Patents

Literature

248results about "Magnetostrictive device manufacture/assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

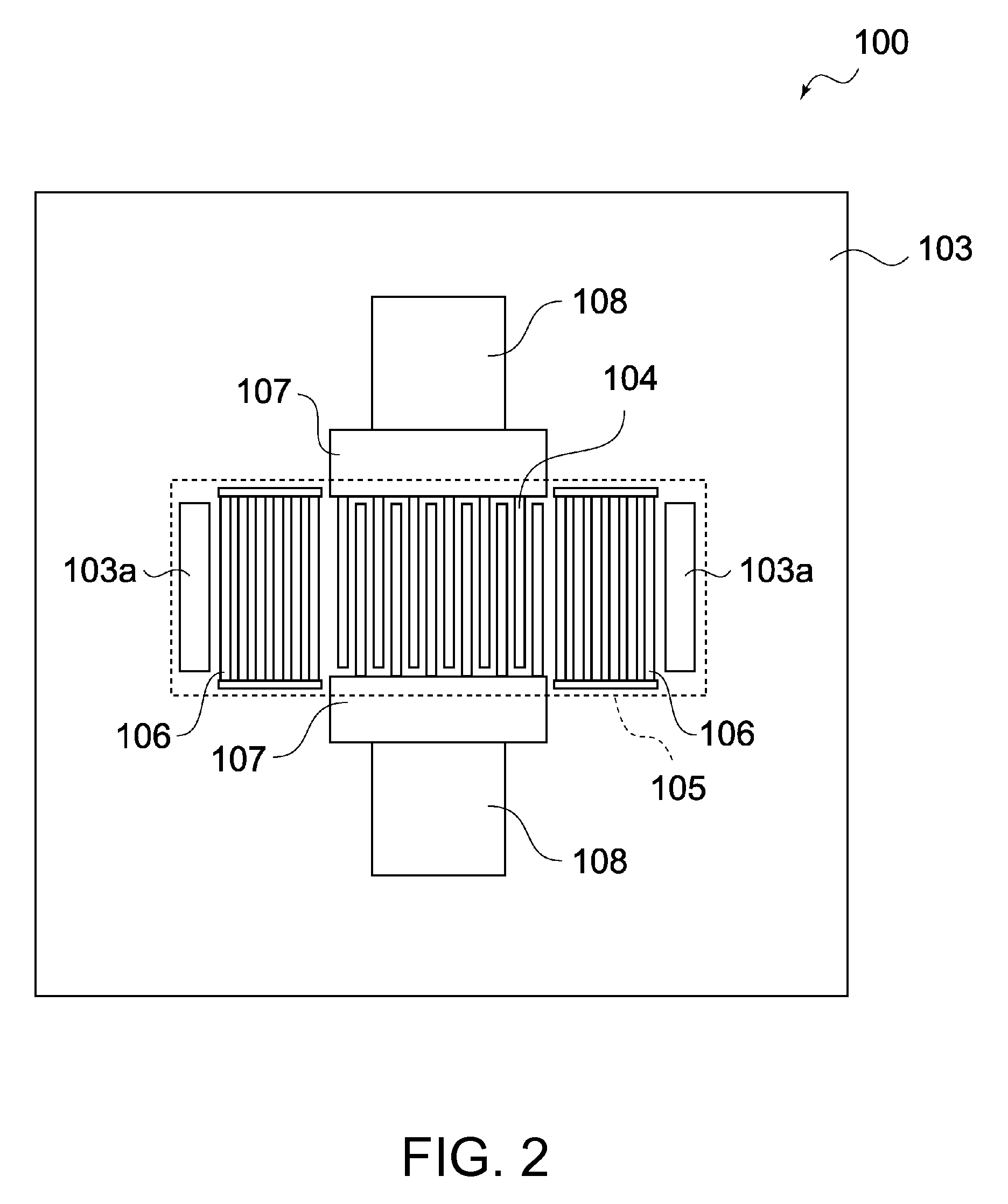

Diagnostic ultrasound transducer

ActiveUS20090034370A1Easy to guaranteeGood electrical contactUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorEngineering

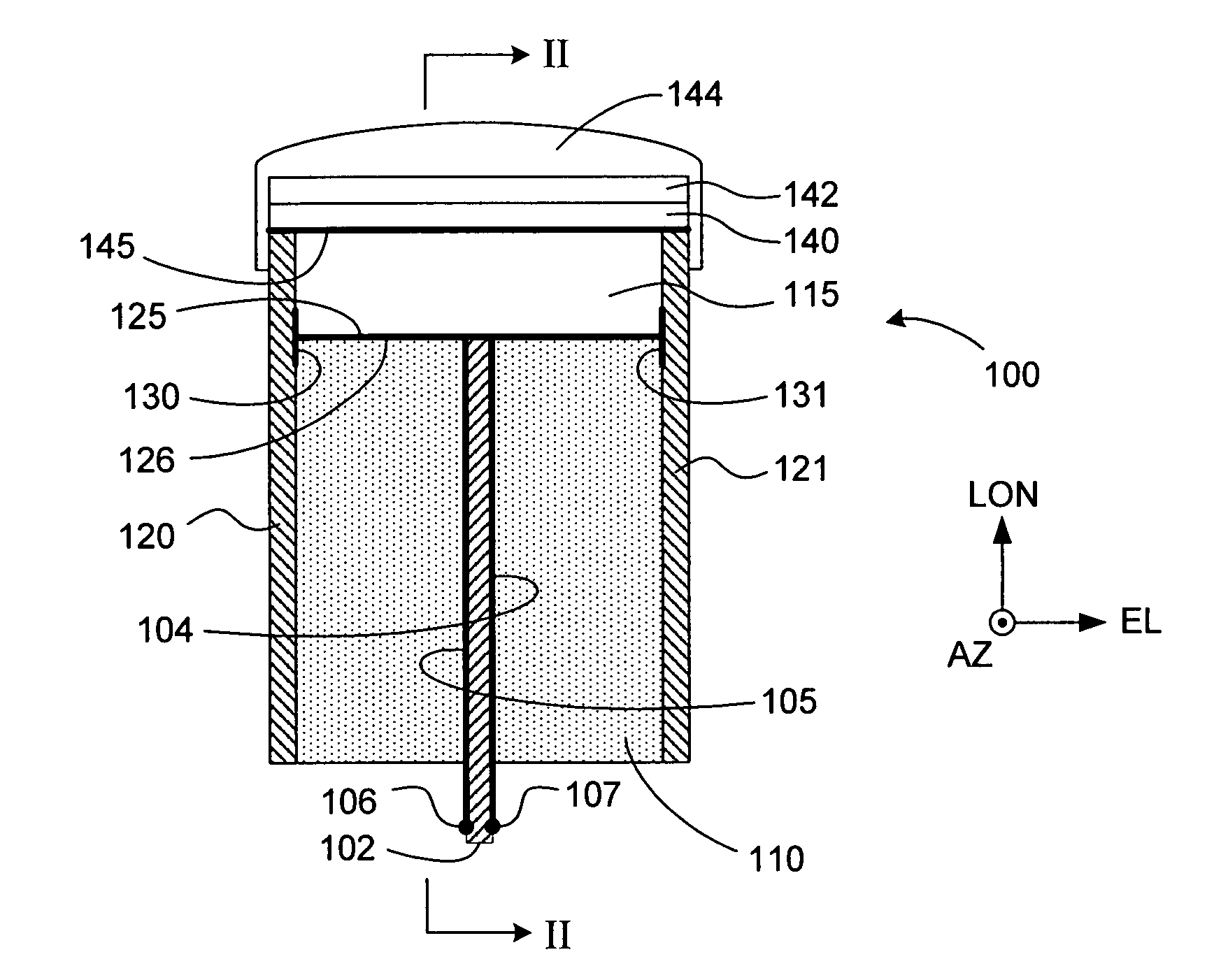

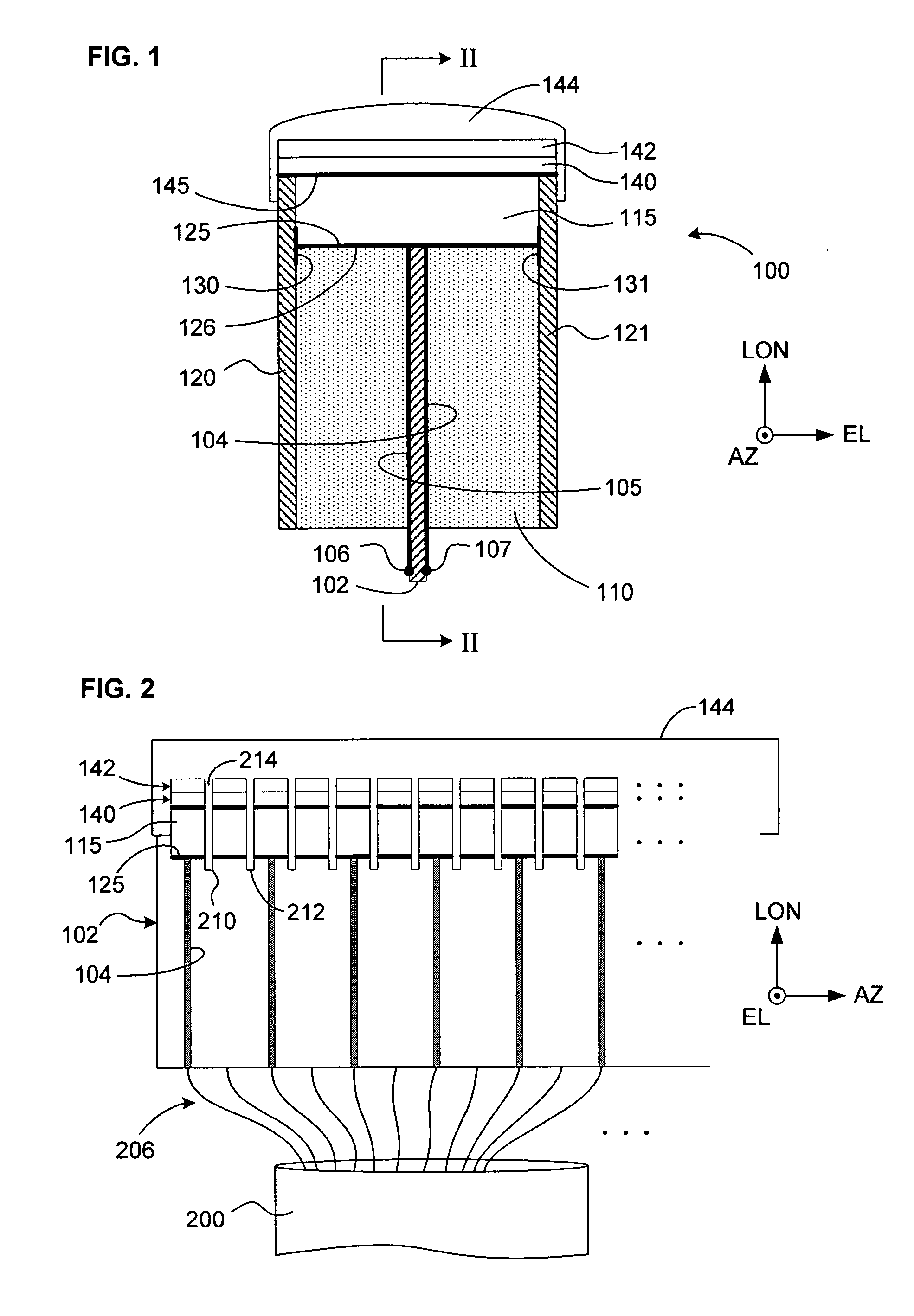

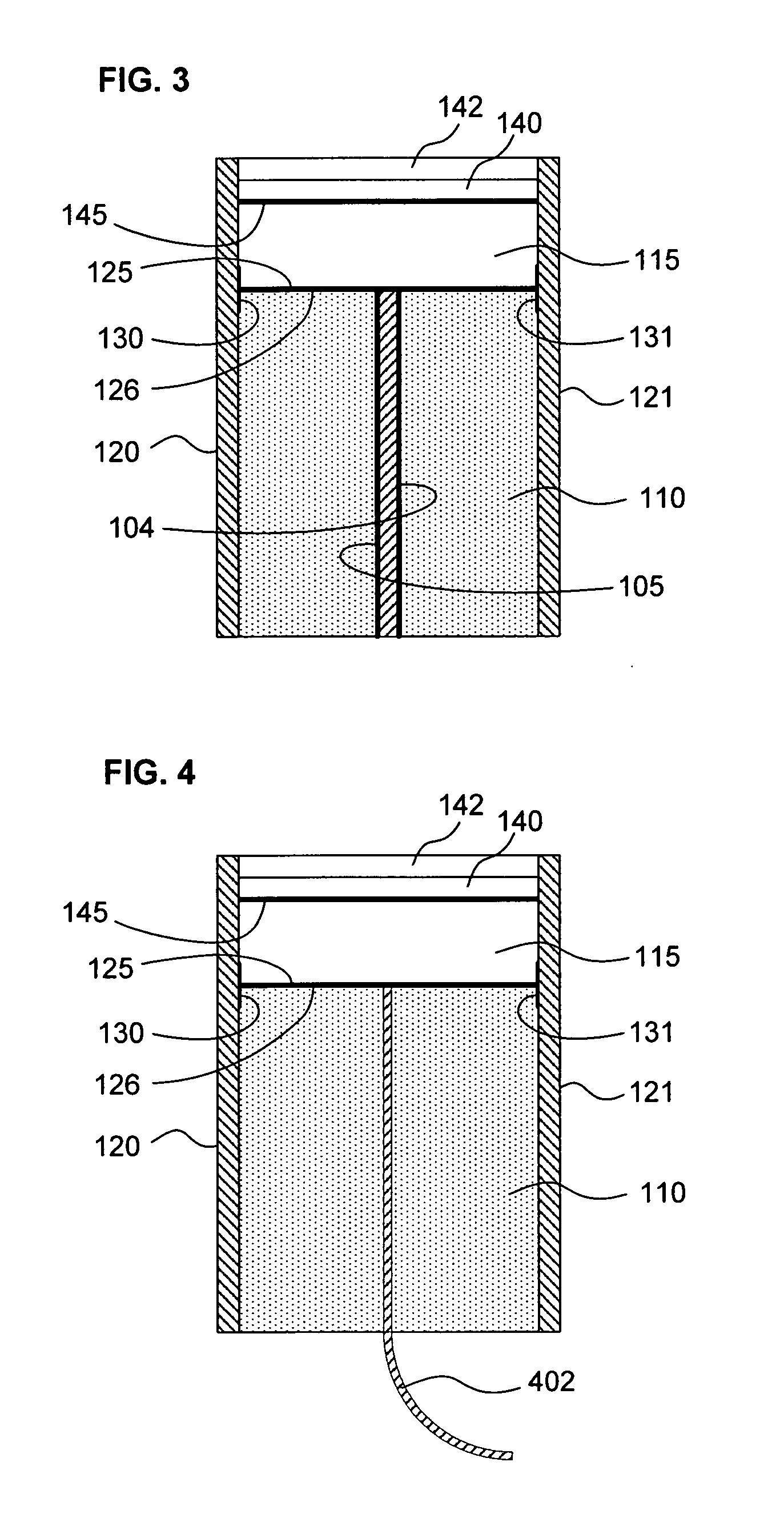

An ultrasound transducer includes an array of PZT elements mounted on a non-recessed distal surface of a backing block. Between each element and the backing block is a conductive region formed as a portion of a metallic layer sputtered onto the distal surface. Traces on a longitudinally extending circuit board—preferably, a substantially rigid printed circuit board, which may be embedded within the block—connect the conductive region, and thus the PZT element, with any conventional external ultrasound imaging system. A substantially “T” or “inverted-L” shaped electrode is thereby formed for each element, with no need for soldering. At least one longitudinally extending metallic member mounted on a respective lateral surface of the backing block forms a heat sink and a common electrical ground. A thermally and electrically conductive layer, such as of foil, transfers heat from at least one matching layer mounted on the elements to the metallic member.

Owner:SHENZHEN MINDRAY SCIENTIFIC CO LTD

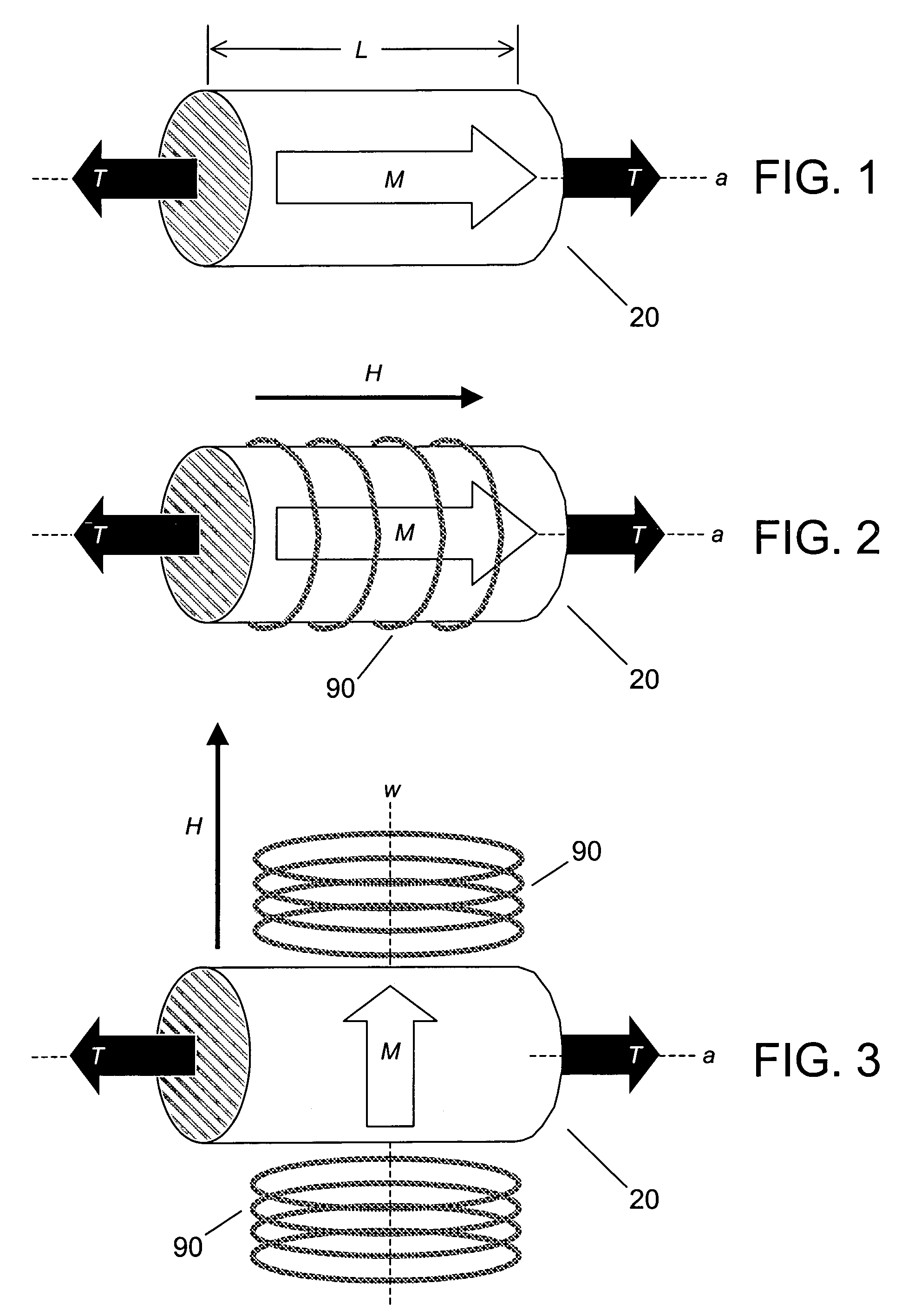

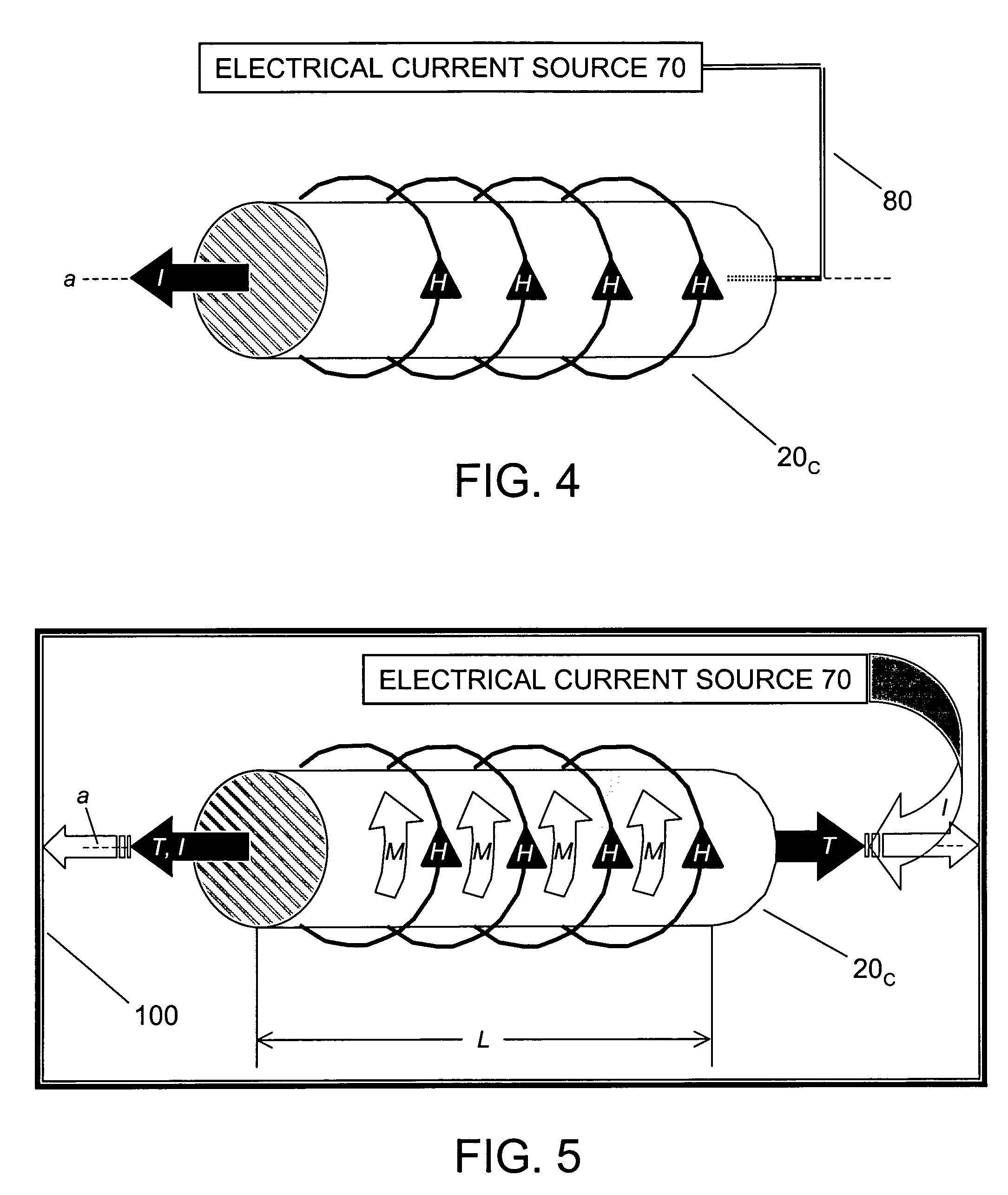

High magnetostriction of positive magnetostrictive materials under tensile load

InactiveUS7564152B1Magnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorMagnetization

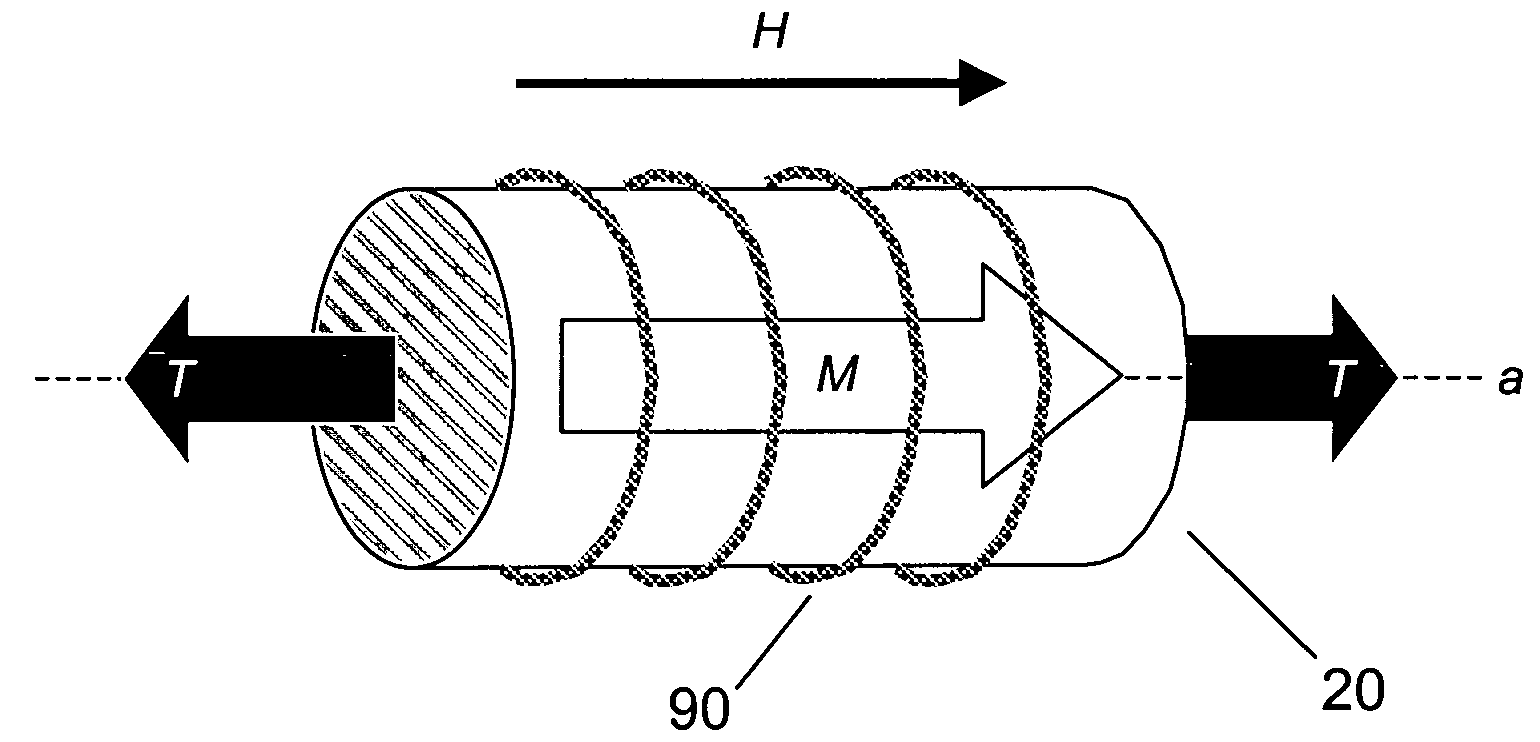

An elongate structure having a magnetostrictive material composition is subjected to tensile stress in the longitudinal-axial direction, thereby generally orienting the magnetization of the elongate structure in the longitudinal-axial direction. Electrical current is conducted through the elongate structure and / or through at least one adjacent elongate conductor, thereby generally orienting the magnetization of the elongate structure in the transverse direction, generally in parallel with the transverse direction of the magnetic field concomitant the conduction of current through the elongate structure. The elongate structure magnetostrictively contracts due to the (generally 90°) repositioning of the magnetization of the elongate structure. Examples of inventive configurational variants include: (i) an elongate structure itself conducting current; (ii) a hollow elongate structure accommodating placement therethrough of at least one elongate conductor; (iii) an elongate structure flanked by a pair of elongate conductors conducting current in opposite directions; (iv) plural elongate structures bordering a centralized elongate conductor.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

