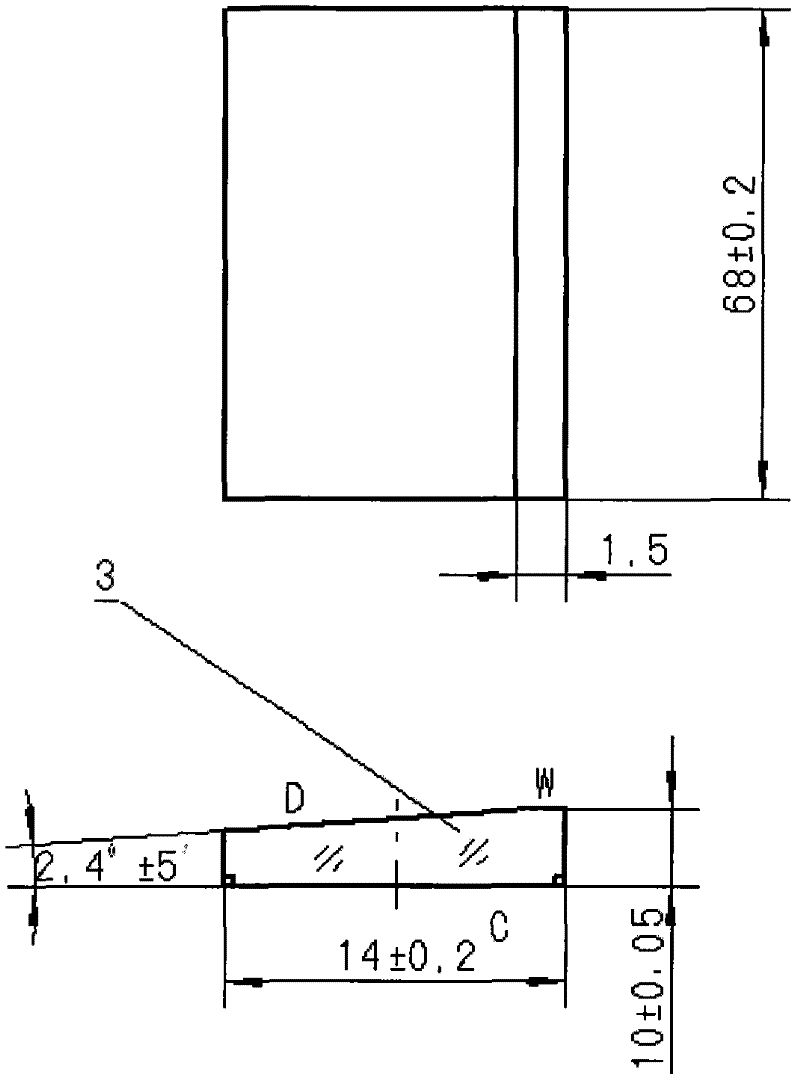

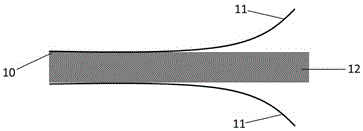

Manufacturing method of wedge-shaped lens

ActiveCN102229082ANovel technologyUnique process methodOptical surface grinding machinesOptical processingEngineering

The invention discloses a manufacturing method of a wedge-shaped lens, belonging to the technical field of optical cold processing. The manufacturing method comprises the specific steps of: manufacturing a wedge-shaped lens blank and a high-precision glass clamp by adopting a conventional optical processing technology so as to ensure that a first guide through face of the wedge-shaped lens as well as the surface shape and the surface defects of the wedge-shaped glass clamp meet formulated requirements; optically cementing the first light through face of the wedge-shaped lens onto the inclined surface of the wedge-shaped glass clamp which is already optically cemented onto a parallel planer optical cementing base plate, carrying out fine grinding and polishing on a second light through face of the wedge-shaped lens, and obtaining the wedge-shaped lens with second-level precision by controlling the thickness, the parallel difference and the surface shape precision of the second light through face and the parallel planer optical cementing base plate. The manufacturing method for machining the wedge-shaped lens, disclosed by the invention, not only has a simple process, strong operability and a greatly-prolonged manufacturing period, but also is easy to ensure the single-batch finished product ratio of wedge-shaped lens parts with small sizes, large angles and second-level precision and overcomes the difficulties of unstable quality, low efficiency and low finished product ratio in the conventional processing method.

Owner:CHINA NORTH IND NO 205 RES INST

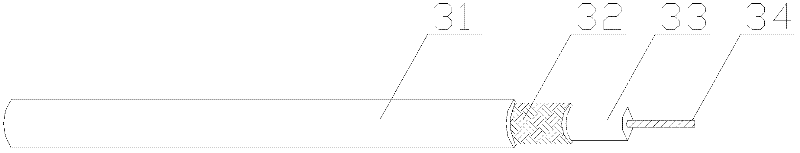

Semi-automatic tin dipping machine

InactiveCN102259223AGuaranteed levelConsistent immersion tin depthSolder feeding devicesSemi automaticEngineering

The invention discloses a semi-automatic wicking machine comprising a workbench, a fixing plate and a tin melting furnace. The semi-automatic wicking machine is characterized by further comprising a wicking groove, a soldering flux groove, a wiring plate, a guide rail, a first up-and-down moving device, a horizontal driving device and a second up-and-down moving device. The wicking groove is arranged above an opening of the tin melting furnace, the first up-and-down moving device is connected with the wicking groove, the soldering flux groove is arranged above the workbench, the second up-and-down moving device is connected with the wiring plate, the back end of the second up-and-down moving device is connected with the guide rail arranged on the fixing plate, and the horizontal driving device arranged on the fixing plate is connected with the second up-and-down moving device. The invention solves the problem that woven flare opening and bulging usually generate, the wicking length isinconsistent, and the sizes of finished produces are unstable due to the hard guarantee of the appearance and the quality of products because wire rods are wicked manually in prior art, and provides a semi-automatic wicking machine with unity in wicking, order appearance and good size consistency.

Owner:雷特威连接系统(苏州工业园区)有限公司

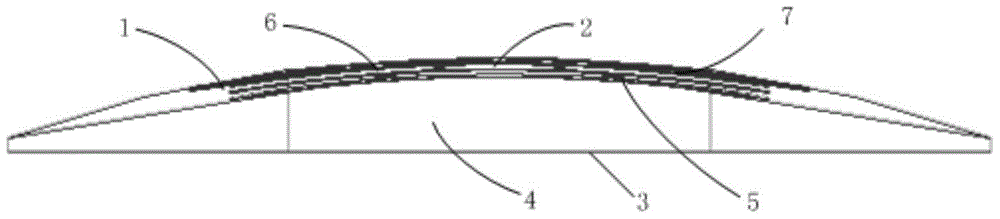

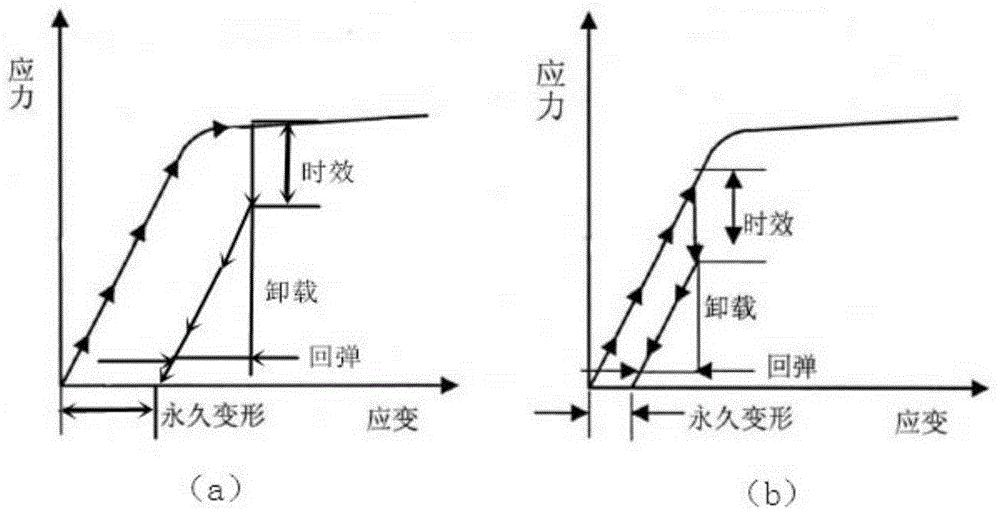

Method for manufacturing large-curvature aluminum alloy integral wall board component

The invention provides a method for manufacturing a large-curvature aluminum alloy integral wall board component. The method includes the steps that A, solution hardening is conducted on a wall board; B, the wall board obtained in the step A is arranged in a sealed environment formed by a thin film covering layer and a forming die jointly, the wall board is elastically deformed and plastically deformed in sequence under the vacuumized condition, and then the deformed wall board is obtained, wherein the temperature in the sealed environment where the wall board is located ranges from 15 DEG C to 35 DEG C, the vacuum degree ranges from -0.1 MPa to -0.05 MPa, and the treatment time ranges from 5 min to 60 min; C, in-situ creep stress relaxation aging is conducted on the deformed wall board obtained in the step B, wherein creep stress relaxation aging time is more than 2 h; D, unloading operation is conducted, and then the large-curvature aluminum alloy integral wall board component is obtained. When the method is used for manufacturing the large-curvature aluminum alloy integral wall board component, the residual stress of the product is greatly reduced, the strength of the product is improved, and the product with high forming accuracy and good performance is obtained.

Owner:CENT SOUTH UNIV

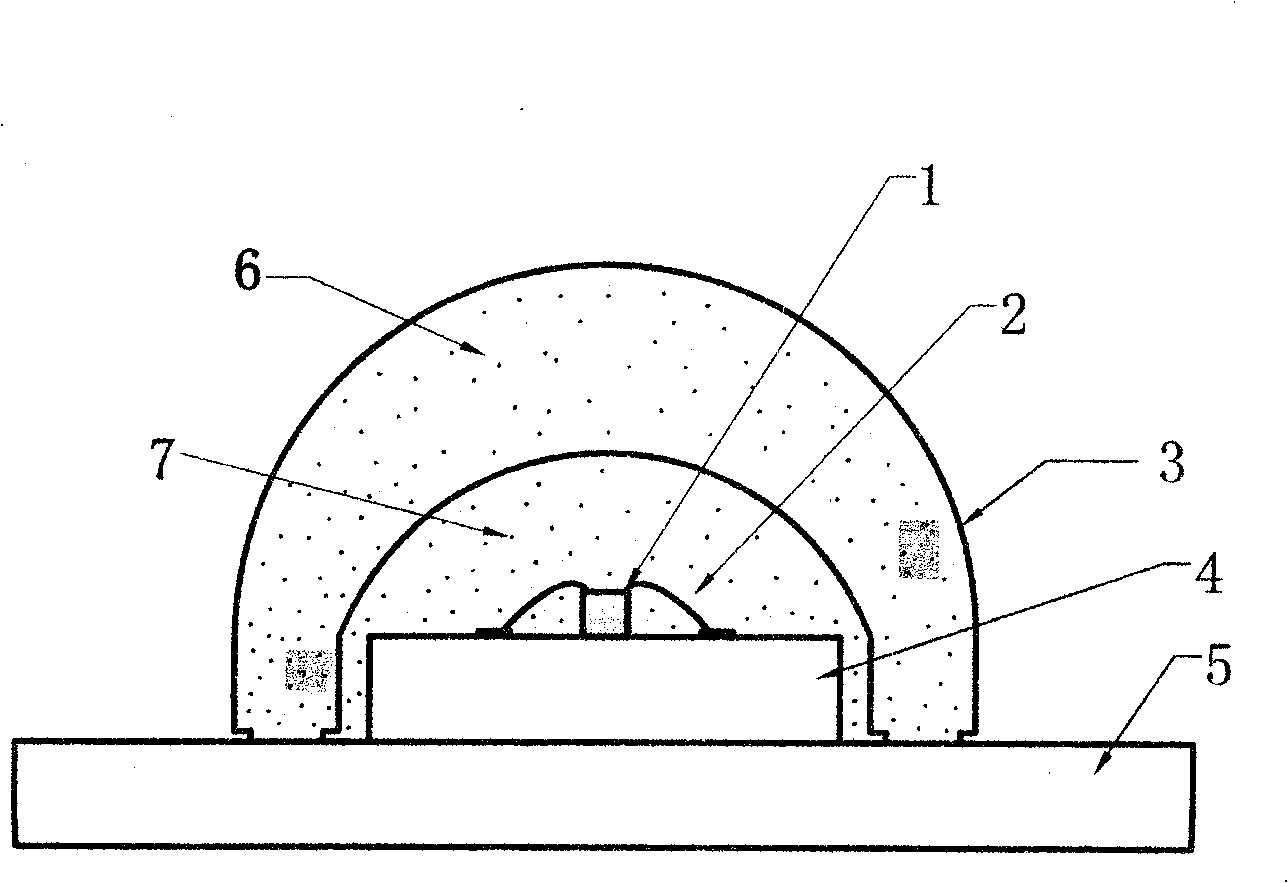

Low attenuation high light efficiency LED illuminating apparatus and preparation method

InactiveCN101338865AImprove light extraction efficiencyGood light extraction efficiencyLighting support devicesPoint-like light sourceUltrasound attenuationFilling materials

The invention discloses a low-attenuation high-lighting effect LED lighting device and a preparation method thereof, and relates to a semiconductor LED lighting device and a preparation method thereof. The lighting device comprises a heat dissipation plate is equipped with an aluminum basal plate, a blue LED chip is fived on the aluminum basal plate and the outer cover of the blue LED chip is a transparent cover. The preparation process is as follows: bonding material is filled on the aluminum basal plate; the luminescent material is fixedly positioned on the bonding material of the aluminum basal plate; the bonding material is baked and dried; a gold wire is used to connect the electrode; the transparent cover material and the fluorescent powder are molded to form the transparent cover; the transparent cover is fixed on the aluminum basal plate; the aluminum basal plate is fixed on a heat-dissipating aluminum plate; the filling material is filled into the space between the aluminum basal plate and the transparent cover; the LED lighting device is baked or dried at ambient temperature; The invention can prolong the service life of the LED lighting device, and promote the luminescence efficiency and the consistency of light and color.

Owner:段永成

Aluminum oxide pure black ceramic material and processing method thereof

The invention discloses an aluminum oxide pure black ceramic material. The aluminum oxide pure black ceramic material comprises the following components in percentage by weight: 77.5 to 95.0 percent of alpha-aluminum oxide, 2.5 to 7.5 percent of ferric oxide, 2.0 to 10.0 percent of manganese dioxide and 0.5 to 5.0 percent of nickel oxide. The invention also discloses a formula and a processing method of the aluminum oxide pure black ceramic material. The ferric oxide, the manganese dioxide, the nickel oxide and the alpha-aluminum oxide are mixed according to the design ratio, so that the internal and external consistency of the ceramic material is greatly improved and the ceramic material is pure black. The sintered product has low shrinkage ratio and good consistency.

Owner:XINHUA COUNTY XINTIAN ELECTRONICS CERAMICS

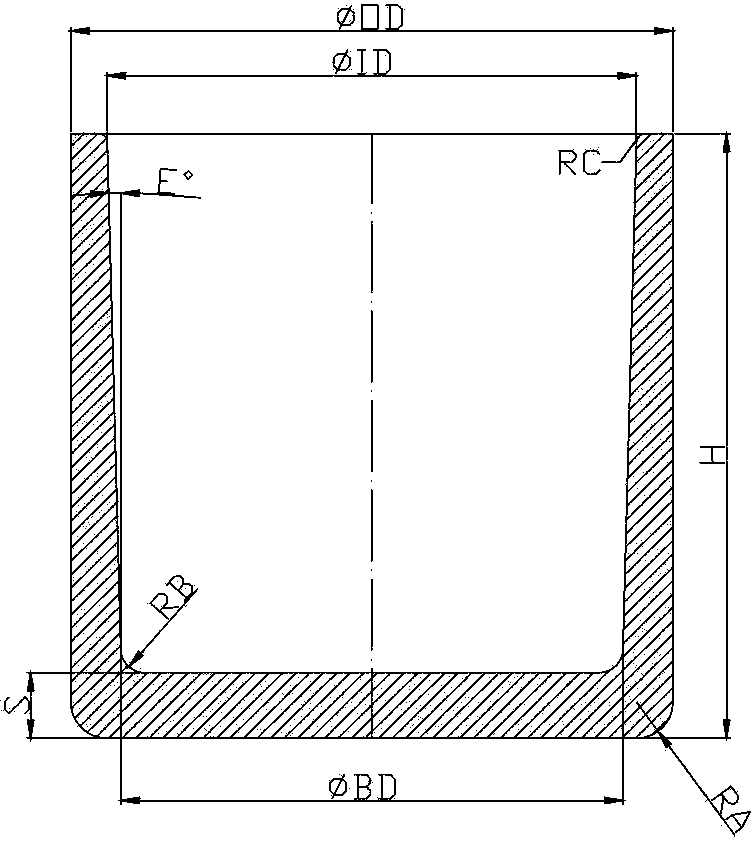

Large-size high-density tungsten crucible and preparation method thereof

The invention provides a large-size high-density tungsten crucible which is mainly used for sapphire crystal growth industry, and particularly provides a preparation method for the large-size high-density tungsten crucible. The method comprises the following steps: raw materials processing, mould core manufacturing, mould setting and forming, high-temperature sintering and mechanical processing. Compared with the prior art, the produced crucible is large in size range and suitable for mass production. Moreover, no binding agent is added in the production process, and impurity content of the product is low; the finished product has the advantages of being high in density, large in size (maximal external diameter of phi 650 mm and maximal height of 800 mm), good in size adaptability and consistency, and high in yield and surface finish, can bear 2000-2300 DEG C high temperature under the protective atmosphere, and can not react with sapphire raw materials under the high temperature.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

