Patents

Literature

243results about "Electrode melt handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode electrode, method for manufacturing the same and lithium battery containing the same

InactiveUS20030113624A1Continuous fillingNon-aqueous electrolyte accumulatorsFinal product manufactureSimple Organic CompoundsConductive materials

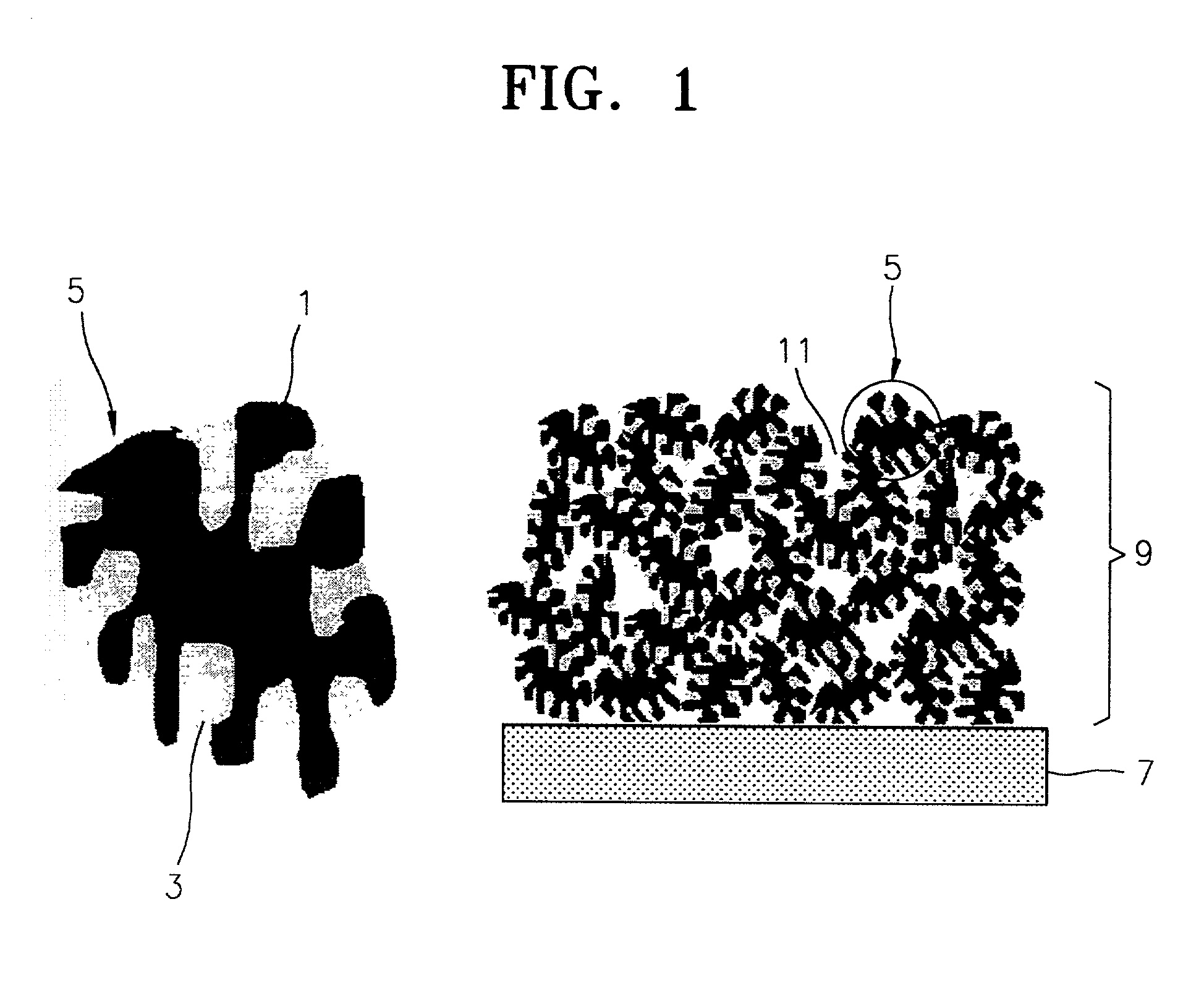

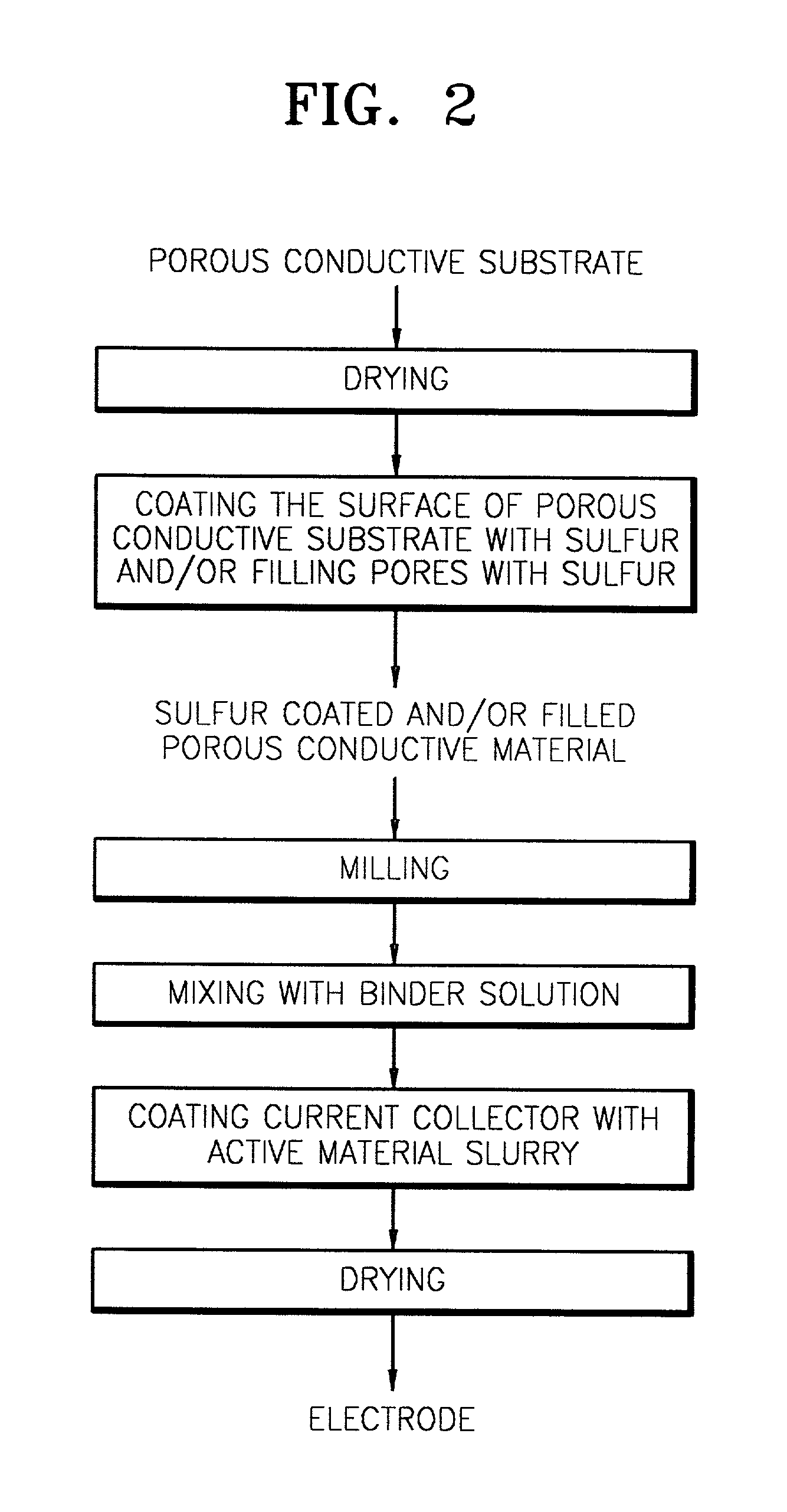

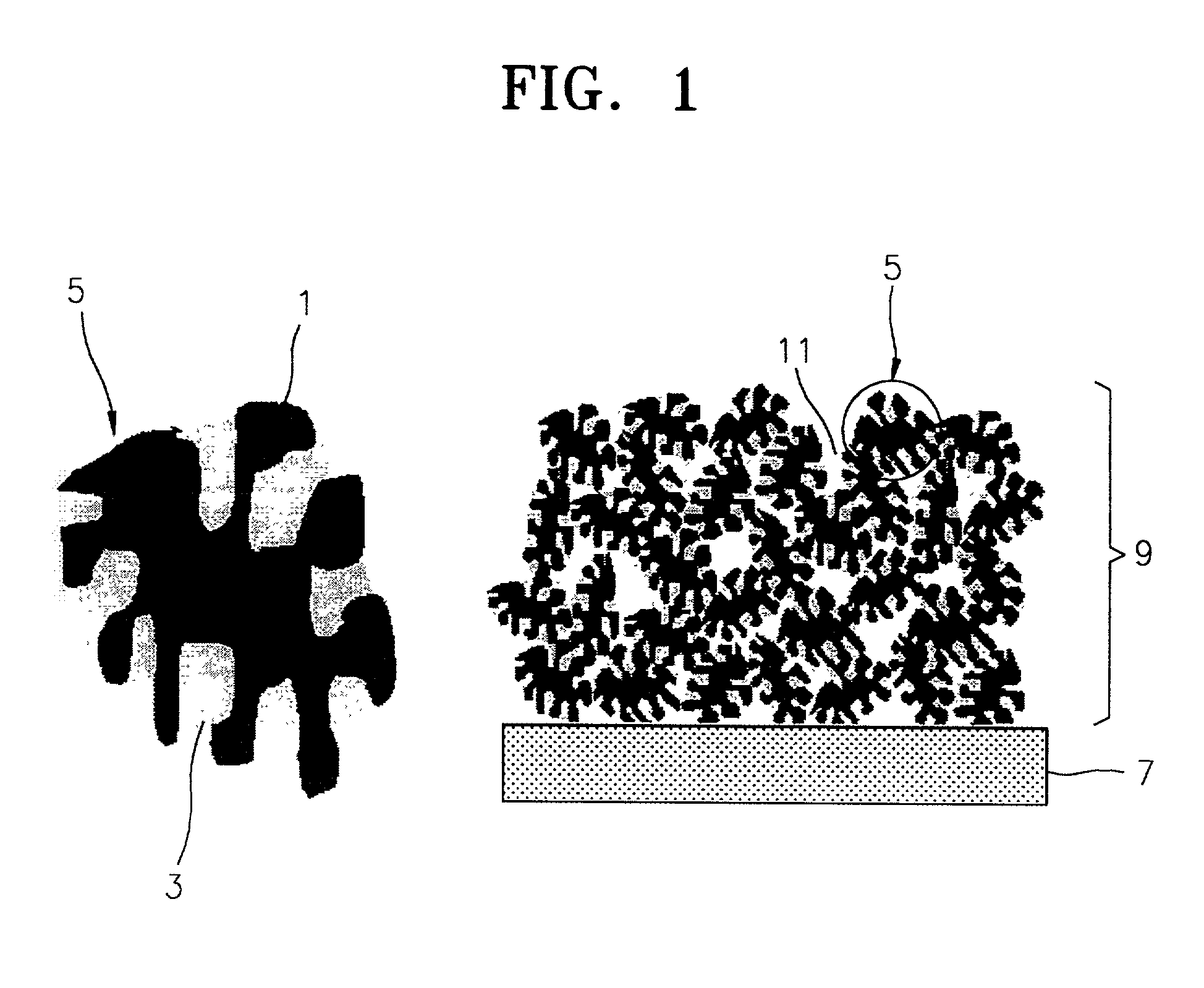

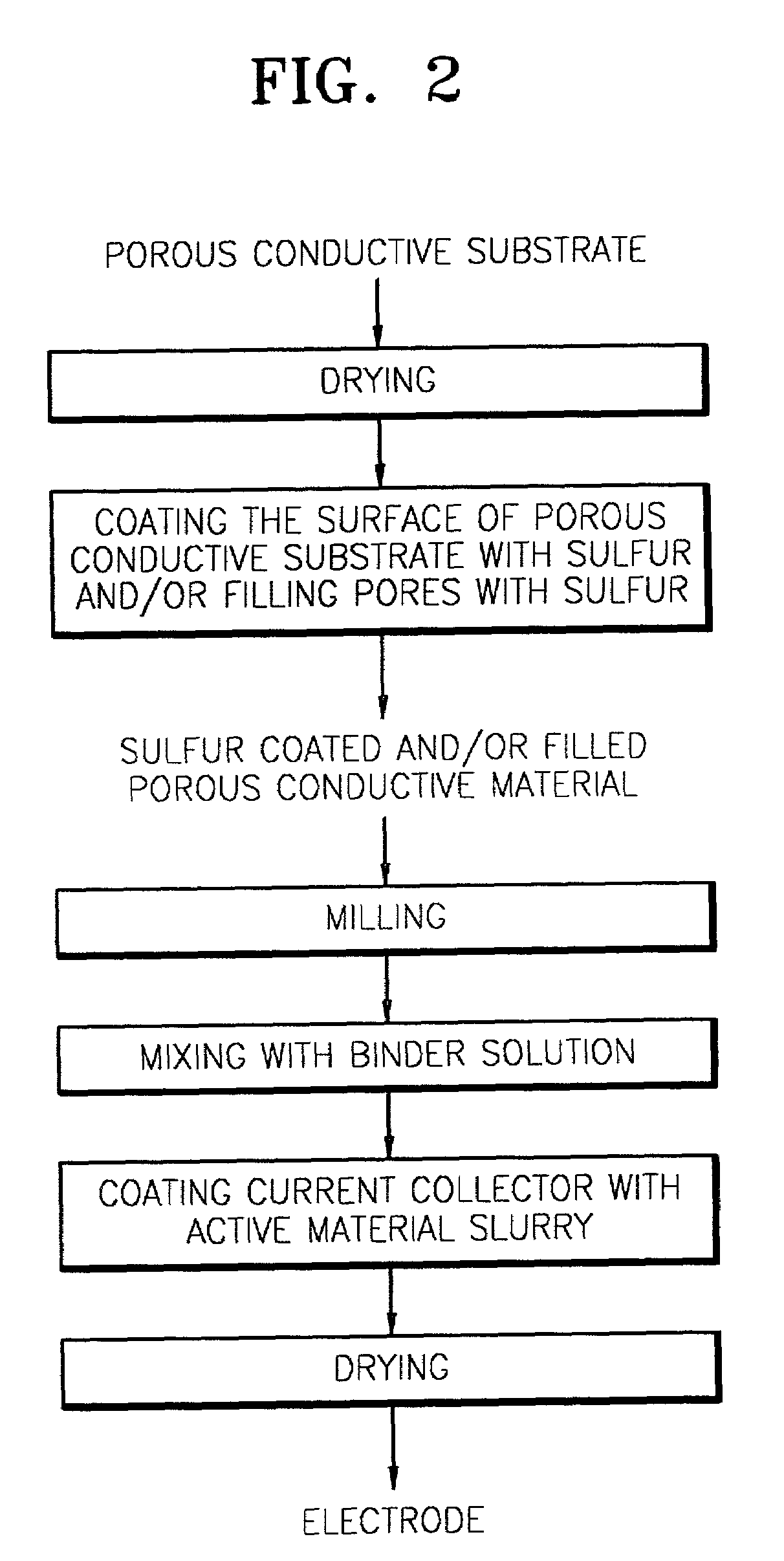

Disclosed is a cathode electrode having a cathode active material layer stacked on a current collector. The cathode active material layer includes a porous conductive material having a surface coated with sulfur and / or a sulfur-containing organic compound and / or pores filled with sulfur and / or a sulfur-containing organic compound. A lithium secondary battery employing the cathode electrode also is disclosed. The cathode electrode is structurally stable during charging and discharging since the structure of the cathode active material layer can be maintained even at the phase transition of sulfur during charging and discharging.

Owner:SAMSUNG SDI CO LTD

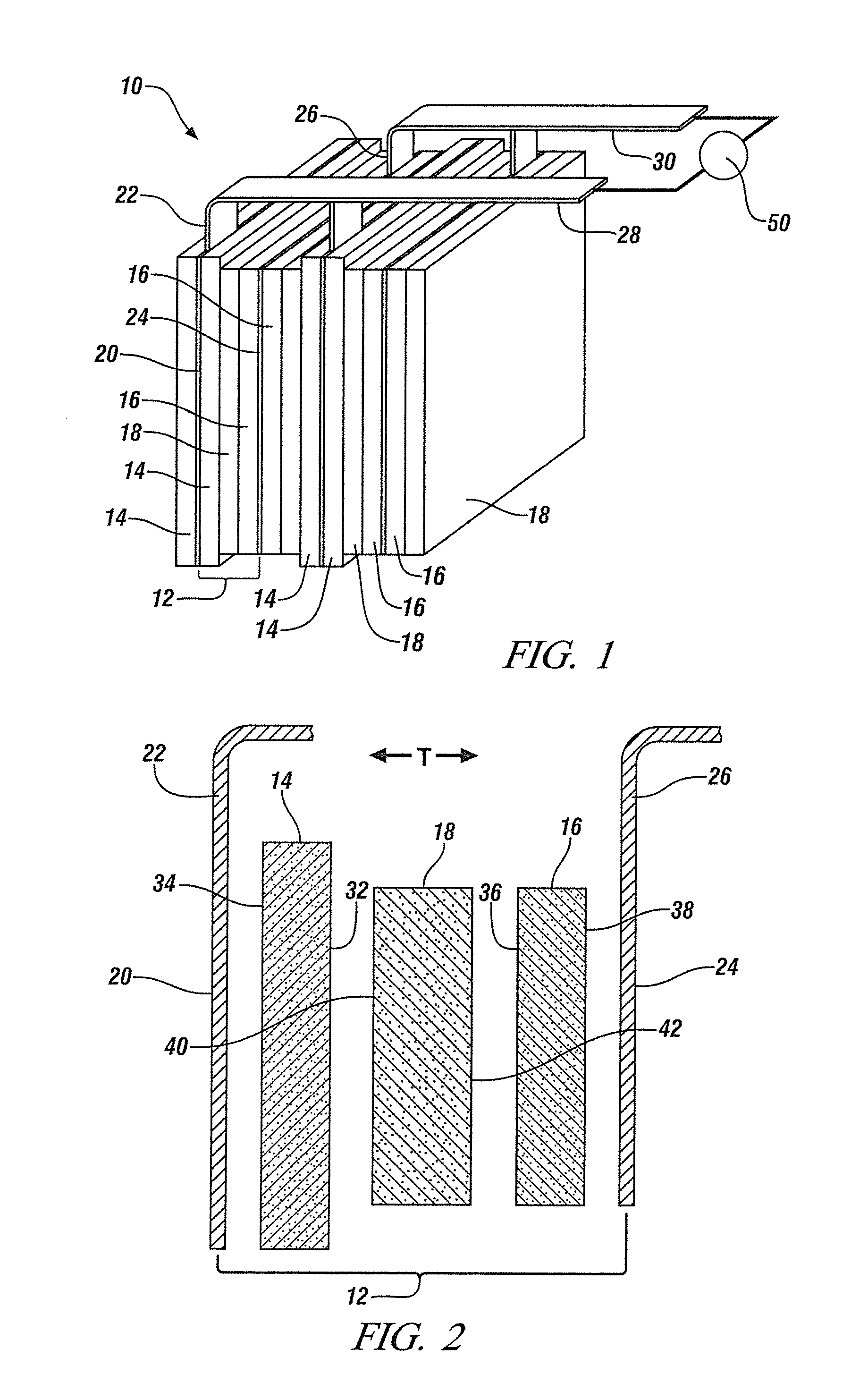

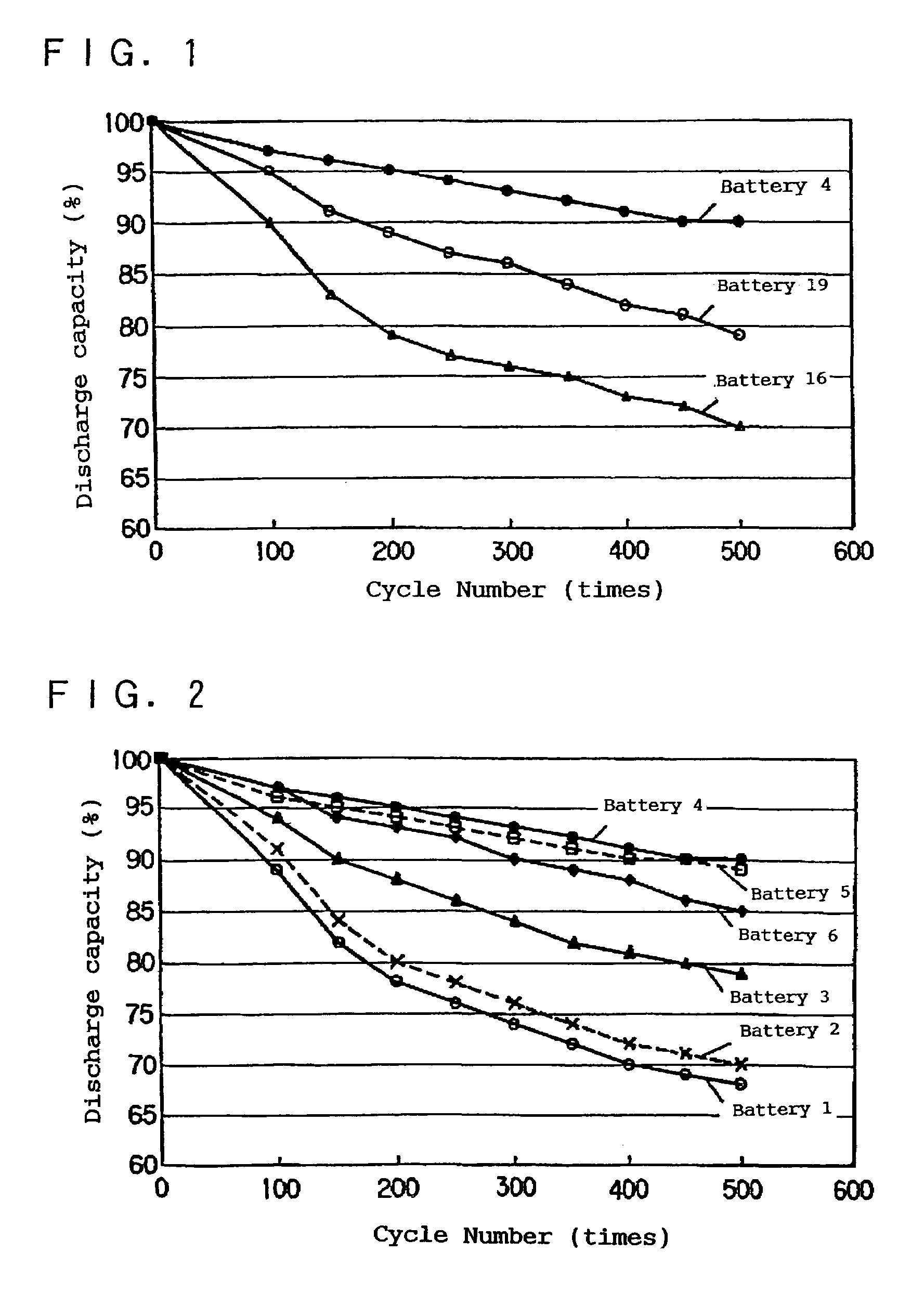

Lithium secondary battery

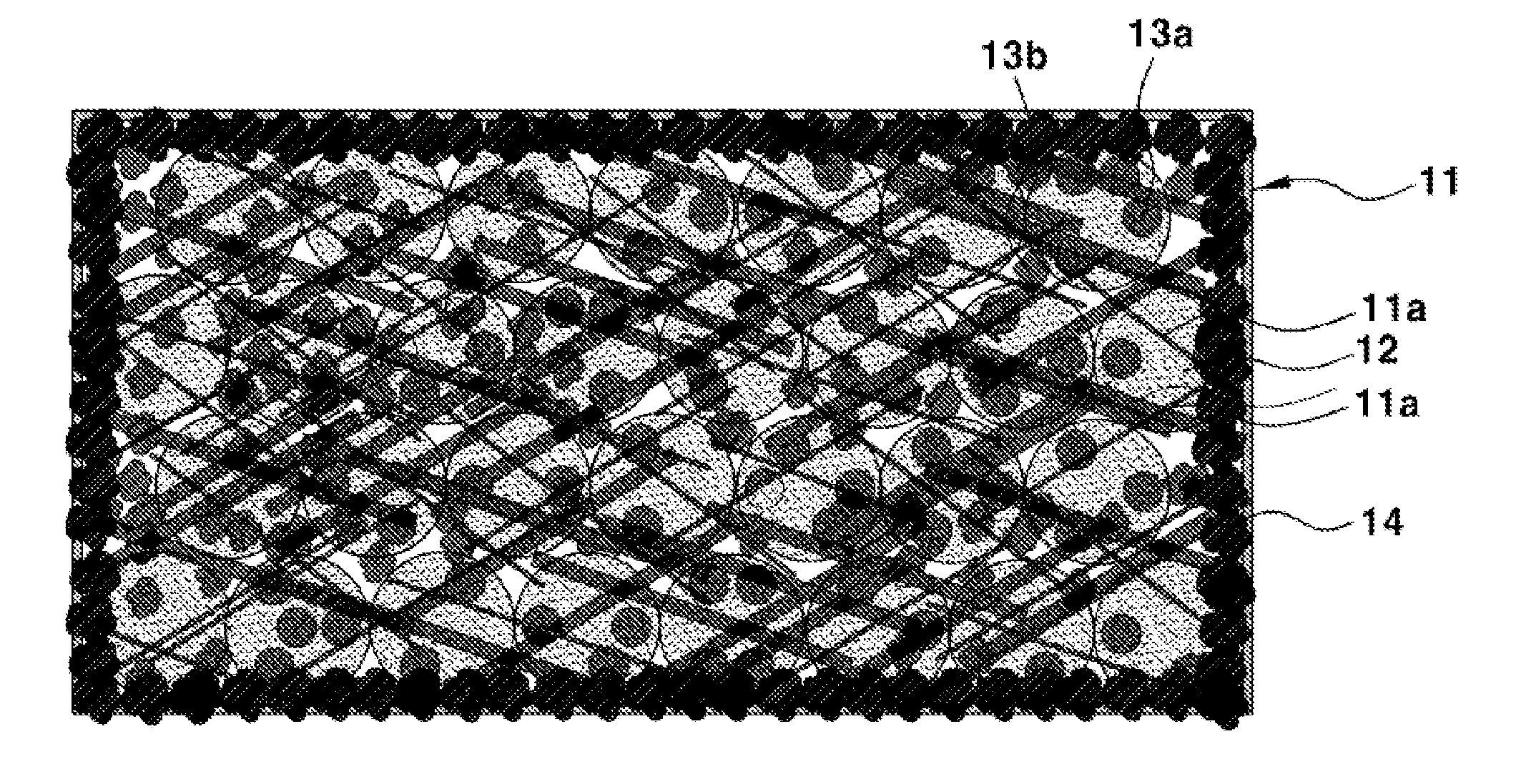

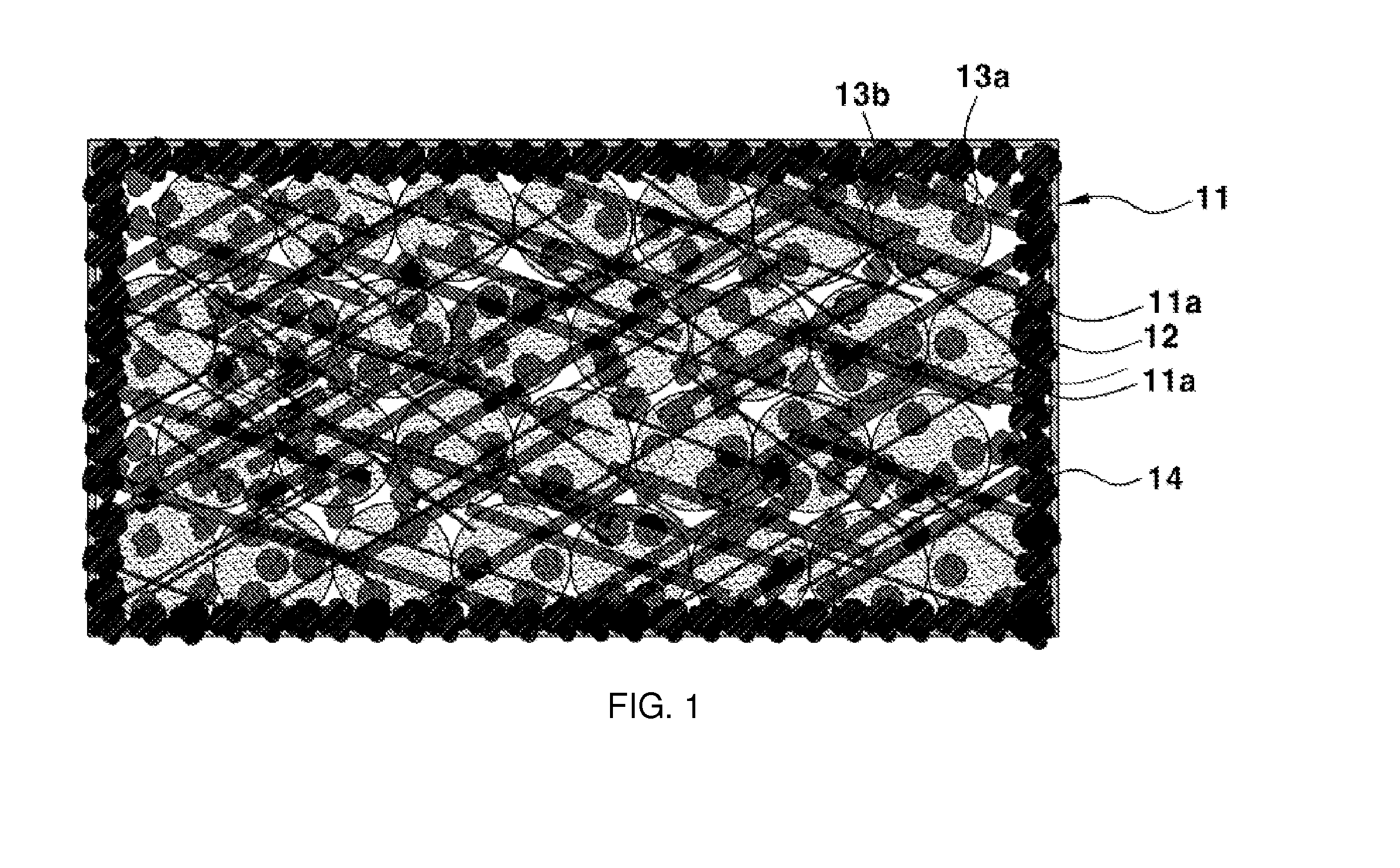

InactiveUS7476469B2Improve featuresElectrode melt handlingElectrode carriers/collectorsEngineeringSolvent

