Giant magnetostrictive rotary ultrasonic vibration knife handle

A giant magnetostrictive and rotating ultrasonic technology, which is applied in the direction of fluid, stone processing tools, stone processing equipment, etc. using vibration, can solve the temperature rise of giant magnetostrictive ultrasonic transducer, affect the stability and safety of output amplitude, etc. problem, to achieve the effect of high output power, high magnetostriction coefficient and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

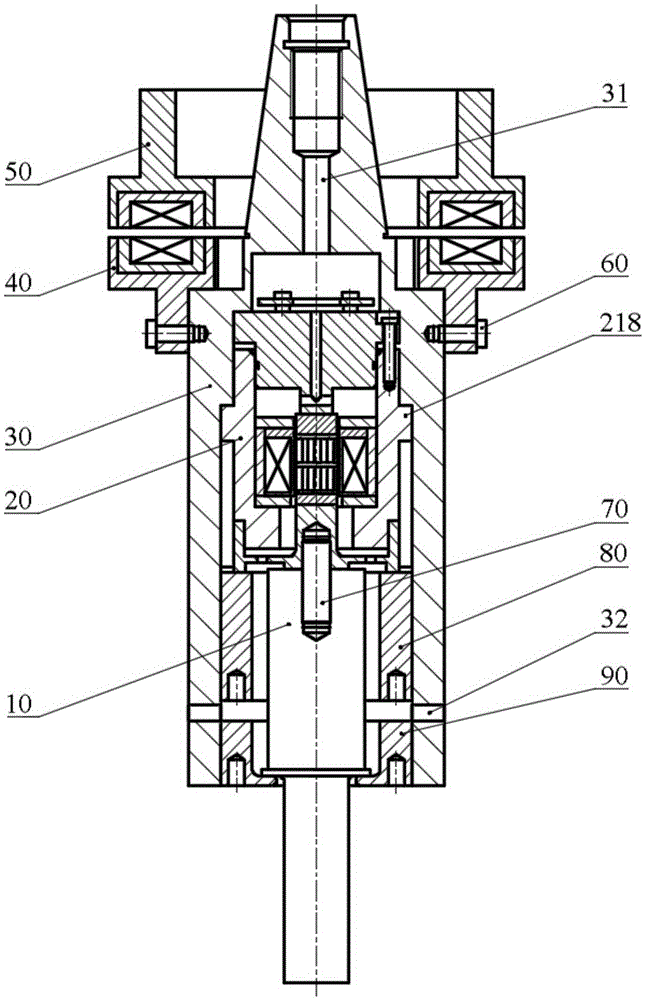

[0024] In order to achieve the above purpose, a giant magnetostrictive rotary ultrasonic vibration tool holder provided by the present invention is described as follows in conjunction with the accompanying drawings and embodiments:

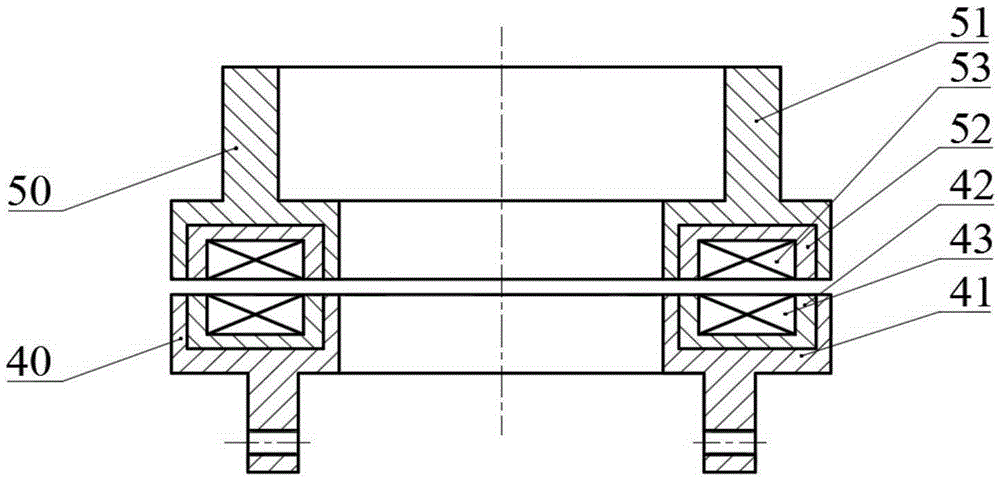

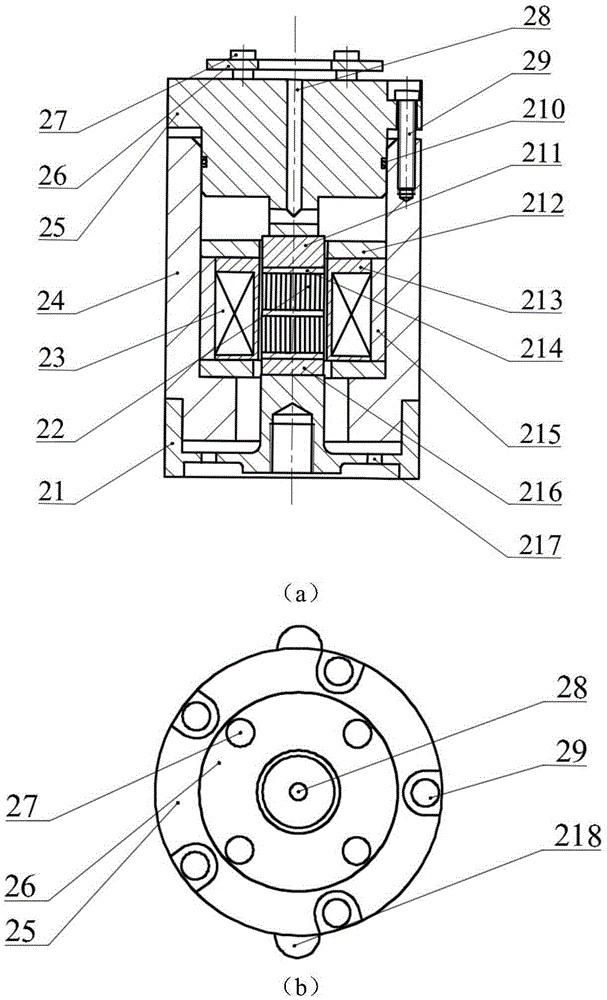

[0025] The embodiment structure of a giant magnetostrictive rotary ultrasonic vibration tool holder proposed by the present invention is as follows: figure 1 As shown, the structure is suitable for cooling by an air-cooling system, including a horn 10, a giant magnetostrictive ultrasonic transducer 20, a casing 24, a hollow handle 30 (with a central hole 31 in the handle, and an air hole 32 in the handle. ), a non-contact power transmission system made up of secondary side parts 40 and primary side parts 50, screws 60, screw rods 70, threaded pressing blocks 80 and 90; the connection and matching relationship of each part is: giant magnetostrictive ultrasonic transducer 20 is connected with the horn 10 through the screw rod 70 to form an integral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com