Patents

Literature

155 results about "Interfacial resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

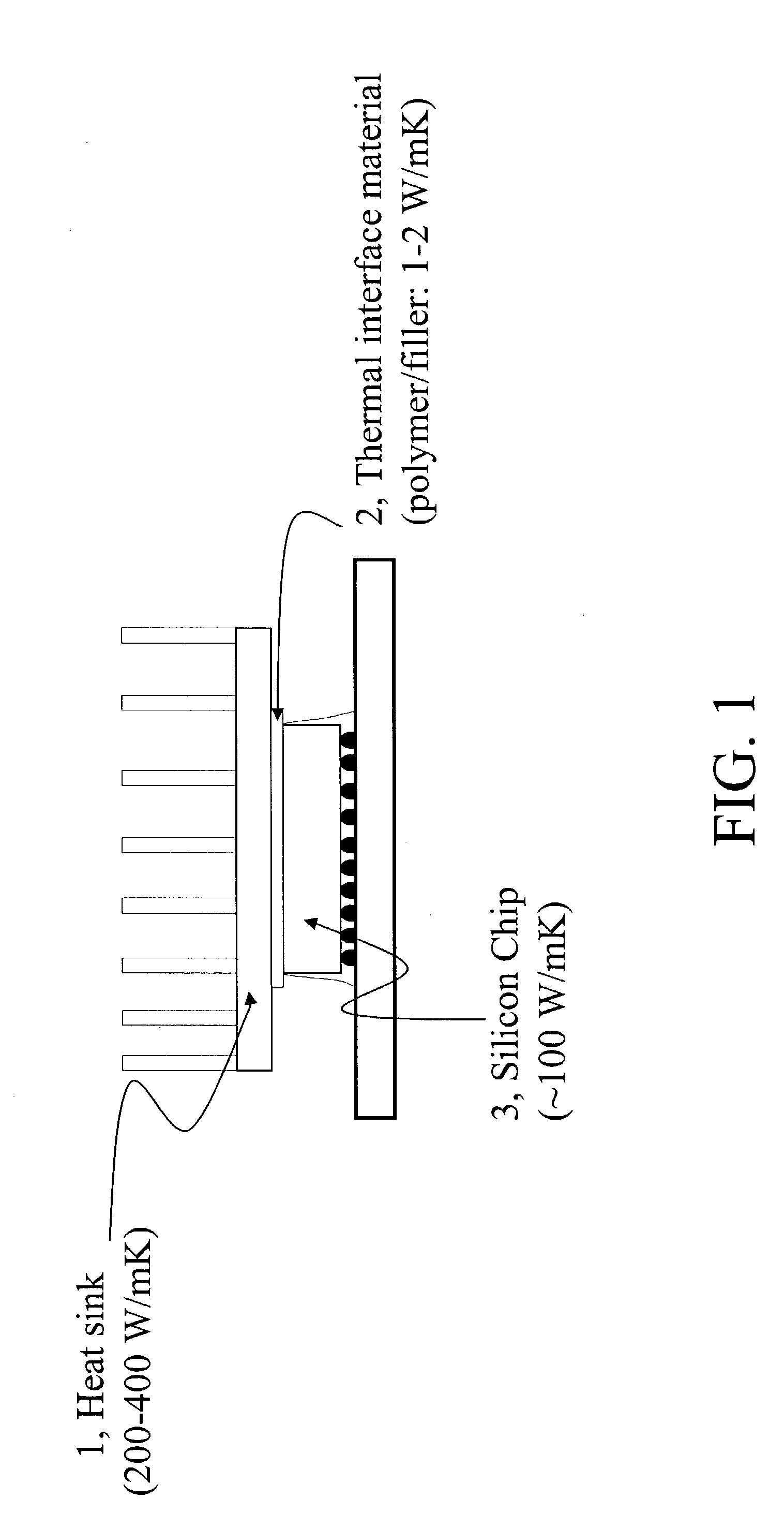

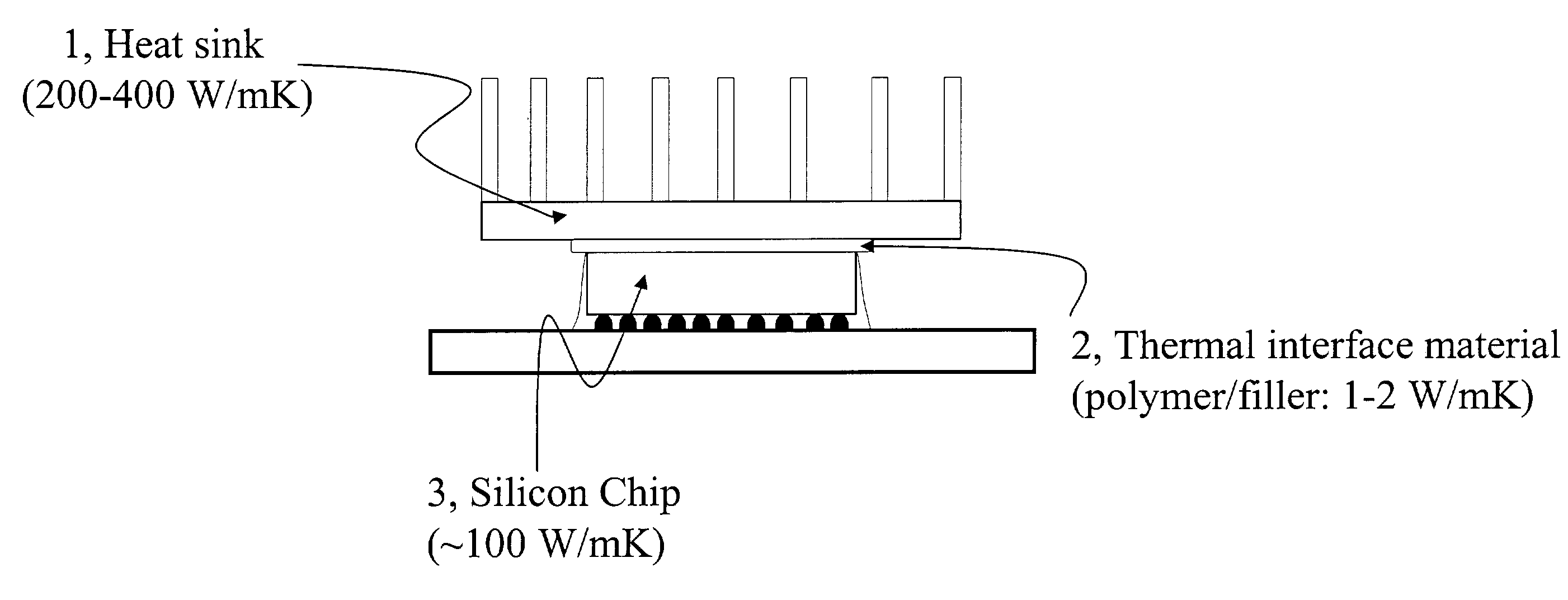

Thermal conductive material utilizing electrically conductive nanoparticles

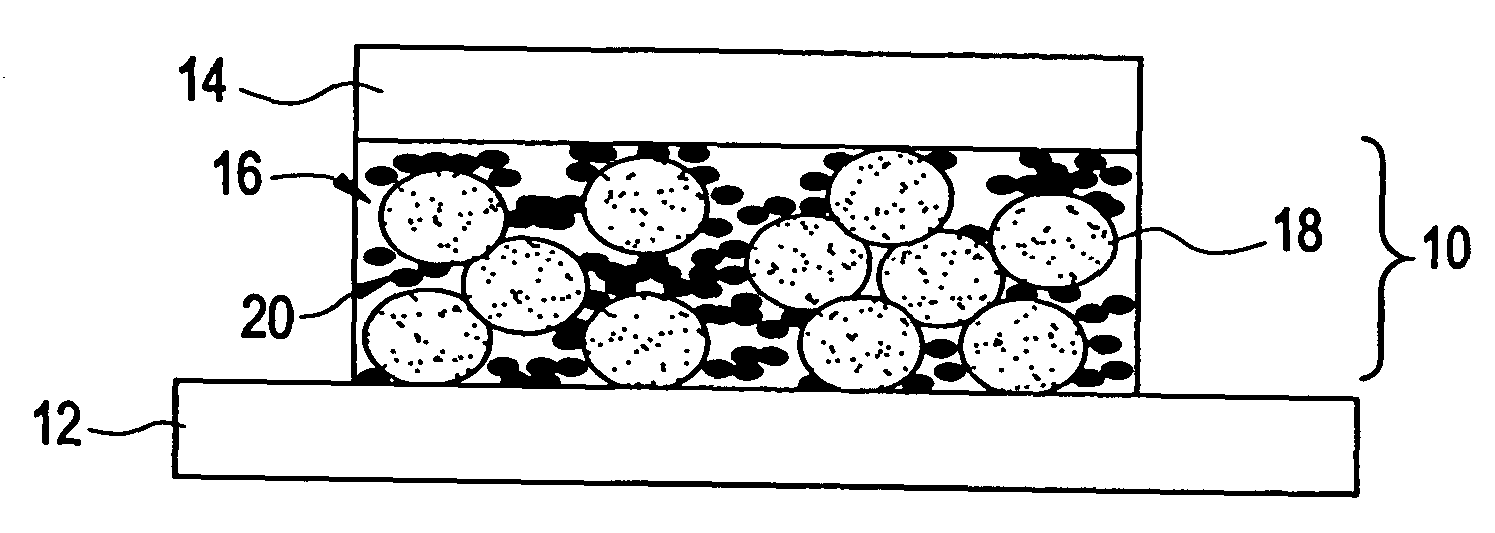

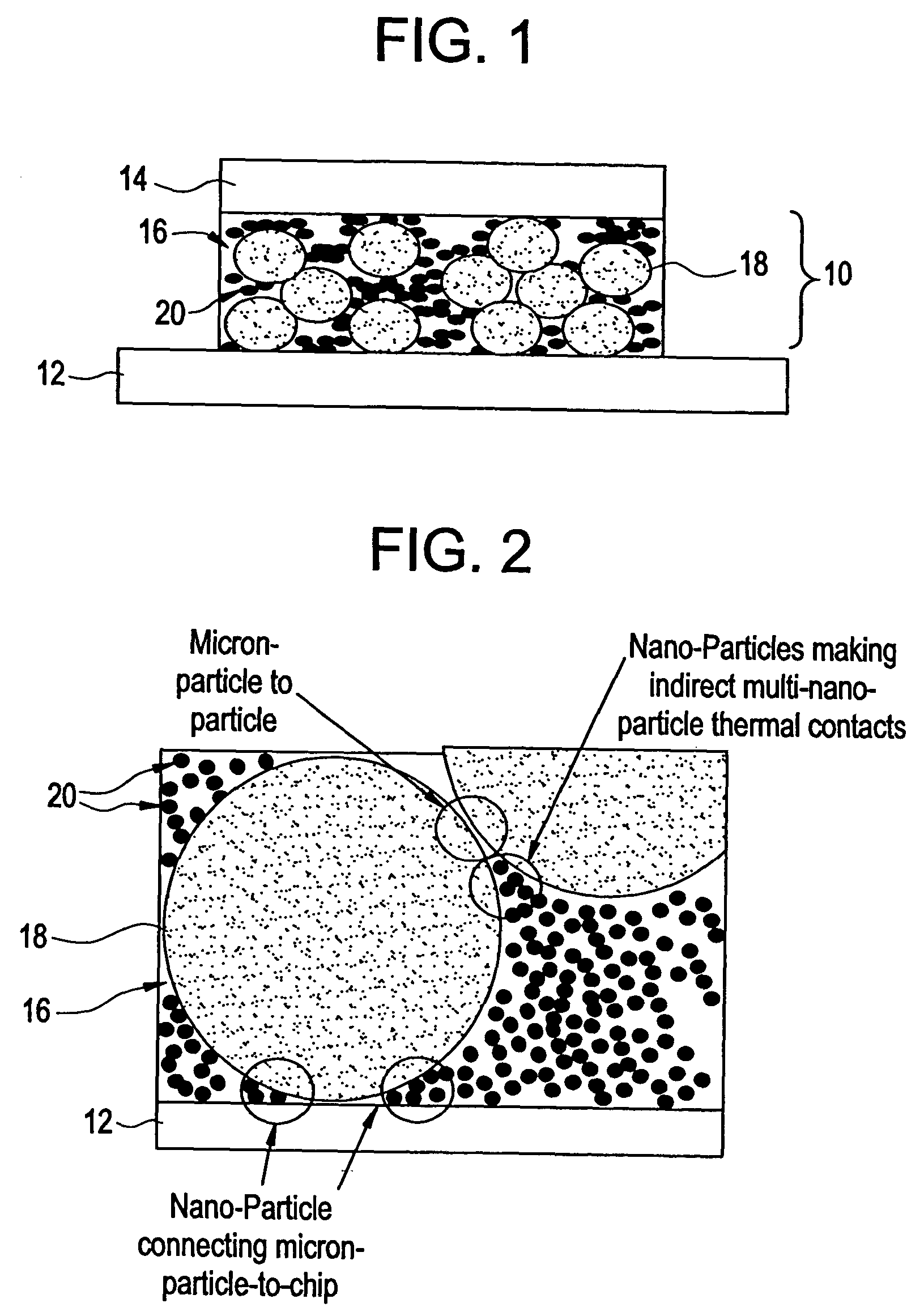

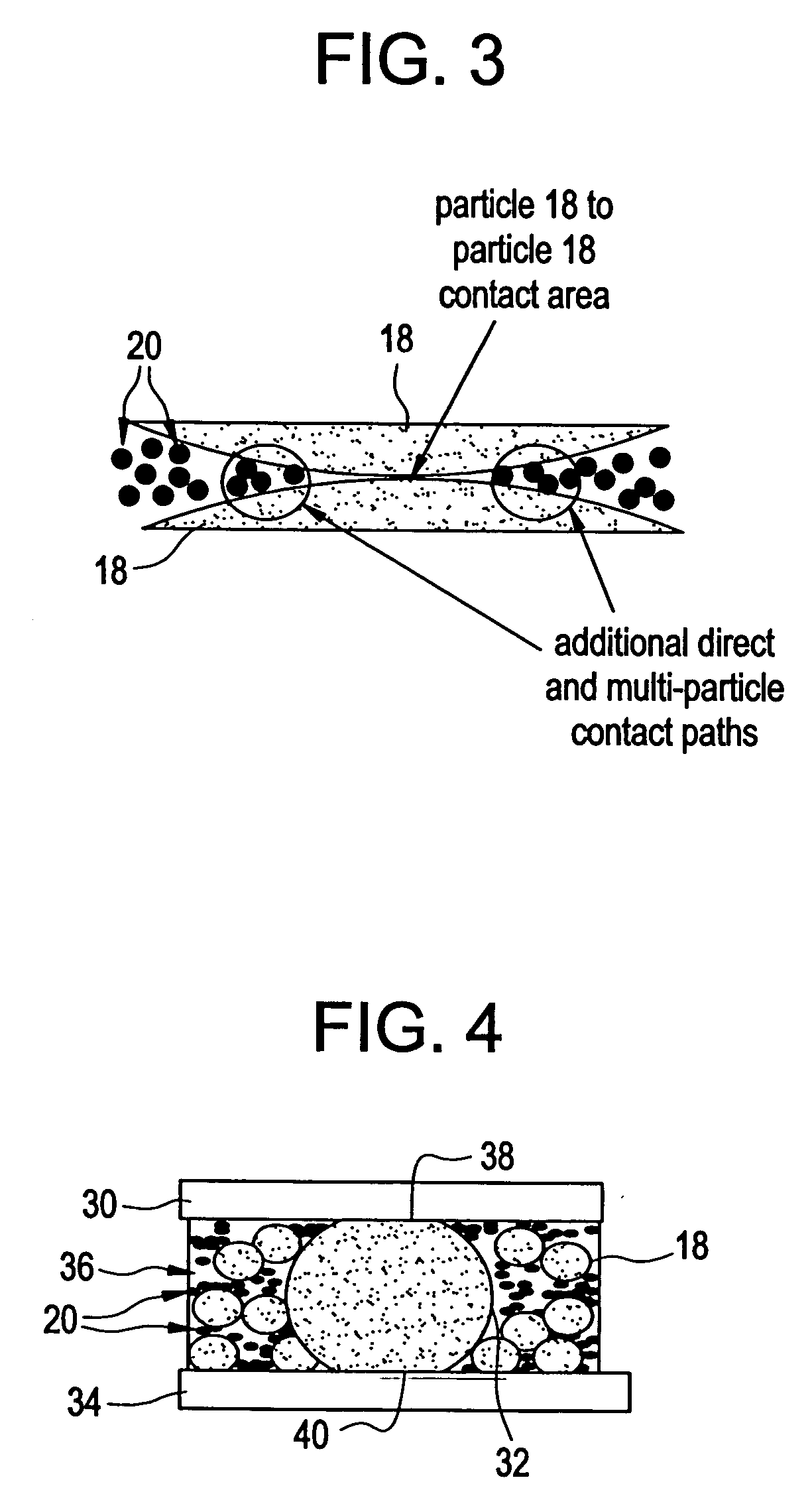

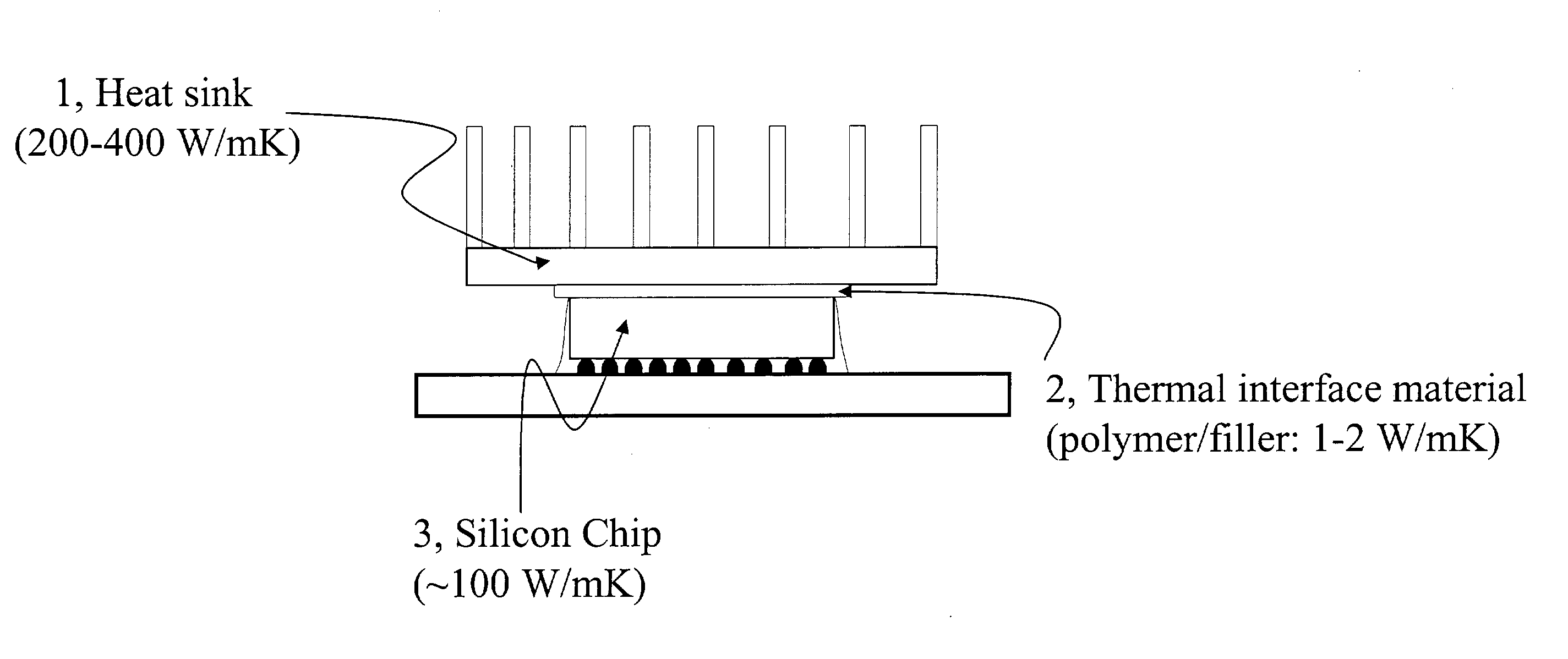

ActiveUS20050045855A1Improve heat transfer efficiencySemiconductor/solid-state device detailsConductive materialNanoparticleInterfacial resistance

