Patents

Literature

57results about How to "Improve interface resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode materials with high surface conductivity

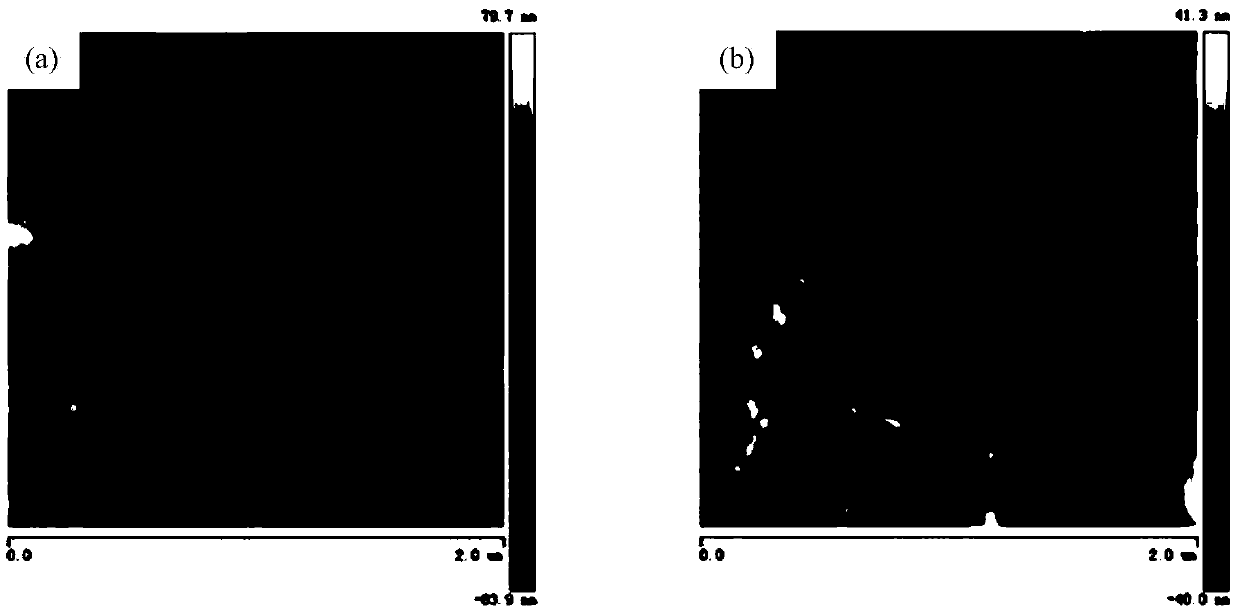

InactiveUS20040140458A1Simple structureHigh crystallinityElectrode manufacturing processesDouble layer capacitorsSurface conductivityIon exchange

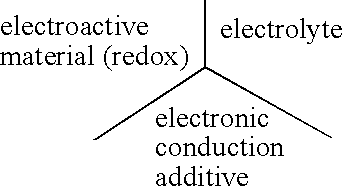

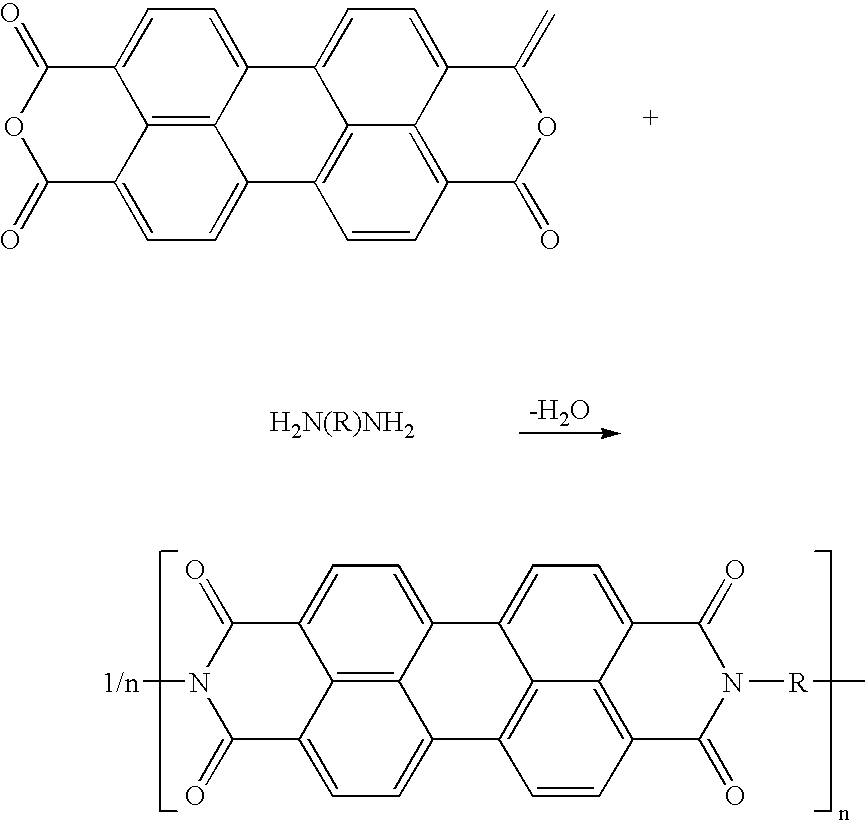

The present invention concerns electrode materials capable of redox reactions by electrons and alkaline ions exchange with an electrolyte. The applications are in the field of primary (batteries) or secondary electrochemical generators, super capacitors and light modulating system of the super capacitor type.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Positive electrode body for nonaqueous electrolyte battery, method for producing same, and nonaqueous electrolyte battery

InactiveCN102893431AImprove output characteristicsImprove interface resistanceLi-accumulatorsNon-aqueous electrolyte accumulator electrodesHigh resistanceBattery charge

Owner:SUMITOMO ELECTRIC IND LTD

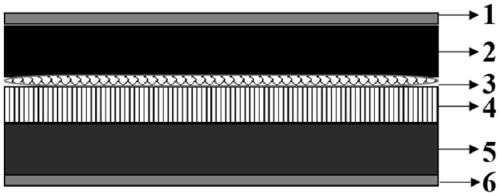

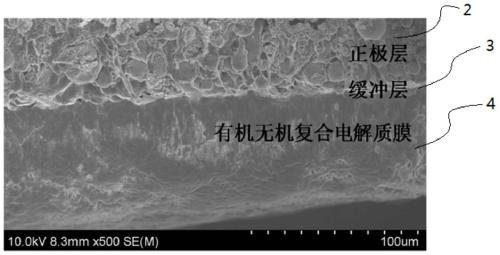

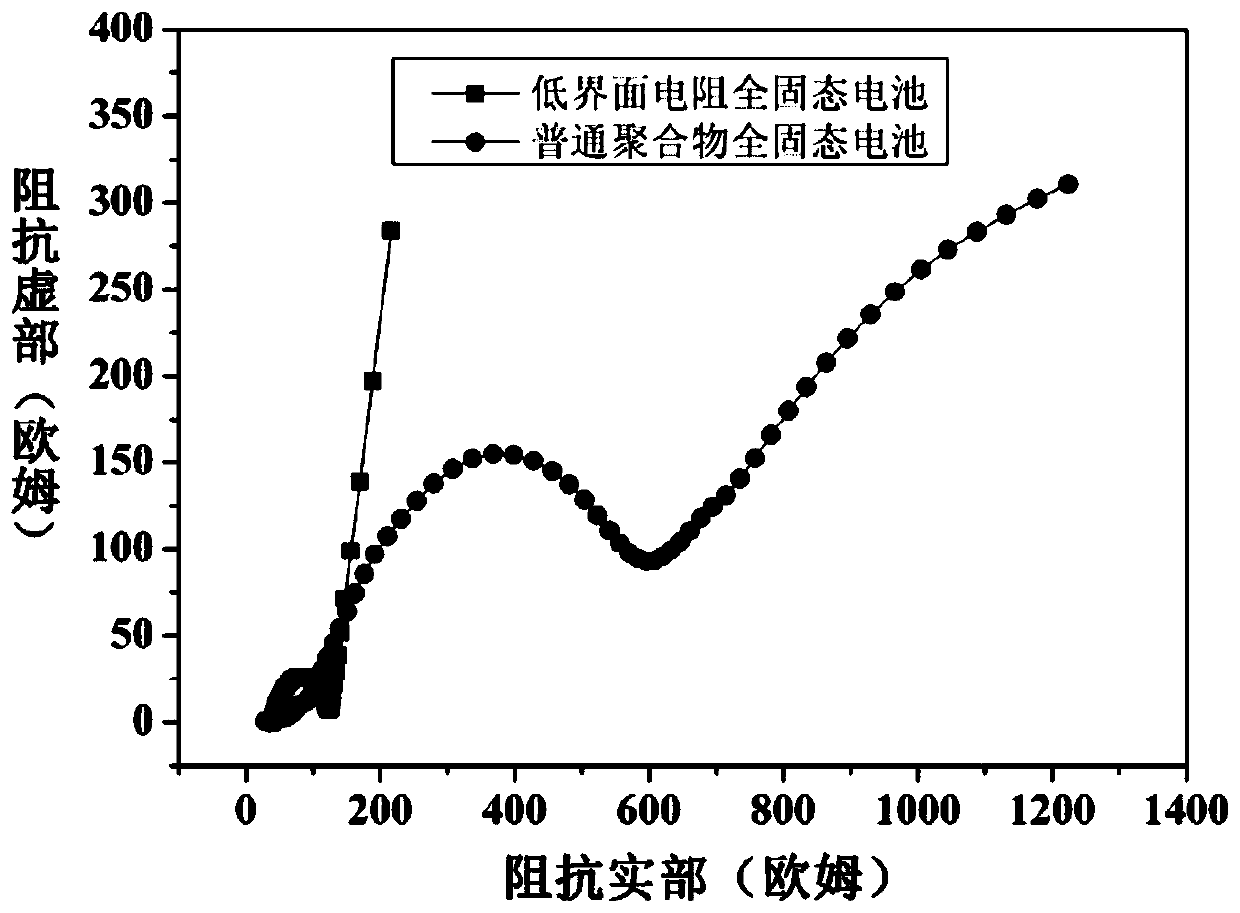

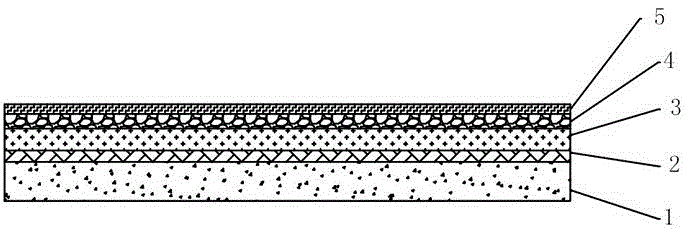

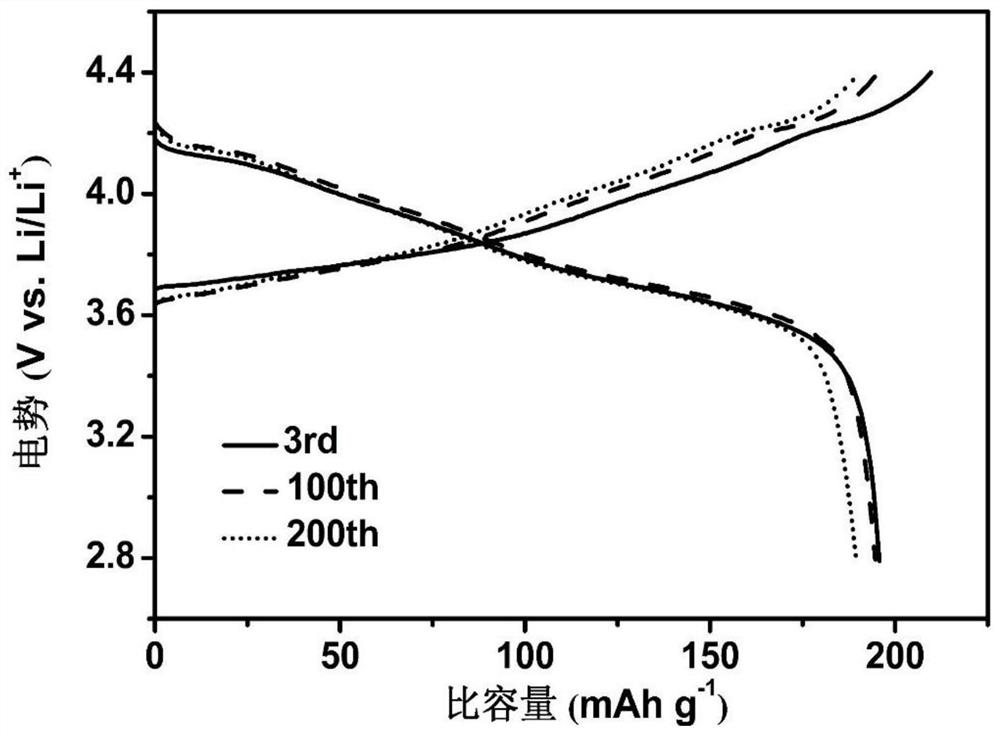

All-solid-state battery with low interface resistance and preparation method of all-solid-state battery

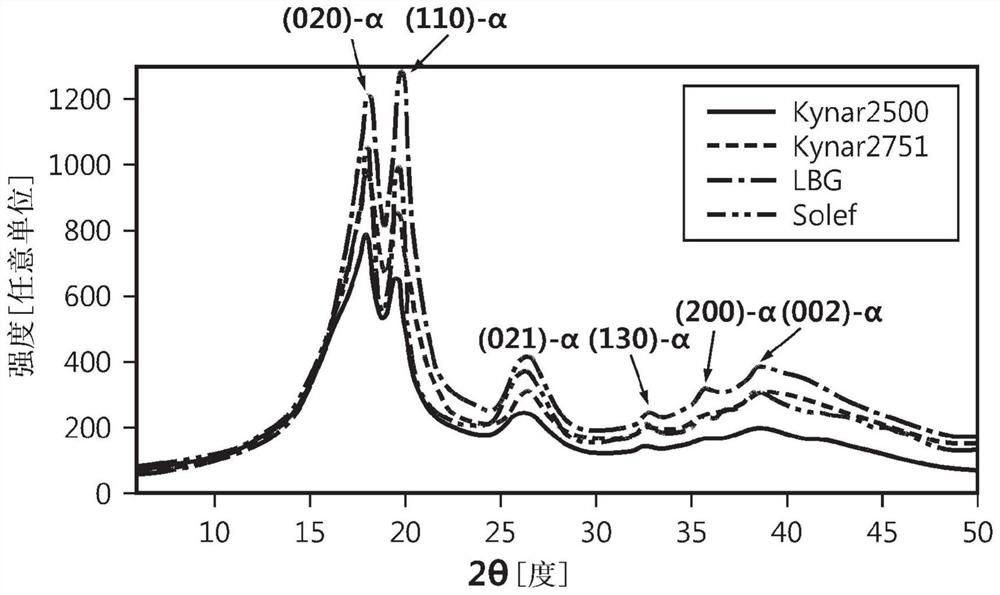

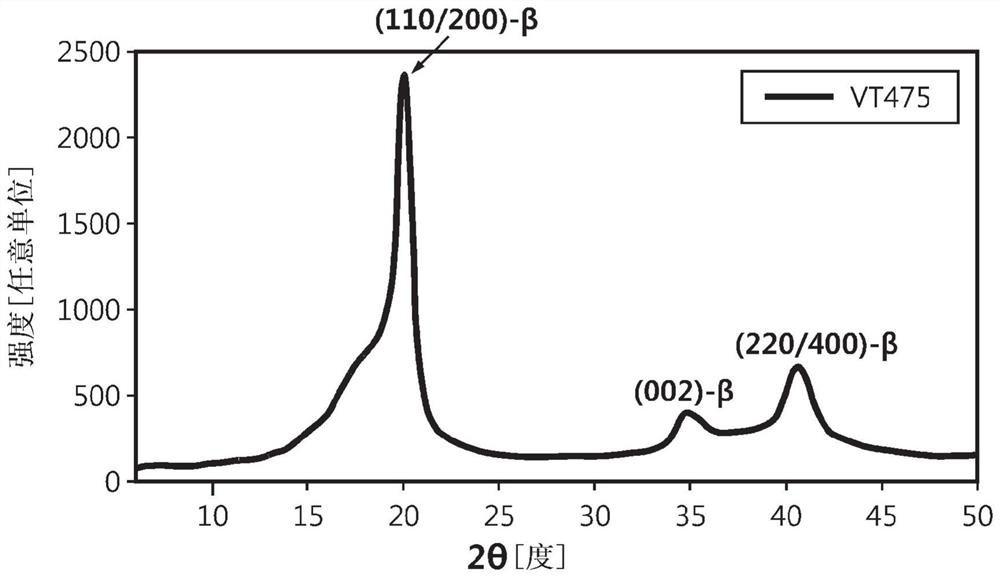

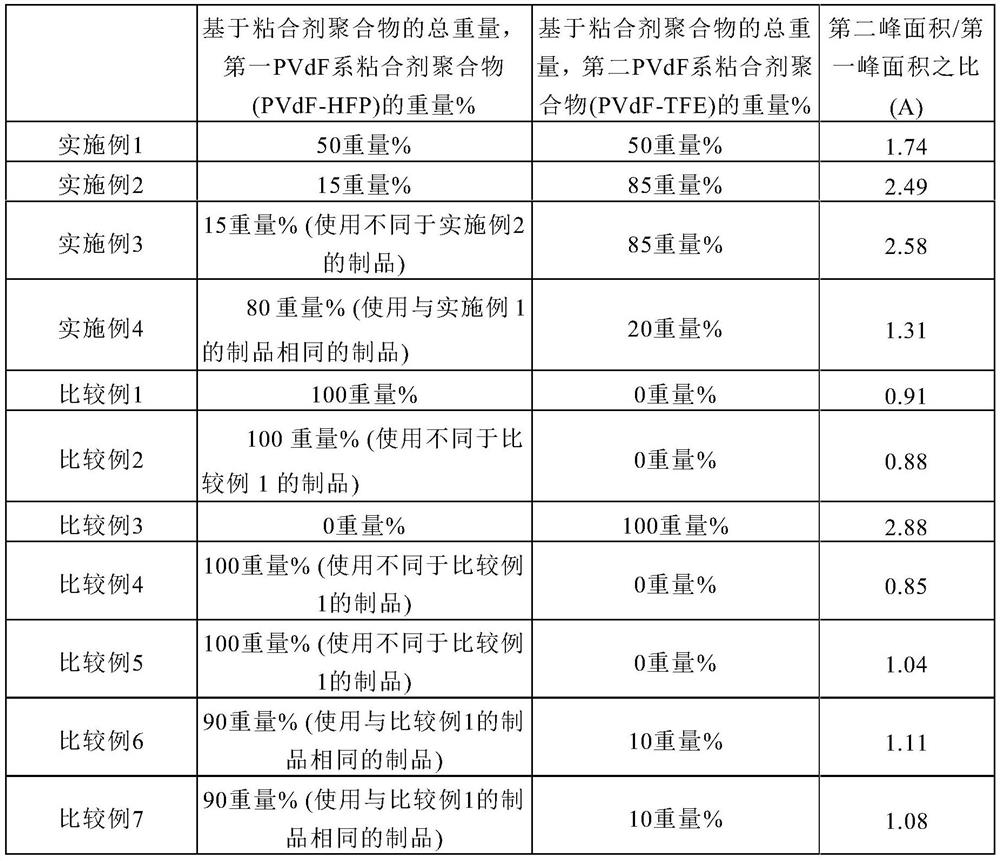

ActiveCN111525181ARealize large-scale preparationResolve Microscopic DefectsSolid electrolytesFinal product manufactureComposite electrolyteHexafluoropropylene

The invention discloses an all-solid-state battery with low interface resistance and a preparation method of the all-solid-state battery, the all-solid-state battery comprises an integrated battery cell, and the integrated battery cell comprises a positive electrode current collector layer, a positive electrode layer, a buffer layer, an organic-inorganic composite electrolyte membrane, a negativeelectrode layer and a negative electrode current collector layer which are arranged in sequence; the organic-inorganic composite electrolyte membrane comprises a high-molecular polymer matrix, a lithium salt and an inorganic filler, the high-molecular polymer matrix is selected from polyvinylidene fluoride or a polyvinylidene fluoride-hexafluoropropylene copolymer; the lithium salt is selected from at least one of LiTFSI, LiFSI, LiClO4, LiPF6, LiBF4, LiBOB, LiDFOB and LiPF2O2. According to the invention, a layer of soft contact is formed between hard interfaces of the positive electrode and the negative electrode, multiple layers of films are integrally formed, different component film structures are seamlessly interconnected, and the interface problem of the solid-state battery is effectively improved. The solid-state battery provided by the invention has excellent capacity exertion and cycling stability, and the preparation method is high in efficiency and low in cost.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Electrode foil, current collector, electrode, and energy storage element using same