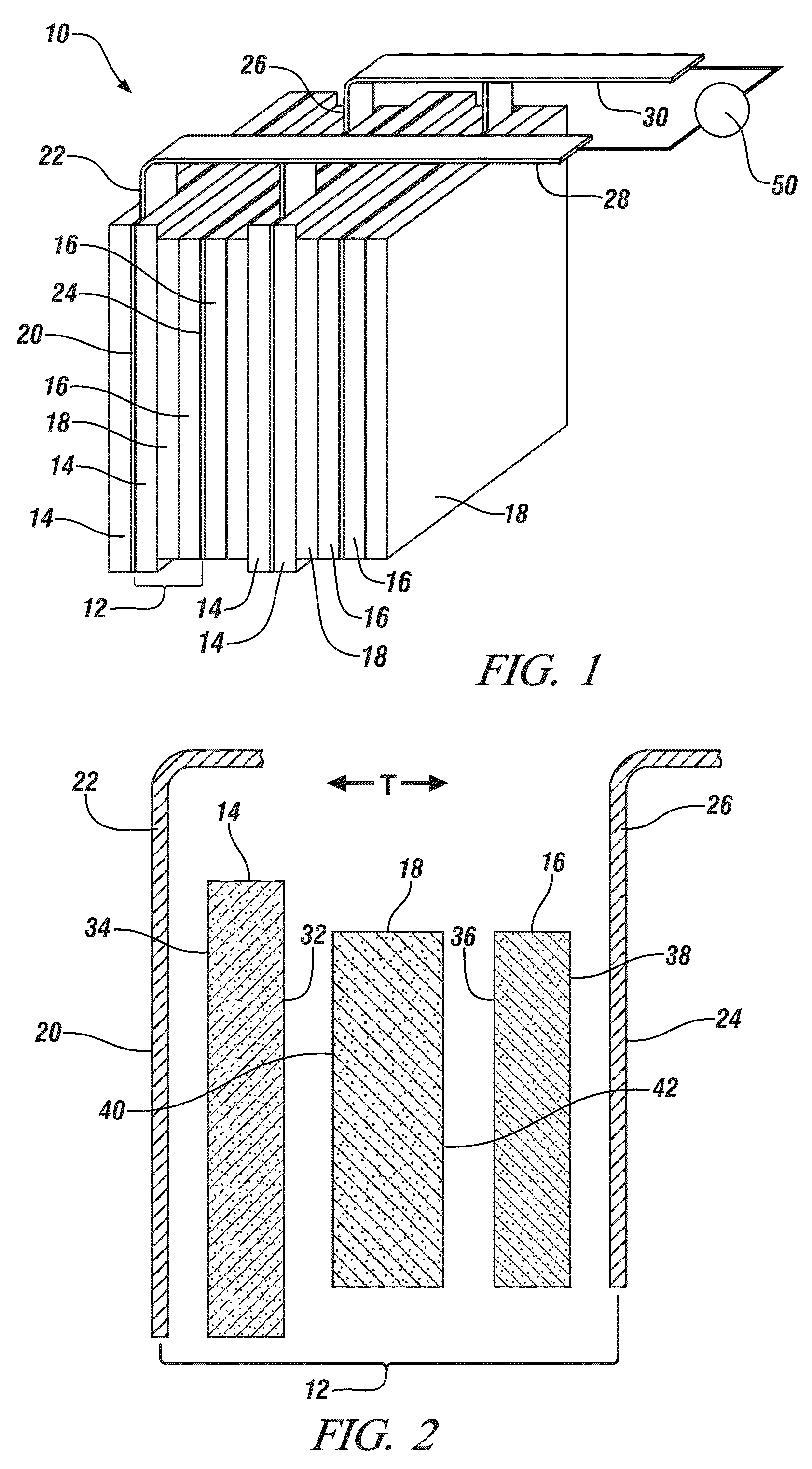

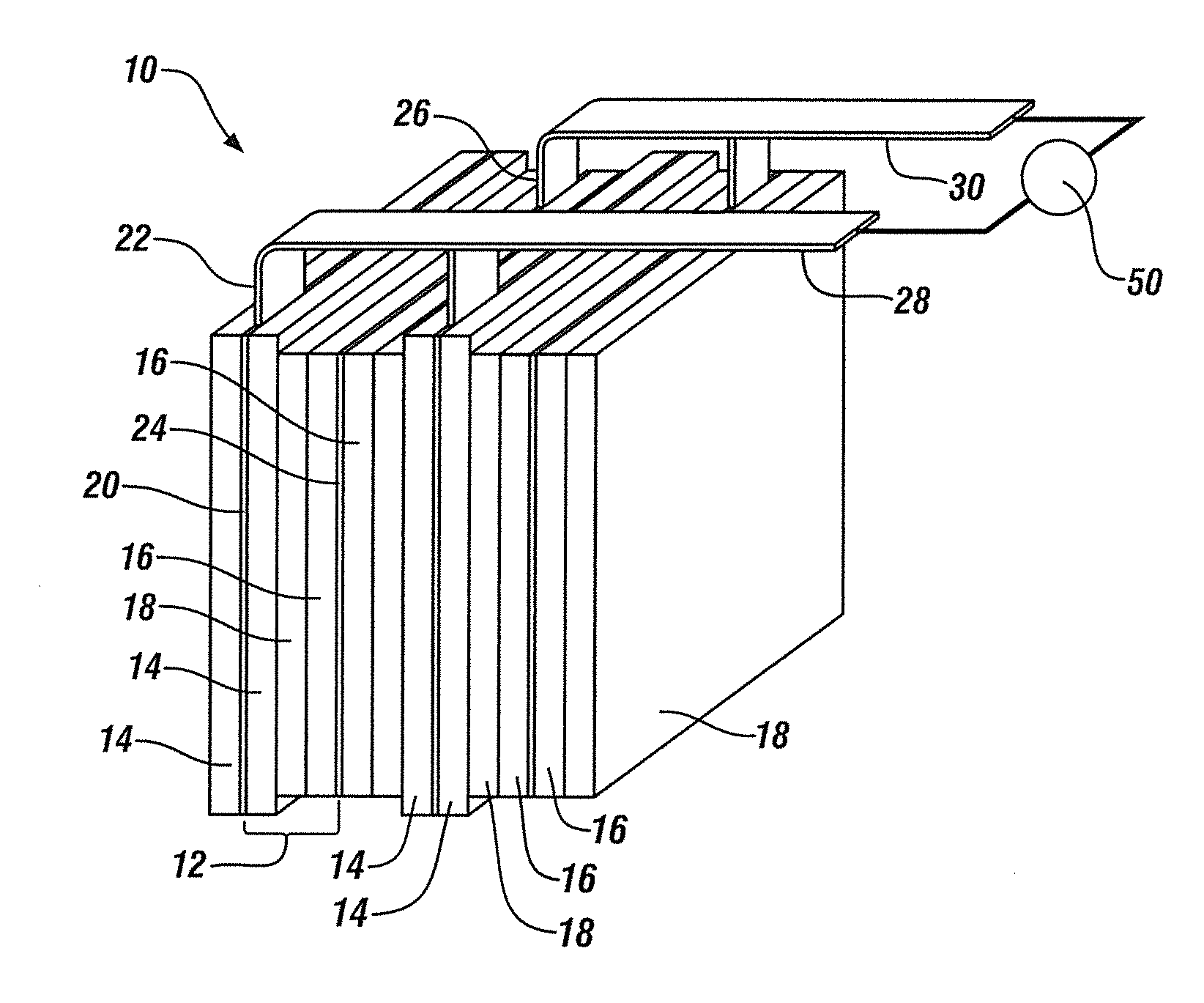

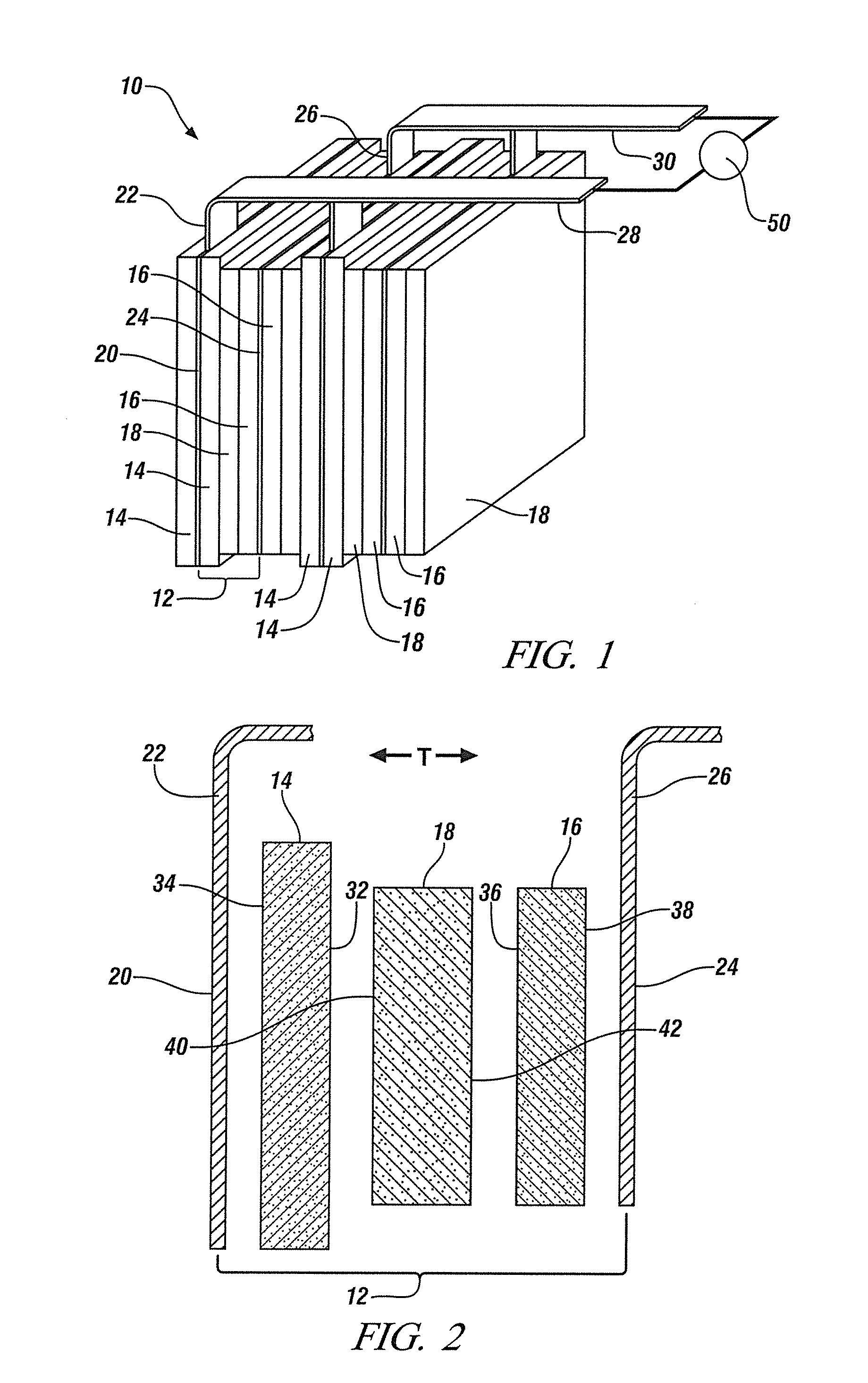

A rechargeable lithium battery including a positive electrode, a negative electrode and a nonaqueous electrolyte, said positive or negative electrode being an electrode which has, on a current collector, a thin film of active material that stores and releases lithium, the thin film of active material being divided into columns by gaps formed therein in a manner to extend in its thickness direction, and the columnar portions being at their bottoms adhered to the current collector, the rechargeable lithium battery being characterized in that the nonaqueous electrolyte includes a mixed solvent consisting of two or more different solvents and containing at least ethylene carbonate and / or vinylene carbonate as its constituent.

Owner:SANYO ELECTRIC CO LTD

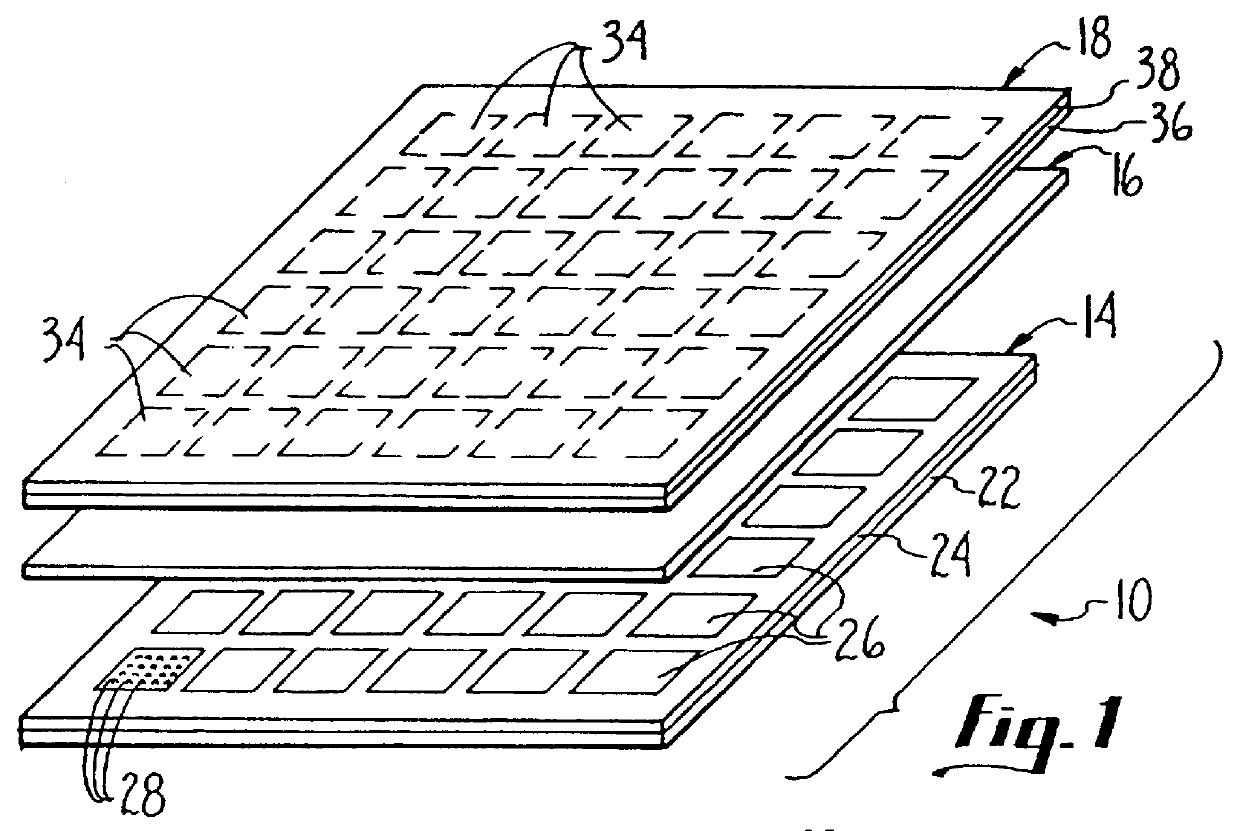

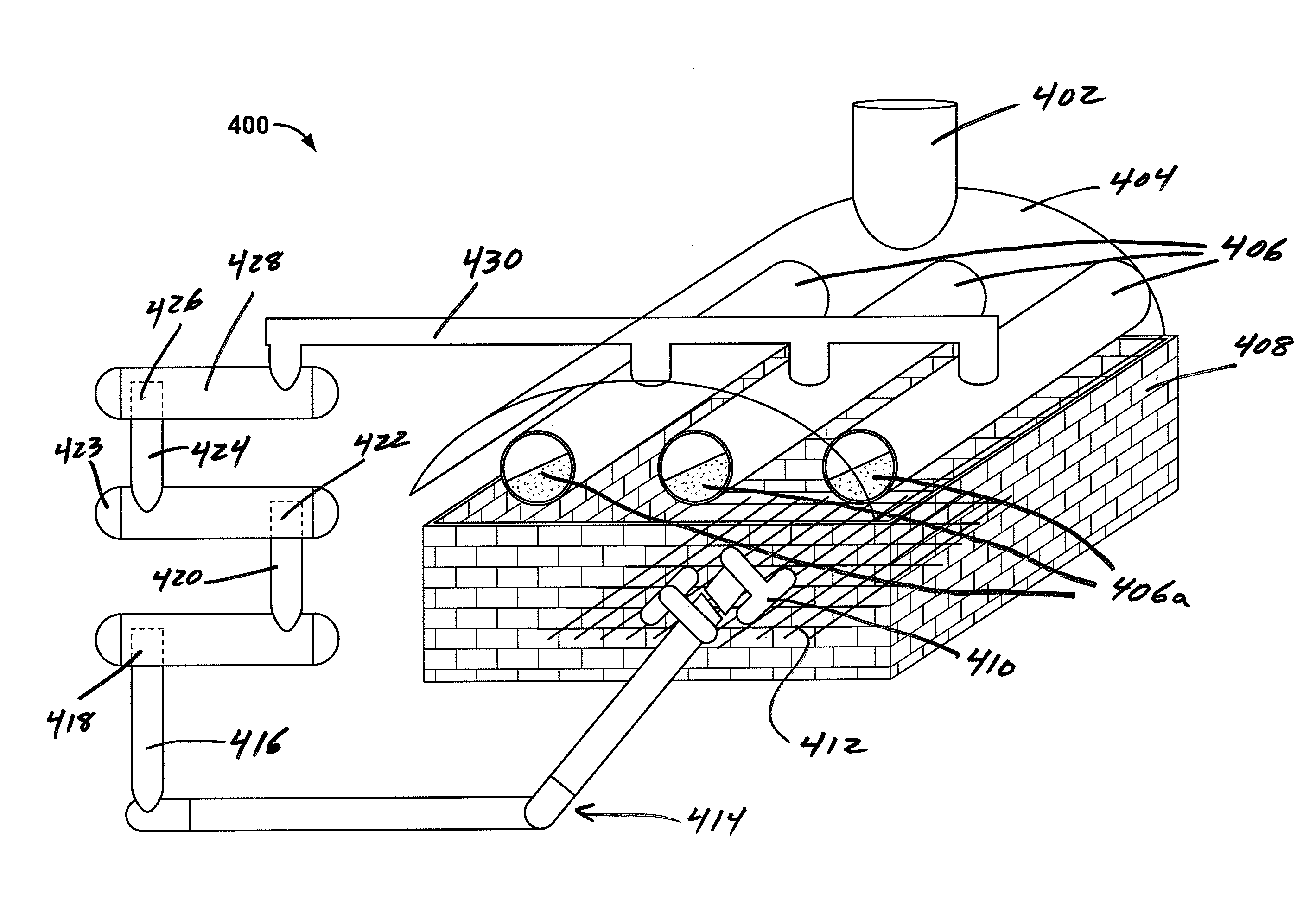

Polymer-lithium batteries and improved methods for manufacturing batteries

InactiveUSRE36843E1Prevent and minimize electrical shortingHigh voltageElectrode rolling/calenderingFinal product manufactureEngineeringDeposition process

Improved polymer batteries and improved methods of manufacturing such polymer batteries are provided. One improved method of manufacture involves the formation of a laminated array structure that includes a number of individual battery cells. After formation of the laminated array the individual batteries are singulated from the array by cutting, shearing or stamping. Other manufacturing improvements include the use of a printing process (e.g. stenciling) to form the cathodes, the use of permanent mask layers to contain and insulate the cathodes and anodes, and the use of a molten lithium deposition process for forming the anodes.

