Patents

Literature

83 results about "Particulate composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PARTICULATE REINFORCED COMPOSITES. Composites refer to a material consisting of two or more individual constituents. The reinforcing constituent is embedded in a matrix to form the composite. One form of composites is particulate reinforced composites with concrete being a good example.

Nanocomposite particulates and methods of using nanocomposite particulates

The present invention relates to particulate composites comprising at least one resin and at least one nanoparticle material. Some embodiments of the present invention provide methods of treating a portion of a subterranean formation comprising providing a nanocomposite particulate comprising at least one resin and at least one nanoparticle material; substantially slurrying the nanocomposite particulate into a servicing fluid to create a slurry; and, placing the slurry a well bore penetrating the portion of the subterranean formation. Other embodiments of the present invention provide nanocomposite particulates suitable for use in a subterranean application comprising at least one resin and at least one nanoparticle material wherein the nanocomposite particulate comprises from about 0.1% to about 30% nanoparticle material by weight of the nanocomposite particulate.

Owner:HALLIBURTON ENERGY SERVICES INC

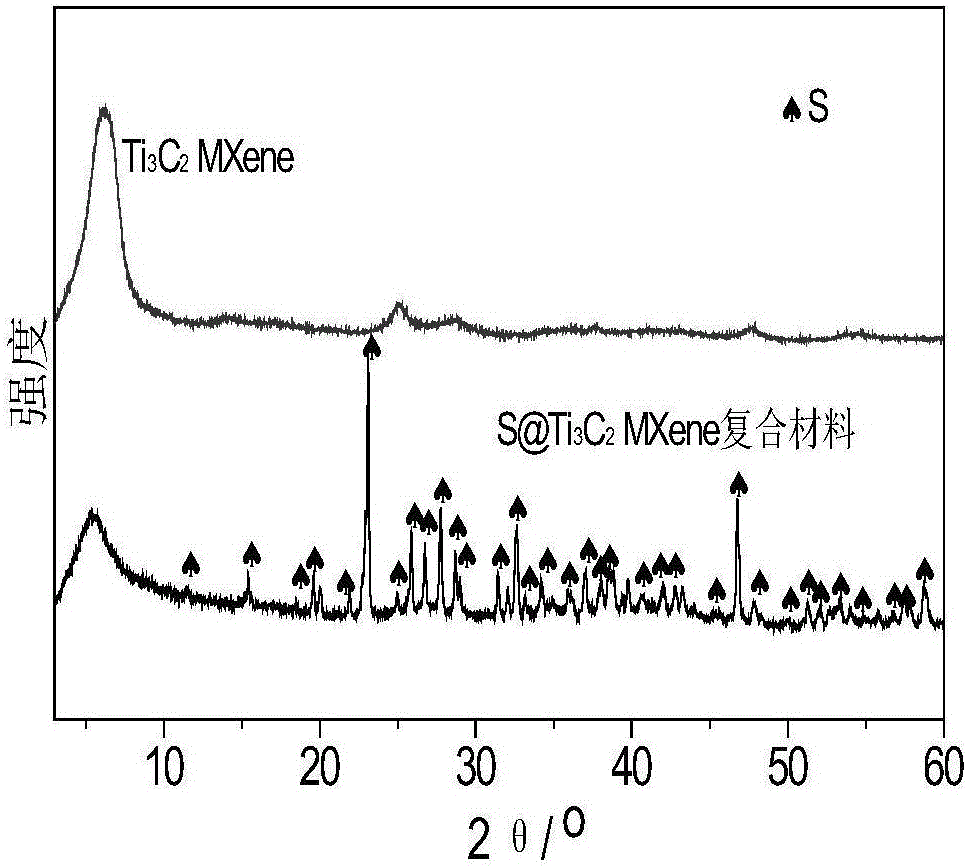

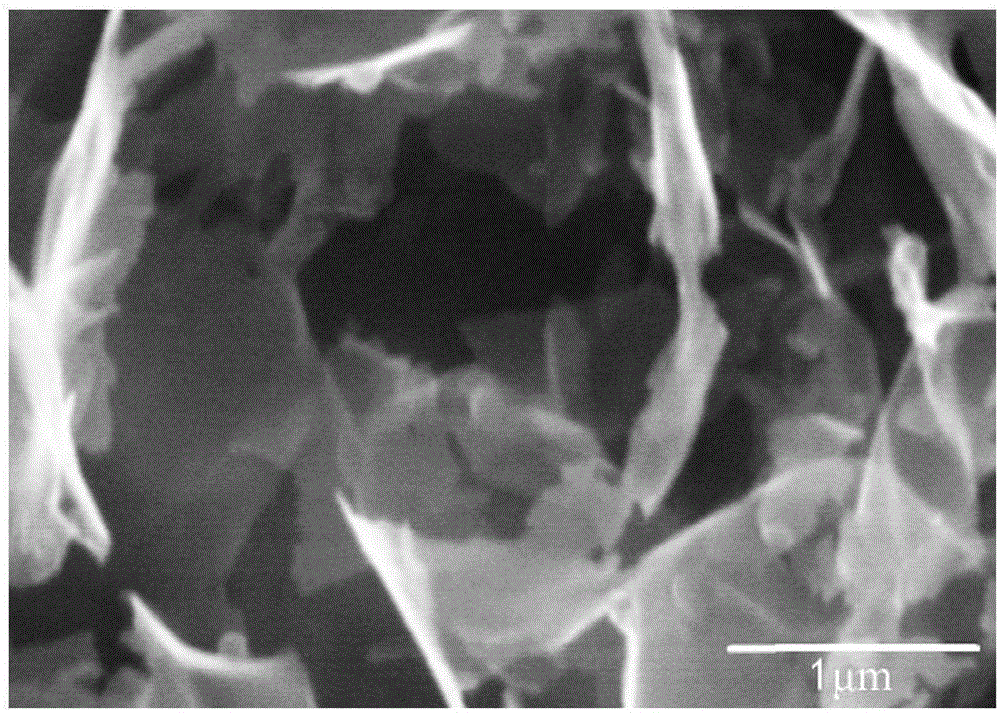

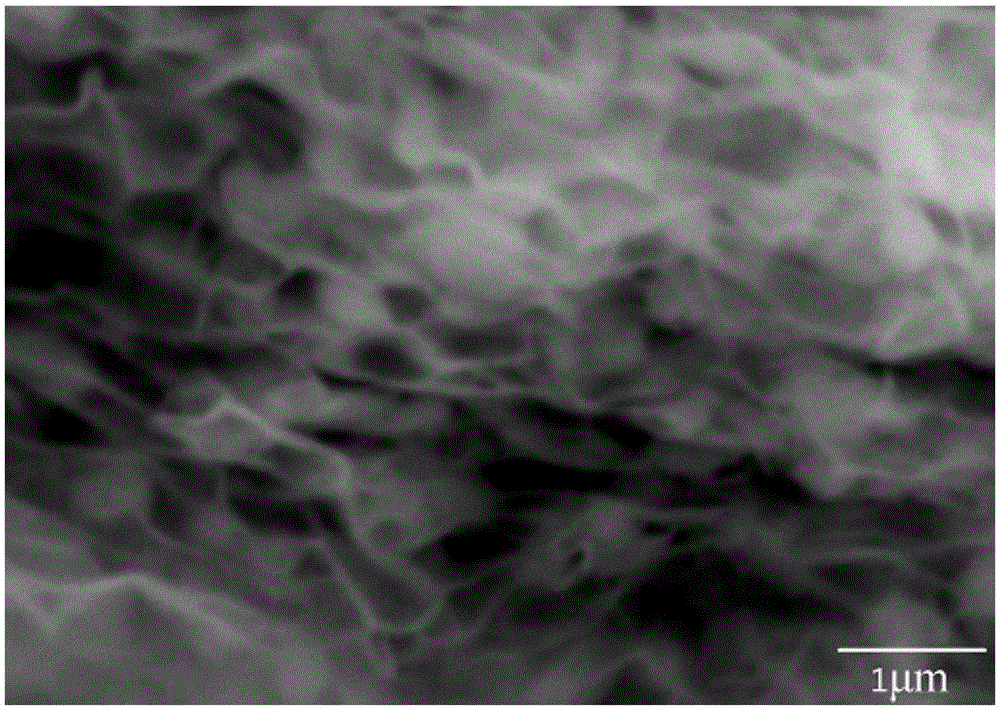

Two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof

ActiveCN106450205AGive full play to the sulfur fixation effectEvenly dispersedMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSodium polysulfideReducing agent

The invention relates to a two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof. The composite is formed by two-dimensional transition metal carbide (nitride) MXene nanosheets and nano sulfur particles, wherein the nano sulfur particles grow on the surface of the two-dimensional transition metal carbide (nitride) MXene nanosheets in an in-situ manner, marked as S@MXene. The stable suspension of a single layer or a few layers of two-dimensional transition metal carbide (nitride) MXene nanosheets is mixed with a sodium thiosulfate or sodium polysulfide solution; with formic acid as a reducing agent, the nano sulfur generated by the reaction uniformly grows on the surface of the two-dimensional MXene nanosheet; and the two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite is obtained through neutralization, washing and centrifugation and serves as the anode of a lithium-sulfur battery. According to the invention, a high-conductivity two-dimensional transition metal carbide (nitride) MXene nanosheet carrier is uniformly compounded with nano sulfur particles, introduction of a binder and a conductive agent is not needed, and the composite has excellent electrochemical performance as the anode of a lithium-sulfur battery; and moreover, the technology is simple and can meet the requirements of large-scale production.

Owner:NANJING TECH UNIV

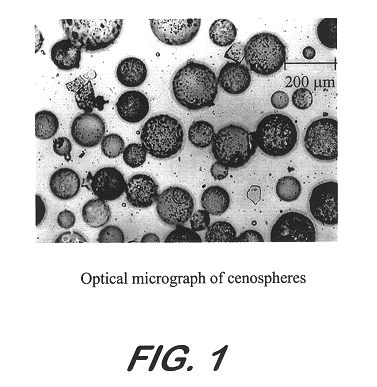

Light weight particulate composite materials with cenospheres as reinforcements and method for making the same

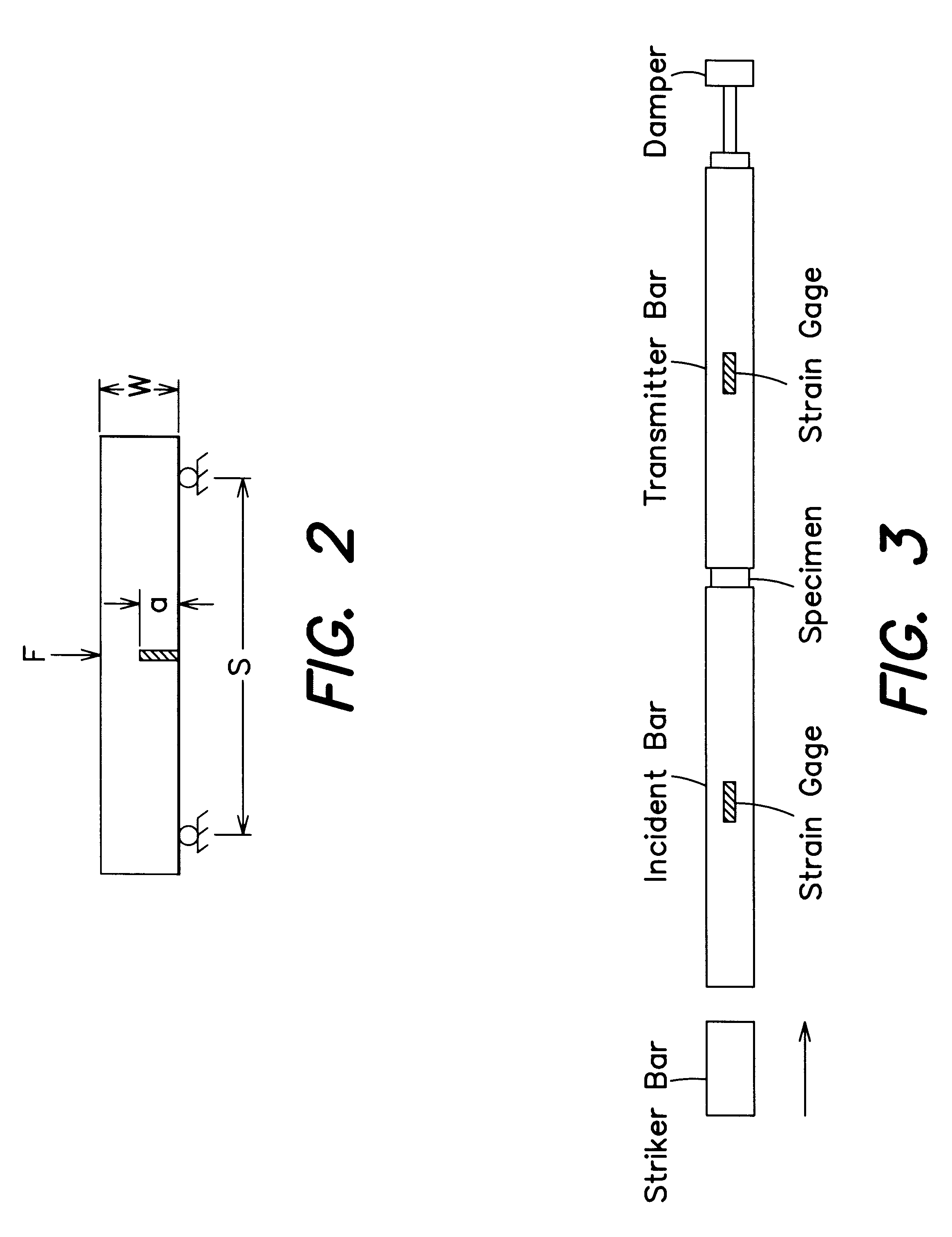

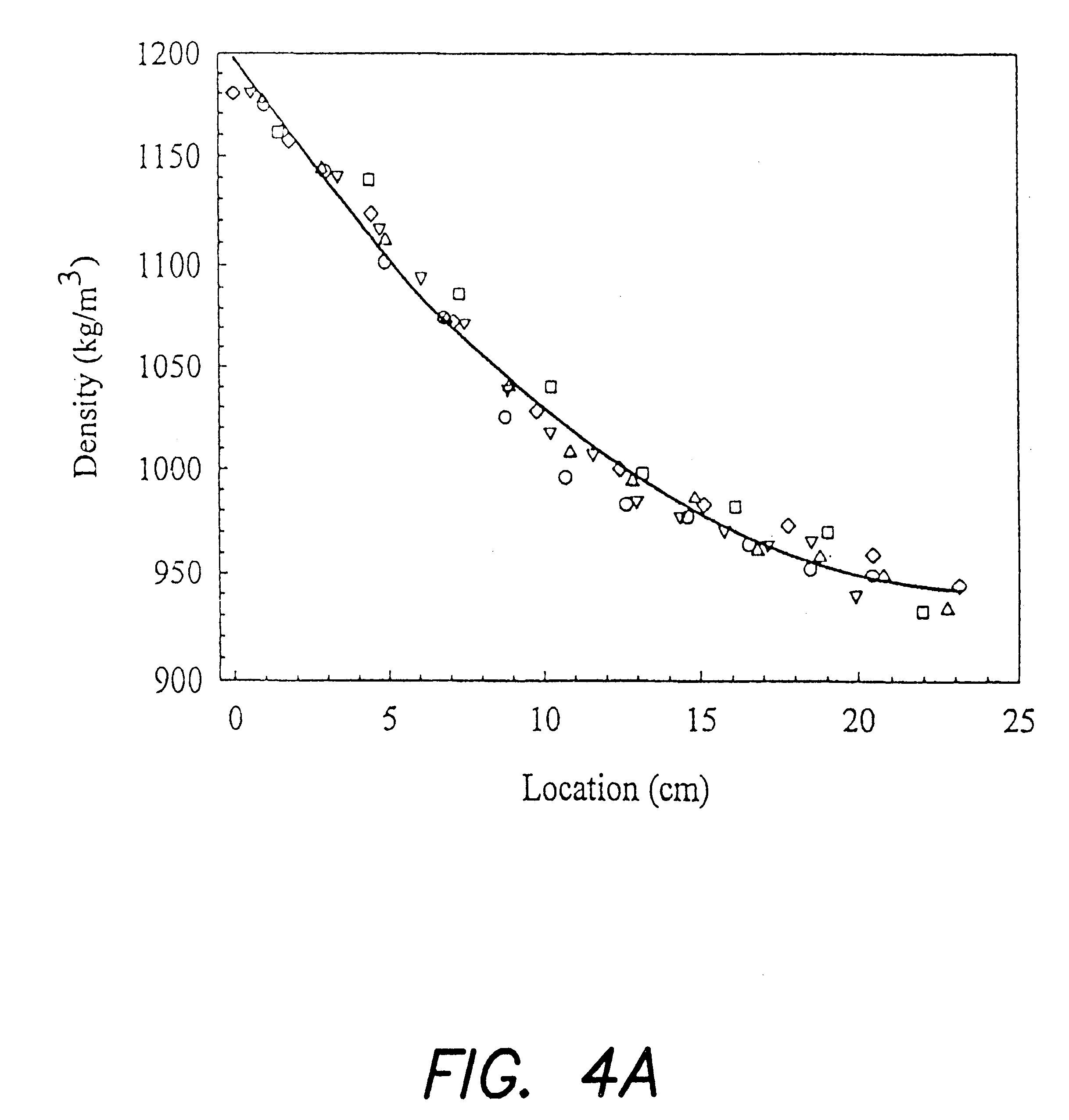

This invention provides a particulate composite comprising a polyester resin, a plasticizer, and a plurality of cenospheres. The polyester resin and the plasticizer form a matrix wherein the cenospsheres are distributed nonhomogeneously in the matrix. The nonhomogenous distribution of cenospheres further comprises a continuously varying particle volume fraction along a single dimension.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE PLATATIONS THE

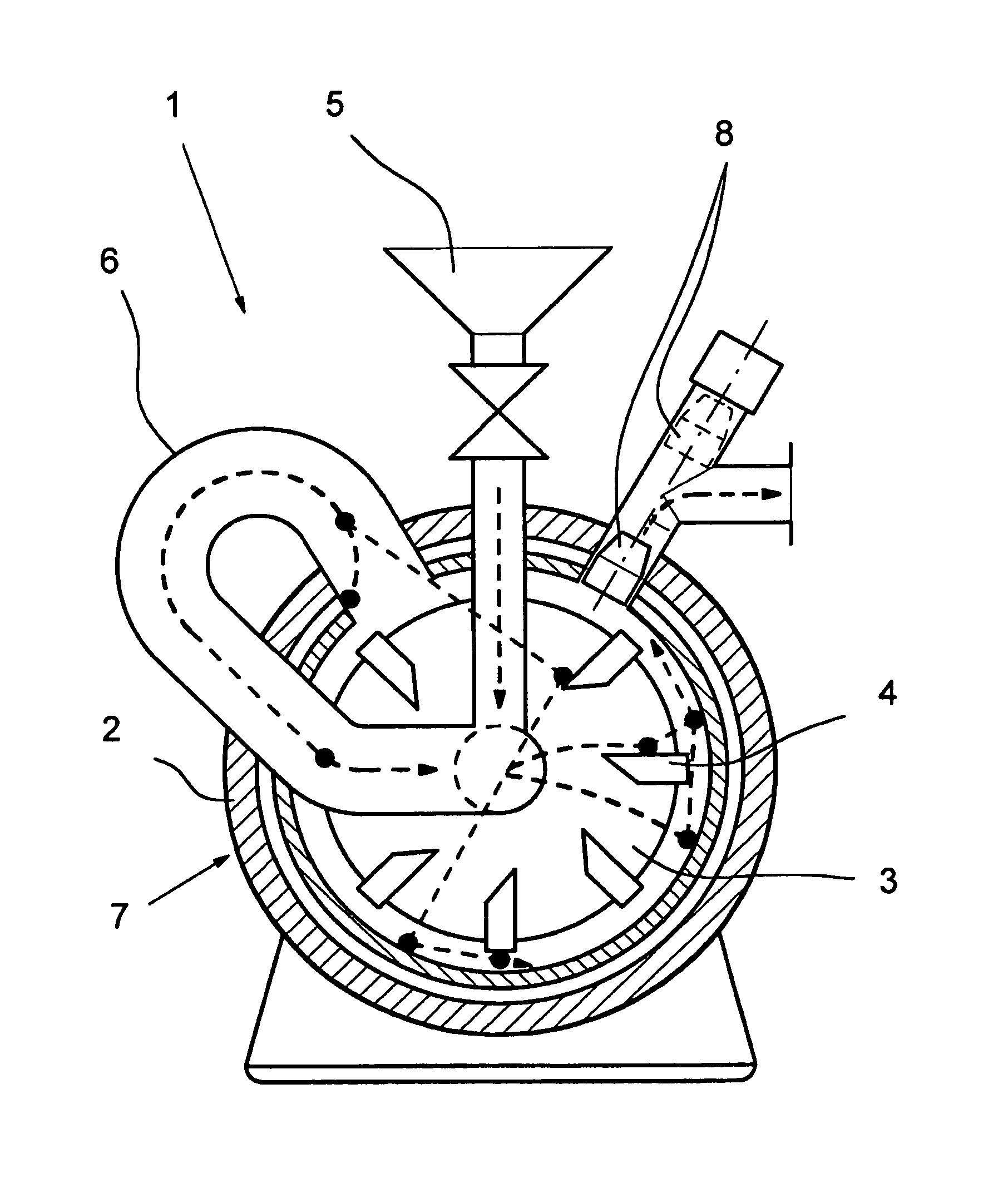

Production of nanoparticles, especially nanoparticle composites, from powder agglomerates

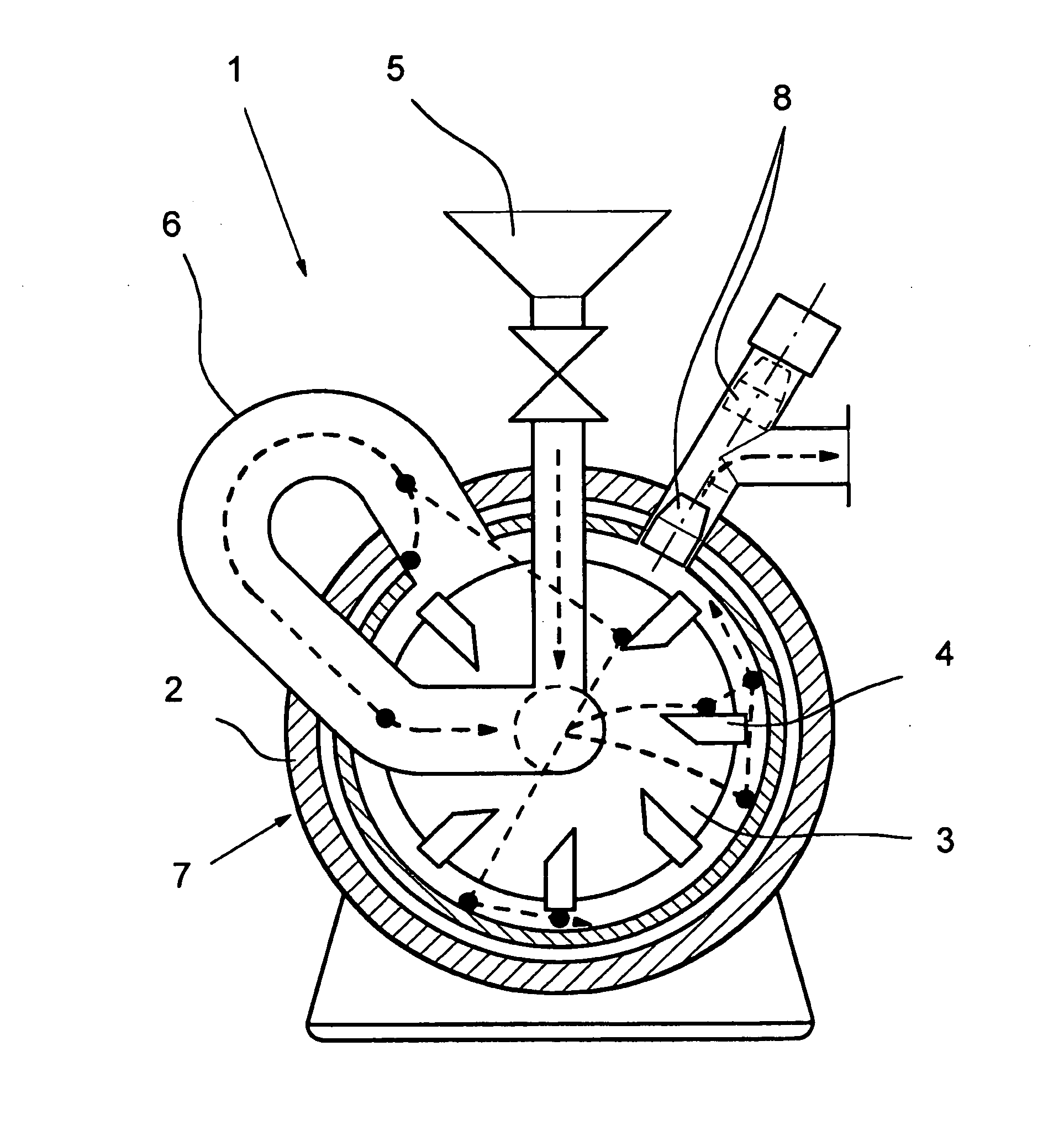

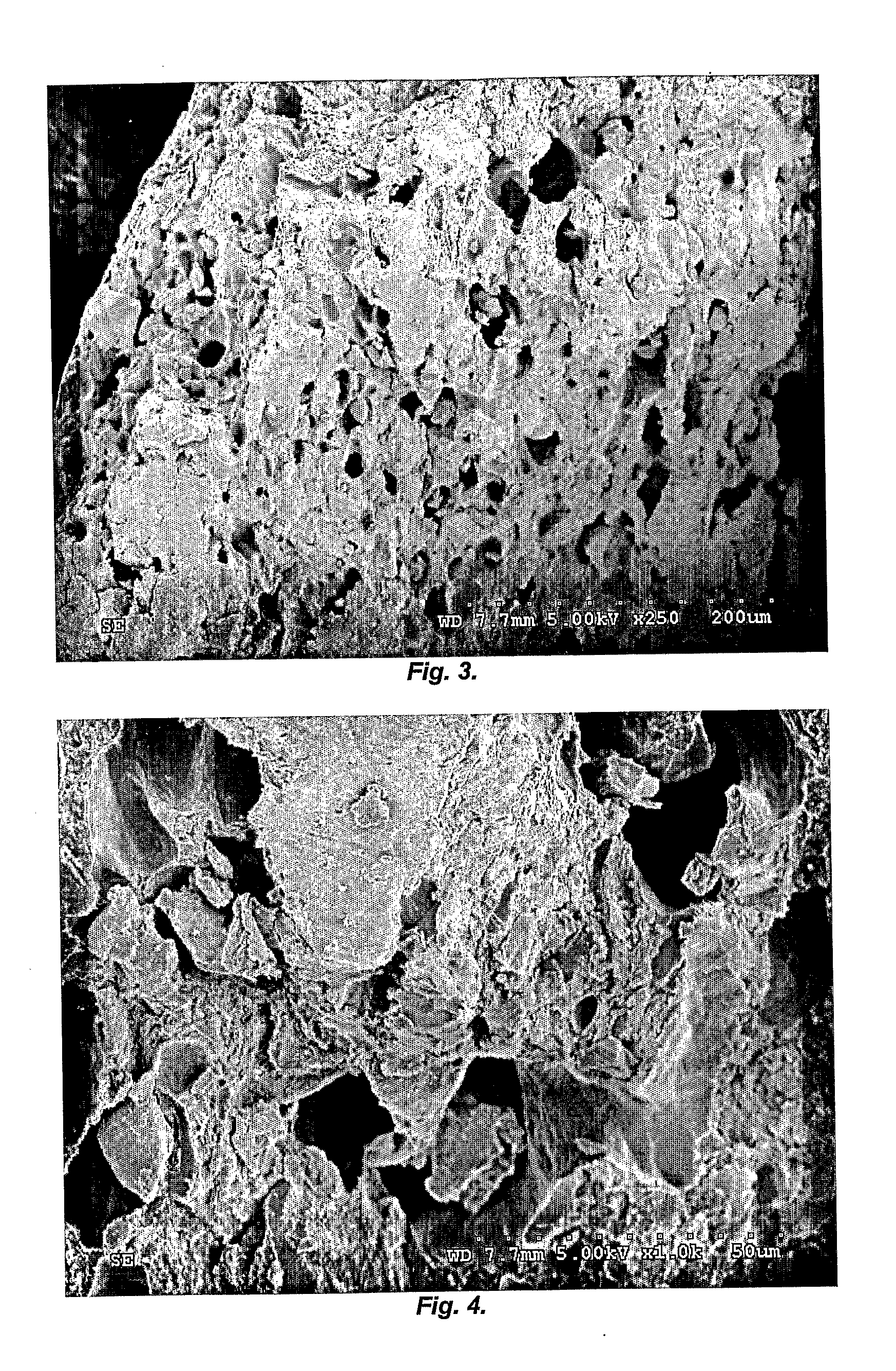

The invention relates to a method for producing particulate composite materials. According to the method, solid inorganic or organic particle agglomerates or particle aggregates that are provided in a dry state, particularly in powder form, are first reduced in size in the gas phase or in a gaseous carrier medium in the presence of organic matrix particles by applying energy. The obtained comminuted particles are dispersed into the organic matrix particles, especially embedded thereinto and / or attached thereto. The composite materials produced in said manner can be used in many different ways and are suitable in particular for use in a large variety of plastic materials, coating materials, paints, and lacquers, especially coating powders, to modify properties during use in the corresponding products and similar.

