Patents

Literature

183results about How to "Address volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and battery

ActiveCN107293700AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsCarbon layerCarbon composites

The invention provides a lithium ion battery negative electrode active material. The lithium ion battery negative electrode active material has a three-layer composite structure and comprises an inner core, an intermediate layer and an outermost layer, wherein the inner core is silicon carbon composite particles, the intermediate layer is a porous carbon layer, and the outermost layer is a compact carbon layer. The invention also provides a preparation method of the lithium ion battery negative electrode active material, a negative electrode comprising the negative electrode active material and a battery. By the lithium ion battery negative electrode active material, the technical problems that the volume of nanometer silicon particles in the silicon carbon negative electrode lithium ion battery in the prior art is expanded and the electrical conductivity is reduced are solved, meanwhile, an electrolyte can be effectively isolated by the compact carbon layer of the prepared negative electrode material, the electrolyte invasion is prevented, and the initial efficiency and the cycle property of the battery are improved.

Owner:BYD CO LTD

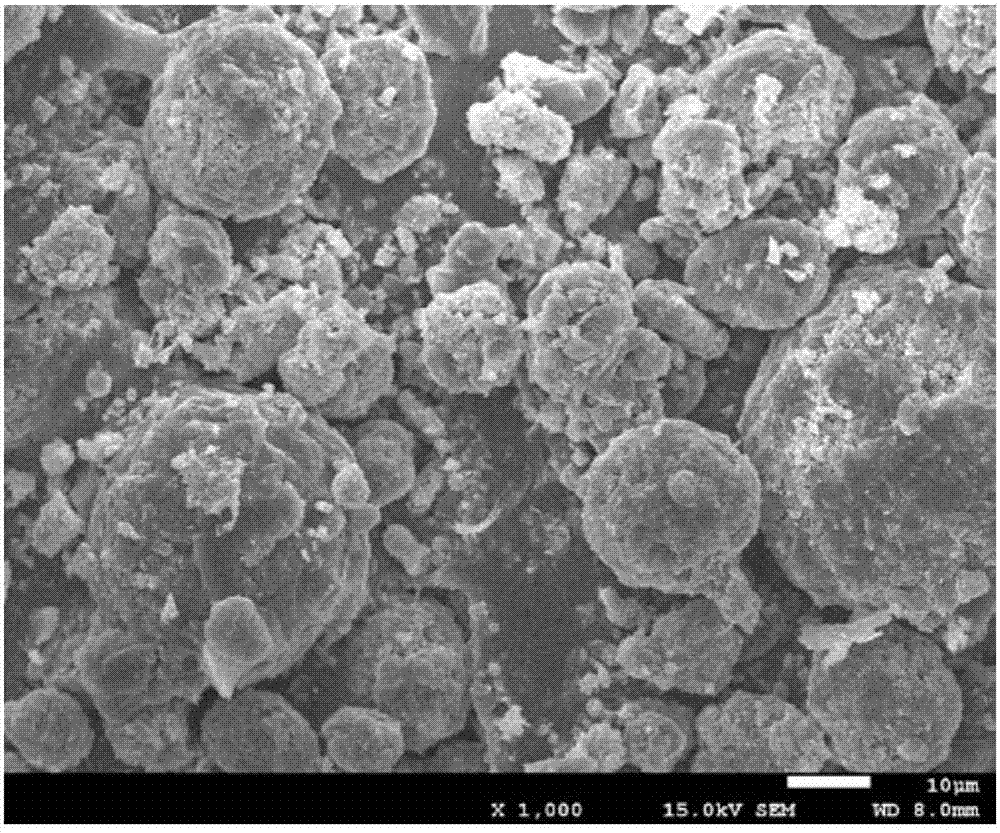

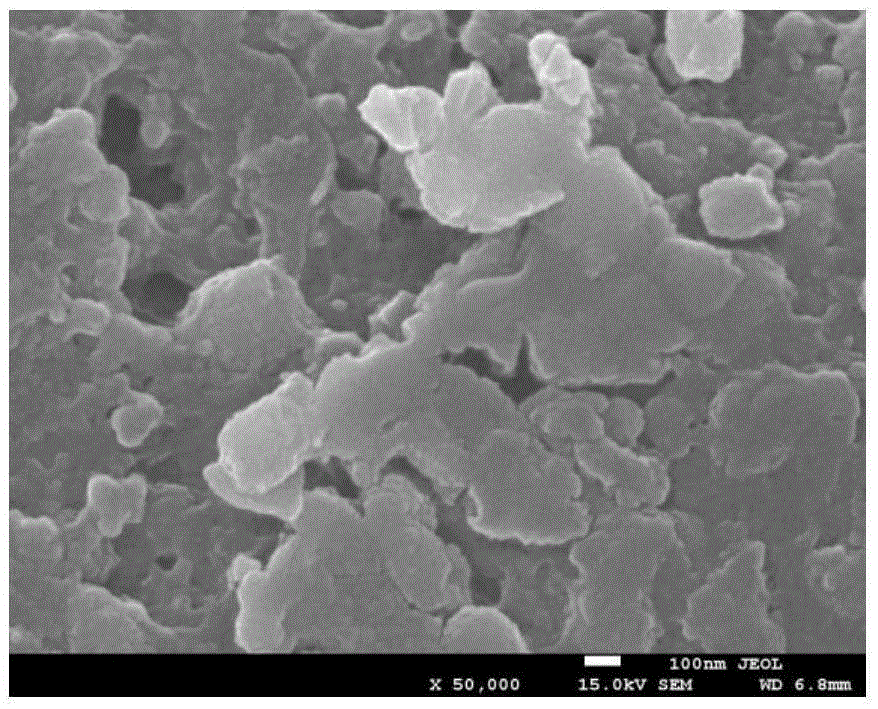

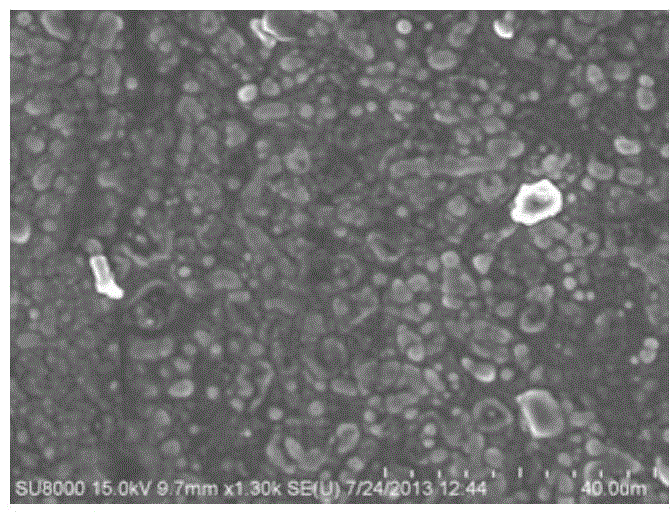

Preparation and application method of graphene-coated porous silicon composite anode material

InactiveCN106920954AThe preparation process is simple and easy to controlLow costCell electrodesSecondary cellsCvd grapheneCarbon source

Preparation and an application method of a graphene-coated porous silicon composite anode material belong to the field of electrode material preparation. According to the preparation, aluminium-silicon, which is used as a raw material, successively undergoes smelting, mechanical milling and chemical etching to prepare porous silicon; and then the porous silicon, graphene oxide and a carbon source undergo ball milling, spray drying and high-temperature pyrolysis to form a graphene-coated porous silicon composite material. Mass percent of silicon in the prepared porous silicon material is 20-80%; mass percent of metal impurities is 20-80%; particle size distribution is 10 nm- 10 microns; pore size distribution is 1-1000 nm; and porosity is 1-90%. According to the obtained graphene-coated porous silicon composite material, particle size is 1-100 microns, the shape is spherical, particle distribution is uniform, and morphology is consistent. When the material is applied to a lithium ion battery anode material, volume expansion of silicon alloying can be effectively prevented, and initial charge-discharge efficiency, theoretical specific capacity, cycle performance and the like are enhanced. The material of the invention is an ideal anode material in the field of lithium ion battery. The preparation has advantages of simple process, low energy consumption, low cost, good reappearance and high yield.

Owner:UNIV OF SCI & TECH BEIJING

Molybdenum disulfide-coated carbon nanofiber used as negative electrode material for lithium-ion battery and preparation method of molybdenum disulfide-coated carbon nanofiber

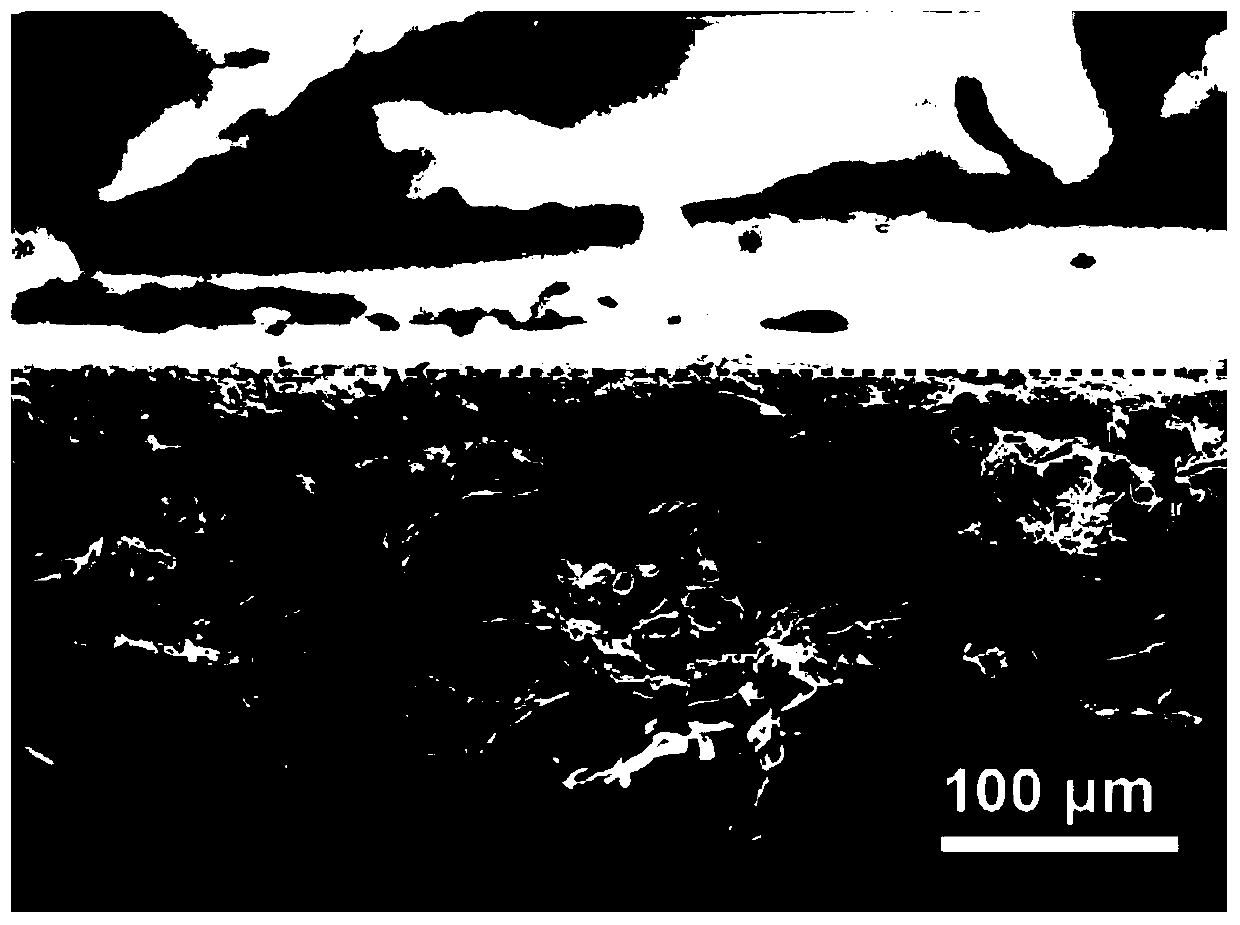

ActiveCN107681142AHigh cycle capacityImprove cycle performanceMaterial nanotechnologyCell electrodesFiberPorous carbon

The invention discloses a molybdenum disulfide-coated carbon nanofiber used as a negative electrode material for a lithium-ion battery and a preparation method of the molybdenum disulfide-coated carbon nanofiber. The molybdenum disulfide-coated carbon nanofiber is characterized in that the outer surface of a mesoporous carbon nanofiber is coated with a layer of molybdenum disulfide nanosheet; andduring preparation, a nanofiber containing ZIF-8 is firstly prepared by using an electrostatic spinning assembly method, a porous carbon nanofiber is formed after high-temperature carbonization of thefiber, and the surface of the carbon nanofiber is coated with a layer of flaky molybdenum disulfide through a hydrothermal method, thereby obtaining a target product used as a negative electrode material for a lithium-ion battery. The molybdenum disulfide-coated carbon nanofiber is the negative electrode material for the lithium-ion battery capable of being charged and discharged, the problems ofpoor stability and poor conductivity of the flaky molybdenum disulfide material in charging and discharging processes of the battery are effectively solved, the cycle performance and the rate capability of the battery are improved and the electron transport rate in the cycle process of the battery is improved; and the preparation method is simple, massive production can be achieved and the preparation method has a good application prospect.

Owner:HEFEI UNIV OF TECH

Anode material for Li-ion batteries and preparation method thereof

InactiveCN106450251AImprove cycle performanceExcellent rate performanceCell electrodesSilica nanoparticlesHydrofluoric acid

The invention discloses an anode material for Li-ion batteries and a preparation method thereof. The anode material for Li-ion batteries is characterized in that silica nanoparticles are taken as raw materials, and firstly the surface of the silica nanoparticles is coated with a SiO2 coating to obtain a precursor Si@SiO2; then the surface of the precursor is coated with a PANI coating to obtain a compound material Si@SiO2@PANI; then the PANI is carbonized into porous carbon through calcining the compound material, a compound material Si@SiO2@NOC is obtained; finally SiO2 is removed through mechanical erosion with a hydrofluoric acid, and a compound material Si@SiO2@NOC is obtained to be the anode material for Li-ion batteries. According to the method, the discharged Anode material for Li-ion batteries can be charged, the problem of volume dilation of batteries is effectively solved, circulation property and rate property of batteries are improved; the preparation method is simple, and large scale production can be achieved.

Owner:HEFEI UNIV OF TECH

Porous core-shell structure negative electrode material, preparation method and battery thereof

ActiveCN106558685AImprove cycle performanceAddress volume expansionNegative electrodesLi-accumulatorsPorosityGraphite

The invention relates to a porous core-shell structure negative electrode material. The porous core-shell structure negative electrode material comprises a core layer formed by at least one carbonaceous material of graphite, hard carbon and soft carbon and a carbon shell layer coating the core layer, wherein the carbon shell layer contains amorphous carbon cobalt element and tin element, and has a porous structure with porosity of more than 10%. The invention also discloses a preparation method of the porous core-shell structure negative electrode material, and a battery with the negative electrode containing the porous core-shell structure negative electrode material. The porous core-shell structure negative electrode material provided by the invention can overcome the volume expansion problem in the charge-discharge process, and accordingly through use of the negative electrode formed by the porous core-shell structure negative electrode material provided by the invention, the obtained battery can have good cycle performance.

Owner:BYD CO LTD

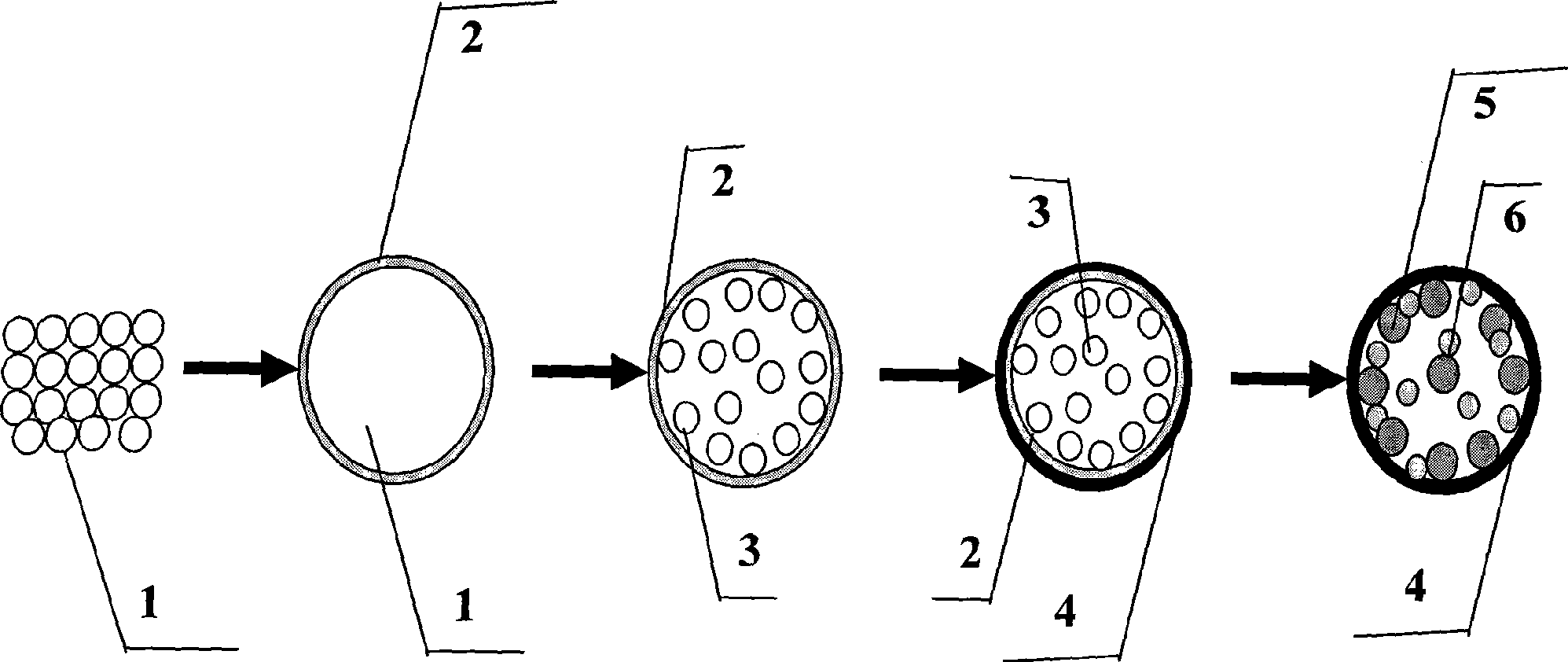

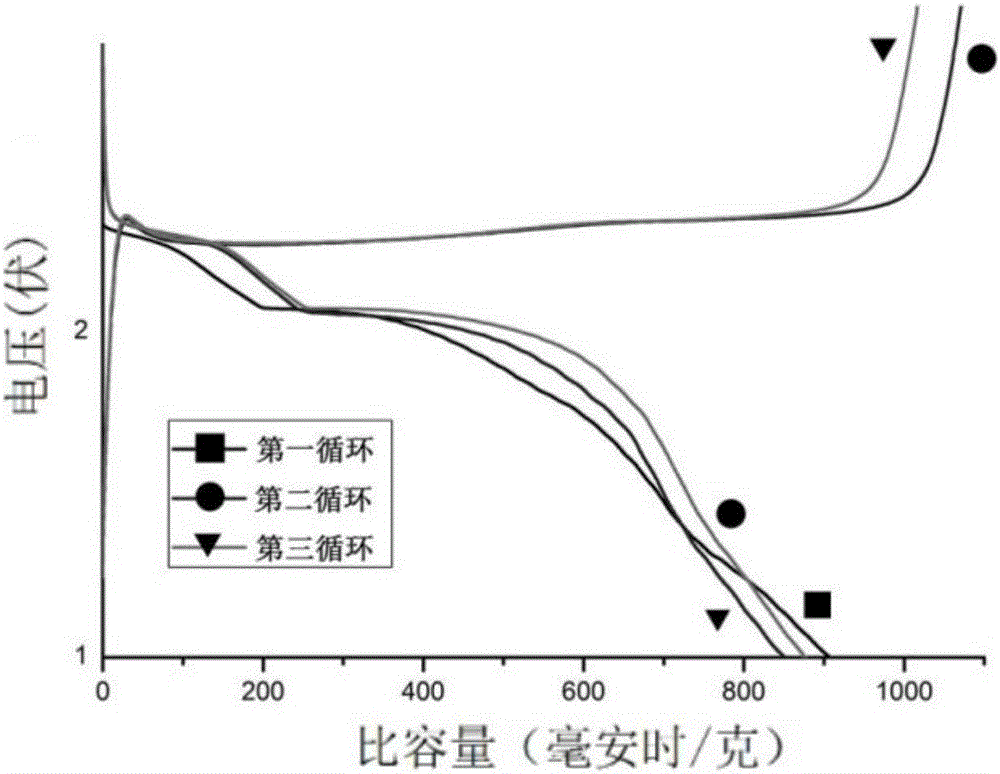

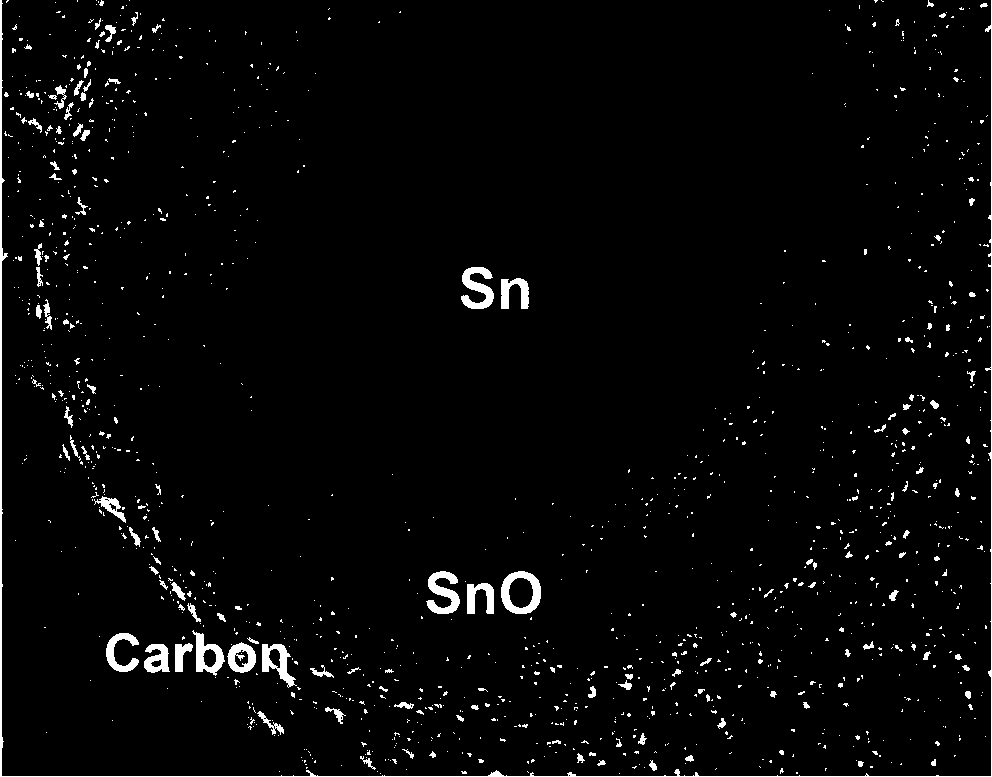

Method for preparing silicon stannum alloy cathode material of lithium ion battery

InactiveCN101510601ARaw materials are easy to getSimple processElectrode manufacturing processesAlloyRates reactions

The invention discloses a preparation method for a silicon-tin alloy cathode material in a Li-ion battery. The preparation method comprises the following steps: an oxide ball of silicon is taken as a template, a silicide intermediate coated with tin oxides is prepared at first, and the silicide intermediate is coated with carbon, and then deoxidized to produce the cathode material of nanometer silicon-tin alloy. The preparation method has simple process and rich material sources. The high temperature reaction atmosphere adopted by the preparation method can shorten the reaction time and promote the reaction efficiency. And the material produced by the method has high actual capacity and excellent cycle performance. The preparation method is applicable to the industrialized production of the silicon-tin alloy of Li-ion battery cathode material.