Owner:ROUND ROCK RES LLC

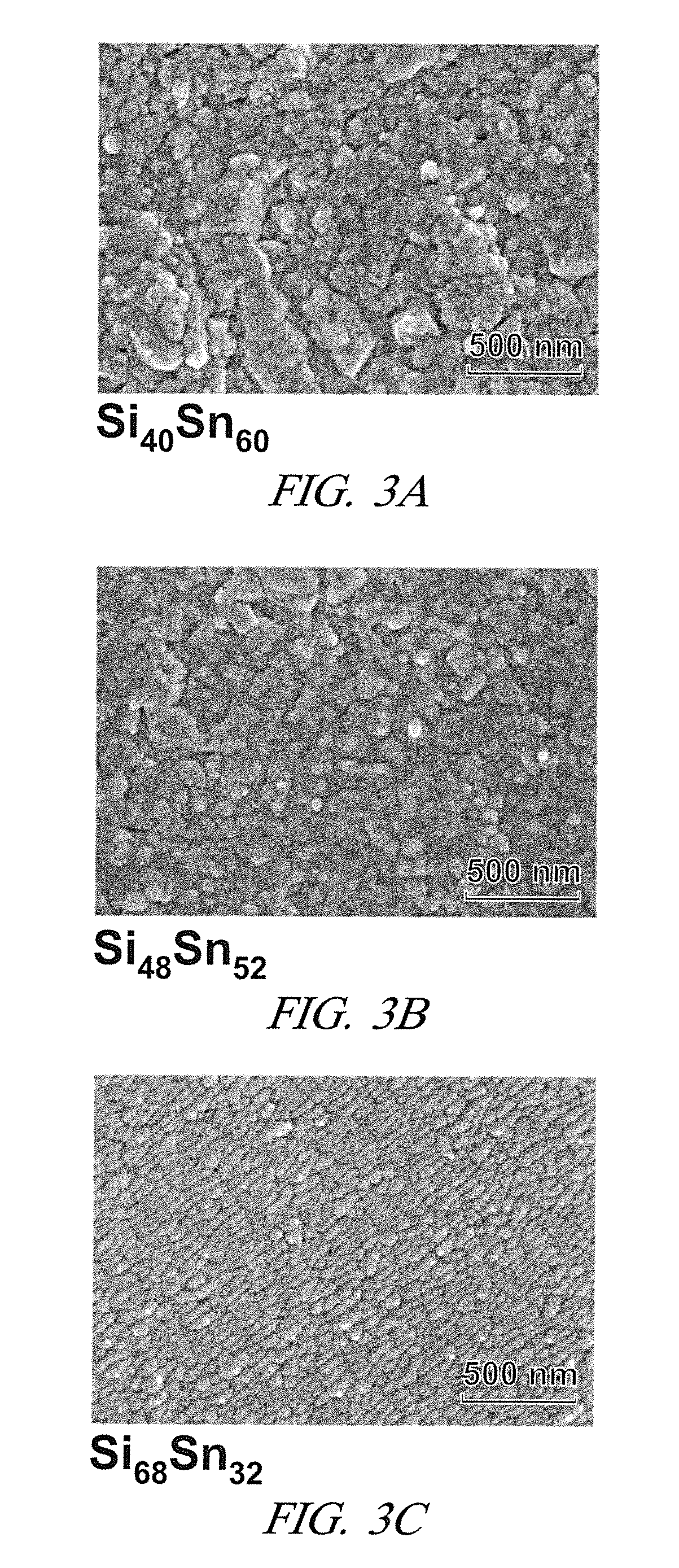

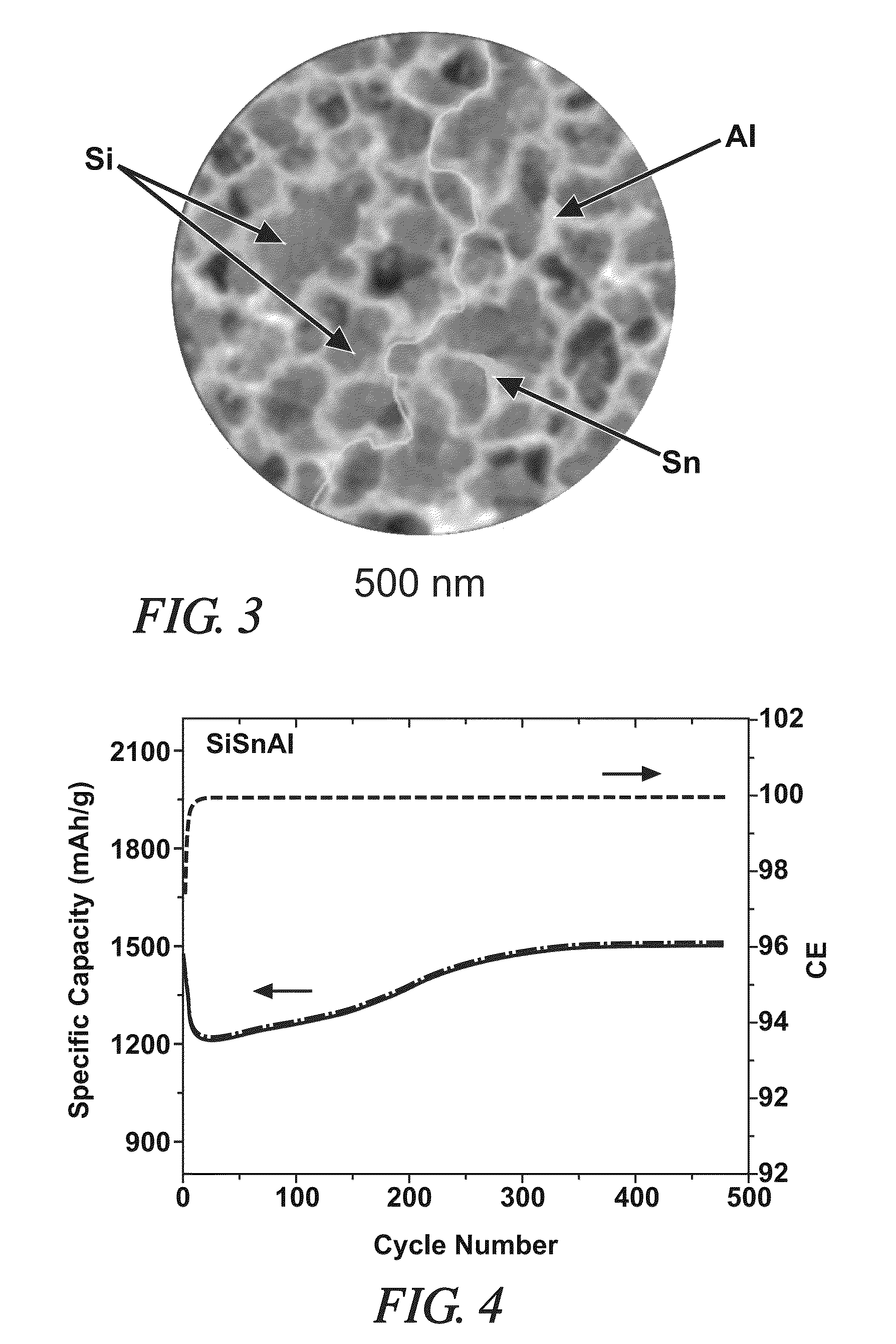

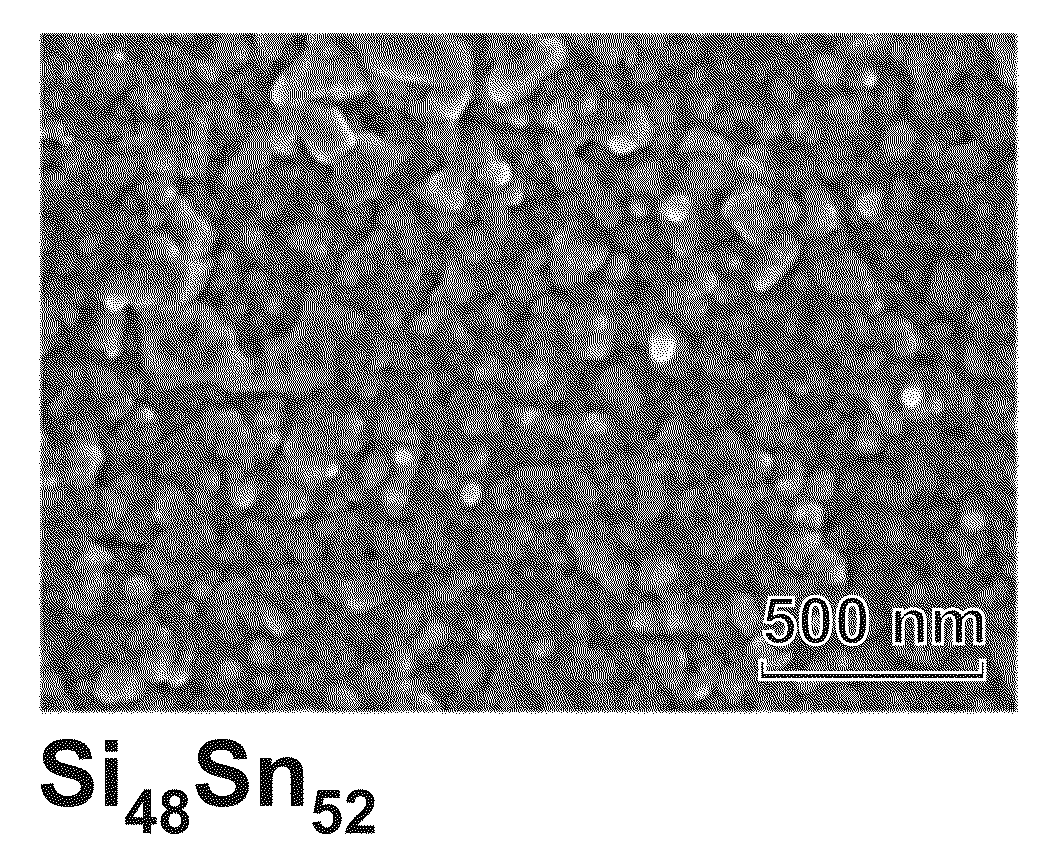

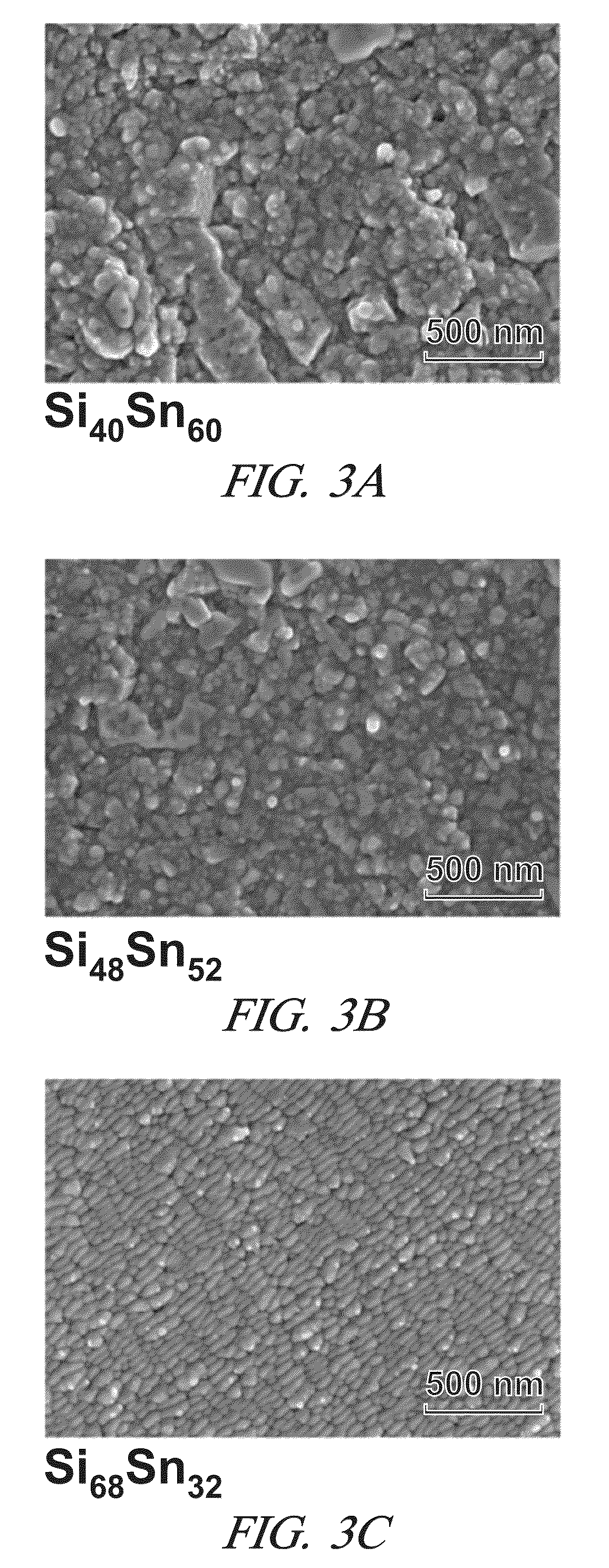

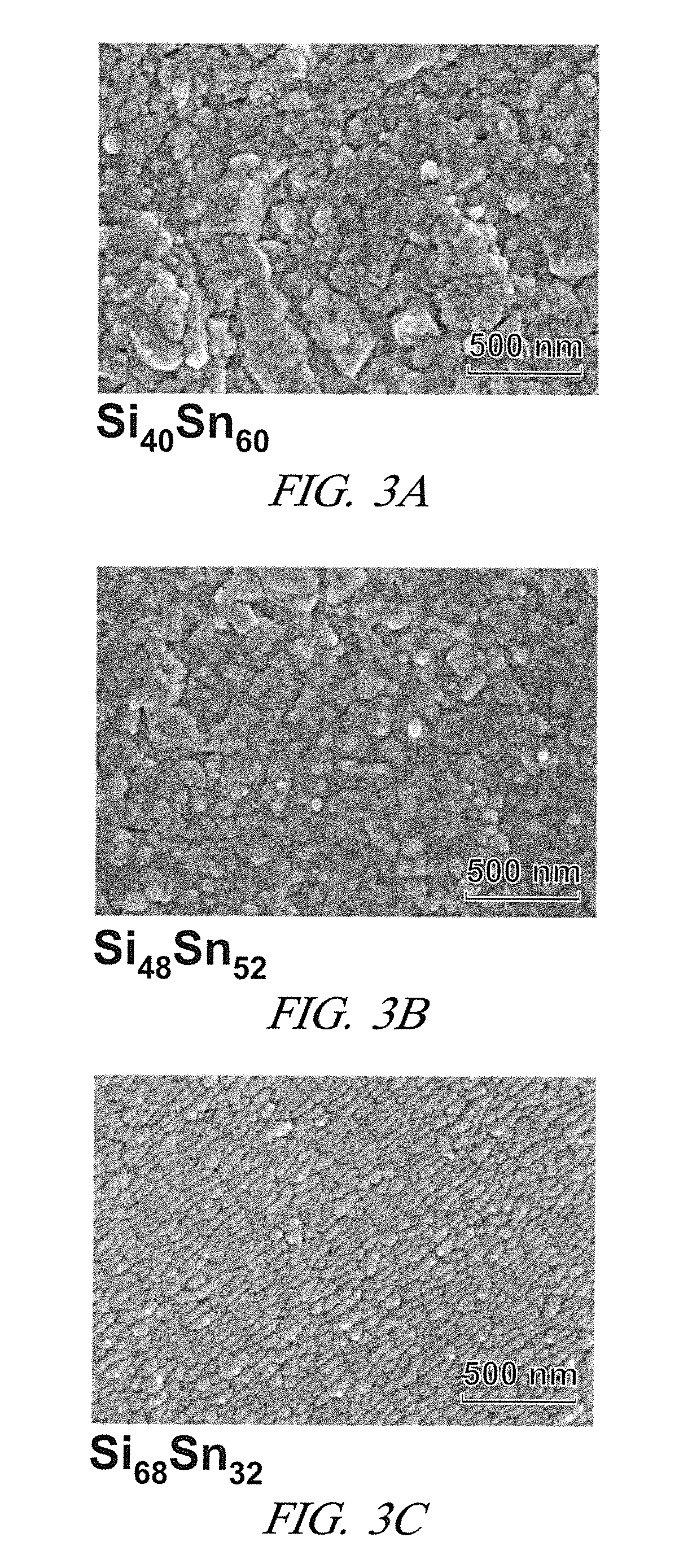

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

ActiveUS9142830B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyConductive materialComposite electrodeAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

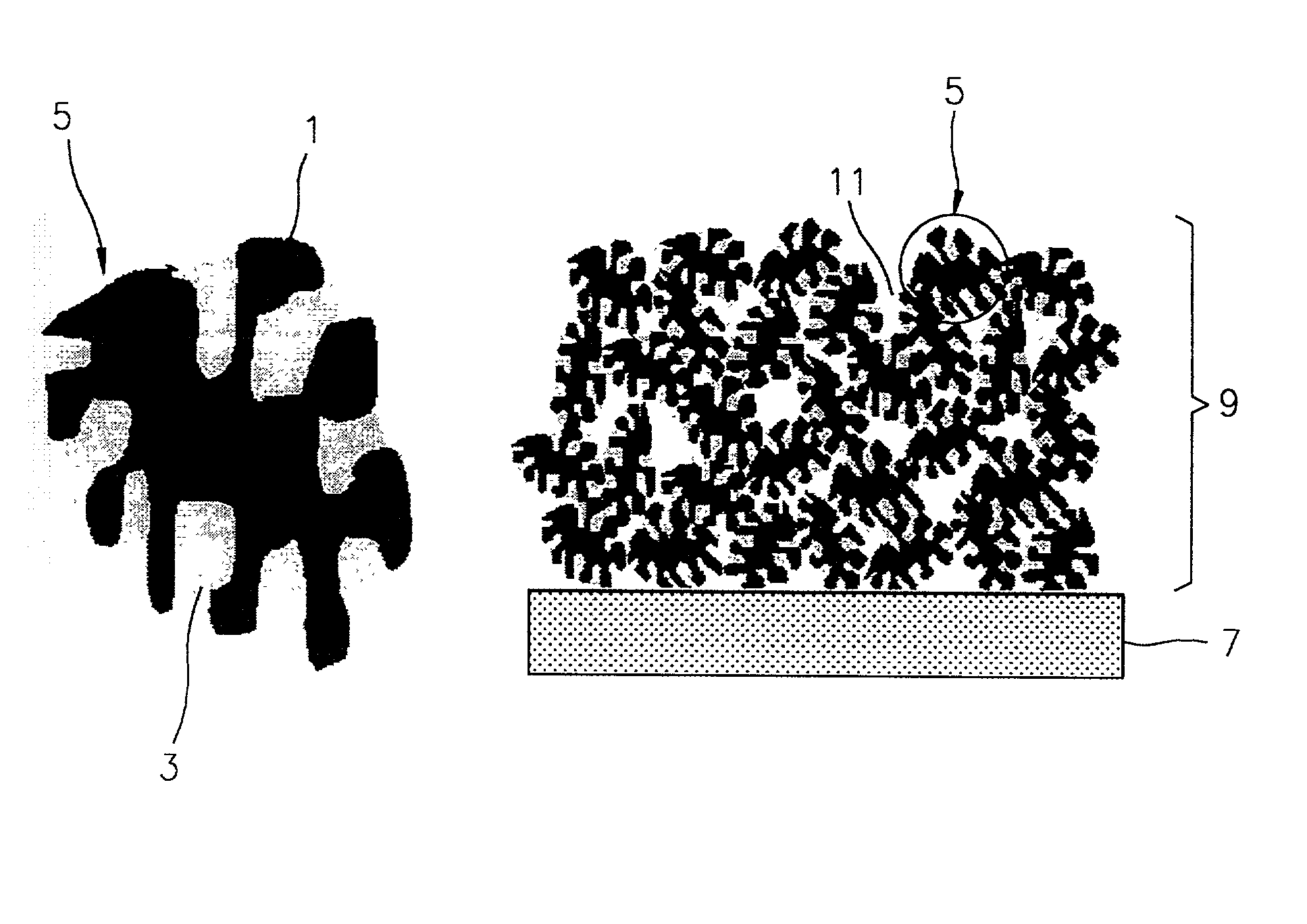

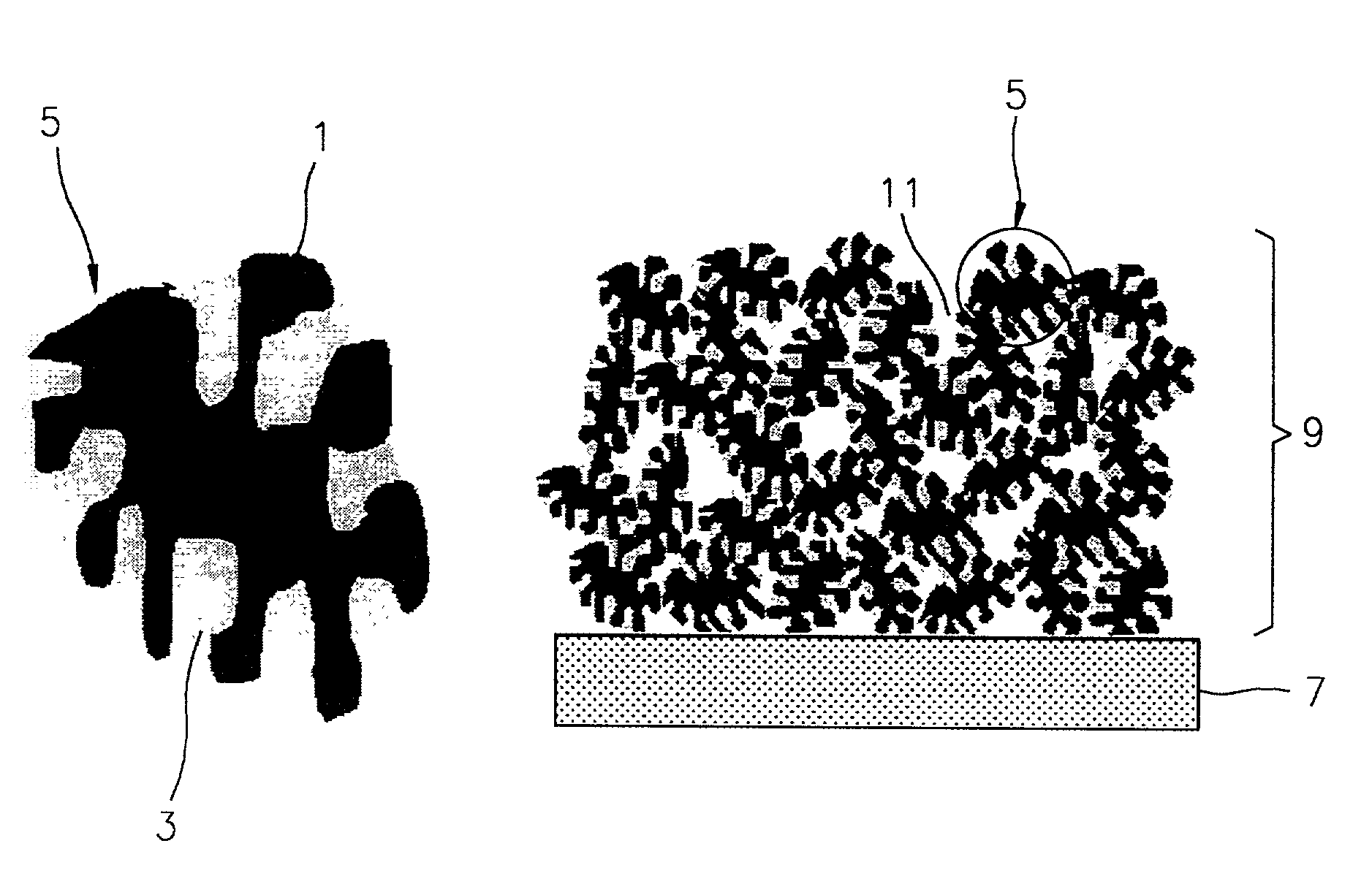

Cathode electrode including a porous conductive material coated and/or filled with sulfur and/or a sulfur-containing organic compound and lithium battery containing the same

InactiveUS7361431B2Continuous fillingNon-aqueous electrolyte accumulatorsFinal product manufactureElectrical batteryConductive materials

Disclosed is a cathode electrode having a cathode active material layer stacked on a current collector. The cathode active material layer includes a porous conductive material having a surface coated with sulfur and / or a sulfur-containing organic compound and / or pores filled with sulfur and / or a sulfur-containing organic compound. A lithium secondary battery employing the cathode electrode also is disclosed. The cathode electrode is structurally stable during charging and discharging since the structure of the cathode active material layer can be maintained even at the phase transition of sulfur during charging and discharging.

Owner:SAMSUNG SDI CO LTD

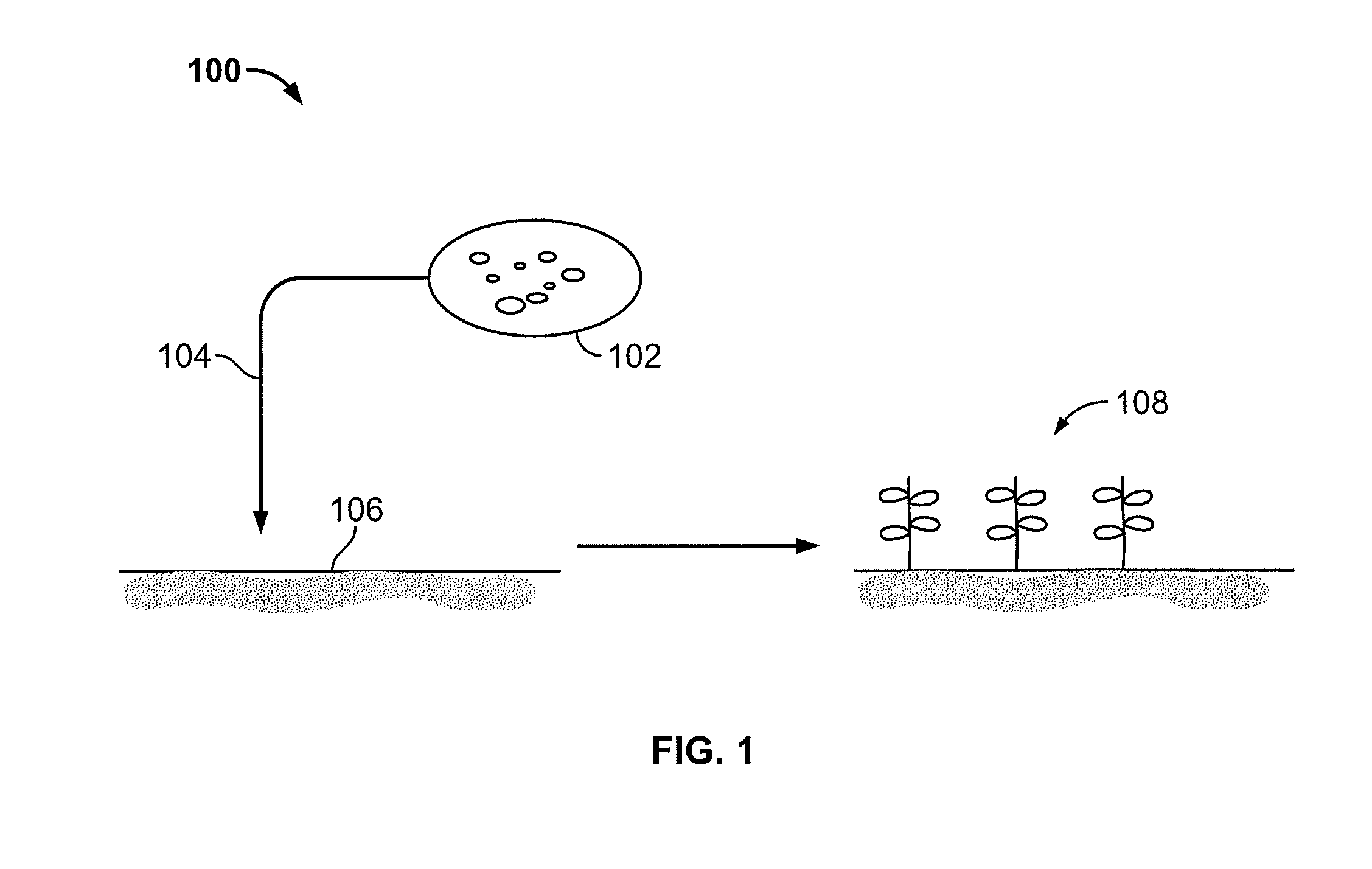

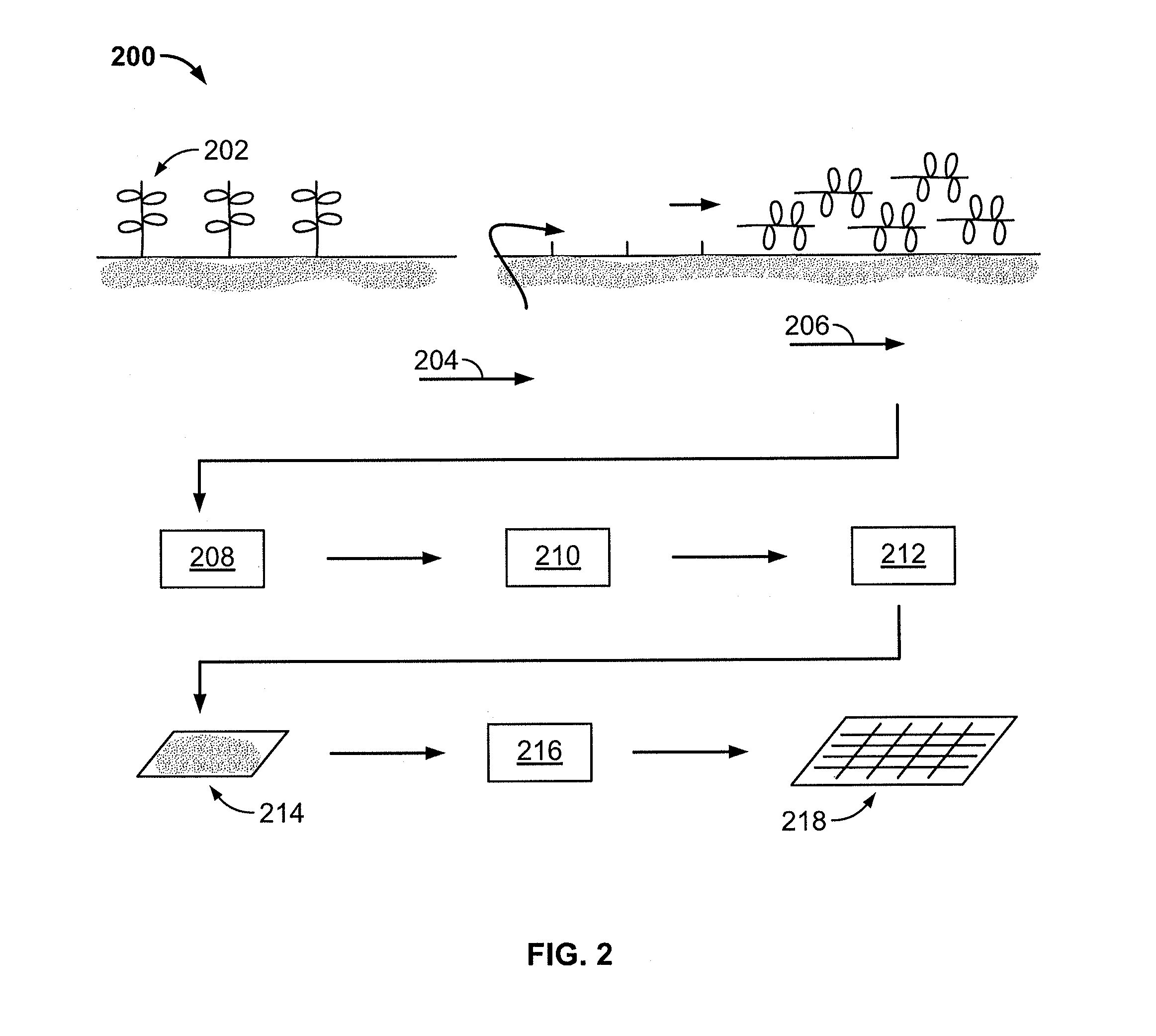

Systems and methods for producing biochar-based products

An end-to-end system / process for producing advantageous end products from a raw biomass feedstock is provided. The process includes steps for enhancing biomaterial feedstock, biochar generation and end-product fabrication. The method steps may be employed in selecting, treating and handling biomass materials and their additive inputs to tailor their end performance. Each operative step in the process may be employed to enhance the overall effectiveness of biochar generation and use. Charring furnace design and operational parameters are provided that generate desirable biochar material for various applications, including specifically fabrication of ultra-capacitor electrodes and electric battery components.

Owner:CARBONCHARGE TECH LLC

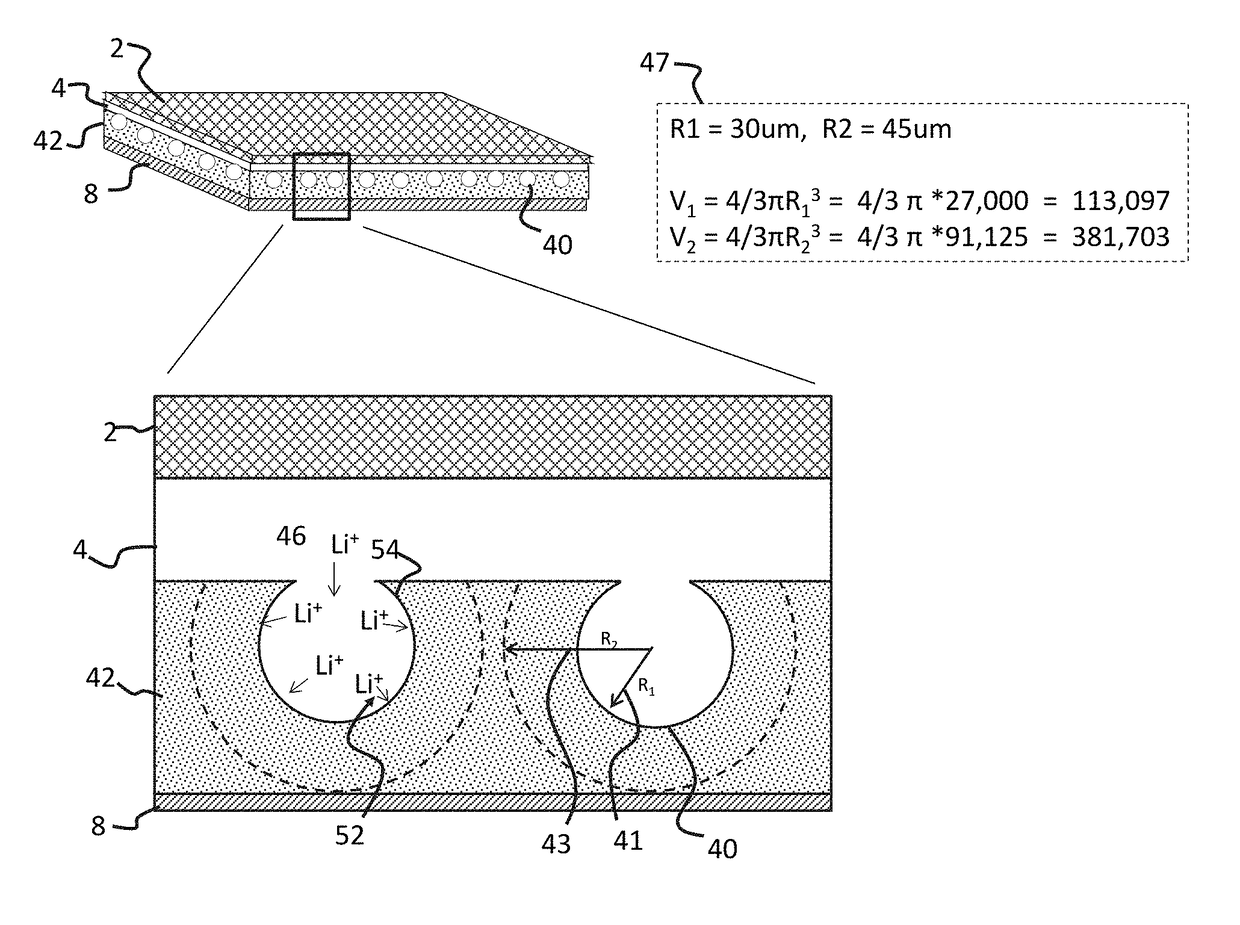

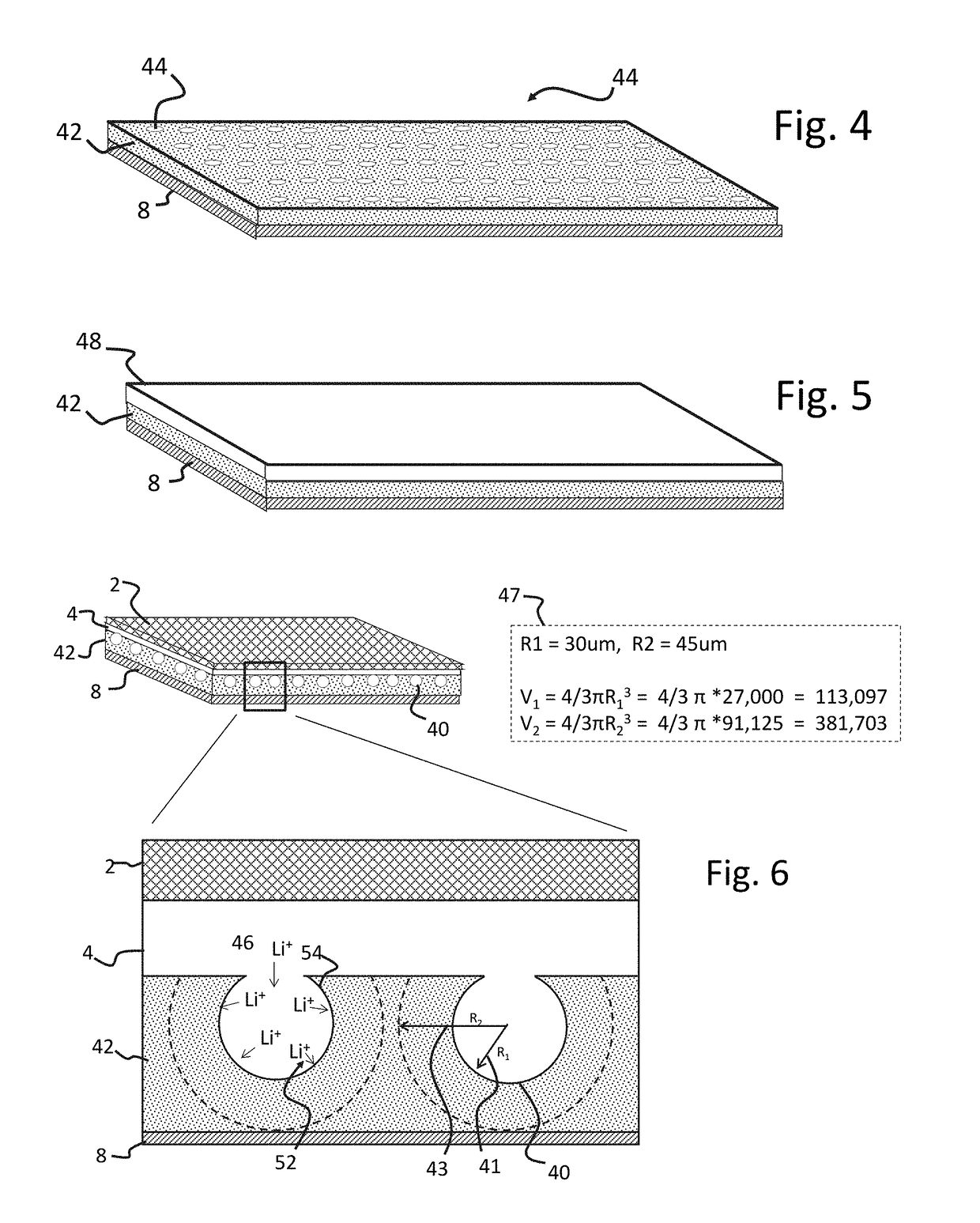

Solid-state batteries, separators, electrodes, and methods of fabrication

ActiveUS20170179472A1Improve conductivityLow melting pointSolid electrolytesElectrode thermal treatmentParticulatesSolid particle

Solid-state batteries, battery components, and related processes for their production are provided. The battery electrodes or separators contain sintered electrochemically active material, inorganic solid particulate electrolyte having large particle size, and low melting point solid inorganic electrolyte which acts as a binder and / or a sintering aid in the electrode.