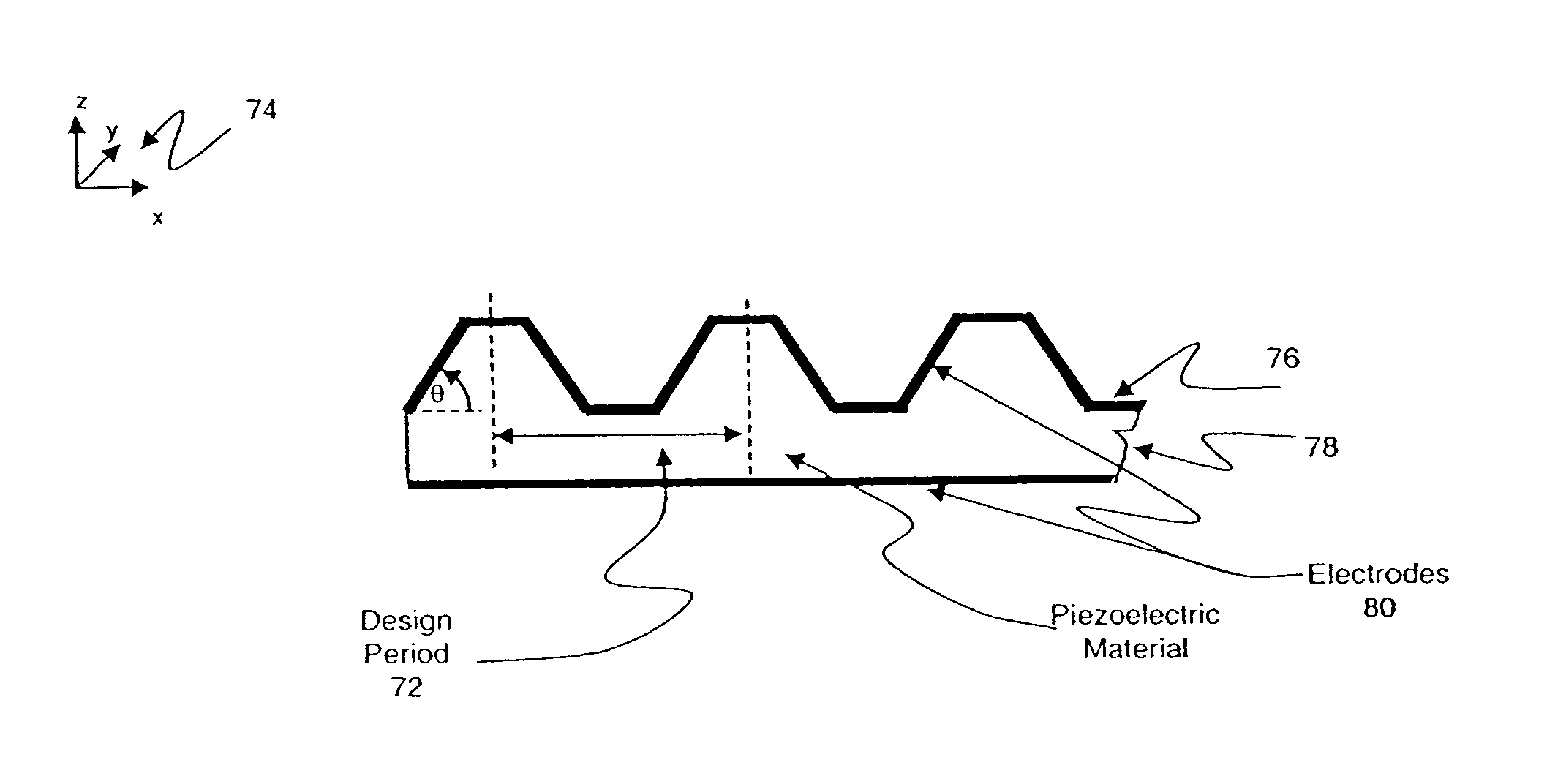

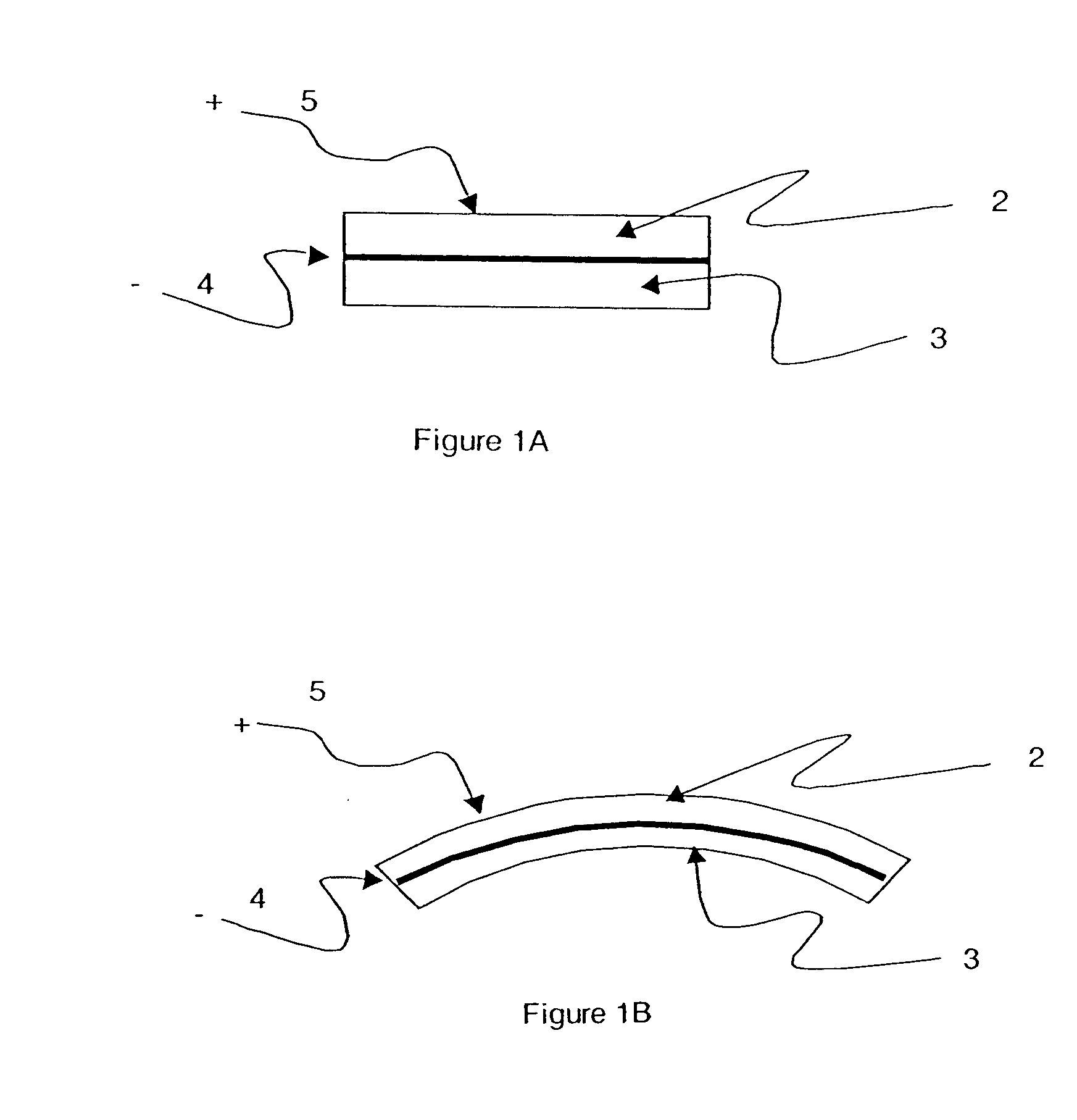

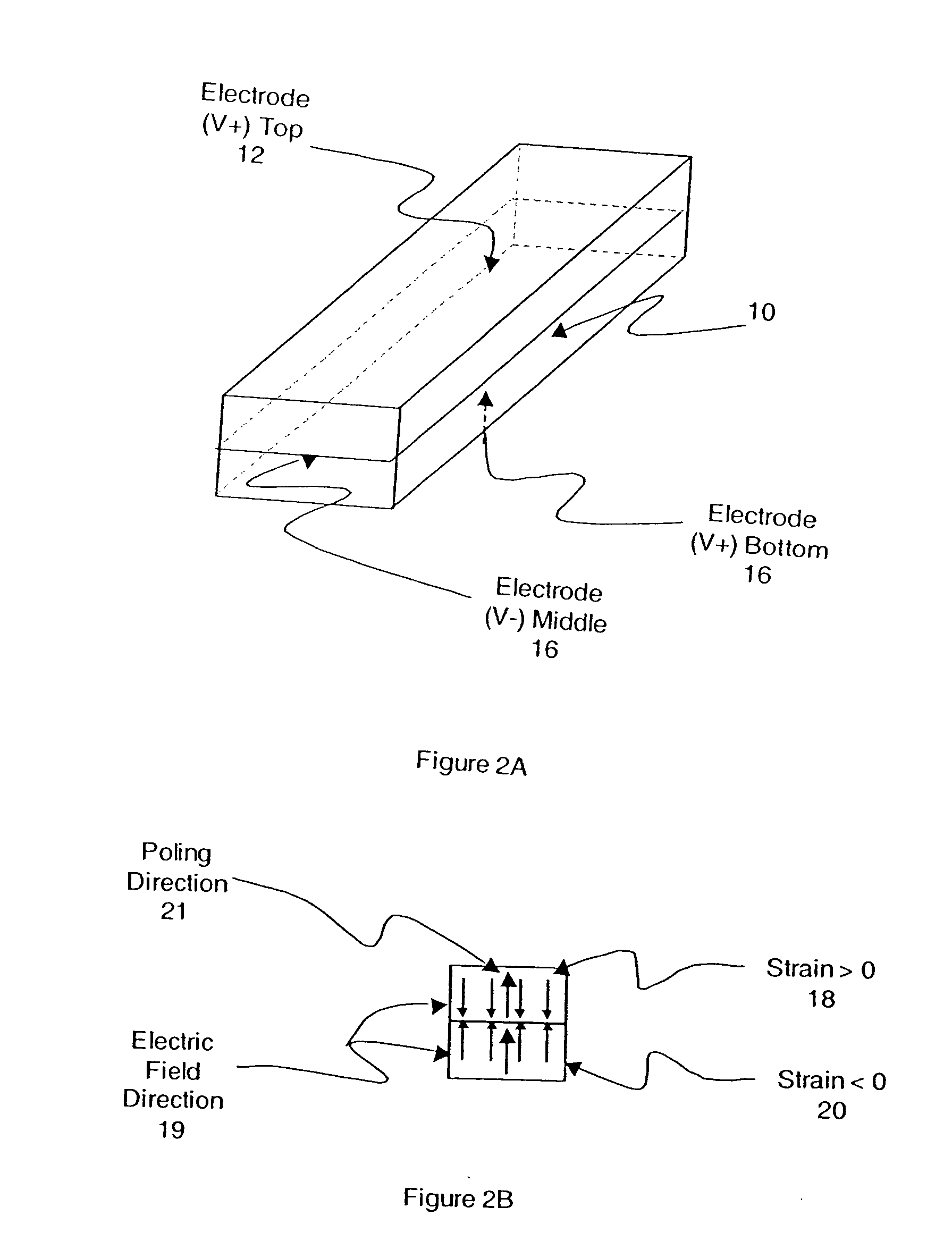

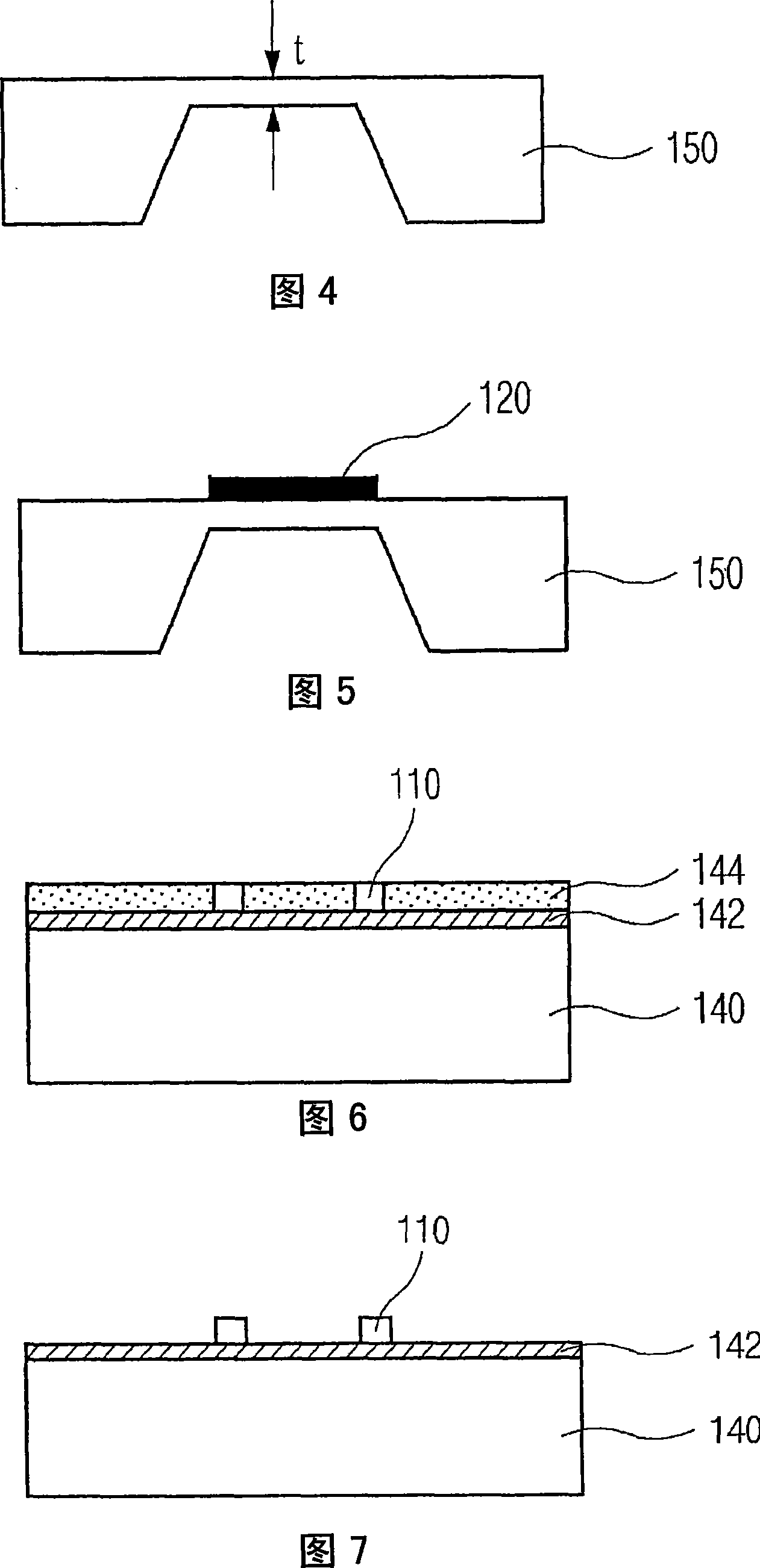

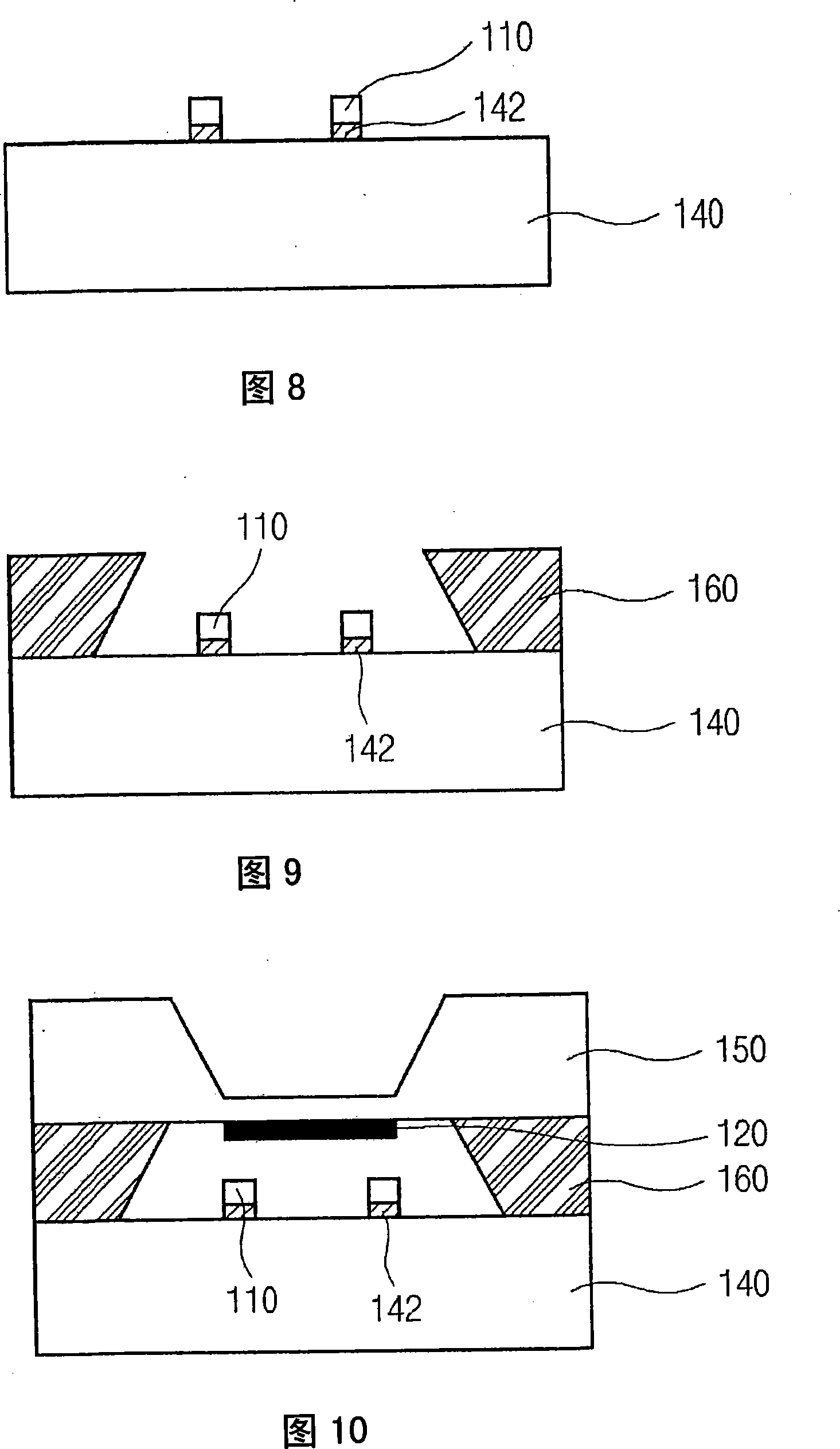

Bending actuators and sensors constructed from shaped active materials and methods for making the same

InactiveUS20040056567A1Increase stiffnessMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrode placementUniform field

Bender devices are demonstrated by developing non-uniform fields within a homogeneous, non-planar single slab active member material of non-uniform thickness through geometrical constraints and electrode placement. Single slab actuators are demonstrated for semiconductor designs including MEMS applications. Single slab bender periodic designs are demonstrated to be well suited for MEMS fabrication. Shaped actuators having a topological pattern formed across at least one portion are demonstrated to induced strain at the patterned portion of the actuator, causing the patterned portion to flare into open and close positions upon application of an external field. Voltage transformers, spark generators, power sources, and sensors are developed using the non-planar, homogeneous, single slab active member material of non-uniform thickness. Last, semiconductor process design techniques are demonstrated for periodic and other non-planar single slab actuators.

Owner:MONODRIVE

Large dimension, flexible piezoelectric ceramic tapes

InactiveUS6964201B2Piezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesControl signalTransducer

A flexible detection / test tape includes a first flexible conductive layer, and a second flexible conductive layer positioned opposite the first conductive layer. A plurality of at least one of sensors, actuators or transducers are positioned between and are bonded to the first flexible conductive layer and the second flexible conductive layer. An insulative material is inserted around the plurality of at least one of the sensors, actuators or transducers. An electrical contact network connects to the first flexible conductive layer and the second flexible conductive layer, whereby power and control signals are provided to the flexible detection / test tape.

Owner:PALO ALTO RES CENT INC

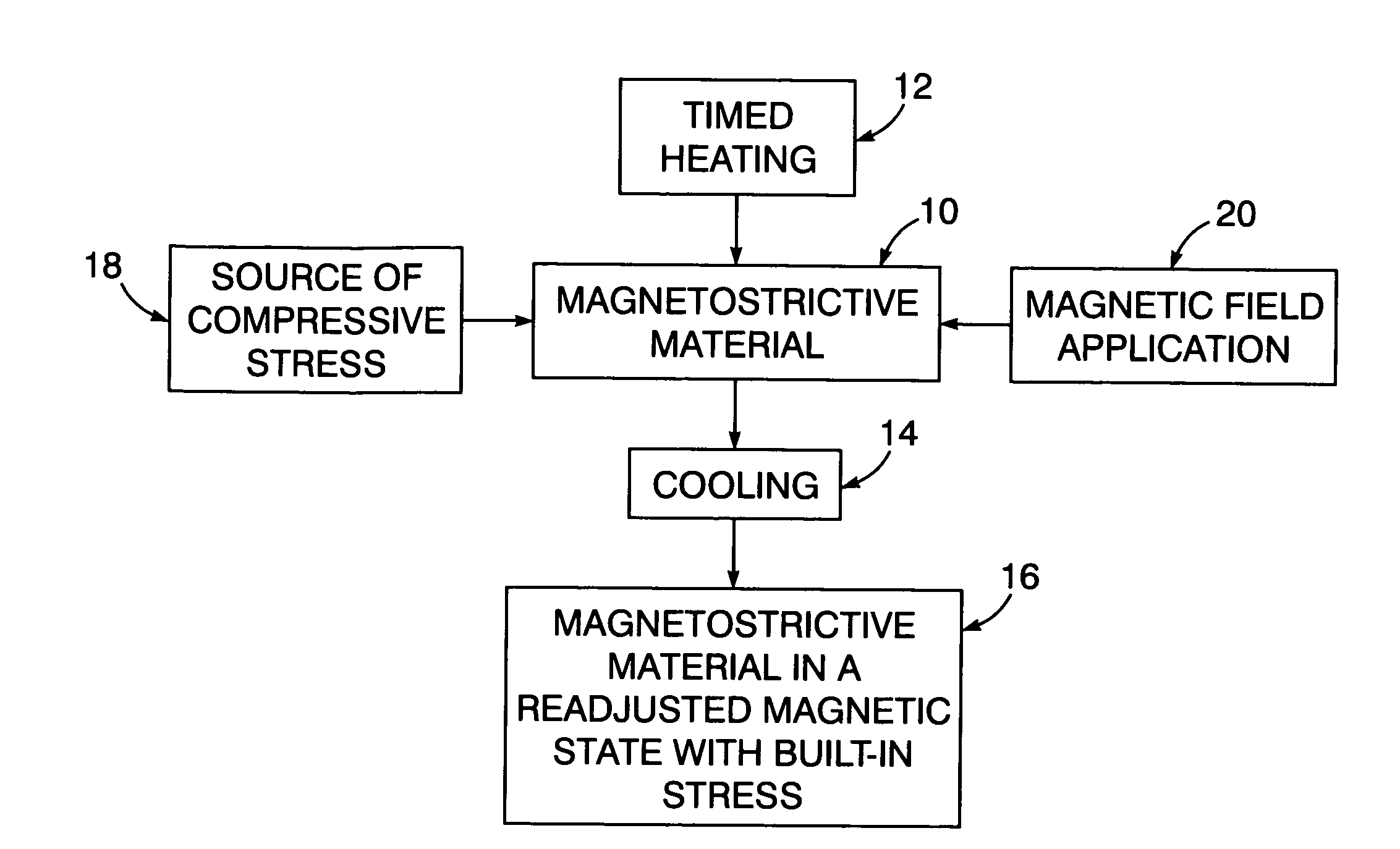

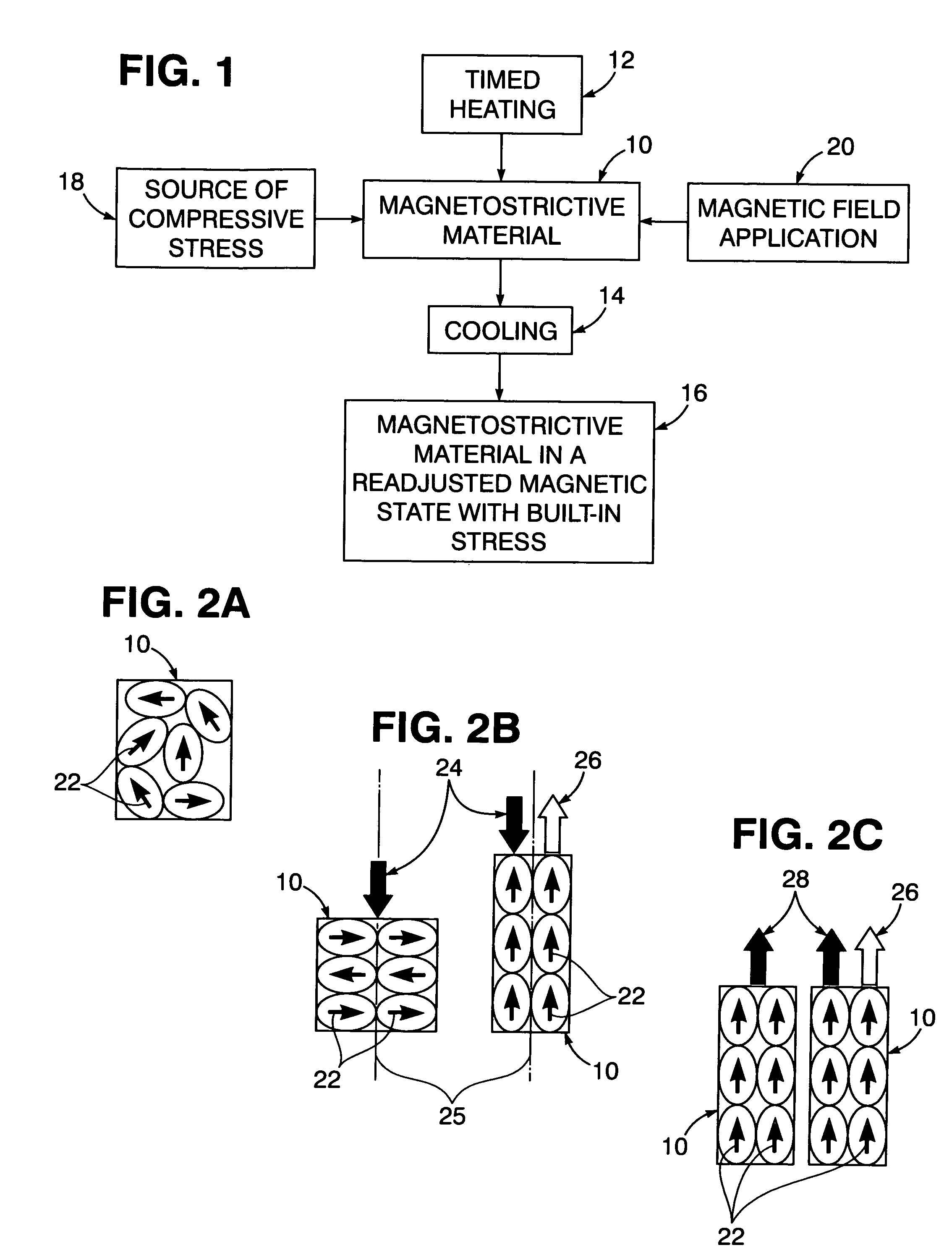

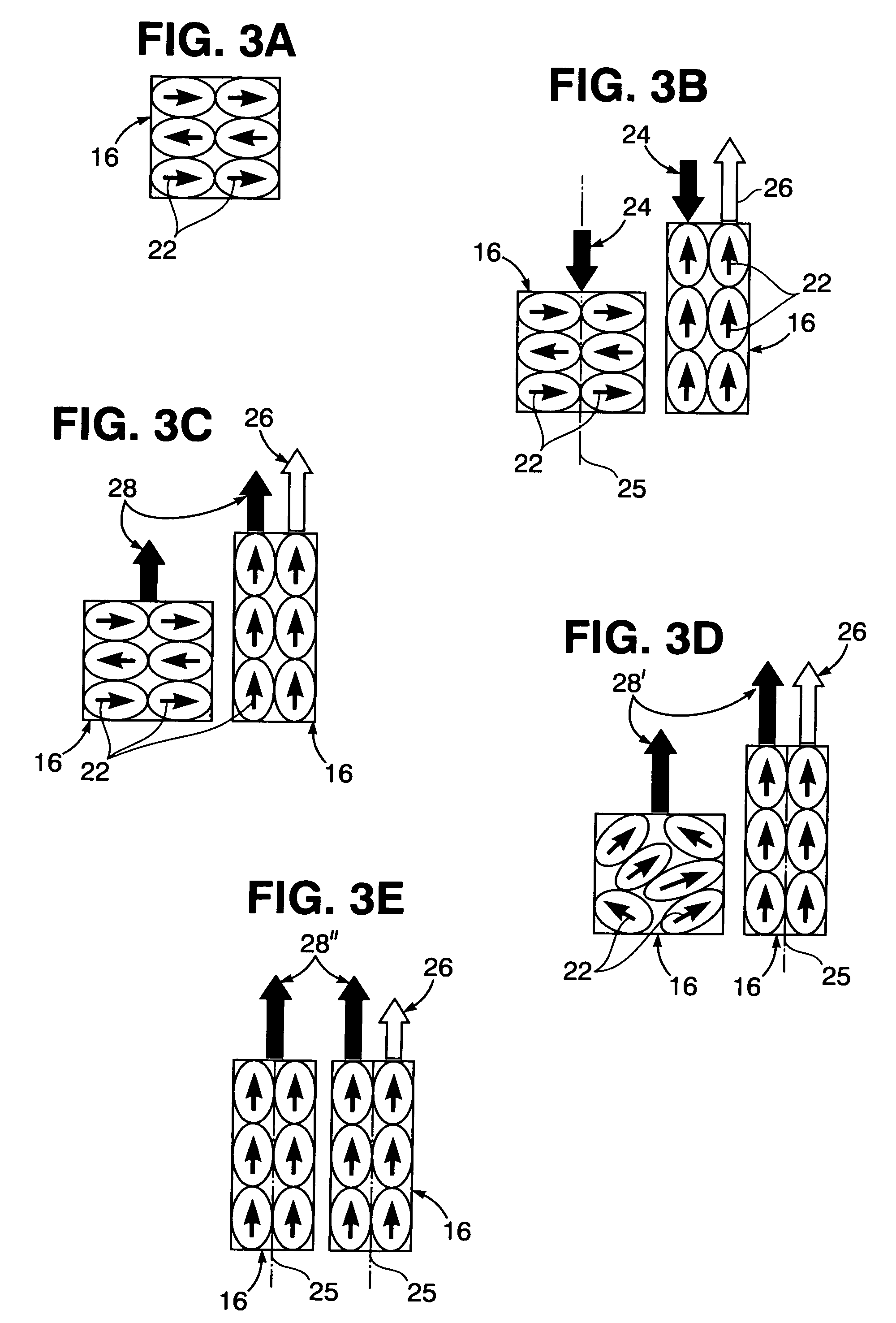

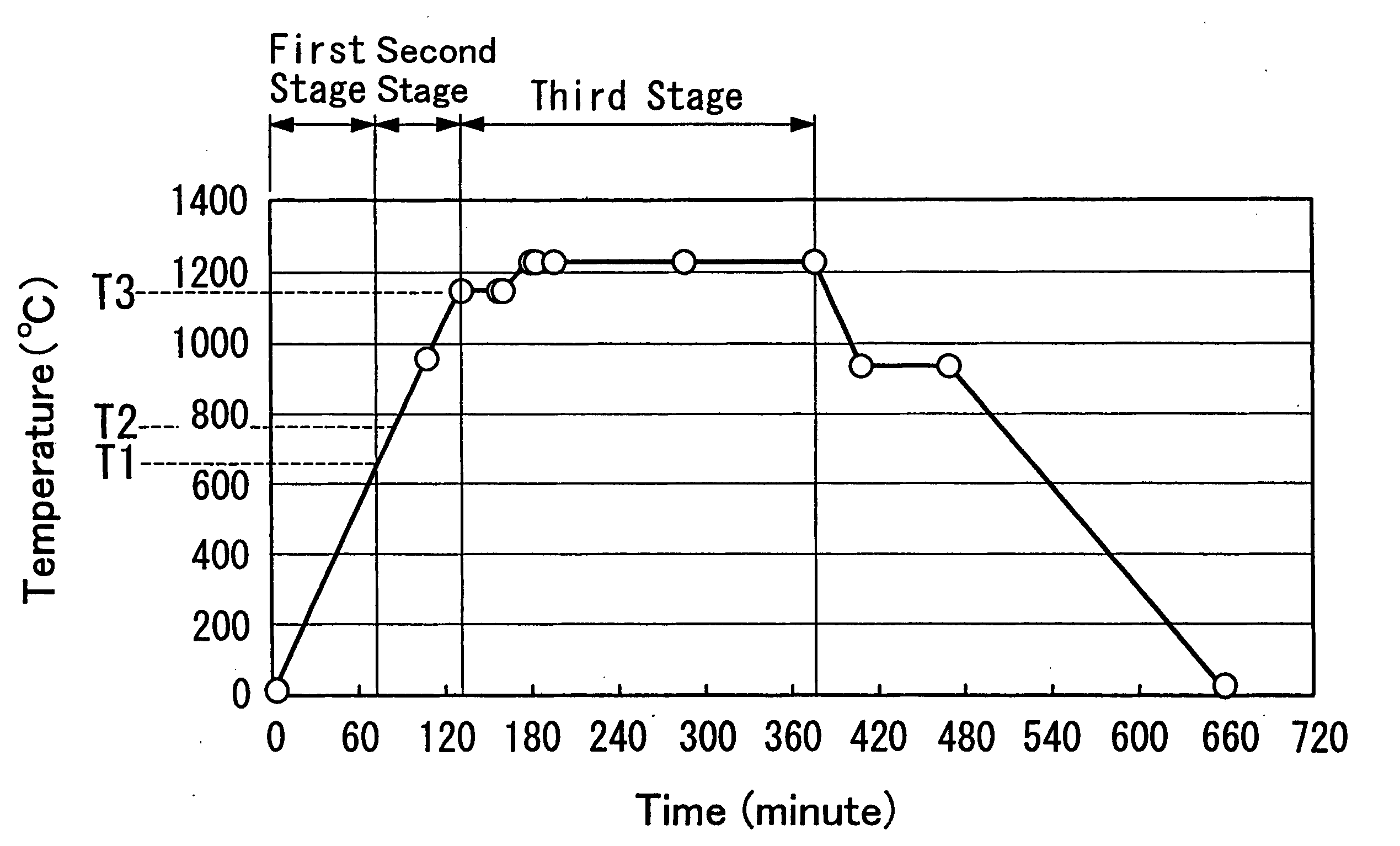

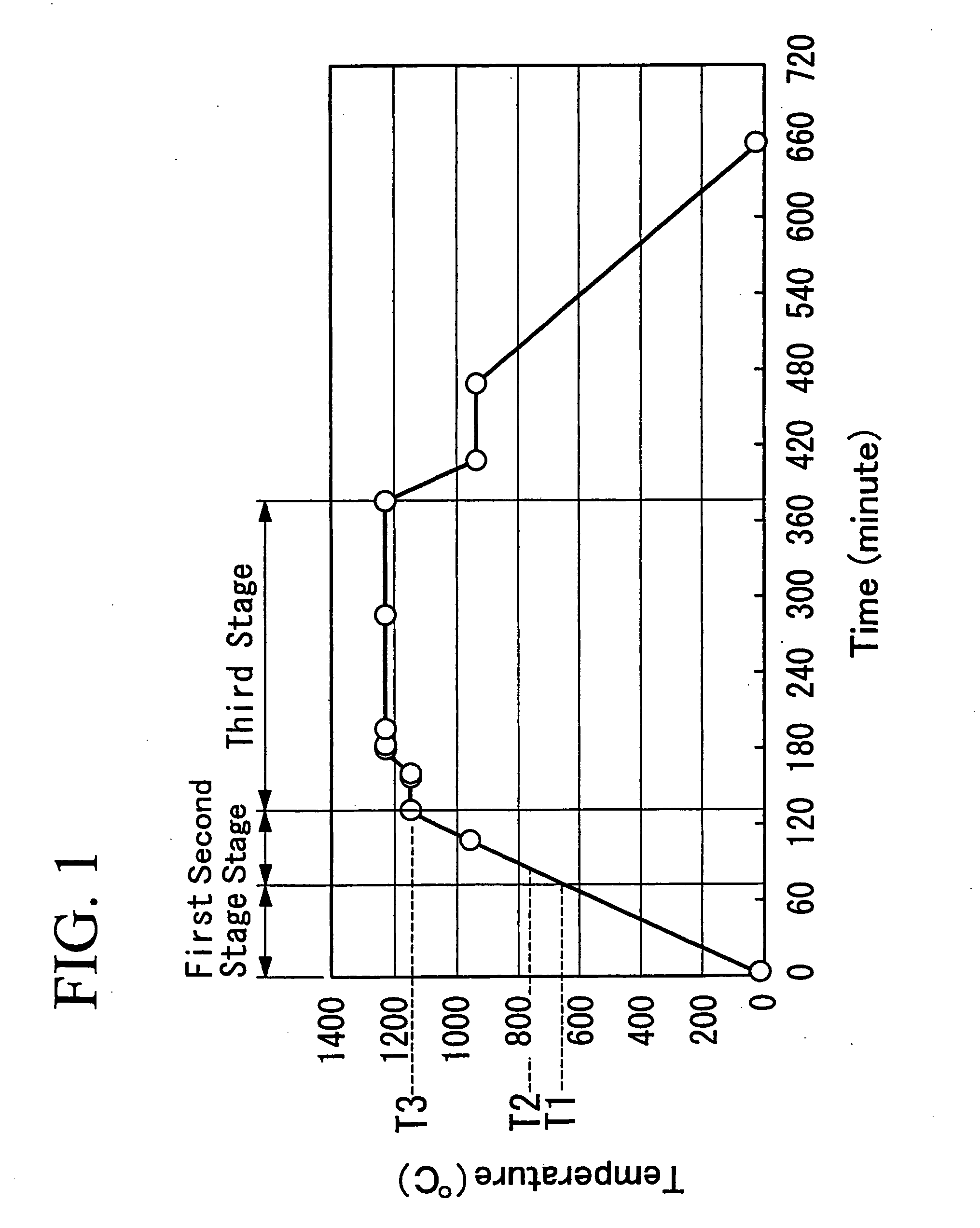

Preparation of positive magnetostrictive materials for use under tension

ActiveUS7479193B1Magnetostrictive device manufacture/assemblyInorganic material magnetismAlloyUltimate tensile strength

A positive magnetostrictive material such as a ferromagnetic alloy is subjected to a magnetic field during annealing treatment while being heated for a predetermined period of time at an elevated temperature below its softening temperature followed by cooling resulting in a treated ferromagnetic material having high tensile strength and positive magnetostriction properties for enhancing use thereof under tensile loading conditions. Such treatment of the ferromagnetic alloy may be augmented by application thereto of a compressive stress.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for producing magnetostrictive element and sintering method

InactiveUS20050061401A1Increase productionInhibition formationPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyMetallurgyVacuum pump

In the step of sintering a compact that is finally to be a magnetostrictive element, when the temperature in a furnace is elevated, the atmosphere in the furnace is evacuated by a vacuum pump to keep the pressure in the furnace at negative pressure in a temperature range that allows thermal decomposition of hydride present in the compact to release hydrogen gas to accelerate release of hydrogen from the compact.

Owner:TDK CORPARATION

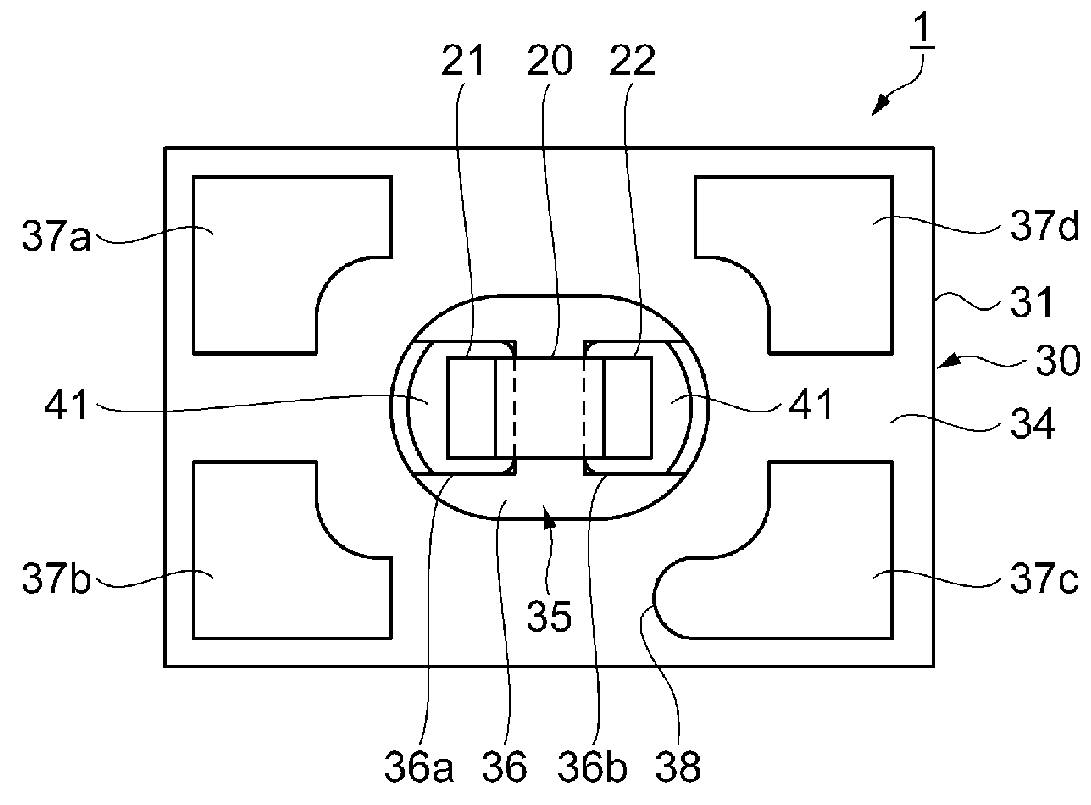

Resonator, frequency filter, duplexer, electronic device, and method of manufacturing resonator

InactiveUS9112134B2Piezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyFrequency filteringAcoustic wave

A resonator according to the present invention includes a supporting substrate, a piezoelectric layer, a pair of excitation electrodes, and a bonding layer. The piezoelectric layer is made of a piezoelectric material. The pair of excitation electrodes is formed on the upper surface of the piezoelectric layer so as to excite bulk acoustic waves. The bonding layer has a cavity formed therein so as to face the excitation electrode pair through the piezoelectric layer, and the bonding layer bonds the supporting substrate to the lower surface of the piezoelectric layer.

Owner:TAIYO YUDEN KK

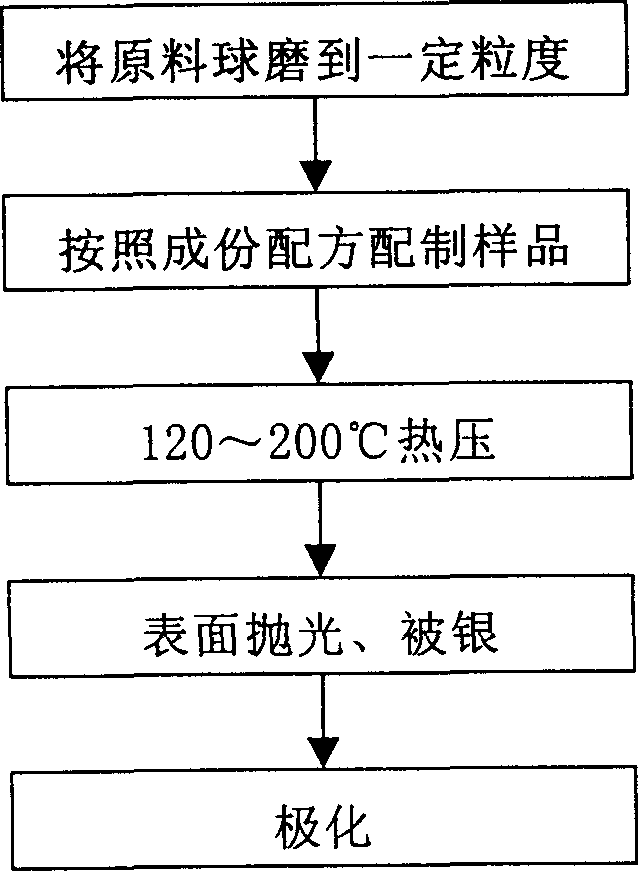

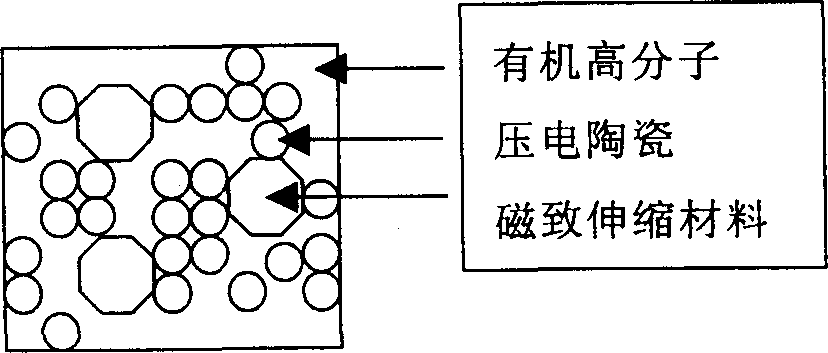

Three-component compound magnetoelectric material using organic polymer as adhesive and its preparation method

InactiveCN1395325AImprove mechanical propertiesHigh magnetoelectric conversion coefficientPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLead zirconate titanateBarium titanate

The invention relates to the ternary compound magneto-electric material by use of the organic macromolecule as the agglomerant as well as its preparation method.With the organic macromolecule being as the agglomerant the piezoelectric ceramic(such as lead zirconate titanate etc.)and the magnetostriction material(such as terbium-dysprosium-iron alloy)are taken shape by hot pressing at low temperature.The magneto-electric compound material can be made by the method.Comparing the prior art,the invention possesses the advantages of simple process,good mechanical characters of the material and high magneto-electric transformation factor.The hotpressing technique provides the features of low pressing temperature(about 120-200 deg.C),easy to change the magneto-electric characters by changing the sequence for adding the constituent and the relative content.