Owner:BYK CHEM GMBH

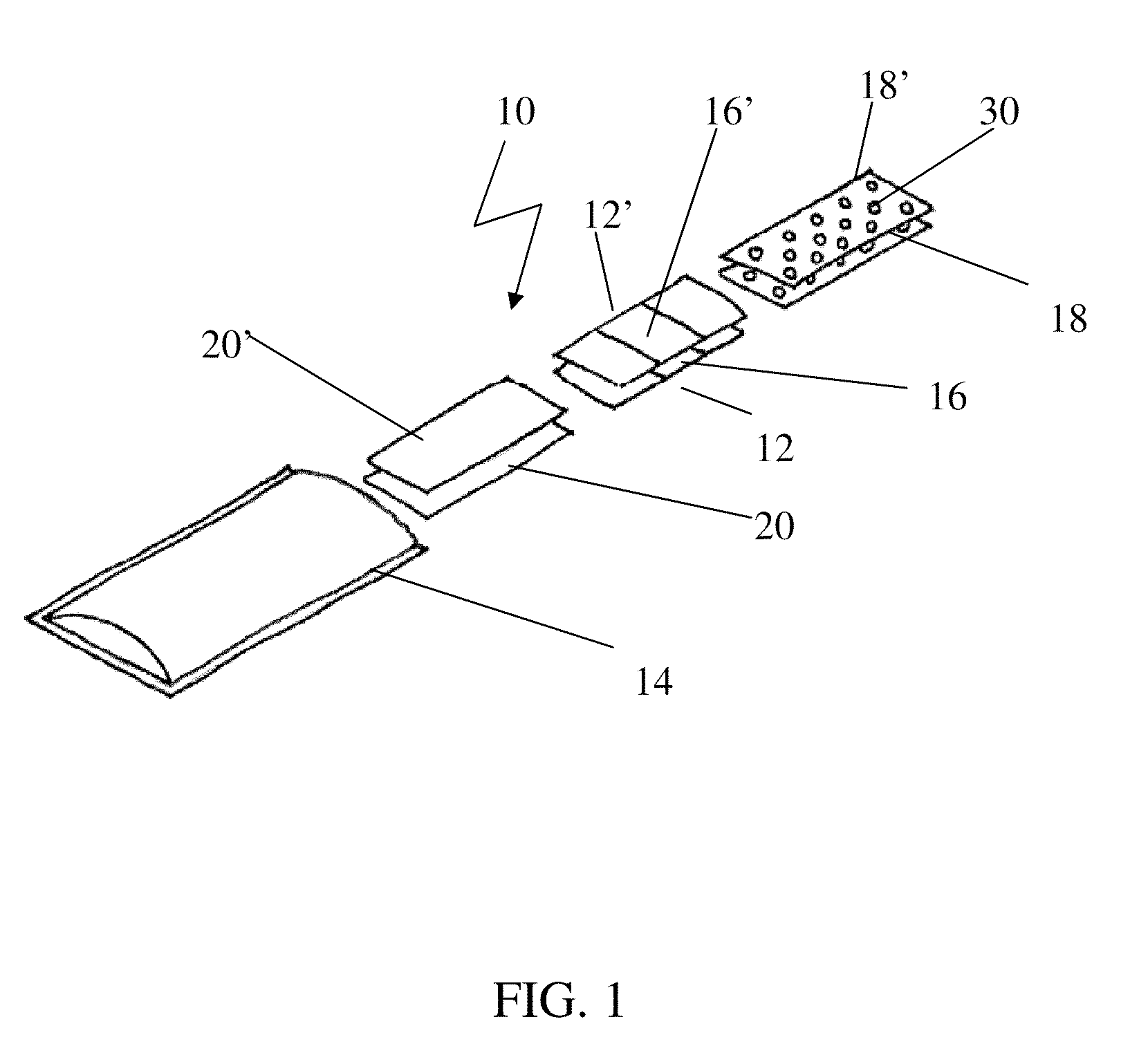

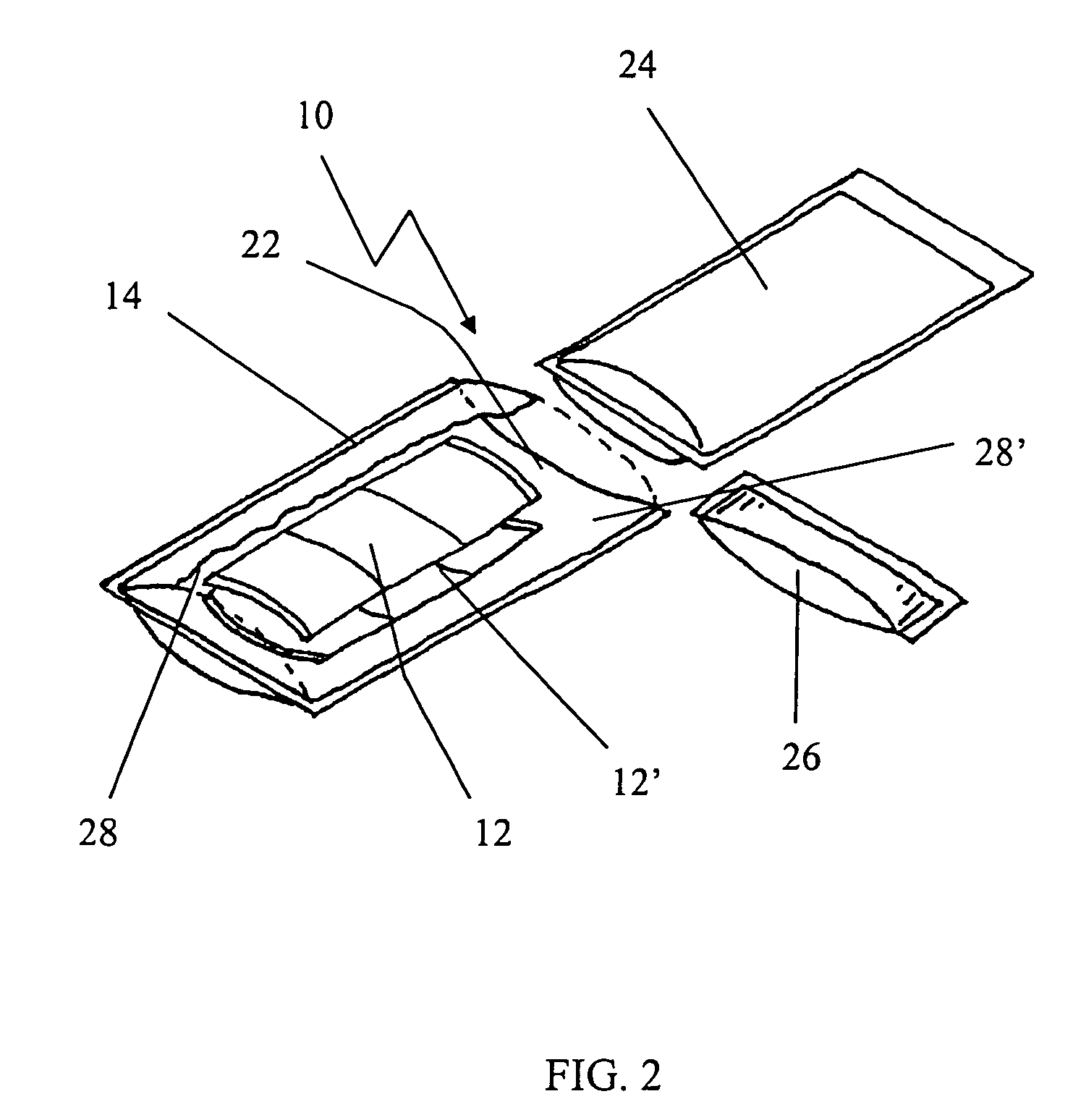

Portable heating apparatus and metal fuel composite for use with same

ActiveUS7722782B2Minimizes weight and cost and complexity and sizeExtended shelf lifeExothermal chemical reaction heat productionOther chemical processesEngineeringOxygen

A particulate composite fuel of metal preferably of aluminum for a portable heater. The fuel reacts with oxygen in the air, producing heat. The composite fuel may also be flaked aluminum or iron nanopowder. A portable heater having a fuel mass, at least one thermal conductive member, and at least one insulating member. The heater transfers the heat of the oxidation of the metal particulate fuel to a desired mass to be heated, typically a food item. The multilayered heater also acts as a buffer absorbing released heat and releasing the heat to the desired mass at a rate slower than the absorbing.

Owner:RBCE TECH LLC

Production of nanoparticles, especially nanoparticle composites, from powder agglomerates

The invention relates to a method for producing particulate composite materials. According to the method, solid inorganic or organic particle agglomerates or particle aggregates that are provided in a dry state, particularly in powder form, are first reduced in size in the gas phase or in a gaseous carrier medium in the presence of organic matrix particles by applying energy. The obtained comminuted particles are dispersed into the organic matrix particles, especially embedded thereinto and / or attached thereto. The composite materials produced in said manner can be used in many different ways and are suitable in particular for use in a large variety of plastic materials, coating materials, paints, and lacquers, especially coating powders, to modify properties during use in the corresponding products and similar.

Owner:BYK CHEM GMBH

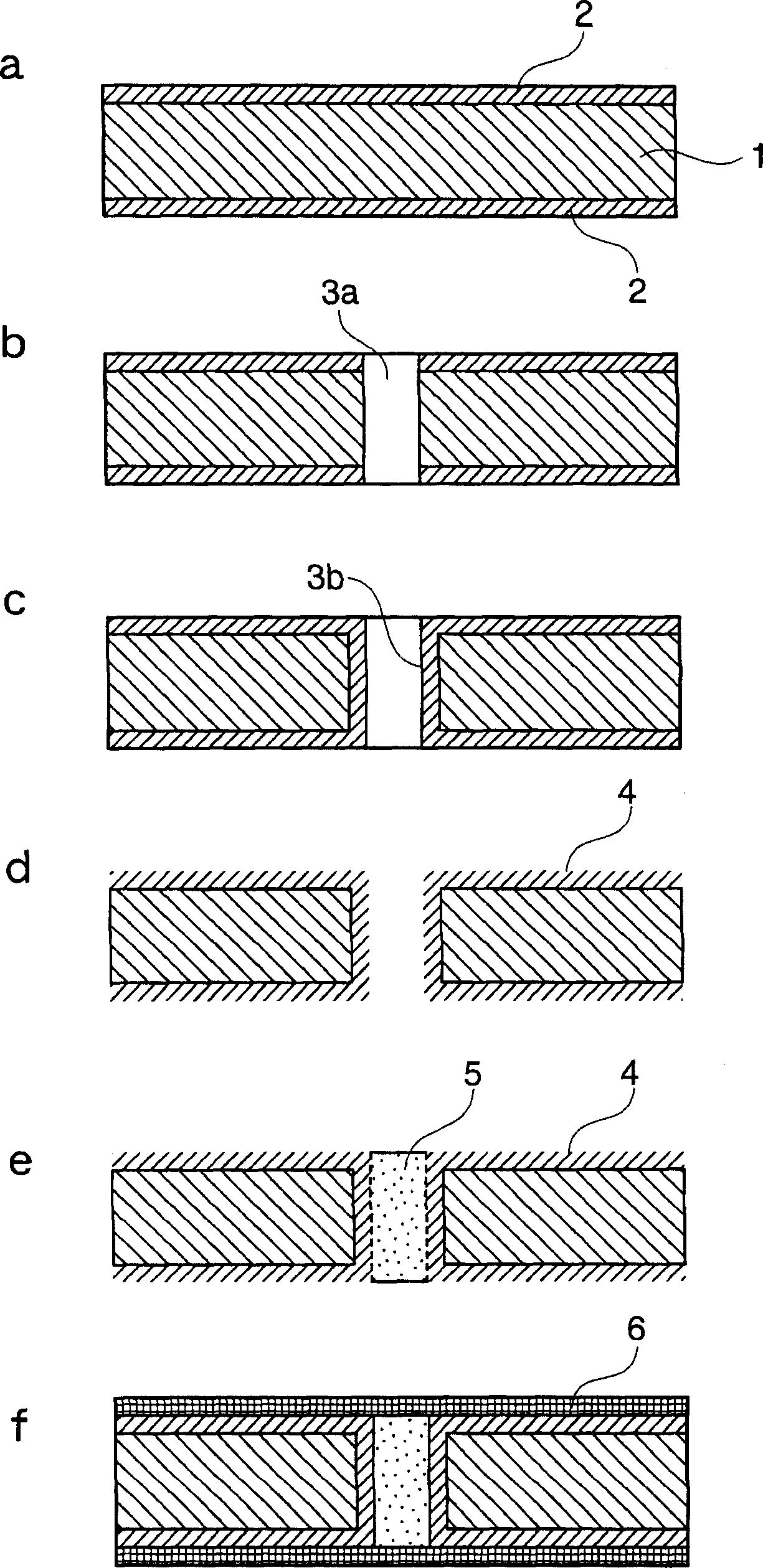

Composite particle for dielectrics, ultramicro particulate composite resin particle, composition for forming dielectrics and use thereof

InactiveCN1455933ASemiconductor/solid-state device detailsSolid-state devicesInorganic particleInorganic particles

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. <??>In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultrafine particles with the average particle size of 0.1 mu m or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mu m and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