Owner:广州鸿森材料有限公司

Preparation method of composite microsphere lithium ion battery cathode material in yolk structure

InactiveCN105565265AEasy to operateNovel structureMaterial nanotechnologyCell electrodesMicrosphereSilicon dioxide

The invention discloses a preparation method of a composite microsphere lithium ion battery cathode material in a yolk structure. A nuclear layer of a composite microsphere is made of Fe3O4, a shell layer comprises a layer C and a layer N, a cavity is formed through etching between the nuclear layer and the shell layer, and the cavity is in a yolk structure. The preparation method of the composite microsphere comprises the following steps: firstly, compounding Fe3O4 nano particles by a hydrothermal method; then, coating a layer of SiO2 outside Fe3O4 by a sol-gel method; coating a layer of melamine resin polymer outside SiO2, and roasting in argon protection, so as to obtain an N-doped carbon encapsulated material; and finally, etching the layer of SiO2, so as to obtain the Fe3O4 composite microsphere lithium ion battery cathode material which is coated with N-doped carbon and is in the yolk structure. According to the preparation method, the material structure is novel, the operation is simple, and the material used in a lithium ion battery cathode has good electrochemical performance.

Owner:QILU UNIV OF TECH

Adhesive film for organic electronic device and sealing material for organic electronic device comprising same

InactiveCN105219285AExtend your lifeIncreased durabilityNon-macromolecular adhesive additivesSolid-state devicesPolymer sciencePolymer chemistry

Owner:INNOX ADVANCED MATERIALS CO LTD

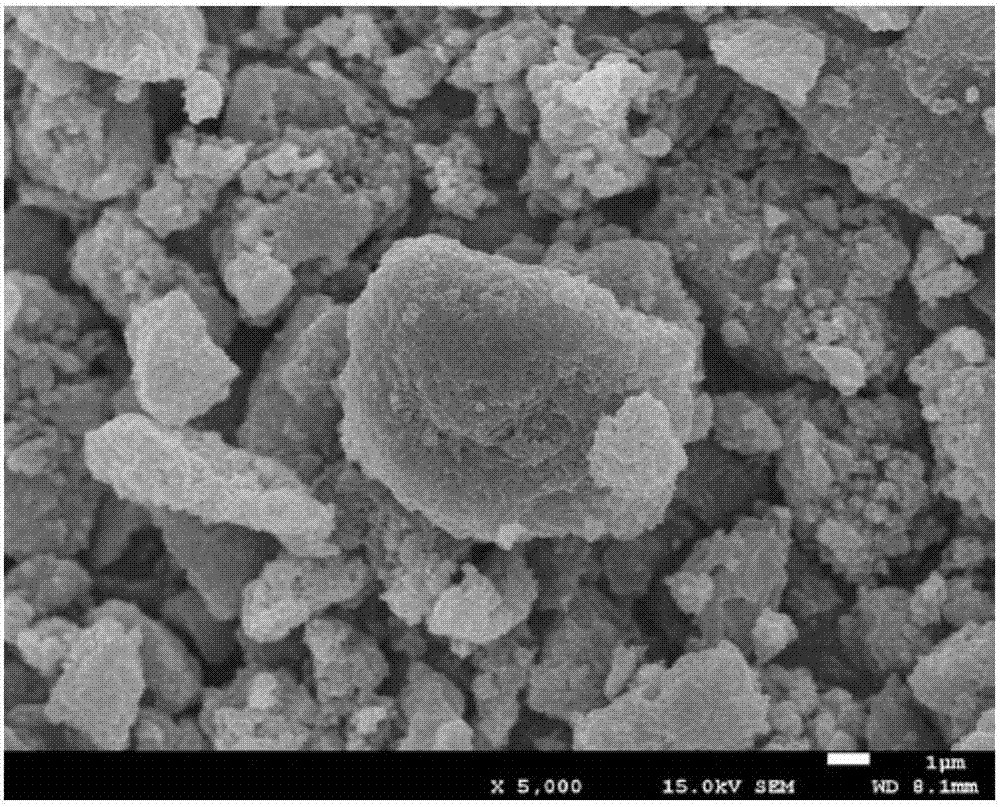

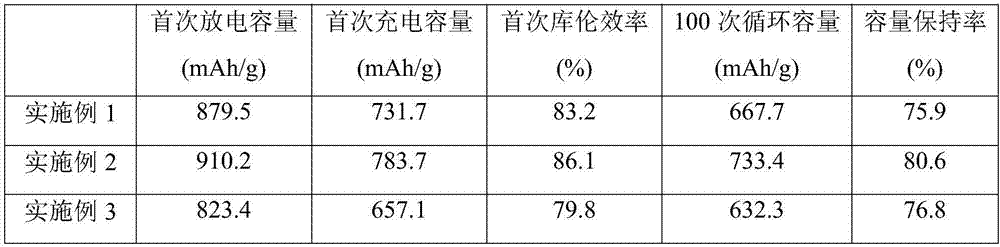

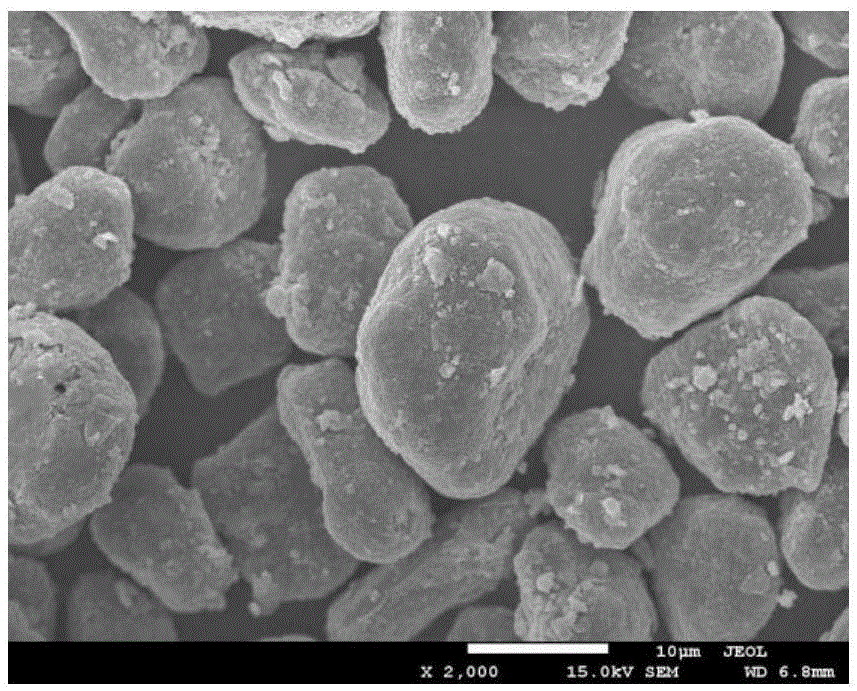

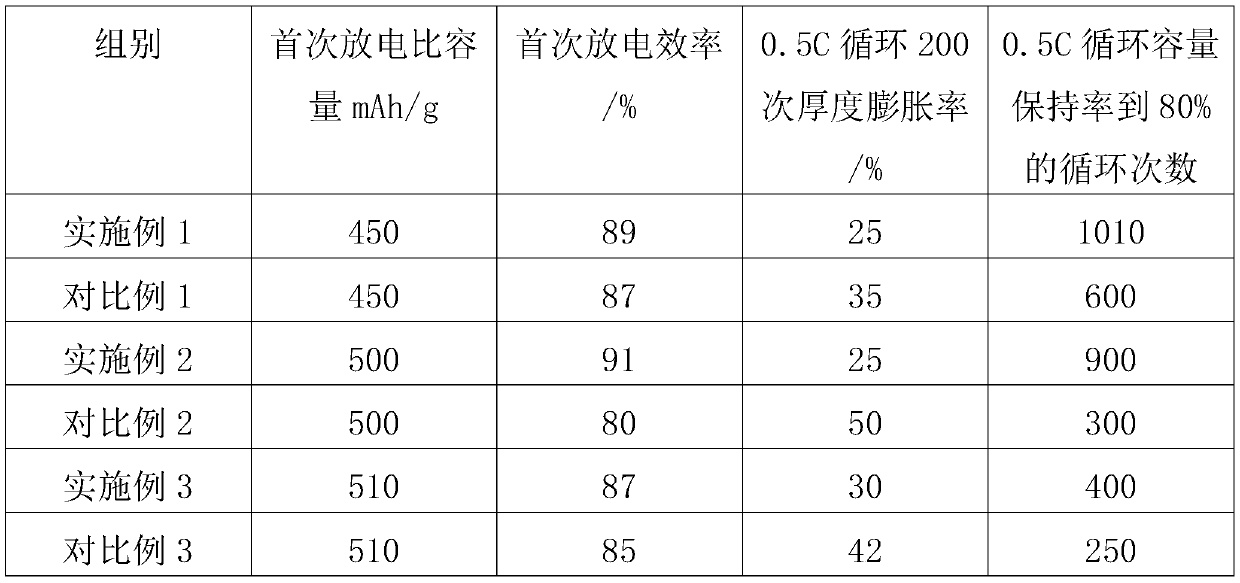

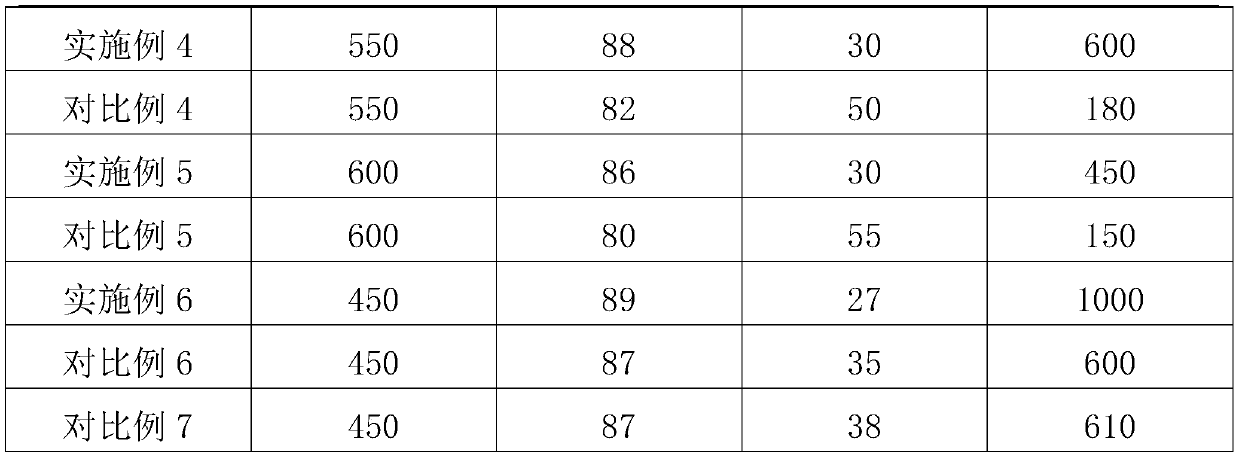

Silicon-carbon negative electrode material for lithium ion secondary batteries and preparation method thereof

ActiveCN107316982ACharge and discharge gram capacity increaseSolve the volume expansion problemCell electrodesSecondary cellsSolventGram

The invention relates to the technical field of negative materials for lithium ion batteries, and specifically relates to a silicon-carbon negative electrode material for lithium ion secondary batteries and a preparation method thereof. The silicon-carbon negative electrode material is prepared from the following raw materials in percentages by weight: 3wt% to 10wt% of silicon and / or silicon dioxide, 30wt% to 57wt% of a solvent and 40wt% to 60wt% of coal tar pitch, wherein the solvent is at least one of carbolic oil, scrubbing oil and anthracene oil. Compared with the prior art, nanometer silicon and / or nanometer silicon dioxide are / is added into carbon material, and the gram volume of the negative electrode material for lithium ion secondary batteries is improved, so that the charging and discharging gram volume of the battery is increased; simultaneously, nanometer silicon and / or nanometer silicon dioxide particles are wrapped by external carbon, expansion of silicon and / or silicon dioxide is restricted, and the problem of volume expansion is preferably solved, so that the cycle performance is improved; the technological process is simple and easy to control, the used equipment is industrial common equipment respectively, and industrial production is easy to realize.

Owner:SHANGHAI SHANSHAN TECH CO LTD

High-safety double-doped high-nickel ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN111646523AIncrease the force and bond energy between ionsImprove crystal structure stabilitySecondary cellsPositive electrodesLithium electrodeManganate

The invention discloses a high-safety double-doped high-nickel ternary positive electrode material, a preparation method thereof and a lithium ion battery. The high-nickel ternary positive electrode material comprises a polycrystalline nickel cobalt lithium manganate matrix, wherein the molar content of Ni element in the polycrystalline nickel cobalt lithium manganate matrix accounts for more than80% of the total molar weight of Ni, Co and Mn, and Zr and Sr elements are doped in the polycrystalline nickel cobalt lithium manganate ternary positive electrode matrix. Compared with the prior art,the high-nickel ternary positive electrode material has the advantage that the thermal stability of the high-nickel ternary positive electrode material is remarkably improved on the premise of not reducing the proportion of the Ni element in the high-nickel ternary positive electrode material, namely, not reducing the specific capacity of the high-nickel ternary positive electrode material. Meanwhile, the price of the nickel element is far lower than that of the cobalt element, so that the nickel element accounts for a high proportion, transition metals such as cobalt account for a low proportion, and the advantage of reducing the cost of raw materials is considered.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Negative electrode material of flexible sodium metal battery and preparation method thereof

InactiveCN108461732APrecise size controlIncrease profitCell electrodesSecondary cellsPorosityCyclic process

The invention relates to a negative electrode material of a flexible sodium metal battery and a preparation method thereof and belongs to the technical field of sodium metal batteries. The negative electrode material is characterized in that graphene aerogel is adopted as a skeleton, and sodium metal is distributed in a skeleton structure; the hole diameter range of the skeleton is 20-200mu m, andthe mass percentage of the sodium metal in the negative electrode material is 90-98%. The preparation method of the negative electrode material comprises the following steps of: adding a conducting material into water, then adding a reducing agent, and reacting for 6-24 hours at the temperature of 50-200 DEG C to obtain an intermediate product; washing with water, freezing drying under 5-10 MPa to form the graphene aerogel; then adopting the graphene aerogel as a skeleton, and compounding with liquid metal sodium to obtain the negative electrode material. The negative electrode material has good flexibility, uniform porosity and large specific surface area; as a negative electrode of the sodium metal battery, uniform nucleation of sodium ions is ensured, the volume expansion in the circulating process is relieved, and due to higher conductivity, the overpotential is effectively reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

