Vehicle-used slowly-springback polyurethane foam composite material

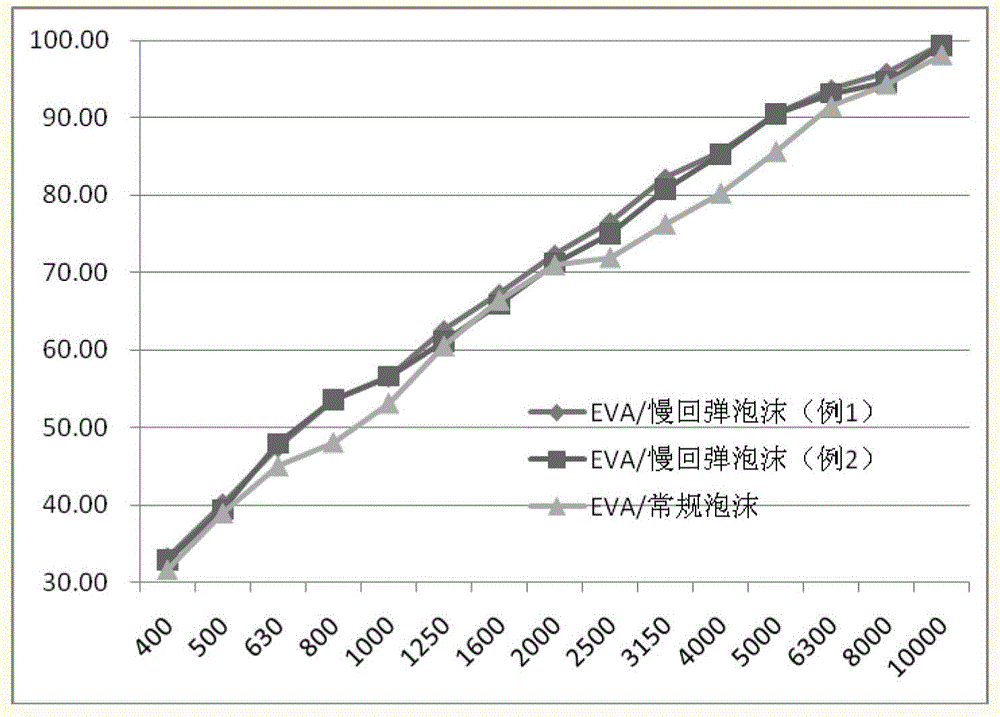

A polyurethane foam and composite material technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of strength, toughness, uneven distribution of pores, hidden safety hazards, etc., and achieve slow resilience It can last longer, increase the transmission path, and ensure the connectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

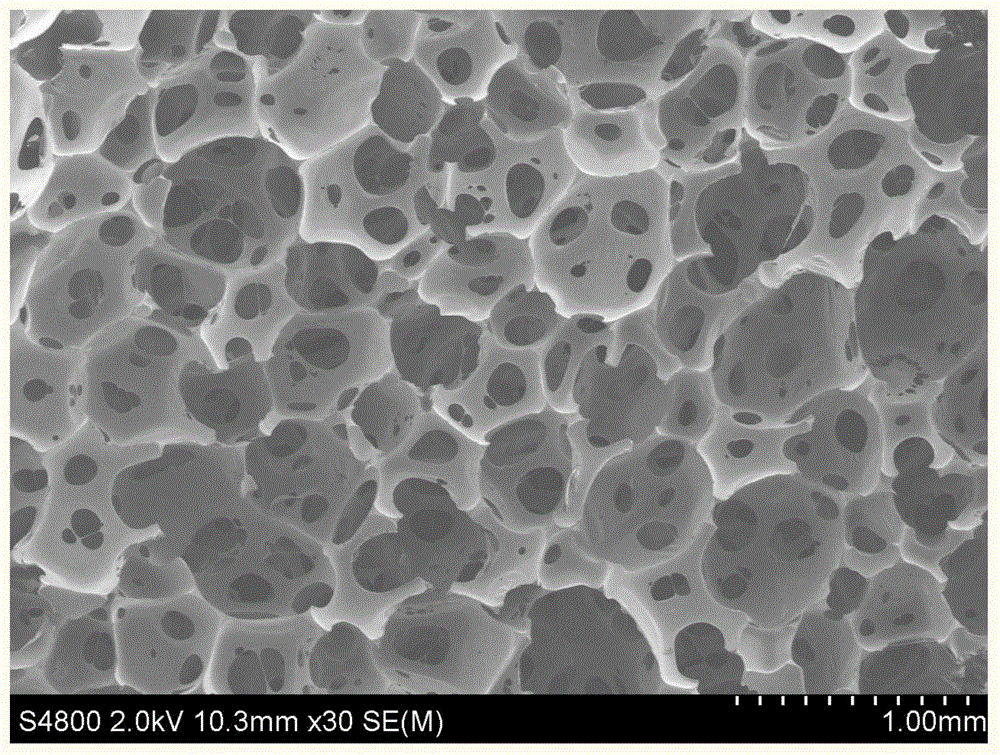

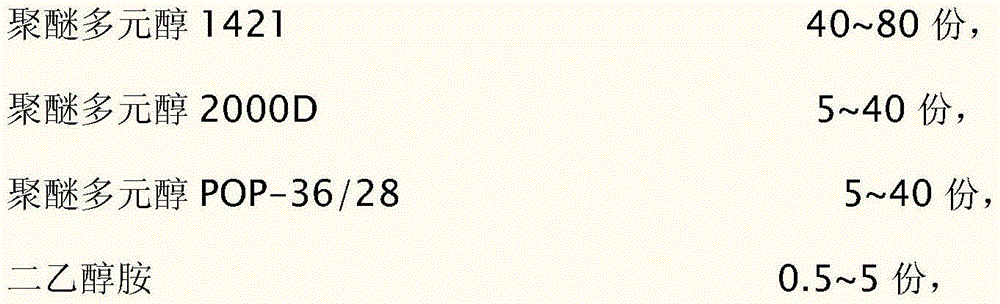

[0052] First, the following proportions by weight: polyether polyol 1421, polyether polyol 2000D, polyether polyol POP-36 / 28, diethanolamine, water, catalyst EF-600 (as sold by Momentive) , catalyst ZF-10 and silicone oil L-580, put into a plastic beaker, stir with an electric stirrer, fully mix, obtain A material, stand-by; then press A material:B material=100:60 weight proportion, weigh a certain amount A large amount of modified MDI (such as MDI-2412 sold by Hemu New Materials (Shanghai) Co., Ltd.), quickly mixed with material A, stirred for 6-8s, and quickly poured into 400*200*150mm aluminum with EVA sheet at the bottom During mold making, keep the mold temperature at 56°C, open the mold after 5-7 minutes, and cut into 10mm slow-rebound polyurethane foam sheets for experimental testing.

[0053] Industrial production adopts large-capacity and high-efficiency reactors, fully and quickly stirs according to the weight ratio of each component, prepares material A, and then in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com