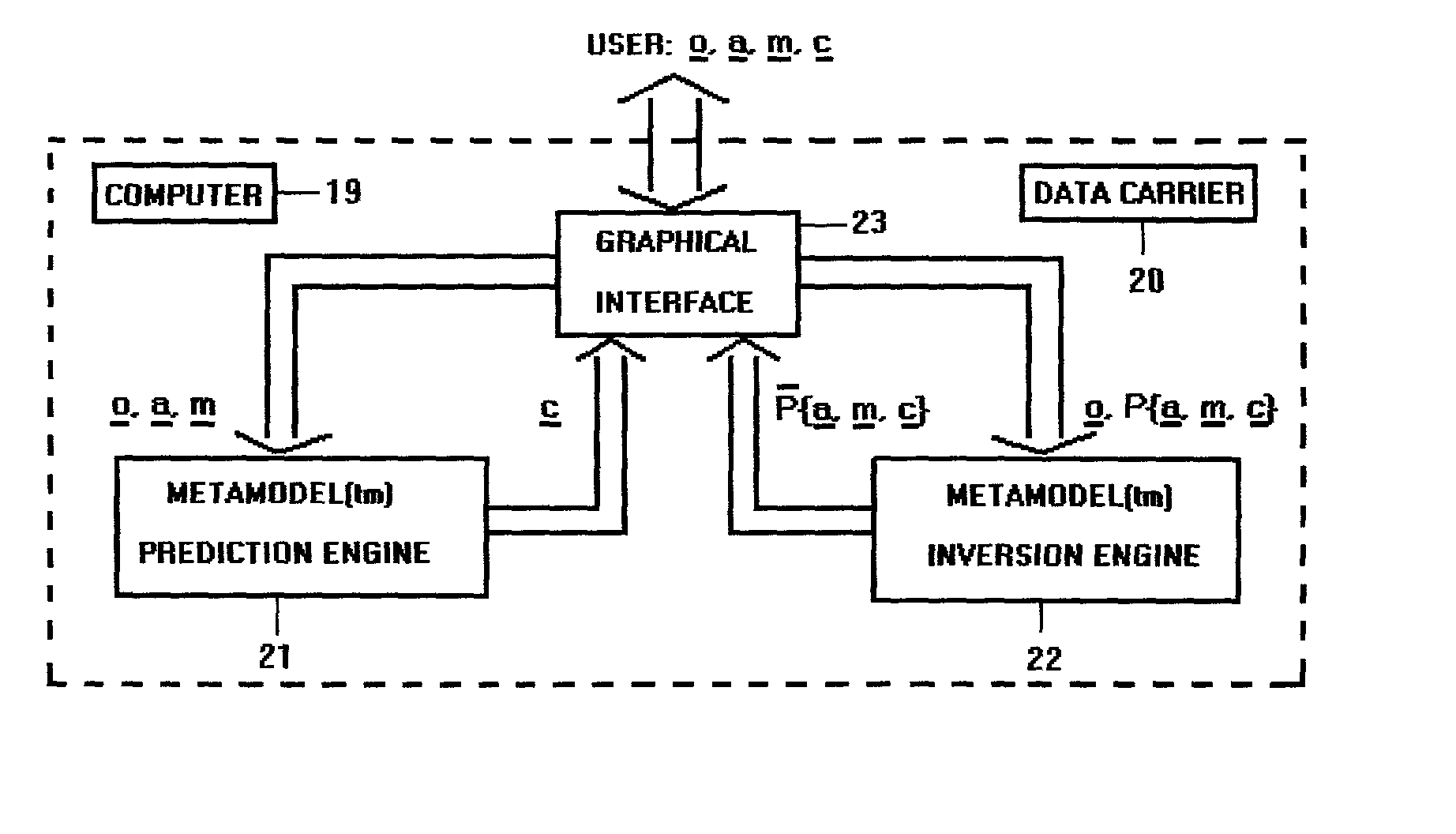

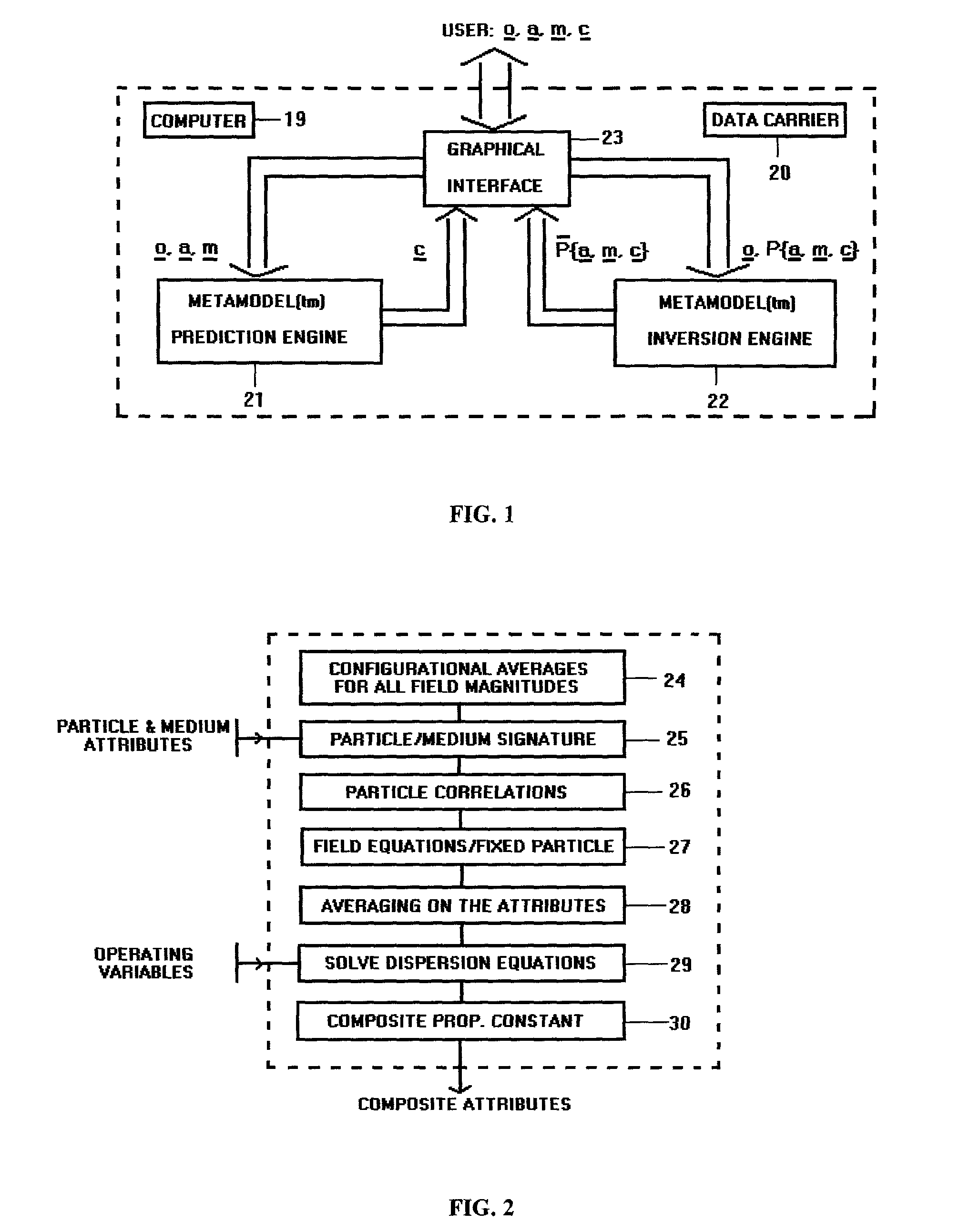

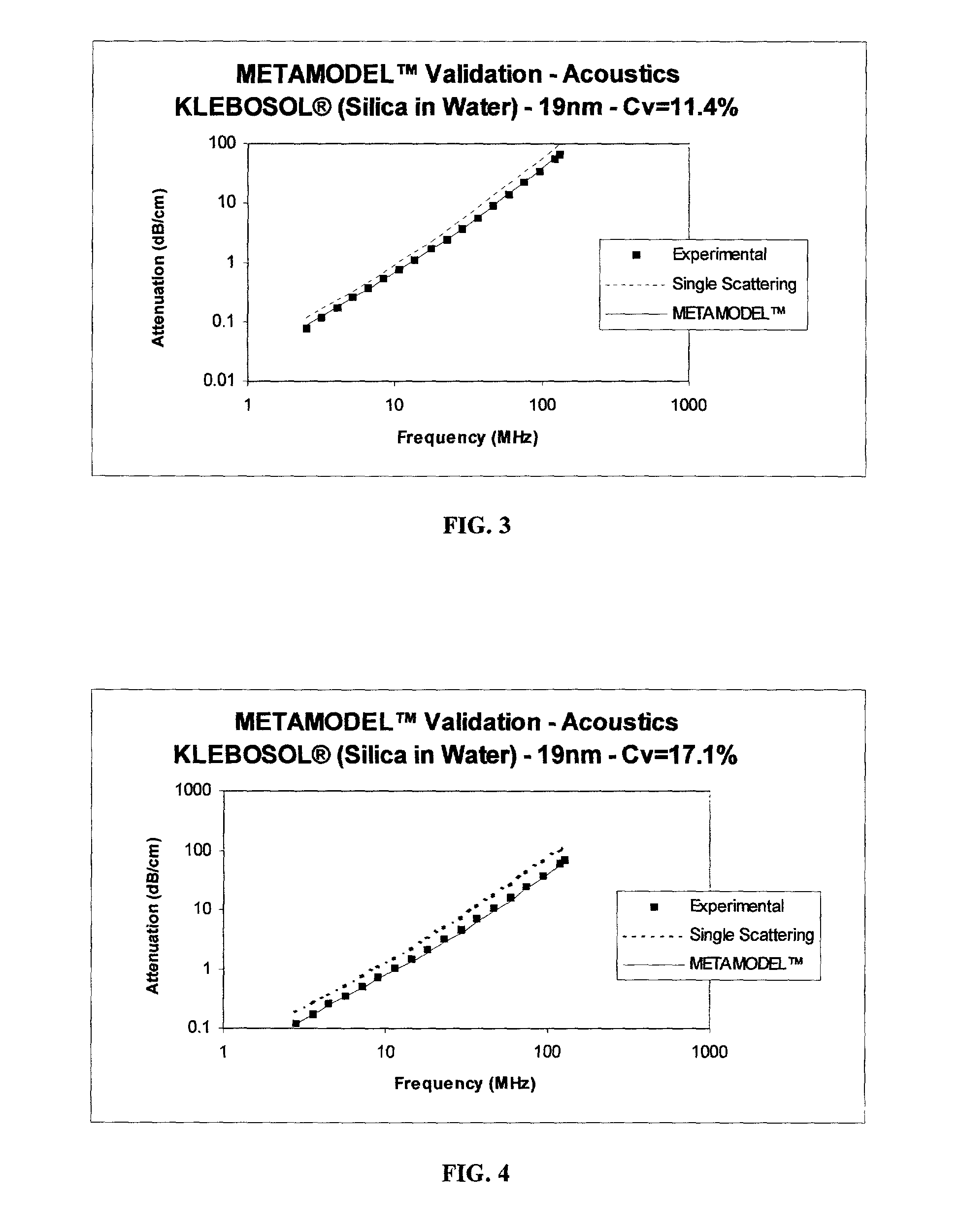

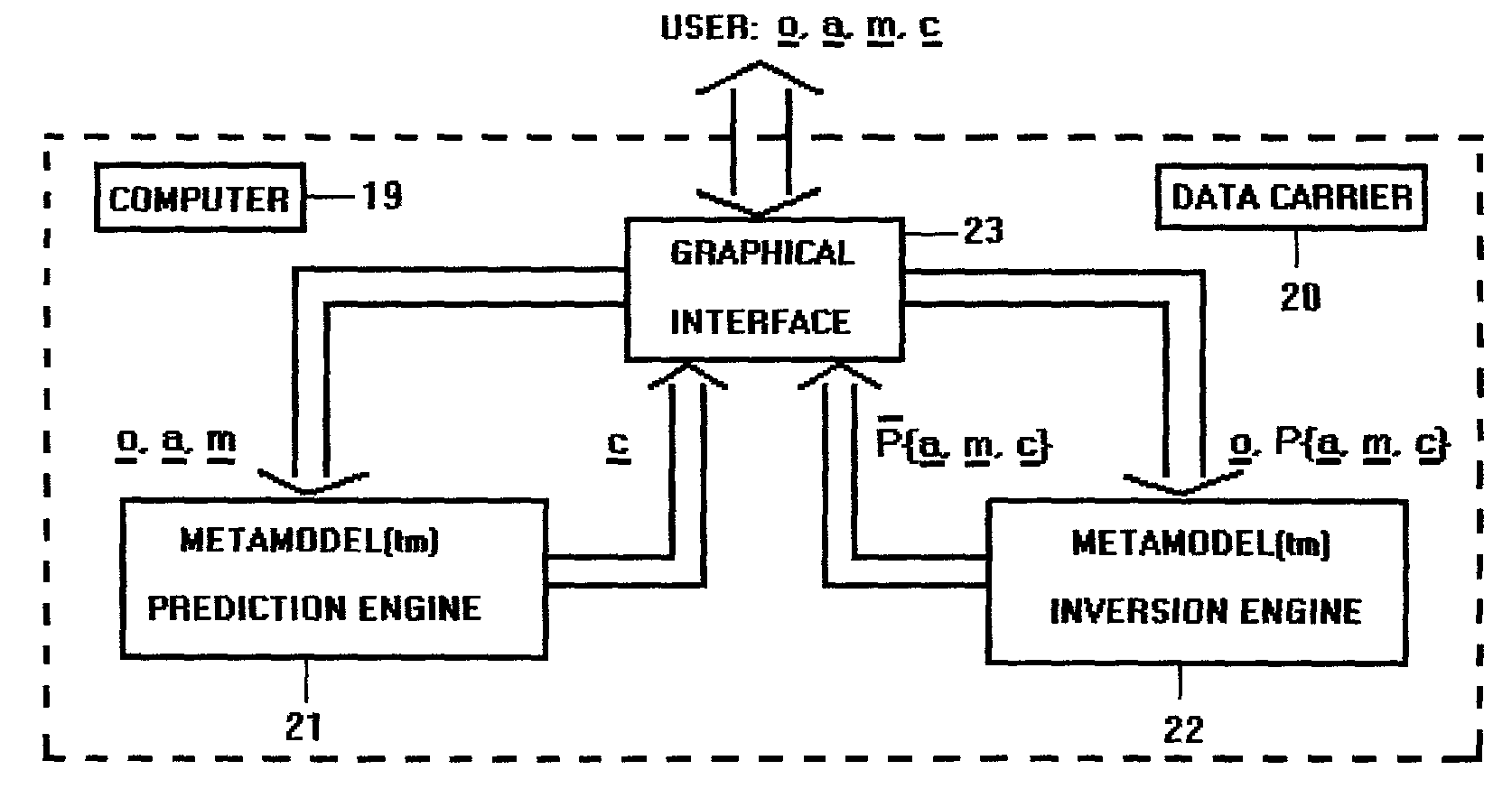

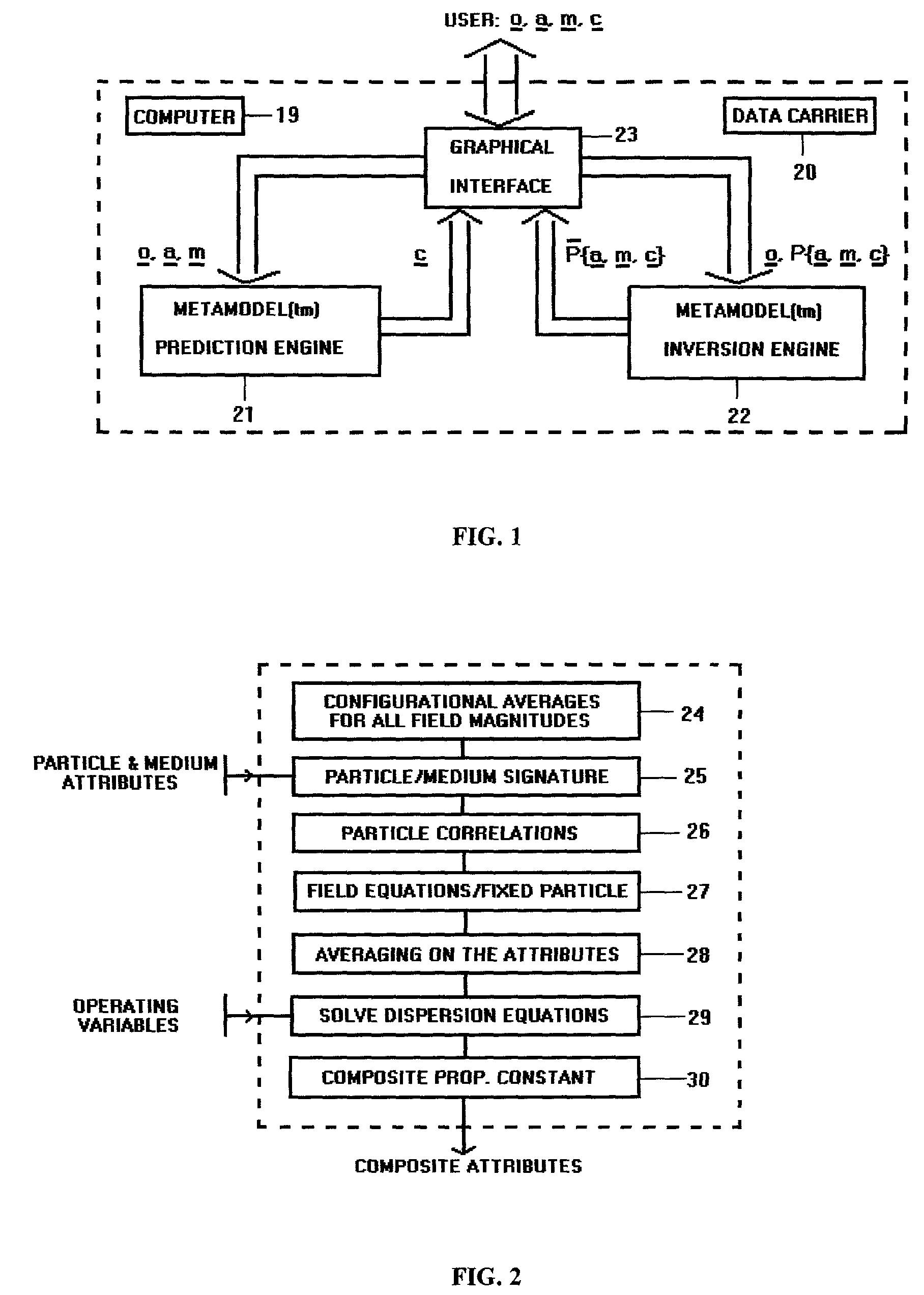

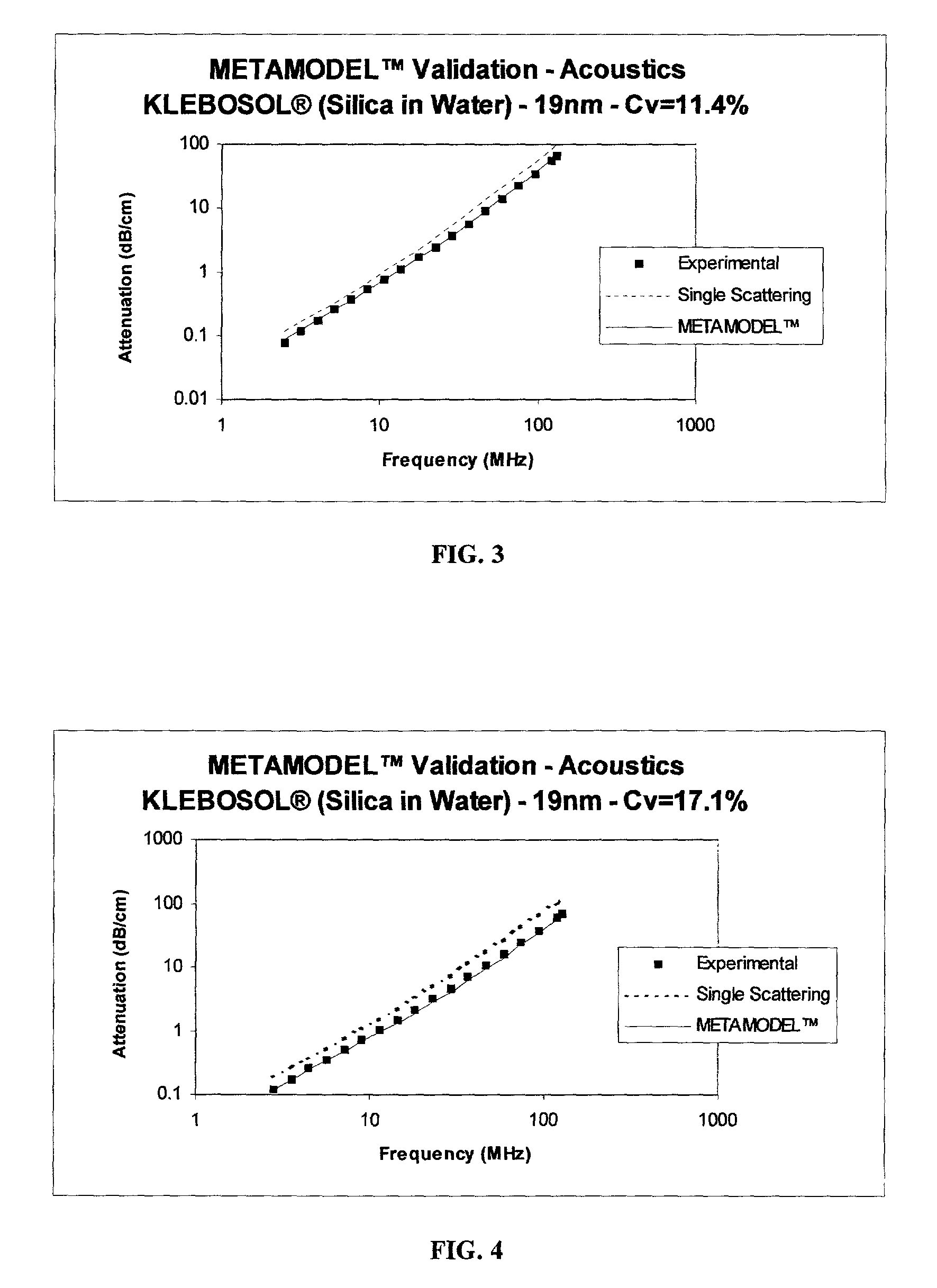

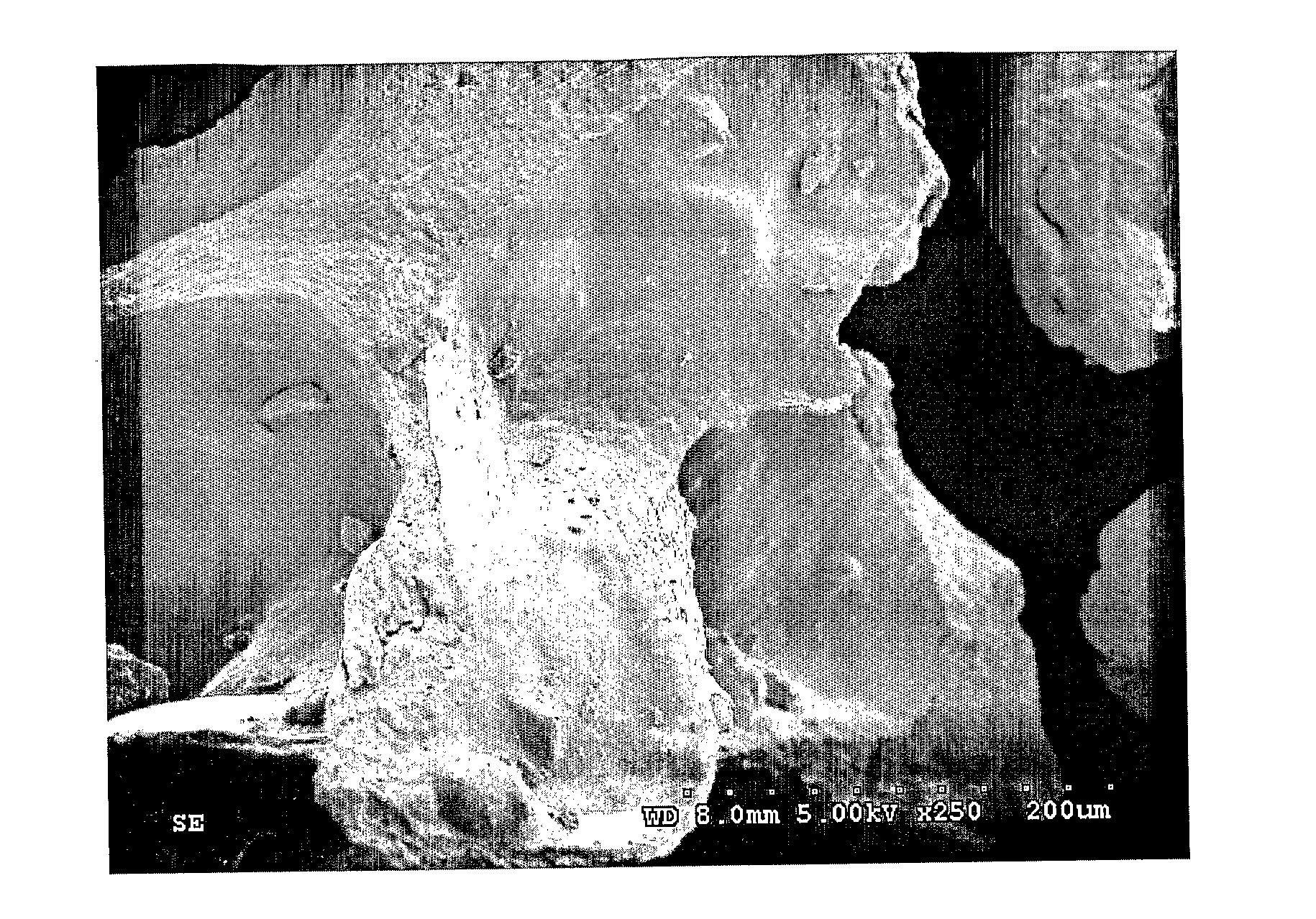

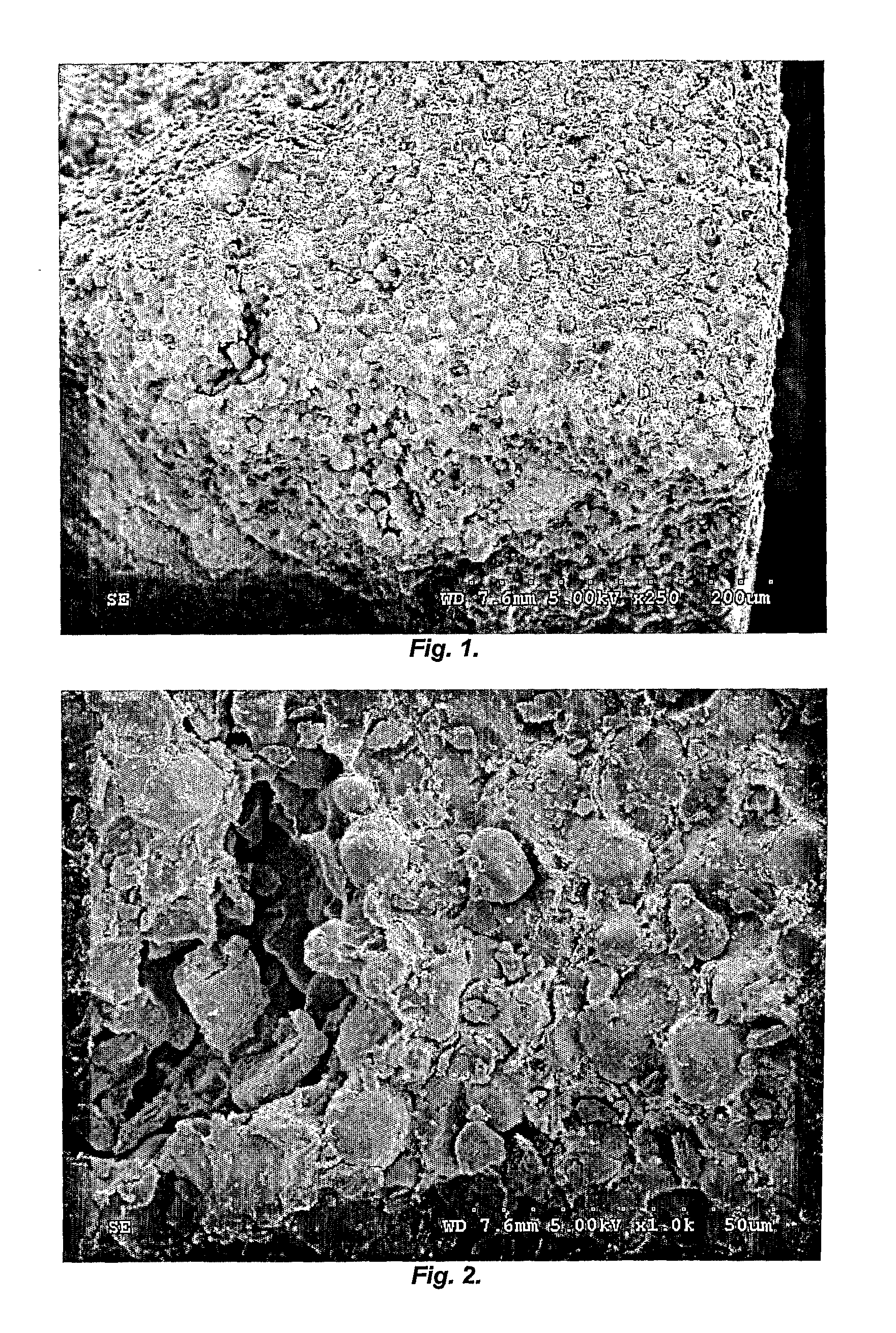

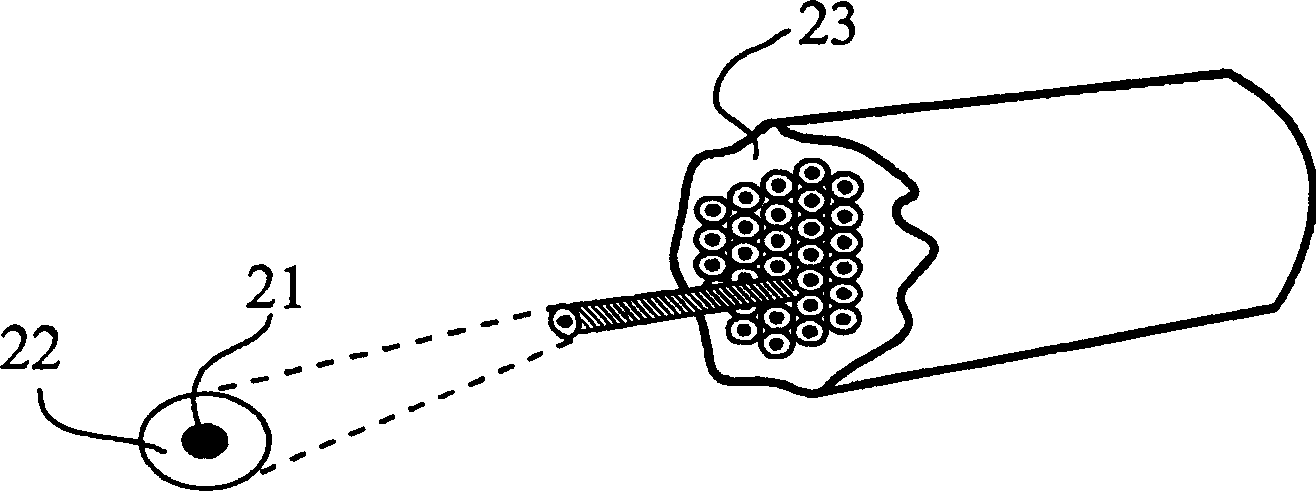

Fundamental method and its hardware implementation for the generic prediction and analysis of multiple scattering of waves in particulate composites

InactiveUS20030167156A1Computation using non-contact making devicesScattering properties measurementsReal systemsFluid phase

This invention relates to a method and apparatus for the fundamental prediction, analysis, and parametric studies of the interaction of multiply scattered waves of any nature (acoustic, electromagnetic, elastic) with particulate composites (solid or fluid particulate phases included in a solid or fluid phase). It comprises of: a) a Prediction Engine 21 to predict the composite physical attributes from those of the constituent phases, b) an Inversion Engine 22 to estimate a subset of the attributes of the constituent phases and composite from the rest of those attributes, and c) an ergonomic Graphical Interface 23 to allow the user to easily set up complex simulation experiments to assist in parametric studies, analysis, and synthesis of real systems in which waves of any nature interact with composites. The Prediction Engine 22 is suitable for integration into existing acoustic or optical particle size analyzers to thereby extending substantially their concentration ranges.

Owner:FELIX ALBA CONSULTANTS

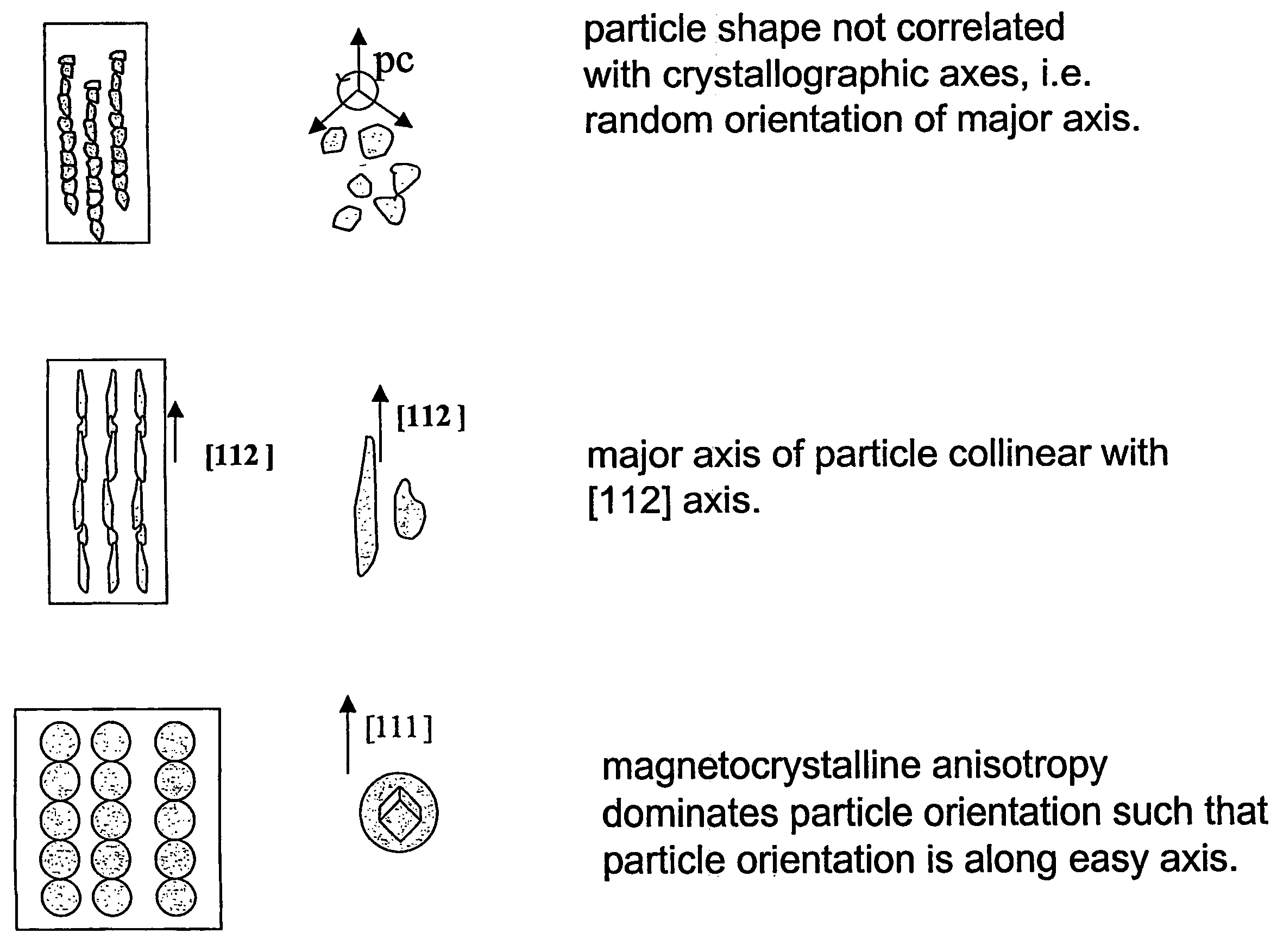

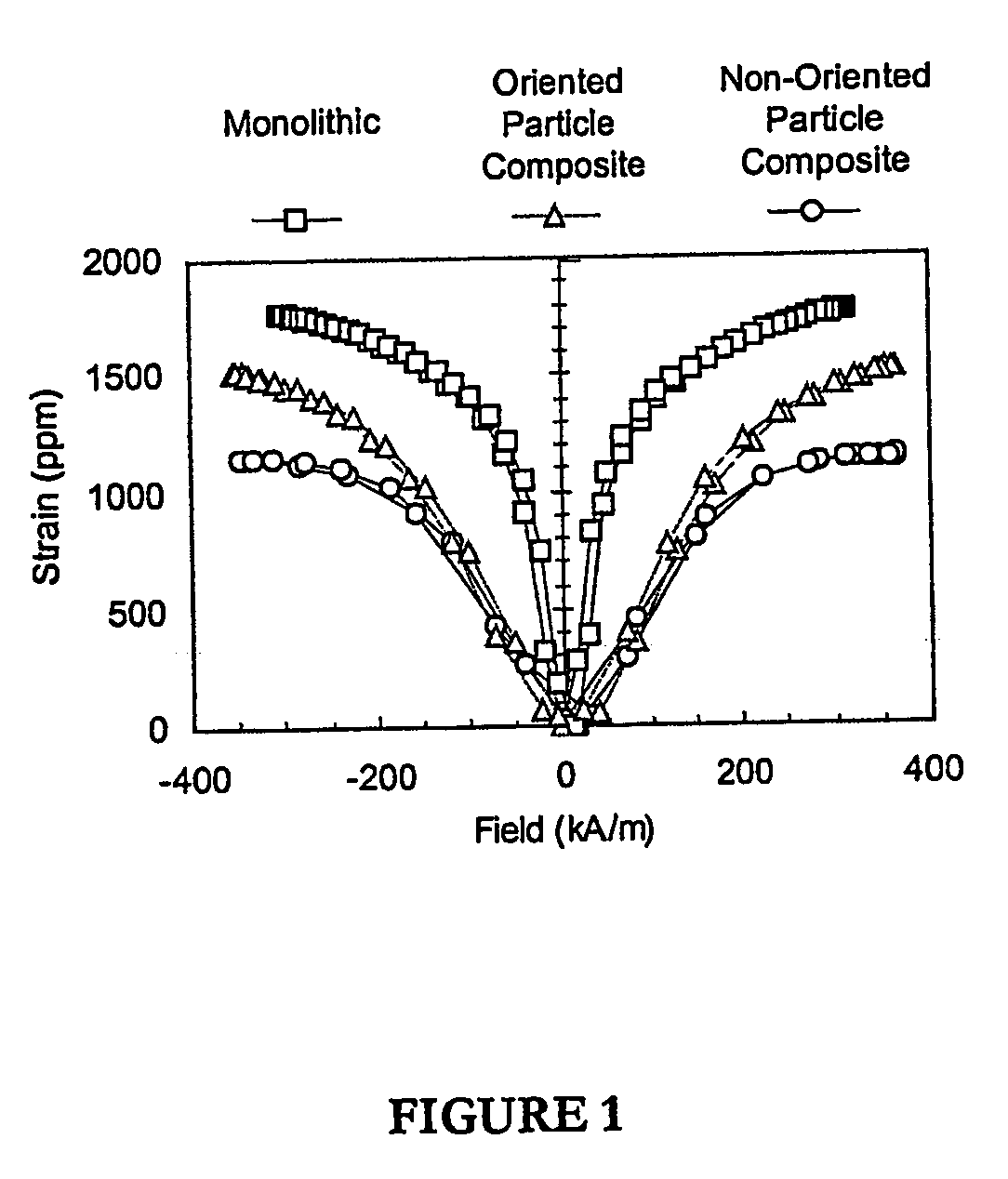

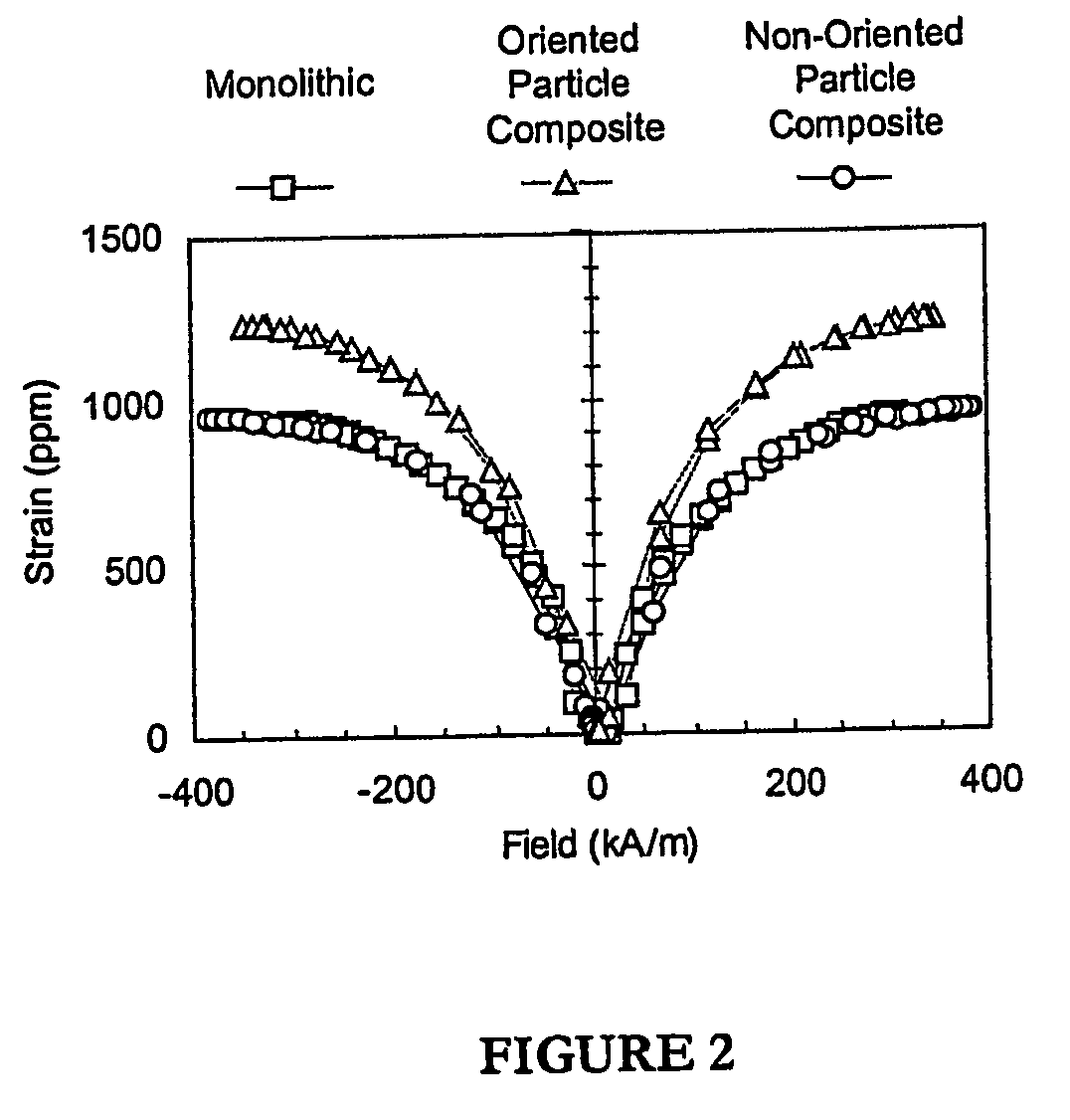

Directionally oriented particle composites

InactiveUS20050161119A1Large saturation strainImprove propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCrystal orientationMaterials science

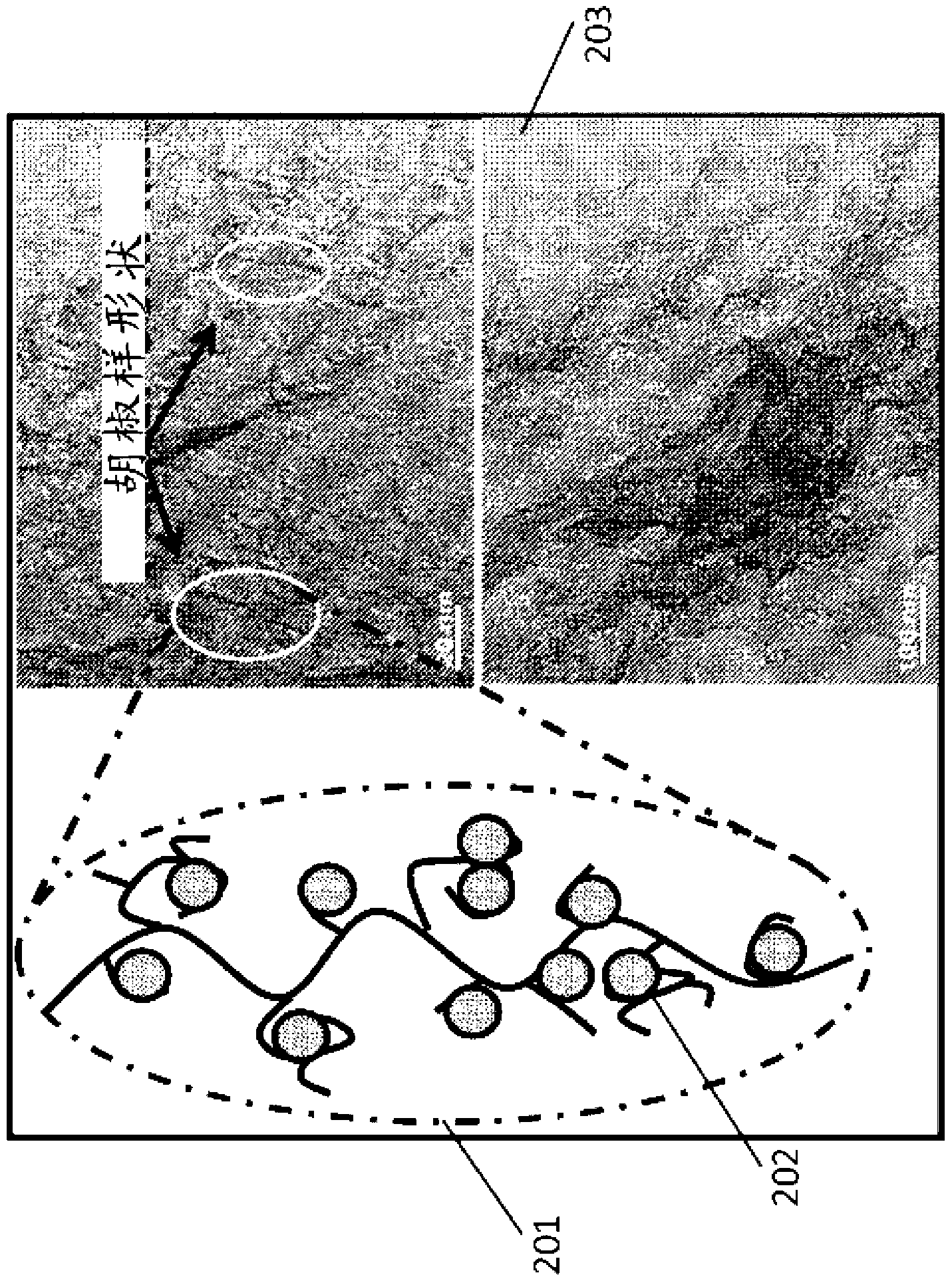

Magnetostrictive particulate composites with a preferred crystal orientation of the particles and methods for their manufacture are described. In a representative embodiment, a 25% volume Terfenol-D fraction polymer matrix composite was fabricated in a magnetic field using geometric anisotropy to orient needle shaped particles with long axis [112] orientation along the length of the composite. Results demonstrate that the magnetostriction of a [112] oriented particle composite saturates near 1600 ppm. This is a significant increase when compared to composites without preferential orientation (1200 ppm) and represents the largest reported magnetostriction for a particulate composite material.

