High-plasticity magnetostrictive material and preparation method thereof

A magnetostrictive material and high plasticity technology, applied in the direction of material selection for magnetostrictive devices, device material selection, etc., can solve the problems of single crystal material mechanical properties to be further improved, complex preparation process, etc., to achieve good production High efficiency, simple and convenient process, and excellent magnetostrictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

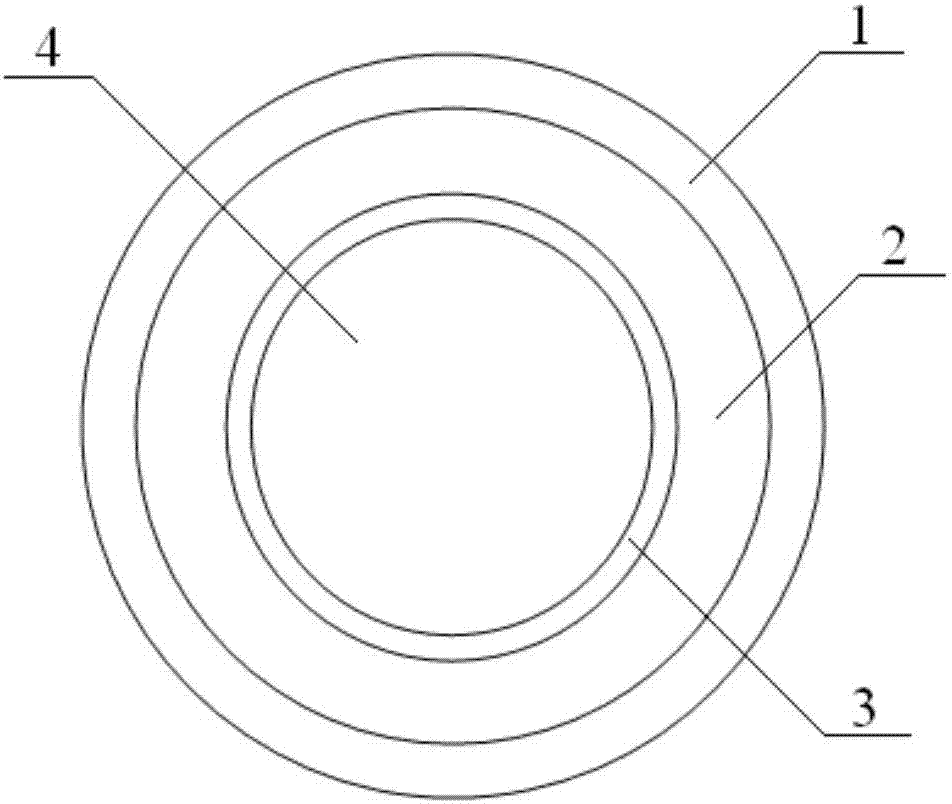

[0045] Embodiment 1 prepares Fe 83 Ga 17 Tb 0.05 High plastic magnetostrictive material

[0046] The preparation formula is Fe 83 Ga 17 Tb 0.05 The steps of highly plastic magnetostrictive material are as follows:

[0047] 1. Ingredients

[0048] The purity of the selected raw materials Fe, Ga and Tb (RE raw materials) is greater than 99.99wt%, and in order to prevent the elements from burning during the smelting process, when the Fe, Ga and Tb raw materials are prepared according to the above composition, the burning loss of about 2wt% Add Ga and Tb respectively. Specifically, 26.5 g of Fe, 6.91 g of Ga, and 0.049 g of Tb were weighed and set aside. Weigh 27.72g of Fe, 7.158g of Ga and 0.048g of Tb for subsequent use.

[0049] 2. Preparation of master alloy ingot

[0050] Put the above-mentioned raw materials Fe, Ga and Tb into the crucible of the vacuum non-consumable arc melting furnace. When placing, put the metal elements that are easy to burn at the bottom of t...

Embodiment 2

[0065] Embodiment 2 prepares Fe 81 Ga 19 PR 0.2 High plastic magnetostrictive material

[0066] In addition to the batching step, take 27.8g of Fe, 8.31g of Ga and 0.088g of Pr for subsequent use; in the step of preparing high plastic magnetostrictive material, the furnace body is heated to 1650 ° C, and the temperature gradient is controlled to be 5 × 10 5 K / m, except that the growth rate is 3000mm / h, other steps are the same as in Example 1, and the obtained composition is Fe 81 Ga 19 PR 0.2High plastic magnetostrictive material (size Φ7mm×20mm).