Owner:JOHNSON IP HLDG LLC

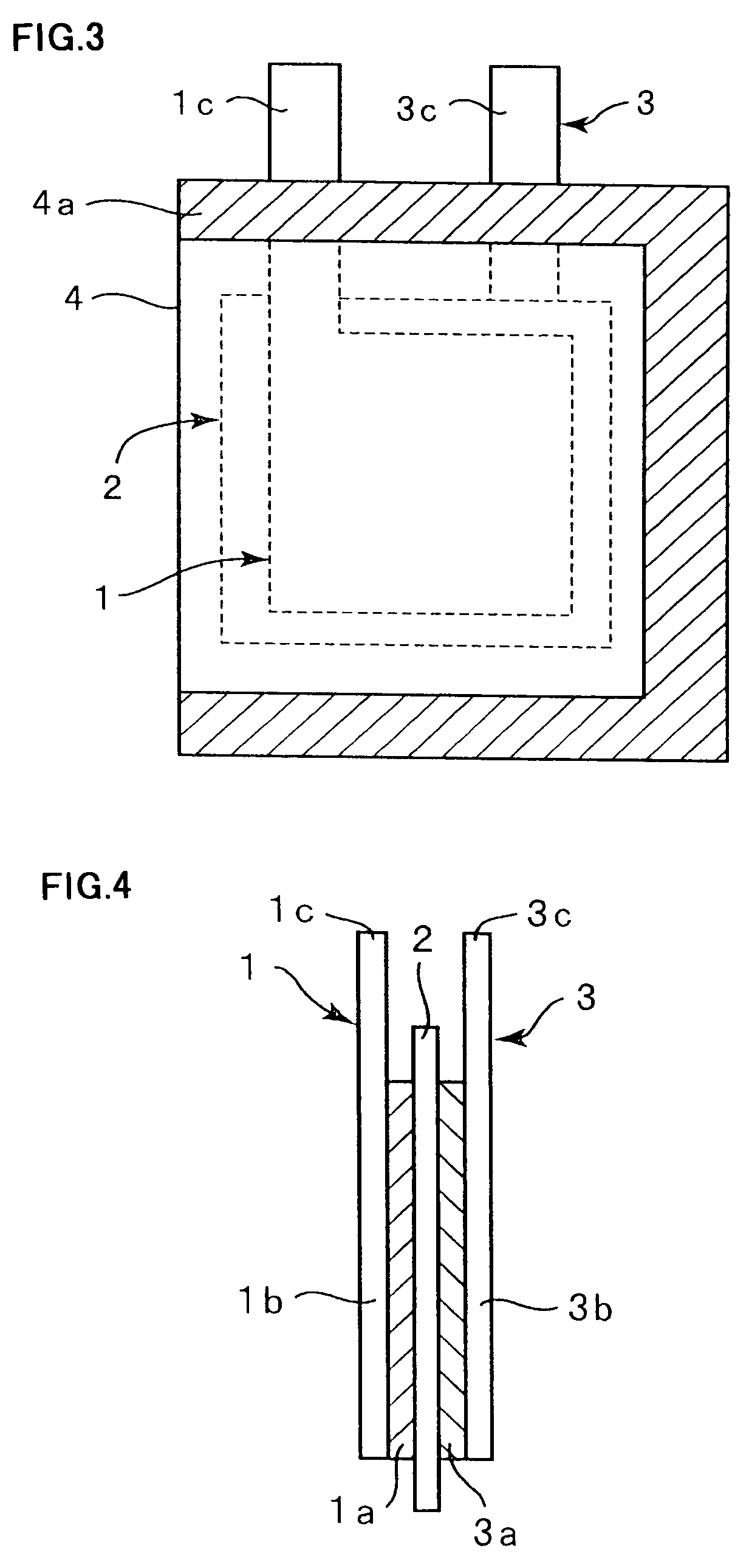

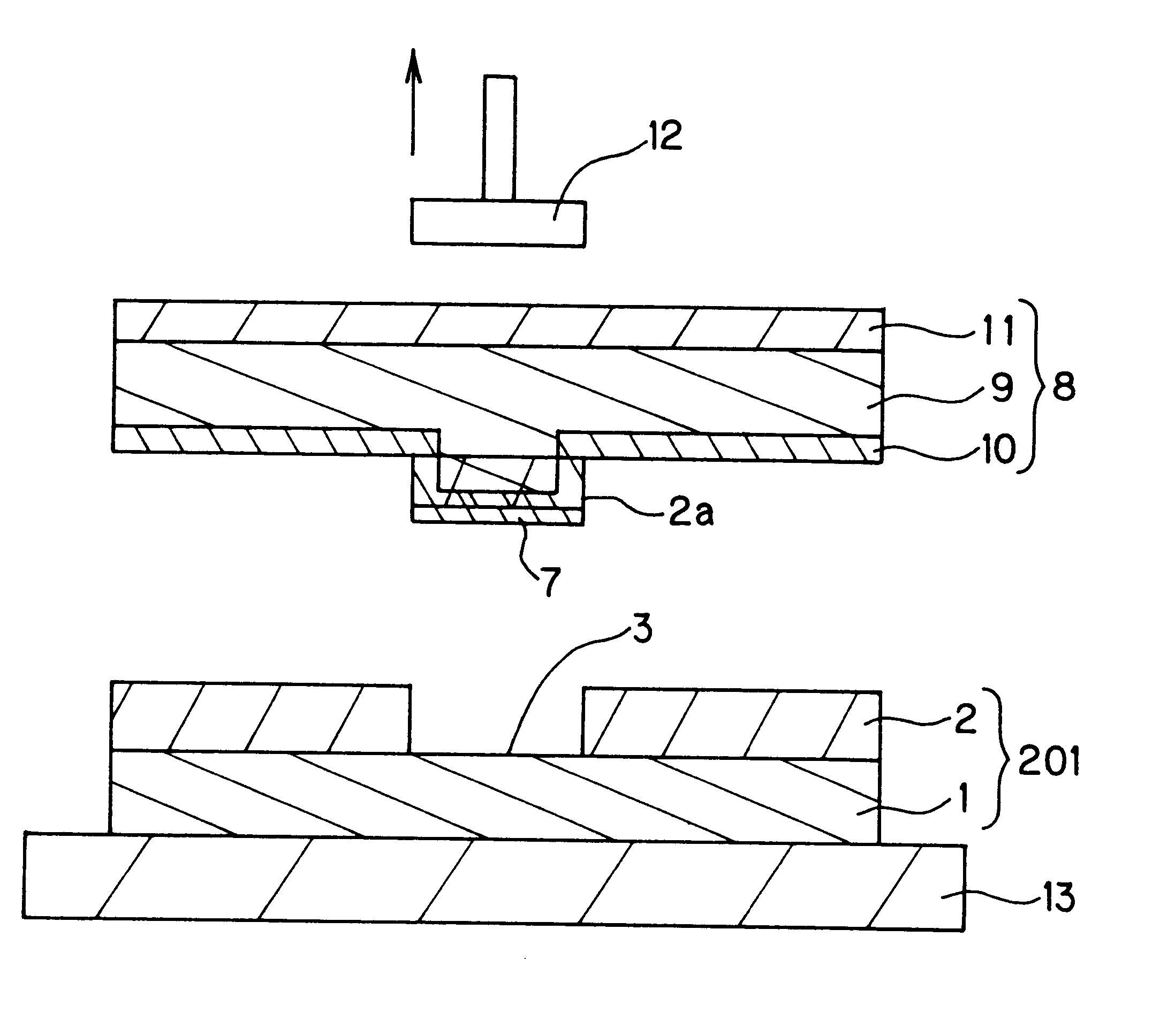

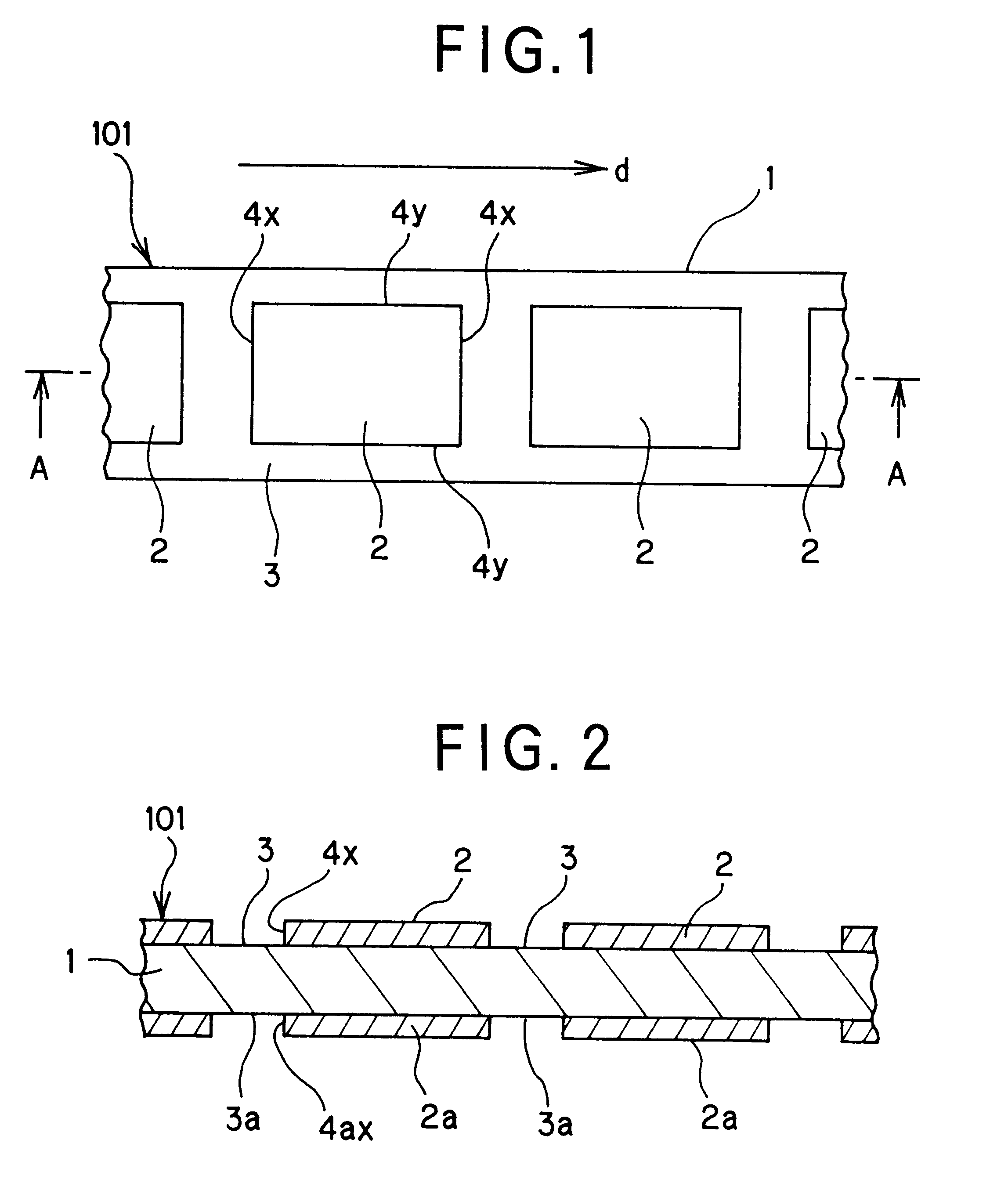

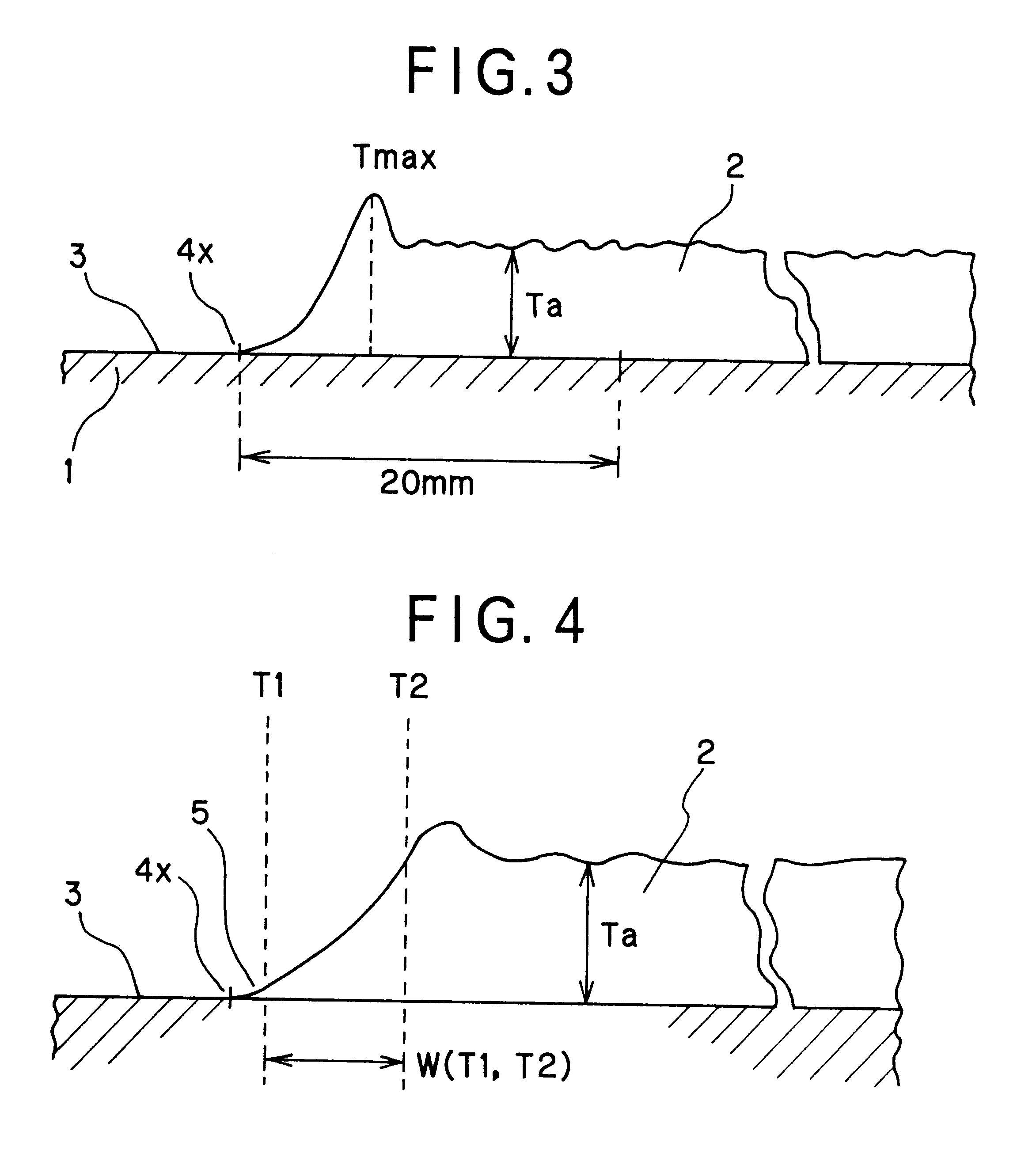

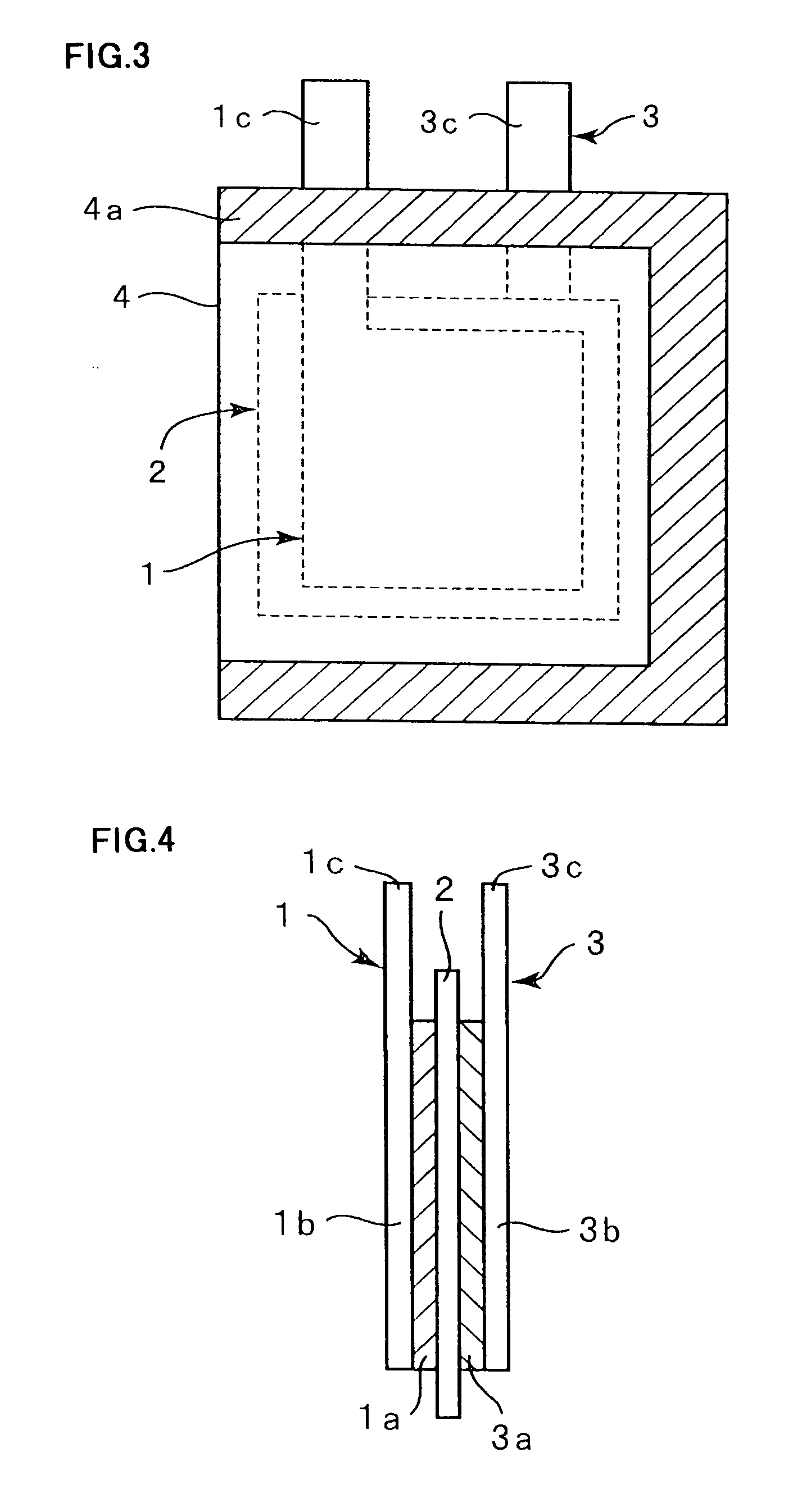

Electrode plate for secondary battery with nonaqueous electrolyte and process for producing same

InactiveUS6423446B1High dimensionalHigh thickness accuracyElectrode rolling/calenderingElectrode melt handlingEngineeringElectrolyte

The present invention provides an electrode plate having a collector 1, an active material layer 2 and a non-coated portion 3 and satisfies at least one of the following conditions. (1) The maximum thickness in an area inside by 20 mm from an edge portion of the active material layer is not more than the sum of an average thickness of the active material layer and 10 mum. (2) In an inclined portion of the peripheral edge portion of the active material layer, an area in which the thickness of the active material layer is not less than 1 mum and less than an average thickness of the active material layer has a width of not more than 1 mm. (3) An absolute value of a positional shifting of an actually formed pattern with respect to a true boundary line of a predetermined pattern is not more than 1 mm. (4) The active material layers are formed in a plane symmetry to front and back surfaces of the collector, and an absolute value in the positional shifting between the patterns formed on front and back side surfaces of the collector is not more than 1 mm.

Owner:DAI NIPPON PRINTING CO LTD

Lithium-rich electrode plate of lithium-ion battery and preparation method thereof

ActiveUS20150357628A1Low production costReduce gapElectrode melt handlingElectrode collector coatingRoom temperatureShielding gas

The present disclosure provides a lithium-rich electrode plate of a lithium-ion battery and a preparation method thereof. The preparation method of the lithium-rich electrode plate of the lithium-ion battery comprises steps of: (1) in a protective gas environment, melting a lithium ingot to obtain a melting lithium; (2) in a vacuum environment, heating and drying ceramic particles to obtain dried and anhydrous ceramic particles; (3) in a protective gas environment, adding the dried and anhydrous ceramic particles into the melting lithium, stirring to make them uniformly mixed to obtain a modified melting lithium; (4) in a protective gas environment, uniformly coating the modified melting lithium on a surface of an electrode plate to be lithium rich to form a lithium-rich layer, which is followed by cooling to room temperature to obtain a lithium-rich electrode plate of a lithium-ion battery. The lithium-rich electrode plate is prepared according to the preparation method.