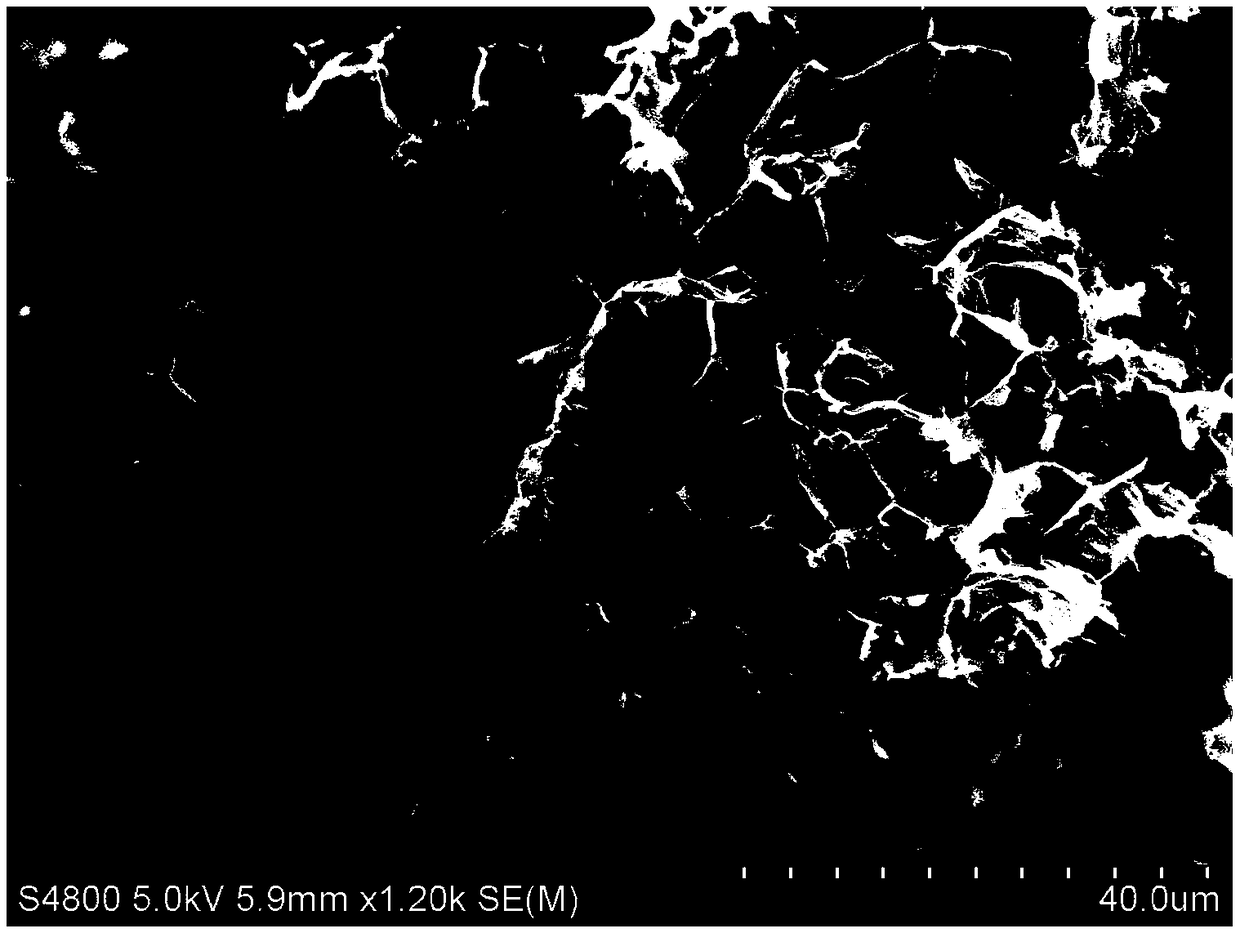

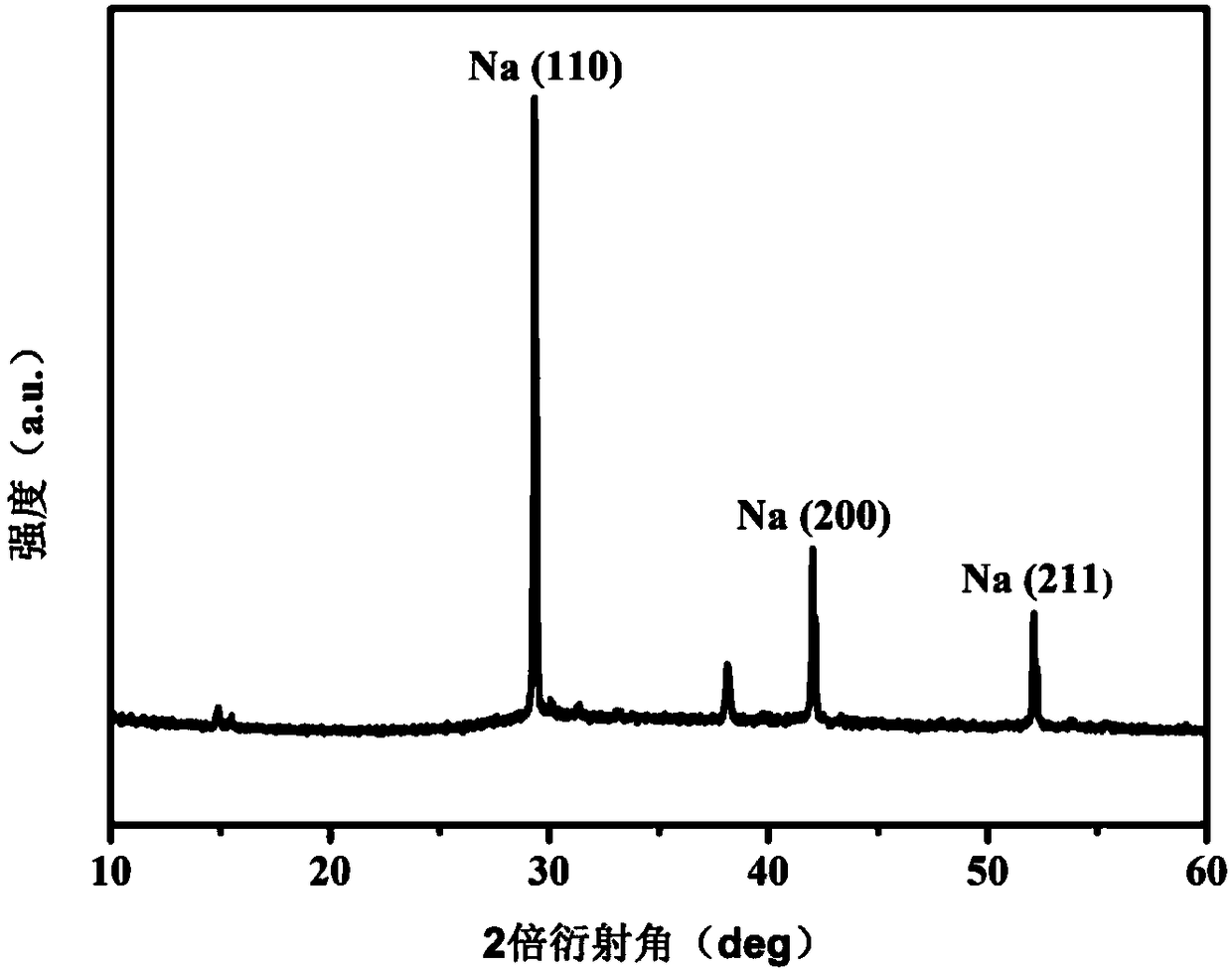

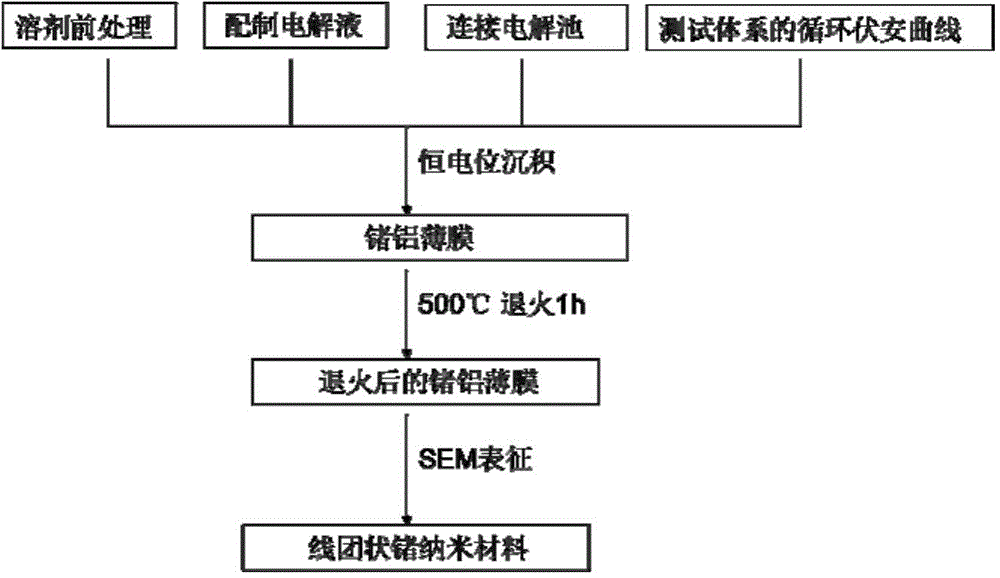

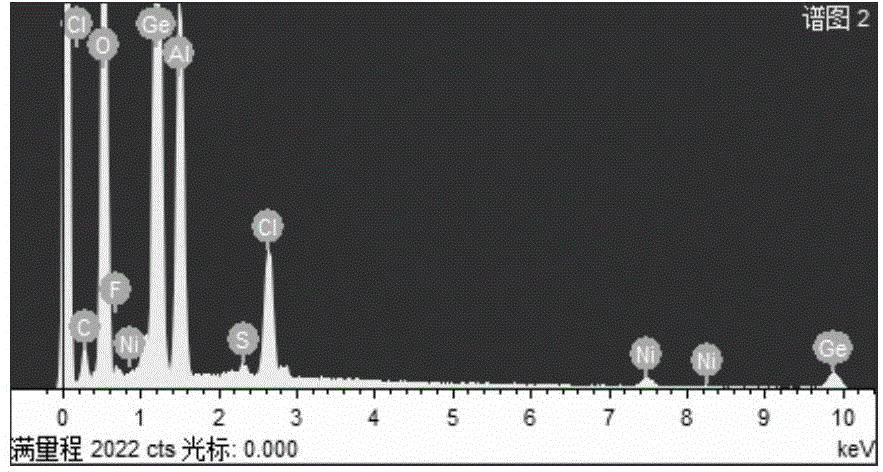

Coiling-type germanium nanomaterial and preparation method thereof

ActiveCN103606683AThe process steps are simpleImproved magnification performanceMaterial nanotechnologyCell electrodesPower batteryElectrical battery

The invention provides a coiling-type germanium nanomaterial and a preparation method thereof. The coiling-type germanium nanomaterial can be used as a negative electrode of a lithium ion battery. According to the preparation method, a metal layer prepared by adopting an ionic liquid electroposition method and a germanium layer are combined, and the coiling-type germanium nanomaterial is prepared by combining with a metal induced crystallization theory. The coiling-type germanium nanomaterial provided by the invention can be used as the negative electrode of the lithium ion battery, so that volume expansion of the germanium-based material can be effectively slowed down; the coiling-type germanium nanomaterial can be used for preparing the lithium ion power battery with high capacity, large multiplying power and long service life.

Owner:HARBIN INST OF TECH

Preparation method and application of low-volume-change metal secondary battery negative electrode

ActiveCN109980235AImprove securitySolution to short lifeElectrode carriers/collectorsLi-accumulatorsElectrical batteryCrystal growth

The invention provides a spinning membrane composite three-dimensional porous current collector as well as a preparation method and application thereof; the spinning membrane composite three-dimensional porous current collector comprises a three-dimensional porous current collector material and a spinning membrane which covers the surface of the three-dimensional porous current collector materialand is formed by an electrostatic spinning technology, wherein the spinning membrane is a solid electrolyte interface membrane. The current collector can be used for realizing high-surface-capacity metal deposition, inhibiting dendritic crystal growth and relieving the electrode volume change, so that the safety and the cycle life of the metal negative electrode are improved and prolonged.

Owner:INST OF CHEM CHINESE ACAD OF SCI

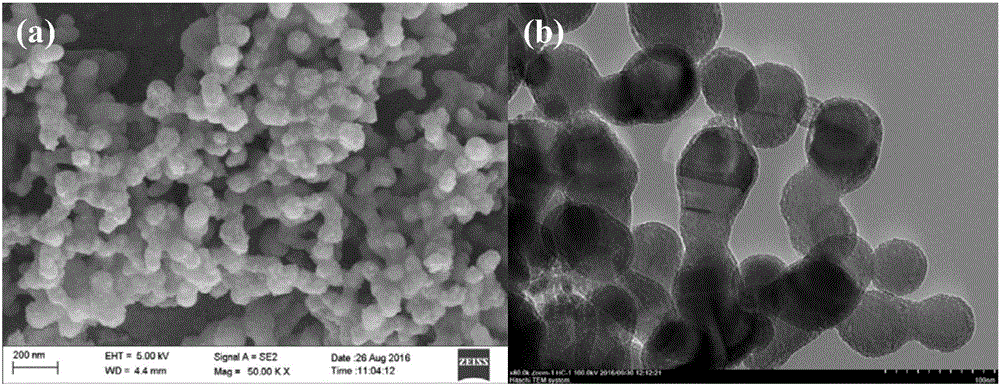

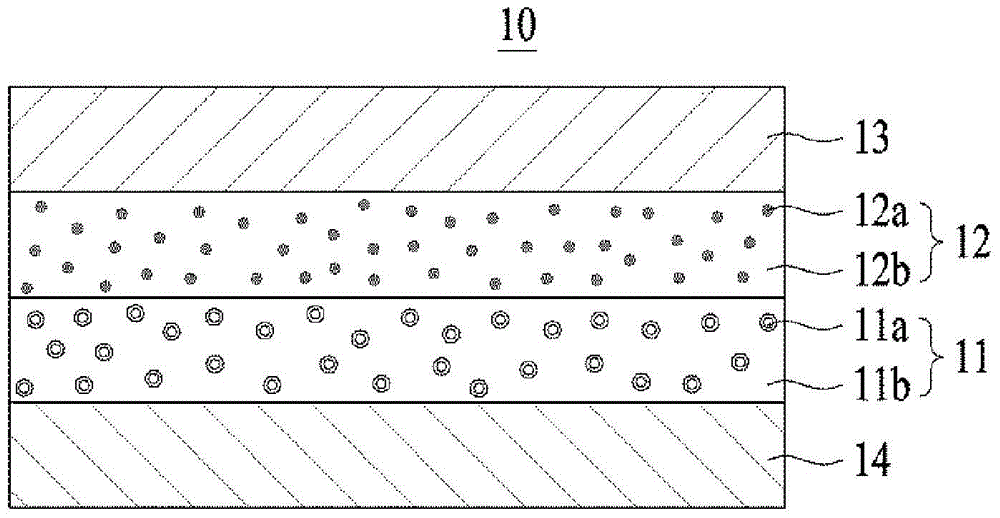

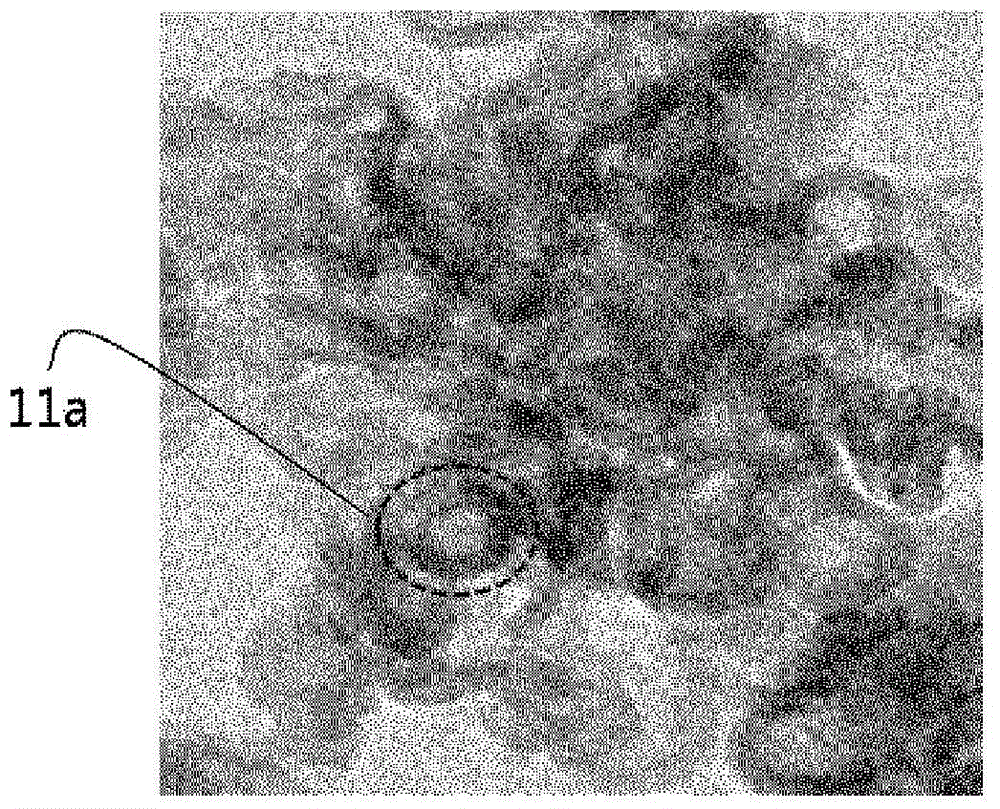

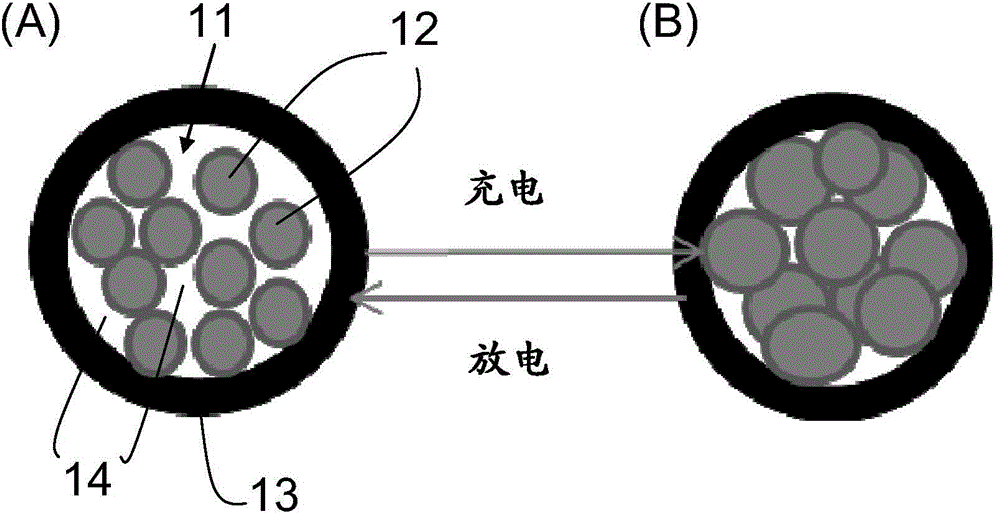

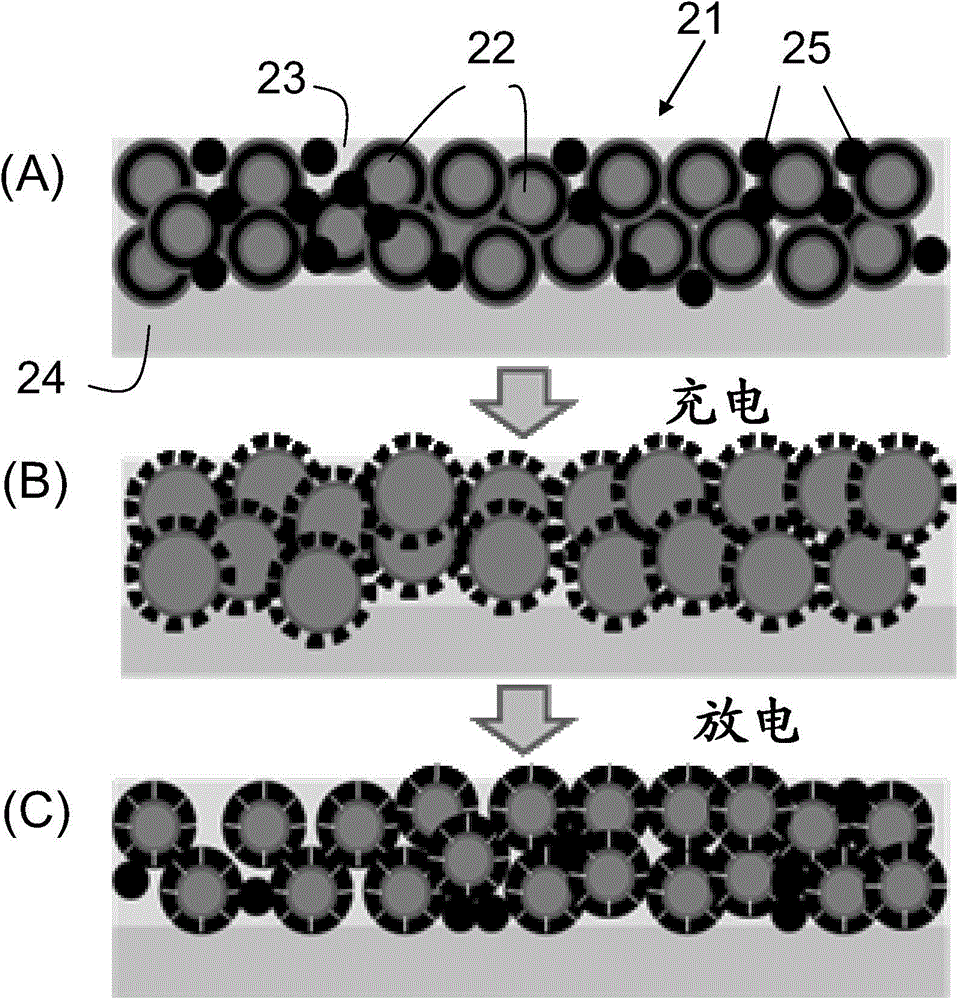

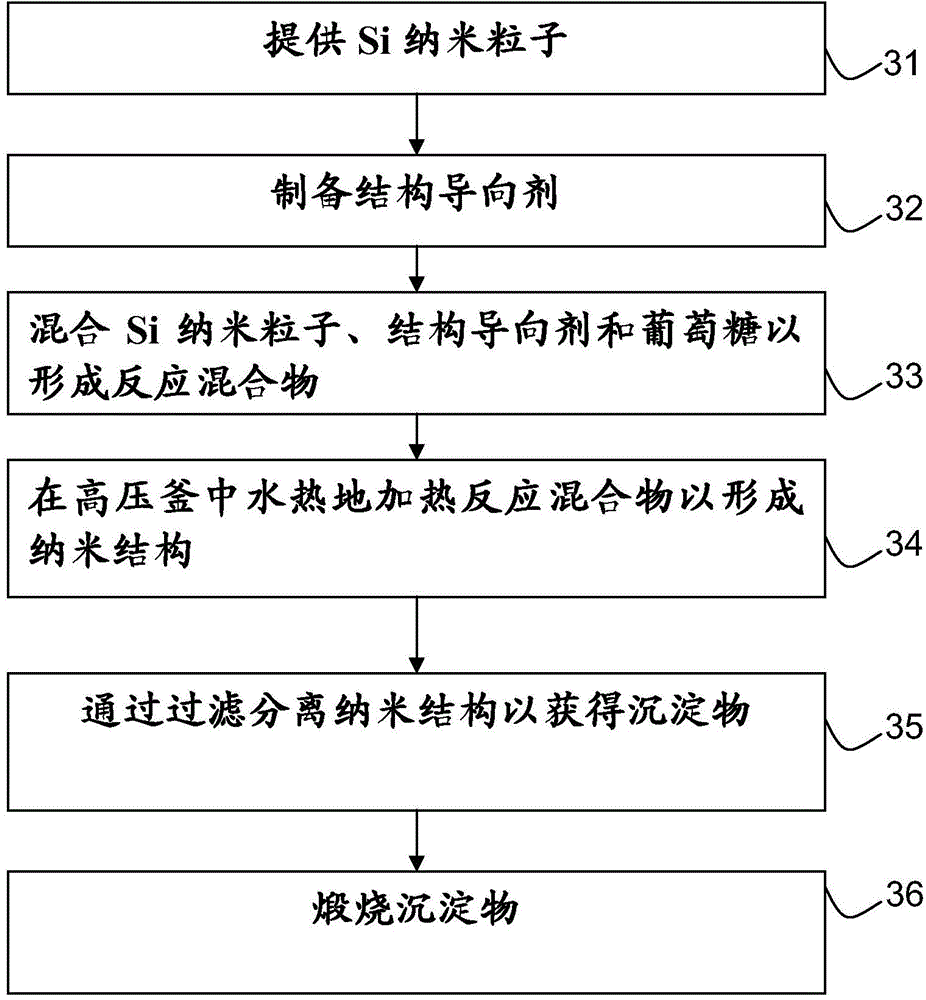

Sic core/shell nanomaterials for high performance anode of lithium ion batteries

ActiveCN104701512AAddress volume expansionImprove battery performanceElectrode thermal treatmentNegative electrodesCarbon coatingSodium-ion battery

Owner:NANO & ADVANCED MATERIALS INST

Method for preparing three-dimensional germanium/carbon nano composite film through ionic liquid electrodeposition

InactiveCN104894630AEasy deposition processReduce energy consumptionMaterial nanotechnologyCell electrodesComposite filmElectrical battery

The invention relates to a method for preparing a three-dimensional germanium / carbon nano composite film through ionic liquid electrodeposition, which relates to the method for preparing the germanium / carbon nano composite film. The method solve the technical problem that the circularity and multiplying power performance of a lithium ion battery are reduced during a charge and discharge process by a germanium cathode material of the current lithium ion battery. The method comprises the following steps: 1)electrophoretic deposition; 2)preparation of an ionic liquid electrodeposition liquid; 3)constant potential deposition; and 4)cleaning and drying. The prepared three-dimensional germanium / carbon nano composite film can effectively enhance the combination force between an active material and a current collector, volume expansion of the active material is reduced, transmission rate of the lithium ion and electron in the cathode material are increased, and the cycle performance, multiplying power performance and safety performance of the lithium ion battery are effectively increased.