Owner:TSINGHUA UNIV

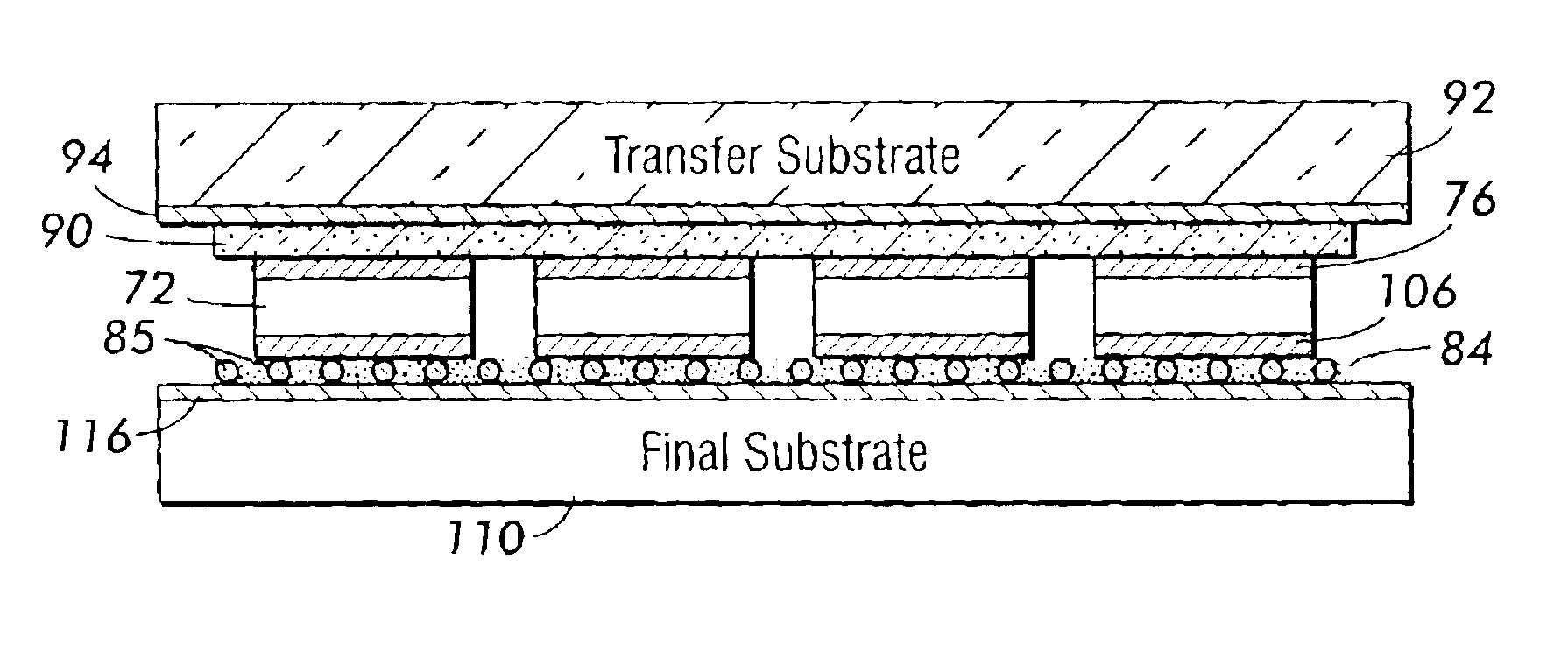

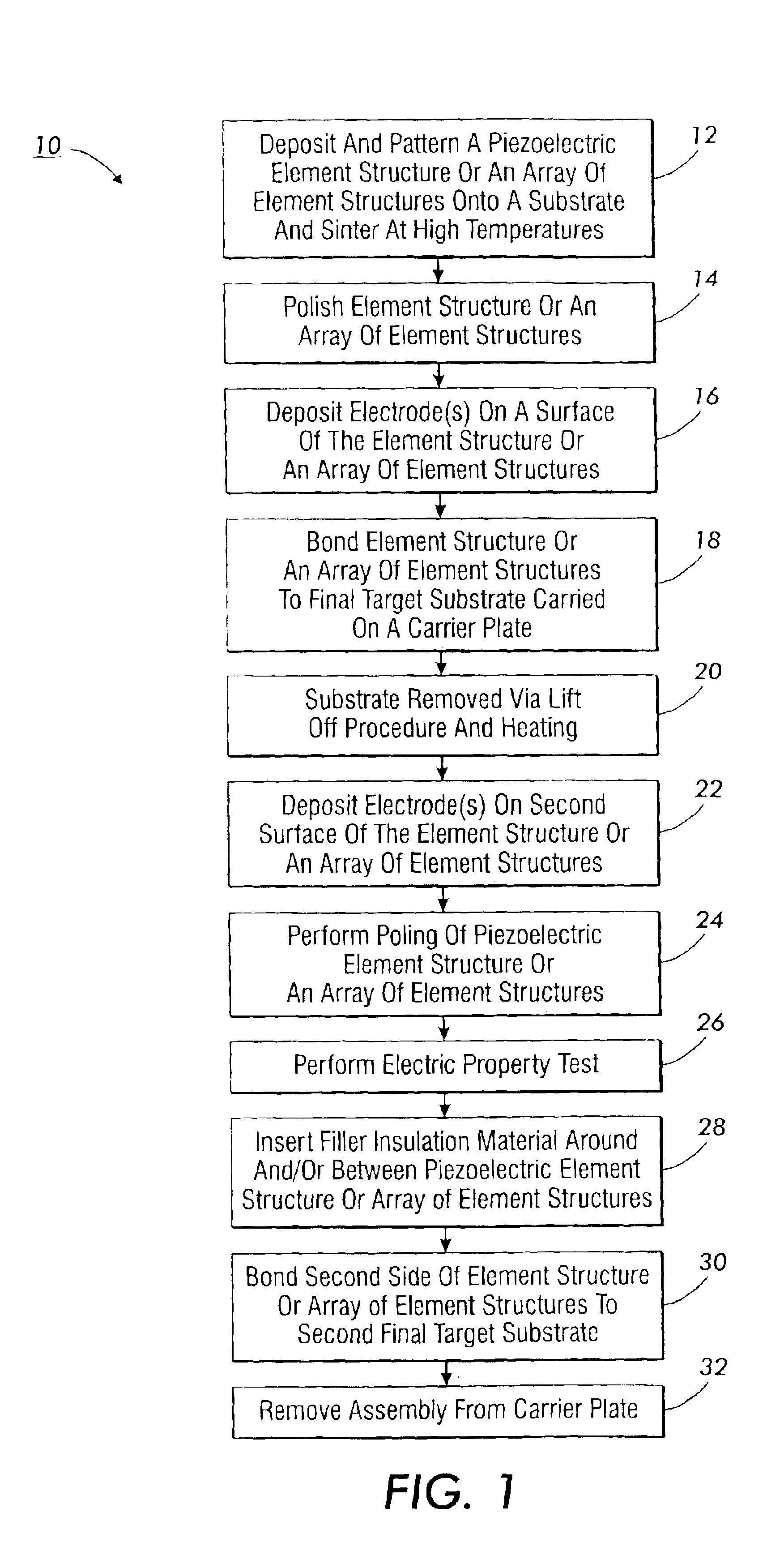

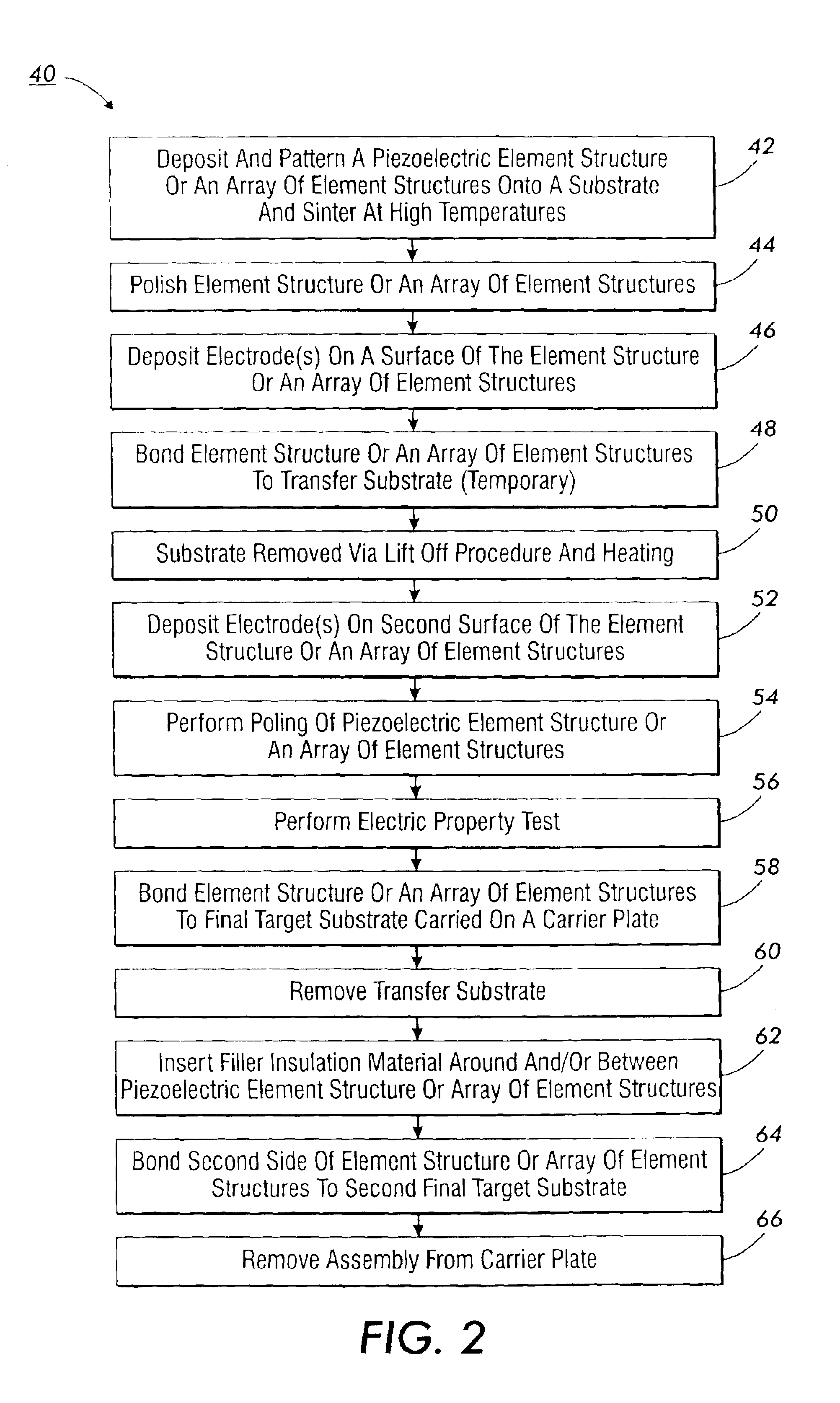

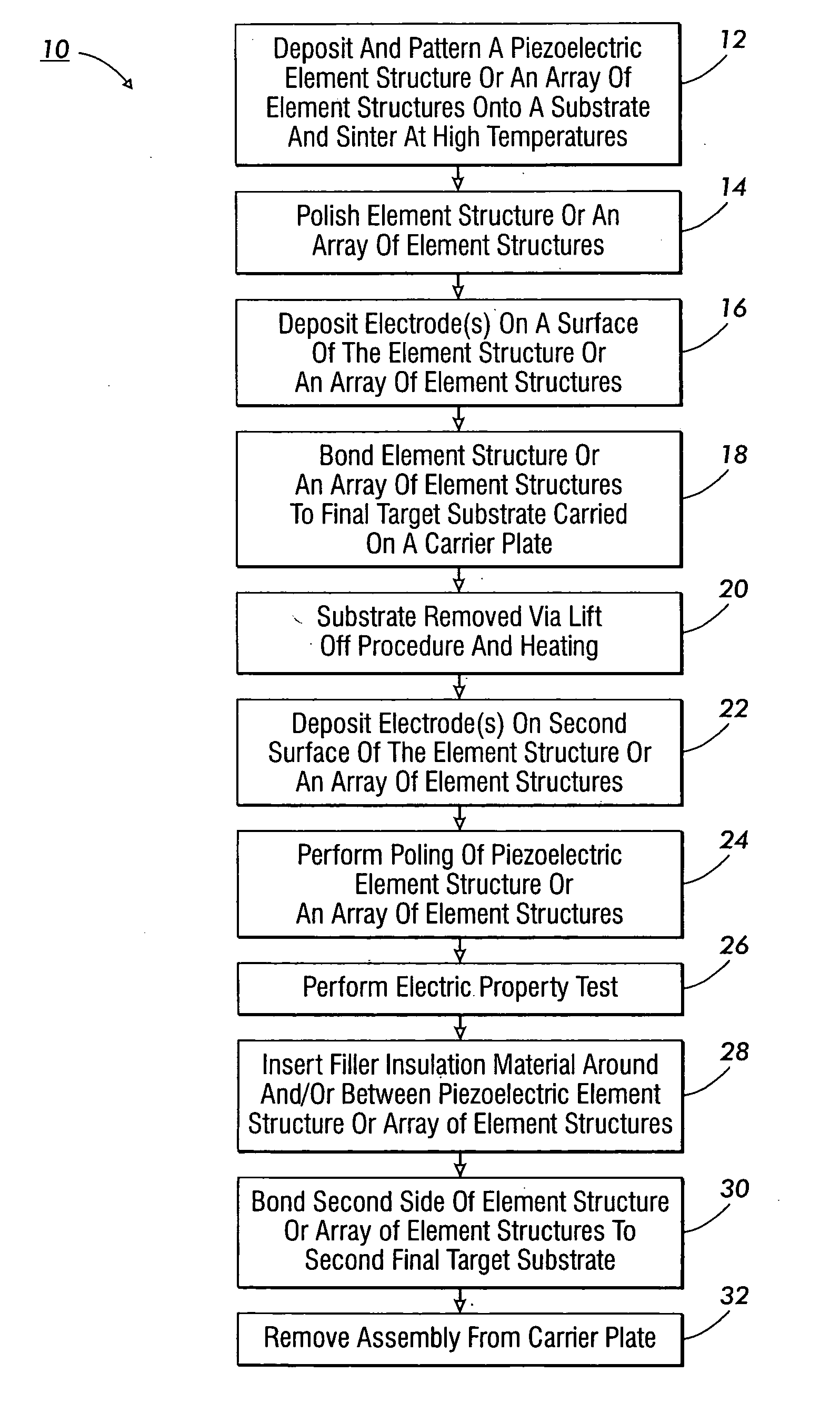

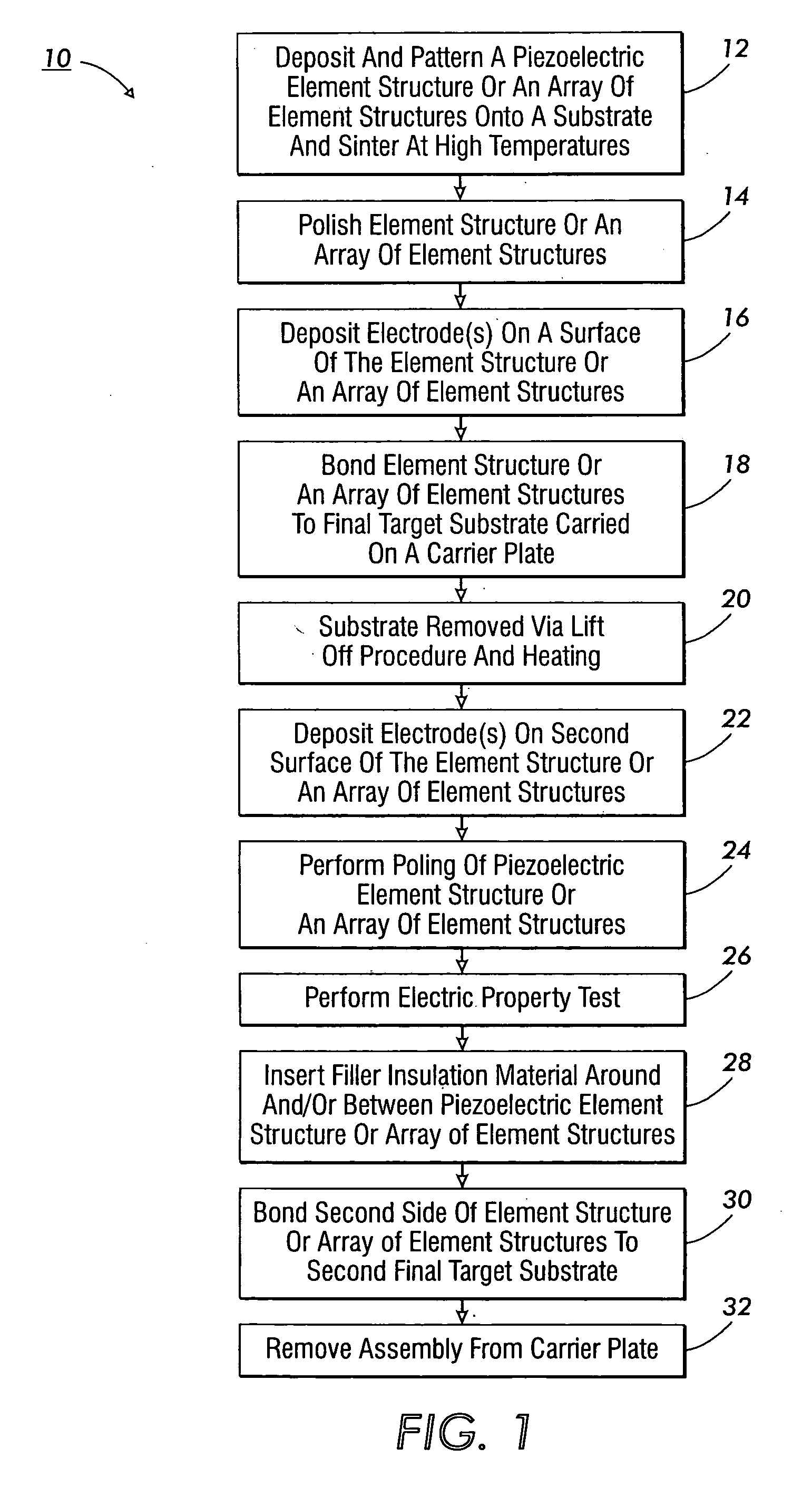

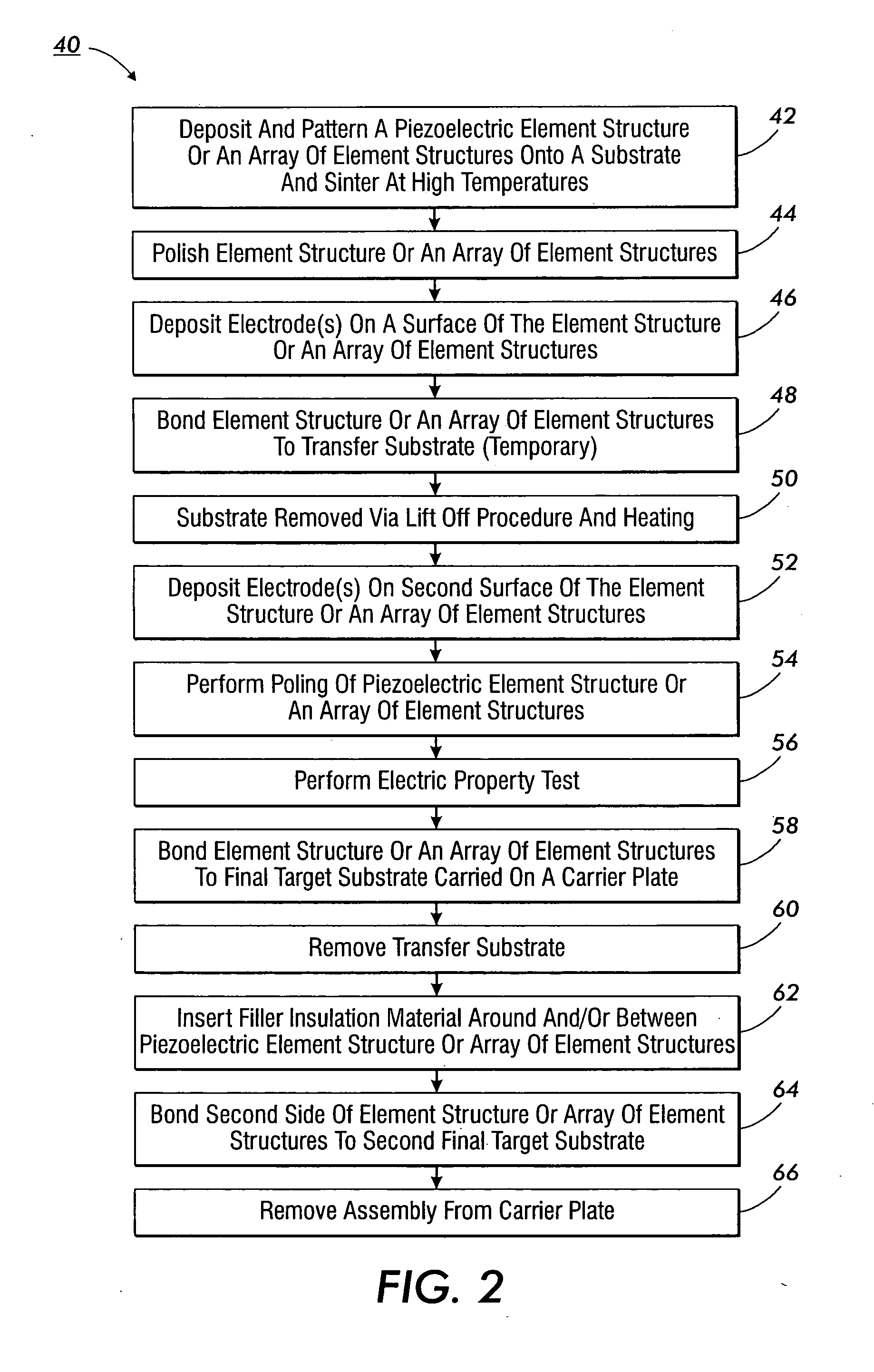

Methods for making large dimension, flexible piezoelectric ceramic tapes

InactiveUS20060211217A1Piezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterials scienceTest tape

A method for producing a detection / test tape includes depositing a material onto a surface of at least one first substrate to form a plurality of element structures. Electrodes are deposited on a surface of each of the plurality of element structures, and the element structures are bonded to a second substrate, where the second substrate is conductive or has a conductive layer, and the second substrate is carried on a carrier plate. The at least one first substrate is removed from the element structures and second side electrodes are deposited on a second surface of each of the plurality of element structures. An insulative material is inserted around the element structures to electrically isolate the two substrates used to bond the element structures. A second side of the element structures is then bonded to another substrate, where the other substrate is conductive or has a conductive layer. Thereafter, the carrier plate carrying the second substrate is removed.

Owner:PALO ALTO RES CENT INC

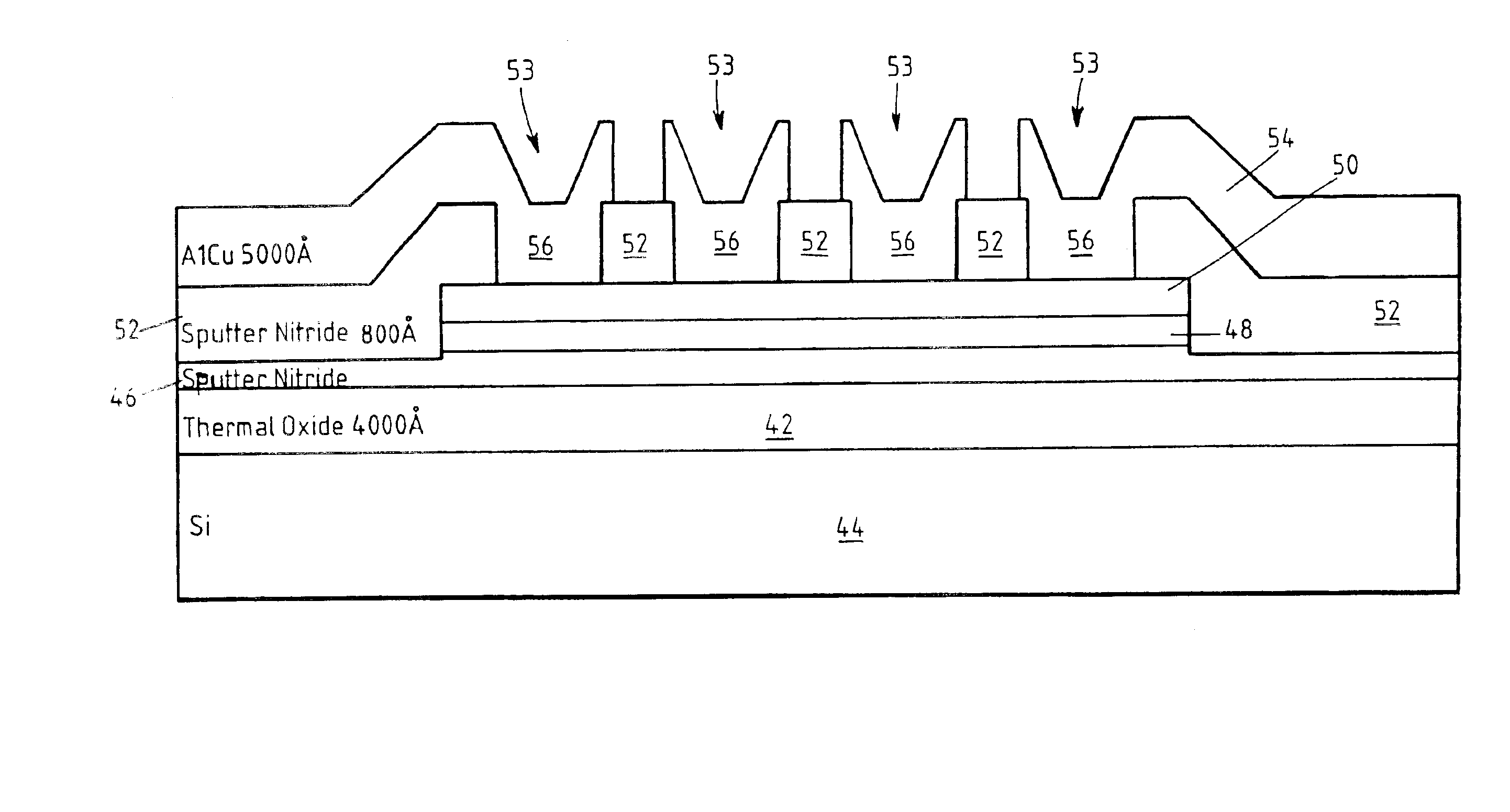

Barber pole structure for magnetoresistive sensors and method of forming same

InactiveUS6850057B2Piezoelectric/electrostrictive device manufacture/assemblyMagnetic field measurement using galvano-magnetic devicesEtchingConductive materials

A method of making a magnetorestrictive sensor involves the deposition of a magnetorestrictive strip over a substrate, the deposition of an insulating layer over the magnetorestrictive strip, the etching of barber pole windows through the insulating layer, the deposition of a conductive material over the insulating layer and into the barber windows, and the etching away of the conductive material between the barber pole windows so as to form barber poles. In this manner, the formation of the barber poles is controlled by the windows formed in the insulating layer.