Owner:RGT UNIV OF CALIFORNIA

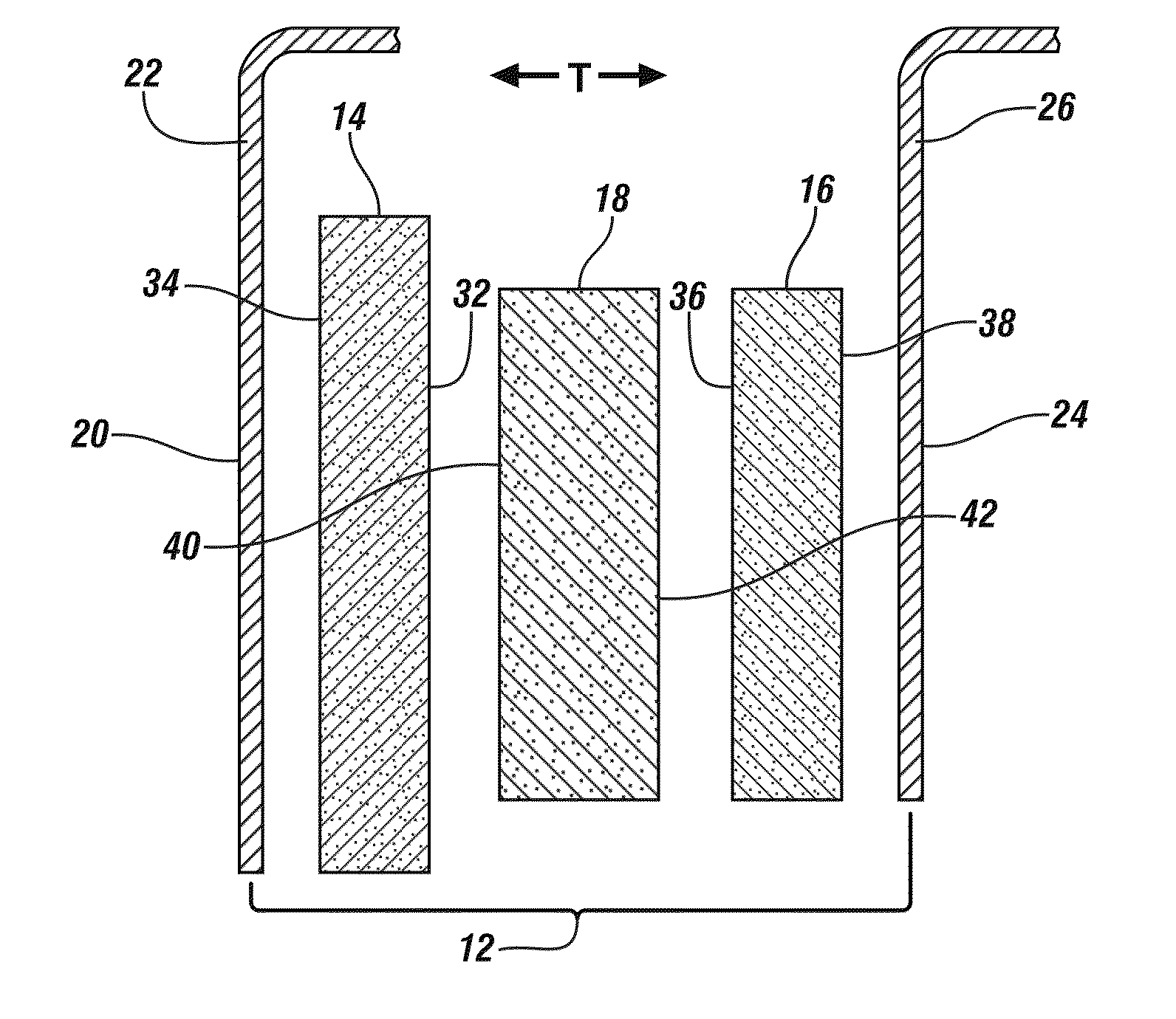

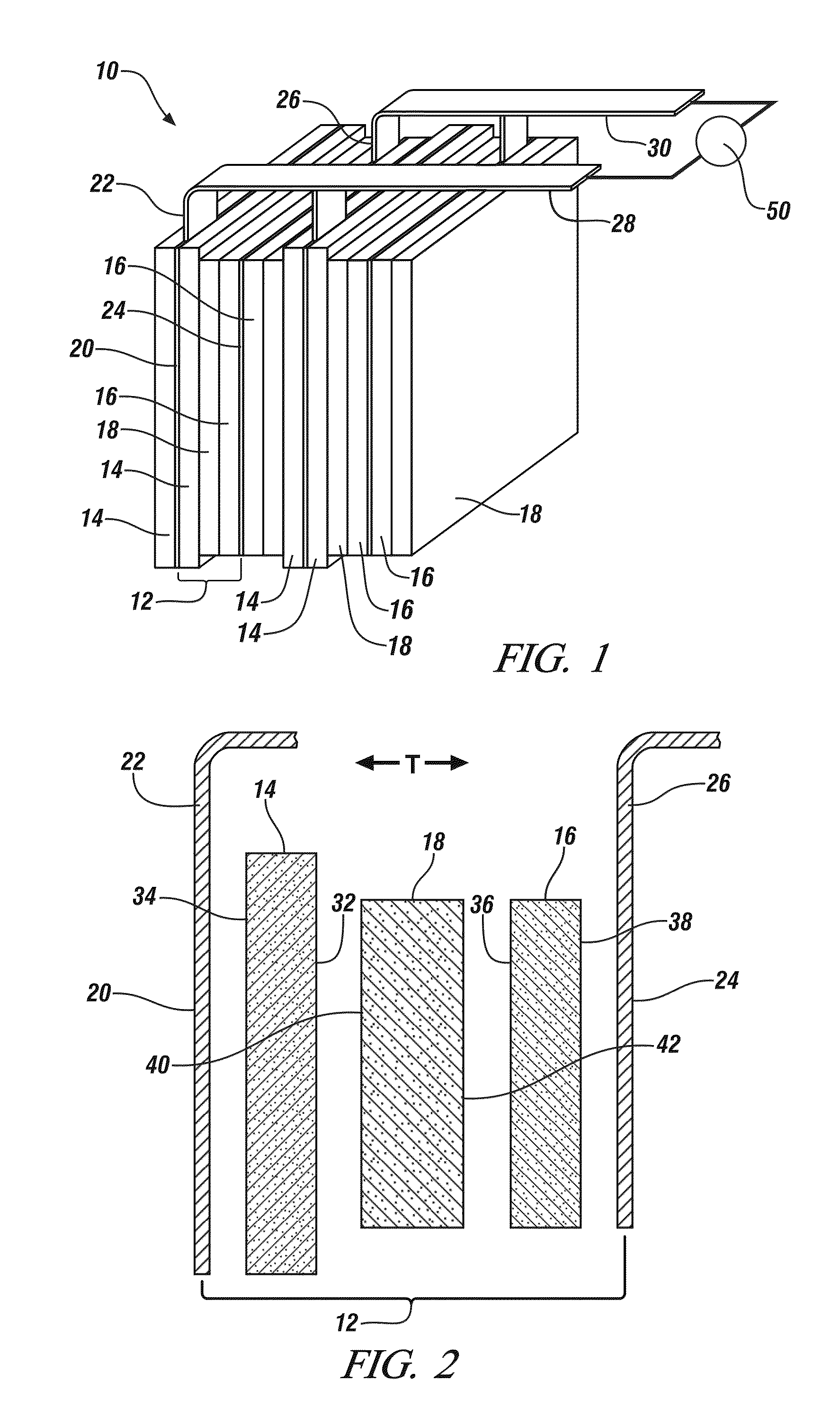

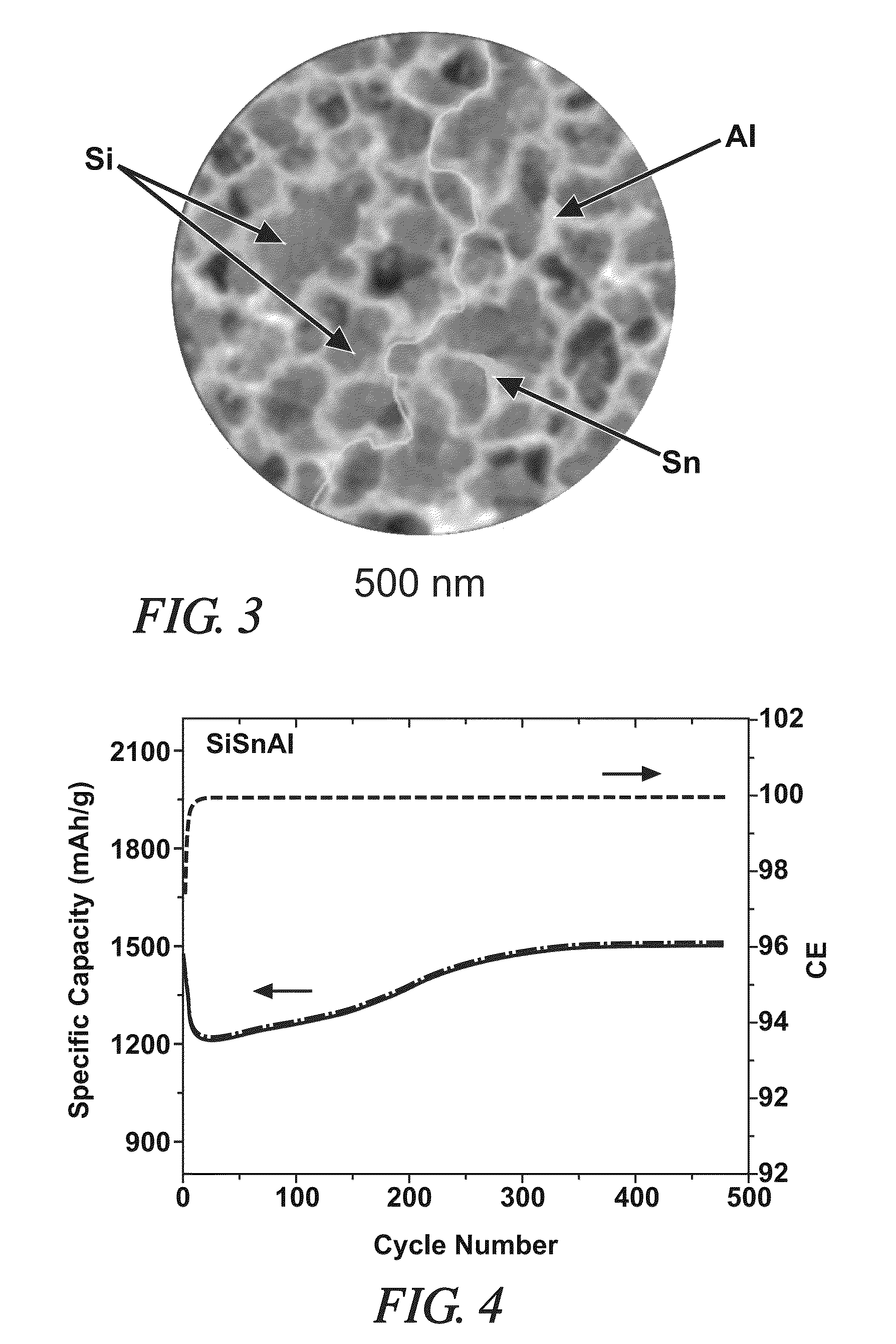

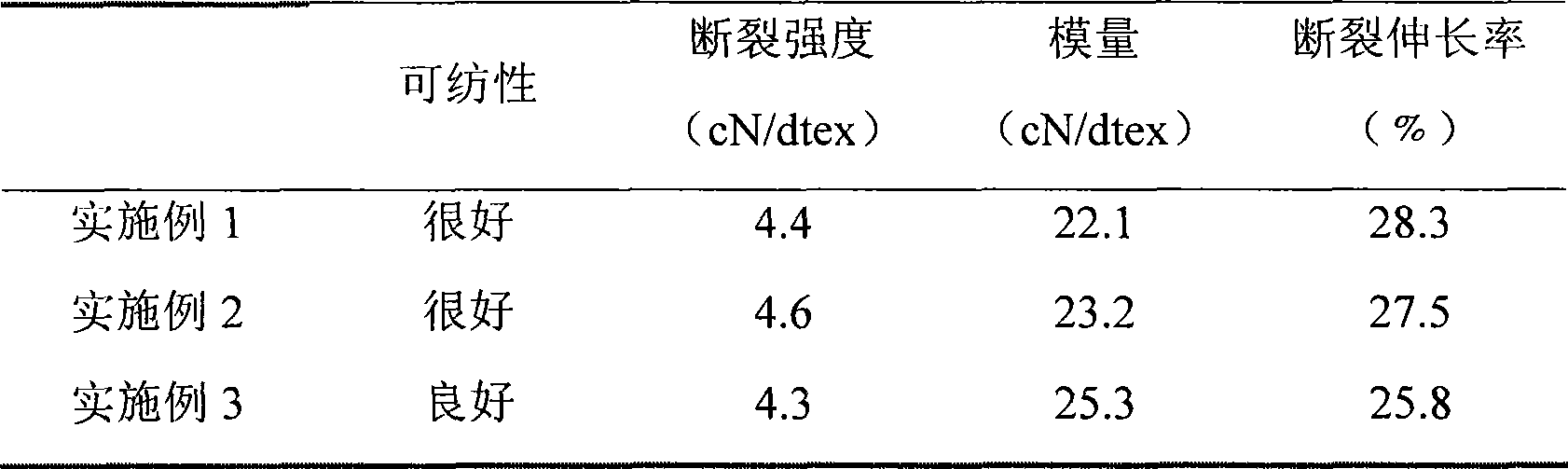

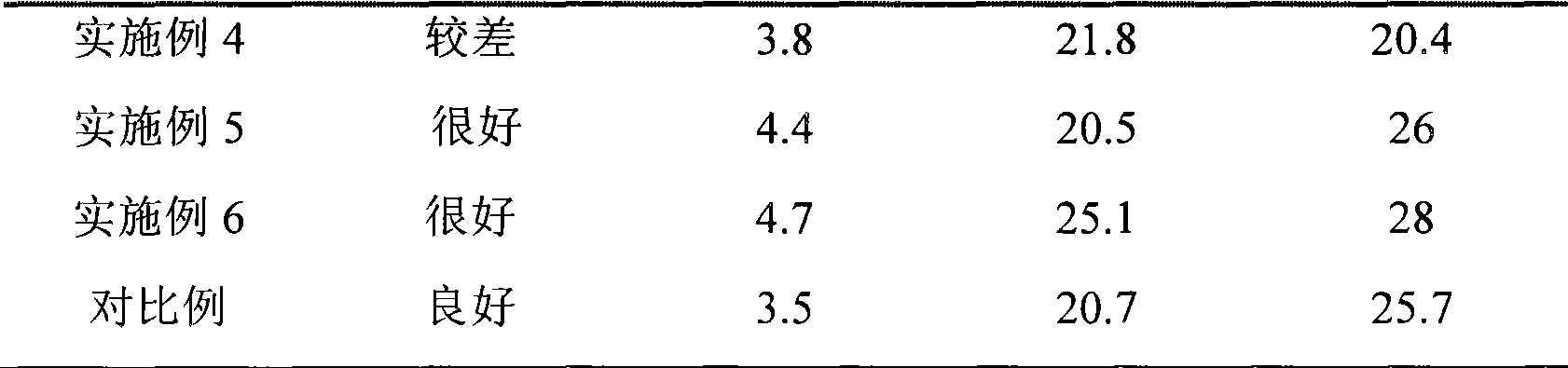

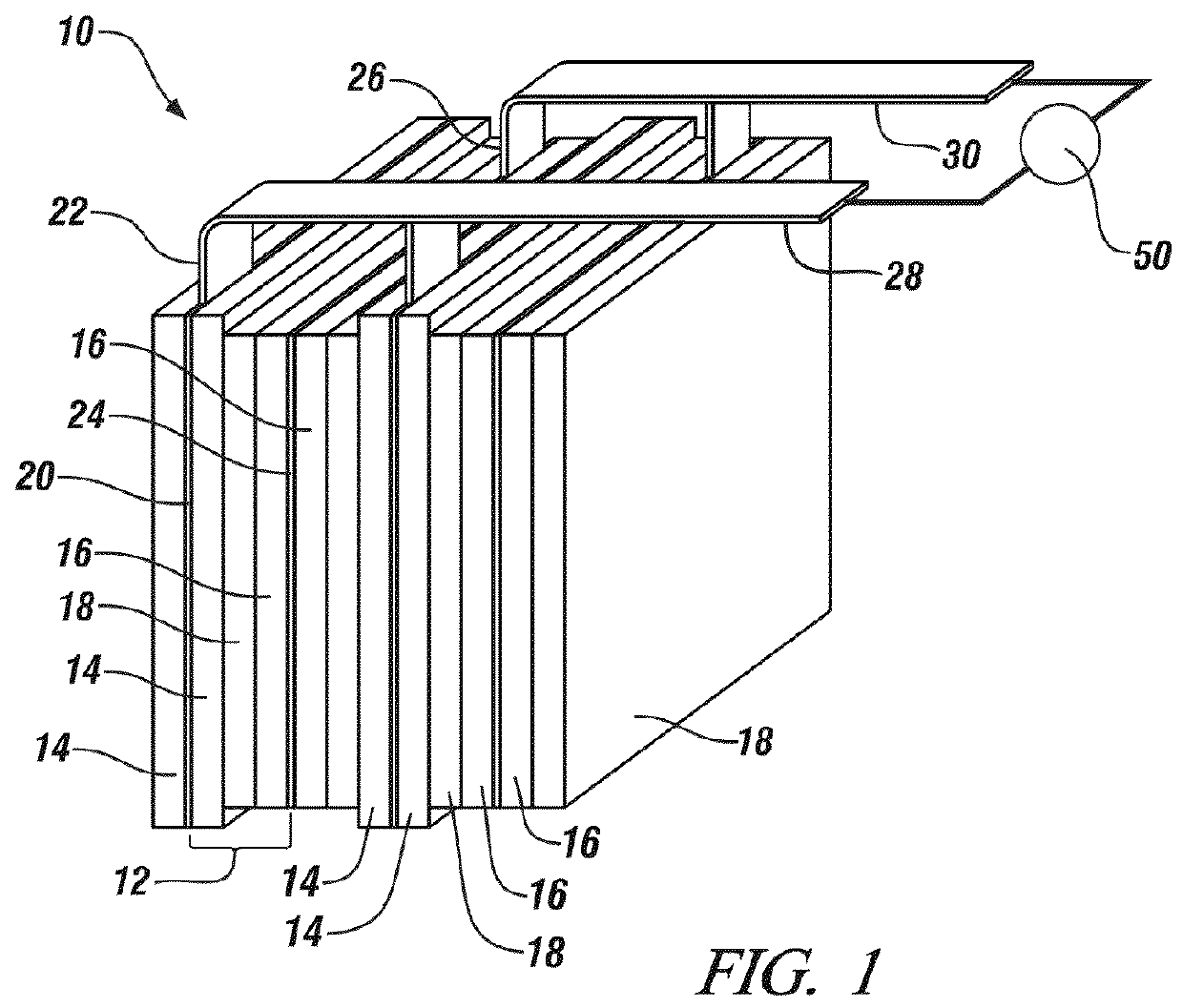

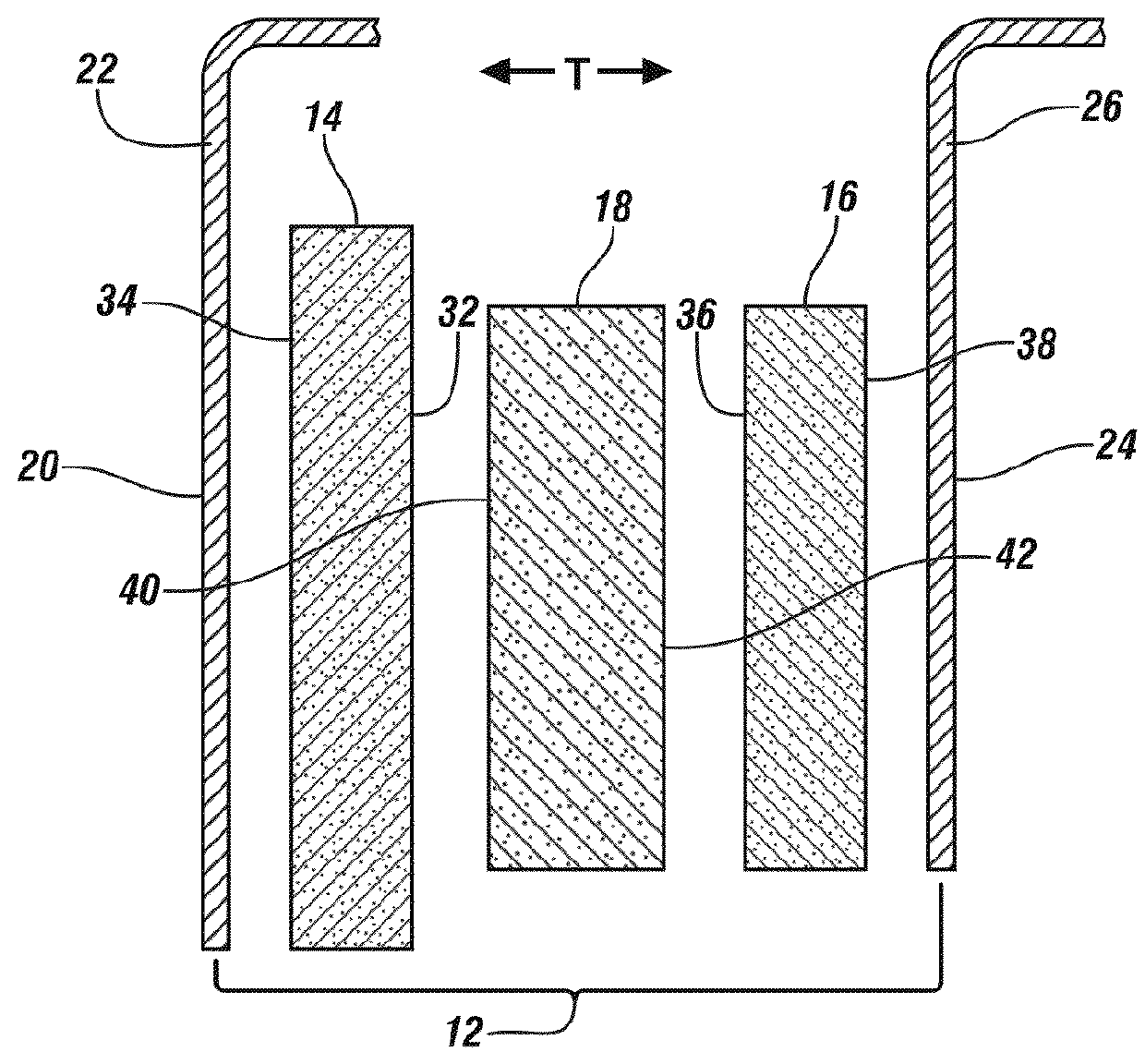

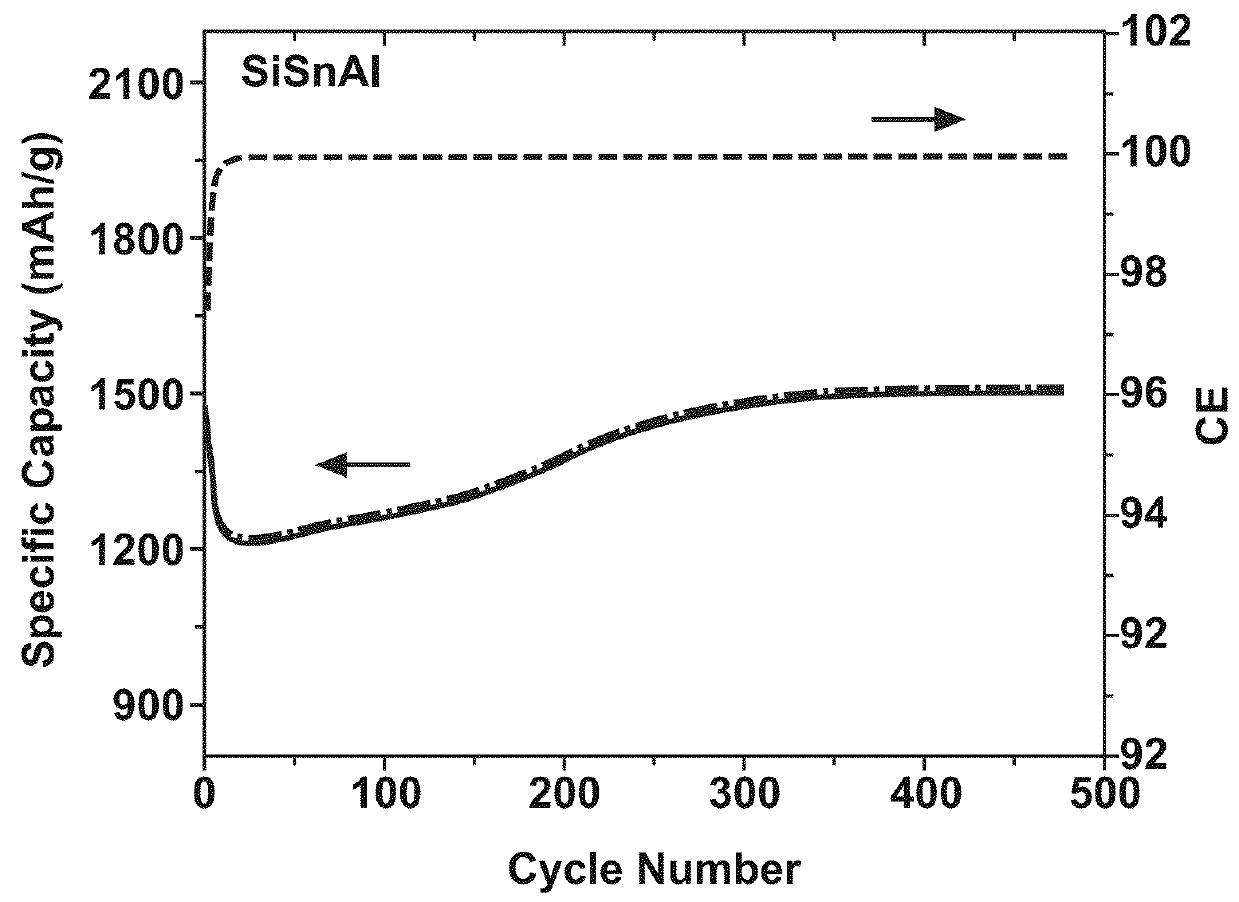

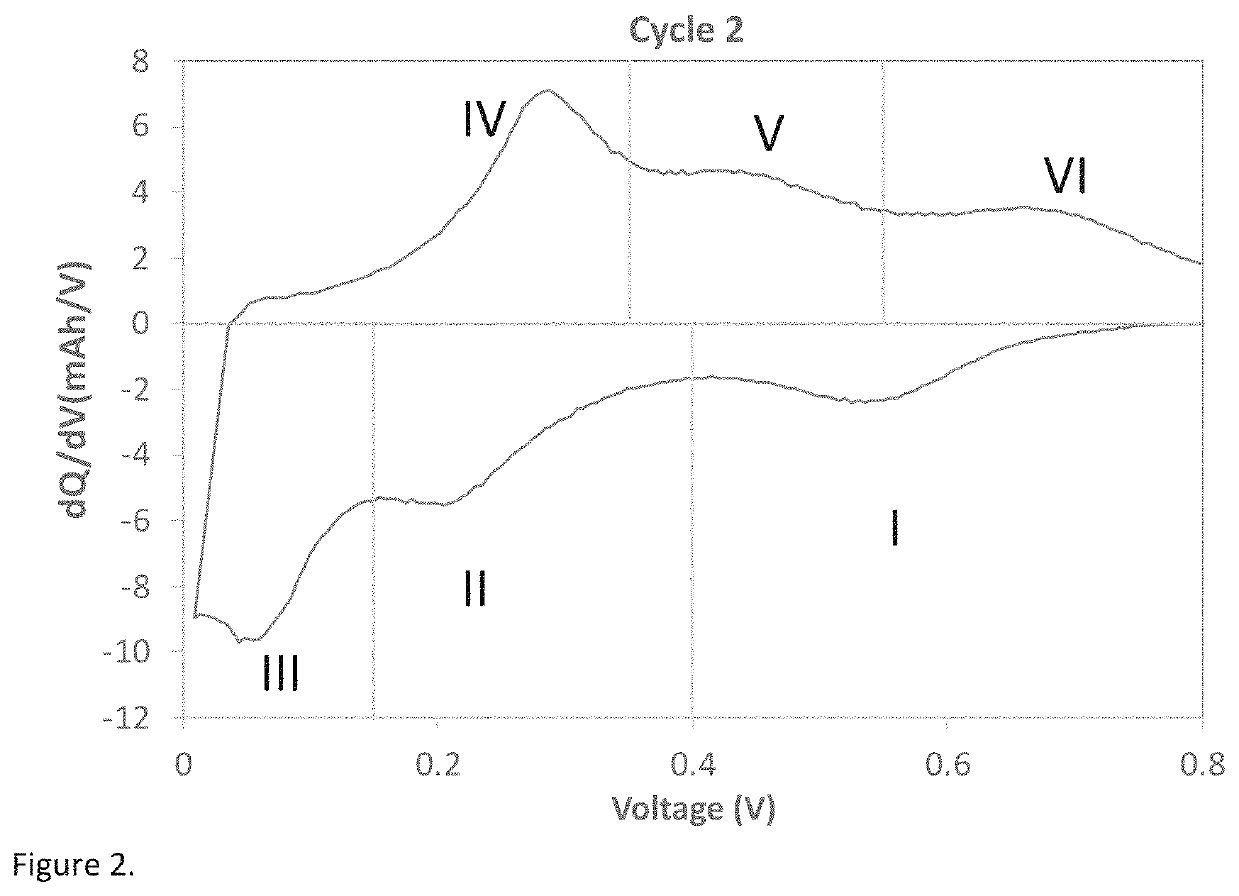

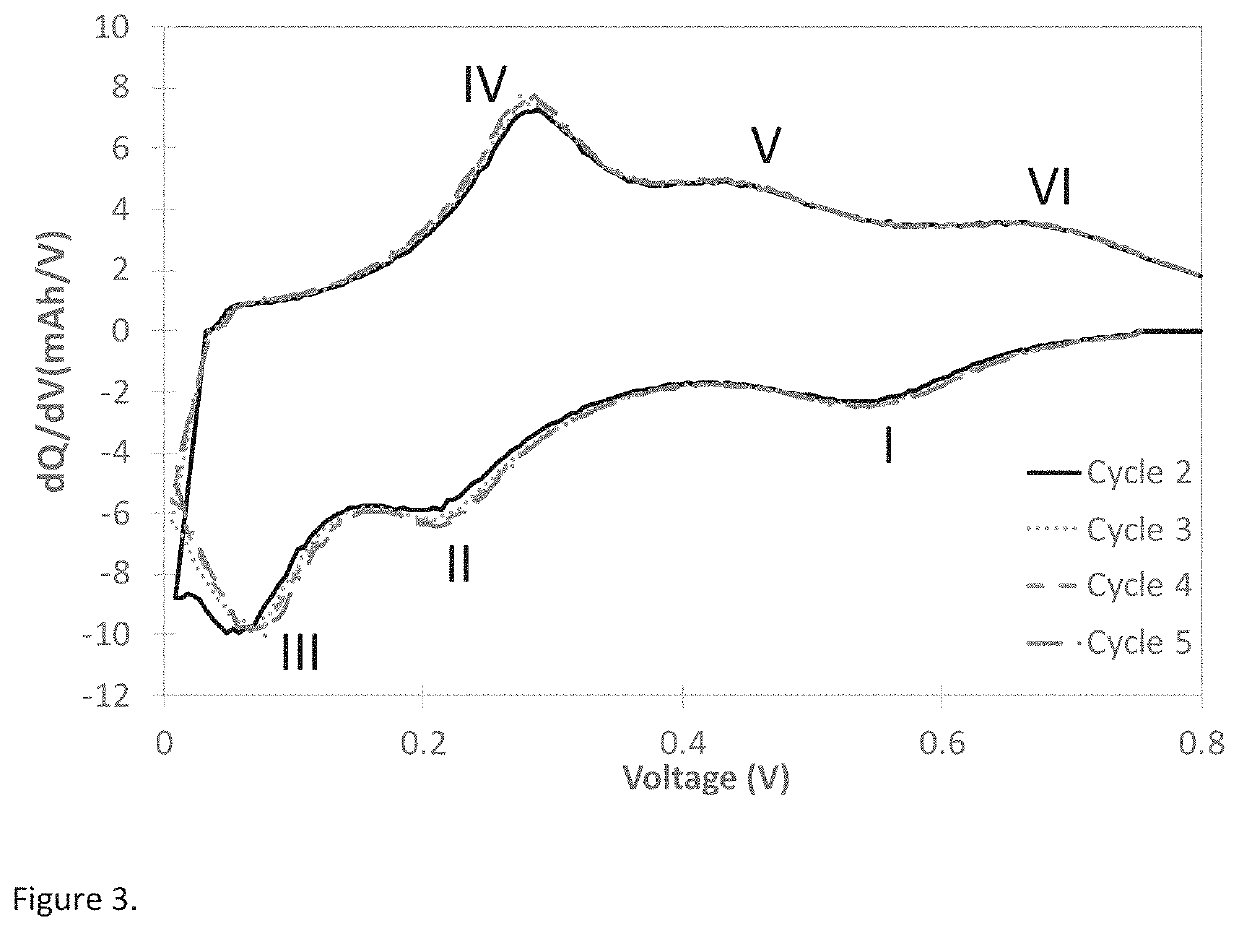

Multi-phase separated silicon based alloys as negative electrode material for lithium batteries

ActiveUS20140127573A1Increased charge storage capacityImprove cycle stabilityMaterial nanotechnologyConductive materialAlloyLithium-ion battery

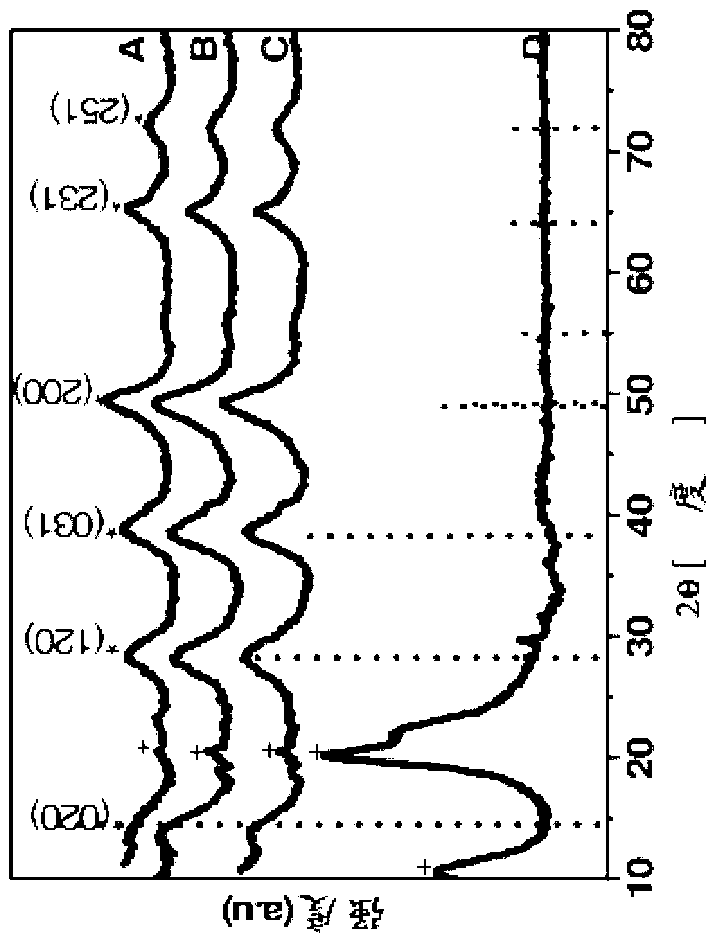

A particulate composite of silicon, tin, and aluminum (or other suitable metal) is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in separate matrix phases of crystalline tin and crystalline aluminum. While the distinct tin and aluminum phases provide electron conductivity, each phase accommodates the insertion and extraction of lithium in the operation of the cell and all phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. Other suitable metals for use in the composite with silicon and tin include copper and titanium.

Owner:GM GLOBAL TECH OPERATIONS LLC

Polyphenyl thioether/ultra-fine calcium carbonate particulate composite fiber and preparation method thereof

InactiveCN101368300ANo severe adhesionsAvoid energy consumptionMonocomponent synthetic polymer artificial filamentMelt spinning methodsTextile fiberChemical industry

The invention relates to polyphenylene sulfide (PPS) / nano-calcium carbonate mixture and a preparation method for the fiber thereof. The method includes the steps of mixing polyester slices, nano-calcium carbonate particulates, reactive monomer and other additives in a high speed mixer while rising the temperature to approximately 205 DEG C so as to enable the polyphenylene sulfide slices to intenerate and the nano-calcium carbonate and other additives to be evenly adhibitted onto the polyphenylene sulfide slices, without heavy conglutination between the particles on the polyphenylene sulfide slices. The polyphenylene sulfide (PPS) / nano-calcium carbonate mixture prepared through the method has excellent processability and can be made into textile fiber, thin film or reinforcement plastics by means of melt blown or melt spinning process. The invention can greatly reduce the production cost and bring good economic benefits. The polyphenylene sulfide(PPS) / nano-calcium carbonate mixture has good thermal stability, flame retardancy, chemical corrosion resistance and good mechanical property and spinning property; therefore the polyphenylene sulfide(PPS) / nano-calcium carbonate mixture is widely applicable to the industrial sectors like chemical industry, light industry and mechanical industry, and is particularly good for accelerating the popularization and application of high-temperature house-bag dust removal. The preparation method has the advantages of simple process, easy control, low cost, short production period, environment friendly and particularly being applicable to the industrial production.