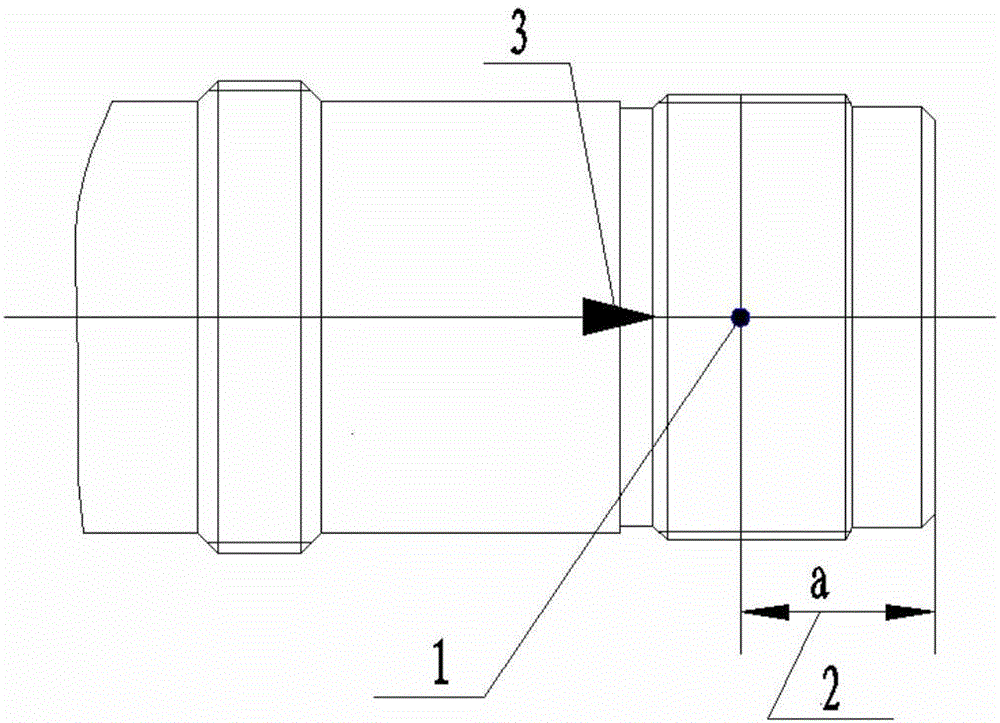

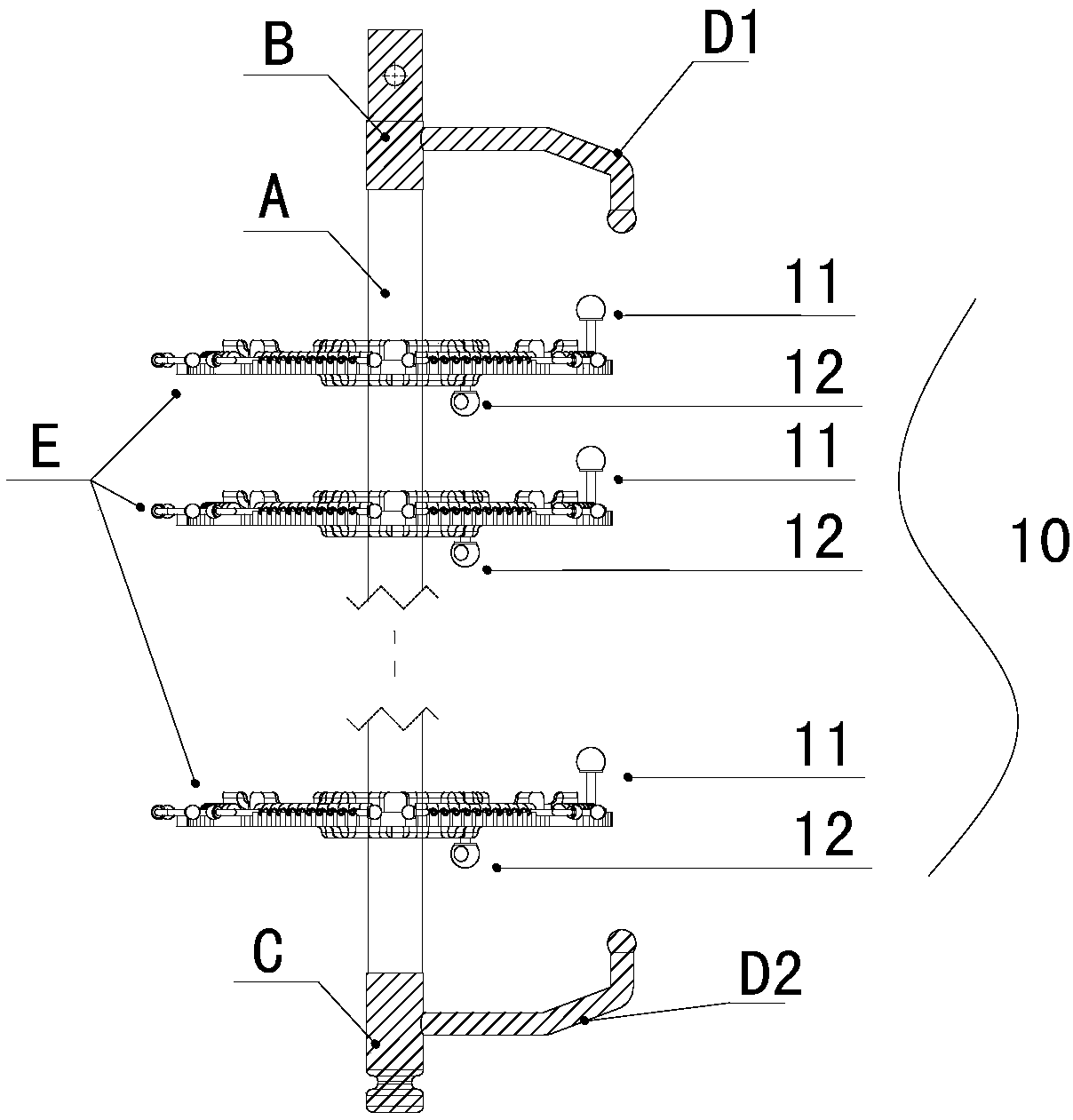

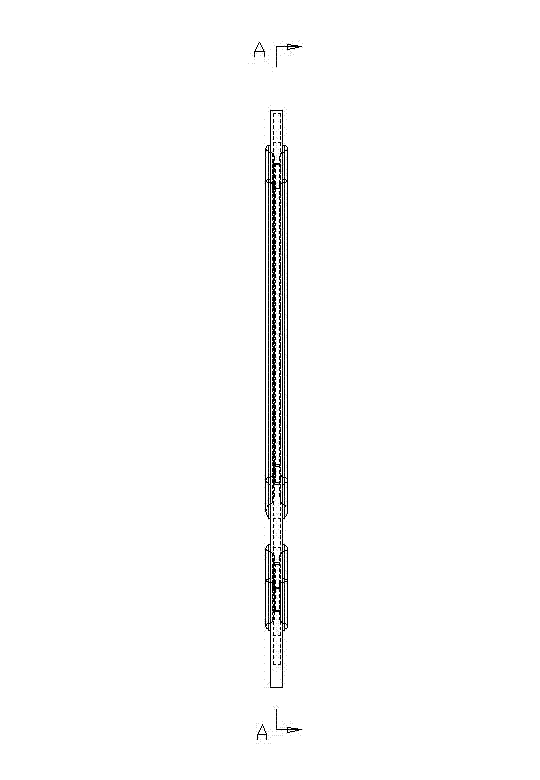

Method and device for machining inner blind hole of perforating gun for oil-gas well

ActiveCN102489738AImprove rigidityEliminate continuityBoring/drilling componentsBoring/drilling machinesInstabilityEngineering

The invention relates to a method and a device for machining an inner blind hole of a perforating gun for an oil-gas well, which solve the problems of rotation instability and the like caused by long-distance power transmission required in the past. The device for machining the inner blind hole of the perforating gun for the oil-gas well, provided by the invention, comprises: (1) a drilling tool assembly and a supporting device, which are arranged on a cutter connecting rod; and (2) a vertical milling machine. During machining, a gun body of the perforating gun is assembled and clamped on a workbench of the vertical milling machine and is moved by using workbench of the vertical milling machine so as to extend the drilling tool assembly and the supporting device into the gun body of the perforating gun and make a drillbit of the drilling tool assembly located at a position at which the inner blind hole is machined; and then, an inner expansion mechanism of the supporting device is utilized to tightly lock a cutter rod and the gun body of the perforating gun to form firm support, a power transmission rod of the vertical milling machine penetrates through a pressure relief hole in the gun body of the perforating gun and is connected with the drillbit of the drilling tool assembly in an engagement manner; and the power transmission rod drives the drillbit of the drilling tool assembly to rotate and realize drilling feeding until the inner blind hole is machined completely.

Owner:XIAN TONGYUAN PETROTECH

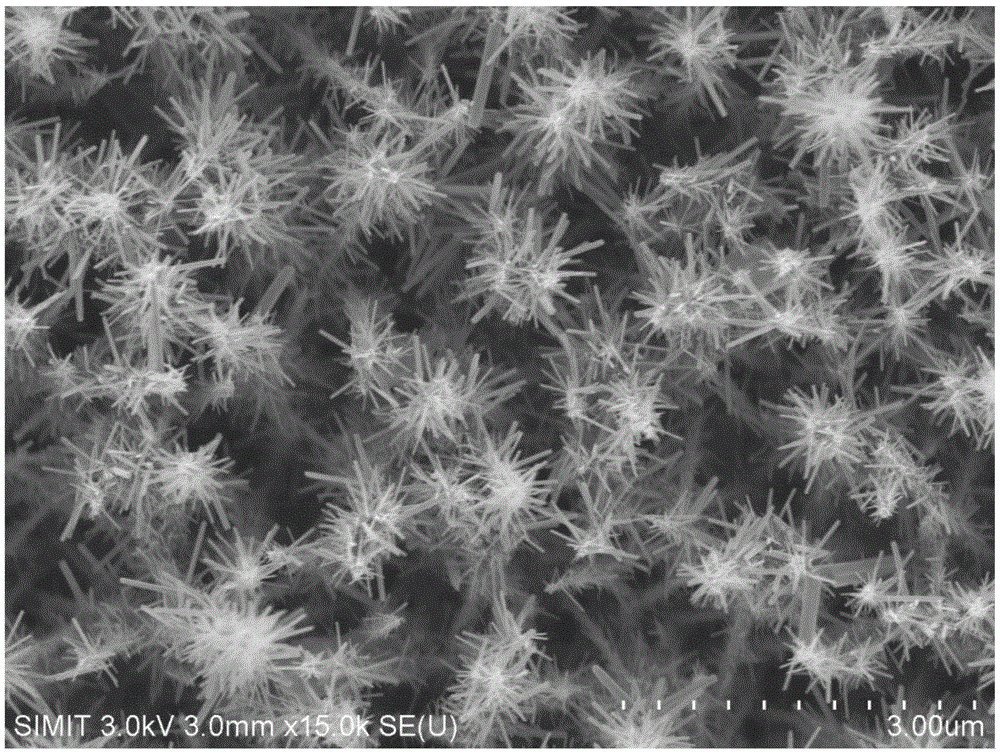

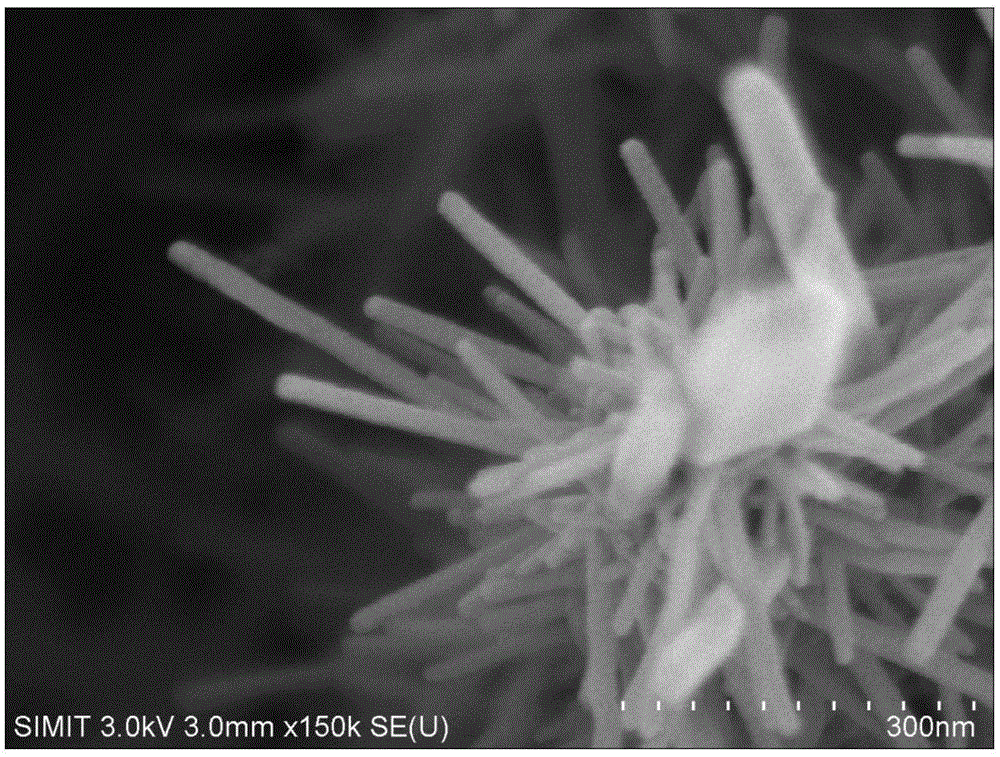

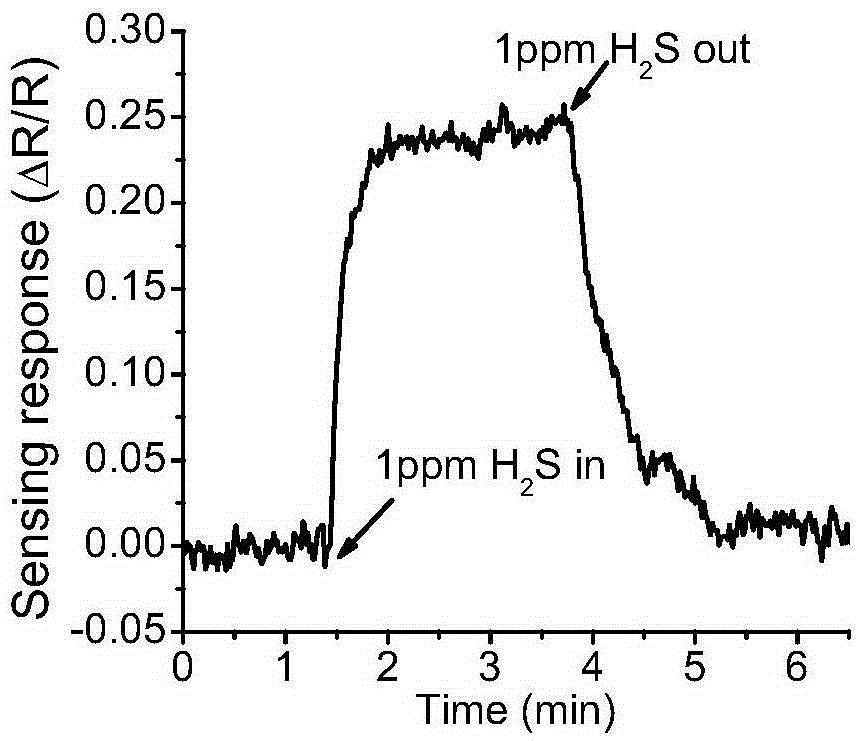

Preparation method of dendritic zinc oxide nanowire array

ActiveCN105271361ALow preparation temperatureSo as not to damageMaterial nanotechnologyZinc oxides/hydroxidesVolumetric Mass DensityNanometre

The invention provides a preparation method of a dendritic zinc oxide nanowire array. The preparation method comprises the following steps of (1) cleaning the surface of a substrate; (2) depositing a zinc oxide seed layer at the surface of the substrate by an atom layer depositing technology; (3) growing a zinc oxide nanowire array on the substrate by a hydration method; (4) cleaning the substrate, and drying, so as to form a bar-shaped zinc oxide nanowire array; (5) depositing one zinc oxide seed layer at the surface of the substrate by the atom layer depositing technology; (6) repeating the steps (3) to (4), so as to form the dendritic zinc oxide nanowire array. The preparation method of the dendritic zinc oxide nanowire array has the advantages that the preparation temperature is low, the nanometer dendritic structure has good uniformity and density, the preparation method is suitable for the substrate with a non-plane or complicated structure, and the preparation method is simple and feasible.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