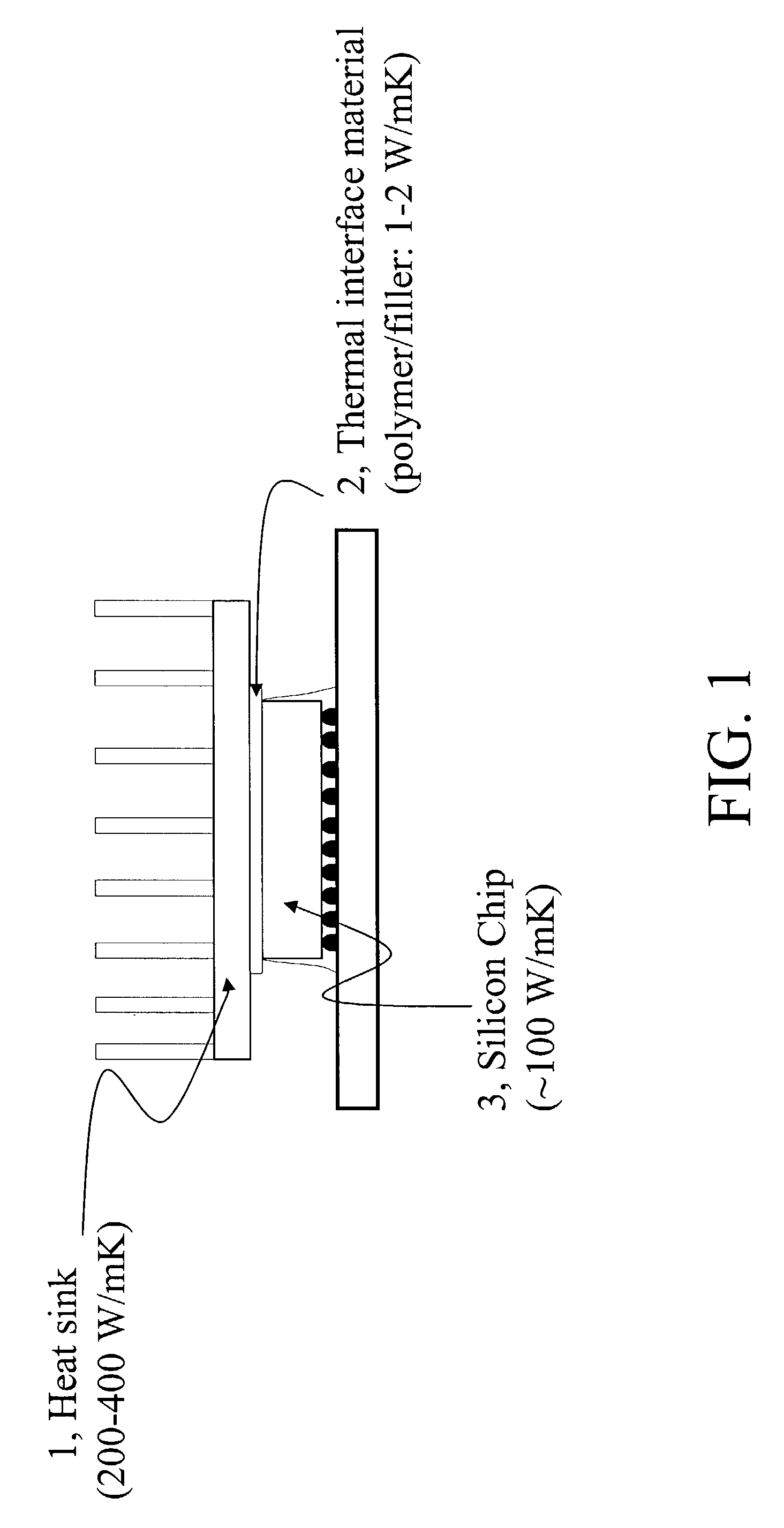

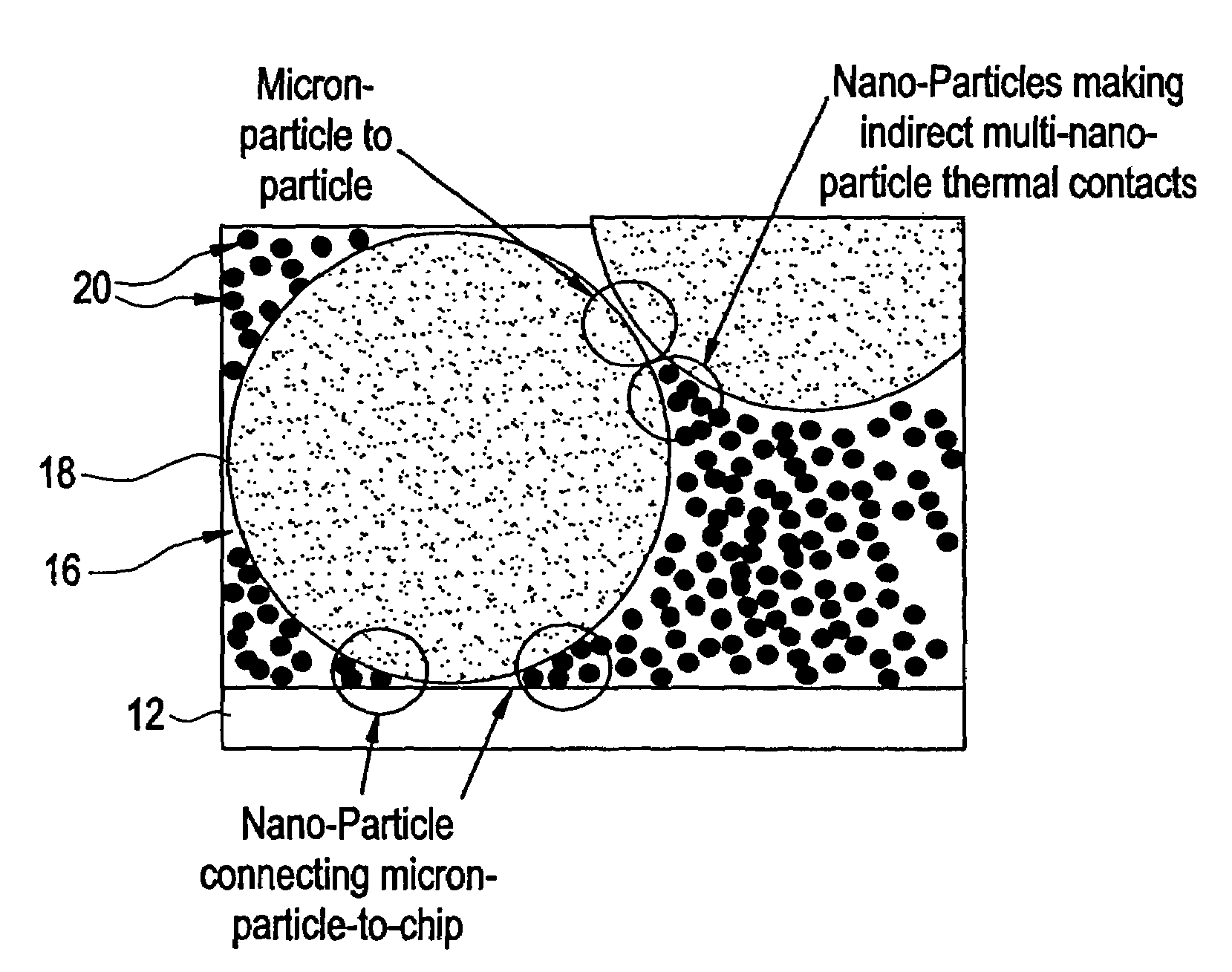

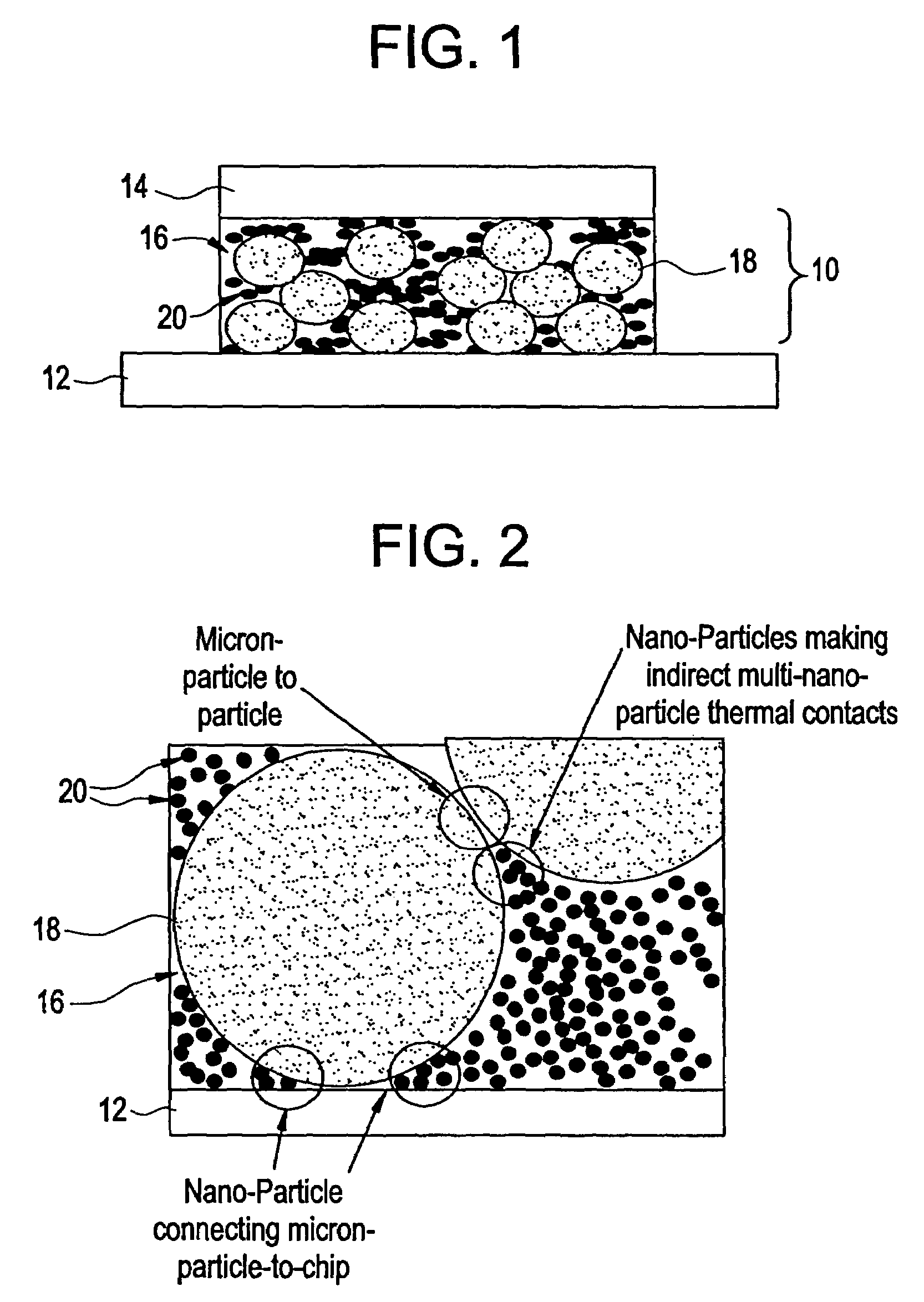

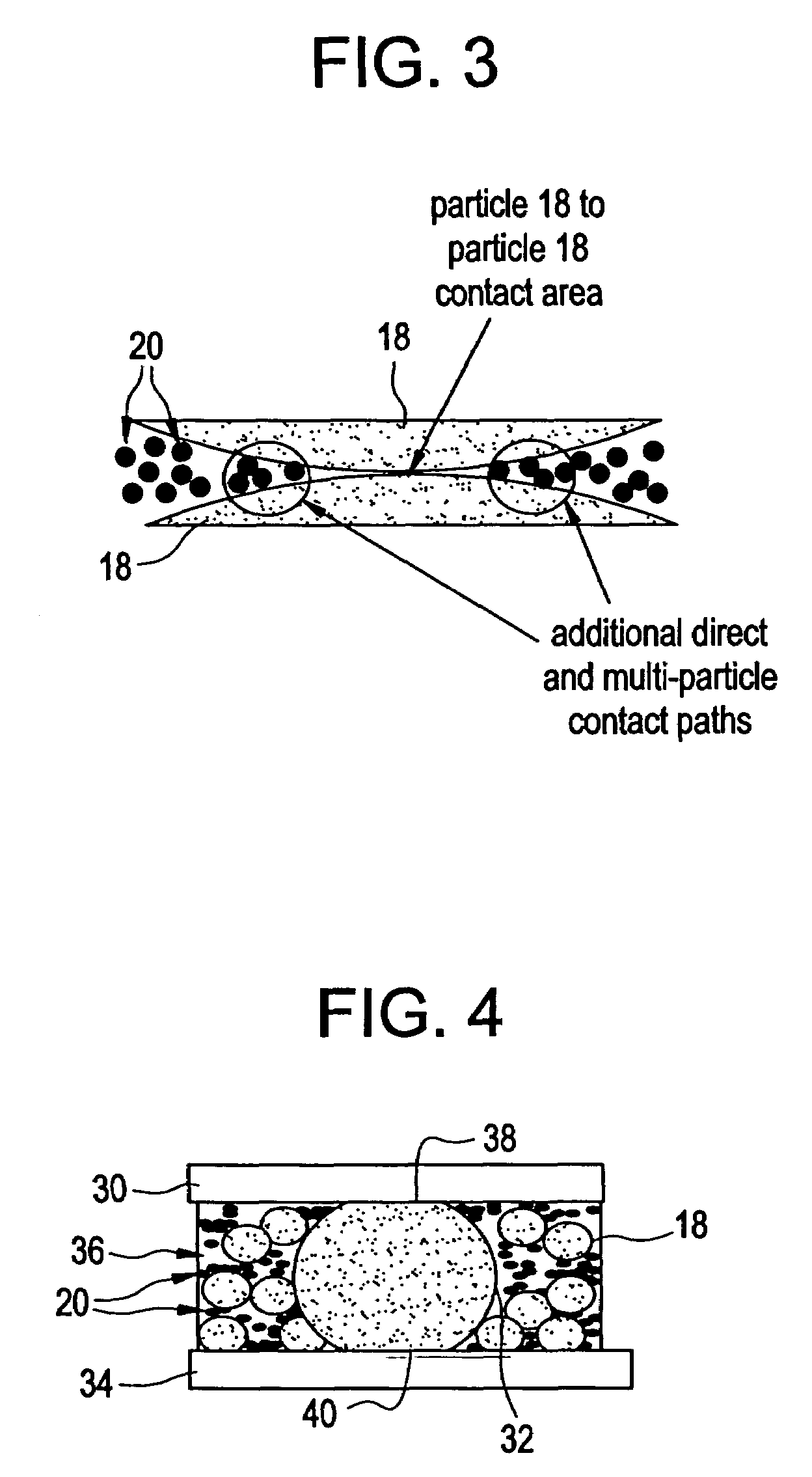

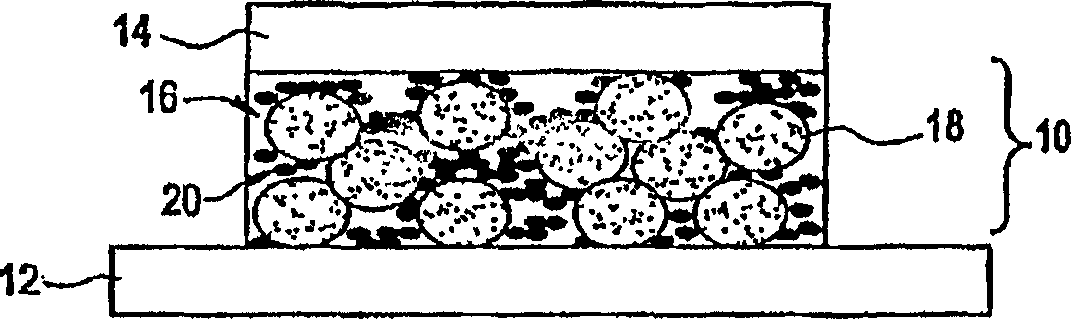

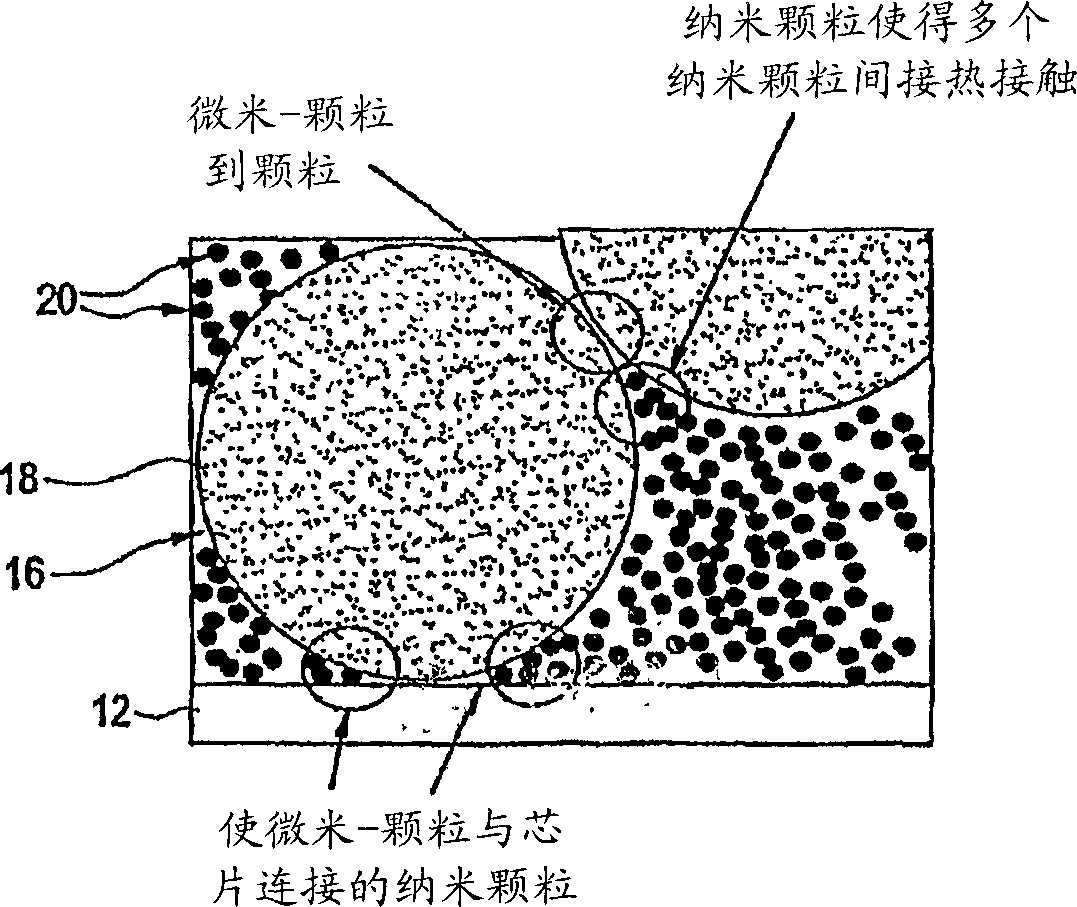

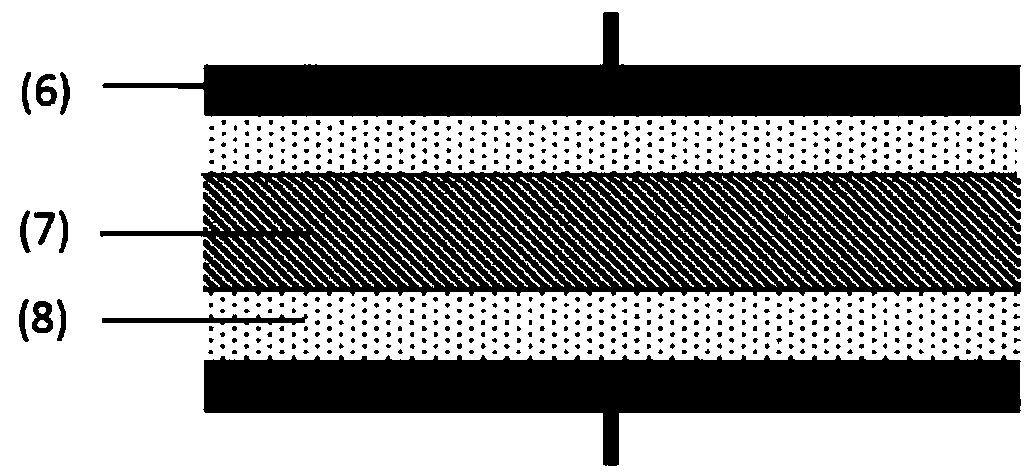

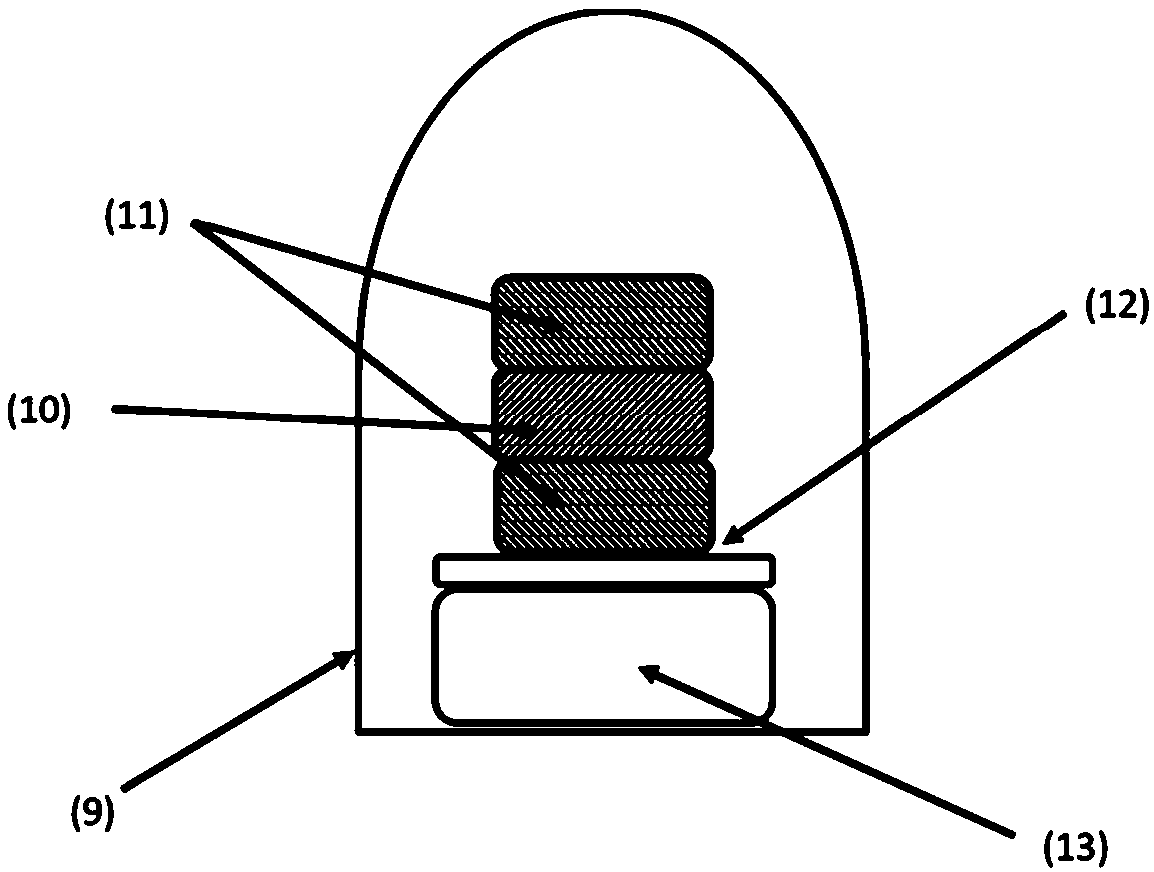

Thermal interface compositions contain both non-electrically conductive micron-sized fillers and electrically conductive nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Such compositions are electrically non-conductive. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

Organic matrices containing nanomaterials to enhance bulk thermal conductivity

InactiveUS20050161210A1Improve heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesNanoparticleInterfacial resistance

Thermal interface compositions contain nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

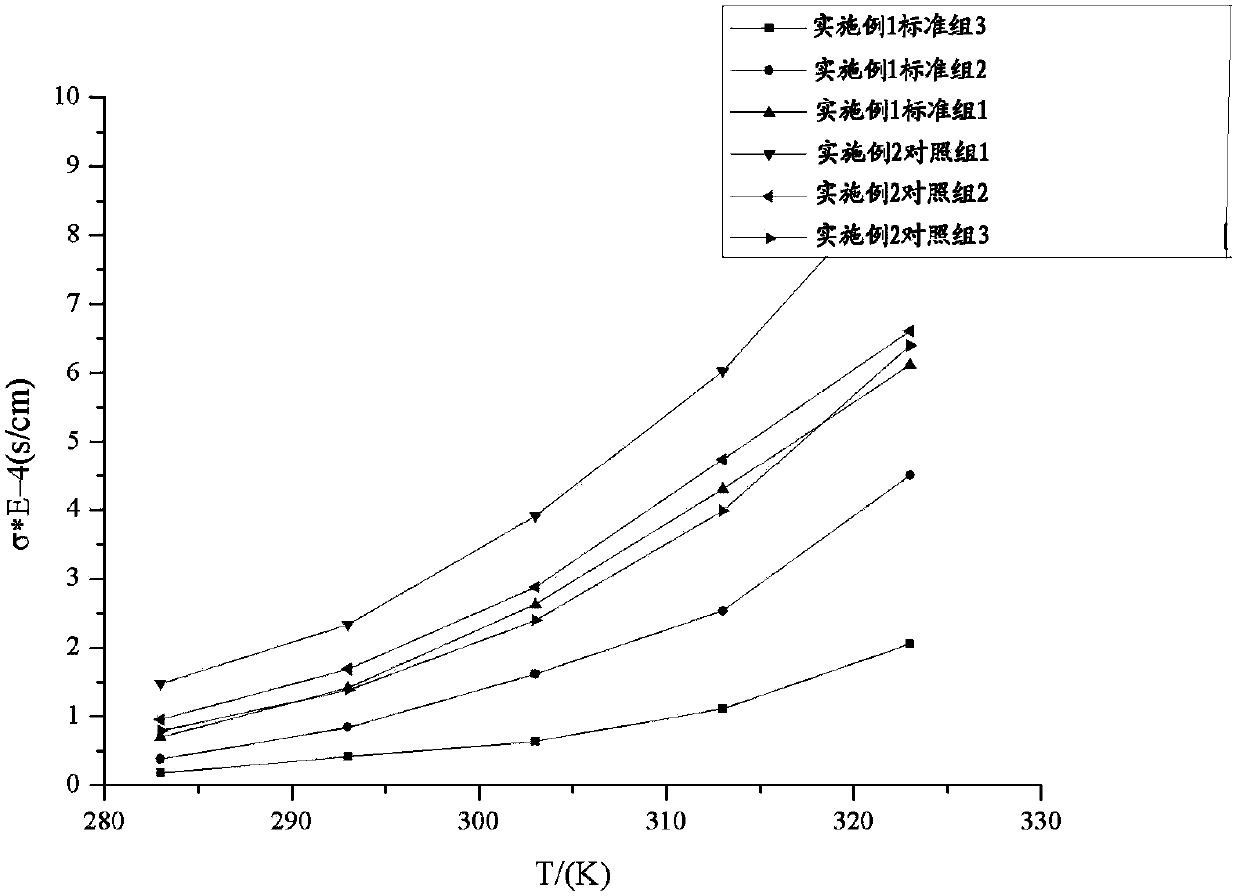

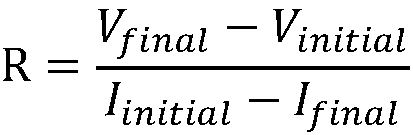

Composite quasi-solid-state electrolyte and preparation method thereof, and lithium battery or lithium ion battery containing composite quasi-solid-state electrolyte

InactiveCN107645013AImprove mechanical propertiesAddress volume expansionFinal product manufactureLi-accumulatorsSolid state electrolyteInterfacial resistance

The present invention provides a composite quasi-solid-state electrolyte, a composite quasi-solid-state electrolyte membrane, preparation methods of composite quasi-solid-state electrolyte and the composite quasi-solid-state electrolyte membrane, and a lithium battery or a lithium ion battery containing the composite quasi-solid-state electrolyte membrane. The composite quasi-solid-state electrolyte comprises a solid electrolyte, a lithium salt-containing liquid electrolyte, inorganic nanoparticles and a binder, wherein the static electricity or functional groups on the surface of the inorganic nanoparticles can adsorb the electrolyte so as to make the composite quasi-solid-state electrolyte have strong adsorption capacity and strong liquid retention ability, and the inorganic nanoparticles can adsorb the lithium salt so as to change the lithium ion conduction mechanism, reduce the interfacial resistance between the liquid electrolyte and the solid-state electrolyte, change the deposition morphology of lithium, hinder the formation of lithium dendrite, and reduce the pulverization of lithium. In addition, by adding the solid electrolyte, the composite quasi-solid-state electrolyteof the present invention can maintain the high conductivity and can effectively reduce the content of the liquid electrolyte so as to improve the safety of the battery.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Organic matrices containing nanomaterials to enhance bulk thermal conductivity

InactiveUS7013965B2Semiconductor/solid-state device detailsSolid-state devicesInterfacial resistanceNanoparticle

Owner:GENERAL ELECTRIC CO

Thermal conductive material utilizing electrically conductive nanoparticles

ActiveUS7550097B2Improve heat transfer efficiencySemiconductor/solid-state device detailsConductive materialInterfacial resistanceNanoparticle