Owner:HONEYWELL INT INC

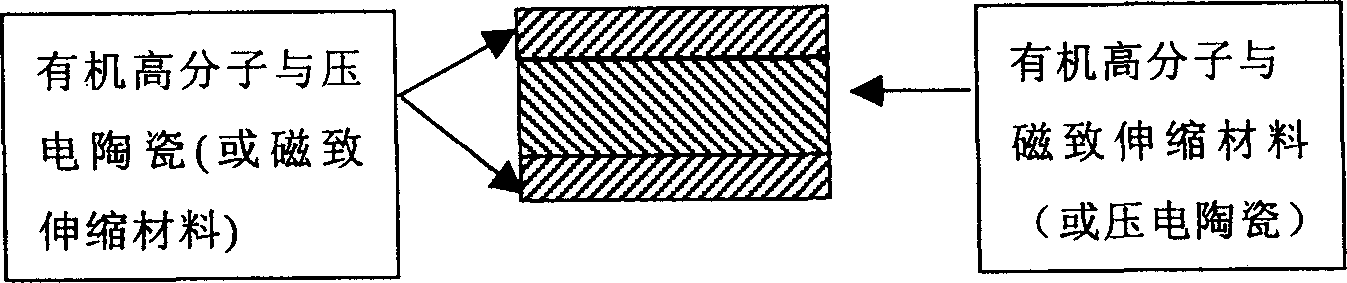

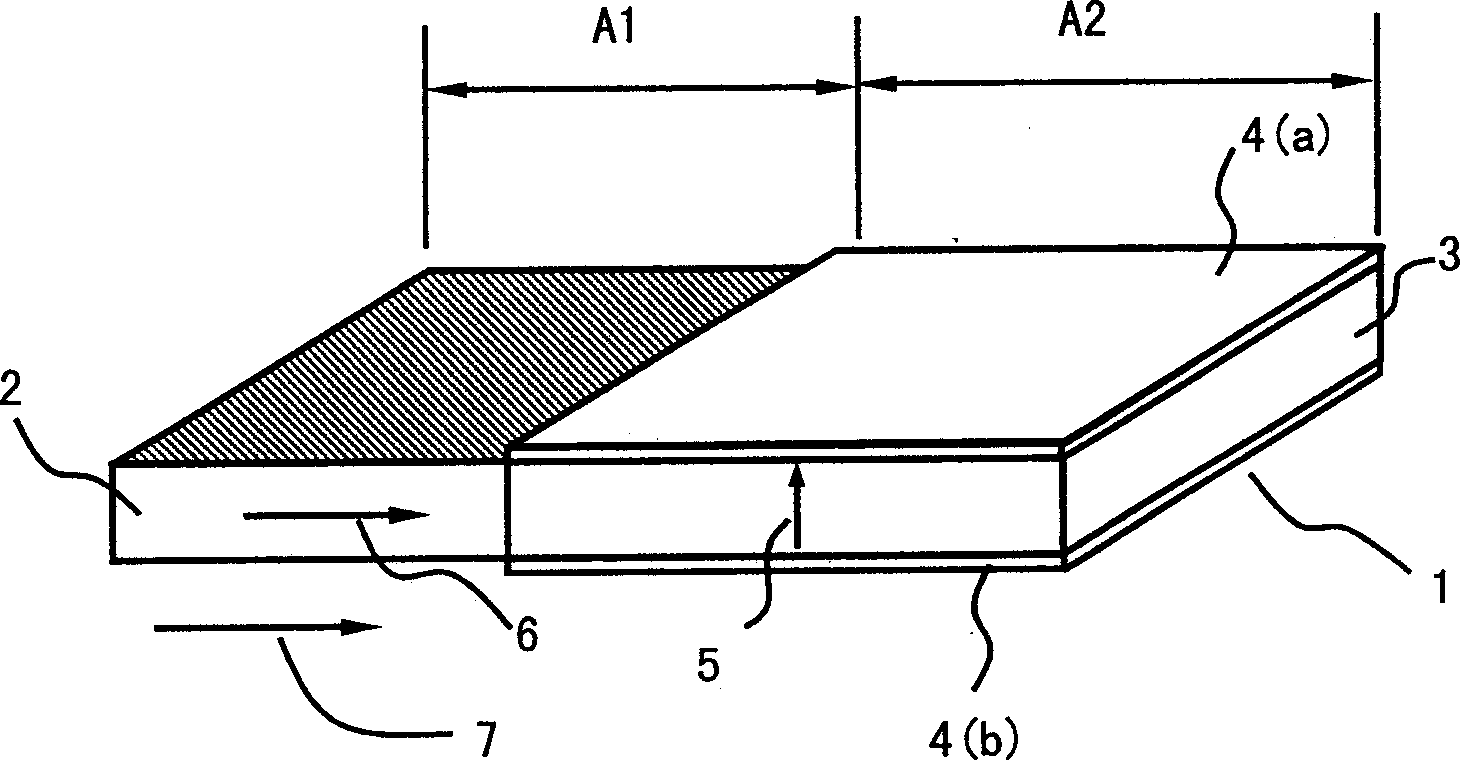

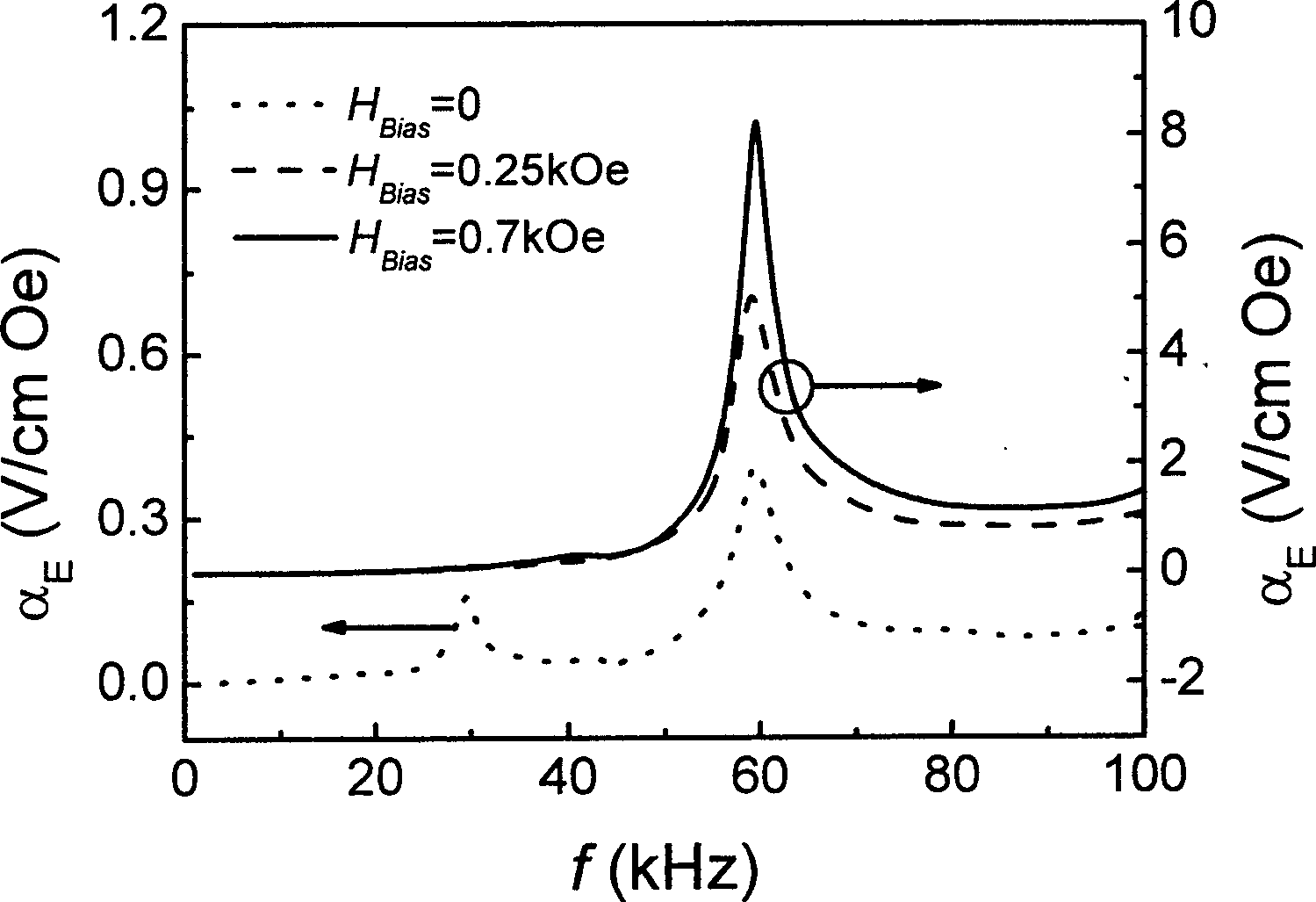

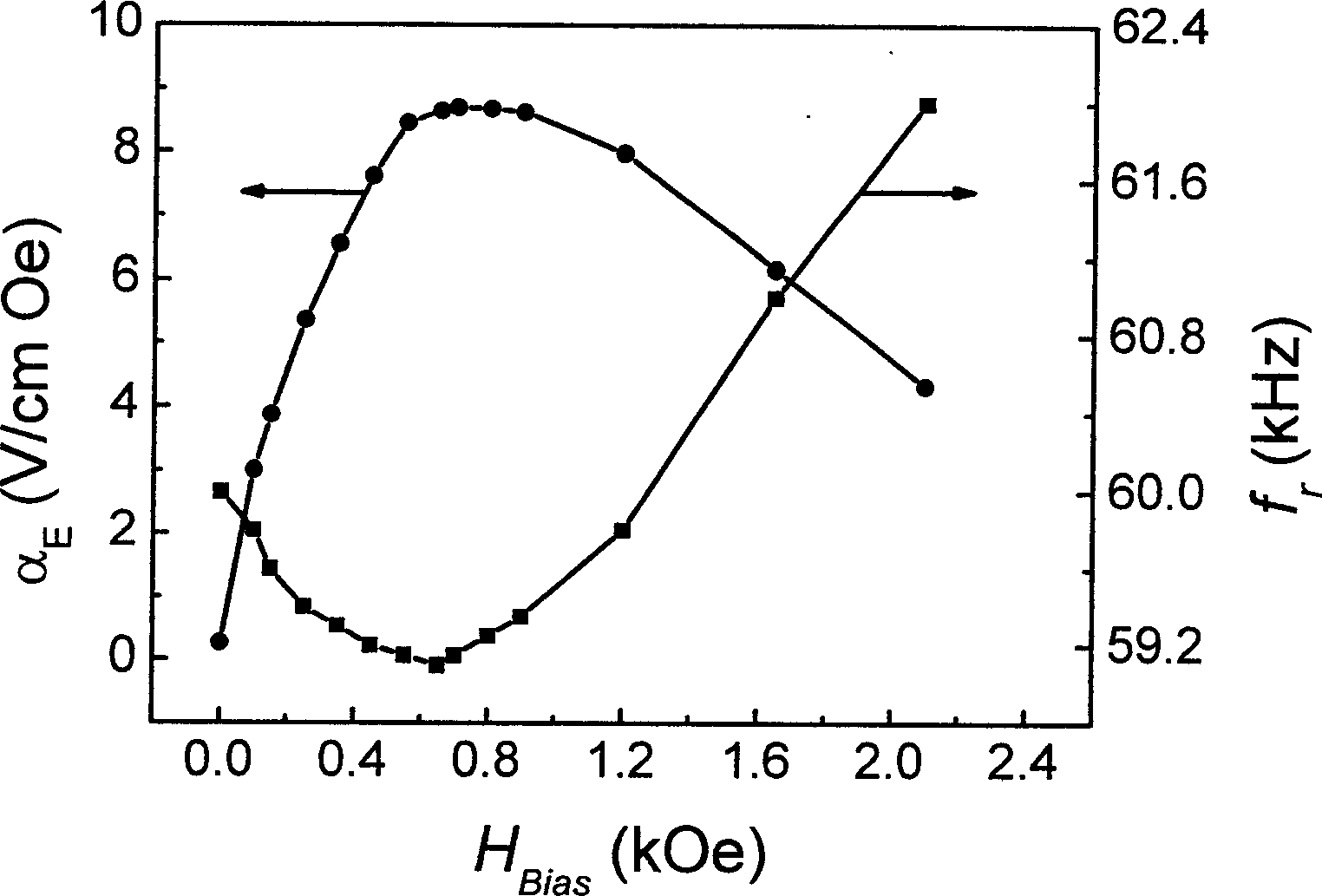

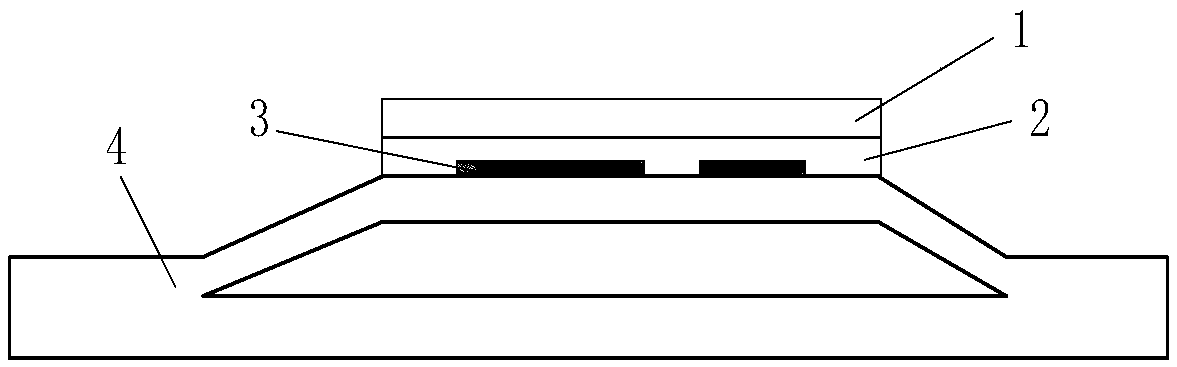

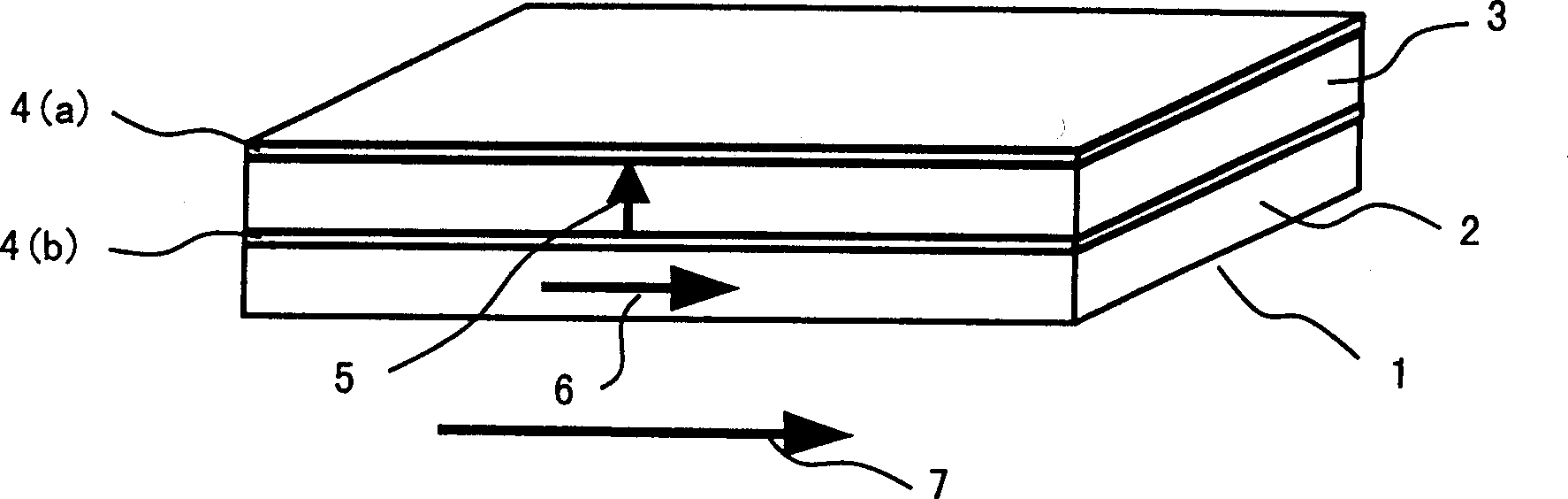

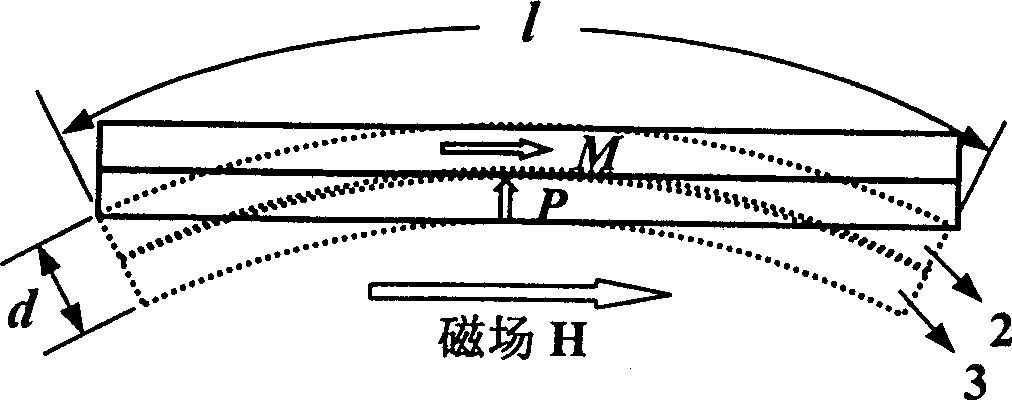

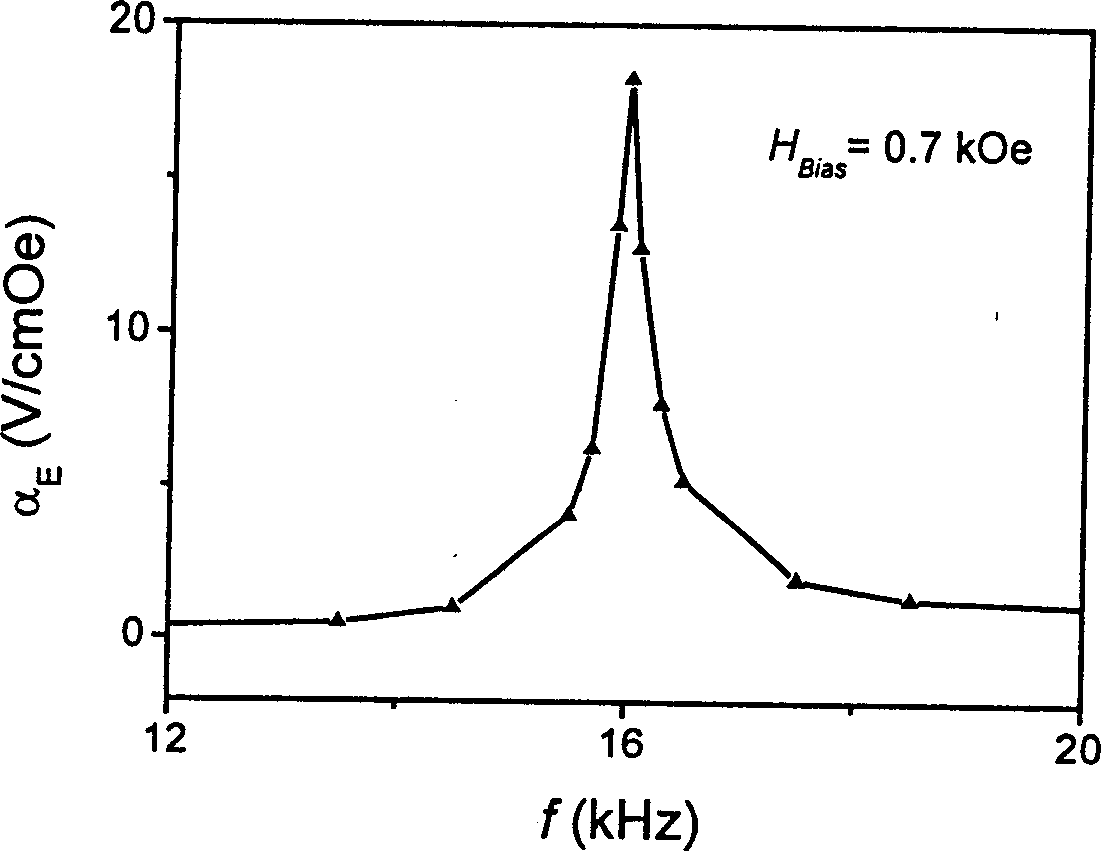

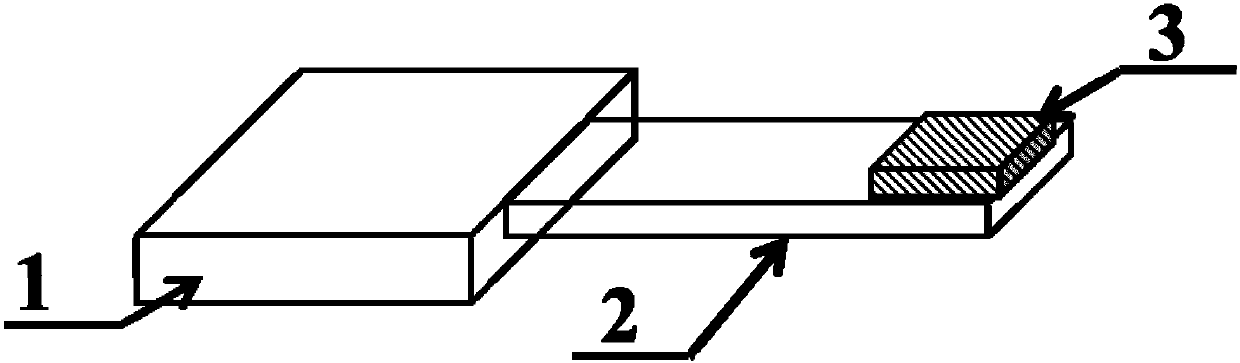

Magne to electric composite material and manufacturing method thereof

InactiveCN1489227AReduce lossImprove conversion efficiencyPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyResonanceAlloy

The magnetoelectricity composite material is a rectangle piece (1) divided into two areas A1 and A2 along longitudinal direction. A1 is made from magnetostrictive material, and A2 is made from piezodielectric material. A1 and A2 are combined through agglomerant. A pair of flat pole (4a and 4b) is in the A2 area. The piezodielectric material is polarized along thick direction. The said magnetostrictive material is magnetostrictive alloy, oxide or their composite material with polymer. The said piezodielectric material is piezoelectric ceramic or a composite material formed from piezoelectric ceramic and polymer. When dc magnetic biasing field and AC magnetic field with small signal are applied to rectangle piece 2 of magnetostrictive material along longitudinal direction, the rectangle piece (1) of magnetoelectricity generates resonance near to 60kHz, and voltage is output through rectangle piece 3 of piezodielectric composite material so as to realize magneto-electric coupling.

Owner:NANJING UNIV

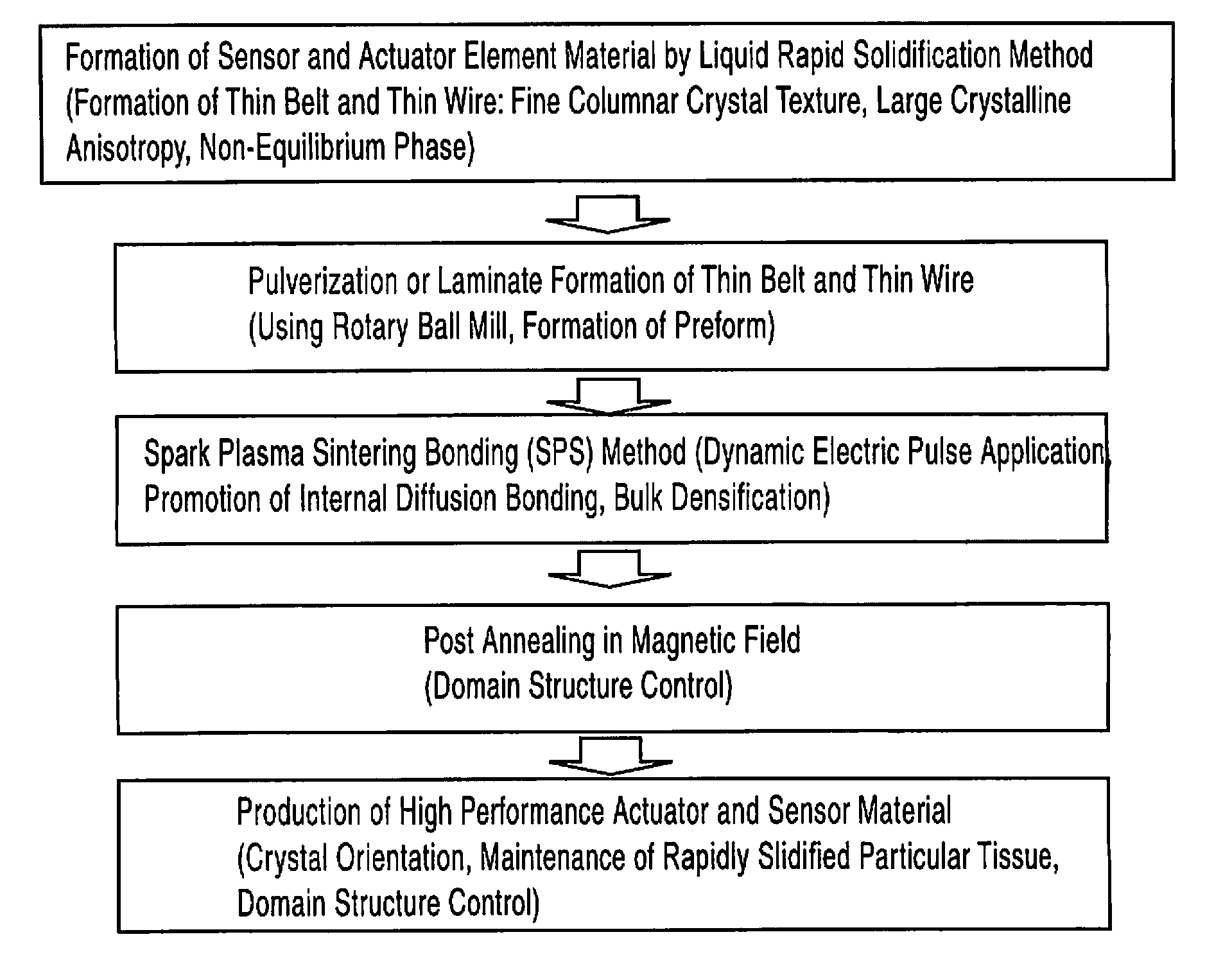

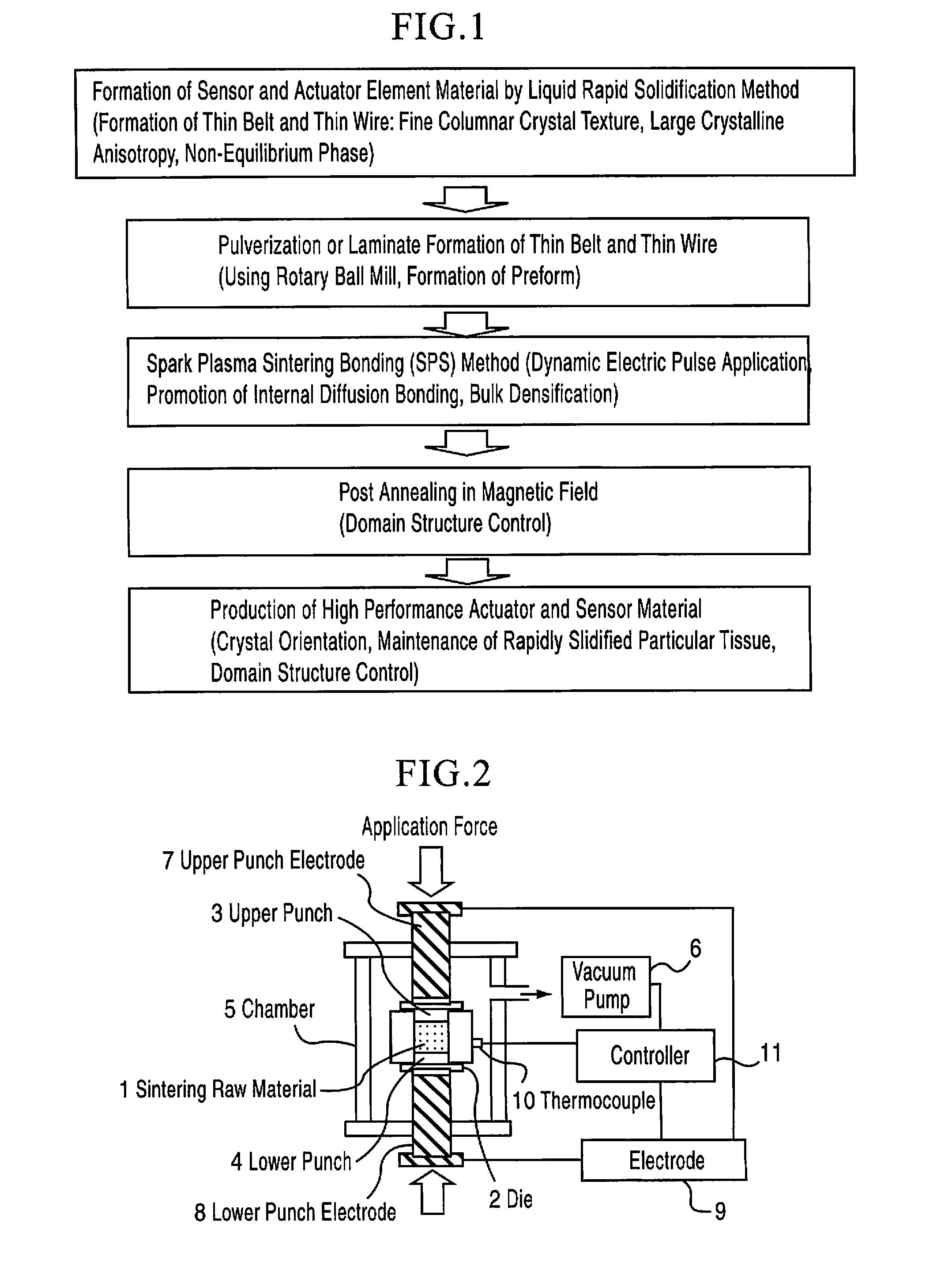

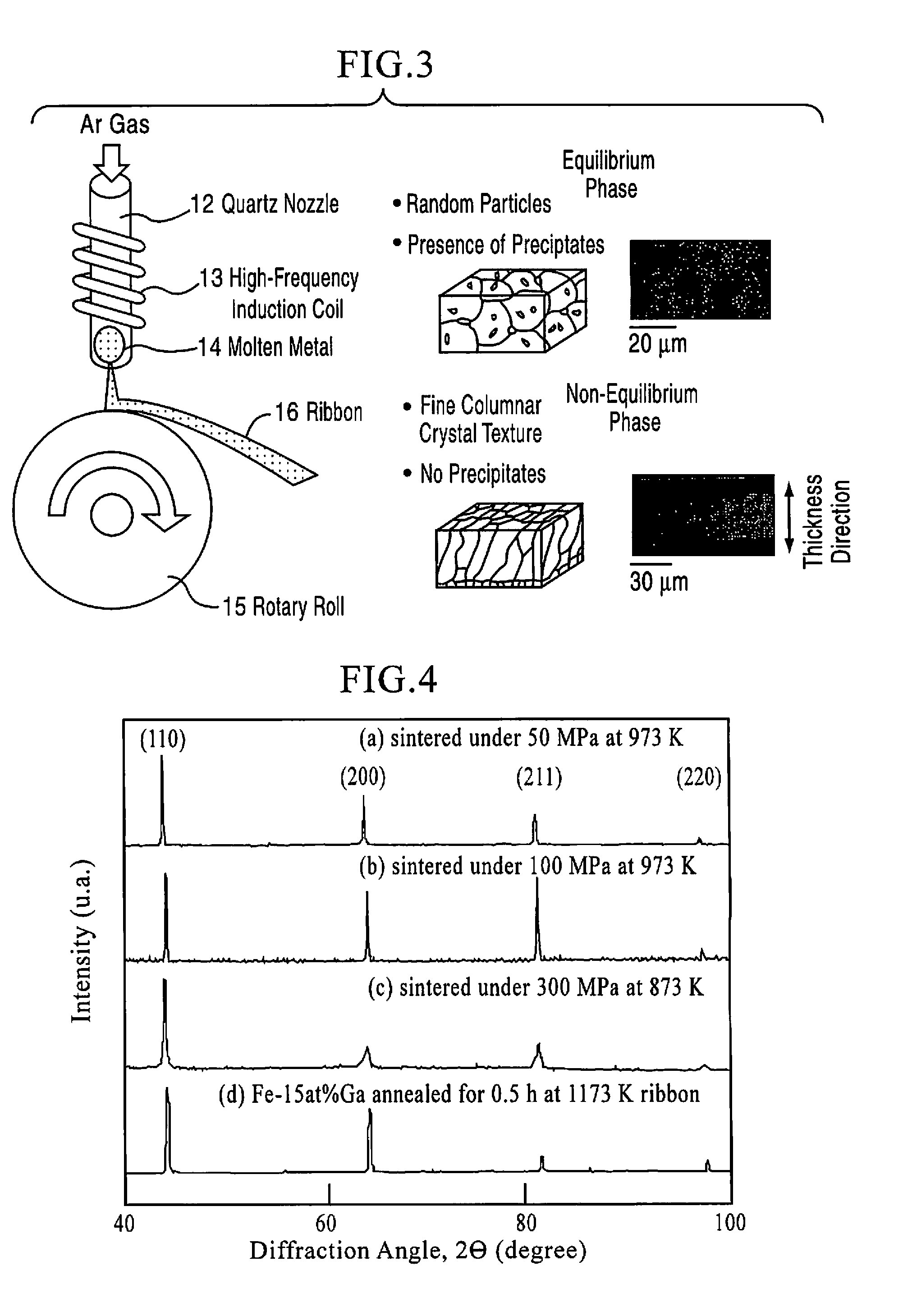

Bulk solidified quenched material and process for producing the same

InactiveUS20070183921A1Improve performanceImprove rigidityPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyHigh densityLiquid state

[Object] A bulk material which is suitably used as a material for actuator and sensor elements is formed from a Fe—Ga base magnetoresistive alloy and a Ti—Ni base shape memory alloy taking advantage of crystal miniaturization and anisotropy as well as reduction of precipitates (equilibrium state in state diagram) and non-equilibrium phases peculiar to liquid rapidly solidified materials, and the performance of the material is enhanced by a production method thereof which has cost advantage over a melt method. [Construction] A rapidly solidified material having a particular rapidly solidified texture of a Fe—Ga magnetostrictive alloy or a TiNi-based shape-memory alloy and properties derived therefrom is formed into slices which are laminated to each other in a die, or is formed into a powder or chops which are filled in the die. Subsequently, spark plasma sintering is performed so that bonds between the slices, grains of the powder, or the chops are formed at a high density to form a bulk alloy, followed by annealing whenever necessary, so that the properties of the alloy are improved.

Owner:JAPAN SCI & TECH CORP

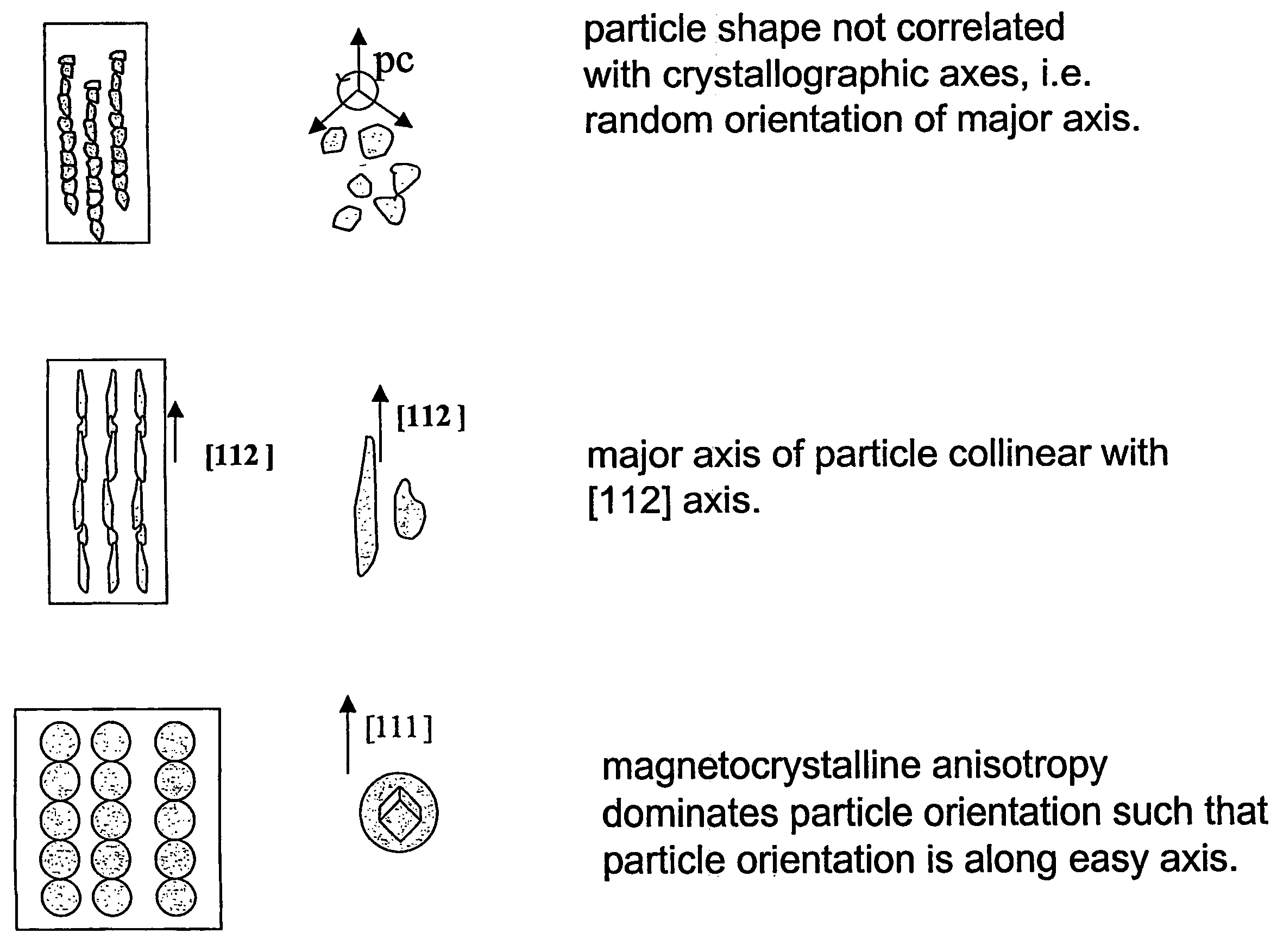

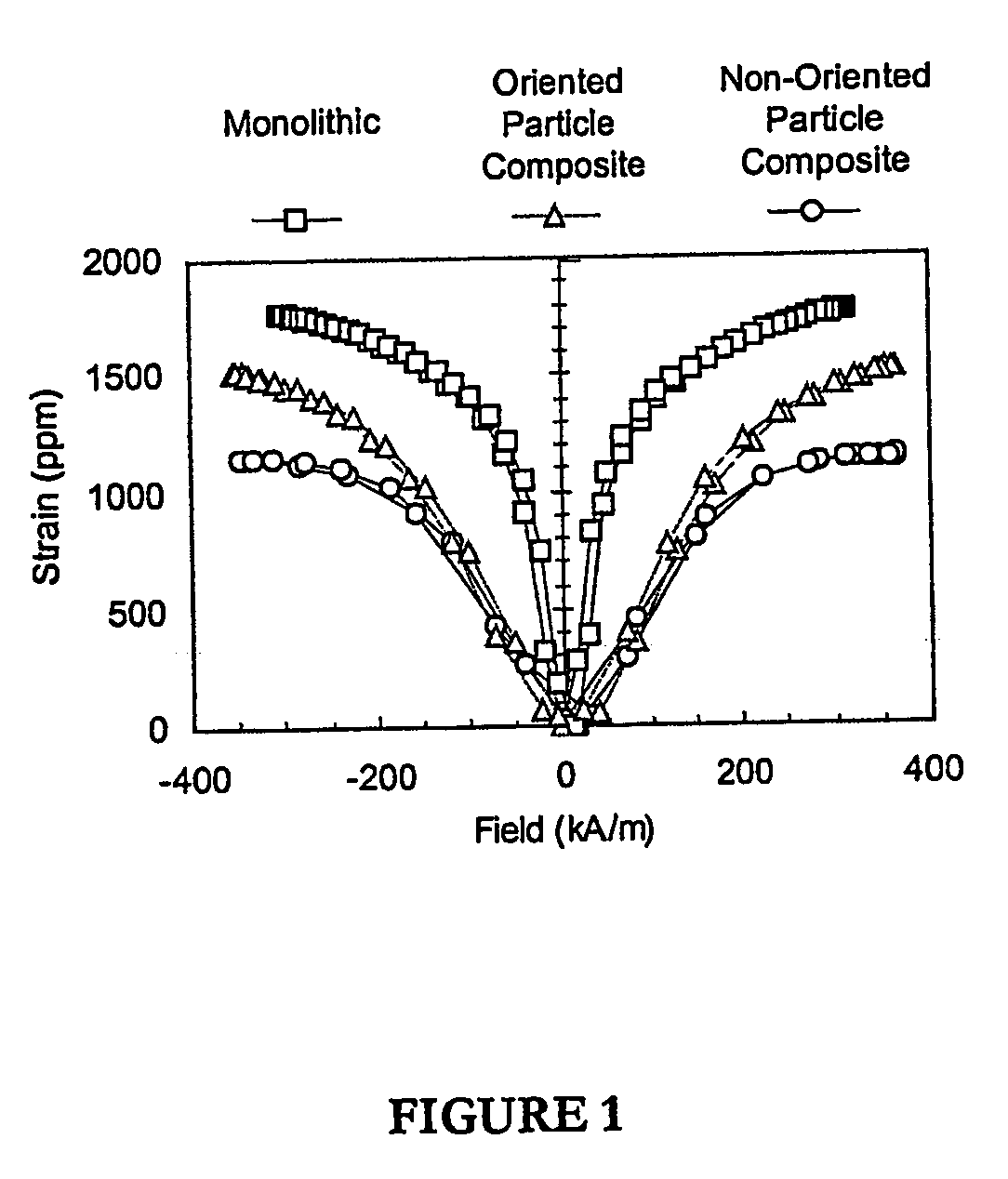

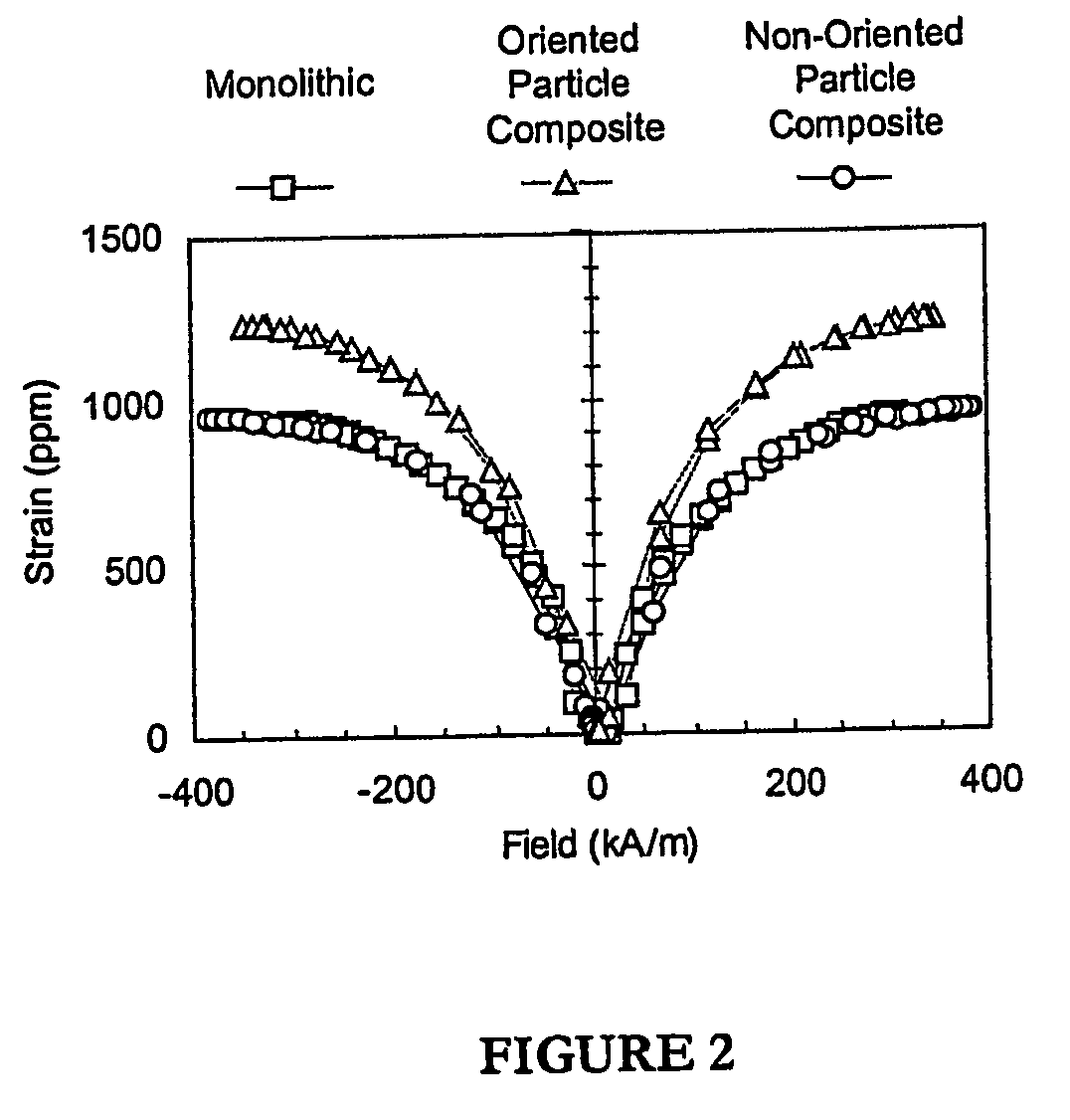

Directionally oriented particle composites

InactiveUS20050161119A1Large saturation strainImprove propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCrystal orientationMaterials science

Magnetostrictive particulate composites with a preferred crystal orientation of the particles and methods for their manufacture are described. In a representative embodiment, a 25% volume Terfenol-D fraction polymer matrix composite was fabricated in a magnetic field using geometric anisotropy to orient needle shaped particles with long axis [112] orientation along the length of the composite. Results demonstrate that the magnetostriction of a [112] oriented particle composite saturates near 1600 ppm. This is a significant increase when compared to composites without preferential orientation (1200 ppm) and represents the largest reported magnetostriction for a particulate composite material.

Owner:RGT UNIV OF CALIFORNIA

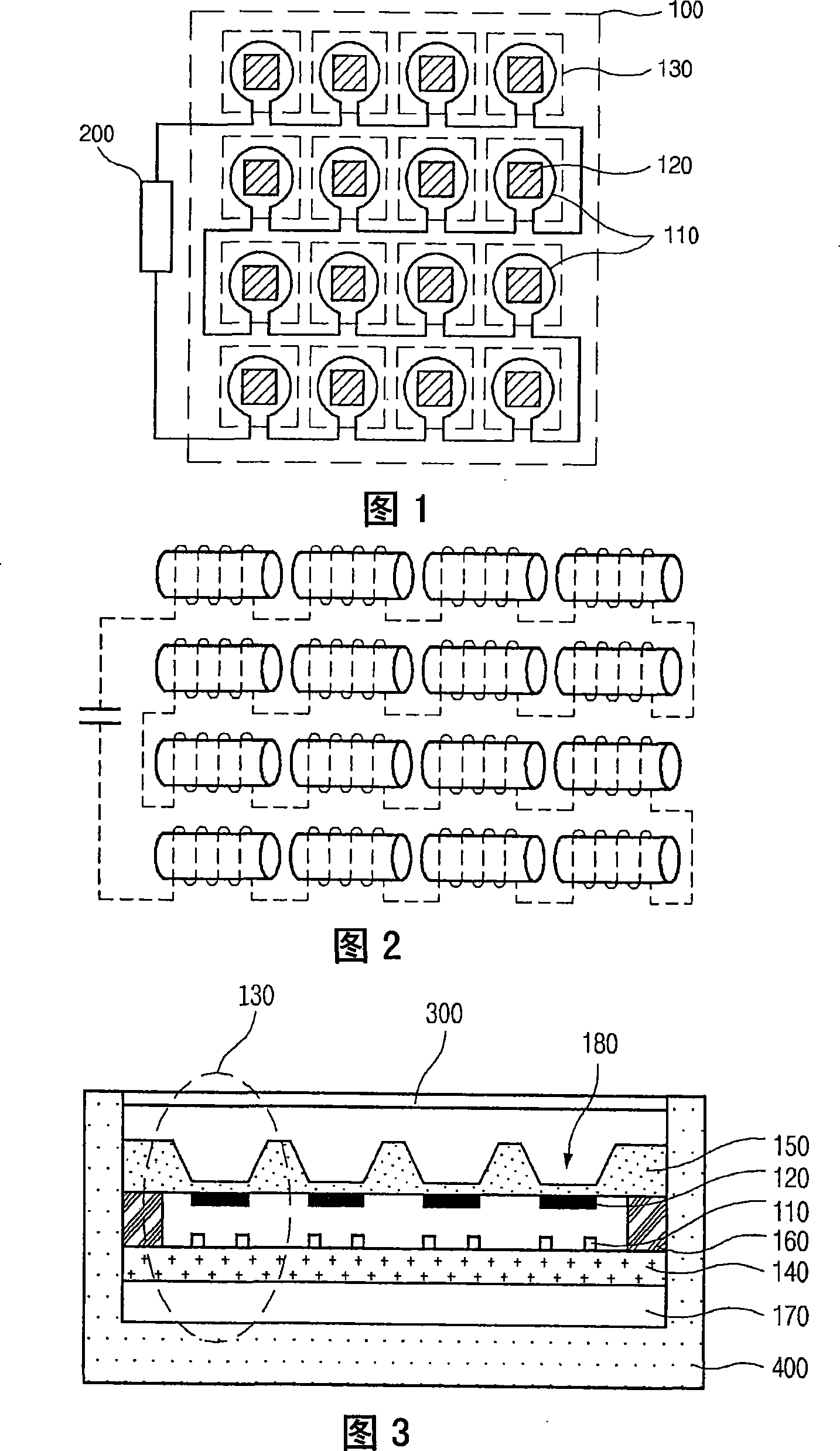

Variable inductor type mems pressure sensor using magnetostrictive effect

InactiveCN101160514AHigh sensitivitySuitable for high frequency applicationsPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLc resonant circuitEngineering

A variable inductor type MEMS pressure sensor using a magnetostrictive effect comprises an inductor array unit and a capacitor unit. The inductor array unit includes a coil unit having a plurality of serially connected circular electrodes formed on a first substrate and a magnetostrictive material thin film corresponding one by one to the circular electrode formed on a second substrate opposite to the first substrate at a predetermined distance in parallel to form an inductor which has the magnetostrictive material thin film as a core of the coil unit for inducing change of magnetic permeability of the magnetostrictive thin film depending on external pressure to vary inductance of the inductor. The capacitor unit constitutes a LC resonant circuit with the inductor array unit to convert magnetic energy discharged in the inductor array unit into a voltage. The variable inductor type MEMS pressure sensor has an excellent resolution because it is more sensitive than a conventional piezoresistive or capacitance sensor, and is manufactured using a MEMS process technology exchangeable with a semiconductor process, thereby enabling miniaturization and a mass package process to reduce the cost of production.

