Patents

Literature

1366 results about "Air cooling system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold aisle isolation

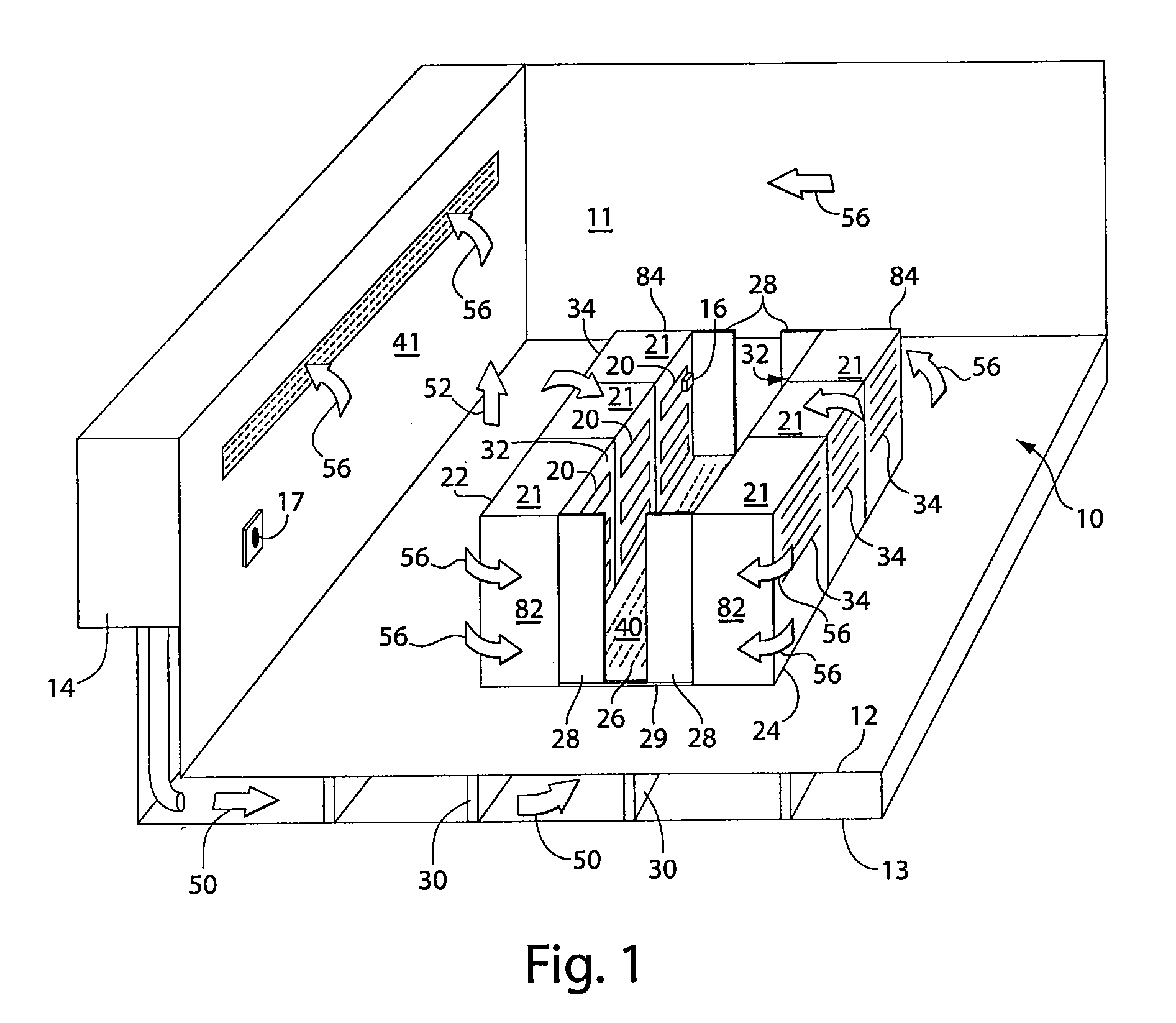

ActiveUS20060260338A1Easy to modifyLarge capacityLighting and heating apparatusDigital data processing detailsEngineeringAir cooling system

A data center cooling solution providing techniques for using baffles, doors and roof sections to prevent warm air from being entrained into a cold aisle in a data center, wherein the data center generally contains an air cooling system and a raised floor structure. The raised floor structure is configured to deliver cool air into the data center through a plurality of grates and perforated tiles in the floor. Electronic equipment racks are disposed around the grates and perforated tiles, such that the front faces of the equipment racks face the grates and perforated tiles. A collection of baffles, doors or roof sections inhibit the mixing of the cool air delivered by the air cooling system and the warm air exhausted by the electronic equipment.

Owner:SCHNEIDER ELECTRIC IT CORP

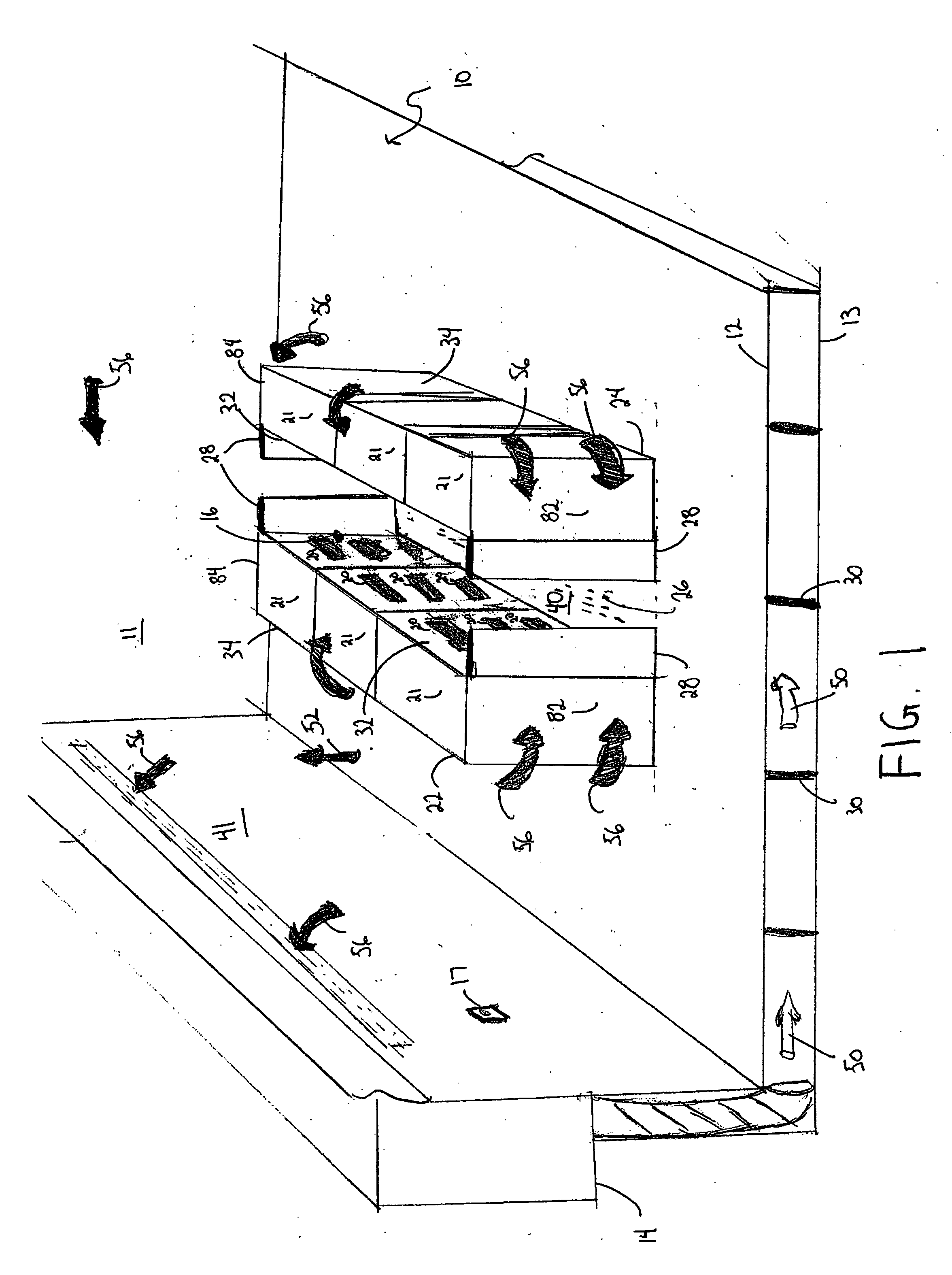

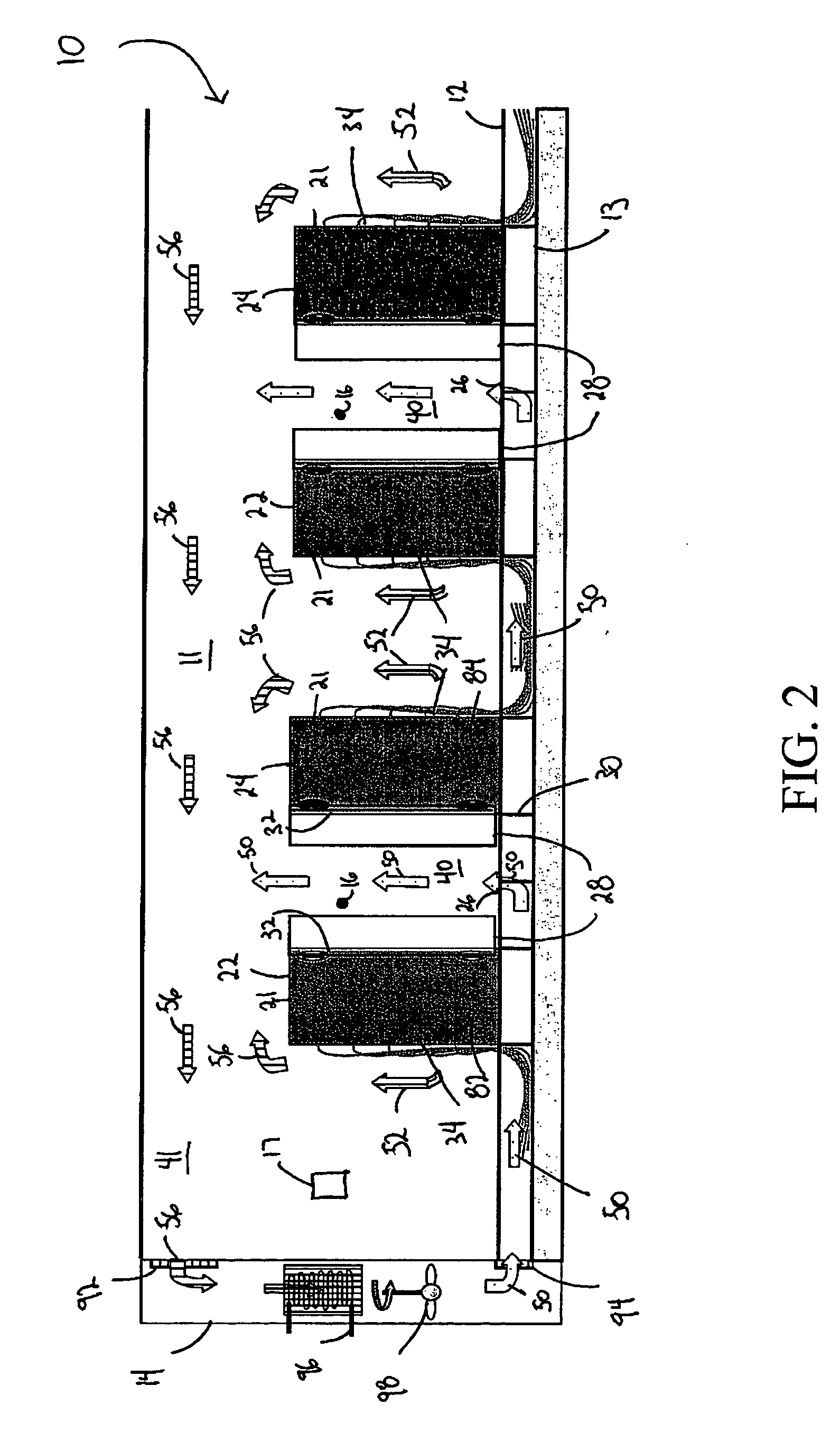

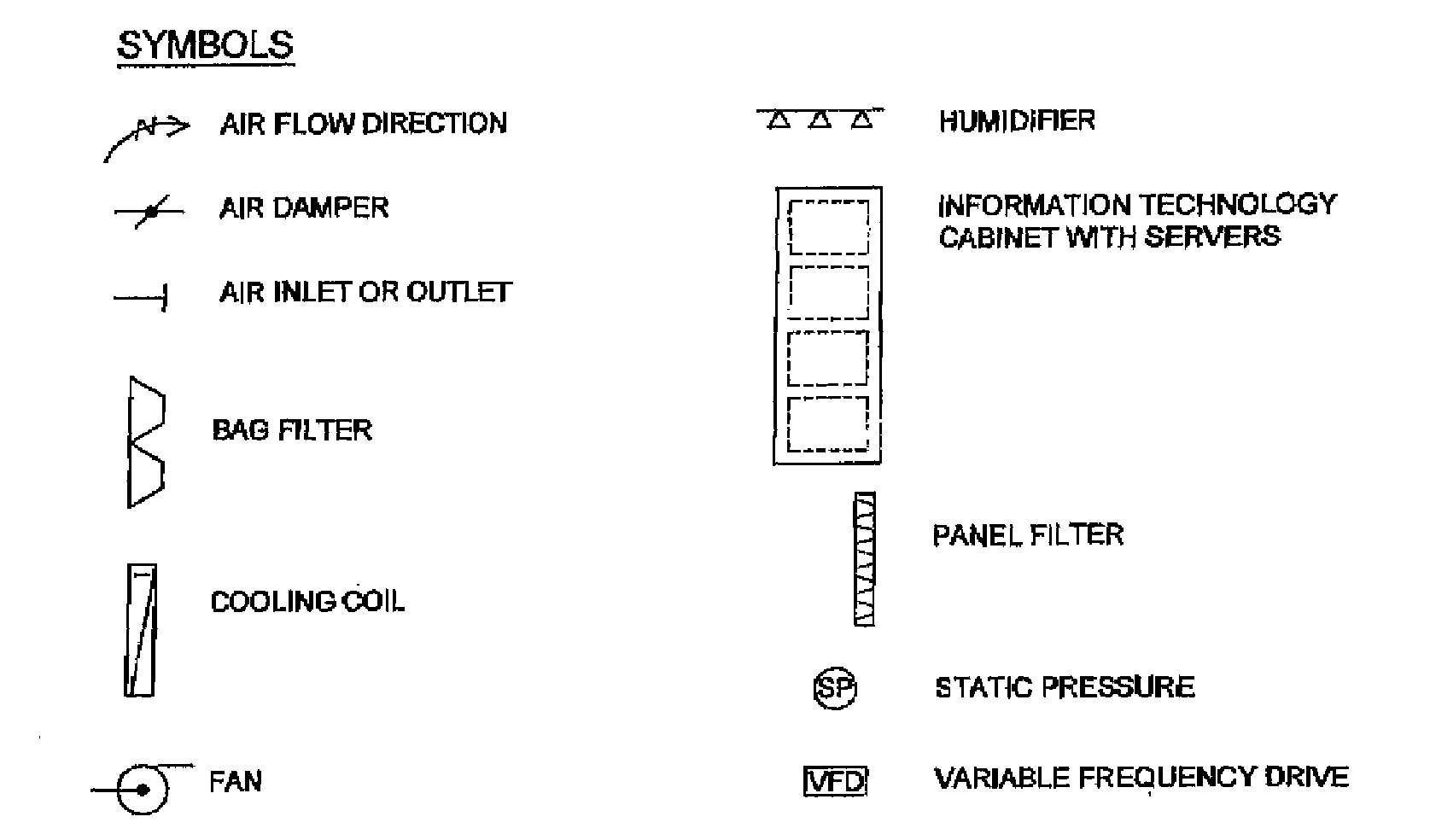

Cool design data center

ActiveUS20080185446A1Easy to solveAvoid uneven loadLighting and heating apparatusElectrical apparatus contructional detailsAir managementAir volume

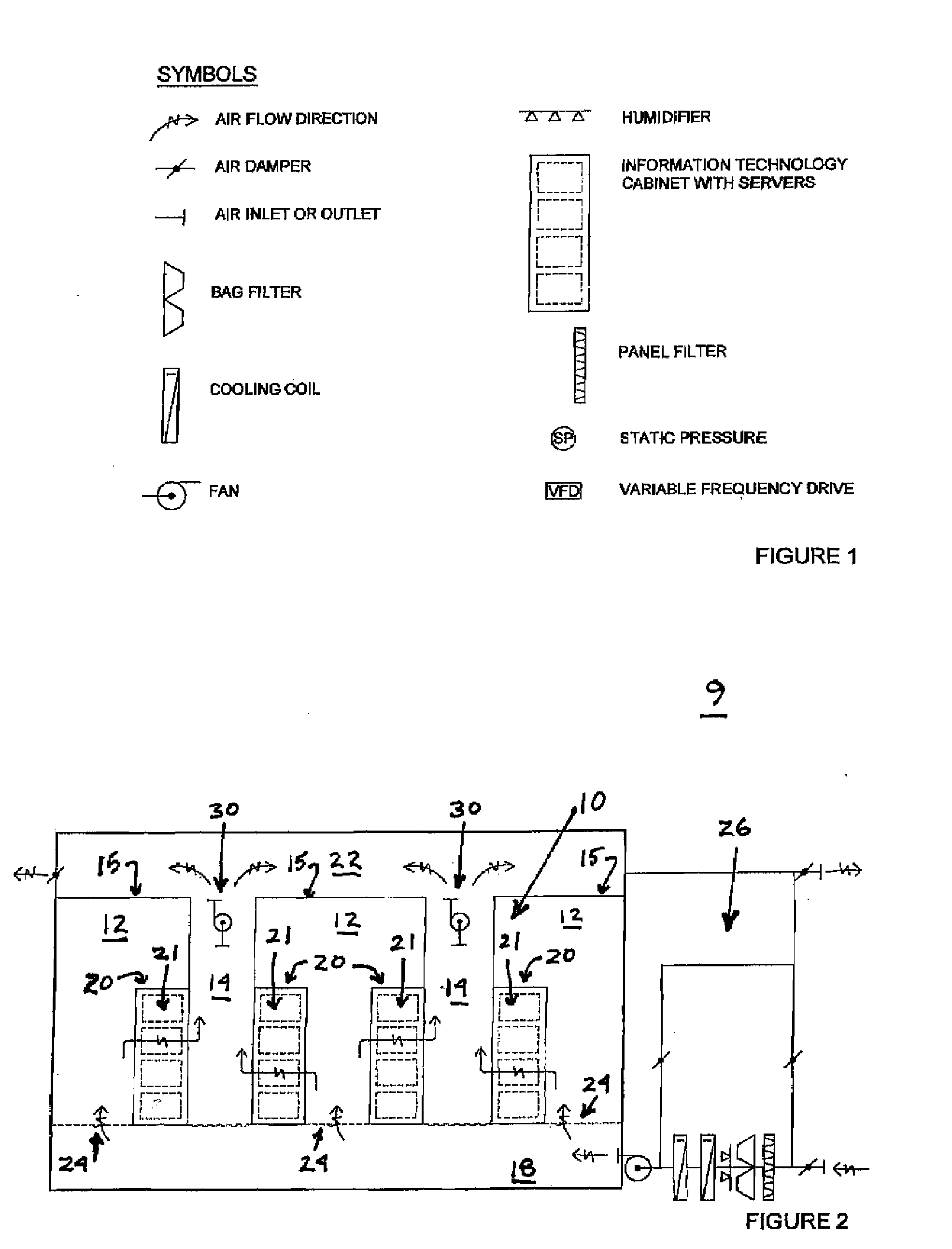

An improved solution for cooling a data center is provided. In an embodiment of the invention, a data center design that combines physical segregation of hot and cold air streams together with a data hall variable air volume system is provided. The invention is a data center design that resolves air management issues of re-circulation, bypass and load balance. Bypass is airflow supplied by the cooling units that directly returns without cooling servers. Recirculation airflow is server discharge warm air that returns directly without being cooled. Load balance is supplying the required server airflow. An embodiment includes physical segregation of cold and hot air streams and by providing variable air volume to match server load. Air segregation is done by enclosing the hot aisle end and above the cabinets. The air conditioning system provides variable air volume to the data hall (cold side) to meet server demands. The cooling plant consists of variable-air-volume air-cooling system, which cools air by air free cooling (economizer) and is supplemented with mechanical cooling in the warmer seasons.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

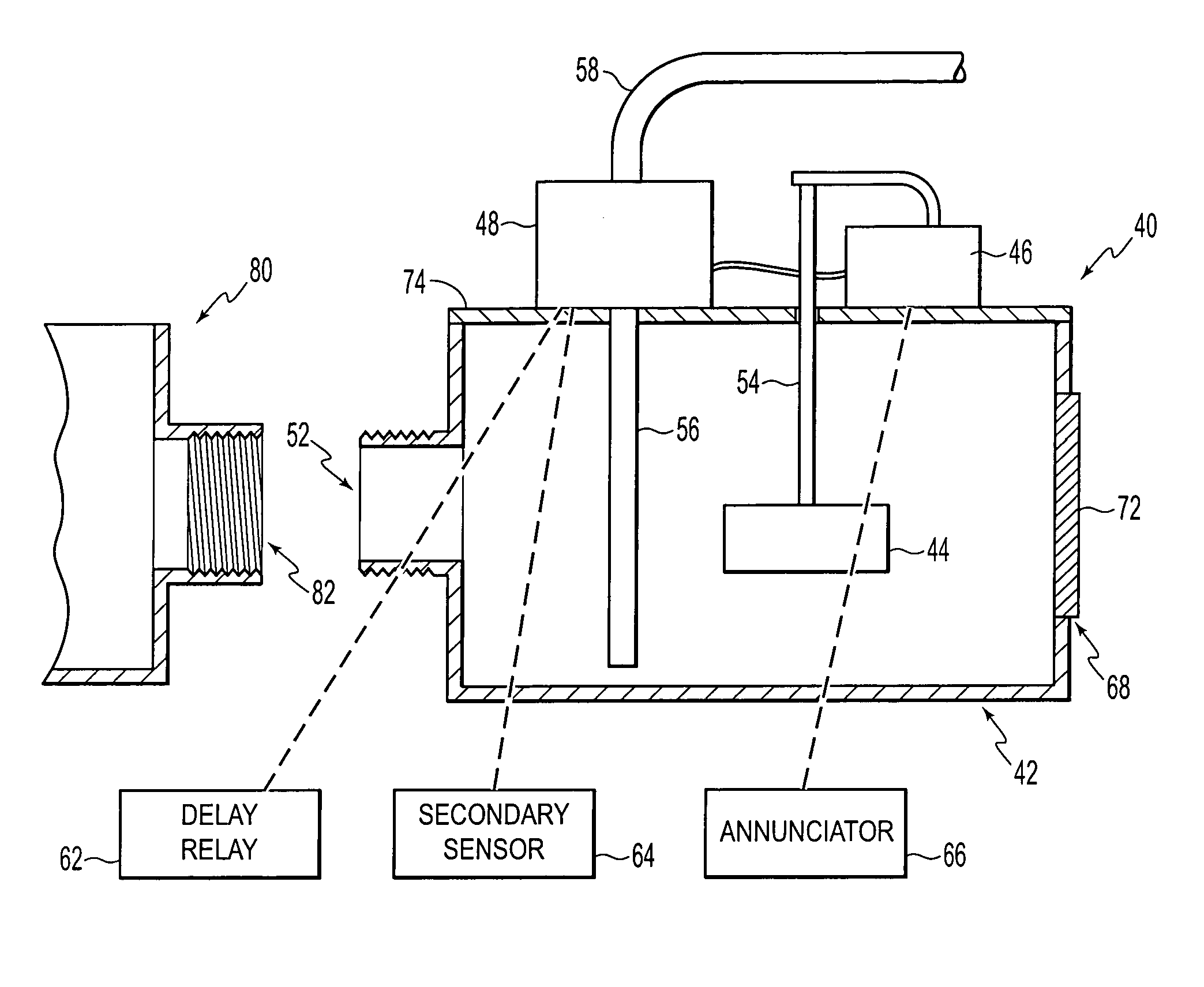

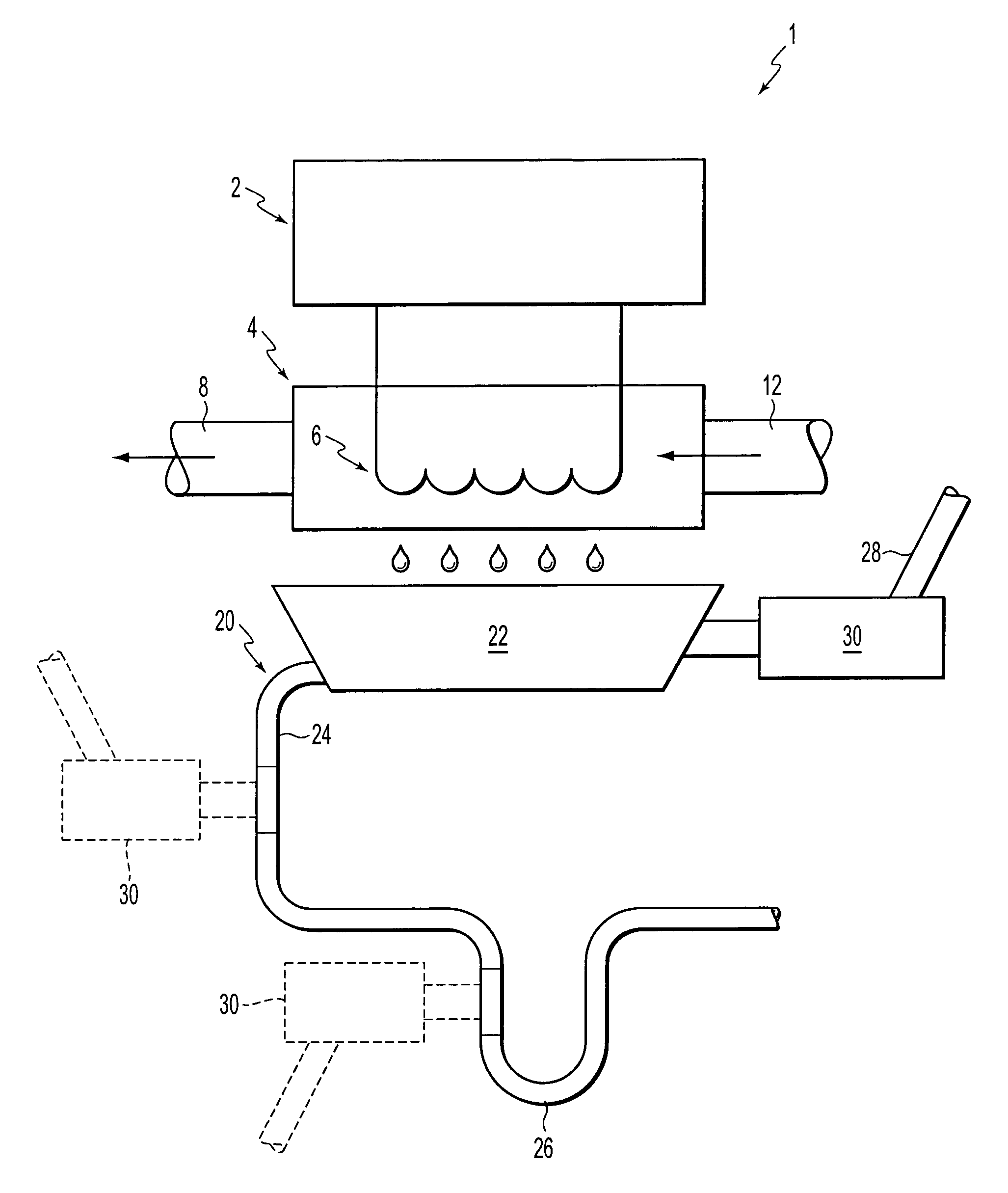

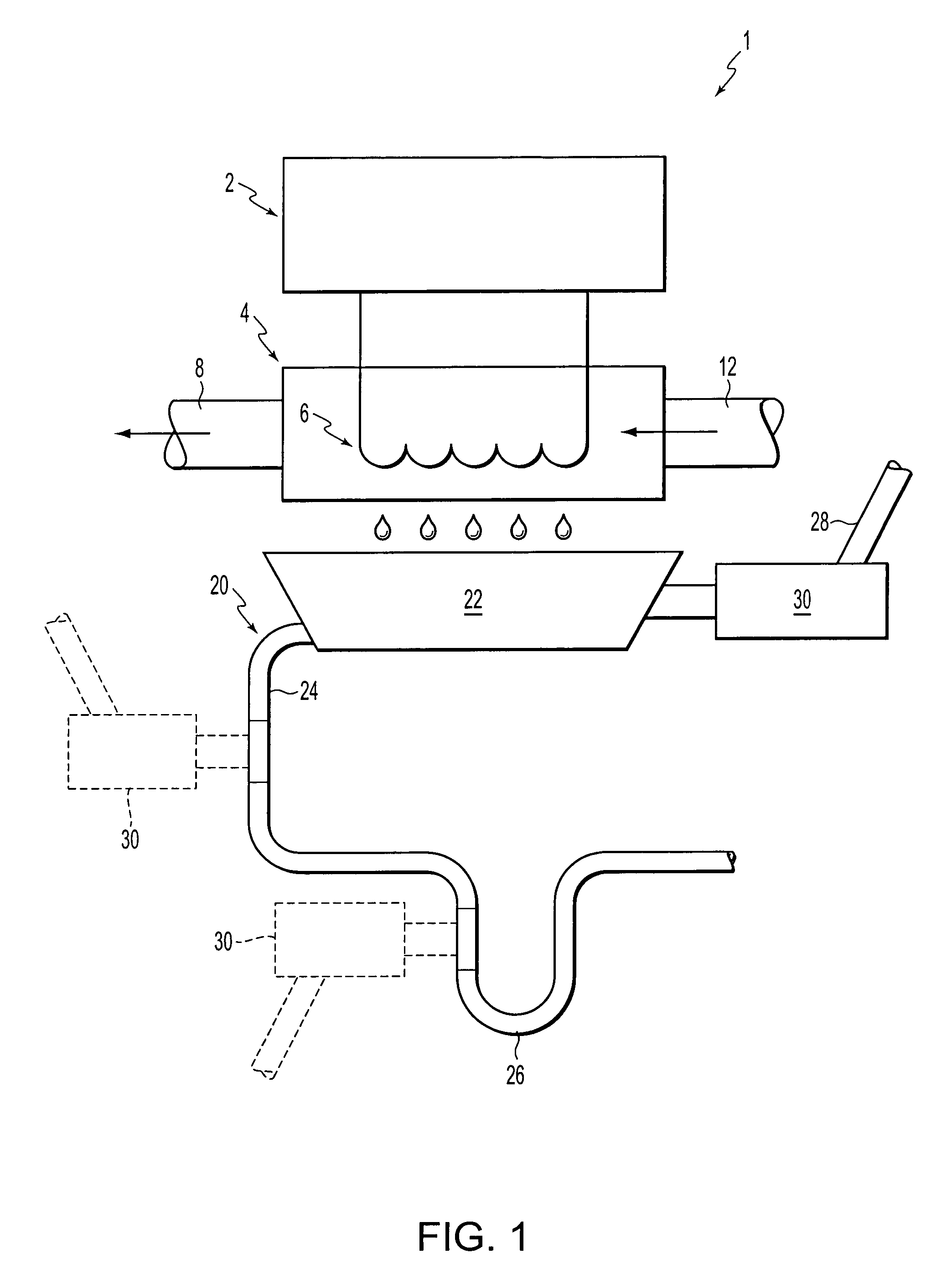

Cooling system for a commercial aircraft galley

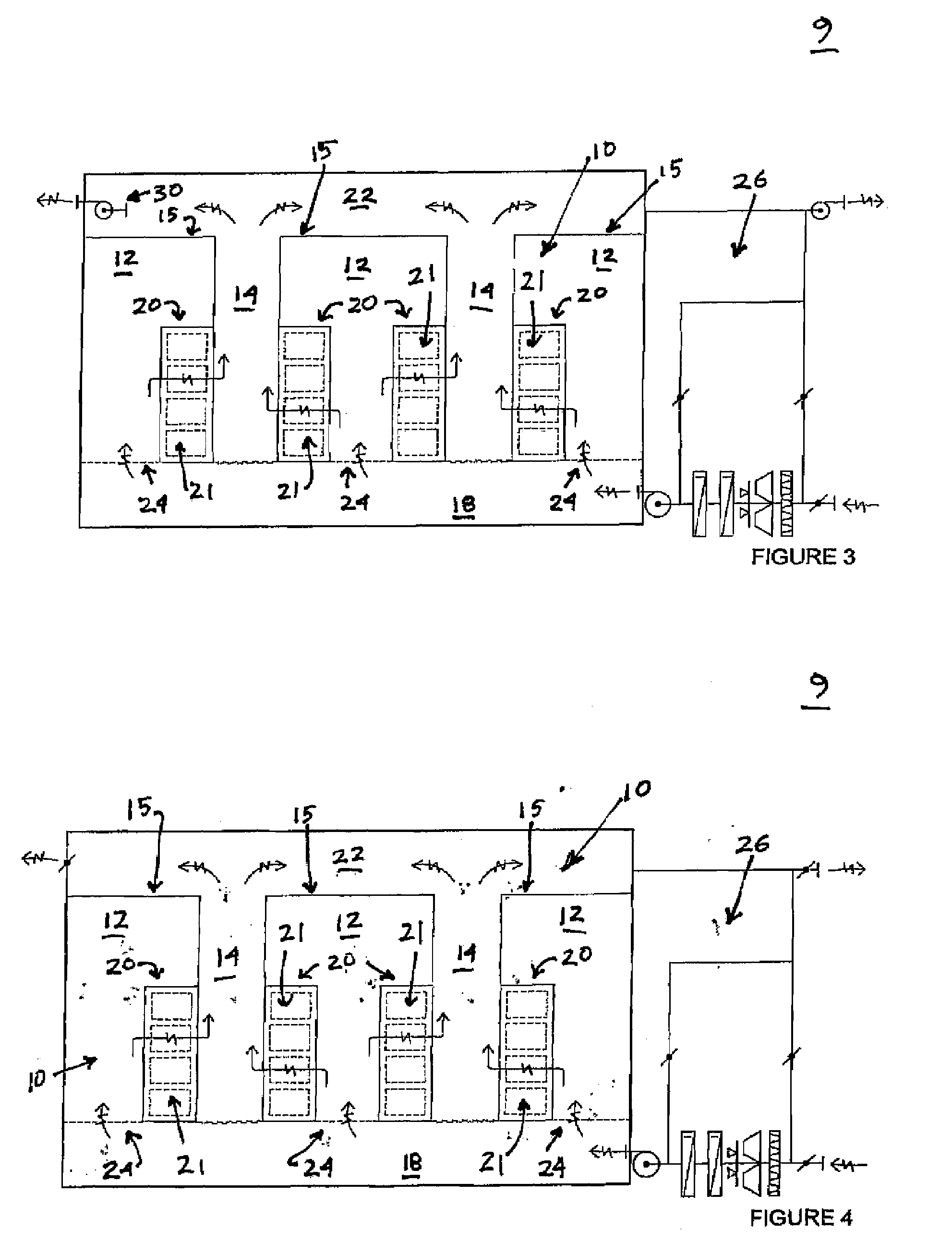

In the improved cooling system for a commercial aircraft galley, heat is transferred from a galley food cart by a point-of-use heat exchange system to a liquid cooled condenser. Liquid coolant for the liquid cooled condenser is circulated in a liquid coolant loop to a heat exchanger expelling heat for cooling the liquid coolant. The liquid coolant may be water or a mixture of water and glycol. A flow of cooling air from a heat exchanger cooled by the liquid cooled condenser is cycled through an air over system, through an air through system, or from a thermal convection air cooling system providing at least one cooled galley food cart surface to provide cooling. Heat may be transferred from a plurality of galley food carts to the circulating liquid coolant.

Owner:BE INTPROP

Cooling system for a commercial aircraft galley

In the improved cooling system for a commercial aircraft galley, heat is transferred from a galley food cart by a point-of-use heat exchange system to a liquid cooled condenser. Liquid coolant for the liquid cooled condenser is circulated in a liquid coolant loop to a heat exchanger expelling heat for cooling the liquid coolant. The liquid coolant may be water or a mixture of water and glycol. A flow of cooling air from a heat exchanger cooled by the liquid cooled condenser is cycled through an air over system, through an air through system, or from a thermal convection air cooling system providing at least one cooled galley food cart surface to provide cooling. Heat may be transferred from a plurality of galley food carts to the circulating liquid coolant.

Owner:BE INTPROP

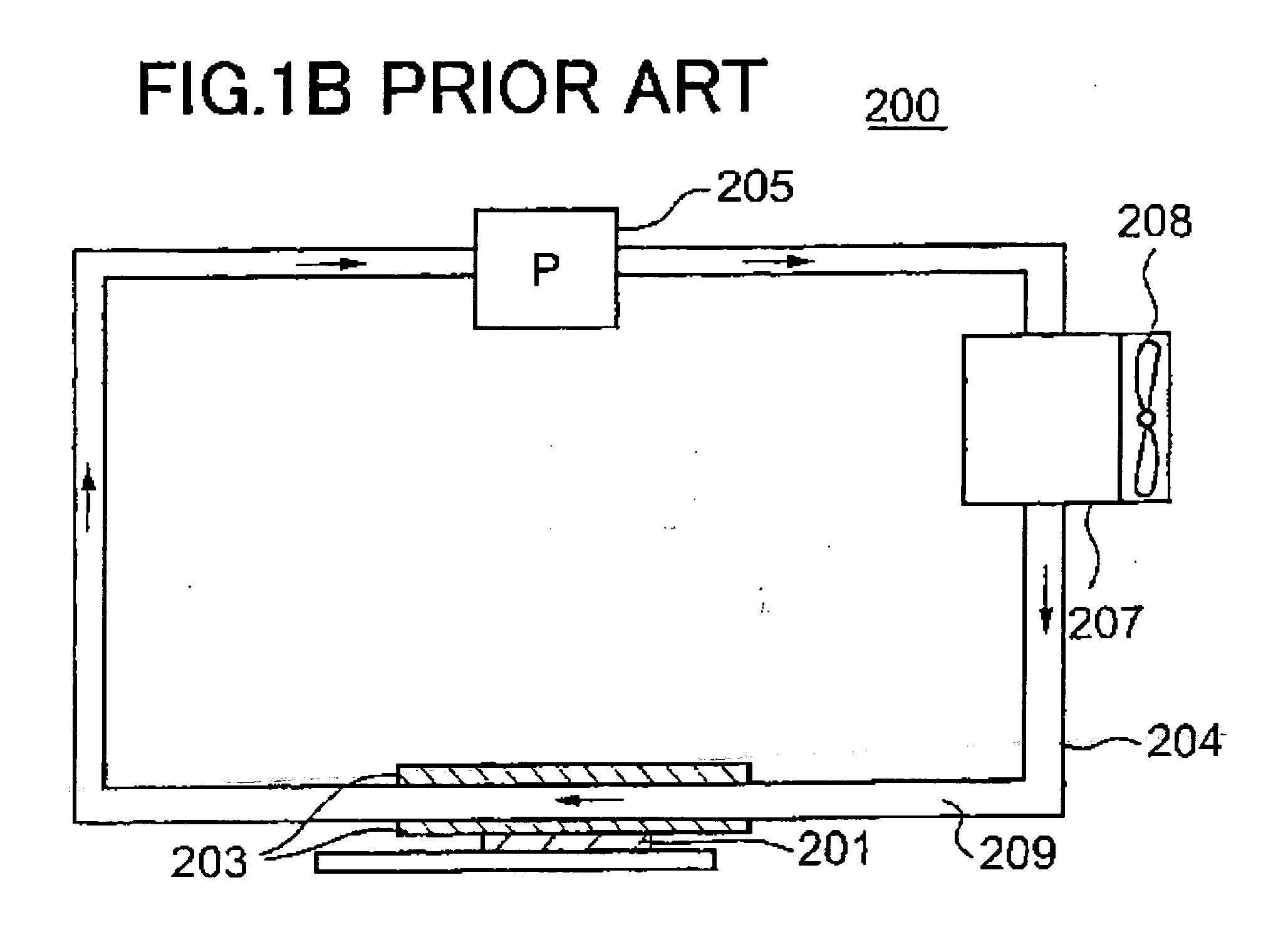

Computer cooling system and method

InactiveUS7079387B2Domestic cooling apparatusDigital data processing detailsComputerized systemAir cooling system

A computer system includes an enclosure, a backplane within the enclosure, a replaceable unit releasably connected to the backplane, an air cooling system configured to create an air flow along the replaceable unit and an air flow blocking system. The air flow blocking system includes a first member coupled to the enclosure and a second member coupled to the replaceable unit. The first member and the second member interact to at least partially block air flow along the replaceable unit based upon at least one characteristic of the replaceable unit.