Owner:NINGDE AMPEREX TECH

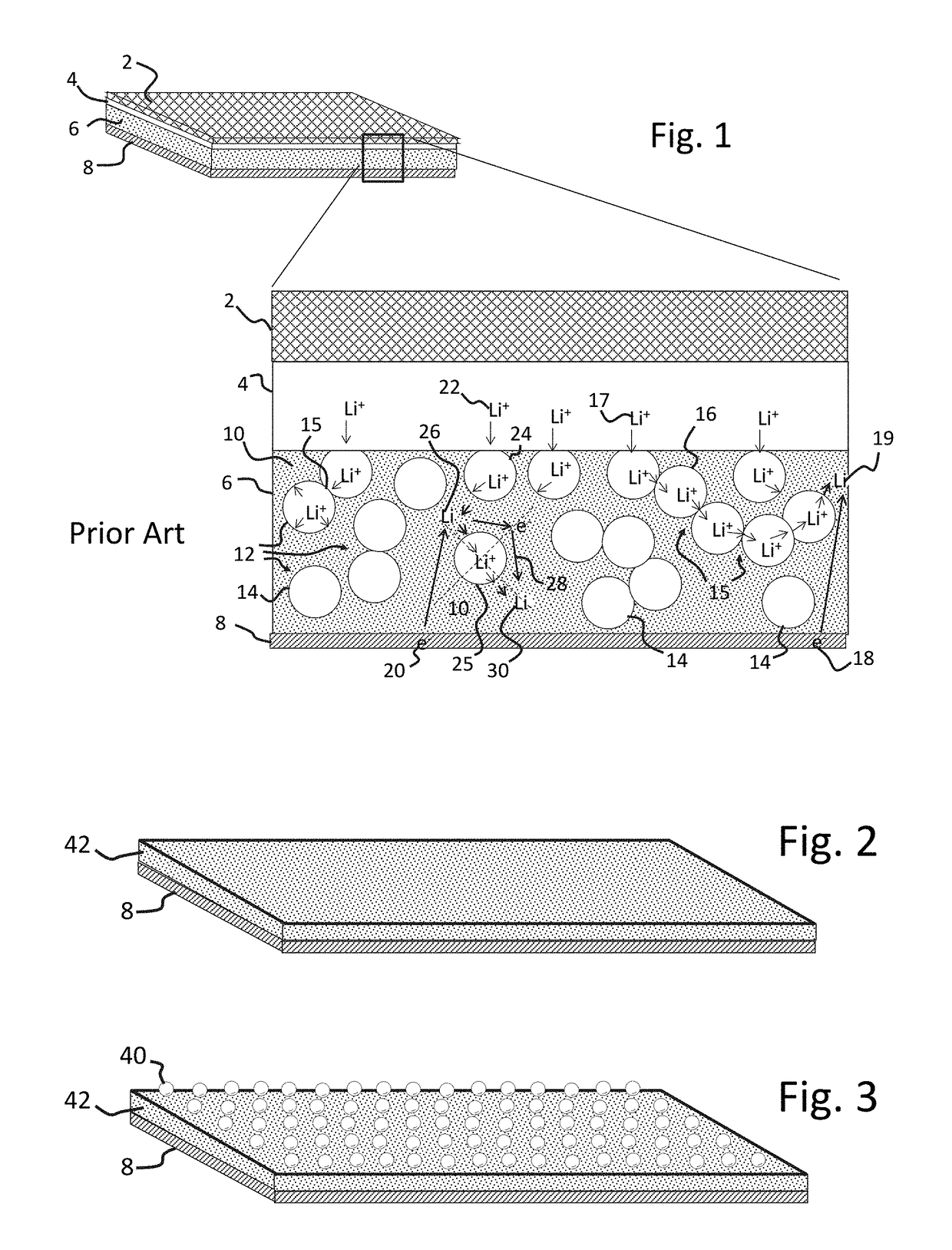

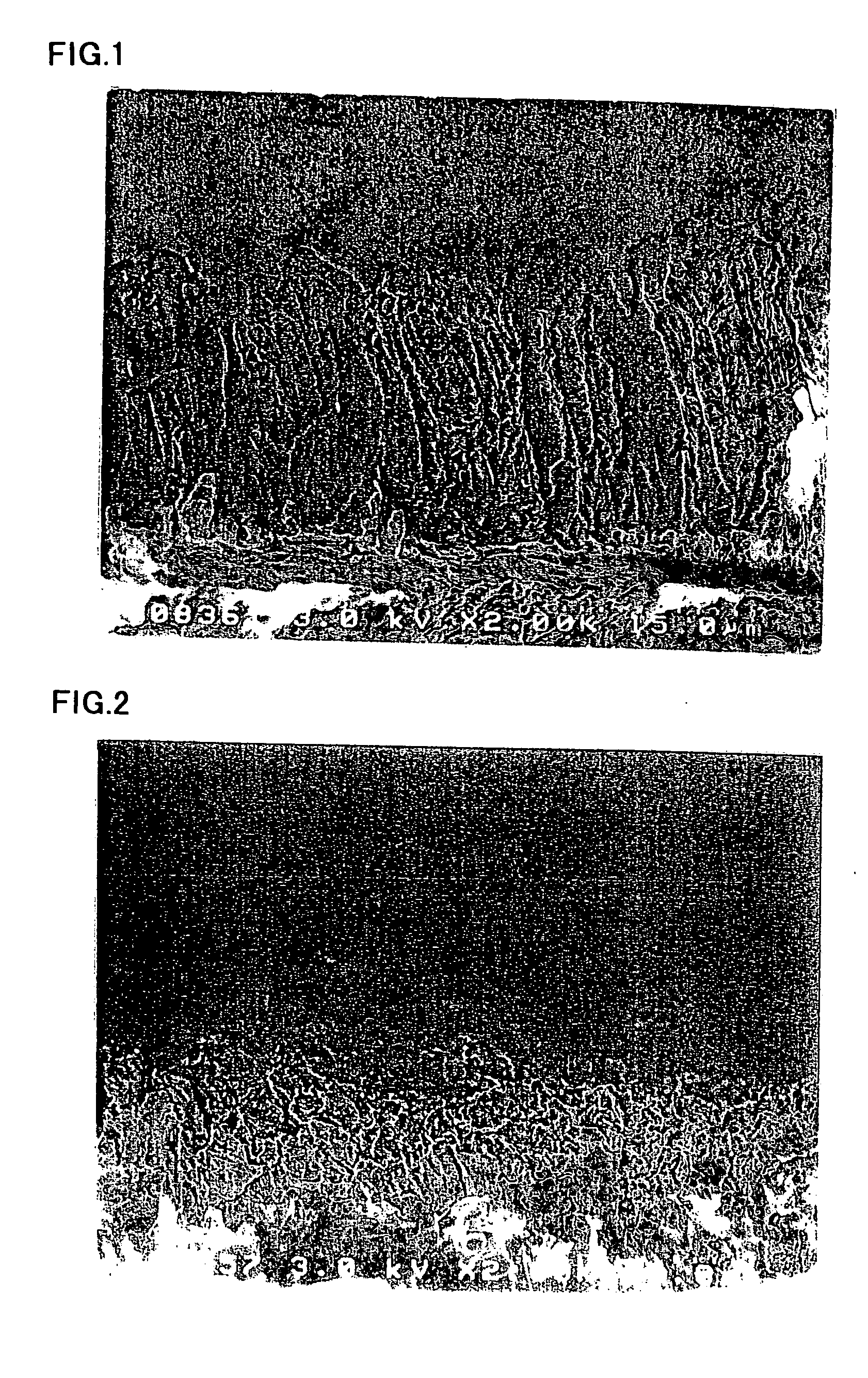

Lithium secondary battery

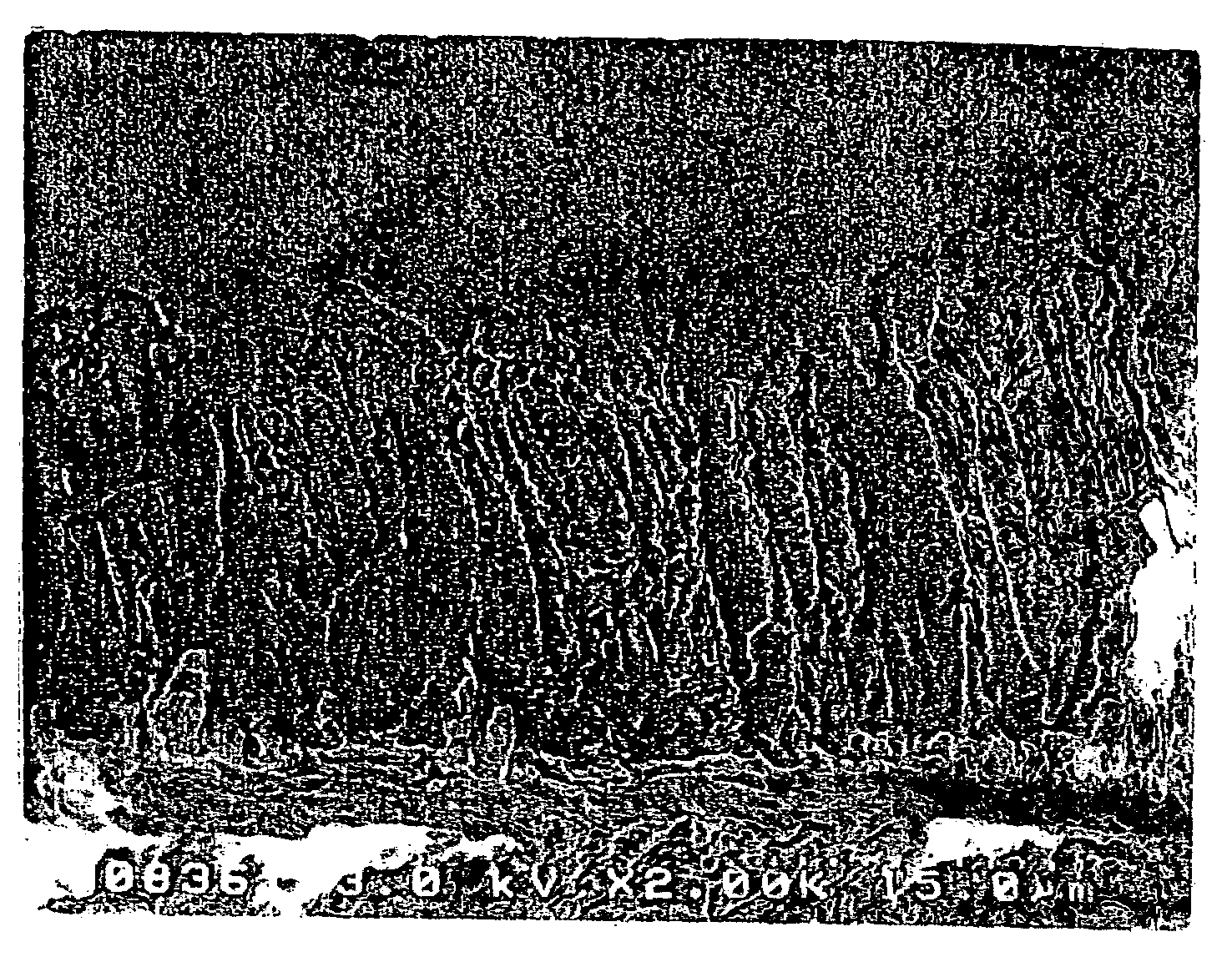

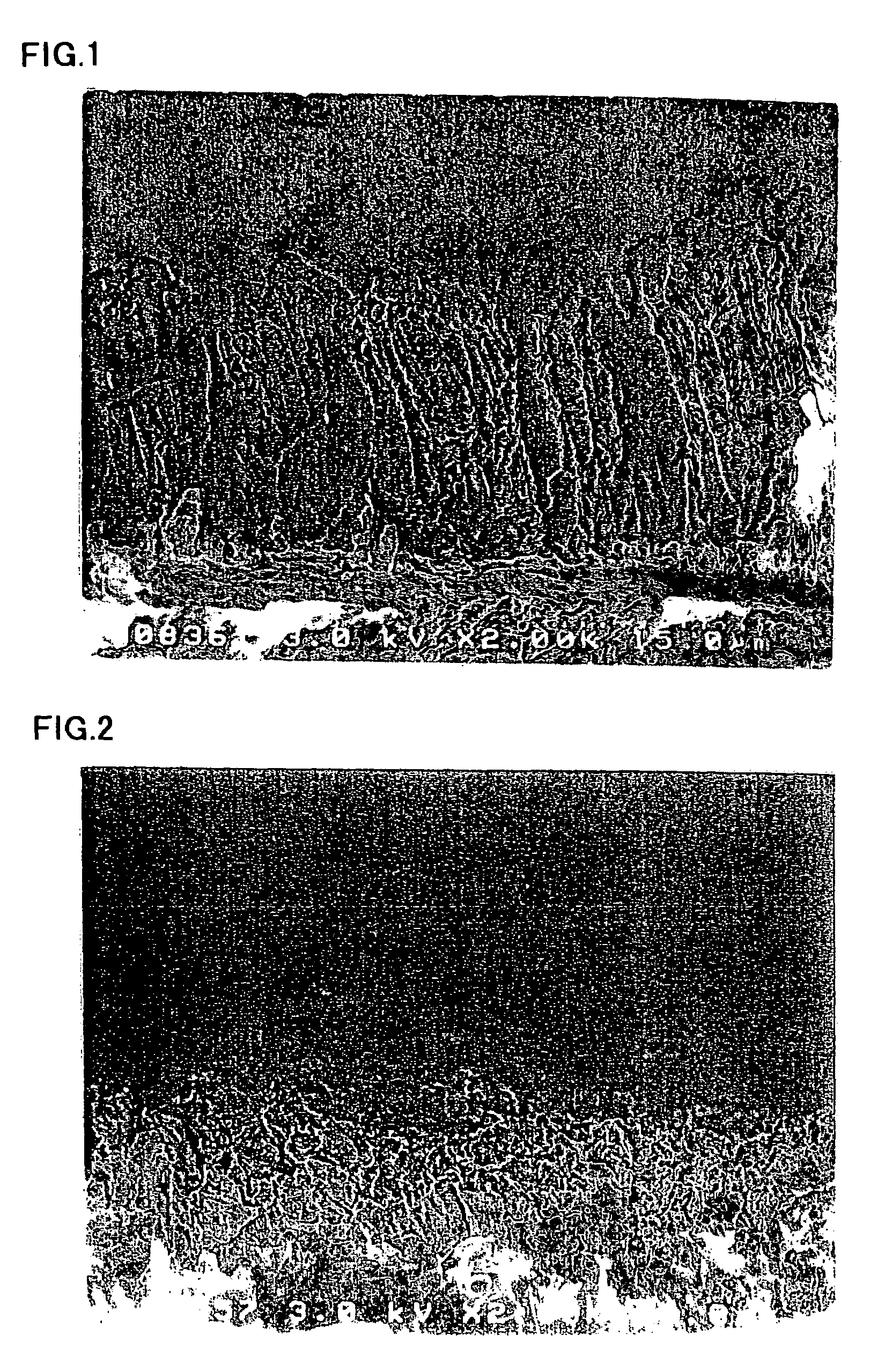

InactiveUS20050100790A1Improve adhesionImprove featuresElectrode carriers/collectorsElectrode melt handlingEngineeringEthylene carbonate

A rechargeable lithium battery including a positive electrode, a negative electrode and a nonaqueous electrolyte, said positive or negative electrode being an electrode which has, on a current collector, a thin film of active material that stores and releases lithium, the thin film of active material being divided into columns by gaps formed therein in a manner to extend in its thickness direction, and the columnar portions being at their bottoms adhered to the current collector, the rechargeable lithium battery being characterized in that the nonaqueous electrolyte includes a mixed solvent consisting of two or more different solvents and containing at least ethylene carbonate and / or vinylene carbonate as its constituent.

Owner:SANYO ELECTRIC CO LTD

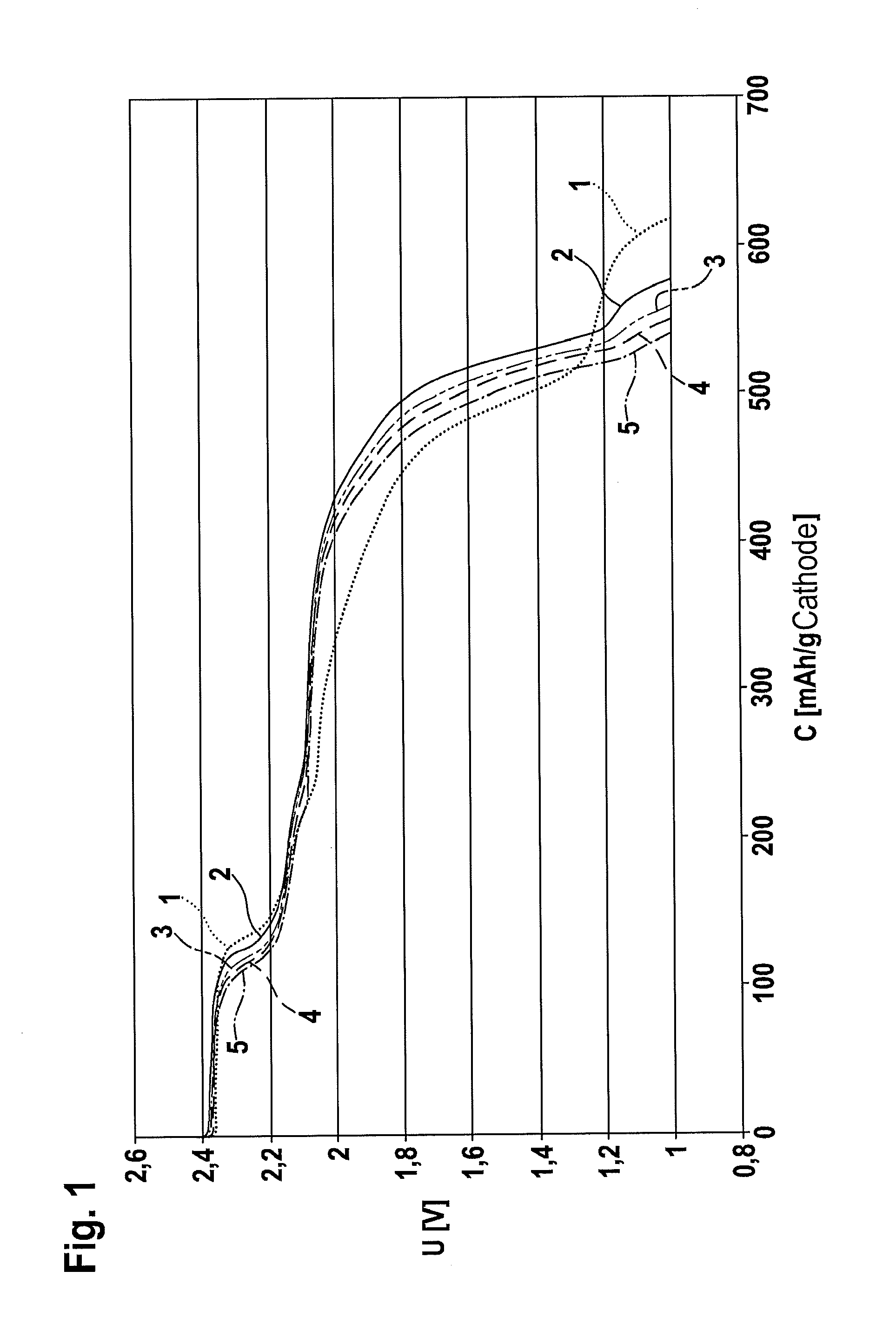

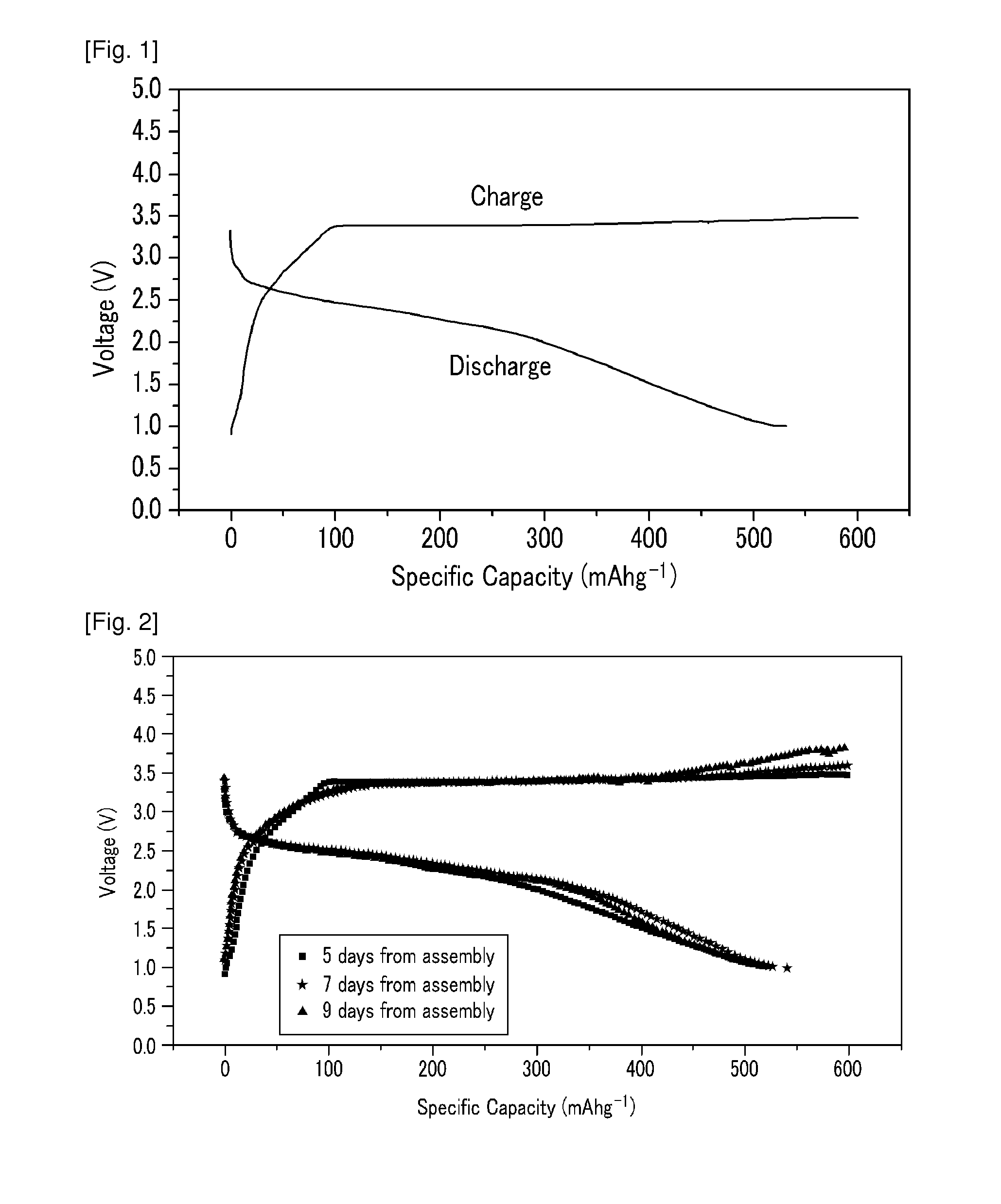

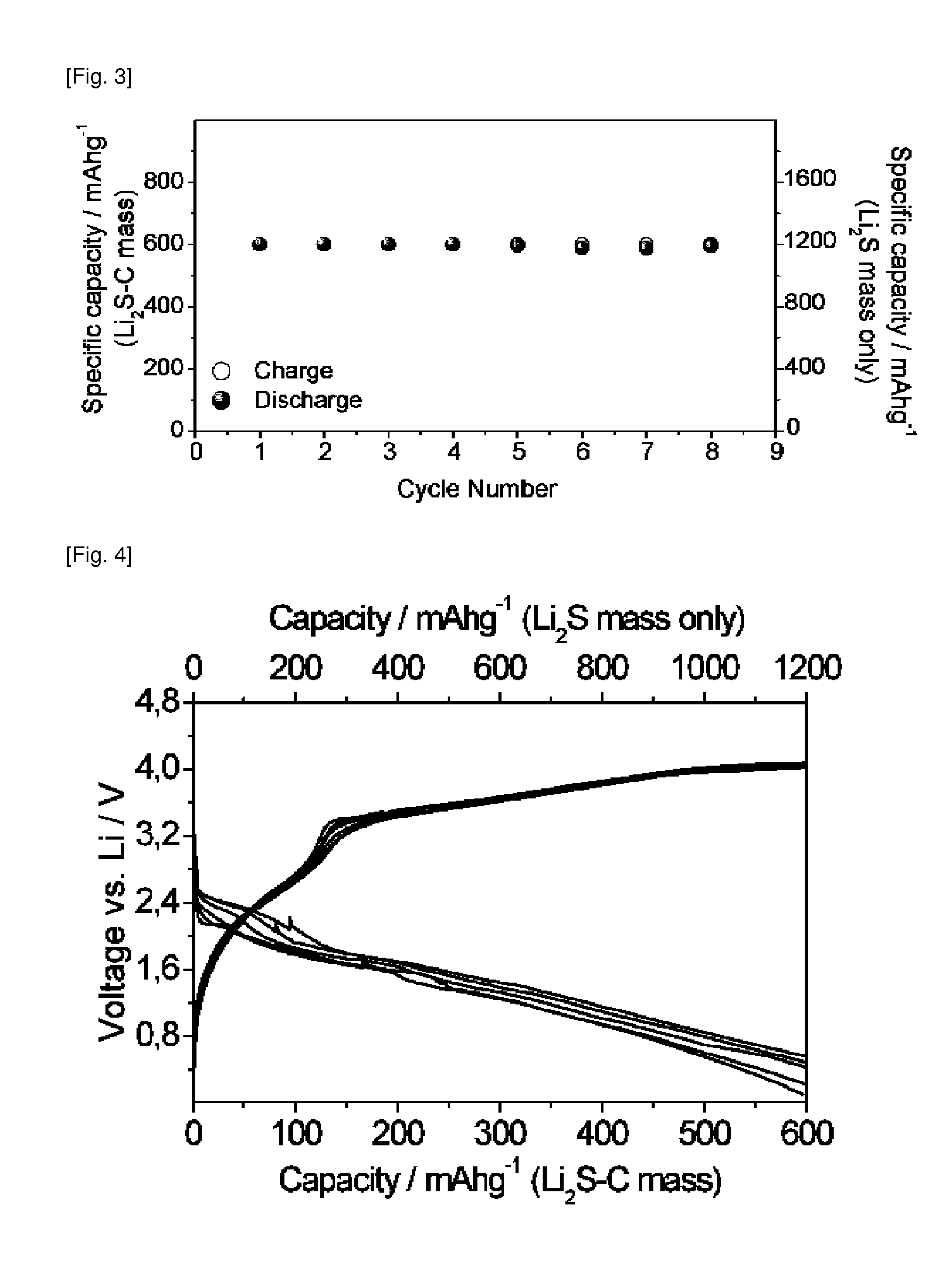

Cathode material for a lithium-sulfur battery

InactiveUS20130292613A1Increase contactImprove distributionElectrode melt handlingConductive materialSulfurGalvanic cell

A method for producing a cathode material for a cathode of a galvanic cell, such as a lithium or natrium sulfur cell. In order to improve the electric and ionic conductivity, the sulfur accessibility and utilization, elemental sulfur, at least one electrically conductive component and a solvent or a solvent mixture are mixed in method step a), the elemental sulfur being completely dissolved in the solvent or in the solvent mixture, and the solvent or solvent mixture is removed in a method step b).

Owner:ROBERT BOSCH GMBH

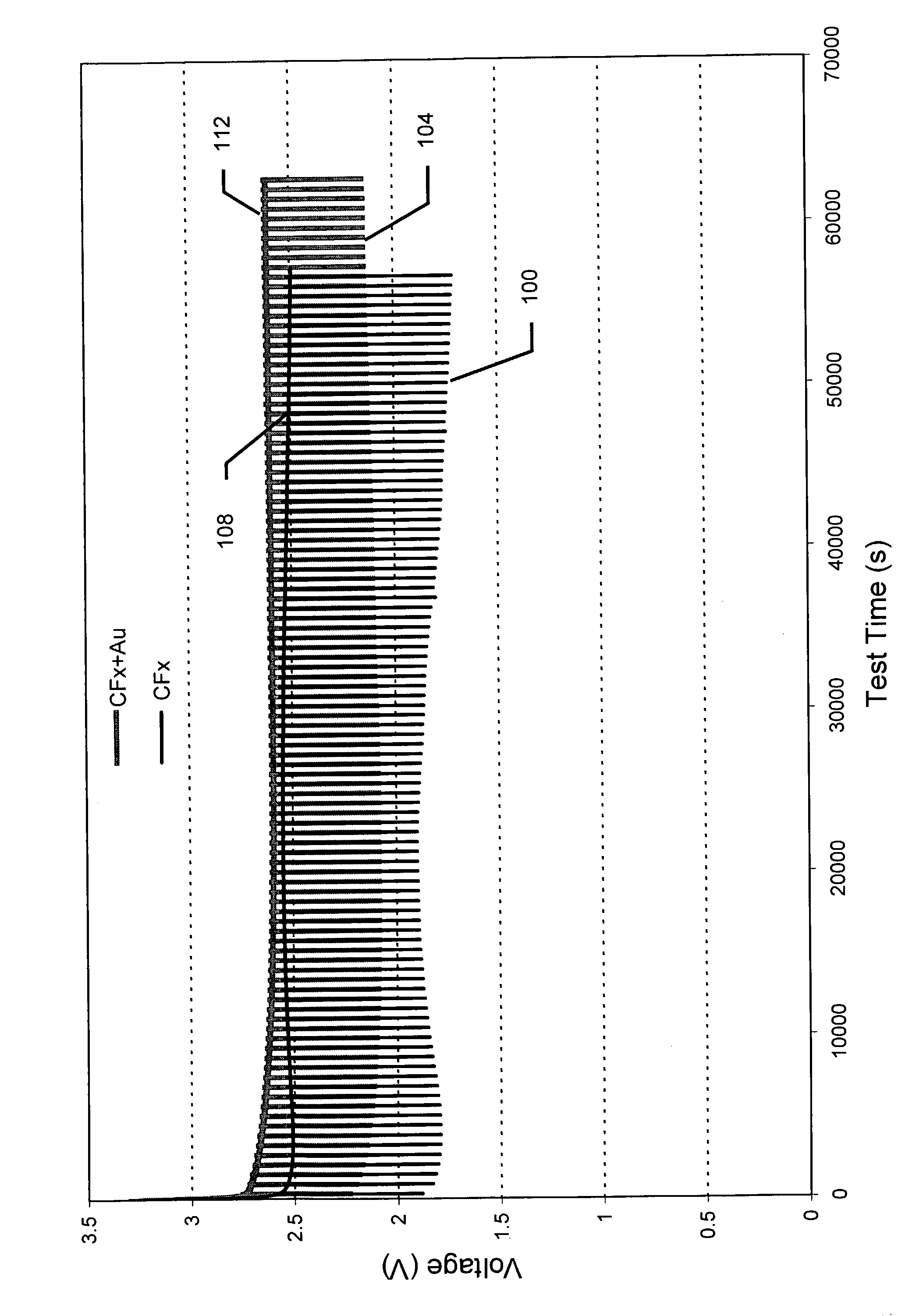

Fluorinated carbon active material

ActiveUS20040072075A1Improve featuresImprove conductivityHybrid capacitor electrodesLiquid electrolytic capacitorsElectrical batteryLithium metal

Disclosed is an improved type of fluorinated carbon (CFx) for use in electrical storage devices such as batteries and capacitors. The CFx is coated with a conductive material such as gold or carbon using vapor deposition. The resulting material exhibits better conductivity with concomitant lower impedance, higher electrical stability, and improved potential throughout the useful life of the device, as compared to uncoated CFx. The improved conductivity reduces the amount of nonactive material (e.g., carbon black) that needs to be added, thus improving the volumetric energy density. In addition, cells made with the subject CFx exhibit more constant voltages and higher overall voltage (2.0 volts with a lithium metal anode) throughout their useful life. Chemical or physical vapor deposition techniques to deposit a variety of metals or carbon may be used to create the improved CFx. The coated CFx may be used in primary or secondary batteries, as well as capacitors and hybrid devices. Methods for making and using the coated CFx are described.

