Functionalized graphene hydrogel/functionalized carbon cloth composite fabric, flexible all-solid-state supercapacitor integrated electrode and preparation method

A composite fabric and hydrogel technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double layer capacitors, can solve the problems of inability to fill the gaps and large pores of carbon cloth, and achieve high redox Effects of activity and charge storage capacity, improved capacitance, and improved cycling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

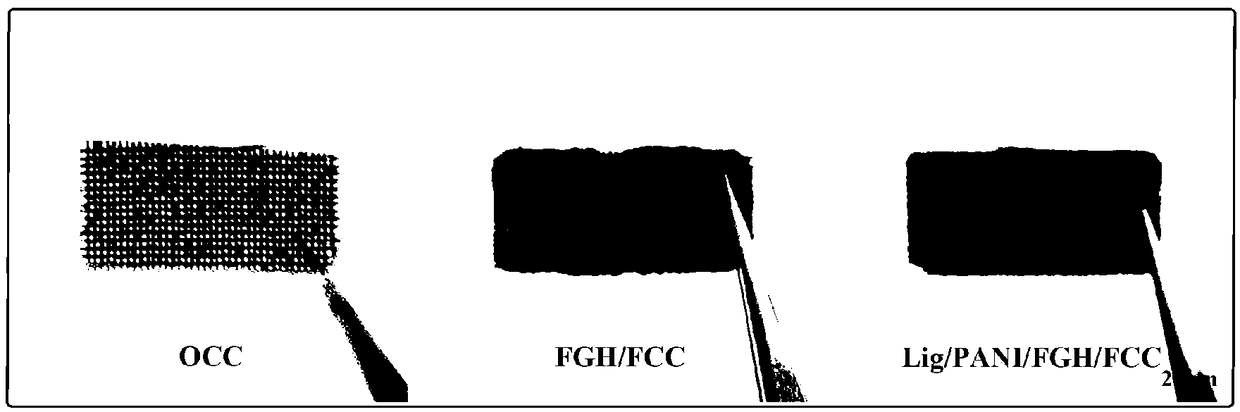

[0042] Step 1: Oxidation of carbon cloth: put 0.5g CC in 30mL concentrated HNO 3 : Concentrated H 2 SO 4 (1:2, v / v%) in the mixture, ice-bathed and stirred. Subsequently, 3g KMnO 4 Slowly added to the above mixture, heated to 35°C and continued to stir for 3h. Then, 100 mL of deionized water was added dropwise into the above mixture, and stirring was continued for 3 h. Finally, add H 2 o 2 The solution was allowed to stop bubbling and the solution became clear. Washing with deionized water and drying yielded oxidized CC (OCC).