Owner:HEWLETT PACKARD DEV CO LP

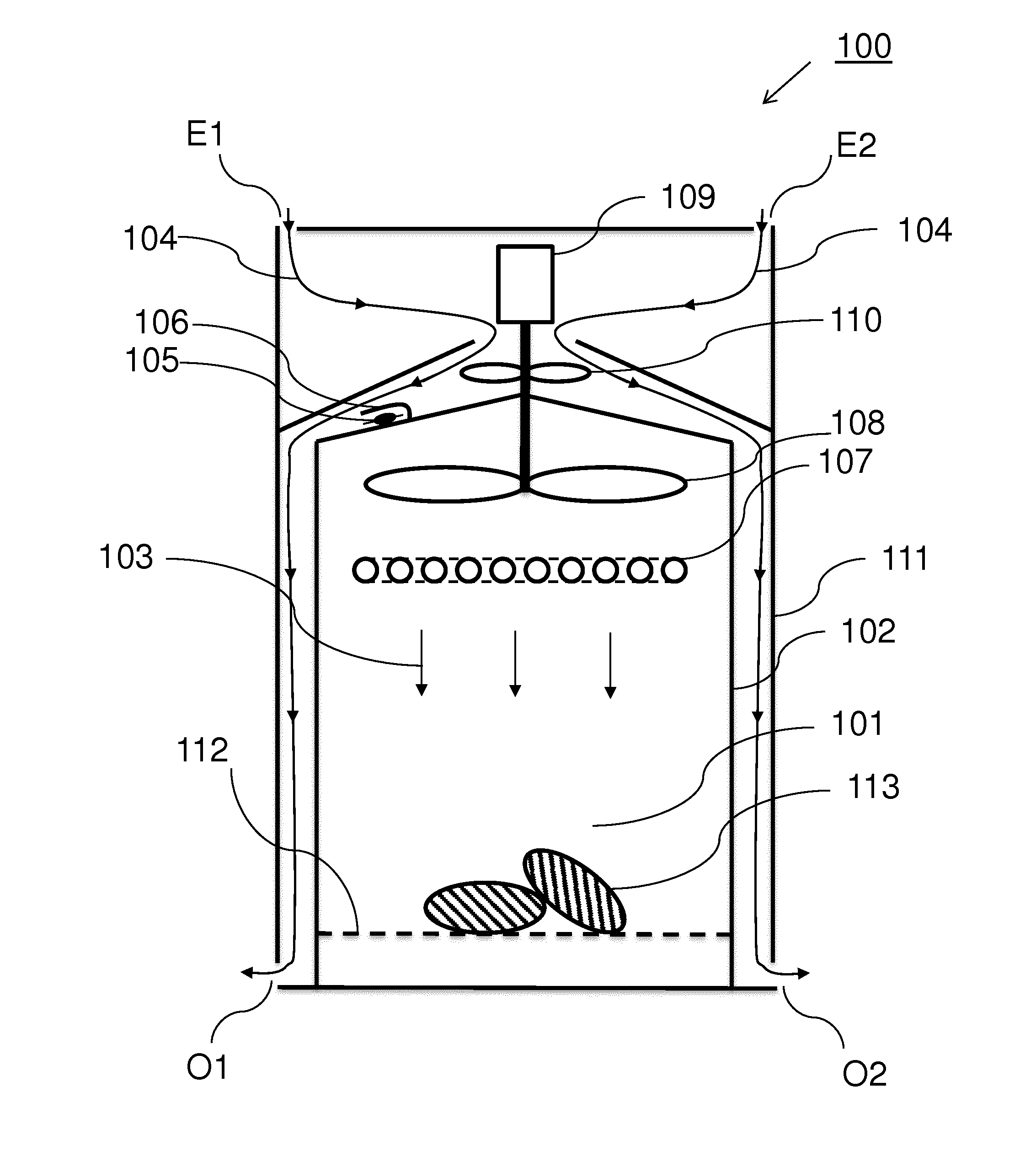

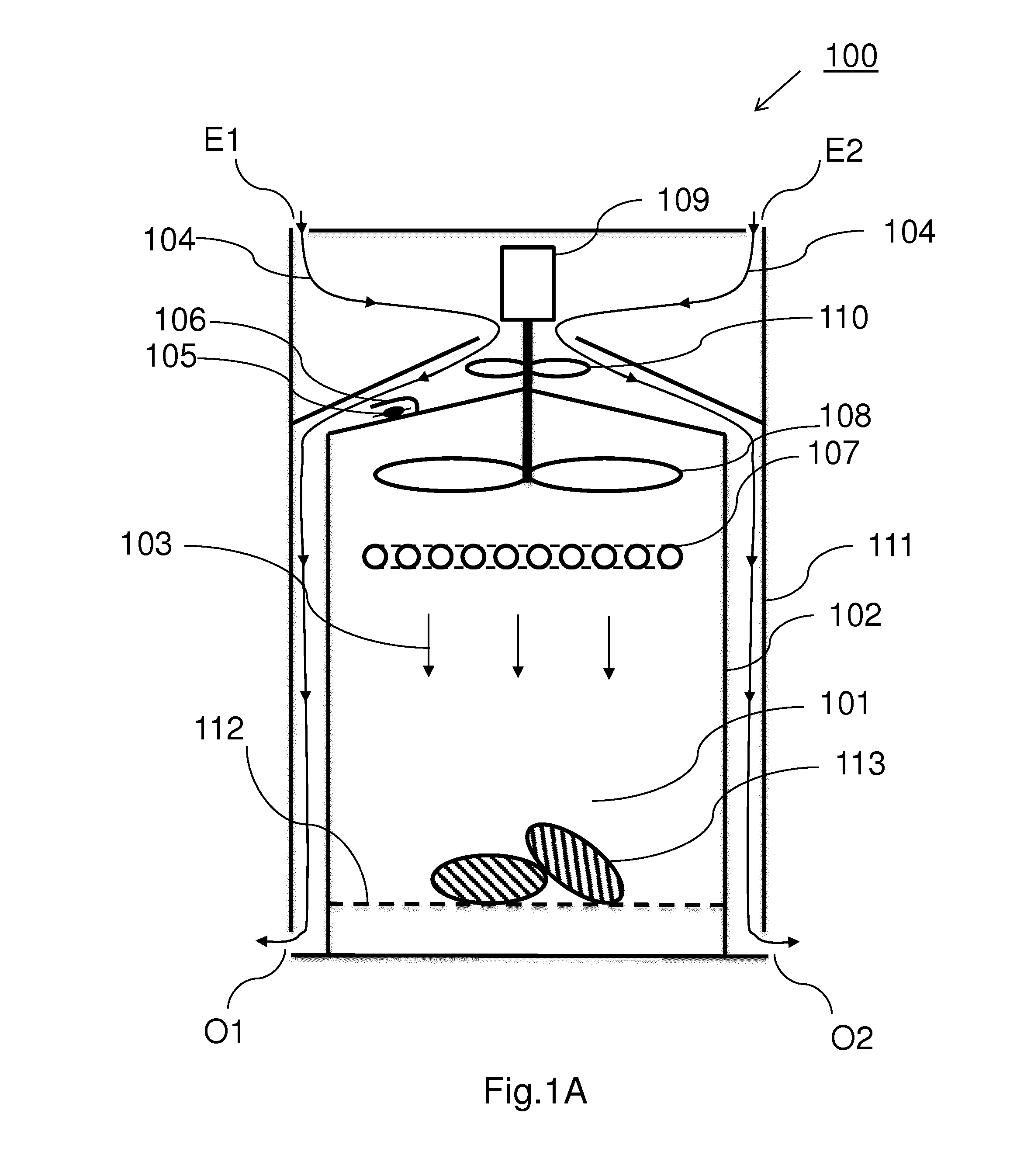

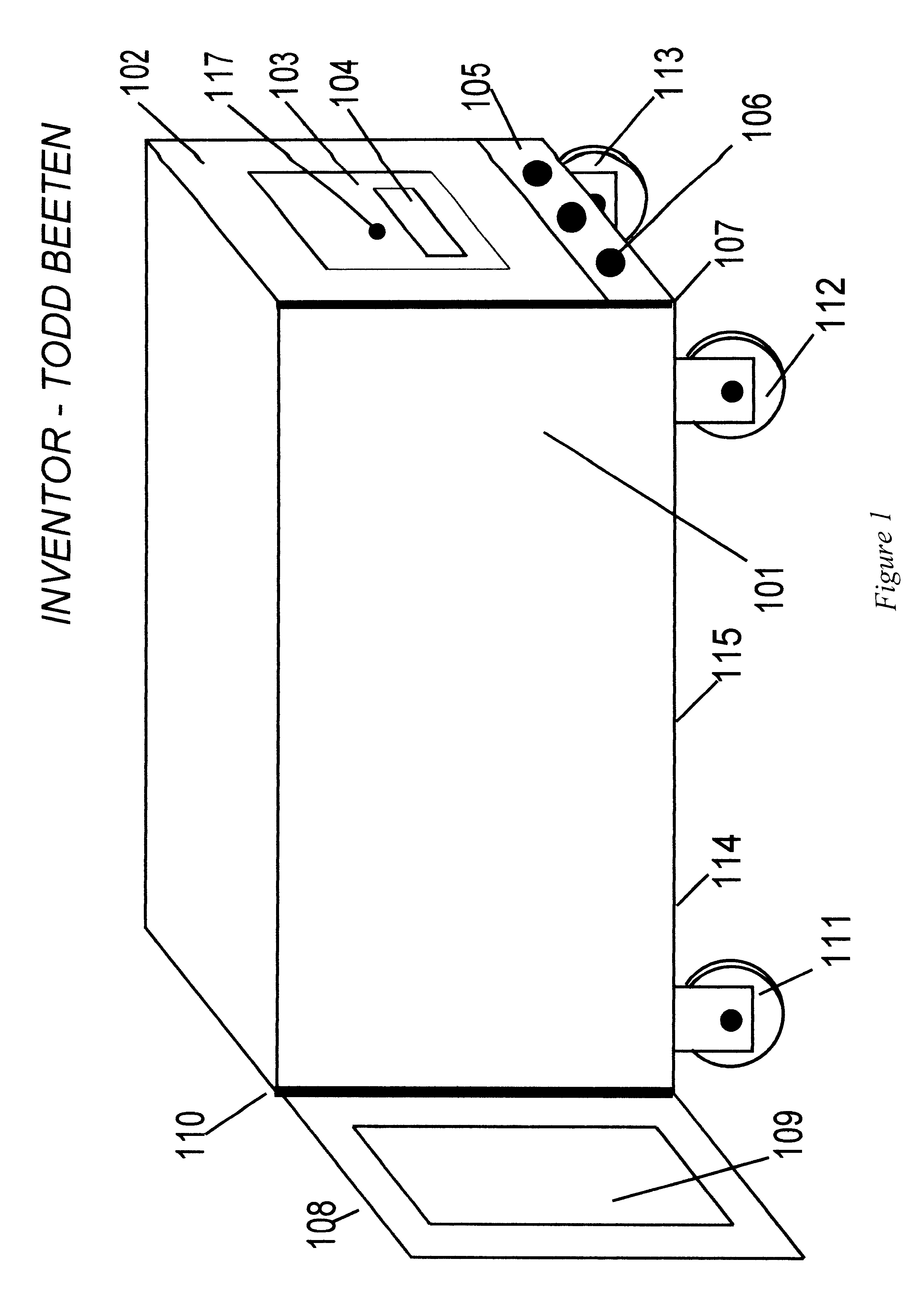

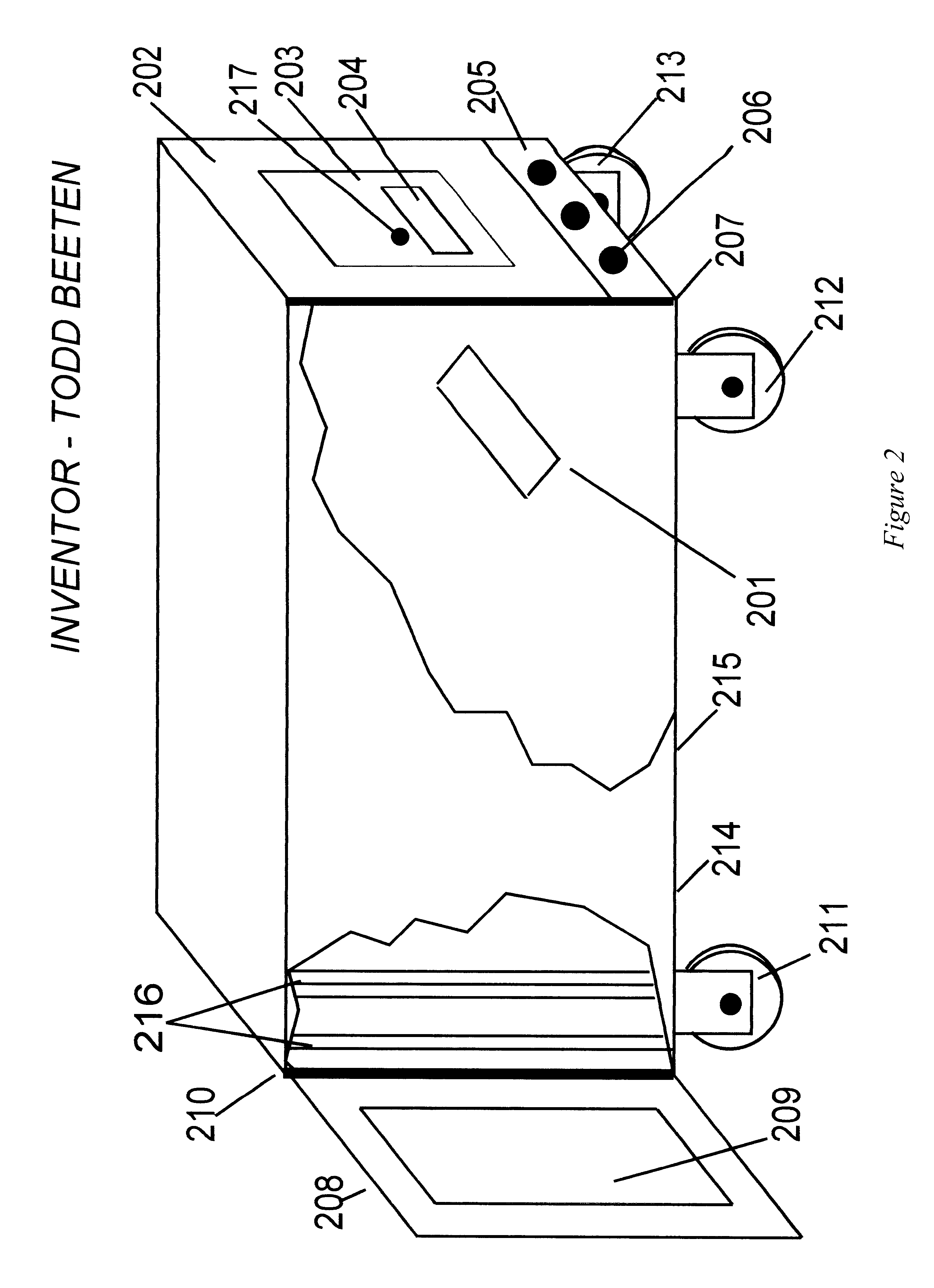

Apparatus for preparing food having an improved thermal protection

The invention relates to an apparatus (100) for preparing food. The apparatus comprises a food preparation chamber (101) having an outer wall (102), an air heating system to circulate hot air (103) inside the food preparation chamber (101), air cooling system to circulate cool air (104) on said outer wall (102) outside the food preparation chamber (102), a thermal fuse system (105) to cut the electrical supply of said apparatus when the temperature of the thermal fuse system (105) exceeds a given threshold (TH), the thermal fuse system (105) being attached to said outer wall (102) outside the food preparation chamber (101), a cover element (106) placed at the proximity of said thermal fuse system (105) to protect the thermal fuse system (105) from the cool air. This invention improves the thermal protection of the apparatus.

Owner:KONINKLJIJKE PHILIPS NV

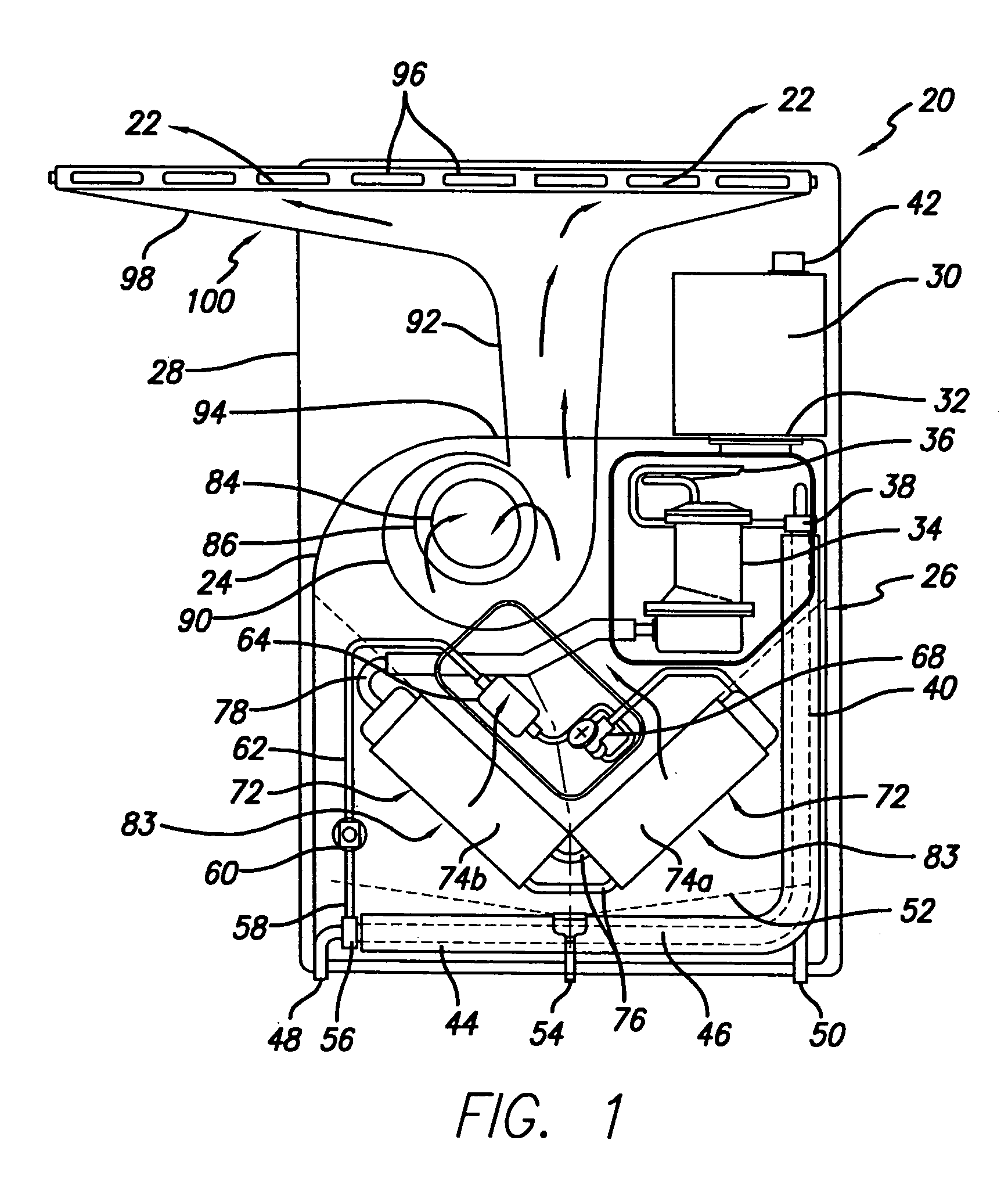

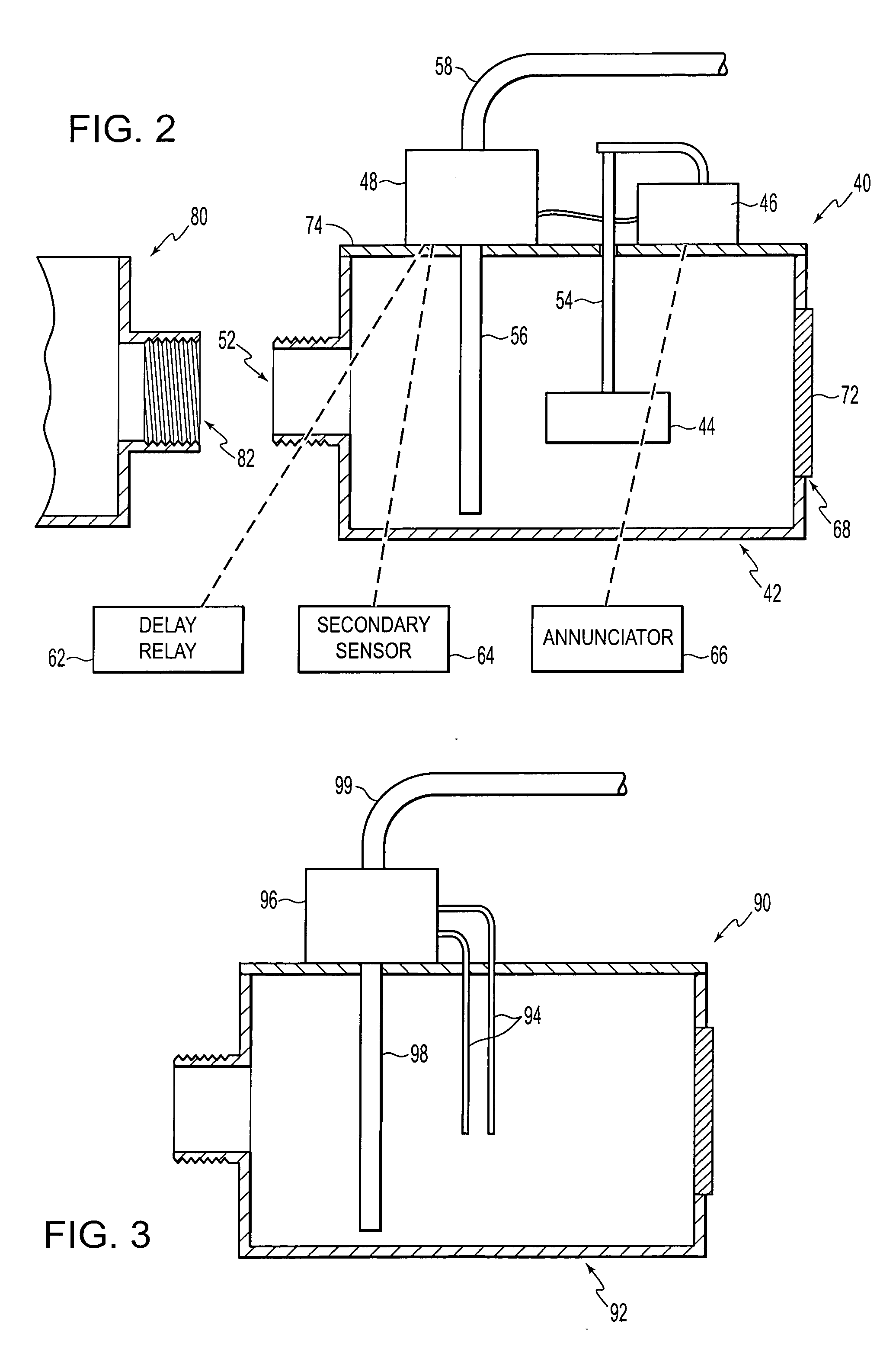

Condensate overflow prevention apparatus

A condensate overflow prevention assembly prevents condensate overflow in an air cooling system using a fluid level sensor and a pump activated by the fluid level sensor to pump the condensate away from a drainage system when a blockage occurs in the drainage system.

Owner:RECTORSEAL

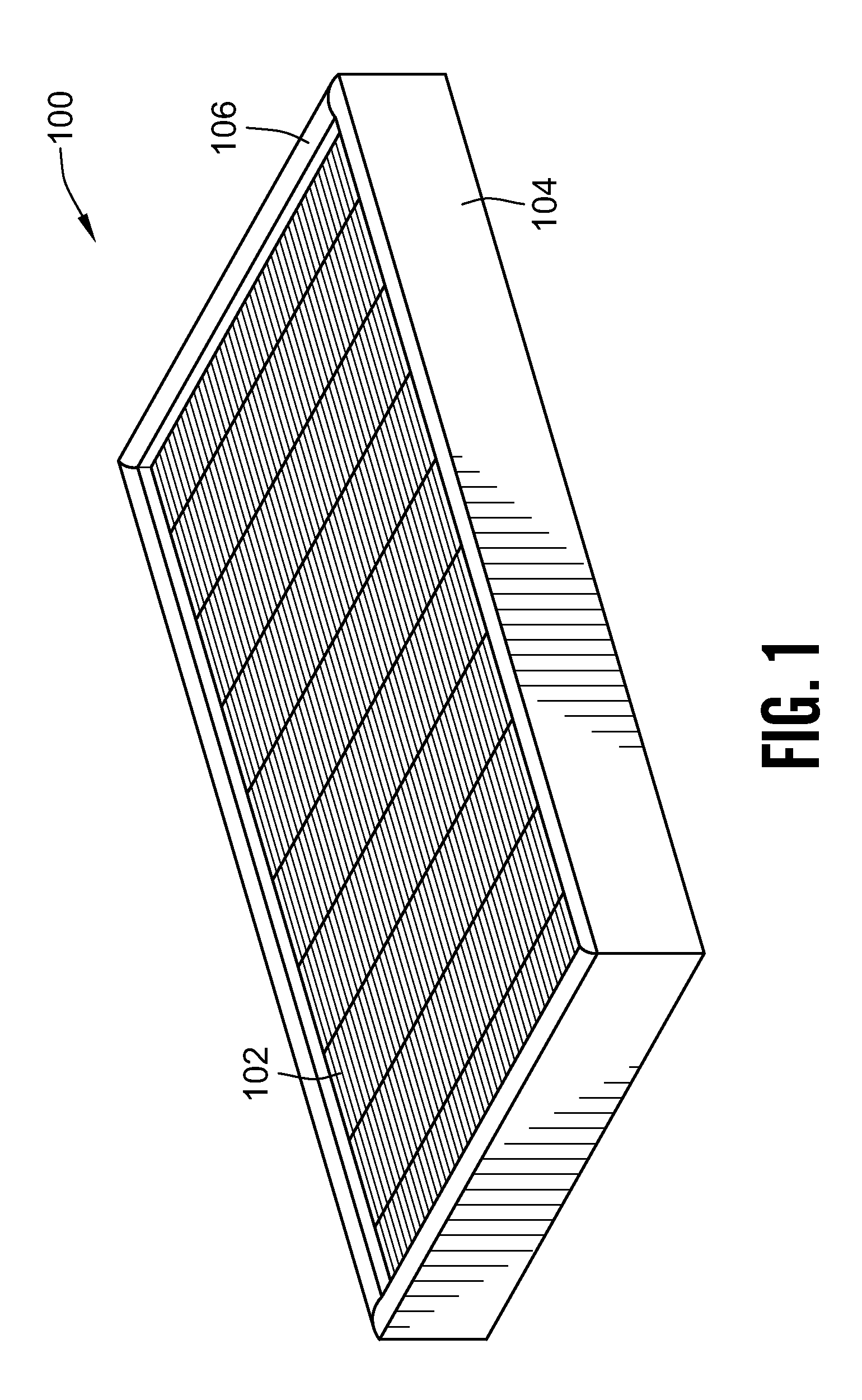

Air cooling system incorporating membrane-free filter and/or integral framing for filter

ActiveUS20100313757A1Prevent scalingSufficient protectionCombination devicesGas treatmentFiberElectronics cooling

A filter for an electronics cooling unit of a telecommunications base station, the electronics cooling unit adapted to receive fresh air into a housing of the cooling unit through an opening communicating with the external environment. The filter includes a structural support configured to be mounted to said housing, a gasket sealingly engaging the structural support and adapted to engage the housing; and a filter media supported by the structural support, the filter media being free of a membrane type layer and including a fiber entanglement selected to prevent ingress of water sufficient to pass a salt fog test consistent with GR-487-CORE and in accordance with ASTM B 117.

Owner:PARKER HANNIFIN CORP

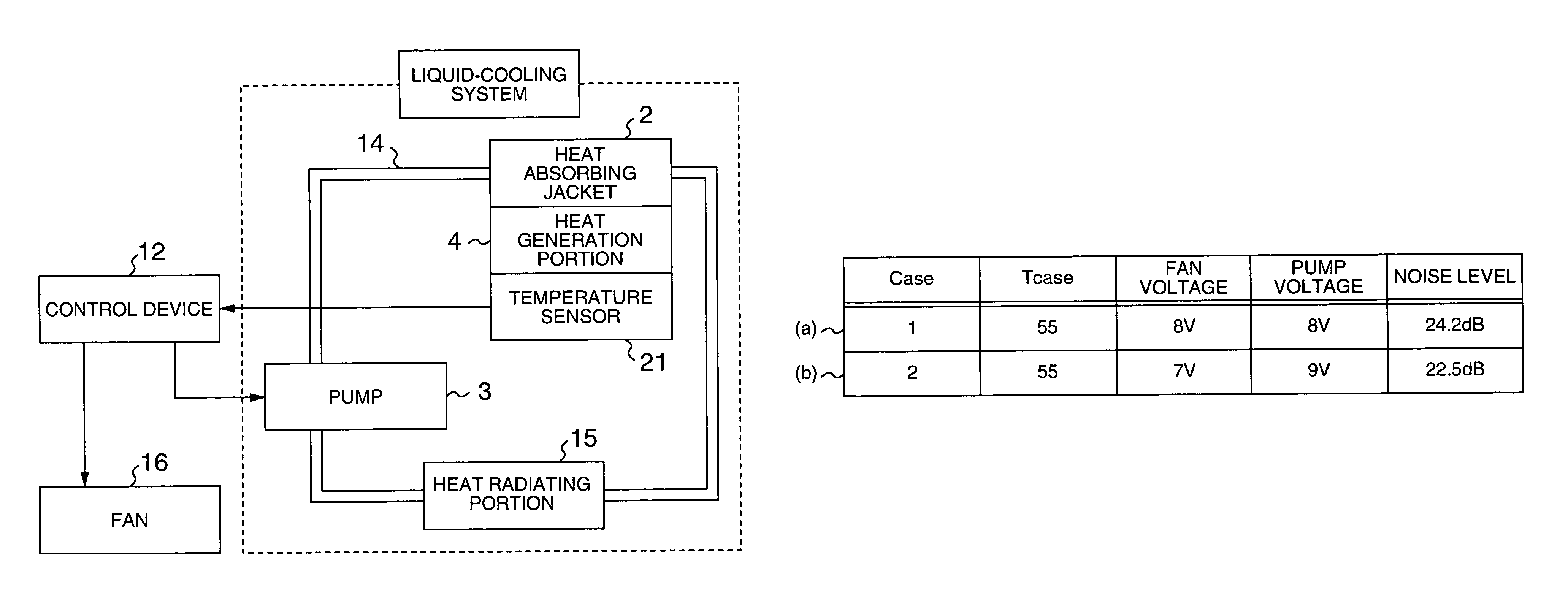

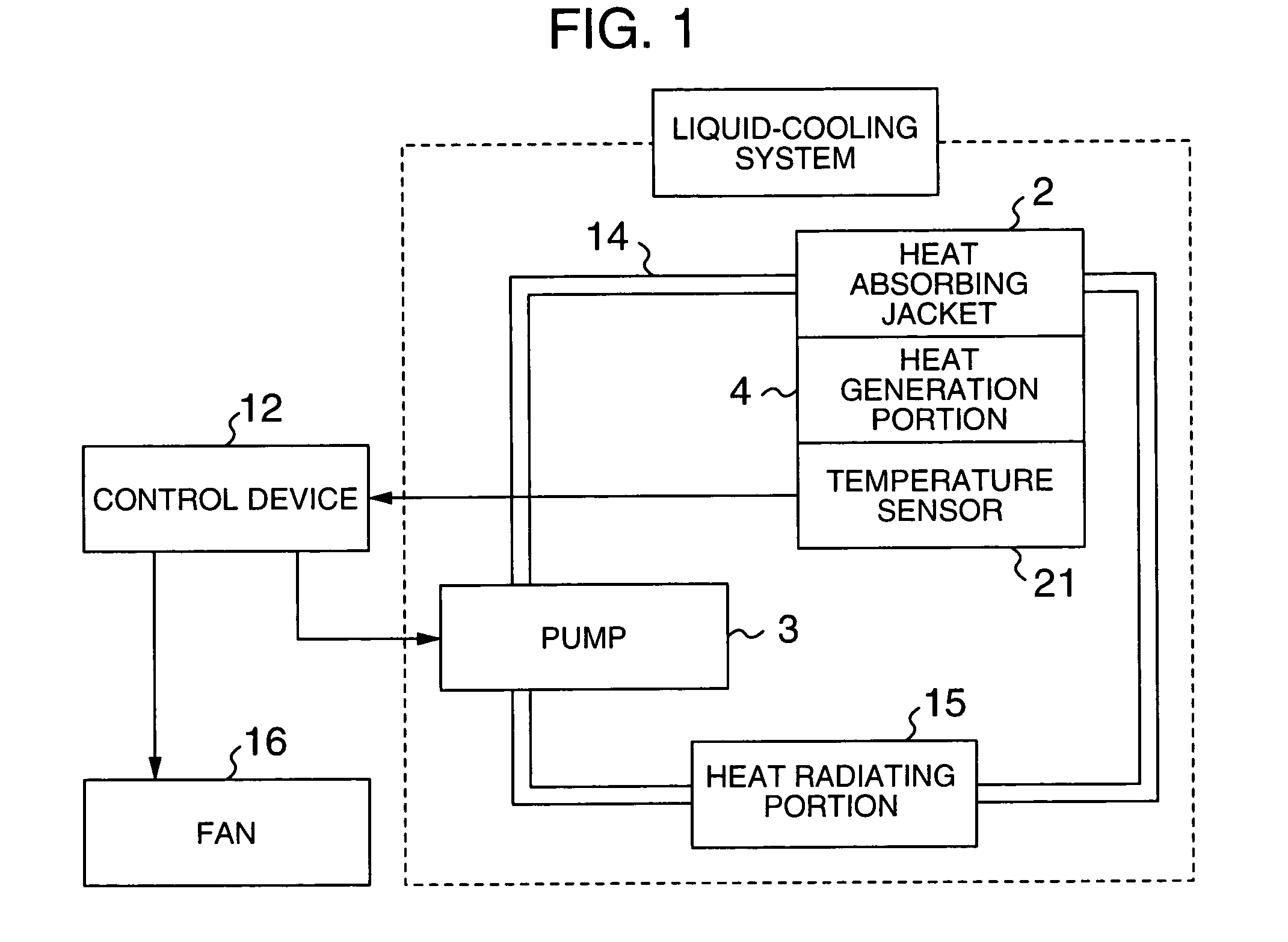

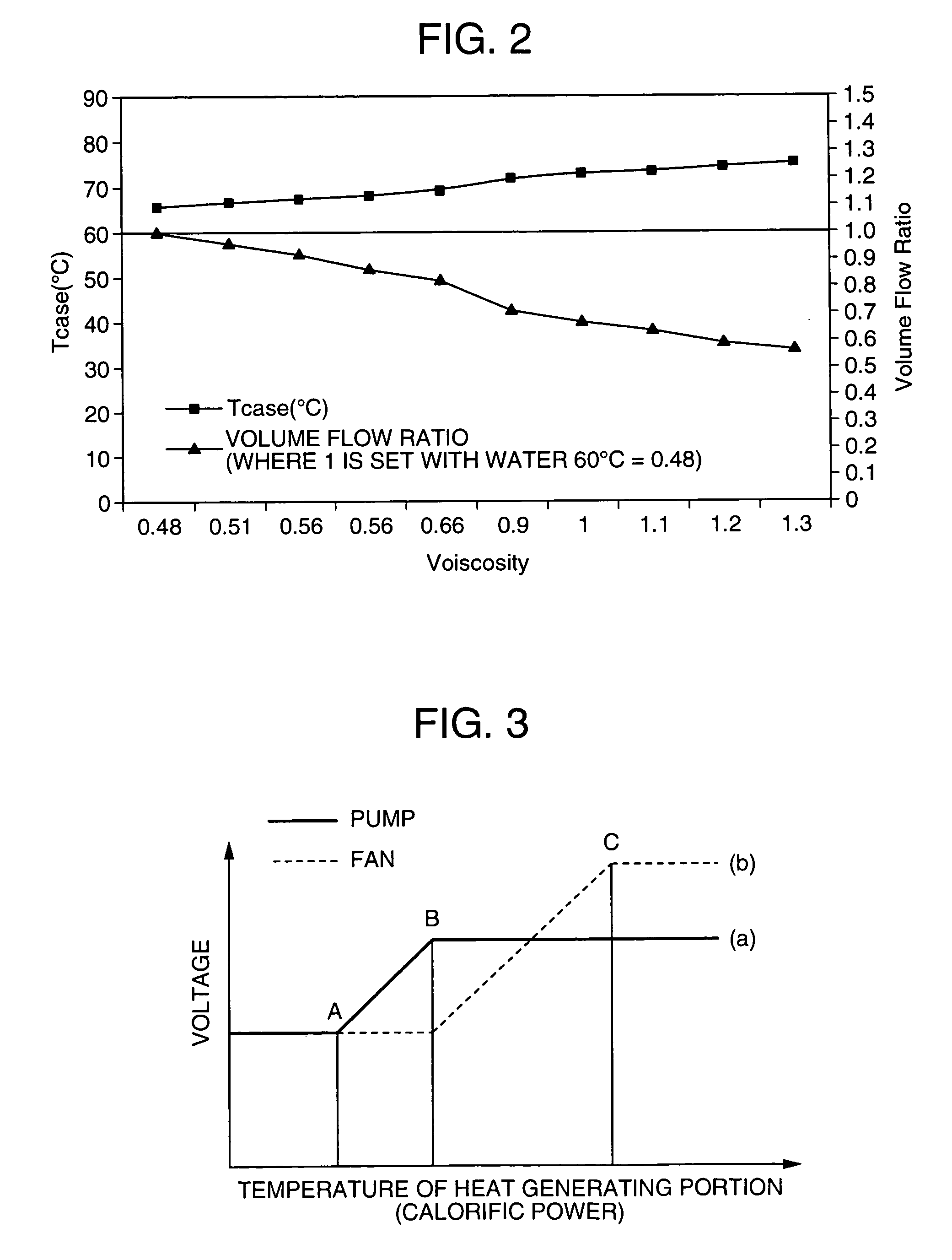

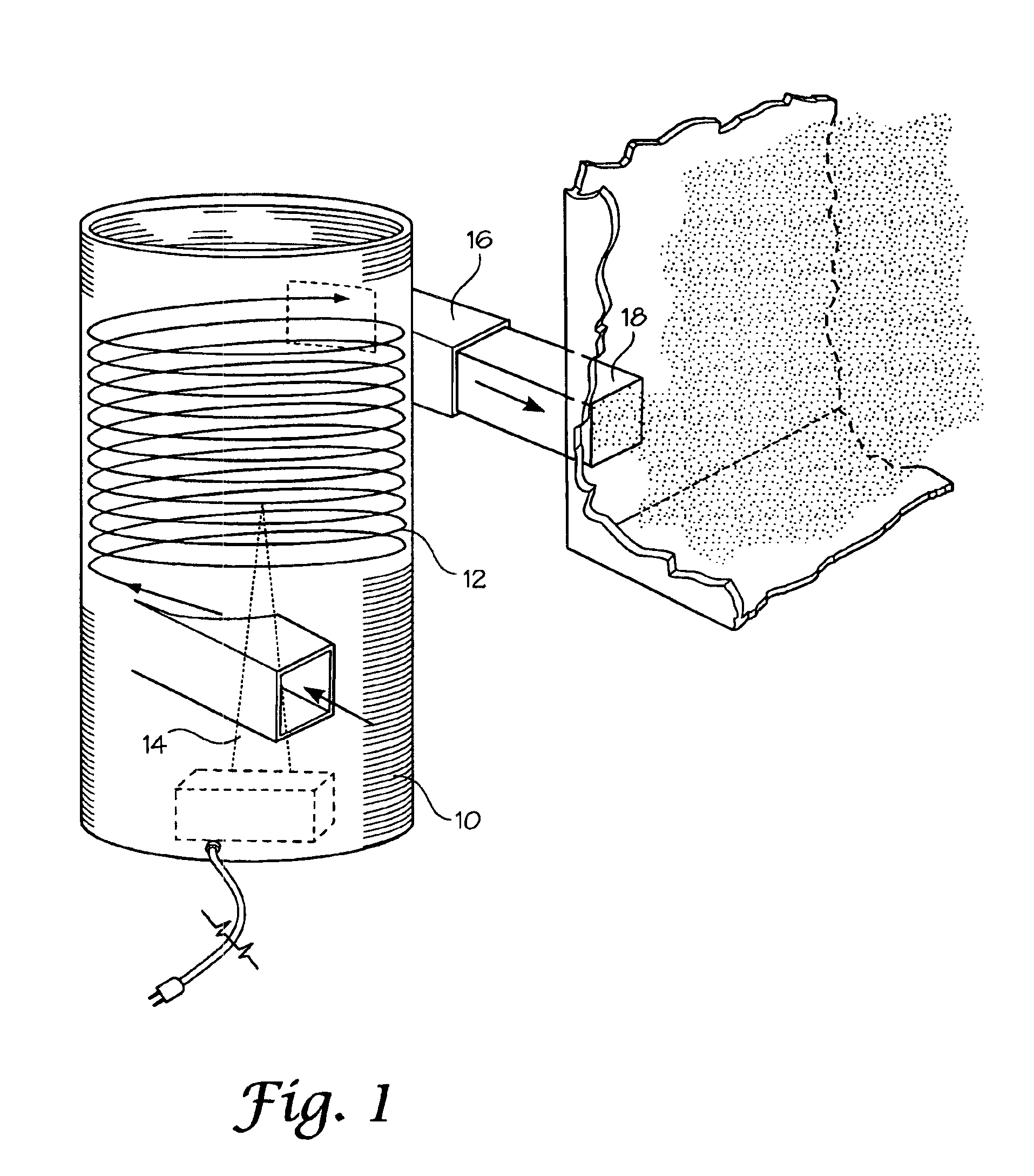

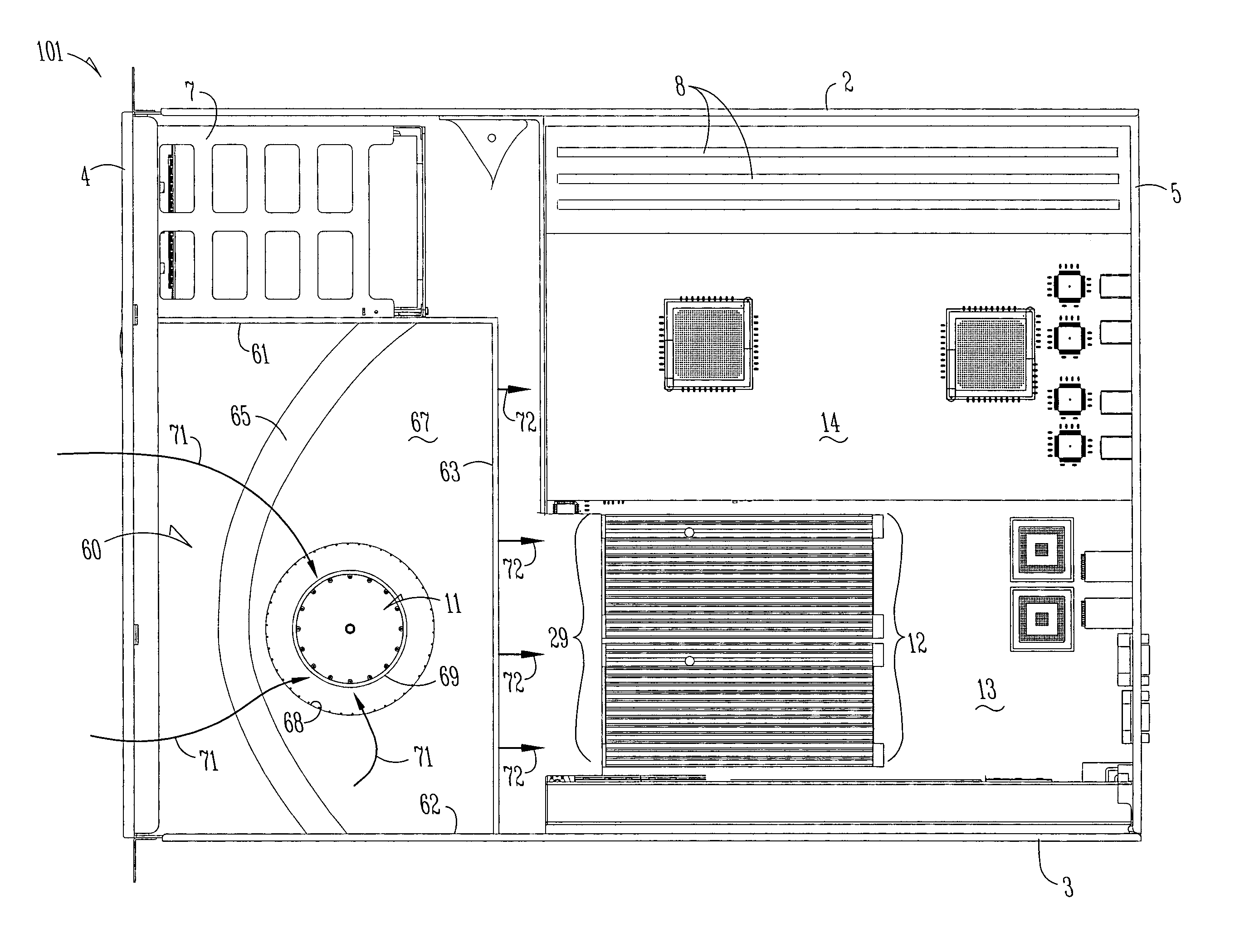

Electronic equipment provided with cooling system

ActiveUS7455103B2Large heat transmitting capacityReduce noiseTemperatue controlHeat storage plantsLiquid cooling systemEngineering

An electronic equipment is provided, which comprises a liquid-cooling system and a cooling fan as a cooling system, efficiently cools the liquid-cooling system, and reduces fan noise. The electronic equipment is provided with a liquid-cooling system, in which heat generated in a heat generating portion is transmitted to a heat radiating portion with a liquid as a medium to achieve cooling, and an air-cooling system, in which heat transmitted to the heat radiating portion is forcedly cooled, and comprises a pump that circulates the liquid between the heat generating portion and the heat radiating portion, a fan that forcedly discharges heat of the heat radiating portion to an outside, a temperature sensor that detects temperature of the heat generating portion, and storage information that beforehand prescribes the relationship between temperature of the heat generating portion and voltages of the pump and the fan, the electronic equipment being constructed such that a pump voltage is raised without changing a fan voltage when the detected temperature exceeds a first temperature, and a fan voltage is raised when temperature detected by the temperature sensor exceeds a second temperature higher than the first temperature, thus further increasing a cooling capacity.

