Method for preparing three-dimensional germanium/carbon nano composite film through ionic liquid electrodeposition

A technology of carbon nanocomposite and ionic liquid, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reducing the cycle performance and rate performance of lithium-ion batteries, and achieve stress relief and enhancement The effect of cycle performance and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

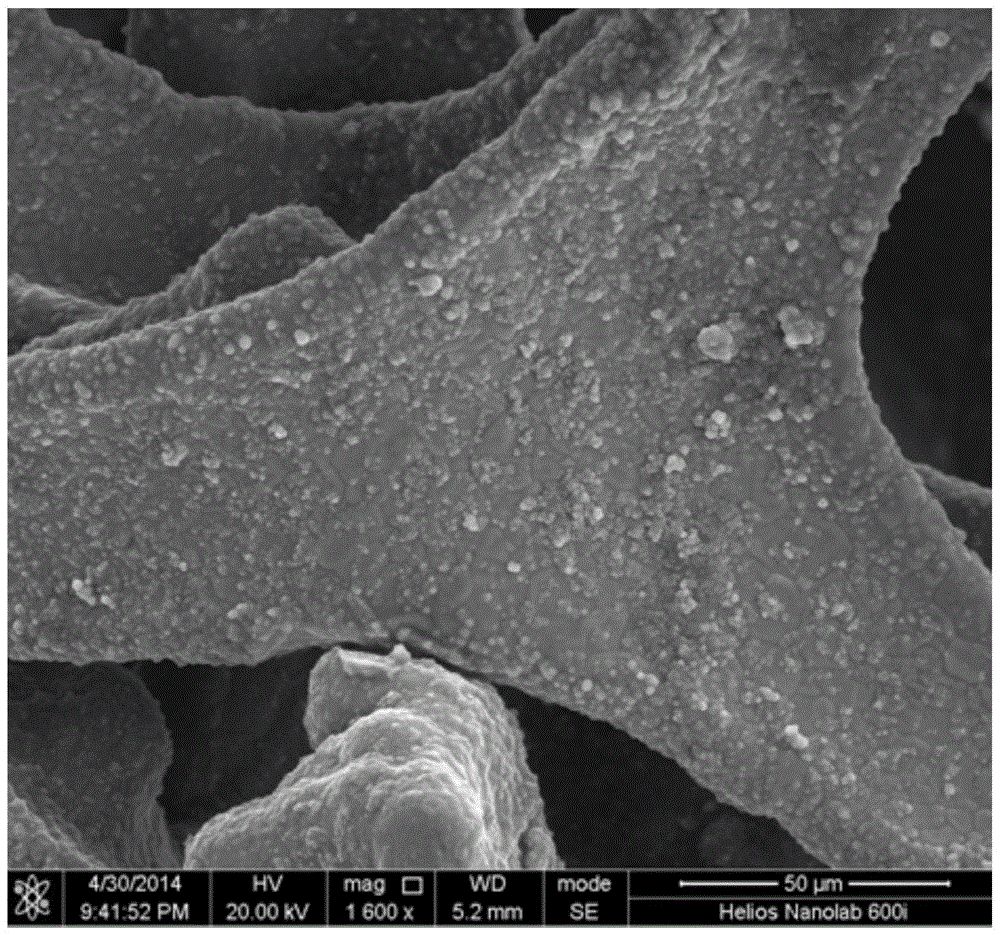

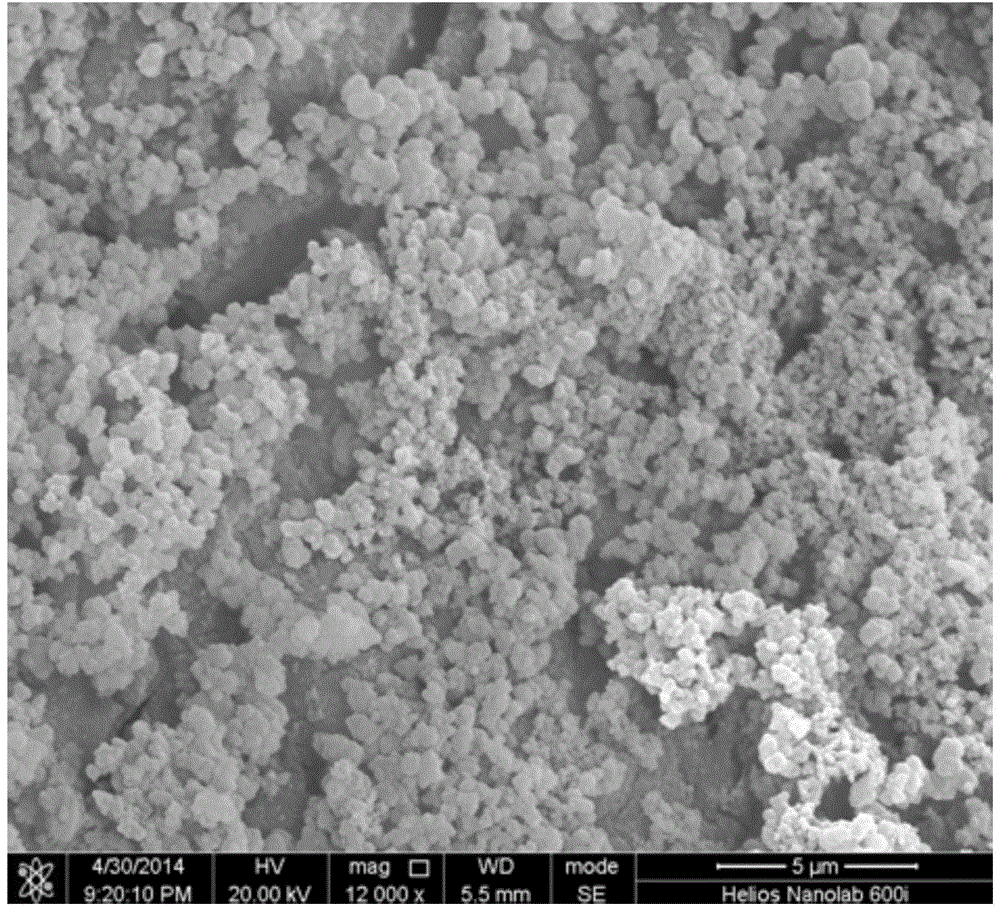

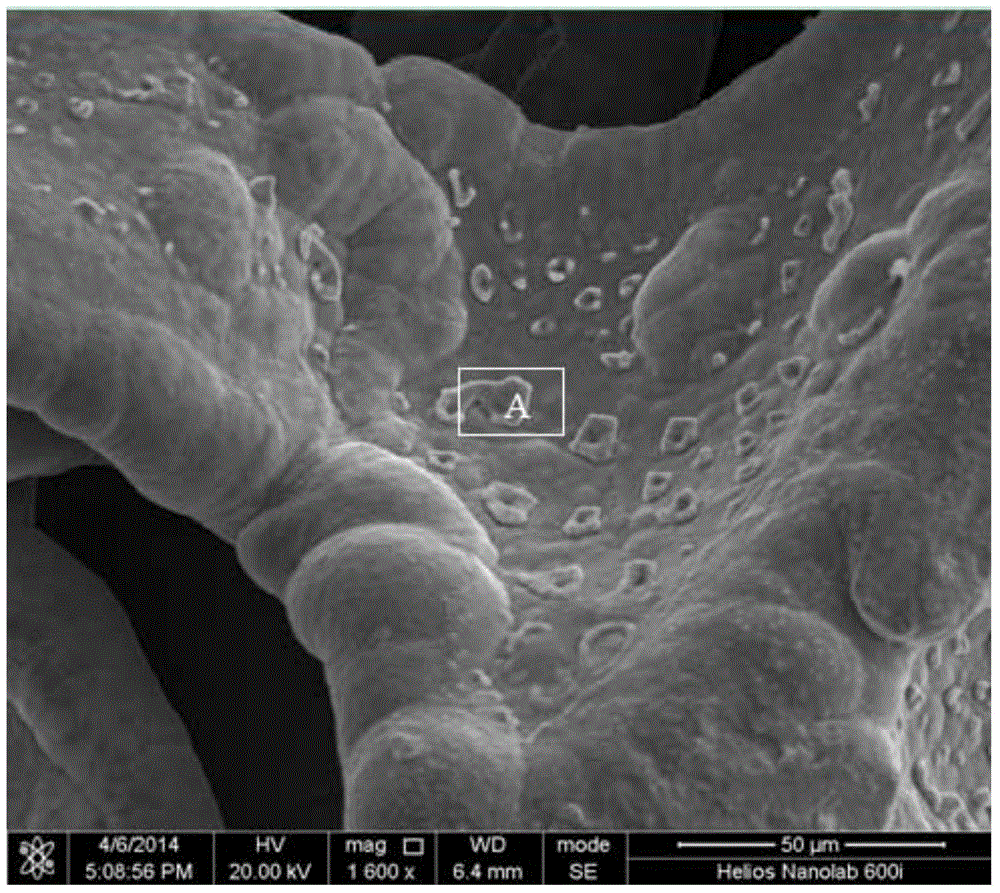

[0023] Specific Embodiment 1: This embodiment is a method for preparing a three-dimensional germanium / carbon nanocomposite film by electrodeposition of ionic liquid, which is specifically carried out according to the following steps:

[0024]1. Electrophoretic deposition: Dissolve acetylene black in isopropanol, add nickel nitrate, and then perform ultrasonic mixing for 6 hours to obtain an acetylene black solution; use clean nickel foam as the anode, copper foil as the cathode, and acetylene black solution as the electrophoresis solution , carry out constant voltage electrophoretic deposition for 2min, and then dry at a temperature of 70°C for 4h to obtain a three-dimensional carbon network; the voltage of the constant voltage electrophoretic deposition is 100V; the quality of the acetylene black is the same as that of isopropanol Volume ratio is 1mg:(2mL~2.5mL); The mass ratio of described acetylene black and nickel nitrate is 1:(0.1~0.3);

[0025] 2. Preparation of ionic li...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of clean nickel foam in step 1: use the HCl solution ultrasonic cleaning foam nickel 5min of 0.5mol / L with concentration, then use ethanol and supernatant successively The nickel foam was ultrasonically washed with pure water for 10 minutes each, and dried for 2 hours at a temperature of 70° C. to obtain clean nickel foam. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt is distilled in a glove box for 24h , to obtain distilled 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonylimide salt. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com