Patents

Literature

88results about How to "High magnetostrictive performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fe-Ga series magnetostriction material and its producing process

InactiveCN1392616AEfficient use ofLow costMagnetostrictive material selectionRoom temperatureSingle crystal

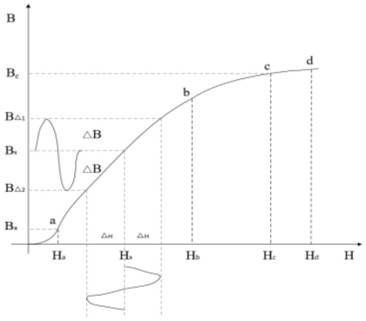

This invention relates to a magnetic material. The components of material are Fe100-x-yGaxMyQ where x=10-40, M is Al, Be, Cr, In, Cd, Mo, Ge, y=0-15, Q is C, N, O additional doping. Main points of its technique are according to the requirement of the invented material components to smelt the mother alloy in a magnetic suspension over or vacuum induction furnace, to process monocrystal or polycrystal oriented materials with the high-temperature gradient quick directional solidification or czochralski or Bridgeman method under 1000-1200 deg.C for 1-48 hours then cool to 750-600 deg.C in the furnace and keep temp. for 0.2-48 hours, then quenching with water, or cool furnace to room temperature with different cooling speed for 750 to 600 deg.C or apply 500-20000 e magnetic field in the cooling process.

Owner:UNIV OF SCI & TECH BEIJING

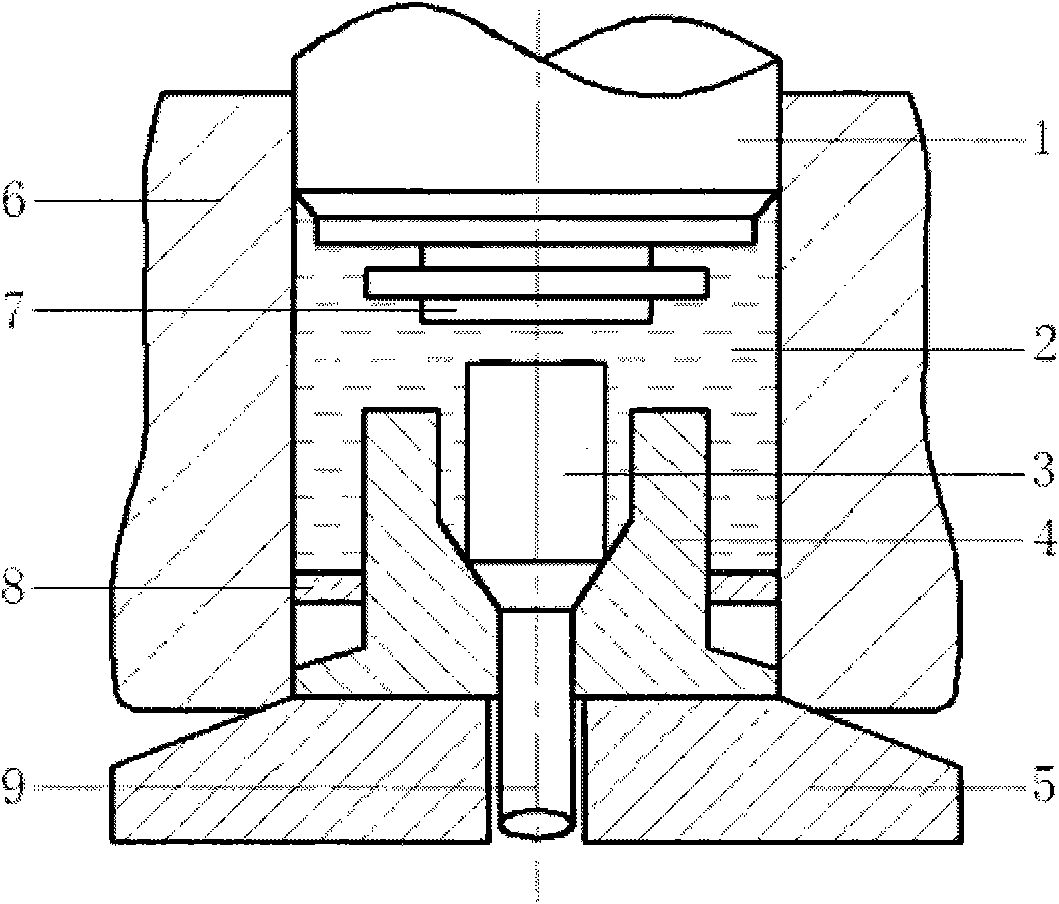

A sort of Fe-Ga magnetostriction alloy wire and preparation method

InactiveCN101003117AReduce manufacturing costGood magnetostrictive performanceRevolution surface grinding machinesFurnace typesAlloyMagnetostriction

Owner:BEIHANG UNIV

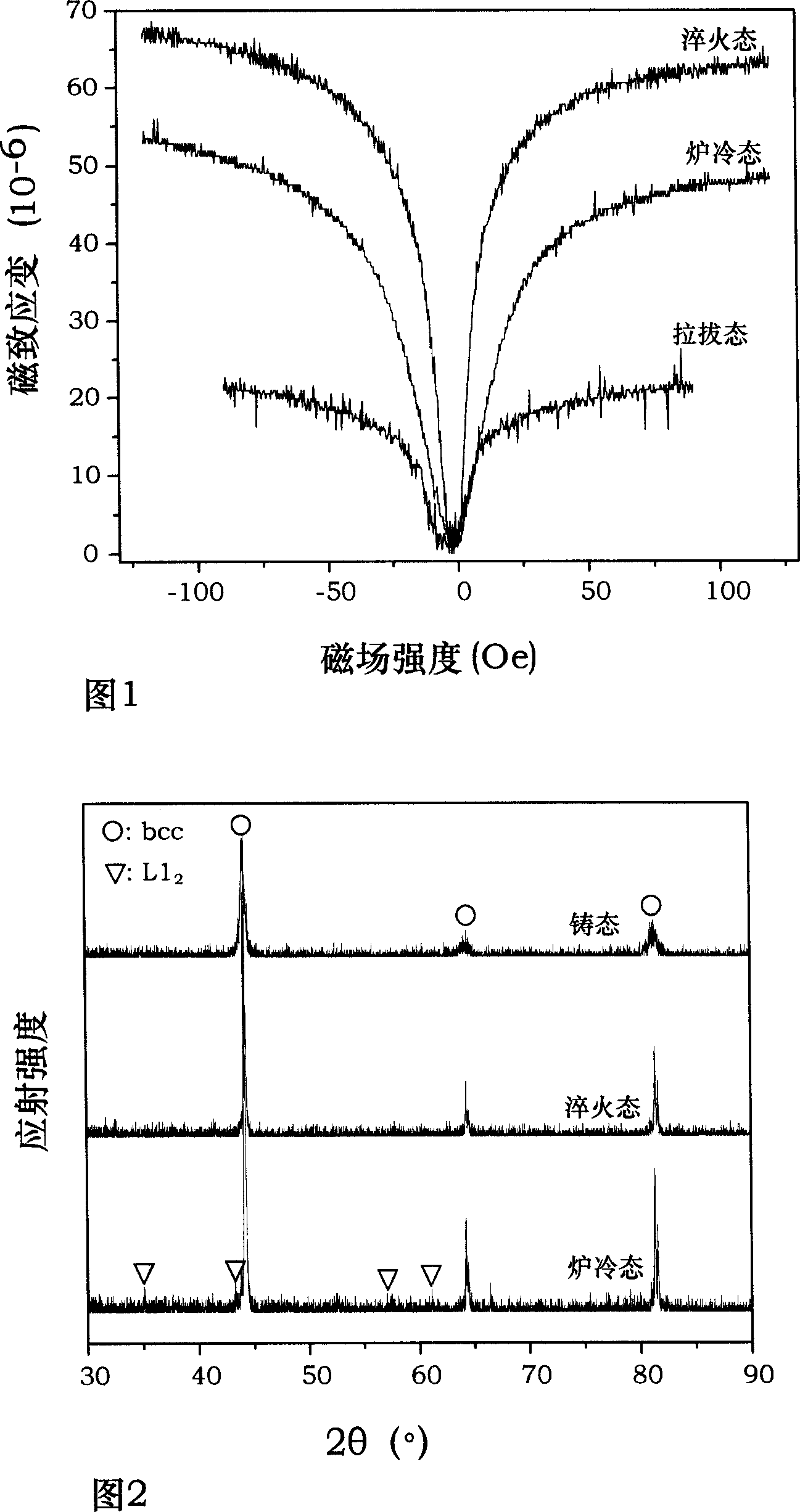

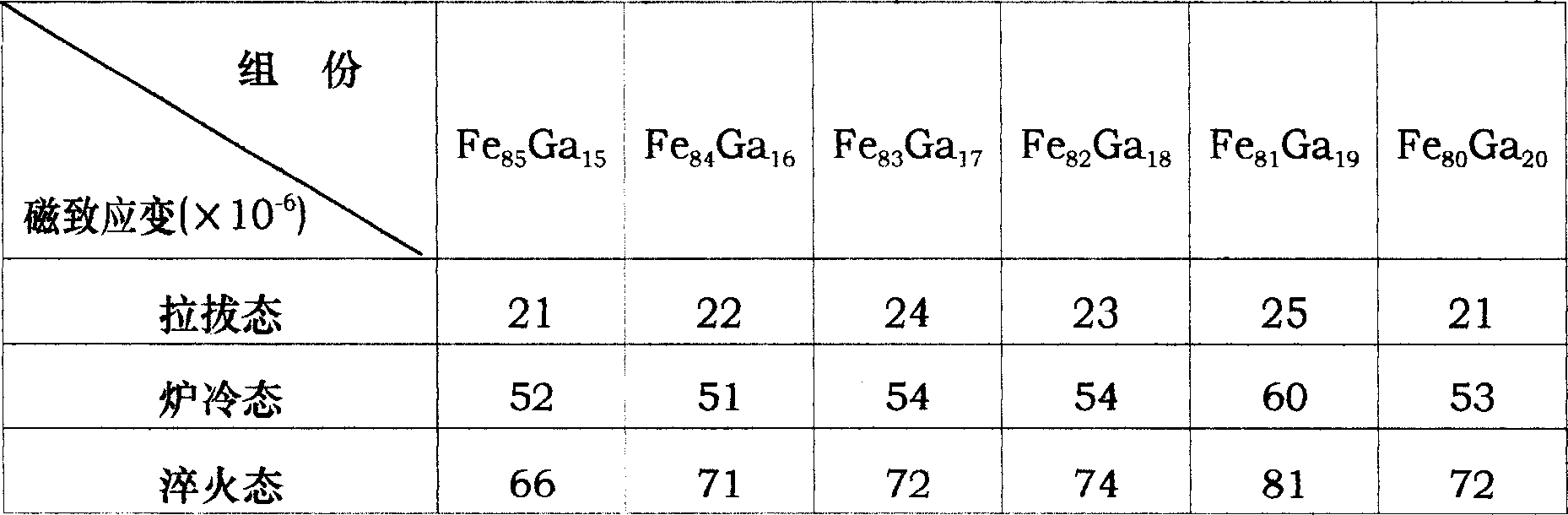

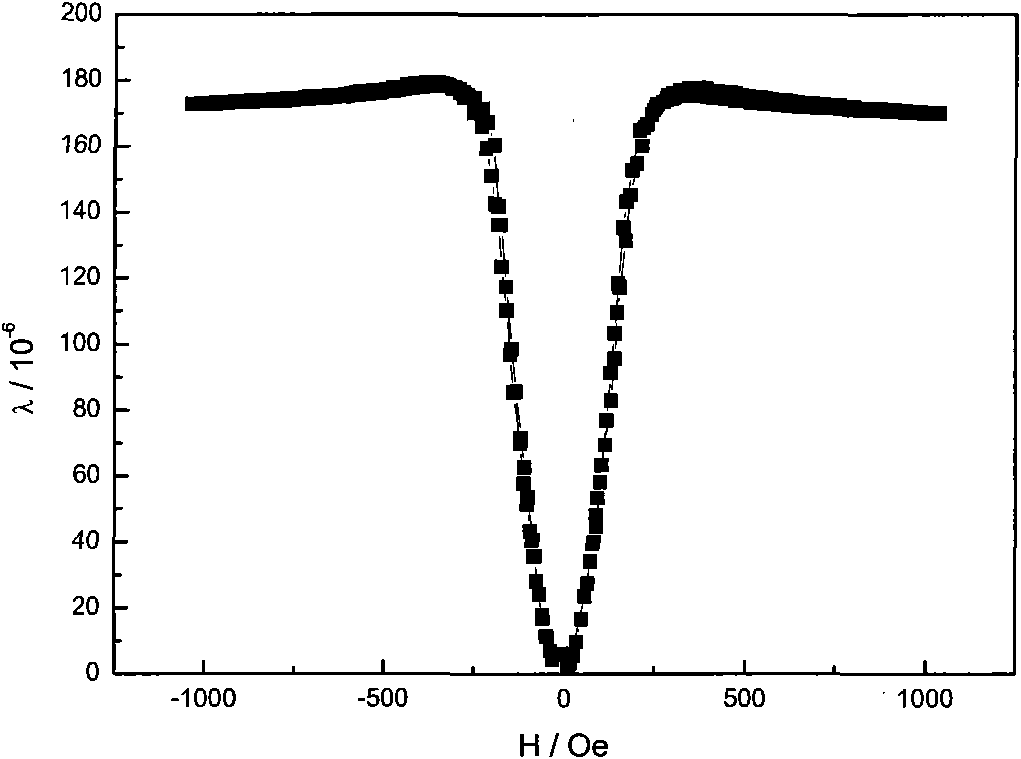

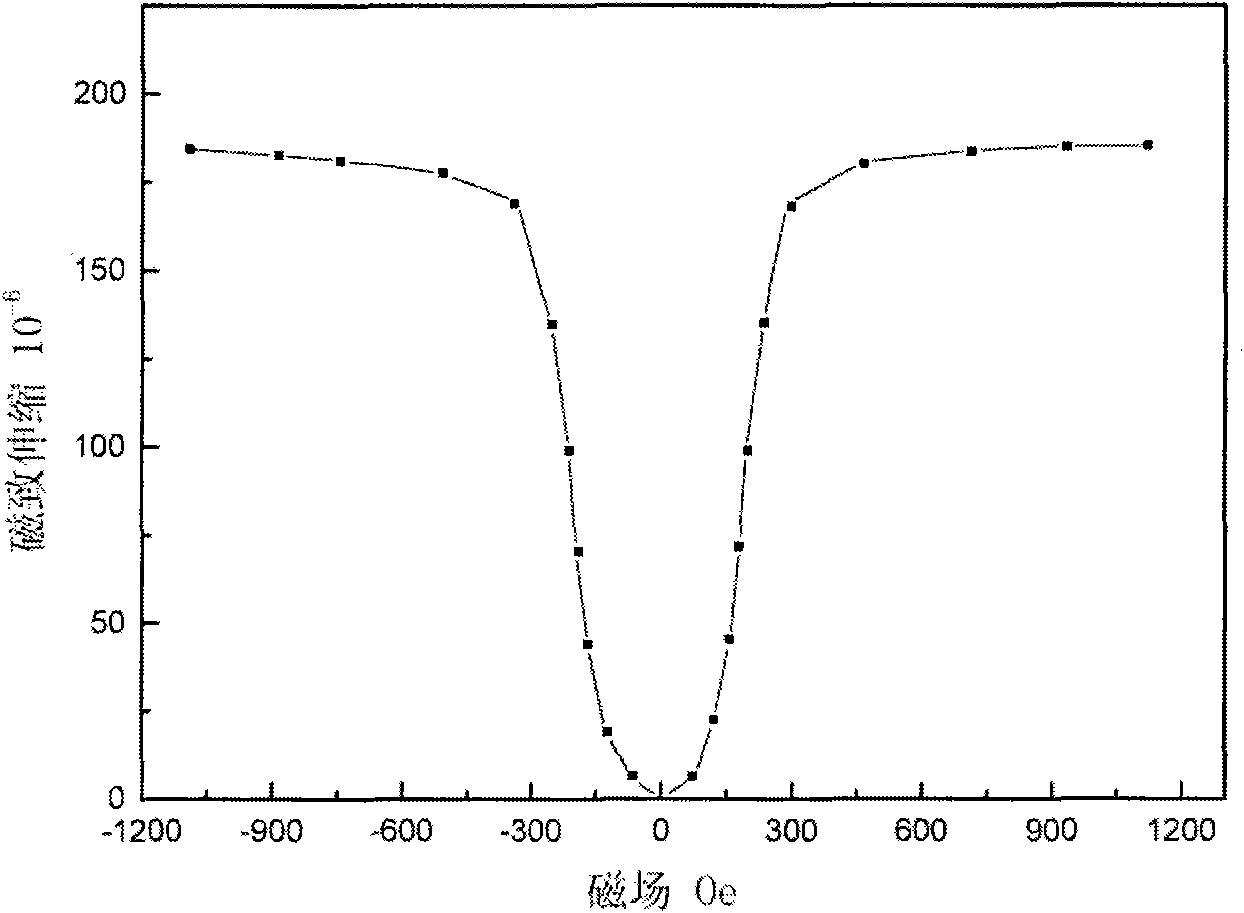

Fe-Ga based magnetostrictive wire and preparation method thereof

ActiveCN101812628AImprove surface qualityExcellent low-field magnetostrictive performanceMagnetostrictive material selectionAlloyProcessing cost

The invention relates to an Fe-Ga based magnetostrictive wire and a preparation method thereof. The raw material component used by the method is (Fel-x-yGaxMy)l-z(NC)z, wherein M is selected from one or more types of all transition elements other than Fe, B, Be, Al, In, Ge, Sn, Sb, Bi, Pb, S and Se, and N is Nb, Ti, Si, Zr, Mo and the like, x is equal to 0.10 to 0.30, y is equal to 0.00 to 0.05, z is equal to 0.00 to 0.02, and the balance Fe. The method processes an Fe-Ga alloy into a finished wire through cold- or warm-hydrostatic extrusion. The invention solves the problems of poor plasticity, larger flow friction resistance and high processing cost when in Fe-Ga alloy plastic processing. The diameter of the prepared Fe-Ga based magnetostrictive wire is between 0.01mm and 2mm, the surface finishment is high, and the magnetostrictive properties under the low-magnetic field environment can reach 180*10-6.

Owner:BEIJING MAGORIENTAL MATERIALS TECH CO LTD

Iron-based magnetostrictive alloy wire and production method thereof

ActiveCN101824578AHigh magnetostrictive performanceImprove machinabilityMagnetic materialsWire rodIngot casting

The invention relates to an iron-based magnetostrictive alloy wire and a production method thereof. The molecular formula of the alloy is Fe1-x-yMxNyREz, M is one or more of Ga, In, Cr, Ni and Co, N is one or more of Al, Mn, V, Nb, Ti and Zr, RE is one or more of La, Ce, Pr, Nb, Tb, Dy, Y and Sc, wherein x is equal to 15 percent to 60 percent, y is equal to 0 percent to 10 percent, z is equal to 0 to 1.0, and the rest is Fe. The technical point is as follows: according to the alloy composition requirement, an ingot casting is smelted, hammer cogging is carried out, and after a wire rod with the diameter of 8mm is rolled, the wire rod is cold-drawn into the alloy wire. The size of the alloy wire produced by the method can be adjusted within a wide range, consequently, a sensor can be conveniently designed, and the magnetostrictive material can be used in more fields. The magnetostriction coefficient of the iron-based magnetostrictive material can reach 367ppm under a 4000Oe applied magnetic field.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

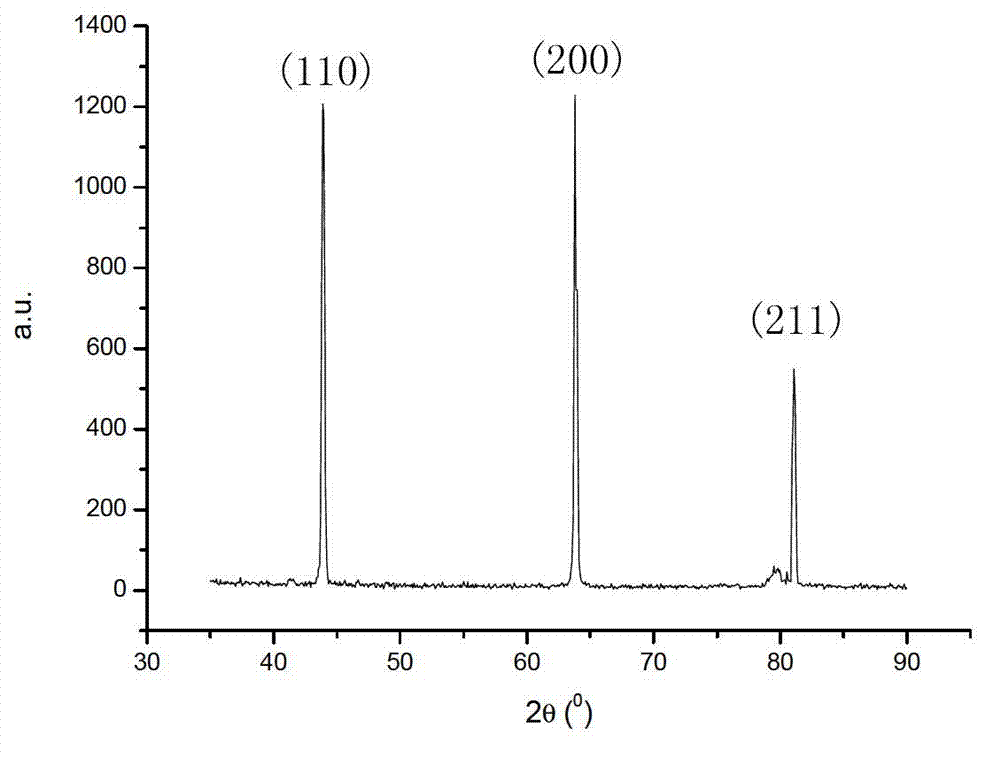

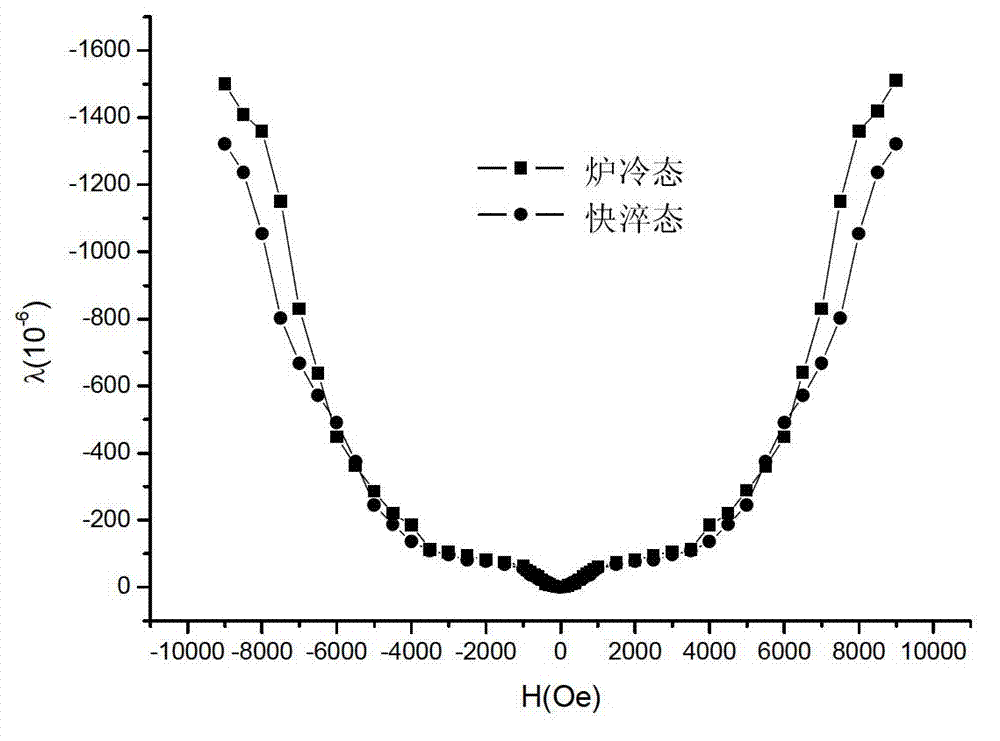

High-performance quick-quenching Fe-Ga based magnetostriction thin strip material and preparation technology thereof

ActiveCN103320682AGood magnetostrictive performanceHigh strengthMagnetic materialsCopperUltimate tensile strength

A preparation technology of a high-performance quick-quenching Fe-Ga based magnetostriction thin strip material is disclosed. The material compositions comprise: Fe100-x-yGaxMy, M represents one or more of Tb, Dy, La, Ce, Y, Al and Mn, wherein x=5-25, y=0.05-15, and the thickness of the thin material is 50 [mu]m-150 [mu]m. According to the preparation technology, melt-spinning and quick-quenching are carried out by employing a vacuum copper roller quick-quenching furnace, and heat treatment is carried out. The advantages are that: the developed Fe-Ga based magnetostriction thin strip material possesses excellent magnetostriction performance, better intensity and corrosion resistance, which can be used in severe environment; the thin strip produced by using the preparation technology is good in flatness and linearity, when the applied magnetic field is perpendicular to the thin strip surface, the thin strip possesses extremely high magnetostriction performance along the thin strip surface direction, and the magnetostriction coefficient reaches -1500*10<-6>; and the thin strip material is simple in preparation technology and high in strip-forming rate, and is beneficial to popularization and application.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Magnetostrictive material and preparation method thereof

ActiveCN104947194AAchieve <100> single crystal orientationRaise the temperature gradientPolycrystalline material growthFrom frozen solutionsRare earthShielding gas

The invention provides a magnetostrictive material and a preparation method thereof. The composition of the magnetostrictive material is (Fe[]1-x]Gax)[100-y]REy, wherein 0.17<=x<=0.19, 0.01<=y<=0.2, and RE is selected from one or more of Tb, La, Sm, Dy, Lu, Ho, Er and Tm. The preparation method comprises the following steps: smelting the Fe Ga and RE prepared according to the composition requirements into a mother alloy cast ingot, preparing a mother alloy bar, putting the mother alloy bar and a <100>-oriented FeGa monocrystal seed in a directional solidification apparatus, vacuumizing the directional solidification apparatus, charging protective gas, heating to melt all the mother alloy bar and melt the upper part of the FeGa monocrystal seed, and drawing the molten material into a coolant along the lower part of the FeGa monocrystal seed to carry out directional solidification, wherein the temperature gradient is controlled at 1*10<5>-9*10<5> K / m, and the growth rate is 1000-20000 mm / hour. The magnetostrictive material prepared by the method is a <100>-oriented monocrystal material in which the RE elements are completely dissolved in the FeGa matrix; the saturated magnetic field is only 100-5000e, and the magnetostriction coefficient is up to 300-1500 ppm; and the magnetostrictive material has favorable comprehensive usability and wide application prospects.