Owner:MAXELL HLDG LTD

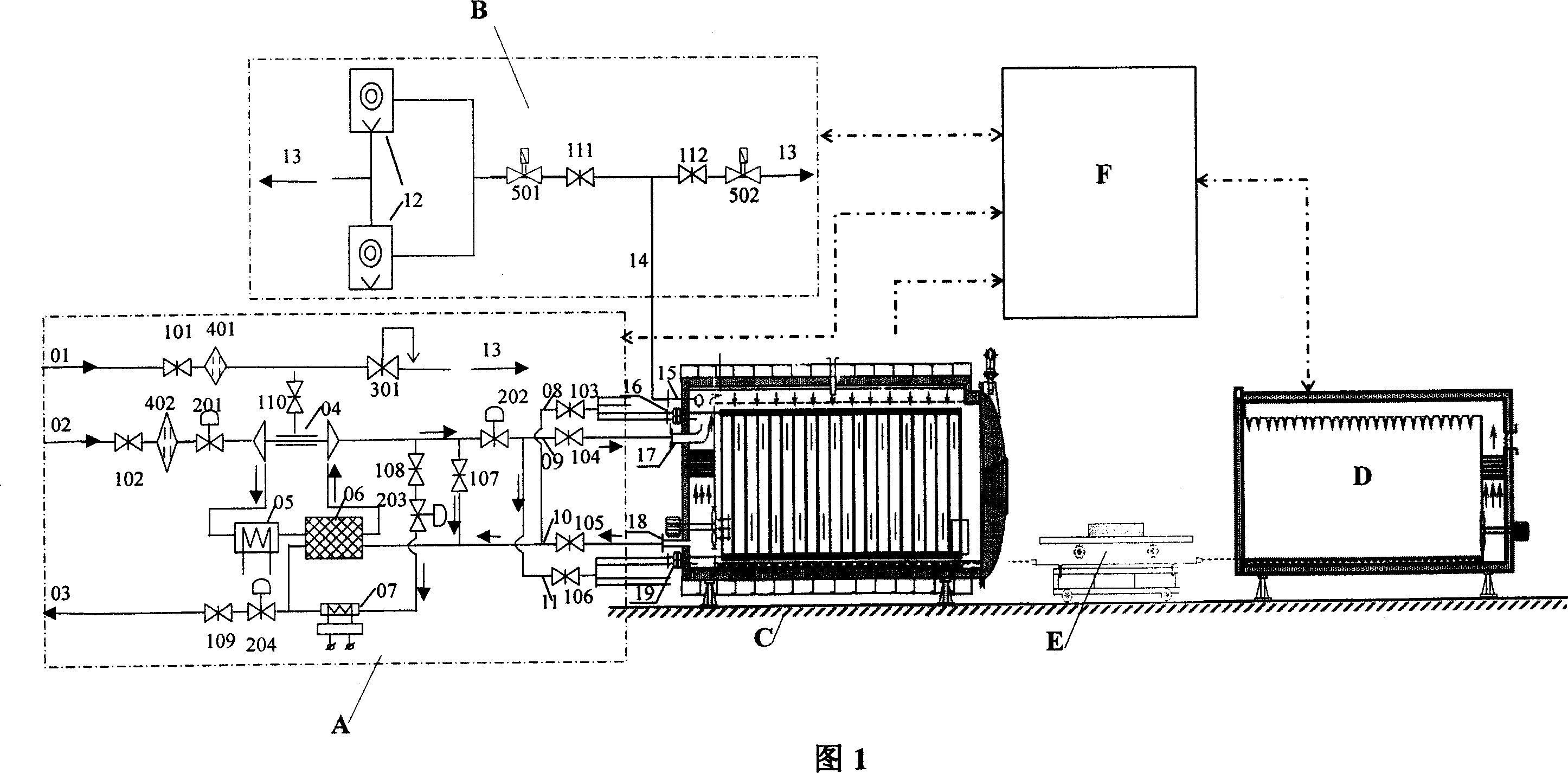

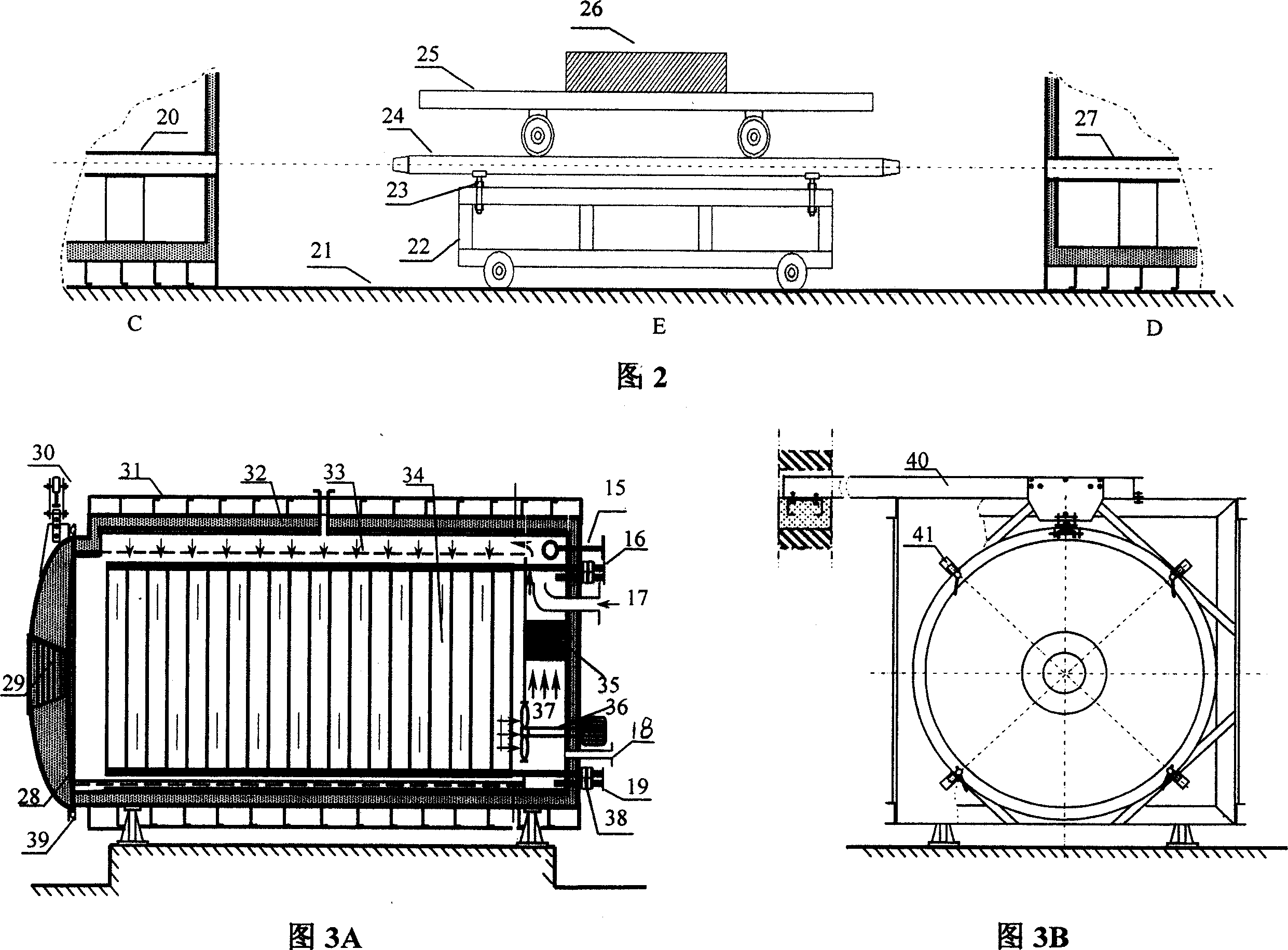

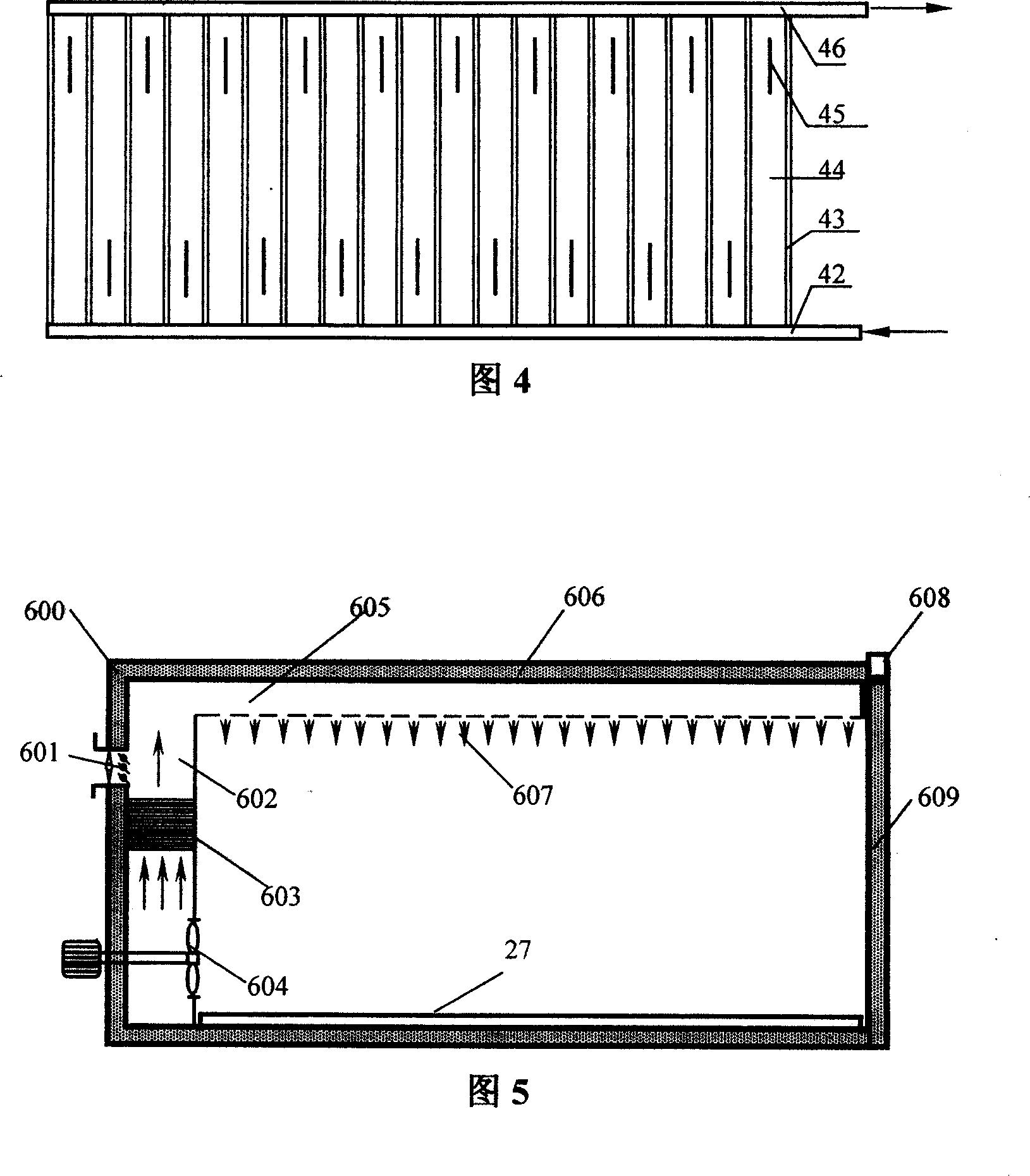

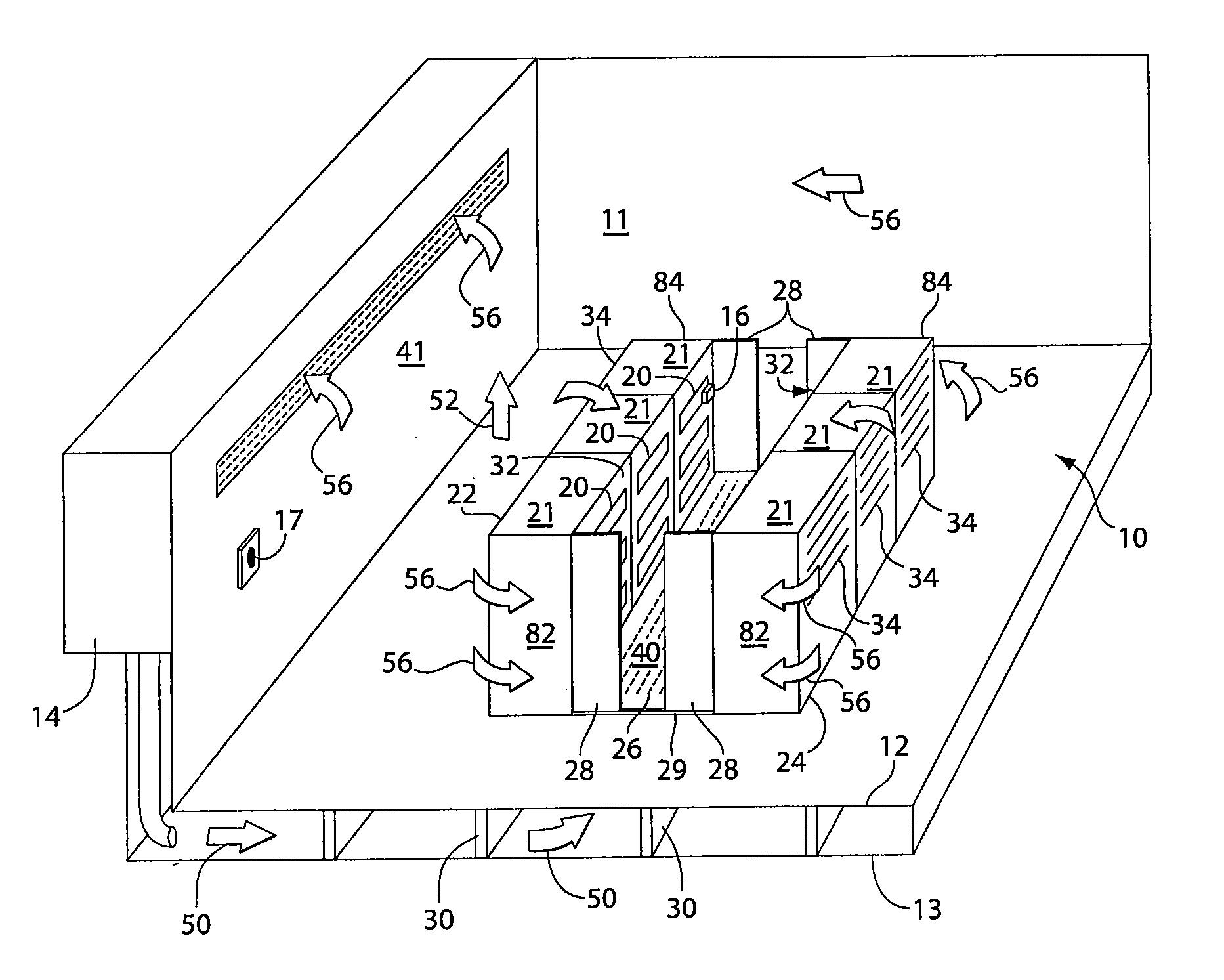

Test apparatus of large-scaled environment simulation

This invention relates to one large integral environment analogue experiment device, which comprises high temperature cabinet, air cooling system, vacuum system, rapid conversion track set and remote test and control system, wherein, the cabinet and temperature cabinet adopts gate to gate parallel distribution; the two cabinet sets rapid conversion track in charge for test parts rapid conversion; the air cooling system and vacuum system is in charge for temperature cabinet cool volume and to lower inside pressure; the temperature cabinet is in constant box structure composed of cooling board recycling system for analogue.

Owner:BEIHANG UNIV

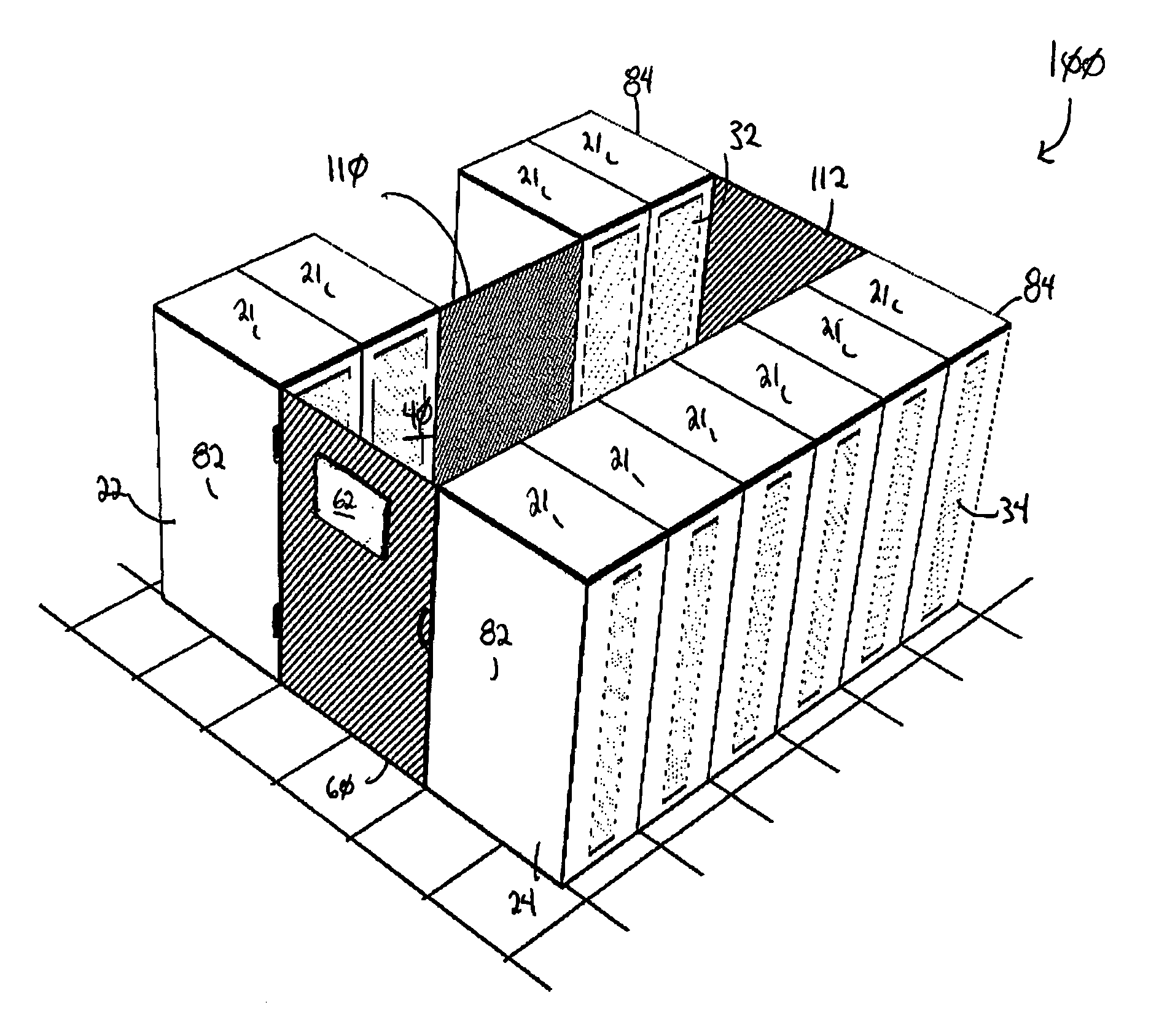

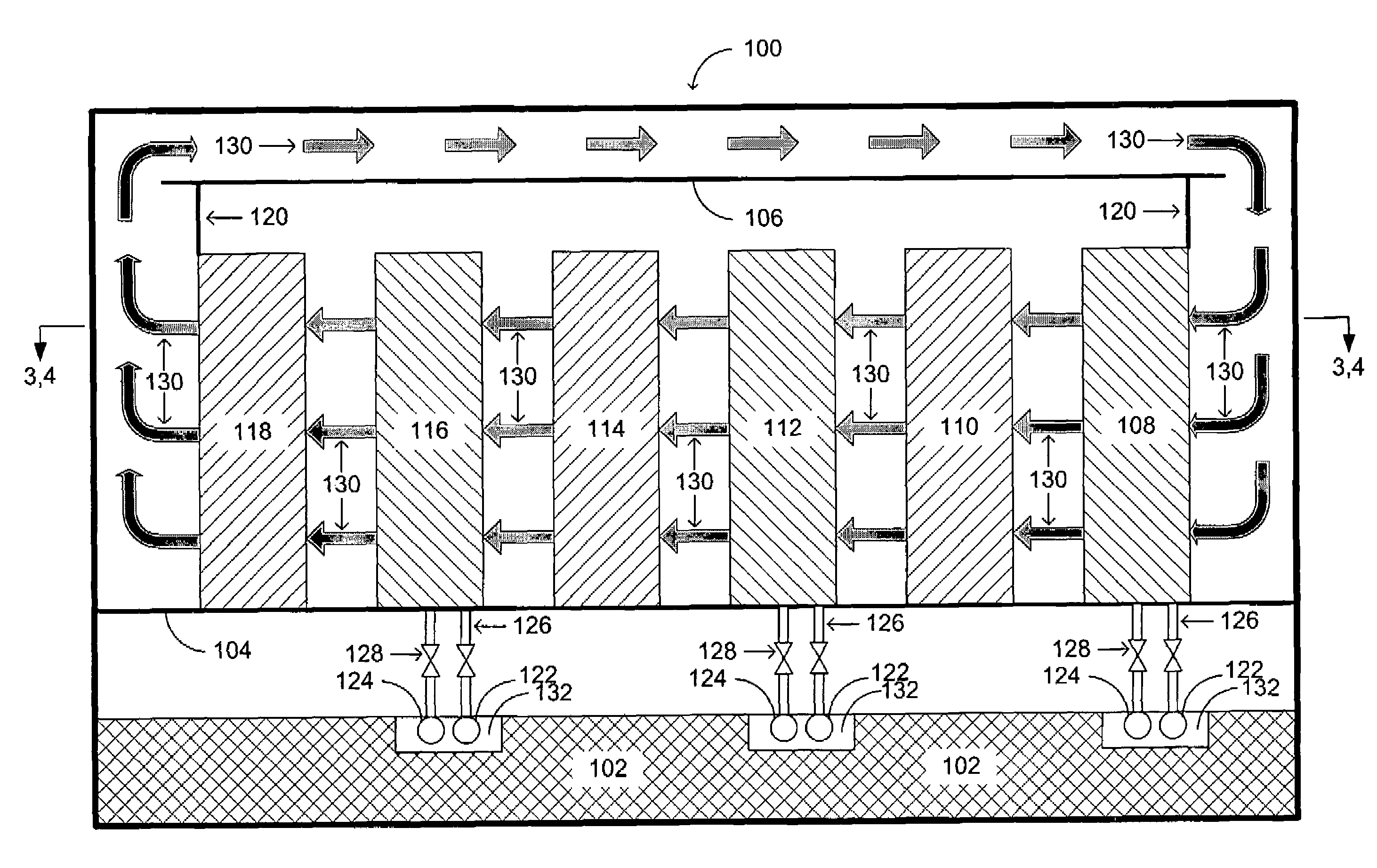

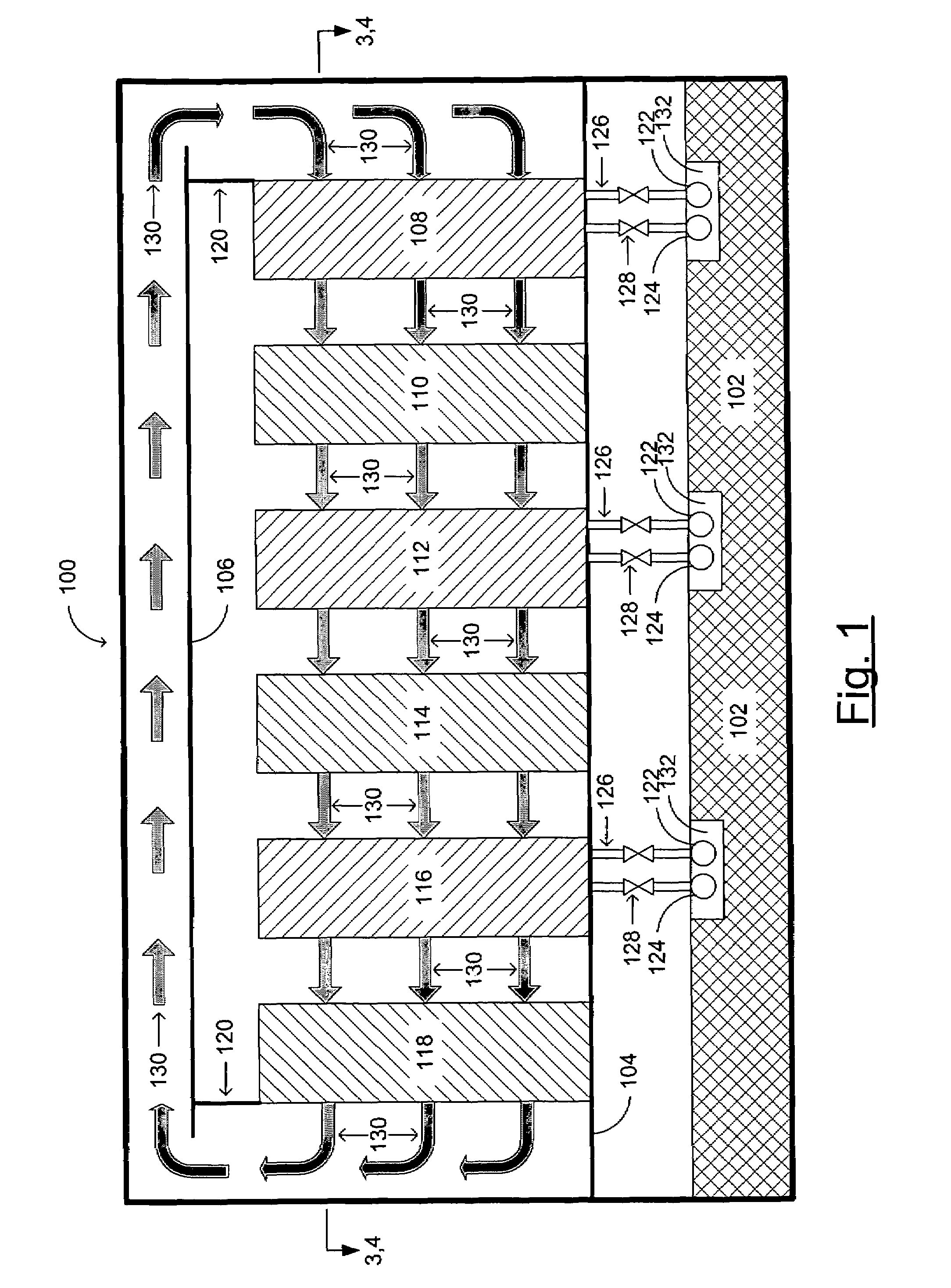

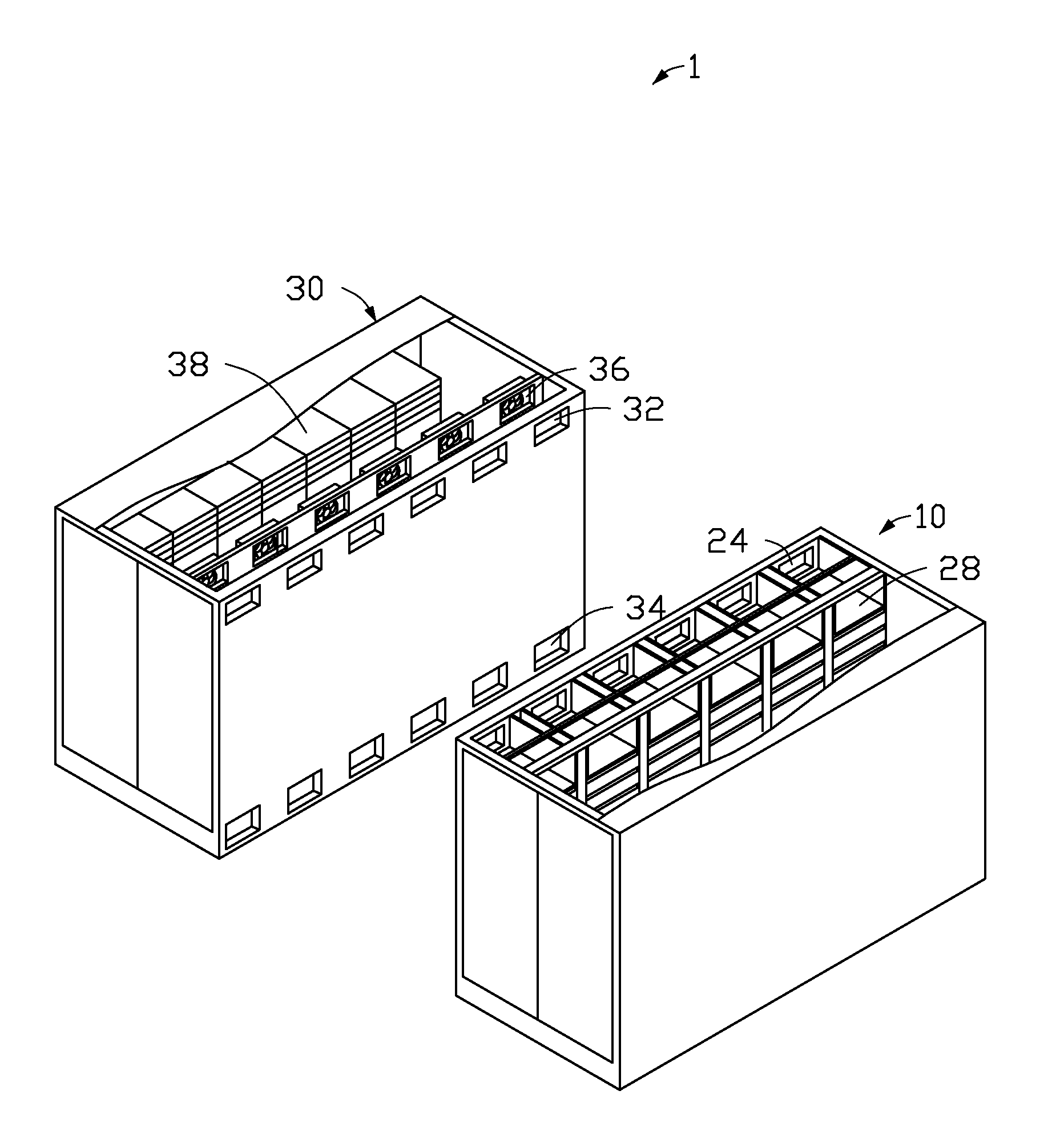

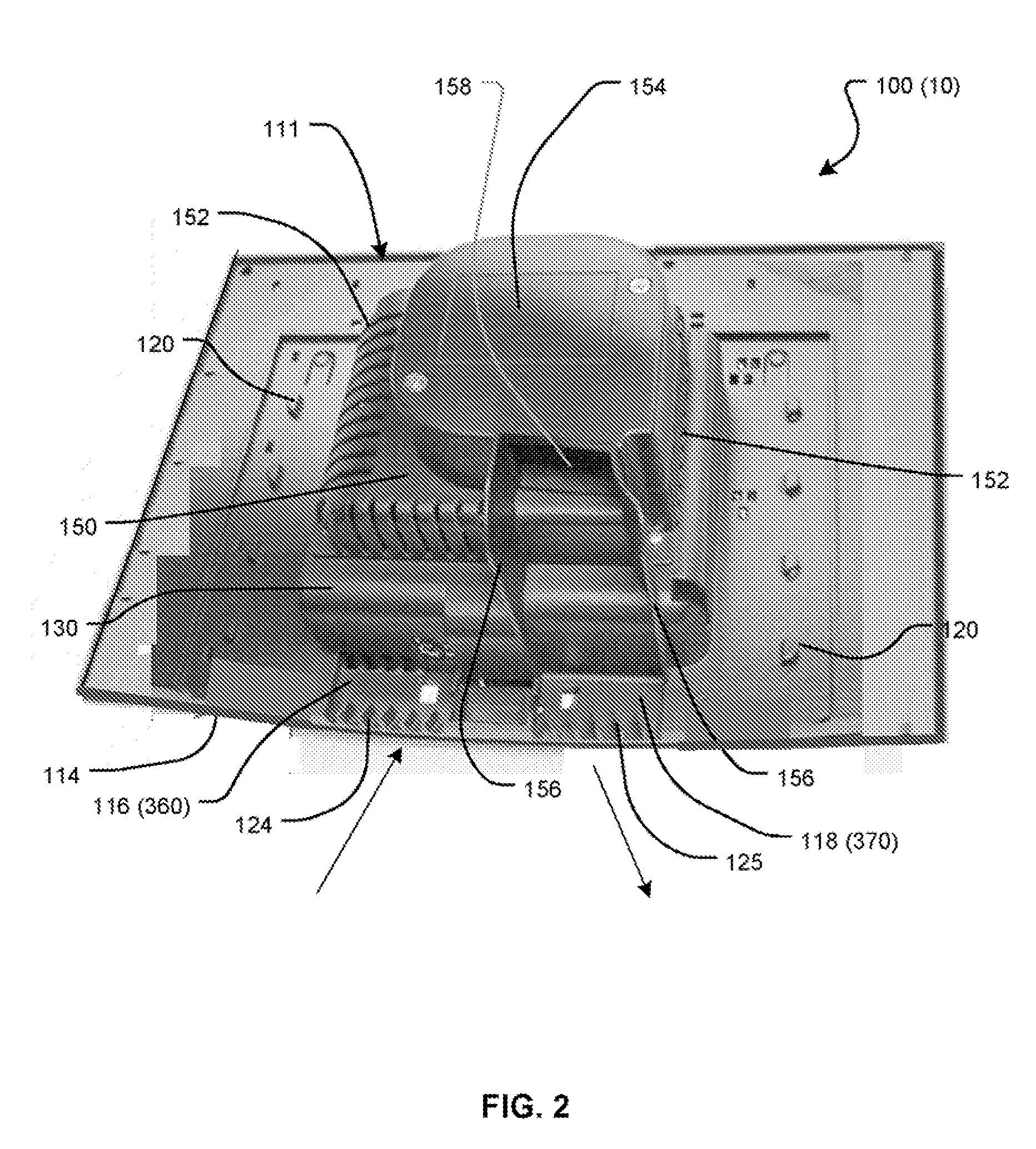

Cold aisle isolation

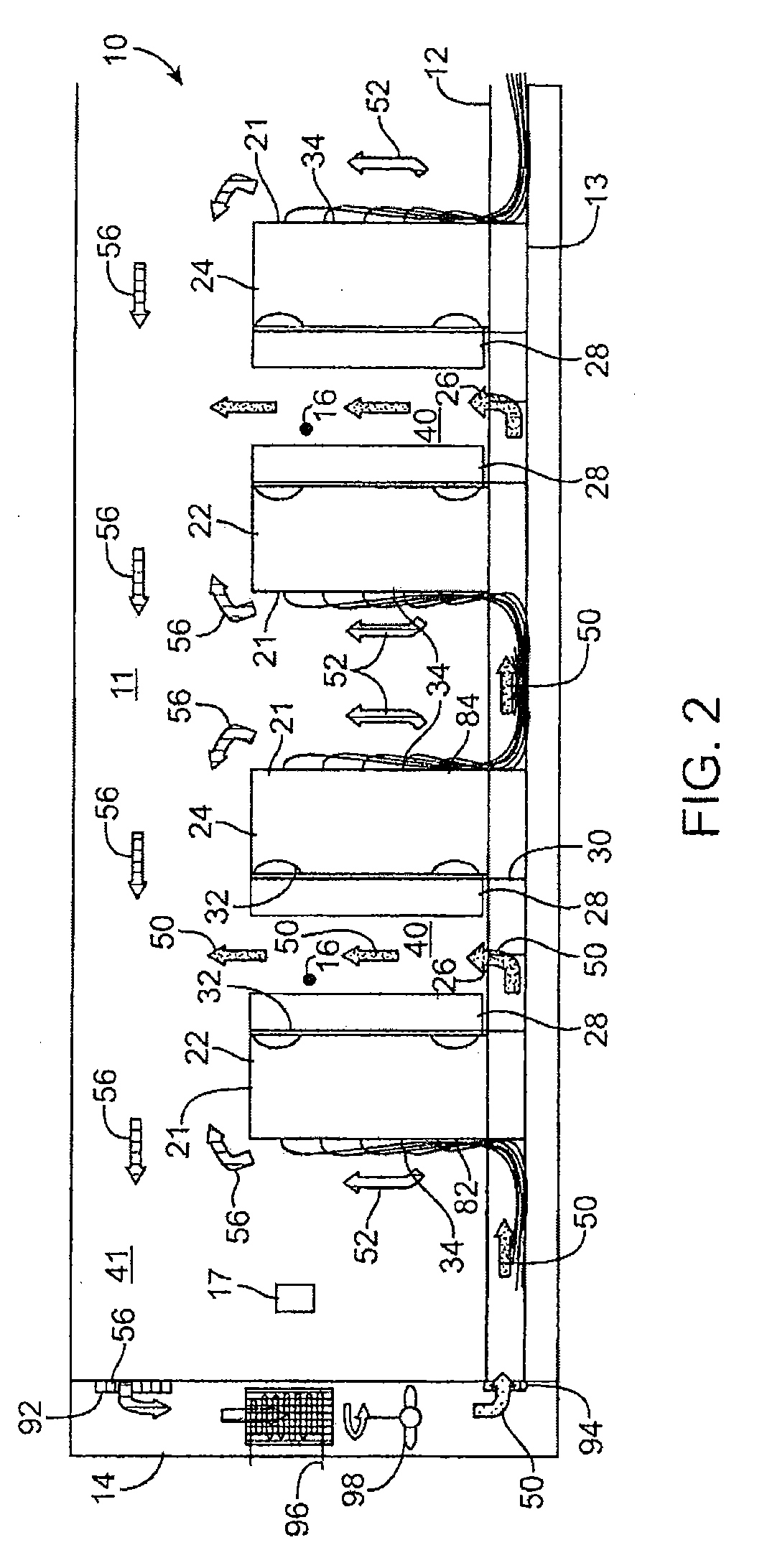

ActiveUS20090107652A1Easy to modifyLarge capacityDigital data processing detailsElectrical apparatus contructional detailsAir cooling systemEngineering

A data center cooling solution providing techniques for using baffles, doors and roof sections to prevent warm air from being entrained into a cold aisle in a data center, wherein the data center generally contains an air cooling system and a raised floor structure. The raised floor structure is configured to deliver cool air into the data center through a plurality of grates and perforated tiles in the floor. Electronic equipment racks are disposed around the grates and perforated tiles, such that the front faces of the equipment racks face the grates and perforated tiles. A collection of baffles, doors or roof sections inhibit the mixing of the cool air delivered by the air cooling system and the warm air exhausted by the electronic equipment.

