Carbon-coated silicon oxide / graphite composite particles, as well as preparation methods and applications of the same

A particle and coating technology, applied in carbon preparation/purification, chemical instruments and methods, graphite, etc., can solve problems such as extending cycle time and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

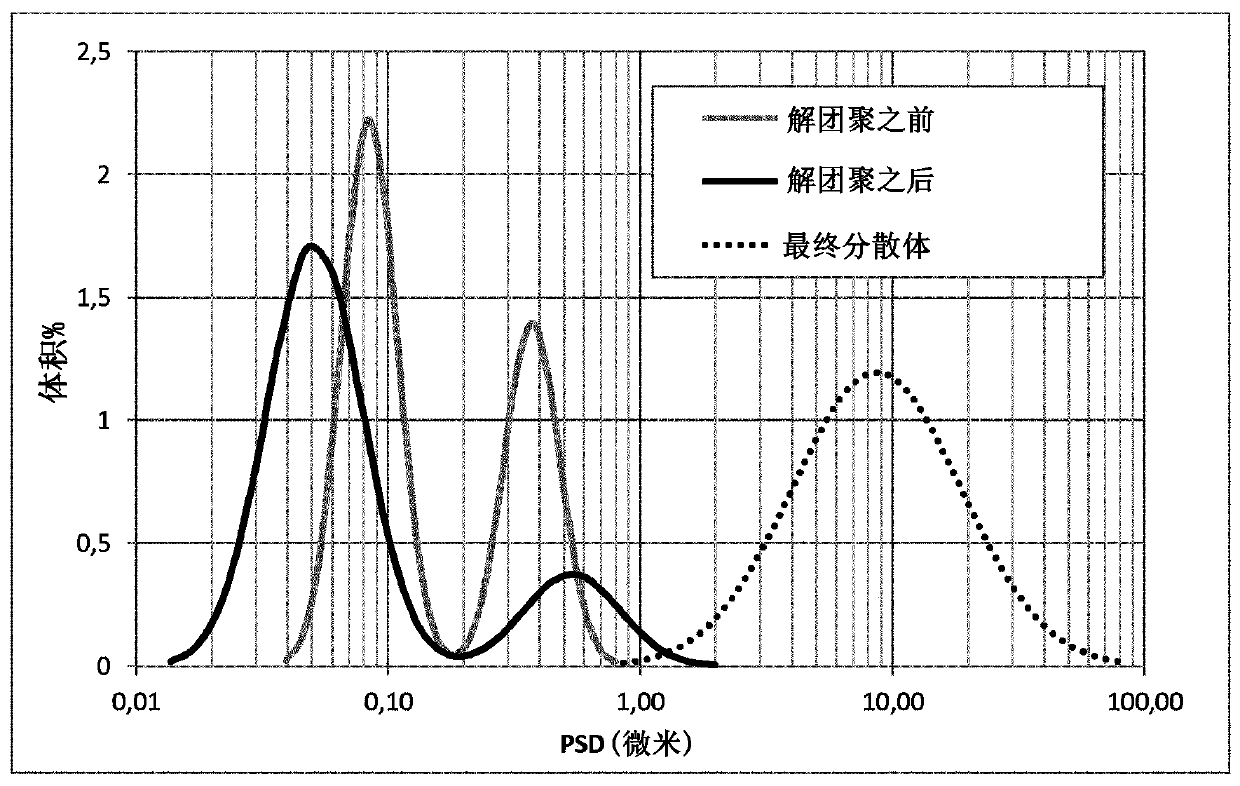

[0048] The preparation of liquid dispersions can be carried out in suitable mills, for example bead mills or planetary mills. Another possibility is that a slurry needs to be prepared followed by a drying step to remove the solvent / liquid.

[0049] In certain embodiments, the drying step is advantageously performed by spray drying, which may optionally be performed in a spray dryer, spouted bed or fluidized bed reactor. found that spray drying is particularly suitable for obtaining X Composite particles with uniform distribution of nanoparticles on graphite core particles.

[0050] The nano-SiO prepared as above can then be X / Graphite composite particles for non-graphitic carbon coating. In some embodiments, the coating is accomplished by chemical vapor deposition (CVD) of pyrolytic carbon. This pyrolytic carbon deposit passivates the surface and reduces the BET SSA by approximately 30% to 90%.

[0051] In general, the amorphous carbon layer should be thick enough to cov...