Owner:QUALLION

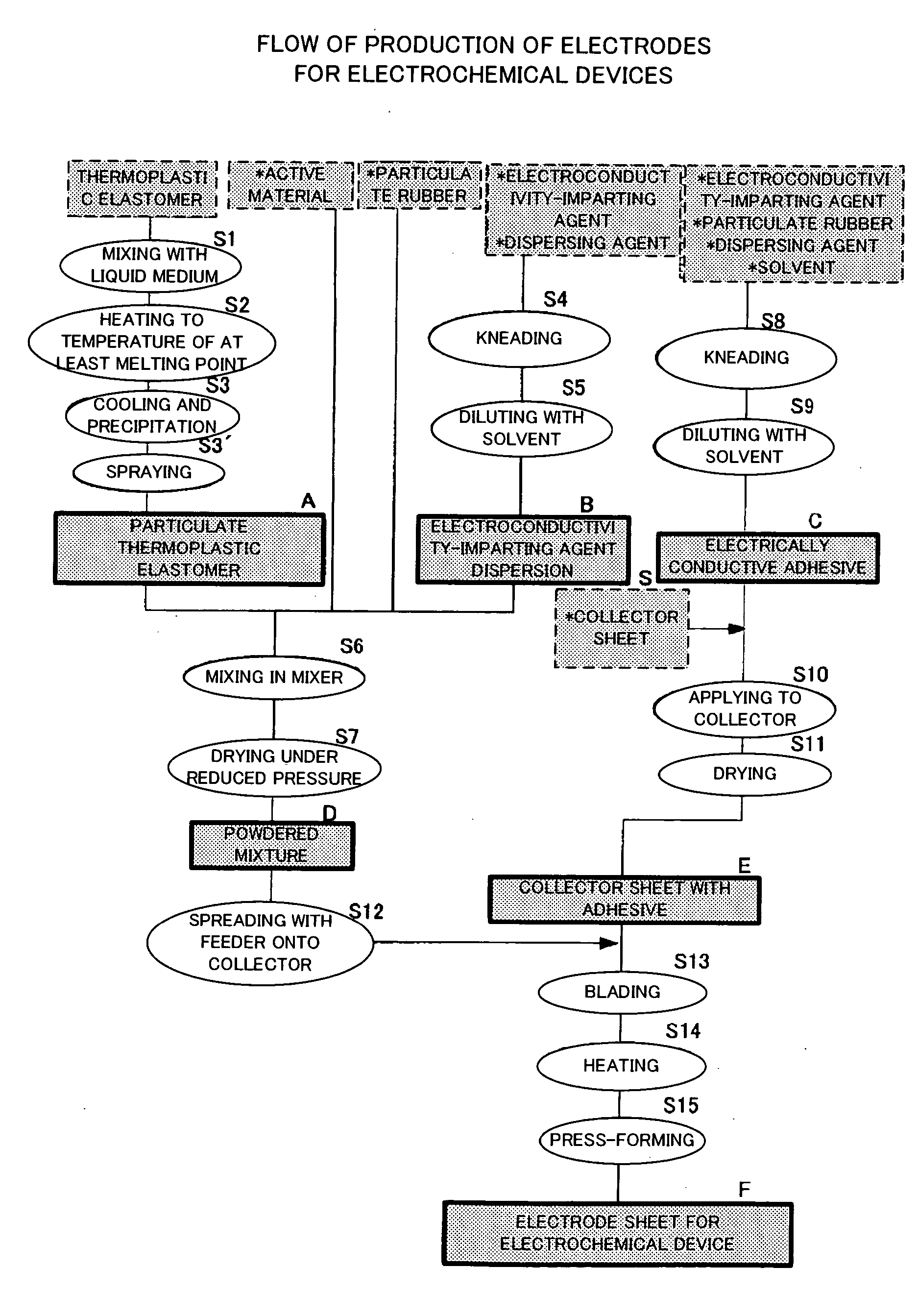

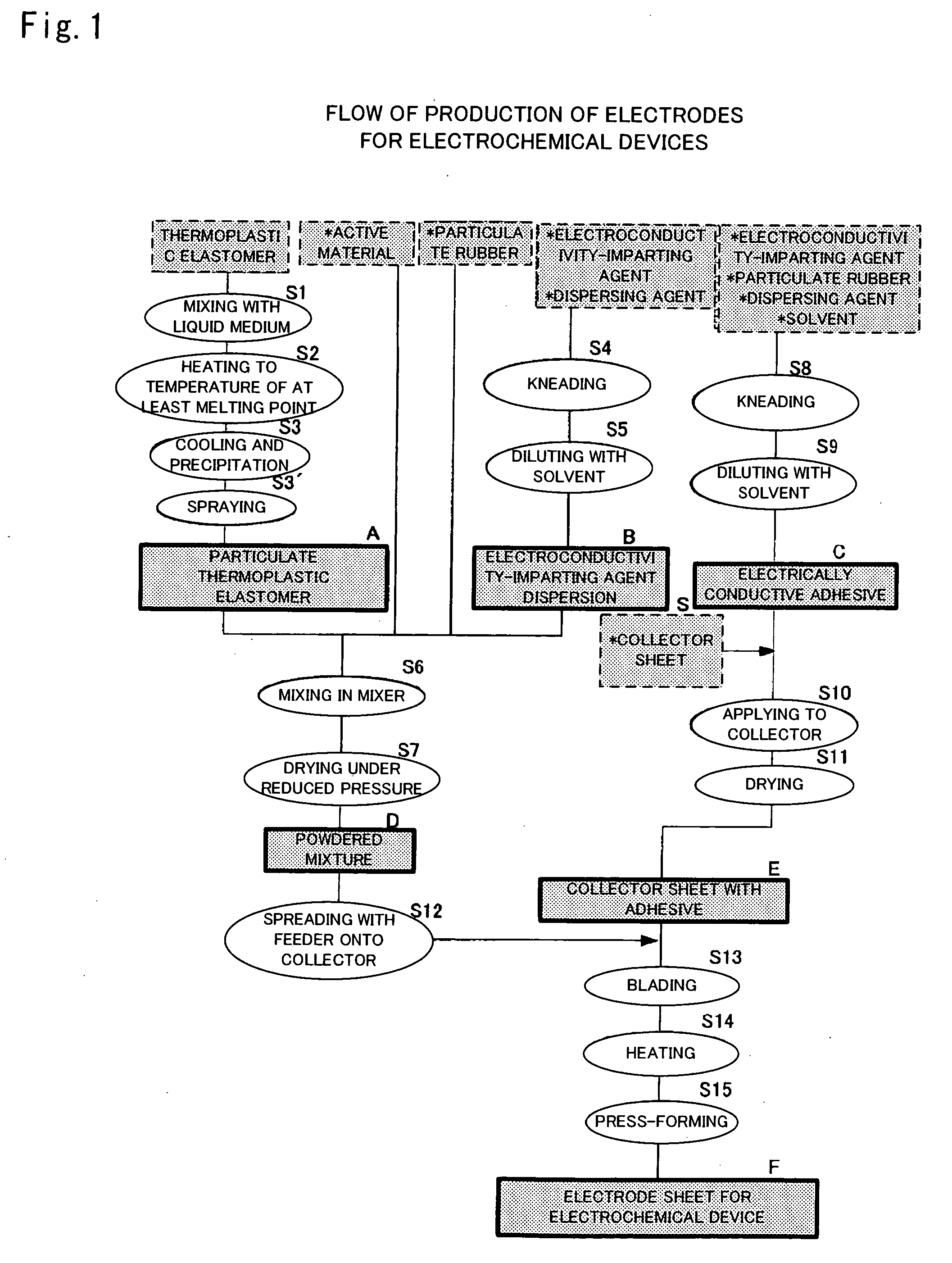

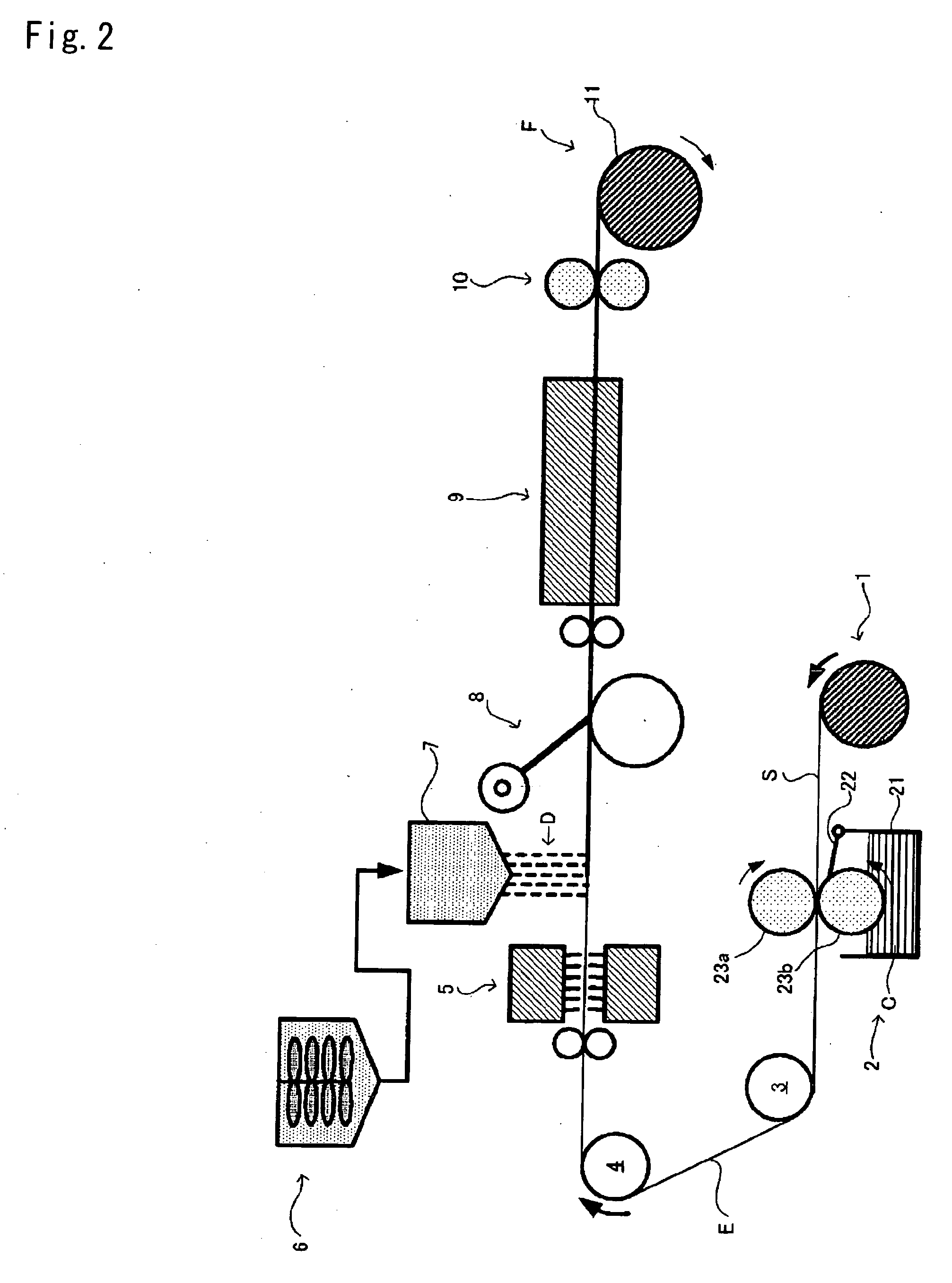

Method of manufacturing electrode for electrochemical device

InactiveUS20060153972A1Electrode thermal treatmentHybrid capacitor electrodesPowder mixtureElectrochemical cell

A method of manufacturing an electrode for an electrochemical device is provided with the steps of: supplying, onto a collector, a powdered mixture containing a binder and an active material; and heating the powdered mixture to form an electrode layer on the collector, that allows continuous mass production of electrodes for electrochemical devices.

Owner:ZEON CORP

Ultra-thin metal lithium complex, preparation method and application thereof

ActiveCN109873122AImprove performanceAct as lithium supplementElectrode thermal treatmentElectrode carriers/collectorsMolten stateLithium

The invention discloses an ultra-thin metal lithium complex, a preparation method and application thereof. The method comprises the following steps: an organic transition layer is prepared on a substrate in advance, under an argon protective atmosphere with the water value less than or equal to 0. 1 ppm and the oxygen value less than or equal to 0. 1 ppm, the substrate with the transition layer isin contact with molten-state lithium, and the molten-state metal lithium is rapidly spread on the surface of the substrate to form a lithium thin layer. The ultra-thin metal lithium can be pre-storedon a current collector in advance, can be used as a safe lithium negative electrode for inhibiting lithium dendrites and can also be used for a negative electrode lithium supplementing process, and also, extremely controllable preparation of the ultra-thin lithium layer can be realized by means of a patterned design of the transition layer on the substrate.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

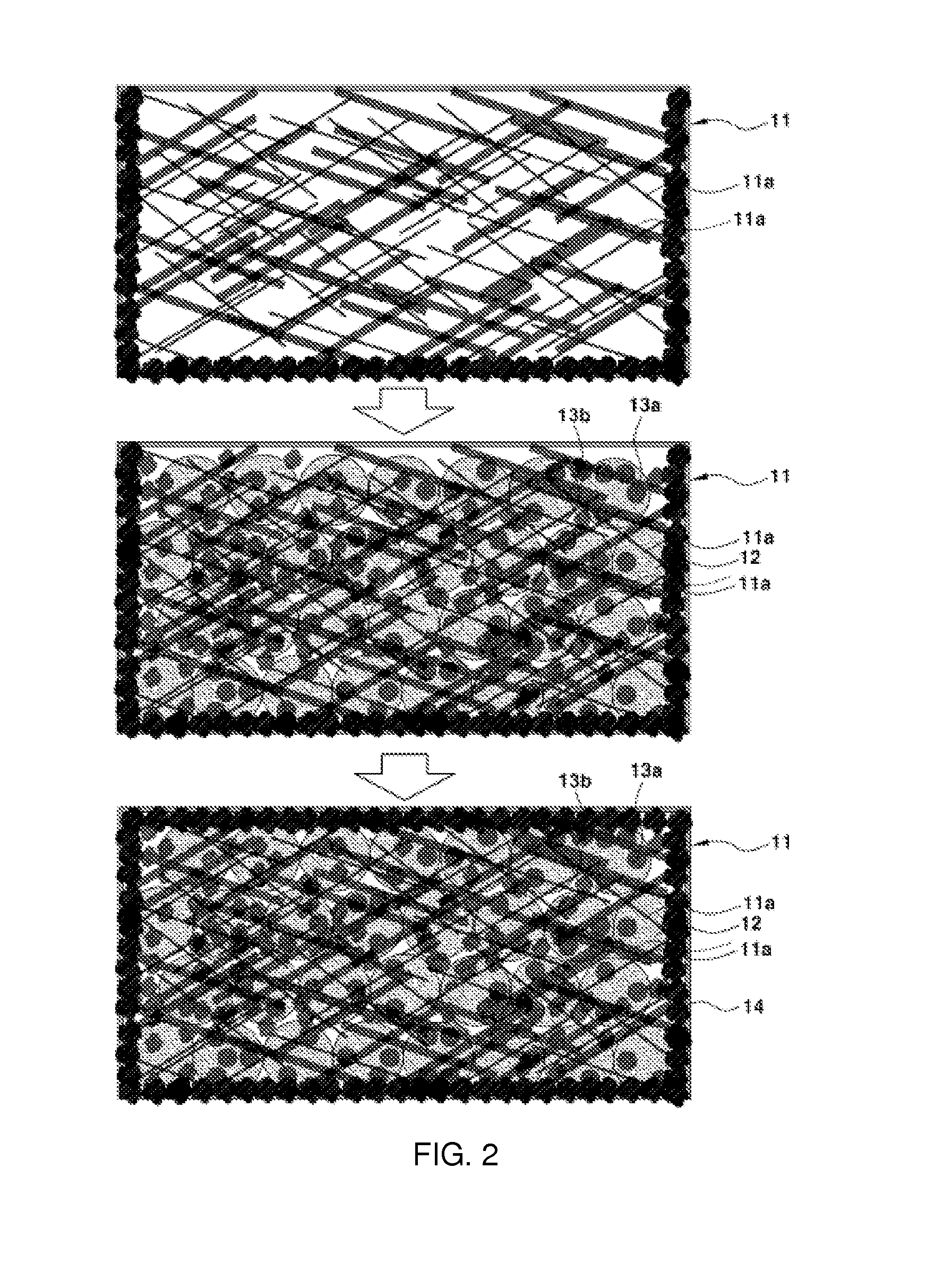

Cathode for lithium-sulfur battery

ActiveUS20150372291A1Improve charging efficiencyStably maintain conductivityElectrode carriers/collectorsElectrode melt handlingDischarge efficiencyPorous carbon

Disclosed is a cathode for lithium-sulfur battery. The cathode for lithium-sulfur battery has a structure for improved in charge / discharge efficiency, charge capacity, and life span. In particular, in the cathode structure, an active material is inserted into a porous carbon structure and a surface of the porous carbon structure is densely coated with the conducting material thereby maximizing the contents of an active material and a conducting material in the cathode without a current collector.

Owner:HYUNDAI MOTOR CO LTD

Lithium ion battery lithium-rich electrode piece and preparation method thereof

ActiveCN105449165AReduce the process of processing into lithium powderReduce manufacturing costElectrode melt handlingElectrode collector coatingRoom temperatureShielding gas

Owner:NINGDE AMPEREX TECH

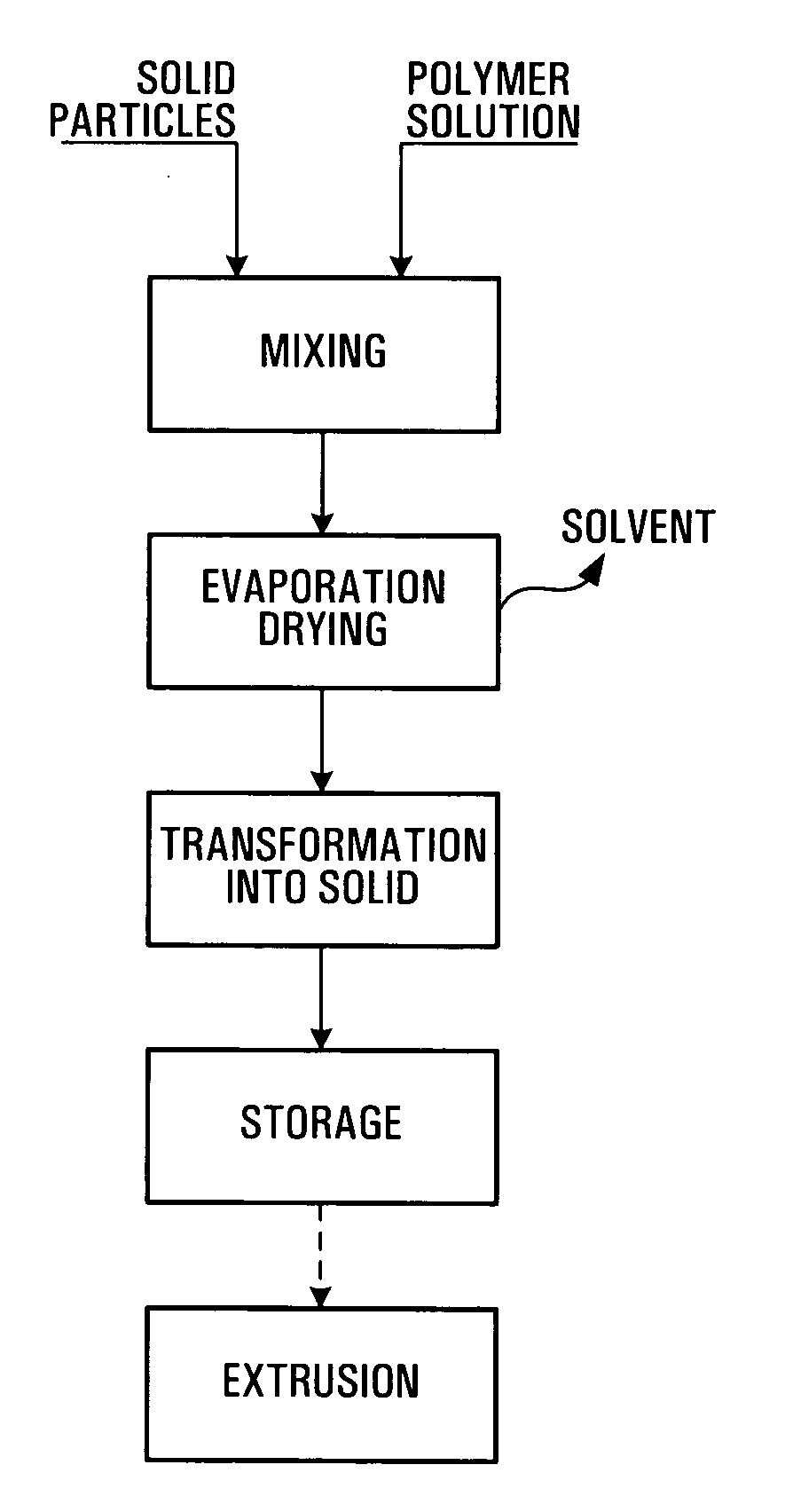

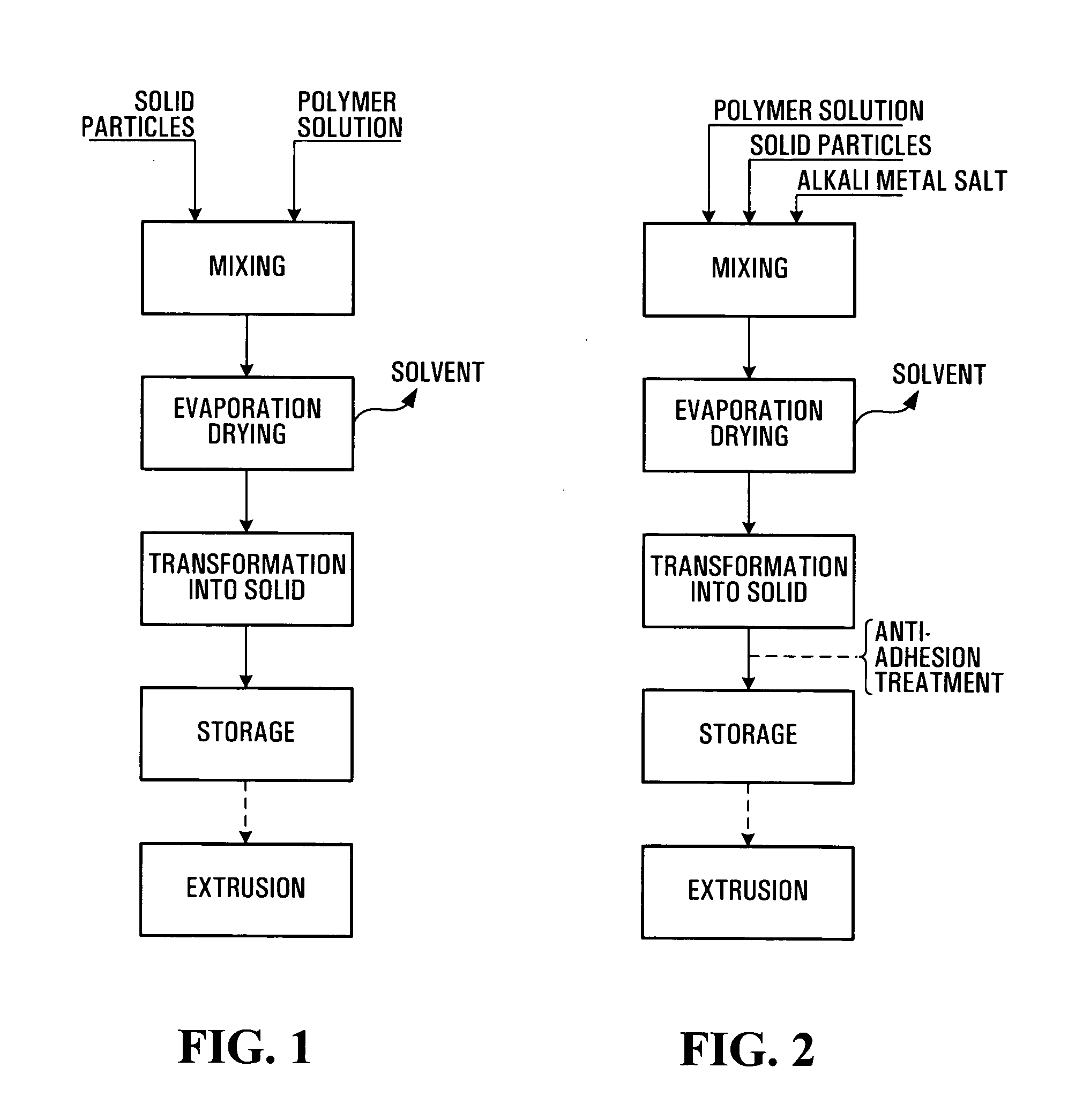

Cathode material for polymer batteries and method of preparing same

The invention provides a pre-mix of positive electrode material in transportable solid form comprising polymer and solid particles of electrochemically active material and / or electronically conductive additives and a process for preparing a pre-mix positive electrode in transportable solid form. The pre-mix positive electrode material may also comprise an alkali metal salt either dissolved or dispersed in the mixture. The invention also provides making a cathode film from the transportable solid pre-mix of positive electrode material.

Owner:BATHIUM CANADA

Method for fabricating lithium ion secondary battery

InactiveUS7252689B2Electrode thermal treatmentFinal product manufacturePolymer chemistryCopolymer composition

By using a winding type electrode plate assembly resistant to displacement by wind-up and buckling, a lithium ion secondary battery, capable of suppressing deterioration in cycle and storage characteristic caused by expansion and shrinkage of the electrode plate due to charge / discharge cycles or by generation of gas during storage at high temperatures or the like, is accomplished. An electrode plate A comprising a binder mainly composed of a polymer material “a” and an electrode plate B, having the opposite polarity to the electrode plate A, with a porous polymer layer mainly composed of the polymer material “a” or a copolymer of the polymer material “a” formed thereon, are wound up in flat form to give a flat electrode plate assembly, which is soaked in a non-aqueous electrolyte and then heated and cooled, with the soaked state maintained, while pressure is applied in the direction of the thickness of the flat electrode plate assembly, to integrate the electrode plate assembly.

Owner:PANASONIC CORP

Aluminium-based light-type grid for plumbic acid cells and preparation method thereof

InactiveCN102315455AIncrease profitIncrease specific energyElectrode melt handlingElectrode carriers/collectorsChemical platingInternal resistance

The invention provides an aluminium-based light-type grid for plumbic acid cells and a preparation method thereof. The aluminium-based light-type grid comprises an open-cell porous aluminum or aluminium alloy (Al-Me) matrix with high specific surface area and a lead or lead alloy (Pb-Me') protective layer. The preparation technological flow of the protective layer mainly comprises four operationsof pretreatment, chemical plating of molten salt, metal bath and heat treatment. In comparison with traditional lead and lead alloy grids, the aluminium-based light-type grid prepared in the invention has high mechanical strength, good conductivity, large specific surface area, light weight and the like, and is used for positive and negative electrodes in plumbic acid cells so as to greatly reduce the weight of plumbic acid cells, improve the active substance utilization rate, specific energy, cycle life and seismic performance of plumbic acid cells, and minimize the internal resistance of cells. The preparation method provided by the invention is suitable for industrial application.

Owner:长沙灿能能源科技有限公司 +1

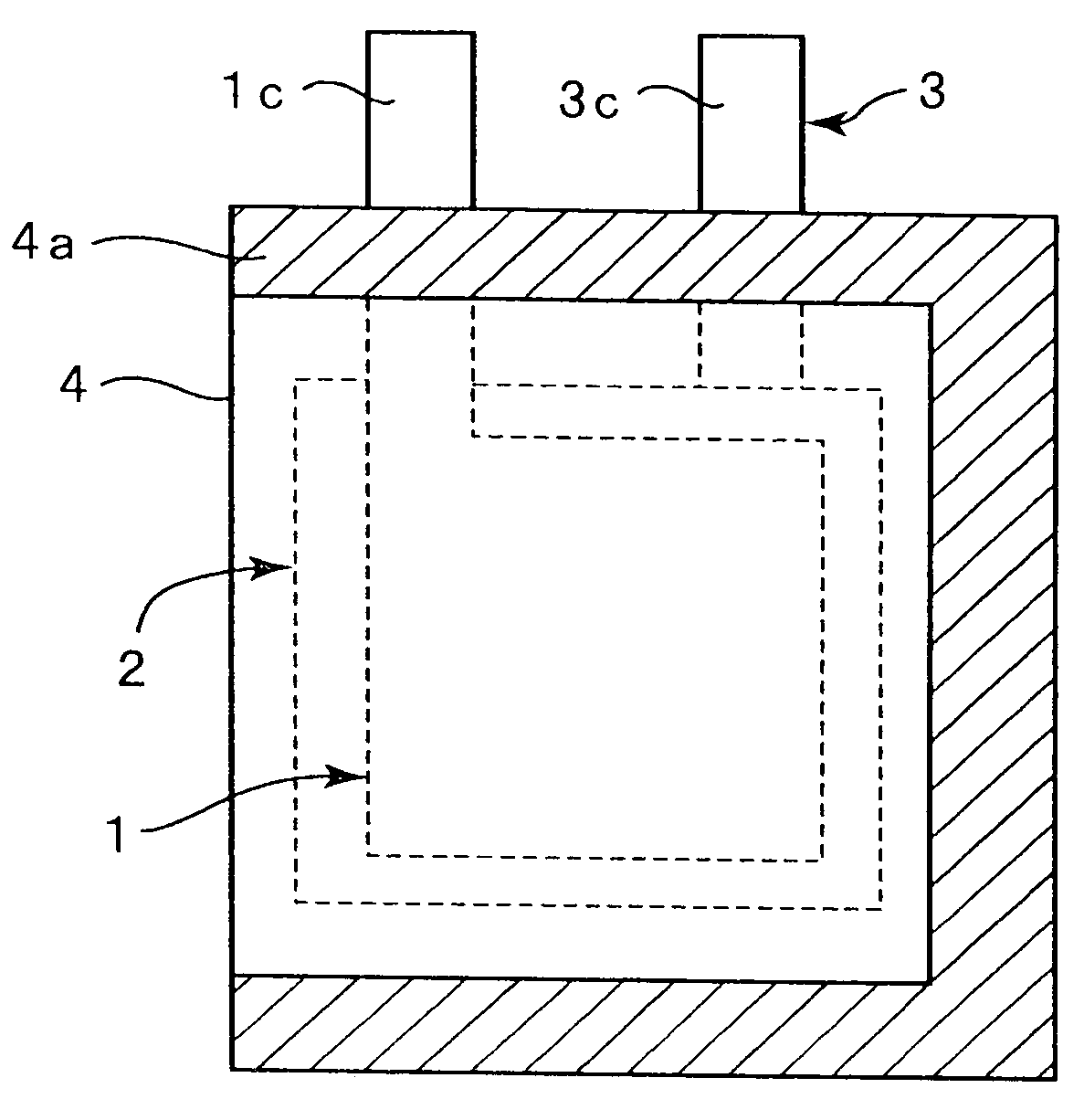

Electrode plate for secondary battery with nonaqueous electrolyte

InactiveUS6051338AElectrode rolling/calenderingElectrode melt handlingEngineeringElectrical and Electronics engineering

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and said electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

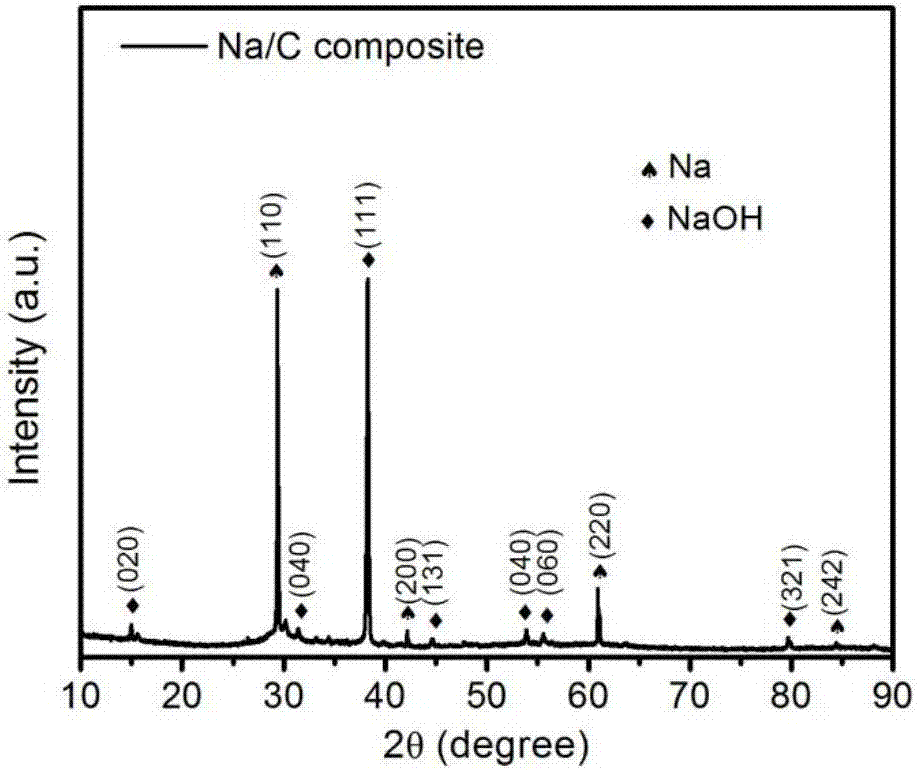

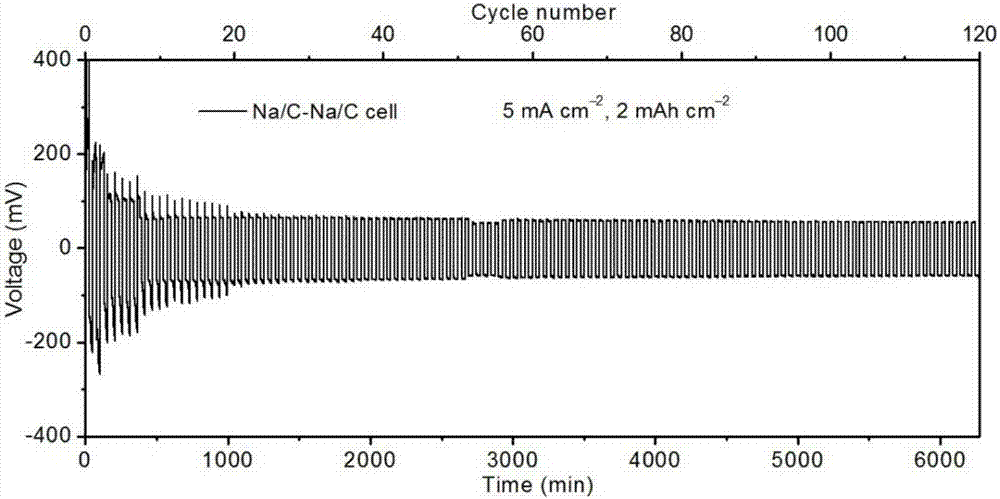

Method for preparing composite sodium negative electrode for sodium-ion battery

InactiveCN107221640AImprove stabilityGrowth inhibitionElectrode melt handlingSecondary cellsHigh current densityNew energy

The invention discloses a method for preparing a composite sodium negative electrode for a sodium-ion battery and belongs to the field of new energy materials. According to the method disclosed by the invention, metal sodium is deposited in gaps of a three-dimensional carbon material or a foamed porous material and other carriers through a hot infusion melting method or an electrodeposition method, so that the composite sodium negative electrode is prepared, wherein the three-dimensional carbon material is applied to providing a sufficient space for pre-stored sodium in the preparation process and providing a carrier for receiving the metal sodium in the battery cycle process. The composite sodium negative electrode can be widely applied to the sodium-ion battery, a sodium air battery, a sodium-sulfur cell and other sodium metal batteries, is assembled into a sodium-ion symmetric cell to still keep a stable voltage platform under high current density, is capable of inhibiting sodium dendritic growth and stabilizing volume change of the sodium electrode in the battery cycle process, and has the advantages of good cycling stability, long service life and the like. The method disclosed by the invention is rich and cheap in carrier materials, controllable in preparation process, low in production cost and capable of realizing batch production.