Owner:SCHNEIDER ELECTRIC IT CORP

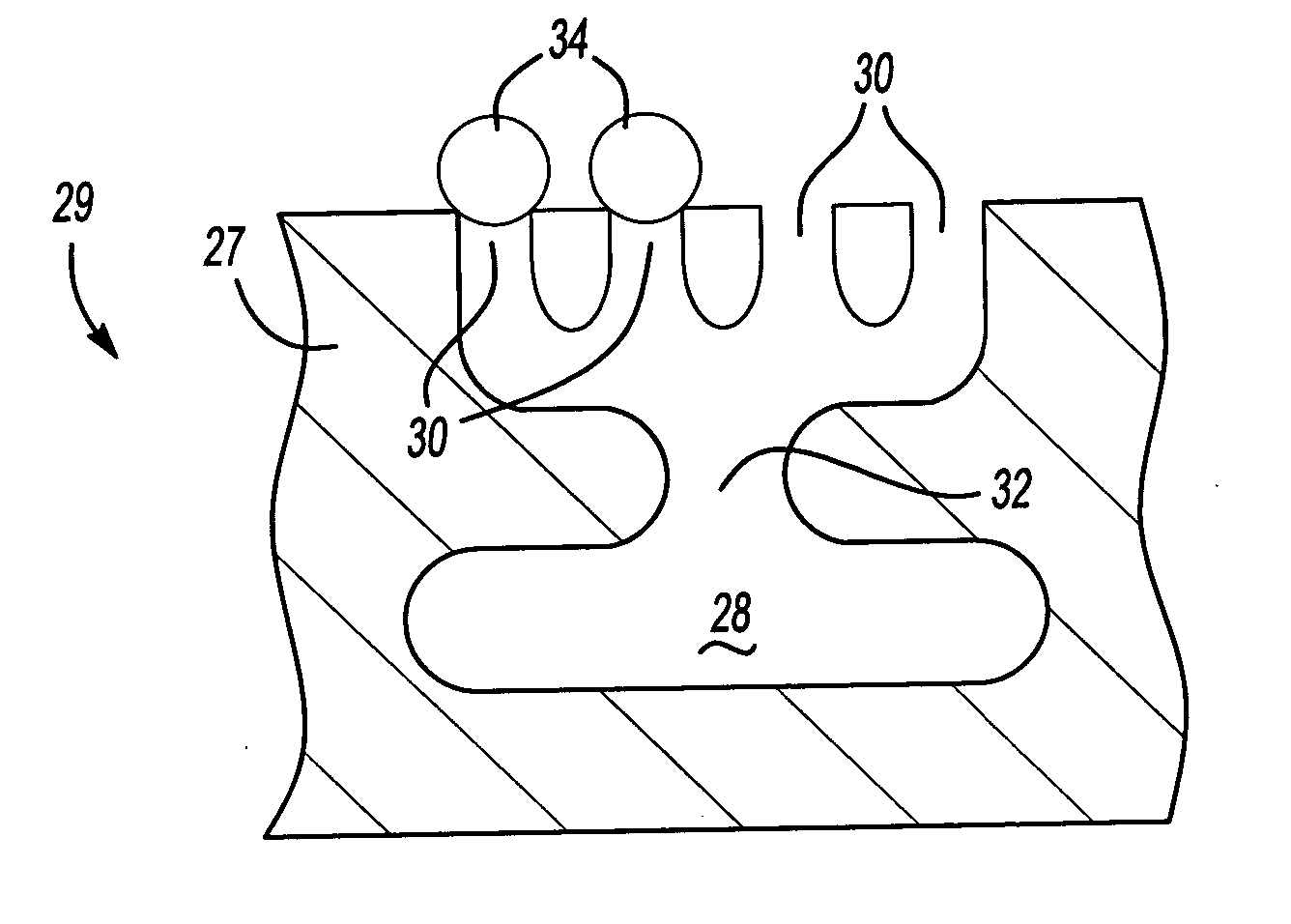

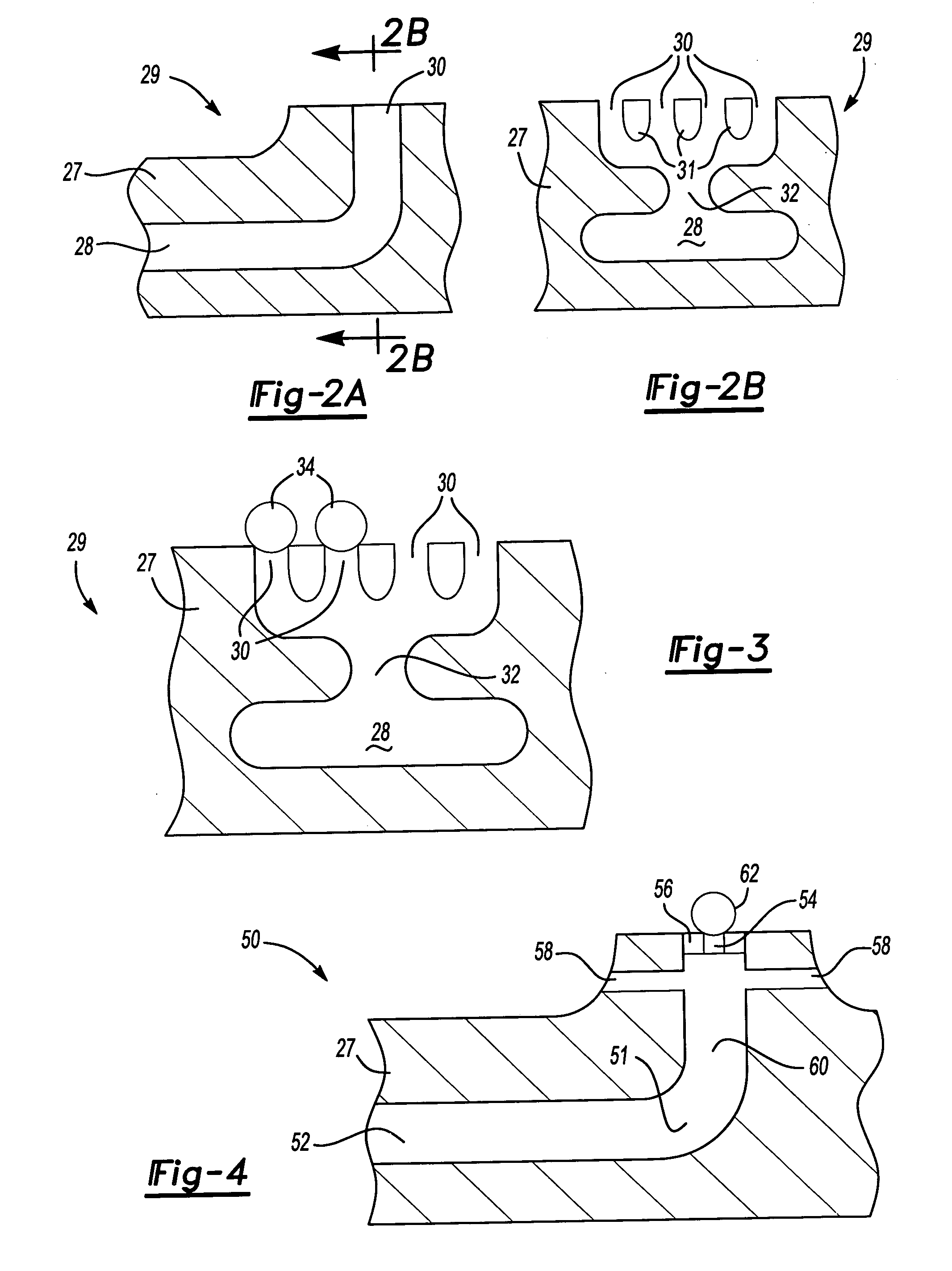

Debris-filtering technique for gas turbine engine component air cooling system

Air cooling passages for a gas turbine engine component, and in particular, a blade outer air seal, are provided with a filtering technique to filter impurities before they can reach a metering location. The air filtering techniques include the provision of a plurality of openings which each have a small cross-sectional area when compared to the cross-sectional area of the metering location. These small openings will filter out impurities before they reach the metering location. The metering location has a cross-sectional area that is greater than the cross-sectional area of any one of the openings, however, the total cross-sectional area of the plurality of openings exceeds the cross-sectional area of the metering location such that adequate air is supplied even if several of the openings are clogged.

Owner:UNITED TECH CORP

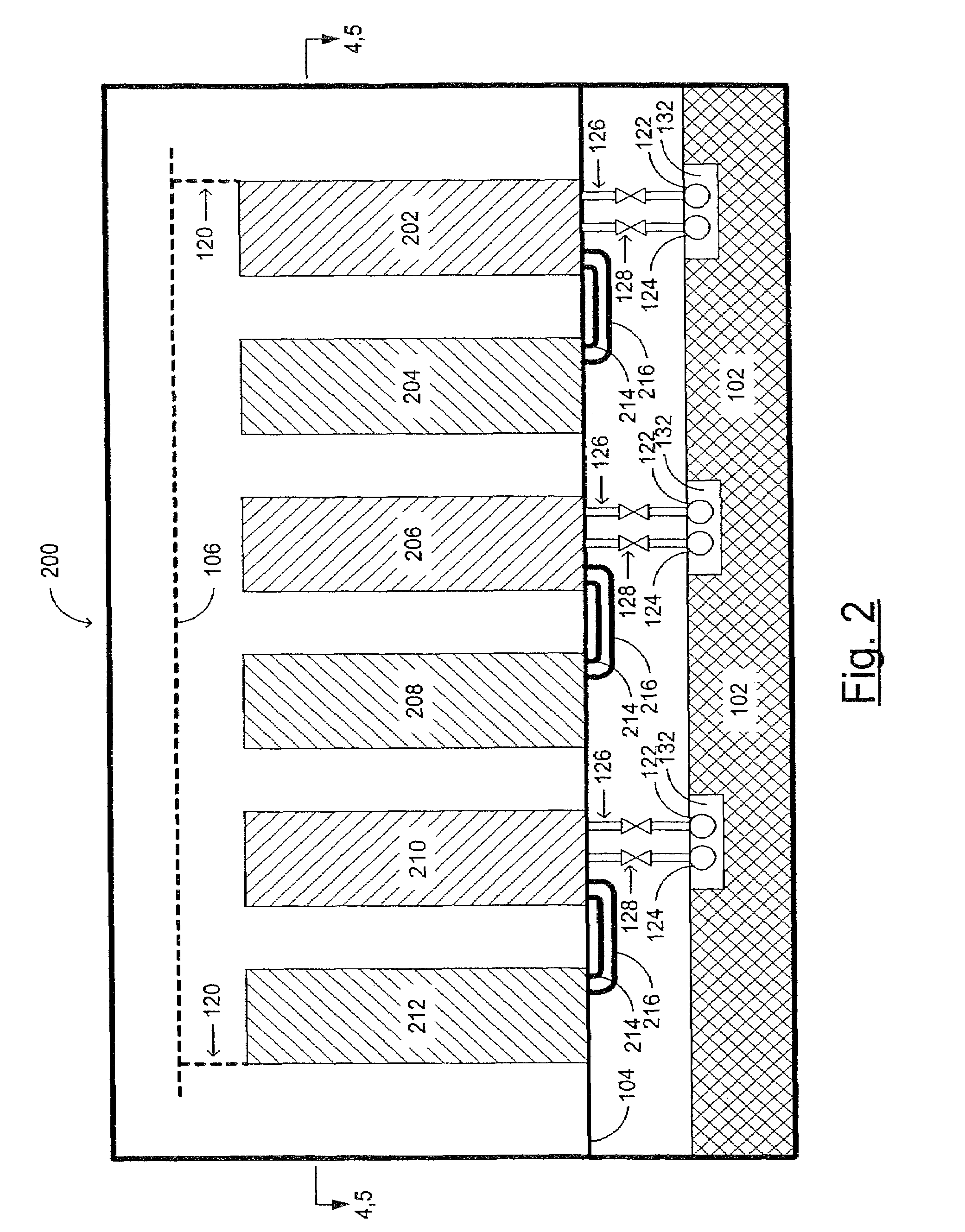

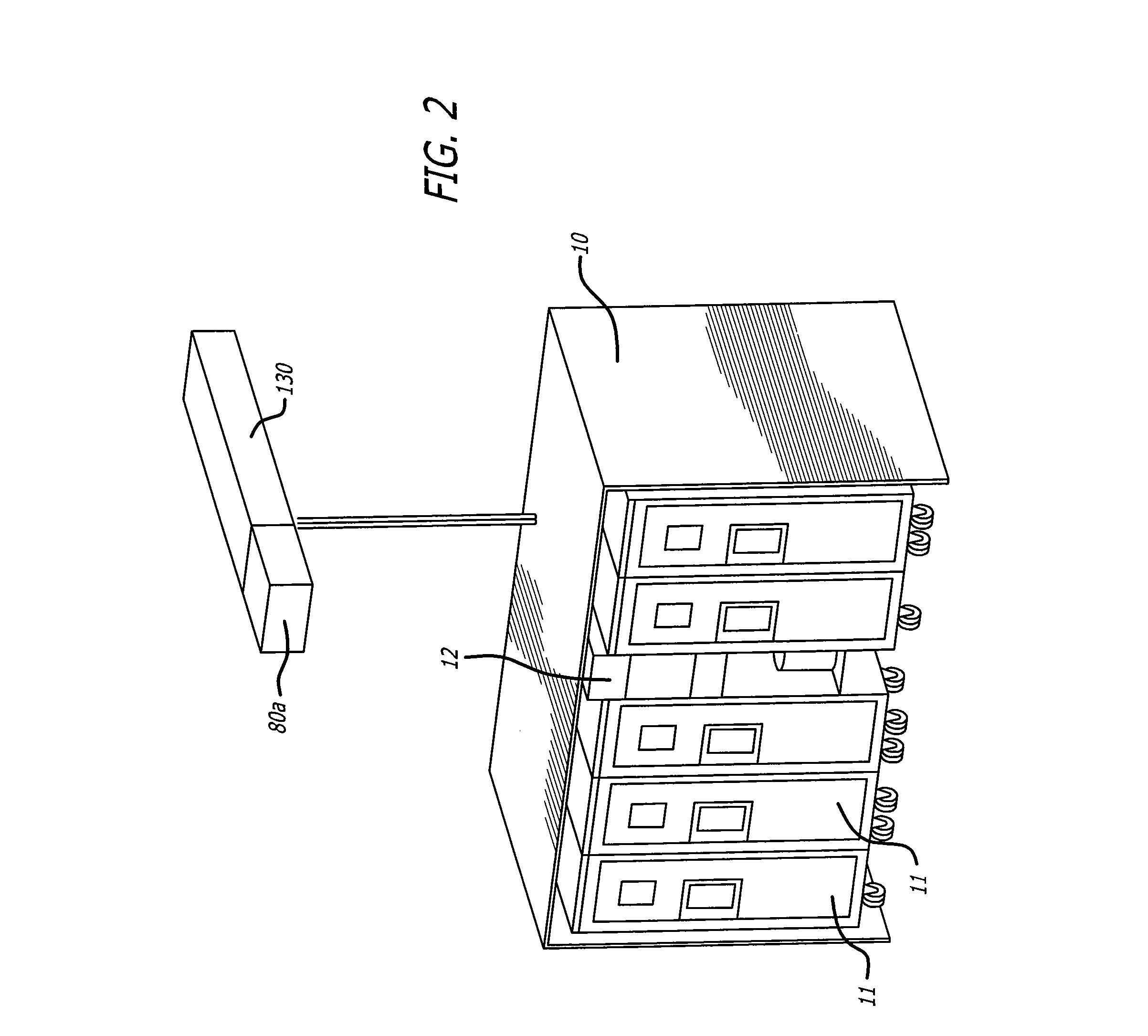

Upgradeable, modular data center cooling apparatus

A data center is configured using alternating rows of racks containing heat-generating electronic devices and air conditioners. Fluid, such as water or a refrigerant, for the air conditioners is supplied through pluming below a raised floor, such as those commonly found in current data centers. Attached to this plumbing are standard fluid couplings configured to couple to either air conditioners or liquid cooling units. These air conditioners and liquid cooling units use the same fluid so that they may share the plumbing. As data center migrates to liquid-cooled racks, a fraction of the air conditioners are replaced with liquid conditioning units in such a way that the data center contains both air-cooled and liquid-cooled racks without substantial reduction in efficiency of the air-cooling system. Since the air conditioners and liquid conditioning units use the same couplings and the same fluid, no infrastructure change is required.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

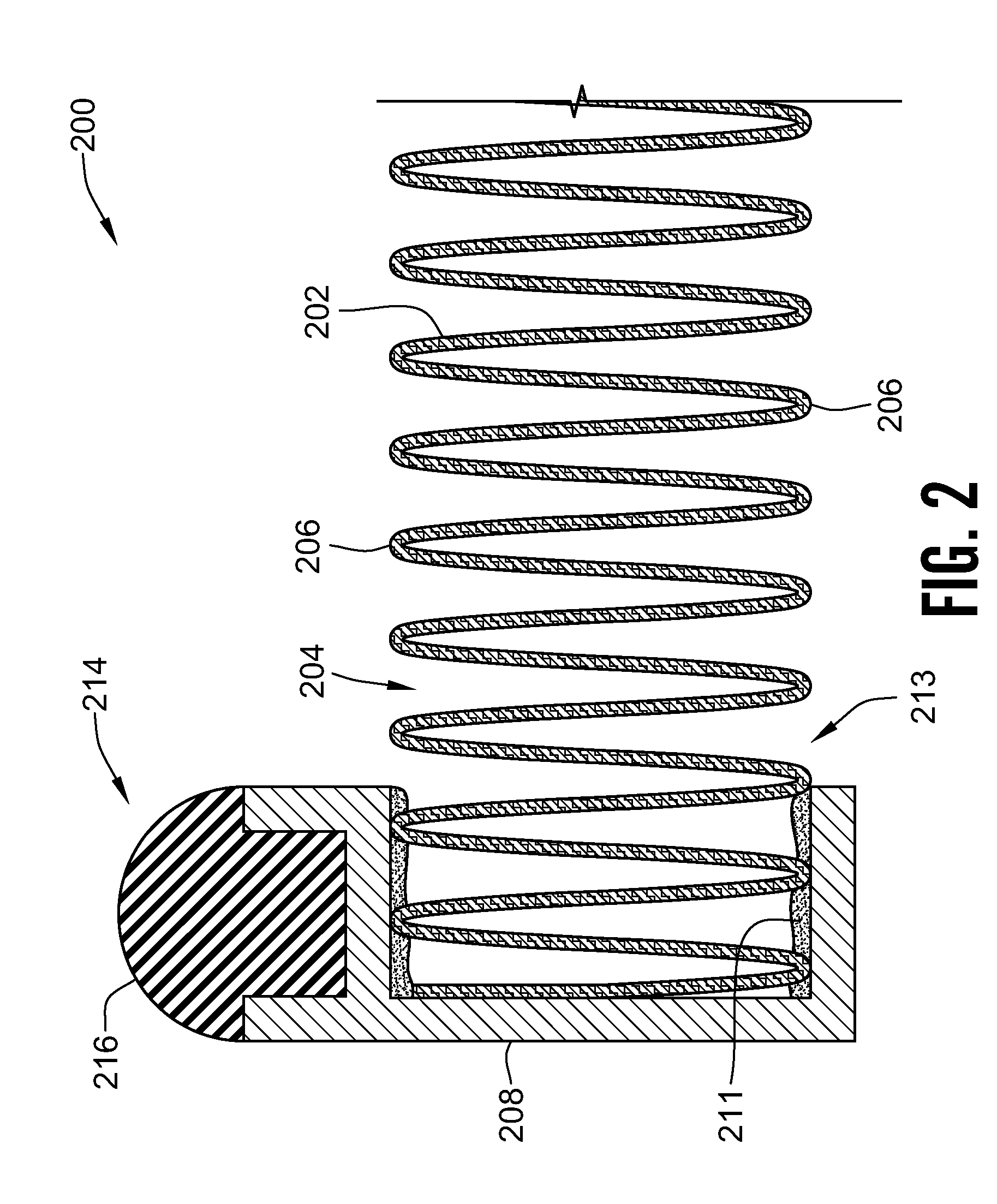

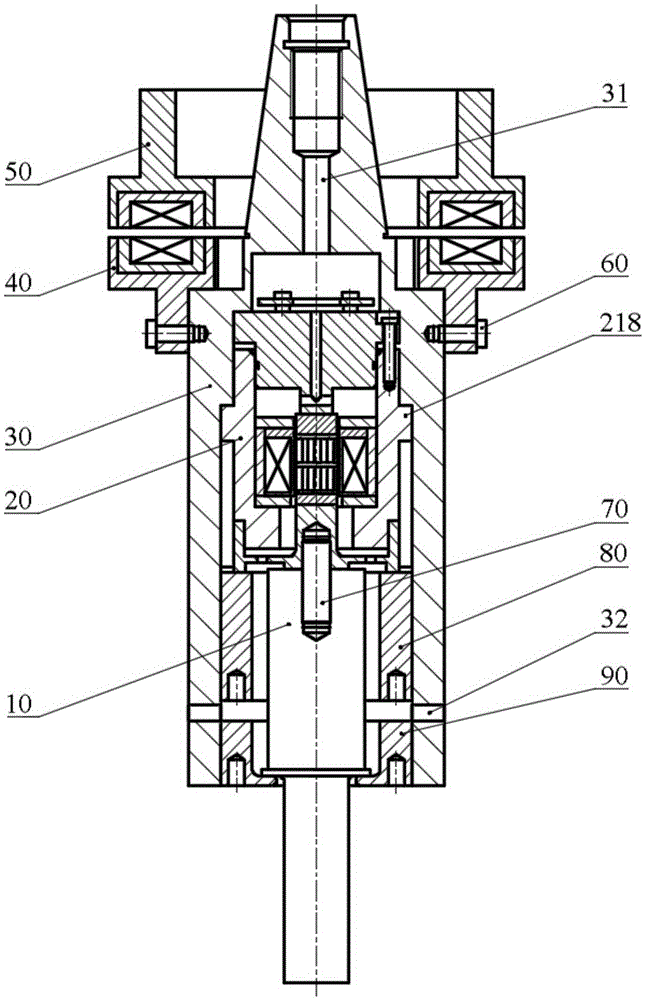

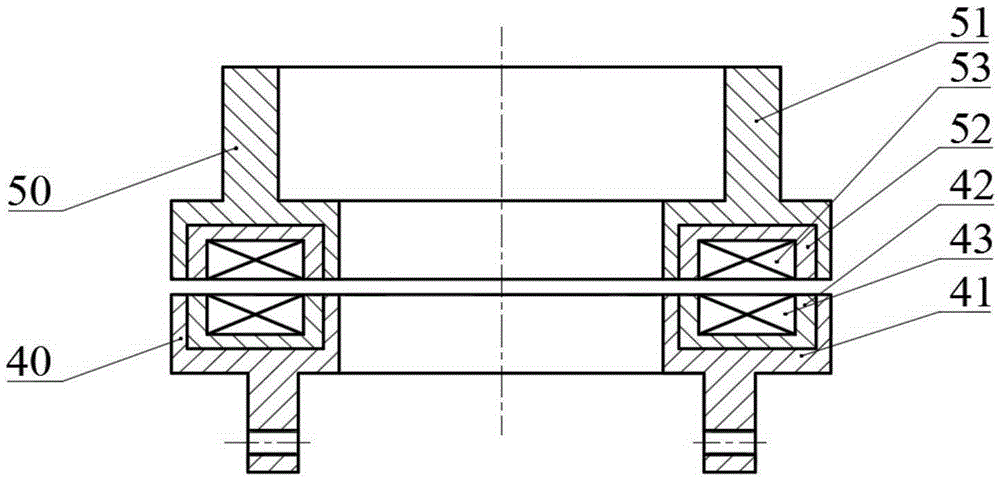

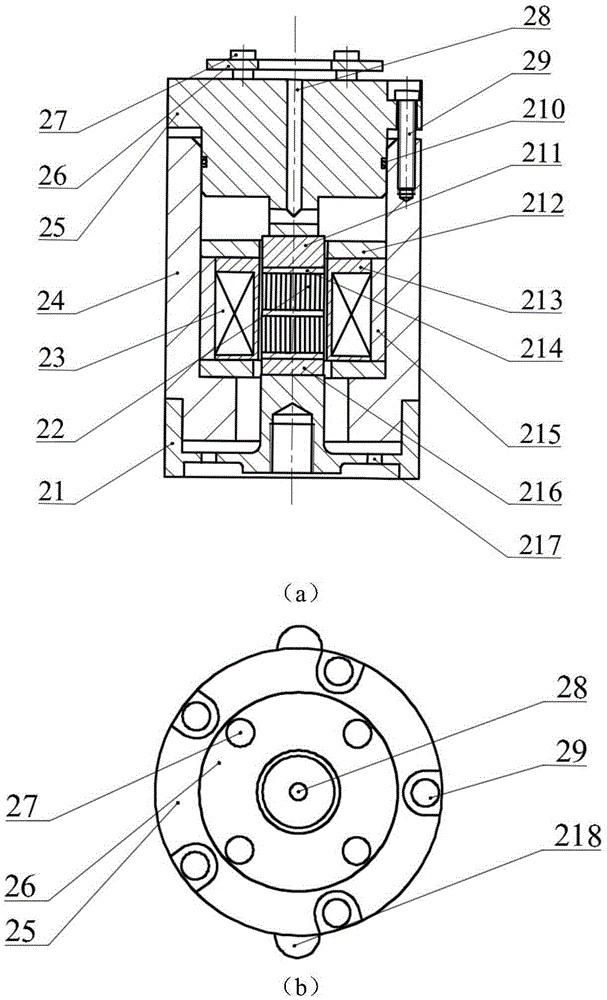

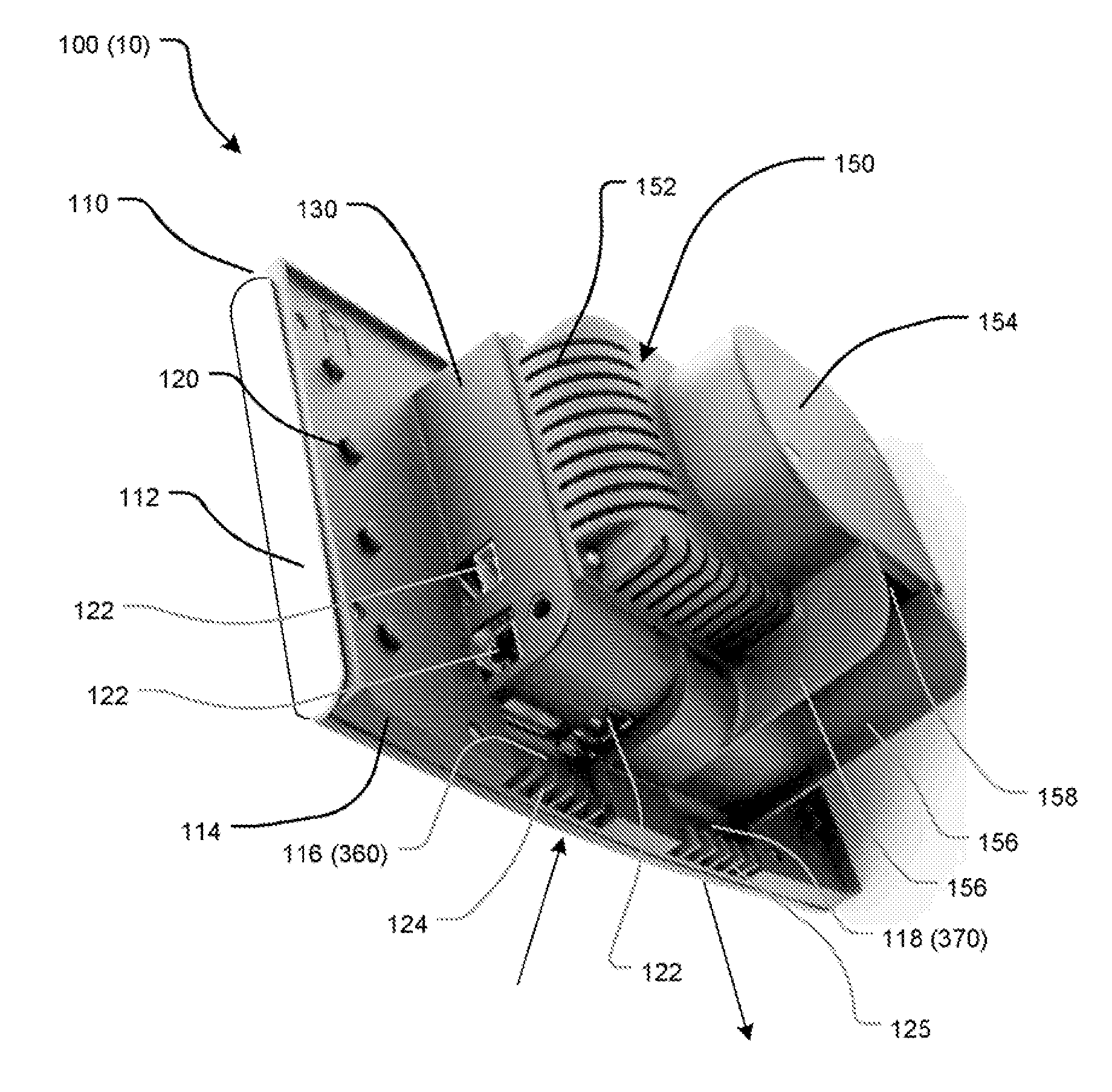

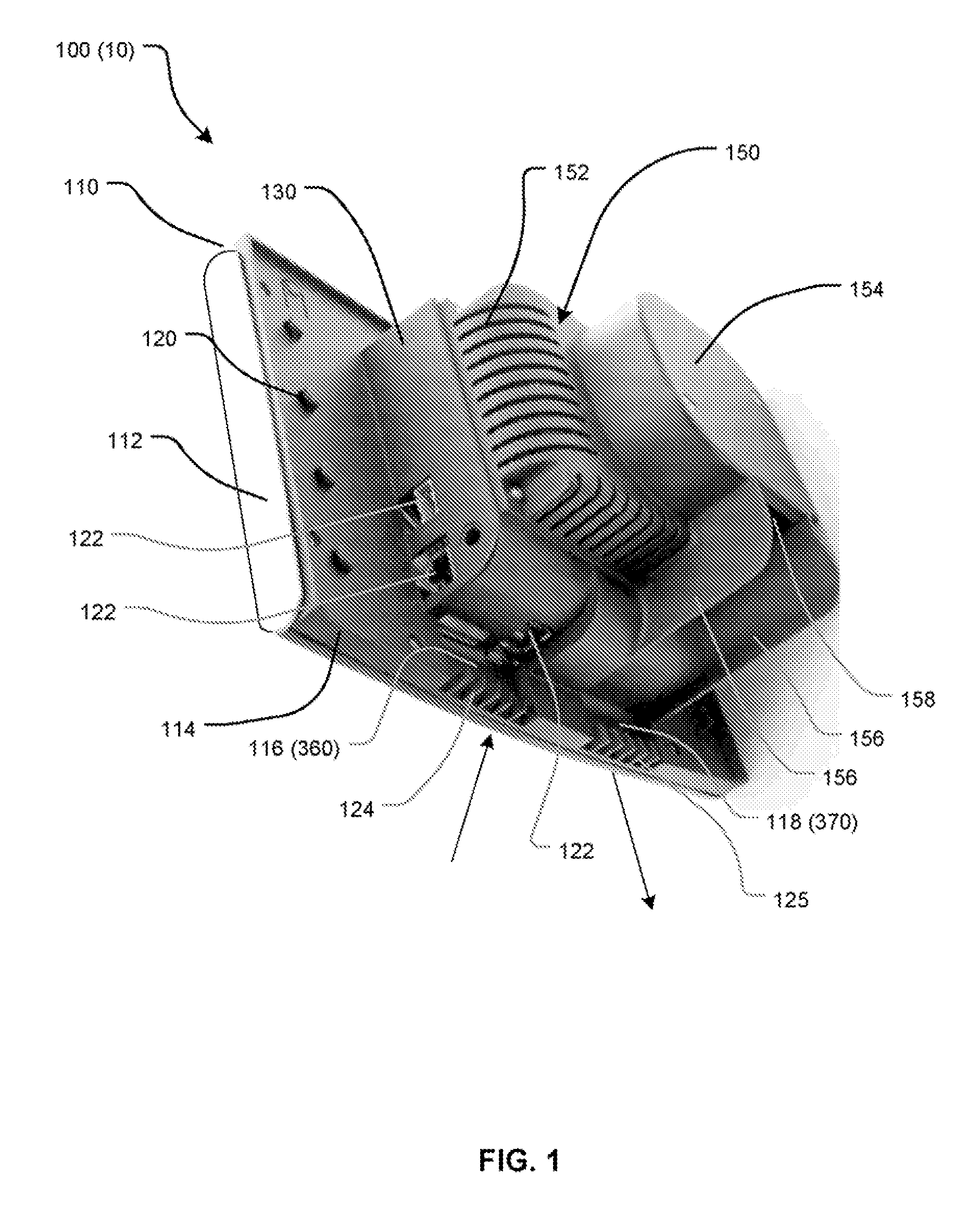

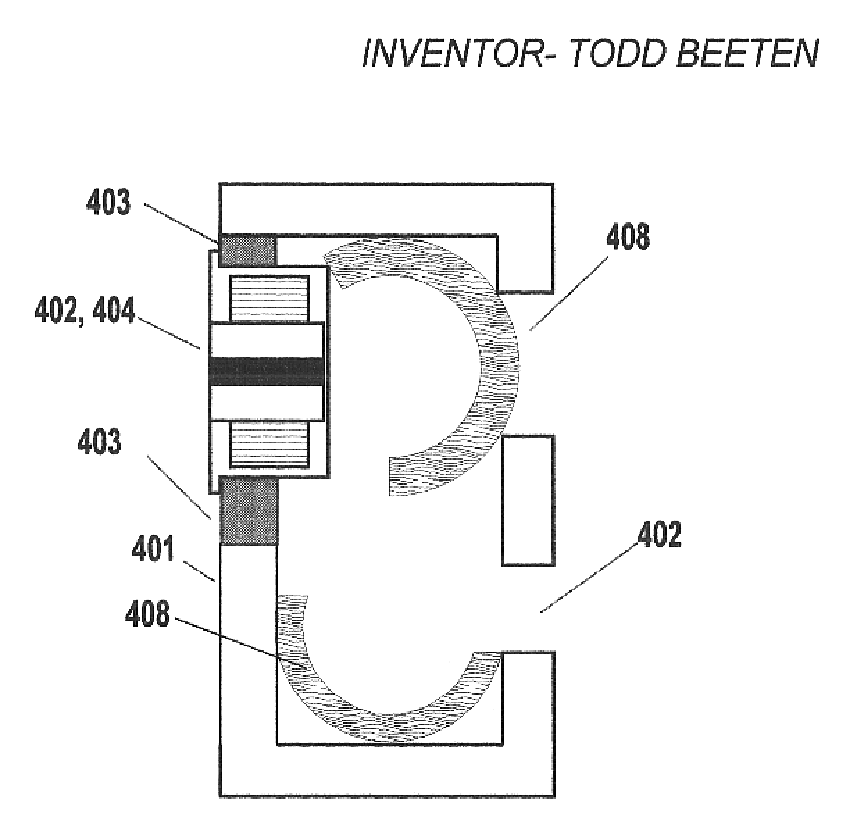

Giant magnetostrictive rotary ultrasonic vibration knife handle

ActiveCN105397920AHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerAir cooling system

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

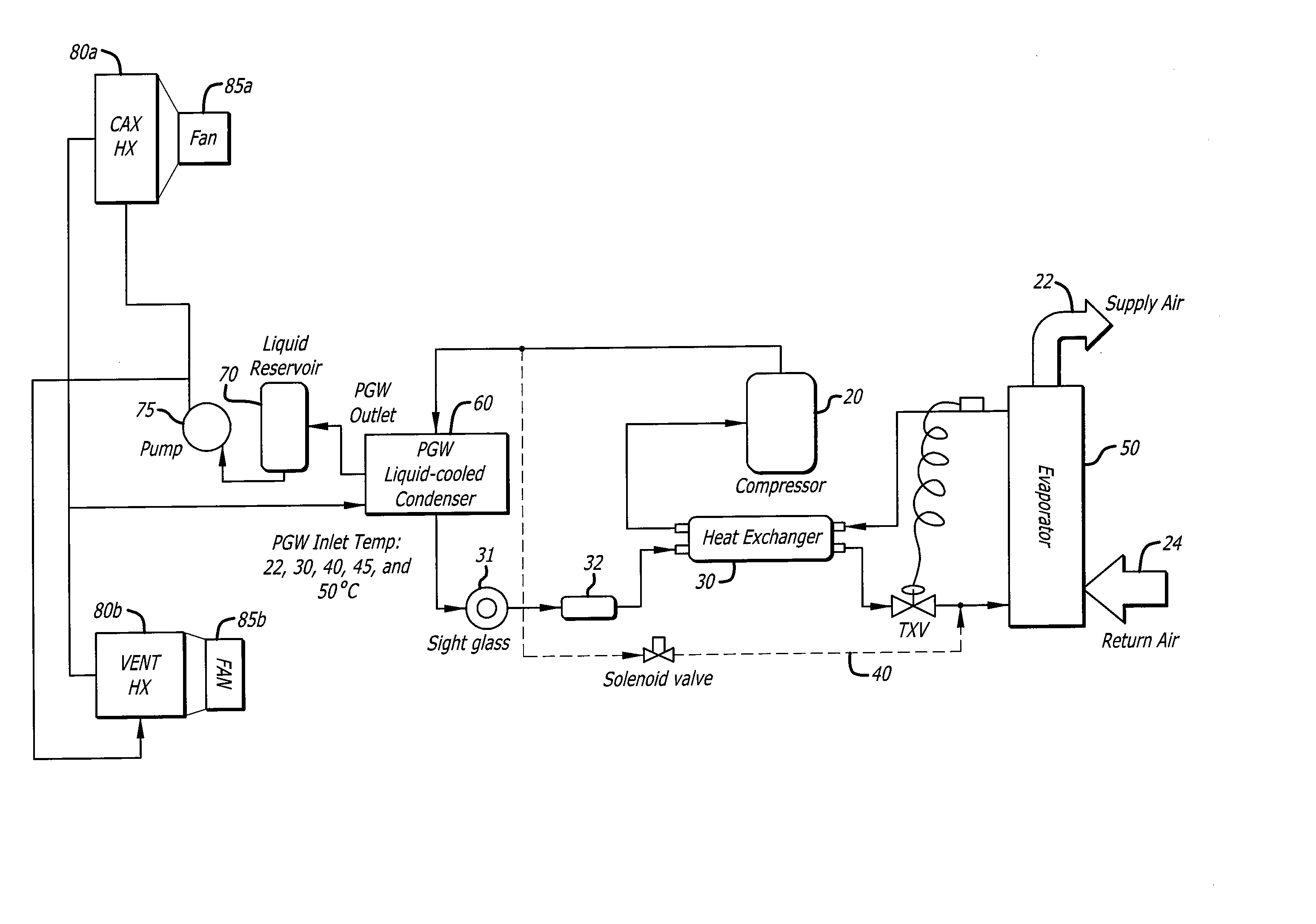

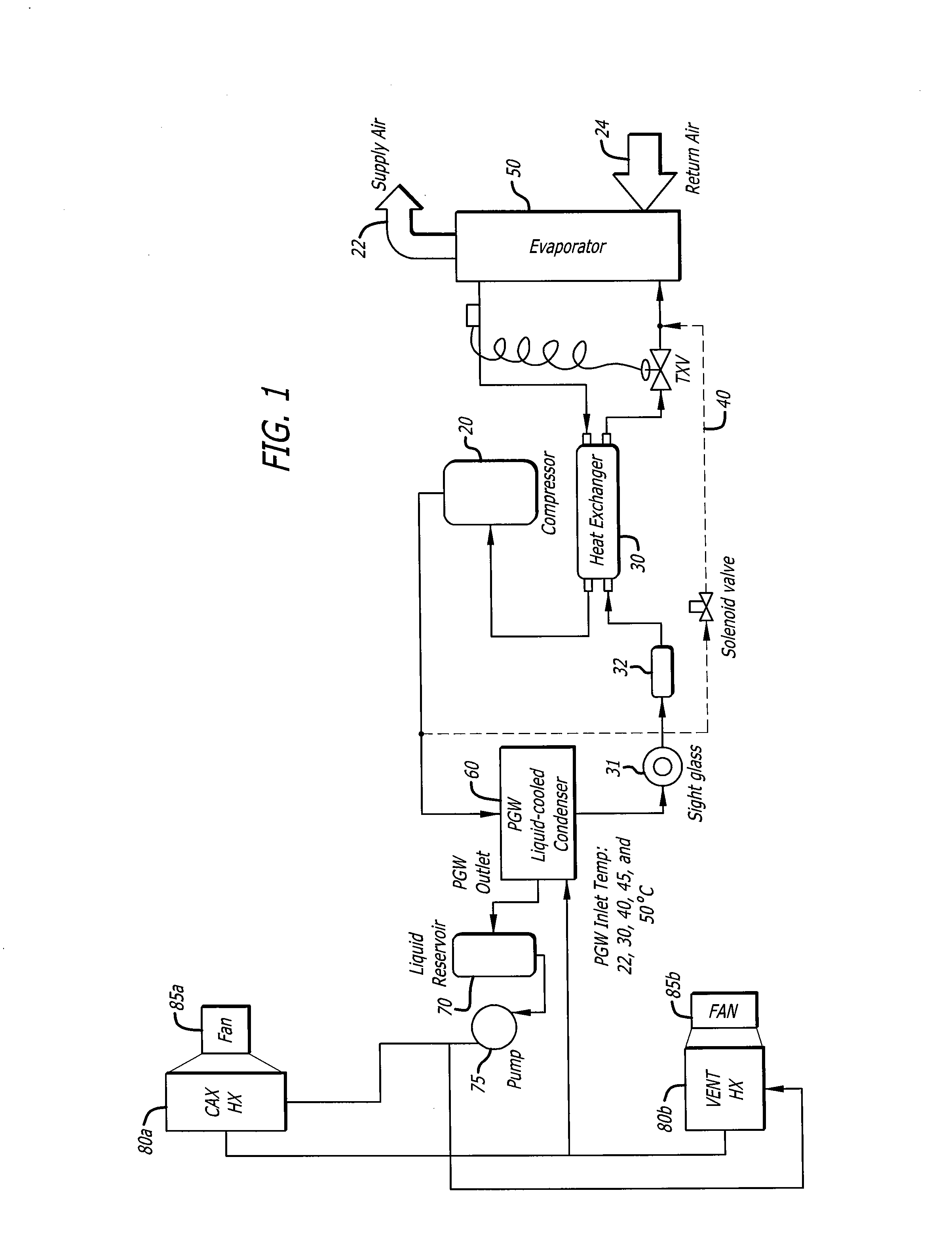

Aircraft galley air chiller system

ActiveUS20150007600A1Improve heat transfer efficiencyReduce weightGalleysAir-treatment apparatus arrangementsAir cooling systemSmall footprint

A chiller for an aircraft galley that is sized to be disposed in a compartment for housing beverage carts, the chiller comprising a vapor cycle refrigeration system with a liquid cooled condenser located within the housing and a liquid cooling unit located within the housing. Further, the vapor cycle refrigeration system and the liquid cooling unit have a combined footprint that is less than a footprint of a food and beverage cart within the housing, such that the space occupied by the chiller displaces no more than one beverage cart.