Owner:MDT CORP

Magnetoelectricity antenna based on magnetostrictive piezoelectric materials and preparation method thereof

ActiveCN108879071ARealize indirect sensingSmall sizePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyElectricityMiniaturization

The invention discloses a magnetoelectricity antenna based on magnetostrictive piezoelectric materials. The magnetoelectricity antenna comprises a magnetostrictive material layer, a piezoelectric material layer, an interdigital electrode and a silicon suspension substrate. A preparation method of the magnetoelectricity antenna based on the magnetostrictive piezoelectric materials comprises the steps that firstly a whole silicon substrate is subject to corrosion to enable the whole silicon substrate to become the silicon suspension substrate, a magnetron sputtering method is further adopted tomake the interdigital electrode on the surface of the silicon suspension substrate, the magnetron sputtering method is further adopted to deposit the piezoelectric material layer on the interdigital electrode, and finally the magnetron sputtering method is adopted to deposit magnetostrictive material layer on the piezoelectric material layer to obtain the magnetoelectricity antenna. The antenna utilizes the magnetostrictive effect to transform electromagnetic wave into mechanical vibration, and utilizes a highly sensitive vibration induction system to transform the mechanical vibration into electrical signals, indirect induction of the electromagnetic wave can be realized, the magnetoelectricity antenna is not limited by the electrics antenna lambada / 4 wavelength theory and has the advantages of being high in sensitiveness and miniaturized, and the size of an existing antenna can be reduced by several orders of magnitudes.

Owner:XIDIAN UNIV

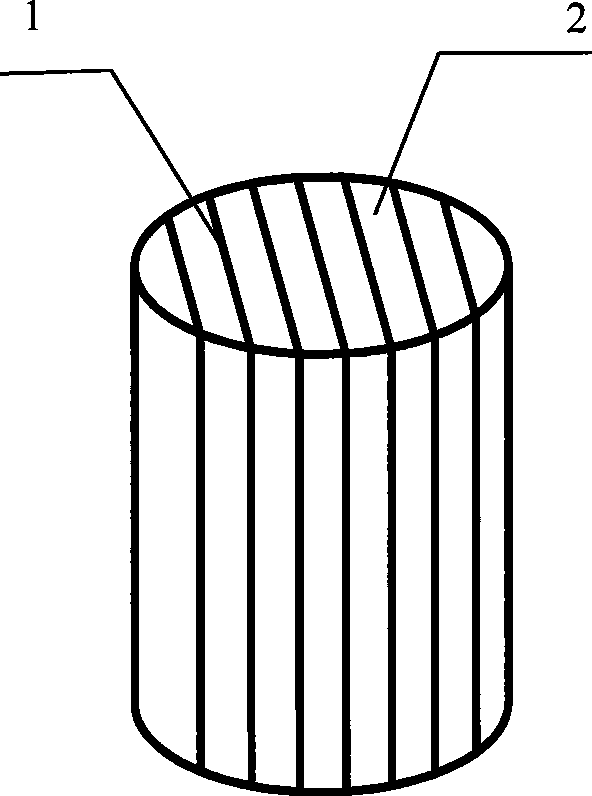

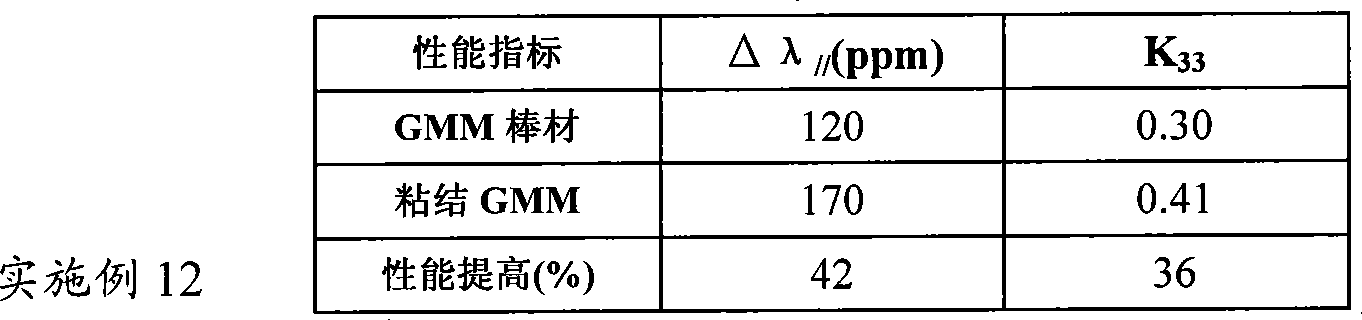

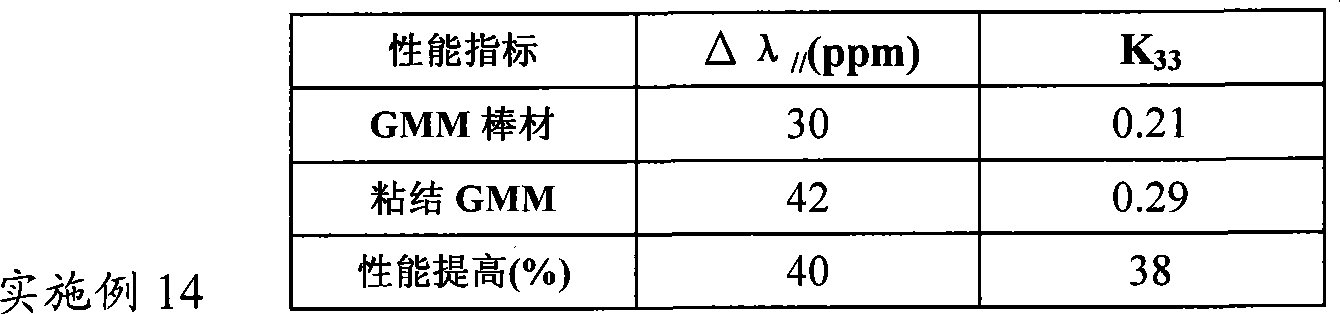

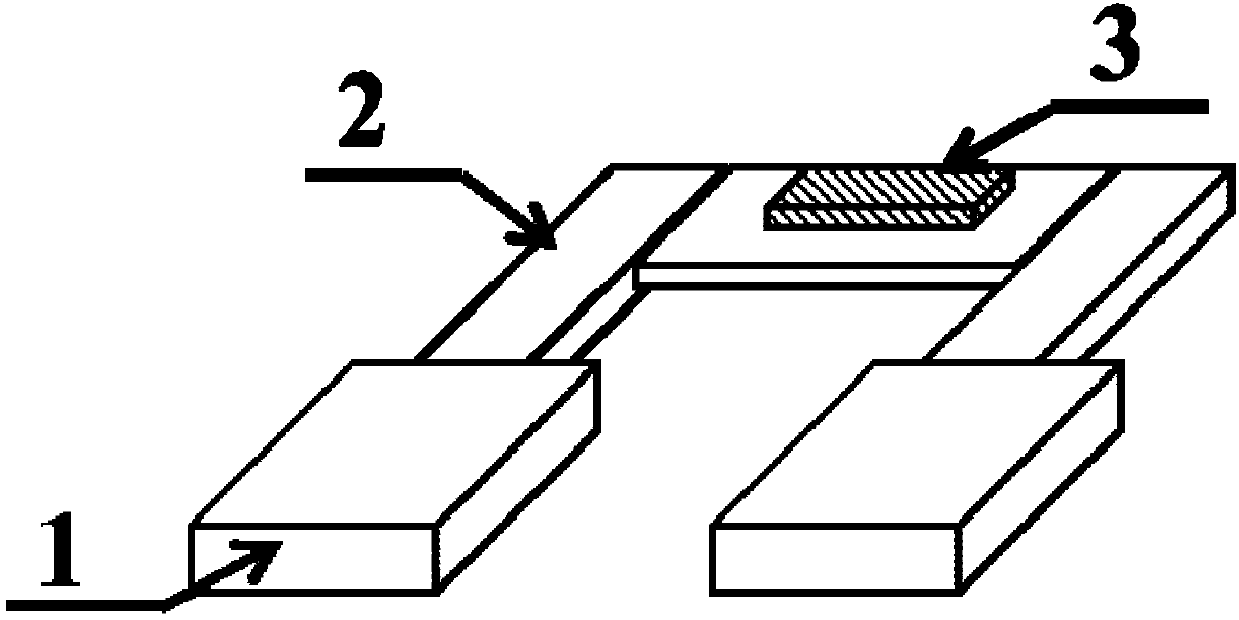

Cementing magnetostrictive material and preparation thereof

ActiveCN101388433APiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyRare earthMagnetostriction

A bonded magnetostrictive composite material and a process for preparation belong to the technical field of magnetic functional materials and preparation, which is characterized by being formed by magnetostrictive sheets with 1-15mm thickness through bonding, wherein the major components of the magnetostrictive sheet is (Tb, Dy) Fe2 rare-earth giant magnetostrictive materials, FeGa and NiMnGa magnetostrictive composite materials. The bonded magnetostrictive composite material has excellent eddy resistance performance, and increases over 30-80% magnetostrictive property under high frequency compared with common mangetostrictive composite materials. In addition, the process for preparation has simple operation and low cost, and has regular product appearance and large freedom degree in dimension, and overcomes the disadvantage that the traditional unidirectional solidification technique hardly obtains magnetostrictive composite material in large dimension.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

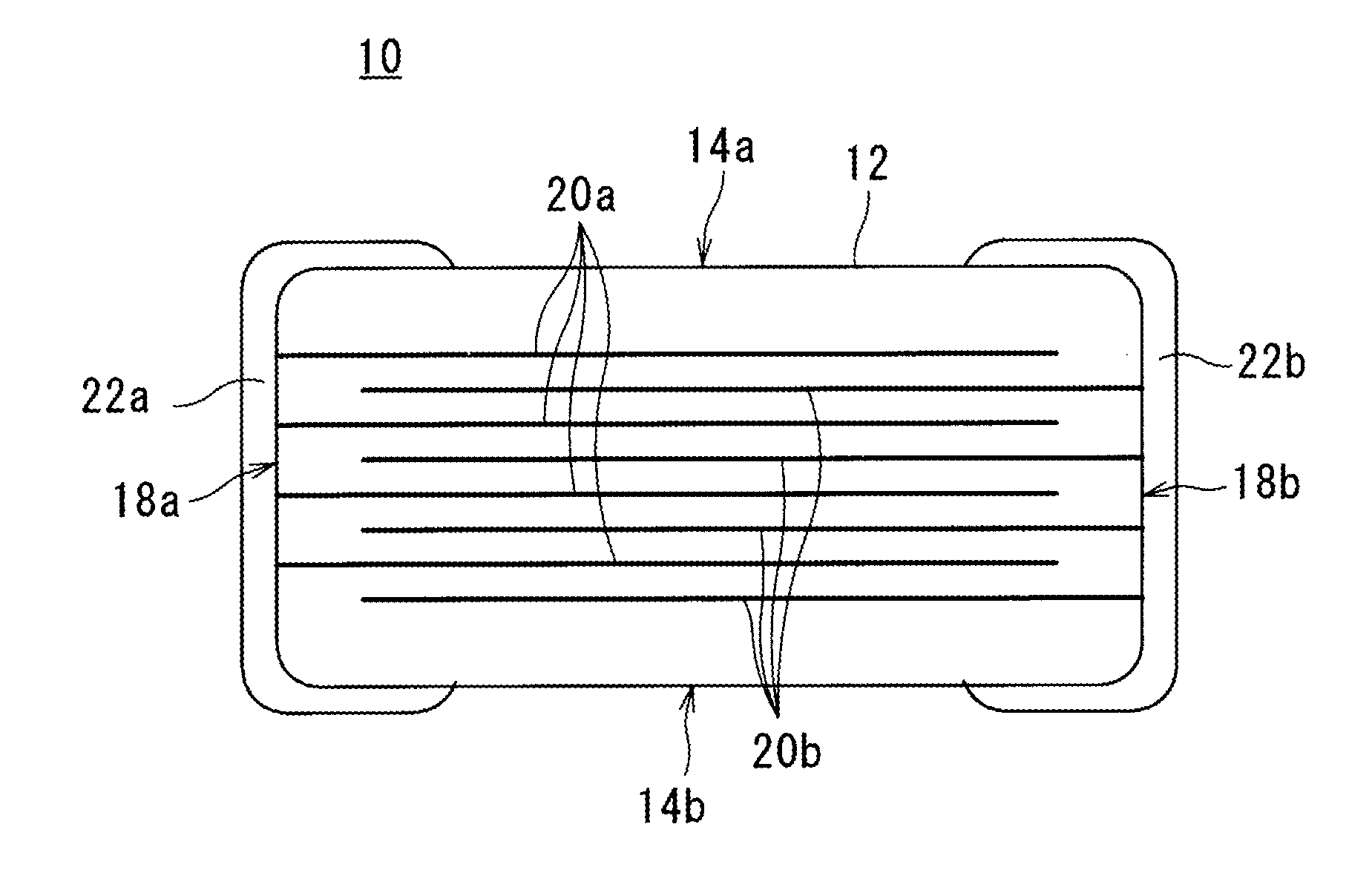

Multilayer ceramic structure, manufacturing method therefor and piezoelectric actuator

ActiveUS20160056366A1Easily subjected to polingWell representedPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyMetallurgyPiezoelectric actuators

A multilayer ceramic structure, which is to be divided into a large number of piezoelectric actuators, includes a rectangular-parallelepiped-shaped multilayer ceramic body. An upper surface opposing electrode is formed on an upper surface, a lower surface opposing electrode is formed on a lower surface and inner opposing electrodes are formed inside the multilayer ceramic body. A silt is provided in the upper surface opposing electrode. Opposing portions are provided where the upper surface opposing electrode, the inner opposing electrodes and the lower surface opposing electrode are superposed with each other when viewed in plan. The slit is provided in the upper surface opposing electrode in a portion of a region between the opposing portion and the first side surface and so as to extend in a first direction linking a first end surface and a second end surface.