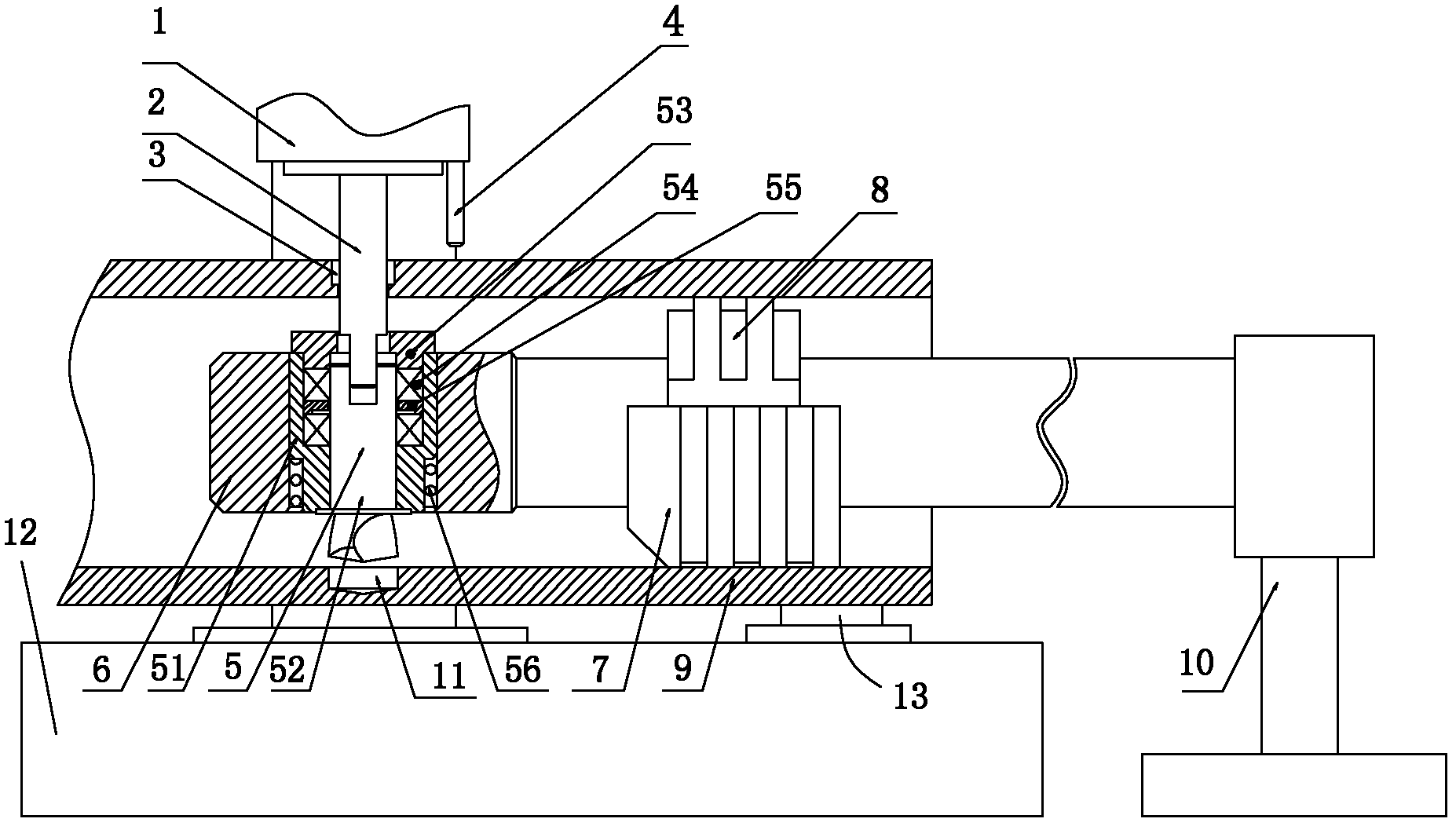

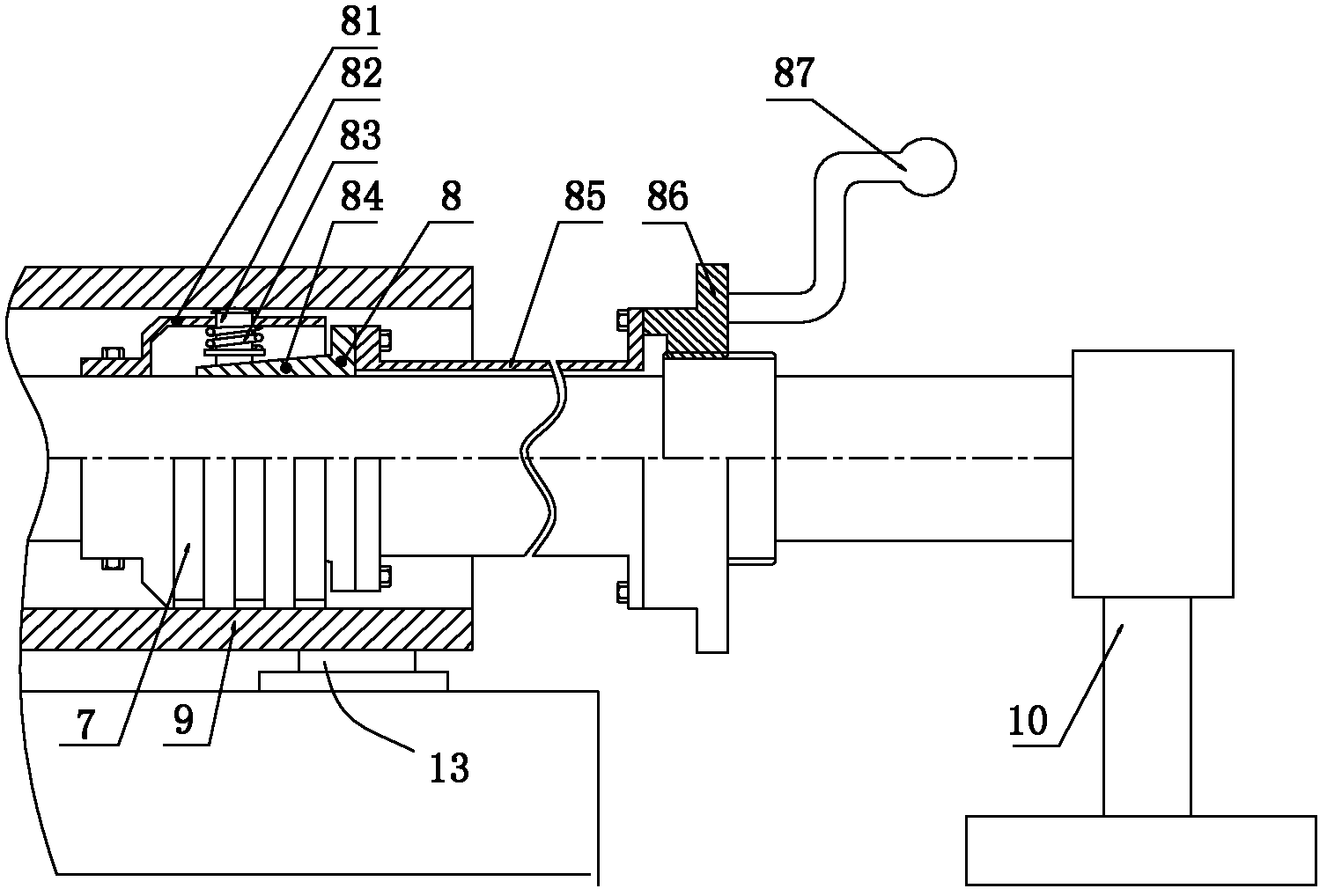

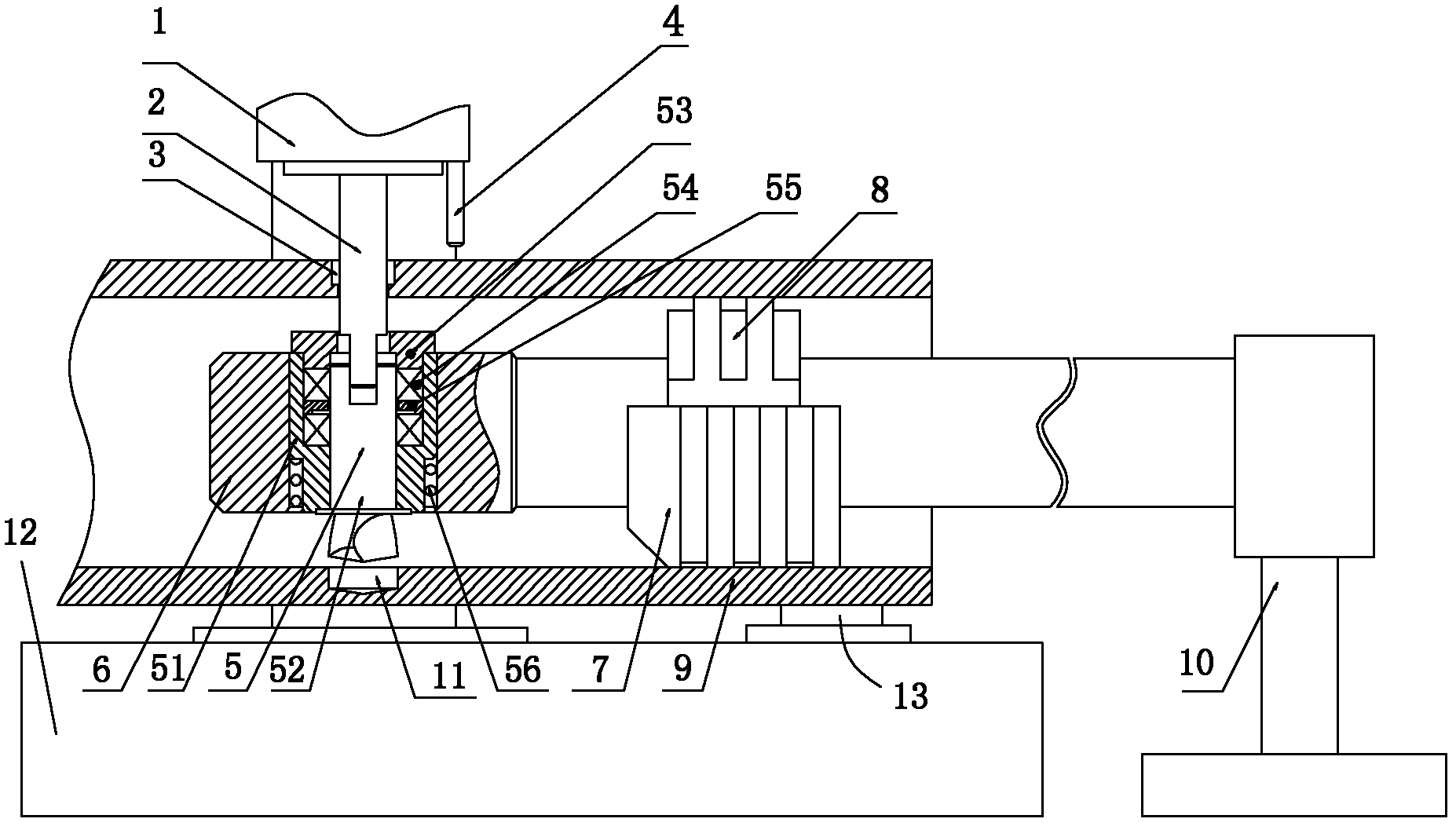

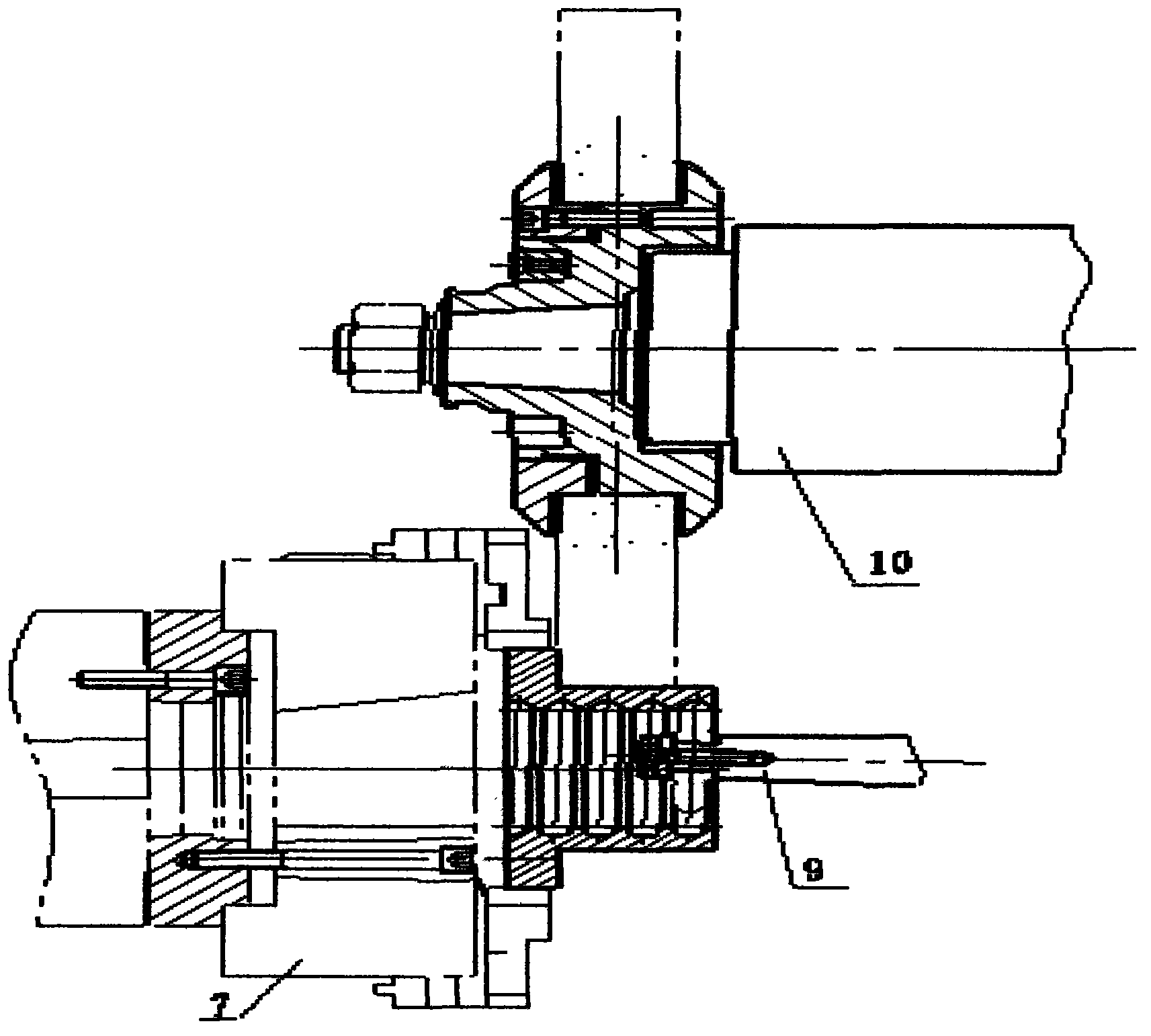

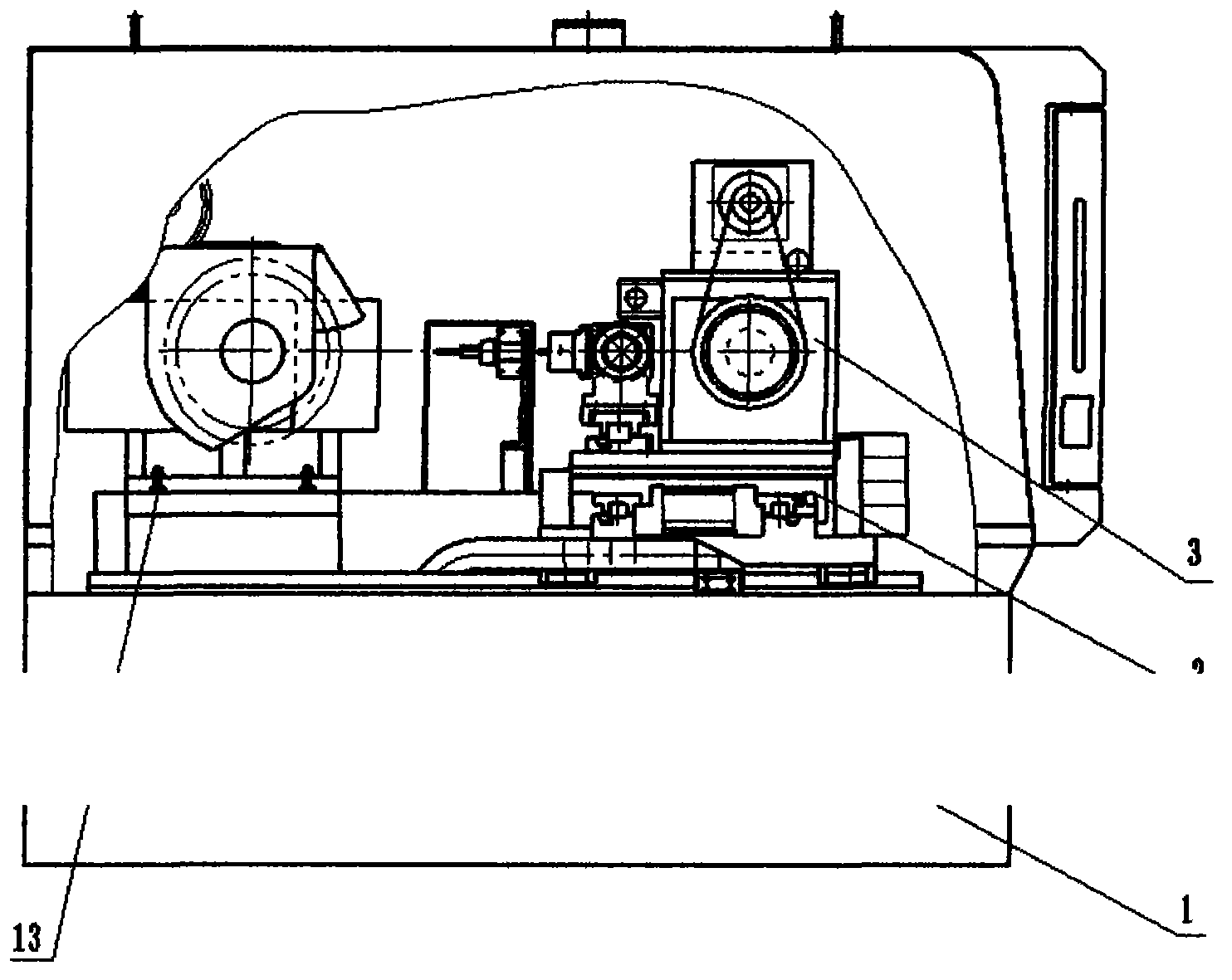

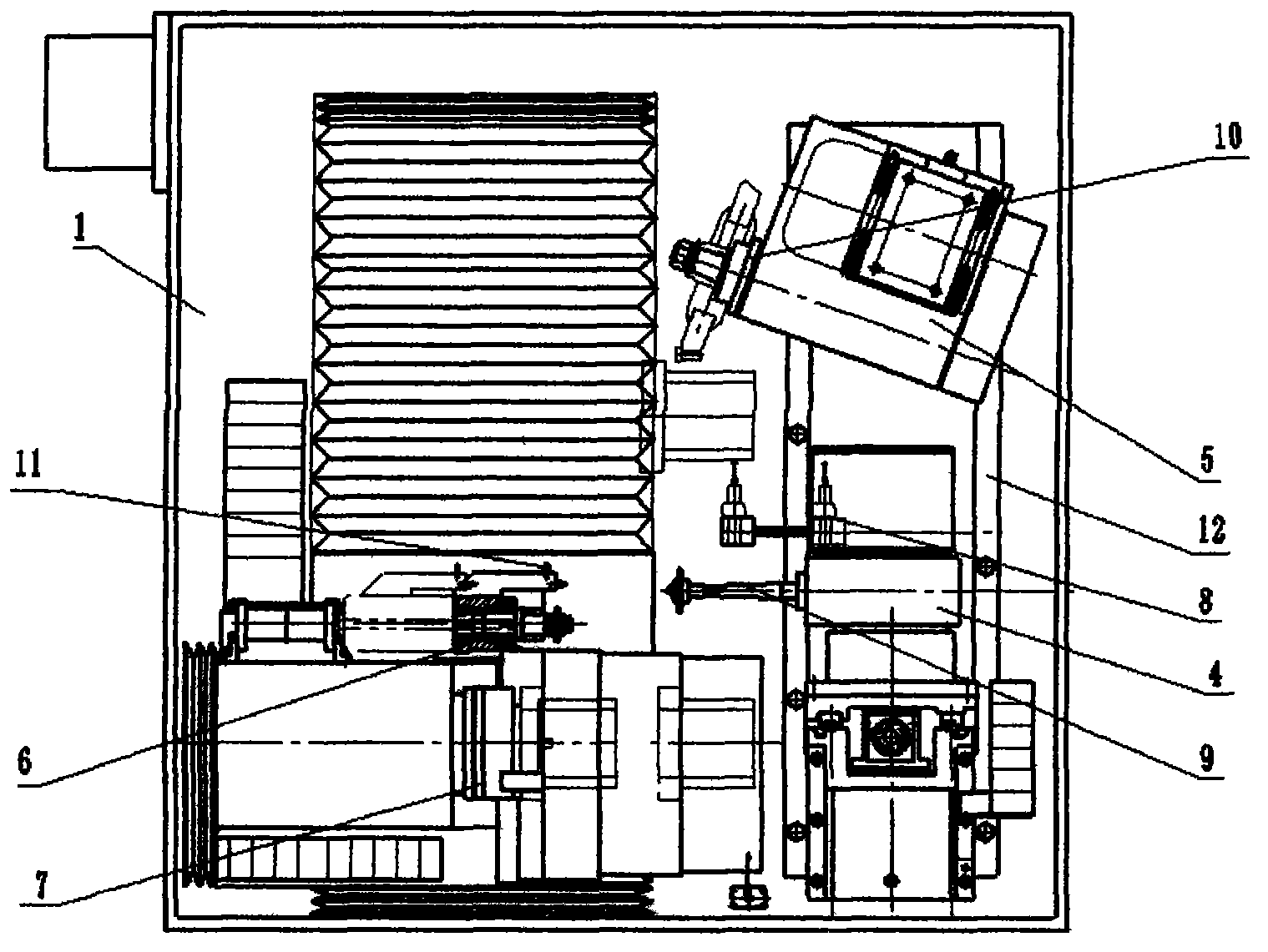

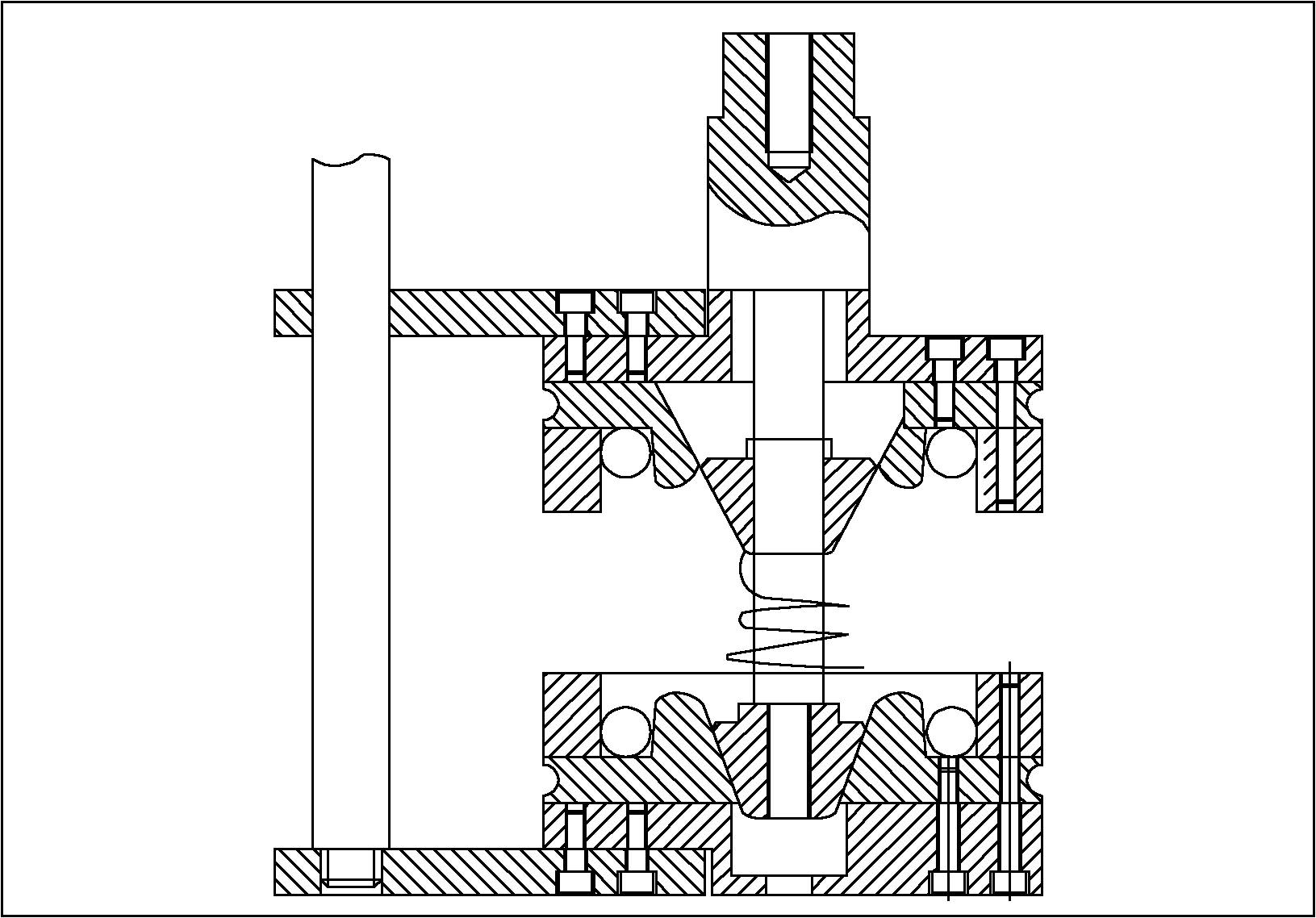

Center complete machine for internal thread grinding

InactiveCN103418860AIncrease productivityImprove machining accuracyThread cutting machinesEngineeringScrew thread