Owner:BE AEROSPACE INCORPORATED

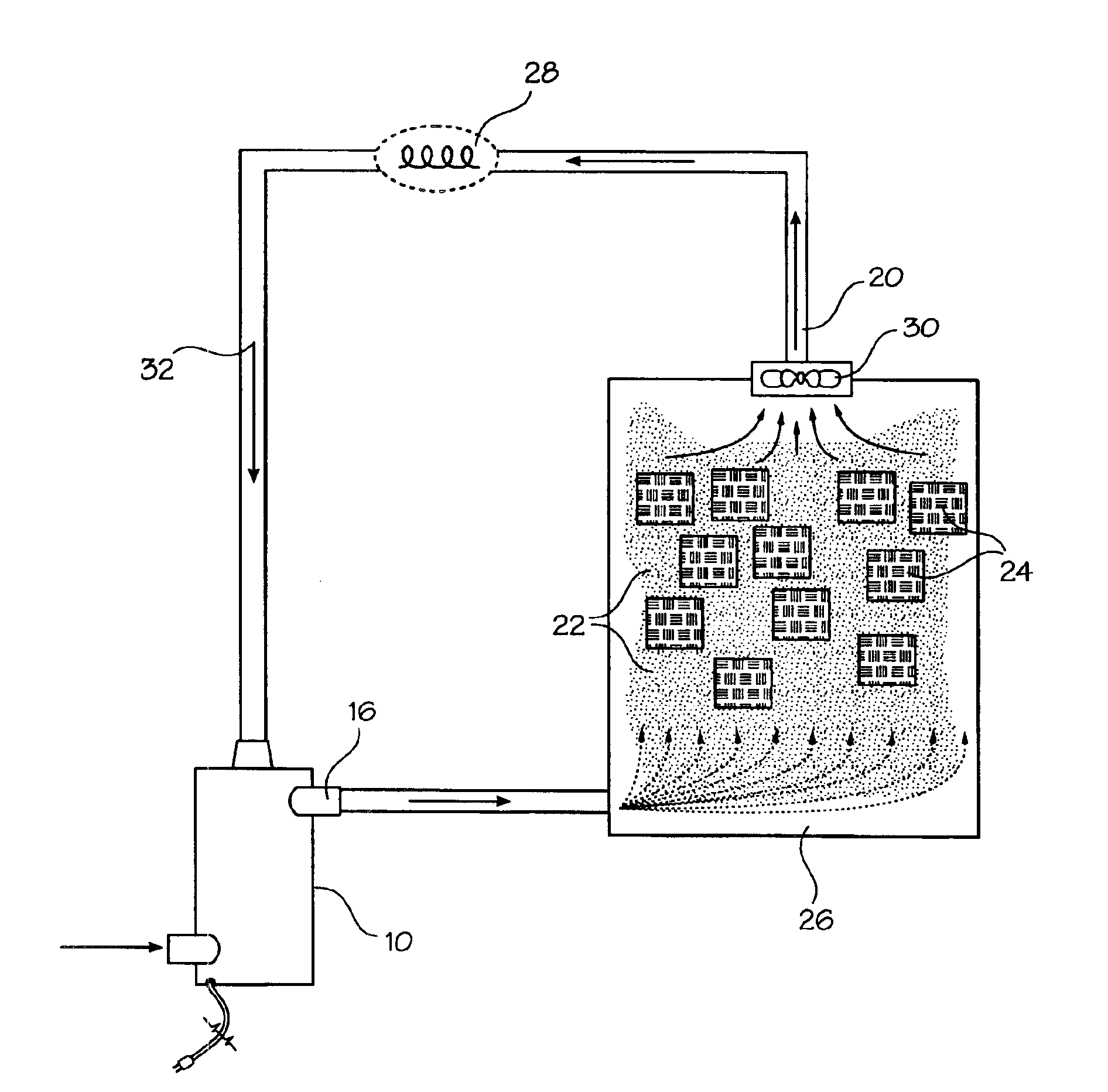

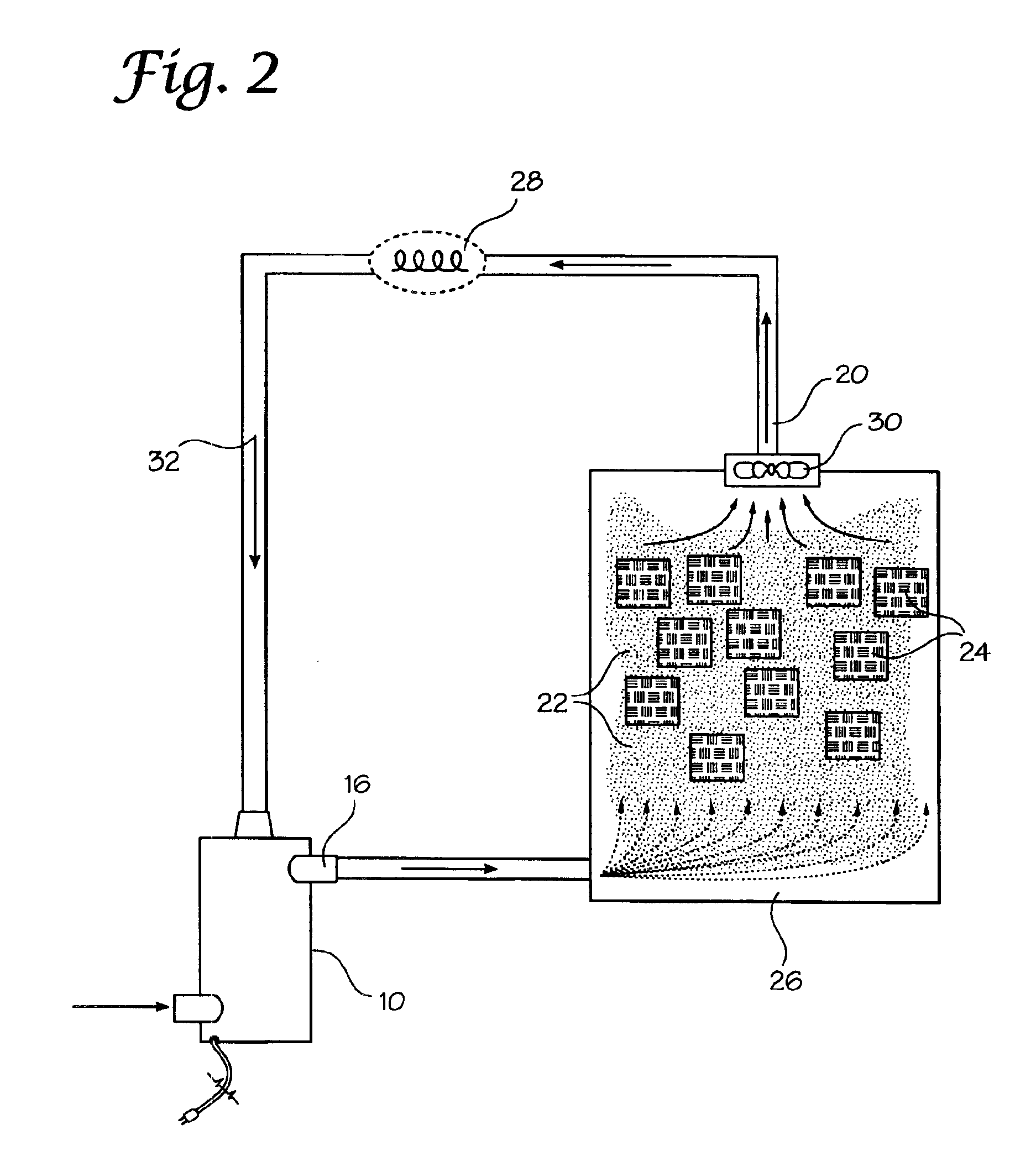

Cooling of electronics and high density power dissipation systems by fine-mist flooding

InactiveUS6955063B2Vaporization fastImprove cooling effectDomestic cooling apparatusSemiconductor/solid-state device detailsElectricityMomentum

A cooling method and apparatus including a mist-generating device is configured to generate a mist of droplets from water, dielectric liquids or any cooling liquids. The mist is produced having such volume, momentum, concentration and quality of scale so as to deter or avoid impingement or deposition of the mist droplets on a surface to be cooled or on surfaces within a heat dissipating system to be cooled. Effective cooling is provided by the high latent heat of vaporization of water or other suitable fluid, while surfaces normally subject to possible damage by wetting are protected from harmful contact from the fluid.Tangential flow technology and electronic ultrasonic atomizing devices may be used as one possible means to generate the required mist and control mist volume, momentum, concentration and quality. Other variables may be controlled to enhance the cooling of the mist, such as flow patterns and flow directions of the mist. Vaporized mist may be condensed and recovered. The cooling method may be used to replace or complement existing air-cooled systems.

Owner:NANOMIST SYST

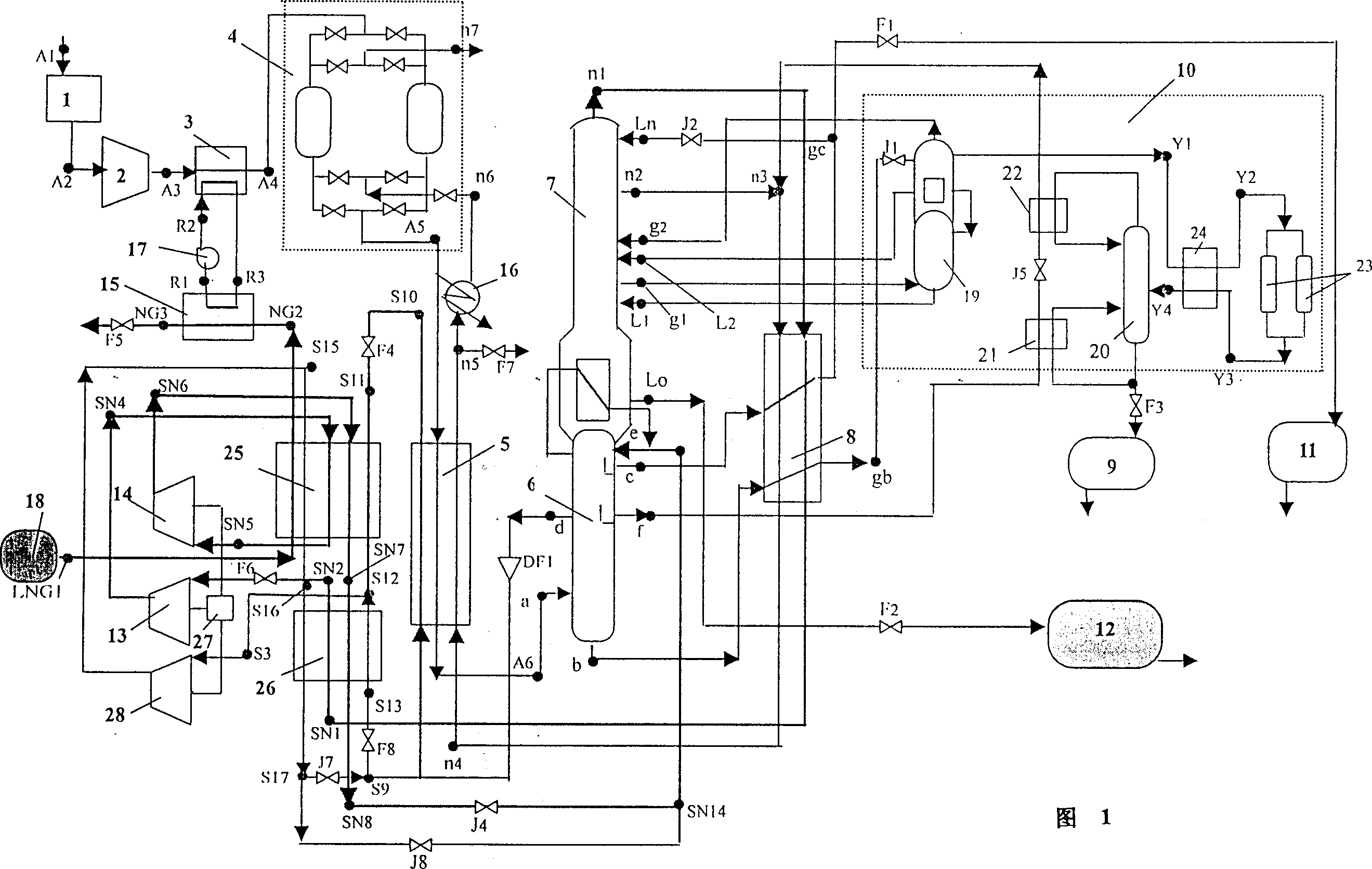

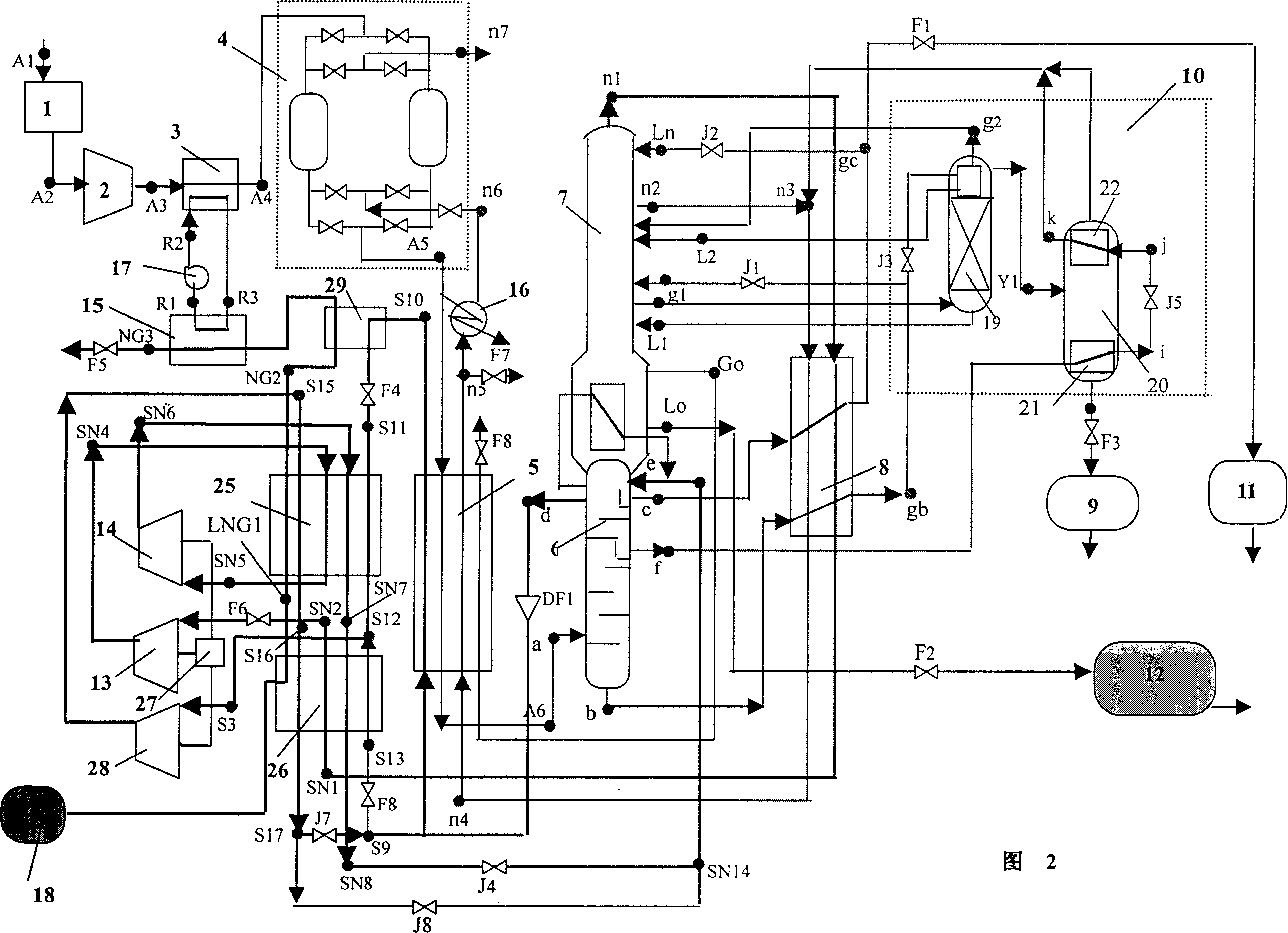

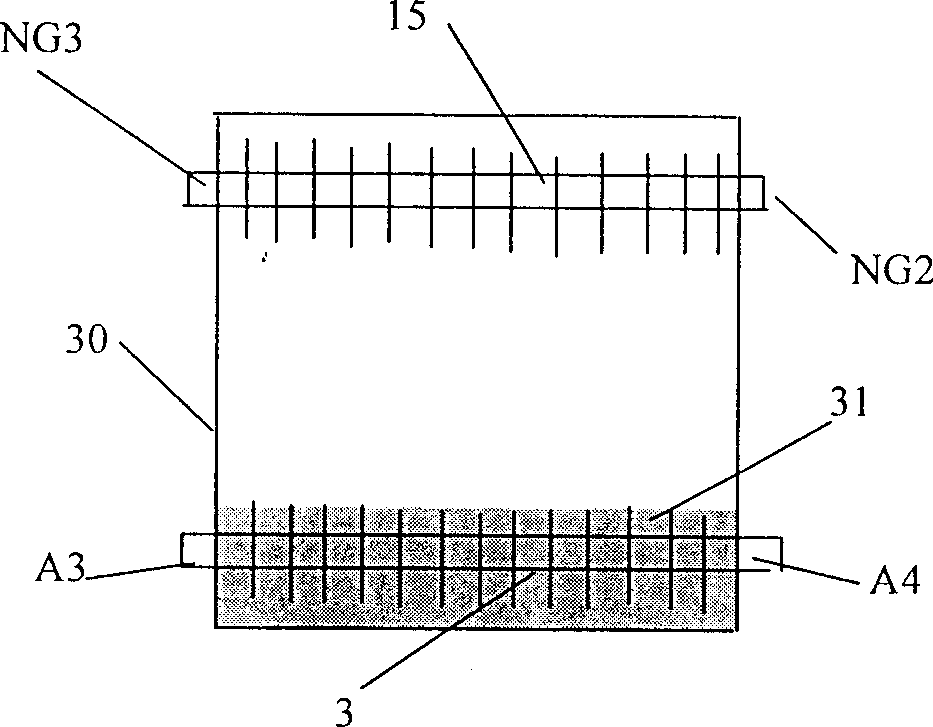

Air separator by utilizing cold energy of liquefied natural gas

InactiveCN1407303AReduce power consumptionRetrofit smallSolidificationLiquefactionEngineeringNitrogen gas

An air separator using the cold energy generated by liquefying natural gas to prepare liquefied oxygen, liquefied nitrogen and liquefied argon is based on existing air separator, and features that the multi-stage circulating nitrogen compressors, LNG heat exchanger and circulated nitrogen heat exchanger are additionally used to form a combined refrigerating system, and an air cooling system is also used.

Owner:UNIV OF SCI & TECH OF CHINA

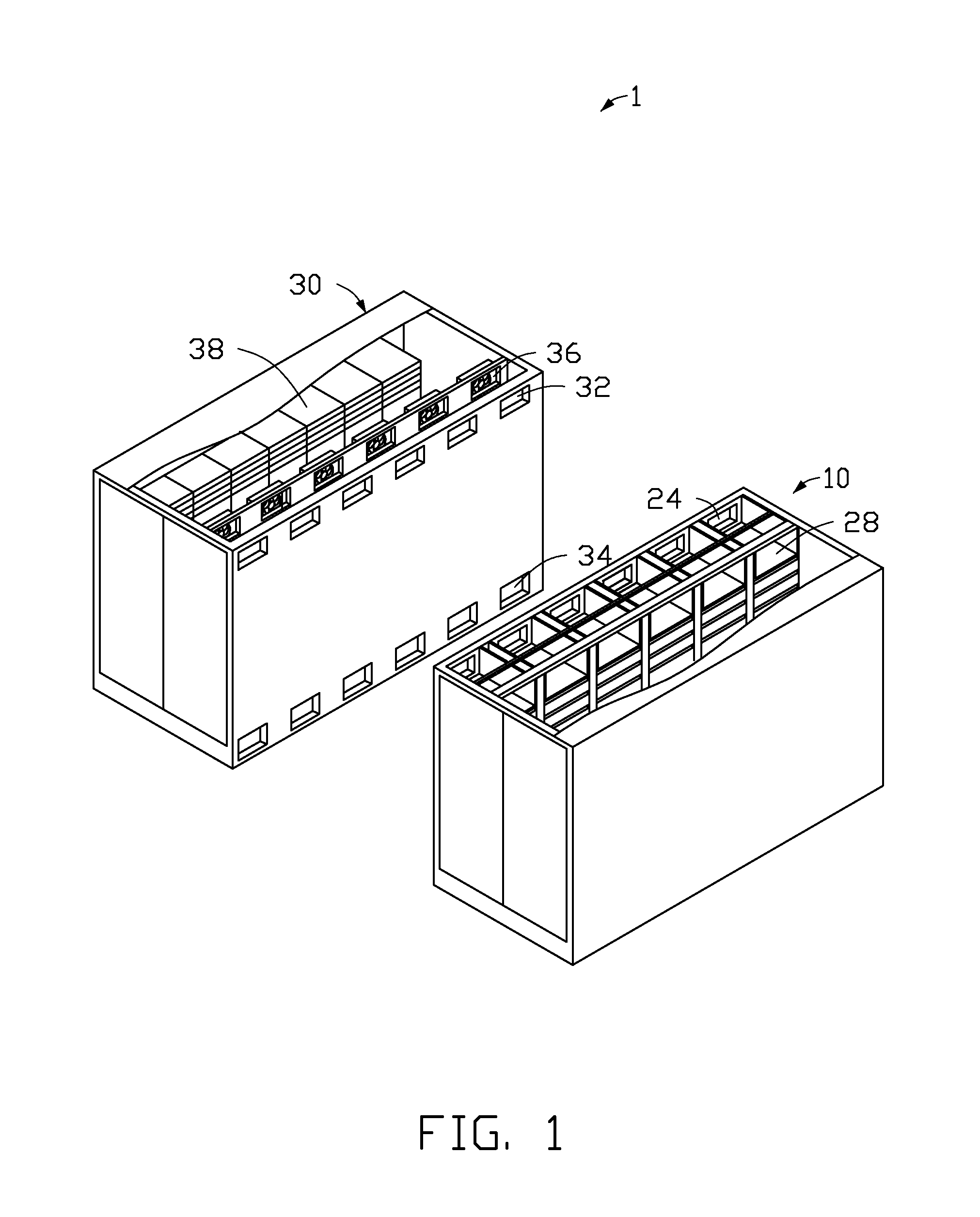

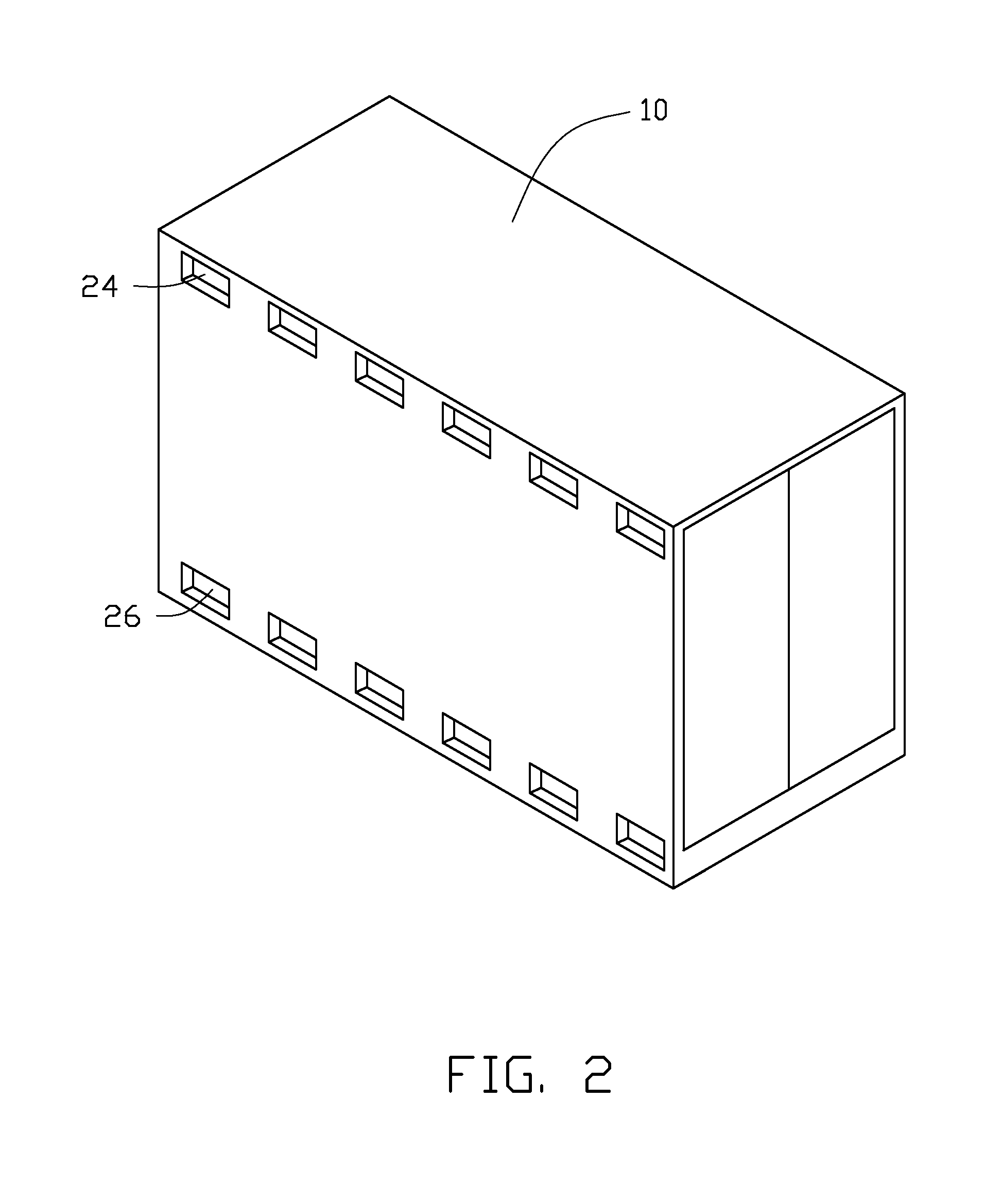

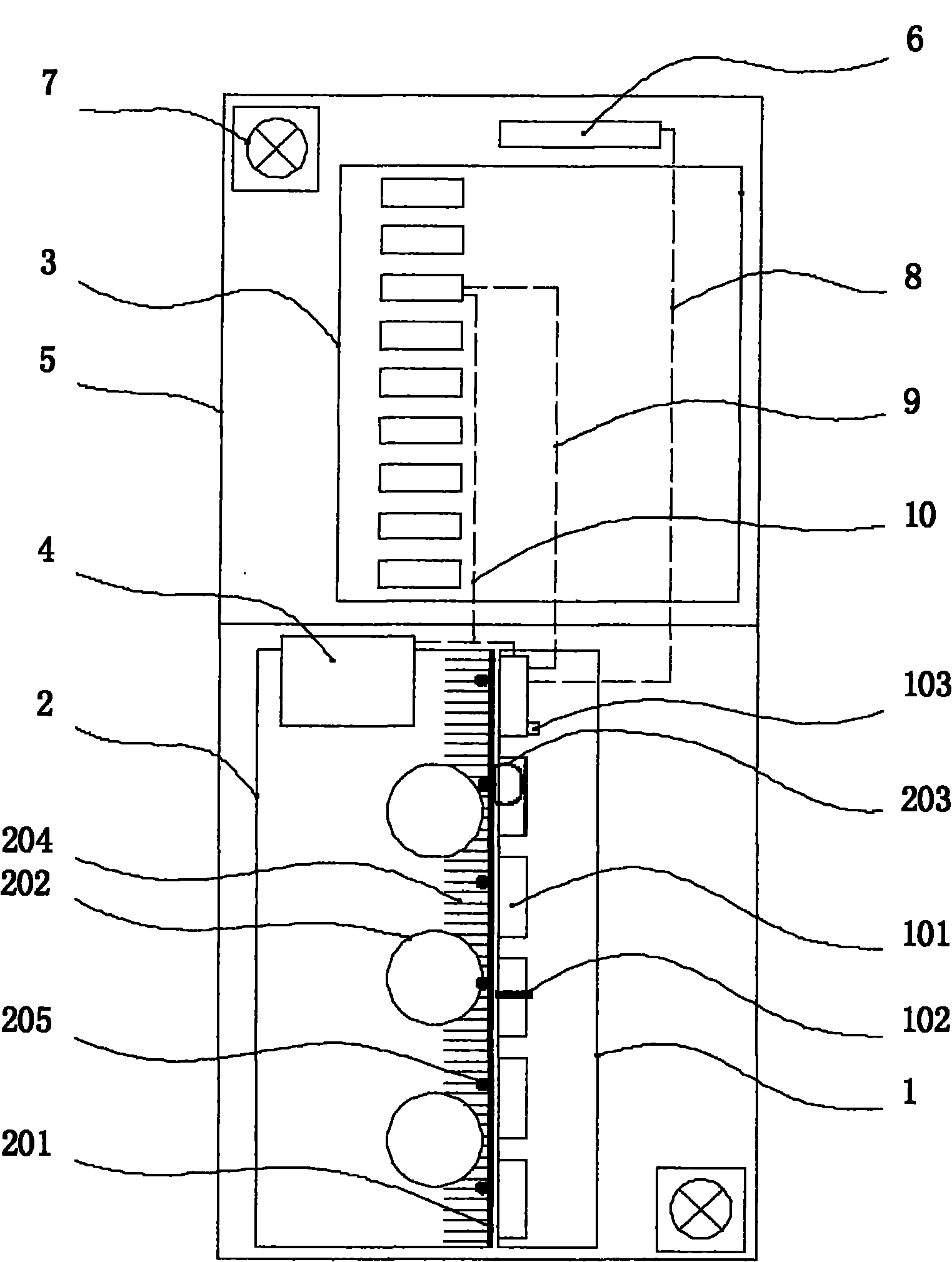

Container data center

A container data center includes a first container installed with a plurality of servers, and at least one cold air inlet and at least one hot air outlet are defined on the first container. The container data center further includes a second container installed with a cooling system, and at least one hot air inlet and at least one cold air outlet are defined on the second container. Cold air flows from the second container to the first container through the cold air outlet and the cold air inlet, and hot air flows from the first container to the second container through the hot air outlet and the hot air inlet. The cold air is generated from the cooling system and becomes the hot air after flowing through the servers and removing heat generated from the servers. The cooling system removes heat of the hot air and generates the cold air.

Owner:HON HAI PRECISION IND CO LTD

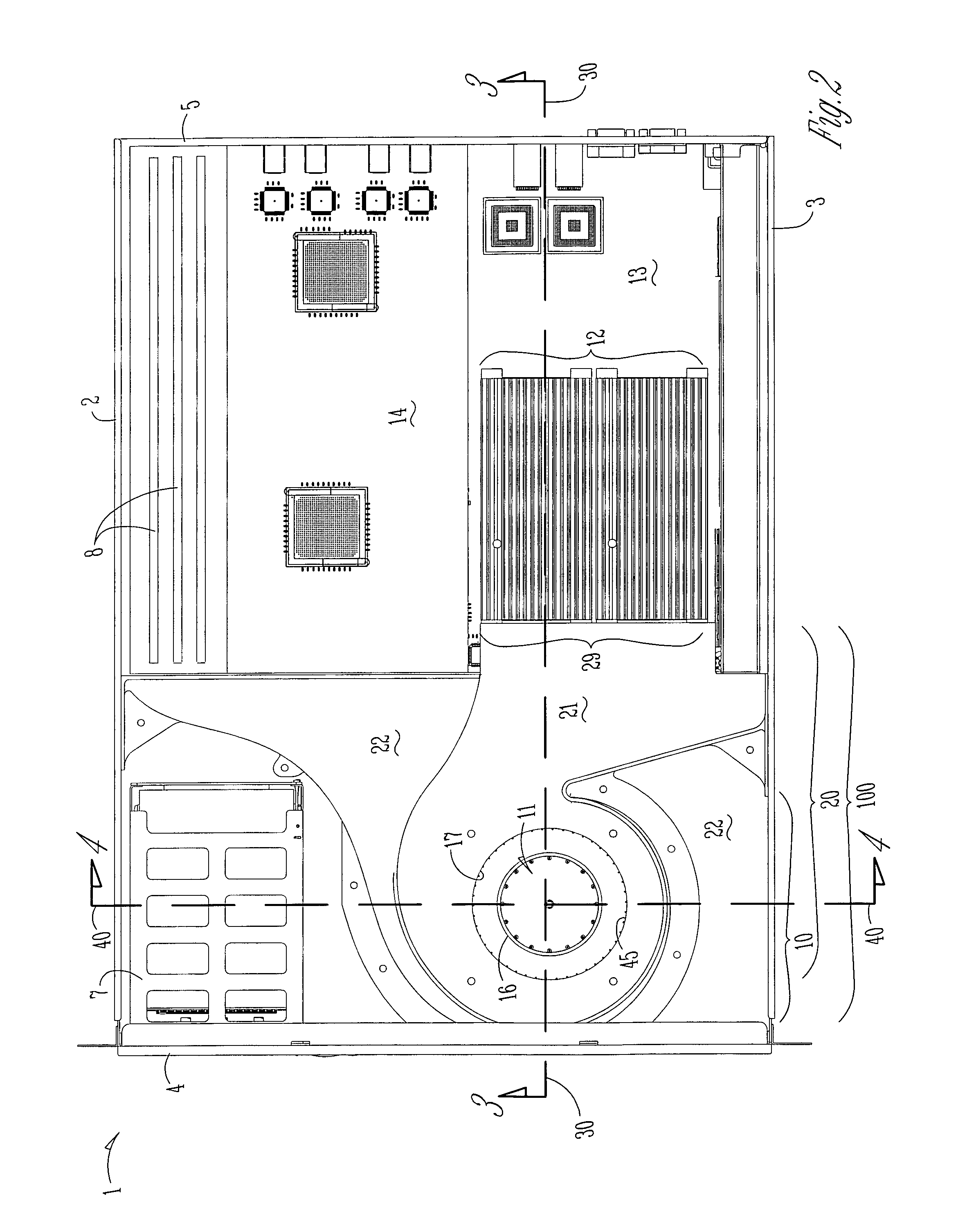

Air-cooling system configuration for touch screen

A cooling system for an electrical device includes a receptacle unit having a main opening with an inner chamber, a cooling unit operably associated with the electrical device arranged in the chamber of the receptacle unit, intake and exhaust openings arranged between the electronic device and the receptacle unit, an intake path extending from the intake opening to the cooling unit via the chamber of the receptacle unit and an exhaust path extending from the cooling unit to the exhaust opening via the inner space of the receptacle unit.

Owner:EXCEPTIONAL INNOVATION INC

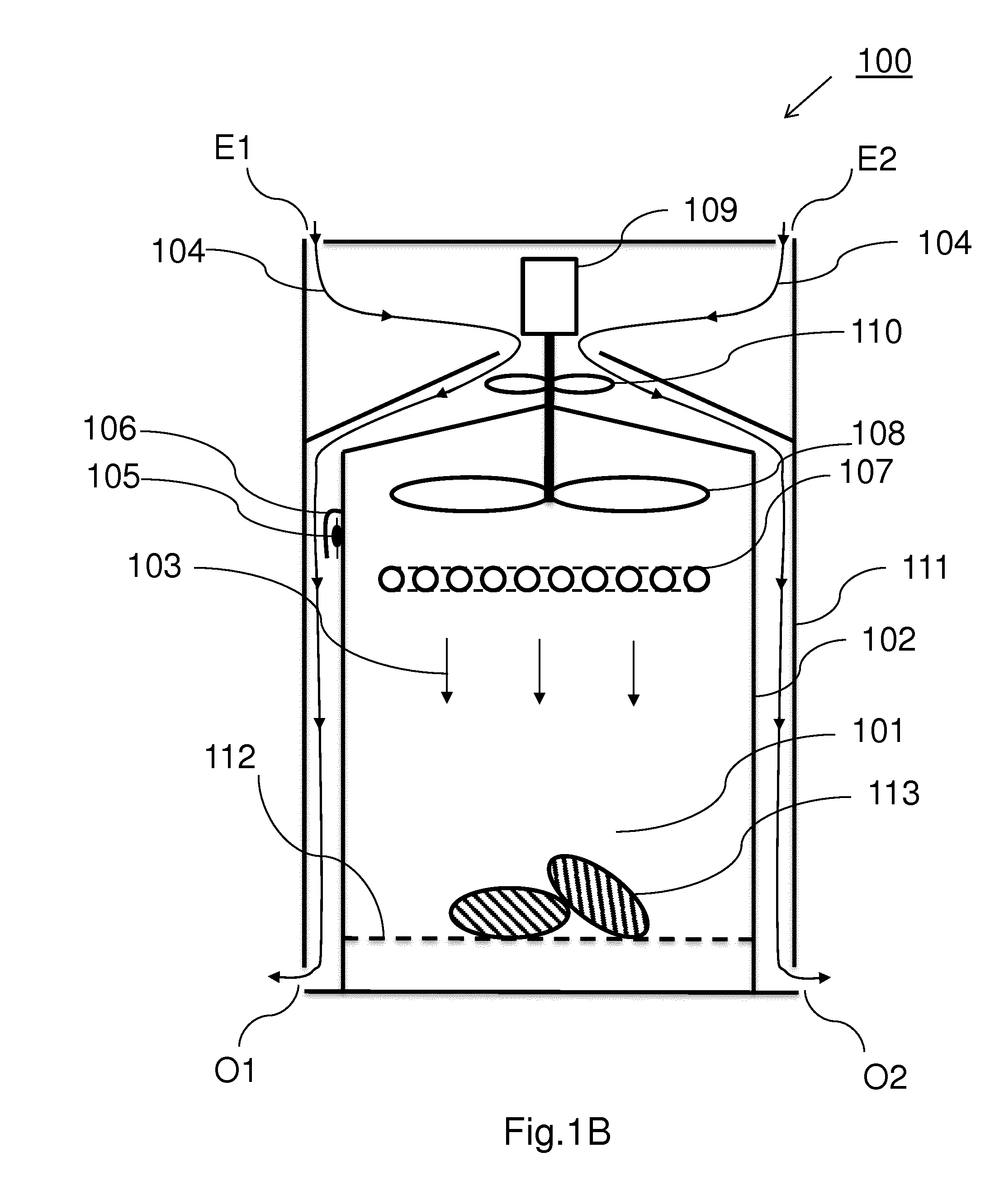

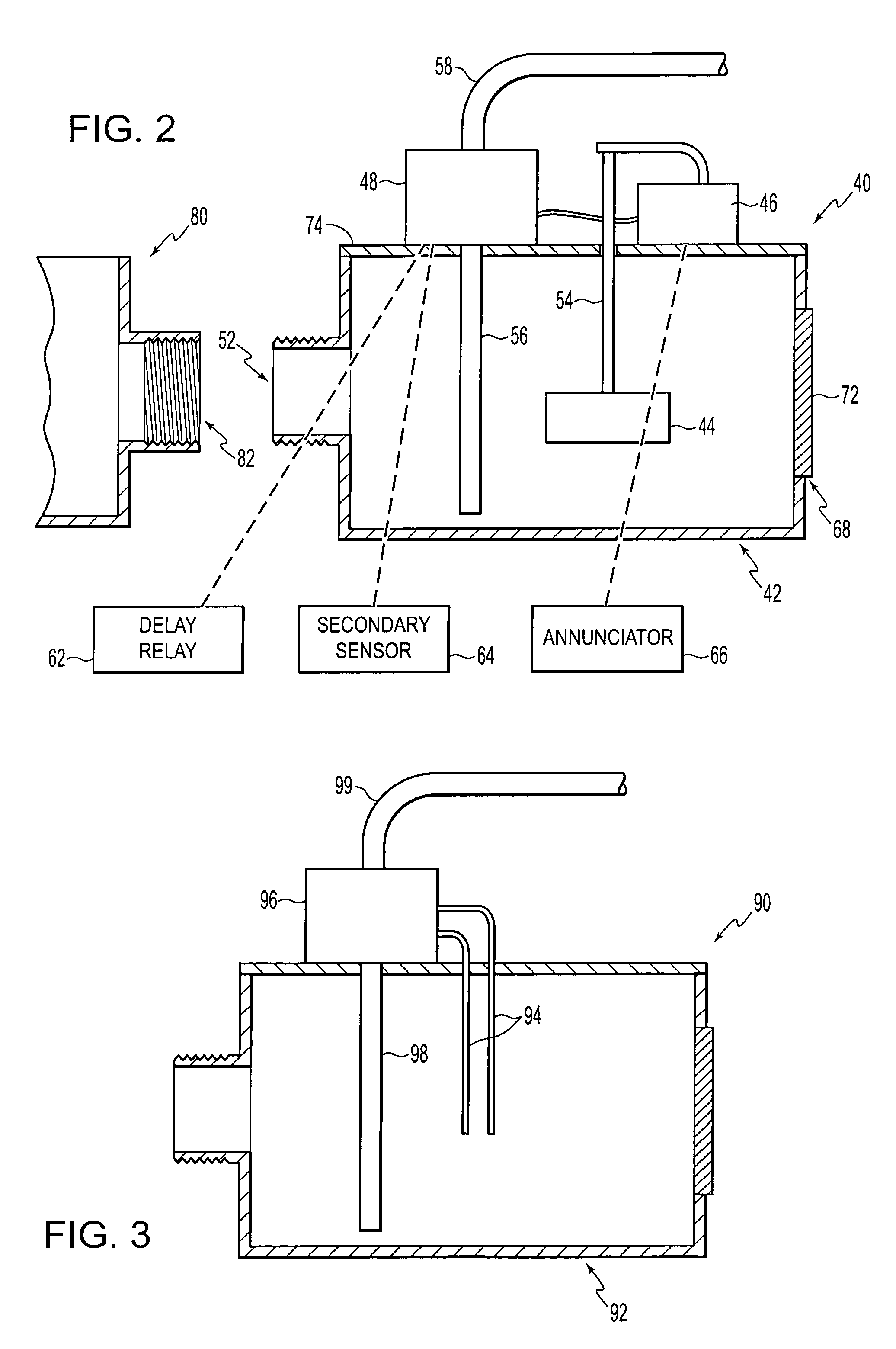

Condensate overflow prevention apparatus

InactiveUS6976367B2Mechanical apparatusSpace heating and ventilation safety systemsAir cooling systemFluid level

A condensate overflow prevention assembly prevents condensate overflow in an air cooling system using a fluid level sensor and a pump activated by the fluid level sensor to pump the condensate away from a drainage system when a blockage occurs in the drainage system.