Owner:MURATA MFG CO LTD

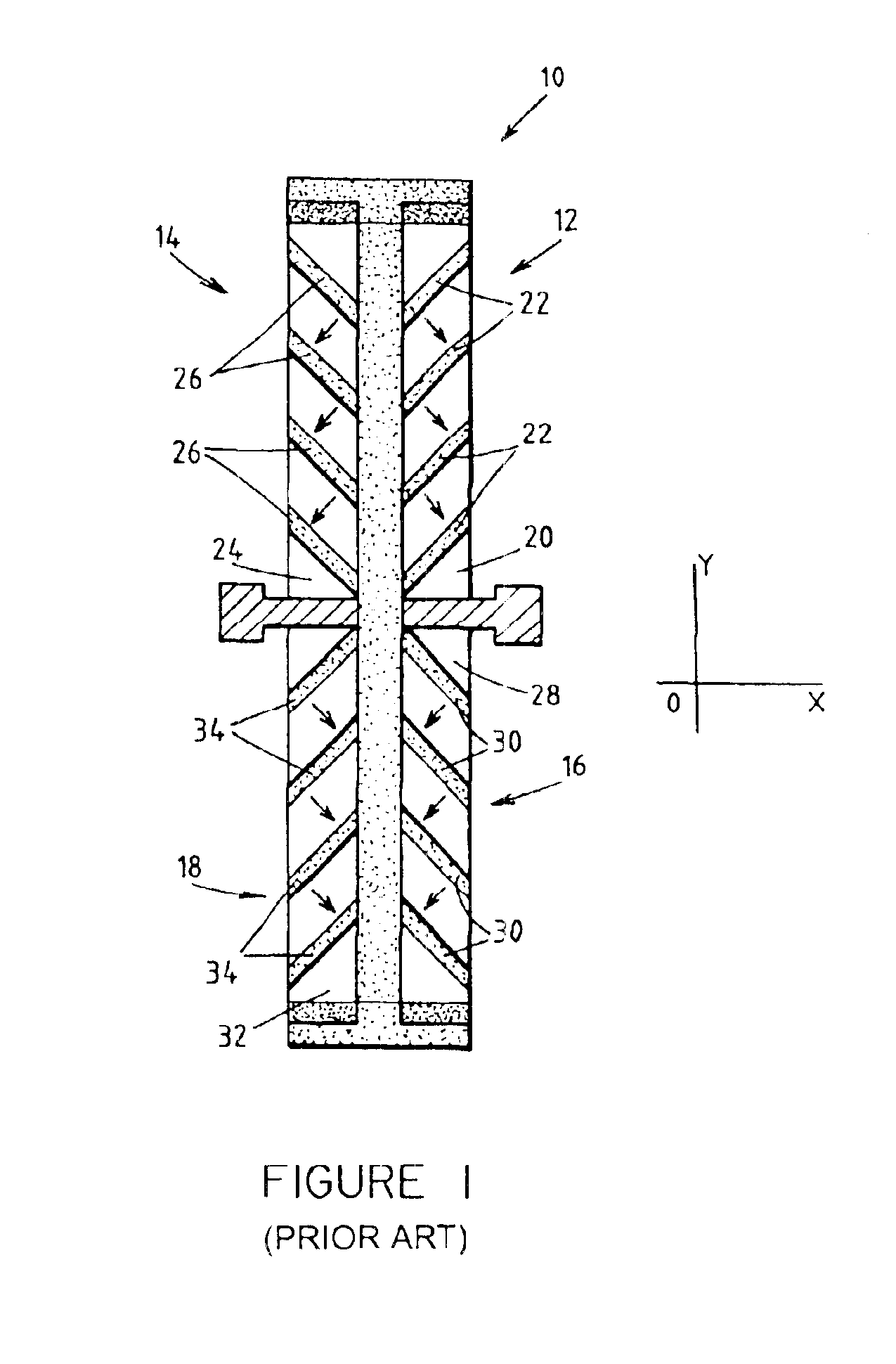

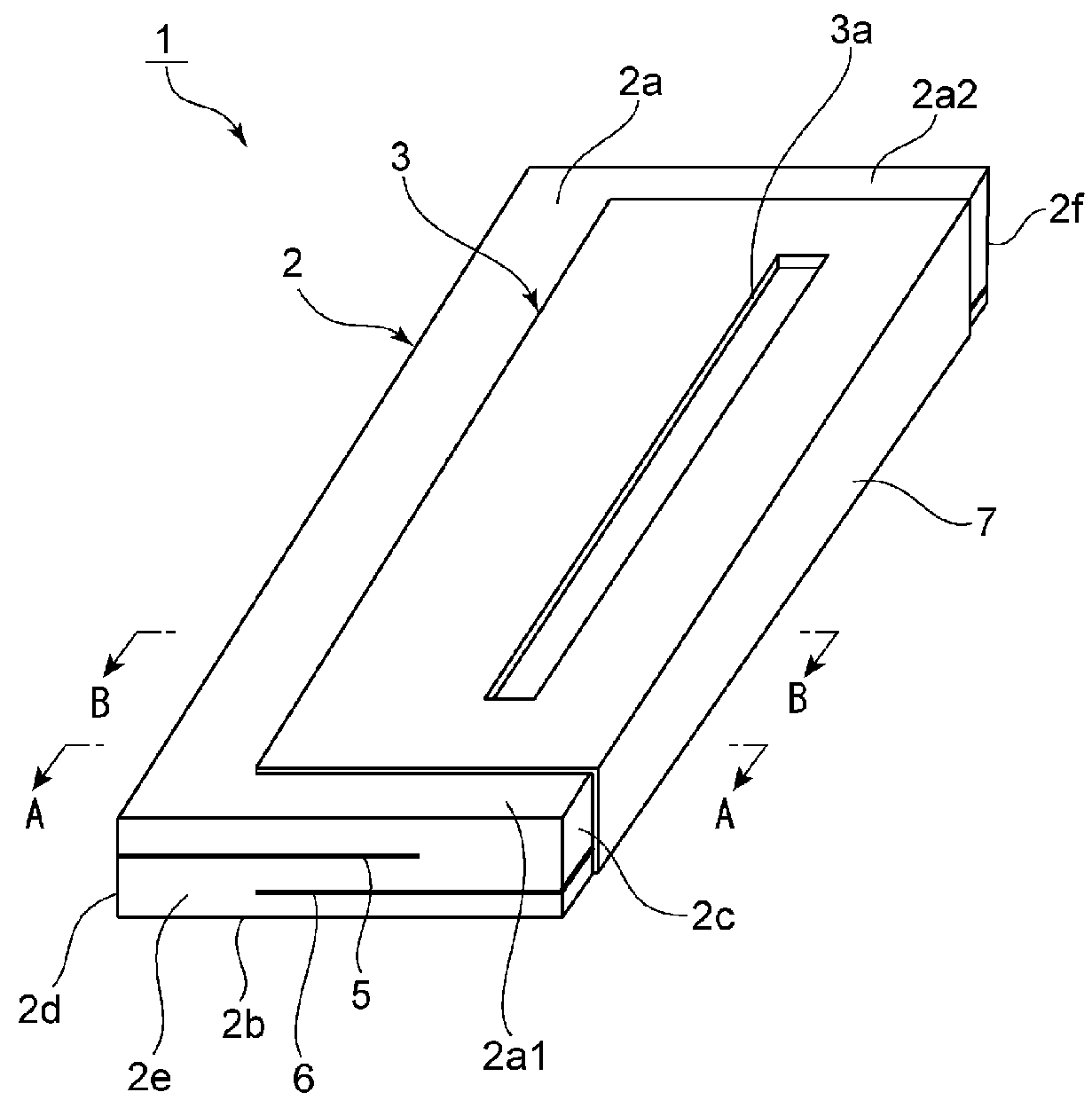

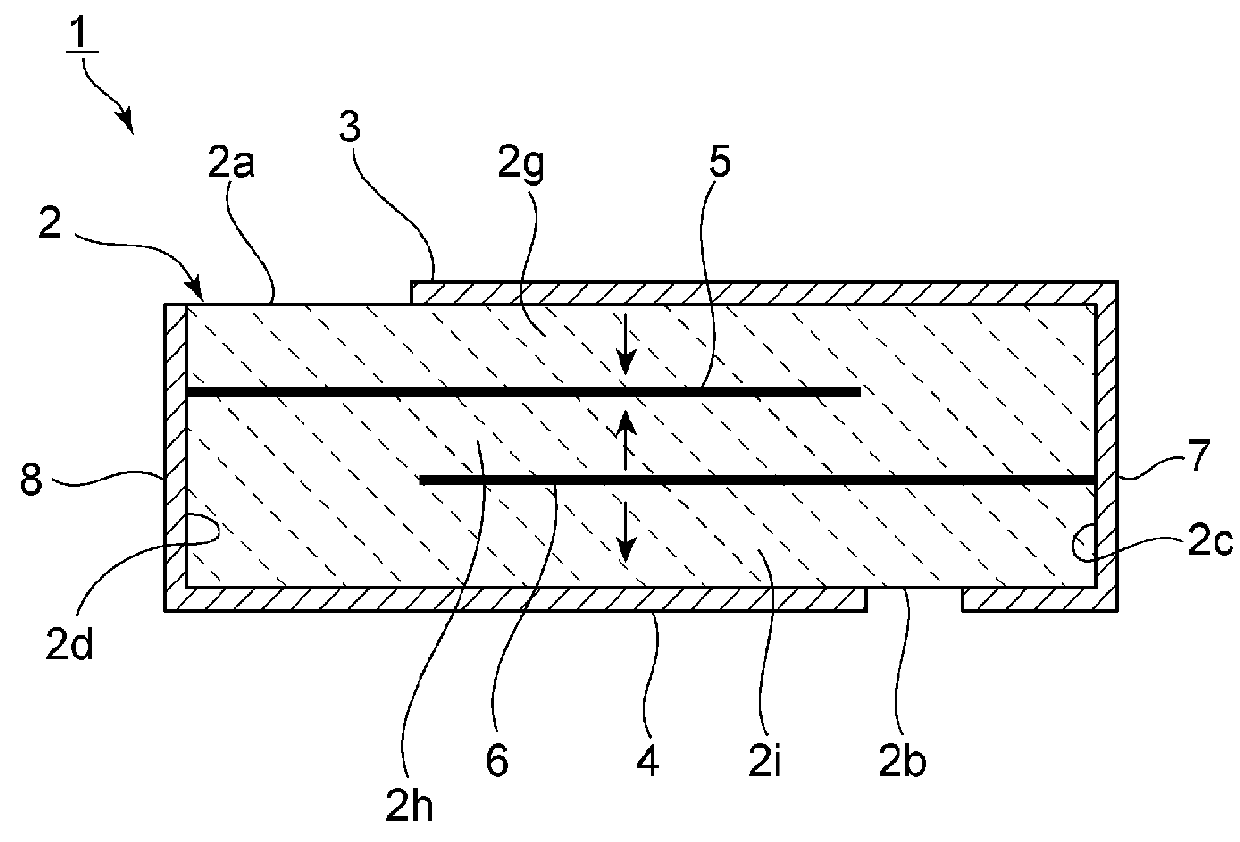

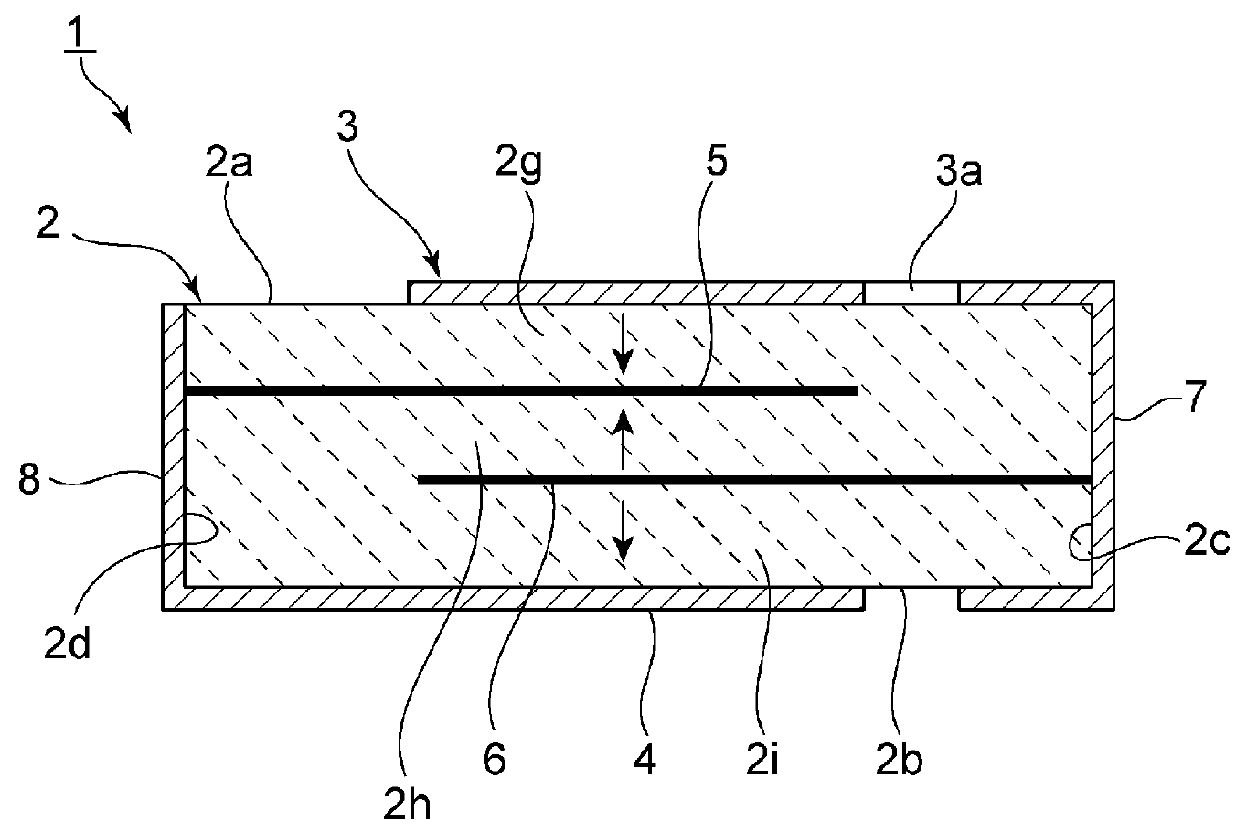

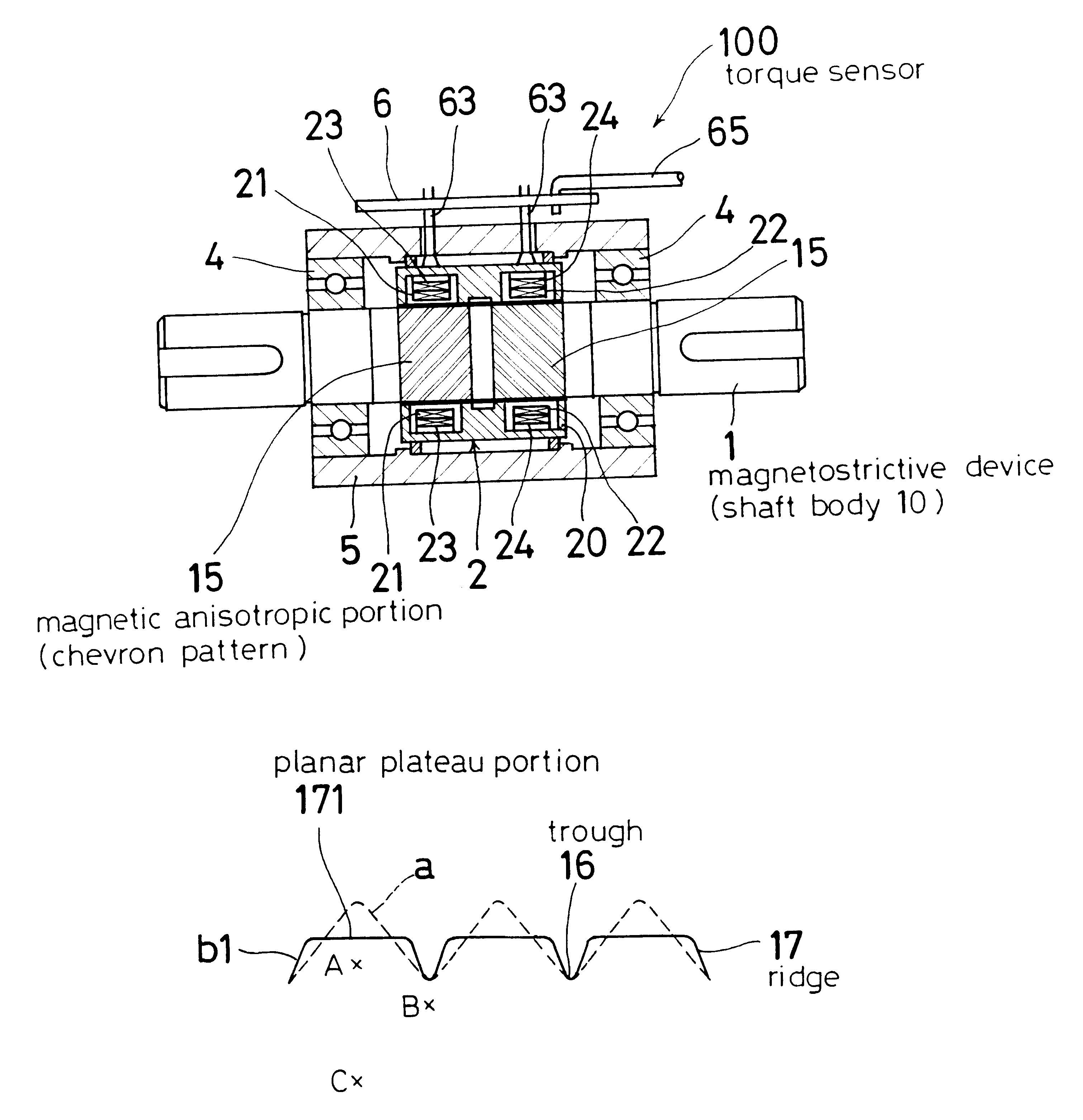

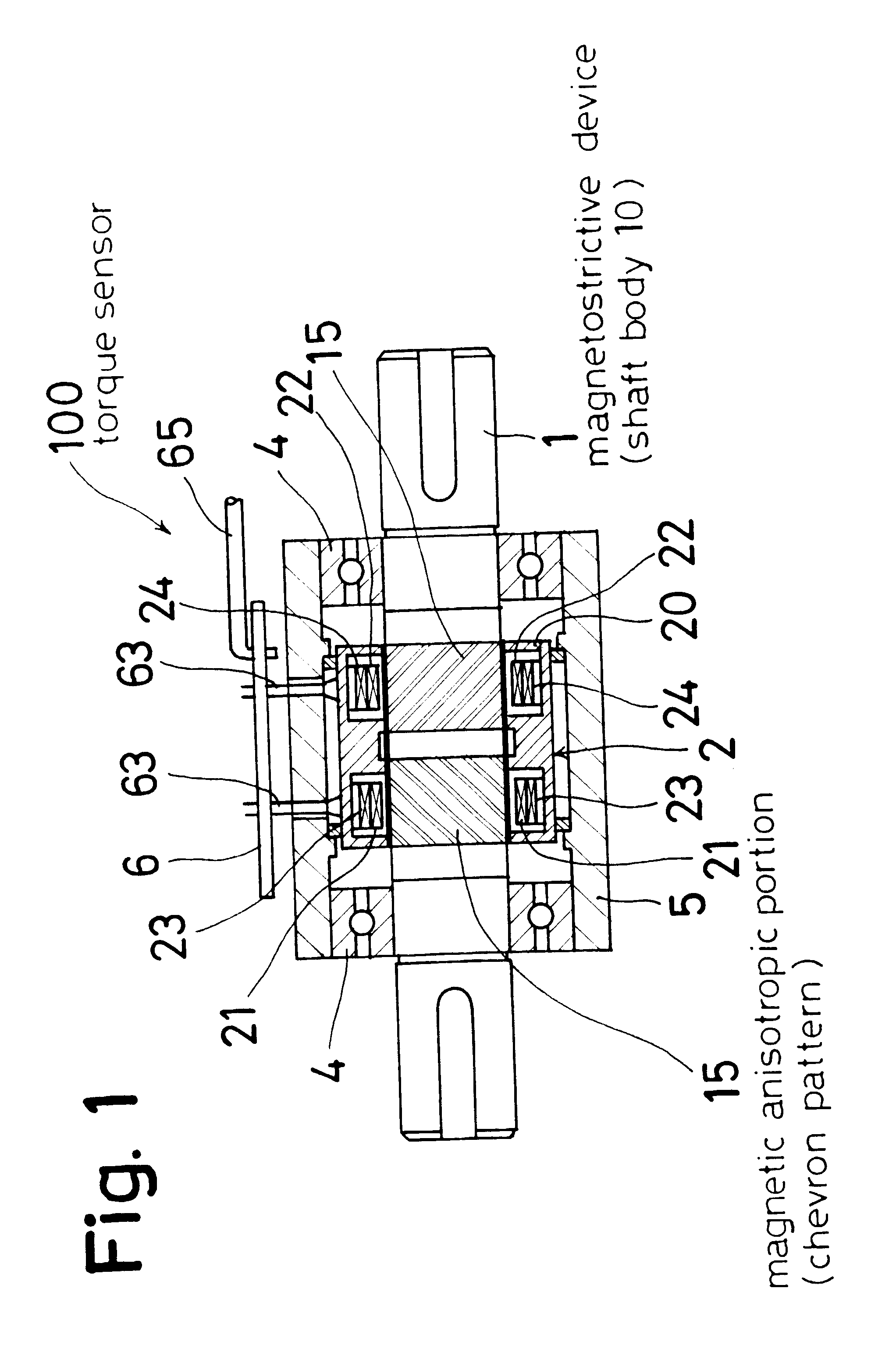

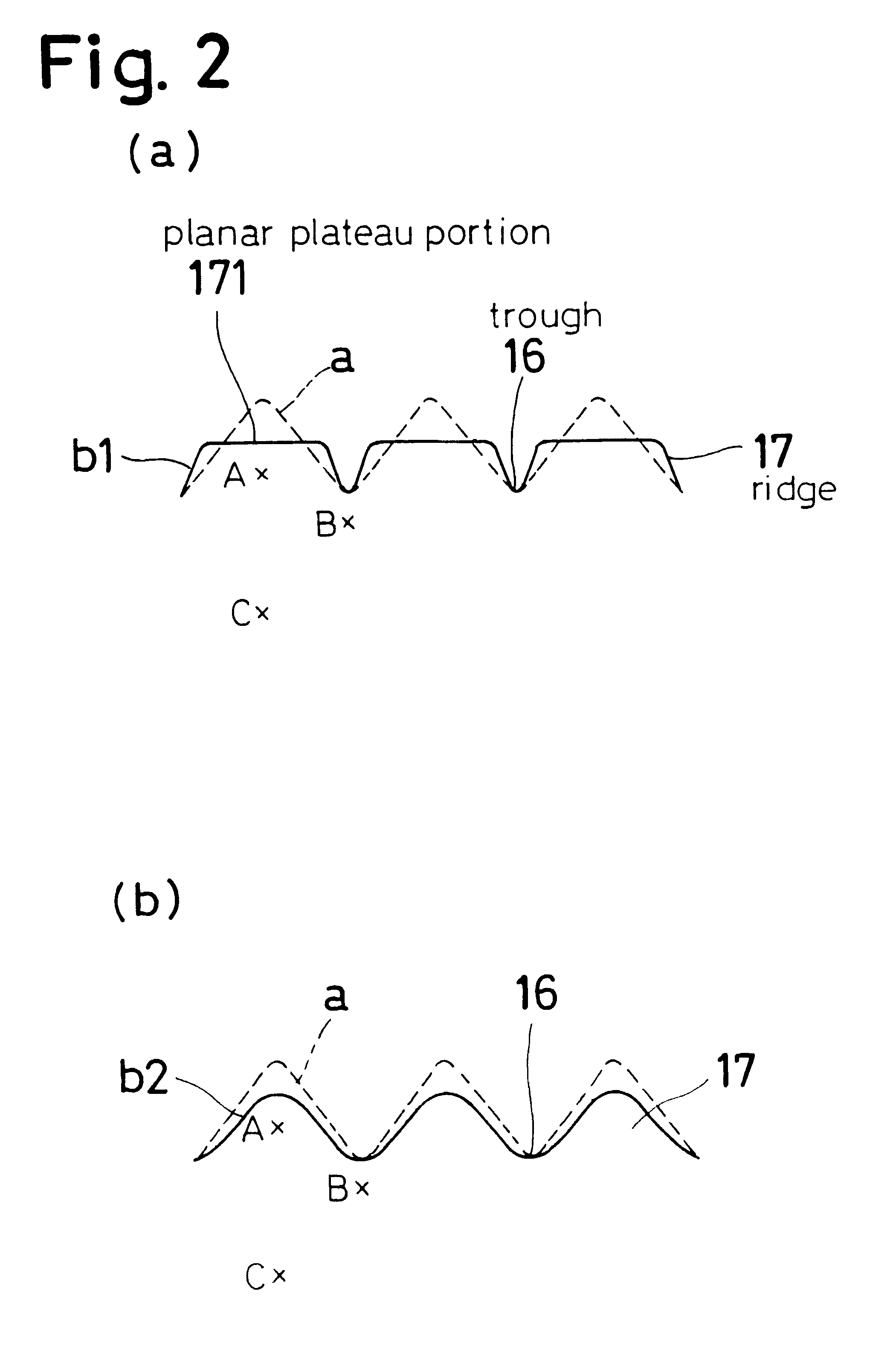

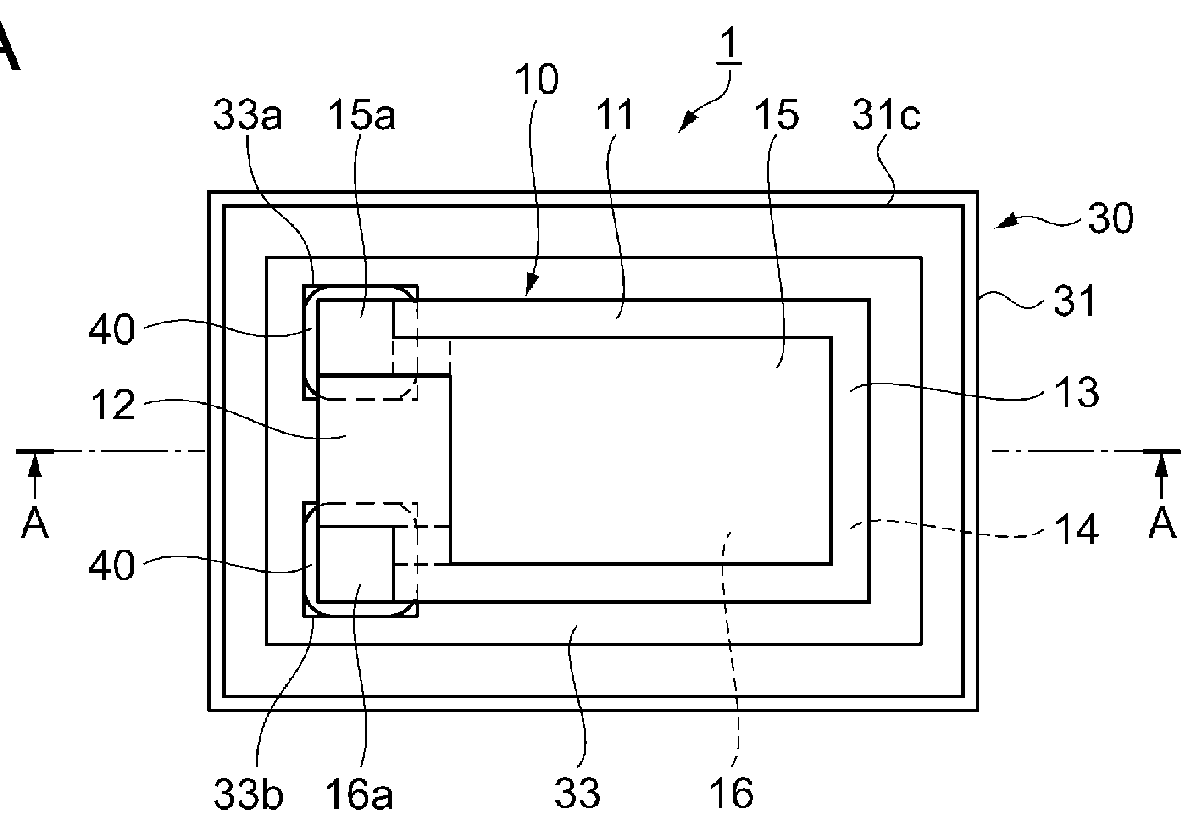

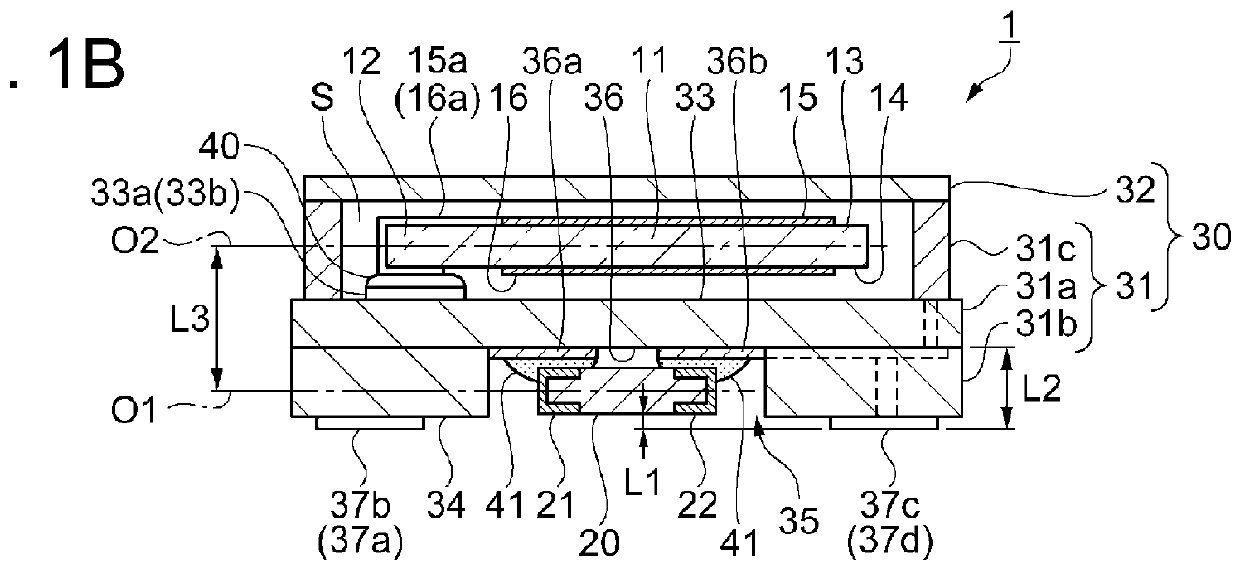

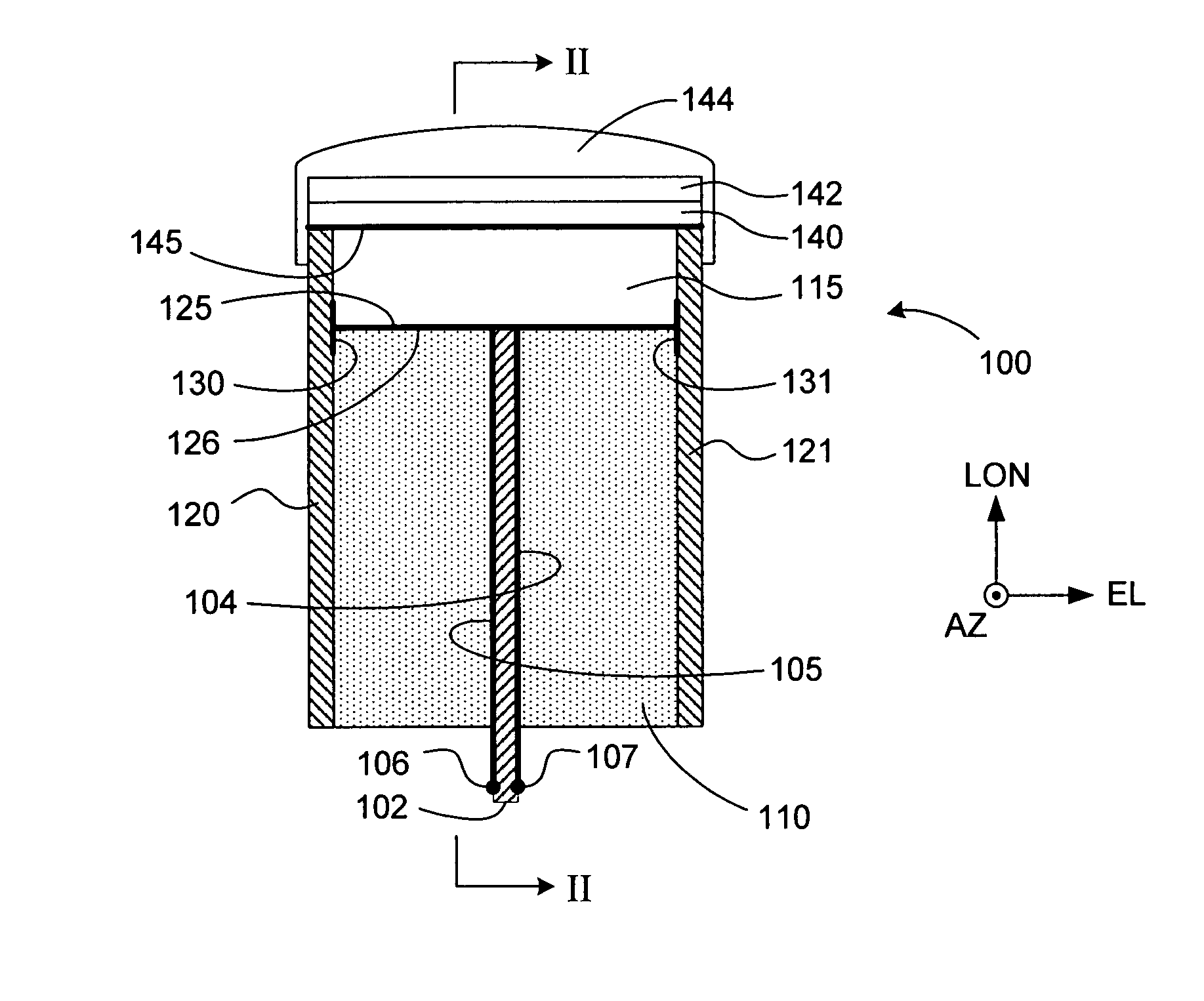

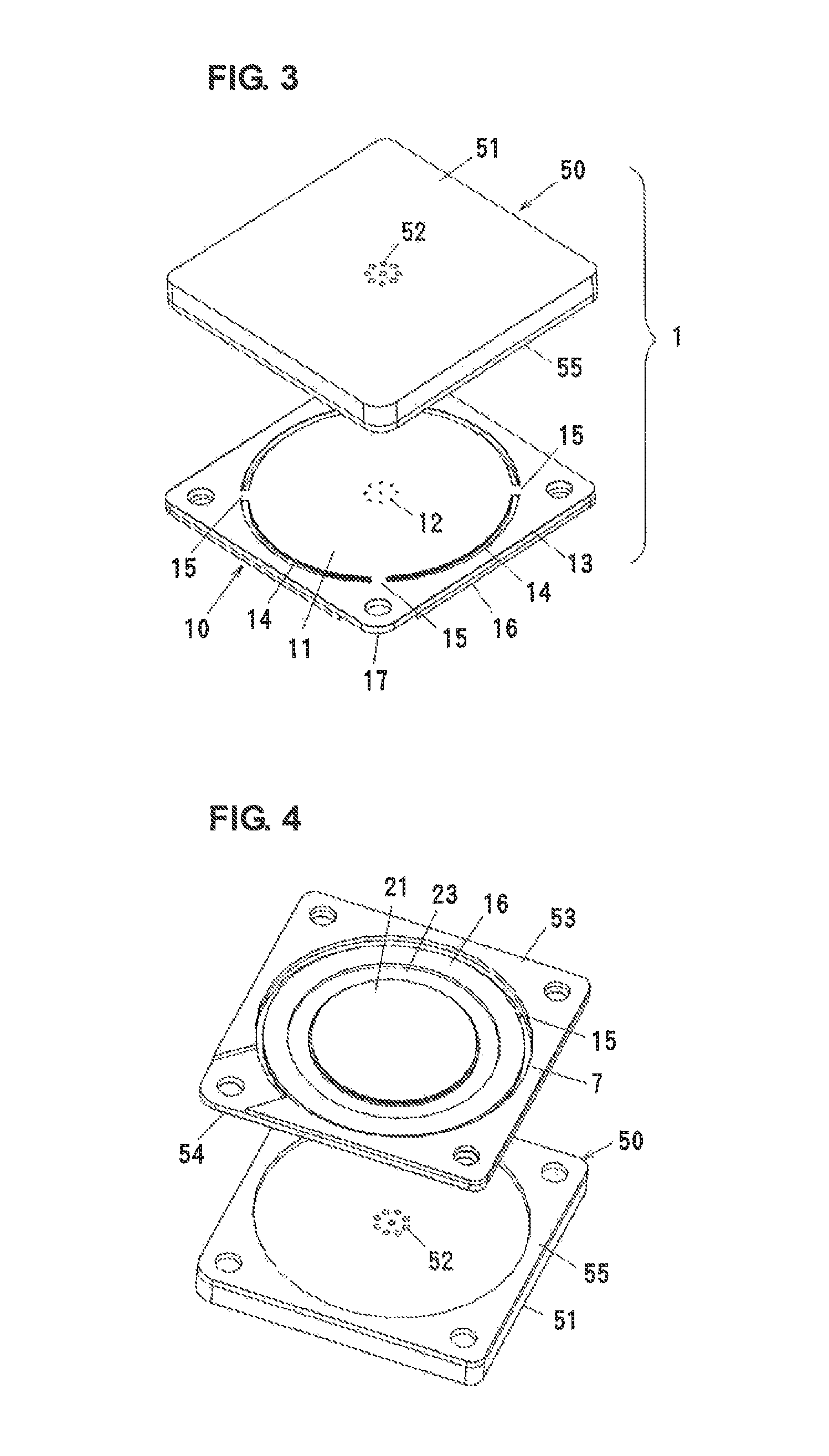

Magnetostrictive device for torque sensor and method of manufacture of the same

InactiveUS6595073B1Piezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyMagnetic anisotropyLoad torque

A magnetostrictive device for a torque sensor which has a high sensor sensitivity whether the excitation frequency is in a high frequency range or in a low frequency range and can withstand excess load torques well, and also a method of easily manufacturing the device. In manufacturing the magnetostrictive device 1 for a torque sensor, which has a magnetic anisotropic portion 15 formed on the surface of a shaft body 10 thereof, the method of forming the magnetic anisotropic portion 15 comprises the steps of: forming spiral grooves in the surface of the shaft body 10 to form a plurality of troughs 16 and ridges 17 alternately; and directly applying a compressive stress only to the ridges 17 to cause deformations accompanied by plastic flow and to provide an almost planar plateau portion 171 at a crest portion of each of the ridges 17.

Owner:AISIN SEIKI KK

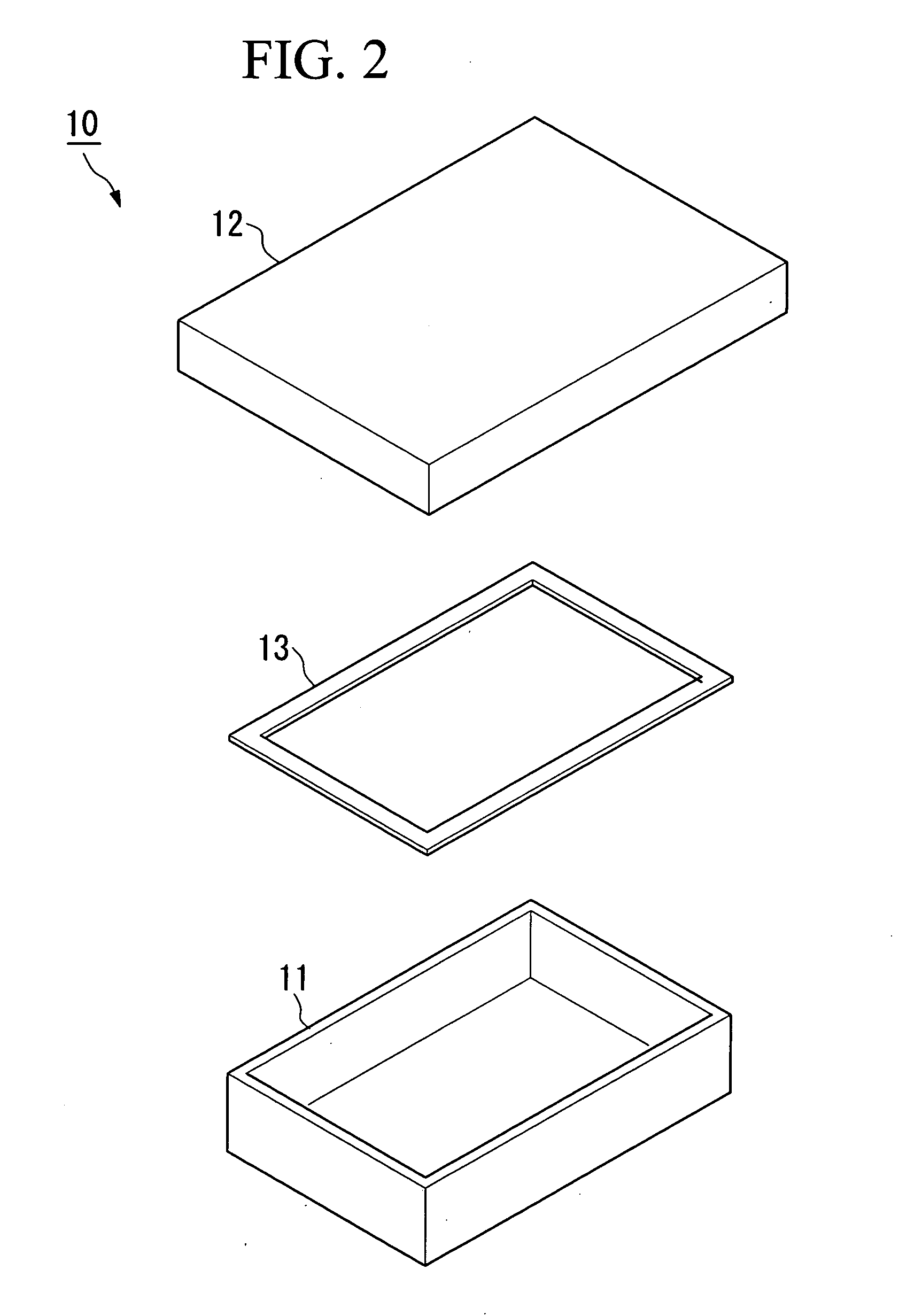

Resonator device, electronic device, and mobile object

ActiveUS20160035962A1Improve performanceEasy to moveMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesQuartz crystal resonatorEngineering

A quartz crystal resonator includes a quartz crystal resonator element, a thermistor, and a package base having a first principal surface and a second principal surface having an opposed surface relationship with each other, the quartz crystal resonator element is mounted on the first principal surface side, the thermistor is housed in a recessed section of the second principal surface side of the package base, a plurality of electrode terminals connected to the quartz crystal resonator element or the thermistor is disposed on the second principal surface side of the package base, and a distance in a first direction perpendicular to the first principal surface from a mounting surface of the electrode terminals to the thermistor is equal to or longer than 0.05 mm.

Owner:SEIKO EPSON CORP

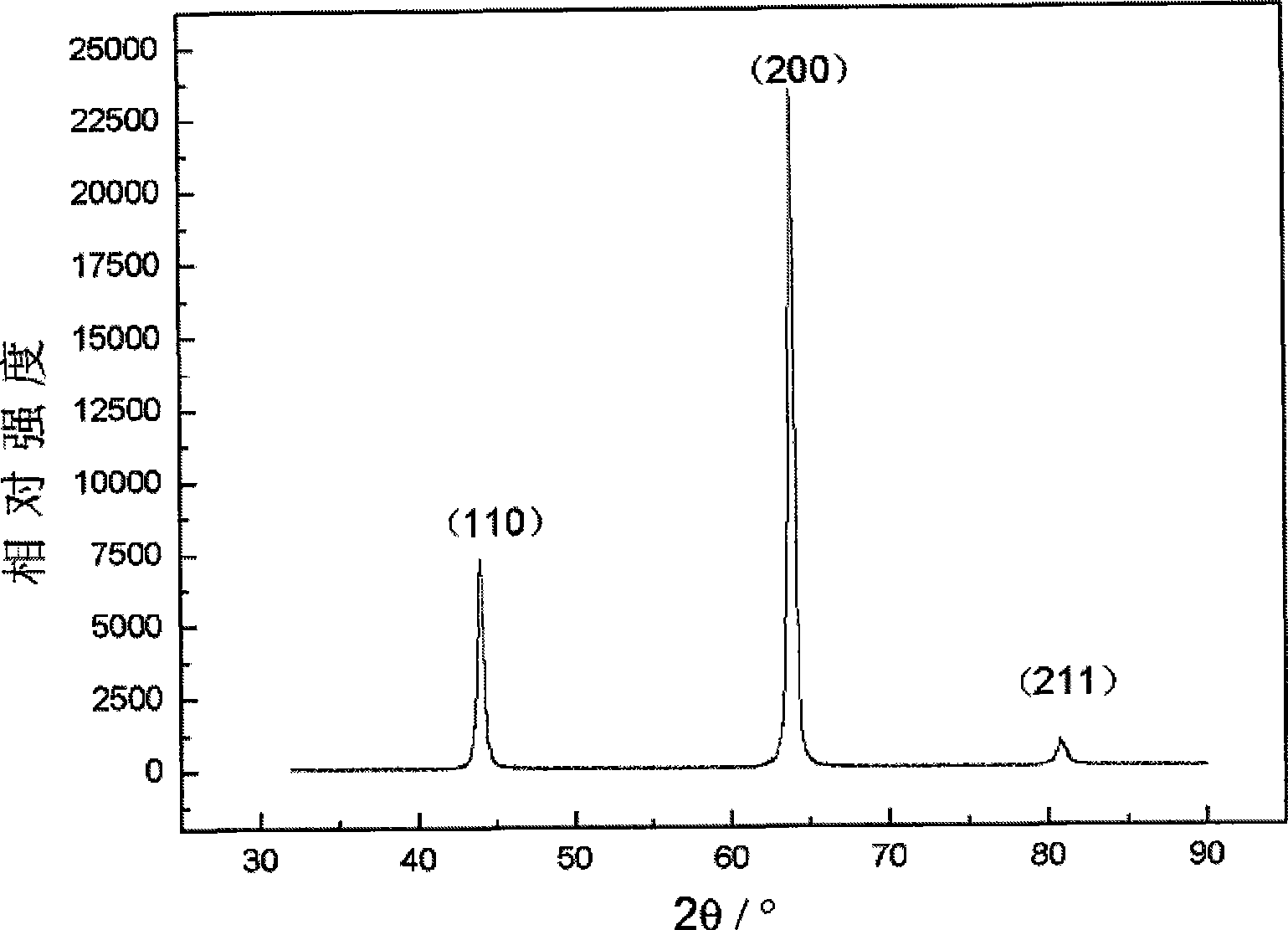

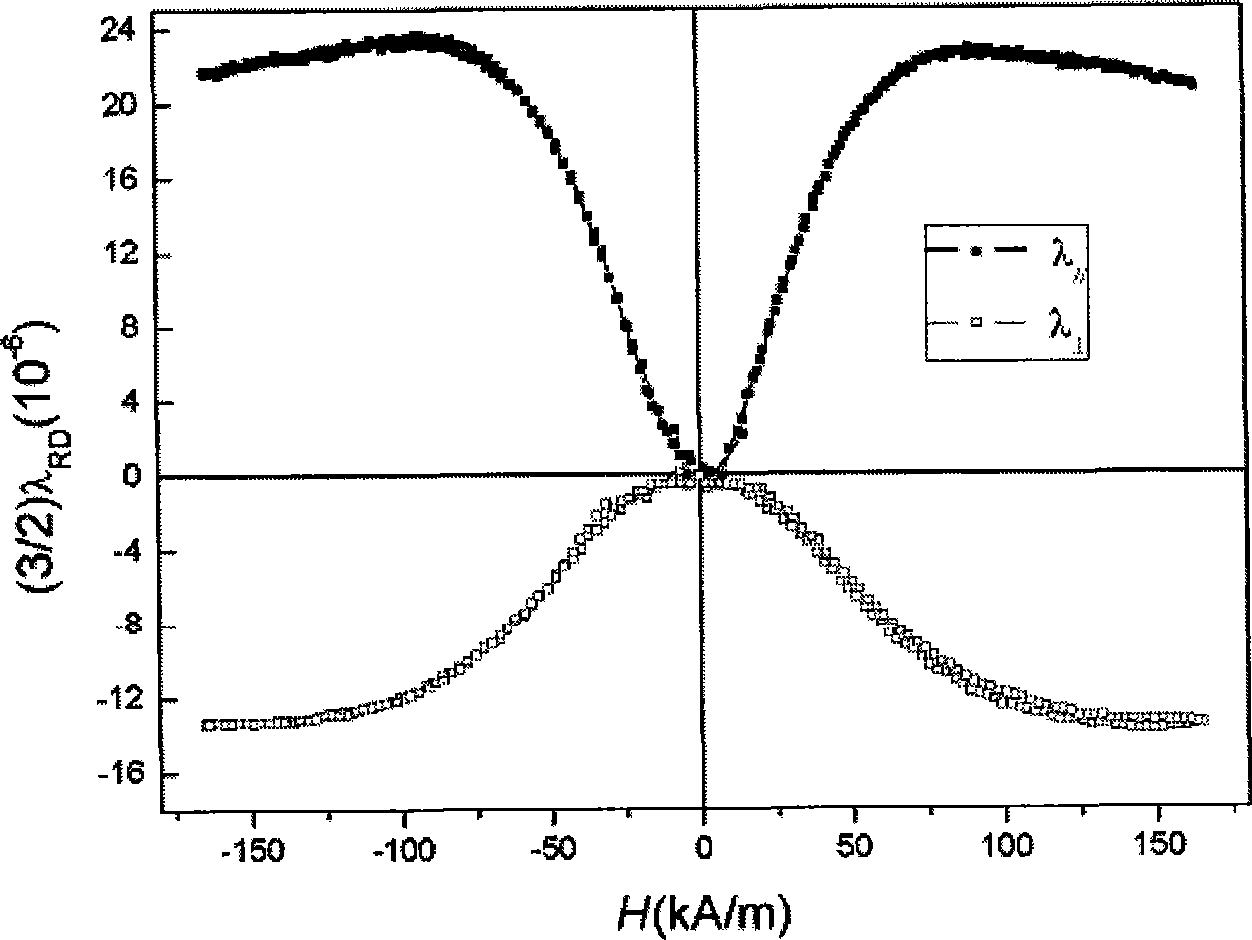

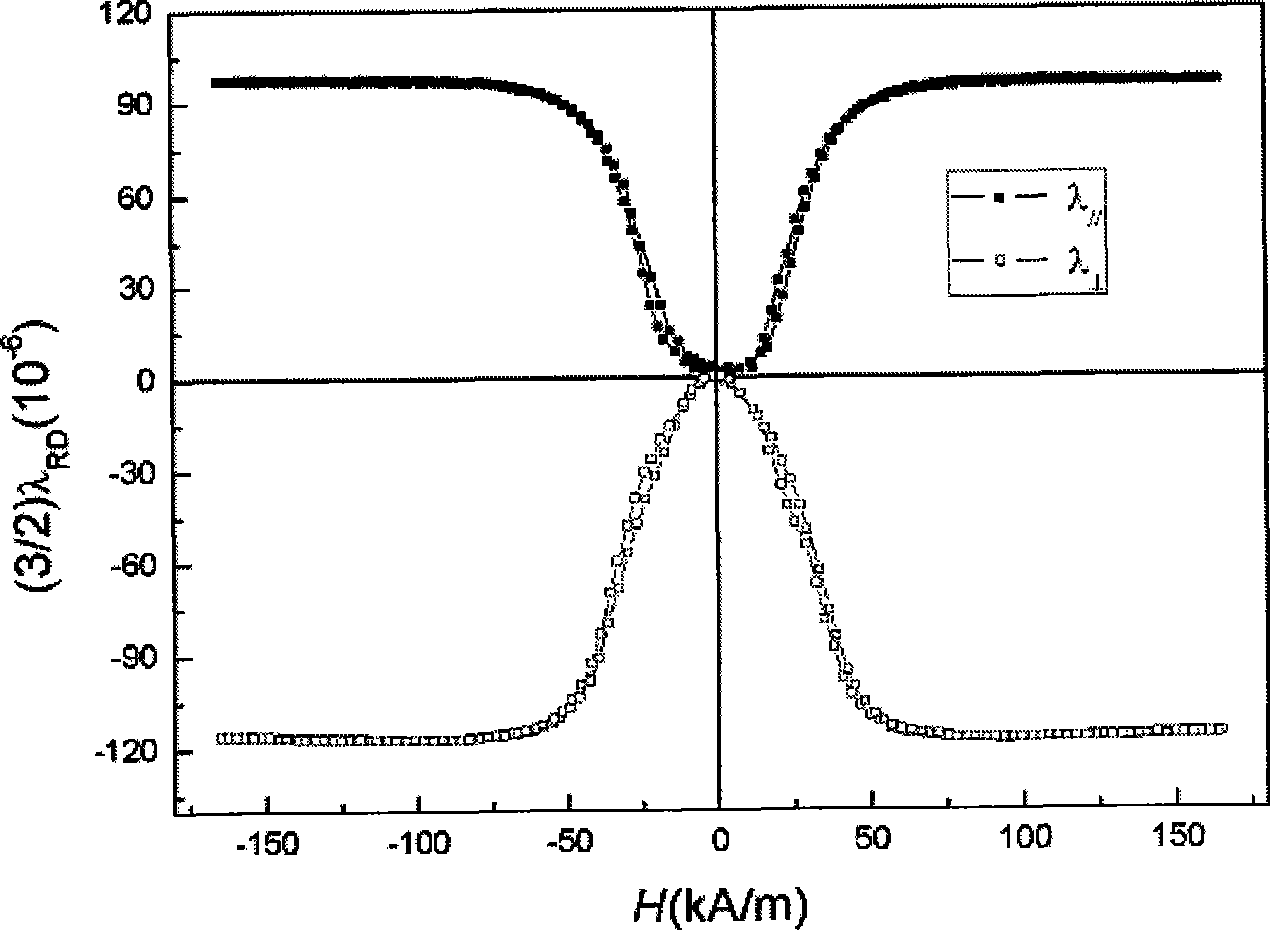

High-performance polycrystal texture Fe-Ga-based magnetic deformation slice material and preparation method thereof

InactiveCN101465406AImprove textureHigh magnetostrictive performancePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyIngotHeat treated

The invention relates to a high-performance polycrystalline texture Fe-Ga-based magnetostrictive thin material and a preparation method thereof; the component of the material is Fe100-x-y-zGaxMyNz; M stands for one or more among B, Nb, Cr, VC, TiC, MnS and AlN; N stands for one or more among S, Sb and Sn; wherein, x is equal to 15-25; y is equal to 0.5-3.0; z is equal to 0.01-0.05; and the residual is iron. The method has the following process key points: based on the requirements of the material composition, melting master alloy; casting alloy ingot; hot-forging and cogging; rolling the material into the appropriate thickness; and a variety of follow-up heat treatment. The Fe-Ga-based magnetostrictive thin material has obvious (100)<001>cubic texture or (110) <001> goss texture; and the maximum magnetostriction coefficient (3 / 2)lambdas is up to 280 multiplying 10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

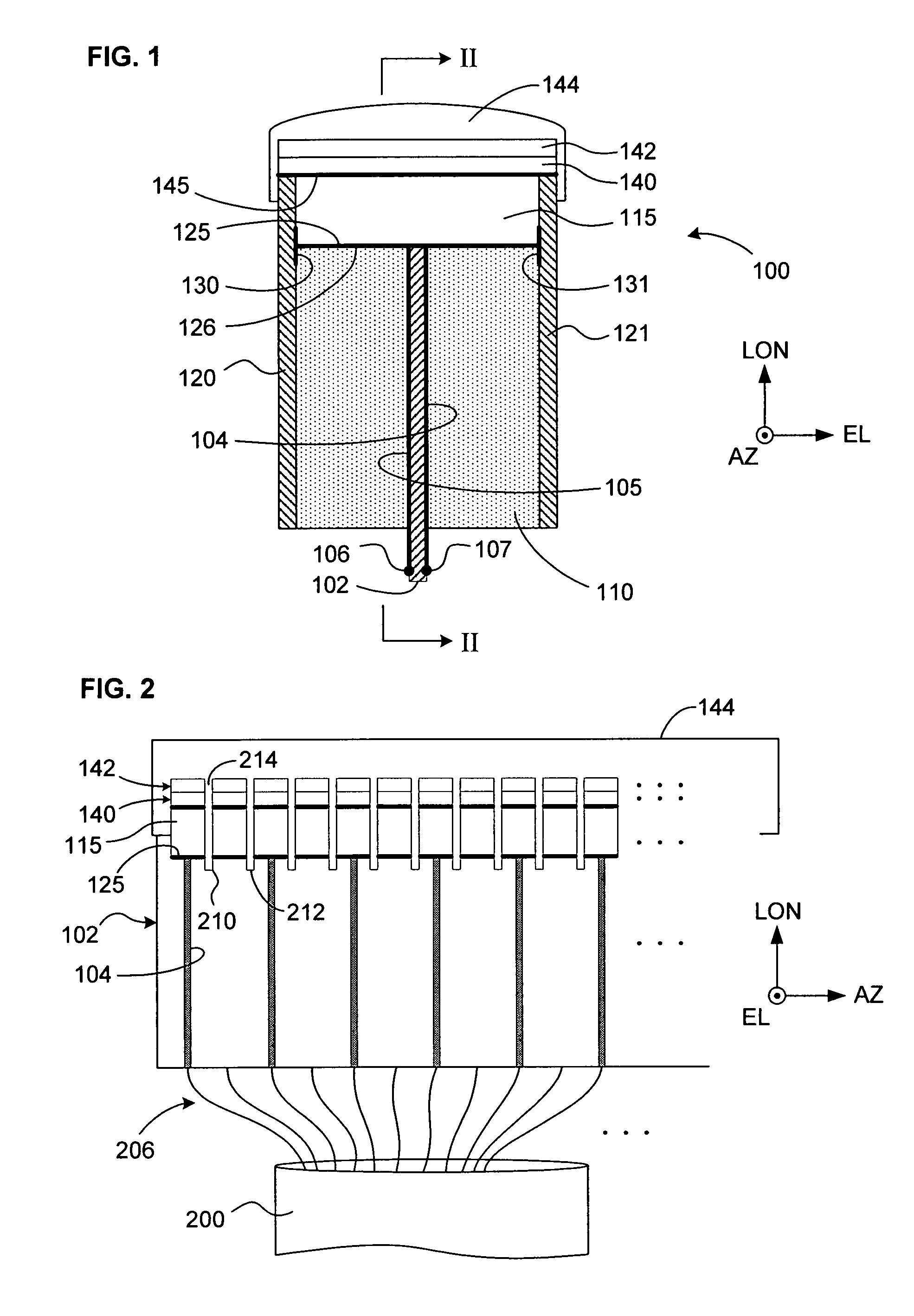

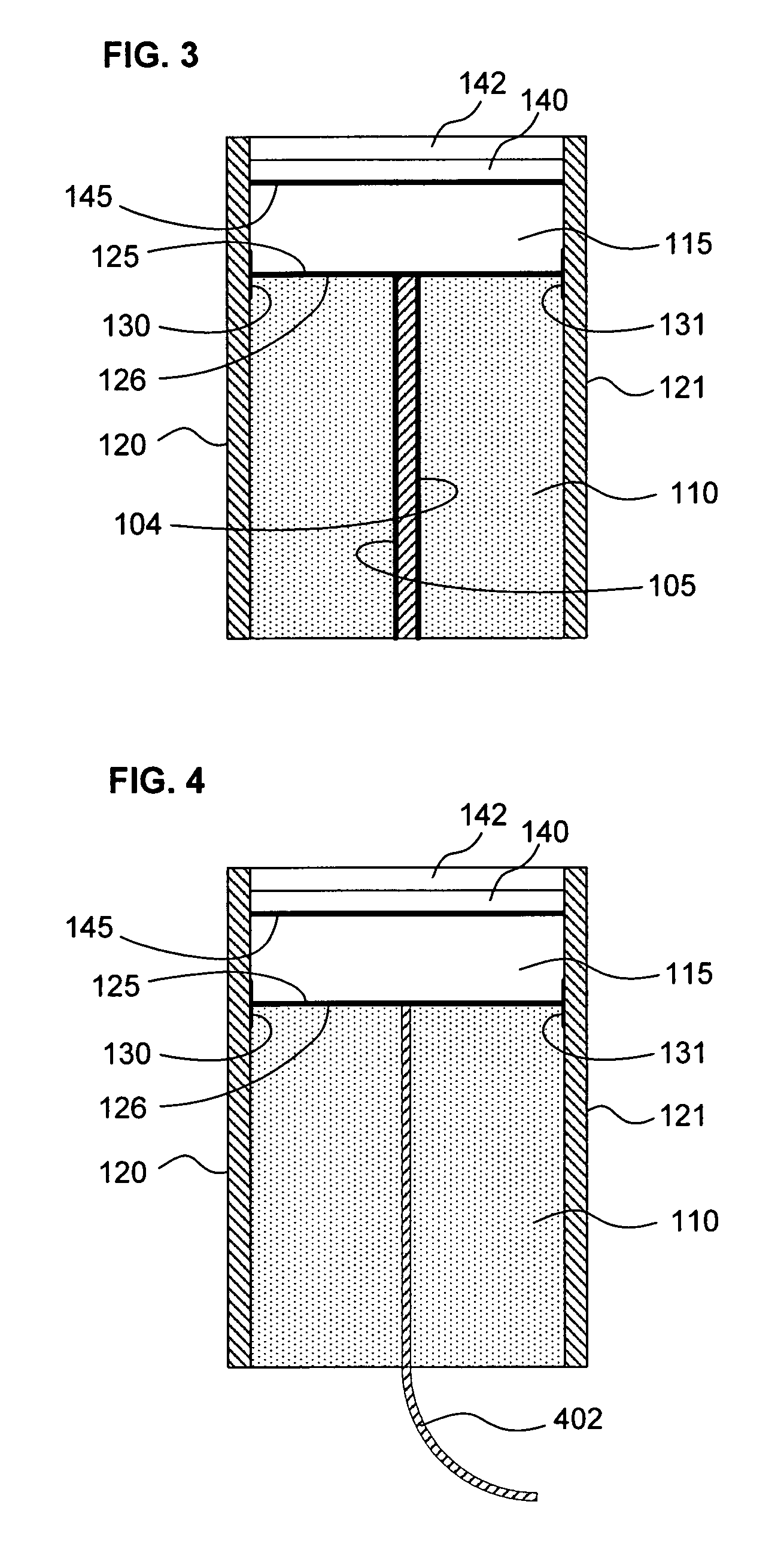

Diagnostic ultrasound transducer

ActiveUS7834522B2Good electrical contactEasy to installUltrasonic/sonic/infrasonic diagnosticsMicrophonesUltrasound imagingSputtering

An ultrasound transducer includes an array of PZT elements mounted on a non-recessed distal surface of a backing block. Between each element and the backing block is a conductive region formed as a portion of a metallic layer sputtered onto the distal surface. Traces on a longitudinally extending circuit board—preferably, a substantially rigid printed circuit board, which may be embedded within the block—connect the conductive region, and thus the PZT element, with any conventional external ultrasound imaging system. A substantially “T” or “inverted-L” shaped electrode is thereby formed for each element, with no need for soldering. At least one longitudinally extending metallic member mounted on a respective lateral surface of the backing block forms a heat sink and a common electrical ground. A thermally and electrically conductive layer, such as of foil, transfers heat from at least one matching layer mounted on the elements to the metallic member.