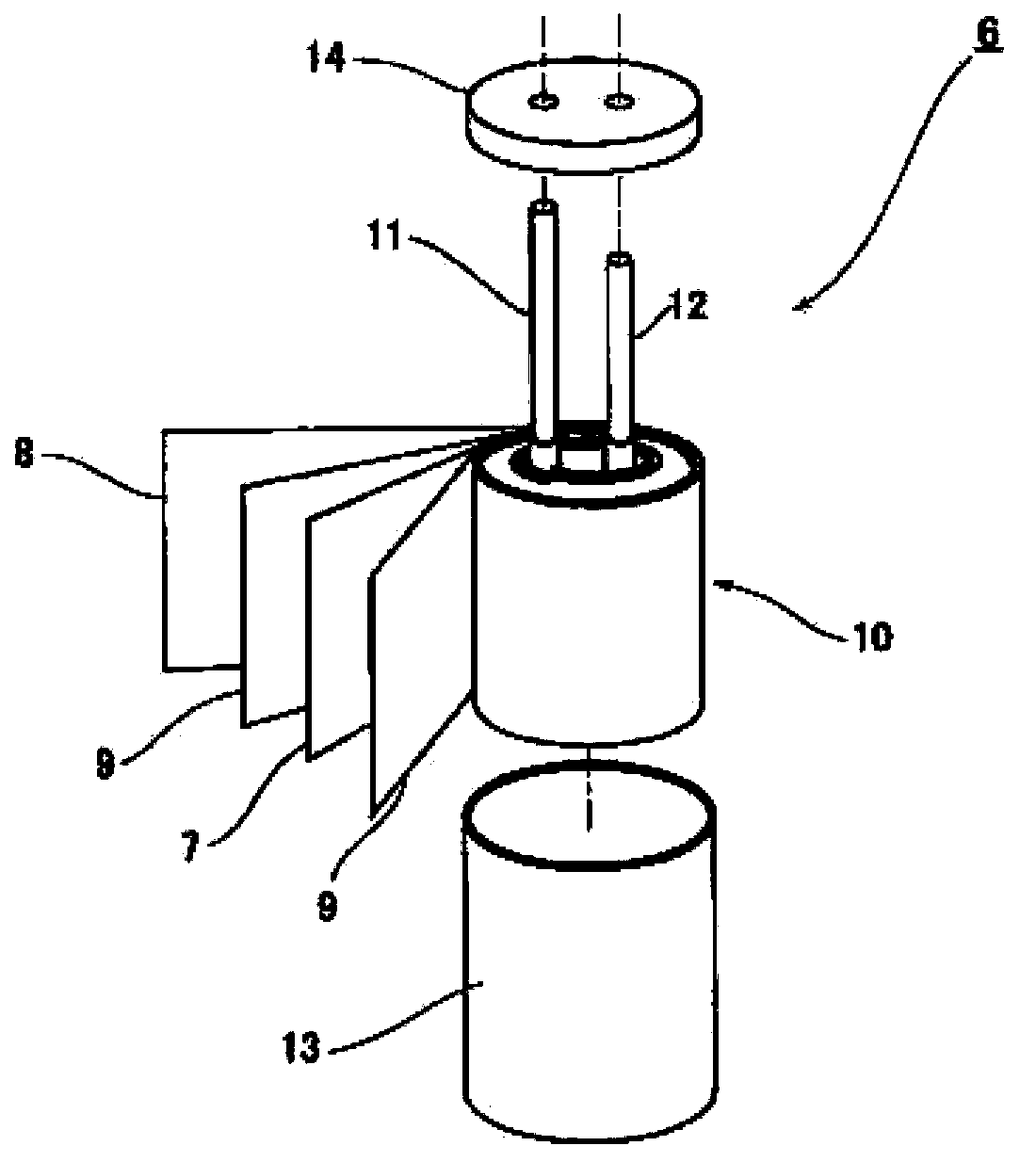

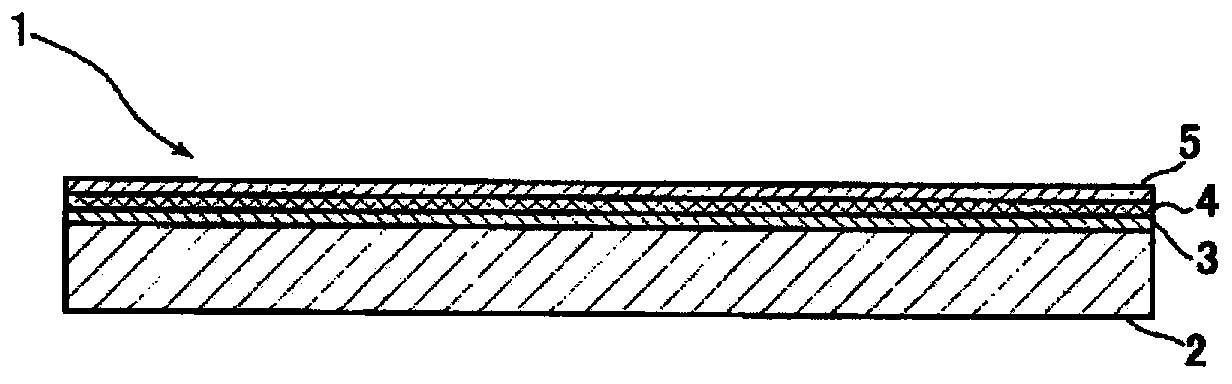

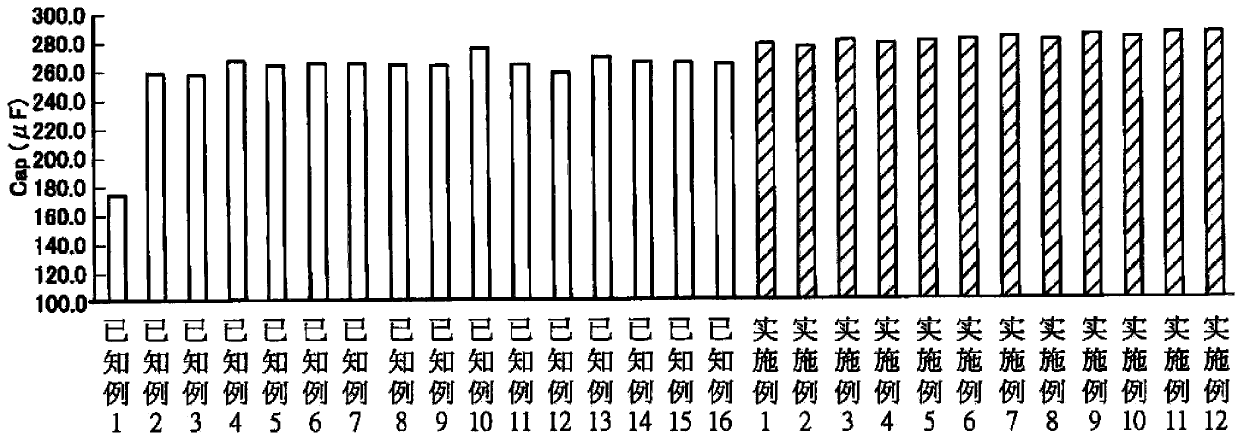

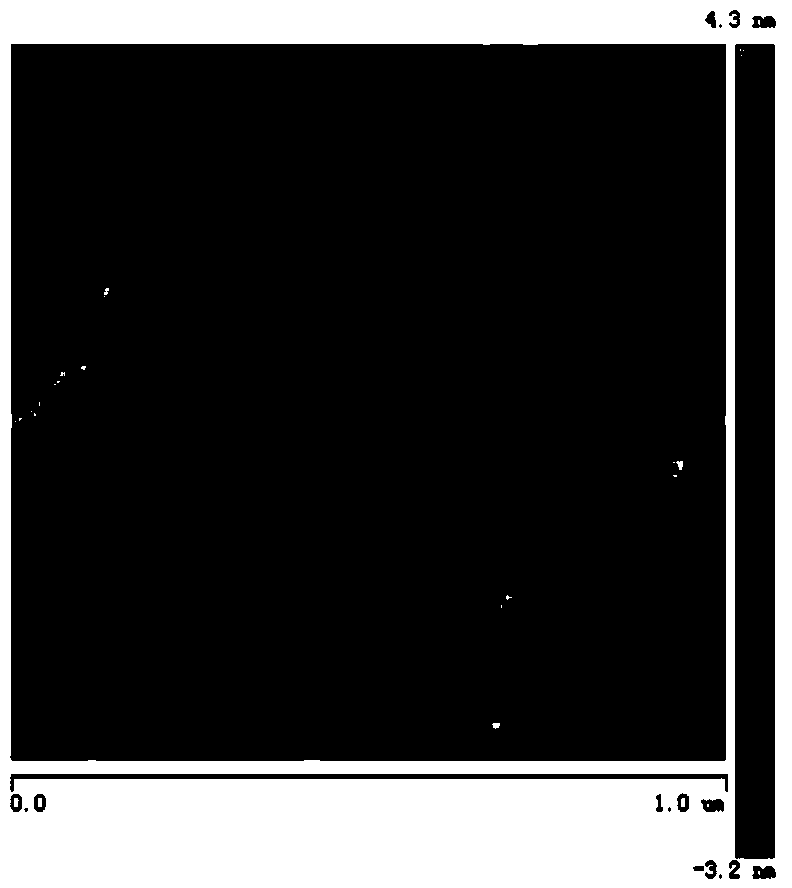

ActiveCN103380469APrevent oxidationImprove interface resistanceSolid electrolytic capacitorsHybrid capacitor electrodesCarbon layerCapacitance

This negative electrode foil for a solid electrolyte capacitor: increases capacitance, reduces ESR and leakage current, improves heat resistance, and reduces manufacturing costs; and improves the power density, achieves rapid charging / discharging, and improves the lifespan characteristics of energy storage elements such as rechargeable batteries, electric double-layer capacitors, and hybrid capacitors. The negative electrode foil or a current collector is used, which: is obtained by forming a metal layer, a mixed layer obtained by mixing a material constituting the metal layer with carbon, and a carbon layer substantially comprising carbon, on a metal foil; and is configured in such a manner as to change as the components of the mixed layer change from a component containing only the material substantially constituting the metal layer to a component substantially containing only carbon, and from the metal layer to the carbon layer.

Owner:JAPAN CAPACITOR IND CO LTD

Membrane compounded by polyolefin porous membrane and aramid nano-fibers as well as compounding method and application of membrane

ActiveCN104201309APossesses low-temperature closed-cell propertiesImprove securityCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinPolymer science

The invention belongs to the technical field of membrane materials of chemical power sources or chemical energy storage elements and discloses a membrane which has high size stability and is compounded by a polyolefin porous membrane and aramid nano-fibers, a compounding method of the membrane and application of the membrane to a lithium ion battery or other chemical energy storage elements. The compounding method comprises the following steps: introducing positive charges to the surface of the polyolefin porous membrane, soaking the polyolefin porous membrane with aramid nano-fiber dispersion liquid, taking out the polyolefin porous membrane, washing and drying, and soaking, washing and drying in a cyclic manner to obtain the compound membrane with a plurality of layers of aramid nano-fibers which are adsorbed on the surface of the polyolefin porous membrane. The compound membrane has low-temperature pore-closing property and high-temperature resistance and is suitable for electrochemical devices working at relatively high temperature; the compound membrane has relatively high ionic conductivity; the bonding force between the aramid nano-fibers and the polyolefin porous membrane is improved; the aramid nano-fibers are unlikely to be peeled from the polyolefin porous membrane in charging and discharging cycles; the interface resistance is unlikely to be increased along with the increase of the battery cycle number, so that the cycle performance of the battery is improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

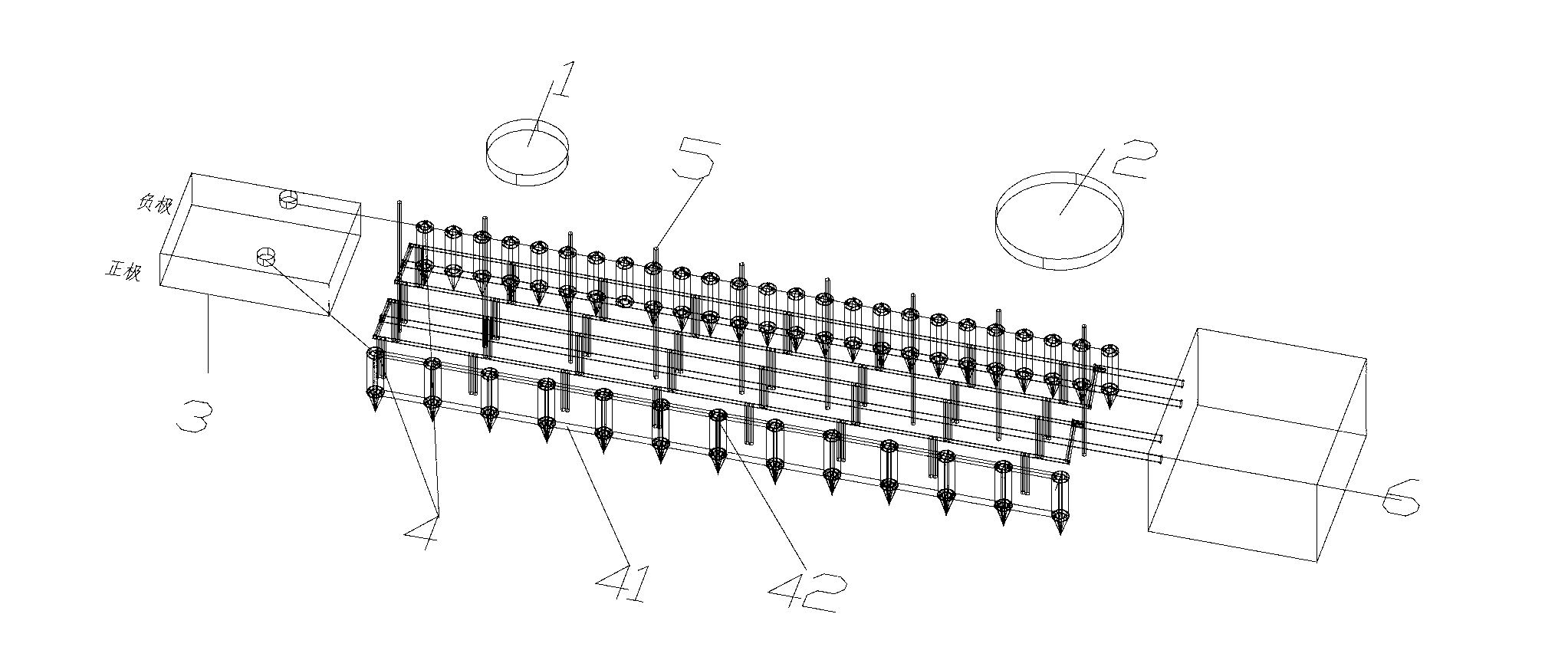

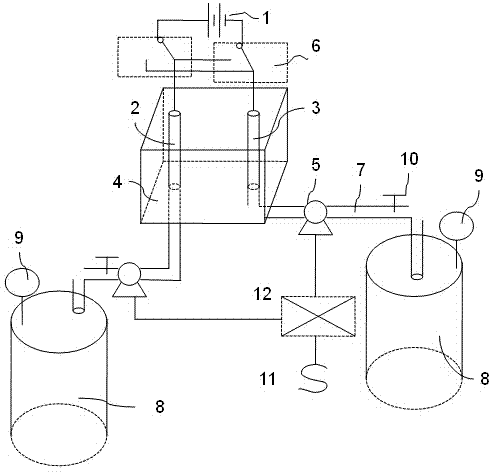

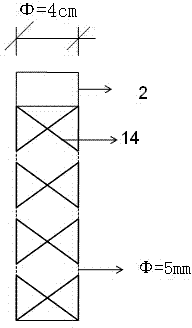

Apparatus and method for stabilizing clay by microbiological-electroosmosis processes

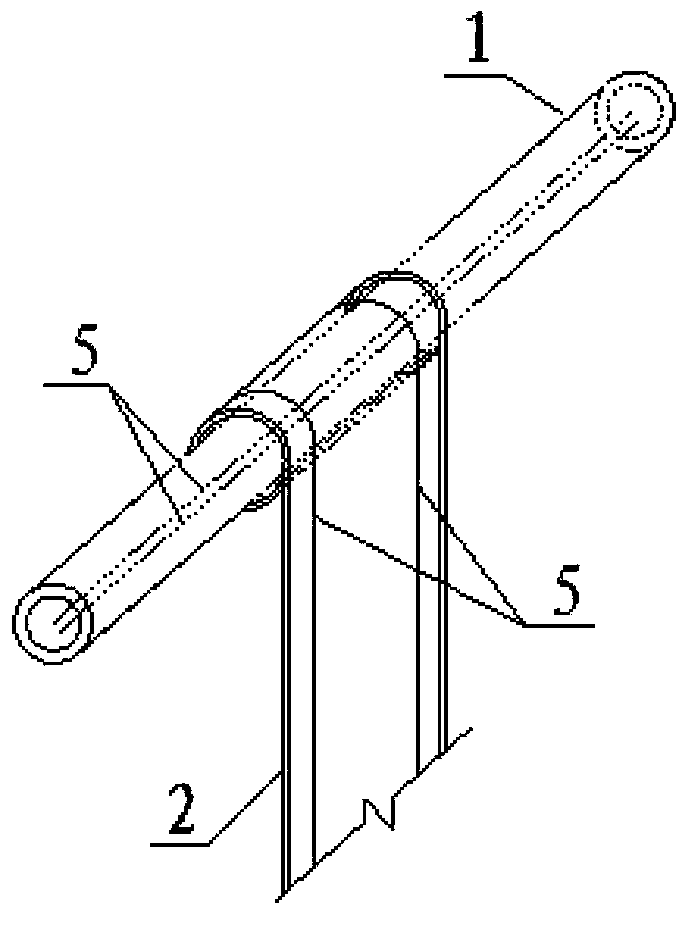

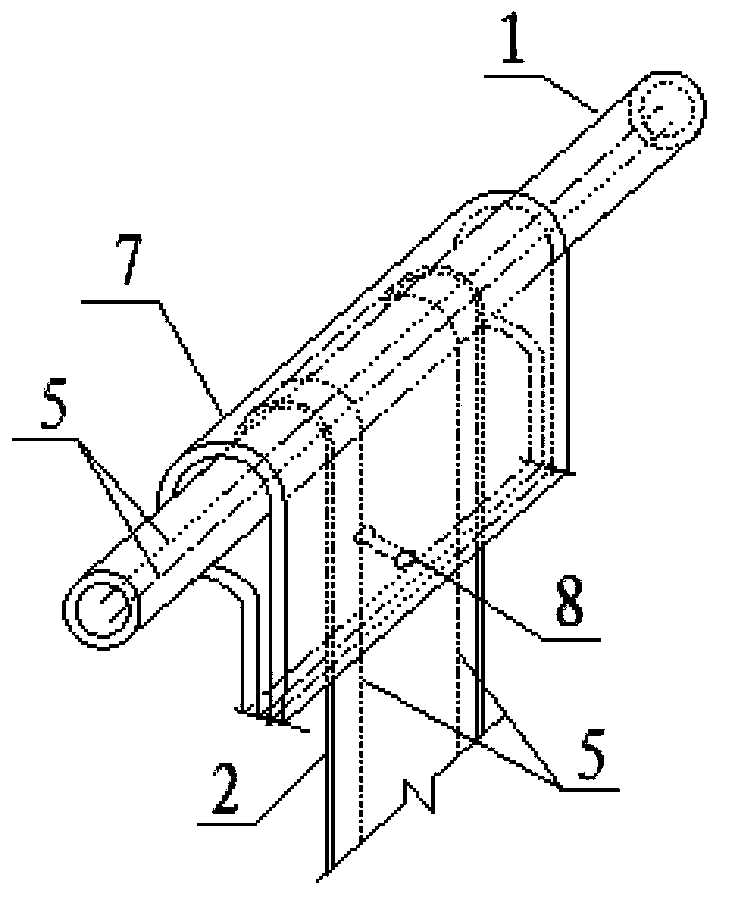

InactiveCN103276719AHigh porosityImprove reinforcement effectSoil preservationNutrient solutionDirect current

The invention discloses an apparatus and a method for stabilizing clay by microbiological-electroosmosis processes. The apparatus comprises culture dishes, nutrient solution dishes, a direct-current power supply, microbiological-electroosmotic devices, thermometers and cooling devices. The method includes the steps of firstly, burying cathodes and anodes of the microbiological-electroosmotic devices on two sides of clay to be treated, inserting the thermometers to the center line of the clay to be treated, and arranging the culture dishes and the nutrient solution dishes near the microbiological-electroosmotic devices; secondly, putting Bacillus pasteurii into the culture dishes, putting urea containing dissolved calcium salt into the nutrient solution dishes, culturing strains, and injecting the urea nutrient solution mixed with the strains and the dissolved calcium salt into the microbiological-electroosmotic devices and the clay; thirdly, turning on the direct-current power supply to perform electroosmosis while controlling the temperature to be lower than 50 DEG C. Compared with the prior art, the apparatus and the method have the advantages of good stabilization effect, high cost performance and convenience in operation without weather effect.

