Device and method for preparing metal microballoons by using ultrasonic surface standing waves

A technology of ultrasonic surface wave and metal microspheres, which is applied in the field of devices for preparing metal microspheres, can solve the problems of complex metal microsphere devices and inflexible size control, achieve good size consistency, avoid sticking, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

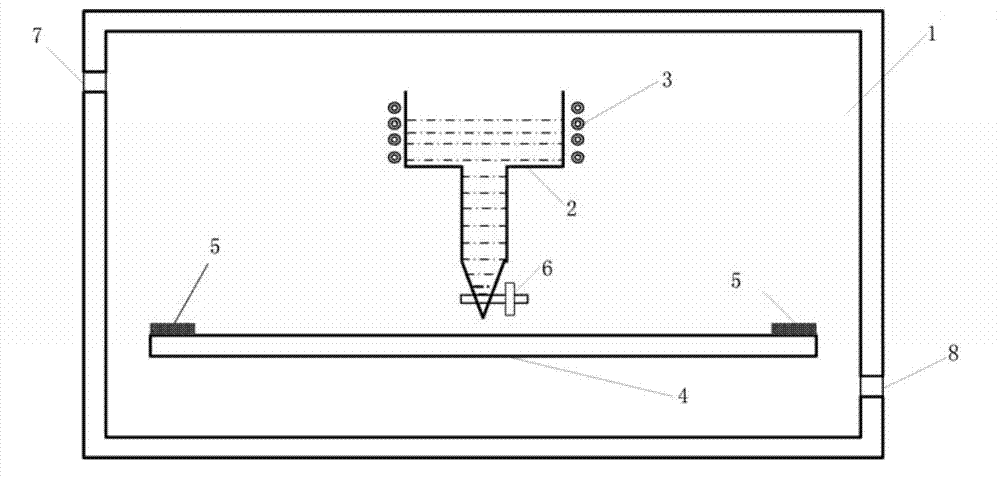

[0025] Specific implementation mode one: combine figure 1 Describe this specific embodiment, a device for preparing metal microspheres using ultrasonic surface standing waves in this embodiment, consists of an air chamber 1 and a titanium alloy casting mold 2 located in the air chamber, a heating element 3, a substrate 4, and two ultrasonic surfaces The wave emitting device 5 and the droplet flow control device 6 are composed, the heating element 3 is arranged on the outer surface of the titanium alloy casting mold 2, the bottom of the titanium alloy casting mold 2 is provided with a droplet flow control device 6, and the upper surface of the substrate 4 is The two ends of the surface are provided with ultrasonic surface wave emitting devices 5 respectively, the substrate 4 is located directly below the titanium alloy mold 2, and an air inlet 7 is arranged at the upper end of a side wall of the gas chamber 1, and an air inlet 7 is arranged on the side opposite to the air inlet....

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment is different from Embodiment 1 in that: the heating element 3 is an induction or resistance heating element. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment three: In this embodiment, a method for preparing metal microspheres by using ultrasonic surface standing waves is realized in the following steps:

[0028] 1. Put the metal material in the titanium alloy casting mold 2, and at the same time pass inert gas into the gas chamber 1 for protection, then start the heating element 3, heat the metal material to 20°C~100°C above the melting point, and keep it warm for 10~30min. After the material is completely melted, the metal material melt is obtained, and then the ultrasonic surface wave emitting device 5 is started, and the droplet flow control device 6 is turned on at the same time to make the metal material melt drip onto the surface of the substrate 4 drop by drop, forming a spherical shape with the same size under the action of ultrasonic waves. metal droplets;

[0029] 2. Stop the ultrasonic surface wave emitting device 5 and the heating element 3, start cooling with an air cooling system at a cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com