Owner:HARBIN INST OF TECH

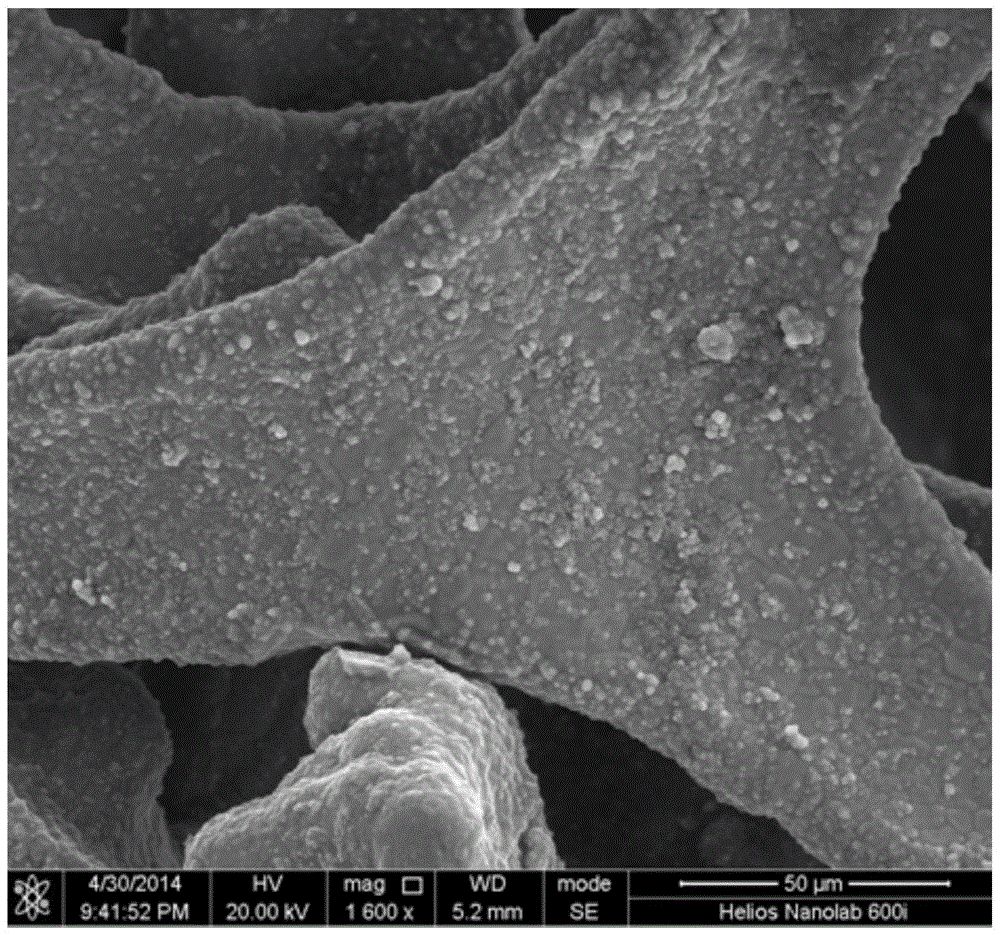

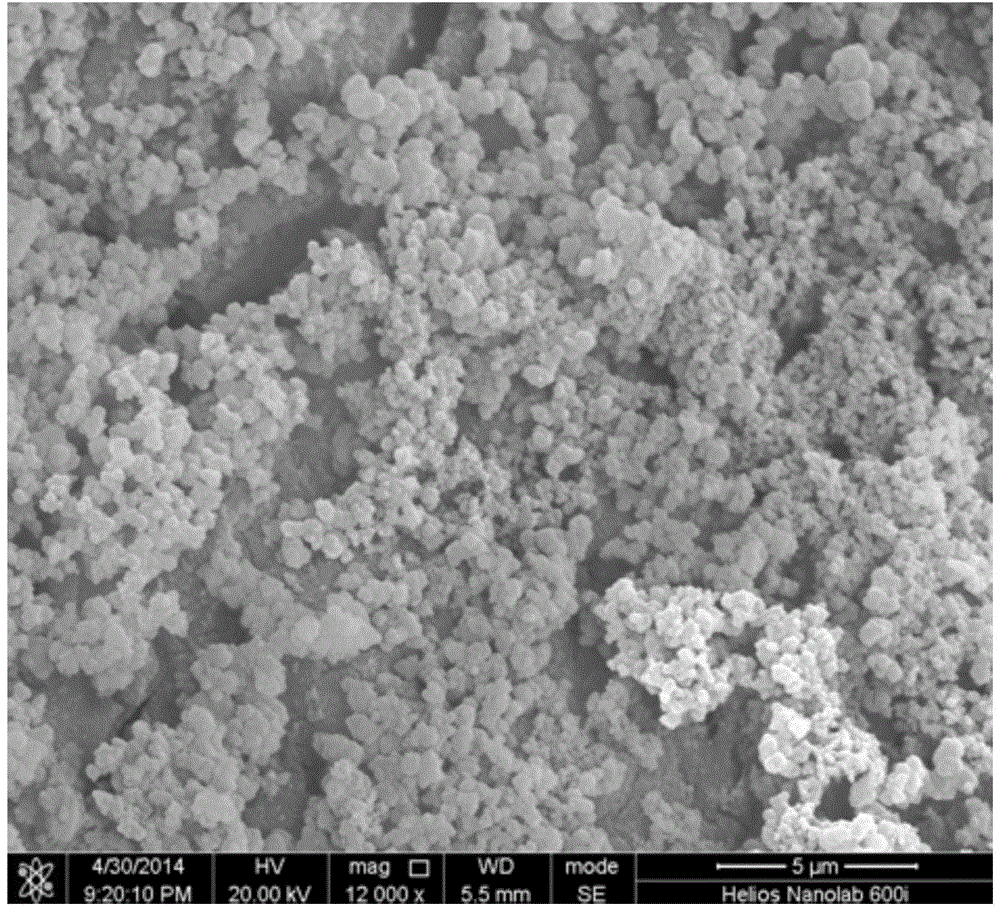

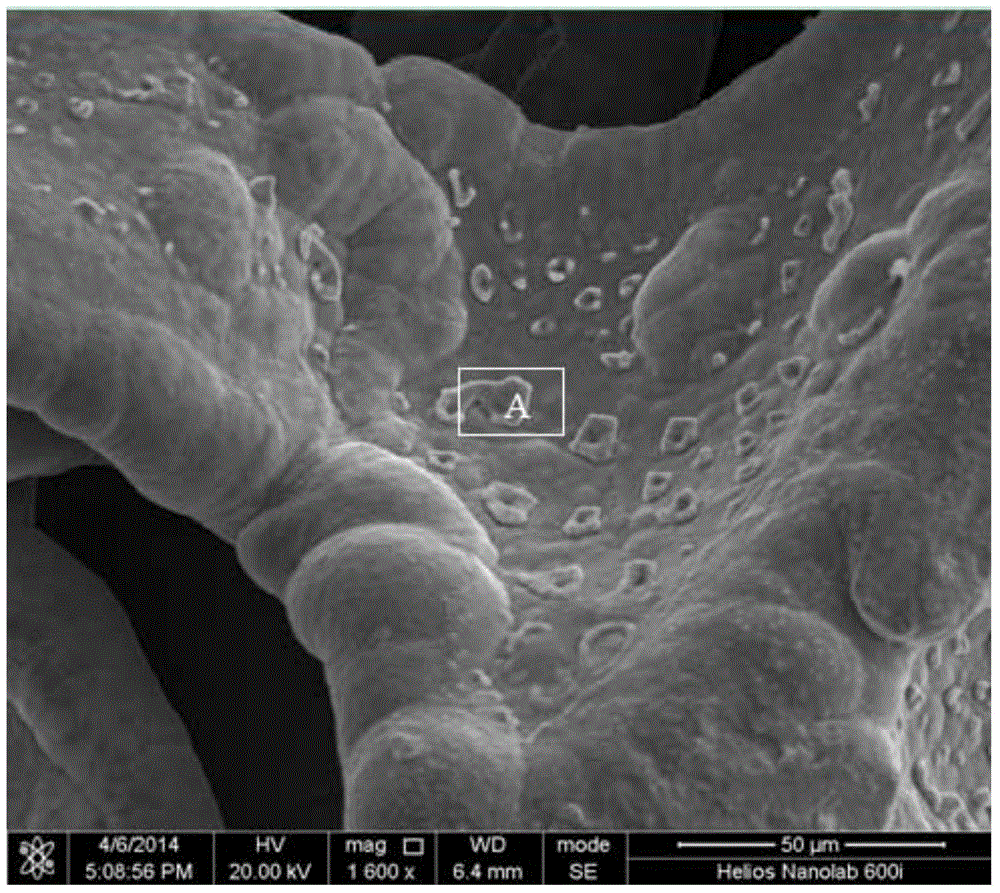

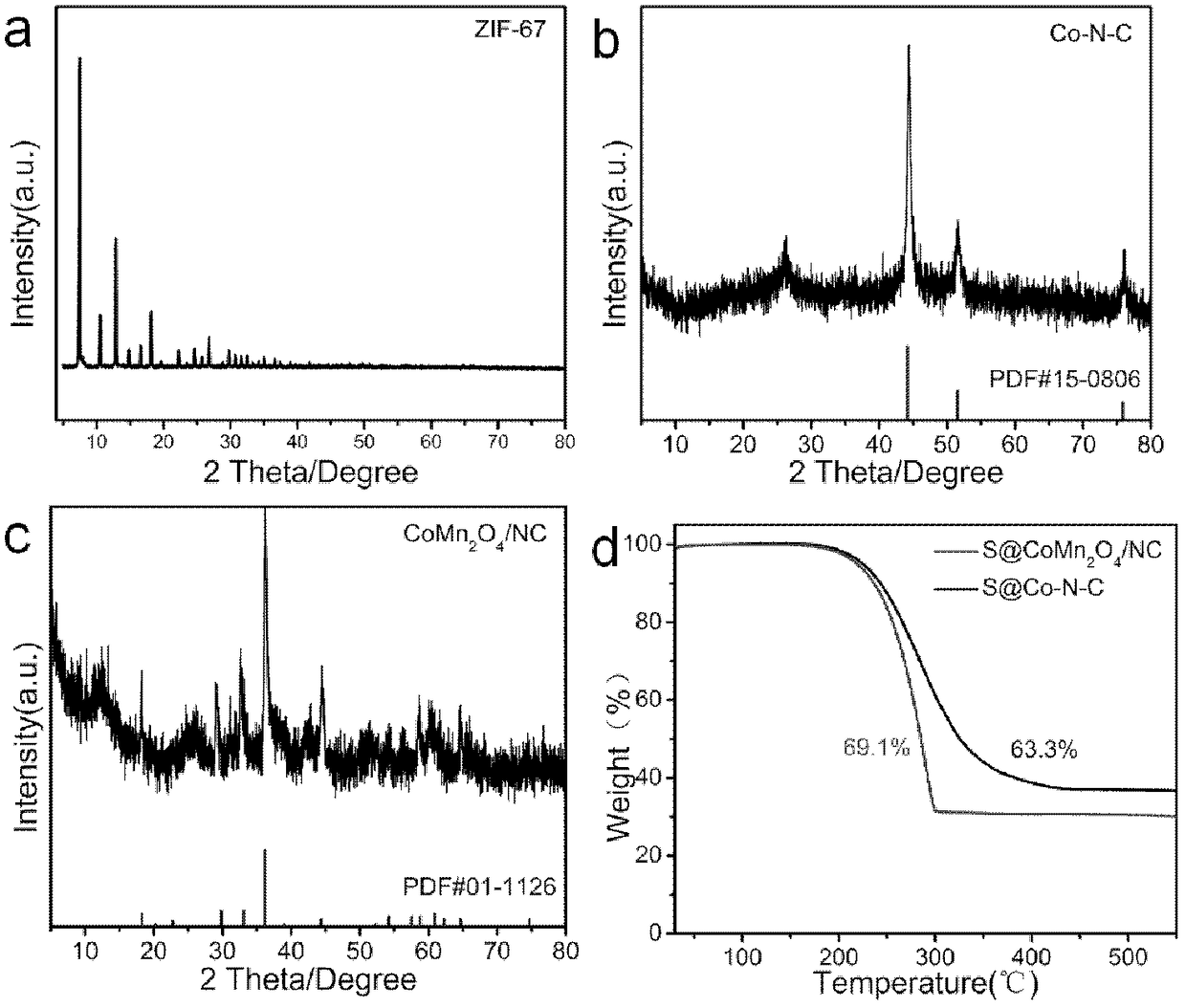

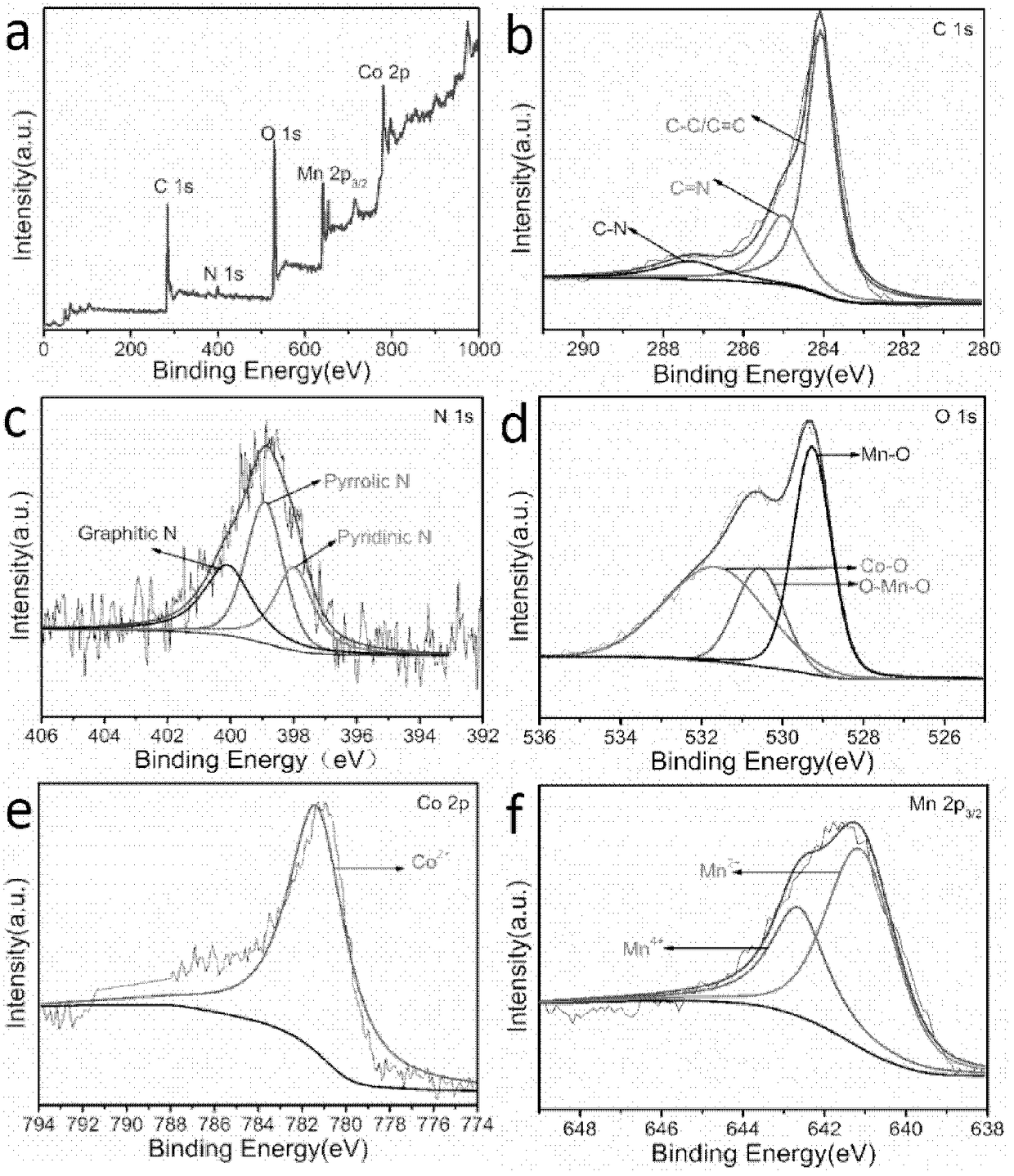

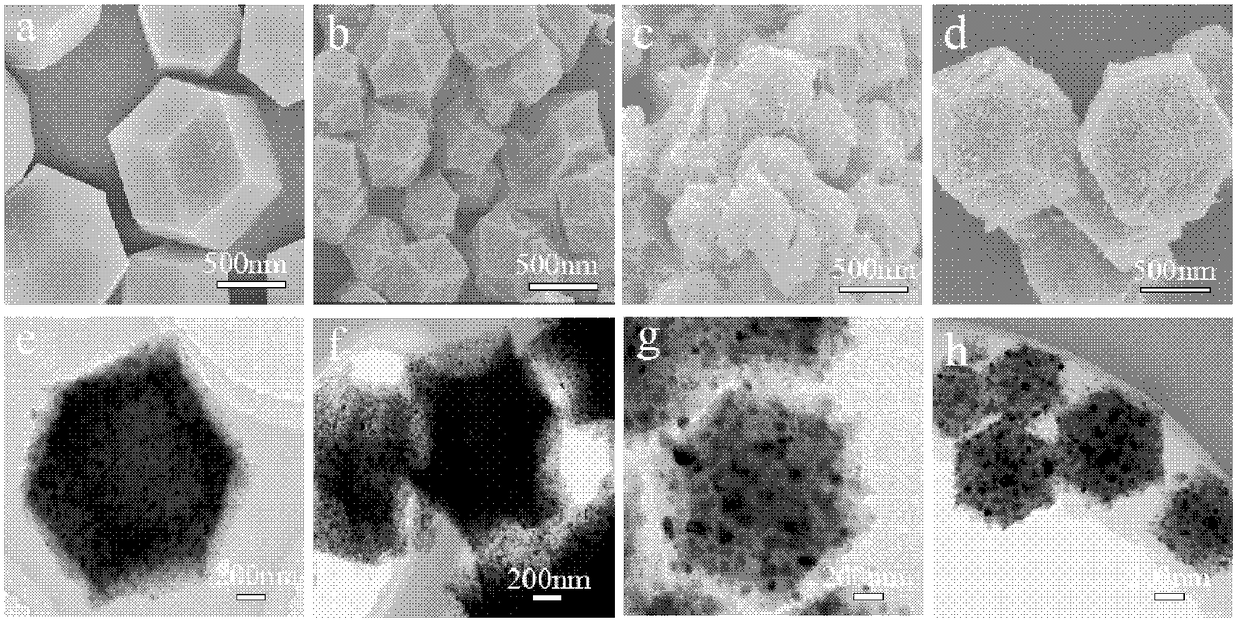

CoMn2O4/NC/S composite material as well as preparation method thereof and application thereof as Li-S secondary battery cathode material

ActiveCN108511723AHigh specific surface areaSkeleton structure is stableCell electrodesSecondary cellsMetal-organic frameworkNanoparticle

The invention discloses a CoMn2O4 / NC / S composite material as well as a preparation method thereof and application thereof as a Li-S secondary battery cathode material. The CoMn2O4 / NC / S composite material is formed by anchoring CoMn2O4 nanoparticles on NC (Nitrogen doped graphitized porous Carbon) and then compounding with sulfur. The preparation method comprises the following steps: carrying out roasting treatment on an MOF (Metal Organic Framework) material ZIF-67, thus obtaining a Co-N-C composite material; then carrying out hydrothermal reaction on the Co-N-C composite material, manganese salt and hypermanganate, thus obtaining a CoMn2O4 / NC composite material; further compounding with the sulfur, thus obtaining the CoMn2O4 / NC / S composite material. The CoMn2O4 / NC / S composite material disclosed by the invention is capable of simultaneously carrying out strong chemical adsorption and physical adsorption on polysulfide formed during a charging-discharging process of a Li-S secondary battery, and is capable of effectively inhibiting dissolution loss of the polysulfide, reducing the generation of a shuttle effect and prolonging the service life of the Li-S secondary battery. Meanwhile, the preparation method adopts low-cost and low-toxicity Mn to partially replace expensive and toxic Co for being applied to the Li-S secondary battery, and important innovation and practice significances are obtained.