Owner:HOHAI UNIV

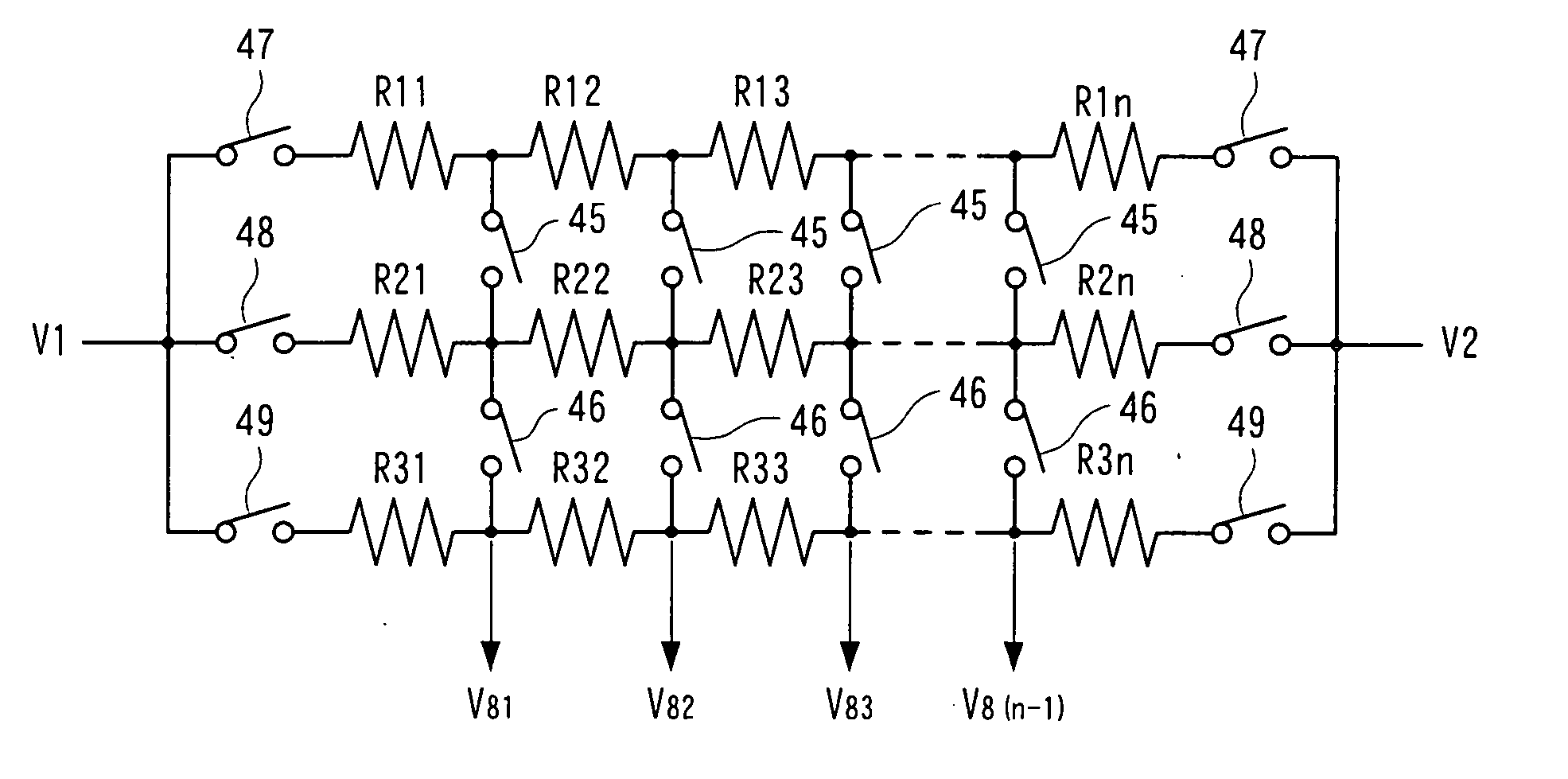

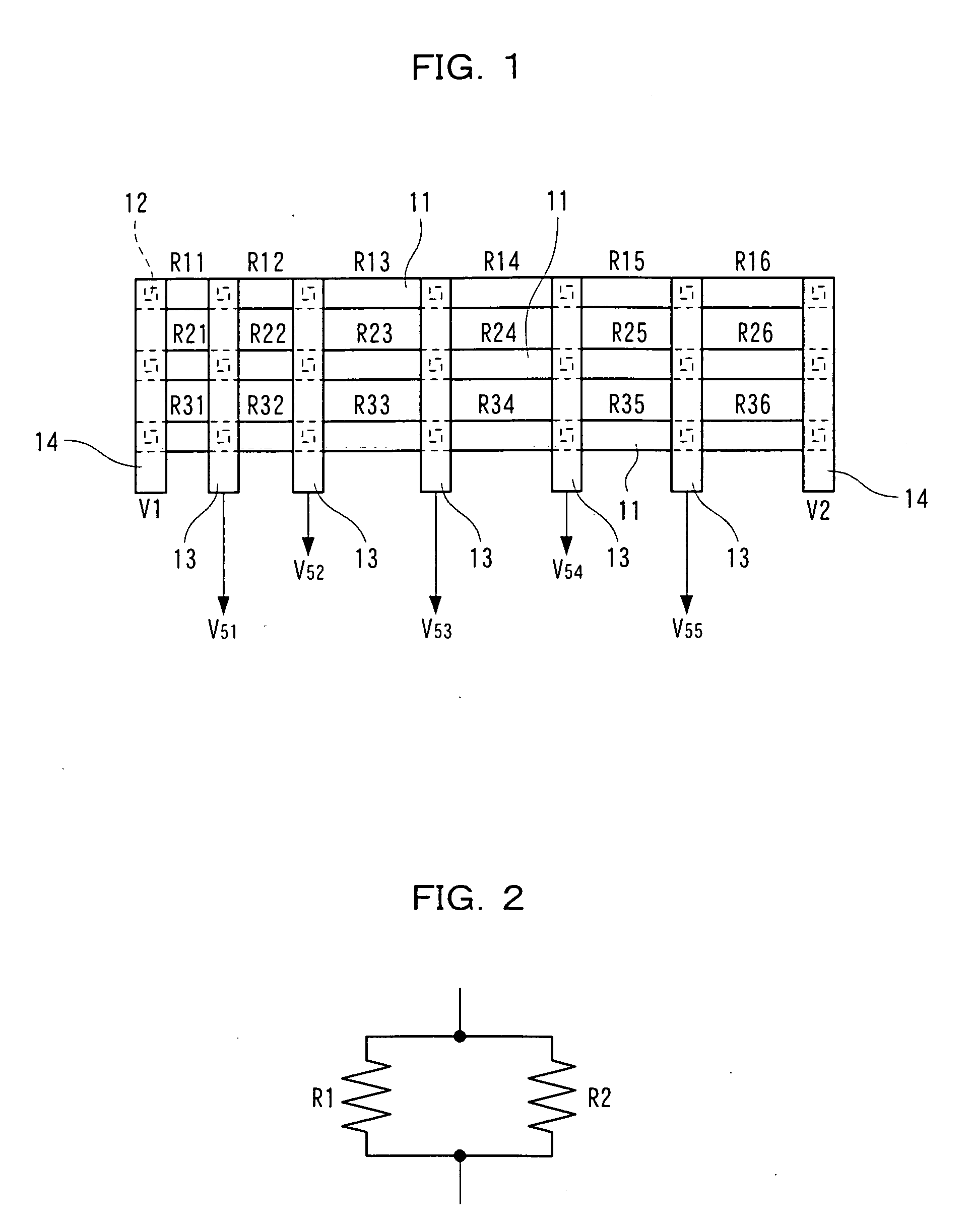

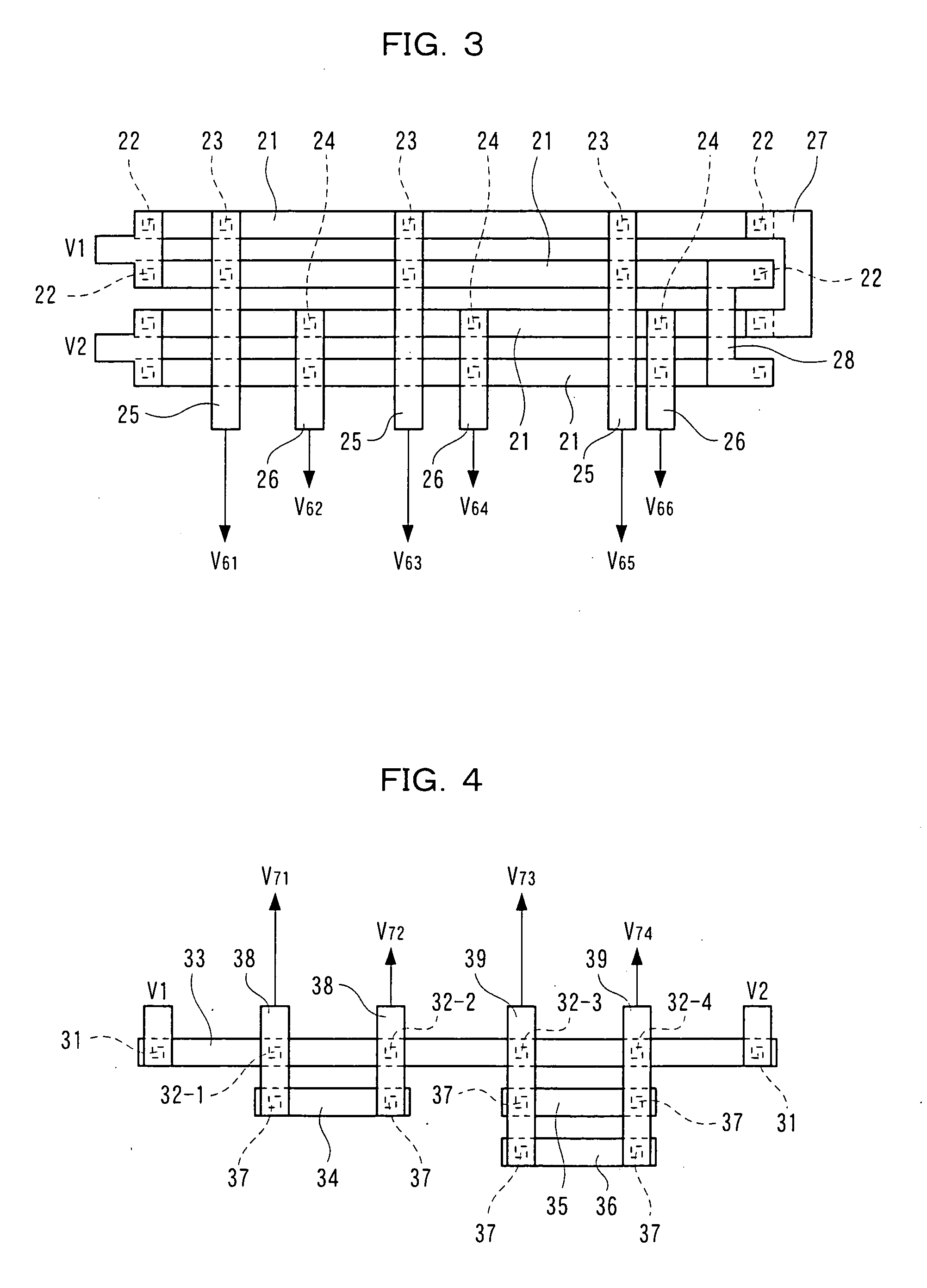

Resistance voltage divider circuit, liquid crystal display driving apparatus using resistance voltage divider circuit, and liquid crystal display apparatus

InactiveUS20050140534A1Accurate gradation voltageImprove gradation displayElectric signal transmission systemsStatic indicating devicesLiquid-crystal displayJunction point

A resistance voltage divider circuit of a gradation potential generation circuit for adjustment, which generates a gradation potential for driving a liquid crystal device. The circuit includes three resistors (11) which are equal in resistance value and have contacts (12) at equal positions. The contacts (12) at the equal positions of each resistors (11) are connected to one another so as to connect the resistors in parallel, reference potentials V1 and V2 are inputted across the resistors connected in parallel, and a gradation potential is generated on a junction point of the contact (12) according to a voltage divided by the resistors (11).

Owner:PANASONIC CORP

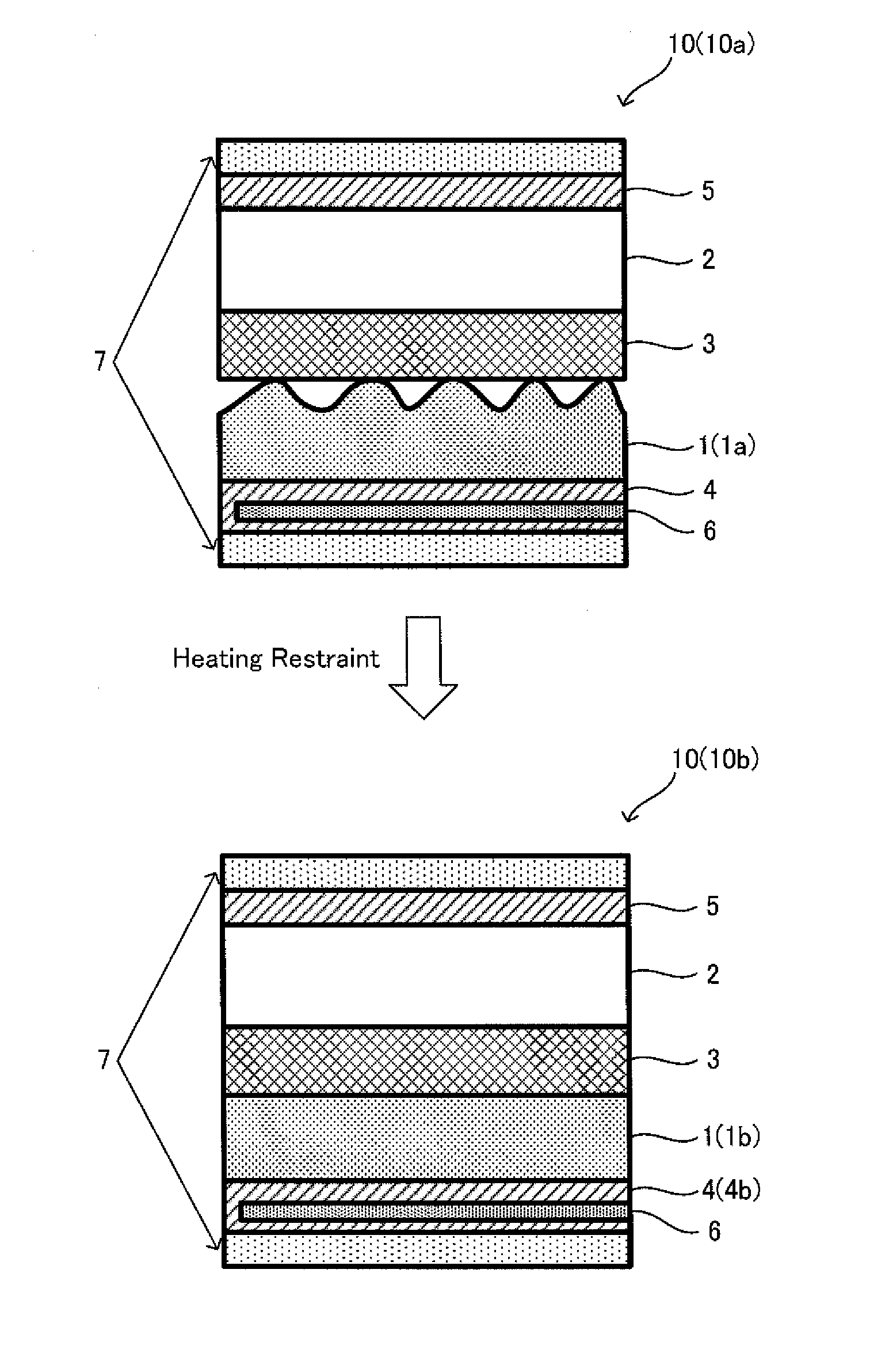

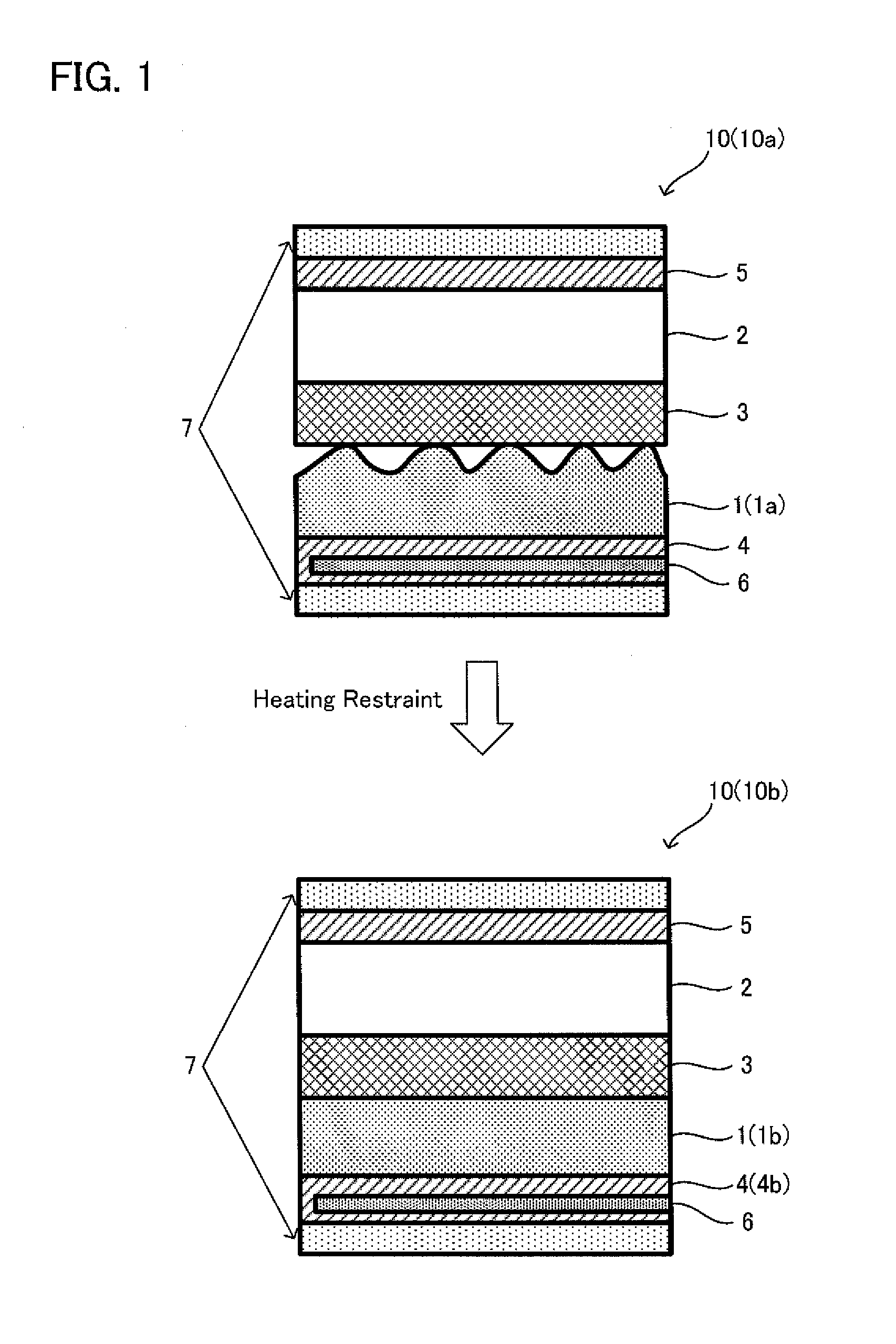

Solid battery and method for regenerating the same

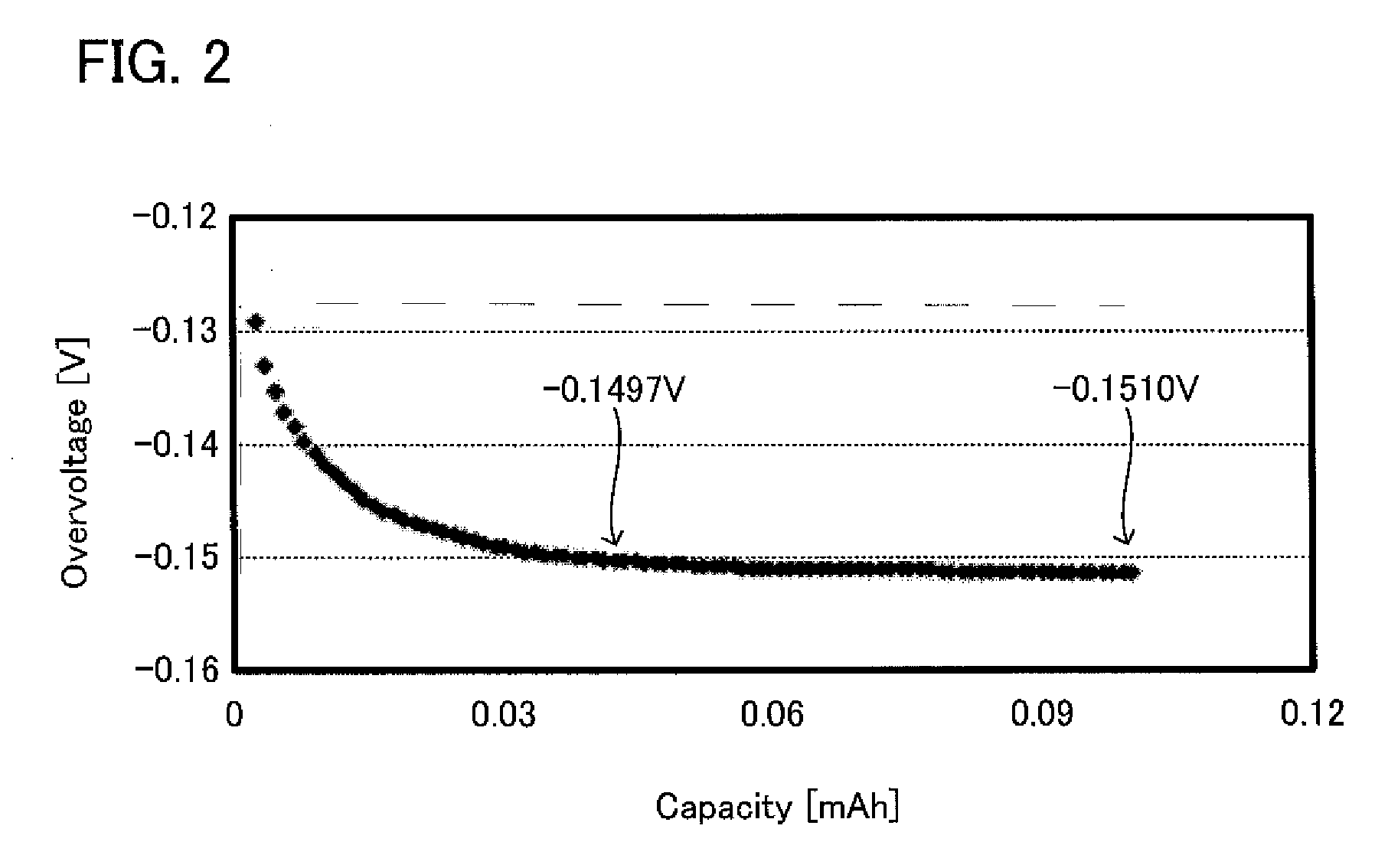

ActiveUS20130164571A1Improve interface resistanceReduce interface resistanceAlkaline accumulatorsPrimary cell maintainance/servicingOvervoltageAlkaline earth metal

Provided are a solid battery which can reduce overvoltage and a regeneration method thereof. The solid battery comprises: an anode capable of absorbing and releasing an alkali metal ion or alkaline earth metal ion; a solid electrolyte layer containing a solid electrolyte having ion conductivity and disposed in a manner to contact the anode; a cathode capable of releasing and absorbing the alkali metal ion or alkaline earth metal ion which moves between the anode and cathode; a heating device to heat the anode to a temperature at which it softens; and a fastening device capable of applying force to closely contact the solid electrolyte layer with the anode. The regeneration method comprises the steps of heating the anode to a temperature at which it softens, and compressing the softened anode, in a direction intersecting a face of the anode which contacts with the solid electrolyte layer.

Owner:TOYOTA JIDOSHA KK

Functionalized graphene hydrogel/functionalized carbon cloth composite fabric, flexible all-solid-state supercapacitor integrated electrode and preparation method

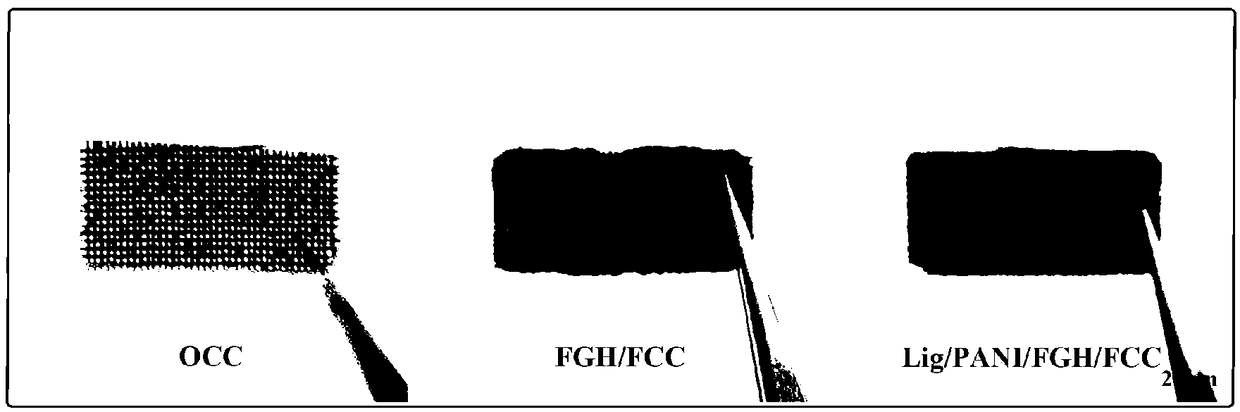

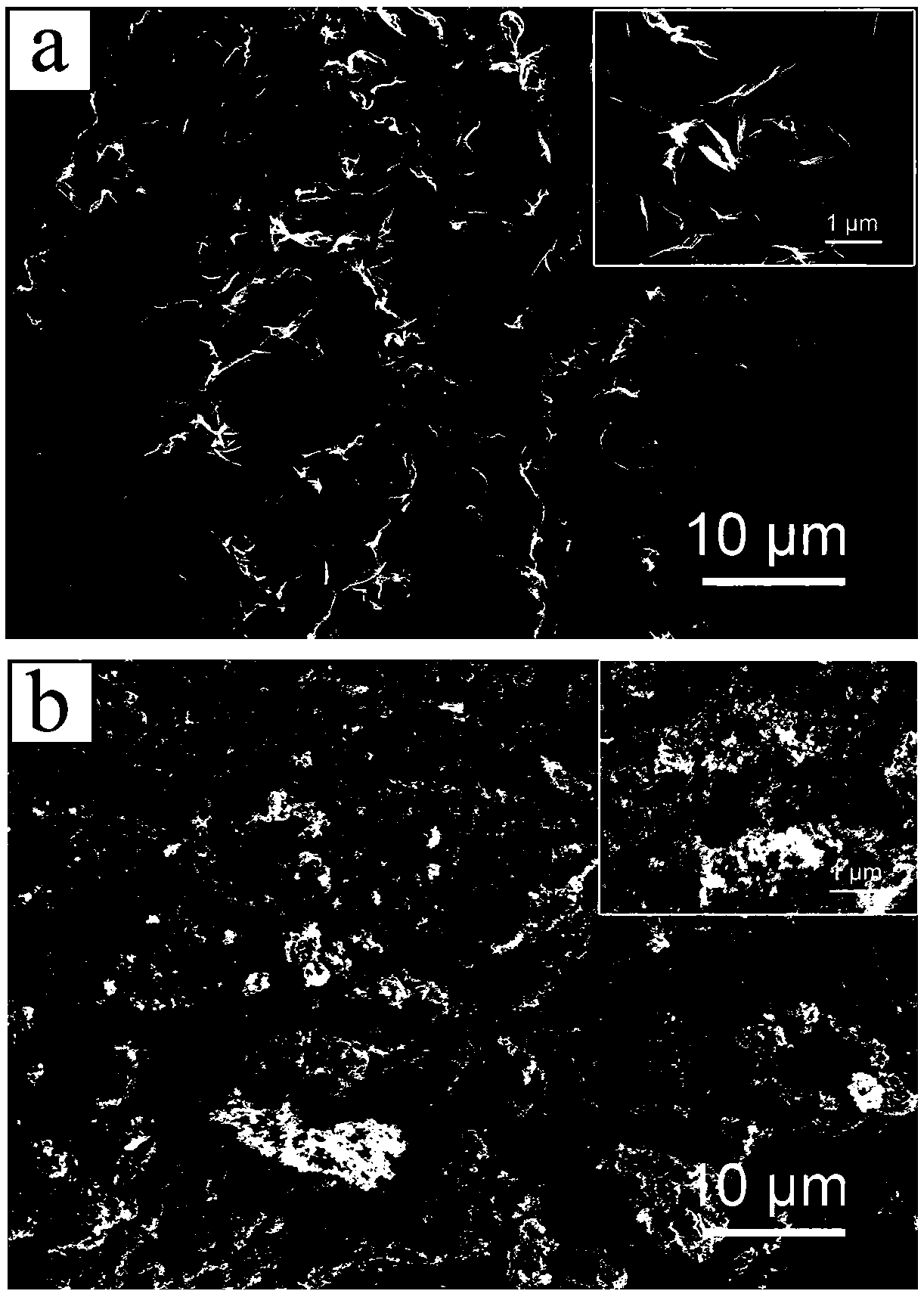

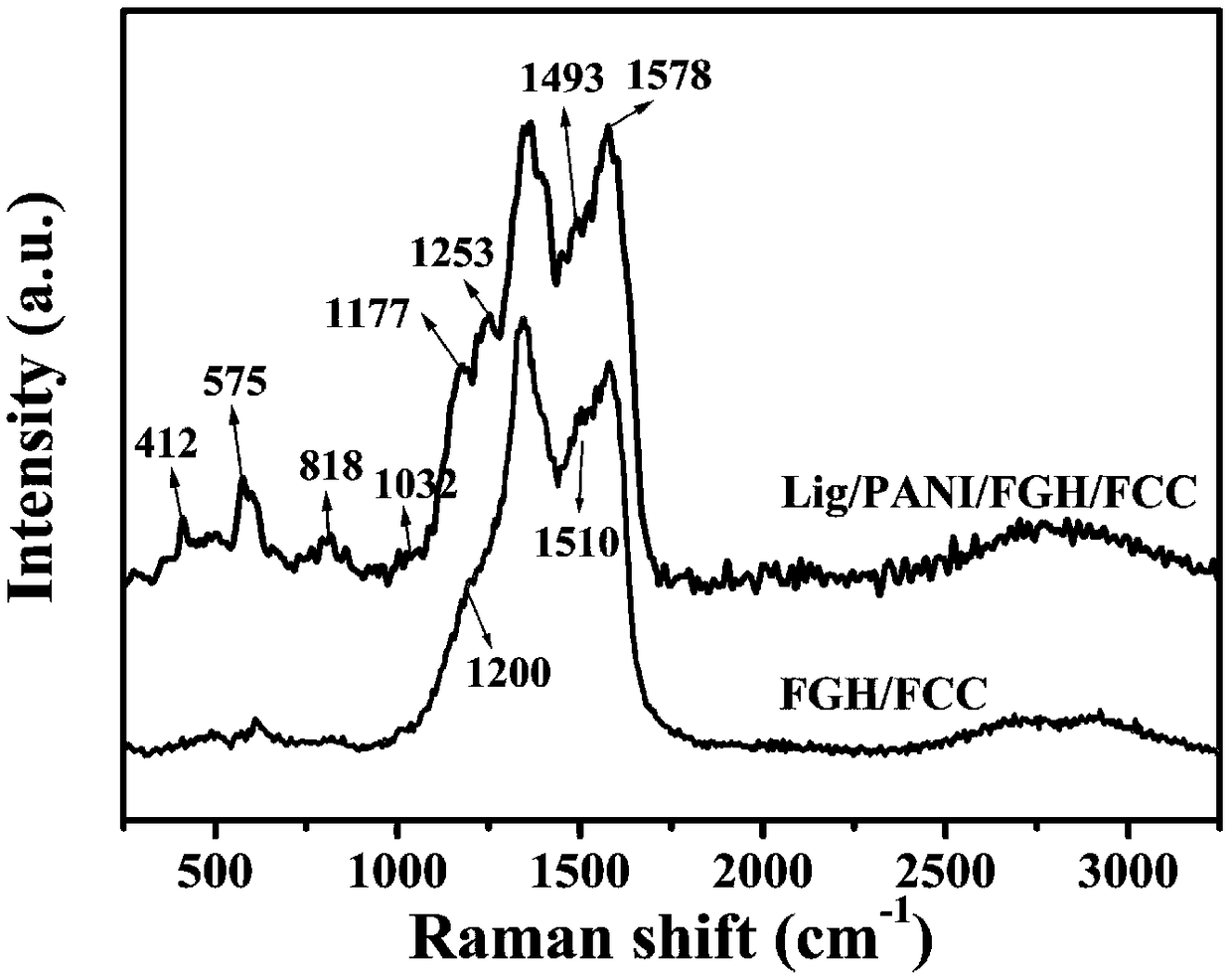

ActiveCN109461593AReduce interface resistanceImproved Capacitance and Rate CapabilityHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneIn situ polymerization

The invention discloses a functionalized graphene hydrogel / functionalized carbon cloth composite fabric, a flexible all-solid-state supercapacitor integrated electrode and a preparation method. Functionalized graphene hydrogel is fixed in a functionalized carbon cloth frame through a one-step hydrothermal method, and then lignin / polyaniline composite hydrogel and the functionalized graphene hydrogel / functionalized carbon cloth composite fabric are prepared into the flexible all-solid-state supercapacitor integrated electrode by adopting an in-situ polymerization method. According to the method, the functionalized graphene hydrogel is used for filling gaps and macroscopic macropores in carbon cloth, and serves as a 3D conductive scaffold, so that the load of active substances in the electrode can be obviously increased, the interface resistance of the electrode is reduced, and the conductivity of the electrode is improved; and the prepared integrated electrode is assembled into a symmetric supercapacitor which shows excellent area capacitance, super-high energy density, high mechanical flexibility and cycling stability.