Owner:RECTORSEAL

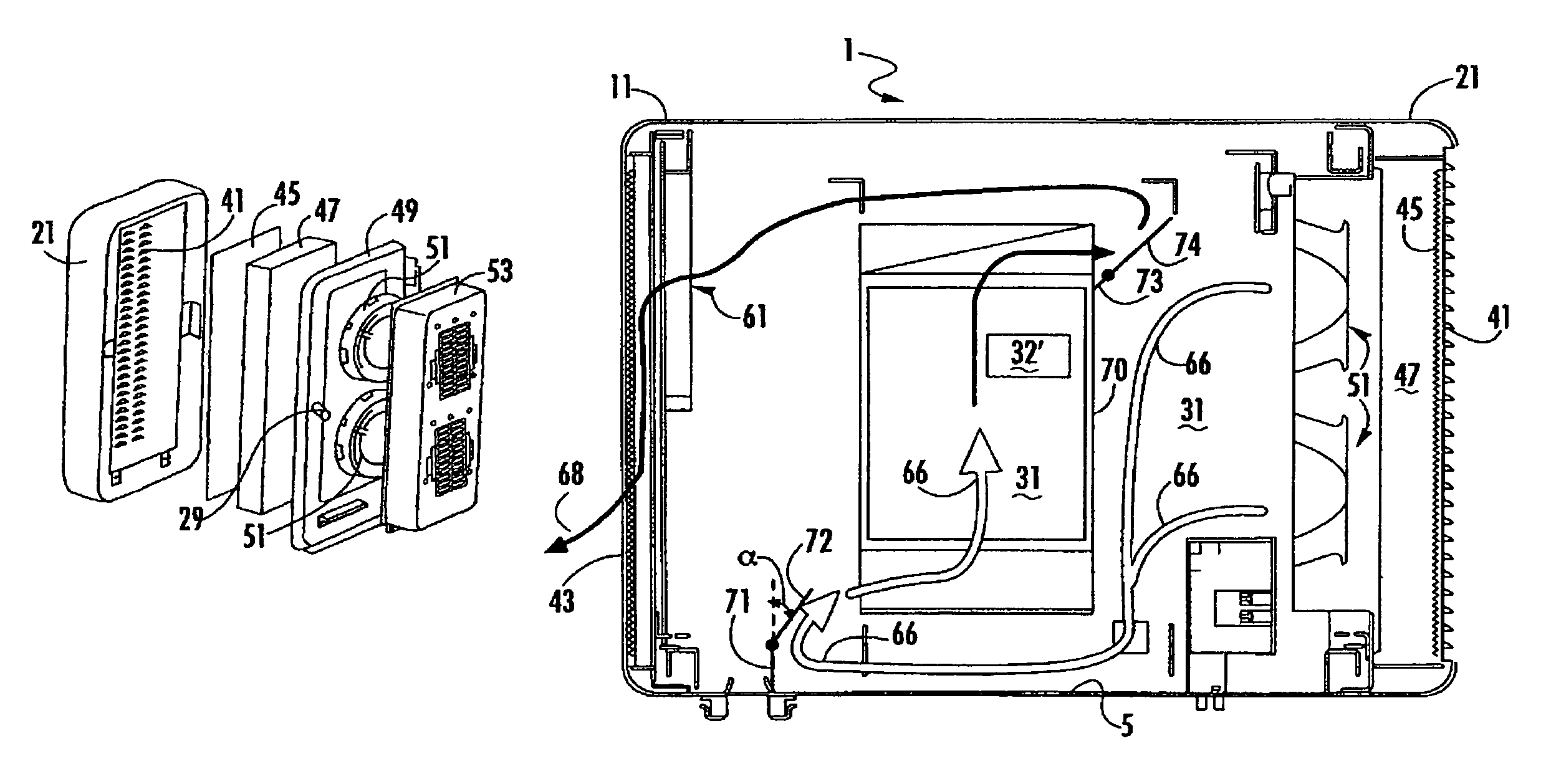

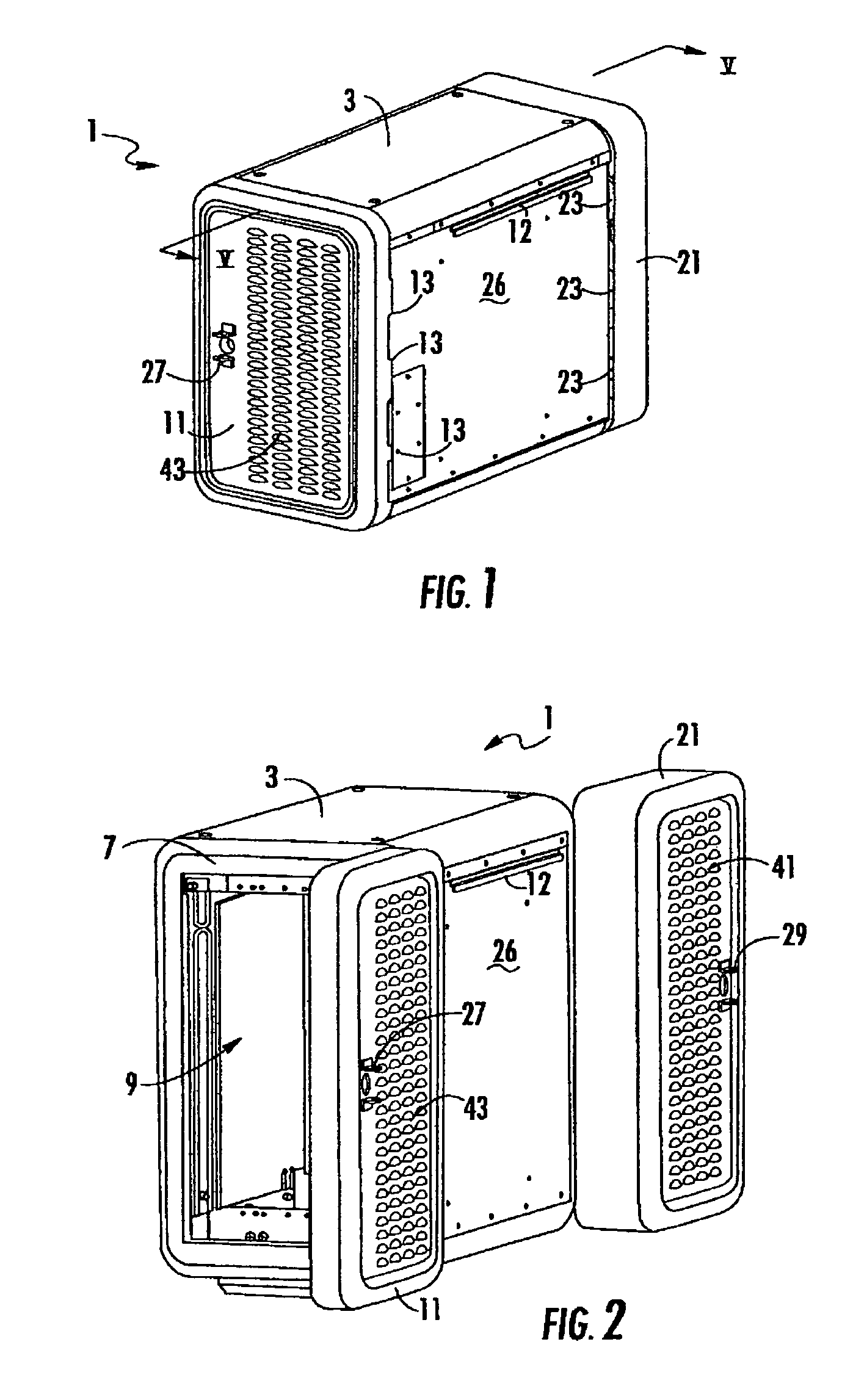

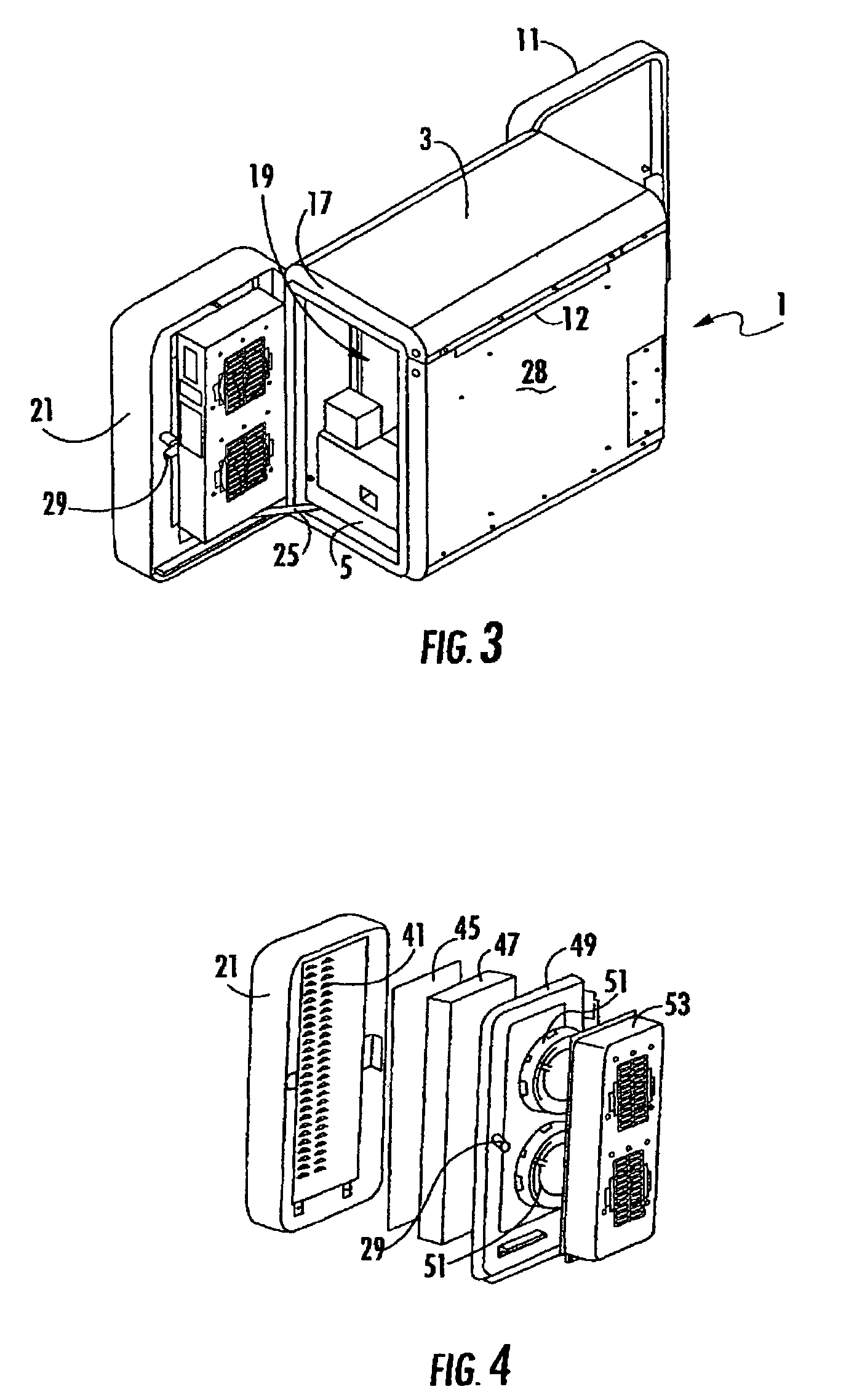

Acoustical noise reducing enclosure for electrical and electronic devices

InactiveUS6745149B2Reducing and controlling noiseTemperature safetyThermometer detailsLighting and heating apparatusEngineeringAir cooling system

The invention disclosed herein is a system for controlling acoustical noise generated by electrical or electronic equipment.The invention consists of a sealed enclosure having acoustically absorbent inner walls, a transparent sealed front door, a hinged sealed rear access panel to facilitate equipment wiring and installation and a high volume / low pressure air cooling system and additional sound and vibration absorption elements. Means for monitoring and controlling internal cabinet temperature and sealed electrical ports for interfacing the equipment housed within the enclosure to the outside while substantially reducing acoustical noise generated by that equipment.

Owner:SCS HLDG LLC

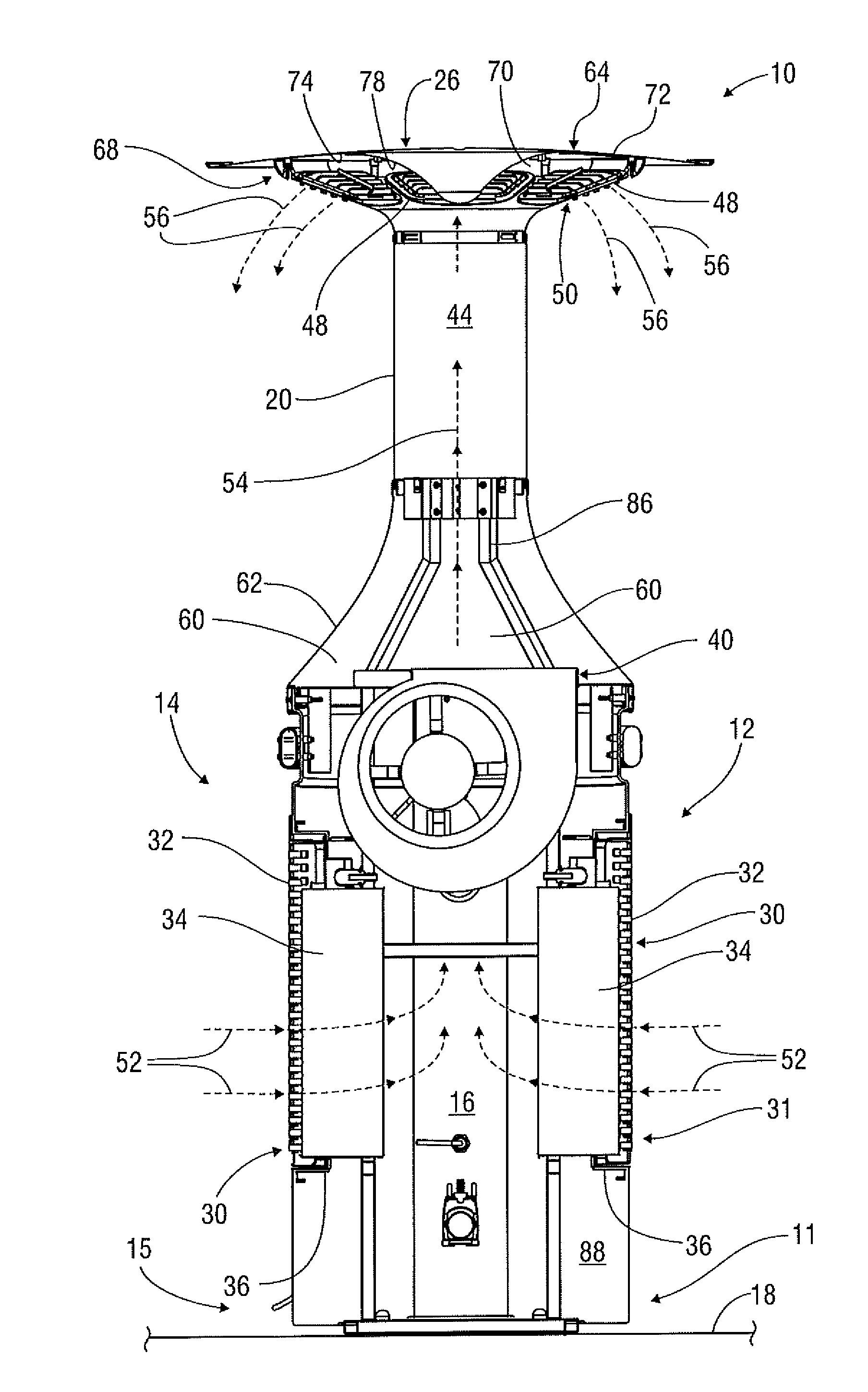

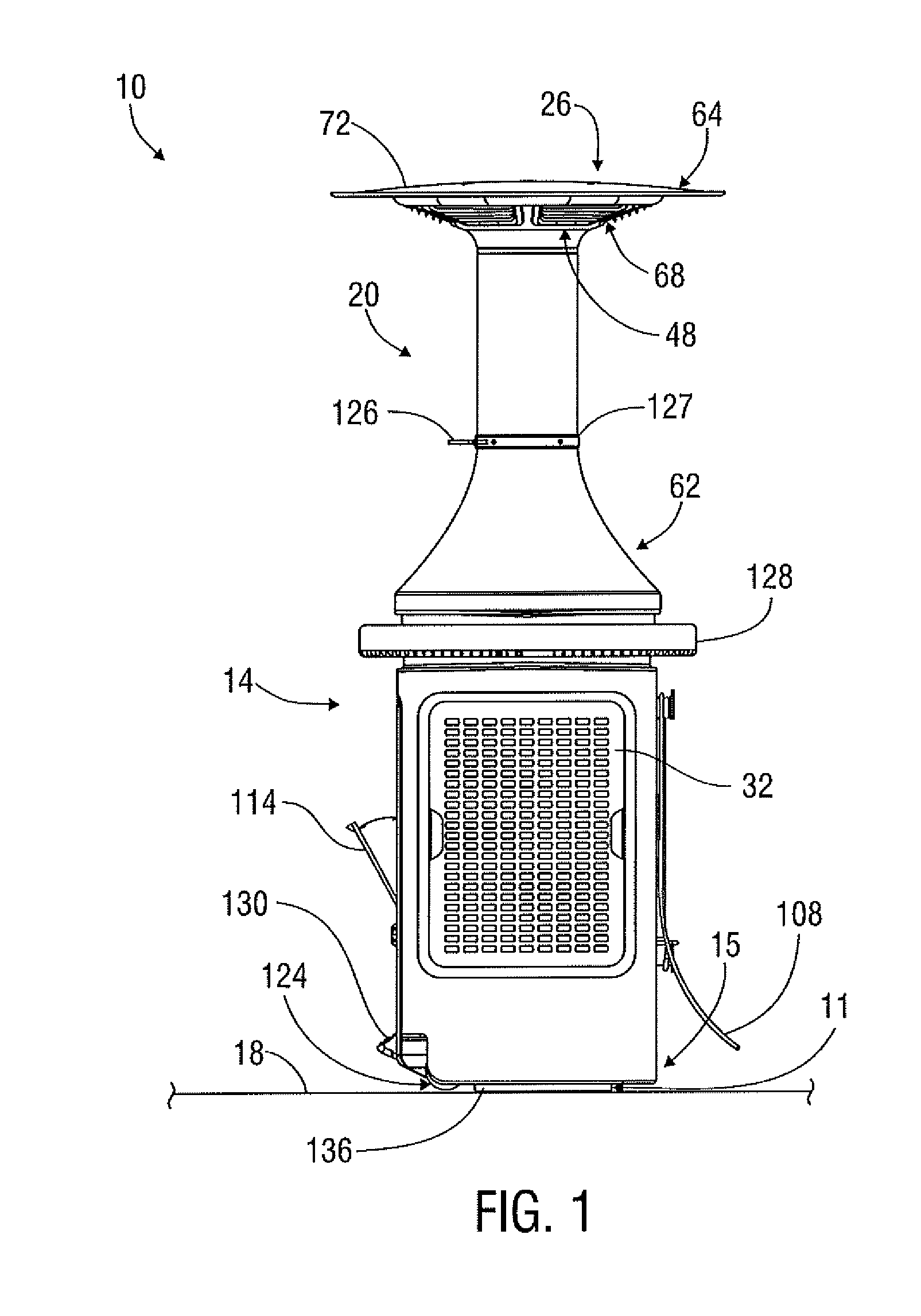

Free-standing evaporative air cooling apparatus

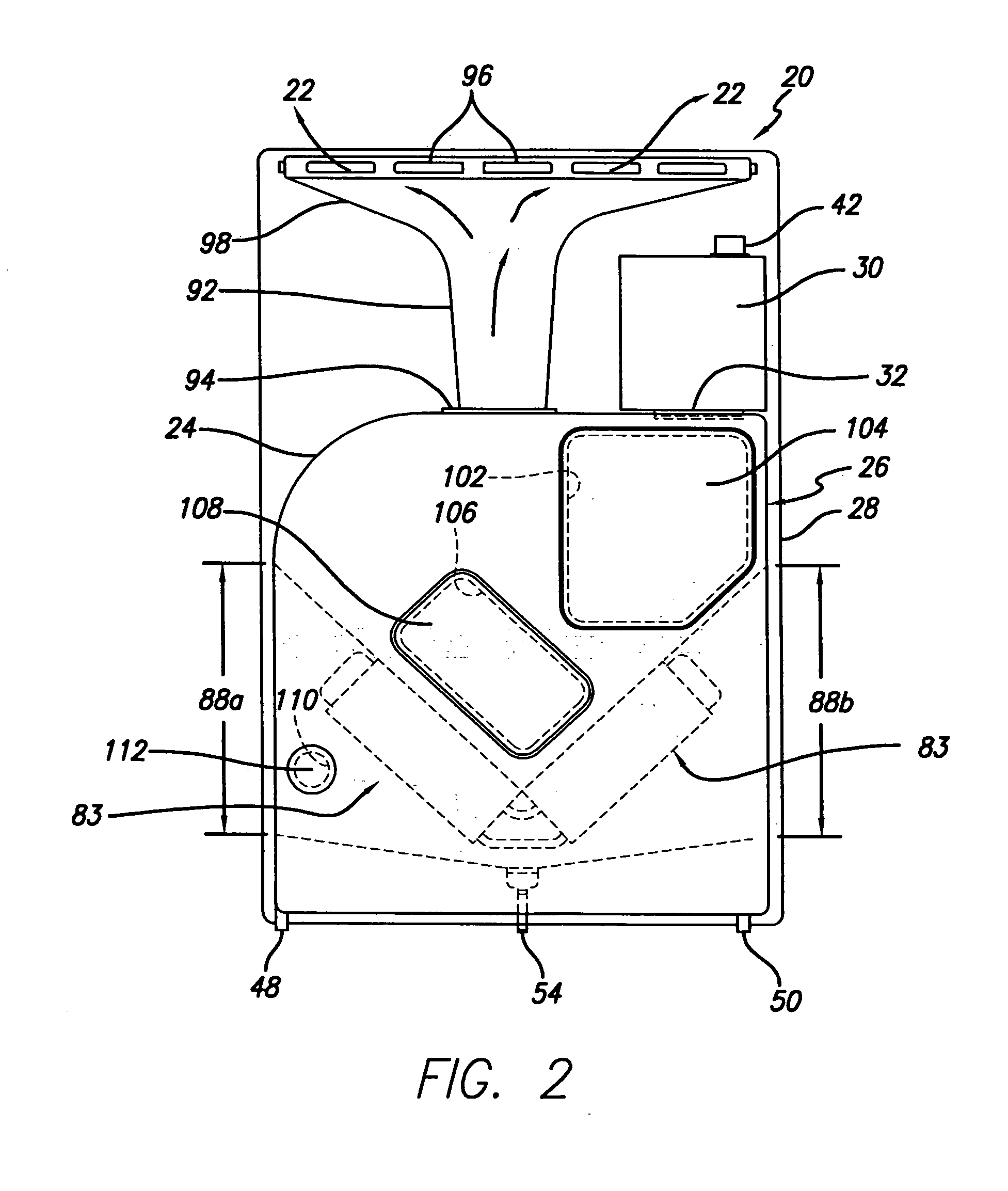

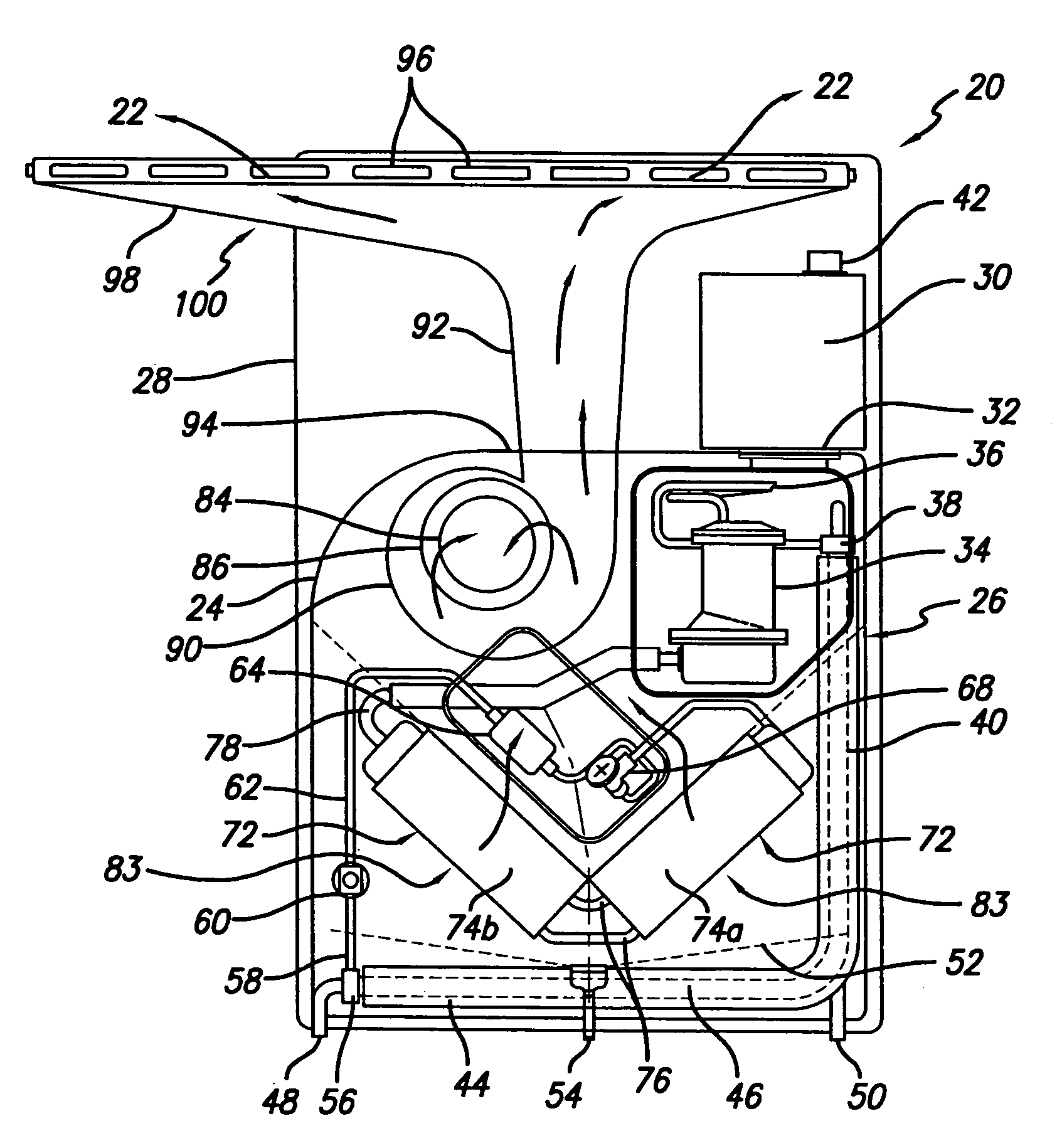

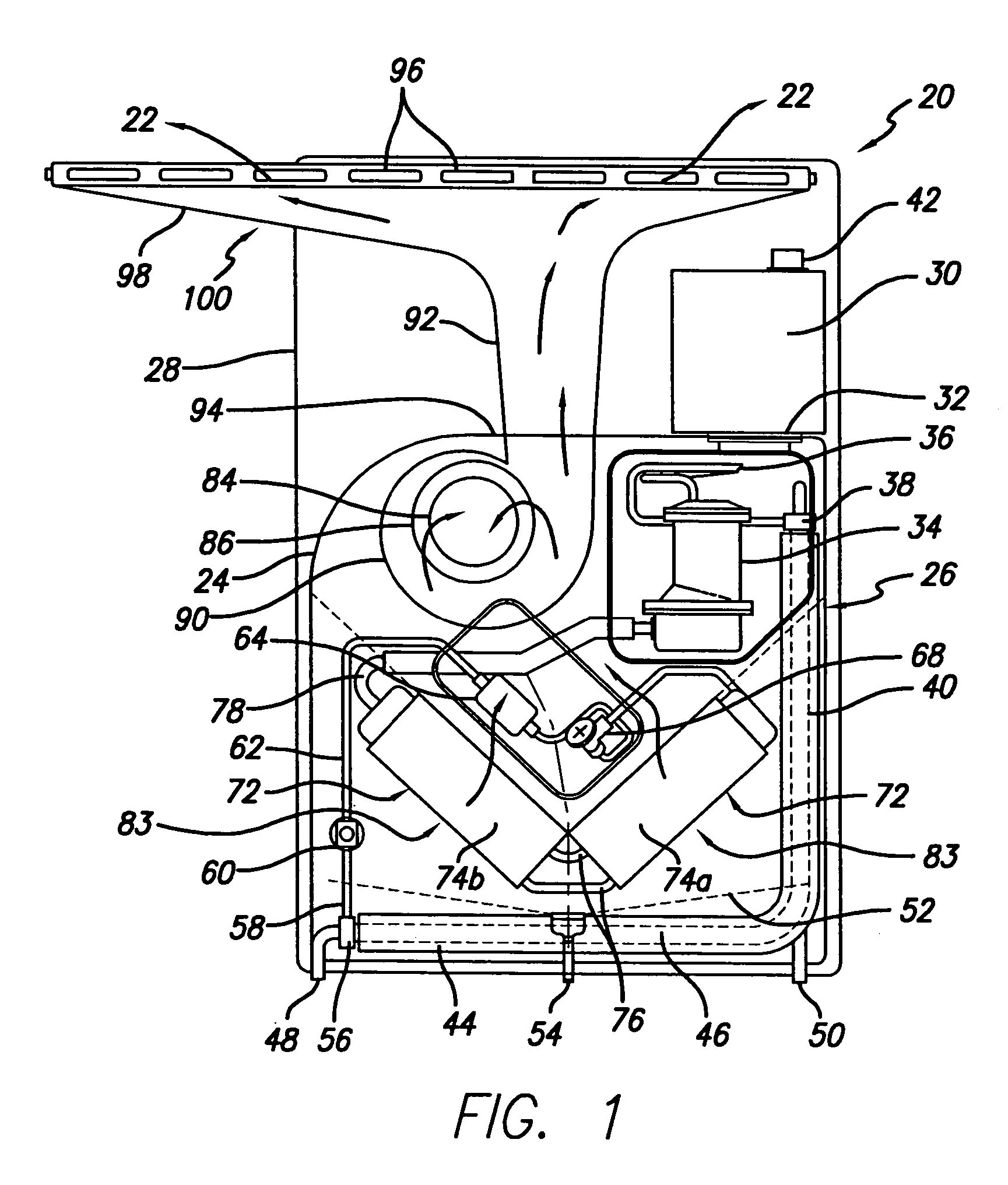

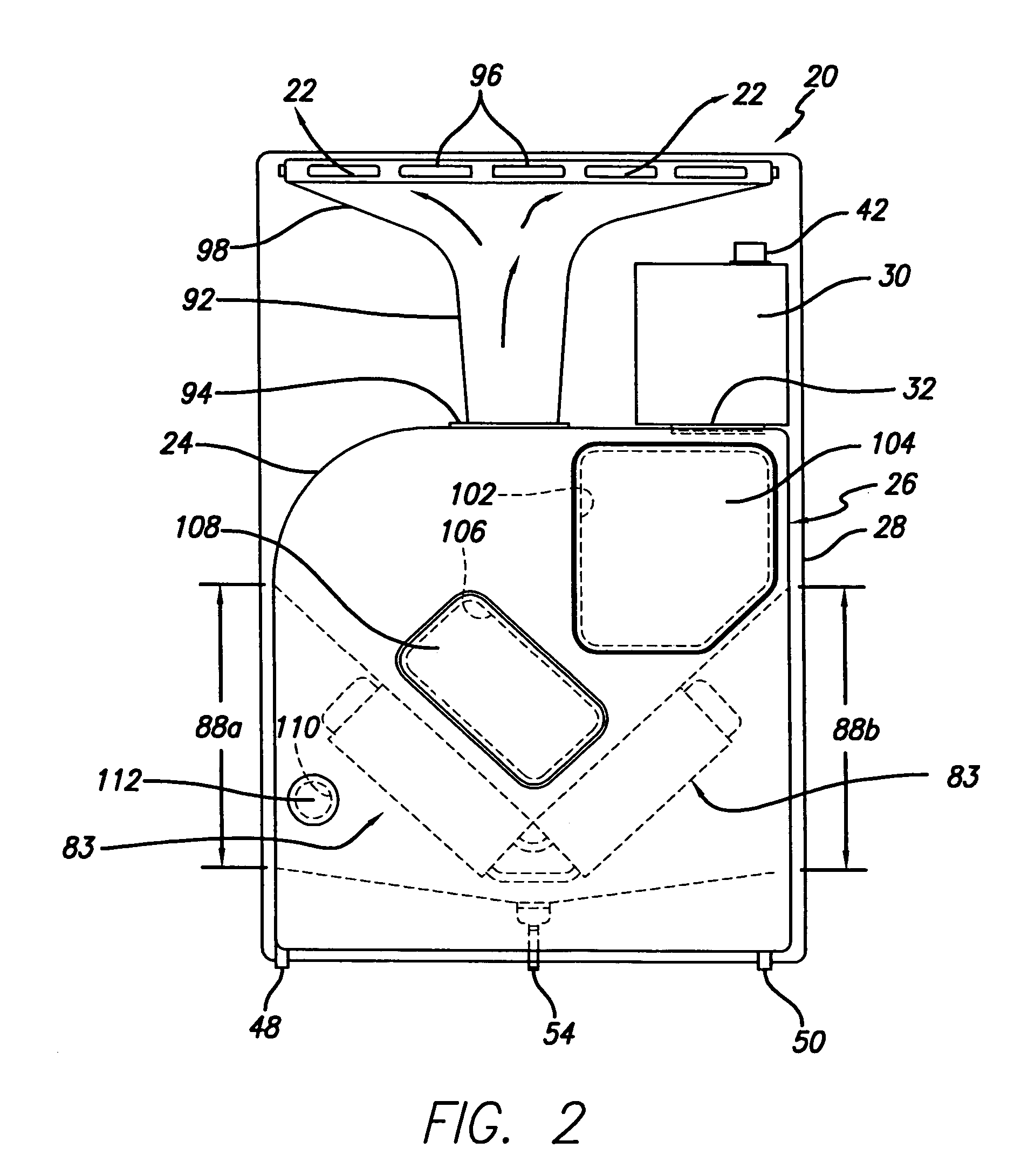

InactiveUS20140109610A1Free-cooling systemsStationary conduit assembliesEngineeringAir cooling system

A free-standing evaporative air cooling system includes a base, at least one air inlet and at least one cooling pad. A neck extends upwardly relative to the base and includes at least one upwardly-oriented air flow passageway in gaseous communication with the air inlet(s). At least one air outlet is disposed proximate to the upper end of the neck and is in gaseous communication with the air flow passageway.