Owner:CENT SOUTH UNIV

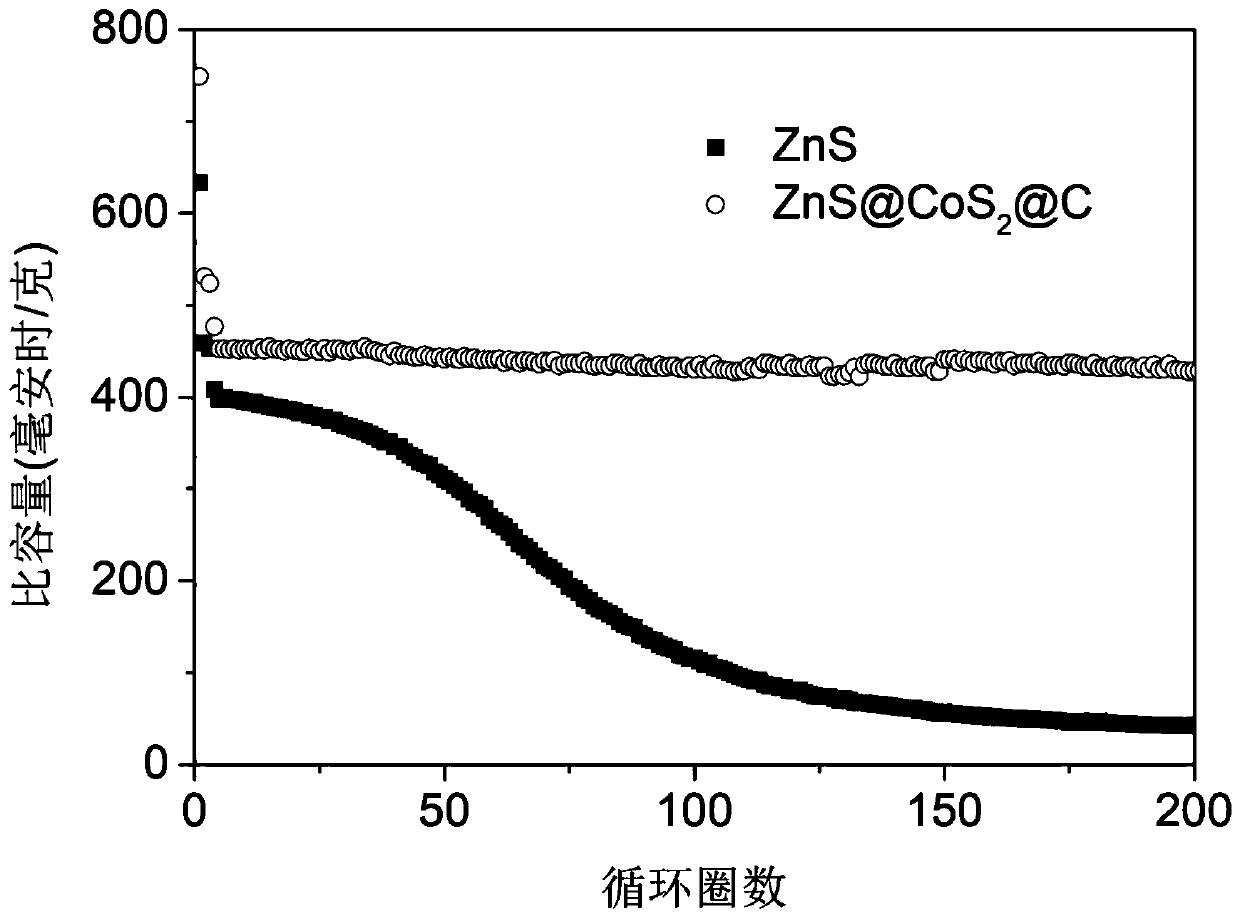

Preparation method of sodium ion battery negative electrode material of zinc-cobalt bimetal sulfide

ActiveCN110828785AImprove efficiencyImprove Coulombic efficiencyCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of material chemistry, particularly discloses a preparation method of a sodium ion battery negative electrode material of zinc-cobalt bimetal sulfide, andsynthesizes a ZnS@CoS2@C heterostructure by a simple and convenient method so as to enhance electrochemical property of the sodium ion battery. The method comprises steps that ZnO precursor is synthesized; the ZnS@CoS2@C is obtained by growing a layer of Co-MOF structure on the surface through performing hydrothermal vulcanization and calcining in an Ar atmosphere, and the ZnS@CoS2@C has a uniformheterogeneous interface structure, so the ion diffusion kinetics is improved, electron conductivity is improved, and electrochemical performance of the sodium ion battery is further improved. Compared with pure ZnS, the ZnS@CoS2@C heterostructure is utilized as SIB of a negative electrode, so the specific capacity can be remarkably improved, and excellent cycling stability and rate performance are shown.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

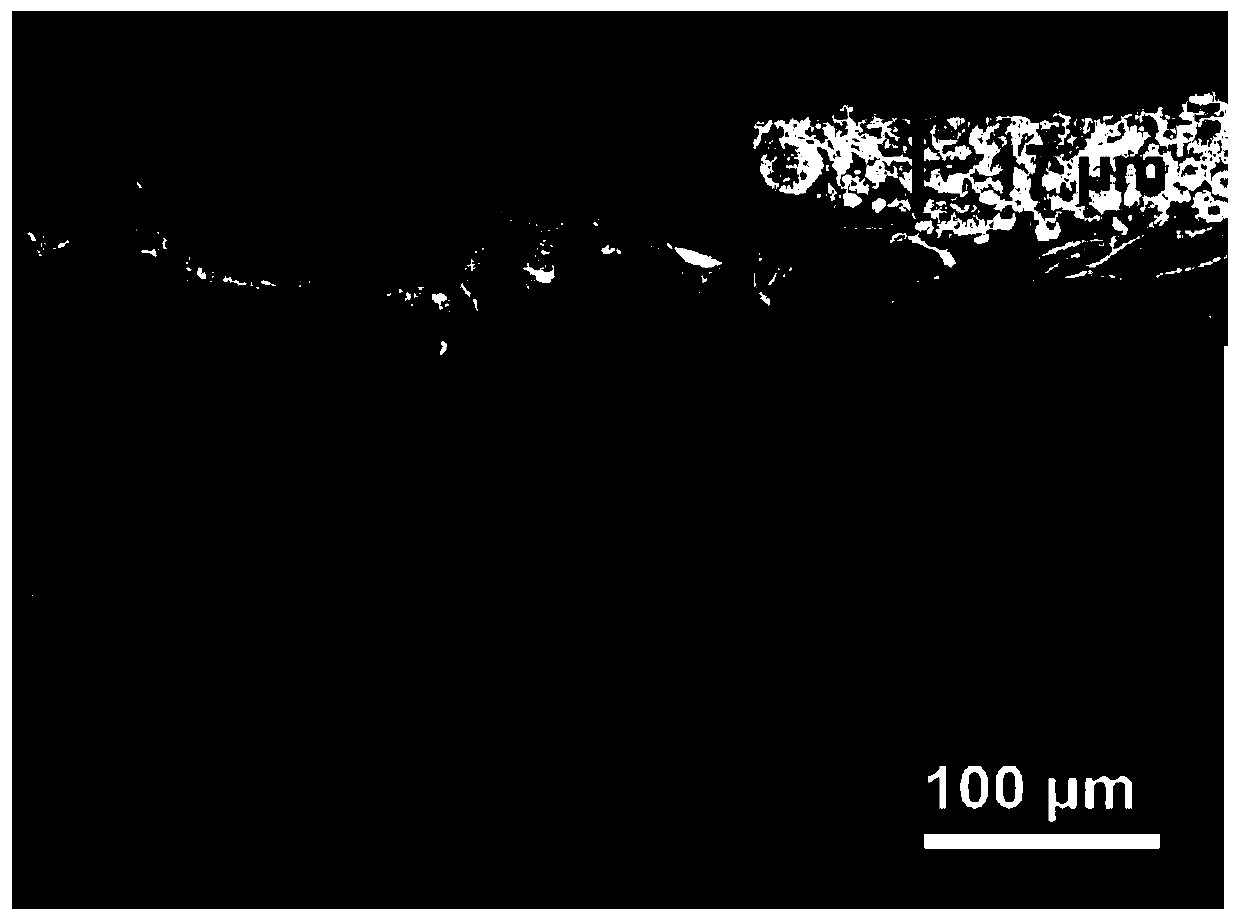

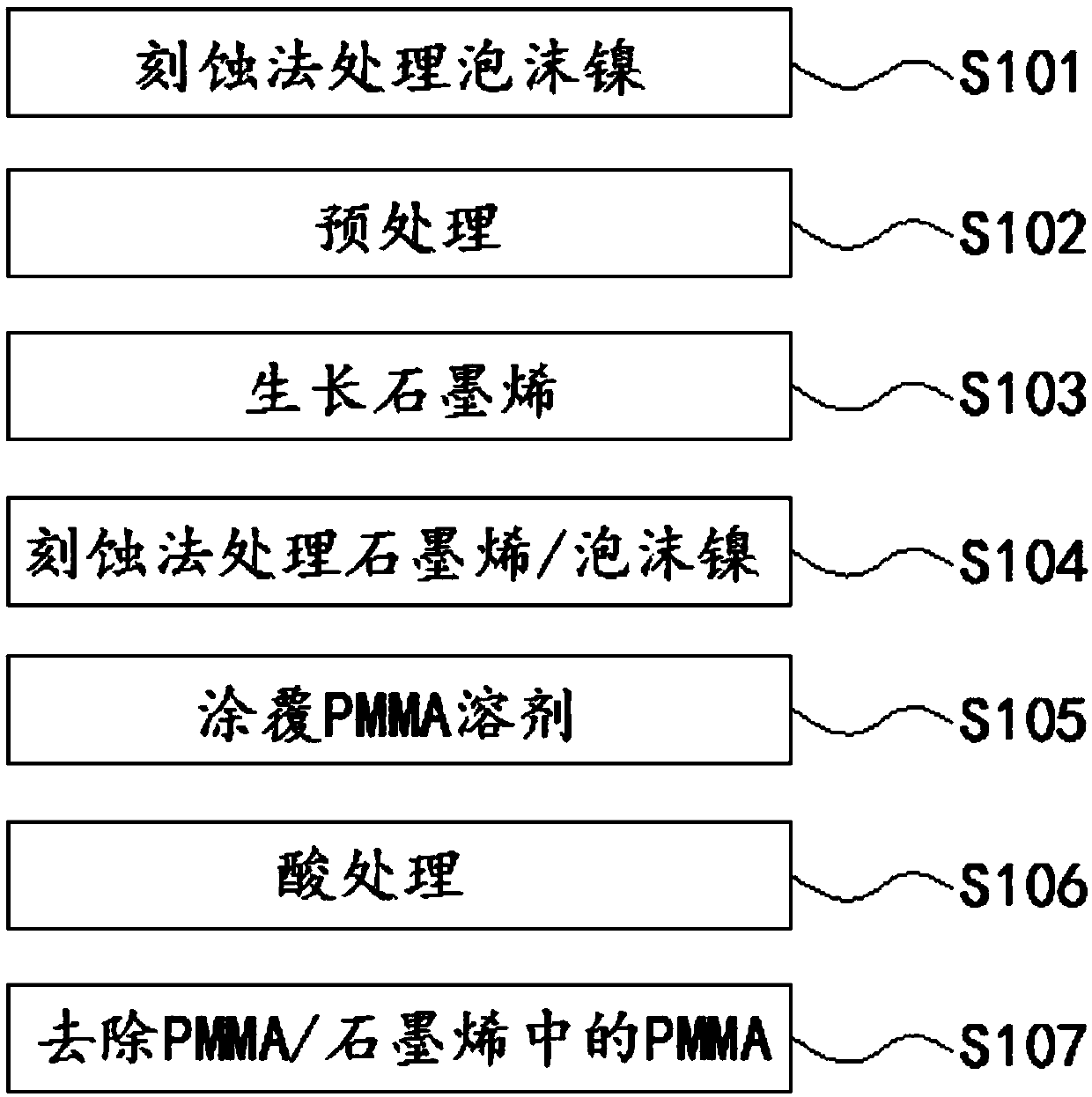

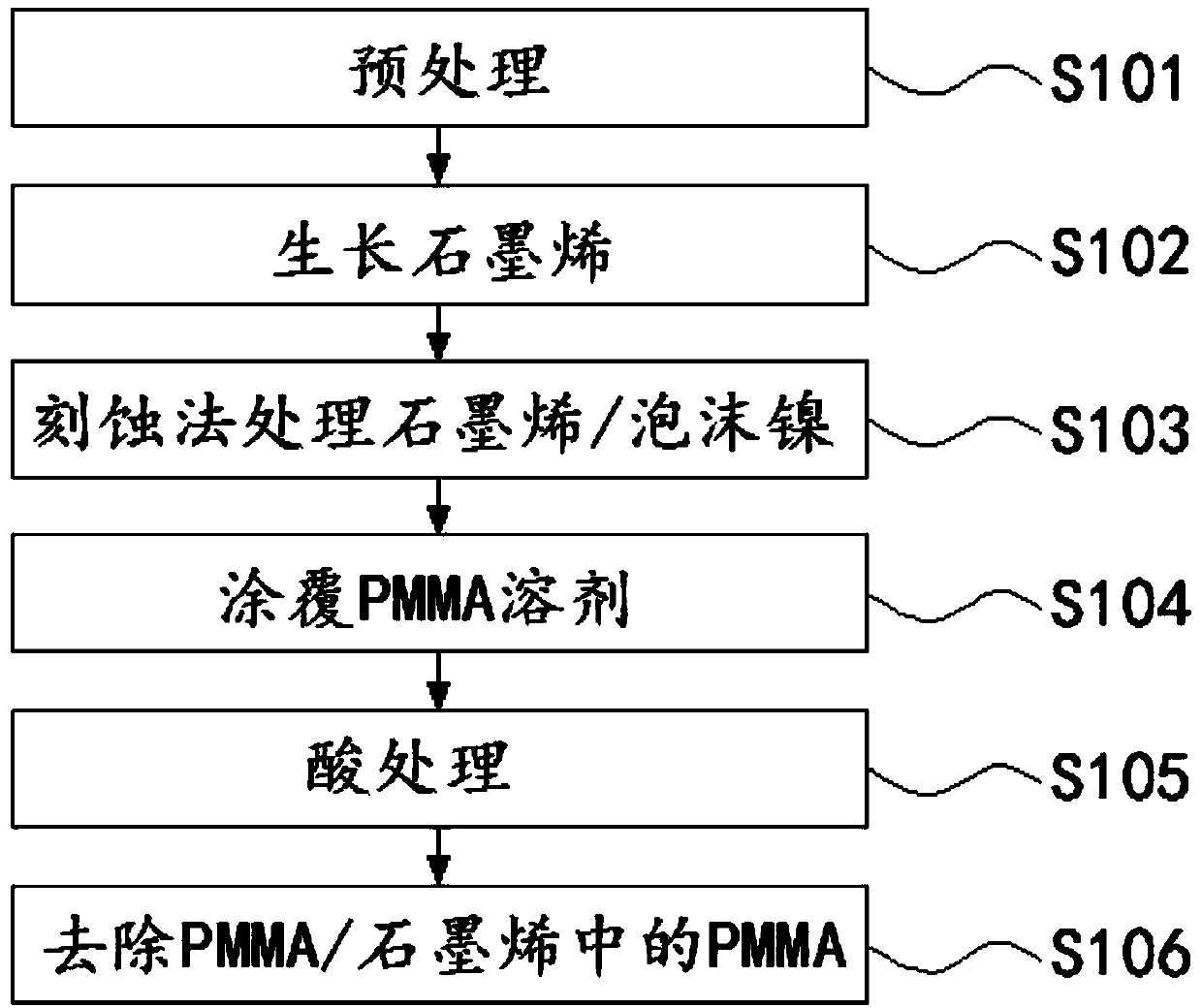

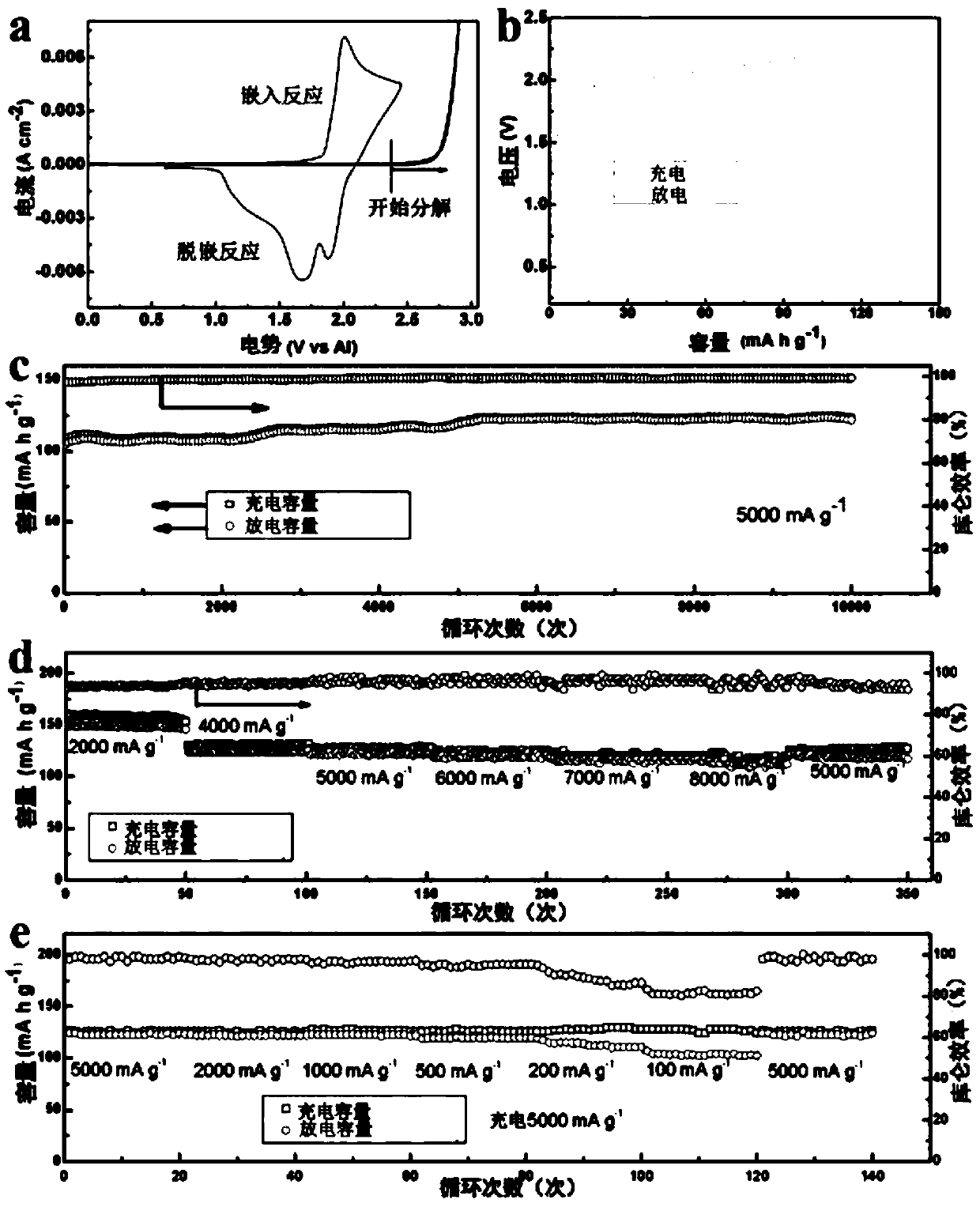

Preparation method of aluminum-ion battery positive electrode material

The invention discloses a preparation method of an aluminum-ion battery positive electrode material. The method comprises the following steps of firstly, processing foamed nickel by an etching method;secondly, pre-processing a surface of the foamed nickel; thirdly, growing graphene on the surface of the foamed nickel to form a graphene / foamed nickel structure; fourthly, etching the graphene / foamed nickel; fifthly, coating a layer of PMMA solvent on a surface of the graphene / foamed nickel, and performing baking and film formation to obtain a PMMA / graphene / foamed nickel structure; sixthly, performing acid processing on the PMMA / graphene / foamed nickel, and dissolving the foamed nickel to obtain a PMMA / graphene structure; and finally, removing PMMA in the PMMA / graphene to obtain foam structure-based graphene. The synthesis of the aluminum-ion battery positive electrode material without a binding agent is achieved by chemical vapor deposition and an etching technology, the aluminum-ion battery positive electrode material has ultra-large capacity, relatively low charging voltage and excellent cycle stability, and the volume expansion of the material during the charge-discharge process is prevented.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

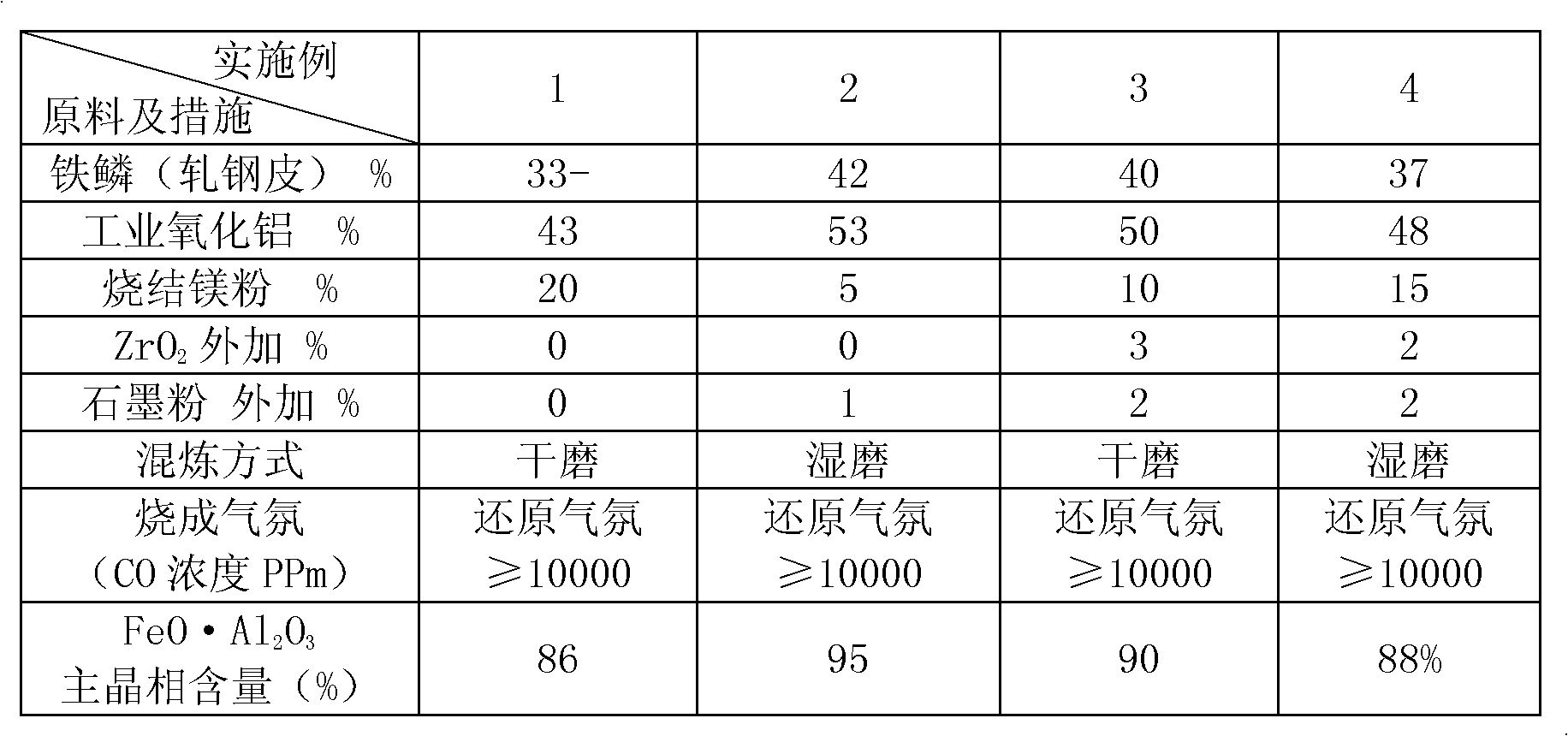

Industrially-synthesized magnesium-iron-aluminum compound spinel and synthetic method thereof

The invention relates to an industrially-synthesized magnesium-iron-aluminum compound spinel and a synthetic method thereof, belonging to the technical field of refractory materials. The compound spinel comprises the following chemical components in percentage by weight: 25-45 percent of Fe2O3, 35-55 percent of Al2O3, 0-30 percent of MgO and 0-5 percent of ZrO2. The synthetic method comprises the following steps of: preparing materials, blanking and sintering, wherein an industrial kiln is taken as a sintering kiln, and the temperature is raised freely below 600 DEG C; and transferring into a reducing atmosphere in the process of raising the temperature from 600 DEG C to 1,200 DEG C, preserving heat at the sintering temperature between 600 DEG C and 1,200 DEG C for 3-8 hours when the CO concentration is over 10,000 PPm, preserving the reducing atmosphere, lowering the temperature to 800-600 DEG C and naturally cooling to room temperature. The synthetic method is simple in synthetic process, convenient for industrial control and easy for mass production.