Owner:HUNAN UNIV

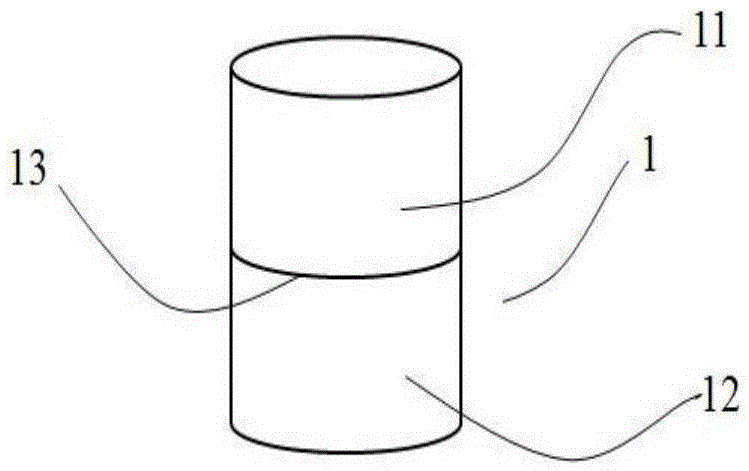

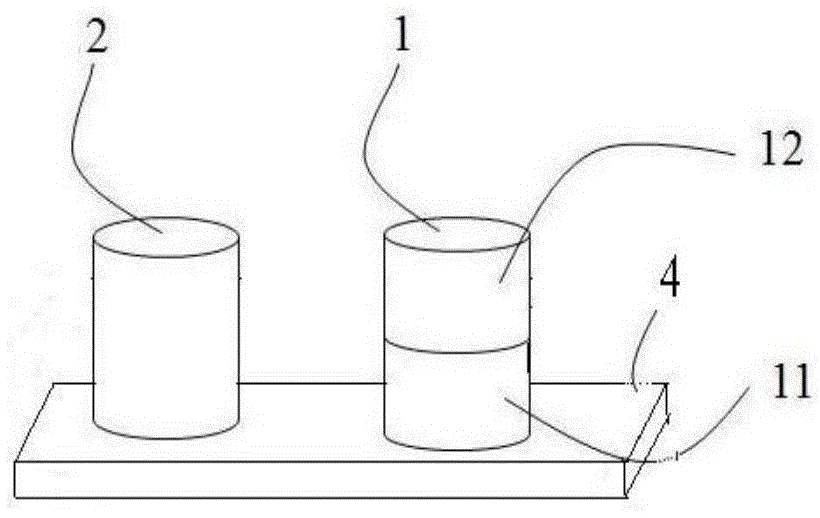

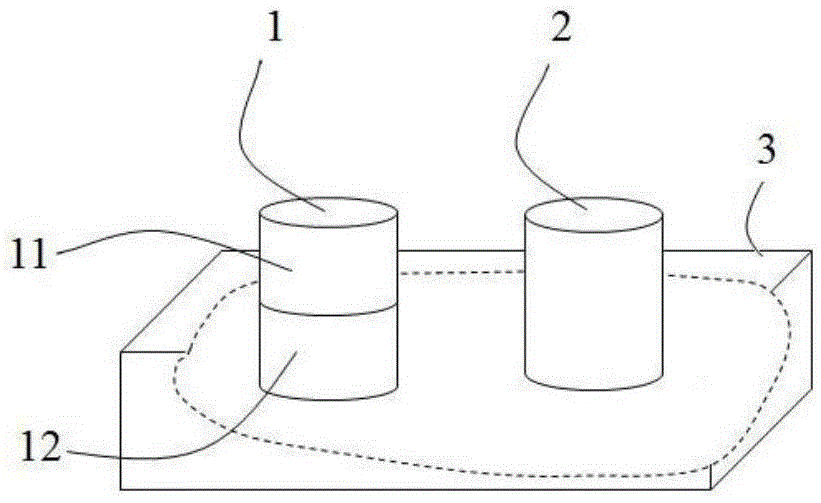

Composite pole and battery module with same

InactiveCN105679991ANot prone to electrical corrosionEasy to operateSmall-sized cells cases/jacketsElectrical conductorMetallic materials

The invention discloses a composite pole. The composite pole comprises a first end and a second end which are made of different metal materials, wherein the end connected with an external conductor is made of a metal material same with the external conductor; the welding between the same metals has no difficulty in the welding of different metals during the welding process; compared to the welding of different metals, easiness in operation is realized; and meanwhile, the same strength is easy to achieve at a welding point, and the electrocorrosion is unlikely to occur.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

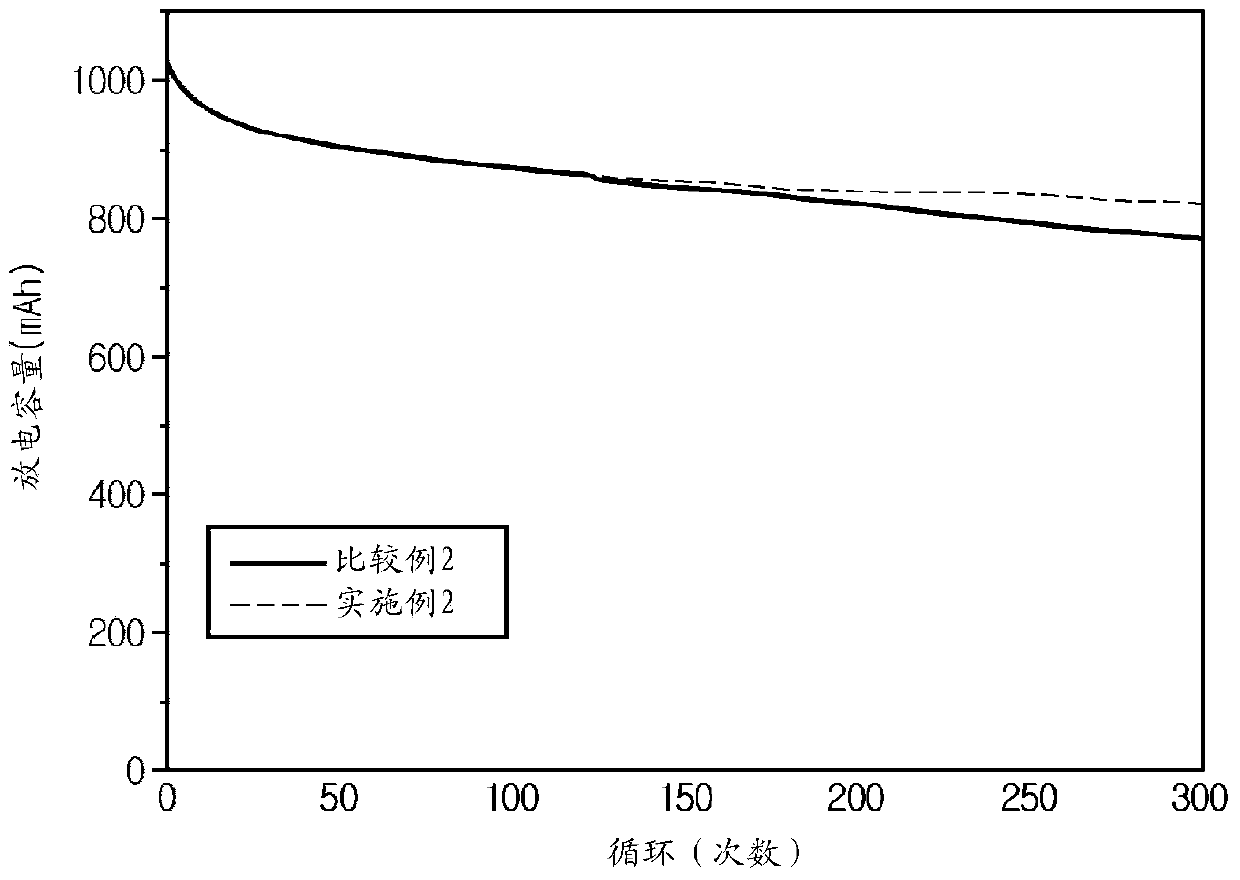

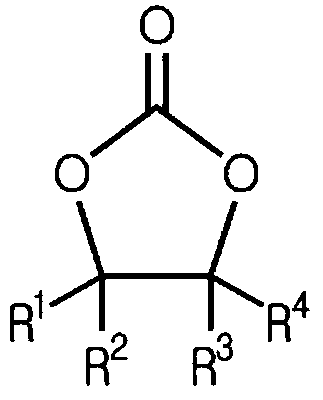

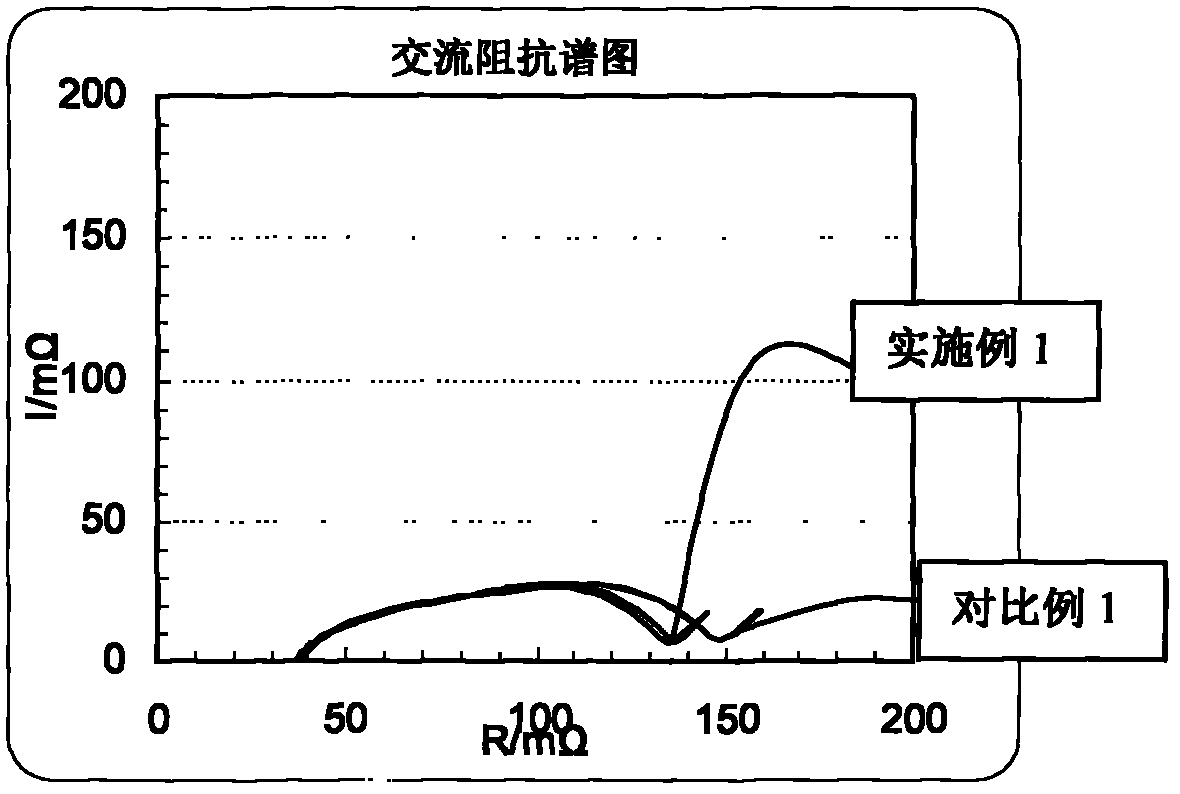

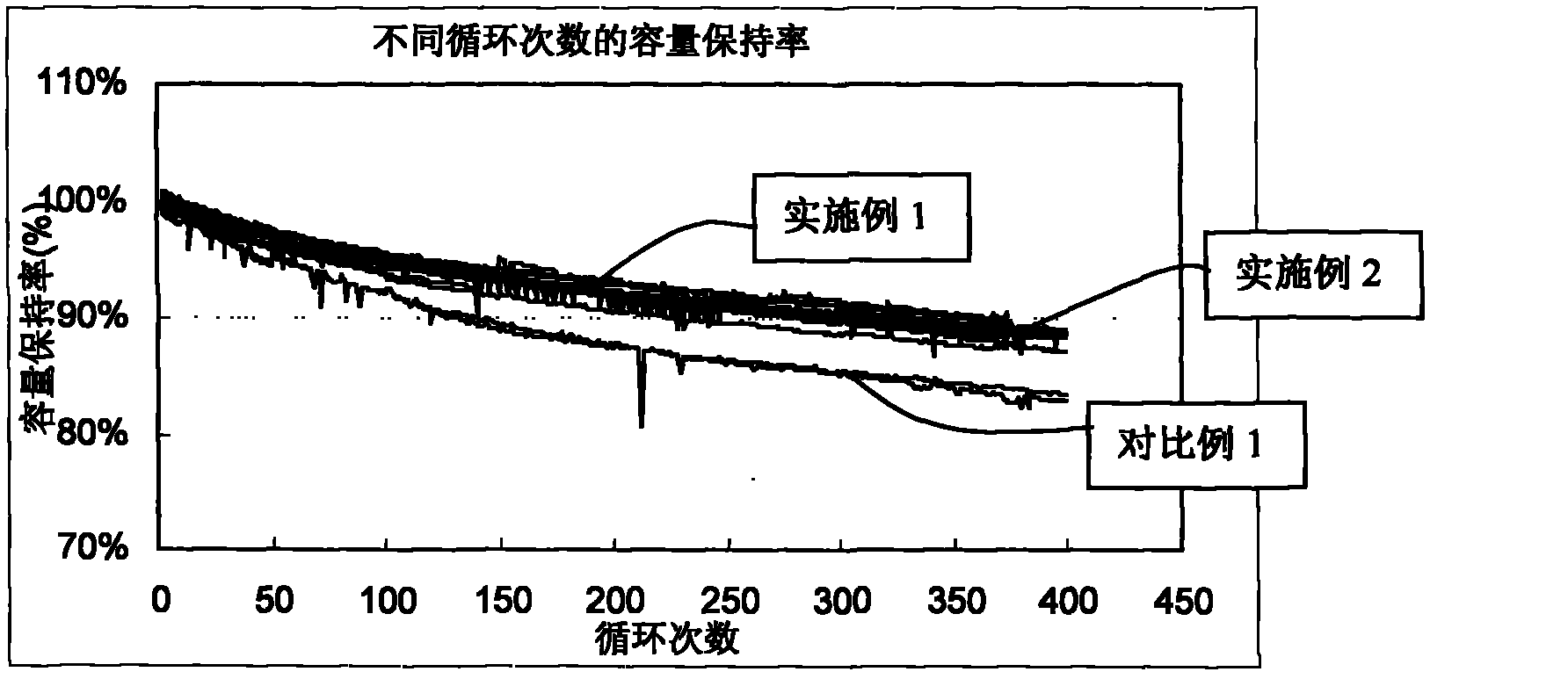

Lithium secondary battery

ActiveCN104956536AIncrease capacityImprove performancePositive electrodesLi-accumulatorsOrganic solventElectrical battery

Owner:LG ENERGY SOLUTION LTD

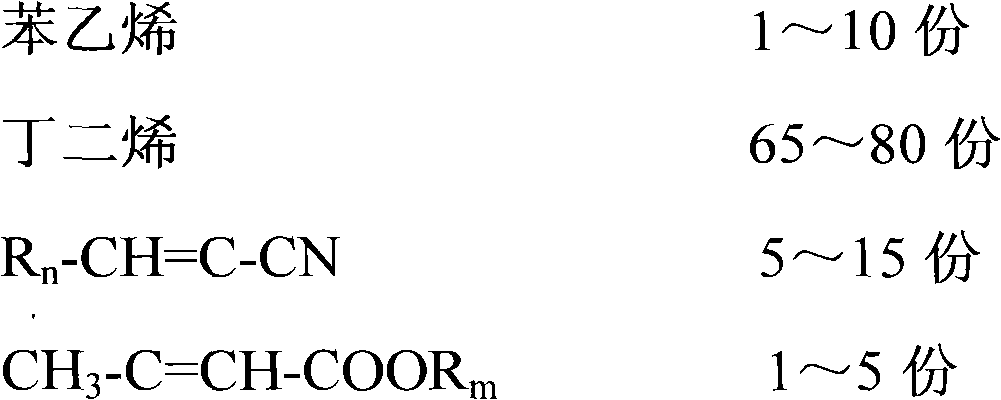

Lithium ion battery, cathode thereof and binder for cathode

ActiveCN102306788AImprove ionic conductivityGood compatibilitySecondary cellsNon-aqueous electrolyte accumulator electrodesWater basedSlurry

The invention belongs to the field of lithium ion battery material and particularly relates to a lithium ion battery, a cathode thereof and a binder for the cathode. The binder is formed by polymerizing the monomer emulsion of butadiene, Rn-CH=C-CN and CH3-C=CH-COORm; and the product is purified to obtain emulsion containing 35-55% of glue. The invention also provides a method for manufacturing a cathode plate by using the binder and battery performance thereof. The slurry of cathode active substance comprises active substance, conductive carbon, binder, sodium carboxymethylcellulose and deionized water based on the proportion of (85-98):(0-3):(1-10):(1-2):(100-150). The method comprises the following steps: coating the slurry on copper foil; drying; compacting with a rolling machine; chopping to obtain an electrode plate; and winding the electrode plate with an anode plate to obtain the battery. The manufactured battery has good low-temperature performance, ensures that lithium is not separated out under the condition of 0.7C charge and 0.5C discharge at the temperature of 10 DEG C, and has the characteristics of safety, reliability and long cycle life.

Owner:DONGGUAN AMPEREX TECH +1

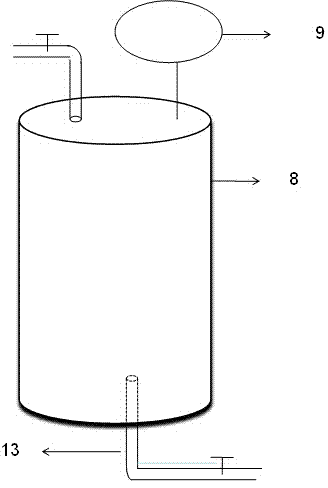

Vacuum electroosmosis curing water supply plant sludge device and use method thereof

ActiveCN104496149AImprove dehydration effectReduce electroosmosis timeSludge treatment by de-watering/drying/thickeningIonEngineering

The invention discloses a vacuum electroosmosis curing water supply plant sludge device and a use method thereof. The positive electrode and the negative electrode of a direct-current power supply of the device are respectively connected with negative electrode metal and positive electrode metal inside a sludge tank; the other ends of the negative electrode metal and the positive electrode metal are respectively connected with vacuum tanks through drain tubes; vacuum pumps and valve are arranged on the drain tubes; the vacuum pumps are both connected with a timing switch. According to the method, curing is performed firstly and electroosmosis is performed secondly, and the timing switch is adopted to control the vacuum pumps to be opened or closed. The vacuum electroosmosis curing water supply plant sludge device is good in water supply sludge curing effect, the sludge obtained after metal ions are removed meets the national soil reuse discharge standard, and the operation cost is low when being compared with that of a conventional vacuum combined electroosmosis device.

