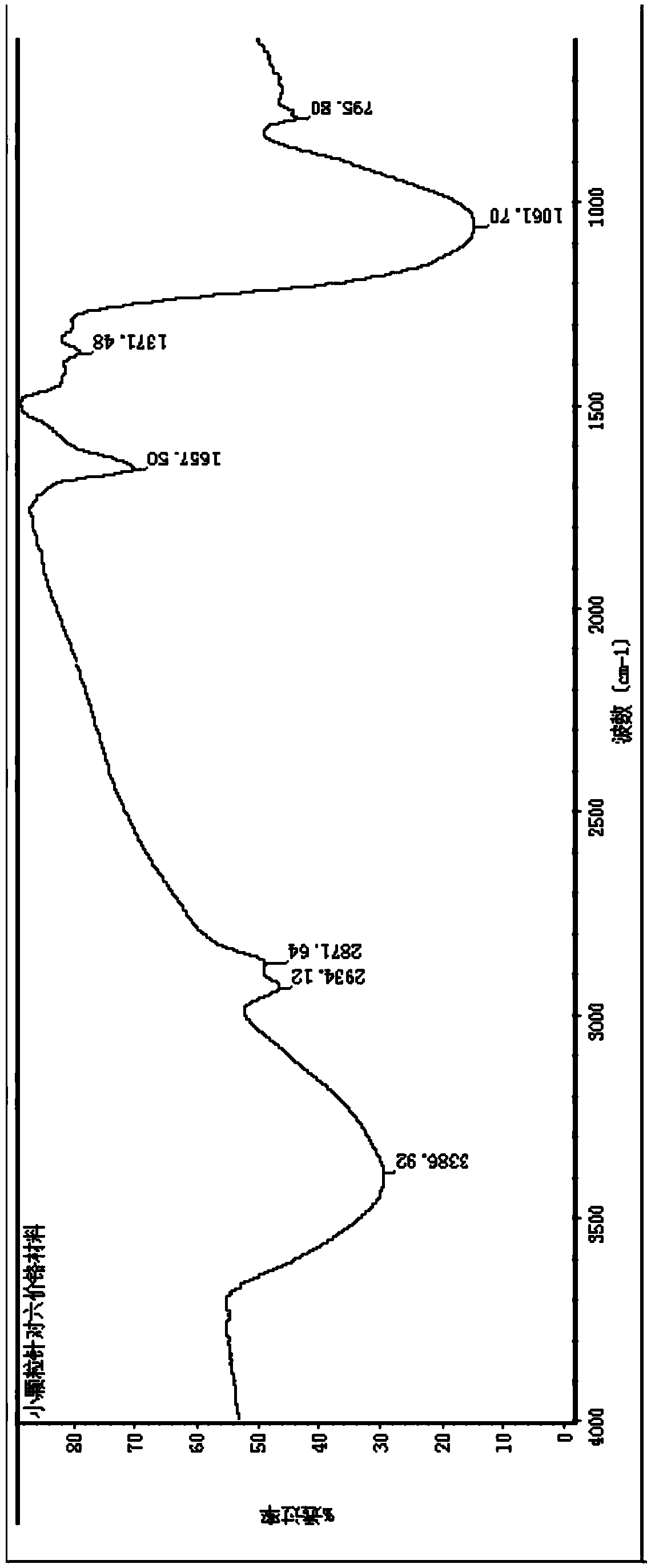

Preparation method of fly ash and chitosan composite particle adsorbing material

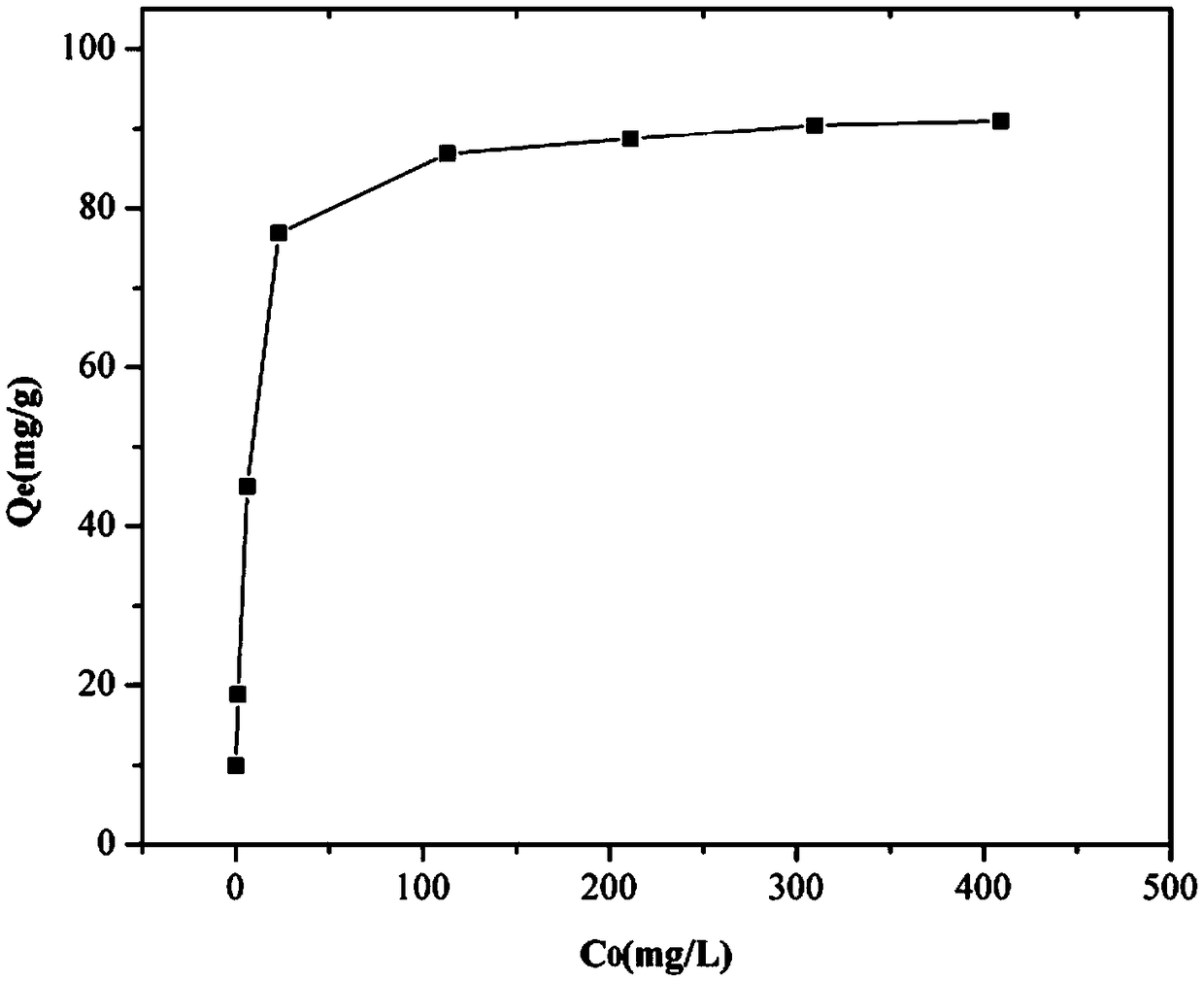

A technology of composite particles and adsorption materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of limited application and insufficient adsorption performance of fly ash, and achieve significant hydrophilicity, Realize the effect of resource utilization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of fly ash-chitosan composite particle adsorption material, and it comprises the steps:

[0035] S1. Take fly ash from a thermal power plant, remove impurities and dry it, pass through a 200-mesh sieve, and use 2.5mol / L hydrochloric acid as an activator to activate the fly ash: mix fly ash and hydrochloric acid solution according to 1 : The volume ratio of 6 was stirred and activated at a stirring speed of 80r / min for 3.5h at 70°C to obtain activated fly ash.

[0036] S2. Wash the activated fly ash obtained after the activation treatment with deionized water to neutrality, then settle naturally in deionized water, separate the upper layer of suspended fly ash after the sedimentation, take the lower layer of settled fly ash, filter and dry, and obtain Heavy activated fly ash, the density of the heavy activated fly ash is 1.9cm 3 / g, the specific surface area of fly ash before activation is about 3.0~5.2m 2 ...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of fly ash-chitosan composite particle adsorption material, and it comprises the steps:

[0048] S1, get fly ash from thermal power plant, after removing impurity and drying, cross 200 mesh sieves, adopt the sulfuric acid of 1mol / L as activator, carry out activation treatment to fly ash: fly fly ash and sulfuric acid solution according to 1: The volume ratio of 2 was stirred and activated at 100° C. at a stirring speed of 100 r / min for 1 hour to obtain activated fly ash.

[0049] S2. Wash the activated fly ash obtained after the activation treatment with deionized water to neutrality, then settle naturally in deionized water, separate the upper layer of suspended fly ash after the sedimentation, take the lower layer of settled fly ash, filter and dry, and obtain Heavy activated fly ash, the density of the heavy activated fly ash is 1.9cm 3 / g, the specific surface area of fly ash before activation is about ...

Embodiment 3

[0059] The present embodiment provides a kind of preparation method of fly ash-chitosan composite particle adsorption material, and it comprises the steps:

[0060] S1, get fly ash from thermal power plant, after removing impurity and drying, cross 200 mesh sieves, adopt the sulfuric acid of 5mol / L, hydrochloric acid mixed solution as activator (the volume ratio of described sulfuric acid, hydrochloric acid is 1:1), Activate the fly ash: stir and activate the fly ash, sulfuric acid and hydrochloric acid mixed liquid solution at a volume ratio of 1:10 at 20°C for 6 hours at a stirring speed of 50r / min to obtain activated fly ash.

[0061] S2. Wash the activated fly ash obtained after the activation treatment with deionized water to neutrality, then settle naturally in deionized water, separate the upper layer of suspended fly ash after the sedimentation, take the lower layer of settled fly ash, filter and dry, and obtain Heavy activated fly ash, the density of the heavy activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com