Owner:BEIHANG UNIV

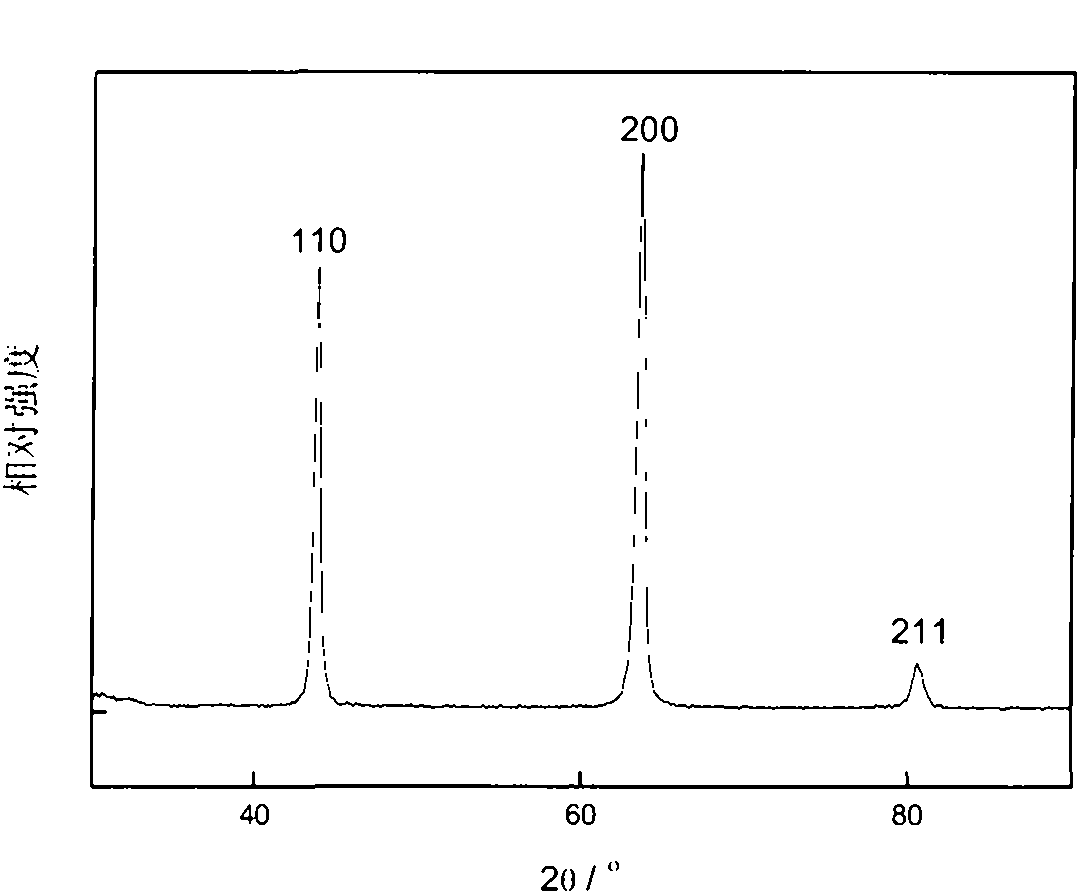

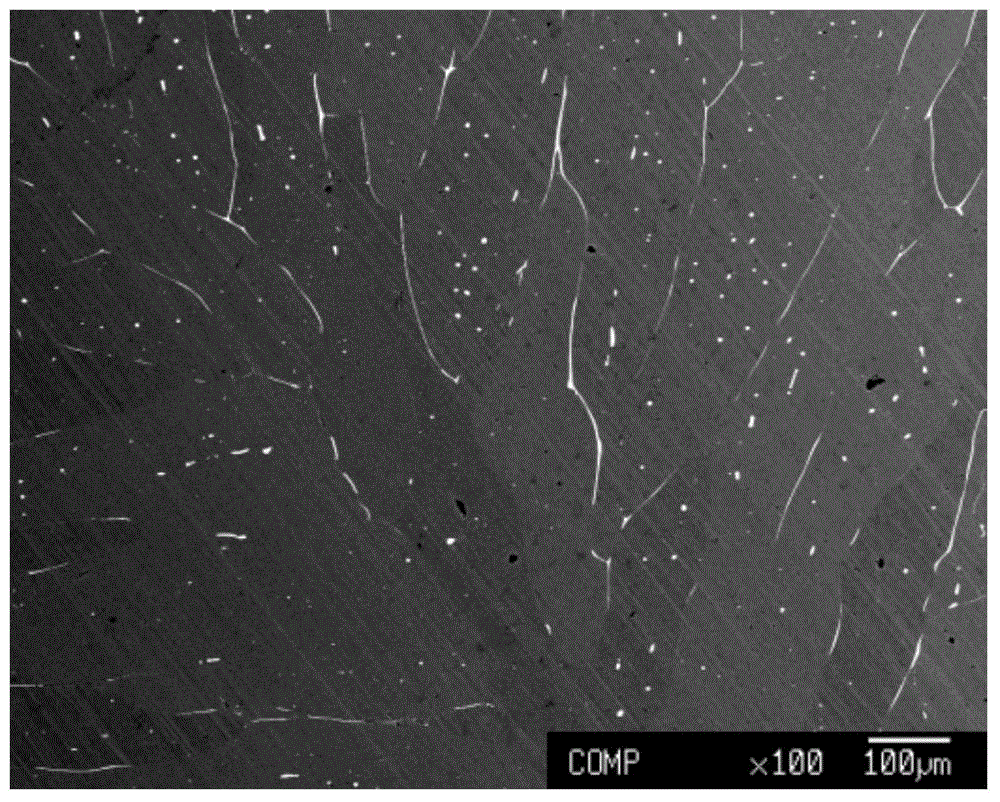

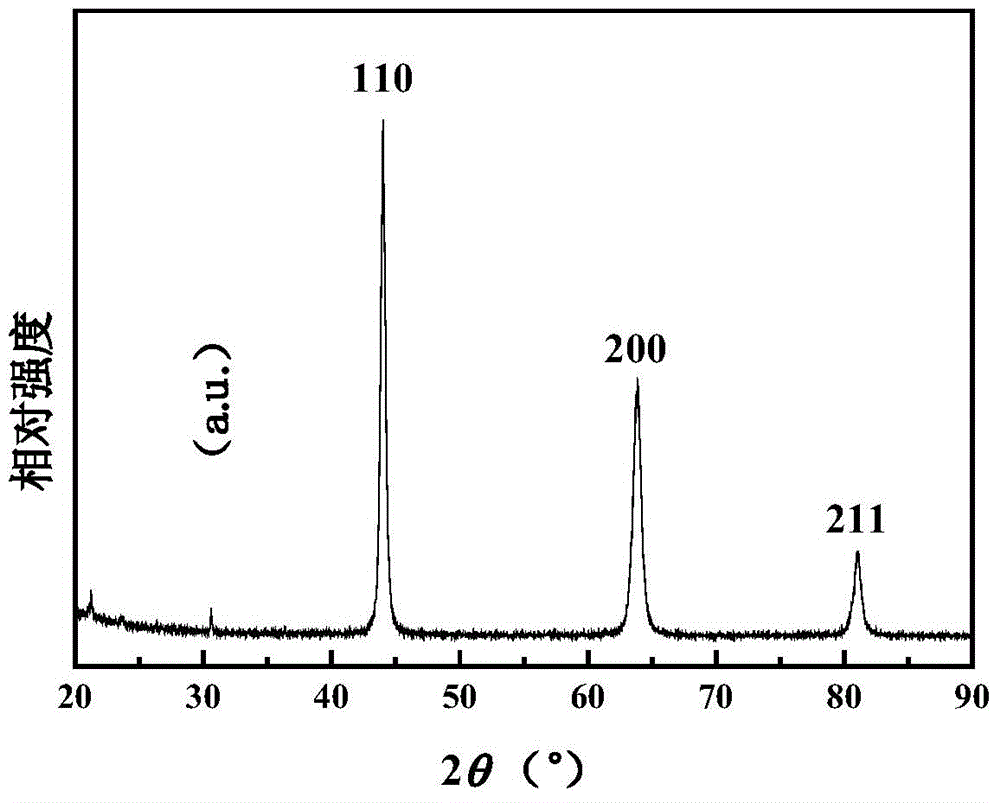

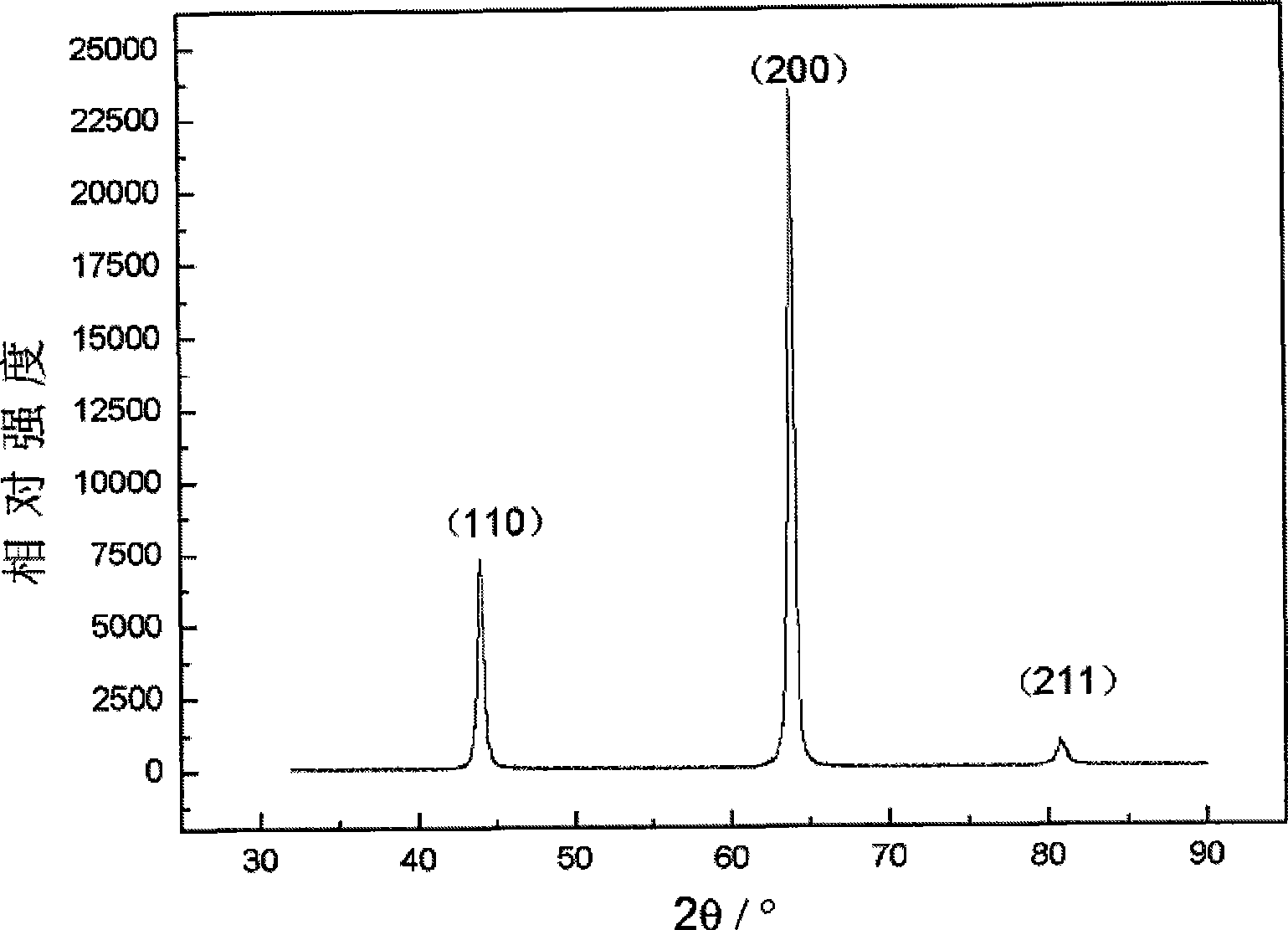

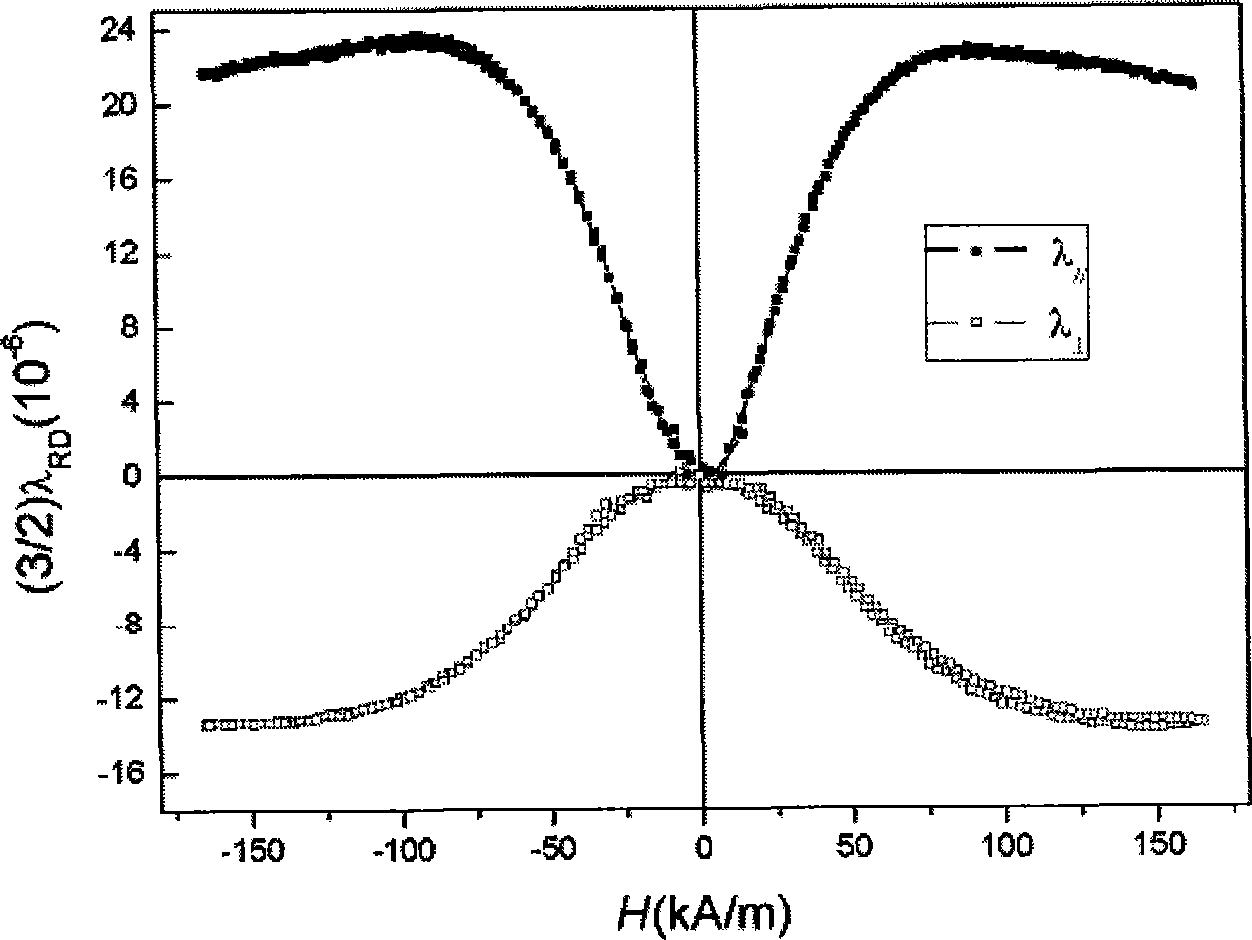

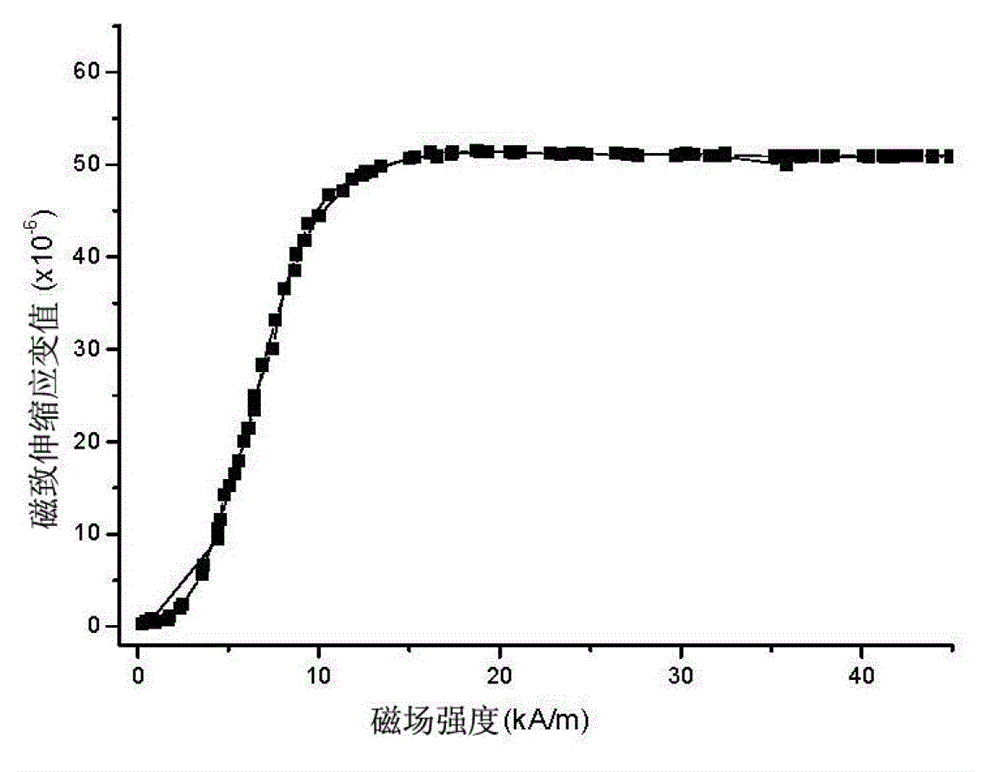

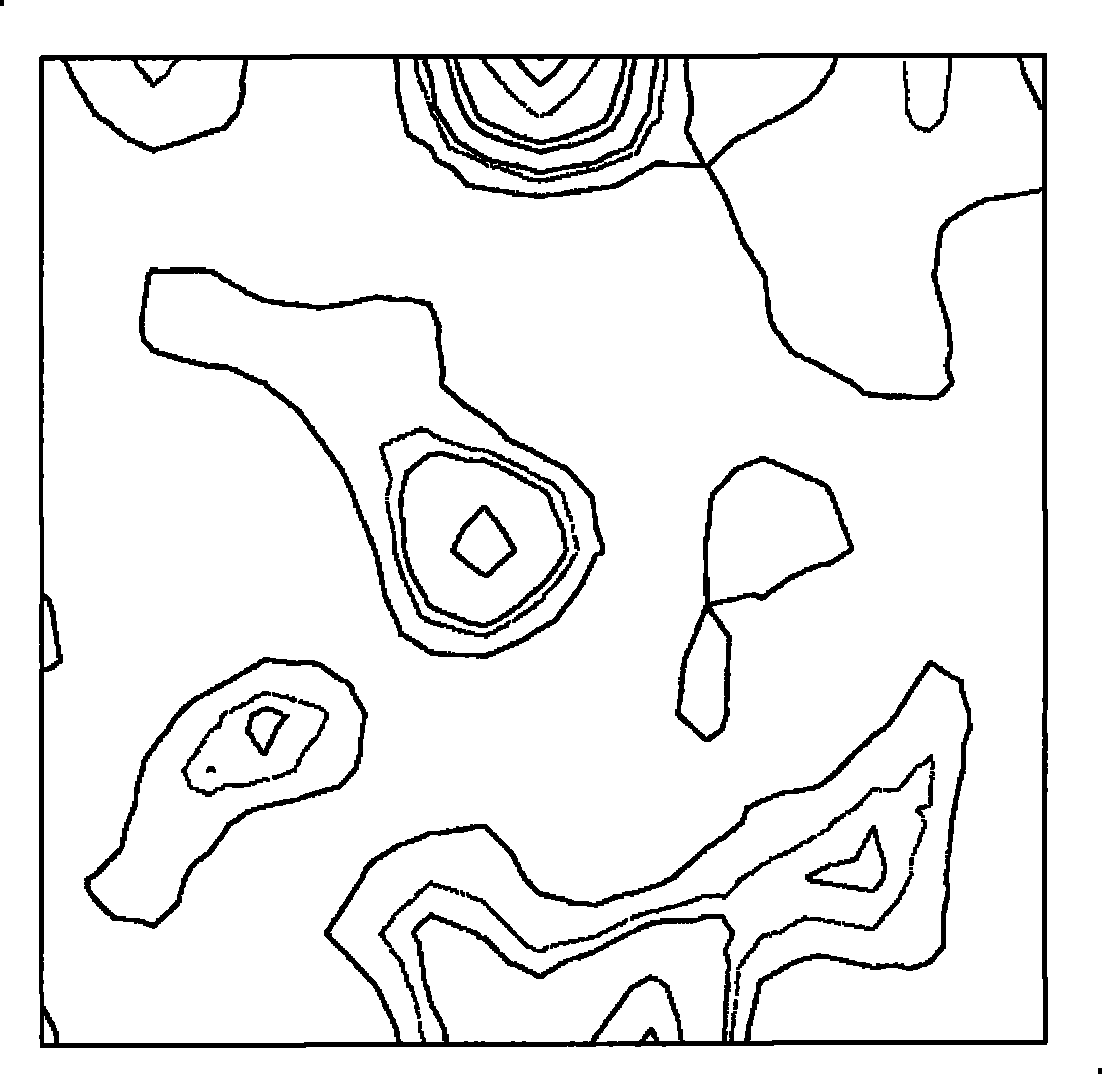

High-performance polycrystal texture Fe-Ga-based magnetic deformation slice material and preparation method thereof