Owner:GENERAL ELECTRIC CO

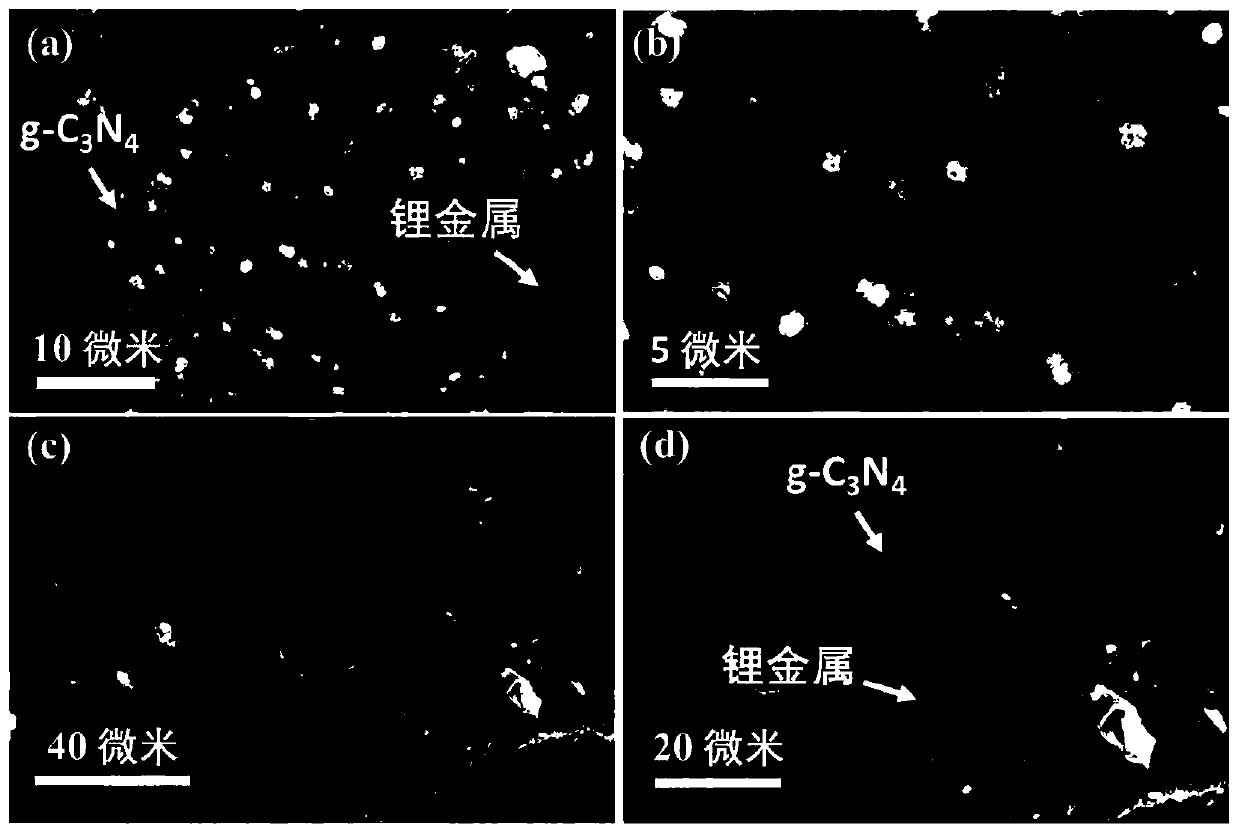

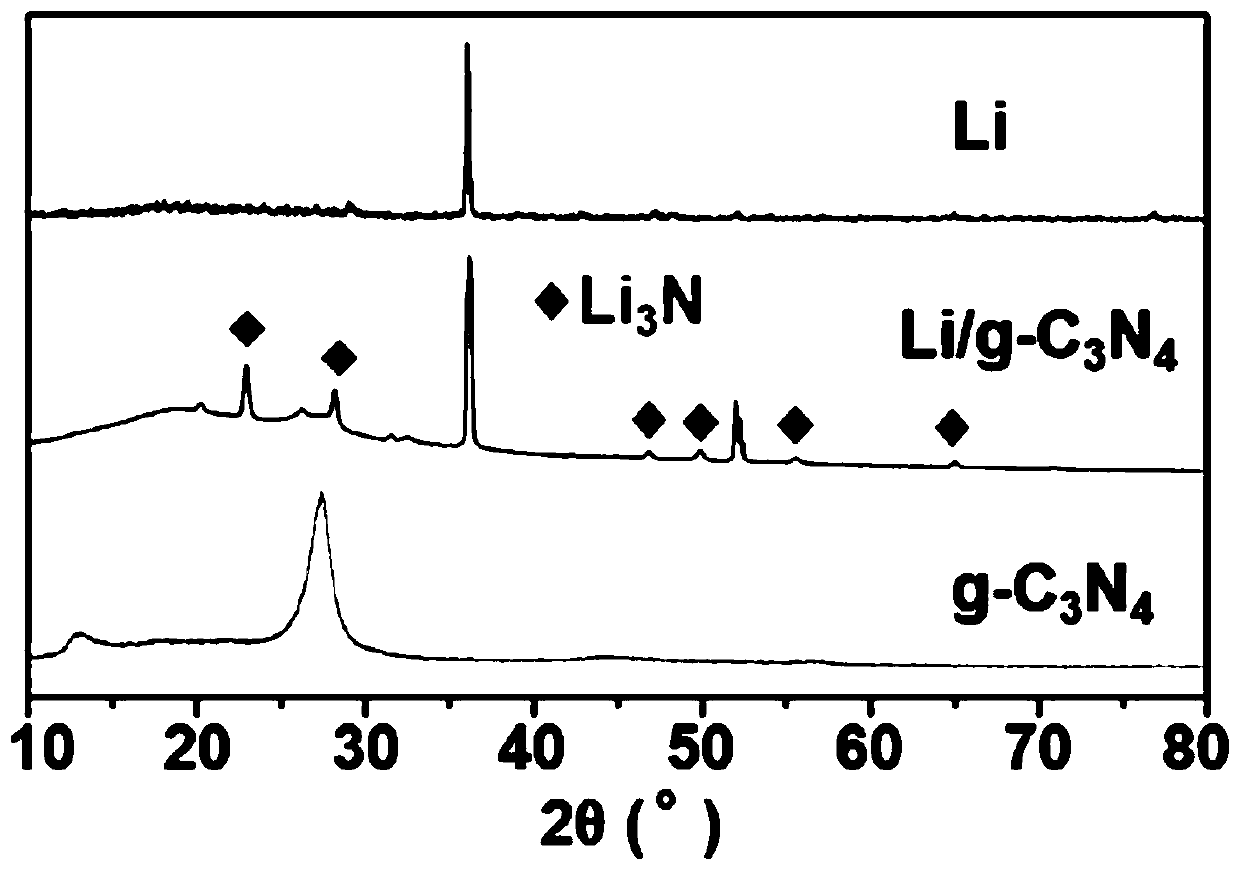

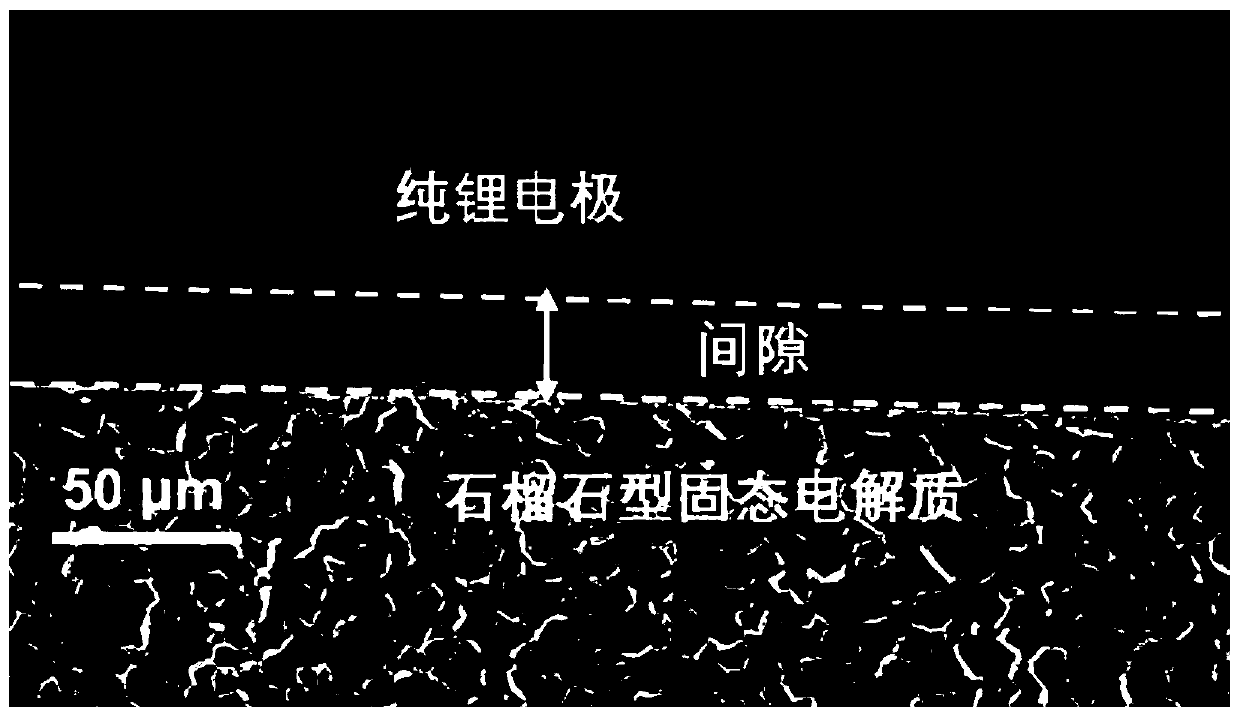

Modified lithium-based composite negative material for solid state battery and preparation and application of material

InactiveCN109841817AOptimize interface compositionImprove cyclic charge and discharge capacityElectrode manufacturing processesSecondary cellsSolid state electrolyteInterfacial resistance

The invention relates to a modified lithium-based composite negative material for a solid state battery and preparation and application of the material. The modified lithium-based composite negative material comprises 50-95 parts of lithium and 5-50 parts of a modified additive by weight; and the modified additive comprises one or multiple nitride or fluoride. The preparation method comprises thatthe lithium and modified additive are mixed, heated to 180-400 DEG C, stirred uniformly, and cooled to the room temperature; and the modified composite negative material is used to the solid state battery, and combined with a solid electrolyte. Compared with the prior art, the lithium metal is mixed with the modified additive by mixing in a heating fusing way, the surface energy of the lithium metal can be reduced effectively, elements including nitrogen and fluorine are introduced in a controllable way, the interfacial resistance between the solid electrolyte and lithium cathode is reduced effectively, the limit current that can be born by the solid electrolyte is increased, the recyclable charge and discharge capacity is improved, and the solid electrolyte and cathode interface is stable for a longer time in the long circulation process.

Owner:TONGJI UNIV

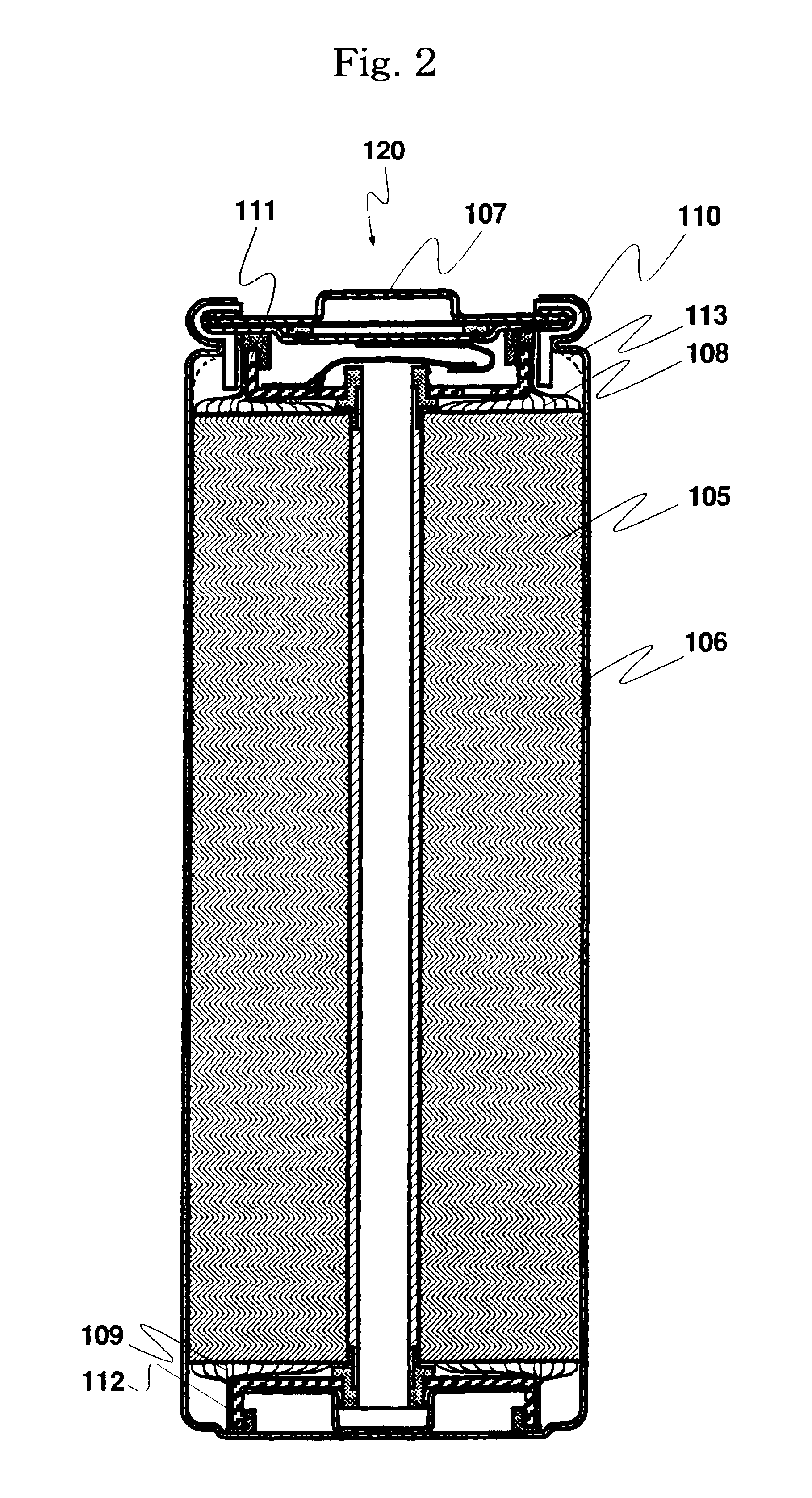

Capacitors with Low Equivalent Series Resistance

InactiveUS20090168305A1Increase energy densityIncrease the equivalent series resistanceBatteries circuit arrangementsHybrid capacitor electrolytesElectrical resistance and conductanceInterfacial resistance

An electric double layer capacitor (EDLC) in a coin or button cell configuration having low equivalent series resistance (ESR). The capacitor comprises mesh or other porous metal that is attached via conducting adhesive to one or both the current collectors. The mesh is embedded into the surface of the adjacent electrode, thereby reducing the interfacial resistance between the electrode and the current collector, thus reducing the ESR of the capacitor.

Owner:TPL SRL

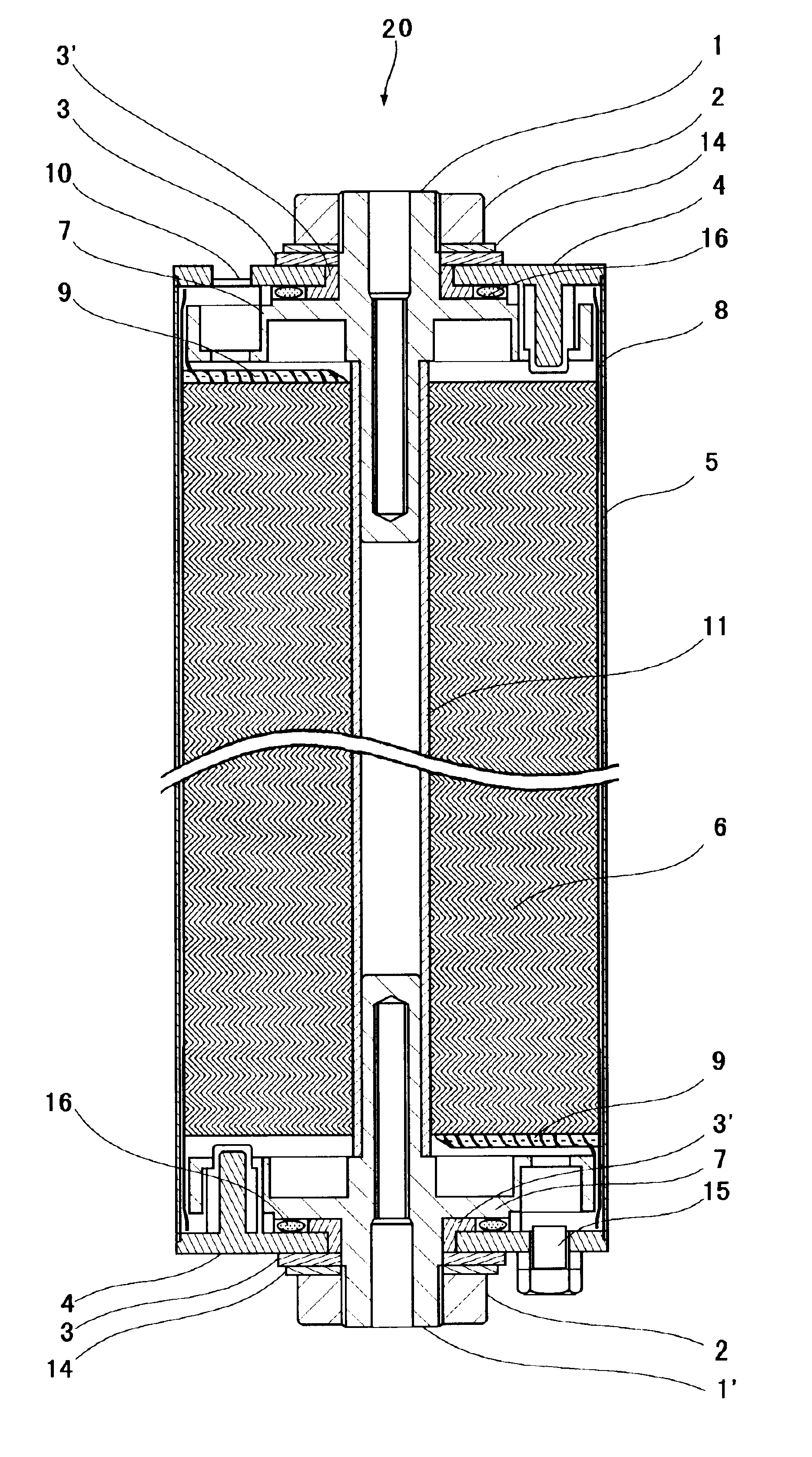

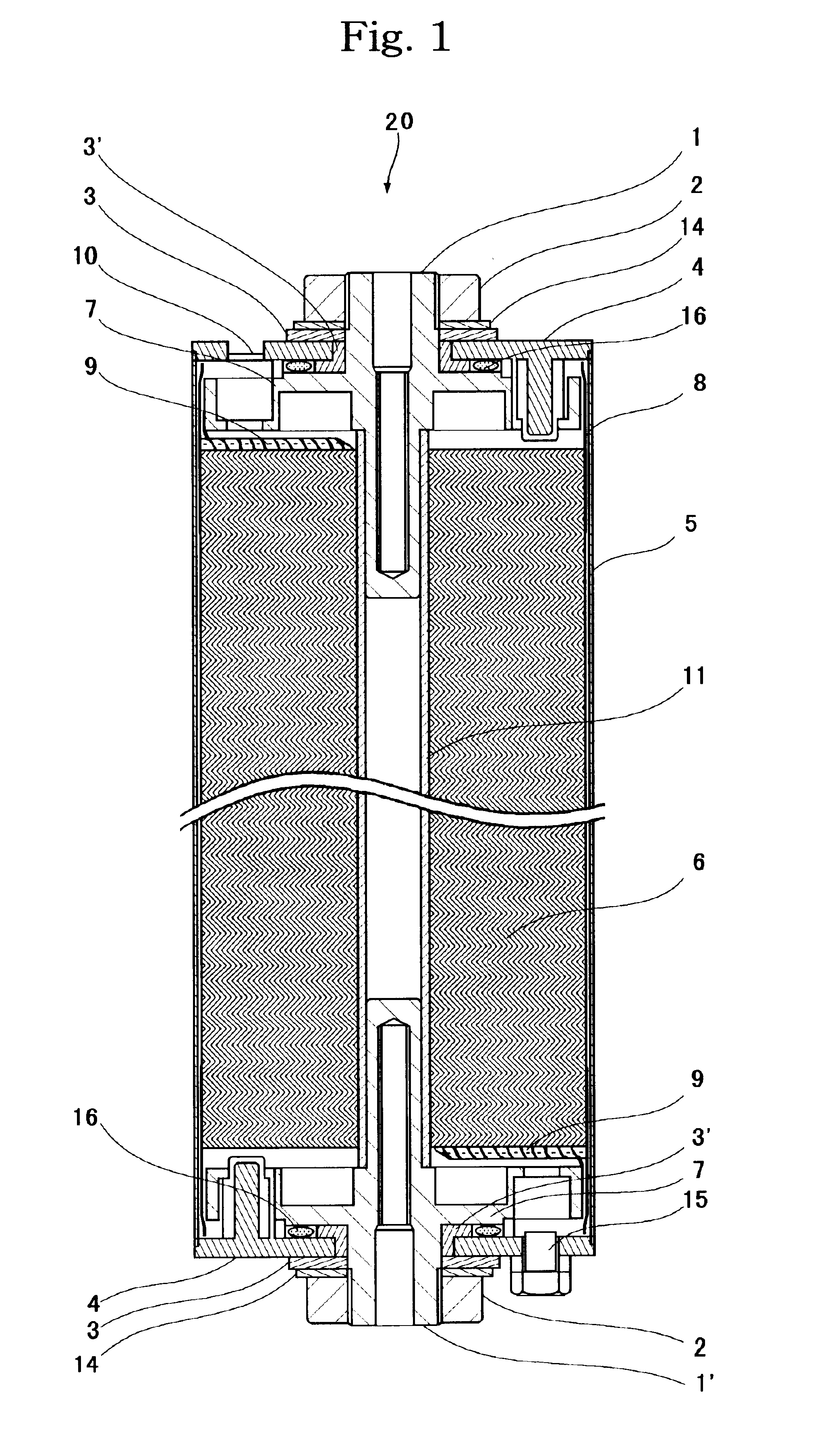

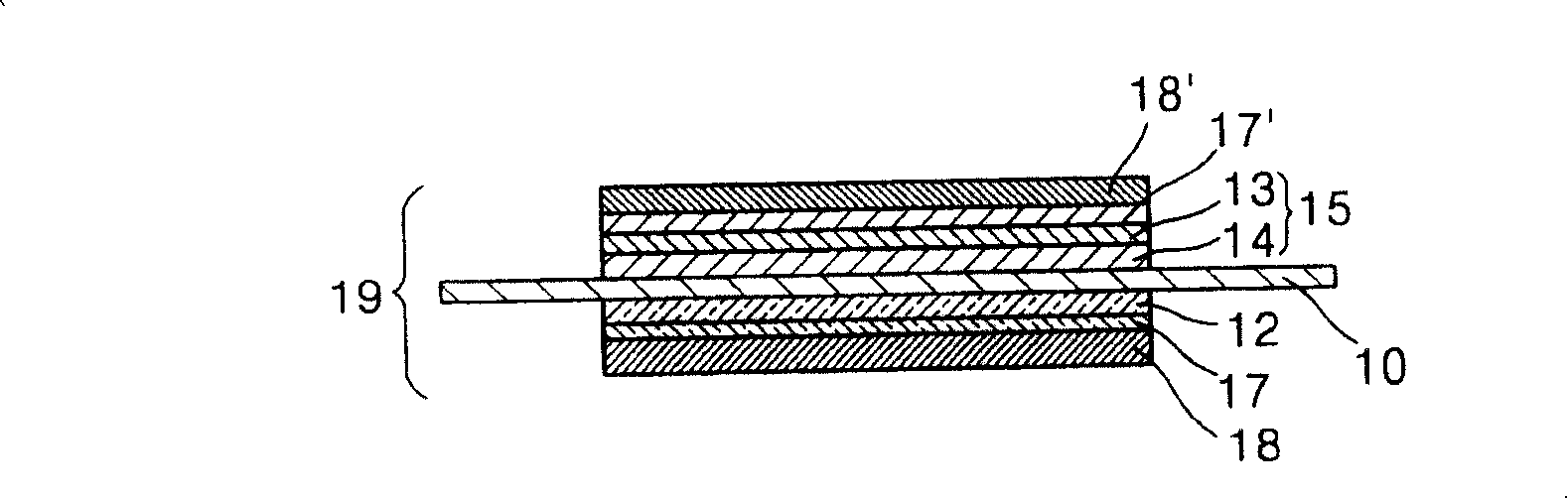

Non-aqueous electrolytic solution secondary battery

InactiveUS20010031391A1Final product manufactureSmall-sized cells cases/jacketsPorosityInterfacial resistance

A non-aqueous electrolytic secondary battery that can prevent a drop in the power even in a large current discharge is provided. Porosity of a separator is larger than or the same as porosity of a positive electrode mixture and a porosity of a negative electrode mixture. Particularly, the porosity of the positive electrode mixture is 20% to 50%, the porosity of the negative electrode mixture is 20% to 50%, and the porosity of the separator is 20% to 60%. The separator becomes rich in the volume of the electrolytic solution that infiltrates into interfacial aperture between the separator and the negative electrode. When the large current discharge is carried out in a short time, lithium-ions are released / occluded from the electrodes and the electrolytic solution can gain the released / occluded lithium-ions with a small interfacial resistance.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