Owner:ZIBO GT INDAL CERAMICS

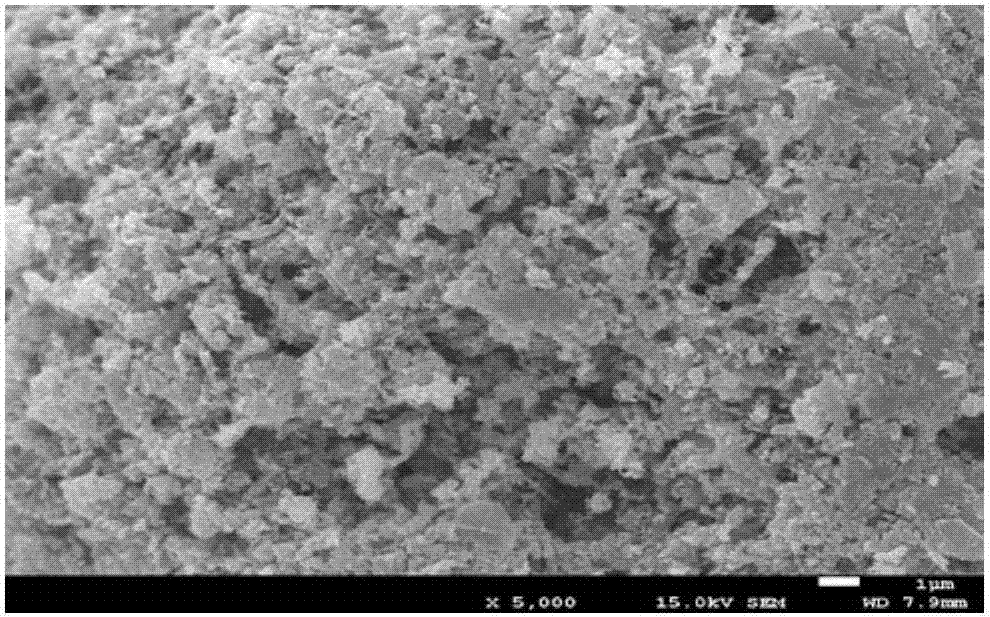

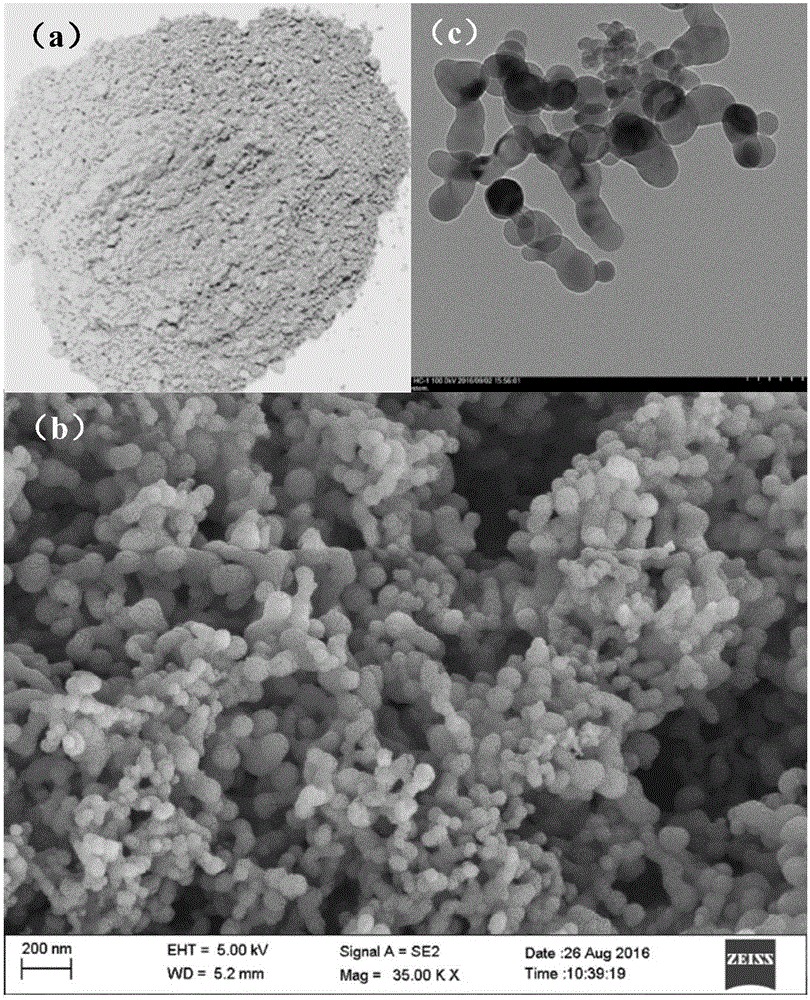

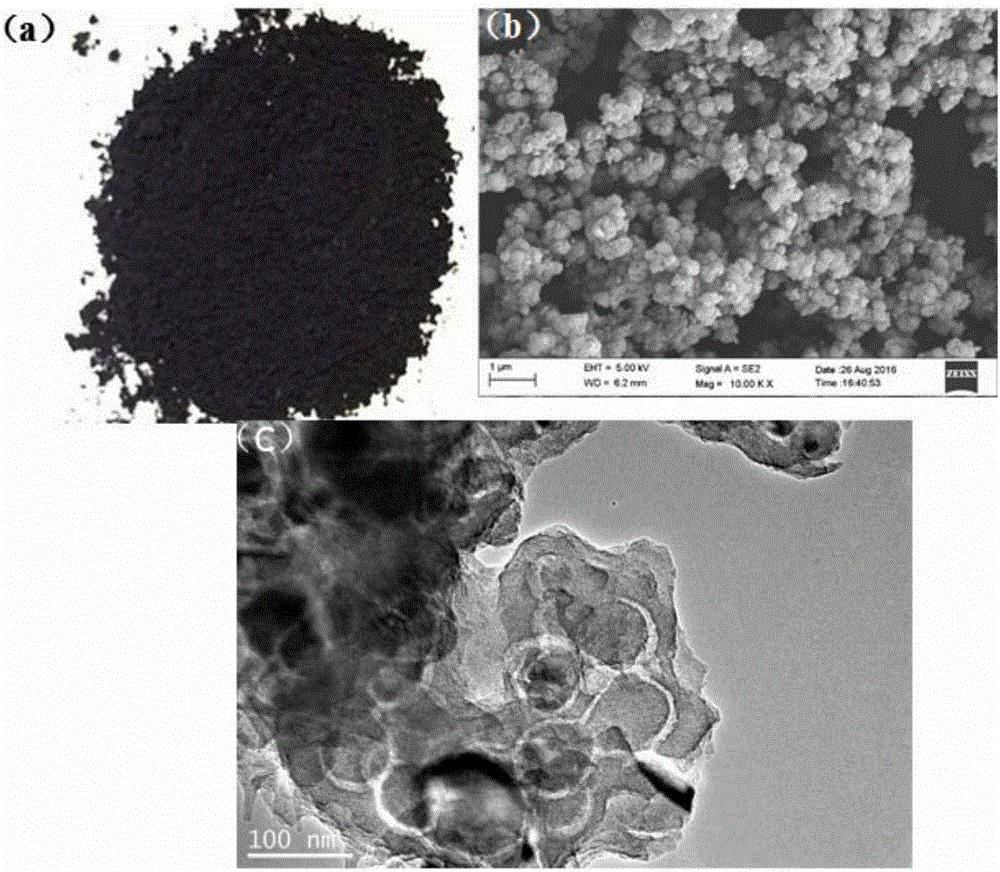

Nano silicon alloy based composite negative pole material and preparation method thereof

ActiveCN106058201AGood effectAddress volume expansionNegative electrodesSecondary cellsNano siliconMicrosphere

The invention discloses a nano silicon alloy based composite negative pole material. The nano silicon alloy based composite negative pole material has a three-shell layer structure, wherein a core layer is a nano carbon material coated nano silicon alloy core layer, and a three-shell layer is of a three-shell layer structure and is a conductive polymer film layer which is prepared by taking Fe3O4 nano-microspheres as sacrificial templates. The invention further discloses a preparation method of the nano silicon alloy based composite negative pole material. According to the preparation method, firstly, a nano silicon alloy material is prepared by a ball milling method and is subjected to wet grinding with a nano carbon material, then, hot coating is carried out so as to form the nano carbon material coated nano silicon alloy core layer, and then, the conductive polymer film layer with the three-shell layer structure is formed on the surface of the core layer by using a sacrificial Fe3O4 microsphere template method, so that the volume expansion of the nano silicon alloy material is effectively buffered. The nano silicon alloy based composite material disclosed by the invention has the advantages of high specific capacity, excellent cycle performance and rate performance, high tap density, and the like. The preparation method of the negative pole material, provided by the invention, is simple, environmentally friendly and pollution-free.

Owner:威海南海碳材料有限公司 +1

Silicon-based slurry and preparation method and application thereof

ActiveCN110148718AIncrease capacityAddress volume expansionNegative electrodesSecondary cellsCyclic processSlurry

The invention relates to the field of lithium ion batteries, in particular to silicon-based slurry and a preparation method and application thereof. Raw materials of the silicon-based slurry comprisea silicon-based material, a non-silicon-based ceramic material, a carbon material, a curing agent, a dispersing agent, a defoaming agent and a solvent, and the silicon-based slurry is obtained throughstirring, mixing, dispersing and filtering in batches. The carbon material and the silicon-based material are compounded, the capacity of the electrode material is improved through the silicon-basedmaterial, the volume expansion of the silicon material in the circulation process is inhibited to a certain extent by use of the carbon material, and meanwhile, the conductivity, the electron mobilityand the electrochemical stability of the silicon-based slurry are improved through the carbon material. The added ceramic-based material can play a role of a framework, so that the expansion of the silicon material is further inhibited, and the cycle performance is improved. The silicon-based slurry serves as a lithium ion battery negative electrode material, it is facilitated that the battery capacity and the high capacity retention rate cycle index can be improved, and the electrochemical performance is improved.

Owner:深圳市沃伦特新能源有限公司

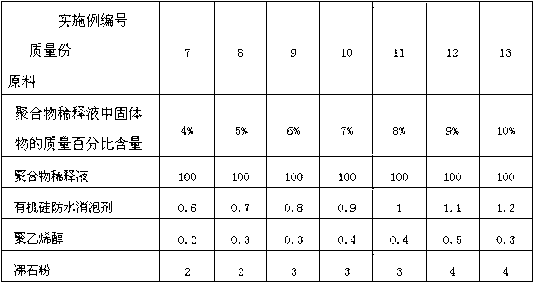

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

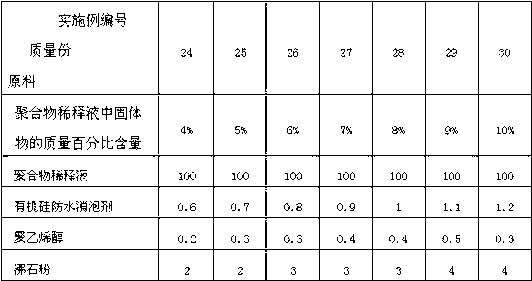

ActiveCN103073210AFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetatePolyvinyl alcohol

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

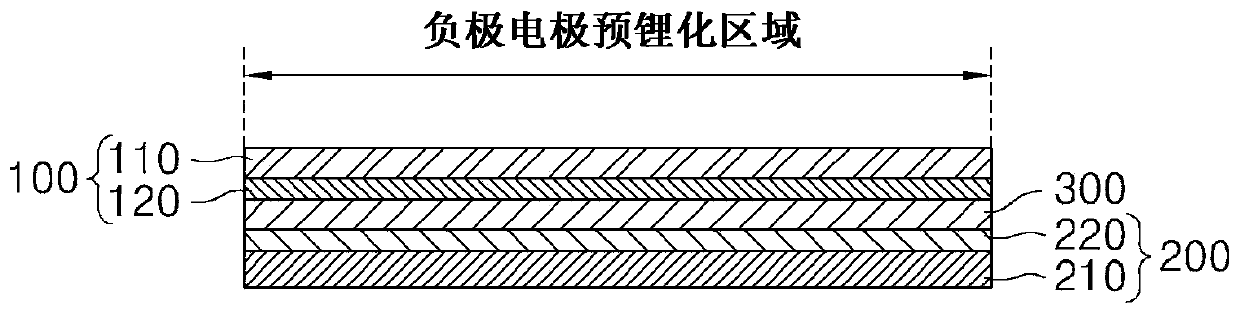

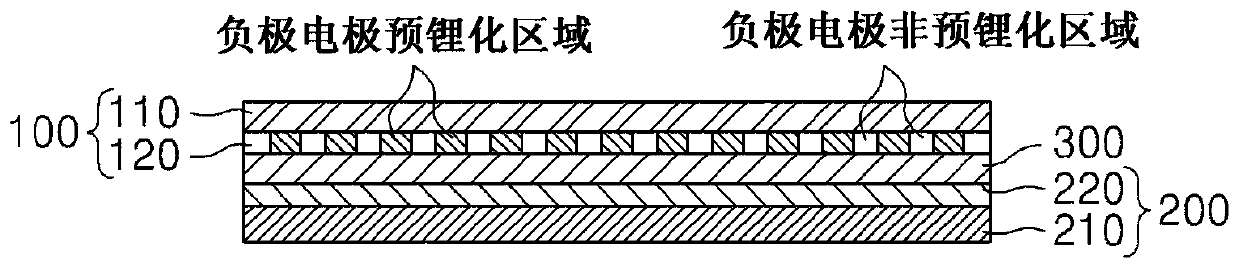

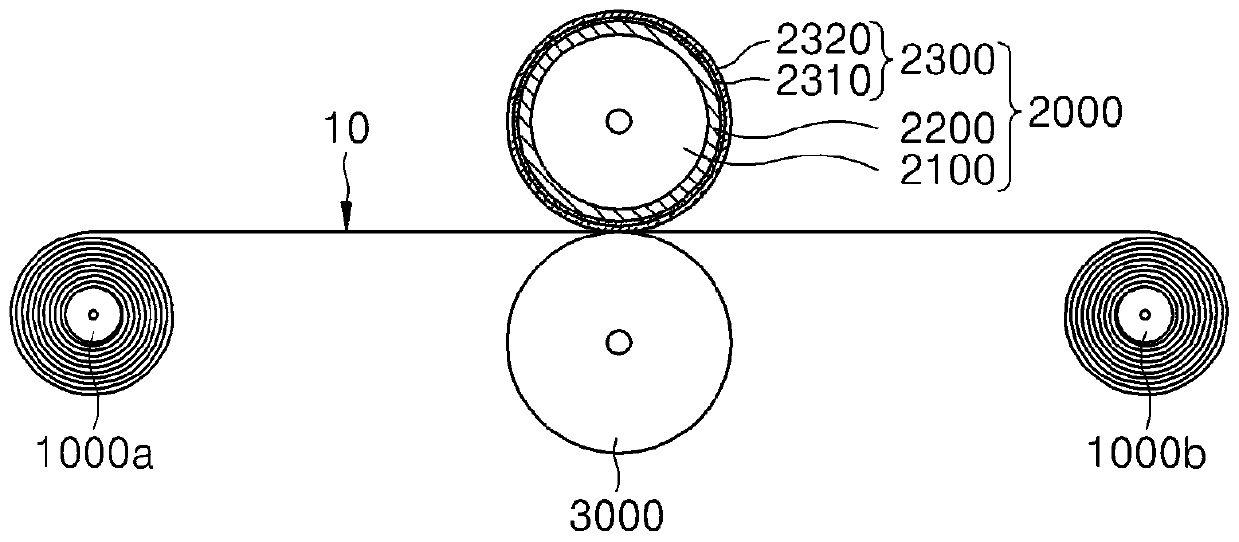

Pre-lithiation apparatus, method for manufacturing negative electrode part using same, and negative electrode part

ActiveCN110476275AReduced process time for pre-lithiationIncrease productionElectrode rolling/calenderingFinal product manufactureLithiumBiomedical engineering

By using a pre-lithiation apparatus according to one embodiment of the present invention, the processing time for pre-lithiating a negative electrode can be shortened compared to conventional technologies, and thus productivity can be increased. Also, as a lithium roll comprises an elastic member, pre-lithiation can be performed thoroughly and evenly.

Owner:LG ENERGY SOLUTION LTD

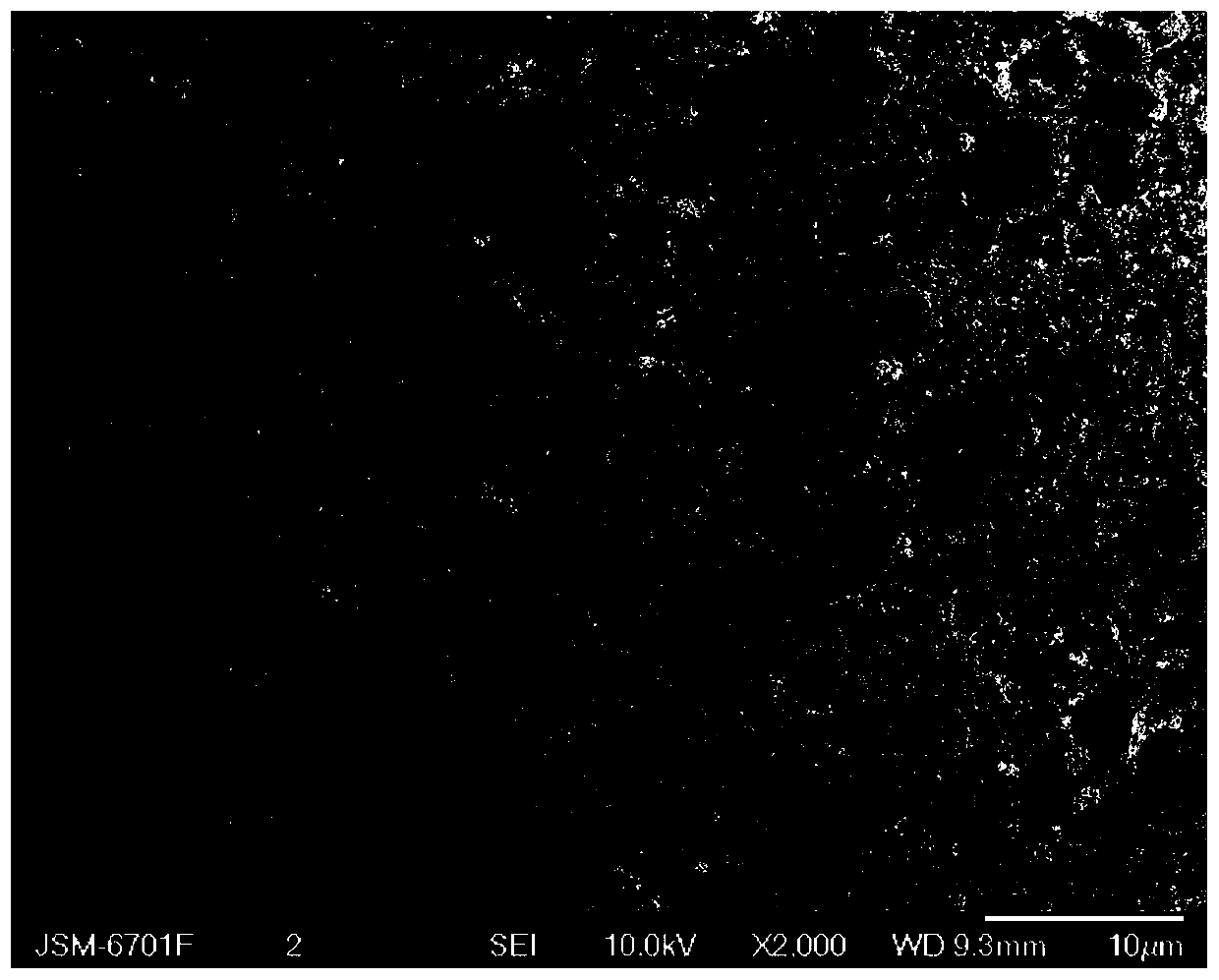

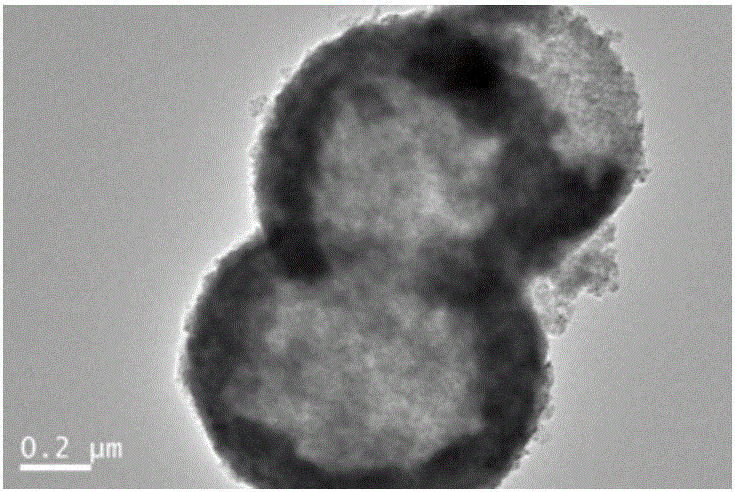

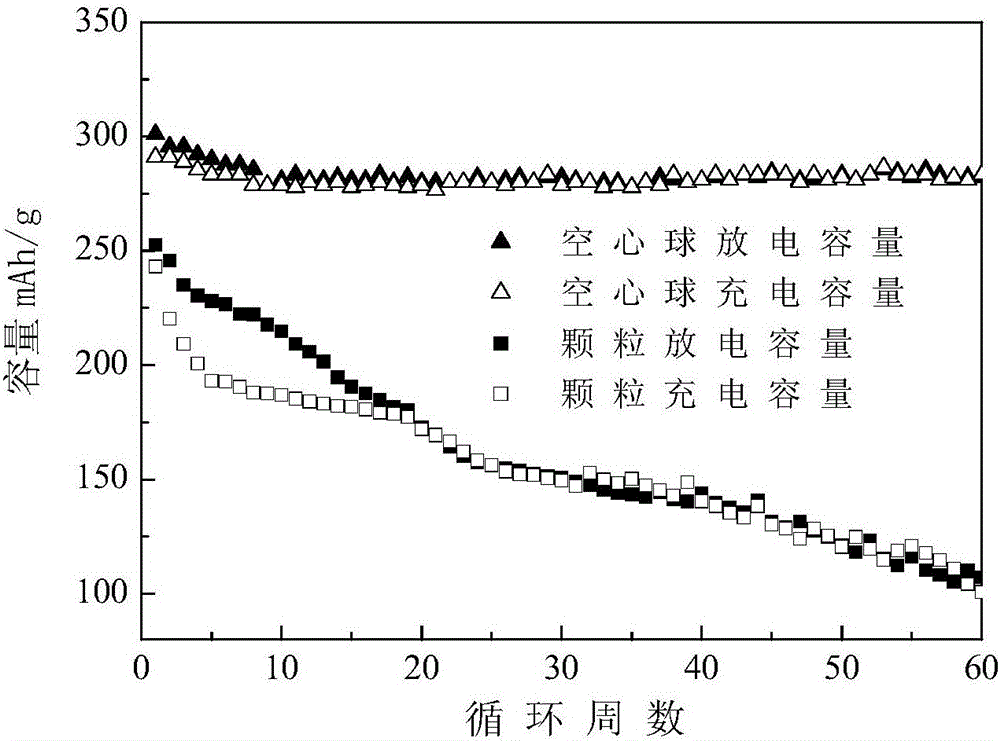

Preparation method and application of hollow sphere nickel sulfide positive electrode material