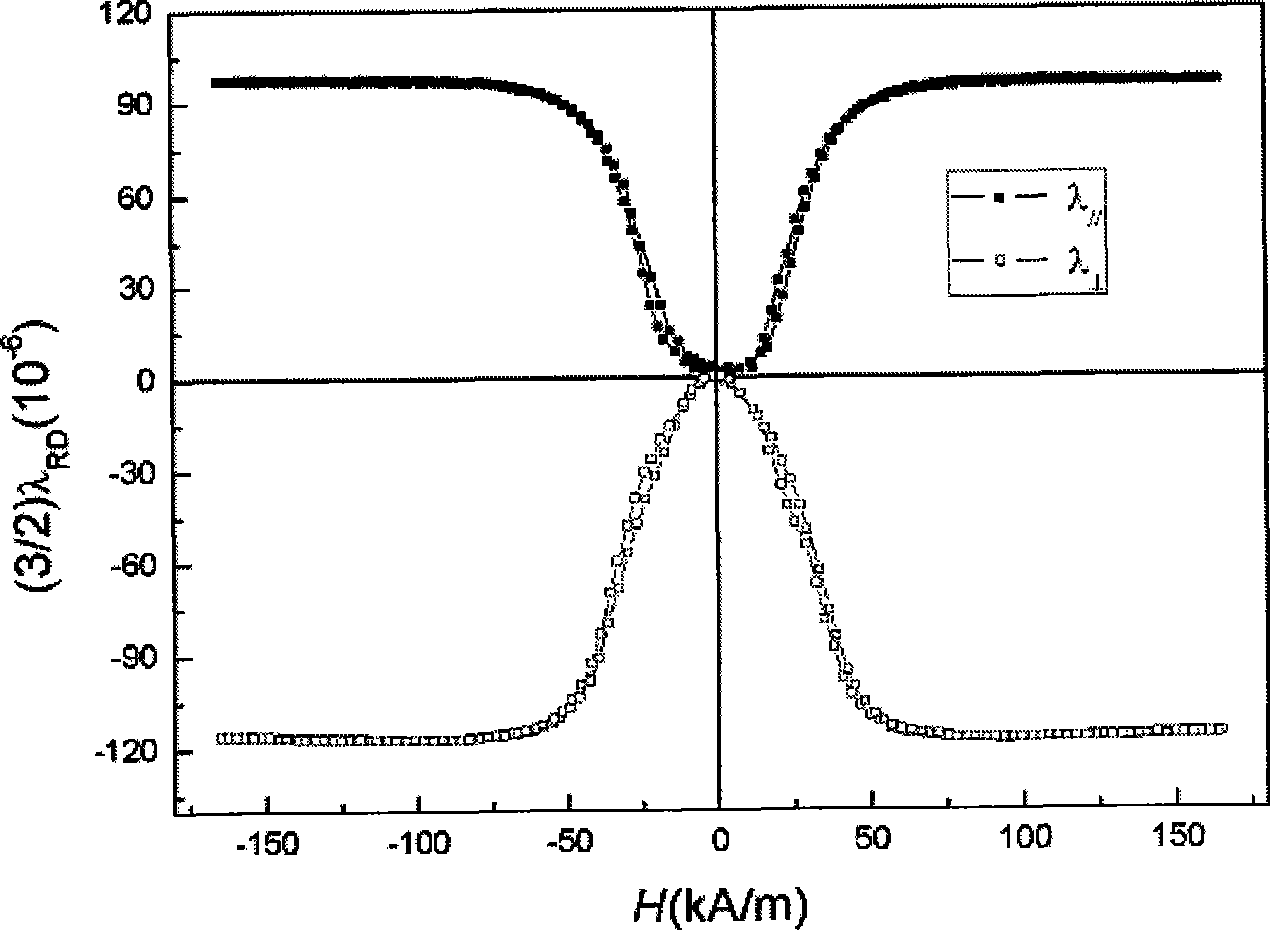

InactiveCN101465406AImprove textureHigh magnetostrictive performancePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyIngotHeat treated

The invention relates to a high-performance polycrystalline texture Fe-Ga-based magnetostrictive thin material and a preparation method thereof; the component of the material is Fe100-x-y-zGaxMyNz; M stands for one or more among B, Nb, Cr, VC, TiC, MnS and AlN; N stands for one or more among S, Sb and Sn; wherein, x is equal to 15-25; y is equal to 0.5-3.0; z is equal to 0.01-0.05; and the residual is iron. The method has the following process key points: based on the requirements of the material composition, melting master alloy; casting alloy ingot; hot-forging and cogging; rolling the material into the appropriate thickness; and a variety of follow-up heat treatment. The Fe-Ga-based magnetostrictive thin material has obvious (100)<001>cubic texture or (110) <001> goss texture; and the maximum magnetostriction coefficient (3 / 2)lambdas is up to 280 multiplying 10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

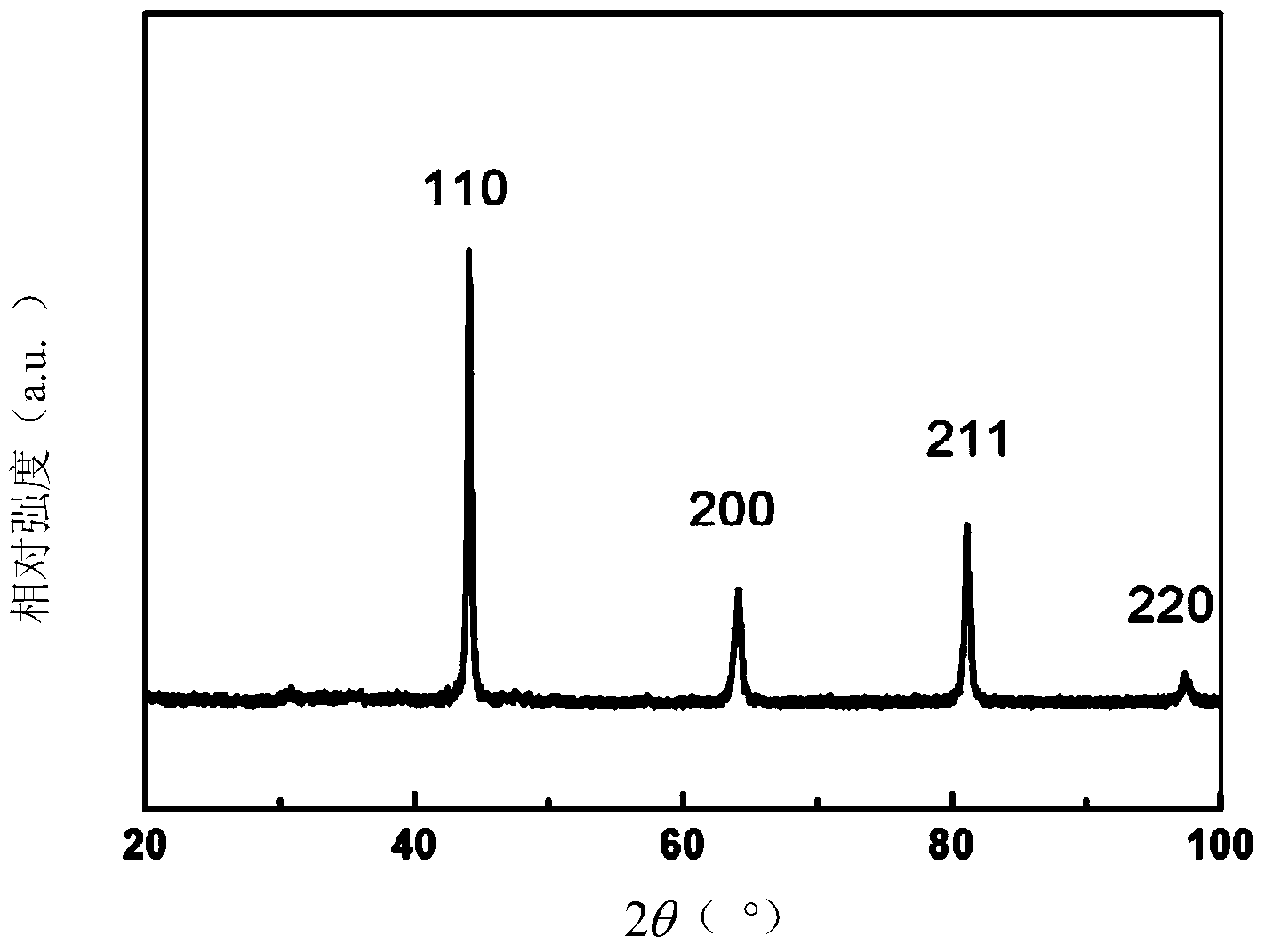

Giant magnetostrictive large volume Fe81Ga19 alloy material and preparation method thereof

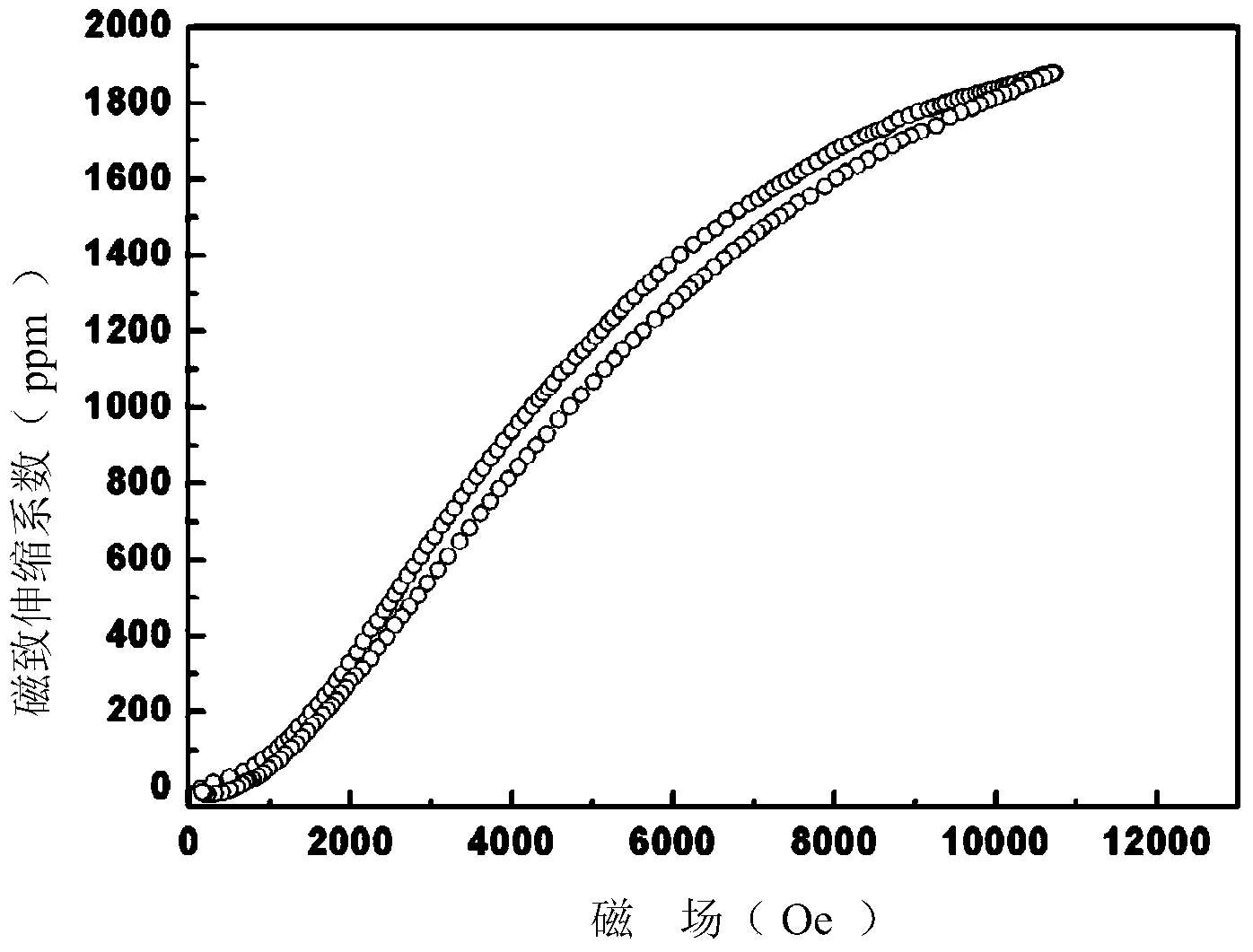

The invention relates to a giant magnetostrictive large volume Fe81Ga19 alloy material and a preparation method thereof, belonging to the technical field of the alloy material and the atom percent of the alloy material is Fe81at.% and Ga19 at.%; the preparation method comprises the steps of Fe element and Ga element arc melting, solidification remelting superheat cycle process and high undercooling activation unidirectional solidification. The invention adopts high undercooling activation process so that Fe-Ga alloy blocks can be obtained while the alloy has the giant magnetostrictive property. The magnetostrictive strain of the Fe-Ga alloy blocks is above 500*10 generally and the maximum magnetostrictive strain can reach 830*10.

Owner:SHANGHAI JIAO TONG UNIV

Magnetostrictive material and preparation method thereof

ActiveCN101654759AImprove plasticityHigh elongationMagnetostrictive material selectionMagnetic layersThin sheetMagnetostriction

The invention relates to a method for preparing a Fe-Ga-Al-based flaky magnetostrictive material from a Fe-Ga-Al-based raw material, and the Fe-Ga-Al-based flaky magnetostrictive material prepared thereby. The component (in atom fraction) of the used Fe-Ga-Al-based raw material is Fe1-x-y-zGaxAlyMz, wherein x is between 0.10 and 0.30, y is between 0.01 and 0.10, z is between 0.001 to 0.05, and M is one or more of V, Cr, Zr, Sb, Sn, Ti, SiC and the like.

Owner:BEIJING MAGORIENTAL MATERIALS TECH CO LTD

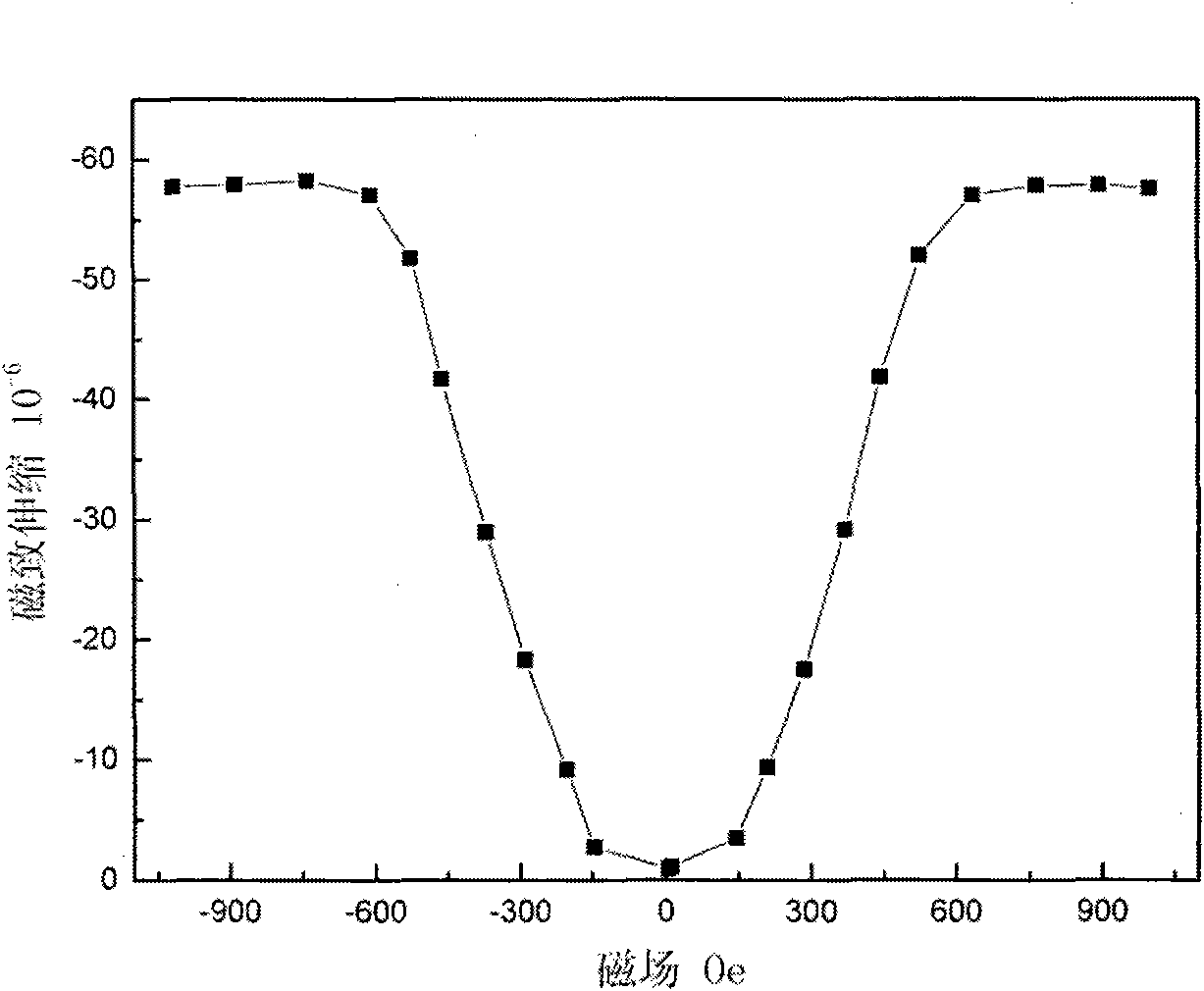

Novel magnetostrictive material designed according to FeGa-RFe2 magnetocrystalline anisotropy compensation principle and preparation method thereof

ActiveCN103556045ALow coercivityHigh magnetostrictive performanceMagnetostrictive material selectionMaterial DesignRare earth

The invention discloses a novel magnetostrictive material designed according to a FeGa-RFe2 magnetocrystalline anisotropy compensation principle and a preparation method thereof. The composition of the magnetostrictive material is (Fe100-XGaX)Y(RFe2)Z, wherein X is more than or equal to 10 and less than or equal to 40, the compensation compositions ratio of Y:Z in a Y-Z regulating pseudo-binary system is 1-20, RFe2 is one or more than one of TbFe2, SmFe2, DyFe2, HoFe2, ErFe2 and TmFe2, and X, Y, and Z are mole percentage contents. In the novel magnetostrictive material designed according to a FeGa-RFe2 magnetocrystalline anisotropy compensation principle, since a trace of rare-earth RFe2 component with large magneto-strain property is added into non-rare-earth FeGa based magnetostrictive alloy compositions, and magnetocrystalline anisotropy compensation is carried out on FeGa compositions, thus obtaining the novel magnetostrictive material with advantageous properties such as large magneto-strain, low drive field, high mechanical property, low cost, and the like.

Owner:BEIHANG UNIV

High specific resistance magnetic striction composite material and preparation

InactiveCN101476079AIncrease resistanceHigh magnetostrictive performanceElectrical resistance and conductanceGranularity

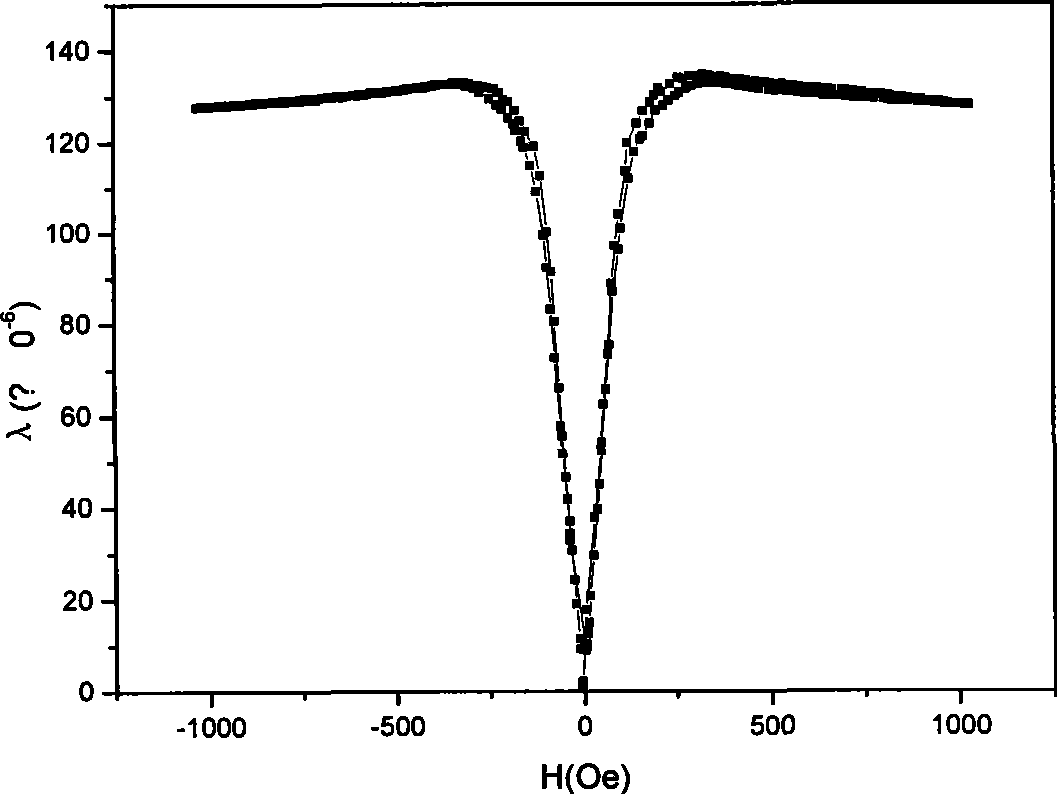

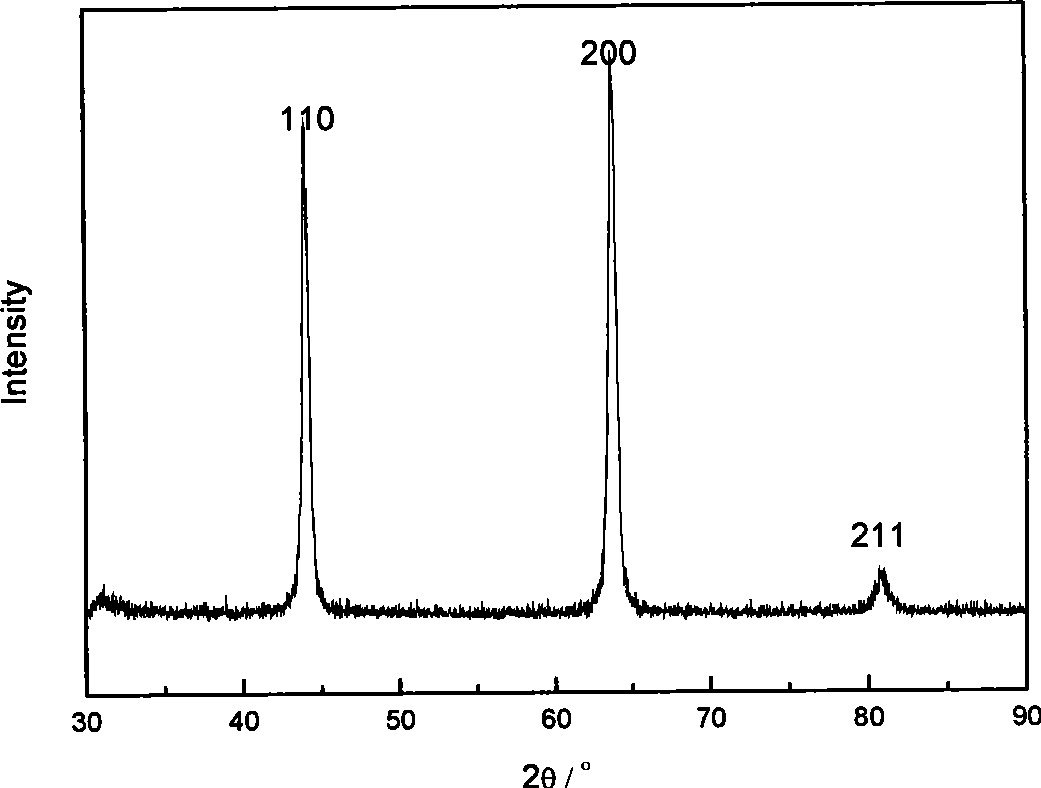

The invention provides a high-resistivity supermagnetostrictive composite material and a method of preparing the same and relates to the components of supermagnetostrictive material and a manufacturing process. The composite material consists of a powdered alloy and a binder, wherein, the component of the powdered alloy is Fe1-x and x is 10-30at%, the binder is a non-metal material. The method comprises steps of smelting the master alloy according to the component of the material, pulverizing the master alloy into powder with the granularity from micrometer to hundreds of micrometers by using gas flow grinding, air atomizing or other methods; mixing the obtained power with a certain amount of binder uniformly, then pressing the mixture for forming.The composite material prepared by a powdered alloy and a binder through an agglutinating technique has a high resistivity which can be up to 48.8 omega*m and a high supermagnetostrictive value and the maximum supermagnetostrictive coefficient can be over 130*10 6.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing magnetostriction material by utilizing spent lithium ion batteries