Owner:DONGHUA UNIV

Multi-phase separated silicon based alloys as negative electrode material for lithium batteries

ActiveUS8859144B2Reduce concentrationReduce fracturesMaterial nanotechnologyElectrode melt handlingNickel–lithium batteryAlloy

A particulate composite of silicon, tin, and aluminum (or other suitable metal) is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in separate matrix phases of crystalline tin and crystalline aluminum. While the distinct tin and aluminum phases provide electron conductivity, each phase accommodates the insertion and extraction of lithium in the operation of the cell and all phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. Other suitable metals for use in the composite with silicon and tin include copper and titanium.

Owner:GM GLOBAL TECH OPERATIONS LLC

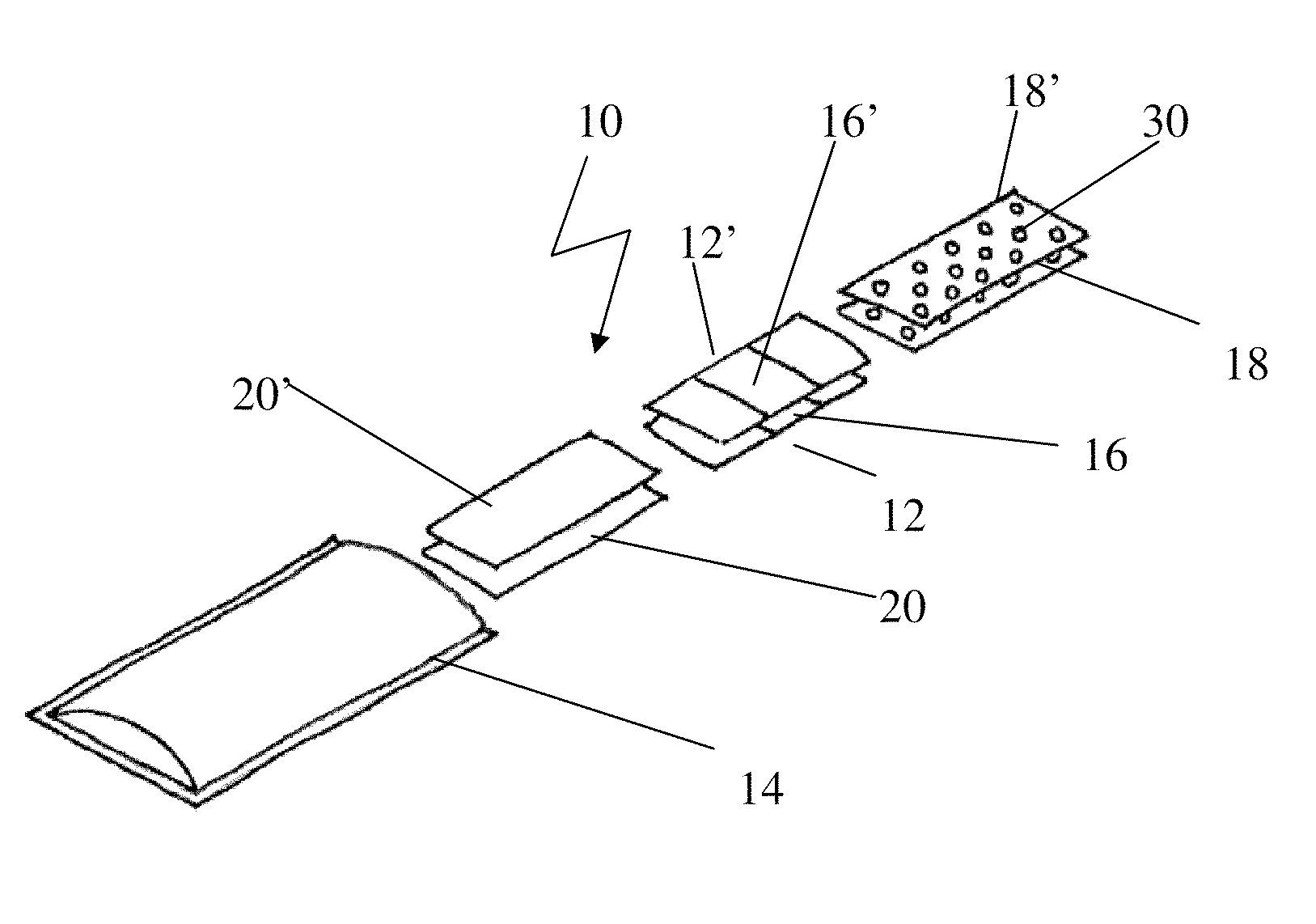

Shingle

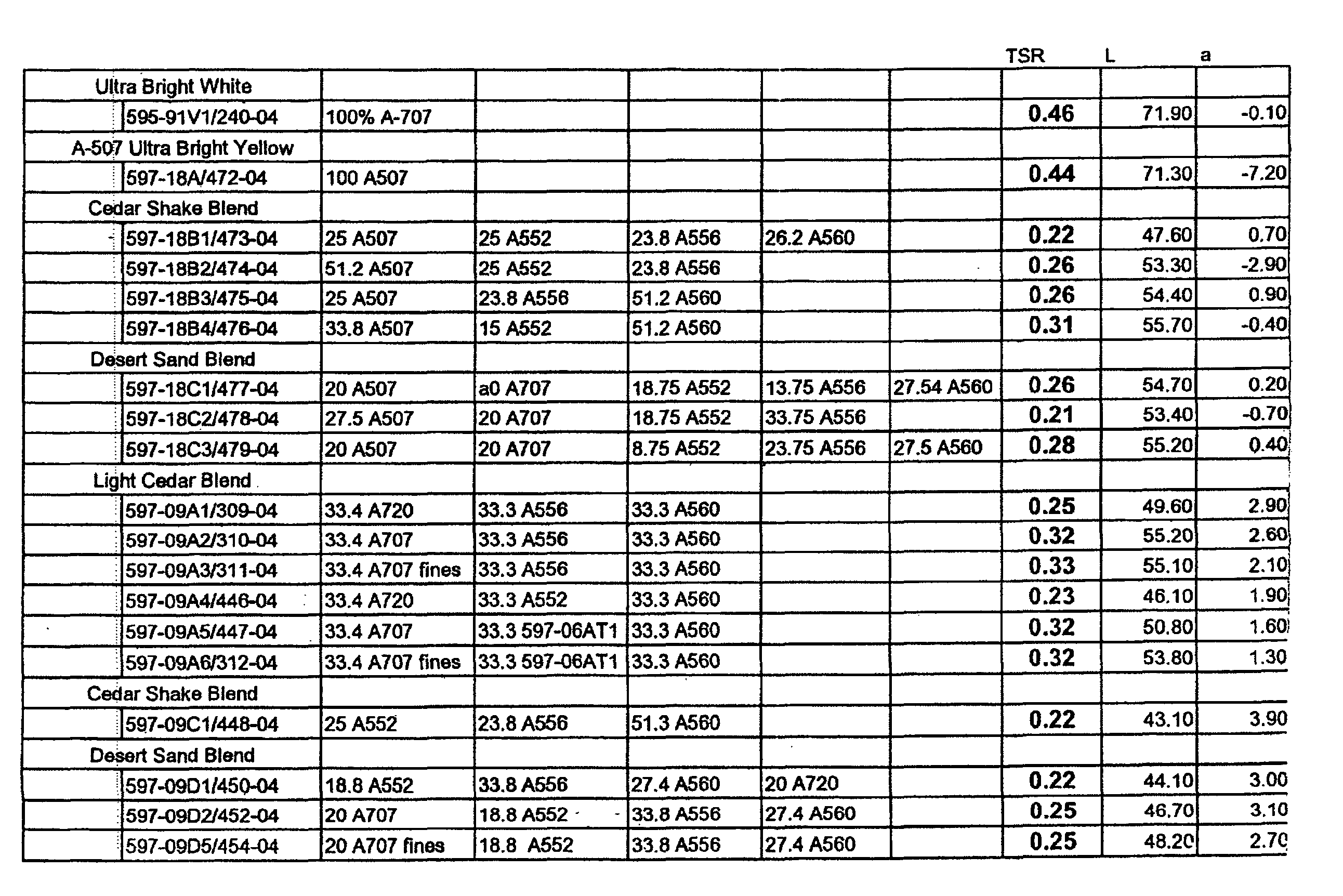

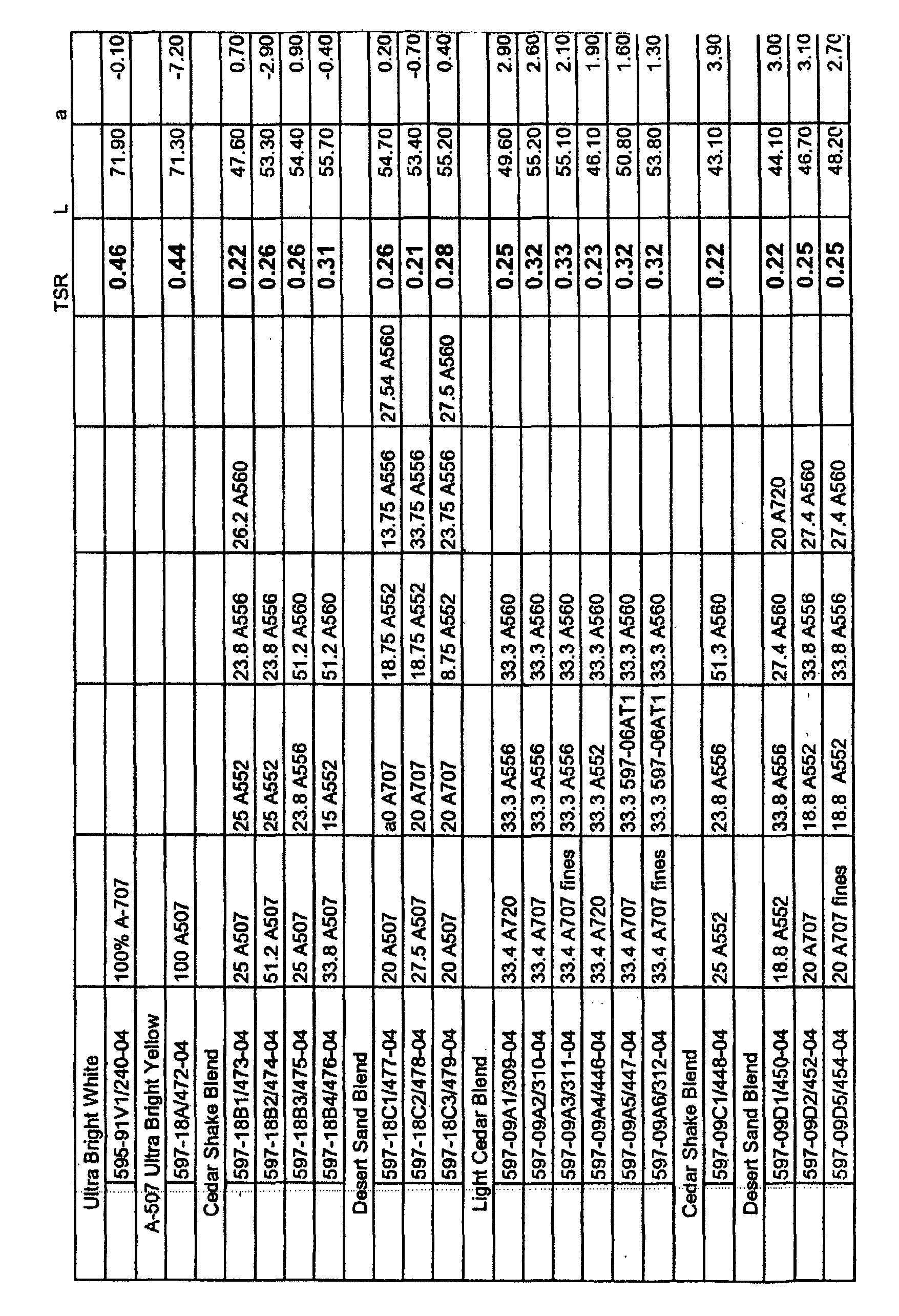

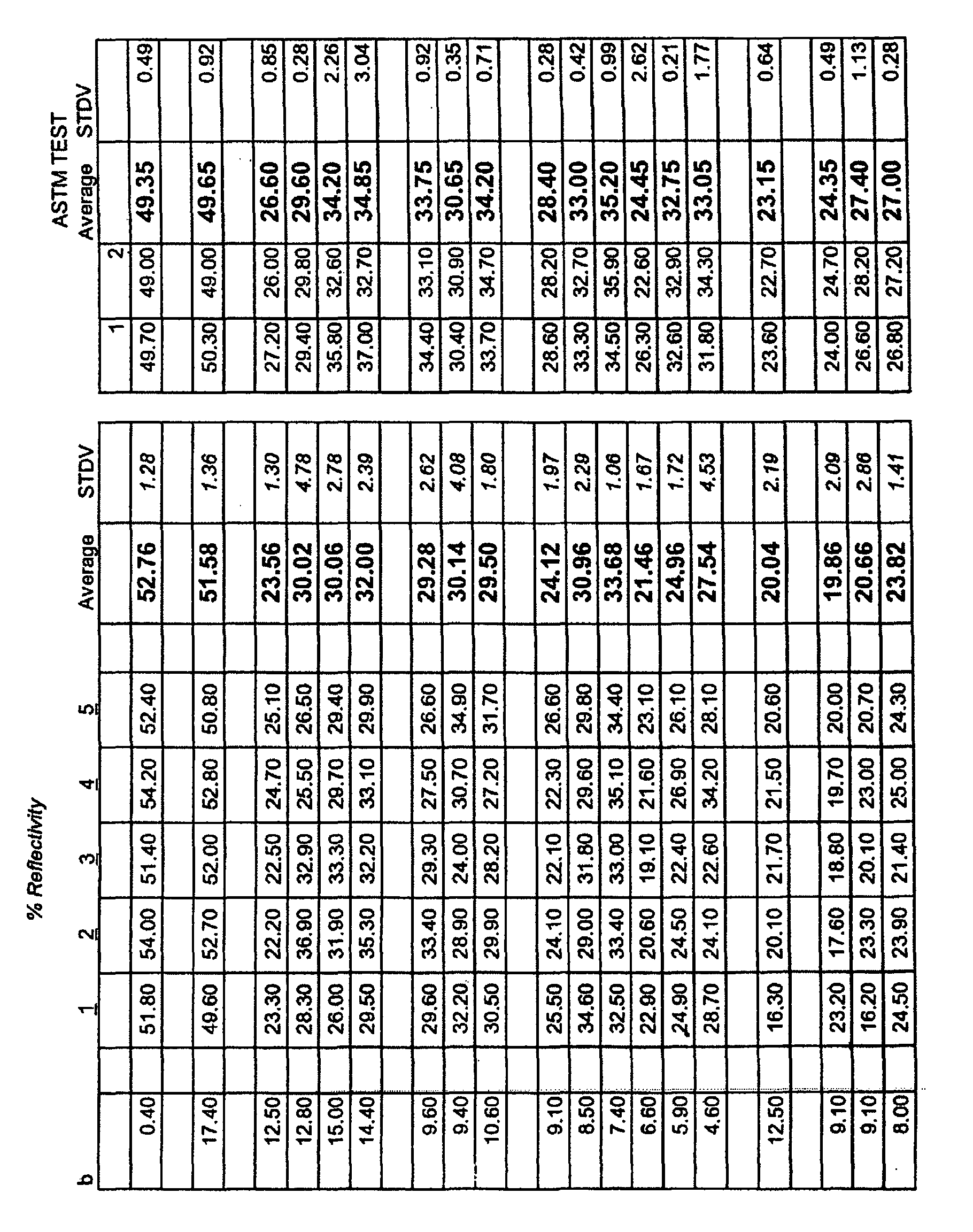

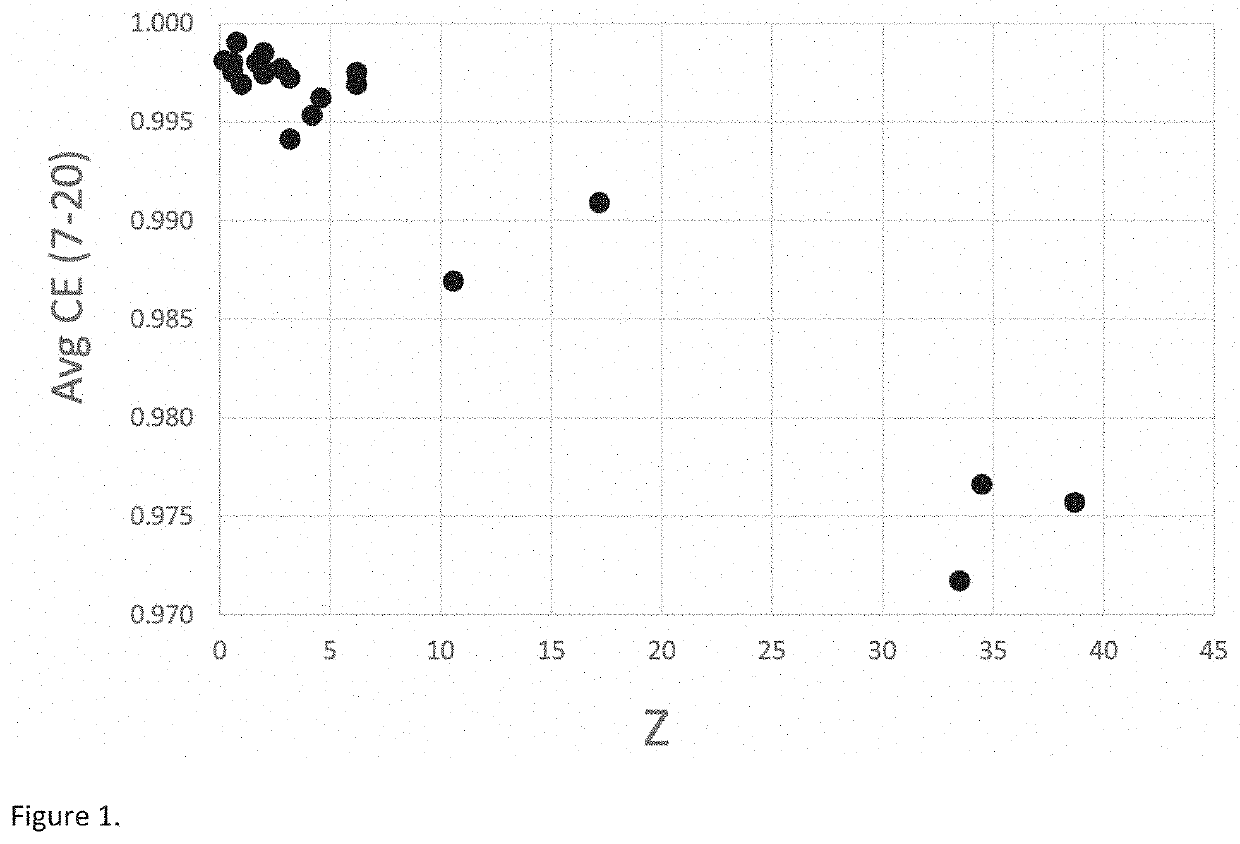

A granular composite and roofing material covered by such composite comprising reflective roofing granules and traditional roofing granules to create a granule composite having a total solar reflectance of greater than 0.19, and a CIELAB coordinate L* of less than 75.

Owner:BUILDING MATERIALS INVESTMENT

Finely particulate composite latices and use thereof in solvent-free paints

PCT No. PCT / FR96 / 01633 Sec. 371 Date Jan. 20, 1998 Sec. 102(e) Date Jan. 20, 1998 PCT Filed Oct. 18, 1996 PCT Pub. No. WO97 / 15604 PCT Pub. Date May 1, 1997Composite latex whose average particle size is between 30 and 150 nm, as these particles result from polymerization of a mixture hydrophobic monomers composed of styrene and (meth)acrylic esters to produce an emulsion in an aqueous solution of a water-soluble or water-dispersible amphiphilic copolymer having a molecular weight of between 500 and 5,000 and whose acid number of less than 500, said latex being composed of a combination of hydrophobic and hydrophilic monomers incorporating carboxylic acid functions in the presence of a radical-producing initiator, wherein said aqueous water-soluble amphiphilic polymer is free of any other surfactant or protective colloid and wherein the mass percentage of amphiphilic copolymer in relation to the dry extract of the latex between 10 and 50%.