ActiveCN106654262ALarge specific surface areaAddress volume expansionCell electrodesSecondary cellsCharge dischargeNickel sulfide

The invention relates to the field of a functional material, in particular to a preparation method and application of a hollow sphere nickel sulfide positive electrode material. In the hollow sphere nickel sulfide material obtained through the method, the specific surface area of the material is effectively expanded, and the initial charge-discharge capacity of the battery can be correspondingly improved; and meanwhile, by such a hollow sphere structure, the problem of material volume expansion during battery circulation can be effectively solved, and the cycle performance of the battery is improved.

Owner:CHANGZHOU UNIV

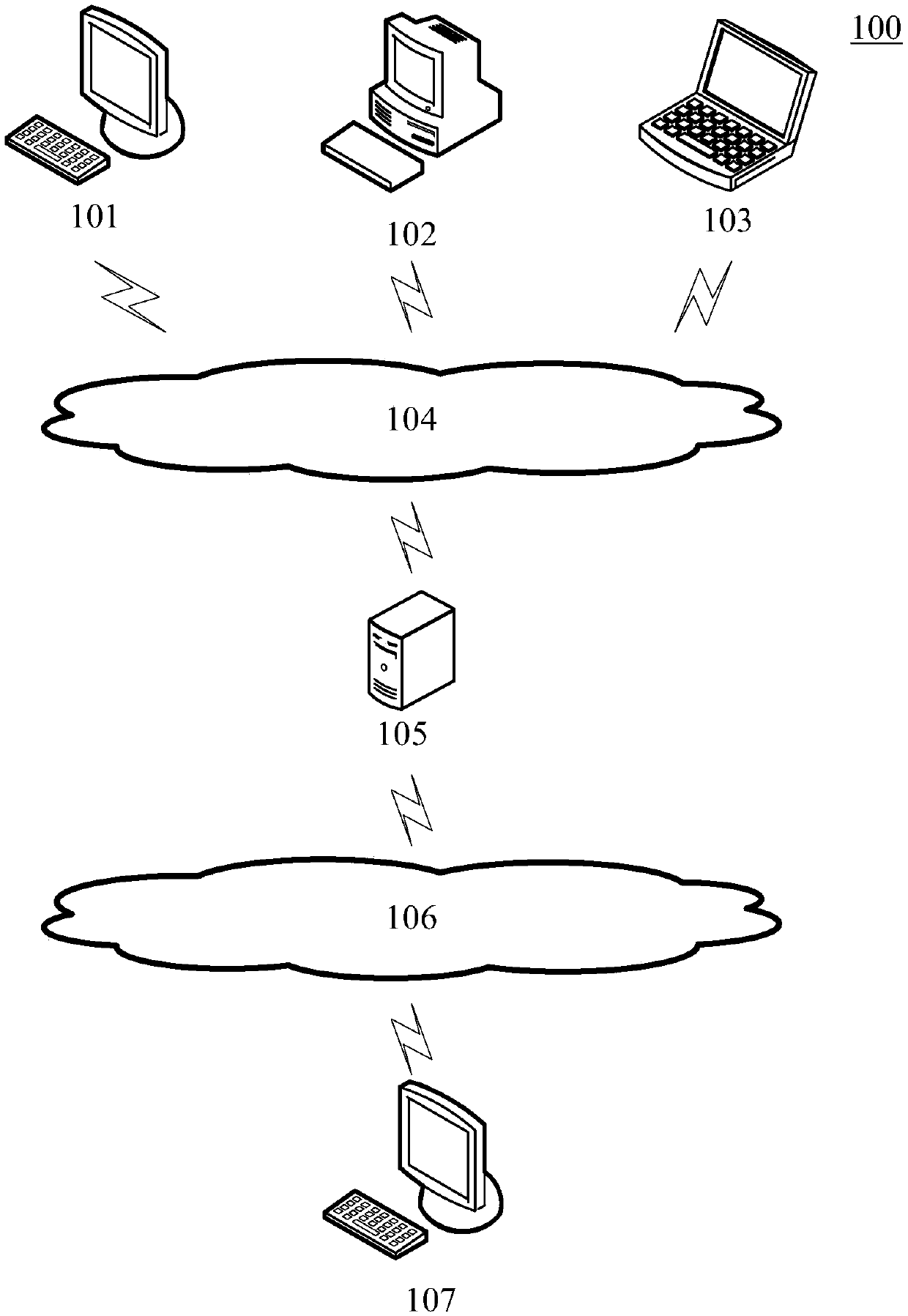

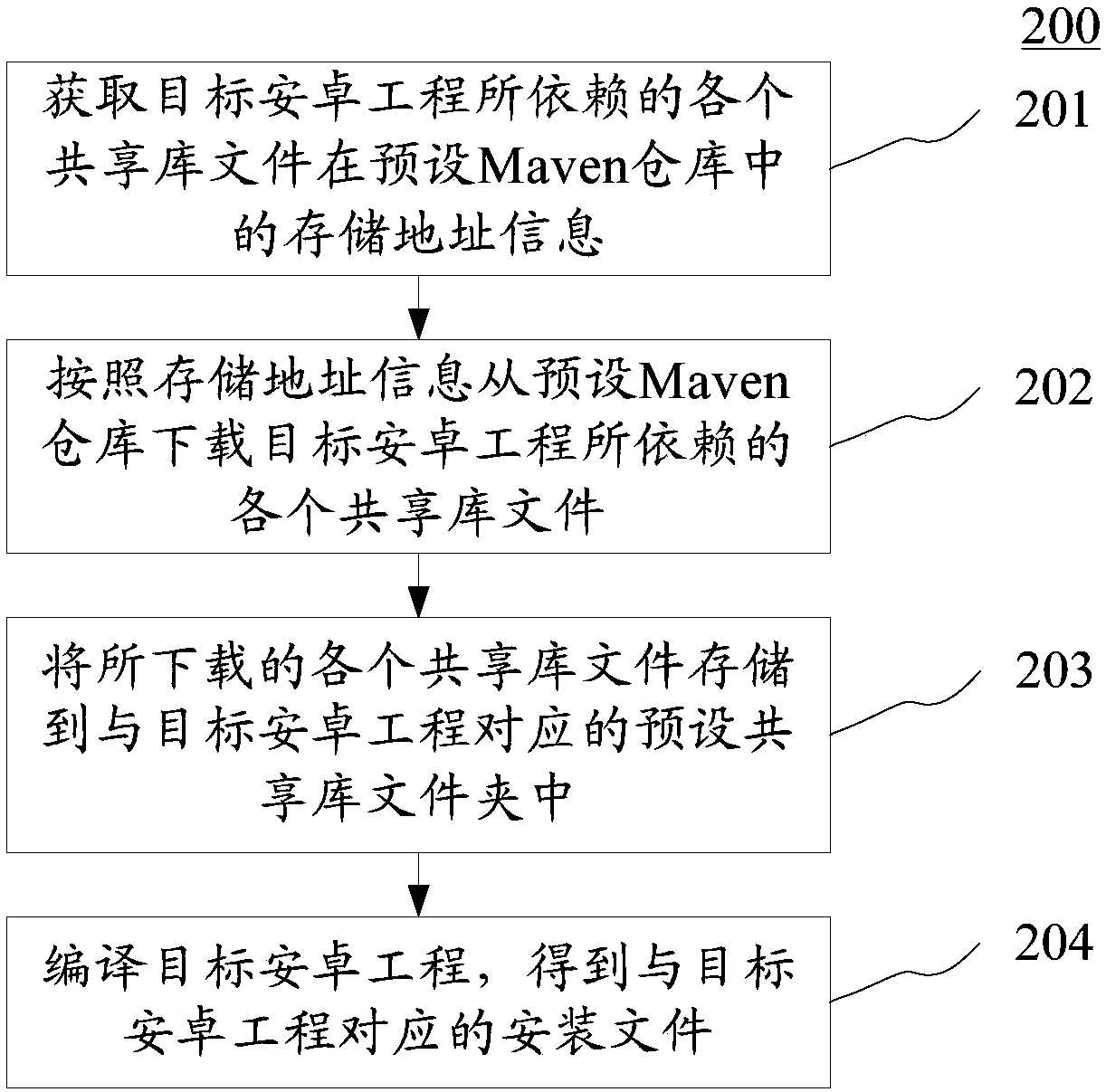

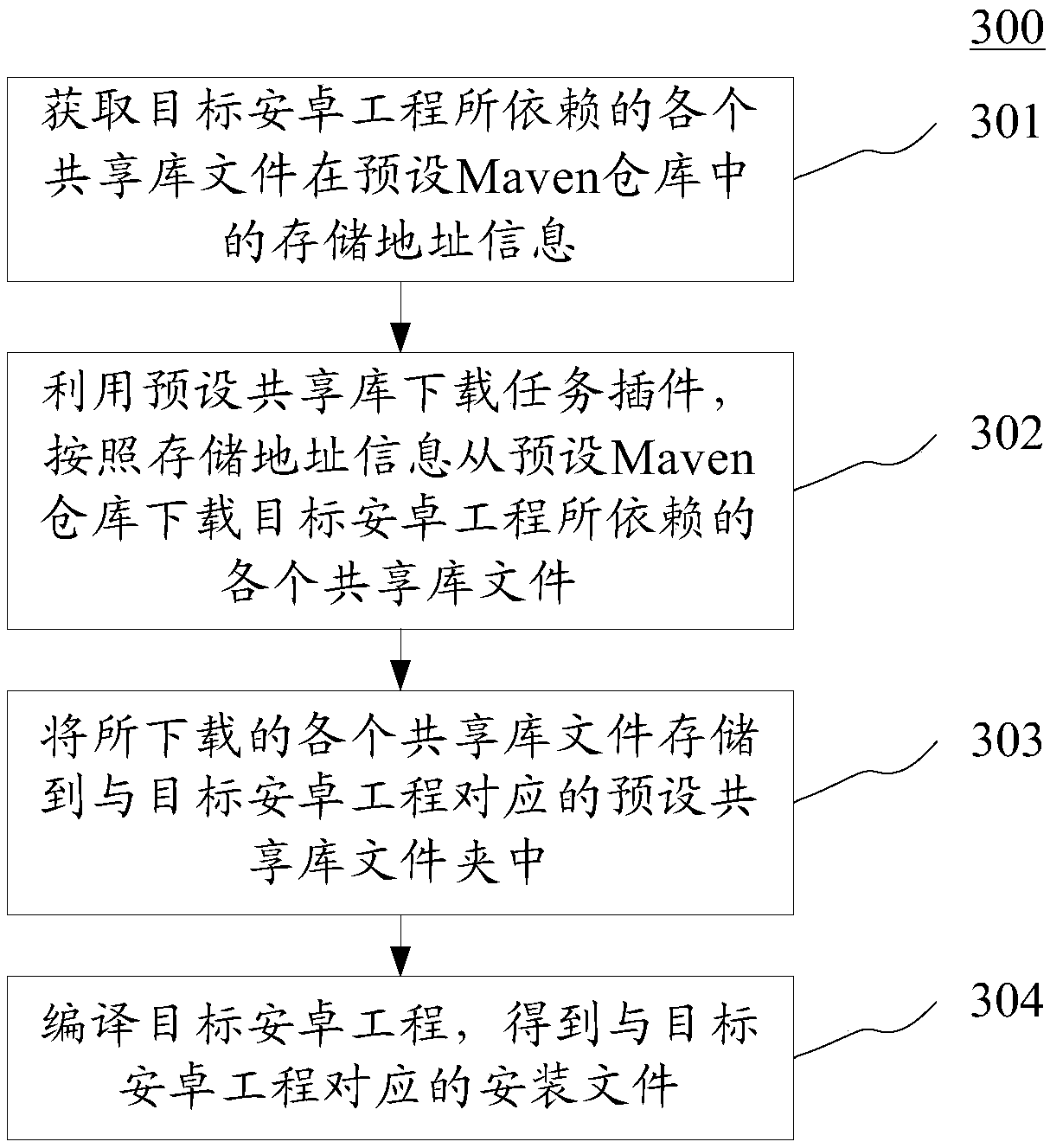

Method and device for compiling Android project

PendingCN110554876AAddress volume expansionVersion controlSoftware deploymentSoftware engineeringFile storage

The embodiment of the invention discloses a method and a device for compiling an Android project. A specific embodiment of the method comprises the steps of obtaining storage address information of each shared library file depended by a target Android project in a preset Maven warehouse; downloading each shared library file on which the target Android project depends from a preset Maven warehouseaccording to the storage address information; storing each downloaded shared library file into a preset shared library folder corresponding to the target Android project; and compiling the target Android project to obtain an installation file corresponding to the target Android project. According to the implementation mode, the Android project is compiled under the condition that the size of the code warehouse is reduced.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Carbon-based compounded ferric cyanamide material and preparation method thereof

ActiveCN108321370AAddress volume expansionHigh reactivityCell electrodesSecondary cellsCyanamideFerric

The invention relates to a carbon-based compounded ferric cyanamide material and a preparation method thereof. The carbon-based compounded ferric cyanamide material comprises ferric cyanamide and carbon compounded with the ferric cyanamide. According to the material, the ferric cyanamide is compounded with the carbon, so that the problem that the volume of ferric cyanamide is increased can be effectively solved, meanwhile due to compounding of the two materials, the reaction activity of a battery can be further improved, the battery can be relatively stable in structure, and the multiplying power and the circulation performance of the battery can be improved.

Owner:MONALISA GRP CO LTD

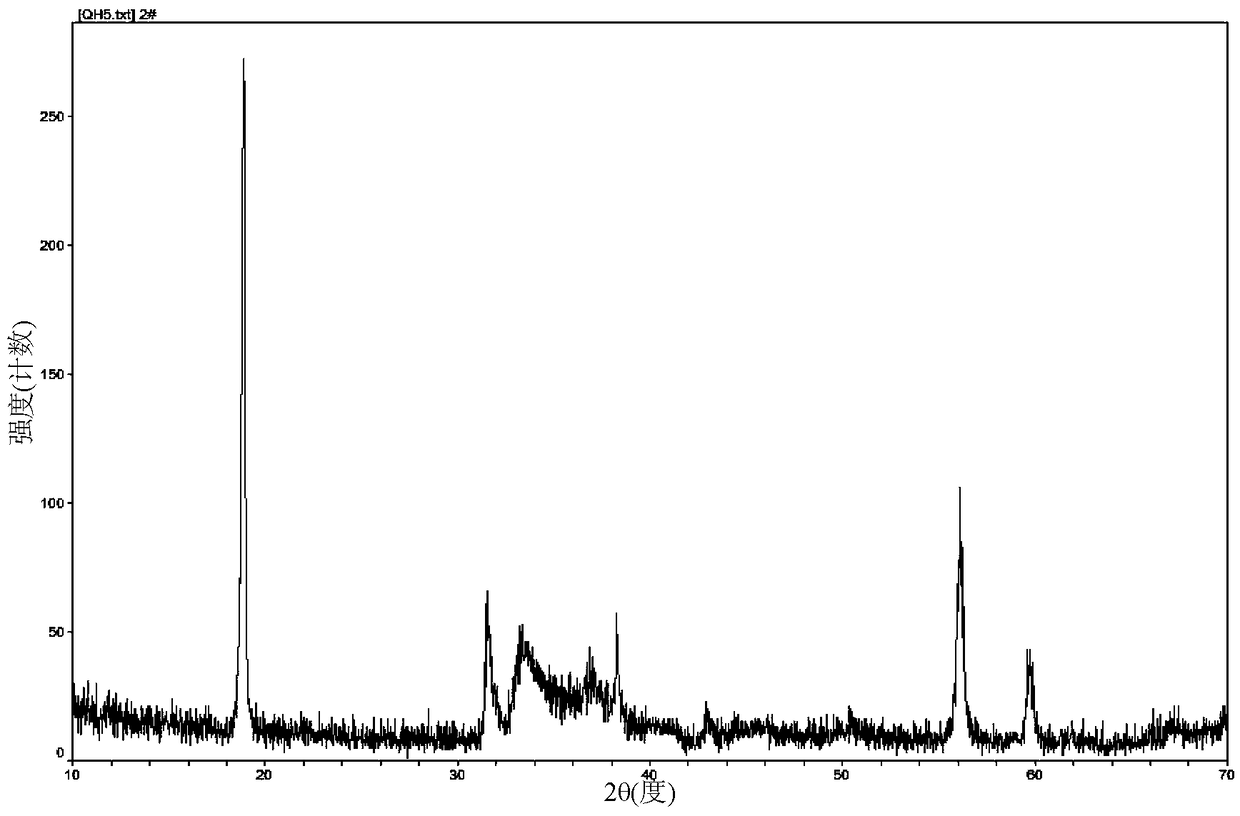

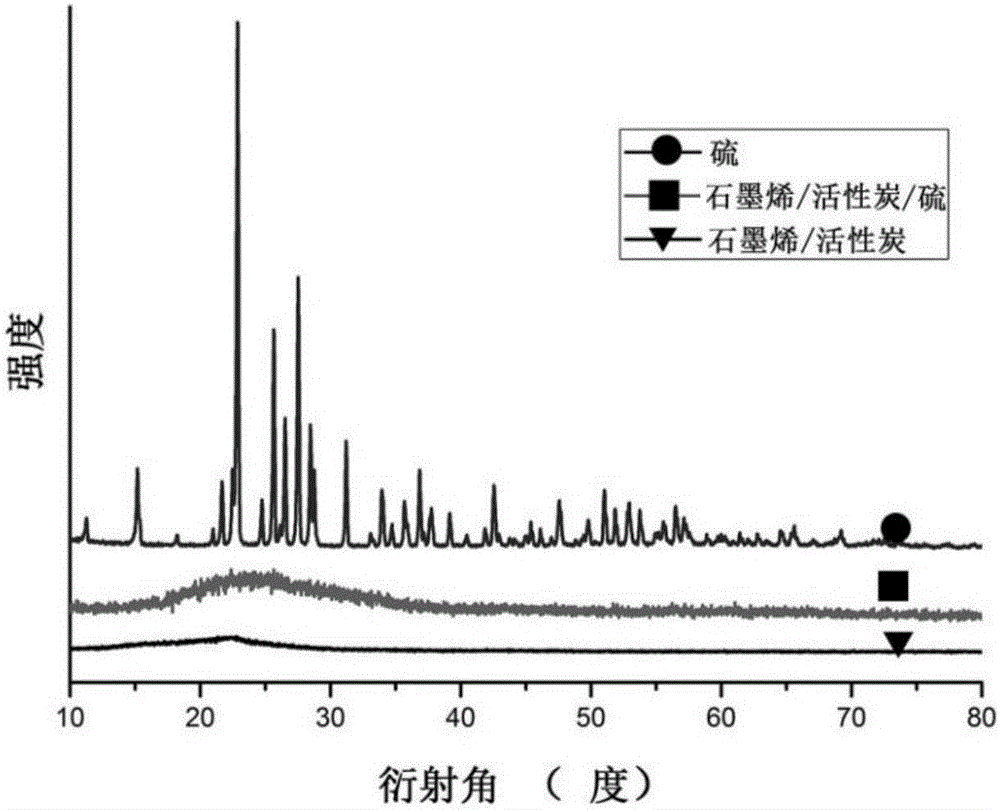

Method for preparing positive electrode composite material

InactiveCN106784757AImprove conductivityIncrease profitCell electrodesLi-accumulatorsArgon atmosphereSodium ascorbate

The invention relates to a method for preparing a positive electrode composite material. The method comprises the following steps: adding activated carbon subjected to acid treatment to graphene oxide suspension to obtain a mixed solution; and then adding a sodium ascorbate solution to obtain graphene hydrogel; and drying the graphene hydrogel, mixing and grinding the dry graphene hydrogel with sulfur, calcining the mixture at 150-200 DEG C for 3-15h in an argon atmosphere to obtain a graphene / activated carbon / sulfur positive electrode composite material. The method for preparing the positive electrode material of lithium-sulfur batteries provided by the invention has the advantages that the used raw materials are cheap and easy to obtain, the preparation process is simple, the flow is short, the process is easy to control, and the industrial production is easy to realize.