InactiveCN104600390AHigh magnetostrictive performanceSave energyWaste accumulators reclaimingMagnetostrictive material selectionSodium-ion batteryHYDROSOL

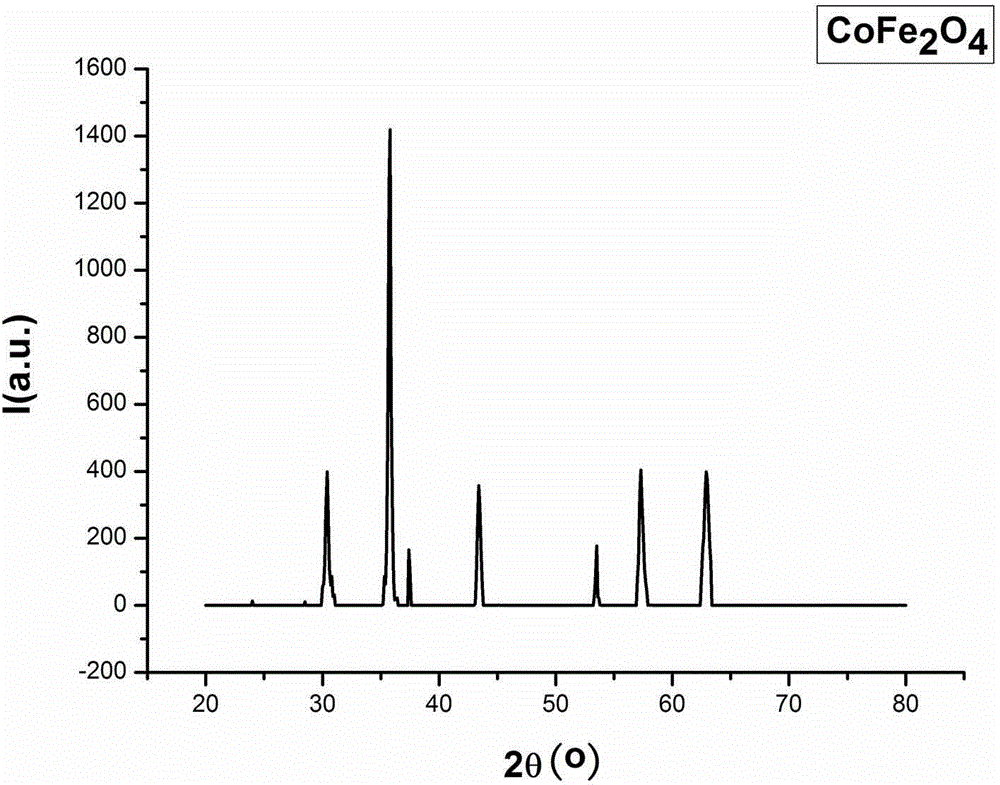

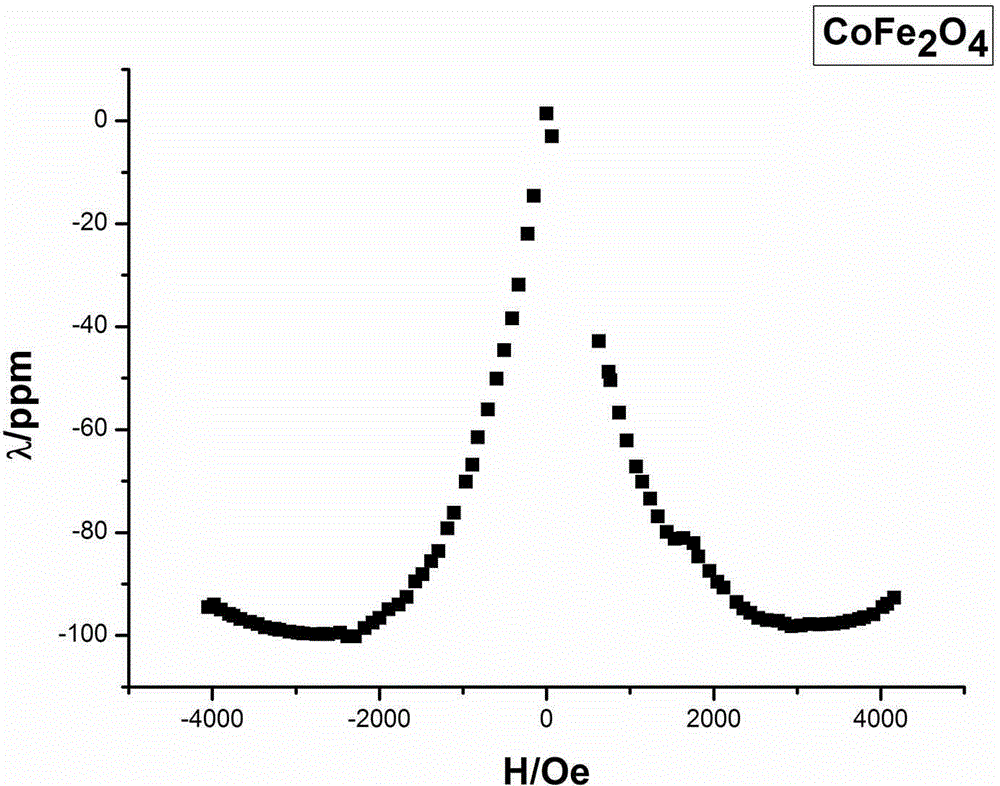

The invention discloses a method for preparing a magnetostriction material by utilizing spent lithium ion batteries, belonging to the technical fields of spent lithium ion battery recycling and preparation of magnetostriction materials. According to the key points of the technical scheme in the invention, the method for preparing the magnetostriction material by utilizing spent lithium ion batteries is characterized in that cobalt ferrite magnetostriction material with high magnetostriction property is obtained through a sol-gel-hydrothermal coupling method by utilizing the spent lithium ion batteries. According to the method disclosed by the invention, the spent lithium ion batteries are recycled, the energy is saved, the environment is protected, and the prepared cobalt ferrite magnetostriction material has high magnetostriction property and has obvious applications in pressure sensors, brakes, non-contact type sensors, sonar probes and magnetic force ejection devices.

Owner:HENAN NORMAL UNIV

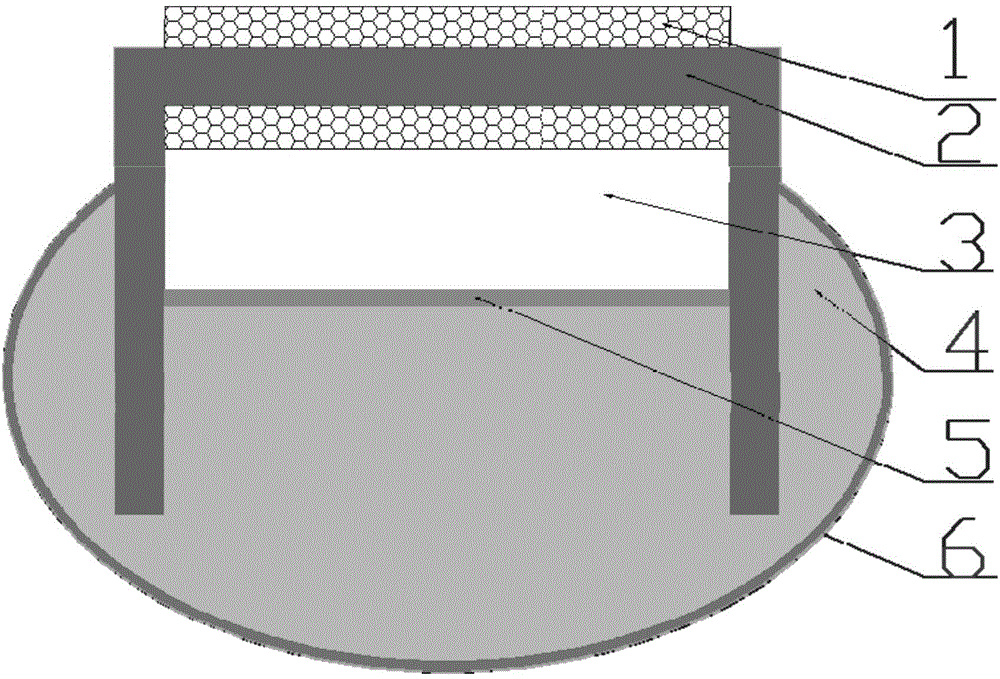

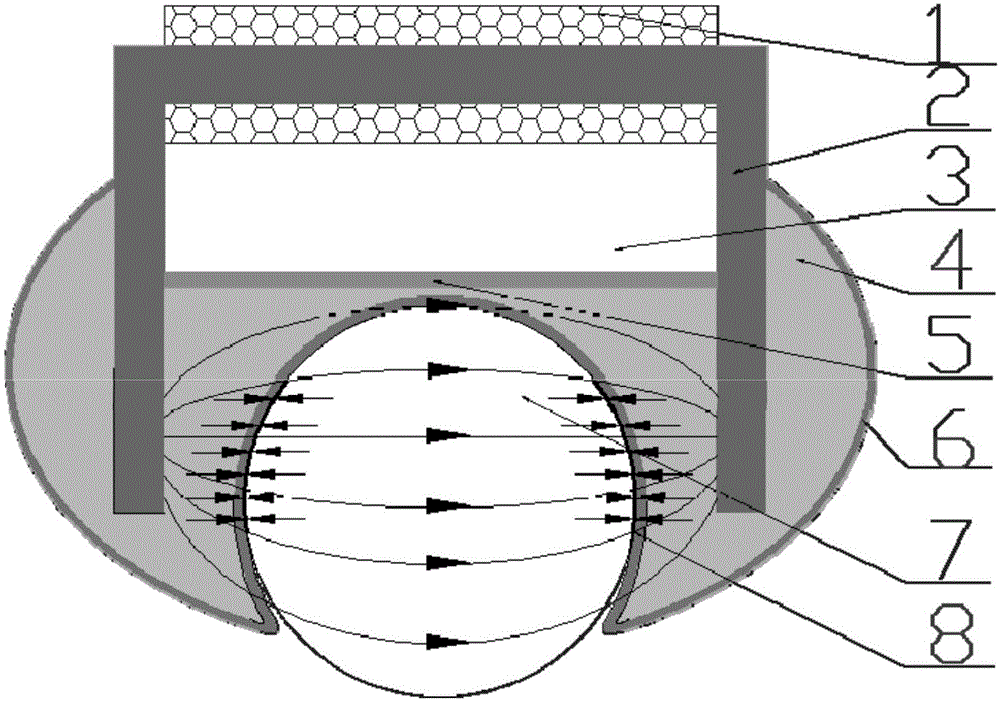

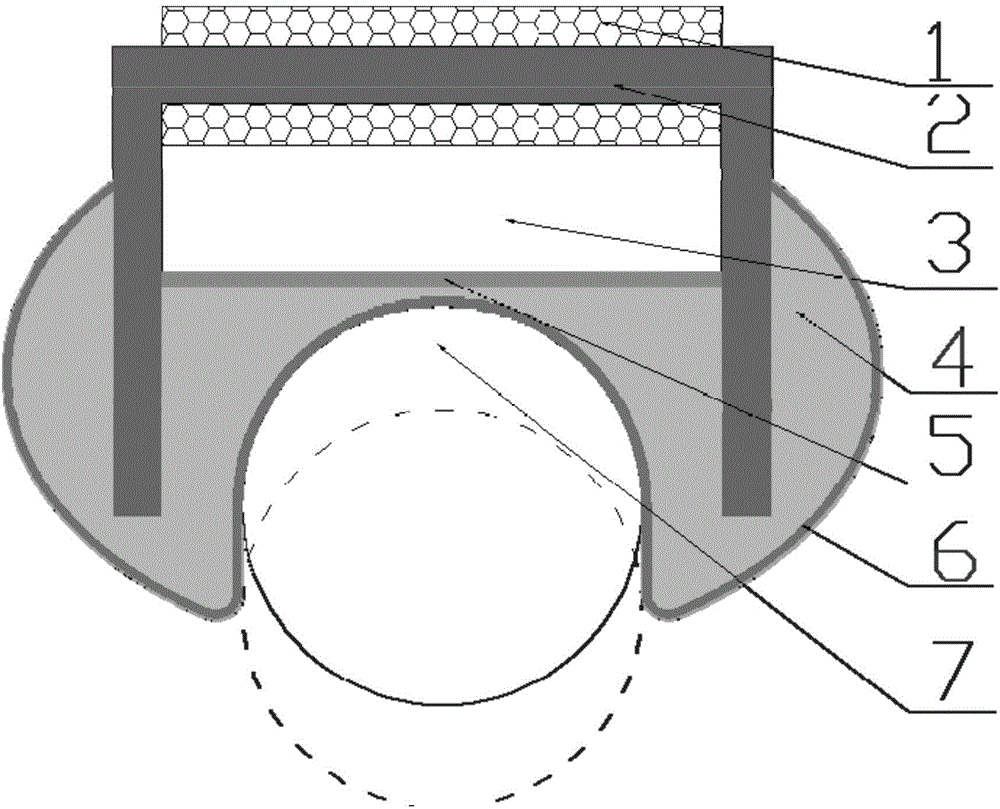

Universal gripper using magneto-rheological plastic body

InactiveCN104057461AImprove plasticityEnhance the magnetorheological effectGripping headsPower flowGrip force

The invention relates to an universal gripper using a magneto-rheological plastic body. The universal gripper comprises a U-shaped supporting frame, a coil, a partitioning plate and a partitioning layer, wherein the coil is wound at the middle part of the supporting frame; the partitioning plate is arranged at the middle part of the supporting frame; the partitioning layer is formed among the partitioning plate, the coil and the U-shaped supporting frame; a charging battery and a current control circuit are placed in the partitioning layer; a rubber jacket is tightly coated outside; the high-performance magneto-rheological plastic body is filled between the U-shaped bracket and the rubber jacket. The universal gripper has the advantages that the gripping force can be adjusted; the shape of the gripper can be changed to enable the gripper to be better attached to the surface of an object; in addition, the whole structure is simple and the manufacturing cost is lower.

Owner:UNIV OF SCI & TECH OF CHINA

High temperature radiation resistant magnetostriction alloy

ActiveCN103556071AHigh curie temperatureGood radiation resistanceMagnetostrictive device manufacture/assemblyMagnetostrictive material selectionHigh dosesChemical composition

The invention discloses a high temperature radiation resistant magnetostriction alloy as well as a preparation method thereof. The alloy comprises the following chemical components in percent by weight: 43.0-66.0% of Ni, 0-5.0% of Cr, 1.0-3.5% of Mo, 1.0-3.0% of Ti, 0-1.0% of Al and the balance of Fe. The high temperature radiation resistant magnetostriction alloy disclosed by the invention has higher Curie temperature, good magnetostriction performance in a wider temperature range and great saturated magnetostriction coefficient, is excellent in resistance to radiation in a reactor and free from irradiation activation or disintegration caused by high dose of neutrons or gamma rays, and can satisfy the using demands of great irradiation dose at high temperatures of a reactor core of the reactor.

Owner:CHONGQING MATERIALS RES INST

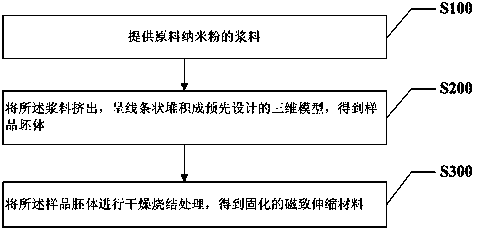

Preparation method for magnetostrictive material and magnetostrictive material

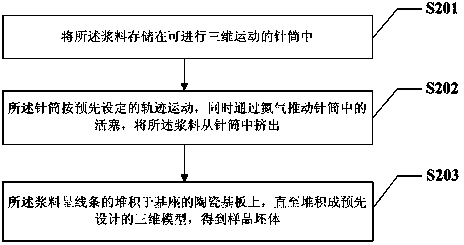

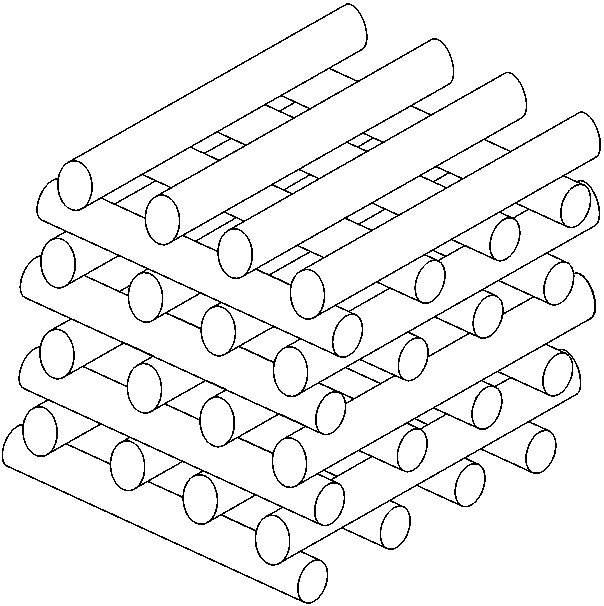

InactiveCN104201279ASimple processReduce manufacturing costMagnetostrictive material selectionSlurryNanotechnology

The invention discloses a preparation method for magnetostrictive material and the magnetostrictive material. The preparation method for the magnetostrictive material includes that providing raw material nanometer powder slurry; extruding the slurry, accumulating in linear shape to form a pre-designed three-dimensional model to obtain a sample blank; drying and sintering the sample blank to obtain the cured magnetostrictive material. The preparation method for the magnetostrictive material realizes to manufacture the magnetostrictive material through a three-dimensional mold-less slurry direct-write forming technique, the technique is simple and controlled through program, and different slurry and structure models can be prepared according to needs; the preparation method for the magnetostrictive material manufactures the magnetostrictive material with the complex grid structure in one time, and accordingly the production cost is lowered, the agility is improved, and the magnetostrictive characteristic is greatly improved.