Owner:ARKEMA FRANCE SA

Particulate composite materials

ActiveUS20220055906A1Novel propertyMaterial nanotechnologySecondary cellsMaterials scienceComposite material

Owner:GRP 14 TECH INC

Retroreflective adherent particles and their use

InactiveUS6153671AImprove retroreflectivityImproved adhesion to surfaceSpecial tyresReflectorsMaterials scienceParticulate composite

Owner:POTTERS INDS

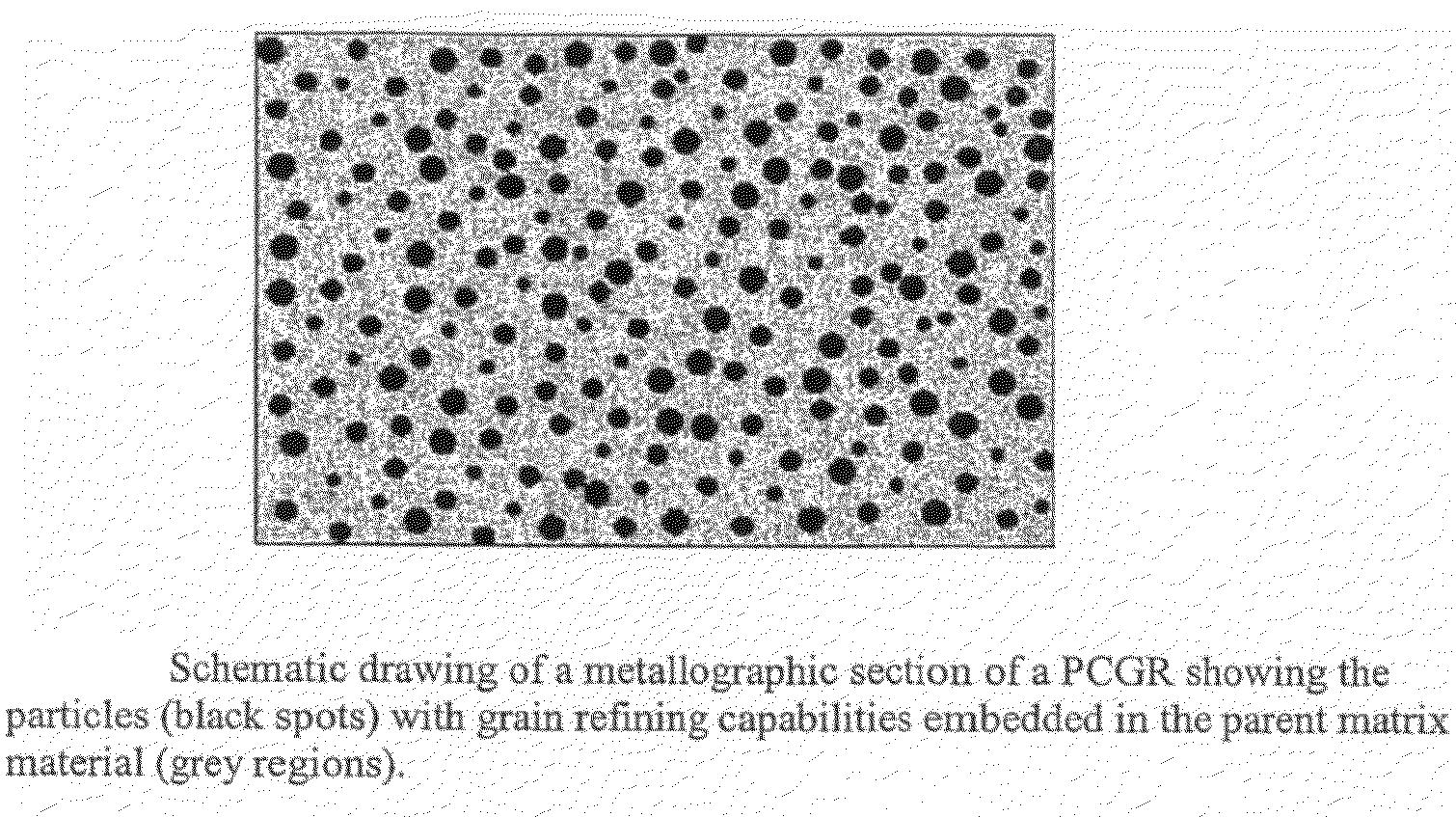

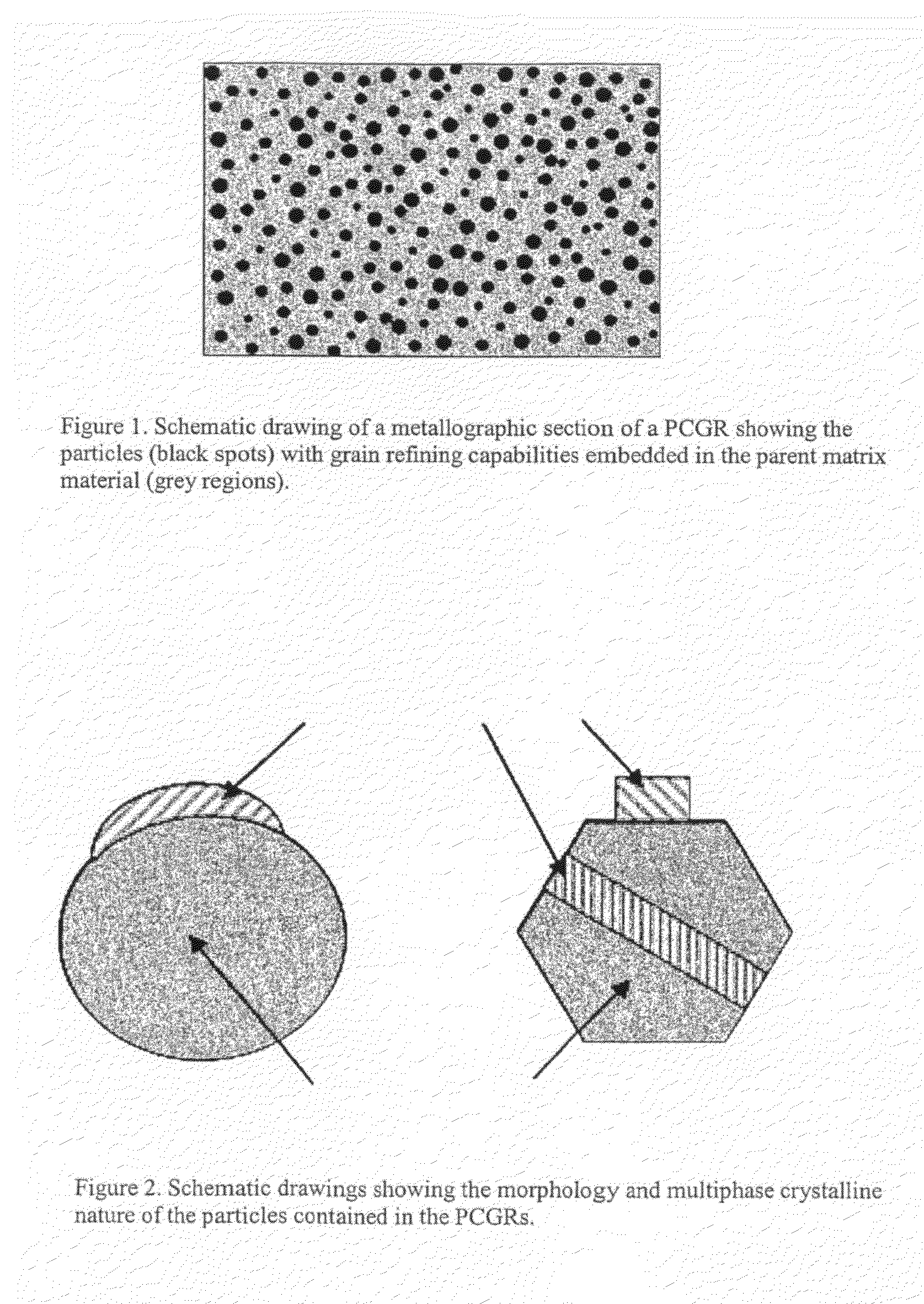

Grain Refiners for Steel-Manufacturing Methods and Use

InactiveUS20090211400A1Increase the number densityBlast furnace componentsBlast furnace detailsMetallurgyNitrogen

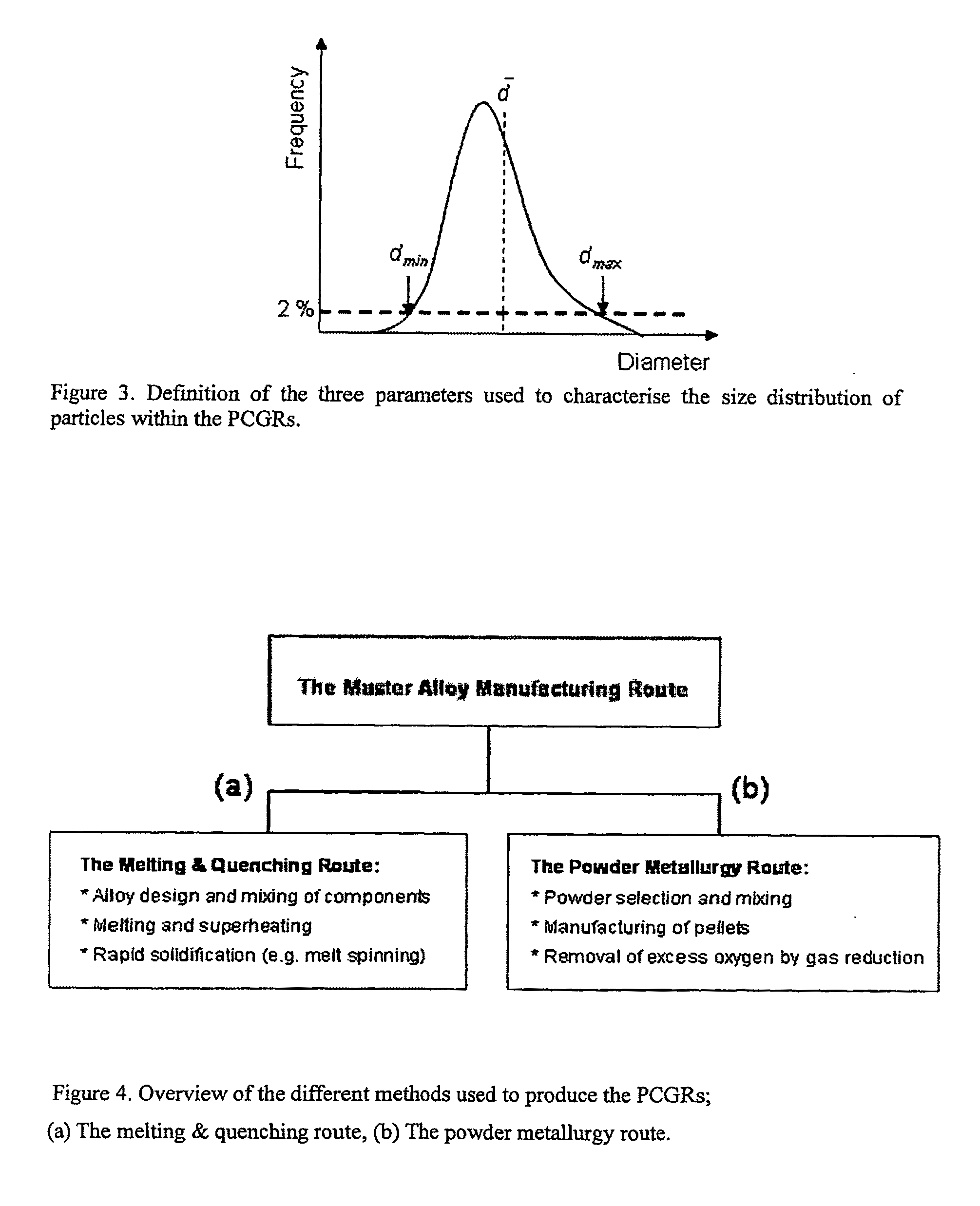

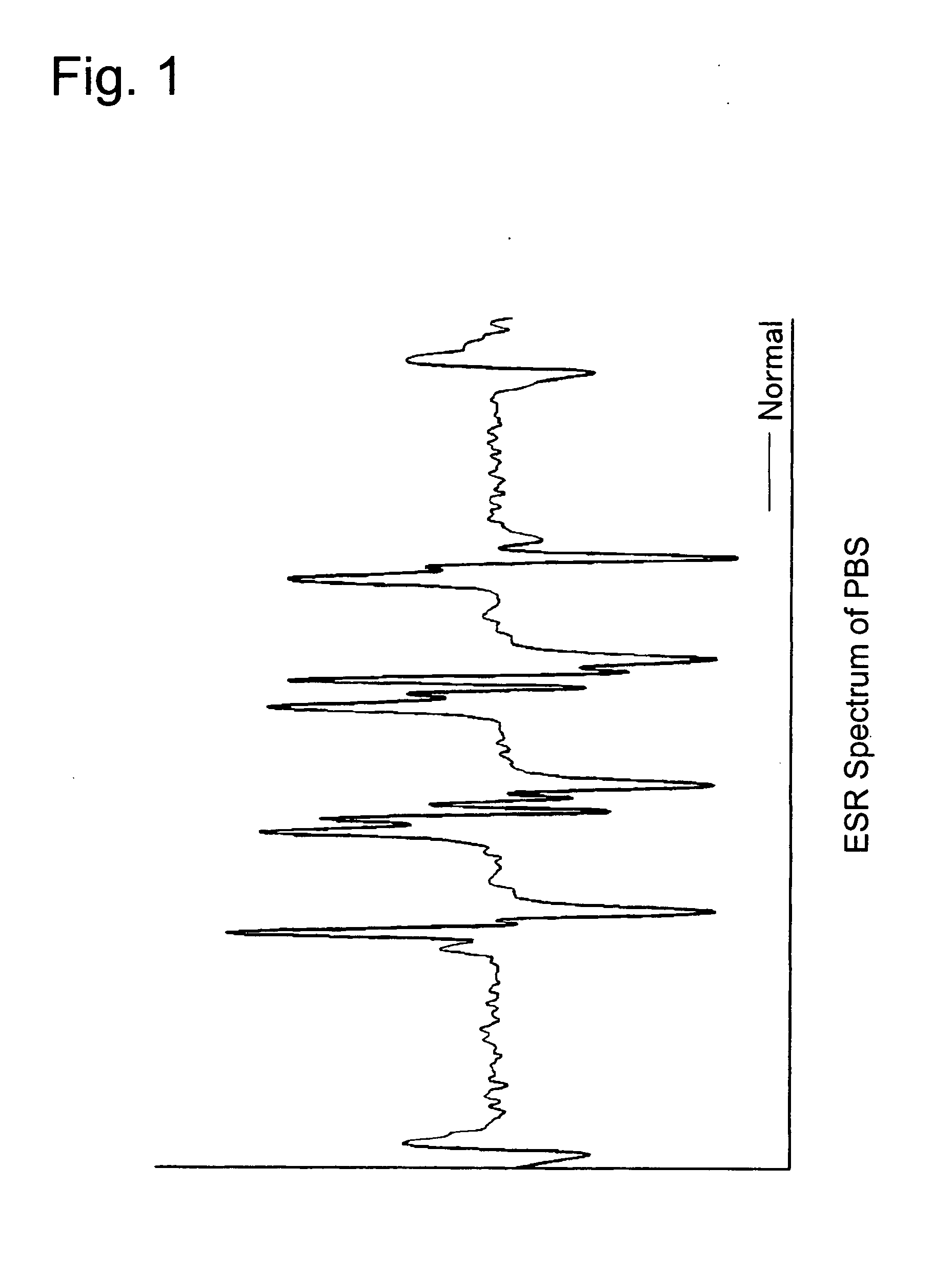

The present invention concerns a new type of grain refiners for steel, in the form of a particulate composite material, containing a high volume fraction of tailor-made dispersed particles, with the purpose of acting as potent heterogeneous nucleation sites for iron crystals during solidification and subsequent thermo-mechanical treatment of the steel. The material comprises a composition of particles of XaSb or XaOb and the element(s) X, where X is one or more elements selected from the group Ce, La, Pr, Nd, Y, Ti, Al, Zr, Ca, Ba, Sr, Mg, Si, Mn, Cr, V, B, Nb, Mo and Fe, and S is sulphur, (O is oxygen), wherein said material additionally contains oxygen, sulphur, carbon and nitrogen, wherein the sulphur (or oxygen) content is between 2 and 30% by weight of said material, while the total content of oxygen (or sulphur), carbon and nitrogen and said other elements selected from the group X is between 98 and 70% by weight of said material, and the said material contains a high volume fraction of finely dispersed XaSb or XaOb particles embedded in a metallic matrix X. The invention further concerns methods for production and use of the composite material.

Owner:SINVENT AS

Finely particulate composite containing carbon compound encapsulated therein

InactiveUS20070077432A1Good water solubilityImprove solubilityCosmetic preparationsMaterial nanotechnologyMeth-Side chain

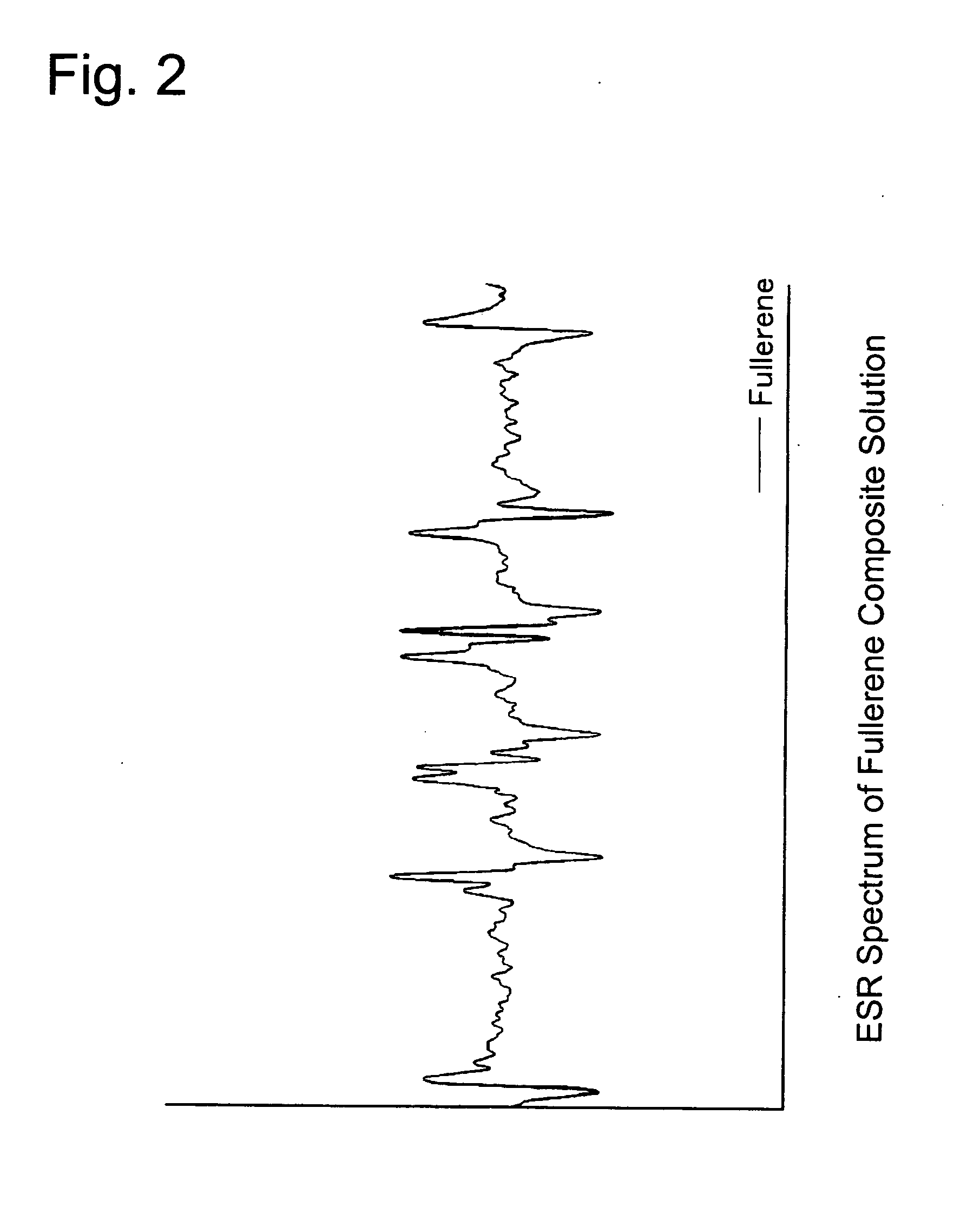

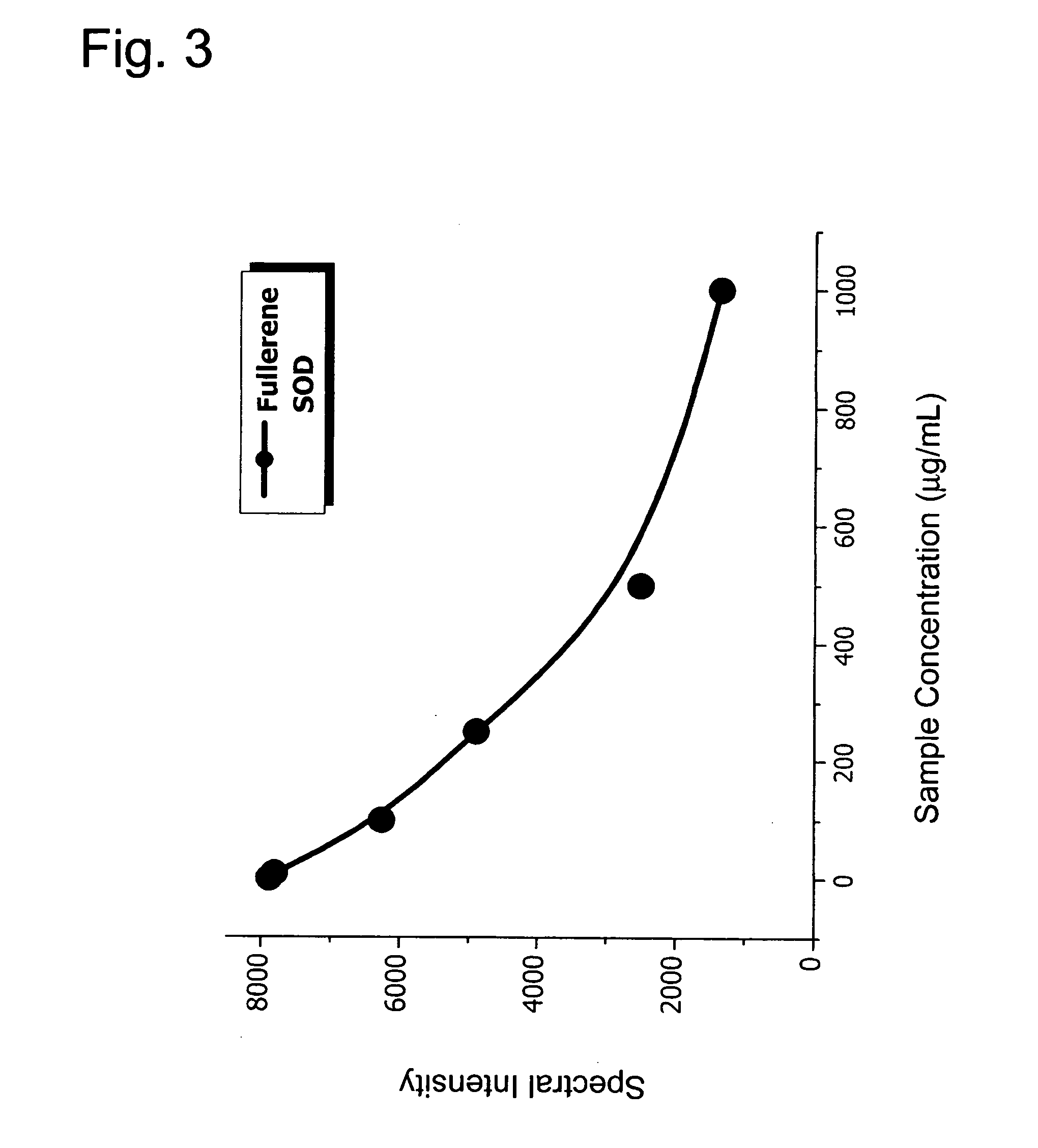

This invention provides a finely particulate composite wherein a fine particle of block copolymer having a poly(ethyleneglycol) chain segment and a poly(meth)acrylate ester chain segment containing, on its side chain, a tertiary amino group and / or a secondary amino group has, encapsulated therein, a carbon compound, e.g., fullerene or carbon nanotube which may contains, encapsulated therein, a metal. This composite is water-soluble, and is usable as an active oxygen scavenger. This composite, when it has a metal encapsulated therein, is usable as a contrast medium.

Owner:JAPAN SCI & TECH CORP

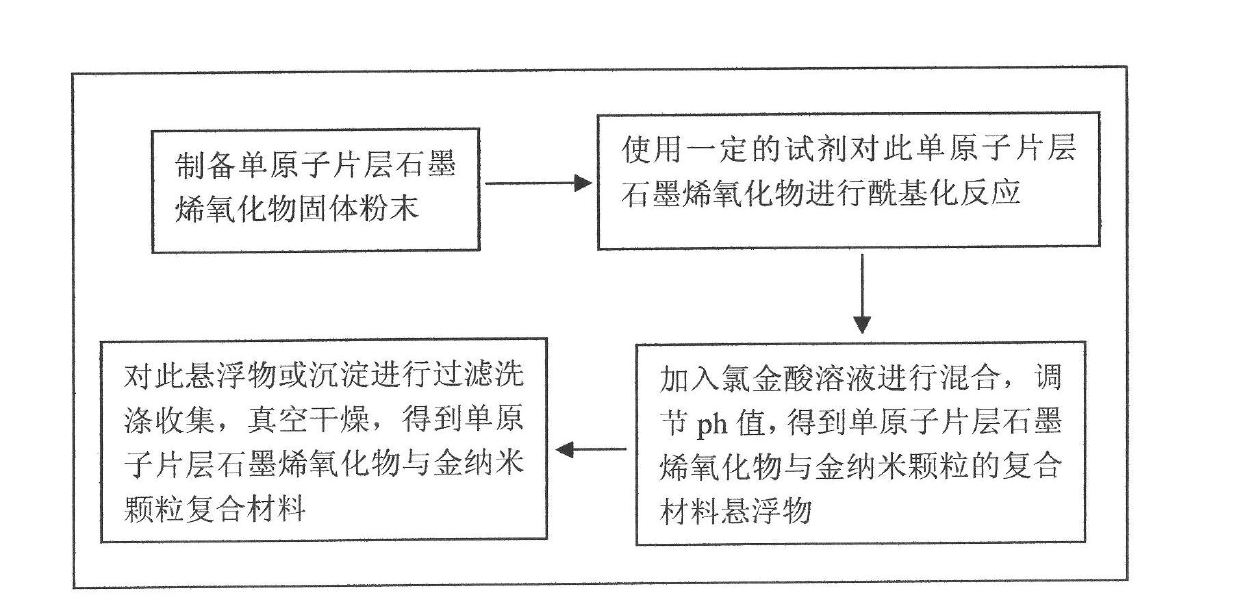

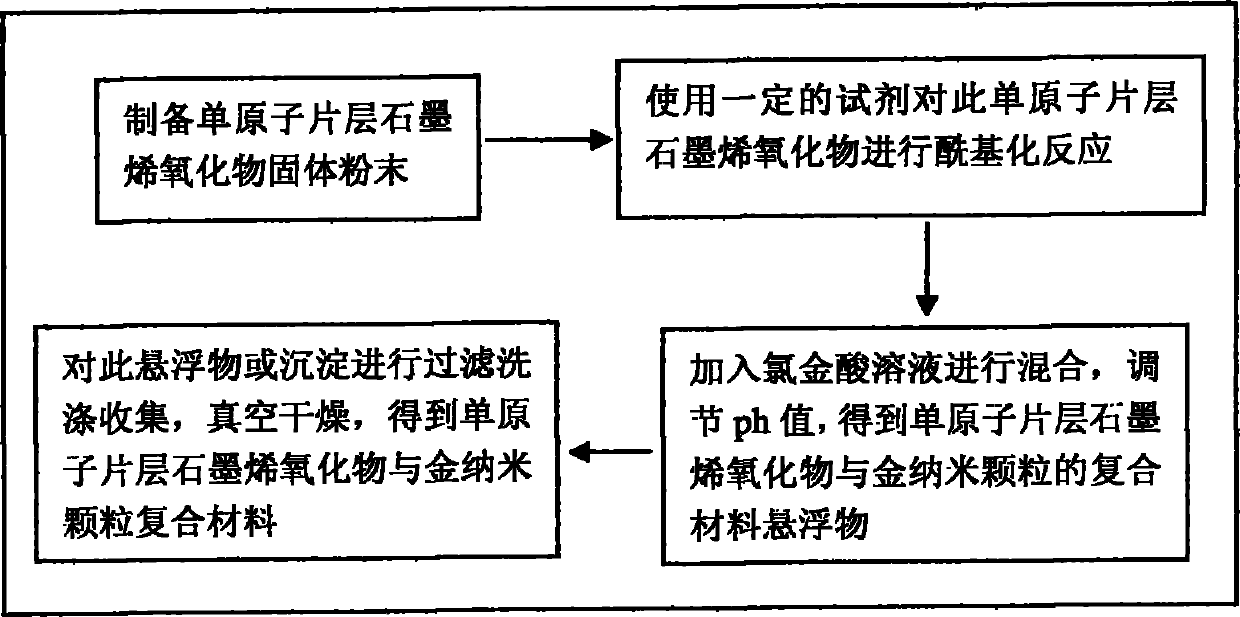

Preparation method of graphene oxide/nano-gold particulate composite material with mono-atomic thickness

InactiveCN102199415AHigh mechanical strengthLarge specific surface areaOther chemical processesNanotechnologyNanoparticleCvd graphene

The invention relates to the field of graphene preparation, and discloses a preparation method of graphene oxide / nano-gold particulate composite material with mono-atomic thickness. In prior arts, the preparation of mono-atomic thickness graphene oxide / nano-gold particulate composite material is complicated, requires special equipment, and cannot be prepared with industrialized production. The present invention assists in solving the problems, and provides a simple method for preparing the composite material with high efficiency. The preparation method comprises the steps that: (1) obtained graphene oxide is subject to an acylation reaction; (2) graphene oxide processed through the acylation reaction is subject to a reaction with a chlorauric acid solution; (3) the pH value of the material is regulated, the depositions are filtered, such that the graphene oxide / nano-gold particulate composite material is obtained. The method of the present invention has advantages of simple technology, high yield, large output, good product quality, and is suitable for industrialized production.