Owner:江苏海壹环境科技有限公司

Method for preparing large-area perovskite solar cell based on spraying technology

InactiveCN105655489AEasy to prepareGood prospects for industrializationSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrically conductive

The invention discloses a method for preparing a large-area perovskite solar cell based on spraying technology. The method comprises the following steps: firstly putting a transparent conductive base on a platform and spraying an electronic transmission layer; and preparing a perovskite optical absorption layer by a continuous spraying method: firstly spraying a PbI2 solution on the electronic transmission layer, and heating for 30min at 70-90 DEG C; further spraying a CH3NH3I solution and heating for 120min at 90-110 DEG C; cooling to room temperature, washing with isopropyl alcohol and drying; spraying a hole conduction layer; and finally, spraying a silver nanowire / graphene to prepare a counter electrode. In the invention, the parameters of the spraying technology are adjusted to realize preparation of the large-area perovskite solar cell; and the preparation method is simple and easy to implement, can realize low-cost preparation of an efficient perovskite solar cell and has a good industrialization prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

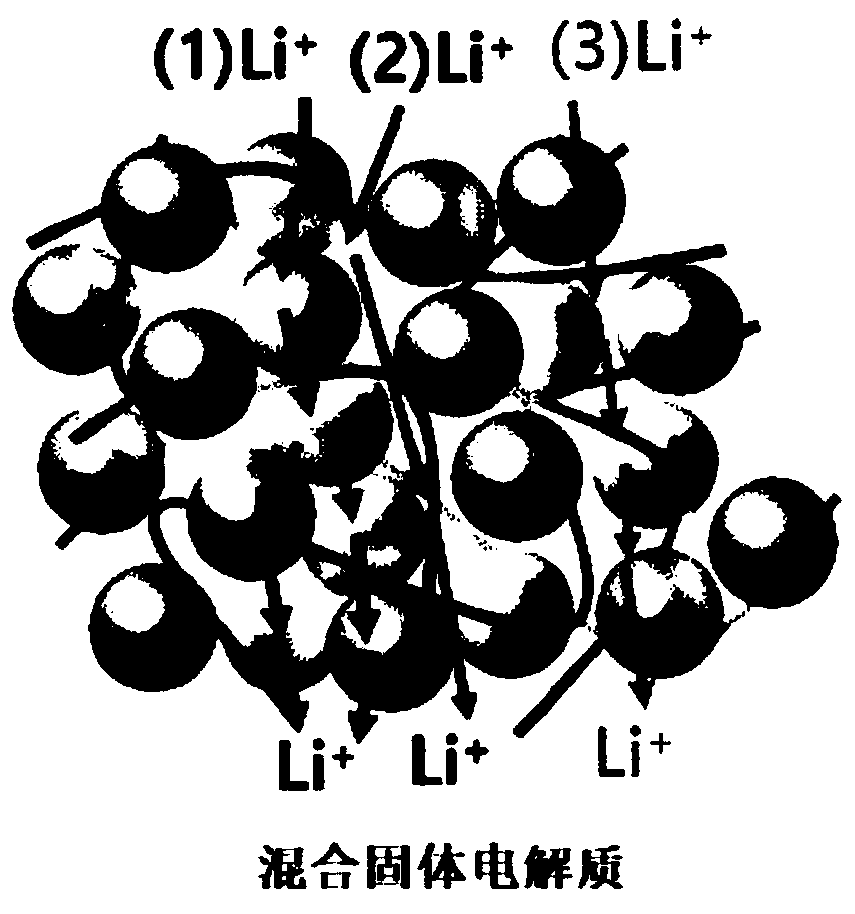

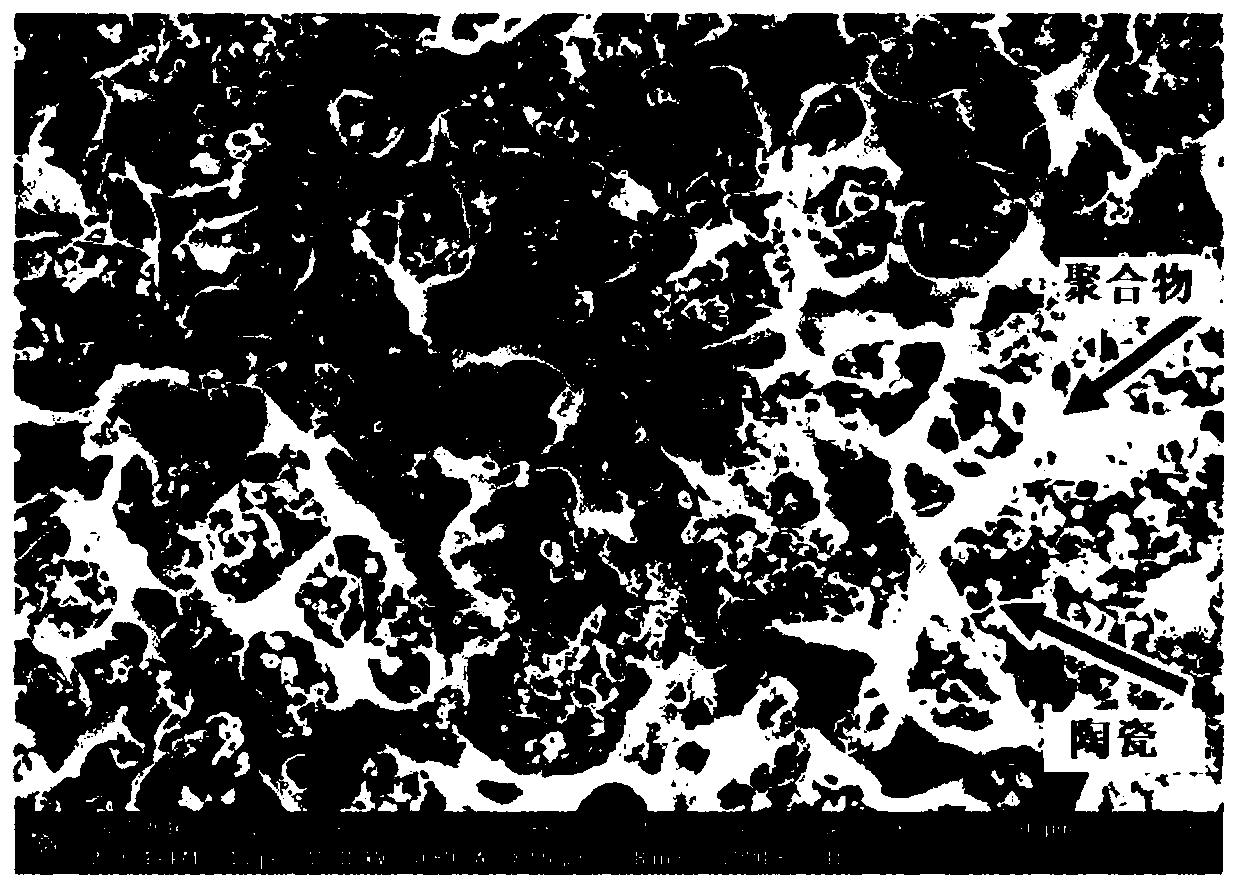

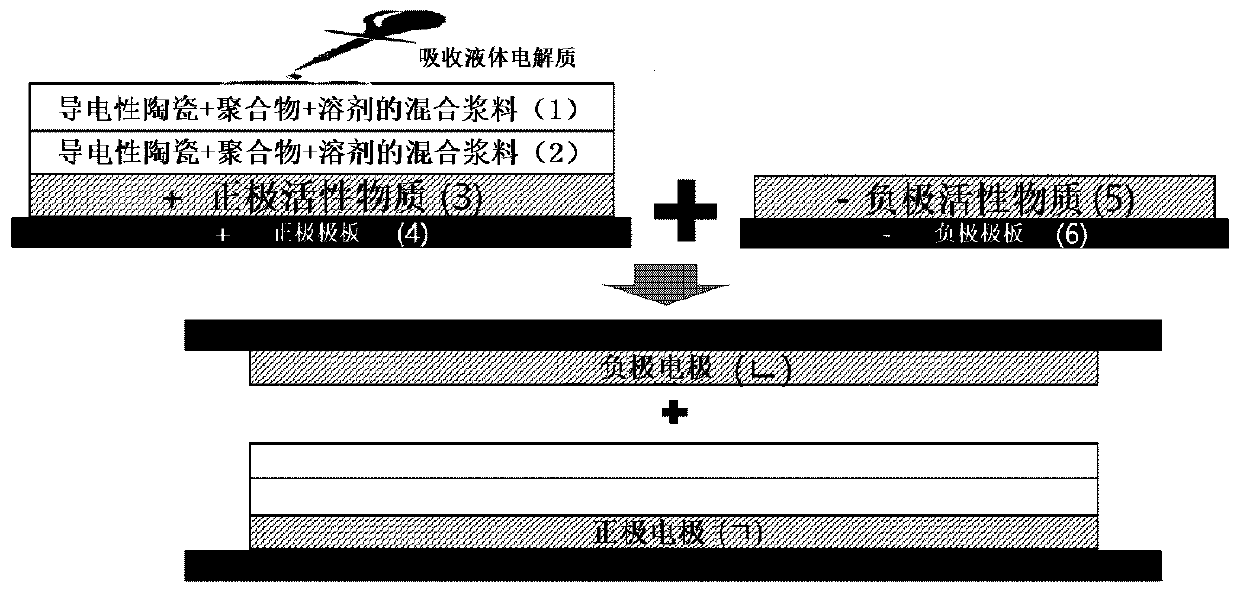

Multi-layer structured composite electrolyte and secondary battery using same

PendingCN110495037ALow ionic conductivityFix stability issuesSolid electrolytesLi-accumulatorsComposite electrolytePhysical chemistry

The present invention relates to a multi-layer structured composite electrolyte for a secondary battery and a secondary battery using the same. The multi-layer structured composite electrolyte of thepresent invention is prepared by laminating two or more layers of composite electrolyte containing a small amount of liquid electrolyte in addition to a mixture of a polymer and a ceramic material. The multi-layer structured composite electrolyte of the present invention has equal or superior electrochemical characteristics compared with a liquid electrolyte while having equal stability to the solid electrolyte. The multi-layer structured composite electrolyte of the present invention can also be used in wearable apparatuses since the multi-layer structured composite electrolyte can be arbitrarily folded.

Owner:SEVEN KING ENERGY

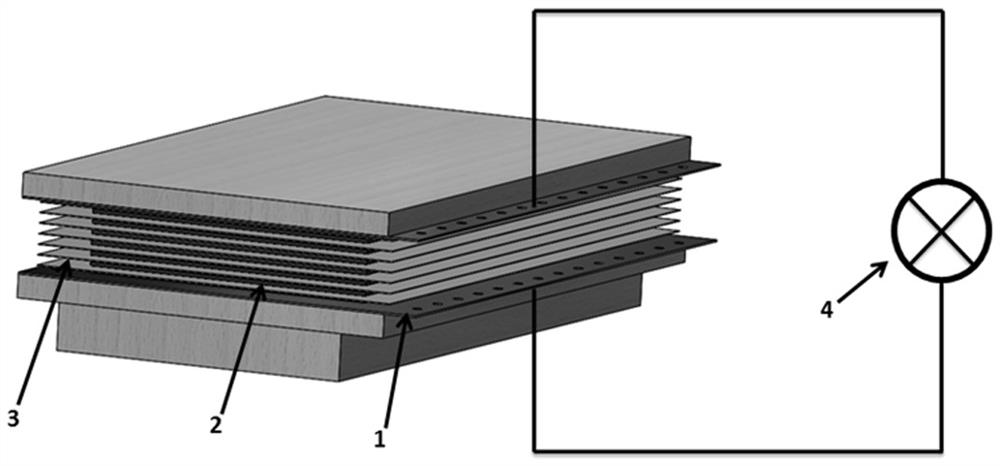

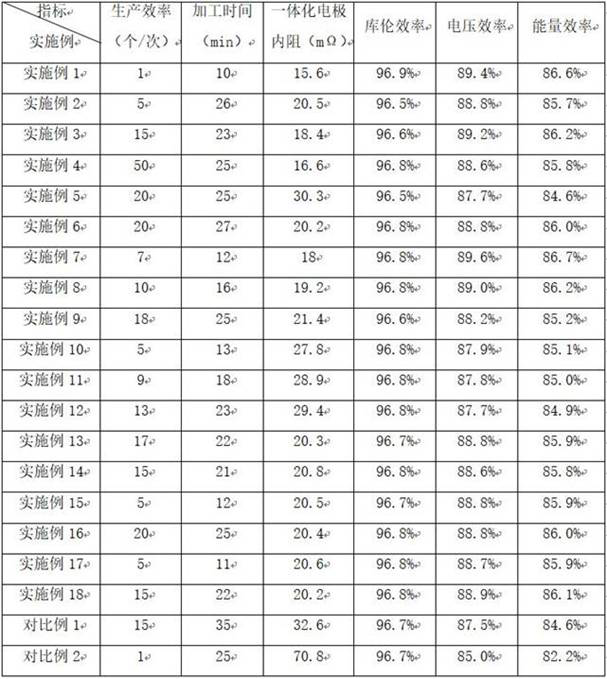

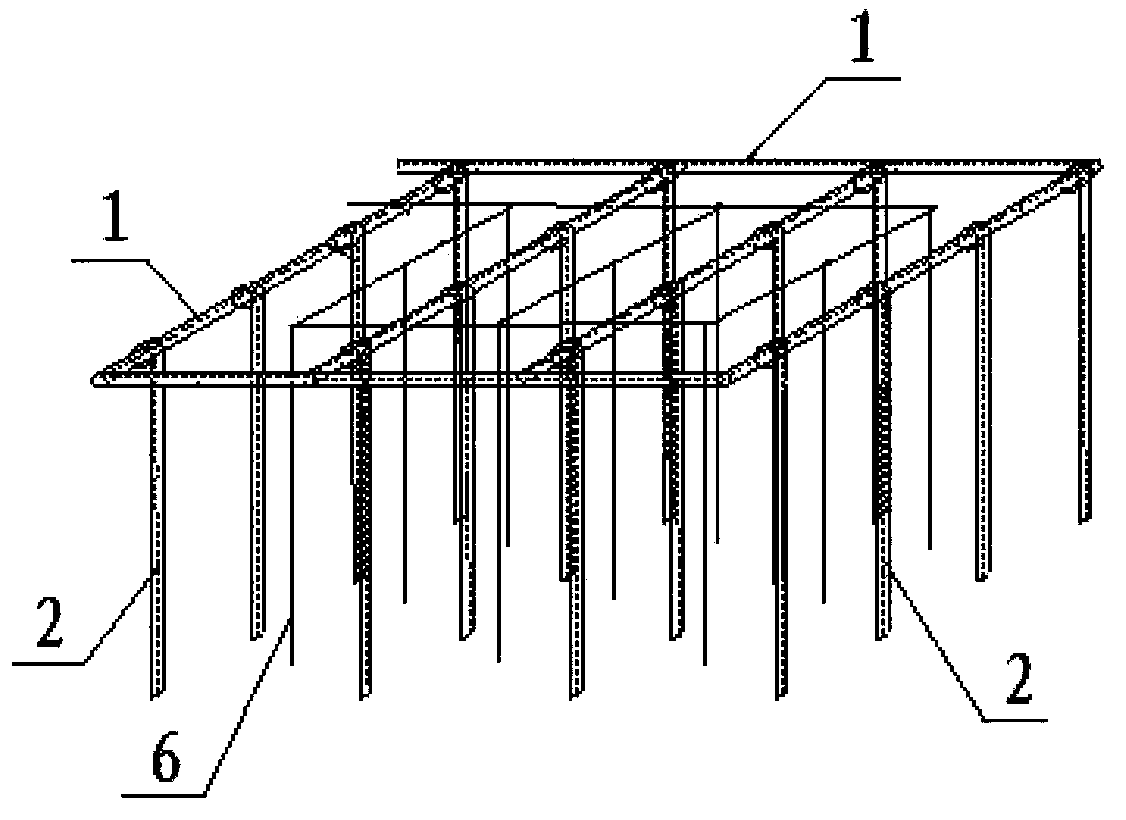

Method for efficiently preparing integrated electrode of flow battery

ActiveCN113809339ASimple methodEasy to mass produceCell electrodesRegenerative fuel cellsCarbon fibersInternal resistance

The invention discloses a method for efficiently preparing an integrated electrode of a flow battery, which comprises the following steps of: S1, well mixing plastic, a conductive auxiliary agent and an auxiliary agent, and processing a bipolar plate from the mixture; S2, pretreating graphite felts; S3, attaching a layer of volatile solvent to the surface of the bipolar plate; S4, tightly attaching the two pretreated graphite felts to the two sides of the bipolar plate with the volatile solvent attached to the surface to form a graphite felt / bipolar plate / graphite felt sandwich structure; and S5, stacking multiple layers of the graphite felt / bipolar plate / graphite felt sandwich structure, tightly laminating the multiple layers through a tablet press, introducing a direct current or an alternating current, and embedding graphite felt carbon fibers into the bipolar plate to form an integrated electrode. The flow battery integrated electrode is prepared in a current mode, the internal resistance in the finished integrated electrode can be remarkably reduced, and the efficiency of the flow battery is improved. The preparation method is simple, multiple integrated electrodes can be produced at a time, the production time is short, the efficiency is high, energy is saved, environment friendliness is achieved, and mass production is facilitated.

Owner:杭州德海艾科能源科技有限公司

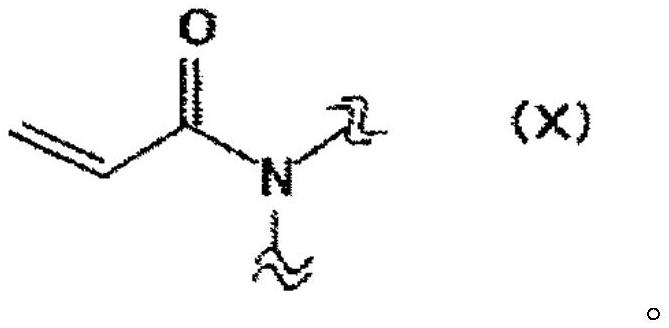

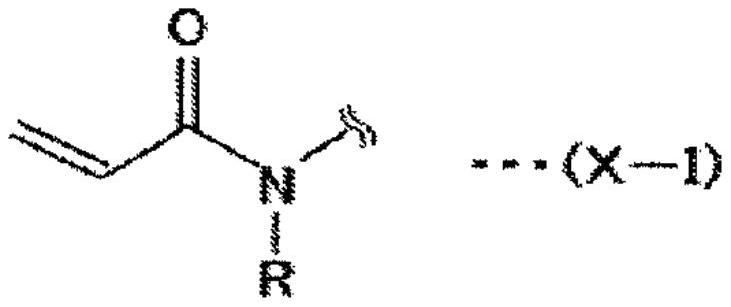

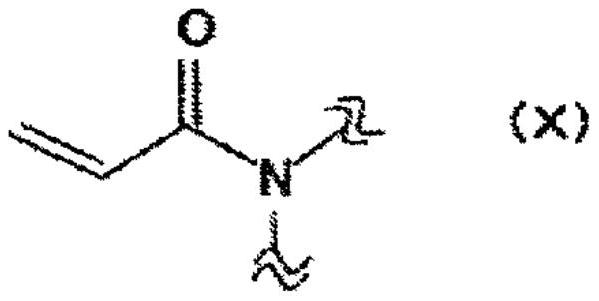

Hydrogel and uses therefor

ActiveCN112533997APrevent precipitationGuaranteed softnessAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersPolymer scienceEster bond

The present invention relates to a hydrogel and uses therefor. The present invention specifically relates to a hydrogel containing water and a macromolecular matrix and uses for said hydrogel, the hydrogel being characterized in that: the macromolecular matrix includes a copolymer of a monofunctional monomer having a hydrophilic group and one ethylenically unsaturated group and a polyfunctional monomer having an amide group and three to six ethylenically unsaturated groups but not having an ester bond; 40-95 parts by mass of water and 5-60 parts by mass of the macromolecular matrix are included per 100 parts by mass of the hydrogel; and when the hydrogel has been immersed in a 4M KOH aqueous solution at a temperature of 25 DEG C for 14 days, the degree of swelling of the hydrogel is no more than 650%.