Owner:UNIV OF SCI & TECH BEIJING

Lithium-sulfur battery

InactiveUS20120094189A1High energyProlong lifeElectrode melt handlingSolid electrolyte cellsOrganic solventLithium–sulfur battery

Disclosed is a lithium-sulfur polymer battery having a anode and a cathode separated by an electrolyte formed by a membrane containing a solution of a lithium salt in aprotic organic solvents with the addition of lithium sulfide and / or lithium polysulfides until saturation, this solution being trapped in a polymer matrix.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

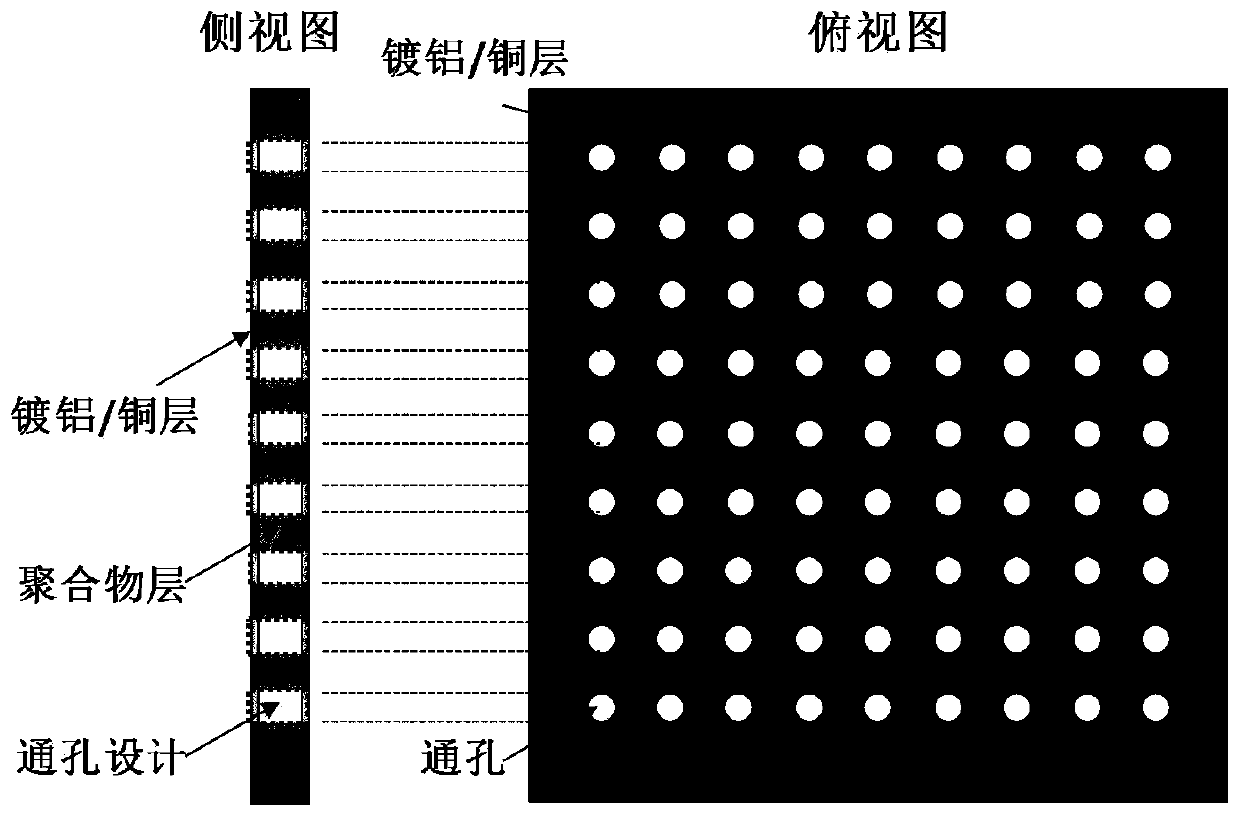

Composite current collector with electrical interconnection and through-hole structure, preparation method thereof, battery pole pieces and lithium ion battery

InactiveCN109698359AImprove conductivityImproved current distributionElectrode thermal treatmentFinal product manufacturePolymeric surfaceMetal coating

The invention relates to a composite current collector with electrical interconnection and a through-hole structure, a preparation method thereof, battery pole pieces and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The preparation method of the composite current collector includes the following steps: (1) coloring, casting and forming to prepare a polymer base layer; (2) carrying out first vacuum metal plating on the surface of the polymer base layer; (3) making holes in the surface of the metal-coated polymer layer; and (4) carrying out second vacuum metal plating on the surface of the polymer layer. The prepared current collector is of an inner and outer double-layer structure with the through-hole structure. The inner layer is a polymer layer withthe through-hole structure, and the surface layers are metal coatings. The metal coatings cover the surface of the through holes, the through holes communicate the metal coatings. The preparation method is simple and easy in large-scale production, and can customize the thickness and hole structure distribution according to specific application indicator. Compared with a conventional foil material, the composite current collector with the electrical interconnection and the through-hole structure has the advantages of light weight, bending resistance, low cost and the like, and has a significant effect on the energy density improvement of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

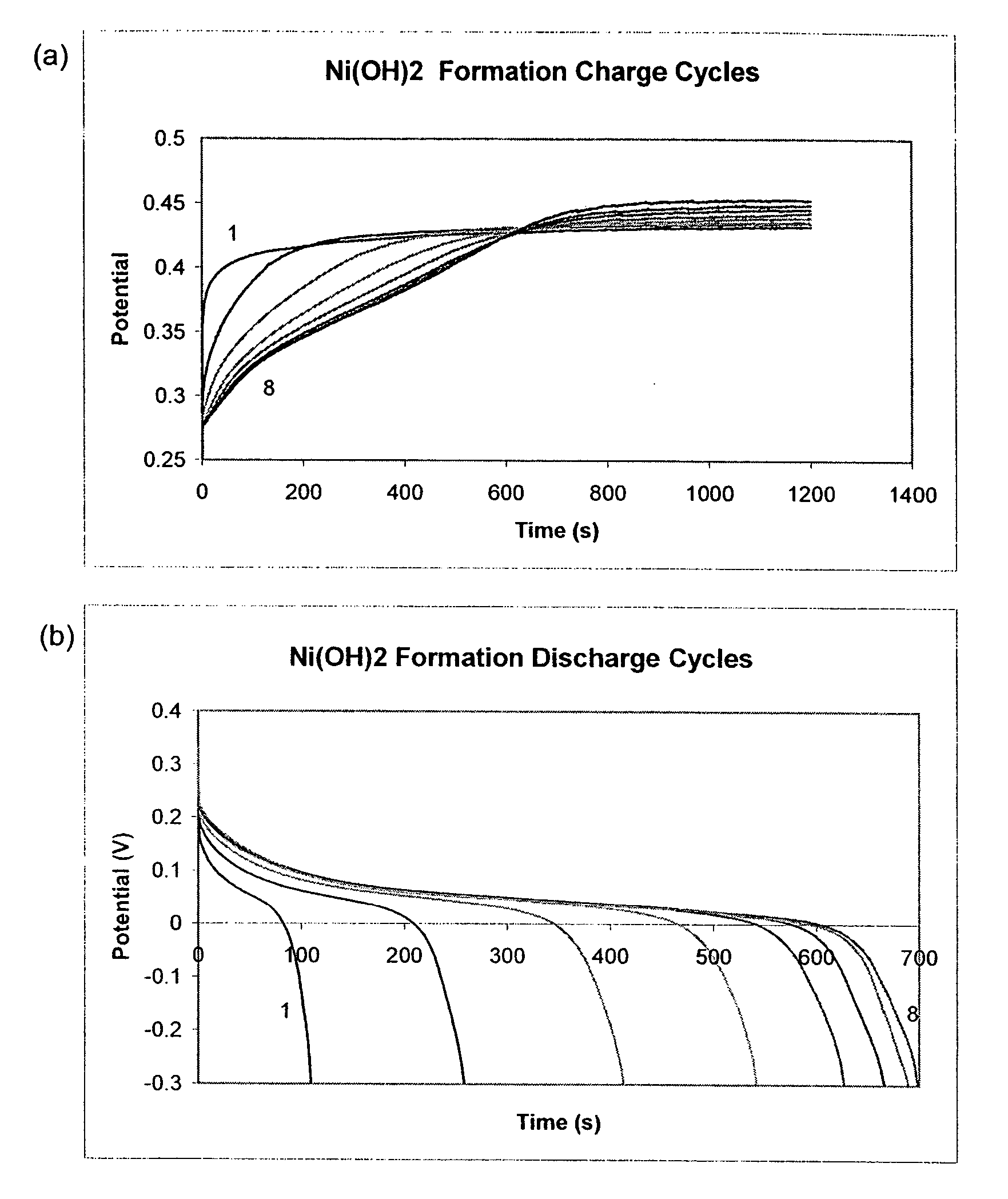

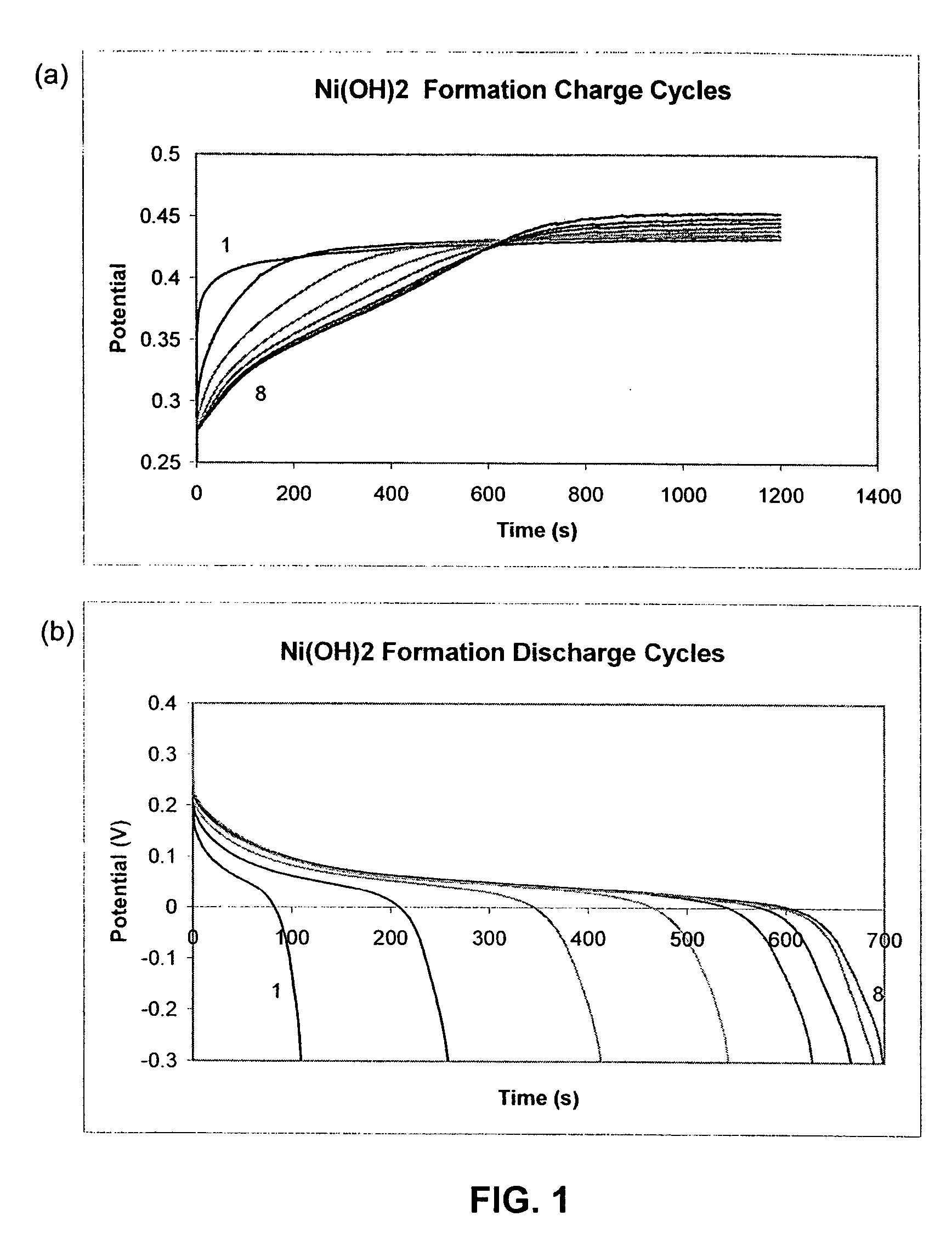

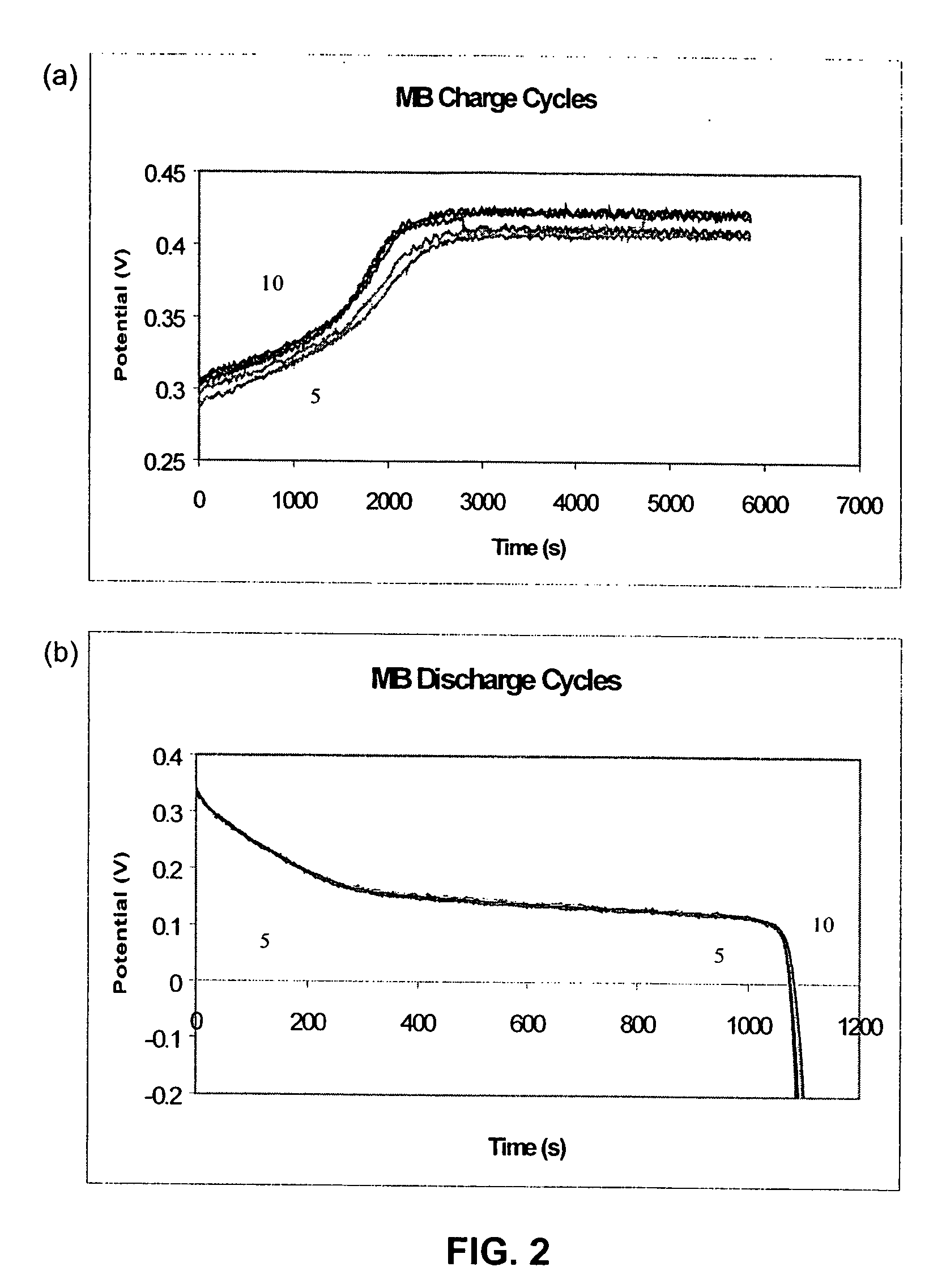

Nickel hydroxide impregnated carbon foam electrodes for rechargeable nickel batteries

InactiveUS20060024583A1Electrochemical processing of electrodesFinal product manufactureElectrical batteryCharge discharge

A novel nickel-carbon electrode, and methods for making the same, have been developed. The nickel-carbon electrode comprises an active mass (e.g., a nickel oxyhydroxide, hydroxide or oxide) deposited to a carbon foam using any one of chemical deposition, thermal deposition or electrochemical deposition. The nickel-carbon electrode is formed or “activated” through a series of charge-discharge cycles. The nickel-carbon electrode is comparable in volumetric capacities (mAh / cc) with commercial nickel electrodes but higher in gravimetric capacities (mAh / g). The nickel-carbon electrode may be used in rechargeable nickel-based batteries which have applications in cordless appliances, portable devices, standby power systems, the aerospace industry, and hybrid electric vehicles.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