The invention relates to a central complete machine for internal thread grinding. The central complete machine for internal thread grinding is characterized by comprising a bed, a linear roller guide is arranged above the left side of the bed, a cross table is mounted on a slider of the linear guide rail, a headstock is fixed on the cross table, a workpice clamping device is fixed on a spindle end face of the headstock, an internal thread grinding wheel dressing mechanism is fixed right ahead a shell of the headstock, an external-grinding grinding wheel dressing mechanism is fixed right astern the shell of the headstock, a grinding carriage mounting body is fixed on the right surface of the bed, a grinding carriage for internal thread grinding is fixed right ahead the grinding carriage mounting body, a grinding wheel spindle for internal thread grinding is fixed in a shell of the grinding carriage for internal thread grinding, a grinding carriage for external grinding and face grinding of nuts is clamped right astern a fixed mounting body of the grinding carriage for internal thread grinding through T-slot nuts and bolts, a grinding wheel spindle for external grinding and face grinding of the nuts is fixed in a shell of the grinding carriage for external grinding and face grinding of the nuts, and a measuring device is fixed on the top. The central complete machine for internal thread grinding is high in production efficiency and machining precision.

Owner:陕西汉江机床有限公司

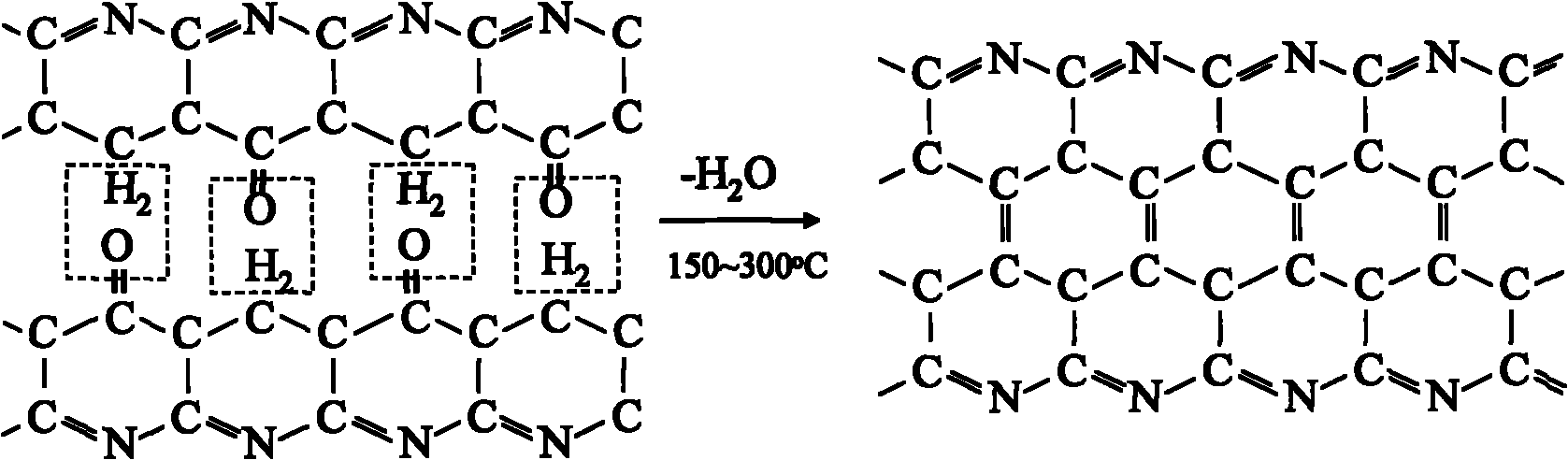

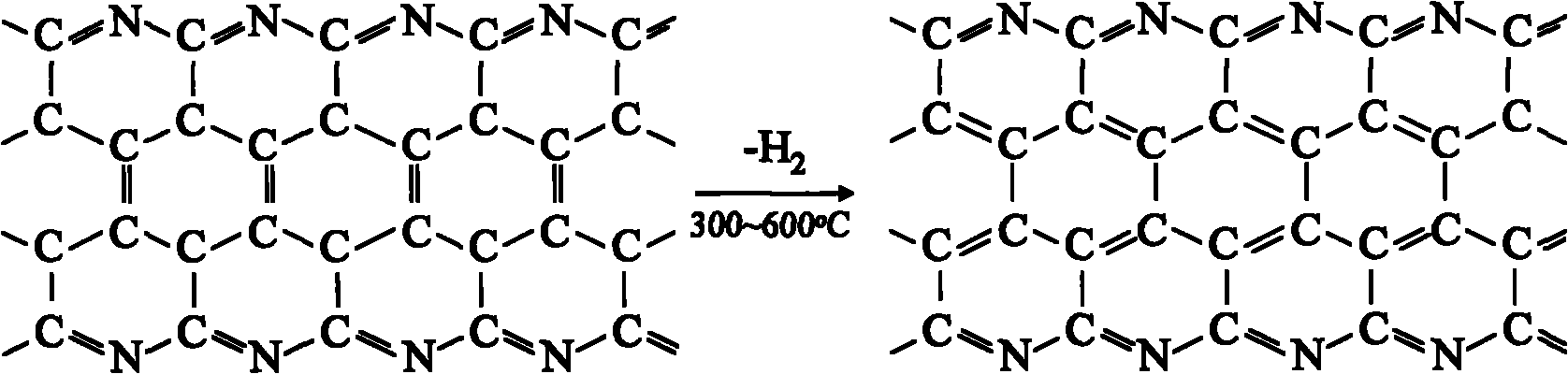

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

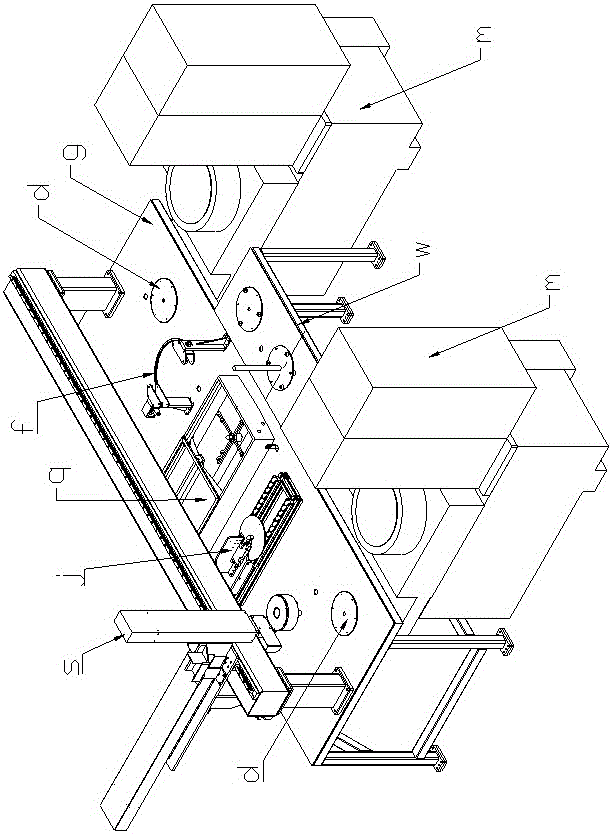

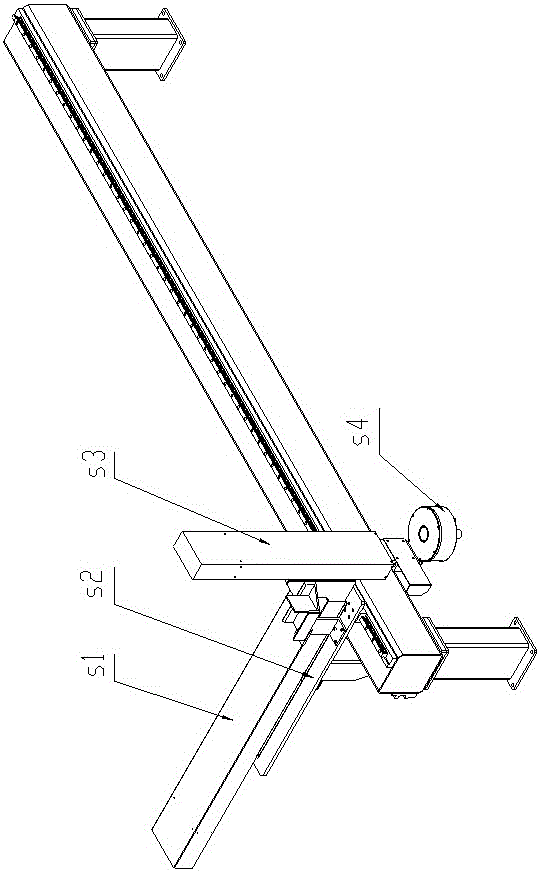

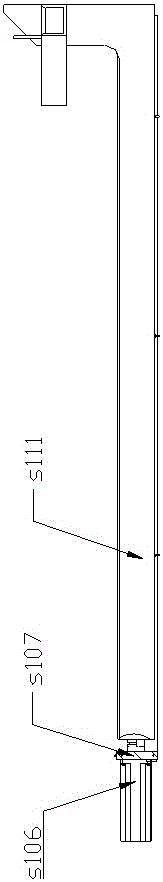

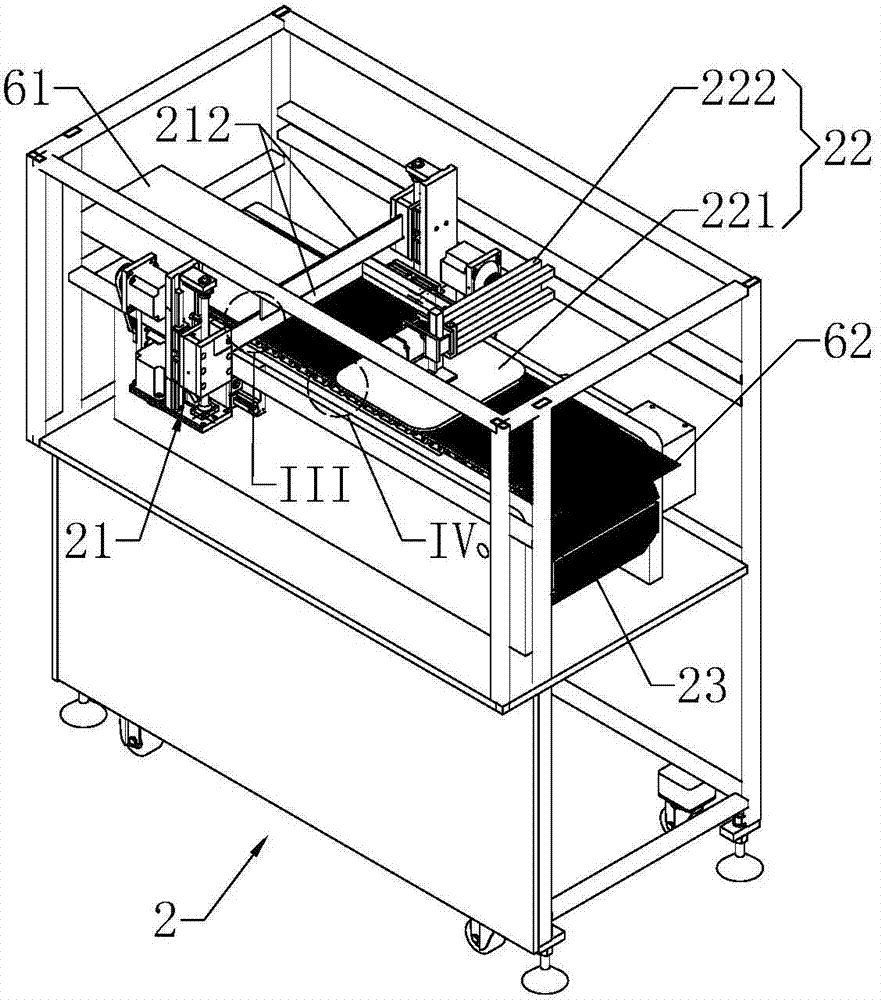

High-precision efficient automatic grinding and detecting production line and high-precision efficient automatic grinding and detecting production method

ActiveCN105728851ARealize automatic detection functionRealize fully automatic processingMetal sawing tool makingMeasurement/indication equipmentsProduction lineThree degrees of freedom

The invention discloses a high-precision efficient automatic grinding and detecting production line which comprises a manipulator mechanism (s) with three degrees of freedom, a cleaning mechanism (q), a turnover mechanism (f), a detecting mechanism (j), a working table (g), a material table (w) and two grinding machines (m). The two grinding machines (w) are respectively arranged at two ends of the working table (g); the manipulator mechanism (s) with the three degrees of freedom is used for loading and unloading materials; the working table (g) is used for mounting the manipulator mechanism (s) with the three degrees of freedom, the cleaning mechanism (q), the turnover mechanism (f), the detecting mechanism (j) and the material table (w); the material table (w) is used for arranging workpieces. The invention further provides a high-precision efficient automatic grinding and detecting production method. The high-precision efficient automatic grinding and detecting production line and the high-precision efficient automatic grinding and detecting production method have the advantages that the high-precision efficient automatic grinding and detecting production line is compact in structure, material grabbing, workpiece cleaning, workpiece turnover and workpiece detecting and mounting can be carried out on the same working table, the two grinding machines can be in simultaneous working states under various actions of manipulators, and accordingly the work efficiency can be greatly improved.