Owner:SEKISUI PLASTICS CO LTD

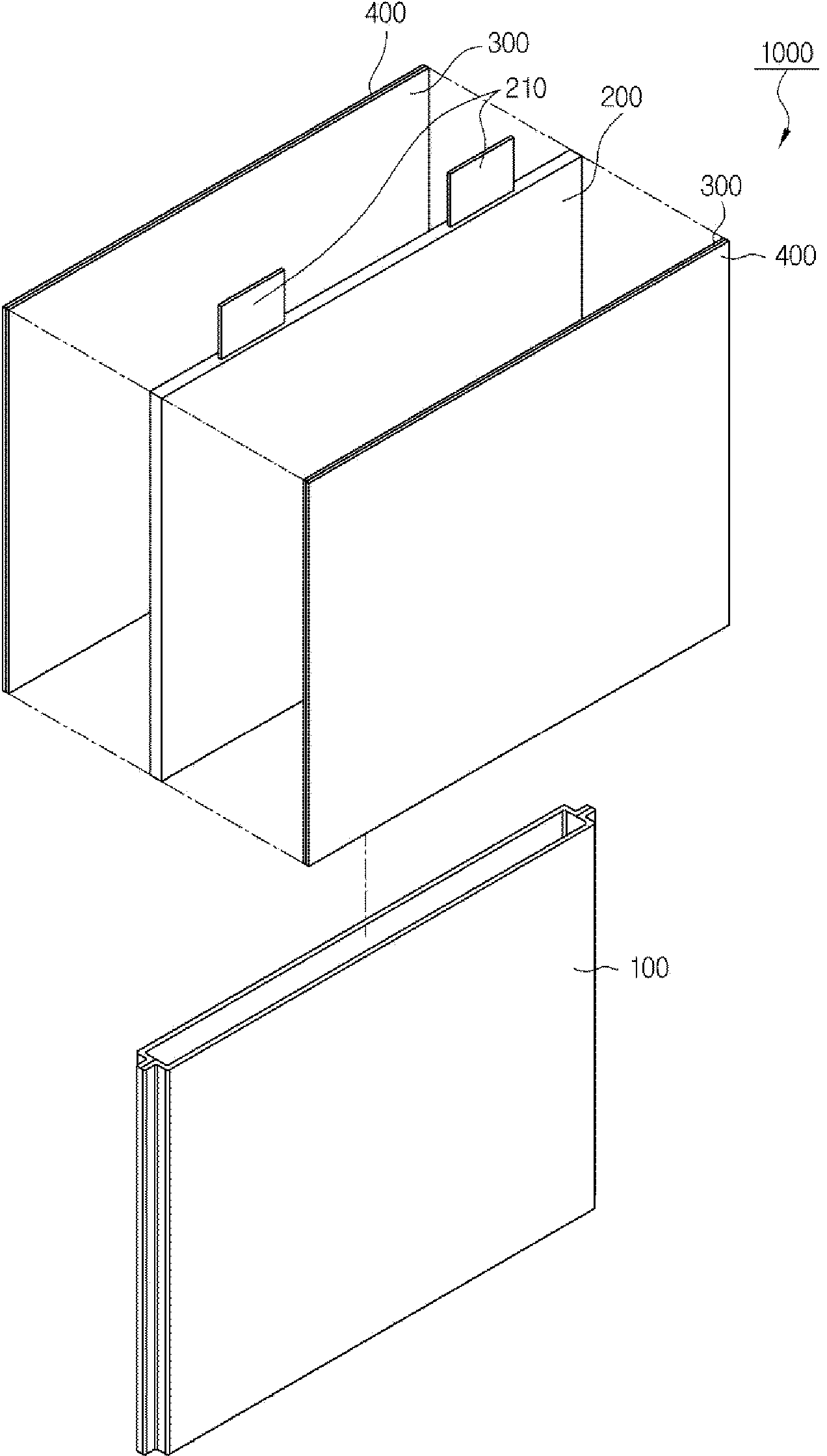

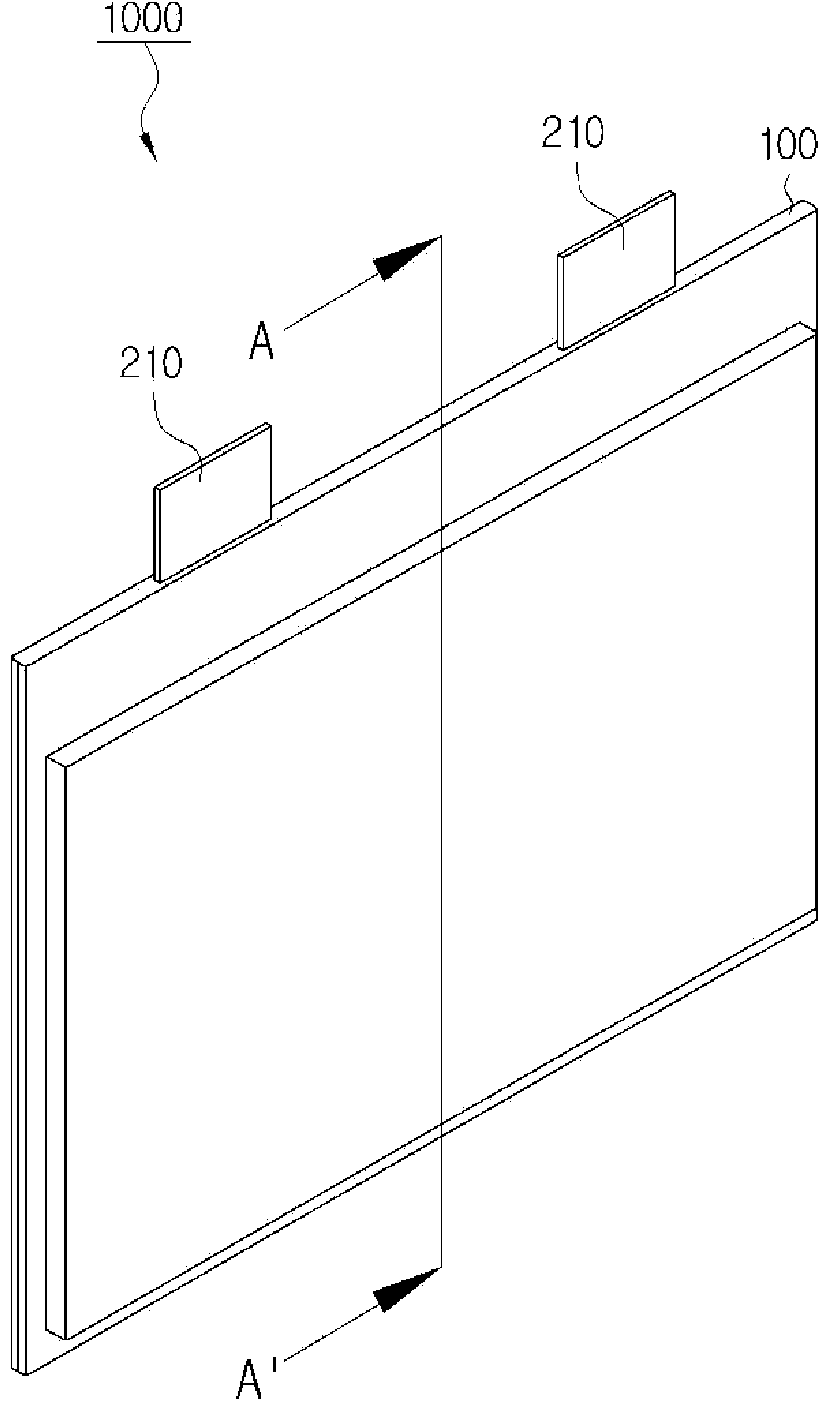

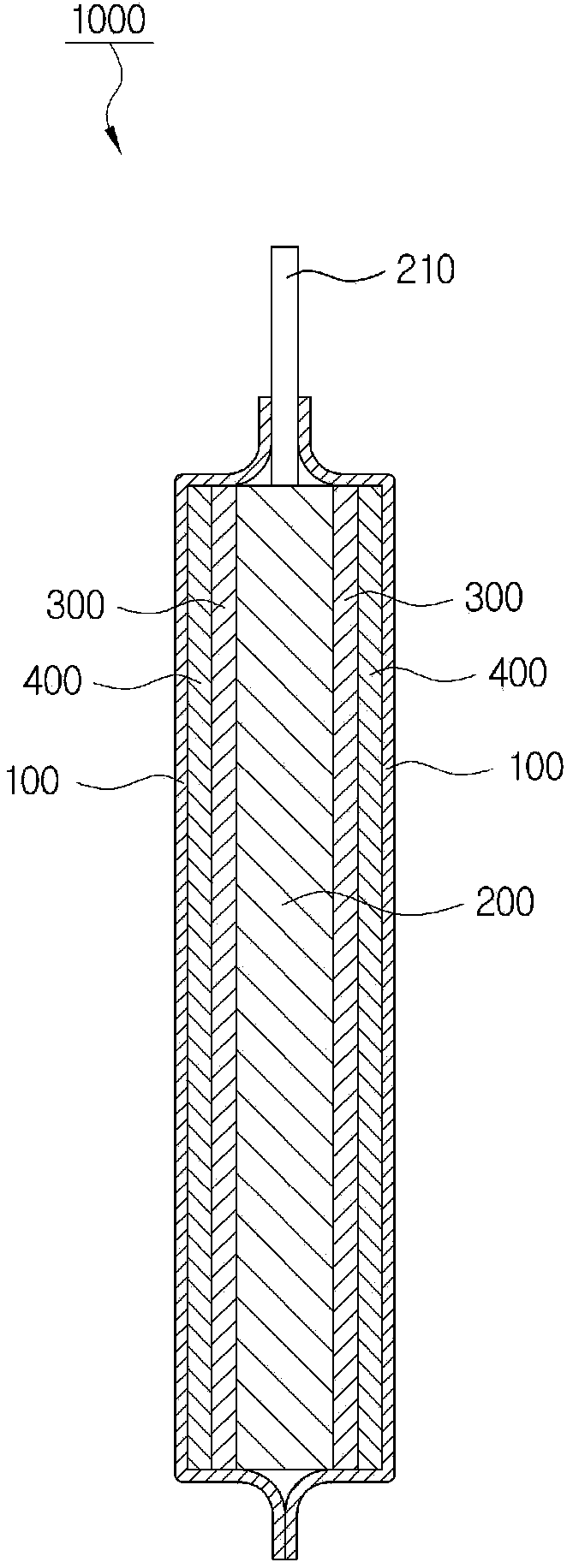

Secondary Battery and Secondary Battery Pack Having the Same

ActiveCN104241591AReduce performanceImprove interface resistanceFinal product manufactureSmall-sized cells cases/jacketsEngineeringUltimate tensile strength

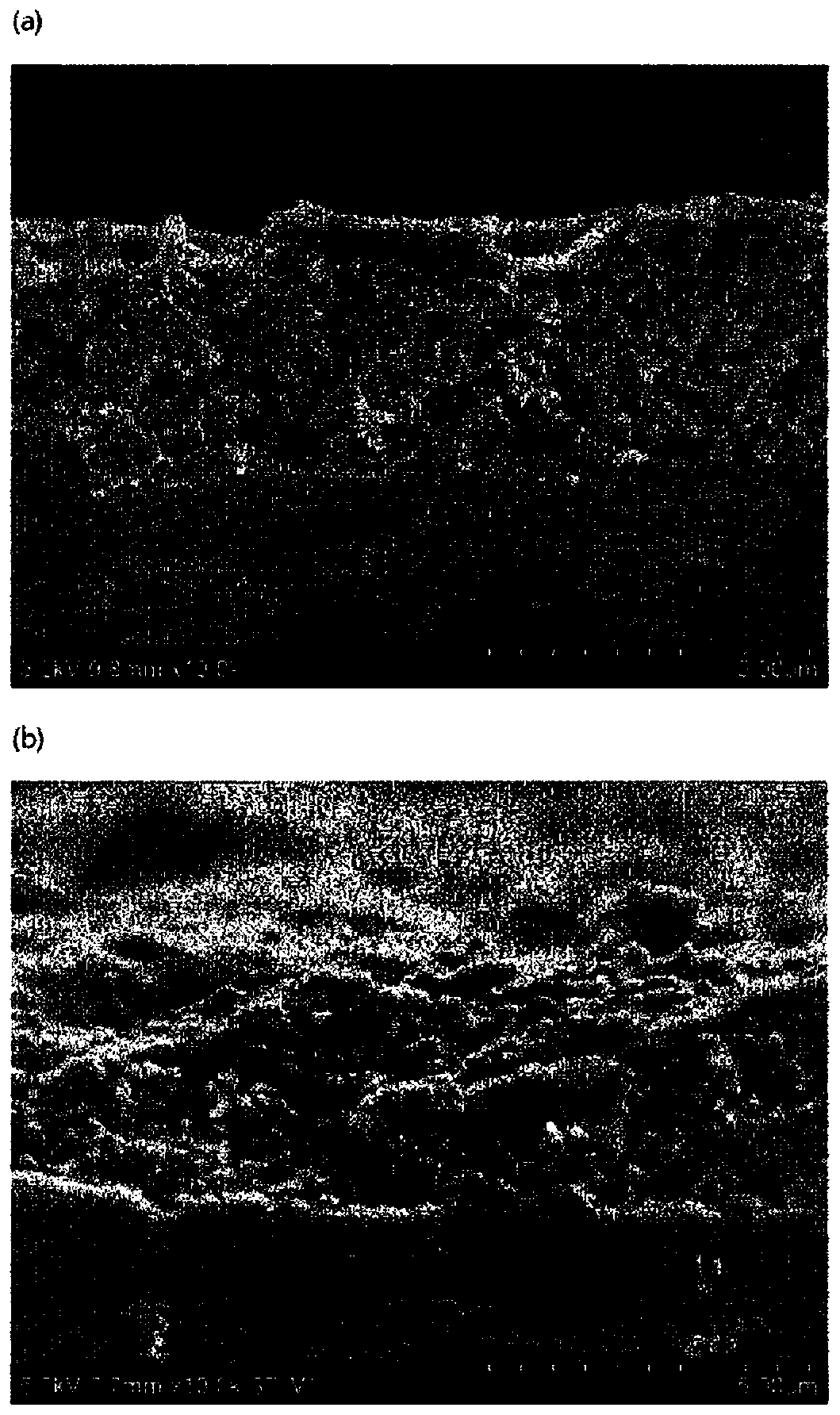

Provided are a secondary battery and a secondary battery pack having the same capable of preventing performance degradation by preventing an increase in an interface resistance of an electrode body accommodated in a pouch and capable of improving stability by preventing deformation of the electrode body to thereby prevent a fine short circuit even though the pouch is swelled due to a gas generate at a high temperature, by providing first members for reinforcing rigidity and second members deformed at the high temperature and capable of adhering the electrode body to one side or both sides of the electrode body accommodated and sealed in the pouch.

Owner:SK ON CO LTD

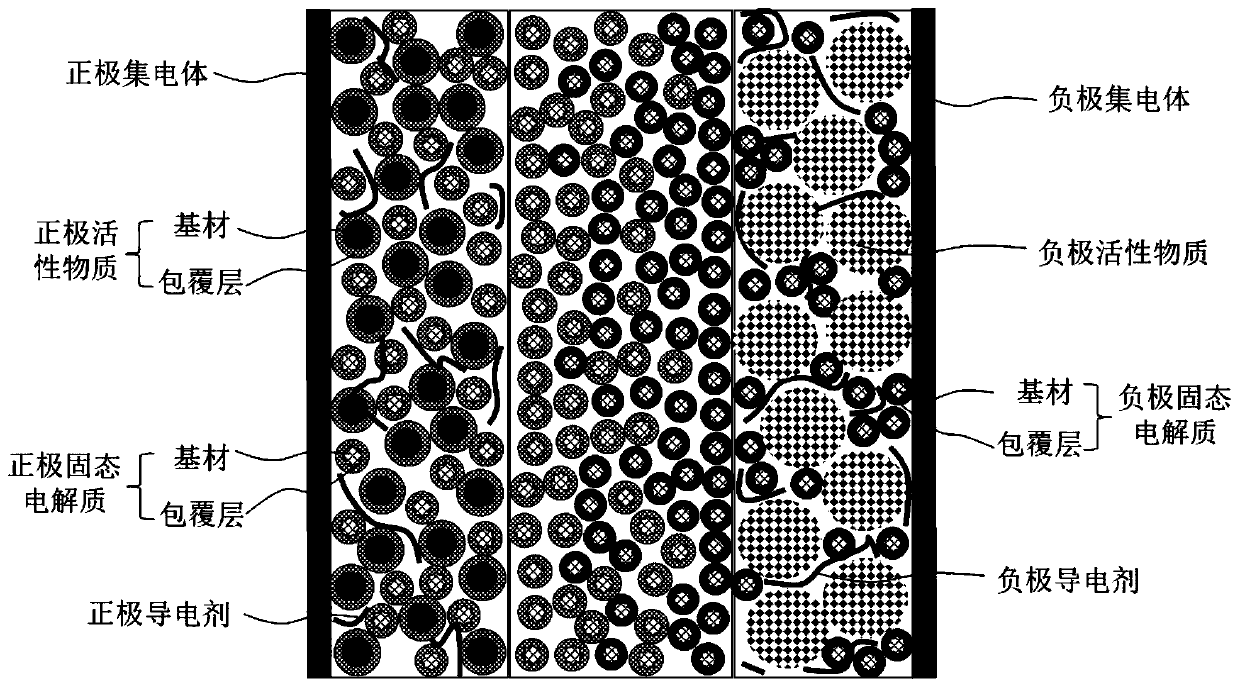

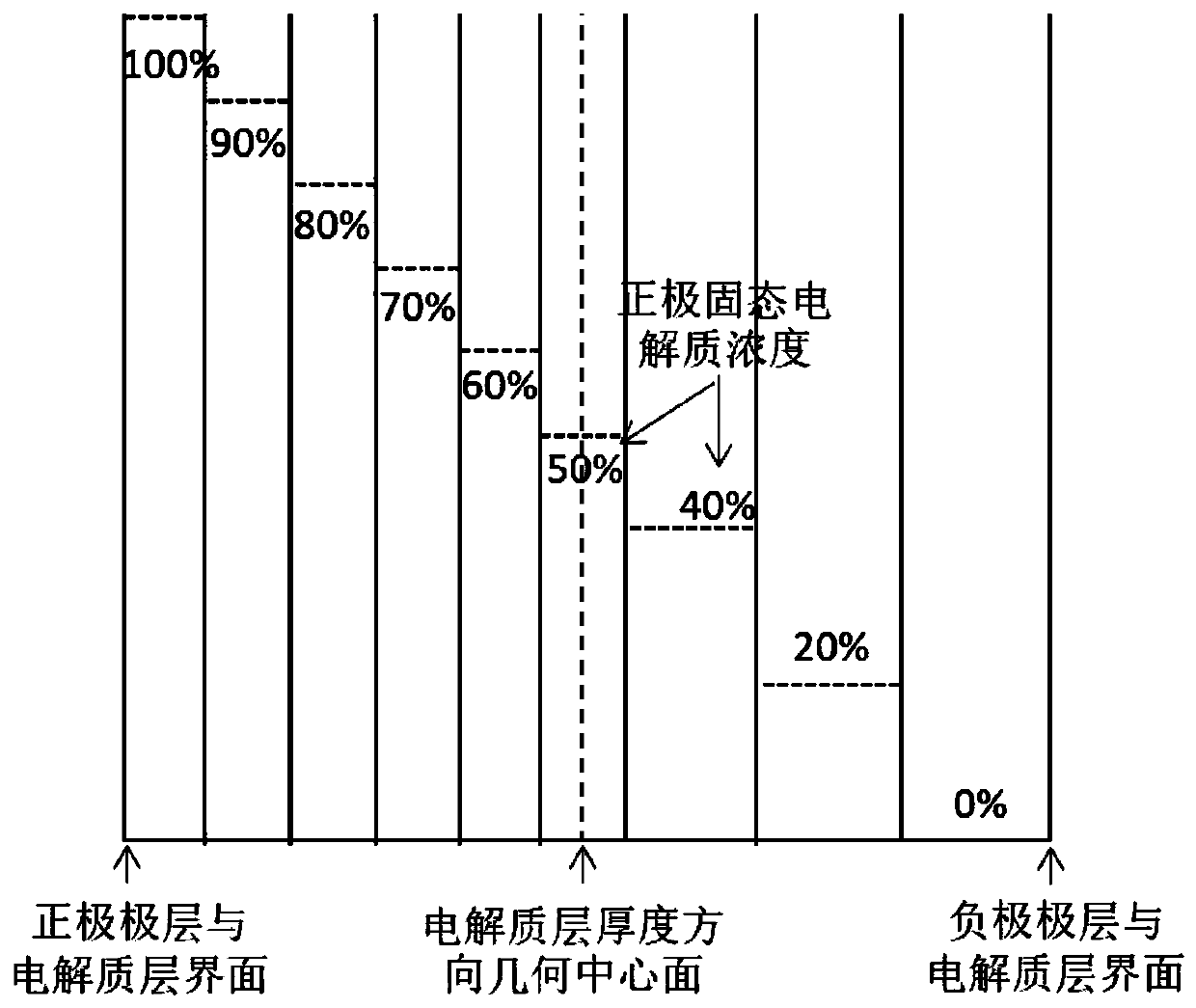

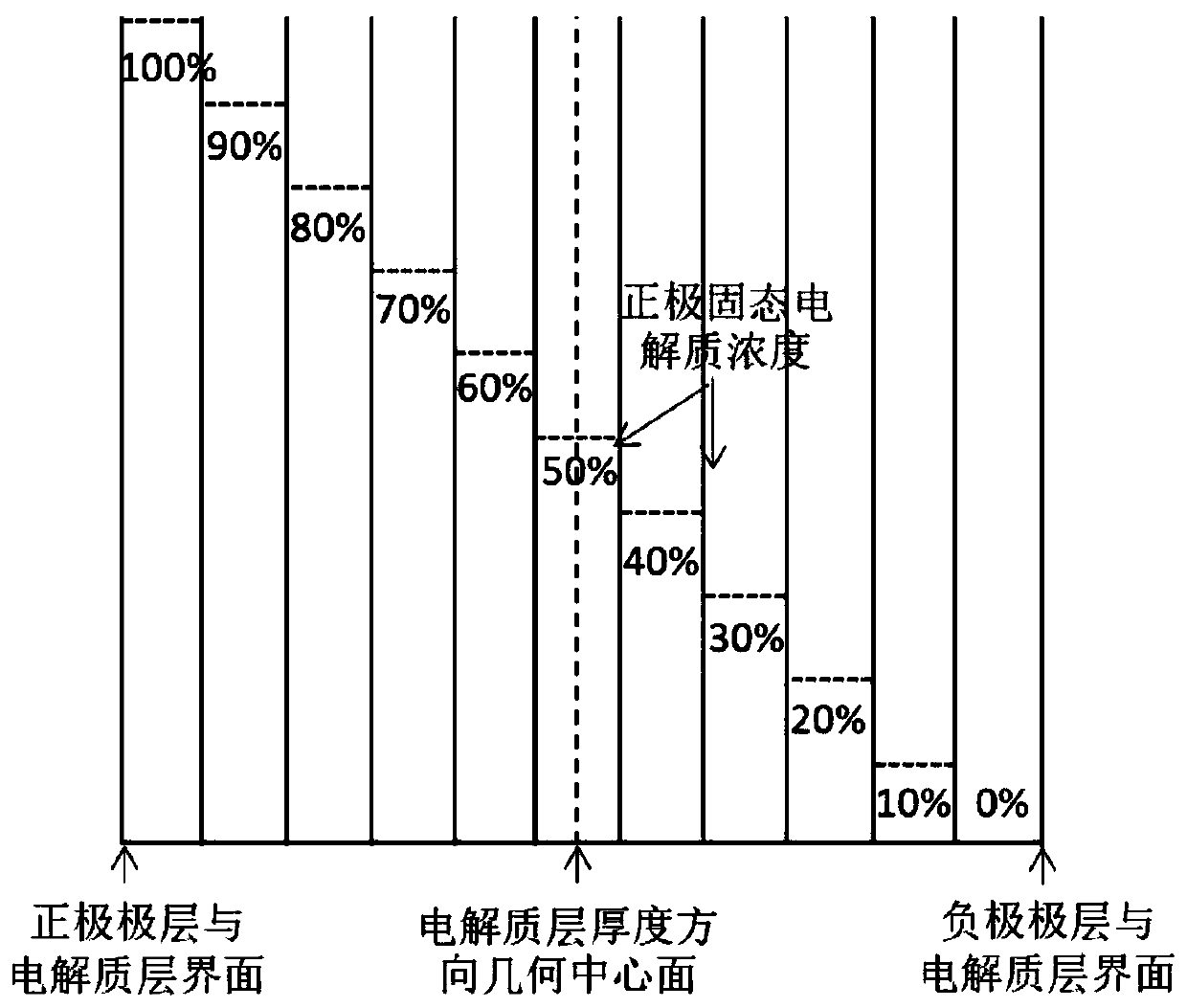

Solid-state battery electrode unit

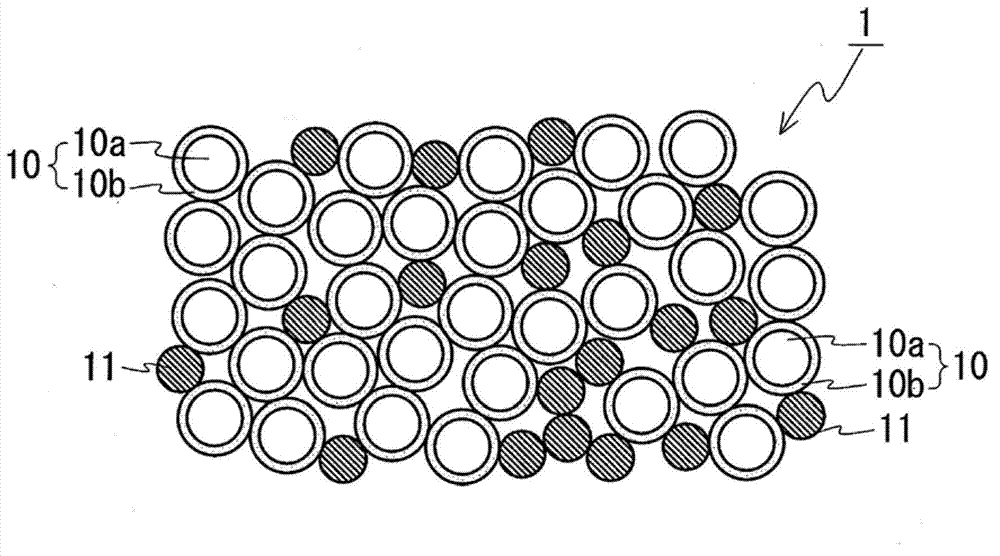

ActiveCN111092261AImprove securityIncrease energy densitySolid electrolytesFinal product manufactureSolid state electrolytePhysical chemistry

The invention relates to a solid-state battery electrode unit. The solid-state battery electrode unit comprises a positive electrode layer, a negative electrode layer and an electrolyte layer, whereinthe electrolyte layer includes positive electrode solid electrolyte having concentration gradient distribution and a negative electrode solid electrolyte having concentration gradient distribution. The solid-state battery contains the continuous transition gradient electrolyte, so the interface resistance condition of the solid-state battery is greatly improved, electrical property of the solid-state battery is improved, and safety of the battery is not reduced, moreover, the solid electrolyte layer can be prepared by a conventional method, and the process is simple and convenient.

Owner:CHINA FIRST AUTOMOBILE

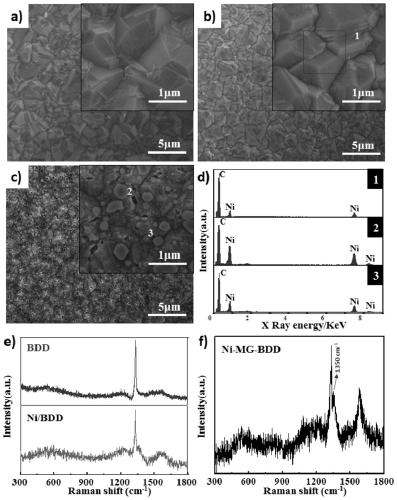

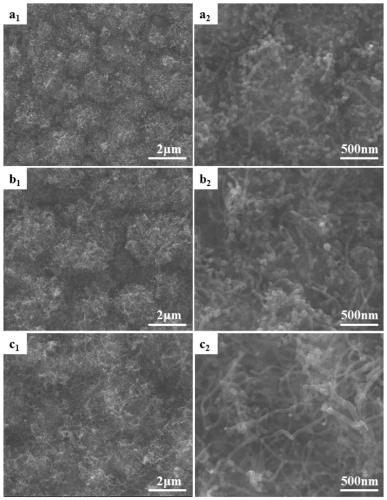

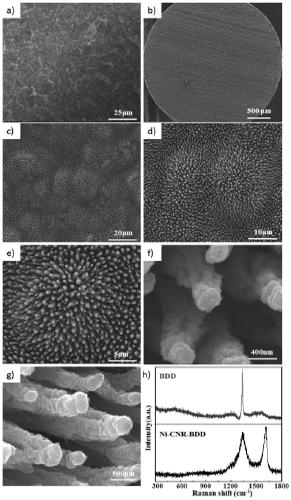

Non-enzymatic biosensor based on carbon material/boron-doped diamond composite electrode as well as preparation method and application of non-enzymatic biosensor

ActiveCN111562297ACatalytic activityHigh catalytic activityVacuum evaporation coatingMaterial analysis by electric/magnetic meansGlucose sensorsComposite electrode

The invention relates to a non-enzymatic biosensor based on a carbon material / boron-doped diamond composite electrode as well as a preparation method and application of the non-enzymatic biosensor. Aworking electrode of the non-enzyme biosensor is a carbon material / boron-doped diamond composite electrode; the carbon material / boron-doped diamond composite electrode comprises a substrate, a boron-doped diamond layer arranged on the surface of the substrate and a carbon material arranged on the surface of the boron-doped diamond layer, the carbon material is selected from at least one of microcrystalline graphite, carbon nanotubes, carbon nanofibers and graphene, the carbon nanotubes are carbon nanotubes growing at the bottom end, the boron-doped diamond film is of a surface porous structure, and meanwhile the surface of the boron-doped diamond film is further modified with nickel nanoparticles. By combining chemical vapor deposition, magnetron sputtering and annealing, nickel catalyticpreparation of different composite material electrodes is realized. The prepared composite carbon material electrode has the characteristics of high sensitivity, high stability, high resolution and high selectivity, and can be widely applied to the construction of glucose sensors.