Embodiment 1

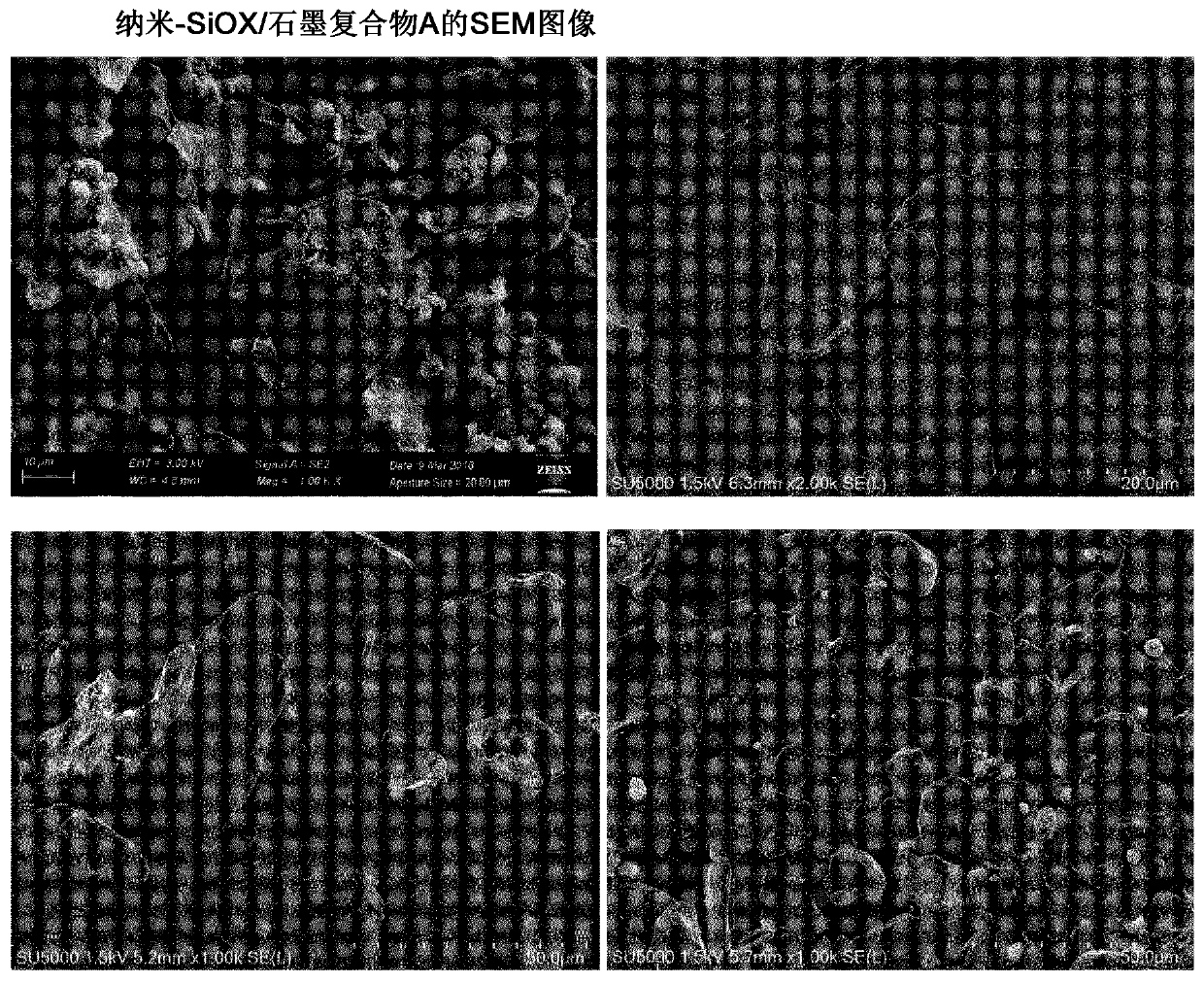

[0133] Example 1: Nano-SiO X / Preparation of graphite composites

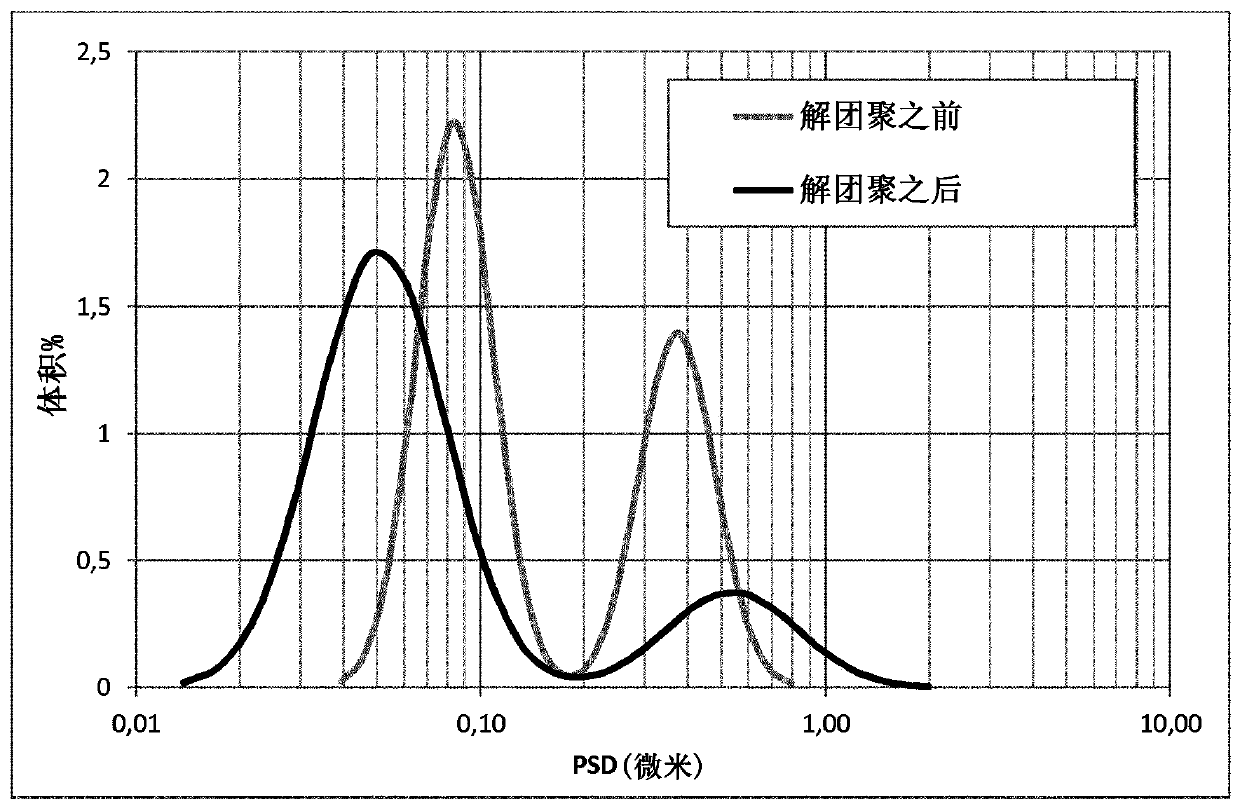

[0134] Silicon oxide nanopowder (SiO X , 99.5% of the first predispersion (predispersion No. 1) having a size of 15-20 nm). Contains water and SiO X Dispersions of nanoparticles can be prepared to have a solids content of 4 to 16%. In the examples described further below, the solids contents were 9.5% and 15%, respectively.

[0135] This dispersion was then treated in a Buhler bead mill MMP1-EX (FDCP) to deagglomerate the nanoparticles in the dispersion.

[0136] The parameters used for this process step are described in Table 3.

[0137] table 3:

[0138] Velocity Dispersion 42% Corresponding to 2.5kg / min bead size 0.3–0.4 mm filter 0.15 mm torque 1000 rpm cooling temperature 20 ℃ applied energy 150 KWh / t estimated processing time 10 minutes (for the volume tested)

[0139] After this treatment, the dispersion weight and solids content wer...

Embodiment 2

[0154] Example 2: Carbon-coated nano-SiO X / Graphite Composite (“Coated Composite A”) Preparation

[0155] Preparation of the first nano-SiO using "Recipe 1" of Table 4 X / graphite composite ("Composite A"). Compound A having a silicon content (based on total ash) of 2.8% by weight was charged into a rotary furnace and subjected to CVD coating with propane gas as the carbon source. The rotary kiln was heated to 1050°C and the compound was then continuously fed into the rotary kiln which was still at a temperature of 1050°C. Propane gas ((C 3 h 8 , 3L / min) and nitrogen as a carrier gas (N 2 , 1 L / min) into the reactor to maintain the pressure in the reactor at about 0-20 mbar above atmospheric pressure. A residence time of approximately 20 minutes was triggered by setting the rotary oven to an inclination of 4° and a rotation speed of 6 rpm. Then, depending on whether a hydrophobic or hydrophilic surface is required, the CVD-coated nano-SiO X / Graphite composite (carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com