Owner:SHENZHEN QINGYAN HUACHUANG NEW MATERIAL

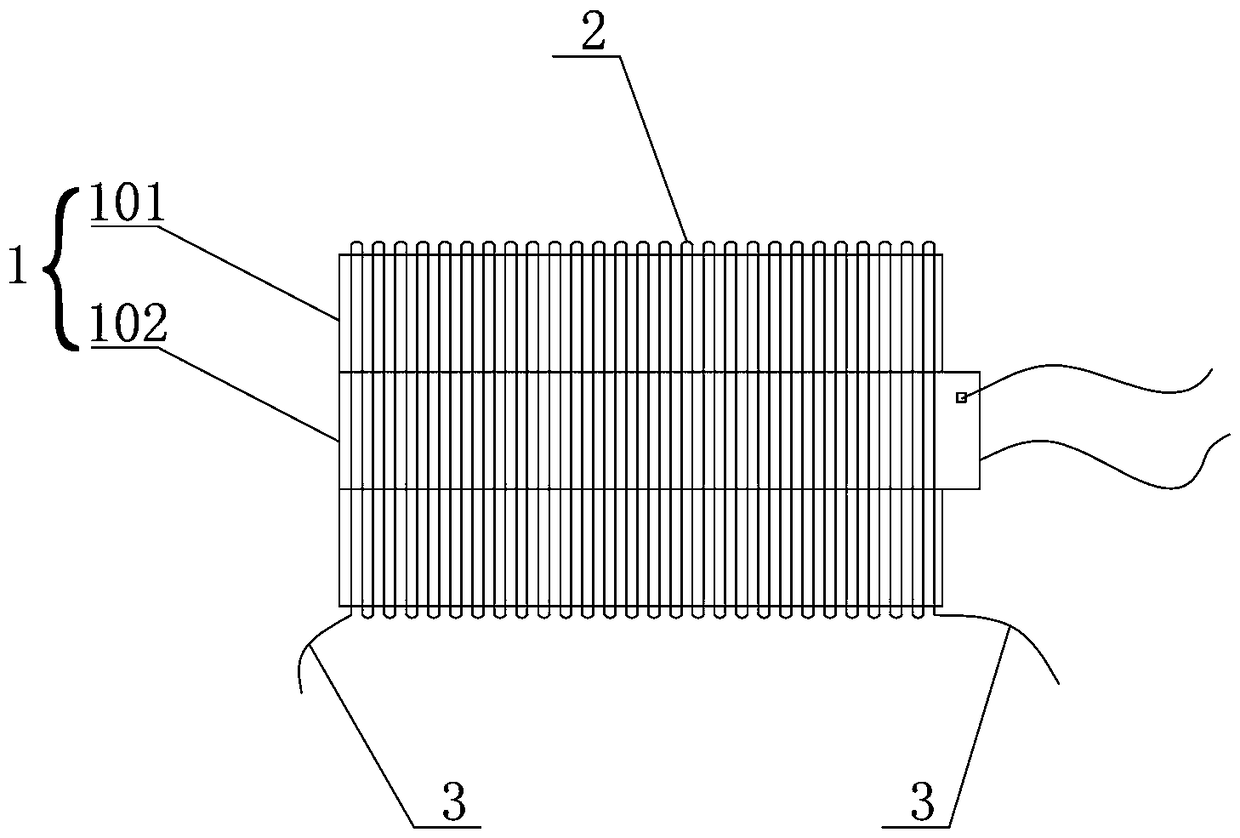

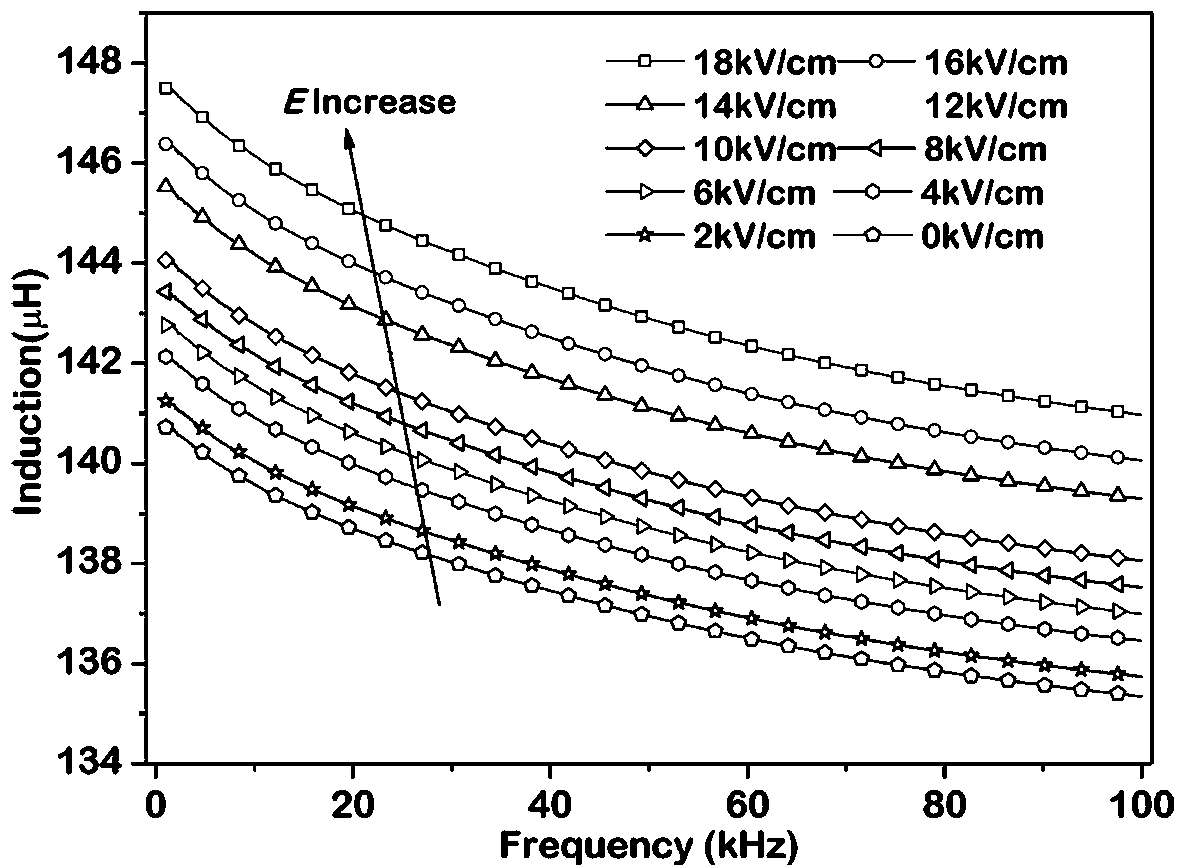

A bi-directionally adjustable magnetoelectric inductor

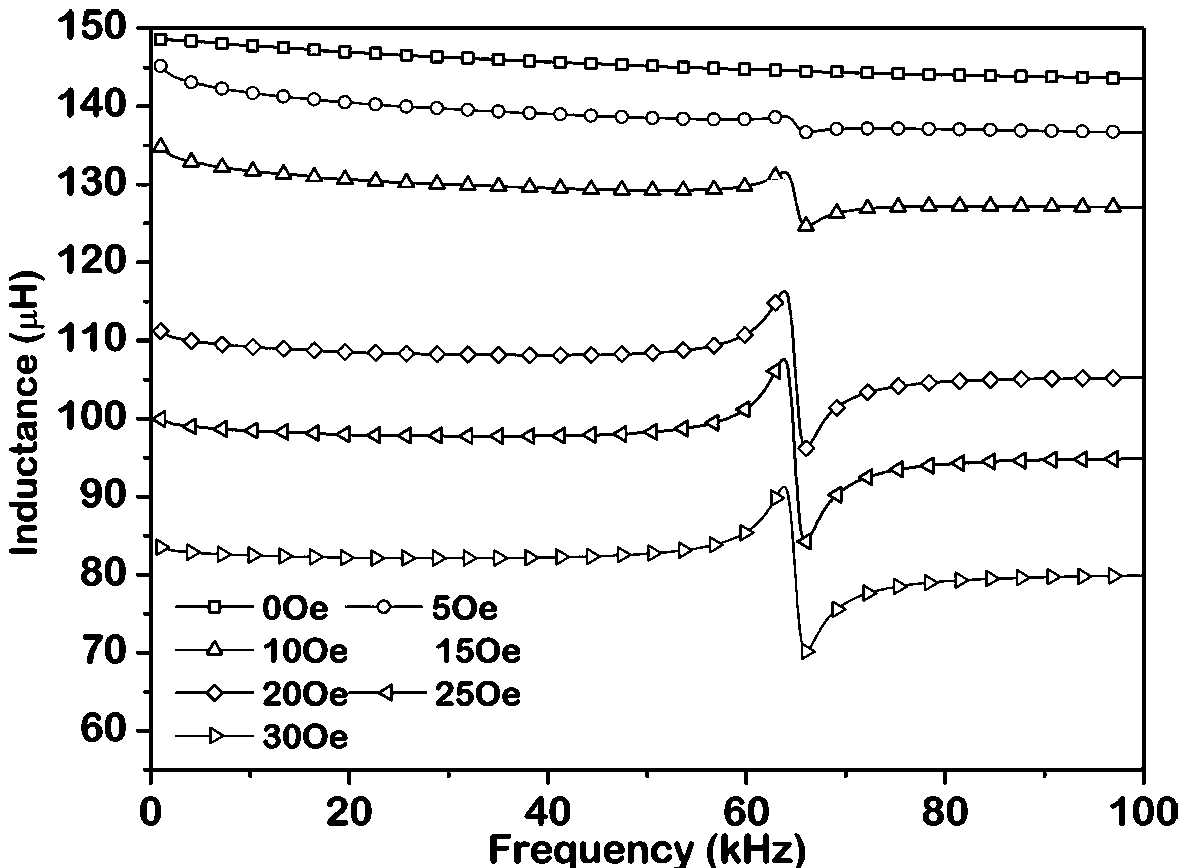

ActiveCN109003780AHigh magnetostrictive performanceGood dynamic shrinkage performanceTransformers/inductances magnetic coresElectric component structural associationInductorComposite element

The invention belongs to the technical field of electronic components, and discloses a bi-directionally adjustable magnetoelectric inductor, comprising a layered magnetoelectric composite element anda copper coil uniformly wound around the periphery of the layered magnetoelectric composite element. The layered magnetoelectric composite element comprises a rectangular ferromagnetic element and a rectangular piezoelectric element, wherein the rectangular ferromagnetic element forms a sandwich-shaped symmetrical structure on the upper and lower sides of the rectangular piezoelectric element; andthe material of the rectangular ferromagnetic element is a Ga-doped nickel-zinc ferrite material, and the material of the rectangular piezoelectric element is PZT-8. Elongation or shortening of a magnetostrictive layer is caused by an additional electric / magnetic field to change the magnetic permeability so as to correspond to the increase or decrease of the inductance of a peripheral closely-wound coil, thereby realizing the bi-directional adjustability of inductance under the control of an external field, the adjustment mode is expanded and the application range of the adjustable inductanceis expanded.

Owner:河南北斗电气设备有限公司

High temperature FeNiCo magnetostriction alloy as well as preparation method thereof

ActiveCN103556005AImprove magnetic propertiesMeet the requirements of high temperature useChemical compositionCurie temperature

The invention discloses a high temperature FeNiCo magnetostriction alloy as well as a preparation method thereof. The alloy comprises the following chemical components in percent by weight: 30.0-55.0% of Ni, 1.0-22.0% of Co, 1.0-3.5% of Cr, 1.0-3.5% of Mo, 1.0-3.0% of Ti, 0-2.0% of Al, 0-0.006% of B and the balance of Fe. The high temperature magnetostriction alloy disclosed by the invention has high Curie temperature, good magnetic performance and great saturated magnetostriction coefficient in a relatively wide temperature range, and can satisfy the using demands of high precision instruments and meters at high temperatures.

Owner:CHONGQING MATERIALS RES INST

Fe-Al-B magnetostrictive thin piece material and preparation method thereof

InactiveCN102943202ASimple manufacturing processImprove plasticityMagnetostrictive material selectionComposite materialMagnetostriction

Owner:无锡正一生源科技有限公司

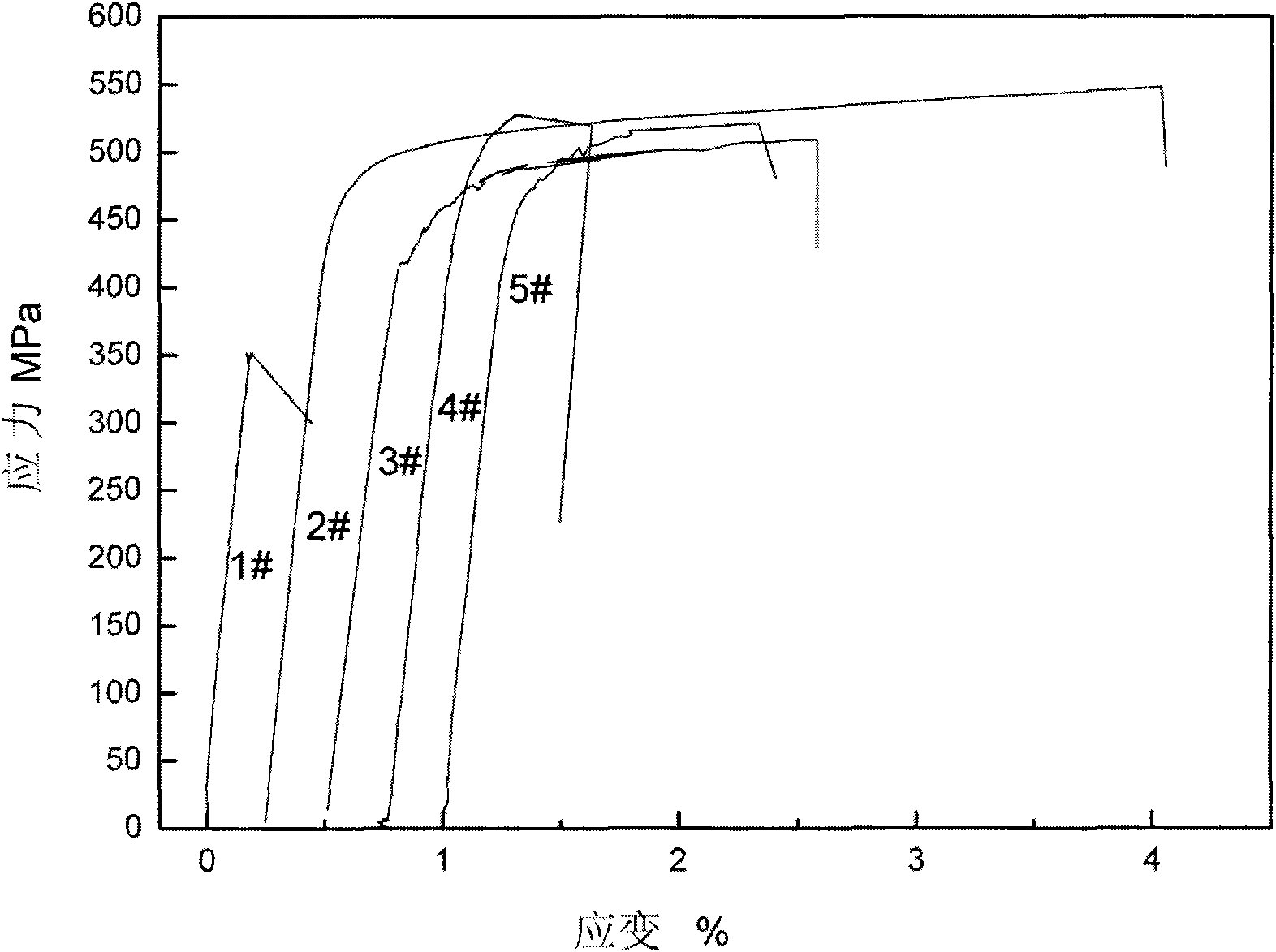

High-plasticity magnetostrictive material and preparation method thereof

ActiveCN106957986AGood mechanical propertiesSimple processMagnetostrictive material selectionAdditive ingredientCrucible

The invention provides a high-plasticity magnetostrictive material and a preparation method of the high-plasticity magnetostrictive material. The chemical formula of the high-plasticity magnetostrictive material is Fe100-xGaxREy, wherein x is larger than or equal to 16.9 and smaller than or equal to 20.6 or is larger than or equal to 22.5 and smaller than or equal to 28.5, y is larger than or equal to 0.01 and smaller than or equal to 1, and RE is selected from one or more of Tb, Dy, Ho, Nd, Pr and Ce. After the Fe, Ga and RE raw materials which are prepared according to ingredient requirements are smelted to be a master alloy ingot, the master alloy ingot is smelted and prepared to be a master alloy bar through vacuum suction casting, then, the master alloy bar is placed into a crucible sleeved with a heat insulation sleeve, the master alloy bar is heated to be completely smelted, the smelted materials are drawn into cooling liquid for directional solidification, and the high-plasticity magnetostrictive material is prepared. The high-plasticity magnetostrictive material has both the excellent magnetostriction property and mechanical property.