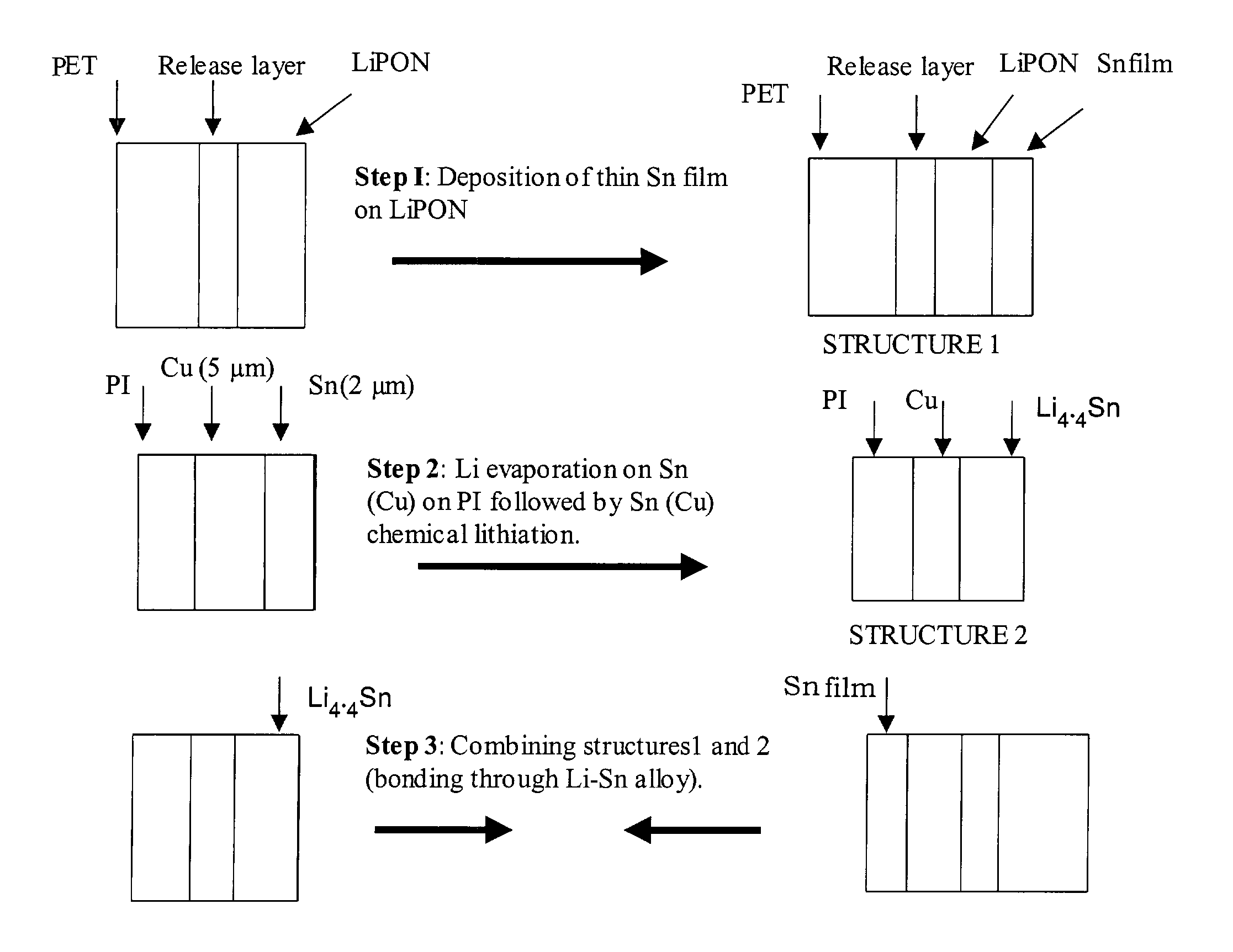

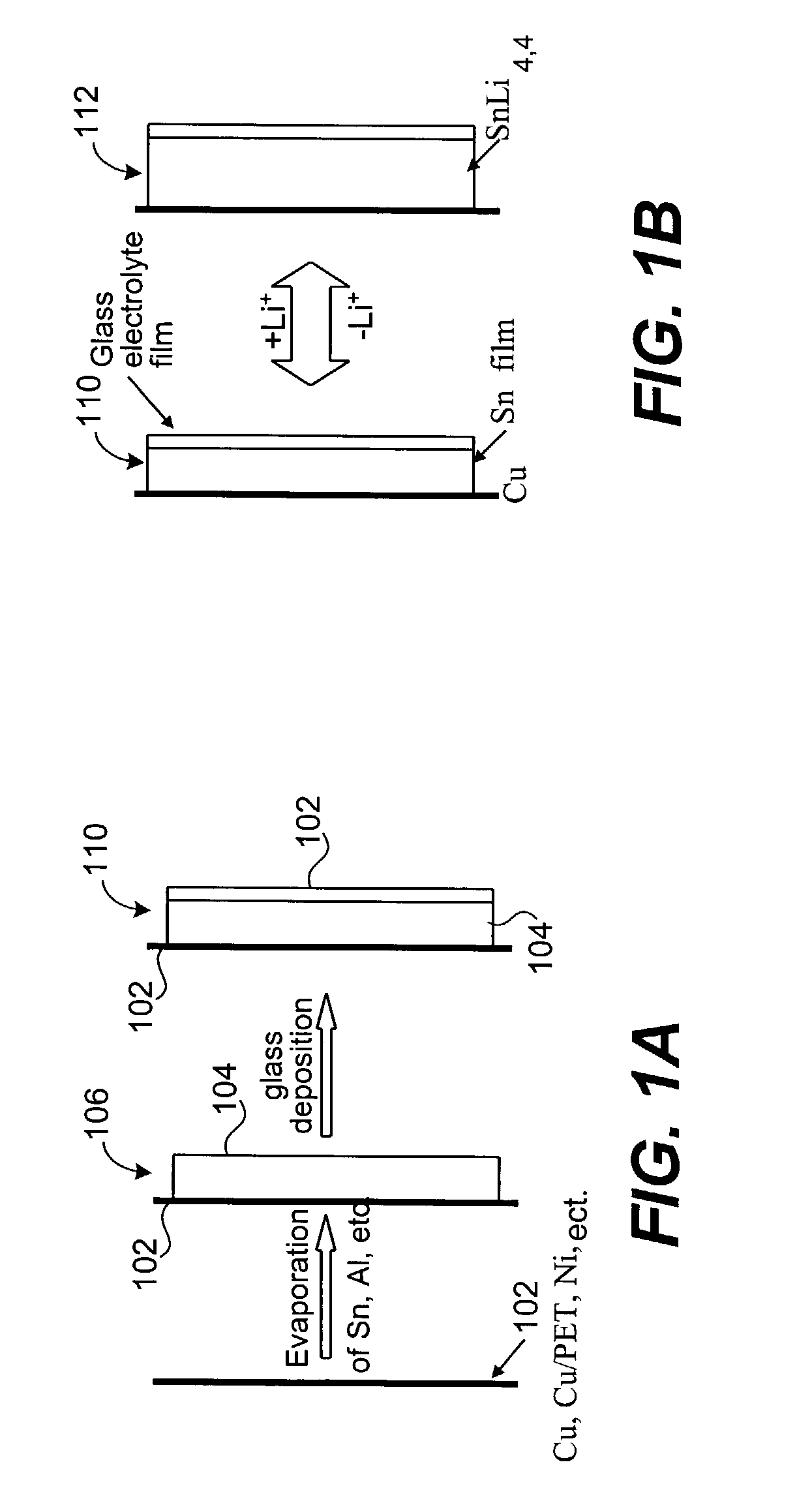

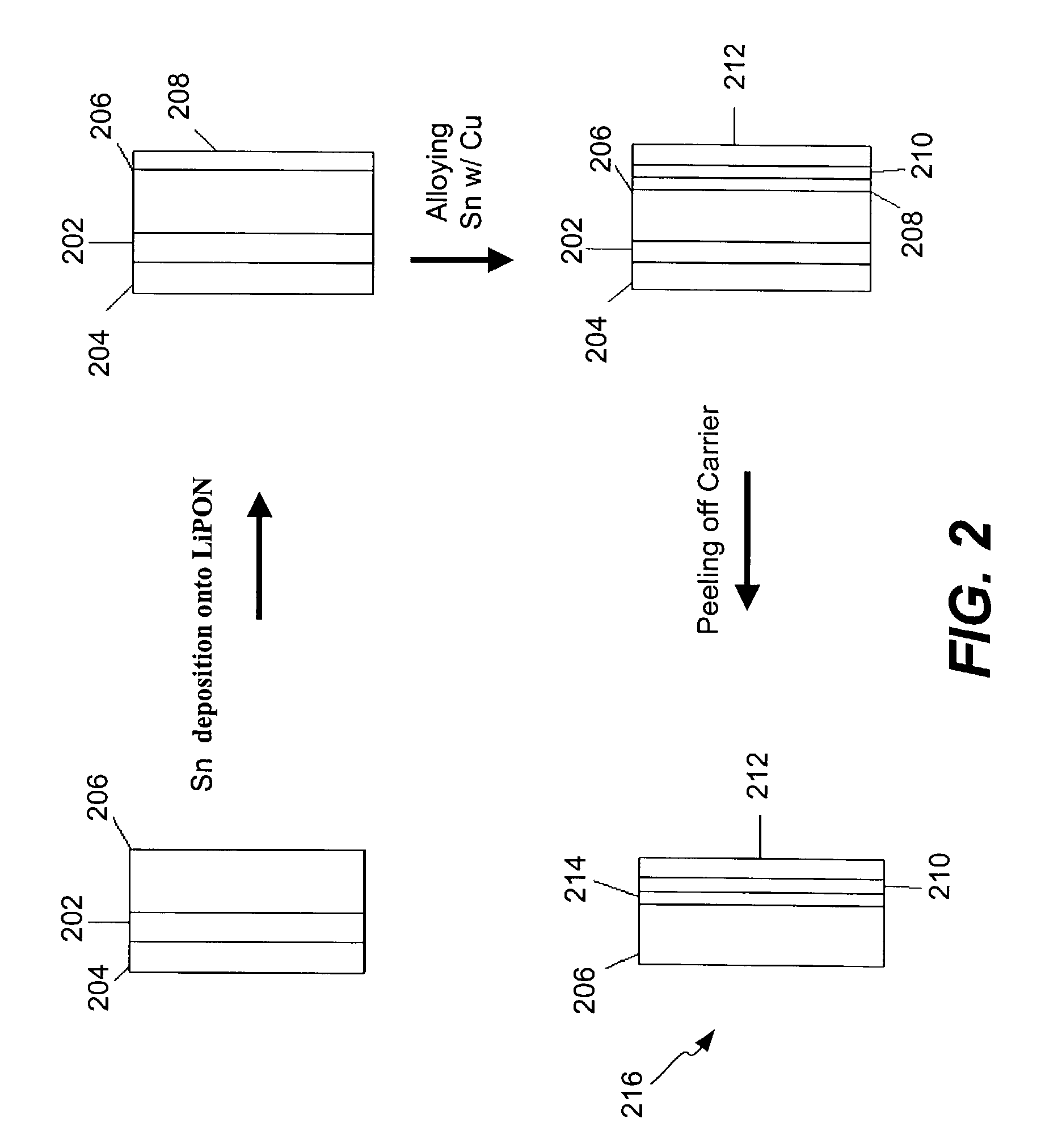

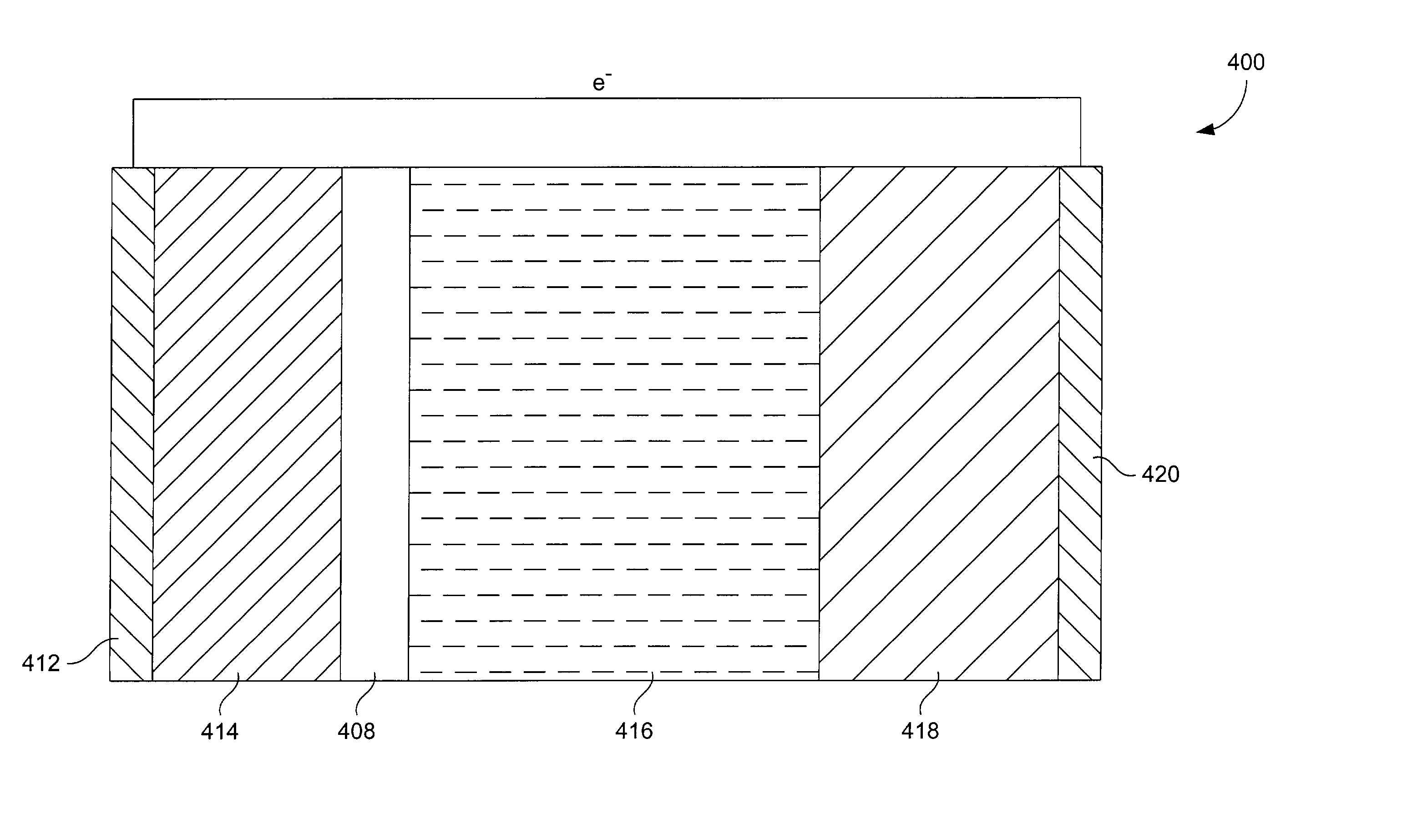

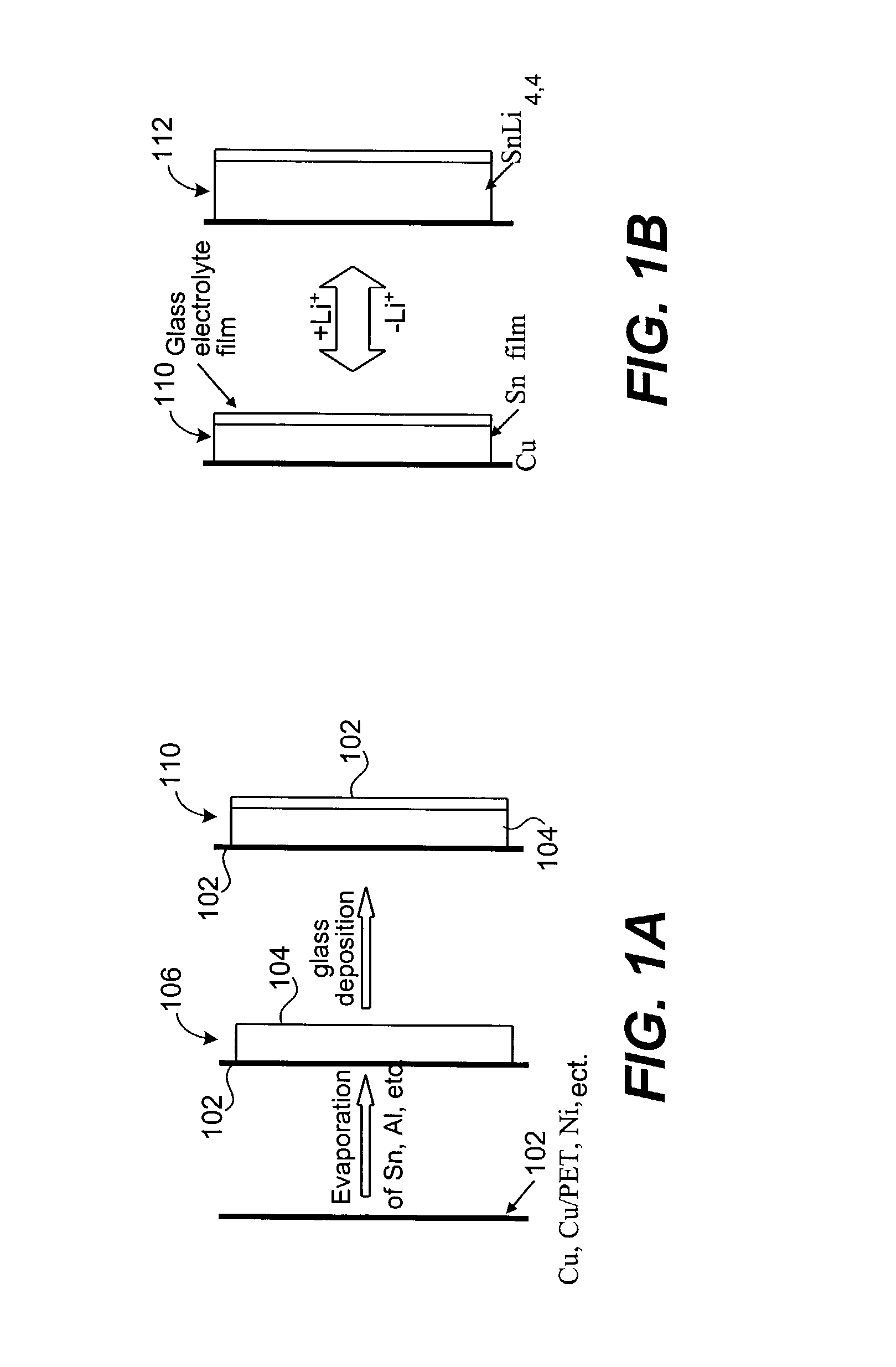

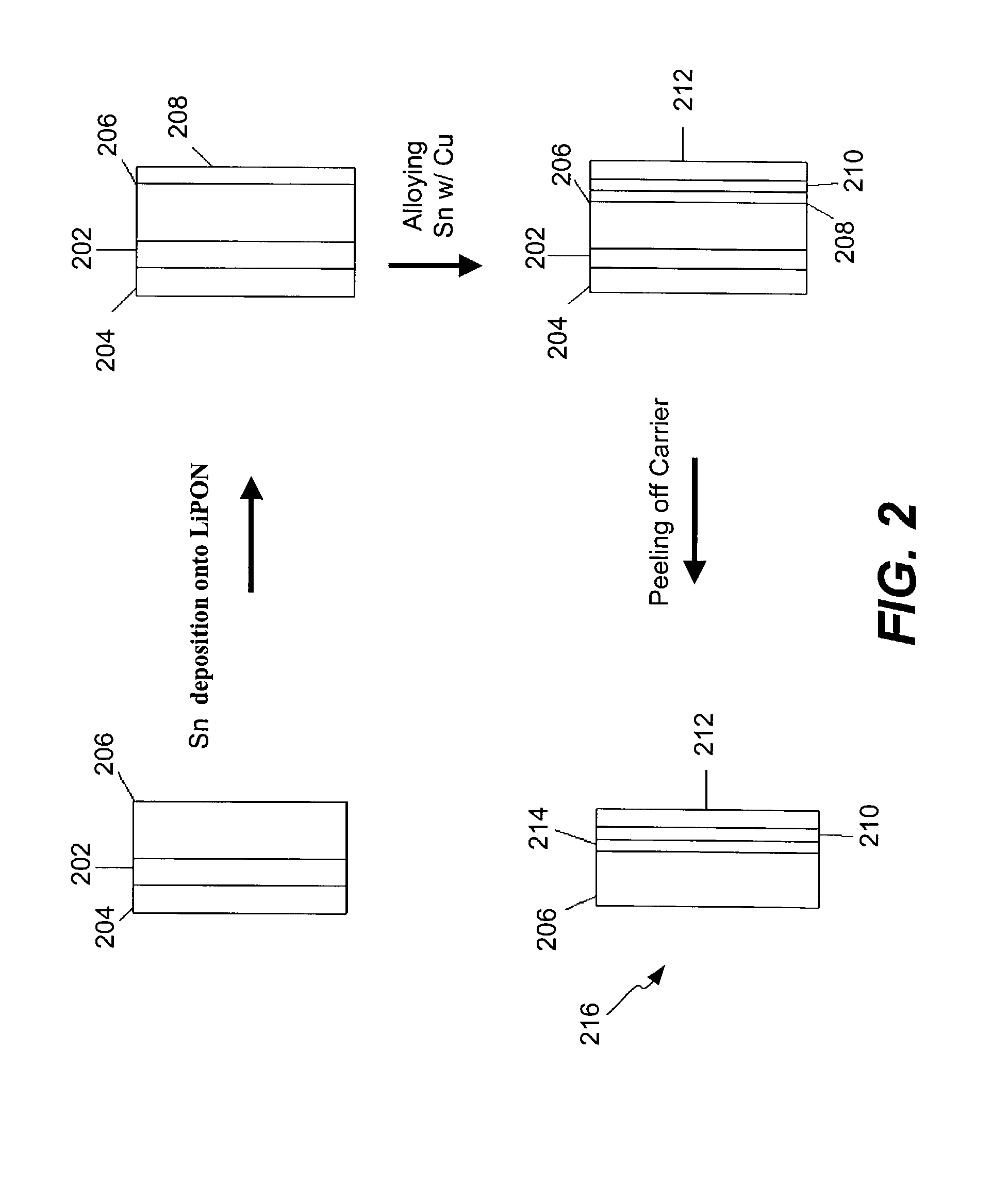

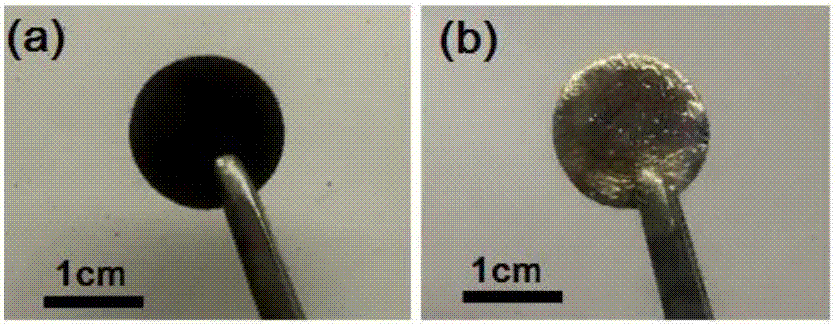

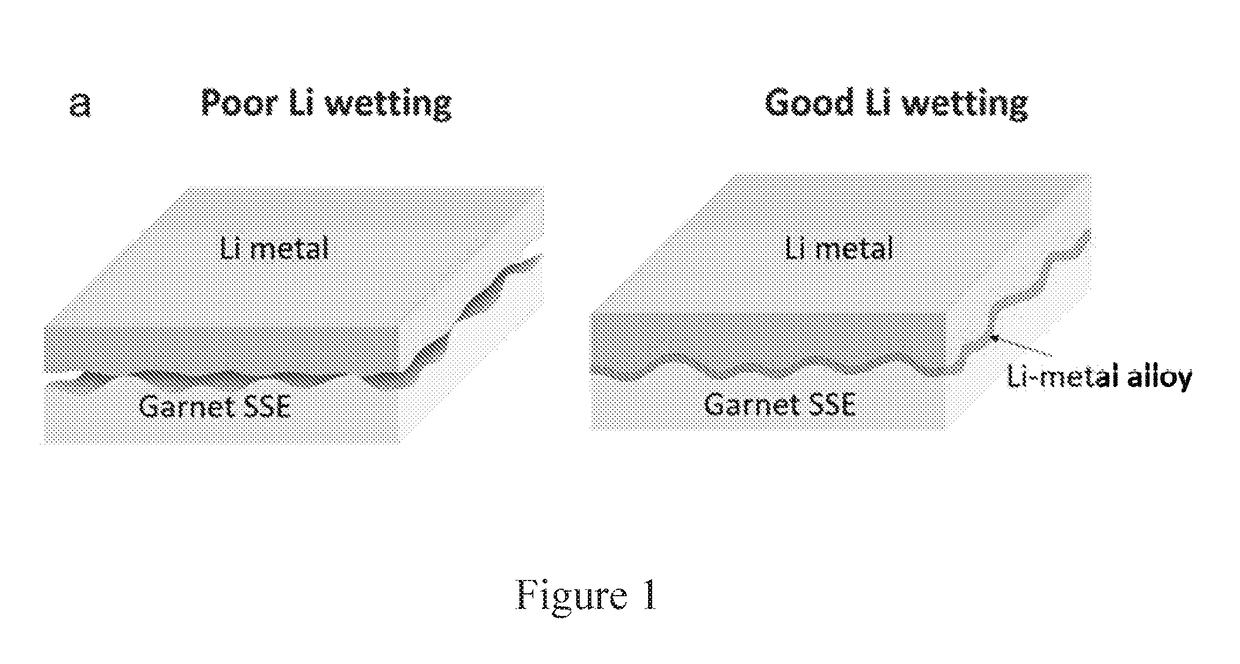

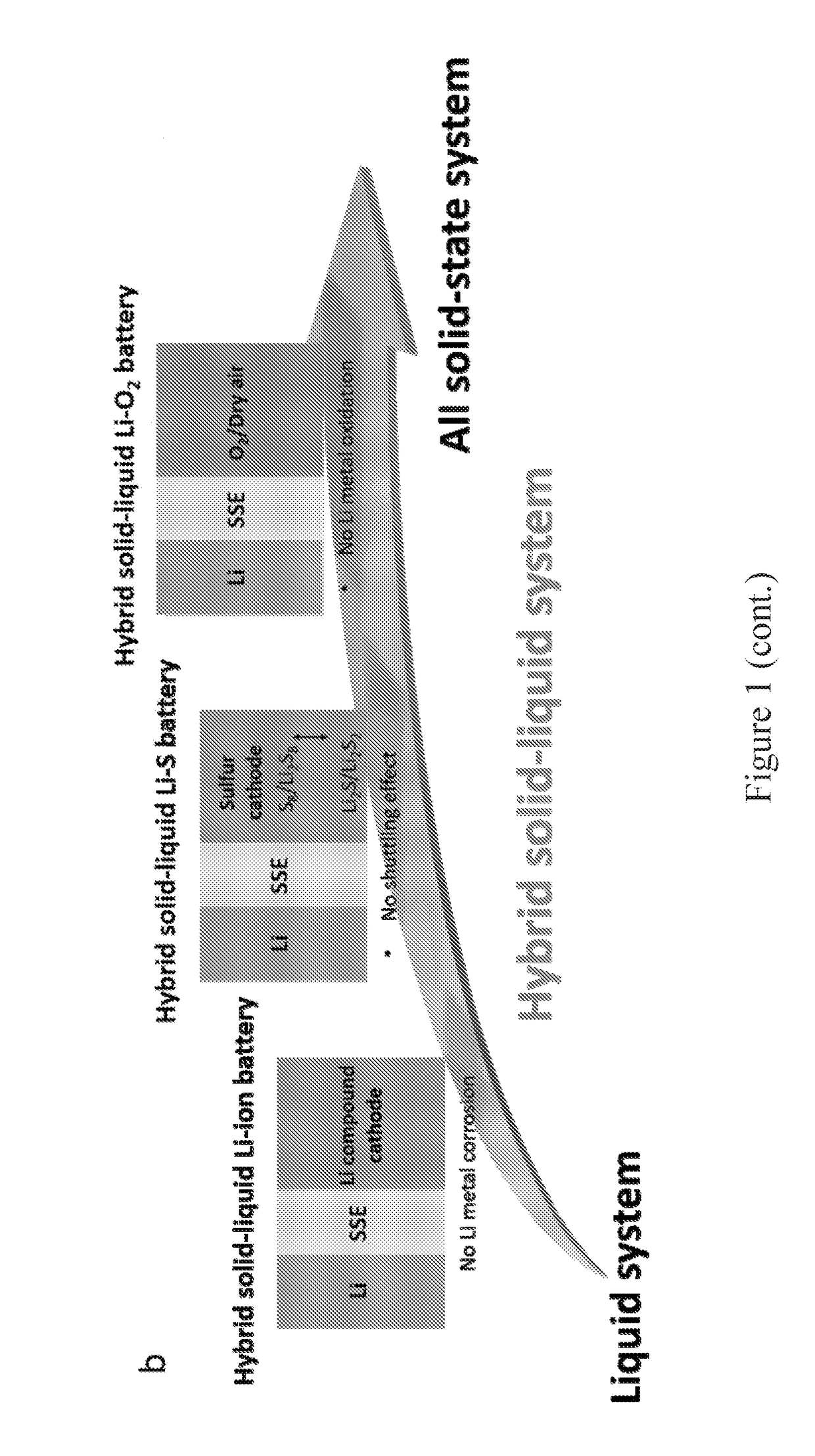

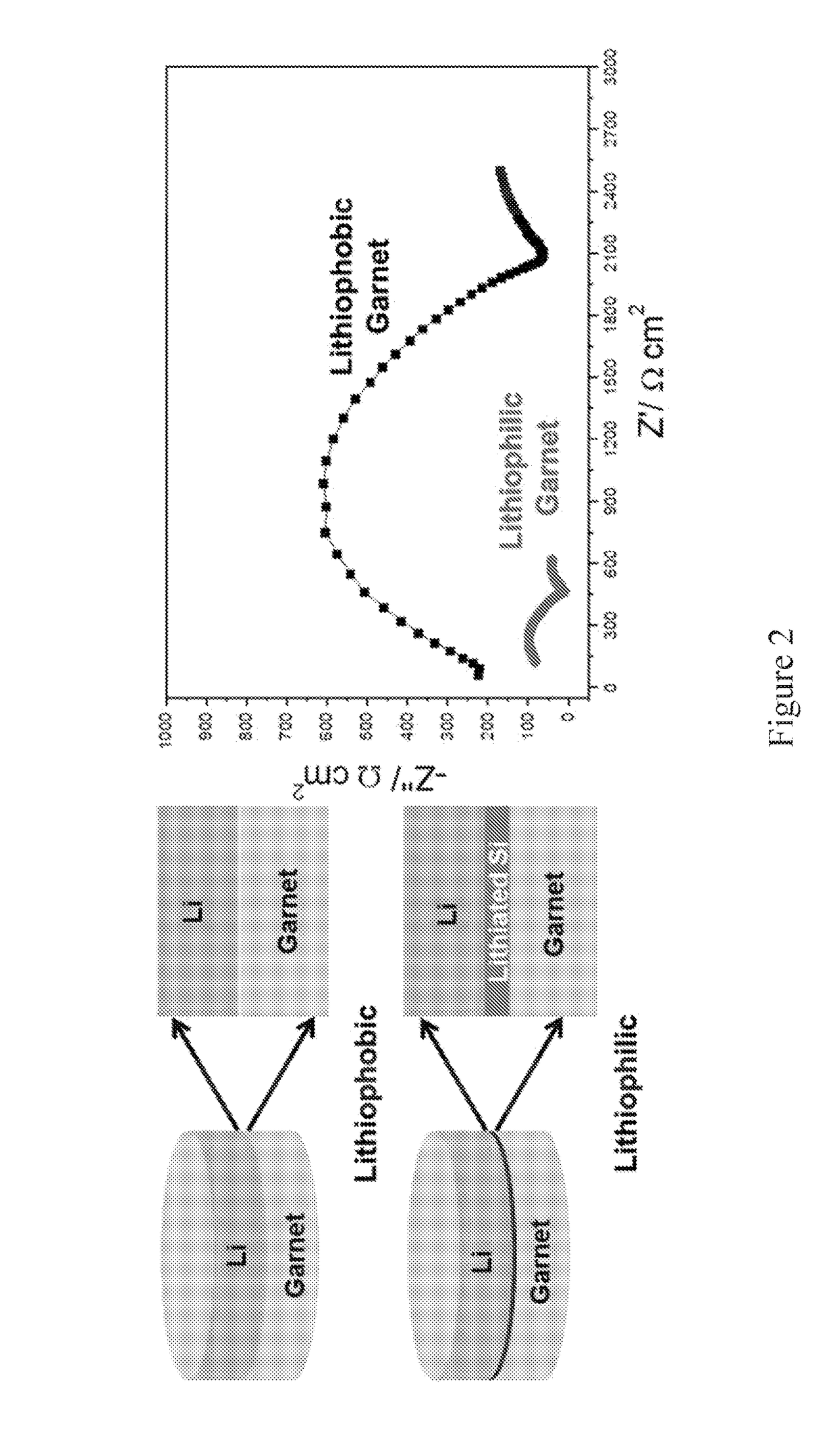

Metal alloy layers on substrates, methods of making same, and uses thereof

ActiveUS20190088986A1Improve interface resistanceImprove thermal stabilityFuel and secondary cellsElectrochemical processing of electrodesSolid state electrolyteLithium metal

Metal alloy layers on substrates. The metal-alloy layers (e.g., lithium-metal layers, sodium-metal layers, and magnesium-metal layers) can be disposed on, for example, a solid-state electrolyte material. The metal-alloy layers can be used in, for example, solid-state batteries. A metal alloy layer can be an anode or part of an anode of a solid state battery.

Owner:UNIV OF MARYLAND

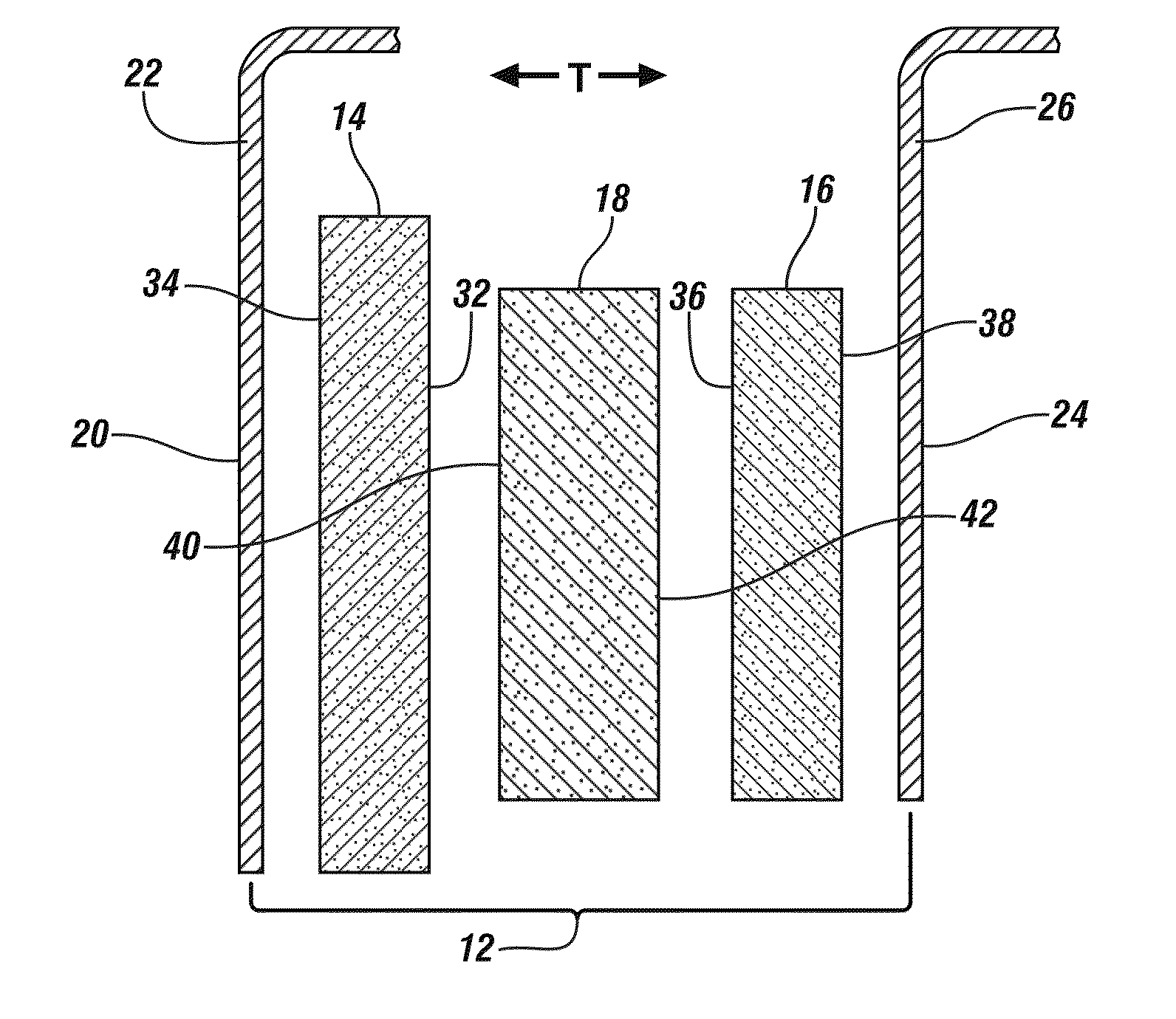

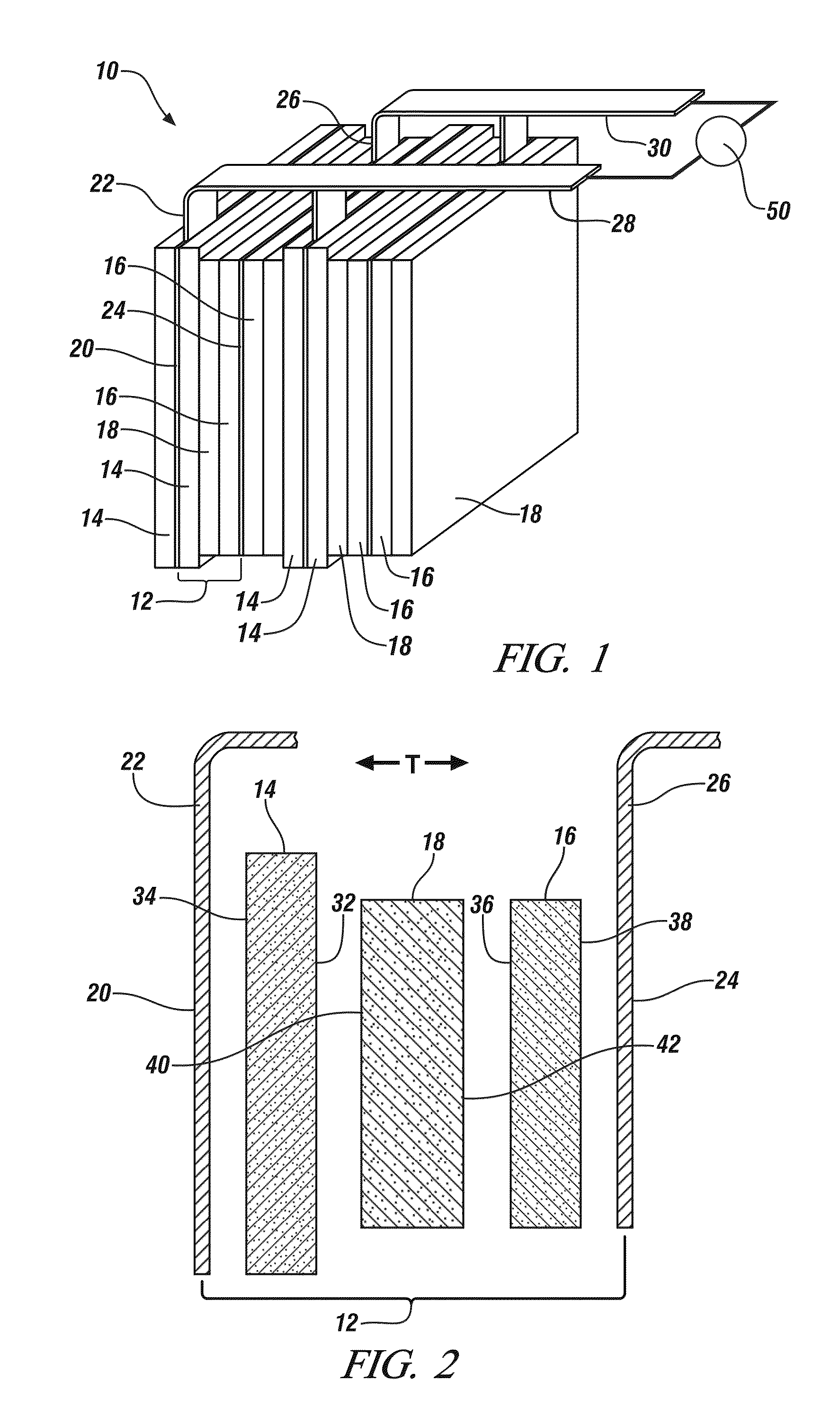

Multi-phase separated silicon based alloys as negative electrode material for lithium batteries

ActiveUS20140127573A1Increased charge storage capacityImprove cycle stabilityMaterial nanotechnologyConductive materialAlloyLithium-ion battery

A particulate composite of silicon, tin, and aluminum (or other suitable metal) is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in separate matrix phases of crystalline tin and crystalline aluminum. While the distinct tin and aluminum phases provide electron conductivity, each phase accommodates the insertion and extraction of lithium in the operation of the cell and all phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. Other suitable metals for use in the composite with silicon and tin include copper and titanium.

Owner:GM GLOBAL TECH OPERATIONS LLC

Phase separated silicon—tin composite as negative electrode material for lithium-ion and lithium sulfur batteries

ActiveUS9005811B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyElectrode melt handlingElectrical batteryLithium sulfur

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This negative electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

ActiveUS20130071736A1Reduces induced stressReduce stressMaterial nanotechnologyElectrode carriers/collectorsComposite electrodeAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com