Owner:SHENZHEN MINDRAY SCIENTIFIC CO LTD

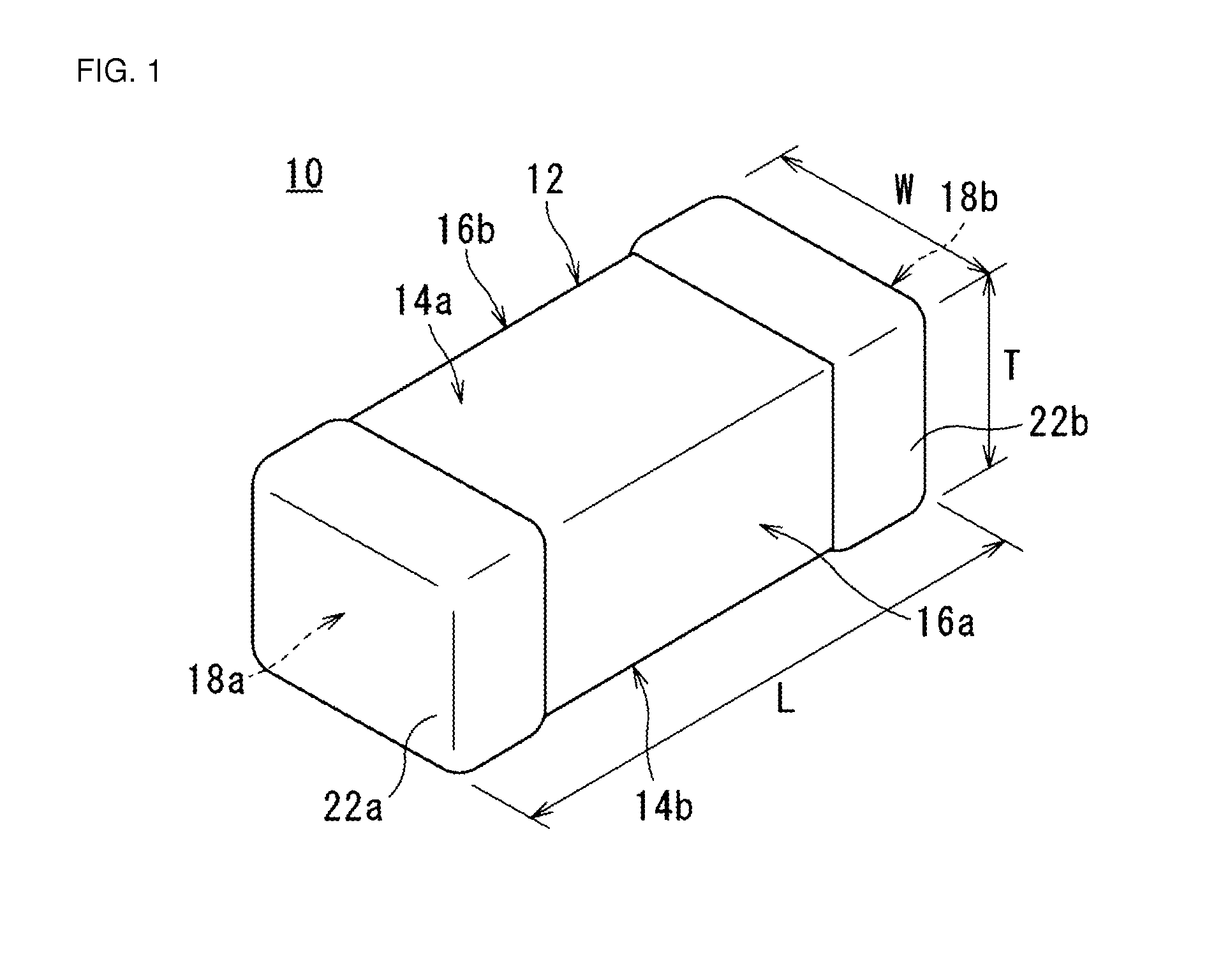

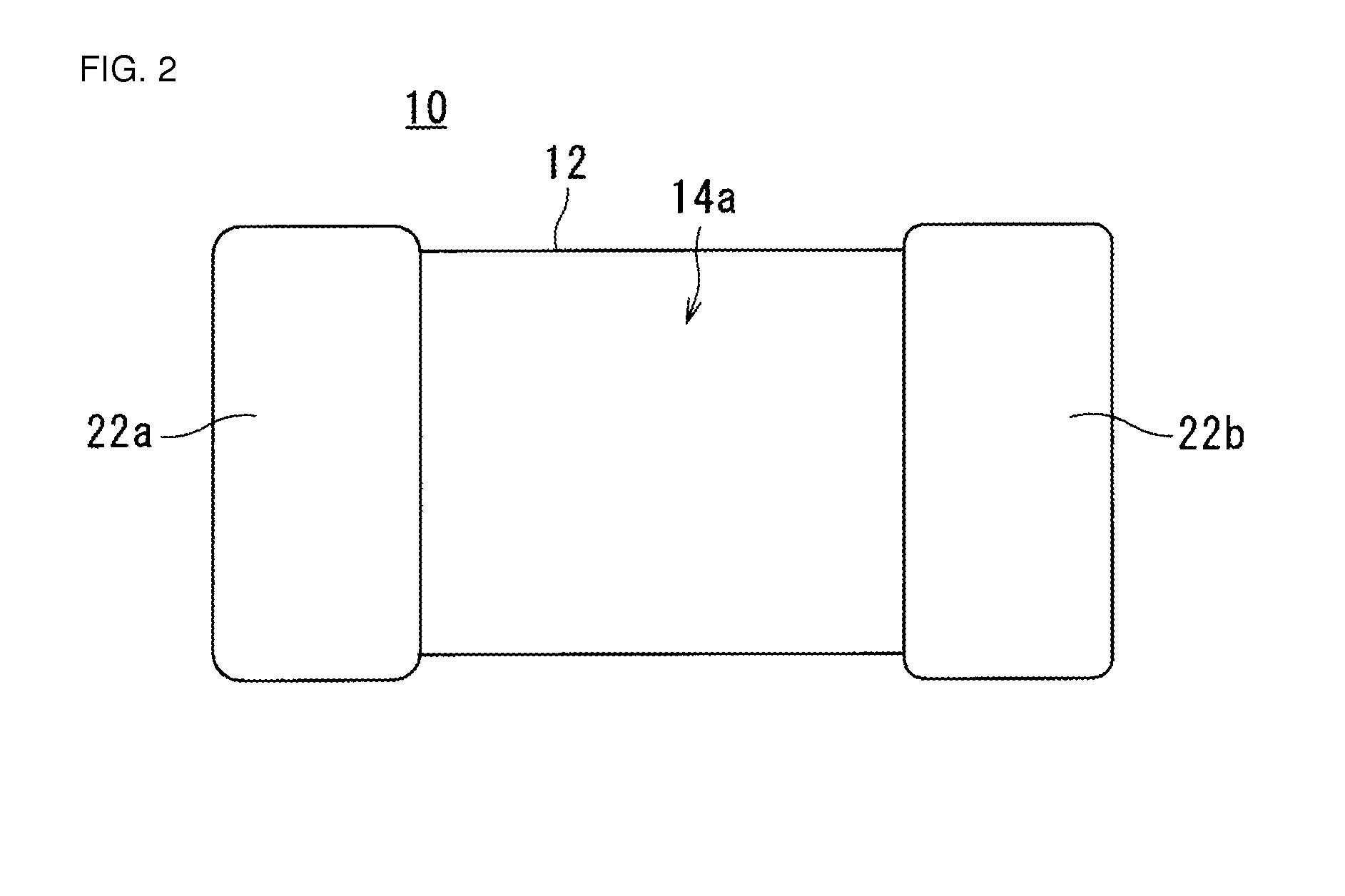

Monolithic ceramic electronic component

ActiveUS20150001998A1Avoid short circuit failureInhibit migrationMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyElectronic component

A monolithic ceramic electronic component includes a ceramic body including a stack of ceramic layers. Inner electrodes are disposed within the ceramic body and include exposed portions at the end surfaces of the ceramic body. A pair of outer electrodes is arranged on the end surfaces of the ceramic body so as to extend from the end surfaces to the main surfaces and side surfaces of the ceramic body. Each of the outer electrodes includes a lower electrode layer provided on the ceramic body, an intermediate electrode layer located on the lower electrode layer and defined by a plated Ni layer, and an upper electrode layer located on the intermediate electrode layer and defined by a plated Pd layer. A thickness of the intermediate electrode layer on the main surfaces and the side surfaces of the ceramic body is larger than a thickness of the intermediate electrode layer on the end surfaces of the ceramic body.

Owner:MURATA MFG CO LTD

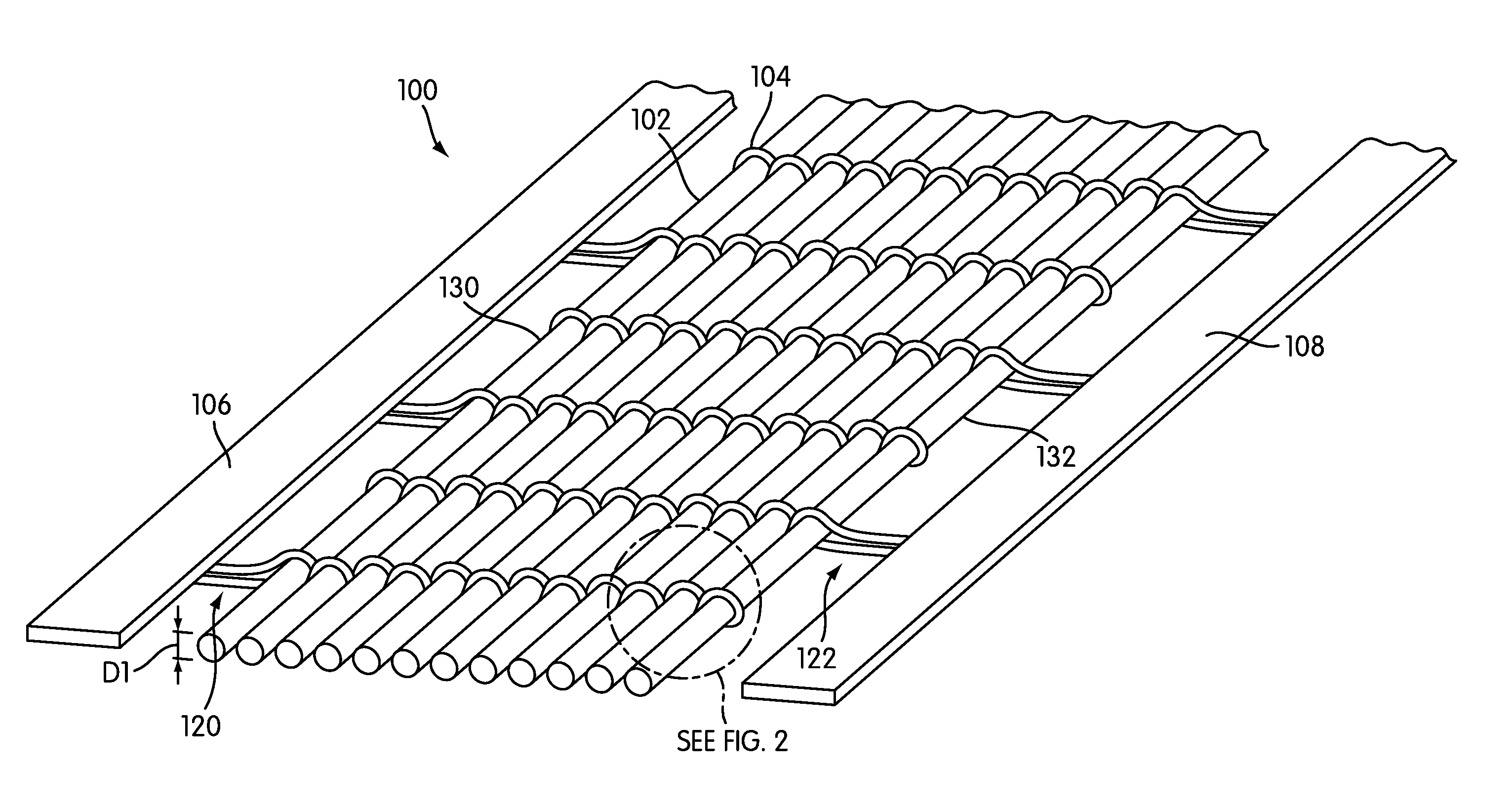

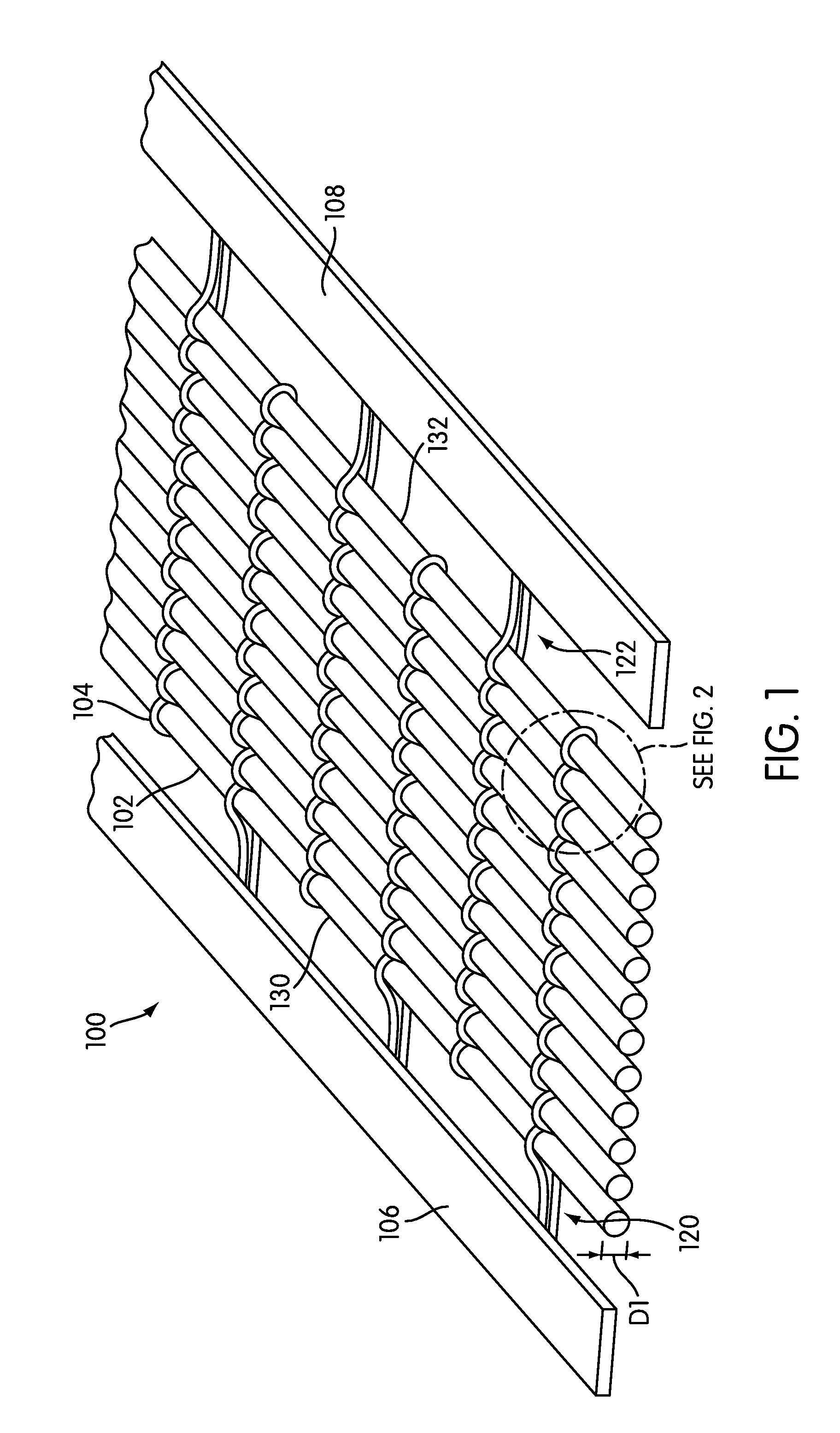

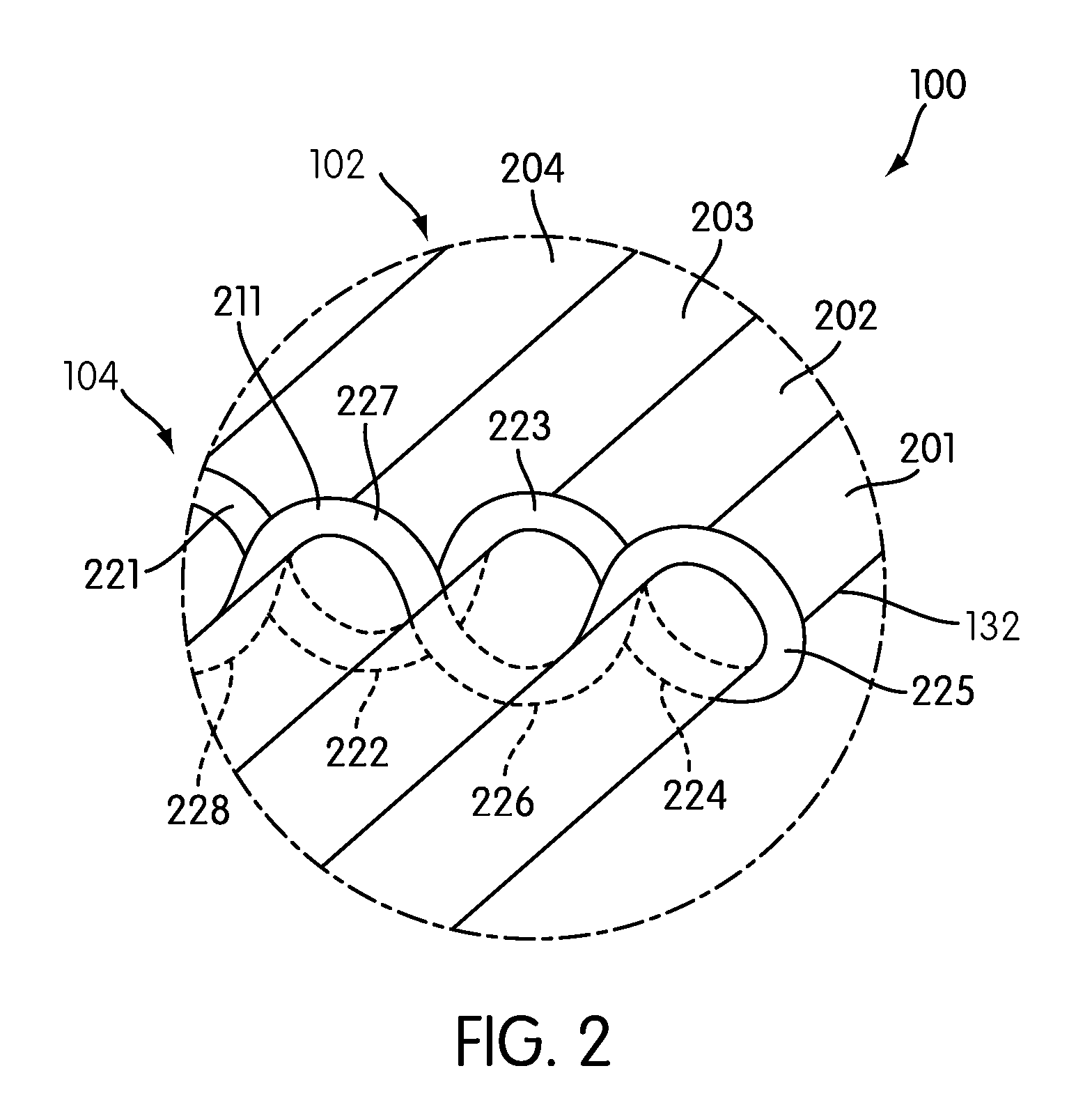

Woven active fiber composite

ActiveUS8922100B2Easy to drivePrevent sharp pointPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyOptoelectronicsFibrous composites

Owner:HONDA MOTOR CO LTD

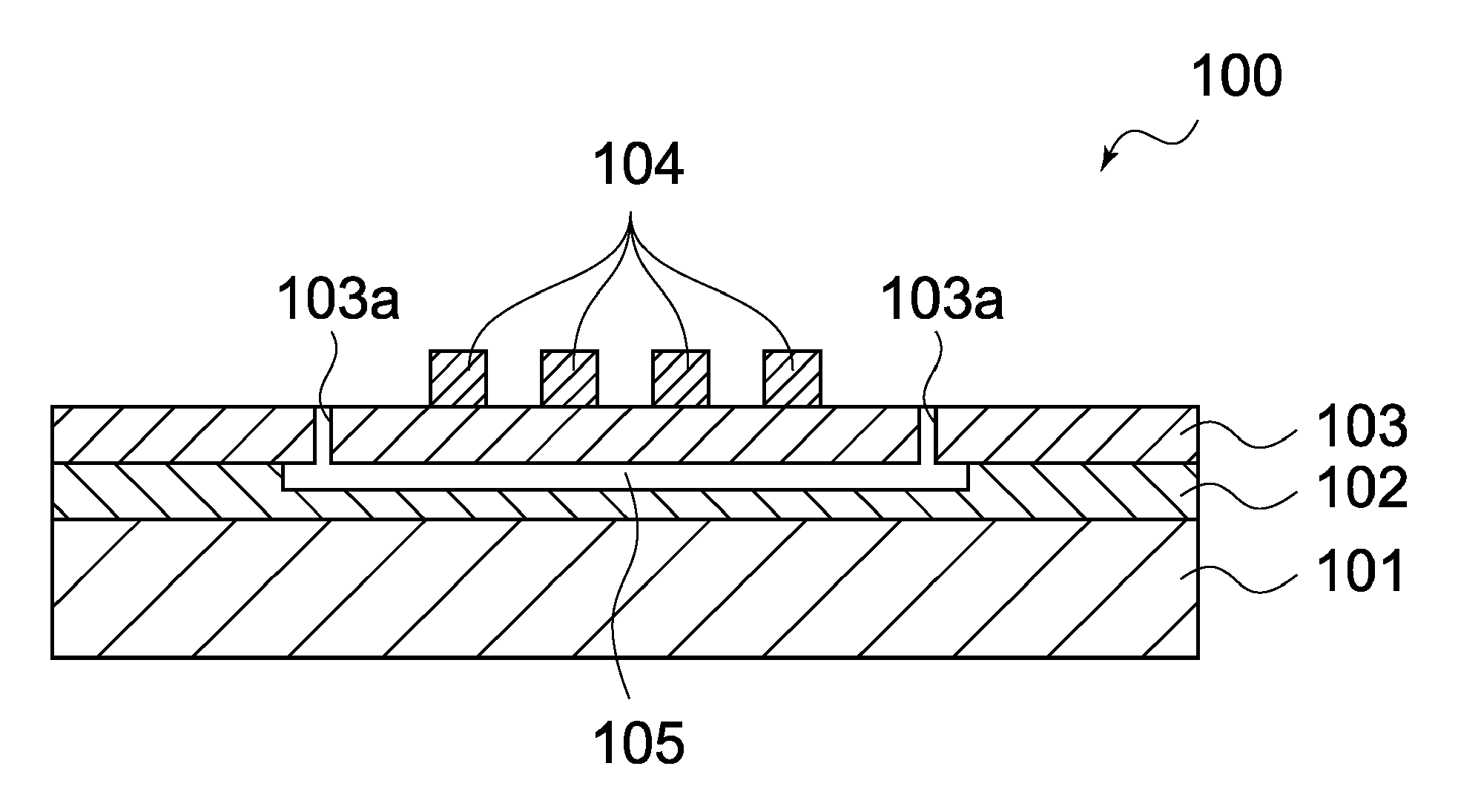

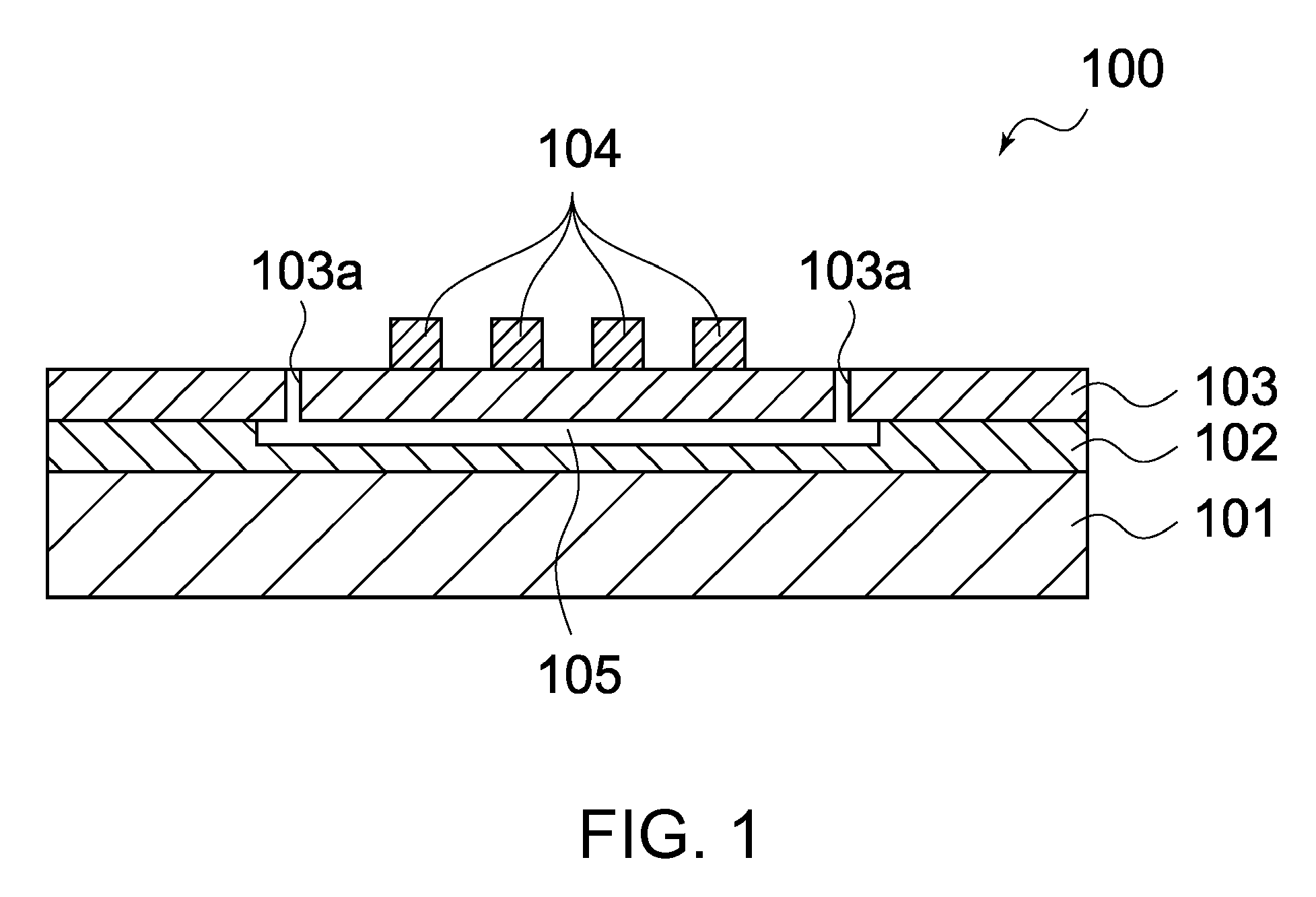

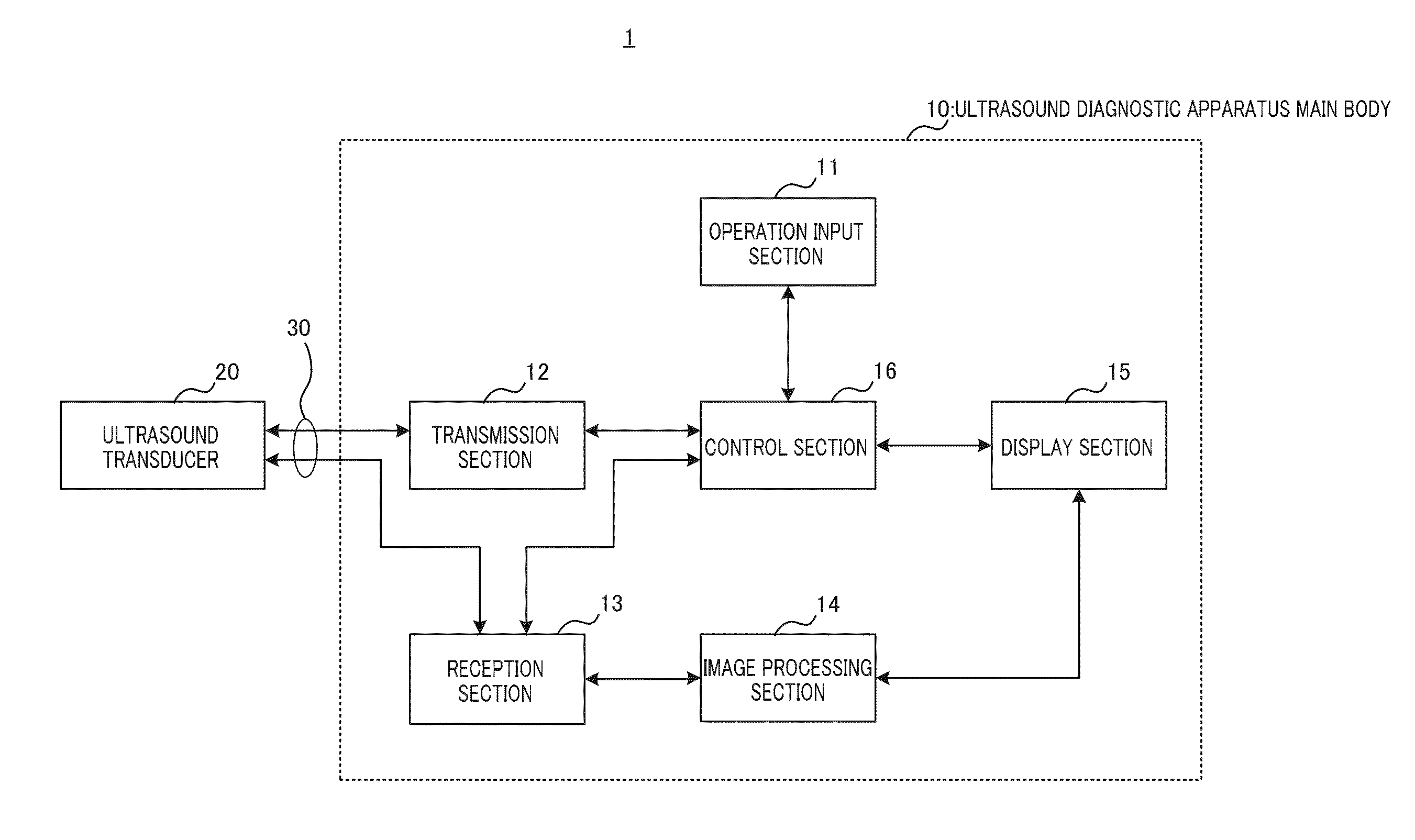

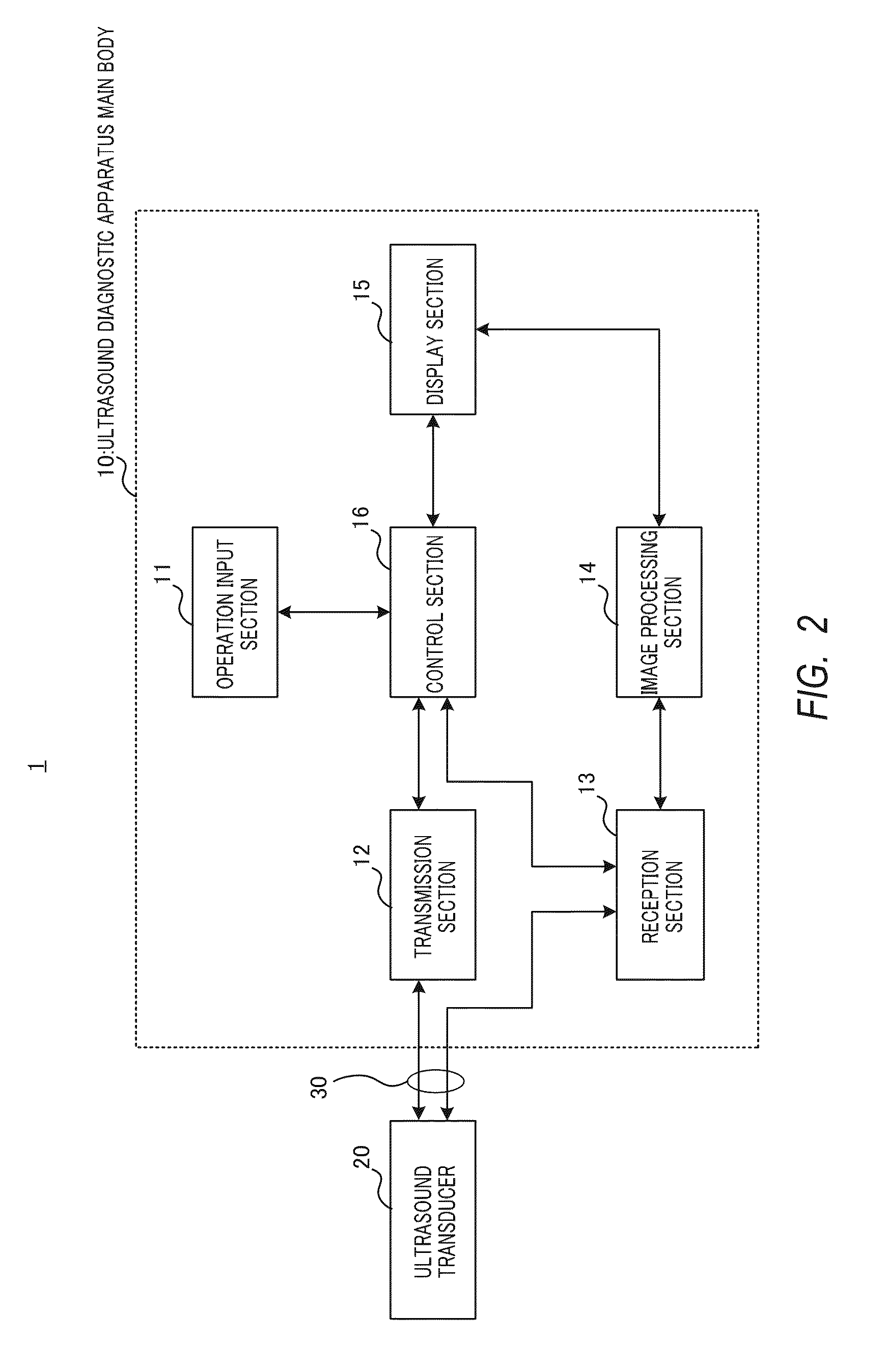

Ultrasound transducer and ultrasound diagnostic apparatus

ActiveUS20160027991A1Broadband characteristicsMagnetostrictive device manufacture/assemblyOrgan movement/changes detectionUltrasonic sensorSonification

An ultrasound transducer that achieves broadband characteristics without degrading the sensitivity of the ultrasound transducer. Piezoelectric element (202) includes piezoelectric thin film (203), first electrode (204) that is disposed on a first surface of piezoelectric thin film (203) in a thickness direction of piezoelectric thin film (203), and second electrode (205) that is disposed on a second surface of piezoelectric thin film (203) in the thickness direction of piezoelectric thin film (203), and at least two of parameters of a spring constant, a viscosity coefficient, and a mass in an equivalent single damped oscillation model representing a structure of a diaphragm composed of each piezoelectric cell (200) are each set to a value that is different among the piezoelectric cells (200) such that a relationship between a driving frequency ratio and a phase in the diaphragm is substantially identical among the piezoelectric cells (200).