Owner:BEIHANG UNIV

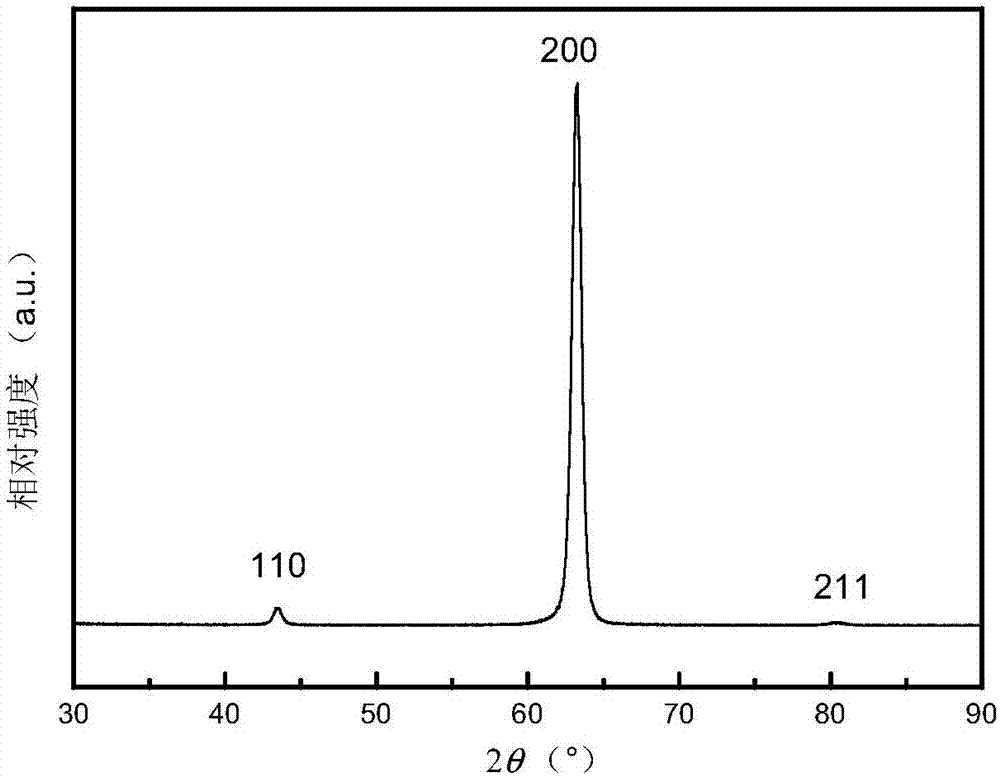

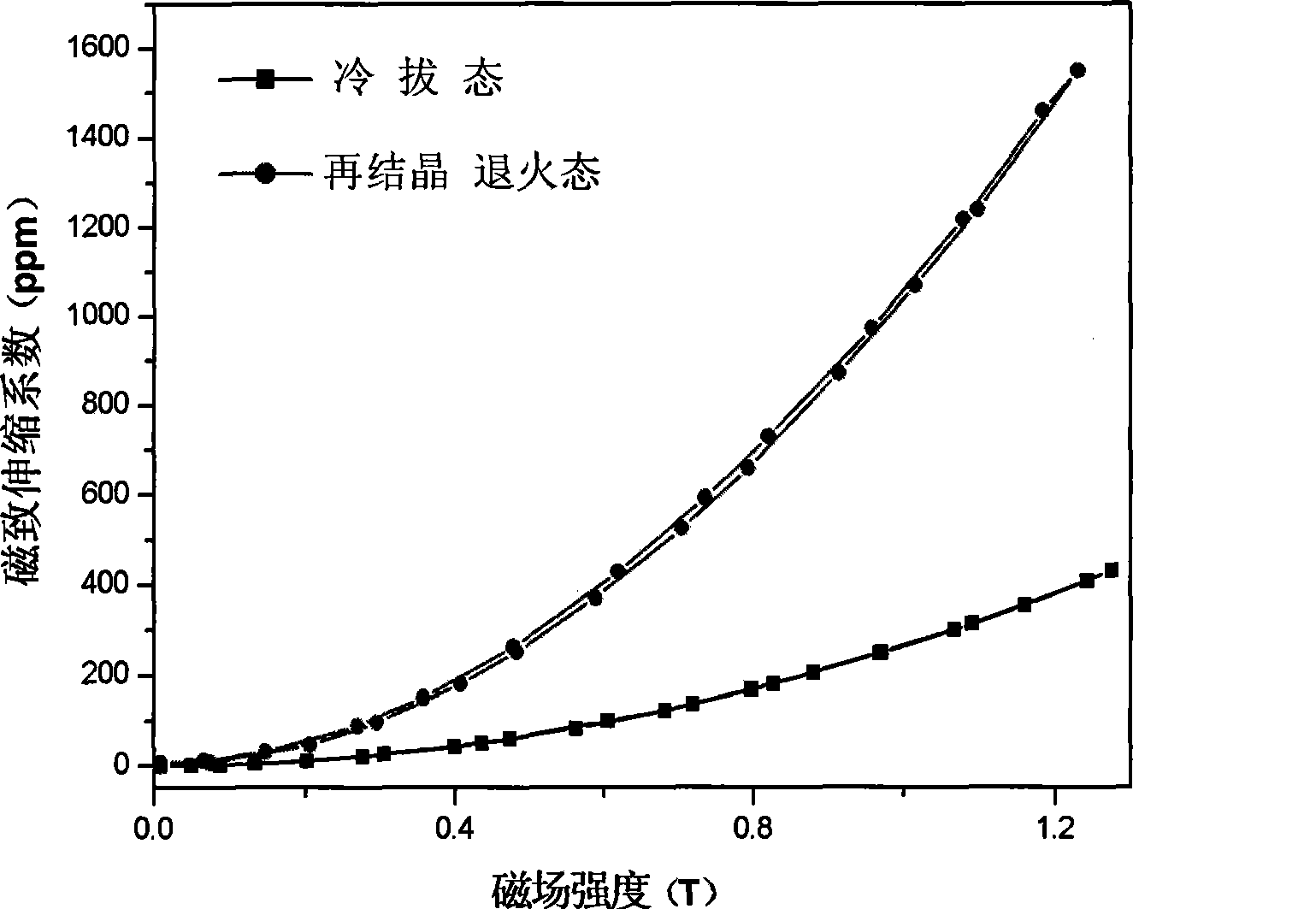

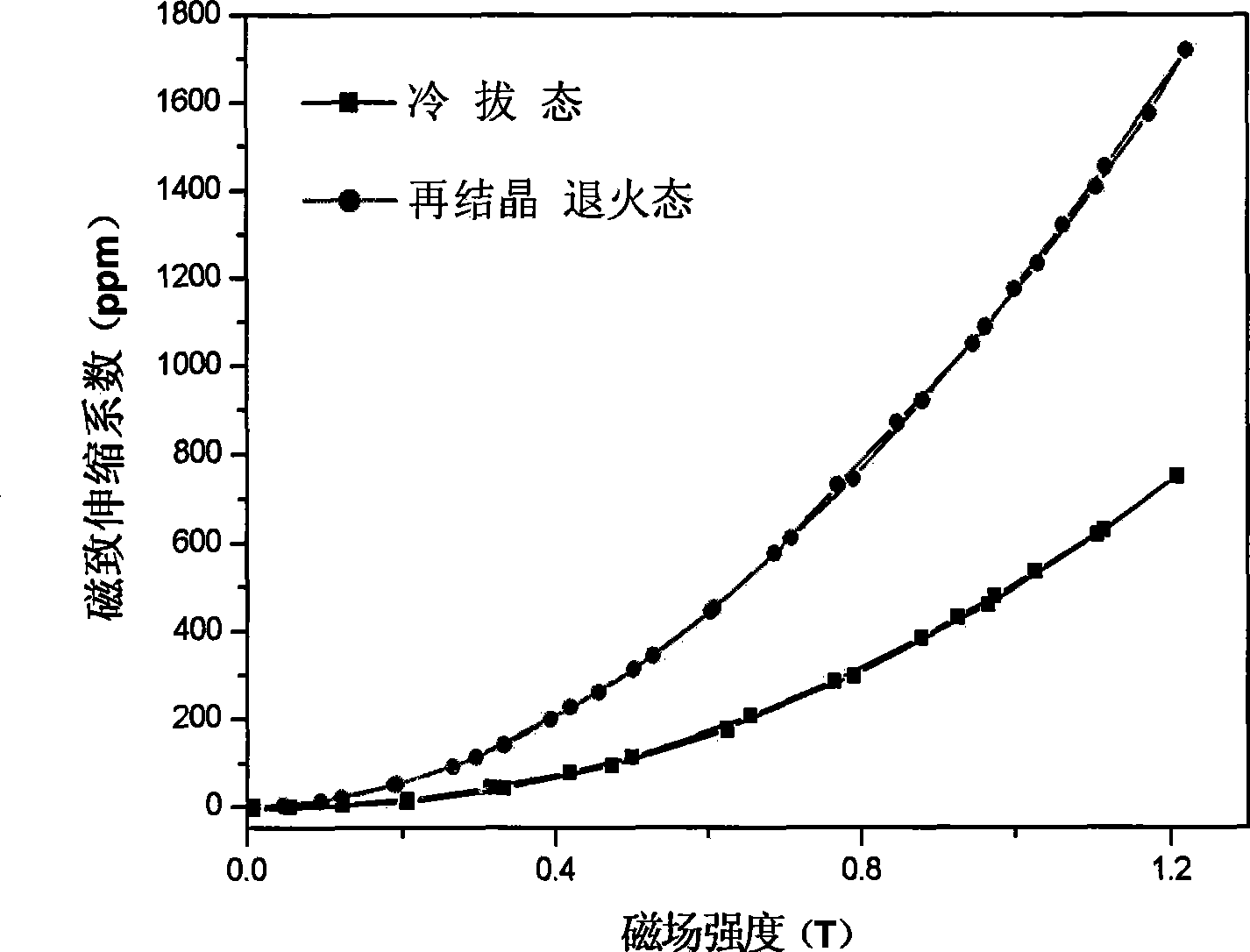

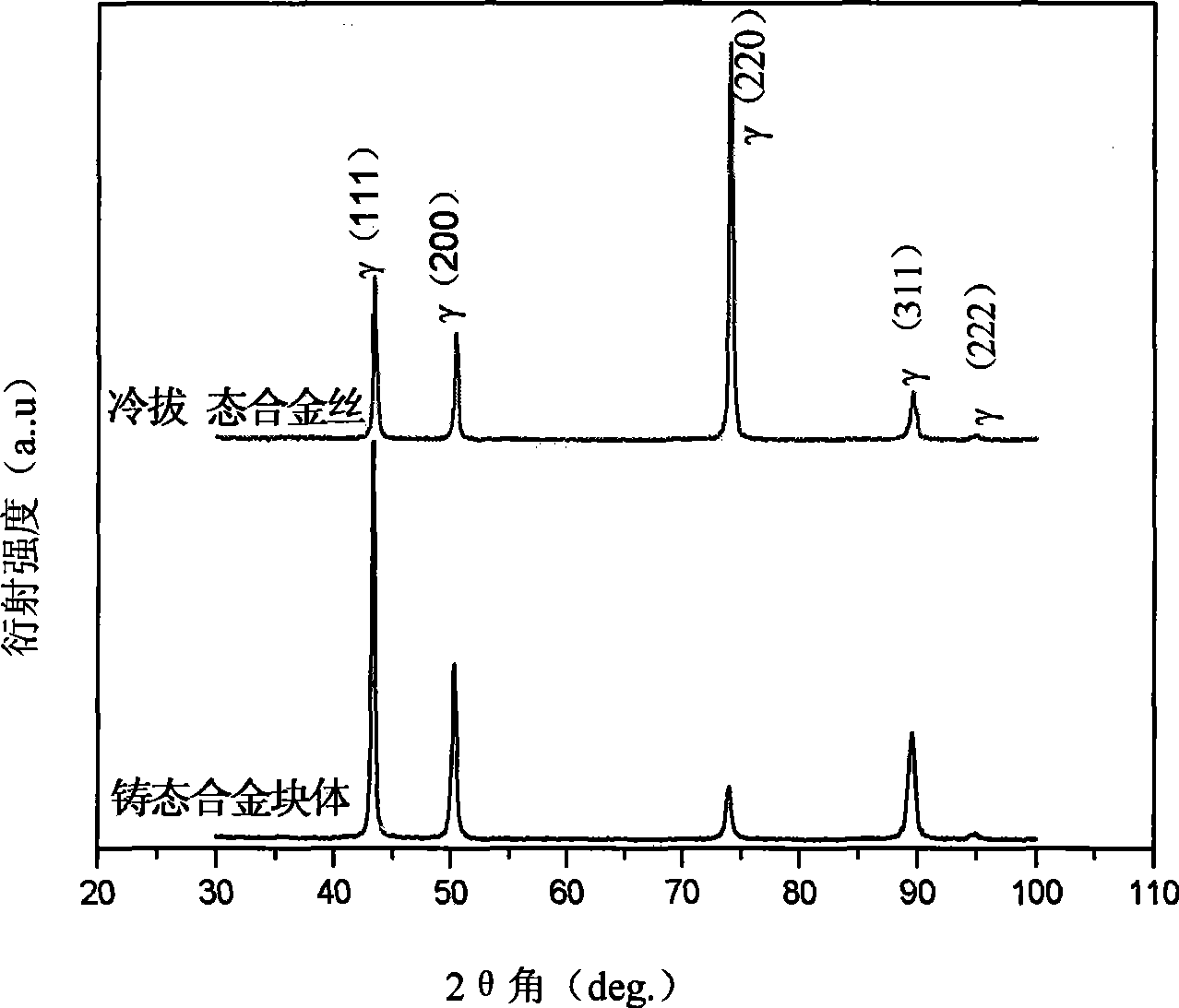

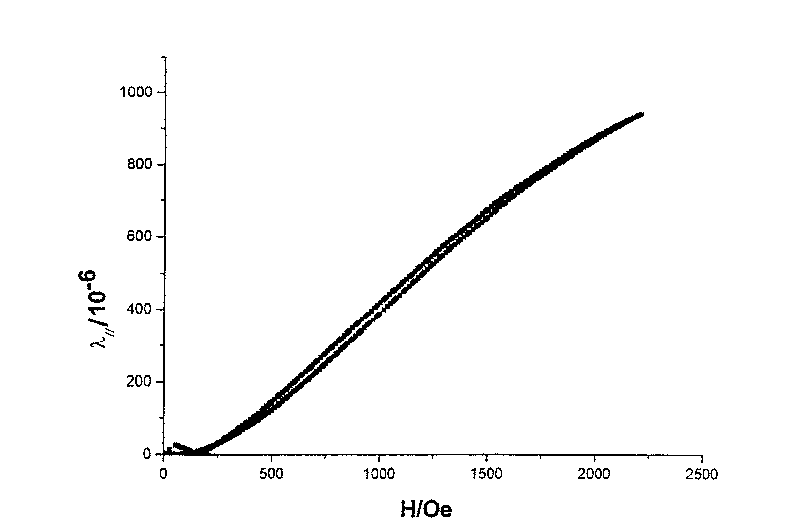

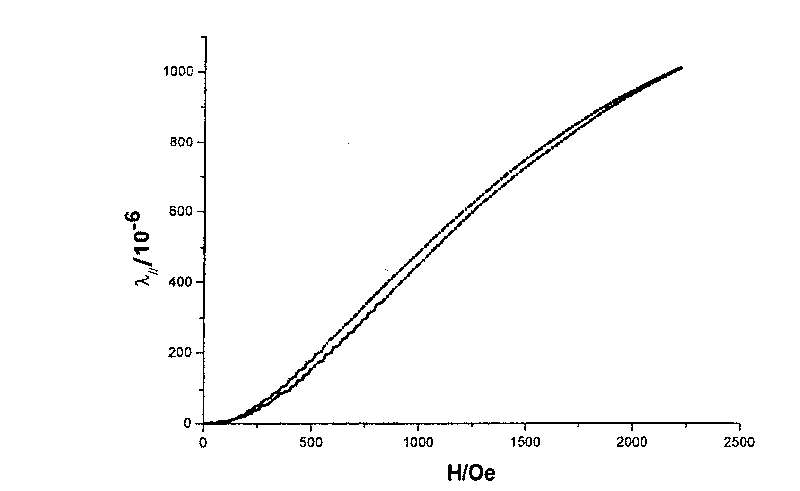

Preparation of giant magnetostriction alloy wire

The invention discloses a method for preparing a large magnetostriction alloy wire, which comprises the following steps: (1) smelting of a cast rod; (2) uniformity of the compositions; (3) milling; (4) cold rolling; (5) wire cutting; (6) relief annealing; (7) cold drawing; and (8) recrystallization annealing. The method adopts a plastic working process combining cold rolling and cold drawing and can prepare the novel Fe-Mn magnetostriction alloy wire with large magnetostriction at the room temperature. The alloy comprises the following compositions and atoms in percentage: 30 to 60 percent of iron and 70 to 40 percent of manganese. The Fe-Mn magnetostriction alloy wire can generate large magnetostriction between 456 and 1,660 ppm in the environment of 1.2T external magnetic field. The preparation method has low energy consumption, reduces the production cost of the Fe-Mn alloy wire, can adjust the size of the alloy wire within a large range, is convenient for the design of miniature devices, and widens the use field of magnetostriction materials.

Owner:ZHEJIANG UNIV

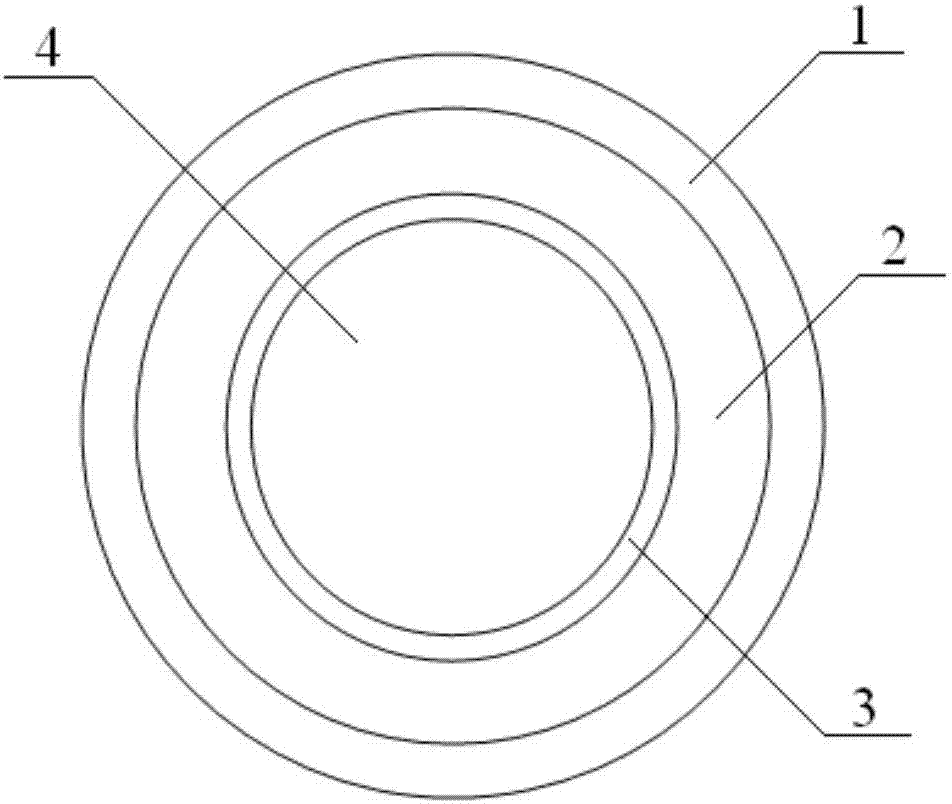

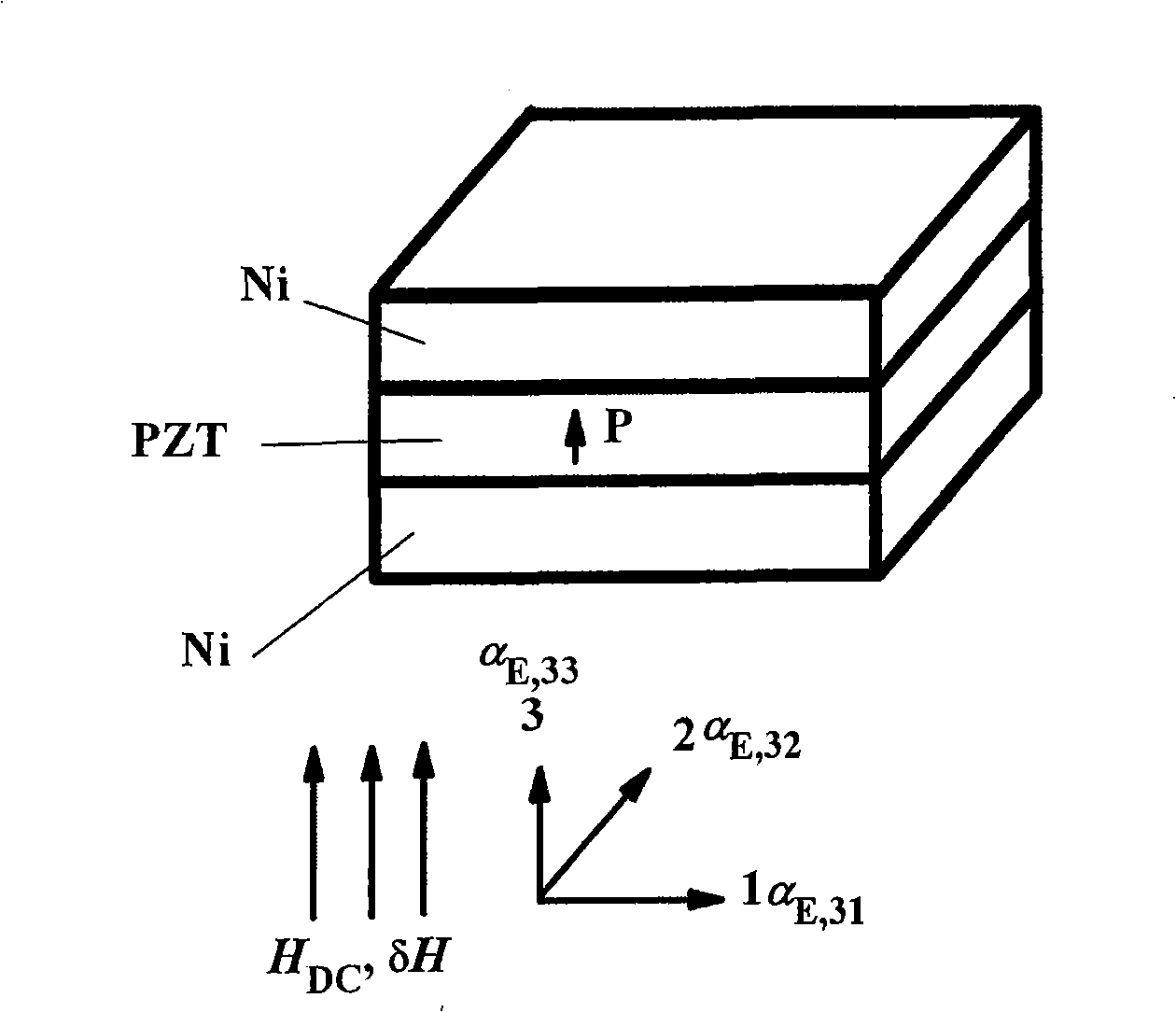

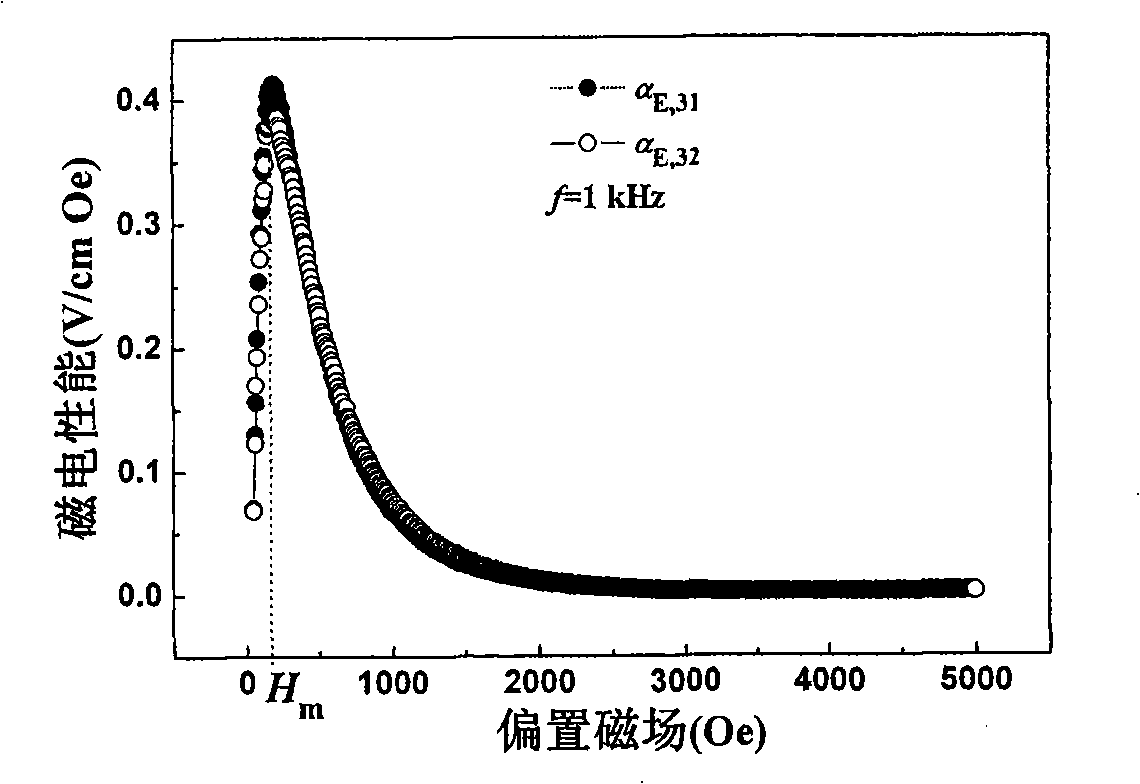

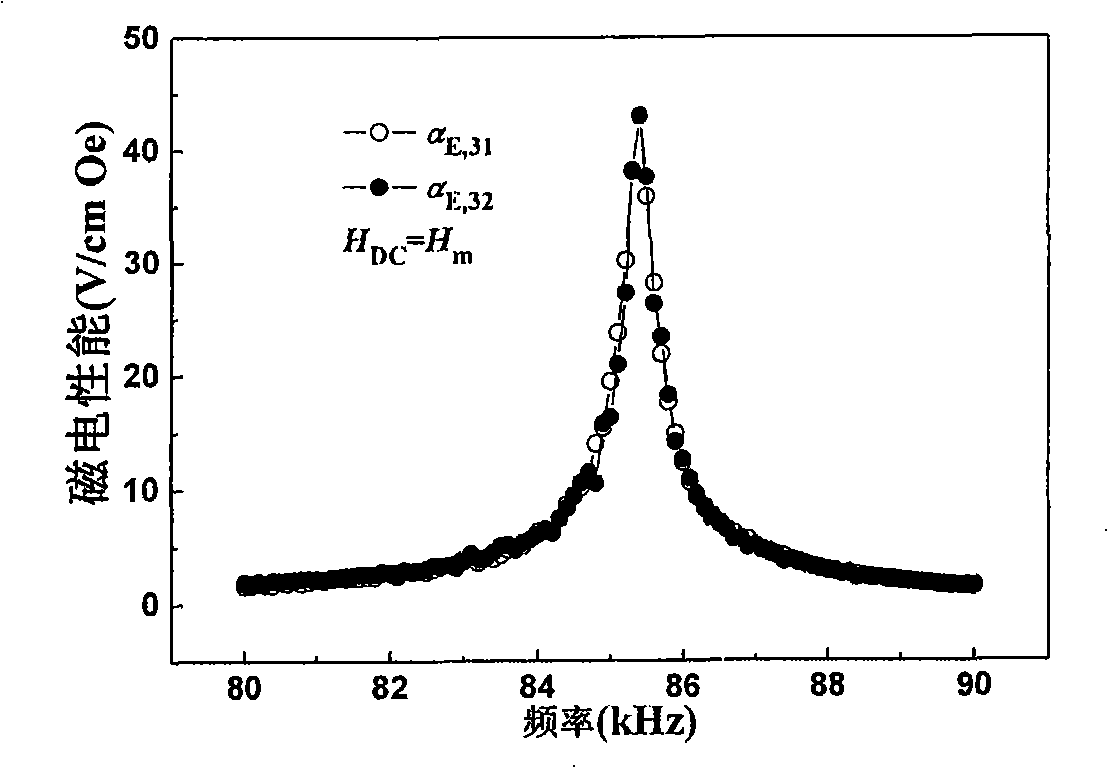

Method for designing and preparing spherical shell layered magnetoelectric composite material structure

InactiveCN101330124AHigh modulus of elasticityImprove magnetoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCompression moldingChemical plating

The invention discloses a spherical shell laminar magneto-electric composite material structure and a manufacturing method, and relates to the design and manufacture method of an isotropic magneto-electric effect laminar magneto-electric composite material structure. The method comprises the following steps: hemispherical shell piezoelectric ceramic is achieved through compression molding and sintering, after the high-temperature polarizing is performed, metallizing is performed by adopting the chemical plating method, two metallized piezoelectric ceramic hemispherical shells are bonded into a complete piezoelectric ceramic hemispherical shell through the strong glue, and then the shell is laid in the prepared electroplating solution to be electroplated till a magnetic layer with the required thickness is electroplated, thereby the spherical shell laminar magneto-electric composite material is achieved. Compared with the prior simple laminar composite material, such as a flat plate, because the dimensions of the structure in the three-dimensional direction are identical, the magneto-electric performances of the structure in all directions are identical, and by adopting the isotropic magneto-electric performance, the spherical shell laminar magneto-electric composite material can be applied to the magnetic field detection in the unknown directions.

Owner:UNIV OF SCI & TECH BEIJING

High-performance polycrystal texture Fe-Ga-based magnetic deformation slice material and preparation method thereof

InactiveCN101465406BHigh magnetostrictive performanceIdeal texturePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyIngotHeat treated

Owner:UNIV OF SCI & TECH BEIJING

High-performance rare-earth-iron-based giant magnetostrictive material and preparation method thereof

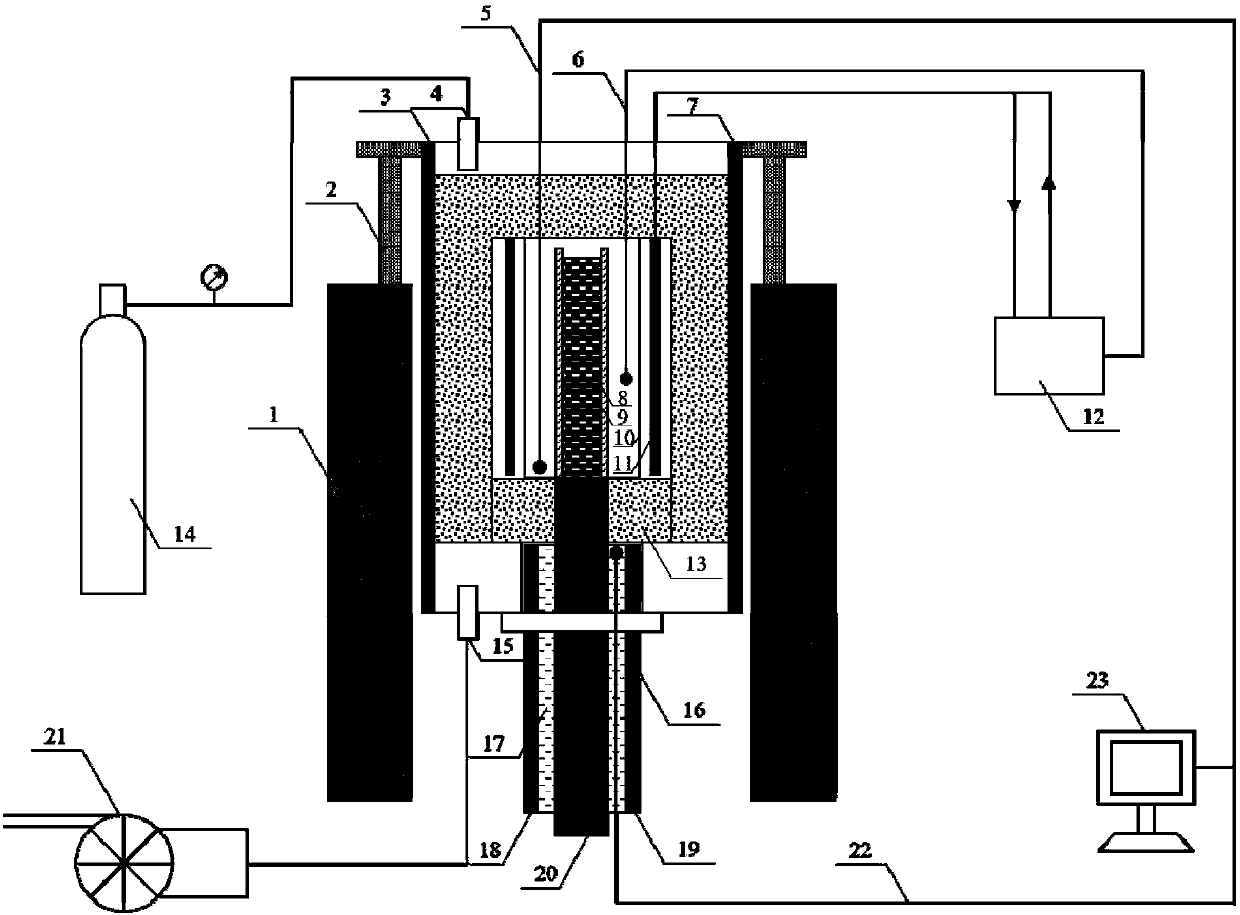

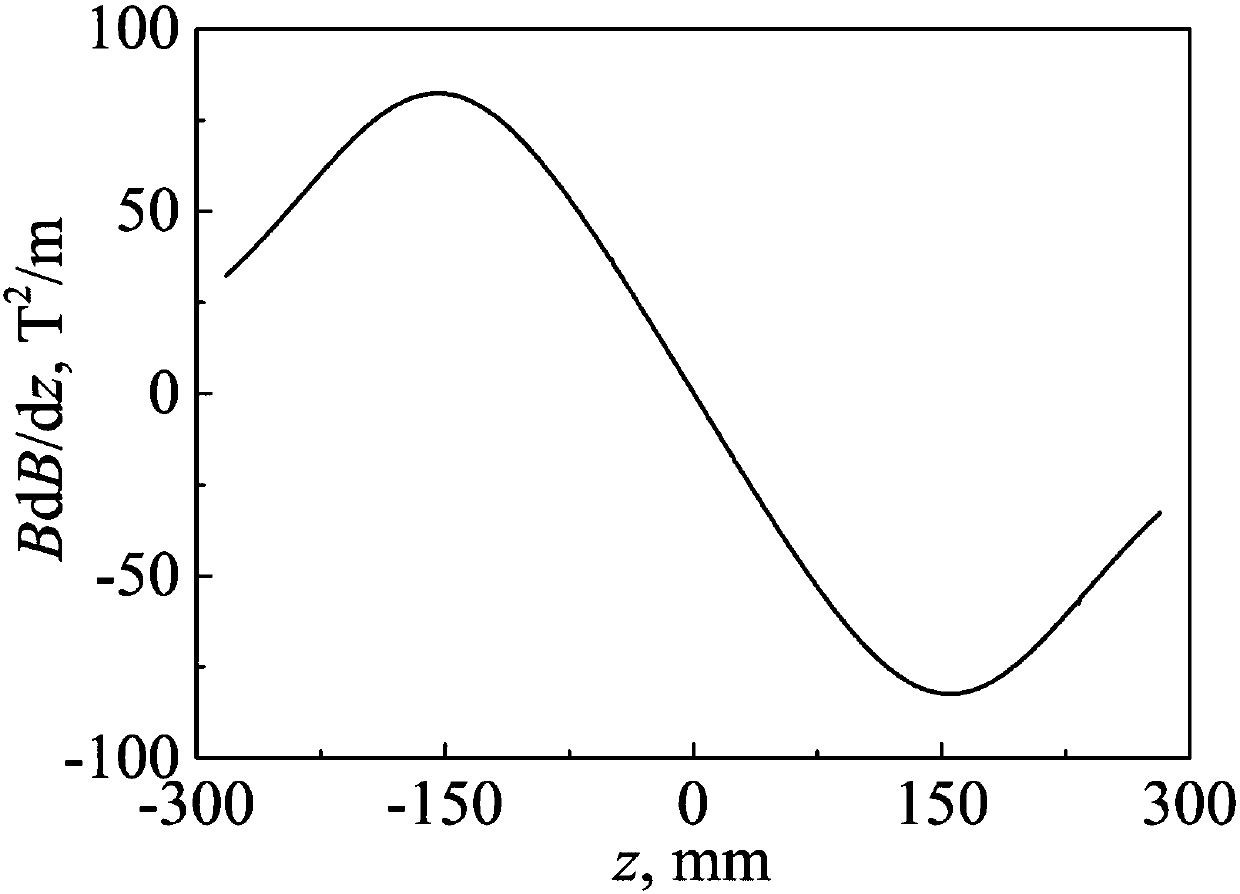

InactiveCN108018483AHigh magnetostrictive performanceGood magnetostrictive performanceRare earthLiquid metal

The invention discloses a high-performance rare-earth-iron-based giant magnetostrictive material and a preparation method thereof, and belongs to the technical field of magnetic functional materials.The method comprises the following steps that 1, induction smelting is carried out on a (TB1-XMX) fey alloy, M is equal to at least one of Dy, Sm, Ce, Pr, Nd, Ho and Er, X is equal to 0 to 0.70, and Yis equal to 1.75-2.25; 2, the alloy is placed in an inert gas and gradient strong magnetic field environment, and the alloy is at least heated to 150 DEG C above the liquidus temperature, and the temperature is kept for at least 8 minutes; and 3, the rate of 5-120 microns per second is taken, then an alloy liquid is pulled into a liquid metal cooling liquid to achieve directional solidification,and after the temperature of a heating chamber is cooled to the room temperature, the sample is taken out. The prepared magnetostrictive material has the advantages of high mechanical property, the large magnetostriction coefficient and the like; and the method has the advantages that operation is simple, control is accurate, the product performance is excellent, and the high-performance magnetostriction material can be produced in batches.

