Magnetostrictive film target material structure and preparation method thereof

A magnetostrictive and thin film technology, applied in the field of magnetostrictive thin film target structure, can solve the problems of large difference in film composition and complex process, and achieve the effects of low saturation field, convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

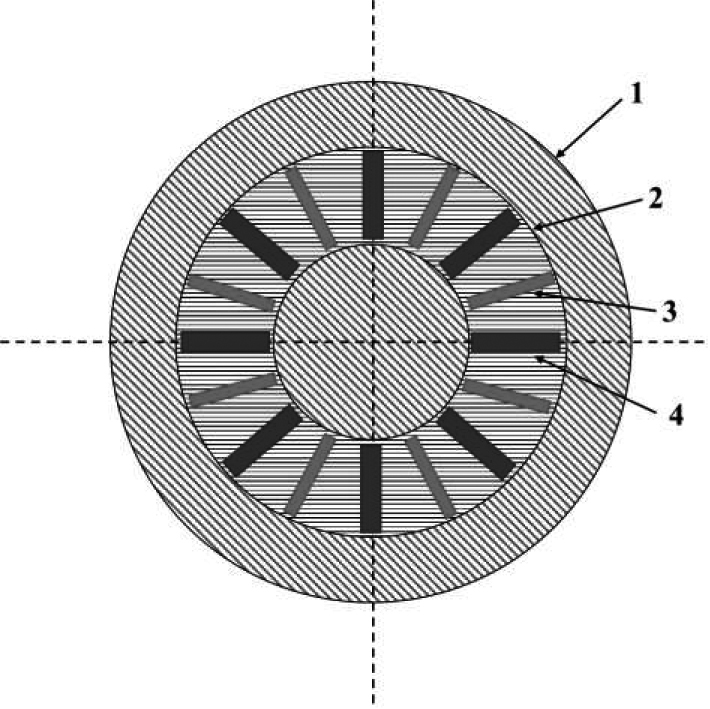

[0019] The implementation of the present invention will be described in detail below with reference to the drawings and specific examples, and those skilled in the art can understand other advantages and effects of the present invention from this description. It should be noted that the diagrams provided in this embodiment are only schematic diagrams to illustrate the basic idea of the present invention, and the relevant components in the schematic diagrams are not necessarily drawn according to the number, shape and size of components in actual implementation. The shape, number, layout and proportion of each component may be more complicated.

[0020] According to the working principle of magnetron sputtering, during sputtering, the sputtering rate at each position of the target surface is determined by the energy distribution of ions on the target surface, that is, the energy distribution of ions is the same as the glow discharge during sputtering. The distribution of brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com