Owner:KONICA MINOLTA INC

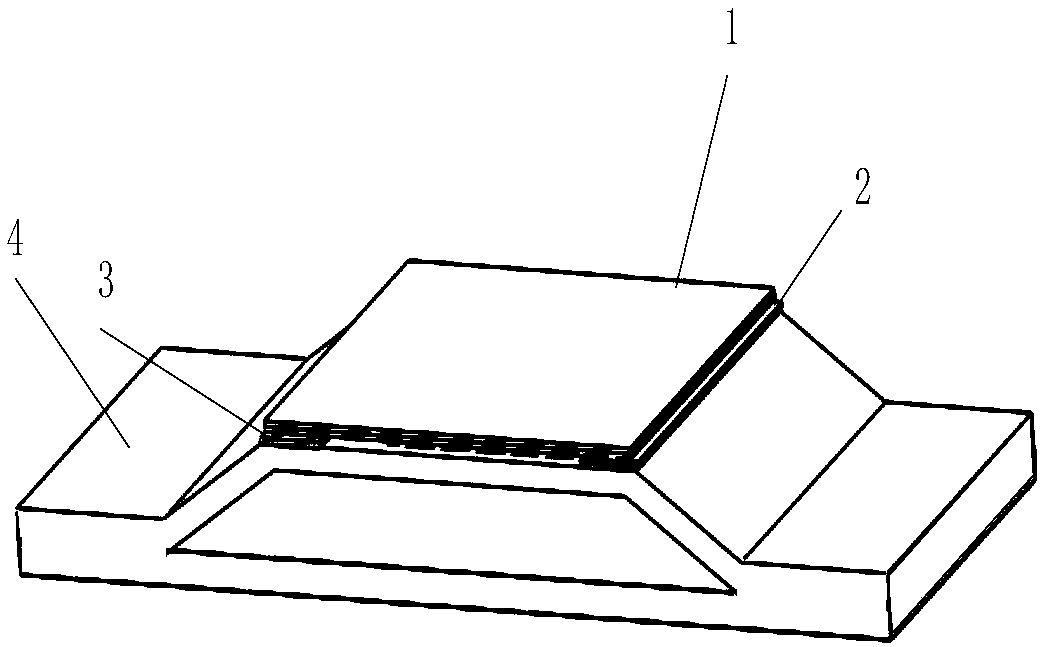

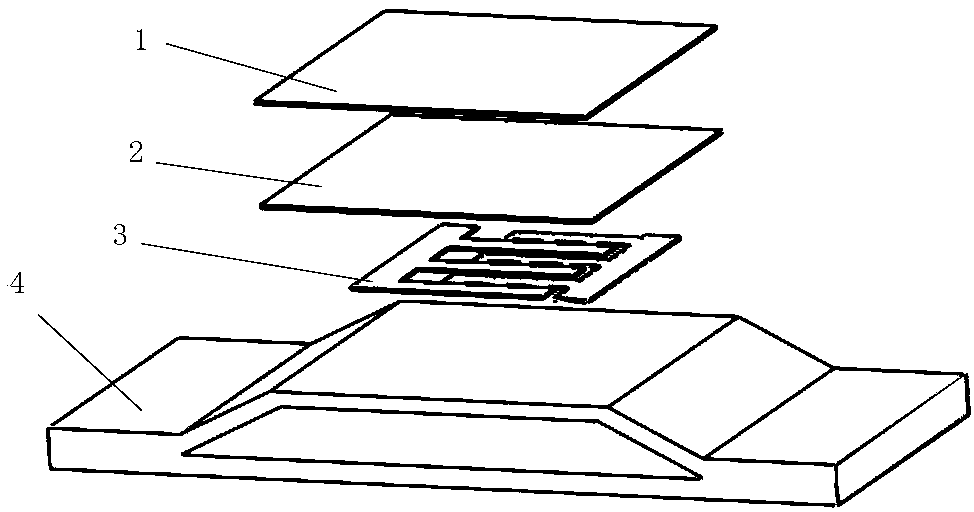

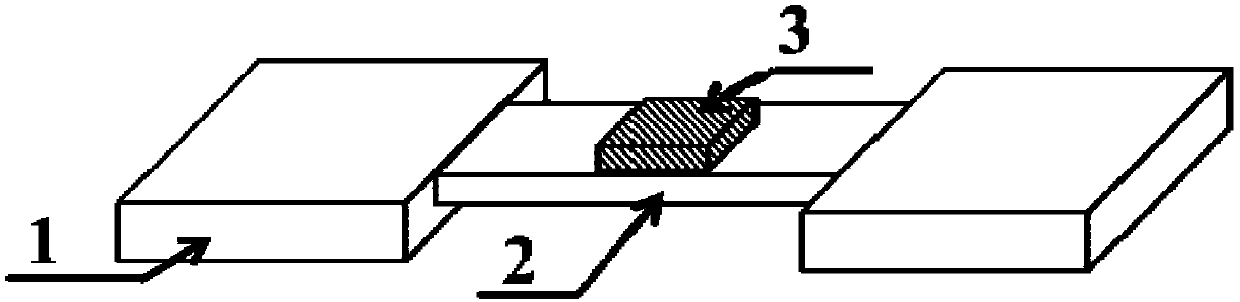

Bending resonance type magnetoelectric composite material and its manufacturing method

InactiveCN1794480AMiniaturizationLow bending resonance frequencyMagnetostrictive device manufacture/assemblyDevice material selectionResonanceMiniaturization

An electromagnetic compound material is formed by laminating a rectangular plate of magnetostrictive material and rectangular plates of piezoelectric materials in a same shape having a pair of plane electrodes and being polarized along the thickness direction, in which, the electromagnetic compound rectangular plate is applied with an AC magnetic field and a DC bias magnetic field along the length direction, when the frequency of the AC magnetic field equals to a stage curved resonance frequency of the electromagnetic complex material rectangular plate, the plate will generate bend resonance and the piezoelectric layer will output voltages to realize the transformation from magnetic energy to electric energy, when the applied DC bias magnetic field strength is suitable, the voltage output by the piezoelectric layer reaches to the maximum and the energy conversion efficiency is the maximum.

Owner:NANJING UNIV

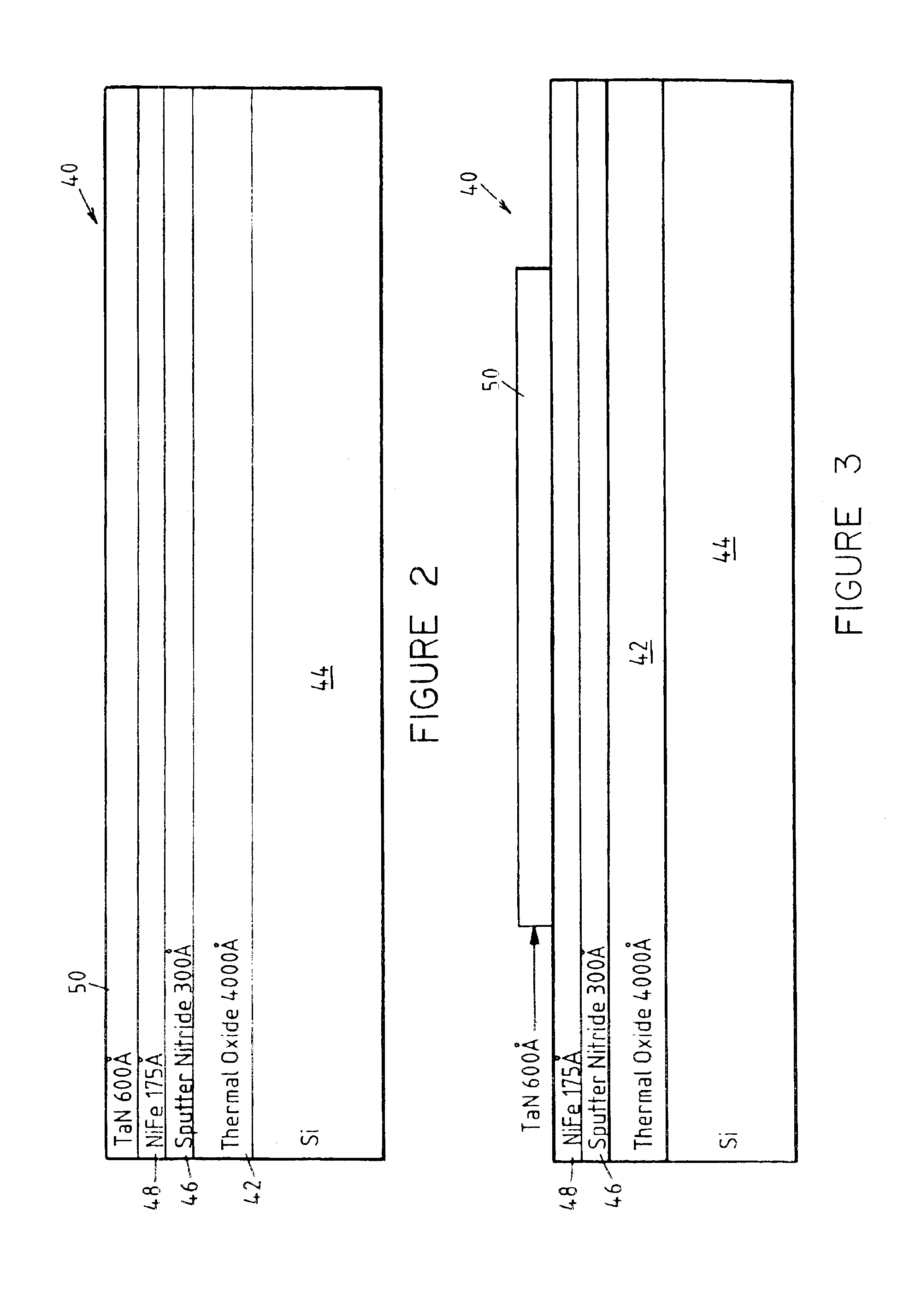

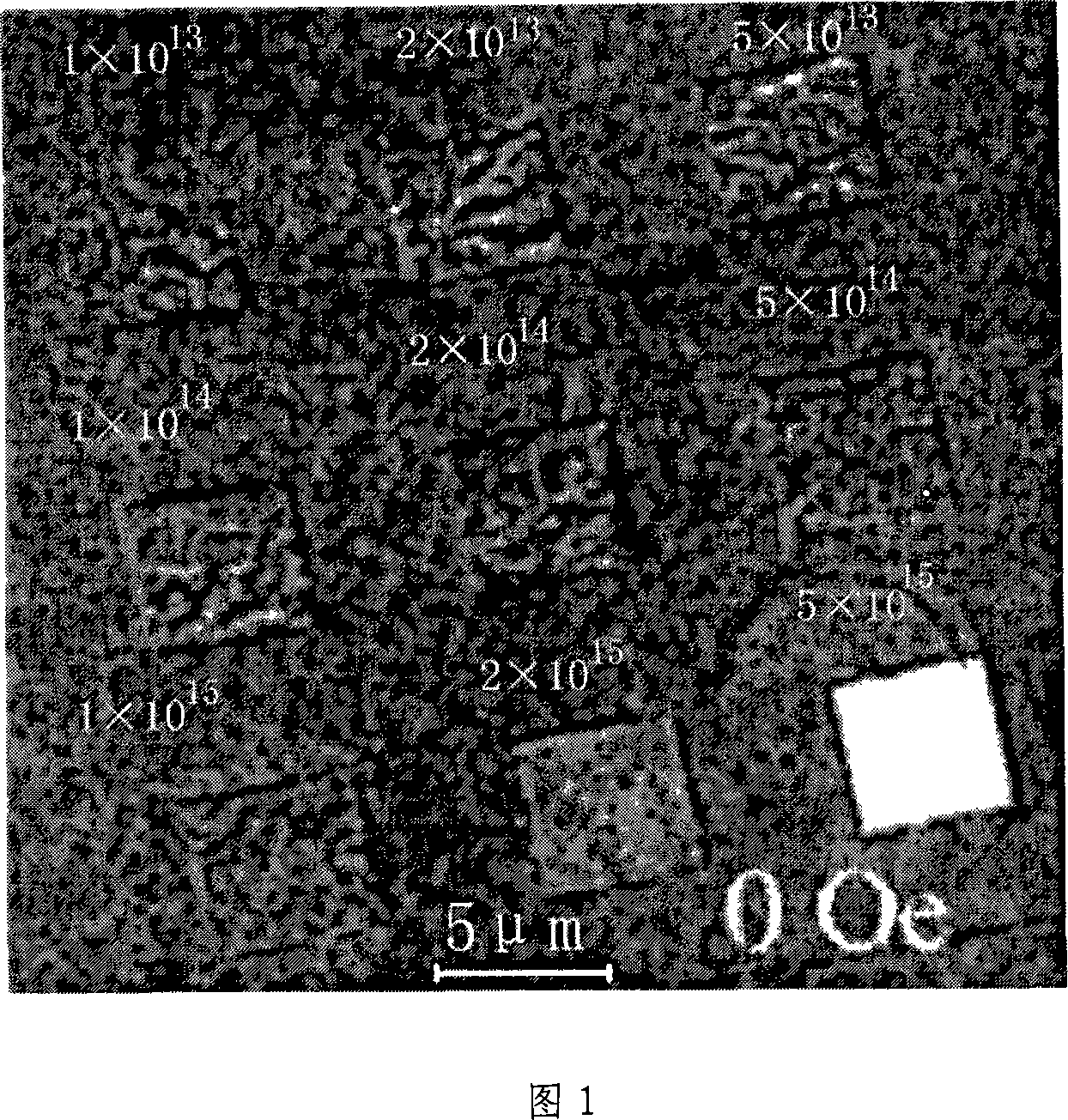

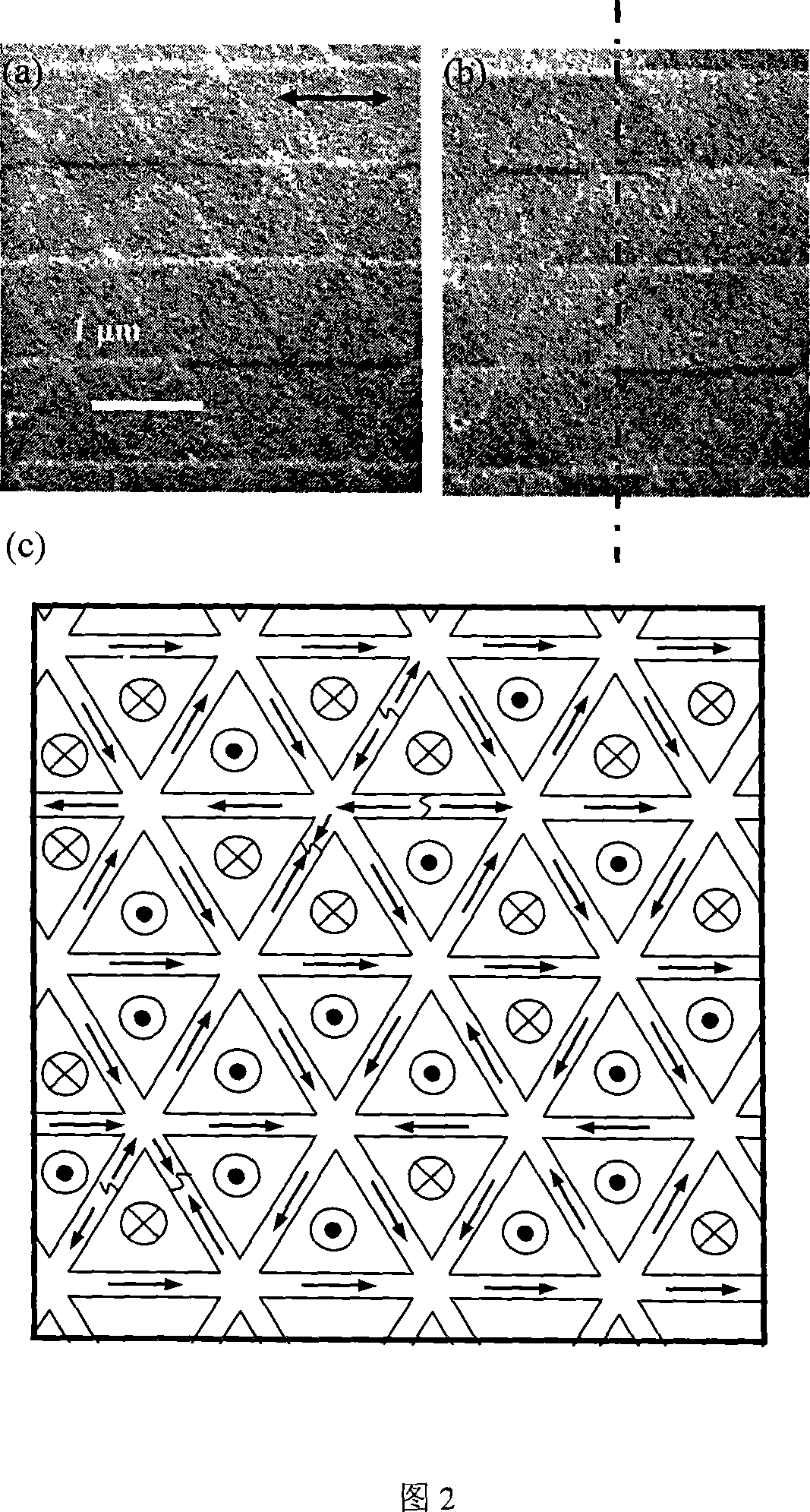

Non mask preparation method based on thin film multiple layer film nano magnetic electron device

InactiveCN101140978ASimple methodImprove efficiencyPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyManufacturing technologyWorkstation

A preparation method for maskless based on membrane or multi-membrane namometer magneto-electronic device is belongs to magneto-electronic device fabrication technique field. It is characterized in following procedures: first, depositing magnetism device matrix in order of underlay, cushion breaker, magnetic layer and covering layer; when deposit magnetic layer, 50-5000e plane abducting magnetic field should be added or magnetic field heat processing should be carried out after the deposition if needed; second, using focus gallium ion workstation as processing equipment to make maskless ion irradiation processing; third, the ion irradiation parameter is: dosage of ion irradiation is 1 is multipled by 10<>13<> swung dash 1 is multipled by 10<>18<>ions / cm<>2<>, ion beam energy is 20 to 30keV, ion beam stream is 100pA to 5nA; fourth, using focus gallium ion workstation to deposit needed electrode around magnetic membrane device. The method is characterized in dispense with preparation mask, easy to carry out and high efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

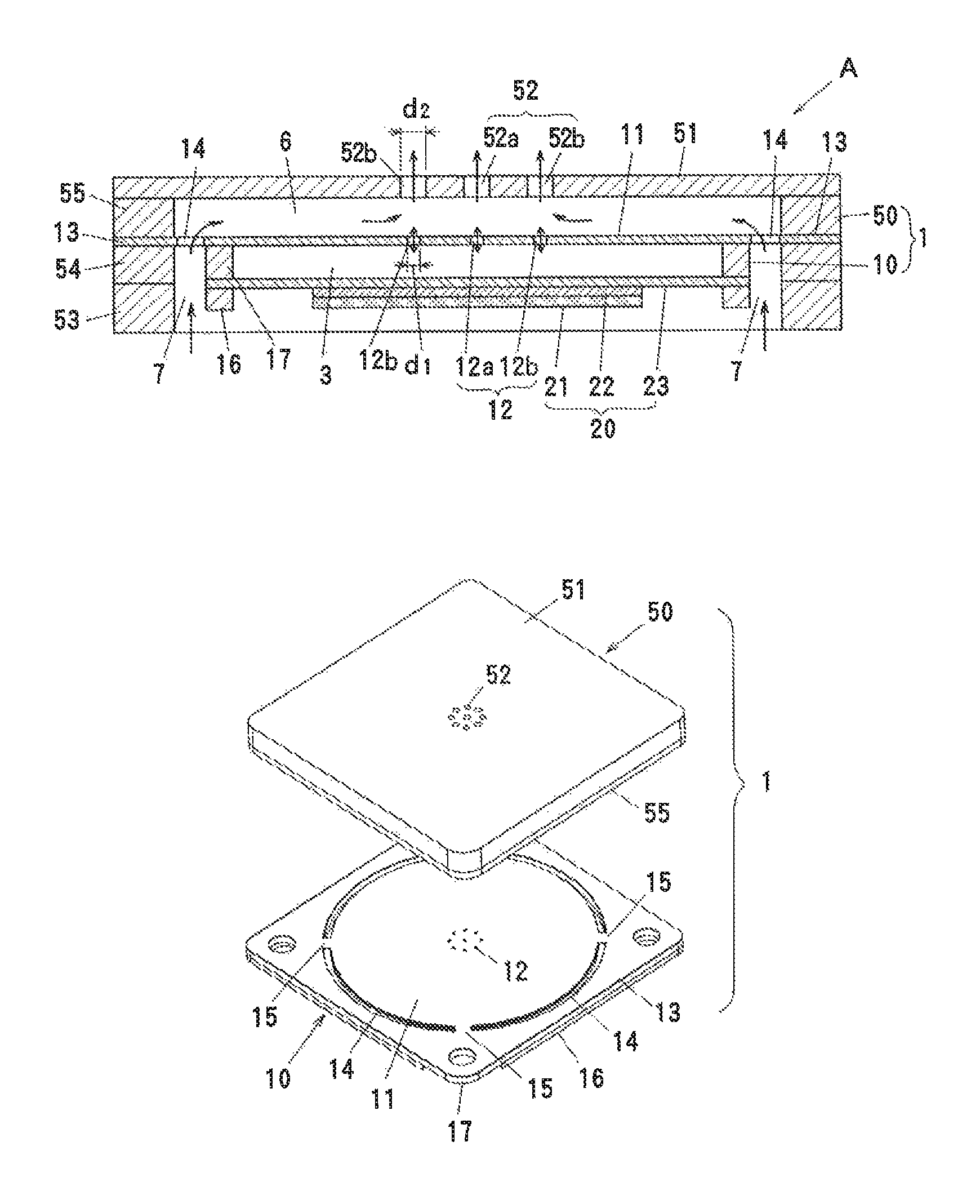

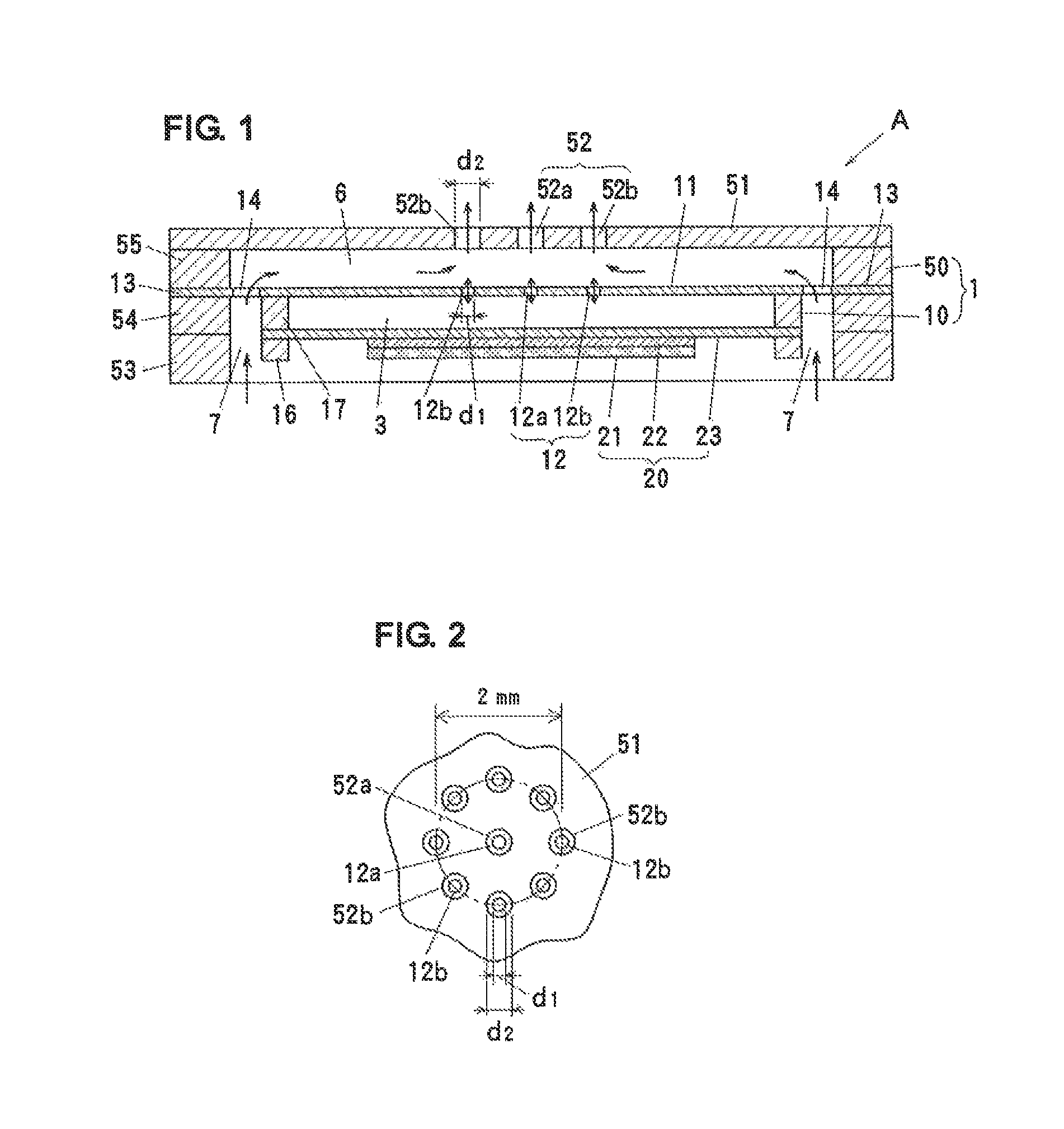

Piezoelectric micro-blower

ActiveUS8721303B2Magnetostrictive device manufacture/assemblyFlexible member pumpsEngineeringMechanical engineering

A piezoelectric micro-blower includes a blower chamber located between a blower body and a vibrating plate, a first wall portion of the blower body arranged to face the vibrating plate across the blower chamber so as to vibrate with vibrations of the vibrating plate, a first opening in the first wall portion, a second wall portion on the opposite side of the first wall portion with respect to the blower chamber, a second opening in a portion of the second wall portion which faces the first opening, and an inflow passage located between the first wall portion and the second wall portion. Each of the first and second openings includes a plurality of holes, and each hole of the first opening and each hole of the second opening are arranged to face each other. Thus, noise is significantly reduced while the flow characteristic is maintained.

Owner:MURATA MFG CO LTD

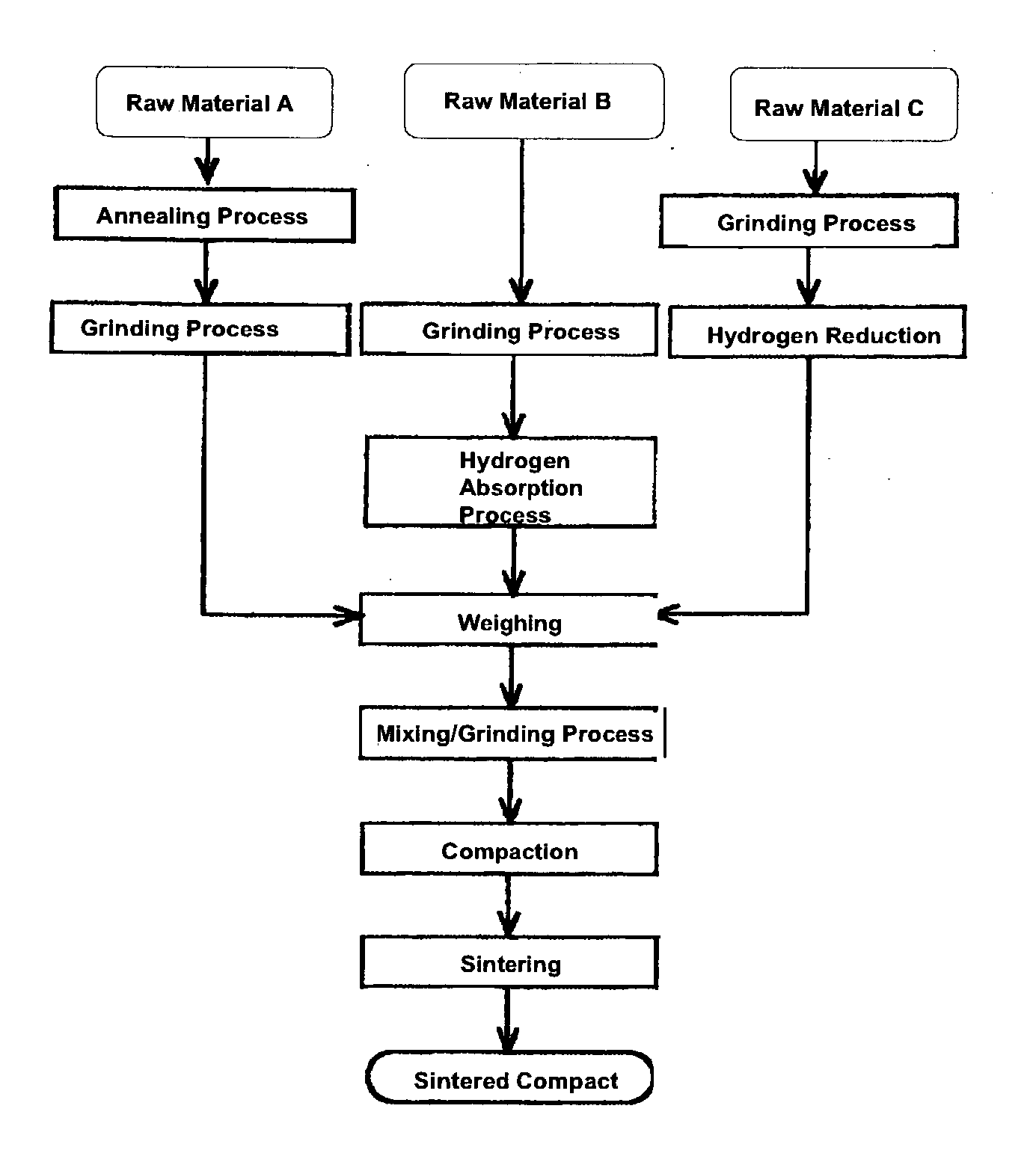

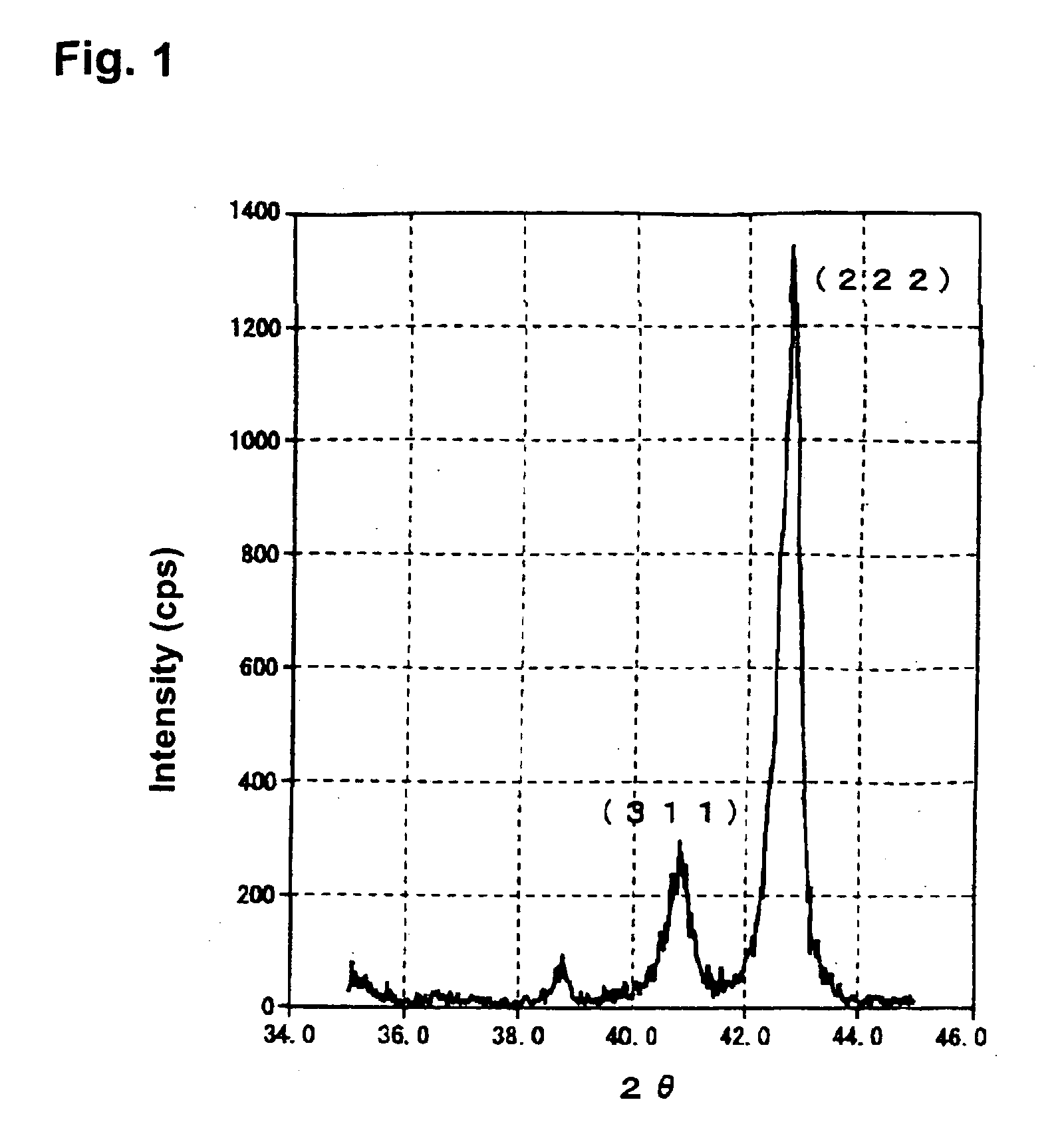

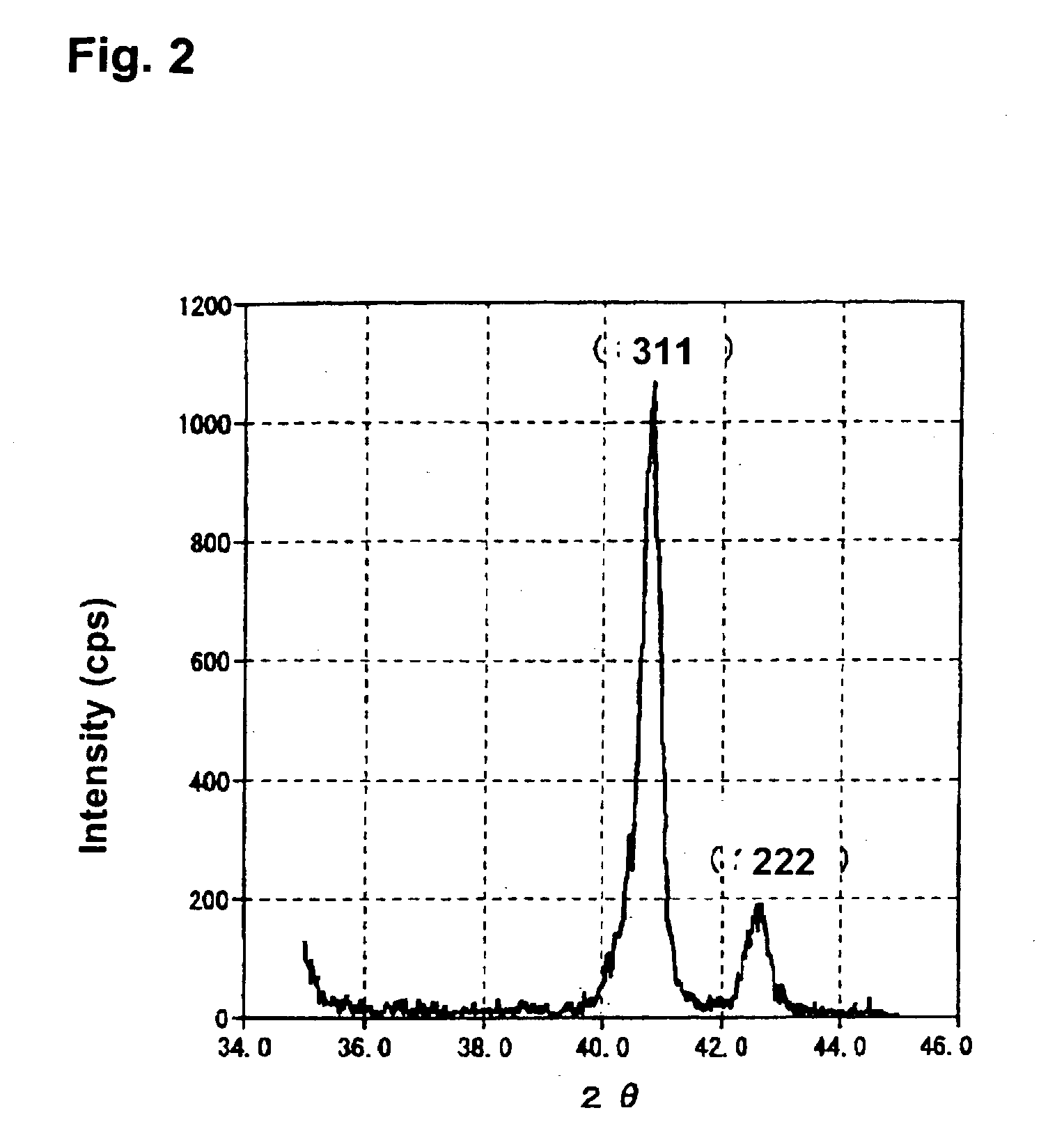

Method for preparing sintered product, sintered product and magnetostriction material

InactiveUS20030190250A1Little internal strainLow internal pressureMagnetostrictive device manufacture/assemblyMagnetostrictive material selectionAir atmosphereHigh density

A method for manufacturing a sintered compact includes the steps of preparing an alloy powder having a composition represented by Expression 1: RTW (where, R is at least one kind of rare earth metal, T is at least one kind of transition metal, and w defines a relation of 1<w<4), sintering the alloy powder in a vacuum atmosphere or an atmosphere containing gas with a molecular weight of 30 or less, and processing the alloy powder by a hot isostatic pressing. The sintered compact has a high density, and reduces deteriorations in its sintered compact properties such as magnetostrictive properties in an air atmosphere at high-temperatures.

Owner:TDK CORPARATION

Cantilever magnetic sensor, as well as preparation method and using method thereof

PendingCN108039404AImplement detectionHigh sensitivityMagnetostrictive device manufacture/assemblyMagnetostrictive device detailsCantilevered beamMagnet

The invention provides a cantilever magnetic sensor. The sensor comprises a base and a cantilever beam, wherein one end of the cantilever beam is fixed on the base, and the other end of the cantileverbeam is a free end; a magnet is arranged on the cantilever beam; and the cantilever beam vibrates under the act of a vibrating source in the working state, the frequency and amplitude of vibration are changed due to the magnetic torque generated by the magnet when an external magnetic field acts on the magnet, and the magnetic field can be detected by detecting the frequency and amplitude of thevibration. The magnetic sensor is simple in structure, and can realize high-sensitivity magnetic field detection.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of complex phase multiferroic material

ActiveCN107910436AMagnetization state changeRealize the technical effect of electromagnetismMagnetostrictive device manufacture/assemblyMagnetostrictive material selectionSputteringPre deformation

The present invention relates to a preparation method of a complex phase multiferroic material. The method of the present invention comprises the steps of applying an electric field on a substrate toenable a ferroelectric substrate to generate the stress pre-deformation, or applying the tensile stress or pressure stress on the ferroelectric substrate via a mechanical device to generate the pre-deformation; growing a ferromagnetic film on a pre-deformed ferroelectric film substrate via the methods, such as the pulsed laser deposition, the magnetron sputtering, the molecular beam epitaxy, etc.;after the ferromagnetic film is prepared, removing the electric field or the mechanical device on the ferroelectric substrate, and obtaining the complex phase multiferroic material. The ferroelectricsubstrate cannot recover to an original shape under the constraint of the ferromagnetic film, so that the stress is generated at an interface, and the magnetism of the ferromagnetic film is regulatedand controlled by the stress. With the existence of the pre-stress in the complex phase multiferroic material obtained by the present invention, a smaller external electric field can change the magnetization state of the ferromagnetic film, thereby reducing a response field.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com