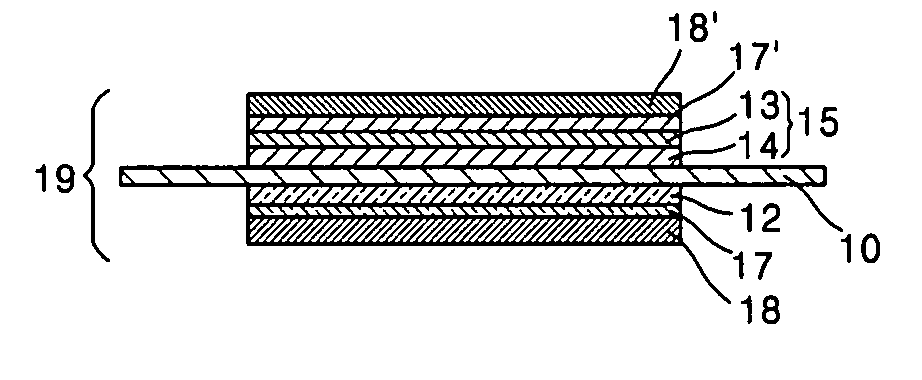

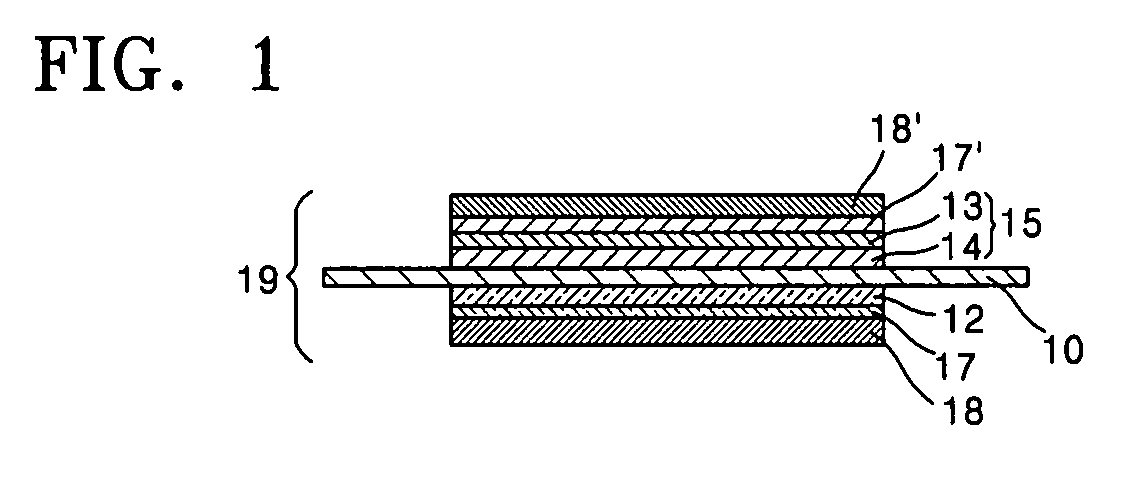

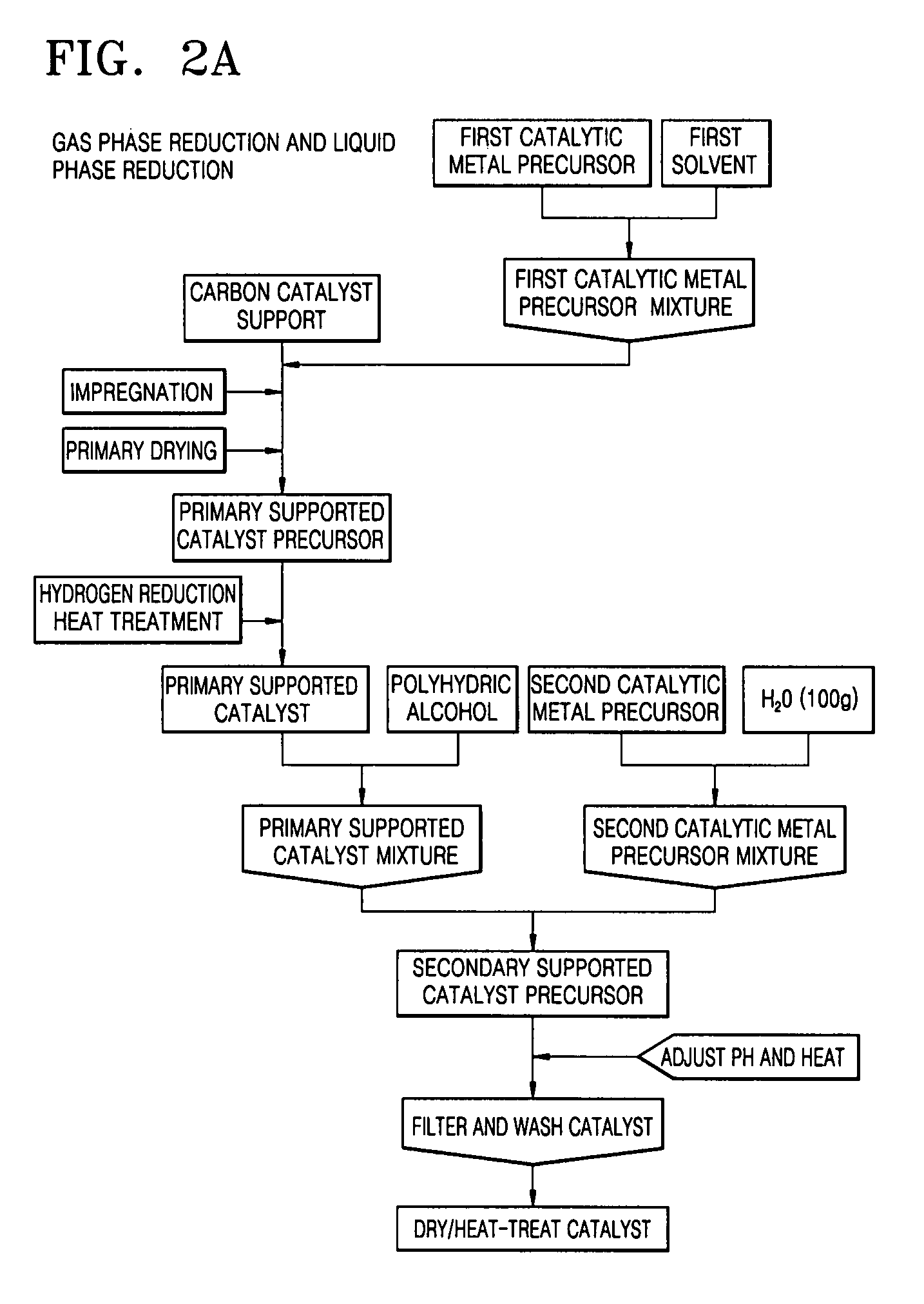

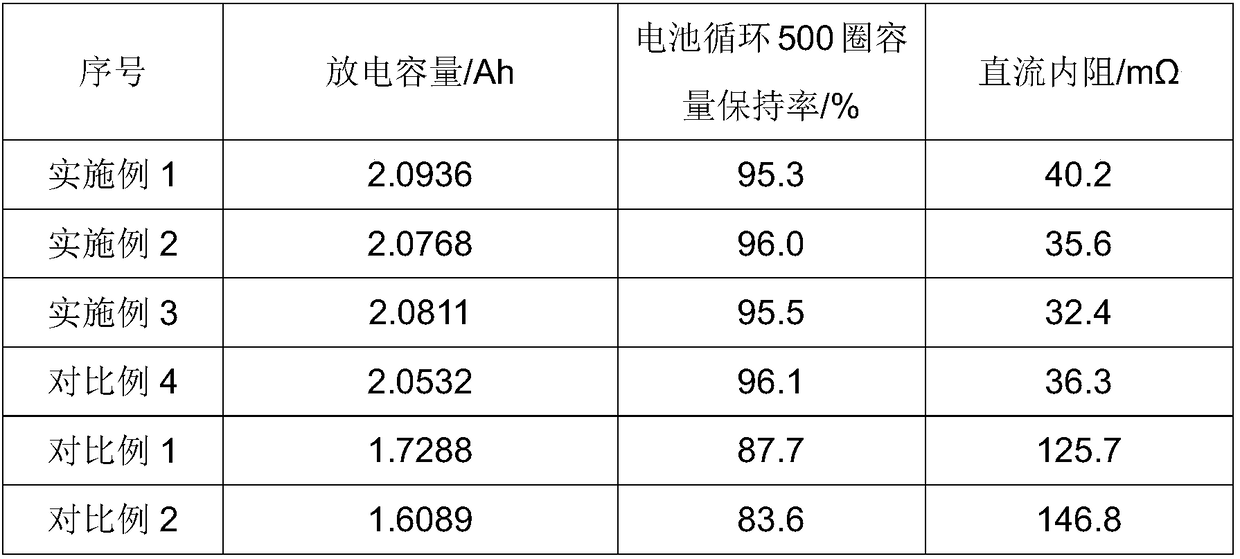

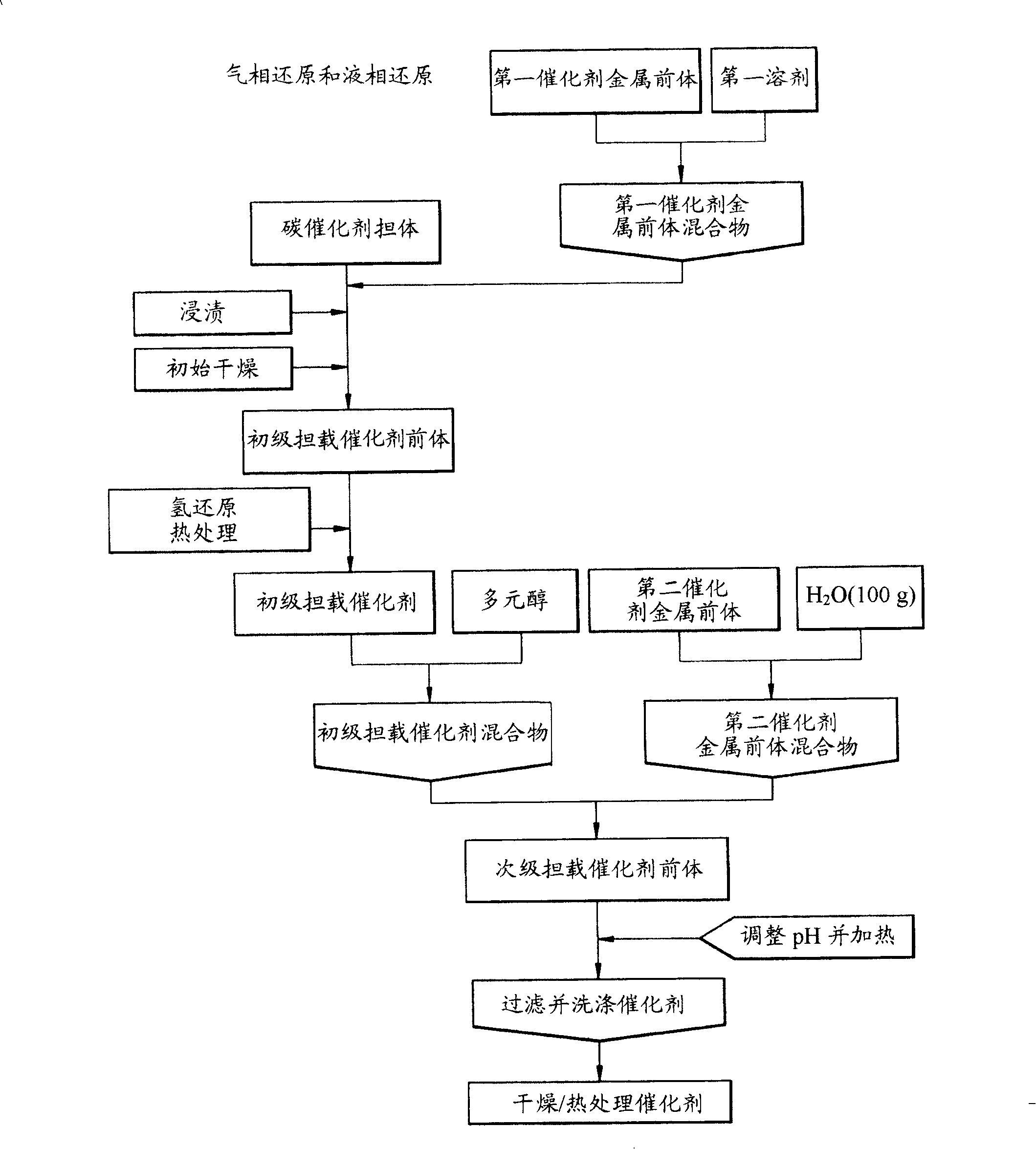

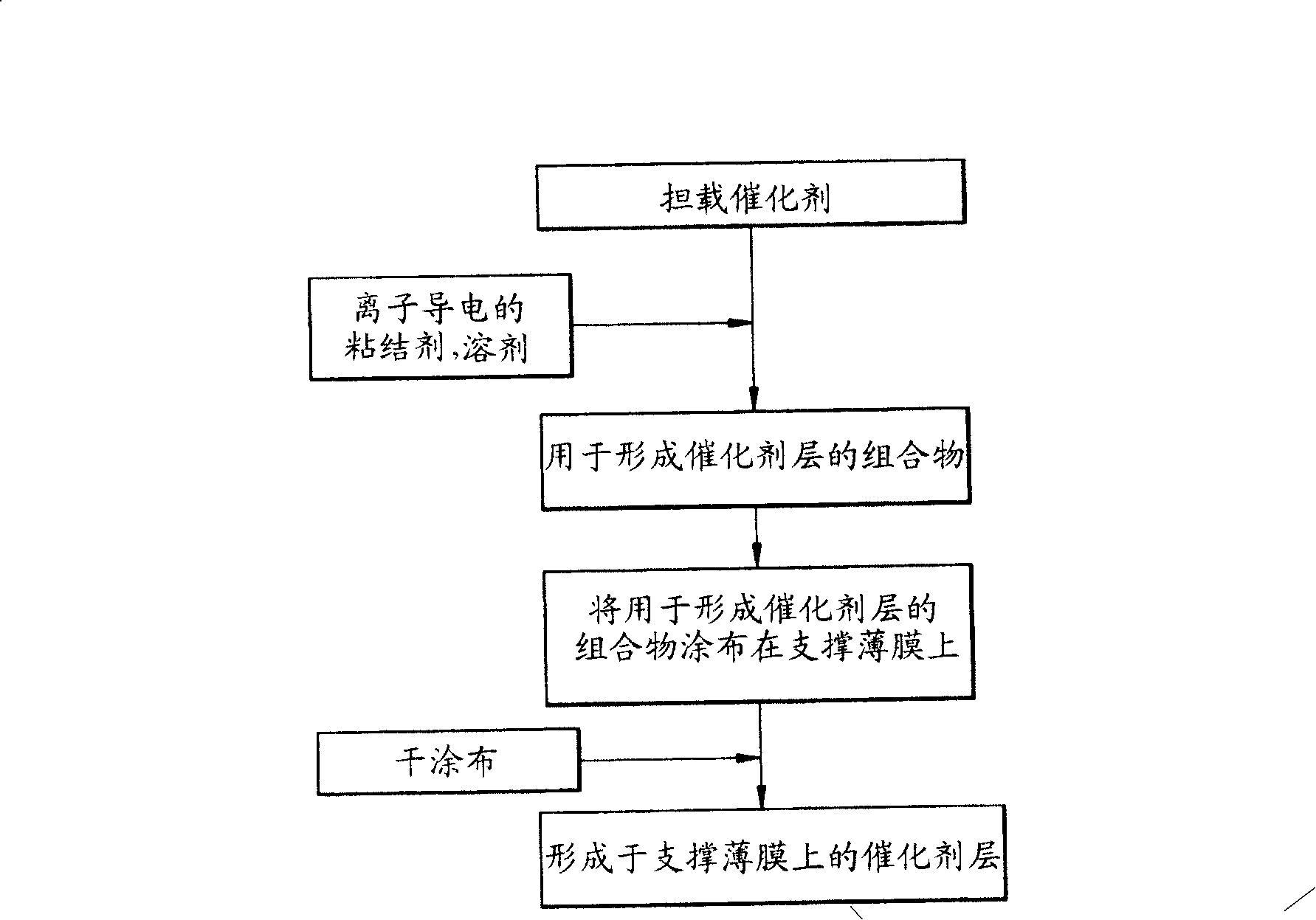

Catalyst coated membrane, membrane electrode assembly containing the same, method of producing the same, and fuel cell including the membrane electrode assembly

InactiveUS20070269699A1Improve unit performanceMaximum catalyst activityActive material electrodesNon-aqueous electrolyte accumulator electrodesCoated membraneFuel cells

A catalyst coated membrane (CCM) comprising an anode catalyst layer having a first catalyst layer composed of a non-supported catalyst and a second catalyst layer composed of a supported catalyst, a cathode catalyst layer composed of a supported catalyst, and an electrolyte membrane interposed between the anode catalyst layer and a cathode catalyst layer, the first catalyst layer of the anode catalyst layer being disposed adjacent to the electrolyte membrane; a membrane electrode assembly (MEA) comprising the catalyst coated membrane; a method of preparing the membrane electrode assembly; and a fuel cell comprising the membrane electrode assembly, are provided. The CCM, which comprises a bilayered anode catalyst layer including the first catalyst layer composed of a non-supported catalyst and the second catalyst layer composed of a supported catalyst, exhibits reduced electrical resistance and interfacial resistance, and has increased catalyst availability. The use of the CCM and an MEA having the same results in a decrease in the interfacial resistance between the electrodes and the electrolyte membrane, a decrease in the amount of the catalyst used in the electrode catalyst layer, and a decrease in the thickness deviation in the electrode layers. The fuel cell employing the MEA exhibits maximal activity of the supported catalyst, and has improved cell characteristics such as output voltage, output density, efficiency, and the like.

Owner:SAMSUNG SDI CO LTD

Non-aqueous electrolytic solution secondary battery with electrodes having a specific thickness and porosity

InactiveUS6733925B2Electrode manufacturing processesFinal product manufacturePorosityInterfacial resistance

A non-aqueous electrolytic secondary battery that can prevent a drop in the power even in a large current discharge is provided. Porosity of a separator is larger than or the same as porosity of a positive electrode mixture and a porosity of a negative electrode mixture. Particularly, the porosity of the positive electrode mixture is 20% to 50%, the porosity of the negative electrode mixture is 20% to 50%, and the porosity of the separator is 20% to 60%. The separator becomes rich in the volume of the electrolytic solution that infiltrates into interfacial aperture between the separator and the negative electrode. When the large current discharge is carried out in a short time, lithium-ions are released / occluded from the electrodes and the electrolytic solution can gain the released / occluded lithium-ions with a small interfacial resistance.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

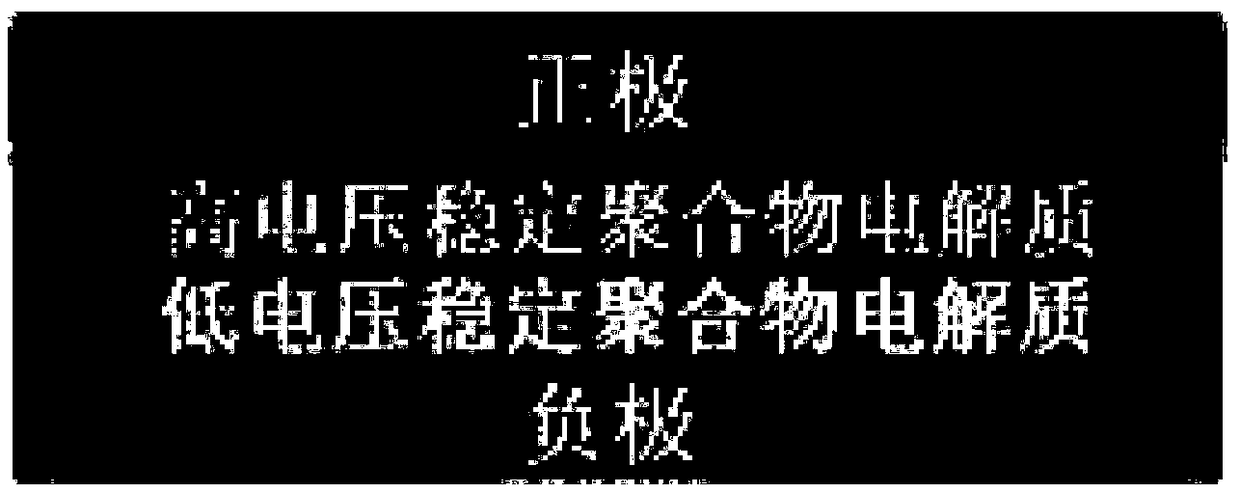

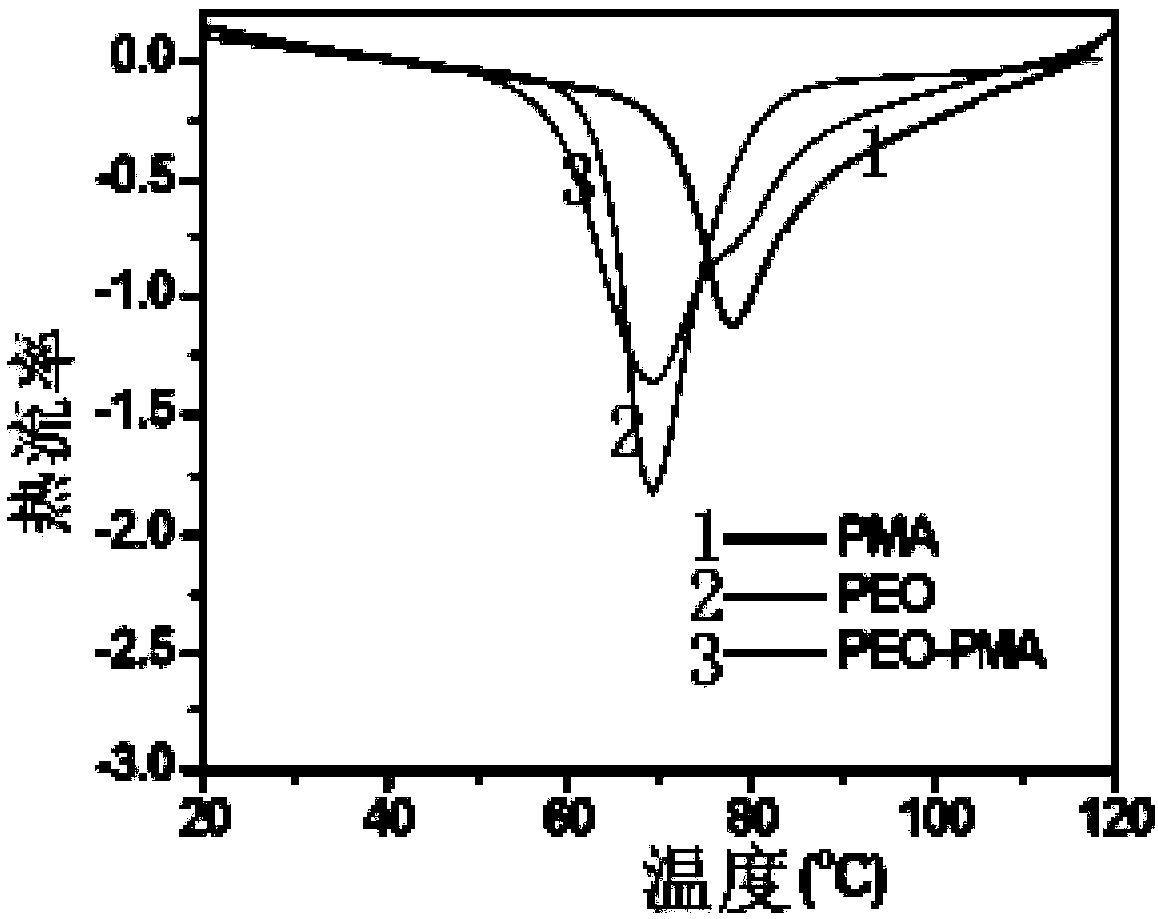

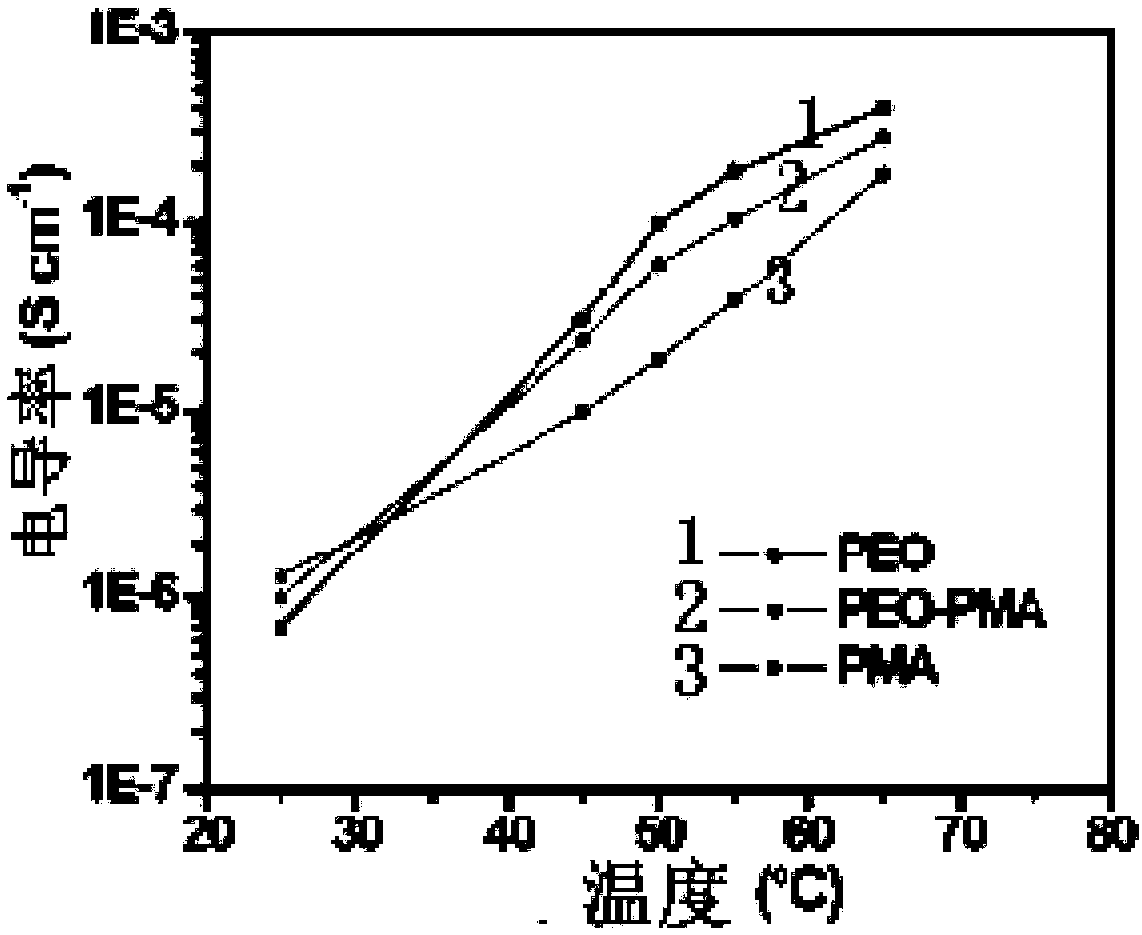

A two-layer or multi-layer polymer electrolyte and a battery

ActiveCN108963334ASimple reductionNot easily oxidizedSolid electrolytesSecondary cellsSolid state electrolytePolymer electrolytes

The present invention provides a two-layer or multilayer polymer electrolyte comprising a laminated arrangement of a first electrolyte layer for contacting and electrochemically stabilizing a positiveelectrode and a second electrolyte layer for contacting and electrochemically stabilizing a negative electrode. In the two-layer polymer solid electrolyte provided by the invention, a high-voltage stable polymer electrolyte layer is in contact with a positive electrode, and a low-voltage stable polymer electrolyte layer is in contact with a negative electrode. At the same time, the stability conditions of the positive electrode and the negative electrode are satisfied, and a wide redox window is obtained. In addition, the flexibility of the polymer helps to reduce the interfacial resistance.The present invention provides a novel strategy for the design and optimization of solid polymer electrolyte materials, in which a high-voltage positive electrode and a low-voltage metal negative electrode coexist in a battery by utilizing a two-layer structure. This new solid-state electrolyte design will greatly accelerate the development and commercialization of solid-state secondary batteries.