Owner:CENT SOUTH UNIV

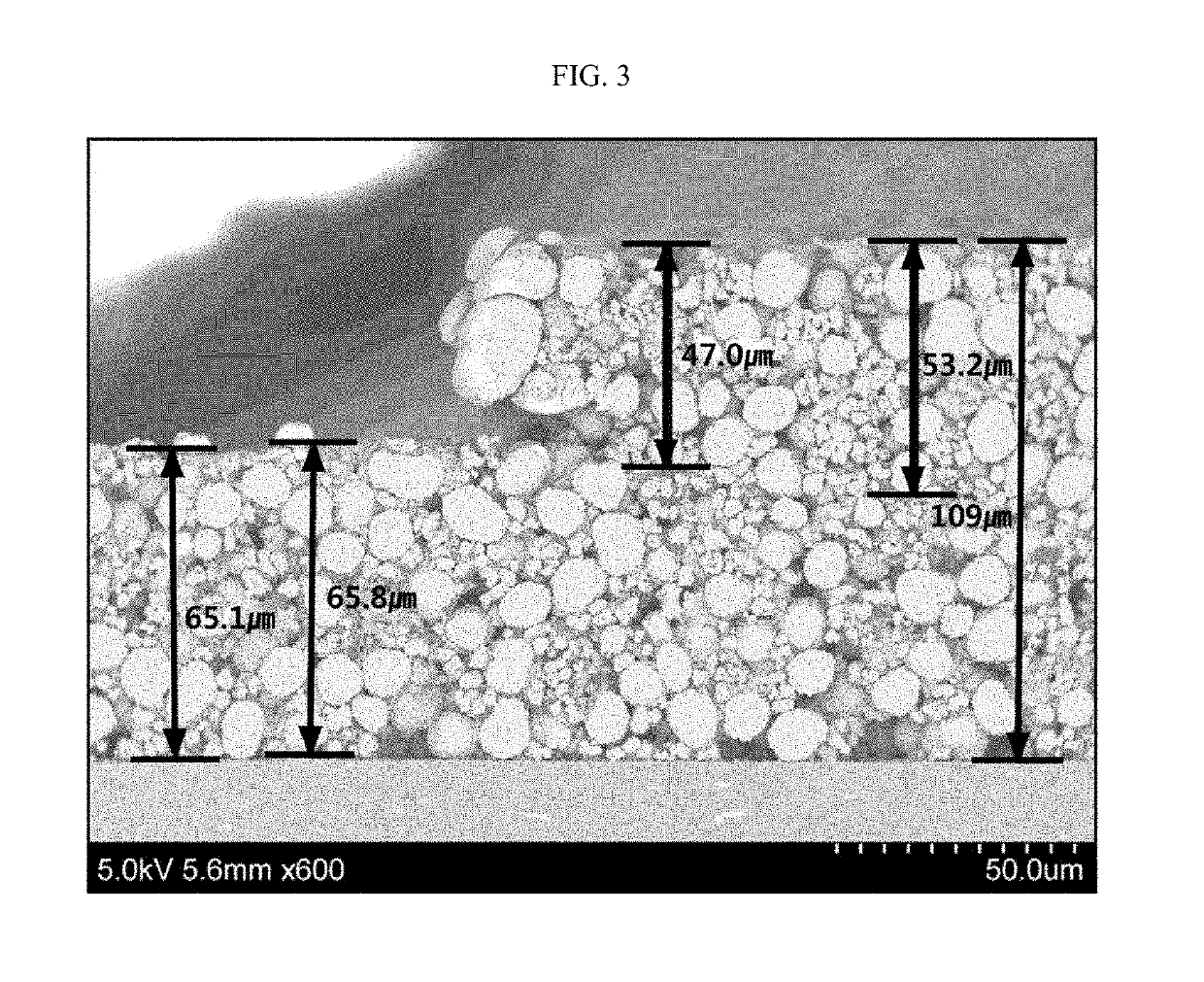

Positive Electrode For Lithium Secondary Battery And Method For Manufacturing The Same

ActiveUS20190312259A1Improve high temperature storage performanceIncreased diffusion resistanceElectrode thermal treatmentFinal product manufactureLithiumEngineering

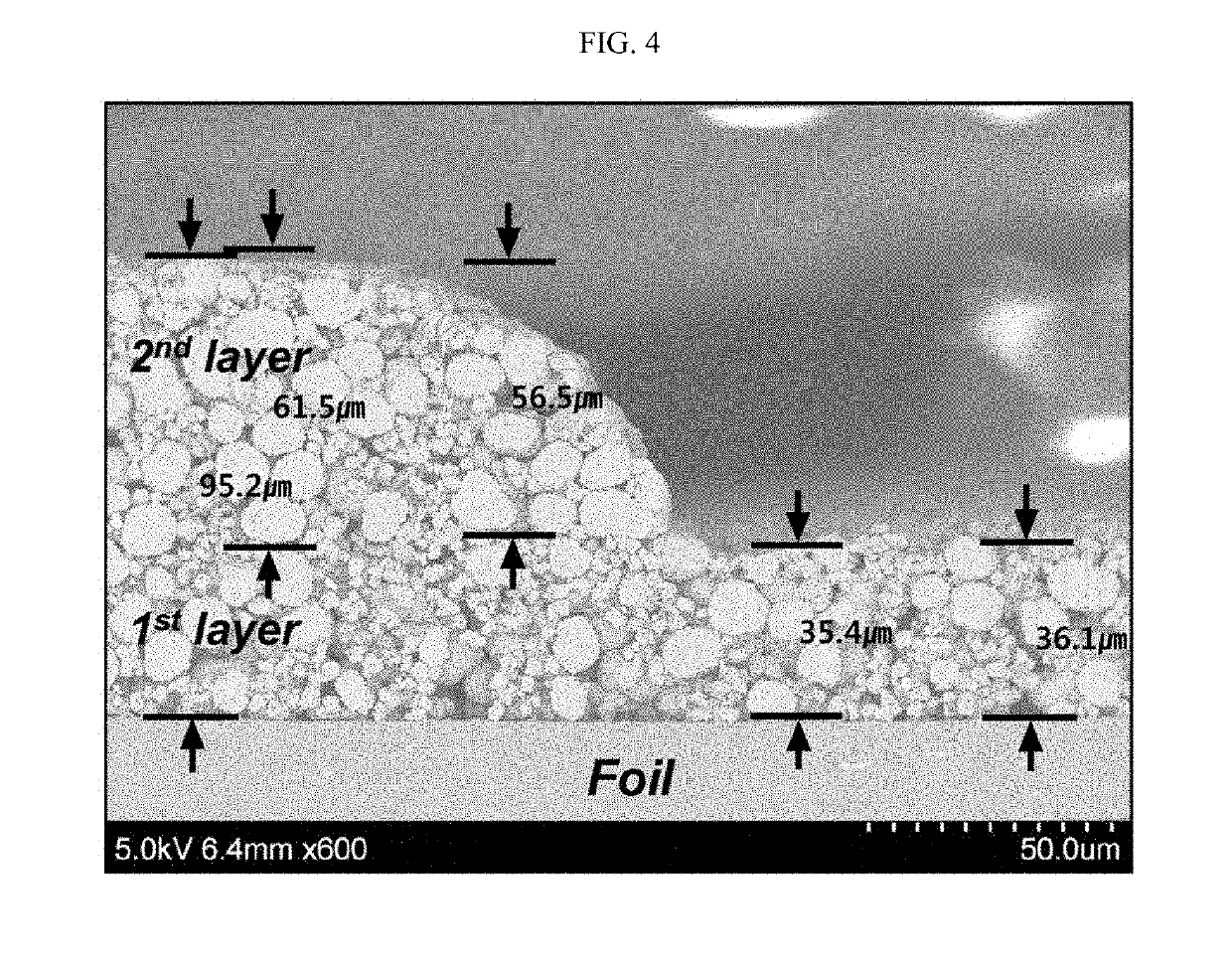

A positive electrode for a lithium secondary battery includes a positive electrode current collector; a lower positive electrode active material layer disposed on at least one surface of the positive electrode current collector; and an upper positive electrode active material layer disposed on the lower positive electrode active material layer, wherein the lower positive electrode active material layer includes 90% or more of a sphere-type carbonaceous conductive material as a conductive material, the upper positive electrode active material layer includes 90% or more of a needle-type carbonaceous conductive material as a conductive material, and the content of the conductive material contained in the lower positive electrode active material layer is larger than the content of the conductive material contained in the upper positive electrode active material layer.

Owner:LG ENERGY SOLUTION LTD

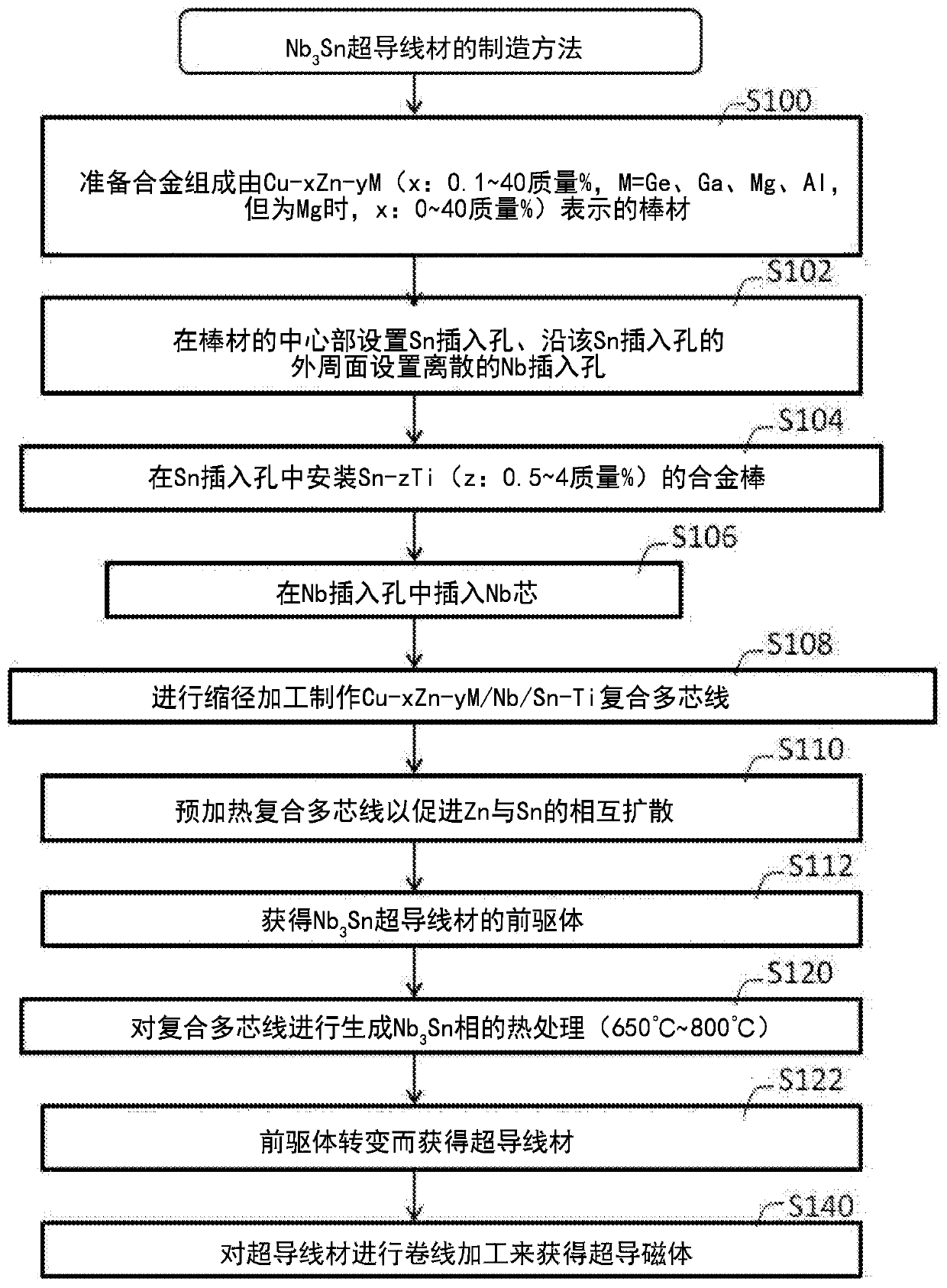

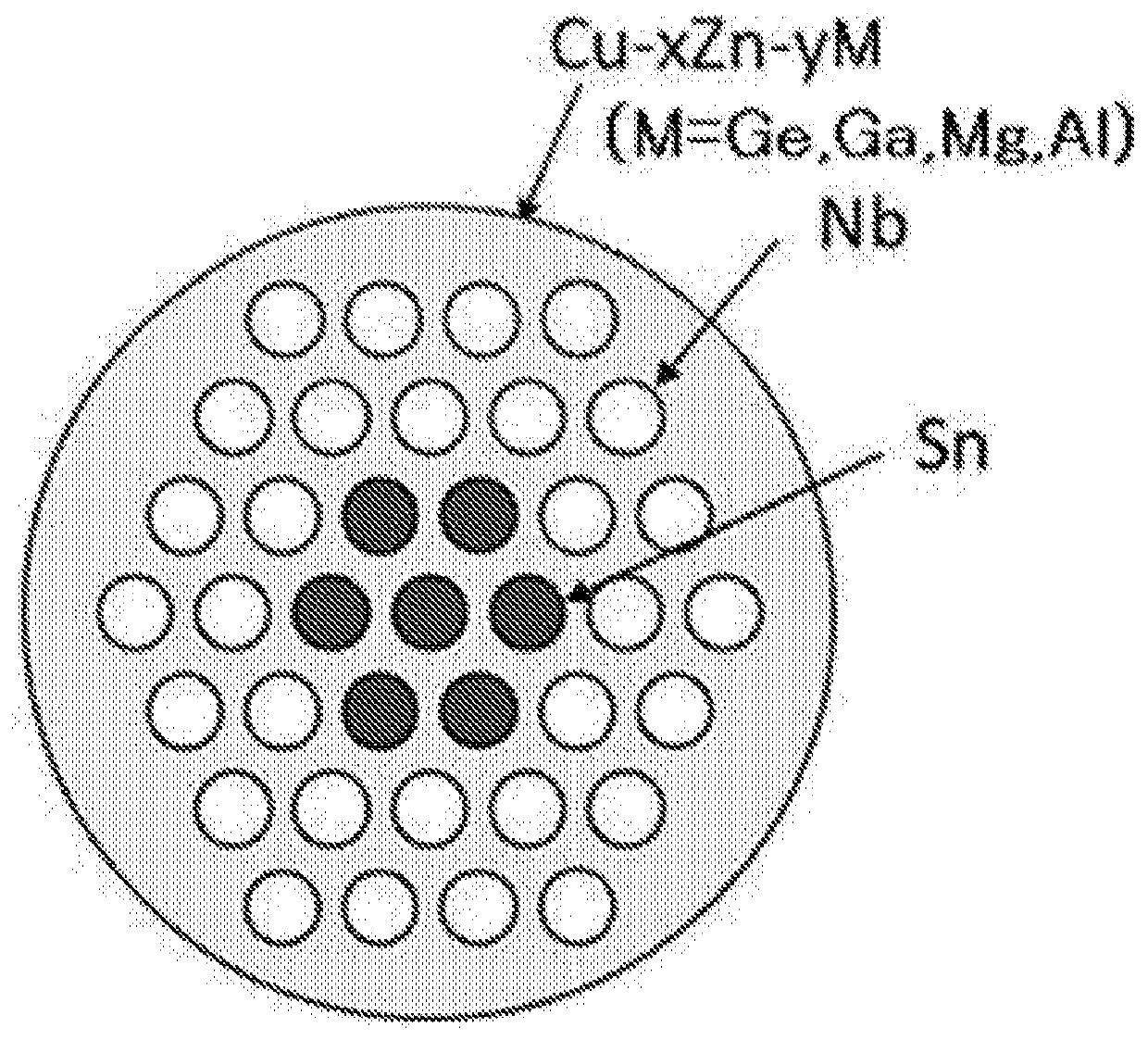

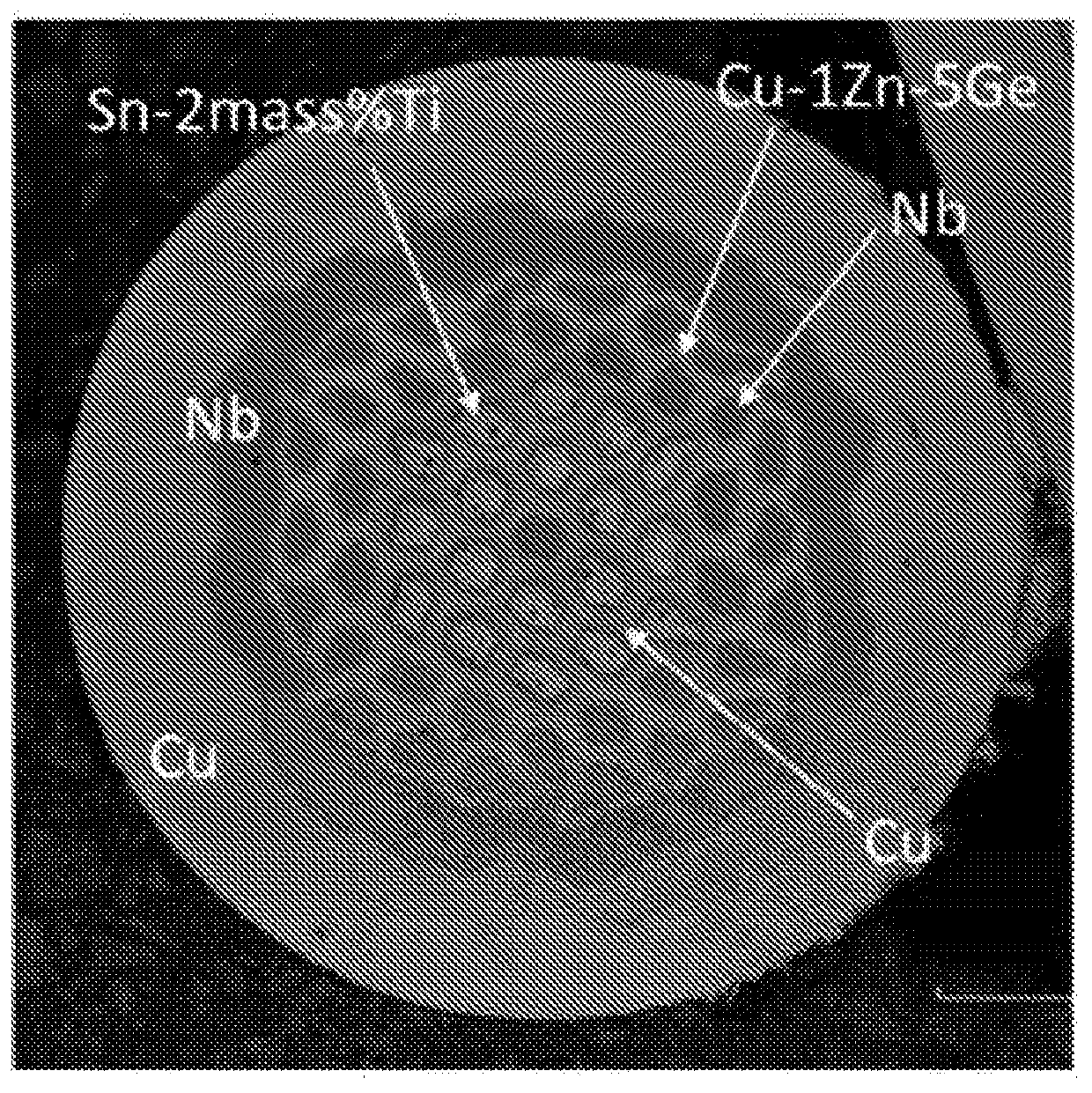

Production method for nb3sn superconducting wire rod, precursor for nb3sn superconducting wire rod, and nb3sn superconducting wire rod using same

ActiveCN110612578AHigh mechanical strengthImprove the critical temperatureSuperconductors/hyperconductorsSuperconductor devicesInterfacial resistanceMaterials science

Owner:NAT INST FOR MATERIALS SCI

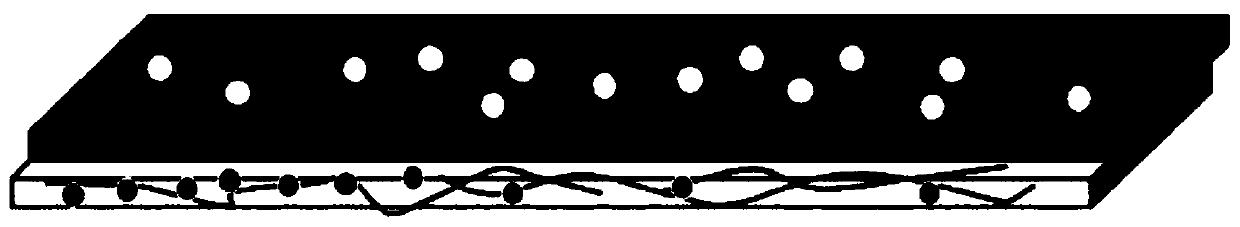

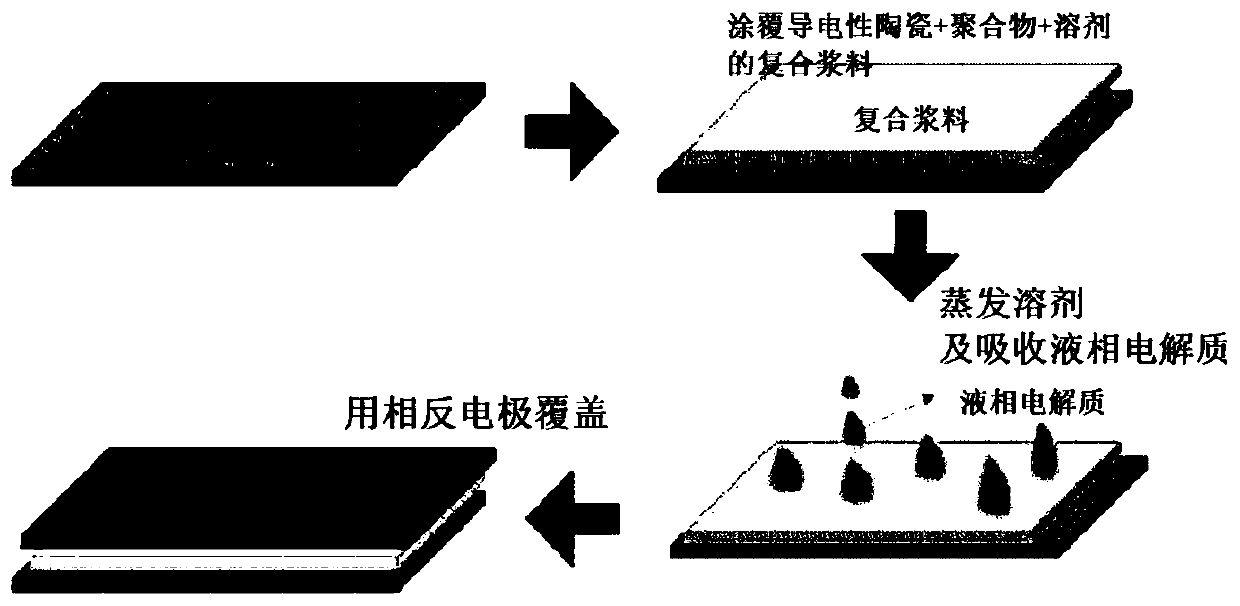

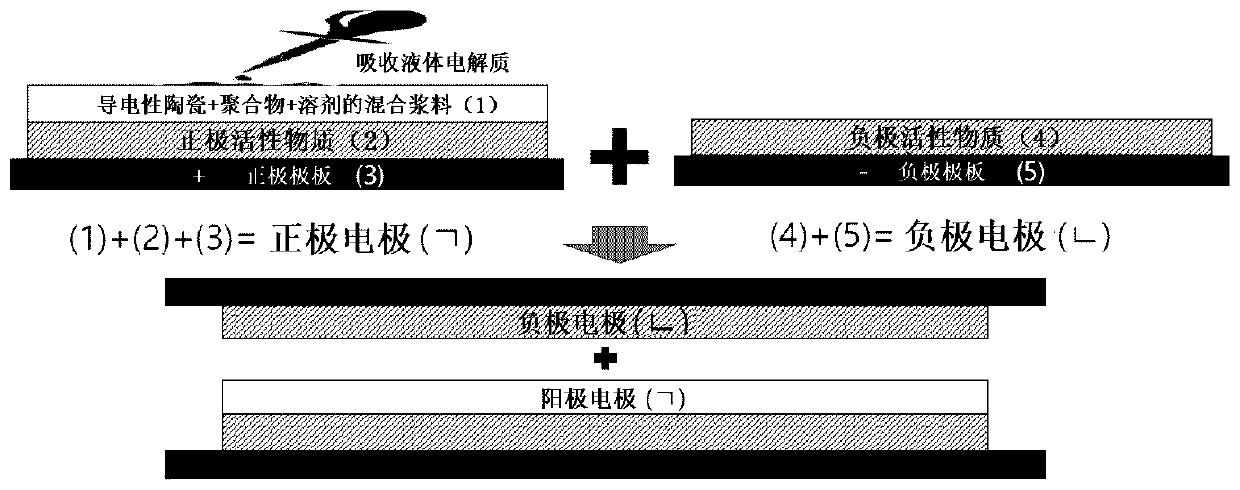

Integrated all-solid-state secondary battery

PendingCN111164815AImprove interface resistanceLow costSolid electrolytesLarge-sized flat cells/batteriesChemical physicsInterfacial resistance

Methods for fabricating secondary batteries using a solid electrolyte in order to enhance the stability of secondary batteries are under study. However, a process in which an electrode and a solid electrolyte are separately prepared and then stacked to fabricate an all-solid-state secondary battery is not only complicated, but also may cause a side reaction due to the residual moisture between theelectrode and the solid electrolyte. In addition, additional processes are required for reducing interfacial resistance between an electrode and a solid electrolyte. In order to overcome such drawbacks, the present invention fabricates an integrated all-solid-state secondary battery by applying, to an electrode, a mixed slurry of a conductive ceramic material and a polymer in a solvent, evaporating the solvent, followed by absorbing the liquid electrolyte, and covering with a counter electrode. Such a fabrication method of an integrated all-solid-state secondary battery has the effect of simplifying fabrication steps, restraining side reactions, and reducing an interfacial resistance between an electrode and a solid electrolyte.