Owner:PLA AIR FORCE OIL MATERIAL RES INST +1

Fundamental method and its hardware implementation for the generic prediction and analysis of multiple scattering of waves in particulate composites

InactiveUS7257518B2Computation using non-contact making devicesScattering properties measurementsReal systemsFluid phase

This invention relates to a method and apparatus for the fundamental prediction, analysis, and parametric studies of the interaction of multiply scattered waves of any nature (acoustic, electromagnetic, elastic) with particulate composites (solid or fluid particulate phases included in a solid or fluid phase). It comprises of: a) a Prediction Engine 21 to predict the composite physical attributes from those of the constituent phases, b) an Inversion Engine 22 to estimate a subset of the attributes of the constituent phases and composite from the rest of those attributes, and c) an ergonomic Graphical Interface 23 to enable the user to easily set up complex simulation experiments for the analysis, and synthesis of real systems in which generic waves interact with composites. The Prediction Engine 22 is suitable for integration into existing acoustic or optical particle size analyzers to thereby extending their concentration ranges by at least two orders of magnitude.

Owner:FELIX ALBA CONSULTANTS

Polysaccharide-Inorganic Composite Particles as Performance Additives for Superabsorbent Polymers

InactiveUS20080261807A1Improve performanceOther chemical processesSynthetic resin layered productsSuperabsorbent polymerPolysaccharide

The present invention relates to discrete particulate composite additives for superabsorbent polymers and includes a method of making same. The discrete particulate composite additives generally comprise a polysaccharide and an inert inorganic component. Advantageously, these discrete particulate composite additives functionally improve superabsorbent performance. They are suitable for a number of applications, including the use and manufacture of hygiene products.

Owner:ARCHER DANIELS MIDLAND CO

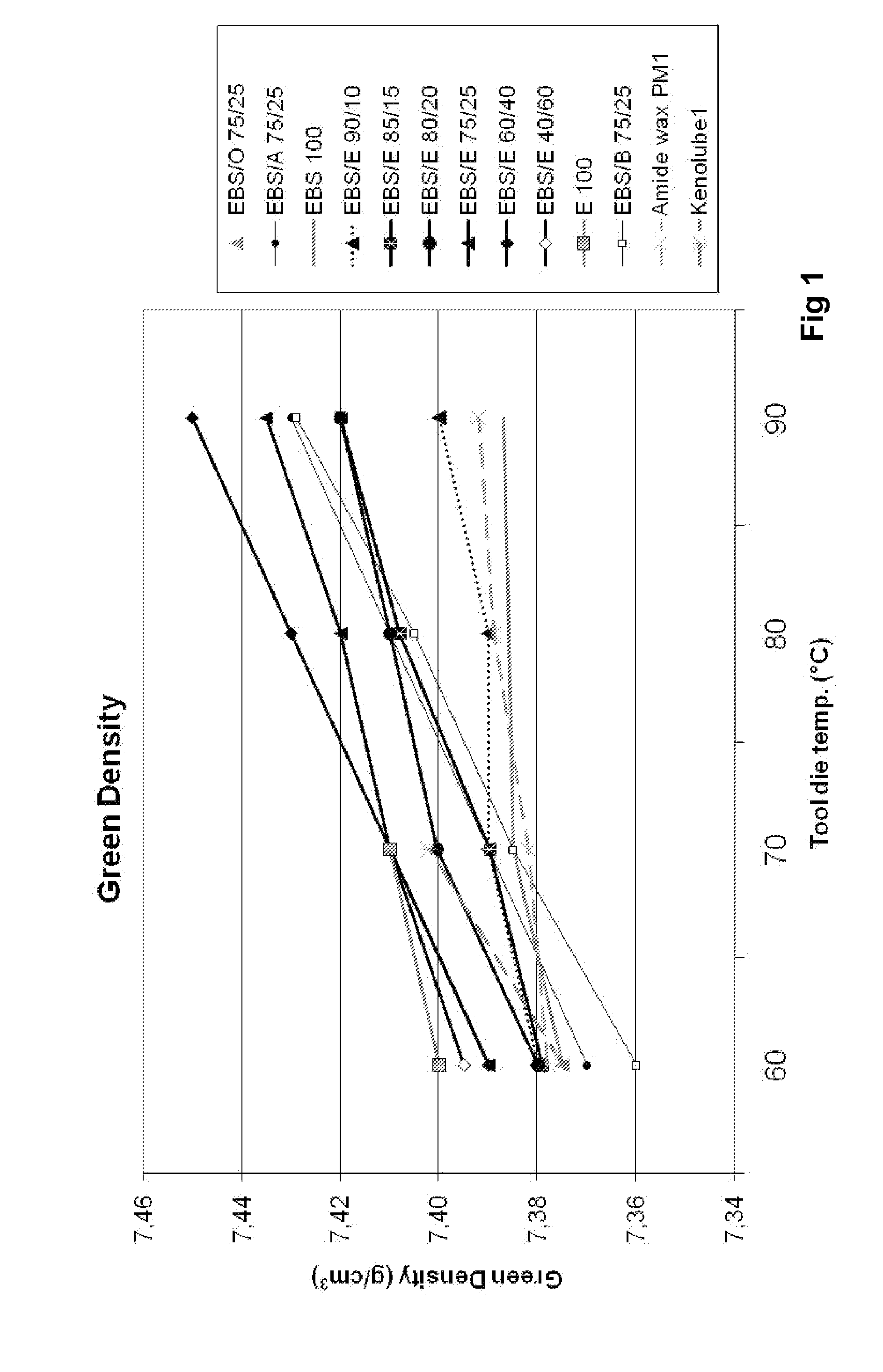

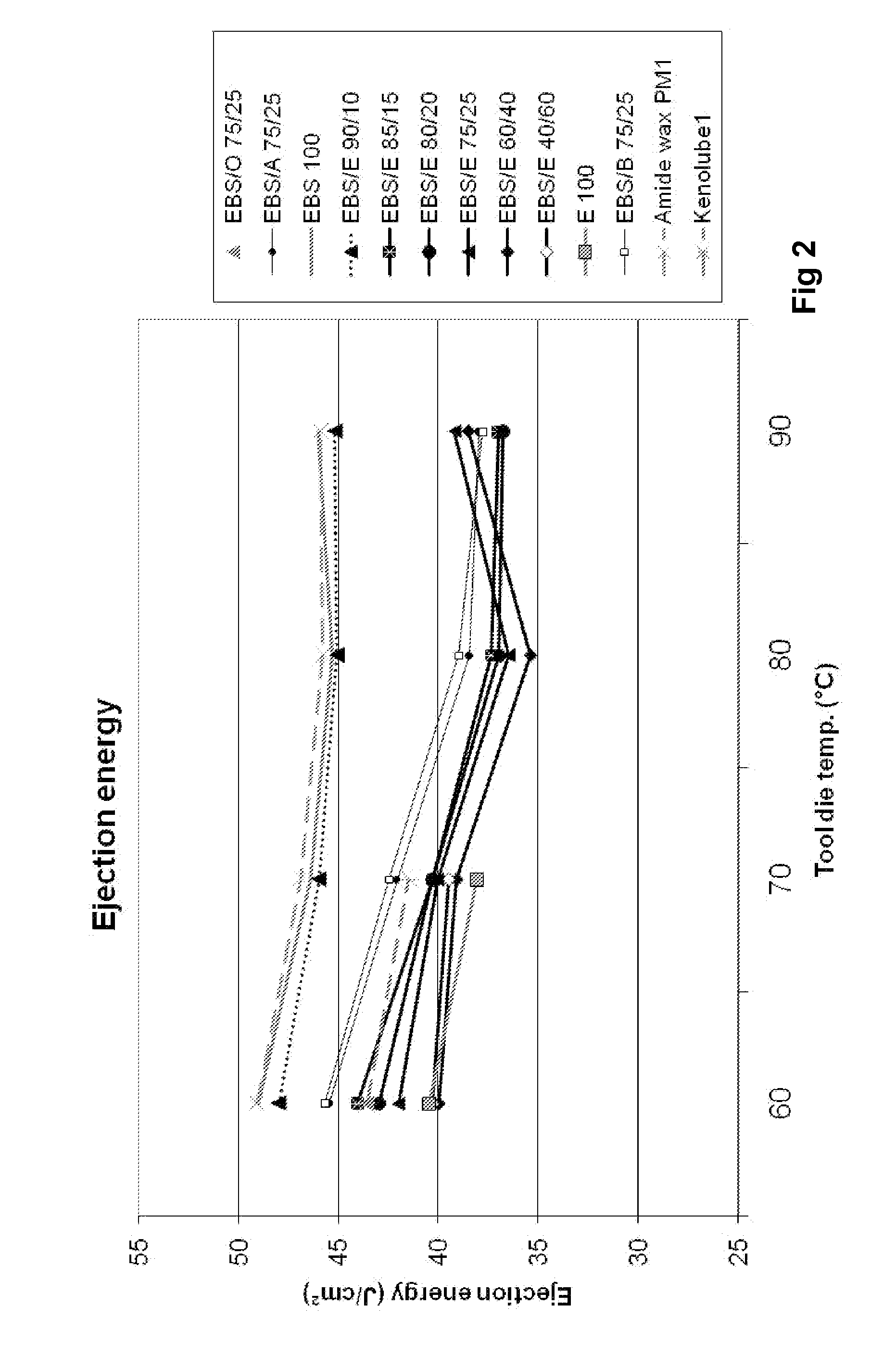

Lubricant for powder metallurgical compositions

ActiveUS7993429B2Easy to produceInternal frictionTransportation and packagingMetal-working apparatusCarbon particleLubricant

An iron-based powder metallurgical composition is provided comprising an iron or iron-based powder and a particulate composite lubricant, the composite lubricant comprising particles having a core comprising a solid organic lubricant having fine carbon particles adhered thereon. A particulate composite lubricant and a method for producing the same also are provided.

Owner:HOGANAS AB

Carbon-coated silicon oxide / graphite composite particles, as well as preparation methods and applications of the same

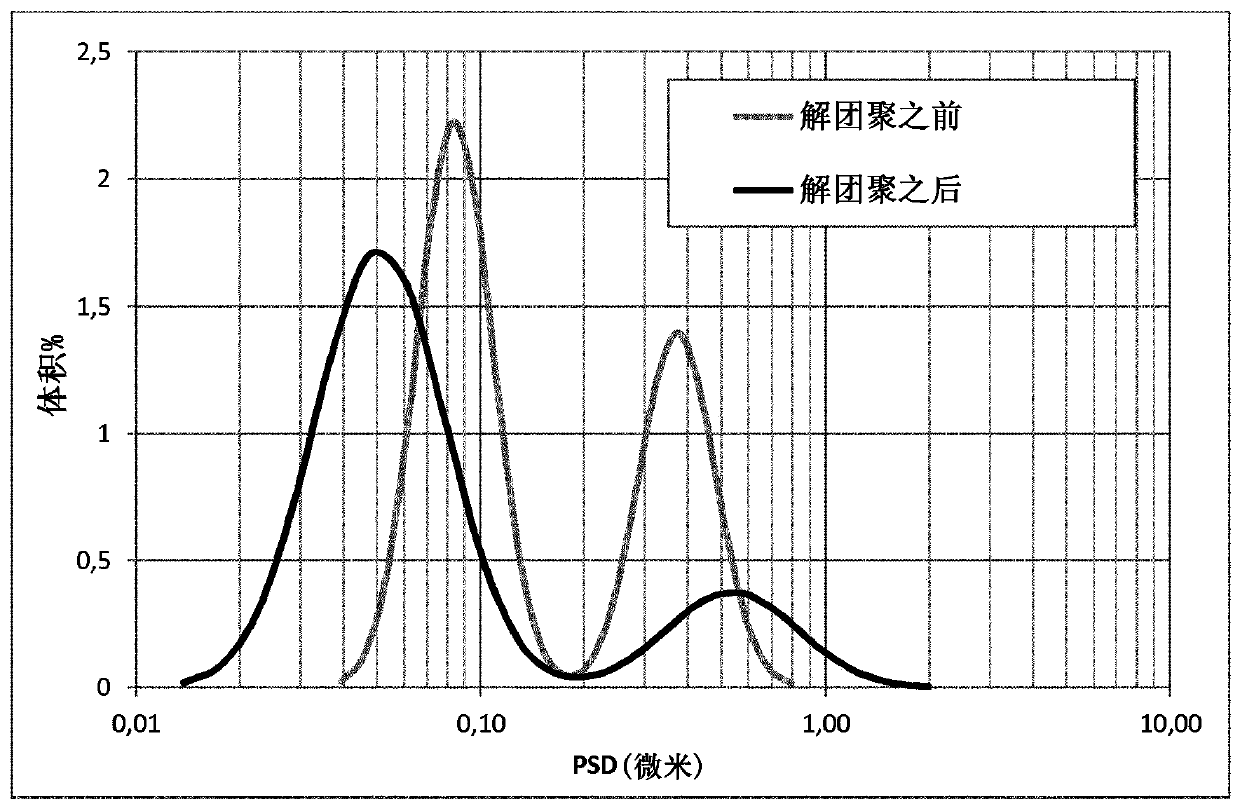

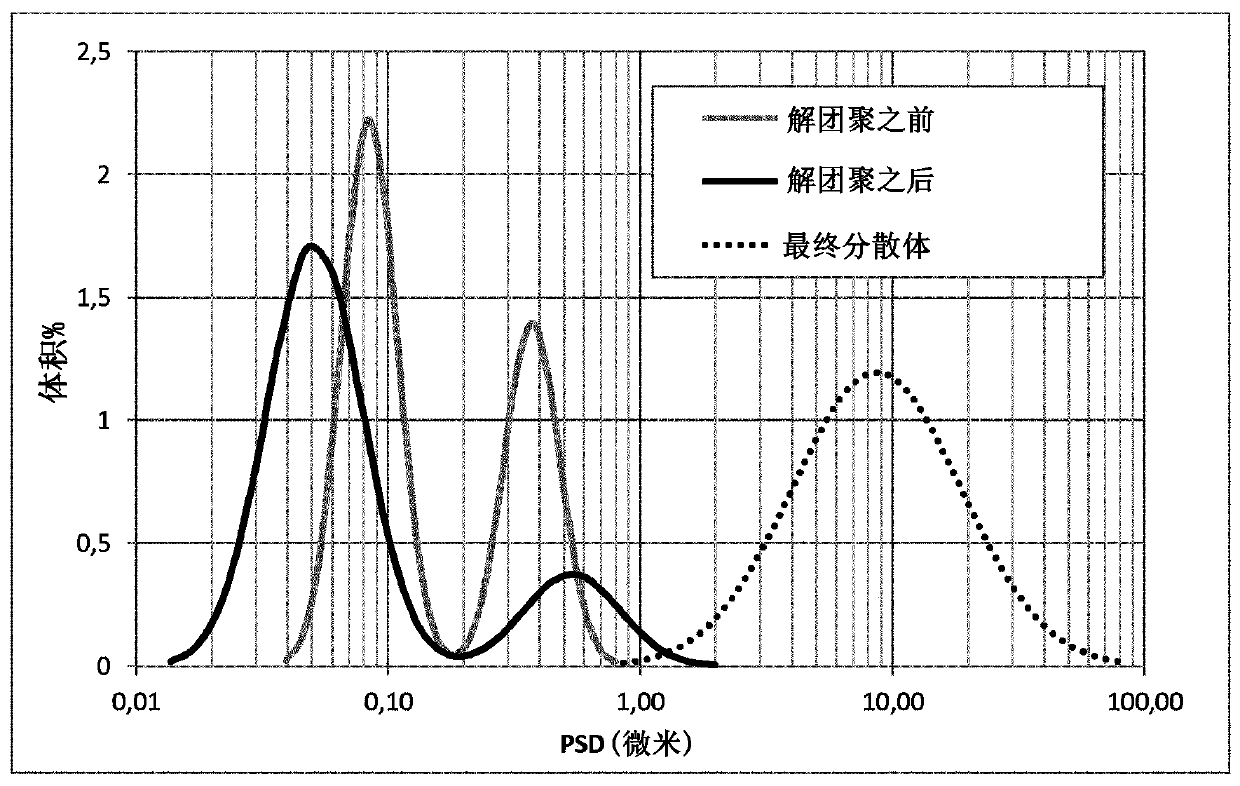

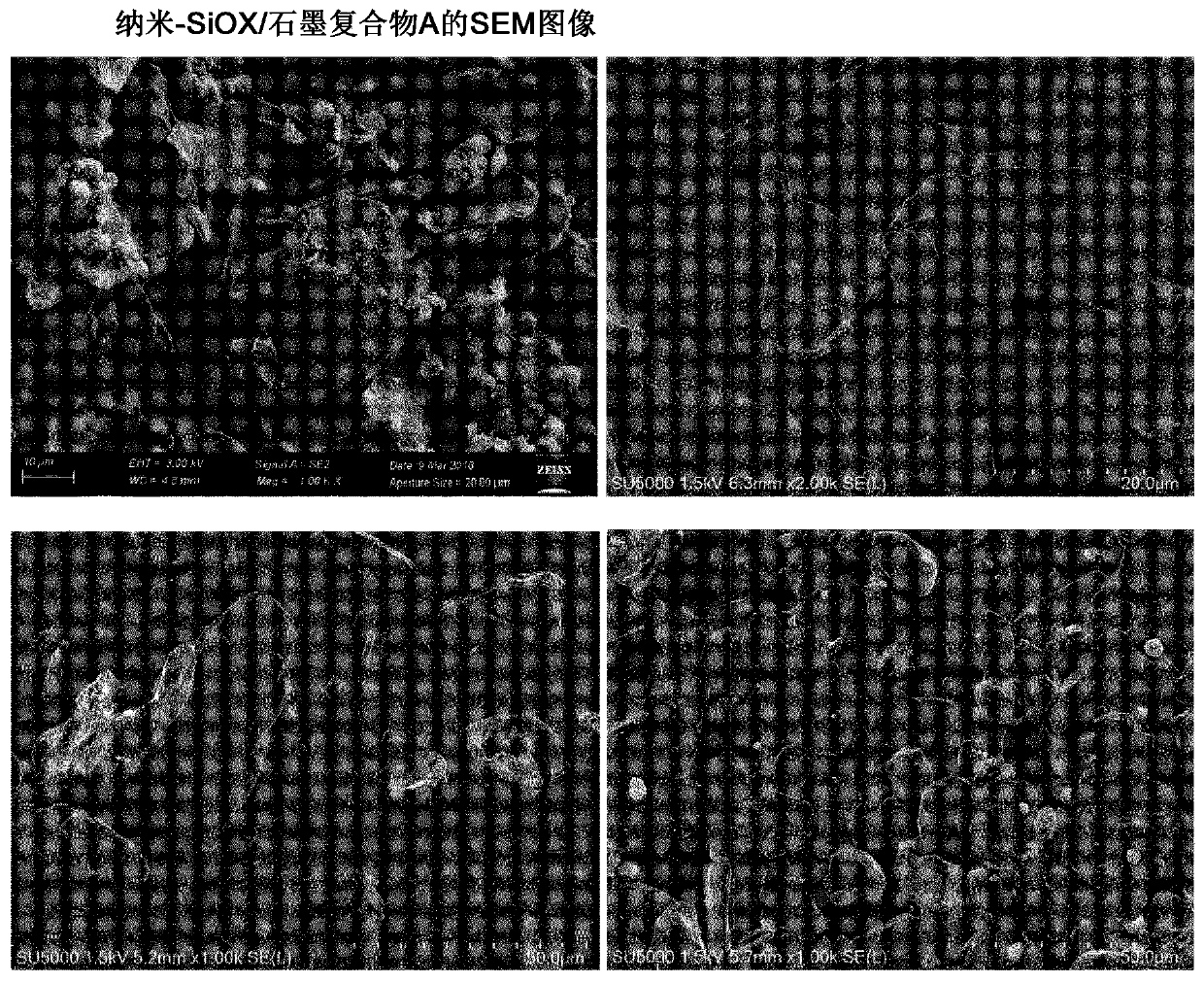

The present disclosure relates to novel particulate composite materials comprising a graphitic core particle associated with SiOx nanoparticles (0.2<=X<=1.8), and coated by a layer of non-graphitic carbon, e.g., pyrolytic carbon deposited by chemical vapor deposition (CVD). Also included are processes for making such particles as well as uses and downstream products for the novel composite material, in particular as an active material in negative electrodes in Li-ion batteries.

Owner:IMERYS GRAPHITE & CARBON SWITZERLAND

Lubricant for Powder Metallurgical Compositions

ActiveUS20090107292A1Improve the lubrication effectNo and reduced tendency to agglomerateTransportation and packagingMetal-working apparatusCarbon particleFerric

An iron-based powder metallurgical composition is provided comprising an iron or iron-based powder and a particulate composite lubricant, the composite lubricant comprising particles having a core comprising a solid organic lubricant having fine carbon particles adhered thereon. A particulate composite lubricant and a method for producing the same also are provided.

Owner:HOGANAS AB

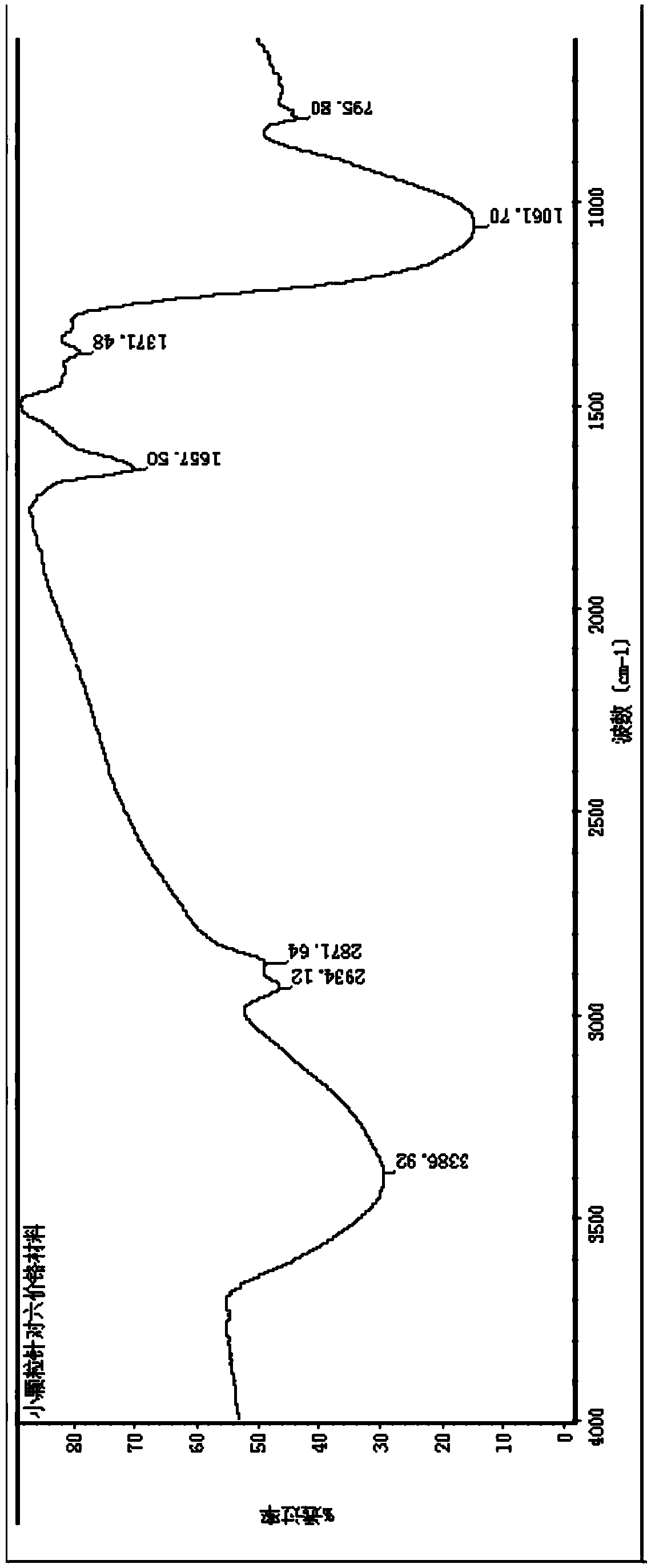

Preparation method of fly ash and chitosan composite particle adsorbing material

InactiveCN108889280AImprove pore structureRealize resource utilizationOther chemical processesWater contaminantsHydration reactionDesorption

The invention discloses a preparation method of fly ash and chitosan composite particle adsorbing material. Fly ash is used as a raw material that is activated before separation; as the fly ash has good pore structure and rich hydroxy radicals may occur to the surface of fly ash particles during hydration reaction, the fly ash can gain significant hydrophilicity, adsorbability and surface chemicalactivity; functionalized fly ash is prepared by modification with functional groups; the functionalized fly ash and chitosan are made into particulate composite particle adsorbing material; the synergy of the functionalized fly ash and rich functional groups (amino groups) on the surface of chitosan is given to full play, the material herein can adsorb negatively-charged heavy metal ions, such asCu2+, Ni2+, Zn2+, Pb2+, Cd2+, CrO42+, and Cr2O72+. Recycling of fly has is achieved; the specific surface area of the fly ash modified by activation may be increased by 15-20 times; the functionalized fly ash and chitosan material prepared herein can be reused through desorption, so that no secondary pollution is caused.

Owner:深圳中天景程环保咨询有限公司 +1

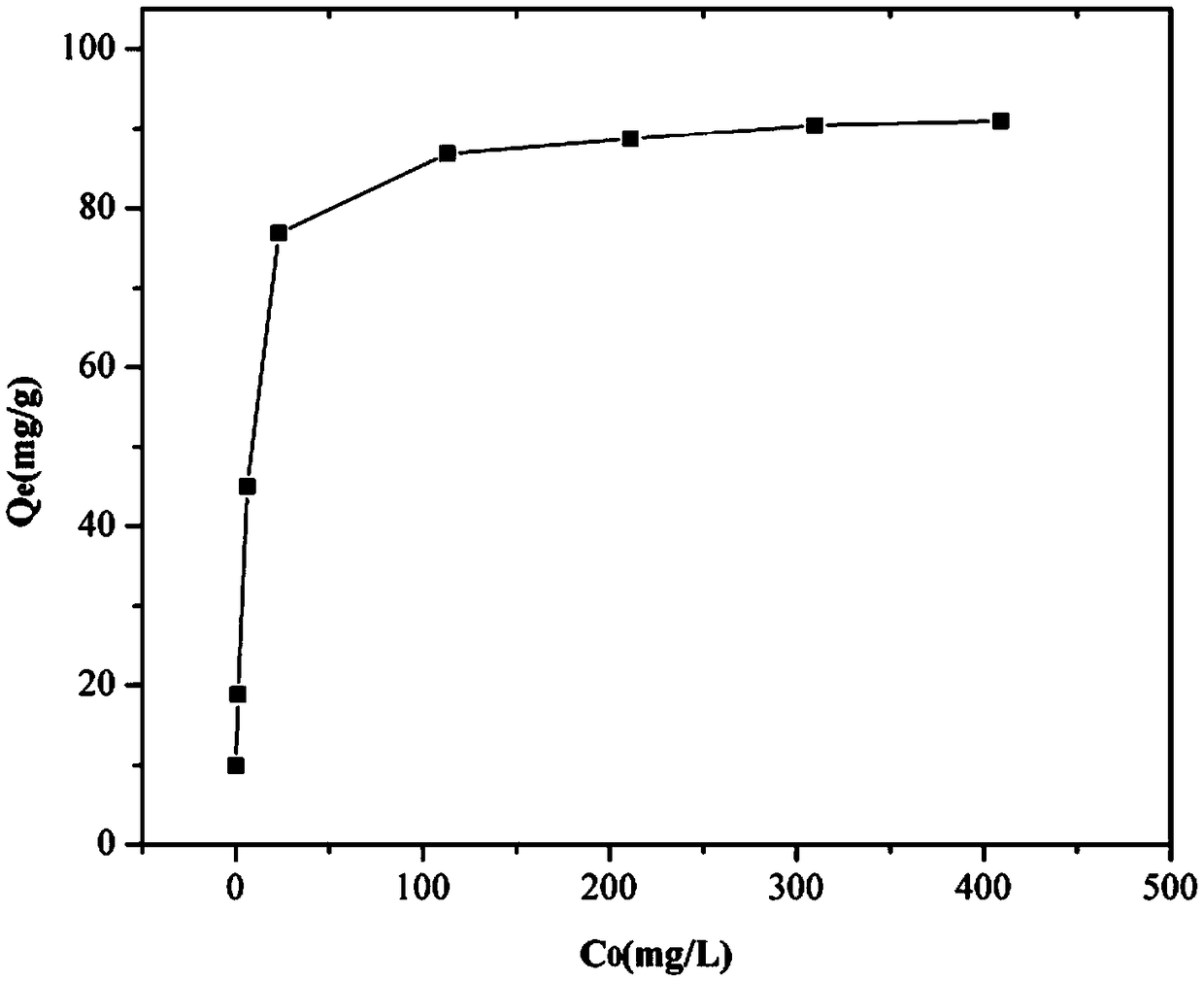

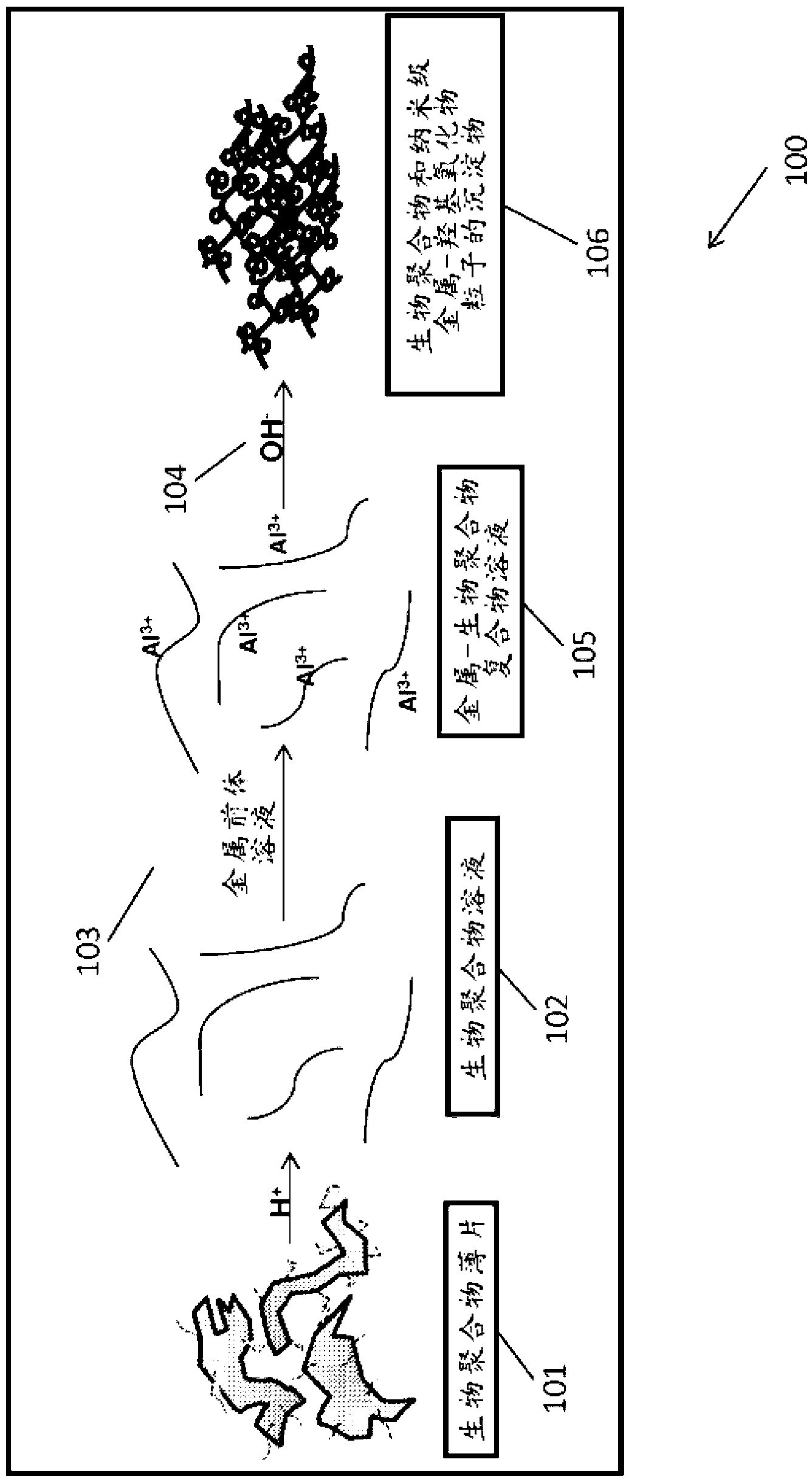

Organic templated nanometal oxyhydroxide

Disclosed are granular composites comprising a biopolymer and one or more nanometal- oxyhydroxide / hydroxide / oxide particles, along with methods for the preparation and use thereof.

