Method for designing and preparing spherical shell layered magnetoelectric composite material structure

A magnetoelectric composite material and structural design technology, applied in the manufacture/processing of electromagnetic devices, manufacture/assembly of magnetostrictive devices, manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problem of inability to manufacture question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

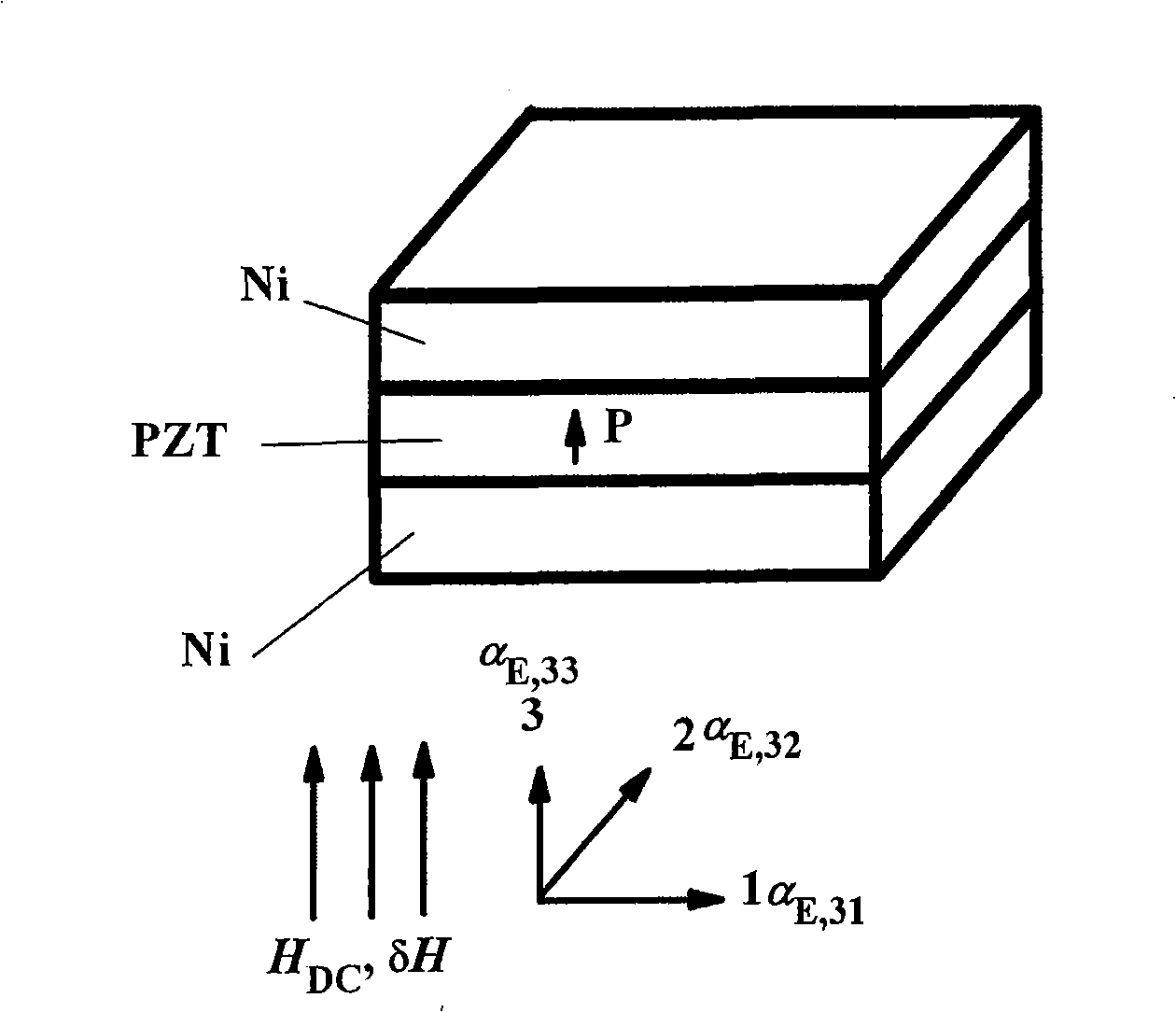

[0018] Now refer to the attached Figure 8 , are described as follows in conjunction with the examples: the spherical shell layered magnetoelectric composite structure design and preparation method relate to piezoelectric ceramics (such as PZT) powder molding and sintering into hemispherical shell piezoelectric ceramics (such as Figure 7shown), the metallization of hemispherical shell piezoelectric ceramics, the bonding of hemispherical shell piezoelectric ceramics into complete spherical shell piezoelectric ceramics and the electroplating preparation method of complete spherical shell layered magnetoelectric composite materials. The following is an example of PZT piezoelectric ceramics. First, the prepared PZT powder is molded into a hemispherical shell-shaped blank of the corresponding size using a designed abrasive tool, and the corresponding PZT sintering process is sintered to obtain a hemispherical shell-shaped PZT ceramic; the inner and outer surfaces of the spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com