Owner:周伟东

Nickel-based multiple components cathode material and its preparation method

ActiveCN102496710AProtectiveInhibition of phase transitionCell electrodesInterfacial resistanceLITHIUM PHOSPHATE

The invention relates to a nickel-based multiple components cathode material and its preparation method, a chemical formula of the nickel-based multiple components cathode material is LiaNixCoyM1-x-yO2 / (zLi3PO4(1-z)M')b; M in the chemical formula is one or more than two elements selected from Mn, Al, Zr, Ba, Sr and B, M' is one or more than two oxidate selected from Al, Zr, Ti, Mg and La, wherein 0.8<=a<=1.2, 0.7 <x<1, 0<y<1, x+y<1, 0<z<1, 0<b<0.05. The invention also provides a preparation method of the nickel-based multiple components cathode material. The nickel-based multiple components cathode material is characterized in that lithium phosphate and metal oxide are used for carrying out compound coating treatment on the surface, the interfacial resistance can be minimized, the conductivity performance of the surface lithium ion can be increased, the nickel-based multiple components cathode material can be protected, the generation of phase transformation of the nickel-based multiple components cathode material can be inhibited, simultaneously, the heating can be inhibited, the thermal stability can be enhanced, the capacity of the lithium ion secondary cell prepared by the product is high, and the security is good.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

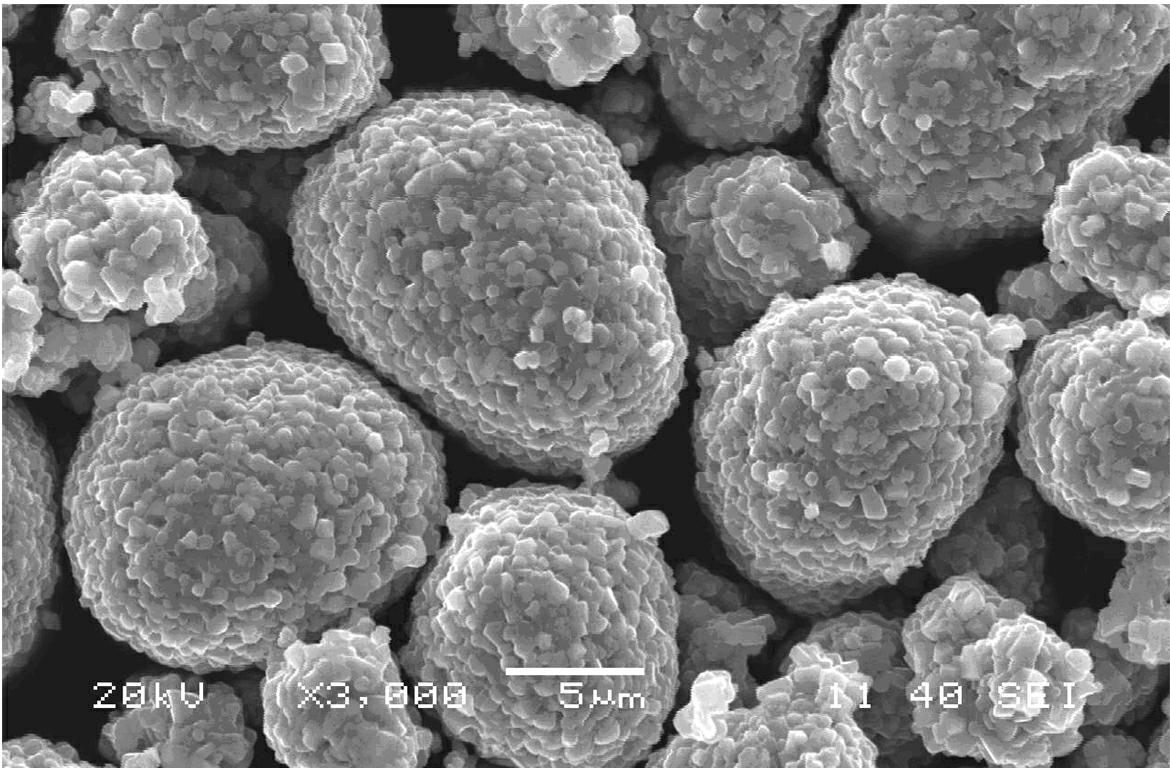

Preparation method of layered lithium (Li)-rich manganese (Mn)-based anode material having multiple core-shell structures

InactiveCN103326016APerfect balance of securityPerfect balance of magnification performanceCell electrodesInterfacial resistancePhysical chemistry

The invention discloses a preparation method of a layered lithium (Li)-rich manganese (Mn)-based anode material having multiple core-shell structures. The layered (1-t)LiNixCoyMn1-x-yO2@tLi2MnO3 having the multiple core-shell structures is prepared by taking LiNixCoyMn1-x-yO2 (the x is greater than or equal to 0 while the y is less than or equal to 1) as cores and Li2MnO3 with the concentration in gradient change as shells. According to the method, the core-shell structures are applied into the lithium (Li)-rich layered material, namely, the concept of the multiple core-shell structures is put forward, so that the defects reported in the literature that the simple core-shell structure material has poor performance and the concentration gradient material is complicated to operate and difficult to realize are overcome. In the method, the core-shell concentrations are in antigradient change according to a certain arithmetic progression, namely, from the cores to the outer shells, the concentrations of the core materials are in gradually-decreased arithmetic progression distribution while the concentrations of the shell material are in gradually-increased arithmetic progression distribution. During the design, the equal concentration of transition metal ions in every layer is ensured, so that the interfacial resistance of the materials is reduced as far as possible. As a result, the material performance is improved.

Owner:JISHOU UNIVERSITY

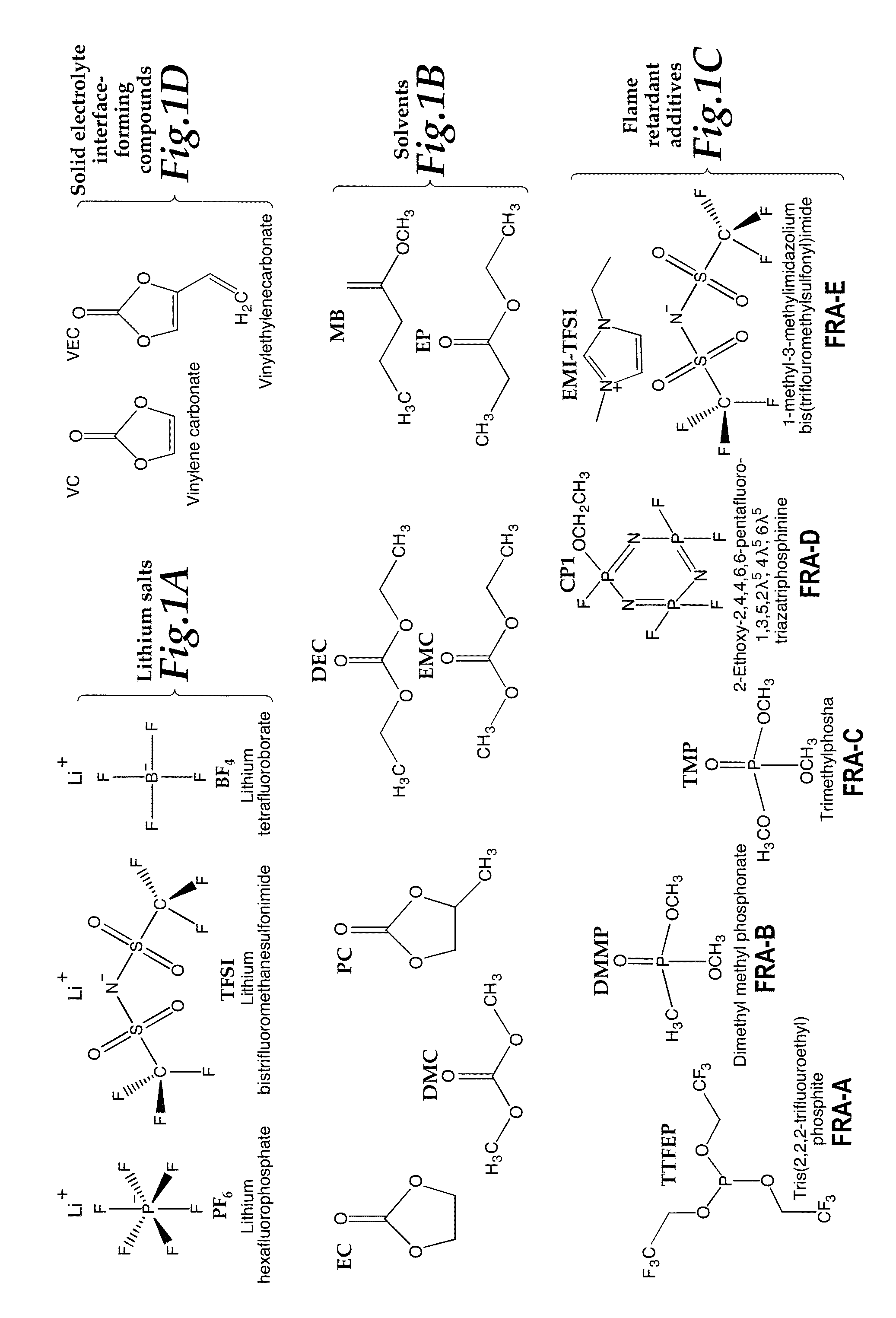

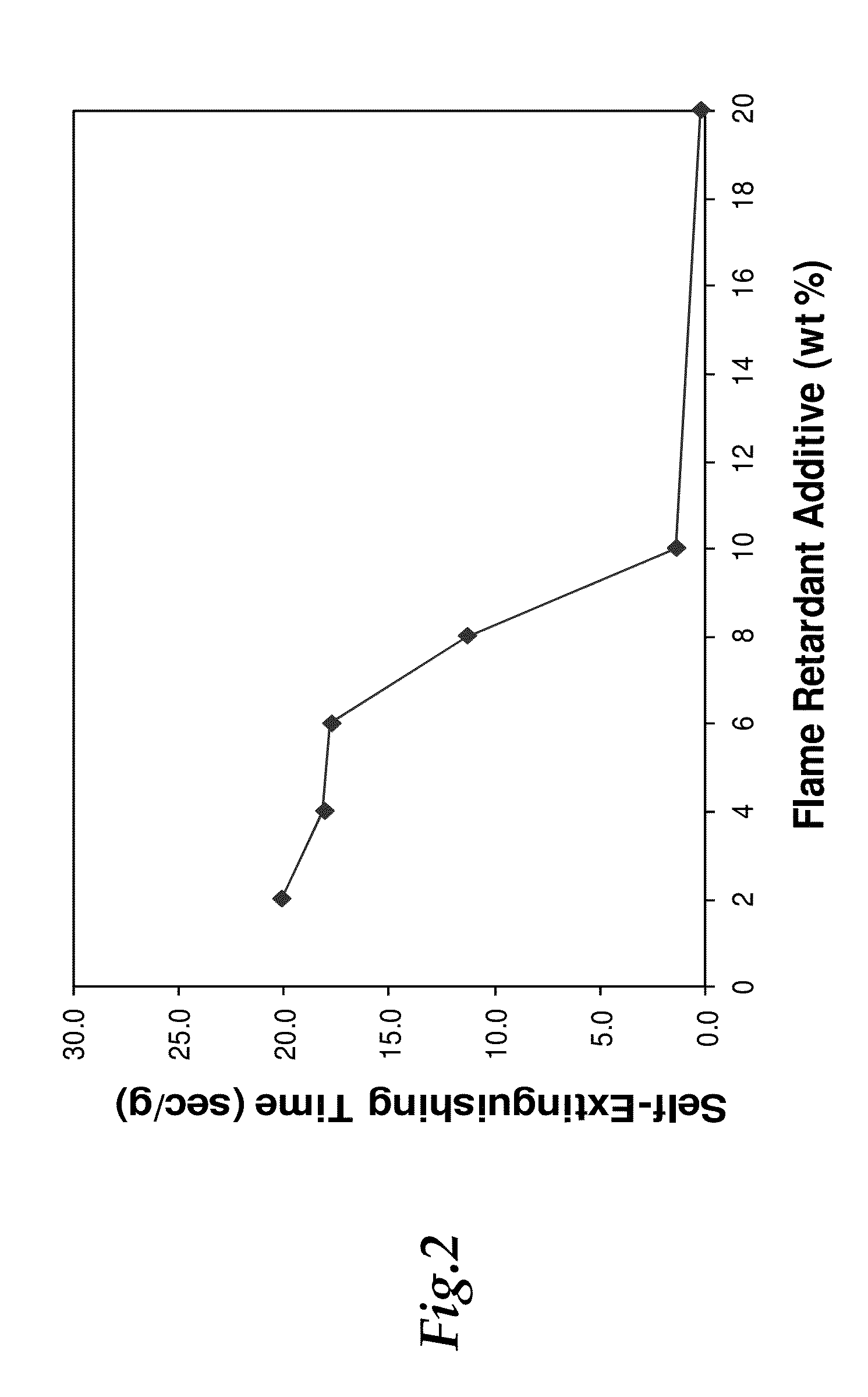

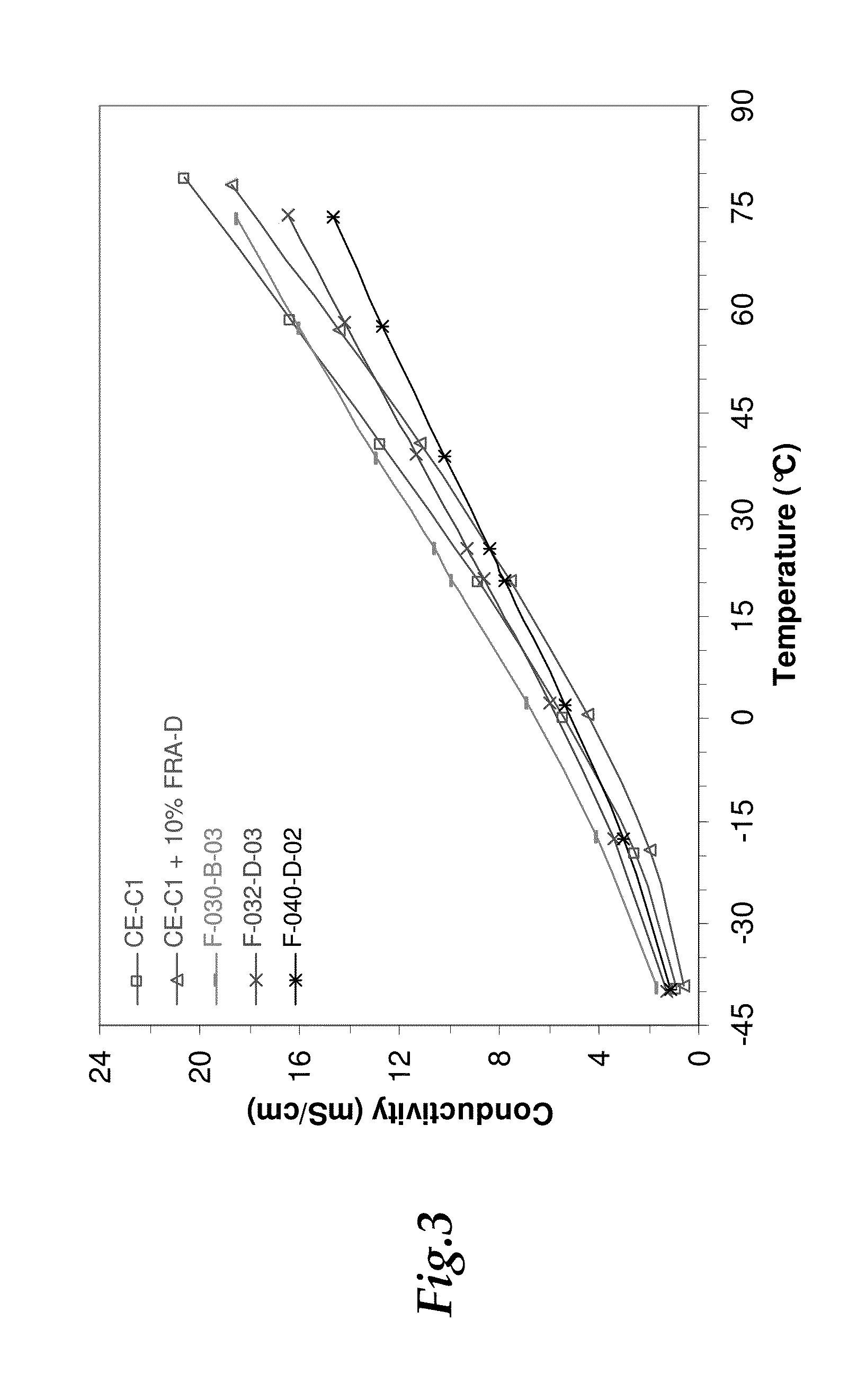

Electrolyte for Electrochemical Energy Storage Devices

ActiveUS20160020489A1Improve flammabilityImprove securityHybrid capacitor electrolytesElectrolytic capacitorsInterfacial resistanceOperating temperature range

An electrolyte for an electrochemical storage device is disclosed. In one embodiment, the electrolyte includes a lithium salt from about 3% to about 20% by weight, a primary solvent from about 15% to about 25% by weight, wide-temperature co-solvents from about 14% to about 55% by weight, interface forming compounds from about 0.5% to about 2.0% by weight, and a flame retardant compound from about 6% to about 60% by weight. The electrolyte interacts with the positive and negative electrodes of the electrochemical storage device to provide both high performance and improved safety such that the electrolyte offers adequate ionic conductivity over the desired operating temperature range, a wide electrochemical stability window, high capacities for both the cathode and anode, low electrode-electrolyte interfacial resistance, and reduced flammability.

Owner:LYNNTECH

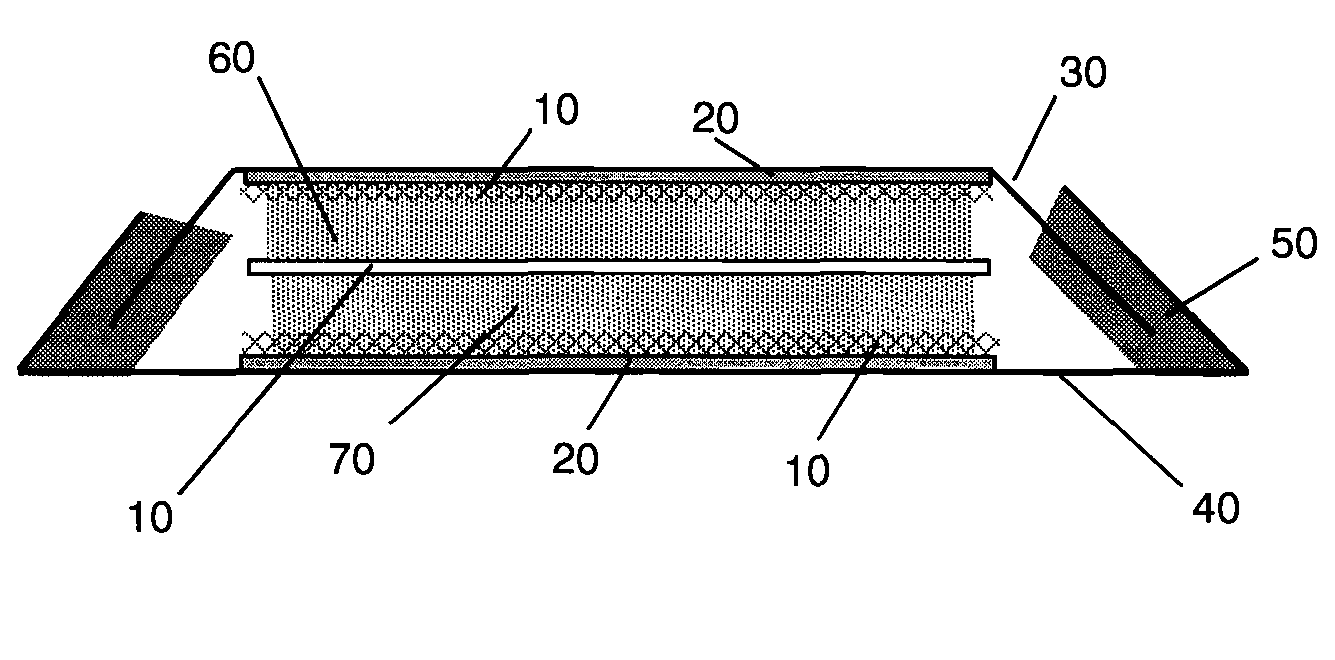

Preparation method of all-solid-state lithium battery with high specific energy

ActiveCN108258323AIncrease the interface contact areaReduce interface resistanceFinal product manufactureElectrolyte accumulators manufactureHigh energyInterfacial resistance

The invention discloses a preparation method of an all-solid-state lithium battery with high specific energy. The preparation method comprises the following steps: forming pores in coating processes of a positive pole piece and a negative pole piece by using a pore forming agent; rolling the prepared pole pieces, and then, coating a thin-layer polymer electrolyte solution on the surface of one side of each pole piece; and finally, winding or laminating the positive pole piece and the negative pole piece with electrolyte layers at one sides so as to be assembled into an all-solid-state lithiumion battery. Compared with the prior art, the method disclosed by the invention has the advantages that the polymer electrolyte solutions can permeate into the pole pieces through the pores obtained by the pore forming agent, and the interfacial contact area between each pole piece and the polymer electrolyte is larger, so that the ionic conductivity of an electrode material is increased; and theall-solid-state lithium battery prepared by the method has the advantages of low interfacial resistance, high energy density, high stability and safety and the like.