Owner:PORT A COOL

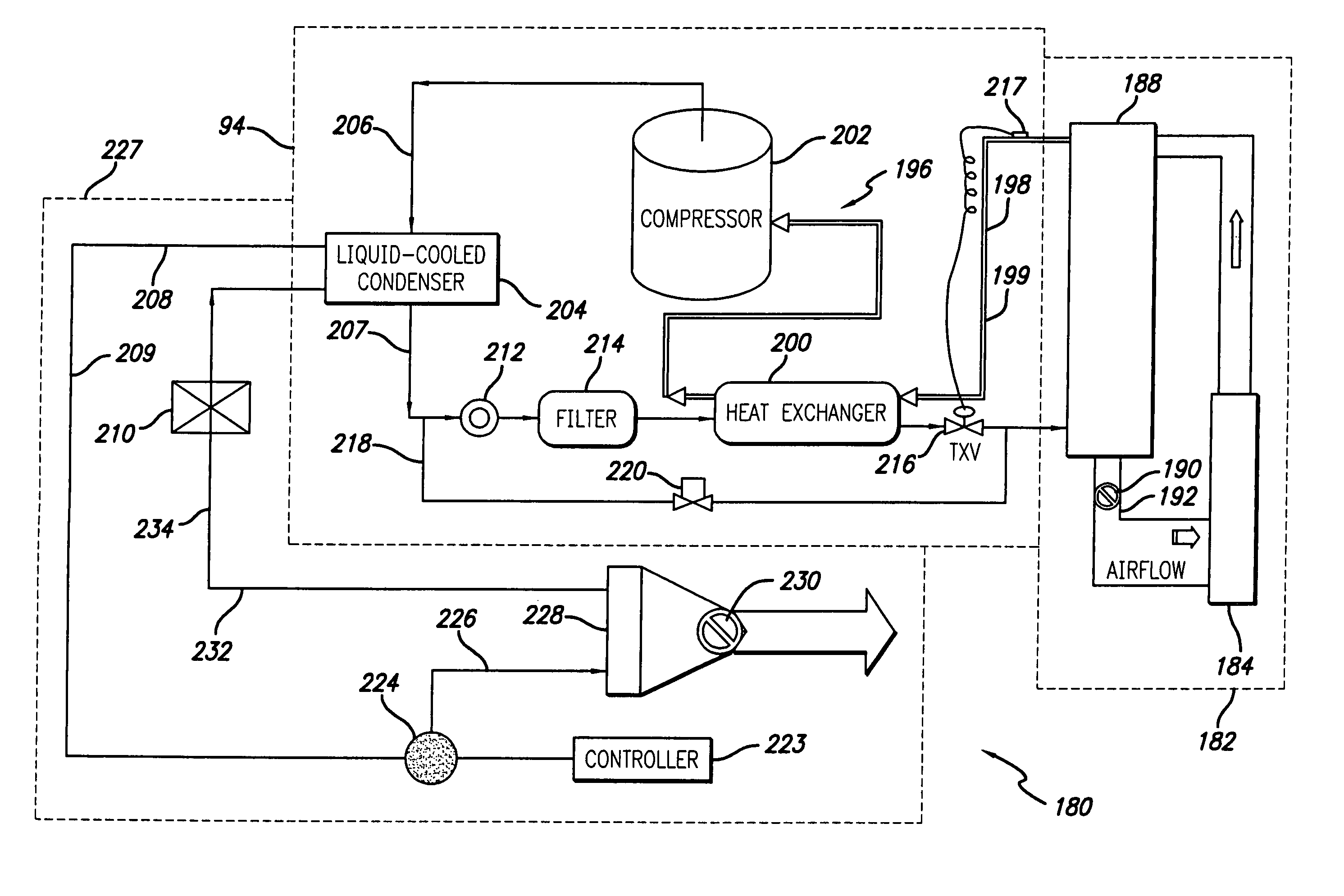

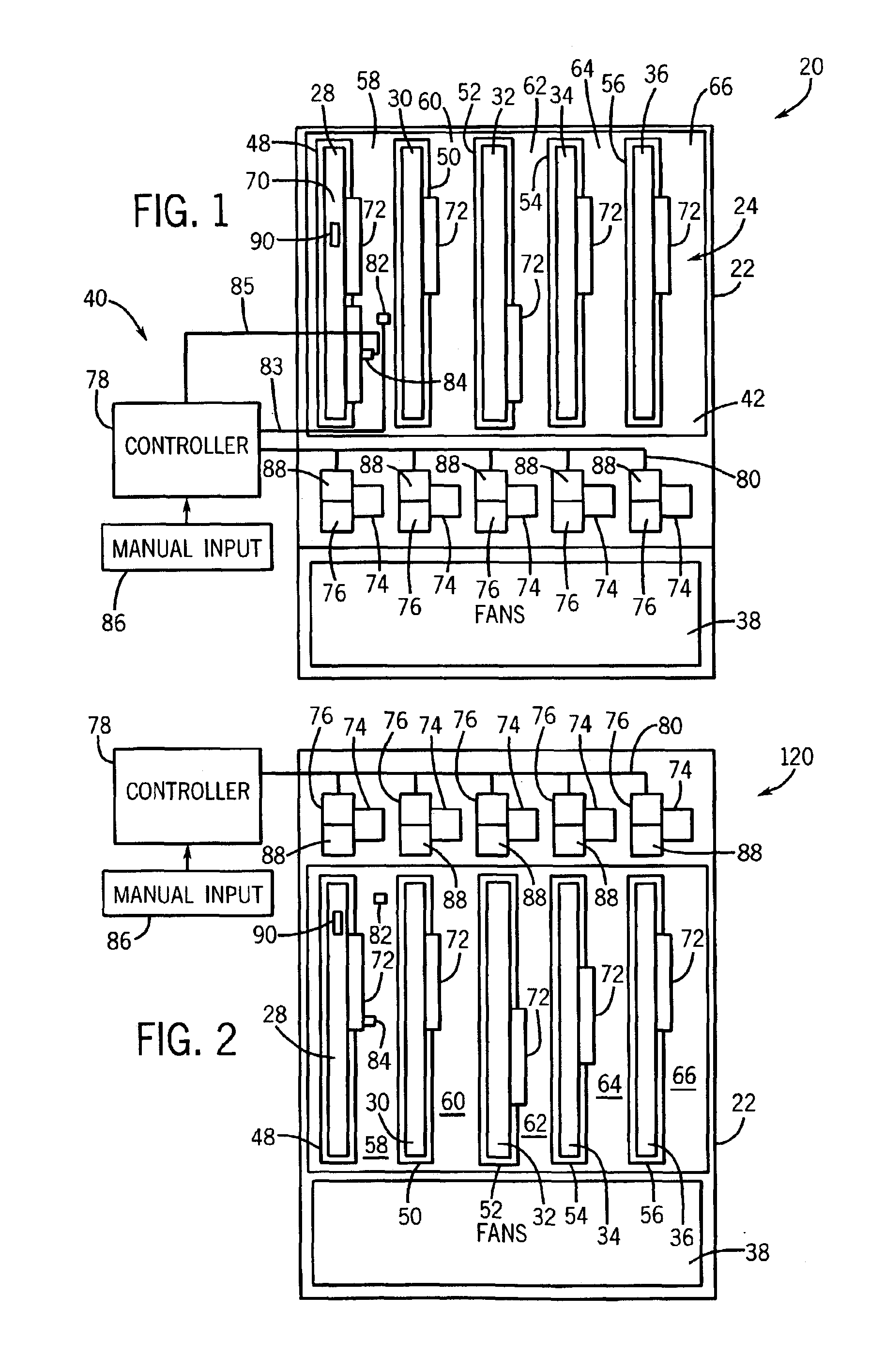

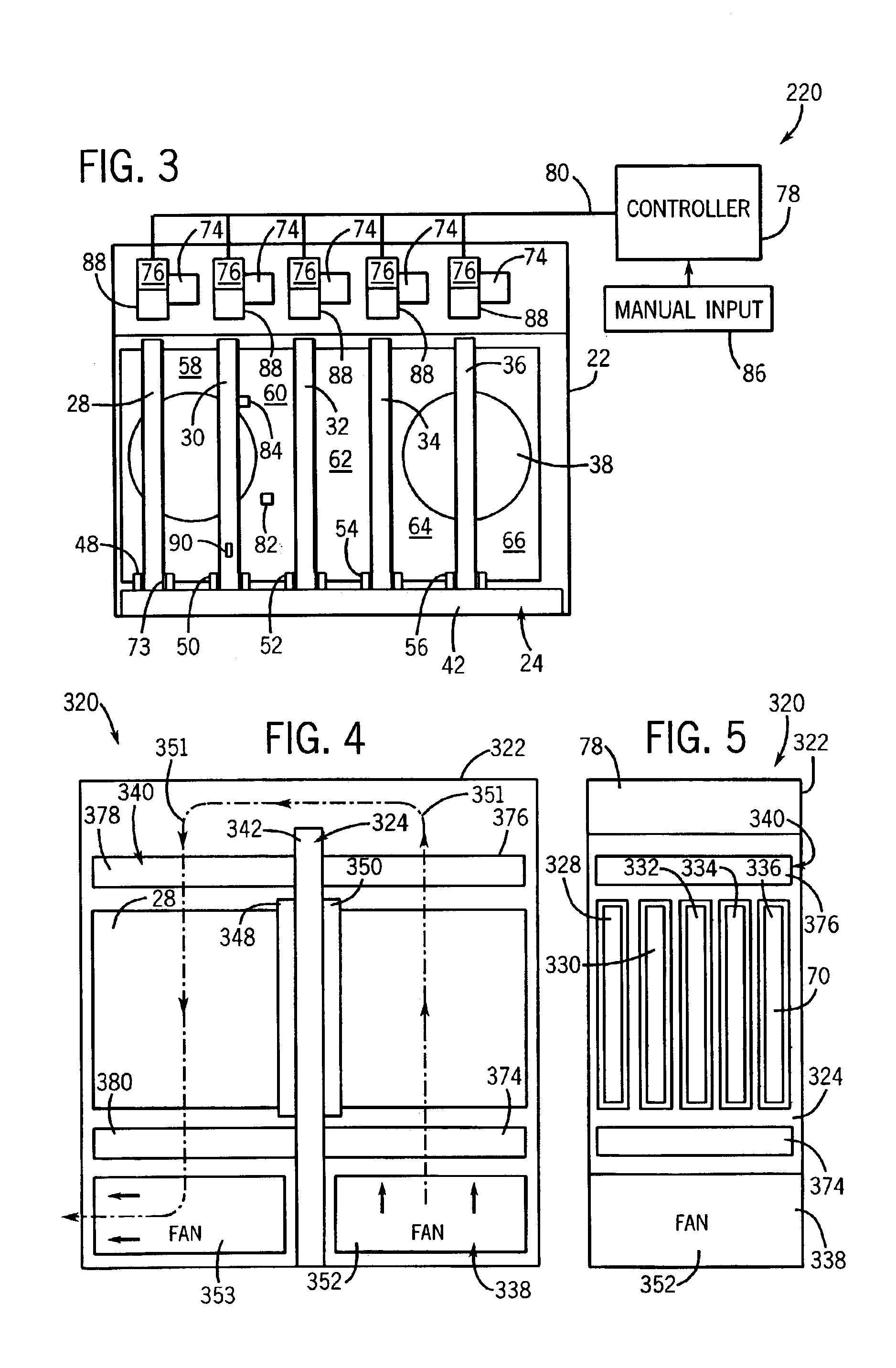

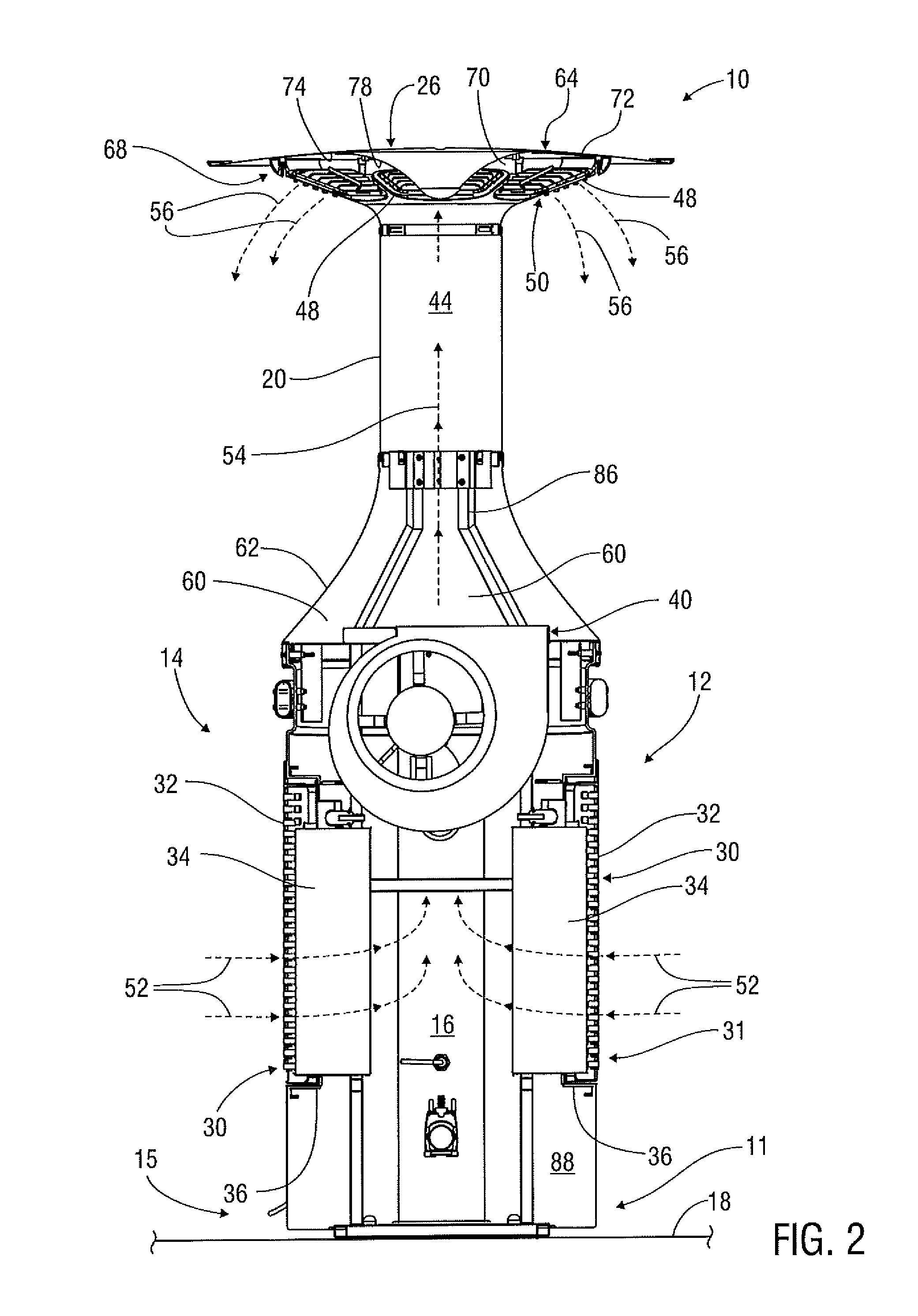

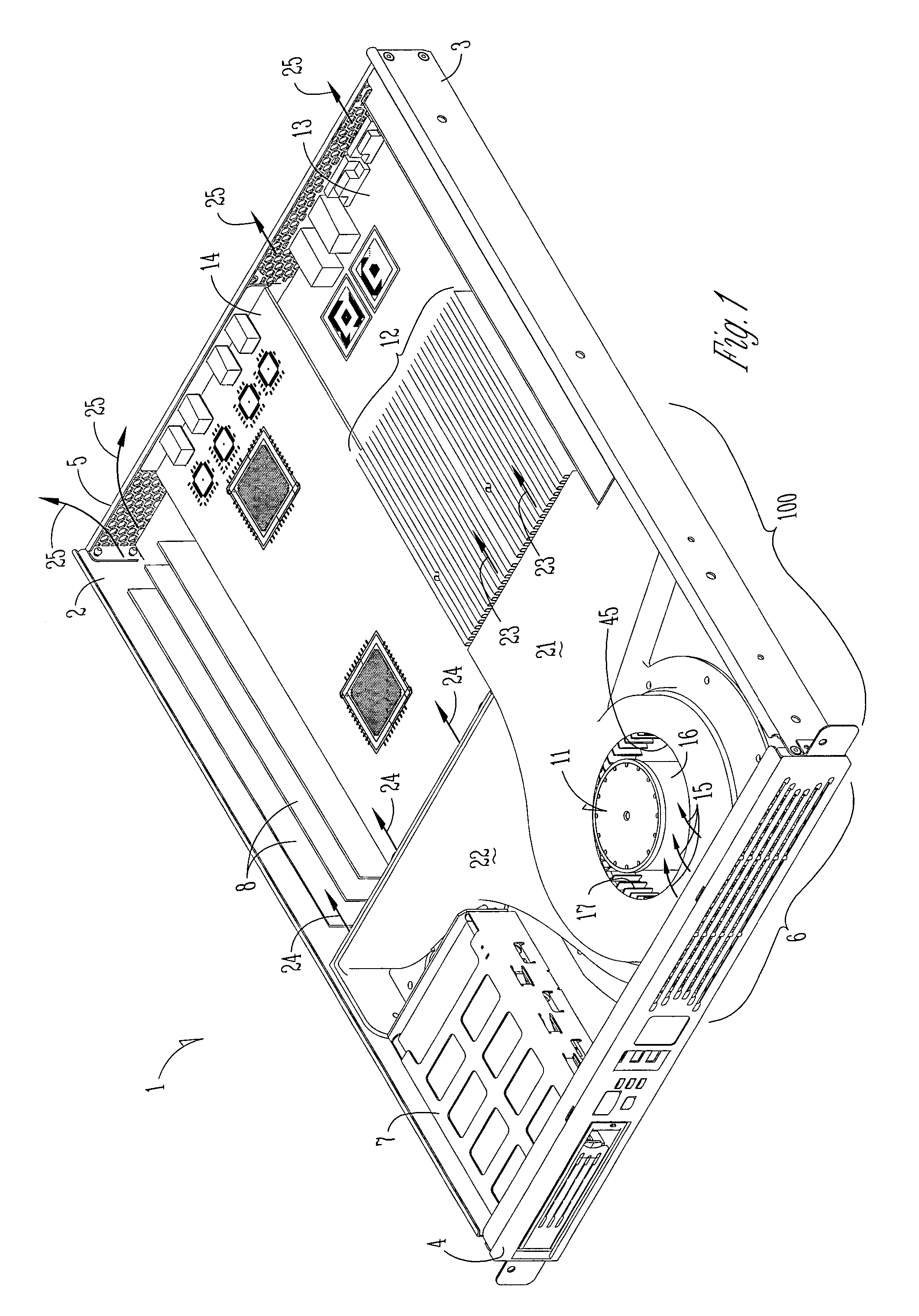

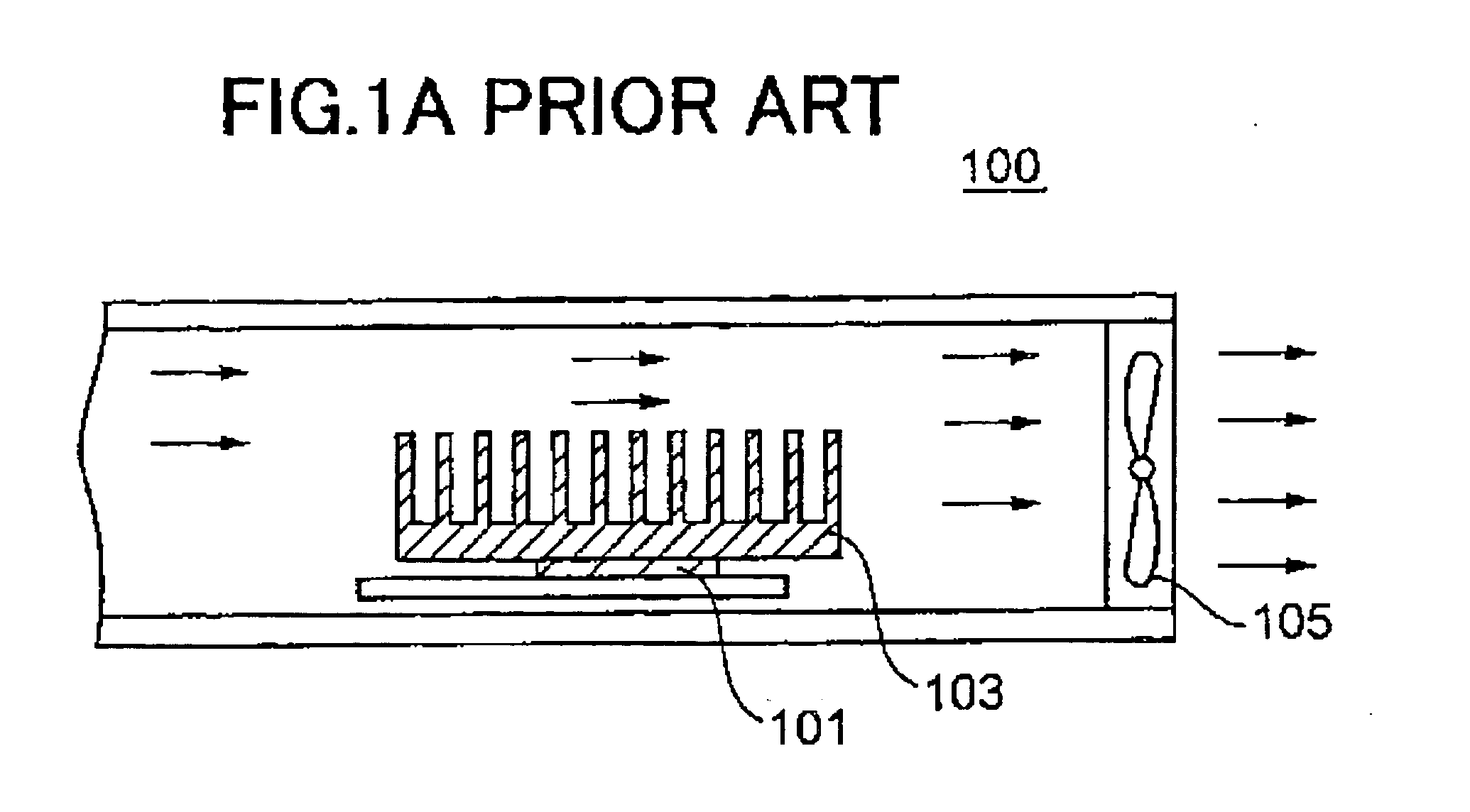

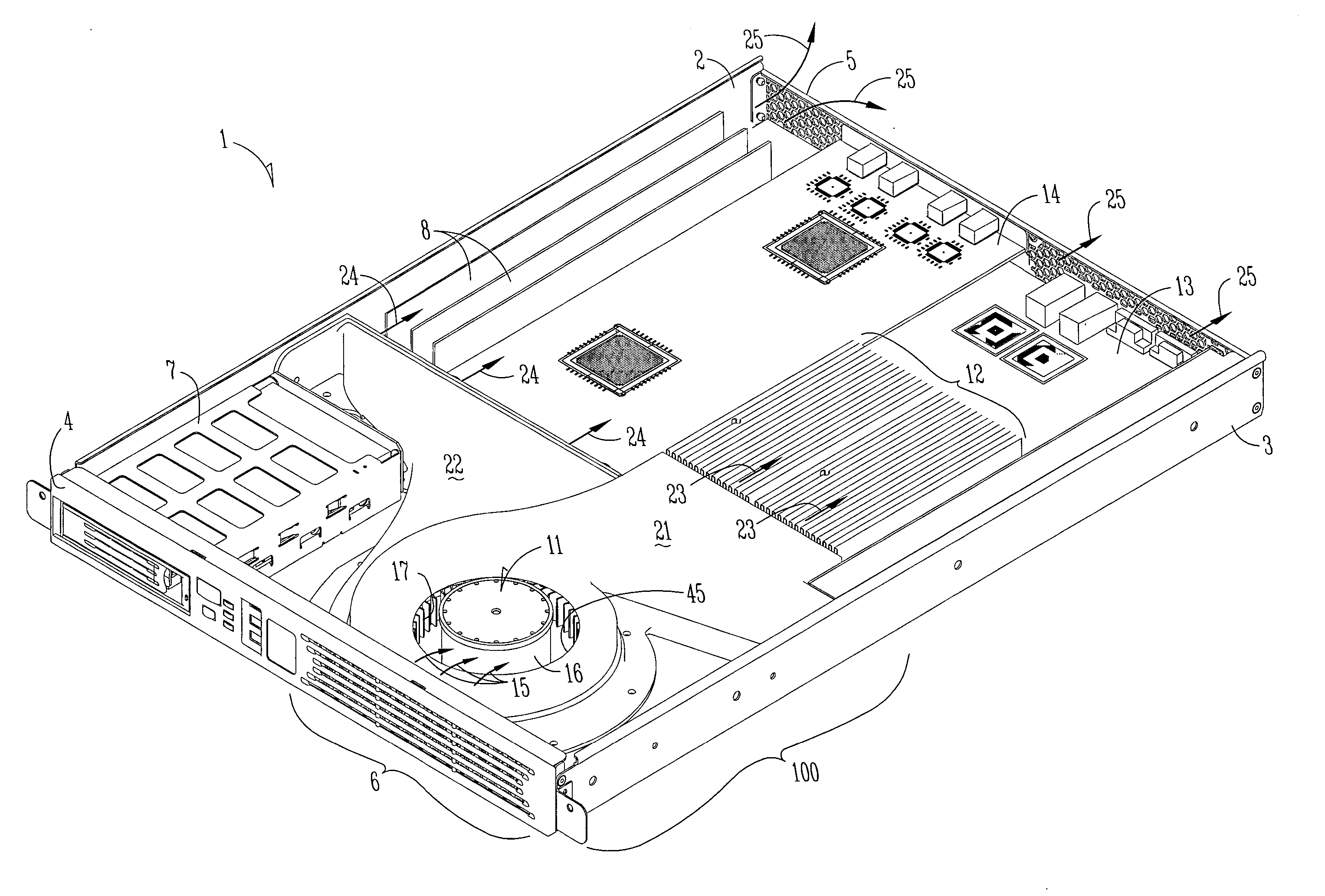

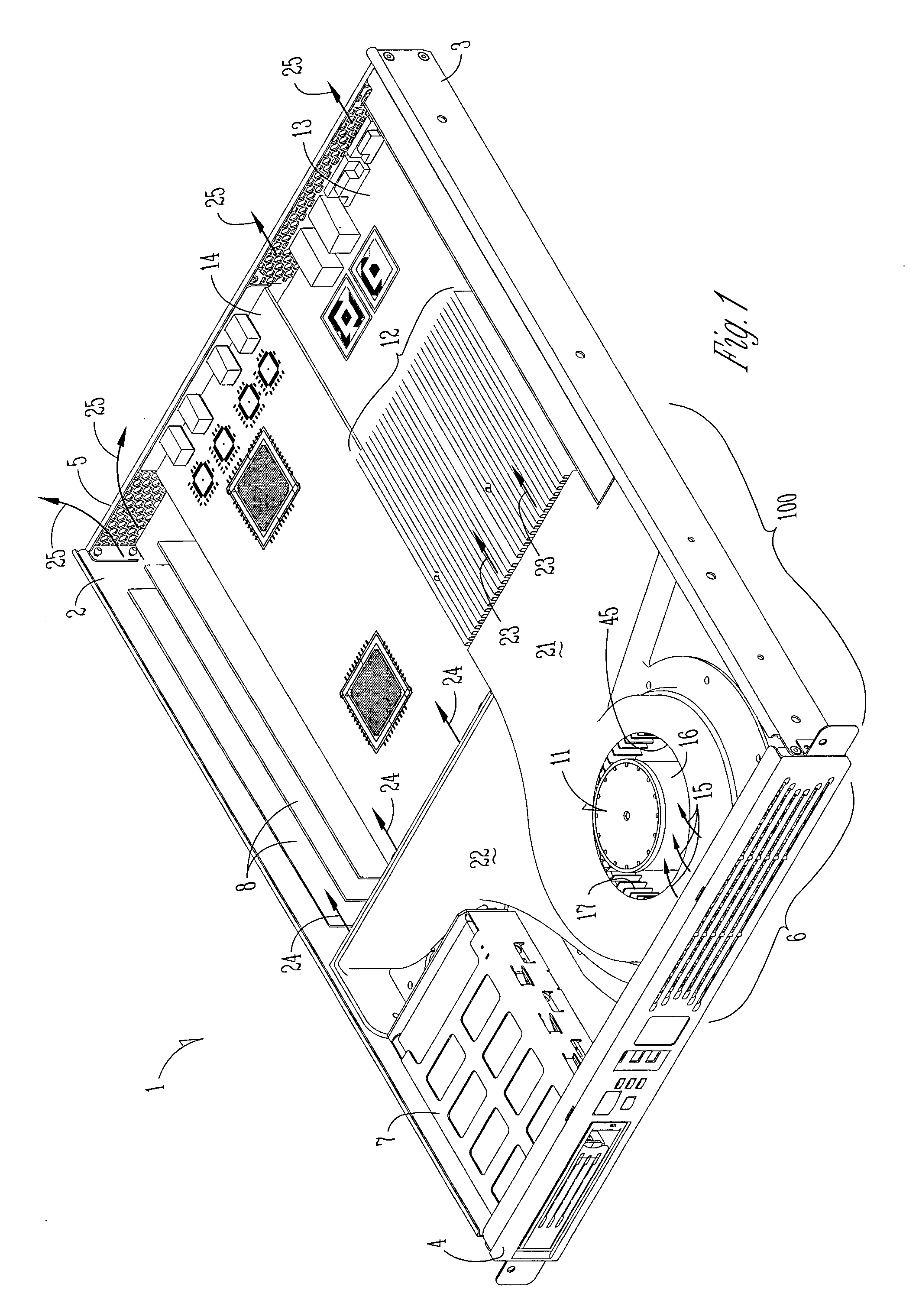

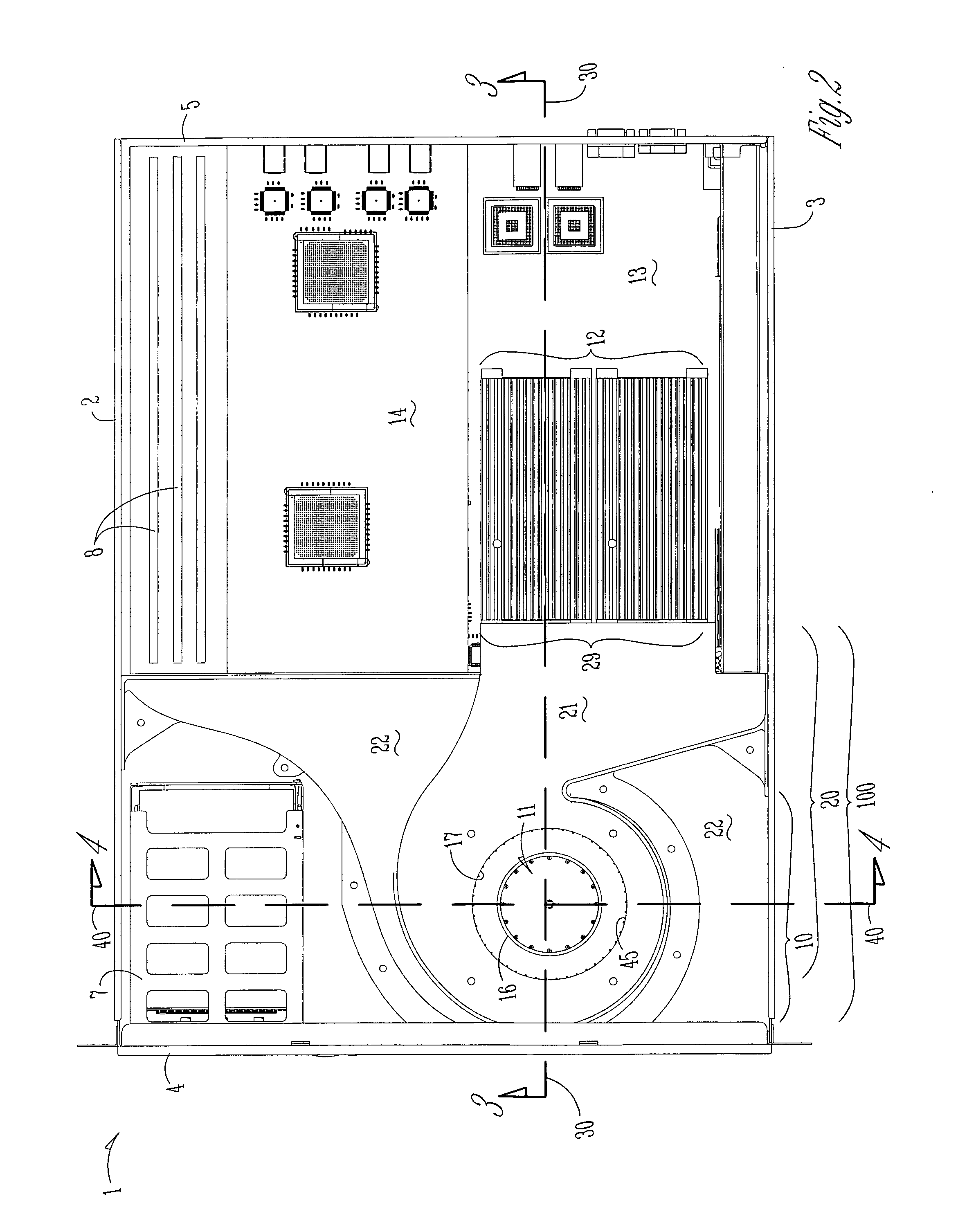

Baffles for high capacity air-cooling systems for electronics apparatus

An improved air-cooling system for high performance, high density electronic equipment comprises, in one embodiment, a single fan having a radial impeller, a baffle having an inlet portion to efficiently direct air into the fan intake, and a two-tiered outlet plenum to direct one airflow specifically at the highest heat-generating components and another airflow at all components. The air-cooling system is designed to provide maximum cooling for a low-height, high heat-generating electronics module such as a server. By using only a single fan that is matched to the low resistance airflow characteristics of the baffle, the air-cooling system offers significant advantages over multi-fan systems. Also described are a computer server and methods of making heat-dissipation equipment.

Owner:INTEL CORP

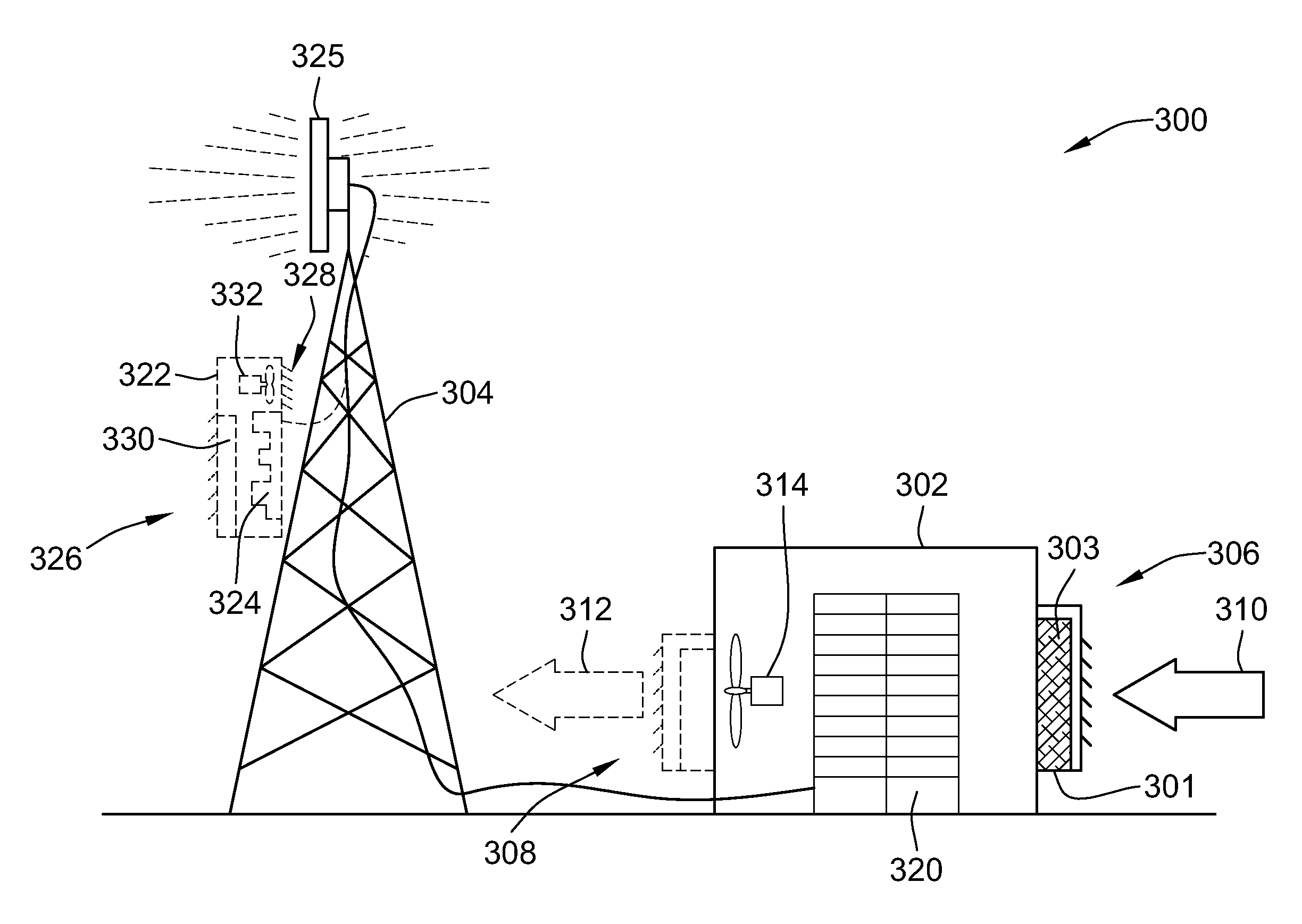

Outside plant telecommunications cabinet direct air cooling system

ActiveUS7974094B2Increase heatHigh densityDomestic cooling apparatusLighting and heating apparatusAir cooling systemOutside plant

An outdoor equipment cabinet includes a housing with an equipment compartment therein. An intake air vent and an exit air vent are formed in the housing. A fan is mounted within the housing for pulling air into the intake air vent, moving an air stream through the equipment compartment, and pushing air out of the exit air vent. A membrane is disposed adjacent the intake air vent. The membrane allows air to pass therethrough, but resists the passage of water and contaminants therethrough. In some embodiments, a baffling plate is disposed to direct the air stream within the equipment compartment, and / or the fan speed is controlled by a temperature sensor, and / or a clogging of the membrane is monitored and reported, and / or the intake air vent is located in a first door and the exit air vent is located in a second door of the cabinet.

