Granular composite material containing metal fiber and its mfg. method

A metal fiber and composite material technology, applied in the field of plastic objects, can solve the problems affecting the antistatic and EMI shielding effects of plastic objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

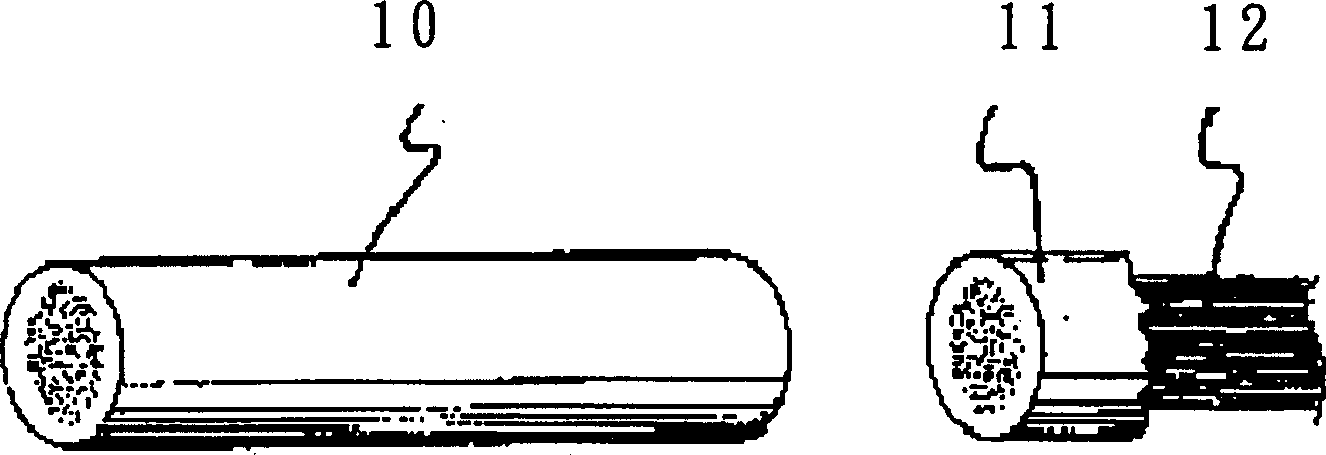

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

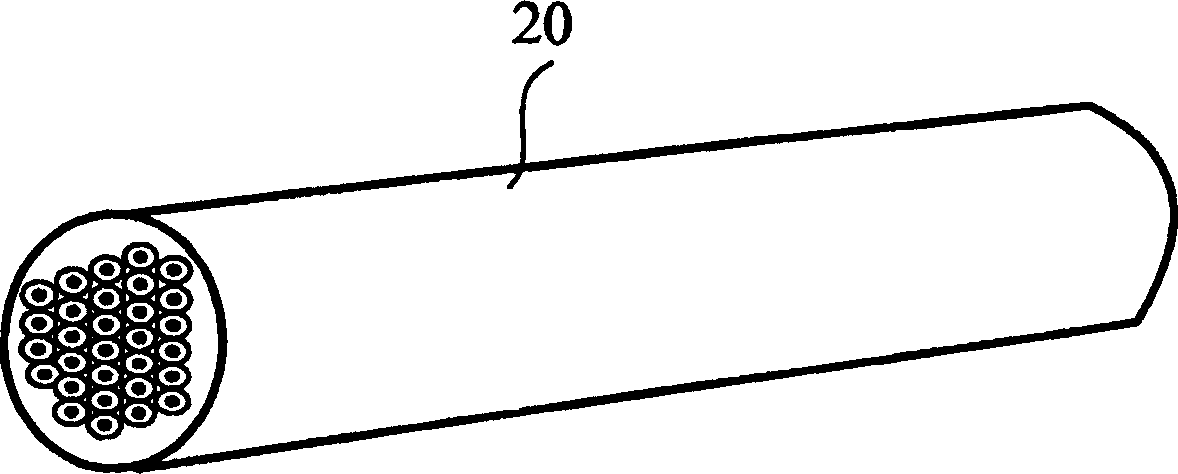

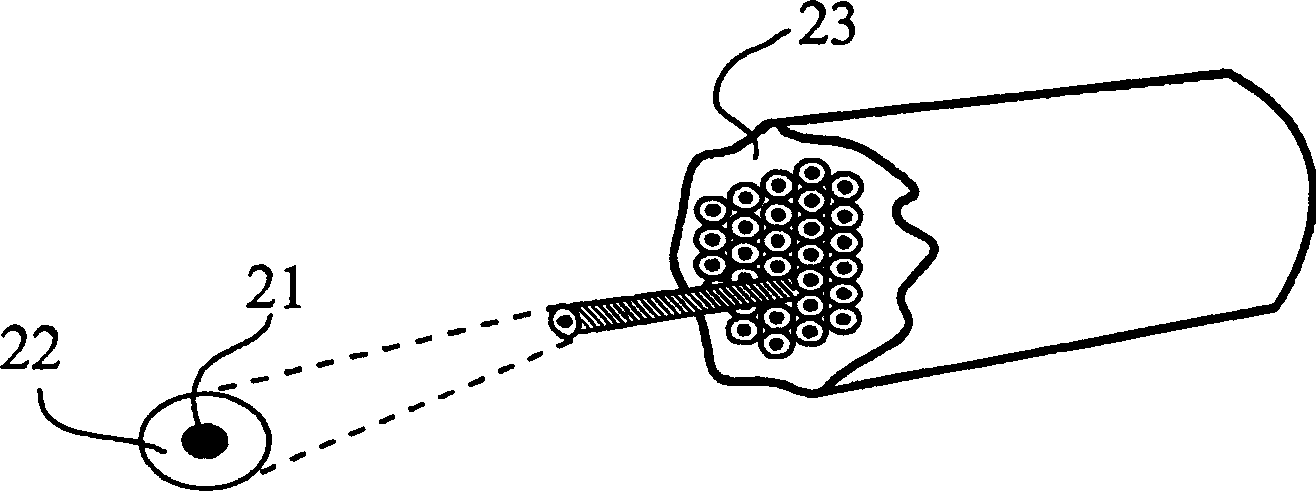

[0032] The invention provides a granular composite material containing metal fibers and a manufacturing method thereof. In particular, the metal fibers in the composite material are separated by polymer materials, and the metal fiber is a material with high surface conductivity. metal fibers. The granular composite material according to the present invention can be directly used as a raw material for molding plastic objects. During the molding of plastic objects, the metal fibers can be easily dispersed uniformly and the overlapping phenomenon is obvious. The application of the granular polymer composite material of the present invention can achieve reasonable antistatic and EMI shielding effects under the condition of low metal fiber content.

[0033] Please refer to Figure 2A and Figure 2B , Figure 2A and Figure 2B Disclosed is the morphology of a granular polymer composite material 20 according to a preferred embodiment of the present invention. Such as Figure 2A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com