Owner:LINQING XINGHE HONGXIN MACHINE

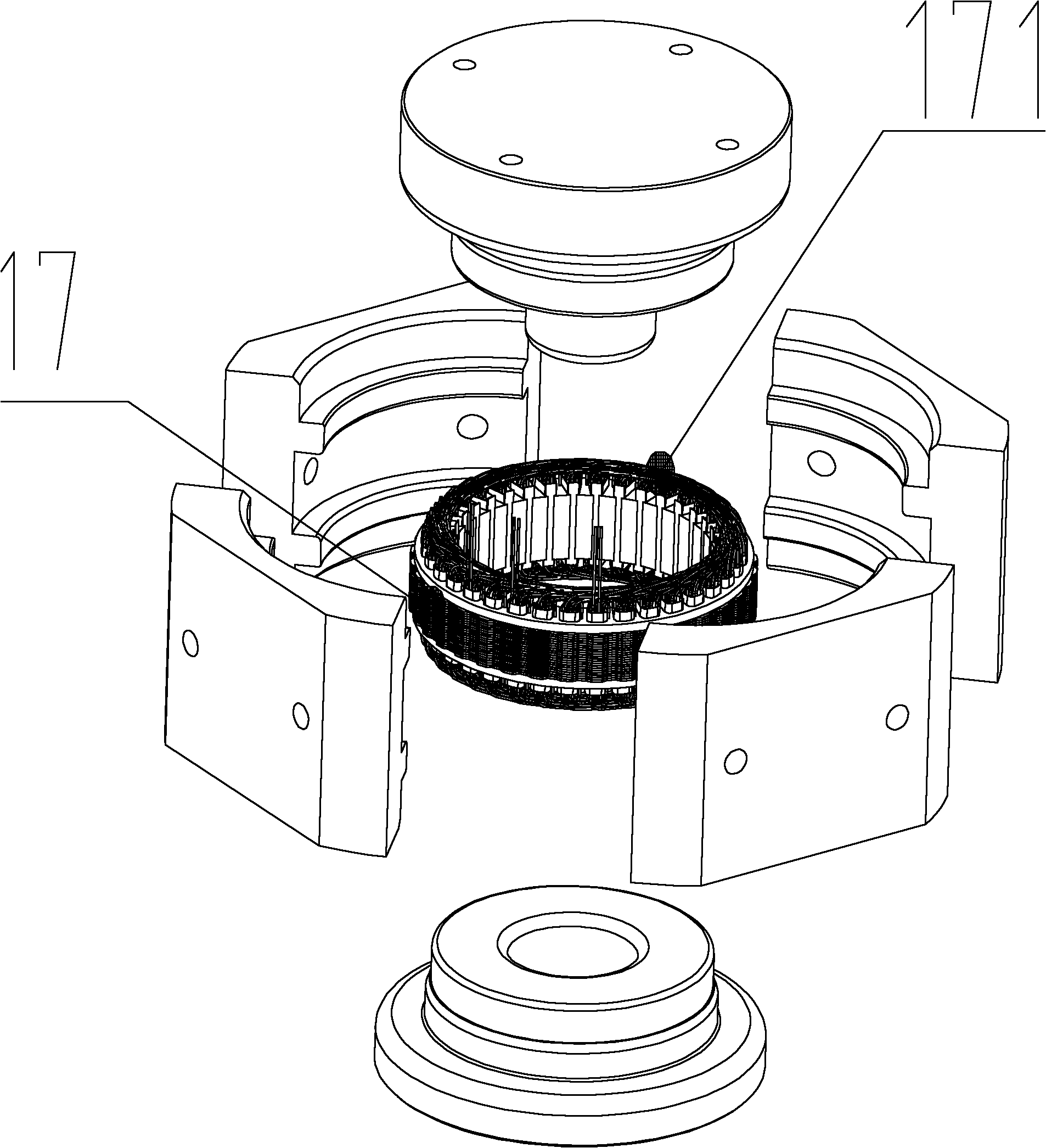

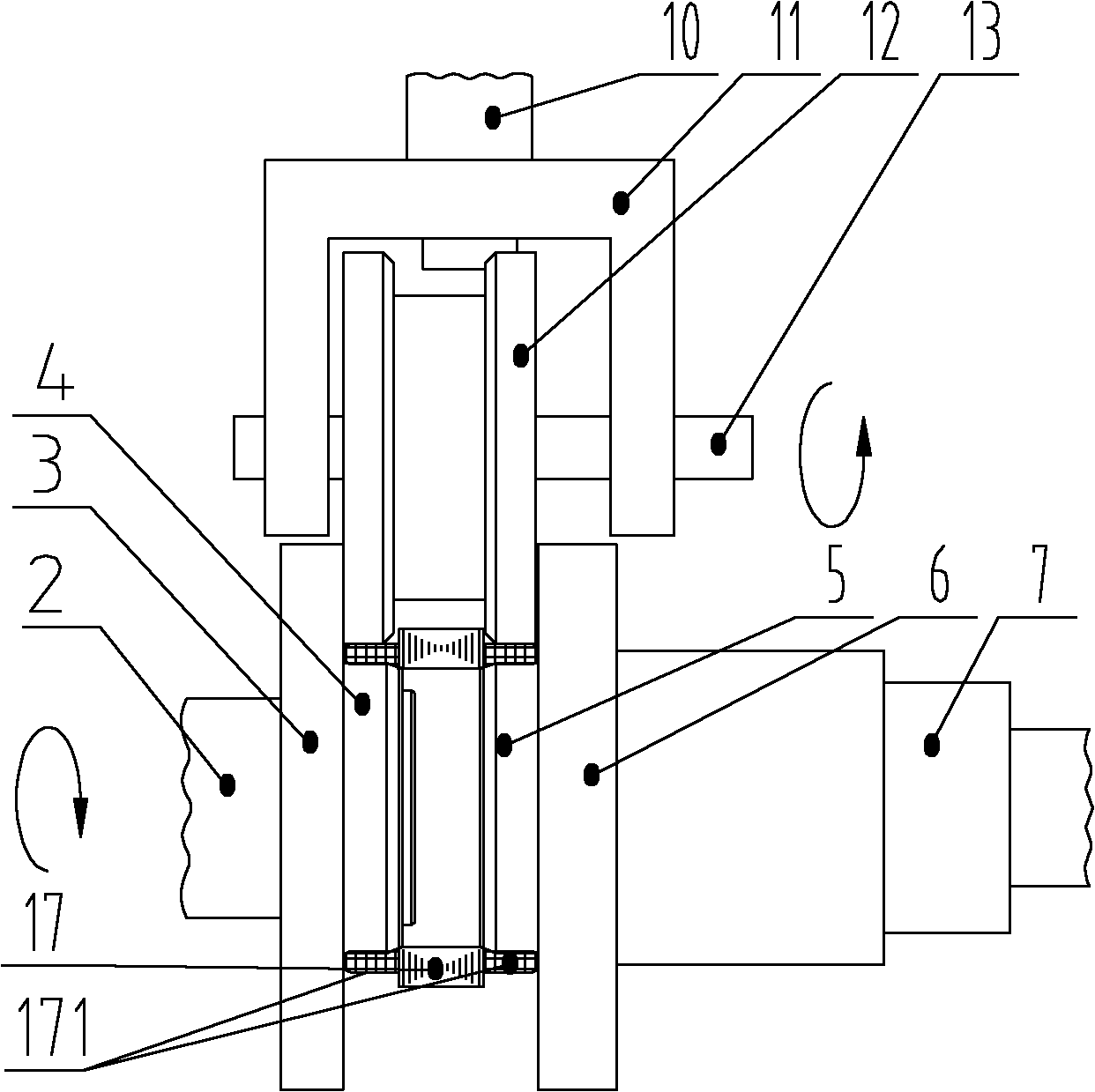

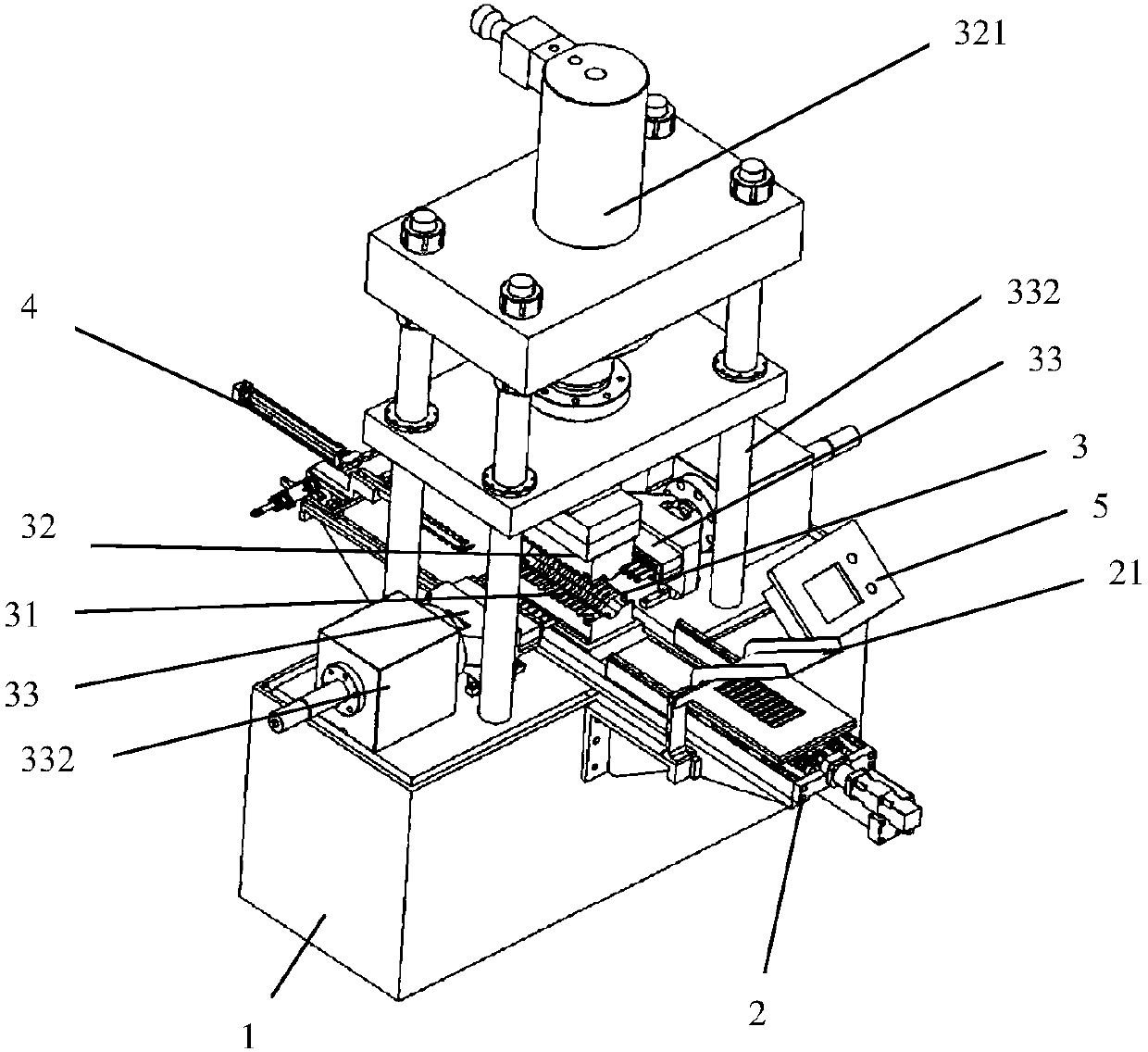

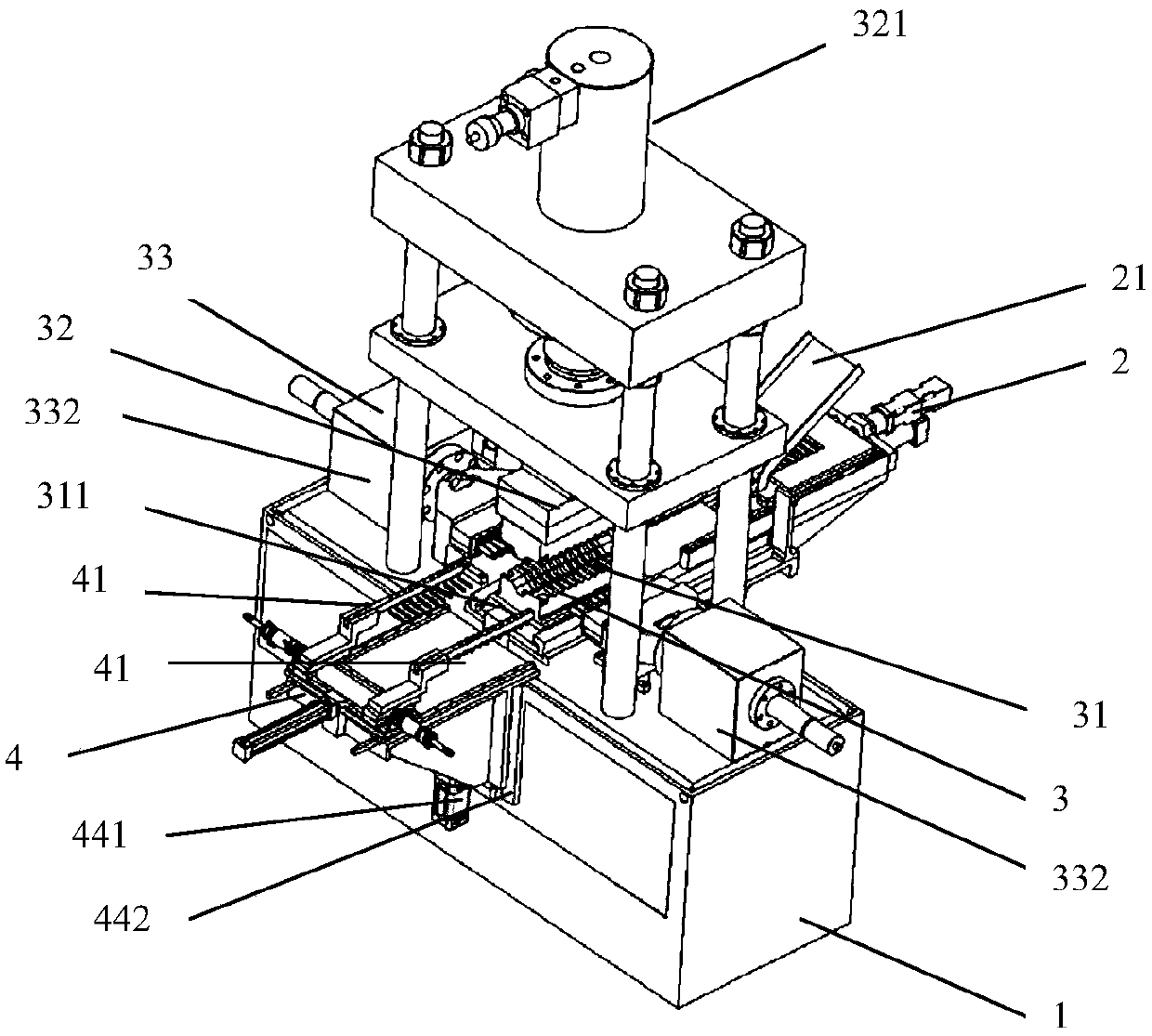

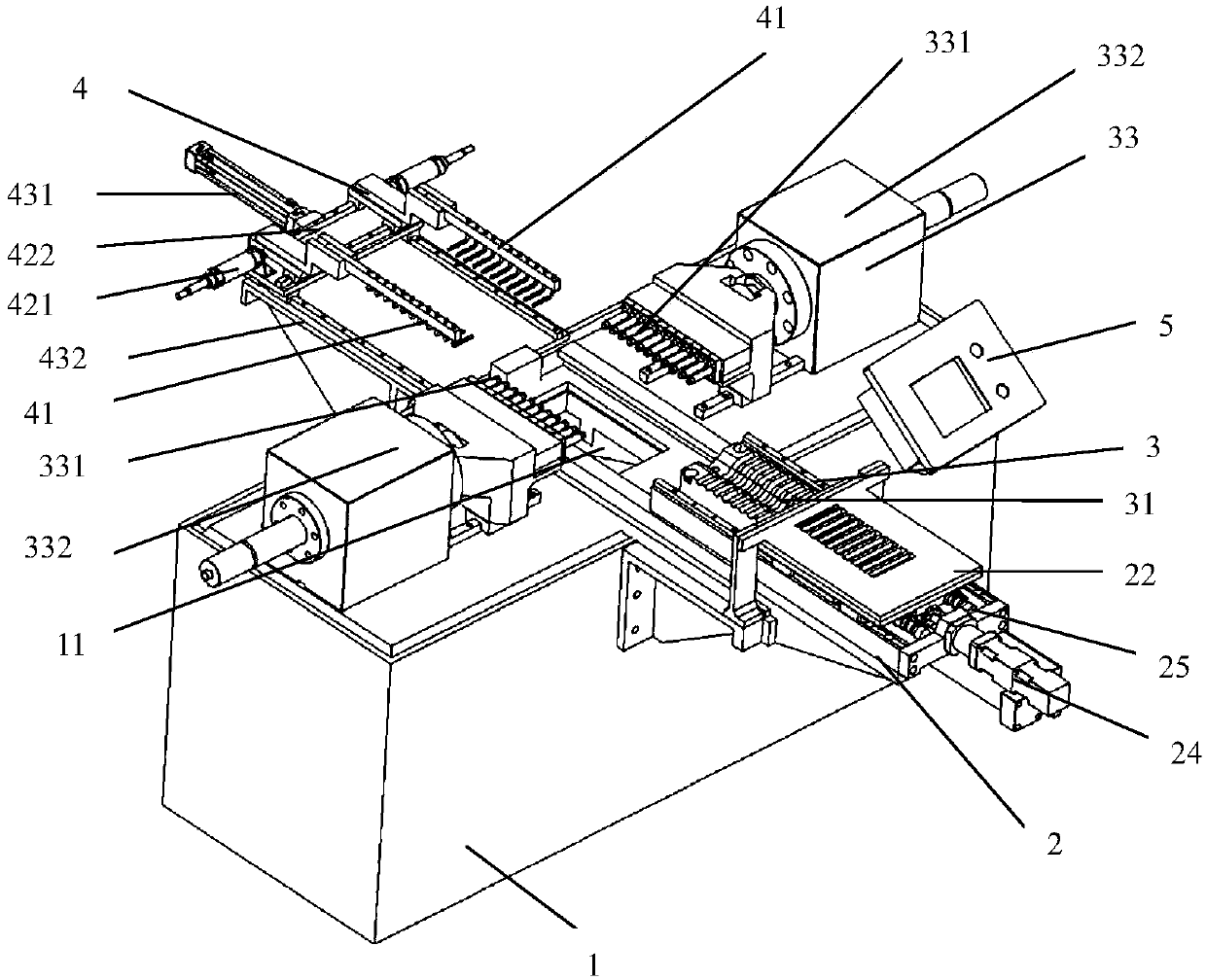

Motor stator coil reshaping method and device

ActiveCN101877519ABeautiful appearanceClosely arrangedManufacturing dynamo-electric machinesDrive shaftStator coil

The invention relates to a motor stator coil reshaping device which comprises a reshaping clamp, a driving mechanism, a transverse motion mechanism and a longitudinal motion mechanism, wherein the reshaping clamp comprises a left flange, a rolling wheel, a right flange, a fixed mandrel and a roller assembly; the right flange is fixed to the moving member of the transverse motion mechanism; the fixed mandrel is fixed on one side of the axial line of the right flange; the left flange is connected with the driving shaft of the driving mechanism; the rolling wheel is fixed on one side of the axial line of the left flange; the rolling wheel and the fixed mandrel are arranged on the same axial line; the left flange is over against the right flange; the roller assembly is fixed on the moving member of the longitudinal motion mechanism; and the roller is over against a position between the left flange and the right hand flange. Conductors in the reshaped coil are compact, can not easily loosen, and have the advantages of favorable dimensional uniformity and small degree of roundness. The invention increases the percent of pass of stator reshaping, and maximally reduces the slippage between the roller and the coil, thereby reducing the damage of the roller on the insulating layer of the coil. The invention has the advantages of simple reshaping operation, high reshaping efficiency and good product quality.

Owner:NINGBO YUNSHENG +2

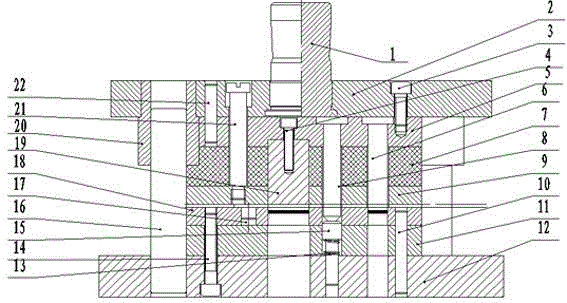

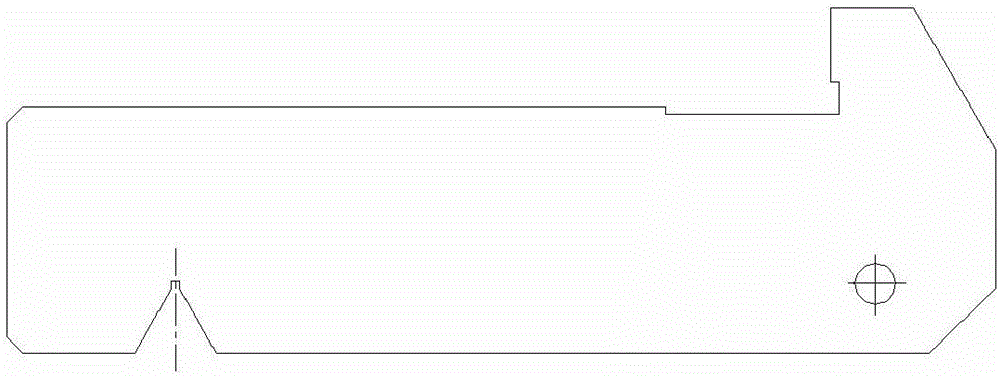

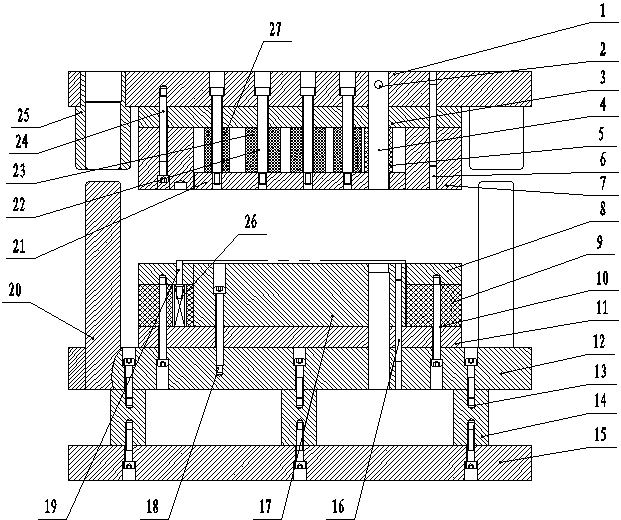

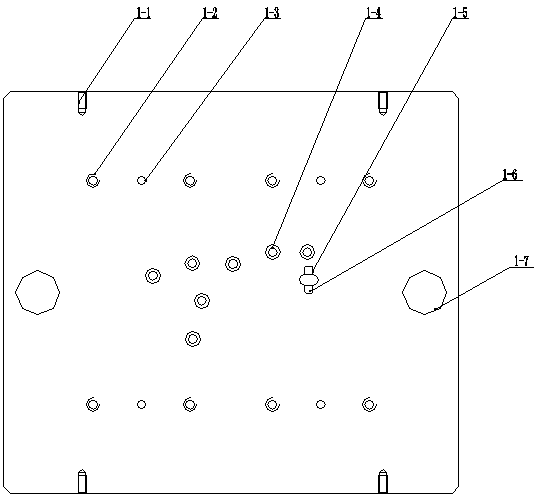

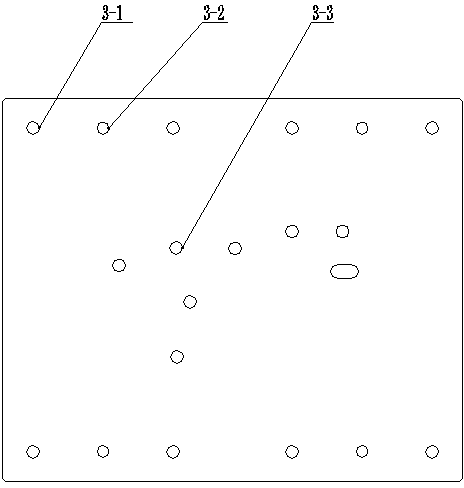

Oil pipe supporting hole punching, side turning and blanking continuous die

InactiveCN104162601ATechnical requirements to ensure product qualityGood size consistencyShaping toolsPerforating toolsEngineeringPipe support