Owner:COMMSCOPE INC

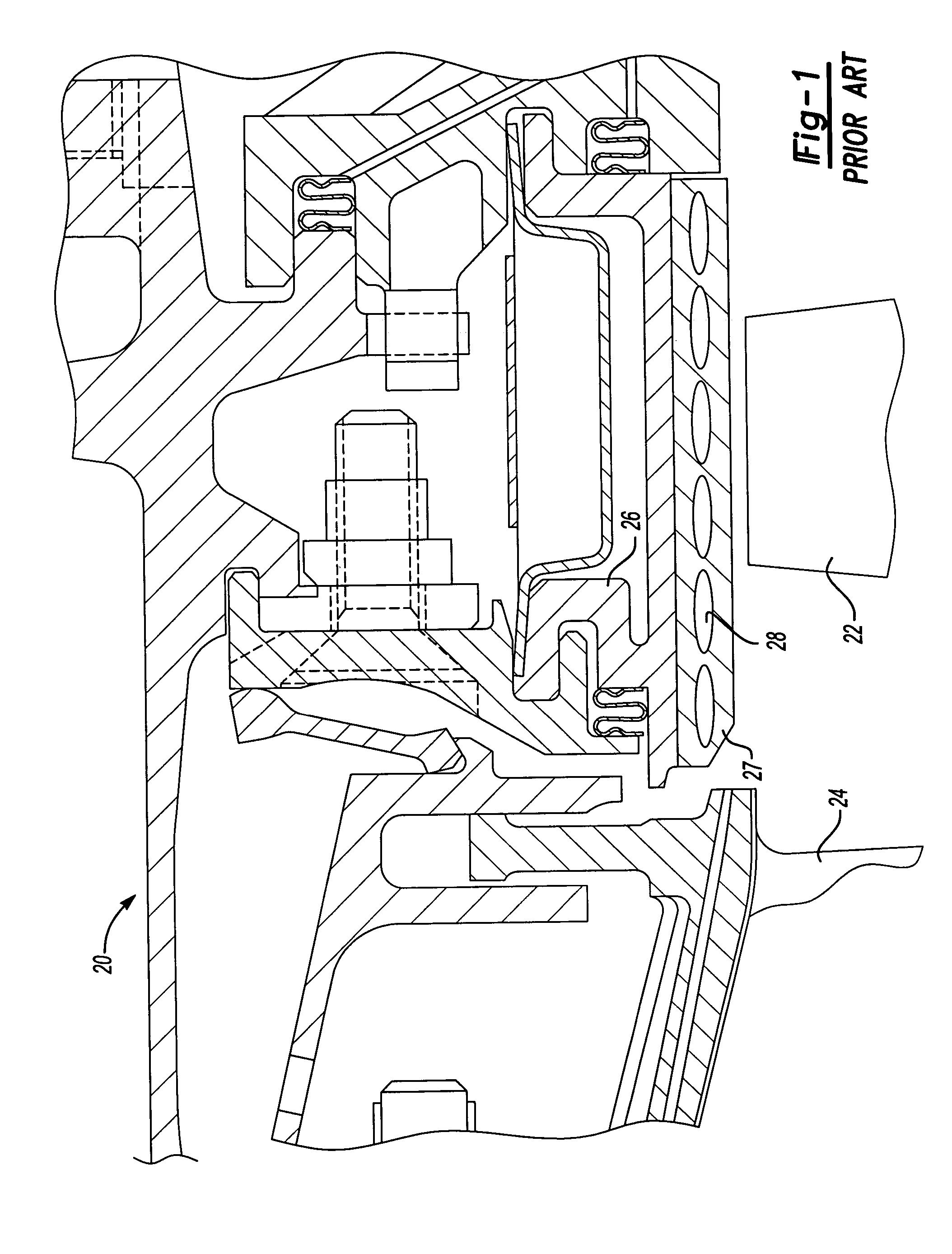

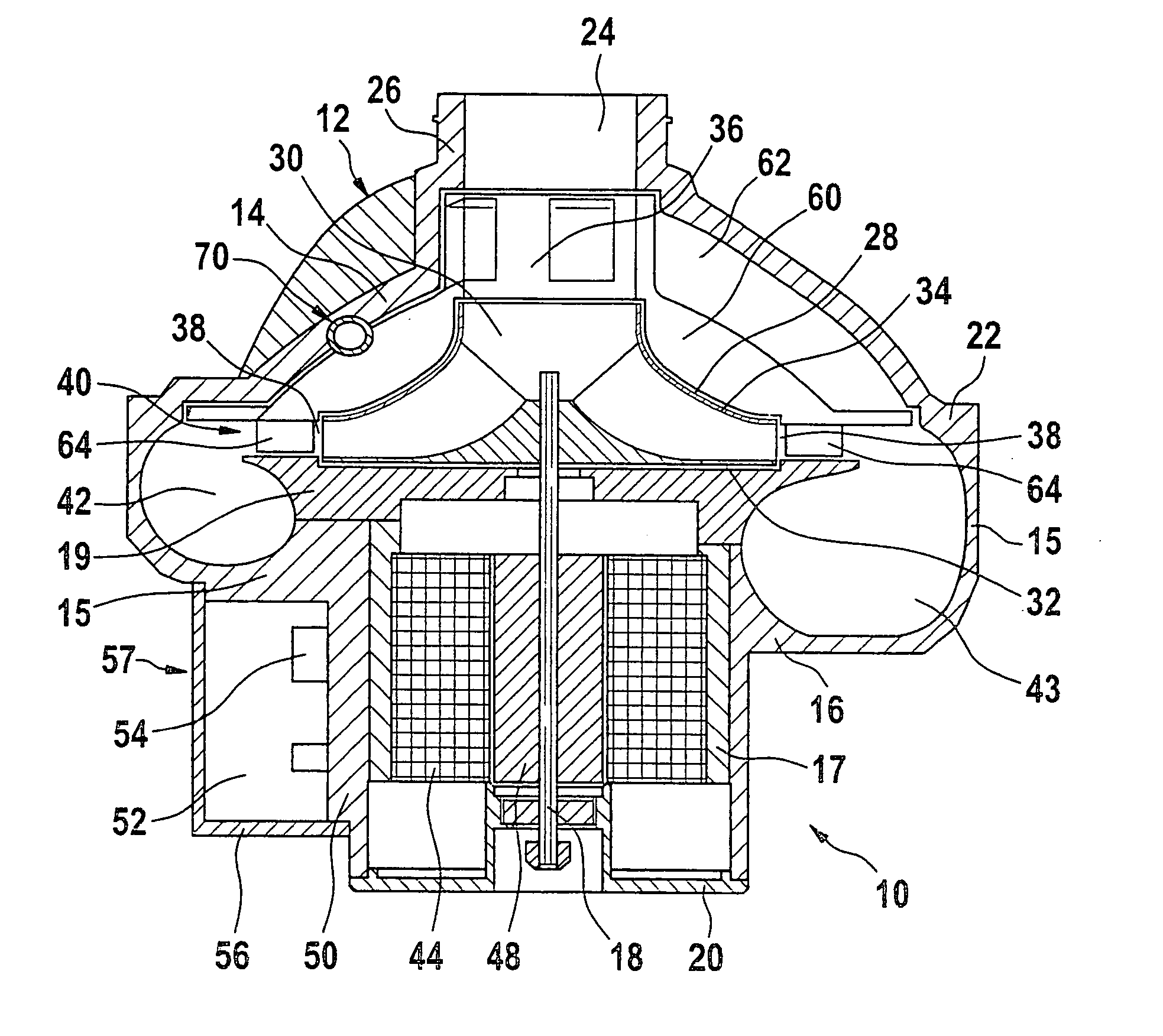

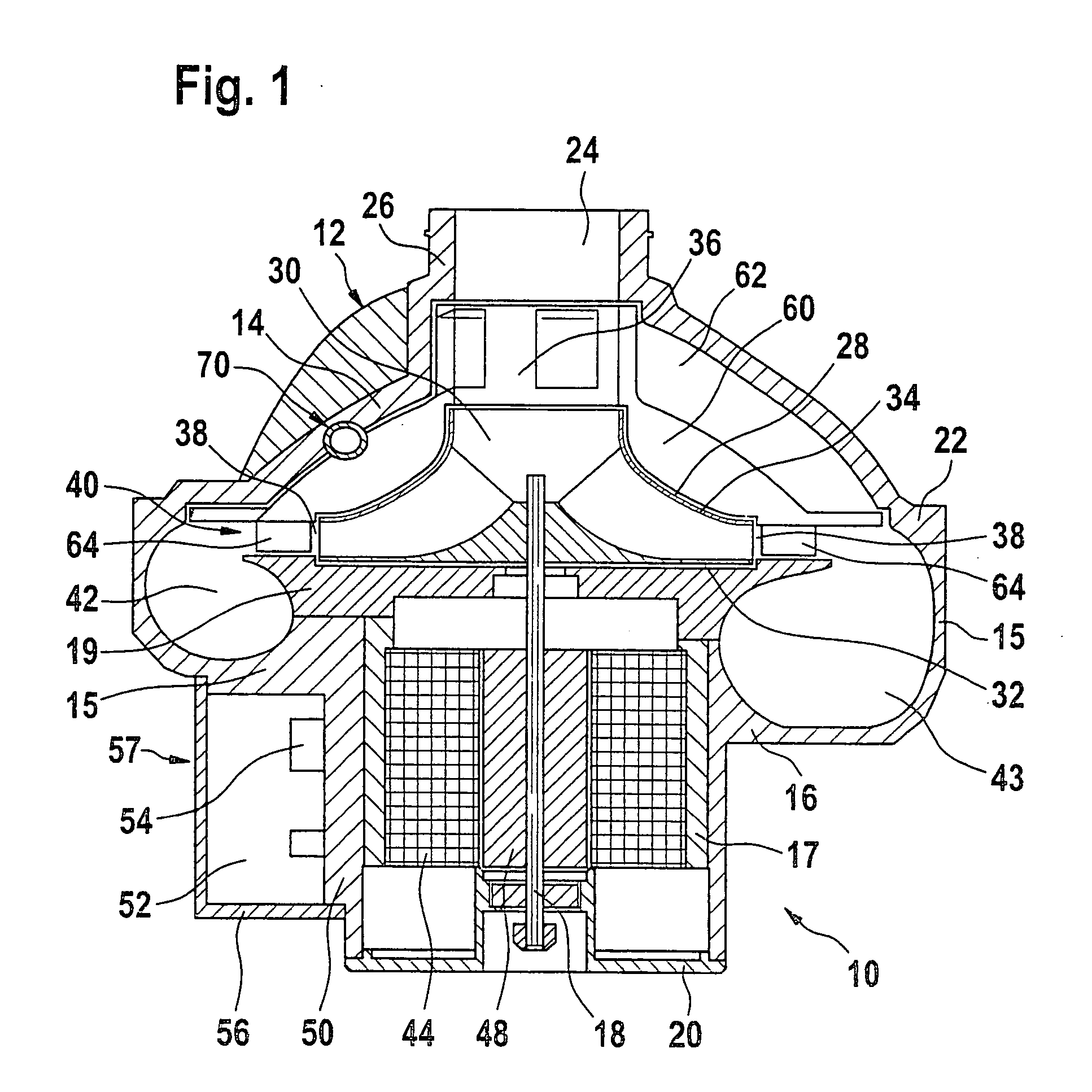

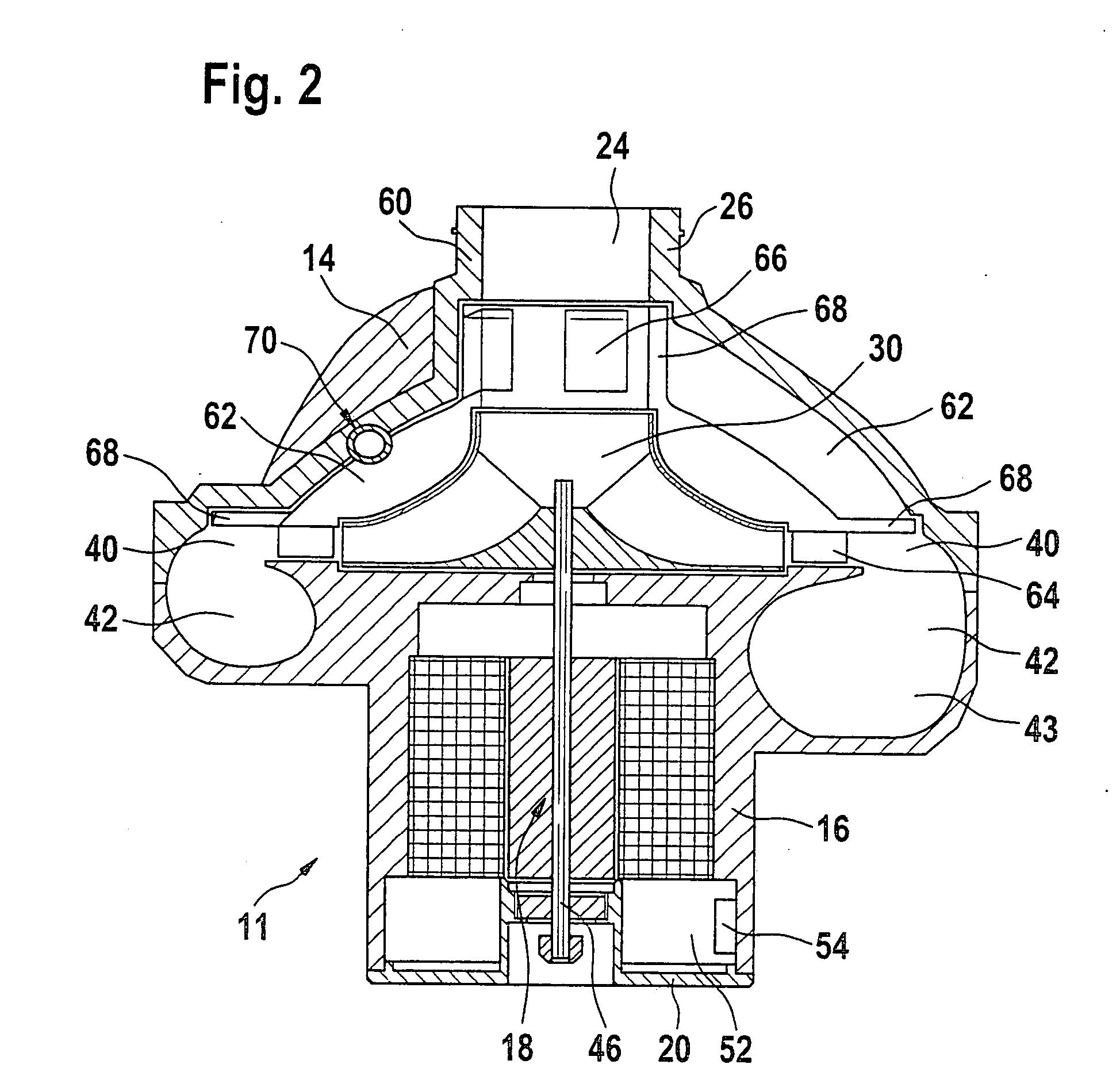

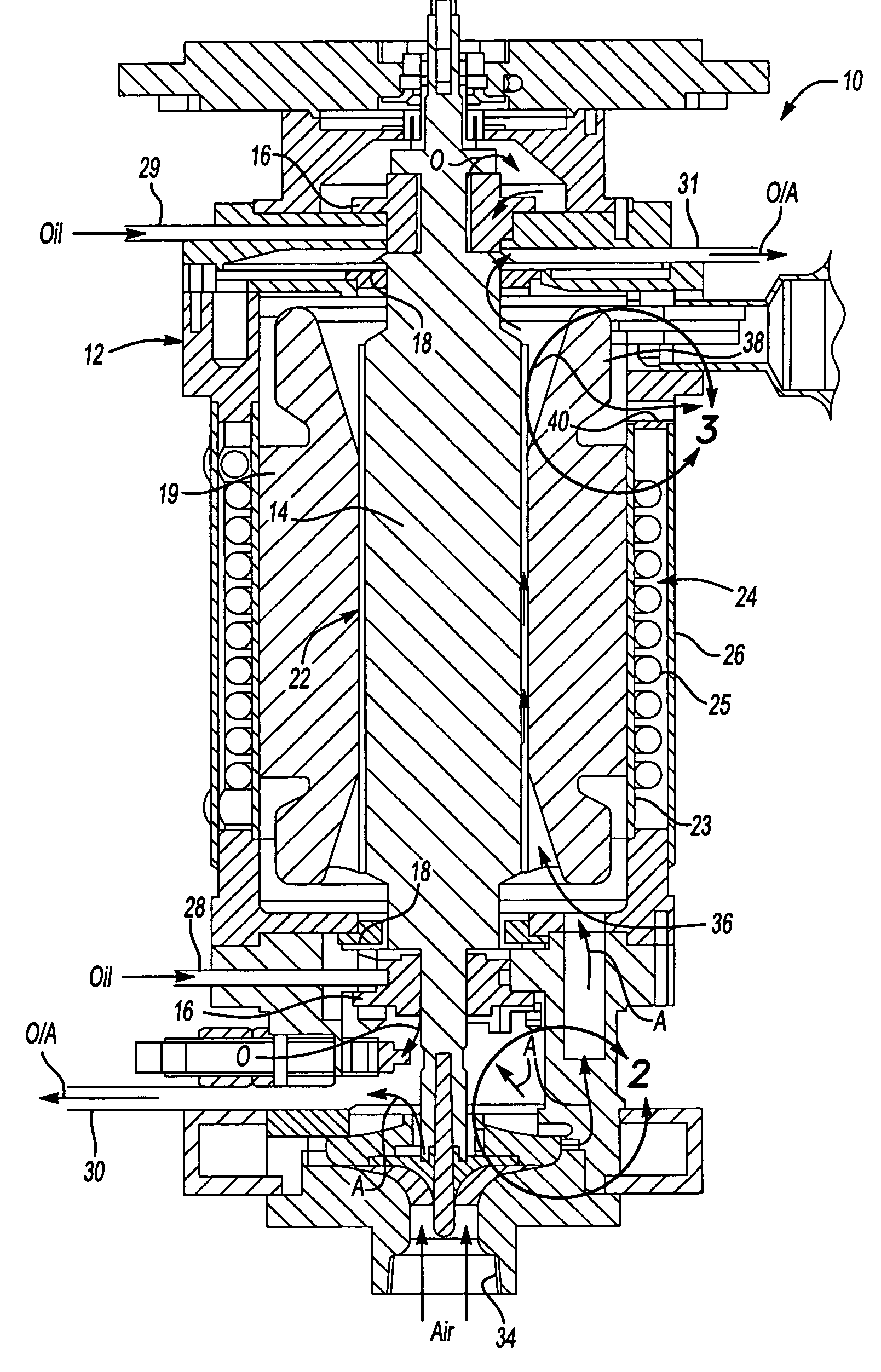

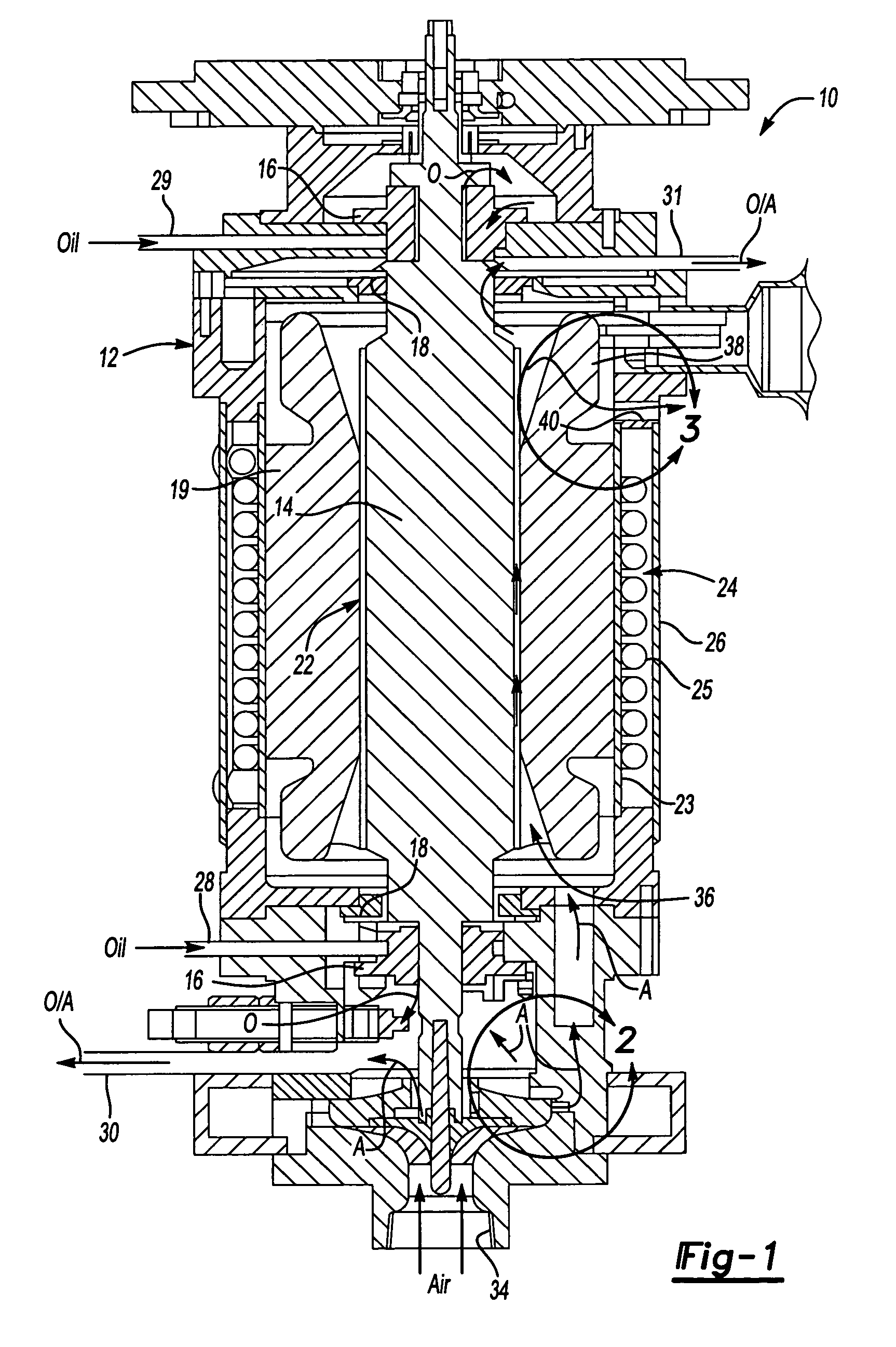

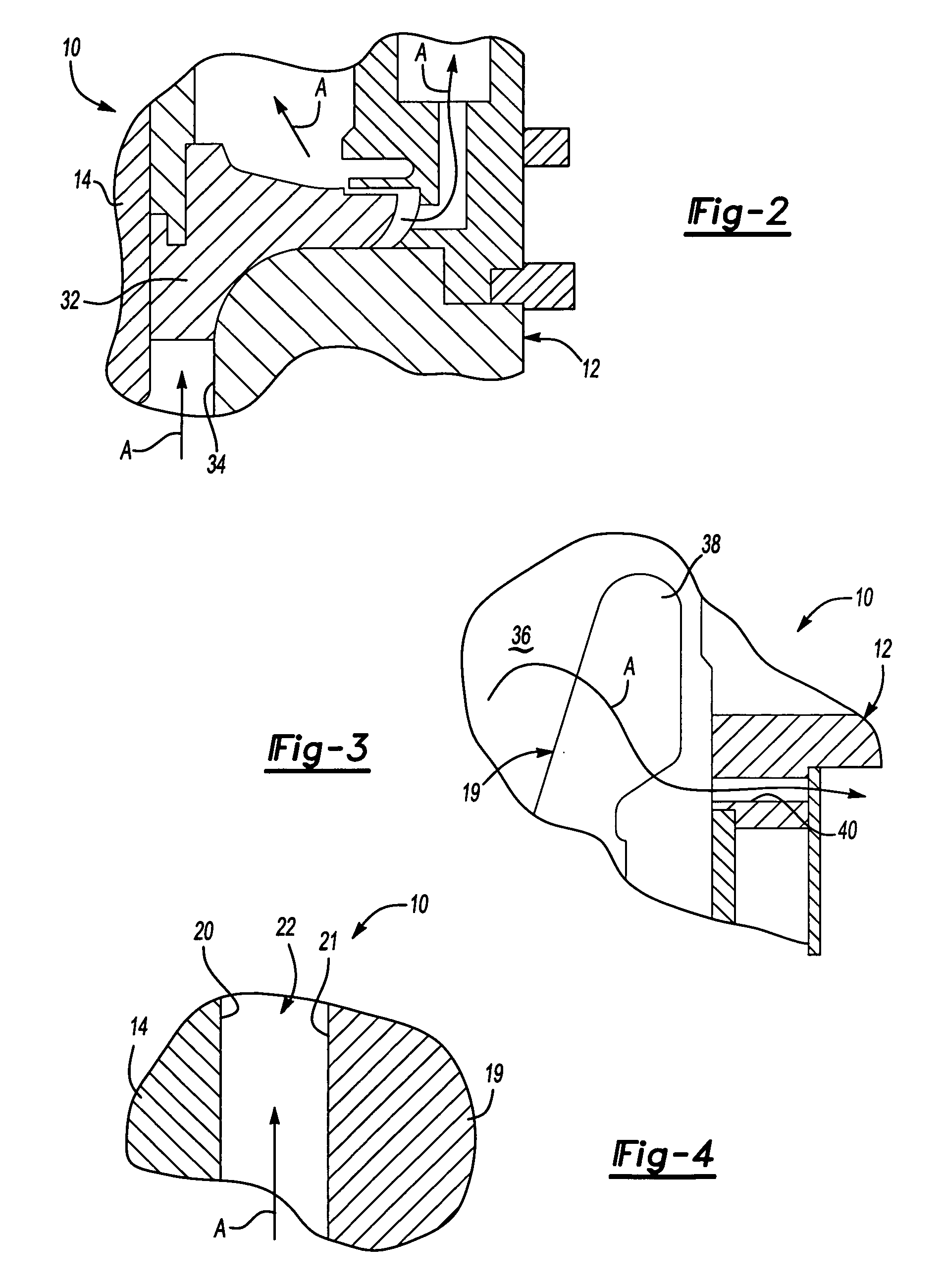

Electrical charge air compressor provided with an integrated air cooling system

InactiveUS20060081226A1Positive displacement pump componentsSemiconductor/solid-state device detailsImpellerCombustion

The invention relates to a device to compress combustion air, in particular a device to compress combustion air for a combustion engine of a motor vehicle, with a housing (12), with at least one compressor impeller (30) arranged in a compression area (28) of a first housing part (14), which is arranged in the flow direction between an air inlet (24) and an air outlet (43) of the housing (12), as well as with an electric motor (18) arranged in a second housing part (16) of the housing (12) to operate the compressor impeller (30). It is proposed in accordance with the invention that a flow channel (42) running in the circumferential direction of the first housing part (12) and connecting the compression space (28) with the air outlet (43) surrounds the electric motor (18) at least partially.

Owner:ROBERT BOSCH GMBH

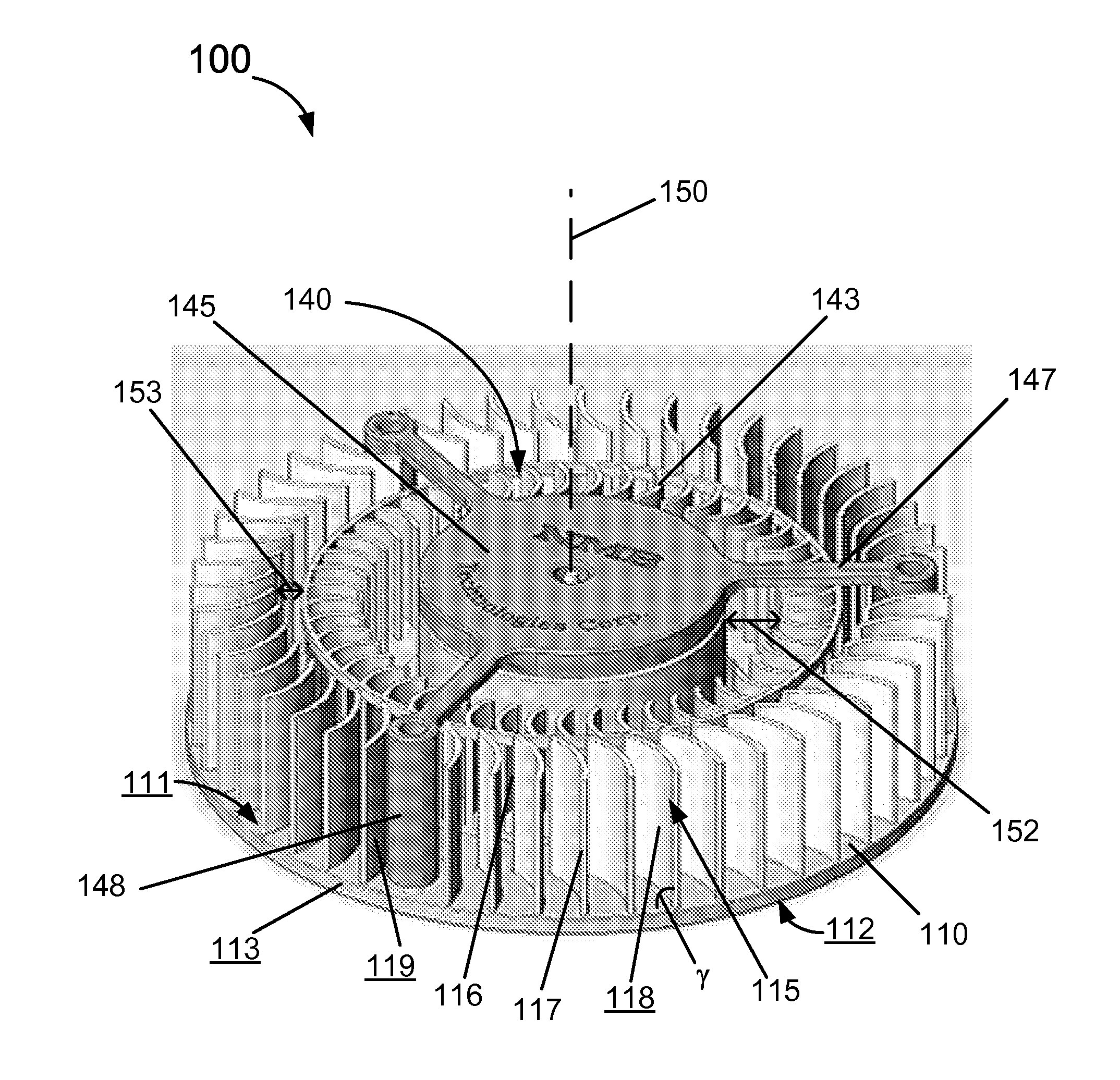

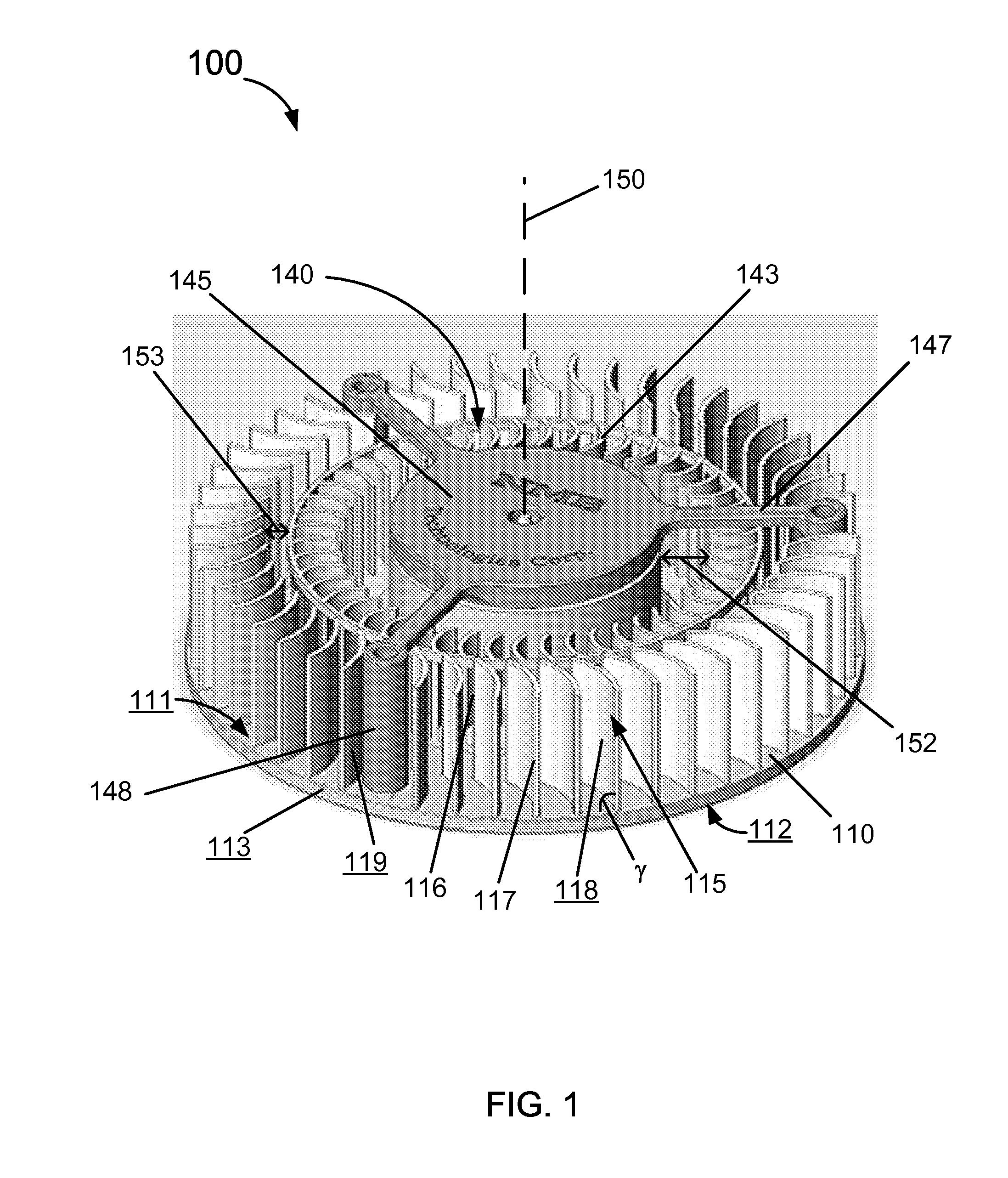

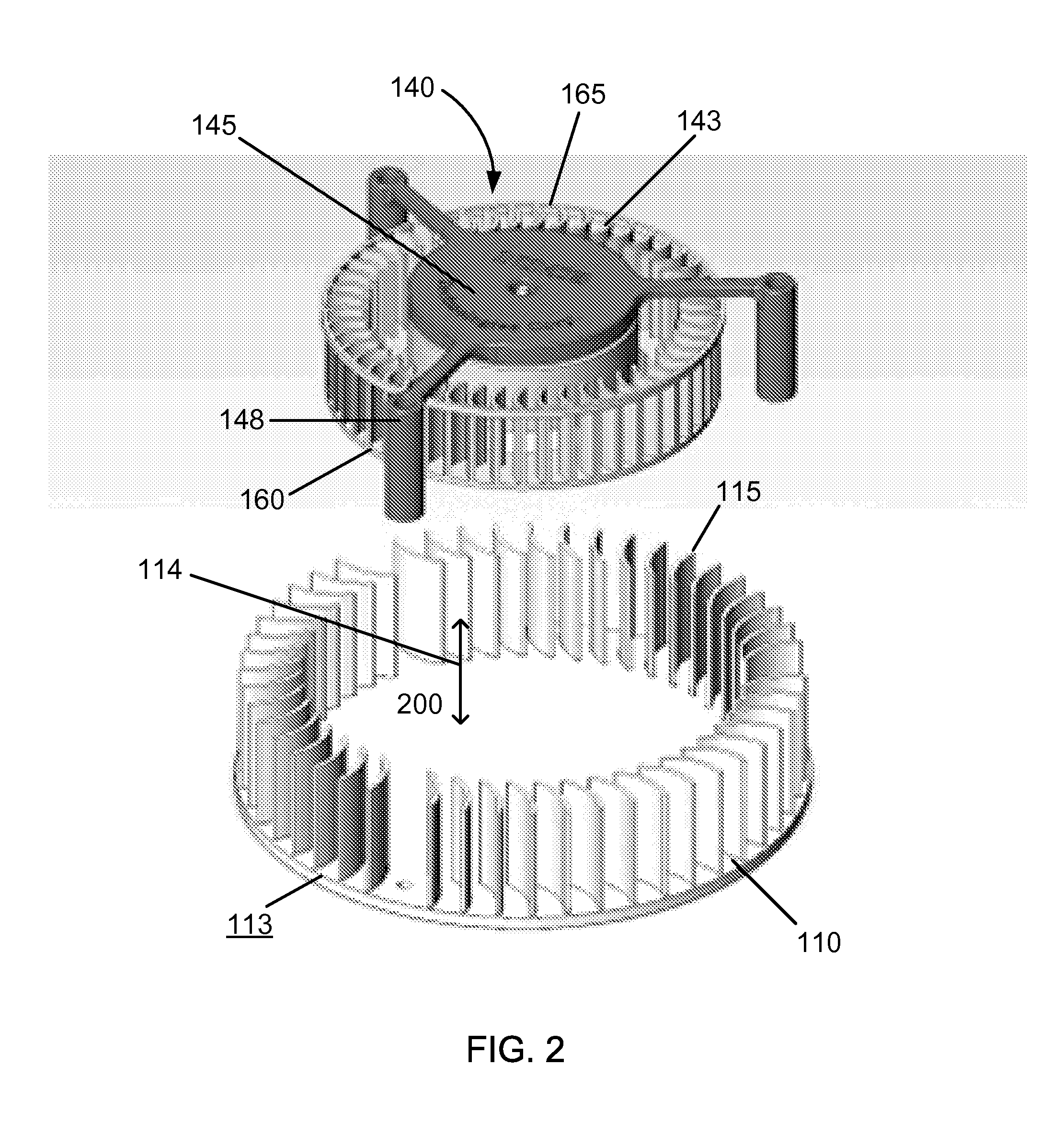

Compact air cooling system

InactiveUS20090263232A1Improve cooling effectReduce manufacturing costPump componentsWind motor controlImpellerAir cooling system

An apparatus for air cooling an object. The apparatus includes a plate including a first surface and a second surface and a plurality of aerodynamic fins being fixedly disposed on the first surface in an arrangement along periphery of the plate. The arrangement of the plurality of aerodynamic fins defining a central volume of space. Additionally, the apparatus includes a blower including a plurality of impeller blades rotatably disposed within the central volume of space for rotary motion about an axis of rotation. In particular, the second surface is for thermally contacting with the object and the axis of rotation is substantially perpendicular to the first surface. Furthermore, the rotary motion of the blower creates an air inflow along the axis of rotation into the central volume of space and an air outflow through the plurality of aerodynamic fins in radial directions.

Owner:MINEBEA CO LTD

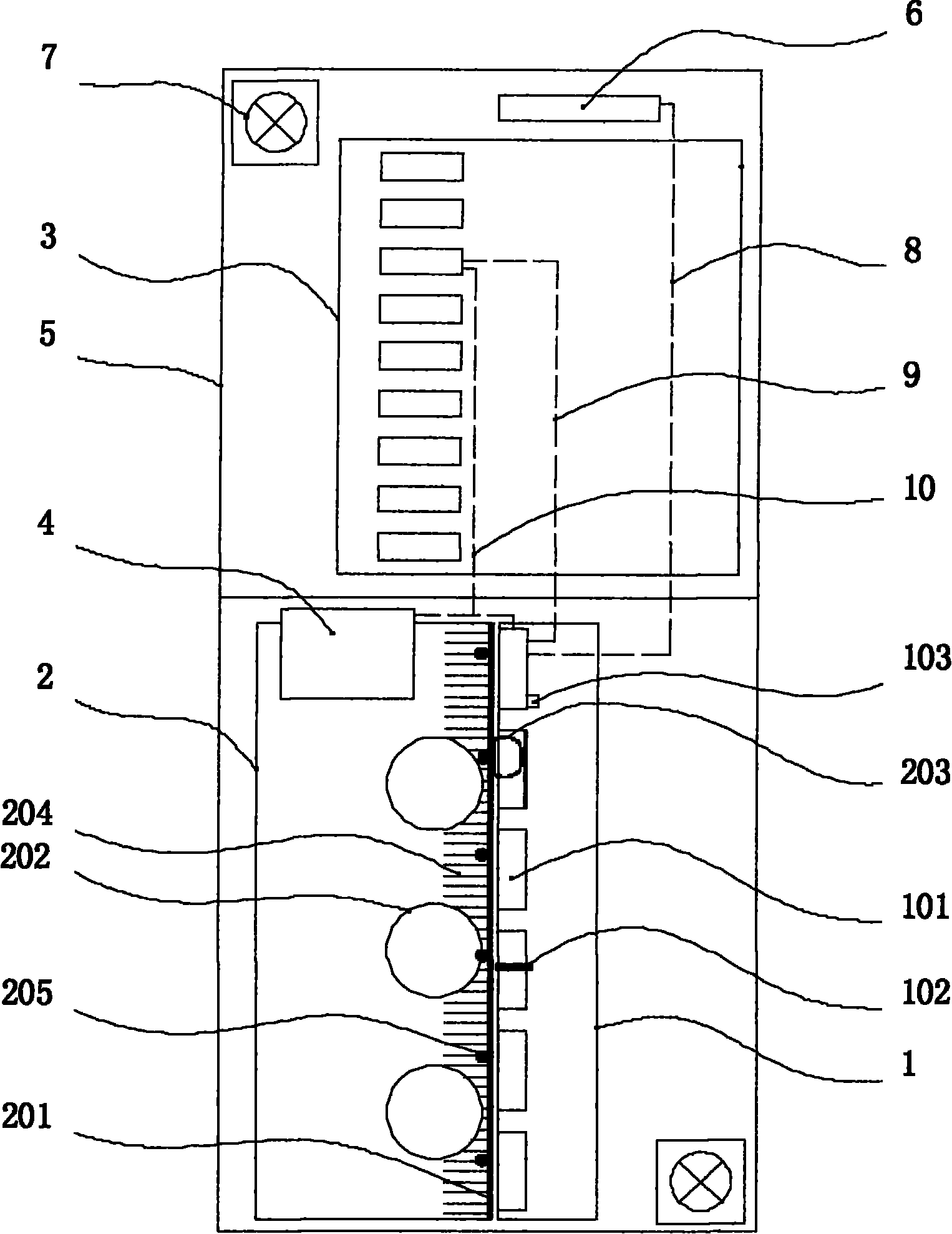

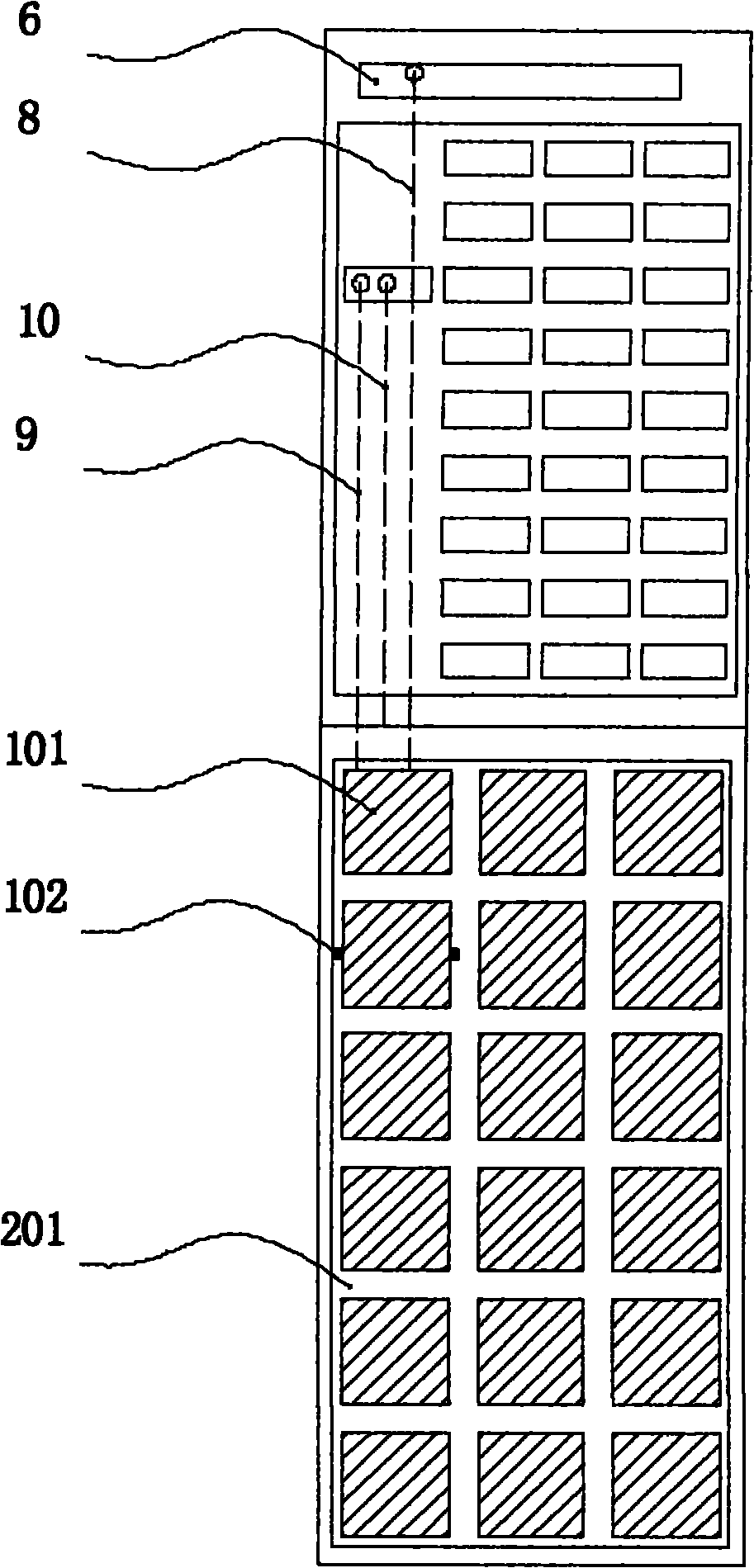

Cloud computing server system for heat dissipation, energy conservation and safe data storage

ActiveCN101853059ASave electricityImprove cooling efficiencyEnergy efficient ICTDigital data processing detailsEnergy conservationServer

The invention discloses a cloud computing server system for heat dissipation, energy conservation and safe data storage. The system comprises a network cabinet, a power system, a server array, a hard disk array and a heat radiating system. The cloud computing server system is characterized in that a bare computer is fixedly connected with a metal radiating panel to form the server array; a CPU ona main board and a north bridge chip transfer heat through a radiating connection piece to the metal radiating panel for heat dissipation, and a radiating pipe carries out heat dissipation on the metal radiating panel; the server array is separated from the hard disk array at a certain distance, and the data port of the main board is connected with the hard disk array through a data line; the power system carries out DC supply on the server array and the hard disk array, and the heat radiating system carries out heat dissipation on the power system; and the heat radiating system can be simultaneously connected with a natural air-cooling system and a water-cooling system. The server system configured by the invention can concentrate heating sources and directly carry out heat dissipation, thus improving heat dissipation efficiency and saving energy; and the computing part and the storage part of a server are separately configured, thus facilitating maintenance and safe data storage.

Owner:姚学民

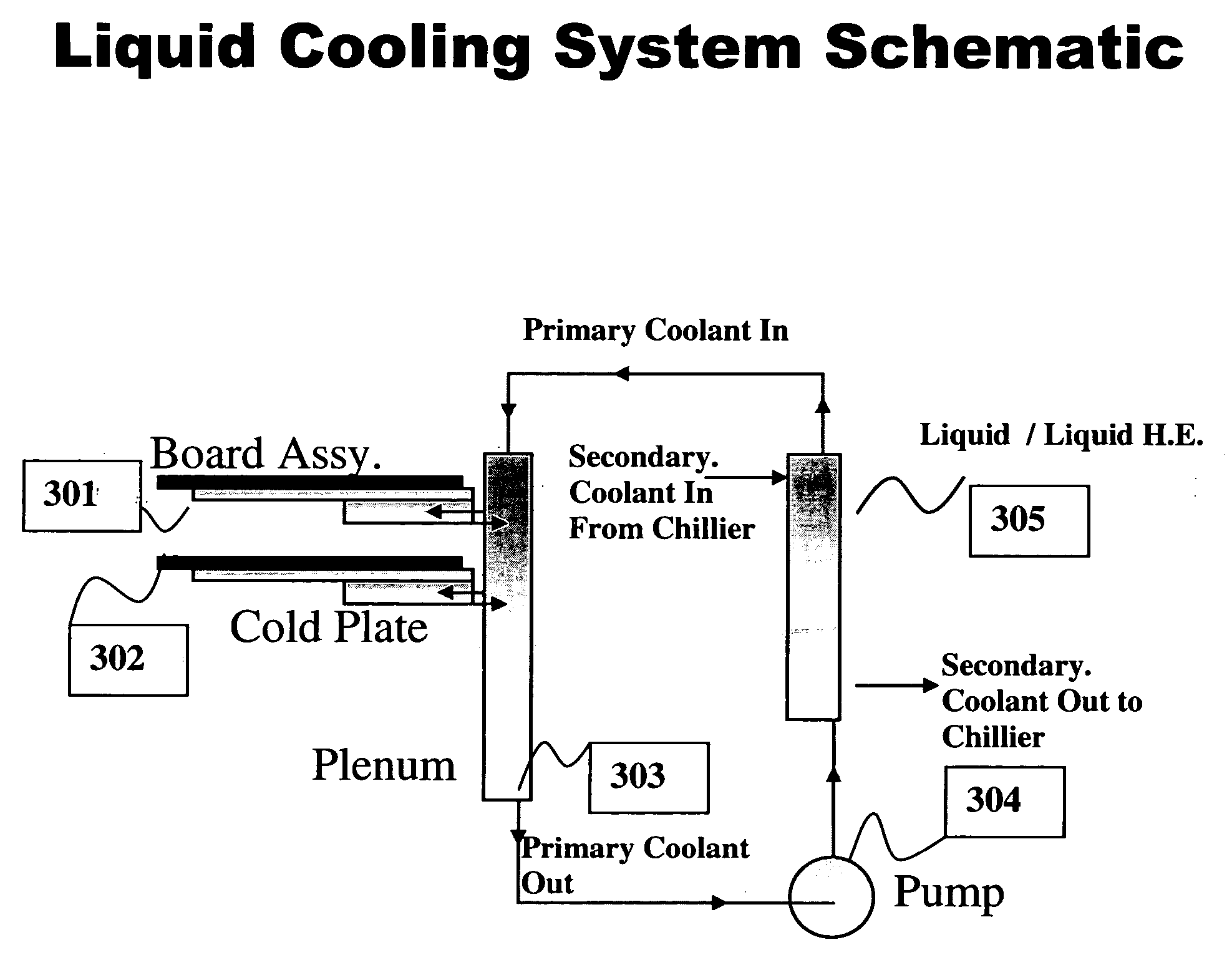

High performance cooling systems

InactiveUS20050174735A1Large capacityIncrease power consumptionIndirect heat exchangersCooling/ventilation/heating modificationsNuclear engineeringLiquid cooling system

High Performance cooling systems for cooling a heat source is disclosed. The cooling systems can be air cooling system, liquid cooling system, or space radiation cooling system. Air cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and liquid to air heat exchanger. Liquid cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and liquid to liquid heat exchanger. Space radiation cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and space radiator. Several coolant fluids are available and can be used as a primary system coolant depending on the application.

Owner:DELTA ENGINEERS

Rotary machine cooling system

ActiveUS7160086B2Reduce air volumeMinimized in sizePositive displacement pump componentsPiston pumpsImpellerFriction reduction

A rotary machine cooling system is provided that includes a housing having an inlet and outlet. A rotor supported in the housing for rotation about an axis with the rotor including an outer surface. A stator is disposed within the housing about the rotor having an inner surface adjacent to the outer surface of the rotor. A gap is formed between the inner and outer surfaces sufficient to reduce friction and permit convection cooling. The gap is in fluid communication with the inlet and outlet, and a pumping device pumps a cooling gas from the inlet into the gap and through said outlet. The pumping device includes an impeller affixed to an end portion of the rotor to create an axial airflow into the gap. Preferably, the present invention air cooling system is used in conjunction with a liquid cooling system arranged exteriorly to the stator. The liquid cooling system reduces the amount of air needed to flow between the gap to remove the desired amount of heat from the machine.

Owner:SUNDYNE LLC

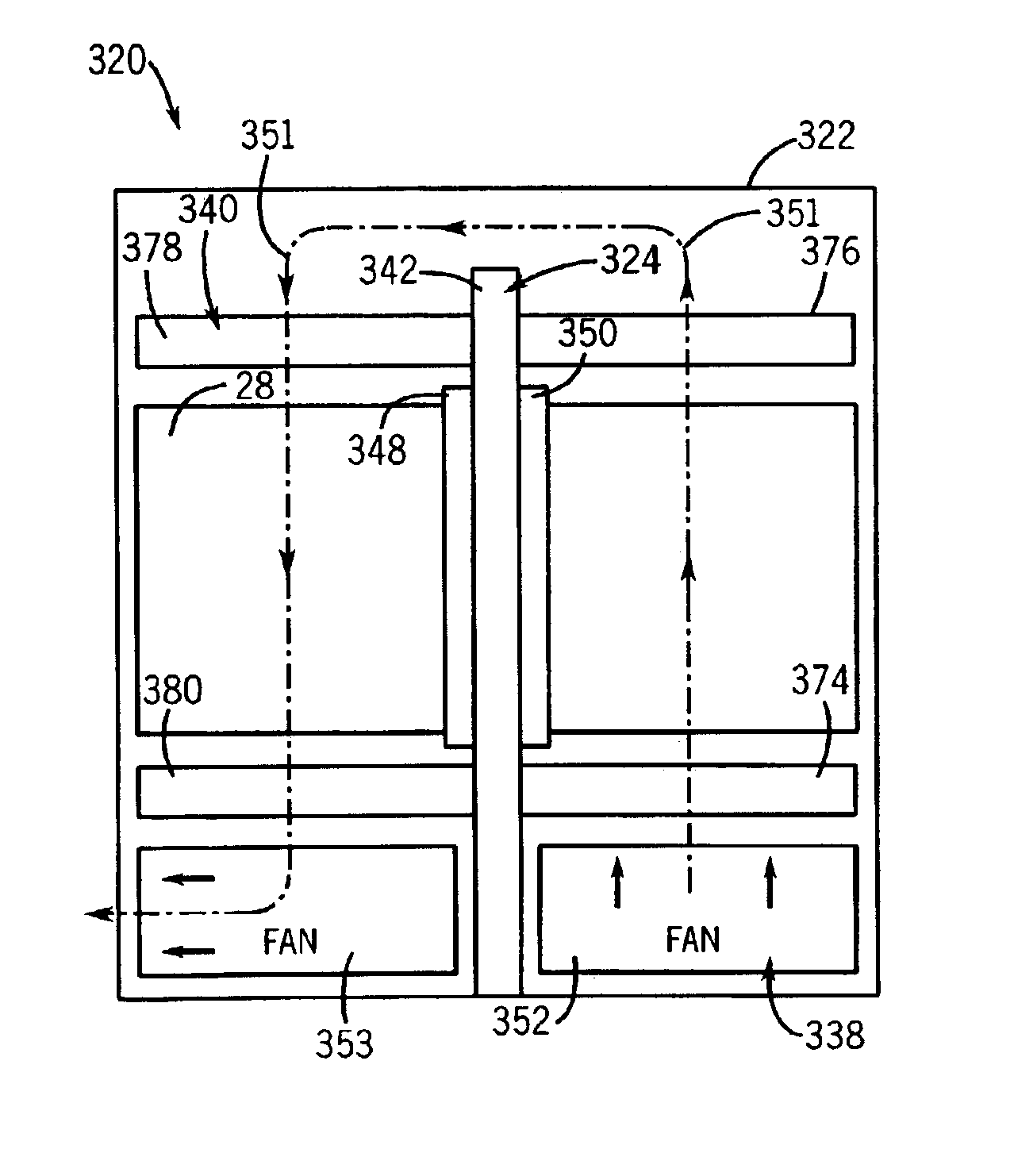

High capacity air-cooling systems for electronic apparatus

An improved air-cooling system for high performance, high density electronic equipment comprises, in one embodiment, a single fan having a radial impeller, a baffle having an inlet portion to efficiently direct air into the fan intake, and a two-tiered outlet plenum to direct one airflow specifically at the highest heat-generating components and another airflow at all components. The air-cooling system is designed to provide maximum cooling for a low-height, high heat-generating electronics module such as a server. By using only a single fan that is matched to the low resistance airflow characteristics of the baffle, the air-cooling system offers significant advantages over multi-fan systems. Also described are a computer server and methods of making heat-dissipation equipment.

Owner:INTEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com