Owner:NORTHEASTERN UNIV

Method for preparing Fe-Ga-In-Tb alloy by double-feeding vacuum induction smelting

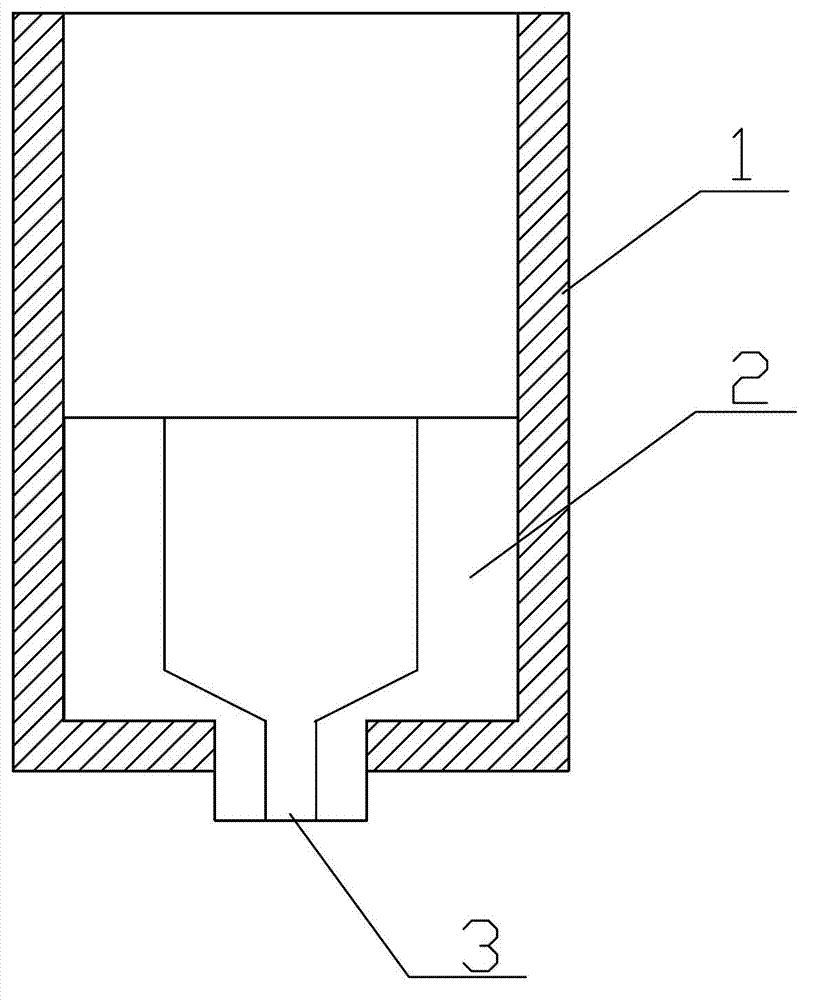

InactiveCN103060660AOvercome the disadvantages of poor fluidity and non-dense alloyFast heat conductionMaterials scienceQuartz crucible

The invention relates to a method for preparing an Fe-Ga-In-Tb alloy by double-feeding vacuum induction smelting. According to the method, high-purity Fe, Ga, In and Tb are used as raw materials to prepare the mother alloy of which the target composition is Fe100-(x+y+z)GaxInyTbz. The method comprises the following steps: putting high-purity iron in a quartz crucible without holes in the bottom, and carrying out induction smelting by using a vacuum induction smelting furnace; after the iron is molten, adding In, Tb and Ga by in a double-feeding mode, and continuing applying power for smelting; and taking out, putting in a quartz crucible with a hole in the bottom, resmelting in the vacuum induction smelting furnace, and casting. In the casting process, a lifting accelerator is utilized, so that the alloy solution acquires a certain inertia, and thus, the alloy solution can be completely cast into a high-volume red copper mold to be subjected to forced cooling. The resmelting is repeated 3-4 times, so that the smelted alloy has more uniform composition. The alloy prepared by the method provided by the invention has the advantages of low burning loss, smooth surface, uniform composition and obviously higher casting properties.

Owner:NANCHANG INST OF TECH

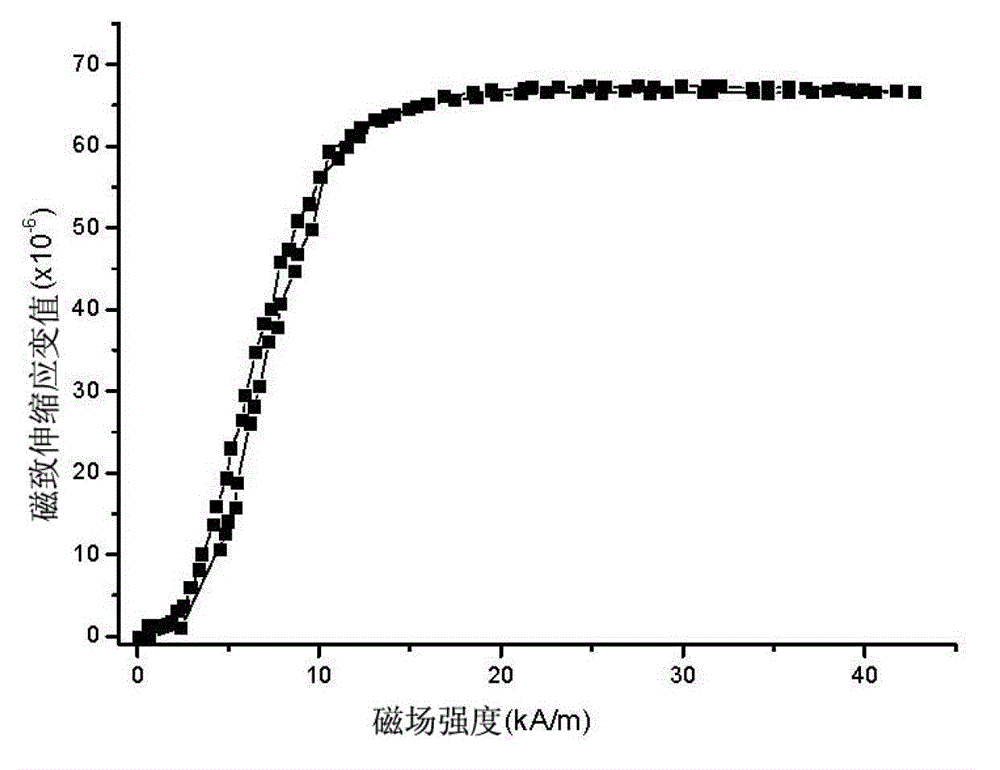

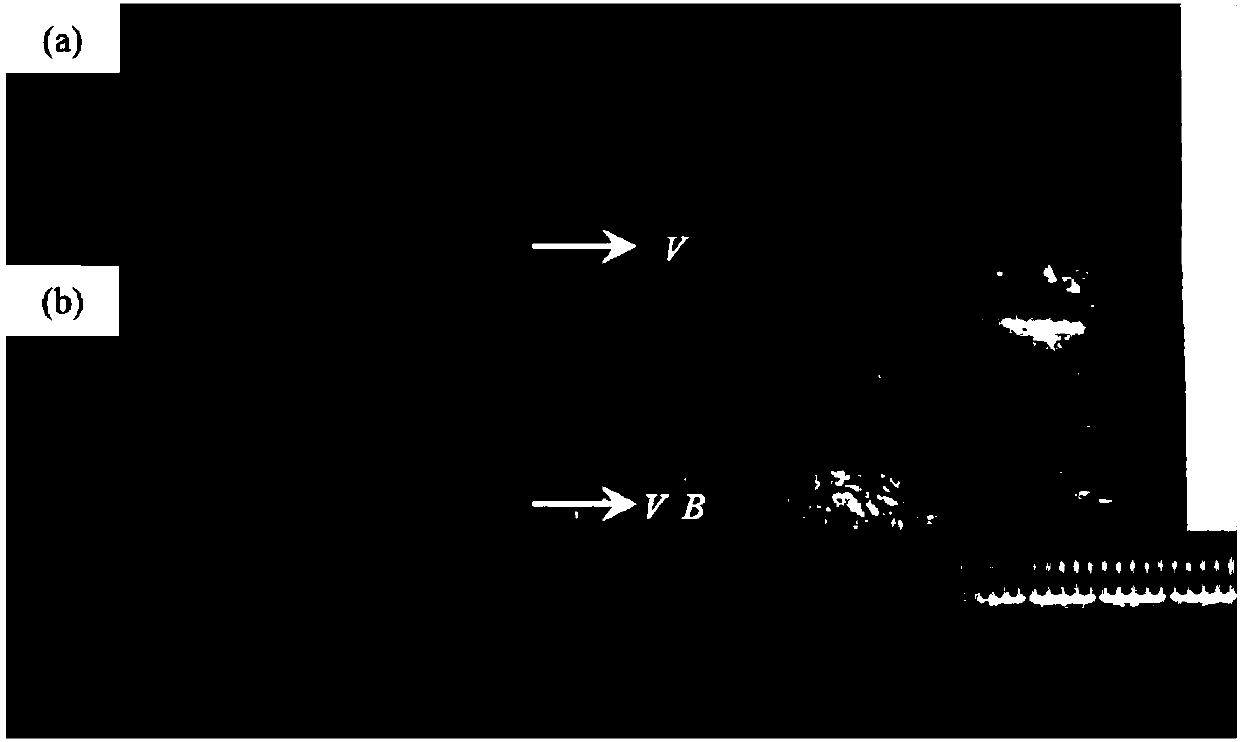

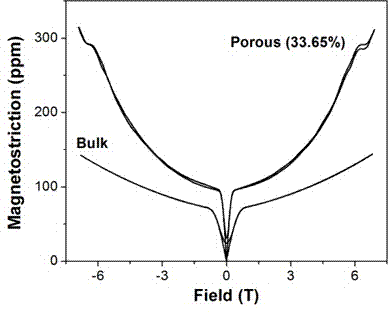

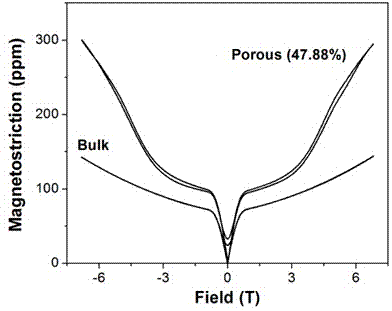

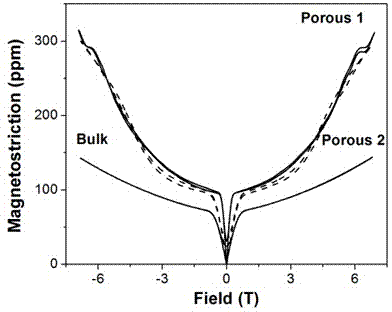

High-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and preparation process thereof

InactiveCN104775068AGood magnetostrictive performanceHigh magnetostrictive performanceMagnetostrictive material selectionSodium aluminateAlloy

The invention discloses a high-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and a preparation process thereof. Holes are introduced into an Fe73Ga27 alloy by preparing a porous sodium metaaluminate precursor so as to ensure that the magnetostrictive performance of the Fe73Ga27 alloy can be improved; the pore size is 20-100 microns, and the porosity is 30-50%; and the preparation process comprises the following step: performing spray casting in a copper mold by using a vacuum spray casting furnace. According to the high-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and the preparation process thereof disclosed by the invention, the hindering effect of magnetic domain rotation in Fe73Ga27 can be reduced based on introduced pores, the macroscopic foam-state Fe73Ga27 magnetostrictive material can be developed, and large magnetic-induced strain, low driving fields and relatively high mechanical performance can be achieved; and a foam material prepared by using a method disclosed by the invention is uniform in pore, ensures that the magnetostrictive coefficient exceeds 300ppm, also is simple and convenient in process and high in finished product rate, and is beneficial to popularization and application.

Owner:ZHEJIANG UNIV +1

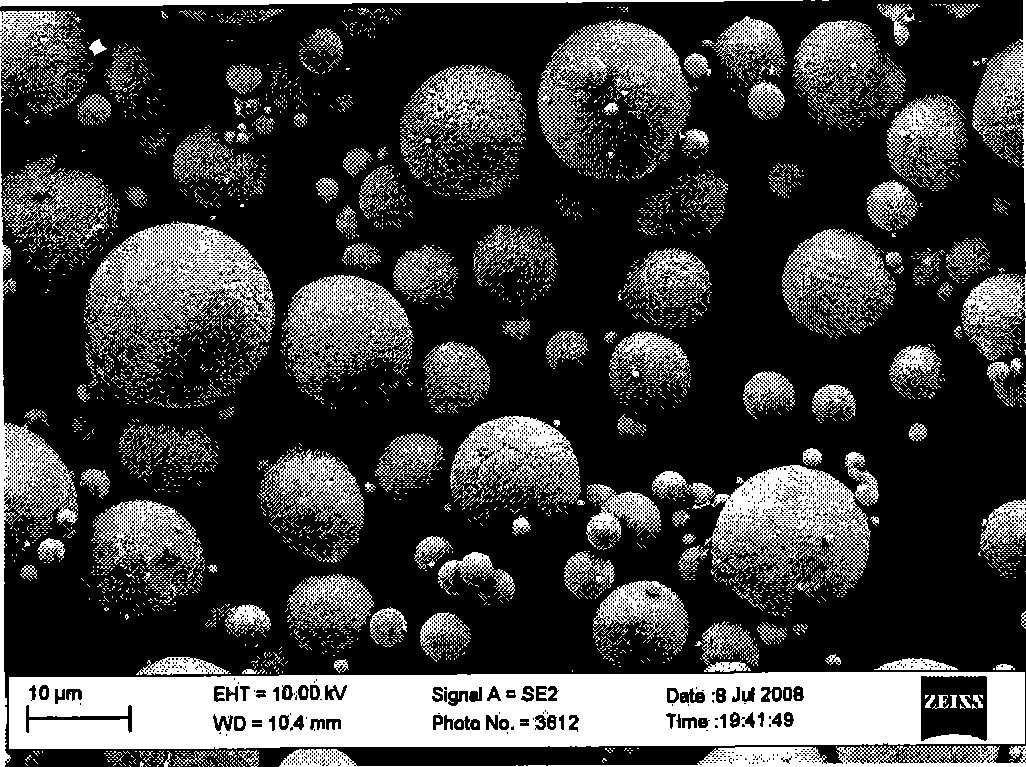

Bonded rare earth GMM preparing method

InactiveCN1845272BIncrease profitHigh magnetostrictive performanceInductances/transformers/magnets manufactureMagnetic materialsCouplingRare earth

The preparation technique for a bonding rare-earth ultra-magnetostrictive material comprises: with material, a sieve and a small ball mill in glove box, vacuumizing on protection of inert gas; weighing proper bonding agent and coupling agent by intergradient proportion to mix with the powder for cold isostatic press; curing the blank to obtain the final product. This invention has high usage on material, and can prepare the product with large scale, complex shape and super properties.