Owner:SHAANXI COAL & CHEM TECH INST

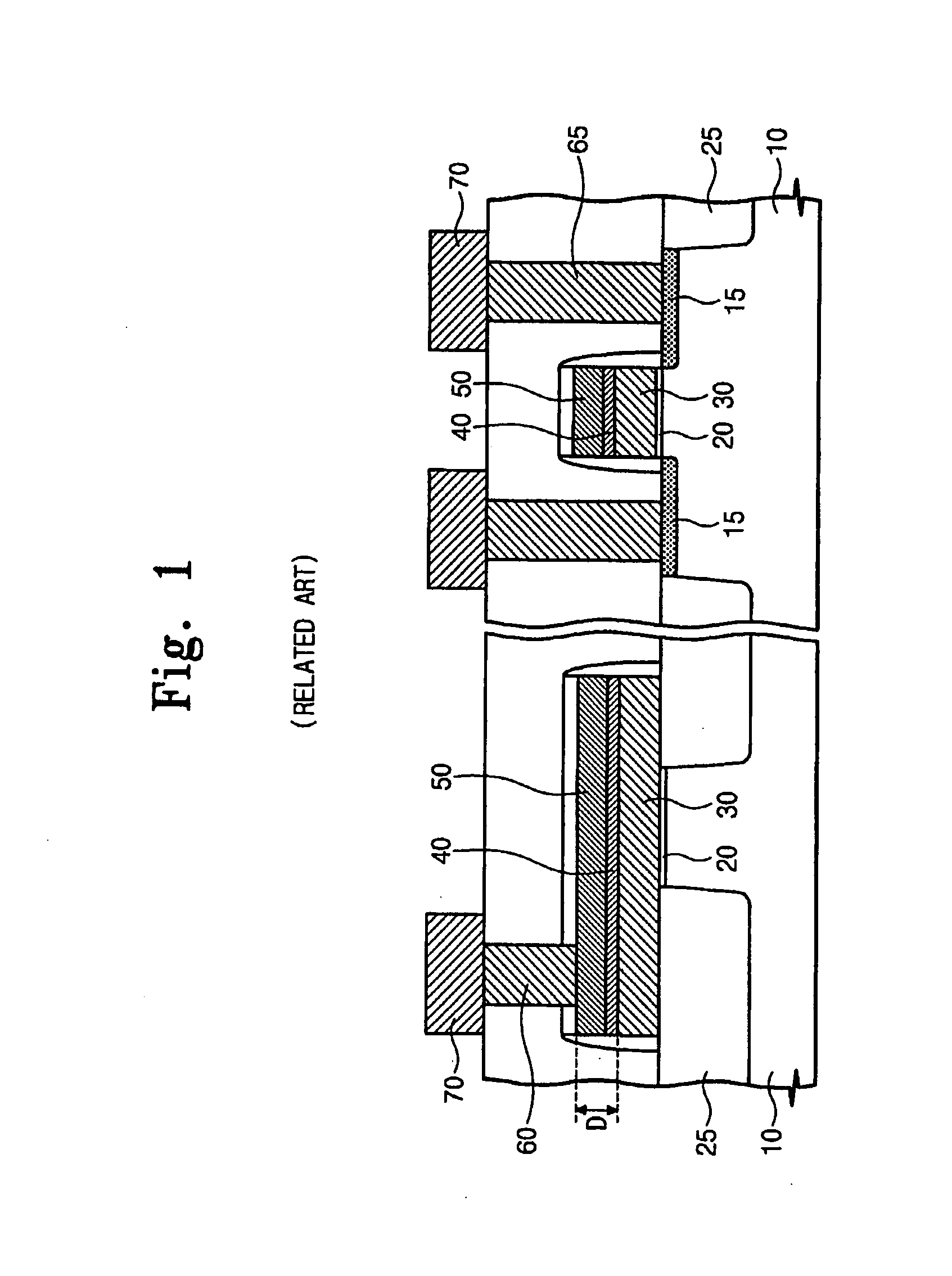

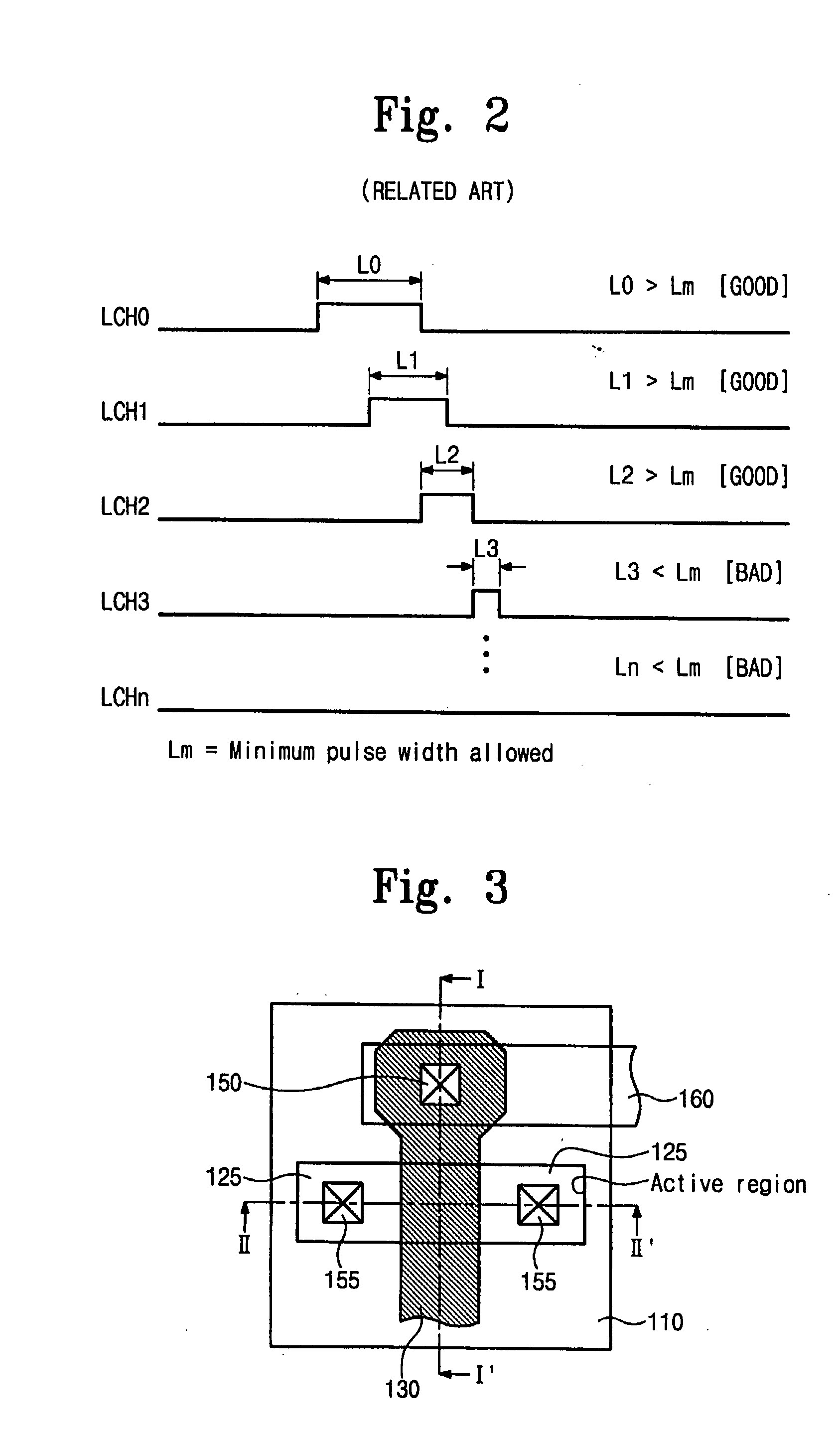

Semiconductor device having a gate contact structure capable of reducing interfacial resistance and method of forming the same

A semiconductor device has a gate contact structure, including a semiconductor substrate, a polycrystalline silicon layer used as a gate electrode of a transistor, a middle conductive layer, a top metal layer having an opening exposing the polycrystalline silicon layer, and a contact plug directly contacting the polycrystalline silicon layer through the opening.

Owner:SAMSUNG ELECTRONICS CO LTD

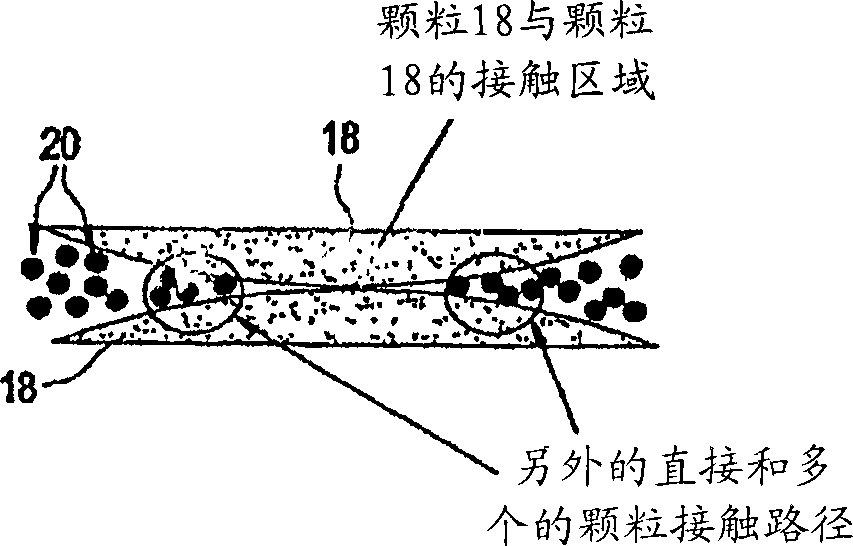

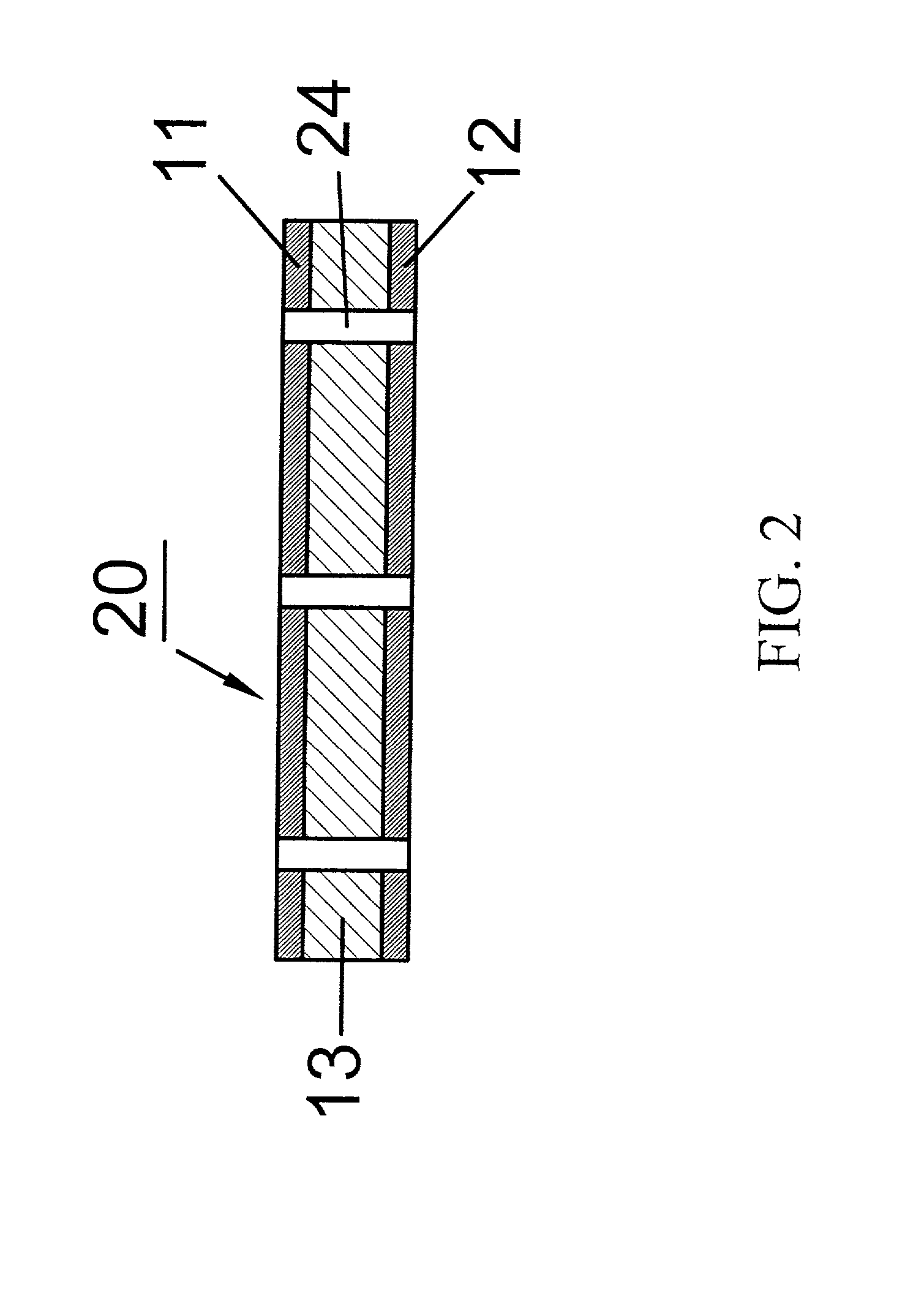

Thermal conductive material utilizing electrically conductive nanoparticles

InactiveCN1875480AImprove heat transfer efficiencySemiconductor/solid-state device detailsIndividual molecule manipulationInterfacial resistanceNanoparticle

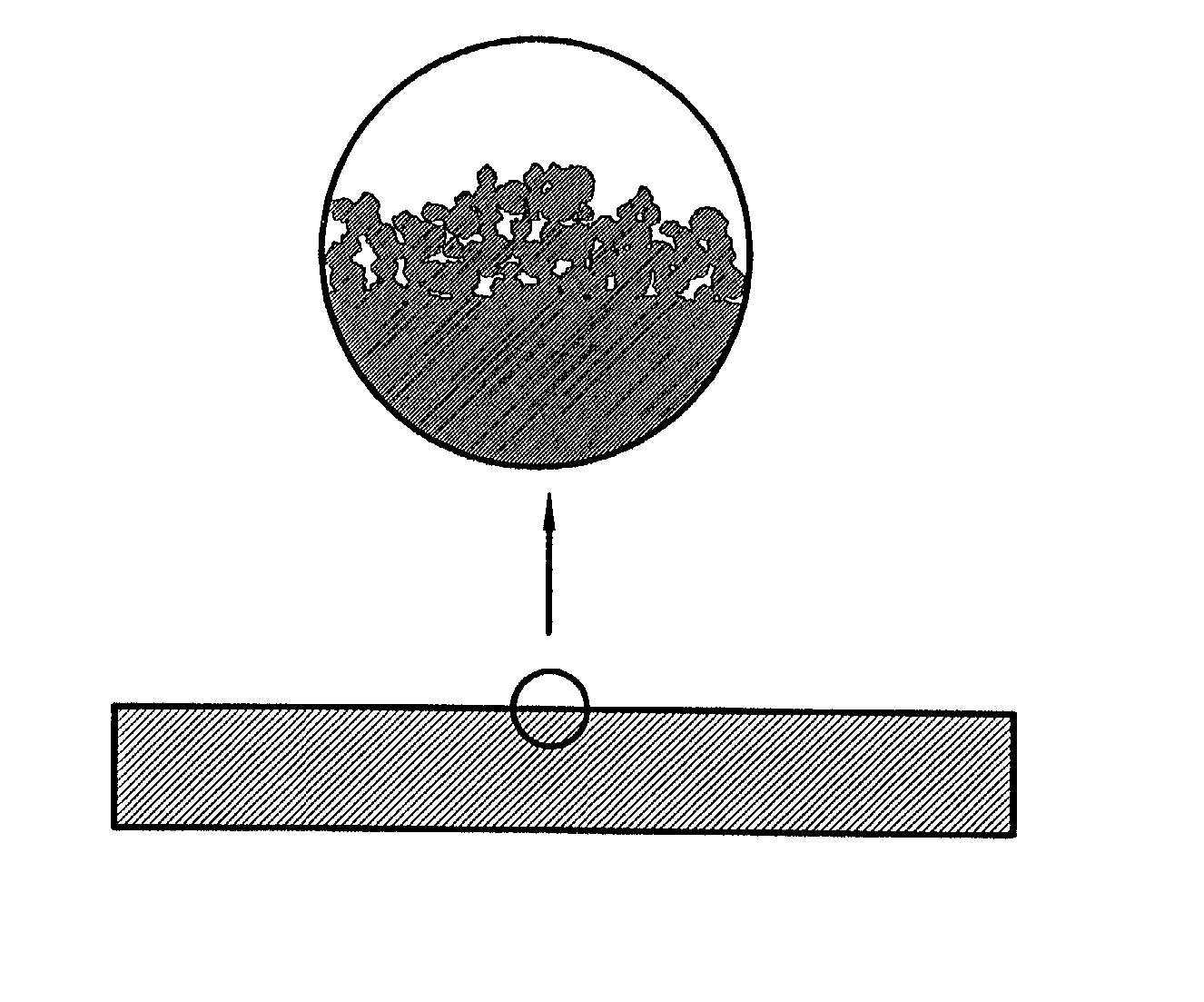

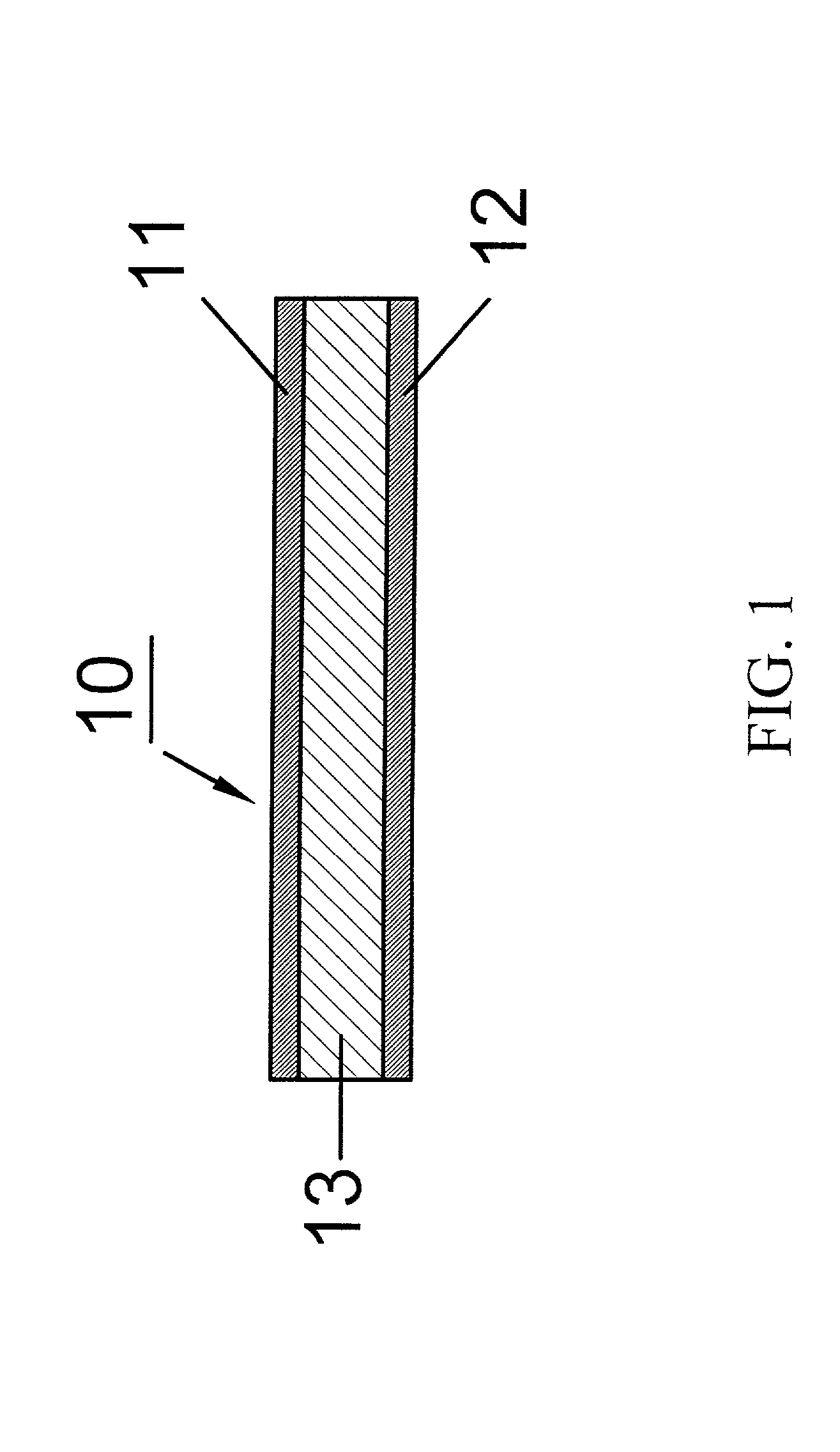

Thermal interface compositions (10) contain both non-electrically conductive micronsized fillers (18) and electrically conductive nanoparticles (20) blended with a polymer matrix (16). Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Such compositions are electrically non-conductive. Formulations containing nanoparticles (20) also show less phase separation of micron-sized particles (18) than formulations without nanoparticles (20). Methods for increasing heat transfer include using such compositions between heat producing components (12) and heat sinks (14). Electronic components utilizing such compositions are also disclosed.