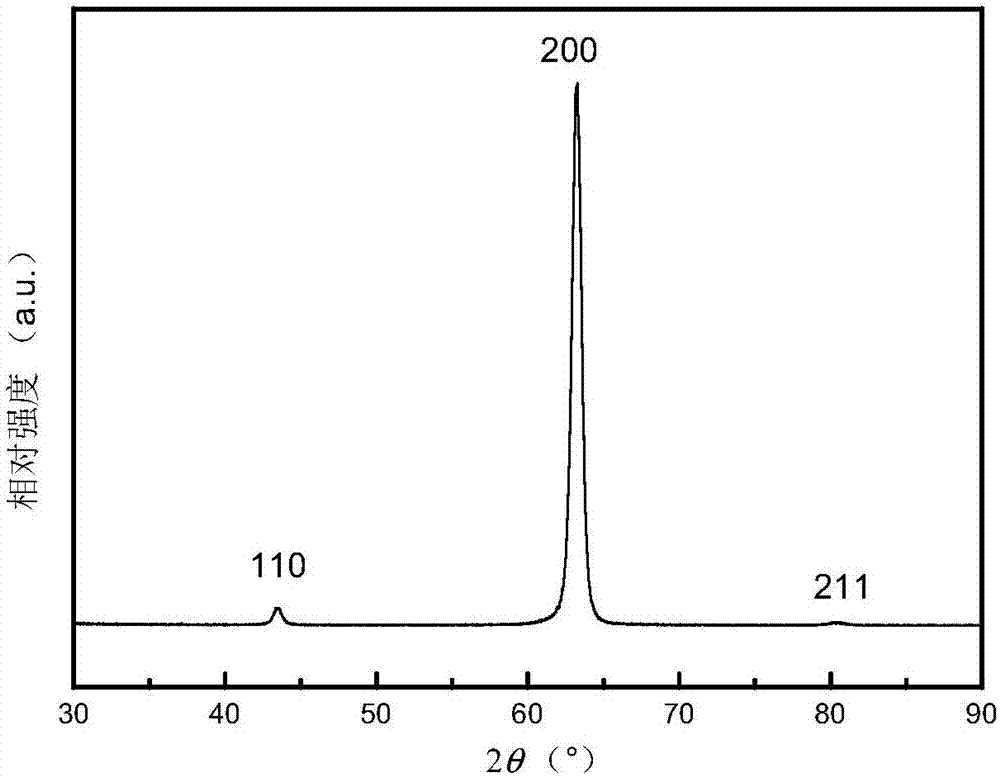

[0067] Adopt embodiment 1 method to the Fe of above-mentioned preparation 81 Ga 19 PR 0.2 High plastic magnetostrictive materials were tested; the results showed that: the Fe 81 Ga 19 PR 0.2 The highly plastic magnetostrictive material is polycrystalline material with orientation, and the orientation degree of crystal direction is 96%. The precipitated phases are arranged vertically along the grain growth direction. ...

Embodiment 3

[0069] Embodiment 3 prepares Fe 76.5 Ga 23.5 Dy 0.1 High plastic magnetostrictive material

[0070] In addition to the batching step, weigh 26.2g of Fe, 10.25g of Ga and 0.1g of Dy for later use; in the step of preparing high plastic magnetostrictive material, the furnace body is heated to 1625 ° C, and the temperature gradient is controlled to be 3 × 10 5 K / m, except that the growth rate is 1000mm / h, other steps are the same as in Example 1, and the obtained composition is Fe 76.5 Ga 23.5 Dy 0.1 High plastic magnetostrictive material (size Φ7mm×20mm).

[0071] Adopt embodiment 1 method to the Fe of above-mentioned preparation 76.5 Ga 23.5 Dy 0.1 High plastic magnetostrictive materials were tested; the results showed that: the Fe 76.5 Ga 23.5 Dy 0.1 The highly plastic magnetostrictive material is a polycrystalline material with orientation, and the orientation degree of crystal direction is 98%. The precipitated phases are arranged vertically along the grain grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com