Owner:SEVEN KING ENERGY CO LTD

Preparation method of anti-static coating

InactiveCN109852195AReduce bond strengthEasy accessBiochemical fibre treatmentVegetal fibresEpoxyNitrate

The invention discloses a preparation method of an antistatic coating, and belongs to the technical field of high polymer materials. The preparation method comprises the following steps: mixing and fermenting sisal fibers, a bacillus pasteurii bacterial solution, urea and water, dropwise adding an iron nitrate solution, stirring and mixing, filtering, freezing, ball-milling, sieving, drying and carbonizing the mixture, performing gradual heating, and carrying out high-temperature treatment to obtain the modified fibers. According to weight ratio, 40-60 parts of modified epoxy resin, 40-60 parts of a diluent, 10-20 parts of pretreated mica powder, 10-20 parts of modified fiber, 10-20 parts of modified additive, 5-8 parts of a curing agent, 5-8 parts of modified sepiolite, 20-30 parts of alkaline phenolic resin and 10-20 parts of modified diatomite are stirred and mixed to obtain the antistatic coating. The anti-static coating provided by the invention has excellent anti-static performance.

Owner:陈可

Vacuum pre-compaction and electro-osmosis combined reinforcing device and method for muck foundation

InactiveCN102704463BIncrease moisture contentImprove reinforcement effectSoil preservationBound waterEngineering

The invention discloses a vacuum pre-compaction and electro-osmosis combined reinforcing device and a method for a muck foundation. Sand-free cushion vacuum pre-compaction and electro-osmosis are combined to remove pore water and air under the super-soft musk foundation. Through the vacuum pre-compaction effect at the earlier stage, most of free water in the soil is removed, and part of the free water and weak bound water which cannot be removed by the vacuum pre-compaction can be further removed via the electro-osmosis, thus the reinforcing effect can be greatly improved, the manufacturing cost is increased a little on the basis of the vacuum pre-compaction, and the economical efficiency is remarkable.

Owner:南京科冠工程技术有限公司

High-voltage-resistant composite solid electrolyte, preparation method thereof and all-solid-state lithium battery

PendingCN114744291AResistantIncrease transfer rateFinal product manufactureLi-accumulatorsElectrolysisLithium metal

The invention discloses a high-voltage-resistant composite solid electrolyte, a preparation method of the high-voltage-resistant composite solid electrolyte and an all-solid-state lithium battery, and relates to the technical field of lithium ion batteries, and the high-voltage-resistant composite solid electrolyte is formed by hot pressing of a first composite solid electrolyte layer and a second composite solid electrolyte layer; the first composite solid electrolyte layer comprises a COFs matrix and a polymer electrolyte A loaded on the surface of the COFs matrix, and the polymer electrolyte A comprises polyoxyethylene, bismuth trioxide, a lithium salt and polyvinylidene fluoride; the second composite solid electrolytic layer comprises a COFs matrix and a polymer electrolyte B loaded on the surface of the COFs matrix; and the polymer electrolyte B comprises polymethyl methacrylate, bismuth trioxide, lithium salt and polyvinylidene fluoride. According to the composite solid electrolyte, the electrochemical window of the solid electrolyte is widened, the interface resistance is reduced, the interface stability of the positive electrode and the negative electrode and the lithium ion transmission performance are improved, the composite solid electrolyte can be simultaneously suitable for a lithium metal negative electrode and a high-voltage ternary positive electrode, and the cycle performance of a battery is improved.

Owner:WANXIANG 123 CO LTD

Copolymerization solid electrolyte, preparation method thereof and solid polymer lithium battery

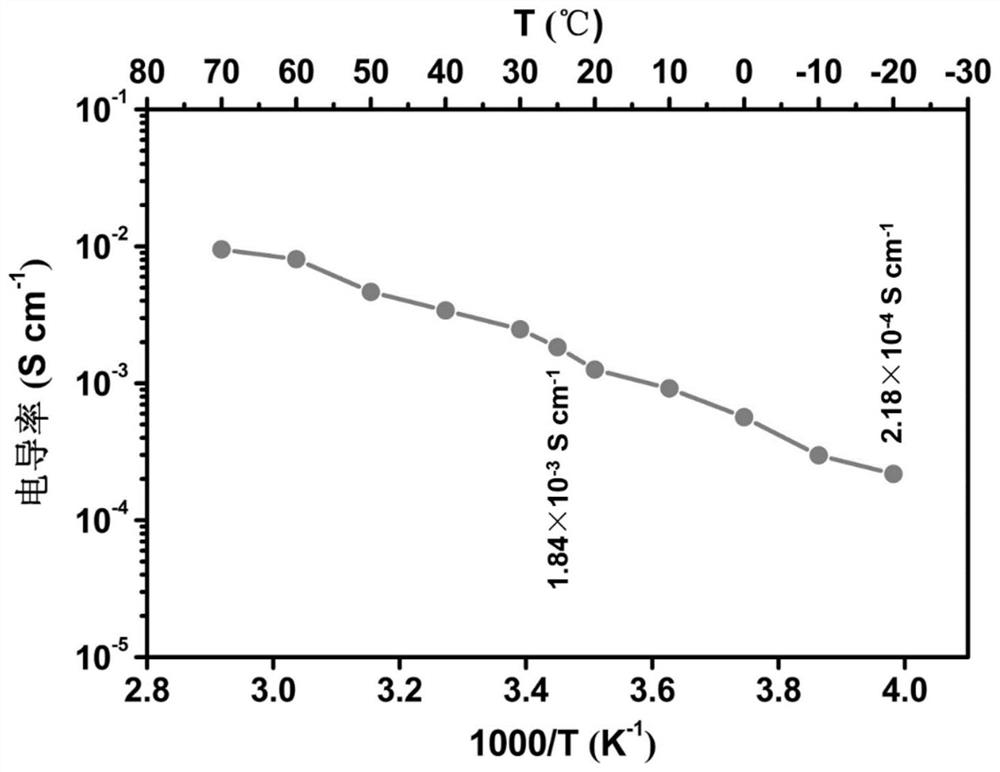

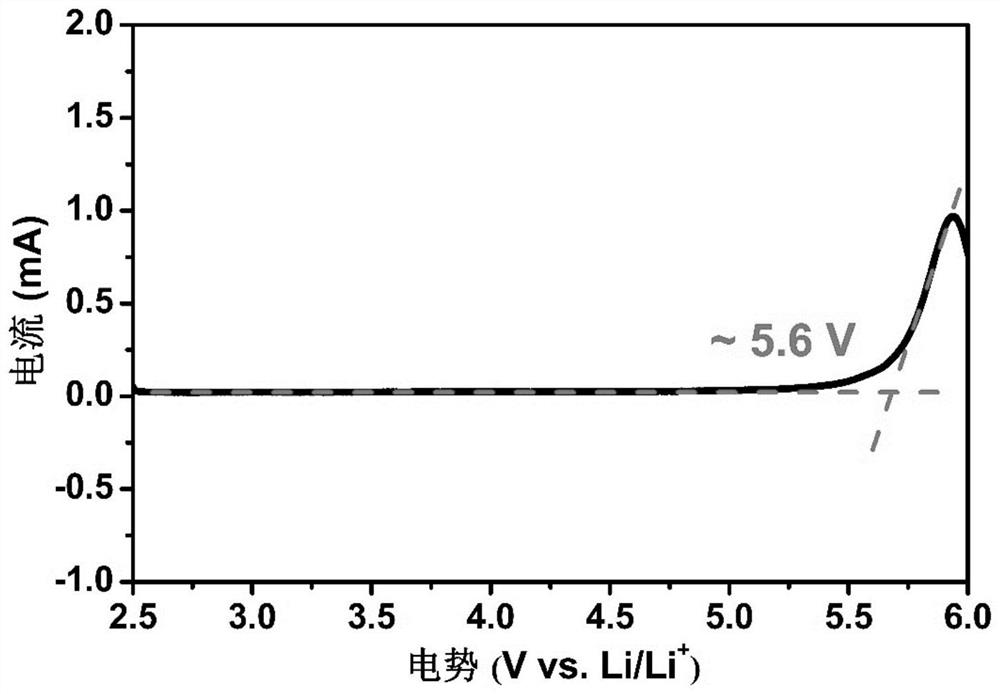

ActiveCN114024025AGood electrical conductivityImprove interface performanceFinal product manufactureElectrolyte accumulators manufactureIn situ polymerizationPolymer chemistry

The invention provides a copolymerization solid electrolyte, a preparation method thereof and a solid polymer lithium battery. The preparation method of the copolymerization solid electrolyte comprises the following steps: (1) uniformly mixing a polymer monomer and a copolymer, adding a lithium salt, and completely dissolving to obtain an electrolyte precursor, the copolymer being a fluorinated amide compound; and (2) adding an initiator into the electrolyte precursor, and carrying out copolymerization reaction on the polymer monomer and the copolymer under a heating condition to obtain the solid electrolyte. The solid electrolyte disclosed by the invention is simple in preparation process and high in applicability, can be matched with a relatively high-voltage positive electrode material in a room-temperature / low-temperature environment, and is obviously improved in ionic conductivity; and the in-situ polymerization technology improves the interface contact problem of the electrode / electrolyte, the interface resistance is also greatly improved, and excellent interface performance and cycle performance can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

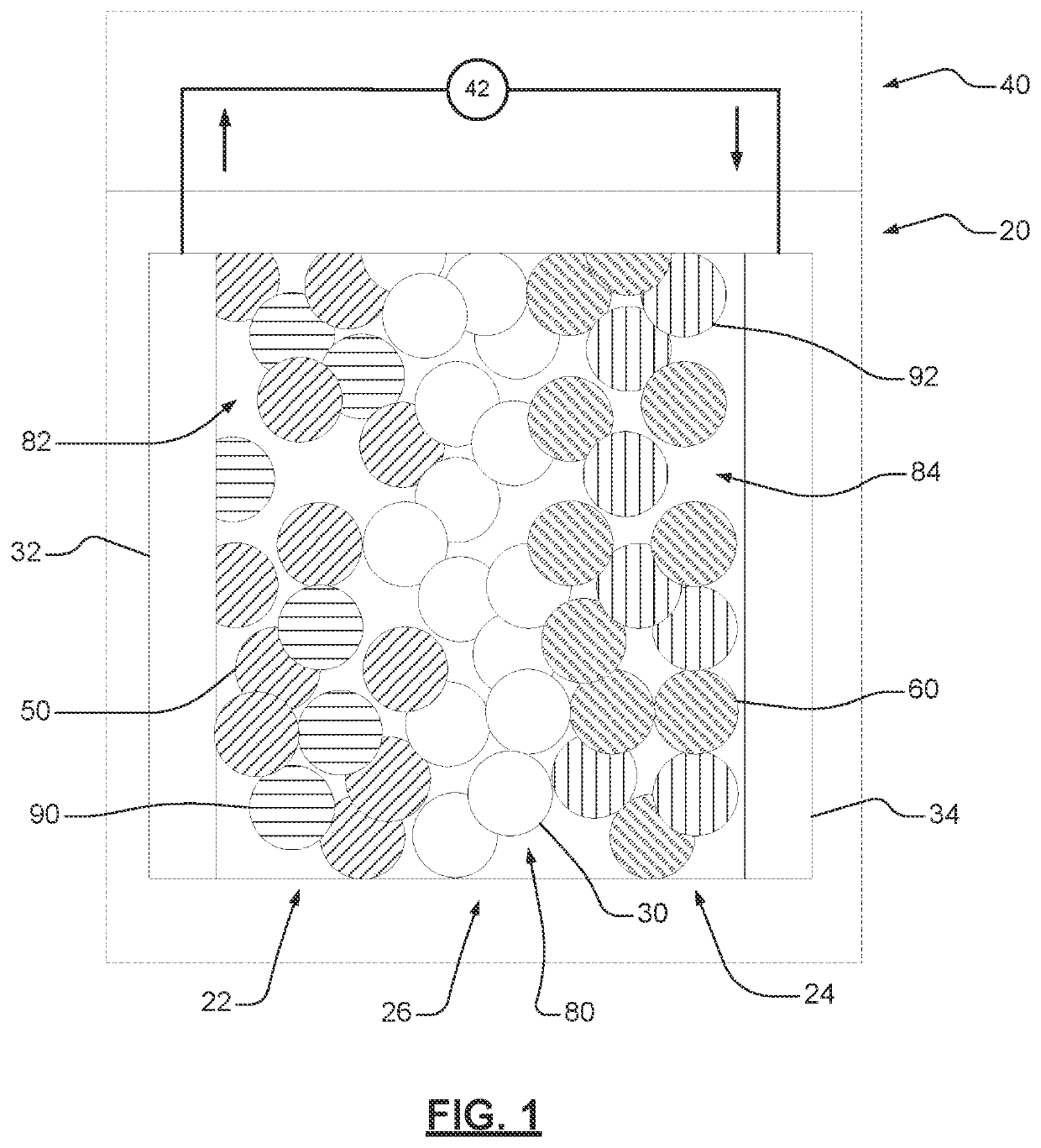

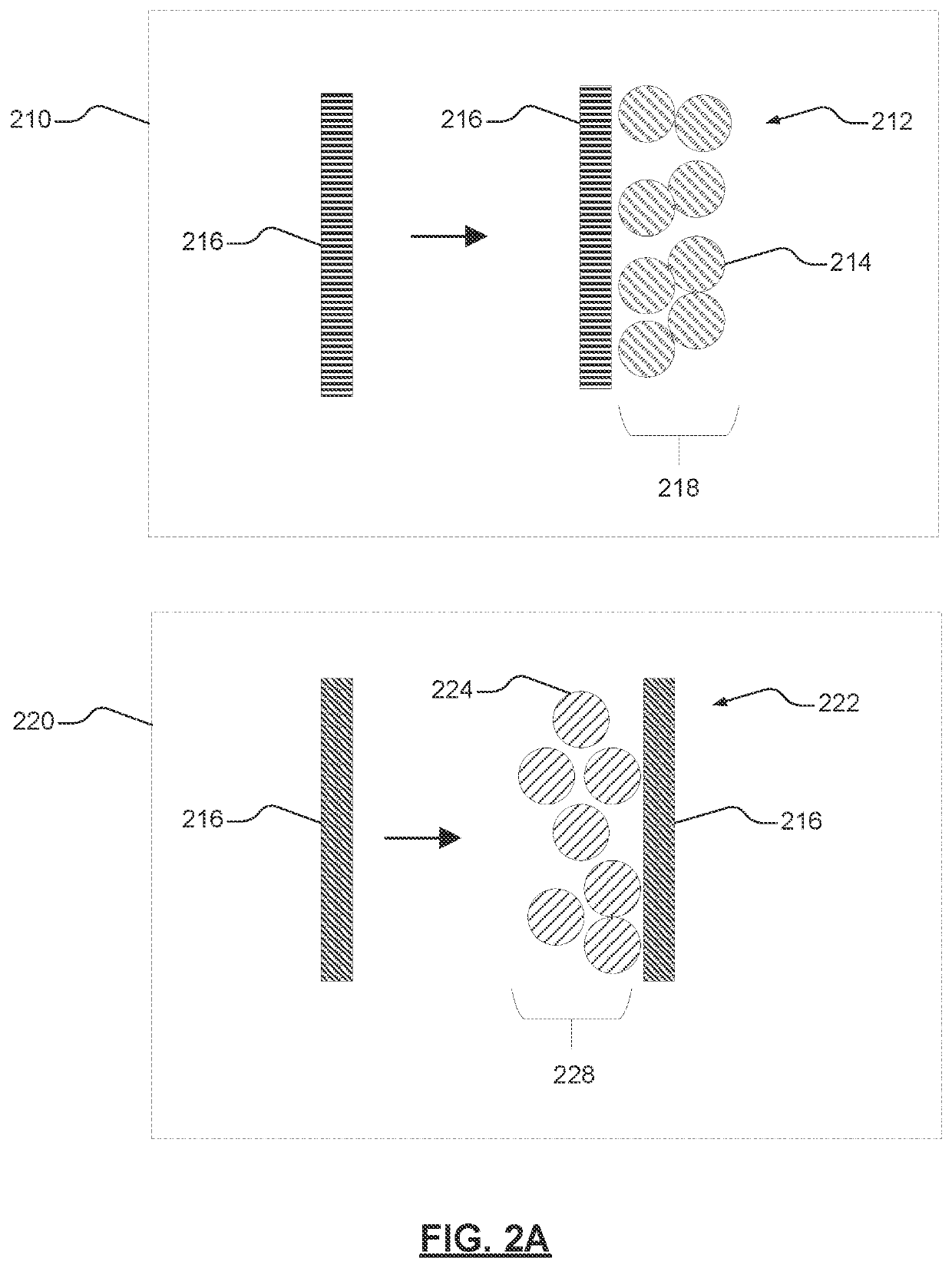

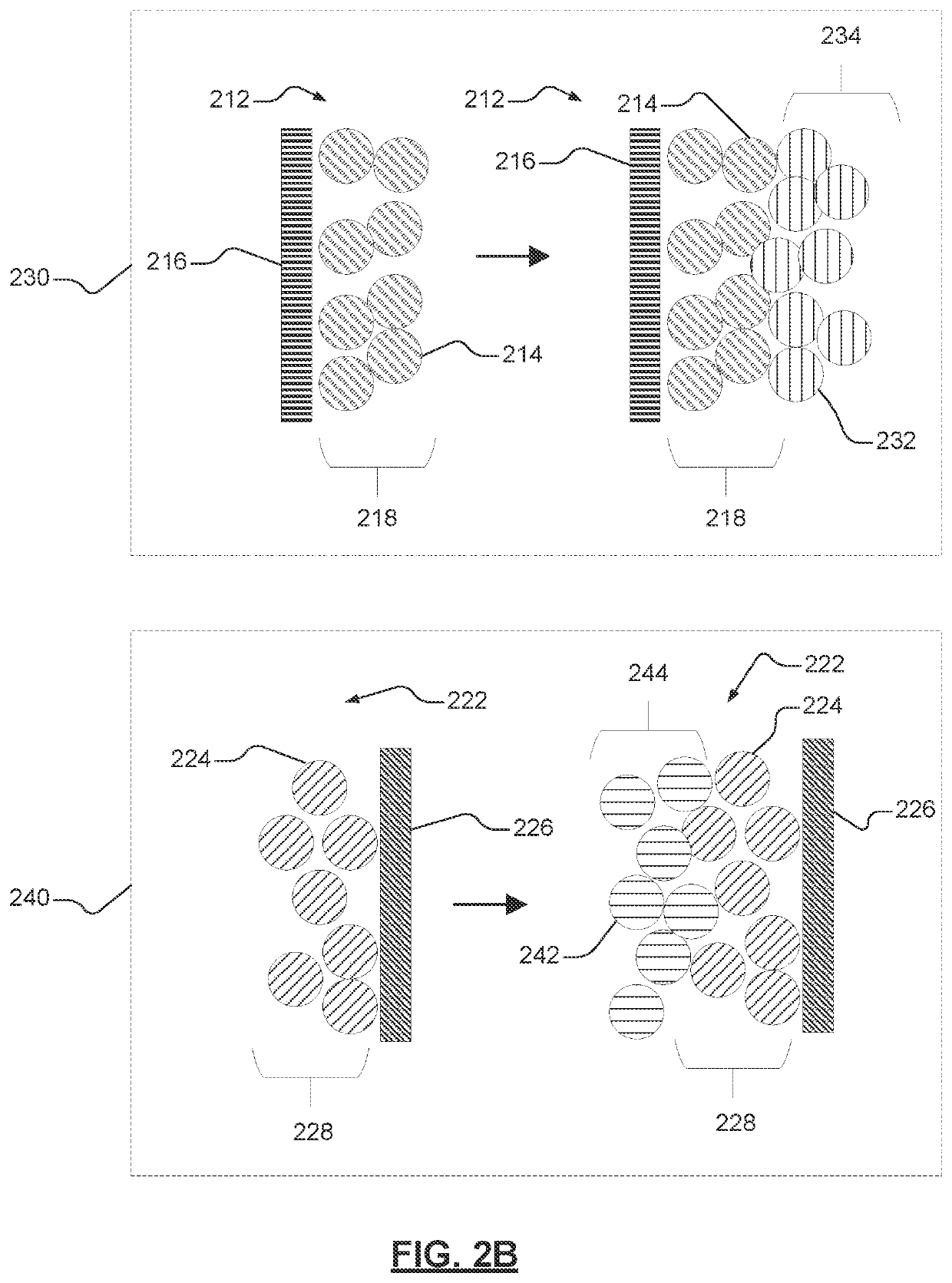

Solid state battery with uniformly distributed electrolyte, and methods of fabrication relating thereto

PendingUS20220181598A1Reduce needExtended shelf lifeSolid electrolytesNon-aqueous electrolyte accumulator electrodesPhysicsSolid-state battery

The present disclosure relates to a solid-state electrochemical cell having a uniformly distributed solid-state electrolyte and methods of fabrication relating thereto. The method may include forming a plurality of apertures within the one or more solid-state electrodes; impregnating the one or more solid-state electrodes with a solid-state electrolyte precursor solution so as to fill the plurality of apertures and any other void or pores within the one or more electrodes with the solid-state electrolyte precursor solution; and heating the one or more electrodes so as to solidify the solid-state electrolyte precursor solution and to form the distributed solid-state electrolyte.

Owner:GM GLOBAL TECH OPERATIONS LLC

Separator for lithium secondary battery having enhanced electrode adhesive strength and improved resistance characteristics, and

PendingCN114144931AIncreased surface area for adhesionImprove adhesionCell seperators/membranes/diaphragms/spacersLi-accumulatorsPorous coatingInorganic particle

Owner:LG CHEM LTD

Separation film for lithium secondary battery having adhesive layer

ActiveCN110249447AImprove adhesionImprove interface resistanceLi-accumulatorsCell component detailsPorous substrateInorganic particle

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com