Owner:GENERAL ELECTRIC CO

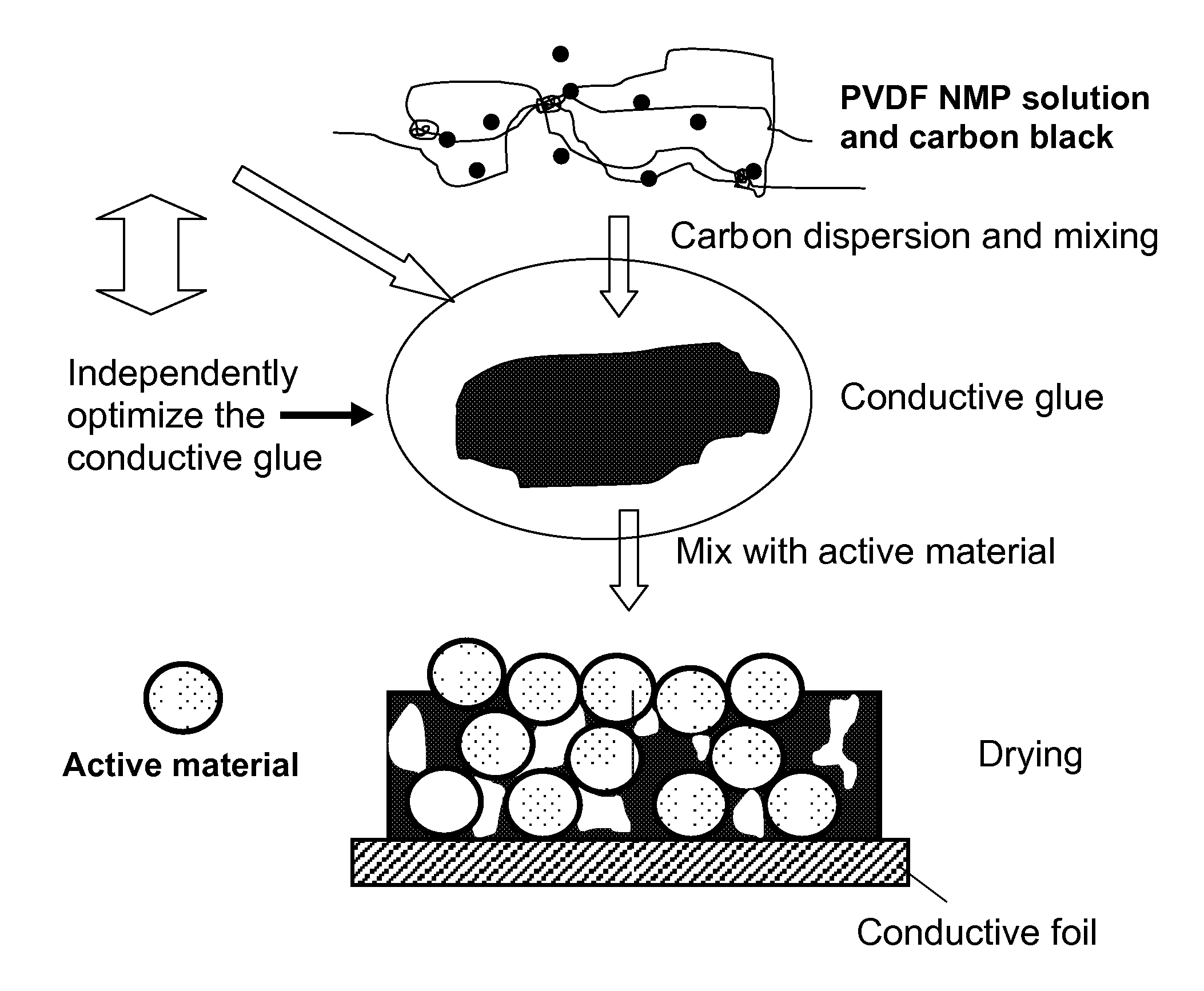

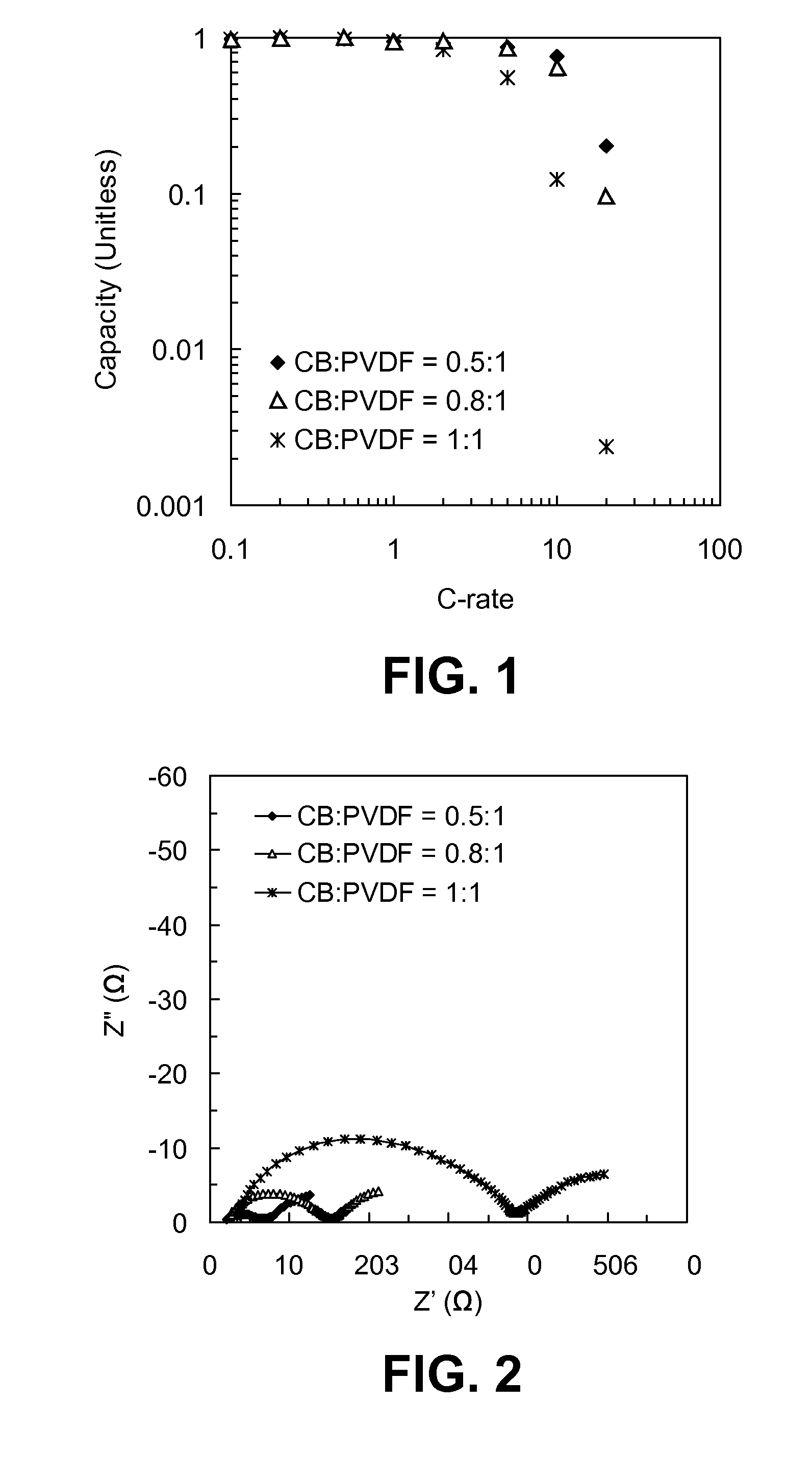

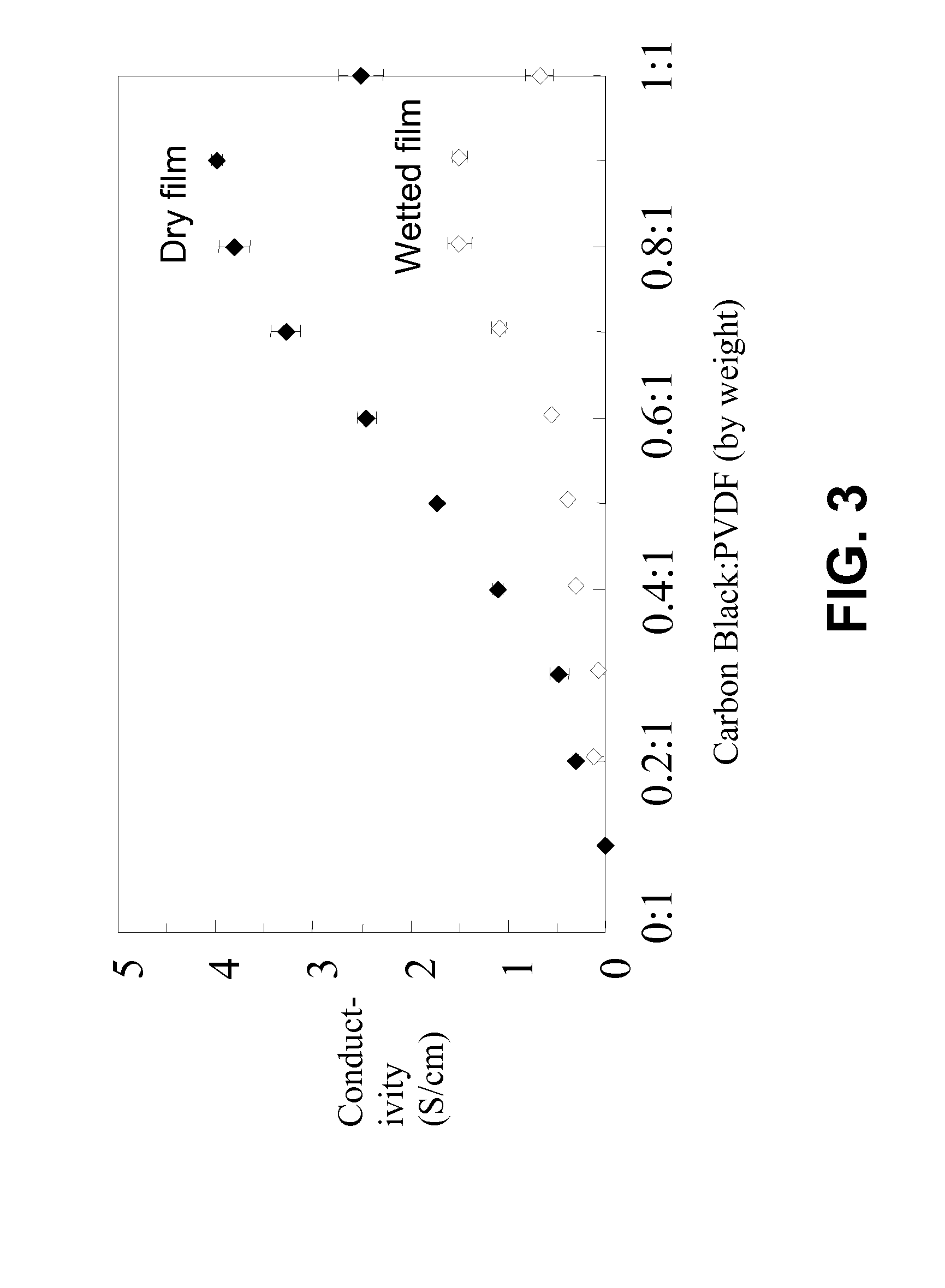

High-discharge-rate lithium ion battery

InactiveUS20100167118A1Improve performanceCell cycleability is significantly improvedElectrode rolling/calenderingFinal product manufactureElectrical conductorInterfacial resistance

The present invention provides for a lithium ion battery and process for creating such, comprising higher binder to carbon conductor ratios than presently used in the industry. The battery is characterized by much lower interfacial resistances at the anode and cathode as a result of initially mixing a carbon conductor with a binder, then with the active material. Further improvements in cycleability can also be realized by first mixing the carbon conductor with the active material first and then adding the binder.

Owner:RGT UNIV OF CALIFORNIA

Catalyst coated membrane, membrane electrode assembly containing the same, method of producing the same, and fuel cell including the membrane electrode assembly

Owner:SAMSUNG SDI CO LTD

Capacitors with low equivalent series resistance

InactiveUS7864507B2Increase energy densityIncrease the equivalent series resistanceHybrid capacitor electrolytesBatteries circuit arrangementsElectrical resistance and conductanceButton battery

Owner:TPL INC

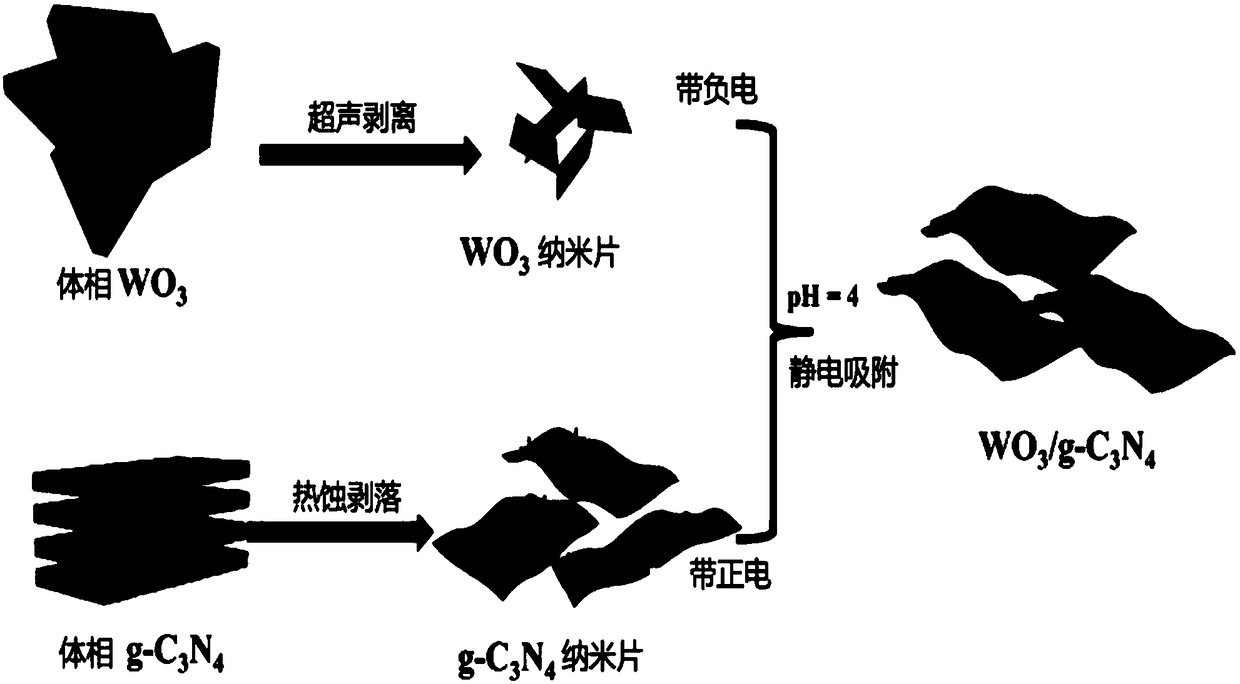

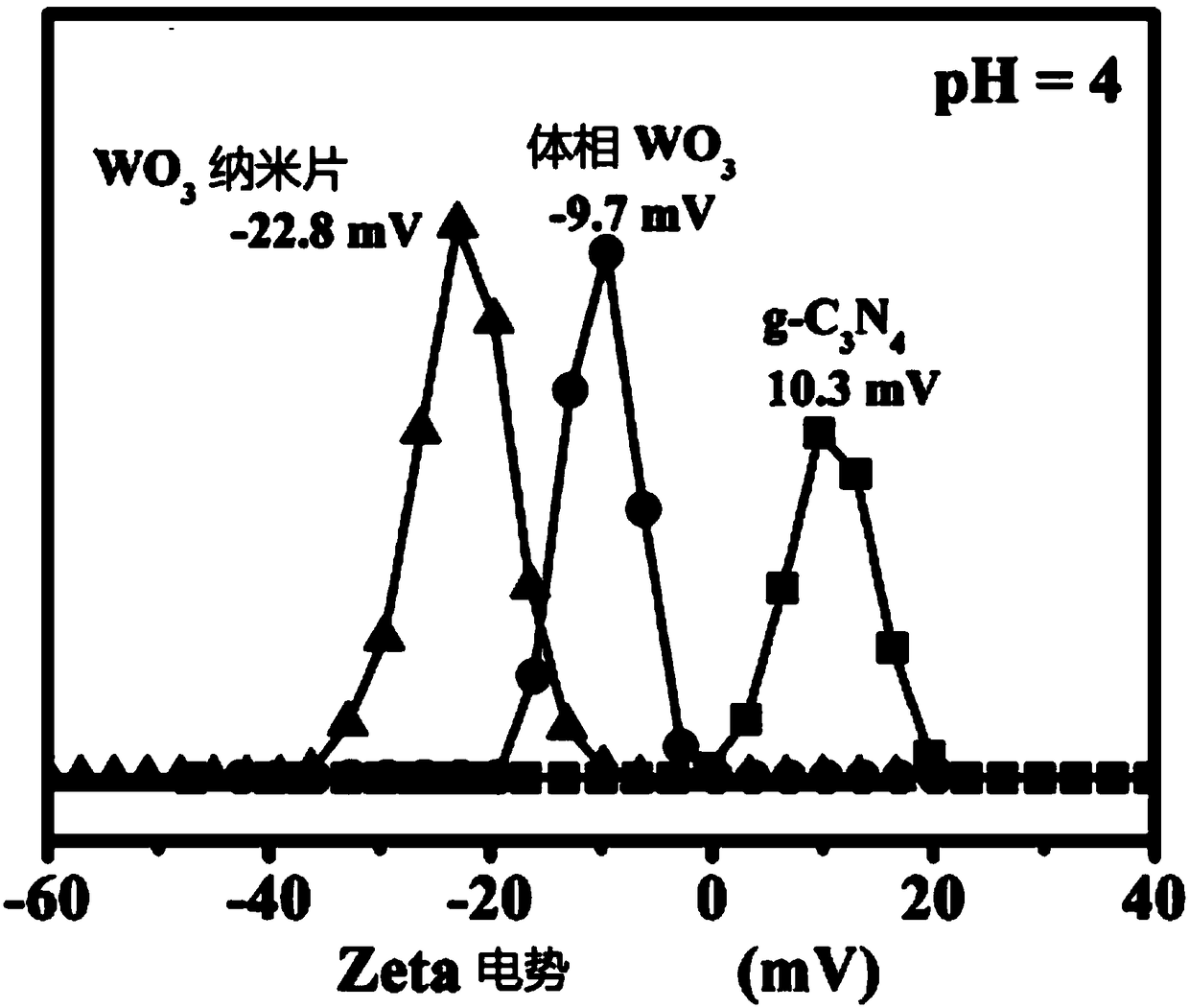

Ultrathin 2D (two-dimensional) WO3/g-C3N4 type-Z heterojunction photocatalyst and preparation method thereof

ActiveCN108525699AImprove transfer efficiencyImprove performancePhysical/chemical process catalystsHydrogen productionHeterojunctionInterfacial resistance

The invention provides a preparation method of an ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalyst. The preparation method of the ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalystcomprises the following steps of S1, preparing ultrathin 2D WO3 nanosheets; S2, preparing ultrathin 2D g-C3N4 nanosheets; S3, preparing the ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalystthrough the ultrathin 2D WO3 nanosheets and the ultrathin 2D g-C3N4 nanosheets. The invention also provides the ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalyst. The ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalyst is composed of 2D WO3 and 2D g-C3N4 at a weight ratio of 1-3:10. The type-Z energy band structure of the ultrathin 2D WO3 / g-C3N4 type-Z heterojunction photocatalyst improves the photocatalytic efficiency; meanwhile, face-to-fact contacted 2D / 2D heterojunction can present a large interfacial contact area and a smaller interfacial resistance, thereby improving the charge transfer efficiency and further improving the photocatalytic performance and stability.

Owner:HUAIBEI NORMAL UNIVERSITY

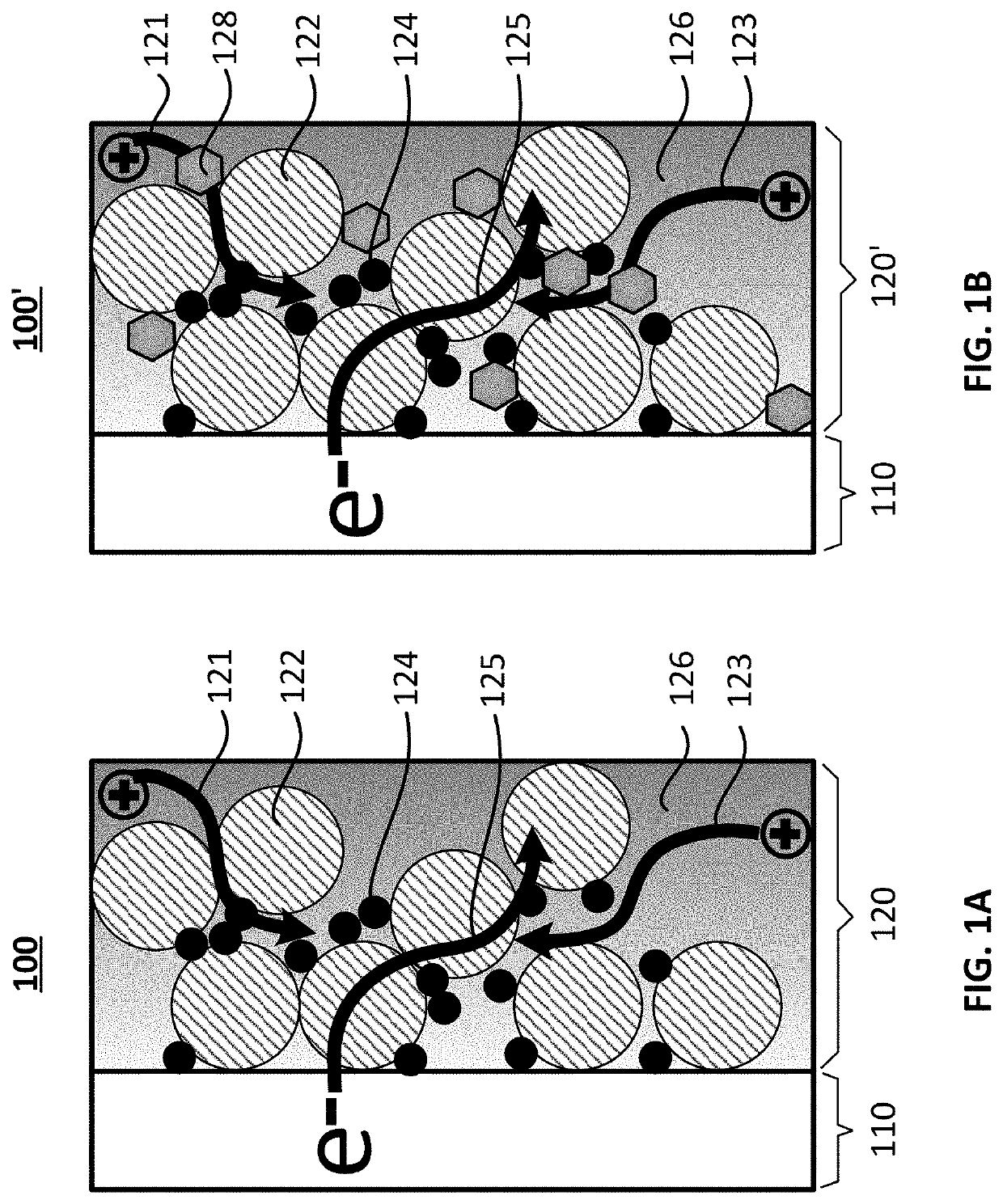

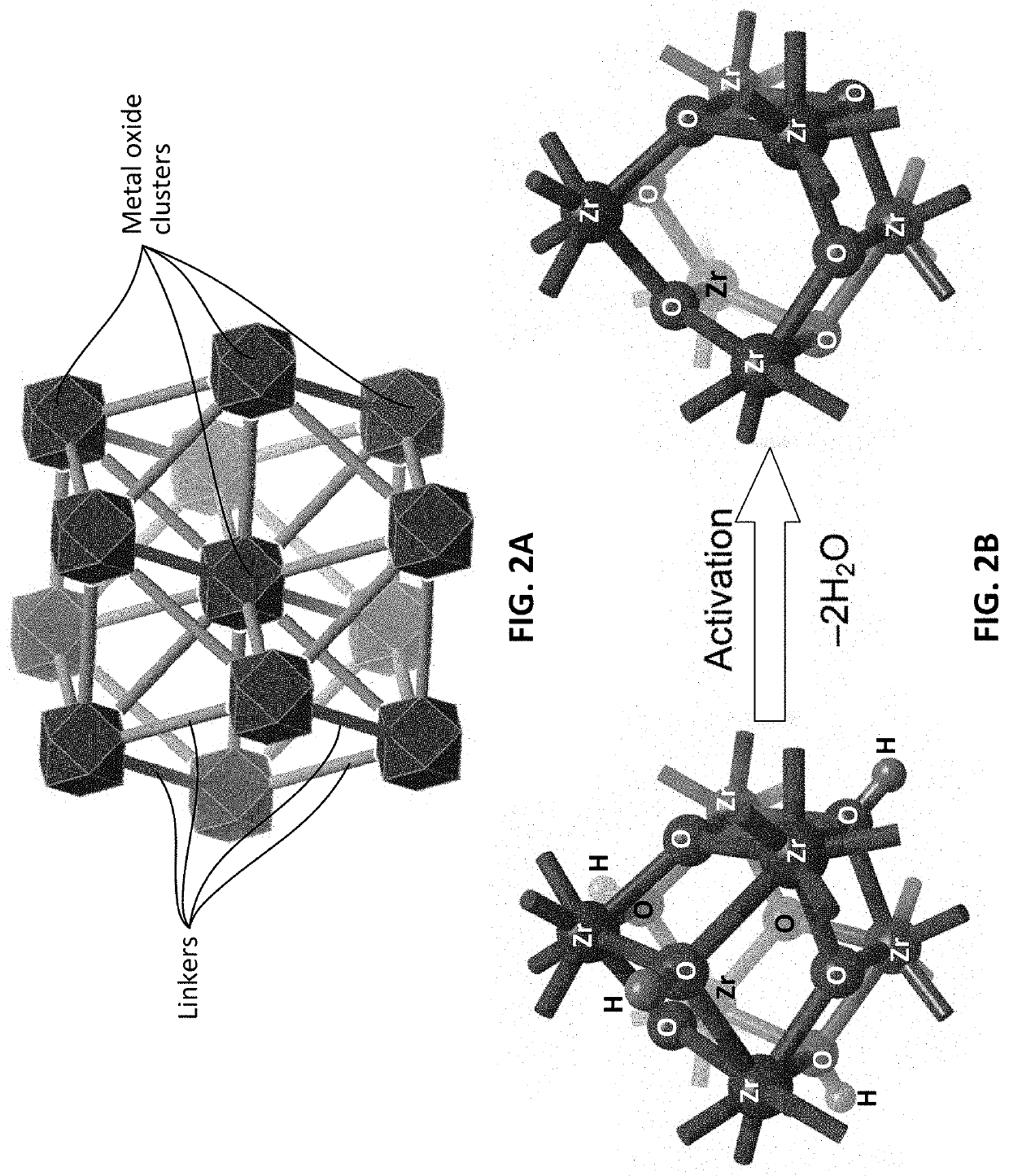

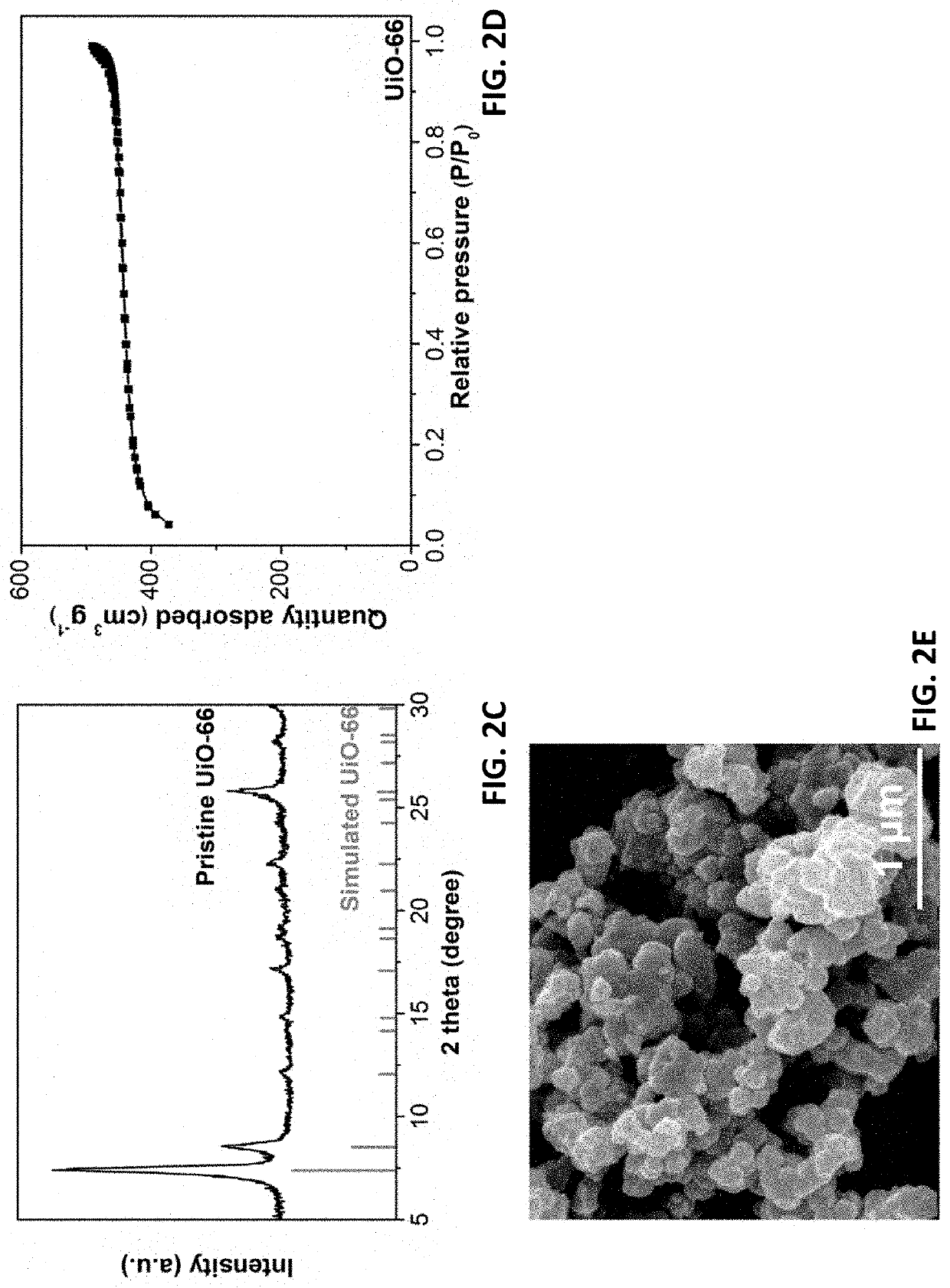

Electrodes having electrode additive for high performance batteries and applications of same

PendingUS20200185788A1Improve thermal stabilityIncrease ratingsCell electrodesWaste accumulators reclaimingInterfacial resistanceElectrical battery

The invention provides a general type of porous coordination solids, metal-organic frameworks (MOFs), as an electrode additive to improve thermal stability, rate and cycle performances of batteries, and an electrode having the electrode additive. The incorporation of the MOF additive into the electrode is fully compatible with current battery manufacturing process. Activated MOF additive serves as an electrolyte modulator to enhance cationic transport and alleviates interfacial resistance by interacting liquid electrolyte with unsaturated open metal sites. Moreover, the flow-free liquid in solid configuration is realized by encapsulating liquid electrolyte into porous scaffold of MOF, which offers superior thermal stability.