Owner:青岛亨迈新能源有限公司

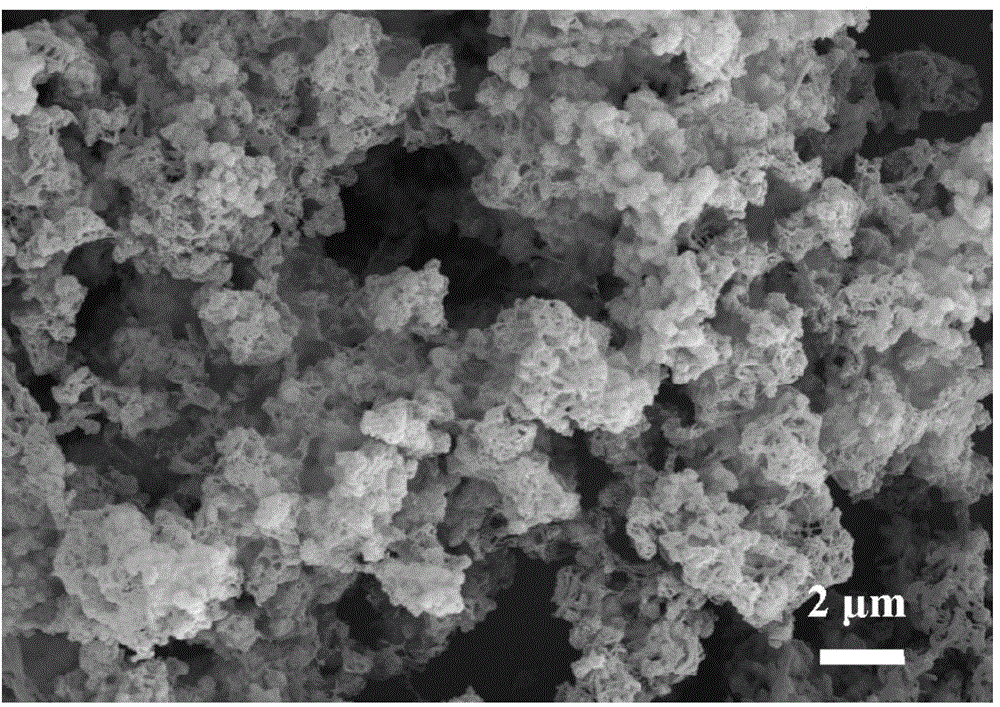

Preparation method of carbon-coated nano tin balls and products and application thereof

InactiveCN107658462AFully coveredWrap implementationMaterial nanotechnologyCell electrodesShielding gasLithium-ion battery

The invention discloses a preparation method of carbon-coated nano tin balls and products and application thereof. The preparation method includes: preparing tin oleate mixed liquid, adding the tin oleate mixed liquid into a crystal template, sufficiently stirring and dispersing to enable tin oleate to effectively cover the surface of the crystal template; transferring a mixture of tin oleate andthe crystal template into a tubular furnace, calcining in an atmosphere of protective gas to obtain solid powder, washing the solid powder, and drying to finally obtain a carbon / tin nano composite material. By the preparation method, preparation of a nanocrystal / carbon material is realized through only one step of direct heating, and obtained tin balls are small in nanocrystal size and complete incarbon coating; the preparation method is simple in step and process and easy to control. The products are conducive to shortening lithium ion transmission path and can inhibit volume expansion of tin in the process of charging and discharging and can avoid the problem of agglomeration of tin in the process of intercalation and deintercalation, lithium storage performance of tin is improved effectively, and the tin balls have great application potential in lithium ion battery electrode materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Lithium-sulfur battery composite positive electrode material and preparation method thereof

InactiveCN104538608AIncrease the areaImprove conductivityCell electrodesFinal product manufactureIn situ polymerizationCarbon black

The invention discloses a lithium-sulfur battery composite positive electrode material and a preparation method of the lithium-sulfur battery composite positive electrode material. By adopting an in-situ polymerization method, a spherical network pore structure is formed by utilizing a conductive polymer in a carbon black grafting method, and is used as a conductive framework of a lithium-sulfur battery composite material; elemental sulfur is deposited in a hydrothermal method and sulfur is injected into network pores; the carbon black grafted conductive polymer is high in specific surface area and conductivity; the spherical network pore structure can uniformly cover sulfur and can be uniformly mixed with sulfur, so that the utilization rate of active substances is improved. The conductive polymer is high in tensile property and can be used for inhibiting volume expansion of sulfur in a charging / discharging process; bond energy constraint exists between the surface of fibers and sulfur, so that adsorption capacity is provided to prevent sulfur from being diffused and lost toward the outside, thereby increasing the circulation stability and capacity retention ratio of the lithium-sulfur battery.

Owner:CHANGCHUN UNIV OF TECH

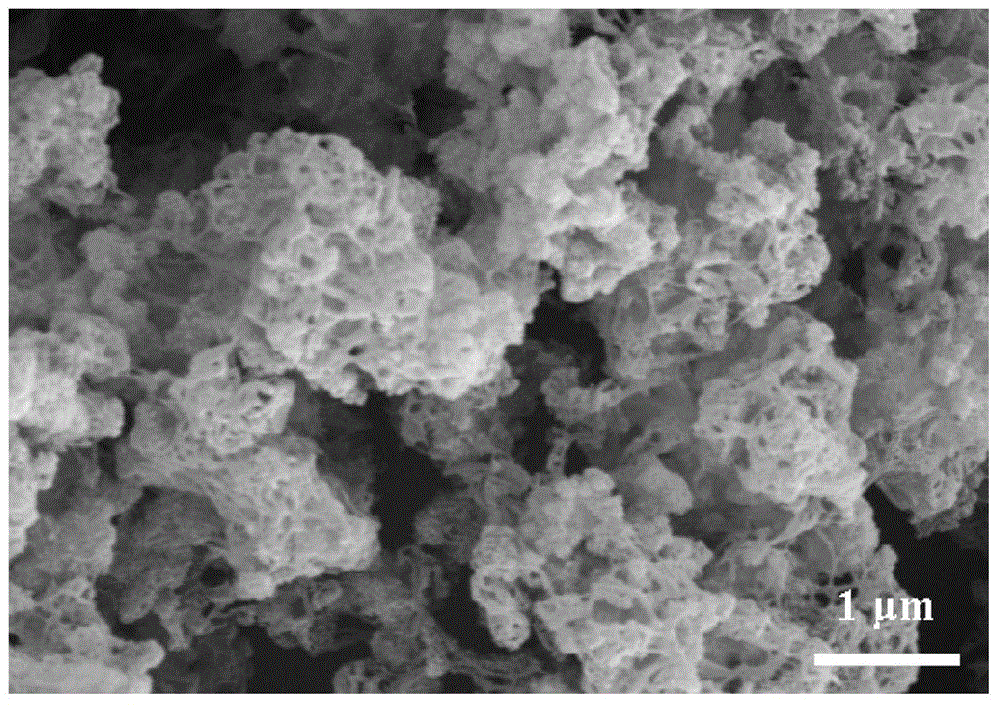

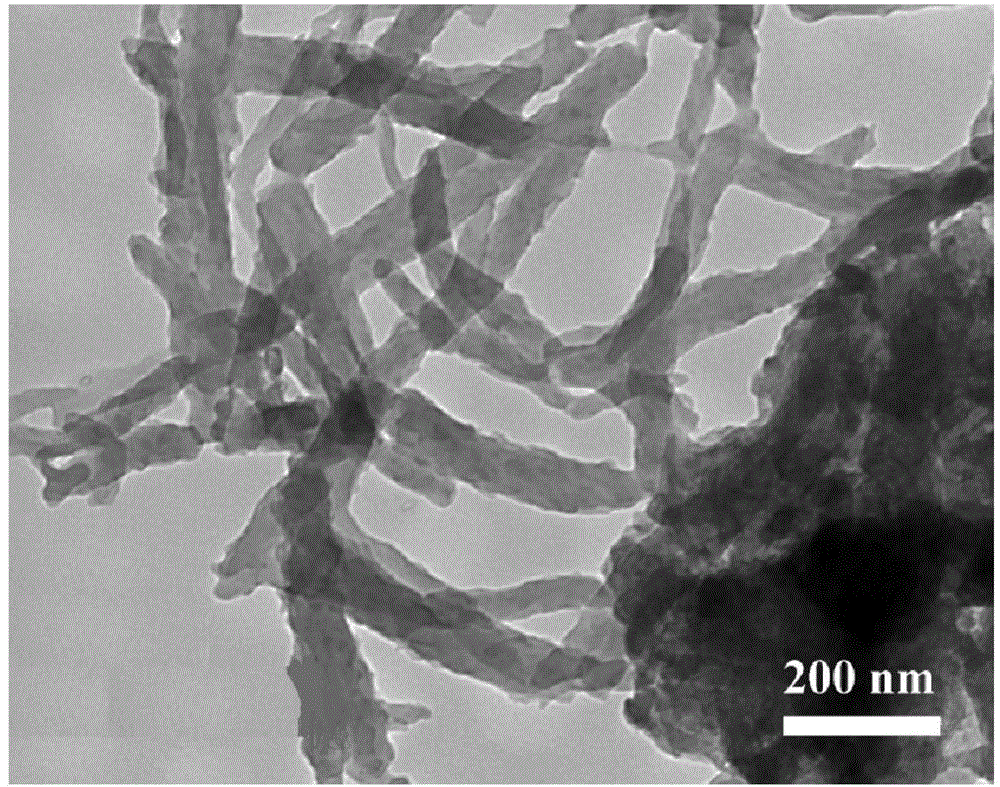

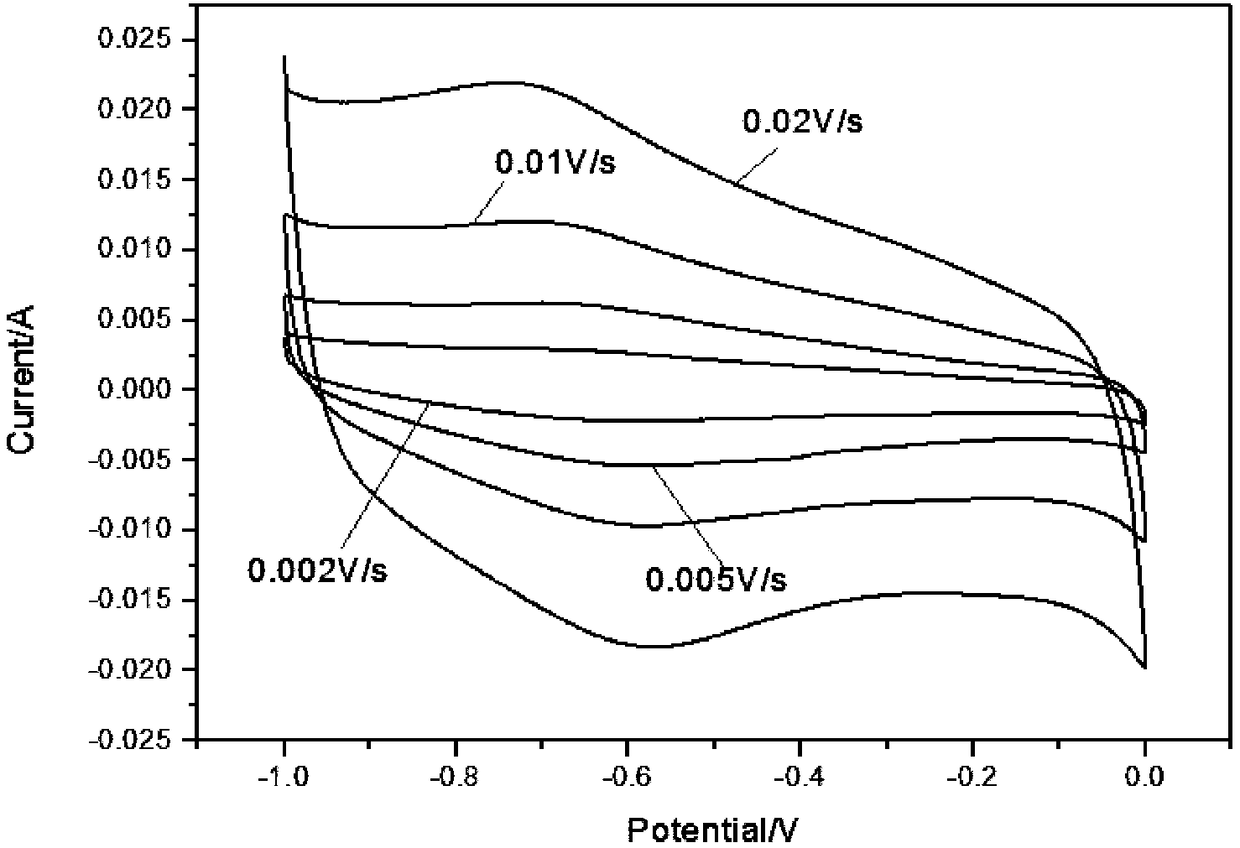

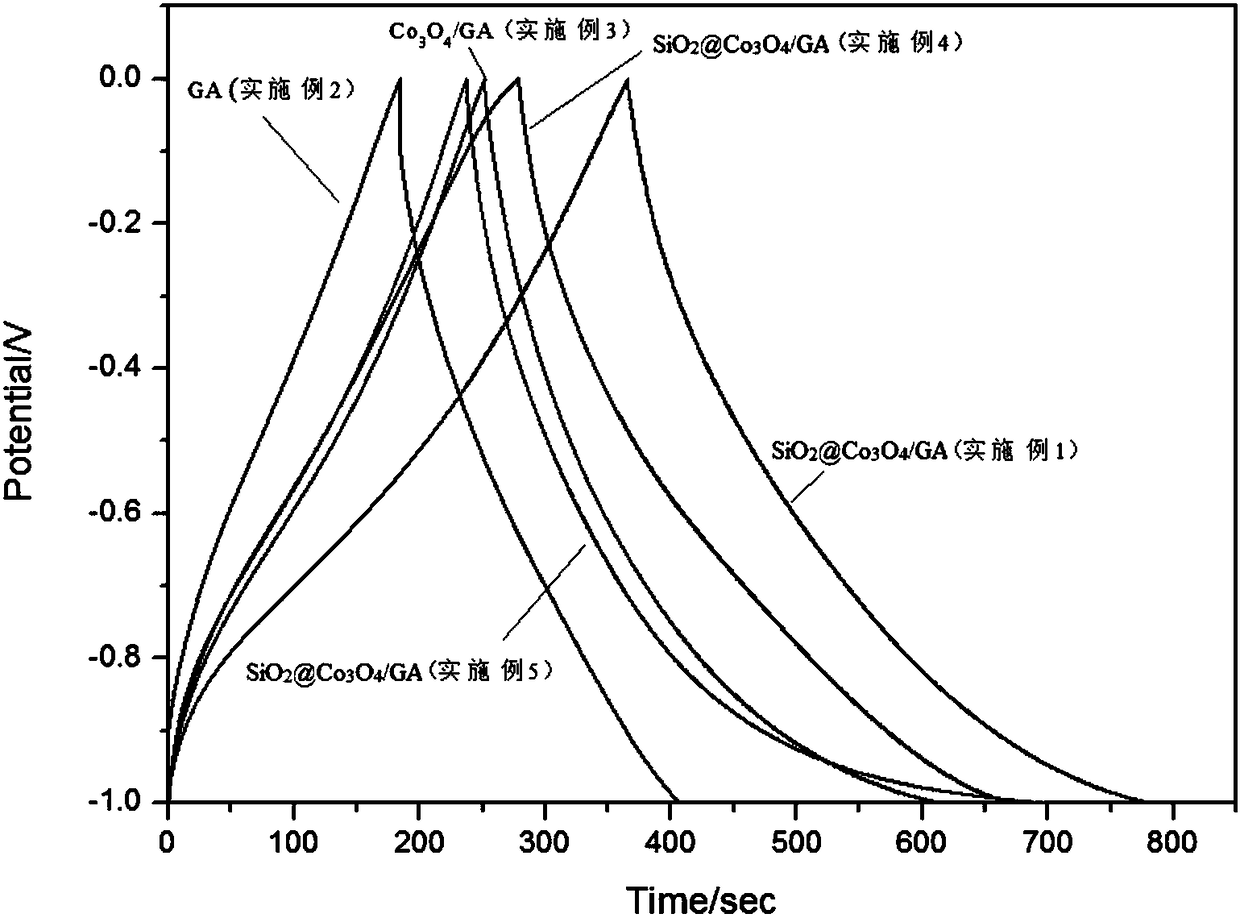

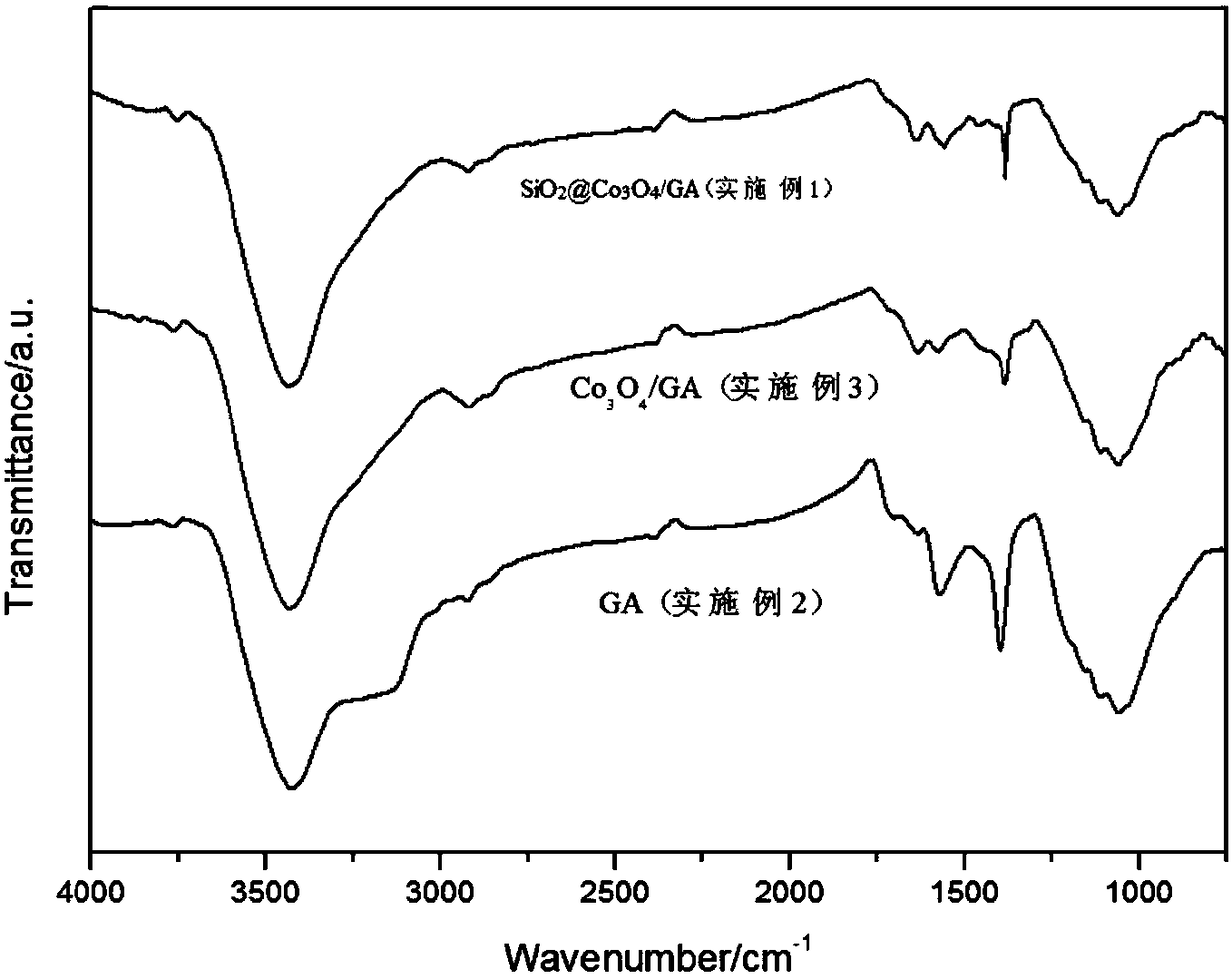

Silicon dioxide@metal oxide/graphene aerogel dual-loaded dual-coated composite material and preparation method and application thereof

ActiveCN108597891AAddress volume expansionImprove stabilityHybrid capacitor electrodesMetal oxide nanoparticlesSupercapacitor

The invention discloses a silicon dioxide@metal oxide / graphene aerogel dual-loaded dual-coated composite material and preparation method and application thereof. The composite material is formed by dispersing silicon dioxide-coated metal oxide nanoparticles in a graphene aerogel-loaded hole structure. The preparation method comprises the steps of dropwise adding a solution containing a metal source and a silicon source into a graphene oxide dispersing liquid, performing hydrothermal reaction after ultrasonic mixing, and performing freezing, drying and calcination on the product obtained by hydrothermal reaction to obtain the composite material. The composite material shows favorable electrochemical performance when used as a supercapacitor electrode material; and moreover, the preparationmethod is simple, is low in cost and is friendly to environment, and the industrial production standard is satisfied.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com