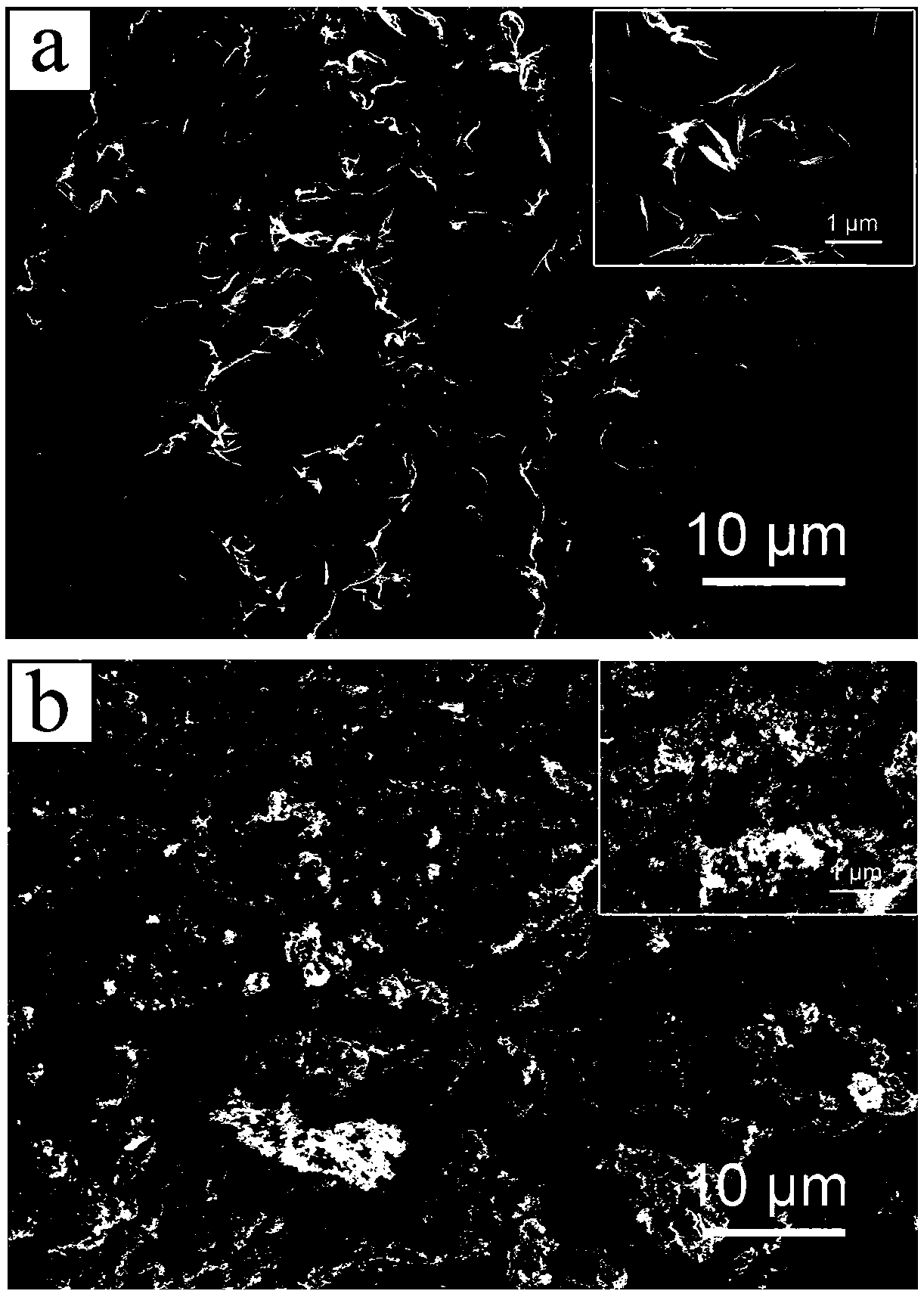

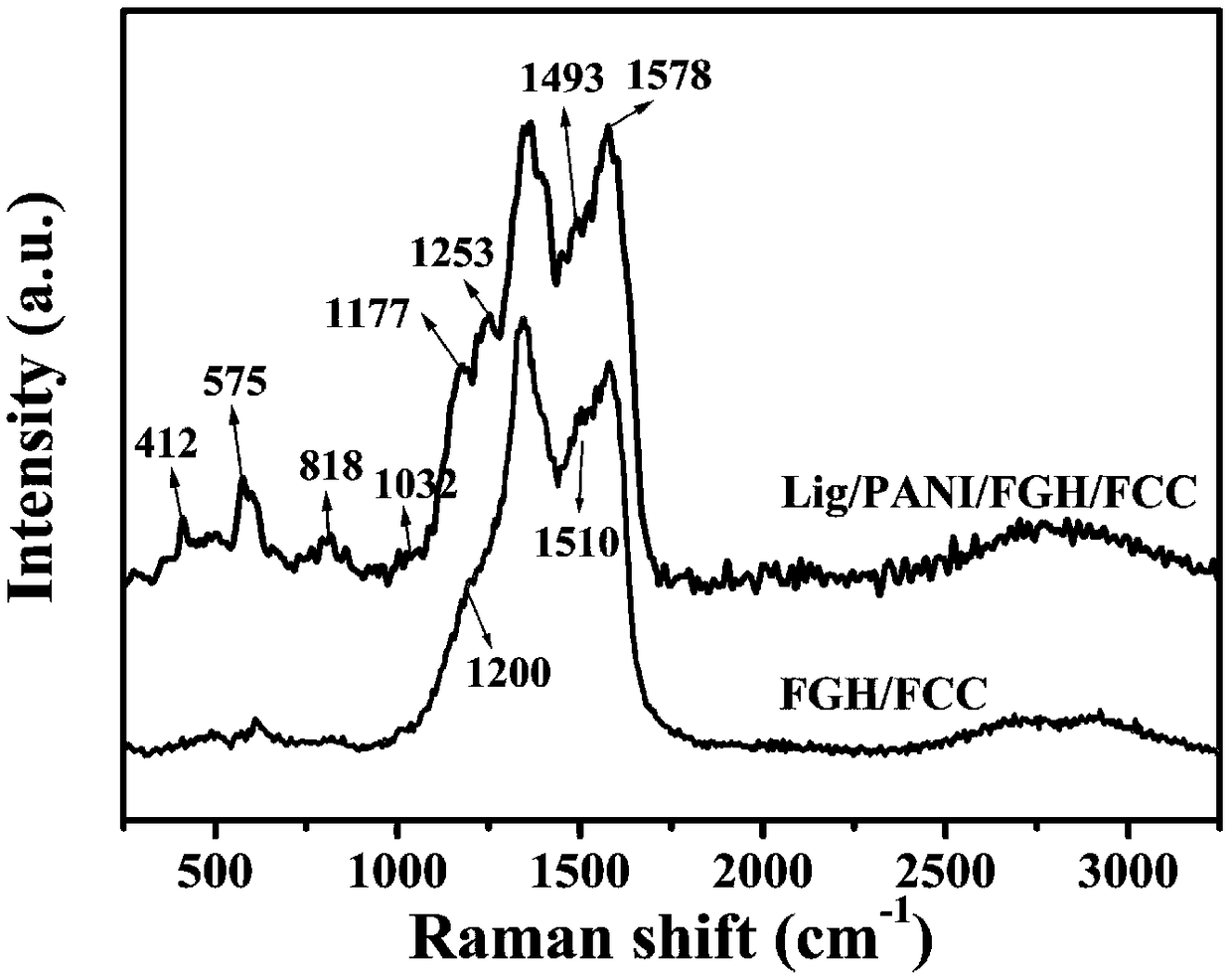

[0043] Step 2: Preparation of FGH / FCC: FGH / FCC is prepared by a one-step hydrothermal method. First, graphene oxide (GO) prepared by Hummer’s method was added to PPD aqueous solution to obtain GO / PPD dispersion. Among them, the final concentration of GO was 2 mg / mL, and the mass ratio of GO to PPD was 1:5, that is, the PPD concentration was 10 mg / mL. Then the OCC was submerged in the GO / PPD dispersion and sonicated for 10 minutes, and then th...

Embodiment 2

[0060] Embodiment 1 is the best preferred solution of the present invention, and the following Table 1 and Table 2 are the single factor optimization experiment part carried out in the process of obtaining the best preferred solution of Example 1. Except that the conditions of investigation are different from Example 1, other conditions are all the same as Example 1.

[0061] Table 1: Effect of reaction conditions on the electrochemical performance of Lig / PANI / FGH / FCC during the hydrothermal reaction

[0062]

[0063] Table 2. Influence of reaction conditions during in situ polymerization on the electrochemical performance of Lig / PANI / FGH / FCC

[0064]

[0065]

Embodiment 3

[0067] Electrochemical performance comparison experiments of OCC, rOCC, rGO / rOCC, FGH / FCC, Lig / PANI / rOCC, Lig / PANI / rGO / rOCC and Lig / PANI / FGH / FCC:

[0068] The symmetric supercapacitor (SSC) assembled by FGH / FCC operates at a current density of 1mA cm -2 When the area capacitance is 816mF cm -2 , significantly higher than OCC, rOCC and rGO / rOCC without PPD doping. When the current density increases to 20mA cm -2 , the rate performance of FGH / FCC is as high as 78%. The higher electrochemical performance of FGH / FCC is mainly due to two reasons: (1) PPD functionalization and N-doping can provide a larger pseudocapacitance; (2) the introduction of FGH greatly increases the specific capacitance of the electrode. The surface area, the contact area between the electrolyte and the material increases, and the number of active sites increases. More importantly, when the loading of Lig / PANI in a single electrode is 2.5 mg cm -2 , the SSC assembled by Lig / PANI / FGH / FCC showed more exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Area capacitance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com