Owner:INDIAN INST OF TECH

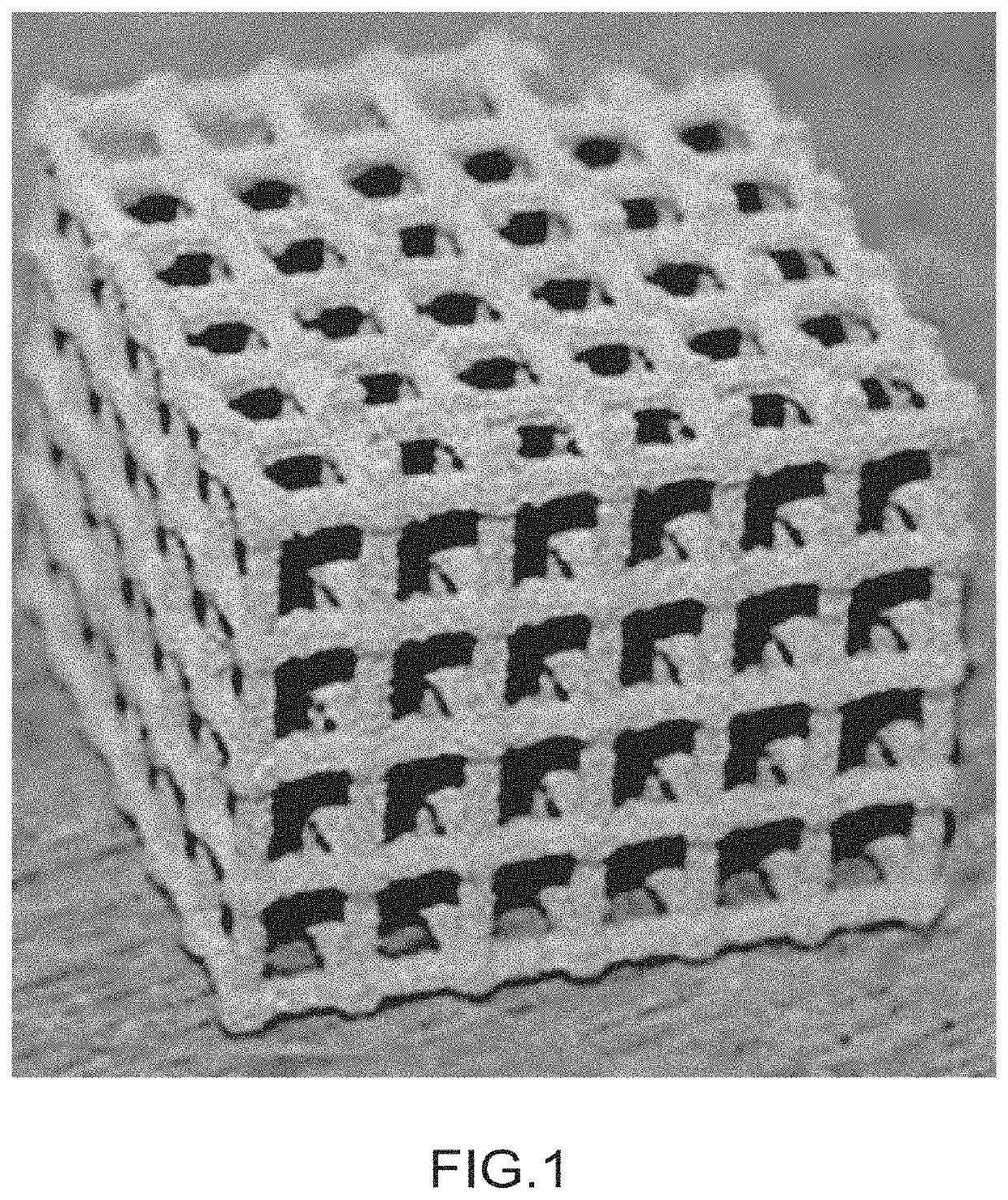

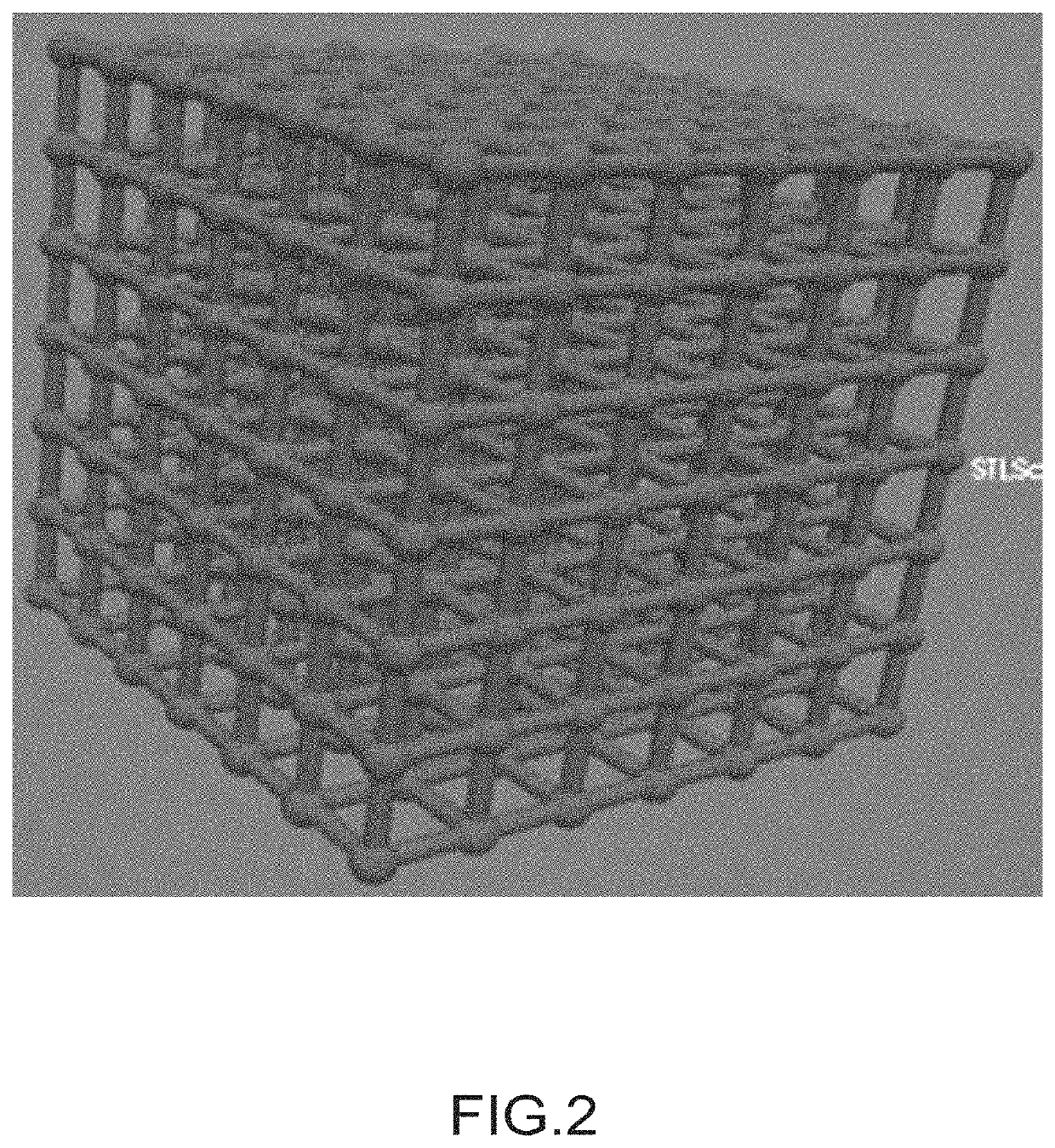

Particulate composite ceramic material, part comprising said material, and method for the preparation of said part

PendingUS20200392046A1High densityImprove dynamic performanceAdditive manufacturing apparatusCeramic shaping apparatusCeramic compositeUltra-high-temperature ceramics

A particulate composite ceramic material comprising: particles of at least one first ultra-high-temperature ceramic “UHTC”, the outer surface of said particles being at least partially covered by a porous layer made of at least one second ultra-high-temperature ceramic in amorphous form; and the particles defining a space therebetween; optionally, porous clusters of said at least one second ultra-high-temperature ceramic in amorphous form, distributed in said space; a dense matrix and at least one third ultra-high-temperature ceramic in crystallized form at least partially filling said space; optionally, a dense coating made of at least said third ultra-high-temperature ceramic in crystallized form, covering the outer surface of said matrix, said matrix and said coating representing 5% to 90% by mass with respect to the total mass of the material.Part comprising said particulate ceramic composite material.Method for manufacturing said part.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

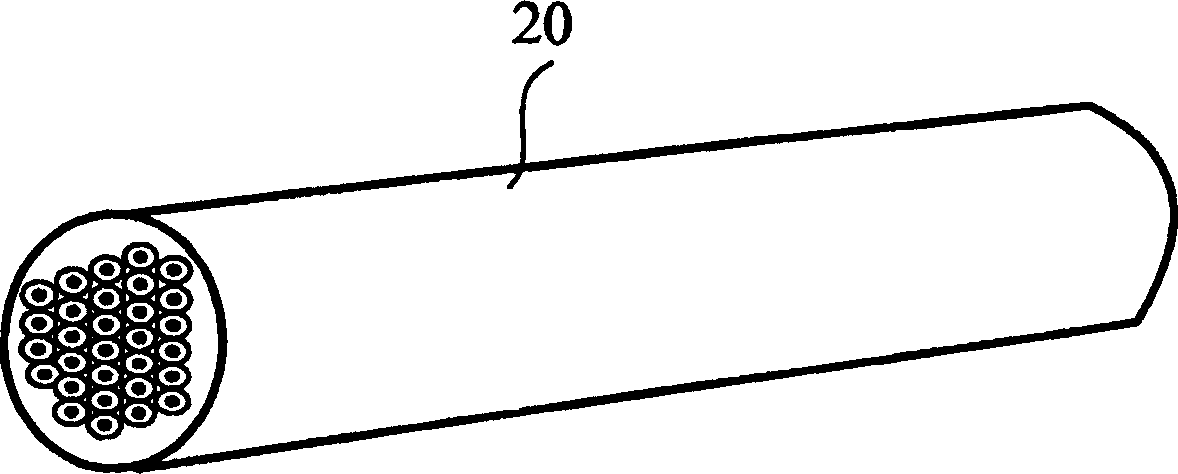

Granular composite material containing metal fiber and its mfg. method

InactiveCN1415649AEvenly dispersedOverlap phenomenon is obviousElectromagnetic shieldingMetal fibers

A granular polymer composition contains a bundle of metallic fibres parallel to each other, the first high-molecular material used as the first coated layer of each metallic fibre, and the second high-molecular material used as the second coated layer of each metallic fibre. It car be used as the raw material of plastic objects for low cost and higher antistatic and electromagnetic sheiding effect.

Owner:KINGS METAL FIBER TECH

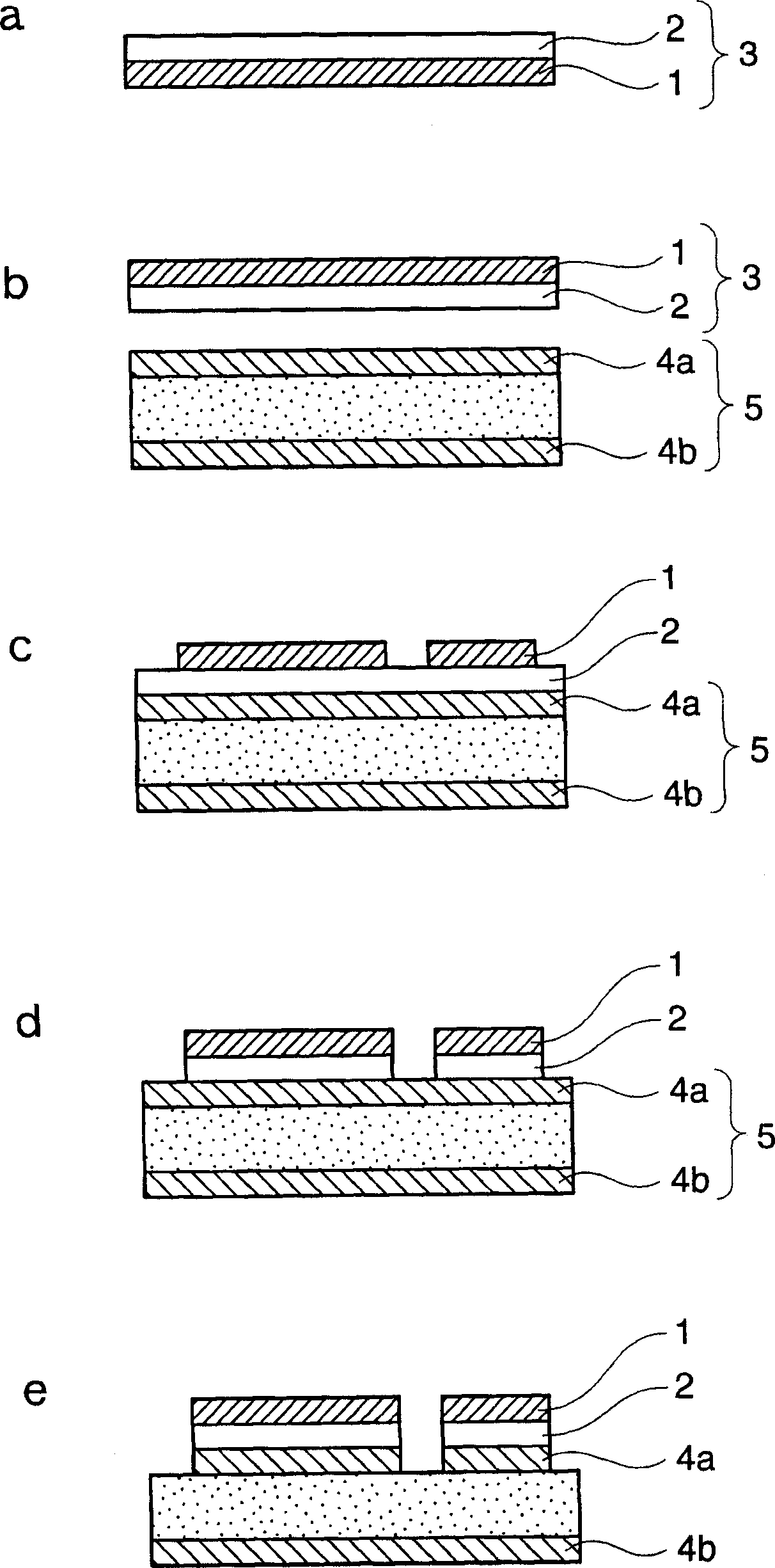

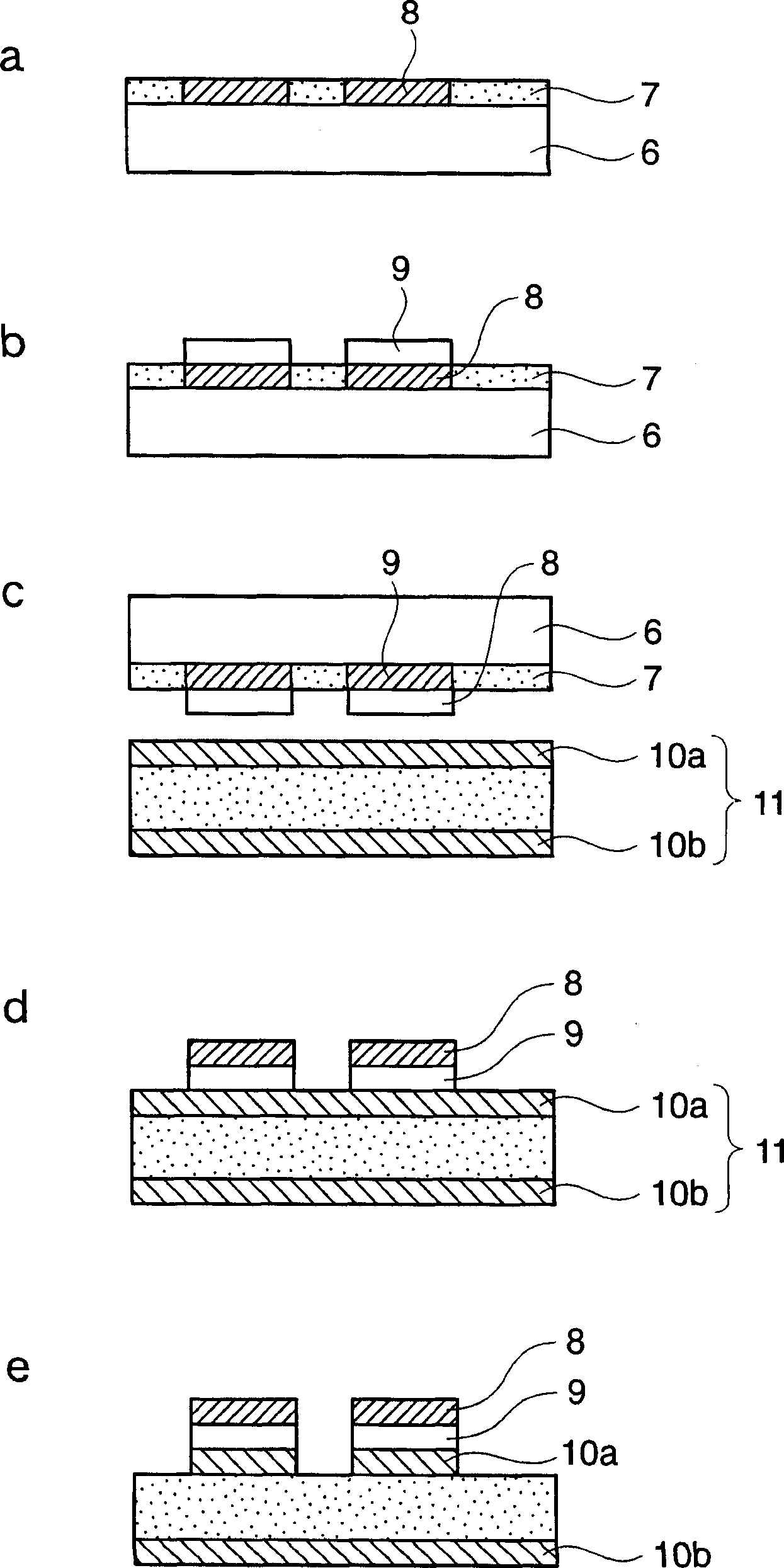

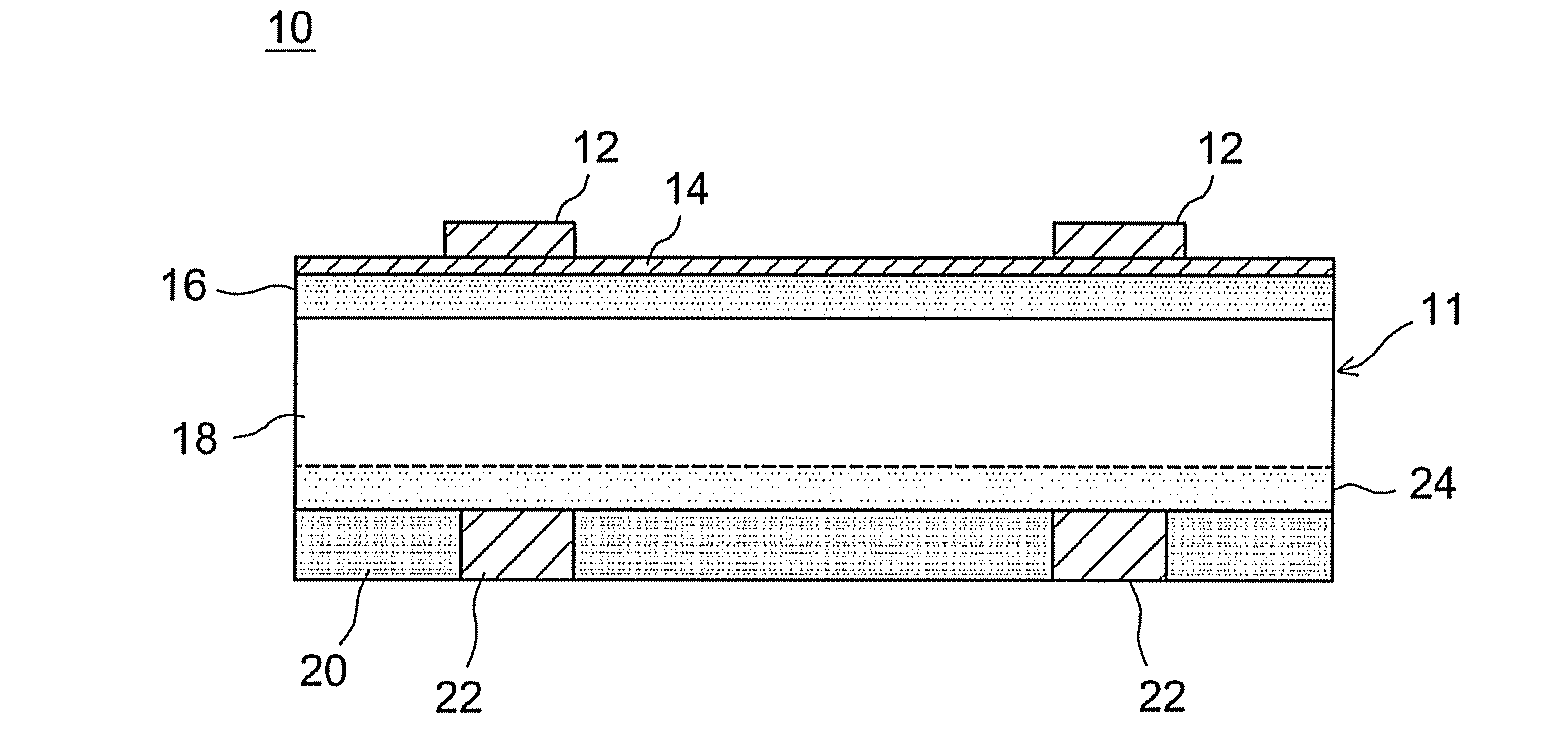

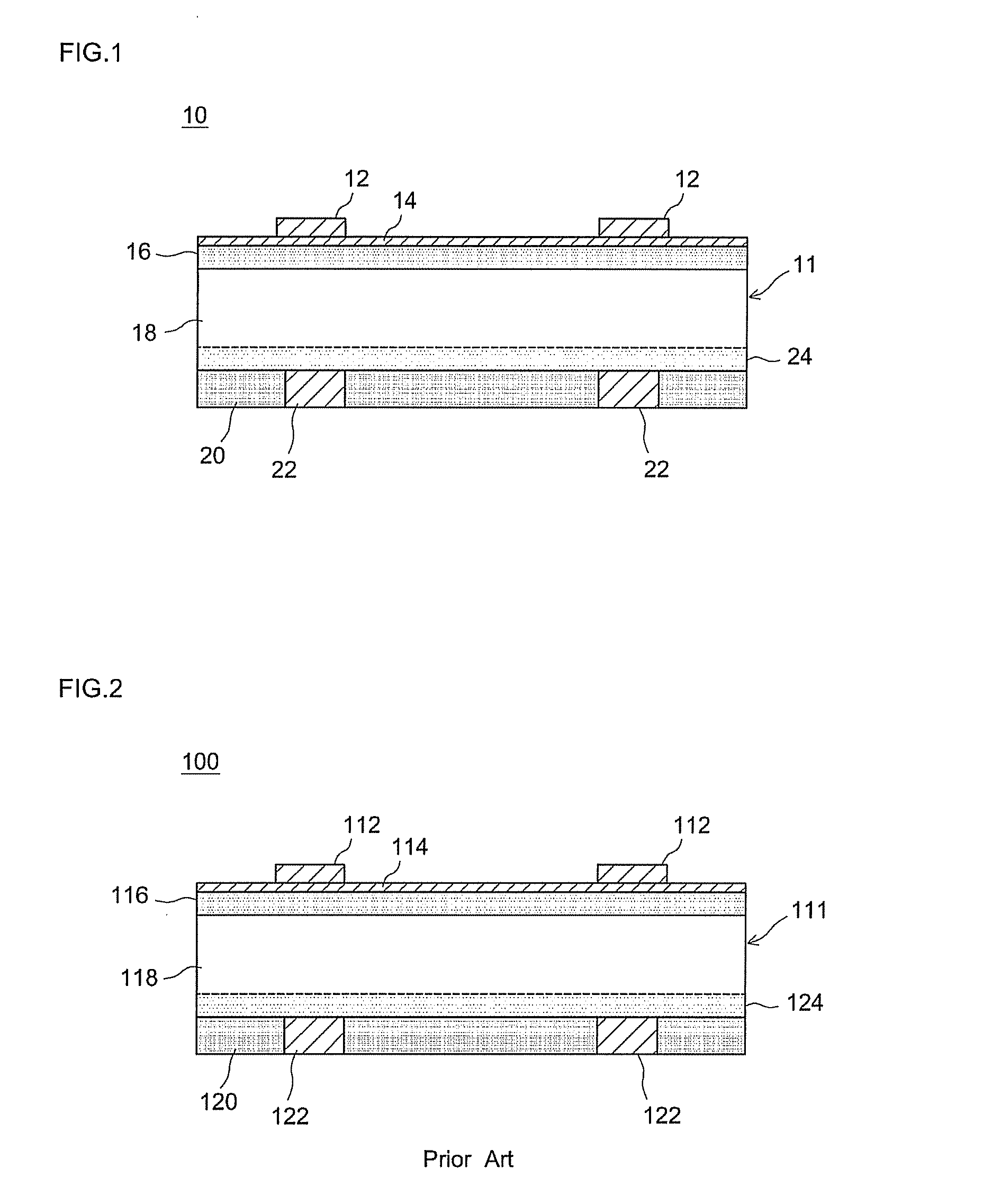

Paste composition for solar cell, manufacturing method therefor and solar cell

InactiveUS20110155967A1Prevent warpage and other deformationGood lookingConductive materialNon-conductive material with dispersed conductive materialAluminium powderInorganic compound

The paste composition for forming a back electrode of solar cell 10 provided by the present invention contains, as solids, an aluminum powder, a glass powder and a composite powder composed of a particulate composite of a metal oxide with a silicon-containing organic or inorganic compound. This composite powder is contained in an amount of at least 0.01 mass % but less than 0.45 mass % given 100 mass % as the total of the composite powder, the aluminum powder and the glass powder.

Owner:NORITAKE CO LTD

Lubricant for powder metallurgical compositions

ActiveUS20110265602A1Easy to optimizeImproved particulate lubricantMaterial nanotechnologyTransportation and packagingNanoparticleMaterials science

An iron-based powder metallurgical composition is provided comprising an iron or iron-based powder and composite lubricant particles, with the composite lubricant particles comprising a core of 10-60% by weight of at least one primary fatty acid amide having more than 18 and not more than 24 carbon atoms and 40-90% by weight of at least one fatty acid bisamide, with the core having nanoparticles of at least one metal oxide adhered thereon. Further provided is a particulate composite lubricant as well as a method of preparing such lubricant.

Owner:HOGANAS AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com