Owner:UNIV OF SCI & TECH BEIJING

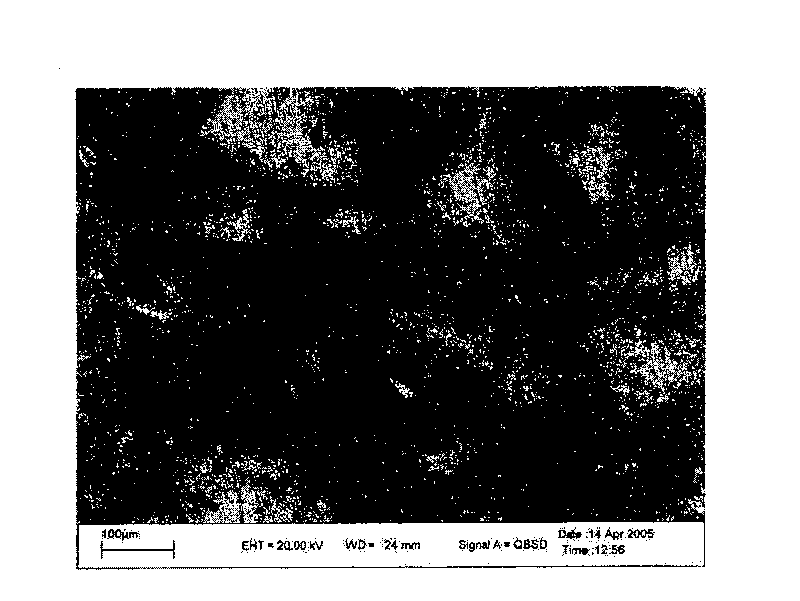

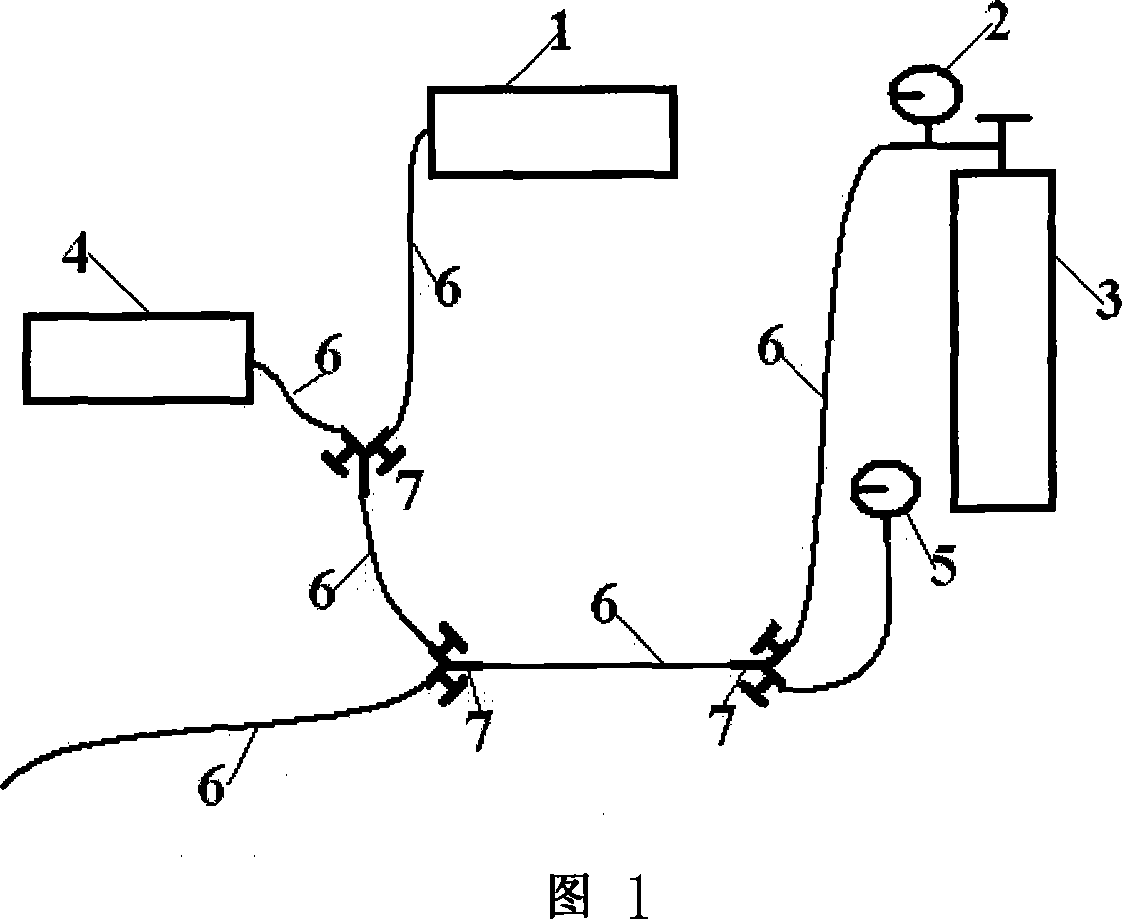

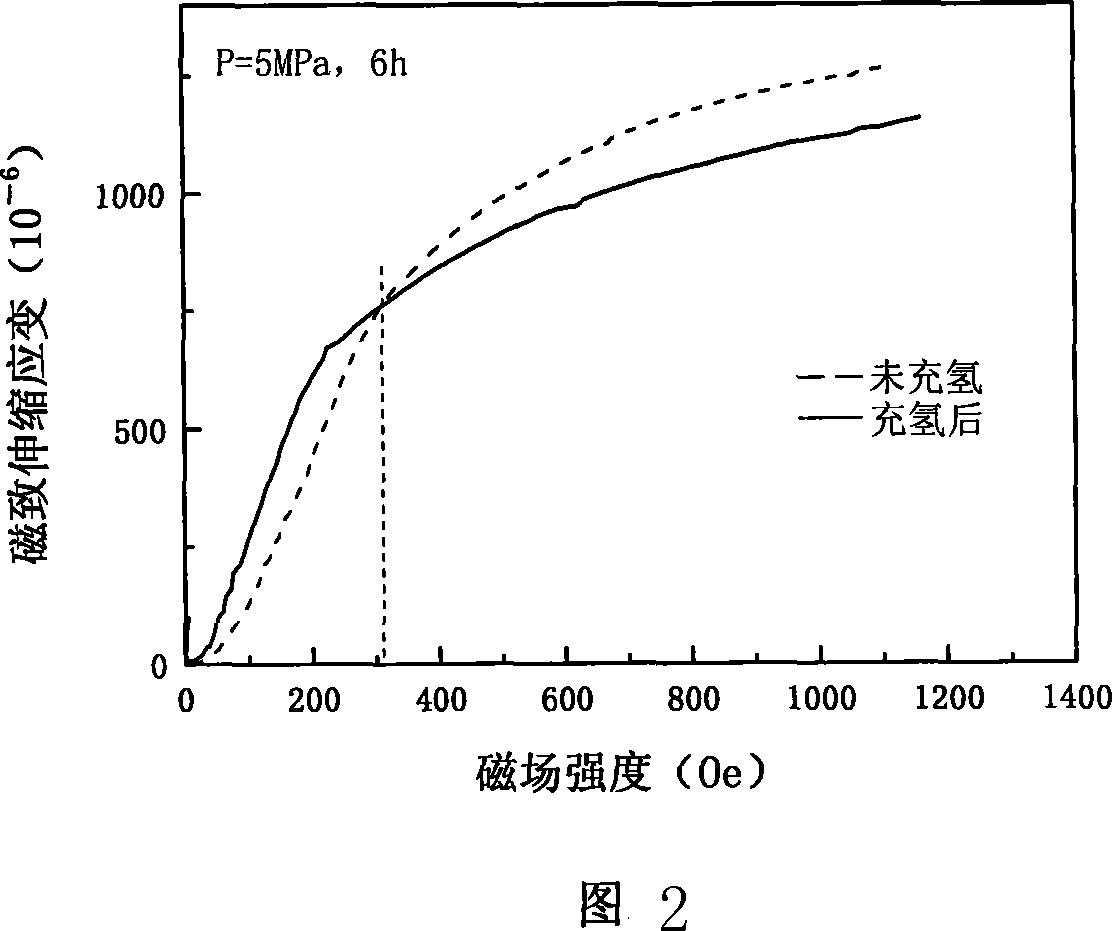

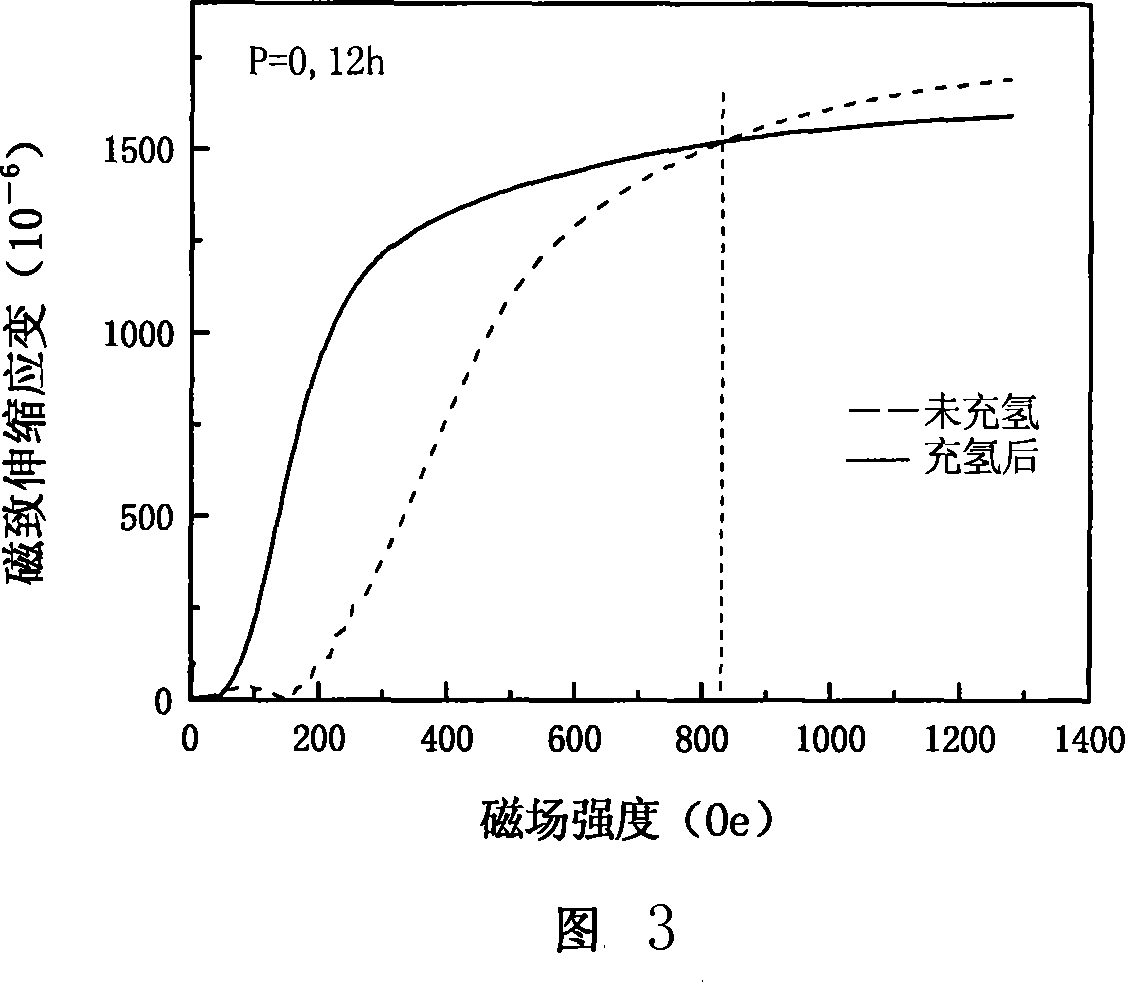

Method for enhancing super-magnetostriction material performance

InactiveCN101075493AHigh magnetostrictive performanceLow magnetostrictive performanceInorganic material magnetismMagnetostrictive material selectionHydrogenGas phase

A hydrogen charge-in method to a super magnetostrictive material (Tb,Dy)Fe2 includes the following steps: put the rod of Tb0.3Dy0.73Fe1.95 with an orientation of [110] into the hydrogen charge-in chamber; vacuum the chamber around 10Pa; clean the chamber with hydrogen; charge-in hydrogen at a pressure of 0.1-10 atm and temperature at 20-300oC for 1-24hr.

Owner:UNIV OF SCI & TECH BEIJING

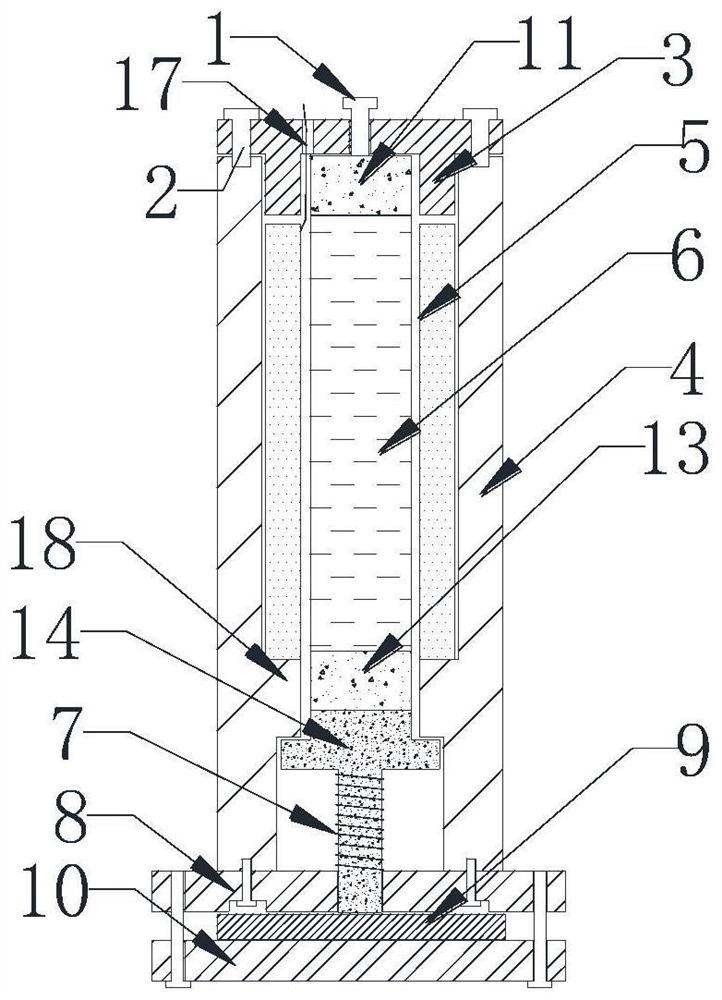

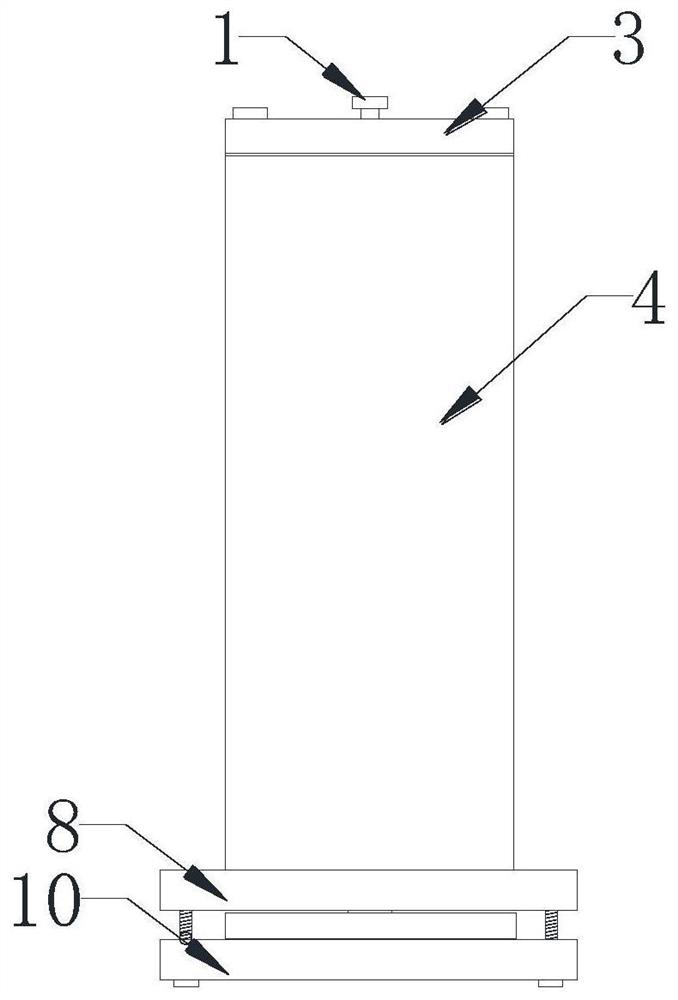

Giant magnetostrictive vibration source

PendingCN112994514AImprove energy conversion efficiencyImprove mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesElastic vibrationEngineering

The invention discloses a giant magnetostrictive vibration source which comprises an exciting coil (5), a magnetostrictive material rod (6) is arranged in the exciting coil (5) in the axial direction, an elastic vibration output piece (14) is arranged in the telescopic end direction of the magnetostrictive material rod (6), and a limiting end cover (3) is arranged at the end, away from the telescopic end, of the magnetostrictive material rod (6), when the magnetostrictive material rod (6) deforms in the direction of the telescopic end under the action of the excitation coil (5), the detection end of the elastic vibration output piece (14) moves in the deformation direction of the elastic vibration output piece (14). By transmitting a step excitation signal to the excitation coil, the giant magnetostrictive material rod is triggered to excite so as to generate vibration.

Owner:CHONGQING CUILU DETECTION TECH CO LTD

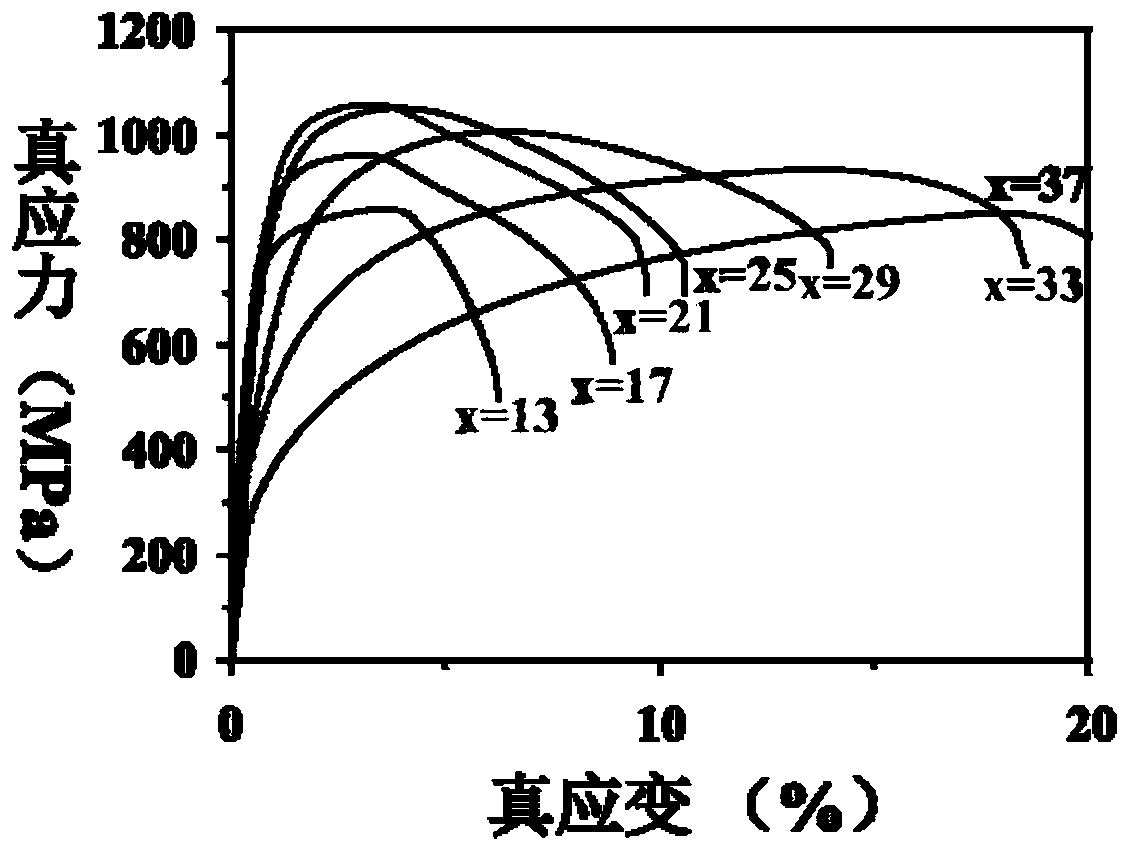

Magnetostrictive alloy with excellent mechanical performance and preparation method for magnetostrictive alloy

ActiveCN110066956AGood magnetostrictive performanceGood mechanical propertiesMagnetostrictive material selectionEnvironmentally friendlyInstrumentation

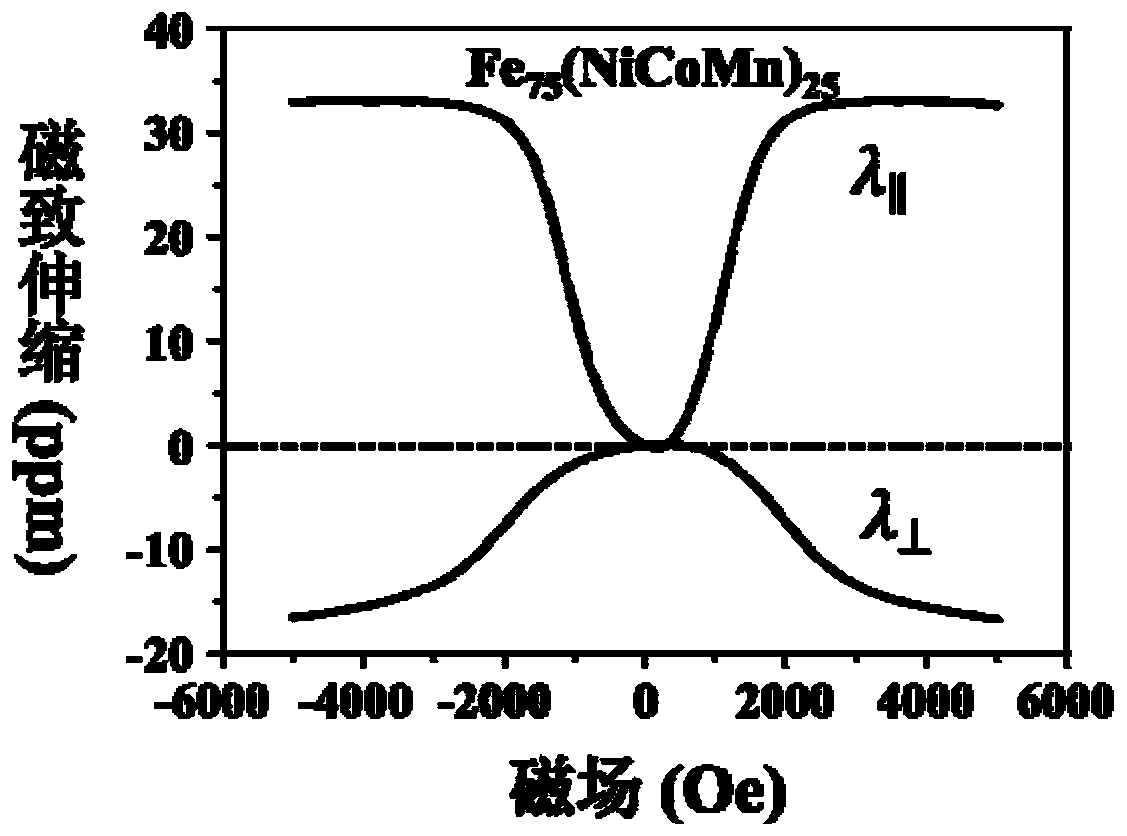

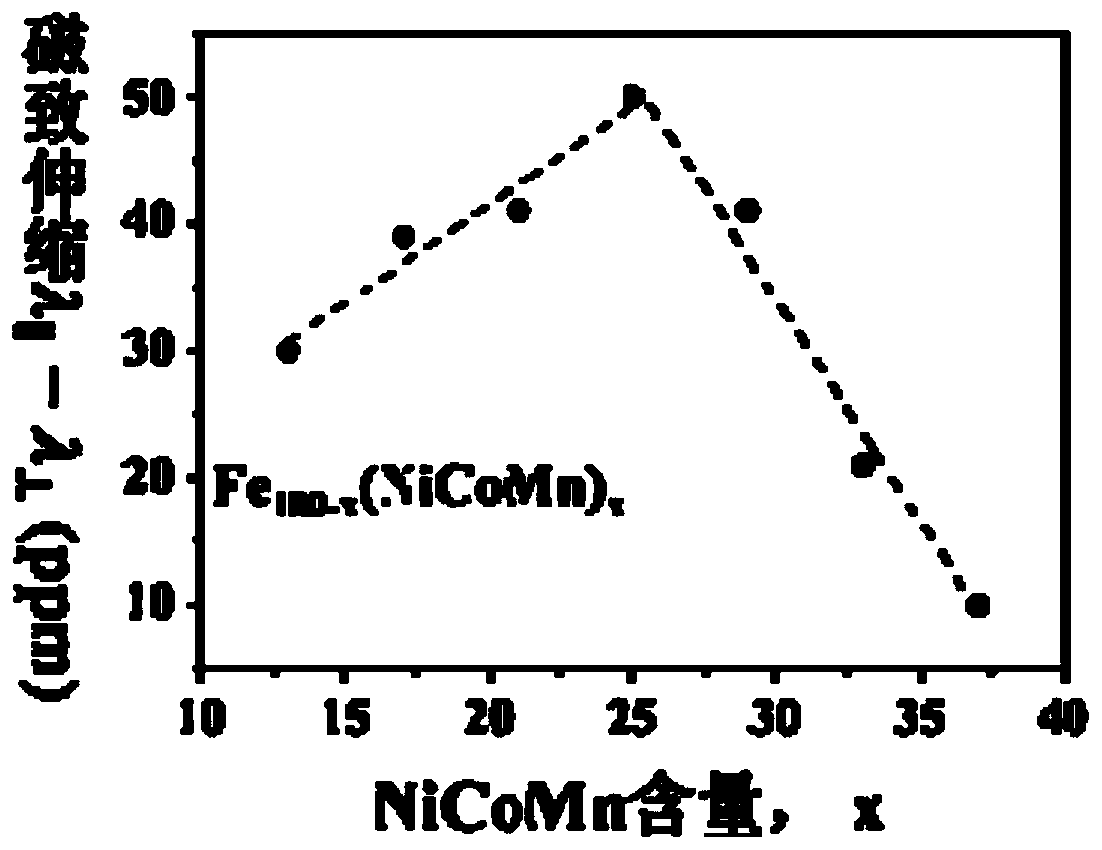

The invention relates to a magnetostrictive alloy with excellent mechanical performance and a preparation method for the magnetostrictive alloy and belongs to the technical field of magnetic materials. For Fe 100-x(NiCoMn)x as an alloy provided by the invention, x is equal to 13-37, and the alloy has excellent mechanical performance and low driving field while good magnetostriction performance isensured; and moreover, the alloy is simple, convenient and rapid in preparation process, low in defect rate and high in rate of finished products, is environmentally friendly, does not need to use expensive large-scale instrument equipment and can be popularized and applied in industrial production with low cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing Co-Gd alloy capable of improving soft magnetic performance

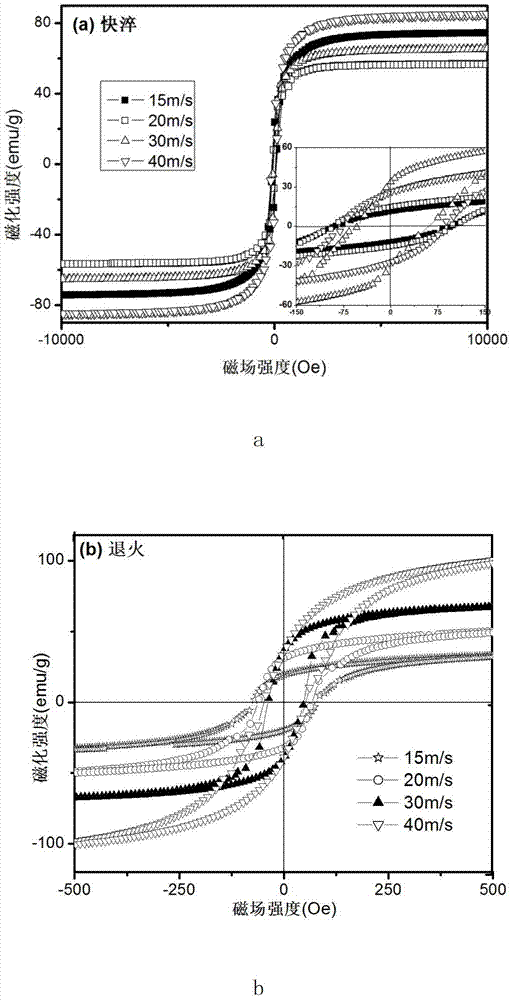

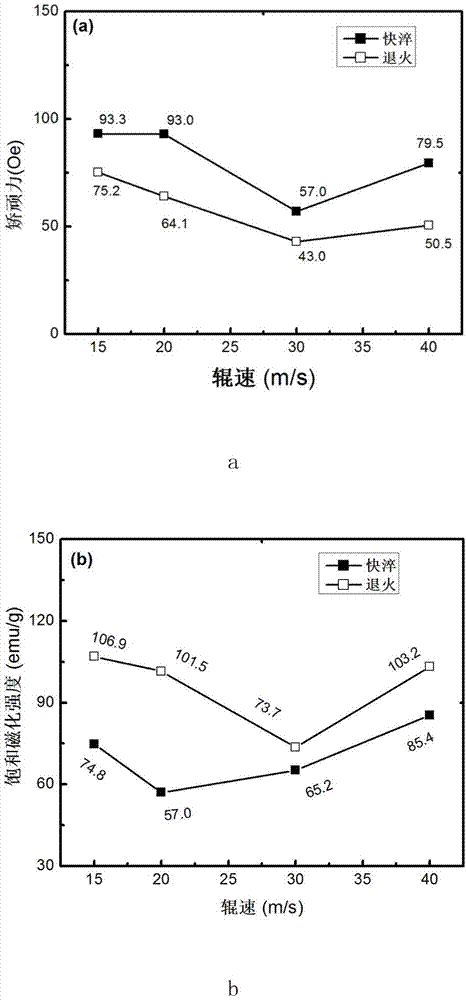

The invention relates to a method for preparing Co-Gd alloy capable of improving soft magnetic performance, which is characterized by comprising the steps of fusing Co with purity of 99.99% and Gd with purity of 99.9% under protection of high-pure Ar gas to obtain alloy; preparing an alloy thin belt from the fused alloy; and placing the prepared alloy stripe into a tubular furnace and introducingAr gas into the tubular furnace, and annealing at 422 to 1175 degrees centigrade. According to the invention, structure regulation and dislocation cancellation occur after the alloy stripe is annealed; the coercive force is reduced; the saturated magnetization intensity is improved; and the soft magnetic performance is enhanced obviously. As a result, it is possible to widely apply the Co-Gd alloy to the magnetostriction field. The method disclosed by the invention has advantages of simple procedures, convenient treatment, quick and convenient forming. Simultaneously, the method solves the application limitation caused by high coercive force and can be widely applied to the magnetostriction field.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com