An oil pipe supporting hole punching, side turning and blanking continuous die comprises an upper die part and a lower die part. The upper die part comprises a die handle, an upper die base, a first screw, a second screw, a male die fixing plate, a hole punching male die, discharging rubber, a side turning male die assembly, a discharging plate, a blanking male die, a guiding sleeve, a discharging screw and a first cylinder pin. The lower die part comprises a second cylinder pin, a female fixing plate, a lower die base, a spring, a third screw, a guiding pin, a guiding column, a locating pin and a female die. The die is simple in structure, three processes can be carried out at the same continuously, size accuracy and production efficiency are greatly improved, and the die is suitable for part large-scale production.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Device and method for preparing metal microballoons by using ultrasonic surface standing waves

The invention discloses a device and method for preparing metal microballoons by using ultrasonic surface standing waves, relates to a device and a method for preparing the metal microballoons, and aims to solve the problems that the conventional device for preparing the metal microballoons is complicated, and the size cannot be controlled flexibly. The device consists of an air storehouse and a titanium alloy casting die, a heating element, a base plate, two ultrasonic surface wave emission devices and a droplet flow control device which are positioned in the air storehouse. The method comprises the following steps of: 1, completely dissolving a metal material to obtain a metal solution, gradually dropping the metal solution on the surface of the base plate, and forming spherical metal droplets with the same size under the action of ultrasonic waves; and 2, cooling the metal microballoons by an air-cooling system until the metal microballoons are cooled to be solids, and thus obtaining the metal microballoons with the same size. By the device and the method, various metal microballoons with relatively small sizes can be prepared; the preparation process takes 1 to 2 minutes at one time, so that the production efficiency is greatly improved; and the device and the method are applied to the field of preparation of the metal microballoons.

Owner:HARBIN INST OF TECH

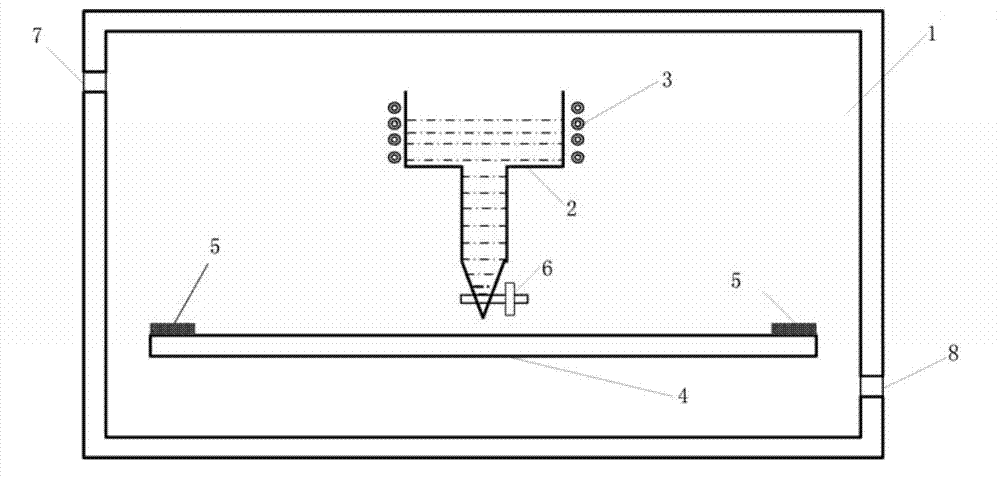

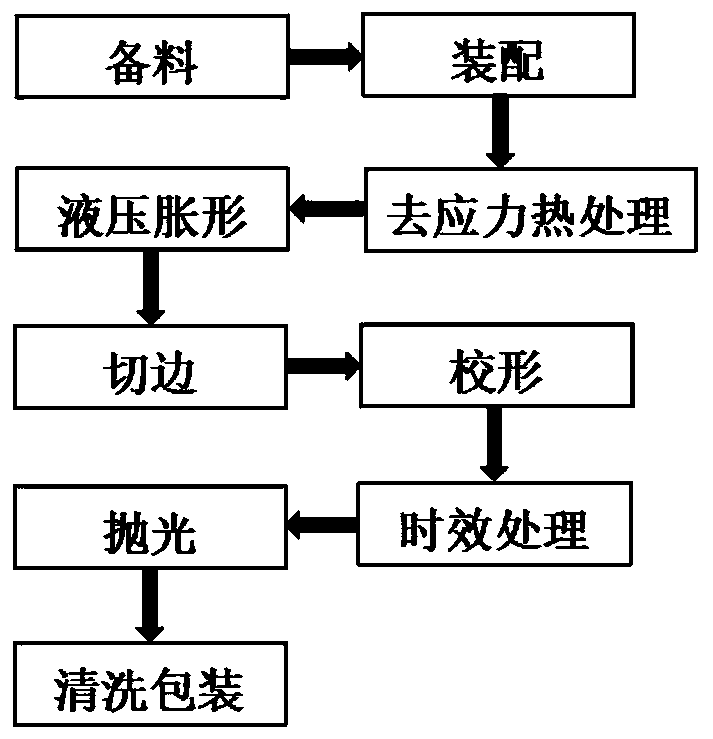

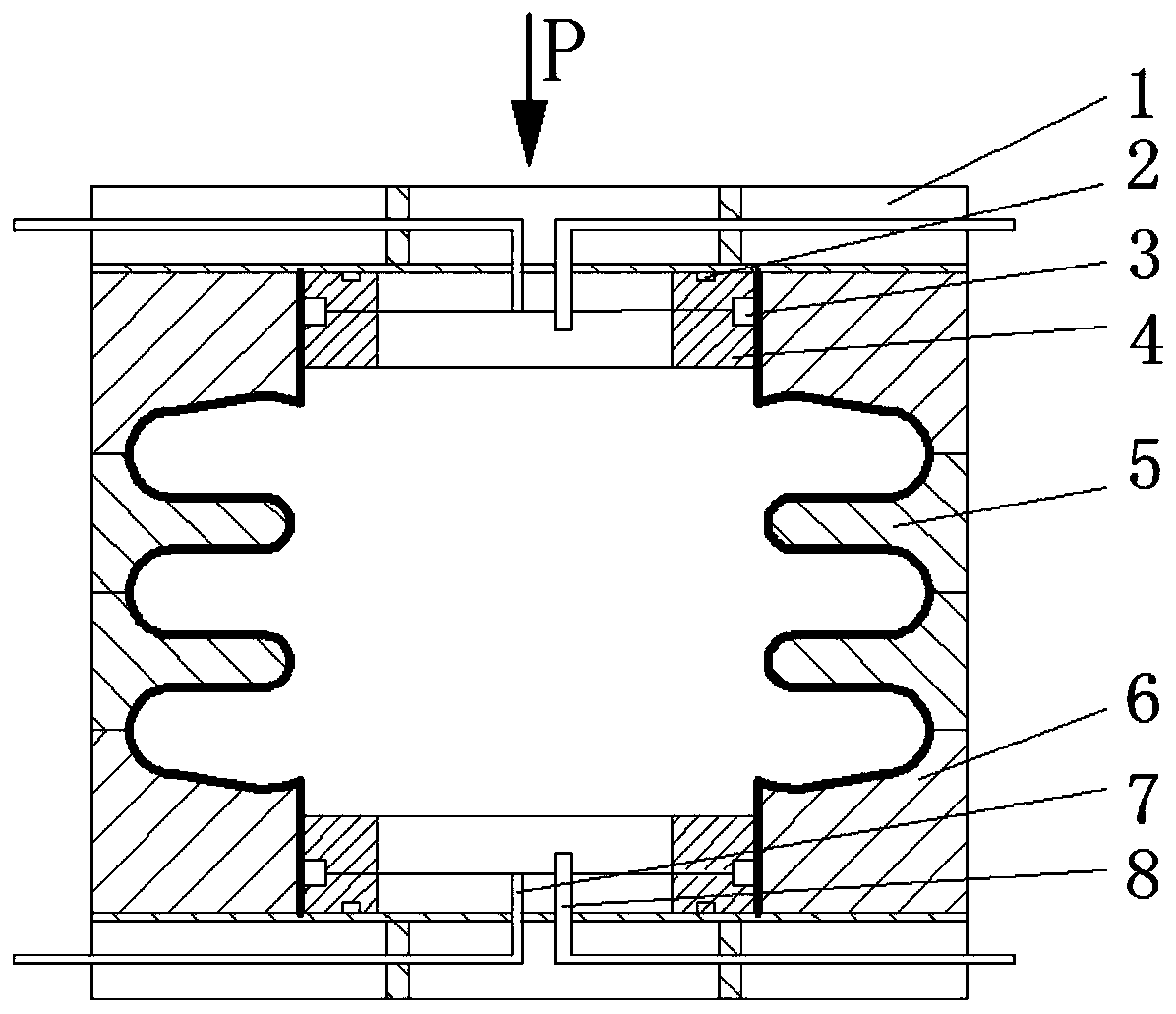

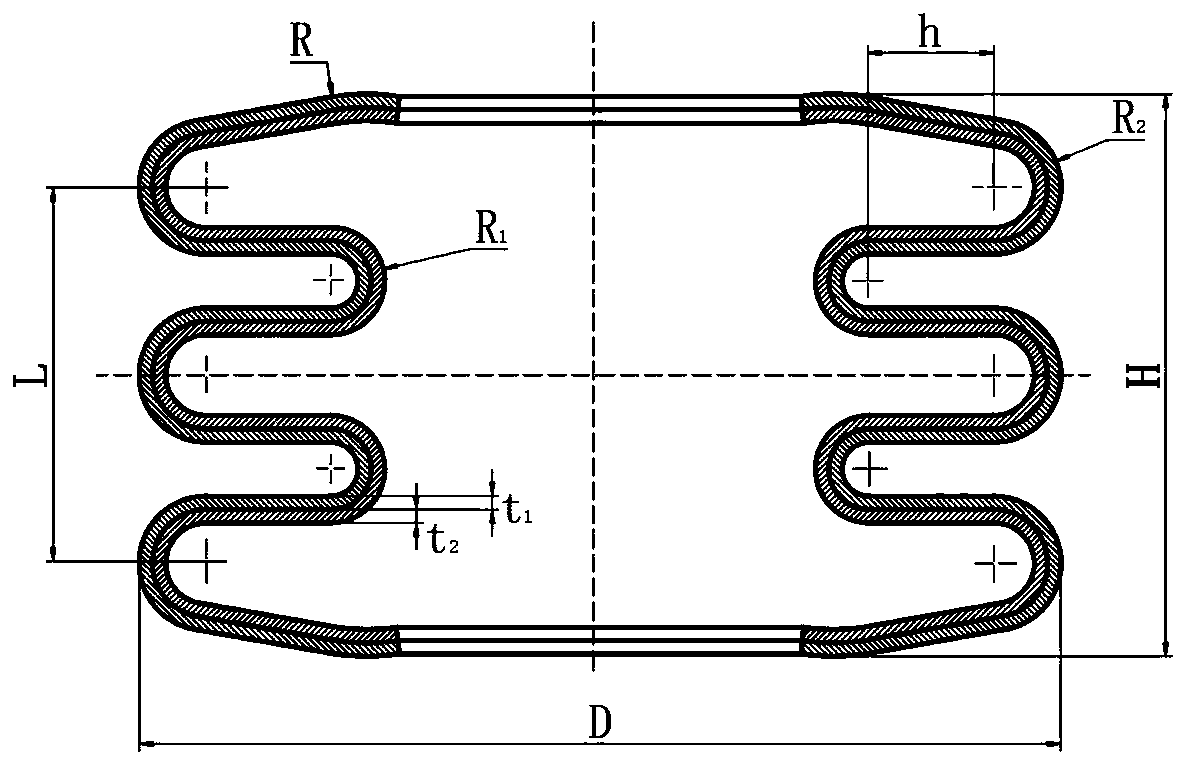

Hydroforming method for manufacturing multilayer metal sealing gasket

The invention discloses a hydroforming method for manufacturing a multilayer metal sealing gasket. The method comprises the following steps of (1) material preparing: manufacturing cylindrical blanks;(2) assembly: sequentially assembling the cylindrical blank of each layer of metal sealing gasket in a sleeve mode; (3) stress relief heat treatment; (4) hydraulic bulging: machining a hydraulic bulging mold consistent with the outline of the multilayer metal sealing gasket product to form a multilayer metal sealing gasket semi-finished workpiece; (5) trimming: removing the hydraulic bulging mold; (6) shape correction: machining a shape correcting mold consistent with the outline of the multilayer metal sealing gasket semi-finished workpiece; (7) aging treatment: carrying out aging strengthentreatment on the multilayer metal sealing gasket semi-finished workpiece; (8) polishing: polishing the sealing surface of the multilayer metal sealing gasket semi-finished workpiece; and (9) cleaningand packaging: carrying out surface cleaning on the multilayer metal sealing gasket semi-finished workpiece to obtain the multilayer metal sealing gasket product. The hydroforming method for manufacturing the multilayer metal sealing gasket has the characteristics of simple and convenient operation and good product quality.

Owner:XI'AN PETROLEUM UNIVERSITY

Machining method of fixed starting point thread

ActiveCN106238834AHigh precisionBreak down barriers of difficultyThread cutting machinesThread cutting auxillary apparatusMachiningIndustrial engineering

The invention discloses a machining method of a fixed starting point thread. The machining method comprises the following steps: machining an outer-diameter size of a part to a thread to be machined state; then carrying out axial tool setting and circumferential tool setting respectively; finally, machining the fixed starting point thread according to a determined tool starting point. By adopting the machining method of the fixed starting point thread, the precision of a fixed starting point position can be effectively improved, and a difficulty barrier of machining the fixed starting point thread is broken; the reliable machining quality is guaranteed, and size consistency and interchangeability are good; the machining method of the fixed starting point thread has the effect of improving the machining efficiency and the yield.

Owner:SHANXI NORTH MACHINE BUILDING

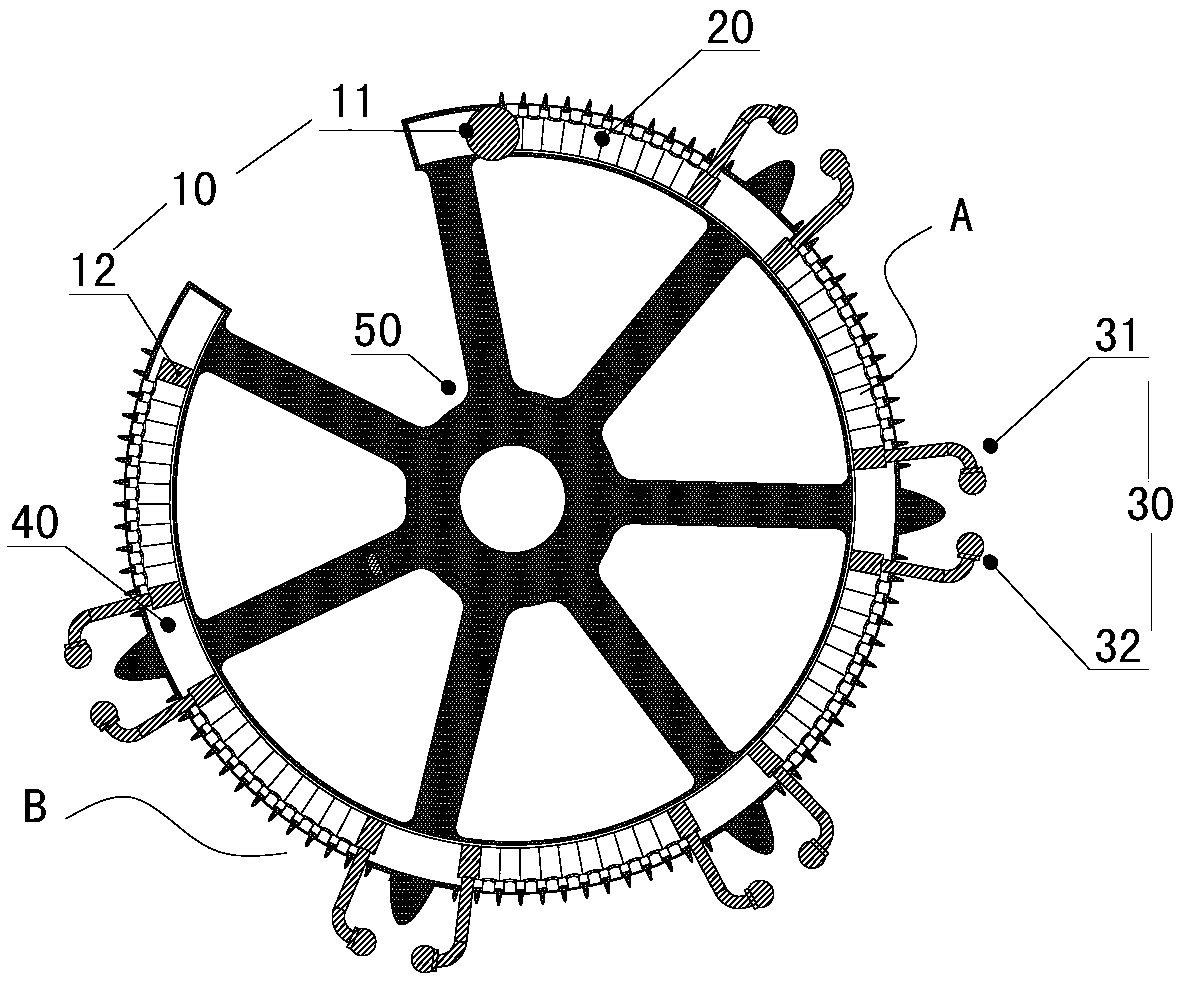

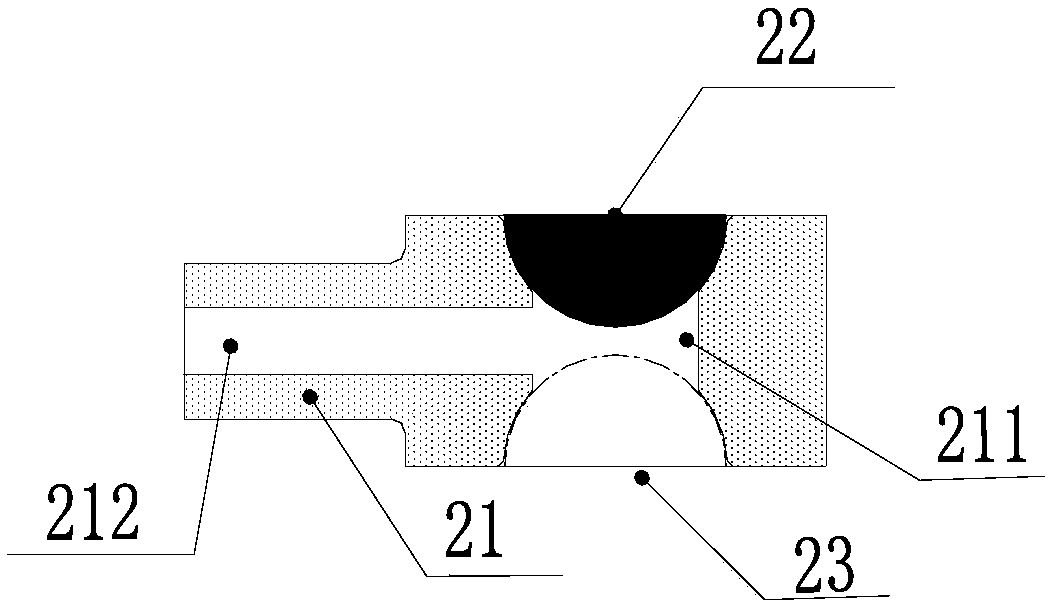

Combined lightning arrester based on disc-shaped multi-gap arc extinguishing and lightning protection device