Owner:RGT UNIV OF CALIFORNIA +1

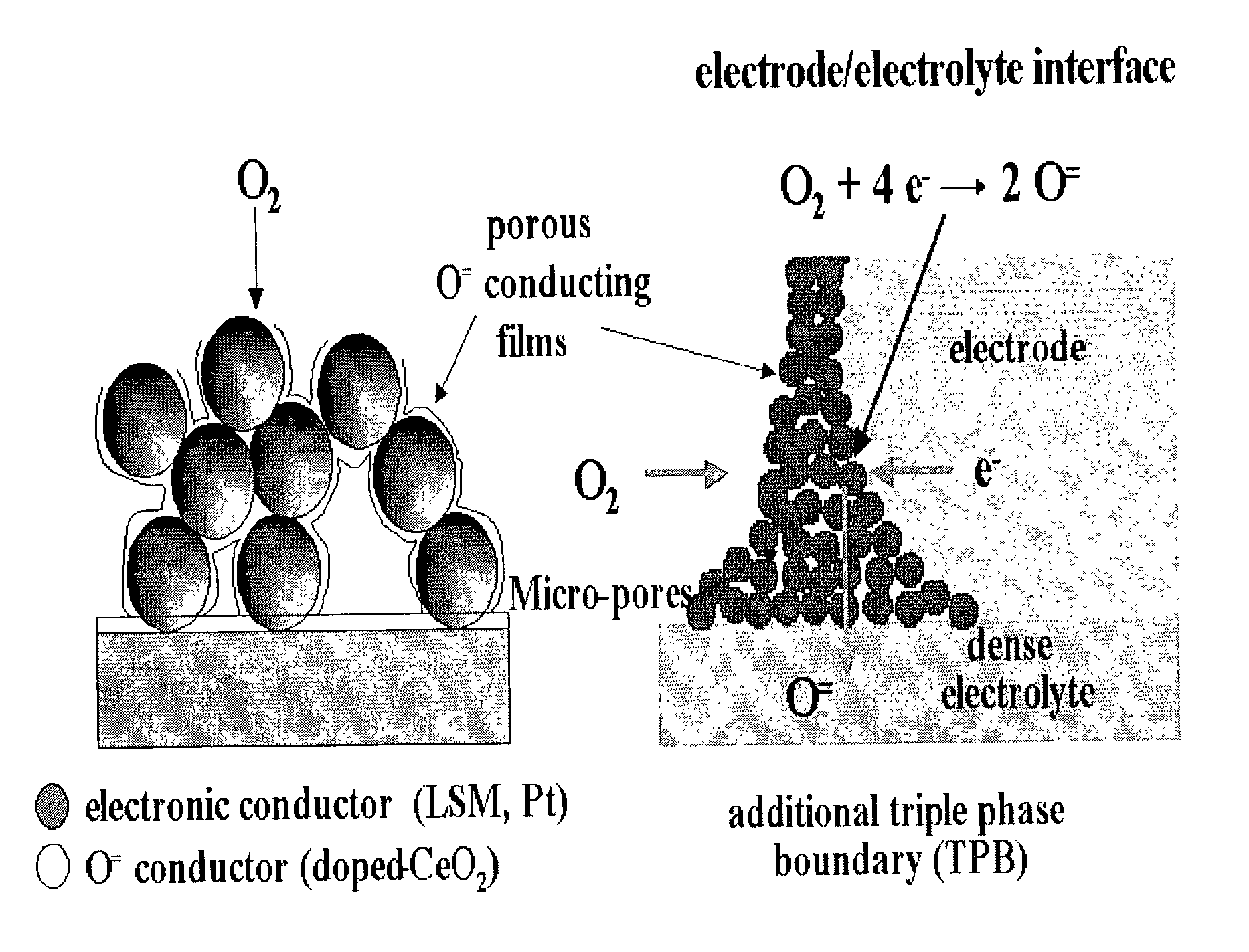

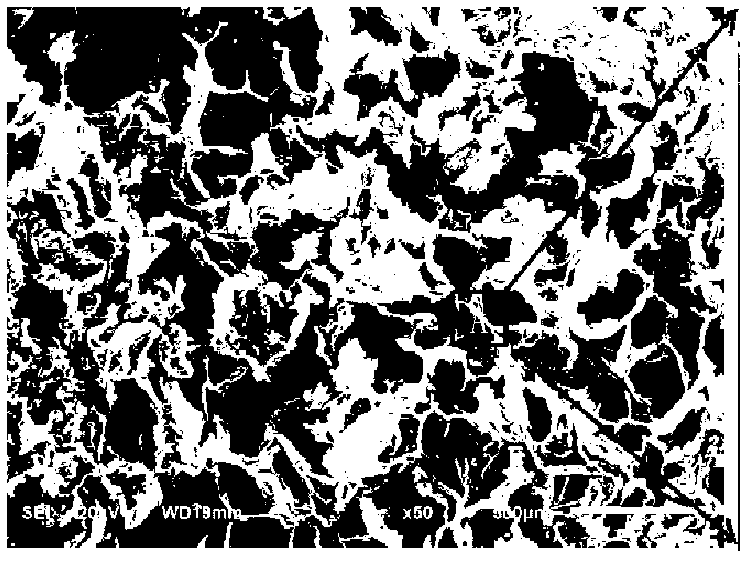

Electrode having microstructure of extended triple phase boundary by porous ion conductive ceria film coating and method to manufacture the said electrode

InactiveUS7141329B2Improve electrode performanceAvoid it happening againFinal product manufactureActive material electrodesInterfacial resistanceOxygen ions

Disclosed is an electrode having a novel configuration for improving performance of the electrode used in solid-oxide fuel cells, sensors and solid state devices, in which the electrode providing electron conductivity is coated with ion conductive ceramic ceria film, enabling an electron conductive path and an ion conductive path to be independently and continuously maintained, and additionally extending a triple phase boundary where electrode / electrolyte / gas are in contact, and a method for manufacturing the same. The electrode is manufactured by coating the prefabricated electrode for use in a SOFC or sensor with a porous oxygen ion conductive ceramic ceria film by a sol-gel method, whereby the electron conductive material and ion conductive material exist independently, having a new microstructure configuration with a greatly extended triple phase boundary, thus improving electrode performance. Accordingly, such electrode does not require high cost equipment or starting materials, owing to the sol-gel method by which low temperature processes are possible. Moreover, the electrode microstructure can be controlled in an easy manner, realizing economic benefits, and the electrode / electrolyte interfacial resistance and electrode resistance can be effectively decreased, thereby improving performance of electrodes used in SOFCs, sensors and solid state devices.

Owner:KOREA INST OF SCI & TECH

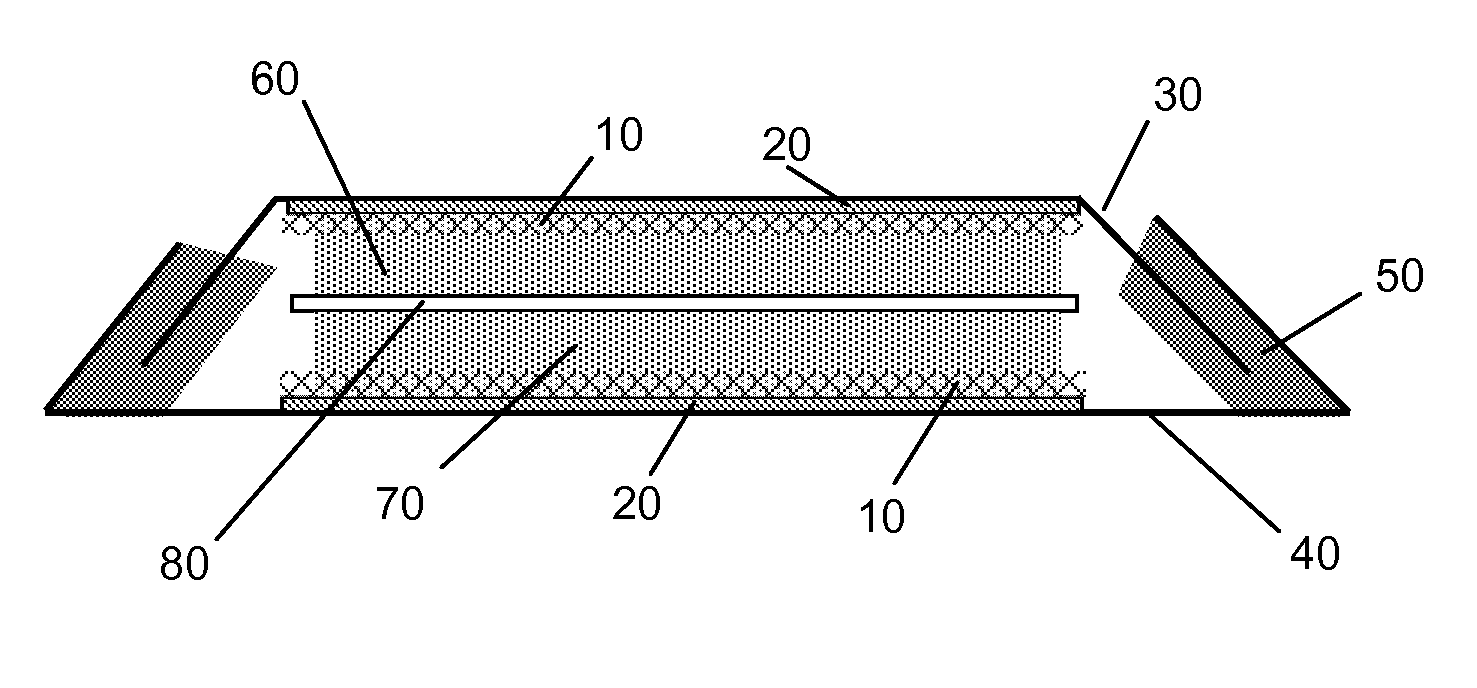

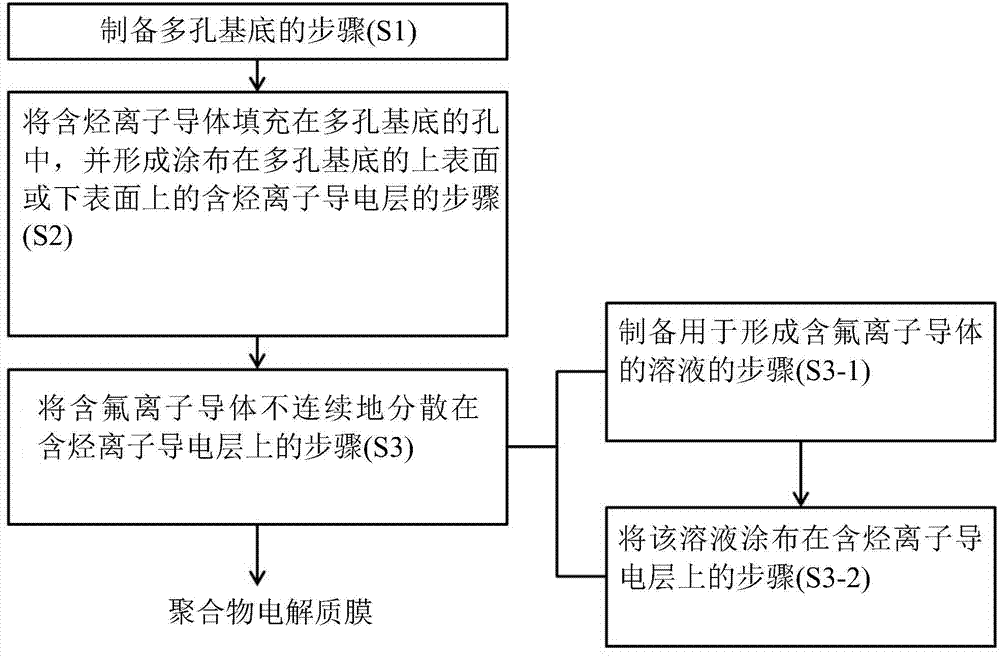

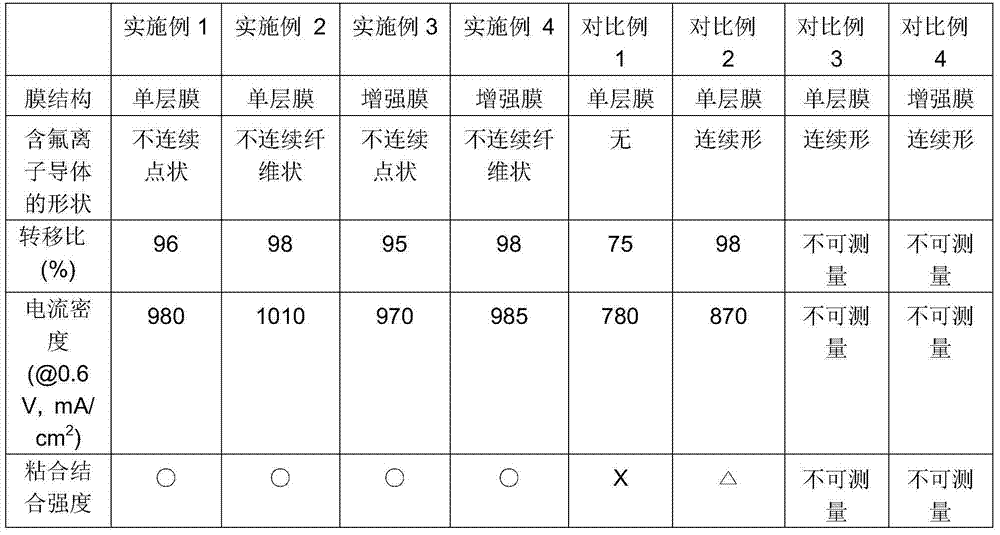

Polymer electrolyte membrane, a method for fabricating the same, and a membrane-electrode assembly including the same

ActiveCN104247118AImprove adhesionImprove performanceSolid electrolytesFinal product manufactureElectrical resistance and conductancePolymer electrolytes

Owner:KOLON IND INC

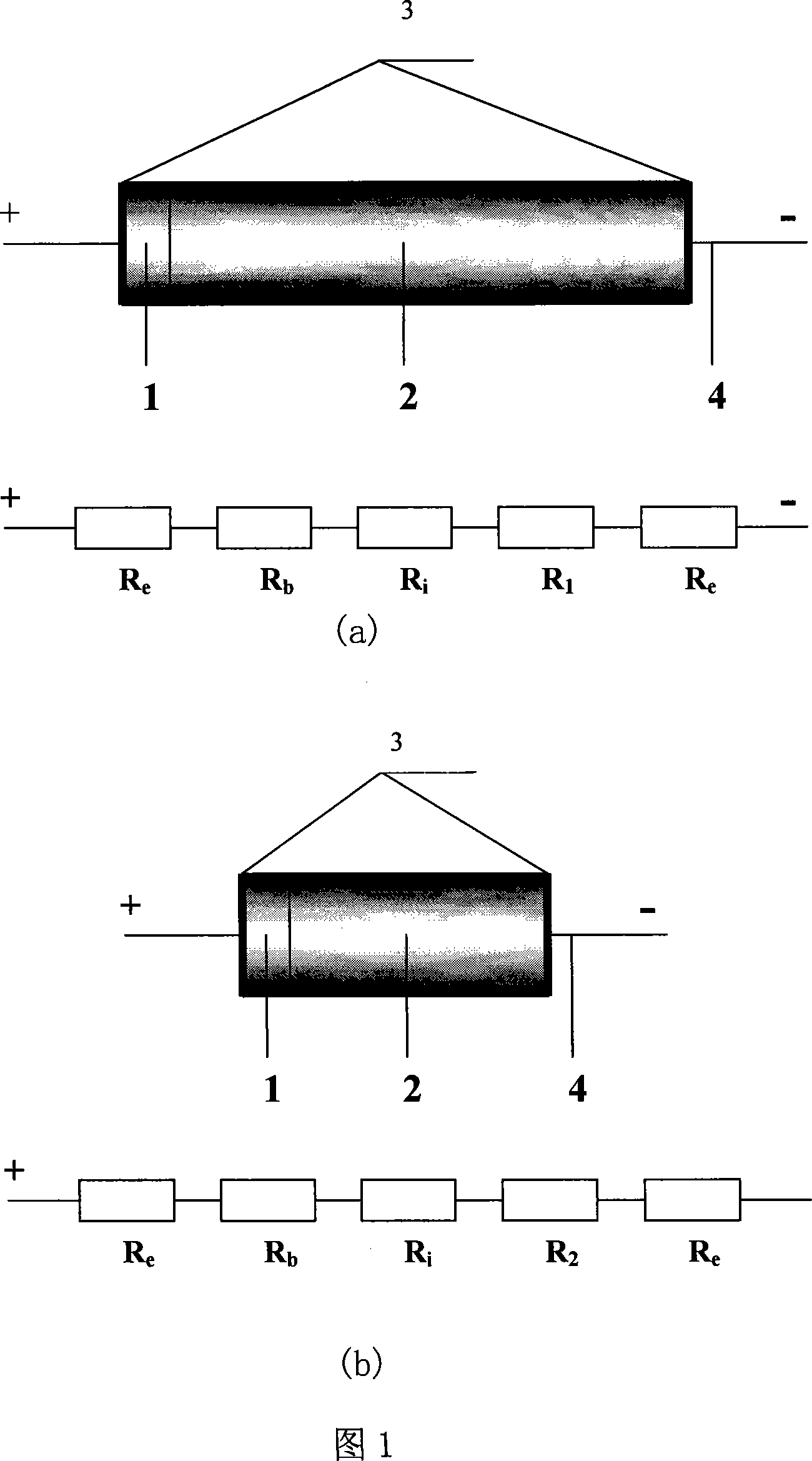

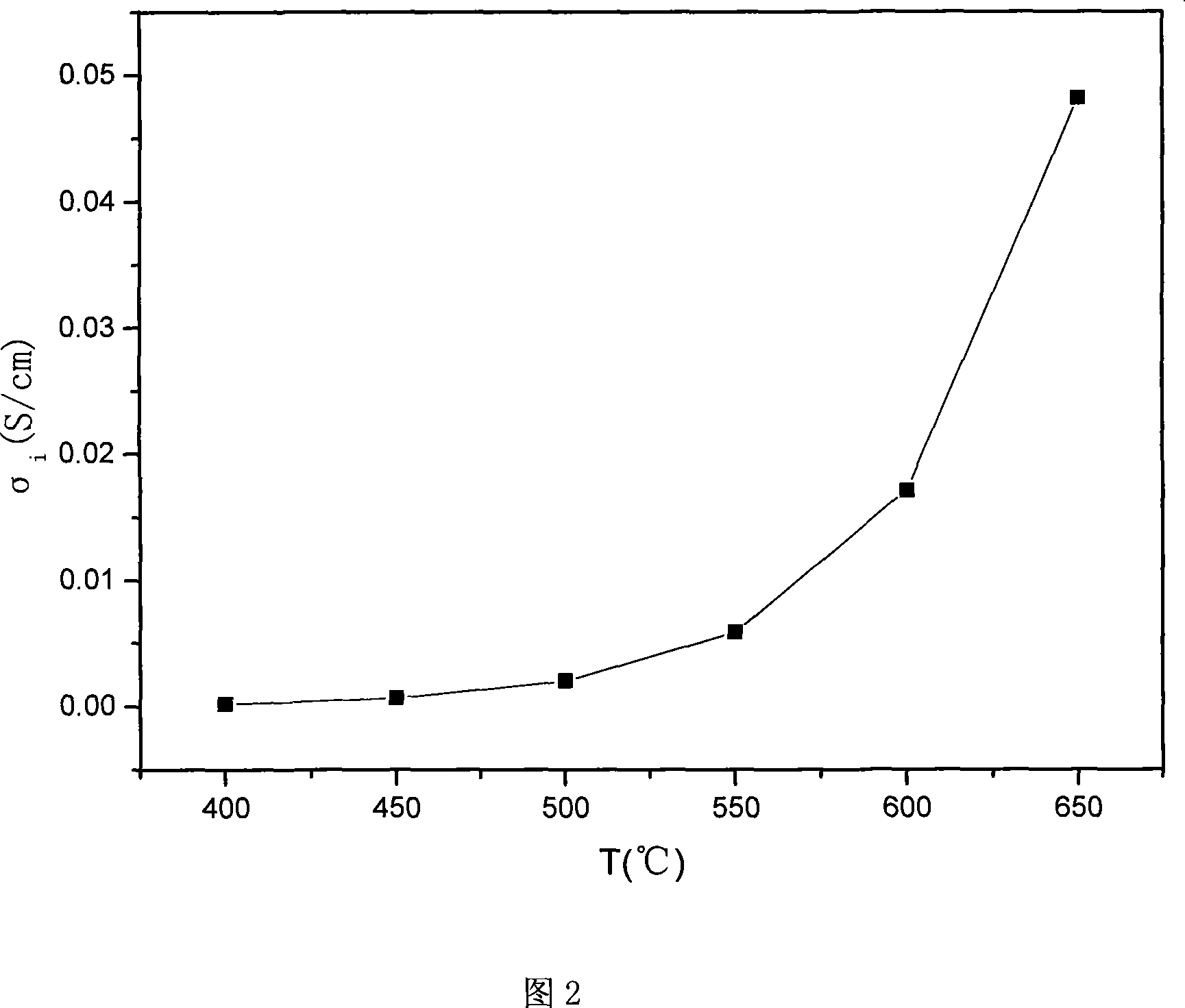

Oxygen ion-electron mixed conductor ion electric conductivity measuring method

InactiveCN101101271ASimple structureAvoid errorsMaterial impedanceSpecial data processing applicationsElectrical resistance and conductanceElectrical conductor

The invention relates to measuring method of the oxyanion hyphen electron mixed conductor material ionic conductivity. The mixed conductor is a ceramic material which has oxyanion and electron conduction power. The characteristics of measuring method is that it calculates and gets the ionic conductivity resulting the changes of resistance with the change of needed detection mixed conductor sample geometry after the electron block; because the tangent condition has not any changed before and after of mixed conductor block electrode, not considering the interfacial resistance, block electrode resistance and Pt electrode resistance, avoiding the error from this. The calculating formula of mixed conductor ionic conductivity is sigma i= (L1-L2) / [S*(R-R')].The measuring method of this invention is simply and convenience, the structure of measuring battery is simplify, reducing the factors of importing error.

Owner:SHANGHAI UNIV

Preparation method of three-dimensional porous graphene

ActiveCN103130217AReduce interface resistanceFirmly connectedGraphenePorous grapheneElectrical resistance and conductance

The invention relates to a preparation method of three-dimensional porous graphene, which comprises the following steps: preparing a graphene oxide water solution through a modified Hummers method; mixing the graphene oxide water solution and toluene-soluble asphalt, performing hydrothermal reaction at 160-240 DEG C for 8-15 hours, cooling, washing, and drying; and under the protection of inert gas, performing heat treatment on the dried sample at 900-1100 DEG C for 0.5-3 hours, and cooling to obtain the cylindrical solid three-dimensional porous graphene. The preparation method of the graphene material having a porous structure has the advantages that the process is simple, the course is easy to control, the interfacial resistance of the graphene is greatly reduced, and the conductivity of the material is excellent.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Layered double hydroxide film and composite material containing layered double hydroxide

InactiveUS20170260048A1Reduce interfacial resistanceFuel and primary cellsFuel and secondary cellsHydrogenInterfacial resistance

Provided is a layered double hydroxide membrane containing a layered double hydroxide represented by the formula: M2+1−xM3+x(OH)2An−x / n.mH2O (where M2+ represents a divalent cation, M3+ represents a trivalent cation, An− represents an n-valent anion, n is an integer of 1 or more, and x is 0.1 to 0.4), the layered double hydroxide membrane having water impermeability. The layered double hydroxide membrane includes a dense layer having water impermeability, and a non-flat surface structure that is rich in voids and / or protrusions and disposed on at least one side of the dense layer. The present invention provides an LDH membrane suitable for use as a solid electrolyte separator for a battery, the LDH membrane including a dense layer having water impermeability, and a specific structure disposed on at least one side of the dense layer and suitable for reducing the interfacial resistance between the LDH membrane and an electrolytic solution.

Owner:NGK INSULATORS LTD

Process for modifying the interfacial resistance of a metallic lithium electrode

InactiveUS20090280405A1Reduce interface resistancePrevent degradationAlkaline accumulatorsElectrode manufacturing processesMetallic lithiumInterfacial resistance

The invention relates to a method of modifying the interfacial resistance of a lithium metal electrode immersed in an electrolytic solution, which consists in depositing a film of metal oxide particles on the surface of this electrode.The invention also relates to a lithium metal electrode, the surface of which is covered with a film of metal oxide particles, and to a battery of the lithium metal type.

Owner:SANNIER LUCAS +4

Lithium-ion-conducting composite material, comprising at least one polymer and lithium-ion-conducting particles

ActiveCN109155428ASolid electrolytesCell seperators/membranes/diaphragms/spacersInterfacial resistancePhysical chemistry

A lithium-ion-conducting composite material is described, comprising at least one polymer and lithium-ion-conducting particles, wherein the interfacial resistance for the lithium-ion conductivity between the polymer and the particles is reduced as a result of a change in the surface of the particles, and consequently the lithium-ion conductivity is greater than in the case of a comparable composite material in which the interfacial resistance between the polymer and the particles is not reduced.

Owner:SCHOTT AG

Structure for composite materials of positive temperature coefficient thermistor devices and method of making the same

InactiveUS20020125983A1Simple processEasy to manufactureInsulating substrate metal adhesion improvementElectrolytic coatingsInterfacial resistanceHeat sensitive

The present invention discloses a structure for composite materials of a positive temperature coefficient thermistor and a method of making the same. A carbon black is electroplated onto a surface of the metal electrodes of a metal laminated material to form a continuous porous structure having carbon black. Then a thermal laminating process is used to laminate the metal laminated material and a conductive crystallized polymeric composite material plaque filled with carbon black, to form a fine point between surfaces of the metal electrodes of metal laminated material and the conductive crystallized polymeric composite material plaque filled with carbon black. In the meantime, it can also lower down interfacial resistance by allowing carbon black particles of conductive crystallized polymeric composite material filled with carbon black to fully contact with the surface electroplated layer of the metal electrodes.

Owner:PROTECTRONICS TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com