ActiveCN109217112ASimple structureImprove reliabilitySpark gap detailsWind energy generationLightning strikeEngineering

The invention discloses a combined type lightning arrester based on a disc-shaped multi-gap arc extinguishing and lightning protection device, in particular to a lightning arrester applied to overheadlines above 10KV. The structure of the invention is as follows: upper and lower connecting fittings are respectively arranged on the upper and lower parts of the insulating support rod, the upper spherical electrode is connected with the upper connecting fittings, the lower spherical electrode is connected with the lower connecting fittings, a first, second,.. N-th disk-shaped multi-gap arc extinguishing lightning protection device is serially connected between the upper connecting fittings and the lower connecting fittings, N is a natural number, 1 <= N <= 8. The lightning current is elongated, elongated and ejected to extinguish the electric arc, thereby avoiding the occurrence of inter-phase short circuit fault and reducing the counterattack probability caused by lightning strike lightning protection wire; and the lightning current is elongated, elongated and ejected. Strong ability to withstand lightning surge, large flow capacity, high security; Good consistency of discharge gapsize; Simple structure; The special multi-gap arc will not be reignited because of the rapid recovery of dielectric insulation after the power frequency continues to flow through the zero-extinguishing arc.

Owner:WUHAN WEICHUANGYUAN ELECTRONICS TECH CO LTD

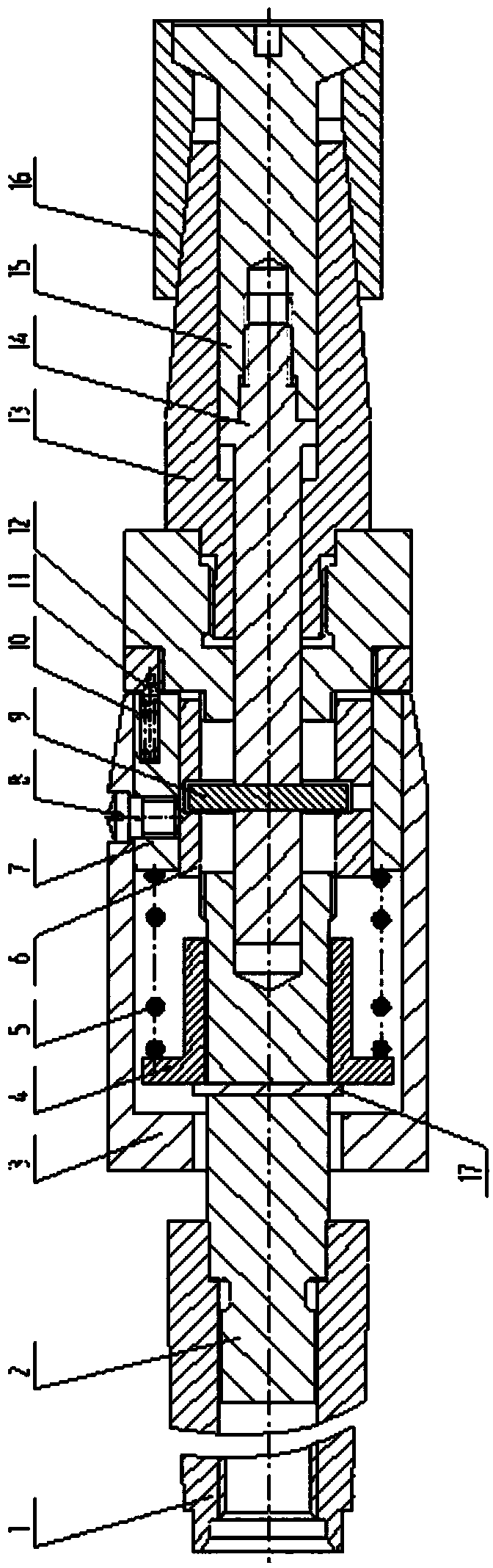

Diameter size interchangeable adjustable grinding rod and system

ActiveCN104385119AGood stabilityImprove processing cost and efficiencyLapping toolsEngineeringPore diameter

The invention provides a diameter size interchangeable adjustable grinding rod. The diameter size interchangeable adjustable grinding rod comprises a connecting rod, a transmission device, a first pull rod, a second pull rod, a spring bushing and a guide sleeve, wherein a first blind hole is formed in one end of the connecting rod; the first blind hole is in clearance fit with the first pull rod; one end of the first pull rod is in threaded connection with one end of the second pull rod; the guide sleeve is arranged outside the first pull rod and the second pull rod; one end of the guide sleeve is in threaded connection with the connecting rod; the other end of the guide sleeve and the other end of the second pull rod are both inserted into elastic grooves which are formed in the two end surfaces of the spring bushing along the circumferential direction; the other end of the guide sleeve is conical; the first pull rod and the second pull rod are driven to translate axially by the transmission device. The invention also provides a corresponding system. According to the diameter size interchangeable adjustable grinding rod and the system, an adjustable function that the worn diameter can be compensated during a grinding process can be realized; through an interchangeable function, the machining requirements of products with different pore diameters are met.

Owner:SHANGHAI INST OF SPACE PROPULSION

Wafer level packaging method of light emitting diode with adjustable lens focus

InactiveCN102569563AQuick GlueImprove light outputDecorative surface effectsChemical vapor deposition coatingLight-emitting diodeMaterials science

The invention discloses a wafer level packaging method of a light emitting diode with an adjustable lens focus. The method comprises the following steps: in a first step, etching a light emitting diode lens mould microchannel array and a spacing control mould microchannel array surrounding a light emitting diode lens mould groove on a silicon wafer, and disposing proper amount of thermal outgassing agents in a light emitting diode lens mould microchannel; in a second step, carrying out anode bonding of the silicon wafer and a borosilicate glass water in vacuum to form a sealed cavity; in a third step, carrying out heating and heat preservation on a bonding wafer in the air, forming a spherical glass micro-cavity and a spacing control projection ring, carrying out cooling and annealing, and removing silicon to obtain a light emitting diode packaging lens array; in a fourth step, pasting a light emitting diode chip on a substrate; in a fifth step, bonding a wafer level glass micro-cavity and the substrate; in a sixth step, filling up glue into a gap between a light emitting diode chip and the wafer level glass micro-cavity through a spacing control ring gap, and carrying out solidification. The method can be carried out on a wafer level, and the method has the advantages of simplicity and low cost.

Owner:吕思远

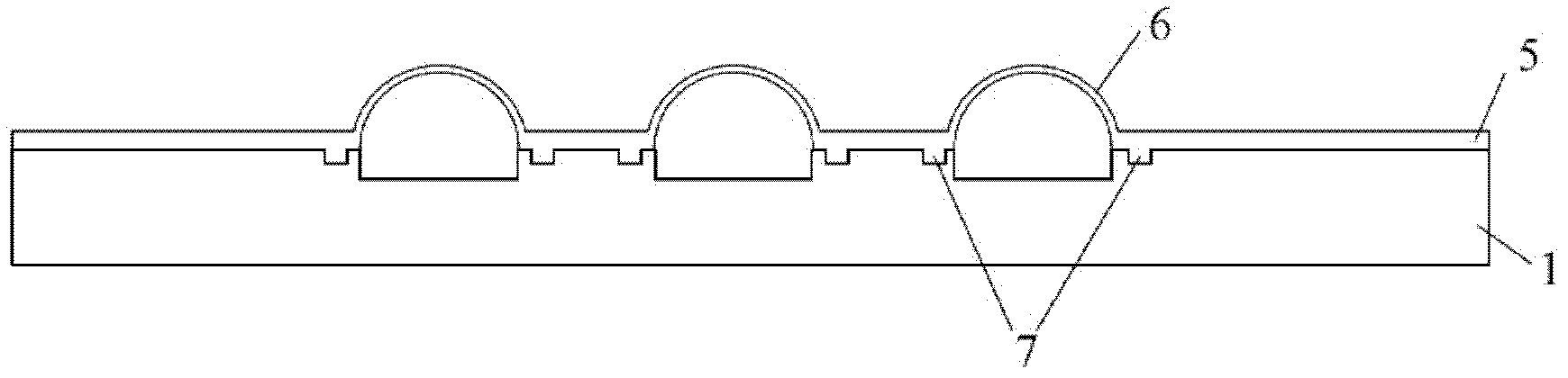

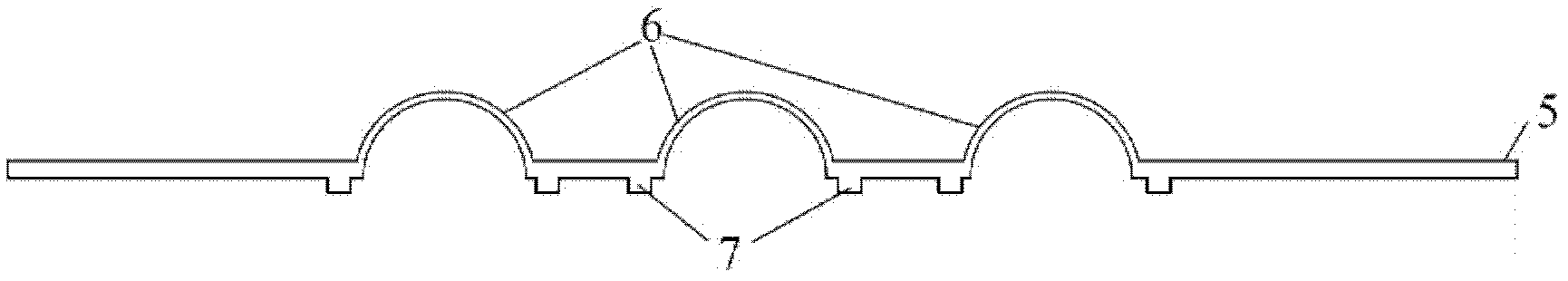

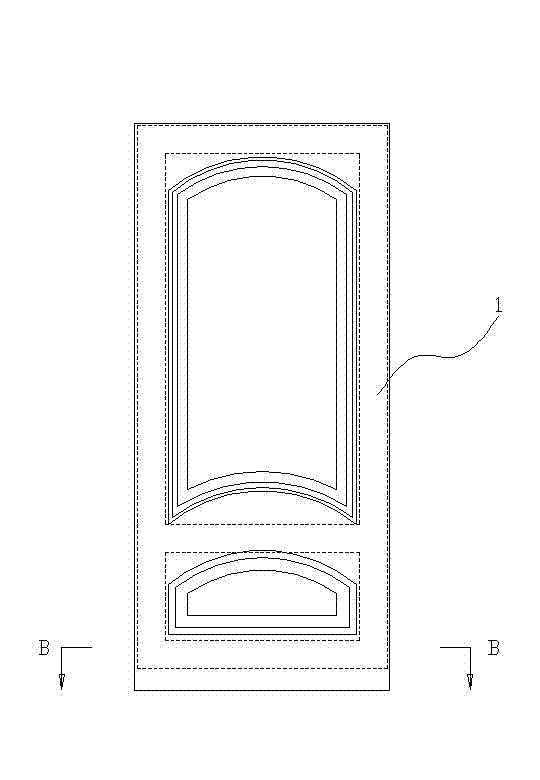

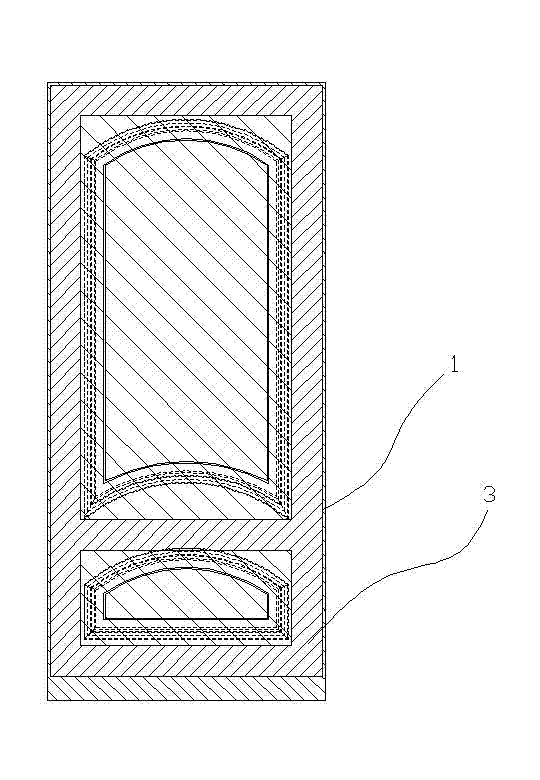

Wood-like polyurethane door and preparation method thereof

ActiveCN102758582ADimensionally stableSmall expansion coefficientDoor leavesPolymer scienceThermal insulation

The invention discloses a wood-like polyurethane door and a preparation method thereof. The wood-like polyurethane door comprises a door body, wherein a multilayer-spliced multilayer board body having a supporting function is integrally formed in the door body. The preparation method of the wood-like polyurethane door comprises the following steps: heating a die to 30-70 DEG C, putting the multilayer board body in the die; proportionally mixing raw materials; spraying a stripping agent in the die; injecting the mixture in the step 2 into the die until the mixture covers the whole spliced board body, and curing for 30-90 minutes; stripping, taking the product out of the die, and carrying out constant-temperature setting in a thermal insulation chamber; carrying out trimming, deburring and the like on the product; and spraying paint to complete the manufacture of the wood-like polyurethane door. The invention has the advantages of stable dimension, small expansion coefficient, no warping or bending, no cracking, and high dimensional uniformity of the manufactured product.

Owner:黄吉力

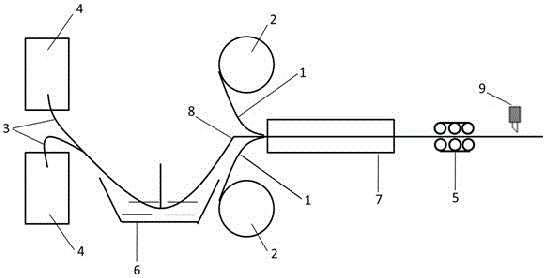

Method for improving surface roughness and dimension consistency of wind turbine blade root pultrusion preformed units

InactiveCN105881936AGood size consistencyUniform thicknessDomestic articlesRenewable energy source integrationGlass fiberYarn

A method for improving surface roughness and dimension consistency of wind turbine blade root pultrusion preformed units at least comprises the steps of a, preparing an underpressed strip-shaped demolding cloth; b, arranging a demolding cloth releasing device on the peripheral of a forming mold, and winding the underpressed strip-shaped demolding cloth around the demolding cloth releasing device; c, arranging glass fiber yarn on a creel, and pulling the glass fiber yarn with a pultrusion device to pass through a glue tank and then enter into the forming mold together with the underpressed strip-shaped demolding cloth synchronously, wherein the underpressed strip-shaped demolding cloth is attached to the inner surface of the forming mold, in other words, the impregnated glass fiber yarn is wrapped in the underpressed strip-shaped demolding cloth; d, pulling the impregnated glass fiber yarn and the underpressed strip-shaped demolding cloth with the pultrusion device to pass through the mold to be heated, cured and formed, and then conducting cutting with a cutter into a specified length according to dimension requirement, so that the root pultrusion preformed units with the demolding cloth are obtained; e, tearing off the demolding cloth before placing the root pultrusion preformed units in a shell mold, so that the wind turbine blade root pultrusion preformed units are obtained.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

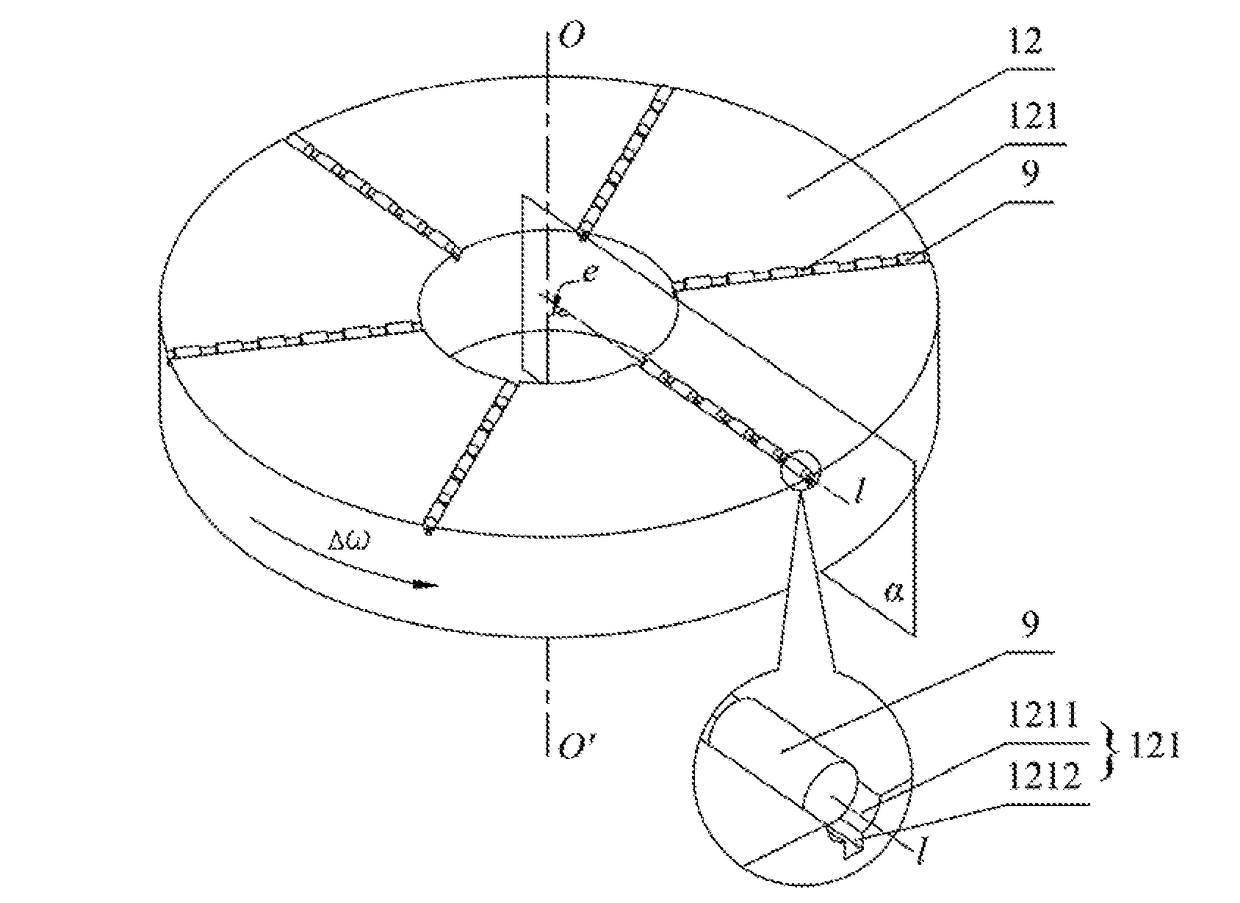

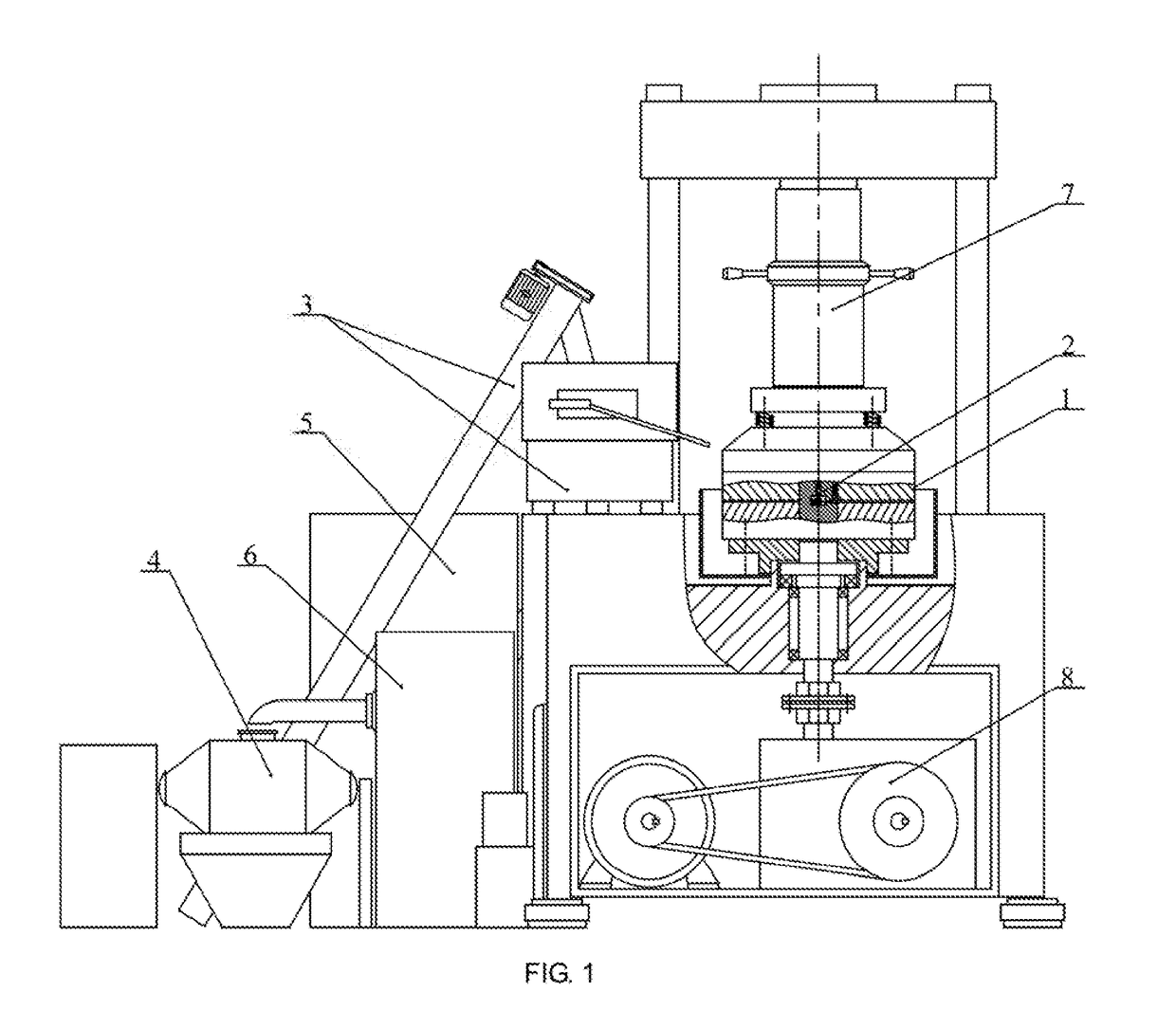

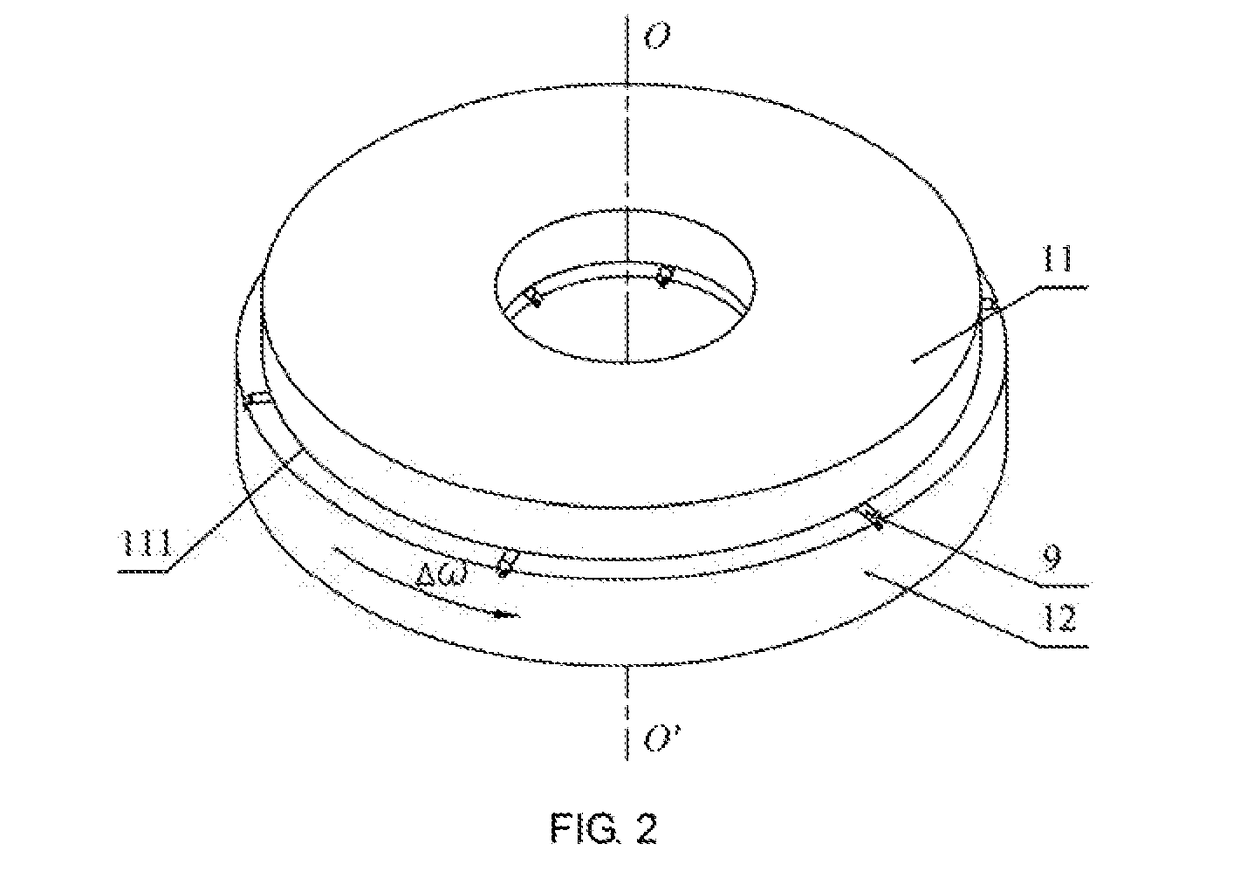

Cylindrical-component grinding device, and workpiece advancing apparatus and grinding method thereof

ActiveUS20170274494A1High shape accuracyHigh dimensional consistencyLapping machinesLapping toolsHigh volume manufacturingSurface grinding

A double-disc straight groove cylindrical-component surface grinding disc, includes a first grinding disc and a second grinding disc, rotating relative to each other; the the first grinding disc's working face is planar; the second grinding disc's surface, opposite the first grinding disc, includes a set of radial straight grooves, with groove faces of the straight grooves are the working face of the second grinding disc; the cross-sectional outline of the working face of the second grinding disc is arcuate or V-shaped or is a V-shape having an arc; during grinding, a workpiece spins inside the straight grooves, while under the effect of an advancing apparatus, the workpiece slides in translational motion along the straight grooves. The described grinding disc device has high-volume production capabilities, and the shape accuracy and size consistency of the cylindrical roller's cylindrical surface and the efficiency in machining are improved, and machining cost is reduced.

Owner:TIANJIN UNIV

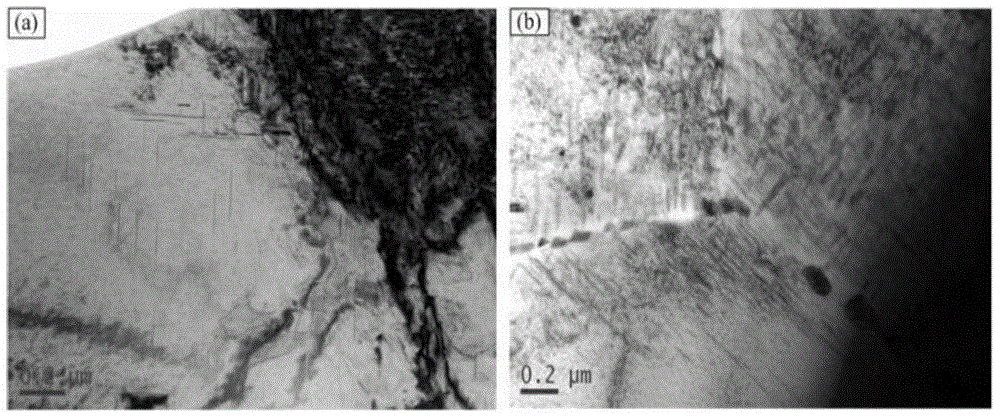

Deep conical copper shaped charge liner tissue ultrafine crystallization gradient control method

ActiveCN108517477AImprove plasticityEvenly distributedExplosive chargesTissue distributionSuperficial mass

The invention provides a deep conical copper shaped charge liner tissue ultrafine crystallization gradient control method, which comprises the steps of extrusion shaping, re-crystallization heat treatment and high-frequency percussion, wherein in the extrusion shaping step, multi-pass extrusion is used; the high-frequency impact knocking speed is 15000 to 40000 times / minute; the knocking force is1200 to 2000 N; the times is 1 to 3 times. The control technology provided by the invention realizes the deep conical copper shaped charge liner shaping and surface quality control; the material plasticity is improved; the fine crystal tissues can be obtained; the ultrafine crystal gradient tissues distributed in the thickness direction are formed on the surface layer in the charge shaped liner. The ultrafine crystal gradient tissues distributed in the thickness direction of the charge shaped liner are obtained by using the method; the tissue distribution in the bus direction is uniform; a novel preparation method is provided for the invention of the high-performance deep conical copper shaped charge liner.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

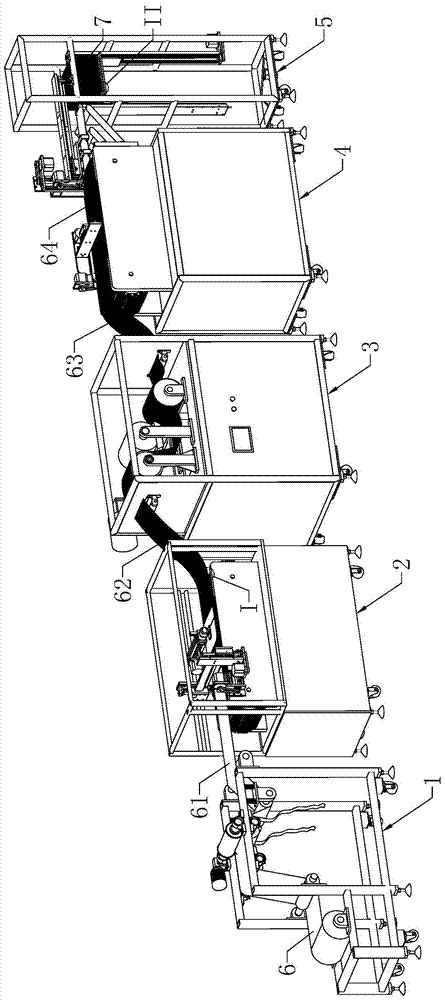

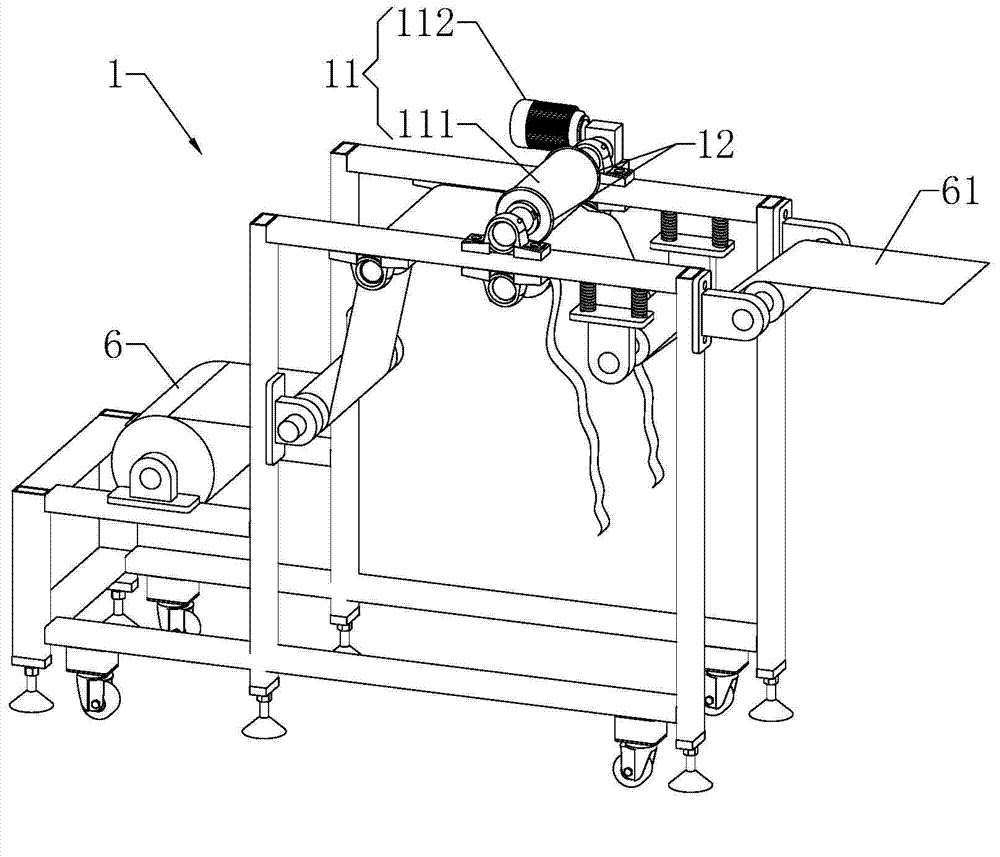

Automatic production equipment and method of metal honeycomb core

ActiveCN103481546AHigh degree of automationIncrease productivityPaper/cardboard articlesMetal foilHoneycomb

The invention provides automatic production equipment of a metal honeycomb core. The automatic production equipment comprises an edge cutting device used for cutting a metal foil to required width, a forming device used for corrugating the cut metal foil, an adhesive coating device used for coating adhesive on the corrugated metal foil, a cutting device used for cutting the adhesive-coated metal foil into unit metal foils with the required length and a stacking device used for stacking and bonding the unit metal foils to form the metal honeycomb core; and the devices are sequentially converged to form a production line. The automatic production equipment is capable of producing metal honeycomb cores automatically, manual intervention is omitted, automation is high, producing efficiency is high, and producing cost is low. The invention further provides an automatic production method of the metal honeycomb core, the method is implemented by the aid of the automatic production equipment of the metal honeycomb core, manual intervention is omitted, and producing efficiency is high. Rejection rate of the metal honeycomb cores produced by the aid of the equipment and the method is extremely low.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Welding technology for rear automobile frame assembly shaped like Chinese character 'jing'

InactiveCN105252154AGood size consistencyImprove welding qualityVehicle componentsMetal working apparatusChinese charactersVehicle frame

A welding technology for a rear automobile frame assembly shaped like a Chinese character 'jing' is characterized in that all installed and welded parts to be installed and welded are firstly clamped on a special welding clamp for locating and clamping, gas shielded welding is adopted for carrying out manual spot welding on all spot welding positions, the rear automobile frame assembly obtained after spot welding is finished is arranged on a full welding clamp of a robot to be located, then a pneumatic clamp is used for clamping, and the robot is started for sequence welding; and full welding is carried out on a bracket assembly and a supporting plate, full welding is carried out on a stabilization rod support assembly and an auxiliary arm support assembly, the bracket assembly is mounted in a full welding manner, gas shielded welding is manually utilized for carrying out welding supplementary on missing welded positions of the robot, re-tapping is carried out on nuts, and welding slag around a welding seam is cleared away. The weld penetration rate completely reaches the standard, the frame size consistency is good after welding, the quality of the welding seam is good, missing welding is avoided, operation by workers is convenient, labor intensity is low, production efficiency is high, cost is low, and wide application value is achieved in production of products of the same kind.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Red copper bent pipe fitting forming integrated machine

ActiveCN107695146AHigh degree of automationImprove processing efficiencyMetal-working feeding devicesStripping-off devicesEngineeringCopper

Owner:NINGBO JINTIAN COPPER TUBE

Right mounting bracket blanking and punching composite die

The invention provides a right mounting bracket blanking and punching composite die. The right mounting bracket blanking and punching composite die comprises an upper die assembly and a lower die assembly. The upper die assembly comprises an upper die base, a fixing pin, an upper die base plate, a square male die, rubber, a female die splicing block, a stripper plate, stripper screws, stripping rubber, guide sleeves and small round rubber. The upper die base is located on the uppermost portion of the die. The upper die base plate is located below the upper die base. The female die splicing block is located below the upper die base plate. The square male die is located in the upper die base. The fixing pin is located in the square male die. The lower die assembly comprises ejector plates, ejection rubber, a lower die base plate, a lower die base, cushion blocks, a base plate, a male die splicing block, locating pins, guide posts and small cylindrical springs. The base plate is located on the lowermost portion of the die. The cushion blocks are located above the base plate. The lower die base is located above the cushion blocks. The lower die base plate is located above the lower die base. The male die splicing block is located above the lower die base plate. The ejector plates are located beside the male die splicing block. According to the right mounting bracket blanking and punching composite die, a male die and a female die are made into splicing block inverted-mounting structures, so that the die is convenient to replace and maintain.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com